Page 1

TOSHIBA Barcode Printer

B-EX6T SERIES

Owner’s Manual

Mo

de d’emploi

Bedienungsanleitung

Manual de instrucciones

Gebruikershandleiding

Manuale Utente

Manual do Utilizador

Page 2

TOSHIBA Barcode Printer

B-EX6T SERIES

Owner's Manual

Page 3

This product is designed for commercial usage and is not consumer product.

CE Compliance (for EU only)

This product complies with the requirements of EMC and Low Voltage Directives including their amendments.

CE marking is the responsibility of TOSHIBA TEC GERMANY IMAGING SYSTEMS GmbH, Carl-Schurz-Str. 7,

41460 Neuss, Germany.

For a copy of the related CE Declaration of Conformity, please con

tact your dealer or TOSHI

BA TEC

.

FCC Notice

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial environment. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operations of this equipment in a

residential area is likely to cause harmful interference in which case the user will be required to correct the

interference at his own expense.

WARNING

Changes or modifications not expressly approved by the party responsible for compliance could void the user's

authority to operate the equipment.

(for USA only)

CAN ICES-3 (A) / NMB-3 (A)

This Class A digital apparatus complies with Canadian ICES-003.

(for CANADA only)

This is a Class A product. In a domestic environment this product may cause radio interference in which case

the user may be required to take adequate measures.

California Proposition 65 Warning: USA-California only

This Product contains chemicals known to the State of California to cause cancer, birth defects, or other

reproductive harm.

VORSICHT:

• Schallemission: unter 70dB (A) nach DIN 45635 (oder ISO 7779)

• Die für das Gerät Vorgesehene Steckdose muß in der Nähe des Gerätes und leicht zugänglich sein.

Centronics is a registered trademark of Centronics Data Computer Corp.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a trademark of Microsoft Corporation.

Changes or modifications not expressly approved by the manufacturer for compliance could void the

user’s authority to operate the equipment.

Page 4

Notification (for Turkey)

AEEE Yönetmeliğine Uygundur

The following information is for EU

-

member states only:

Disposal of products

(based on EU-Directive 2002/96/EC,

Directive on Waste electrical and electronic equipment – WEEE)

The use of the symbol indicates that t

his product may not be disposed as unsorted municipal waste

and has to be collected separately. Integrated batteries and accumulators can be disposed of with

the product. They will be separated at the recycling centers.

The black bar indicates that the product was placed on the market after August 13, 2005.

By ensuring this product is disposed of correctly, you will help prevent potential negative

consequences for the environmental and human health, which could otherwise be caused by

inappropriate waste handling of this product.

For more detailed information about the take-back and recycling of this product, please contact your

supplier where you purchased this product.

Following information is only for India:

The use of the symbol indicates that this product may not be treated as household waste. By ensuring

this product is disposed of correctly, you will help prevent potential negative consequences for the

environment and human health, which could otherwise be caused by inappropriate waste handling of

this product.

For more detailed information about the take-back and recycling of this product, please contact your

supplier where you purchased the product.

This product complies with the “India E-waste

Rule 2011” and prohibits use of lead, mercury, hexavalent

chromium, polybrominated biphenyls or polybrominated diphenyl ethers in concentrations exceeding

0.1% by weight and 0.01% by weight for cadmium, except for the exemption set in Schedule II of the

Rule.

Page 5

Precautions for the handling of Wireless Communication Devices

Wireless LAN Module: GS2100MIP(B-EX706-WLAN2-QM-R and B-EX6T1-GS/TS16-CN-R)

RFID Module: TRW-USM-10 (B-EX706-RFID-U4-US-R, B-EX6T1-GS18/TS18-CN-R), TRW-EUM-10 (B-

EX706-RFID-U4-EU-R), TRW-AUM-10 (B-EX706-RFID-U4-AU-R)

For Europe

This device was tested and certified by Notified Body.

Hereby, Toshiba TEC Corporation declares that this device is in compliance with the essential requirements

and other relevant provisions of Directive 1999/5/EC.

This equipment uses the radio frequency band which has not been standardized throughout the EU and

EFTA countries. It can be used in the following countries.

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Hungary, Germany,

Greece, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania,

Slovakia, Slovenia, Spain, Sweden, United Kingdom, Norway, Liechtenstein, Iceland, Switzerland

For USA

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation.

Changes or modification not expressly approved by manufacturer for compliance could void the user’s

authority to operate the equipment.

For Canada

Operation is subject to the following two conditions:

(1) This device may not cause interference, and

(2) This device must accept any interference, including interference that may cause undesired operation of

the device.

For Taiwan

Caution

根據低功率電波輻射性電機管理辦法

For safety

Do not operate this product in locations where its use may be prohibited. For example, in an aeroplane or

hospital. If you are unsure whether operation is permitted, please refer to and follow the airline company or

medical institution guidelines.

Otherwise, flight instrument or medical equipment may be affected, causing a serious accident.

This product may affect the operation of some implanted cardiac pacemakers and other medically

implanted equipment. Pacemaker patients should be aware that the use of this product in close proximity to

a pacemaker might cause the device to malfunction.

If you have any reason to suspect that interference is taking place, immediately turn off the product and

contact your TOSHIBA TEC sales agent.

Do not disassemble, modify, or repair the product as doing so may cause injury.

Modification is also against the Laws and Regulations for Radio Equipment. Please ask your TOSHIBA

TEC sales agent for repair.

Page 6

Safety Summary ENGLISH VERSION

( )

i

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this manual

should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, and then contact your

authorised TOSHIBA TEC representative for assistance.

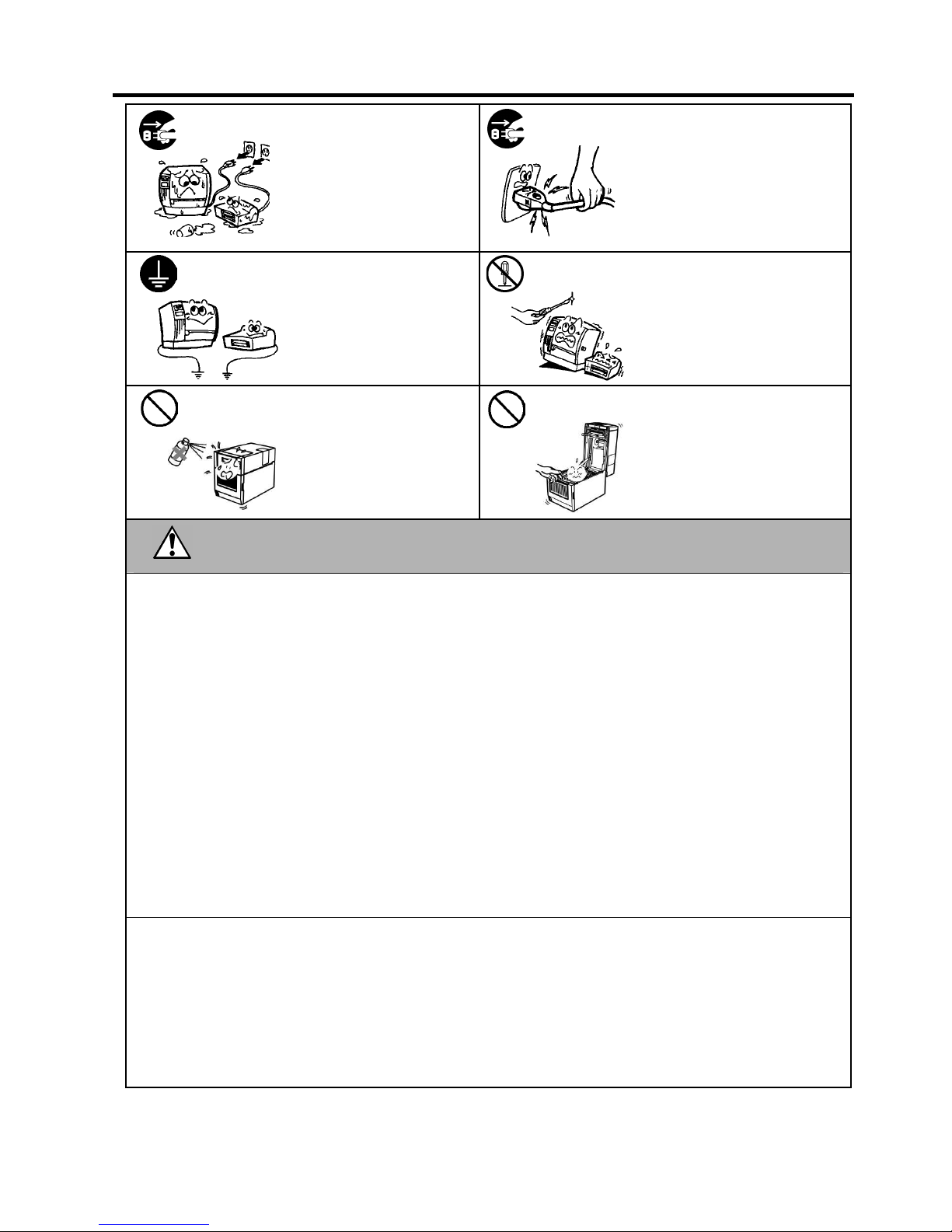

Meanings of Each Symbol

T

his symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

This indicates that there is the risk of death or serious injury if the

machine is improperly handled contrary to this indication.

Do not use voltages other than

the AC voltage specified on the

rating plate, as this may cause

fire or electric shock.

Do not plug in or unplug the power

cord with wet hands as this may

cause electric shock.

If the machine shares the same

electrical outlet, with any other

appliance that consumes a large

amount of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for

the machine as this may cause

fire or electric shock.

Do not place metal objects or

water-filled containers (flower

vases, flower pots or mugs etc) on

top of the machine. If metal

objects or spilled liquids enter the

machine, this may cause fire or

electric shock.

Do not insert or drop metal,

flammable or other foreign

objects into the machine through

ventilation slits, as this may

cause fire or electric shock.

Do not scratch, damage or modify

the power cords. Do not place

heavy objects on, pull on, or

excessively bend the power cords,

as this may cause fire or electrical

shock.

If the machine is dropped or the

cabinet is damaged, turn off the

power switch and disconnect the

power cord plug from the outlet,

and then contact your authorised

TOSHIBA TEC representative

for assistance. Continued use of

a damaged machine may cause

fire or electric shock.

Continued use of the machine in an

abnormal condition (the machine is

producing smoke or a strange

smell) may cause fire or electric

shock. In these cases, immediately

turn off the power switch and

disconnect the power cord plug

from the outlet. Then, contact your

authorised TOSHIBA TEC

representative for assistance.

WARNING

Use only

specified

AC voltage.

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Disconnect

the plug.

Disconnect

the plug.

Page 7

Safety Summary ENGLISH VERSION

( )

ii

If foreign objects (metal

fragments, water, liquids) enter

the machine, turn off the power

switch and disconnect the power

cord plug from the outlet, and

then contact your authorised

TOSHIBA TEC representative

for assistance. Continued use of

the machine in that condition may

cause

fire

or

electric shock.

When unplugging the power cords,

be sure to hold and pull on the plug.

Pulling on the cord may cut or

expose the internal wires and cause

fire or electric shock.

Ensure that the equipment is

properly grounded. Extension

cables should also be grounded.

Fire or electric shock could

occur on improperly grounded

equipment.

Do not remove covers, repair or

modify the machine yourself.

Contact your TOSHIBA TEC

representative for assistance. You

may be injured by high voltage,

very hot parts or sharp edges inside

the machine.

Do not use a spray cleaner

containing flammable gas for

cleaning this product, as this may

cause a fire.

Care must be taken not to injure

yourself with the printer paper

cutter.

This indicates that there is the risk of personal Injury or damage to

objects if the machine is improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent solution. NEVER

USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust,

or gas.

• Ensure the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during a printer fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains

interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machine, as these items may become unbalanced and fall causing injury.

• Do not block the ventilation slits of the machine, as this will cause heat to build up inside the machine and may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Unplug the machine when it is not used for a long period of time.

• Place the machine on a stable and level surface.

• RISK OF EXPLOSION IF BATTERY IS REPLACED BY AN INCORRECT TYPE. DISPOSE OF

USED BATTERIES ACCORDING TO THE INSTRUCTIONS.

Request Regarding Maintenance

• Utilize our maintenance services.

After purchasing the machine, contact your authorized TOSHIBA TEC representative for assistance once a year to have the

inside of the machine cleaned. Dust will build up inside the machines and may cause a fire or a malfunction. Cleaning is

particularly effective before humid rainy seasons.

• Our preventive maintenance service performs periodic checks and other work required to maintain the quality and performance

of the machine.

For details, please consult your authorized TOSHIBA TEC representative.

• Do not expose the machine to insecticides or other volatile solvents. This may cause the cabinet, or other parts, to deteriorate

and may

cause the paint to peel.

CAUTION

Disconnect

the plug.

Disconnect

the plug.

Connect a

grounding wire.

No

disassembling.

Prohibited

Prohibited

Page 8

ENGLISH VERSION

( )

3

TABLE OF CONTENTS

Page

1. PRODUCT OVERVIEW ......................................................................................................... E1- 1

1.1 Introduction ................................................................................................................... E1- 1

1.2 Features ....................................................................................................................... E1- 1

1.3 Unpacking ..................................................................................................................... E1- 1

1.4 Accessories ................................................................................................................. E1- 2

1.5 Appearance .................................................................................................................. E1- 3

1.5.1 Dimensions ....................................................................................................... E1- 3

1.5.2 Front View ......................................................................................................... E1- 3

1.5.3 Rear View ......................................................................................................... E1- 3

1.5.4 Operation Panel ................................................................................................ E1- 4

1.5.5 Interior ............................................................................................................... E1- 4

1.6 Options ......................................................................................................................... E1- 5

2. PRINTER SETUP .................................................................................................................. E2- 1

2.1 Installation .................................................................................................................... E2- 2

2.2 Connecting the Power Cord ......................................................................................... E2- 3

2.3 Loading Supplies .......................................................................................................... E2- 4

2.3.1 Loading the Media ............................................................................................ E2- 5

2.3.2 Loading the Ribbon .......................................................................................... E2-10

2.4 Connecting the Cables to Your Printer ........................................................................ E2-12

2.5 Turning the Printer ON/OFF ........................................................................................ E2-13

2.5.1 Turning ON the Printer ..................................................................................... E2-13

2.5.2 Turning OFF the Printer ................................................................................... E2-13

2.6 Printer Setting .............................................................................................................. E2-14

2.6.1 Scope ............................................................................................................... E2-14

2.6.2 Outline .............................................................................................................. E2-14

2.6.3 Operation panel ............................................................................................... E2-14

2.6.4 Outline of each Mode ....................................................................................... E2-15

2.6.5 General View of Key Operation ....................................................................... E2-16

2.6.6 Initial Setting Wizard ........................................................................................ E2-18

2.7 Printer Drivers .............................................................................................................. E2-21

2.8 Print Test ..................................................................................................................... E2-23

3. ONLINE MODE ...................................................................................................................... E3- 1

3.1 Key Functions ............................................................................................................... E3- 1

3.2 LCD .............................................................................................................................. E3- 2

3.3 Icon ............................................................................................................................... E3- 3

3.4 Operation Example ....................................................................................................... E3- 4

3.5 User System Mode ....................................................................................................... E3- 7

3.5.1 Outline of use system mode .............................................................................. E3-7

3.5.2 Exit ..................................................................................................................... E3-7

3.6 Power Save Function .................................................................................................... E3-8

3.6.1 Entering the Power Saving Mode....................................................................... E3-8

3.6.2 Exiting the Power Saving Mode ......................................................................... E3-8

4. MAINTENANCE .................................................................................................................... E4- 1

4.1 Cleaning ....................................................................................................................... E4- 1

4.1.1 Print Head/Platen/Sensors ................................................................................ E4- 1

4.1.2 Covers and Panels ............................................................................................ E4- 2

4.1.3 Optional Cutter Module ..................................................................................... E4- 3

5. TROUBLESHOOTING .......................................................................................................... E5- 1

Page 9

ENGLISH VERSION

( )

4

5.1 Error Messages ............................................................................................................ E5- 1

5.2 Possible Problems ........................................................................................................ E5- 4

5.3 Removing Jammed Media ............................................................................................ E5- 5

6. PRINTER SPECIFICATIONS ................................................................................................ E6- 1

7. SUPPLY SPECIFICATIONS ................................................................................................. E7- 1

7.1 Media ............................................................................................................................ E7- 1

7.1.1 Media Type ....................................................................................................... E7- 1

7.1.2 Detection Area of the Transmissive Sensor ...................................................... E7- 3

7.1.3 Detection Area of the Reflective Sensor ........................................................... E7- 4

7.1.4 Effective Print Area of Paper ............................................................................. E7- 5

7.2 Ribbon .......................................................................................................................... E7- 6

7.3 Recommended Media and Ribbon Types .................................................................... E7- 6

7.4 Care/Handling of Media and Ribbon ............................................................................ E7- 7

APPENDIX 1 MESSAGES AND LEDS ...................................................................................... EA1-1

APPENDIX 2 INTERFACE ......................................................................................................... EA2-1

APPENDIX 3 PRINT SAMPLES ................................................................................................ EA3-1

APPENDIX 4 GLOSSARIES ...................................................................................................... EA4-1

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorised Service representative with regard to any queries you may have in

this manual.

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

WARNING!

Page 10

1. PRODUCT OVERVIEW ENGLISH VERSION

1.1 Introduction

E1- 1

1. PRODUCT OVERVIEW

1.1 Introduction

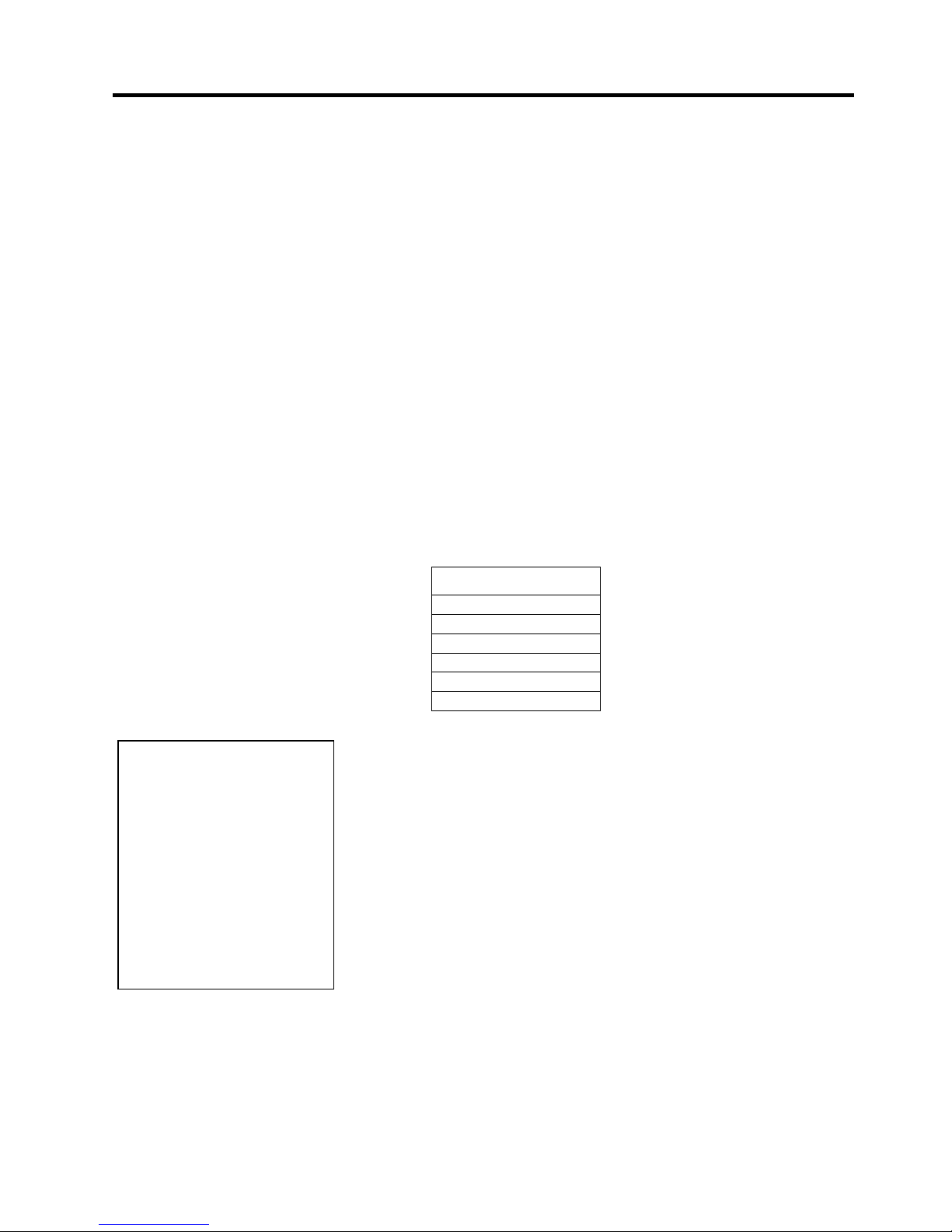

1.2 Features

1.3 Unpacking

T

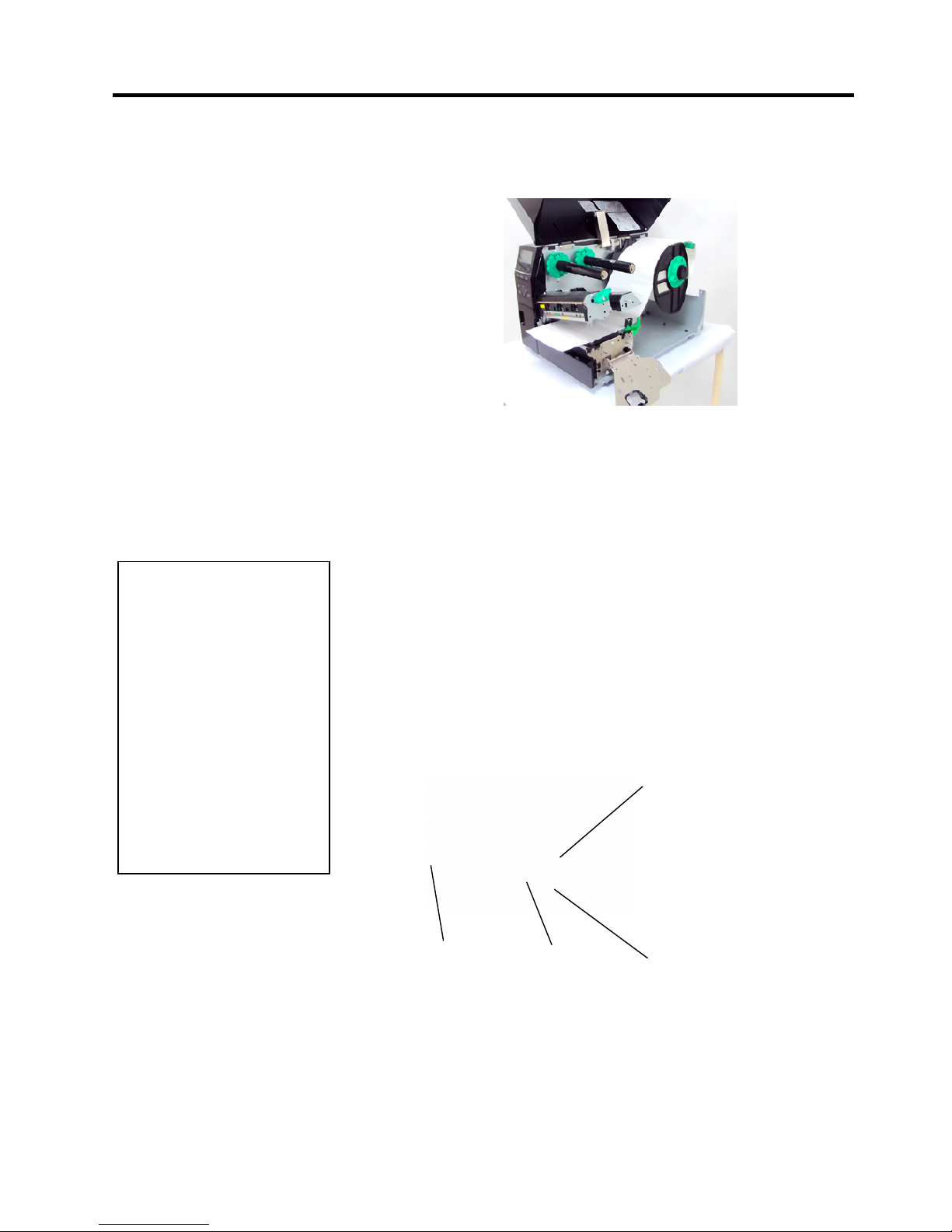

hank you for choosing the TOSHIBA B-EX6T series bar code printer.

This Owner’s Manual contains from general set-up through to how to

c

onfirm the printer operation using a test print, and should be read carefully

to help gain maximum performance and life from your printer. For most

queries please refer to this manual and keep it safe for future reference.

Please contact your TOSHIBA TEC representative for further information

concerning this manual.

T

his printer has the following features:

• The print head block can be opened enabling easy loading of media

and ribbon.

• Various types of media can be used as the media sensors can be

moved from the centre to the left edge of the media.

• Web based functions such as remote maintenance and other advanced

network features are available.

• Superior hardware, including the specially developed 8 dots/mm (203

dots/inch) or 12 dots/mm (305 dots/inch) thermal print head which

will allow very clear print at a printing speed of 3, 5, 8, 10 or 12

inches/sec.

B-EX6T1/T3-TS/GS12

305dpi/203dpi

3ips

5ips

8ips

10ips

12ips

• Comes with USB I/F, LAN I/F, the RTC/USB host I/F card,

Ribbon Save Module (for Type 1)

Besides the optional Cutter Module, there is also an optional Peel

off Module, Fanfold paper guide, RS-232C I/F card, Centronics

I/F card, Expansion I/O Card, Wireless LAN I/F card, and RFID

module

Unpack the printer as per the Unpacking Instructions supplied with the

printer.

NOTES:

1. Check for damage or

scratches on the printer.

However, please note that

TOSHIBA TEC shall have

no liability for any damage

of any kind sustained during

transportation of the

product.

2. Keep the cartons and

internal packing for future

transportation of the

printer.

Page 11

1. PRODUCT OVERVIEW ENGLISH VERSION

1.4 Accessories

E1- 2

1.4 Accessories

When unpacking the printer, please make sure all the following

accessories are supplied with the printer.

Power cord (for China) CD-ROM(1pc.)

Safety precautions Quick installation manual

Page 12

1. PRODUCT OVERVIEW ENGLISH VERSION

1.5 Appearance

E1- 3

1.5 Appearance

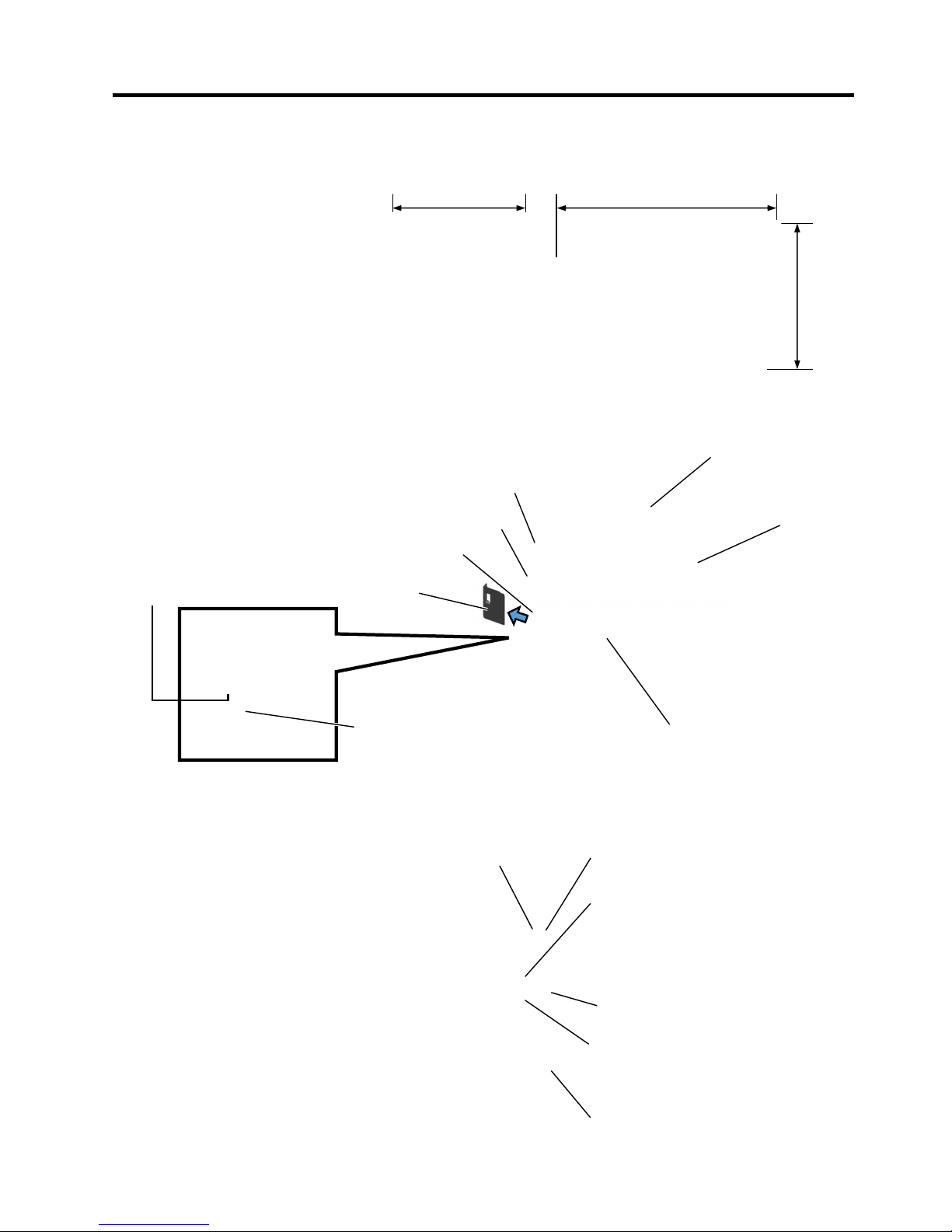

1.5.1 Dimensions

1.5.2 Front View

1.5.3 Rear View

The names of the parts or units introduced in this section are used in the

following chapters.

331 (13.03)

460 (18.1)

Dimensions in mm (inches)

309.7

(12.2)

Top Cover

Media Outlet

Supply Window

LCD Message Display

Operation Panel

For GS/TS12 and GS/TS18 models,

Reserved for Serial Interface.

For GS/TS16 models, WLAN

Interface

LAN Interface

AC Power Inlet

Reserved for Expansion I/O

interface

Reserved for Parallel Interface

USB Interface

Power Switch

Cover for USB

USB Bluetooth dongle

Connect Smart device (Mobile phone)

for Parameter setting

USB memory

Install firmware/ to copy log data

Standard USB Host I/F for

USB memory or USB Bluetooth

Page 13

1. PRODUCT OVERVIEW ENGLISH VERSION

1.5 Appearance

E1- 4

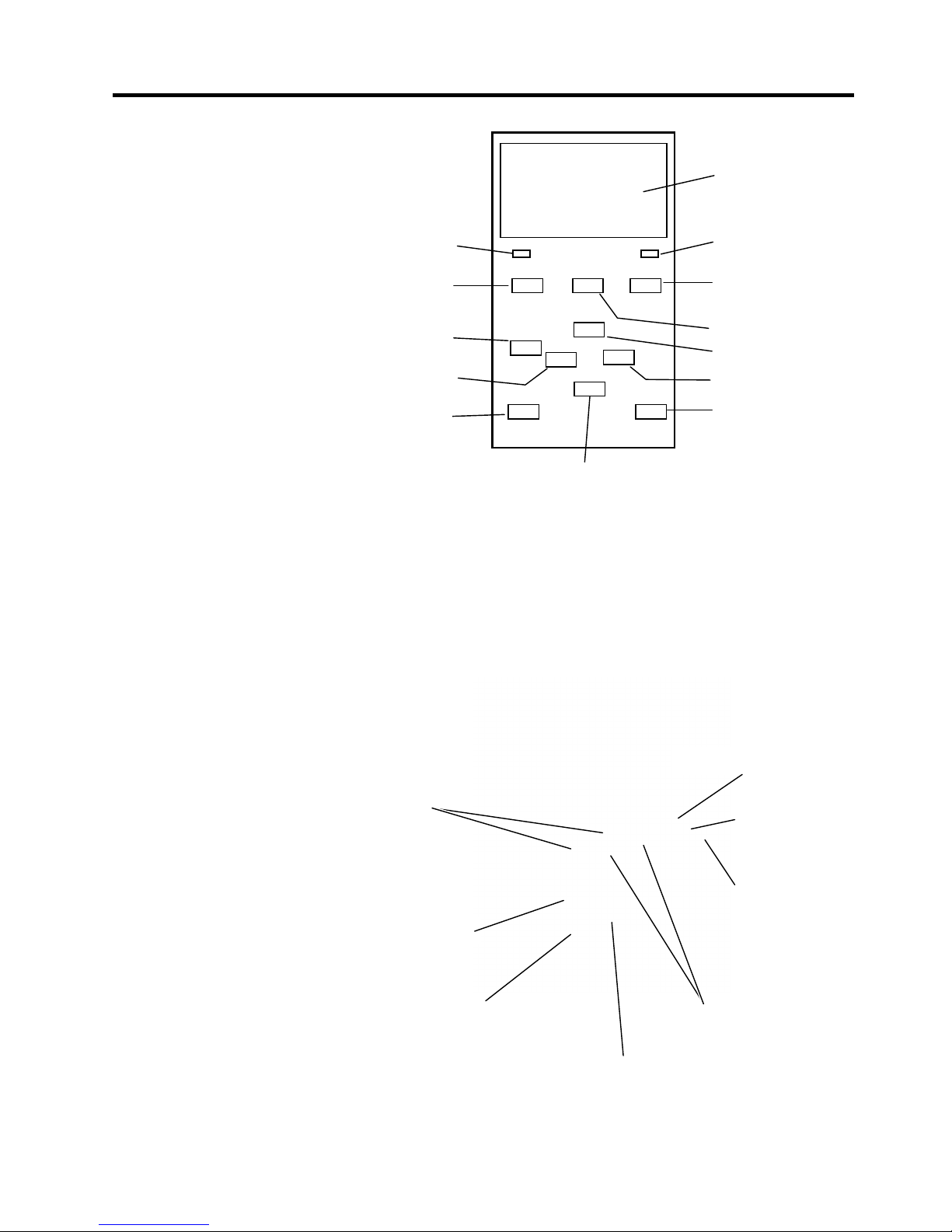

1.5.4 Operation Panel

1.5.5 Interior

Please see Section 3 for further information about the Operation Panel.

Graphic LCD

ERROR LED

PAUSE

RESTART key

UP

RIGHT

ENTER

DOWN

CANCEL key

MODE

LEFT key

FEED key

ONLINE LED

Platen

Head Lever

Ribbon Shaft

Supply Shaft

Supply Holder

Locking Ring

Ribbon Stopper

Print Head Block

Page 14

1. PRODUCT OVERVIEW ENGLISH VERSION

1.6 Options

E1- 5

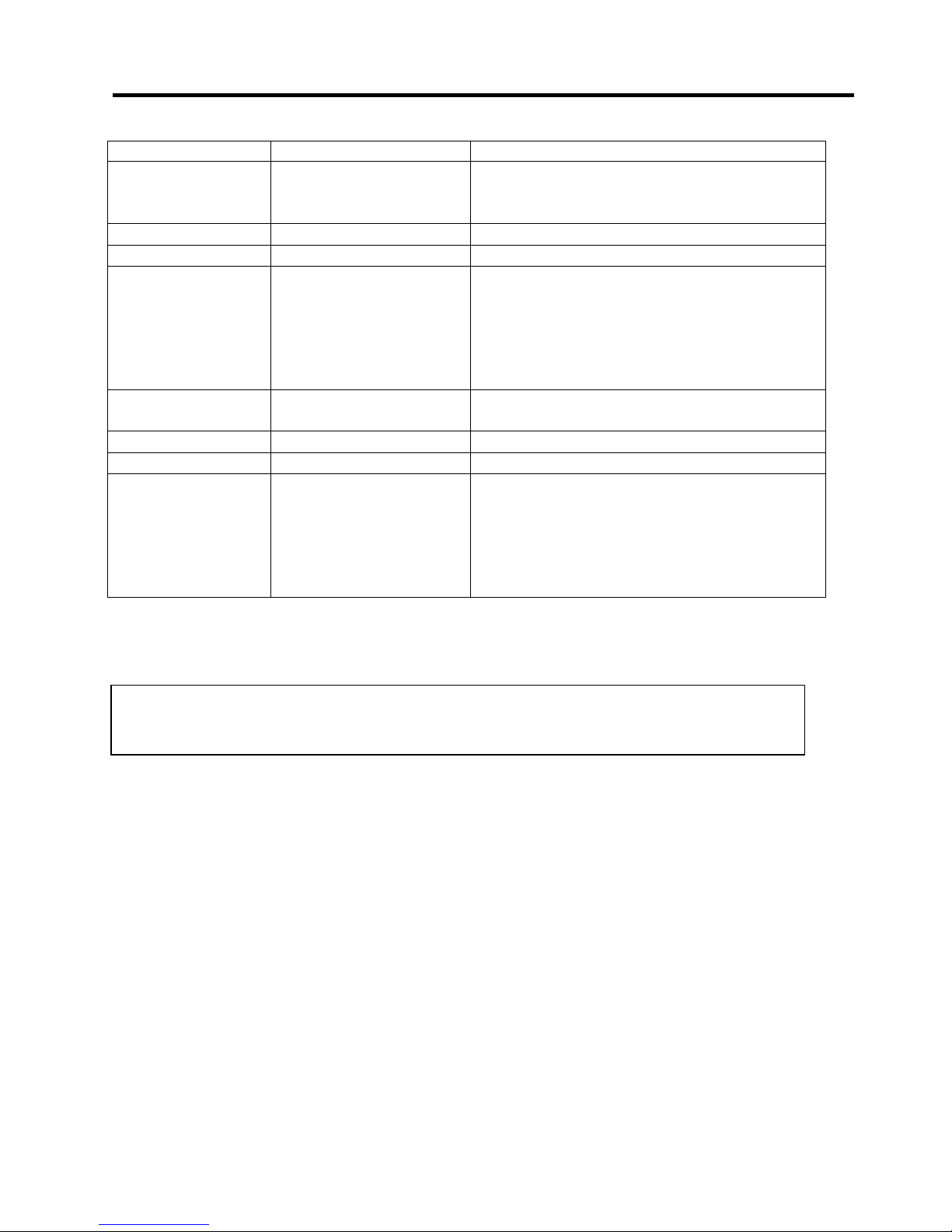

1.6 Options

O

ption Name Type Description

Disc cutter module B-EX206-QM-R Disc cutter

To perform a cut the media feeds to the cut position,

stops and is cut , then back feeds to the print position

Peel Off module B-EX906-H-QM-R This eanables on-demand (peel-off) operations.

Fanfold paper guide B-EX906-FF-QM-R

RFID module B-EX706-RFID-U4-EU-R

B-EX706-RFID-U4-US-R

B-EX706-RFID-U4-AU-R

Installing this module enables read and write of

UHF RFID tags.

Note

GS/TS12-CN-R do not support the RFID option I/F.

(Please purchase the GS/TS18-CN-R whenRFID is

needed.)

Expansion I/O interface

card

B-EX700-IO-QM-R Installing this card in the printer allows connection to an

external device with the exclusive interface.

Parallel interface card B-EX700-CEN-QM-R Installing this card provides a Centronics interface port.

Serial interface card B-EX700-RS-QM-R Installing this card provides an RS-232C interface port.

Wireless LAN interface

card

B-EX700-WLAN2-QM-R Installing this card provides Wireless LAN

Communication.

Note:

GS/TS12-CN-R do not support theWLAN option I/F.

(Please purchase the GS/TS16-CN-R when WLAN I/F is

needed.)

NOTE:

To purchase the optional kits, please contact the nearest authorised TOSHIBA TEC representative or

TOSHIBA TEC Head Quarters.

Page 15

2. PRINTER SETUP ENGLISH VERSION

2. PRINTER SETUP

E2- 1

2. PRINTER SETUP

This section outlines the procedures to setup your printer prior to its operation. The section includes precautions,

loading media and ribbon, connecting cables, setting the operating environment of the printer and performing an

online print test.

Reference Procedure Setup Flow

After referring to the Safety Precautions in this

manual, install the printer i

n a safe and stable

location.

Connect a power cord to the power inlet of the

printer, then to an AC outlet.

Load a label stock or tag stock.

Adjust the position of feed gap sensor or black

mark sensor according to the media being used.

If using thermal transfer media then

load the

ribbon.

Connect the printer to a host computer or

network.

Set the printer parameters in the system mode.

Installation

Connecting the power cord

Loading the media

Printer setting

Media sensor position

alignment

Loading the ribbon

Connecting to a host computer

Make a print test from

your operating

environment and check the print result.

Print test

2.1 Installation

2.2 Connecting the Power

Cord

2.3.1 Loading the Media

2.3.1 Loading the Media

2.3.2 Loading the Ribbon

2.4

Connecting the Cables

to Your Printer

2.6 Printer Setting

2.8 Print Test

Automatic threshold setting

Manual threshold setting

If necessary, install the printer driver o

n your

host computer.

2.7 Installing the Printer

Drivers

If the print start posi

tion cannot be detected

properly when pre-printed label are

used, set the

threshold automatically.

If the print start position cannot be detected

properly even after

automatic threshold setting is

performed manually set the threshold.

2.10 Threshold Setting

2.10 Threshold Setting

Turn on the printer power.

Turning the power ON

2.5

Turning the Printer

ON/OFF

Position and Print Tone Fine

adjustment

If necessary, fine adjust the print start position,

cut/strip position, print tone, etc.

2.9 Position and Print Tone

Fine Adjustment

Installing the printer driver

Page 16

2. PRINTER SETUP ENGLISH VERSION

2.1 Installation

E2- 2

2.1 Installation

To insure the best operating environment and to assure the safety of the

operator and equipment, please observe the following precautions.

• Operate the printer on a stable, level surface in a location free from

excessive humidity, high temperature, dust, vibration and direct

sunlight.

• Keep your work environment static free. Static discharge can cause

damage to delicate internal components.

• Make sure the printer is connected to a clean source of AC power and

no other high-voltage devices, that may cause line noise interference,

are connected to the same mains.

• Assure that the printer is connected to the AC mains with a three-

prong power cable that has the proper ground (earth) connection.

• Do not operate the printer with the cover open. Be careful not to

allow fingers or articles of clothing to get caught in any of the

moving parts, especially the optional cutter mechanism.

• For best results, and longer printer life, use only TOSHIBA TEC

recommended media and ribbons.

• Store the media and ribbons in accordance with their specifications.

• This printer mechanism contains high-voltage components; therefore

you should never remove any of the covers of the machine as you

may receive an electrical shock. Additionally, the printer contains

many delicate components that may be damaged if accessed by

unauthorised personnel.

• Clean the outside of the printer with a clean, dry cloth or a clean cloth

slightly dampened with a mild detergent solution.

• Use caution when cleaning the thermal print head as it will become

very hot while printing. Wait until it has had time to cool before

cleaning. Use only the TOSHIBA TEC recommended print head

cleaner to clean the print head.

• Do not turn off the printer power or remove the power plug while the

printer is printing or while the ON LINE lamp is flashing.

Page 17

2. PRINTER SETUP ENGLISH VERSION

2.2 Connecting the Power Cord

E2- 3

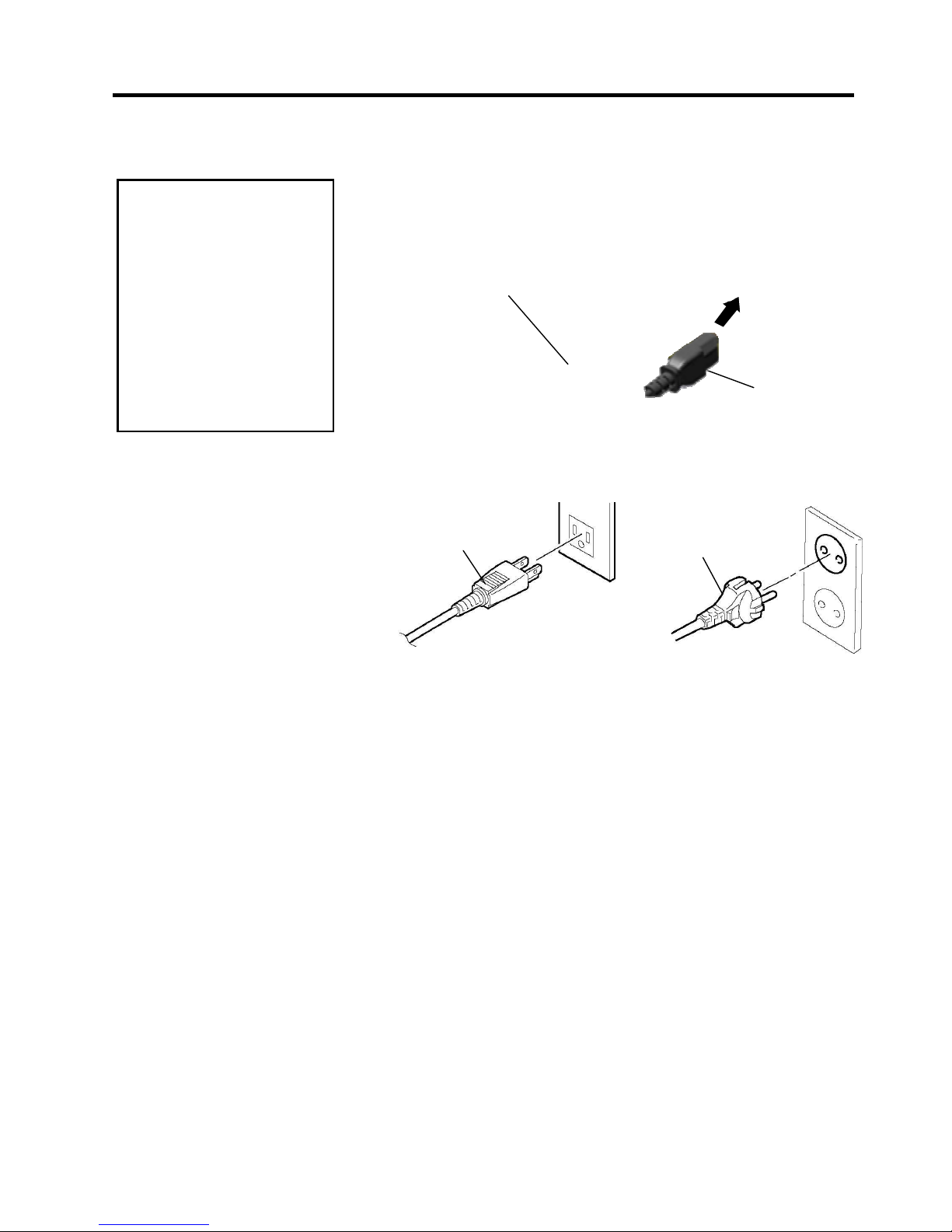

2.2 Connecting the

Power Cord

1. Make sure that the printer Power Switch is in the OFF () position.

Connect the Power Cord to the printer as shown in the figure below.

2.

Plug the other end of the Power Cord into a grounded outlet as shown

in the figure below.

[US Type][EU Type]

CAUTION!

1. Make sure that the printer

Power Switch is turned to

the OFF position ()

before connecting the

Power Cord to prevent

possible electric shock or

damage to the printer.

2. Connect the Power Cord

to a supply outlet with a

properly grounded

(earthed) connection.

Power Cord

Power Switch

Power Cord

Power Cord

Page 18

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2- 4

2.3 Loading Supplies

1. Do not touch any moving parts. To reduce the risk of fingers, jewellery, clothing, etc., being

drawn into the moving parts, be sure to load the media once the printer has stopped moving

completely.

2. The Print Head becomes hot immediately after printing, allow it to cool before loading the media.

3. To avoid injury, be careful not to trap your fingers while opening or closing the cover.

WARNING!

CAUTION!

1. Be careful not to touch the Print Head Elements when lifting the Print Head Block. This may

cause missing dots due to static electricity or other print quality problems.

2. When loading or replacing the media or ribbon, be careful not to damage the print head with hard

objects like watches or rings.

Since the print head element can be easily damaged by shock, please treat it carefully and do not

hit it with hard objects.

Care must be taken not to allow

the metal or glass part of a watch

to touch the print head edge.

Care must be taken not to allow

a metal object like a ring to touch

the print head edge.

Page 19

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-5

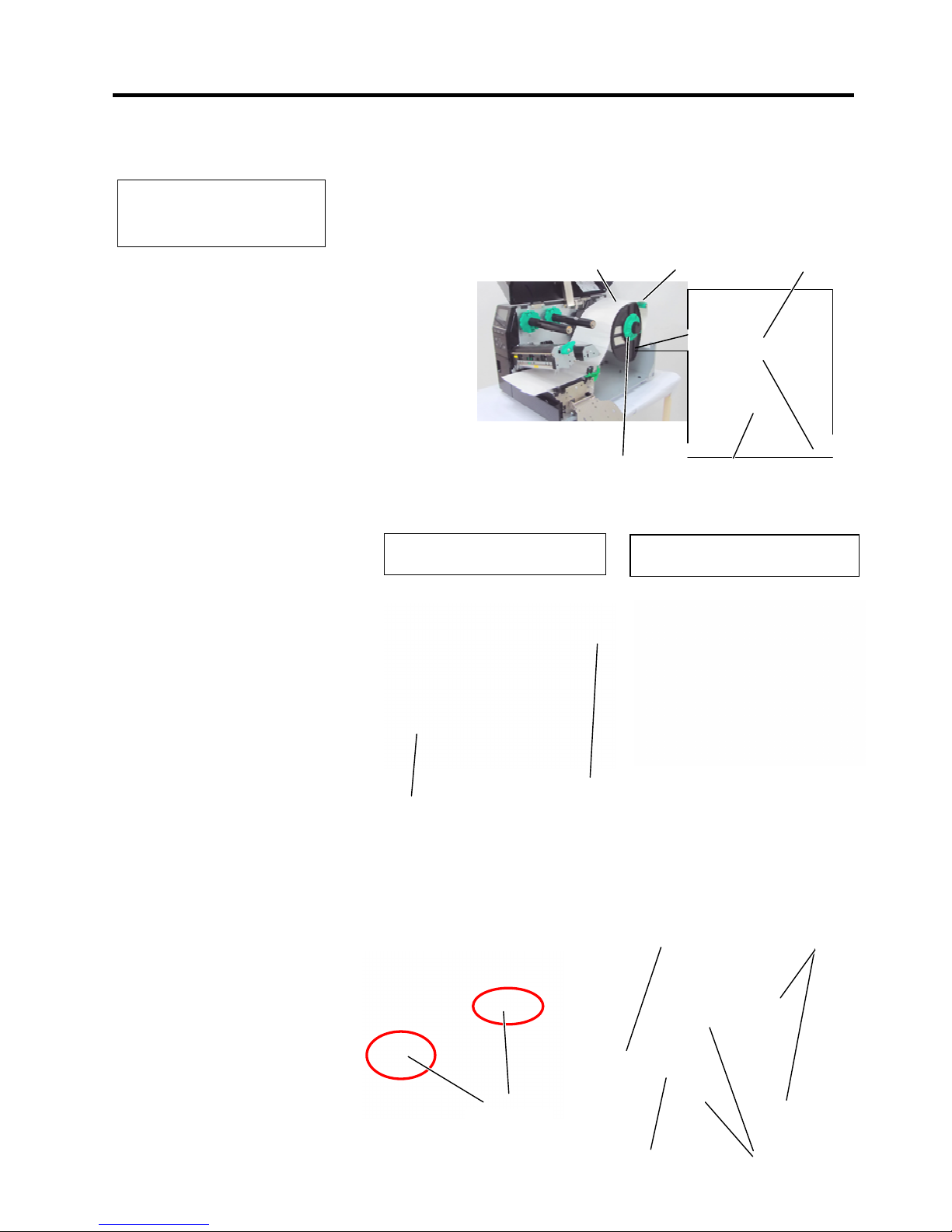

2.3.1 Loading the Media

T

he following procedure shows the steps to properly load the media into

the printer so that it feeds straight through the printer.

The printer prints both labels and tags.

1. Open the Top Cover.

2. Turn the Head Lever to the FREE position and release the Print Head

Block Holder Plate.

3. Open the Print Head Block.

4. Turn the Locking Ring counterclockwise and remove the Supply

Holder from the Supply Shaft.

5. Put the media on the Supply Shaft.

6. Pass the media around the Guide Shaft, then pull the media towards

the front of the printer.

Locking

Supply

Holder

Supply Shaft

NOTES:

1. When the Head Lever is

turned to FREE position, the

Print Head can be raised.

2. Do not turn the Locking Ring

on the supply holder counterclockwise too far or it may

come off the Supply Holder.

Top Cover

Print Head Block

Head

Lever

Print Head Block Holder Plate

Position1

Position2

FREE

Page 20

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-6

2.3.1 Loading the Media

(Cont.)

7. Align the tab of the Supply Holder with the groove in the Supply

Shaft, and push the Supply Holder against the media until the media

is held firmly in place. This will center the media automatically.

Turn the Locking Ring clockwise to secure the Supply Holder.

8. Place the media between the Media Guides and adjust them to the

media width. Once in the correct position tighten the Locking Screw.

9. Check that the media’s path through the printer is straight. The

media should be centered under the Print Head.

NOTE:

Do not over-tighten the Locking

Ring of the Supply Holder.

Supply Holder

Media Guide

Print Head

Paper guide

holder

Media

Guide Shaft

In

the

case of

media which is

inside wound.

In

the

case of

media which is

outside wound.

Tab

Locking Ring

Supply Holder

Guide Shaft

Groove

Supply Shaft

Page 21

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-7

2.3.1 Loading the Media

(Cont.)

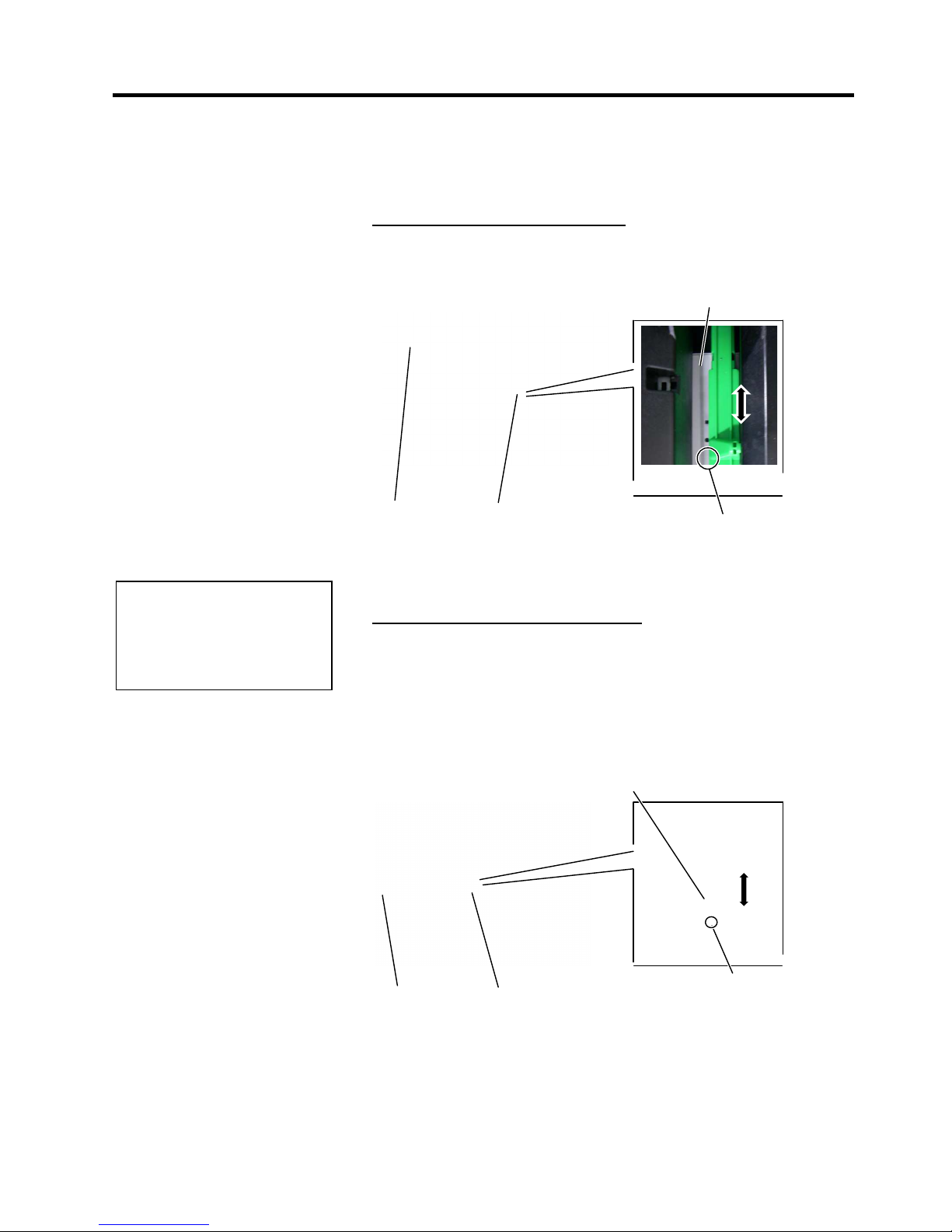

10. Lower the Print Head Block.

11. Once the media is loaded it may be necessary to set the Media

Sensors used to detect the start position for label or tag.

Setting the Feed Gap Sensor position

(1) Manually move the Media Sensor so that the Feed Gap Sensor is

positioned at the centre of the labels. ( indicates the position of the

Feed Gap Sensor).

Setting the Black Mark Sensor position

(1) Pull about 500 mm of media out of the front of the printer, turn the

media back on itself and feed it under the Print Head past the sensor

so that the black mark can be seen from above.

(2) Manually move the Media Sensor so that the Black Mark Sensor is

in line with the center of the black mark on the media. ( indicates

the position of the Black Mark Sensor).

NOTE:

Be sure to set the black mark

sensor to detect the centre of the

black mark, otherwise a paper

jam or no paper error may occur.

Label

Media Sensor

Feed Gap Sensor ()

Gap

Media

Media Sensor

Black Mark Sensor ()

Black Mark

Page 22

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-8

2.3.1 Loading the Media

(Cont.)

12. Batch mode

In batch mode, the media is continuously printed until the number of

labels/tags specified in the issue command has been printed.

13. Loading with peel off module

When the optional Strip Module is fitted, the label is automatically

re

moved from the backing paper at the Strip Plate as each label is

printed.

(1) Remove enough labels from the leading edge of the media to leave

500mm of backing paper free.

(2) Insert the backing paper under the Strip Plate.

(3) Wind the backing paper onto the Take-up Spool and fix it in position

with the Take-up Clip. (Wind the paper counter-clockwise around

the spool.)

(4) Rotate the Take-up Spool counter-clockwise a few times to remove

any slack in the backing paper.

NOTES:

1. Be sure to set the Selection

Switch to STANDARD/

PEEL OFF position.

2. The backing paper is easier

to feed back to the Take-Up

Spool if the Front Plate is

removed.

3. Fit the Take-Up Clip so that

the longer side of the clip is

fitted into the shallow groove

in the Take-Up Spool.

4. The backing paper can be

wound directly onto the

Take-up Spool or a paper

core.

Backing Paper Strip Plate

Take-up Spool

Take-up Clip

Page 23

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-9

2.3.1 Loading the Media

(Cont.)

14. Loading with cutter

When the optional Cutter Module is fitted, the media is

automatically cut. A disc cutter is available as an option.

Insert the leading edge of the media into the cutter until it comes out

the Media Outlet of the Cutter Module.

CAUTION!

1. Be sure to cut the backing

paper of the label. Cutting

labels will cause the glue to

stick to the cutter which

may affect the cutter quality

and shorten the cutter life.

2. Use of tag paper when the

thickness exceeds the

specified value may affect

the cutter life.

Cutter Module

Media Outlet

WARNING!

The cutter is sharp, so care

must be taken not to injure

yourself when handling the

cutter.

Page 24

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-10

2.3.2 Loading the Ribbon

There are two types of media available for printing on: thermal transfer

and direct thermal (which has a chemically treated surface). DO NOT

LOAD a ribbon when using direct thermal media.

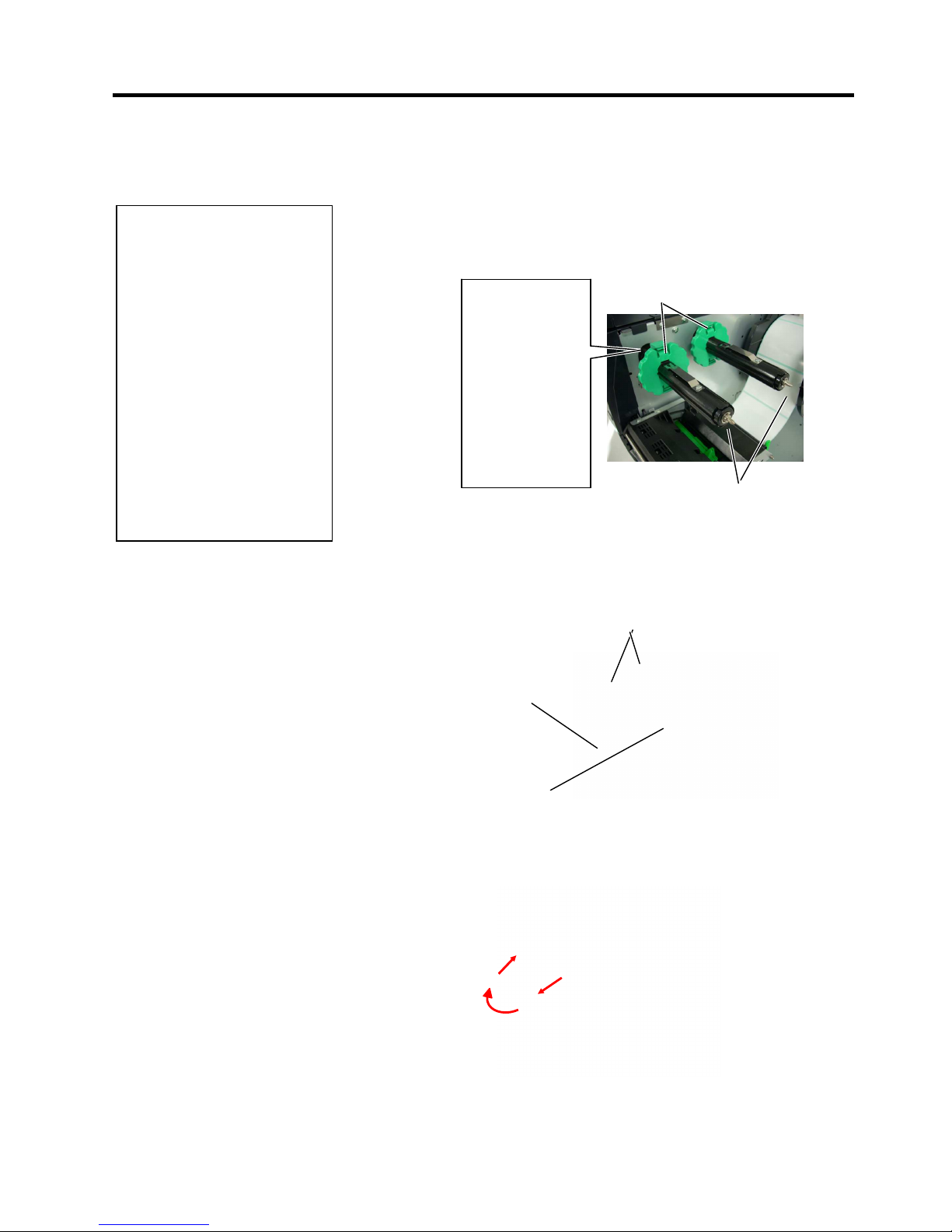

1. Grasp the tabs on the top and bottom of the Ribbon Stoppers and

move them back to the end of the Ribbon Shaft.

2. Leaving plenty of slack between the ribbon spools, place the ribbon

onto the Ribbon Shafts as shown below.

Ribbon path

Ribbon Shaft

Ribbon Take

-

up Roll

Print Head Block

Ribbon Stopper

Ribbon Shaft

NOTES:

1. When attaching the ribbon

stoppers, make sure that the

pinchers face into the printer

2.

Be sure to remove any slack in

the ribbon before printing.

Printing with a wrinkled

ribbon will reduce the print

quality.

3. The Ribbon Sensor is mounted

on the rear of the Print Head

Block to detect a ribbon end.

When a ribbon end is detected

a “NO RIBBON” message

will appear on the display and

the ERROR LED will

illuminate.

Page 25

2. PRINTER SETUP ENGLISH VERSION

2.3 Loading Supplies

E2-11

2.3.2 Loading the Ribbon

(Cont.)

3. Slide the Ribbon Stoppers along the Ribbon Shafts so that the ribbon

will be centered when fitted.

4. Lower the Print Head Block and set the Print Head Block Holder

Plate .

5. Take up any slack in the ribbon. Wind the leading tape onto the

ribbon take-up roll until the ink ribbon can be seen from the front of

the printer.

6. Turn the Head Lever to Lock position to close the Print Head.

7. Close the Top Cover.

Auto Ribbon Saving Mode

B-EX6T1 has a ribbon saving function, it is possible to reduce ribbon

waste by stopping the ribbon feed for non-print areas. To activate the

ribbon save a minimum non-print area is required as below.

203 & 305 dpi models

Print speed 3

ips 5 ips 8 ips 10 ips 12 ips

Min. non-print area 20 20 25 35 60

Print Head Holder

Bl

ock Plate

(mm)

Page 26

2. PRINTER SETUP ENGLISH VERSION

2.4 Connecting the Cables to Your Printer

E2-12

2.4 Connecting the Cables

to Your Printer

The following paragraphs outline how to connect the cables from the

printer to your host computer, and will also show how to make cable

connections to other devices. Depending on the application software

you use to print labels, there are 5 ways to connect the printer to your

host computer. These are:

• An Ethernet connection using the printer’s standard LAN connector.

• A USB cable connection between the printer’s standard USB connector

and your host computer’s USB port. (Conforming to USB 2.0)

• A serial cable connection between the printer’s optional RS-232 serial

connector and one of your host computer’s COM ports.

• A parallel cable connection between the printer’s optional parallel

connector and your host computer’s parallel port (LPT).

• Wireless LAN using an optional Wireless LAN board.

For details, refer to APPENDIX 2.

Reserved for

Parallel

Interface

For GS/TS12 and GS/TS18 models,

reserved for Serial Interface.

For GS/TS16 models, WLAN

Interface

Reserved for

Expansion I/O Interface

USB Interfa

ce

LAN Interface

AC Power Inlet

Page 27

2. PRINTER SETUP ENGLISH VERSION

2.5 Turning the Printer ON/OFF

E2-13

2.5 Turning the Printer

ON/OFF

2.5.1 Turning ON the Printer

2

.5.2 Turning OFF the Printer

W

hen the printer is connected to your host computer it is good practice to

turn the printer ON before turning on your host computer and turn OFF

your host computer before turning off the printer.

1. To turn ON the printer power, press the Power Switch as shown in the

diagram below. Note that ( | ) is the power ON side of the switch.

2

. Check that the ON LINE message appears in the LCD Message

Display and that the ON LINE and POWER LED lights are

illuminated.

1. Before turning off the printer Power Switch verify that the ON LINE

message appears in the LCD Message Display and that the ON LINE

LED light is on and is not flashing.

2. To turn OFF the printer power press the Power Switch as shown in the

diagram below. Note that () is the power OFF side of the switch.

CAUTION!

Use the power switch to turn

the printer On/Off. Plugging

or unplugging the Power Cord

to turn the printer On/Off may

cause fire, an electric shock,

or damage to the printer.

NOTE:

If a message other than ON

LINE appears on the display or

the ERROR LED lamp is

illuminated, refer to Section 5.1,

Error Messages

.

Power Switch

CAUTION!

1. Do not turn off the printer

power while the media is

being printed, as this may

cause a paper jam or

damage to the printer.

2. Do not turn off the printer

power while the ON LINE

lamp is blinking as this

may cause damage to

your computer.

Power Switch

Page 28

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-14

2.6 Printer Setting

2.6.1 SCOPE

This specification describes key operations using the keys and the LCD of the B-EX6T series high-end

industrial bar code printers.

2.6.2 OUTLINE

Key operations are different depending on the printer mode: Online mode in which operations are carried out

t

hrough the keys and error messages are displayed while the printer is connected to the host such as a PC, and

the system mode in which self-diagnosis and setting of various parameters are performed.

This specification describes the key operation procedures with the printer keys and the LCD.

The names of the keys and LCD messages used in this specification are written in English

2.6.3 OPERATION PANEL

Graphic LCD

ERROR LED

PAUSE key

ENTER key

RIGHT key

UP key

RESTART key

ONLINE LED

FEED key

MODE key

CANCEL key

LEFT key

DOWN key

Page 29

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-15

2.6.4 OUTLINE OF EACH MODE

This chapter describes the outline of each mode supported by the printer. Refer to each chapter for detailed

information.

2.6.4.1 ONLINE MODE

This mode is mainly used by users (operators).

The label or tag can be issued in the online mode. When an error occurs, the help function shows the

cause of the error, troubleshooting, and recovery from the error. The threshold setting, described

below, is also a part of the online mode.

2.6.4.1.1 Threshold setting mode

Threshold setting mode is provided to correct a print failure with pre-printed media.

When using pre-print label, print start positions may not be detected correctly with the usual media

sensor threshold, depending on the ink type. Such error can be prevented by setting the threshold just

for the pre-printed media to be used. Since the threshold setting value is stored in the non-volatile

memory, it is unnecessary to set the threshold again as long as the same pre-print media is used.

2.6.4.1.2 RFID calibration mode

In the RFID calibration mode, the distance to the optimum tag write/read position and AGC value

required for properly writing/reading data on/from RFID tags are obtained through a calibration, the

obtained values are set on the printer automatically, and they are reflected in the printer operation.

To write/read data on/from RFID tags with the bar code printer, it was necessary to manually set a

distance to the write/read position and an AGC value, used for detecting the target tag, with @003

command and in the system mode. However, these are automatically done in the RFID calibration

mode.

2.6.4.1.3 Information mode

In the information mode, the total feed amount counted during feeding and printing operations is

displayed on the LCD in units of centimeter and inch.

Printing of the feed amount is performed on request.

2.6.4.2 USER SYSTEM MODE

The user system mode is accessible from the online mode. This mode contains parameters and

settings which might be frequently changed by users (administrator) or service persons.

In addition to the functions of parameter setting and fine adjustment (in common with the System

Mode), there are the following additional features, issue condition display function, manual threshold

setting, and system tools menu .

The values set in thiese modes are stored in the non-volatile memory.

2.6.4.3 SYSTEM MODE

This mode is mainly used by service persons or the production department staff for adjustment of the

printer before shipment. System mode contains settingswhich should not be changed so frequently.

In addition to the parameter setting and fine adjustment menus (in common with the User System

Mode), there are sensor adjustment, interface, RFID, RTC and BASIC setting menus.

Other extended functions are self-diagnosis, test print, RAM clear (re-initialize the printer), preshipment adjustments for factory use, and the menu which enables saving parameter settings, external

characters, TPCL commands to an external USB memory stick or copying data from aUSB memory

stick to the printer. The values set in this mode are stored in the non-volatile memory.

2.6.4.4 DOWNLOAD MODE

This mode is used to download boot and main programs.

2.6.4.4.1 AUTO CONFIGURATION MODE

In this mode, the printer firmware is automatically updated with the program stored in a USB

memory stick.

Page 30

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-16

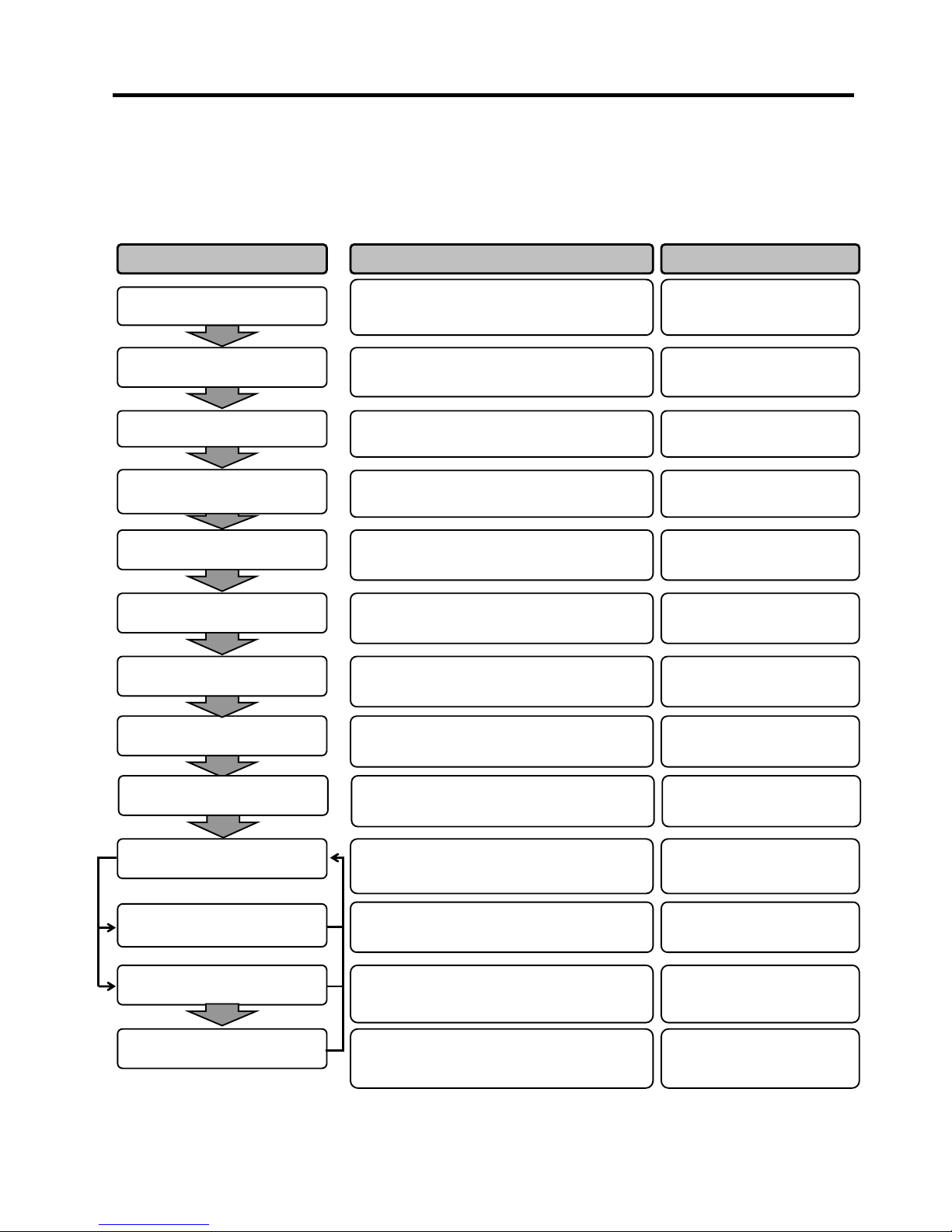

2.6.5 GENERAL VIEW OF KEY OPERATION

[

Power OFF]

[PAUSE] key

[RESTART] key

[FEED] key

Hold down the [PAUSE] key for a

few seconds.

Hold down the [RESTART] or

[MODE] key for a few seconds.

Power on

Threshold setting mode

User system mode

Download mode

System mode

Online mode

Feeds one label.

Pause state

Hold down the [MODE]

key for a few seconds.

Auto configuration mode

Hold down the [ENTER] key for a

few seconds.

RFID calibration mode

Hold down the [UP] key for a few

seconds.

Information mode

Turn the power on while holding down the [FEED] and

[PAUSE] keys at the same time or while holding down the

[MODE] key.

Turn the power on while holding down the [CANCEL]

key.

Turn the power on while holding down the [FEED],

[RESTART] and [PAUSE] keys at the same time.

Hold down the [MODE] and [ENTER]

keys at the same time for a few seconds.

Page 31

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-17

<Example of the screens>

Pause state

Threshold setting mode

RFID calibration mode

Information mode

User system mode

System mode

Download mode

Auto configuration mode

Notes:

1. To enter the download mode, system mode or auto configuration mode, keep holding down the specified key

until the menu is displayed.

2. Power off

When the power of the printer is turned off, the ONLINE and ERROR LEDs synchronously flash at a 500-ms

interval (ON: 250ms, OFF: 250ms). When the LEDs are unlit, the printer power turns off.

The printer power should not be turned on again while these LEDs are flashing. Otherwise, a “SYSTEM

ERROR 02 POWER FAILURE” message will be displayed, and the LCD message may corrupt before the

error message is displayed.

Page 32

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-18

2.6.6 Initial Setting Wizard

THE first time the printer is used after opening carton box or after a RAM clear, the initial setting wizard

will start when the power is switched on. This wizard enables setting basic parameters, such as the LCD

language and print mode. The values set with this wizard can be changed in the system mode and also by

command.

Example of the Initial Setting Wizard Operation

RAM clear with QM type

selected

1. Perform a RAM clear.

QM TYPE

CLEAR...

↓

QM TYPE

COMPLETED

Turn off the pr inter

↓ Power OFF/ON

B-EX Series

Initializing...

↓

2.The initial setting wizard

starts.

STARTUP SETTINGS

PRESS ENTER

↓ [ENTER] key

3. Select a language.

LANGUAGE ENGLISH

▲

ENGLISH

G

ERMAN

▼

Select ENTER:Set

FRENCH

Choose the desired option

with the [UP] or [DOWN] key

and press ENTER to set.

↓ [ENTER] key

4. Print mode

PRINT MODE w/ RIBBON

▲

With RIBBON

Without RIBBON

▼

Select ENTER:Set

Choose the desiredoption

with the [UP] or [DOWN] key

and press ENTER to set.

↓ [ENTER] key

5. Select a calibration type.

CALIBRATE OFF

▲

OFF

LABEL/GAP

▼

Select ENTER:Set

BLACK MARK

Choose the desired option

with the [UP] or [DOWN] key

and press ENTER to set.

6.-1 When an option other than “OFF” is selected for CALIBRATE

Page 33

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-19

6.-1-1

Finish

INITIAL CONFIGURATION

FINISH?

◀Prev ENTER:Finish

Press ENTER to finish.

↓ [ENTER] key.

7. The settings are saved.

6.-2 When “OFF” is selected for CALIBRATE

6.-2-1

Media detection

PAPER DETECT FEED/GAP

▲

CONTINUOUS

LABEL/GAP

▼

Select ENTER:Set

BLACK MARK

Choose the desired option

with the [UP] or [DOWN] key

and press ENTER to set.

↓ [ENTER] key

6.-2-2

Media length

PAPER LENGTH 76mm

Select ENTER:Set

76 mm

(1

0 - 1500mm)

Set thepaper length with the

[UP] or [DOWN] key and

press ENTER to set.

↓ [ENTER] key

6.-2-3

Finish

INITIAL CONFIGURATION

FINISH?

◀Prev ENTER:Finish

Press ENTER to finish.

↓ [ENTER] key.

7. The settings are saved.

7. The settings are saved.

SAVING SETTING...

↓

8.DHCP client is initialized.

DHCP CLIENT INIT...

↓

9. Online mode

B-EX4T1-G C1.6

PRINTED 000000

IP:192.168.010.020

ONLINE

Page 34

2. PRINTER SETUP ENGLISH VERSION

2.6 Printer Stting

E2-20

Key functions (Wizard screen)

Key Substitute key Function

[MODE] None Returns to the top page without saving the changes.

[CANCEL] [FEED] + [RESTART] Returns to the upper level menu without saving the changes.

[ENTER] [PAUSE] In the case of option selection screen, saves the changes and

displays the next screen.

[UP] [RESTART] Moves the cursor upward. When the cursor is positioned at the

top of the list, it scrolls from the top to the bottom.

[DOWN] [FEED] Moves the cursor downward. When the cursor is positioned at

the bottom of the list, it scrolls from the bottom to the top.

[LEFT] None Displays the next screen without saving the changes.

[RIGHT] None Displays the upper-level screen without saving the changes.

Page 35

2. PRINTER SETUP ENGLISH VERSION

2.7 Printer Driver

E2-21

2.7 Printer Drivers

Once you install the TOSHIBA printer driver on your Windows host computer, you can use the TOSHIBA

bar code printer in the same way you would a laser or ink jet printer.

You can use the printer by connecting a USB or LAN cable to your host computer.

The installation procedure of the printer driver differs depending on the printer model and the connection

method.

The Printer driver and installation manual can be downloaded from the Toshiba TEC Web-site

http://www.toshibatec-ris.com/products/barcode/download/driver_agreement.html

If an older version of the printer driver has been already installed, you must uninstall it and restart the

computer before installing a newer version.

Page 36

2.PRINTER SETUP ENGLISH VERSION

2.8 Print test

E2-23

2.8 Print Test

After your drivers have been installed , perform a print test.

Performing a print test using the Printer Driver

The printer driver’s Properties screen allows you to set the

communication conditions, media size, and other printing conditions

in accordance with your operating environment. For details, refer to

the Help for the Windows Printer Drivers screen.

Example: Stock tab display of the Printer Driver’s Properties Screen

Print Method: Direct thermal or thermal transfer is selectable.

Sensor: Media sensor type is selectable.

Issue Mode: Batch, strip or cut is selectable.

Post-print Action:

Whether to use the cutter or not is selectable.

Fine Adjustment: Adjustment values for the feed amount, cut/strip

position, etc. can be set.

Print Method

Sensor

Issue

Mode

Post-print Action

(Cut)

Print Speed

Label Gap

Fine Adjustment

B-EX6T

Page 37

3. ONLINE MODE ENGLISH VERSION

3.1 Key Functions

E3- 1

3. ONLINE MODE

3.1 Key Functions

This chapter describes the usage of the keys on the Operation Panel in

Online mode.

When the printer is in Online mode and connected to a host computer, the

normal operation of printing on labels or tags can be accomplished.

Key functions in the online mode

Key Function

[FEED] (1) Feeds the set media length.

(2) Prints the data in the image buffer according to

the system mode setting.

(3) Clears the help message.

[RESTART] (1) Resumes printing after a temporary pause in

printing or after an error.

(2) Places the printer in the initial state which is

obtained when the power is turned on.

(3) Places the printer in the user system mode.

(4) Clears the help message.

[PAUSE] (1) Stops printing temporarily.

(2) Programs the threshold values.

(3) Clears the help message.

[MODE] (1) Places the printer in the user system mode.

(2) Clears the help message.

[CANCEL] (1) Clears the job.

(2) Displays previous help message page.

[ENTER] (1) Displays next help message page.

(2) Clears the help message.

[UP] (1) Scrolls up

[DOWN] (1) Scrolls down

[LEFT] (1) Displays previous help message page.

[RIGHT] (1) Displays next help message page.

Page 38

3. ONLINE MODE ENGLISH VERSION EO1-33089

3.2 LCD

E3- 2

3.2 LCD

Online state

Error state

(Example: Head open error)

No.

Description

(1) Model name and firmware version

(2) Message

(3) The number of labels printed

(4) IP address (only when LAN/WLAN is enabled.)

(5) Radio signal strength (only when WLAN is enabled.)

Indicates the strength of the radio signal in 4 levels.

(6) WLAN connection (only when WLAN is enabled.)

Ԃ Lights up when connecting to an access point.

Ԃ Flashes while roaming.

Ԃ Goes off when disconnected.

(7) Presence of a print job

Appears when a print job exists.

(8) RFID (only when RFID module is installed.)

Ԃ Appears when a communication between the printer and the

RFID module is enabled.

Ԃ Flashes while communicating with the RFID module.

(9) Ribbon near end

Flashes when a ribbon near end state is detected.

(10) The number of remaining labels to print

(11) Error description and solution

(12) Help guide

Appears when a help guide message is provided. Press the

[RIGHT] key to see the help guide message.

(1)

(2)

(3)

(4)

(5) (6) (8)

(7) (9)

(10)

(12)

(11)

Page 39

3. ONLINE MODE ENGLISH VERSION EO1-33089

3.3 Icon

E3- 3

3.3 Icon

Five kinds of icon are displayed in the bottom line of the online mode screen.

These icons are displayed only in the online mode screen.

Icon Explanation

Wireless LAN icon Displayed and used when the wireless LAN module is installed.

The graph shows the radio field strength.

Graph 0: Outside of communication range

Graph 1: Radio field strength is weak.

Graph 2: Radio field strength is middle.

Graph 3: Radio field strength is strong.

Link icon Displayed and used when the wireless LAN module is installed.

Displayed while the printer is communicating by wireless LAN.

Flashes while roaming.

OFF: No connection

ON: Connecting to an access point

Flashing: Roaming (*1)

Data transmission icon Appears when a print job is present.

ON: Print job is present.

RFID icon Displayed and used when the RFID module is installed.

Appears when the RFID module type has been set and a

communication between the printer and the RFID module is enabled.

Flashes while communications and operating sequence are made with

the RFID module.

-

ON: Module type has been set and the printer is ready to

communicate with the RFID module.

⇔

Flashing: Communicating

Ribbon near end icon Ribbon near end is detected.

Flashes when the ribbon is close to the end.

Ribbon near end is detected depending on the diameter of unused

ribbon. ∅38 mm is equivalent to 30-meter ribbon and ∅43 mm is

equivalent to 70-meter ribbon.

Flashing: Ribbon near end state (*1)

(*1) The icon flashes at a 1-second interval (ON: 500 msec., OFF: 500 msec.)

Page 40

3. ONLINE MODE ENGLISH VERSION

3.4 Operation Example

E3- 4

3.4 Operation Example

Online Mode

Idling or normal issuing

Printing is stopped.

Help guide is displayed.

Help guide message for head open

Printing is stopped and

Help guide is displayed.

Help guide message for no paper

If the print head is

opened during idling:

If an error occurs

while printing:

When [PAUSE] key is

pressed while printing:

When [RESTART] key is pressed,

the printer resumes printing if there

is remaining data.

Close the print head.

Load media.

When [RESTART] key is pressed, the

printer resumes printing if there is

remaining data.

Press [RIGHT]

key

Press [RIGHT] key

Page 41

3. ONLINE MODE ENGLISH VERSION

3.4 Operation Example

E3- 5

3.4 Operation Example (Cont.)

Help Guide Message

Idling or normal issuing

Printing is stopped and

Help guide is displayed.

Cause of the error

Troubleshooting

How to restore to online

If an error occurs

while

printing

:

Load media.

When [RESTART] key is pressed, the

printer resumes printing if there is

remaining data.

[RIGHT] or [ENTER]

[RIGHT] or

[ENTER]

[RIGHT] or

[ENTER]

[LEFT] or

[CANCEL]

[LEFT] or

[CANCEL]

[RIGHT] or

[ENTER]

Page 42

3. ONLINE MODE ENGLISH VERSION

3.4 Operation Example

E3- 6

3.4 Operation Example (Cont.)

Cancellation of Print Job

Idling or normal issuing

If an error occurs while

printing:

When [PAUSE] key is

pressed while printing:

Hold down [CANCEL] for 3 sec. or more.

Hold down [CANCEL] for 3 sec. or more.

While [CANCEL] is held down, the received data is discarded.

(Quick reset)

Page 43

3. ONLINE MODE ENGLISH VERSION

3.5 User System Mode

E3- 7

3.5 USER SYSTEM MODE

3.5.1 OUTLINE OF USER SYSTEM MODE

1. The printer enters the user system mode with the following operations.

While the printer is in pause state, perform either of the following operations:

・ Hold down the [RESTART] key for 3 sec. or more.

・ Hold down the [MODE] key for 3 sec. or more.

While the printer is in online, perform the following operation:

・ Hold down the [MODE] key for 3 sec. or more.

2. The user system mode is intended for performing parameter and other settings.

3. The key operations for the user system mode are described below.

For the key functions and display, please refer B-EX6T key operation manual.

Display

USER SYSTEM MODE C1.6

▲

<2>SET PARAMETERS

<4>SYSTEM TOOLS

▼

<1>EXIT

<3>DETECTION LEVEL

Top menu list

Outline of the top menu

<1>EXIT

Used to return the printer to online state. (The printer is not reset.)

<2>SET PARAMETERS

Used to set the parameters for each printer function.

<3>DETECTION LEVEL

Used to set the threshold value.

<4>SYSTEM TOOLS

Used to print data sent from the host or store it in USB memory.

<5>SHOW ISSUE CONDITION

Used to display the print conditions (such as sensor type, print speed and

orientation).

<6>RESET

Used to reset the printer.

3.5.2 EXIT

The printer is returned from the user system mode to the online mode. (No reset is performed.)

S

ome parameter settings are reset when the Exit is performed. The parameters to be reset are indicated with

“Reset Req.”. Other parameters are not reset

Page 44

3. ONLINE MODE ENGLISH VERSION

3.6 Power Save Function

E3- 8

3.6 Power Save Function

3.6.1 Entering the Power

Saving Mode

3.6.2 Exiting the Power

Saving Mode

When the printer stays in any of the following statuses for the

specified length of time, it enters power saving mode.

• Online (Idle, communicating)

• Pause

• Error

• Waiting for label to be removed

• System mode (except for self-diagnosis, test print, sensor

adjustment)

• User system mode (except for dump)

• Pause state of the expansion I/O

When the printer enters the power saving mode, “POWER SAVING

MODE” is displayed on the LCD and the backlight goes off.

When the following occurs in the power saving mode, the LCD wakes

up.

• A key is pressed. (Except for [RESTART] or [FEED] key

which causes printing or paper feed.)

• The head lever is released and locked.

• The status of the pause or active signal of the expansion I/O

changes.

The LCD shows “POWER SAVING MODE” and the backlight goes

off again if no status change occurs on the printer for 15

minutes.

The printer exits the power saving mode when:

• Printing (printing caused by a depression of the [RESTART]

key is included.) is performed.

• paper feed or re-print s caused by a depression of the [FEED]

key

• printing or paper feed is initiated through the expansion I/O

• automatic calibration is performed

• sensor adjustment is performed in the system mode

• the printer receives commands (U1/U2, T, XS, IB, or RFID-

related commands).

Page 45

4. MAINTENANCE ENGLISH VERSION

4.1 Cleaning

E4- 1

4. MAINTENANCE

4.

1 Cleaning

4.1.1 Print Head/Platen/

Sensors

This chapter describes how to perform routine maintenance.

T

o ensure the continuous high quality operation of the printer, you should

perform a regular maintenance routine. For high usage it should be done

on a daily basis. For low usage it should be done on a weekly basis.

T

o maintain the printer performance and print quality, please clean the

printer regularly, or whenever the media or ribbon is replaced.

1.

Turn off the power and unplug the printer.

2. Open the Top Cover.

3. Turn the Head Lever to the “FREE” position, and then release the

Print Head Block Holder Plate.

4. Open the Print Head Block.

5. Remove the ribbon and media.

CAUTION!

When cleaning the print head, be careful not to damage the print head

with hard objects like watches or rings.

Since the print head element can be easily damaged by shock, please

treat it carefully and do not hit it with hard objects.

WARNING!

1. Be sure to disconnect the

power cord before

performing maintenance.

Failure to do this may

cause an electric shock.

2. To avoid injury, be careful

not to pinch your fingers

while opening or closing

the cover and print head

block.

3. The print head becomes

hot immediately after

printing. Allow it to cool

before performing any

maintenance.

4. Do not pour water directly

o

nto the printer.

CAUTION!

1. Do not use any volatile

solvent including thinner

and benzene, as this may

cause discoloration to the

cover, print failure, or

breakdown of the printer.

2. Do not touch the Print

Head Element with bare

hands, as static may

damage the Print Head.

Care must be taken not to allow

the metal or glass part of a watch

to touch the print head edge.

Care must be taken not to allow a

metal object like a ring to touch

the print head edge.

Page 46

4. MAINTENANCE ENGLISH VERSION

4.1 Cleaning

E4- 2

4.1.1 Print Head/Platen/

Sensors (Cont.)

4.1.2 Covers and Panels

6. Clean the Print Head Element with a Print Head Cleaner or a cotton

swab or soft cloth slightly moistened with alcohol.

7. Wipe the Platen, Feed Roller, and Pinch Roller with a soft cloth slightly

moistened with alcohol. Remove dust or foreign substances from the

internal parts of the printer.

8. W

ipe the Feed Gap Sensor and Black Mark Sensor with a dry soft

cloth.

Wipe the covers and panels with a dry soft cloth or a cloth slightly

moistened with a mild detergent solution.

CAUTION!

1. DO NOT POUR WATER

directly onto the printer.

2. DO NOT APPLY cleaner

or detergent directly onto

any cover or panel.

3. NEVER USE THINNER

OR OTHER VOLATILE

SOLVENT on the plastic

covers.

4. DO NOT clean the panel,

covers, or the supply

window with alcohol as it

may cause them to

discolour, lose their shape

or develop structural

weakness.

NOTE:

Please purchase the Print

Head Cleaner from your

authorised TOSHIBA TEC

service representative.

Print Head

Print Head

Element

Platen

Black Mark Sensor/

Feed Gap Sensor

Feed Roller

Pinch Roller

Page 47

4. MAINTENANCE ENGLISH VERSION

4.1 Cleaning

E4- 3

4.1.3 Optional Cutter Module

T

he disc cutter is available as an option.

1. Turn off the power and open the Top Cover.

2. Turn the Head Lever to Free position, then release the Print Head

Block Holder Plate

3. Open the Print Head Block.

4. Unscrew the Plastic Head Screw so that the Cutter Unit will open

5. Clean the Cutter with a soft cloth slightly moistened with alcohol.

6. Attach the Cutter Cover.

WARNING!

1. Be sure to turn the power

off before cleaning the

Cutter Module.

2. As the cutter blade is

sharp, care should be

taken not to injure

yourself while cleaning.

Print Head block Holder

Plate

Head Lever

Top Cover

Plastic Head Screw

Cutter

Cutter Unit

Page 48

5. TROUBLESHOOTING ENGLISH VERSION

5.1 Error Messages

E5- 1

5. TROUBLESHOOTING

This chapter lists the error messages, possible problems, and their solutions.

5

.1 Error Messages

Error Messages

Problems/Causes

Solutions

HEAD OPEN The Print Head Block is opened in

Online mode.

Close the Print Head Block.

Feeding or printing has been attempted

with the Print Head Block open.

Close the Print Head Block. Then press

the [RESTART] key.

COMMS ERROR A communication error has occurred. Make sure the interface cable is correctly

connected to the printer and the host and

the host is turned on.

PAPER JAM

1. The media is jammed in the media

path. The media is not fed smoothly.

1. Remove the jammed media, and clean

the Platen. Reload the media

correctly. Press the [RESTART] key.

⇒ Section 5.3.

2. The media is not loaded properly.

2. Reload the media correctly. Then

press the [RESTART] key.

⇒ Section 2.3.

3. Wrong Media Sensor is selected for

the media being used.

3. Turn the printer off and then on.

Select the Media Sensor for the media

type being used. Resend the print job.

4. The Black Mark Sensor is not

correctly aligned with the Black

Mark on the media.

4. Adjust the sensor position, then press

the [RESTART] key.

⇒ Section 2.3.1.

5. Size of the loaded media is different

from the programmed size.

5. Replace the loaded media with one

that matches the programmed size,

press the [RESTART] key, or turn the

printer off and then on, select a

programmed size that matches the

loaded media. Resend the print job.

6. Media sensor has not been properly

calibrated for the media being used.

6. Refer to Section 2.10 to set the

threshold. If this does not solve the

problem, turn off the printer, and call a

TOSHIBA TEC authorised service

representative.

NOTES:

• If an error is not cleared by pressing the [RESTART] key, turn the printer off and then on.

• After the printer is turned off, all print data in the printer is cleared.

WARNING!

If a problem cannot be solved by taking the actions described in this chapter, do not attempt to repair the

printer. Turn off and unplug the printer, then contact an author TOSHIBA TEC service representative for

assistance.

Page 49

5. TROUBLESHOOTING ENGLISH VERSION

5.1 Error Messages

E5- 2

5.1 Error Messages (Cont.)

Error Messages

Problems/Cause

Solutions

CUTTER ERROR

(Only when the cutter

module is installed on

the printer.)

1. The media is jammed in the cutter. 1. Remove the jammed media. Press the

[RESTART] key. If this does not

solve the problem, turn off the printer,

and call a TOSHIBA TEC authorised

service representative.

⇒ Section 4.1.3.

2. The Cutter Cover is not attached

properly.

2. Attach the Cutter Cover properly.