Toshiba B-EX4T2 SERIES, B-EX4T2-GS12-QMR, B-EX4T2-GS12-CN-R, B-EX4T2-TS12-QMR, B-EX4T2-TS12-CN-R Owner's Manual

...Page 1

TOSHIBA Barcode Printer

B-EX4T2 SERIES

Owner’s Manual

Mode d’emploi

Bedienungsanleitung

Manual de instrucciones

Gebruikershandleiding

Manuale Utente

Manual do Utilizador

Page 2

TOSHIBA Barcode Printer

B-EX4T2 SERIES

Owner's Manual

Page 3

Copyright © 2012

by TOSHIBA TEC CORPORATION

All Rights Reserved

6-78 Minami-cho, Mishima-shi, Shizuoka-ken, JAPAN

< For EU Only >

TOSHIBA TEC Europe Retail Information Systems S.A.

Rue de la Célidée 33 BE-1080 Brussels

CE Compliance (for EU only)

This product complies with the requirements of EMC and Low Voltage Directives including their

amendments.

VORSICHT:

• Schallemission: unter 70dB (A) nach DIN 45635 (oder ISO 7779)

• Die für das Gerät Vorgesehene Steckdose muß in der Nähe des Gerätes und leicht zugänglich sein.

Centronics is a registered trademark of Centronics Data Computer Corp.

Microsoft is a registered trademark of Microsoft Corporation.

Windows is a trademark of Microsoft Corporation.

This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and set in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operations of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

(for USA only)

Changes or modifications not expressly approved by the manufacturer for compliance could void the

user’s authority to operate the equipment.

N258

“This Class A digital apparatus meets all requirements of the Canadian Interference-Causing

Equipment Regulations.”

“Cet appareil numérique de la classe A respecte toutes les exigences du Règlement sur le matériel

brouilleur du Canada.”

(for CANADA only)

IP20

Page 4

Waste Recycling information for users:

Following information is only for EU-member states:

The use of the crossed-out wheeled bin symbol indicates that this product

may not be treated as general household waste.

By ensuring this product is disposed of correctly you will help prevent

potential negative consequences for the environment and human health, which could

otherwise be caused by inappropriate waste handling of this product. For more detailed

information about the take-back and recycling of this product, please contact your supplier

where you purchased the product.

Page 5

Precautions for the handling of Wireless Communication Devices

Wireless LAN Module: SD-Link 11g

RFID Module: TEC-RFID-EU1 (B-EX700-RFID-H1-QM-R)

For Europe

This device was tested and certified by Notified Body.

Hereby, Toshiba TEC Corporation declares that this device is in compliance with the essential requirements and

other relevant provisions of Directive 1999/5/EC.

This equipment uses the radio frequency band which has not been standardised throughout the EU and EFTA

countries. It can be used in the following countries.

Austria, Belgium, Bulgaria, Cyprus, Czech Republic, Denmark, Estonia, Finland, France, Hungary, Germany,

Greece, Ireland, Italy, Latvia, Lithuania, Luxembourg, Malta, Netherlands, Poland, Portugal, Romania, Slovakia,

Slovenia, Spain, Sweden, United Kingdom, Norway, Liechtenstein, Iceland, Switzerland

For USA

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) This device must accept any interference received, including interference that may cause undesired

operation.

Changes or modification not expressly approved by manufacturer for compliance could void the user’s authority

to operate the equipment.

For Canada

Operation is subject to the following two conditions:

(1) This device may not cause interference, and

(2) This device must accept any interference, including interference that may cause undesired operation of the

device.

For Taiwan

Caution

根據低功率電波輻射性電機管理辦法

For safety

Do not operate this product in locations where its use may be prohibited. For example, in an aeroplane or

hospital. If you are unsure whether operation is permitted, please refer to and follow the airline company or

medical institution guidelines.

Otherwise, flight instrument or medical equipment may be affected, causing a serious accident.

This product may affect the operation of some implanted cardiac pacemakers and other medically implanted

equipment. Pacemaker patients should be aware that the use of this product in close proximity to a pacemaker

might cause the device to malfunction.

If you have any reason to suspect that interference is taking place, immediately turn off the product and contact

your TOSHIBA TEC sales agent.

Do not disassemble, modify, or repair the product as doing so may cause injury.

Modification is also against the Laws and Regulations for Radio Equipment. Please ask your TOSHIBA TEC

sales agent for repair.

Page 6

Safety Summary ENGLISH VERSION EO1-33094

( )

i

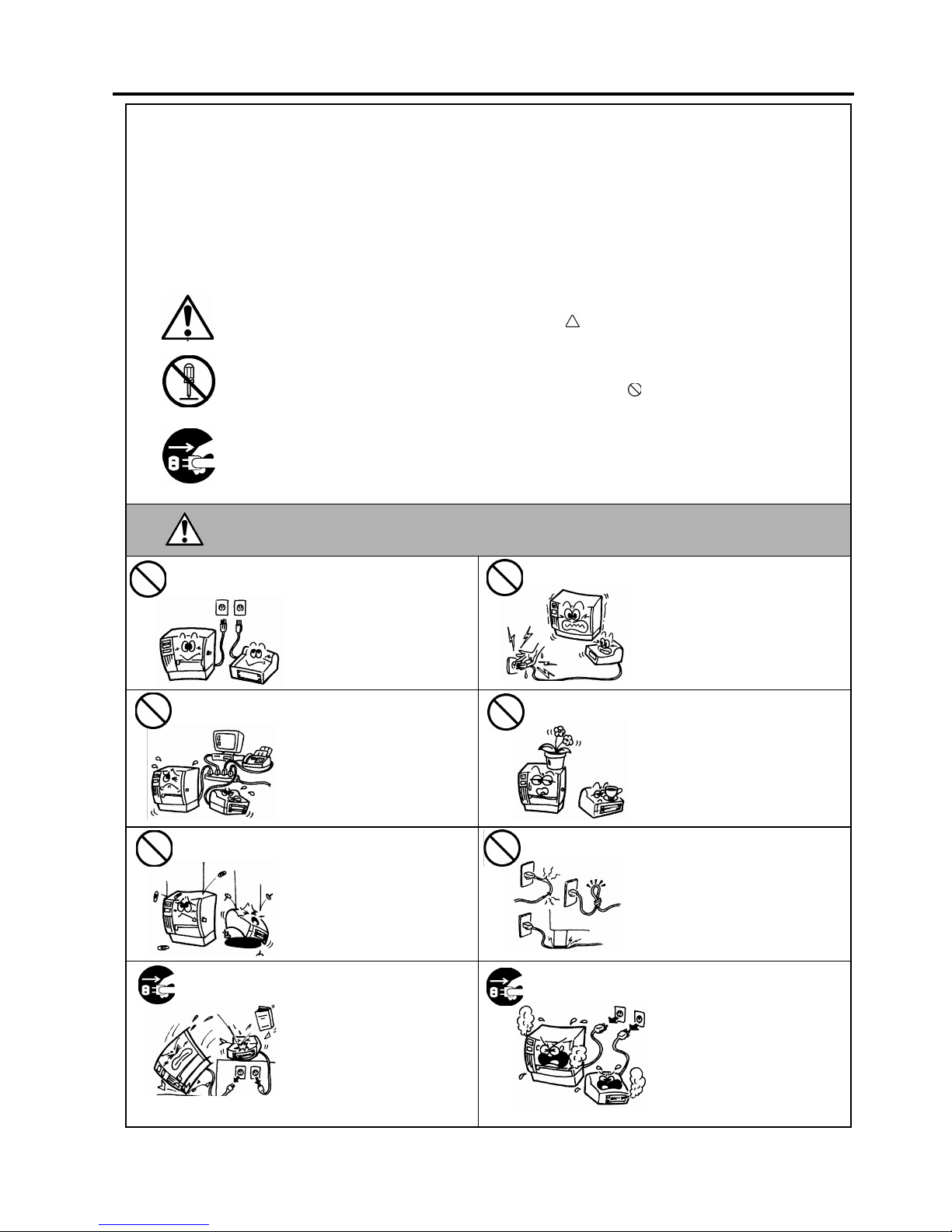

Safety Summary

Personal safety in handling or maintaining the equipment is extremely important. Warnings and Cautions

necessary for safe handling are included in this manual. All warnings and cautions contained in this manual

should be read and understood before handling or maintaining the equipment.

Do not attempt to effect repairs or modifications to this equipment. If a fault occurs that cannot be rectified

using the procedures described in this manual, turn off the power, unplug the machine, and then contact your

authorised TOSHIBA TEC representative for assistance.

Meanings of Each Symbol

This symbol indicates warning items (including cautions).

Specific warning contents are drawn inside the

symbol.

(The symbol on the left indicates a general caution.)

This symbol indicates prohibited actions (prohibited items).

Specific prohibited contents are drawn inside or near the

symbol.

(The symbol on the left indicates “no disassembling”.)

This symbol indicates actions which must be performed.

Specific instructions are drawn inside or near the symbol.

(The symbol on the left indicates “disconnect the power cord plug from the outlet”.)

This indicates that there is the risk of death or serious injury if the

machine is improperly handled contrary to this indication.

Do not use voltages other than

the AC voltage specified on the

rating plate, as this may cause

fire or electric shock.

Do not plug in or unplug the power

cord with wet hands as this may

cause electric shock.

If the machine shares the same

electrical outlet, with any other

appliance that consumes a large

amount of power, the voltage will

fluctuate widely each time these

appliances operate. Be sure to

provide an exclusive outlet for

the machine as this may cause

fire or electric shock.

Do not place metal objects or

water-filled containers (flower

vases, flower pots or mugs etc) on

top of the machine. If metal

objects or spilled liquids enter the

machine, this may cause fire or

electric shock.

Do not insert or drop metal,

flammable or other foreign

objects into the machine through

ventilation slits, as this may

cause fire or electric shock.

Do not scratch, damage or modify

the power cords. Do not place

heavy objects on, pull on, or

excessively bend the power cords,

as this may cause fire or electrical

shock.

If the machine is dropped or the

cabinet is damaged, turn off the

power switch and disconnect the

power cord plug from the outlet,

and then contact your authorised

TOSHIBA TEC representative

for assistance. Continued use of

a damaged machine may cause

fire or electric shock.

Continued use of the machine in an

abnormal condition (the machine is

producing smoke or a strange

smell) may cause fire or electric

shock. In these cases, immediately

turn off the power switch and

disconnect the power cord plug

from the outlet. Then, contact your

authorised TOSHIBA TEC

representative for assistance.

W

ARNING

Use only specified

AC voltage.

Prohibited

Prohibited

Prohibited

Prohibited

Prohibited

Disconnect

the plug.

Disconnect

the plug.

Page 7

Safety Summary ENGLISH VERSION EO1-33094

( )

ii

If foreign objects (metal

fragments, water, liquids) enter

the machine, turn off the power

switch and disconnect the power

cord plug from the outlet, and

then contact your authorised

TOSHIBA TEC representative

for assistance. Continued use of

the machine in that condition may

cause fire or electric shock.

When unplugging the power cords,

be sure to hold and pull on the plug.

Pulling on the cord may cut or

expose the internal wires and cause

fire or electric shock.

Ensure that the equipment is

properly grounded. Extension

cables should also be grounded.

Fire or electric shock could

occur on improperly grounded

equipment.

Do not remove covers, repair or

modify the machine yourself.

Contact your TOSHIBA TEC

representative for assistance. You

may be injured by high voltage,

very hot parts or sharp edges inside

the machine.

Do not use a spray cleaner

containing flammable gas for

cleaning this product, as this may

cause a fire.

Care must be taken not to injure

yourself with the printer paper

cutter.

This indicates that there is the risk of personal Injury or damage to

objects if the machine is improperly handled contrary to this indication.

Precautions

The following precautions will help to ensure that this machine will continue to function correctly.

• Try to avoid locations that have the following adverse conditions:

* Temperatures out of the specification * Direct sunlight * High humidity

* Shared power source * Excessive vibration * Dust/Gas

• The cover should be cleaned by wiping with a dry cloth or a cloth slightly dampened with a mild detergent solution. NEVER

USE THINNER OR ANY OTHER VOLATILE SOLVENT on the plastic covers.

• USE ONLY TOSHIBA TEC SPECIFIED paper and ribbons.

• DO NOT STORE the paper or ribbons where they might be exposed to direct sunlight, high temperatures, high humidity, dust,

or gas.

• Ensure the printer is operated on a level surface.

• Any data stored in the memory of the printer could be lost during a printer fault.

• Try to avoid using this equipment on the same power supply as high voltage equipment or equipment likely to cause mains

interference.

• Unplug the machine whenever you are working inside it or cleaning it.

• Keep your work environment static free.

• Do not place heavy objects on top of the machine, as these items may become unbalanced and fall causing injury.

• Do not block the ventilation slits of the machine, as this will cause heat to build up inside the machine and may cause fire.

• Do not lean against the machine. It may fall on you and could cause injury.

• Unplug the machine when it is not used for a long period of time.

• Place the machine on a stable and level surface.

Request Regarding Maintenance

• Utilise our maintenance services.

After purchasing the machine, contact your authorised TOSHIBA TEC representative for assistance once a year to have the

inside of the machine cleaned. Dust will build up inside the machines and may cause a fire or a malfunction. Cleaning is

particularly effective before humid rainy seasons.

• Our preventive maintenance service performs periodic checks and other work required to maintain the quality and performance

of the machine.

For details, please consult your authorised TOSHIBA TEC representative.

• Do not expose the machine to insecticides or other volatile solvents. This may cause the cabinet, or other parts, to deteriorate

and may cause the paint to peel.

Notification (for Turkey)

EEE Yönetmeliğine Uygundur

CAUTION

Disconnect

the plug.

Disconnect

the plug.

Connect a

grounding wire.

No

disassembling.

Prohibited

Prohibited

Page 8

ENGLISH VERSION EO1-33094

TABLE OF CONTENTS

Page

1. PRODUCT OVERVIEW....................................................................................................... E1- 1

1.1 Introduction................................................................................................................. E1- 1

1.2 Features ..................................................................................................................... E1- 1

1.3 Unpacking................................................................................................................... E1- 1

1.4 Accessories ............................................................................................................... E1- 2

1.5 Appearance ................................................................................................................ E1- 3

1.5.1 Dimensions ............................................................................................................... E1- 3

1.5.2 Front View................................................................................................................. E1- 3

1.5.3 Rear View ................................................................................................................. E1- 3

1.5.4 Operation Panel........................................................................................................ E1- 4

1.5.5 Interior....................................................................................................................... E1- 4

1.6 Options ....................................................................................................................... E1- 5

2. PRINTER SETUP ................................................................................................................ E2- 1

2.1 Installation .................................................................................................................. E2- 2

2.2 Connecting the Power Cord........................................................................................ E2- 3

2.3 Loading Supplies ........................................................................................................ E2- 4

2.3.1 Loading the Media .................................................................................................... E2- 5

2.3.2 Loading the Ribbon.................................................................................................. E2-10

2.4 Connecting the Cables to Your Printer....................................................................... E2-12

2.5 Turning the Printer ON/OFF....................................................................................... E2-13

2.5.1 Turning ON the Printer............................................................................................. E2-13

2.5.2 Turning OFF the Printer........................................................................................... E2-13

2.6 Printer Setting...........................................................................................................................

E2-14

2.6.1 User System Mode .................................................................................................. E2-15

2.6.2 Parameter Setting.................................................................................................... E2-16

2.6.3 Enabling LAN/WLAN ............................................................................................... E2-24

2.6.4 Basic Program Setting............................................................................................. E2-24

2.6.5 Enabling Z-Mode...................................................................................................... E2-25

2.6.6 Automatic Calibration............................................................................................... E2-26

2.6.7 Dump Mode Setting................................................................................................. E2-27

2.6.8 Logging .................................................................................................................... E2-29

2.6.9 System Mode........................................................................................................... E2-30

2.6.10 Interface Setting....................................................................................................... E2-31

2.6.11 Real Time Clock (RTC)............................................................................................ E2-38

2.6.12 Copying Data to/from USB Memory........................................................................ E2-39

2.7 Installing the Printer Drivers....................................................................................... E2-40

2.7.1 Introduction .............................................................................................................. E2-40

2.7.2 General Description................................................................................................. E2-40

2.7.3 Installing the Printer Driver ...................................................................................... E2-40

2.7.4 Preparation for installation....................................................................................... E2-41

2.7.5 Installation under Windows2000/XP/Server2003.................................................... E2-43

2.7.6 Installation under WindowsVista/Server2008/7/Server2008R2 .............................. E2-48

2.7.7 Installation under Windows2000 (USB with Plug & Play enabled) ......................... E2-51

2.7.8 Installation under WindowsXP/Server2003 (USB with Plug & Play enabled)......... E2-53

2.7.9 Installation under Windows Vista/Server2008/7/Server2008R2

(USB with Plug & Play enabled).............................................................................. E2-54

2.7.10 Uninstalling the Printer Driver.................................................................................. E2-55

2.8 Print Test ................................................................................................................... E2-58

Page 9

ENGLISH VERSION EO1-33094

2.9 Position and Print Tone Fine Adjustment .................................................................. E2-60

2.9.1 Fine Adjustment....................................................................................................... E2-60

2.10 Threshold Setting....................................................................................................... E2-67

2.11 Sensor Setting ........................................................................................................... E2-69

3. ONLINE MODE ................................................................................................................... E3- 1

3.1 Key Functions............................................................................................................. E3- 1

3.2 LCD ............................................................................................................................ E3- 2

3.2 Operation Example ..................................................................................................... E3- 3

4. MAINTENANCE .................................................................................................................. E4- 1

4.1 Cleaning ..................................................................................................................... E4- 1

4.1.1 Print Head/Platen/Sensors ....................................................................................... E4- 1

4.1.2 Covers and Panels ................................................................................................... E4- 2

4.1.3 Optional Cutter Module............................................................................................. E4- 3

5. TROUBLESHOOTING ........................................................................................................ E5- 1

5.1 Error Messages .......................................................................................................... E5- 1

5.2 Possible Problems ...................................................................................................... E5- 4

5.3 Removing Jammed Media .......................................................................................... E5- 5

6. PRINTER SPECIFICATIONS .............................................................................................. E6- 1

7. SUPPLY SPECIFICATIONS................................................................................................ E7- 1

7.1 Media.......................................................................................................................... E7- 1

7.1.1 Media Type ............................................................................................................... E7- 1

7.1.2 Detection Area of the Transmissive Sensor............................................................. E7- 3

7.1.3 Detection Area of the Reflective Sensor .................................................................. E7- 4

7.1.4 Effective Print Area................................................................................................... E7- 4

7.1.5 RFID Tags................................................................................................................. E7- 6

7.2 Ribbon ........................................................................................................................ E7- 8

7.3 Recommended Media and Ribbon Types ................................................................. E7- 10

7.4 Care/Handling of Media and Ribbon ......................................................................... E7- 17

APPENDIX 1 MESSAGES AND LEDS ....................................................................................EA1-1

APPENDIX 2 INTERFACE .......................................................................................................EA2-1

APPENDIX 3 PRINT SAMPLES...............................................................................................EA3-1

APPENDIX 4 GLOSSARIES ....................................................................................................EA4-1

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA TEC.

2. The contents of this manual may be changed without notification.

3. Please refer to your local Authorised Service representative with regard to any queries you may have in

this manual.

This is a Class A product. In a domestic environment this product may cause radio interference in

which case the user may be required to take adequate measures.

WARNING!

Page 10

1. PRODUCT OVERVIEW

ENGLISH VERSION EO1-33094

1.1 Introduction

E1- 1

1. PRODUCT OVERVIEW

1.1 Introduction

1.2 Features

1.3 Unpacking

Thank you for choosing the TOSHIBA B-EX4T2 series bar code

printer. This Owner’s Manual contains from general set-up

through to how to confirm the printer operation using a test print,

and should be read carefully to help gain maximum performance

and life from your printer. For most queries please refer to this

manual and keep it safe for future reference. Please contact your

TOSHIBA TEC representative for further information concerning

this manual.

This printer has the following features:

• The print head block can be opened providing smooth loading

of media and ribbon.

• Various types of media can be used as the media sensors can

be moved from the centre to the left edge of the media.

• Web based functions such as remote maintenance and other

advanced network features are available.

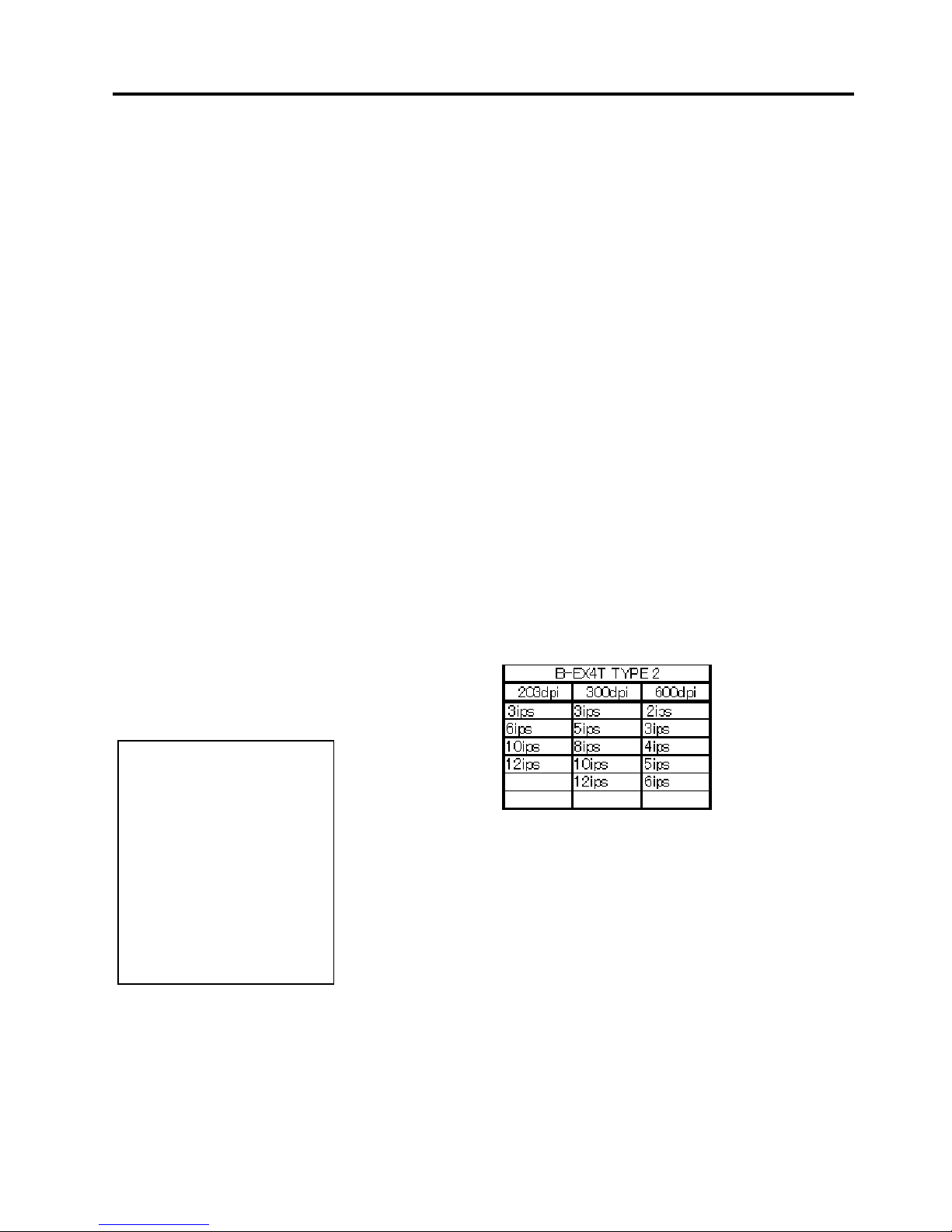

• Superior hardware, including the specially developed 8

dots/mm (203 dots/inch) thermal print head which will allow very

clear print at a printing speed of 3, 6, 10, or 12 inches/sec. and

3, 5, 8, 10, or 12 inches/sec. with 11.8 dots/mm (300 dots/inch)

thermal head. 23.6 dots/mm (600 dpi) thermal print head which

will allow very clear print at a printing speed of 2, 3, 4, 5, or 6

inches/sec.

• Besides the optional Cutter Module, there is also an optional

Peel off Module, RS-232C I/F card, Centronics I/F card,

Expansion I/O Card, Wireless LAN I/F card, the RTC/USB host

I/F card, HF band RFID mount kit and Narrow width platen kit.

Unpack the printer as per the Unpacking Instructions supplied with

the printer.

NOTES:

1. Check for damage or

scratches on the printer.

However, please note that

TOSHIBA TEC shall have

no liability for any damage

of any kind sustained

during transportation of the

product.

2. Keep the cartons and

internal packing for future

transportation of the

printer.

Page 11

1. PRODUCT OVERVIEW

ENGLISH VERSION EO1-33094

1.4 Accessories

E1- 2

1.4 Accessories

When unpacking the printer, please make sure all the following

accessories are supplied with the printer.

Power cord

Safety precautions

Quick installation manual

CD-ROM(1pc.)

Page 12

1. PRODUCT OVERVIEW

ENGLISH VERSION EO1-33094

1.5 Appearance

E1- 3

1.5 Appearance

1.5.1 Dimensions

1.5.2 Front View

1.5.3 Rear View

The names of the parts or units introduced in this section are used

in the following chapters.

278

(10.9) 460 (18.1)

Dimensions in mm (inches)

310

(12.2)

Top Cover

Media Outlet

Supply Window

LCD Message Display

Operation Panel

Reserved for Serial or

WLAN Interface

LAN Interface

AC Power Inlet

Reserved for Expansion I/O

interface

Re

served for Parallel Interface

Power Switch

USB Interface

Reserved for USB Host

Interface

Page 13

1. PRODUCT OVERVIEW

ENGLISH VERSION EO1-33094

1.5 Appearance

E1- 4

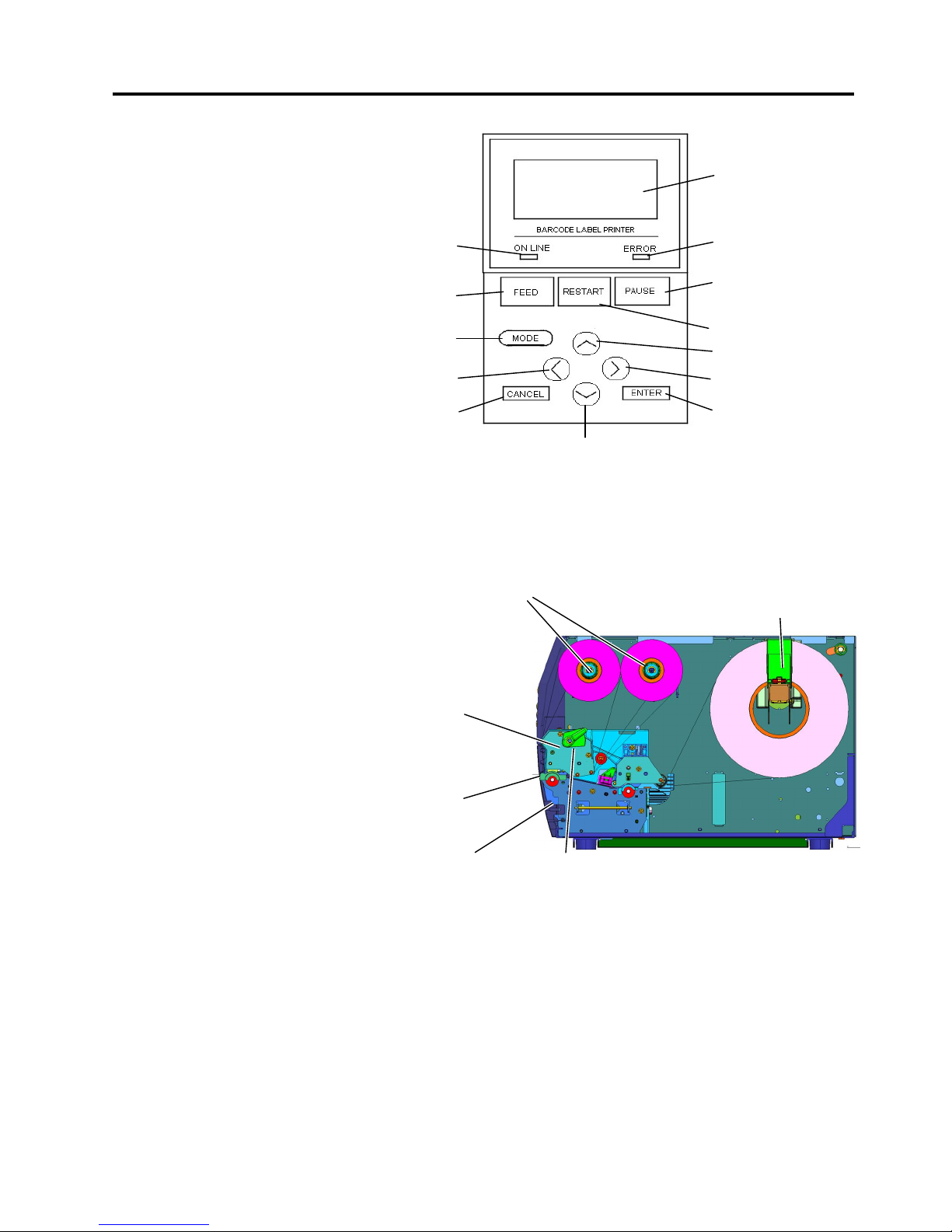

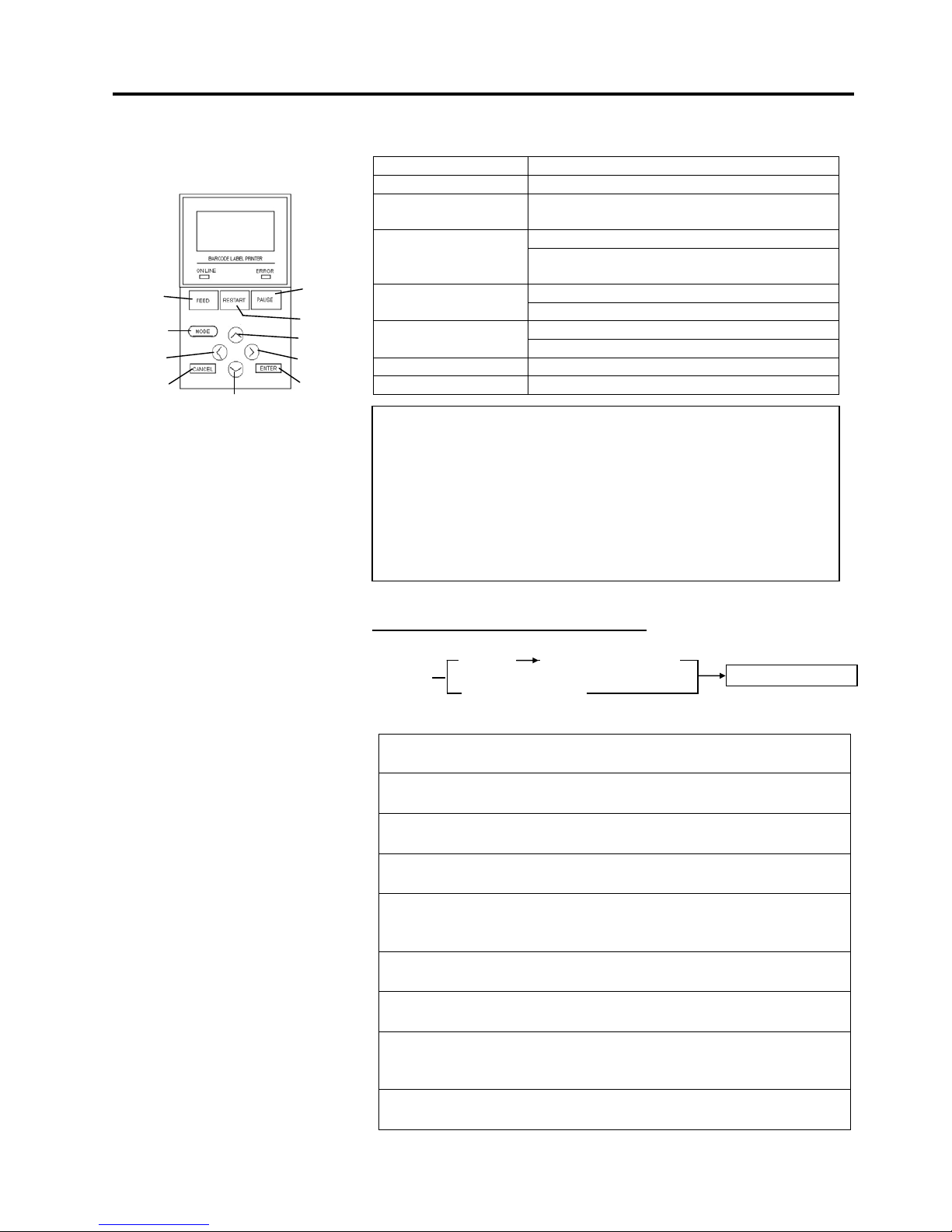

1.5.4 Operation Panel

1.5.5 Interior

Please see Section 3 for further information about the Operation

Panel.

1.6 Options

LCD

ERROR LED

PAUSE

RESTART

UP

RIGHT

ENTER

DOWN

CAN

CEL

MODE

LEFT

FEED

ONLINE LED

Print Head

Platen

Head Lever

Ribbon Shaft

Print Head Block

Paper Guide R

Page 14

1. PRODUCT OVERVIEW

ENGLISH VERSION EO1-33094

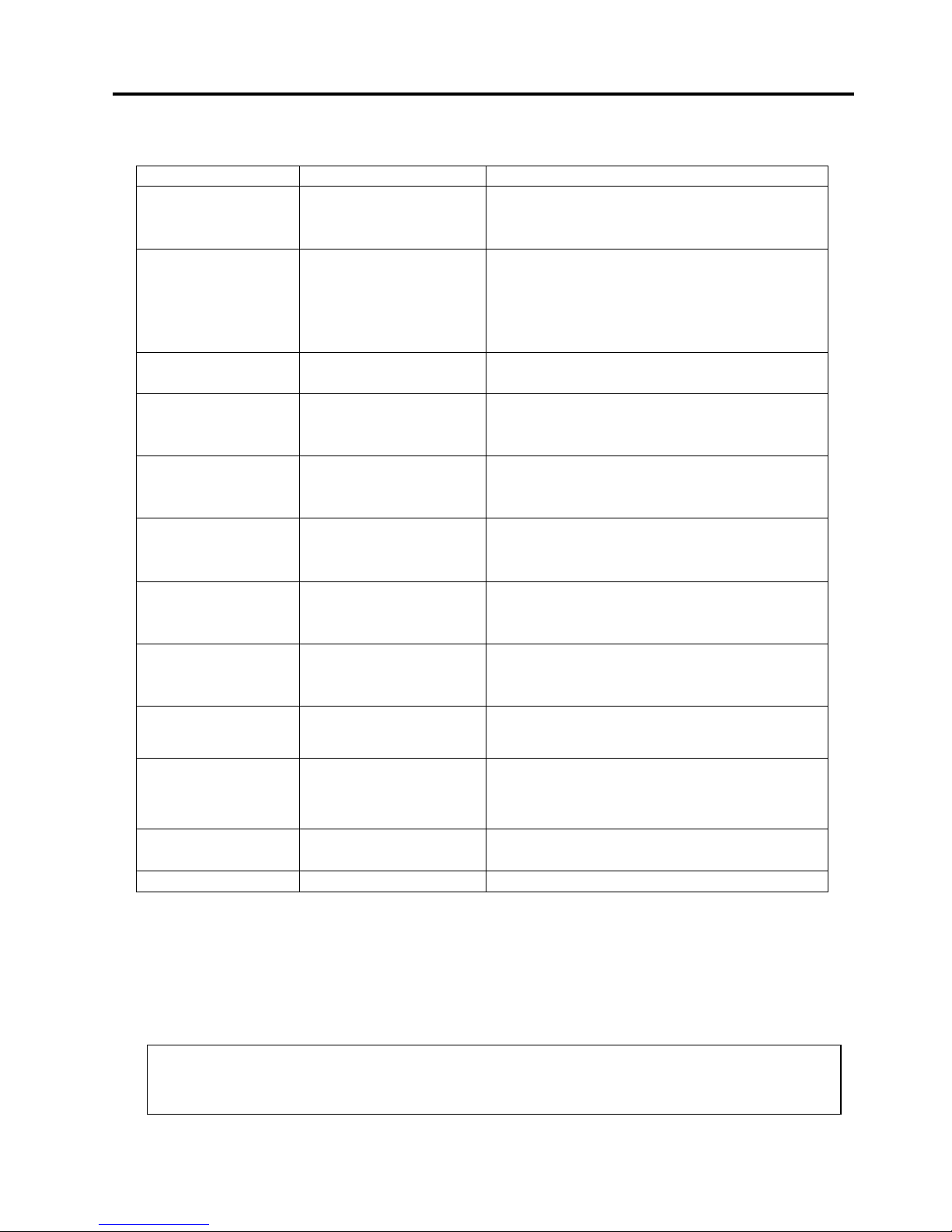

1.6 Options

E1- 5

Option Name Type Description

Disc cutter module B-EX204-QM-R

Disc cutter

Each time media is cut, the media feed is

stopped.

Strip module B-EX904-H-QM-R This allows use of on-demand (peel-off)

operation or to take-up labels and backing

paper together when using the rewind guide

plate. To purchase the strip module, please

inquire with your local distributor.

RFID module mount

kit

B-EX700-RFID-H1-QM-R This kit is to mount Tagsys HF band RFID

module and antenna.

203-dpi print head B-EX704-TPH2-QM-R This print head enables a conversion of a

300dpi print head of the B-EX4T2-TS12 model

into 203dpi print head.

300-dpi print head B-EX704-TPH3-QM-R This print head enables a conversion of a

203dpi print head of the B-EX4T2-GS12 model

into 300dpi print head.

600-dpi print head B-EX704-TPH6-QM-R Only with B-EX4T2-HS12 Model

RTC & USB host

interface card

B-EX700-RTC-QM-R This card holds the current time: year, month,

day, hour, minute, second and provides a USB

host interface.

Expansion I/O

interface card

B-EX700-IO-QM-R Installing this card in the printer allows

connection to an external device with the

exclusive interface.

Parallel interface

card

B-EX700-CEN-QM-R Installing this card provides a Centronics

interface port.

Serial interface card B-EX700-RS-QM-R Installing this card provides an RS-232C

interface port.

Wireless LAN

interface card

B-EX700-WLAN-QM-R Installing this card provides Wireless LAN

communication.

NOTE:

To purchase the optional kits, please contact the nearest authorised TOSHIBA TEC representative or

TOSHIBA TEC Head Quarters.

Page 15

2. PRINTER SETUP

ENGLISH VERSION EO1-33094

2. PRINTER SETUP

E2- 1

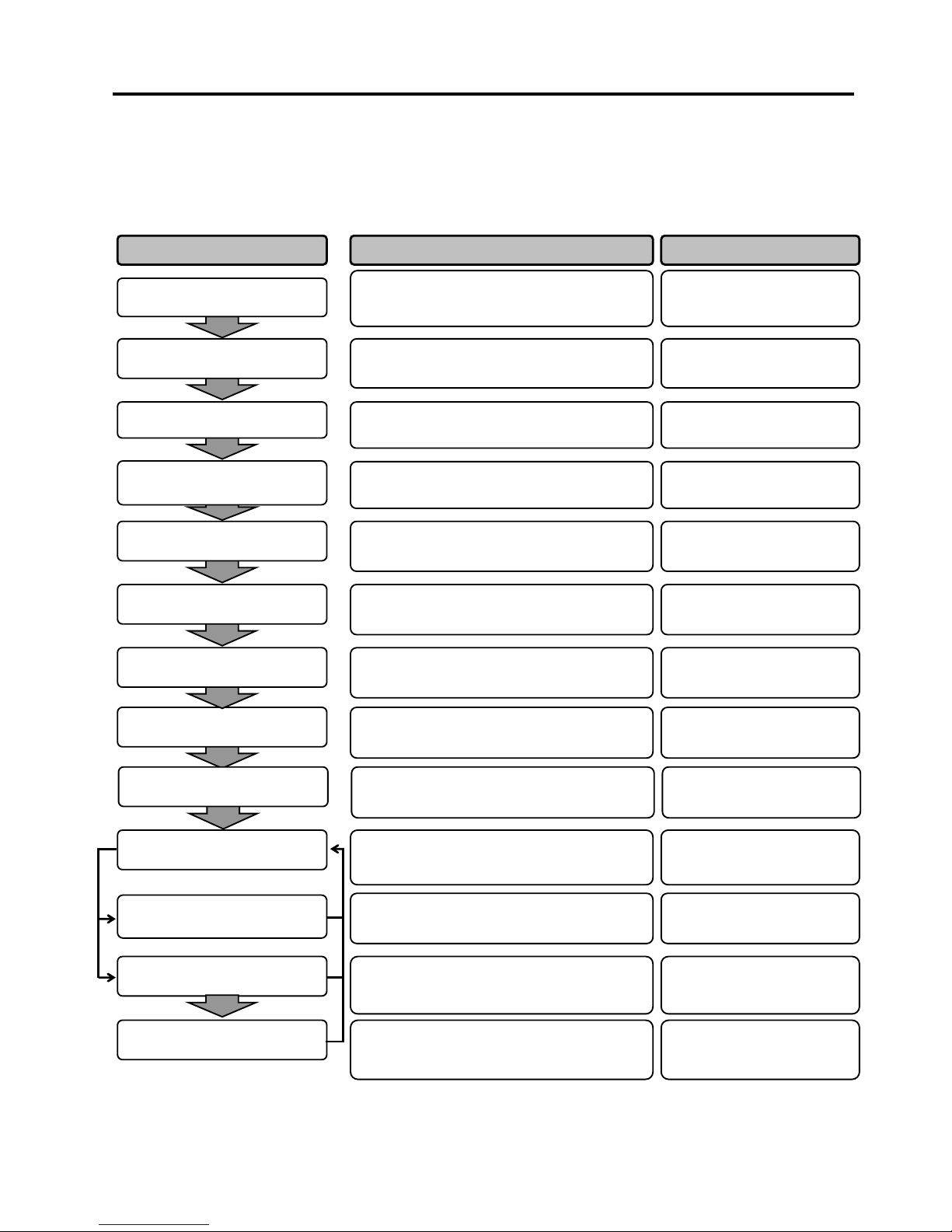

2. PRINTER SETUP

This section outlines the procedures to setup your printer prior to its operation. The section includes precautions,

loading media and ribbon, connecting cables, setting the operating environment of the printer and performing an

online print test.

Reference Procedure Setup Flow

After referring to the Safety Precautions in this

manual, install the printer in a safe and stable

location.

Connect a power cord to the power inlet of the

printer, then to an AC outlet.

Load a label stock or tag stock.

Adjust the position of feed gap sensor or black

mark sensor according to the media being used.

If using thermal transfer media then load the

ribbon.

Connect the printer to a host computer or

network.

Set the printer parameters in the system mode.

Installation

Connecting the power cord

Loading the media

Printer setting

Media sensor position

alignment

Loading the ribbon

Connecting to a host computer

Make a print test from your operating

environment and check the print result.

Print test

2.1 Installation

2.2 Connecting the Power

Cord

2.3.1 Loading the Media

2.3.1 Loading the Media

2.3.2 Loading the Ribbon

2.4 Connecting the Cables to

Your Printer

2.6 Printer Setting

2.8 Print Test

Automatic threshold setting

Manual threshold setting

If necessary, install the printer driver on your

host computer.

2.7 Installing the Printer

Drivers

If the print start position cannot be detected

properly when pre-printed label are used, set the

threshold automatically.

If the print start position cannot be detected

properly even after automatic threshold setting is

performed manually set the threshold.

2.10 Threshold Setting

2.10 Threshold Setting

Turn on the printer power.

Turning the power ON

2.5 Turning the Printer

ON/OFF

Position and Print Tone Fine

adjustment

If necessary, fine adjust the print start position,

cut/strip position, print tone, etc.

2.9 Position and Print Tone

Fine Adjustment

Installing the printer driver

Page 16

2. PRINTER SETUP

ENGLISH VERSION EO1-33094

2.1 Installation

E2- 2

2.1 Installation

To insure the best operating environment and to assure the safety of the

operator and equipment, please observe the following precautions.

• Operate the printer on a stable, level surface in a location free from

excessive humidity, high temperature, dust, vibration and direct

sunlight.

• Keep your work environment static free. Static discharge can cause

damage to delicate internal components.

• Make sure the printer is connected to a clean source of AC power and

no other high-voltage devices, that may cause line noise interference,

are connected to the same mains.

• Assure that the printer is connected to the AC mains with a three-

prong power cable that has the proper ground (earth) connection.

• Do not operate the printer with the cover open. Be careful not to

allow fingers or articles of clothing to get caught in any of the

moving parts, especially the optional cutter mechanism.

• For best results, and longer printer life, use only TOSHIBA TEC

recommended media and ribbons.

• Store the media and ribbons in accordance with their specifications.

• This printer mechanism contains high-voltage components; therefore

you should never remove any of the covers of the machine as you

may receive an electrical shock. Additionally, the printer contains

many delicate components that may be damaged if accessed by

unauthorised personnel.

• Clean the outside of the printer with a clean, dry cloth or a clean cloth

slightly dampened with a mild detergent solution.

• Use caution when cleaning the thermal print head as it will become

very hot while printing. Wait until it has had time to cool before

cleaning. Use only the TOSHIBA TEC recommended print head

cleaner to clean the print head.

• Do not turn off the printer power or remove the power plug while the

printer is printing or while the ON LINE lamp is flashing.

Page 17

2. PRINTER SETUP

ENGLISH VERSION EO1-33094

2.2 Connecting the Power Cord

E2- 3

2.2 Connecting the

Power Cord

1. Make sure that the printer Power Switch is in the OFF () position.

Connect the Power Cord to the printer as shown in the figure below.

2. Plug the other end of the Power Cord into a grounded outlet as shown

in the figure below.

[Example of US Type] [Example of EU Type]

CAUTION!

1. Make sure that the printer

Power Switch is turned to

the OFF position ()

before connecting the

Power Cord to prevent

possible electric shock or

damage to the printer.

2. Connect the Power Cord

to a supply outlet with a

properly grounded

(earthed) connection.

Power Cord

Power Switch

Power Cord

Power Cord

Page 18

2. PRINTER SETUP

ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2- 4

2.3 Loading Supplies

1. Do not touch any moving parts. To reduce the risk of fingers, jewellery, clothing, etc., being

drawn into the moving parts, be sure to load the media once the printer has stopped moving

completely.

2. The Print Head becomes hot immediately after printing, allow it to cool before loading the media.

3. To avoid injury, be careful not to trap your fingers while opening or closing the cover.

WARNING!

CAUTION!

1. Be careful not to touch the Print Head Elements when lifting the Print Head Block. This may

cause missing dots due to static electricity or other print quality problems.

2. When loading or replacing the media or ribbon, be careful not to damage the print head with hard

objects like watches or rings.

Since the print head element can be easily damaged by shock, please treat it carefully and do not

hit it with hard objects .

Care must be taken not to allow

the metal or glass part of a watch

to touch the print head edge.

Care must be taken not to allow

a metal object like a ring to touch

the print head edge.

Page 19

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2- 5

2.3.1 Loading the Media

The following procedure shows the steps to properly load the media into

the printer so that it feeds straight through the printer.

The printer prints both labels and tags.

1. Open the Top Cover.

2. Turn the Head Lever to the FREE position and release the Ribbon

Shaft Holder Plate.

3. Open the Print Head Block.

4.

Move the Paper guide R to the rightmost position or shift the

guide to the horizontal position.

5. Put the media on the Paper Holder.

6. Pass the media around the Paper Holder, and the n pull

the media towards the front of the printer.

7. Push the Paper Guide against the media until the media is

held firmly in place. To lock the Media, shift the Paper Guide

R to vertical position

NOTES:

1. When the Head Lever is

turned to

FREE position, the

Print Head can be raised.

2. To enable printing the Head

Lever must be set to the

LABEL / TAG position.

(This ensures that the Print

Head is closed.)

There are two head pressure

levels in the

LABEL / TAG

position. Set the Head Lever

depending on the media type:

Position LABEL: Labels

Position TAG : Tags

However, proper position

may differ depending on

media. For details, refer to

your TOSHIBA TEC

authorised service

representative.

Top Cover

Print Head Block

Head

Lever

Ribbon Shaft Holder Plate

TAG

LABEL

FREE

Paper Guide R

Paper Guide L

Page 20

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2- 6

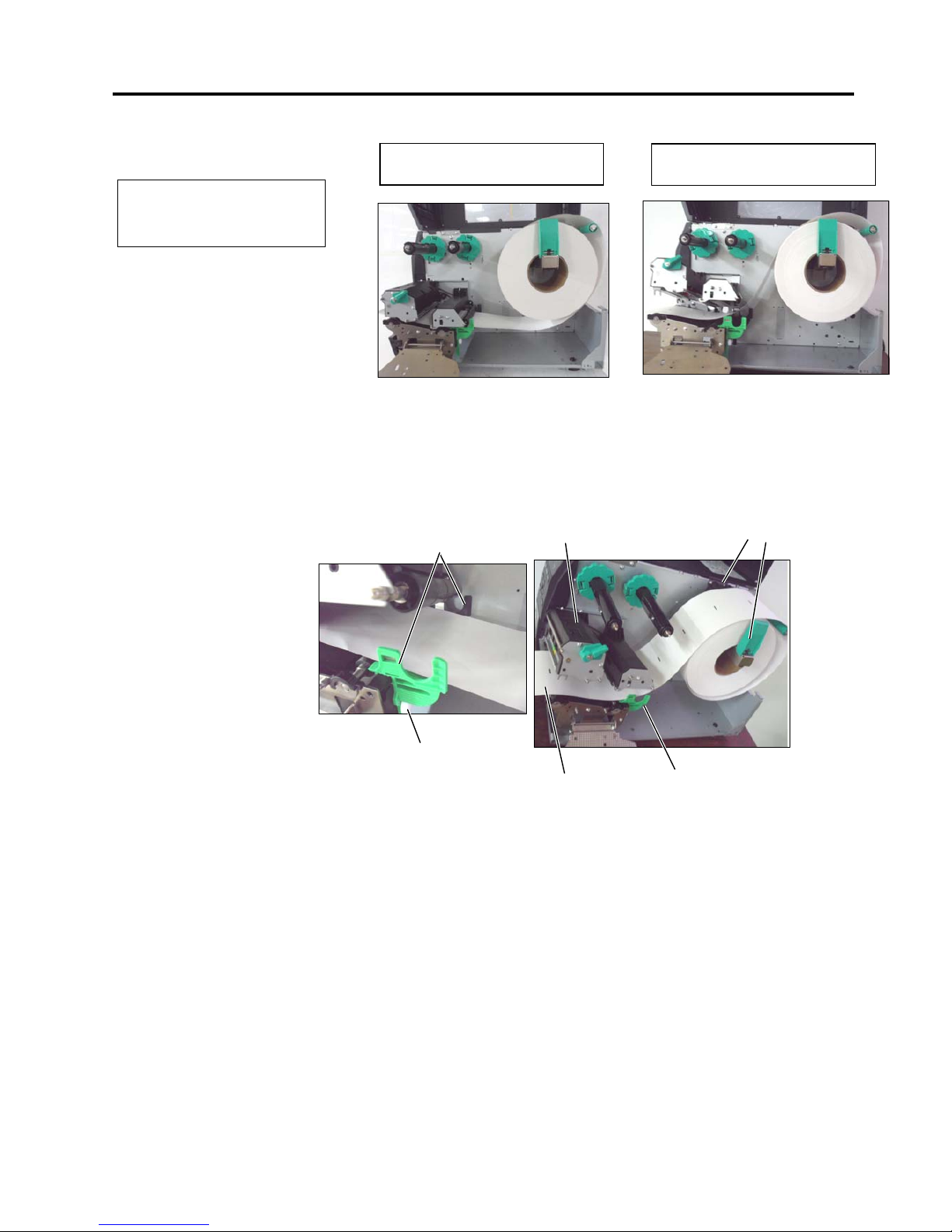

2.3.1 Loading the Media

(Cont.)

8. Place the media between the Media Guides and adjust them to the

media width. Once in the correct position tighten the Locking

Screw.

9. Check that the media’s path through the printer is straight. The

media should be to the left side of the print head

NOTE:

Do not over-tighten the Locking

Ring of the Supply Holder.

In the case of labels rolled with

the print side facing inside.

In the case of labels rolled with

the print side facing outside.

Media Guide

Locking Screw

Paper Guide

Media Guide

Print Head

Media

Page 21

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2- 7

2.3.1 Loading the Media

(Cont.)

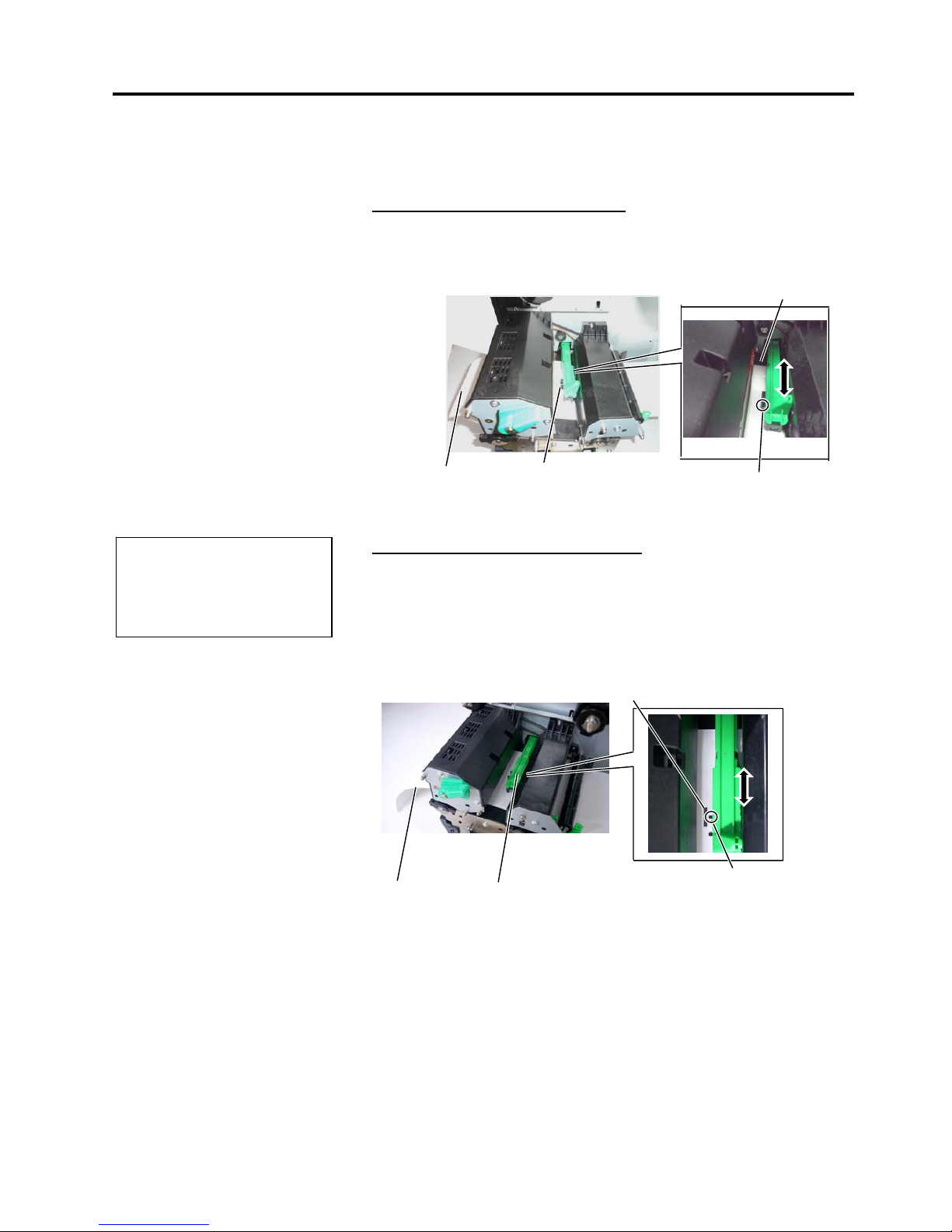

10. Lower the Print Head Block.

11. Once the media is loaded it may be necessary to set the Media

Sensors used to detect the start position for label or tag.

Setting the Feed Gap Sensor position

(1) Manually move the Media Sensor so that the Feed Gap Sensor is

positioned at the centre of the labels. (z indicates the position of the

Feed Gap Sensor).

Setting the Black Mark Sensor position

(1) Pull about 500 mm of media out of the front of the printer, turn the

media back on itself and feed it under the Print Head past the sensor

so that the black mark can be seen from above.

(2) Manually move the Media Sensor so that the Black Mark Sensor is

in line with the centre of the black mark on the media. ( indicates

the position of the Black Mark Sensor).

NOTE:

Be sure to set the black mark

sensor to detect the centre of the

black mark, otherwise a paper

j

am or no paper error may occur.

Label Media Sensor

Feed Gap Sensor (z)

Media

Media Sensor

Black Mark Sensor ()

Black Mark

Gap

Page 22

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2- 8

2.3.1 Loading the Media

(Cont.)

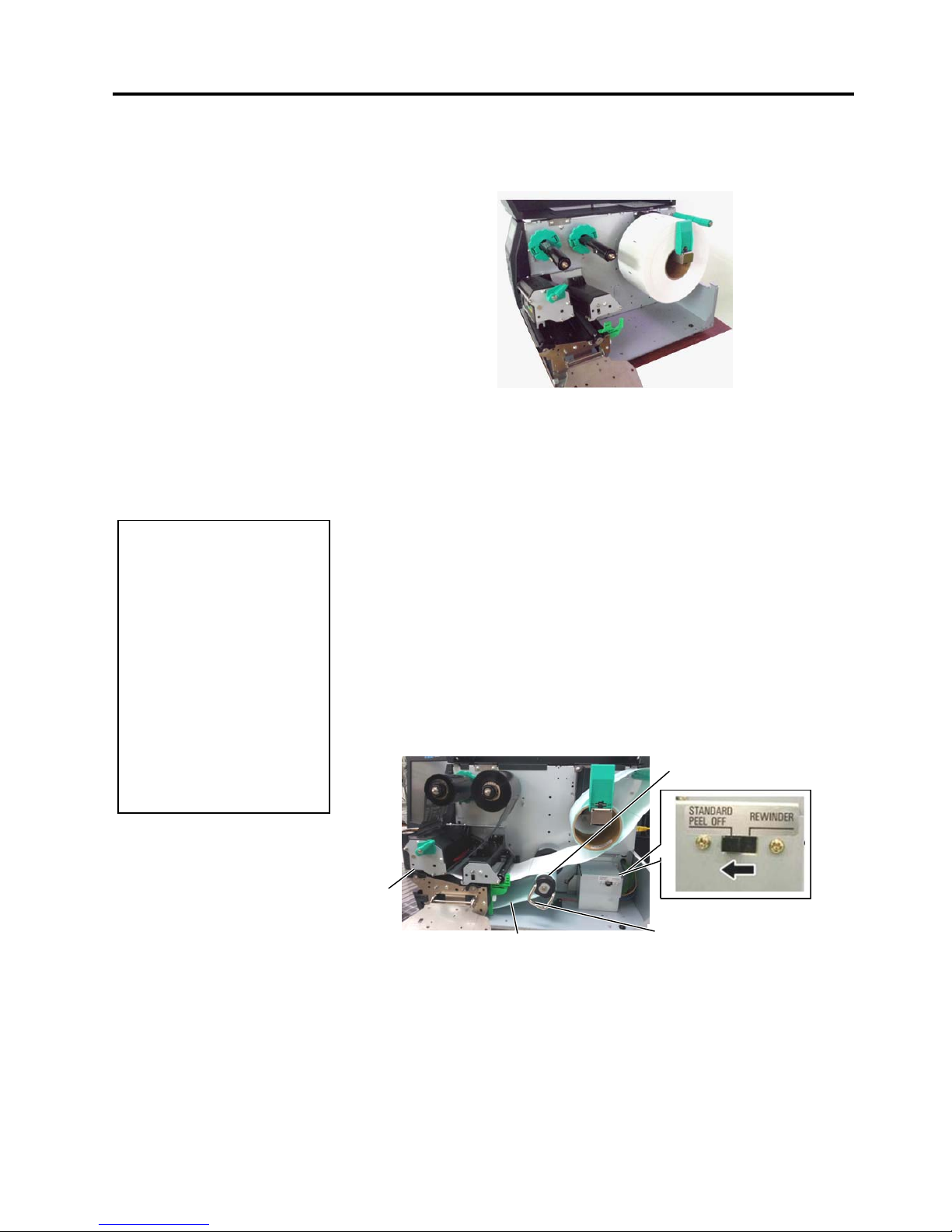

12. Batch mode

In batch mode, the media is continuously printed until the number of

labels/tags specified in the issue command has been printed.

13. Loading with peel off module

When the optional Strip Module is fitted, the label is automatically

removed from the backing paper at the Strip Plate as each label is

printed.

(1) Remove enough labels from the leading edge of the media to leave

500mm of backing paper free.

(2) Insert the backing paper under the Strip Plate.

(3) Wind the backing paper onto the Take-up Spool and fix it in position

with the Take-up Clip. (Wind the paper counter-clockwise around

the spool.)

(4) Rotate the Take-up Spool counter-clockwise a few times to remove

any slack in the backing paper.

(5) Set the Selection Switch mounted on the Rewinder Assembly to

STANDARD/PEEL OFF position.

NOTES:

1. Be sure to set the Selection

Switch to STANDARD/

PEEL OFF position.

2. The backing paper is easier

to feed back to the Take-Up

Spool if the Front Plate is

removed.

3. Fit the Take-Up Clip so that

the longer side of the clip is

fitted into the shallow groove

in the Take-Up Spool.

4. The backing paper can be

wound directly onto the

Take-up Spool or a paper

core.

Backing Paper

Strip Plate

Take-up Spool

Take-up Clip

Page 23

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2- 9

Media Outlet

Cutter Module

2.3.1 Loading the Media

(Cont.)

14. Loading with cutter

When the optional Cutter Module is fitted, the media is

automatically cut. A disc cutter is available as option.

Insert the leading edge of the media into the cutter until it comes out

the Media Outlet of the Cutter Module.

CAUTION!

1. Be sure to cut the backing

paper of the label. Cutting

labels will cause the glue to

stick to the cutter which

may affect the cutter quality

and shorten the cutter life.

2. Use of tag paper when the

thickness exceeds the

specified value may affect

the cutter life.

WARNING!

The cutter is sharp, so care

must be taken not to injure

yourself when handling the

cutter.

Page 24

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2-10

2.3.2 Loading the Ribbon

There are two types of media available for printing on: thermal

transfer and direct thermal (which has a chemically treated

surface). DO NOT LOAD a ribbon when using direct thermal

media.

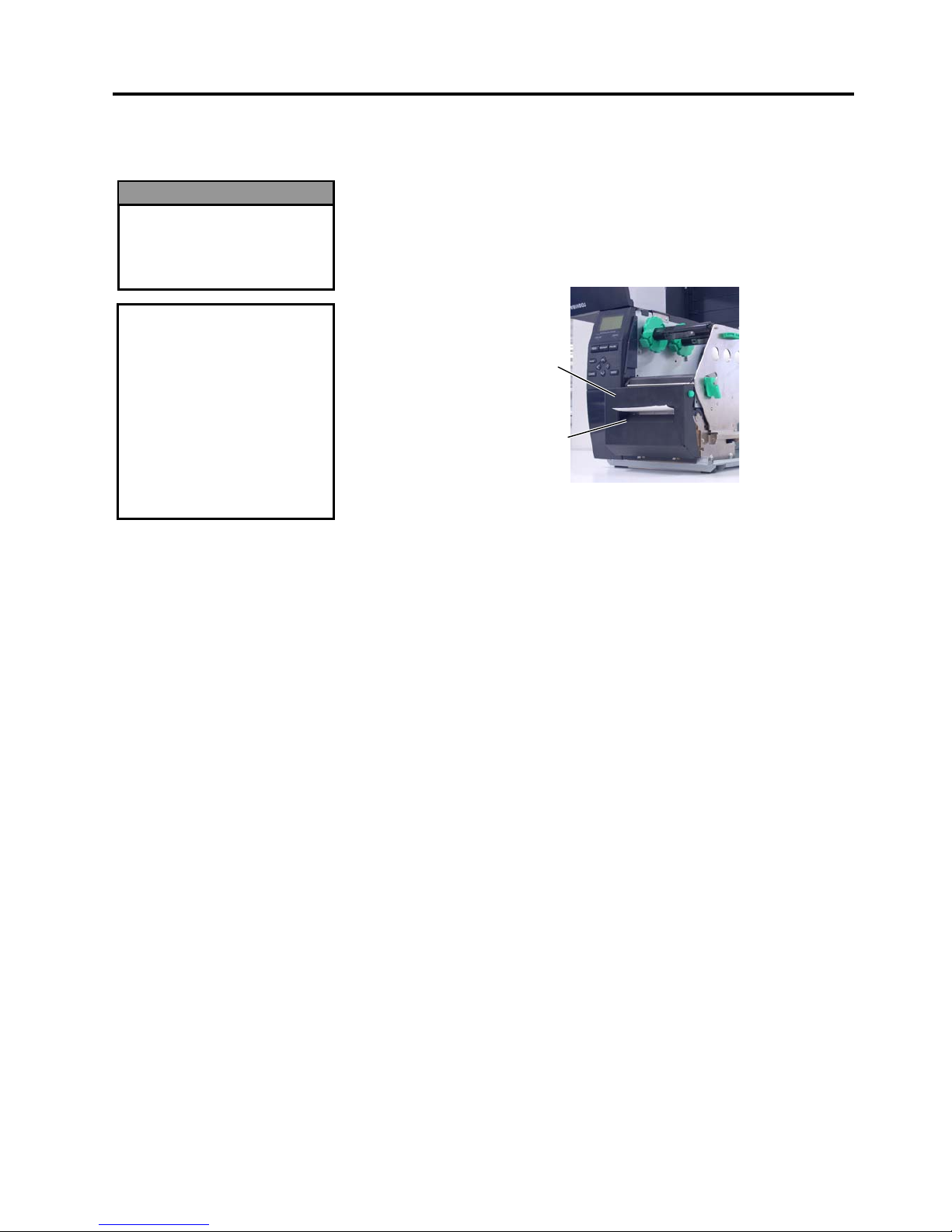

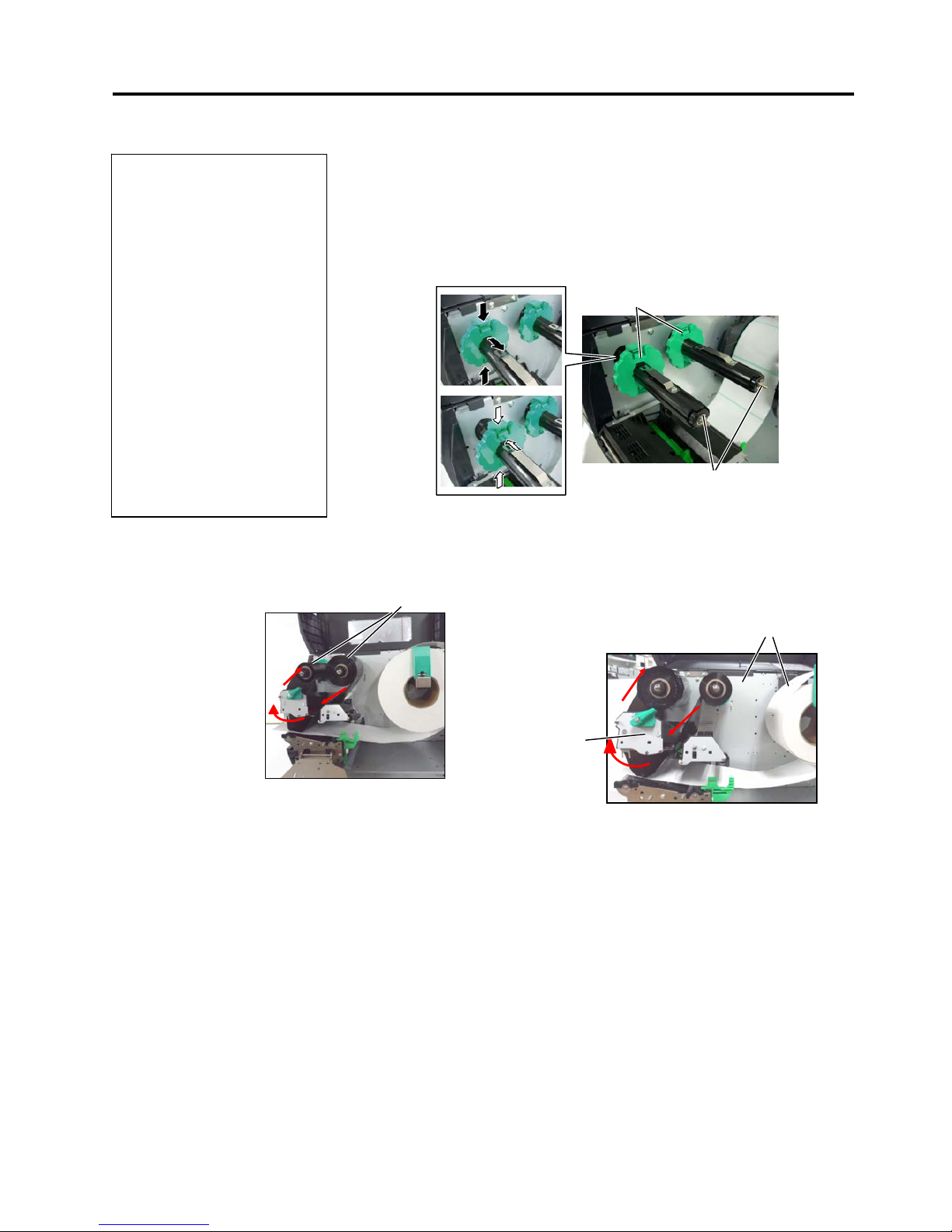

1. Grasp the tabs on the top and bottom of the Ribbon Stoppers

and move the Ribbon Stoppers back to the end of the Ribbon

Shaft.

2. Leaving plenty of slack between the ribbon spools, place the

ribbon onto the Ribbon Shafts as shown below.

There are 2

possible ways to load the ribbon.

NOTE:

To check or change settings on which type of Ribbon winding to be

used, you must go to SYSTEM Mode in the Printer. For more details

refer to Key Operation Specification, “8.4.1 PRINTER SET”.

NOTES:

1. When attaching the ribbon

stoppers, make sure that

the pinchers face into the

printer

2. Be sure to remove any

slack in the ribbon before

printing. Printing with a

wrinkled ribbon will reduce

the print quality.

3. The Ribbon Sensor is

mounted on the rear of the

Print Head Block to detect

a ribbon end. When a

ribbon end is detected a

“NO RIBBON” message will

appear on the display and

the ERROR LED will

illuminate.

Ribbon Stopper

Ribbon Shaft

Print Head Block

Ribbon Shaft

Ribbon Shaft

Outside Wound Ribbon

Inside Wound Ribbon

Page 25

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.3 Loading Supplies

E2-11

2.3.2 Loading the Ribbon

(Cont.)

3. Push Ribbon along the Ribbon Shafts to a position where the

ribbon is fully to the Left against the stoppers when fitted.

4. Lower the Print Head Block and set the Ribbon Shaft Holder

Plate aligning its holes with the Ribbon Shafts.

5. Take up any slack in the ribbon. Wind the leading tape onto the

ribbon take-up roll until the ink ribbon can be seen from the

front of the printer.

6. Turn the Head Lever to Lock position to close the Print Head.

7. Close the Top Cover.

Ribbon Shaft Holder Plate

Page 26

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.4 Connecting the Cables to Your Printer

E2-12

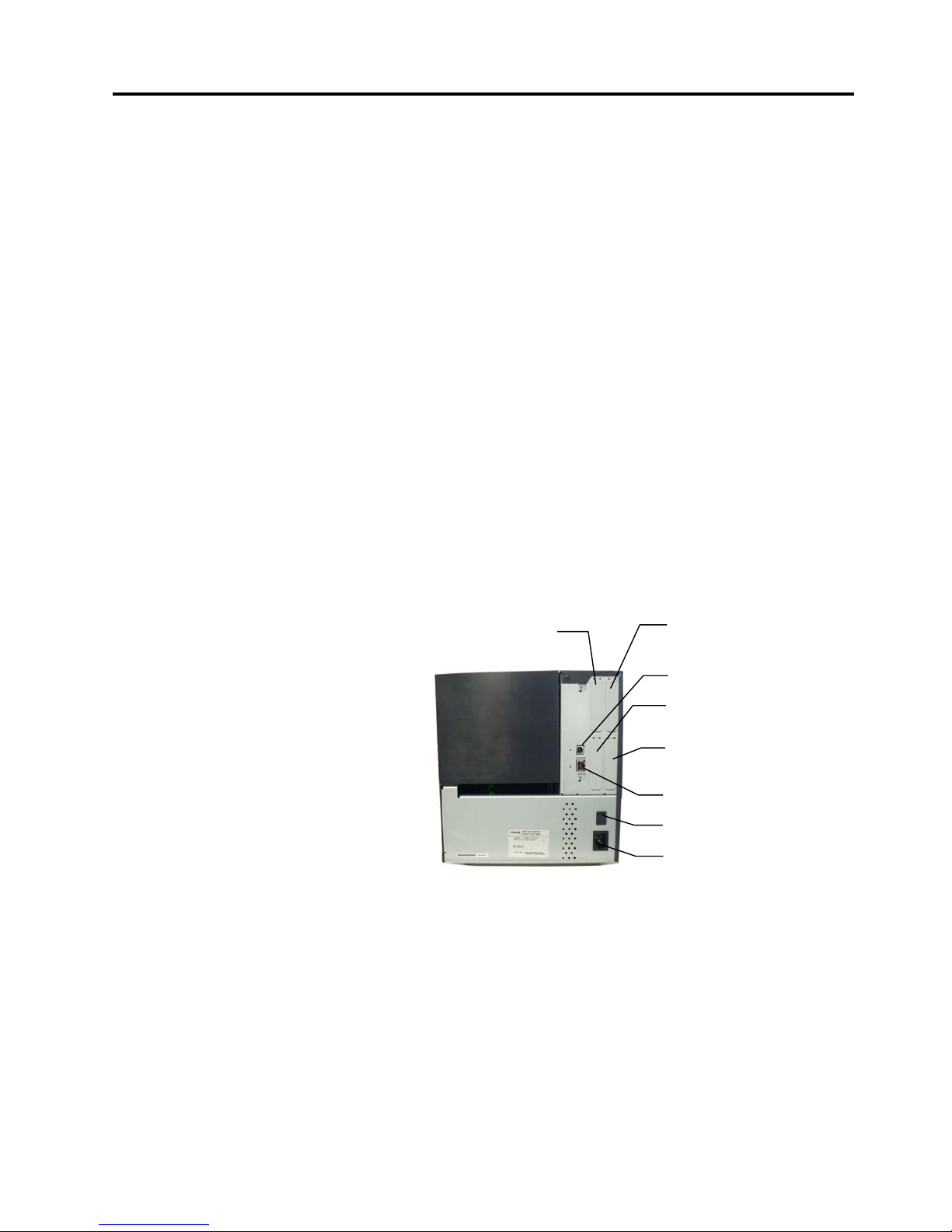

2.4 Connecting the

Cables to Your

Printer

The following paragraphs outline how to connect the cables from

the printer to your host computer, and will also show how to

make cable connections to other devices. Depending on the

application software you use to print labels, there are 5 ways to

connect the printer to your host computer. These are:

• An Ethernet connection using the printer’s standard LAN

connector.

• A USB cable connection between the printer’s standard USB

connector and your host computer’s USB port. (Conforming

to USB 2.0)

• A serial cable connection between the printer’s optional RS232 serial connector and one of your host computer’s COM

ports.

• A parallel cable connection between the printer’s optional

parallel connector and your host computer’s parallel port

(LPT).

• Wireless LAN using an optional Wireless LAN board.

For details, refer to APPENDIX 2.

Reserved for

Parallel Interface

Reserved for Serial or

WLAN Interface

Reserved for

Expansion I/O Interface

USB Interface

LAN Interface

Power Switch

AC Power Inlet

Reserved for USB Host

interface

Page 27

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.5 Turning the Printer ON/OFF

E2-13

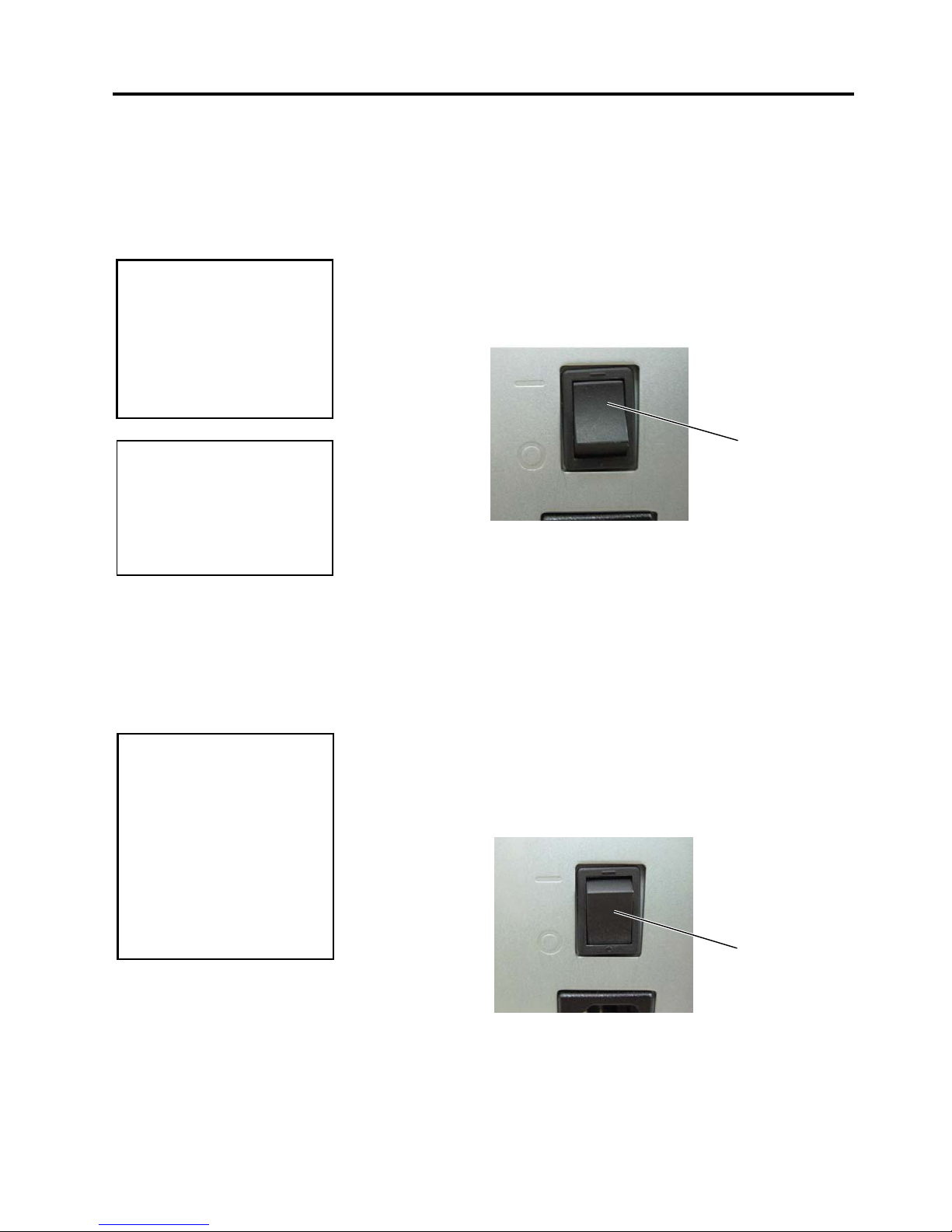

2.5 Turning the Printer

ON/OFF

2.5.1 Turning ON the Printer

2.5.2 Turning OFF the Printer

When the printer is connected to your host computer it is good

practice to turn the printer ON before turning on your host

computer and turn OFF your host computer before turning off the

printer.

1. To turn ON the printer power, press the Power Switch as shown

in the diagram below. Note that ( | )

is the power ON side of the

switch.

2. Check that the ON LINE message appears in the LCD Message

Display and that the ON LINE and POWER LED lights are

illuminated.

1. Before turning off the printer Power Switch verify that the ON

LINE message appears in the LCD Message Display and that

the ON LINE LED light is on and is not flashing.

2. To turn OFF the printer power press the Power Switch as

shown in the diagram below. Note that ({) is the power OFF

side of the switch.

CAUTION!

Use the power switch to turn

the printer On/Off. Plugging

or unplugging the Power Cord

to turn the printer On/Off may

cause fire, an electric shock,

or damage to the printer.

NOTE:

If a message other than ON

LINE appears on the display

or the ERROR LED lamp is

illuminated, refer to Section

5.1, Error Messages.

Power Switch

CAUTION!

1. Do not turn off the printer

power while the media is

being printed, as this may

cause a paper jam or

damage to the printer.

2. Do not turn off the printer

power while the ON LINE

lamp is blinking as this

may cause damage to

your computer.

Power Switch

Page 28

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-14

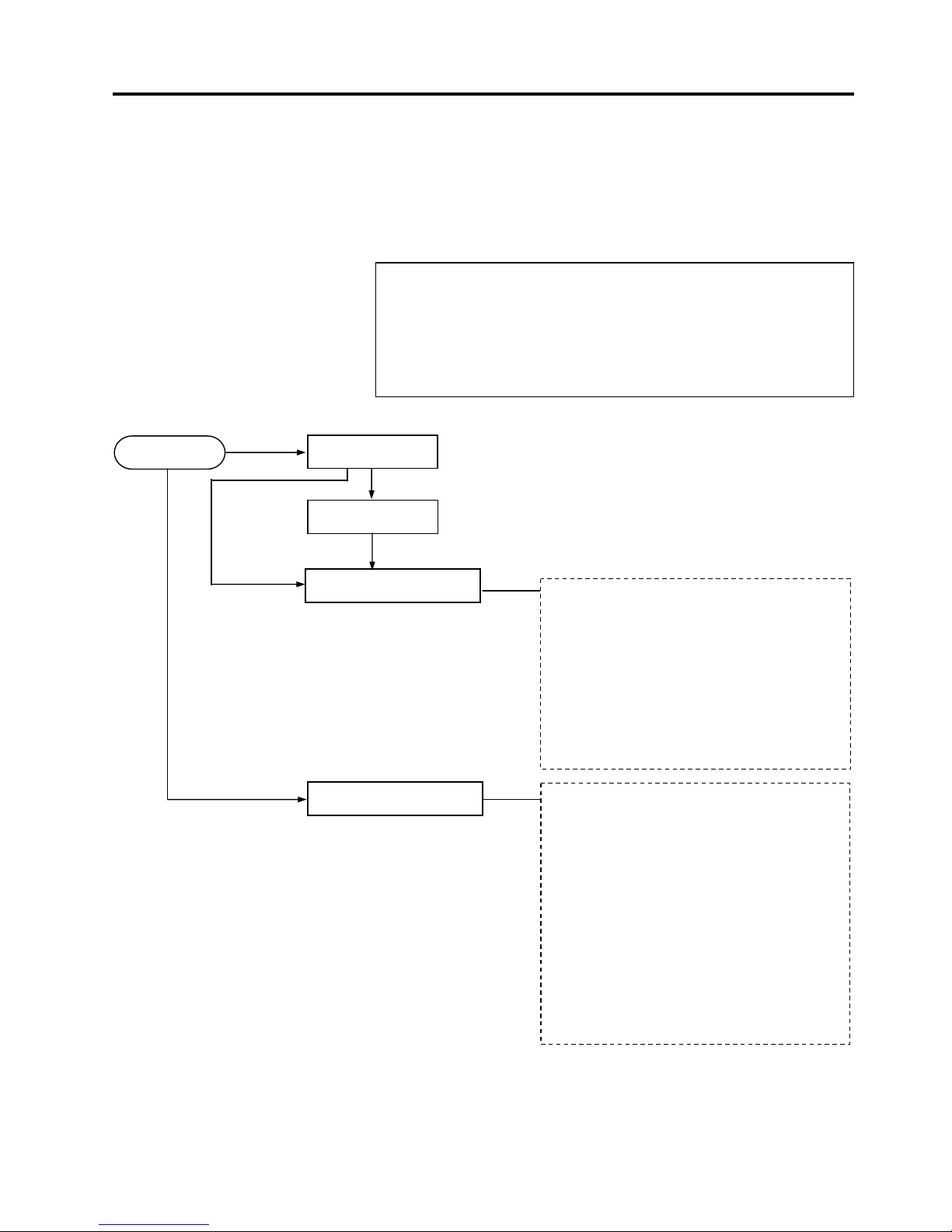

2.6 Printer Setting

Depending on the settings of your host computer or the interface

being used it may be necessary to change the printer parameter

settings.

Follow the procedures described below to change the printer

parameter settings to correspond to your environment.

NOTE:

Incorrect settings can cause the printer not to function correctly. If

you have any problems with the parameter settings, please contact

your nearest TOSHIBA TEC service representative.

For the settings this manual does not cover, please contact your

nearest TOSHIBA TEC service representative, or refer to the B-EX4T

Series Key Operation Specification manual.

ONLINE Mode

User System Mode

Power ON

[PAUSE]

PAUSE state

Hold down [RESTART]

Power OFF

Hold down [MODE]

• Reset

• Parameter setting (⇒Section 2.6.2)

• Fine adjustment (⇒Section 2.9)

• LAN/WLAN (⇒Section 2.6.3)

• BASIC (⇒Section 2.6.4)

• Z-MODE (⇒Section 2.6.5)

• Auto calibration (⇒Section 2.6.6)

• Dump mode (⇒Section 2.6.7)

• Log (⇒Section 2.6.8)

System Mode

Turn on the power while holding

down [FEED] & [PAUSE] or

[MODE].

• Self diagnosis

• Parameter setting

• Fine adjustment

• Test print (⇒Section 2.8)

• Sensor adjustment

• RAM clear

• Interface setting (⇒Section 2.6.10)

• BASIC mode

• RFID setting

• Real Time Clock (⇒Section 2.6.11)

• Z-MODE

• USB memory (⇒Section 2.6.12)

• Reset

Page 29

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-15

2.6 Printer Setting

(Cont.)

2.6.1 User System Mode

Key functions in system mode

Key Function

[MODE] Returns to the system mode menu.

[CANCEL] or

[FEED]+[RESTAR]

Returns to the previous menu.

Displays the next screen. [ENTER] or

[PAUSE]

Saves the settings and returns to the

previous menu.

Moves the cursor up.

(Note 1)

[UP] or [RESTART]

Increases a value.

(Note 2)

Moves the cursor down.

(Note 1)

[DOWN] or [FEED]

Decreases a value.

(Note 3)

[LEFT] Moves the cursor to the left.

(Note 3)

[RIGHT] Moves the cursor to the right.

(Note 3)

How to enter the User System Mode

The User System Mode consists of the following menus.

<1>RESET

Used to reset the printer.

<2>PARAMETER SET (⇒ Section 2.6.2)

Used to set the printer parameters.

<3>ADJUST SET (⇒ Section 2.9)

Used to fine adjust the print start position, cut position, etc.

<4>LAN/WLAN (⇒ Section 2.6.3)

Used to enable or disable the LAN communication and SNMP.

<5>BASIC (⇒ Section 2.6.4)

Used to set the function of basic program when it is loaded to

the printer.

<6>Z-MODE (⇒ Section 2.6.5)

Same as BASIC

<7>AUTO CALIB (⇒ Section 2.6.6)

Used to enable or disable the automatic calibration function.

<8>DUMP MODE (⇒ Section 2.6.6)

Used to print the data in the receive buffer for debugging

purposes.

<9>LOG (⇒ Section 2.6.7)

Used to save print logs in USB memory.

NOTES:

1. The cursor will not scroll from the bottom to the top or top to bottom

of a menu.

2. The value will not increase or decrease any further than the maximum

or minimum values of a parameter.

3. The cursor will not move any further than the left- or right-most

positions of a field.

4. Any values changed will not become effective if the printer is turned

off without pressing the [ENTER] key.

PAUSE

RESTART

UP

RIGHT

ENTER

DOWN

CANCEL

MODE

LEFT

FEED

ONLINE

User System Mode

[PAUSE] Hold down [RESTART]

Hold down [MODE]

Page 30

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-16

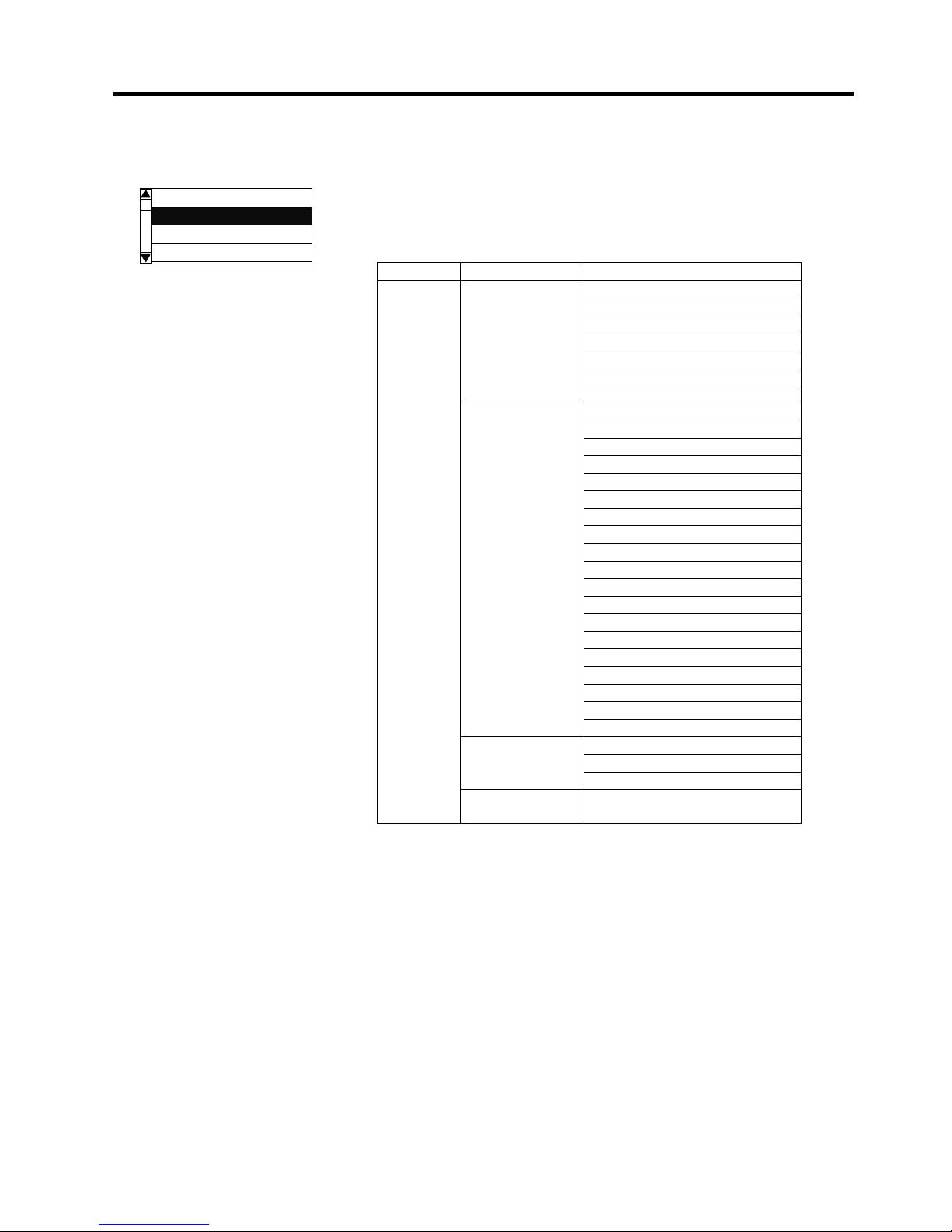

2.6.2 Parameter Setting

The Parameter Set menu allows the printer parameter settings to

be modified.

The following table shows the contents of the Parameter Set

menu.

Contents of the Parameter Set Menu

Menu Sub menu Parameter

Printer Set MEDIA LOAD Parameter

set

(Section 2.6.2.1) FORWARD WAIT

FW/BK ACT

HU CUT/RWD

RBN SAVE

PRE PEEL OFF

BACK SPEED

Software Set FONT CODE

TYPE OF RIBBON

(Section 2.6.2.2) ZERO FONT

CODE

PEEL OFF STATUS

USB I/F STATUS

FEED KEY

KANJI CODE

EURO CODE

AUTO HD CHK

WEB PRINTER

RBN NEAR END

EX I/O

LBL/RBN END

MAX CODE

XML

THRESHOLD SELECT

ENERGY TYPE

PW SAVE TIME

Panel LCD LANGUAGE

(Section 2.6.2.3) DISPLAY

CONTRAST

Password PASSWORD

(Section 2.6.2.4)

USER SYSTEM MODE

<1>RESET

<2>PARAMETER SET

<3>ADJUST SET

<4>LAN/WLAN

Page 31

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-17

2.6.2 Parameter Setting

(Cont.)

2.6.2.1 Printer Set

(1) MEDIA LOAD

Determines how the use of the [FEED] key enables the printer

to detect the home position. This parameter is effective only

when the sensor type is set to other than “None”.

• OFF Media loading function is disabled (Same as a

feed by [FEED] key)

• STD When the [FEED] key is pressed after the

printer is tuned on, reset in batch mode, or the

print head is closed, the printer detects the

next gap/black mark and feeds the paper from

the sensor to the print start position.

• ECO When the [FEED] key is pressed after the

printer is tuned on, reset in batch mode, or the

print head is closed, the printer detects the

next gap/black mark and feeds the paper to the

print start position based on the last label pitch

printed.

• ECO+Bfeed Since optional ribbon saving module is not

available to the B-EX4T2, MEDIA LOAD

setting and the printer behavior will be

automatically changed to “ECO” setting even if

“ECO+Bfeed” is selected for these models.

(2) FORWARD WAIT

This parameter allows you to choose whether or not to activate

the auto forward wait function. This function, used in the cut

mode, automatically feeds the media forward if there is more

than a 1-second idle time after printing. This prevents the top

edge of the media from curling.

• OFF Disables the auto forward feed wait

• ON Enables the auto forward feed wait → c

c When ON is selected, the feed amount can be fine adjusted.

(3) FORWARD WAIT POS.

(Default: 0.0mm)

.

+5.0mm

-5.0mm

+4.9mm

-4.9mm

NOTE:

1. If the pitch of the media used

for the previous issue was less

than 20mm, the forward wait

will not be activated regardless

of the parameter setting.

2. The media will stay at the

forwarded position even if the

power is turned off/on, the

printer is reset, the print head

is opened/closed.

NOTE:

Underlined setting is the factory

default.

Page 32

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-18

2.6.2 Parameter Setting

(Cont.)

(4) FW/BK ACT.

• MODE1

The printer waits for next issue after 13.7-mm

media has been fed forward.

• MODE2 When thermal transfer and cut mode are

selected, the printer feeds 6-mm media

backward, then waits for next issue after 3-mm

media has been fed forward. From this position,

the printer starts the on-the-fly printing for next

issue. The 3-mm distance to the home position

is fed at 3 ips.

(5) PRE PEEL OFF

Select whether to activate the pre-strip function. When this

parameter is set to ON, the top edge of a label is separated

(pre-stripped) from the backing paper before the label is printed.

This function is intended to make the strip issue easier in the

case of labels that are hard to strip due to the label density,

strength of the adhesive used, or the print speed.

• OFF

Disables pre peel off

• ON Enables pre peel off

(6) BACK SPEED

Select back feed speed.

In strip issue a back feed speed of 3 ips may cause the correct

distance not to be fed due to a lack of torque, slippery media

surface, etc. In such cases reduce the back feed speed to 2 ips

to ensure the correct feed amount.

• STD

3ips

• LOW 2ips

(7) TYPE OF RIBBON

Select type of ribbon.

When a coating side of the ribbon is the outside, chooses CSO.

When a coating side of the ribbon is the inside, chooses CSI.

• CSO

Coated side out

• CSI Coated side in

NOTE:

Pre-strip function is automatically

enabled when the print speed is

set to 10 ips or faster. However,

the print speed is corrected

depending on the EX I/O

parameter setting, as follows.

EX I/O: TYPE 1

10 ips (203 dpi)

8 ips (305 dpi)

EX I/O: TYPE 2

Specified speed

Page 33

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-19

2.6.2 Parameter Setting

(Cont.)

2.6.2.2 Software Set

(1) FONT CODE

Allows you to select the character code used for printing.

Printed characters differ depending on the chosen character

code and font.

• PC-850

• PC-852

• PC-857

• PC-8

• PC-851

• PC-855

• PC-1250

• PC-1251

• PC-1252

• PC-1253

• PC-1254

• PC-1257

• LATIN9

• Arabic

• PC-866

• UTF-8

(2) ZERO FONT

Allows you to select the way the zero character is printed.

Select between “0” and “

Ø”.

• 0 No slash used

• Ø Slash used

(3) CODE

Select the command control code to be used.

• AUTO Automatically selected.

• {,|,}

• ESC, LF, NUL

• MANUAL The control code is specified by the user. → c

c When MANUAL is selected, you need to specify each of the

control codes 1 to 3 with a hex. code.

NOTE:

The following fonts do not support

a zero with a slash.

(If a zero with a slash is specified,

a zero without a slash will be

printed.)

[Bit map fonts]

OCR-A, OCR-B, GOTHIC725

Black, Kanji, Chinese character

[Outline fonts]

Price fonts 1, 2, and 3,

DUTCH801 Bold, BRUSH738

Regular, GOTHIC725 Black,

TrueType font

FF

00

FE

01

CODE1 CODE2 CODE3

Page 34

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-20

2.6.2 Parameter Setting

(Cont.)

(4) PEEL OFF STATUS

Specifies whether the printer sends a strip wait status to the

host in response to a status request command.

• OFF

• ON

(6) USB I/F STATUS

Specifies whether to return a response to the host via USB.

• OFF

Disables sending a response via USB

• ON Enables sending a response via USB

(7) FEED KEY

Selects the function of the FEED key.

• FEED

Feeds one label.

• PRINT Prints the data in the image buffer (The last label

printed)

(8) KANJI CODE

Select the KANJI code.

• TYPE1

Windows code

• TYPE2 Original code

(9) EURO CODE

Specifies the Euro code (€).

“20” to “FF” (Specify the hex code in 2 bytes of ASCII code)

(10) AUTO HD CHK

Select whether to perform the auto print head check when the

printer is powered on.

• OFF Auto print head check is not performed.

• ON Auto print head check is performed.

FF

20

FE

21

Page 35

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-21

2.6.2 Parameter Setting

(Cont.)

(11) WEB PRINTER

Select whether to use the printer as a web printer.

When the web printer is enabled, the status of the printer

connected to a network can be monitored through the web

browser.

• OFF

Disables web printer function

• ON INTERNAL Enables web printer function (using internal

memory)

• ON EXTERNAL Enables web printer function (using an

external usb memory)

(12) RBN NEAR END

Select the remaining ribbon length when the ribbon near end is

detected.

• OFF

Ribbon near end is not detected.

• 30m Ribbon near end is detected when the remaining

ribbon is 30-m long. (Equivalent to ribbon

diameter of 38 mm)

• 70m Ribbon near end is detected when the remaining

ribbon is 70-m long. (Equivalent to ribbon

diameter of 43 mm)

(13) EX.I/O

Select the type of expansion I/O interface operating mode. This

parameter needs to be set depending on the expansion I/O

control specification of the device to be connected via the

expansion I/O interface.

• TYPE1 Standard mode

• TYPE2 In-line mode

(14) LBL/RBN END

Select the operation to be performed when a label end or ribbon

end is detected.

• TYPE1

When a label/ribbon end is detected in the

middle of printing, the printer immediately stops

printing.

• TYPE2 Selectable only when the ribbon saving function

is not activated.

When a label/ribbon end is detected in the

middle of printing, the printer prints the halffinished label as far as possible, and stops when

the next label is at the home position.

(15) MAXI CODE

Select the Maxicode specification.

• TYPE1

Compatible with the current version

• TYPE2 Special specification

NOTE:

The type specified by the

command may differ from the

actual mode, depending on

the status of this parameter.

Also, the data transmission

method is slightly different.

For details, refer to the

External Equipment Interface

Specification.

NOTE:

Since detecting the remaining

ribbon length has a margin of

error, use the specified length

as a guide.

Page 36

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-22

2.6.2 Parameter Setting

(Cont.)

(16) XML

Select the type of XML data to be printed.

• OFF Disables XML data printing.

• STD Standard specification

• ORACLE Oracle

• SAP SAP

• STD EXT Standard specification (External memory)

• ORACLE EXT Oracle using an external memory

• SAP EXT SAP using an external memory

(17) THRESHOLD SELECT

This parameter is to choose which threshold value for the

media sensor to validate.

• REFLECT Reflective sensor

• TRANS. Transmissive sensor

Then, choose which value to use.

• MANUAL SET Threshold set in the Threshold mode

takes effect.

• COMMAND SET

Threshold set by command takes effect.

(18) ENERGY TYPE

This parameter is intended to make the printer perform

appropriate printing for the supplies to be used. If you use a

different supply from the setting, poor printing may occur.

• TRANSFER Thermal transfer print method → c

• DIRECT Thermal direct print method → d

c When TRANSFER is selected for the Energy type parameter,

choose a ribbon type.

Case of B-EX4T2-GS/TS

• Wax1 Wax 1

• Wax2 Wax 2

• Wax3 Wax 3

• Semi resin1

Semi-resin 1

• Semi resin2 Semi-resin 2

• Semi resin3 Semi-resin 3

• Resin1 Resin 1

• Resin2 Resin 2

• Reserve1 to Reserve2 Reserved

Case of B-EX4T2-HS

• Resin1

Resin 1

• Resin2 Resin 2

• Reserve1 to Reserve8 Reserved

d When DIRECT is selected for the Energy type parameter

• Standard

Standard

• Reserve1 to Reserve9 Reserved

Page 37

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-23

2.6.2 Parameter Setting

(Cont.)

(19) PW SAVE TIME

Sets the length of time until the printer enters the power saving

mode. (Unit: minute)

(Default: 15 minutes)

2.6.2.3 PANEL

(1) LCD LANGUAGE

Choose a language in which the LCD messages are displayed.

• ENGLISH

• GERMAN

• FRANCH

• DUTCH

• SPANISH

• JAPANESE

• ITALIAN

• PORTUGUESE

• SIMP. CHINESE

(2) DISPLAY

Choose whether the model name, the number of labels printed

and the IP address are displayed or hidden.

• MACHINE NAME OFF: Hidden

ON

: Displayed

• PRINT PAGE OFF: Hidden

ON

: Displayed

• IP ADDRESS OFF

: Hidden

ON: Displayed

(3) CONTRAST

Adjust the contrast of the LCD.

(Default: 40)

NOTE:

• The language displayed

on panel is Japanese

when Japanese is

selected, and English

when English, German,

French, Dutch, Spanish,

Italian; or Portuguese is

selected.

240 min.

1 min.

239 min.

2 min.

NOTE:

For details of the power saving

mode, refer to Section 3.4

Power Save Function.

50

24

48

26

High

Low

Page 38

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-24

2.6.2 Parameter Setting

(Cont.)

2.6.3 Enabling LAN/WLAN

2.6.2.4 PASSWORD

(1) PASSWORD

This parameter is for the system administrator only. Please do

not change the setting for this parameter.

The LAN/WLAN menu allows selecting whether or not to enable

the LAN communication and SNMP.

(1) LAN/WLAN

• OFF LAN and Wireless LAN are disabled.

• ON (AUTO)

Automatically selected.

• ON (LAN) LAN is enabled.

• ON (WLAN) Wireless LAN is enabled.

(2) SNMP

• OFF SNMP is disabled.

• ON SNMP is enabled.

USER SYSTEM MODE

<1>RESET

<2>PARAMETER SET

<3>ADJUST SET

<4>LAN/WLAN

Page 39

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-25

2.6.4 Basic Program Setting

2.6.5 Enabling Z-Mode

The following table shows the contents of the Basic program

setting menu.

Contents of the Basic Program Setting Menu

Menu Sub menu

BASIC BASIC

FILE MAINTENANCE

TRACE

EXPAND MODE

(1) BASIC

Select whether to enable the BASIC program.

• OFF

Disables BASIC program.

• ON Enables BASIC program.

(2) FILE MAINTENANCE

The block number and BASIC program file name (up to 12

characters) stored in the BASIC program storage area are

displayed. If the file name exceeds 12 characters, the overflowing

characters are not displayed.

When no file is stored, a hyphen (“-“) is displayed in place of the

file name.

(3) TRACE

Allows you to enable tracing in the BASIC program.

• OFF

Disables tracing the BASIC program.

• ON Enables tracing the BASIC program.

(4) EXPAND MODE

The printer switches the mode to execute the BASIC program.

The Z-Mode menu allows you to select whether or not to enable

the Z-Mode

.

(1) Z-MODE

• OFF

Z-Mode is disabled.

• ON SETTING OFF Z-Mode is enabled. BASIC system mode

program is not started automatically.

• ON SETTING ON Z-Mode is enabled. BASIC system mode

program is started automatically.

USER SYSTEM MODE

<3>ADJUST SET

<4>LAN/WLAN

<5>BASIC

<6>Z-MODE

USER SYSTEM MODE

<2>PARAMETER SET

<3>ADJUST SET

<4>LAN/WLAN

<5>BASIC

Page 40

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-26

2.6.6 Automatic Calibration

The Auto Calibration menu allows you to select whether or not to

enable automatic calibration at power on time. When automatic

calibration is activated, the printer feeds the media for about 160

mm each time the power is turned on or the print head is open

then closed to detect the print start position.

(1) AUTO CALIB

• OFF Disabled.

• ON TRANS. Enabled. (Transmissive sensor)

• ON REFLECT Enabled. (Reflective sensor)

• ON ALL Enabled. (Transmissive & Reflective

sensors)

• ON TRANS.+Bfeed same as “ON TRANS” setting

• ON REFLECT+Bfeed same as “ON REFLECT” setting

• ON ALL+Bfeed same as “ON ALL” setting

NOTES:

1. When AUTO CALIB is enabled, an automatic calibration is

performed at an open/close of the print head and at a power on

time.

2. After the automatic calibration is performed, the media length,

effective print length, sensor type and whether the ribbon is used

or not, obtained through the calibration, will take effect until next

calibration is performed or the printer power is turned off.

(Settings specified by commands are ignored.)

3. This function is available only when the media pitch is 10.0 mm to

150.0 mm.

4. When the printer cannot detect the second black mark/gap, it will

continue to feed the media for up to 500.0mm. If a black mark/gap

is still not detected, the printer will stop, resulting in a paper jam.

5. During an automatic calibration, the printer also feeds the ribbon.

Even if the ribbon is not loaded, this will not result in an error.

However, the print condition will be automatically changed to “No

ribbon” after the calibration ends.

6. When the cutter is installed and a previous issue was performed in

cut issue mode, the media is cut and ejected after the automatic

calibration is completed.

7. When a label end occurs during an automatic calibration, the

printer stops, resulting in an error. Loading new media and

closing the print head can clear the error and resume the

automatic calibration.

8. Since the optional ribbon saving module is not available for the BX4T2, Setting + Bfeed will have no effect and the setting will revert

to without BFeed.

9. The feed speed during automatic calibration is 3 ips.

10. Do not open the print head during automatic calibration. The

subsequent printer operation is not guaranteed. If you open the

print head, turn off the power and back to on.

USER SYSTEM MODE

<4>LAN/WLAN

<5>BASIC

<6>Z-MODE

<7>AUTO CALIB

NOTE:

• Since the head-up function is

not provided to the B-EX4T2

and B-EX6T2, the setting and

the printer behavior will be

automatically changed to

“ON TRANS”,”ON

REFLECT”,”ON ALL” even

if “+Bfeed” is selected for

these models.

Page 41

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-27

2.6.7 Dump Mode Setting

In Dump Mode, the data in the receive buffer is printed. The data

is expressed in hexadecimal values. This operation allows

verification of the programming commands or the debug of the

program.

(1) BUFFER

Select the receive buffer to dump.

• RS-232C RS-232C receive buffer

• CENTRONICS Centronics receive buffer

• LAN Network I/F receive buffer

• BASIC1 BASIC Interpreter:

I/F → Interpreter buffer

• BASIC2 BASIC Interpreter:

Interpreter buffer → I/F

• USB USB receive buffer

• RFID RFID receive buffer

(2) DUMP LIST

This parameter is to choose the output destination.

• USB MEMORY Saves in the USB memory. → c

• PRINT Prints out → d

c When USB MEMORY is selected:

A file is automatically created in the USB memory and named in

the following format based on the printer model and saved date.

/ATA0/DUMP/B-EX4T1_DUMP_1007291030.BIN

(e.g. B-EX4T Type1, 10:30, July 29, 2010)

d When PRINT is selected:

Choose a printing method.

• ON DEMAND Prints 166 lines of data (approx. 50 cm), then

stops. Subsequent data is printed when the

[ENTER] key is pressed.

• ALL Prints all data in the receive buffer.

USER SYSTEM MODE

<5>BASIC

<6>Z-MODE

<7>AUTO CALIB

<8>DUMP MODE

NOTES:

1. If a file with the same name

already exists in the USB

memory, it will be

overwritten.

2. Selecting “RS-232C” or

“CENTRONICS” without

the optional board installed

causes a 0-KB file to be

output.

3. If an error occurs while

using the USB memory, the

error message is displayed.

For details, refer to Section

2.6.12 Copying Data

to/from USB Memory.

Page 42

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-28

2.6.7 Dump Mode Setting

(Cont.)

The data in the receive buffer is printed as follows.

Receive Buffer Size

Interface B-EX4T2-GS/TS/HS

RS-232C 1MB (65536 lines)

Centronics 1MB (65536 lines)

LAN 1MB (65536 lines)

BASIC 1 8KB (512 lines)

BASIC 2 8KB (512 lines)

USB 1MB (65536 lines)

RFID 8KB (512 lines)

Required Media Length

Interface B-EX4T2-GS/TS B-EX4T2-HS

RS-232C 198.2 m 198.6 m

Centronics 198.2 m 198.6 m

LAN 198.2 m 198.6 m

BASIC 1 2 m 2 m

BASIC 2 2 m 2 m

USB 198.2 m 198.6 m

RFID 2 m -

*: Media length required for printing all data in the receive buffer.

:

:

:

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ................

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ................

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ................

00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 ................

7B 41 58 3B 2B 30 30 30 2C 2B 30 30 30 2C 2B 30 {AX;+000,+000,+0

30 7C 7D 7B 44 30 37 37 30 2C 31 31 30 30 2C 30 0|}{D0760,1100,0

37 34 30 7C 7D 7B 43 7C 7D 7B 4C 43 3B 30 30 33 740|}{C|}{LC;003

30 2C 30 30 32 30 2C 30 30 33 30 2C 30 36 36 30 0,0020,0030,0660

2C 30 2C 32 7C 7D 7B 4C 43 3B 30 30 37 30 2C 30 0,2|}{LC;0070,0

30 32 30 2C 30 30 37 30 2C 30 36 36 30 2C 30 2C 020,0070,0660,0,

39 7C 7D 7B 4C 43 3B 30 30 35 30 2C 30 30 32 30 9|}{LC;0050,0020

:

:

:

44 45 46 47 48 49 4A 7C 7D 7B 50 43 31 30 3B 30 DEFGHIJ|}{PC10;0

33 35 30 2C 30 34 30 30 2C 31 2C 31 2C 4B 2C 30 350,0400,1,1,K,0

30 2C 42 3D 41 42 43 44 65 66 67 68 69 6A 6B 6C 0,B=ABCDefghijkl

6D 6E 6F 70 7C 7D 7B 50 56 30 32 3B 30 33 33 30 mnop|}{PV02;0330

2C 30 36 36 30 2C 30 32 37 30 2C 30 32 35 30 2C 0660,0270,0250,

41 2C 30 30 2C 42 3D 42 7C 7D 7B 50 56 30 33 3B A,00,B=B|}{PV03;

:

:

:

3B 30 39 30 30 2C 30 31 38 30 2C 54 2C 48 2C 30 ;0900,0180,T,H,0

35 2C 41 2C 30 3D 31 32 33 34 35 36 37 38 39 30 5,A,0=1234567890

41 42 43 44 45 7C 7D 00 00 00 00 00 00 00 00 00 ABCDE|}.........

:

:

:

Print Conditions

• Printing width: 3.9 inches

(Approx. 100 mm)

• Sensor selection: None

• Print speed: 6”/sec. (203 dpi)

5”/sec. (300 dpi)

3”/sec. (600dpi)

• Printing mode: Depends on

the selection in use.

• 16 bytes/line

• Data is printed in the order

from the new one to the old.

• Data specified by the receive

buffer write pointer will be

printed in boldface.

NOTE:

If an error occurs while

printing, the printer stops

printing and shows an error

message.

To clear the error, press the

[PAUSE].

After clearing the error the

printer does not resume

printing automatically.

Page 43

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-29

2.6.8 Logging

The Log menu allows the saving of print logs to USB memory.

(1) LOG

• PRINTER TO USB Saves print logs in the USB memory.

A file is automatically created in the USB memory and named in

the following format based on the printer model and saved date.

/ATA0/LOG/B-EX4T1_LOG_1007291030.TXT

(e.g. B-EX4T Type1, 10:30, July 29, 2010)

USER SYSTEM MODE

<6>Z-MODE

<7>AUTO CALIB

<8>DUMP MODE

<9>LOG

NOTES:

1. If a file with the same

name already exists in the

USB memory, it will be

overwritten.

2. If an error occurs while

using the USB memory,

the error message is

displayed. For details, refer

to Section 2.6.12 Copying

Data to/from USB Memory.

After clearing the error the

printer does not resume

logging automatically.

Page 44

2. PRINTER SETUP ENGLISH VERSION EO1-33094

2.6 Printer Setting

E2-30

2.6.9 System Mode

How to enter the System Mode

The System Mode consists of the following menus.

<1>DIAG.

Used to check and print the printer system information and

maintenance counter status.

<2>PARAMETER SET (⇒ Section 2.6.2)