Page 1

TEC Thermal Printer

B-SX4T/SX5T SERIES

Product Description

Document No. EO10-33013B

Original Jan., 2003

(Revised Feb., 2003)

Jan., 2006)

PRINTED IN JAPAN

Page 2

EO10-33013B

A

(Revision Date: May 22, 2009)

TABLE OF CONTENTS

Page

1. OUTLINE -------------------------------------------------------------------------------------------------1- 1

1.1 PRINTER SPECIFICATIONS---------------------------------------------------------------------------1- 1

1.2 DESCRIPTION OF MODEL NUMBER---------------------------------------------------------------1- 1

1.3 APPEARANCE AND DIMENTIONS (APPROXIMATE) -----------------------------------------1- 2

1.4 BASIC SPECIFICATIONS-------------------------------------------------------------------------------1- 3

1.5 ELECTRONICS SPECIFICATIONS-------------------------------------------------------------------1- 6

2. SUPPLY SPECIFICATIONS-------------------------------------------------------------------------2- 1

2.1 MEDIA --------------------------------------------------------------------------------------------------------2- 1

2.2 RIBBON ------------------------------------------------------------------------------------------------------2- 4

2.3 CARE AND HANDLING OF THE MEDIA AND RIBBON ----------------------------------------2- 5

2.4 SPECIFICATION OF RFID TAG (B-9704-RFID-U1-US/EU-R, H1-QM-R)------------------2- 6

2.5 SPECIFICATION OF RFID TAG (B-SX704-RFID-U2-EU/AU-R)-----------------------------2-11

2.6 SPECIFICATION OF RFID TAG (B-SX704-RFID-U2-US-R)----------------------------------2-18

2.7 SPECIFICATION OF RFID TAG (B-SX704-RFID-U2-CN-R)---------------------------------- 2-26

3. OPTIONAL KIT -----------------------------------------------------------------------------------------3- 1

3.1 CUTTER MODULE: B-4205-QM/QM-R (Swing Cutter),

B-8204-QM/QM-R (Rotary Cutter) -----------------------------------------------------------3- 2

3.2 STRIP MODULE: B-9904-H-QM/QM-R (option for the B-SX4T)-------------------------------3- 2

3.3 RIBBON SAVING MODULE: B-9904-R-QM (option for the B-SX4T) ------------------------3- 2

3.4 RIBBON SAVING MODULE: B-9904-R2-QM/QM-R (option for the B-SX4T)--------------3- 2

3.5 PCMCIA INTERFACE BOARD: B-9700-PCM-QM/QM-R ---------------------------------------3- 3

3.6 EXPANSION I/O INTERFACE BOARD: B-7704-IO-QM/QM-R (option for the B-SX4T) 3- 3

3.7 BUILT-IN LAN INTERFACE BOARD: B-9700-LAN-QM/QM-R---------------------------------3- 3

3.8 USB INTERFACE BOARD: B-9700-USB-QM/QM-R ---------------------------------------------3- 3

3.9 RFID MODULE: B-9704-RFID-U1-US/U1-EU/U1-EU-R/H1-QM/H1-QM-R-----------------3- 4

3.10 RFID MODULE: B-SX704-RFID-U2-EU/AU/US/CN-R -------------------------------------------3- 5

3.11 WIRELESS LAN MODULE (B-9700-WLAN-QM-R)-----------------------------------------------3- 7

• This manual is intended for both B-SX4T series and B-SX5T series. Please note that the

illustrations and pictures provided are of the B-SX4T series.

• The SP40II has been developed from the B-SX4T-GS10-QP, and the differences between

two are the color of the front cover and the operation panel ass’y, the model name label, and

the CD-ROM. The other specifications including the firmware are common.

CAUTION!

1. This manual may not be copied in whole or in part without prior written permission of TOSHIBA

TEC.

2. The contents of this manual may be changed without notification.

Copyright © 2004

by TOSHIBA TEC CORPORATION

ll Rights Reserved

570 Ohito, Izunokuni-shi, Shizuoka-ken, JAPAN

Page 3

1. OUTLINE EO10-33013B

(Revision Date: Jan 22, 2009)

1.1 PRINTER SPECIFICATIONS

1. OUTLINE

1.1 PRINTER SPECIFICATIONS

1) Various bar codes, characters and graphic data can be printed using both thermal transfer and

thermal direct methods. This printer can also print writable characters and logos at designated

coordinates by using a graphic command.

2) The Centronics and RS-232C are available as standard interfaces between the printer and a PC. In

addition, optional interfaces such as PCMCIA interface, USB interface, LAN interface and Wireless

LAN interface are available. The expansion I/O interface, which is an option for the B-SX4T series,

is provided on the B-SX5T series as standard.

3) A 32-bit CPU and a Field Programmable Gate Array (FPGA) equipped with several peripheral LSIs

realizes high system performance.

4) With the element positioned at the edge of the print head, print quality is improved because the

media passes straight through.

5) The B-SX4T series accommodates a max. format size of 104.0 mm wide by 1498.0 mm long and a

max. printing speed of 10”/sec.

The B-SX5T series accommodates a max. format size of 128.0 mm wide by 1498.0 mm long and a

max. printing speed of 8”/sec.

6) High throughput can be obtained with “on-the-fly” formatting.

7) Installation space is minimized because the media is loaded internally.

8) The metal cover and damper provide a heavy-duty enclosure.

9) Various optional devices, including the Strip module including the rewinder, the ribbon saving

module which economizes ribbon usage, rotary cutter module, swing cutter module, RFID module,

wireless LAN module and are available.

The strip module and the ribbon saving module are standard on the B-SX5T series.

NOTE: Every size is written in millimeter (mm) in this manual. To obtain the size in inch, divide by 25.4.

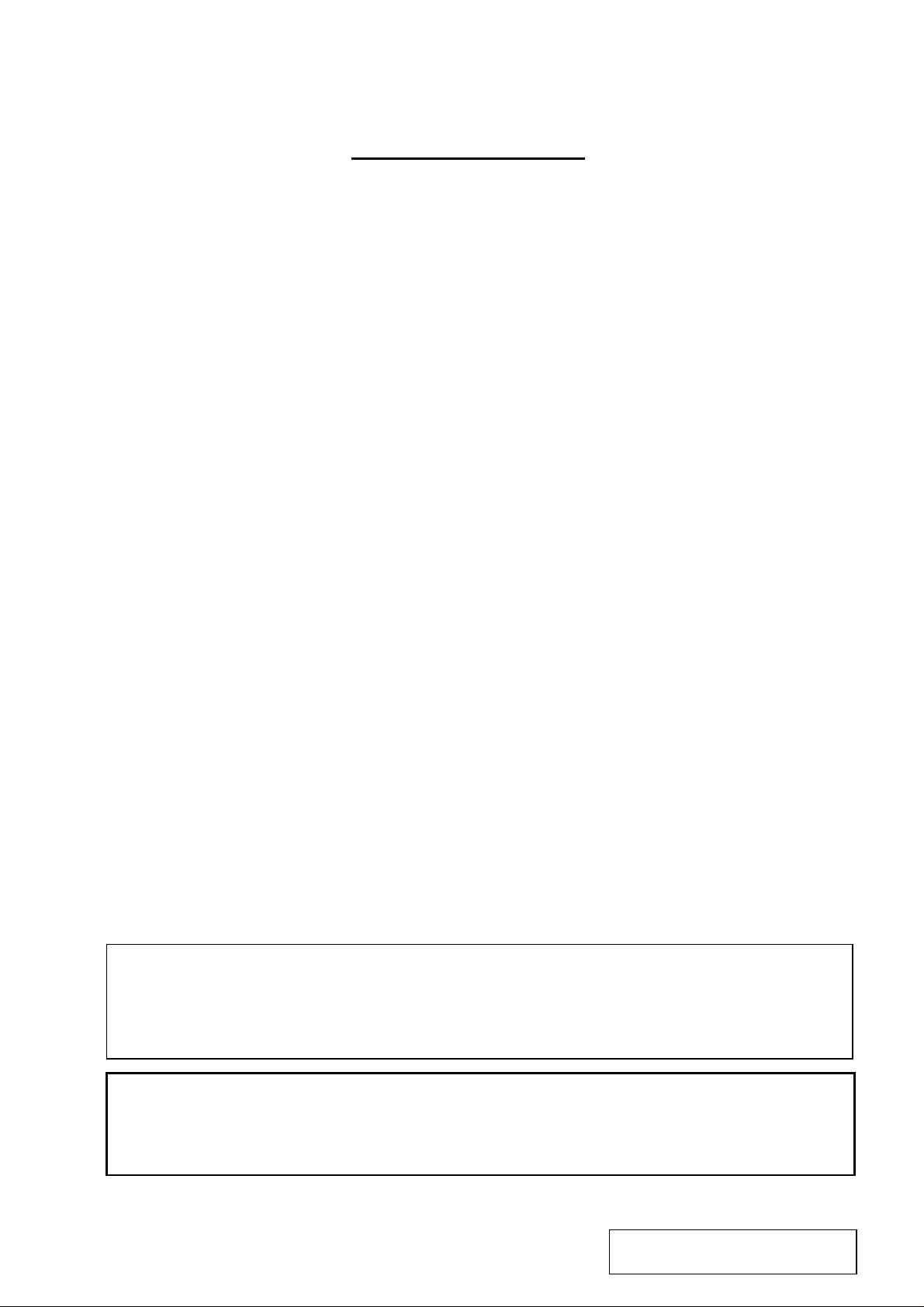

1.2 DESCRIPTION OF MODEL NUMBER

B – S X 4 T – G S 1 0 – Q Q - R

RoHS compliance model

Destination Code

QP: Europe Bloc.

QM: Standard for Worldwide

QQ-US: United States of America

CN: China

QQ: North America Bloc.

Machine Type

0: Standard

2: Including the ribbon saving module, strip module, and

Machine Version

1: TEC brand

2: TOSHIBA brand

Issue mode

S: Batch

Resolution

G: 8 dots/mm

T: 12 dots/mm

Printing method:

Thermal direct or Thermal transfer

Printing width

4: 4 inches

5: 5 inches

expansion I/O PC board

1- 1

Page 4

1. OUTLINE EO10-33013B

y

y

(Revision Date: May 18, 2006)

1.3 APPEARANCE AND DIMENSIONS (APPROXIMATE)

1.3 APPEARANCE AND DIMENSIONS (APPROXIMATE)

1.3.1 Front View/Rear View

Front View

LCD Message Display

Operation

Panel

Media Outlet

Rear View

PCMCIA Card Slot (Option),

Top Cover

Parallel Interface

Connector (Centronics)

Supply Window

Serial Interface

Connector (RS-232C)

AC Power Inlet

USB Connector (Option), or

LAN Connector (Option)

USB Connector

(Option), Wireless

LAN module

(Option) or LAN

Connector (Option)

Expansion I/O

Interface Connector

(B-SX4T: Option)

Power Switch

{: OFF

|: ON

1.3.2 Operation Panel

LCD Message Display

When the power is turned on and it is ready to print, ON

LINE is displayed.

POWER LED (Green)

Lights when the power is turned on.

ON-LINE LED (Green)

1) Flashes when communicating with a host PC.

2) Lights while printing.

ERROR LED (Red)

Lights when the printer does not operate correctly.

FEED key

Feeds paper.

RESTART key

Resets the printer when paused or when an error occurs.

Used to set the threshold. (Refer to the Owner’s Manual.)

PAUSE key

Pauses printing.

Message display shows PAUSE and a remaining count.

Used to set the threshold (Refer to the Owner’s Manual.)

POWER LED

(Green)

[FEED] ke

[RESTART] ke

LCD Message Display

ON LINE LED

(Green)

ERROR LED

(Red)

[PAUSE] key

1.3.3 Dimensions (Approximate)

Standard: 291 mm (W) x 460 mm (D) x 308 mm (H)

With cutter module: 291 mm (W) x 521 mm (D) x 308 mm (H)

1- 2

Page 5

1. OUTLINE EO10-33013B

1.4 BASIC SPECIFICATIONS

1.4 BASIC SPECIFICATIONS

1) Printing method ................... Thermal direct printing or thermal transfer printing

2) Print head

[B-SX4T: 4 inches]

(1) Total number of dots ...... 832 dots (3) Effective print width ....... 104.0 mm

(2) Dot density ..................... 8 dots/mm (4) Thermal pitch .......…...... 0.125 mm

[B-SX5T: 5 inches]

(1) Total number of dots ...... 1536 dots (3) Effective print width ....... 128.0 mm

(2) Dot density ..................... 12 dots/mm (4) Thermal pitch .......…...... 0.083 mm

3) Print speed

B-SX4T.................................3”/sec., 6”/sec., 10”/sec.

B-SX5T.................................3”/sec., 5”/sec., 8”/sec.

NOTE: These print speeds are available when printing ratio is less than 15% of the entire label or tag

paper.

4) Format size (W) x (L)

B-SX4T.................................Max. 104.0 mm x 1498.0 mm

B-SX5T.................................Max. 128.0 mm x 1498.0 mm

5) Issue mode ..........................Batch

Auto cut (Auto cut mode is available only when the optional cutter is

attached.)

Strip (In case of the B-SX4T, the strip mode is available only when the

optional strip module is attached.)

6) Type of bar code/two dimensional code

(1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

7) Bar code rotation ................. 0

JAN8, EAN8, JAN13, EAN13, UPC-A, UPC-E

EAN8, EAN13, UPC-A, UPC-E + 2digit

EAN8, EAN13, UPC-A, UPC-E + 5digit

NW-7

CODE39 (STANDARD)

CODE39 (FULL ASCII)

ITF

MSI

CODE93

CODE128

EAN128

Data Matrix

°, 90°, 180°, 270°

(13)

(14)

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

PDF417

QR Code

Industrial 2 of 5

Customer Bar Code

POSTNET

RM4SCC

(Royal Mail 4 State Customer Code)

KIX CODE

Maxi Code

Micro PDF417

CP CODE

RSS14

1- 3

Page 6

1. OUTLINE EO10-33013B

1.4 BASIC SPECIFICATIONS

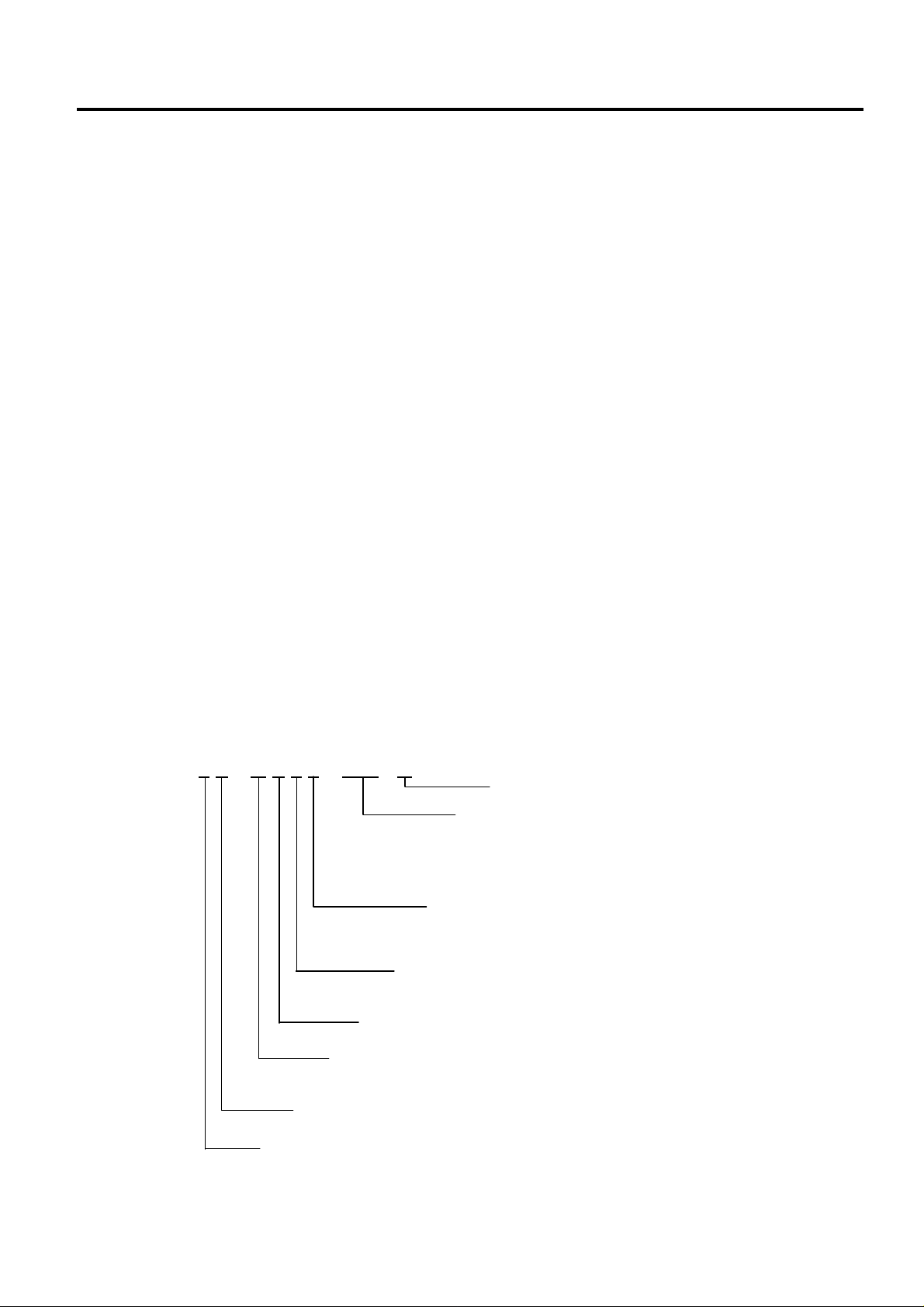

8) Magnification of bar code

UPC/EAN/JAN/CODE93/128/PDF417.........Up to 6 modules can be automatically calculated

using 1-module width designation (1 to 15 dots).

Dots/Module

Bar code

UPC-A/E

EAN8/13

JAN8/13

CODE93

EAN128

CODE128

PDF417

Bar code

UPC-A/E

EAN8/13

JAN8/13

CODE93

EAN128

CODE128

PDF417

Min. Module Width (mm)

Magnification (times)

Min. Module Width (mm)

Dots/Module

Min. Module Width (mm)

Magnification (times)

Min. Module Width (mm)

2 3 4 5 6 7 8

0.25 0.38 0.50 0.63 – – –

0.76 1.14 1.51 1.91 – – –

0.25 0.38 0.50 0.63 0.75 0.88 1.00

9 10 11 12 13 14 15

– – – – – – –

– – – – – – –

1.13 1.25 1.38 1.50 1.63 1.75 1.88

1.13 1.25 – – – – –

NW-7/CODE39/ITF/MSI/Industrial 2 of 5 ....The width of narrow bars, wide bars and spaces can

be optionally changed in a range of 1 to 99 dots.

Data Matrix...................................................The width of one cell can be changed in a range of 1

to 99 dots.

9) Type of characters

[B-SX4T]

(1) Times Roman medium (12, 15 point) (9) Prestige Elite medium (10.5 point)

(2) Times Roman bold (15, 18, 21 point) (10) Prestige Elite bold (15 point)

(3) Times Roman Italic (18 point) (11) Courier medium (15 point)

(4) Helvetica medium (9, 15, 18 point) (12) Courier bold (18 point)

(5) Helvetica bold (18, 21 point) (13) OCR-A, B (12 point)

(6) Helvetica Italic (18 point) (14) Outline font (Helvetica bold, Helvetica bold proportional,

(7) Presentation bold (27 point) Price Font (1,2,3), Times roman proportional, Pop

(8) Letter Gothic medium (14.3 point) Proportional, Proportional)

(15) Writable characters (2-byte character is available.)

[B-SX5T]

(1) Times Roman medium (8, 10 point) (9) Prestige Elite medium (7 point)

(2) Times Roman bold (10, 12, 14 point) (10) Prestige Elite bold (10 point)

(3) Times Roman Italic (12 point) (11) Courier medium (10 point)

(4) Helvetica medium (6, 10, 12 point) (12) Courier bold (12 point)

(5) Helvetica bold (12, 14 point) (13) OCR-A, B (12 point)

(6) Helvetica Italic (12 point) (14) Outline font (Helvetica bold, Helvetica bold proportional,

(7) Presentation bold (18 point) Price Font (1,2,3), Times roman proportional, Pop

(8) Letter Gothic medium (9.5 point) Proportional, Proportional)

(15) Writable characters (2-byte character is available.)

10) Character code

(1) PC-850 (2) PC-8 (3) PC-852 (4) PC-857 (5) Arabic (6) LATIN 9 (7) PC-1257 (8) PC-1254

(9) PC-1253 (10) PC-1252 (11) PC-1251 (12) PC-1250 (13) PC-855 (14) PC-851

11) Character magnification

(1) Regular font: 0.5 ~ 9.5 times (magnified by 0.5 times in each direction)

(2) Outline font: 2.0 ~ 85.0 mm (magnified 0.1 mm in each direction)

NOTE: When the outline font size is large, the ribbon may wrinkle according to the quality of the

ribbon or print tone.

1- 4

Page 7

1. OUTLINE EO10-33013B

1.4 BASIC SPECIFICATIONS

12) White or black background all types of characters are available.

13) Character rotation ...........................0

14) Character strings rotation ...............0

°, 90°, 180°, 270°

°, 90°, 180°, 270°

15) Type of line

(1) Horizontal line (2) Vertical line (3) Slant line (4) Square (5) Rounded Rectangle (6) Circle

16) Line Width .......................................0.1 to 0.9 mm can be specified (in unit of 0.1 mm)

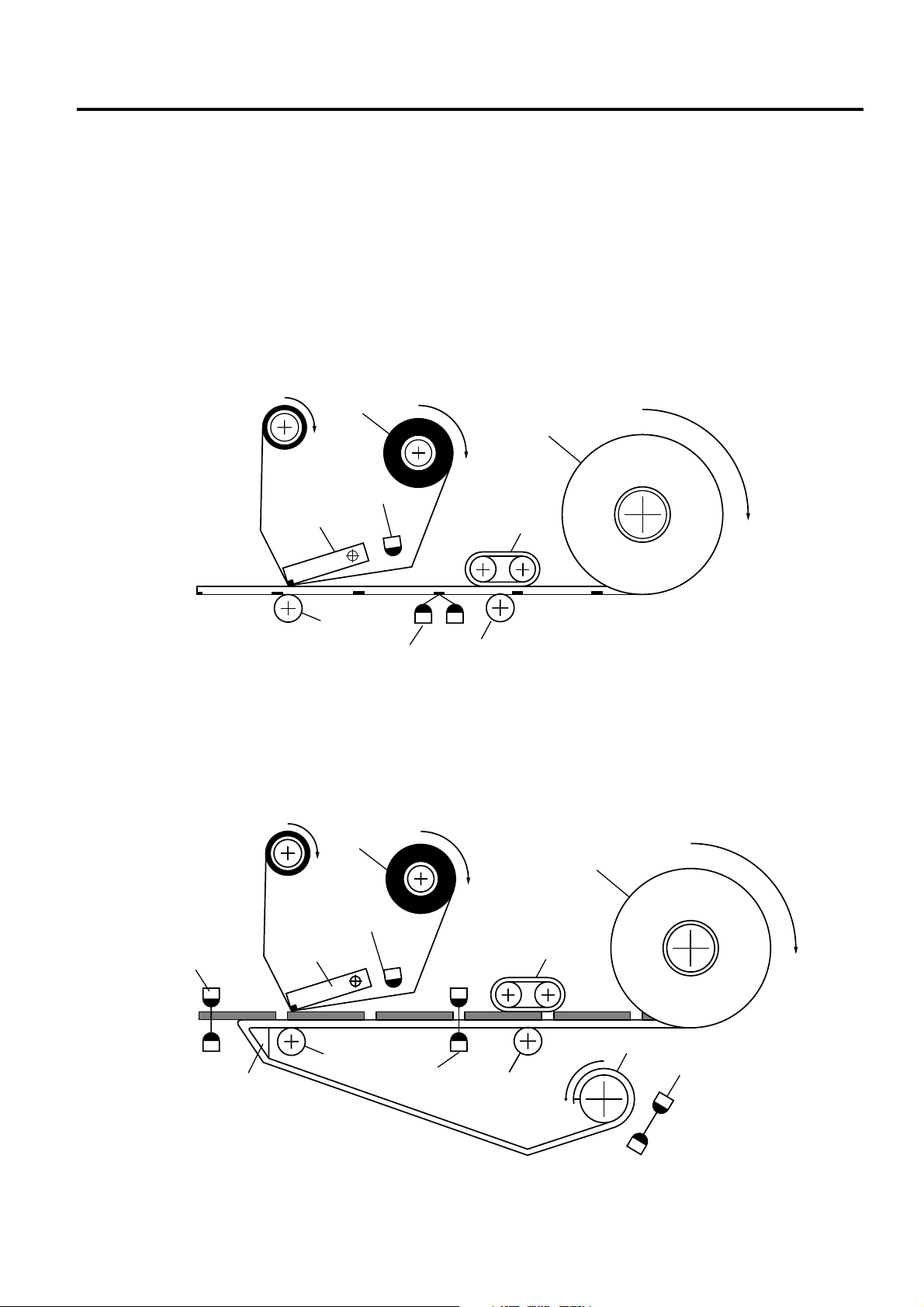

17) Mechanism

(1) Batch mechanism

This is the standard mechanism which lets the printer print continuously without winding the

label or tag paper.

Ribbon

Tag

Ribbon End Sensor

Print Head

Pinch

Roller

Platen

Black Mark

Sensor

Feed

Roller

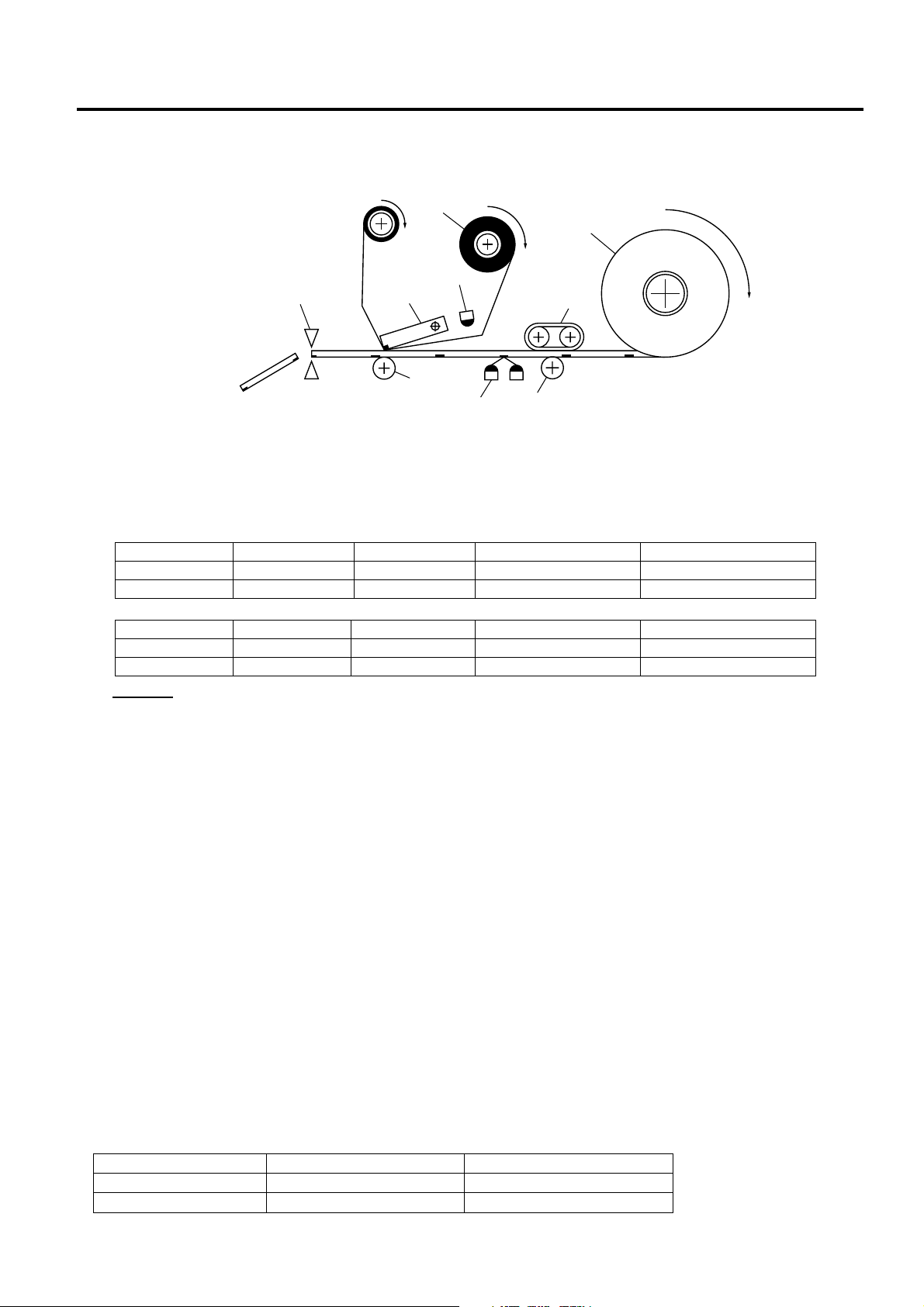

(2) Strip mechanism (B-SX4T series: Option)

When the strip module is attached, labels are stripped from the backing paper by the strip

shaft. The next label will not be printed until the preceding label is taken away. The backing

paper is wound onto the take-up spool. By installing the rewinder guide plate the tag paper

and label can be wound onto the take-up spool.

Ribbon

Label

Strip Sensor

Ribbon End Sensor

Print Head

Pinch

Roller

Strip Shaft

Platen

Feed Gap

Sensor

Feed

Roller

Take-up Spool

Rewind Full Sensor

1- 5

Page 8

1. OUTLINE EO10-33013B

(Revision Date: Jan. 22, 2009)

1.5 ELECTRONICS SPECIFICATIONS

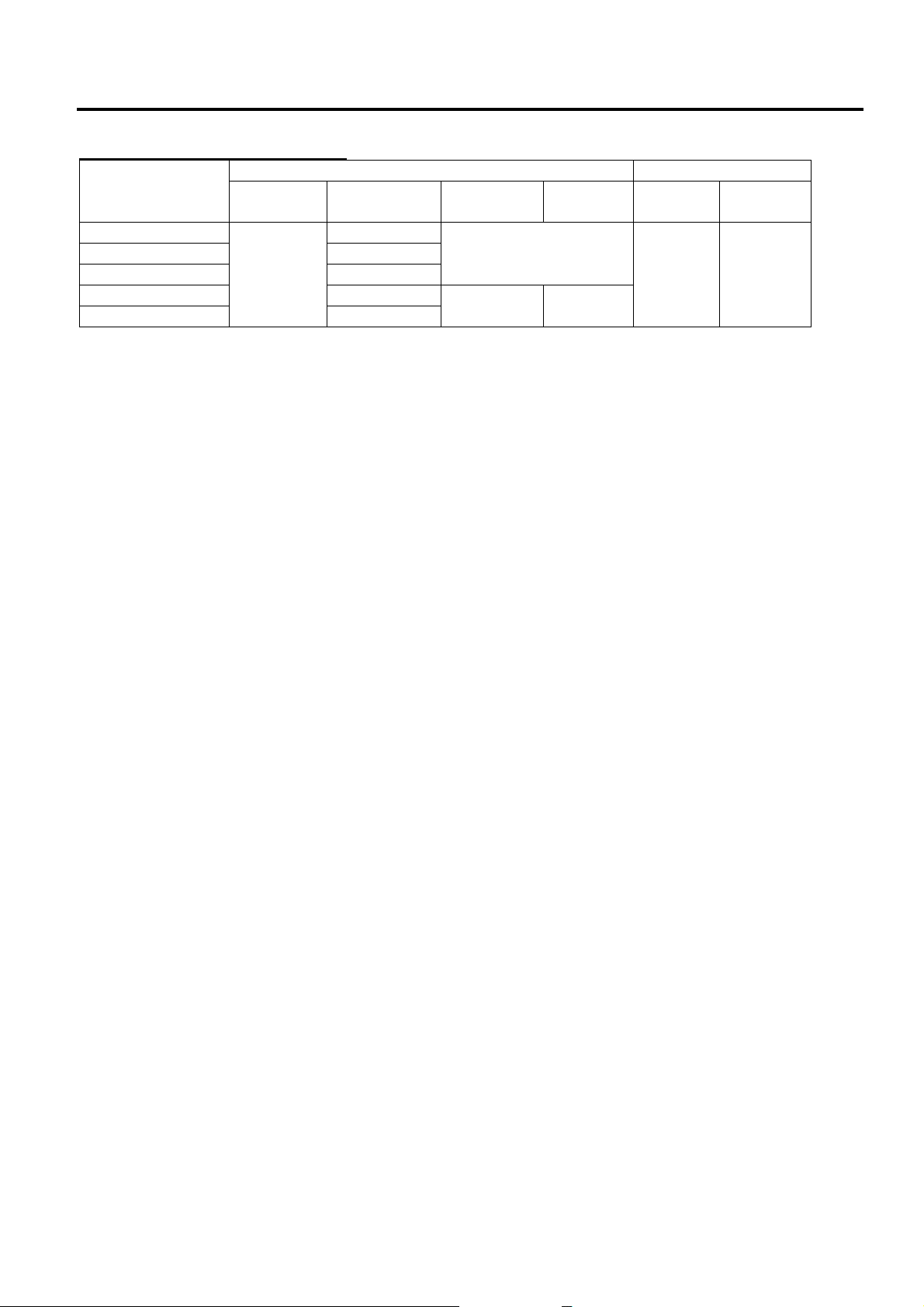

(3) Auto cut mechanism (Option)

When the cutter module is installed, the backing paper of the label stock or tag paper is cut

individually (stop and cut).

Ribbon

Tag

Cutter

Ribbon End Sensor

Print Head

Pinch

Roller

Platen

Black Mark

Sensor

Feed

Roller

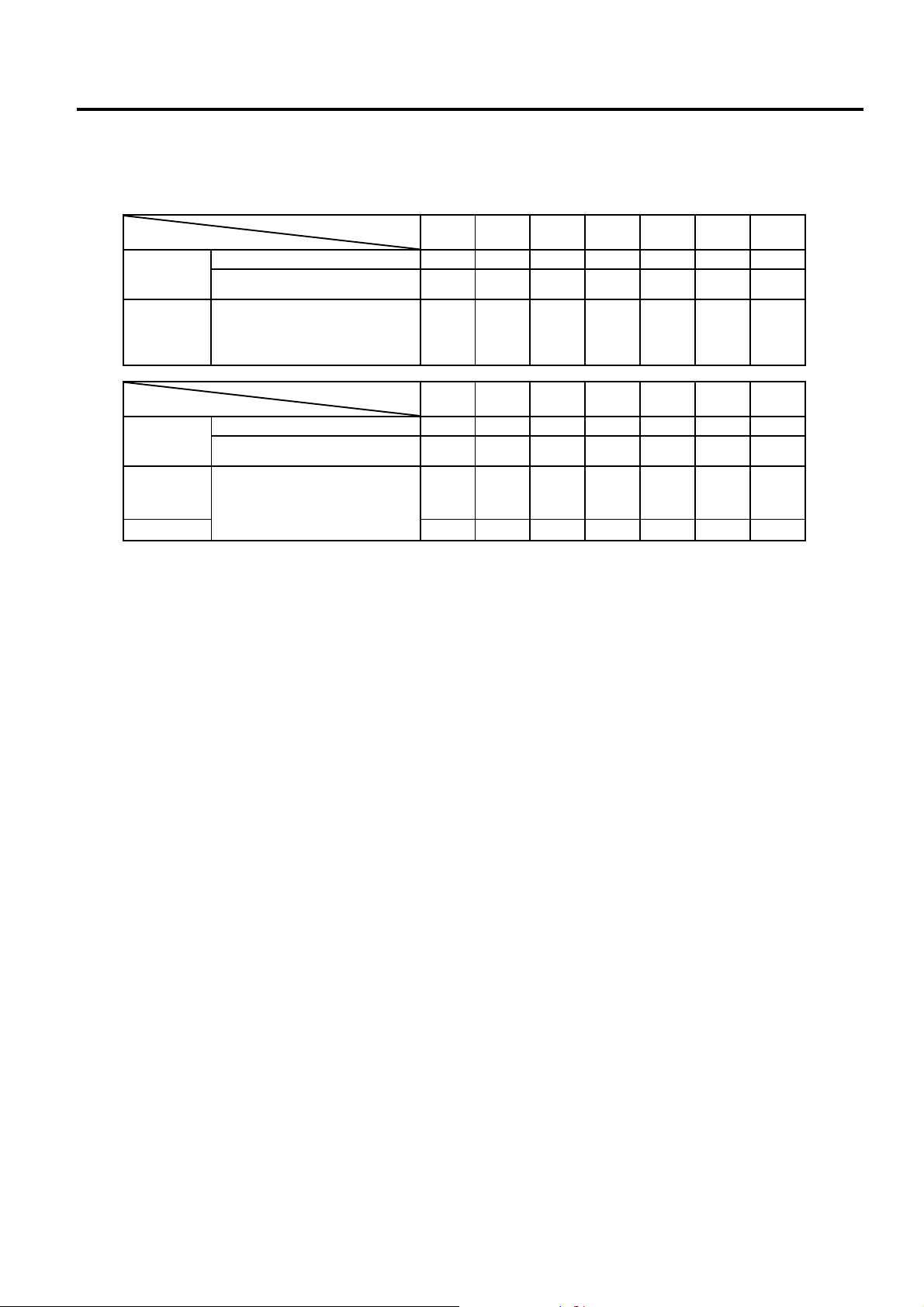

18) Power supply

QQ model: AC100 ~ 120 V ±10%, 50/60Hz QP/CN model: AC220 ~ 240 V ±10%, 50Hz

QM model: AC100 ~ 240 V ±10%, 50/60Hz

19) Current consumption

[B-SX4T]

QQ model QP/CN model QM-R model (100V) QM-R model (240V)

Printing 133 W, 1.6A 134W, 1.0A 130W, 2.5A 138W, 1.1A

Stand-by 14W, 0.18A 14W, 0.13A 11W, 0.18A 20W, 0.17A

[B-SX5T]

QQ model QP/CN model QM-R model (100V) QM-R model (240V)

Printing 130 W, 1.7A 124W, 0.7A 144W, 3.0A 142W, 1.3A

Stand-by 15W, 0.19A 16W, 0.16A 13W, 0.19A 21W, 0.17A

NOTES:

1. Be sure to provide an exclusive AC outlet for this machine.

2. Universal type PS unit is used for QM-R, CN-R, and SP40II-R models.

20) Rush current

QQ model: 11A

QP/CN model: 14A

QM model: 100V: 10A, 240V: 21A

1.5 ELECTRONICS SPECIFICATIONS

1) CPU ..................................... HD6417709SF100B

2) Memory

Note: For QM-R and SP40II-R models, the MAIN4 PC board containing large-capacity memory has

been used since January 2009 (Serial No. 2609Axxxxxx and after). For CN-R model, the MAIN4

PC board is to be used as from February 2009 (Serial No. 2609Dxxxxxx and after).

(1) Program ............................4MB Flash ROM (MAIN4 PC Board: 8MB)

(2) Backup..............................512 Byte EE-PROM

(3) Image buffer + Work

B-SX4T............................8MB SD-RAM (MAIN4 PC Board: 16MB)

B-SX5T............................16MB SD-RAM (MAIN4 PC Board: 32MB)

(4) Chinese Font ROM ...........8MB Flash ROM (CN model only Serial No. 2609Dxxxxxx or later))

Note: Program area size and Registry area size of the MAIN3 and MAIN4 PC boards

MAIN3 PC Board MAIN4 PC Board

Program area size 2304KB 4096KB

Registry area size 896KB 3072KB

1- 6

Page 9

1. OUTLINE EO10-33013B

(Revision Date: Jan. 22, 2009)

1.5 ELECTRONICS SPECIFICATIONS

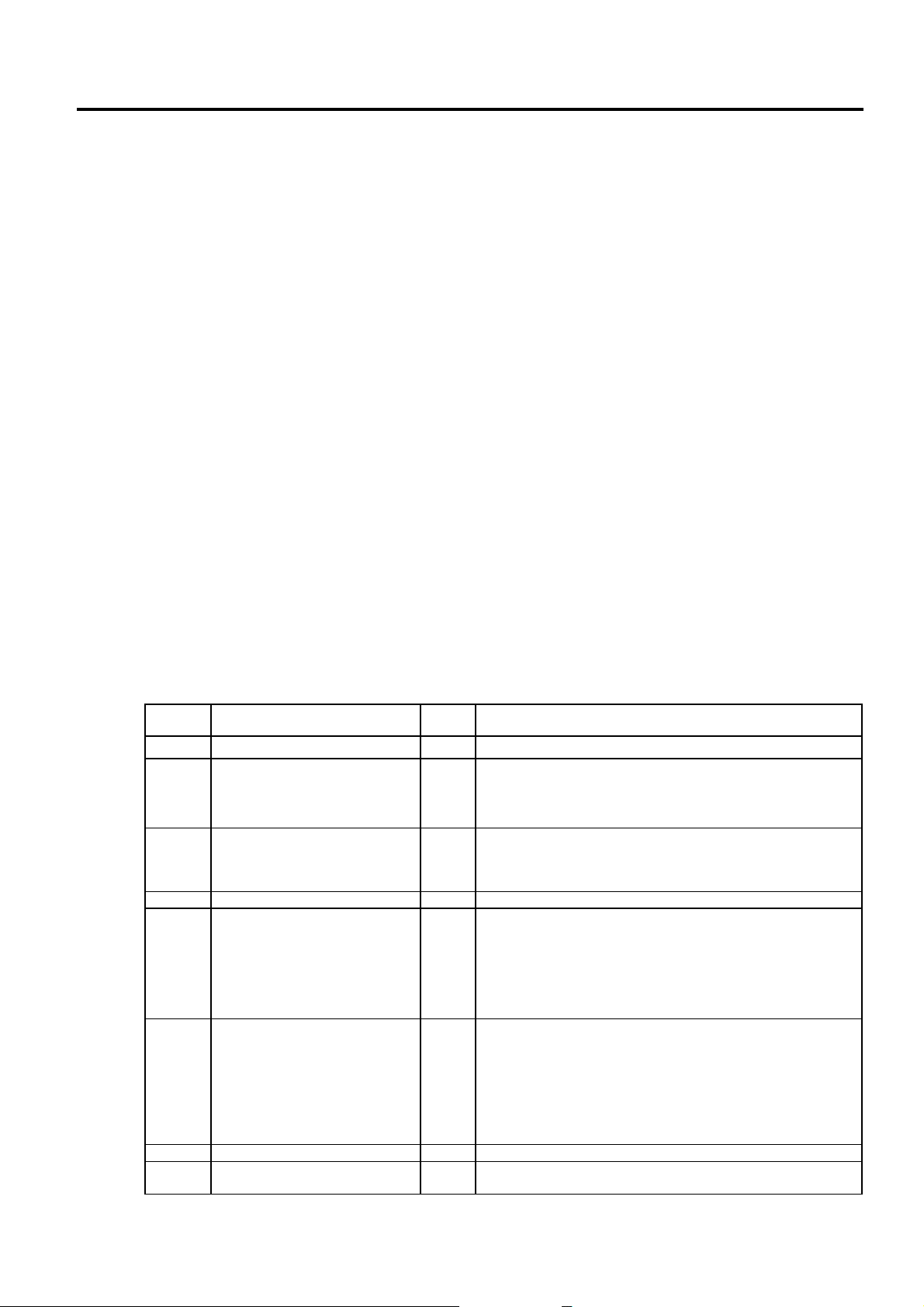

Specification of the MAIN4 PC Board

Hardware Software

Model

B-SX5T-TS22-QM-R 16MB → 32MB

B-SX4T-GS20-QM-R 8MB → 16MB

SP40II-R 8MB → 16MB

B-SX5T-TS22-CN-R 16MB → 32MB

B-SX4T-GS20-CN-R

Flash ROM RAM

4MB → 8MB

8MB → 16MB

Kanji ROM

(IC7)

None → 8MB

None

Kanji Font

Simplified

Chinese

Registry

area size

896KB

↓

3072KB

Program

area size

2304KB

↓

4096KB

Except for the memory capacity, the specification of the MAIN4 PC board is equivalent to that of the

MAIN3 PC board. However, the firmware V5.0 and greater (Main program V5.0, Boot program V3.0) is

installed into the MAIN4 PC board only.

3) Interface

(1) RS-232C interface

c Communication mode: Full-duplex

d Transmission speed: 2400,4800,9600,19200, 38400, 115200 bps (selectable)

e Synchronization: start-stop synchronization

f Transmission parameter

Parity: None, EVEN, ODD

Start bit: 1-bit

Stop bit: 1-bit or 2-bit

Word length: 7-bit or 8-bit

g Error detection

Parity check: VRC (Vertical Redundancy Checking)

Framing error: This error occurs when no stop bit is found in the frame specified

starting with the start bit.

h Data entry code: ASCII, 8-bit code for European characters, 8-bit code for graphic

i Receiving buffer: B-SX4T: 1MB, B-SX5T: 6MB

j Protocol

XON/XOFF (DC1/DC3) protocol

• When initialized after power on, this printer becomes ready to receive data and sends an

XON code (11H). (Transmission or non-transmission of XON code is selectable by means of

the parameter setting.)

• The printer sends an XOFF code (13H) when the free area in the receive buffer becomes

10K Bytes or less.

• The printer sends an XON code (11H) when the free area in the receive buffer are 512KB or

more.

• When there is no free area in the receive buffer, the printer discards received data which

exceeds the receive buffer capacity without storing it in the buffer. (After detecting the XOFF

code, the host computer must stop transmission before the printer receive buffer becomes

full.)

• The printer sends an XOFF code (13H) at power off time. (Transmission or non-transmission

of XOFF code is selectable with the parameter setting.)

• The DTR signal is always “High” level (Ready).

• The RTS signal is always “High” level (Ready).

READY/BUSY (DTR) protocol

• When initialized after power on, this printer becomes ready to receive data and converts the

DTR signal to "High" level (READY).

• The printer converts the DTR signal to "Low" level (BUSY) when the free area in the receive

buffer amount to 10K bytes or less.

• The printer converts the DTR signal to "High" level (READY) when the free area in the

receive buffer amount to 512KB or more.

• When there is no free area in the receive buffer, the printer discards received data which

exceeds the receive buffer capacity without storing it in the buffer. (After detecting a BUSY

signal, the host computer must stop transmission before the printer receive buffer becomes

full.)

• The RTS signal is always “High” level.

1- 7

Page 10

1. OUTLINE EO10-33013B

1.5 ELECTRONICS SPECIFICATIONS

XON/XOFF (DC1/DC3) protocol + READY/BUSY (DTR) protocol

• When initialized after power on, this printer becomes ready to receive data and converts the

DTR signal to "High" level (READY). The printer sends an XON code (11H).

• When the free area in the receive buffer are 10K bytes or less, the printer converts the DTR

signal to "Low" level (BUSY) and sends an XOFF code (13H).

• When the free area in the receive buffer are 512KB or more, the printer converts the DTR

signal to "High" level (READY) and sends an XON code (11H).

• When there is no free area in the receive buffer, the printer discards received data which

exceeds the receive buffer capacity without storing it in the buffer. (After detecting the XOFF

code or BUSY signal, the host computer must stop transmission before the printer receive

buffer becomes full.)

• The printer sends an XOFF code (13H) at power off time.

• The RTS signal is always “High” level.

READY/BUSY (RTS) Protocol

• When initialized after power on, this printer becomes ready to receive data and converts

the RTS signal to "High" level (READY).

• The printer converts the RTS signal to “Low” level (BUSY) when the free area in the

receive buffer amount to 10K bytes or less.

• The printer converts the RTS signal to “High” level (READY) when the free area in the

receive buffer amount to 512KB or more.

• When there is no free area in the receive buffer, the printer discards received data which

exceed the receive buffer capacity without storing it in the buffer. (After detecting a

BUSY signal, the host computer must stop transmission before the printer receive buffer

becomes full.)

• The DTR signal is always “High” level (READY).

• The host should keep the DSR signal “High” level.

NOTE: Be sure to select the READY/BUSY (RTS) protocol when controlling the flow between

the Windows. Also, be sure to select “Hardware” for the flow control in the Windows

communication port setting.

k Pin description

Pin No. Signal I/O Description

1 FG (Frame Ground) --- Ground line for circuit protection.

Data line from which the printer receives data from the host

2 RD (Received Data) Input

3 TD (Transmit Data) Output

4 CTS (Clear to Send) Input Input signal from the host. This printer ignores this signal.

5 RTS (Request to Send) Output

6 DTR (Data Terminal Ready) Output

7 SG (Signal Ground) --- Ground line for all data and control signals.

20 DSR (Data Set Ready) Input

(receive data line).

Logic “1” is “Low”, and “0” is “High”. It is LOW (MARK) while

no data is being sent.

Data line from which the printer sends data to the host (send

data line).

Logic “1” is “low”, and “0” is “High”. It is LOW (MARK) while

no data is being sent.

Output signal to the host.

When READ/BUSY (RTS) protocol is selected,

this signal means READY to receive data.

When the receive buffer is nearly full, the signal turns to

“Low”, and “High” when nearly empty.

In case of other protocol is selected, this signal is always

“High” level after the power is turned on.

Output signal from the printer.

When READY/BUSY (DTR) or XON/XOFF

(DC1/DC3)+READY/BUSY (DTR) is selected, this signal

means READY to receive data.

When the receive buffer is nearly full, the signal turns to

“Low”, and “High” when nearly eimpty.

In case of XON/XOFF (DC1/DC3) or READY/BUSY (RTS),

this signal is always “High” level after the power is turned on.

Input signal from the host. It must be “High” for the printer to

receive data.

1- 8

Page 11

1. OUTLINE EO10-33013B

R

C

D

nt

nt

S

nt

1.5 ELECTRONICS SPECIFICATIONS

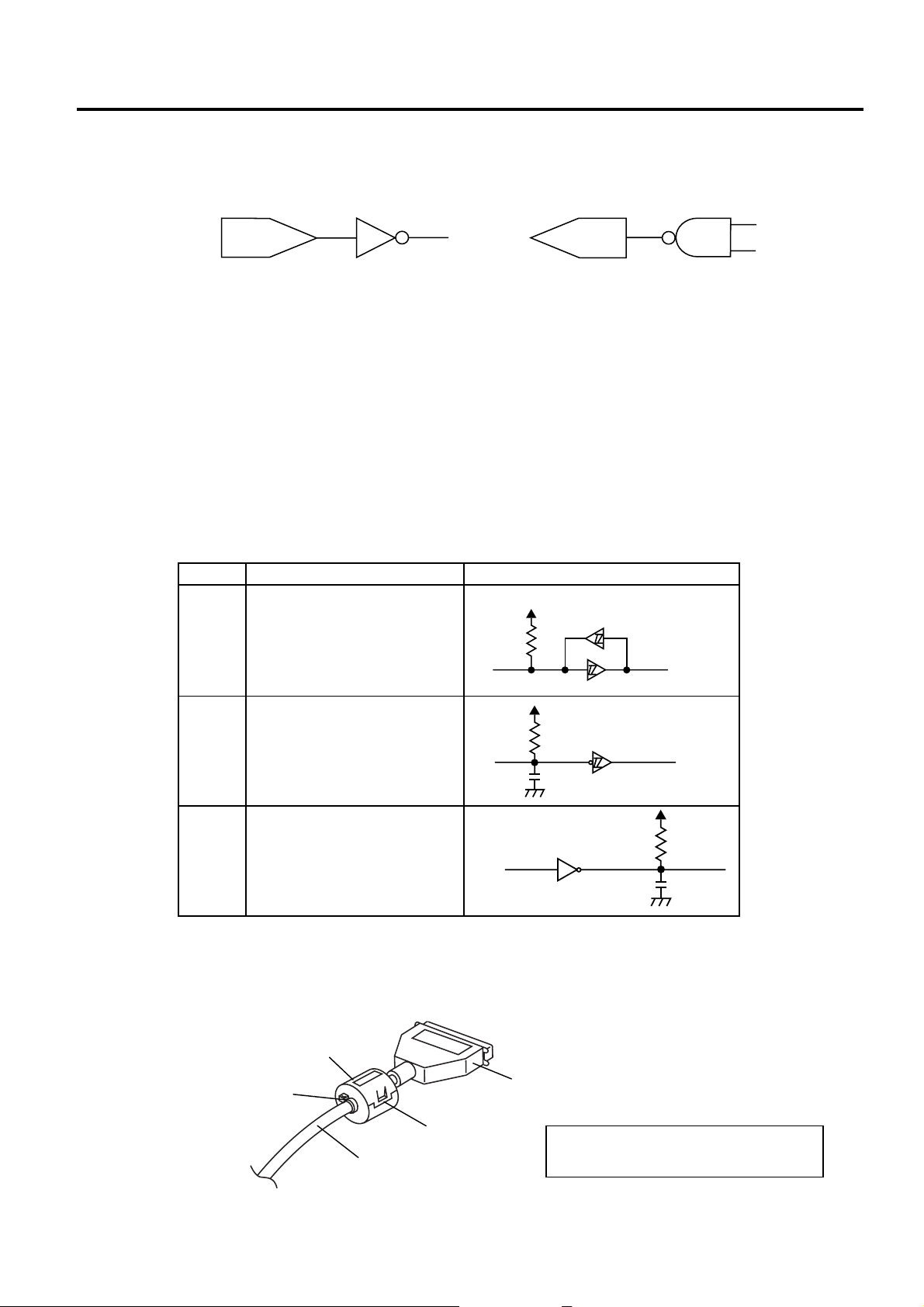

l Interface circuit

Input circuit Output circuit

D

TS

SR

SN75189 or equivalent

TD

RTS

DTR

SN75188 or equivale

Signal level

Input voltage: "H" .. +3V~ + 15V Output voltage: "H" .. +6V ~ +13V

"L" ... –3V~ – 15V "L" ... –6V ~ –13V

(2) Centronics interface

c Data input method: 8-bit parallel (DATA 1~8)

d Control signals

Compatibility mode: nStrobe, nAck, Busy, PError, Select, nAutoFd, nInit, nFault, nSelectIn

ECP mode: HostClk, PeriphClk, PeriphAck, nAckReverse, XFlag, HostAck,

nReverseRequest, nPeriphRequest, IEEE1284Active

e Data input code: ASCII, JIS 8-bit code for European characters, 8-bit code for graphic

f Receiving buffer: 1MB

g Input/Output circuit configuration and Input/Output conditions

Type Signal Name Configuration

SN74LS14 or equivale

Input/

Output

Data 1 ∼ 8

+5V

1K

Input

Output

nStrobe/HostClk

nInit/nReverseRequest

nAutoFd/HostAck

nSelectIn/IEEE1284Active

Busy/PeriphAck

nFault/nPeriphRequest

nAck/PeriphClk

Select/XFlag

+5V

1K

100P

N7406 or equivalent

SN74LS14 or equivale

+5V

1K

100P

Logical level (input)

"1" = 2~5V

"0" = 0~0.4V

Logical level (input)

"1" = 2.4~5V

"0" = 0~0.4V

PError/nAckReverse

NOTE: When using a Centronics Interface Cable on the B-SX5T Series

Please put the ferrite core on the Centronics interface cable, close to the connector (printer side),

and secure it with a cable band as shown below.

Ferrite Core

Cable Band

Hook

Centronics Interface Cable

Connector (Printer Side)

NOTE: Be sure to close the ferrite

core until it snaps.

1- 9

Page 12

1. OUTLINE EO10-33013B

1.5 ELECTRONICS SPECIFICATIONS

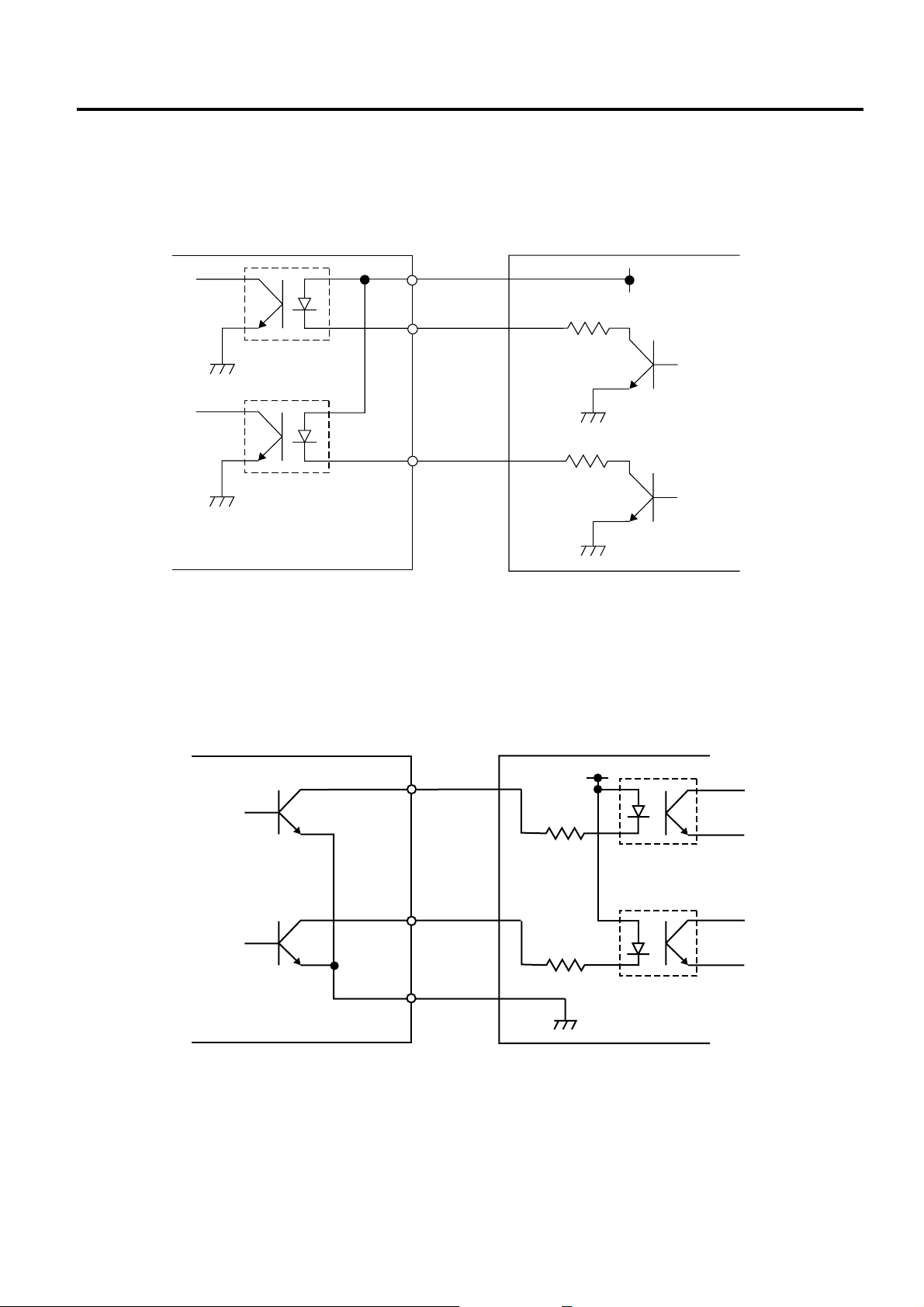

(3) Expansion I/O interface (B-SX4T: Option)

Interface circuit

Input circuit

There are six input circuits, and each input is a current loop using a photo-coupler.

The anode of the photo-coupler is connected to common pin COM1 in each of the six circuits.

Each cathode is independent. The voltage of Vcc is 24 V (max.) while the diode operating

current is 16 mA.

Output circuit

There are seven output circuits, and each output is an open collector. The voltage of Vcc is

24V (max.) while the operating current is 150 mA.

For other details, please refer to the Expansion I/O specifications stored in the enclosed CD-

ROM or posted on the web site with the URL, http://barcode.toshibatec.co.jp.

Printer

Photo-coupler

TPL521 (TOSHIBA)

TLP521 (TOSHIBA)

Printer

~

COM1

IN0

~

IN5

OUT0

~

OUT6

COM2

External controller, etc.

Vcc

R

R

External controller, etc.

(In the case of photo-coupler)

Vcc

1-10

Page 13

1. OUTLINE EO10-33013B

Main Frame

Black Mark Sensor

Feed Gap Sensor

Black Mark

Tag Paper

Center

93 mm

Side Frame

1.5 ELECTRONICS SPECIFICATIONS

(4) USB

c Standard: Conforming to Rev. 1.1

d Transfer type: Control transfer, Bulk transfer

e Transfer rate: Full speed (12M bps)

(5) Network interface (LAN, PCMCIA)

c Constitution: • PCMCIA board + LAN card

• 10 Base-T or 100 Base-TX LAN board

d Protocol: TCP/IP

e Network specifications: • LPR server function

• WEB printer function

• Socket communication function

• FTP server function

• E-mail function

4) Sensor/switch

(1) Head up sensor (Transmissive sensor)

This sensor, located on the left front of the printer inside as viewed from the media outlet,

detects whether the print head is in position or not. When the head lever is turned to the Free

position, the arm on the edge of the head lever shaft turns the sensor on.

(2) Head block position switch (Transmissive sensor)

This sensor, located on the left side of the print head block, detects whether the print head

block is in position or not. According to the position of the print head block, the arm on it turns

the sensor on/off.

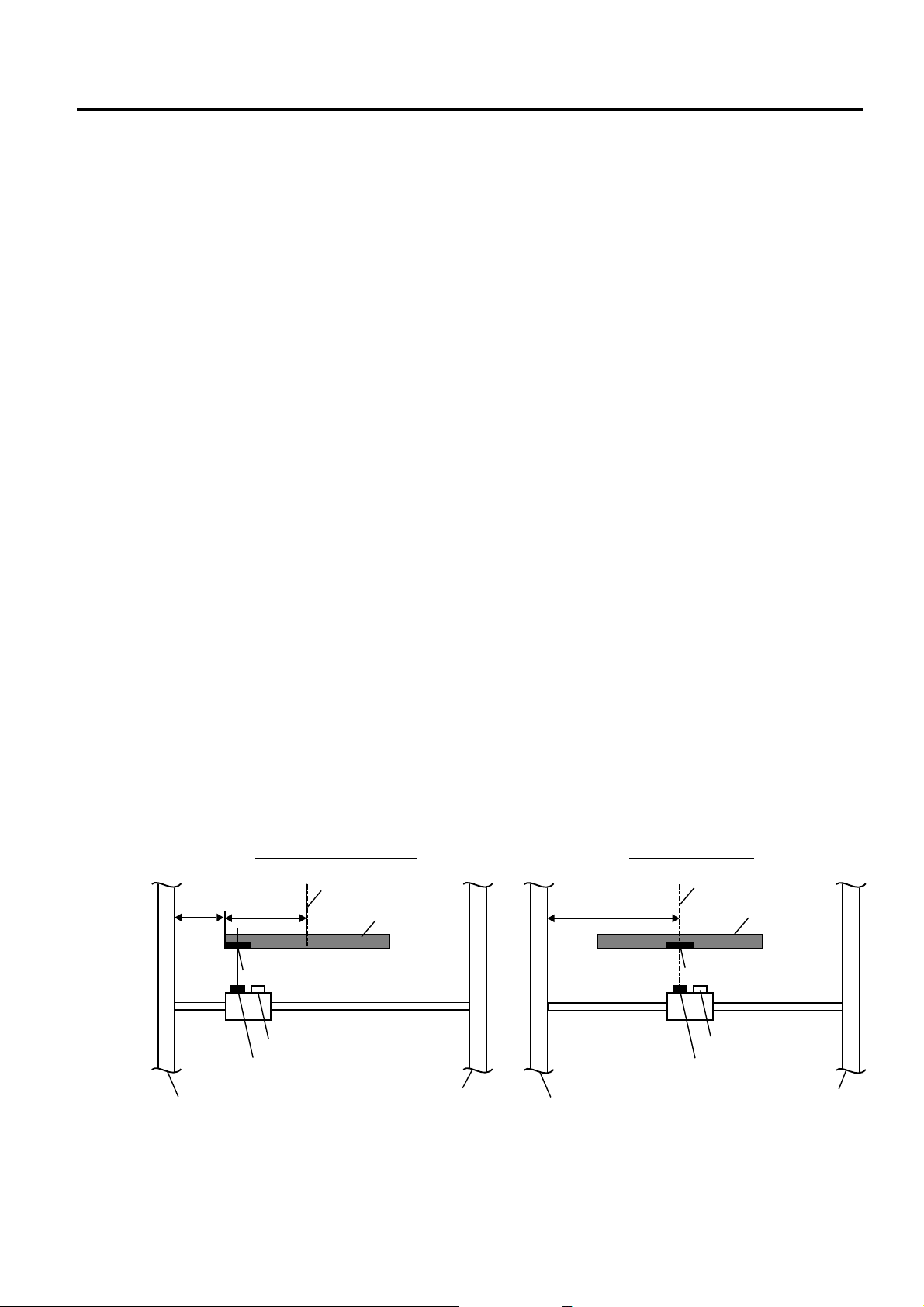

(3) Media sensor

This sensor is comprised of the black mark sensor and feed gap sensor. It is positioned 92.1

mm from the platen.

The sensor position is adjustable according to the black mark position. It can be manually

moved from the center to the left edge of media.

Black mark sensor (Reflective sensor)

This sensor detects the difference of potential between the black mark and tag paper to find

the print position of the tag paper.

Side detection (max.)

Center detection

23 mm

70 mm

Center

Tag Paper

Black Mark

Main Frame

Feed Gap Sensor

Black Mark Sensor

Side Frame

1-11

Page 14

1. OUTLINE EO10-33013B

e

m

r

1.5 ELECTRONICS SPECIFICATIONS

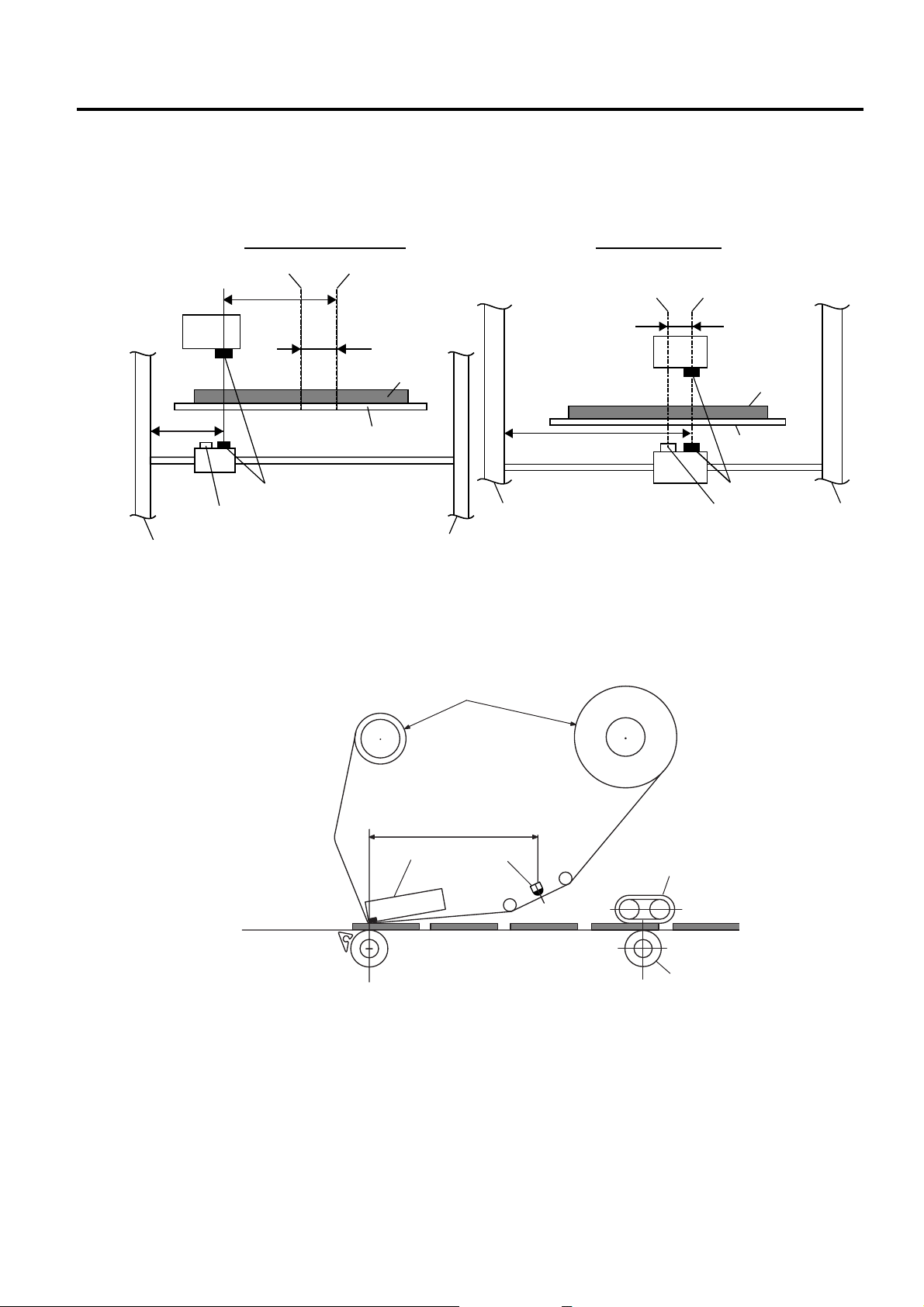

Feed gap sensor (Transmissive sensor)

This sensor detects the difference in potential between the backing paper and the label to

find the print position of the label. The feed gap sensor is located at 8 mm to the right of the

black mark sensor.

Side detection (max.)

78.5 mm

Home PositionCenter of Label

8 mm

Center detection

Home PositionCenter of Label

8 mm

22.5 mm

Backing Paper

Label

101 mm

Label

Backing Paper

Main Frame

Feed Gap Sensor

Black Mark Sensor

Side Fram

Main Frame

Feed Gap Sensor

Black Mark Sensor

Side Fra

(4) Ribbon end sensor (Reflective sensor)

When printing in thermal transfer mode (using the ribbon), this sensor detects the difference in

potential between the ribbon and the ribbon end to indicate the ribbon end. It is positioned at

48.28 mm from the platen.

Ribbon

Print Head

48.28 mm

Ribbon End

Sensor

Pinch Roller

Feed Rolle

1-12

Page 15

1. OUTLINE EO10-33013B

r

1.5 ELECTRONICS SPECIFICATIONS

(5) Slit sensor (Transmissive sensor)

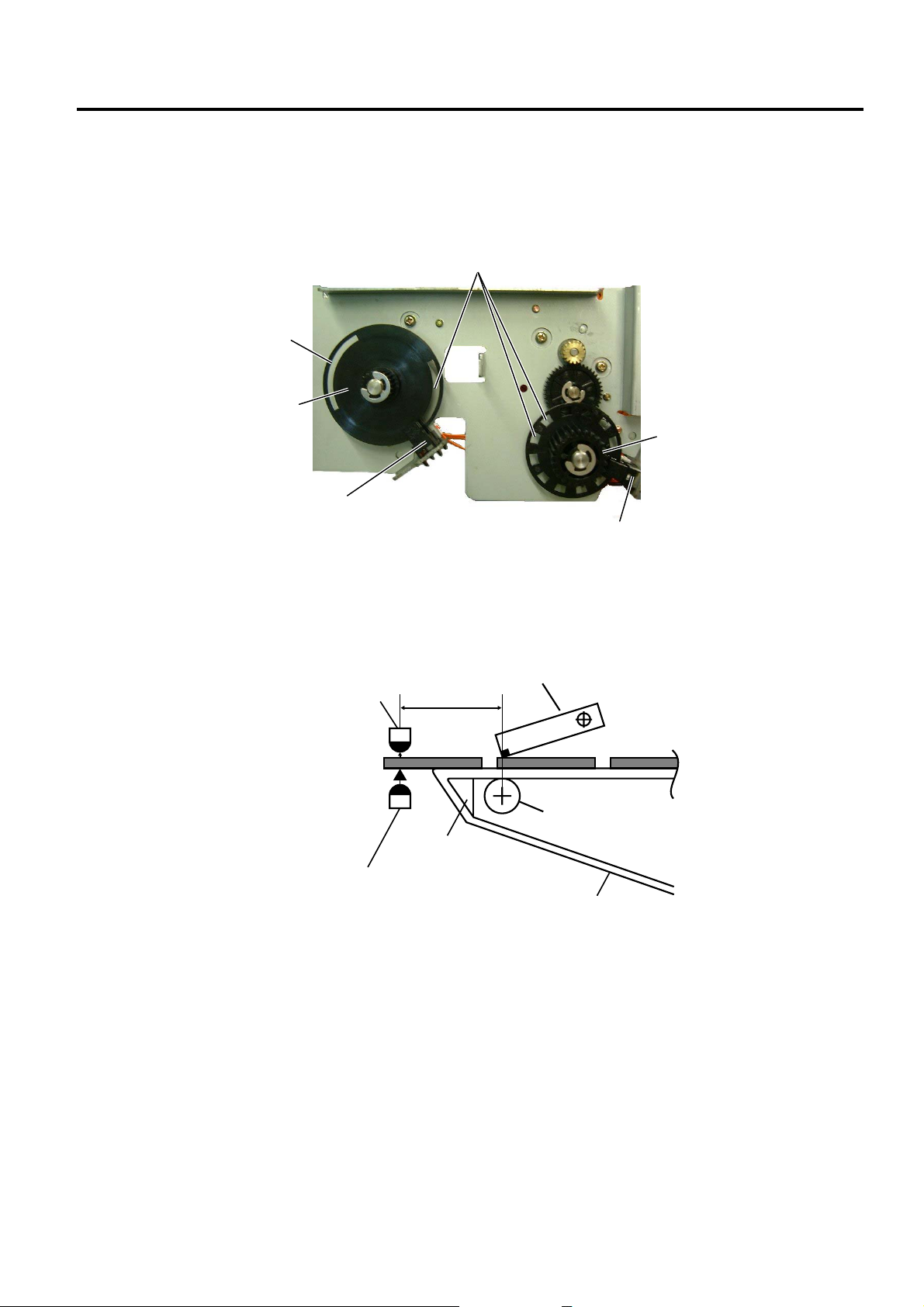

This sensor detects the rotation count of the ribbon shaft and the ribbon motors. The ribbon

motors torque works to take up slack in the ribbon and is dependent on the detected count.

The slit sensor is a photo coupler combining an LED and a transistor.

Slit

Slit

Rewind Slit Gea

Feed Slit Gear

Slit Sensor (Rewind)

Slit Sensor (Feed)

(6) Strip sensor (Transmissive sensor)

This sensor detects whether or not the label has been taken away from the media outlet and

controls the label feed. It is positioned 17.8 mm from the platen.

Strip Sensor (Tr)

17.8 mm

Print Head

Platen

Strip Sensor (LED)

Strip Shaft

Backing Paper

1-13

Page 16

1. OUTLINE EO10-33013B

1.5 ELECTRONICS SPECIFICATIONS

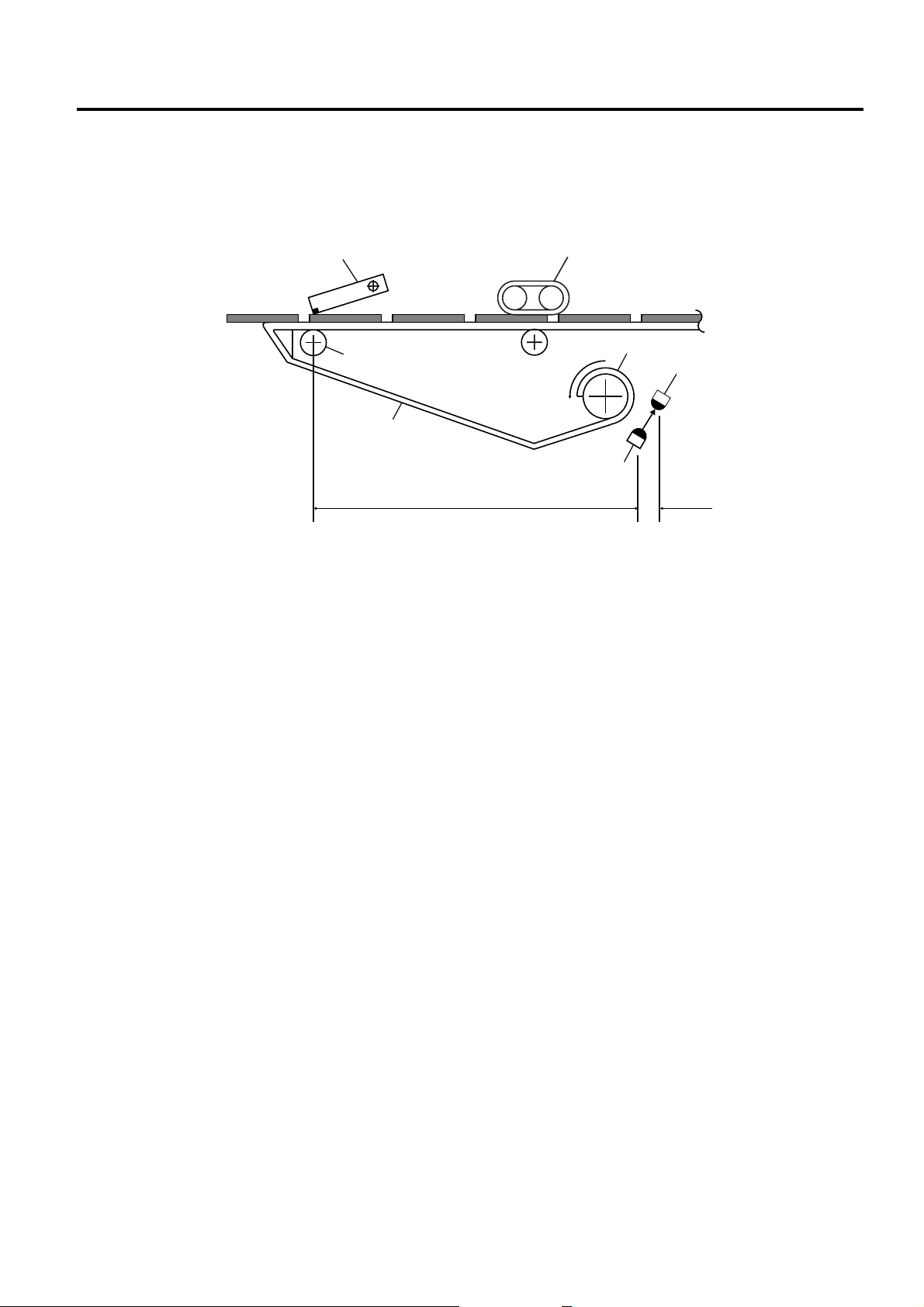

(7) Rewind full sensor (Transmissive sensor)

This sensor detects that the built-in rewinder is full when winding backing paper or printed

media onto the take-up spool. It is positioned at 316.4 mm (Tr side) and 272 mm (LED side)

from the platen. A rewinder full status is detected when the backing paper blocks the light from

the LED.

Print Head

Pinch Roller

Platen

Take-up Spool

Rewind Full Sensor (Tr)

Backing Paper

Rewind Full Sensor (LED)

272 mm 44.4 mm

(8) Cutter home position switch (micro switch) for Swing Cutter

A cam positioned at the end of the cutter motor arm turns the micro switch on/off in accordance

with the cutter motion cycle (one rotation). The micro switch status indicates if the cutter is in

the home position.

1-14

Page 17

2. SUPPLY SPECIFICATIONS EO10-33013B

2.1 MEDIA

2. SUPPLY SPECIFICATIONS

Information regarding the supply specifications contained in Product Description is essential to service

engineers. Detail specifications and other information on the media and ribbon are described in Supply

Manual by model. It is issued by and sent from TOSHIBA TEC H.Q (Sales Division) upon release of

new model or manual's revision. When purchasing the supplies locally, be sure to refer to the Supply

Manual for details. Use of non-specified media may shorten the print head life and result in problems

with bar code readability or print quality. Be sure to read carefully and understand the Supply Manual

since it also includes the details about notes, precision of the print start position, limitations on printing,

etc. When selling the products to VARs, instruct them to buy media and ribbons that the substances

described in the following precautions are not included

2.1 MEDIA

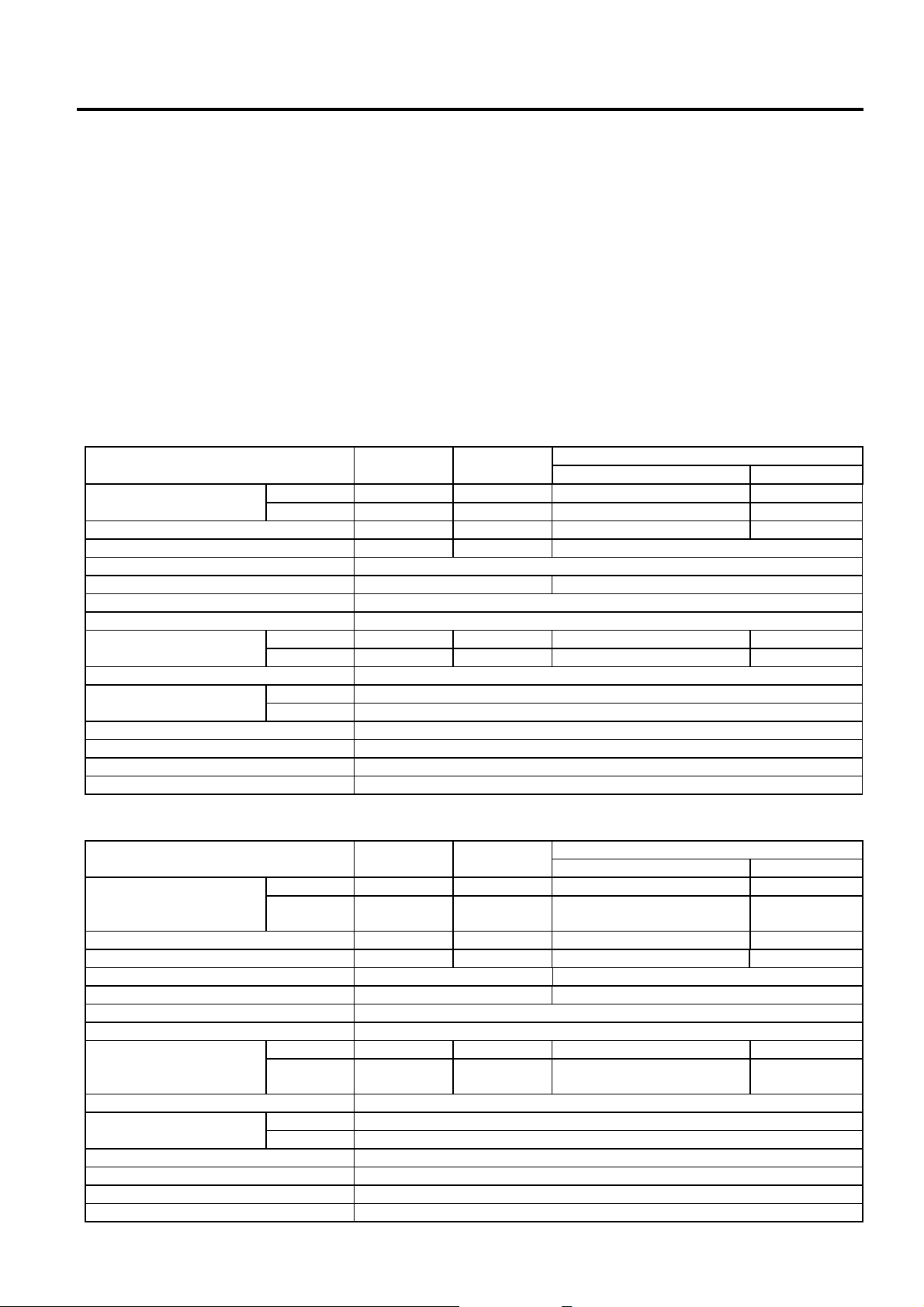

[B-SX4T]

(Unit: mm)

Label dispensing mode

Item

Media pitch

Label length 8.0 – 1498.0 23.4 – 1498.0 3”/sec., 6”/sec.: 32.0 – 1494.0 25.0 – 1494.0(*1)

Width including backing paper (See NOTE 5.) 30.0 – 112.0 50.0 – 112.0 30.0 – 112.0

Label width (See NOTE 5.) 27.0 – 109.0

Gap length 2.0 – 20.0 6.0 – 20.0

Black mark length (Tag paper) 2.0 – 10.0

Effective print width 10.0 – 104.0±0.2

Effective print length

Print speed up/slow down area 1.0

Thickness

Max. effective length for on the fly issue 1361.0

Maximum outer roll diameter Ø200 (See NOTE 9.)

Roll direction Inside

Inner core diameter Ø76.2±0.3

Label 10.0 – 1500.0 25.4 – 1500.0 3”/sec., 6”/sec.: 38.0 - 1500.0 38.0 – 1500.0

Tag 10.0 – 1500.0 ---- 3”/sec., 6”/sec.: 30.0 – 1500.0 25.4 – 1500.0

Label 6.0 – 1496.0 21.4 – 1496.0 3”/sec., 6”/sec.: 30.0 - 1492.0 23.0 – 1492.0

Tag 8.0 – 1498.0 ---- 3”/sec., 6”/sec.: 28.0 – 1498.0 23.4 – 1498.0

Label 0.13 – 0.17

Tag 0.15 – 0.29

Batch mode Strip mode

Rotary cutter (*2) Swing cutter

Cut mode

[B-SX5T]

(Unit: mm)

Label dispensing mode

Item

Label 10.0 – 1500.0 25.4 – 1500.0 38.0 - 1500.0 38.0 – 1500.0

Media pitch

Label length 8.0 – 1498.0 23.4 – 1498.0 32.0 – 1494.0 25.0 – 1494.0(*1)

Width including backing paper (See NOTE 5.) 30.0 – 140.0 50.0 – 140.0 30.0 – 112.0 30.0 – 140.0

Label width (See NOTE 5.) 27.0 – 137.0 27.0 – 109.0

Gap length 2.0 – 20.0 6.0 – 20.0

Black mark length (Tag paper) 2.0 – 10.0

Effective print width 10.0 – 128.0±0.2

Effective print length

Print speed up/slow down area 1.0

Thickness

Max. effective length for on the fly issue 749.0

Maximum outer roll diameter Ø200 (See NOTE 9.)

Roll direction Inside

Inner core diameter Ø76.2±0.3

Tag 10.0 – 1500.0 ----

Label 6.0 – 1496.0 21.4 – 1496.0 30.0 - 1492.0 23.0 – 1492.0

Tag 8.0 – 1498.0 ----

Label 0.13 – 0.17

Tag 0.15 – 0.29

Batch mode Strip mode

Rotary cutter Swing cutter

3”/sec., 5”/sec.: 30.0 – 1500.0

8”/sec.: 38.0 – 1500.0

3”/sec., 5”/sec.: 28.0 – 1498.0

8”/sec.: 36.0 – 1498.0

Cut mode

25.4 – 1500.0

23.4 – 1498.0

2- 1

Page 18

2. SUPPLY SPECIFICATIONS EO10-33013B

2

m

(

(

B

e)

2.1 MEDIA

NOTES:

1. To ensure print quality and print head life use only TOSHIBA TEC specified media.

2. The media length specifications for use of the cutter are:

*1: When issuing a label using the swing cutter, label length should be 35.0 mm – (Gap length/2).

*2: The rotary cutter does not support the print speed of 10”/sec.

3. When marking black marks on the label rolls, they should be marked at the gaps.

4. “On the fly issue” means that the printer can feed and print without stopping between labels.

5. There are restrictions in use of the media which is narrower than 50 mm. For details, refer to TOSHIBA

TEC Head Quarters.

6. When perforating the media, it should be done from the print side to the reverse side.

7. The reflectance of the black mark should be 10% or less when the wavelength is 950nm.

8. The label length should be at least three times as long as the gap.

9. When taking up the printed media onto the take-up spool in batch mode, the outer roll diameter must

not exceed 180mm.

10. When cutting the thermal label, secure a gap of 6 mm or more, and cut in the middle of the gap.

11. For the backing paper Glassine paper 7K white or equivalent should be used. Also, the light

transmission rate of the backing paper should be 22% or above.

12. Ink used for pre-printing the media should not contain hard substances such as carbonic calcium

(CaCO

13. Thermal paper used for the direct thermal printing must not have the specifications which exceed Ca

K

14. Avoid using media containing SiO

) and Kaolin (Al2O3, 2SiO2, 2H2O).

3

+

, Na+ 800 ppm, K + 250 ppm, and Cl – 500 ppm.

or talc which wears the print head protection layer.

2

2+

,

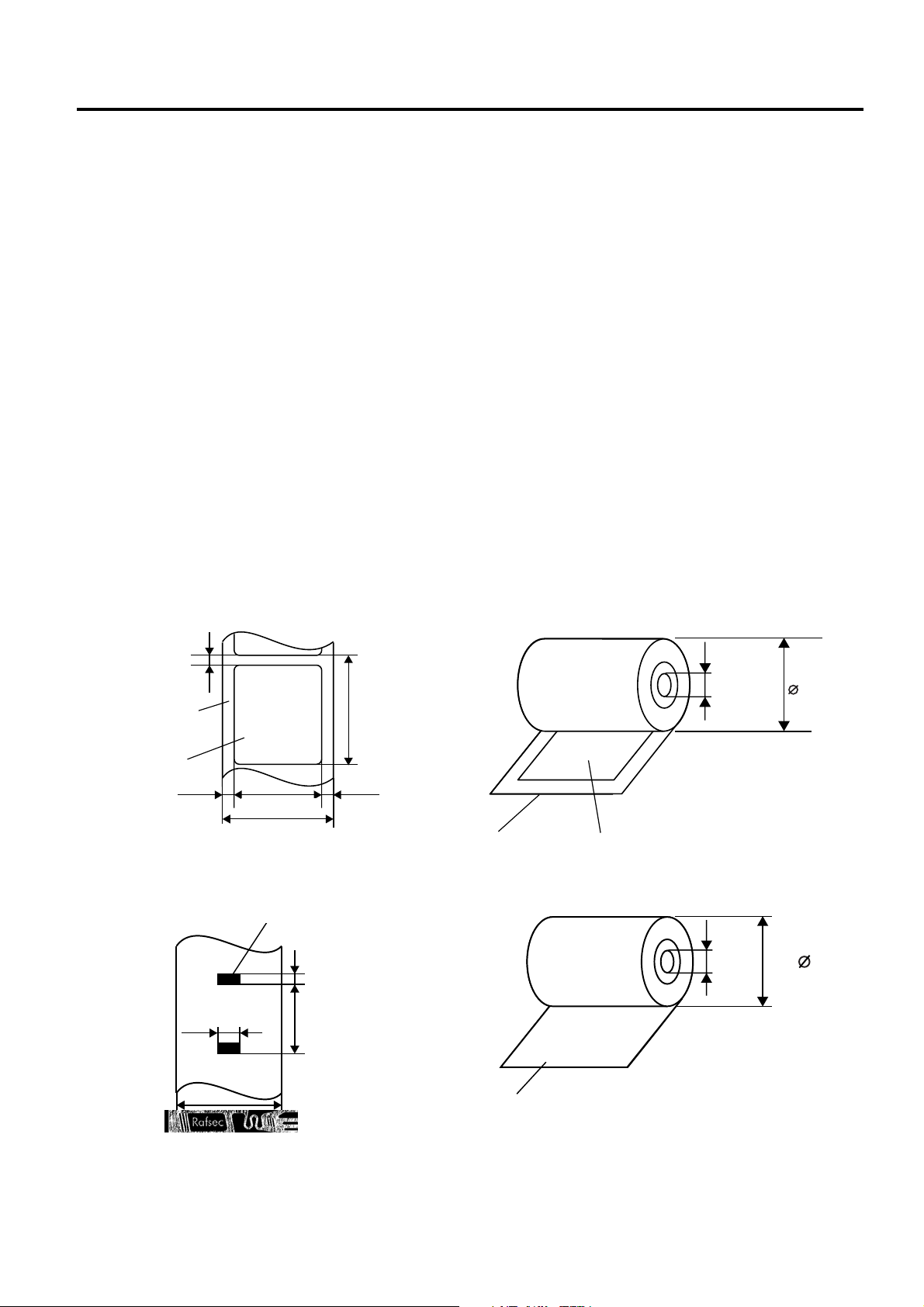

1) Label

< Design >

.0~20.0 mm

Backing

Paper

10.0 ~ 1500.0m

76.2 mm

Max.

200.0 mm

(Reference V alu

Label

2) Tag paper

1.5 mm

27.0 – 109.0 mm

27.0 - 137.0 mm)

30.0 – 112.0 mm

(30.0 – 140.0 mm)

( ): SX5T

Black mark or Square holes

(Round holes are not acceptable.)

Black Mark

1.5 mm

acking Paper

Label

2.0 ~ 10.0 mm

76.2 mm

Max. 200.0

Min.12 mm

10.0 ~ 1500.0 mm

NOTE: The reflection rate of the black mark is 10% or less at wavelength of 950nm. A square hole can

30.0 ~ 112.0 mm

3

( ): SX5T

substitute for the black mark. When the square hole is used, no printing is allowed on the black

side.

Print Side

Label

2- 2

Page 19

2. SUPPLY SPECIFICATIONS EO10-33013B

m

m

Head effective print width

Outside the print rangeOutside the print range

2.1 MEDIA

< Non Print Area >

2 mm

Cut Position

Printing AreaPrinting Area

1.0 m

2 mm

1.5 mm1.5 mm

Black Mark

1.5 mm

1.0 m

1.5 mm

3) Relationship between the head effective print width and paper.

[B-SX4T]

Head effective print width

Outside the print rangeOutside the print range

4.0

mm

4.0

mm104.0 mm 0.2 mm

112.0 mm

(Maximum paper width)

[B-SX5T]

6.0 mm

128.0 mm 0.2 mm

140.0 mm

(Maximum paper width)

6.0 mm

NOTE: The specifications differ depending on the issue mode. For details, refer to the media

specification table on page 2-1.

2- 3

Page 20

2. SUPPLY SPECIFICATIONS EO10-33013B

2.2 RIBBON

2.2 RIBBON

No. Item Specification

1 Shape Spool type

2 Width

3 Max. length 600 m

4 Max. OD ø 90 mm

5 Back treatment Coated

7 Leader tape

8 End tape

9 Winding method The ink side faces outside of ribbon winding

NOTES: 1. To ensure print quality and print head life use only TOSHIBA TEC specified ribbons.

2. To avoid ribbon wrinkles use a ribbon which is wider than the media by 5 mm or more.

However, too much difference in width between the two may cause wrinkles.

3. When using a 112 mm wide media, be sure to use a 108 mm wide ribbon. Use of other

ribbons may cause ribbon wrinkles.

4. When using a 134 mm wide media, be sure to use a 130 mm wide ribbon. Use of other

ribbons may cause ribbon wrinkles.

[B-SX4T]

Ribbon width 41 mm 50 mm 68 mm 84 mm 112 mm

Proper media width 30 to 36 mm 36 to 45 mm 45 to 63mm 63 to 79 mm 71 to 112mm

[B-SX5T]

Ribbon width 41 mm 50 mm 68 mm 102 mm 134 mm

Proper media width 30 to 36 mm 36 to 45 mm 45 to 63mm 63 to 97 mm 97 to 140 mm

NOTE: When purchasing ribbon locally, they must meet the above size. There may be TOSHIBA TEC-

approved ribbons which do not fall within the above size, however, they have no functional problem.

B-SX4T 41 to 112 mm

B-SX5T 41 to 134 mm

Material Cardboard 6 Core

Shape See the following figures.

Polyester film (Opaque), 300 ± 5 mm long

Polyester film (Opaque), 250 ± 5 mm long

B-SX4T: 41 – 112 mm

B-SX5T: 41 – 134 mm

25.7 ±0.2 mm

(NOTE 3)

(NOTE 4)

2- 4

Page 21

2. SUPPLY SPECIFICATIONS EO10-33013B

A

A

A

e

2.3 CARE AND HANDLING OF THE MEDIA AND RIBBON

This inked surfac

faces the outside

This ribbon should be wound at center of the core.

dhesive tape

Leader tape

Ink ribbon

End tape

(Non transmissive)

dhesive tape

Core

Base

dhesive tape

Ink outside

Core

Treated back side

2.3 CARE AND HANDLING OF THE MEDIA AND RIBBON

CAUTION!

Be sure to read carefully and understand the Supply Manual. Use only media and ribbon which

meet specified requirements. Use of non-specified media and ribbon may shorten the head life and

result in problems with bar code readability or print quality. All media and ribbon should be handled

with care to avoid any damage to the media, ribbon or printer. Read the following guideline

carefully.

• Do not store the media and ribbon for longer than the manufactures recommended shelf life.

• Store media rolls on the flat end, do not store them on the curved sides as this might flatten that

side causing erratic media advance and poor print quality.

• Store the media in plastic bags and always reseal after opening. Unprotected media can get dirty

and the extra abrasion from the dust and dirt particles will shorten the print head life.

• Store the media and ribbon in a cool, dry place. Avoid areas where they would be exposed to

direct sunlight, high temperature, high humidity, dust or gas.

For further information please contact your local distributor or your media and ribbon manufacturer.

2- 5

Page 22

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.4 SPECIFICATION OF RFID TAG (for B-9704-RFID-U1-US/EU-R, H1-QM-R)

2.4 SPECIFICATION OF RFID TAG (for B-9704-RFID-U1-US/EU-R, H1-QM-R)

2.4.1 General Description

The RFID supplies are RFID tag (wireless IC tag) inlays designed to be converted into tag and label

applications. Printers, which are equipped with an RFID kit, can print data on the surface of RFID tags

as well as write data on them.

The B-SX series optional RFID kit, B-9704-RFID-U1-US, is destined for North America and operates in

the UHF band 902MHz to 928MHz. And B-9704-RFID-U1-EU/U1-EU-R is destined for Europe and

operates in the UHF band 869.5MHz.

B-9704-RFID-H1-QM/H1-QM-R operates in the HF band 13.56MHz, to which Tagsys RFID module

Medio002 (to be separately purchased) can be attached.

NOTE: Regarding the specification of RFID supplies and the ribbon used for printing on them, refer to

Section 2.1 MEDIA and Section 2.2 RIBBON.

2.4.2 Available RFID Tag

Available RFID tag types are different depending on the RFID modules, as follows:

(1) B-9704-RFID-U1-US and B-9704-RFID-U1-EU/U1-EU-R

• EPC C0

• EPC C1

• EPC C1 Gen2 (Only when the RFID module supports GEN2.)

• ISO18000-6B

(2) B-9704-RFID-H1-QM/H1-QM-R

• TAGSYS C210

• TAGSYS C220

• TAGSYS C240

• TAGSYS C320 (Only when the TAGSYS S003 module is used.)

• I-Code

• Tag-it

• ISO15693

2- 6

Page 23

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.4 SPECIFICATION OF RFID TAG (for B-9704-RFID-U1-US/EU-R, H1-QM-R)

2.4.3 Location of RFID Tag

The location of an RFID tag on a label influences on the accuracy of writing data on the RFID tag.

It is impossible to define the one best location for every RFID tag on labels because the best location

depends on the type of RFID tag and RFID tag antenna.

The B-SX RFID Analyze Tool (7FM001113) can evaluate the accuracy of writing data on the RFID tag.

For the usage of this tool, refer to the B-SX RFID Analyze Tool Operation Specification (TAA-2195).

As a guideline, the best location for some common RFID tags is given below.

It is recommended to use the B-SX RFID Analyze Tool to check the accuracy of writing data on an

RFID tag to be used, then determine a specific location of the RFID tag.

If the RFID tag cannot be placed on the best location specified, perform a forward/reverse feed before

an issue using the RFID tag position adjustment command ([ESC]@[003)

(1) Alien’s EPC C1 Squiggle Tag

It is recommended to locate the vertical center of an RFID tag in the area 45mm ±5mm from a leading

edge of a label and the horizontal center with the horizontal center of the label.

45 mm + 5mm

Media feeding direction

2- 7

Page 24

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.4 SPECIFICATION OF RFID TAG (for B-9704-RFID-U1-US/EU-R, H1-QM-R)

(2) X-ident’s ISO 18000-6B Tag

It is recommended to locate the vertical center of an RFID tag in the area 40mm ±5mm from a leading

edge of a label and the horizontal center with the horizontal center of the label.

40 mm + 5mm

Media feeding direction

2.4.4 Cautions for using RFID Tags

(1) Lift-up of Print Head

An RFID tag chip or the print head may be damaged when the print head passes over the chip.

This can be prevented by using the ribbon saving module (standard feature for the B-SX5T and

optional for the B-SX4T). The print head is lifted by the ribbon saving module when it passes over the

chip to prevent it from touching the chip.

The print head is lifted by approximately 1 mm from the platen.

2) Storage of RFID Supplies

Do not store RFID tags close to printers, or their communication performance may not be as specified

when they are used.

3) Roll-type RFID Supplies

When RFID supplies are to be rolled, roll hardness must be concerned.

Although it depends on the type of glue, tag, and backing paper, RFID-tag embedded labels tend to

stay rolled. Especially, when they are wound outside, a media jam error may occur. Unless otherwise

specified, it is recommended that the RFID-tag embedded labels be wound inside.

4) Sensor

When the transmissive sensor or reflective sensor is enabled, transmissivity or reflectivity of a label or

tag may vary at an RFID-tag embedded area depending on the pattern of an antenna or other factors.

In such cases, a manual threshold setting is required in Online mode. For details, refer to the B-SX

Key Operation Specifications (TAA-1379).

2- 8

Page 25

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.4 SPECIFICATION OF RFID TAG (for B-9704-RFID-U1-US/EU-R, H1-QM-R)

5) Cutter

When an RFID label or tag is used in cut issue mode, care must be taken not to cut an antenna of the

RFID tag or an IC chip in order not to damage the cutter.

6) Static Electricity

When printing is performed in a place where humidity is low or under some specific conditions, writing

data on an RFID tag may fail due to static electricity generated by a label or a ribbon.

7) Printing on Bump (Chip/Antenna) Area

Embedding an RFID tag in labels creates bumps in a chip/antenna area in the labels, causing

incomplete printing.

Uneven printing or incomplete printing can occur easily, especially within 5 mm back and forth of the

RFID tag, and right and left sides of the RFID-tag embedded area, as shown in the figure below.

NOTE: The degree of poor printing quality differs depending on height of a chip/antenna used.

5 mm

Media feeding

direction

RFID-tag

Embedded area

Poor printing may occur in

this area due to bump.

5 mm

Poor printing may occur in

this area due to bump.

8) Ambient Temperature

Low temperature deteriorates wireless performance, under which conditions writing data on an RFID

tag may fail.

9) Head-up Back feed

When an RFID label is used, a back feed may be required before an issue depending on the location

of an RFID tag in the label.

A printer without the ribbon saving module may not be able to perform a back feed properly because

the print head may be caught by an edge of the label. For this reason, the ribbon saving module must

be installed in the printer when media, which requires a back feed before an issue, is used.

2- 9

Page 26

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.4 SPECIFICATION OF RFID TAG (for B-9704-RFID-U1-US/EU-R, H1-QM-R)

10) Strip Issue

Stripping performance in strip issue mode depends on the type of glue, tag, and backing paper. For

some RFID supplies used, an issue may not be performed properly in strip issue mode.

11) Caution for Minimum Label Pitch Length

When media, of which label pitch length is short, is used, data may be written on an RFID tag next to

the target RFID tag.

As the location, where data is to be written, differs among RFID tag types, a check must be performed

to make sure that the data is written on the target RFID tags.

The B-SX RFID Analyze Tool (7FM001113) can be used for this purpose.

12) Defective RFID Supply

RFID supplies may include defective RFID tags at the time of shipment from the maker. The defect

rate differs depending on tag types, method of converting to supplies, etc.

The RFID supply maker should provide a way to distinguish defective tags by printing a mark on them

or any other methods.

Or, defective tags should be rejected in the production process.

How to distinguish a defective tag from good one must be notified to end users.

2.4.5 Improvement of Writing Accuracy

As RFID tags use wireless technologies, writing data on the RFID tag may fail depending on

environment and characteristics of the RFID tags.

In order to improve the accuracy of writing data on the RFID tags, the following method can be used:

1) Change of the maximum number of RFID write retries

The maximum number of RFID write retries is variable and can be changed by the RFID settings in

System mode. Setting the high number can improve the writing accuracy. However, overall printing

throughput may become worse because a retry is also performed for tags on which data cannot be

written.

For details of settings, refer to the B-SX Key Operation Specification (TAA-1379).

2) Enabling of RFID adjustment for retry

The printer has the RFID adjustment for retry feature. If writing data on the RFID tag fails, the printer

automatically feeds the RFID tag forward or backward for a specified length in order to retry writing

data.

Enabling this feature can improve the writing accuracy. However, overall printing throughput may

become worse because a retry is also performed for tags on which data cannot be written.

For details of settings, refer to the B-SX Key Operation Specification (TAA-1379).

3) Adjustment of location of antenna

The RFID antenna, which is attached to the bottom area of the printer head, is fixed with the screw to

the mold side for B-9704-RFID-U1-EU/U1-EU-R and B-9704-RFID-H1-QM/H1-QM-R and to the metal

side for B-9704-RFID-U1-US when it is shipped.

Whether the antenna is attached to the mold side or metal side is currently determined based on the

best distance for common RFID tags. The antenna can be attached to the metal side for B-9704RFID-U1-EU/U1-EU-R and B-9704-RFID-H1-QM/H1-QM-R and to the mold side for B-9704-RFID-U1US in order to improve writing accuracy.

The location of the antenna must be determined after measuring the distance using the B-SX RFID

Analyze Tool (7FM001113).

2-10

Page 27

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU-R)

2.5.1 General Description

The RFID supplies are RFID tag (wireless IC tag) inlays designed to be converted into tag and label

applications. Printers, which are equipped with an RFID kit, can print data on the surface of RFID

supplies as well as write data on the embedded RFID tags.

The B-SX704-RFID-U2-EU-R is destined for Europe and operates in the UHF band (869.7-870.0 MHz).

The B-SX704-RFID-U2-AU-R is destined for Australia and operates in the UHF band (918.25-925.75

MHz).

2.5.2 Available RFID Tag

• EPC Generation 2

2.5.3 Location of RFID Tag

The location of an RFID tag in a label influences on the accuracy of writing data on the RFID tag. It is

impossible to define the one best location for every RFID tag in labels because the best location

depends on the type of RFID tag and RFID tag antenna.

The RFID Analyze Tool (7FM001113) can evaluate the accuracy of writing data on the RFID tag. For

the usage of this tool, refer to the RFID Analyze Tool Operation Specification (TAA-2195).

As a guideline, the best location for some common RFID tags is given below.

It is recommended to use the RFID Analyze Tool to evaluate the accuracy of writing data on an RFID

tag to be used, then determine a specific location of the RFID tag.

If the RFID tag cannot be placed on the best location specified, perform a forward/reverse feed before

a data write using the RFID Tag Position Adjustment Command ([ESC]@003).

Note that the best location described in this specification may not be applicable depending on the type

or paper or glue even if the same RFID tags are used. This guideline applies to RFID labels for

thermal transfer issue. When using the media made of PET or thermal paper, the best location needs

to be found again.

2-11

Page 28

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

(1) UPM Raflatac’s Rafsec Short Dipole 2 Tag

It is recommended to locate the vertical center of an RFID tag at 35 mm ± 3 mm from a leading edge of

a label and align the horizontal center with the horizontal center of the label.

35 mm ±3 mm

Media feed direction

2-12

Page 29

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: May 29, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

2.5.4 Short-pitch Tag

A short-pitch tag kit is supplied with the B-SX704-RFID-U2-EU/AU-R to enable the RFID kit to encode

short-pitch tags properly. When the short-pitch tag kit is attached to the printer, the write field will be

narrower.

The RFID kit is designed so that the second label is positioned just above the antenna while the first

label is at the print start position, when using the following short-pitch label.

For B-SX704-RFID-U2-EU-R

For B-SX704-RFID-U2-AU-R

5 mm

3 mm

20 mm

After printing a label, a reverse feed for a distance equivalent to one label pitch is required to write data

onto its tag. During this reverse feed, the bottom edge of the printed label may be stuck on the print

head edge, causing a feed jam. This is because the labels become thicker due to embedded tags.

When several labels are issued in a batch, set the offset printing parameter to 1 (Offset printing is

performed without a reverse feed of the first label.) in order to make the printer issue labels without

performing a reverse feed. In this case, however, the printer does not print or write data on the first

label, so it is wasteful. This mode is not suitable for applications where a small number of labels are

issued on an as-needed basis.

For details of the offset printing feature, refer to the B-SX4T/SX5T External Equipment Interface

Specification (EAA-1380).

2.5.5 Cautions for using RFID Tags

16 mm

1) Lift-up of Print Head

An RFID tag chip or the thermal head may be damaged when the thermal head passes over the chip.

This can be prevented by using the ribbon saving module (standard feature for the B-SX5T and

optional for the B-SX4T) by which the thermal head is lifted up preventing it from touching the chip

when it passes over the chip.

When the thermal head is lifted up, the distance from the platen roller to the head is approximately 1

mm.

2) Storage of RFID Supplies

Do not store RFID tags close to printers, or their communication performance may not be as specified

when they are used.

2-13

Page 30

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

3) Roll-type RFID Supplies

When RFID supplies are to be rolled, roll hardness must be concerned.

Although it depends on the type of glue, tag, and backing paper, RFID-tag embedded labels tend to

stay rolled. Especially, when they are wound outside, a media jam error may occur. Unless otherwise

specified, it is recommended that the RFID-tag embedded labels be wound inside.

4) Sensor

When the transmissive sensor or reflective sensor is enabled, transmissivity or reflectivity of a label or

tag may vary at an RFID-tag embedded area depending on the pattern of an antenna or other factors.

In such cases, a manual threshold setting is required in the printer system mode. For details, refer to

the B-SX4T/5T Key Operation Specifications (EAA-1379).

5) Cutter

When an RFID label or tag is used in cut issue mode, care must be taken not to cut the antenna or the

IC chip of an RFID tag in order not to damage the cutter.

6) Static Electricity

When printing is performed in a place where humidity is low or under some specific conditions, writing

data on an RFID tag may fail due to static electricity generated by a label or a ribbon.

2-14

Page 31

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

7) Printing on Bump (Chip/Antenna) Area

Embedding RFID tags in labels creates bumps in a chip/antenna area in the labels, causing incomplete

printing.

Especially, in the areas 5 mm from and left and right sides of the RFID-tag embedded area shown in

the figure below, uneven printing or incomplete printing can occur easily.

* The degree of poor printing quality differs depending on height of a chip/antenna used.

Print quality on

bumps is not

guaranteed.

RFID tag

embedded

area

Print quality on the

sides of RFID tag is

not guaranteed.

Media

feed

direction

5mm

Print quality on

the IC chip is not

guaranteed.

Print quality on

bumps is not

guaranteed.

5mm

8) Ambient temperature

Low operating temperature deteriorates wireless performance, under which conditions writing data on

an RFID tag may fail.

9) Strip issue

Stripping performance in strip issue mode depends on the type of glue, tag, and backing paper. For

some RFID supplies used, an issue may not be performed properly in strip issue mode.

2-15

Page 32

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

10) Caution for minimum label pitch length

When short-pitch media is used, data may be written on a next RFID tag instead of the target RFID tag.

As the location, where data is to be written, differs among RFID tag types, a check must be performed

using the labels to be used to make sure that the data is written on the target RFID tags.

The RFID Analyze Tool (7FM001113) can be used for this purpose.

11) Defective RFID Tag

Defective tags could be embedded while they are converted into labels, and the error rate differs

depending on the tag types or the conversion methods.

Label manufacturers should mark such defective labels with something to indicate the tag is defective,

or should prevent defective tags from being used.

Also, how to identify defective tags and good tags should be properly notified to end users.

12) PRINT POSITION ACCURACY

When using RFID tag embedded media, the print position accuracy may exceed the guaranteed

tolerance of ±1 mm in all issue modes.

It is required to check the print position accuracy for each media type.

13) PAPER JAM ERROR

Depending on the type of glue or the flexibility of labels, a label may come unstuck in front of the

sensor unit, which cause a paper jam. Particularly, the frequency of paper jam could become higher

on the condition of low operating temperature or use of short-pitch labels.

It is required to check the media feed using the media to be used under the actual operating

environment.

2-16

Page 33

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Apr. 24, 2008)

2.5 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-EU/AU -R)

2.5.6 Improvement of Writing Accuracy

As RFID tags use wireless technologies, writing data on the RFID tag may fail depending on

environment and characteristics of the RFID tags.

In order to improve the accuracy of writing data on the RFID tags, the following method can be used:

(1) Change of the maximum number of write retries

The maximum number of write retries is variable and can be changed in the system mode. Setting

the greater value can improve the writing accuracy. However, overall printing throughput may

become worse because a retry is also performed for tags on which data cannot be written.

For details of settings, refer to the B-SX4T/SX5T Key Operation Specification (EAA-1379).

(2) Enabling of RFID adjustment for retry

The printer has the RFID adjustment for retry feature. If writing data on the RFID tag fails, the

printer automatically feeds the RFID tag forward or backward for a specified length in order to retry

a data write.

Enabling this feature can improve the writing accuracy. However, overall printing throughput may

become worse because a retry is performed even for defective tags.

For details of settings, refer to the B-SX4T/SX5T Key Operation Specification (EAA-1379).

(3) Adjustment of location of antenna

When writing data on tags, especially on short-pitch tags, the antenna may communicate with nontarget tags, and this lowers the write rate.

The B-SX4T/SX5T has a feature to pinpoint a target tag by evaluating the output power (AGC) of

tags. Setting an AGC threshold for data write enables choosing a tag of which AGC is higher than

the threshold, determining this tag to be a target tag positioned just above the antenna, and writing

data on it. This feature can prevent writing data to non-target tags (= off the antenna).

For details of settings, refer to the B-SX4T/SX5T Key Operation Specification (EAA-1379).

2-17

Page 34

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Feb. 6, 2009)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

2.6.1 General Description

The RFID supplies are RFID tag (wireless IC tag) inlays designed to be converted into tag and label

applications. Printers, which are equipped with an RFID kit, can print data on the surface of RFID supplies

as well as write data on the embedded RFID tags.

The B-SX704-RFID-U2-US-R (Serial Number: 2808Yxxxxxx and earlier) is destined for U.S.A./Canada and

operates in the UHF band (902.75-927.5 MHz).

The B-SX704-RFID-U2-US-R (Serial Number: 2809Axxxxxx or later) is destined for U.S.A./Canada,

Australia, South Korea, Taiwan and operates in the following UHF band.

U.S.A./Canada: 902.75 to 927.5 MHz

Australia: 918.25 to 925.75 MHz

South Korea: 910.4 to 913.6 MHz

Taiwan: 922.25 to 927.25 MHz

2.6.2 Available RFID Tag

• EPC Generation 2, ISO-18000-6C

2.6.3 Location of RFID Tag

The location of an RFID tag in a label influences on the accuracy of writing data on the RFID tag. It is

impossible to define the one best location for every RFID tag in labels because the best location

depends on the type of RFID tag and RFID tag antenna.

The RFID Analyze Tool (7FM001113) can evaluate the accuracy of writing data on the RFID tag. For

the usage of this tool, refer to the RFID Analyze Tool Operation Specification (TAA-2195).

As a guideline, the best location for some common RFID tags is given below.

It is recommended to use the RFID Analyze Tool to evaluate the accuracy of writing data on an RFID

tag to be used, then determine a specific location of the RFID tag.

If the RFID tag cannot be placed on the best location specified, perform a forward/reverse feed before

a data write using the RFID Tag Position Adjustment Command ([ESC]@003).

Note that the best location described in this specification may not be applicable depending on the type

or paper or glue even if the same RFID tags are used. This guideline applies to RFID labels for

thermal transfer issue. When using the media made of PET or thermal paper, the best location needs

to be found again.

2-18

Page 35

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

(1) Avery Dennison AD-222 Tag

It is recommended to locate the vertical center of an RFID tag at 35 mm ± 3 mm from a leading edge of

a label and align the horizontal center with the horizontal center of the label.

35 mm ±3 mm

Media feed direction

2-19

Page 36

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

(2) Alien Squiggle Tag

It is recommended to locate the vertical center of an RFID tag at 35 mm ± 3 mm from a leading edge of

a label and align the horizontal center with the horizontal center of the label.

35 mm ±3 mm

Media feed direction

2-20

Page 37

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

2.6.4 Short-pitch Tag

A short-pitch tag kit is supplied with the B-SX704-RFID-U2-US-R to enable the RFID kit to encode

short-pitch tags properly. When the short-pitch tag kit is attached to the printer, the write field will be

narrower.

The RFID kit is designed so that the second label is positioned just above the antenna while the first

label is at the print start position, when using the following short-pitch label.

Rafsec Short Dipole2 Tag

After printing a label, a reverse feed for a distance equivalent to one label pitch is required to write data

onto its tag. During this reverse feed, the bottom edge of the printed label may be stuck on the print

head edge, causing a feed jam. This is because the labels become thicker due to embedded tags.

In most cases, this problem can be avoided by enabling the ribbon saving function of the printer which

raises the thermal head during a reverse feed. When using short-pitch tags, enable the ribbon saving

function.

When several labels are issued in a batch, set the offset printing parameter to 1 (Offset printing is

performed without a reverse feed of the first label.) in order to make the printer issue labels without

performing a reverse feed. In this case, however, the printer does not print or write data on the first

label, so it is wasteful. This mode is not suitable for applications where a small number of labels are

issued on an as-needed basis.

For details of the offset printing feature, refer to the B-SX4T/SX5T External Equipment Interface

Specification (TAA-1380).

[Printer settings for use of short-pitch tags]

In the printer system mode, set the RFID-related parameters as follows:

Q value: 2, WT AGC (AGC threshold for data write): 10, WT MIN AGC (AGC threshold lower limit for

retry): 10

When using short-pitch tags, a target tag is identified by measuring the AGC of tags within the read

range. A tag of which AGC is equal to or higher than the specified threshold (10) is considered to be

positioned just above the antenna (=target tag), and a data write is performed on it.

When the AGC is less than the threshold, a data write is not performed on such tag.

5 mm

20 mm

Media feed direction

2-21

Page 38

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

2.6.5 Cautions for using RFID Tags

1) Lift-up of Print Head

An RFID tag chip or the thermal head may be damaged when the thermal head passes over the chip.

This can be prevented by using the ribbon saving module (standard feature for the B-SX5T and

optional for the B-SX4T) by which the thermal head is lifted up preventing it from touching the chip

when it passes over the chip.

When the thermal head is lifted up, the distance from the platen roller to the head is approximately 1

mm.

2) Storage of RFID Supplies

Do not store RFID tags close to printers, or their communication performance may not be as specified

when they are used.

3) Roll-type RFID Supplies

When RFID supplies are to be rolled, roll hardness must be concerned.

Although it depends on the type of glue, tag, and backing paper, RFID-tag embedded labels tend to

stay rolled. Especially, when they are wound outside, a media jam error may occur. Unless otherwise

specified, it is recommended that the RFID-tag embedded labels be wound inside.

4) Sensor

When the transmissive sensor or reflective sensor is enabled, transmissivity or reflectivity of a label or

tag may vary at an RFID-tag embedded area depending on the pattern of an antenna or other factors.

In such cases, a manual threshold setting is required in the printer system mode. For details, refer to

the B-SX4T/5T Key Operation Specifications (EAA-1379).

5) Cutter

When an RFID label or tag is used in cut issue mode, care must be taken not to cut the antenna or the

IC chip of an RFID tag in order not to damage the cutter.

6) Static Electricity

When printing is performed in a place where humidity is low or under some specific conditions, writing

data on an RFID tag may fail due to static electricity generated by a label or a ribbon.

2-22

Page 39

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

7) Printing on Bump (Chip/Antenna) Area

Embedding RFID tags in labels creates bumps in a chip/antenna area in the labels, causing incomplete

printing.

Especially, in the areas 5 mm from and left and right sides of the RFID-tag embedded area shown in

the figure below, uneven printing or incomplete printing can occur easily.

* The degree of poor printing quality differs depending on height of a chip/antenna used.

Print quality on

bumps is not

guaranteed.

RFID tag

embedded

area

Print quality on the

sides of RFID tag is

not guaranteed.

Media

feed

direction

5mm

Print quality on

the IC chip is not

guaranteed.

Print quality on

bumps is not

guaranteed.

5mm

8) Ambient temperature

Low operating temperature deteriorates wireless performance, under which conditions writing data on

an RFID tag may fail.

9) Strip issue

Stripping performance in strip issue mode depends on the type of glue, tag, and backing paper. For

some RFID supplies used, an issue may not be performed properly in strip issue mode.

2-23

Page 40

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

10) Caution for minimum label pitch length

When short-pitch media is used, data may be written on a next RFID tag instead of the target RFID tag.

As the location, where data is to be written, differs among RFID tag types, a check must be performed

using the labels to be used to make sure that the data is written on the target RFID tags.

The RFID Analyze Tool (7FM001113) can be used for this purpose.

11) Defective RFID Tag

Defective tags could be embedded while they are converted into labels, and the error rate differs

depending on the tag types or the conversion methods.

Label manufacturers should mark such defective labels with something to indicate the tag is defective,

or should prevent defective tags from being used.

Also, how to identify defective tags and good tags should be properly notified to end users.

12) PRINT POSITION ACCURACY

When using RFID tag embedded media, the print position accuracy may exceed the guaranteed

tolerance of ±1 mm in all issue modes.

It is required to check the print position accuracy for each media type.

13) PAPER JAM ERROR

Depending on the type of glue or the flexibility of labels, a label may come unstuck in front of the

sensor unit, which cause a paper jam. Particularly, the frequency of paper jam could become higher

on the condition of low operating temperature or use of short-pitch labels.

It is required to check the media feed using the media to be used under the actual operating

environment.

2-24

Page 41

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: Jul. 15, 2008)

2.6 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-US-R)

2.6.6 Improvement of Writing Accuracy

As RFID tags use wireless technologies, writing data on the RFID tag may fail depending on environment and

characteristics of the RFID tags.

In order to improve the accuracy of writing data on the RFID tags, the following method can be used:

(1) Change of the maximum number of write retries

The maximum number of write retries is variable and can be changed in the system mode. Setting

the greater value can improve the writing accuracy. However, overall printing throughput may

become worse because a retry is also performed for tags on which data cannot be written.

For details of settings, refer to the B-SX4T/SX5T Key Operation Specification (TAA-1379).

(2) Enabling of RFID adjustment for retry

The printer has the RFID adjustment for retry feature. If writing data on the RFID tag fails, the

printer automatically feeds the RFID tag forward or backward for a specified length in order to retry

a data write.

Enabling this feature can improve the writing accuracy. However, overall printing throughput may

become worse because a retry is performed even for defective tags.

For details of settings, refer to the B-SX4T/SX5T Key Operation Specification (TAA-1379).

(3) Adjustment of location of antenna

When writing data on tags, especially on short-pitch tags, the antenna may communicate with nontarget tags, and this lowers the write rate.

The B-SX4T/SX5T has a feature to pinpoint a target tag by evaluating the output power (AGC) of

tags. Setting an AGC threshold for data write enables choosing a tag of which AGC is higher than

the threshold, determining this tag to be a target tag positioned just above the antenna, and writing

data on it. This feature can prevent writing data to non-target tags (= off the antenna).

For details of settings, refer to the B-SX4T/SX5T Key Operation Specification (TAA-1379).

2-25

Page 42

2. SUPPLY SPECIFICATIONS EO10-33013B

(Revision Date: May 22, 2009)

2.7 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-CN -R)

2.7 SPECIFICATION OF RFID TAG (for B-SX704-RFID-U2-CN-R)

2.7.1 General Description

The RFID supplies are RFID tag (wireless IC tag) inlays designed to be converted into tag and label

applications. Printers, which are equipped with an RFID kit, can print data on the surface of RFID