Page 1

Publish Date: 99/02/25

M-FSA29001a.pdf

.

.

BSI No.: A29001

Subject:

Change the Service Manual

Model: TF631, TF671

Category Field Application Unit

Modification/Correction of

Service Manual

Factory Application:

To be applied when necessary Operator's Manual/Service

Manual

CONTENT

1. Document No.

For TAIS

For except TAIS

Discontinue to use Lubricant Type 1, Silicon Grease G501, and use Lubricant Type 3 Floil

G-258, instead. See the pages, 8-107, 110, 111,112,113, and 114, attached.

E0-26145

E0-26148

.

.

.

.

Attached Files

2. Reason for Change

For common use with other parts of TF631/TF671.

Refer to ECR, TSB-TF631/671-ECR-570.

Page 2

4. Lubrication

4.1 Mechanisms and Parts not to be Lubricated

• Drum unit

• Retard pad assembly

• White plate

• CIS unit

• Laser scanner unit (especially laser beam slit)

• All PBA

• Fuser unit

• Transfer unit

• Rubber rollers

• Cover and plastic part

NOTE: Avoid lubricating the areas around the above mechanism and parts. Should

they be lubricated or if oil runs down into them, thoroughly remove oil with

clean rags.

TF631/TF671

4.2 Notes on Lubrication

Before lubrication, thoroughly remove old oil, rust-prev enting oil, dust and dirt with rags. Then, apply a

proper amount of oil. Oil should be applied to only the specified points.

4.3 Oil types and Makers

Lubricant T ype Specified oil Maker

2 Multipurpose No.00 ICI Co., Ltd.

3 Floil G-258 Kanto Chemicals Co., Ltd.

4 Floil GE-334C Kanto Chemicals Co., Ltd.

5 Floil GE-676 Kanto Chemicals Co., Ltd.

SERVICE MANUAL 8-107 Chapter 8

Page 3

TF631/TF671

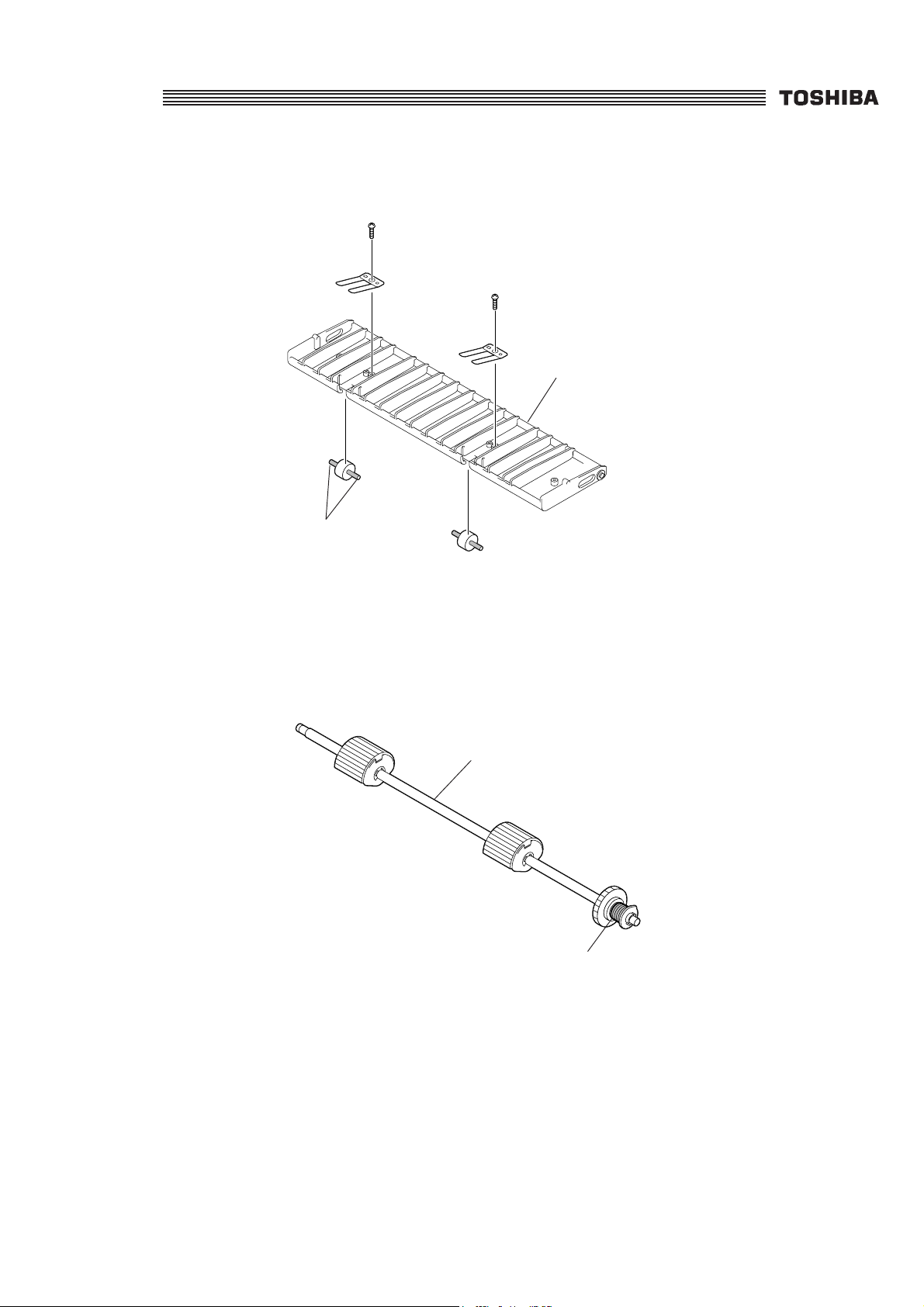

• Lubricate the Pinch Rollers of Paper Supply Guide Assembly

Paper supply guide

Lubricant type 3

Fig. 01-05.EPS

• Lubricate the Paper Pickup Roller Spring

Fig. 01-06.EPS

Paper pic kup roller

Lubricant type 2

Chapter 8 8-110 SERVICE MANUAL

Page 4

• Lubricate the Paper Supply Pinch Roller Gear Teeth

Paper supply pinch roller

Lubricant type 3

Fig. 01-07.EPS

TF631/TF671

• Lubricate the Shafts and Gear Teeth of Gear Plate Assembly

Gear plate assembly

Lubricant type 3

Lubricant type 3

Fig. 01-08.EPS

SERVICE MANUAL 8-111 Chapter 8

Page 5

TF631/TF671

• Lubricate the Main Motor Shaft

• Lubricate the Pinch Roller Assembly Shaft

Main motor assembly

Lubricant type 3

Fig. 01-09.EPS

Lubricant type 3

Fig. 01-10.EPS

Pinch roller

Chapter 8 8-112 SERVICE MANUAL

Page 6

TF631/TF671

• Lubricate the area between the front side of Paper Feed Roller Shaft and Ground Plate

Paper feed roller

Lubricant type 4

Fig. 01-11.EPS

• Lubricate the Shaft and Gear Teeth of Gear Assembly

Lubricant type 3

NEVER

LUBRICA TE

NEVER LUBRICA TE

Lubricant type 3

Gear assembly

Fig. 01-12.EPS

SERVICE MANUAL 8-113 Chapter 8

Page 7

TF631/TF671

• Lubricate the Pulley, Shaft, Gear Teeth and Motor Gear Teeth of Developer Assembly

Developer assembly

Lubricant type 3

Lubricant

type 2

Lubricant type 2

Lubricant type 3

Fig. 01-13.EPS

• Lubricate the Shafts and Gear Teeth of Optional Motor Assembly

Lubricant

type 3

Fig. 01-14.EPS

Optional motor assembly

Lubricant type 3

Chapter 8 8-114 SERVICE MANUAL

Loading...

Loading...