Page 1

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

PROGRAMMABLE CONTROLLER

PROSEC

USER’S MANUAL

----

Basic Hardware and Function

UM-TS01

T1 / T1S

***

-E001

----

TOSHIBA CORPORATION

Page 2

Important Information

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Misuse of this equipment can result in property damage or human injury.

Because controlled system applications vary widely, you should satisfy yourself

as to the acceptability of this equipment for your intended purpose.

In no event will Toshiba Corporation be responsible or liable for either indirect

or consequential damage or injury that may result from the use of this equipment.

No patent liability is assumed by Toshiba Corporation with respect to use of

information, illustrations, circuits, equipment or examples of application in this

publication.

Toshiba Corporation reserves the right to make changes and improvements to this

publication and/or related products at any time without notice. No obligation shall be

incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book

may be reproduced, stored in a retrieval system, or transmitted, in any form or by any

means ¾ electrical, mechanical, photocopying, recording, or otherwise ¾ without

obtaining prior written permission from Toshiba Corporation.

6F3B0250

© TOSHIBA Corporation 1995. All rights reserved

PROSEC and TOSLINE are registered trademarks of TOSHIBA Corporation.

IBM is a registered trademark of International Business Machines Corporation.

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Publication number: UM-TS01

***

-E001

1st edition December 1995, 4th edition February 1998

Page 3

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

CE Marking

The Programmable Cont r oller PROSEC T1 and T1S (hereafter called T1/T1S) complies with the

requirements of t he EMC Directive 89/336/EEC and Low Voltage Directive 72/23/EEC under the

condition of use according to the instructions described in this manual.

The contents of the conformity are shown below.

Application of EMC : 89/336/EEC (as amended by 91/263/EEC and 92/31/EEC)

Council Directive LVD : 72/23/EEC (as amended by 93/68/EEC)

Manufacture’s Name : Toshiba Corporation, Fuchu Works

Address : 1, Toshiba-Cho

Fuchu-shi

TOKYO 183

Japan

declares, that the product

Product Name : Programmable Controller , T1 Series

Model Number : TDR116*6S, TAR116*6S, TDR116*3S

TDR128*6S, TAR128*6S, TDR128*3S

TDR140*6S, TAR140*6S, TDR140*3S

TDR140S6S, TAR140S6S, TDR140S3S

conforms to the following Product Specifications:

EMC

Radiated Interference : EN 55011 Group 1 Class A

Mains Interference : EN 55011 Group 1 Class A

Radiated Susceptibility : ENV50140

Conducted RFI Susceptibility : ENV50141, IEC100-4-6.

Electrostatic Discharge : IEC1000-4-2

Electrical Fast Transient : IEC1000-4-4

LVD : EN61131-2:1995 3.10 Dielectric Properties

4. Mechanical Requirements

Supplementary information :

(1) Included Handy Programmer THP911A*S.

(2) Included each type of associated input/output unit in a typical configuration.

(3) Product must be installed in accordance with manufacturers instructions

Basic Hardware and Function

1

Page 4

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

UL/c-UL Listing

The Programmable Cont r oller PROSEC T1 and T1S (hereafter called T1/T1S) are UL/c-UL listed

as shown below.

UL and c-UL Listing

File Number : E95637

Product Name : Programmable Controller , T1 Series

Product Covered : Main Unit

TDR116*6S, TAR116*6S, TDR116*3S,

TDR128*6S, TAR128*6S, TDR128*3S,

TDR140*6S, TAR140*6S, TDR140*3S,

TDR140S6S, TAR140S6S, TDR140S3S

Option Card

TDI116*BS, TDD116*BS, TDO116*BS,

TAD121*BS, TAD131*BS, TDA121*BS, TDA131*BS,

TFR112*BS

Expansion Unit

TDR132E*S, TAR132E*S

Expansion Rack

TBU152**S, TBU154**S

Peripherals

TRM102**S, TCU111**S, THP911A*S

UL and c-UL Listing For Use in Hazardous Locations

File Number : E184034

Product Name : Programmable Controller , T1 Series

Product Covered : Main Unit

TDR116*6S, TAR116*6S, TDR116*3S,

TDR128*6S, TAR128*6S, TDR128*3S,

TDR140*6S, TAR140*6S, TDR140*3S,

Locations Class : Class I, Division 2, Groups A, B, C, D

Important Notice : 1. THIS EQUIPMENT IS SUITABLE FOR USE IN CLASS I,

DIVISION 2, GROUPS A, B, C, D OR NON-HAZARDOUS

LOCATIONS ONLY.

2. WARNING - EXPLOSION HAZARD - SUBSTITUTION OF

COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS I,

DIVISION 2.

3. WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT

EQUIPMENT UNLESS POWER HAS BEEN SWITCHED OFF

OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

T1/T1S User’s Manual

2

Page 5

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Safety Precautions

This manual is prepared for users of Toshiba’s Programmable Controller T1/T1S.

Read this manual thoroughly before using the T1/T1S. Also, keep this manual and related manuals

so that you can read them anytime while the T1/T1S is in operation.

General Information

1. The T1/T1S has been designed and manufactured for use in an industr ial environment.

However, the T1/T1S is not intended to be used for systems which may endanger human

life. Consult Toshiba if you intend t o use the T1/T1S for a special applicat ion, such as

transportation machines, medical apparat us, aviation and space systems, nuclear

controls, submarine systems, etc.

2. The T1/T1S has been manufactured under strict quality control. However, to keep safety

of overall automated system, fail-safe systems should be considered outside the T1/T1S.

3. In installation, wiring, operation and maintenance of the T1/T1S, it is assumed that the

users have general knowledge of industrial elect r ic cont r ol system s.

If this product is handled or operat ed im pr operly, electrical shock, fire or dam age to this

product could result.

4. This manual has been written for users who are f am iliar with Prog rammable Controllers

and industrial control equipment. Cont act Toshiba if you have any questions about this

manual.

5. Sample programs and circuits described in this manual are provided for explaining the

operations and applications of the T1/T1S. You should test completely if you use them as

a part of your application system.

Hazard Classifications

In this manual, the following two hazard classifications are used to explain the safety

precautions.

!

WARNING

!

CAUTION

Even a precaution is classified as CAUTION, it may cause serious results depending on the

situation. Observe all the safety precautions described on this manual.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injur y. I t m ay also be used to aler t

against unsafe practices.

Basic Hardware and Function

3

Page 6

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Installation:

!

CAUTION

1. Excess temperature, humidity, vibration, shock s, or dusty and corrosive gas

environment can cause electrical shock, fire or malfunction. Install and use the T1/T1S

and related equipment in the environment described in this manual.

2. Improper installation directions or insufficient installation can cause fir e or t he units to

drop. Install the T1/T 1S and r elated equipment in accordance with the instructions

described in this manual.

3. Turn off power before installing or removing any units, modules, r acks or terminal

blocks. Failure to do so can cause electrical shock or dam age to the T1/T1S and

related equipment.

6F3B0250

4. Entering wire scraps or other foreign debris into to the T1/T 1S and r elated equipment

can cause fire or malfunction. Pay att ention to prevent entering them into the T1/T1S

and related equipment during inst allat ion and wiring.

5. Turn off power immediat ely if the T1/T1S or related eq uipm ent is emitting smoke or

odor. Operation under such situation can cause fire or electrical shock. Also

unauthorized repairing will cause fire or serious accidents. Do not attempt to repair.

Contact Toshiba for repairing.

Wiring:

!

CAUTION

1. Turn off power before wiring to minimize the risk of electrical shock.

2. Exposed conductive parts of wire can cause electrical shock. Use crimp-style terminals

with insulating sheath or insulating tape to cover the conductive parts . Also close t he

terminal covers securely on the terminal blocks when wiring has been completed.

3. Operation without grounding may cause electrical shock or malfunction. Connect the

ground terminal on the T1/T1S to the system ground.

4. Applying excess power voltage to the T1/T1S can cause explosion or fire. Apply power

of the specified rating s descr ibed in t he manual.

5. Improper wiring can cause fire, electr ical shock or malfunction. Obser ve local

regulations on wiring and grounding.

T1/T1S User’s Manual

4

Page 7

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Operation:

!

WARNING

1. Configure emergency stop and safety interlocking circuits out side t he T1/T1S.

Otherwise, malfunction of t he T1/T1S can cause injury or serious accidents.

!

CAUTION

2. Operate the T1/T1S and t he r elated modules with closing the terminal covers. Keep

hands away from terminals while power on, to avoid the risk of electrical shock.

3. When you attempt to perform force outputs, RUN/HALT controls, etc. during operation,

carefully check for safety.

6F3B0250

4. Turn on power to the T1/T1S before turning on power to the loads. Failure to do so may

cause unexpected behavior of the loads.

5. Do not use any modules of the T1/T1S for the purpose other than specified. This can

cause electrical shock or injury.

6. Do not modify the T1/T1S and r elat ed equipment in hardware nor software. This can

cause fire, electrical shock or injury.

7. Configure the external circuit so that the external 24 Vdc power required for t r ansistor

output circuits and power to the loads are switched on/off simultaneously.

Also, turn off power to the loads before turning of f power to the T1/T1S.

8. Install fuses appropriate to t he load cur rent in the external circuits for t he outputs.

Failure to do so can cause fire in case of load over-cur r ent .

9. Check for proper connections on wires, connector s and m odules. Insufficient contact

can cause malfunction or damage to t he T1/T1S and related equipment .

Basic Hardware and Function

5

Page 8

Safety Precautions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Maintenance:

!

CAUTION

1. Turn off power before removing or replacing units, modules, terminal blocks or wires.

Failure to do so can cause electrical shock or damag e t o the T1/T1S and related

equipment.

2. When you remove both input and out put terminal blocks with wires for maintenance

purpose, pay attention to prevent inserting them upside down.

3. Do not insert your finger into t he expansion rack’s ventilation hole during power on.

This can cause electrical shock.

6F3B0250

4. Do not disassemble the T1/T1S because ther e ar e hazardous voltag e par ts inside.

5. Perform daily checks, periodical checks and cleaning to maintain the system in normal

condition and to prevent unnecessary troubles.

6. Check by referring “T r oubleshooting” section of this manual when operating

improperly. Contact Toshiba for repairing if t he T1/T1S or related eq uipm ent is failed.

Toshiba will not guarantee proper operation nor safety for unauthorized repairing.

7. The contact reliability of t he out put relays will reduce if the switching exceeds the

specified life. Replace the unit or module if exceeded.

T1/T1S User’s Manual

6

Page 9

Safety Label

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The safety label as shown on the right is

attached to the power terminal of the

T1/T1S.

Remove the mount paper before wiring.

Peel off the label fr om the mount paper

and stick it near the power terminals

where it can be readily seen.

Contact Toshiba if the label is damaged.

Safety Precautions

CAUTION

!

Do not touch terminals

while power on.

Hazardous voltage can shock , bur n or c ause death.

Do not touch terminals while power on.

Read related manual thoroughly for safety.

Stick this seal on uni t or near unit.

Take off this sheet before wiring.

6F3B0250

Basic Hardware and Function

7

Page 10

About This Manual

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

About This Manual

This manual has been prepared for first-time users of Toshiba’s Programmable Controller

T1 and/or T1S to enable a full under standing of the configuration of the equipment, and to

enable the user to obtain the maximum benefit s of the equipment.

This manual introduces the T1 and T1S, and explains the system configuration,

specifications, installation and wiring for T1/T1S’s basic hardware. This manual provides

the information for designing T1/T1S user program, such as the internal operation, memory

configuration, I/O allocation and programming instructions. Information for maintenance

and troubleshooting are also provided in this manual.

The specifications of the option cards, expansion units, and I/O modules, and how to use

them, are explained in the separate manual. Read the T1/T1S User’s Manual - Expansion

I/O - when using the option cards, expansion units, and/or I/O modules.

The T1/T1S’s computer link function and T1S’s multi-purpose communication functions are

covered by the separate manual. Read the T1/T1S User ’s Manual - Comm unicat ion

Function - for details.

6F3B0250

Inside This Manual

This manual consists of 10 main sections and an appendix.

Section 1 outlines the T1/T1S configuration. To fully understand the T1/T1S, it is important

to read this section carefully. Sections 2, t o 4 descr ibe the hardware used in designing

external circuits and panels. Sections 5 to 7 are mainly concerned with software. Section 8

explains the T1/T1S’s special I/O functions. Sections 9 and 10 describe the maintenance

procedure for the T1/T1S, to ensure safe operation and long service life.

Related Manuals

The following related manuals are available for T1/T1S. Besides this manual, read t he

following manuals for your better under st anding.

T1/T1S User’s Manual - Basic Hardware and Function -

T1/T1S User’s Manual - Expansion I/O T1/T1S User’s Manual - Communication Function T-Series Handy Programmer (HP911) Operation Manual

T-Series Program Development System (T-PDS) User’s Manual

NOTE

Other than the listed above, some T1 related manuals for special I/O modules

and data transmission modules are available. Contact Toshiba for more

information.

(this manual)

T1/T1S User’s Manual

8

Page 11

Terminology

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The following is a list of abbreviations and acronyms used in this m anual.

6F3B0250

About This Manual

s

mmmm

ASCII

AWG

BCC

CCW

CPU

CW

EEPROM

H

I/O

LED

LSB

ms

MSB

PWM

RAM

ROM

Vac

Vdc

microsecond

American Standard Code For Infor m at ion I nt erchange

American W ir e Gage

Block Check Code

Counter-Clockwise

Central Processing Unit

Clockwise

Electrically Erasable Programmable Read O nly Memory

hexadecimal (when it appears in front of an alphanumer ic st r ing)

Input/Output

Light Emitting Diode

Least Significant Bit

millisecond

Most Significant Bit

Pulse Width Modulation

Random Access Memory

Read Only Memory

AC voltage

DC voltage

Basic Hardware and Function

9

Page 12

Contents

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Contents

6F3B0250

Safety Precautions

About This Manual

1. System Configuration

1.1 Introducing the T1 and T1S ................................................................ 14

1.2 Features .............................................................................................. 16

1.3 System configuration .......................................................................... 19

1.4 I/O expansion ...................................................................................... 20

1.5 Components ........................................................................................ 22

1.5.1 Basic unit ......................................................................................... 22

1.5.2 Option cards .................................................................................... 28

1.5.3 Expansion rack ................................................................................ 29

1.5.4 I/O modules ..................................................................................... 30

1.5.5 Expansion unit ................................................................................. 31

1.5.6 Options ............................................................................................ 32

1.6 Computer link system ........................................................................ 33

1.7 T1S communication function .............................................................. 34

1.8 Real-time data link system ................................................................. 36

1.9 Peripheral tools .................................................................................. 37

2. Specifications

..................................................................................

..................................................................................

....................................................................

..................................................................................

13

41

3

8

2.1 General specifications ........................................................................ 42

2.2 External dimensions ........................................................................... 43

2.3 Functional specifications .................................................................... 46

2.4 I/O specifications ................................................................................ 48

2.4.1 T1-16 ............................................................................................... 48

2.4.2 T1-28 ............................................................................................... 52

2.4.3 T1-40/T1-40S .................................................................................. 56

3. I/O Application Precautions

3.1 Application precautions for input signals ............................................ 62

3.2 Application precautions for output signals .......................................... 65

4. Installation and Wiring

4.1 Environmental conditions ................................................................... 68

4.2 Installing the unit ................................................................................. 69

4.3 Wiring terminals .................................................................................. 71

4.4 Grounding ........................................................................................... 76

4.5 Power supply wiring ............................................................................ 78

4.6 I/O wiring ............................................................................................ 80

..........................................................

...................................................................

61

67

T1/T1S User’s Manual

10

Page 13

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Contents

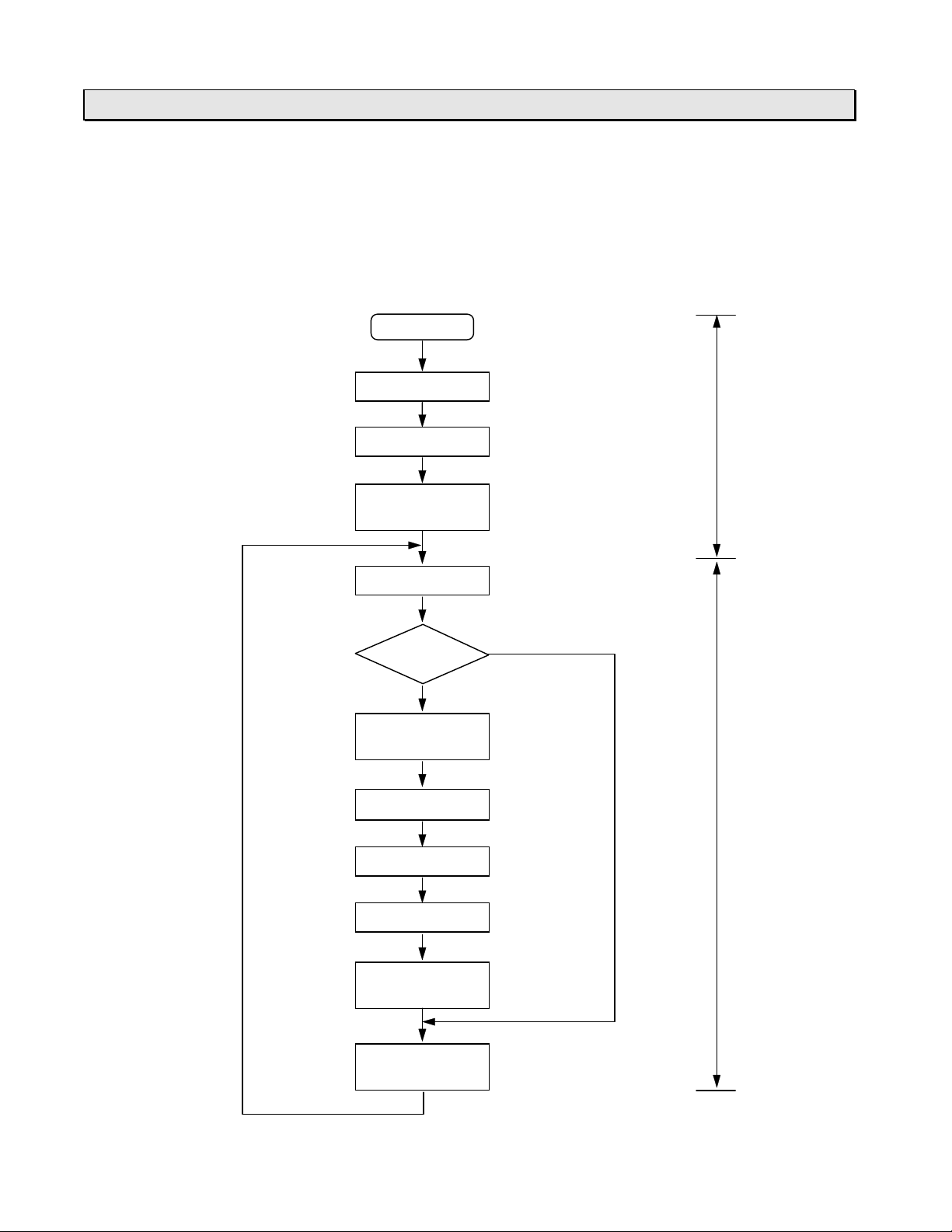

5. Operating System Overview

5.1 Operation modes ................................................................................ 82

5.2 About the built-in EEPROM ................................................................ 84

5.3 Scanning ............................................................................................. 87

6. Programming Information

6.1 Devices and registers ......................................................................... 92

6.2 Index modification ............................................................................... 104

6.3 Real-time clock/calendar .................................................................... 106

6.4 I/O allocation ....................................................................................... 107

6.5 T1S memory mode setting ................................................................. 109

6.6 User program configuration ................................................................ 110

6.6.1 Main program .................................................................................. 112

6.6.2 Sub-program #1 .............................................................................. 113

6.6.3 Timer interrupt program .................................................................. 113

6.6.4 I/O interrupt programs ..................................................................... 114

6.6.5 Subroutines .................................................................................... 115

6.7 Programming language ...................................................................... 116

6.8 Program execution sequence ............................................................ 117

6.9 On-line debug support functions ........................................................ 118

6.10 Password protection ........................................................................... 121

.........................................................

.............................................................

81

91

7. Instructions

7.1 List of instructions .............................................................................. 124

7.2 Instruction specifications .................................................................... 134

8. Special I/O Functions

8.1 Special I/O function overview ............................................................. 268

8.2 Variable input filter constant .............................................................. 272

8.3 High speed counter ............................................................................ 273

8.3.1 Single phase up-counter ................................................................. 273

8.3.2 Single phase speed-counter ............................................................ 275

8.3.3 Quadrature bi-pulse counter ............................................................ 277

8.4 Interrupt input function ........................................................................ 280

8.5 Analog setting function ....................................................................... 282

8.6 Pulse output function .......................................................................... 283

8.7 PWM output function .......................................................................... 285

9. Maintenance and Checks

9.1 Precautions during operation ............................................................. 288

9.2 Daily checks ........................................................................................ 289

9.3 Periodic checks ................................................................................... 290

9.4 Maintenance parts ............................................................................... 291

......................................................................................

....................................................................

..............................................................

123

267

287

Basic Hardware and Function

11

Page 14

Contents

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

6F3B0250

10. Troubleshooting

10.1 Troubleshooting procedure ................................................................ 294

10.1.1 Power supply check ......................................................................... 295

10.1.2 CPU check ....................................................................................... 296

10.1.3 Program check ................................................................................. 296

10.1.4 Input check ....................................................................................... 297

10.1.5 Output check .................................................................................... 298

10.1.6 Environmental problem .................................................................... 299

10.2 Self-diagnostic items .......................................................................... 300

Appendix

A.1 List of models and types ..................................................................... 306

A.2 Instruction index ................................................................................. 309

.........................................................................................................

..............................................................................

293

305

T1/T1S User’s Manual

12

Page 15

Section 1

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

System Configuration

6F3B0250

1.1 Introducing the T1 and T1S, 14

1.2 Features, 16

1.3 System configuration, 19

1.4 I/O expansion, 20

1.5 Components, 22

1.6 Computer link system, 33

1.7 T1S Communication function, 34

1.8 Real-time data link system, 36

1.9 Peripheral tools, 37

Basic Hardware and Function

13

Page 16

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.1 Introducing the T1 and T1S

The T1 Series are compact, block style, high-performance programmable controllers

with a range of 16 to 328 input and output points.

The T1 Series are available in two versions, T1 and T1S. T he T1S is an enhanced

version against the standard T1.

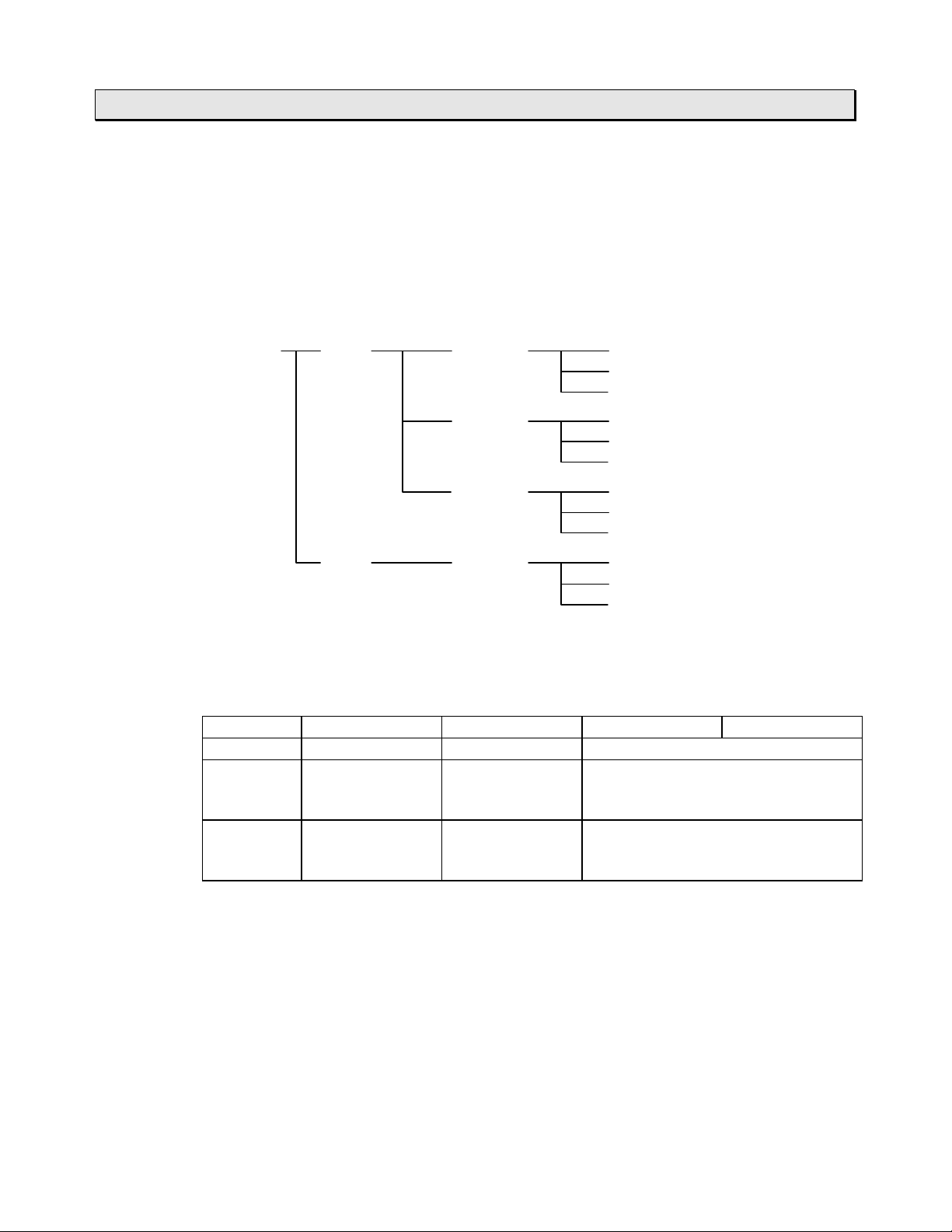

The figure below shows the T1 Series line-up. The T1 Series consists of the total 12

types.

T1 Seri es T1 T1-16 T1-MDR 16

6F3B0250

T1-MAR16

T1-MDR16D

T1-28 T1-MDR28

T1-MAR28

T1-MDR28D

T1-40 T1-MDR40

T1-MAR40

T1-MDR40D

T1S T1-40S T1-MDR40S

T1-MAR40S

T1-MDR40SD

I/O points:

The T1 Series are available in four models, T1-16, T1-28, T1- 40 and T1-40S. Each

model has the following I/O points.

T1-16 T1-28 T1-40 T1-40S

Input

Output

Expansion

The T1-16 and T1-28 are fixed I/O non-expandable controllers.

The T1-40 and T1-40S, however, provides additional flexibility. They are expandable in

three ways, option cards, expansion rack and expansion unit.

The T1-40/T1-40S can hold two option cards. These are approximately 1/2 the size of a

credit card. Also, the T1-40/ T1-40S can be connected to either one expansion rack or

one expansion unit. The expansion rack (2-slot type or 4-slot type) allows the T140/T1-40S to use most T2 series I/O modules. The expansion unit is a fixed I/O unit. It

has 32 I/O points (16 inputs and 16 outputs).

If two 16 points option cards are inserted and t he 4- slot expansion rack with four 64

points modules is connected to the T1-40/T1-40S, it can control up to 328 points.

8 points 14 points 24 points

8 points

(6 relay plus

2 slid-state)

No No 2 option cards plus

14 points

(12 relay plus

2 slid-state)

16 points

(14 relay plus 2 solid-state)

1 expansion rack or unit.

Total up to 382 points.

T1/T1S User’s Manual

14

Page 17

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Memory capacity:

Program memory capacity of the T1 is 2 k steps. And that of the T1S is 8 k steps. Whole

the program and a part of data registers are stored in built - in EEPRO M.

T1 T1S

Memory

Program capacity

Data capacity

EEPROM back-up

RAM back-up

RAM (for execution) and EEPROM (for back-up)

2 k steps 8 k steps

(4 k mode or 8 k mode)

Auxiliary relay: 1024 points

Timer: 64 points

Counter: 64 points

Data register: 1024 words

Program and leading 512 words

of Data register

Capacitor

(6 hours or more at 25°C)

Auxiliary relay: 4096 points

Timer: 256 points

Counter: 256 points

Data register: 4096 words

Program and the user specified

range of Data regist er ( 0 to

2048 words)

Capacitor

(168 hours or more at 25°C)

Control functions:

In addition to the basic relay ladder functions, t he T1/T1S provides functions such as

data operations, arithmetic operations, various functions, etc. Furthermore, its high

speed counter functions, pulse output functions and data communication funct ions

allow its application to a wide scope of control systems.

T1 T1S

Language

Number of

instructions

Subroutines

Execution speed

Real-time clock/

calendar

Communication

Construction:

The T1/T1S is a compact, easy-handling block style programmable contr oller . The

T1/T1S has all of the features of a block style controller. In addition, the T1-40/T1-40S

has modular expandability. The T1-40/T 1 - 40S pr ovides flexibility into the block style

controller.

Ladder diagram with function block

Basic: 17 types

Function: 76 types

16 (nesting not allowed) 256 (up to 3 levels of nesting)

1.4 ms/contact, 2.3 ms/coil, 4.2 ms/transfer, 6.5 ms/addition

No Yes (year, month, day, week,

RS-232C (programmer por t) RS-232C (programmer por t),

Basic: 21 types

Function: 99 types

hours, minutes, seconds)

RS-485 (multi-purpose)

Series compatibility:

Programming instruct ions ar e upward compat ible in the T-Series programmable

controllers. The T1/T1S programs can be used for other models of the T-Ser ies, T2,

T2E, T2N, T3 and T3H. Peripheral tools can also be shared.

Basic Hardware and Function

15

Page 18

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.2 Features

Option card support:

The T1-40/T1-40S has two slots for the option card, which is approximately 1/2 the size

of a credit card. The following eight types of the option cards ar e available.

16 points DC input

·

16 points DC output

·

8 DC inputs + 8 DC outputs

·

1 channel analog input (0 to 5 V/0 to 20 mA)

·

1 channel analog input (±10 V)

·

1 channel analog output (0 to 20 mA)

·

1 channel analog output (±10 V)

·

Field network TOSLINE-F10 rem o t e

·

By using the 16 points input and 16 points output cards, t he T1-40/T1-40S can control

up to 72 I/O points without enlarging the mounting space.

Built-in high speed counter:

Two single-phase or one quadrature (2-phase) pulses can be counted. The acceptable

pulse rate is up to 5 kHz. (DC input t ype only)

6F3B0250

Built-in analog setting adjust ers:

Two analog setting adjusters are pr ovided on the T1/T1S. This allows operators to

adjust time or other control par am eters easily using a screwdriver.

High speed processing:

Sophisticated machine control applications require high speed data manipulations. The

T1/T1S is designed to meet these requirements.

1.4 ms per contact

·

4.2 ms per 16-bit transfer

·

The T1/T1S also supports int errupt input function (DC input type only). This allows

immediate operation independent of pr ogram scan.

High performance software:

The T1 offers 17 basic ladder instructions and 76 function instructions. The T1S offers

21 basic ladder instructions and 99 function instructions.

Subroutines, Interrupt functions, Indirect addressing, For /Next loops, Pre-derivative

real PID, etc. are standard on the T1/T1S. These f unct ions allow the T1/T1S to be

applied to the most demanding control applicat ions.

Battery-less operation:

The T1/T1S has a standard built-in EEPROM, permitting operation without need of a

battery. Also, the variable data can be written into and/or r ead from the EEPROM,

providing completely maintenance-free back-up operation.

This function is an important feature for OEMs, because it can eliminate the need for

changing the battery every few years. The cost of the battery is also eliminated.

2.3 ms per coil

·

6.5 ms per 16-bit addition

·

T1/T1S User’s Manual

16

Page 19

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Pulse output / PWM output:

One point of variable frequency pulses (m ax. 5 kHz) or variable duty pulses can be

output. These functions can be used to drive a stepping motor or to simulate an analog

output. (DC input type only)

Built-in computer link function:

The T1/T1S’s RS-232C prog rammer port can accept the comput er link protocol (data

read/write). This results in easy connection to a hig her level comput er, an operator

interface unit, etc.

The parity setting of the programmer port can be selected either odd or none. The none

parity mode is provided especially for telephone modem connection. Using m odems,

remote programming/monitoring is available.

Real-time control data link network:

By inserting the TOSLINE-F10 rem ote card (option card) into the T1-40/T1-40S, high

speed data link network can be established. In this network, upper T-series PLC model

(T2/T2E/T2N or T3/T3H) works as master and up t o 16 T1-40/T1-40Ss can be

connected as remote. Each T1-40/T1-40S can exchange data with the master through

1 word input and 1 word output. The transmission speed can be selected either 750

kbps or 250 kbps.

T2 Series I/O module interface:

In addition to the option cards, the T1-40/T1-40S has a interface for connecting the T2

Series I/O modules. Up to four modules can be connected to the T1-40/T1-40S. The

following I/O modules are available.

16 points DC input (DI31)

·

32 points DC input (DI32)

·

64 points DC input (DI235)

·

16 points AC input (IN51/IN61)

·

8 points isolated relay output (RO62)· 12 points relay output (RO61)

·

4 channels analog input

·

(AI21/AI22/AI31/AI 32) (AO31/AO22/AO32)

1 channel pulse input (PI21)

·

Communication interface (CF211)

·

Sampling trace function:

The sampling trace is the function to collect the user specified data every user specified

timing (minimum every scan), and to display the collected data on the programmer

screen in time chart and/or trend graph format. This function is useful for check ing the

input signals changing.

The collecting capacities between T1 and T1S are different as follows.

T1 ..... 1 register - 128 times, or 8 devices - 256 times

·

T1S ... 3 reg isters and 8 devices - 256 times

·

16 points DC output (DO31/DO233P)

·

32 points DC output (DO32)

·

64 points DC output (DO235)

·

12 points AC output (AC61)

·

2 channels analog output

·

1 axis position control (MC11)

·

Basic Hardware and Function

17

Page 20

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Password protection:

By registering your passwords, four levels of pr ot ection is available according to the

security levels required for your application.

Level 4: Reading/writing program and writing data are prohibited

Level 3: Reading/writing program are pr ohibit ed

Level 2: Writ ing program is prohibited

Level 1: No protection (changing passwords is available only in this level)

Two points of solid-st at e out put :

Each model of the T1/T1S has two points of solid-state output (transistors for DC input

type and triacs for AC input type). T hese solid- s t at e outputs are suitable for f requent

switching application.

Removable terminal blocks:

The T1-28, T1-40 and T 1- 40S ar e equipped with removable terminal blocks. This

supports the easy maintenance work.

6F3B0250

DIN rail mounting:

The T1/T1S is equipped with brackets for mounting on a standard 35 mm DIN rail. The

T1/T1S can be mounted on a DIN r ail as well as screw mounting.

On-line program changes: (T1S only)

When the T 1S’s memory mode is set to 4 k steps mode, on-line (in RUN mode)

program changes are available. Furthermore, progr am writ ing into the built-in

EEPROM is also available in RUN mode. These functions are usef ul in pr ogram

debugging stage.

Real-time clock/calendar function: (T1S only)

The T1S has the real-time-clock / calendar function (year, month, day, day of the week,

hours, minutes, seconds) that can be used for performing scheduled operations, data

gathering with time stamps, et c. The real-time-clock/calendar data is backed up by

built-in capacitor for power off. The back-up period is mor e than 7 days at 25 °C.

RS-485 multi-purpose communication port: ( T1S only)

The T1S has an RS-485 multi-purpose communication port. Using this port, one of the

following communication modes can be selected.

Computer link mode:

····

Up to 32 T1Ss can be connected to a master comput er . By using this mode,

MMI/SCADA system can be easily configured.

Data link mode:

····

linked together. This direct link is inexpensive, easily configur ed and r equires no

special programming.

Free ASCII mode:

····

received through this port. A ter m inal, pr int er , bar-code reader, or other ser ial

ASCII device can be directly connected.

T-series computer link prot ocol can be used in this mode.

Two PLCs (any combination of T1S, T2E or T2N) can be directly

User defined ASCII messages can be t r ansm it t ed and

T1/T1S User’s Manual

18

Page 21

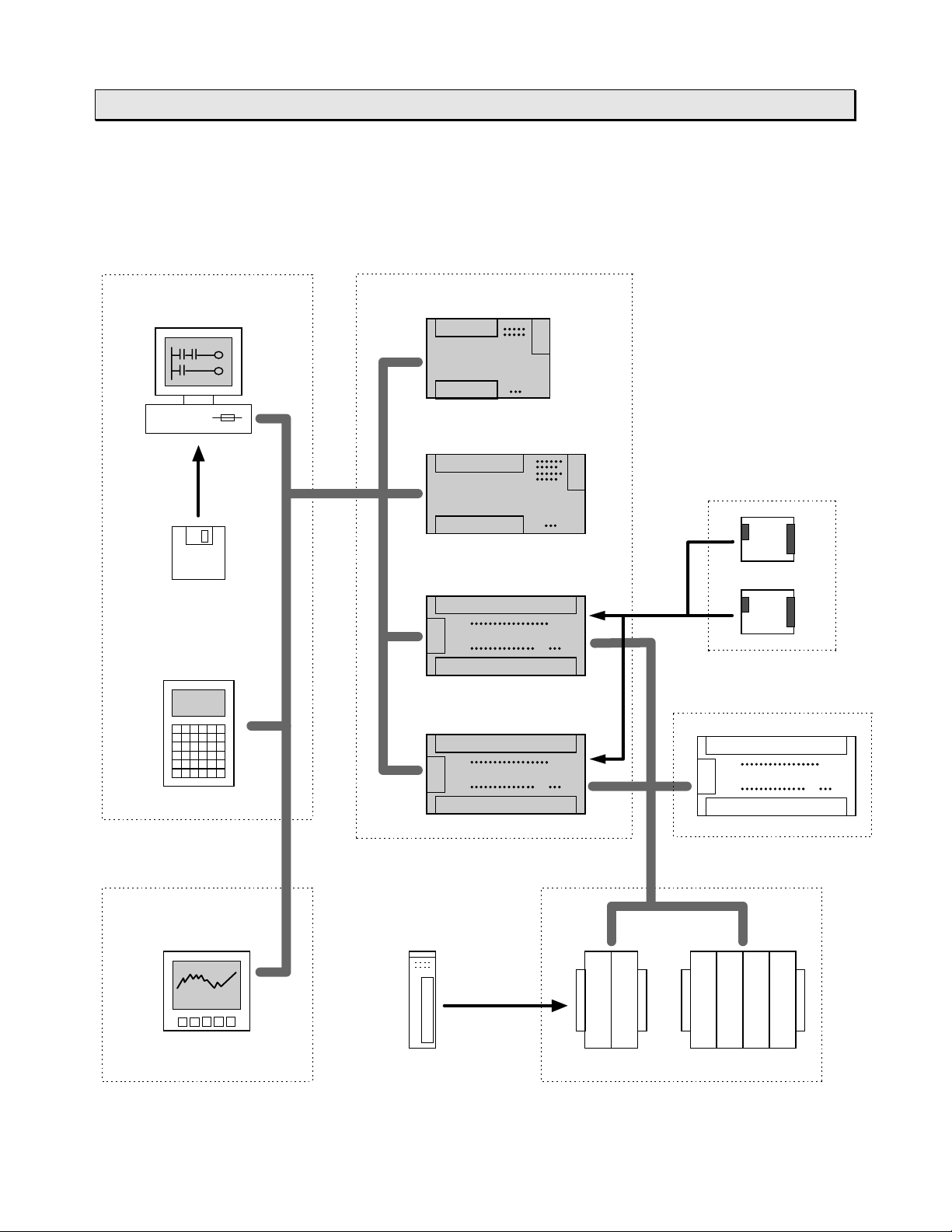

1.3 System configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The following figure shows the T1/ T1S system configuration.

6F3B0250

1. System Configuration

T1 basic unitPeripheral tool

IBM-PC compatible

personal computer

T-PDS

software

Handy programmer

HP911A

T1-16

T1-28

Option cards

T1-40

Expansion unit

T1-40S

Expansion rackComputer link function

MMI/SCADA

system

T2 I/O modules

4-slot2-slot

Basic Hardware and Function

19

Page 22

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.4 I/O expansion

The I/O points on the T1-16 and T1-28 are not expandable. The T1-40 and T1-40S,

however, provides I/O expandability by using the option cards, expansion rack and

expansion unit.

The T1-40/T1-40S can hold up to two option cards. Also, the T1-40/T1- 40S can be

connected to either one expansion rack (2-slot or 4- slot) or one expansion unit. By

using the expansion rack, most of the T2 Series I/O modules can be used with the

T1-40/T1-40S.

Available option cards

·

DI116: 16 points DC input

DO116: 16 points DC output

DD116: 8 points DC input + 8 points DC output

AD121: 1 channel analog input (0 to 5V or 0 to 20mA)

AD131: 1 channel analog input (-10 to +10V)

DA121: 1 channel analog output (0 to 20mA)

DA131: 1 channel analog output (-10 to +10V)

FR112: TOSLI NE- F10 r emote station

6F3B0250

Available expansion racks

·

BU152: Up to 2 I/O modules can be mounted

BU154: Up to 4 I/O modules can be mounted

Available expansion units

·

T1-EDR32: 16 points DC input + 16 points relay output

T1-EAR32: 16 points AC input + 16 points relay output

Available I/O expansion configuration

·

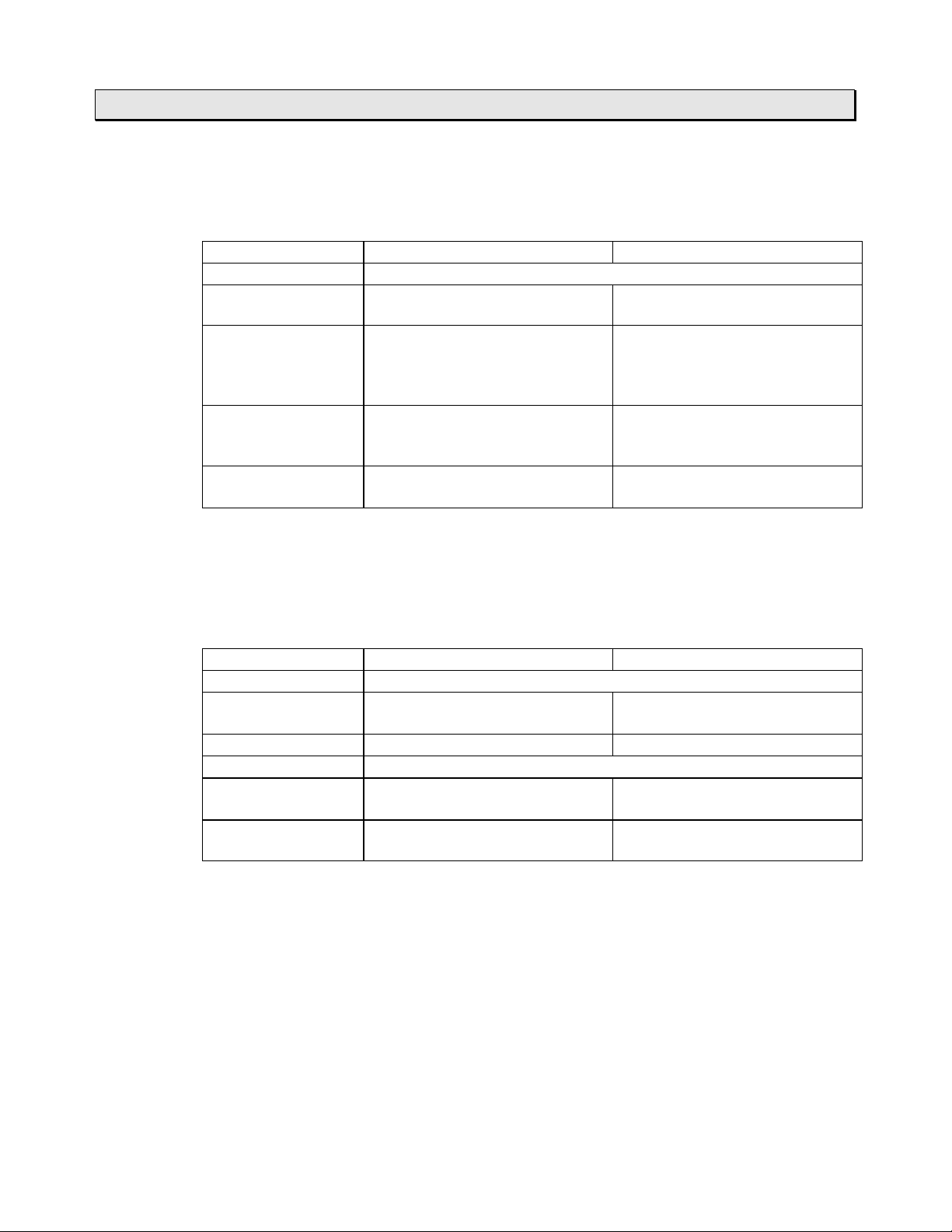

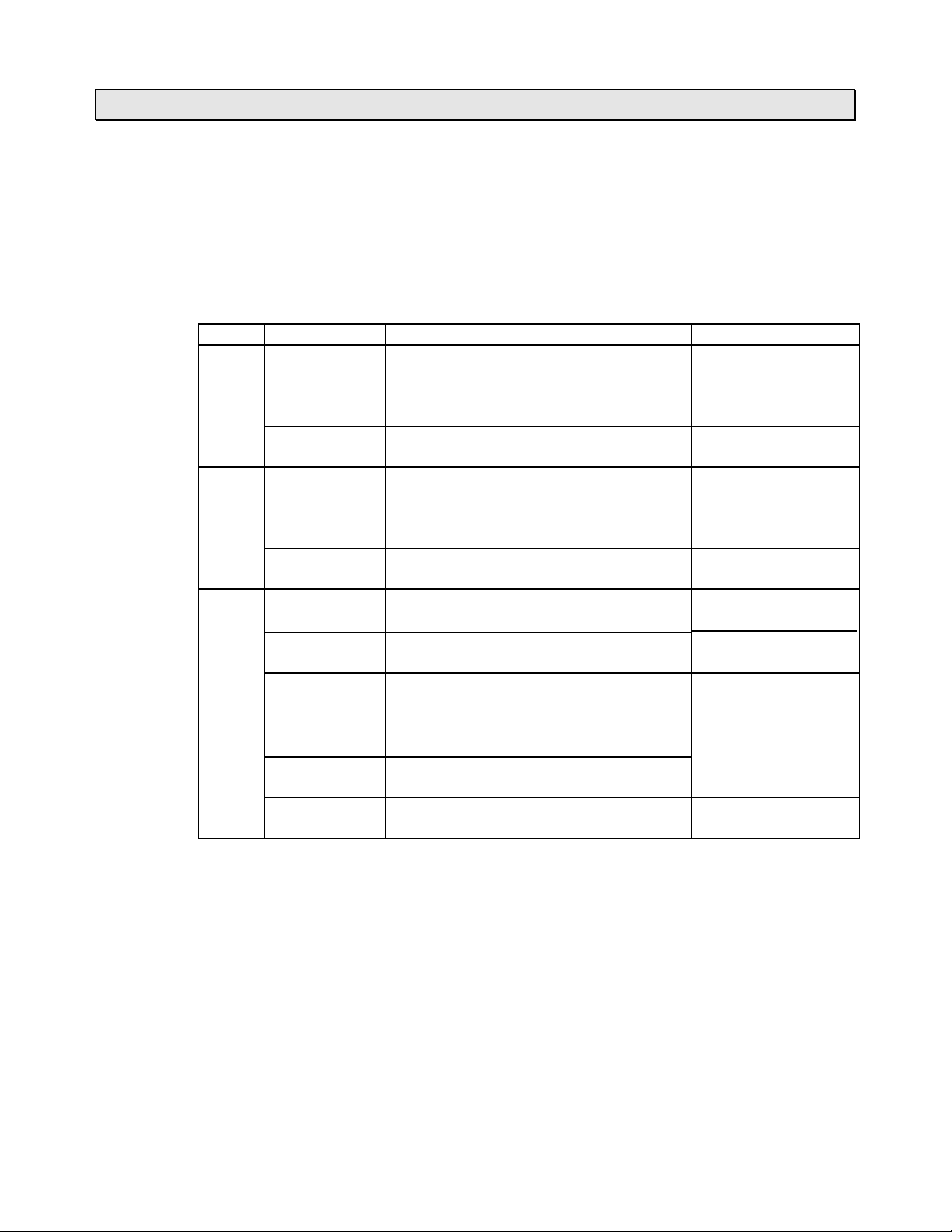

Model Unit configuration I/O points

T1-16 16 points (8 in / 8 out)

T1-28 28 points (14 in / 14 out)

T1-40

or

T1-40S 56 points (40 in / 16 out)

T1-16

T1-28

T1-40(S)

T1-40(S)

T1-40(S)

T1-40(S)

T1-40(S)

+

DD116

+

DO116

+

+

DI116

DI116

+

DI116

40 points (24 in / 16 out)

56 points (32 in / 24 out)

56 points (24 in / 32 out)

72 points (56 in / 16 out)

T1-40(S)

T1/T1S User’s Manual

20

+

DI116

+

DD116

72 points (48 in / 24 out)

Page 23

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Available I/O expansion configuration (continued)

·

Model Unit configuration I/O points

T1-40

or

T1-40S

T1-40(S)

T1-40(S)

+

+

DI116

or

DD116

DO116

+

DD116

+

72 points (40 in / 32 out)

6F3B0250

T1-40(S)

T1-40(S)

T1-40(S)

T1-40(S)

T1-40(S)

T1-40(S)

T1-40(S)

DD116

+

DO116

+

Exp 32T1-40(S)

+

Exp 32

+

Option cards

+

(any combinations)

+

+

Option cards

+

(any combinations)

+

+

DO116

+

DO116

+

(BU152)

(BU152)

(BU154)

(BU154)

72 points (32 in / 40 out)

72 points (24 in / 48 out)

72 points (40 in / 32 out)

104 points

168 points

200 points

296 points

328 points

Option cards

+

(any combinations)

NOTE

(1) When the TOSLINE-F10 remote station (FR112) is used, only one

additional option card can be inserted into the T1- 40/ T1-40S.

(2) In t he above table, “ Exp 32” m eans t he expansion unit ( T1-EDR32 or

T1-EAR32).

(3) In the above table, I/O points of the combinations with an expansion rack

show the maximum points using 64 points I/O modules.

Basic Hardware and Function

21

Page 24

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

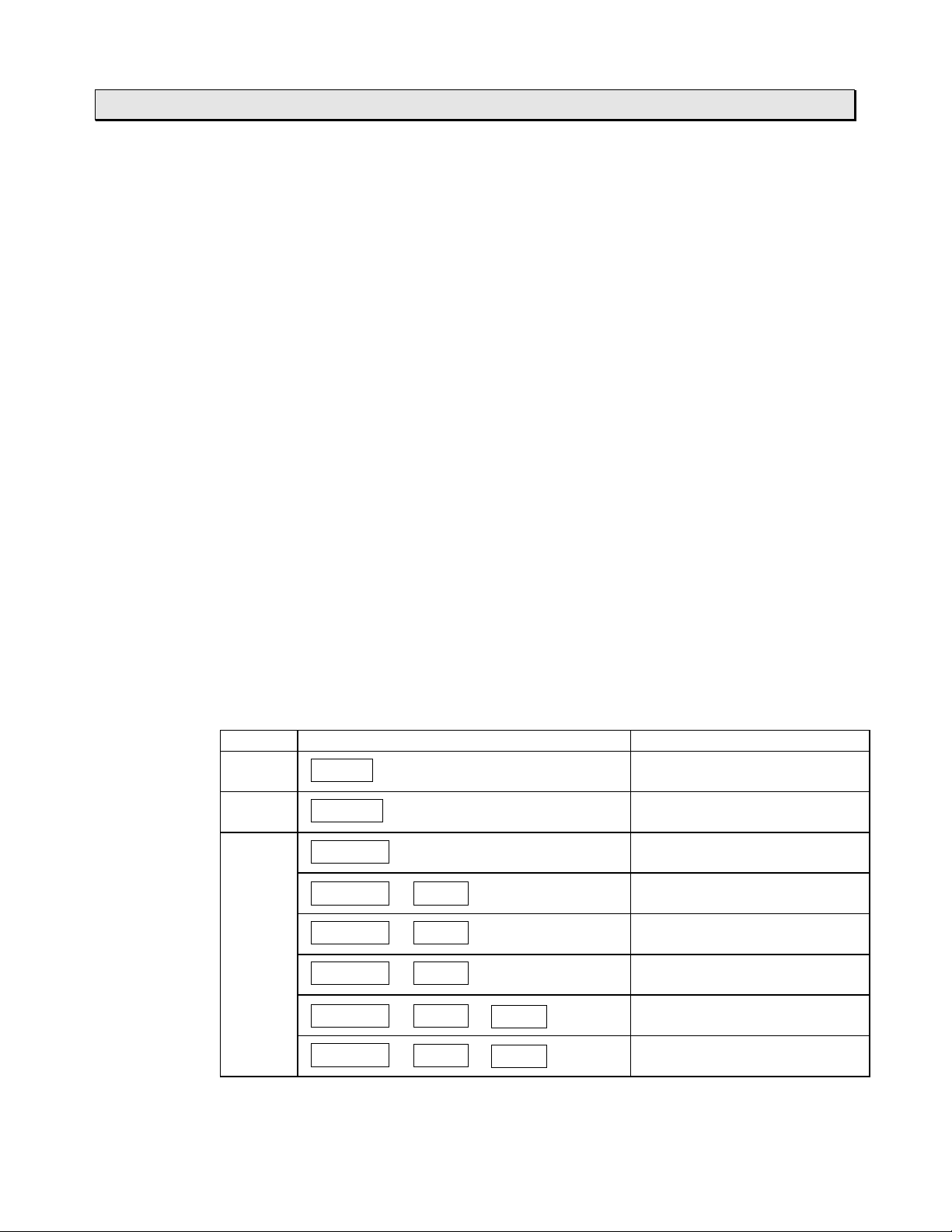

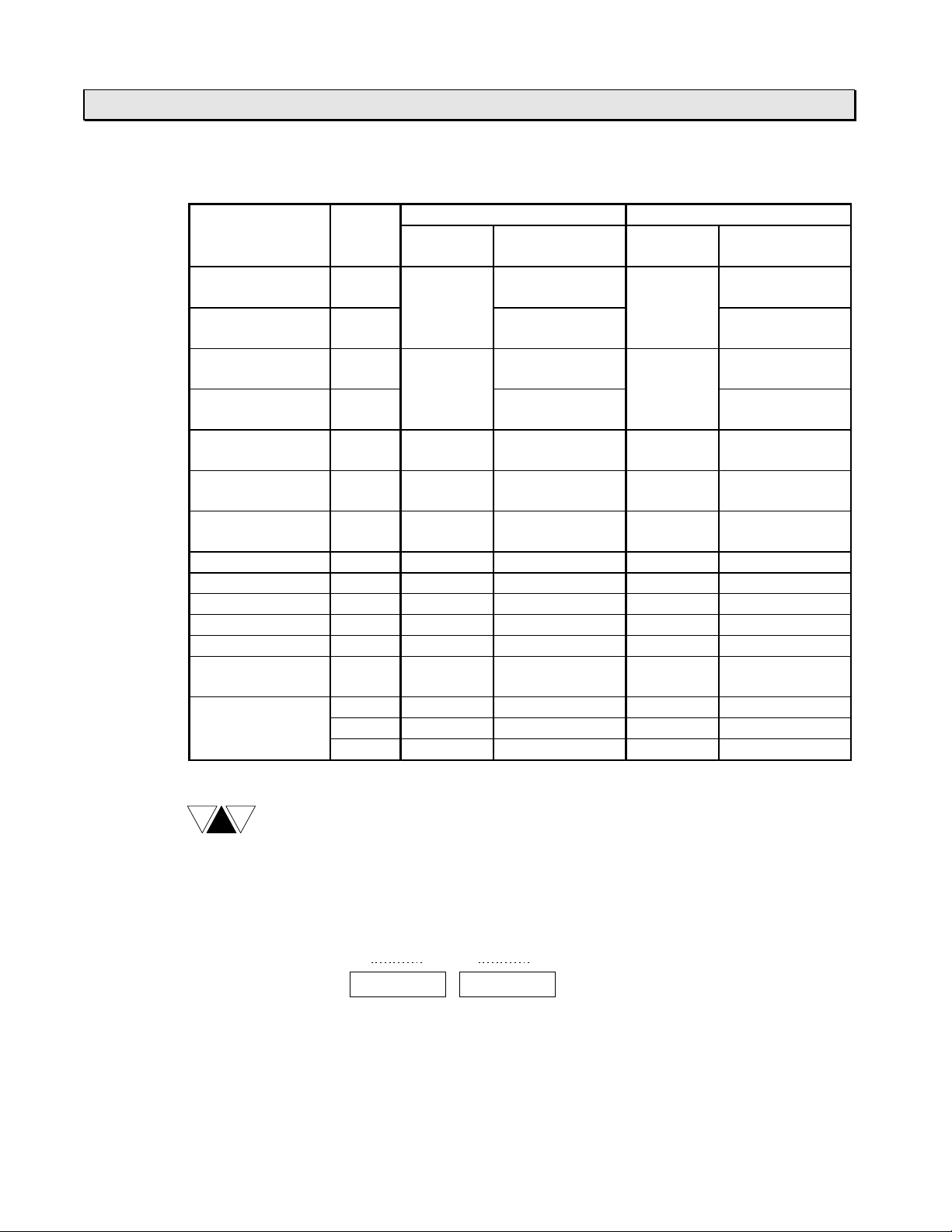

1.5 Components

1.5.1 Basic unit

The basic unit is available in four models, the T 1- 16, T1-28, T1-40 and T1- 40S.

And each model is available in three types, depending on the power supply and input

types.

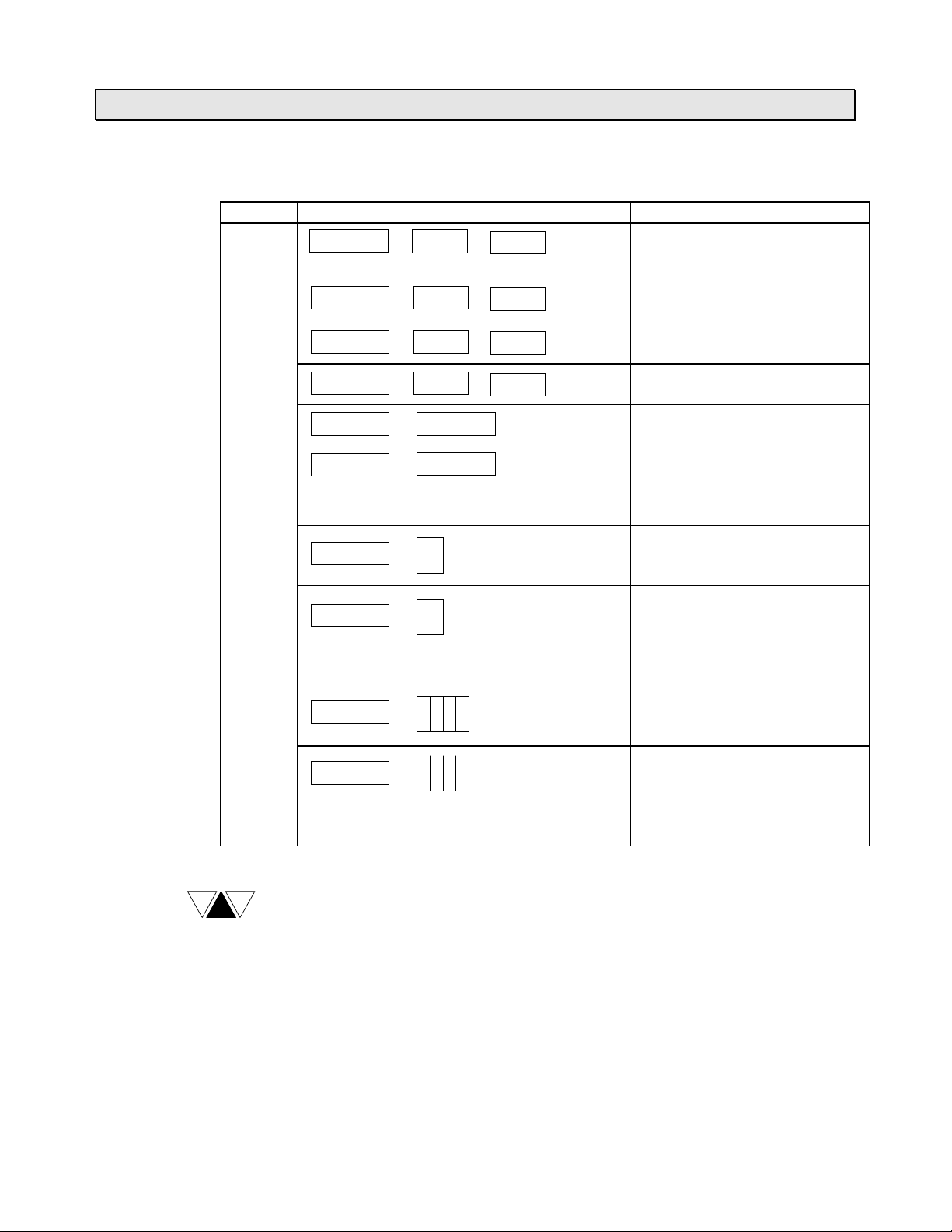

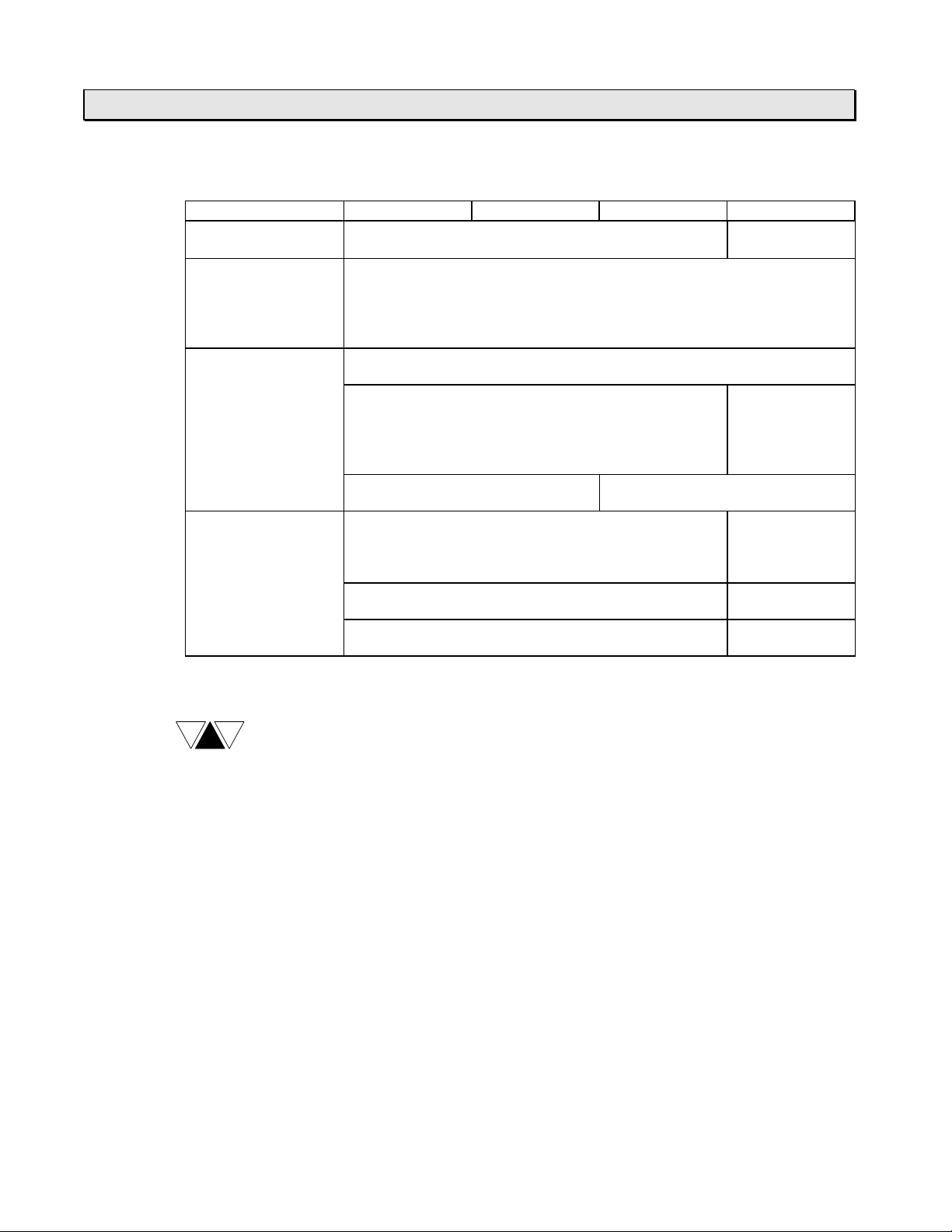

Model Type Power supply Input Output

T1-16 T1-MDR16 100- 240 Vac,

T1-MAR16 100-240 Vac,

T1-MDR16D 24 Vdc 8 points - 24 Vdc 6 points - relay,

T1-28 T1-MDR28 100- 240 Vac,

T1-MAR28 100-240 Vac,

T1-MDR28D 24 Vdc 14 points - 24 Vdc 12 points - relay,

T1-40 T1-MDR40 100- 240 Vac,

T1-MAR40 100-240 Vac,

T1-MDR40D 24 Vdc 24 points -24 Vdc 14 points - relay,

T1-40S T1-MDR40S 100-240 Vac,

T1-MAR40S 100-240 Vac,

T1-MDR40SD 24 Vdc 24 points -24 Vdc 14 points - relay,

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

50/60 Hz

6F3B0250

8 points - dry contact

(24 Vdc)

8 points - 120 Vac 6 points - relay,

14 points - 24 Vdc 12 points - relay,

14 points - 120 Vac 12 points - relay,

24 points -24 Vdc 14 points - relay,

24 points - 120 Vac 14 points - relay,

24 points -24 Vdc 14 points - relay,

24 points - 120 Vac 14 points - relay,

6 points - relay,

2 points - transistor

2 points - triac

2 points - transistor

2 points - transistor

2 points - triac

2 points - transistor

2 points - transistor

2 points - triac

2 points - transistor

2 points - transistor

2 points - triac

2 points - transistor

T1/T1S User’s Manual

22

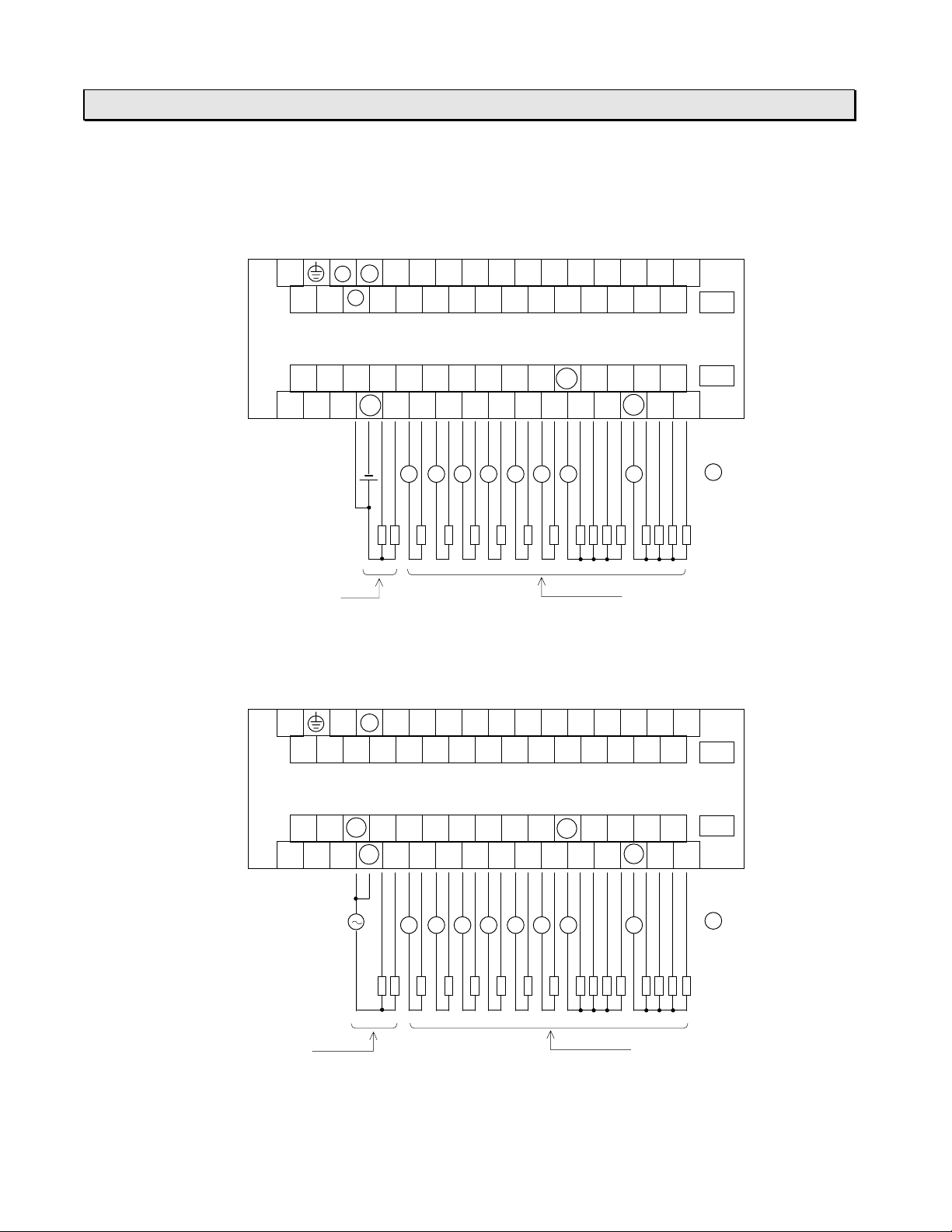

Page 25

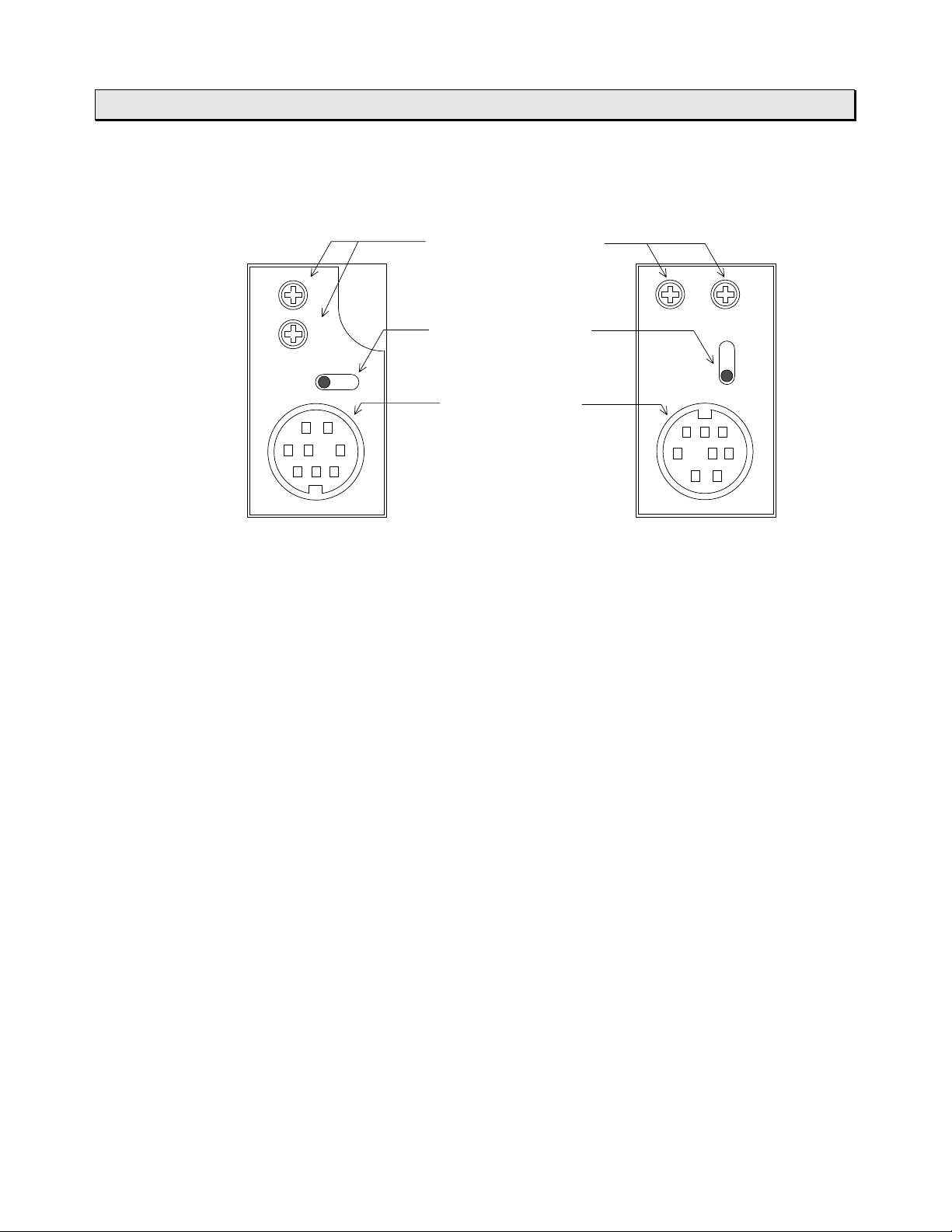

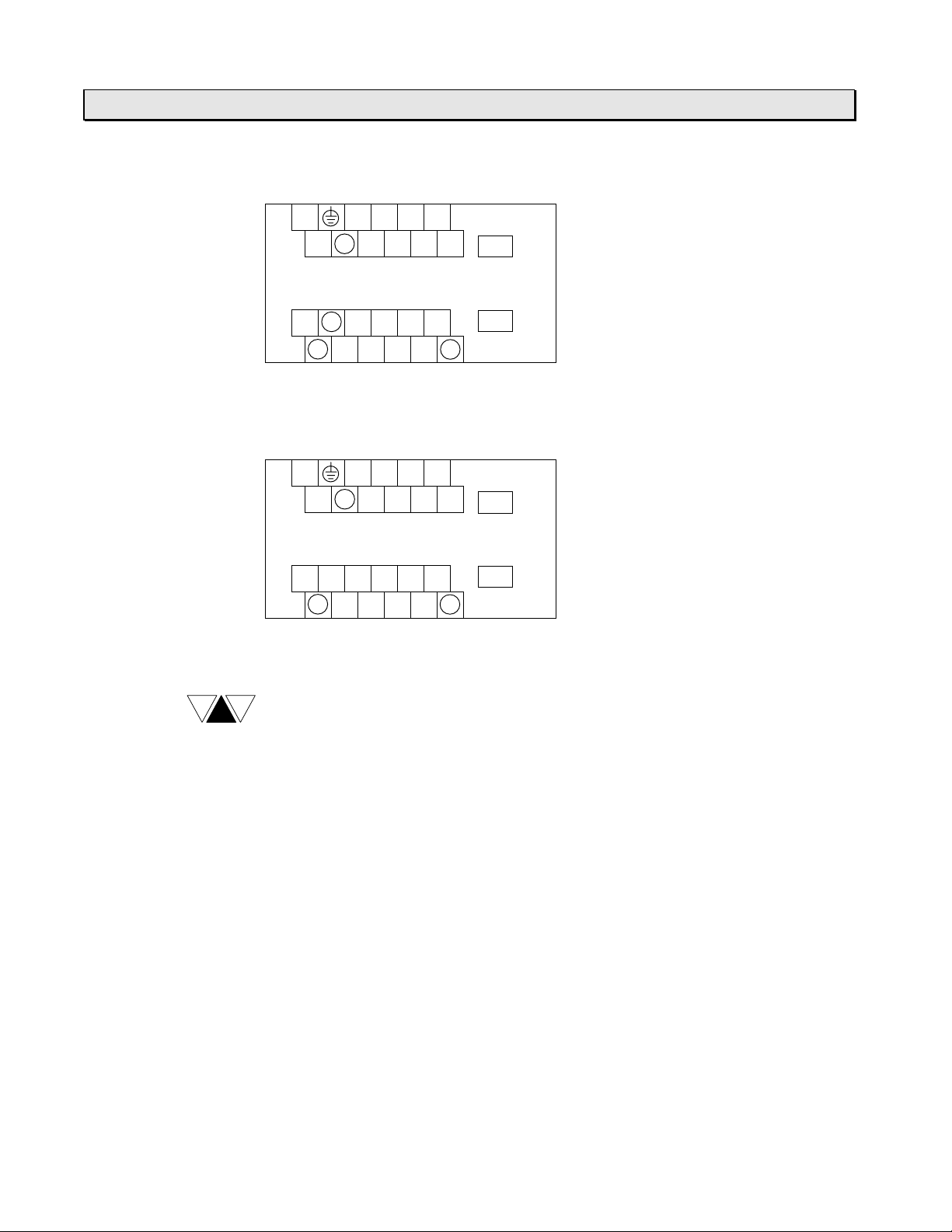

¨¨¨¨

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

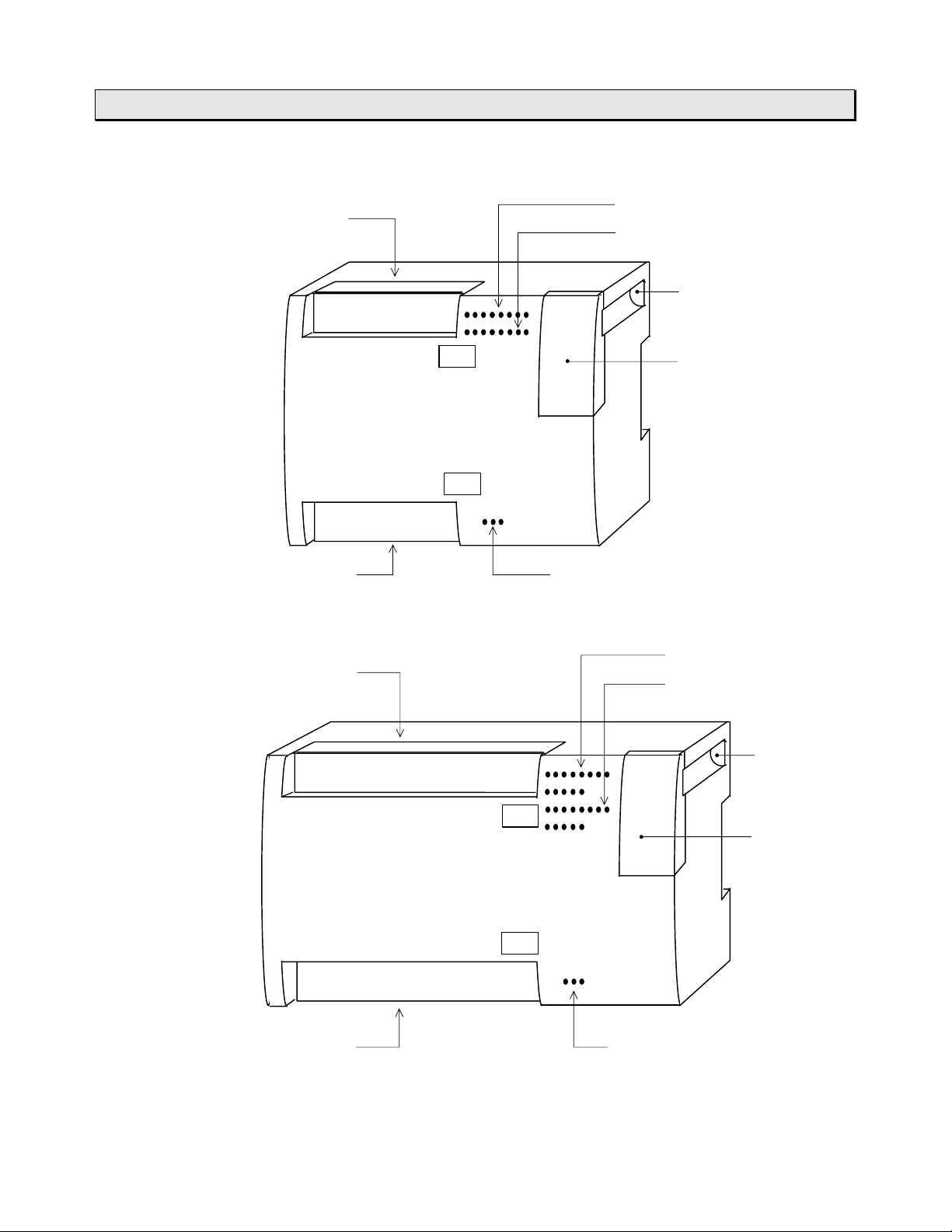

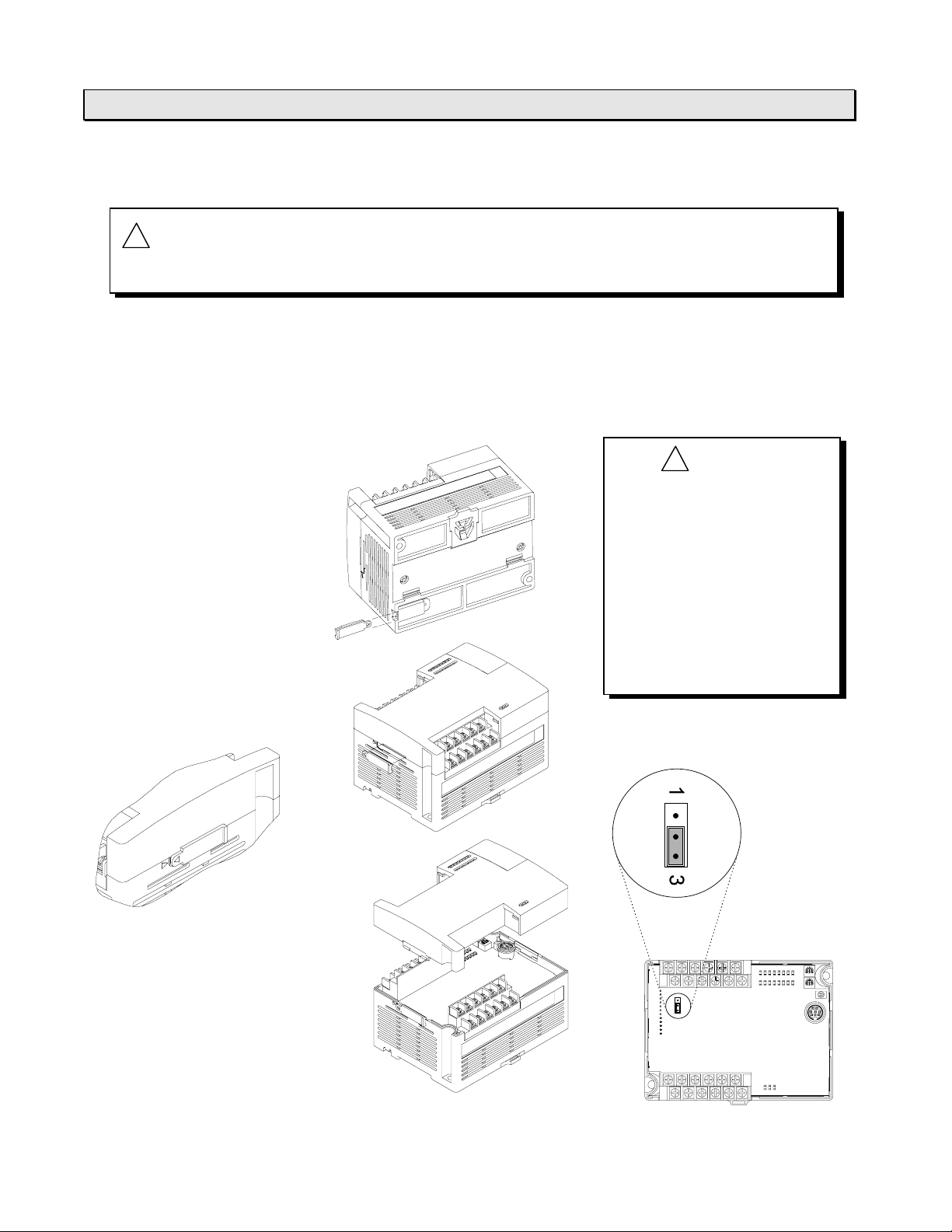

T1-16

6F3B0250

1. System Configuration

Power supply and

Input terminals

Output terminals

T1-28

¨¨¨¨

Power supply and

Input terminals

TOSHIBA

PROSEC

T1

IN

OUT

Input status LEDs

Output status LEDs

Mounting hole

Programmer port cover

MDR16

Operation status LEDs

Input status LEDs

Output status LEDs

TOSHIBA

Output terminals

IN

PROSEC

T1

OUT

MDR28

Operation status LEDs

Basic Hardware and Function

Mounting

hole

Programmer

port cover

23

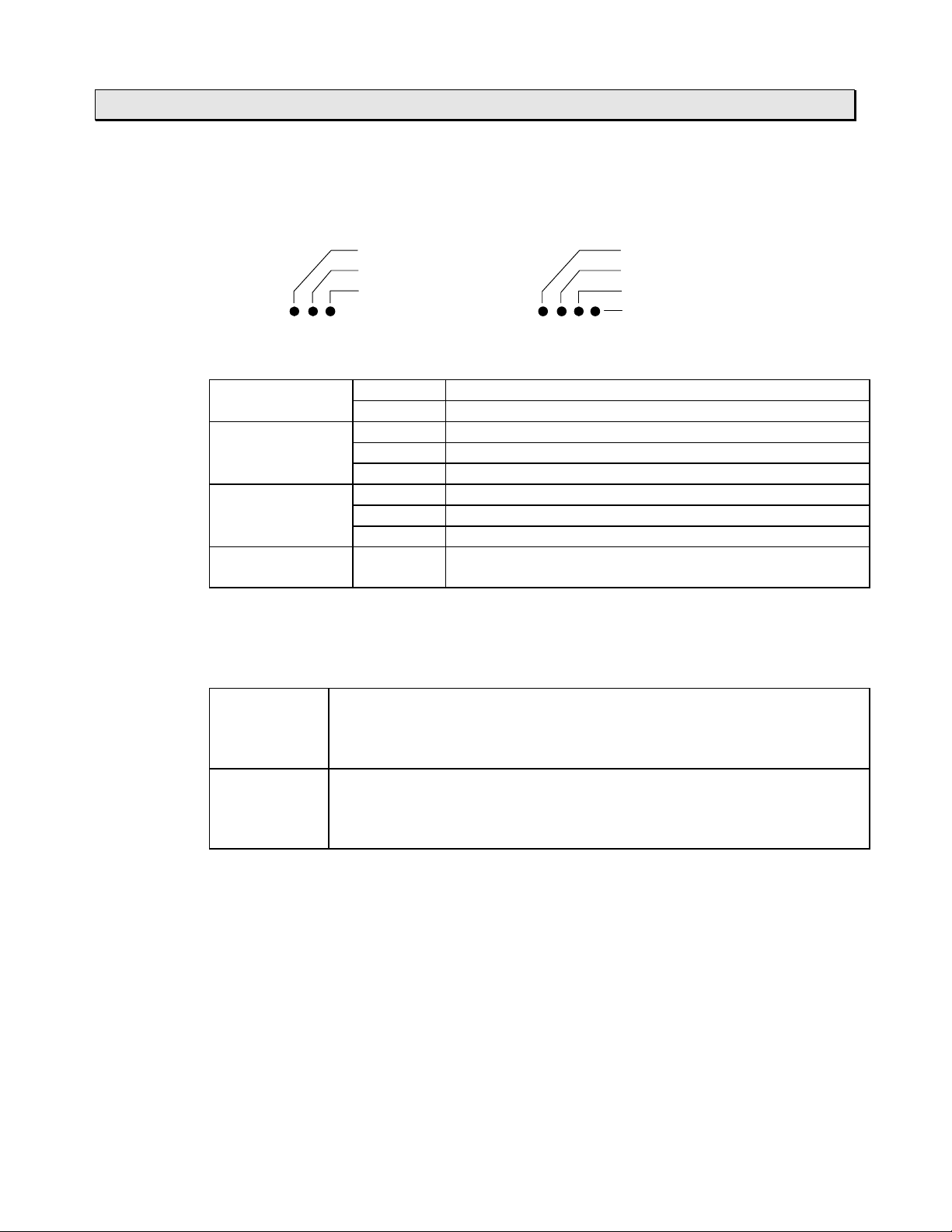

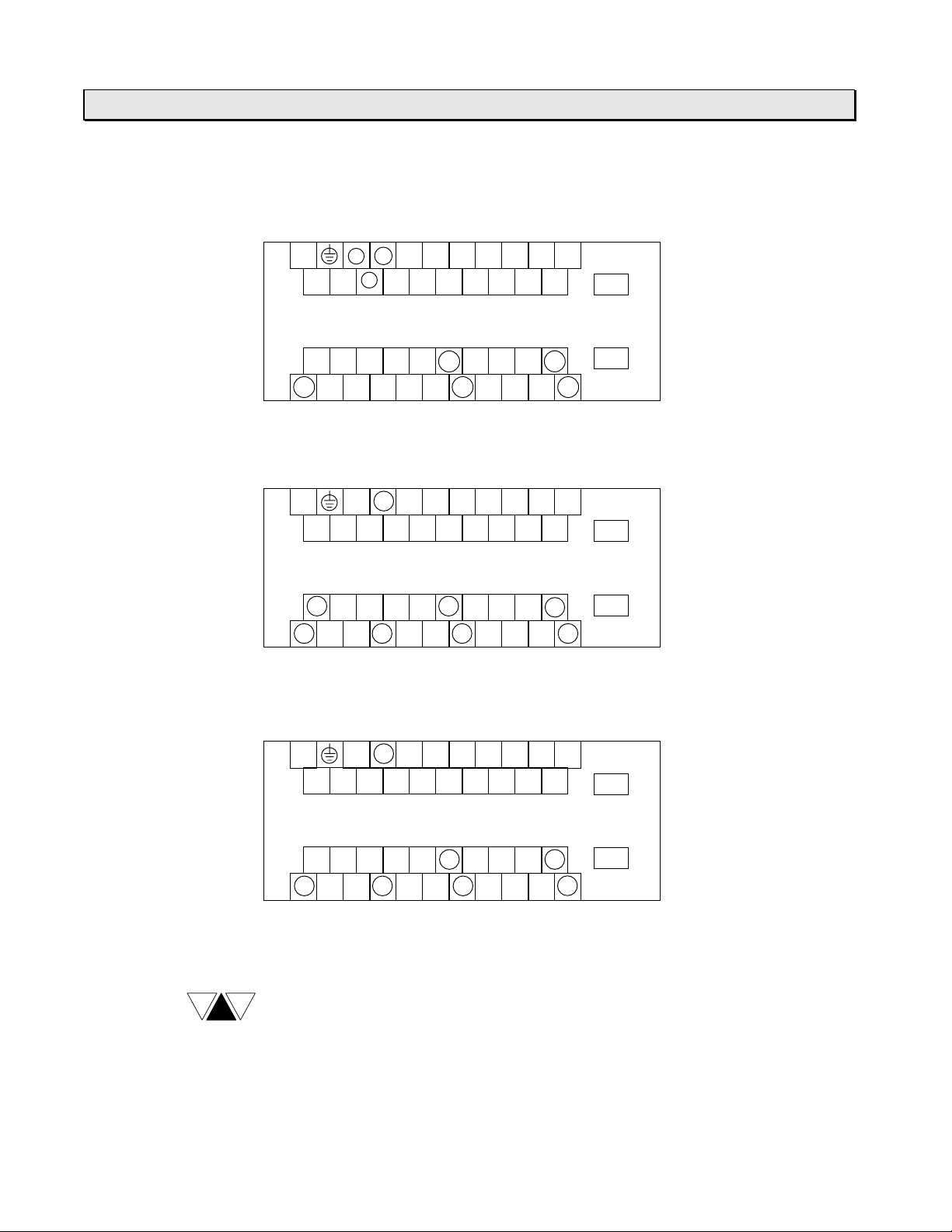

Page 26

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

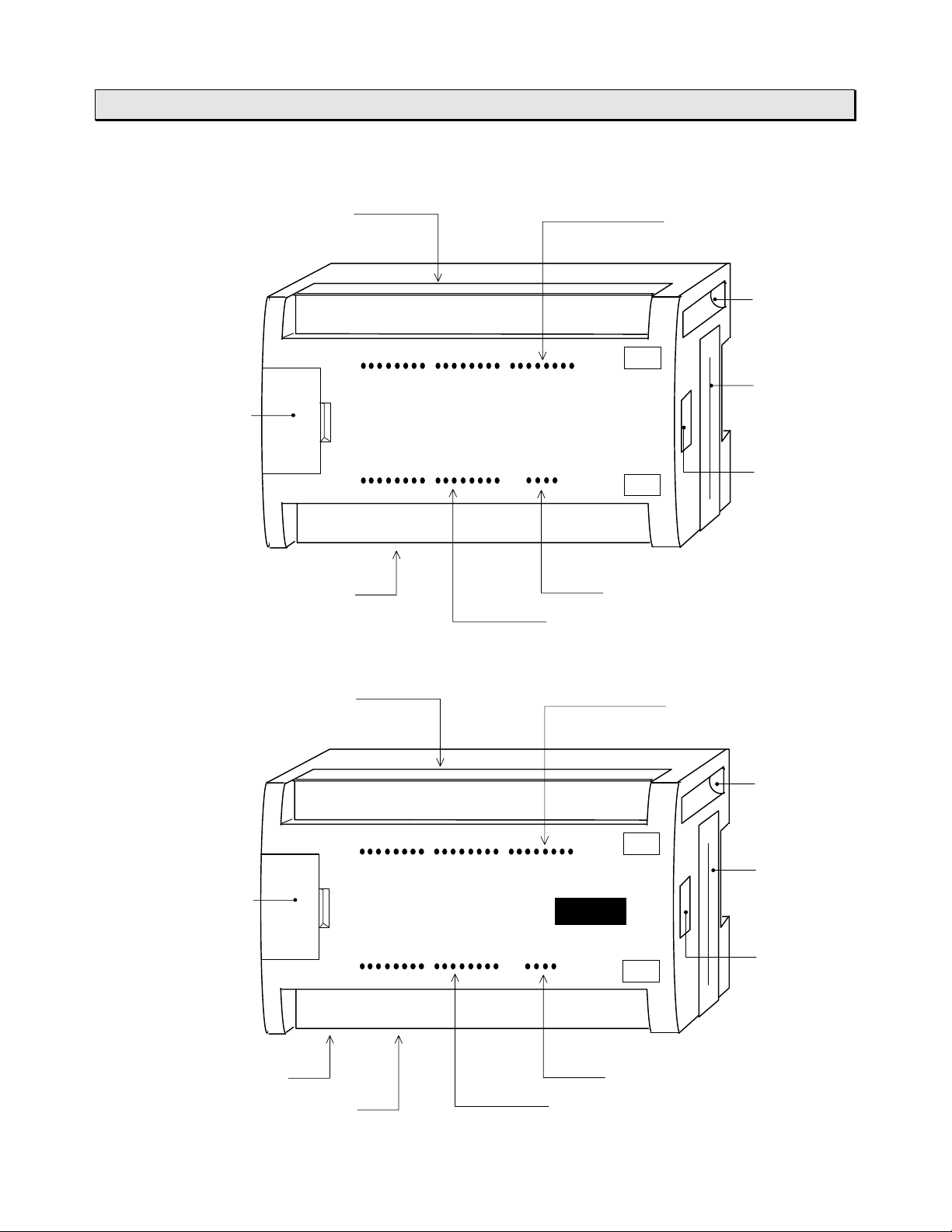

T1-40

¨¨¨¨

6F3B0250

Power supply and

Programmer

port cover

Output terminals

T1-40S

¨¨¨¨

Input terminals

TOSHIBA

PROSEC

T1

Input status LEDs

IN

MDR40

OUT

Operation status LEDs

Output status LEDs

Mounting

hole

Option card

slot

Expansion

connector

Power supply and

Programmer

port cover

Output terminals

Input terminals

TOSHIBA

PROSEC

T1

IN

MDR40S

OUT

Operation status LEDsRS-485 port (terminals)

Output status LEDs

Input status LEDs

Mounting

hole

Option card

slot

Expansion

connector

T1/T1S User’s Manual

24

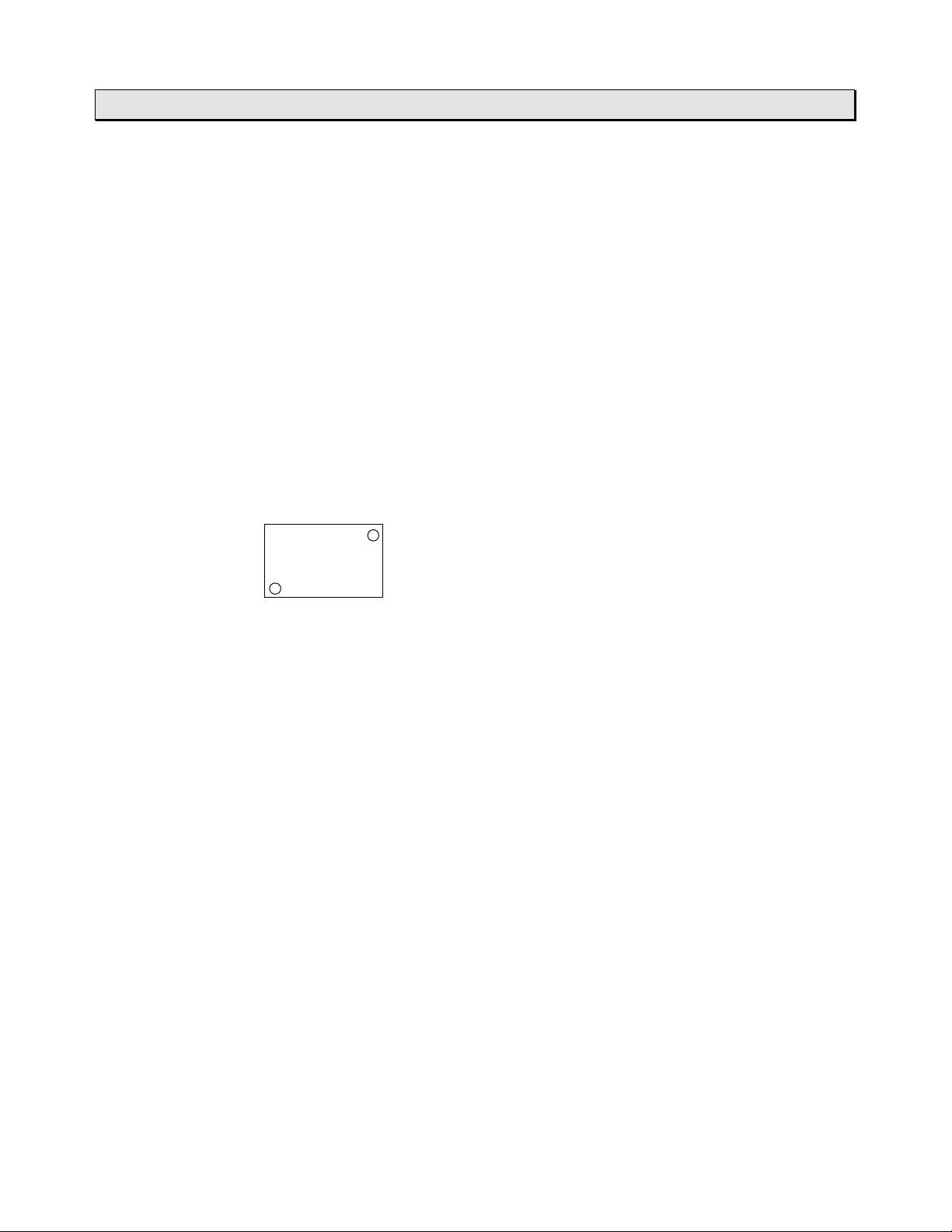

Page 27

Behind the programmer port cover

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

¨¨¨¨

Analog setting adjusters

6F3B0250

1. System Configuration

(V0 and V1)

V

0

V

1

PRG

V

0

Mode control switch

(HALT / RUN)

H / R

Programmer port

connector

V

1

R

/

H

PRG

T1-16 / T1-28 T1-40 / T1-40S

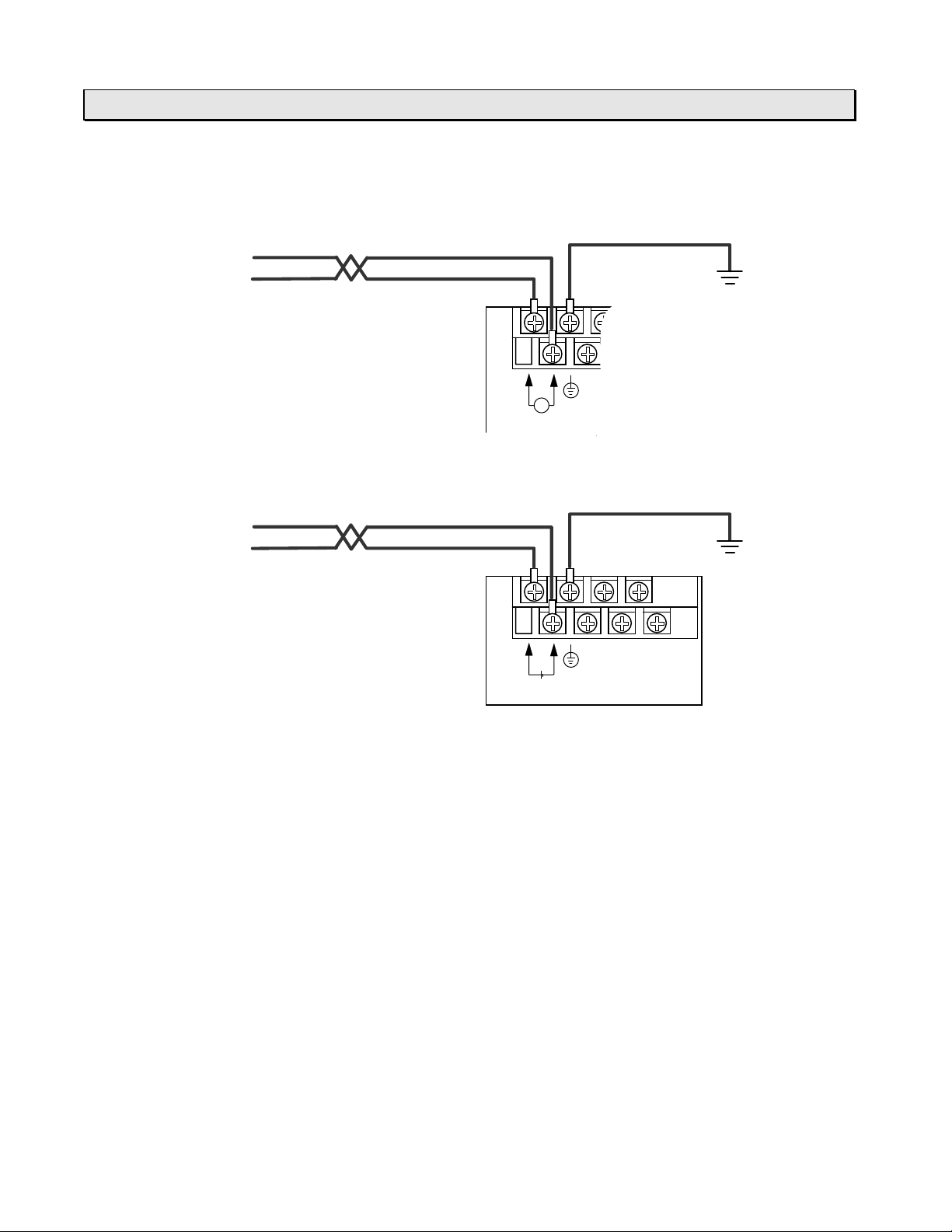

Power supply terminals:

Connect the power cable and grounding wire. The terminal scr ew size is M3.5.

See sections 4.4 and 4.5 for wiring.

Input terminals:

Connect input signal wires. The terminal screw size is M3.5. See section 2.4 for details.

Output terminals:

Connect output signal wires. The terminal scr ew size is M3.5. See section 2.4 f or

details.

Input status LEDs:

Indicate the ON status of each input signal. (color: red)

Output status LEDs:

Indicate the ON status of each out put signal. (color: red)

Basic Hardware and Function

25

Page 28

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Operation status LEDs:

Indicate the operation status of the T1/T1S.

T1-16 / T1-28 T1-40 / T1-40S

PWR Lit Int er nal 5 Vdc power is norm a l.

(Power) (g r een) Not lit Internal 5 Vdc power is not nor m al.

RUN (green) Blinking HOLD mode

FLT Lit ERRO R mode

(Fault) ( r ed) Blinking Har dware error (programmer cannot be connect ed)

AUX

(Auxiliary) (red)

PWR PWR

RUN RUN

FLT FLT

AUX

Lit RUN mode (in oper at ion)

Not lit HALT mode or ERRO R mode

Not lit Normal

-

Can be controlled by user program. Lit when S320 is

ON and unlit when S320 is OFF. (T1-40/T1-40S)

6F3B0250

Mode control switch:

Controls the operation modes of t he T1/T1S.

H (HALT) When the switch is turned to H (HALT) side, the T1/T1S stops

program execution (HALT mode) . In this position, RUN/HALT

command from the prog rammer is disabled. In case of the T1,

programming is available only in the HALT m ode.

R (RUN) When the switch is turned to R (RUN) side, the T1/T1S starts program

execution. This is the position during normal oper ation.

In this position, RUN/HALT com m and from the progra m m er is also

available.

Analog setting adjusters:

Two analog setting adjusters are provided. The V0 value is stored in SW30 and the V1

value is stored in SW31. The converted value range is 0 to 1000. Refer t o sect ion 8.5

for details of the analog setting function.

Programmer port connector:

Used to connect the programmer cable. The interface is RS-232C. T his por t can also

be used for the computer link funct ion. Ref er to section 1.6 for more inform at ion about

the computer link funct ion.

T1/T1S User’s Manual

26

Page 29

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Option card slot (T1-40/T1-40S):

Used to insert the option cards. Two slots are pr ovided. Refer to separate “T1/ T1S

Use’s Manual - Expansion I/O -” for details of the option cards.

Expansion connector (T1-40/T1-40S):

Used to connect the expansion rack or expansion unit. Refer to separate “T1/T1S Use’s

Manual - Expansion I/O -” for details of the T2 type I/O modules.

RS-485 port (T1-40S only):

Used to connect a computer (SCADA system), operator interface unit, ot her T1S, or

many kinds of serial ASCII devices including Toshiba’s I nverter through RS-485

interface. Refer to section 1.7 for more information about the T1S’s RS-485 m ult ipurpose communication functions.

Mounting holes:

Used to fix the T1/T1S on a mount ing frame by screws. The mounting holes ar e

provided at two opposite corners.

Use two M4 screws for mounting. See section 4.2 for

T1

DIN rail bracket:

The DIN rail bracket is pr ovided at the rear for mounting the T1/T1S on a 35 mm DIN

rail. See section 4.2 for inst alling the unit.

installing the unit.

Basic Hardware and Function

27

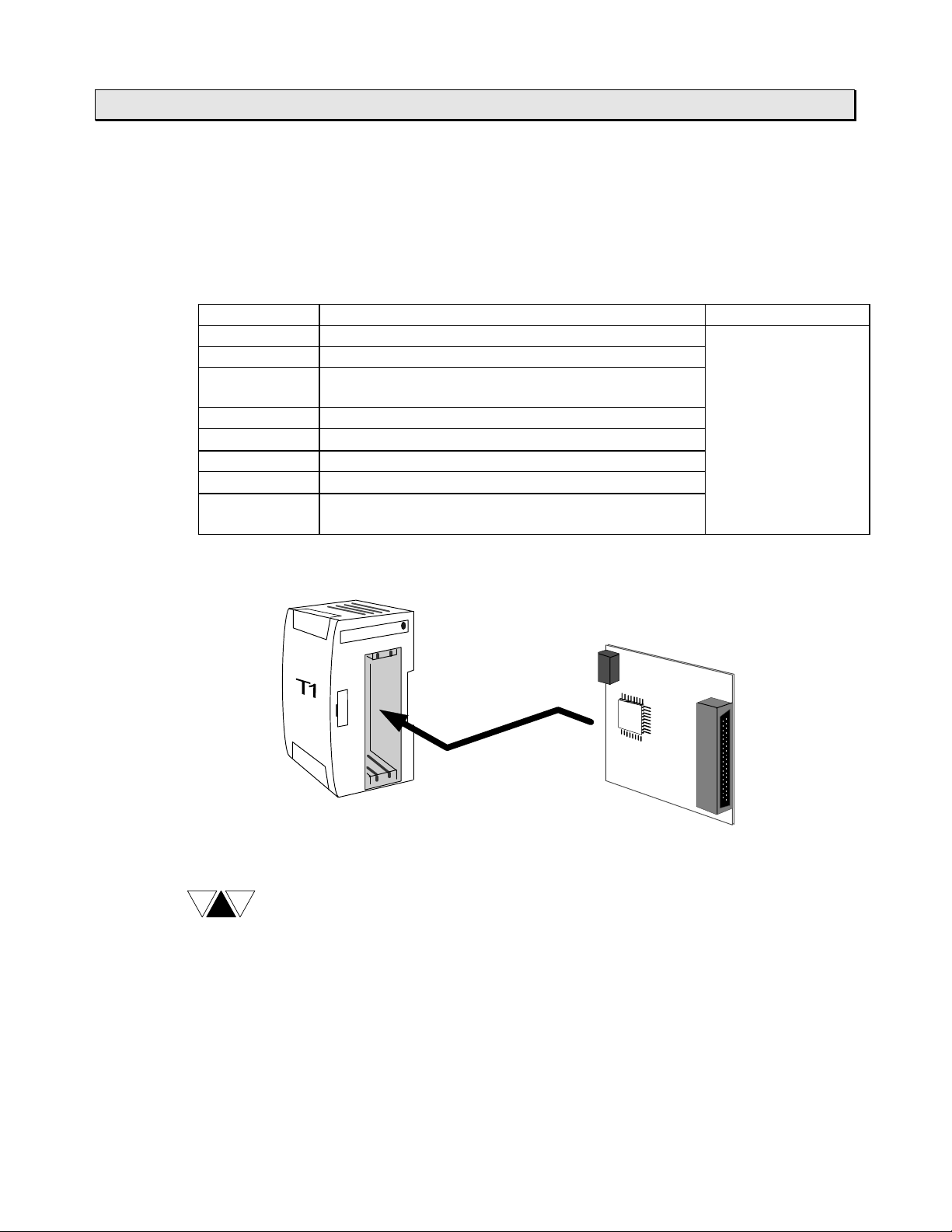

Page 30

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.5.2 Option cards

The T1-40/T1-40S can hold up to two option cards for expanding I/O points, etc.

The following eight types of t he opt ion car ds are available.

For details of the option cards, r efer to the separate manual “T1/T1S User’s Manual

Expansion I/O -“.

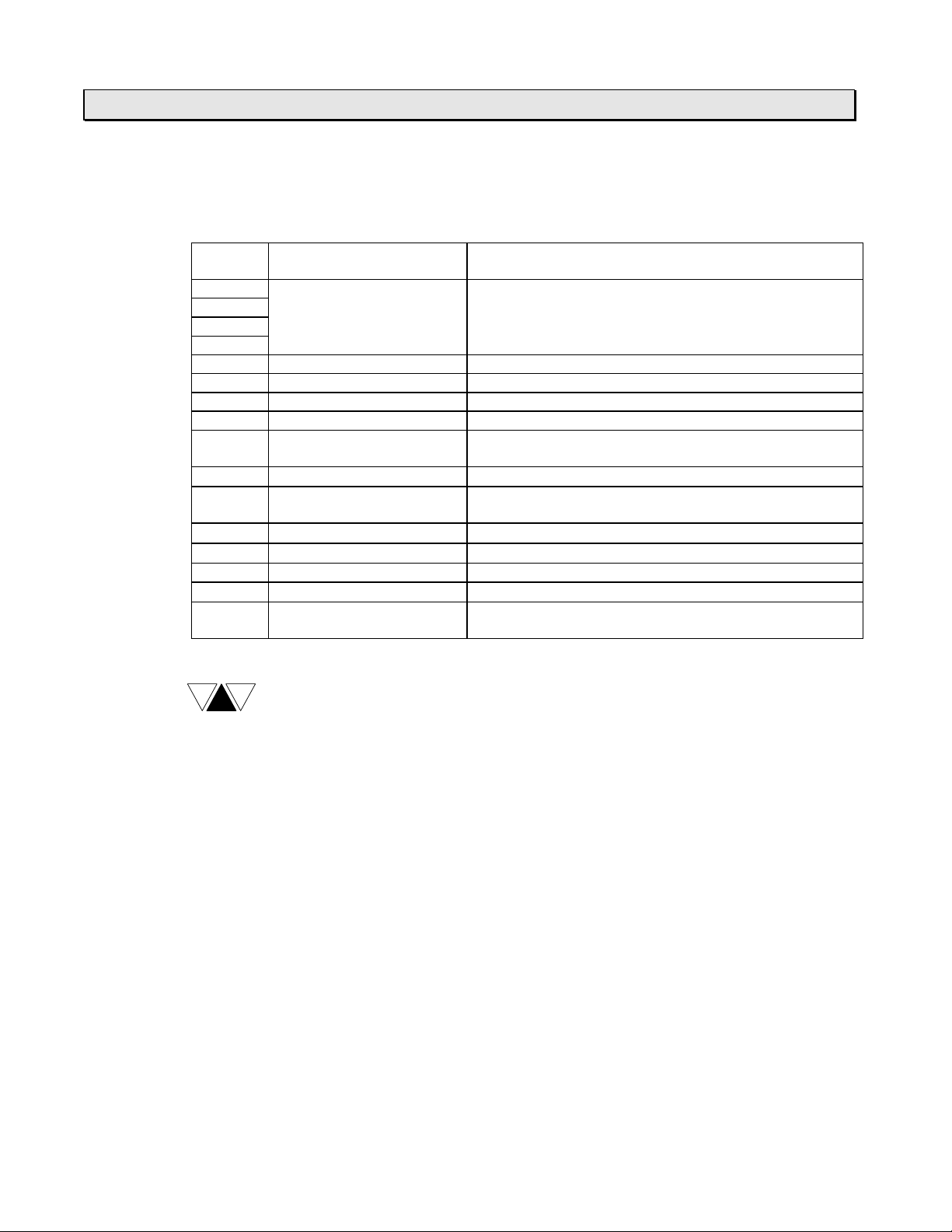

Type Description Power supply

DI116 16 points input, 24 Vdc - 5 mA Supplied from the

DO116 16 points output, 24 Vdc - 100 mA basic unit (5 Vdc)

DD116 8 point s input, 24 Vdc - 5 mA

+ 8 points output, 24 Vdc - 100 mA

AD121 1 channel analog input, 0 to 5 V / 0 t o 20 m A

AD131

DA121 1 channel analog output, 0 to 20 m A

DA131

FR112 TOSLINE-F10 remote station,

1 channel analog input, ±10 V

1 channel analog output, ±10 V

1 word input + 1 word output

6F3B0250

-

T1-40

or

T1-40S

NOTE

Option card

The TOSLINE-F10 remote car d ( FR112) can be used with other cards.

However two FR112s cannot be used together.

T1/T1S User’s Manual

28

Page 31

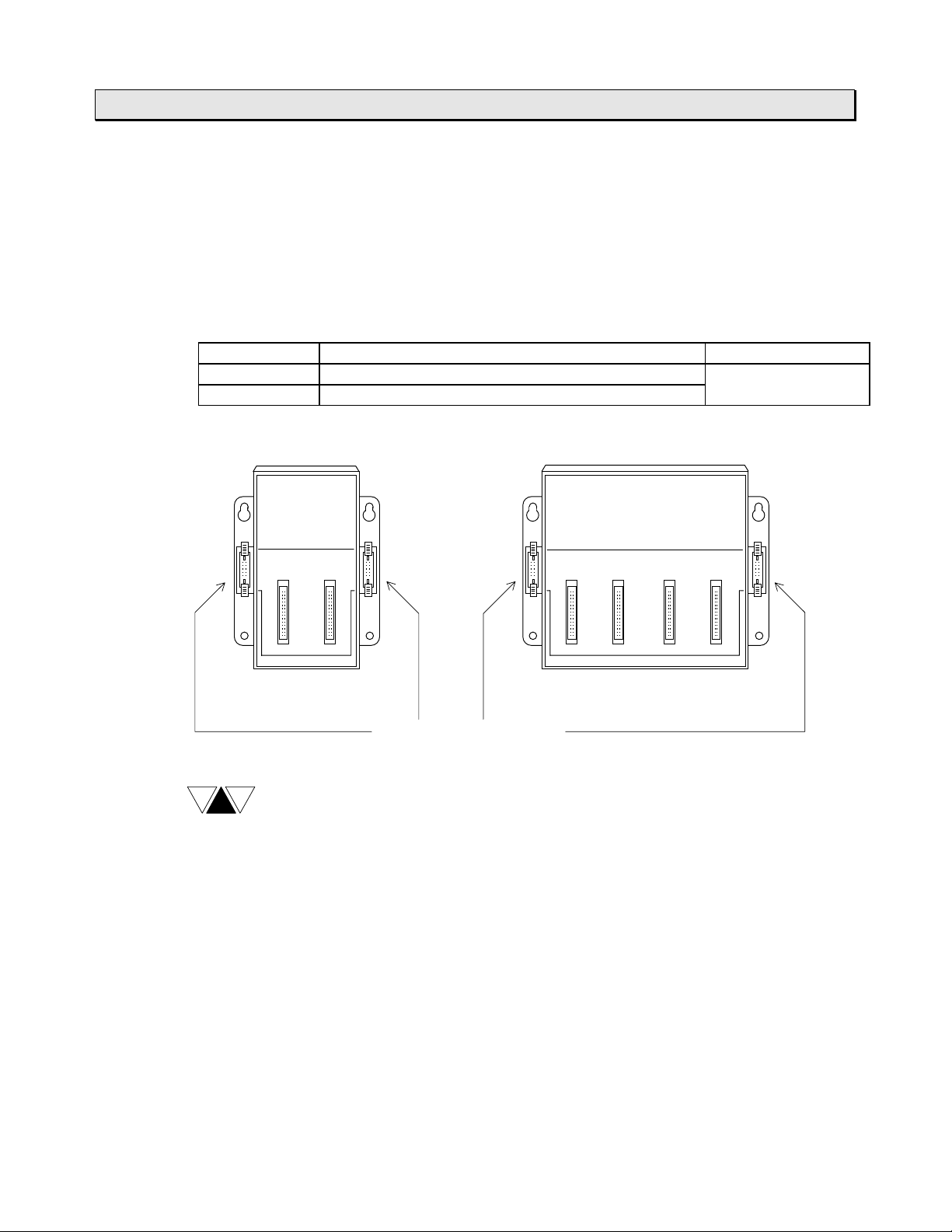

1.5.3 Expansion rack

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The T1-40/T1-40S can be connected to either one expansion rack or one expansion

unit.

The following two types of the expansion racks are available. By using the expansion

rack, T2 Series I/O modules can be used with the T1-40/T1-40S.

For details of the expansion rack, refer to the separate manual “T1/T1S User’s Manual

Expansion I/O -“.

-

Type Description Power supply

BU152 2 slots for I/O modules Supplied from the

BU154 4 slots for I/O modules basic unit

BU152 BU154

6F3B0250

1. System Configuration

NOTE

Expansion connectors

(1) A 0.15 m expansion cable is supplied with the expansion rack.

(2) Internal 5 Vdc power for I/O modules is supplied from the T1-40/T1-40S

basic unit. No power supply module is required on the expansion rack.

(3) Expansion connectors are provided on the both sides. However either one

can be used at a time.

(4) DIN r ail br acket is not provided.

Basic Hardware and Function

29

Page 32

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.5.4 I/O modules

As listed below, various I/O modules are available for the T1-40/T1-40S, allowing it to

be used for a wide variety of applications. Up to four I/O modules can be used with the

T1-40/T1-40S by connecting the expansion rack .

For details of the I/O modules, refer to the separate manual “T1/T1S User’s Manual

Expansion I/O -“.

Type Name Specifications

DI31 DC/AC input 16 points (16 points/common), 12 to 24 Vdc/Vac

DI32 DC input

DI235

IN51 AC input 16 points (16 points/common), 100 to 120 Vac

IN61 16 points (16 points/common), 200 to 240 Vac

RO61 Relay output

RO62 8 points (isolated), 240 Vac/24 Vdc (max.),

DO31 Transistor

output

DO32 (current sink)

DO235

DO233P Transistor

output

(current source)

AC61 Triac out put

AI21 Analog input 4 channels, 1 to 5 V / 4 to 20 mA, 8-bit resolution

AI22 4 channels, 1 to 5 V / 4 to 20 mA, 12-bit resolution

AI31 4 channels, 0 to 10 V, 8-bit resolution

AI32

AO31 Analog output 2 channels, 1 to 5 V / 4 to 20 mA / 0 t o 10 V,

AO22 2 channels, 1 t o 5 V / 4 to 20 mA, 12-bit resolution

AO32

PI21 Pulse input 1 channel (2-phase and zero marker), 5/12 V,

MC11 Positioning

CF211 Communication

interface

6F3B0250

-

32 points (4 ´ 8 points/common), 24 Vdc

64 points (8 ´ 8 points/common), 24 Vdc

12 points (3 ´ 4 points/common),

240 Vac/24 Vdc (max.), 2 A/point, 4 A/com m on (max.)

2 A/point (max.)

16 points (16 points/common), 5 to 24 Vdc,

1 A/point, 1.2 A/4 points (max.)

32 points (4 ´ 8 points/common), 5 to 24 Vdc,

0.1 A/point (max.)

64 points (8 ´ 8 points/common), 5 to 24 Vdc,

0.1 A/point (max.)

16 points (16 points/common), 5 to 24 Vdc,

1 A/point, 1.2 A/4 points (max.)

12 points (3 ´ 4 points/common), 100 to 240 Vac,

0.5 A/point, 0.6 A/SSR (m ax.)

4 channels, ±10 V, 12-bit resolution

8-bit resolution

2 channels, ±10 V, 12-bit resolution

100 kHz (max.), 24-bit counter

1 axis, 200 kHz (max.), 5 to 24 Vdc, ±999999 pulses

1 port of RS-232C, f u ll- duplex, ASCI I code,

300 / 600 / 1200 / 2400 / 4800 / 9600 / 19200 bps

T1/T1S User’s Manual

30

Page 33

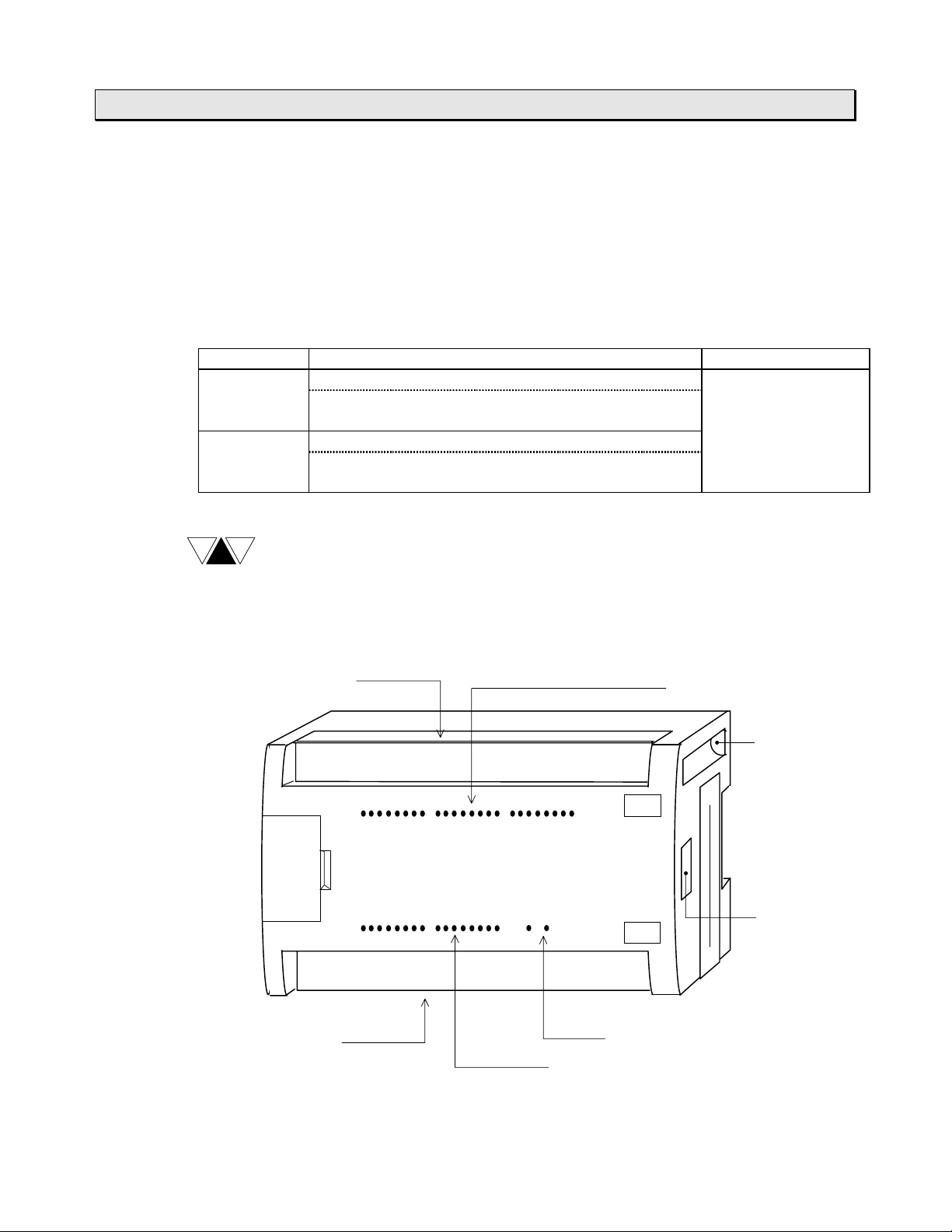

1.5.5 Expansion unit

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The T1-40/T1-40S can be connected to either one expansion rack or one expansion

unit.

The following two types of the expansion units are available. Each expansion unit has

32 points I/O (16 inputs and 16 outputs).

For details of the expansion unit, refer to the separate manual “T1/T1S User’s Manual

Expansion I/O -“.

Type Description Power supply

T1-EDR32 Input: 16 points, 24 Vdc - 7 mA Supplied from the

Output: 16 points, relay, 240 Vac/24 Vdc (max.) -

T1-EAR32 Input : 16 points, 100 to 120 Vac - 7 mA

Output: 16 points, relay, 240 Vac/24 Vdc (max.) -

2 A/point (max.)

2 A/point (max.)

6F3B0250

1. System Configuration

basic unit (5Vdc)

-

NOTE

(1) A 0.5 m expansion cable is supplied with the expansion unit.

(2) Internal 5 Vdc power for expansion unit is supplied from the T1-40/T1-40S

(3) 24 Vdc power for output relay coils is required externally.

(4) DIN r ail br acket is provided.

Power supply and

Input terminals

basic unit.

TOSHIBA

PROSEC

T1

EDR40

Input status LEDs

IN

OUT

Mounting

hole

Expansion

connector

Output terminals

Output status LEDs

Power LEDs (5V and 24V)

Basic Hardware and Function

31

Page 34

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.5.6 Options

The following optional items are available.

Item Type Description

Programmer port

connector

Option card PT15S Cable side connector for DI116, Soldering type

I/O connector PT15F DO116, or DD116 Flat cable type

Expansion cable CS1R2 For connecting the expansion rack , 0. 15 m length,

Empty slot cover

6F3B0250

PT16S For RS-232C computer link, with 2 m cable

(spare parts)

CS1R5B For connecting the expansion unit, 0.5m length,

(spare parts)

-

For covering empty slot on the expansion rack

T1/T1S User’s Manual

32

Page 35

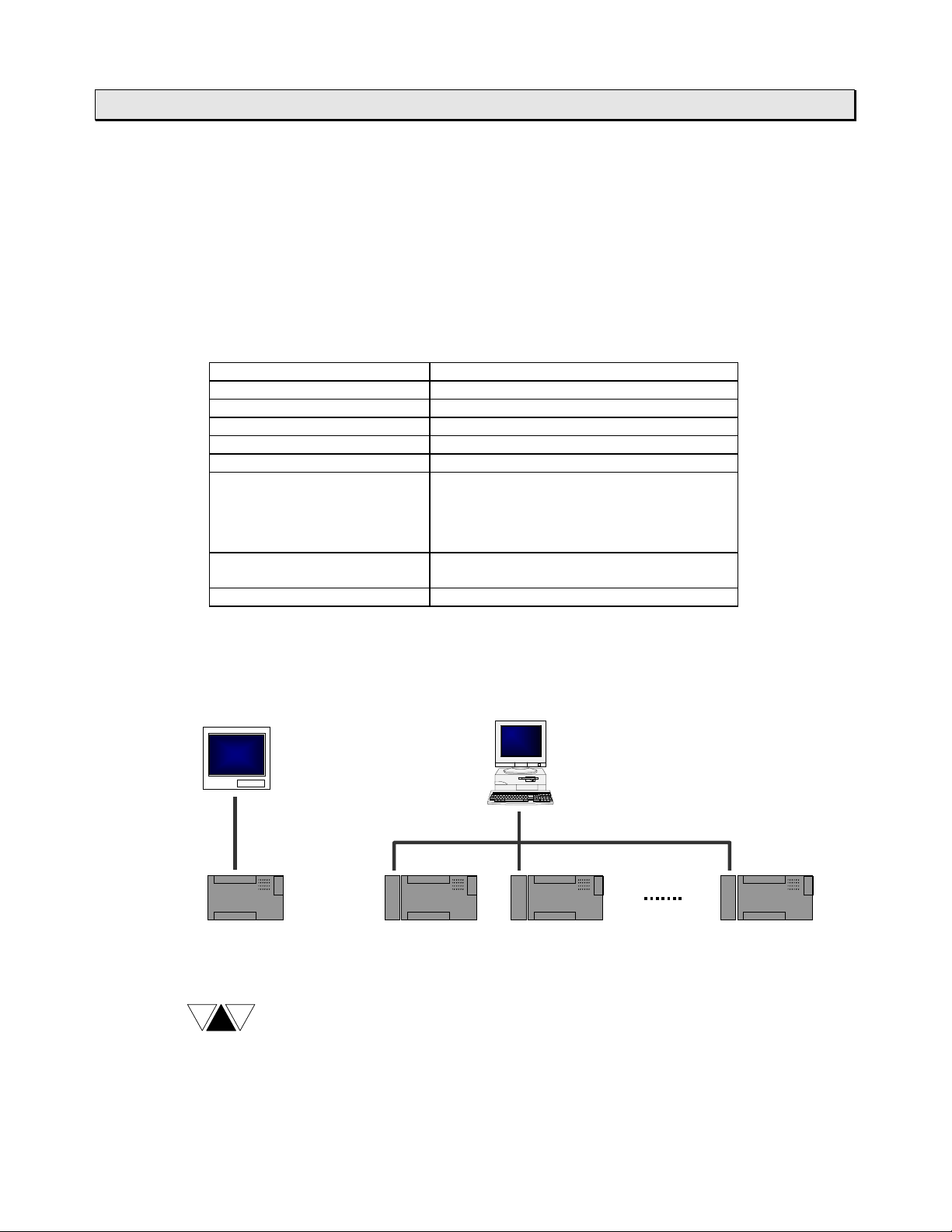

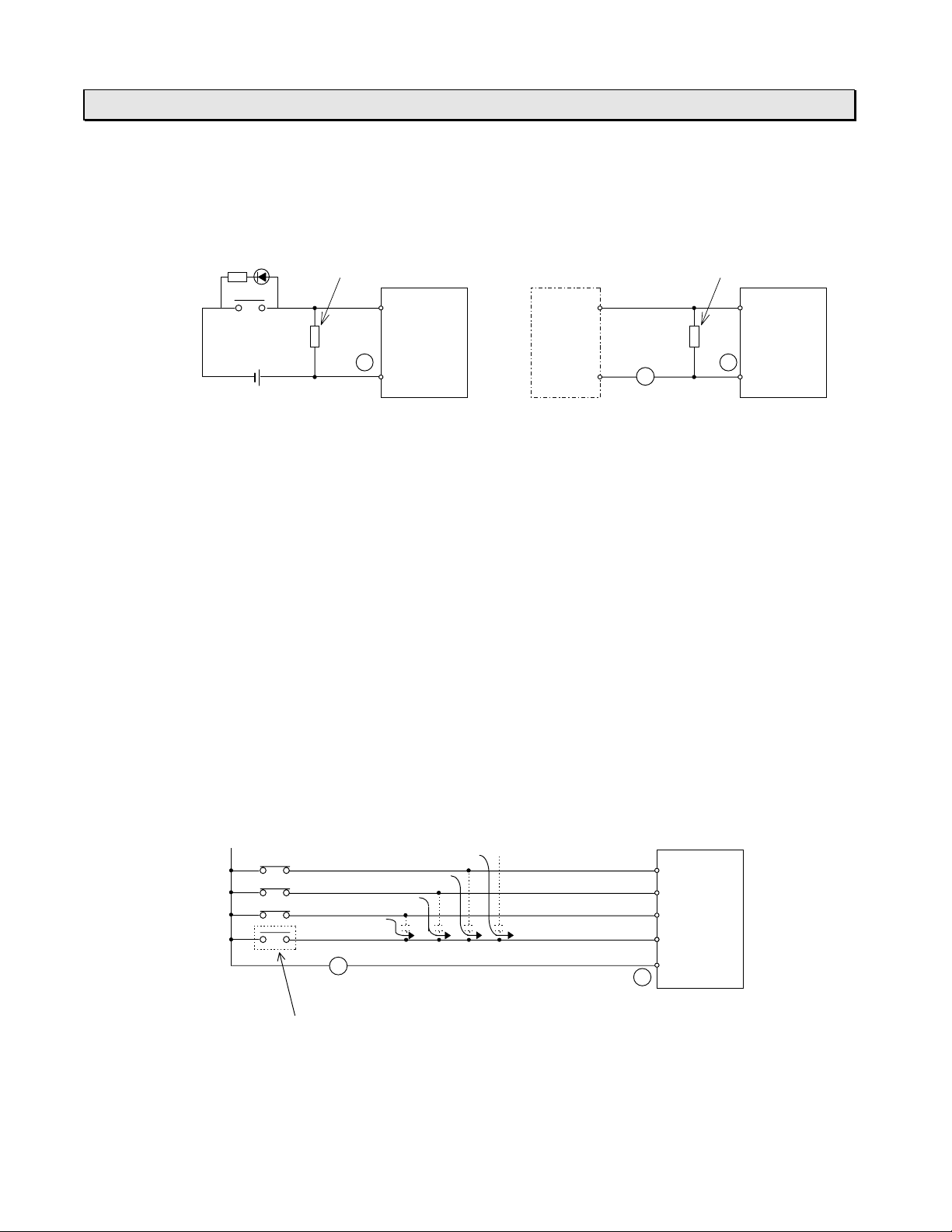

1.6 Computer link system

g

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The interface of t he T1/T1S’s programm er por t is RS-232C. Normally this port is used

to connect the programmer . However, this por t can also be used for the computer link

function.

The computer link is a data comm unicat ion function between computer or operator

interface unit and the T1/ T1S. The data in the T1/T1S can be read and written by

creating simple communication prog r am on the computer. The computer link protocol

of the T1/T1S is published in “ T1/T1S User’s Manual - Communication Function -”.

Item Specifications

Interface Conforms to RS-232C

Transmission system Half-duplex

Synchronization Star t - stop system (asynchronous)

Transmission speed 9600 bps (fixed)

Transmission distance 15 m max.

Framin

Protocol T-series computer link (ASCII)

Transmission delay option 0 t o 300 m s

Start bit:

Data bits:

Parity:

Stop bit:

1 bit

8 bits (fixed)

Odd or none

1 bit (fixed)

Programmer (binary)

6F3B0250

1. System Configuration

By using the multi-drop adapter (CU111), multiple T1/T1Ss can be connected on an

RS-485 line. The T-series PLC programming software (T-PDS) can also be used in this

configuration.

Operator Interface

RS-232C RS-485 (1 km max.)

T1 T1

NOTE

In case of the T1, ther e ar e functional limitations as follows.

·

·

C

U

Multi-drop configuration is available with version 1.10 or lat e r .

Programmer connection in t he m u lt i-drop configuration, none parity and

Master Com puter

C

U

T1

C

U

Max. 32 T1s

T1

transmission delay options are available with version 1.20 or later.

Basic Hardware and Function

33

Page 36

1. System Configuration

y

y

g

y

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

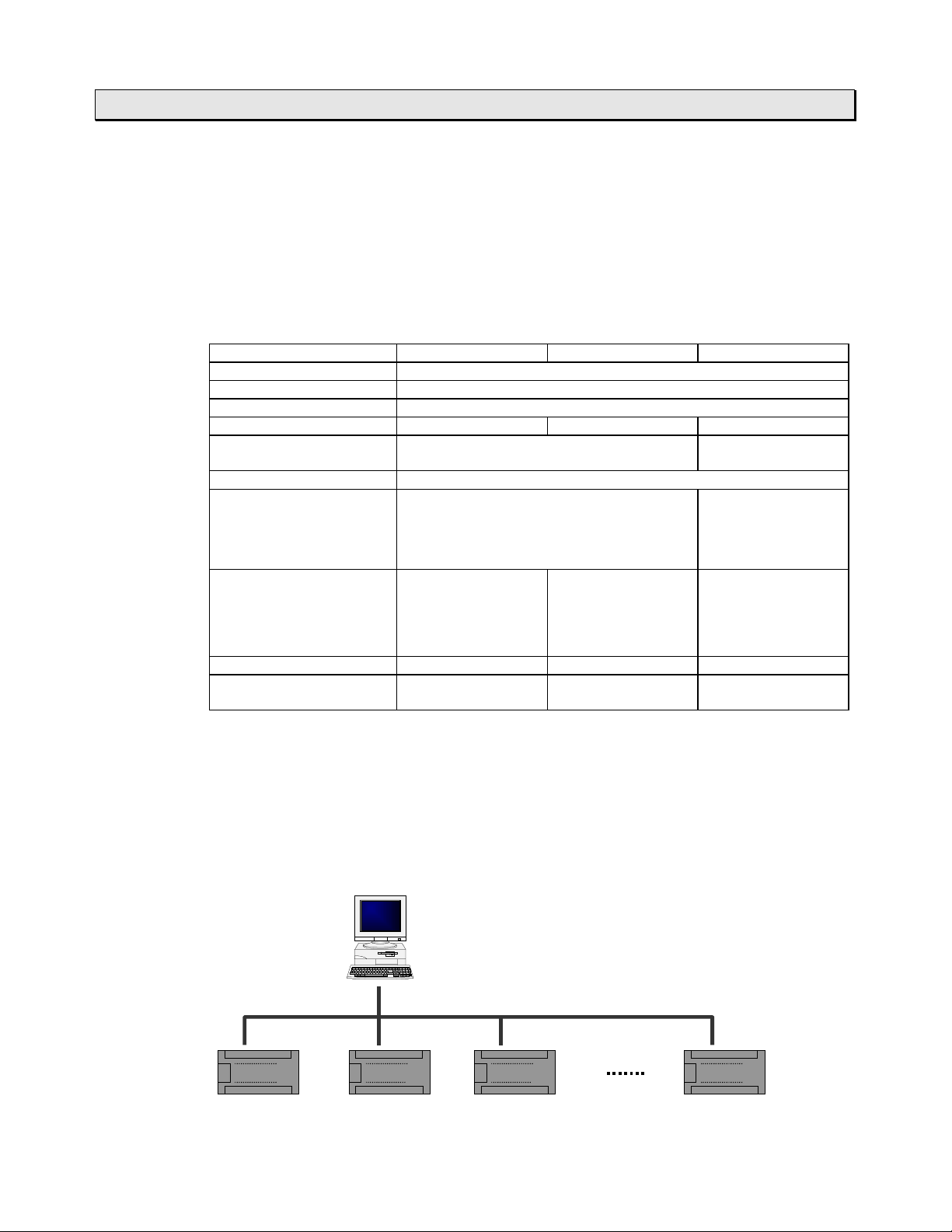

1.7 T1S communication function

The T1S has an RS-485 muiti-purpose comm unication port. This port can work

independent of the programmer port.

By using this communication port, one of t he following three communication modes is

available, computer link mode, data link m ode and free ASCII mode.

For details of these funct ions, refer to the separate manual “T1/T1S User’s Manual

Communication Function -”.

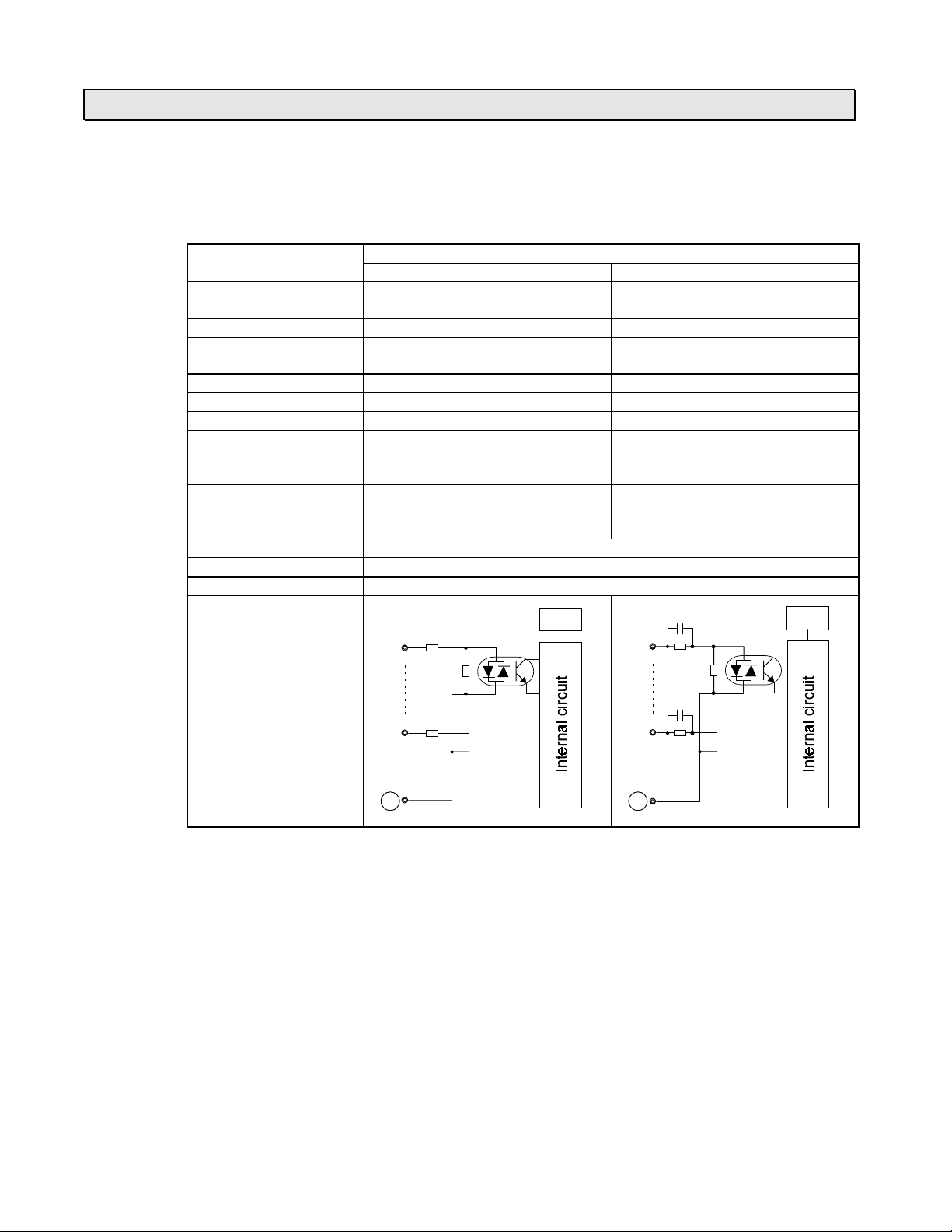

Item Computer link Free ASCII Data link

Interface Conforms to RS-458 (4-wire or 2-wire)

Transmission system Half-duplex

Synchronization Start-stop system (asynchronous)

Transmission code ASCII/binar

Transmission speed 300, 600, 1200, 2400, 4800, 9600, or

Transmission distance 1 km max.

Framin

Protocol T-series

Link configuration 1-to-N N/A 1-to-1

Transmission dela

option

ASCII Binar

19200 bps (fixed)

19200 bps

Start bit: 1 bit

Data bits: 7 or 8 bits

Parity: Odd, even, or none

Stop bit: 1 or 2 bits

User defined

computer link

(ASCII),

Programmer

(binary)

0 to 300 ms N/A N/A

ASCII messages

Special

Special

6F3B0250

-

Computer link mode

T-series computer link prot ocol can be used in this mode. A maximum of 32 T1Ss can

be connected to a master computer.

By using this mode, all the T1S’s data can be accessed by a master com put er.

The T-series PLC programming software (T-PDS) can also be used in t his

configuration.

T1/T1S User’s Manual

34

Master Com puter

RS-485 (1 km max.)

T1 T1 T1T1

Max. 32 T1Ss

Page 37

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1. System Configuration

Data link mode

Two PLCs (any combination of T1S, T 2 E or T2N) can be directly linked together. This

direct link is inexpensive, easily configured and requires no special programming. Data

registers D0000 to D0031 are used for the data transfer.

T1S

T1 T1

RS-485 (1 km max.)

Station No. 1

D0000

D0015

D0016

D0031

T1S

Station No. 2

D0000

D0015

D0016

D0031

Free ASCII mode

User defined ASCII messages can be t r ansmitted and received through this port.

A terminal, printer, bar- code reader, or other serial ASCII device can be directly

connected. This mode also allows the T1S to communicat e with other PLCs ( T1, T2E,

T2N, etc.), Toshiba’s I nvert ers (such as VF-S7/A5, G3), Toshiba’s motor protection

relay (S2E21), or others.

T1S

T1

Bar-code re ader,

Printer, etc.

RS-485 (1 km max.)

T1

T1

Inverter VF-S7

Motor Protection Relay

S2E21

Basic Hardware and Function

35

Page 38

1. System Configuration

(S)

)

)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

1.8 Real-time data link system TOSLINE-F10

TOSLINE-F10 is a high speed data transm ission system suit ed for small points I/O

distribution system. By inserting the T O SLI NE- F10 r em ote card (FR112) into the T140/T1-40S, the T1-40/ T1-40S can work as a remote station of the TOSLINE-F10

network. On this network, the T1-40/T1-40S sends 1 word data to the mast er station

and receives 1 word data from the master stat ion.

Item TOSLINE-F10 system specifications

Topology Bus (terminated at both ends)

Transmission distance

(without repeater)

Transmission speed 750 kbps 250 kbps

Scan transmission

capacity

Scan cycle 7 ms / 32 words 12 ms/32 words

Error checking CRC check

6F3B0250

High speed mode Long distance mode

500 m max. (total) 1 km max. (tot al)

512 points (32 words) max.

NOTE

(1) Ref er to the separate “T1 User’s Manual - Option Card and I/O

Module -“ for details of the TOSLINE-F10 remote card (FR112) .

(2) Ref er to the separate TOSLINE-F10 User’s Manual for details of overall

TOSLINE-F10 system.

Typical data link configuration

The figure below shows the typical data link configuration.

Master

computer

T2E

(master)

TOSLINE-F10

T1-40(S

T1-40(S

T2E

(remote)

RI/ORI/OT1-40

RI/O: remote I/O

Operator interface units

T1/T1S User’s Manual

36

Page 39

1.9 Peripheral tools

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

The following peripheral tools are available for the T1/T1S.

T-Series Program Development System (T-PDS)

The T-Series Program Development System ( T-PDS) is a software which runs on any

IBM-PC compatible personal computers such as Toshiba’s Notebook com puters. The

same T-PDS software supports on-line/off-line prog r am m ing, debugging and program

documentation for all the T-Series programmable controllers T1/T1S, T2/T2E/T2N and

T3/T3H.

User-friendly program editor includes cut & paste, address search & replace,

·

program block move/copy, etc.

Group programming - part program development by multiple desig ner s and

·

merging them into a complete program - enhance the software productivity.

Powerful monitoring, I/O force and data set functions fully support your program

·

debugging.

Documentation of programs with commentary makes your maintenance work easy.

·

Remote monitoring/prog r amming via modem (radio/phone) is possible.

·

6F3B0250

1. System Configuration

The table below shows the T-PDS versions that support the T1/ T1S.

Type Part number Versions available for

T1 T1S

T-PDS for Windows TMW33E1SS Ver 1.0 or later

T-PDS for MS-DOS TMM33I1SS Ver 1.61 or later

*1)

*1)

Ver 1.2 or later

Ver 2.1 or later

*1) The T1S can be used with these versions. However, in this case, t her e are the

following functional limitat ions.

The program size setting is only available as 2 k. It is set to 4 k mode in the T1S.

·

Some of the added instructions (MAVE, DFL, HT OA, ATOH) may not be

·

edited/monitored. (depending on t he version)

NOTE

The connection cable for the T1 Series is different from that for upper T-Series

PLCs. These cables are supplied separately.

Connection cable for T1/T1S . . . Type: CJ105, 5 m length

Connection cable for T2/T3 ¼. Type: CJ905, 5 m length

Basic Hardware and Function

37

Page 40

1. System Configuration

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T-Series Handy Programmer (HP911A)

The HP911A is a hand-held programmer, that can be used to program the T1/T1S

using ladder diagram. I t s por t abilit y makes it ideal for maint enance use at r e m ot e

locations.

The HP911A has the following features.

The HP911A supports ladder diagram pr ogramming of T- Series programmable

·

controllers T1/T1S, T2/T2E/T2N and T3.

Built-in EEPROM allows program copy between T-Series controller s .

·

Two display modes are available,

·

- Normal: 5 lines and 12 columns

- Zoom: Full device description

On-line data set and I/O force are useful for system checking.

·

Backlit LCD display allows operation in dim light.

·

6F3B0250

There are two types of the Handy Programm er (HP911) depending on the cable

included with.

Type Part number Cable included with Versions available for T1/T1S

HP911A

HP911

The T1S can be used with the HP911(A). However, there are the following functional

limitations.

The program size setting is only available as 2 k. I t is set to 4 k mode in the T1S.

·

Some of the added instructions (MAVE, DFL, HT OA, ATOH) cannot be

·

edited/monitored.

NOTE

THP911A*S

THP911**S

A 2 m connection cable for the T1/T1S (Type: CJ102) is supplied with the

HP911A. The cable for the T2/T3 is available separately. (Type: CJ902, 2 m

length)

2 m cable for T1/T1S Ver 1.1 or later

2 m cable for the upper

T-series PLCs

Ver 1.1 or later

T1/T1S User’s Manual

38

Page 41

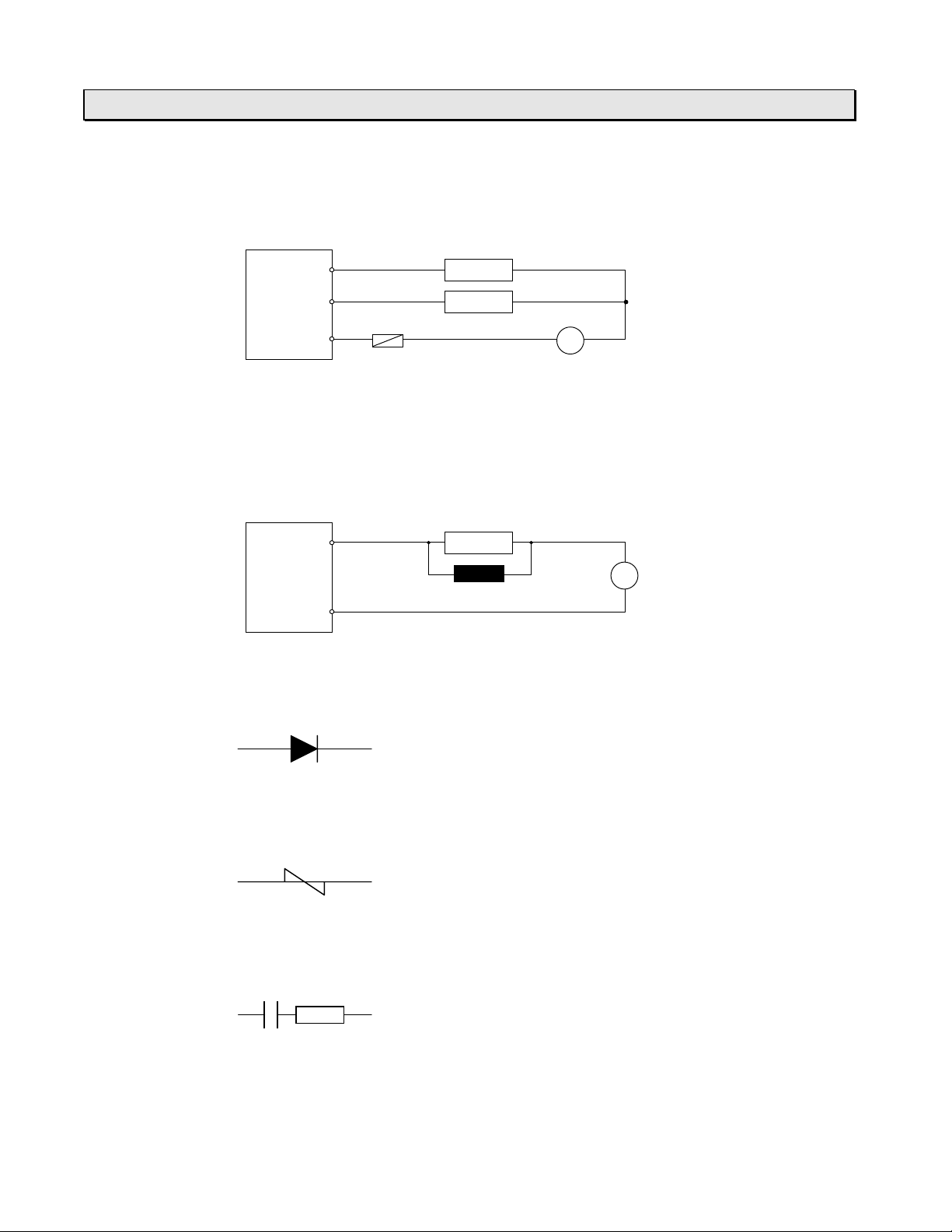

Program Storage Module (RM102)

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

6F3B0250

1. System Configuration

The program storag e m odule (RM102) is an

external memory for storing the T1/T1S

program. By using the RM102, program saving

from the T1/T 1S to the RM102, and program

loading from the RM102 to the T1/ T1S can be

done without need of a programmer.

Because the RM102 has an EEPROM,

maintenance-free progr am storage and quick

saving/loading are available.

Multi-drop adapter (CU111)

The T1/T1S’s RS-232C programmer port

supports the computer link function.

When two or more T1/T1Ss are connected with

a master computer, the multi-drop adapter

(CU111) can be used. (One-to-N configuration)

The CU111 is an RS-232C/RS-485 converter

specially designed for the T1/T1S’s

programmer port.

Basic Hardware and Function

39

Page 42

6F3B0250

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T1/T1S User’s Manual

40

Page 43

Section 2

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

Specifications

6F3B0250

2.1 General specifications, 42

2.2 External dimensions, 43

2.3 Functional specifications, 46

2.4 I/O specifications, 48

Basic Hardware and Function

41

Page 44

2. Specifications

g

g

g

g

g

g

g

g

g

g

g

g

g

g

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2.1 General specifications

Power supply voltage 100 to 240 Vac (+10/-15 %), 50/60 Hz

Power consumption 30 VA or less 38 VA or less 45 VA or less

Inrush current 50 A or less (at 240 Vac, cold start)

24 Vdc output ratin

(24 Vdc, ±10%)

5 Vdc output ratin

Power supply voltage 24 Vdc (+20/-15 %)

Power consumption 12 W or less 18 W or less

Inrush current 25 A or less (at 24 Vdc)

5 Vdc output ratin

Retentive power interruption 10 ms or less

Insulation resistance

Withstand voltage 1500 Vac - 1 minute

Ambient temperature

Ambient humidity 20 to 90% RH, no condensation

Noise immunity

Vibration immunity 16.7 Hz - 3 mm p-p (3 mutually perpendicular axes)

Shock immunity 98 m/s2 (10 g)

Approximate weight 500

6F3B0250

Item T1-16 T1-28 T1-40 T1-40S

0.1 A for

service power

+

power for dry

contact inputs

-

-

10 MW or more

(between power terminals and

(between power terminals and

0 to 55 °C (operation), -20 to 75 °C (stora

1000 V p-p/1 ms, Conform to EMC Directive 89/336/EEC

(3 shocks per axis, on 3 mutually perpendicular axes)

Option card: 50

Expansion unit: 600

0.2 A (for external devices and/or for input

nals)

si

1 A (for option card and/or

expansion rack/unit)

1 A (for option card and/or

expansion rack/unit)

round terminal)

round terminal)

e)

700

800

2-slot expansion rack: 600

4-slot expansion rack: 800

NOTE

(1) 24 Vdc service power output is not provided on the AC input type and DC

power supply type.

(2) 5 Vdc output capacity of T1-40/T1-40S is reduced by 0.2 A with using

HP911A, and by 0.1 A with using RS-485 port.

T1/T1S User’s Manual

42

Page 45

2.2 External dimensions

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T1-16

¨¨¨¨

6F3B0250

2. Specifications

2-Æ5

¨¨¨¨

T1-28

2-Æ5

[mm]

Basic Hardware and Function

43

Page 46

2. Specifications

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

T1-40/T1-40S, Expansion unit

¨¨¨¨

6F3B0250

2-Æ5

Option card

¨¨¨¨

43.18

A

Additional space for Option card connector

Card type A

DI116, DO116, DD116 55

AD121, AD131, DA121, DA131 16

FR112 11

[mm]

T1/T1S User’s Manual

44

Page 47

4-Æ5

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

2-slot expansion rack

¨¨¨¨

69.0

83.0

97.0

6F3B0250

2. Specifications

106.5

115.0

143.0 (terminal block)

168.0 (connector)

4-Æ5

4-slot expansion rack

¨¨¨¨

135.0

149.0

163.0

[mm]

Basic Hardware and Function

45

Page 48

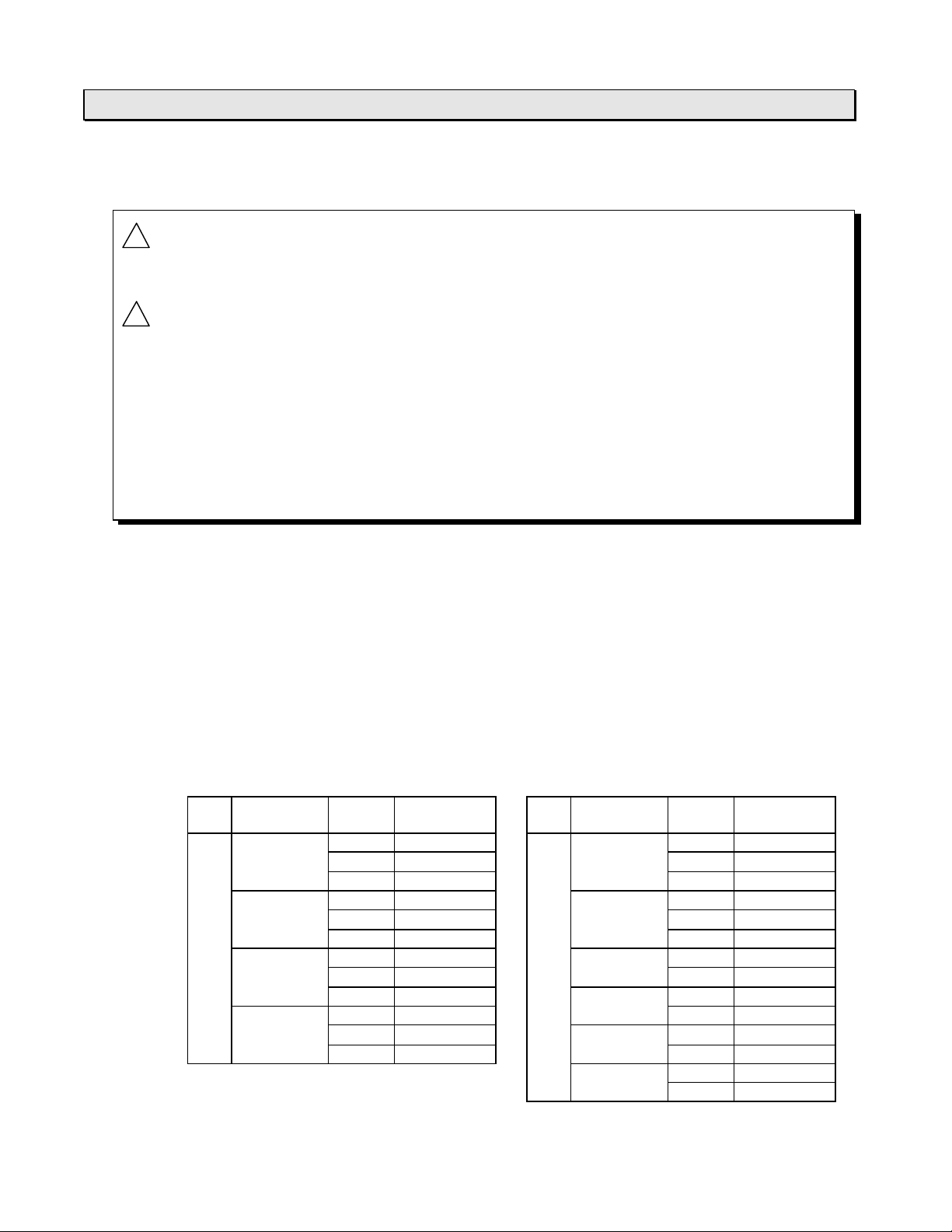

2. Specifications

g

g

g

g

g

CTi Automation - Phone: 800.894.0412 - Fax: 208.368.0415 - Web: www.ctiautomation.net - Email: info@ctiautomation.net

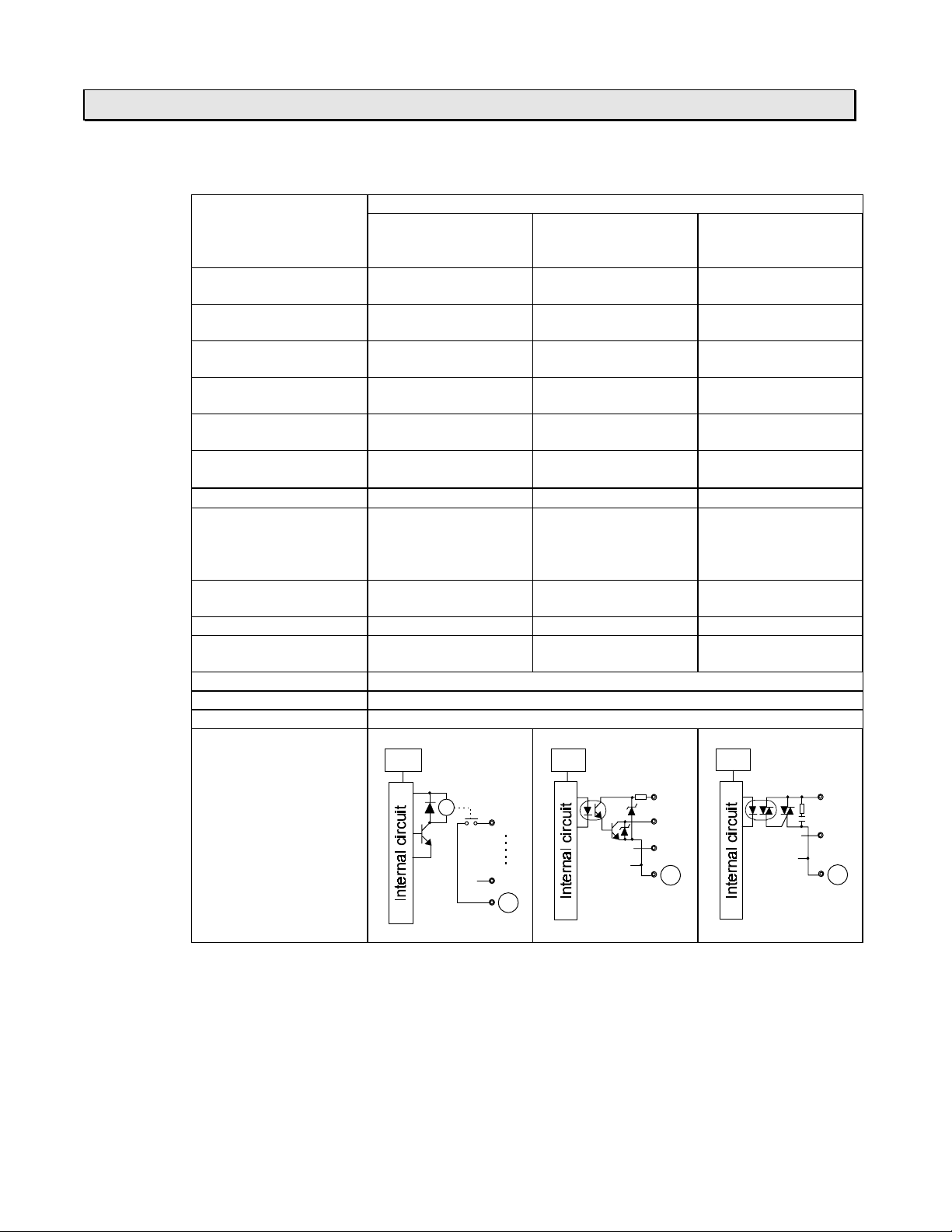

2.3 Functional specifications

Item T1-16 T1-28 T1-40 T1-40S

Control method Stored program, cyclic scan system

Scan system Floating scan or constant scan (10 - 200 ms, 10 ms units)

I/O update Batch I/O refresh (direct I/O instruction available)

Program memory RAM (capacitor back-up) and EEPROM (no back-up battery required)

RAM memory backup

Program capacity 2 k steps 8 k steps

Programmin

language

Instructions Basic ladder instructions: 17

Execution speed

Program types 1 main program

User I/O register 512 points/32 words (X/XW, Y/YW)

data Auxiliary

relay

Special

relay

Timer 64 points (T./T), 32 @ 0.01 s, 32 @ 0.1 s 256 points (T./T)