Page 1

6F3A4508

Maintenance Tool For Drive

Wi Tool

Instruction manual

Jun, 2002

© TOSHIBA Corporation

All Rights Reserved.

2002

Page 2

TOSHIBA 6F3A4508

Wi Tool Operation Description Table of Contents

[1] Introduction 2

Before you begin

Notes on rewriting drive equipment data

Maintenance

[2] Wi Tool connection 3

[3] Starting Wi Tool 6

[4] Wi Tool main window 8

[5] Wi Tool functions 10

[6] Wi Tool function detail description

[6-1] Word detail description 11

[6-2] String detail description 14

[6-3] Bit detail description 17

[6-4] Set point control detail description 21

[6-5] Traceback detail description 29

[6-6] Snapshot detail description 36

[6-7] Trend view detail description 38

[6-8] Step response detail description 40

[6-9] Password control detail description 42

[6-10] Property detail description 44

[6-11] Preparation detail description 48

[6-12] Ending detail description 49

[7] Wi Tool 1:N connection, 1:N RIO connection 50

- 1 -

Page 3

TOSHIBA 6F3A4508

[1] Introduction

This document describes the Wi Tool which is a tool for the Toshiba Wi Series drive equipment.

For information on how to install Wi Tool on your PC, refer to the "Installation manual"

(6F3A4507). Note that the drive equipment cannot be connected unless the correct connection

method and PC settings are used. Be sure to understand the concept of these settings

thoroughly.

The following topics are described:

Chapter 2: Connection Method

Chapter 3: Startup Method

Chapter 4: Main Window Description

Chapter 5: Function Summary

Chapter 6: Function Details

Chapter 7: Connection Other than 1:1 Connection

<Before you begin>

Microsoft and Toshiba have the Copyrights to this software. Copying this software to

unauthorized PC is prohibited.

Do not install programs other than the above on your PC. The settings of your PC may be

altered causing the Wi Tool to slow down or become inoperable.

<Notes on rewriting drive equipment data>

Observe the following when rewriting the drive equipment data.

1) Rewriting the data may disturb the drive equipment. (For example, if the speed setting is

rewritten, the motor speed will change. If the control gain is rewritten, the control system will

change causing it to trip or become unstable. ) Be very careful when rewriting. When the motor

is running, the message "OK to rewrite while running?" appears on the screen.

2) When rewriting the data, there is a password function on the drive equipment side. If the

correct password is not provided, a password error occurs and the data remains unchanged.

3) The setting in the drive equipment is normally written in RAM. Wi Tool normally modifies this

data in RAM. However, this data in RAM is erased once the power is turned off. Therefore, the

drive equipment also holds the settings in EEPROM which is not erased when the power is

turned off and the settings are copied to RAM from EEPROM when the power is turned on.

When data is changed with the Wi Tool, only the data in RAM is changed. Therefore, the

settings must be copied from RAM to EEPORM before turning the power off.

<Maintenance>

This software is supplied on CD-ROM. Keep it as backup.

- 2 -

Page 4

TOSHIBA 6F3A4508

Ethernet

Ethernet

Ethernet

[2] Wi Tool connection

The following three types of network connections are available for Wi Tool:

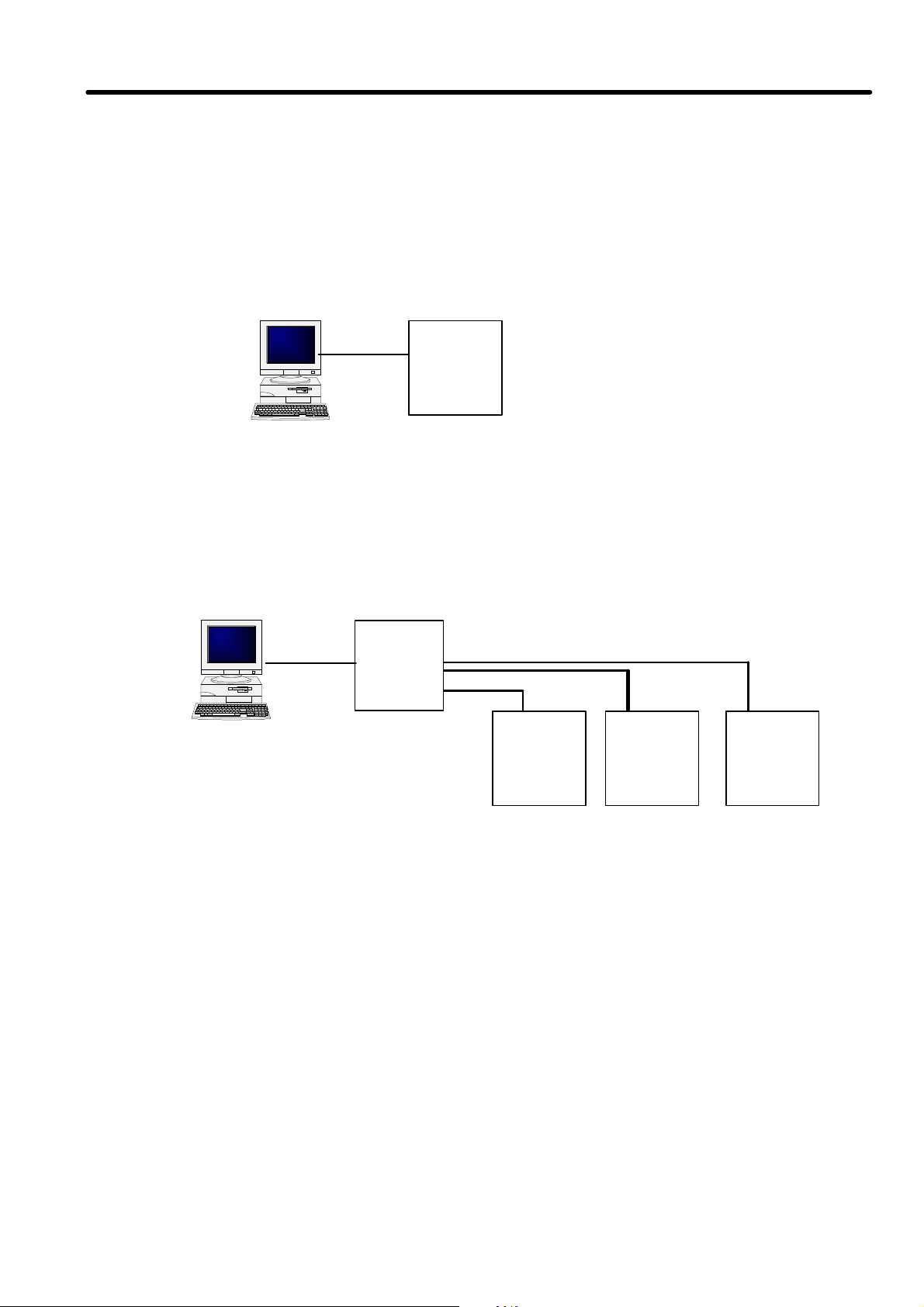

1) 1:1 connection

PC and drive are connected 1 to 1.

Therefore, only one PC and drive equipment are connected to the network.

Figure 2 1:1 connection

2) 1:N connection

Multiple drive equipments are connected to a single PC.

Normally, the network is connected through a device called the HUB.

In this case, an IP address is required for the PC and each drive unit.

Figure 2 1:N connection

Hub

250Wi

T-

T-

T-

- 3 -

Page 5

TOSHIBA 6F3A4508

ASC

ASC

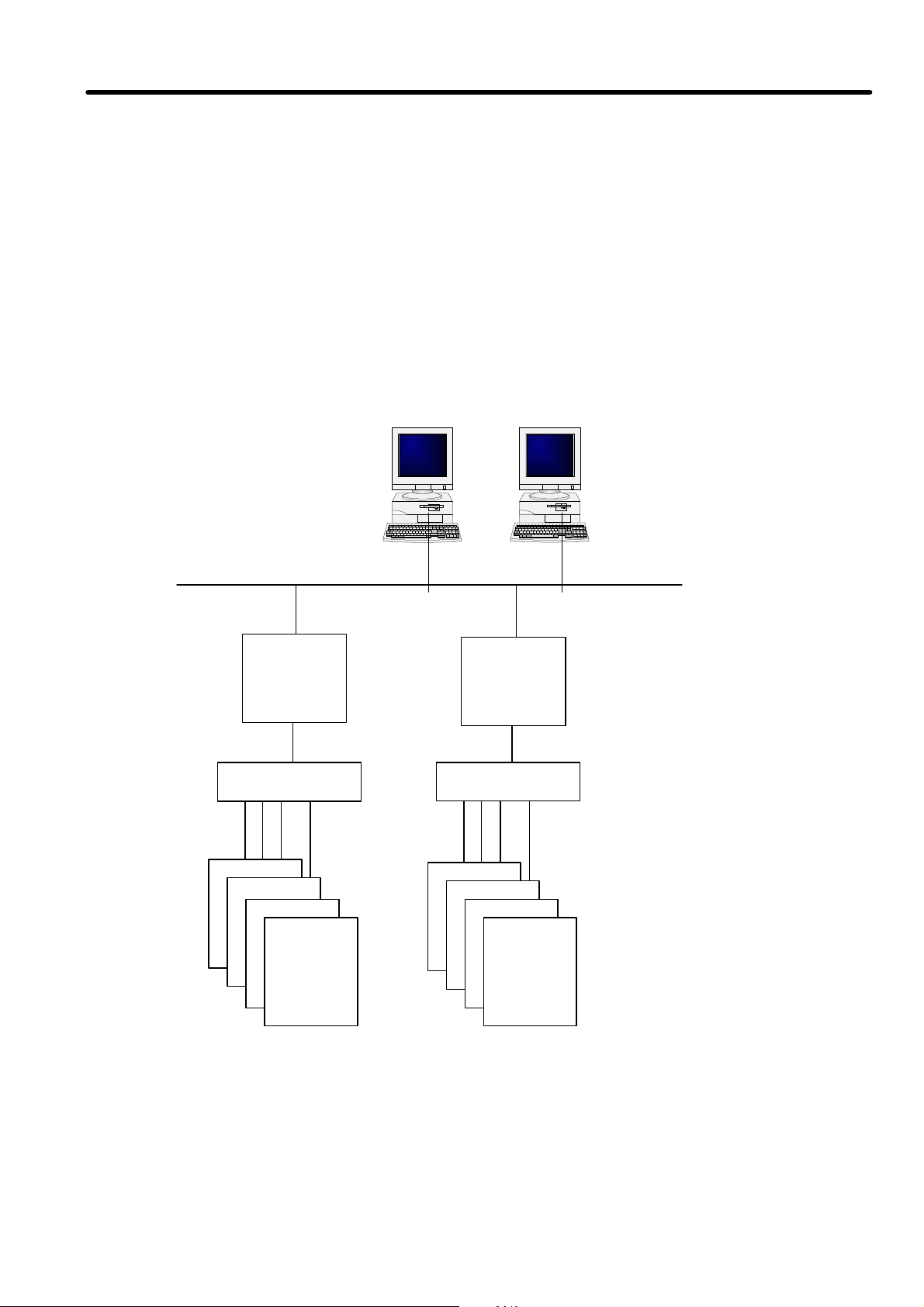

3) 1:N RIO connection

This is a connection made via Integrated Controller V Series.

The PC is connected to the Integrated Controller network and exchanges messages with the

Integrated Controller RIO (Remote I/O Controller).

RIO and drive equipment exchange messages using the message transmission function of

the Transmission Unit TL-S20. Consequently, the PC exchanges messages with the drive

equipment.

In this case, an IP address is required for the PC and each RIO.

The drive equipment does not need an IP address because message is exchanged using the

TL-S20.

Ethernet

RIO RIO

TL-S20

250Wi

T-250Wi

Figure 2.3 RIO connection

250Wi

T-250Wi

TL-S20

- 4 -

Page 6

TOSHIBA 6F3A4508

The necessary information, the creation of setup file based on this information, PC setup, and

the window display depend on the selected connection method ((1) 1:1, (2) 1:N, or (3) 1:N

RIO).

Refer to the "Installation manual" (6E3A4507) for details.

4) Connection between PC and drive equipment

The actual connection between the PC and drive equipment is made by an Ethernet cable.

(1) In the case of 1:1 connection, connect the TOOL connector on the drive equipment board

and the Ethernet connector of the PC with an Ethernet cross cable. The Ethernet cross cable

is provided with

Wi Tool.

(2) In the case of 1:N, it is not possible to connect to the drive equipment board. Connect the

Ethernet connector of the PC and the hub with an Ethernet straight cable because the signal

from the drive equipment is connected to the Ethernet hub.

(3) In the case of 1:N RIO connection, connect the Ethernet connector of the PC and the hub

with an Ethernet straight cable as with (2) 1:N connection.

Cross cable and straight cable are available as Ethernet cable. Note that the correct cable

must be used. A single cross cable is included with Wi Tool. Straight cables must be

purchased separately.

- 5 -

Page 7

TOSHIBA 6F3A4508

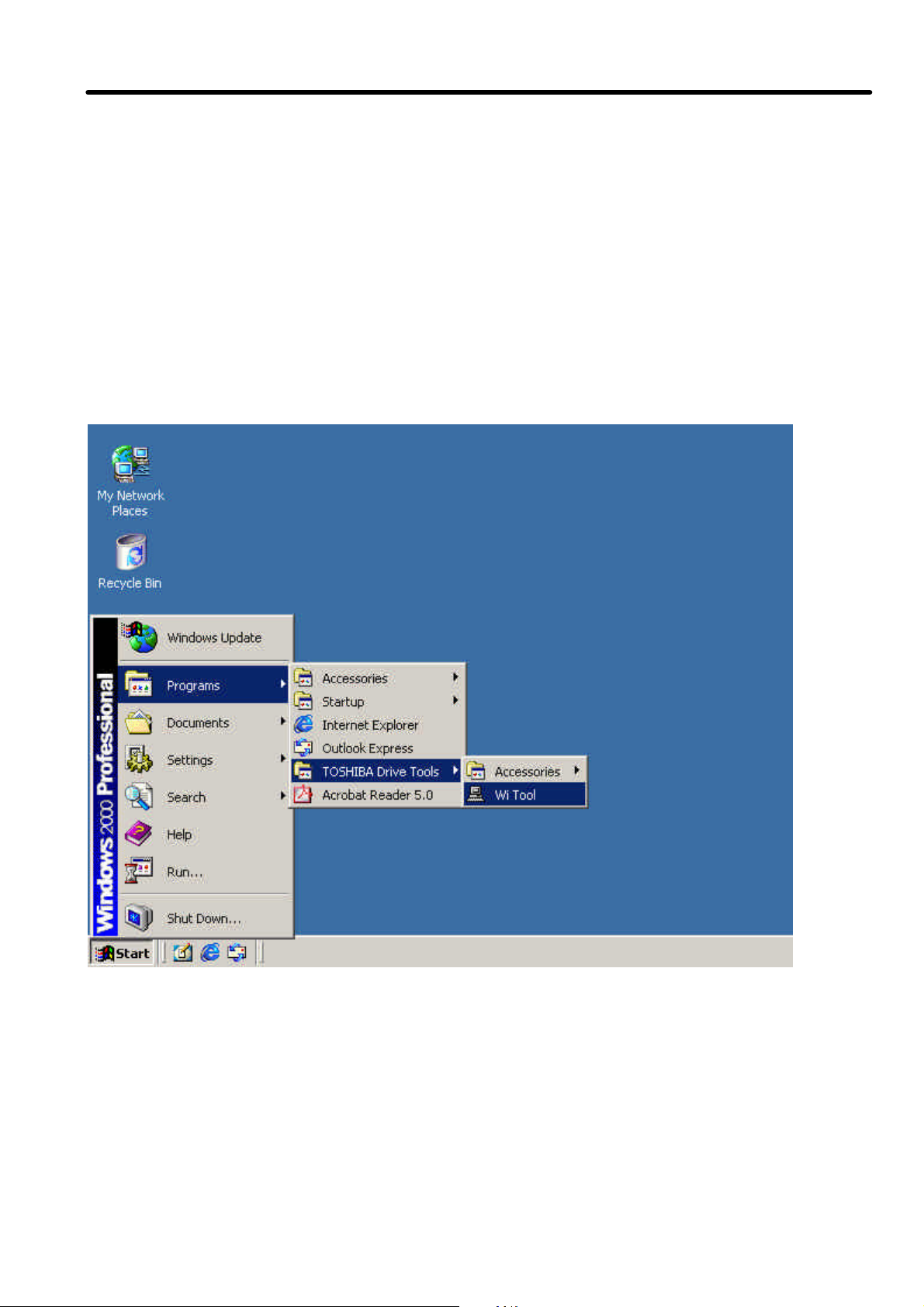

[3] Starting Wi Tool

If installation is finished, Wi Tool can be started according to the following procedure:

1) Click the START button at the bottom left corner of the screen.

2) Select Program/TOSHIBA Drive Tools.

3) When Wi Tool appears, click it.

4) If TOSHIBA Drive Tools or Wi Tool is not displayed:

Wi Tool may not be installed.

Install it.

Refer to the "Installation manual" (6F3A4507) for details.

Figure 3.1 Starting Wi Tool

- 6 -

Page 8

TOSHIBA 6F3A4508

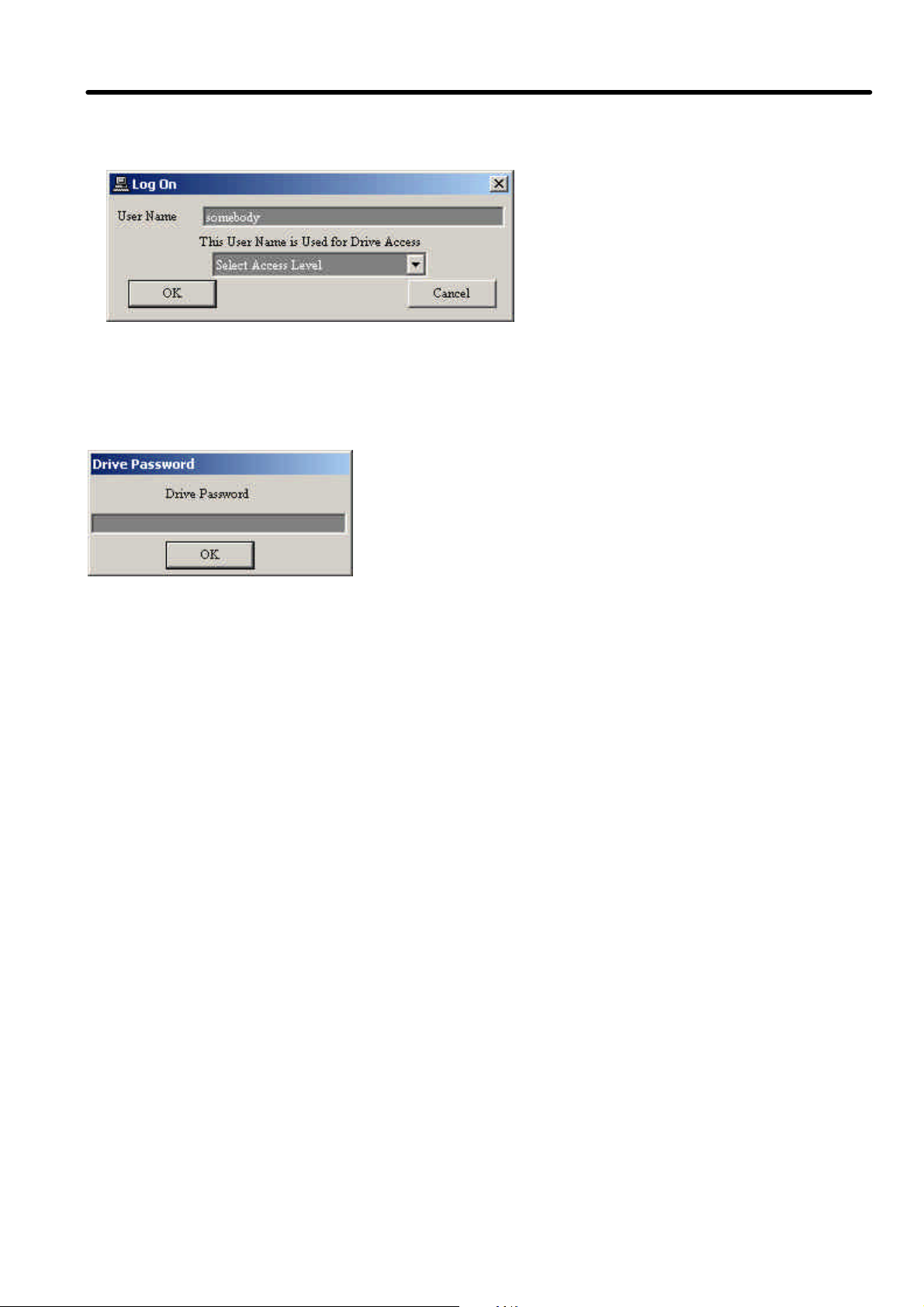

The following window appears when Wi Tool is started.

Figure 3.2 Logon window

Enter the User Name and Access Level and then click OK.

A password input window appears when connecting to the drive equipment.

Figure 3.3 Password prompt

Enter the password and click OK.

<<User Name, Access Level, Password>>

The name of the operator allowed to connect to the drive equipment, access level of the

operator, and the password for that operator are registered in each drive equipment.

This operator name is referred to as the User Name.

The access level is divided into ten levels from 0 (Read Only) to 9 (Full Access).

If the User Name and Access Level do not match those registered in the drive equipment, the

drive equipment returns access level 0.

The User Name and Password are set to "TOSHIBA" at factory shipment.

Access level 9 is allowed with this user name.

This User Name and Access Level are entered when starting Wi Tool and are used to

connect to the drive equipment.

- 7 -

Page 9

TOSHIBA 6F3A4508

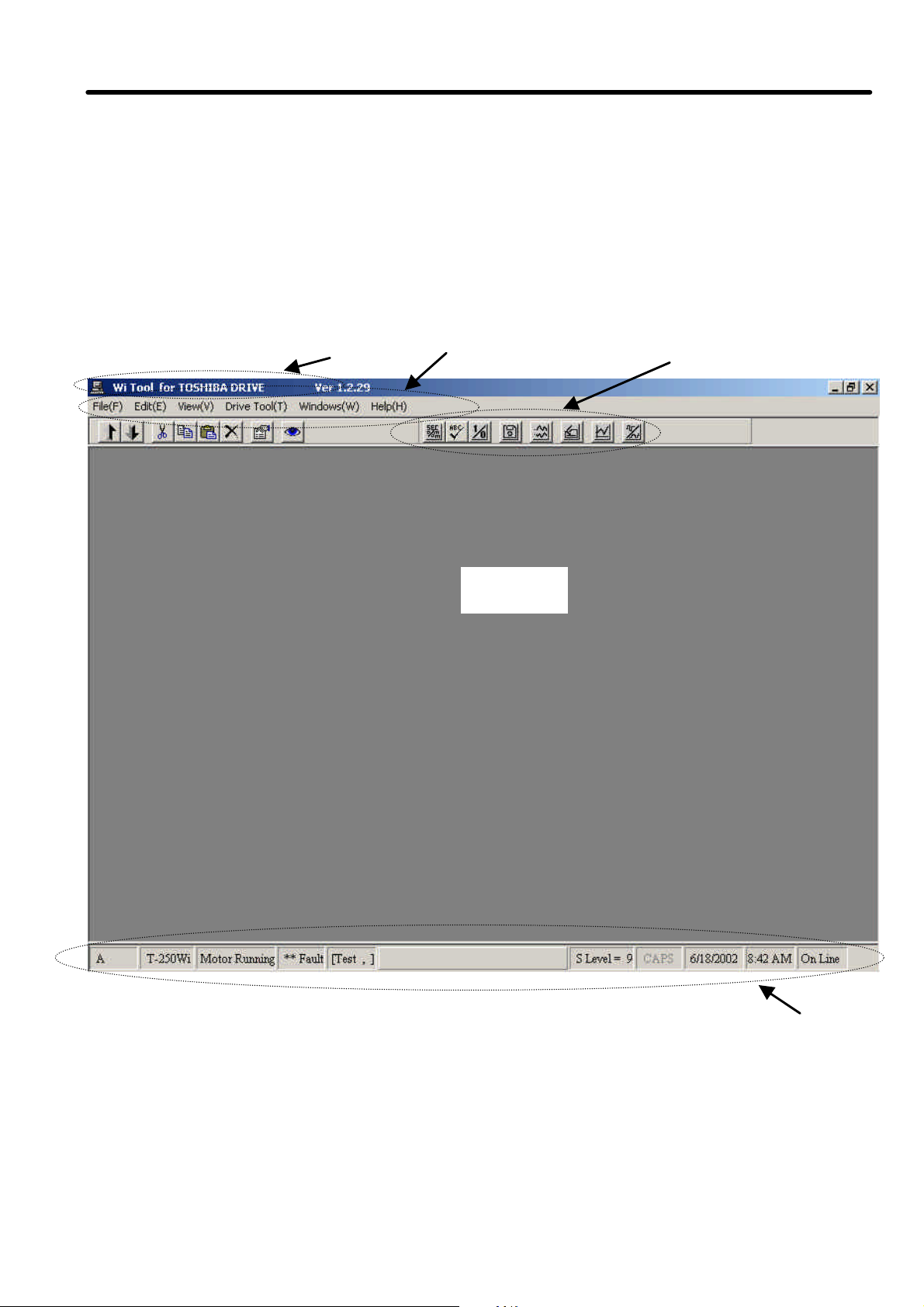

[4] Wi Tool main window

The main window opens when the password is entered.

The standard 1:1 connection windows are described.

The main window consists of five main components:

1) Title

2) Menu bar

3) Command buttons

4) Main

5) Status bar

Title

Menu bar Command

Figure 4.1 Main window

Main

Status bar

- 8 -

Page 10

TOSHIBA 6F3A4508

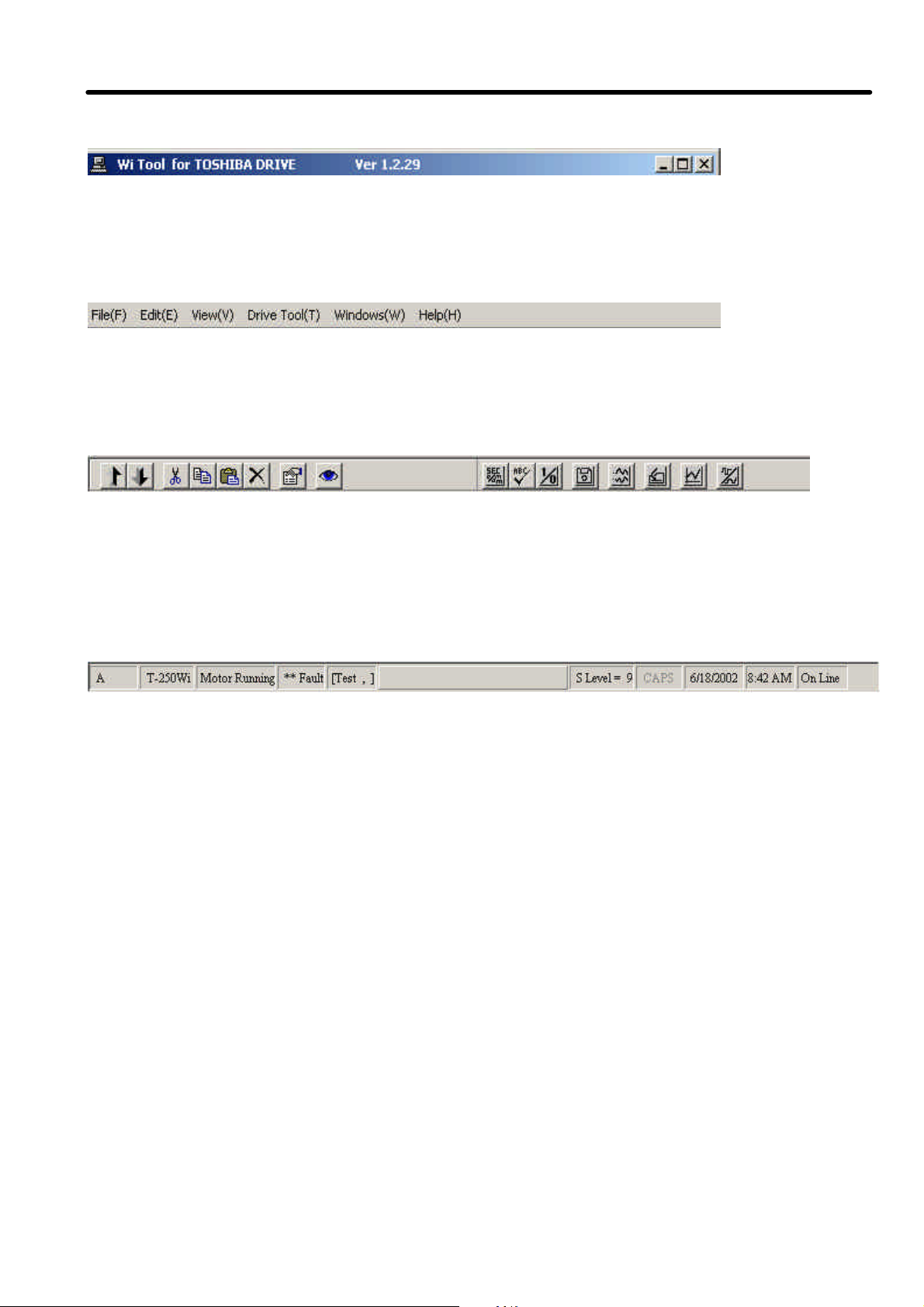

1) Title

Figure 4.2 Title

The Title shows the Wi Tool program version etc.

Click the x at the right end to quit Wi Tool.

2) Menu bar

Figure 4.2 Menu bar

The Menu bar is used to select the function to be performed with Wi Tool. The following

command buttons are also available for frequently used functions.

3) Command buttons

Figure 4.4 Command buttons

Command buttons are used to select the function to be performed with Wi Tool.

4) Main

Main shows the function selected from the Menu bar or with a Command button.

5) Status bar

Figure 4.5 Status bar

The Status bar shows the status of the connected driver unit.

The following items appear from left to right

(1) Panel name of the connected drive equipment

(2) Drive Type name of the connected drive equipment

(3) Whether the status motor of the connected drive equipment is running/stopped

Click to see the preparation view.

(4) Fault status fault/alarm

(5) Test mode, simulation mode

(6) Allowed access level

(7) PC keyboard status

(8) PC date

(9) PC time

(10) Online (communicating with drive unit)

Click when online to change to offline.

Click when offline to change to online.

- 9 -

Page 11

TOSHIBA 6F3A4508

[5] Wi Tool functions

Wi Tool has the following functions. The details of the function are described in the next chapter.

(1) Word

Reads and writes data (control value motor speed, control gain, etc.) inside the drive equipment.

(2) Char string

Reads and writes character string data inside the drive equipment.

(3) Bit

Reads and writes data (sequence data etc.) inside the drive equipment.

Displays and write in bit units.

(4) Set point control

Saves set points in the drive equipment to a file. Or loads the data saved in file to the drive

equipment and compares the set point in the drive equipment with the data saved in file. Also,

transfers the set points in the drive equipment RAM to EEPROM.

(5) Traceback

Reads, displays as graph, prints, and saves to file the control data (motor speed, motor current,

etc.) when there is a drive equipment fault.

(6) Snapshot

Controls the data record function of the drive equipment which specifies a trigger condition and

saves the specified signal.

(7) Trend display

Collects drive equipment data from PC and displays them on the PC.

(8) Step response

Provides step reference for test to drive equipment from PC, starts step response, and

displays/prints this data.

Also, saves data during step response to file and prints/displays data in file.

(9) Control password

Adds/deletes User Name, Access Level, and Password recorded in the drive equipment.

(10) Property

Displays and updates information in the drive equipment. The target data are, Panel Name,

Toshiba Order No., Toshiba Item No., and drive internal clock data.

(11) Preparation

Displays the drive equipment operating conditions. Displays the missing condition if there is any.

(12) End

Ends Wi Tool.

- 10 -

Page 12

TOSHIBA 6F3A4508

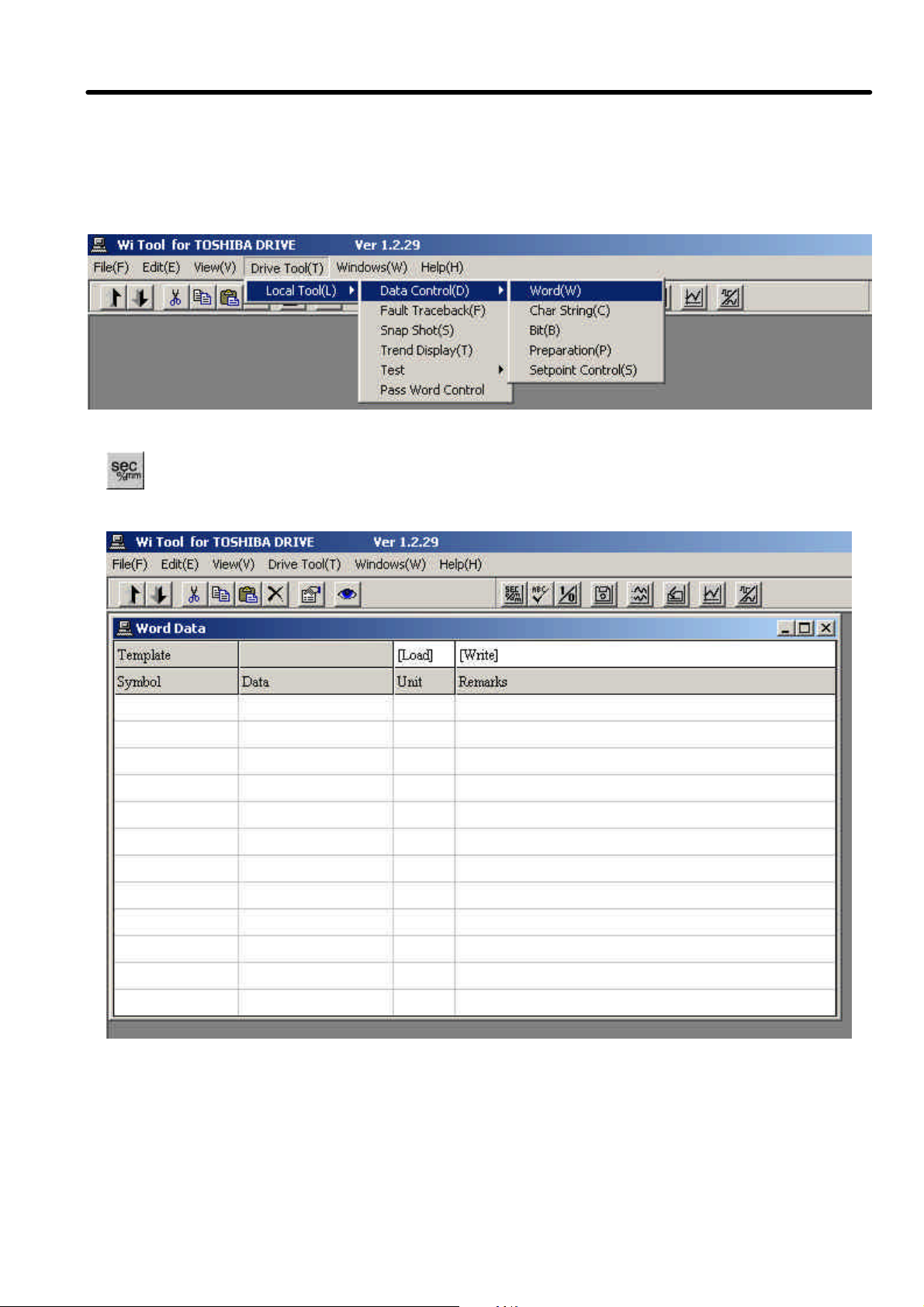

[6] Wi Tool functions detail description

[6-1] Word detail description

This function loads and writes data (control amount motor speed, control gain, etc.) inside the

drive equipment.

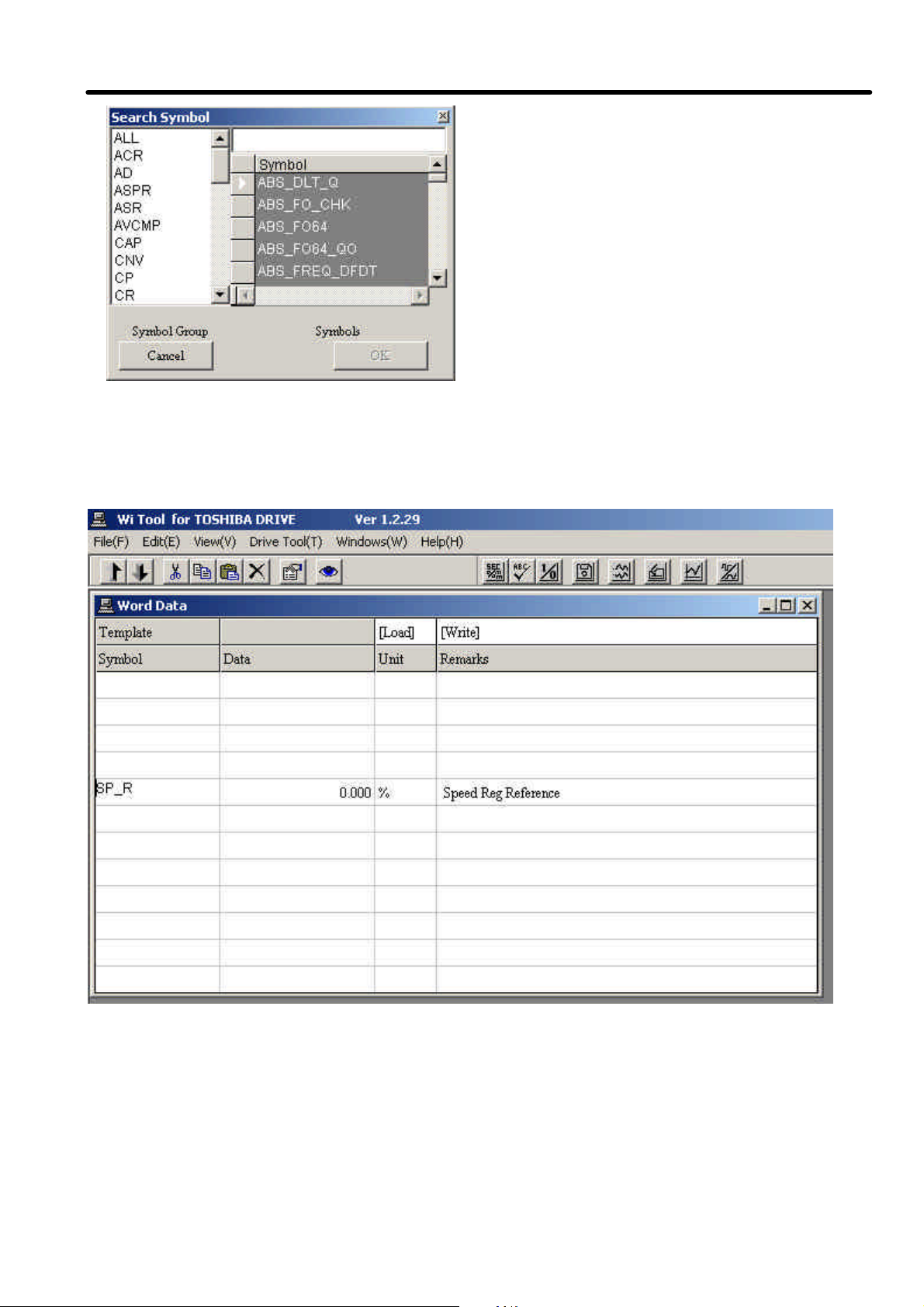

Select Drive Tool/Data Control/Word from the menu bar

or click the command button

to select. The following window appears.

Figure 6.1.1 Word window

To load the motor speed, first place the cursor on the symbol box on the left side and double

click. (You can click any of the 12 lines.)

Then the symbol input window appears.

- 11 -

Page 13

TOSHIBA 6F3A4508

Figure 6.1.2 Input Symbol

Next, enter "SP_R" which is the motor speed symbol. If this symbol is registered in the

computer, it appears in the box at bottom. Click this SP_R in the bottom box and then click the

OK button to select SP_R and display SP_R in the original window.

Figure 6.1.3 Word window

The data displayed in the box below the data is this data. In this case, 0.000% is shown. The

unit is show at right. (% in this case) The description of this SP_R appears at the right end (if

registered).

To rewrite the data, place the cursor on the data box, click and enter a value, and then press

Enter to write the data.

(SP_R returns immediately to the original value because it is written inside the drive equipment.)

- 12 -

Page 14

TOSHIBA 6F3A4508

To rewrite the data, refer to "Chapter 1 Notes on Rewriting Drive Equipment Data."

Saving and loading template

Frequently used symbols can be registered to avoid repeated key entry. This is referred to as

template.

For example, Speed Reference (SP_R), Motor Speed (SP_F), and Motor Current (I1_F) can be

registered by first entering these data and then entering a name by clicking [Write]. Then next

time the Word window appears, these symbols can be loaded simply by clicking [Load] and

entering the previously specified name.

- 13 -

Page 15

TOSHIBA 6F3A4508

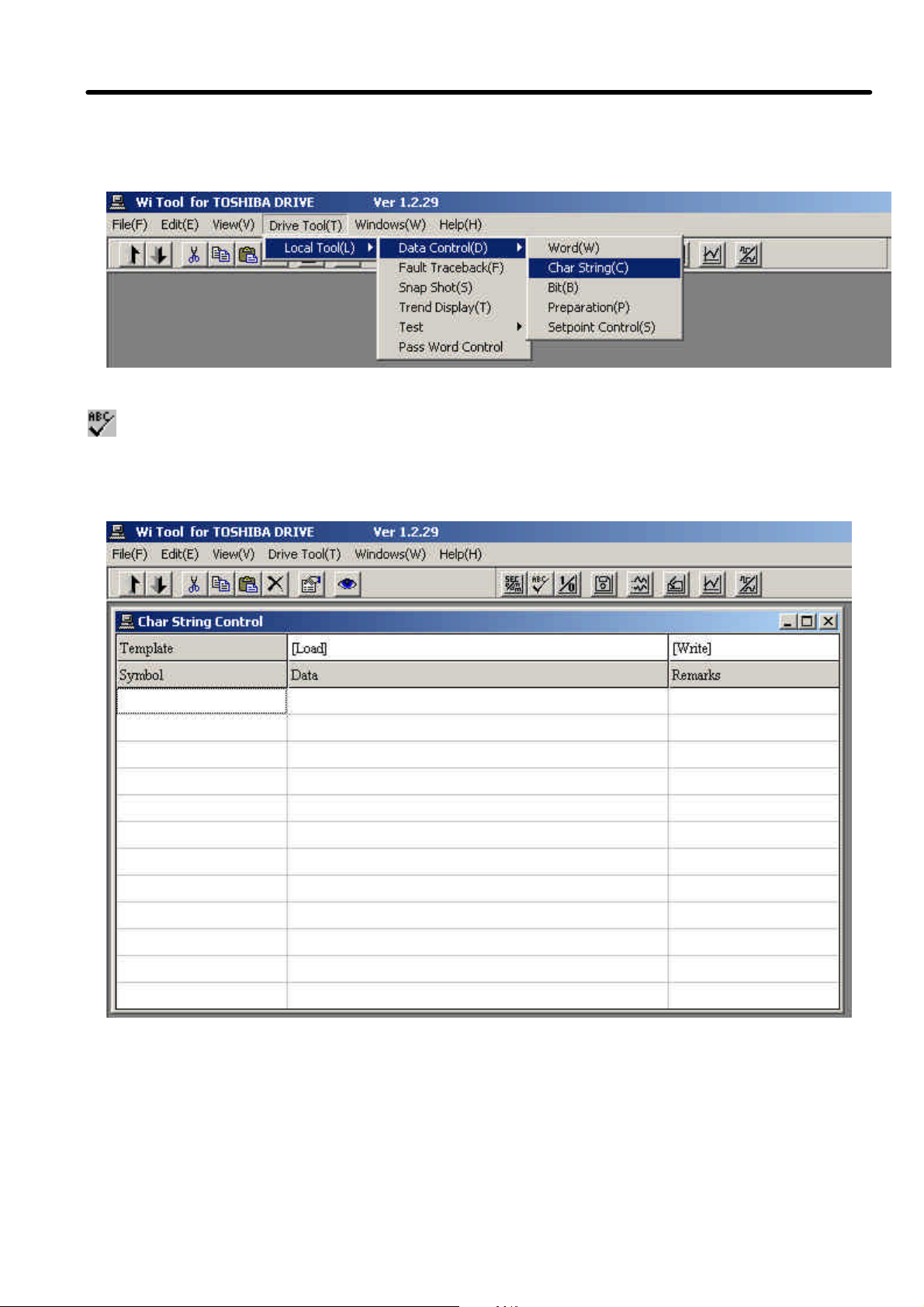

[6-2] String detail description

This function loads and writes character string data inside the drive equipment.

Select Drive Tool/Data Control/Char String from the menu bar

or click the command button

to select.

The following window appears.

Figure 6.2.1 Char String window

To load the drive equipment panel name, first place the cursor on the symbol box on the left

side and double click. (You can click any of the 12 lines.)

Then the symbol input box appears.

- 14 -

Page 16

TOSHIBA 6F3A4508

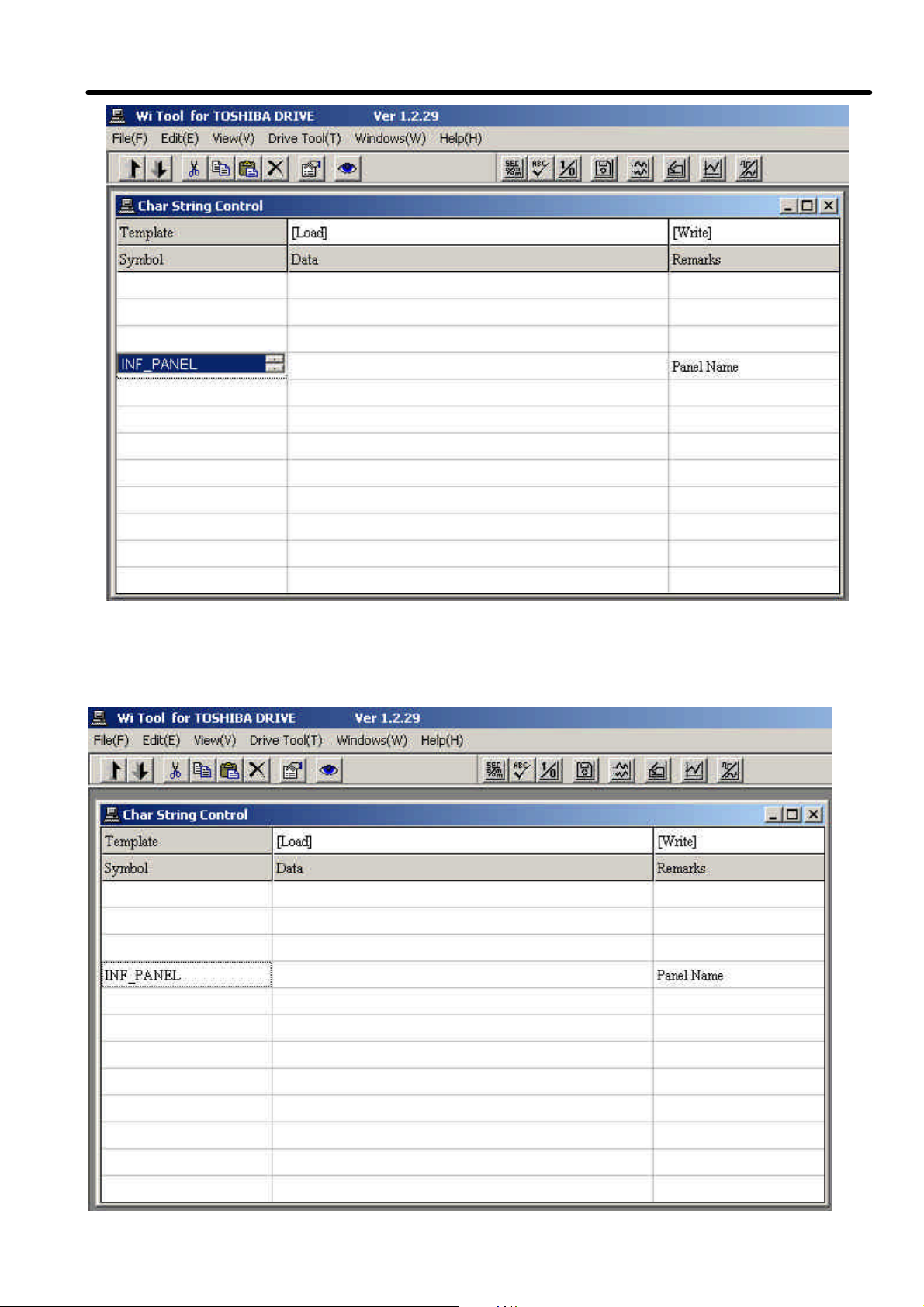

Figure 6.1.2 Input Symbol

Then click INF_PANEL which is the drive equipment panel name symbol. The panel name is

selected and appears in the window.

- 15 -

Page 17

TOSHIBA 6F3A4508

Figure 6.2.3 Char String window

The data displayed in the box under the data is the Char string data. In this example, it is empty.

The description of INF_PANEL appears on the right.

To rewrite the data, place the cursor on the data box, click and enter the char string, and then

press Enter to write the data.

- 16 -

Page 18

TOSHIBA 6F3A4508

[6-3] Bit detail description

This function loads and writes data (sequence data etc.) inside the drive equipment.

It displays and writes in bit units.

Select Drive Tool/Data Control/Bit from the menu bar

or click the command button

to select. The following window appears.

Figure 6.3.1 Bit window

To load the sequence data BLR1, first place the cursor on the ? symbol at the top left box and

click.

Then the symbol selection list appears.

- 17 -

Page 19

TOSHIBA 6F3A4508

Figure 6.3.2 Symbol selection window

Next click BLR1 in the symbol selection list to close the symbol selection list and display BLR1

in the box. Then press the select button to select BLR1 and display its data.

- 18 -

Page 20

TOSHIBA 6F3A4508

Figure 6.3.3 Bit window

The name of each bit appears on the left side and its comment appears on the right side. The

bit data of the symbol registered in the computer appears as a vertical column of 16 cells at the

center (If BLR1 is selected, four columns of bit data appear as shown in the window above. The

number of columns depends on the selected symbol). The top cell is bit no. F and the bottom

cell is bit no. 0. The number in the cell is the current data ("1", "0").

To change the rewrite data, click the cell of that bit. When clicked, the number in the cell

changes to "0" if it was "1" and to "1" if it was "0".

When a cell is clicked, the following window appears.

(The following figure shows the window when the cell for bit no. E for MSK data is clicked.) )

- 19 -

Page 21

TOSHIBA 6F3A4508

Figure 6.3.4 Bit Write window

When the data to write is determined, click [Write]. Then the data in the cell is written to the

drive equipment. If you do not click, the data is not written.

To rewrite the data, refer to "Chapter 1 Notes on Rewriting drive equipment Data."

- 20 -

Page 22

TOSHIBA 6F3A4508

[6-4] Set point control detail description

This function saves set points in the drive equipment to a file or loads the data saved in file to

the drive equipment and compares the set point in the drive equipment with the data saved in

file. It also, transfers the set points in the drive equipment RAM to EEPROM.

Select Drive Tool/Data Control/Setpoint Control from the menu bar

or click the command button

to select. The following window appears.

[Note]

Your access level must be 9 in order to write set points to the drive equipment.

The value in the set point file can be written to the drive equipment only when you login with

access level 9 when starting Wi Tool.

- 21 -

Page 23

TOSHIBA 6F3A4508

Figure 6.4.1 Set Point Control

The set points in the drive equipment are processed together.

The set points in the drive equipment are in internal RAM.

The internal RAM is saved in EEPROM because it is erased when the power is turned off.

(Normally EEPROM0 is used.)

When the drive equipment power is turned on, the set points in EEPROM are copied to internal

RAM.

When a value in internal RAM is changed (when set point is rewritten or the set point file is

written in the drive equipment), the data in internal RAM must be transferred to EEPROM.

- 22 -

Page 24

TOSHIBA 6F3A4508

The main functions are:

1) Display set points in drive equipment internal RAM

2) Display set points in drive equipment EEPROM

3) Display set point file

4) Compare drive equipment internal RAM with EEPROM

5) Compare drive equipment internal RAM with set point file

6) Compare drive equipment EEPROM with set point file

7) Transfer set points in drive equipment RAM to EEPROM

8) Write data in drive equipment internal RAM to set point file

9) Write data in drive equipment internal EEPROM to set point file

10) Load set point file to drive equipment internal RAM

11) Compare set point file with set point file

(7)

(2)

(9)

(6)

(8)

(4)

(1)

(5)

(10)

(3)

(11)

Figure 6.4.2 Set Point Control

- 23 -

Page 25

TOSHIBA 6F3A4508

These functions are described below.

1) Display set points in drive equipment internal RAM

Click the Data Display button (1).

Set point data is read from the drive equipment and displayed as follows:

Figure 6.4.3 RAM display

In Wi Tool, some representative set points are maintained as template and the actual set points

of the drive equipment are referenced as the difference from the number of this template and

the template.

In the above example, the template number is 0 and the values different from this template

appear below.

You can print this data by clicking Print.

2) Display set points in drive equipment EEPROM

Click the Data Display button (2).

Set point data is read from the drive equipment and displayed.

3) Display set point file

Click the Select File button (3).

Select a set point file and then click Show File Data below button (3).

The content of the file is displayed.

- 24 -

Page 26

TOSHIBA 6F3A4508

4) Compare drive equipment internal RAM with EEPROM

Click arrow (4).

Figure 6.4.4

The Start Compare with EEPROM button appears at bottom left of the window. Click this to

start compare and display the result.

- 25 -

Page 27

TOSHIBA 6F3A4508

Figure 6.4.5 Set Point Compare

5) Compare drive equipment internal RAM with set point file

First, select a set point file. Click the Select File (3) button and select a set point file.

Then click arrow (5) to display the Compare File button at bottom left of the screen and click

this button to start compare.

The result is displayed when compare is finished.

6) Compare drive equipment EEPROM with set point file

First, select a set point file. Click the Select File (3) button and select a set point file.

Then click arrow (6) to display the Start Compare with EEPROM button at bottom left of the

screen and click this button to start compare.

The result is displayed when compare is finished.

7) Transfer set points in drive equipment RAM to EEPROM

Click arrow (7) to display the following window.

- 26 -

Page 28

TOSHIBA 6F3A4508

Figure 6.4.6 Write EEPROM

A new EEPROM comment appears. Enter the comment (up to 32 characters) to write in

EEPROM and then click the Write EEPROM button that appears at bottom left of the window to

start transfer to EEPROM.

8) Write data in drive equipment internal RAM to set point file

First, select a set point file. Click the Select File (3) button and select a set point file.

Then click arrow (8) to display the Save to File button at bottom left of the screen and click this

button to start write to file.

9) Write data in drive equipment internal EEPROM to set point file

First, select a set point file. Click the Select File (3) button and select a set point file.

Then click arrow (9) to display the Save EEPROM button at bottom left of the screen and click

this button to start write to file.

- 27 -

Page 29

TOSHIBA 6F3A4508

10) Load set point file to drive equipment internal RAM

First, select a set point file. Click the Select File (3) button and select a set point file.

Then click arrow (10) to display the Load from File button at bottom left of the screen and click

this button to start load to file.

11) Compare set point file with set point file

First, select the first set point file. Click the Select File (3) button and select a set point file.

Then select the second set point file. Click the Select File button below arrow (11) and select a set point file.

Then click arrow (11) to display the Compare File button at bottom left of the screen and click

this button to start compare.

- 28 -

Page 30

TOSHIBA 6F3A4508

[6-5] Traceback detail description

Reads, displays as graph, prints, and saves to file the control data (motor speed, motor current, etc.) when

there is a drive equipment fault.

Select Drive Tool/Traceback from the menu bar

or click the command button

to select. The following window appears.

Figure 6.1.5 Traceback selection

First, select where the fault data is read from.

Click From Drive or From File to select.

To read from file, click Select File and select a file from the list.

The following window appears if From Drive is clicked.

- 29 -

Page 31

TOSHIBA 6F3A4508

Figure 6.5.2 Fault selection

This list contains a list of fault data in the drive equipment. (Up to 16 faults) Click the down

arrow to display the data list and click an item to select.

Then click the Display button.

The data is read and displayed as graph.

- 30 -

Page 32

TOSHIBA 6F3A4508

Figure 6.5.3 Traceback window

When data read completes, a graph similar to the one above appears.

Control data is obtained with different sampling data depending on the drive equipment and a

graph is displayed for each sampling data.

Click the Option tab on the graph to display the following window.

- 31 -

Page 33

TOSHIBA 6F3A4508

Figure 6.5.4 Traceback print

Then click the Write button to save this data to file with the specified file name. You can also

click the Print button to print this data.

In addition to the graph, the detected fault signals (first faults) are also displayed.

- 32 -

Page 34

TOSHIBA 6F3A4508

Figure 6.5.5 First faults

The First Faults window shows the sequence data for up to 9 faults in the order of detection.

The sequence signal abbreviation appears on the left and a simple description appears on the

right.

A more detailed description appears when you click the abbreviation or the description.

- 33 -

Page 35

TOSHIBA 6F3A4508

Next, click the Setting tab on the graph to change the graph settings.

Figure 6.5.6 Select traceback signal

1) The number at top center is the number of graphs per window.

You can select 1, 2, 4, 8, or 12 signals per window.

2) The Signal name displayed on the graph appears on the left side.

Click a signal name to change it.

- 34 -

Page 36

TOSHIBA 6F3A4508

Figure 6.5.7 Select Signal

The names of signals that can be displayed as graph appears as a list. Click one of the signal

names in the list.

Then double click to confirm the signal name.

The number on the right of the signal name is the graph no. Specify the display order from top

of the window for the selected signal. If more than one signal are set to display in the graph with

the same number, multiple signals are displayed.

3) Set the scale of the graph on the left side.

Set each graph to Maximum or Minimum.

To set to the same scale as another graph, specify its graph number in the SameAs field.

- 35 -

Page 37

TOSHIBA 6F3A4508

[6-6] Snapshot detail description

This function controls the data record function of the drive equipment which specifies a trigger

condition and saves the specified signal.

The difference with traceback described above is that whereas the trigger condition of traceback is limited to

faults, the user can set the trigger condition freely with snapshot. Also there is a difference in the number of

saved signals (up to 60 signals for traceback and 8 signals for snapshot) and the number of samples that can

be saved (up to 512 samples for traceback and up to 1024 signals for snapshot).

Select Drive Tool/Local Tool/Snap Shot from the menu bar

or click the command button

to select. The following window appears.

Figure 6.6.1 Snapshot

Set the snapshot condition in this window.

1) Number of Signals: Specify the number of signals to save.

For snapshot, you can select from

2 signals 1024 samples

- 36 -

Page 38

TOSHIBA 6F3A4508

4 signals 512 samples

8 signals 256 samples

2) Signal Name: Specify the saved signal name.

Click a signal name to display a list of selectable signal names.

Then select a name from the list and double click to confirm.

3) Select Hi Speed/STD Speed sampling time

Click STD Speed to select standard sampling speed

Click Hi Speed to select High sampling speed

Normally, select standard sampling (1mSec).

With high speed sampling, there is a restriction on the selectable signal names.

Whether standard sampling or high speed sampling is currently selected is displayed below.

4) Trigger condition

In the window on the previous page, trigger conditions where:

(1) Trigger signal 0x0000

(2) Trigger mode Boolean

(3) Trigger type Level Trigger

(4) Trigger bit "0"

(5) Pre-trigger "0"

In other words data save start when there is a level trigger with the 0th bit of signal 0x0000 set

to 1.

The following trigger modes are available:

Trigger when Boolean bit signal is 1 (specify the bit with the trigger bit)

Trigger when Inverted Boolean bit signal is 0 (specify the bit with the trigger bit)

Trigger when "equal" signal is at trigger level

Trigger when "Not equal" signal is different from trigger level

Trigger when "Greater Than" signal is greater than trigger level

Trigger when "Less Than" signal is less than trigger level

The following trigger types are available:

Trigger when edge trigger signal changes

Trigger at level trigger signal level

Setting the time

Set to full scale (time from end to end of the window).

Also set the re-enable time. Re-enable time is the time until trigger becomes ready after there is

a trigger. (Normally, this is not used. To use, check Re-Enable.)

Status display

Displays the current status.

(1) Data Empty: Status when there is no data.

(2) Data Triggered: Triggered status.

(3) Trigger Ready: Waiting for a trigger.

Normally, the trigger condition and signal name are set during Data Empty status and the Set

Trigger button is clicked to enter the Trigger Ready status. The button becomes Reset Trigger.

When there is a trigger, the status becomes Data Triggered and the Display button is enabled.

At this point, click the Display button to display the graph.

- 37 -

Page 39

TOSHIBA 6F3A4508

[6-7] Trend view detail description

This function collects drive equipment data from the PC and displays them on the PC.

Select Drive Tool/Local Tool/Trend Display from the menu bar

or click the command button

to select. The following window appears.

Figure 6.7.1 Trend setup window

- 38 -

Page 40

TOSHIBA 6F3A4508

This window is similar to the traceback graph. However, in the case of Trend Display, the user

must specify the signal to display.

Also, the user must set the graph scale. In addition, the sampling time must be set in Trend

Display. (Minimum is 50mSec.)

Set these items and click the Graph tab to display the following window.

Figure 6.7.2 Trend graph

There is a Start button at bottom left of the graph.

Click this button to start the Trend Display.

Click the same button to stop the graph display (button is changed to Stop ).

When clicking the Setting tab once more, to change the signal to display for example, stop the

graph display before clicking.

- 39 -

Page 41

TOSHIBA 6F3A4508

[6-8] Step response detail description

This function provides step reference for test to drive equipment from PC, starts step response,

and displays/prints this data. It also, saves data during step response to file and prints/displays

data in the file.

Select Drive Tool/Local Tool/Test/Step Response from the menu bar

or click the command button

to select. The following window appears.

Figure 6.8.1 Step response

First, determine which test mode to select.

Click the Mode Select down arrow and select a mode.

- 40 -

Page 42

TOSHIBA 6F3A4508

Figure 6.8.2 Select Test Mode

If the drive equipment is already in test mode as in the window on the previous page, the Select

button is disabled. To cancel test mode, click the End Test button.

After selecting the test mode, click the Start Step button to automatically add step reference to the drive

equipment and display the resulting graph.

The time width and size of the applied step are set at the right side of the window.

- 41 -

Page 43

TOSHIBA 6F3A4508

[6-9] Password control detail description

This function adds/deletes User Name, Access Level, and Password recorded in the drive equipment. This

window opens only when the access level is 9.

Select Drive Tool/Local Tool/PassWord Control from the menu bar

to select. The following window appears.

Figure 6.9.1 Password control

First, enter the operator name to add or delete.

When deleting, select from a list of operator names stored in the drive equipment. When adding,

enter an operator name that is different from any operator name in the list.

- 42 -

Page 44

TOSHIBA 6F3A4508

Then enter the password and security level if entering an operator name. These are not

necessary when deleting.

Click the Add or Delete button to display the following window.

Figure 6.9.2 Password control verification

Click OK to execute.

Note that if you delete all operators with security level 9, you will not be able to add passwords.

- 43 -

Page 45

TOSHIBA 6F3A4508

[6-10] Property detail description

This function displays and updates information in the drive equipment. The target data are,

Panel Name, Toshiba Order No., Toshiba Item No., and drive internal clock data.

Select File/Property from the menu bar

or click the command button

to select. The following window appears.

Figure 6.10.1 Drive property

This window displays the Panel Name, Drive Type, Data Base Version, Toshiba Order Number, Item Number,

and Tag of the drive equipment. The Panel Name, Toshiba Order Number, Item Number, and Tag are

rewritable. To rewrite, click the item to change, enter the new item, and then click the Write button.

- 44 -

Page 46

TOSHIBA 6F3A4508

1) Comments

Click the Comments tab to display comments stored in the drive equipment. Comments can

also be rewritten.

Figure 6.10.2 Comments

- 45 -

Page 47

TOSHIBA 6F3A4508

2) Setting time

Click the Date_Time tab to display the drive equipment time and the current time (of the PC).

Click Set Current Time to synchronize the drive equipment time with the PC time.

Figure 6.10.3 Time

3) Rating

Click the Rating tab to display the drive equipment and motor rating. This window is read only.

Figure 6.10.4 Rating

- 46 -

Page 48

TOSHIBA 6F3A4508

4) Trouble records

Click the Trouble Records tab to display the trouble records of the drive equipment. This

window is read only.

Figure 6.10.5 Trouble records

5) Event counter

Click the Event Counter tab to display the drive equipment event counts. Event counts are

items, such as contact open/close count, that depend on the drive equipment type.

Figure 6.10.6 Event counter

- 47 -

Page 49

TOSHIBA 6F3A4508

[6-11] Preparation detail description

This function displays the drive equipment operating conditions.

It displays the missing condition if there is any.

Select Drive Tool/Local Tool/Data Control/ Preparation from the menu bar

or click Fault/Alarm drive status display on the status bar

to select. The following window appears.

Figure 6.11.1 Preparation

Click Fault Reset in this window to reset faults.

- 48 -

Page 50

TOSHIBA 6F3A4508

[6-12] Ending detail description

Click x at top right of the main window to end Wi Tool.

The following window appears. If set points are changed, but not transferred to EEPROM, click

Cancel and transfer the set points to EEPROM.

Figure 6.12.1 Ending

- 49 -

Page 51

TOSHIBA 6F3A4508

[7] Wi Tool 1:N connection, 1:N RIO connection

[1:N connection]

The following window appears when Wi Tool is started after connecting to the drive equipment

by 1:N connection via Ethernet.

Figure 7.1 1:N connection

The network connection appears on the left side of the window.

Click the drive equipment name in this network connection to connect to that drive equipment.

Figure 7.2 Connect Drive

After connecting the drive equipment, functions similar to 1:1 connection become available.

- 50 -

Page 52

TOSHIBA 6F3A4508

[1:N RIO connection]

The following window appears when Wi Tool is started after connecting to the drive equipment

by 1:N connection through RIO (remote I/O).

Figure 7.3 RIO connection

The network connection appears on the left side of the window.

Click the drive equipment name in the same manner as Ethernet connection to connect to that

drive unit.

- 51 -

Page 53

Loading...

Loading...