Toshiba 51h83, 57h83, 65h83svm schematic

FILE NO. 020-200307

DOCUMENT CREATED IN JAPAN, Apr., 2003

SERVICE MANUAL

COLOR TELEVISION

N3PSP Chassis

51H83, 57H83, 65H83

(TAC0353)(TAC0351)(TAC0352)

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS .............................................................................................................................................. 3

CRT ASSEMBLY REPLACEMENT AND MOUNTING ................................................................................................... 4

PICTURE TUBE COMPONENTS ADJUSTMENT.......................................................................................................... 6

REPLACEMENT OF THE CRT....................................................................................................................................... 9

SERVICE MODE .......................................................................................................................................................... 10

ELECTRICAL ADJUSTMENT ...................................................................................................................................... 12

GENERAL ADJUSTMENTS

CONVERGENCE ADJUSTMENT ................................................................................................................................ 13

SCREEN AND MIRROR ALIGNMENTS ...................................................................................................................... 16

CIRCUIT CHECKS ....................................................................................................................................................... 17

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA .................................................................................................................................... 18

LOCATION OF CONTROLS ......................................................................................................................................... 19

ADDING CHANNELS TO THE TV'S MEMORY ............................................................................................................ 21

MECHANICAL DISASSEMBLY .................................................................................................................................... 23

TABLE OF CONTENTS

SPECIFIC INFORMATIONS

CHASSIS REPLACEMENT PARTS LIST ..................................................................................................................... 27

PC BOARDS BOTTOM VIEW ...................................................................................................................................... 47

TERMINAL VIEW OF TRANSISTORS ......................................................................................................................... 60

CIRCUIT BLOCK DIAGRAM ........................................................................................................................................ 63

SPECIFICATIONS .................................................................................................................................................... END

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous

X-RAY RADIATION. To avoid such hazards, the high voltage must not be above the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a 120V AC

power source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B).

(See SETTING & ADJUSTING DATA on page 18)

Each time a receiver requires servicing, the high voltage

should be checked following the HIGH VOLTAGE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by anyone unfamiliar with the necessary precautions on this receiver. The following are the necessary precautions to be observed before

servicing this chassis.

1. An isolation Transformer should be connected in the power

line between the receiver and the AC line before any service is performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube. The picture tube is highly evacuated and if broken, glass fragments

will be violently expelled. Use shatter proof goggles and

keep picture tube away from the unprotected body while

handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place,

such as; non-metallic control knobs, insulating covers,

shields, isolation resistor-capacitor network etc.

4. Before returning the set to the customer, always perform

an AC leakage current check on the exposed metallic parts

of the cabinet, such as antennas, terminals, screwheads,

metal overlays, control shafts etc. to be sure the set is safe

to operate without danger of electrical shock. Plug the AC

line cord directly into a 120V AC outlet (do not use a line

isolation transformer during this check). Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the

following manner:

PRODUCT SAFETY NOTICE

2. This receiver is equipped with a Fail Safe (FS) circuit which

prevents the receiver from producing an excessively high

voltage even if the B+ voltage increases abnormally. Each

time the receiver is serviced, the FS circuit must be checked

to determine that the circuit is properly functioning, following the FS CIRCUIT CHECK procedure in this manual.

3. The only source of X-RAY RADIATION in this TV receiver

is the picture tube. For continued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

4. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NOTICE below.

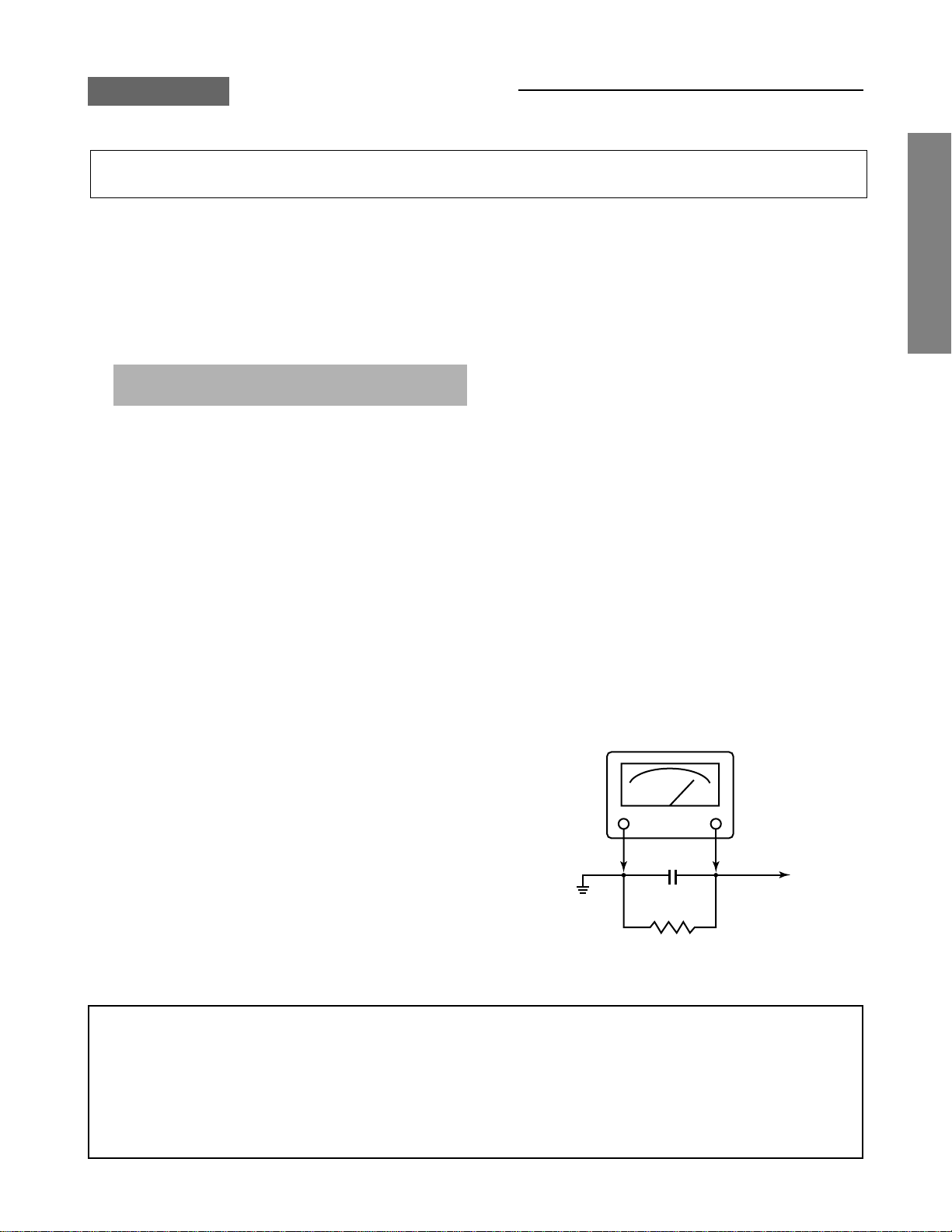

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15

µF, AC type capacitor, between a known good earth ground

(water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the AC voltage across the combination of 1500 ohm resistor and 0.15 µF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Voltage

measured must not exceed 0.675 volts rms. This corresponds to 0.45 milliamp. AC. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected

immediately.

AC VOLTMETER

0.15µF

Place this probe on

Good earth ground

such as a water

pipe, conduit, etc.

1500 ohm

10 watt

each exposed

metallic part.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained by using

replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this manual and its supplements; electrical components having such features are identified by the

international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray radiation or other hazards.

– 3 –

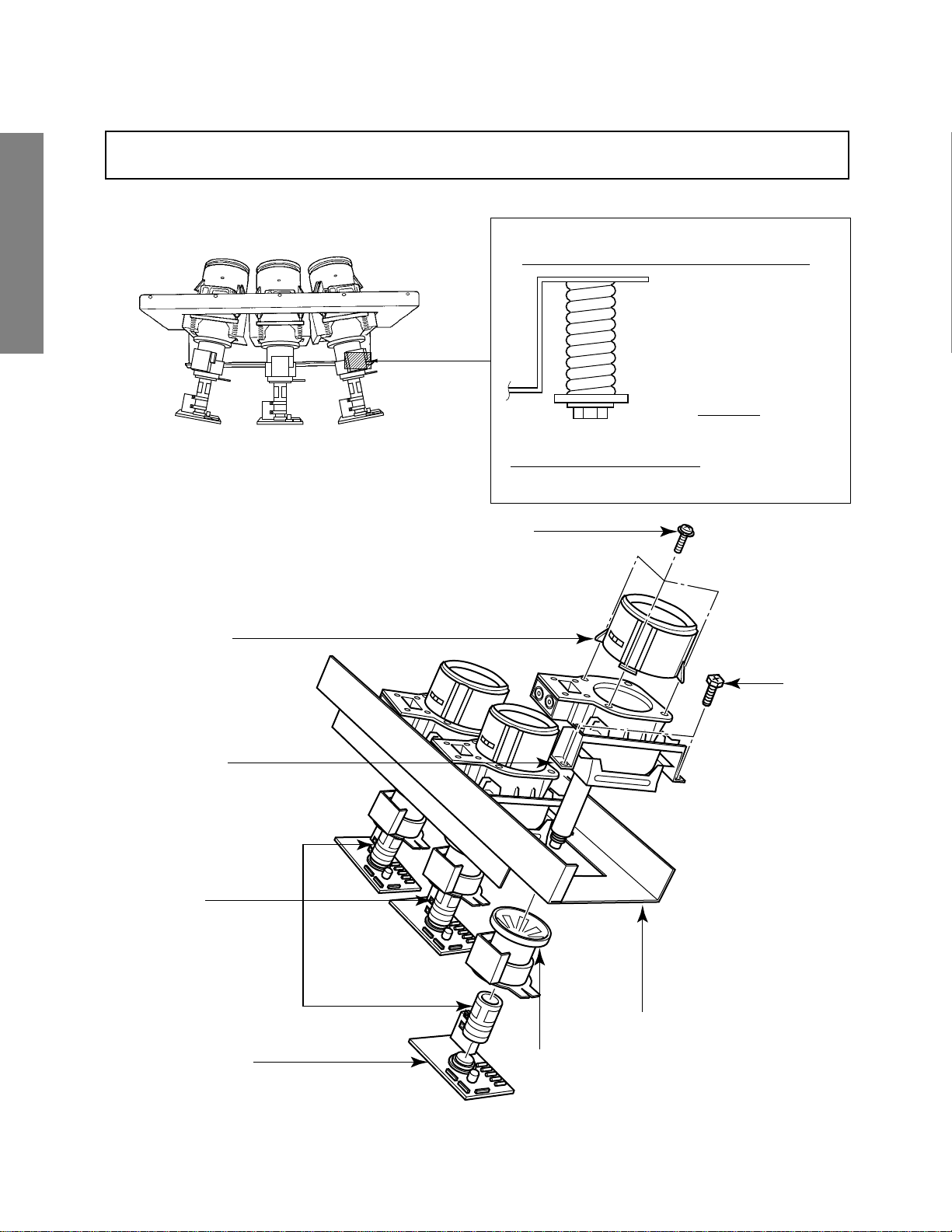

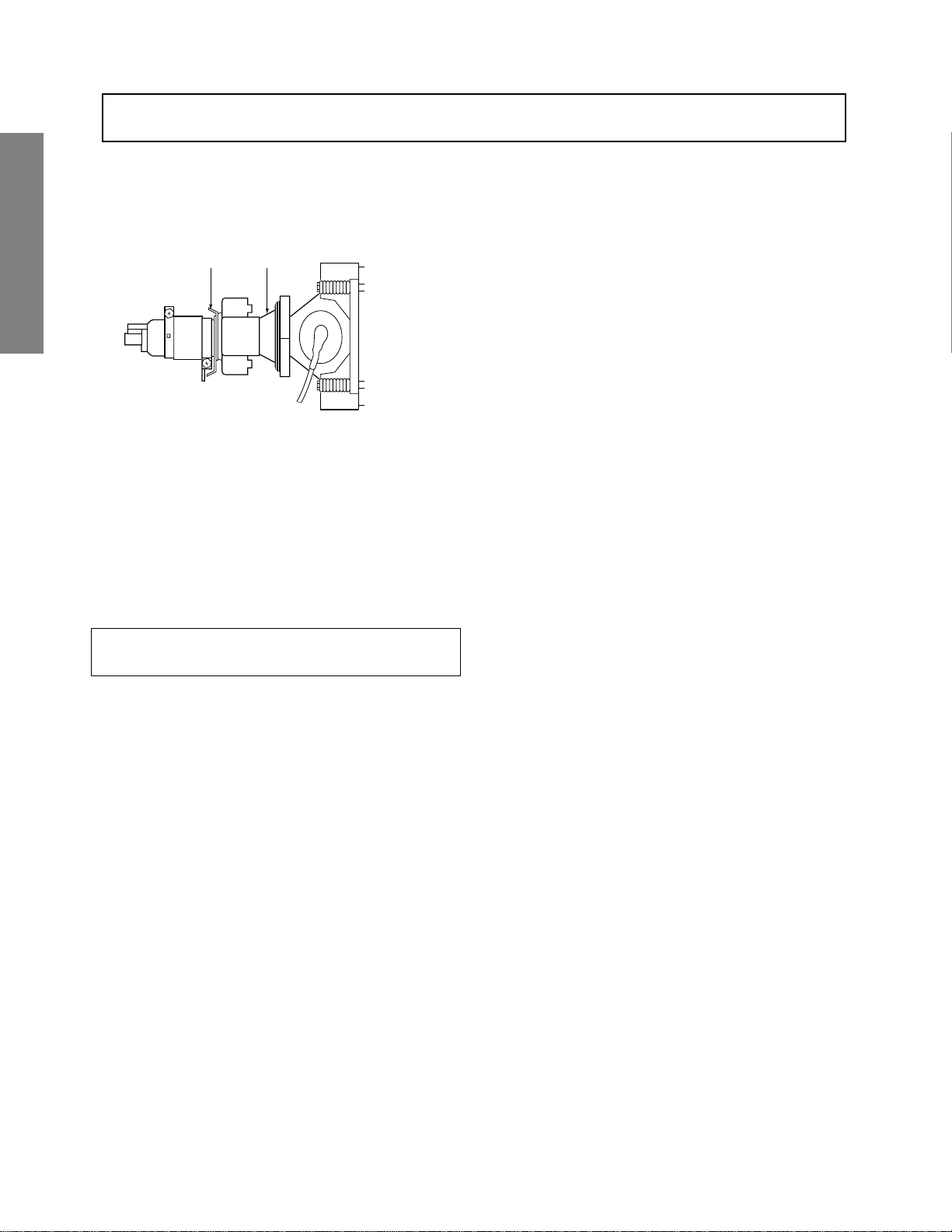

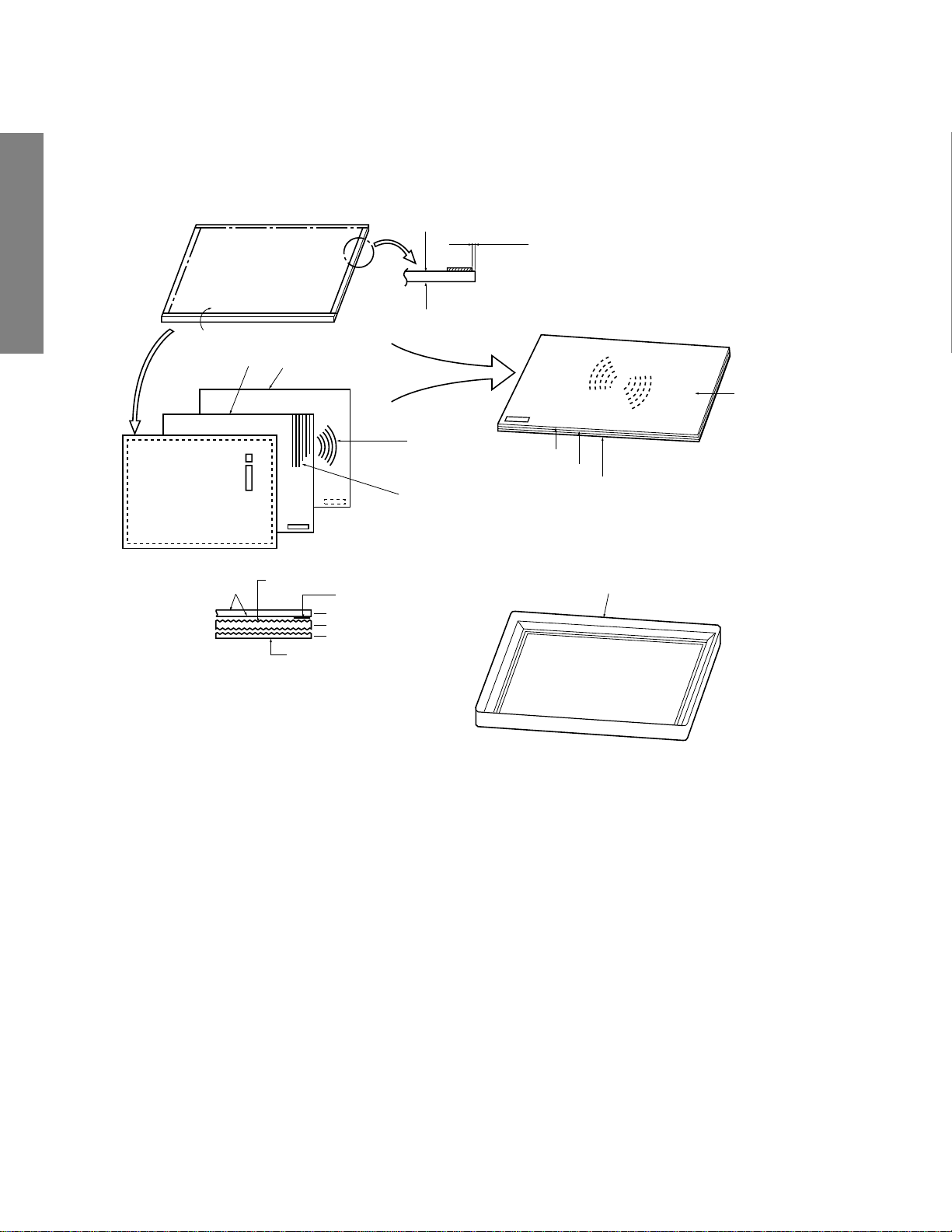

CRT ASSEMBLY REPLACEMENT AND MOUNTING

CAUTION : DO NOT LOOSEN THE HEX HEAD BOLTS WITH SPRINGS (12 PCS), BECAUSE THOSE ARE FOR

SEALING OF CRT COOLANT.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Lens Assembly

R

GB

Attention Serviceman

The Hex Head

Bolts with

Springs. (see

sketch) used on

CRT assembly,

are NOT

Adjustment Screws

DO NOT LOOSEN-FLUID

LEAKAGE WILL OCCUR.

4 Screws

4 Screws

CRT Assembly

S.V.M. Coil

CRT DRIVE Board

CRT Mounting

Deflection Yoke and Conver Yoke

Lens and Neck Components View

– 4 –

TO REMOVE CRT (Same procedure for R, G, B)

1. Remove CRT DRIVE Board, S. V. M. COIL and

DEF. YOKE from CRT.

2. Remove Lens Assembly.

3. Detach CRT Anode Cap from CRT.

4. Remove CRT Assembly from CRT Mounting.

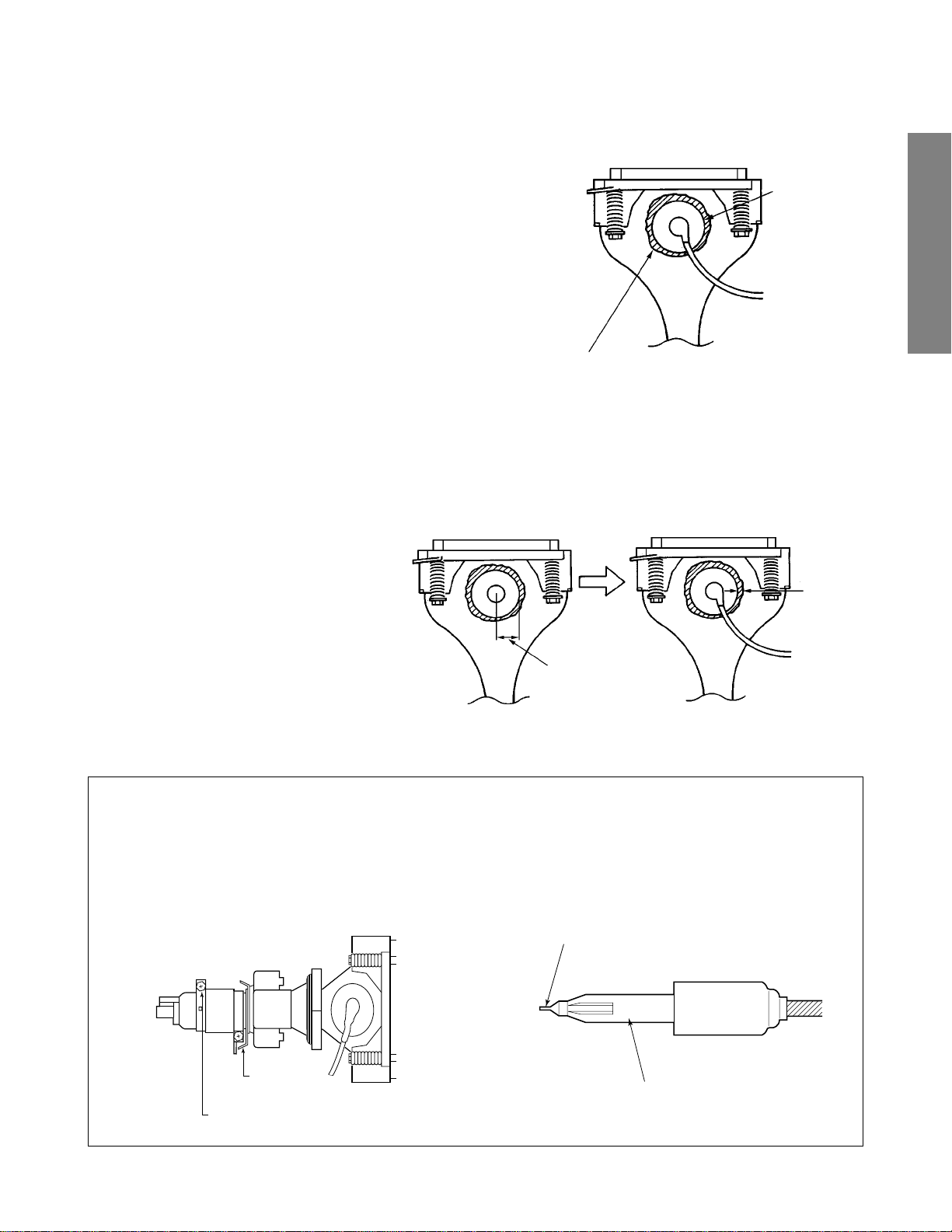

CRT REPLACEMENT (Same procedure for R, G, B)

Reverse the removal procedures except the followings.

1. Anode Cable should be replaced with new one.

See “SERVICING PRECAUTIONS” shown below.

2. Install silicon (T461B) to the CRT, replace the Anode

cable and put enough silicon again on around the Anode Cap as illustrated.

CAUTION: Align the Anode cable as illustrated on page

4.

ADJUSTING PROCEDURE IN REPLACING CRT

1. R.G.B. FOCUS ADJUSTMENT (page 7.)

2. PICTURE TILT ADJUSTMENT (page 7.)

3. USER CONVERGENCE CENTER CHECK

(See owner's manual.)

4. CENTERING ADJUSTMENT (page 7.)

5. CONVERGENCE ADJUSTMENT (page 13.)

6. WHITE BALANCE ADJUSTMENT (page 12.)

Adjustments are complete.

Anode Cap

GENERAL ADJUSTMENTS

Silicon

(On shaded area)

TSE3843W #23960136

SERVICING PRECAUTIONS

■ Do not use a magnetized screw driver for screws

of Deflection Yoke and Velocity Modulation Coil to

avoid magnetization of electron gun.

Magnetization of electron gun will degrade basic

function and result in unbalance of right and left

shift of user static convergence, and result in no

variable quantity.

2 ~ 5 mm

SPECIFIC INFORMATIONS

15 ~ 25 mm

■ When replacing the anode cap assembly (CRT) or

anode lead assembly (F.B.T.), remove the anode

lead holder from old one and attach the holder

again to new anode lead.

■ Check the point of anode lead in a straight

line, if it is winding, please revise it.

Screw for

D.Y

Screw for SVM coil

Anode lead holder

– 5 –

WARNING : BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRE-

CAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

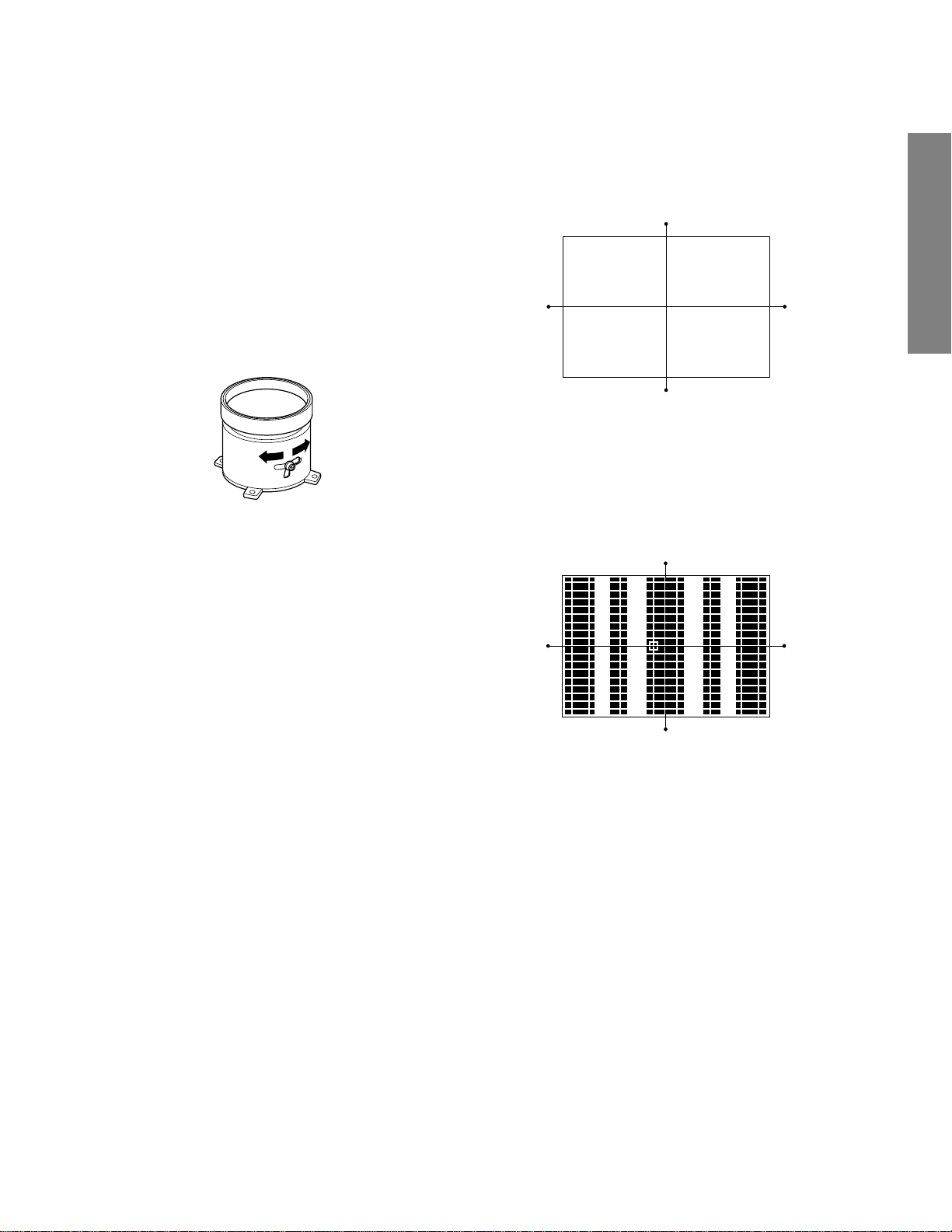

DESCRIPTION OF NECK COMPONENTS

GENERAL ADJUSTMENTS

Deflection yoke and convergence yoke

The position on the neck is required most front

(CRT funnel side) and the screw is fastened after

rotating yoke adjusting picture tilt.

Centering magnet

After adjusting picture tilt, picture position is finally

fixed by this magnet.

In order to get maximum margin of user conver-

SPECIFIC INFORMATIONS

gence control for center of screen, this magnet

have to be used for center convergence adjustment.

PICTURE TUBE COMPONENTS ADJUSTMENT

PREPARATION

Operate the receiver for at least 5 minutes.

– 6 –

R, G, B FOCUS ADJUSTMENT

1. Before adjusting the R, G, B FOCUS, remove the 4 screws

of Lens Assembly which is fixed on the CRT Assembly.

(See page 4.)

Then turn around the Lens Assembly by 180˚ to adjust

the fastening screw (Fig. a) and fasten the 4 screws to

secure Lens Assembly.

2. Select the adjustment mode. (See page 10.)

3. Press “7” button to display the built-in cross-hatch.

4. Press “0” and “RTN” buttons to make the picture a single

Red color.

100 button ................ to erase Red color

0 button .................... to erase Green color

RTN button .............. to erase Blue color.

5. Loosen the fasten screw and adjust Red lens focus to best

focusing point of picture center. Then fasten the screw.

(See Fig. a.)

Fig. a

6. Adjust FOCUS VR “R” of FOCUS PACK to find best focusing point of picture center.

7. Repeat steps 3 to 5 for Green and Blue colors.

TILT ADJUSTMENT

Rotate R, G, B deflection yoke so that picture becomes horizon, then fasten screw.

CENTERING ADJUSTMENT

1. Stretch a thread between two center of screen edge (top

and bottom, left and right).

GENERAL ADJUSTMENTS

2. Receive NTSC.

Then select SERVICE MODE. (See Page 10.)

3. Select CONVERGENCE ADJUSTING mode, and press

"7" button to display the internal net pattern.

Move Cursol and recognize horizontal line indicated Y:4.

This line is vertical center. Push "9" button to display the

vertical stripes, and recognaize horizontal center.

SPECIFIC INFORMATIONS

4. Perform VCEN adjustment. (See page 12.)

5. Adjust G centering magnet so that the cross-bar pattern

center comes to screen center.

6. Perform HEIGHT adjustment . (See page 13.)

7. Perform VERT. LINEARITY adjustment.

8. Perform WIDTH adjustment. (See page 12.)

9. Check whole quality of green line.

10

. Adjust R, B centering magnet so that the cross-bar pat-

tern center comes to screen center.

– 7 –

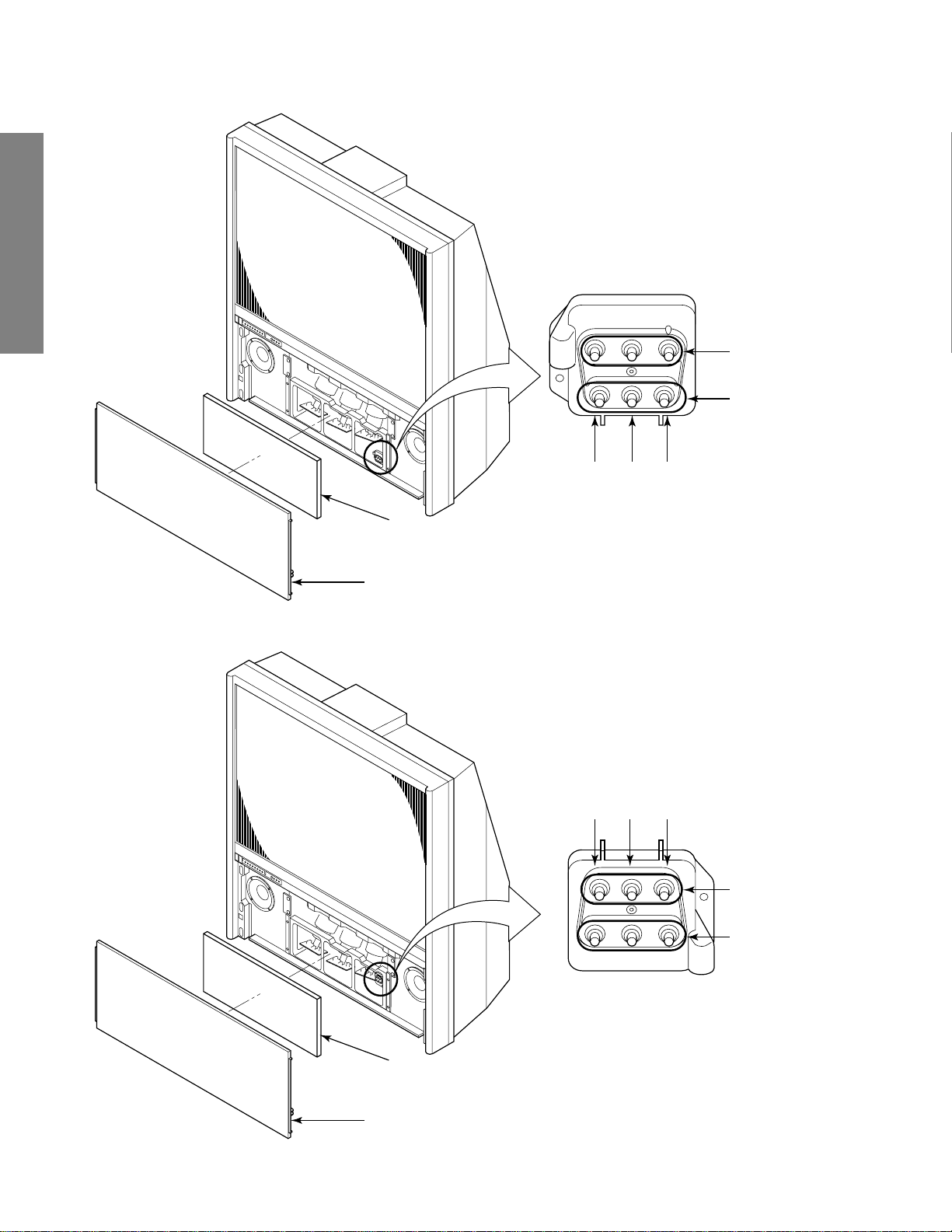

LOCATION OF SCREEN AND FOCUS VR’S (57", 65")

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

LOCATION OF SCREEN AND FOCUS VR’S (46", 51")

SCREEN VR

FOCUS VR

RGB

Cover

Speaker grille

Cover

Speaker grille

RGB

FOCUS VR

SCREEN VR

– 8 –

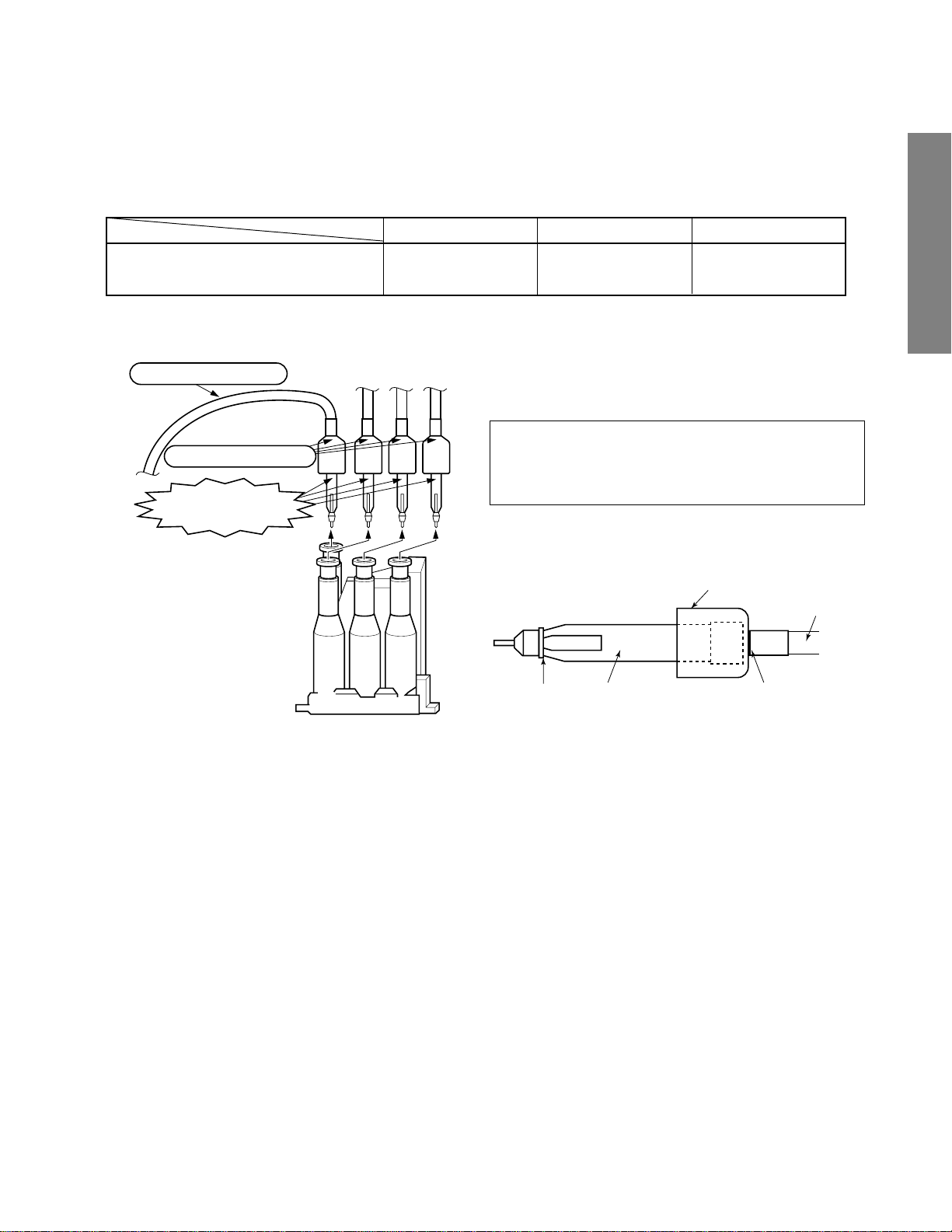

REPLACEMENT OF THE CRT

Service parts are provided for each R, G and B.

The contents of the parts are as follows.

HITACHI

CRT 23008174 23008175 23008176

RG B

REPLACEMENT OF HIGH VOLTAGE CABLE

ANODE LEAD

RUBBER BOOT

LEAD HOLDER

Z450 TPA5007

Fig. a

1. When replacing Anode Lead or Anode Cap with new one,

remove Lead Holder from old lead as shown in figure

below, and put it on new lead. Do not throw away Lead

Holder.

NOTE : THE LEAD HOLDER IS ATTACHED TO TPA5007

(Z450), BUT IS NOT ATTACHED TO ANODE

LEAD AND ANODE CAP. RUBBER BOOT IS ATTACHED TO ANODE LEAD AND ANODE CAP.

2. Detaching Lead Holder

RUBBER BOOT

LOCK LEAD HOLDER

Fig. b

Cut here rubber boot

and lead together to

detach Lead Holder.

OLD

ANODE LEAD

or

ANODE CAP

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

– 9 –

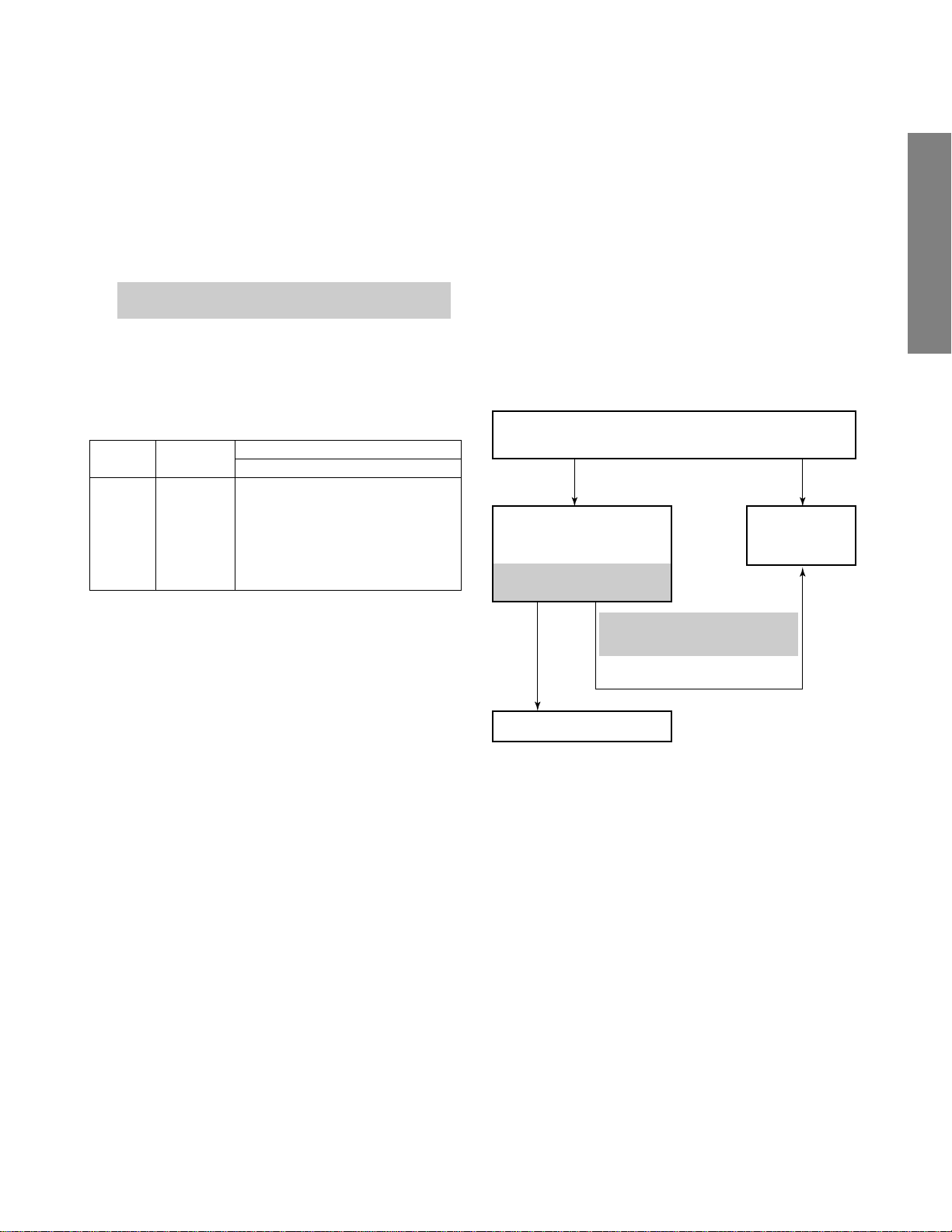

1. ENTERING TO SERVICE MODE

1) Press MUTE button twice

on Remote Control.

MUTE

SERVICE MODE

2) Press MUTE button

again to keep pressing.

3) While pressing the MUTE button,

press MENU button on TV set.

S

(Service mode display)

GENERAL ADJUSTMENTS

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

SPECIFIC INFORMATIONS

Screen adjustment mode ON/OFF: TV (ANT)/VIDEO button (on TV)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume s/t (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : RECALL+Channel button on TV (s)

Initialization of the self diagnostic data: RECALL+Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“SCNT” selection : 4 button

“SCOL” selection : 5 button

“TNTC” selection : 6 button

Convergence adj : 7 button

Self diagnostic display : 9 button

Adjustment mode

S

Press

Press

Item

Data

– 10 –

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 18)

5. ADJUSTING THE DATA

1) Pressing of VOLUME s or t button will change the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the RECALL button on the Remote, then press the CHANNEL s button on the TV. The initialization of QA02

has been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Programming Channel Memory” on the owner's manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

7. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

GENERAL ADJUSTMENTS

SELF CHECK

NO. 23 * * * * * *

POWER : 000

BUS LINE : OK

BUS CONT : OK

BLOCK : MAIN SUB

SET ID : 01

EEP VER : 02

OPT1 : 05 OPT2 : 70

DVI

NO * * * * * * * *

ERR CODE : \\\\\\

IR BLASTER VER : NG

Part number of microprocessor (QA01)

Operation number of protection circuit (current limiter) . . . . “000” is normal.

BUS line check “OK” ................... Normal

“SCL-GND” or “NG” ........... SCL-GND short circuit

“SDA-GND” or “NG” ........... SDA-GND short circuit

“SCL-SDA” or “NG” ............ SCL-SDA short circuit

BUS line ACK (acknowledge) check

“OK” ..................... Normal

Display of Location Number . . . . NG

(Display example)

“QA02 NG”, “H001 NG”, “Q501 NG” etc.

Note: The indication of failure place is only one place though failure places are plural. When

repair of a failure place finishes, the next failure place is indicated. (The order of priority of

indication is left side.)

Sync. signal check Green display..... Normal

Red display ........ NG

MAIN ........ Main sync

SUB .......... Sub sync (when turn on the PIP)

ID code for TV Set

Version of "EEP"

Data for "OPT"

Part number of DVI microprocessor (Q203)

DVI error code ........ "\\\\\\" is normal. (When DVI signal is received)

Version of IR braster IC ("NG" is displayed for models without TheaterLink.)

SPECIFIC INFORMATIONS

– 11 –

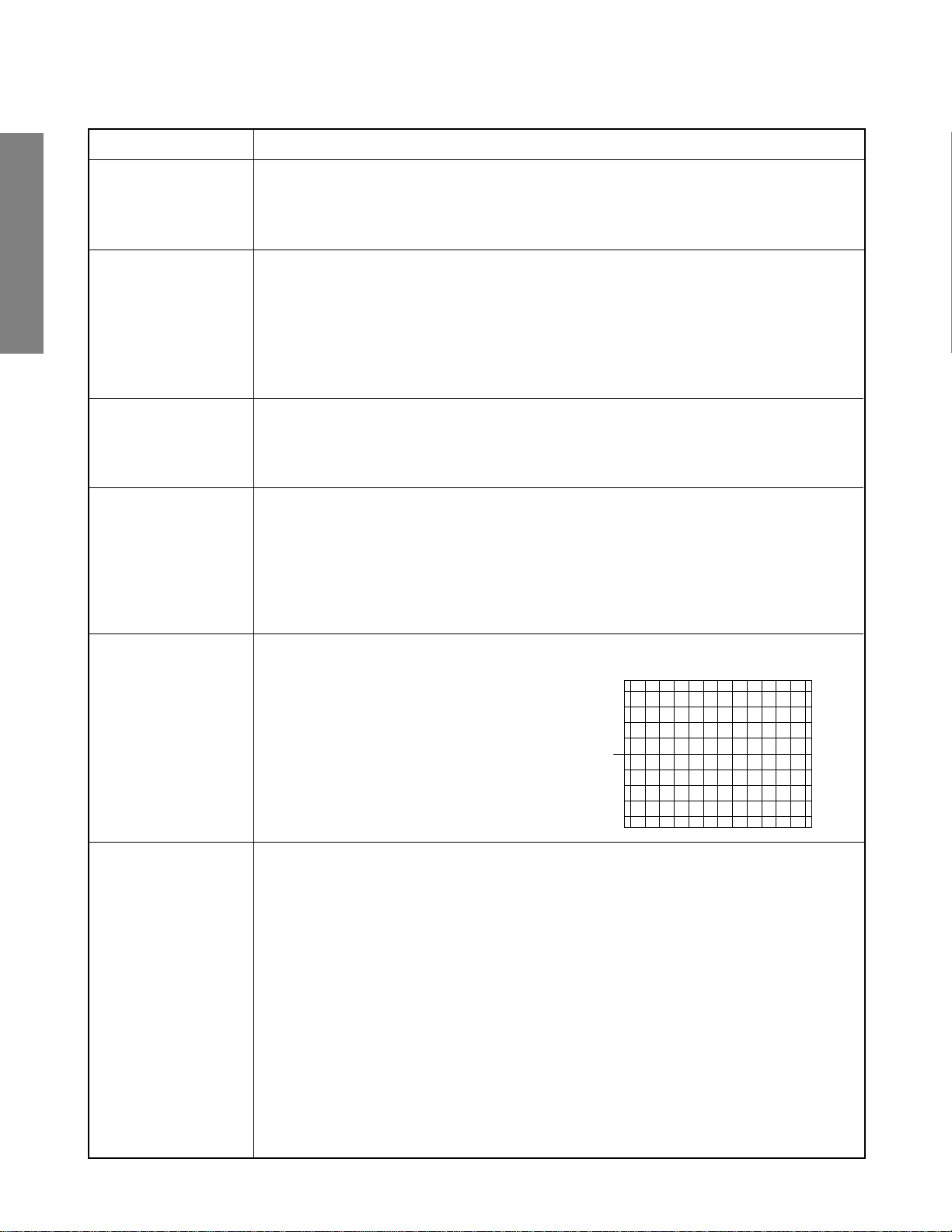

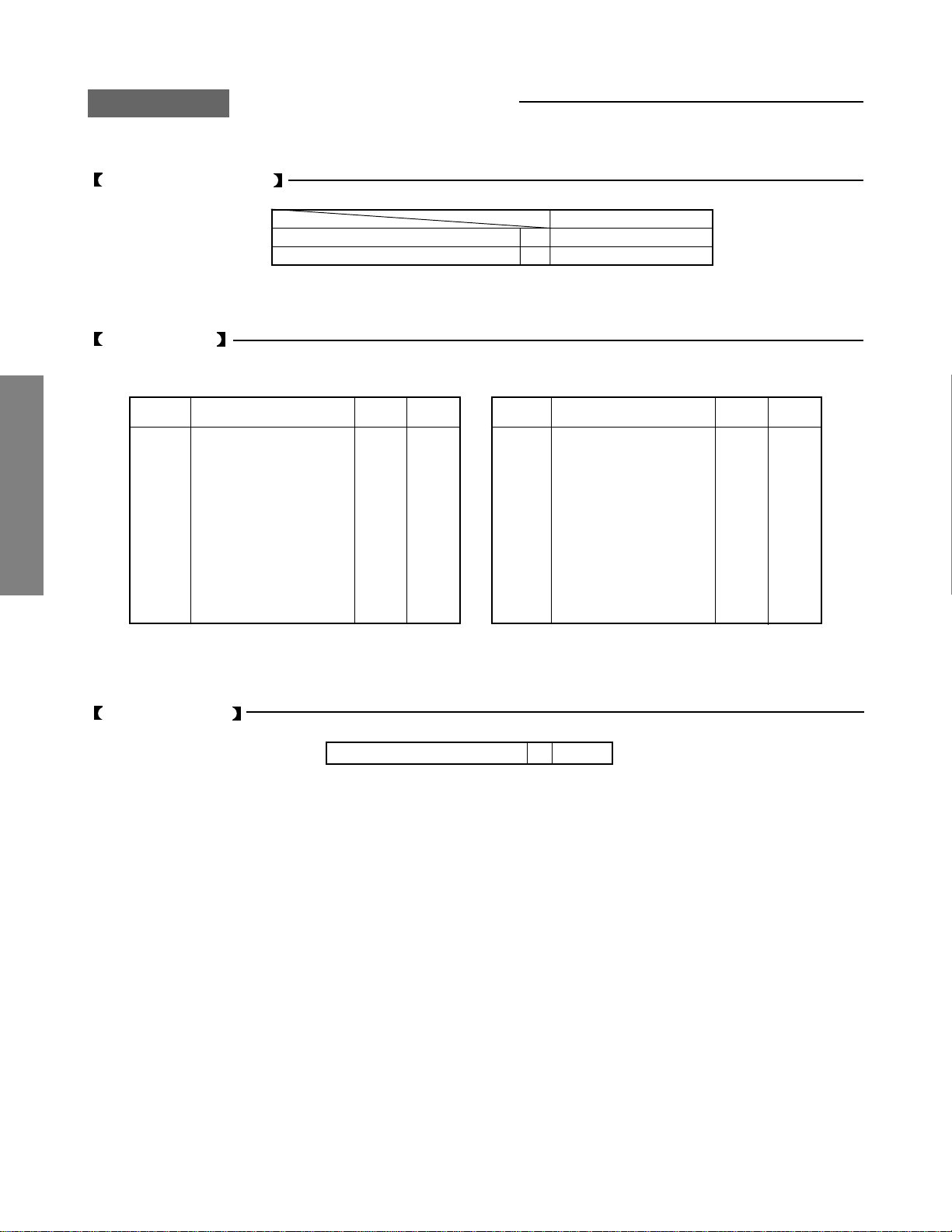

ELECTRICAL ADJUSTMENT

ITEM ADJUSTMENT PROCEDURE

VERTICAL POSITION

(VPSI)

WIDTH

(WID)

GENERAL ADJUSTMENTS

SUB-BRIGHTNESS

(BRTC)

HEIGHT

(HIT)

SPECIFIC INFORMATIONS

1. Receive NTSC signal.

2. Connect he probe of digital voltmeter to TP-V and TP-G on SIGNAL Board.

3. Call up the adjustment mode display, then select the item VCEN.

4. Press the VOLUME s or t button to get the voltage 0±10 mV.

1. Receive NTSC signal.

2. Select the "FULL" mode by PIC SIZE button on Remote Control.

3. Call up the adjustment mode display, then select the item WID.

4. Press the VOLUME s or t button to get the picture so that left and right eddes of video

signal begin to lack.

5. Press the VOLUME s button to advance the data by 8 steps.

NOTE: Check the horizontal picture position is correct.

1. Receive the air signal or aux Video signal.

2. Enter sports mode on user menu.

3. Enter the service mode, then select “BRTC” register.

4. Adjust the data to set dark area of picture to proper level.

1. Receive NTSC signal.

2. Select the "FULL" mode by PIC SIZE button on Remote Control.

3. Call up the adjustment mode display and select the item HIT.

4. Press the VOLUME s or t button to get the picture so that top and bottom of video signal

begin to lack.

5. Press the VOLUME s button to advance the data by 8 steps.

Note: Check the vertical picture position is correct.

Adjust the data of height after vertical linearty.

VERTICAL LINEARITY

(VLIN)

(FULL mode only)

WHITE BALANCE

(RCUT)

(GCUT)

(BCUT)

(RDRV)

(BDRV)

1. Receive cross-hatch pattern.

2. Call up the adjustment mode display, then select the item VLIN.

3. Press the VOLUME s or t button to obtain the

picture of the best linearity.

4. Then readjust the item HIT.

1. Press RESET button on TV or remote hand set.

2. Call up the adjustment mode display, then adjust the data of items RCUT, GCUT and BCUT

to “80”.

3. Press TV (ANT)/VIDEO button on TV.

4. Gradually rotate R, G and B SCREEN volume of FOCUS PAC (page 9) clockwise or

counterclockwise until the raster appears slightly on the CRT through the each lens, and

leave them.

(Look into the lens in order to check the raster.)

5. Press TV (ANT)/VIDEO button on TV again.

6. Exit from service mode.

7. Receive white laster pattern signal, and adjust the contrast to the minimum to make white

picture to low light.

8. Adjust the data of items RCUT, GCUT and BCUT for low light area.

9. Adjust the contrast to the maximum to make white picture to high light.

10. Adjust the data of items RDRV and BDRV Controls for proper white-balanced picture in high

light area.

11. Check the white balance in both low and high light areas. If necessary, perform again steps

from 7 to 9.

– 12 –

CONVERGENCE ADJUSTMENT

1. Receive NTSC signal.

2. Enter to the service mode. (See Page 10.)

RCUT

40H

3. Press "7" button to enter the convergence adjusting mode,

and the internal net pattern will be displayed. Then, press

"9" button to display veritcal stripes.

4. Select the point and the color by pressing following buttons. (Cursor should be blinking.)

"2", "8", "4", "6" : To select point

"3" : To select color

5. Then press "5" button, and adjust the convergence by

pressing following buttons. (Cursor should not be

blingking.)

"2", "8", "4", "6" : To adjust convergence

"3" : To select color

6. Repeat from steps 3 to 4 until the convergence and the

geometry become fine. (See Page 14.)

7. Press "7" button to momorize the adjusted data.

8. Message of "PLEASE PUSH TOUCH FOCUS" will be displayed, and press TOUCH FOCUS button which is located

on the front panel.

9. TOUCH FOCUS CALIBRATION will start.

10. Soon message of "CALIBRATION FINISHED" will be displayed, and then a normal picture will be displayed.

11. Then push TOUCH FOCUS button again, and confirm that

the convergence does not change.

EXPLANATION OF KEY-FUNCTION IN THE CONVERGENCE ADJUSTMENT MODE

Load BACK UP DATA: 1 button

Up : 2 button

Selet Green color: 3 button

Left : 4 button

Blinking of cursor ON/OFF: 5 button

Right: 6 button

Adjust mode ON/OFF: 7 button

Down: 8 button

Vertical stripe ON/OFF 9 button

Erase Green line: 0 button

Erase Red line: 100 button

Erase Blue line: ENT button

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Note: If message of "TOUCH FOCUS ERROR" is displayed,

1) Check the connection between four sensors and

Convergence Unit.

2) Check the geometry of internal net pattern. (See Page

14.)

If any problem cannnot be found, hardware might have

problem.

– 13 –

DEFLECTION and CONVERGENCE

5

7

ITEM NAME SETTING

VPS1

VERTICAL

Raster

centering

Adjusment

Centering

Adjusment

WID

Horizontal

Adjustment

GENERAL ADJUSTMENTS

HIT

VLIN

(FULL)

Vertical

Adjustment

(FULL)

Conver-

SPECIFIC INFORMATIONS

gence

CONTRAST:MAX

BRIGHNESS:CNT

COLOUR :CNT

TINT :CNT

CONTRAST:MAX

BRIGHNESS:CNT

COLOUR :CNT

TINT :CNT

PIC SIZE :FULL

CONTRAST:MAX

BRIGHNESS:CNT

COLOUR :CNT

TINT :CNT

PIC SIZE :FULL

CONTRAST:MAX

BRIGHNESS:CNT

COLOUR :CNT

TINT :CNT

PIC SIZE :FULL

INPUT

SIGNAL POINT

Retma

Signal

TEST

Between

TP-G to

TP-V

Retma

Signal

Retma

Signal

Retma

Signal

Retma

Signal

Picture

Adjustment

Picture

Adjustment

Picture

Adjustment

Picture

Adjustment

MEASUREMENT

INSTRUMENT

Digital Volt

Meter

Picture

To adjust the voltage between TPG and TP-V

1. To adjust the Magnet about

Adjustment

2. To adjust each R, G, B.

Picture

Adjustment

To adjust the Horizontal Amplitude

by WID.

Picture

Adjustment

Picture

Adjustment

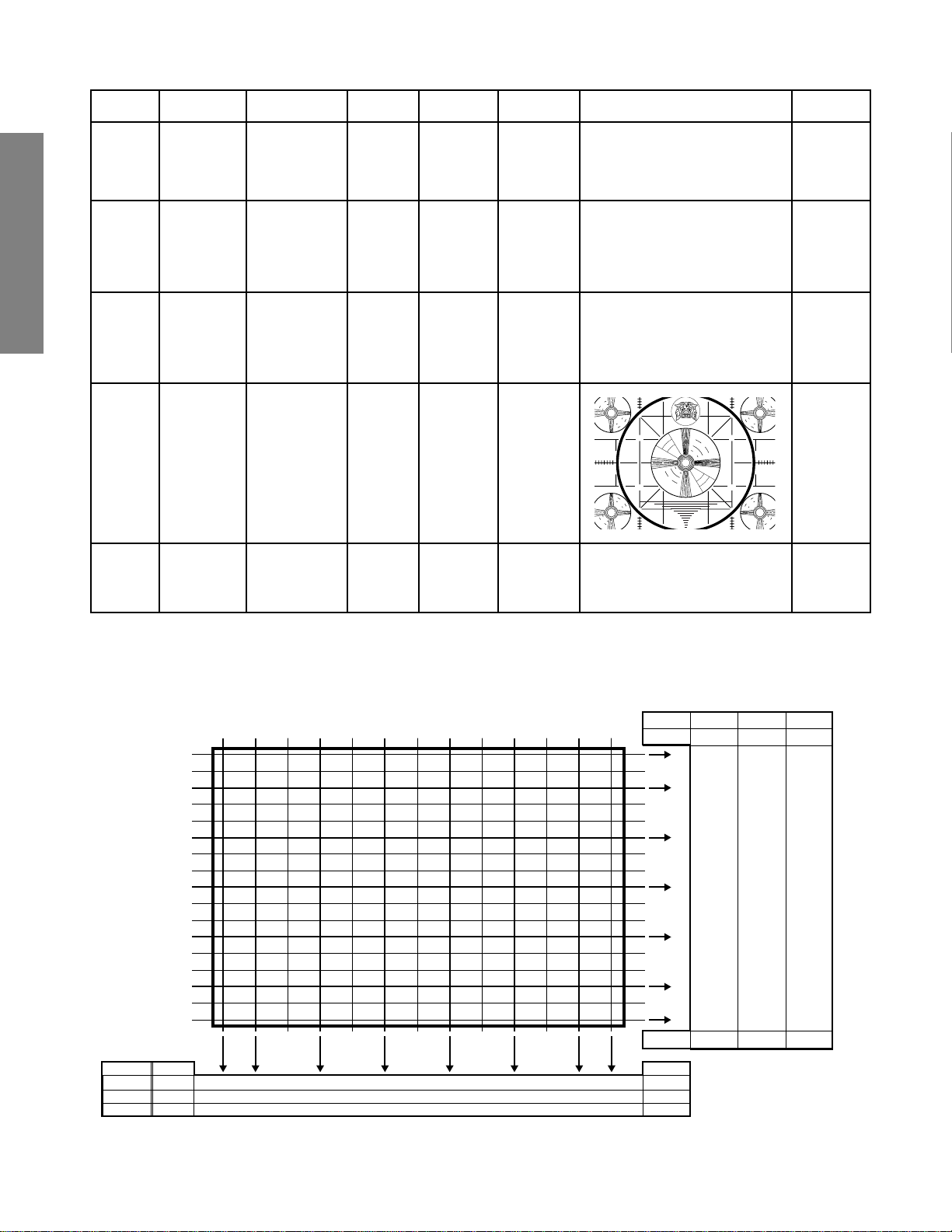

Refer to the following (Convergence Net Geometry)

ADJUSTMENT METHOD

Horizntal position and Vertical

position should center of picture.

3

20

1

25

30

30

35

325

7531

575 300

35

30

30

25

20

525 LINE

35

45

30

30

20

30

35

50

35

30

1

3

20

25

30

531

30

25

20

ADJUSTMENT

SPEC

0 ± 10mV

11 ± 1 bar

Upper ......

Circle of Lion

just touch to

line of Mask.

Bottom ....

To hide the

12 bars by

line of Mask.

CONVERGENCE (51 / 57 / 65 WIDE)

Net Pattern Geometry

Model H size H span

51WIDE 1129.0 549.7 458.1 274.9 91.6 0.0 91.6 274.9 458.1 549.7 91.6

57WIDE 1260.0 613.5 511.3 306.8 102.3 0.0 102.3 306.8 511.3 613.5 102.3

65WIDE 1442.0 702.1 585.1 351.1 117.0 0.0 117.0 351.1 585.1 702.1 117.0

Model 51WIDE 57WIDE 65WIDE

V size 635.085 780.750 810.000

308.0 344.0 392.8

231.0 258.0 294.6

115.5 129.0 147.3

0.0 0.0 0.0

115.5 129.0 147.3

231.0 258.0 294.6

308.0 344.0 392.8

V span 38.5 43.0 49.1

UNIT: mm

– 14 –

NOTES

In many cases, color misconvergence may be corrected by returning HIT and WID data in main deflection side to initial adjusting

values. Following cases will surely require readjustment of convergence.

CRT REPLACEMENT

When CRT is replaced, main deflection readjustment and color matching are required.

Perform following procedures.

1. Replace two CRT’s of blue and red.

2. Perform horizontal adjustment for blue and red yokes on base of green CRT data. Mount yoke and velocity mod. coil alignment, pushing towards CRT without gap.

3. Adjust alignment of blue and red. (Refer Alignment adjustment for details.)

4. Rotating centering magnet, adjust CRT centers of red and blue to CRT center of green.

(Picture position adjustment)

5. Adjust HIT and WID data of main deflection, and decide data at the most precise screen comparing to green data.

6. Adjust convergence of screen picture for color matching. Do not move green one at this time.

7. After convergence adjustment of screen picture finishes, replace green CRT.

For green CRT as well, repeat steps 2 to 5 above on bases of red and blue color matching to adjust convergence.

8. Execute TOUCH FOCUS following instructions displayed on the screen after finishing convergence adjustments of all the

colors.

Note: Press button "7" again after "PLEASE PUSH TOUCH FOCUS" has been displayed. Then, TOUCH FOCUS will not be

executed, and the current state of convergence will be displayed.

REPLACING CONVERGENCE UNIT

1. Confirm that the initial data, which is specified by a model name, is memorized in the new unit.

(It's not allowed to use the data of other models.)

2. Mount the new unit to the SET, and turn the POWER on.

3. Adjust centering magnets, Hight (HIT) and Width (WID). (See Page 7.)

4. Adjust the convergence. (See Page 13.)

GENERAL ADJUSTMENTS

If the memory in the defective module is available, following steps are allowed.

1. Remove the memory (Q173) from the defective unit, and mount it to the new unit.

2. Mount the new unit to the SET, and turn the POWER on.

3. Enter to the convergence adjusting mode, and load BACKUP DATA by pressing "1" button. (See Page 13.)

4. Adjust centering magnets. (See Page 7.)

5. Adjust the convergence. (SeePage 13.)

SPECIFIC INFORMATIONS

– 15 –

SCREEN AND MIRROR ALIGNMENTS

ASSEMBLING OF FRONT SCREEN

GENERAL ADJUSTMENTS

<OUTSIDE>

SPECIFIC INFORMATIONS

K503 FRONT PANEL

LENTICULAR

SMOOTH

K501

BLACK STRIPES

K502

FRESNAL

<INSIDE>

SMOOTH

INSIDE

OUT SIDE

BLACK STRIPES

SPACER

FRONT PANEL

LENTICULAR

FRESNEL

MOUNTING OF FRONT SCREEN

0 to 1 mm

SMOOTH

LENS

FRESNEL

LENTICULAR

FRONT PANEL

BEZEL

CAUTION : Do not hold the optical system parts (lens and

mirror) with bare hand to avoid finger-prints on

the surface of those parts.

HOW TO CLEAN LENS AND MIRROR

1. Be sure to remove sand dust with an air brush, etc.

2. When it is stained slightly, breathe upon it and wipe away

with the specified cleaning cloth.

For other stains than the above, wipe the stains away with

the specified cloth into which a cleaning liquid has been

soaked.

Cleaning liquid.................... LENS LUSTER (Manufac-

tured by Edmund Scientific

Co.), etc.

HOW TO CLEAN SCREEN

When cleaning the screen, use a soft cloth so as not to

damage the screen.

1. Wipe the screen with a dry cloth to remove moisture on

the screen.

Note : Absolutely do not use detergent, water, alcohol,

benzine, thinner, etc. for cleaning in order not to

wipe away the black print on the surface.

– 16 –

CIRCUIT CHECKS

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on

this chassis. Checking should be done following

the steps below.

1. Connect an accurate high voltage meter to the anode of

the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 18)

4. Vary the BRIGHTNESS to both extremes to be sure the

high voltage does not exceed the limit under any conditions.

CAUTION:

When the following parts fail, check the High Voltage after

replacing.

Location

No.

T461

C440

C443

C444

C467

C468

Name

Flyback

Capacitor

Capacitor

Capacitor

Capacitor

Capacitor

Descriptions

51", 57", 65"

TFB3092AD

1000pF, ±3%

5100pF, ±3%

3300pF, ±3%

6800pF, ±5%

6800pF, ±5%

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final

check in servicing. Checking should be done following the

steps below.

1. Turn the receiver on.

2. Temporarily short TP- (R) and TP- (X) on the DEF/CONVER

Board with a jumper wire.

Raster and sound will disappear.

3. The receiver must remain in this state even after removing

the jumper wire. This is the evidence that the FS circuit is

functioning properly.

4. To obtain a picture again, temporarily turn the receiver off

and allow the FS circuit more than 5 seconds to reset. Then

turn the receiver on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

Check that the set returns to normal operation when

pin of P813A is grounded with jumper wire.

YES NO

Check the voltage across

Capacitor C419 is

approximately (

Refer to table –3 for

fall safe voltage (

C)

volts.

C)

.

Faulty power

circuit or horizontal circuit.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

ANODE VOLTAGE MEASURING METHOD

CAUTION: Take extra precaution when measuring this high

voltage. High voltages are also present in

surrounding circuit boards (CRT DRIVE assembly, DEFLECTION assembly, and POWER

SUPPLY assembly).

1. Disconnect the FBT anode cable as outlined below. Measure high voltage at the point where the cable enters the

FBT.

2. Holding the rubber cover firmly, turn it counterclockwise

and check that the lock has been disengaged. (See Fig. b

on page 9.)

3. Determine the extent of the rubber cover before disconnecting the cable.

4. Pull straight up the anode cable to disconnect.

5. When reconnecting the cable, proceed in the reverse order.

After reconnecting, tug on the cable to check that it is secure.

YES

Defective Fail Safe Circuit

(See SETTING & ADJUSTING

DATA on page 18)

NO

– 17 –

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA

SAFETY INSTRUCTIONS

HIGH VOLTAGE AT ZERO BEAM: (A) 31.0 kV

MAX HIGH VOLTAGE:

Table-1

51", 57", 65"

(B) 32.5 kV

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

SERVICE MODE

ADJUSTING ITEMS AND DATA IN THE SERVICE MODE:

Item Name of adjustment

RCUT

BCUT

GDRV

BDRV

BRTC

HIT

VLIN

VSC

WID

CIRCUIT CHECKS

R CUT OFF

B CUT OFF

G DRIVE

B DRIVE

BRIGHT CENTER

PICTURE HIT

V LINEARITY

V S CORRECTION

PICTURE WIDTH

Preset Data

80H

80H

40H

40H

80H

32H

13H

29H

32H

HIGH VOLTAGE DET (C) 8.7 V

←

←

←

←

←

←

←

←

←

Table-2

Table-3

Item Name of adjustment Preset Data

COLC

VCP

PARA

CNR

HCP

VFC

VPSI

TVOP

COLOR CENTER

V COMPENSATION

EW PARABOLA

EW M CORRECTION

H COMPENSATION

V f CORRECTION

V CENTERRING

TV OPTION

52H

04H

11H

10H

00H

00H

4DH

58H

←

←

←

←

←

←

←

←

– 18 –

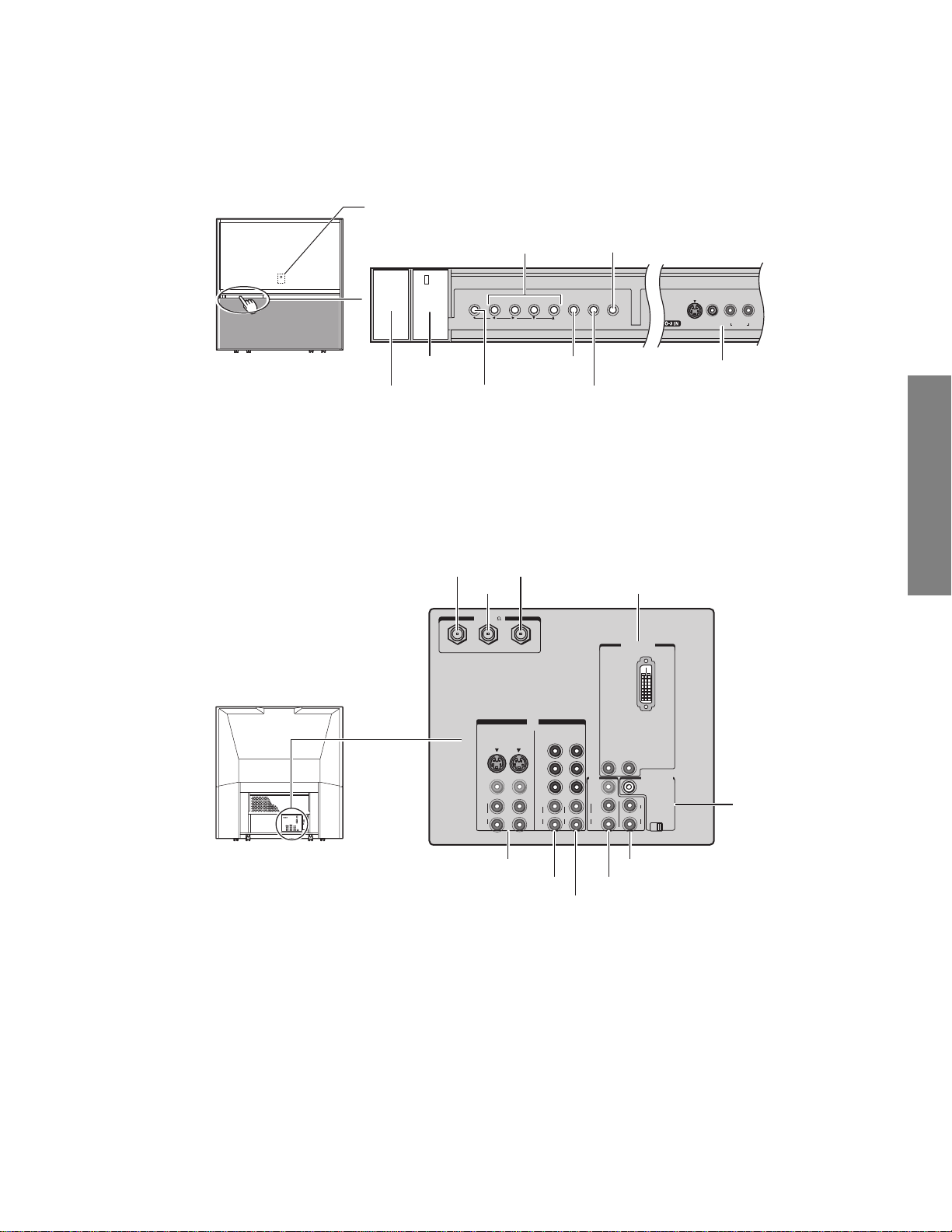

LOCATION OF CONTROLS (Representative: 51H83)

TV front

Remote sensor (Behind the screen)

VOLUME T S

ALS

ANT-1 IN

CHANNEL st

VOLUME

MENUPOWER

ANT-2 IN

CHANNEL

EXIT

TouchFoucus

TV/VIDEO

EXITMENU

TV/VIDEO

ANT OUT

)

ANT( 75

ANT-1 ANT-2OUT

TM

TouchFocus

DVI/HDCP IN

DVI/HDCP IN

L/MONO

VIDEO

R

AUDIO

S-VIDEO

VIDEO-3

Video/audio inputs

(Behind the door)

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

TV rear

VIDEO 2

VIDEO 1

S-VIDEO

VIDEO

L/

MONO

AUDIO

R

VIDEO 1/2

ColorStream

HD1

IN

COLOR

COLOR

STREAM

STREAM

HD-1

HD-2

Y

Y

P

B

P

B

P

R

P

R

L

L

AUDIO

AUDIO

R

R

ColorStream

HD2

AUDIO

R

L

OUT

VIDEO

L/

MONO

AUDIO

R R

AUDIO CENTER

CHANNEL IN

L

VAR

AUDIO

ON OFF

Variable Audio OUT

AUDIO OUT

Audio Center

Channel

– 19 –

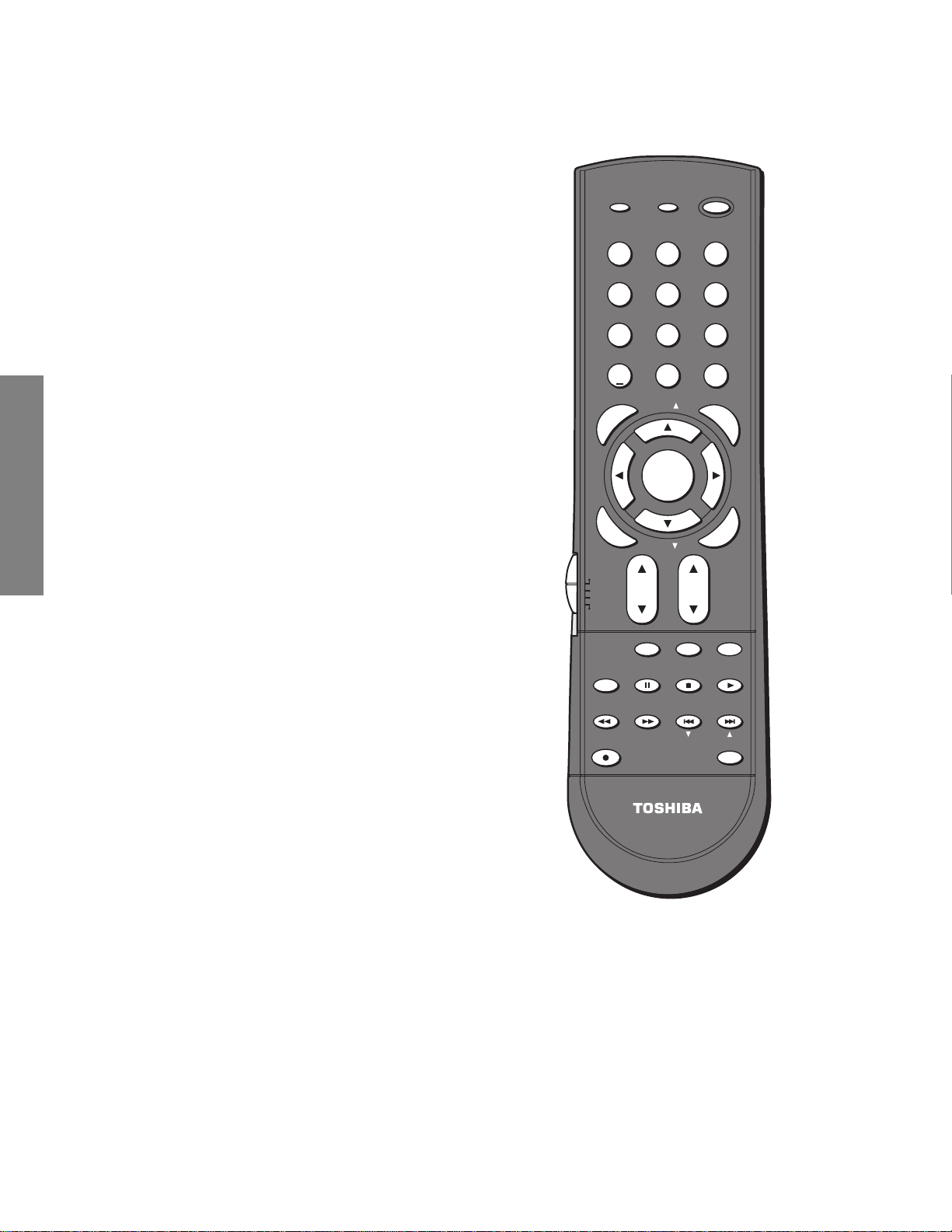

Remote control

POWER turns the TV on and off

RECALL displays screen information

SLEEP sets the TV to turn off at a specific time

TV/VIDEO selects video input source

MUTE mutes the sound

Device Switch switches between TV, CLB/SAT/VCR and

GENERAL ADJUSTMENTS

DVD

sets to “TV ” to control the TV.

CH (channel) st cycles through programmed channels

Channel Numbers (0-9,100) allow direct access to channels

VOL (volume) st adjusts the volume level

CH RTN returns to the memorized channel

MENU allows access to on-screen programming menus

ENTER sets programmed menu information

SPECIFIC INFORMATIONS

89; S select or adjust programming menus

POP CH st selects the POP (picture-out-picture) channel

FAV ts cycles through favorite channels

FAVORITE allows access to the favorite channel search func-

tion

PIC SIZE cycles through the five picture sizes: Normal, Theater

Wide 1,2,3,and Full

TV / VIDEO

RECALL

INFO

123

456

7

100

N

E

M

P

O

T

FAVO

E

N

T

E

E

R

N

T

E

R

TV

CBL/SAT

VCR

DVD

TV/VCR PAUSE

CH SCAN

REC

89

+10

0

U

FAV

E

IT

R

MENU

DVDMENU

FAV

VOLCH

POP DIRECT CH MUTE SLEEP

STOP

FREEZE SOURCE

FFREW

SKIP / SEARCH

SWAP POP CH

POWER

CHRTN

ENT

G

PIC SIZE

EXI

PLAY

SPLIT

LIGHT

U

I

D

E

T

R

A

E

L

C

EXIT exits programming menus

SPLIT turns the POP feature on and off

SOURCE selects the POP picture source

FREEZE freezes the POP picture

SWAP switches the main and POP pictures

POP DIRECT CH allows direct access to POP channels

CH SCAN allows access to the programmed channel search

function

LIGHT illuminates the keypad for five seconds

Note:

The error message “Not Available ” will appear

if you press a key for a function that is not available.

– 20 –

ADDING CHANNELS TO THE TV'S MEMORY

When you press Channel 8 or 9, your TV will stop only on the channels stored in the TV ’s channel memory.

Follow the steps below to program all active channels into the TV ’s memory.

Programming channels automatically

Your TV can automatically detect all active channels in your

area and store them in its memory.After the channels are stored

automatically, you can manually add or erase individual channels.

To program channels automatically:

1 Press MENU, and then press ; or : until the SET UP

menu appears.

2 Press 8 or 9 until the TV/CABLE is highlighted.

3 Press ; or : to highlight either TV or CABLE, depending

on which you use. If you use an antenna, highlight TV; if

you use cable, highlight CABLE.

4 Press 9 to select CH PROGRAM.

5 Press ; or : to start channel programming.The TV will

automatically cycle through all the TV or Cable channels

(depending on which you selected),and store all active

channels in the channel memory.

While the TV is cycling through the channels,the message

“Programming Now —Please Wait ” appears.

6 When channel programming is complete,the message

“Completed ” appears.

Adding and erasing channels manually

After you have programmed the channels automatically, you

can manually add or erase specific channels.

To add or erase channels:

1 Select the channel you want to add or erase.If you are

adding a channel,you must select the channel using the

Channel Number buttons.

2 Press MENU,and then press ; or : until the SET UP menu

appears.

3 Press 8 or 9 to highlight ADD/ERASE.

4 Press ; or : to select ADD or ERASE, depending on the

function you want to perform.

5 Repeat steps 1-4 for other channels you want to add or

erase.

Note:

To tune TV to a channel not pargrammed in the channel

memory, you must use the Channel Number buttons on the

remote control.

* Please refer to owner's manual in detail.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

7 Press Channel 8 or 9 to view the programmed channels.

– 21 –

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

THIS PAGE IS

INTENTIONALLY LEFT

BLANK.

– 22 –

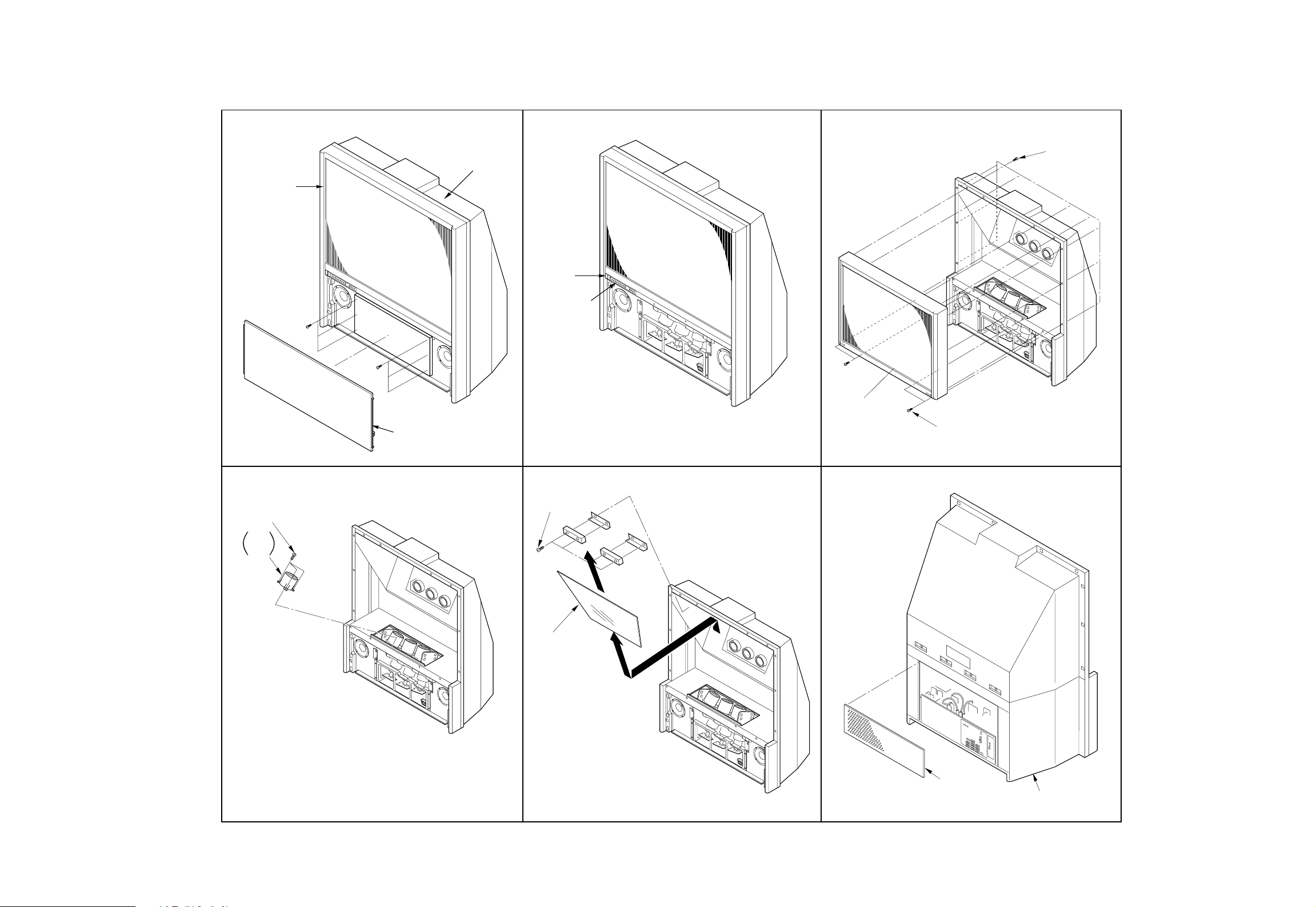

MECHANICAL DISASSEMBLY

K601

4 screws

A160 (CASTER)

A421

(A424)

1 Speaker Grille Removal 2 Control Panel Removal

A001

A201

A223

A202

A102

3 Front Mask Removal

K501

K502

K503

10 screws

4 screws

4 Shield Plate, Lens Removal 5 Mirror Removal

4 screws

K111

K112

K113

6 Back Board Removal

– 23 – – 24 –

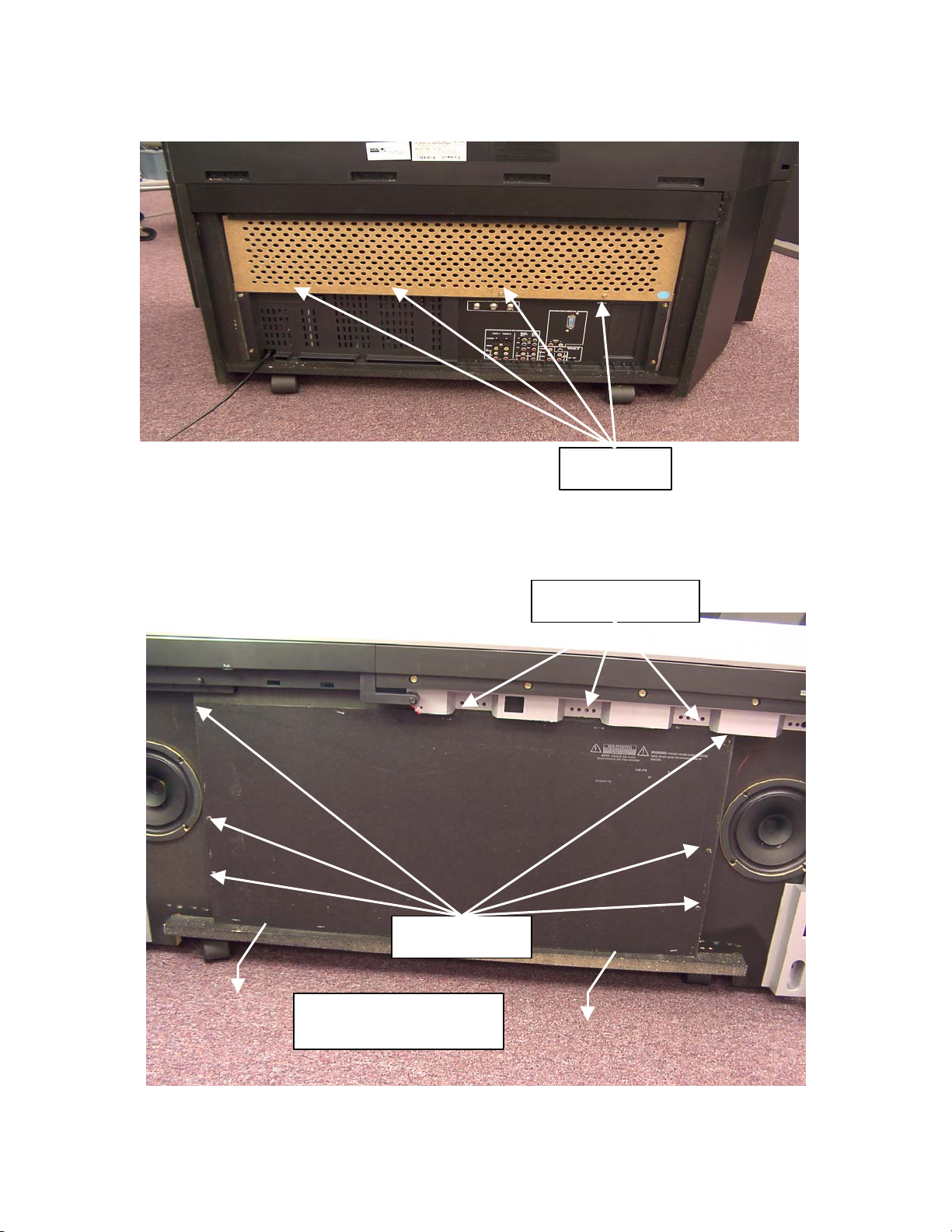

N3PSP DISASSEMBLY

DISASSEMBLY INSTRUCTIONS

Disassembly for the N3PSP is a 15-step procedure designed to provide the

preferred method to remove the light box in this chassis family. The unit used for

an example in this procedure is the 51-inch 51H83. This method applies to this

and 46-inch version of the same chassis. Using this method, one person is able

to disassemble the unit and remove the light box without assistance.

1. Remove the speaker grille first. Apply outward pressure to the grille at the

left top (Figure 1a). This will allow the mounting clamp to release. Move

to the center, then the right side of the grille and repeat the process. After

the three clamps at the top of the speaker grille are disengaged and the

top is loose, release two more clamps at the bottom right and left sides

and remove the grille.

Figure 1a

N3PSP DISASSEMBLY

Next remove the back cover by removing 4 screws at the bottom (Figure 1b).

Figure 1b

4 Screws

2. Now remove the front cover located at the bottom between the speakers.

To do this, remove 3 screws securing it to the bezel at the top and 3 on

each side (Figure 2). After removing the screws pull the cover out at the

bottom, then straight down.

3 Screws at top

3 Each Side

Pull out, then down

Figure 2

Loading...

Loading...