Page 1

FILE NO. 050-200122

SERVICE MANUAL

PLASMA DISPLAY MONITOR

50WP16A, 50WP16C

50WP16H, 50WP16R

50WP16EA, 50HP81

PRINTED IN JAPAN Oct.,2001

P

Page 2

CONTENTS

1 Plasma Display Technology 4

1.1. Plasma display panel

1.2. Plasma display panel structure

1.3. Rear Glass Structure

1.4. Front Glass Structure

1.5. Pixel Structure

1.6. Sub Field Drive system

1.7. Initialization

1.8. Write

1.9. Wall Voltage

1.10. Sustain Step 1

1.11. Sustain Step 2

1.12. Sustain Step 3

1.13. Sustain Step 4

1.14. Sustain Step 5

1.15. Repeat Step 1 to Step 5

1.16. Sub-Field drive

1.17. Dual Scan

1.18. Plasma AI (Adaptive brightness Intensifier)

1.19. Real Black drive

2 Service Hint

3 Adjustment Procedure

3.1. +B Set-up

3.2. Driver Set-up

3.3. Adjustment Volume Location

3.4. Test Point Location

3.5. Initialization Pulse Adjust

4 Alignment Setting

4.1. How to access Alignment

4.2. Exit

4.3. IIC menu structure

5 Alignment

5.1. DG contrast

5.2. DVCO adjust

5.3. NTSC panel white balance

5.4. PAL/SECAM panel white balance

5.5. Pedestal setting

5.6. PC/RGB panel white balance

5.7. HD/ 525i /525p panel white balance

5.8. 625i panel balance

5.9. Sub brighness setting

5.10. Pos./Size setting

5.11. Panel APL/ABL

5.12. SG Hold

5.13. Aging

5.14. LSI 33 Adjust

Page Page

5.15. CAT (Computer Aided Test) mode

6SelfCheck

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

9

10

10

10

11

11

12

13

13

13

14

16

16

16

17

18

20

21

23

25

26

28

28

28

28

28

6.1. Display Indication

7 Trouble shooting guide

7.1. No Power

7.2. No Picture

7.3. Local screen failure

8 P.C.B. (Printed Circuit Board) exchange

8.1. Caution

8.2. Quick adjustment after P.C.B. exchange

9 Location of Lead Wiring

10 Basic Circuit Explanation

10.1. Power Supply Circuit

10.2. Energy Recovery Drive Pulse Output

11 IC Block Diagram

12 Conductor Views

12.1. F-Board

12.2. P1-Board

12.3. P4-Board

12.4. P3, P5, P6, P7, P8, P9 and T11-Board

12.5. H, H3, S1 and V1-Board

12.6. DG-Board

12.7. D-Board

12.8. C1-Board

12.9. C2-Board

12.10. C3-Board

12.11. C4-Board

12.12. C5-Board

12.13. C6-Board

12.14. C7-Board

12.15. C8-Board

12.16. SC-Board

12.17. SD-Board

12.18. SU-Board

12.19. SS, SS2 and SS3-Board

13 Block and Schematic Diagrams

13.1. Schematic Diagram Notes

13.2. Main Block Diagram

13.3. Power (F, P1, P3, P4, P5, P6, P7, P8 and P9 Board)

Block Diagram

13.4. P1-Board (1/2) Schematic Diagram

13.5. P1-Board (2/2) Schematic Diagram

13.6. P3 and P4-Board Schematic Diagram

13.7. P5, P6, P7 and P8-Board Schematic Diagram

13.8. P9 and F-Board Schematic Diagram

13.9. H-Board Block Diagram

28

29

29

30

30

31

31

32

32

32

33

34

34

35

36

39

39

40

43

45

47

50

52

55

56

57

58

59

60

61

62

63

66

67

68

71

71

72

73

74

75

76

77

78

79

2

Page 3

13.10. H-Board (1/4) Schematic Diagram 80

13.11. H-Board (2/4) Schematic Diagram

13.12. H-Board (3/4) Schematic Diagram

13.13. H-Board (4/4) Schematic Diagram

13.14. DG Board Block Diagram

13.15. DG-Board (1/4) Schematic Diagram

13.16. DG-Board (2/4) Schematic Diagram

13.17. DG-Board (3/4) Schematic Diagram

13.18. DG-Board (4/4) Schematic Diagram

13.19. T11 Board Schematic Diagram

13.20. D-Board IC Location

13.21. D-Board Information (1/4)

13.22. D-Board Information (2/4)

13.23. D-Board Information (3/4)

13.24. D-Board Information (4/4)

13.25. D-Board Block Diagram

13.26. D-Board (1/36) Schematic Diagram

13.27. D-Board (2/36) Schematic Diagram

13.28. D-Board (3/36) Schematic Diagram

13.29. D-Board (4/36) Schematic Diagram

13.30. D-Board (5/36) Schematic Diagram

13.31. D-Board (6/36) Schematic Diagram

13.32. D-Board (7/36) Schematic Diagram

13.33. D-Board (8/36) Schematic Diagram

13.34. D-Board (9/36) Schematic Diagram

13.35. D-Board (10/36) Schematic Diagram

13.36. D-Board (11/36) Schematic Diagram

13.37. D-Board (12/36) Schematic Diagram

13.38. D-Board (13/36) Schematic Diagram

13.39. D-Board (14/36) Schematic Diagram

13.40. D-Board (15/36) Schematic Diagram

13.41. D-Board (16/36) Schematic Diagram

13.42. D-Board (17/36) Schematic Diagram

13.43. D-Board (18/36) Schematic Diagram

13.44. D-Board (19/36) Schematic Diagram

13.45. D-Board (20/36) Schematic Diagram

13.46. D-Board (21/36) Schematic Diagram

13.47. D-Board (22/36) Schematic Diagram

13.48. D-Board (23/36) Schematic Diagram

13.49. D-Board (24/36) Schematic Diagram

13.50. D-Board (25/36) Schematic Diagram

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

13.51. D-Board (26/36) Schematic Diagram

13.52. D-Board (27/36) Schematic Diagram

13.53. D-Board (28/36) Schematic Diagram

13.54. D-Board (29/36) Schematic Diagram

13.55. D-Board (30/36) Schematic Diagram

13.56. D-Board (31/36) Schematic Diagram

13.57. D-Board (32/36) Schematic Diagram

13.58. D-Board (33/36) Schematic Diagram

13.59. D-Board (34/36) Schematic Diagram

13.60. D-Board (35/36) Schematic Diagram

13.61. D-Board (36/36) Schematic Diagram

13.62. C1, C2, C3, C4, C5, C6, C7 and C8 Board Block Diagram

13.63. C1-Board Schematic Diagram

13.64. C2-Board Schematic Diagram

13.65. C3-Board Schematic Diagram

13.66. C4-Board and V1-Board Schematic Diagram

13.67. C5-Board Schematic Diagram

13.68. C6-Board Schematic Diagram

13.69. C7-Board Schematic Diagram

13.70. C8-Board Schematic Diagram

13.71. SC-Board Block Diagram

13.72. SC-Board (1/2) Schematic Diagram

13.73. SC-Board (2/2) Schematic Diagram

13.74. SD-Board (1/2) Schematic Diagram

13.75. SD-Board (2/2) Schematic Diagram

13.76. SU-Board (1/2) Schematic Diagram

13.77. SU-Board (2/2) Schematic Diagram

13.78. SS, SS2 amd SS3 Board Block

13.79. SS-Board (1/2) Schematic Diagram

13.80. SS-Board (2/2) SS2-Board, SS3-Board and S1-Board

Schematic Diagram

14 Panel drive signal wave form

15 Signal Waveform

16 Mechanical Parts Location

17 Mechanical Replacement Parts List

18 Replacement Parts List

18.1. Relpacement Parts List Notes

18.2. Electrical Replacement Parts List

19 Specifications

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

155

156

156

157

180

3

Page 4

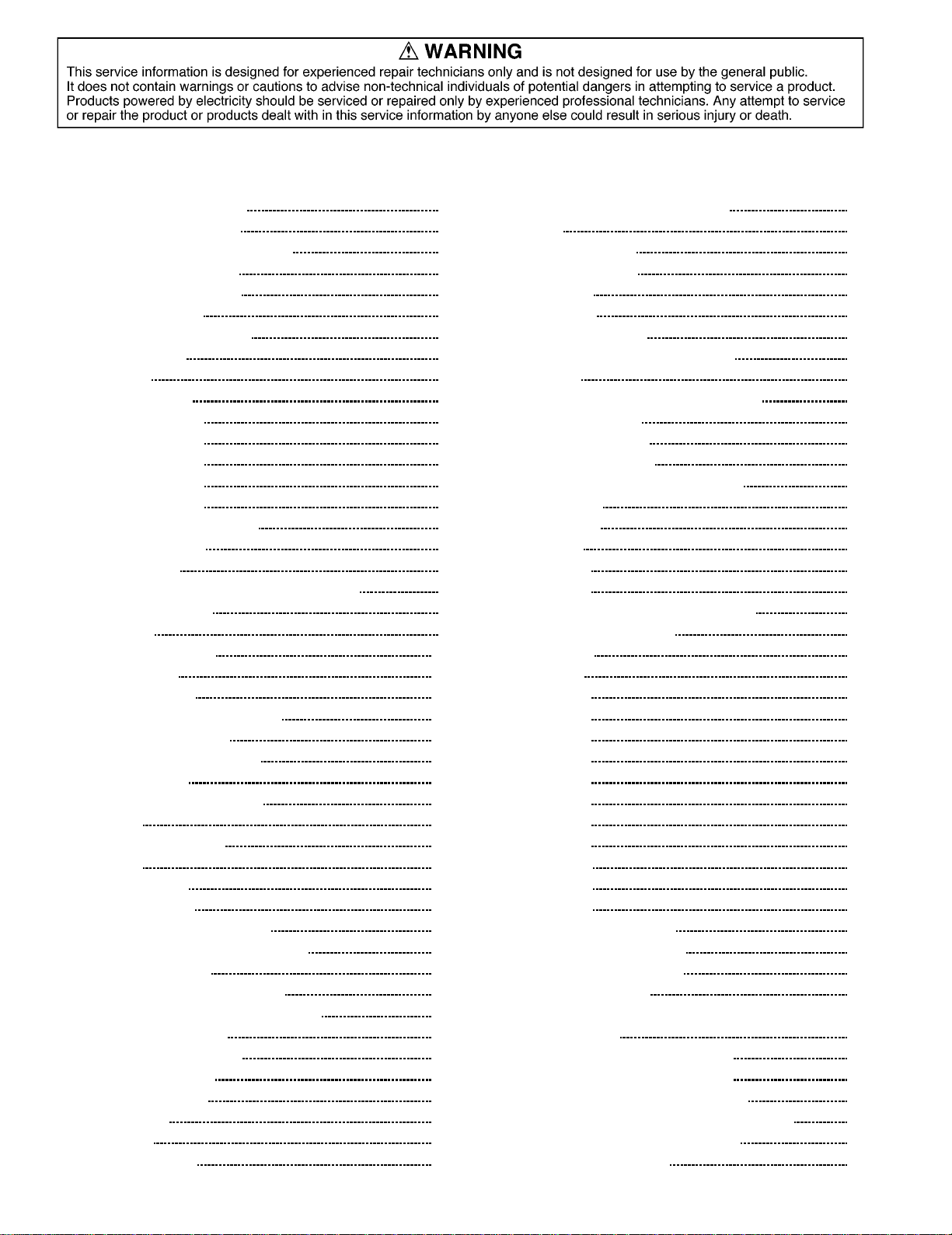

1 Plasma Display Technology

1.1. Plasma display panel

Fig. A

Toshiba 50 wide plasma display panel is develope for large

screen multimedia display with space saving.

The plasma display panel use AC type Sub-field drive system

with Dual scanning system.

This panel have also Asymmetric cell and Plasma AI

technology.

Fig. A Is the CRT and Plasma Display Panel(PDP) comparison

chart.

1.3. Rear Glass Structure

Fig. C

On the rear glass the data electrode is mounted.

The dielectric is coated on the rear glass.

Red, Green and Blue colour phosphors are formed on the data

electrode with the ribs. However to improve colour reproduction

and brightness, each colour phosphors are formed different

width This is called " Asymmetrical cell ".

1.4. Front Glass Structure

1.2. Plasma display panel structure

Fig. B

Plasma display panel structure

Plasma display panel is consist of front glass, rear glass and

Aluminum base.

The front glass has each 768 lines scan and sustain

transparence electrodes.

The rear glass has 4098 (1366 x 3 ) data electrodes on the

inner surface. These electrodes are connected to the data drive

circuit boards directory.

Fig. D

On the front glass scan and sustain transparent electrodes are

mounted in pair.

The dielectrics is coated on the front grass.

MgO over coat is also applied on the dielectrics.

The front and rear glasses are piled and sealed . And low

presser gas are charged between two glasses.

4

Page 5

1.5. Pixel Structure

Fig. E

50 inch plasma display panel has 1,049,088 pixels.

Each pixels structure is shown fig. E.

1.6. Sub Field Drive system

1.7. Initialization

Fig. G

To clear any remaining electric charge into the pixel, trapezoid

voltage is applied between the scan and sustain electrodes.

Plasma discharge is started but the discharge become small

gradually.

Then any electric charge is cleared.

1.8. Write

Fig. F

Brightness control of plasma display panel is carried out by

plasma discharge time change. To control each pixelís

brightness Sub-field drive system is used.

A sub-field is consist of Initialize, Write and sustain operation.

Fig. H

Data Pulse which is positive polarity is input to data electrode

and Scan pulse which is negative polarity is input to scan

electrode simultaneously.

That means sum of data and scan pulses voltage is applied

between two electrodes as discharge start voltage.

Discharge is started into the pixel and gas is ionized.

During discharging Ion is c harged on the scan electrode side

and electron is charged on data electrode side.

5

Page 6

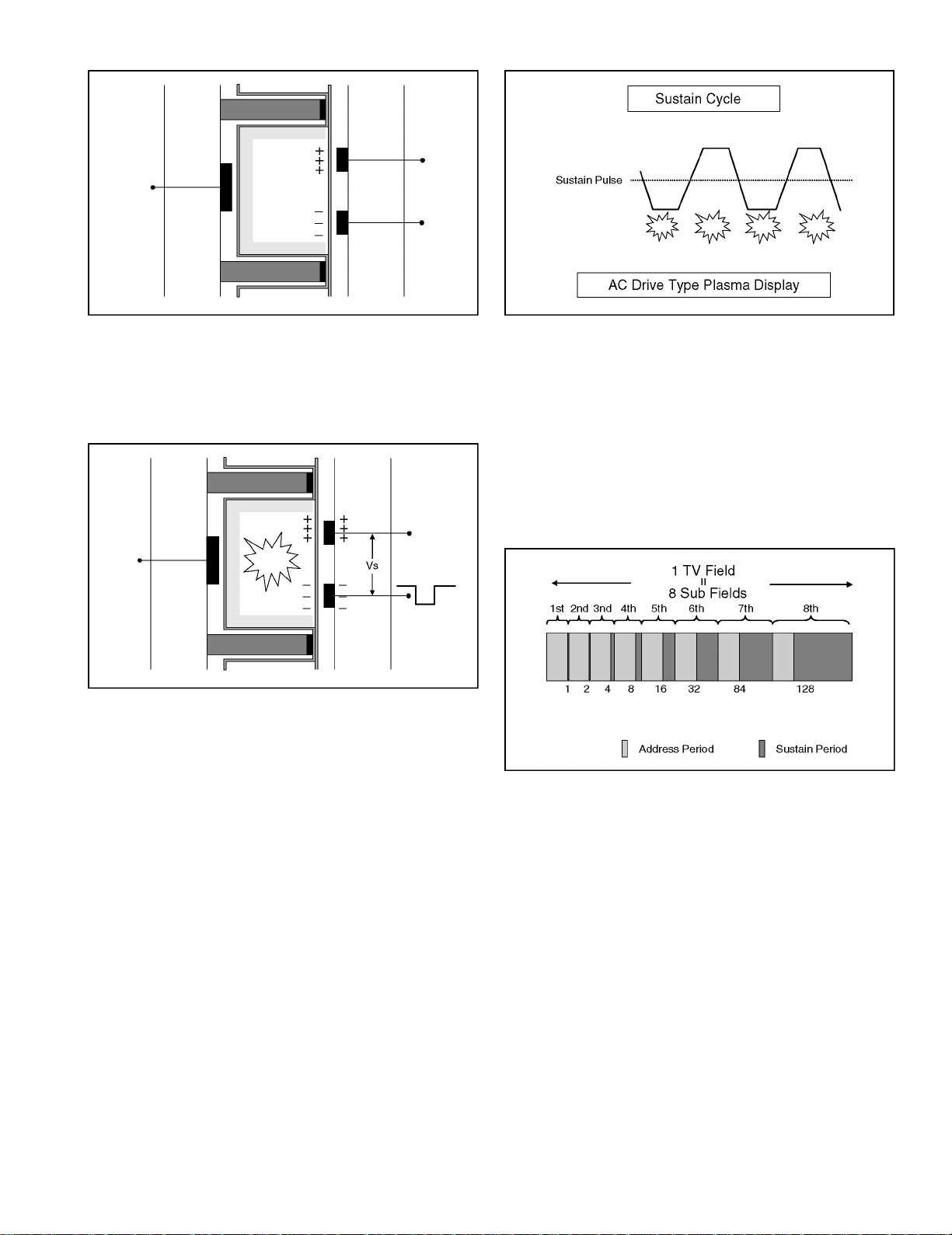

1.9. Wall Voltage

1.11. Sustain Step 2

Fig. I

When input pulses are stopped, Ions and Electrons which are

charged on the dielectric around the electrodes are remained.

This charge is called Wall Voltage (Pilot voltage).

This operation is called Write .

1.10. Sustain Step 1

Fig. J

Negative polarityís Sustain pulse is input between sustain and

scan electrodes and voltage potential between two electrodes

becomes sum of Sustain pulse and wall voltage.

Then discharge start.

Fig. K

When sustain pulse is stopped, Ions and Electrons are

remained again as Wall voltage. However polarity of wall

voltage is reversed.

1.12. Sustain Step 3

Fig. L

Positive polarity´s Sustain pulse is input between sustain and

scan electrodes and discharge start again.

6

Page 7

1.13. Sustain Step 4

1.15. Repeat Step 1 to Step 5

Fig. M

When sustain pulse is stopped, Ions and Electrons are

remained again as Wall voltage. However polarity of wall

voltage is reversed.

1.14. Sustain Step 5

Fig. N

Ions and Electrons which is generated by 2nd sustain

discharge are charged on the pixel wall(dielectric) around the

electrodes.

Fig. O

To keep discharge continuously step 1 to 5 operation will be

repeated.

As the result sustain pulse is alternated. Therefore we call this

drive system AC Drive type.

If sustain operation is repeated longer, brightness level of the

pixel is increased. Therefore depend on sustain discharge time

brightness of pixel is controlled.

1.16. Sub-Field drive

Fig. P

Sub-Field drive is PDP unique system.

While one TV field period, 8 bits digital video signal component

is reproduced by 8 s ub-fields operation.

Each Sub-Field´s address period are all same.(Consist of one

initialization and 768 scanning operation)

But Sustain period of each Sub-Field are different.1st Sub-

Field(SF) reproduce only 1 step brightness.

2nd SF reproduce 2 steps brightness.

Each sub-field´s sustain period are increased gradually.

However total 256 brightness difference can be reproduced on

the screen.

7

Page 8

1.17. Dual Scan

1.19. Real Black drive

Fig. Q

The sustain period of sub-field drive system. Therefore

brightness peak is limited. Because 768 horizontal lines

scanning is carried out during address period.

Dual scan system can reduce scanning time from 768 to 384 in

the address period.

Then spaced time by dual scanning can be used for sustain

operation.

As the result Brightness peak level can be increased.

1.18. Plasma AI (Adaptive brightness Intensifier)

Fig. S

For standard sub field drive, initialization discharge is done at

each sub field. So that during one TV field period same sub

field numbers of discharges are done even black signal was

displayed.

Therefore there are small emission at the black area.

The Real Black drive system improve black reproduction.

Initialization discharge is done at first sub field only.

Remaining sub field are not required discharge because Real

Black drive circuit applies initialization electric field remainder

pulse.

Fig. R

Plasma AI control sub-field drive operation which is called

Multi-Sprit Sub-Field drive control system.

Depend on the picture contents ( APL : Average Picture Level

) sustain time format of each sub-field are also rearranged from

binary format to linear cording sustain time. (Linear coding subfield)

Plasma AI select the best display condition for Plasma display

panel to display natural and crisp picture.

8

Page 9

2 Service Hint

Baord name Function Board name Function

C1 Data drive (Upper Left) P4 Panel drive power

C2 Data drive (Upper Center) P5 Processing voltage control

C3 Data drive (Upper Right) P6 PFC oscillator

C4 Data drive (Lower Left) P7 High Voltage protect

C5 Data drive (Lower Center) P8 Low Voltage protect

C6 Data drive (Lower Right) P9 Regulator

C7 Saving power S1 Power switch

C8 Saving power SC Scan drive

D Digital process & control SD Scan drive output (Lower)

DG RGB/IF SS Sustain drive

F Line Filter SS2 Sustain connection (Upper)

F Line Filter SS3 Sustain connection (Lower)

H Rear terminal SU Scan drive output (Upper)

H3 Speaker terminal T11 Interface

P1 Power supply V1 Front switch & Remote Receiver

P3 Sustain voltage control

9

Page 10

3 Adjustment Procedure

3.1. +B Set-up

3.1.1. Item / Preparation

1.Confirm the main voltage set switch Is set to 230V. (A, B,

and E version) Confirm the main voltage set switch is set to

110V. (U version)

Note:

230V covers input AC voltage from 200V till 260V, and

110V covers from 90V till 130V.

2.Input a Grey scale signal.

3.Set the picture controls: Picture mode: Normal

White balance: Normal

3.1.2. Adjustments

Adjust and confirm indicated test point for the specified voltage.

Test point Voltage Volume Name

P4 pin 1 (Hot) 400V ±1V R548 PFC

Confirmation (Cold)

P27 pin 5 16V ±0.5V +15V

D5 pin 1 14V ±0.5V +13.5V

DG6 pin 1 14V ±0.5V Audio15V

DG6 pin 3 -14V ±0.5V Audio-15V

D5 pin 5 5.2V ±0.3V +5.25V

D5 pin 8 3.6V ±0.2V +3.65V

D7 pin 4 5V ±0.3V STB5V

3.2. Driver Set-up

3.2.1. Item / Preparation

1.Input an APL 100 % white signal.

2.Set the picture controls: Picture mode: Normal

White balance: Cool

Aspect: 16:9

3.2.2. Adjustments

Adjust driver section v oltages referring the panel data on the

panel data label.

Test point Voltage Volume Name

TPVSUS

(SS-BOARD)

TPVBK

(SC-BOARD)

TPVE

(SS-BOARD)

TPVSET

(SC-BOARD)

TPVAD

(SC-BOARD)

P27 pin2 (P1BOARD

Between TPVscn

and TPVAD

(SC-BOARD)

VSUS ±1V R639(P3-BOARD) Vsus

140 V ±5V R513(P1-BOARD) Vbk

VE ±0.5V R6829(SS-BOARD) Ve

224 V ±1V R6490(SC-BOARD) Vset

VAD ±1V R960(P4-BOARD) Vad

75 V ±0.5V R528 (P1-BOARD) Vda

120 + (Vad)

±0.5V

R967 (P4-BOARD) Vscan

10

Page 11

3.3. Adjustment Volume Location

3.4. Test Point Location

11

Page 12

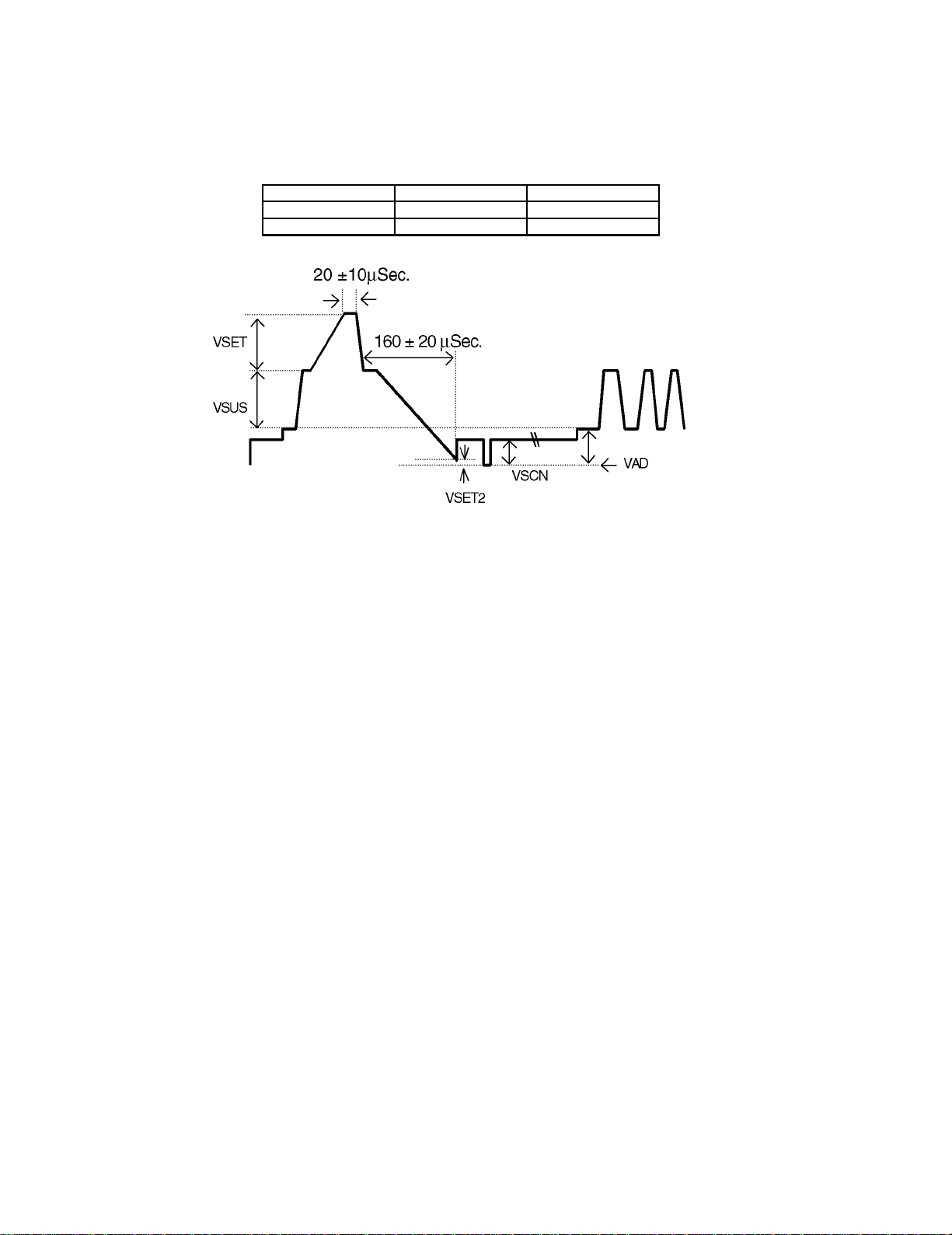

3.5. Initialization Pulse Adjust

1.Input a Cross hatch signal.

2.Set the picture controls: Picture mode: Normal

White balance: Cool

Adjust the indicated test point for the specified wave form.

Test point Volume

TPSC1 (SC) R6524 (SC) 20 ± 10µ Sec

TPSC1 (SC) R6556 (SC) 160 ± 20µ Sec

12

Page 13

4 Alignment Setting

4.1. How to access Alignment

1.Press and hold the Volume down / - button on the front panel of the unit and press the status [ + ] button on the remote

control 3 times quickly within 1 second, this will place the unit into the CAT menu (Main service mode)

2.Press the Access button on the remote control.

4.2. Exit

1.To exit the IIC mode,presstheR button on the remote control.

2.To exit the CAT mode, access the ID mode by the down button of cross buttons and switch off the main power and on again.

13

Page 14

4.3. IIC menu structure

14

Page 15

15

Page 16

5 Alignment

5.1. DG contrast

(Composit video signal)

INPUT Equipment Test Point Level Remark

Alignment menu

Subject Item

1 NTSC Oscilloscope TP8004 VPC SETTING

Colour Bar

2 PAL Oscilloscope TP8004 VPC SETTING

Colour Bar

(DG Boad)

(DG Board)

5.2. DVCO adjust

Alignment menu

Subject Item

1 NTSC or PAL - - VPC SETTING

Colour Bar

Standard signal

DG CONTRAST

DG CONTRAST

DVCO SETTING

0.7V+-0.02V

(3A)

100IRE

0.55V+-0.02V

(3A)

ProcedureINPUT Equipment Test Point

1) Access to DVCO SETTING mode.

2) Press ACCESS key on remote then automatic

DVCO setting is started.

3) When data becomes " 1 "adjustment is completed. .

* Do not use this function without input signal.

16

Page 17

5.3. NTSC panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 NTSC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-01.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-01.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -01

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

17

Page 18

5.4. PAL/SECAM panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PAL Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-02.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-02.

9) Repeat procedure 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -02

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

18

Page 19

Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

Cool

Normal

Warm

SECAM signal 2) Input SECAM signal.

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

3) Copy PAL R,G,B drive and cut off data of each white

balance mode to SECAM position.

19

Page 20

5.5. Pedestal setting

INPUT Alignment menu ProcedureEquipment Setting

** Adjust at the dark room.

1 Component Picture: PANEL W/B

(525i, 525p, 625i, Normal R cut off 1) Set R,G and B cut off to "

720i or 1080i) White balance: G cut off

Cool B cut off

Gray Scale Aspect:

Pattern 16:9

Black 2 %

Black 0 % at black 2% area and no emission at black 0% area.

2 RGB(PC) Picture: 1) Change input to RGB signal.

Gray Scale Normal PANEL W/B

Pattern White balance: R,G,B cut off 2) Repeat procedure 1) to 7) of Component input signal.

Aspect: R,G,B Drive

Chroma Control:

RGB Sub Adjust:

G Sub Bright

Chroma Control:

RGB Sub Adjust:

B Sub Bright

Chroma Control:

RGB Sub Adjust:

R Sub Bright

Cool PANEL W/B

16:9

2) Set Gun off to "

Gun off

3) Adjust G Sub bright to start some of green pixels emission

at black 2% area and no emission at black 0% area.

4) Set Gun off to "

Gun off

5) Adjust B Sub bright to start some of blue pixels emission

6) Set Gun off to "

Gun off

7) Adjust R Sub bright to start some of red pixels emission

at black 2% area and no emission at black 0% area.

5". (Only green pixels can emit.)

3". (Only blue pixels can emit.)

6". (Only red pixels can emit.)

80 ".

Black 0 %

Black 2 %

20

Page 21

5.6. PC/RGB panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-03.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-03.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -03

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

21

Page 22

INPUT Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy PC R,G,B drive and cut off data of each white

Cool

Normal

Warm

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2) Input RGB signal.

balance mode to RGB position.

22

Page 23

5.7. HD/ 525i /525p panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1HD(720i or 1080i) Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-04.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

R Drive as shown Fig.-04.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

exactly.

2

to 10 cd/m

6)Find 75% of white area by color sensor.

B Drive 8) Adjust B and R Drive to set color temperature

9) Repeat item 4) to 7) to set both Low light and

high light.

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -04

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

23

Page 24

INPUT Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy HD drive and cut off data of each white

Cool

Normal

Warm

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2)Change input signal to 525i and 525p.

balance mode to each signals position.

24

Page 25

5.8. 625i panel balance

INPUT Alignment menu ProcedureEquipment Setting

1 625i Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-05.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " D8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-05.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -05

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

25

Page 26

5.9. Sub brighness setting

INPUT Alignment menu ProcedureEquipment Setting

** Adjust at the dark room.

1 NTSC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

Cool.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

** Adjust at the dark room.

2 PAL Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

SECAM 8) Change to SECAM signal.

Gray Scale

Pattern 9) Copy PAL All cut off data to SECAM mode.

Nornal.

warm.

Cool.

Nornal.

warm.

** Adjust at the dark room.

3 PC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

RGB 8) Change to RGB input signal.

Gray Scale

Pattern 9) Copy PAL All cut off data to SECAM mode.

Cool.

Nornal.

warm.

26

Page 27

Alignment menu ProcedureINPUT Equipment Setting

** Adjust at the dark room.

4 525i Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

Cool

.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

525p 8) Change to 525p signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to 525p mode.

HD

(720i or 1080i) 8) Change to HD signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to HD mode.

** Adjust at the dark room.

5 625i Picture: PANEL W/B

Cool

Gray Scale Normal All cut off 1) Set white balance to

.

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

27

Page 28

5.10. Pos./Size setting

1.Receive the test pattern signal which can be found the

center and edge position and align properly.

Alignment Item Reference Setting/Special feature

HPosition 9A Optimum setting

VPosition C3 Optimum setting

HSize A8 Optimum setting

VSize 5E Optimum setting

5.11. Panel APL/ABL

1.Confirm each data.

Alignment Item Reference Setting/Special feature

APL Shift Level E2 Confirmation only

ABL Point 10 Confirmation only

ABL Gain E0 Confirmation only

ABL Bank Select 3F Confirmation only

5.12. SG Hold

SG Hold is the alignment tool for data copy function. Color /

Signal system can be set regardless of input signal.

5.13. Aging

Aging mode is internal pattern generator for panel setting

confirmation and the after image removal.

1.Access desired colour pattern by the Volume Up or Down

button on the remote control.

2.To exit press Menu button

5.13.1. Panel Colour

There are 4 colour pattern White, Red, Blue and Green.

5.13.2. Scroll Bar

Scroll bar is for the after image removal. Display scroll bar

approximately 15 minutes after alignment is competed.

5.14.1. Side panel color setting

Colour of side panel which are left and right side blank area of

4:3 aspect mode can be adjusted as desired color and

brightness.

1.Access Side panel Y(G), U(B) and V(R) by the left or right

button on the remote control.

2.Adjust desired color and brightness of side panel Y(G), U(B)

and V(R) by Volume UP or Down button on the remote

control.

(If 4:3 aspect will be used long time, change side panel

brightness optimum level for screen burn protection.)

5.15. CAT (Computer Aided Test) mode

Mode Function Access button

IIC Service Alignment Action

CD

(Complete

Diagnostics)

IT (Integrated Text) Not use

SD

(Status Display)

OSD on/off OSD display

ID (Initial Data) Not use

Software version

information EEP

ROM edit

Factory use Action

switch

Mute

Mute

5.13.3. Ramp pattern

Ramp pattern is for digital contrast reproduction confirmation.

5.14. LSI 33 Adjust

LSI 33 PIPCR, LSI 27 Through and ABL Bank are for factory

parameter setting for Format converter (IC9204).

(IT Mode, and ID Mode is unused in serving.)

28

Page 29

6SelfCheck

6.1. Display Indication

1.Self-check is used to automatically check the bus line

controlled circuit of the Plasma display.

2.To get into the Self-check mode press the volume down

button on the customer controls at the front of the set, at the

same time pressing the OFF-TIMER button on the remote

control, and the screen will show :-

If the CCU ports have been checked and found to be incorrect

Or not located then " - - " will appear in place of " OK "

29

Page 30

7 Trouble shooting guide

7.1. No Power

First check point

There are following 3 states of No Power indication by power LED.

1.No lit

2.Green is lit then turns red blinking a few seconds later.

3.Only red is lit.

1.No lit

2.Red LED Blinking

When one or some of supply voltages from power supply circuit are declined red LED will be blinking as power

30

Page 31

7.2. No Picture

7.3. Local screen failure

Plasma display may have local area failure on the screen. Fig - 1 is the possible defect P.C.B. for each local area.

Fig - 1

31

Page 32

8 P.C.B. (Printed Circuit Board) exchange

8.1. Caution

1.To remove P.C.B. , wait 1 minute after power was off for discharge from electrolysis capacitors.

8.2. Quick adjustment after P.C.B. exchange

P.C.B. Item Volume Test point Level

P board Vsus R639 TPVsus (SS) Vsus ± 1 V

Vbk R513 TPVBK (SC) 140V ± 5 V

Vda R528 P27 connector

pin2

PFC R548 P4 connector pin 1 400V ± 1 V

DG board DG contrast DG contrast TP8004(DG) Refer to the alignment procedure

DVCO DVCO adjust Automatic

SC board Vset R6940 TPSET(SC) 224V ± 1 V

Vad R960 TPVAD VAD ± 1 V

SS board Ve R6829 TPVE VE ± 1 V

D board White balance, Pedestal and Sub brightness for NTSC, PAL, HD, PC and 625I signals.

75V ± 0.5 V

32

Page 33

9 Location of Lead Wiring

33

Page 34

10 Basic Circuit Explanation

10.1. Power Supply Circuit

10.1.1. Power Factor Control (PFC)

10.1.1.1. Basic operation of the Full wave bridge rectifier

Feature:

1.Power Factor 05~0.7

2.Spick AC current with high frequency component.

10.1.1.2. Power Factor control circuit

Feature:

1.Power Factor More than 0.9

2.Automatic Power Factor Control by OFF period change

3.Lower high frequency noise.

34

Page 35

10.2. Energy Recovery Drive Pulse Output

10.2.1. Plasma Panel Energy Loss

When The Sustain, Scan and Data drive pulses are supplied to the plasma panel a lot of energy was lost by resistance of the

electrodes lead and many of switching elements. Because plasma panel has the stray capacitance and this capacitance makes

high level inrush current during the charge and dischange.

This energy loss becomes high temperature from the plasma panel itself.

10.2.2. Energy Recovery circuit

10.2.2.1. Basic operation of the energy recover circuit

35

Page 36

11 IC Block Diagram

C0JBAF000405

TC74LCX574F

(D-TYPE FLIP-FLOP)

C0JBAD000080

(QUAD 2-INPUT

NOR GATE)

C0JBAZ001201

TC74HC244AF

(BUS BUFFER)

C0JBAB000155

C0JBAB000226

(HEX SCHMITT

INVERTER)

CXA1315M

(IIC-DAC CONVERTER)

UC2715N

(FET DRIVER)

TC74LCX74F

C0ZBZ0000205

(RS232C DRIVER)

C1AA00000561

(AMPLIFIER)

36

C0ABFA000012

(HIGH-PERFORMANCE

PHASE-LOCKED LOOP)

Page 37

BH3866S

(AUDIO AMP)

C0ZBZ0000138

(HALF BRIGE DRIVER)

37

Page 38

38

Page 39

12 Conductor Views

12.1. F-Board

6

F-BOARD (FOIL SIDE)

TXN/F10L32 (50HP81)

5

4

F-BOARD (FOIL SIDE)

TXN/F10HAS (50WP16 SERIES)

3

2

1

ABCDEFGHI

39

Page 40

12.2. P1-Board

6

5

P1-BOARD (FOIL SIDE)

TXNP110L32

4

3

2

1

ABCDEFGHI

40

Page 41

P1

PARTS LOCATION

P1-BOARD (FOIL SIDE)

IC

IC406 C-3

IC407 B-5

IC410 C-1

IC411 B-3

IC412 C-4

IC421 C-1

TARNSISTOR

Q401 G-3

Q402 G-2

Q403 G-2

Q404 G-3

Q405 H-3

Q406 F-2

Q407 F-2

Q408 F-2

Q409 F-2

Q410 H-1

Q411 G-2

Q412 H-1

Q413 H-1

ADDRESS INFORMATION

Q414 G-1

Q415 G-1

Q416 E-4

Q417 C-5

Q418 C-6

Q419 H-3

Q422 C-5

Q423 F-3

Q424 G-3

Q425 G-3

Q426 C-3

Q427 C-5

Q428 C-5

Q429 C-5

Q430 D-2

Q431 D-2

Q432 C-5

Q434 C-1

Q436 C-1

Q437 B-4

PARTS LOCATION

P1-BOARD (COMPONENT SIDE)

IC

IC406 G-3

IC407 H-5

IC410 G-1

IC411 H-3

IC412 G-5

IC421 G-1

TRANSISTOR

Q400 B-3

Q401 C-3

Q402 C-2

Q403 D-2

Q404 C-3

Q405 B-3

Q406 D-2

Q407 D-2

Q408 D-2

Q409 D-2

Q410 B-2

Q411 C-2

Q412 B-1

ADDRESS INFORMATION

Q413 B-1

Q414 D-1

Q415 C-1

Q416 D-4

Q417 G-5

Q418 B-3

Q418 G-6

Q421 G-5

Q422 G-5

Q423 D-3

Q424 C-3

Q425 C-3

Q426 G-3

Q427 G-5

Q428 G-5

Q429 G-5

Q430 F-3

Q431 F-3

Q432 G-5

Q434 G-1

Q436 G-1

Q437 H-4

41

Page 42

P1-BOARD (COMPONENT SIDE)

TXNP110L32

6

5

4

3

2

1

ABCDEFGHI

42

Page 43

12.3. P4-Board

6

P4-BOARD (FOIL SIDE)

TNPA1908

5

4

P4-BOARD (COMPONENT SIDE)

TNPA1908

3

2

1

ABCDEFGHI

43

Page 44

PARTS LOCATION

P4-BOARD (FOIL SIDE)

IC

IC921 C-4

IC931 G-4

IC932 H-5

IC934 G-5

TRNSISTOR

Q921 D-5

Q922 F-4

Q924 B-5

Q925 B-4

Q926 G-5

Q927 G-5

Q932 G-4

Q933 G-5

ADDRESS INFORMATION

P4

PARTS LOCATION

P4-BOARD

(COMPONENT SIDE)

IC

IC921 G-2

IC931 C-1

IC932 B-2

IC934 C-2

TRANSISTOR

Q921 F-2

Q922 D-1

Q924 H-2

Q925 H-2

Q926 C-2

Q927 C-3

Q932 C-1

Q933 C-2

ADDRESS INFORMATION

44

Page 45

12.4. P3, P5, P6, P7, P8, P9 and T11-Board

T11-BOARD (FOIL SIDE)

TNPA1996

6

5

P9-BOARD (FOIL SIDE)

TNPA1906

P5-BOARD (FOIL SIDE)

TNPA1909

P6-BOARD (FOIL SIDE)

TNPA1910

4

P7-BOARD (FOIL SIDE)

TNPA1911

P8-BOARD (FOIL SIDE)

TNPA1912

3

2

P3-BOARD (FOIL SIDE)

TNPA1907

P1 P8

P9 P9

P7

P3

P5

P6

1

ABCDEFGHI

45

Page 46

T11-BOARD (COMPONENT SIDE)

TNPA1996

6

5

P6-BOARD (COMPONENT SIDE)

TNPA1910

P5-BOARD (COMPONENT SIDE)

TNPA1909

P9-BOARD (COMPONENT SIDE)

TNPA1906

4

P8-BOARD (COMPONENT SIDE)

TNPA1912

P7-BOARD (COMPONENT SIDE)

TNPA1911

3

2

P3-BOARD (COMPONENT SIDE)

TNPA1907

P1 P8

P9 P9

P7

P3

P5

P6

1

ABCDEFGHI

46

Page 47

12.5. H, H3, S1 and V1-Board

6

V1-BOARD (FOIL SIDE)

TNPA1783

5

S1-BOARD

TNPA1784

H3-BOARD

TNPA1756AB

H-BOARD (FOIL SIDE)

4

TNPA1755

3

2

1

ABCDEFGHI

47

Page 48

H

PARTS LOCATION

H-BOARD (FOIL SIDE)

IC

IC3509 C-4

TEST POINT

TP097 D-3

TP104 F-3

TP118 G-4

TP119 G-4

TP120 G-4

TP121 G-4

TP122 G-3

TP123 G-3

TP124 C-4

TP125 D-3

TP126 C-4

TP127 C-3

TP128 C-3

TP129 C-4

TP130 C-3

TP131 C-3

TP132 D-3

TP133 E-4

ADDRESS INFORMATION

TP134 D-3

TP135 D-3

TP136 C-4

TP137 D-3

TP138 D-3

TP139 C-4

TP140 E-4

TP141 E-3

TP142 E-4

TP143 E-4

TP144 D-3

TP145 E-4

TP146 E-4

TP147 D-3

TP148 E-3

TP149 E-3

TP150 E-4

PARTS LOCATION

H-BOARD (COMPONENT SIDE)

IC

IC3502 D-2

IC3503 B-3

IC3504 E-3

IC3505 E-3

IC3506 H-3

IC3507 F-3

IC3508 D-3

IC3509 G-4

IC3510 I-3

IC3511 B-2

IC3513 B-3

IC3514 C-3

IC3515 B-2

TRNSISTOR

Q3501 I-3

Q3502 I-3

Q3503 H-3

Q3504 E-2

Q3505 F-2

Q3506 F-2

Q3507 D-2

Q3508 D-2

Q3509 D-2

ADDRESS INFORMATION

Q3510 C-2

Q3511 C-2

Q3512 C-2

Q3513 E-2

Q3514 E-2

Q3515 E-2

Q3517 G-2

Q3518 G-2

Q3519 G-2

Q3520 G-2

Q3521 C-2

Q3522 C-2

Q3523 C-2

Q3524 B-2

Q3525 H-3

Q3526 G-3

Q3527 H-2

Q3528 H-2

Q3529 H-3

Q3530 G-3

Q3531 H-3

Q3532 H-2

Q3533 G-3

Q3534 H-3

Q3535 B-3

Q3536 C-3

48

Page 49

6

V1-BOARD (COMPONENT SIDE)

TNPA1783

5

H-BOARD (COMPONENT SIDE)

4

TNPA1755

3

2

1

ABCDEFGH I

49

Page 50

12.6. DG-Board

DG-BOARD (FOIL SIDE)

TXNDG10L33

6

DG

SEE REVERSE FOR ORDER NO.

TNPA1754

3

4

DG4

1

3

DG5

1

DG

TP8017

C8162

TP8014

C8060

R8095

R8088

R8084

R8083

R8042

R8147

JS8004

C8059

C8050

R8085

C8081

R8244

Q8022

R8071

C8074

C8030

R8082

C8098

C8094

R8093

C8064

C8053

C8054

R8140

R8130

R8086

IC8010

C8011

R8080

R8120

TP8016

R8278

C8082

R8098

R8063

21

22

5

39

40

1

2

JK8502

19

20

C8160

JS8024

C8158

C8087

C8156

C8086

4

C8185

R8040

31

32

3

59

60

2

1

2

R8005

R8006

R8002

JK8501

C8001

29

30

C8027

R8035

R8050

C8004

Q8005

C8002

C8003

R8017

R8019

Q8001

R8252

R8021

R8015

R8029

R8053

R8011

R8007

R8008

R8009

R8010

R8038

R8249

R8012

R8033

R8054

Q8006

C8017

C8163

R8020

R8016

R8018

R8048

R8069

C8033

R8075

R8251

R8025

R8026R8027

C8036

JS8019

R8432

R8046

R8013

R8023

R8074

R8066

R8034

C8022 C8023C8024

R8068

R8078

R8065

C8178

R8250

R8089

R8081

C8041

Q8014

C8034

JS8001

R8072

C8047

R8091

R8090

C8172

R8145

C8080

C8065

C8057

R8430

R8087

R8062

R8136

11

10

R8092

Q8021

Q8020

C8079

C8100

Q8012

C8068

R8137

C8184

R8067

R8058

R8070

20

1

R8114

R8101

C8176

R8131

R8429

C8101

R8103

JS8002

C8168

TP8015

R8435

R8434

Q8033

R8132

JS8003

R8332

C8026

R8052

R8032

C8015

R8431

C8012

C8072

R8100

R8079

R8613

C8014

R8047

R8612

C8170

R8282

R8134

C8044

C8025

Q8003

R8133

C8046

R8028

R8245

R8185

Q8030

R8030

R8024

R8043

R8182

C8048

C8167

R8036

R8617

R8124

R8044

JS8023

TP8013

R8615

R8127

JS8021

R8280R8281

JS8022

R8614

R8192

C8303

TP8018

R8333

R8334

R8191

R8193

R8311

R8184

R8247

C8136

C8128

R8176

C8124

R8173

C8105

R8335

R8248

C2344

R8306

C8304

R8313

R8317

C8130

C8126

R8160

C8116

C8119

C8149

C8134

R8181

R8187

C2340

R8327

C8151

C8305

R8315

R8319

C8308

C8148

C8138

C8131

C8133

R8156

R8194

R8174

C8309

C2316

R2322 R2323

C2318 C2319

C2320 C2321

C2328 C2329

IC2301

C2322

C2341

C2323

C2338

R2335

C2349

R2321

R8304

R8305

R2319

C8302

R8303

Q8050

R8301

R8328

R8323

Q8049

R8321

R8320

C8140

C8153

R8189

R8190

C8139

R8228

R8227

R8226

R8225

R8222

R8221

R8205

R8201

R8198

R8197

R8196

C8110

C8107

R8179

R8180

R8427

C8150

Q8032

R8310

R8307

R8316

R8322

R8325

C8109

TP8004

C8127

20

C2345

C8142

C8135

R8177

C2326

R8183

R8326

L2301

R8324

R8309

R8308

R8178

C2330

L2303

C2337

R2330

R2426

R2447

R2326

C2331

1110120

R2460

C2412

C2409

R2434

C2426

C2432

R2449

R2448

R2466

D2306

Q2301

R2467

C2411

R2423

JS2302

C2327

R2468

R2463

1

C2433

32

R2417

C2437

R2431

C2347

R2419

1

R2317

C2315

R2318

IC2401

R2441

C2452

L2302

IC2302

R2418

C2415

R2452

C2414

R2442

D2305

R2453

C2434

JS2303

C2343

R2304

R2416

R2444

C2428

R2454

C2453

C2408

R2446

R2347

R2428

R2436

R2301

C2455

C2436

R2346

JS3

JS2301

C2346

R2456

C2324

C2325

JS8

R2435

C2317

R2308

JS2

C2313

Q2306

R2433

R2427

R2405

C2342

R2307

C2461

JS7

C2418

C2332

C2463

R2432

C2339

R2430

R2429

R2331

R2348

L2304

R2336

D2308

R2425

C2431

C2314

C2312

R2327

C2333

C2350

R2476

1110

C2402

C2429

C2464

R2305

R2324

C2336

R2329

17

Q2302

R2477

16

C2458

C2460

R2333

C2462

PARTS LOCATION

DG-BOARD (FOIL SIDE)

IC

IC2301 D-5

IC2302 E-5

IC2401 E-3

IC8010 C-2

TRANSISTOR

Q2301 E-4

Q2306 E-3

Q8001 B-3

Q8003 C-3

Q8005 B-3

Q8006 B-3

Q8012 C-3

Q8020 C-3

Q8022 C-4

Q8023 C-5

Q8026 B-2

Q8030 C-5

Q8032 D-2

Q8049 E-3

ADDRESS INFORMATION

Q8050 E-3

TEST PONIT

TP8004 D-2

TP8013 D-5

TP8014 C-5

TP8015 C-5

TP8016 C-5

TP8018 D-5

1

DG98

14

ZIG

1

IIC

DG99

7

123

DG6

18

1

C8173

11

DG17

C8164

C8165

ABCDEFGHI

50

Page 51

DG-BOARD (COMPONENT SIDE)

TXNDG10L33

6

DG4

DG5

SP LOUT

D2301

D2302D2303 D2304

C2454

IC2402

C2457

R2 424

D2403D2404

C2421

L2305

C2325

C2317

Q2303Q2304

Q2401Q2402

R2445

R2469

C2313

C2455

R2411

R2412

C2413

C2401

C2459

C2420

C2451

C2414

C2427

L2302

R2334

R2443

D2307

C2437

C2410

C2435

Q2403

D2305

R2309

R2310

R2345

R2332

C2419

R2440

C2430

C2450

C2334

R2473

R2421

L2303

C2389

C2388

C2348

R2408

R2471

R2462

R2472

Q2404

R2422

C2423

R2439

R2450

C2347

R2461

C2440

C2456

R2470

C2465

Q2406

R2328

R2320

D2306

R2420

R2342

R2341

JS6

C2409

D2314

C2441

R8200

C8152

IC8019

L8025

L8026

C2323

C8146

IC8021

C2316

C8301

R8302

L2304

C2391

5

4

3

2

R2325

R2344

R2343

IC2304

Q2305

IC2302

C2335

C2422

C2466

C2467

IC2401

C2314

D2315

R2410

L2306

C2390

C2402

C2429

C2474

C2417

R2306

Q2405

C2346

D2405

R2437

C2416

R8329

R8330

TP8012

C8111

L8009

Q8042

L8024

IC8020

R8331

JS8101

R8318

L8023

JS8102

R8312

C8108

B

C8306

Q8048

Q8047

C8114

Q8043

L2301

IC2301

C2345

R8314

Q8045

C8311C8312

R8188

C8132

IC8015

G

C8177

C8106

C8129

R8186

R8175

Q8044

C8310

X8003

JK8001JK8002JK8003

IC8032

Q8046

L8201

Q8031

L8018

R

DG

3

DG1

R8276

R8113

R8112

C8180

Q8013

TP8008

TP8010

R8039

C8021

Q8010

C8018

C8020

C8019

IC8002

IC8003

R8057

R8234

IC8025

R8240

L8015

L8016

C8032

R8041

R8037

C8038

D8017

IC8001

R8061

R8277

R8236

R8242

C 8016

C8084

C8063

IC8004

C8008

Q8007

R8022

C8009

C8049

R8004

C8179

R8014

L8001

C8037

TS8001

TP8003

C8010

R8001R8003

C8005

C8155

R8235

R8243

L8029

IC8027

JK8502

IC8008

TP8001

C8007

JK8501

TP8002

TS8003

TS8002

TP8005

C8175

IC8031

IC8014

C2344

L8022

C8141

C8307

IC8018

C8103

C8174

TP8009

Q8002

C8061

IC8011

C8095

C8013

L8017

C8166

C8137

IC8016

L8008

IC8006

R8049

TP8011

R8245

L8019

R8045

Q8004

LC8001

R8129

R8125

R8121

D8005

IC8017

C8006

Q8008

R8031

TP8006

IC8012

C8093

R8123

L8020

C8300

L8011

C8075

JS8005

R8426

R8118

R8104

R8051

IC8030

L8002

R8141

IC8009

Q8009

R8055

C8052

C8089

JS8006

Q8023

C8055

R8139

R8094

R8135

R8146

R8056

C8096

C8056

R8237

C8083

C8058

C8169

IC8033

C8051

R8064

C8071

C8070

R8428

L8013

LC8003

Q8016

C8031

R8142

C8045

R8244

C8090

R8073

C8161

L8012

C8091

C8035

C8092

R8117

C8073

C8039

C8099

C8088

L8010

R8077

IC8005

R8143

L8028

IC8028

L8027

R8144

IC8029

R8231

R8239

C8085

R8126

R8138

C8078

C8042

Q8019

IC8010

L8014

C8076

C8077

C8067

Q8018

C8040

X8001

IC8007

C8062

TS8004

R8232

R8238

R8128

R8116

IC8023

C8043

C8024

C8023

R8233

R8241

Q8015

C8022

C8029

LC8002

C8171

L8003

R8122

TP8007

D8016

SP ROUT

TNPA1754

DG

PARTS LOCATION

DG-BOARD (COMPONENT SIDE)

IC

IC2301 C-5

IC2302 A-5

IC2304 A-1

IC2401 A-3

IC2402 A-3

IC8001 E-3

IC8002 E-2

IC8003 E-2

IC8004 E-2

IC8005 D-2

IC8006 D-3

IC8007 E-4

IC8008 E-4

IC8009 D-2

IC8010 E-2

IC8011 C-2

IC8012 D-4

IC8014 C-2

IC8015 C-2

IC8016 D-5

IC8017 D-4

IC8018 C-3

IC8019 B-3

IC8020 B-2

IC8021 B-1

IC8023 E-5

IC8025 E-5

IC8027 E-5

IC8028 D-5

IC8029 D-1

ADDRESS INFORMATION

IC8030 D-2

IC8031 C-4

IC8032 C-3

IC8033 D-5

TRANSISTOR

Q2303 B-4

Q2304 A-4

Q2305 A-3

Q2401 B-2

Q2402 A-2

Q2403 B-3

Q2404 B-2

Q2405 A-2

Q2406 B-2

Q8002 C-3

Q8004 D-3

Q8007 E-3

Q8008 D-3

Q8009 D-3

Q8010 E-3

Q8013 E-3

Q8015 E-3

Q8016 D-3

Q8018 E-3

Q8019 E-3

Q8023 D-4

Q8031 C-2

Q8042 B-4

Q8043 C-4

Q8044 C-4

Q8045 C-4

Q8046 C-4

Q8047 C-4

Q8048 C-4

TEST POINT

TP8001 E-4

TP8002 E-3

TP8003 E-3

TP8005 E-2

TP8006 D-1

TP8007 E-3

TP8008 E-5

TP8009 C-2

TP8010 E-3

TP8011 D-2

TP8012 B-3

TS8001 E-2

TS8002 E-2

TS8003 E-2

TS8004 E-2

1

DG6

DG99

DG98

DG17

ABCDEFGHI

51

Page 52

12.7. D-Board

6

5

4

3

2

D-BOARD (FOIL SIDE)

TZTNP010GYS

123

C003

C004

D002

LC023

R532

R538

LC026

R533

LC027

R695

R698

R701

R696

R697

R726

R732

R733

R728

R730

R822

R827

R828

R824

C002

D001

R062

Q010

R104

C024

R858

R054

Q002

R096

C029

R852

R043

R058

Q006

R100

C033

R518

R694

1

10

1

R723

10

R819

1

10

R826

LC028

R022

R021

C015

R048

R049

R047

Q011

Q009

C022

R103

IC006

16

C036

1

R859

R112

R039

Q001

C028

R110

Q005

C032

R520

R113

R040

R041

Q003

C023

R095

IC004

R094

16

1

R853

R109

R044

R045

Q007

R099

C021

16

1

8

IC005

R855

L002

IC560

C382

20

C512

C513

11

IC564

20

C397

C514

C515

11

IC510

20

C449

C510

C511

R862

11

R864

R652

R779

R686 R687

R683

R682

R679

R678

R850

R848 R654

R846

R844

R842

R840

R838

R836

R834

1

1

2

2

34

34

LC007

LC008

IC000

IC001

3

R027

4

R102

R101

C035

9

8

C049

R093

C027

9

8

C046

C182

R097

C031

9

R098

R857

C043

R861

R863

R020

R025

1

5

4

R019

R034

R038

C563

R860

C579

C184

10 11

R206

C561

R854

C577

10

C570

1

C562

C578

C232

10

R856

C041

1

10

C426

C367

3

R018

R023

3

1

5

4

R017

C016

C014

L001

C042

C253

R433

IC021

1

C566

R203

IC019

1

C564

C565

IC020

IC520

20

11

11

IC504

20

96

97

C376

C363

128

1

L554

96

97

C455

128

L504

C430

1

1

2

34

LC009

C040

C025

1

5

L003

IC002

R036

L019

R227

R226

C268

C573

R369

20

R290

R330

L018

C576

C261

C569

R194

R331

20

C571

R209

R329

C071

L017

C567

C574

11

R432

R118

20

R368

C255

C572

C265

R211

C277

R189

C575

11

R191

C568

R192

C287

20

D717

R293

IC047

1

R507

C522

C523

C524

10

1

C379

IC558

65

64

C371

IC512

C434

32

C457

65

64

32

C451

R366

R367

R186

8

9

R373

C222

R481

R495

C239

C243

R554

C279

R512

11

R438

R987

10

R506

R989

C377

R702

R703

C419

33

C368

C364

C420

C456

R830

R829

33

C435

C431

R309

1

16

IC202

C134

R372

C223

C224

C225

R479

R450

R497

R499

R484

R511

C249

R508

R500

Q021

C281

C280

R482

R494

R986

C533

R984

C534

R983

R982

C537

C536

R985

C535

L501

51

R761

R763

R765

R767

R769

80

81

R051

R310

R311

R375

R374

C275

R435

R417

C236

R405

R436

C246

R515

C166

C273

R526

R553

R528

C160

R400

C282

R398

R396

C531

C530

C532

R981

IC503

C418

3150

30

R798

1

100

R762

R764

R766

C414

R768

R053

R052

R502

C272

R337

IC209

80

81

R428

100

C172

1

R430

R431

R552

80

81

C153

100

1

R567

IC502

C410

50

51

C411

80

81

R793

R789

R785

R781

R032

TNPA1901

SEE REVERSE FOR ORDER NO.

C207

R468

R474

R540

R449

C197

C198

R444

C136

IC201

C289

R451

R404

R448

R317

C466

R427

51

50

C176

31

30

C170

C168

50

51

C135

51

50

80

81

C152

C144

C125

31

30

C130

R556

R569

R584

C408

R562

R573

R583

C293

R571

C297

C311

R560

R559

R579

R580

C309

C303

C498

C497

C427

100

50

31

30

51

R778

1

80

R794

R776

81

R790

R774

R786

R772

R770

R782

C423

C415

C416

31

30

IC200

1

100

C143

C124

R402

R403

C164

C165

C294

R561

C307

C312

C305

R734

R736

C398

R739

5

C403

8

IC516

C407

IC506

L036

C417

31

R799

51

30

C409

C412

1

80

100

R795

C413

R777

R791

R775

R787

R773

R783

R771

R460

R452

R458

C193

R461

R455

R459

C194

C465

C119

1

1011

IC707

C718

20

C323

C316

R613

R873

14

C463

IC404

1

C318

C317

R735

C401

C400

4

1

X500

IC507

50

C203

C212

R467

C204

C213

C211

R475

C206

R473

Q050

R463

R545

R469

C472

C476

R547

C479

C475

C238

L350

C230

C288

IC048

8

R874

R875

7

R876

R614

C404

C428

31

30

1

10081

C424

C471

C205

R542

C474

R541

R543

C226

R483

C233

R480

R498

R496

R501

R555

C283

R531

C284

11

20

R530

10

1

R504

R503

R993

R992

R991

C324

C315

C326

C325

C422

L502

C352

C421

51

R634

R636

R640

R644

R648

R796

R792

R788

R784

80

R031

R029

2

D

IC213

C215

IC214

C216

IC217

C227

R513

C254

C546

L026

50

IC061

R030

94V-0

D011

R119

C492

R955

R956

C601

C602

C600

C603

R890

R891

C173

C229

C228

C237

C248

C167

R517

C274

R527

R664

R617

R529

R509

C285

L551

C353

C161

R401

R399

C286

R397

C541

R568

C290

L450

C351

C343

31

50

51

30

R674

C344

1

80

R635

R639

10081

C347

81

R643

R647

R669

R665

R660

R656

C199

IC259

80

81

R429

100

1

80

81

C156

100

1

C304

R570

R574

R586

R582

C341

IC552

C360

100

51

50

C179

31

C171

30

C200

C138

IC251

R572

C306

R585

C120

R581

R563

C313

C310

C496

C495

R618

31

51

30

R651

1

80

R670

R649

R666

R645

R661

R641

R657

R637

C356

C348

C169

50

51

C137

51

50

80

81

C155

C127

C146

31

30

R565

R566

C298

R564

C314

C336

IC556

50

81

C349

31

30

IC250

1

100

C145

C126

C132

C319

R615

C308

C296

C295

R612

C340

C350

31

30

1

100

C345

R650

R646

R642

R638

R877

C327

14

C157

IC454

1

C329

C330

R607

C334

R608

R609

C331

5

8

IC057

L028

50

R675

51

C342

C346

80

81

R671

R667

R662

R658

C338

C333

4

C335

1

X004

IC557

C361

31

100

C357

L900

C076

R234

R228

C500

C501

C105

C923

C051

R137

C052

R271

R272

C103

R139

R881

Q013

C736

R306

C104

20

C102

R292

R307

IC703

C099

R286

R280

R158

R157

R145

C320

C328

8

R878

R879

R880

7

R616

C322

C321

C339

L550

L552

C354

C355

30

R672

R668

R663

R659

1

R150

C493

C904

C089

IC702

R231

C088

R239

R248

C927

R916

R255

C100

R882

C908

C096

11

10

1

IC704

R148

R332

R165

R149

R283

R205

R166

C097

R174

R172

R171

R177

R162

R333

C062

R176

R327

C063

C064

44

C065

R156

C058

C078

C081

IC705

1

L027

32

33

R700

R699

C372

64

65

C370

C369

C365

32

33

R832

R833

C453

64

65

C436

C432

R212

R214

C922

C920

R146

R179

R180

C921

C901

R202

R168

R167

R106

R282

R275

40

1

C101

D013

20

IC559

R962

R963

R287

C929

R365

R364

21

C086

R221

R233

R220

C079

R219

C080

C077

R238

R218

R334

D014

D015

R321

R315

R314

IC521

11

C527

C526

C525

20

IC555

11

20

C358

C378

1

128

97

96

C366

C458

IC513

1

128

97

96

C452

CR NO. 9

R322

R270

R250

Q903

R252

R213

R261

R303

R920

R262

R919

R921

R269

R264

R258

R263

R266

R267

R265

C924

R947

R289

1

R285

C932

C925

C098

4

R965

C930

R948

3

4

C933

R869

1

5

R870

R284

R281

C106

R362

R230

C084

R235

R254

R241

C373

C454

C433

IC909

R353

R288

R361

C116

R354

R355

R359

C117

R363

R356

R360

R243

C083

R256

C091

R300

C090

R259

R278

R257

23

C112

C113

22

R688

R690

R693

C517

R689

C516

R691

C383

R692

C519

R724

C518

R727

C396

R722

R725

R729

R731

R301

10

C520

R302

R304

R305

1

R653

10

1

C362

C429

R655

L553

L503

R831

C114

C115

R918

Q902

C926

R937

R954

C108

C109

R953

R945

8

R944

R950

R949

R946

IC907

R917

5

L005

R318

C910

R534

Q901

R320

R319

R441

R357

R358

C745

R141

R535

10

11

20

1

IC561

11

10

20

1

IC565

10

11

C521

C450

R780

R685

R684

R681

R680

R677

R676

R849

R847

R845

R843

R841

R839

R837

R835

1

20

R817

IC511

R820

R825

R818

R821

R823

1

ABCDEFGHI

52

Page 53

D

PARTS LOCATION

D-BOARD (FOIL SIDE)

IC

IC000 B-5

IC001 B-5

IC002 B-5

IC005 B-4

IC019 B-4

IC020 B-4

IC021 B-5

IC047 B-4

IC048 E-4

IC061 E-1

IC067 G-2

IC200 D-4

IC201 D-3

IC202 C-5

IC209 D-5

IC213 E-5

IC214 E-5

IC217 E-5

IC251 F-4

IC259 F-5

IC260 G-4

IC404 E-3

IC454 G-3

IC502 D-2

IC503 C-2

ADDRESS INFORMATION

IC504 B-2

IC506 D-2

IC507 E-2

IC510 B-3

IC511 I-3

IC512 B-2

IC513 H-2

IC518 E-2

IC520 B-3

IC521 H-3

IC552 F-2

IC555 H-3

IC556 F-2

IC557 G-2

IC558 B-2

IC559 H-2

IC560 B-3

IC561 I-3

IC564 B-3

IC565 I-3

IC702 H-5

IC703 G-4

IC704 G-4

IC705 H-4

IC707 D-4

IC907 H-5

IC909 H-4

TRANSISTOR

Q001 B-4

Q002 A-4

Q003 B-4

Q005 A-4

Q006 B-4

Q007 B-4

Q009 B-5

Q010 A-5

Q011 B-5

Q013 G-4

Q021 C-4

Q050 E-5

Q901 I-4

Q902 H-5

Q903 H-5

PARTS LOCATION

D-BOARD (COMPONENT SIDE)

IC

IC003 H-3

IC007 H-4

IC008 H-4

IC009 H-5

IC010 H-3

IC012 H-4

IC014 F-3

IC015 G-5

IC016 G-5

IC017 G-5

IC018 H-3

IC023 H-3

IC024 E-5

IC036 F-5

IC068 C-2

IC093 G-5

IC204 F-5

IC206 F-5

IC207 E-5

IC210 F-5

IC211 E-5

IC212 E-5

IC215 E-5

IC223 F-5

IC225 G-4

IC226 E-3

IC254 D-4

ADDRESS INFORMATION

IC302 G-4

IC352 E-4

IC400 F-3

IC401 G-3

IC402 E-3

IC403 E-3

IC450 D-3

IC451 D-3

IC452 C-3

IC453 C-3

IC500 F-2

IC501 F-2

IC505 B-2

IC509 B-1

IC508 H-1

IC551 D-2

IC554 H-2

IC562 H-2

IC563 B-2

IC701 B-3

IC706 C-5

IC900 B-5

IC901 A-5

IC902 B-5

IC903 B-5

IC904 B-5

IC905 B-4

IC906 B-4

IC908 C-5