Toshiba 50L4333D-G Schematic

SERVICE MANUAL

LCD Color Television

50L4333D(G), (F)

REVISED:01

50L4331D(G)

50L4337D(G), (F)

REVISION HISTORY

REV

Date

Reason for Change

1

Jul/31/2013

- Addition of the 50L4331D(G) and 50L4337D(G)/(F) model

- Updating of the Parts List (Exploded View)

CONTENTS

1. IMPORTANT NOTICE

2. GREEN PRODUCT PROCUREMENT

3. LEAD-FREE SOLDER

4. SAFETY INSTRUCTION

5. SERVICE MODE

6. LED INDICATIONS FOR SERVICE

7. HOTEL MODE

8. HOTEL CLONE

9. INTERCONNECT

10. EXPLODED VIEW

11. PANEL IDENTIFICATION

12. MAIN BOARD EXCHANGE

13. ABOUT THE MAIN BOARD

1

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data provided

herein without prior written consent by Toshiba. Toshiba shall not be liable to

anybody for any damages, losses, expenses or costs, if any, incurred in connection

with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY

WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED WARRANTY OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of use of any information or data provided

herein.

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing

its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase

and use products, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts

used in manufacture must also be used as replacement parts.

LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder

must be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 30ºC to

40ºC (54ºF to 72ºF). Use of a soldering iron designed for lead-based solders to repair

product made with lead-free solder may result in damage to the component and or PCB

being soldered. Great care should be made to ensure high-quality soldering when servicing

this product especially when soldering large components, through-hole pins, and on PCBs

as the level of heat required to melt lead-free solder is high.

(1/4)

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY PRECAUTION"

AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE UNFAMILIAR WITH

THE NECESSARY PRECAUTIONS ON THIS RECEIVER. THE FOLLOWING ARE THE

NECESSARY PRECAUTIONS TO BE OBSERVED BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These items

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

mark is indicated

(2/4)

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation,

malfunction, or electrical leakage and flame, which may be hazardous.

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer for

this check.

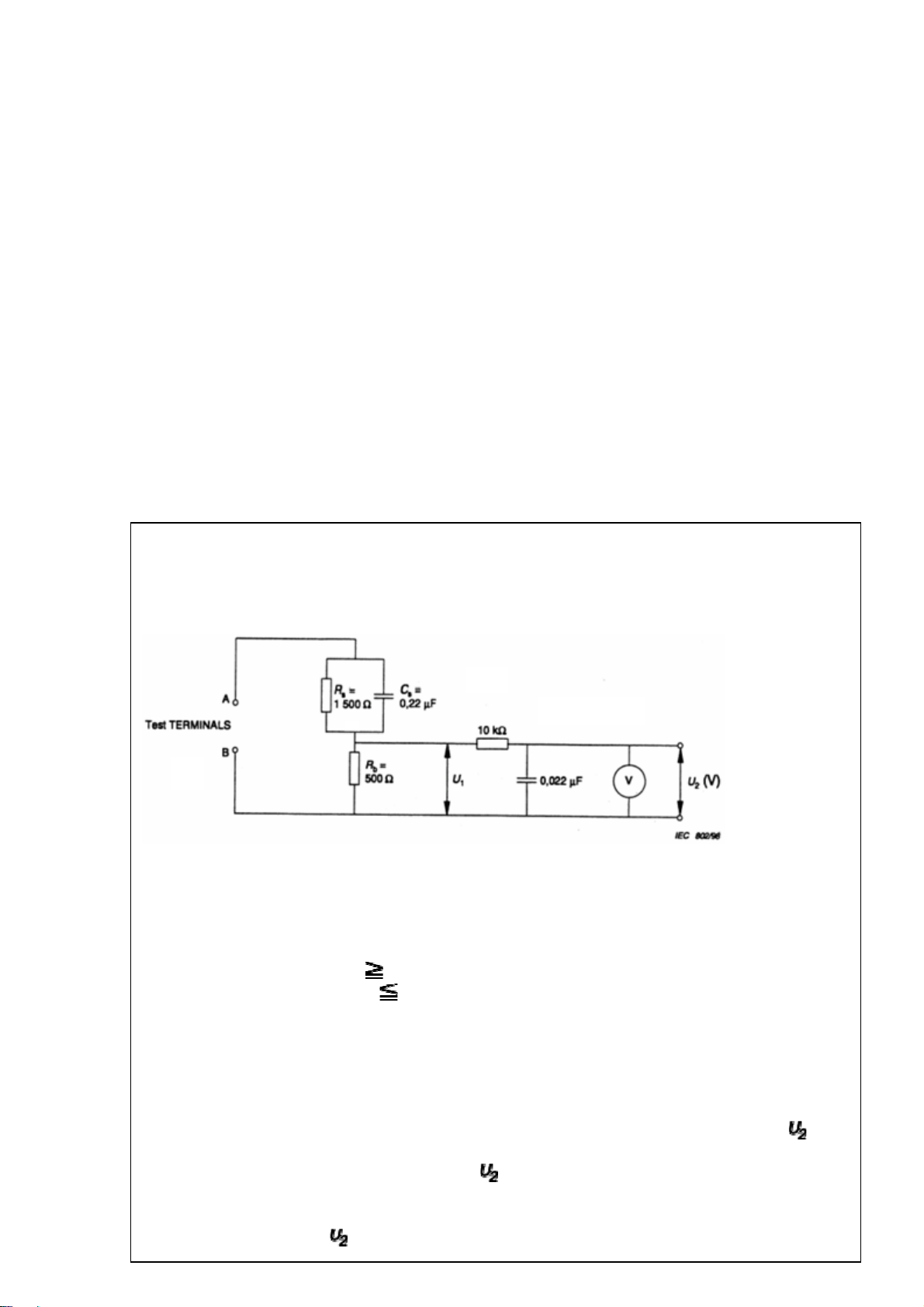

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Input resistance :

1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with

the solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of

from the ideal curve as a function of

frequency.

TOUCH CURRENT =

/ 500 (peak value).

(3/4)

The potential at any point (TOUCH CURRENT) expressed as voltage and does

not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is

not met.

b)

The measurement of the TOUCH CURRENT shall be carried out in accordance

with IEC 60990, with the measuring network described in Annex D of this

standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c.

correspond to the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

(4/4)

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related characteristics.

These characteristics are often passed unnoticed by a visual inspection and the protection

afforded by them cannot necessarily be obtained by using replacement components rated for

higher voltage, wattage, etc. Replacement parts which have these special safety

characteristics are identified in this manual and its supplements; electrical components having

such features are identified by the international hazard symbols on the schematic diagram and

the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use

of substitute replacement parts which do not have the same safety characteristics as specified

in the parts list may create electrical shock, fire, or other hazards.

SERVICE MODE

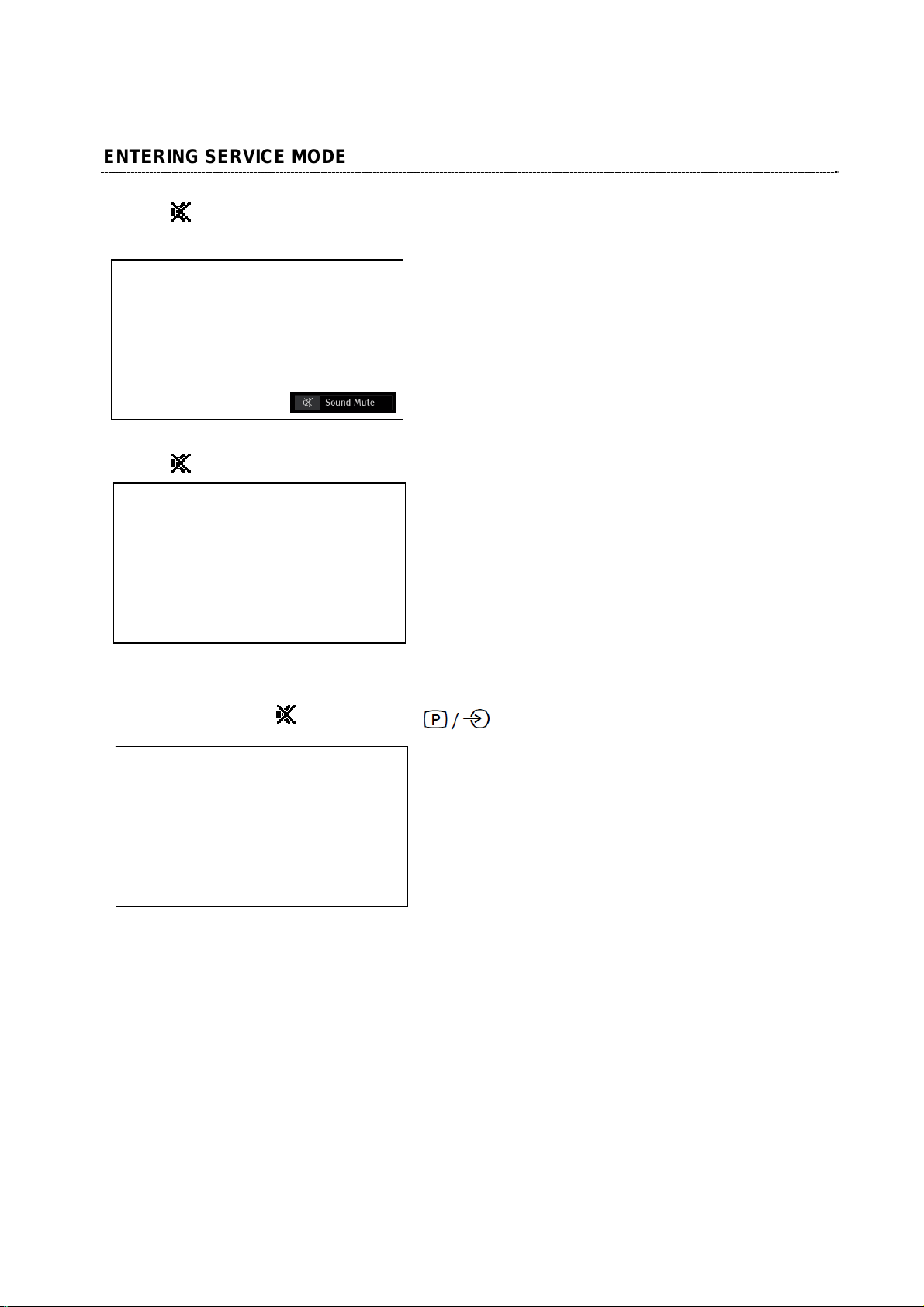

ENTERING SERVICE MODE

1. Press button once on Remote Control.

TV mode changes as follows. Un-Mute => Mute

(1/3)

2. Press

button again and keep pressing.

(Sound Mute is canceled)

3. While pressing the button, press button on TV control panel.

S

(Enter Service Mode)

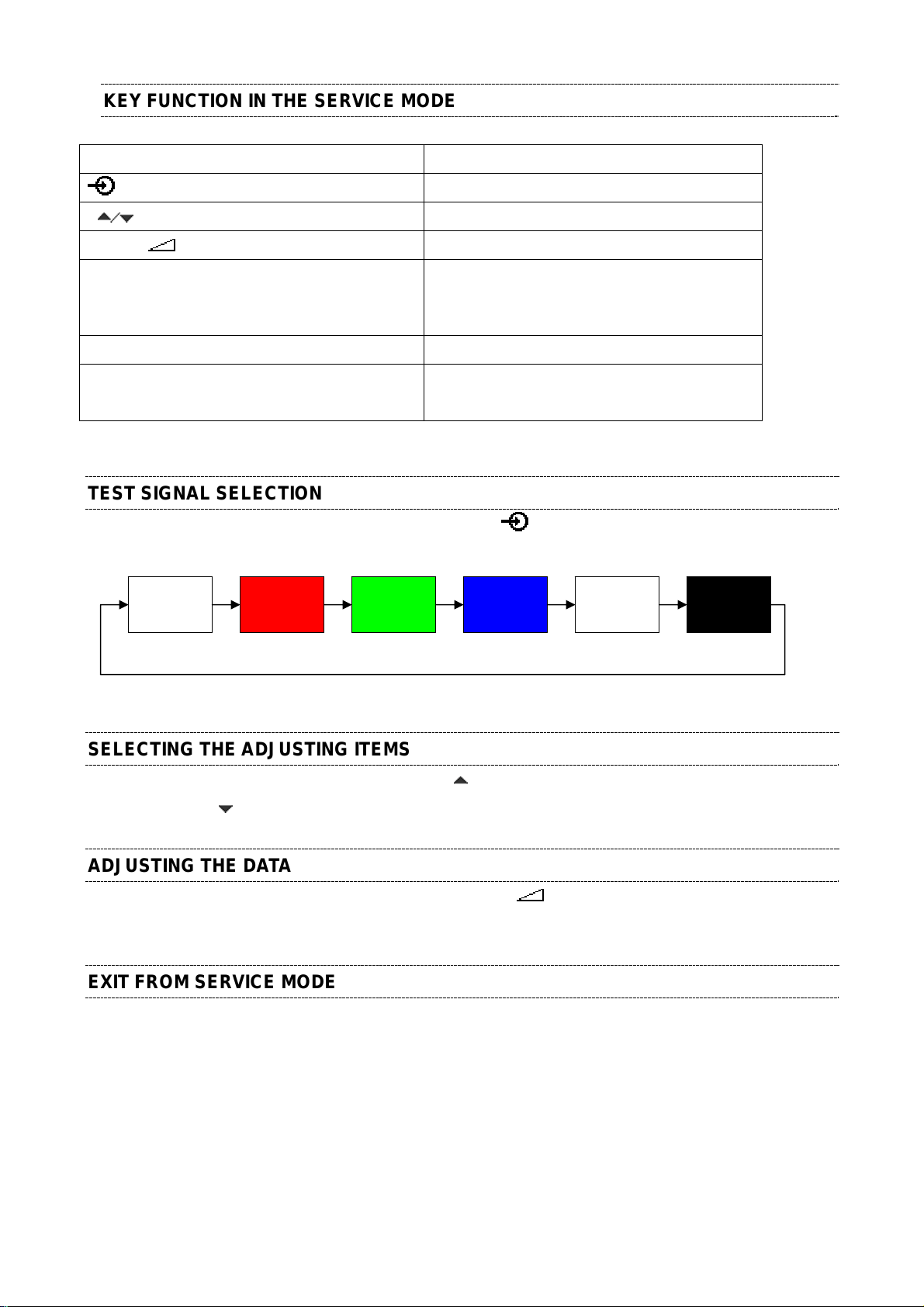

KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Button Function

(2/3)

button (on Remote)

P (on Remote) Selection of the adjustment items

Volume +/– (on Remote) Change of the data value

[7] button Automatic A/D Adjustment

[9] button Self Check display ON

[Exit] button Exit from Service mode

CAUTION: Never try to perform initialization unless you have changed the memory IC.

Test signal selection

(PC, Component, Composite(PAL, NTSC))

Self Check display Off

TEST SIGNAL SELECTION

1) While displaying the adjustment menu, every pressing of button on the Remote Control changes the

built-in test patterns on screen as described below.

Normal

Picture

Blue screen Green screenRed screen

When

a pattern is changed at the time of an ATV display, it can display only for a moment.

SELECTING THE ADJUSTING ITEMS

1) While displaying the adjustment menu, press the P button to cycle through the adjustment items in the

order of table. (P

button for reverse order)

ADJUSTING THE DATA

1) While displaying the adjustment menu, press the VOLUME +/– button to change the value of data in

the range from 00H to FFH. The variable range depends on the adjusting item.

EXIT FROM SERVICE MODE

1) Press the [Exit] button on Remote.

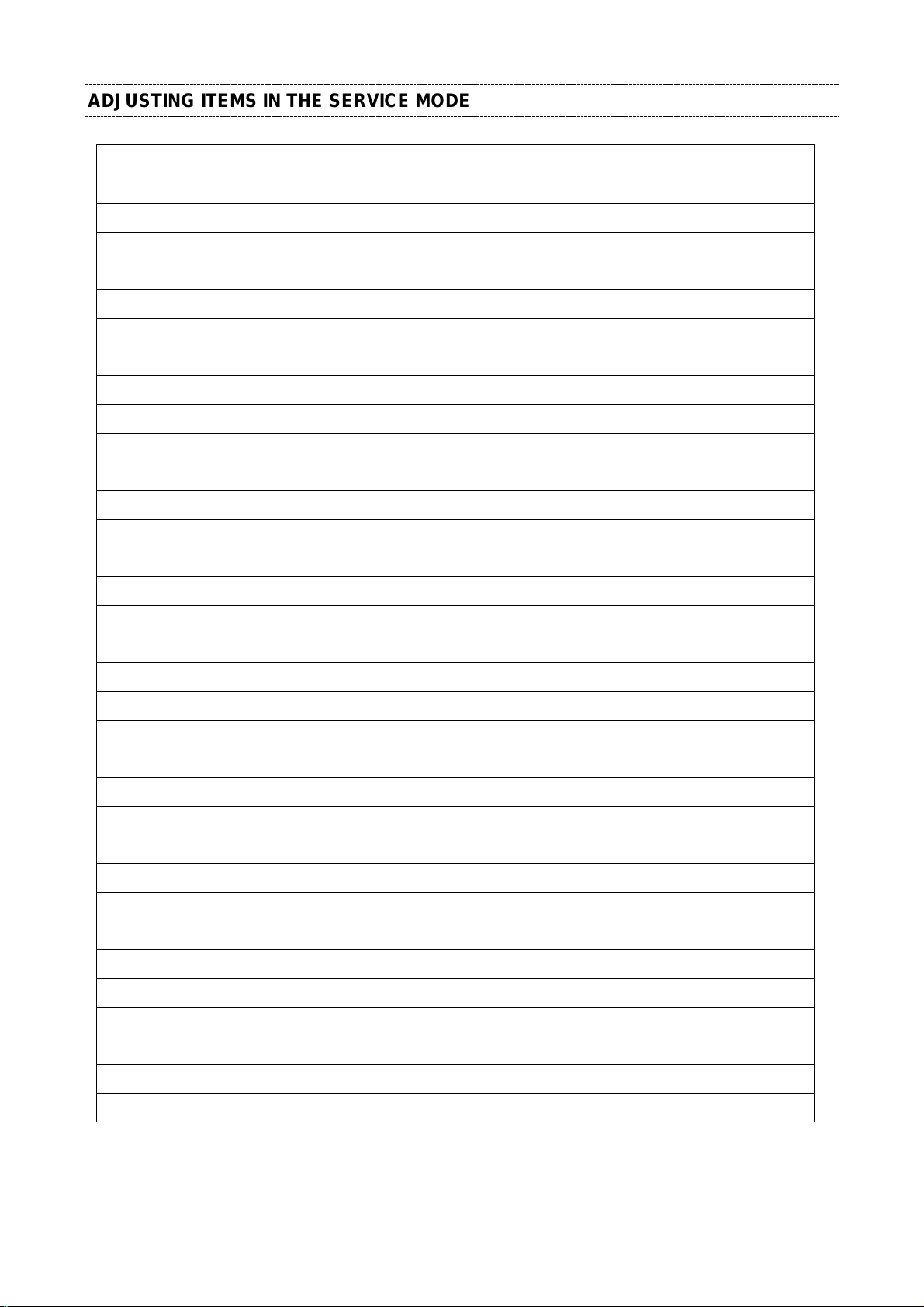

ADJUSTING ITEMS IN THE SERVICE MODE

Item Description

RCUT RED CUTOFF

GCUT GREEN CUTOFF

BCUT BLUE CUTOFF

RDRV RED DRIVE

GDRV GREEN DRIVE

BDRV BLUE DRIVE

OSRC COOL R-CUTOFF-OFFSET for COOL

OSRC NATURAL R-CUTOFF-OFFSET for NATURAL

OSRC WARM R-CUTOFF-OFFSET for WARM

OSGC COOL G-CUTOFF- OFFSET for COOL

OSGC NATURAL G-CUTOFF -OFFSET for NATURAL

OSGC WARM G-CUTOFF-OFFSET for WARM

(3/3)

OSBC COOL B-CUTOFF-OFFSET for COOL

OSBC NATURAL B-CUTOFF-OFFSET for NATURAL

OSBC WARM B-CUTOFF-OFFSET for WARM

OSRD COOL R-DRIVE-OFFSET for COOL

OSRD NATURAL R-DRIVE-OFFSET for NATURAL

OSRD WARM R-DRIVE-OFFSET for WARM

OSGD COOL G-DRIVE-OFFSET for COOL

OSGD NATURAL G-DRIVE-OFFSET for NATURAL

OSGD WARM G-DRIVE-OFFSET for WARM

OSBD COOL B-DRIVE-OFFSET for COOL

OSBD NATURAL B-DRIVE-OFFSET for NATURAL

OSBD WARM B-DRIVE-OFFSET for WARM

OSRD 3D COOL R-DRIVE-OFFSET for COOL (3D)

OSRD 3D NATURAL R-DRIVE-OFFSET for NATURAL (3D)

OSRD 3D WARM R-DRIVE-OFFSET for WARM (3D)

OSGD 3D COOL G-DRIVE-OFFSET for COOL (3 D)

OSGD 3D NATURAL G-DRIVE-OFFSET for NATURAL (3D)

OSGD 3D WARM G-DRIVE-OF FSET for WARM (3D)

OSBD 3D COOL B-DRIVE-OFFSET for COOL (3D)

OSBD 3D NATURAL B-DRIVE-OFFSET for NATURAL (3D)

OSBD 3D WARM B-DRIVE-OFFSET for WARM (3D)

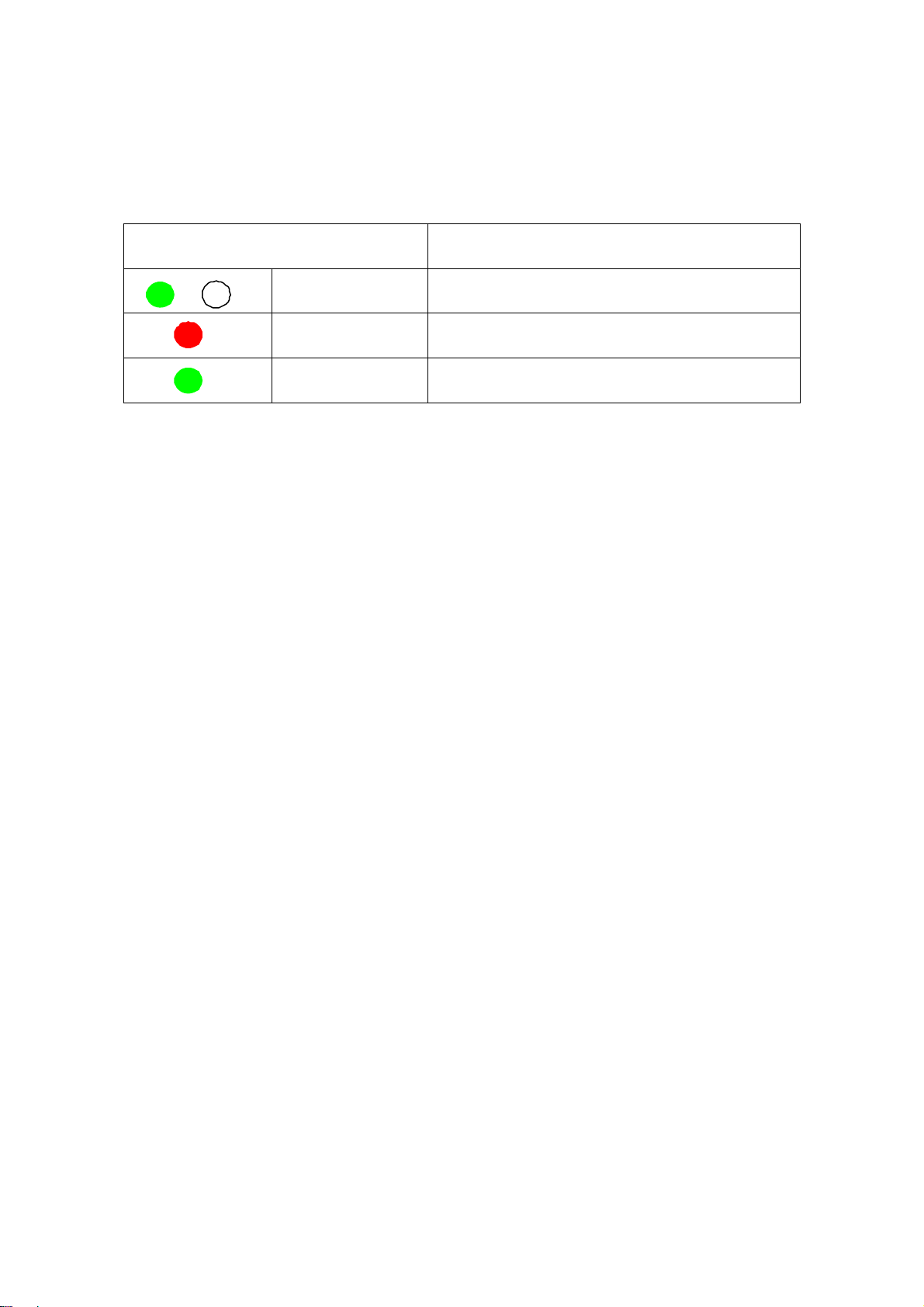

LED INDICATIONS FOR SERVICE

SW Upgrade and Error conditions indicated by the Power LED is described below.

Power LED

/

Green blink SW Upgrade in Progress

Red SW Upgrade Failed

Green SW Upgrade Successful

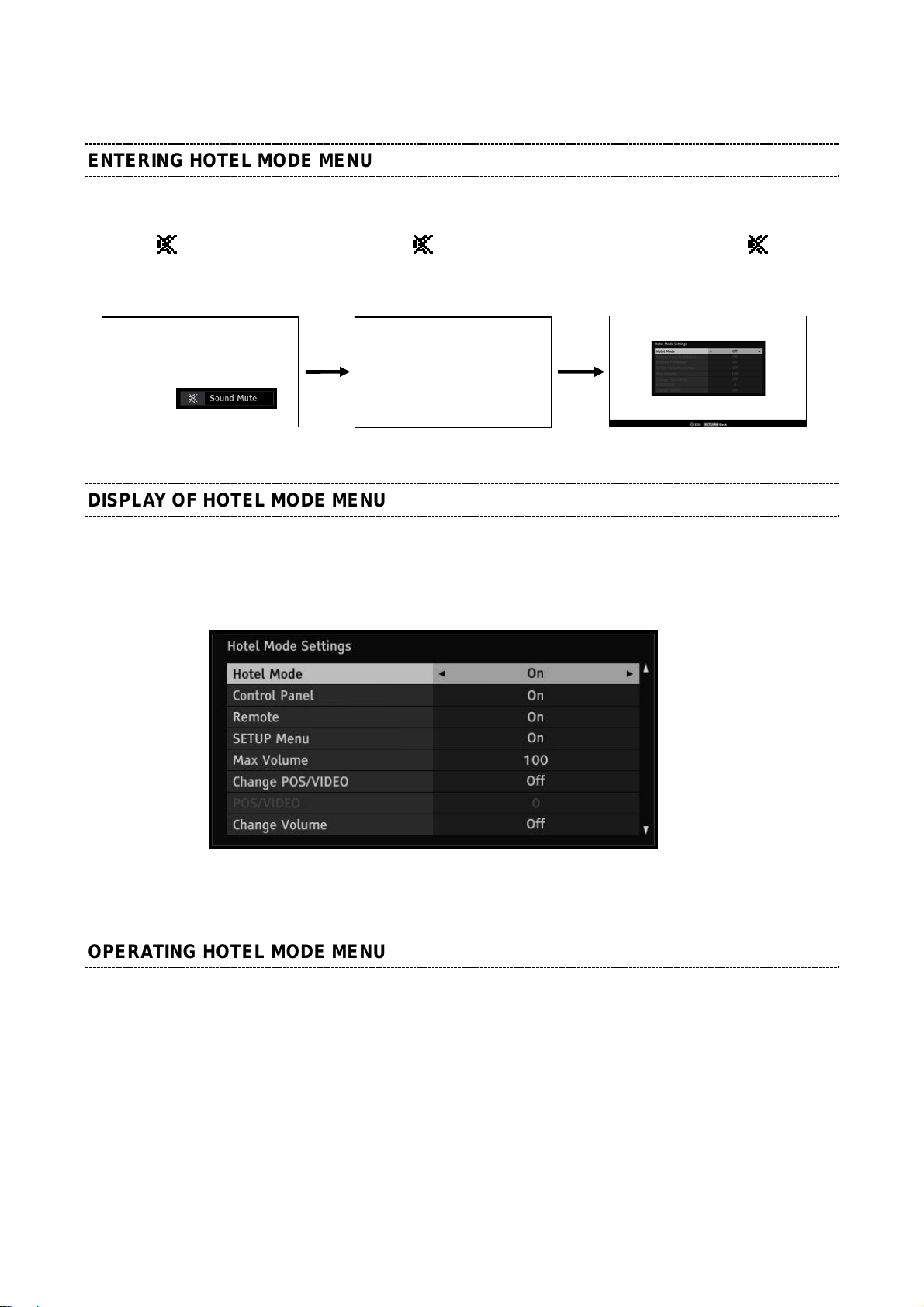

HOTEL MODE

ENTERING HOTEL MODE MENU

Hotel Mode Menu should be shown by the following operation.

1) Press any button on TV to activate Touch Sensor. White LED will light up.

(1/6)

2) Press

Remote Control. keep pressing. press “+” button on TV.

button once on the 3) Press button again and 4) While pressing the button,

(Hotel Mode Settings Menu)

DISPLAY OF HOTEL MODE MENU

- The Graphic Design and color of Hotel Mode Menu is the same as the User menu.

(Small differences which do not affect to operation will be acceptable)

- The language will follow the “Menu Language” setting in the menu

(Example of Menu Image)

OPERATING HOTEL MODE MENU

- To enable Hotel Mode, use the or arrow keys while “Hotel Mode” item is highlighted to select “On”.

Once Hotel Mode is on, the Hotel Mode settings will be enabled for adjusting.

- Use ▲ and ▼ buttons to access the hotel mode settings.

Use and buttons to change the settings.

See the table below for explanation of each setting.

- Press Exit when finished adjusting the settings.

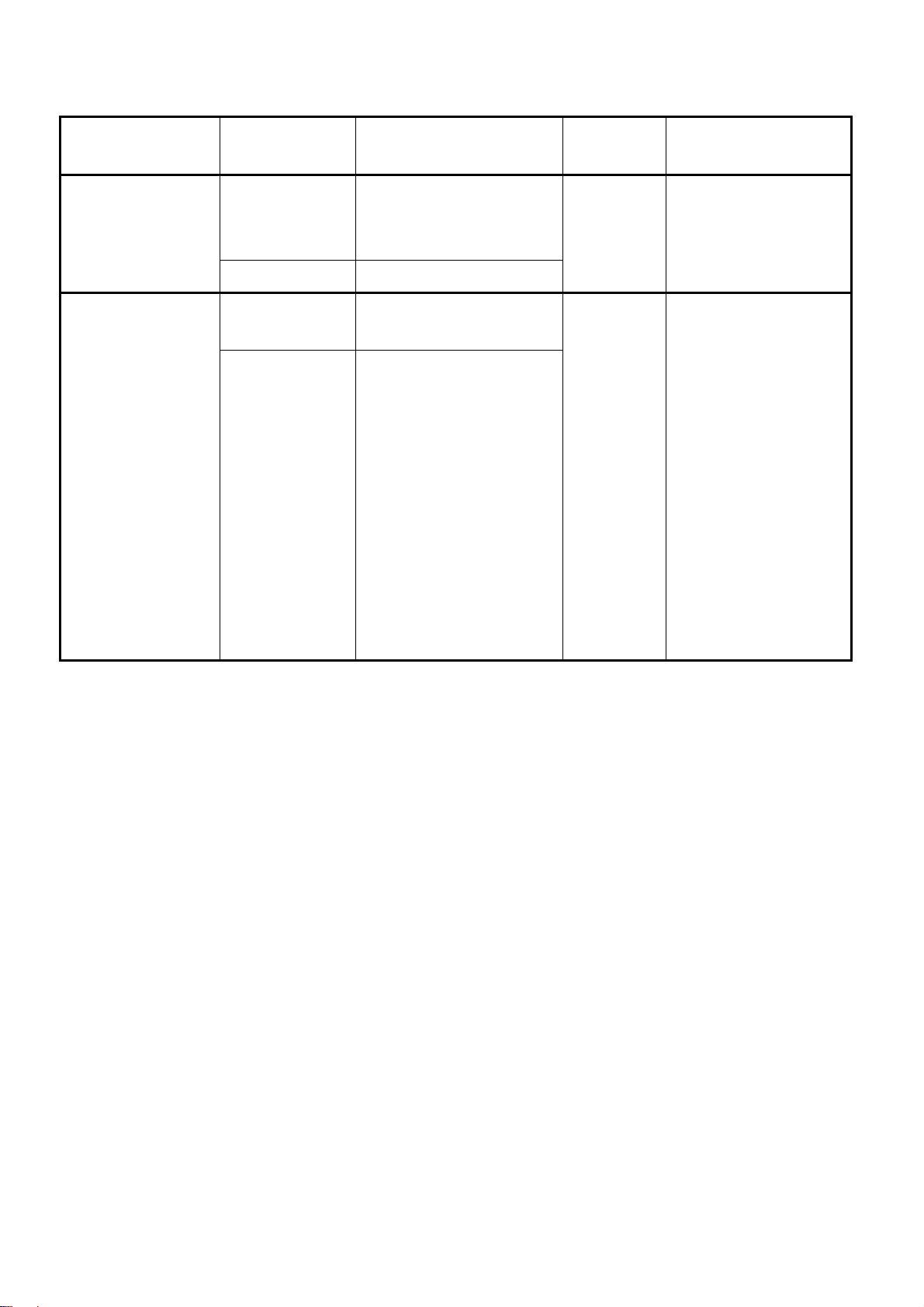

(2/6)

Item Options Description

Hotel Mode

Control Panel

Off Disable Hotel Mode.

All the settings of Hotel Mode

are disabled.

On Enable Hotel Mode

On Allow use of all Control panel

buttons

Off Prohibit use of all control panel

buttons.

But, Power Off -> On by control

panel POWER button is not

prohibited.

(Power On -> Off is prohibited.)

* Entering Service mode/Hotel

mode Menu/Hotel Clone is not

Off -

On - Grayed out when "Hotel

Factory

Gray Out Conditions

settings

Mode" = [Off]

prohibited.

* Control panel buttons are

available during Service mode.

(3/6)

Setup Menu

On Remote Enabled Remote Control

Off Remote Disabled

* The following remote codes are

not disabled.

- SOUND MUTE (40BF10)

- Super User mode (40BFFE)

- S mode (40EEC3)

* Remote Enabled during Service

mode/Hotel mode Menu/Hotel

Clone.

* When Remote Control is set to

“Off”, the [Panel Lock] setting in

the main menu will be grayed out

and forced to “Off”.

On Allow access to SETUP menu

Off Prohibit access to the setup

On - Grayed out when "Hotel

Mode" = [Off]

On - Grayed out when "Hotel

Mode" = [Off]

menu.

SETUP menu icon is grayed out

and it is prohibited to select

(skip).

(If gray-out of SETUP menu icon

is difficult,

skipping without gray-out is

acceptable )

Off (Except

Language)

Max Volume 0-100 Set maximum volume level.

Prohibit access to all items in the

setup menu except for the

Language setting.

The prohibited items are not

shown on the menu. (Gray-out

instead of erasing is acceptable)

It limits the volume level which

100 - Grayed out when "Hotel

Mode" = [Off]

can be set by Volume button.

If you set it to 70, Volume bar can

not go to 71 or higher.

(4/6)

Change POS/VIDEO

POS/VIDEO

(only available when

“Change POS/VIDEO”

is On)

Off TV Tunes to the last channel or

input viewed when powered on

On TV tunes to preset

“POS/VIDEO” (channel or input)

when TV is powered on.

On (AC) TV tunes to preset

“POS/VIDEO” (channel or input)

only when AC power is applied.

When TV is powered on by

power button, tune to the last

channel or input.

0-99 0-99 (ATV Channel Position)

DTV DT V (DTV channel number can

not be set. The last selected

channel is shown.)

Off - Grayed out when "Hotel

Mode" = [Off]

0

- Grayed out when Hotel

Mode = [Off]

- Grayed out when

"Change POS/VIDEO" =

Change Volume

Volume

(only available when

VIDEO1 VIDEO1

VIDEO2 VIDEO2

VIDEO3 VIDEO3

HDMI1 HDMI1

HDMI2 HDMI2

HDMI3 HDMI3

HDMI4 HDMI4

PC PC

Off TV volume level does not

change when TV powers on

On TV volume level is forced to

“Volume” level when TV is

powered on

0-100 Volume level when TV is

powered on

* The input which

does not exist on

the model should

not be shown.

(eg. “DTV” is not

shown on ATV

models.)

[Off]

Off - Grayed out when "Hotel

Mode" = [Off]

30

- Grayed out when "Hotel

Mode" = [Off]

“Change Volume” is

On)

- Grayed out when

"Change Volume" = [Off]

(5/6)

Change Picture Mode

Picture Mode

(only available when

“Change Picture Mode”

is On)

Off Picture setting mode does

not change when TV is

powered on

On Picture setting mode is

forced to “Picture Mode”

mode when TV is powered

on

AutoView AutoView

Dynamic Dynamic

Standard Standard

Movie 1

(EU: Hollywood

Day)

Movie 2

(EU: Hollywood

Night)

Movie 1

(EU: Hollywood Day)

Movie 2

(EU: Hollywood Night)

Off - Grayed out when "Hotel

Mode" = [Off]

AutoView - Grayed out when "Hotel

Mode" = [Off]

- Grayed out when

"Change Selectable

Picture" = [Off]

TV Power

Position Change on

HDMI Input

Disabled TV returns to previous

Standby/On State when

AC power is applied

Force On Power TV on when AC

power is applied

Force Standby Put TV in Standby when

AC power is applied

On

Off When viewing HDMI input,

RF tuning via P

RETURN, and number

buttons is allowed.

(Normal operation)

RF tuning via P▲, P▼,

RETURN, and number

buttons is disabled

▲, P▼,

Disabled - Grayed out when "Hotel

Mode" = [Off]

On - Grayed out when "Hotel

Mode" = [Off]

(6/6)

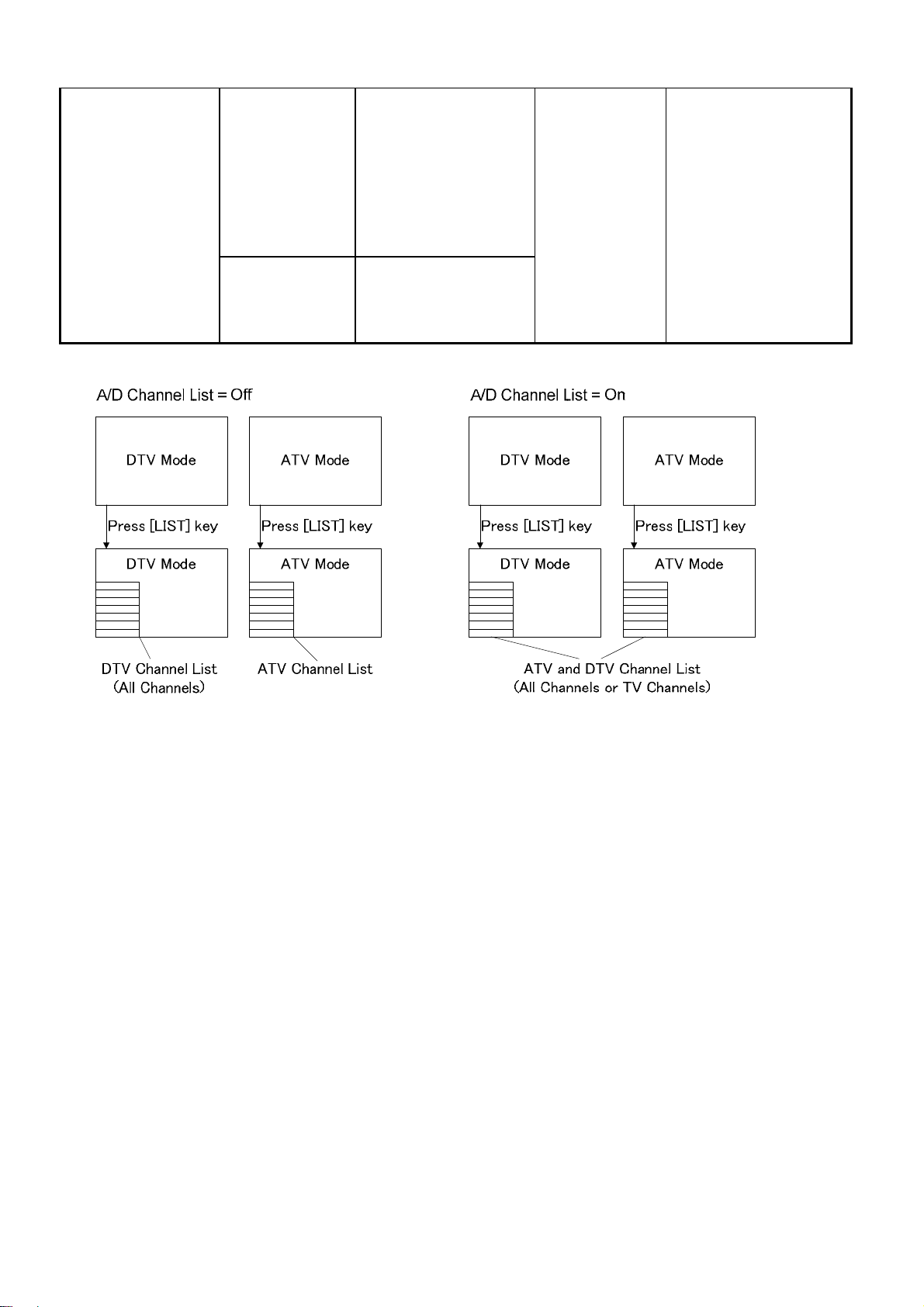

A/D Channel List

On TV shall combine both

Analogue & Digital

channels in one channel

list, and select the

ATV/DTV channel without

boarder.

Off DTV Channel List and

ATV DTV Channel List are

separated.

Off - Grayed out when "Hotel

Mode" = [Off]

HOTEL CLONE

The following settings can be copied between sets using the Hotel clone menu:

● Hotel mode menu settings

● DTV Channel Setup (DTV models only)

● ATV Channel Setup

▪ Programme (position)

▪ System

▪ Colour System

▪ Programme Skip

▪ Channel

▪ Manual Fine Tuning

▪ Label

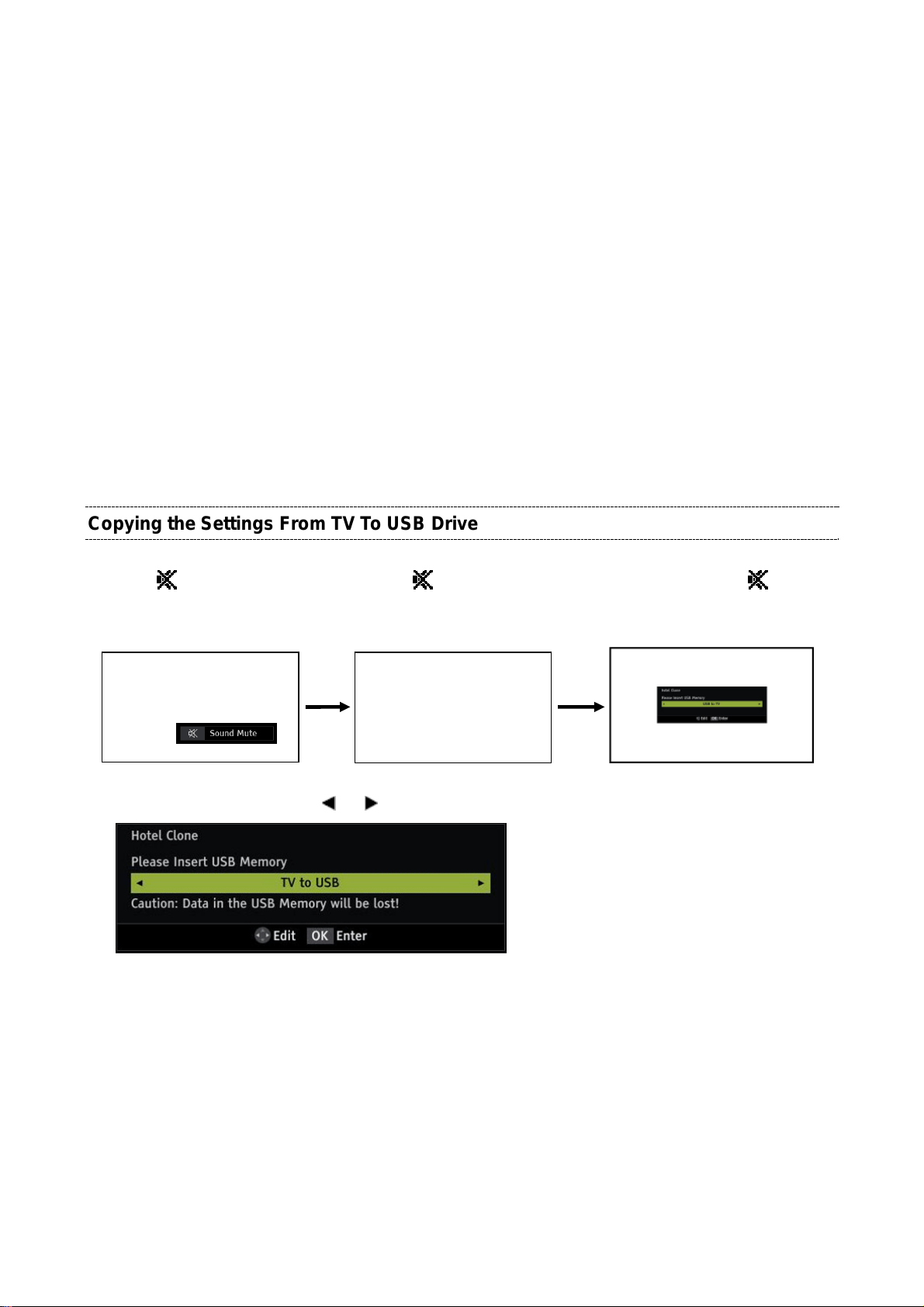

Copying the Settings From TV To USB Drive

(1/2)

1) Press

Remote Control. keep pressing. press “-” button on TV.

4) Select "TV to USB" using the

5) Insert USB Drive and press OK to copy settings to the USB drive.

6) Wait for window that indicates the copying process is complete before removing the USB drive.

button once on the 2) Press button again and 3) While pressing the button,

(Hotel Clone menu display)

or arrow keys.

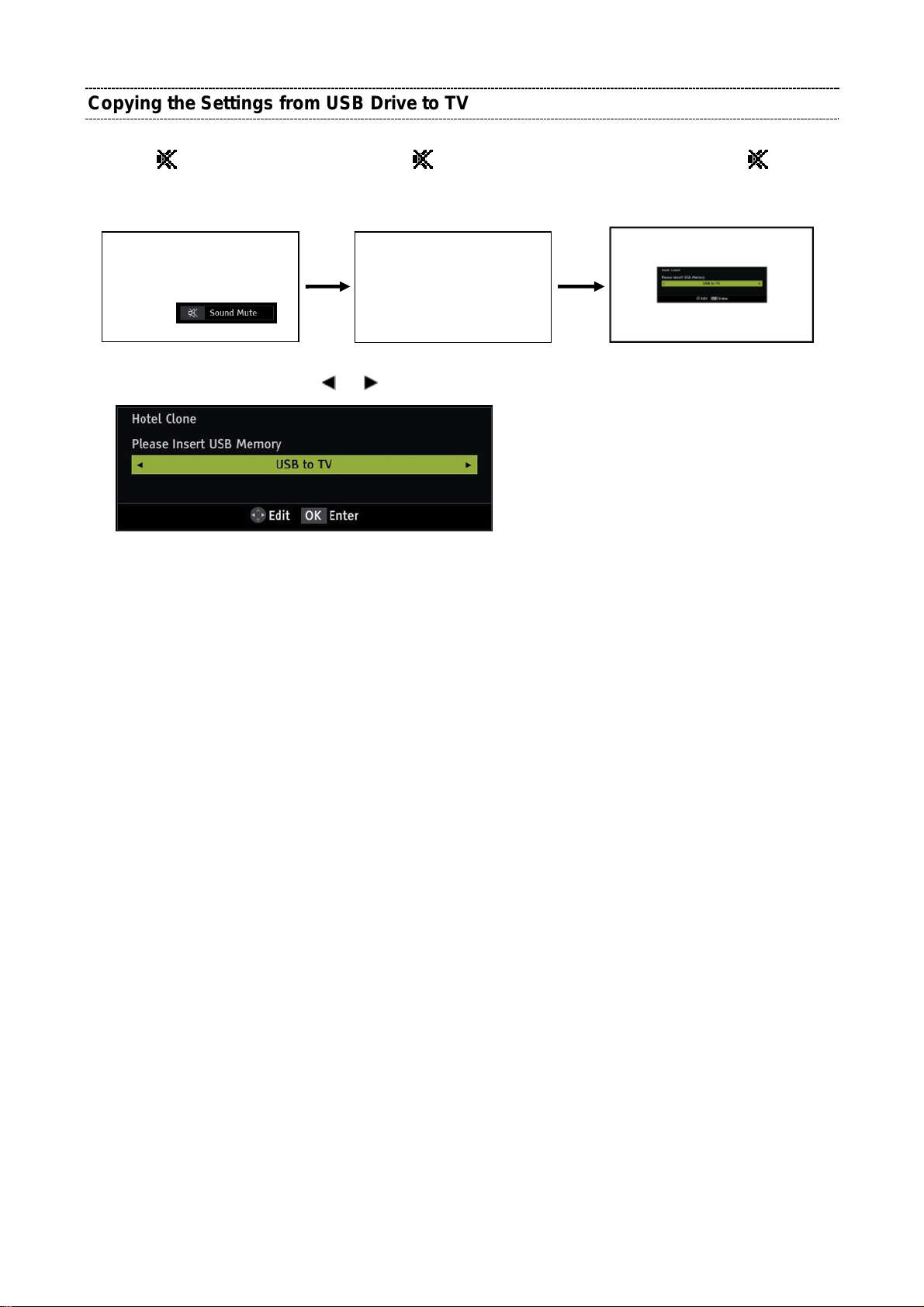

Copying the Settings from USB Drive to TV

(2/2)

1) Press

button once on the 2) Press button again and 3) While pressing the button,

Remote Control. keep pressing. press “-” button on TV.

4) Select "USB to TV" using the or arrow keys.

5) Insert USB Drive that settings have previously been saved to and press OK to copy settings to the TV.

6) Wait for settings to be copied.

When the copying has finished successfully, the message "The TV will reboot when this window is

(Hotel Clone menu display)

closed." will be displayed. If the copying is not successful, an error message will be displayed.

7) Exit the menu and the TV will reboot.

8) Remove the USB drive.

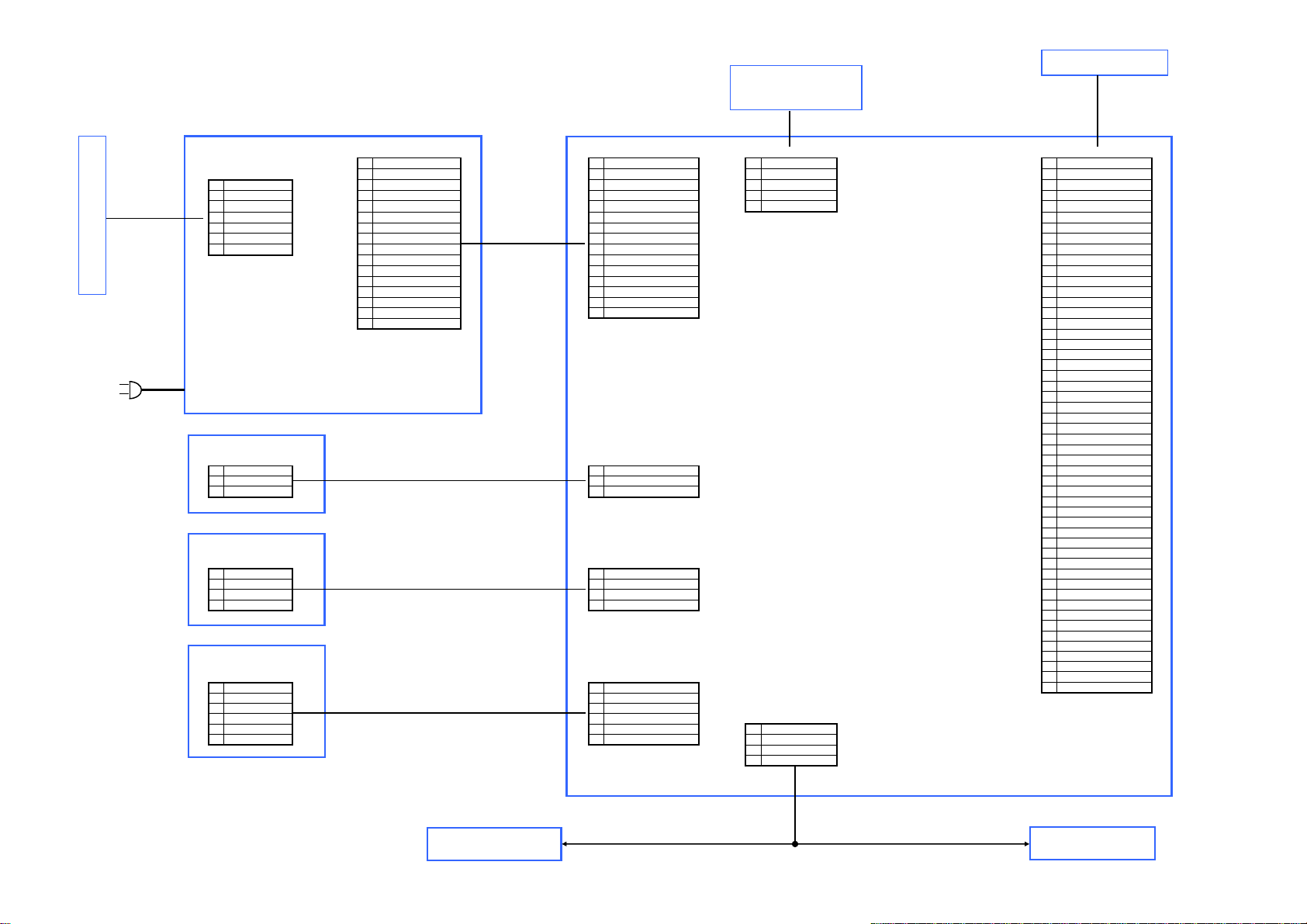

E352

PANEL (LED B/L)

E320

E280

E260

E270 IR BORAD

PANEL (T-CON)

E290

WLAN MODULE

E350

CN2 CN90 CN162 CN650

CN3 2 12V 2 12V 2 GND 2 VCC_LCD

1 L2 Cathode 3 12V 3 12V 3 M_USB1DP 3 VCC_LCD

2 NC 4 GND 4 GND 4 M_USB1DM 4 VCC_LCD

3 L2 Anode 5 GND 5 GND 5 5V_WLAN 5 NC

4 NC 6 NC/12V_AUDIO 6 12V_AUDIO 6 GND

5 L1 Cathode 7 GND_AUDIO 7 GND_AUDIO 7 GND

6 NC 8 5VS/NC 8 (NC) 8 GND

7 L1 Anode 9 5VS/NC 9 GND 9 GND

E250

POWER BOARD

KEY BORAD

1 GND 1 GND 30 LVA3N

2 ADC_IN 2 Func Key 31 GND_T1

3 POWER_KEY 3 Power Key 32 LVACKP

LED BORAD

1 LED_5V1 1 RED 40 LVA0N

2 GND 2 GREEN 41 GND

3 GREEN 3 GND 42 NC/NC/LD-Ena

4 RED 4 5V1 43 NC/TMPS1/NC

1 3.3VD_IR 1 3.3VD 51 NC/NC/3D-En

2 GND 2 GND

3 Br Sensor 3 Br Sensor

4 GND 4 GND CN300

5 3.3V_STNBY_IR 5 3.3V_STNBY 1 R-SPK

6 RMT_IN 6 RMT_IN 2 R+SPK

1 12V 1 12V 1 GND 1 VCC_LCD

E344

10 5VS 10 5V1 10 GND

11 GND 11 AC_DETECT 11 LVB4P

12 ACD 12 POWER_TV 12 LVB4N

13 POWER_ON 13 BL On/Off 13 LVB3P

14 BL_ON_OFF 14 PWM2 14 LVB3N

15 NC 15 PWM1 15 GND_T1

16 PWM1 16 LVBCKP

E200

MAIN BOARD

E348

CN743 29 LVA3P

CN742 39 LVA0P

17 LVBCKN

18 GND_T1

19 LVB2P

20 LVB2N

21 LVB1P

22 LVB1N

23 LVB0P

24 LVB0N

25 NC/LR_SW/NC

26 NC/3D_EN/NC

27 LVA4P

28 LVA4N

33 LVACKN

34 GND_T1

35 LVA2P

36 LVA2N

37 LVA1P

38 LVA1N

E346

44 NC/TMPS0/NC

45 LVDS_SEL(L)

46 NC/NC/NC (PWM)

47 NC/NC/I2CCK

48 NC/NC/I2CDA

CN741 50 NC/NC/NC

49 NC

E342

3 L-SPK

4 L+SPK

E310A

75034289 (RA)

75034290 (RB)

Speaker

E340

Speaker

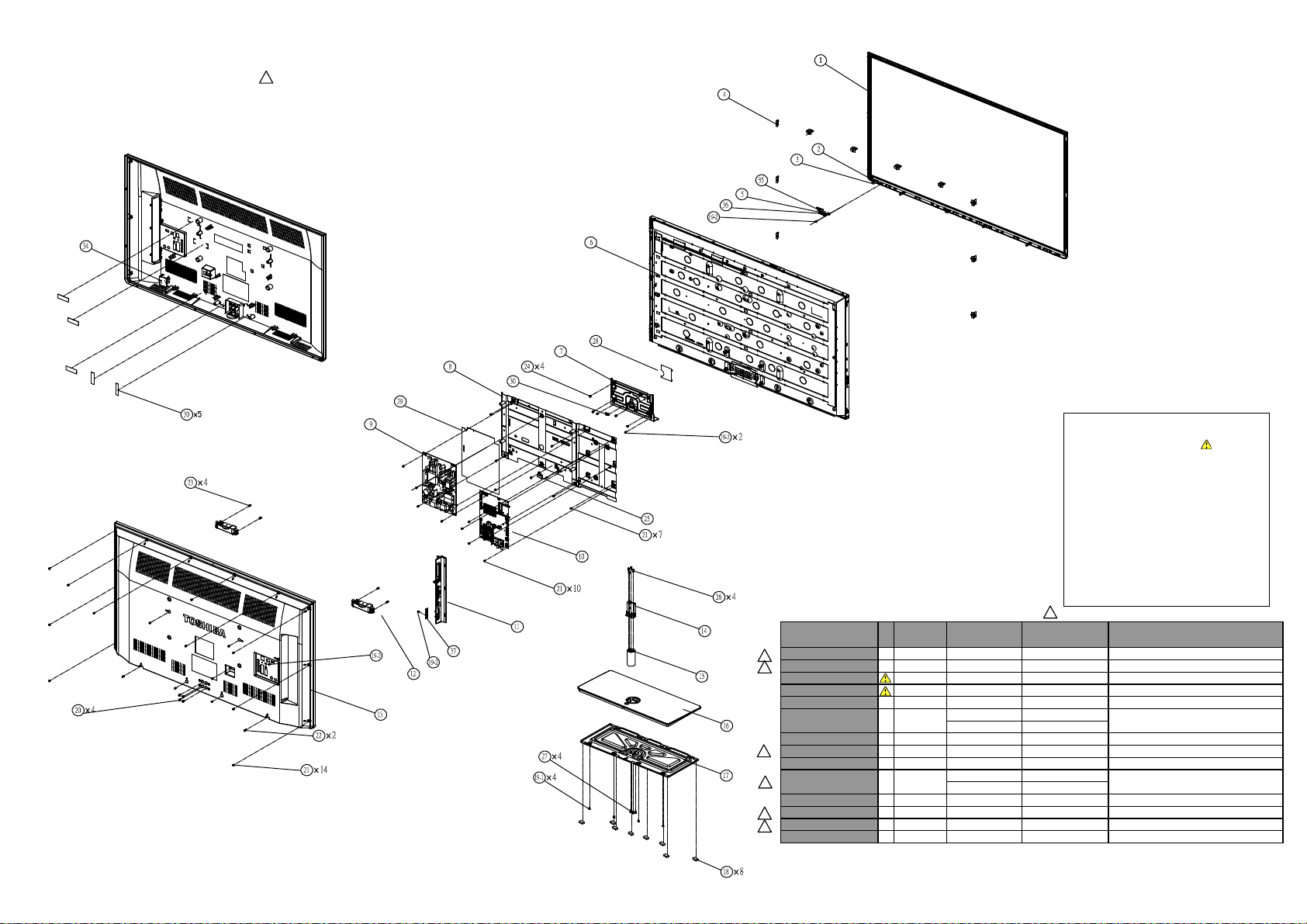

Exploded View

)

(

)

Y

(

)

Y

Y

Y

Y

r

t

e

y

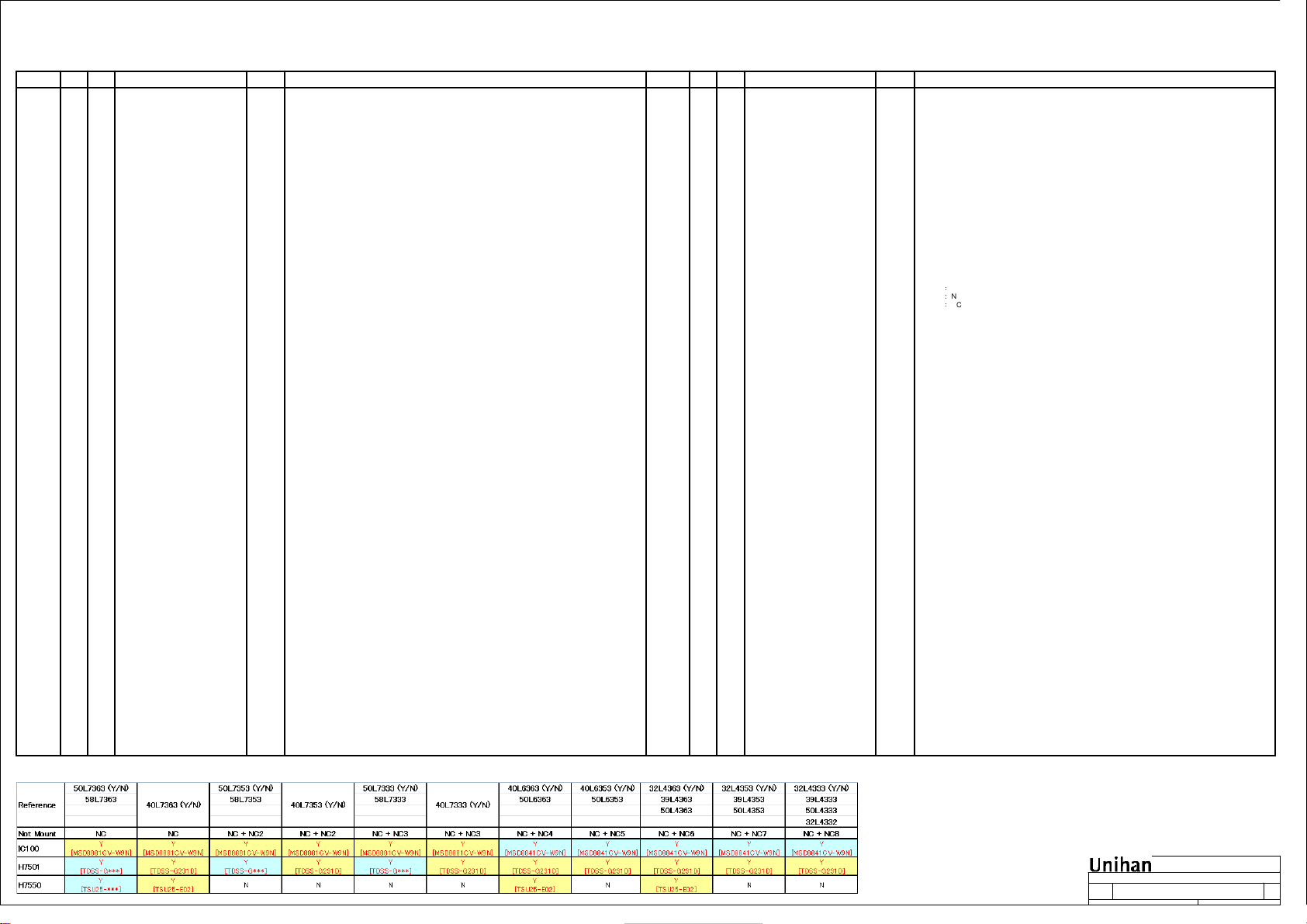

50L4333D/50L4331D/50L4337D

1

SAFETY PRECAUTION

The parts identified by mark

are critical for safety. Replace only

with part number specified. Th

mounting position of replacement

is to be identical with originals.

The substitute replacement parts

which do not have the same safet

characteristics as specified in the

parts list may create shock, fire or

other hazards.

50L4333D(G)/(F),50L4331D(G),50L4337(G)/(F

No. Location

1+2+3

1

5

1

6

9

10

12

13 E110

1

14+15+26

16+17+18+(19-1) E120 STAND ASSY

1

34

35

1

36

1

37

Toshiba

Service Par

E100 75033887 13EB-43B0601 FRONT COVER

E106 75034305 13EB-43Q0W11 SUPPORT FOR SMALL BOARD

E300A 75032896 LCD PANEL,LG,LC500DUE-SFR1

E250 75034288 0433-0082000 POWER BOARD ASSY

E200 75034222 9C-EB40M01G0 MAIN BOARD ASS

E330 75034229 04A4-01CK000 SPEAKER

E150 75034287 13EB-46B0711 NECK ASS

E290 75034226 0C05-00JK0TB WLAN MODULE

E260 75034223 9C-EB40S02E0 LED BOARD ASS

E270 75034224 9C-EB40S02D0 IR BOARD ASS

E280 75034225 9C-EB40S02C0 KEYPAD BD

75034285 13EB-46B0D01

75034286 13EB-46B0B01

75034282 13EB-46B0E11 BACK COVER ASS

75035521 13EB-46B0301

75035522 13EB-46B0G01

1

ODM Partne

Part

Description

FRONT BEZEL

SIDE KEY BEZEL ASSY11 E140

LEFT AND RIGHT

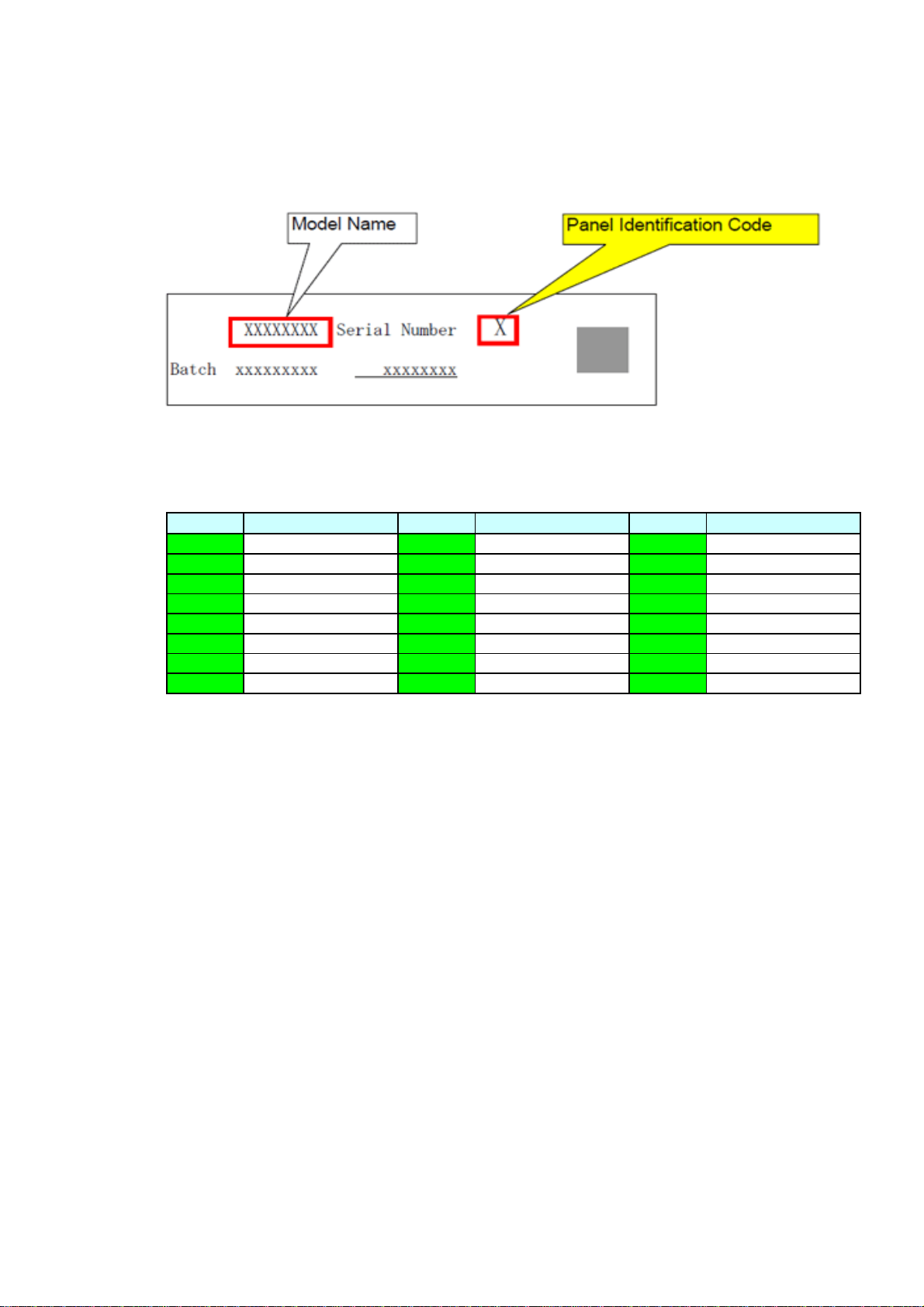

PANEL IDENTIFICATION

A

Serial No. part printed on Rating Label

Panel Identification Code

Marking Marking Marking

BKT

CLU

DMV

ENW

FPX

GQY

HRZ

Panel Vendor

AUO

BriView

CMO

CHILIN

IPS

JS

Panel Vendor

SAMSUNG

LPL/LGD

CPT

Panel Vendor

SHARP

(1/3)

MAIN BOARD EXCHANGE

When Main board is exchanged, the Application SW (Firrmware) and Model Setting need to

be updated.

Please update in the following procedures.

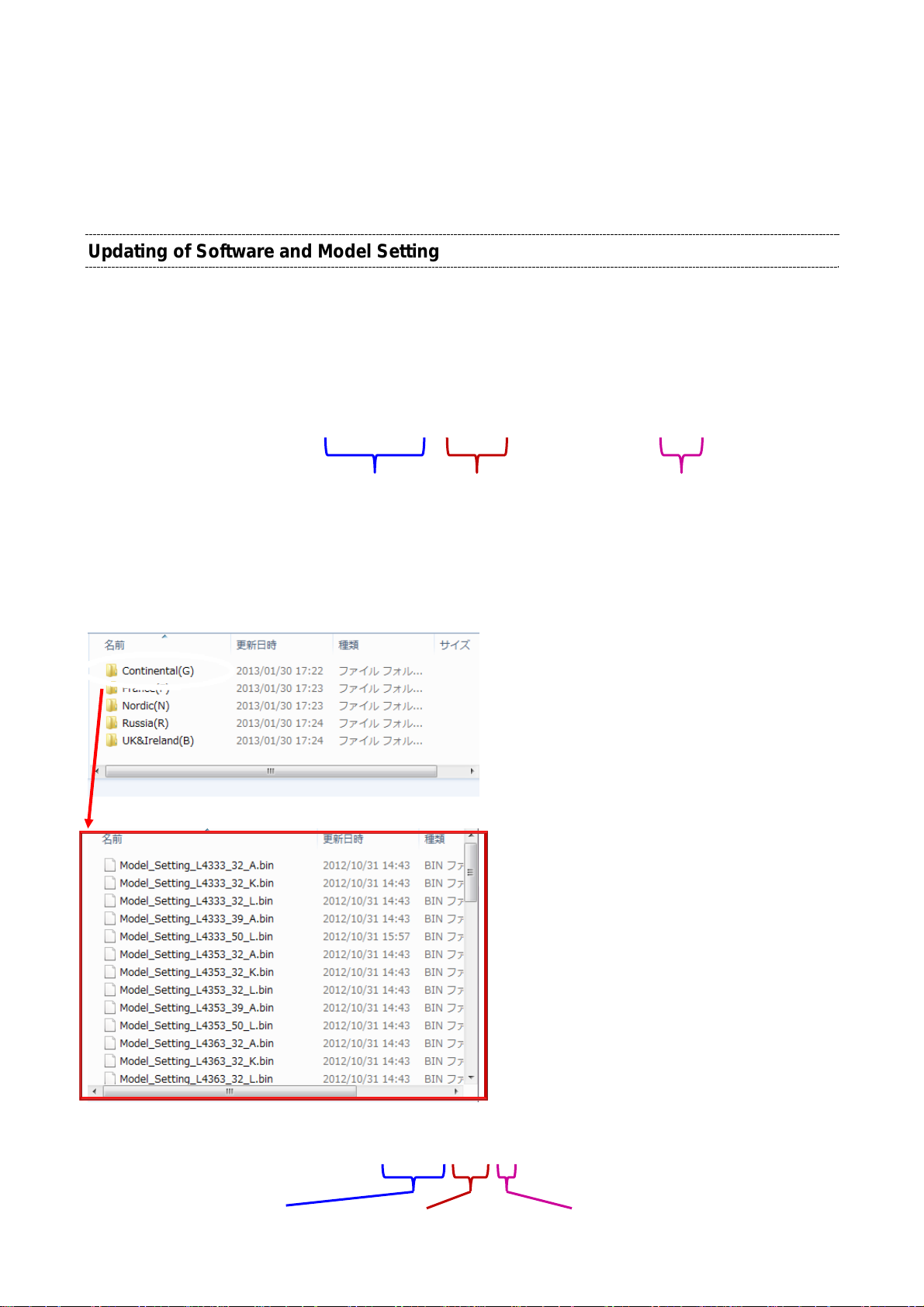

Updating of Software and Model Setting

1. Copy the Application SW (Firmware) file and the Model Setting file to the root of the USB

mass storage device.

Application SW:

[Example] UPDATE_50L7363C_12800_INIT_CLEAR#.enc

This Application SW is for not

only 50L7363C but also the other

models, i.e. all of L73/L63/L43

models.

Model Setting File:

This number is

an example.

“enc” means encrypted.

This SW is encrypted for

security.

Model setting files are

Each Shipout folder contains model setting files.

categorized by shipout.

[Example] Model_Setting_L4333_32_A.bin

TV series

Panel size Panel Vendor

2. Unplug TV, and then Insert the USB mass storage device to the USB slot of the TV.

3. Plug TV.

Software updating starts.

If Software updating does not start and the front LED lights red, then press [Power] key on

Remote Control to start Software updating.

4. After updating complete, unplug TV and remove the USB mass storage device.

(2/3)

5. Plug TV, then check the updating b

y using self check screen.

Refer to “Confirmation of Software updating” section on next page.

6. Update to the newest SW.

This model can be updated from aerial or network to the newest Software.

Refer to the user manual of this model for the updating method.

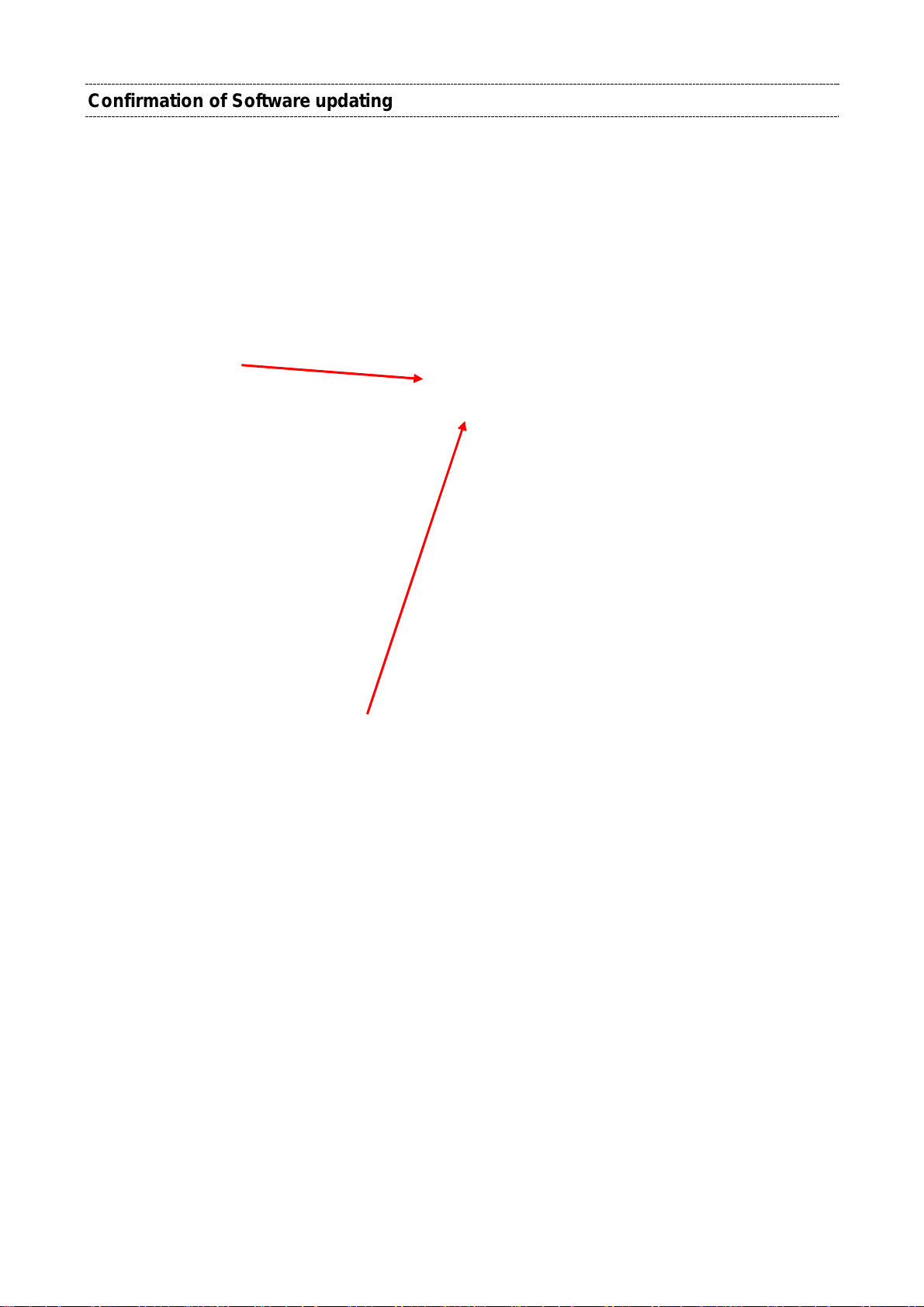

Confirmation of Software updating

Check the TV Model and Model Info by using self check screen.

1. Press SETUP on Remote Control.

2. Select “Get Help” >> “System Information”

3. Press “3” “5” “7” “4”

Self check screen is displayed.

TV model and

Panel vendor

(3/3)

th

[The 4

number and Shipout]

10 UK&Ireland (B)

11 France (F)

12 Continental(G)

13 Russia (R)

14 Nordic (N)

ABOUT THE MAIN BOARD

The Main PCB is changed to enable easier removal of Tuner.

The old one is 1.02, the new one is 1.02A. For Service Parts, only new type is used.

The new type (1.02A) have larger land pattern for soldering the Tuner.

And around the land, attached white silk marking.

REV. 01

Jul. /31/2013

TOSHIBA 2013 L7363 Series Models

VerDate

Stage

SR

2012/10/04 1.01 R_SPI_CLK / R_SPI_CS swap R_SPI_CLK / R_SPI_CS net swap in IC760 side:

ER

2012/10/29

ER

Design Notes

1.002012/09/20 SR Stage Release

1.012012/10/04 1. Change IC790 pin19’s net name to S_CI_BUFFER_ENZ

Add S_CI_BUFFER_ENZ to

ctrl CI Data buffer

ER

2012/10/23 1.01 Test Point change Chage CN741,CN742,CN743,CN652,CN162,CN100 test point size for DFM review

ER

2012/10/26 1.01 Add schumitt buffer on 796 and GPIO

ER

ER

ER

2012/10/26 1.01 GPIO change from IC100 to CI BUS3

ER

ctrl

1.012012/10/26

PC EDID & debug by VGA

IC790

IC790

2012/10/29 1.01 PJ601 change 603 PJ601 was changed to 1242-00KB000ER

2012/10/29 Remove Resistances list below:

2012/10/29 1. Change: R6580 100 KOhm → 4.7KOhm

ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

ER2012/10/29 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/29 ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/30 R6584 optional change from NC to NC4NC5NC6NC7NC8658Circuit Change Notes 2012/10/26:

2012/10/30 950 12V & 12V_3 swap in the both side of FL957ER 1.01 Circuit Change Notes_2012/10/26:

2012/10/30 ER 1.01 791 1. Change IC789 from TPS2553DBV-1 to R5524N001B-TR-FE

2012/10/30 ER 1.01 Circuit_Notes_TUNER_Demod_2:

2012/10/31 ER 1.01 Test Point requested by production test 660 Add DP716 in net H_PWR4

2012/10/31 ER 1.01 R1218 NC 135 R1218: Mount -> Not Mount

2012/11/01 ER 1.01 Add DP721 for DFM 658 Add DP721 for DFM

ER 1.01 Add Bead for EMI 658

2012/11/01

ER 1.01 D7410 & D7411 NC 9512012/11/07 Keypad D7410 & D7411 NC

2012/11/14 ER 1.01 Change R6580 => 12k Ohm 658 Change R6580 => 12k Ohm

Circuit Change Notes_2012/10/26:

1.01ER

Remove below 0 ohm resistors for

current measure and connect directly

FET Unmount and Relevant Changes

in 3D GLASSES I/F

Insert FL909 & FL957

Place R1218 near IC100.

R6712 and R6713 are deleted

T-CON POWER SW change

Tuner component fine tune

1.01ER

correction

correction

Circuit Change Notes_2012/10/30:

Circuit_Change_Notes_CI3

SHT755 S TUNER

Description

Page

760

R_SPI_CS => IC760.33 / R_SPI_CLK => IC760.28

Res R7613 & RM761C SWAP for easy layout ( 2012/10/29 add)

113, 794

2. Connect S_CI_BUFFER_ENZ to IC100.C7 (GPIO81)

3. reserve a pull-up resistor R1002 on S_CI_BUFFER_ENZ

Tuner H7550 => 04A9-00DF0TB & H7501 => 04A9-00DB0TB2012/10/04 1.01 Tuner change

755,

750

121, 658,

700

104, 796 1. Add R_TSCLK_CI ( from R1130 to IC794.2 ) & R_TSCLK ( from R1131 to R7740 & R7742 )

2. Add Scheumitt buffer ( IC794, R7950, C7963 )

1. Delete DP100 and DP102

113, 609GPIO & related circuit change for DSUB

2. Connect IC100's GPIO5 -> VGA_EEP_WP ( -> Q6110.G, Q6025.G & Q6026.G )

GPIO16 -> M_VDBG_EN ( -> IC620.7 )

GPIO110 -> M_DSUB_I2CCLK ( -> Q6026.S )

GPIO108 -> M_DSUB_I2CDATA ( -> Q6025.S )

113, 6692012/10/26 1.01 GPIO change from IC100 to CI BUS3

1. Delete DP103.

2. Connect IC100's GPIO81 and R6637 by M_WP_HDCP

113, 794 1. Delete DP109.

2. Connect IC100's GPIO8 and R7900 by C_CI_BUS_ENZ

117, 129,

R1103, R1232, R1237, R1601, R1604, R1606, R1608, R6520, R6650, R6651,

160, 653,

R6710, R6711, R6728, R7803, R7804, R7805, R7806, R7807, R7808, R7809,

665, 674,

R7810, R7811, R7812, R7919, R7920, R9000, R9001, R9090,R9091

780, 791,

901, 906

658

2. Mount → Unmount:

Q6582, R6585, R6586, R6587, R6589, C6581

3. Add: C6582 0.1UF/16V, R6590 0 Ohm, R6591 220 Ohm

1. Change Net Name of Power of IC905, Insert FL909 (220ohm/100MHz), and connected FL909 to 12V_3

905, 950

2. Change Net Name of 12V, Insert FL957 (220 ohm/100MHz), and add net 12V_3

135 Place R1218 near IC100.

677 R6712 and R6713 are deleted and it connects directly

653 T-CON POWER SW change

750, 751 1. Change C7506, R7514, R7557, R7714

2. Add C7524, R7610, C7617, C7563, C7731

3. Delete R7513,R7515

2. Remove R7911

755 C7563 connect to R7557 & H7550

CN652: Add FL652, FL653

700

CN741: Add FL737, FL738, FL739, FL740, FL741

CN742: Add FL743, FL744, FL745, FL746

CN743: Add FL747, FL748, FL749

653Add L6541 for T-CON circuit1.01ER2012/11/01 Add L6541 for T-CON circuit

VerDate Design Notes DescriptionStage Page

2012/11/14 PR 1.02 Part change to reduce DDR 800MHz

2012/11/28 PR 1.02 Part change to improve T-COM PWR

2012/12/05 PR 1.02 CN100 NC 121 CN100 NC

2012/12/12 PR 1.02 FL664, FL665 => 0 ohm 660 FL664, FL665 were changed to 0 ohm array for MHL

2012/12/17 PR 1.02 Change part reference 674 FL619 was renamed as FL162

2012/12/18 PR 1.02 Add test point 906 DP901 was add for IC911 pin1

2012/12/24 PR 1.02 PJ601 local use footprint for DFM 603 PJ601 change local use footprint for DFM, floating issue in 1.2mm PCB

2012/12/26 PR 1.02 ON/OFF function of the WLAN power 160 R1608 : 0 Ω -> NC

Emisson

sequence

EMI solution 600 Page 600: Add C6015, C6016, C6017, FL616~FL618

MHL VBUS / IC673 circuit change Remove R6740 & Add R6735, Q6710 near IC673674

The dischage res for T-CON PWR 653 Add R6546

1.02PR2013/01/02 700LED luminosity is adjustted R7032 : 100 -> 680Ω

improve X-tal accuracy for DVB-T2

1.022013/01/08 PR 760

& DVB-S2/S

658, 700 FL652, FL653: P/N: 0901-0019000 GBK160808T-300Y-N

FL737-FL741: P/N: 0901-0027000 GBK160808T-121Y-S<G>

FL743-FL746: P/N: 0901-0027000 GBK160808T-121Y-S<G>

FL747-FL749: P/N: 0901-0027000 GBK160808T-121Y-S<G>

653 C6543 was changed from 0.22uF to 1UF/25V (0603)

Page 602: Add C6032~C6039, FL610~FL612

Page 603: Add C6090~C6093, FL613~FL615

160 FL619 was added for wifi

Remove IC620 and C6085 & Add Q6027 & Q6028To improve the leak current from I2C 609

Add R1608, R1609, R1610USB connector for WLAN 160

R1609 : NC -> 0 Ω

R1610 : NC -> 4.7K Ω

C7614,C7615 27p -> 10p

R7606 0 ohm -> 1.8Kohm

770

C7714,C7715 6p -> 10p

R7710 0 ohm -> 1.5Kohm

improve IFAGC voltage of SoC 751 R7522 : 10Kohm -> 0ohm

Optional Information

000. History & Description

000. History & Description

000. History & Description

Title :

Title :

Title :

Engineer:

Engineer:

Engineer:

CVP DM HW

CVP DM HW

MAIN BOARD

MAIN BOARD

MAIN BOARD

Size Project Name

Size Project Name

Size Project Name

A2

EU Lv.2

A2

EU Lv.2

A2

EU Lv.2

Date: Sheet of

Date: Sheet of

Date: Sheet of

CVP DM HW

001 76Tuesday, January 08, 2013

001 76Tuesday, January 08, 2013

001 76Tuesday, January 08, 2013

Rev

Rev

Rev

1.00

1.00

1.00

Loading...

Loading...