TOSHIBA 50HX70, 55HX70, 61HX70, 55H70, 61H70 Service Manual

50HX70

Televisión a color

Capítulo 1: Ajustes generales

Instrucciones de seguridad

Reemplazo y montaje del ensamble de TRC

Ajustes de los componentes del tubo de imagen

Reemplazo del TRC

Modo de servicio

Ajustes eléctricos

Ajustes de convergencia

Alineación de pantalla y espejo

Revisión de circuitos

Capítulo 2: informaciones específicas

Fijación y ajuste de datos

Localización de controles

Programación de la memoria de canales

Diagrama a bloques del circuito

Desensamble mecánico

Lista de partes de reemplazo del gabinete y el chasis

Vista inferior de placas de circuito impreso

Vista de terminales de transistores

Especificaciones

Diagrama esquemático

Segur idad

Con versión de señal

DEF/Encendido

TR C/SVM

A/V

Con versión digital

HYPER

FILE NO. 020-200026

SERVICE MANUAL

COLOR TELEVISION

N0PSP Chassis

50HX70, 55HX70,61HX70

(TAC0067)

(TAC0066)

55H70

(TAC0069)

(TAC0065)

,

61H70

(TAC0068)

PUBLISHED IN JAPAN, Aug., 2000 So

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS........................................................................................................................................3

CRT ASSEMBLY REPLACEMENT AND MOUNTING .............................................................................................4

PICTURE TUBE COMPONENTS ADJUSTMENT.................................................................................................... 6

REPLACEMENT OF THE CRT................................................................................................................................. 9

SERVICE MODE ....................................................................................................................................................10

ELECTRICAL ADJUSTMENT ................................................................................................................................ 12

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

CONVERGENCE ADJUSTMENT .......................................................................................................................... 14

SCREEN AND MIRROR ALIGNMENTS ................................................................................................................16

CIRCUIT CHECKS .................................................................................................................................................17

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA.............................................................................................................................. 18

LOCATION OF CONTROLS...................................................................................................................................19

PROGRAMMING CHANNEL MEMORY.................................................................................................................21

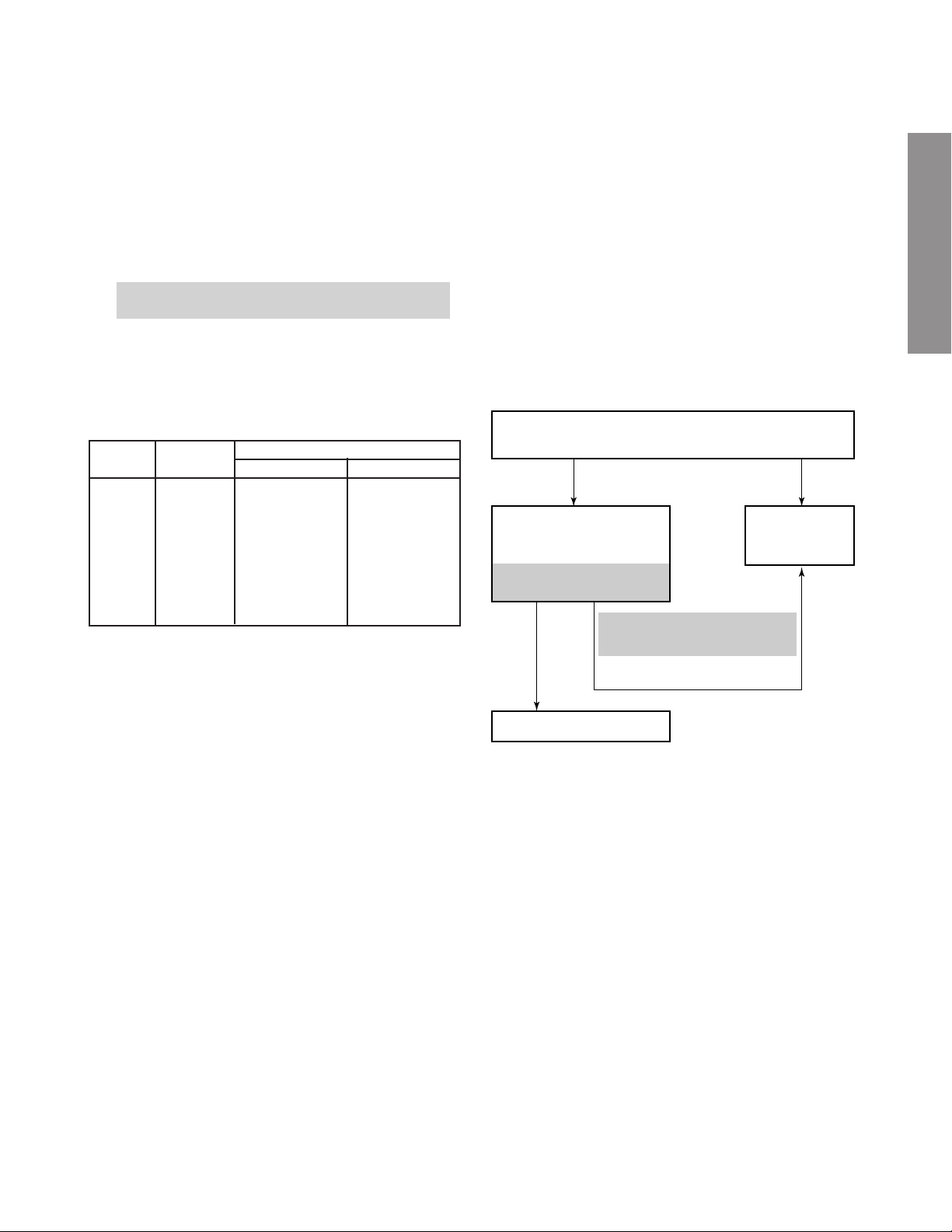

CIRCUIT BLOCK DIAGRAM ..................................................................................................................................23

TABLE OF CONTENTS

MECHANICAL DISASSEMBLY ..............................................................................................................................25

CHASSIS AND CABINET REPLACEMENT PARTS LIST......................................................................................27

PC BOARDS BOTTOM VIEW.................................................................................................................................57

TERMINAL VIEW OF TRANSISTORS ................................................................................................................... 70

SPECIFICA TIONS .................................................................................................................................................. 71

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous

X-RAY RADIATION. To avoid such hazards, the high voltage must not be above the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a 120V AC

power source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B).

(See SETTING & ADJUSTING DATA on page 18)

Each time a receiver requires servicing, the high voltage

should be checked f ollowing the HIGH VOL TAGE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by any one unf amiliar with the necessary precautions on this receiver. The f ollowing are the necessary precautions to be observed before

servicing this chassis.

1. An isolation T ransf ormer should be connected in the power

line between the receiver and the AC line bef ore any service is performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube . The picture tube is highly evacuated and if broken, glass fr agments

will be violently expelled. Use shatter proof goggles and

keep picture tube away from the unprotected body while

handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place,

such as; non-metallic control knobs, insulating covers,

shields, isolation resistor-capacitor network etc.

4. Before returning the set to the customer, always perform

an AC leakage current check on the exposed metallic parts

of the cabinet, such as antennas, terminals, screwheads,

metal overlays, control shafts etc. to be sure the set is saf e

to operate without danger of electrical shock. Plug the A C

line cord directly into a 120V AC outlet (do not use a line

isolation transformer during this check). Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the

following manner:

PRODUCT SAFETY NOTICE

2. This receiver is equipped with a Fail Safe (FS) circuit which

prevents the receiver from producing an excessively high

voltage ev en if the B+ voltage increases abnormally. Each

time the receiver is serviced, the FS circuit must be checked

to determine that the circuit is properly functioning, following the FS CIRCUIT CHECK procedure in this manual.

3. The only source of X-RAY RADIATION in this TV receiver

is the picture tube. F or contin ued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

4. Some part in this receiver have special saf ety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NO TICE below.

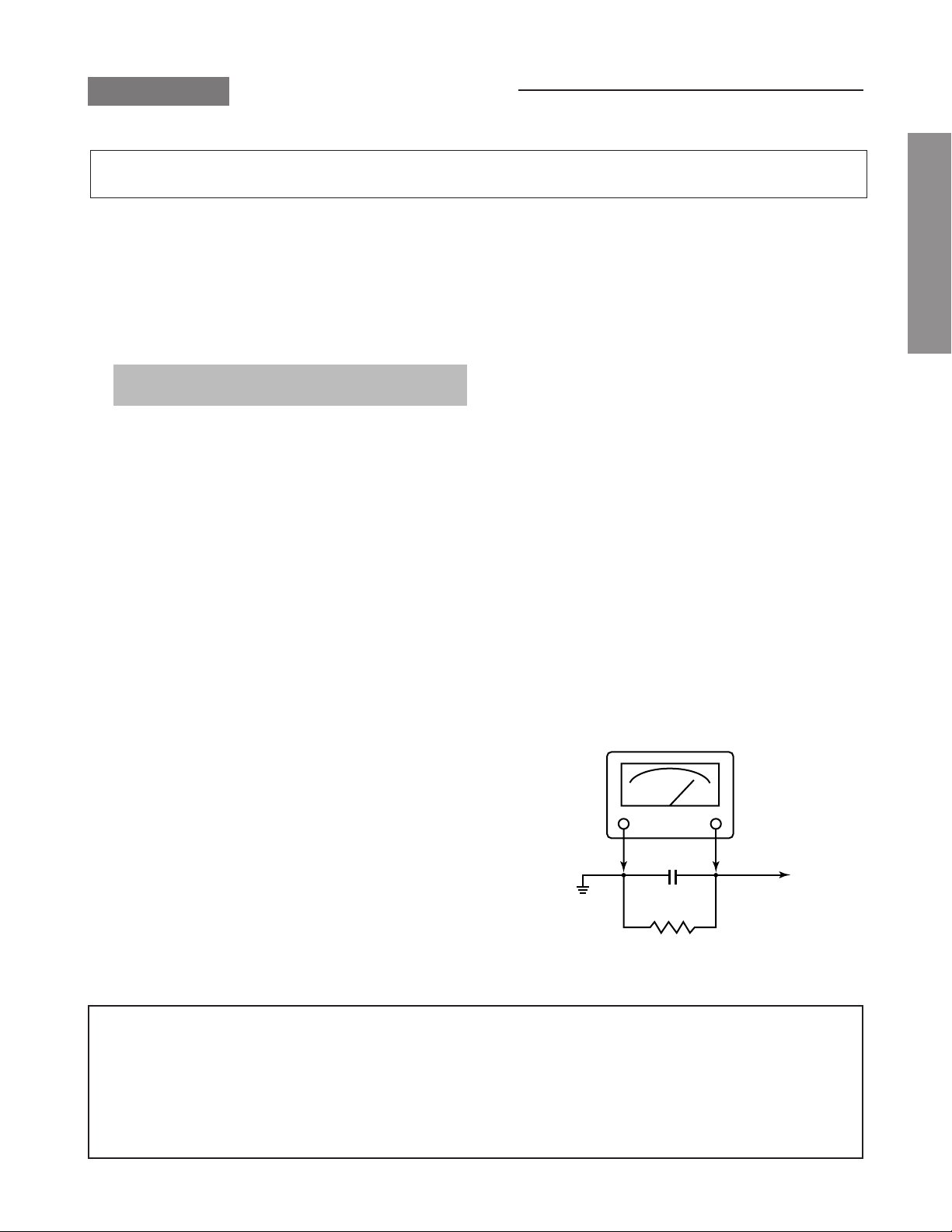

Connect a 1500 ohm 10 watt resistor , paralleled b y a 0.15

µF, AC type capacitor, betw een a known good earth ground

(water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the AC voltage across the combination of 1500 ohm resistor and 0.15 µF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Voltage

measured must not exceed 0.3 volts rms. This corresponds

to 0.2 milliamp. AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

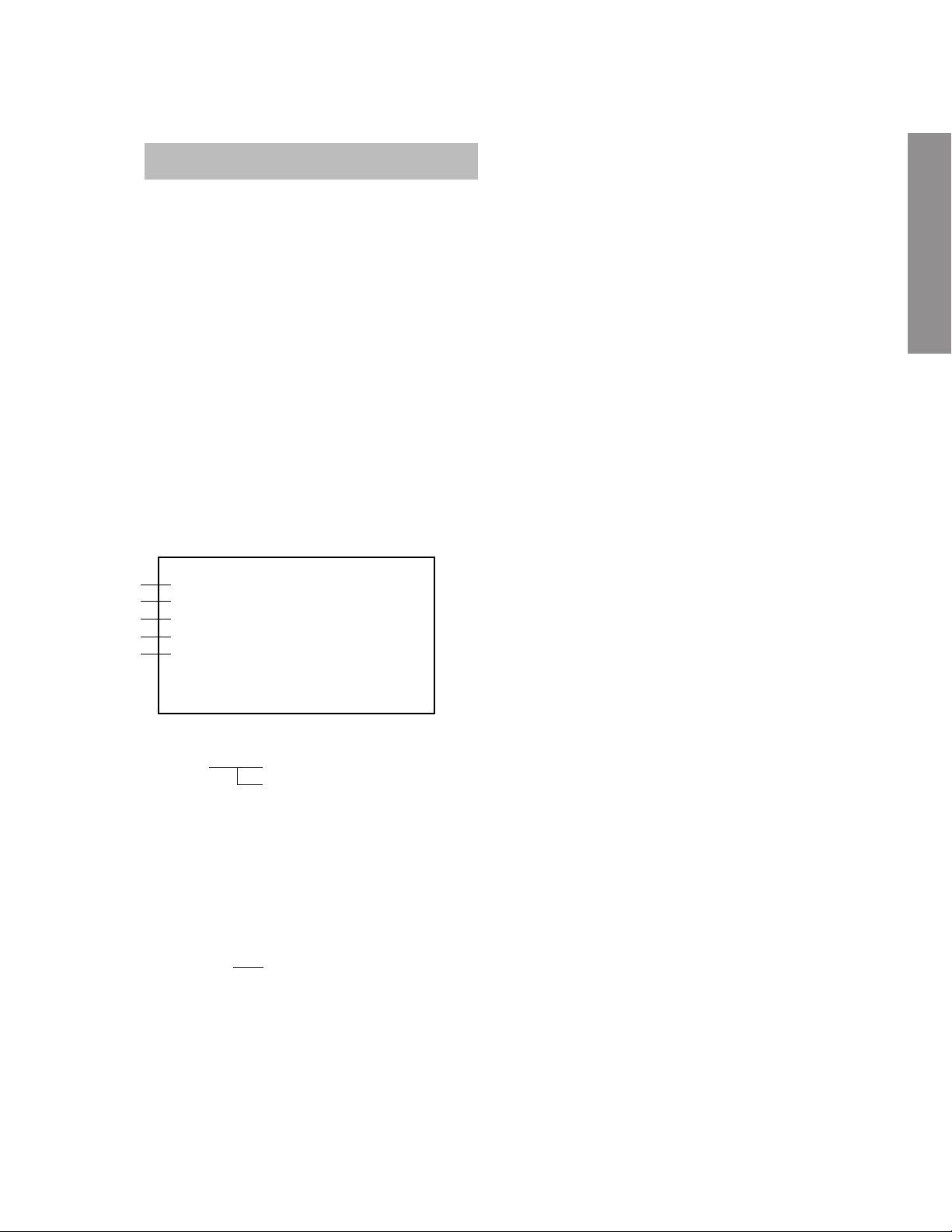

AC VOLTMETER

0.15µF

Place this probe on

Good earth ground

such as a water

pipe, conduit, etc.

1500 ohm

10 watt

each exposed

metallic part.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained b y using

replacement components rated for higher voltage, w attage, etc. Replacement parts which have these special saf ety characteristics are identified in this manual and its supplements; electrical components having such features are identified by the

international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray radiation or other hazards.

– 3 –

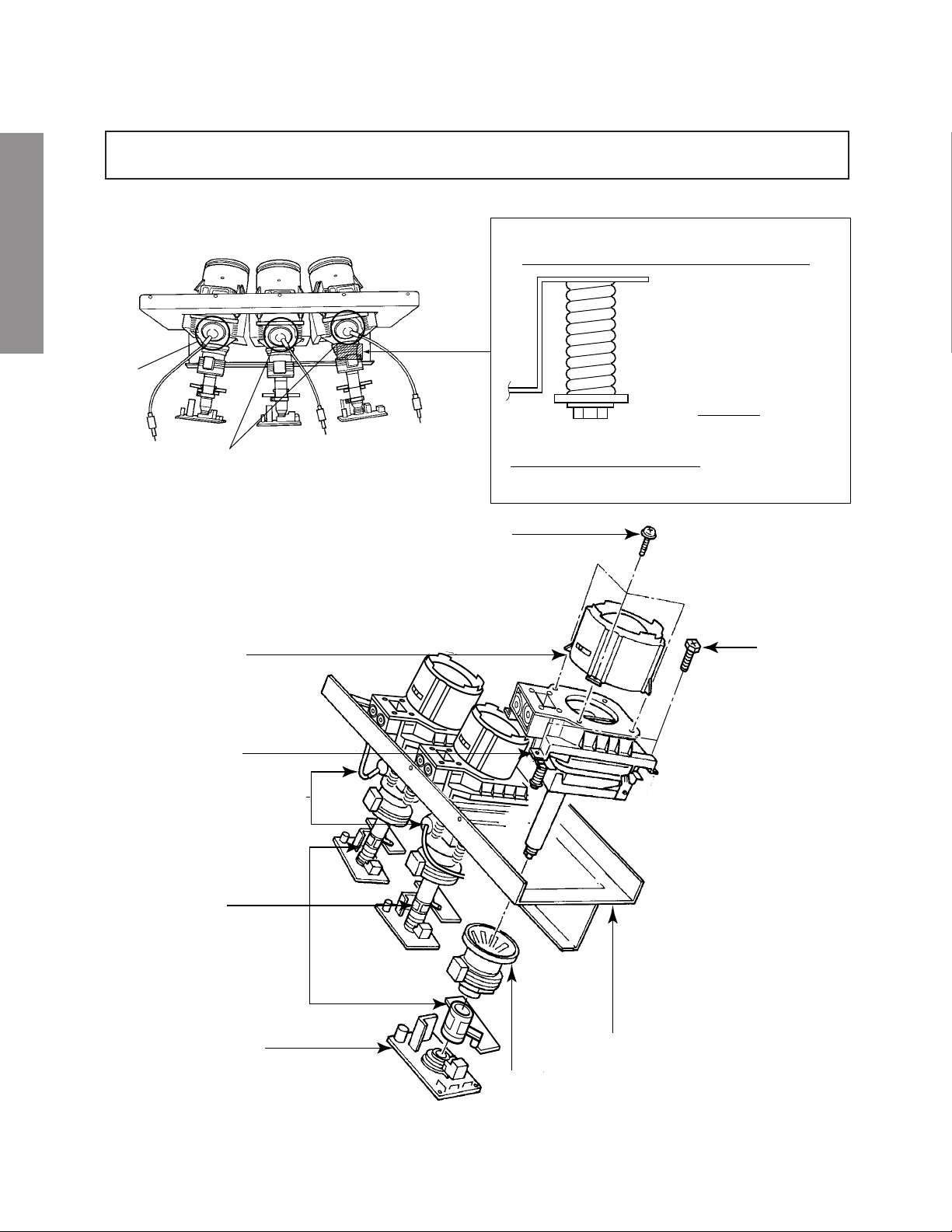

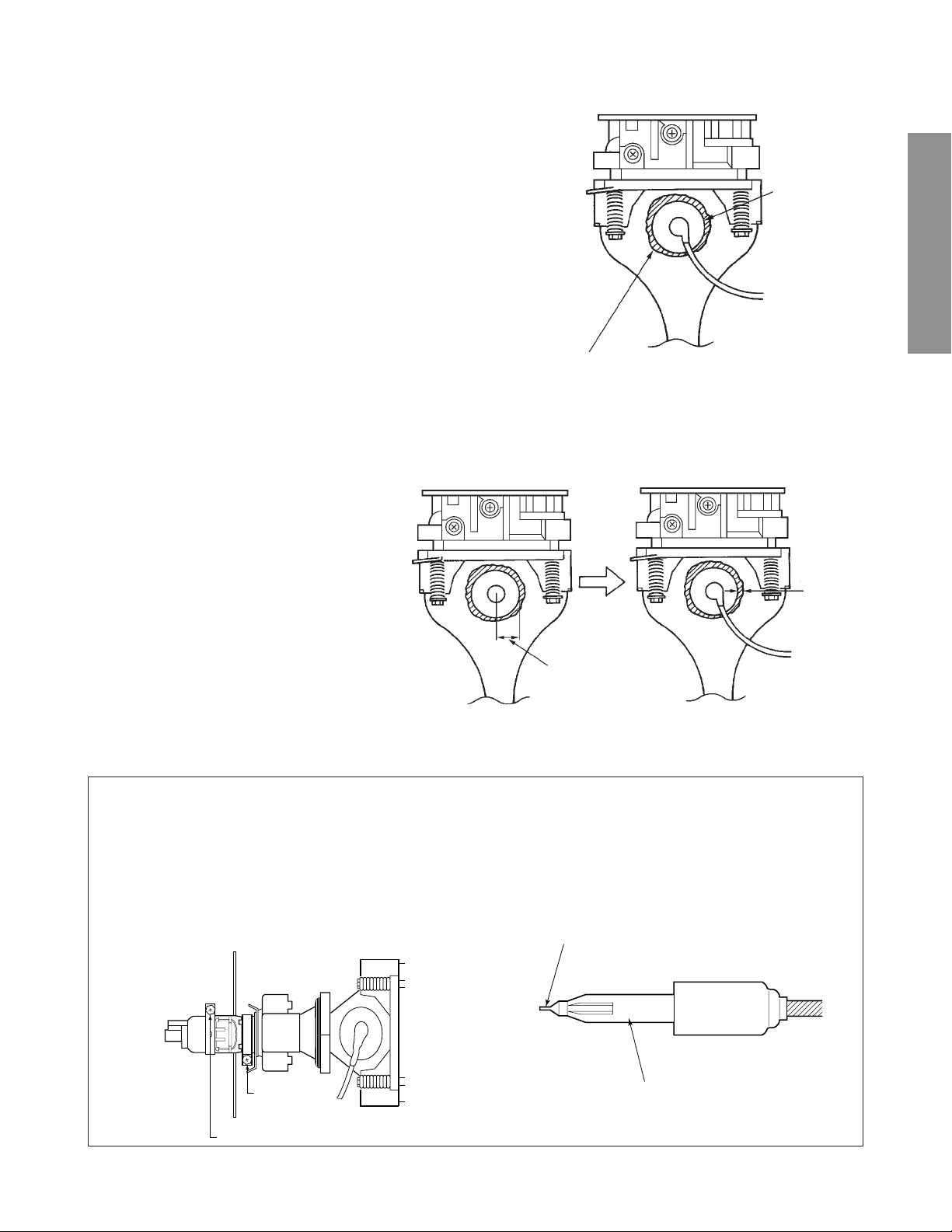

CRT ASSEMBLY REPLACEMENT AND MOUNTING

CAUTION : DO NOT LOOSEN THE HEX HEAD BOLTS WITH SPRINGS (12 PCS), BECAUSE THOSE ARE FOR

SEALING OF CRT COOLANT.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

8 o’clock

4 o’clock

Lens Assembly

R

GB

Attention Serviceman

The Hex Head

Bolts with

Springs. (see

sketch) used on

CRT assembly,

are “NOT”

Adjustment Screws

DO NOT LOOSEN-FLUID

LEAKAGE WILL OCCUR.

4 Screws

4 Screws

CRT Assembly

CRT Anode Cap Assembly

S.V.M. Coil

CRT DRIVE Board

CRT Mounting

Deflection Yoke and Conver Yoke

Lens and Neck Components View

– 4 –

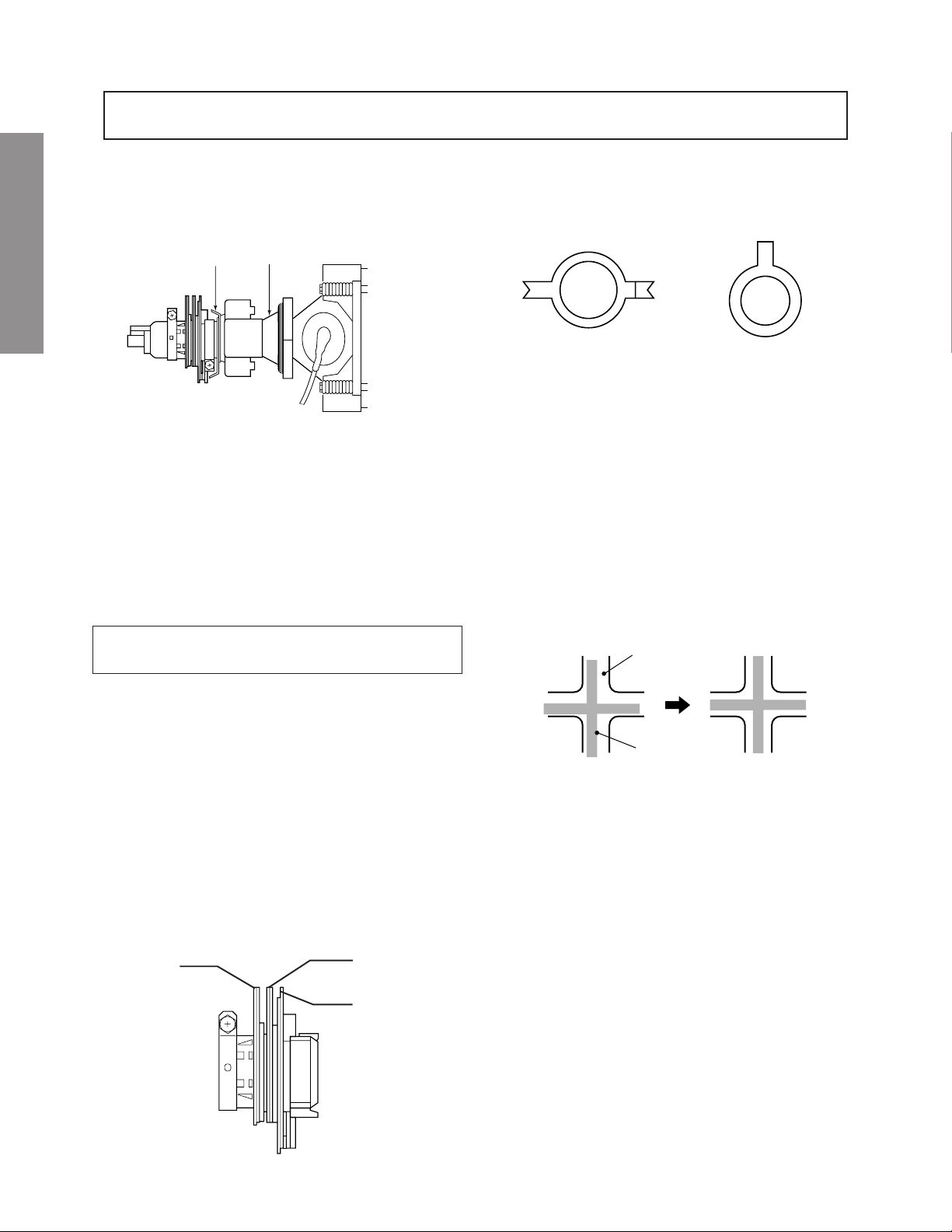

TO REMOVE CRT (Same procedure for R, G, B)

1. Remove CRT DRIVE Board, S. V. M. COIL and

DEF. YOKE from CRT.

2. Remove Lens Assembly.

3. Detach CRT Anode Cap from CRT.

4. Remove CRT Assembly from CRT Mounting.

CRT REPLACEMENT (Same procedure for R, G, B)

Reverse the removal procedures except the followings.

1. Anode Cable should be replaced with new one.

See “SERVICING PRECAUTIONS” shown below.

2. Install silicon (T461B) to the CRT, replace the Anode

cable and put enough silicon again on around the Anode Cap as illustrated.

CAUTION: Align the Anode cable as illustrated on page

4.

ADJUSTING PROCEDURE IN REPLACING CRT

1. R.G.B. CUTOFF (SCREEN VR) ADJUSTMENT

(page 6.)

2. R.G.B. FOCUS ADJUSTMENT (page 6.)

3. PICTURE TILT ADJUSTMENT (page 7.)

4. USER CONVERGENCE CENTER CHECK

(See owner's manual.)

5. CENTERING ADJUSTMENT (page 7.)

6. CONVERGENCE ADJUSTMENT (page 14.)

7. WHITE BALANCE ADJUSTMENT (page 13.)

Adjustments are complete.

Anode Cap

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Silicon

(On shaded area)

TSE3843W #23960136

2 ~ 5 mm

SERVICING PRECAUTIONS

■ Do not use a magnetized screw driver for screws

of Deflection Yoke and Velocity Modulation Coil to

avoid magnetization of electron gun.

Magnetization of electron gun will degrade basic

function and result in unbalance of right and left

shift of user static convergence, and result in no

variable quantity.

Screw for

D.Y

15 ~ 25 mm

■ When replacing the anode cap assembly (CRT) or

anode lead assembly (F.B.T.), remove the anode

lead holder from old one and attach the holder

again to new anode lead.

■ Check the point of anode lead in a straight

line, if it is winding, please revise it.

Anode lead holder

Screw for SVM coil

– 5 –

WARNING : BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECA UTION”, “SAFETY PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

PICTURE TUBE COMPONENTS ADJUSTMENT

DESCRIPTION OF NECK COMPONENTS

2

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

1 Deflection yoke and convergence yoke

The position on the neck is required most front

(CRT funnel side) and the screw is fastened after

rotating yoke adjusting picture tilt.

2 Centering magnet

After adjusting picture tilt, picture position is finally

fixed by this magnet.

In order to get maximum margin of user convergence control for center of screen, this magnet

have to be used for center convergence adjustment.

PREPARATION

Operate the receiver for at least 5 minutes.

1

Pole 2 magnet

Pole 4, 6 magnet

2. Select adjustment mode (see page 10).

3. Adjust the centering magnets for the RED, GREEN and

BLUE colors. (See CENTERING ADJUSTMENT.)

4. Press “7” button to display the built-in cross-hatch.

5. Press “0” and “RTN” buttons to make the picture a single

Red color.

100 button ............... to erase Red color

0 button ............... to erase Green color

RTN button ............... to erase Blue color5.

6. Adjust the alignment of the projection tube for RED . (See

steps (1) to (3) below .

(1) Slightly turn the focus VR of RED to the left.

(2) Adjust the pole 2 magnet so that the bright section of

the cross hatch on the center of the dark section (flare).

Dark secton (Flare)

R, G, B CUTOFF (SCREEN VR) ADJUSTMENT

1. Adjust before replacing the SCREEN assembly.

2. Press RESET button on TV or remote hand set.

3. Call up the adjustment mode display, then adjust the

data of items RCUT, GCUT and BCUT to “40”.

4. Press TV (ANT)/VIDEO button on TV.

5. Gradually rotate R, G and B SCREEN volume of FOCUS PAC (page 8) clockwise or counterclockwise until the raster appears slightly on the CRT through the

each lens, and leave them.

(Look into the lens in order to check the raster.)

6. Press TV (ANT)/VIDEO button on TV again.

RGB ALIGNMENT ADJUSTMENT (ONLY 61HX70)

1. Set the knobs of the pole 2, 4, 6 magnets of the SVM

coil so that their magnetic fields override each other.

Pole 6

Pole 4

Pole 2

Bright section (Core)

(3) Readjust the centering magnets for the LED colors.

(4) Reconfirm that the alignment, and centering are cor-

rect. If necessary, repeat the steps (1) to (3) above to

adjust appropriately.

7. Adjust the electric focus of RED as well as possible. (See

RGB FOCUS ADJUSTMENT.)

8. Adjust the alignment of GREEN and BLUE using the above

procedure for adjusting RED.

– 6 –

R, G, B FOCUS ADJUSTMENT

1. Before adjusting the R, G, B FOCUS, remov e the 4 screws

of Lens Assembly which is fixed on the CRT Assembly.

(See page 4.)

Then turn around the Lens Assembly by 180˚ to adjust

the fastening screw (Fig. a) and fasten the 4 screws to

secure Lens Assembly.

2. Select the adjustment mode. (See page 10.)

3. Press “7” button to display the built-in cross-hatch.

4. Press “0” and “RTN” buttons to make the picture a single

Red color.

100 button ............... to erase Red color

0 button ............... to erase Green color

RTN buttonto erase Blue color5.

5. Loosen the fasten screw and adjust Red lense focus to

best focusing point of picture center. Then fasten the scre w.

(See Fig. a.)

Fig. a

6. Adjust FOCUS VR “R” of FOCUS PACK to find best focusing point of picture center.

7. Repeat steps 3 to 5 for Green and Blue colors.

TILT ADJUSTMENT

Rotate R, G, B deflection yoke so that picture becomes horizon, then fasten screw.

CENTERING ADJUSTMENT

1. Stretch a thread between two center of screen edge (top

and bottom, left and right).

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2. Select the adjustment mode.

3. Press TV/VIDEO button on the Remote Control to displa y

the white cross-bar.

4. Perform VCEN adjustment. (See page 12.)

5. Adjust G centering magnet so that the cross-bar pattern

center comes to screen center.

6. Perform HEIGHT adjustment . (See page 13.)

7. Perform VERT. LINEARITY adjustment.

8. Perform WIDTH adjustment. (See page 13.)

9. Check whole quality of green line.

10

. Adjust R, B centering magnet so that the cross-bar pat-

tern center comes to screen center.

– 7 –

LOCATION OF SCREEN AND FOCUS VR’S

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SCREEN VR

FOCUS VR

RGB

– 8 –

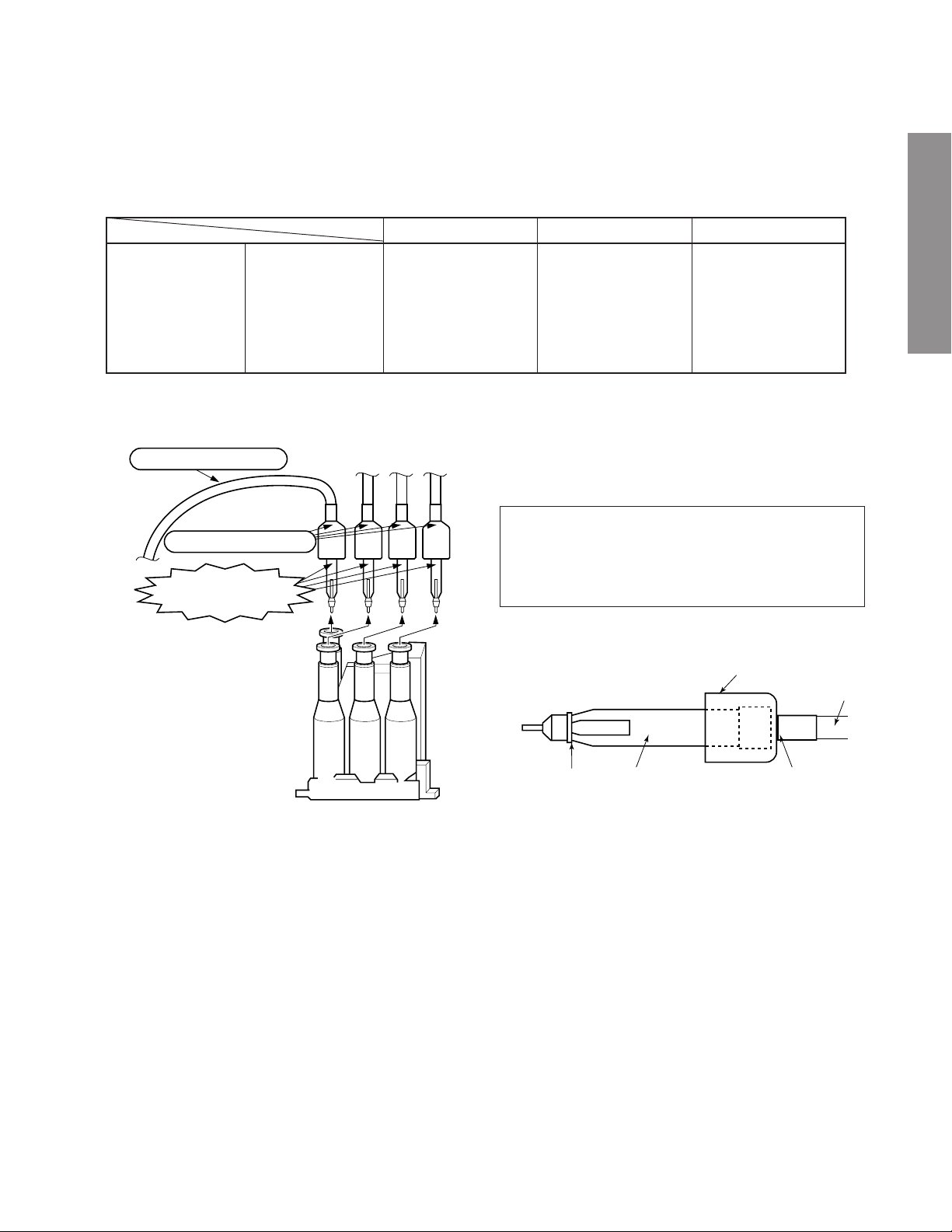

REPLACEMENT OF THE CRT

Service parts are provided for each R, G and B.

The contents of the parts are as follows.

50HX70 23005770 23005771 23003382

HITACHI

CRT

55HX70 23005777 ↑↑

55H70 23005723 23005808 23005724

61HX70 23007215 23007216 23007217

61H70 23005689 23005808 23005690

RGB

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

REPLACEMENT OF HIGH VOLTAGE CABLE

ANODE LEAD

RUBBER BOOT

LEAD HOLDER

Fig. a

Z450 TP A5007

1. When replacing Anode Lead or Anode Cap with new

one, remove Lead Holder from old lead as shown in

figure below , and put it on new lead. Do not throw awa y

Lead Holder.

NOTE : THE LEAD HOLDER IS ATTACHED TO

TP A5007 (Z450), BUT IS NO T A TTACHED T O

ANODE LEAD AND ANODE CAP. RUBBER

BOOT IS ATTACHED TO ANODE LEAD AND

ANODE CAP.

2. Detaching Lead Holder

RUBBER BOOT

LOCK LEAD HOLDER

Fig. b

Cut here rubber boot

and lead together to

detach Lead Holder.

OLD

ANODE LEAD

or

ANODE CAP

– 9 –

1. ENTERING TO SERVICE MODE

1) Press MUTE button once

on Remote Control.

MUTE

SERVICE MODE

2) Press MUTE button

again to keep pressing.

3) While pressing the MUTE button,

press MENU button on TV set.

S

(Service mode display)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Screen adjustment mode ON/OFF: TV (ANT)/VIDEO button (on TV)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume s/t (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : RECALL+Channel button on TV (s)

Initialization of the self diagnostic data: RECALL+Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“SCNT” selection : 4 button

“SCOL” selection : 5 button

“TNTC” selection : 6 button

Convergence adj : 7 button

Test audio signal ON/OFF (1kHz) : 8 button

Self diagnostic display : 9 button

Adjustment mode

S

Press

Press

Item

Data

– 10 –

4. SELECTING THE ADJUSTING ITEMS

1)Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 18)

5. ADJUSTING THE DATA

1) Pressing of VOLUME s or t button will cahnge the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the RECALL button on the Remote, then press the CHANNEL s button on the TV. The initialization of QA02

has been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Programming Channel Memory” on the owner's manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

7. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SELF CHECK

1

2

3

4

5

1 Part number of microprocessor (QA01)

2 Operation number of protection circuit (current limiter) . . . . “000” is normal.

3 BUS line check “OK” ................... Normal

4 BUS line ACK (acknowledge) check

5 Sync. signal check Green display..... Normal

NO. 23 * * * * * *

POWER : 000

BUS LINE : OK

BUS CONT : OK

BLOCK : MAIN SUB

“SCL-GND” or “NG” ........... SCL-GND short circuit

“SDA-GND” or “NG” ........... SDA-GND short circuit

“SCL-SDA” or “NG” ............ SCL-SDA short circuit

“OK” ..................... Normal

Display of Location Number . . . . NG

(Display example)

“QA02 NG”, “H001 NG”, “Q501 NG” etc.

Note: The indication of failure place is only one place though failure places are plural. When

repair of a failure place finishes, the next failure place is indicated. (The order of priority of

indication is left side.)

Red display ........ NG

MAIN ........ Main sync

SUB .......... Sub sync (when turn on the PIP)

– 11 –

ELECTRICAL ADJUSTMENT

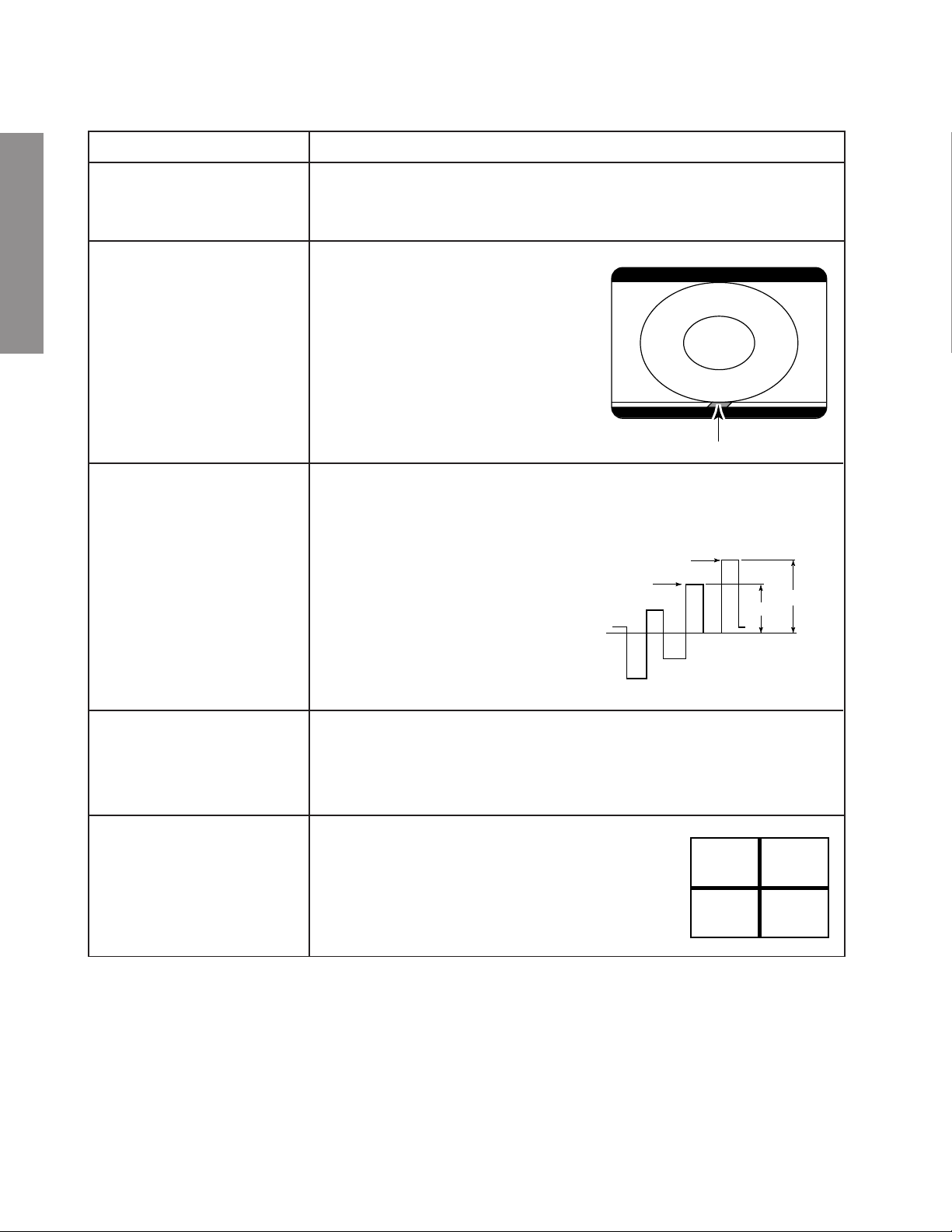

ITEM ADJUSTMENT PROCEDURE

VERTICAL POSITION (VCEN)

SUB-BRIGHTNESS

(BRTC)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SUB-COLOR

(SCOL)

SUB-TINT

(TNTC)

1. Call up the adjustment mode display, then select item VCEN.

2. Press the VOLUME s or t button to get the voltage 0 ±10 mV.

3. Measuring the terminals voltage are TP-V and TP-G on SIGNAL Board.

1. Constrict the picture height until the

vertical retrace line appears adjusting

the HEIGHT control on the MAIN board.

2. Adjust the CONTRAST to the minimum

and BRIGHTNESS to the center.

3. Enter the service mode, then select

“BRTC” register.

4. Adjust the data value so the belt of

vertical retrace line just disappear.

5. Adjust the HEIGHT control.

* Adjust the SUB-BRIGHTENESS after

adjusting the WHITE BALANCE.

Vertical retrace line

1. Receive color-bar signal from color-bar generator.

2. Adjust the BRIGHTNESS and CONTRAST to the center (RESET status).

3. Connect oscilloscope to TP501on the MAIN board.

4. Enter the service mode, then select “SCOL”.

5. Temporarily adjust the data value to

achieve about 1V0-p of blue bar.

6. Select “TNTC” register.

Magenta

Blue

7. Adjust the data value to obtain the blue

bar to magenta bar ratio of 3:2 as

shown.

0

2

8. Select “SCOL” register .

9. Adjust the data value to achieve 1.8V

of blue bar on scope.

0-p

10. Check the picture with off-air signal.

3 (1.8V

0-P

)

SUB-CONTRAST

(SCNT)

1. Tune in a color program and adjust the BRIGHTNESS and CONTRAST to

normal mode(RESET).

2. Enter the service mode, then select "SCNT" register.

3. Change "SCNT" data to13H.

4. Check the picture contrast.

PICTURE POSITION 1. Receive the pattern signal which shows it's center

on the screen.

2. Adjust the picture position alternately by turning

CENTERING MAGNETS for proper picture position.

3. Check the picture with off-air signal.

– 12 –

ITEM ADJUSTMENT PROCEDURE

HEIGHT

(HIT)

* Except 16:9 mode

HEIGHT

(HIT)

* Only 16:9 mode

WIDTH

(WID)

VERTICAL LINEARITY

(VLIN)

1. Call up the adjustment mode display, then select the item HIT.

2. Press the VOLUME s or t button to get the picture so the top of raster begins

to lack.

3. Press the VOLUME s button to advance the data by 10 steps.

Note : Check the vertical picture position is correct.

1. Call up the adjustment mode display, then select the item HIT.

2. Press the VOLUME s or t button so that picture height becomes 75% of the

front mask.

1. Call up the adjustment mode display, then select the item WID.

2. Press the VOLUME s or t button to get the picture so the left and right edges

of raster begins to lack.

3. Press the VOLUME s or t button to advance the data by 13 steps.

Note : Check the horizontal picture position is correct.

1. Call up the adjustment mode display, then select the item VLIN.

2. Receive cross-hatch pattern signal.

3. Press the VOLUME s or t

button to obtain the picture of

the best linearity.

4. Then readjust the item HIT.

Center

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

WHITE BALANCE

(RCUT)

(GCUT)

(BCUT)

(RDRV)

(BDRV)

1. Press RESET button on TV or remote hand set.

2. Call up the adjustment mode display, then adjust the data of items RCUT, GCUT

and BCUT to “40”.

3. Press TV (ANT)/VIDEO button on TV.

4. Gradually rotate R, G and B SCREEN volume of FOCUS PAC (page 8) clockwise or counterclockwise until the raster appears slightly on the CRT through

the each lens, and leave them.

(Look into the lens in order to check the raster.)

5. Press TV (ANT)/VIDEO button on TV again.

6. Exit from service mode.

7. Receive white laster pattern signal, and adjust the contrast to the minimum to

make white picture to low light.

8. Adjust the data of items RCUT, GCUT and BCUT for low light area.

9. Adjust the contrast to the maximum to make white picture to high light.

10. Adjust the data of items GDRV and BDRV Controls for proper white-balanced

picture in high light area.

11. Check the white balance in both low and high light areas. If necessary, perform

again steps from 7 to 9.

– 13 –

CONVERGENCE ADJUSTMENT

Adjust convergence from center to circumference in order.

1. Select the adjustment mode following the steps on page 10.

KEY FUNCTION IN THE

CONVERGENCE ADJUSTMENT:

RCUT

40H

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Up : 2 button

Selet Green color: 3 button

Left : 4 button

Blinking of cursor ON/OFF: 5 button

Right: 6 button

Adjust mode ON/OFF: 7 button

Down: 8 button

Erase Green line: 0 button

Erase Red line: 100 button

Erase Blue line: CHRTN (ENT) button

Note:

Adjusting procedure in replacing convergence board.

1. User convergence center check. Make

sure the best convergence setting is

about the center of adjustable range.

2. CENTERING ADJUSTMENT

3. PICTURE POSITION ADJUSTMENT

4. HIT, WID ADJUSTMENT

5. CONVERGENCE ADJUSTMENT

2. Press “7” button to display the built-in cross-hatch pattern.

27.5

Cursor

P = 50.5 x14 (50")

55.8 x14 (55")

62 x14 (61")

27.5

44

P = 84 x12 (50")

92 x12 (55")

103 x12 (61")

The pattern includes three colors (R, G, B).

The cursor should be blinking in Red.

This means that the Red color is adjustable.

Adjustment around cursor can be done.

3. Press “3” button to select Green color to be adjusted.

4. Press “5” button to stop the blinking of cursor.

5. Press “2 (up)”, “8 (down)”, “4 (left)” or “6 (right)” to obtain the correct

cross-hatch pattern as above.

If necessary, the specified color line can be erased from the screen.

100 button .................. to erase Red line

0 button .................. to erase Green line

RTN (ENT) button .................. to erase Blue line

6. Press “5” button to make the cursor blinking.

7. Press “2”, “8”, “4”, “6” buttons to move the cursor to other point to be

adjusted.

8. Repeat steps 4 to 7.

9. Repeat steps 3 to 8 to adjust Red and Blue colors.

Converge the selected color line into the Green line.

10. Press “7” button to enter the adjusted states.

At this time, picture changes for about 1 second.

11. Press “7” button again to return to the normal picture.

– 14 –

NOTES

In many cases, color misconvergence ma y be corrected by returning HIT and WID data in main deflection side to initial adjusting

values. Following cases will surely require readjustment of convergence.

CRT REPLACEMENT

When CRT is replaced, main deflection readjustment and color matching are required.

Perform following procedures.

1. Replace two CRT’s of blue and red.

2. Perform horizontal adjustment for blue and red y okes on base of green CRT data. Mount yoke and velocity mod. coil alignment, pushing towards CRT without gap.

3. Adjust alignment of blue and red. (Refer Alignment adjustment for details.)

4. Rotating centering magnet, adjust CRT centers of red and blue to CRT center of green.

(Picture position adjustment)

5. Adjust HIT and WID data of main deflection, and decide data at the most precise screen comparing to green data.

6. Adjust convergence of each screen picture for color matching. Do not move green one at this time.

7. After convergence adjustment of each screen picture finishes, replace green CRT.

For green CRT as well, repeat steps 2 to 5 above on bases of red and blue color matching to adjust convergence.

REPLACING CONVERGENCE UNIT

When replacing convergence unit, all picture screens require readjustment basically, but the following method allows process be

reduced considerably.

1. Replace the memor y (Q713) on defective unit with memory on new unit. Mounting the unit on the SET after the above

working realizes picture screen before replacement immediately.

2. Mount unit which has combination of old and new memories, on SET and turn it on. Screen shows whole picture looks like

straightly shifted towards vertical or horizontal direction.

3. Adjust again centers of green, red and blue with centering magnets.

4. Check each picture screen for slight disparity of color and picture size. If necessary, add some adjustments of main deflection and color matching of convergence.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 15 –

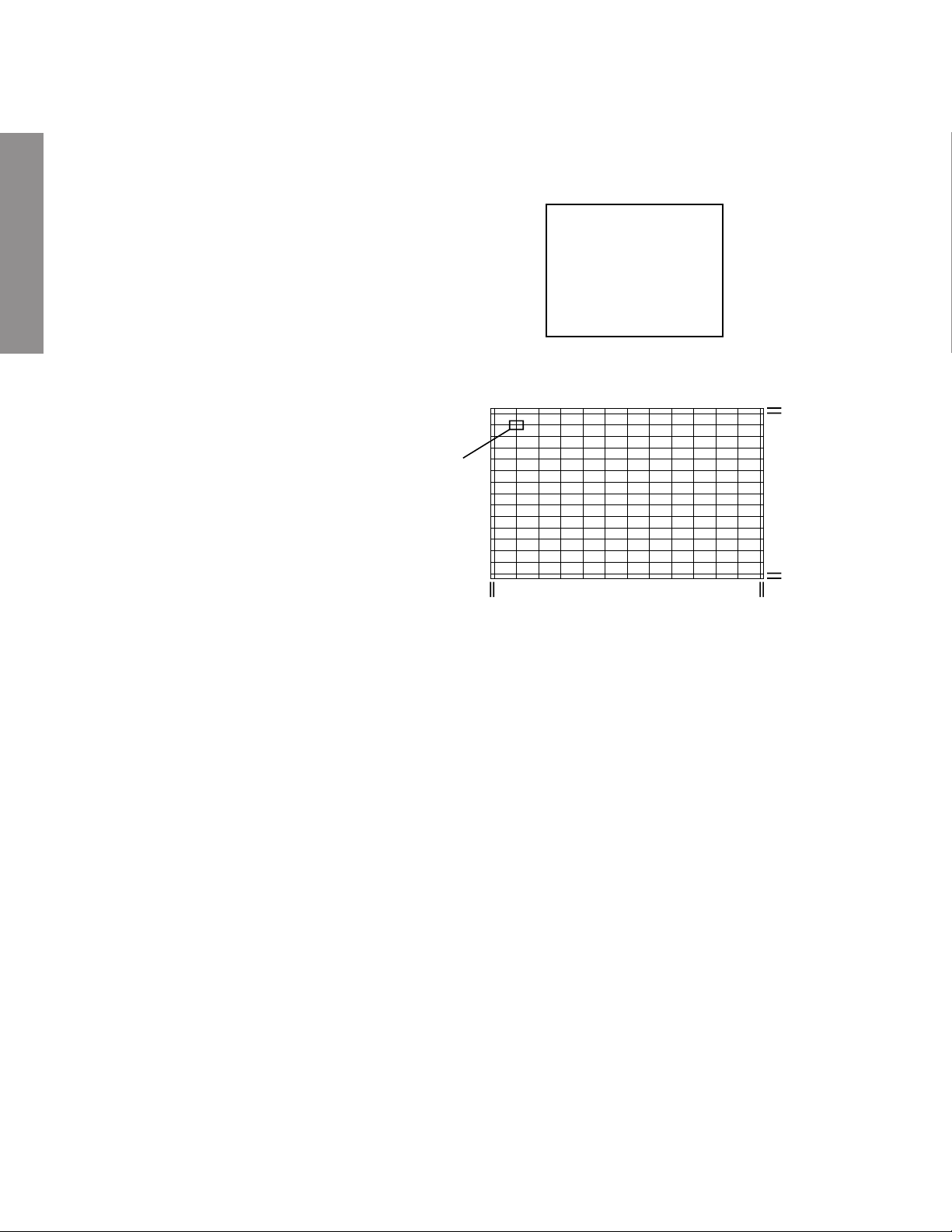

SCREEN AND MIRROR ALIGNMENTS

ASSEMBLING OF

FRONT SCREEN

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

FRONT

(for 50”)

Protect shield

FRONT

Label with part

number

Protect shield

Lenticular sheet

Fresnel sheet

Stick cotton

cloth tape

Label with part

number

MOUNTING OF

FRONT SCREEN

Fresnel sheet

5 screws

Lenticular

shield

3 screws

3 screws

3 screws

(for 55”, 61”)

Lenticular sheet

Protect shield

FRONT

Label with part

number

Stick contton

cloth tape

Fresnel sheet

Label with part

number

CAUTION : Do not hold the optical system parts (lens and

mirror) with bare hand to avoid finger-prints on

the surface of those parts.

HOW TO CLEAN LENS AND MIRROR

1. Be sure to remove sand dust with an air brush, etc.

2. When it is stained slightly, breathe upon it and wipe a way

with the specified cleaning cloth.

For other stains than the above, wipe the stains away

with the specified cloth into which a cleaning liquid has

been soaked.

Cleaning liquid.................... LENS LUSTER (Manufac-

tured by Edmund Scientific

Co.), etc.

4 screws

Please refer to Mechanical Disassembly on page 25.

*

HOW TO CLEAN SCREEN

When cleaning the screen, use a soft cloth so as not to

damage the screen.

1. Wipe the screen with a dry cloth to remove moisture on

the screen.

Note : Absolutely do not use detergent, water, alcohol,

benzine, thinner, etc. for cleaning in order not to

wipe away the black print on the surface.

– 16 –

CIRCUIT CHECKS

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on

this chassis. Checking should be done following

the steps below.

1. Connect an accurate high voltage meter to the anode of

the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 18)

4. Vary the BRIGHTNESS to both extremes to be sure the

high voltage does not exceed the limit under any conditions.

CAUTION:

When the following parts fail, check the High Voltage after

replacing.

Location

No.

T461

C407

C408

C445

C446

C447

C448

C449

ANODE VOLTAGE MEASURING METHOD

CAUTION: Take extra precaution when measuring this high

Name

Flyback

Capacitor

Capacitor

Capacitor

Capacitor

Capacitor

Capacitor

Capacitor

voltage. High voltages are also present in

surrounding circuit boards (CRT DRIVE assembly, DEFLECTION assembly, and POWER

SUPPLY assembly).

TFB3088AD

4300pF, ±3%

0.027µF, ±5%

0.015µF, ±5%

0.011µF, ±5%

6200PF, ±3%

8200PF, ±5%

1000PF, ±3%

40", 43"

Descriptions

50", 55", 61"

←

5100pF, ±3%

0.022µF, ±3%

0.022µF, ±5%

0.012µF, ±5%

5600pF, ±3%

←

←

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final

check in servicing. Checking should be done following the

steps below.

1. Turn the receiver on.

2. Temporarily short TP- (R) and TP- (X) on the DEF/POWER

Board with a jumper wire.

Raster and sound will disappear.

3. The receiver must remain in this state even after removing

the jumper wire. This is the evidence that the FS circuit is

functioning properly.

4. To obtain a picture again, temporarily turn the receiver off

and allow the FS circuit more than 5 seconds to reset. Then

turn the receiver on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

Check that the set returns to normal operation when

pin 12 of Z801 is grounded with jumper wire.

YES NO

Check the voltage across

Capacitor C471 is

approximately (

Refer to table –4 for

fall safe voltage (

YES

Defective Fail Safe Circuit

C)

volts.

C)

(See SETTING & ADJUSTING

DATA on page18)

.

NO

Faulty power

circuit or horizontal circuit.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

1. Disconnect the FBT anode cable as outlined below. Measure high voltage at the point where the cable enters the

FBT.

2. Holding the r ubber cover firmly, turn it counterclockwise

and check that the lock has been disengaged. (See Fig. b

on page 9.)

3. Determine the extent of the rubber cover before disconnecting the cable.

4. Pull straight up the anode cable to disconnect.

5. When reconnecting the cable, proceed in the re verse order.

After reconnecting, tug on the cable to check that it is secure.

– 17 –

CHAPTER 2 SPECIFIC INFORMATIONS

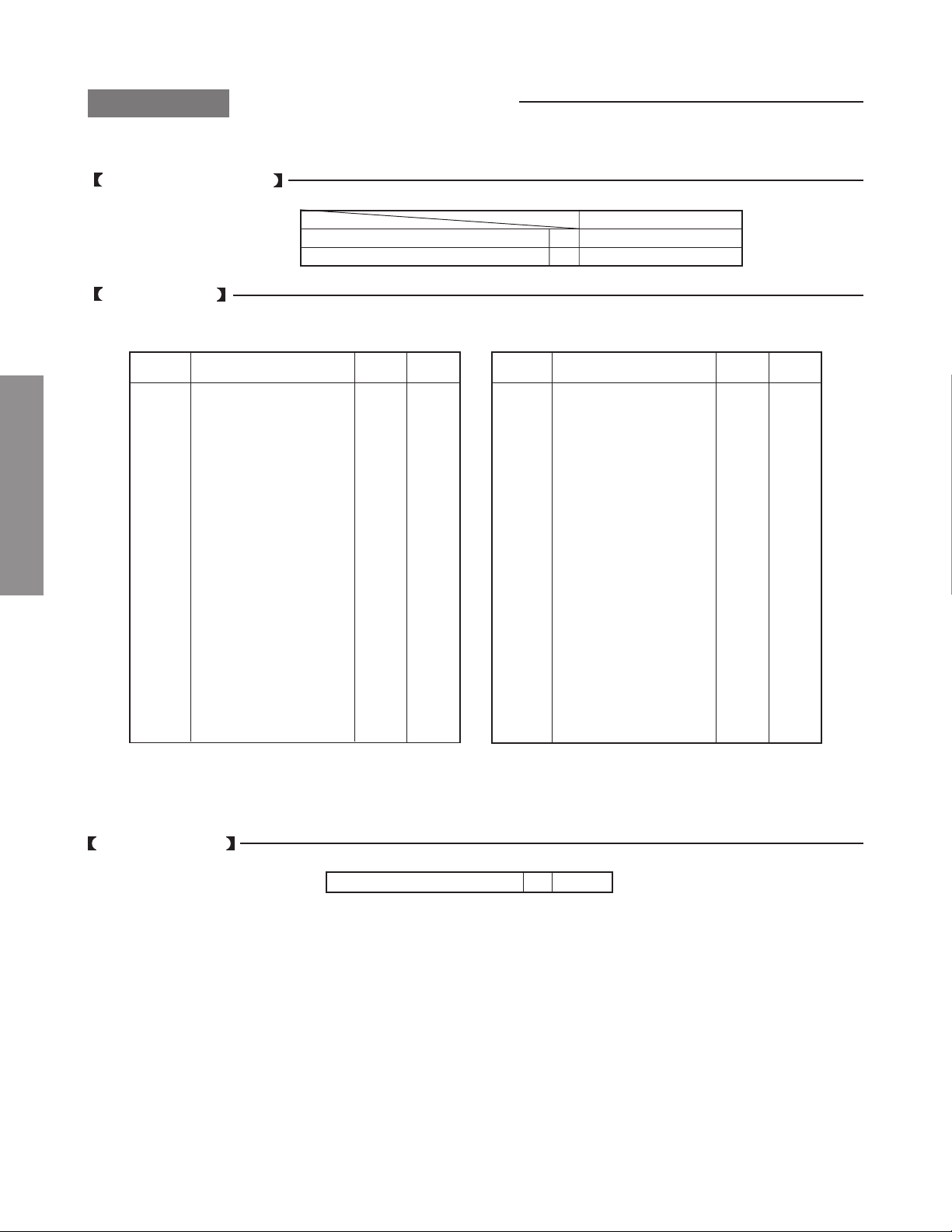

SETTING & ADJUSTING DATA

SAFETY INSTRUCTIONS

HIGH VOLTAGE AT ZERO BEAM: (A) 31.5 kV

MAX HIGH VOLTAGE:

Table-1

SERVICE MODE

40~61"

(B) 32.6 kV

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

ADJUSTING ITEMS AND DATA IN THE SERVICE MODE:

Item Name of adjustment

RCUT

GCUT

BCUT

RDRV

BDRV

CNTX

BRTC

COLC

TNTC

SCOL

SCNT

HPOS

VPOS

HIT

LIN

VSC

WID

R CUTOFF

G CUTOFF

B CUTOFF

R DRIVE

B DRIVE

SUB CONT MAX

SUB-BRIGHT

SUB-COLOR

SUB-TINT

SUB COLOR

SUB-CONTRAST

HORIZ. POSITION

VERT. POSITION

HEIGHT

V-LINEARITY

V-S CORRECTION

PICTURE WIDTH

Preset Date

40H

40H

40H

40H

40H

7FH

80H

50H

44H

05H

10H

6DH

00H

64H

12H

10H

23H

←

←

←

←

←

←

←

←

←

←

←

←

←

55H

←

←

←

Item Name of adjustment Preset Date

VPS

PYOF

PIOF

PQOF

VCP

PARA

CNR

TRAP

HCP

VFC

PHUE

PCNT

PCOL

VCEN

TVOP

OPT0

OPT1

V-SHIFT

PIP Y OFFSET

PIP I OFFSET

PIP Q OFFSET

V-COMPENSATE

E-W PARABOLA (DPC)

E-W CORNER

TRAPEZIUM

H-COMPENSATE

V-F CORRECT

PIP TINT

PIP CONT

PIP COLOR

V POSITION

TV OPTION

TV SET OPTION

TV SET OPTION

0AH

17H

24H

1EH

0AH

29H

08H

0CH

00H

00H

40H

10H

15H

70H

00H

50H

05H

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

CIRCUIT CHECKS

T able-2

FBT DETECTION VOLTAGE (C) 24.5V

Table-3

– 18 –

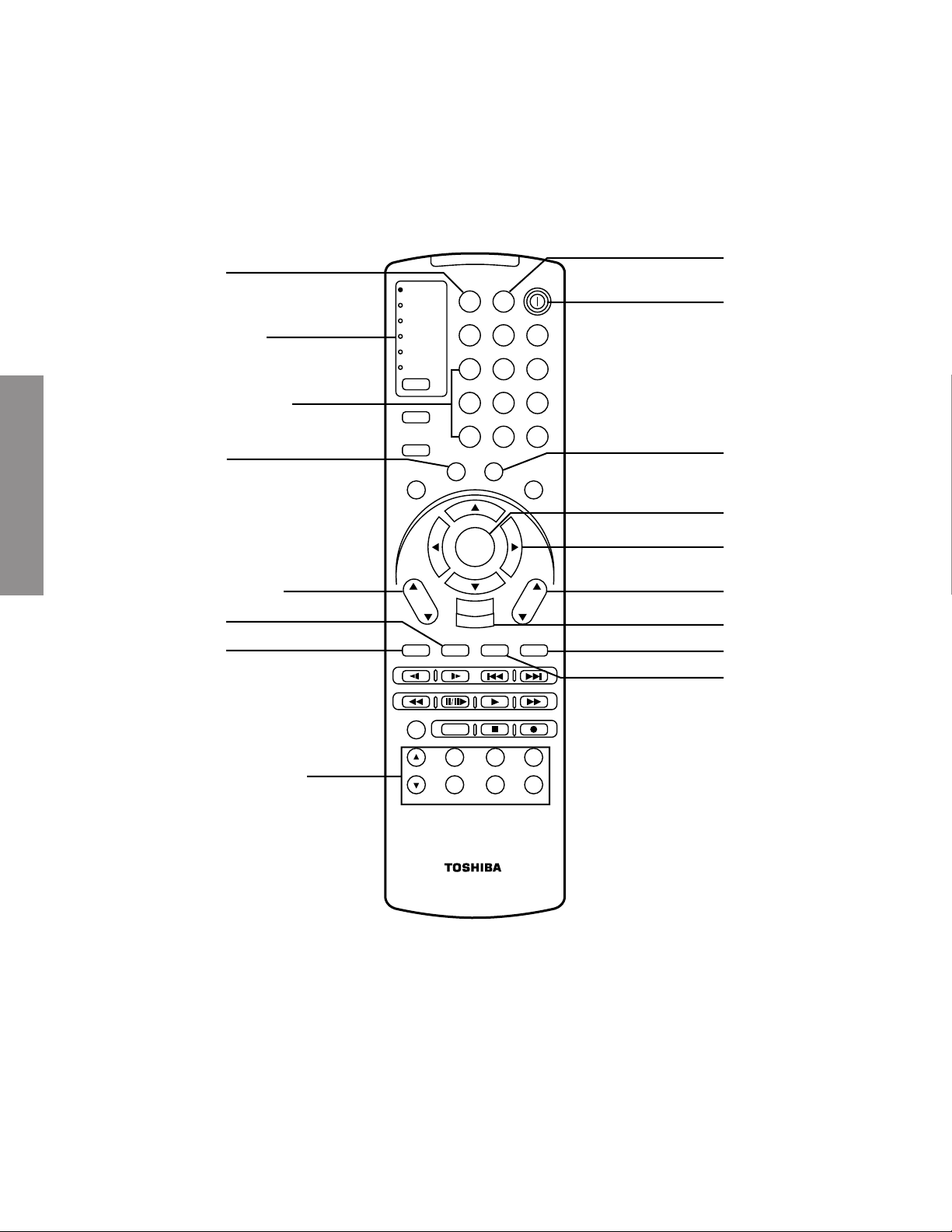

TV front

LOCATION OF CONTROLS (Representative : 61HX70)

Behind the door

Video Audio inputs

(Video3)

Remote sensor

(Behind the screen)

T Sst

MENU EXIT TV/VIDEO DEMO POWER

VOL VOL

CH

CH

VOLUMET S

TV/VIDEO

Power Indicator

POWER

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

TV rear

MENU

S-VIDEO

VIDEO

L/

MONO

AUDIO

R

VIDEO-2VIDEO-1

– 19 –

CHANNEL st

OUT

R

Y

P

B

P

R

COLOR

AUDIO

STREAM

HD-1

DEMO

EXIT

ANT (75Ω)

AUDIO CENTER

CHANNEL IN

ON OFF

L

VAR

AUDIO

Y

VIDEO

L/

MONO

AUDIO

RLR

OUTININ

COLOR

STREAM

HD-2

L

P

B

AUDIO

P

R

R

IN

ANT-1

OUT

ANT-2

Remote Control

LIGHT

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

MODE switch

Set to “TV” to control the TV.

Channel Number

INFO

CHANNEL s/t

MUTE

INPUT

TV

CABLE/SAT

VCR

DVD

AUDIO1

AUDIO2

MODE

PIC SIZE

ACTION

D

I

U

G

CH VOL

INPUT

REW

TV/

VCR

E

P

U

T

E

S

SLOW/DIR

PAUSE/STEP

LIGHT

SLEEP

MOVIE

SPORTS NEWS

123

LIST

SERVICES

456

78

100/

0

–

F

A

V

O

O

F

N

I

T

MUTE

DISC

AM/FM

S

E

L

T

I

MENU/

ENTER

EXIT

DVD CLEAR

R

I

T

U

B

T

I

T

L

E

RECALL CH RTN

SKIP/SEARCH

PLAY

STOP REC

E

A

POWER

9

ENT

A

L

S

O

R

U

D

I

O

DVD RTN

FF

P

H

T

SLEEP

POWER

FAVORITE

A

MENU/ENTER

stT S/FAV T S

VOLUME s/t

EXIT

CH RTN

RECALL

PIP functions button

PIP CH

PIP

SWAP

– 20 –

MULTI STILL

LOCATE SOURCE

PROGRAMMING CHANNEL MEMORY

The channel memory is the list of TV channel numbers the TV tunes in when you press the CHANNEL s or t button.

First, use the TV/CABLE and CH PROGRAM functions to preset all active channels in your area automatically.

If necessary, arrange the preset channels with the ADD/ERASE functions so that you can tune into only desired channels.

Note: If you utilize both ANT-1 and ANT-2 terminals for some model, perform programming channels for each input source.

TV/CABLE function

1 Press MENU, then press S or T until the SET UP menu

appears.

2 Press t (or s) until “TV/CABLE” is highlighted.

3 Press : or ; to highlight either “TV” or “CABLE”, whichever

you use.

CH PROGRAM function

1 Select “CH PROGRAM” following steps 1 and 2 above.

2 Press : or ; to start channel programming.

The TV will automatically cycle through all the TV or

CABLE channels selected by the TV/CABLE function, and

store active channels in the channel memory.

3 When channel programming is complete, you will see the

message to the right appears.

4 Press CHANNEL s or t to make sure the channel

programming has been done properly.

ADD/ERASE function

After performing the CH PROGRAM function, you can add or

erase specific channels.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

1 Select the channel you want to erase using the CHANNEL

s or t button, or select the channel you want to add using

the Channel Number buttons.

2 Press MENU, then press S or T until the SET UP menu

appears.

3 Press t (or s) until “ADD/ERASE” is highlighted.

4 Press S or T :

To erase the channel press the button until “ERASE” is

highlighted.

To add the channel press the button until “ADD” is

highlighted.

5 Repeat steps 1 to 4 for other channels.

You have now completed the channel programming.

Note: The CHANNEL t/s buttons on the TV function as the

t/s buttons while a menu is on the screen.

* Please refer to owner's manual in detail.

– 21 –

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

THIS PAGE IS

INTENTIONALLY LEFT

BLANK.

– 22 –

CIRCUIT BLOCK DIAGRAM

– 23 –

– 24 –

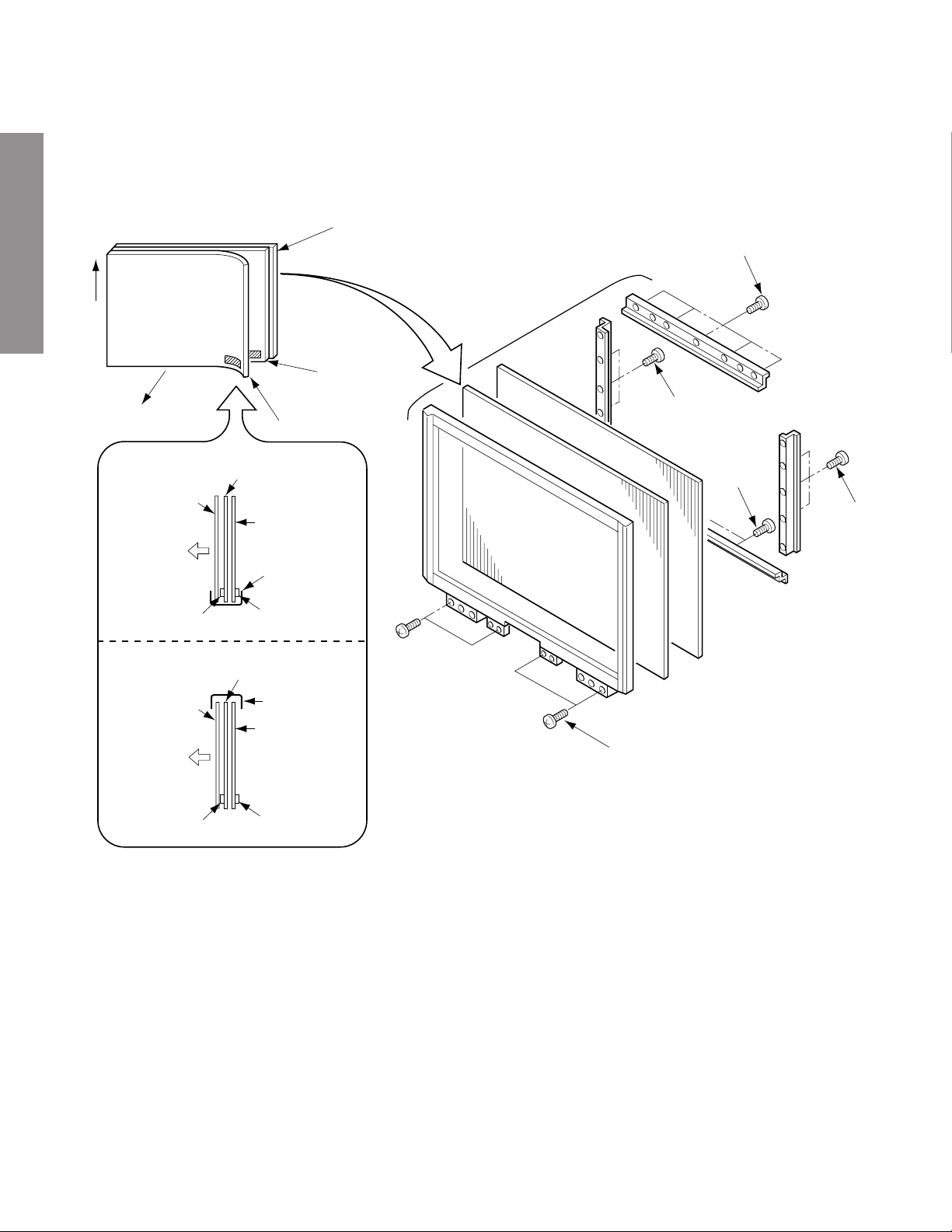

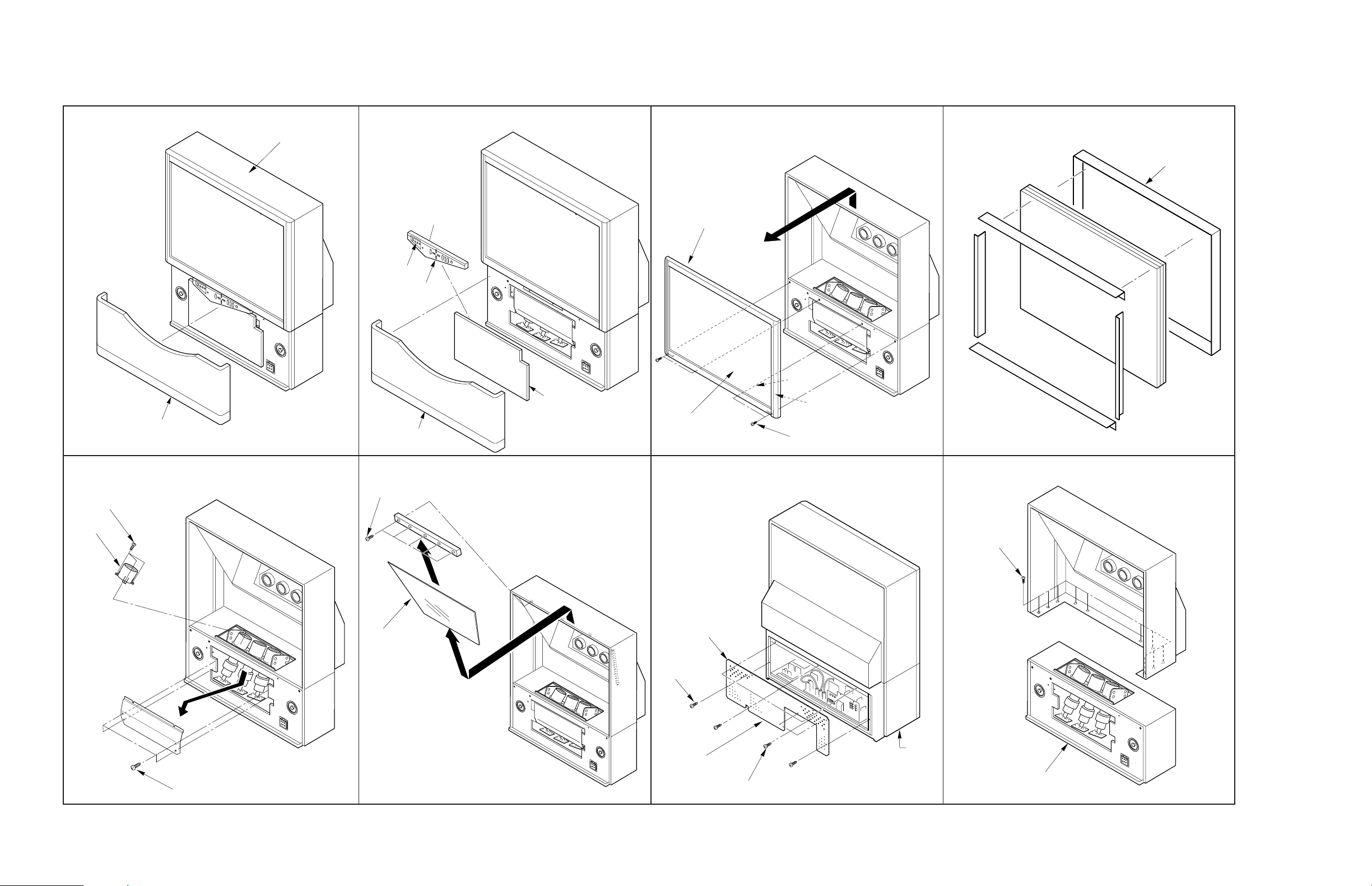

MECHANICAL DISASSEMBLY

K501

4 screws

A201

K502

K503

A424

A160

3 screws

5 screws

A424

(10 screw)

(A150)

A201

1 Speaker Grille Removal 2 Control Panel Removal

A001

A202

A213

A224

A102

A102

A268

3 Front Mask Removal

4 Mask Removal

5 Shield Plate, Lens Removal 6 Mirror Removal

5 screws

K601

K111

K112

K113

4 screws

4 screws

– 25 –

7 Back Board Removal

8 Light Box Removal

– 26 –

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SER VICING THIS CHASSIS, READ THE “X-RA Y RADIATION PRECAUTION”, “SAFETY PRE-

CAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

CAUTION: The international hazard symbols “ ” in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in the

original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE. Do not degrade the

safety of the receiver through improper servicing.

NOTICE:

•

The part number must be used when ordering parts, in order to assist in processing, be sure to include the Model

number and Description.

•

The PC board assembly with * mark is no longer available after the end of the production.

Models : 50HX70/55HX70/61HX70/55H70/61H70

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are ±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

Location

No.

CAPACITORSCAPACITORS

CAPACITORS

CAPACITORSCAPACITORS

C102 24665221 EL, 220?F, ±20%, 10V

C105 24109102 Chip, 1000pF, ±10%

C106 24669479 EL, 4.7?F, ±20%, 50V

C107 24666221 EL, 220?F, ±20%, 16V

C112 24665221 EL, 220?F, ±20%, 10V

C115 24109102 Chip, 1000pF, ±10%

C117 24666221 EL, 220?F, ±20%, 16V

C151 24212102 CD, 1000pF, ±10%

C201 24092730 Chip, 0.1?F, ±10%, 16V

C205 24206229 EL, 2.2?F, ±20%, 50V

C207 24105100 Chip, 10pF, ±0.5pF

C208 24105100 Chip, 10pF, ±0.5pF

C209 24105100 Chip, 10pF, ±0.5pF

C212 24666100 EL, 10?F, ±20%, 16V

C221 24567104 PF, 0.1?F

C301 24567683 PF, 0.068?F

C302 24567224 PF, 0.22?F

C303 24666101 EL, 100?F, ±20%, 16V

C304 24567104 PF, 0.1?F

C305 24567104 PF, 0.1?F

C306 24567103 PF, 0.01?F

C307 24617912 EL, 2.2?F, ±10%, 50V

C308 24567183 PF, 0.018?F

C309 24212102 CD, 1000pF, ±10%

C310 24073020 EL, 1000?F, ±20%, 10V

C311 24567103 PF, 0.01?F

C312 24591102 PF, 1000pF

C313 24567474 PF, 0.47?F

C314 24567104 PF, 0.1?F

C315 24073020 EL, 1000?F, ±20%, 10V

C315 24206229 EL, 2.2?F, ±20%, 50V

C316 24666101 EL, 100?F, ±20%, 16V

C317 24591222 PF, 2200pF

C318 24591182 PF, 1800pF

C319 24667101 EL, 100?F, ±20%, 25V

C320 24669101 EL, 100?F, ±20%, 50V

C321 24669101 EL, 100?F, ±20%, 50V

C322 24567393 PF, 0.039?F

C323 24092748 Chip, 0.056?F, ±10%, 16V

C324 24669101 EL, 100?F, ±20%, 50V

Part No. Description

Location

No.

C325 24082057 PF, 0.22?F, 100V

C326 24567334 PF, 0.33?F

C327 24567224 PF, 0.22?F

C328 24082260 PF, 4700pF, 100V

C329 24669100 EL, 10?F, ±20%, 50V

C330 24085946 EL, 10?F, ±20%, 16V,

C331 24109333 Chip, 0.033?F, ±10%, 25V

C332 24669221 EL, 220?F, ±20%, 50V

C333 24693473 PF, 0.047?F, 100V

C334 24109471 Chip, 470pF, ±10%

C335 24567224 PF, 0.22?F

C336 24666100 EL, 10?F, ±20%, 16V

C340 24567224 PF, 0.22?F

C350 24669229 EL, 2.2?F, ±20%, 50V

C351 24567104 PF, 0.1?F

C352 24666220 EL, 22?F, ±20%, 16V

C401 24214332 CD, 3300pF, ±10%, 500V

C402 24092463 Chip, 0.22?F, ±10%, 16V

C402 24214391 CD, 390pF, ±10%, 500V

C403 24676220 EL, 22?F, ±20%, 100V

C404 24206229 EL, 2.2?F, ±20%, 50V

C405 24567124 PF, 0.12?F

* C406 24109223 Chip, 0.022?F, ±10%, 25V

* C407 24082609 PF, 5100pF, ±3%, 1800V

* C408 24820223 PF, 0.022?F, 630V

C410 24095900 PF, 3.3?F, ±10%, 100V

C410 24108221 Chip, 220pF

C411 24678220 EL, 22?F, ±20%, 200V

C412 24828823 PF, 0.082?F, 200V

C413 24214221 CD, 220pF, ±10%, 500V

* C414 24082647 PF, 0.27?F, 400V

C415 24092484 CD, 1500pF, ±10%, 2kV

C416 24095716 PF, 1.5?F, ±10%, 250V

C417 24082648 PF, 0.3?F, 400V

C418 24679330 EL, 33?F, ±20%, 250V

C419 24669479 EL, 4.7?F, ±20%, 50V

C423 24640908 EL, 33?F, ±20%, 160V

C424 24591102 PF, 1000pF

C426 24211222 CD, 2200pF, ±10%, 2kV

C426 24666331 EL, 330?F, ±20%, 16V

Part No. Description

Non-Polar

SPECIFIC INFORMATIONS

– 27 –

Location

No.

Part No. Description

Location

No.

Part No. Description

C427 24109103 Chip, 0.01?F, ±10%, 25V

C427 24828473 PF, 0.047?F, 200V

C428 24797010 EL, 1?F, ±20%, 50V

C429 24109103 Chip, 0.01?F, ±10%, 25V

C429 24591472 PF, 4700pF

C430 24085903 EL, 1?F, ±20%, 50V,

C430 24567123 PF, 0.012?F

C431 24567104 PF, 0.1?F

C431 24591102 PF, 1000pF

C432 24567103 PF, 0.01?F

C432 24567333 PF, 0.033?F

C434 24501561 PF, 560pF

C435 24501272 PF, 0.0027?F

C436 24669479 EL, 4.7?F, ±20%, 50V

C437 24567103 PF, 0.01?F

C438 24591272 PF, 2700pF

C439 24669229 EL, 2.2?F, ±20%, 50V

C440 24669229 EL, 2.2?F, ±20%, 50V

C441 24501272 PF, 0.0027?F

C442 24501102 PF, 0.001?F

C443 24567104 PF, 0.1?F

C444 24666331 EL, 330?F, ±20%, 16V

C445 24567103 PF, 0.01?F

C445 24820223 PF, 0.022?F, 630V

C446 24501151 PF, 150pF

* C447 24082610 PF, 5600pF, ±3%, 1800V

* C447 24567104 PF, 0.1?F

SPECIFIC INFORMATIONS

* C448 24666331 EL, 330?F, ±20%, 16V

* C448 24820822 PF, 0.0082?F, 630V

C449 24082592 PF, 1000pF, ±3%, 1800V

C449 24591332 PF, 3300pF

C451 24567563 PF, 0.056?F

C452 24567823 PF, 0.082?F

C453 24669010 EL, 1?F, ±20%, 50V

C454 24567103 PF, 0.01?F

C455 24668331 EL, 330?F, ±20%, 35V

C455 24669010 EL, 1?F, ±20%, 50V

C456 24567104 PF, 0.1?F

C456 24666221 EL, 220?F, ±20%, 16V

C457 24092730 Chip, 0.1?F, ±10%, 16V

C457 24567104 PF, 0.1?F

C458 24092730 Chip, 0.1?F, ±10%, 16V

C458 24666331 EL, 330?F, ±20%, 16V

C459 24105101 Chip, 100pF

C460 24109103 Chip, 0.01?F, ±10%, 25V

C461 24109103 Chip, 0.01?F, ±10%, 25V

C462 24109103 Chip, 0.01?F, ±10%, 25V

C463 24105101 Chip, 100pF

C464 24666101 EL, 100?F, ±20%, 16V

C465 24567104 PF, 0.1?F

C467 24436220 CD, 22pF

C468 24567474 PF, 0.47?F

C469 24666100 EL, 10?F, ±20%, 16V

C470 24212101 CD, 100pF, ±10%

C472 24567474 PF, 0.47?F

C481 24666101 EL, 100?F, ±20%, 16V

C482 24591223 PF, 0.022?F

C484 24591102 PF, 1000pF

C485 24567104 PF, 0.1?F

C493 24567104 PF, 0.1?F

C501 24109103 Chip, 0.01?F, ±10%, 25V

C502 24092730 Chip, 0.1?F, ±10%, 16V

C503 24203101 EL, 100?F, ±20%, 16V

Non-Polar

C504 24109222 Chip, 2200pF, ±10%

C505 24108120 Chip, 12pF

C506 24108120 Chip, 12pF

C507 24108120 Chip, 12pF

C508 24100104 Chip, 0.1?F, +80%, -20%, 25V

C509 24203101 EL, 100?F, ±20%, 16V

C509 24666101 EL, 100?F, ±20%, 16V

C510 24092730 Chip, 0.1?F, ±10%, 16V

C510 24666101 EL, 100?F, ±20%, 16V

C511 24109103 Chip, 0.01?F, ±10%, 25V

C511 24203101 EL, 100?F, ±20%, 16V

C512 24206228 EL, 0.22?F, ±20%, 50V

C513 24100104 Chip, 0.1?F, +80%, -20%, 25V

C513 24109103 Chip, 0.01?F, ±10%, 25V

C514 24203100 EL, 10?F, ±20%, 16V

C524 24092730 Chip, 0.1?F, ±10%, 16V

C525 24092730 Chip, 0.1?F, ±10%, 16V

C526 24092730 Chip, 0.1?F, ±10%, 16V

C527 24092730 Chip, 0.1?F, ±10%, 16V

C528 24092730 Chip, 0.1?F, ±10%, 16V

C529 24092730 Chip, 0.1?F, ±10%, 16V

C529 24109103 Chip, 0.01?F, ±10%, 25V

C530 24669010 EL, 1?F, ±20%, 50V

C531 24666101 EL, 100?F, ±20%, 16V

C532 24666100 EL, 10?F, ±20%, 16V

C535 24092730 Chip, 0.1?F, ±10%, 16V

C536 24109103 Chip, 0.01?F, ±10%, 25V

C537 24109103 Chip, 0.01?F, ±10%, 25V

C547 24109103 Chip, 0.01?F, ±10%, 25V

C551 24092730 Chip, 0.1?F, ±10%, 16V

C552 24092730 Chip, 0.1?F, ±10%, 16V

C553 24092730 Chip, 0.1?F, ±10%, 16V

C554 24092730 Chip, 0.1?F, ±10%, 16V

C555 24092730 Chip, 0.1?F, ±10%, 16V

C556 24092730 Chip, 0.1?F, ±10%, 16V

C563 24206229 EL, 2.2?F, ±20%, 50V

C564 24666100 EL, 10?F, ±20%, 16V

C565 24669229 EL, 2.2?F, ±20%, 50V

C566 24669010 EL, 1?F, ±20%, 50V

C567 24109103 Chip, 0.01?F, ±10%, 25V

C568 24109103 Chip, 0.01?F, ±10%, 25V

C569 24109103 Chip, 0.01?F, ±10%, 25V

C570 24669010 EL, 1?F, ±20%, 50V

C601 24109102 Chip, 1000pF, ±10%

C602 24109102 Chip, 1000pF, ±10%

C603 24669100 EL, 10?F, ±20%, 50V

C604 24669100 EL, 10?F, ±20%, 50V

C605 24667101 EL, 100?F, ±20%, 25V

C606 24667101 EL, 100?F, ±20%, 25V

C607 24567104 PF, 0.1?F

C608 24567104 PF, 0.1?F

C609 24669102 EL, 1000?F, ±20%, 50V

C610 24669102 EL, 1000?F, ±20%, 50V

C611 24667221 EL, 220?F, ±20%, 25V

C612 24666221 EL, 220?F, ±20%, 16V

C621 24206479 EL, 4.7?F, ±20%, 50V

C622 24206108 EL, 0.1?F, ±20%, 50V

C623 24100472 Chip, 0.1?F, +80%, -20%, 25V

C624 24206479 EL, 4.7?F, ±20%, 50V

C625 24206479 EL, 4.7?F, ±20%, 50V

C626 24206479 EL, 4.7?F, ±20%, 50V

C627 24206479 EL, 4.7?F, ±20%, 50V

C628 24206100 EL, 10?F, ±20%, 50V

C629 24206100 EL, 10?F, ±20%, 50V

– 28 –

Location

No.

Part No. Description

Location

No.

Part No. Description

C630 24206108 EL, 0.1?F, ±20%, 50V

C631 24100472 Chip, 0.1?F, +80%, -20%, 25V

C632 24203470 EL, 47?F, ±20%, 16V

C633 24567224 PF, 0.22?F

C634 24206108 EL, 0.1?F, ±20%, 50V

C635 24203220 EL, 22?F, ±20%, 16V

C636 24206479 EL, 4.7?F, ±20%, 50V

C637 24206100 EL, 10?F, ±20%, 50V

C638 24794101 EL, 100?F, ±20%, 16V

C639 24109103 Chip, 0.01?F, ±10%, 25V

C640 24109223 Chip, 0.022?F, ±10%, 25V

C641 24109822 Chip, 8200pF, ±10%, 25V

C642 24206100 EL, 10?F, ±20%, 50V

C643 24206479 EL, 4.7?F, ±20%, 50V

C644 24206339 EL, 3.3?F, ±20%, 50V

C645 24109333 Chip, 0.033?F, ±10%, 25V

C646 24109153 Chip, 0.015?F, ±10%, 25V

C647 24092748 Chip, 0.056?F, ±10%, 16V

C648 24092748 Chip, 0.056?F, ±10%, 16V

C649 24109223 Chip, 0.022?F, ±10%, 25V

C650 24109822 Chip, 8200pF, ±10%, 25V

C651 24109103 Chip, 0.01?F, ±10%, 25V

C652 24109103 Chip, 0.01?F, ±10%, 25V

C653 24100103 Chip, 0.01?F, +80%, -20%

C654 24763101 EL, 100?F, ±20%, 16V

C661 24206010 EL, 1?F, ±20%, 50V

C662 24206010 EL, 1?F, ±20%, 50V

C663 24206010 EL, 1?F, ±20%, 50V

C664 24669220 EL, 22?F, ±20%, 50V

C665 24109103 Chip, 0.01?F, ±10%, 25V

C666 24206010 EL, 1?F, ±20%, 50V

C680 24669471 EL, 470?F, ±20%, 50V

C681 24666100 EL, 10?F, ±20%, 16V

C682 24567104 PF, 0.1?F

C690 24109103 Chip, 0.01?F, ±10%, 25V

C704 24232103 CD, 0.01?F, +80%, -20%

C705 24206479 EL, 4.7?F, ±20%, 50V

C707 24797470 EL, 47?F, ±20%, 50V

C712 24797470 EL, 47?F, ±20%, 50V

C713 24790470 EL, 47?F, ±20%, 160V

C715 24214472 CD, 4700pF, ±10%, 500V

C717 24214472 CD, 4700pF, ±10%, 500V

C718 24666470 EL, 47?F, ±20%, 16V

C719 24435560 CD, 56pF, 500V

C720 24790220 EL, 22?F, ±20%, 160V

C721 24666470 EL, 47?F, ±20%, 16V

C722 24436820 CD, 82pF

C726 24212102 CD, 1000pF, ±10%

C760 24797470 EL, 47?F, ±20%, 50V

C761 24212102 CD, 1000pF, ±10%

C762 24797470 EL, 47?F, ±20%, 50V

C765 24214472 CD, 4700pF, ±10%, 500V

C766 24214472 CD, 4700pF, ±10%, 500V

C767 24790470 EL, 47?F, ±20%, 160V

C768 24666470 EL, 47?F, ±20%, 16V

C769 24666470 EL, 47?F, ±20%, 16V

C770 24435560 CD, 56pF, 500V

C771 24790220 EL, 22?F, ±20%, 160V

C780 24797470 EL, 47?F, ±20%, 50V

C781 24212102 CD, 1000pF, ±10%

C782 24797470 EL, 47?F, ±20%, 50V

C784 24214472 CD, 4700pF, ±10%, 500V

C786 24214472 CD, 4700pF, ±10%, 500V

C787 24790470 EL, 47?F, ±20%, 160V

C788 24666470 EL, 47?F, ±20%, 16V

C789 24666470 EL, 47?F, ±20%, 16V

C790 24435560 CD, 56pF, 500V

C791 24790220 EL, 22?F, ±20%, 160V

C792 24669229 EL, 2.2?F, ±20%, 50V

C801 24082001 PF, 0.47?F, AC125V

C809 24086067 EL, 1000?F, ±20%, 200V

C810 24086067 EL, 1000?F, ±20%, 200V

C811 24092597 CD, 4700pF, ±20%, AC250V

C812 24092597 CD, 4700pF, ±20%, AC250V

C813 24092597 CD, 4700pF, ±20%, AC250V

C830 24567334 PF, 0.33?F

C831 24666101 EL, 100?F, ±20%, 16V

C833 24666470 EL, 47?F, ±20%, 16V

C834 24667101 EL, 100?F, ±20%, 25V

C835 24667470 EL, 47?F, ±20%, 25V

C836 24567334 PF, 0.33?F

C840 24668102 EL, 1000?F, ±20%, 35V

C842 24664101 EL, 100?F, ±20%, 6.3V

C843 24567105 PF, 1?F

C857 24668332 EL, 3300?F, ±20%, 35V

C858 24668332 EL, 3300?F, ±20%, 35V

C860 24214103 CD, 0.01?F, ±10%, 500V

C863 24567224 PF, 0.22?F

C864 24092474 CD, 220pF, ±10%, 2kV

C866 24567105 PF, 1?F

C867 24591472 PF, 4700pF

C868 24669101 EL, 100?F, ±20%, 50V

C869 24678229 EL, 2.2?F, ±20%, 200V

C870 24082889 PF, 0.068?F, 800V

C871 24092484 CD, 1500pF, ±10%, 2kV

C872 24092478 CD, 470pF, ±10%, 2kV

C873 24567224 PF, 0.22?F

C874 24212102 CD, 1000pF, ±10%

C876 24567474 PF, 0.47?F

C881 24678478 EL, 0.47?F, ±20%, 200V

C882 24794220 EL, 22?F, ±20%, 16V

C883 24082229 PF, 0.1?F, ±10%, 250V

C884 24086916 EL, 330?F, ±20%, 160V

C885 24669229 EL, 2.2?F, ±20%, 50V

C888 24666100 EL, 10?F, ±20%, 16V

C889 24669010 EL, 1?F, ±20%, 50V

C890 24669222 EL, 2200?F, ±20%, 50V

C892 24669229 EL, 2.2?F, ±20%, 50V

C894 24668222 EL, 2200?F, ±20%, 35V

C895 24666332 EL, 3300?F, ±20%, 16V

C898 24212102 CD, 1000pF, ±10%

C901 24211102 CD, 1000pF, ±10%, 2kV

C902 24794101 EL, 100?F, ±20%, 16V

C903 24232103 CD, 0.01?F, +80%, -20%

C904 24436681 CD, 680pF

C905 24214102 CD, 1000pF, ±10%, 500V

C907 24214101 CD, 100pF, ±10%, 500V

C908 24436390 CD, 39pF

C909 24794470 EL, 47?F, ±20%, 16V

C911 24211102 CD, 1000pF, ±10%, 2kV

C912 24794101 EL, 100?F, ±20%, 16V

C913 24232103 CD, 0.01?F, +80%, -20%

C914 24436821 CD, 820pF

C915 24679330 EL, 33?F, ±20%, 250V

C916 24794102 EL, 1000?F, ±20%, 16V

C917 24214101 CD, 100pF, ±10%, 500V

C918 24567104 PF, 0.1?F

C919 24794470 EL, 47?F, ±20%, 16V

SPECIFIC INFORMATIONS

– 29 –

Location

No.

Part No. Description

Location

No.

Part No. Description

C921 24211102 CD, 1000pF, ±10%, 2kV

C922 24794101 EL, 100?F, ±20%, 16V

C923 24436681 CD, 680pF

C924 24232103 CD, 0.01?F, +80%, -20%

C926 24214101 CD, 100pF, ±10%, 500V

C927 24567104 PF, 0.1?F

C928 24203100 EL, 10?F, ±20%, 16V

C929 24794470 EL, 47?F, ±20%, 16V

C961 24763102 EL, 1000?F, ±20%, 16V

C962 24203100 EL, 10?F, ±20%, 16V

C963 24567104 PF, 0.1?F

C964 24567104 PF, 0.1?F

C7704 24667101 EL, 100?F, ±20%, 25V

C7705 24567334 PF, 0.33?F

C7706 24567334 PF, 0.33?F

C7707 24667101 EL, 100?F, ±20%, 25V

C7708 24105150 Chip, 15pF

C7709 24105150 Chip, 15pF

C7710 24105150 Chip, 15pF

C7711 24105150 Chip, 15pF

C7712 24105150 Chip, 15pF

C7713 24105150 Chip, 15pF

C7714 24105150 Chip, 15pF

C7715 24105150 Chip, 15pF

C7716 24105150 Chip, 15pF

C7717 24105150 Chip, 15pF

C7718 24105150 Chip, 15pF

C7719 24105150 Chip, 15pF

SPECIFIC INFORMATIONS

C7721 24109102 Chip, 1000pF, ±10%

C7722 24105331 Chip, 330pF

C7724 24667331 EL, 330?F, ±20%, 25V

C7725 24667331 EL, 330?F, ±20%, 25V

C7726 24109102 Chip, 1000pF, ±10%

C7727 24105331 Chip, 330pF

C7729 24109102 Chip, 1000pF, ±10%

C7730 24105331 Chip, 330pF

C7732 24105331 Chip, 330pF

C7733 24105331 Chip, 330pF

C7735 24667331 EL, 330?F, ±20%, 25V

C7736 24667331 EL, 330?F, ±20%, 25V

C7737 24109102 Chip, 1000pF, ±10%

C7738 24105331 Chip, 330pF

C7740 24105331 Chip, 330pF

C7741 24105331 Chip, 330pF

C7751 24667101 EL, 100?F, ±20%, 25V

C7752 24567334 PF, 0.33?F

C7753 24567334 PF, 0.33?F

C7754 24667101 EL, 100?F, ±20%, 25V

C7760 24667470 EL, 47?F, ±20%, 25V

C7761 24667100 EL, 10?F, ±20%, 25V

C7763 24667470 EL, 47?F, ±20%, 25V

C7767 24667101 EL, 100?F, ±20%, 25V

C7768 24667101 EL, 100?F, ±20%, 25V

C7769 24109103 Chip, 0.01?F, ±10%, 25V

C7774 24105101 Chip, 100pF

C7776 24667100 EL, 10?F, ±20%, 25V

C7779 24105331 Chip, 330pF

C7812 24109103 Chip, 0.01?F, ±10%, 25V

C7816 24667100 EL, 10?F, ±20%, 25V

C7817 24109103 Chip, 0.01?F, ±10%, 25V

CA10 24105101 Chip, 100pF

CA13 24109221 Chip, 220pF, ±10%

CA14 24666100 EL, 10?F, ±20%, 16V

CA18 24666470 EL, 47?F, ±20%, 16V

CA20 24105181 Chip, 180pF

CA21 24092442 Chip, 0.47?F,

+80%, -20%, 16V

CA22 24109103 Chip, 0.01?F, ±10%, 25V

CA23 24105181 Chip, 180pF

CA24 24092442 Chip, 0.47?F,

+80%, -20%, 16V

CA25 24666100 EL, 10?F, ±20%, 16V

CA26 24092538 Chip, 1?F, +80%, -20%, 10V

CA27 24092538 Chip, 1?F, +80%, -20%, 10V

CA29 24109221 Chip, 220pF, ±10%

CA30 24105101 Chip, 100pF

CA34 24105101 Chip, 100pF

CA45 24666100 EL, 10?F, ±20%, 16V

CA49 24666100 EL, 10?F, ±20%, 16V

CA50 24100103 Chip, 0.01?F, +80%, -20%

CA52 24109272 Chip, 2700pF, ±10%

CA54 24105101 Chip, 100pF

CA59 24105101 Chip, 100pF

CA60 24105101 Chip, 100pF

CA61 24666220 EL, 22?F, ±20%, 16V

CA64 24109103 Chip, 0.01?F, ±10%, 25V

CA68 24666100 EL, 10?F, ±20%, 16V

CA69 24109103 Chip, 0.01?F, ±10%, 25V

CA71 24105101 Chip, 100pF

CA72 24085970 EL, 10?F, ±20%, 16V,

Non-Polar

CA73 24666100 EL, 10?F, ±20%, 16V

CB01 24105101 Chip, 100pF

CB02 24105101 Chip, 100pF

CB11 24100103 Chip, 0.01?F, +80%, -20%

CB11 24794470 EL, 47?F, ±20%, 16V

CB12 24666100 EL, 10?F, ±20%, 16V

CB13 24085970 EL, 10?F, ±20%, 16V,

Non-Polar

CB14 24105100 Chip, 10pF, ±0.5pF

CB15 24794100 EL, 10?F, ±20%, 16V

CB33 24109103 Chip, 0.01?F, ±10%, 25V

CB37 24105101 Chip, 100pF

CB38 24105101 Chip, 100pF

CB40 24109103 Chip, 0.01?F, ±10%, 25V

CB41 24666100 EL, 10?F, ±20%, 16V

CB42 24109103 Chip, 0.01?F, ±10%, 25V

CB42 24232103 CD, 0.01?F, +80%, -20%

CB43 24109103 Chip, 0.01?F, ±10%, 25V

CB62 24105331 Chip, 330pF

CB90 24109103 Chip, 0.01?F, ±10%, 25V

CB91 24666100 EL, 10?F, ±20%, 16V

CD01 24206478 EL, 0.47?F, ±20%, 50V

CD02 24206478 EL, 0.47?F, ±20%, 50V

CD03 24503041 PF, 0.1?F, 63V

CD05 24567103 PF, 0.01?F

CD06 24206478 EL, 0.47?F, ±20%, 50V

CD07 24591472 PF, 4700pF

CD08 24206478 EL, 0.47?F, ±20%, 50V

CD10 24503041 PF, 0.1?F, 63V

CD11 24203100 EL, 10?F, ±20%, 16V

CD12 24203100 EL, 10?F, ±20%, 16V

CD13 24666101 EL, 100?F, ±20%, 16V

CD15 24203100 EL, 10?F, ±20%, 16V

CD16 24206479 EL, 4.7?F, ±20%, 50V

CH001 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH004 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH005 24100104 Chip, 0.1?F, +80%, -20%, 25V

– 30 –

Location

No.

Part No. Description

Location

No.

Part No. Description

CH006 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH007 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH008 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH009 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH010 24092743 Chip, 0.47?F,

+80%, -20%, 10V

CH011 24762221 EL, 220?F, ±20%, 10V

CH012 24763101 EL, 100?F, ±20%, 16V

CH013 24763101 EL, 100?F, ±20%, 16V

CH014 24108101 Chip, 100pF

CH015 24108330 Chip, 33pF

CH016 24108330 Chip, 33pF

CH017 24108330 Chip, 33pF

CH018 24108330 Chip, 33pF

CH019 24108330 Chip, 33pF

CH020 24108330 Chip, 33pF

CH040 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH041 24108101 Chip, 100pF

CH042 24108101 Chip, 100pF

CH043 24108101 Chip, 100pF

CH044 24108101 Chip, 100pF

CH045 24108101 Chip, 100pF

CH046 24108101 Chip, 100pF

CH047 24108101 Chip, 100pF

CH048 24108101 Chip, 100pF

CH051 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH052 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH053 24105070 Chip, 7pF, ±0.5pF

CH061 24109103 Chip, 0.01?F, ±10%, 25V

CH062 24092730 Chip, 0.1?F, ±10%, 16V

CH063 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH101 24105070 Chip, 7pF, ±0.5pF

CH102 24105070 Chip, 7pF, ±0.5pF

CH120 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH121 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH122 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH123 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH124 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH125 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH126 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH127 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH128 24108221 Chip, 220pF

CH129 24108221 Chip, 220pF

CH140 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH141 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH142 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH143 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH144 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH145 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH146 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH147 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH148 24108221 Chip, 220pF

CH149 24108221 Chip, 220pF

CH160 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH161 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH162 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH163 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH164 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH165 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH166 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH167 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH168 24108221 Chip, 220pF

CH169 24108221 Chip, 220pF

CH170 24105681 Chip, 680pF

CH171 24105681 Chip, 680pF

CH172 24105331 Chip, 330pF

CH173 24105102 Chip, 1000pF, 25V

CH174 24105391 Chip, 390pF

CH175 24105220 Chip, 22pF

CH176 24105391 Chip, 390pF

CH177 24105220 Chip, 22pF

CH178 24105151 Chip, 150pF

CH179 24105102 Chip, 1000pF, 25V

CH180 24105681 Chip, 680pF

CH181 24105681 Chip, 680pF

CH182 24105391 Chip, 390pF

CH183 24105220 Chip, 22pF

CH184 24105391 Chip, 390pF

CH185 24105220 Chip, 22pF

CH186 24105331 Chip, 330pF

CH187 24105102 Chip, 1000pF, 25V

CH188 24105151 Chip, 150pF

CH189 24105102 Chip, 1000pF, 25V

CH190 24105681 Chip, 680pF

CH191 24105681 Chip, 680pF

CH192 24105391 Chip, 390pF

CH193 24105220 Chip, 22pF

CH194 24105331 Chip, 330pF

CH195 24105102 Chip, 1000pF, 25V

CH196 24105391 Chip, 390pF

CH197 24105220 Chip, 22pF

CH198 24105151 Chip, 150pF

CH199 24105102 Chip, 1000pF, 25V

CH200 24105681 Chip, 680pF

CH201 24105681 Chip, 680pF

CH202 24105220 Chip, 22pF

CH203 24105391 Chip, 390pF

CH204 24105391 Chip, 390pF

CH205 24105220 Chip, 22pF

CH206 24105331 Chip, 330pF

CH207 24105102 Chip, 1000pF, 25V

CH208 24105151 Chip, 150pF

CH209 24105102 Chip, 1000pF, 25V

CH210 24105681 Chip, 680pF

CH211 24105681 Chip, 680pF

CH212 24105331 Chip, 330pF

CH213 24105102 Chip, 1000pF, 25V

CH223 24105391 Chip, 390pF

CH224 24105220 Chip, 22pF

CH225 24105391 Chip, 390pF

CH226 24105220 Chip, 22pF

CH227 24105151 Chip, 150pF

CH228 24105102 Chip, 1000pF, 25V

CH229 24105681 Chip, 680pF

CH230 24105681 Chip, 680pF

CH231 24105391 Chip, 390pF

CH232 24105220 Chip, 22pF

CH233 24105391 Chip, 390pF

CH234 24105220 Chip, 22pF

CH235 24105331 Chip, 330pF

CH236 24105102 Chip, 1000pF, 25V

CH237 24105151 Chip, 150pF

CH238 24105102 Chip, 1000pF, 25V

CH241 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH245 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH247 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH248 24100104 Chip, 0.1?F, +80%, -20%, 25V

CH249 24092730 Chip, 0.1?F, ±10%, 16V

SPECIFIC INFORMATIONS

– 31 –

Loading...

Loading...