Toshiba 50H81 Service Manual

FILE NO. 020-200109

SERVICE MANUAL

COLOR TELEVISION

N0NSP Chassis

50H81

(TAC0151)

PUBLISHED IN JAPAN, Jun., 2001 So

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS.............................................................................................................................................. 3

CRT ASSEMBLY REPLACEMENT AND MOUNTING ................................................................................................... 4

PICTURE TUBE COMPONENTS ADJUSTMENT.......................................................................................................... 6

REPLACEMENT OF THE CRT....................................................................................................................................... 8

SERVICE MODE ............................................................................................................................................................9

ELECTRICAL ADJUSTMENT ...................................................................................................................................... 11

GENERAL ADJUSTMENTS

CONVERGENCE ADJUSTMENT ................................................................................................................................ 13

SCREEN AND MIRROR ALIGNMENTS ......................................................................................................................15

CIRCUIT CHECKS .......................................................................................................................................................16

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA .................................................................................................................................... 17

LOCATION OF CONTROLS ......................................................................................................................................... 18

PROGRAMMING CHANNEL MEMORY....................................................................................................................... 20

CIRCUIT BLOCK DIAGRAM ........................................................................................................................................21

TABLE OF CONTENTS

SPECIFIC INFORMATIONS

MECHANICAL DISASSEMBLY .................................................................................................................................... 23

CHASSIS REPLACEMENT PARTS LIST ..................................................................................................................... 25

PC BOARDS BOTTOM VIEW....................................................................................................................................... 53

TERMINAL VIEW OF TRANSISTORS ......................................................................................................................... 67

SPECIFICATIONS ........................................................................................................................................................ 69

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous

X-RAY RADIATION. To avoid such hazards, the high voltage must not be above the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a 120V AC

power source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B).

(See SETTING & ADJUSTING DATA on page 17)

Each time a receiver requires servicing, the high voltage

should be checked f ollowing the HIGH VOLT A GE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

WARNING : Service should not be attempted by any one unf amiliar with the necessary precautions on this receiver. The following are the necessary precautions to be observed before

servicing this chassis.

1. An isolation Transformer should be connected in the power

line between the receiver and the AC line bef ore any service is performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube . The picture tube is highly evacuated and if broken, glass fr agments

will be violently expelled. Use shatter proof goggles and

keep picture tube away from the unprotected body while

handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place,

such as; non-metallic control knobs, insulating covers,

shields, isolation resistor-capacitor network etc.

4. Before returning the set to the customer, always perform

an AC leakage current check on the e xposed metallic parts

of the cabinet, such as antennas, terminals, screwheads,

metal overlays, control shafts etc. to be sure the set is saf e

to operate without danger of electrical shock. Plug the A C

line cord directly into a 120V AC outlet (do not use a line

isolation transformer during this check). Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the

following manner:

PRODUCT SAFETY NOTICE

2. This receiver is equipped with a F ail Safe (FS) circuit which

prevents the receiver from producing an excessively high

voltage ev en if the B+ voltage increases abnormally. Each

time the receiver is serviced, the FS circuit must be checked

to determine that the circuit is properly functioning, following the FS CIRCUIT CHECK procedure in this manual.

3. The only source of X-RAY RADIA TION in this TV receiver

is the picture tube. F or contin ued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

4. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NO TICE below .

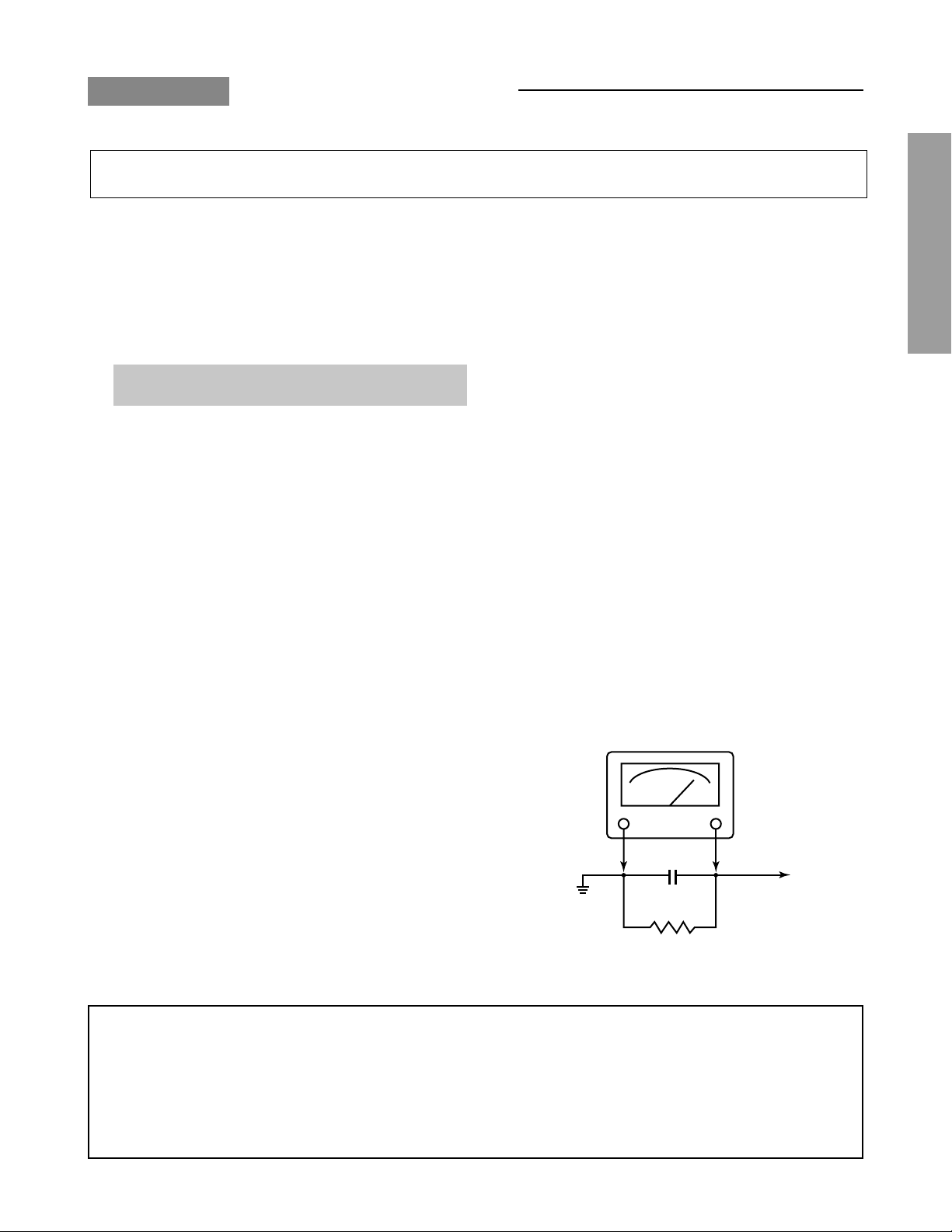

Connect a 1500 ohm 10 watt resistor , paralleled b y a 0.15

µF, AC type capacitor, between a known good earth ground

(water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the AC voltage across the combination of 1500 ohm resistor and 0.15 µF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Voltage

measured must not exceed 0.3 volts rms. This corresponds

to 0.2 milliamp. AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

AC VOLTMETER

0.15µF

Place this probe on

Good earth ground

such as a water

pipe, conduit, etc.

1500 ohm

10 watt

each exposed

metallic part.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained b y using

replacement components rated for higher voltage, w attage, etc. Replacement parts which have these special saf ety characteristics are identified in this manual and its supplements; electrical components having such features are identified by the

international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray radiation or other hazards.

– 3 –

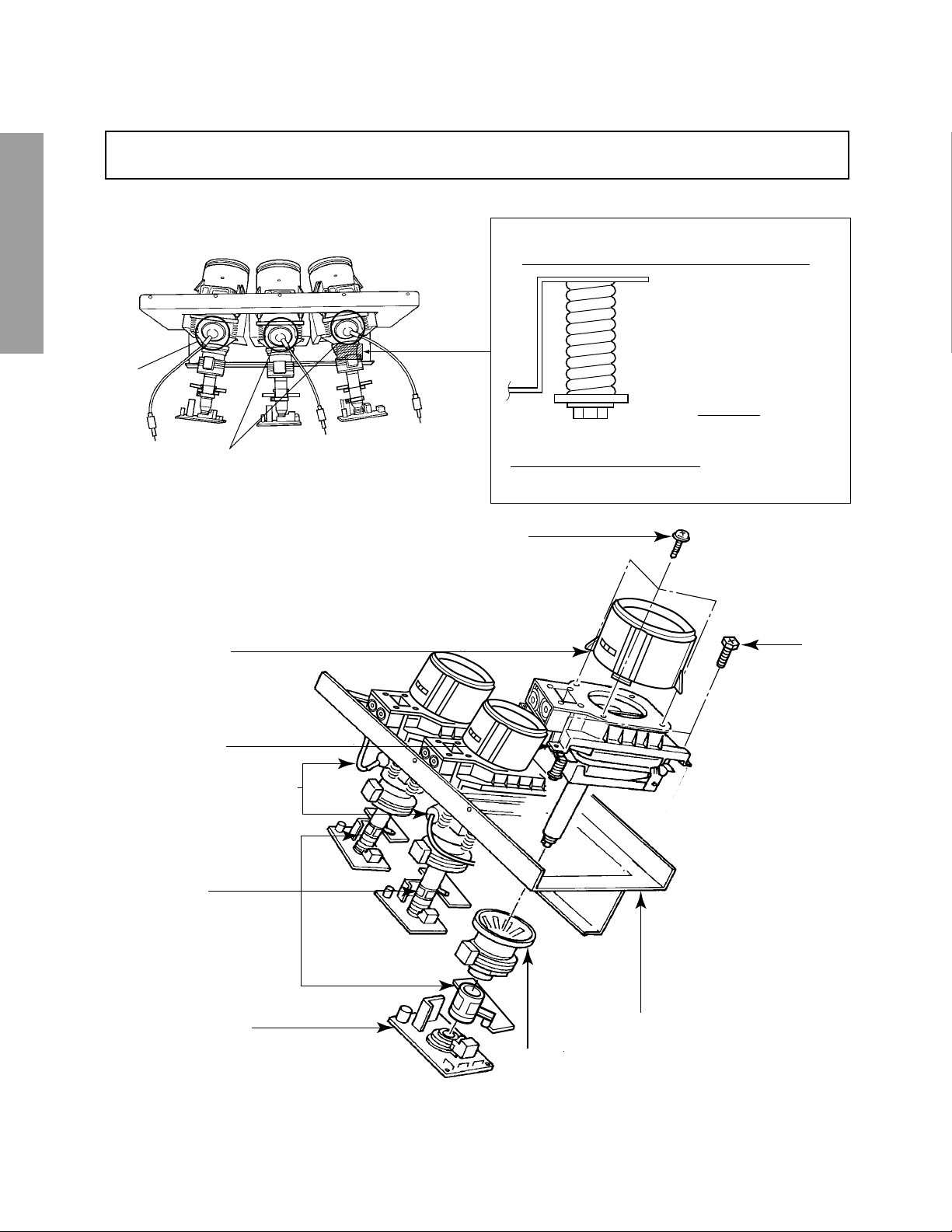

CRT ASSEMBLY REPLACEMENT AND MOUNTING

CAUTION : DO NOT LOOSEN THE HEX HEAD BOLTS WITH SPRINGS (12 PCS), BECAUSE THOSE ARE FOR

SEALING OF CRT COOLANT.

GENERAL ADJUSTMENTS

8 o’clock

4 o’clock

SPECIFIC INFORMATIONS

Lens Assembly

R

GB

Attention Serviceman

The Hex Head

Bolts with

Springs. (see

sketch) used on

CRT assembly,

are “NOT”

Adjustment Screws

DO NOT LOOSEN-FLUID

LEAKAGE WILL OCCUR.

4 Screws

4 Screws

CRT Assembly

CRT Anode Cap Assembly

S.V.M. Coil

CRT DRIVE Board

CRT Mounting

Deflection Yoke and Conver Yoke

Lens and Neck Components View

– 4 –

TO REMOVE CRT (Same procedure for R, G, B)

1. Remove CRT DRIVE Board, S. V. M. COIL and

DEF. YOKE from CRT.

2. Remove Lens Assembly.

3. Detach CRT Anode Cap from CRT.

4. Remove CRT Assembly from CRT Mounting.

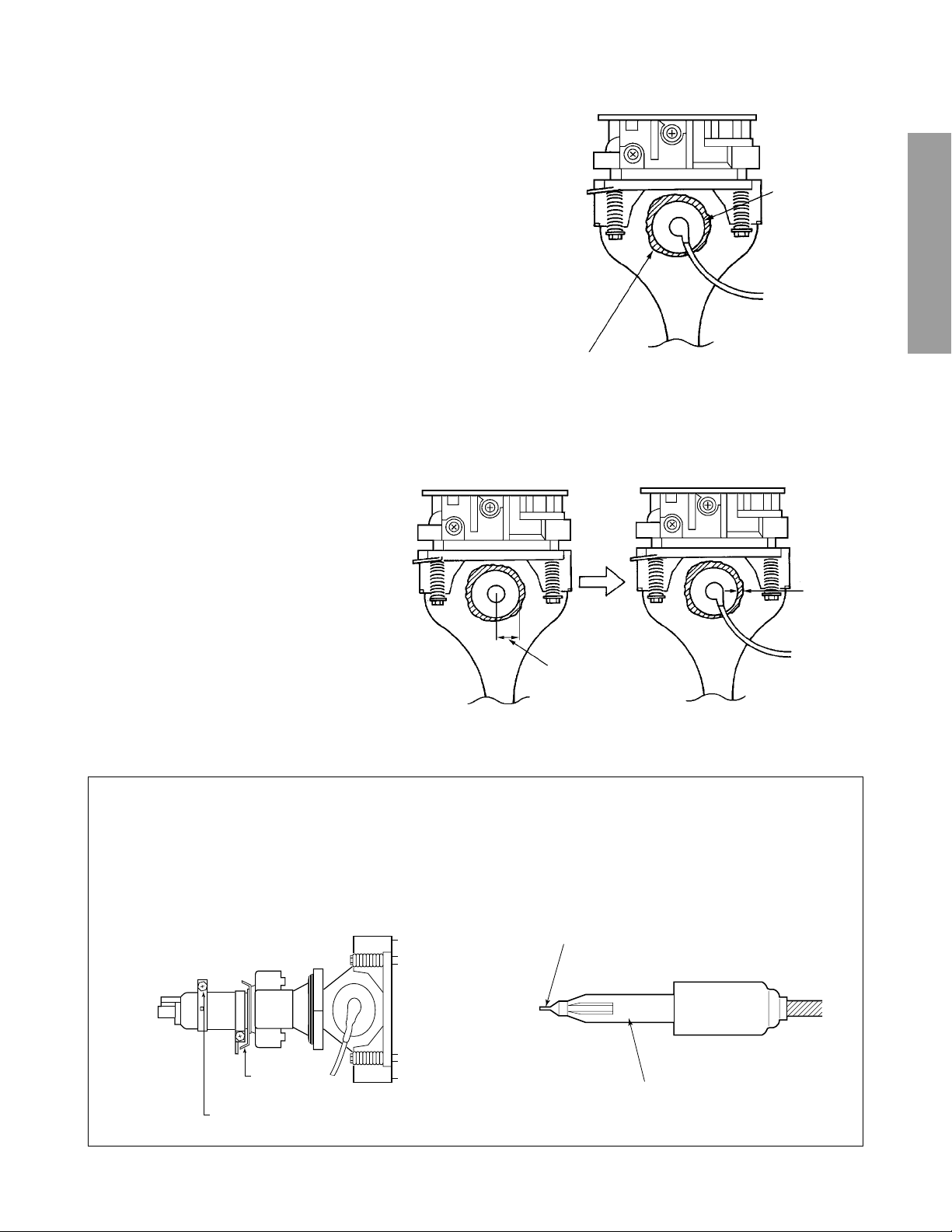

CRT REPLACEMENT (Same procedure for R, G, B)

Reverse the removal procedures except the followings.

1. Anode Cable should be replaced with new one.

See “SERVICING PRECAUTIONS” shown below.

2. Install silicon (T461B) to the CRT, replace the Anode

cable and put enough silicon again on around the Anode Cap as illustrated.

CAUTION: Align the Anode cable as illustrated on page

4.

ADJUSTING PROCEDURE IN REPLACING CRT

1. R.G.B. FOCUS ADJUSTMENT (page 6.)

2. PICTURE TILT ADJUSTMENT (page 6.)

3. USER CONVERGENCE CENTER CHECK

(See owner's manual.)

4. CENTERING ADJUSTMENT (page 6.)

5. CONVERGENCE ADJUSTMENT (page 13.)

6. WHITE BALANCE ADJUSTMENT (page 12.)

Adjustments are complete.

Anode Cap

GENERAL ADJUSTMENTS

Silicon

(On shaded area)

TSE3843W #23960136

SERVICING PRECAUTIONS

■ Do not use a magnetized screw driver for screws

of Deflection Yoke and Velocity Modulation Coil to

avoid magnetization of electron gun.

Magnetization of electron gun will degrade basic

function and result in unbalance of right and left

shift of user static convergence, and result in no

variable quantity.

2 ~ 5 mm

SPECIFIC INFORMATIONS

15 ~ 25 mm

■ When replacing the anode cap assembly (CRT) or

anode lead assembly (F.B.T.), remove the anode

lead holder from old one and attach the holder

again to new anode lead.

■ Check the point of anode lead in a straight

line, if it is winding, please revise it.

Screw for

D.Y

Screw for SVM coil

Anode lead holder

– 5 –

WARNING : BEFORE SERVICING THIS CHASSIS , READ THE “X-RAY RADIA TION PRECA UTION”, “SAFETY PRE-

CAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

PICTURE TUBE COMPONENTS ADJUSTMENT

DESCRIPTION OF NECK COMPONENTS

GENERAL ADJUSTMENTS

Deflection yoke and convergence yoke

The position on the neck is required most front (CRT

funnel side) and the screw is fastened after rotating

yoke adjusting picture tilt.

Centering magnet

After adjusting picture tilt, picture position is finally

fixed by this magnet.

In order to get maximum margin of user convergence

SPECIFIC INFORMATIONS

control for center of screen, this magnet have to be

used for center convergence adjustment.

PREPARATION

Operate the receiver for at least 5 minutes.

R, G, B FOCUS ADJUSTMENT

1. Before adjusting the R, G, B FOCUS, remov e the 4 screws

of Lens Assembly which is fixed on the CRT Assembly.

(See page 4.)

Then turn around the Lens Assembly by 180˚ to adjust

the fastening screw (Fig. a) and fasten the 4 screws to

secure Lens Assembly.

2. Select the adjustment mode. (See page 9.)

3. Press “7” button to display the built-in cross-hatch.

4. Press “0” and “RTN” buttons to make the picture a single

Red color.

100 button ............... to erase Red color

0 button ............... to erase Green color

CH RTN button ............... to erase Blue color

5. Loosen the fasten screw and adjust Red lense focus to

best focusing point of picture center . Then fasten the scre w.

(See Fig. a.)

TILT ADJUSTMENT

Rotate R, G, B deflection yoke so that picture becomes horizon, then fasten screw.

CENTERING ADJUSTMENT

1. Stretch a thread between two center of screen edge (top

and bottom, left and right).

2. Select the adjustment mode.

3. Press TV/VIDEO button on the Remote Control to displa y

the white cross-bar.

4. Perform VCEN adjustment. (See page 11.)

5. Adjust G centering magnet so that the cross-bar pattern

center comes to screen center.

6. Perform HEIGHT adjustment . (See page 12.)

7. Perform VERT. LINEARITY adjustment.

8. Perform WIDTH adjustment. (See page 11.)

9. Check whole quality of green line.

10

. Adjust R, B centering magnet so that the cross-bar pat-

tern center comes to screen center.

Fig. a

6. Adjust FOCUS VR “R” of FOCUS PACK to find best fo-

cusing point of picture center.

7. Repeat steps 3 to 5 for Green and Blue colors.

– 6 –

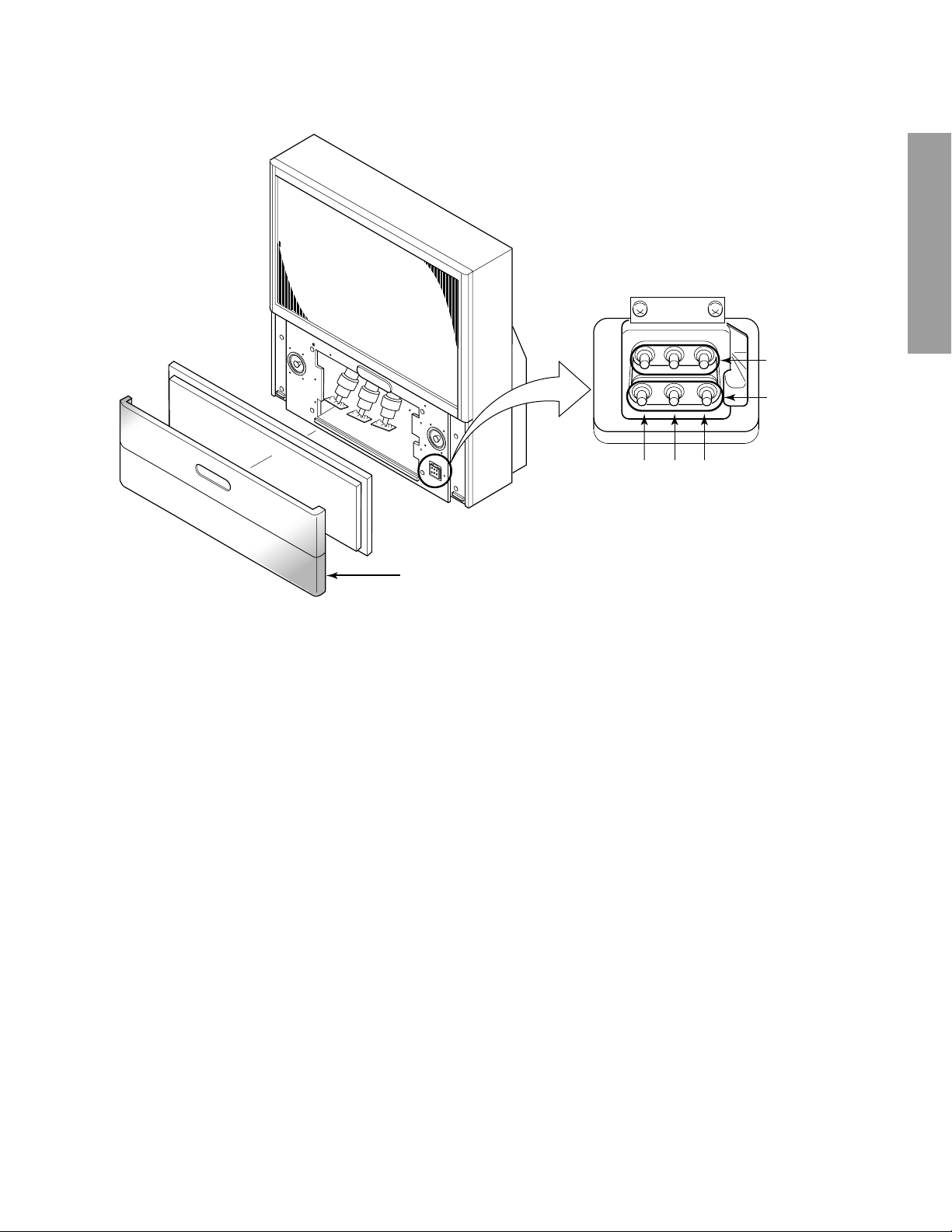

LOCATION OF SCREEN AND FOCUS VR’S

GENERAL ADJUSTMENTS

SCREEN VR

FOCUS VR

RGB

Speaker grille

SPECIFIC INFORMATIONS

– 7 –

REPLACEMENT OF THE CRT

Service parts are provided for each R, G and B.

The contents of the parts are as follows.

HITACHI

CRT 23008174 23008175 23008176

RGB

GENERAL ADJUSTMENTS

REPLACEMENT OF HIGH VOLTAGE CABLE

ANODE LEAD

RUBBER BOOT

LEAD HOLDER

SPECIFIC INFORMATIONS

Fig. a

Z450 TP A5007

1. When replacing Anode Lead or Anode Cap with ne w one,

remove Lead Holder from old lead as shown in figure

below, and put it on new lead. Do not throw away Lead

Holder.

NOTE : THE LEAD HOLDER IS ATTACHED TO TPA5007

(Z450), BUT IS NOT ATTACHED TO ANODE

LEAD AND ANODE CAP. RUBBER BOOT IS ATTACHED TO ANODE LEAD AND ANODE CAP.

2. Detaching Lead Holder

RUBBER BOOT

LOCK LEAD HOLDER

Fig. b

Cut here rubber boot

and lead together to

detach Lead Holder.

OLD

ANODE LEAD

or

ANODE CAP

– 8 –

1. ENTERING TO SERVICE MODE

1) Press MUTE button twice

on Remote Control.

SERVICE MODE

2) Press MUTE button

again to keep pressing.

3) While pressing the MUTE button,

press MENU button on TV set.

S

1/2 MUTE

MUTE

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

S

Press

Press

Adjustment mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Screen adjustment mode ON/OFF: TV (ANT)/VIDEO button (on TV)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume s/t (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : RECALL+Channel button on TV (s)

Initialization of the self diagnostic data: RECALL+Channel button on TV (t)

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“SCNT” selection : 4 button

“SCOL” selection : 5 button

“TNTC” selection : 6 button

Convergence adj : 7 button

Test audio signal ON/OFF (1kHz) : 8 button

Self diagnostic display : 9 button

(Service mode display)

GENERAL ADJUSTMENTS

Item

Data

SPECIFIC INFORMATIONS

– 9 –

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 17)

5. ADJUSTING THE DATA

1) Pressing of VOLUME s or t button will change the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

GENERAL ADJUSTMENTS

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the RECALL button on the Remote, then press the CHANNEL s button on the TV . The initialization of QA02

has been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Programming Channel Memory” on the owner's manual.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

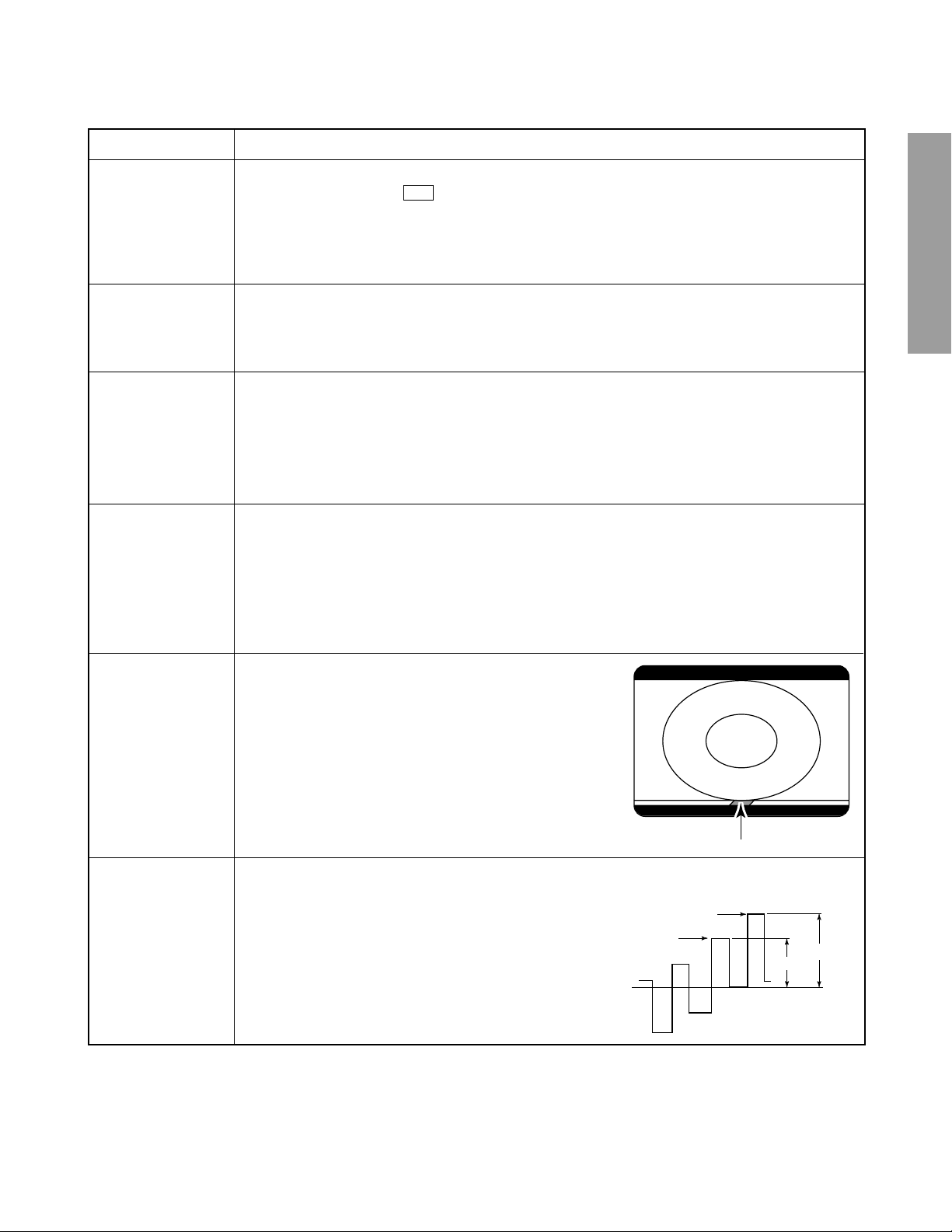

7. SELF DIAGNOSTIC FUNCTION

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

SPECIFIC INFORMATIONS

Part number of microprocessor (QA01)

Operation number of protection circuit (current limiter) . . . . “000” is normal.

BUS line check “OK” ................... Normal

BUS line ACK (acknowledge) check

Sync. signal check Green display..... Normal

ID code for TV Set

Version of "EEP"

Data for "OPT"

SELF CHECK

NO. 23 * * * * * *

POWER : 000

BUS LINE : OK

BUS CONT : OK

BLOCK : MAIN SUB

SET ID : 01

EEP VER : 02

OPT1 : 05 OPT2 : 70

“SCL-GND” or “NG” ........... SCL-GND short circuit

“SDA-GND” or “NG” ........... SDA-GND short circuit

“SCL-SDA” or “NG” ............ SCL-SDA short circuit

“OK” ..................... Normal

Display of Location Number . . . . NG

(Display example)

“QA02 NG”, “H001 NG”, “Q501 NG” etc.

Note: The indication of failure place is only one place though failure places are plural. When

repair of a failure place finishes, the next failure place is indicated. (The order of priority of

indication is left side.)

Red display ........ NG

MAIN ........ Main sync

SUB .......... Sub sync (when turn on the PIP)

– 10 –

ELECTRICAL ADJUSTMENT

ITEM ADJUSTMENT PROCEDURE

ƒH

(free-running frequency of Hor.

oscillator)

VERTICAL POSITION (VCEN)

PICTURE POSITION

(HPOS)

WIDTH

(WID)

1. Receive NTSC signal.

2. Short the terminal “TP +9V ” and the terminal “ TP (F ree run) ” on the signal board with a jumper

wire.

3. Connect the probe of frequency counter to the lead of R426 and GND.

4. Adjust the frequency to “33.75±0.2 kHz” by turning R4034 on DPC Board.

5. Disconnect the shorted wire, then confirm that the picture is synchronized.

1. Receive NTSC signal.

2. Connect he probe of digital voltmeter to TP-V and TP-G on SIGNAL Board.

3. Call up the adjustment mode display, then select the item VCEN.

4. Press the VOLUME s or t button to get the voltage 0±10 mV.

1. Receive NTSC signal.

2. Call up the adjustment mode display.

3. Select the item “HPOS”, and adjust the data to “80H”.

4. Adjust the picture position alternately by turning CENTERING MAGNETS for proper picture

position.

5. Check the picture with off-air signal.

1. Receive NTSC signal.

2. Select the "FULL" mode by PIC SIZE button on Remote Control.

3. Call up the adjustment mode display, then select the item WID.

4. Press the VOLUME s or t button to get the picture so that left and right eddes of video signal

begin to lack.

5. Press the VOLUME s button to advance the data by 8 steps.

NOTE: Check the horizontal picture position is correct.

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

SUB-BRIGHTNESS

(BRTC)

SUB-COLOR

(SCOL)

1. Constrict the picture height until the vertical retrace line

appears adjusting the HEIGHT control on the MAIN board.

2. Adjust the CONTRAST to the minimum and BRIGHTNESS

to the center.

3. Enter the service mode, then select “BRTC” register.

4. Adjust the data value so the belt of vertical retrace line just

disappear.

5. Adjust the CONTRAST for the desired contrast.

6. Adjust the HEIGHT control.

Vertical retrace line

1. Receive color-bar signal from color-bar generator.

2. Adjust the BRIGHTNESS and CONTRAST to the center (RESET status).

3. Connect oscilloscope to TP501on the MAIN board.

4. Enter the service mode, then select “SCOL”.

5. Adjust the data value to achieve 1.8V

of blue bar on

0-p

Magenta

Blue

scope.

6. Check the picture with off-air signal.

0

2

3 (1.8V

0-P

)

– 11 –

ITEM ADJUSTMENT PROCEDURE

HEIGHT

(HIT)

VERTICAL LINEARITY

(VLIN)

(FULL mode only)

GENERAL ADJUSTMENTS

WHITE BALANCE

(RCUT)

(GCUT)

(BCUT)

(RDRV)

SPECIFIC INFORMATIONS

(BDRV)

1. Receive NTSC signal.

2. Select the "FULL" mode by PIC SIZE button on Remote Control.

3. Call up the adjustment mode display and select the item HIT.

4. Press the VOLUME s or t button to get the picture so that top and bottom of

video signal begin to lack.

5. Press the VOLUME s button to advance the data by 8 steps.

Note: Check the vertical picture position is correct.

Adjust the data of height after vertical linearty.

1. Receive cross-hatch pattern.

2. Call up the adjustment mode display, then select the item VLIN.

3. Press the VOLUME s or t button to obtain

the picture of the best linearity.

4. Then readjust the item HIT.

1. Press RESET button on TV or remote hand set.

2. Call up the adjustment mode display, then adjust the data of items RCUT, GCUT

and BCUT to “80”.

3. Press TV (ANT)/VIDEO button on TV.

4. Gradually rotate R, G and B SCREEN volume of FOCUS PAC (page 8) clockwise or counterclockwise until the raster appears slightly on the CRT through

the each lens, and leave them.

(Look into the lens in order to check the raster.)

5. Press TV (ANT)/VIDEO button on TV again.

6. Exit from service mode.

7. Receive white laster pattern signal, and adjust the contrast to the minimum to

make white picture to low light.

8. Adjust the data of items RCUT, GCUT and BCUT for low light area.

9. Adjust the contrast to the maximum to make white picture to high light.

10. Adjust the data of items RDRV and BDRV Controls for proper white-balanced

picture in high light area.

11. Check the white balance in both low and high light areas. If necessary, perform

again steps from 7 to 9.

– 12 –

CONVERGENCE ADJUSTMENT

Adjust convergence from center to circumf erence in order.

KEY FUNCTION IN THE CONVERGENCE ADJUSTMENT:

Up : 2 button

Selet Green color: 3 button

Left : 4 button

Blinking of cursor ON/OFF: 5 button

Right: 6 button

Adjust mode ON/OFF: 7 button

Down: 8 button

Vertical stripe ON/OFF 9 button

Erase Green line: 0 button

Erase Red line: 100 button

Erase Blue line: ENT button

Note:

Adjusting procedure in replacing convergence board.

1. User convergence center check. Make sure the best

convergence setting is about the center of adjustable

range.

2. CENTERING ADJUSTMENT

3. PICTURE POSITION ADJUSTMENT

4. HIT , WID ADJUSTMENT

5. CONVERGENCE ADJUSTMENT

6. Execute TOUCH FOCUS f ollowing instructions displa yed

on the screen after finishing CONVERGENCE ADJUSTMENT.

7. If TOUCH FOCUS ERROR is displayed after finishing

TOUCH FOCUS, the method of CROSS-HATCH PATTERN after CONVERGENCE adjustment is different from

what is exhibited on the right figure, or HARD WARE is out

of order.

1. Select the adjustment mode following the steps on page

9.

RCUT

40H

2. Press “7” button to display the built-in cross-hatch pattern

and press "9" button to display the vertical stripes.

Cursor

X: I

Y: I

FULL

C: R

FULL

3. Adjustment around cursor can be done.

The pattern includes three colors (R, G, B).

The cursor should be blinking in Red.

This means that the Red color is adjustable.

4. Press “3” button to select Green color to be adjusted.

5. Press “5” button to stop the blinking of cursor.

6. Press “2 (up)”, “8 (down)”, “4 (left)” or “6 (right)” to obtain

the correct cross-hatch pattern as above.

If necessary, the specified color line can be erased from

the screen.

100 button ...................... to erase Red line

0 button ...................... to erase Green line

CH RTN button ...................... to erase Blue line

7. Press “5” button to make the cursor blinking.

8. Press “2”, “8”, “4”, “6” buttons to move the cursor to other

point to be adjusted.

9. Repeat steps 5 to 8.

10.Repeat steps 4 to 9 to adjust Red and Blue colors.

Converge the selected color line into the Green line.

11.Press “7” button to memorize the adjusted states.

At this time, picture changes for about 1 second.

12.Press the TOUCH FOCUS button when "PLEASE PUSH

TOUCH FOCUS" is displayed on the screen.

13.TOUCH FOCUS is executed.

14.It returns to the normal screen after displaying "TOUCH

FOCUS FINISHED".

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

– 13 –

Adjusting Dimension of Each Picture Screen

(16:9 screen size:) 50 inches

(1) HD (1080I/NTSC)

GENERAL ADJUSTMENTS

22.0 531.0 442.5 265.5 088.5 88.5 265.5 442.5 531.0

50 inches 16:9 Screen size : Horizontal 1106 mm

NOTES

SPECIFIC INFORMATIONS

In many cases, color misconv ergence may be corrected b y returning HIT and WID data in main deflection side to initial adjusting

values. Following cases will surely require readjustment of convergence.

QH173,16KB CHIP, UFO–* BANK1 Vspan 38.8mm Hspan 88.5mm

271.5

233.0

116.5

Screen center

0

116.5

233.0

271.5

22.0

Vertical 622 mm

CRT REPLACEMENT

When CRT is replaced, main deflection readjustment and color matching are required.

Perform following procedures.

1. Replace two CRT’s of blue and red.

2. Perform horizontal adjustment for blue and red yokes on base of green CRT data. Mount yoke and velocity mod. coil alignment, pushing towards CRT without gap.

3. Adjust alignment of blue and red. (Refer Alignment adjustment for details.)

4. Rotating centering magnet, adjust CRT centers of red and blue to CRT center of green.

(Picture position adjustment)

5. Adjust HIT and WID data of main deflection, and decide data at the most precise screen comparing to green data.

6. Adjust convergence of screen picture for color matching. Do not move green one at this time.

7. After convergence adjustment of screen picture finishes, replace green CRT.

For green CRT as well, repeat steps 2 to 5 above on bases of red and blue color matching to adjust convergence.

8. Execute TOUCH FOCUS following instructions displayed on the screen after finishing convergence adjustments of all the

colors.

Note: Press button "7" again after "PLEASE PUSH TOUCH FOCUS" has been displa yed. Then, TOUCH FOCUS will not be

executed, and the current state of convergence will be displayed.

REPLACING CONVERGENCE UNIT

When replacing convergence unit, picture screen require readjustment basically, but the following method allows process be

reduced considerably.

1. Replace the memory (Q713) on defective unit with memory on new unit. Mounting the unit on the SET after the above

working realizes picture screen before replacement immediately.

2. Mount unit which has old memories, on SET and turn it on. Screen shows whole picture looks lik e straightly shifted tow ards

vertical or horizontal direction.

3. Adjust again centers of green, red and blue with centering magnets.

4. Check picture screen for slight disparity of color and picture size. If necessary, add some adjustments of main deflection and

color matching of convergence.

5. Execute TOUCH FOCUS following instructions displayed on the screen after finishing convergence adjustments of all the

colors.

Note: Press button "7" again after "PLEASE PUSH TOUCH FOCUS" has been displa yed. Then, TOUCH FOCUS will not be

executed, and the current state of convergence will be displayed.

– 14 –

SCREEN AND MIRROR ALIGNMENTS

ASSEMBLING OF FRONT SCREEN

K503 FRONT PANEL

LENTICULAR

K501

<OUTSIDE>

SMOOTH

K502

FRESNAL

BLACK STRIPES

SMOOTH

<INSIDE>

SPACER

FRONT PANEL

LENTICULAR

FRESNEL

INSIDE

OUT SIDE

LENS

BLACK STRIPES

0 to 1 mm

MOUNTING OF FRONT SCREEN

FRESNEL

LENTICULAR

FRONT PANEL

BEZEL

GENERAL ADJUSTMENTS

SMOOTH

SPECIFIC INFORMATIONS

CAUTION : Do not hold the optical system parts (lens and

mirror) with bare hand to avoid finger-prints on

the surface of those parts.

HOW TO CLEAN LENS AND MIRROR

1. Be sure to remove sand dust with an air brush, etc.

2. When it is stained slightly, breathe upon it and wipe away

with the specified cleaning cloth.

For other stains than the above , wipe the stains awa y with

the specified cloth into which a cleaning liquid has been

soaked.

Cleaning liquid.................... LENS LUSTER (Manufac-

tured by Edmund Scientific

Co.), etc.

HOW TO CLEAN SCREEN

When cleaning the screen, use a soft cloth so as not to

damage the screen.

1. Wipe the screen with a dry cloth to remove moisture on

the screen.

Note : Absolutely do not use detergent, water, alcohol,

benzine, thinner, etc. for cleaning in order not to

wipe away the black print on the surface.

– 15 –

CIRCUIT CHECKS

HIGH VOLTAGE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on

this chassis. Checking should be done following

the steps below.

1. Connect an accurate high voltage meter to the anode of

the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 17)

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

4. Var y the BRIGHTNESS to both extremes to be sure the

high voltage does not exceed the limit under any conditions.

CAUTION:

When the following parts fail, check the High Voltage after

replacing.

Location

No.

T461

C407

C408

C441

C432

C433

Name

Flyback

Capacitor

Capacitor

Capacitor

Capacitor

Capacitor

Descriptions

50"

TFB3090AD

4700pF, ±3%

8200pF, ±5%

4700pF, ±5%

8200pF, ±5%

1200pF, ±3%

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final

check in servicing. Checking should be done following the

steps below.

1. Turn the receiver on.

2. T emporarily short TP- (R) and TP- (X) on the DEF/POWER

Board with a jumper wire.

Raster and sound will disappear.

3. The receiver must remain in this state e ven after removing

the jumper wire. This is the evidence that the FS circuit is

functioning properly.

4. To obtain a picture again, temporarily turn the receiver off

and allow the FS circuit more than 5 seconds to reset. Then

turn the receiver on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

Check that the set returns to normal operation when

pin 12 of Z801 is grounded with jumper wire.

YES NO

Check the voltage across

Capacitor C419 is

approximately (

Refer to table –4 for

fall safe voltage (

C)

volts.

C)

.

Faulty power

circuit or horizontal circuit.

ANODE VOLTAGE MEASURING METHOD

CAUTION: Take extra precaution when measuring this high

voltage. High voltages are also present in

surrounding circuit boards (CRT DRIVE assembly, DEFLECTION assembly, and POWER

SUPPLY assembly).

1. Disconnect the FBT anode cable as outlined below . Measure high voltage at the point where the cable enters the

FBT.

2. Holding the rubber cover firmly, turn it counterclockwise

and check that the lock has been disengaged. (See Fig. b

on page 8.)

3. Determine the extent of the rubber cover before disconnecting the cable.

4. Pull straight up the anode cable to disconnect.

5. When reconnecting the cable, proceed in the reverse order .

After reconnecting, tug on the cable to check that it is secure.

YES

Defective Fail Safe Circuit

(See SETTING & ADJUSTING

DATA on page 17)

NO

– 16 –

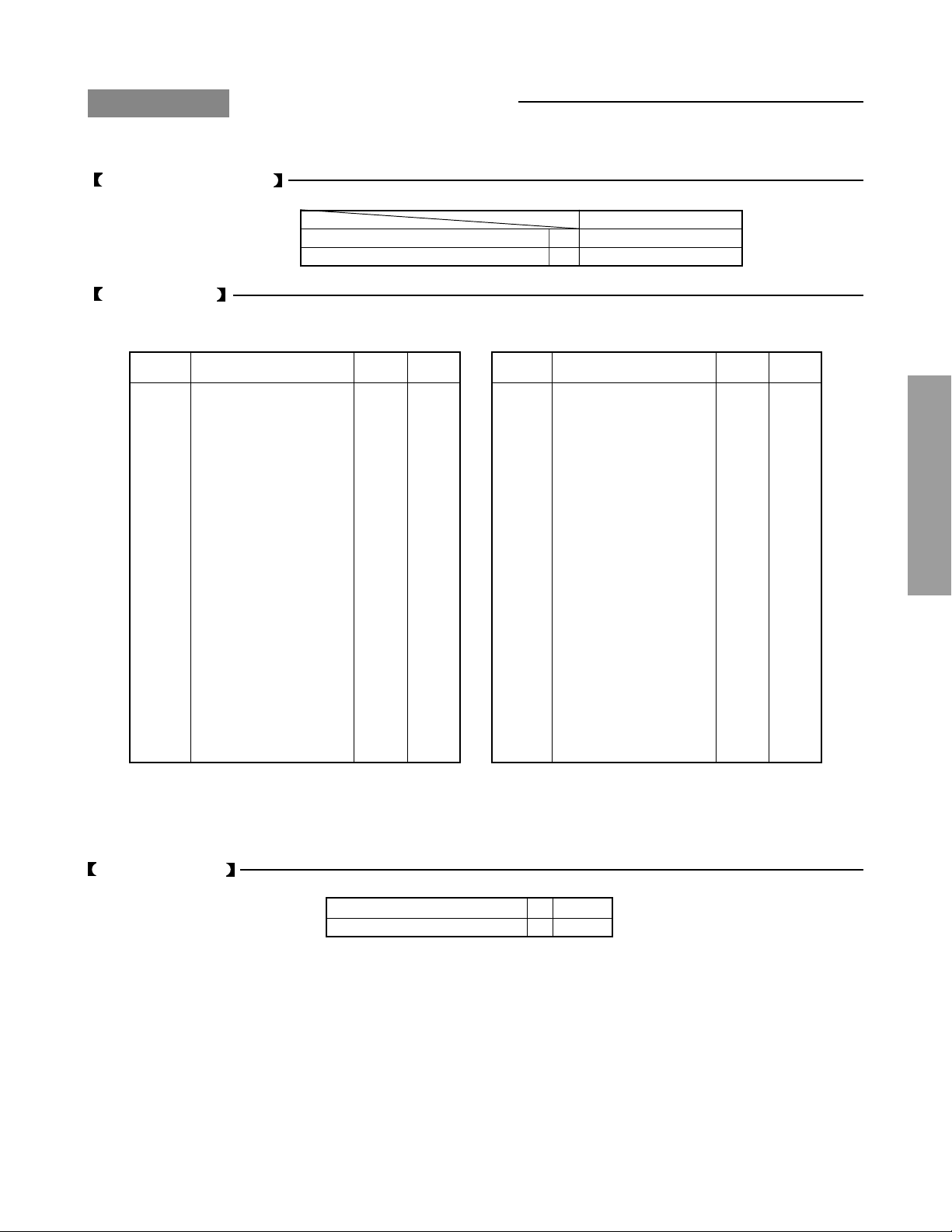

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA

SAFETY INSTRUCTIONS

HIGH VOLTAGE AT ZERO BEAM: (A) 31.0 kV

MAX HIGH VOLTAGE:

Table-1

SERVICE MODE

50"

(B) 32.5 kV

ADJUSTING ITEMS AND DATA IN THE SERVICE MODE:

Item Name of adjustment

RCUT

GCUT

BCUT

RDRV

BDRV

BRTC

TNTC

SCOL

SCNT

HPOS

VPOS

HIT

LIN

VSC

WID

VPS

EYOF

ECNT

R CUTOFF

G CUTOFF

B CUTOFF

R DRIVE

B DRIVE

SUB-BRIGHT

SUB-TINT

SUB COLOR

SUB-CONTRAST

HORIZ. POSITION

VERT. POSITION

HEIGHT

V-LINEARITY

V-S CORRECTION

PICTURE WIDTH

V-SHIFT

Y1 BLACK (Q501)

Y1 SCONT (Q501)

Preset Data

40H

40H

40H

40H

40H

80H

44H

05H

10H

80H

19H

38H

12H

10H

1DH

0AH

07H

16H

←

←

←

←

←

←

←

←

←

←

←

55H

←

←

←

←

←

←

Item Name of adjustment Preset Data

EIOF

EQOF

PYOF

PIOF

PQOF

VCP

PARA

CNR

HCP

VFC

PHUE

PCNT

PCOL

RGBB

VCEN

TVOP

OPT0

OPT1

R-Y BLACK (Q501)

R-Y BLACK (Q501)

PIP Y OFFSET

PIP I OFFSET

PIP Q OFFSET

V-COMPENSATE

E-W PARABOLA (DPC)

E-W CORNER

H-COMPENSATE

V-F CORRECT

PIP TINT

PIP CONT

PIP COLOR

RGB BRIGHT

V POSITION

TV OPTION

TV SET OPTION

TV SET OPTION

20H

20H

17H

24H

1EH

0AH

17H

08H

00H

00H

40H

10H

15H

54H

70H

08H

50H

05H

←

←

←

←

←

←

←

←

←

←

←

←

←

←

←

18H

←

←

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

CIRCUIT CHECKS

Table-2

FBT DETECTION VOLTAGE (C) 24.5 V

HIGH VOLTAGE DET 8.7 V

Table-3

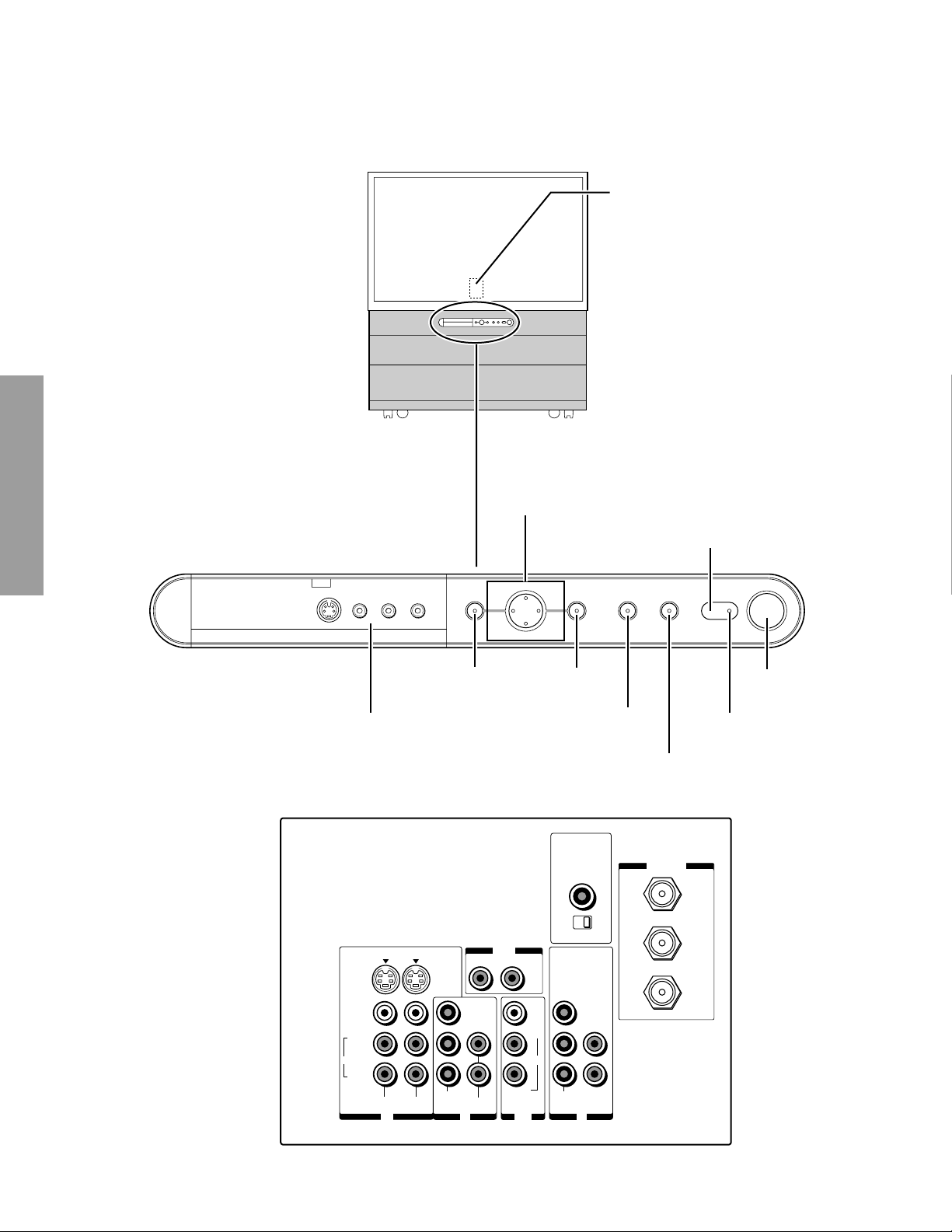

– 17 –

TV front

GENERAL ADJUSTMENTS

LOCATION OF CONTROLS

Remort sensor

(Behibd the screen)

Channel ts

Volume T S

Menu tsT S

Automatic Light Sensor

SPECIFIC INFORMATIONS

TV rear

Video 3

Video/audio inputs

(behind the door)

S-VIDEO

VIDEO

L/

MONO

AUDIO

R

VIDEO-2VIDEO-1

COLOR

STREAM

HD-1

MENU

R

Y

P

B

P

R

AUDIO

CHs

VOL TSVOL

CHt

OUT

L

VAR

AUDIO

VIDEO

L/

L

MONO

AUDIO

R

R

OUTININ

EXIT

AUDIO CENTER

CHANNEL IN

ON OFF

Y

P

B

AUDIO

P

R

COLOR

STREAM

HD-2

IN

TV/VIDEO

TOUCH FOCUS

ANT (75Ω)

L

R

POWER

POWER

Power indicator

ANT-1

OUT

ANT-2

– 18 –

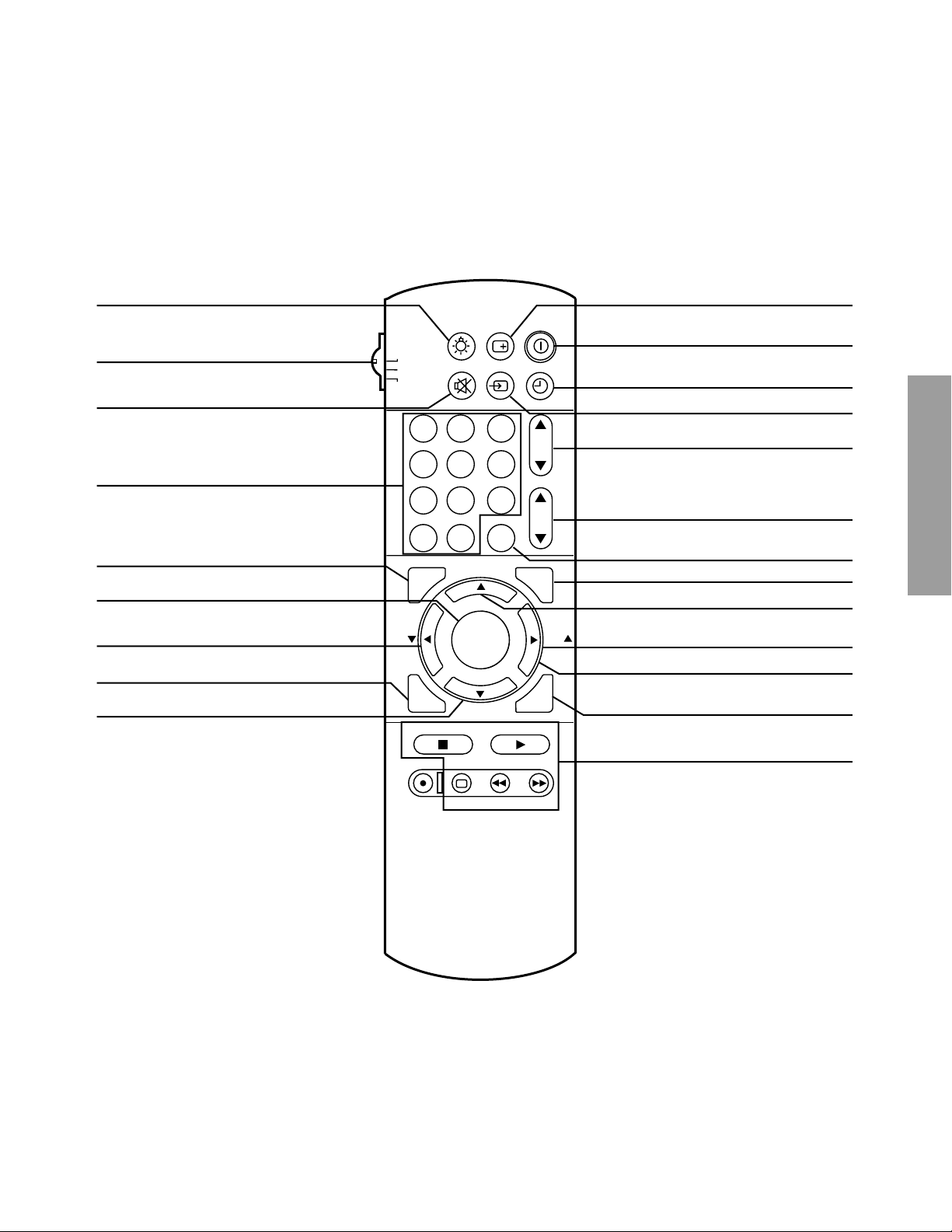

Remote Control

LIGHT

TV/CABLE/VCR switch

Set to “TV” to control the TV.

MUTE

Channel Number

FAVORITE

ENTER

FAV t

C. CAPT

POP CH t

TV

CABLE

VCR

1

4

7

100

FAVORITE

FAV

C. CAPT

STOP SOURCE

REC

RECALL

3

6

9

CH RTN

ENT

PLAY POP

POWER

TIMER

CH

VOL

PIC SIZE

EXIT

LIGHT

MUTE TV/VIDEO

2

5

8

0

ADV/

POP CH

MENU/

ENTER

ADV/

POP CH

TV/VCR REW FF

FAV

RECALL

POWER

TIMER

TV/VIDEO

CHANNEL s/t

VOLUME s/t

CH RTN

PIC SIZE

POP CH

s

FAV s

s/t/T/S

EXIT

POP functions

(For “TV” and “CABLE” modes)

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

STILL SWAP

– 19 –

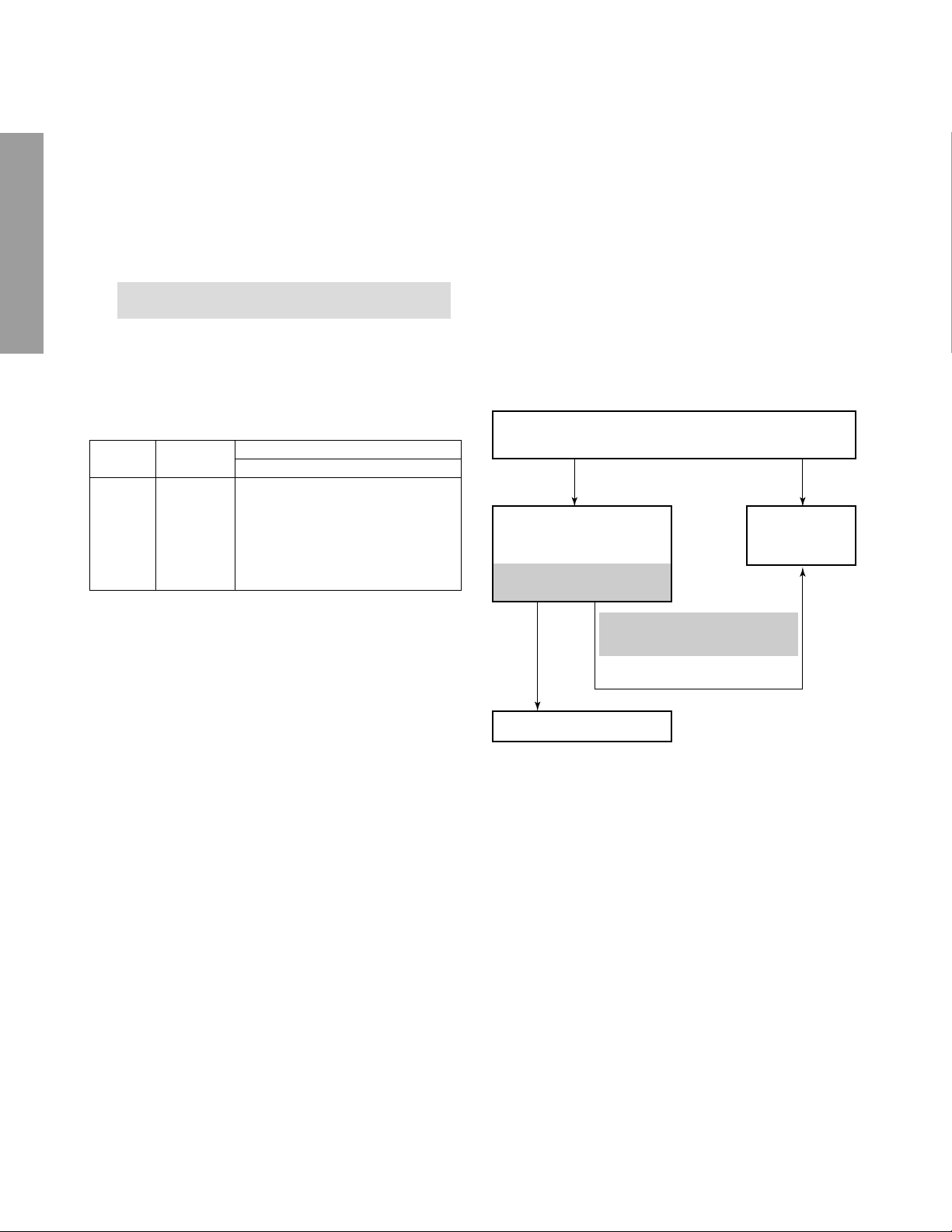

PROGRAMMING CHANNEL MEMORY

The channel memory is the list of TV channel numbers the TV tunes in when you press the CHANNEL s or t button.

First, use the TV/CABLE and CH PROGRAM functions to preset all active channels in your area automatically.

If necessary, arrange the preset channels with the ADD/ERASE functions so that you can tune into only desired channels.

Note: If you utilize both ANT-1 and ANT-2 terminals for some model, perform programming channels for each input source.

TV/CABLE function

1 Press MENU, then press S or T until the SET UP menu

GENERAL ADJUSTMENTS

appears.

2 Press t (or s) until “TV/CABLE” is highlighted.

3 Press : or ; to highlight either “TV” or “CABLE”, whichever

you use.

CH PROGRAM function

1 Select “CH PROGRAM” following steps 1 and 2 above.

2 Press : or ; to start channel programming.

SPECIFIC INFORMATIONS

The TV will automatically cycle through all the TV or

CABLE channels selected by the TV/CABLE function, and

store active channels in the channel memory.

3 When channel programming is complete, you will see the

message to the right appears.

4 Press CHANNEL s or t to make sure the channel

programming has been done properly.

ADD/ERASE function

After performing the CH PROGRAM function, you can add or

erase specific channels.

1 Select the channel you want to erase using the CHANNEL

s or t button, or select the channel you want to add using

the Channel Number buttons.

2 Press MENU, then press S or T until the SET UP menu

appears.

3 Press t (or s) until “ADD/ERASE” is highlighted.

4 Press S or T :

To erase the channel press the button until “ERASE” is

highlighted.

To add the channel press the button until “ADD” is

highlighted.

5 Repeat steps 1 to 4 for other channels.

You have now completed the channel programming.

Note: The CHANNEL t/s buttons on the TV function as the

t/s buttons while a menu is on the screen.

* Please refer to owner's manual in detail.

– 20 –

Loading...

Loading...