Page 1

SAFETY PRECASAFETY PRECA

SAFETY PRECA

SAFETY PRECASAFETY PRECA

SERSER

VICE VICE

SER

SERSER

Only qualified service technicians who are familiar with safety checks

and guidelines should perform service work. Before replacing parts,

disconnect power source to protect electrostatically sensitive parts. Do

not attempt to modify any circuit unless so recommended by the

manufacturer. When servicing the receiver, use an isolation transformer

between the line cord and power receptacle.

SERSER

SER

SERSER

Use EXTREME CAUTION when servicing the high voltage circuits. To

discharge static high voltage, connect a 10K ohms resistor in series with a

test lead between the receiver ground and CRT anode lead. DO NOT lift

the CRT by the neck. Always wear shatterproof goggles when handling

the CRT to protect eyes in case of implosion.

X-RAX-RA

X-RA

X-RAX-RA

Be aware of the instructions and procedures covering X-ray radiation. In

solid-state receivers and monitors, the CRT is the only potential source of

X-rays. Keep an accurate high voltage meter available at all times. Check

meter calibration periodically. Whenever servicing a receiver, check the

high voltage at various brightness levels to be sure it is regulating

properly. Keep high voltage at rated value, NO HIGHER. Excessive high

voltage may cause X-ray radiation or failure of associated components.

DO NOT depend on protection circuits to keep voltage at rated value.

When troubleshooting a receiver with excessive high voltage, avoid close

contact with the CRT. DO NOT operate the receiver longer than

necessary. To locate the cause of excessive high voltage, use a variable

AC transformer to regulate voltage. In present receivers, many electrical

and mechanical components have safety related characteristics which are

not detectable by visual inspection. Such components are identified by a

# on both the schematic and the parts list. For SAFETY, use only

equivalent replacement parts when replacing these components.

GENERAL GUIDELINESGENERAL GUIDELINES

GENERAL GUIDELINES

GENERAL GUIDELINESGENERAL GUIDELINES

Perform a final SAFETY CHECK before returning receiver to customer.

Check repaired area for poorly soldered connections, and check entire

circuit board for solder splashes. Check board wiring for pinched wires or

wires contacting any high wattage resistors. Check that all control knobs,

shields, covers, grounds, and mounting hardware have been replaced. Be

sure to replace all insulators and restore proper lead dress.

WARNINGWARNING

VICE

WARNING

VICE VICE

WARNINGWARNING

VICING VICING

VICING

VICING VICING

Y RADIAY RADIA

Y RADIA

Y RADIAY RADIA

THE HIGH THE HIGH

THE HIGH

THE HIGH THE HIGH

TION AND HIGH TION AND HIGH

TION AND HIGH

TION AND HIGH TION AND HIGH

VV

OLOL

V

OL

VV

OLOL

TT

AA

GE AND CRGE AND CR

T

A

GE AND CR

TT

AA

GE AND CRGE AND CR

VV

OLOL

TT

V

OL

T

VV

OLOL

TT

TT

T

TT

AA

GE LIMITSGE LIMITS

A

GE LIMITS

AA

GE LIMITSGE LIMITS

UTIONSUTIONS

UTIONS

UTIONSUTIONS

SAFETY CHECKS — FIRE AND SHOCK HAZARDSAFETY CHECKS — FIRE AND SHOCK HAZARD

SAFETY CHECKS — FIRE AND SHOCK HAZARD

SAFETY CHECKS — FIRE AND SHOCK HAZARDSAFETY CHECKS — FIRE AND SHOCK HAZARD

Cold LeakaCold Leaka

Cold Leaka

Cold LeakaCold Leaka

Unplug the AC cord, connect a jumper across the plug prongs, and turn

the power switch on (if applicable). Use an ohmmeter to measure the

resistance between the jumped AC plug and any exposed metal cabinet

parts such as antenna screw heads, control shafts, or handle brackets.

Exposed metal parts with a return path should measure between 1M

ohms and 5.2M ohms. Parts without a return path must measure infinity.

Hot LeakaHot Leaka

Hot Leaka

Hot LeakaHot Leaka

Plug the AC cord directly into an AC outlet. DO NOT use an isolation

transformer. Use a 1500 ohms, 10W resistor in parallel with a .15µF

capacitor to connect between any exposed metal parts on the receiver and

a good earth ground. (See figure below.) Use an AC voltmeter with at

least 5000 ohms per volt sensitivity to measure the voltage across the

resistor. Check all exposed metal parts and measure voltage at each point.

Voltage measurements should not exceed .75VAC, 500µA. Any value

exceeding this limit constitutes a potential shock hazard and must be

corrected. If the AC plug is not polarized, reverse the AC plug and repeat

exposed metal part voltage measurement at each point.

gg

e Chece Chec

e Chec

e Chece Chec

ks fks f

ks f

ks fks f

g

gg

gg

e Current Chece Current Chec

g

e Current Chec

gg

e Current Chece Current Chec

or Receiveror Receiver

or Receiver

or Receiveror Receiver

kk

k

kk

s with Isolated Grs with Isolated Gr

s with Isolated Gr

s with Isolated Grs with Isolated Gr

oundound

ound

oundound

PF GOLD 15PF GOLD 15

PF GOLD 15PF GOLD 15

PF GOLD 15

C0175)C0175)

C0175)C0175)

C0175)

AA

AA

A

TT

TT

T

Important Parts Information ..................... 1

Miscellaneous Adjustments ......................1

Parts List ................................................... 6

Placement Chart ....................................... 5

Safety Precautions .................................... 1

Schematic Component Location ..............6

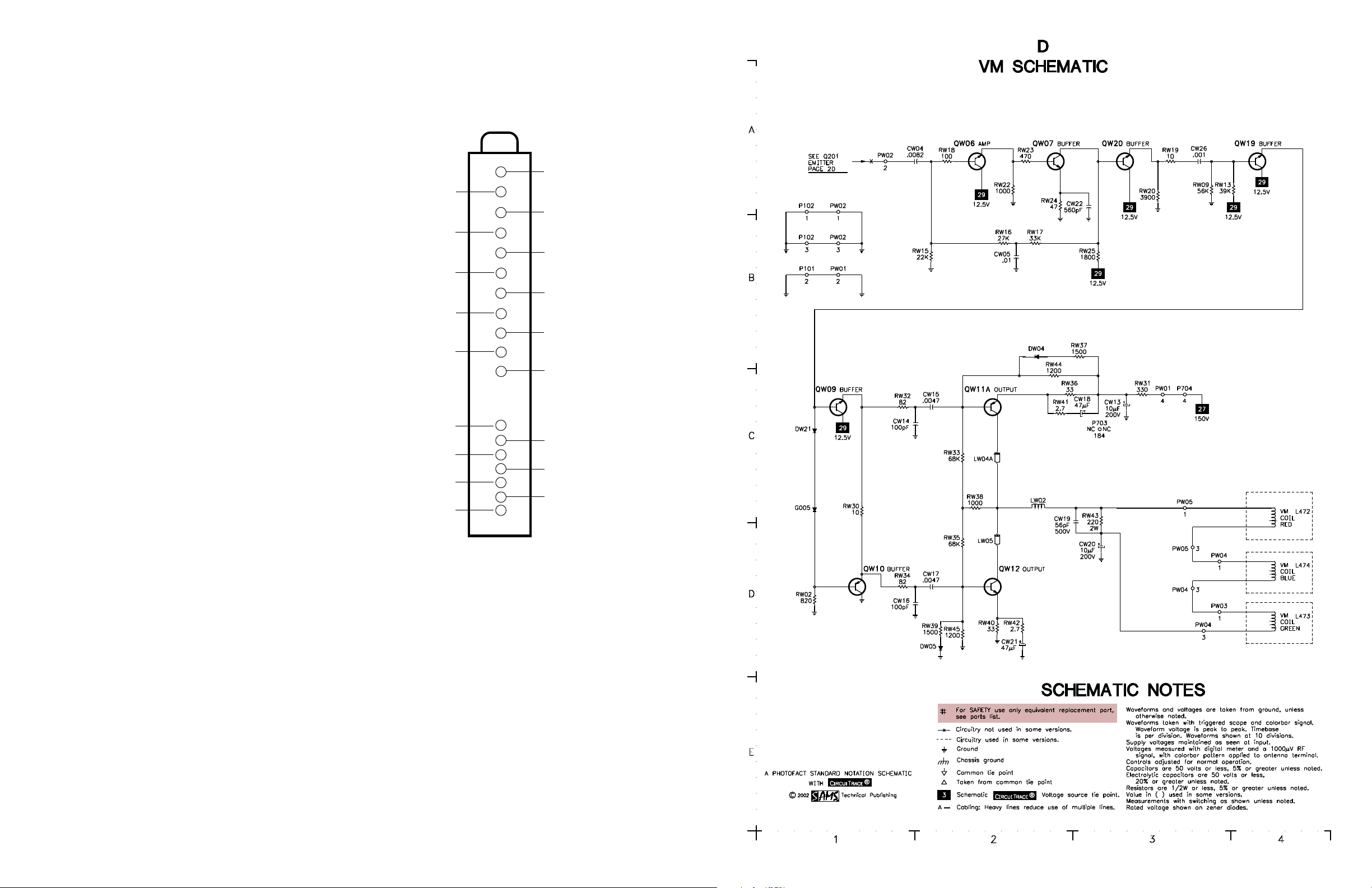

Schematic Notes ....................................... 1

Schematics

Audio ................................................. 3

A/V .................................................... 4

Comb Filter .......................................4

Convergence ...................................... 4

Power Supply ....................................3

System Control .................................. 3

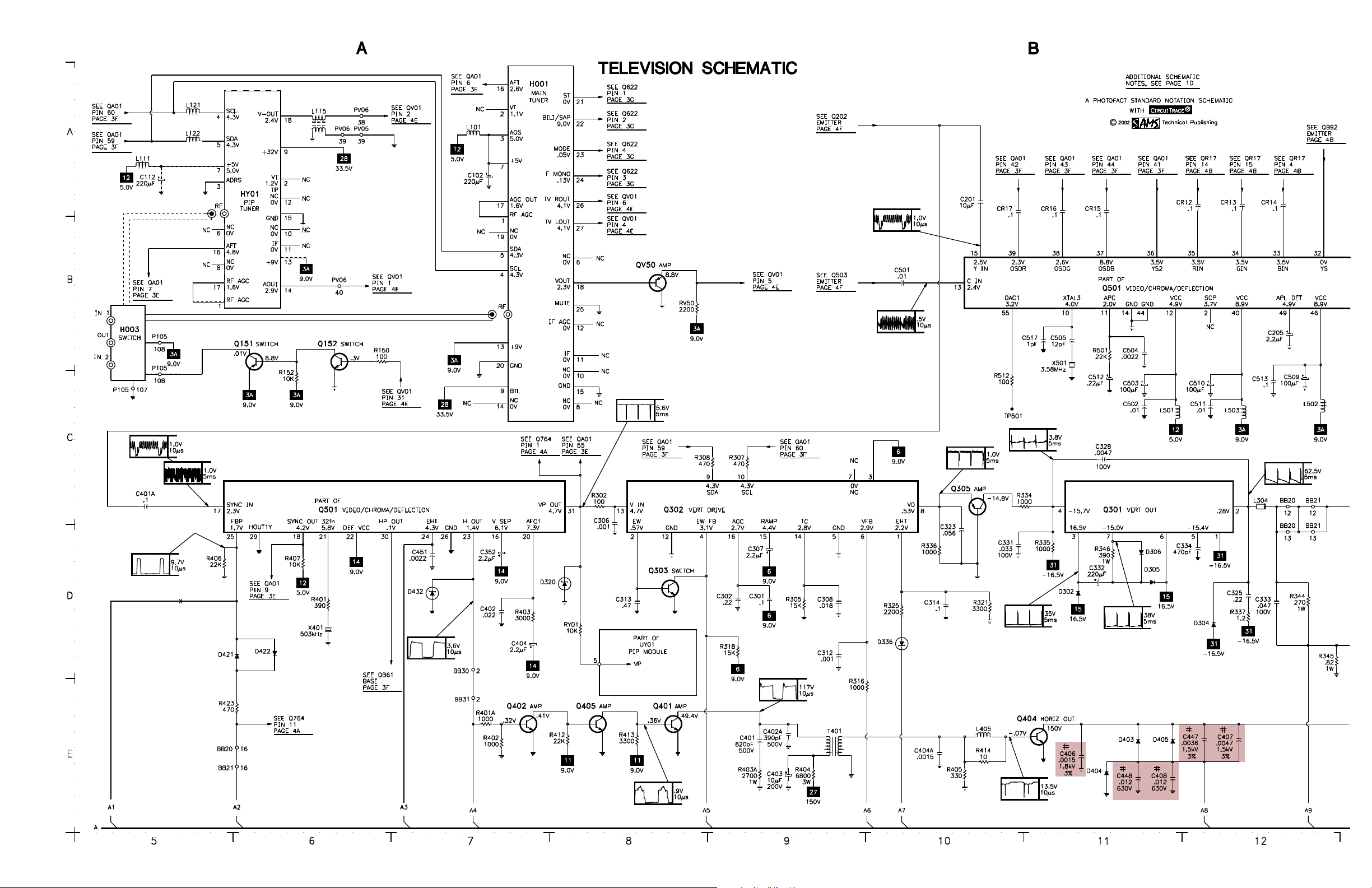

Television .......................................... 2

VM .................................................... 1

Service Precautions .................................. 1

Test Equipment......................................... 4

Tuner Information

H001 Main ........................................ 1

HY01 PIP ..........................................1

INDEXINDEX

INDEX

INDEXINDEX

PF GOLD 15

Technical Service Data

TT

OSHIBOSHIB

T

OSHIB

TT

OSHIBOSHIB

Model 43A61 (Chassis Model 43A61 (Chassis

Model 43A61 (Chassis

Model 43A61 (Chassis Model 43A61 (Chassis

Representative Model

Essential coEssential co

Essential co

Essential coEssential co

ff

or seror ser

f

or ser

ff

or seror ser

vicing a televicing a tele

vicing a tele

vicing a televicing a tele

AA

A

AA

TT

AA

C0175)C0175)

T

A

C0175)

TT

AA

C0175)C0175)

veravera

gg

vera

veravera

vision receivervision receiver

vision receiver

vision receivervision receiver

ee

g

e

gg

ee

......

...

......

The listing of any available replacement part herein in no case constitutes a recommendation, warranty, or guarantee by

SAMS Technical Publishing as to the quality and suitability of such replacement part. The numbers of the listed parts have

been compiled from information furnished to SAMS Technical Publishing by the manufacturers of the specific type of

replacement part listed.

Reproduction or use, without express permission, of editorial or pictorial content, in any manner, is prohibited. No patent

liability is assumed with respect to the use of the information contained herein.

© 2002

5436 West 78th Street

Indianapolis, IN 46268-4149

Printed in the United States of America 5 4 3 2 1

PP

aa

gg

e 1e 1

P

PP

PF GOLD 15 PF GOLD 15

a

g

e 1

PF GOLD 15

aa

gg

e 1e 1

PF GOLD 15 PF GOLD 15

02PT01996

UPC

HERE

MODEL 43A61 (CHASSIS MODEL 43A61 (CHASSIS

MODEL 43A61 (CHASSIS MODEL 43A61 (CHASSIS

MODEL 43A61 (CHASSIS

PF GOLD 15

AA

AA

A

OSHIBOSHIB

OSHIBOSHIB

OSHIB

TT

TT

T

For Supplier AdFor Supplier Ad

For Supplier Ad

For Supplier AdFor Supplier Ad

See PHOSee PHO

See PHO

See PHOSee PHO

TT

T

TT

OFOF

OF

OFOF

AA

CT AnnCT Ann

A

CT Ann

AA

CT AnnCT Ann

dress,dress,

dress,

dress,dress,

ual Indeual Inde

ual Inde

ual Indeual Inde

ScSc

hematicshematics

•

Sc

hematics

ScSc

hematicshematics

Component locationsComponent locations

•

Component locations

Component locationsComponent locations

PP

arar

ts listts list

•

P

ar

ts list

PP

arar

ts listts list

PF GOLD 15

xx

x

xx

SEPTEMBER SEPTEMBER

SEPTEMBER

SEPTEMBER SEPTEMBER

2002 PG GOLD 15 2002 PG GOLD 15

2002 PG GOLD 15

2002 PG GOLD 15 2002 PG GOLD 15

Page 2

PP

aa

gg

e 1e 1

P

a

PP

aa

PF GOLD 15 PF GOLD 15

g

e 1

PF GOLD 15

gg

e 1e 1

PF GOLD 15 PF GOLD 15

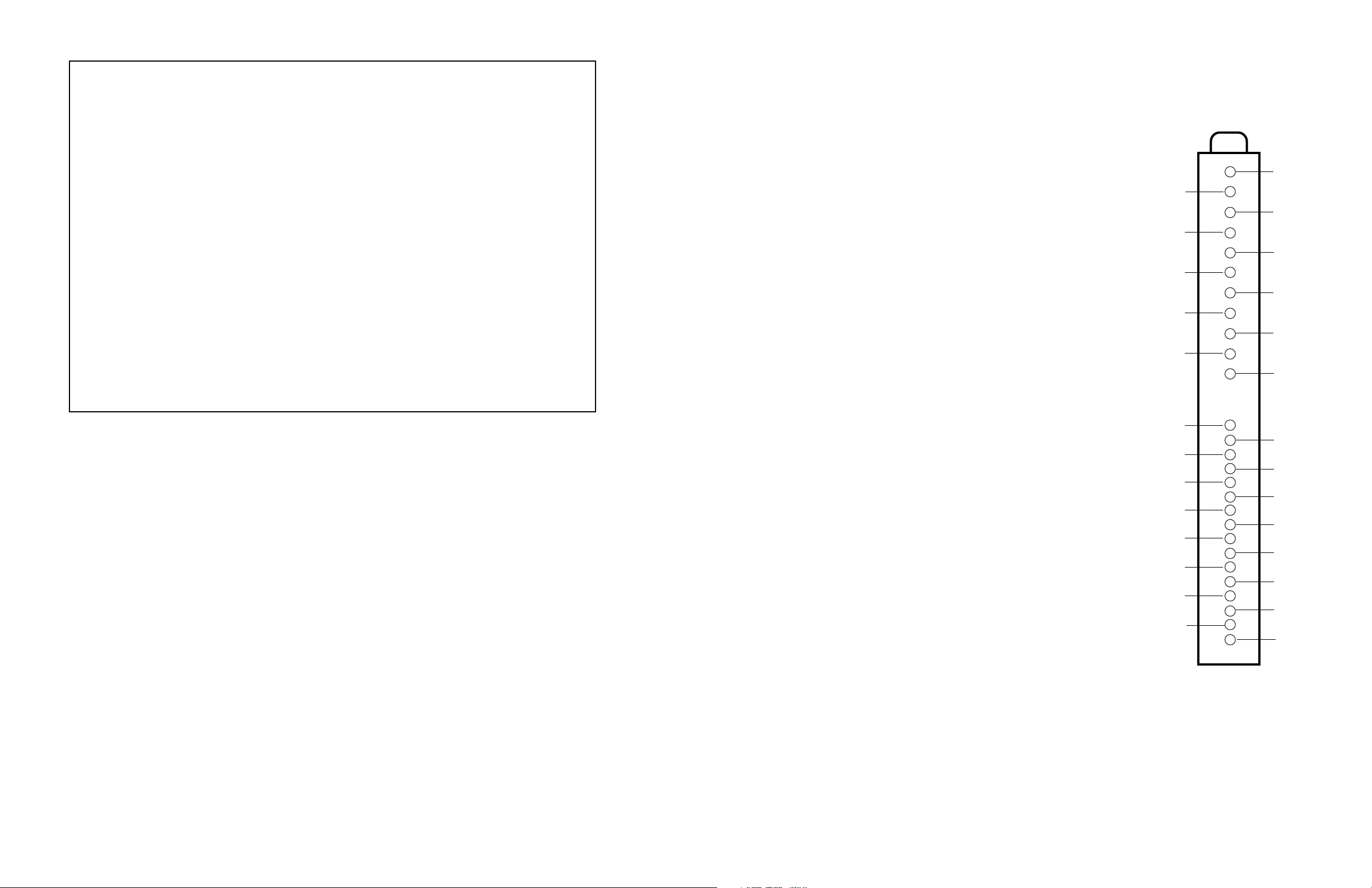

H001 MAIN TUNER INFORMATION

ImporImpor

tant Ptant P

arar

ts Infts Inf

Impor

ImporImpor

tant P

tant Ptant P

ar

arar

ts Inf

ts Infts Inf

ormationormation

ormation

ormationormation

ν The parts listed here are those not usually available from a well-stocked supply cabinet or bin.

ν Where items may be replaced with equivalent parts, several alternates are shown from participating vendors.

ν On the parts lists, safety items are marked with a

these items.

ν When ordering parts, state the model number, part number, and description.

Many of these parts are available from your local Sams authorized distributor or the manufacturer of the equipment. Call

Sams for the name of your nearest distributor:

# #

# to remind you that only exact replacements are recommended for

# #

Obtaining PObtaining P

Obtaining P

Obtaining PObtaining P

arar

ar

arar

tsts

ts

tsts

800-428-7267

Or consult the Sams

Information on test equipment and replacement parts is listed in these pages for the following participating vendors.

Consult the Sams

ν NTE Electronics, Inc. (NTE)

Annual Index

Annual Index

for the address of the original equipment manufacturer.

ss

endorendor

ticipating ticipating

arar

PP

ticipating

ar

P

ticipating ticipating

arar

PP

for their current address.

VV

V

VV

ν Sencore, Inc.

endor

endorendor

s

ss

H001 MAIN MAIN H001 MAIN MAIN

H001 MAIN MAIN

H001 MAIN MAIN H001 MAIN MAIN

PinPin

Pin

PinPin

(1) RF AGC 1.6V 1.6V 1.6V

(2) VT 1.1V 4.4V 5.4V

(3) AOS 5.0V 5.0V 5.0V

(4) SCL 4.3V 4.3V 4.3V

(5) SDA 4.3V 4.3V 4.3V

(6) NC 0V 0V 0V

(7) +5V 5.0V 5.0V 5.0V

(8) NC 0V 0V 0V

(9) BTL 33.5V 33.5V 33.5V

(10) NC 0V 0V 0V

(11) IF 0V 0V 0V

(12) IF AGC 0V 0V 0V

(13) +9V 9.0V 9.0V 9.0V

(14) NC 0V 0V 0V

(15) GND 0V 0V 0V

(16) AFT 2.6V 4.2V 1.9V

(17) AGC OUT 1.6V 1.6V 1.6V

(18) VOUT 2.3V 2.3V 2.3V

(19) NC 0V 0V 0V

(20) GND 0V 0V 0V

(21) ST 0V 0V 0V

(22) BILI/SAP 9.0V 9.0V 9.0V

(23) MODE .05V .05V .05V

(24) F MONO .13V .13V .13V

(25) MUTE 0V 0V 0V

(26) TV ROUT 4.1V 4.1V 4.1V

(27) TV LOUT 4.1V 4.1V 4.1V

NOTE: VHF Low Band voltages taken on channel 2.

VHF High Band voltages taken on channel 7.

UHF Band voltages taken on channel 14.

VHF LoVHF Lo

VHF Lo

VHF LoVHF Lo

w Bandw Band

w Band

w Bandw Band

VV

OLOL

TT

AA

V

OL

T

A

VV

OLOL

TT

AA

VHF High BandVHF High Band

VHF High Band

VHF High BandVHF High Band

GE CHARGE CHAR

GE CHAR

GE CHARGE CHAR

TT

T

TT

UHF BandUHF Band

UHF Band

UHF BandUHF Band

H001 MAIN H001 MAIN

H001 MAIN

H001 MAIN H001 MAIN

(2)

(4)

(6)

(8)

(10)

(12)

(14)

(16)

(18)

(20)

(22)

(24)

(26)

TUNER TUNER

TUNER

TUNER TUNER

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

TERMINAL GUIDETERMINAL GUIDE

TERMINAL GUIDE

TERMINAL GUIDETERMINAL GUIDE

τ

(1)

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

τ

(3)

(5)

(7)

(9)

(11)

(13)

(15)

(17)

(19)

(21)

(23)

(25)

(27)

Page 3

HY01 PIP TUNER INFORMATION

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 1e 1

a

g

e 1

aa

gg

e 1e 1

HY01 PIP HY01 PIP

HY01 PIP

HY01 PIP HY01 PIP

PinPin

Pin

PinPin

(1) RF AGC 1.6V 1.6V 1.7V

(2) VT 1.2V 4.2V 6.0V

(3) ADRS 0V 0V 0V

(4) SCL 4.3V 4.3V 4.3V

(5) SDA 4.3V 4.3V 4.3V

(6) NC 0V 0V 0V

(7) +5V 5.0V 5.0V 5.0V

(8) NC 0V 0V 0V

(9) +32V 33.5V 33.5V 33.5V

(10) NC 0V 0V 0V

(11) IF 0V 0V 0V

(12) NC 0V 0V 0V

(13) +9V 9.0V 9.0V 9.0V

(14) AOUT 2.9V 2.9V 2.9V

(15) GND 0V 0V 0V

(16) AFT 4.8V 3.9V 3.6V

(17) RF AGC 1.6V 1.6V 1.7V

(18) V-OUT 2.4V 2.4V 2.4V

NOTE: VHF Low Band voltages taken on channel 2.

VHF LoVHF Lo

VHF Lo

VHF LoVHF Lo

VHF High Band voltages taken on channel 7.

UHF Band voltages taken on channel 14.

TUNER TUNER

TUNER

TUNER TUNER

w Bandw Band

w Band

w Bandw Band

VV

OLOL

TT

AA

OL

OLOL

T

TT

GE CHARGE CHAR

A

GE CHAR

AA

GE CHARGE CHAR

V

VV

VHF High BandVHF High Band

VHF High Band

VHF High BandVHF High Band

TT

T

TT

UHF BandUHF Band

UHF Band

UHF BandUHF Band

HY01 PIP HY01 PIP

HY01 PIP

HY01 PIP HY01 PIP

(2)

(4)

(6)

(8)

(10)

(12)

(14)

(16)

(18)

TUNER TUNER

TUNER

TUNER TUNER

TERMINAL GUIDETERMINAL GUIDE

TERMINAL GUIDE

TERMINAL GUIDETERMINAL GUIDE

τ

(1)

τ

τ

(3)

τ

τ

(5)

τ

τ

(7)

τ

τ

(9)

τ

τ

(11)

τ

τ

τ

τ

τ

τ

τ

(13)

(15)

(17)

Page 4

HIGH HIGH

HIGH

HIGH HIGH

VV

V

VV

OLOL

OL

OLOL

TT

AA

T

A

TT

AA

GE CHECKGE CHECK

GE CHECK

GE CHECKGE CHECK

SERSER

VICE MODE ADJUSTMENT CHARVICE MODE ADJUSTMENT CHAR

SER

VICE MODE ADJUSTMENT CHAR

SERSER

VICE MODE ADJUSTMENT CHARVICE MODE ADJUSTMENT CHAR

MISCELLANEOUS ADJUSTMENTS

TT

T

TT

SUB COLOR (COLC) & SUB SUB COLOR (COLC) & SUB

SUB COLOR (COLC) & SUB

SUB COLOR (COLC) & SUB SUB COLOR (COLC) & SUB

TINT (TNTC)TINT (TNTC)

TINT (TNTC)

TINT (TNTC)TINT (TNTC)

CONVERGENCE ADJUSTMENTCONVERGENCE ADJUSTMENT

CONVERGENCE ADJUSTMENT

CONVERGENCE ADJUSTMENTCONVERGENCE ADJUSTMENT

Tune in a picture. Set brightness, contrast, and color to MINIMUM. Turn

the set off. Remove one of the high voltage cables. Insert a High Voltage

probe tip into the vacant hole. Turn the set on, high voltage should read

31kV to 32kV. Turn the power off and insert the high voltage cable back

into the vacant hole.

ENTERING ENTERING

ENTERING

ENTERING ENTERING

To enter the service mode, press the mute button on the remote. Press the

mute button again and keep pressing while simultaneously pressing the

menu button on the receiver. The letter S will appear on the screen

indicating that the receiver is in the service mode.

When in the service mode, press the menu button on the receiver to display

the adjustment menu. To select the item to be adjusted, press the channel up

or down button. To adjust the reference value, press the volume up or down

button. To exit from the service mode or the design mode, press the power

button to turn off the receiver.

SELF DIASELF DIA

SELF DIA

SELF DIASELF DIA

Enter the service mode. Press the 9 button on the remote to check for

proper execution of IC interfacing. The following is an explanation of what

is displayed on screen:

yy

DisplaDispla

y

Displa

yy

DisplaDispla

[SELF CHECK] Self diagnostic function.

No. 23000868 Part number of QA01.

POWER : 000 Operation number of protecting circuit.

BUS LINE : OK BUS line check. OK is normal.

BUS CONT : OK Bus line acknowledge check. OK is

BLOCK : MAIN SUB Green display is normal. Cyan display is

SET ID : 01

EEP VER: 04

OPT1: 80

OPT2: 08

ITEM BITEM B

ITEM B

ITEM BITEM B

The following is a list of the buttons on the remote that will go to an item

or perform a different function of the service mode:

1 RCUT 5 COLC

2 GCUT 6 TNTC

3 BCUT 8 Toggles audio test signal on and off.

4 SCNT 9 Self diagnostics

THE SERTHE SER

THE SER

THE SERTHE SER

GNOSTIC FUNCTIONGNOSTIC FUNCTION

GNOSTIC FUNCTION

GNOSTIC FUNCTIONGNOSTIC FUNCTION

UTTUTT

ONSONS

UTT

ONS

UTTUTT

ONSONS

VICE AND DESIGN MODESVICE AND DESIGN MODES

VICE AND DESIGN MODES

VICE AND DESIGN MODESVICE AND DESIGN MODES

ExplanationExplanation

Explanation

ExplanationExplanation

000 display is normal.

NG indicates a short to ground of

the SCL or SDA signal or a short

between SCL and SDA.

normal. A location number is NG.

NG QA02 indicates QA02 is bad.

no check. Red display is NG. UV is TV

mode, V1 is Video 1 mode, and

V2 is Video 2 mode.

erenceerence

AdjustmentAdjustment

Adjustment

AdjustmentAdjustment

ItemItem

Item

ItemItem

RCUT Red Cutoff 80H 84H

GCUT Green Cutoff 80H 80H

BCUT Blue Cutoff 80H 88H

GDRV Green Drive 40H 40H

BDRV Blue Drive 40H 40H

CNTX Sub Contrast Max 7FH 7FH

BRTC Sub Brightness 80H 80H

COLC Sub Color 50H 50H

TNTC Sub Tint 44H 3AH

SCOL Sub Color 05H 08H

SCNT Sub Contrast 10H 0FH

HPOS Horizontal Position 16H 15H

VPOS Vertical Position 00H 00H

HIT Height 64H 61H

LIN Vertical Linearity 12H 13H

VSC V-S Correction 10H 10H

VPS Vertical Shift 18H 18H

VCP Vert Compensation 0AH 0AH

WID Width 28H 2CH

PARA E-W Parabola 29H 29H

CNR E-W Corner 08H 08H

TRAP Trapezium 10H 10H

HCP Horiz Compensation 00H 00H

VFC V-F Correction 00H 00H

PHUE PIP Tint 00H 00H

PCNT PIP Contrast 00H 00H

PCOL PIP Color 0FH 0FH

RGBB RGB Bright 54H 54H

PROF PIP R Offset 00H 00H

PBOF PIP B Offset 00H 00H

PGOF PIP G Offset 00H 00H

STRH Start H 67H 67H

STRP Start Ptn 88H 87H

VLD VLD 41H 42H

VCEN Vert Position 81H 8DH

OPT1 Option 1 80H 80H

OPT2 Option 2 08H 08H

TVOP TV Option 00H 00H

INITIALIZAINITIALIZA

INITIALIZA

INITIALIZAINITIALIZA

NOTE: QA02 must be initialized after replacement.

Enter the service mode. Press and hold the recall button on the remote

while simultaneously pressing the channel up button on the receiver. The

initialization of QA02 is complete. Program channels into memory.

NameName

Name

NameName

TION OF QA02TION OF QA02

TION OF QA02

TION OF QA02TION OF QA02

RefRef

Ref

RefRef

VV

V

VV

erence

erenceerence

aluealue

alue

aluealue

On SetOn Set

On Set

On SetOn Set

aluealue

VV

alue

V

aluealue

VV

Tune in a color bar pattern. Set contrast to maximum and brightness to

midrange. Connect an oscilloscope to the red cathode. Enter the service

mode. Select item COLC and adjust reference value to obtain 150Vp-p.

Tune in an active channel. Select item TNTC and adjust reference value for

proper flesh tones.

SUB BRIGHTNESS (BRSUB BRIGHTNESS (BR

SUB BRIGHTNESS (BR

SUB BRIGHTNESS (BRSUB BRIGHTNESS (BR

Tune in a picture. Set contrast to MINIMUM. Enter the service mode.

Select item BRTC, adjust reference value until vertical retrace line just

disappears. Adjust contrast for normal picture. Perform Height (HIT)

adjustment.

HORIZONTHORIZONT

HORIZONT

HORIZONTHORIZONT

(VPOS)(VPOS)

(VPOS)

(VPOS)(VPOS)

Enter the service mode. Press the TV/video button on remote until a

crossbar pattern is displayed. Select item HPOS or VPOS and adjust

reference value for the horizontal and vertical position alternately until the

pattern is centered on the screen. Check the position of the picture with offair signal.

HEIGHT (HIT)HEIGHT (HIT)

HEIGHT (HIT)

HEIGHT (HIT)HEIGHT (HIT)

Enter the service mode. Press the TV/video button on remote until a

crosshatch pattern is displayed. Select item HIT and adjust reference value

for slight underscan. Advance the data value by 8 steps and check the

vertical position of the picture.

WIDTH (WID)WIDTH (WID)

WIDTH (WID)

WIDTH (WID)WIDTH (WID)

Enter the service mode. Press the TV/video button on remote until a

crosshatch pattern is displayed. Select item WID, adjust reference value for

slight underscan. Advance the reference value by 7 steps. Check for proper

horizontal position of the picture.

E-W PE-W P

E-W P

E-W PE-W P

Enter the service mode. Press the TV/video button on remote until a

crosshatch pattern is displayed. Select item DPC, adjust reference value for

straight vertical lines on both sides of the pattern.

WHITE BWHITE B

WHITE B

WHITE BWHITE B

Turn receiver on. Allow a 10 to 30 minute warm up time. Adjust contrast to

center and brightness to maximum. Enter the service mode. Press the TV/

video button on remote until the white screen pattern is displayed. Select

items RCUT, GCUT, BCUT, GDRV, and BDRV and set the reference value

for each to 40H. Press the video button on the remote to obtain a single

horizontal line. Advance the screen control until a faint line of one

predominant color appears on the screen. Adjust the other two cutoff items

to obtain a dim white line. Press the video button on the remote to get full

deflection. Select items GDRV and BDRV and adjust reference value of

each for the best black and white picture on screen.

AL POSITION (HPOS) & AL POSITION (HPOS) &

AL POSITION (HPOS) &

AL POSITION (HPOS) & AL POSITION (HPOS) &

ARABOLA (DPC)ARABOLA (DPC)

ARABOLA (DPC)

ARABOLA (DPC)ARABOLA (DPC)

ALANCE (RCUTALANCE (RCUT

ALANCE (RCUT

ALANCE (RCUTALANCE (RCUT

TC)TC)

TC)

TC)TC)

,,

GCUT GCUT

,

GCUT

,,

GCUT GCUT

VERVER

VER

VERVER

,,

BCUT BCUT

,

BCUT

,,

BCUT BCUT

TICAL POSITIONTICAL POSITION

TICAL POSITION

TICAL POSITIONTICAL POSITION

,,

GDR GDR

VV

,,

BDR BDR

,

GDR

,,

GDR GDR

V

VV

,

BDR

,,

BDR BDR

V)V)

V)

V)V)

Select the Adjustment mode RCUT, GCUT, or BCUT of the service mode.

Adjust convergence from center to circumference in order. Press “7” button

to display the built-in crosshatch pattern, it includes the three colors (R, G,

B). The cursor should be blinking in Red, this means that the Red convergence around the cursor can be done. Press “3” button to select the Green

color to be adjusted. Press “2” up, “8” down, “4” left, “6” right to move

the cursor to other point to be adjusted. Press “5” button to stop the cursor

from blinking, or to start the cursor blinking again. If necessary a specified

color line can be erased from the screen, press “100” button to erase Red

line. Press “0” button to erase Green line. Press “ENT” or “RTN” button to

erase Blue line. Repeat these steps to adjust the Red and Blue colors.

Converge the selected color into the Green line. Press “7” button to save the

adjustment changes. Press “7” button again to return to normal picture.

SERVICE PRECAUTIONS

Do not use a magnetized screw driver for screws of Deflection Yoke and

Velocity Modulation Coil, to avoid magnetization of electron gun.

Magnetization of electron gun will degrade basic function, and result in

unbalance of right and left shift of user static convergence, and result in no

variable quantity.

When replacing a CRT:

DO NOT LOOSEN OR ADJUST ANY OF THE HEX HEAD SCREWS.

These screws are for sealing of CRT coolant fluid, loosening any of

these screws will cause fluid leakage.

When replacing the anode cap assembly, or the anode lead assembly

remove the anode lead holder from old assembly and attach it to the new

anode lead, and make sure the point of the anode lead would be straight

coming out of the lead holder.

T

TT

TT

OSHIB

OSHIBOSHIB

OSHIBOSHIB

A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

T

TT

TT

A

AA

AA

C0175)

C0175)C0175)

C0175)C0175)

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 1e 1

a

g

e 1

aa

gg

e 1e 1

Page 5

PP

aa

gg

e 2e 2

P

a

PP

aa

PF GOLD 15 PF GOLD 15

g

e 2

PF GOLD 15

gg

e 2e 2

PF GOLD 15 PF GOLD 15

Page 6

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 2e 2

a

g

e 2

aa

gg

e 2e 2

Page 7

PP

aa

gg

e 2e 2

P

PP

PF GOLD 15 PF GOLD 15

a

g

e 2

PF GOLD 15

aa

gg

e 2e 2

PF GOLD 15 PF GOLD 15

Page 8

T

TT

TT

OSHIB

OSHIBOSHIB

OSHIBOSHIB

A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

T

TT

TT

A

AA

AA

C0175)

C0175)C0175)

C0175)C0175)

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 2e 2

a

g

e 2

aa

gg

e 2e 2

Page 9

PP

aa

gg

e 3 PF GOLD 15e 3 PF GOLD 15

P

a

g

e 3 PF GOLD 15

PP

aa

gg

e 3 PF GOLD 15e 3 PF GOLD 15

Page 10

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

Page 11

PP

aa

gg

e 3e 3

P

PP

PF GOLD 15 PF GOLD 15

a

g

e 3

PF GOLD 15

aa

gg

e 3e 3

PF GOLD 15 PF GOLD 15

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

Page 12

T

TT

TT

OSHIB

OSHIBOSHIB

OSHIBOSHIB

A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

T

TT

TT

A

AA

AA

C0175)

C0175)C0175)

C0175)C0175)

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 3e 3

a

g

e 3

aa

gg

e 3e 3

Page 13

PP

aa

gg

e 4 PF GOLD 15e 4 PF GOLD 15

P

a

g

e 4 PF GOLD 15

PP

aa

gg

e 4 PF GOLD 15e 4 PF GOLD 15

Page 14

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 4e 4

a

g

e 4

aa

gg

e 4e 4

Page 15

PP

aa

gg

e 4e 4

P

PP

PF GOLD 15 PF GOLD 15

a

g

e 4

PF GOLD 15

aa

gg

e 4e 4

PF GOLD 15 PF GOLD 15

Page 16

TEST EQTEST EQ

TEST EQ

TEST EQTEST EQ

Test equipment listed by participating manufacturer illustrates typical or

equivalent equipment used by Sams engineers to obtain measurements.

This equipment is compatible with most types used by field service

technicians.

EquipmentEquipment

Equipment

EquipmentEquipment

Oscilloscope SC3100

Generators

RGB CM2125

Multiburst Signal VG91

Color Bar VG91

TV Stereo VG91

Digital VOM SC3100

Frequency Meter SC3100

Hi-Voltage Probe HP200

Accessory Probes TP212

Isolation Transformer PR570

Capacitance Analyzer LC102

CRT Analyzer CR7000

AC Leakage Tester PR570

Inductance Analyzer LC102

Flyback Yoke Tester TVA92

Field Strength Meter SL753

Transistor Tester TF46

Horizontal Analyzer HA-2500

Video Analyzer VG91, TVA92

UIPMENTUIPMENT

UIPMENT

UIPMENTUIPMENT

Sencore No.Sencore No.

Sencore No.

Sencore No.Sencore No.

T

TT

TT

OSHIB

OSHIBOSHIB

OSHIBOSHIB

A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

a

g

aa

gg

T

TT

TT

A

AA

AA

C0175)

C0175)C0175)

C0175)C0175)

e 4e 4

e 4

e 4e 4

Page 17

PP

aa

gg

e 5e 5

P

PP

PF GOLD 15 PF GOLD 15

a

g

e 5

PF GOLD 15

aa

gg

e 5e 5

PF GOLD 15 PF GOLD 15

Page 18

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 5e 5

a

g

e 5

aa

gg

e 5e 5

Page 19

PP

aa

gg

e 5e 5

P

PP

PF GOLD 15 PF GOLD 15

a

g

e 5

PF GOLD 15

aa

gg

e 5e 5

PF GOLD 15 PF GOLD 15

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 5e 5

a

g

e 5

aa

gg

e 5e 5

Page 20

T

TT

TT

OSHIB

OSHIBOSHIB

OSHIBOSHIB

A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

T

TT

TT

A

AA

AA

C0175)

C0175)C0175)

C0175)C0175)

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 5e 5

a

g

e 5

aa

gg

e 5e 5

Page 21

PP

aa

gg

e 6e 6

P

a

PP

aa

PF GOLD 15 PF GOLD 15

g

e 6

PF GOLD 15

gg

e 6e 6

PF GOLD 15 PF GOLD 15

SCHEMASCHEMA

SCHEMA

SCHEMASCHEMA

C102 A7

C105 E46

C106 E47

C107 B47

C112 A5

C115 E47

C117 B46

C151 B46

C201 B10

C203 B17

C204 B15

C205 B12

C206 B16

C207 A18

C208 C18

C209 B18

C212 B47

C214 C16

C301 D9

C302 D9

C303 C46

C304 C58

C305 D57

C306 D8

C307 D9

C308 D9

C309 C21

C311 C23

C312 D9

C313 D8

C314 D10

C315 C47

C316 C47

C317 C22

C318 C21

C319 D51

C320 D52

C321 B50

C322 C21

C323 D10

C324 D52

C325 D12

C326 B24

C327 C59

C328 C11

C329 A22

C330 B23

C331 D10

C332 D11

C333 D12

C334 D12

C335 B23

C336 B24

C350 A23

C351 A23

C352 D7

C380 B24

C401 E9

TIC COMPONENT LOCATIC COMPONENT LOCA

TIC COMPONENT LOCA

TIC COMPONENT LOCATIC COMPONENT LOCA

C402 D7

C403 E9

C404 D7

C405 D16

C406 E11

C407 E12

C408 E11

C410 E23

C412 E18

C413 E22

C414 E19

C415 E17

C416 E19

C417 E19

C418 C51

C423 D16

C426 D15

C427 D17

C429 D26

C430 E23

C431 D23

C432 E23

C433 B27

C434 E22

C447 E12

C448 E11

C450 B49

C451 D7

C452 B50

C481 E47

C482 E27

C484 D27

C485 E26

C497 D44

C498 D43

C501 B10

C502 C11

C503 C11

C504 B11

C505 B11

C508 B14

C509 C12

C510 C12

C511 C12

C512 C11

C513 C12

C514 B17

C515 B17

C517 B11

C520 B47

C531 C19

C532 C20

C601 A66

C602 D66

C603 A67

C604 D67

C605 B67

C606 B67

TION GUIDETION GUIDE

TION GUIDE

TION GUIDETION GUIDE

C607 A68

C608 C68

C609 A68

C610 B68

C611 C67

C612 E66

C621 A61

C627 C61

C628 A62

C629 C62

C632 B61

C633 B62

C635 B62

C636 A61

C637 A62

C638 B46

C639 C65

C640 B63

C641 B63

C642 B63

C643 B63

C644 B63

C645 C63

C646 C63

C647 C63

C648 B63

C649 C63

C650 B63

C651 A64

C652 B63

C653 B46

C654 B46

C661 D65

C662 C64

C663 A64

C664 C65

C665 B47

C666 A65

C667 E65

C680 A44

C681 D67

C682 B66

C690 A44

C701 B70

C702 B70

C703 D71

C704 C71

C705 D50

C706 D50

C707 D49

C708 D49

C709 D49

C710 D49

C711 C72

C712 C70

C713 B70

C714 D49

C717 E73

C718 E73

C719 D49

C720 D49

C721 D71

C724 D50

C725 D50

C726 D49

C727 D50

C728 D49

C730 D50

C731 D50

C732 E70

C735 E70

C736 D50

C739 D49

C740 E49

C741 B79

C742 A79

C743 D50

C744 E49

C745 D79

C746 D79

C747 D50

C748 E49

C749 C79

C750 C79

C761 B81

C762 B81

C763 B81

C765 A81

C766 A81

C767 A82

C769 E81

C770 E81

C771 E81

C772 E50

C773 D81

C774 D81

C775 D82

C777 C81

C778 C81

C779 C82

C781 C81

C782 C81

C783 D81

C784 A82

C785 B81

C786 D81

C787 E81

C788 C82

C789 C81

C790 E72

C795 D49

C798 C50

C799 D52

C801 A37

C809 A40

C810 A40

C814 A38

C815 B38

C816 C27

C817 B38

C830 B47

C831 B46

C832 E45

C833 E47

C840 D39

C842 D41

C843 B54

C857 C43

C858 C44

C860 B40

C863 B41

C864 C41

C866 C40

C867 B40

C868 A41

C869 B40

C870 B42

C871 B42

C872 C41

C873 B41

C874 C41

C876 A41

C879 B41

C883 B39

C884 C43

C890 A43

C891 C40

C894 B43

C895 B43

C898 C41

C901 A35

C902 C47

C903 C47

C904 A32

C908 C52

C911 E35

C912 C47

C914 D32

C915 C52

C916 C47

C918 D33

C921 C36

C922 C47

C923 A32

C924 C47

C925 C33

C926 C31

C929 C31

C961 C47

C962 B30

C963 B31

C964 B34

C401A C5

C402A E9

C404A E10

C7721 C82

C7722 A82

C7724 D52

C7725 B49

C7726 D82

C7727 D82

C7729 A82

C7730 D82

C7732 B84

C7733 B82

C7735 D52

C7736 B50

C7737 E82

C7738 C82

C7740 B82

C7741 E82

C7744 D74

C7747 D49

C7748 D50

C7749 B46

C7750 B46

C7751 C50

C7752 C49

C7753 B49

C7754 B49

C7755 D52

C7765 B82

C7766 C82

C7767 D41

C7769 A70

C7774 D69

C7776 D50

C7801 E78

CA10 D57

CA13 D55

CA18 C57

CA20 A55

CA21 D54

CA22 E41

CA23 A55

CA24 E55

CA25 E41

CA26 E55

CA27 D55

CA29 D55

CA30 D57

CA34 E55

CA45 A57

CA49 E41

CA50 E41

CA52 B57

CA54 B55

CA59 B58

CA60 B58

CA61 E41

CA64 E41

CA68 C59

CA69 C59

CA71 E54

CA72 E53

CA73 B47

CA82 C58

CA84 B55

CA85 B58

CA86 B55

CB11 A53

CB13 D53

CB14 D54

CB15 B47

CB42 D40

CB61 E58

CB91 D41

CD02 C90

CD03 C90

CD04 C91

CD08 D47

CD10 C91

CD12 C91

CD13 C89

CD14 C90

CD15 C91

CD16 C90

CR12 B12

CR13 B12

CR14 B12

CR15 B11

CR16 B11

CR17 B10

CS03 A86

CS04 A85

CS07 A86

CS08 A85

CS09 E86

CS10 E85

CS11 D88

CS12 D88

CS13 D88

CS14 D88

CS15 B88

CS16 B88

CS21 D90

CS22 E90

CS23 E89

CS24 E86

CS25 E85

CS28 C88

CS29 E88

CS32 D89

CS33 E89

CS34 E88

CS35 E88

CS36 E88

CS38 C88

CS41 C86

CS42 C86

CS43 D86

CS44 C86

CV01 D88

CV03 A85

CV04 D86

CV05 D86

CV08 D47

CV09 D47

CV13 B87

CV14 A87

CV15 A87

CV16 D88

CV17 E88

CV19 D88

CV21 C86

CV22 B86

CV23 B86

CV24 B85

CV27 D90

CV28 C90

CV29 D89

CV30 D89

CV31 A88

CV38 D47

CV39 D85

CV46 D47

CV48 D47

CV49 D46

CV61 D86

CV64 B91

CV65 B90

CV66 B90

CV67 B90

CV68 B89

CW04 A1

CW05 B2

CW07 B44

CW08 C47

CW09 C47

CW12 B44

CW13 C3

CW14 C1

CW15 C2

CW16 D1

CW17 D2

CW18 C2

CW19 D2

CW20 D3

CW21 D2

CW22 B3

CW26 A3

CW52 D91

CW53 D91

CW54 E90

CW58 D47

CW59 D47

CY01 E47

CY40 B89

CZ03 A93

CZ05 B94

CZ07 D47

CZ09 B93

CZ10 B93

CZ11 B93

CZ12 B94

CZ13 C95

CZ14 C95

CZ17A B95

CZ19 B94

CZ20 B94

CZ21 B94

CZ22 C95

CZ23 C95

CZ24 C95

CZ25 C95

CZ26 B95

CZ28 B94

CZ29 B94

CZ30 B95

CZ31 D47

CZ32 D94

CZ33 D94

CZ34 E94

CZ35 E94

CZ37 D47

CZ38 D94

CZ41 A94

CZ42 A95

CZ45 B93

D101 E46

D201 C16

D215 B18

D216 C18

D217 B18

D218 B19

D219 C19

D220 B19

D221 D74

D222 C16

D223 C16

D301 C22

D302 D11

D303 C46

D304 D12

D305 D11

D306 D11

D307 A25

D310 C22

D320 D8

D336 D10

D401 E16

D402 E15

D403 E11

D404 E11

D405 E11

D406 E22

D407 D15

D408 C51

D413 D15

D415 E21

D416 E25

D421 D6

D422 D6

D430 B48

D431 B49

D432 D7

D481 B27

D482 C26

D490 D44

D491 D44

D512 C13

D513 B16

D532 C20

D533 D20

D601 A45

D602 A45

D603 A46

D604 A46

D607 A45

D608 A45

D611 E66

D612 E66

D661 C64

D701 C70

D702 C70

D703 D69

D704 D70

D705 A70

D706 C70

D707 D70

D801 A39

D820 D44

D821 D44

D840 D39

D843 B54

D845 B38

D851 C43

D862 B41

D863 C39

D864 A41

D873 B41

D875 B41

D876 A41

D877 C40

D878 B40

D881 B39

D884 C43

D885 A43

D891 B43

D892 B43

D899 A38

D901 A33

D902 A32

D911 D32

D912 D33

D921 C33

D922 C31

D924 B31

D925 C31

D961 B30

D965 A31

D966 A30

D975 D29

D7703 D49

D7705 D69

D7706 D69

D7707 C69

D7708 C69

D7709 D41

D7710 C49

D7711 D52

D7712 A82

D7713 C82

D7717 A69

D7718 A69

D7719 A70

D7801 E77

DA02 C59

DA11 D39

DA34 E54

DA43 C57

DA44 B57

DA45 C58

DA46 B58

DB13 B56

DB21 B56

DB30 B54

DV01 E86

DV02 D86

DV03 D86

DV07 B88

DV08 A88

DV09 A88

DV11 C86

DV12 B86

DV13 B86

DV17 E88

DV25 B91

DW04 C2

DW05 D2

DW21 C1

F470 C44

F801 A37

F850 C43

F851 C44

F860 A40

F889 A43

F890 B43

F891 B43

G005 C1

G031 B34

G032 C34

G033 C34

G034 A33

G036 A33

G037 A33

G039 D34

G040 D34

G041 D34

H001 A7

H003 B5

HY01 A6

IN 1 B5

IN 2 C5

J201 C90

KB11 A53

L101 A7

L111 A5

L115 A6

L121 A5

L122 A5

L301 C46

L302 D51

L303 B48

L304 C12

L400 B49

L401 E22

L402 E22

L403 E19

L404 E19

L405 E10

L406 E16

L407 D14

L408 E22

L409 E22

L462 C13

L463 C14

L464 C14

L472 C4

L473 D4

L474 D4

L481 E46

L501 C11

L502 C12

L503 C12

L701 B70

L702 B70

L707 A74

L708 A74

L709 B74

L710 B74

L711 D74

L712 B74

L713 C74

L714 A74

L720 B81

L721 B81

L722 A81

L723 A81

L724 E81

L725 E81

L726 D81

L727 D81

L728 C81

L729 C81

L730 C81

L731 C81

L737 D49

L738 E49

L739 C49

L740 D52

L752 D71

L851 C42

L852 C42

L853 B48

L854 D51

L861 A40

L862 B41

L881 C42

L882 D42

L885 C44

L888 A42

L889 A42

L891 B42

L892 B42

L893 B42

L894 C42

L895 B43

L896 B43

L897 A43

L898 D41

L961 C47

L962 B31

L963 C51

L7701 A82

L7702 D82

L7703 C82

L7704 B82

L7705 E82

L7706 C82

LA22 E40

LA49 E40

LV01 B88

LV02 A88

LV05 D85

LV06 B85

LV07 D46

LV13 D90

LV14 D46

LV20 A87

LW01 A13

LW02 C2

LW04 C46

LW04A C2

LW05 D2

LW07 D46

LY22 B90

LZ01 A93

LZ02 C95

LZ03 B95

LZ04 C95

LZ05 C95

LZ08 B94

LZ11 D94

LZ12 E94

OUT B5

P801 A37

PS01 C67

PV02 B87

PV02 B87

PV02 C85

PV02 C85

PV02 C87

PV02 D85

PV02 E85

PV02 E85

PV03 B67

PV03 C67

PV03 D90

PV03 D91

PV03 D91

PV03 E87

PV03 E87

PV03 E90

PV03 E90

Q151 C6

Q152 C6

Q201 C17

Q202 A90

Q203 D58

Q261 A15

Q262 A15

Q263 A16

Q301 C11

Q302 C8

Q303 D8

Q304 B23

Q304 B25

Q304 C22

Q304 C24

Q305 C10

Q306 B22

Q306 B23

Q306 B25

Q306 C58

Q308 A23

Q309 A24

Q310 A24

Q401 E8

Q402 E7

Q403 E21

Q404 E10

Q405 E8

Q406 B26

Q407 D23

Q407 D25

Q408 B26

Q409 B27

Q430 B48

Q481 D27

Q481 E25

Q481 E27

Q492 D44

Q501 B11

Q501 B14

Q501 C6

Q502 C14

Q503 A91

Q520 A19

Q521 C19

Q522 B19

Q523 D20

Q524 B20

Q525 C20

Q526 B20

Q601 A67

Q612 E66

Q621 A62

Q622 A63

Q661 D66

Q662 B65

Q663 A64

Q663 C64

Q664 E65

Q681 B66

Q682 D66

Q701 C72

Q702 D72

Q703 A78

Q704 D78

Q705 C78

Q707 D70

Q709 E69

Q709 E70

Q711 B72

Q714 A72

Q715 A80

Q717 D80

Q719 B80

Q751 A83

Q751 C83

Q751 D83

Q752 B83

Q752 B83

Q752 E83

Q754 C48

Q755 C48

Q764 B74

Q764 C69

Q764 C70

Q764 D69

Q765 A82

Q766 C82

Q767 A69

Page 22

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 6e 6

a

g

e 6

aa

gg

e 6e 6

SCHEMASCHEMA

SCHEMA

SCHEMASCHEMA

Q801 B40

Q819 C26

Q830 B45

Q831 E45

Q840 D39

Q841 B53

Q843 B37

Q862 B39

Q863 C39

Q865 D26

Q901 A33

Q902 A32

Q911 D33

Q913 D32

Q921 B33

Q922 B31

Q961 A30

Q962 A31

Q963 B32

Q964 B33

Q965 B34

Q966 B33

Q971 D30

Q972 E30

Q973 D31

Q974 D31

Q975 E31

Q976 E31

Q981 C32

Q982 C31

Q983 C32

Q984 C30

Q7801 E78

Q7802 E79

Q7803 E80

Q7804 E82

QA01 C56

QA02 C59

QA71 E54

QB03 A56

QB14 D54

QB21 B56

QB30 B37

QB61 E58

QB81 D76

QB82 E76

QB83 E76

QB84 E74

QB85 D75

QB86 E75

QB87 E75

QB88 E75

QB92 D74

QD01 C91

QR02 E56

QR14 A74

QR15 C74

QR16 B74

TIC COMPONENT LOCATIC COMPONENT LOCA

TIC COMPONENT LOCA

TIC COMPONENT LOCATIC COMPONENT LOCA

QR17 A75

QR17 B75

QR17 C75

QS01 D89

QS11 E89

QS12 E89

QS13 E89

QS14 D89

QV01 C87

QV20 B91

QV21 B91

QV22 B90

QV23 B89

QV48 C90

QV50 B8

QW01 A14

QW05 A16

QW06 A2

QW07 A2

QW09 C1

QW10 D1

QW11 B16

QW11A C2

QW12 D2

QW17 D56

QW19 A4

QW20 A3

QW52 D91

QW53 D91

QW54 E91

QW60 E91

QW68 E91

QY26 B89

QY27 B91

QZ01 A94

QZ02 D94

QZ03 D95

QZ04 E94

QZ05 D93

QZ06 E95

QZ07 A93

QZ08 E93

R B26

R101 E45

R150 C6

R152 C6

R201 A90

R202 A90

R204 B16

R205 B17

R206 C17

R207 A18

R208 C18

R209 B18

R212 D58

R213 E58

R214 E59

R216 C16

TION GUIDETION GUIDE

TION GUIDE

TION GUIDETION GUIDE

R223 A90

R241 C17

R242 C17

R244 C17

R245 C17

R266 A15

R267 A15

R268 A16

R269 A16

R270 A16

R301 D58

R302 C8

R303 C58

R304 C58

R305 D9

R307 C9

R308 C8

R310 D58

R311 C24

R312 C23

R313 C24

R314 C23

R315 C22

R316 E9

R317 C24

R318 D9

R319 C59

R320 C59

R321 D10

R322 C59

R323 D59

R324 C25

R325 D10

R326 C24

R327 C22

R328 C22

R329 C22

R330 C21

R331 C21

R332 C59

R333 C21

R334 C10

R335 D11

R336 D10

R337 D12

R338 B24

R339 B24

R340 B23

R341 B25

R342 A22

R343 B25

R344 D12

R345 D12

R346 D11

R347 B22

R348 B22

R349 B24

R350 B24

contincontin

uedued

contin

ued

contincontin

uedued

R351 B26

R360 B26

R362 C25

R363 C25

R364 C25

R370 A22

R371 A23

R372 A23

R373 A24

R374 A24

R375 A24

R376 A24

R378 A25

R401 D6

R402 E7

R403 D7

R404 E9

R405 E10

R406 D5

R407 D6

R408 E21

R409 E22

R410 E23

R411 E18

R412 E8

R413 E8

R414 E10

R415 E19

R416 D15

R418 E19

R419 E18

R420 C51

R421 E17

R423 E6

R424 D16

R428 C51

R431 D15

R432 B48

R434 E15

R435 D16

R436 D14

R437 D13

R438 D13

R439 D25

R440 D24

R441 D23

R442 D24

R443 D24

R444 E23

R445 D22

R446 E23

R447 E23

R448 E23

R449 D15

R451 C26

R460 E16

R468 E25

R469 E25

R470 C44

R471 C44

R472 C44

R473 D44

R474 D44

R475 D44

R479 B27

R480 B27

R481 B27

R482 E28

R483 E27

R484 D26

R485 E26

R486 E27

R487 B26

R488 C26

R489 D25

R490 D27

R492 D26

R493 E23

R494 B26

R495 E26

R496 E26

R497 B26

R498 C26

R499 E23

R501 B11

R502 B13

R503 B13

R504 C14

R505 C14

R506 C14

R508 A91

R509 A91

R510 A91

R512 C10

R514 C14

R515 D55

R530 A19

R531 C19

R532 B19

R533 B19

R534 C19

R535 B19

R536 C20

R537 D20

R538 D20

R549 B17

R601 A65

R602 D66

R603 A66

R604 D66

R609 A68

R610 B68

R611 C66

R612 C66

R613 E66

R621 A61

R622 C62

R623 C61

R624 A62

R625 A61

R626 A62

R627 C61

R633 A63

R634 A63

R635 E63

R636 D63

R637 E63

R638 E63

R639 C63

R640 A63

R641 A63

R642 D63

R643 D63

R661 D65

R662 D65

R663 C64

R665 D65

R666 C64

R667 B65

R668 B64

R669 B64

R671 A65

R672 B65

R673 B64

R674 E65

R675 E65

R682 B66

R683 B66

R684 D66

R687 E65

R689 D66

R690 D67

R701 B70

R702 B70

R703 C73

R704 B72

R705 A72

R706 A72

R707 A73

R708 A73

R709 B73

R710 B73

R711 D73

R712 B73

R713 C73

R714 A73

R716 C73

R718 A70

R719 E73

R720 E69

R721 E69

R722 E70

R723 D71

R724 B71

R725 D70

R726 A73

R727 E71

R728 C70

R729 B70

R730 B71

R731 B71

R732 C71

R733 B70

R734 A71

R735 B81

R736 B81

R737 A80

R738 B80

R739 A80

R740 A82

R741 A81

R742 A81

R743 A81

R744 A81

R745 E81

R746 E81

R747 D80

R748 D80

R749 D80

R750 D82

R751 D81

R752 D81

R753 D81

R754 D81

R755 C82

R756 C81

R757 C81

R758 C81

R759 C81

R760 D81

R761 C81

R762 C80

R763 C80

R764 C80

R778 C82

R779 E82

R780 A82

R781 C81

R782 D82

R783 B81

R786 C72

R787 C72

R810 A39

R815 C27

R816 C27

R817 B27

R820 C43

R821 D43

R822 D43

R823 D43

R824 D44

R842 B37

R844 B54

R861 A40

R862 B41

R864 B40

R865 B39

R867 C40

R868 C41

R870 B39

R871 A41

R872 B40

R883 B39

R884 C39

R891 C40

R898 A37

R900 C34

R901 A32

R903 A34

R904 A32

R905 A32

R906 A32

R908 A32

R909 A31

R911 D32

R913 D34

R914 D33

R915 D32

R916 D32

R918 D32

R919 D30

R921 B30

R923 B34

R924 C31

R925 C30

R926 C31

R927 C33

R928 C31

R931 A33

R932 A33

R940 D31

R941 D34

R942 D34

R946 E36

R949 D32

R950 C30

R951 C34

R952 C34

R953 C30

R954 C30

R955 C31

R956 C31

R958 C31

R959 C32

R960 C32

R961 B30

R962 B30

R963 B30

R964 B30

R965 A30

R966 B31

R967 A31

R968 B31

R969 B32

R970 B32

R971 B32

R972 B32

R973 B33

R974 B33

R975 B34

R976 B33

R977 B33

R978 B34

R980 C32

R981 C32

R982 C31

R983 C31

R984 C31

R985 D30

R986 A32

R987 D29

R988 D29

R989 D29

R990 E30

R991 E30

R992 D33

R993 D30

R994 E31

R995 D31

R996 D29

R997 E30

R998 E31

R999 E31

R401A E7

R403A E9

R406A E16

R407A D16

R432A D15

R433A D15

R7707 C82

R7708 A83

R7710 A84

R7711 A83

R7712 D82

R7713 C83

R7715 C84

R7716 D83

R7717 A82

R7718 D83

R7720 D84

R7721 D83

R7722 B84

R7723 B83

R7725 B84

R7726 B83

R7727 E82

R7728 C83

R7730 C84

R7731 C83

R7732 B82

R7733 E83

R7735 E84

R7736 E83

R7766 C69

R7767 C69

R7773 D69

R7775 A82

R7776 A82

R7777 C82

R7778 C82

R7779 A70

R7780 A70

R7781 A70

R7788 D51

R7795 A74

R7796 C74

R7797 B74

R7798 D74

R7801 E77

R7802 E78

R7803 E78

R7804 E80

R7805 E78

R7806 E79

R7807 E80

R7808 E81

R7809 E82

RA01 A55

RA02 C59

RA03 B59

RA04 B55

RA05 B55

RA06 C55

RA07 C55

RA09 D55

RA10 D57

RA11 A55

RA12 B55

RA13 E55

RA15 C54

RA16 B55

RA17 D57

RA18 C57

RA26 E54

RA27 D54

RA29 D55

RA30 D57

RA31 D58

RA33 D57

RA34 E54

RA35 D55

RA39 E58

RA46 B57

RA47 B57

RA48 E55

RA49 B57

RA50 B57

RA51 B57

RA52 C57

RA54 B54

RA55 C55

RA56 C56

RA59 B57

RA60 B57

RA72 E54

RA73 E54

RA74 E54

RA75 E53

RA76 B58

RA77 C58

RA78 B55

RA79 B55

RA80 C59

RA82 C59

RA85 B58

RA91 B53

RA92 B54

RA93 B54

RA96 B54

RA97 B54

RA98 B53

RA99 B53

RB03 A56

RB14 D54

RB15 D53

RB15A A54

RB16 D54

RB17 D54

RB19 A53

RB21 B56

RB24 B56

RB30 C37

RB41 E85

RB41A C39

RB42 C39

RB43 C37

RB61 E59

RB62 E58

RB63 E58

RB81 E76

RB82 E76

RB83 D76

RB84 E76

RB90 E74

RB91 E74

RB92 E75

RB93 E75

RB94 E75

RB95 E75

RB96 D75

RB97 E76

RB98 E74

RD09 C92

RD11 C92

RD13 C89

RD14 C89

RD16 C89

RF B5

RF B7

RR08 E56

RR09 E56

RR10 B57

RR12 A57

RR13 A57

RR14 A57

RR15 A58

RR16 A58

RR17 A58

RR18 E56

RR40 A75

RR42 C75

RR44 B75

RR52 A75

RR53 A74

RR54 C75

RR55 C74

RR56 B75

RR57 B74

RR58 D76

RR59 C76

RR92 D74

RR99 D74

RS02 E88

RS04 A86

RS06 A86

RS07 E85

RS08 E86

RS09 D88

RS10 D88

RS12 C88

RS21 B67

RS22 C67

RS25 D89

RS26 E89

RS27 D90

RS28 E90

RS29 E90

RS30 D90

RS31 E90

RS32 E89

RS33 E89

RS34 D89

RS35 E88

RS36 E88

RS37 C89

RS40 E89

RS42 D89

RS48 C89

RS49 B88

RS51 C86

RS52 C86

RV01 E87

RV03 B86

RV04 B86

RV10 D88

RV11 A89

RV12 A89

RV14 D88

RV15 D89

RV20 B87

RV21 A87

RV22 A87

RV23 B87

RV24 D91

RV25 E90

RV26 D91

RV28 C89

RV31 C86

RV32 B86

RV33 B86

RV34 C85

RV50 B8

RV63 C89

RV67 E86

RV74 D86

RV83 D86

RV84 D86

RV85 D90

RV89 C90

RV90 B92

RV91 B91

RV92 B91

RV93 B90

RV94 B90

RV95 B90

RV96 B90

RV97 B89

RV98 B89

RW02 D1

RW09 A3

RW10 A17

RW13 A3

RW14 B44

RW14A B14

RW15 B2

RW16 B2

RW16A B14

RW17 B2

RW18 A2

RW19 A3

RW20 A3

RW22 A2

RW23 A2

RW24 B2

RW25 B3

RW30 C1

RW30A B16

RW31 C3

RW32 C1

RW33 C2

RW34 D1

RW35 D2

RW36 C2

RW37 C2

RW38 C2

RW39 D2

RW40 D2

RW40A D56

RW41 C2

RW42 D2

RW43 D3

RW44 C2

RW45 D2

RW51 E91

RW52 E91

RW53 D91

RW54 D91

RW55 D92

RW57 E92

RW68 E90

RW69 E91

RW74 E91

RW76 E91

RW77 E91

RW78 E91

RW91 E92

RW92 D91

RW93 E90

RW94 D91

RY01 D8

RY80 B89

RY81 B89

RY82 B90

RY83 B91

RY87 B90

RZ01 A93

RZ02 B93

RZ03 A93

RZ04 D94

RZ05 D93

RZ06 B94

RZ08 D94

RZ09 E93

RZ10 E94

RZ12 E95

RZ13 E94

RZ14 D95

RZ15 E95

RZ17 E93

RZ18 E94

RZ19 D95

RZ20 D93

RZ22 D94

RZ29 A95

RZ30A A94

S602 C66

SA21 B54

SA22 B54

SA23 B53

SA24 B53

SA25 B54

SA26 B54

SA27 B53

SA28 B53

SA29 B53

SL01 C44

SP1 A68

SP2 B68

SR81 A39

SR81 B38

T401 E9

T403 E18

T461 B51

T461 D16

T801 A38

T802 A38

T840 D38

T862 A42

TP501 C10

V901 A36

V902 D36

V903 B36

X B26

X D16

X401 D6

X501 C11

XA01 E56

Z401 C17

Z410 C18

Z702 B79

Z703 A79

Z704 E80

Z705 D79

Z706 C79

Z707 C79

Z711 D70

Z712 C71

Page 23

PARTS LIST

Item No.Item No.

Item No.

Item No.Item No.

D101 MTZJ33D 23316756 D201 MA111 23118041 NTE552

D215 Thru

D223 MA111 23118041 NTE552

D301 MA8068-M 23316577 D302 EU2A 23118094 NTE552

D303 MA8180-M 23316610 D304 SC570A 23316794 D305, 06 ERB12-02 23118822 NTE125

D307, 10 MA111 23118041 NTE552

D320 MA8068-L 23316576 D336 MA8039-H 23316583 D401, 02 EU2A 23118094 NTE552

D403 ERC06-15 23316254 NTE506

D404 ERD29-06 23316969 NTE580

D405 ERC06-15 23316254 NTE506

D406 EU2A 23118094 NTE552

D407 RP-1H 23118707 D408 EU2A 23118094 NTE552

D413 RP-1H 23118707 D415 MTZJ18B 23316731 D416 MTZJ10B 23316690 D421, 22 MA111 23118041 NTE552

D430 MA8100-M 23316591 D431 MA111 23118041 NTE552

D432 MA8100-M 23316591 D481 1SS133 23118859 NTE519

# D482 RD6.2E(FA-1) 23115774 NTE5013A

D490 1SS133 23118859 NTE519

D491 MTZJ36B 23316758 D512 MA111 23118041 NTE552

D513 MA8091-L 23316587 D532 ERB12-02 23118822 NTE125

D533 MA8130-M 23316600 D601 Thru

D604 MA111 23118041 NTE552

D607, 08 MA8220-M 23316616 D611, 12 MA111 23118041 NTE552

D661 MA8056-L 23316570 D701 Thru

D704 1SS131 23115537 NTE519

D705, 06, 07 MTZJ6.2B 23316675 NTE5013T1

D801 LN6SB60-F05 23357041 D820 MTZJ36B 23316758 D821 1SS133 23118859 NTE519

D840 S1WBA20 23316962 NTE5332

D843, 45 1SS133 23118859 NTE519

D851 D4SBS6 23357215 D862 EU2A 23118094 NTE552

# D863 MTZJ10A 23316689 NTE5018A

D864 EU2A 23118094 NTE552

D873 MTZJ27C 23316747 D875 MTZJ9.1C 23316688 D876, 77 MTZJ27C 23316747 D878 MTZJ9.1A 23316686 D881 1SS133 23118859 NTE519

D884 D4SBL40 23357217 D885 D4SBL20U 23357216 D891 D4SBS4 23357214 D892 FMX-12S 23357042 NTE6240

D901, 02 1SS133 23118859 NTE519

D911, 12 1SS133 23118859 NTE519

D921, 22 1SS133 23118859 NTE519

D924, 25 1SS133 23118859 NTE519

D961, 65 1SS133 23118859 NTE519

D966, 75 1SS133 23118859 NTE519

D7703 MTZJ6.2B 23316675 NTE5013T1

D7705 Thru

D7708 MA111 23118041 NTE552

D7709 MTZJ6.2B 23316675 NTE5013T1

D7710 MTZJ11B 23316716 D7711 MTZJ9.1B 23316687 D7712, 13 MA111 23118041 NTE552

D7717, 18, 19 MTZJ6.2B 23316675 NTE5013T1

D7801 MA111 23118041 NTE552

DA02 MA8062-M 23316574 DA11 1SS133 23118859 NTE519

DA34 MA111 23118041 NTE552

TT

ype No.ype No.

T

ype No.

TT

ype No.ype No.

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NTE PNTE P

NTE P

NTE PNTE P

arar

ar

arar

t No.t No.

t No.

t No.t No.

Item No.Item No.

Item No.

Item No.Item No.

DA43 Thru

DA46 MA111 23118041 NTE552

DB13 SIR-56SB3F 23358522 DB21 SLR-56VC3FPQ 23358564 DB30 1SS133 23118859 NTE519

DV01, 02, 03 MTZJ9.1A 23316686 DV07, 08, 09 MTZJ9.1A 23316686 DV11, 12 MTZJ9.1A 23316686 DV13, 17 MTZJ9.1A 23316686 DV25 1SS133 23118859 NTE519

DW04, 05, 21 1SS133 23118859 NTE519

G005 1SS133 23118859 NTE519

Q151 2SA1037AKQ 23205045 NTE2409

Q152 2SC3326B A6359871 Q201, 02 2SC2412K 23314204 NTE2408

Q203 2SC3437-L - Q261 2SC2412K 23314204 NTE2408

Q262, 63 2SA1037AKQ 23205045 NTE2409

Q301 LA7833S 23319787 Q302 TA8859CP B0384625 Q303 2SC2412K 23314204 NTE2408

Q304 TA75902FB 70129117 Q305 2SA1037AKQ 23205045 NTE2409

Q306 TA75902FB 70129117 Q308 2SC2412K 23314204 NTE2408

Q309 2SA1037AKQ 23205045 NTE2409

Q310 2SC2412K 23314204 NTE2408

Q401 2SC2482FA-1 23114755 NTE399

Q402 2SC752GTM-Y 23114437 NTE85

Q403 2SK2920 A6073390 Q404 2SD2553(FA) 23314955 Q405 2SC752GTM-Y 23114437 NTE85

Q406 2SC4686A 23205079 Q407 M5218AP 23319808 Q408 KTA1266Y 23314962 NTE290A

Q409, 30 KTC3198Y 23314965 NTE199

Q481 TA75339AP B0347235 Q492 2SA1321 A6547305 NTE288

Q501 TA1222BN B0385677 Q502 2SC2412K 23314204 NTE2408

Q503 2SA1037AKQ 23205045 NTE2409

Q520, 21, 22 2SA1037AKQ 23205045 NTE2409

Q523 2SC2412K 23314204 NTE2408

Q524, 25, 26 RN1401 23114502 Q601 TA8216H B0376885 Q612 2SA1037AKQ 23205045 NTE2409

Q621 CXA2021S 23000381 Q622 SSOP24 B01A0119 Q661, 62 2SC3326B A6359871 Q663 BA4558 23906596 NTE778A

Q664 RN2404 A6014041 NTE2419

Q681, 82 2SC3326B A6359871 Q701 QFP100 B01B4088 Q702 LC89066M - Q703, 04, 05 LC78816M 23905014 Q707 TLC2932IPW 23905013 Q709 MC33078D 23906908 NTE891SM

Q711 NM24C04EN 23904665 Q714 MC14052BF - Q715, 17, 19 MC33078D 23906908 NTE891SM

Q751, 52 STK392-110 23905094 Q754 AN7805 23904521 NTE960

Q755 AN7809 23904525 NTE1910

Q764 TC74HC14AF 23319720 Q765, 66 2SC2412K 23314204 NTE2408

Q767 TC74HC4066AF 23904442 Q801 STR-Z4267 23906540 Q819 KTC3198Y 23314965 NTE199

Q830 PQ09RD11 23905977 Q831, 40 PQ05RD11 23905976 Q841 PST994D 70129444 Q843 KTC3198Y 23314965 NTE199

Q862 TLP421F(GR) 23000823 -

# Q863 SE140N 23319305 -

Q865 KTA1266Y 23314962 NTE290A

Q901 2SC5360(FA) - Q902, 11, 13 2SC1815-Y 23114433 NTE85

Q921 2SC5360(FA) - -

TT

ype No.ype No.

T

ype No.

TT

ype No.ype No.

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NTE PNTE P

NTE P

NTE PNTE P

arar

ar

arar

t No.t No.

t No.

t No.t No.

Item No.Item No.

Item No.

Item No.Item No.

Q922, 61 2SC1815-Y 23114433 NTE85

Q962 2SA562TM-Y 23114422 NTE290A

Q963 2SC1815-Y 23114433 NTE85

Q964 2SA1015-Y 23114425 NTE290A

Q965 2SC1815-Y 23114433 NTE85

Q966 2SA1015-Y 23114425 NTE290A

Q971 Thru

Q976 2SC1815-Y 23114433 NTE85

Q981, 82 2SA1015-Y 23114425 NTE290A

Q983 2SC1815-Y 23114433 NTE85

Q984 2SA1015-Y 23114425 NTE290A

Q7801 2SC2412K 23314204 NTE2408

Q7802 TA75S393F - Q7803, 04 TC4S66F A6030112 QA01 MN102L35GFB1 23000868 QA02 AT24C1610PC 23905666 QA71 2SA1037AKQ 23205045 NTE2409

QB03 RN1405 - QB14 2SA1037AKQ 23205045 NTE2409

QB21 2SC1740S 23114528 NTE85

QB30 KTC3198Y 23314965 NTE199

QB61 2SC3437-L - QB81, 82 2SC3326B A6359871 QB83 2SA1037AKQ 23205045 NTE2409

QB84 2SC2412K 23314204 NTE2408

QB85 Thru

QB88 2SA1037AKQ 23205045 NTE2409

QB92 2SC2412K 23314204 NTE2408

QD01 TA8173AP B0377277 QR02 2SC2412K 23314204 NTE2408

QR14, 15, 16 2SA1037AKQ 23205045 NTE2409

QR17 MC14053BF 23318981 QS01 2SC2878-A 23114623 NTE85

QS11 2SC2878-A 23114623 NTE85

QS12 RN2204 23114466 NTE2360

QS13, 14 KTC3198Y 23314965 NTE199

QV01 TA8851CN B0384761 QV20 RN1204 23114460 NTE2359

QV21 2SC1740S 23114528 NTE85

QV22, 23 2SA933S 23114530 NTE290A

QV48 2SC1740S 23114528 NTE85

QV50 2SA1037AKQ 23205045 NTE2409

QW01 MC14053BF 23318981 QW05 2SC2412K 23314204 NTE2408

QW06 2SC1815-Y 23114433 NTE85

QW07 2SC752GTM-Y 23114437 NTE85

QW09 2SC1740S 23114528 NTE85

QW10 2SA933S 23114530 NTE290A

QW11 2SC2412K 23314204 NTE2408

QW11A 2SA1837 A6550640 QW12 2SC4793 A6369650 QW17 RN1401 23114502 QW19, 20 2SC1815-Y 23114433 NTE85

QW52, 53, 54 2SC1740S 23114528 NTE85

QW60 2SA933S 23114530 NTE290A

QW68 2SC1740S 23114528 NTE85

QY26 2SC1740S 23114528 NTE85

QY27 2SA933S 23114530 NTE290A

QZ01 TC90A49P 23906904 QZ02 2SA1162-(Y) A6541132 NTE2409

QZ03 2SA1162-(Y) A6541132 NTE2409

QZ04 2SA1162-(Y) A6541132 NTE2409

QZ05 2SC2712Y 23114475 NTE2408

QZ06, 07 2SA1162-(Y) A6541132 NTE2409

QZ08 2SC2712Y 23114475 NTE2408

Item No.Item No.

Item No.

Item No.Item No.

C330 10µF 20% 16V NP 24085946 -

# C406 .0015 3% 1.8kV 24082823 -

# C407 .0047 3% 1.5kV 24082946 -

# C408 .012 5% 630V 24820123 -

# C414 .47 5% 400V 24095782 -

C415 .0015 10% 2kV 24092484 C426 .0022 10% 2kV 24211222 -

# C447 .0036 3% 1.5kV 24082943 -

# C448 .012 5% 630V 24820123 -

C801 .47 20% 125VAC 24082001 -

TT

ype No.ype No.

T

ype No.

TT

ype No.ype No.

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

MfrMfr

Mfr

MfrMfr

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NTE PNTE P

NTE P

NTE PNTE P

NotesNotes

Notes

NotesNotes

arar

ar

arar

t No.t No.

t No.

t No.t No.

PP

aa

gg

e 6e 6

P

a

PP

aa

PF GOLD 15 PF GOLD 15

g

e 6

PF GOLD 15

gg

e 6e 6

PF GOLD 15 PF GOLD 15

Page 24

PARTS LIST continued

Item No.Item No.

Item No.

Item No.Item No.

C814, 15, 17 .0047 20% 250VAC 24092597 C864 220pF 10% 2kV 24092474 C871 .0015 10% 2kV 24092484 C872 220pF 10% 2kV 24092474 C901, 11, 21 .001 10% 2kV 24211102 CA72 10µF 20% 16V NP 24085981 CB13 10µF 20% 16V NP 24085981 CV01, 03, 16 10µF 20% 16V NP 24085981 D899 Varistor 24000948 F470 Fuse 23144906 1.25Amp, 125V

F470A Fuse Holder 23165433 For F470

F801 Fuse 23144481 7Amp, 125V

F801A Fuse Holder 23165433 For F801

F850 Fuse 23144893 3.15Amp, 125V

F850A Fuse Holder 23165433 For F850

F851 Fuse 23144893 3.15Amp, 125V

F851A Fuse Holder 23165433 For F851

F860 Fuse 23144511 4Amp, 125V

F889 Fuse 23144893 3.15Amp, 125V

F889A Fuse Holder 23165433 For F889

F890 Fuse 23144897 2Amp, 125V

F890A Fuse Holder 23165433 For F890

F891 Fuse 23144854 1.6Amp, 125V

F891A Fuse Holder 23165433 For F891

G031 47µH 23289470 G033 220µH 23289221 G034 47µH 23289470 G037 220µH 23289221 G039 47µH 23289470 G041 220µH 23289221 H001 Tuner 23321411 Main, EL967LW

H003 Switch 23344421 Antenna

HY01 Tuner 23321412 PIP, EL936L

J201 Jack - Assembly

K111 Lens 23430111 Assembly

K113 Lens 23430111 Assembly

K501 Screen 23430786 Lenti

K502 Screen 23311894 Fresnel

K503 Screen 23311866 Protection

K601 Mirror 23405042 K912 Transmitter 23306263 Remote, CT-9946

KB11 Receiver 23000852 Remote

L101, 11 - 23289845 L115 - 23103852 L121, 22 - 23238562 L301 - 23237975 L302, 03 - 23248073 L304 Ferrite Bead 23103859 L400 - 23289840 L401 - 23103775 L402 22mH 23248243 -

# L403 - 23233977 -

L404 2.2mH 23248242 L405 2.2µH 23221076 L406 56µH 23289560 L407 - 23248196 -

# L408 - 23248244 -

L409 - 23103775 -

# L462, 63, 64 Yoke 23231220 -

L472, 73, 74 VM 23102457 L481 - 23237975 L501, 02, 03 - 23289853 L701, 02 - 23103866 L707 Thru

L714 1µH 23238562 L720 1000µH 23289102 L721 2200µH 23237805 L722 1000µH 23289102 L723 2200µH 23237805 L724 1000µH 23289102 L725 2200µH 23237805 L726 1000µH 23289102 L727 2200µH 23237805 L728 1000µH 23289102 L729 2200µH 23237805 L730 1000µH 23289102 L731 2200µH 23237805 -

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NotesNotes

Notes

NotesNotes

Item No.Item No.

Item No.

Item No.Item No.

L737 Thru

L740 56µH 23289560 L751 Filter 23103864 L752 - 23103795 L851, 52 Ferrite Bead 23103880 L853, 54 - 23248073 L861 Ferrite Bead 23103880 L862 Ferrite Bead 23103937 L881, 82 Ferrite Bead 23103880 L885 - 23248073 L888, 89 Ferrite Bead 23103880 L891 Thru

L894 Ferrite Bead 23103880 L895, 96 - 23248073 L897, 98 - 23248087 L961 10µH 23289100 L962 4.7µH 23237991 L963 47µH 23289470 L7701 Thru

L7706 Ferrite Bead 23103859 LA22, 49 - 23245858 LV01, 02 Filter 23103852 LV05, 06 56µH 23289560 LV07 - 23238719 LV13, 14 10µH 23289100 LV20 - 23238705 LW01 - 23103845 LW02 Ferrite Bead 23261974 LW04 - 23245834 LW04A, 05 Ferrite Bead 23103859 LW07 - 23289220 LY22 - 23103852 LZ01 - 23238710 LZ02 Thru

LZ05 - 23238714 LZ08 - 23238707 LZ11, 12 - 23238710 P801 Line Cord 23372117 AC, Polarized

PS01 Jack - Audio Center Channel In

PV01 Jack - Assembly

PV02 Jack 23365819 Assembly

PV03 Jack - Assembly

R241, 42, 44 33K 2% 1/6W 24367333 R320 47K 1% 1/4W 24000249 R322 6800 1% 1/4W 24000529 R323 22K 1% 1/4W 24000639 R332 4700 1% 1/4W 24000525 R404 6800 5% 3W 24384682 R409, 10 220 5% 3W 24555220 R473, 74 22K 1% 1/4W 24327223 -

# R487 2200 1% 1/4W 24000366 -

# R488 2000 1% 1/4W 24000365 -

# R494 1800 1% 1/4W 24000364 -

# R498 2700 5% 1/6W 24366272 -

R810 1.2 5% 20W Wirewound 24045007 R820, 21, 22 15K 1% 1/4W 24327153 R823 12K 1% 1/6W 24327123 R900 2.4 5% 2W Fusible 24000906 R931, 32 15K 5% 3W 24555153 R941, 42 15K 5% 3W 24555153 R951, 52 15K 5% 3W 24555153 R971 1500 2% 1/6W 24367152 R972 470 2% 1/6W 24367471 R973, 74 680 2% 1/6W 24367681 R976 5600 2% 1/6W 24367562 R977 3900 2% 1/6W 24367392 R978 680 2% 1/6W 24367681 R7710, 15 68 5% 3W 24555680 R7720, 25 68 5% 3W 24555680 R7730, 35 68 5% 3W 24555680 S602 Switch 23145412 SA21 Switch 23145226 Channel Up

SA22 Switch 23145226 Channel Down

SA23 Switch 23145226 Volume Up

SA24 Switch 23145226 Volume Down

SA25 Switch 23145226 Power

SA26 Switch 23145226 Menu

SA27 Switch 23145226 Video

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NotesNotes

Notes

NotesNotes

Item No.Item No.

Item No.

Item No.Item No.

SA28 Switch 23145226 Demo

SA29 Switch 23145226 Exit

SP1, 2 Speaker 23351131 SR81 Relay 23146577 Power

T401 Horizontal Drive 23224367 T403 - 23224364 -

# T461 Horizontal Output 23236623 -

T801 Line Filter 23211698 T802 Line Filter 23211729 T840 Power 23217530 T862 Converter 23217533 UY01 Module 23148731 PIP, MKMP33

# V901 CRT 23008509 Red

# V901R Protector Coupling 23008895 R

# V902 CRT 23008510 Green

# V902G Protector Coupling 23008896 G

# V903 CRT 23008511 Blue

# V903B Protector Coupling 23013066 B

X401 Resonator 23153721 503kHz

X501 Crystal 23153961 3.58MHz

XA01 Resonator 23153533 -

# Z401 CR-Block 24083013 -

Z402 Spark Gap 23140203 2kV to 3kV

Z410 Focus Pack 23110841 Z702 Thru

Z707 - 23103823 Z711, 12 - 23103823 -

# For SAFETY use only equivalent replacement part.

Function/RatingFunction/Rating

Function/Rating

Function/RatingFunction/Rating

PC Board 23786450 A/V Switching, PD0177A

PC Board 23786936 CRT, Red, PD0178B1

PC Board 23786937 CRT, Green, PD0178B2

PC Board 23786938 CRT, Blue, PD0178B3

PC Board 23708512 CRT-D, PD0178B

PC Board 23786780 Deflection/Power, PD0176D

PC Board 23784601 Comb Filter, PB9398

PC Board 23784783 Digital Convergence, PB9453D

PC Board 23786940 Front A/V, PD0178B5

PC Board 23786939 Front Control, PD0178B4

PC Board 23786942 Remote, PD0178B7

PC Board 23786779 Sig/Conv, PD0175D

PC Board 23786941 SVM, PD0178B6

Socket 23903148 CRT (3 Used)

MfrMfr

Mfr

MfrMfr

..

P P

arar

t No.t No.

.

P

ar

t No.

..

P P

arar

t No.t No.

NotesNotes

Notes

NotesNotes

T

TT

TT

OSHIB

OSHIBOSHIB

OSHIBOSHIB

A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

A MODEL 43A61 (CHASSIS A MODEL 43A61 (CHASSIS

T

TT

TT

A

AA

AA

C0175)

C0175)C0175)

C0175)C0175)

PF GOLD 15 PPF GOLD 15 P

PF GOLD 15 P

PF GOLD 15 PPF GOLD 15 P

aa

gg

e 6e 6

a

g

e 6

aa

gg

e 6e 6

Loading...

Loading...