Page 1

SERVICE MANUAL

Plasma Display

42WP37C

FILE NO. 010-200325

42WP37E

42WP37F

42WP37H

Mar. 2004 (YC)

Page 2

42WP37

CONTENTS

1 Applicable signals 3

2 Safety Precautions

2.1. General Guidelines

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

4 About lead free solder (PbF)

5 PCB Structure sheet of GP6D chassis

6 Service Hint

7 Location of Lead Wiring

8 Adjustmen t Proce dure

8.1.DriverSet-up

8.2. Initialization Pulse Adjust

8.3. P.C.B. (Printed Circuit Board) exchange

8.4. Adjustment Volume Location

8.5. Test Point Location

9 Service mode

9.1. CAT (computer Aided Test) mode

9.2. IIC mode structure (following items value is sample data.)

10 Alignment

10.1. 625i/625p panel white balance

10.2. PC/RGB panel white balance

10.3. HD panel white balance

11 Trouble shooting guide

11.1. Self Check

11.2. No Power

11.3. No Picture

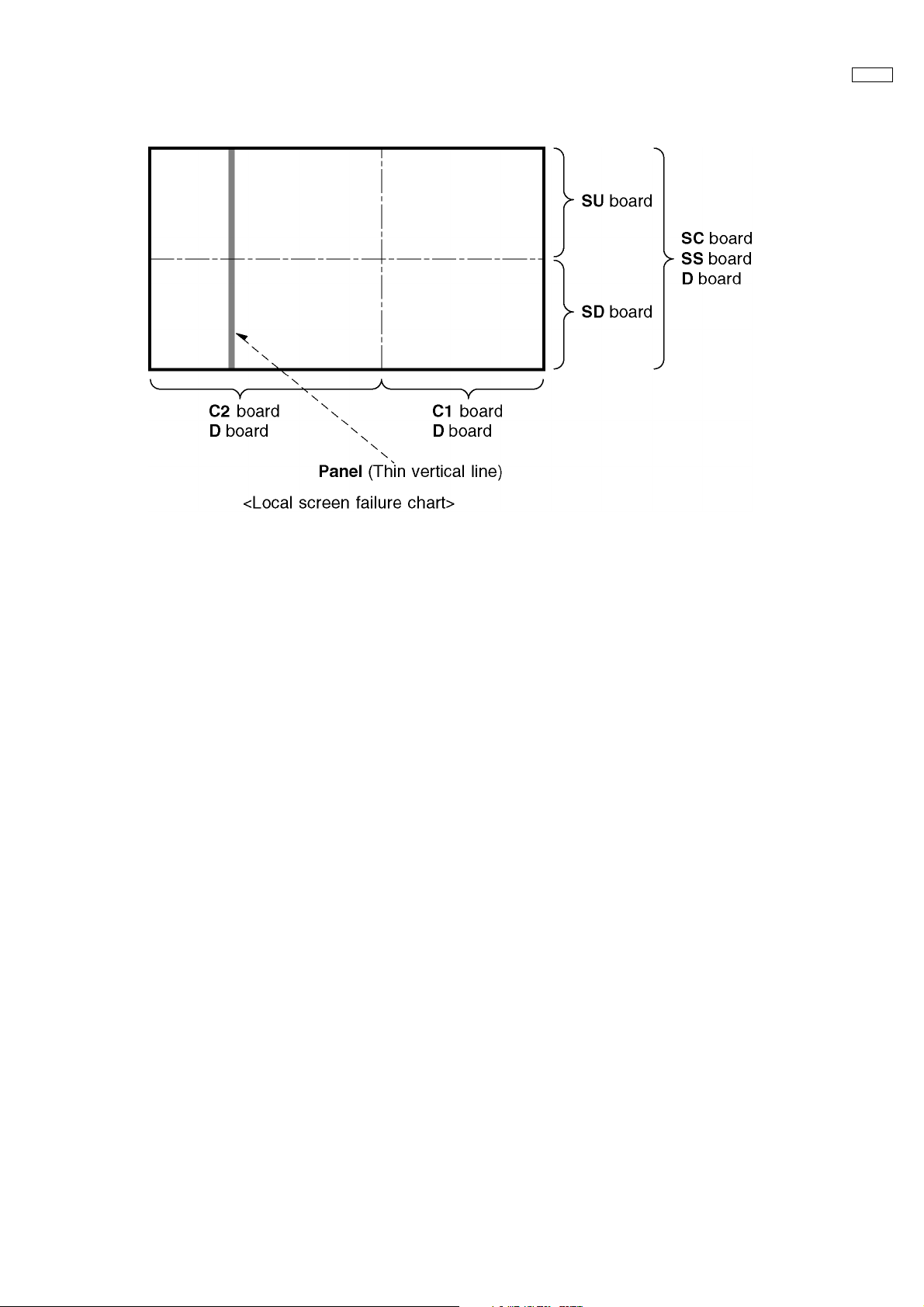

11.4. Local screen failure

12 Conductor Views

12.1. PF-Board

12.2. P-Board

12.3. HX-Board

12.4. HV-Board

12.5. HZ-Board

12.6. HT-Board

12.7. J-Board

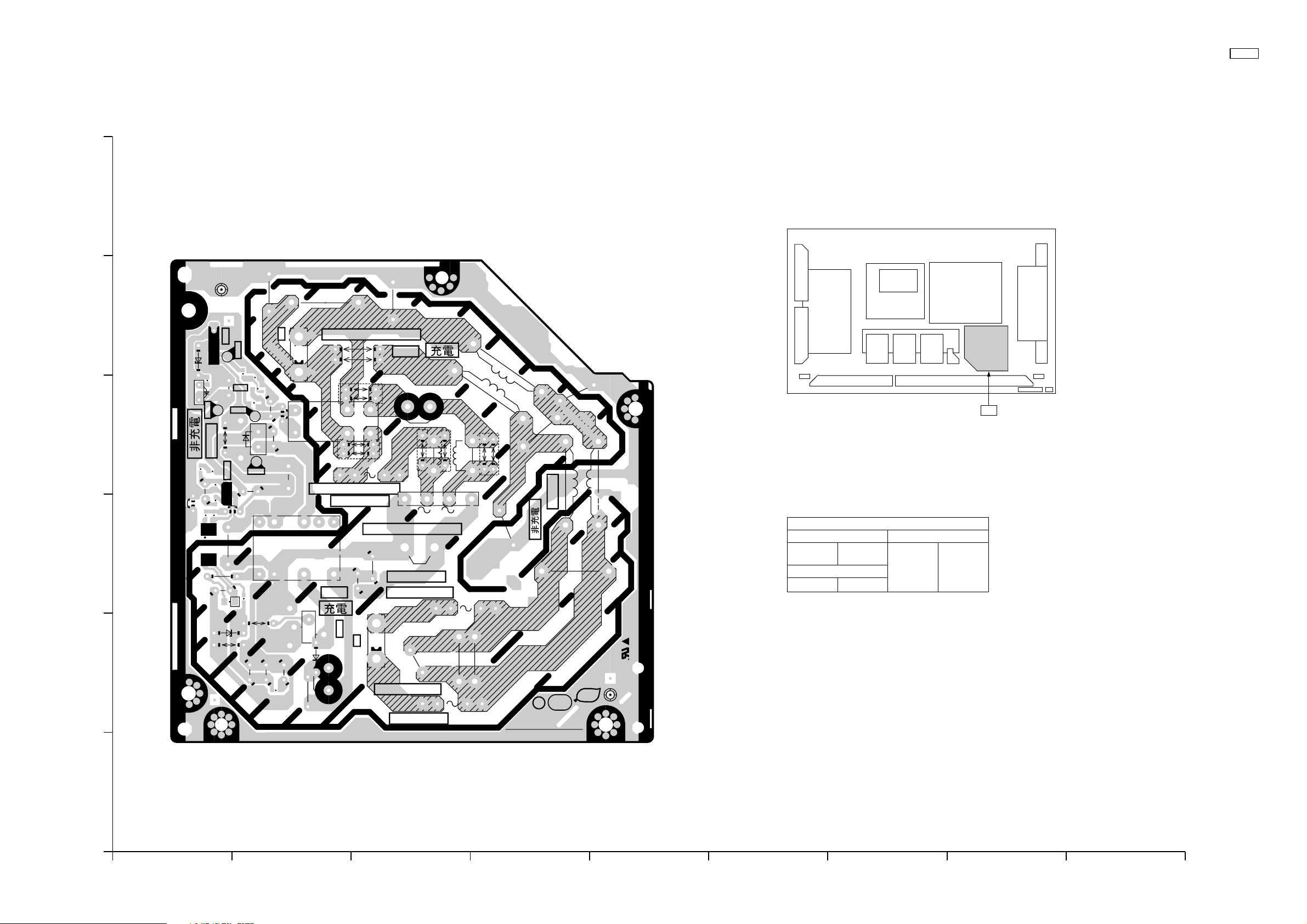

12.8. D-Board

12.9. C1-Board

12.10. C2-Board

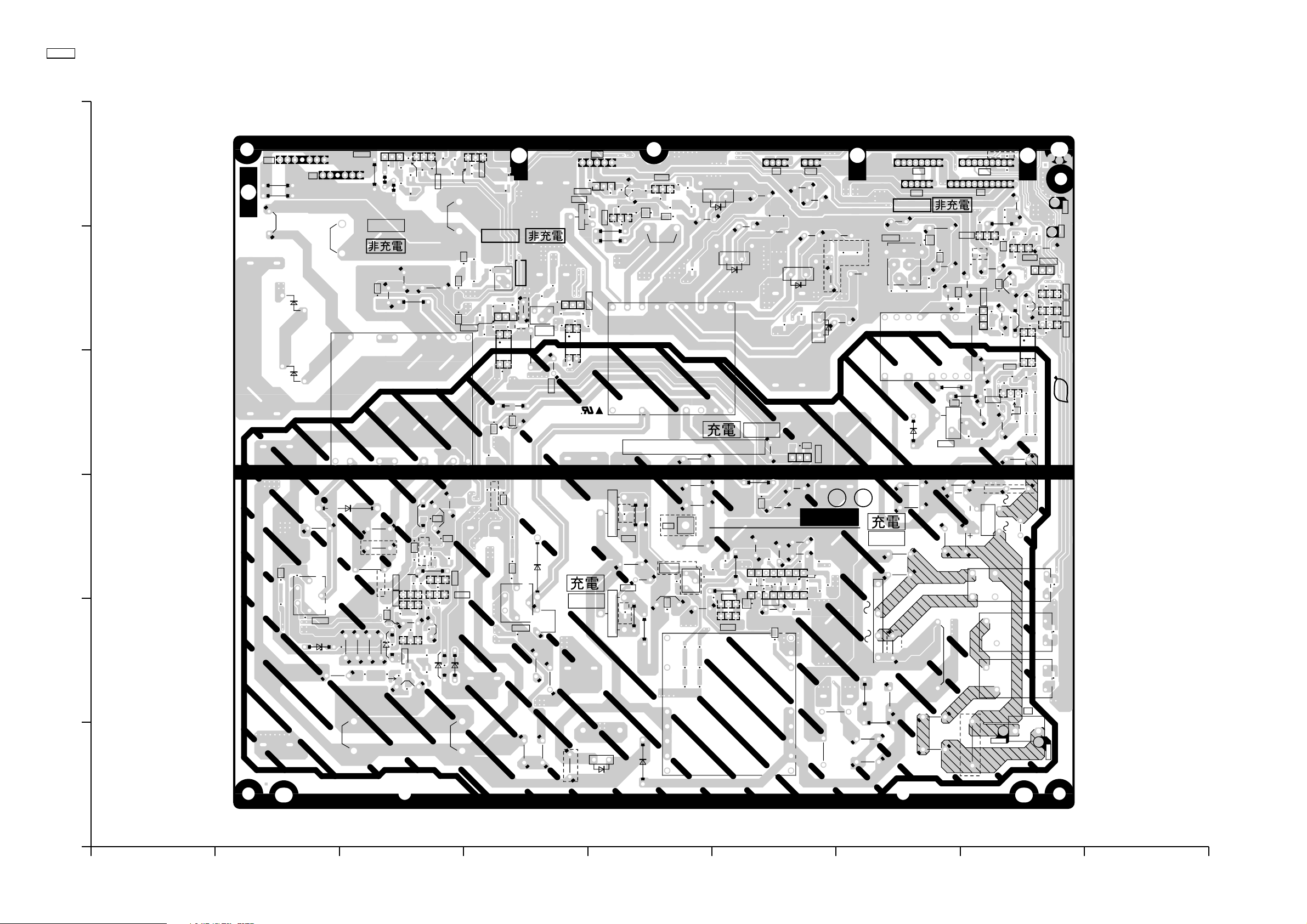

12.11. SC-Board

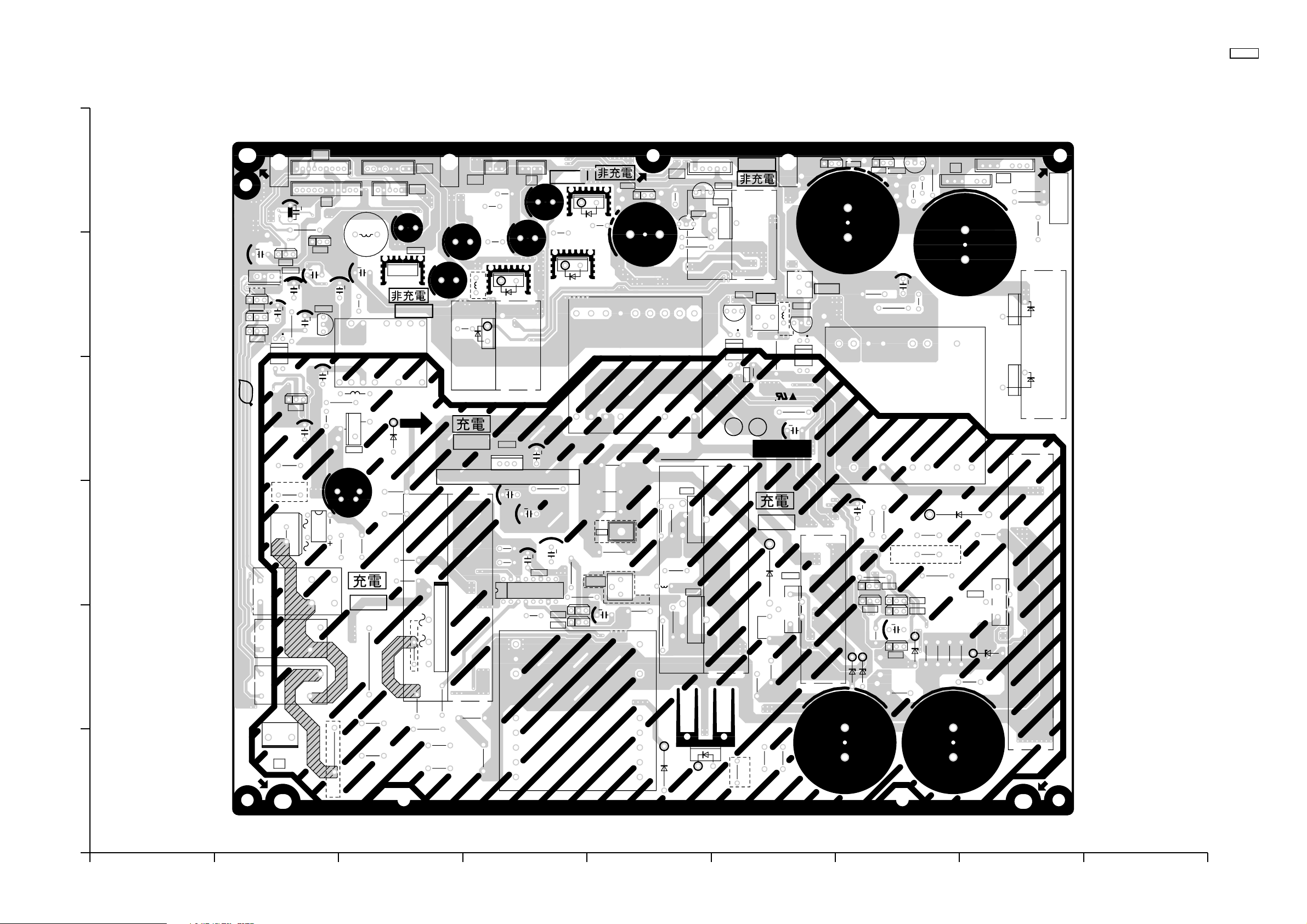

12.12. SU and SD-Board

12.13. SS, SS2 and SS3-Board

12.14. Z-Board

12.15. V1, S1 and H3-Board

Page Page

Replacement panel handling precautions and replacement

13

4

4

5

6

7

8

9

10

10

11

12

12

12

13

13

15

16

16

18

19

20

20

20

22

23

25

25

26

29

30

31

32

33

35

37

38

39

42

43

45

46

procedure

14 Parts Location

15 Chassis and Cabinet Replacement Parts List

16 Specifications

Appendix

Block and Schematic Diagrams

48

49

51

END

– 2 –

Page 3

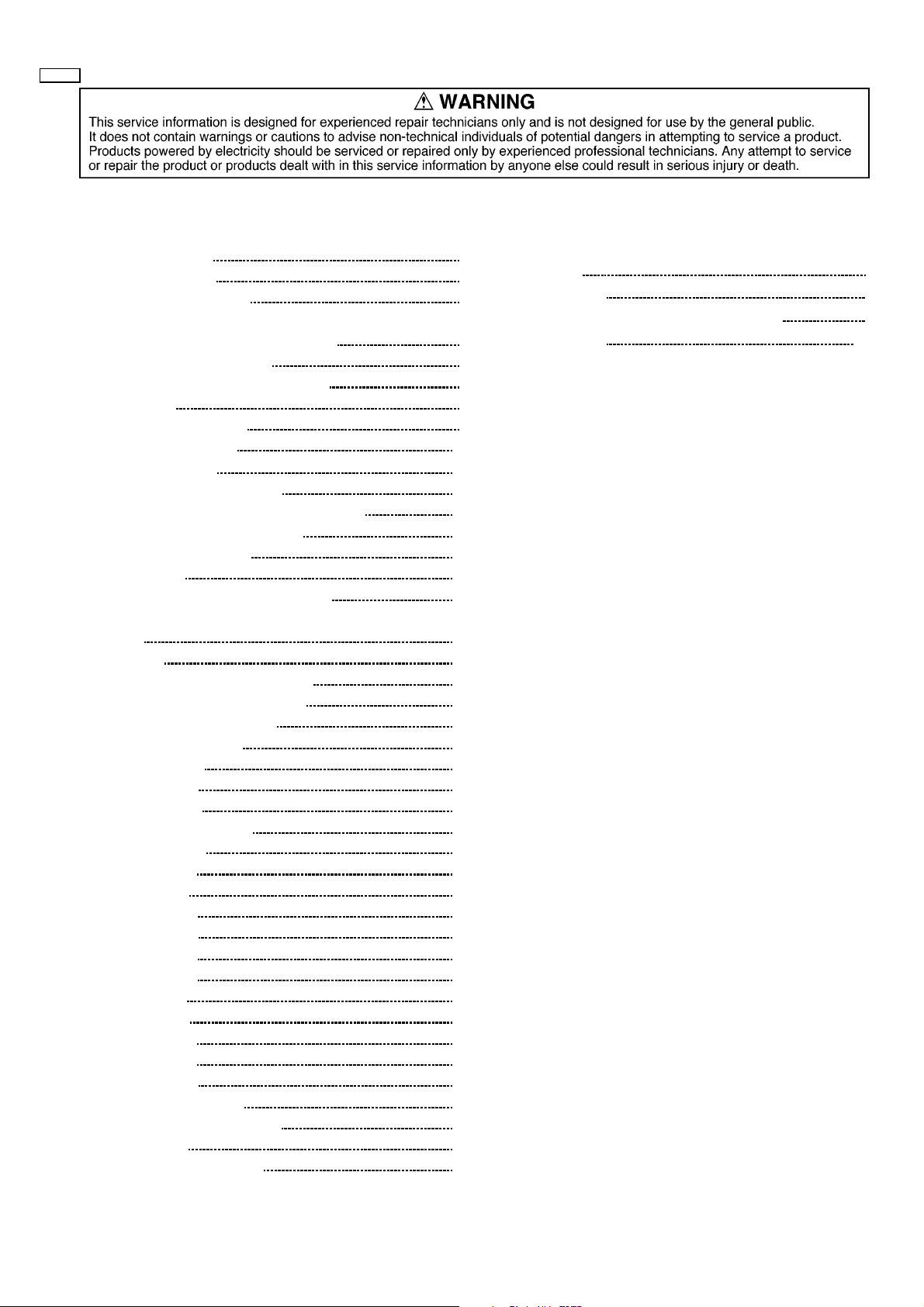

1 Applicable signals

42WP37

– 3 –

Page 4

42WP37

2 Safety Precautions

2.1. General Guidelines

1. When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2. After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3. After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

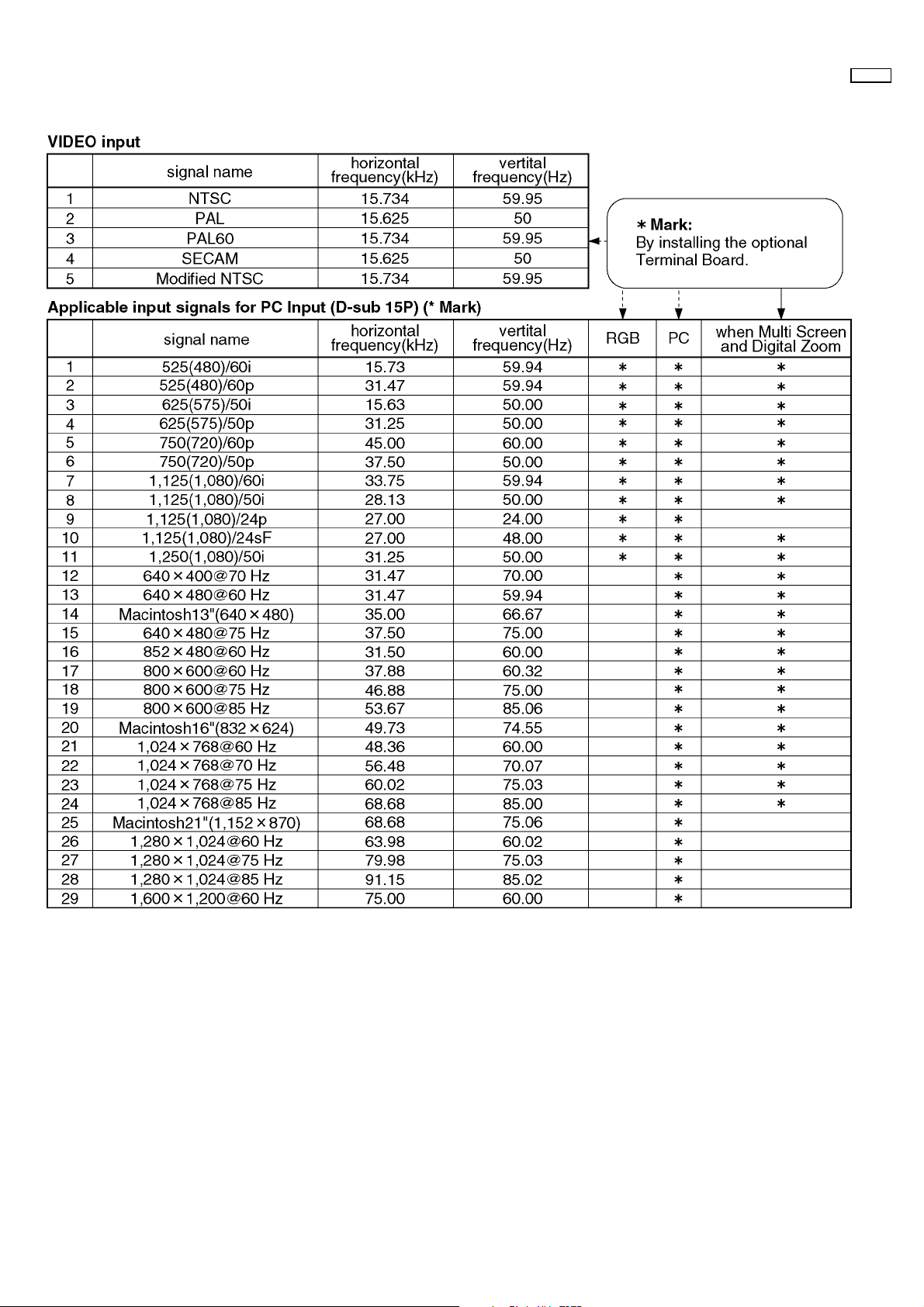

2.1.1. Leakage Current Cold Check

1. Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2. Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1M9 and 5.2M9.

When the exposed metal does not have a return path to

the chassis, the reading must be

.

Figure 1

2.1.2. Leakage Current Hot Check (See

Figure 1.)

1. Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2. Connect a 1.5k9, 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3. Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4. Check each exposed metallic part, and measure the

voltage at each point.

5. Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6. The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

– 4 –

Page 5

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7. Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

42WP37

– 5 –

Page 6

42WP37

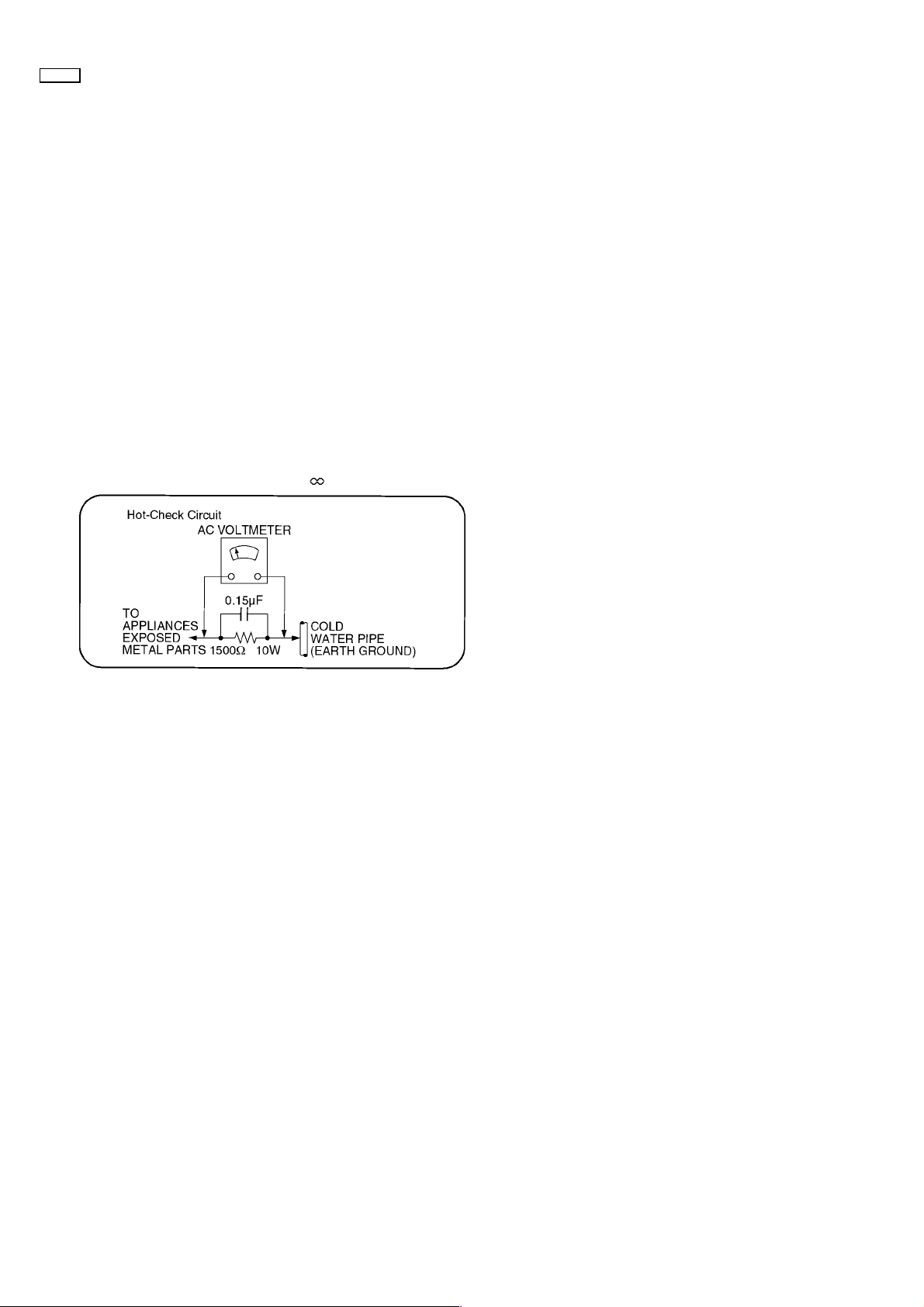

4 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and Copper (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

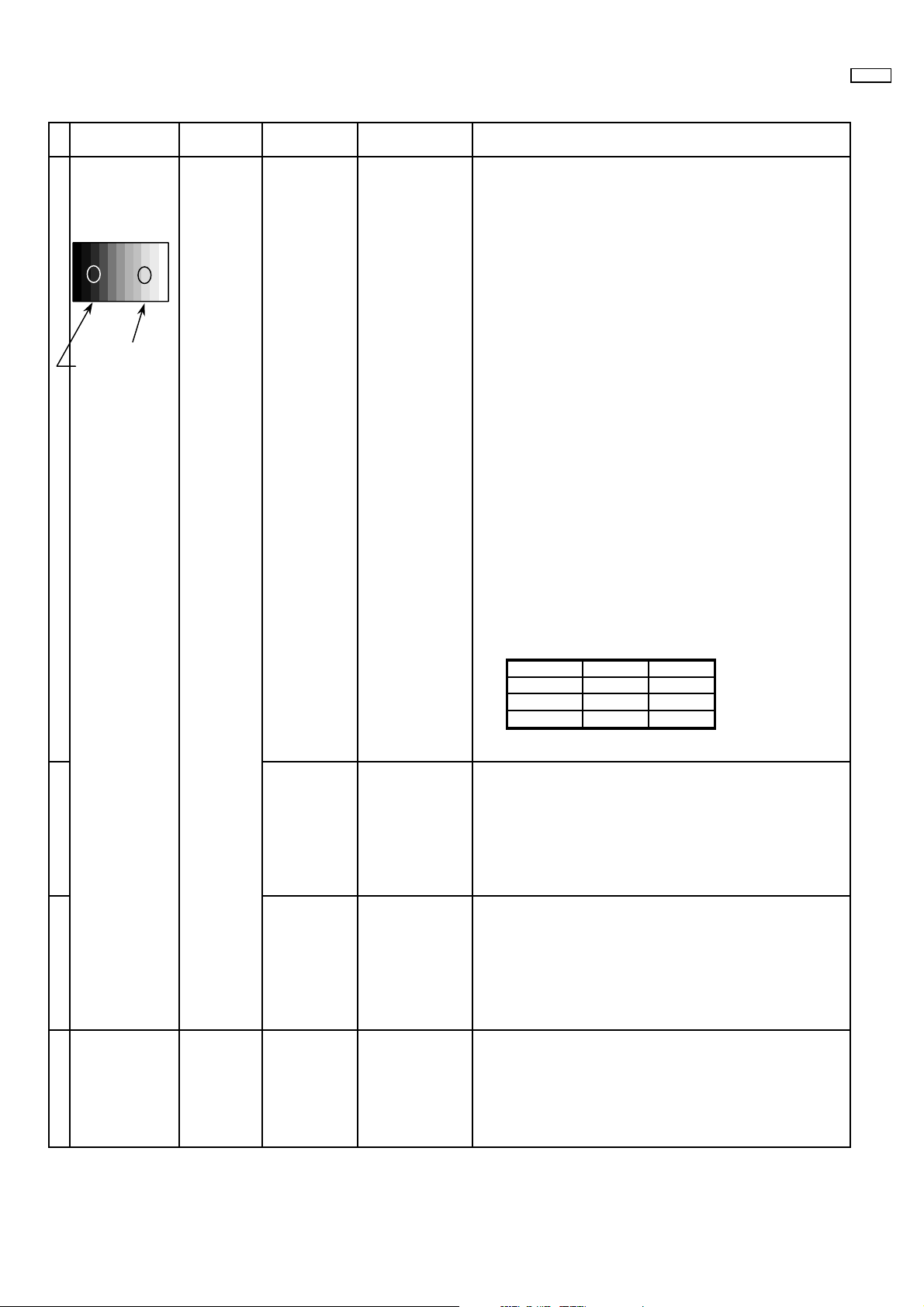

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

·Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

·Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

– 6 –

Page 7

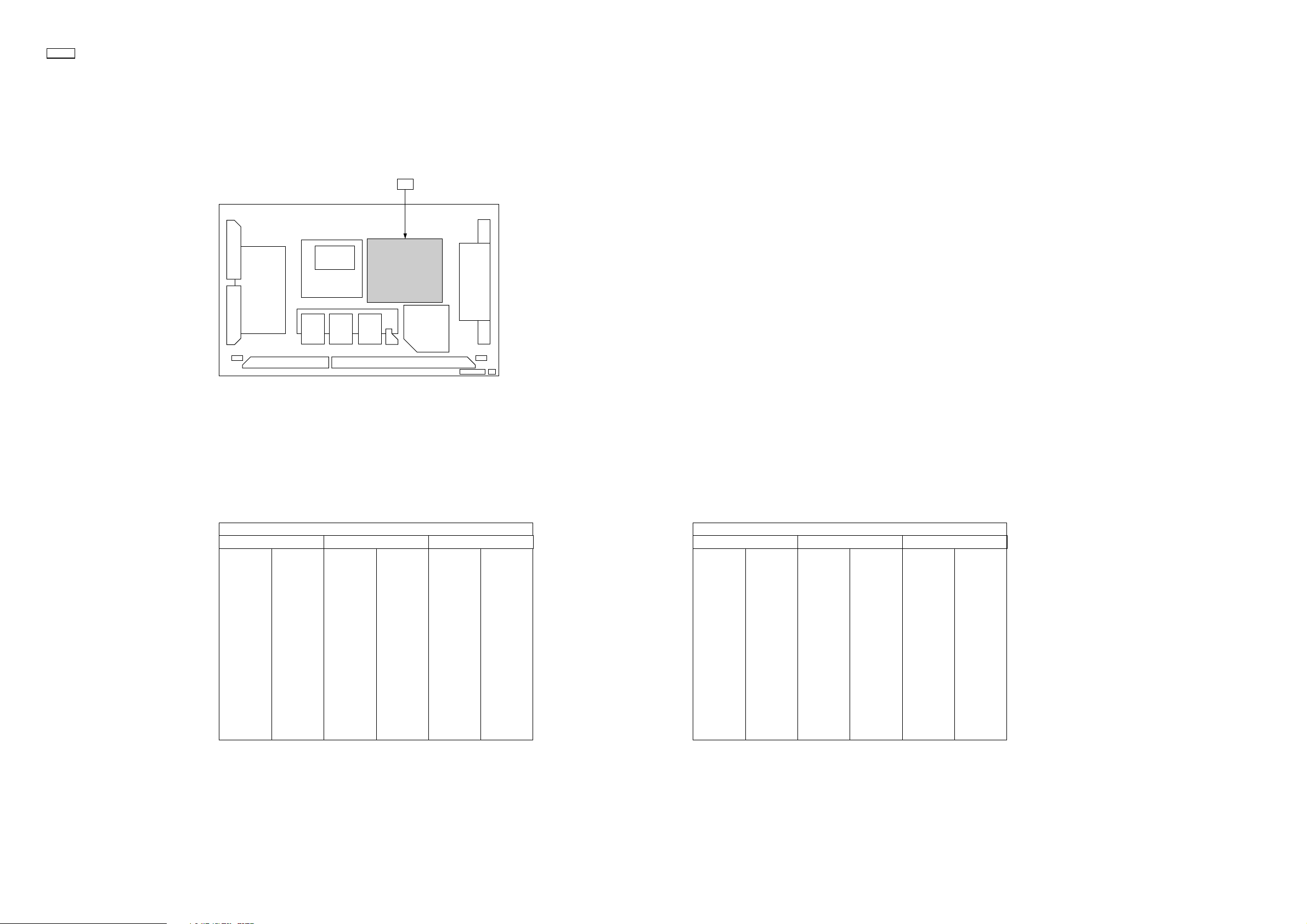

5 PCB Structure sheet of GP6D chassis

Board Name Function Remarks

D Digital Signal Processor 1

J Slot Interfa ce & SYNC processor 1

Z Audio out, DC-DC converter

SS Sustain Out 1

SC Scan out 1

SU Scan connection (Upper) 1

SD Scan connection (Lower) 1

C1 Data Drive (Lower Right)

C2 Data Drive (Lower Left)

H3 Speaker terminal

S1 Power switch

SS2 Sustain connection (Upper)

SS3 Sustain connection (Lower)

V1 Front SW. & Remote receiver

PF Line filter

P Power supply 1

HX PC_type_Input terminal

HZ (RTB033) RCA Component Video terminal

HV (RTB031) RCA Composite Video terminal

HT (RTB032) 21pin SCART terminal

Remarks

1. Recommend PCB´s for initial service for GP6D chassis.

42WP37

1

– 7 –

Page 8

42WP37

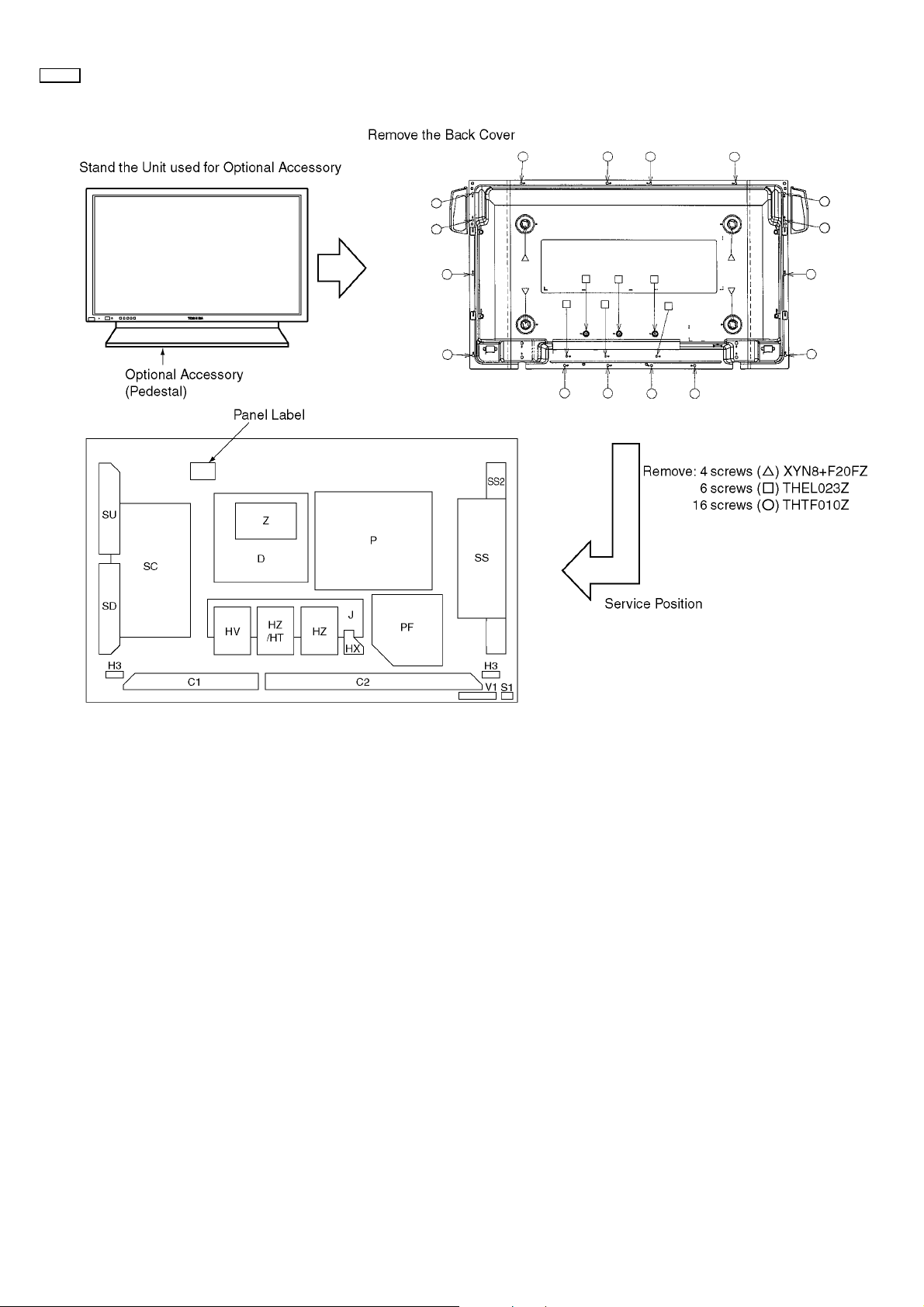

6 Service Hint

SS3

– 8 –

Page 9

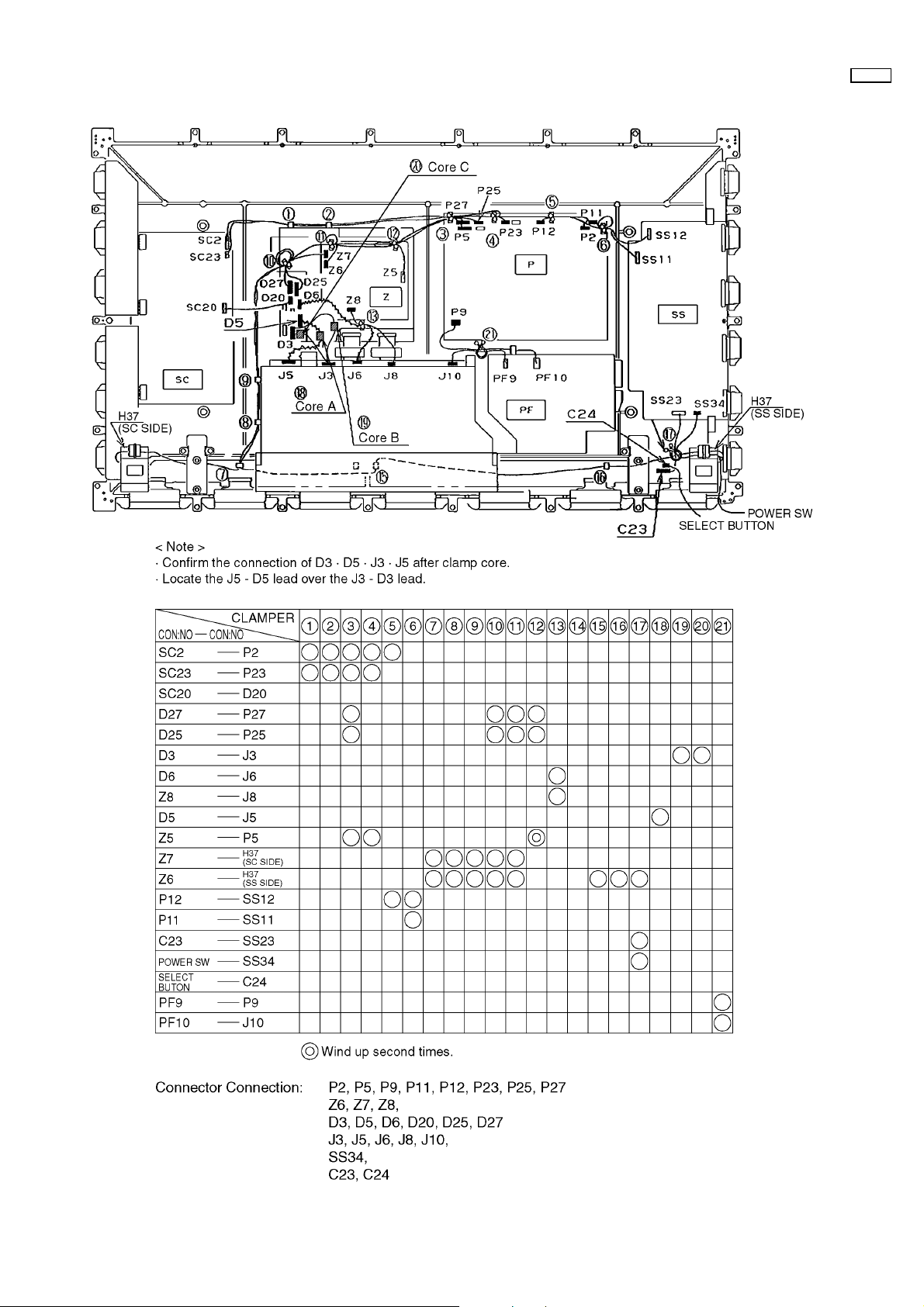

7 Location of Lead Wiring

42WP37

– 9 –

Page 10

42WP37

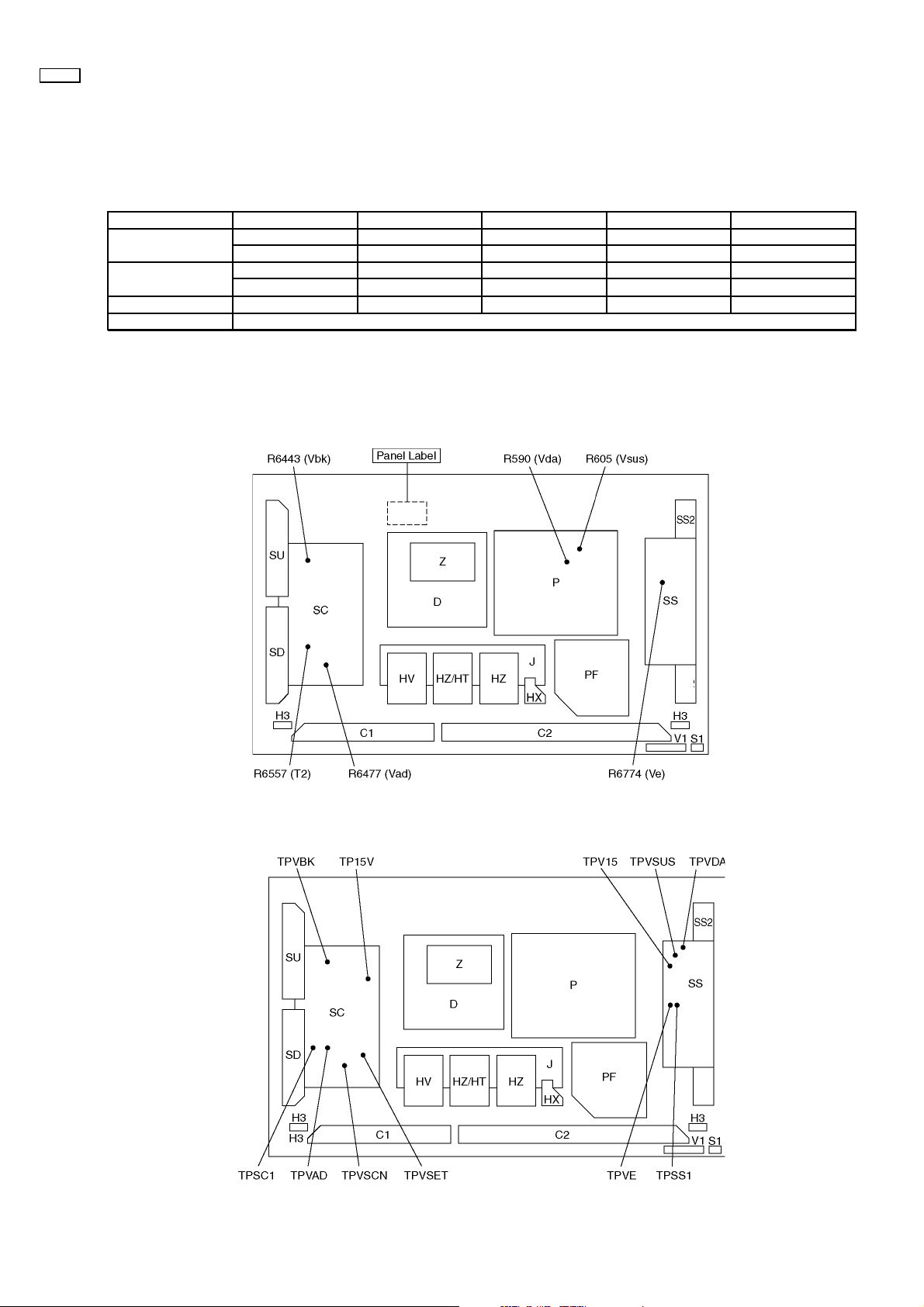

8 Adjustment Procedure

8.1. Driver Set-up

8.1.1. Item / Preparation

1. Input an APL 100 % white signal.

2. Set the picture controls: -

Picture mode: Normal

White balance: Cool

Aspect: 16:9

8.1.2. Adjustments

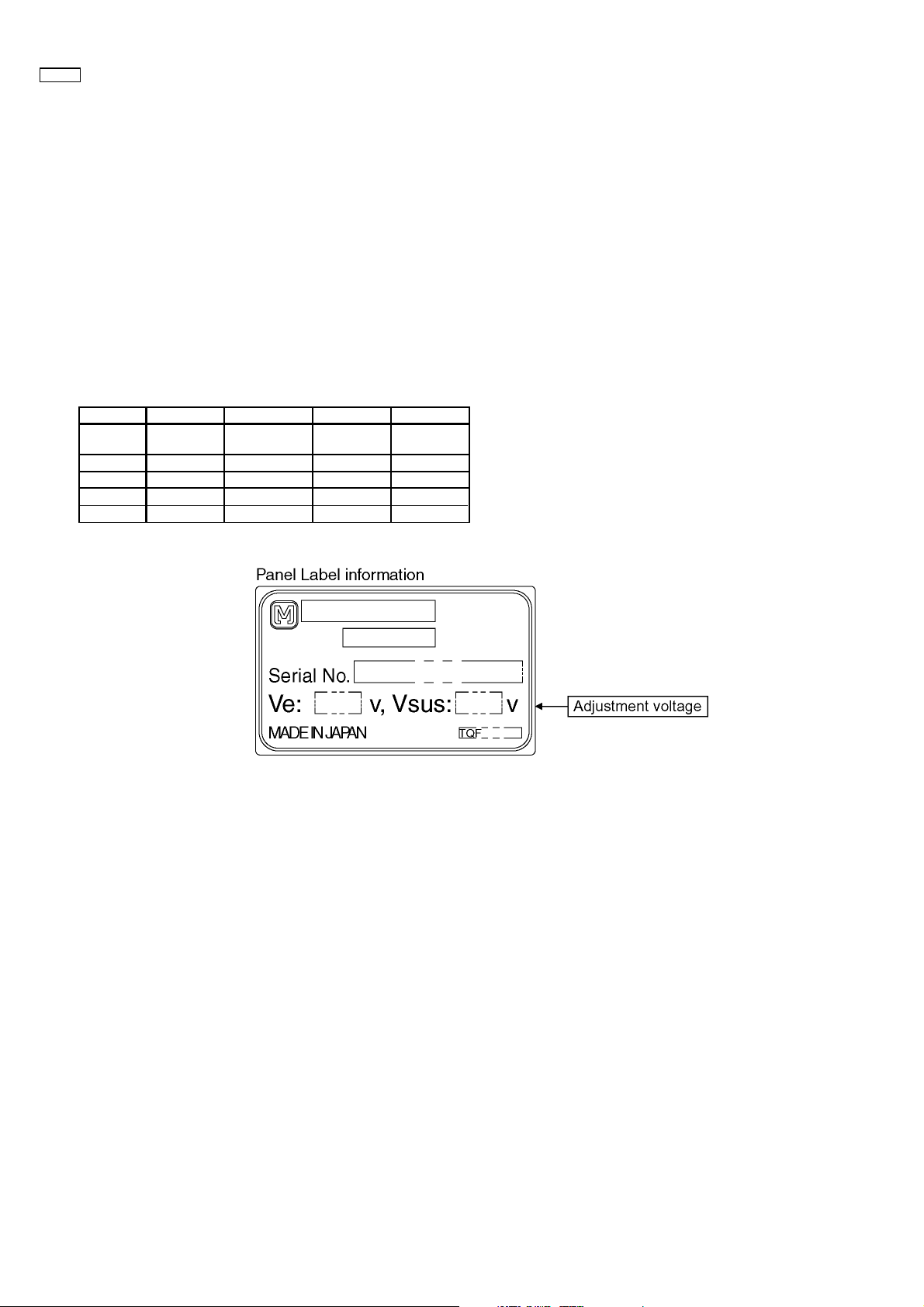

Adjust driver section voltages referring the panel data on the

panel data label.

Use a non conductive tool for adjustment.

Name Test Point Voltage Volume Remarks

Vsus TPVSUS

(SS)

Vbk TPVBK (SC) 155V ± 5V R6443 (SC)

Ve TPVE (SS) Ve* ± 1V R6774 (SS)

Vad TPVA (SC) -90V ± 1V R6477 (SC)

Vda TPVDA (SS) 67V ± 1V R590 (P)

Vsus* ± 1V R605 (P)

*See the Panel label

– 10 –

Page 11

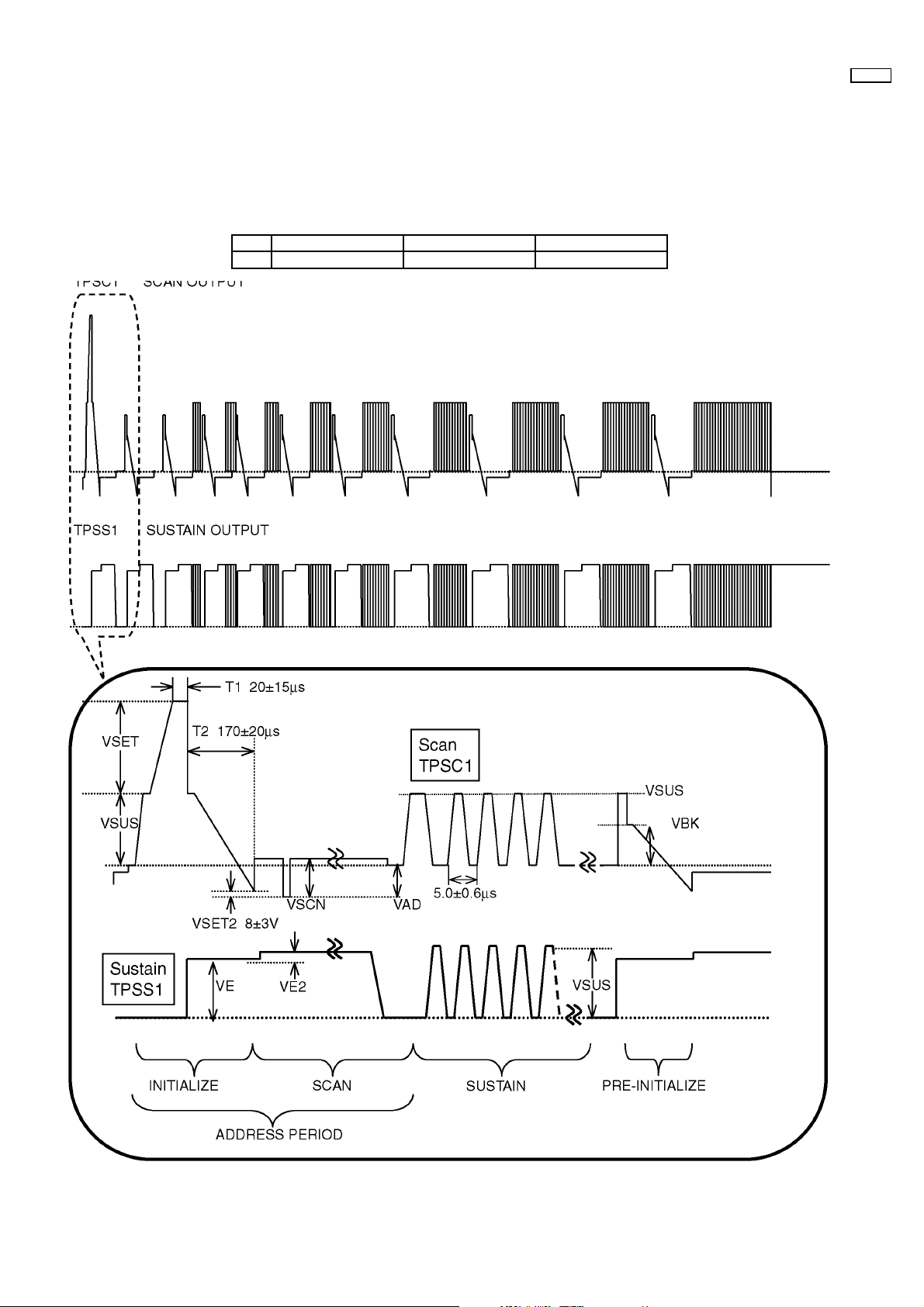

8.2. Initialization Pulse Adjust

1. Input a Cross hatch signal.

2. Set the picture controls: -

Picture mode: Normal

White balance: Cool

Adjust the indicated test point for the specified wave form.

Test point Volume Level

T2 TPSC1 (SC) R6557 (SC) 170 ± 20µ Sec

42WP37

– 11 –

Page 12

42WP37

8.3. P.C.B. (Printed Circuit Board) exchange

8.3.1. Caution

1. To remove P.C.B. , wait 1 minute after power was off for discharge from electrolysis capacitors.

8.3.2. Quick adjustment after P.C.B. exchange

P.C.B. Name Test Point Voltage Volume Remarks

P Board Vsus TPVSUS (SS) Vsus* ± 1V R605 (P)

Vda TPVDA (SS) 67V ± 1V R590 (P)

SC Board Vbk TPVB K (SC) 155V ± 5V R6443 (SC)

Vad TPVAD (SC) -90V ± 1V R6477 (SC)

SS Board Ve TPVE (SS) Ve* ± 1V R6774 (SS)

D Board White blance

*See the Panel label.

8.4. Adjustment Volume Location

8.5. Test Point Location

SS3

SS3

– 12 –

Page 13

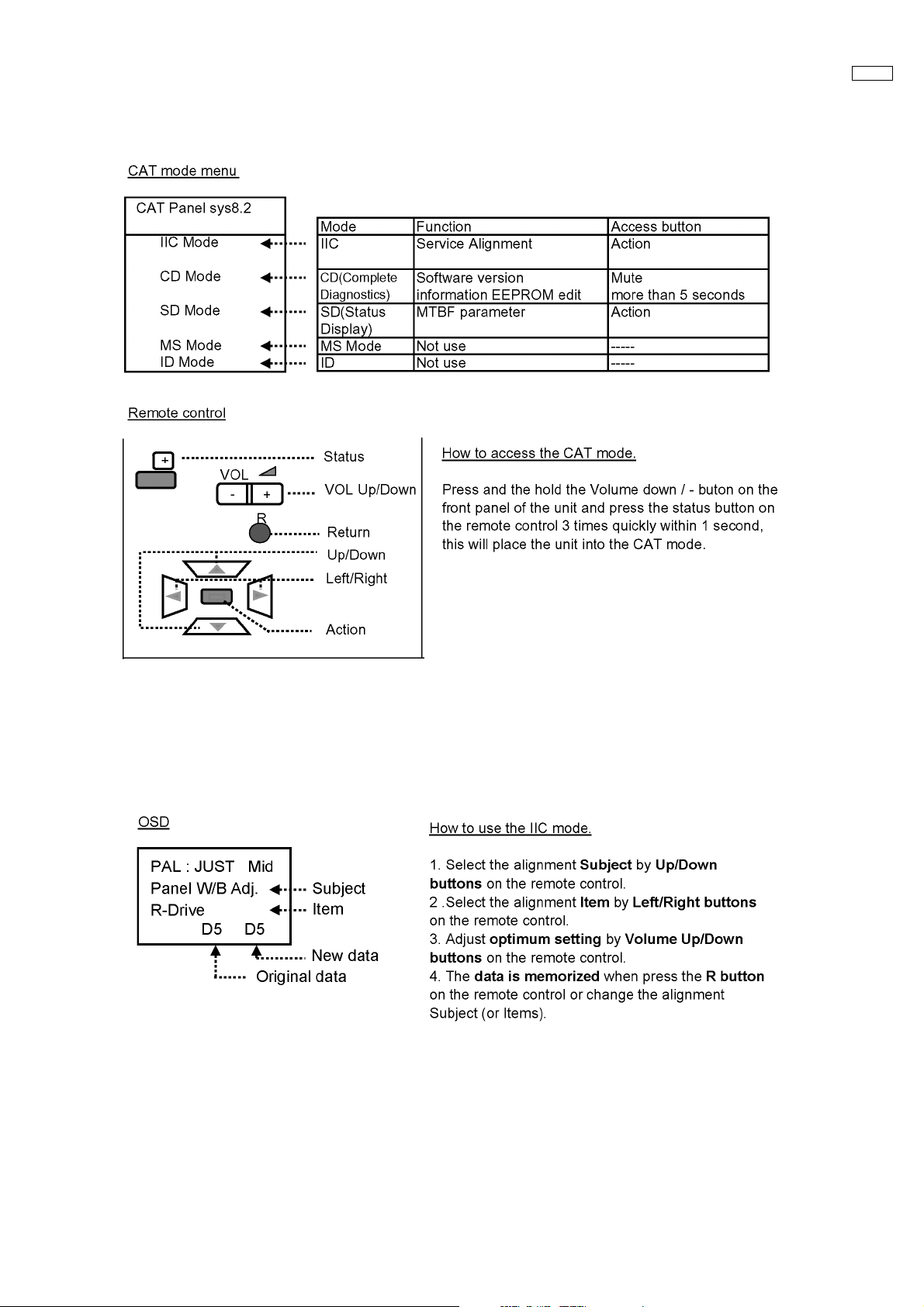

9 Service mode

9.1. CAT (computer Aided Test) mode

42WP37

To exit the CAT mode, access the ID mode and switch off the main power.

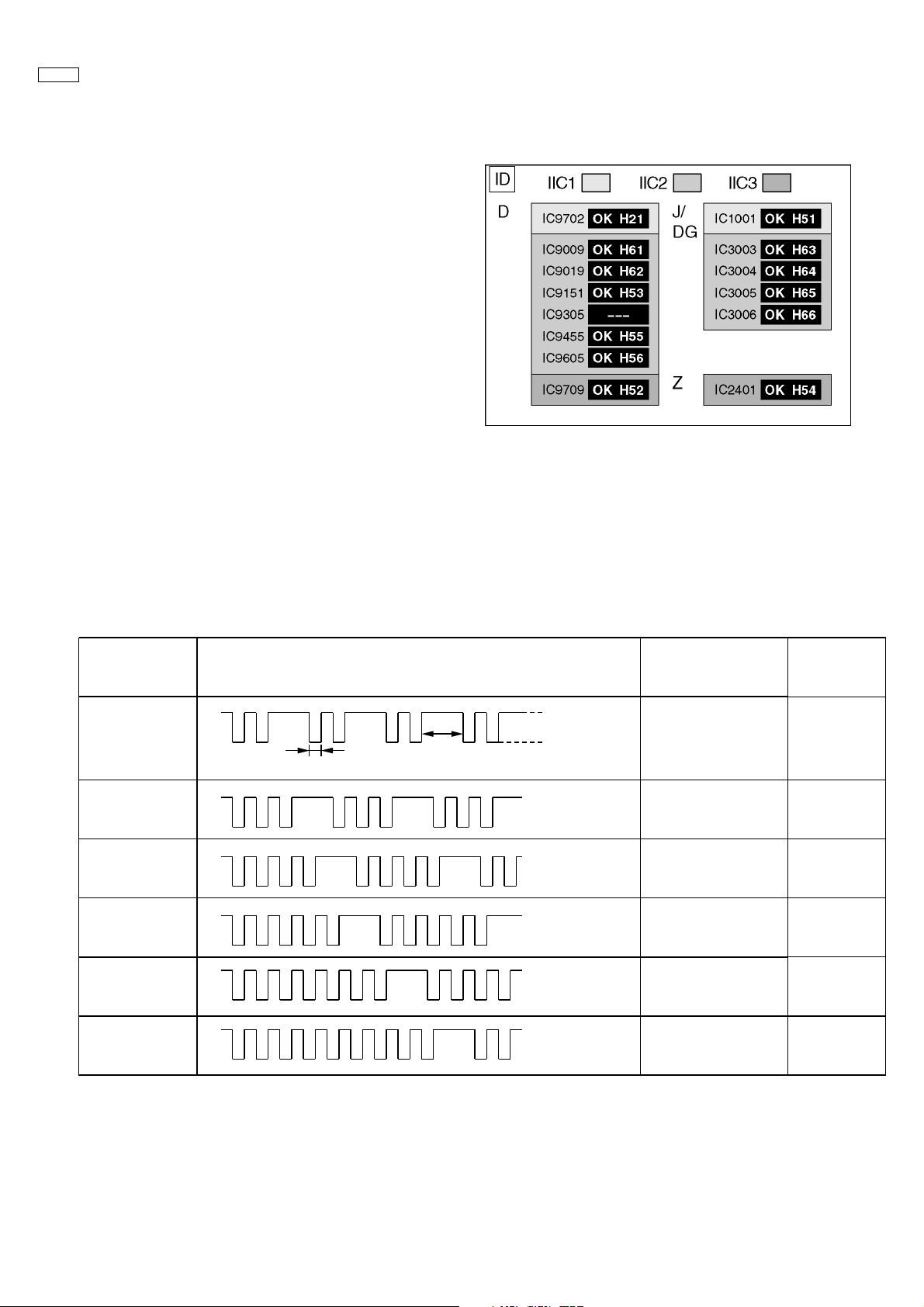

9.1.1. IIC mode

Select the IIC mode by Up/Down button on the remote control at the front page of CAT mode then press the Action button on

the remote control.

Subject and item are mentioned on page 14.

To exit the IIC mode, press the R button on the remote control.

– 13 –

Page 14

42WP37

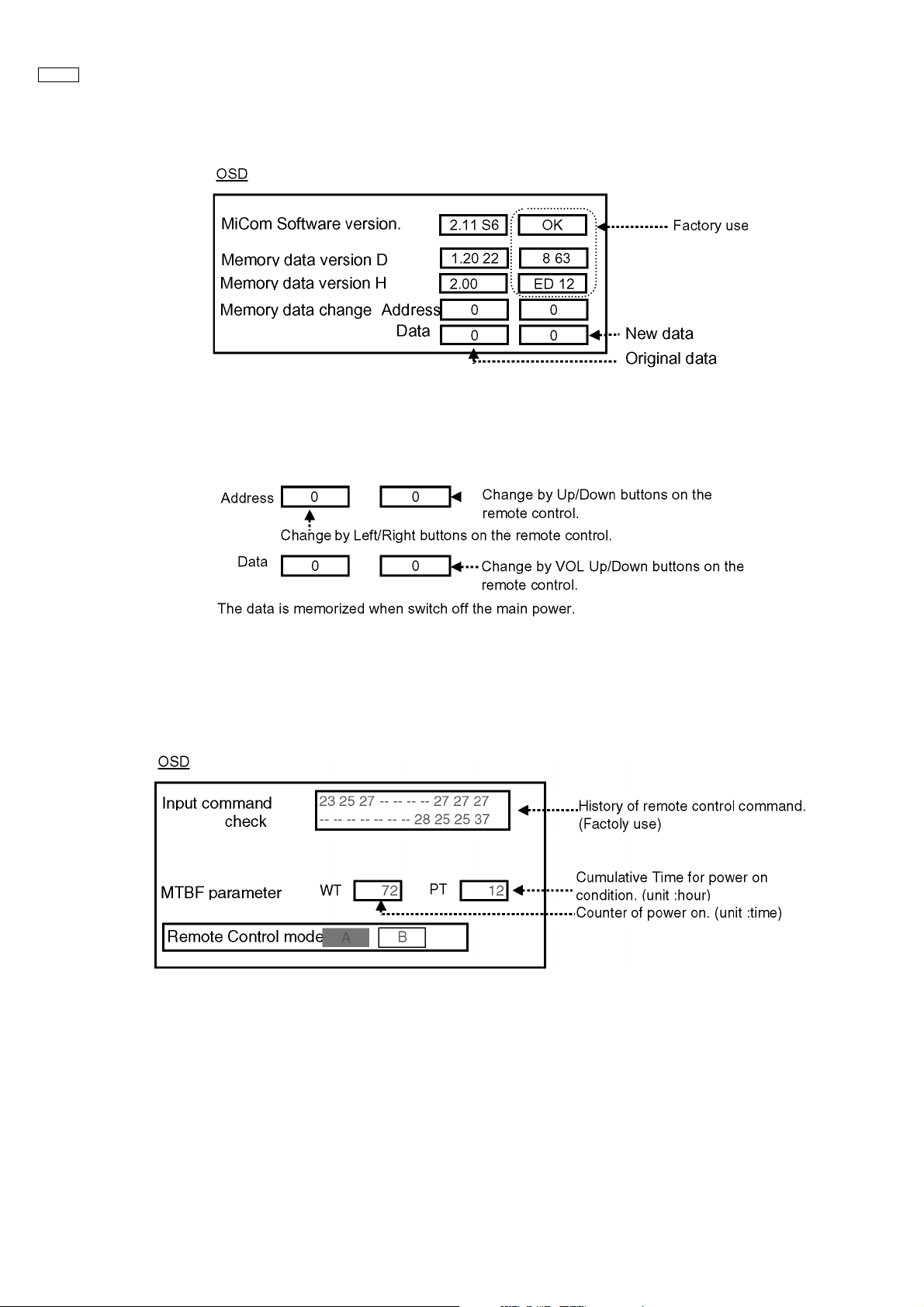

9.1.2. CD mode

Select the CD mode by Up/Down button on the remote control at the front page of CAT mode then press the Mute button on the

remote control more than 5 sec.

Micom software version (IC9705), this version can be upgrade by

1. replace of new version IC

2. Loading the new version software from loader tool, TZSC07036.

Memory data change

To exit the CD mode, press the R button on the remote control.

9.1.3. SD mode

Select the SD mode by Up/Down button on the remote control at the front page of CAT mode then press the Action button on the

remote control.

To exit the SD mode, press the R button on the remote control.

– 14 –

Page 15

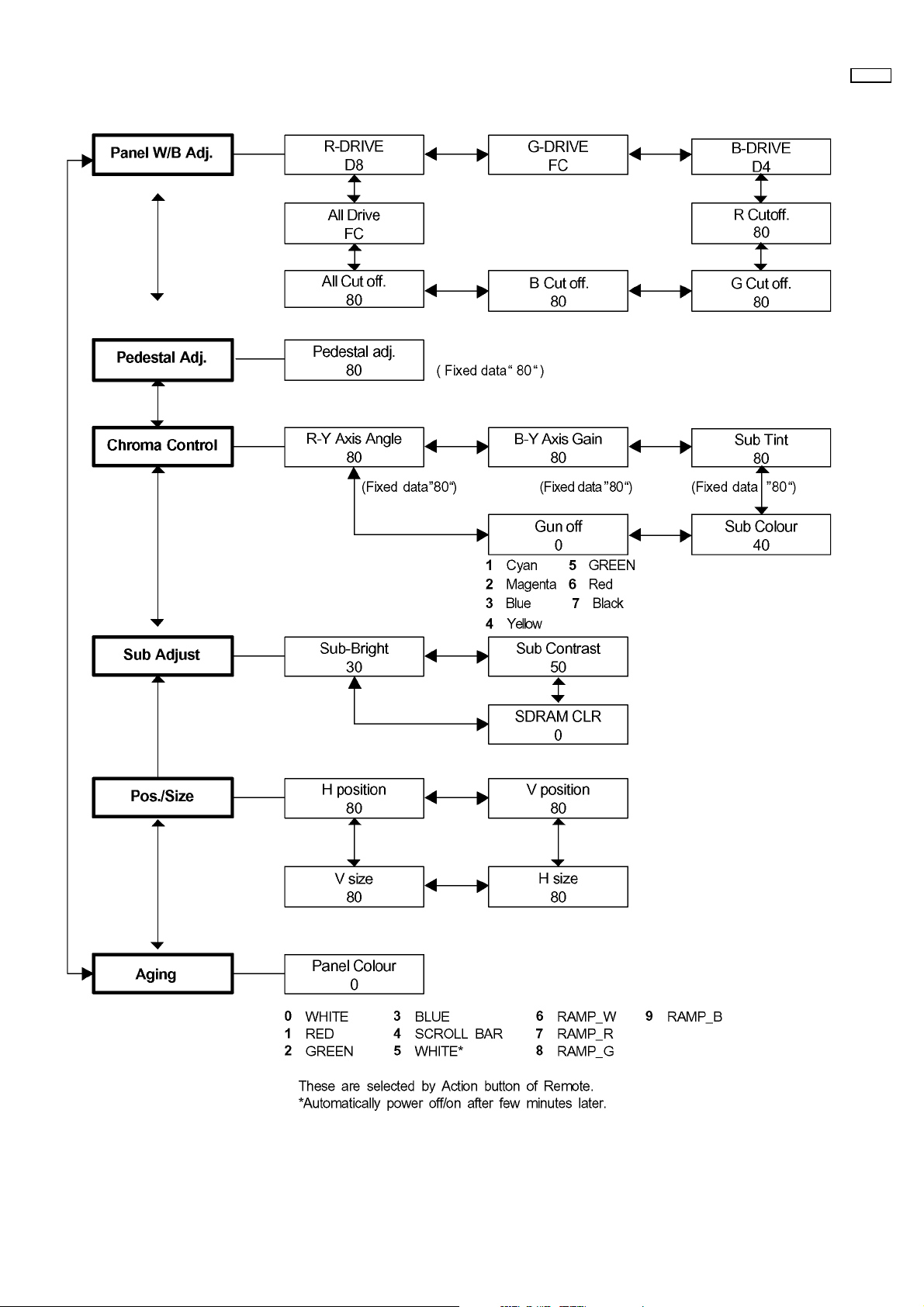

9.2. IIC mode structure (following items value is sample data.)

42WP37

– 15 –

Page 16

42WP37

10 Alignment

10.1. 625i/625p panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PC (625i) Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

Component /RGB-in

Component shown Fig.-02.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

PANEL W/B

PANEL W/B

exactly.

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off

2

to 10 cd/m

6)Find 75% of white area by color sensor.

G Drive 7) Set G Drive to " E8 ".

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-02.

.

2

9) Repeat procedure 4) to 7) to set both Low light and

high light.

PANEL W/B

All Drive 10) Set All Drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

Color Temp. x y

Cool(Hi) 0.276 0.276

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -02

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

– 16 –

Page 17

Alignment menu ProcedureEquipment Setting

5 Picture:PC (525i) 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

Cool

Normal

Warm

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2) Input 525i signal.

3) Copy 625i R,G,B drive and cut off data of each white

balance mode to 525i position.

42WP37

– 17 –

Page 18

42WP37

10.2. PC/RGB panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PC (VGA) Color Picture: 1) Find the nearest area to brightness of 10 cd/m 2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Aspect: PANEL W/B

Component /RGB-in

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

Cool

exactly.

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

RGB shown Fig.-03.

R cut off

to 10 cd/m

2.

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " E8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-03.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

All Drive 10) Set All Drive to "FC".

2

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

Color Temp. x y

Cool(Hi) 0.276 0.276

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -03

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

– 18 –

Page 19

10.3. HD panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1PC(HD:720i or 1080i) Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

Component /RGB-in

Component shown Fig.-04.

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

G Drive 7) Set G Drive to " E8 ".

PANEL W/B

R Drive as shown Fig.-04.

exactly.

2

to 10 cd/m

.

6)Find 75% of white area by color sensor.

B Drive 8) Adjust B and R Drive to set color temperature

42WP37

2

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

All Drive 10) Set All Drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

Color Temp. x y

Cool(Hi) 0.276 0.276

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -04

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

– 19 –

Page 20

42WP37

11 Trouble shooting guide

11.1. Self Check

11.1.1. Display Indication

1. Self-check is used to automatically check the bus line

controlled circuit of the Plasma display.

2. To get into the Self-check mode, press the volume down

button on the customer controls at the front of the set, at the

same time pressing the OFF-TIMER button on the remote

control, and the screen will show :-

If the CCU ports have been checked and found to be incorrect

Or not located then " - - " will appear in place of " OK "

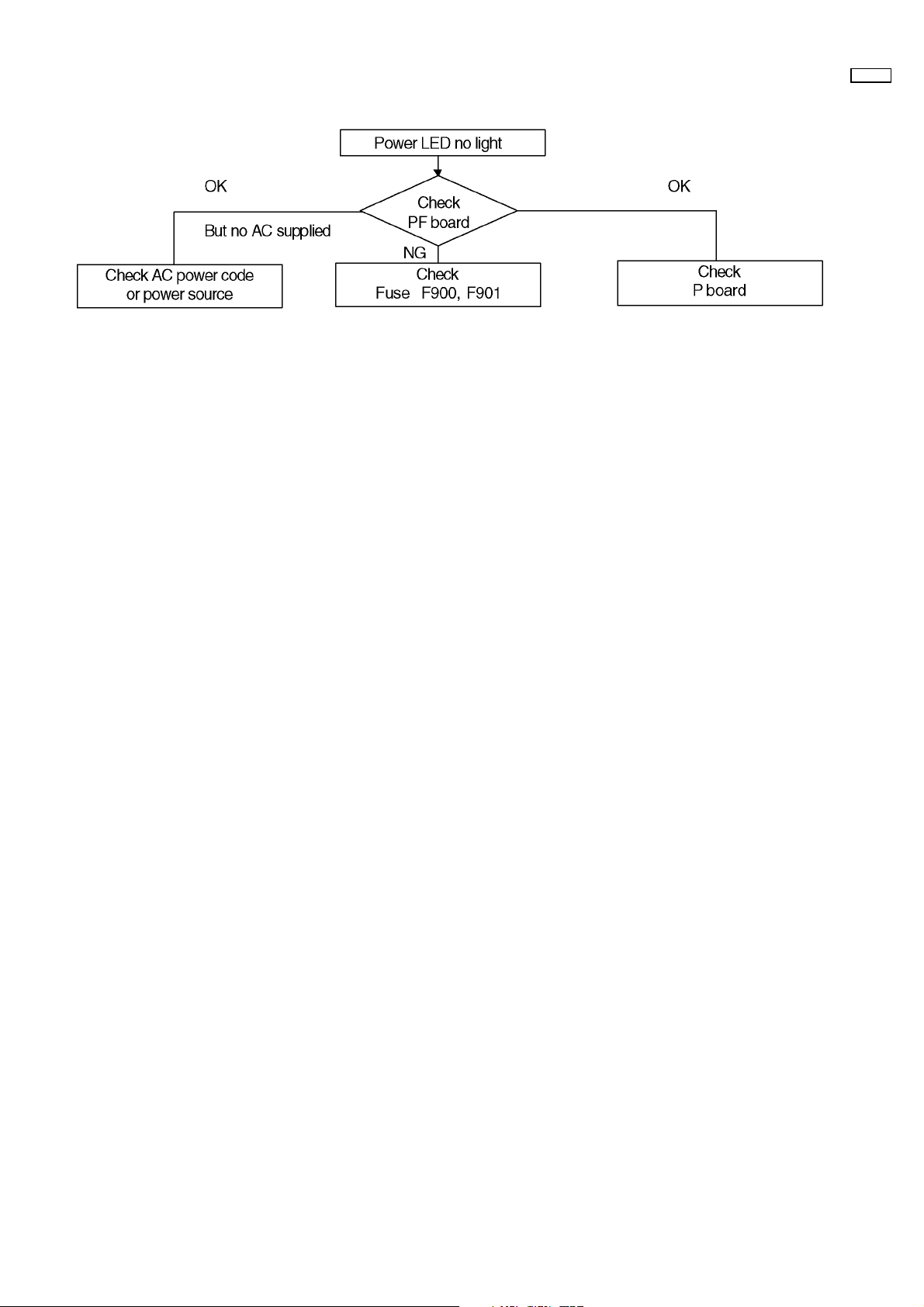

11.2. No Power (Power shut down)

11.2.1. Power LED Blinking timing chart

1. Subject

Information of LED Flashing timing chart.

2. Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinkes of the Power LED on the front panel of the unit.

Blinking

times

2

3

4

5

Blinking timing

Once

3sec

Light

No Light

Contents

SCAN Driver1

3.3V SOS

5V SOS

Power SOS

Board

Name

SC,SU,SD

D

D,P

P

7

9

SCAN Driver2

SUS Driver

SC

SS

– 20 –

Page 21

11.2.2. Power LED no light

42WP37

– 21 –

Page 22

42WP37

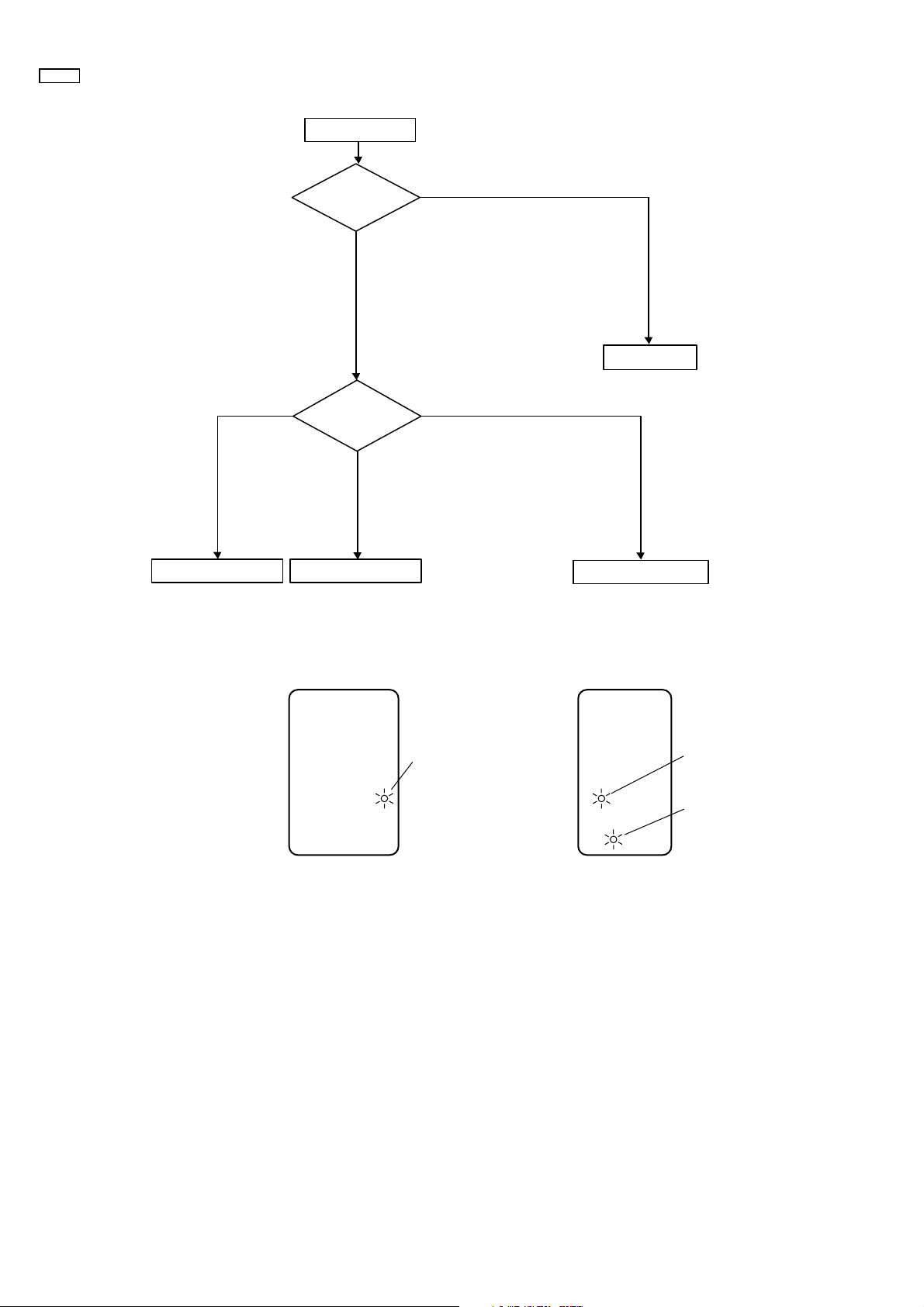

11.3. No Picture

No Picture

Composit/ COMPONENT/ RGB

What's signal ?

HY/ HZ / HT

board

Drive circuits LED indicator

Check

OSD

D, J

OK

all signal

board

NG

PC signal

D board

HX board

SC board SS board

D6583

D6769

(15V detection)

D6765

– 22 –

Page 23

11.4. Local screen failure

Plasma display may have local area failure on the screen. Fig - 1 is the possible defect P.C.B. for each local area.

42WP37

Fig - 1

– 23 –

Page 24

42WP37

– 24 –

Page 25

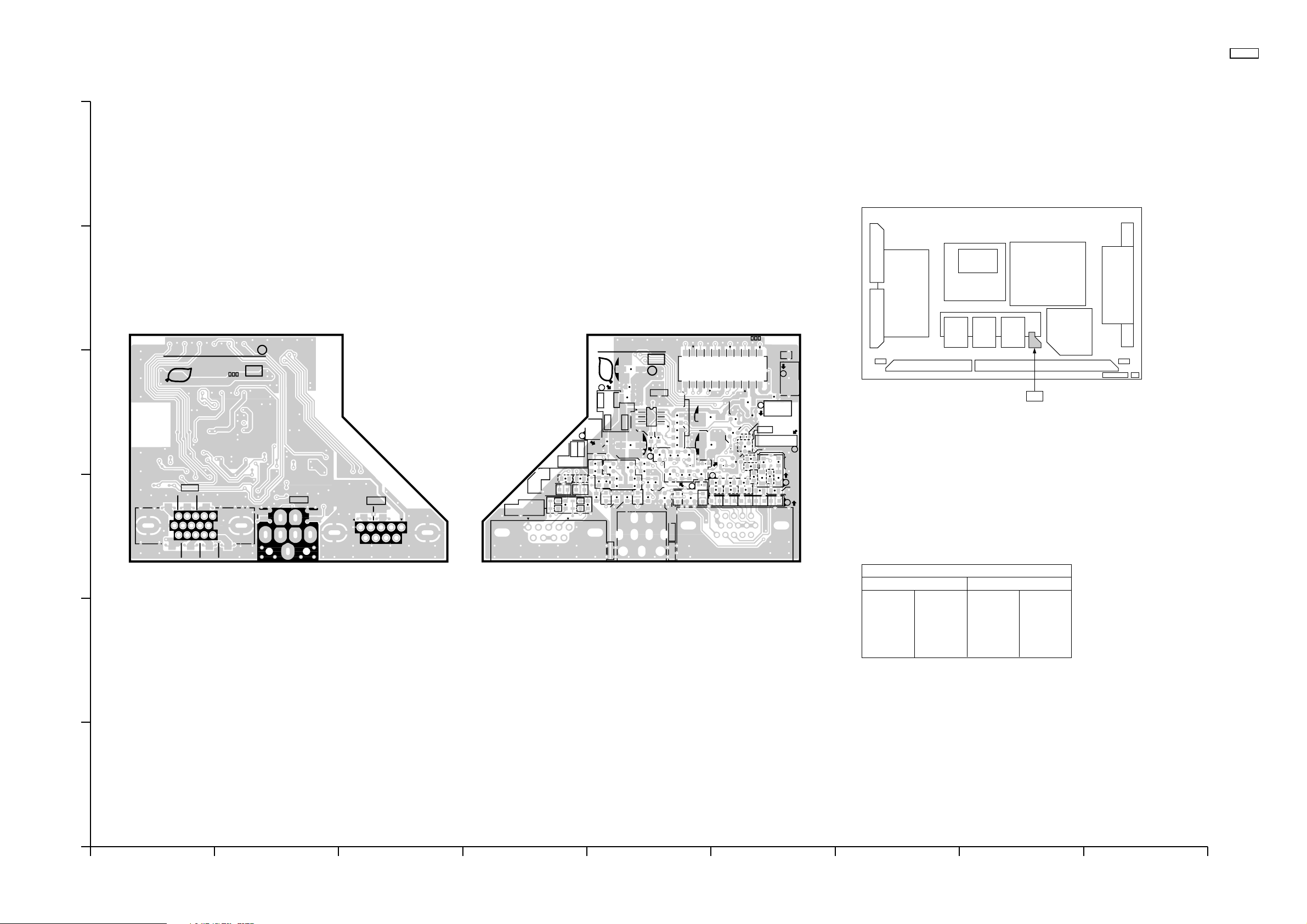

12 Conductor Views

12.1. PF-Board

6

PF-BOARD

TXNPF10QBS

42WP37

C902

C912

C903

5

6

PF10

TP902

1

D921

R928

D923

TP903

4

COLD

R923

R924

R925

C924

R922

R920

D907

C923

R921

IC902

D922

TP901

A

K

Q903

R

R926

D920

C920

L904

R927

TP904

C925

C921

S1

3

V2

V1

R906

C915

D904

2

D906

C917

R907

C918

C916

R905

PF9

C922

S

RL901

T901

S2

C

D903

C914

1

LIVE CIRCUIT

4

T3.15AL250V

CAUTION

PTP2

P1

HOT

D

IC901

L906

R904

F902

C919

1

PF1

4

HOT

R903

-

D902

LIVE CIRCUIT

C913

CAUTION

T8AH250V

D901

T8AH250V

CAUTION

R902

L902

L905

+

C905

F900

R901

F901

SEE REVERSE FOR ORDER NO.

C906

1

TNPA2813

COLD

C901

PF

C904

L901

PbF

94V-0

Parts Location

IC

IC901 B-2

IC902 A-4

TRANSISTOR

Q903 B-4

PF-BOARD

TP

TP901 B-4

TP902 A-5

TP903 A-4

TP904 B-4

PF

1

PF-BOARD TXNPF10QBS PF-BOARD TXNPF10QBS

ABCDEFGH I

– 25 –

Page 26

42WP37

12.2. P-Board

P-BOARD(FOIL SIDE)

TNPA2841AB

6

5

P11

1

P2

R600

R597

C566

D570

D567

4

IC558

S1

R555

R598

COLD

D572

STA STB

7

16

C573

PTAP1

R552

D590

Q555

R613

R554

C569

R617

R614

D583

D584

R616

D585

R587

C574

C575

R592

S2 S4 S3

T501

P2PTB

Q557

R602

R603

D571

R584

D596

D594

COLD

R604

R605

R591

R606

R

A

R581

C561

D564

R573

C555

C568

K

L551

R585

D565

Vsus

C563

D559

R580

R561

R590

Vda

R589

R635

R588

R583

TPP1

94V-0

D595

R626

R623

R625

D592

D593

D586

IC553

V2

V1

P12

5

1

R610

KRA

IC554

Q552

G

D

S

IC557

A

K

R

C567

R582

R586

D566

C562

C578

R611

R609

D580

D578

R612

EBC

R593

Q553

R596

R599

R594

R595

R608

D579

Q554

B

C

E

R607

R601

D575

D576

C565

D574

D577

C571

D660

D661

S8S7S9S5S6S3S4S2S1

T502

P2

P1

PT

V4

V2

V3

V1

C591

14

C577

R621

P7

C590

13

P25

P10

D587

3

2

1

P1PT

8

111

5

L554

D589

C579

R618

C414

R620

S1 S2

V1

V2

V3

L401

R411

D407

P23

C422

C421

R619

C572

C564

R562

D568

D581

D582

L552

C576

D573

C570

1

1

COLD

C581

IC555

R559

5

4

C583

R615

T401

P2

D

D406

C

IC401

LIVE CIRCUIT

R563

HOT

C548

D550

IC550

2

3

1

1

R630

Q558

R631

R419

R418

D409

C416

R415

R416

KRA

V4

C411

C410

S

D405

P5

C412

P27

R628

IC402

C415

C417

Q406

C423

C407

C587

9

C586

C585

C584

R627

D410

R414

EBC

D411

R571

C409

R420

R422

C

B

Q404

R421

R417

C420

C418

C413

R428

R426

R413

R412

D408

Q405

R436

D413

R435

BC

E

R434

R407

R410

R408

R433

C403

TP50

TP51

D412

E

C419

IC403

312

R427

Q403

EBC

R424

Q402

E

C

R423

B

Q401

EBC

R425

R432

PbF

R431

R430

R429

P30

PFC

R462

R578

R572

C559

R475

R471

D454

R480

R474

R479

R473

R478

R472

R579

R650

D560

C554

D551

Q457

Q456

B

R489

R487

R488

D561

R575

R654

R493

C

B

C

R490

R491

EBC

Q455

D458

D459

R486

C558

3

D553

C551

1

2

3

R557

4

5

C550

IC551

R565

D557

2

R483

C469

R550

R560

R484

C557

R568

R577

R570

C470

R574

R502

R503

R567

D555

R485

C556

D562

D650

D651

R657

D654

R655

C

E

B

Q651

C

B

R656

E

E

Q650

E

R653

R492

C471

D460

R556

D552

D558

C468

D556

C553

R566

D

R558

D554

D563

C552

1

2

3

4

5

IC552

R564

R551

R576

R553

R569

C560

HOT

C467

D457

G

D455

R464

R463

S

Q451

C466

L452

Q454

G

R468

D456

D

R467

S

D462

R652

D652

TNPA2841

SEE REVERSE FOR ORDER NO.

R477

R476

R504

C459

R469

B

B

Q452

Q453

C

C

L451

C456

R456

D453

9

R466

R470

8

E

D463

E

R451

C452

C451

C453

C454

R409

C408

C406

C405

C455

R404

R402

C549

C650

C462

C465

C457

R465

R461

C472

C463

R494

IC451

R481

C464

D452

1

P

C461

HOT

16

R453

C460

R460

C458

R459

1

R482

+

-

D451

R452

R458

R457

R455

R454

C404

C401

RL401

C402

D404

RL403

RL402

TP008

R406

1

D401

D403

D402

P9

3

TP009

1

P-BOARD TNPA2841AB P-BOARD TNPA2841AB

ABCDEFGH I

– 26 –

Page 27

P-BOARD(COMPONENT SIDE)

TNPA2841AB

42WP37

P27

COLD

1

IC554

Q552

Vda

R590

P

HOT

D563

R576

R569

3

PMM2

L551

C563

R580

C555

IC552

1

5

C560

IC553

D565

C468

R605

ARK

2

4

G

D

S

IC557

ARK

D566

TPP1

94V-0

1

D

D

1

C581

134

COLD

P1 PT

DIP

R409

C408

C452

C451

D451

R404

D406

1

P10

IC555

52

C453

P25

C454

P12

S4

P2

ORDER

C578

5

ARK

C

Q553

E

B

R594

R595

S1

S2

PT

P1

NO.

C577

C590

D568

1

4

COLD

P7

D574

C591

D660

T502

V2

3

C548

R563

C571

S7S8

V1 V3

Q554

C565

S3

S6S5S9

V4

TNPA2841

3

L552

C421

C564

C422

1

1

IC550

2

P23

PMM4

C572

C576

C570

D573

P2

HOT

LIVE CIRCUIT

L451

R463

R467

R464

C466

G

S

R468

Q451

G

S

Q454

R652

R578

C549

C650

C462

C465

C457

IC451

16

+

1

C464

9

Q452

Q453

C456

8

R572

R469

C559

R456

PFC

P30

C459

L452

R475

R462

-

R458

R452

R451

R455

6

C419

3

5

Q403

Q402

Q401

PbF

4

3

PMM3

Q404

2

1

C420

D408

C403

C402

R406

IC403

Q406

9

11

R628

C409

R412

C585

C413

C417

C418

R

A

K

Q558

C412

D404

IC402

C410

RL401

P5

V4

S

1

C416

T401

V3 V2

IC401

C406

C404

8

1

5

L554

C579

C414

S2

S1

V1

L401

R411

D

C

C405

HOT

C455

2

RL403

RL402

Q557

Q555

IC558

K

R554

C574

C575

Vsus

T501

R592

R587

V2 V1 P2 PTB PTA P1

C556

D558

R650

Q650

D552

C471

R655

Q651

R579

R570

Q455

R577

Q457

Q456

C470

R485

R

A

6

R552

1

P11

1

R600

R597

7

R598

P2

PMM1

C573

C566

D551

C569

C557

R574

R568

D560

S1STASTBS2S4S3

IC551

R550

R560

R483

C558

3

D557

D570

D567

1

2

4

5

C469

3

1

P9

1

C401

R402

R454

R457

D462

D457

C467

R553

R551

P-BOARD TNPA2841AB P-BOARD TNPA2841AB

ABCDEFGH I

– 27 –

Page 28

42WP37

P

Parts Location

IC

IC401 G-4

IC402 H-5

IC403 H-5

IC451 F-3

IC550 F-4

IC551 B-3

IC552 D-2

IC553 D-5

IC554 E-6

IC555 G-5

IC557 D-5

IC558 C-6

P-BOARD (FOIL SIDE)

TRANSISTOR TP

Q401 H-5

Q402 H-5

Q403 H-5

Q404 H-5

Q405 H-4

Q406 H-4

Q451 E-3

Q452 F-2

Q453 F-2

Q454 E-2

Q455 C-2

Q456 C-3

Q457 C-3

Q552 D-6

Q553 E-6

Q554 E-6

Q555 C-6

Q557 D-6

Q558 H-5

Q650 C-3

Q651 C-3

TP008 H-1

TP009 H-1

TP50 H-6

TP61 H-5

TPP1 D-4

Parts Location

IC

IC401 C-4

IC402 B-5

IC403 B-5

IC451 D-3

IC550 D-4

IC551 H-3

IC552 F-3

IC553 F-5

IC554 E-6

IC555 C-5

IC557 F-5

IC558 G-6

P-BOARD (COMPONENT SIDE)

TRANSISTOR TP

Q401 B-5

Q402 B-5

Q403 B-5

Q404 B-5

Q406 B-4

Q451 E-3

Q452 D-2

Q453 D-2

Q454 E-2

Q455 G-2

Q456 G-2

Q457 G-3

Q552 F-6

Q553 E-6

Q554 E-6

Q555 G-6

Q557 G-6

Q558 B-5

Q650 G-2

Q651 G-3

TPP1 F-4

P-BOARD PARTS LOCATION P-BOARD PARTS LOCATION

– 28 –

Page 29

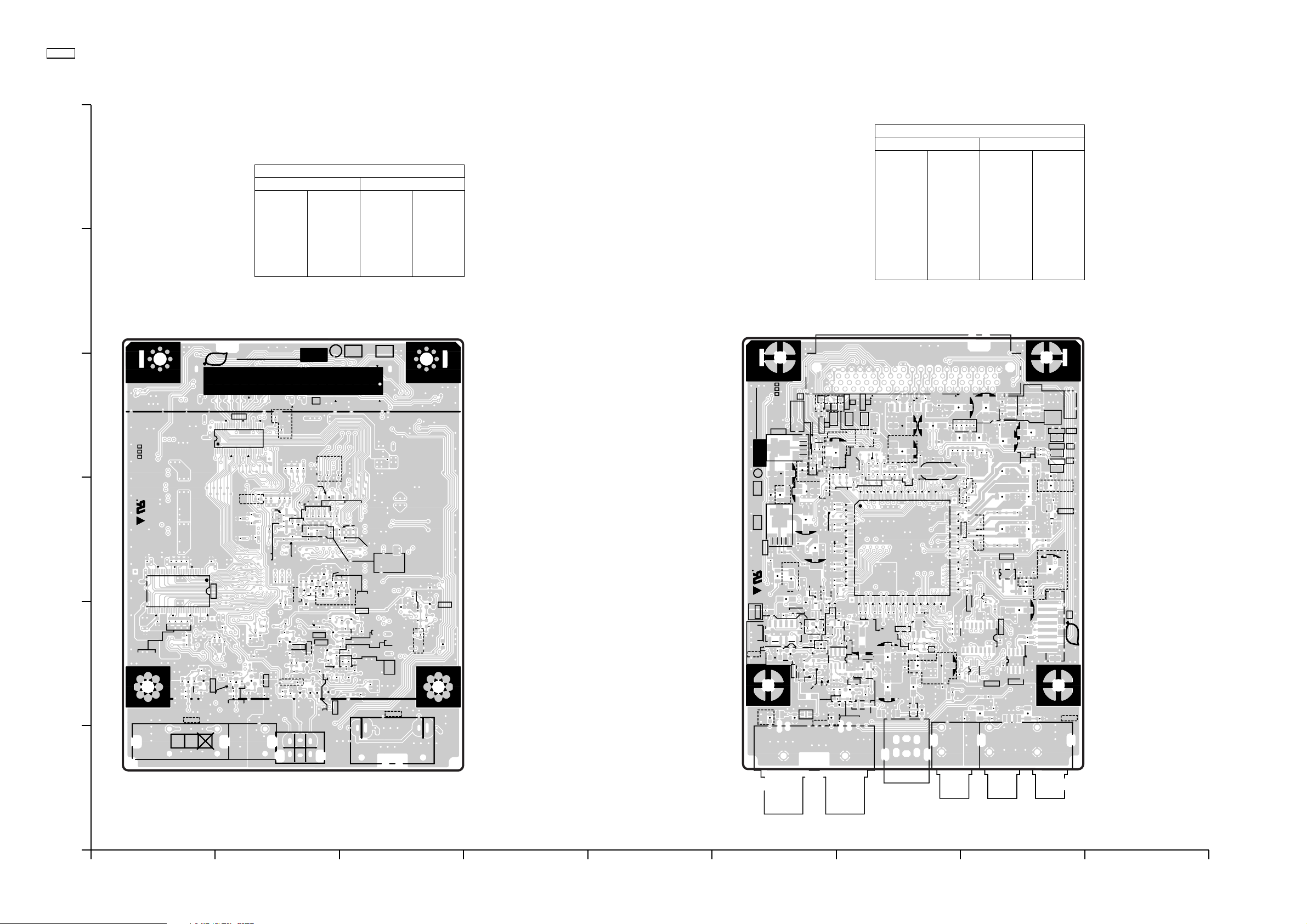

12.3. HX-Board

6

5

HX-BOARD(FOIL SIDE)

TZTNP02SBSE

TNPA2842

SEE REVERSE FOR ORDER NO.

PbF

4

1

6

3

2

11

JK511

CR NO.3

42WP37

HX-BOARD(COMPONENT SIDE)

TZTNP02SBSE

C564

C523

NO.

CR NO.3

D502

R787

R786

E

D506

111

HX1

D

R780

R785

C409

22

L526

C

D504

R794

Q537

R593

D505

R791

C566

C567

R790

L511

L507

L508

L509

L510

R591

R592

R526R527R528

E

R792

C565

D

R509

R508

C

1

HX

Parts Location

HX-BOARD

IC

IC3502 E-4 Q3531 D-4

TRANSISTOR

Q3532 D-4

Q3533 E-4

Q3534 E-4

Q3535 E-4

Q3536 E-4

Q3537 F-4

A

1

R586

HX

IC502

R664

ORDER

12

R400

R589

R778

8

C524

R585

5

R656

C562

B

5

D501

JK511

JK513

1

TNPA2842

PbF

HX

C551

R781

Q534

1

6

R788

R529

R784

JK509

R783

R672

R530

Q535

R782

C563

C405

C404

L555

1

Q536

R590

4

R548

L513

A

Q533

R789

B

L517

L516

D503

C550

Q531

Q532

R776 R777

R653

R511

R538

L514

R537

R655

R547

L512

R668

R663

R654

C561

JK513

5

10

15

JK509

15

6

9

5

9

D507

D508

R510

D509

D510

L515

1

HX-BOARD TZTNP02SBSE HX-BOARD TZTNP02SBSE

ABCDEFGH I

– 29 –

Page 30

42WP37

12.4. HV-Board

6

Parts Location

IC

IC3201 A-3

IC3251 B-4

HV-BOARD

TRANSISTOR

Q3002 B-2

Q3004 B-2

Q3006 B-2

Q3007 C-2

Q3051 B-2

Q3052 A-2

Q3101 B-2

Q3102 C-2

Q3104 B-2

Parts Location

IC

IC3001 G-2

IC3002 F-2

IC3003 G-2

IC3101 F-3

IC3102 G-2

IC3103 G-3

IC3104 F-2

IC3105 H-3

IC3301 H-3

IC3302 F-4

IC3303 H-3

IC3304 H-2

IC3305 H-2

IC3699 H-2

HV-BOARD

TRANSISTOR

Q3001 G-2

Q3003 F-2

Q3005 F-2

5

RTB031

HV-BOARD(FOIL SIDE)

TXNHV10QWS

1

HV

PbF

1

C202

IC201

70

R314

Q052

JK005

56

R315

R313

R051

C053

L

TNPA2844

IC251

R188

C154

C152

C149

C134

C137

R302

R304

R193

R131

JS306

R319

C055

R057

R059

JS310

GRB

28

C171

C153

C151

C150

R192

R053

R053

ORDER

29

C170

C172

R151

R125

R141

R140

R104

R117

C006

Q051

Q051

R008

R009

NO.

C251

C169

C135

R013

R017

H1

C252

R163

R165

R164

C167

C168

R156

R172

R157

R152

C136

R118

R114

C121

R130

R136

R129

R108

R102

Q104

R012

R027

R063

R006

D002

R310

R312

R311

C162

R170

R171

R169

C178

C173

R177

R134

R135

C112

C119

C115

C001

R127

R128

R132

R119

R106

Q101

Q002

Q006

R043

C017

R032

R037

R003

R004

Q004

R030

R020

JK001

CY

A1

A2

4

CR No.3

94V-0

3

C206

35

36

C212

C212

C213

C213

2

SLOT

C204

C203

C205

C208

1

C209

R307

R308

C214

C214

C211

C211

R

R

R

C210

R303

R309

C056

R055

R056

R052

R058

R054

R060

C054

JK004

12 3

HB

A39

A40

B39

B40

R120

C177

C176

C174

C175

C181

R178

C180

R180

R153

R173

R179

C140

JS305

C120

R126

C109

R133

Q102

R115

R107

R101

R042

C015

L005

R026

R007

C016

C022

JK002

R044

JS304

R047

C021

R040

L007

Q007

R046

R045

R041

R050

R039

RTB031

HV-BOARD(COMPONENT SIDE)

TXNHV10QWS

A39

A40

IC002

B39

B40

H1

C311

R301

R300

CR No.3

R159

IC104

TS302

5

C184

1

1

L105

R175

R176

R161

C165

C182

C159

C159

5

C127

Q003

R014

R014

C004

C004

C161

C144

C179

C142

C133

C160

C103

C132

C129

C105

R113

C128

C126

C125

R144

R145

64

64

R146

R142

R142

R143

R143

JS302

JS302

4

5

1

1

R036

12

R049

C007

R018

R021

R064

R031

R031

3

4

5

3

1

4

1

R025

8

5

NP

R023

R015

L003

C002

C005

R010

R011

R002

JK002

IC302

C308

L106

R185

1

IC101

R112

C020

C102

C019

C018

NP

NP

JS301

R038

L006

6

7

R028

Q023

C024

R001

TS301

R182

Q001

R174

R166

256

1

IC001

GBR

R167

R160

C163

65

65

IC003

IC003

5

5

C008

1

1

L001

R016

C330

TS303

L308

C325

R116

C187

D303

D302

D304

D301

R181

C166

C164

C164

R168

C110

C110

C113

C113

R121

R121

C111

C111

R029

R029

IC102

IC102

C114

C114

C104

C104

R122

R122

C108

C108

C023

C023

C107

C107

C014

C014

4

4

3

3

R022

R022

R019

R024

C012

C012

C

JK001

C329

C321

L307

C261

C185

C186

R183

R184

R162

C183

C117

C117

C106

C116

C106

C116

R123

R123

R065

R065

C013

C013

C011

C011

L004

C326

C009

C003

NP

R005

L002

Y

JK005

SEE REVERSE FOR ORDERNO.

TNPA2844

1

HV

HB

94V-0

Q005

R035

C122

C010

R033

R034

R048

A1A2B1 B2

C324

C320

R252

C264

R253

L251

C255

C255 C264

C256

X101

193

192

192

IC103

129

128

C123

C118

89

R139

R138

R138

R124

R124

R137

R137

D001

D001

9

C301

JS303

R061

JS309

C322

C266

L252

C263

C260

C262

C259

C157

R251

C156

C155

C147

R158

R155

C158

C138

C146

C145

C139

C143

R154

C131

IC301

4

4

C130

R189

C216

C124

1

1

14

R195

IC105

5

R194

C188

1

IC305

5

5

8

8

C316

16

C317

IC304

1

4

R062

L051

JS308

B

C051

L306

C328

C319

C265

C323

R255

R254

L104

L103

L103

C148

L102

C141

3

3

C218

C217

R208

2

2

L201

18

1

C207

R337

8

5

R338

1

4

IC699

L052

L

L

C052

325

325

C215

C254

TS100

TS101

TS102

RGR

R

C327

L305

C318

C253

C258

C257

GND

VD

HD

R305

R305

L303

L303

C313

C313

IC303

1

1

C309

R149

R148

C219

H0

PbF

JK004

1

HV-BOARD TXNHV10QWSHV-BOARD TXNHV10QWS

ABCDEFGH I

– 30 –

Page 31

12.5. HZ-Board

42WP37

6

IC

IC3001 G-3

IC3002 H-3

Parts Location

HZ-BOARD

IC

IC3002 A-3

TRANSISTOR

Q3001 G-2

Q3002 H-2

HZ-BOARD

TP

TP032 F-4

TP033 G-4

TP034 G-4

TP035 G-4

TP036 G-4

5

Parts Location

RTB033

HZ-BOARD(FOIL SIDE)

TXNHZ10RCS

TNPA2952

A1

A2

PbF

B1

CR NO.3

4

5

B2

4

1

IC002

8

ORDER

NO.

H1

3

2

JK002

R

L

R

Pr

JK001

HZ

1

A39

A40

B39

B40

B

Pb

GR

Y

RTB033

HZ-BOARD(COMPONENT SIDE)

TXNHZ10RCS

CR NO.3

JS014

R043

PbF

JS001

C016

HZ

TNPA2952

SEE REVERSE FOR ORDERNO.

JS002

R008

R009

R046

C024

1

JS003

C002

C001

A40

TP032

Y

R038

R029

R020

C009

R001

Y

A39

B39

B40

C017

C020

C019

R021

C003

NP

JS011

L001

GR B

R039

JS015

R044

R034

R010R011

C025

R002

TP034

TP033

Pr

Pb

JS016

R035

C014

16

9

8

1

IC001

R047

C013

C005

C004

NP

JS012

R003

L002

R045

R031

Pb

R040

C015

R032

R030

TP035

RL

L007

JS013

JK001

C018

R033

TP036

R041

R027 R028

NP

L003

C022

R012 R013

C026

C006

H1

R042

R024

R048

R

Pr

JS009

C023

JS004

L006

JS005

JS006

C011

C012

R025

R022

C010

Q001

R016

R018

R017

C008

R007

L004

JK002

LR

A2

B2

JS007

JS008

JS010

IC002

58

R037

D003D004

R023

R026

Q002

R014

R019

R015

C007

R006

L005

R004

A1

B1

14

C021

R036

D001

D002

H0

1

8

R005

SLOT

1 2 3

1

HZ-BOARD TXNHZ10RCSHZ-BOARD TXNHZ10RCS

ABCDEFGH I

– 31 –

Page 32

42WP37

12.6. HT-Board

Parts Location

6

IC

IC4601 B-4 Q3441 C-2

HT-BOARD

TRANSISTOR

Q3442 C-2

Q3501 B-2

Q3502 A-2

Q3503 B-2

Q3504 B-3

Q3505 A-3

Q3506 B-3

Parts Location

IC

IC3301 H-3

IC3305 G-4

IC3311 F-3

IC3441 F-2

IC3501 G-2

IC3699 F-4

IC3701 F-3

IC3702 G-3

HT-BOARD

TRANSISTOR

Q3401 G-2

Q3402 G-2

Q3461 H-2

Q3701 F-2

5

RTB032

HT-BOARD(FOIL SIDE)

TXNHT10QYS

TNPA2847

HT

ORDER

NO.

A1

4

3

JS306

94V-0

2

A2

B1

B2

H1

56

1

R413

R530

R544

R529

Q505

C512

R535

R538

TS502

R

R526

TS503

G

R532

R527

Q502

R524

R523

R548

C508

R520

R512

R515

R509

C516

R511

R508

R547

29

IC4601

28

R730

R731

JS315

JS316

R545

C303

Q506

R539

R533

R521

R518

R507

C515

Q504

C510C511

R536

R540R541 R542

TS501

R528

B

R531

R525

Q503

R522

C509

R510

R506

R549

1

R312

R534

R537

R543

Q501

C507

R519

JS307

C513

R505

R504

C517

JS312

R403

C406

1

1

1 23

2

R323

JK102

C720

JS305

C408

PbF

R311

CR NO.3

A39

A40

B39

B40

R308

R310

R309

JS313

C718

C725

C726

C727

R716

R318

JS311

C721

R448

Q441

R404

R442

R446

R443

R314

R325

R324

R316

R315

JS304

C716

C715

C714

C717

C710

R715

R712

L702

C445

R449

C321

Q442

R445

R447

R444

21

20

RTB032

HT-BOARD(COMPONENT SIDE)

TXNHT10QYS

A39A40

B39

D502

D501

IC699

PbF

JS302

C708

C703

C709

HT

TNPA2847

SEE REVERSE FOR ORDER

NO.

1

B40

D503

D504

8

C324

1

1

4

C705

R707

R727

R710

C704

L701

X701

NP

R704

R705

C322

C443

C323

5

JS314

C312

4

8

5

IC311

R327

R326

41

IC701

C706

C702

R706

R708

R709

64

R713

C707

C713

C701

R703

Q701

R452

R453

3

R450

IC441

L442

21

20

TS302

VD

R319

IC305

16

C315

1

R317

L305

C314

40

65

C711

R711

5

R717

C719

C728

C733

R714

C712

L703

NP

C410

R701

R412

R451

R702

C444

4

R408

C412

Q402

R441

C442

L441

HD

TS301

R321

R320

R313

C320

C318

9

8

R718

C724

C731

25

24

1

80

C723

C722

JS310

C409

R402

NP

C411

R410

R406

L404

R405

R407

JS308

C441

C317

R322

R720

R729

R722

R719

R305

R306

R307

C741

R723

R724

C732

IC702

C734

1

3

4

C746

L301

5

R728

C743

C744

C745

R725

C738

C309

C739

C740

C742

LC501

R721

6

C730

C729

7

R550

C514

R401

R411

R409

C402C404

Q401

L402

R551

NP NP

C504

R501

JS309

C302

C319

R4604

R414

R546

A1A2

B1

B2

H1

C4603

C4604

R4607

R4612

C4602

C4608

C4607

R4605

C4605

C4606

R4608

JS301

1

6

7

12

R516

9

16

C501

R303

2

C4609

C4610

C4611

C4612

R4557

C325

1

C326

C301

R302

C311

L302

C304

L303

C306

R502

R304

1

JK102

LC503

1

R513

8

IC501

1

R517

R514

C502 C503

C505

R461

C461

C307

6

12

7

Q461

R462

C4618

R4611

C4617

C4616

L4603

CR NO.3

L4602

L4601

C4615

C4614

C4613

IC301

5

R301

JS303

C316

LC502

NP

C506

R503

R466

R465

R463

R464

C313

L304

C305

C308

C310

94V-0

1

12

H0

1

8

HT-BOARD TXNHT10QYSHT-BOARD TXNHT10QYS

ABCDEFGH I

– 32 –

Page 33

12.7. J-Board

6

5

42WP37

J

Parts Location

J-BOARD (FOIL SIDE)

IC

IC8003 I-2

IC8004 F-2

TRANSISTOR

Q3001 G-3

Q3002 D-2

Q3003 D-2

Q3101 H-2

Q3102 H-2

Q3103 H-1

Q3104 H-2

Q3105 H-2

Q3106 H-2

Q8001 G-2

Q8002 I-2

4

J-BOARD (FOIL SIDE)

TNPA2826

R3025

C8070

C8072

JS8091

B40

B39

A40

A39

D3012

D3010

D3014

D3015

D3011

D3013

R3046

C8073

R3230

B40

B39

A40

A39

3

2

ZA3008

ZA3007

R3059

D3004

J13

B2

B1

A2

A1

ZA3005

R3145

R3146

C3002

C3003

R3005

R3006

R3007

R3008

Q3002

Q3003

R3011

R3013

R3010

R3009

R3012

R3014

C1004

C3005

C3006

R3022

R3160

R3161

JS8090

R1003

PbF

J14

12 22

C3205

111

TNPA2826 1 J

SEE REVERSE FOR ORDERNO.

123

ZA3006

R3035

R3044

R3100

R3099

R3047

R3045

R3034

R3197

R3036

R3084

R3085

R3041

J12

R3040

R3029

R3195

R3039

R3196

R3198

R3028

R8057

R8044

R8046

R8058

R8049

R8051

R8059

C8037

R8042

C8026

R8034

C8024

C8020

IC8004

R8032

R8068

R3188 R3189

R3190

R3260

R3261

R3262

R8054

R8043

R8045

R8055

R8048

R8050

R8056

C8036

R8041

C8025

R8033

R8011

R8018

J11

R8012

IC8003

C8023

C8019

R8017

R8010

R8009

R8031

B2

B1

A2

A1

R8001

R8004

ZA3001

R8002

R8003

D8003

R8025

R8026

D8001

1

20

11

C8013

R8067

R8065

R8066

R8072

C8061

R8093

10

C8060

R8081

R8077

R8079

R8029

Q8002

R8036

R8035

C8027

C8064

C8021

C8065

JS8092

C8028

ZA3002

B2

A2

1

20

11

C8014

R8070

R8082

R8078

R8080

R8069

R951

B1

D3001

A1

R8027

D8004

C8042

10

R8030

ZA3004

R8060

R8028

JS8093

C8041

C8022

D8002

R8061

R8098

R8100

Q8001

C8062

C8043

C8063

R8097

R8099

R8063R8064

R8062

R8091

C3016

C3014

R3056

R3002

R3001

R3058

R3049

R3055

ZA3003

Q3001

R3057

R3052

R3048

C3013

C3017

R3051

R3003

R3063

C3012

C3015

Q3105

Q3104

Q3101

R3130

R3132

Q3102

R3128

R3131

Q3103

C3253

R3199

R3202

R3129

R3133

B40

B39

A40

A39

C3252

C3251

R3251

R3297

C3255

R3117

C3108

R3203

R3257

R3254

R3111

C3261

C3114

R3255

JS8096

R3118

R3114

R3299

R3252

R3110

R3109

C3104

R3298

R3253

R3107

R3108

R3112

C3105

Q3106

R3102

R3105

R3101

R3104

R3204

R3201

C3106

C3113

C3260

R3200

R3113

R3256

R3103

R3106

1

J-BOARD TNPA2826 J-BOARD TNPA2826

ABCDEFGH I

– 33 –

Page 34

42WP37

J

Parts Location

J-BOARD (COMPONENT SIDE)

IC

6

5

4

J-BOARD(COMPONENT SIDE)

IC1001 F-2

IC3001 F-2

IC3002 D-2

IC3003 D-2

IC3004 D-3

IC3005 C-2

IC3006 D-2

IC3007 E-1

IC3108 B-2

IC3109 B-1

IC3201 B-2

IC3251 B-2

IC8001 A-3

IC8002 D-3

IC8003 A-2

IC8004 D-2

IC8005 A-2

IC8006 D-2

IC8007 A-1

IC8008 C-2

IC8009 C-2

IC8015 H-1

IC8016 E-2

IC8020 A-2

IC8021 D-2

IC951 F-3

IC952 F-3

TRANSISTOR

Q3010 E-3

Q3011 E-3

Q8010 E-2

Q8011 E-2

Q8012 E-2

Q8013 E-2

TP

TPJH1 A-2

TPJH2 D-2

TPJV1 A-2

TPJV2 D-2

TNPA2826

C3028

R3067

R3090

R3078

C3018

R3073

R3068

R3074

R952

R3089

L3006

R3069

C3027

R3075

R3077

C3026

R3088

R3076

R8071

5

R8094

C8051

C960

C8044

1

J3

2

L954

C954

4

1

IC8008

C8066

8

C8050

5

8

JS8099

1

4

IC8021

IC8009

R8087

C8048

R8085

R8024

C8006

R8006

NP

C8012

C8018

R8005

D8006

D8008

ZA3004

R8022

IC8002

R8007

JS8095

R8008

C8008

C8011

C8017

D3023

B2

1

B1

A2

A1

C8002

C8004

16

1

8

9

R8020

R8019

R8096

IC8004

20

1

R8040

C8034

C8067

1110

1

TPJV2

TPJH2

7

IC8006

J6

21

R3170

R3026

R3032

C8039

R8013

R8038

IC3004

L8004

C8032

L8007

C8046

R3083

IC3003

IC3002

R3033

1

R3082

1

R3027

16

89

R3030

R3031

1

16

8

16

9

8

16

1

8

9

IC3006

R3172

9

R3086

R3043

C3011

C3009

R3042

R3094

R3095

R3096

R3097

R3098

C3010

R3087

C3032

L3005

Q3011

R3037

R3038

L3003

1

45

IC3007

L8002

R8014

R8015

R8016

C8031

14

8

L8006

Q3010

R3151

C3040

Q8012

Q8013

R3214

R3150

R3219

R3215

D8011

R3231

D3003

R3153

R3152

R3140

R3141

C3041

J12

B40

B39

A40

A39

C956

R3024

Q8011

R3023

R3218

R3211

R3233

R3235

8

7

1

14

8

IC8016

L3050

C3200

D8010

R3216R3217

R3234

C8071

2

20

J8

1

19

C964

C958

L957

L958

L959

ZA3005

C963

C957

C962

R3018

89

R1001

R1002

IC3001

R3021

Q8010

R3213

R3212

R3210

R3232

R3017

C1004

R3020

R3016

C955

IC952

1

16

R3019

R3015

B2

B1

A2

A1

C968

L955

L956

L960

C961

L1001

L3002

C3008

IC1001

D1001

C967

C3004

4

1

8

5

C1003

ZA3006

C970

C969

C3007

C1002

C971

C1001

PbF

C965

C972

IC951

C966

L3001

C3001

X9350

TNPA2826

ORDER

NO.

J13

1

J

16

9

16

L952

J10

C3203

22

L951

C952

C951

J14

111

R3060

ZA3008

R3061

12

B40

B39

A40

A39

ZA3007

IC8015

C3202

1

C3201

C3204

8

32

C3020

C959

R3080

R3091

C953

C3022

C3023

L953

R3079

C3024

R3064

R3054

C3025

40

39

ZA3003

R3070

C3029

C3031

C3030

20

19

R3053

R3050

C3019

1

64

R3072

R3066

R3071

R3065

131

J5

J11

B2

B1

A2

A1

3

C8016

2

JS8098

TPJV1

R8084

C8047

R8083

ZA3002

L8001

C8001

C8033

C3266C3267

16

C8003

9

C8030

C3268

C8029

R8039

C8038

C3135

L8005

14

R8037

C8045

C3136

IC8005

8

C8040

NP

C8049

8

C3134

R8089

5

C3257

C3258

R3127

R8088

IC3251

C3111

14

15

C3110

14

15

R3123

R3124

R8090

R3120

R3122

C3116

C3112

C3117

R3115

C3254

C3256

8

21

22

C3263

C3262

R3126

R3125

C3109

8

21

22

R3121

R3116

R3142

ZA3001

C8010

D8005

D8007

IC8020

1

IC8001

8

R8095 R3081

R8021

C8005

C8007

R8023

L8003

IC8003

20

1

C8009

C8015

JS8094

D3022

11

10

1

TPJH1

7

R8052

R8047

C8035

R8053

1

4

IC8007

B40

B39

A40

A39

R3004

R3143

R3191

C3144

R3192

C3259

C3264

R3258

C3115

IC3201

C3143

C3141

C3142

R3194

R3193

JS8097

D3024

33

C3265

51

IC3109

R3093

D3021

IC3108

R3092

IC3005

52

C3021

7

1

28

R3259

C3107

7

1

28

C3118

1

J-BOARD TNPA2826 J-BOARD TNPA2826

ABCDEFGH I

– 34 –

Page 35

12.8. D-Board

D-BOARD(FOIL SIDE)

6

5

4

3

2

TZTNP01SBSE/TZTNP01SBSC

R909

CR NO.9

SEE REVERSE FOR ORDERNO.

R594

C598

R592R593

C757

R908

R903

R905

R906

R907

R917

R904

R900

R852

C755

R942

D719

R930

C450

C449

R418

R419

PbF

1

2

3

TNPA2825

C479

D1

Q597

Q596

R547

R585

42WP37

R598

R599

R919

R913

4

C760

R915

C758

5

D727

R834

R835

R853

R918

R914

R901

R898

C743

R809

R897

C754

R819

R862

R866

R416

R538

R553

D771

C767

Q716

R941

R940

R939

R449

Q715

R410

R937

R936

R935

C492

C491

C487

C490

C480

C476

C489

C475

R485

R484

C485

R487

C473

R541

R532

R509

R535

R537

1

4

1

IC708

IC710

IC707

5

8

C759

R923

R910

R829

R879

D723

R934

Q714

R933

R931

R932

C488

C481

C478

C477

C483

C482

R486

C740

5

R911

C486

L452

R489

C484

1

8

C750

R921

C748

R820

R871

D769

R839

C768

R840

D720

R451

C452

X451

C451

R452

X452

C453

C454

C455

R490

R491

R488

C470

R479

R478

R477

R482

R483

R475

C474

R870

R827

C745

4

R826

R815

3

R881

R825

R823

R824

C746

R822

R770

R830

R849

R850

R838

R372

R330

C463

1

10

R467

R885

C769

D730

C744

R841

R842

R821

C739

R828

C747

R925

C763

R362

R373

R364

R340

R339

20

IC451

11

R595

R596

C741

Q709

C756

R884

R836

R848

R352

R355

R461

R460

R322

C147

R060

C146

R107

R106

C106

R597

C599

R571

R356

C737

R572

C092

C096

R119

C088

IC016

C090

R051

R052

R053

R054

R055

R056

Q599

R586

Q598

R634

R565

R566

R567

R568

C601

R679

C602

R649

20

11

1

IC706

R577R578

10

R198

R197

C185

C193

1

4

IC156

5

8

R228

IC157

C189

C050

C112

R061

C109

C111

C107

C093

R306

R024

R113

R615

R579

C626

R629

R632

IC601

R643

R640

R653

R641

R814

R220

7

8

C198

R020

R023

11

R650

R651

R652

R945

R601

R946

R600

5

4

Q602

1

3

IC606

R624

C153

R108

R229

C203

R240

C202

R230

R243

C627

R221

C195

R166

1

R218

R217

C191

C192

14

R231

R233

C199

R018

R064

IC004

5

8

C027

IC008

1

C052

IC013

28

R050

5

C084

8

IC018

1

C108

C110

28

C056

C149

C148

R028

R019

R022

R105

R104

C048

IC007

C036

C038

C033

C040

10

11

C603

R207

1

20

10

20

1

10

11

20

1

R680

R683

Q601

R621

R618

C613

R179

R177

R206

R569

R564

R563

C164

C167

C165

C166

C170

R205

R975

R668

R667

R665

R664

60

R063

C636

R659

4

R048

1

56

R030

R126

R125

R124

29

5

C002

4

C001

1

1

56

R049

IC001

R062

C039

C034

IC006

29

R110

C030

C032

5

4

1

3

C043

R609

R994

R617

R619

R608

R604

IC604

R620

C731

R154

C187

C178

C176

C172

C168

C173

R204

C641

40

C638

41

61

R663

R660

R661

R656

R657

R831

C028

D001

C029

C120

C004

C022

4

C005

C006

L001

3

C003

C086

C087

IC012

C054

R029

C037

C051

C053

C049

R115

C076

C035

C114

C042

R114

1

C031

3

4

5

R584

R623

R655

R570

R610

R689

R611

R673

R690

R698

R678

R674

R602

R613

R614

R676

R603

R582

R583

R581

IC603

R677

R580

11

R234

C637

IC003

C011

C121

C094

1

R573

R574

10

1

IC602

20

C604

11

10

1

20

C728

R157

R784

IC703

R783

R169

R153

R167

C159

C158

R247

R246

R152

R111

R155

R151

R208

R227

R236

R202

R118

C180

C179

IC608

21

20

R669

C640

R693

1

80

R658

C015

R989

R662

C014

C018

C016

C023

4

C024

3

1

5

C012

L002

L003

C071

C070

C074

C072

C080

4

C081

3

1

5

C123

C067

R117

5

4

3

3

1

4

5

C097

R797

R622

22

R612

IC705

23

R575

C733

R576

IC704

40

1

R790

C727

R789

Q707

R806

R168

C163

R718

C162

3

4

C161

IC152

5

1

C160

D953

R959

C154

C156

C157

R180

C961

R691

R666

R692

R002

R003

C019

C017

C021

R015

C020

R013

C026

R016

10

C013

R032

11

IC023

C075

R033

C073

C079

R044

R041

C078

R046

C083

C124

L008

D003

C062

C057

L009

C061

C069

5

4

1

3

C098

C100

C101

R793

C734

R801

R802

R800

C730

C729

D729

C714

R791

R761

R725

R736

Q701

R737

R961

R962

5 1

C960

R960

+

R964

IC951

C955

L952

R952

L954

R951

L953

R723

R721

R719

R700

R716

R714

C954

R711

L951

R133

1

R134

R135

R948

C077

20

R694

IC010

C058

C059

R120

C068

C060

R730

R729

R728

L010

R727

R726

C125

IC017

C089

C091

R798

1

C706

D715

D718

1

R344

4

IC702

R764

8

5

44

C724

C726

C719

R799

21

C711

R744

R758

20

R746

C715

C716

C717

C766

R734

R735

D952

C957

R956

R957

R954

R973

D708

D712

D713

R699

R697

R696

R695

D704

R731

R587

R955

R588

R589

R958

R953

D707

D711

C735

R929

D722

R985

R928

R996

R997

R709

R724

R722

R720

R717

R590

R715

R713

R712

R710

D706

D705

R708

R707

Q703

D709

D710

IC711

R739

R738

Q704

14

C700

R949

8

5

Q719

R130

R132

R131

R805

R804

R803

D721

Parts Location

IC

IC9001 D-2

IC9003 D-3

IC9004 D-3

IC9006 D-2

IC9007 D-1

IC9008 D-3

IC9010 E-1

IC9012 D-2

IC9013 D-2

IC9016 C-2

IC9017 E-1

IC9018 D-2

IC9023 E-2

IC9152 E-4

IC9156 C-4

IC9157 C-4

IC9451 B-4

IC9601 D-5

IC9602 D-5

D

D-BOARD (FOIL SIDE)

IC9603 D-5

IC9604 D-5

IC9606 C-5

IC9608 D-3

IC9702 F-5

IC9703 D-4

IC9704 E-5

IC9705 E-6

IC9706 C-5

IC9707 B-6

IC9708 B-6

IC9710 B-6

IC9711 F-2

IC9951 E-4

TRANSISTOR

Q9596 A-1

Q9597 A-2

Q9598 C-1

Q9599 C-1

Q9601 D-5

Q9602 D-5

Q9701 E-4

Q9703 F-3

Q9704 F-2

Q9707 E-5

Q9709 C-5

Q9714 B-4

Q9715 B-5

Q9716 B-5

Q9719 F-2

1

D-BOARD TZTNP01SBSE/TZTNP01SBSC D-BOARD TZTNP01SBSE/TZTNP01SBSC

ABCDEFGH I

– 35 –

Page 36

42WP37

D-BOARD(COMPONENT SIDE)

6

5

4

3

2

TZTNP01SBSE/TZTNP01SBSC

5

4

C723

R792

1

8

R772

X703

C772

R950

C771

IC712

C774

C775

R795

D716

C705

R755

C713

C712

R756

Q710

R747

R867

R741

R748

R745

C765

R749

C707

D22

C647

C646

R591

D4

D728

40

C773

R766

41

80

81

R765

R768

R762

R754

R763

R767

Q702

R794

Q706

R771

R773

C959

C958

R750

R751

R752

R753

R757

R759

R742

1

7

9

11

1

D27

20

19

L601

2

1

12

R706

R705

R704

R703

R702

R701

C703

R732

R733

C709

40

D12

R988

R987

1

2

R774

1

D20

C951

12

1

39

1

C720

R769

C701

C718

L955

C964

D25

D3

R986

R995

C710

8

1

D10

R984

L701

R777

120

R775

R779

R782

R776

R171

R172

R743

R173

R176

C155

C962

R760

R216

R199

R226

R225

C952

R963

R998

C968

C953

C956

D954

C702

1

D6

R005

R007

R008

R009

R011

R014

C025

21

IC011

1

R035

R037

R038

R039

R042

R045

C082

C064

D5

31

C065

C063

C066

C102

C105

R796

X701

1

R170

C971

Thermal pad

C010

C122

C095

C103

C622

C618

C614

R616

C611

R109

R687

R684

R685

C722

R675

R607

R686

R688

IC701

160

R785

R787

121

C708

R778

R780

R781

23

21

19

17

15

13

12

11

10

9

7

5

R190

3

1

R966

R967

IC952

16

1

C969

C970

IC002

1

28

1

28

20

21

40

R786

C607

C609

R788

C610

D717

R682

C725

C732

R561

R112

22

20

18

16

14

8

6

4

2

A

B

9

C966

8

C967

D955

56

29

56

29

41

C606

1

C605

C608

52

53

R681

C612

R557

R242

R248

DEFGHJKLMNPRTUVW

C

C965

R965

R808

R969

R970

L956

R006

R004

R010

R012

R017

C009

R036

R034

R040

R047

R043

C113

C620

C615

208

C181IC151

86

R968

R807

1

R947

C182

R972

IC005

R001

1

28

1

C008

R031

28

1

21

20

80

IC019

61

40

41

60

C099

C623

TNPA2825

R638

157

ORDER

NO.

156

C629

IC605

C630

R991

C631

R990

R992

R993

C632

C633

1

105

104

4

R872

C151

C152

C194

X151

R301

R178

R245

R201

R187

R302

R181

R182

R192

C207

C174

C175

C169

5

R183

1

R465

R466

AAABAC

Y

Q001

R026

C047

R025

56

R129

R128

R127

29

C007

56

R057

C104

Q002

IC015

29

C055

IC009

1

80

61

60

C197

R468

44

R239

R165

C190

R164

IC155

43

C200

R027

R059

R058

C041

C046

C044

C045

R357

R376

R333

R349

15 0

CR NO.9

R122

R121

R548

R315

Q301

C634

C635

R648

R644

C301

R311

R310

R646

PbF

R645

R642

IC607

8

5

R813

R863

R812

R811

R810

C307

C309

C305

C303

5

4

C308

1

3

IC302

C302

4

L155

IC153

3

C150

C196

R219

C205

R368