Page 1

FILE NO. 050-200234

SERVICE MANUAL

PLASMA DISPLAY MONITOR

42WP27B, 42WP27C

42WP27E, 42WP27F

42WP27R

PRINTED IN JAPAN Dec, 2002

Page 2

CONTENTS

Page Page

1 Applicable signals 3

2 Safety Precautions 4

2.1. General Guidelines

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices 5

4 About lead free solder (PbF) 6

5 PCB Structure sheet of GP5D chassis 7

6 Service Hint 8

7 Location of Lead Wiring 9

8 Adjustment Procedure 10

8.1. +B Set-up 10

8.2. Driver Set-up 10

8.3. Initialization Pulse Adjust 11

8.4. P.C.B. (Printed Circuit Board) exchange 12

8.5. Adjustment Volume Location 12

8.6. Test Point Location 12

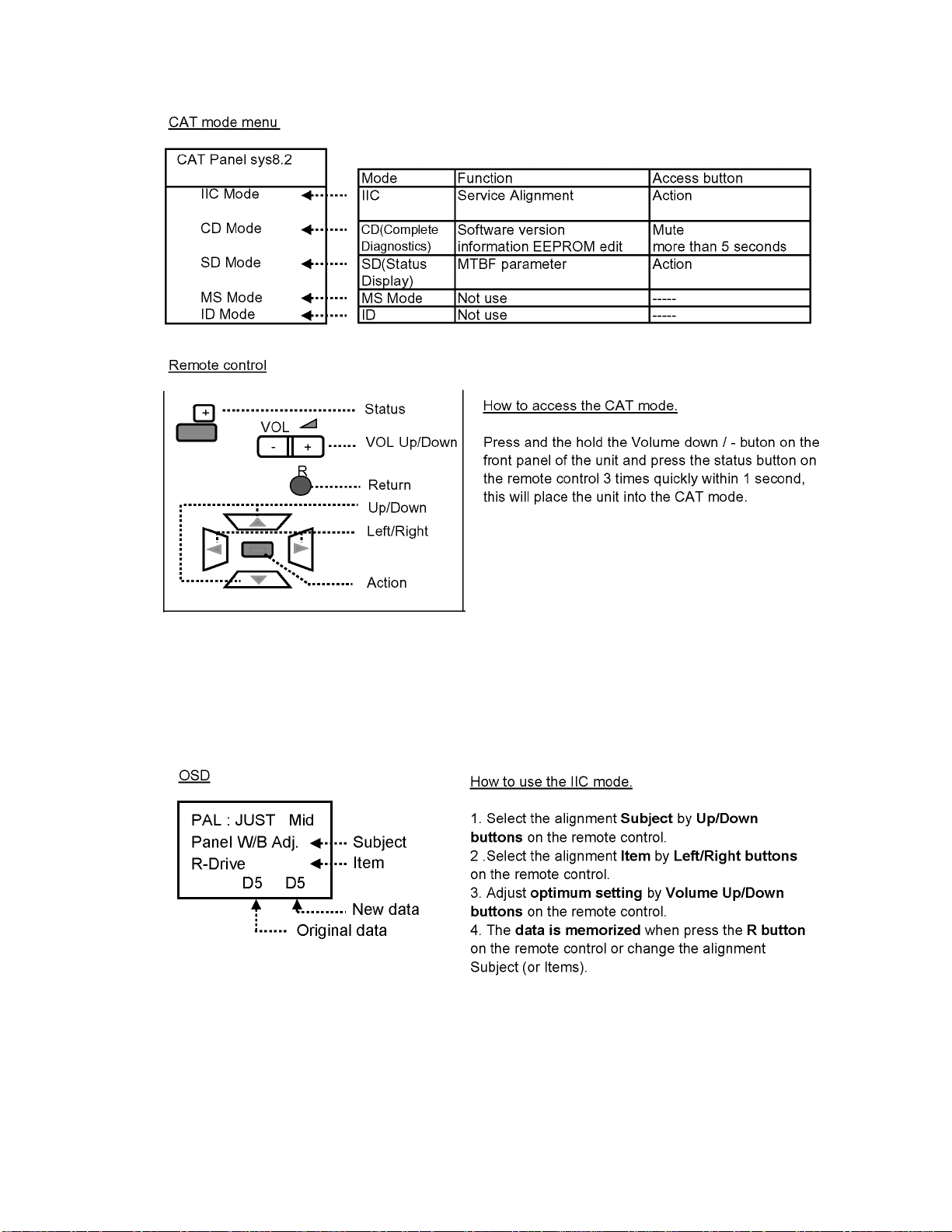

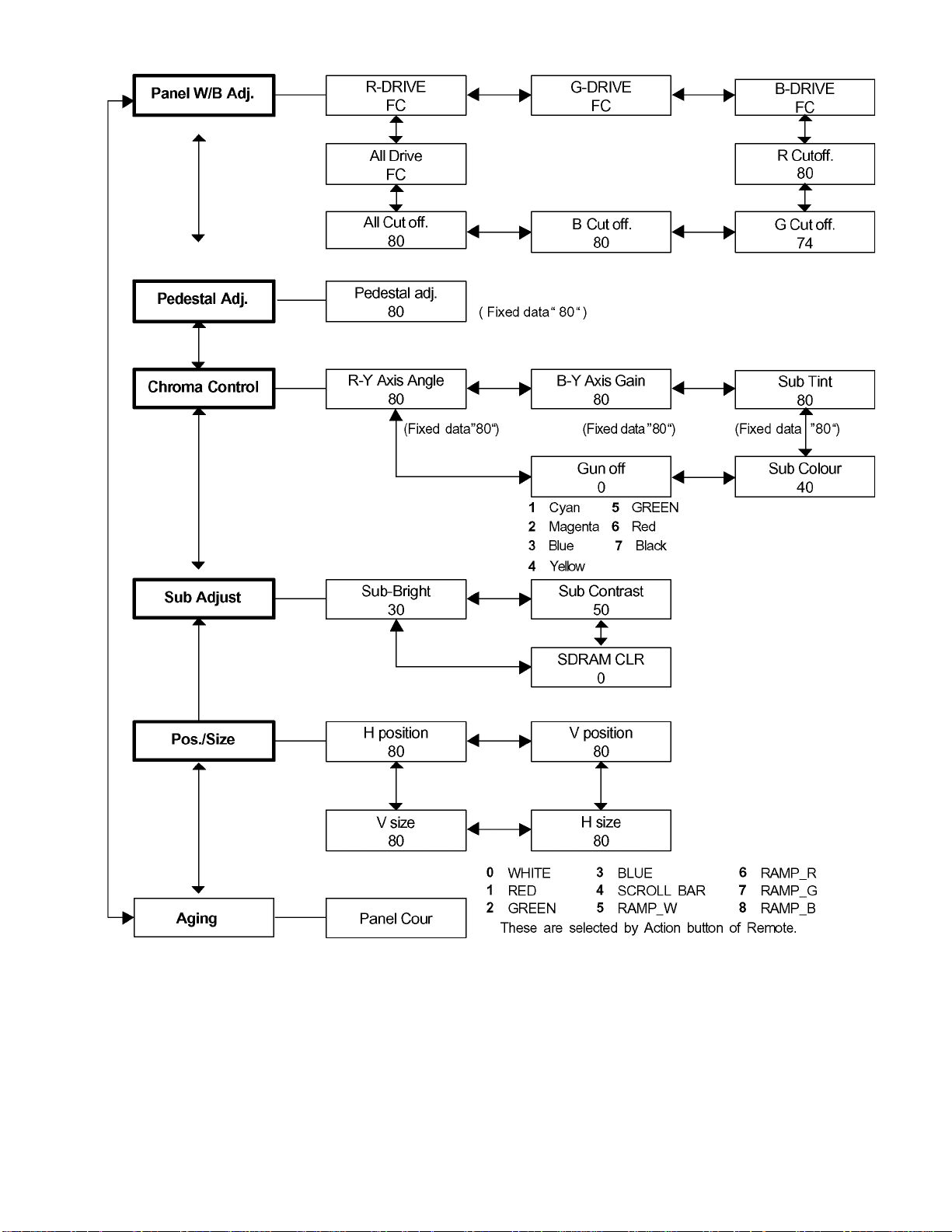

9 Service mode 13

9.1. CAT (computer Aided Test) mode

9.2. IIC mode structure (following items value is sample data.)

10 Alignment 16

10.1. Pedestal setting 16

10.2. NTSC panel white balance

10.3. PAL/SECAM panel white balance 18

10.4. PC/RGB panel white balance 20

10.5. HD/ 525i /525p panel white balance

10.6. 625i panel balance 24

10.7. Sub brightness setting 25

11 Trouble shooting guide

11.1. Self Check 27

11.2. No Power 28

11.3. No Picture 29

11.4. Local screen failure

12 Option Setting 30

13 Conductor Views 33

13.1. F-Board 33

13.2. P-Board 34

13.3. HX-Board 37

13.4. Option RTB421 38

13.5. D1-Board 40

13.6. D2-Board 42

13.7. C1-Board 45

13.8. C2-Board 46

13.9. SC-Board 47

13.10. SU-Board 50

13.11. SD-Board 51

13.12. SS, SS2, SS3-Board 52

13.13. Z-Board

13.14. H3, S1 and V1-Board 56

14 Block and Schematic Diagrams 57

4

13

15

17

22

27

29

55

14.1. Schematic Diagram Notes 57

14.2. Main Block Diagram 58

14.3. F-Board Schematic Diagram 59

14.4. Power Block Diagram 60

14.5. P-Board (1 of 2) Schematic Diagram 61

14.6. P-Board (2 of 2) Schematic Diagram 62

14.7. HX-Board Block Diagram 63

14.8. HX-Board Schematic Diagram 64

14.9. Option RTB421 Block Diagram 65

14.10. Option RTB421 (1 of 2) Schematic Diagram 66

14.11. Option RTB421 (2 of 2) Schematic Diagram 67

14.12. D1-Board Block Diagram 68

14.13. D1-Board (1 of 6) Schematic Diagram

14.14. D1-Board (2 of 6) Schematic Diagram 70

14.15. D1-Board (3 of 6) Schematic Diagram 71

14.16. D1-Board (4 of 6) Schematic Diagram 72

14.17. D1-Board (5 of 6) Schematic Diagram 73

14.18. D1-Board (6 of 6) Schematic Diagram

14.19. D2-Board Block Diagram 75

14.20. D2-Board (1 of 6) Schematic Diagram 76

14.21. D2-Board (2 of 6) Schematic Diagram

14.22. D2-Board (3 of 6) Schematic Diagram 78

14.23. D2-Board (4 of 6) Schematic Diagram 79

14.24. D2-Board (5 of 6) Schematic Diagram

14.25. D2-Board (6 of 6) Schematic Diagram 81

14.26. C1 and C2-Board Block Diagram 82

14.27. C1-Board Schematic Diagram 83

14.28. C2-Board Schematic Diagram

14.29. SC-Board Block Diagram 85

14.30. SC-Board (1 of 2) Schematic Diagram 86

14.31. SC-Board (2 of 2) Schematic Diagram 87

14.32. SD-Board Block Diagram 88

14.33. SD-Board Schematic Diagram 89

14.34. SU-Board Block Diagram 90

14.35. SU-Board Schematic Diagram 91

14.36. SS-Board Block Diagram 92

14.37. SS, SS2, SS3 and S1-Board Schematic Diagram 93

14.38. Z-Board Block Diagram 94

14.39. H3 and Z-Board Schematic Diagram 95

15 Mechanical Parts Location 97

16 Replacement Parts List 99

16.1. Replacement Parts List Notes 99

16.2. Mechanical Replacement Parts List 100

16.3. Electrical Replacement Parts List 101

17 Specifications 111

69

74

77

80

84

2

Page 3

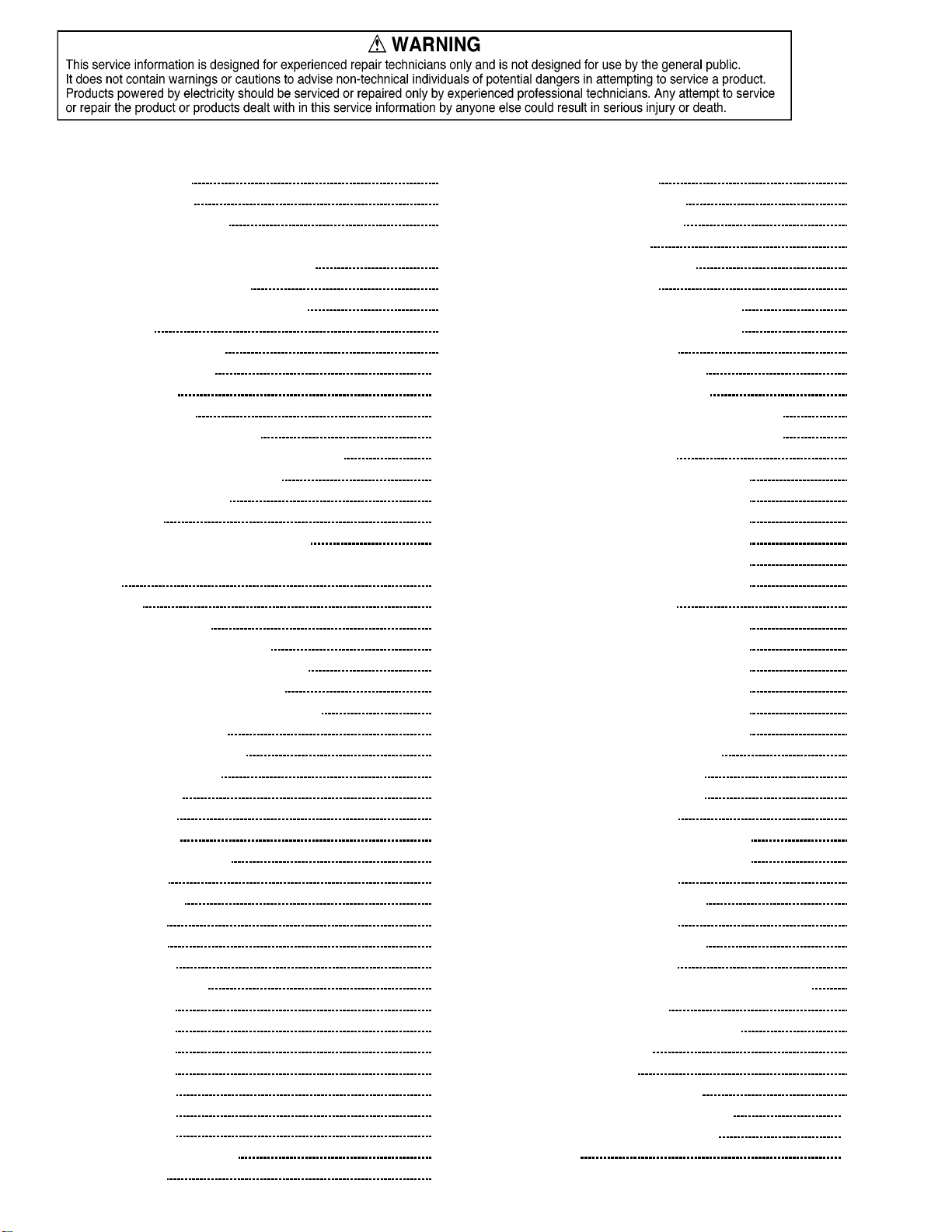

1 Applicable signals

3

Page 4

2 Safety Precautions

2.1. General Guidelines

1.When servicing, observe the original lead dress. If a short circuit is found, replace all parts which have been overheated or

damaged by the short circuit.

2.After servicing, see to it that all the protective devices such as insulation barriers, insulation papers shields are properly

installed.

3.After servicing, make the following leakage current checks to prevent the customer from being exposed to shock hazards.

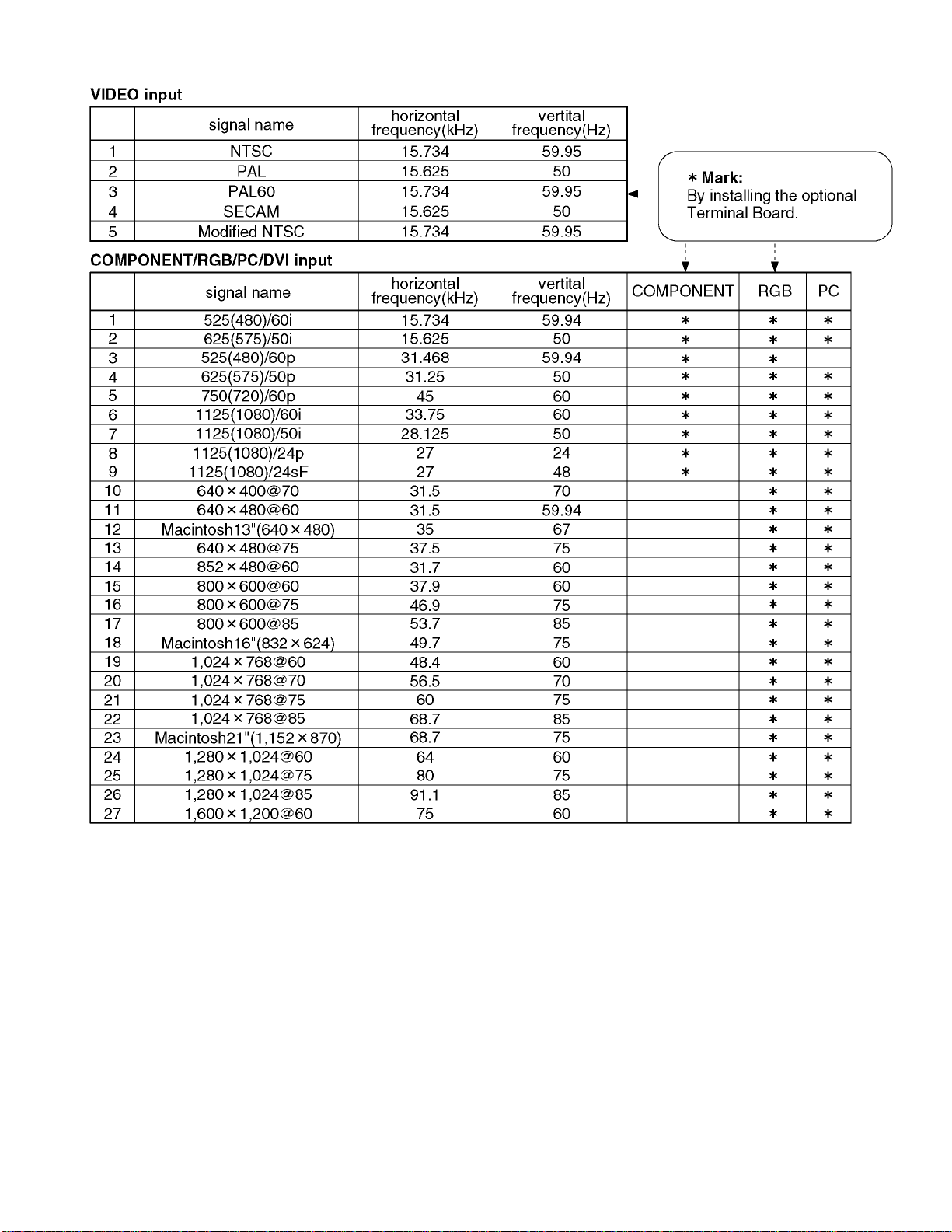

2.1.1. Leakage Current Cold Check

1.Unplug the AC cord and connect a jumper between the two

prongs on the plug.

2.Measure the resistance value, with an ohmmeter, between

the jumpered AC plug and each exposed metallic cabinet

part on the equipment such as screwheads, connectors,

control shafts, etc. When the exposed metallic part has a

return path to the chassis, the reading should be between

1M9 and 5.2M9.

When the exposed metal does not have a return path to

the chassis, the reading must be

.

Figure 1

2.1.2. Leakage Current Hot Check (See

Figure 1.)

1.Plug the AC cord directly into the AC outlet. Do not use an

isolation transformer for this check.

2.Connect a 1.5k9 , 10 watts resistor, in parallel with a 0.15µF

capacitors, between each exposed metallic part on the set

and a good earth ground such as a water pipe, as shown in

Figure 1.

3.Use an AC voltmeter, with 1000 ohms/volt or more

sensitivity, to measure the potential across the resistor.

4.Check each exposed metallic part, and measure the

voltage at each point.

5.Reverse the AC plug in the AC outlet and repeat each of the

above measurements.

6.The potential at any point should not exceed 0.75 volts

RMS. A leakage current tester (Simpson Model 229 or

equivalent) may be used to make the hot checks, leakage

current must not exceed 1/2 milliamp. In case a

measurement is outside of the limits specified, there is a

possibility of a shock hazard, and the equipment should be

repaired and rechecked before it is returned to the

customer.

4

Page 5

3 Prevention of Electro Static Discharge (ESD) to

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques should be used to help reduce the incidence of component damage

caused by electro static discharge (ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any ESD on your

body by touching a known earth ground. Alternatively, obtain and wear a commercia lly available discharging ESD wrist strap,

which should be removed for potential shock reasons prior to applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices, place the assembly on a conductive surface such as alminum

foil, to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static (ESD protected)" can

generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are ready to install it. (Most

replacement ES devices are packaged with leads electrically shorted together by conductive foam, alminum foil or comparable

conductive material).

7.Immediately before removing the protective material from the leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise hamless motion such as the brushing

together of your clothes fabric or the lifting of your foot from a carpeted floor can generate static electricity (ESD) sufficient to

damage an ES device).

5

Page 6

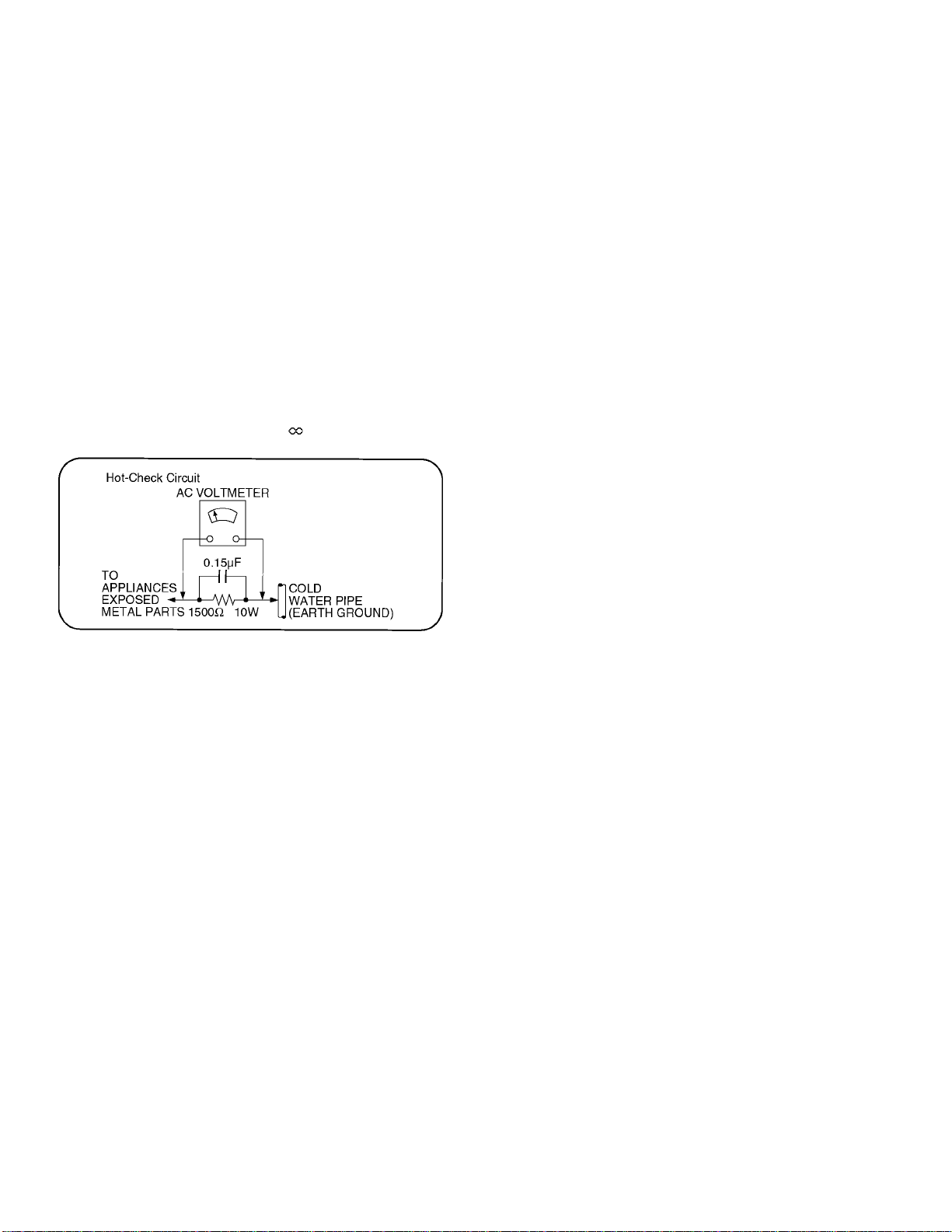

4 About lead free solder (PbF)

Note: Lead is listed as (Pb) in the periodic table of elements.

In the information below, Pb will refer to Lead solder, and PbF will refer to Lead Free Solder.

The Lead Free Solder used in our manufacturing process and discussed below is (Sn+Ag+Cu).

That is Tin (Sn), Silver (Ag) and (Cu) although other types are available.

This model uses Pb Free solder in it’s manufacture due to environmental conservation issues. For service and repair work, we’d

suggest the use of Pb free solder as well, although Pb solder may be used.

PCBs manufactured using lead free solder will have the PbF within a leaf Symbol

Caution

·Pb free solder has a higher melting point than standard solder. Typically the melting point is 50 ~ 70 °F (30~40 °C) higher.

Please use a high temperature soldering iron and set it to 700 ± 20 °F (370 ± 10 °C).

·Pb free solder will tend to splash when heated too high (about 1100 °F or 600 °C).

If you must use Pb solder, please completely remove all of the Pb free solder on the pins or solder area before applying Pb

solder. If this is not practical, be sure to heat the Pb free solder until it melts, before applying Pb solder.

·After applying PbF solder to double layered boards, please check the component side for excess solder which may flow onto

the opposite side. (see figure below)

Suggested Pb free solder

There are several kinds of Pb free solder available for purchase. This product uses Sn+Ag+Cu (tin, silver, copper) solder.

However, Sn+Cu (tin, copper), Sn+Zn+Bi (tin, zinc, bismuth) solder can also be used.

stamped on the back of PCB.

6

Page 7

5 PCB Structure sheet of GP5D chassis

Board Name Function Remarks

D1 Format Converter 1

D2 Plasma AI Sub-Field Processor 1

Z Audio out

SS Sustain Out 1

SC Scan out 1

SU Sustain connection (Upper) 1

SD Sustain connection (Lower) 1

C1 Data Drive (Lower Right)

C2 Data Drive (Lower Left)

H3 Speaker terminal

S1 Power switch

SS2 Sustain connection (Upper)

SS3 Sustain connection (Lower)

V1 Front SW. & Remote receiver

F Line filter

P Power supply 1

HX PC_type_Input terminal

RTB421 RCA type_Input terminal

Remarks

1.Recommend PCB´s for initial service for GP5D chassis.

7

Page 8

6 Service Hint

∗ D1 board is not used for 42WP27C.

8

Page 9

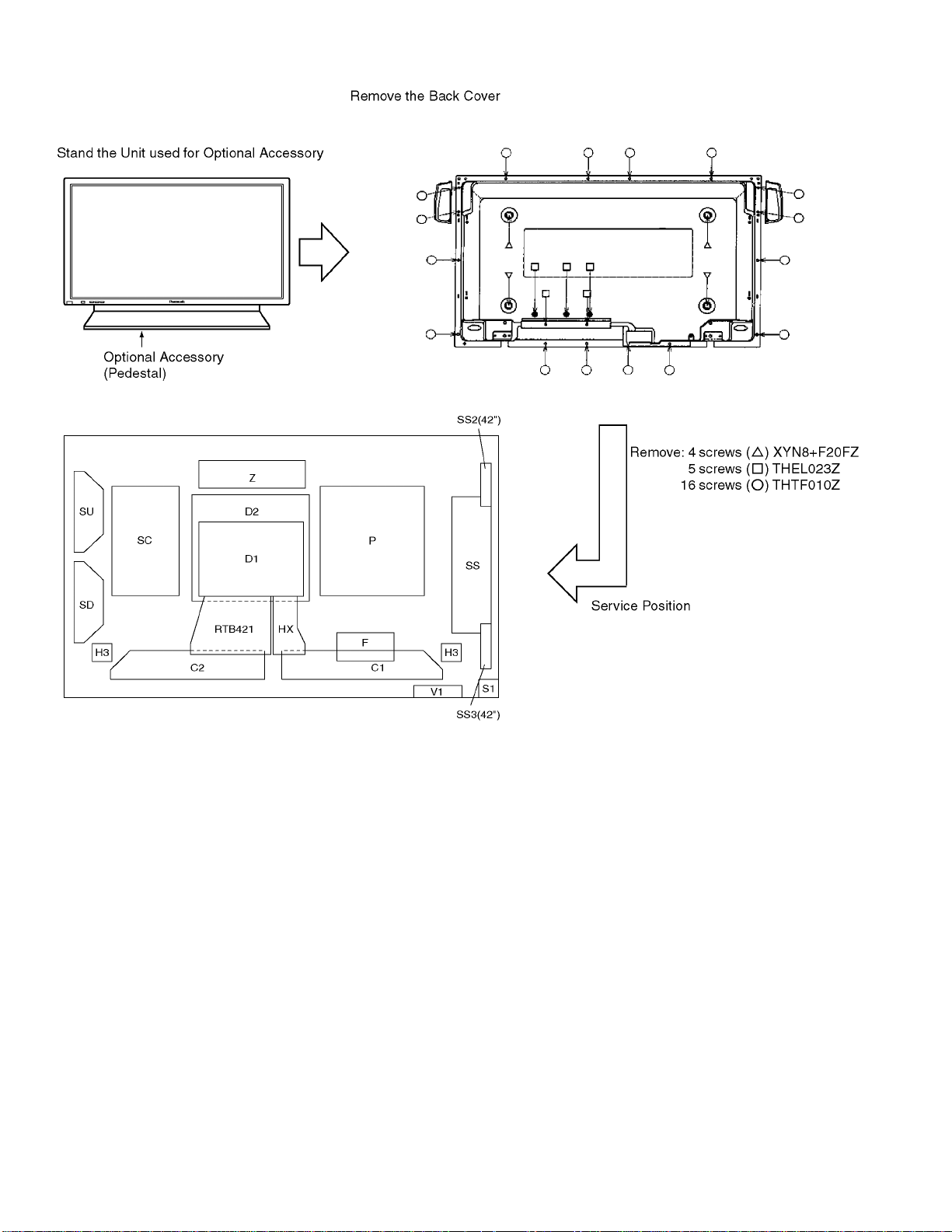

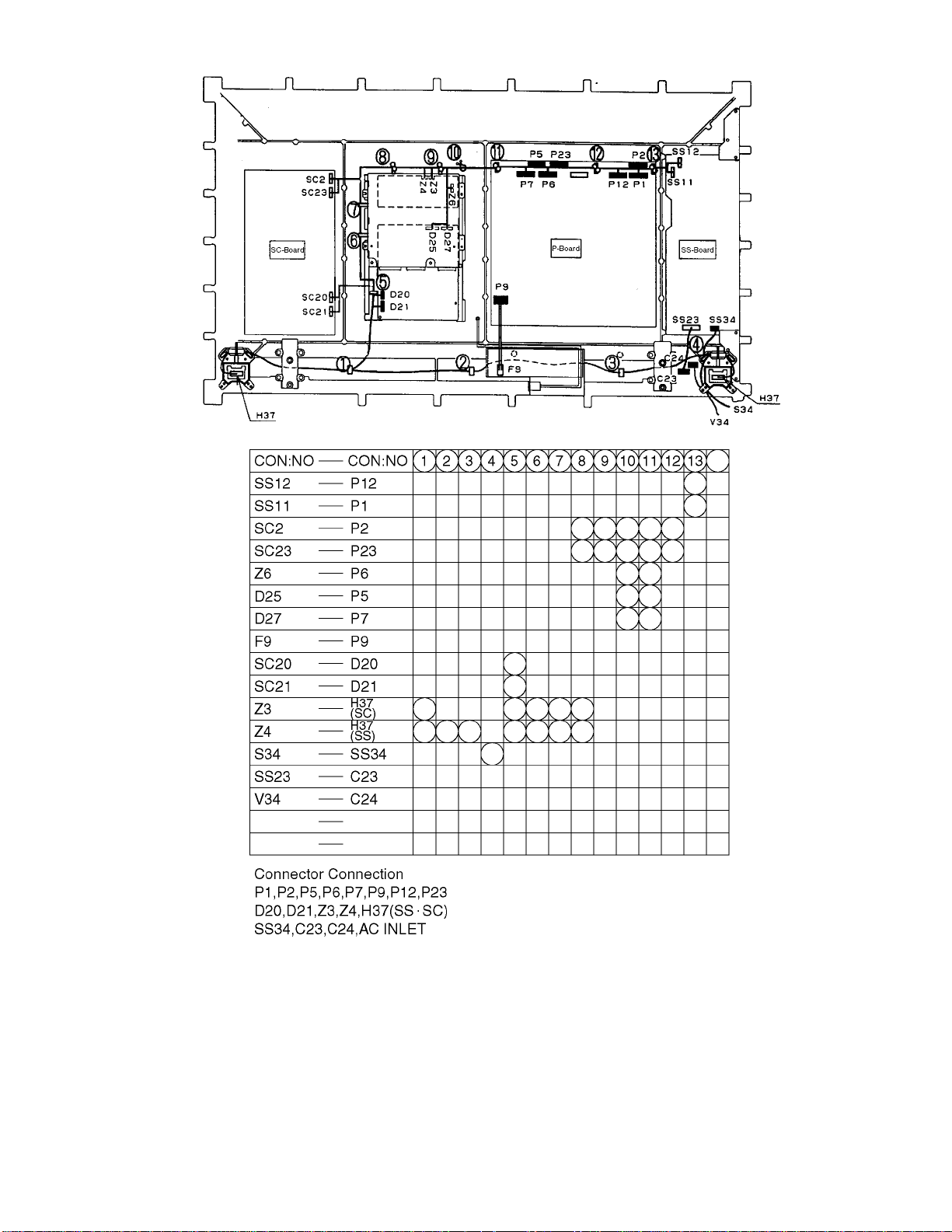

7 Location of Lead Wiring

9

Page 10

8 Adjustment Procedure

8.1. +B Set-up

8.1.1. Item / Preparation

1.Input a Grey scale signal.

2.Set the picture controls: Picture mode: Normal

White balance: Normal

8.1.2. Adjustments

Adjust and confirm indicated test point for the specified voltage.

Adjust

Name Volume Voltage Test Point

Vsus R540 170V ± 1V P1 pin 3

Vda R537 67V ± 0.5V P12 pin 1

Confirm

Name Voltage Test Point

15V 15.3V ± 0.5V P23 pin 2

13V 13.3V ± 0.5V P25 pin 5

15V 15.2V ± 0.5V P25 pin 1

Audio 13V 12.5V ± 0.8V P6 pin 1

Audio-13V -12.5V ± 0.8V P6 pin 3

5V 5.2V ± 0.3V P25 pin 7

STB 5V 5.0V ± 0.3V P27 pin 4

Fan 15V 15.0V ± 0.5V P10 pin 1

Fan 5V 5.2V ± 0.3V P10 pin 4

PFC 380V ± 15V C447(+)

8.2. Driver Set-up

8.2.1. Item / Preparation

1.Input an APL 100 % white signal.

2.Set the picture controls: Picture mode: Normal

White balance: Cool

Aspect: 16:9

8.2.2. Adjustments

Adjust driver section voltages referring the panel data on the

panel data label.

Name Test Point Voltage Volume

Vsus TPVSUS

(SS)

Vbk TPVBK (SC) 155V ± 5V R6443 (SC)

Ve TPVE (SS) 150V ± 1V R6774 (SS)

Vset TPVSET

(SC)

Vad TPVAD (SC) -90V ± 1V R6477 (SC)

Vscn TPVSCN

(SC)

Vda TPVDA (SS) 67V ± 1V R537 (P)

*See the Panel label.

170V ± 1V R540 (P)

218V ± 6V ---

Vad*+118V ±2V---

10

Page 11

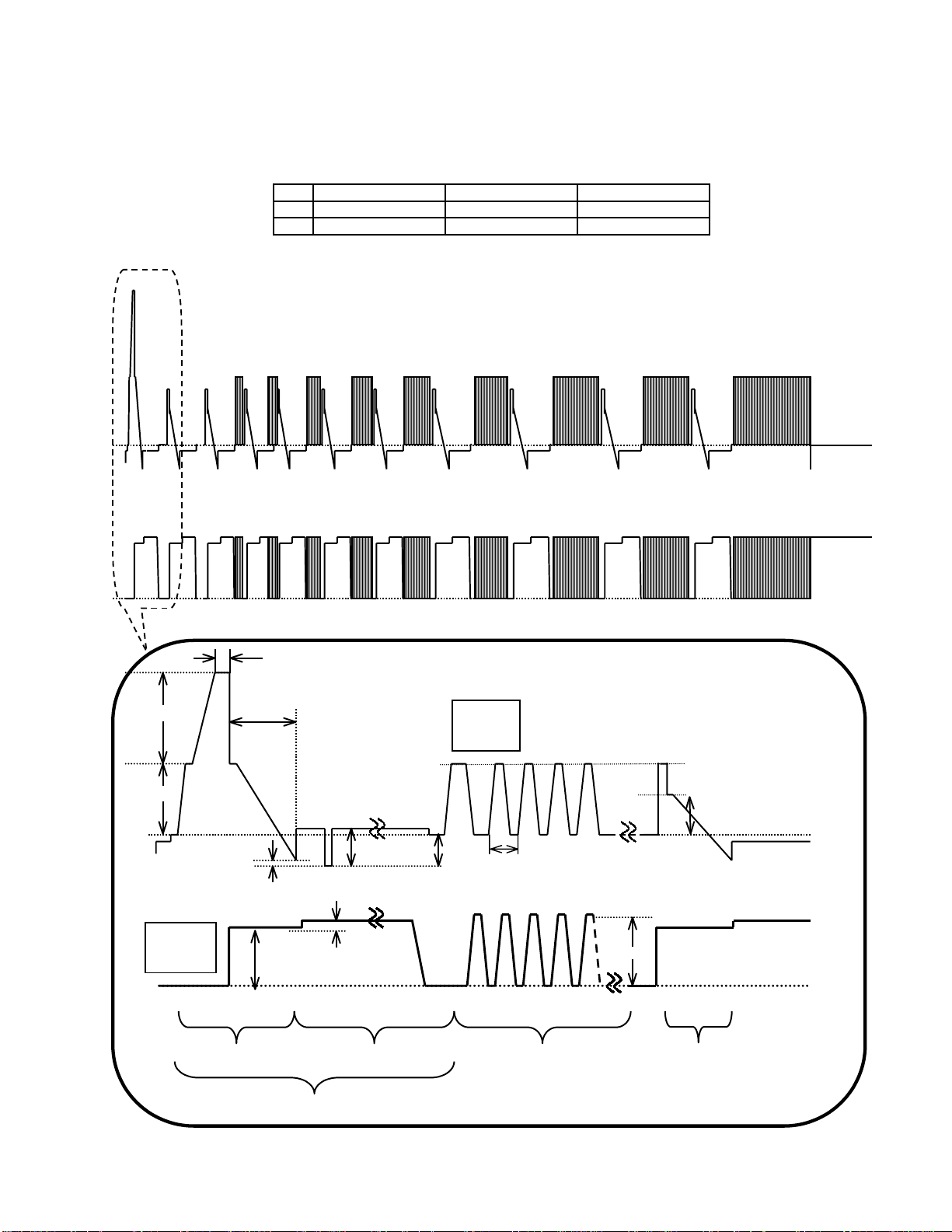

8.3. Initialization Pulse Adjust

1.Input a Cross hatch signal.

2.Set the picture controls: Picture mode: Normal

White balance: Cool

Adjust the indicated test point for the specified wave form.

Test point Volume Level

T1 TPSC1 (SC) --- 20 ± 15µ Sec

T2 TPSS1 (SS) R6557 (SC) 170 ± 20µ Sec

TPSC1 SCAN OUTPUT

TPSS1 SUSTAIN OUTPUT

T1

VSET

T2 170±20µs

Scan

TPSC1

VSUS VBK

VSCN VAD

VSET2 7±3V

5.0±0.6µs

Sustain

TPSS1

VE

VE2

VSUS

VSUS

INITIALIZE SCAN PRE-INITIALIZE

ADDRESS PERIOD

SUSTAIN

11

Page 12

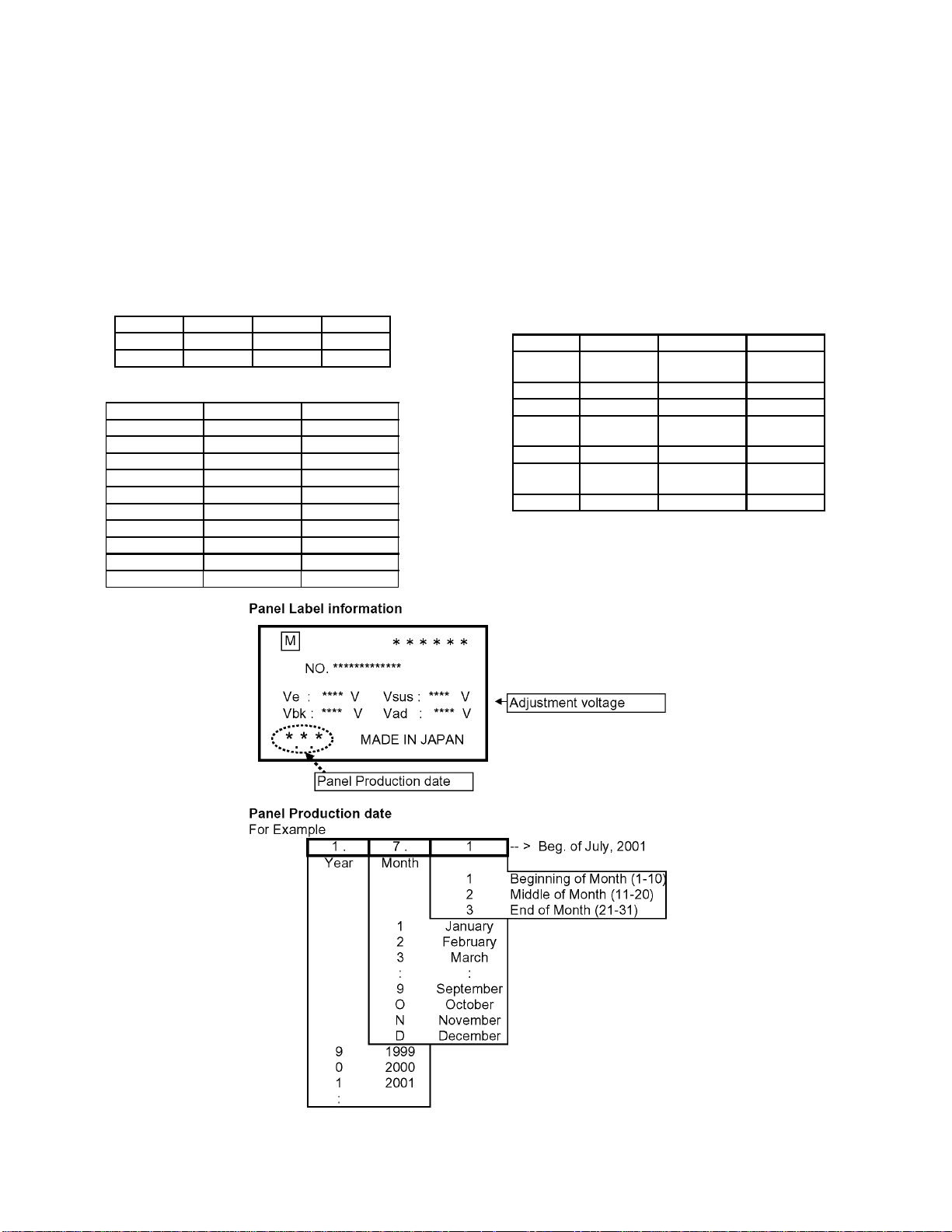

8.4. P.C.B. (Printed Circuit Board) exchange

8.4.1. Caution

1. To remove P.C.B. , wait 1 minute after power was off for discharge from electrolysis capacitors.

8.4.2. Quick adjustment after P.C.B. exchange

P.C.B. Name Test Point Voltage Volume

P Board Vsus TPVSUS (SS) 170V ± 1V R540 (P)

Vda TPVDA (SS) 67V ± 1V R537 (P)

SC Board Vbk TPVBK (SC) 155V ± 5V R6443 (SC)

Vad TPVAD (SC) -90V ± 1V R6477 (SC)

SS Board Ve TPVE (SS) 150V ± 1V R6774 (SS)

153V ± 1V

D1 Board White blance, Pedestal and Sub brightness for NTSC, PAL, HD, PC and 625i signals

*See the Panel label.

8.5. Adjustment Volume Location

8.6. Test Point Location

∗ D1 board is not used for 42WP27C.

12

Page 13

9 Service mode

9.1. CAT (computer Aided Test) mode

To exit the CAT mode, access the ID mode and switch off the main power.

9.1.1. IIC mode

Select the IIC mode by Up/Dow n button on the remote control at the front page of CAT mode then press the Action button on

the remote control.

Subject and item are mentioned on page 14.

To exit the IIC mode, press the R button on the remote control.

13

Page 14

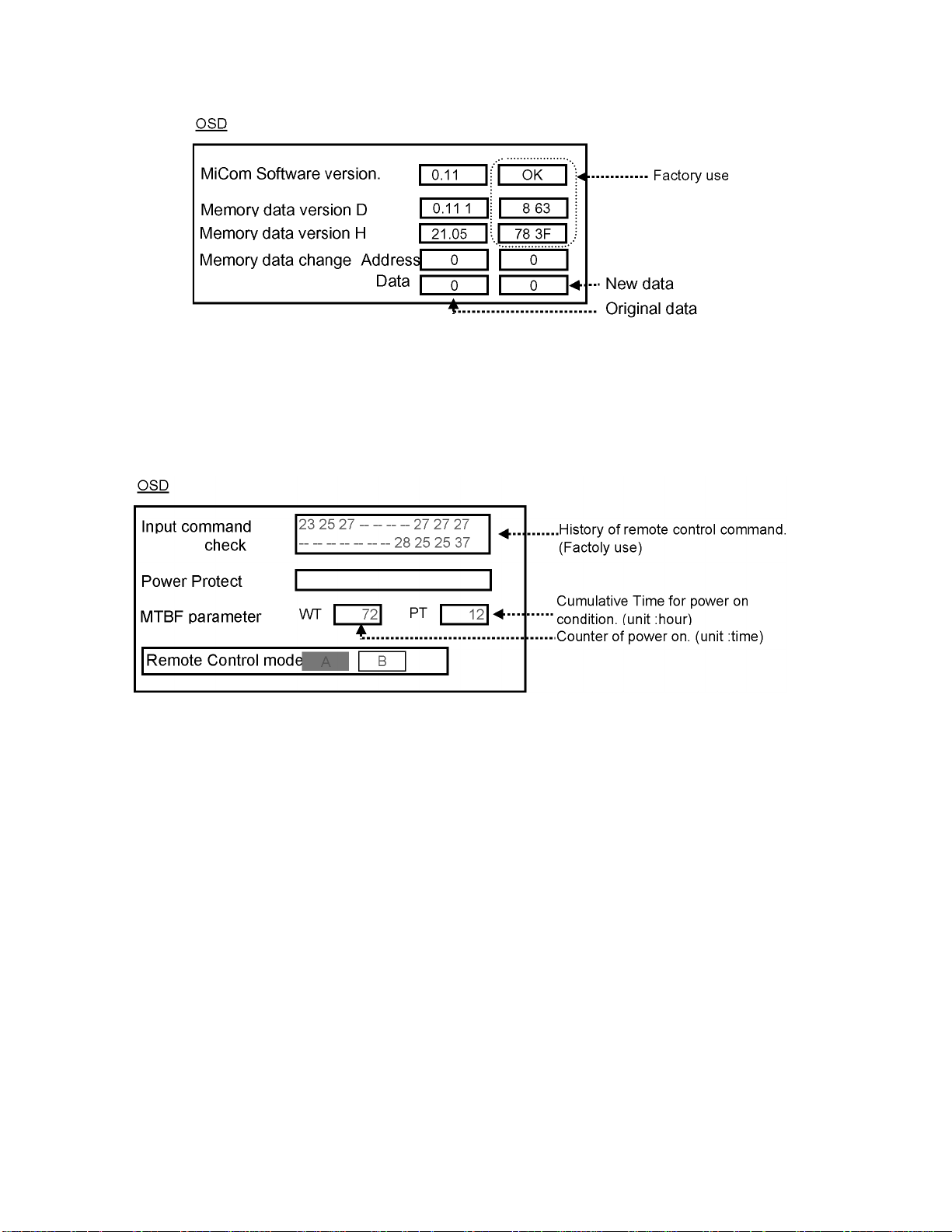

9.1.2. CD mode

Select the CD mode by Up/Down button on the remote control at the front page of CAT mode then press the Mute button on the

remote control more than 5 sec.

Micom software version (IC9354), this version can be upgrade by replace of new version IC.

To exit the CD mode, press the R button on the remote control.

9.1.3. SD mode

Select the SD mode by Up/Down button on the remote control at the front page of CAT mode then press the Action button on the

remote control.

To exit the SD mode, press the R button on the remote control.

14

Page 15

9.2. IIC mode structure (following items value is sample data.)

15

Page 16

10 Alignment

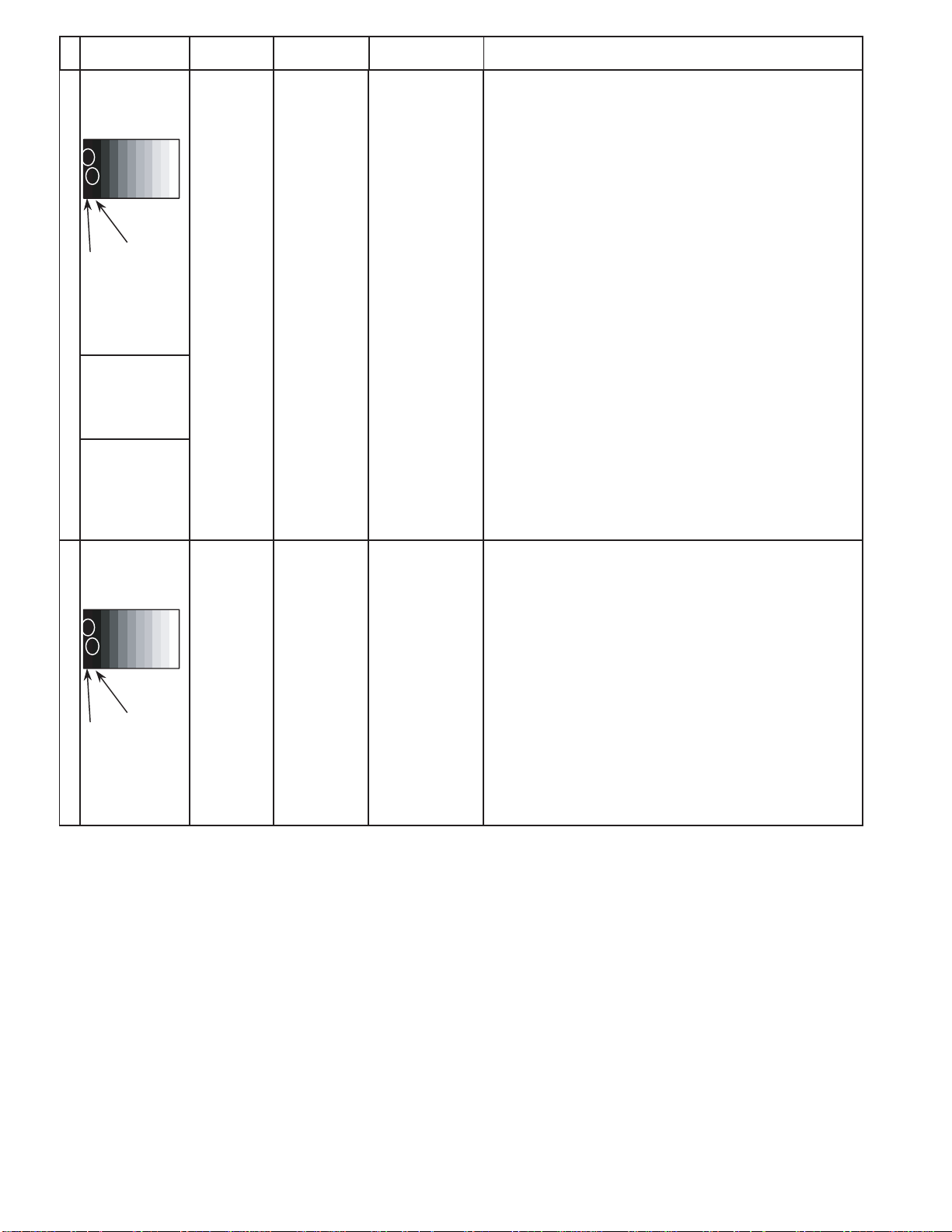

10.1. Pedestal setting

INPUT Alignment menu ProcedureEquipment Setting

** Adjust at the dark room.

1 Component Picture: PANEL W/B

(525i, 525p, 625i, Normal R cut off 1) Set R,G and B cut off to "

720i or 1080i) White balance: G cut off

Cool B cut off

Gray Scale Aspect:

Pattern 16:9

Black 2 %

Black 0 % at black 2% area and no emission at black 0% area.

Chroma Control:

Gun off

RGB Sub Adjust:

G Sub Bright

Chroma Control:

Gun off

RGB Sub Adjust:

B Sub Bright

Chroma Control:

Gun off

RGB Sub Adjust:

R Sub Bright

2) Set Gun off to "

3) Adjust G Sub bright to start some of green pixels emission

at black 2% area and no emission at black 0% area.

4) Set Gun off to "

5) Adjust B Sub bright to start some of blue pixels emission

6) Set Gun off to "

7) Adjust R Sub bright to start some of red pixels emission

at black 2% area and no emission at black 0% area.

5". (Only green pixels can emit.)

3". (Only blue pixels can emit.)

6". (Only red pixels can emit.)

80 ".

2 RGB(PC) Picture: 1) Change input to RGB signal.

Gray Scale Normal PANEL W/B

Pattern White balance: R,G,B cut off 2) Repeat procedure 1) to 7) of Component input signal.

Cool PANEL W/B

Aspect: R,G,B Drive

16:9

Black 2 %

Black 0 %

16

Page 17

10.2. NTSC panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 NTSC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-01.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

PANEL W/B

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

exactly.

2

to 10 cd/m

6)Find 75% of white area by color sensor.

G Drive 7) Set G Drive to " E8 ".

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-01.

9) Repeat item 4) to 7) to set both Low light and

high light.

.

2

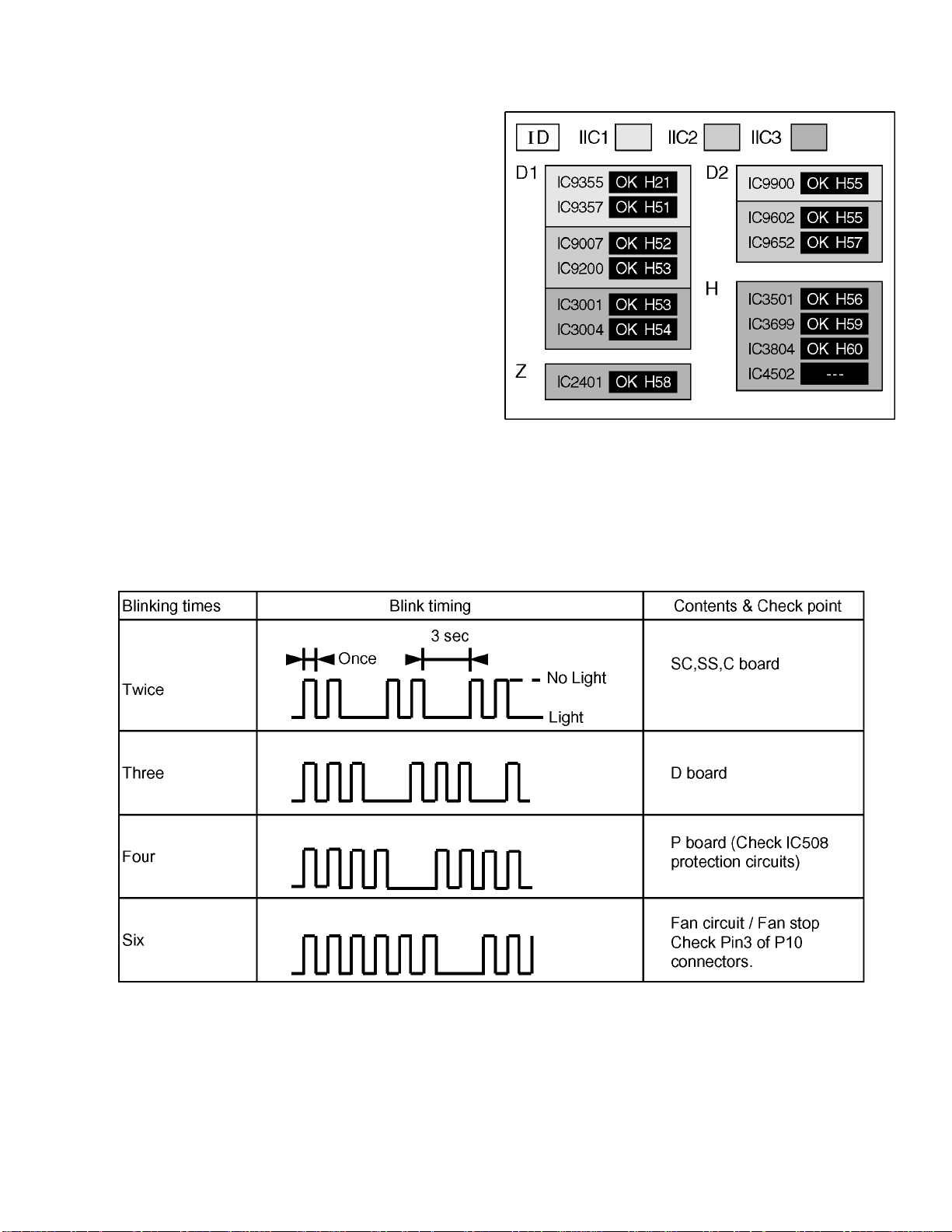

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -01

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

17

Page 18

10.3. PAL/SECAM panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PAL Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-02.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " E8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-02.

9) Repeat procedure 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -02

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

18

Page 19

Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

Cool

Normal

Warm

SECAM signal 2) Input SECAM signal.

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

3) Copy PAL R,G,B drive and cut off data of each white

balance mode to SECAM position.

19

Page 20

10.4. PC/RGB panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1 PC Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-03.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " E8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-03.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -03

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

20

Page 21

INPUT Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

RGB

Gray Scale

Pattern

White balance:

Cool R Drive

Normal G Drive

Warm B Drive

Balance Cool Normal Warm

R Cut off

G Cut off

B Cut off

2) Input RGB signal.

High light 75%

Low light 15% 3) Copy PC R,G,B drive and cut off data of each white

balance mode to RGB position.

6 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

DVI

Gray Scale

Pattern

White balance:

Cool R Drive

Normal G Drive

Warm B Drive

Balance Cool Normal Warm

R Cut off

G Cut off

B Cut off

2) Input DVI signal.

High light 75%

Low light 15% 3) Copy PC R,G,B drive and cut off data of each white

balance mode to DVI position.

21

Page 22

10.5. HD/ 525i /525p panel white balance

INPUT Alignment menu ProcedureEquipment Setting

1HD(720i or 1080i) Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-04.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

PANEL W/B

G Drive 7) Set G Drive to " E8 ".

PANEL W/B

R Drive as shown Fig.-04.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

exactly.

2

to 10 cd/m

6)Find 75% of white area by color sensor.

B Drive 8) Adjust B and R Drive to set color temperature

9) Repeat item 4) to 7) to set both Low light and

high light.

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -04

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal

PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm

PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

22

Page 23

INPUT Alignment menu ProcedureEquipment Setting

5 Picture: 1) Write down each color temaparature of R,G,B drive and

Normal Cut off data as follows.

Aspect:

16:9

White

White balance:

RGB

Gray Scale

Pattern

High light 75%

Low light 15% 3) Copy HD drive and cut off data of each white

Cool

Normal

Warm

Balance Cool Normal Warm

R Drive

G Drive

B Drive

R Cut off

G Cut off

B Cut off

2)Change input signal to 525i and 525p.

balance mode to each signals position.

23

Page 24

10.6. 625i panel balance

INPUT Alignment menu ProcedureEquipment Setting

1 625i Color Picture: 1) Find the nearest area to brightness of 10 cd/m2 as Low

Gray Scale Analyzer Normal Sub Adjust light by color sensor.

Pattern White balance: Sub Bright 2) Adjust Sub bright to set Low light level to 10 cd/m

Cool exactly.

Aspect: PANEL W/B

16:9 G cut off 3) Set G cut off to " 80 ".

PANEL W/B

B cut off 4) Adjust B and R cut off to set color temperature as

R cut off shown Fig.-05.

High light 75% Sub Adjust

Low light 15% Sub Bright 5) If Sub Bright is changed re-adjust it to set Low light

to 10 cd/m

6)Find 75% of white area by color sensor.

PANEL W/B

G Drive 7) Set G Drive to " E8 ".

PANEL W/B

B Drive 8) Adjust B and R Drive to set color temperature

R Drive as shown Fig.-05.

9) Repeat item 4) to 7) to set both Low light and

high light.

PANEL W/B

R,G,B Drive 10) Increase same steps of R, G and B Drive to set

R,G,B Drive largest level of 3 color drive to "FC".

PANEL W/B

R,G,B cut off 11) Re-adjust Low light level again.

2

.

2

Color Temp. x y

Cool(Hi) 0.272 0.290

Normal(Mid) 0.288 0.296

Warm(Low) 0.313 0.329

Fig. -05

2 Picture: 1) Change white balance to "Normal".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Normal PANEL W/B

Aspect: R,G,B Drive

16:9

3 Picture: 1) Change white balance to "Warm".

Normal PANEL W/B

White balance: R,G,B cut off 2) Repeat procedure 3) to 11) of Cool mode.

Warm PANEL W/B

Aspect: R,G,B Drive

16:9

4 Picture: Picture Menu 1) Change color templature to "Cool".

Normal Sub Adjust

White balance: Sub Bright 2)Re-set Sub bright to "30"

Cool

Aspect:

16:9

24

Page 25

10.7. Sub brightness setting

INPUT Alignment menu ProcedureEquipment Setting

** Adjust at the dark room.

1 NTSC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

Cool

.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

** Adjust at the dark room.

2 PAL Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

SECAM 8) Change to SECAM signal.

Gray Scale

Pattern 9) Copy PAL All cut off data to SECAM mode.

Nornal

warm

Cool

Nornal

warm

.

.

.

.

.

** Adjust at the dark room.

3 PC Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

7) Adjust All cut off to set same data of Cool mode.

RGB

Gray Scale

Pattern

DVI

Gray Scale

Pattern

8) Change to RGB input signal.

9) Copy PC All cut off data to RGB mode.

10) Change to DVI input signal.

11) Copy PC All cut off data to DVI mode.

Cool

Nornal

warm

.

.

.

25

Page 26

Alignment menu ProcedureINPUT Equipment Setting

** Adjust at the dark room.

4 525i Picture: PANEL W/B

Gray Scale Normal All cut off 1) Set white balance to

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

Cool

.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

525p 8) Change to 525p signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to 525p mode.

HD

(720i or 1080i) 8) Change to HD signal.

Gray Scale

Pattern 9) Copy 525i All cut off data to HD mode.

** Adjust at the dark room.

5 625i Picture: PANEL W/B

Cool

Gray Scale Normal All cut off 1) Set white balance to

.

Pattern Aspect:

16:9 2) Adjust All cut off to start some pixels emission

at black 2% area and no emission at black 0% area.

3) Write down all cut off data.

4) Set white balance to

Nornal

.

Black 2 %

Black 0 % 5) Adjust All cut off to set same data of Cool mode.

6) Set white balance to

warm

.

7) Adjust All cut off to set same data of Cool mode.

26

Page 27

11 Trouble shooting guide

11.1. Self Check

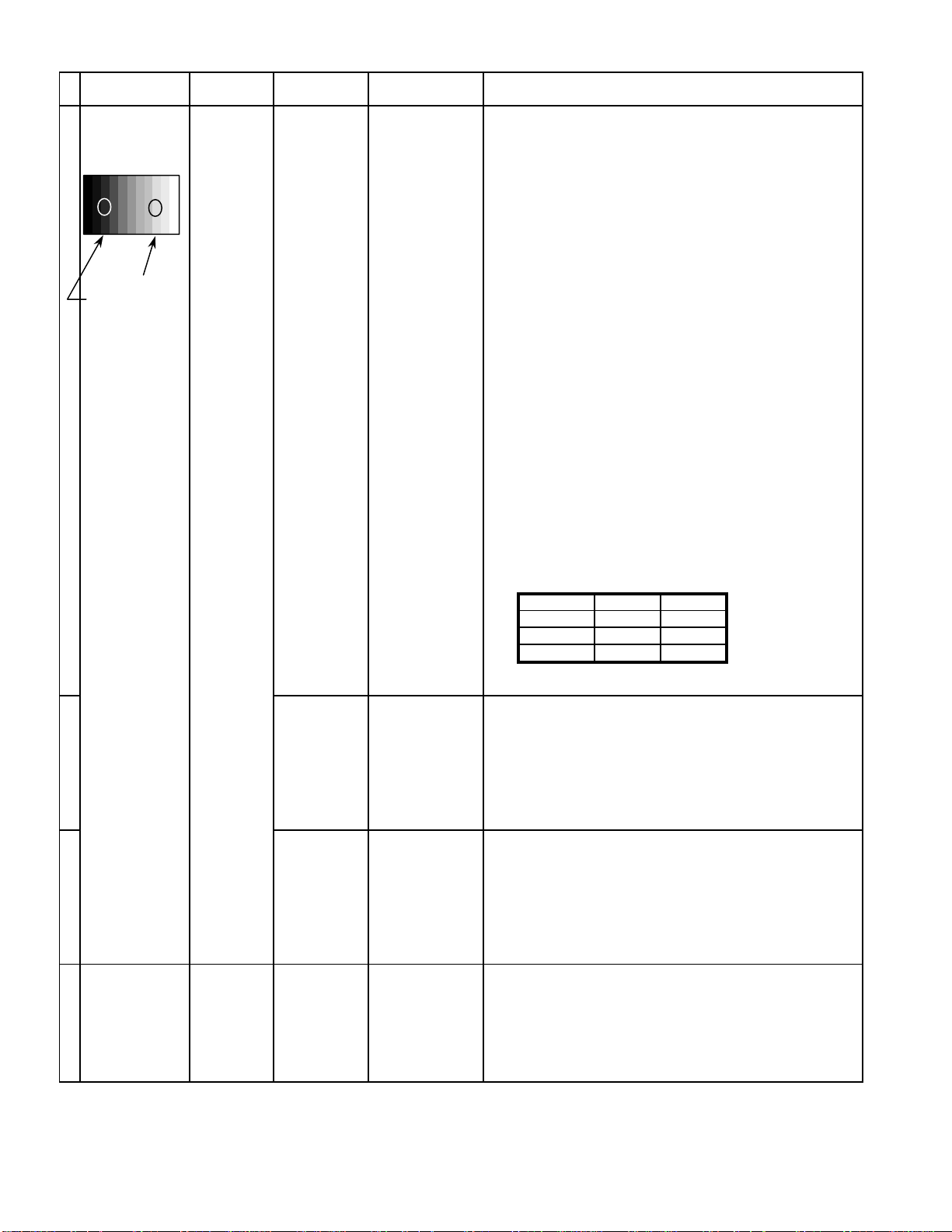

11.1.1. Display Indication

1.Self-check is used to automatically check the bus line

controlled circuit of the Plasma display.

2.To get into the Self-check mode, press the volume down

button on the customer controls at the front of the set, at the

same time pressing the OFF-TIMER button on the remote

control, and the screen will show :-

If the CCU ports have been checked and found to be incorrect

Or not located then " - - " will appear in place of " OK "

Note:

In case of disconnected of RTB421 “IC3699 - -” is

displayed.

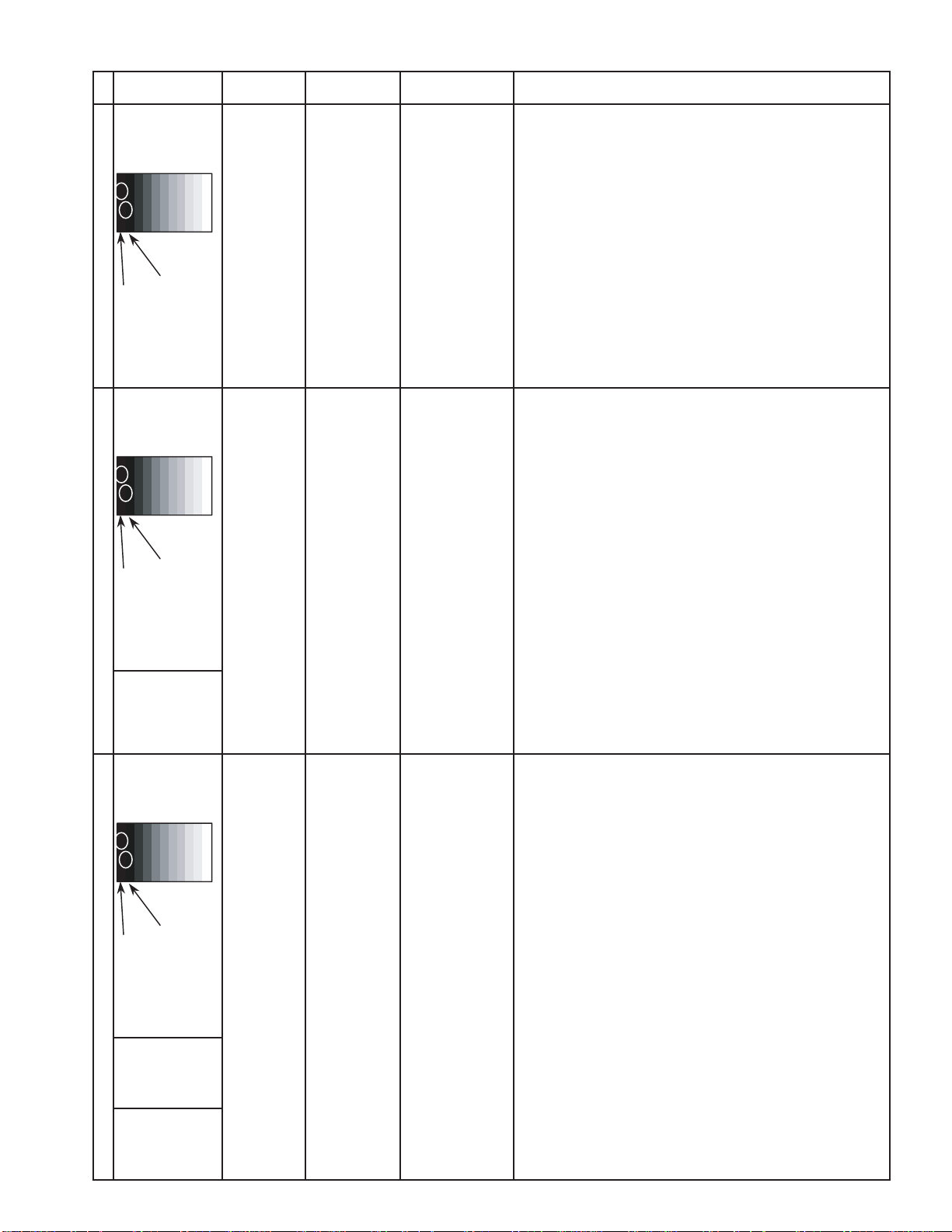

11.1.2. Power LED Blinking timing chart

1.Subject

Information of LED Flashing timing chart.

2.Contents

When an abnormality has occurred the unit, the protection circuit operates and reset to the stand by mode. At this time, the

defective block can be identified by the number of blinkes of the Power LED on the front panel of the unit.

3.Remarks

Above Fan function is operated during the fans are installed.

27

Page 28

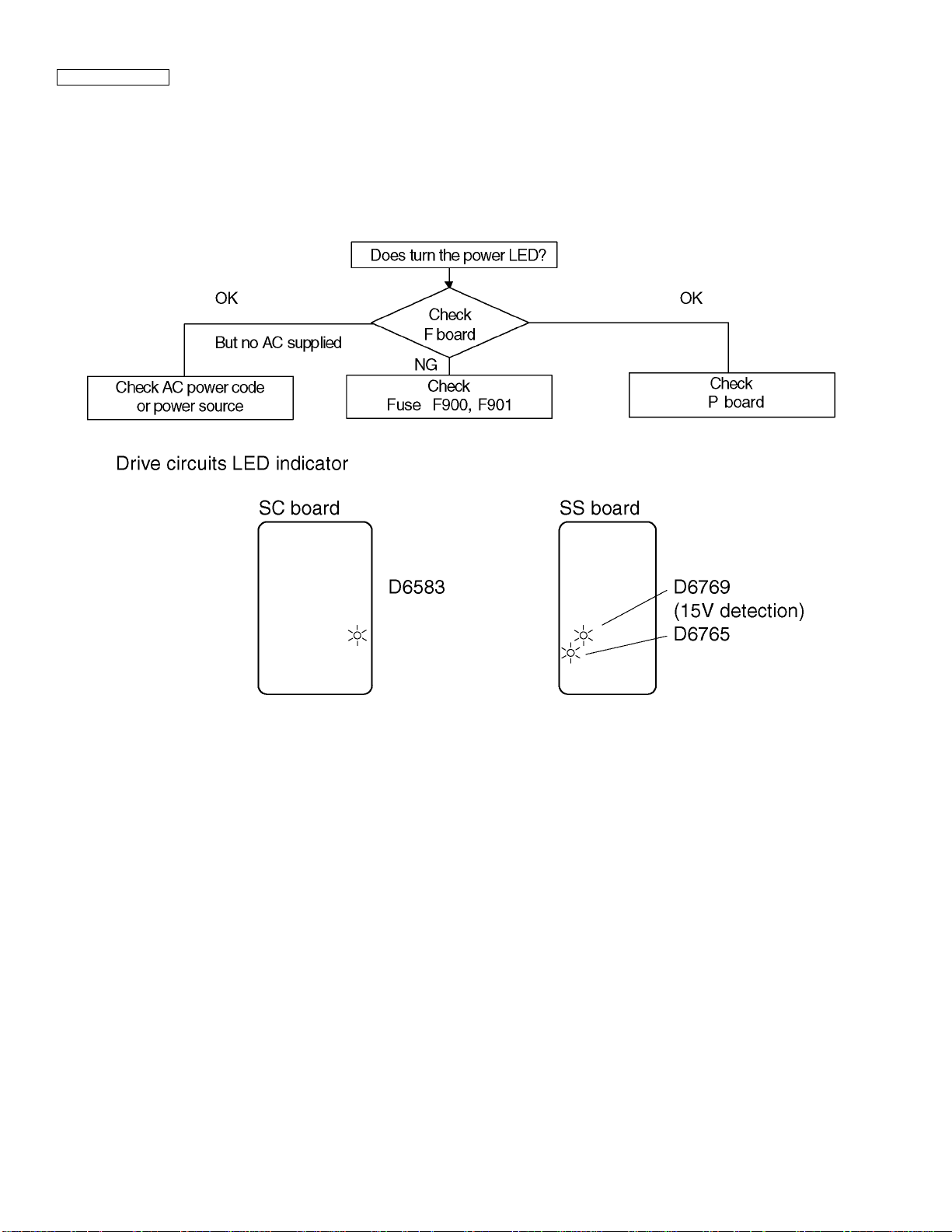

11.2. No Power

First check point

There are following 3 states of No Power indication by power LED.

1.No lit

2.Green is lit then turns red blinking a few seconds later.

3.Only red is lit.

1.No lit

28

Page 29

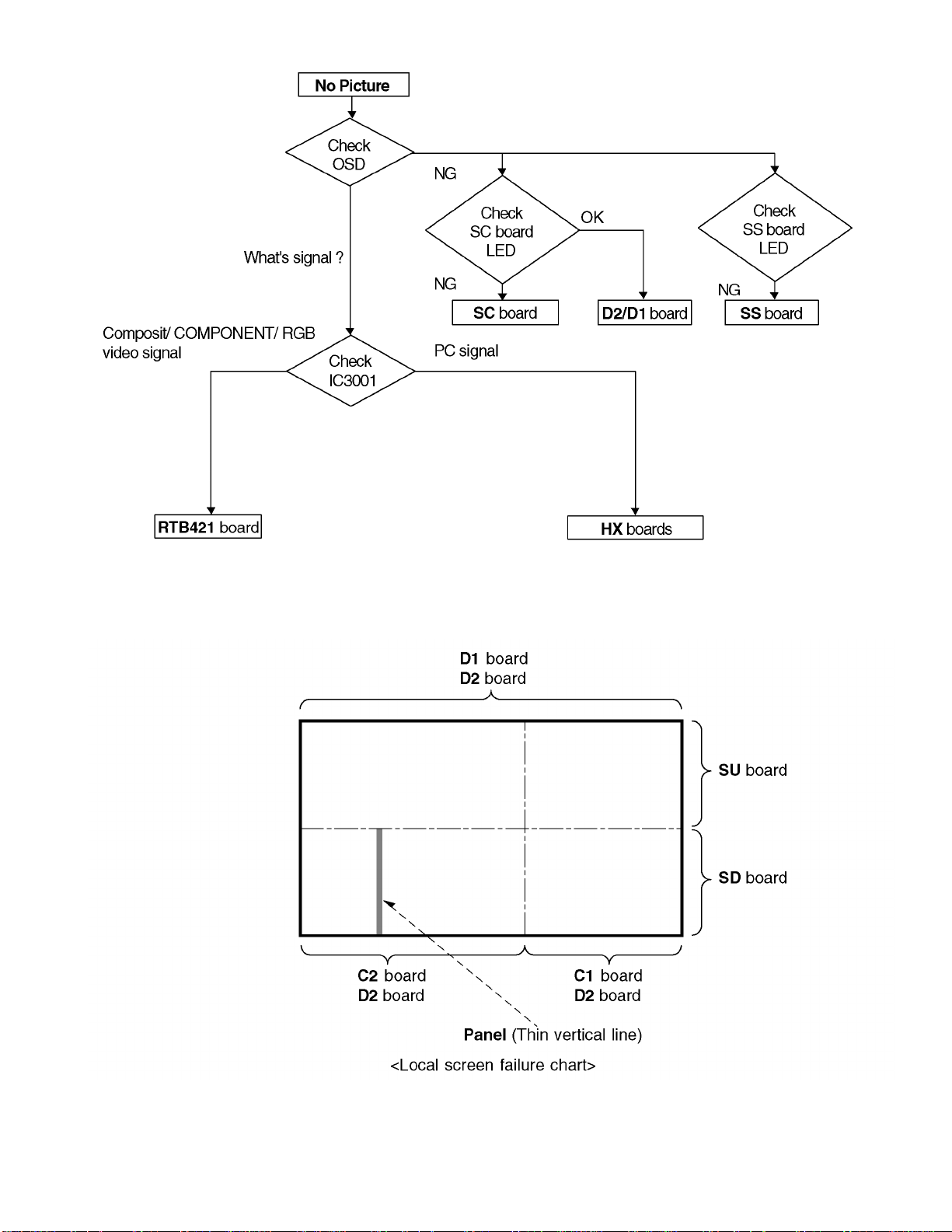

11.3. No Picture

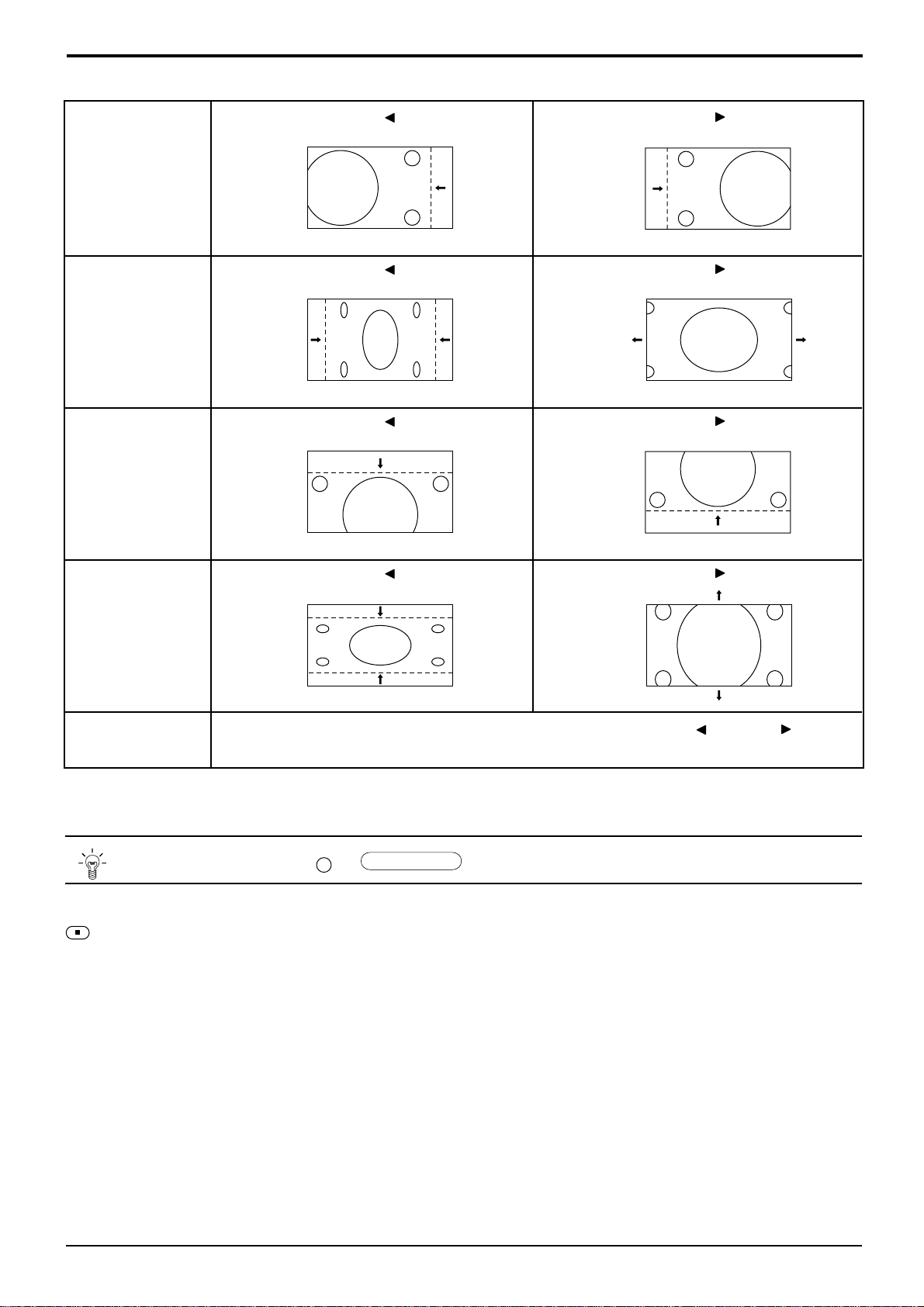

11.4. Local screen failure

Plasma display may have local area failure on the screen. Fig - 1 is the possible defect P.C.B. for each local area.

Fig - 1

29

Page 30

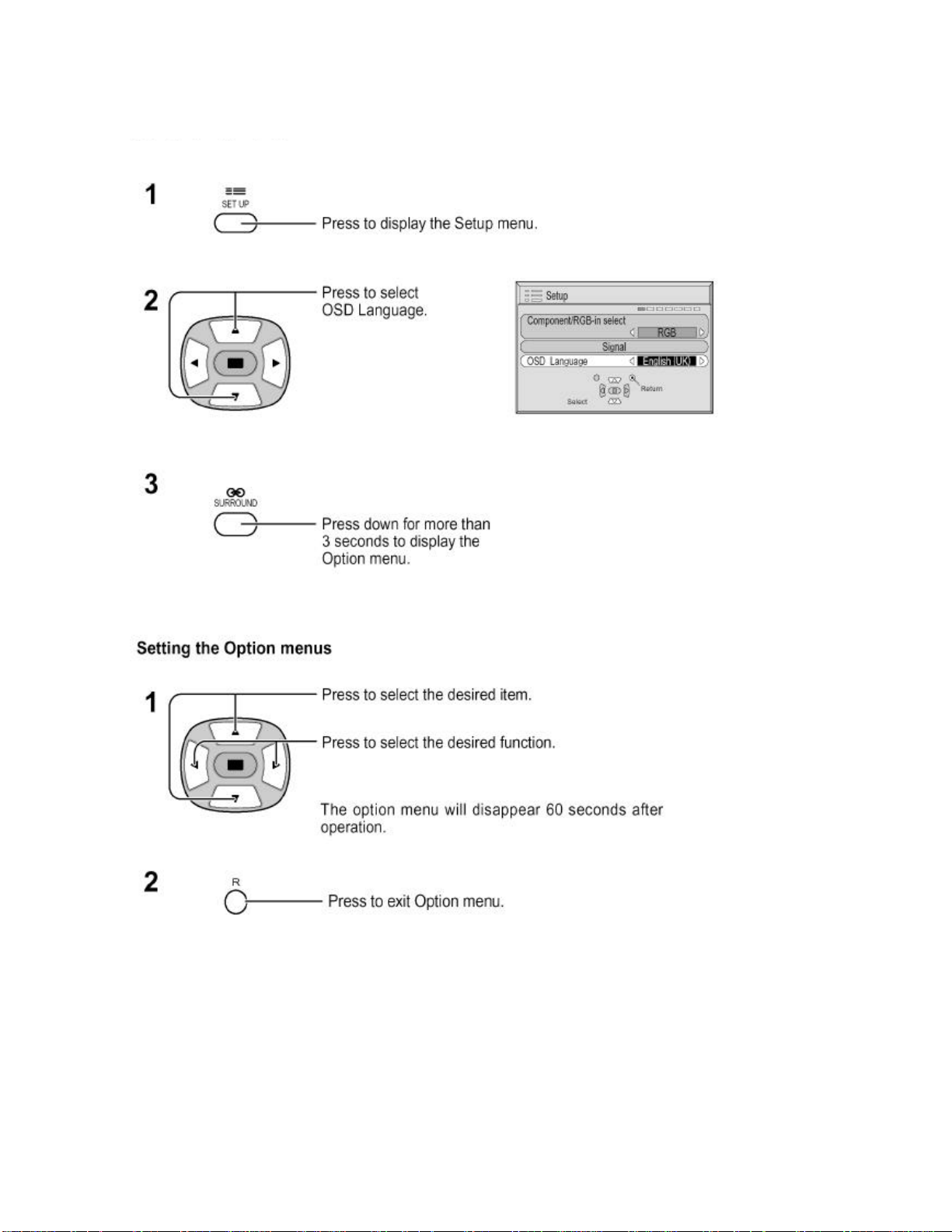

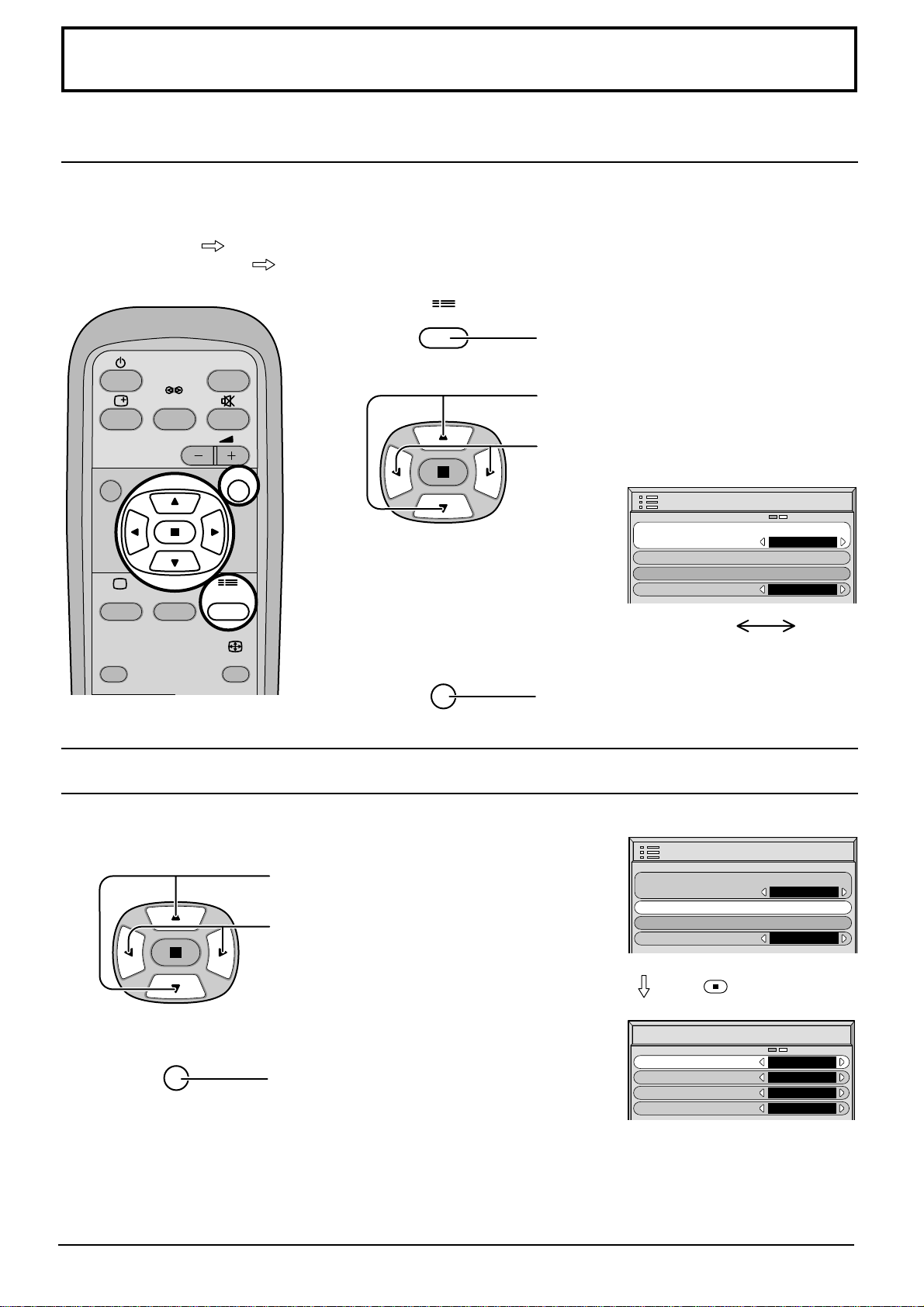

12 Option Setting

How to access the Option menu

30

Page 31

Hidden Option Menu for GP5D series

GP5D chassis series have special function and operation setting facility called Option Menu. This Option Menu is useful for

special function required customers. This should be set at the installation stage. The end user could not set or change these

because of hidden On screen menu.

Option menus default setting Contents

Wobbling Off Wobbling operation On/Off.

Off-timer function Enable Off-timer operation Enable/Disable.

On Screen display On Enable/Disable to display input mode indication after power on and no signal

Initial Input Off Sets the initial input mode when the power is turned on . Allow input mode

Initial VOL. level Off Sets the initial volume level when the power is turned on. Allow Volume control

Maximum VOL. Level Off Sets the maximum volume to desired level. Volume cannot exceed this level.

INPUT lock Off Fixes the input mode to AV, Component/RGB or PC. Can not change input

Button lock Off Enable/Disable front operation buttons (Input and/or volume up/down)

Studio W/B Off Set warm mode color temperature to 3,200 Kelvin.

Remocon User Level Off Remote key invalidation.

ID Select 0to100 Set ID number from 001 to 100.

Remote ID Off Remote ID function On/Off.

Serial Off Serial ID function On/Off

The outline of burnt image will be blurred by intermittent image sift.

indication.

selection while power is on.

while power is on.

mode by input selection key.

Off : Valid key is all key of remote.

User1 : Valid key are only Stand-by (ON/OFF), Input, Status, Surround, Sound

mute On/Off, and volume adjustment.

User2 : Valid key is only Stand-by (ON/OFF).

User3 : All keys are null and void

(While the Remote ID on, standard remote function can not control the unit.)

Note :

How to set Remocon User Level and Remote ID off

1.Access service mode (CAT-mode) and press SET UP key on remote.

2.Accsess Hidden option menu.

3.Change Remocon User Level and/ or Remote ID set to Off.

31

Page 32

This page is not printed.

32

Page 33

13 Conductor Views

13.1. F-Board

6

5

F

4

F-BOARD

TXN/F1MMSE

3

2

1

ABCDEFGH I

33

Page 34

13.2. P-Board

P-BOARD (FOIL SIDE)

TNPA2599

6

5

4

3

2

1

A

C E GIBDFH

34

Page 35

P

Parts Location

IC

IC410 D-4

IC411 E-5

IC430 D-3

IC465 B-5

IC501 B-2

IC502 C-3

IC503 B-3

IC504 C-4

IC505 C-4

IC506 E-5

IC507 D-5

IC508 B-5

P-BOARD (FOIL SIDE)

TRANSISTOR TP

Q401 F-5

Q402 F-5

Q403 F-5

Q410 F-5

Q431 D-2

Q432 D-3

Q433 D-3

Q434 D-3

Q435 B-2

Q436 B-2

Q437 B-2

Q438 B-3

Q439 A-3

Q501 A-2

Q502 C-5

Q503 B-5

Q504 B-5

Q505 B-5

Q506 F-5

TPP1 B-1

Parts Location

IC

IC410 B-4

IC411 A-5

IC430 B-3

IC465 E-5

IC501 E-2

IC502 D-3

IC503 D-3

IC504 D-4

IC505 D-4

IC506 B-5

IC507 C-5

IC508 E-5

P-BOARD (COMPONENT SIDE)

TRANSISTOR TP

Q401 A-5

Q402 A-5

Q403 A-5

Q410 A-6

Q431 C-2

Q432 C-3

Q433 C-2

Q434 C-3

Q435 E-2

Q436 E-2

Q437 E-2

Q438 E-3

Q439 E-3

Q501 E-2

Q502 D-5

Q503 D-5

Q504 D-5

Q505 E-5

Q506 A-5

TPP1 E-1

35

Page 36

P-BOARD (COMPONENT SIDE)

TNPA2599

6

5

4

3

2

1

A

C E GIBDFH

36

Page 37

13.3. HX-Board

6

HX-BOARD(FOIL SIDE)

TZTNP001PMSE

HX-BOARD(COMPONENT SIDE)

TZTNP001PMSE

5

4

HX

Parts Location

HX-BOARD

IC

3

IC3502 F-2

IC3515 E-2

TRANSISTOR

Q3507 F-3

Q3508 F-3

Q3509 F-3

Q3513 E-4

Q3514 E-4

Q3515 F-4

Q3516 F-4

Q3531 E-3

Q3532 F-3

2

1

ABCDEFGH I

37

Page 38

13.4. Option RTB421

6

RTB421-BOARD(FOIL SIDE)

TXNHZ10JJS

5

4

5

JS32

JS31

41

TP327

TP330

IC699

A2

A24

A25

B24

B25

TP328

TP329

R516

R519

R520

8

C506

TP331

R522

R521

R517

R518

C709

C705

C706

C896

C707

C702

C704

C862

C863

R841

C854

H1

Q816

R897

R866

R880

R882

C895

R883

C888

R843

R878

Q814

R888

C869

R887

C867

R847

R842

TP332

JS15

R872

C876

C889

R851

R881

JS14

JS16

R861

C891

R852

C899

R870

Q817

A20

A1

A19

B2

B20

B1

B19

JS13

TP333

C885

C877

R860

TP334

R853

C882

C884

C897

C874

R848

R864

R865

R874

R877

JS28

JS29

JS30

TP323

TP315

R537

R550

R534

JS19

R869

R846

C729

C878

C880

C881

TP316

R549

R509

R514

R508

R503

R879

R886

R875

R873

TP317

JS36

JS35

H2

TP322

TP314

R536

R533

R868

R535

R548

R507

R513

R506

R502

JS23

R876

R885

A2

A1

B2

B1

TP313

C507

R511

R505

R504

R532

JS21

R501

2

JS22

JS24

JS20

HZ

RTB421

3

CR NO.

R340

R337

Q306

R345

R348

TP318

2

R346

R330

R331

JK305

R

C307

TP305

R347

TP319

R327

R336

C306

R328

R329

R306

R342

C309

R344

R343

R341

R326

R321

R315

R314

R308

TP303

TP304

B

C843

JS8

R814

Q808

C807

R305

TP302

TP301

R809

R810

R896

R805

Q804

R804

R310

R319

R307

C302

R303

C301

R304

R309

R349

R350

JK301

C

R819

R807

C819

R821

R822

R817

R322

R384

R381 R382

C356

R359

R352

TP307

JK307

R

3

Q302

R324

R320

R312

R317

R313

R301

Y

GR

C824

C840

C841

R831

R830

C839

R829

Q810

R380

TP306

R832

R833

R823

R824

Q809

R825

R827

R383

C355

R358

R351

L

TP312

R828

C825

R826

JS9

C828

R834

C832

C822

TP321

R378

R366

R379

R361

R367

C352

R357

JK308

GAP11

R

R836

C826

C820

R816

R806

R393

R389

C351

TP311

GAP10

L

C842

JS10

R813

R812

L807

C805

R808

C801

R803

TP320

TP324

R394

R390

R360

R391

C359

R356

R355

TP310

JK306

GAP9

R

L805

TP325

TP326

R392

R385

R368

R365

C358

C360

C357

TP309

C354

R354

C353

R353

TP308

GAP8

GAP7

B

SEE REVERSE FOR ORDERNO.

TNPA2248

Parts Location

RTB421-BOARD (FOIL SIDE)

IC

IC3699 B-4 Q3302 B-2

GR

TRANSISTOR

Q3306 A-2

Q3804 B-2

Q3808 C-3

Q3809 C-2

Q3810 C-2

Q3814 C-4

Q3816 C-4

Q3817 C-3

1

ABCDEFGH I

38

Page 39

6

RTB421-BOARD(COMPONENT SIDE)

TXNHZ10JJS

5

A2

A1

B2

B1

C513

R552

R538

TPHY1

Q501

C502

4

TNPA2248

ORDER

L817

NO.

3

HZ

2

C363

C362

L359

GR B

Q507

NP

L815

C701

L805

JS4

JS1

Q356

Q351

R362

R373

R363

R364

R377

L353

H2

R551

Q510

TPHR1

TPHB1

Q502

NP

C503

L818

Q813

C898

C700

L830

C723

C726

1

C844

C812

C803

C813

C814

L804

Q357

R386

R374

R388

L354

JK306

R540

R539

Q508

Q503

NP

C504

Q815

L819

Q812

R889

R856

R890

R884

1

TPHV1

TPHH1

L820L821

L809

C815

Q805

L803

C802

L806

R811

R387

L355

RL

A20

A2

A19

A1

B20

B2

B19

B1

H1

C509

C510

C511

L501

R892

Q509

Q308

R891

R858

R867

R854

C887

R855

8

C365

5

1

R845

4

IC303

R844

JS18

C864

1120

C855

IC809

10

JS7

Q801

D352

C852

R835

D801

4

5

52

C808

1

IC802

3

NP

Q803

L801

R801

Q358

C806

C804

Q359

L356

JK308

C512

L825

C712C713

C718

C717

R894

L814

C892

C893

R849

R857

C879

R859

R850

C870

IC804

208

53

C833

C836

R818

C818

C835

1

2

3

4

IC801

L808

C817

JS3

Q353

D351

JS17

C875

L813

R863

C872

R871

R862

C883

C868

C830

C834

C838

C837

C821

NP

C816

C823

Q352

C361

R371

R375

C364

L358

L357

GAP5

L822

C711

L824

C710

C716

C728

C890

C727

C871

C873

C886

157

105

104

C831

X801

Q807

R820

Q355

Q354

JS2

R372

R376

L351

L823

R895

C715

C714

C894

3

4

IC805

3

L812

4

156

C865

C866

IC806

L811

C861

R840

C853

R838

C851

C850

C846

C847

JS12

JS11

C810

C809

R815

Q806

Q802

C313

R370

R369

GAP6

C314

L307

L352

JK307

RLR

A24

A25

B24

B25

C505

C501

1

IC501

1

R541

L816

8

2

1

2

1

26

C849

C845

50

16

9

C703

IC803

8

H0

L826

L827

L828

L829

8

IC699

C708

1

C848

R839

L810

C829

45

C857

C858

RTB421

Parts Location

25

C856

R837

1

RTB421-BOARD (COMPONENT SIDE)

R802

Q301

GAP1

R316

L301

C

C859

JS6

LC805

JS5

CR2NO.

L802

R311

L302

JK301

IC

C860

3

C303

GAP2

Y

C811

R396

IC302

R893

R335

Q307

C304

L303

GR

5

C312

JK305

4

3

R395

1

L306

C310

C311

45

Q305

R332

IC301

Q304

GAP3

R339

R338

R333

GAP4

R

L305

1

R325

L304

B

Q309

R334

R323

8

C305

Q303

R318

GAP12

IC3301 E-2

IC3301 E-2

IC3302 D-2

IC3303 B-4

IC3501 D-4

IC3699 D-4

IC3801 B-2

IC3802 B-3

IC3803 D-3

IC3804 C-4

IC3805 C-4

IC3806 C-4

IC3809 B-3

TRANSISTOR

Q3301 D-2

Q3303 D-2

Q3304 E-2

Q3305 E-2

Q3307 D-2

Q3308 B-4

Q3309 D-2

Q3351 A-2

Q3352 C-2

Q3353 B-2

Q3354 C-2

Q3355 C-2

Q3356 A-2

Q3357 B-2

Q3358 B-2

Q3359 B-2

Q3501 A-4

Q3502 A-4

Q3503 B-4

Q3507 A-4

Q3508 B-4

Q3509 B-4

Q3510 B-5

Q3801 B-2

Q3802 C-2

Q3803 B-2

Q3805 B-3

Q3806 C-2

Q3807 C-2

Q3812 B-4

Q3813 B-4

Q3815 B-4

TP

TPHB1 B-5

TPHH1 B-4

TPHR1 B-5

TPHV1 B-4

TPHY1 A-4

1

ABCDEFGH I

39

Page 40

13.5. D1-Board

D1-BOARD(FOIL SIDE)

6

5

4

3

2

TZTNP01PMSF (F VERSION)

TZTNP02PMSF (E/B/R VERSION)

TNPA2426

SEE REVERSE FOR ORDERNO.

3

D1

D9202

12 3

C9307

C9315

C9306

R9291

C9262

R9470

R9125

R9126

R9292

C9001

C9312

C9301

R9421

R9476

C9264

R9300

C9451

C9263

C9452

R9127

C9313

R9459

C9453

R9458

R9290

C9300

R9294

R9288

D9000

R9129

C9454

C9455

R9121

C9255

R9462

C9308

C9404

R9460

C9309

R9123

C9413

C9257

C9303

C9302

R9453

R9461

R9454

R9463

R9262

R9452

R9263

C9405

C9311

R9308

R9455

R9296

C9310

R9451

R9297

R9456

R9295

R9275

R9450

R9457

R9436

R9472

R9473

C9459

C9243

R9464

C9458

C9237

R9438

R9403

C9258

C9259

R9466

R9467

C9226

C9461

C9216

C9229

R9422

R9439

R9468

C9236

C9460

R9465

C9220

C9225

R9471

C9219

C9246

C9464

R9261

C9205

R9469

C9024

IC9004

C9244

R9474

C9206

C9204

R9064

R9244

C9019

C9245

R9188

C9023

R9185

R9245

IC9003

C9407

C9462

C9463

R9186

R9259

R9187

R9061

R9184

C9406

C9018

C9069

C9210

C9209

R9246

C9375

C9372

C9370

C9369

C9367

R9247

C9022

R9168

R9165

R9201

R9437

IC9002

D9353

R9166

R9059

R9402

R9167

C9017

R9397

R9396

R9395

R9394

R9392

R9164

R9208

R9328

C9059

R9202

R9200

R9228

R4602

R3046

R9178

C9043

C9044

R4601

C9373

R9175

R9212

R3045

C9409

R9398

Q3086

R9211

R4604

R4605

C9410

C9378

R4521

C9416

C9211

R9433

R4525

R3047

R9176

C9068

C9058

R4560

C9391

Q9504

R9432

C9063

R4551

C9417

R3106

C3017

R3107

C3016

C9377

C4518

R3108

C3015

D3001

C4519

C9526

C3014

R3105

C9371

R9113

7

R9393

C9033

C9037

C9525

D1

C9383

C9385

C9368

C9353

R9364

C9356

R9426

C9388

R9362

R9363

R9365

R9366

R9355

R9367

R9368

R9369

C9358

R9359

R9358

C9362

R9376

R9110

R9391

C9364

C9365

C9366

C9363

C9048

C9045

R9077

C9039

C9041

C9035

C9032

C9025

6

1

12

8

1

4

5

C9522

C9521

R9038

R3013

C3018

R3012

R3011

R9051

R9039

C3013

R9040

R9041

C9359

R9378

R9390

R9387

R9388

R9389

C9038

R9082

C9040

C9021

R9018

C9014

6

712

8

1

4

5

C9524

R9050

C9361

C9360

R9480

1

C9036

R3010

C9015

R3009

C9042

1

4

R3007

C8021

R9036

R9037

R9010

R3104

R9008

R3103

C3012

R9427

R9425

IC8001

11

6

712

58

C9523

R9048

R9000

R3101

R3102

C3009

C3047

C3046

C3011

R3004

C3010

D9354

R9069

R9080

D8001

C9056

LC9001

C9516

R9092

Q3014

R9034

R8005

C9062

R9072

R3028

D8002

C8003

L9012

R8001

R3016

C3041

R3029

C9061

R3039

R3079

R9035

R8006

C8001

R3018

D9003

R9354

R9357

R3078

R3026

D9008

D9009

R3019

R3036

R9045

Q9502

C9400

R9046

C3040

Q9503

Q3013

R3024

R3035

R3037

R3030

R3031

C9007

R3017

R3042

R3043

D9007

D9005

D9001

R9105

R3041

R9106

R3040

Parts Location

IC

IC8001 E-4

IC9002 C-2

IC9003 C-2

IC9004 C-2

D1-BOARD (FOIL SIDE)

TRANSISTOR

Q3013 E-2

Q3014 E-2

Q3086 C-4

Q9502 E-4

Q9503 E-4

Q9504 C-5

C9389

D9355

R9430

R9429

R9431

R9053

R9065

C8018

10

R9177

1

C9004

1

L3001

C3020

C3045

JS8019

C9005

C9013

C8006

R9152

R9100

C9517

R9099

C9067

R9068

R9078

R9071

R8013

C8009

L9013

R9150

R9086

C8015

C8008

C8005

R8007

C9057

C9066

L9011

R9070

LC9000

LC9002

R9081

C9515

R9151

R9093

R9085

R9073

20

1

B25

B24

A25

A24

D1 D2 D3

B1

B20

B2

B19

A1

A20

A2

A19

B2

B1

A2 A20

A1

B20

B19

A19

B2

B1

A2

A1

ABCDEFGH I

40

Page 41

D1-BOARD(COMPONENT SIDE)

6

TZTNP01PMSF (F VERSION)

TZTNP02PMSF (E/B/R VERSION)

D1

IC9353

C8016

R9084

12

64

L9005

C8017

C3006

C3007

C9357

D9352

R9382

C9354

C9355

R9371

R9356

2223

R9380

R9441

R9381

R9383

R9384

R9424

R9423

R9377

R9379

R9370

1

R9353

R9350

Q9500

C9351

L8001

R8027

C9031

5

4

13

5

4

C9012

13

IC9001

8

1

IC9011

16

9

LC9102

6

1

R9083

7

R9049

NP

L9008

51

C9009

52

1

R9351

C9380

R9361

R9372

32

20

R9400

R9360

R9399

C9028

L9401

R3015

C9374

R3014

R9052

IC9303

L9010

R9020

C9415

16

R9401

120

60

1

12

R9404

1

80

L9009

R9405

Q9350

61

R4552

R9410

R9407

R9406

C9049

IC9007

IC9012

C9047

C4551

L4551

L9400

15

R9323

40

41

R9374

R9375

R9479

80

81

R9385

R9386

D9351

TP59

R9352

21

IC9006

L9006

C9016

R9098

12

IC3001

40

C9034

R9019

R9373

41

C9026

C9027

1

8

IC9010

9

16

6

LC9100

1

R9097

7

R9063

R9060

NP

L9007

C9010

33

19

3D1

D2

B2

B1

A2

A1

120

D9356

21

L9350

R9440

C9400

C9387

40

5

IC9357

C9401

1

TP3088

5

IC3003

Q9103

D9002

R3022

L3008

4

Q9104

IC8002

IC3009

Q9105

5

4

8

1

C9390

R8002

L3003

R8004

16

16

Q9100

R9094

C9402

R8017

C8007

C8011

R8009

R9095

R8036

16

9

R8003

Q9101

R9096

Q8021

R3032

L3002

R3033

C3022

R3038

R9087

C9403

5

4

TP3086

814

R3020

C3024

Q9102

R9088

X9350

C9392

R8019

NP

C3021

C3023

R3027

Q9106

R9089

IC9354

IC9355

44

R8035

R8018

R8015

R8026

R8011

R8008

C8014

C8012

R8010

R8028

R8029

R8030

R8024

R8023

C8002

C9064

R9091

R9090

R9170

R9171

R9172

C9071

R3021

IC9000

C9011

C3019

R3001

R3002

R3003

Q9107

Q9108

TNPA2426

R9117

R9116

R9118

TP3089

C8020

IC8001

1

C8010

C8013

10

C9060

6

7

ORDER

LC9101

C3005

R9174

9

C3003

8

C3004

R8025

R9058

R9047

NP

NO.

C3008

20

11

C9008

C3001

C3002

8

R9104

D9006

D4

R9103

112

LC9003

D9004

R9102

R9115

C9054

R8033

4

3

2

R8012

C8019

17

L8002

C3049

8

R3087

1

Q3085

R3109

1

R3088

IC3004

89

C3050

L3007

1

IC3002

89

R3023

R3034

C3026

C3027

1

R3025

8

D3

1

B2

B1

A2

A1

B20

B19

A20

A19

10

R4561

R9324

R9309

C9321

R9420

R9428

C9379

1

11

R9435

IC9005

R9203

R9204

R9207

R9205

R9206

R9210

14

17

L9201

C9414

20

R9477

L9402

C9412R9322

R9327

120

8

R9416

R9434

11

5

8

X9450

X9200

C9046

IC4551

160

121

R9415

R9293

R9278

1

20

C9393

IC9351

C9381

IC9356

C9260

R9043

R9044

R9277

R9299

R9329

R9408

R9411

10

R9417

R9418

R9409

1

C9382

R9419

R9413

14

12

10

7

6

5

4

4

1

R9414

23

22

21

20

19

18

17

16

15

13

11

8

R9248

R9325

9

3

2

1

IC9302

R9412

R9173

R9254

IC9206

1

C9408

R9326

18

R9109

R9475

C9467

C9466

X9451

IC9452

17

814

8

1

4

L9451

R9160

C9055

C9213

ABCD

C9411

R9271

R9257

R9274

R9273

R9265

R9249

R9268

R9266

R9270

R9269

R9267

R9264

R9076

R9161

L9200

R9298

R9321

IC9210

IC9454

5

C9465

R9444

R9182

C9065

R9180

R9181

R9162

R9163

C9072

C9070

C9000

C9002

45

3

1

IC9203

R9224

C9215

C9212

F

HJKLMNPRTUVWY

G

E

C9217

R9449

R9183

R9448

R9445

D1

B1

B20

B2

B19

A1

A20

A2

A19

R9442

R9447

R9443

C9218

45

R9446

108

R9223

R9241

D17

13

72

73

109

R9242

R9243

IC9200

4486

43

85

1

IC9450

C9450

IC9453

C9456

IC9451

C9457

R9122

R9124

R9128

C9202

C9203

R9239

R9240

C9208

AAABAC

C9207

20

1

10

11

R9285

IC9207

R9287

R9286

R9877

56

IC9300

R9876

R9306

128

R9307

R9301

R9302

R9255

R9878

4

D12

2

D13

C9256

R9253

R9229

R9879

R9303

C3037

50

50

2

1

IC9455

37

144

1

7

R9880

R9304

D10

C9468

36

1

IC9212

29

R9305

1

R9478

C9261

14

R9881

8

C3033

49

1

49

1

C9469

C3035

C9472

45

3

L9450

C3036

C3034

C3042

IC3006

IC3007

4

C3038

C9320

C3031

L9002

L9001

C3028

IC9301

C9318

C3039

C9319

C9471

C9470

IC3008

LC9302

LC9301

LC9300

R9108

R9107

L9003

L9004

LC9006

1

Parts Location

10

D16

C3029

C3032

C3030

C3025

D3002

3

L9300

1

C9317

5

4

C9316

C9003

C9314

C9305

C9304

B25

B24

A25

A24

IC

D1-BOARD (COMPONENT SIDE)

IC3001 B-2

IC3002 A-3

IC3003 A-2

IC3004 A-3

IC3006 E-3

IC3007 E-3

IC3008 E-2

IC3009 A-4

IC4551 C-3

IC8001 B-4

IC8002 A-4

IC9000 B-2

IC9001 B-3

IC9005 C-3

IC9006 B-4

IC9007 C-4

IC9010 C-3

IC9011 B-3

IC9012 C-3

IC9200 D-2

IC9203 D-3

IC9206 D-2

IC9207 D-2

IC9210 D-2

IC9212 E-2

IC9300 D-2

IC9301 E-2

IC9303 C-2

IC9303 D-2

IC9351 C-5

IC9353 B-5

IC9354 B-5

IC9355 B-4

IC9356 C-4

IC9357 A-5

IC9450 D-5

IC9451 D-4

IC9452 D-5

IC9453 D-5

IC9454 D-4

IC9455 E-5

TRANSISTOR

Q3085 A-4

Q8021 A-4

Q9100 A-1

Q9101 A-1

Q9103 A-1

Q9104 A-1

Q9105 A-1

Q9106 A-1

Q9107 B-1

Q9108 B-1

Q9350 C-4

Q9500 B-4

TP

TP3086 A-4

TP3088 A-4

TP3089 B-4

TP59 C-4

ABCDEFGH I

41

Page 42

13.6. D2-Board

D2-BOARD (FOIL SIDE)

TNPA2589

6

5

4

3

2

1

D506

D507

R501

C504

R548

R993

R992

D501

D502

D503

D504

D505

R542

Q902

Q901

Q905

C993

R540

C994

C997

1

3

R538

C506

C921

C502

R536

C559

R563

R533

R990

R991

R969

R532

C995C996

R567

C922

D553

IC905

R561

R562

R564

R766

R765

R762

R767

R726

R727

C709

R731

R751

R750

R805

R804

R807

R806

R808

C802

20

R850

R825

11

R845

R891

R883

R849

C810

IC810

C812

R841

20

R893

R895

R892

20

IC817

11

20

IC819

11

20

IC821

11

R722

X701

Q701

R826

R827

R828

R729

R749

R884

R885

R723

R745

IC804

R761

C721

R741

C722

Q703

R854R855R856

R872

R873

R897

1

10

R863

R864

R865R866

R867

R868

R882

R801

R896

C804

11

R758

R759

R760

R802

L801

R878

R877

R874

R876

R875

L806

L805

R890

R889

20

R898

R899

R881

R886

R888

R887

L808

L807

R709

R816

R703

R702

R701

C817

1

C819

R715

10

10

10

10

10

C711

C712

1

1

1

1

C706

IC808

1

10

C821

R820

C808

R768

C708

R803

R822

C803

R728

R626

C703

R894

20

11

11

R771

R770

R769

R775

R711

R516

R523

R525

R527

123

CRNo.9

R528

R588

R526

R519

C626

R627

R524

C631

C627

R578

R518

R628

C624

D554

C628

C635

R517

C653

C629

R629

C652

R633

C634

R515

X651

C633

R514

R634

C617

C618

R968

X603

X602

C632

R930

R940

C918

R601

R939

R609

Q904

C610

R608

R615

R607

R926

C613

R927

R646

R640

C638

C619

R945

R616

R638

R943

R935

C639

R647

R946

R932

R925

C608

R643

R924

C623

R639

L601

R947

R934

R931

C607

C616

R624

R645

R933

R923

R949

C605

C606

R644

C910

R921

C621

R642

R952

C916

R922

R569

C611

R641

R953

R979

R617

R907

R961

R568

R956

C567

C615

5

8

R625

C622

R919

C566

C620

C612

R618

R918

R917

R914

IC902

C614

C603

C604

R913

C915

R958

R978

R904

R908

R905

R906

4

1

R909

R957

R902

R903

L701

C609

R530

R549

R572

R531

R573

R529

D2

1

C579

SEE REVERSE FOR ORDER NO.

TNPA2589

R552

R556

R557

16

Q501

R558

D550

C556

D551

C555

C553

C552

R553

1

R554

C578

R555

IC550

17

32

C560

R551

C551

R710

C717

C713

R704

R705

R706

R817

R798

C733

L802

R737

R739

R707

R708

R819

R821

R818

R823

R824

R836

R838

R736

R738

C707

R842

C702

IC812

C701

R813

R843

R797

C705

R837

R840

R839

A

C E GIBDFH

42

Page 43

D2

Parts Location

IC

IC9550 B-2

IC9804 F-3

IC9808 E-3

IC9810 F-2

IC9812 E-2

IC9817 F-2

IC9819 F-2

IC9821 F-1

IC9902 D-1

IC9905 B-3

D2-BOARD (FOIL SIDE)

TRANSISTOR

Q9501 B-1

Q9701 F-4

Q9703 F-4

Q9901 B-3

Q9902 B-4

Q9904 C-1

Q9905 B-3

Parts Location

IC

IC9551 F-4

IC9552 D-5

IC9553 E-2

IC9554 E-1

IC9555 E-6

IC9601 D-3

IC9602 D-5

IC9603 E-3

IC9604 E-4

IC9605 E-5

IC9612 D-4

IC9700 C-5

IC9701 C-4

IC9702 B-5

IC9703 C-5

IC9704 B-5

IC9710 B-5

IC9711 B-5

IC9712 A-5

IC9801 A-4

D2-BOARD (COMPONENT SIDE)

IC9802 B-3

IC9803 B-4

IC9805 C-3

IC9806 C-3

IC9807 C-2

IC9809 B-3

IC9811 B-3

IC9813 B-2

IC9814 C-2

IC9815 C-2

IC9816 C-1

IC9818 B-2

IC9820 B-2

IC9822 B-1

IC9900 D-2

IC9904 D-1

IC9907 F-4

TRANSISTOR

Q9502 E-2

Q9702 B-4

Q9802 C-1

Q9903 D-1

Q9906 C-2

Q9907 C-1

Q9908 C-1

TP

TPD21 E-6

TPD22 E-6

43

Page 44

D27

1

D26

D22

50

2

50

2

49

R543

R541

R539

R535

R534

C574

1

49

R521

R520

R522

1

R537

LC505

TPD21

TPD22

R651

R653

R655

LC507

R585R586

1

4

D23

C565

C564

5

1

IC552

IC700

85

1

LC901

R721

R757

20

20

R720

1

1

C730

C714

C727

R756

C726

4

5

1

3

C732

R713

R717

IC702

D20

18111

1

10

11

IC711

10

11

IC710

C731

D21

D2-BOARD (COMPONENT SIDE)

TNPA2589

IC602

4

3

IC712

80

C718

R714

R716

R718

R719

R582

51

C715

C716

5

4

72

C720

R575

IC555

37

10

11

C512

50

81

IC703

36

R574

R652

73

R901

D901

R954

11

LC504

C509

1

R580

10

IC553

C907

R941

R936

C912

48

49

R944

R948

R950

64

1

C903

C901

C902

1

IC814

10

1

C807

20

11

1

1011

C813

20

R862

D32

D25

C505

20

11

R938

D2

1

20

IC818

1

20

R861

R937

IC900

R577

R581

C558

R579

C814

C818

R980

10

R910

11

IC820

B1

10

11

R860

1

R911

R912

R929

IC815

Q502

R972

R974

R576

8

C924

R560

1

R928

R871

33

16

C914

R973

R502

C557

R916

R570

C510

C906

32

17

1

Q906

20

R977

1

20

R870

R571

R965

R963

R869

R559

R503

C815

C820

R504

C904

Q907

10

R844

11

R846

R505

R506

C575

16

IC554

9

IC904

1

34

R964

Q903

C905

R920

D902

R975

IC816

10

11

LC802

C829

R960

R959

5

R507

C923

C828

L804

9

44

R967

C917

R966

R962

X901

Q908

R976

C E GIBDFH

1

C816

20

1

C822

20

IC822

LC803

B40

10

LC508

8

R587

5

R656

R654

9

16

C651

17

D29

R544

16

IC907

1

L552

C563

R584

C573

C568

R583

R657

C630

L553

C507

IC604

X601

1

R630

4

8

1

R631

IC605

1

10

IC612

R620

R619

31

30

1

100

R545

C562

R511

C919

R970

C571

C570

IC603

171819

81

R512

R513

C920

C561

C572

22

20

21

23

LC501

24

1

IC601

CRNo.9

C577

C576

C501

C908

LC502

C554

C909

LC503

C911

C503

L551

R942

R951

R955

C913

1

D24

LC509

D552

5

R508

R510

C508

R509

C925

C992

C926

IC551

5

1

25

48

C625

7

6

13

9

8

101112

141516

R547

R546

9

8

R565

R566

C569

C602

C601

8

5

R632

20

R635

R636

R637

11

2

143

A

B

C

D

E

F

G

H

J

K

L

M

N

P

R

T

U

V

W

Y

AA

AB

AC

TNPA2589

10

C826

IC806

IC811

LC801

C827

C806

R831

R835

R834

IC807

1

10

20

11

R793

1

1011

R794

20

IC813

C811

L803

C719

R725

8

R712

R848

R746

C710

R879

R744

R743

R880

R853

R811

R812

IC803

R852

B1

10

11

10

11

R809

R851

IC701

1

R732

144

R747

109

108

C724

R742

R730

C725

C704

Q702

R748

1

IC801

C801

20

R724

5

4

1

IC704

C723

1

10

R755

C728

11

20

R847

R810

ORDER

NO.

R832 R833

R799

IC805

R800

R814

R815

1

20

20

1

R830

IC802

R795

R829

R858R859

R796

IC809

10

11

10

11

R857

D31

C809

C805

10

1

20

11

1

20

11

B40

A

A1

A40

A1

A40

6

5

4

3

2

1

Page 45

13.7. C1-Board

6

5

C1-BOARD (FOIL SIDE)

C1

TNPA2540

4

23

TNPA22540

SEE REVERSE FOR ORDER NO.

2

1

C1

3

C1-BOARD (COMPONENT SIDE)

TNPA2540

2

R7125

CB1

B1

A1

C7104

B40

C7120

A40

C7119

R7134

R7135

C7121

C7122

L7101

C7114

C7113

R7102

R7101

R7103

R7104

C7123

C7124

R7106

R7105

C7126

R7108

C7125

R7107

CB2

B1

A1

B40

C7105

A40

L7102

C7115

C7116

C1MM1

TNPA2540

ORDER NO.

C1

C7128

C7130

C7127

C7129

PbF

2

C7117

C7118

L7103

R7109

R7112

R7111

R7110

B1

A1

CB3

1

A40

C11

B40

B40

R7126

R7127

R7128

10

IC7101

11

C7106

20

A40

R7130

R7131

R7132

R7133

C7101

A1

C7132

C7131

R7120

B1

R7119

IC7103

C7107

1

5

C7102

R7117

1

L7105

20

1

C12

C7133

C7134

A

C E GIBDFH

45

Page 46

13.8. C2-Board

6

5

C2-BOARD (FOIL SIDE)

C2

TNPA2541

4

12 3

TNPA2541

SEE REVERSE FOR ORDERNO.

C2

2

3

C2-BOARD (COMPONENT SIDE)

TNPA2541

R7223

D7204

R7224

R7221

R7222

Q7202

D7203

D7202

C7210

D7201

C7207

L7204

Q7201

L7205

R7217

C7218

11

C7217

C24

R7216

C7234

2

C21

B40

A1A40

B1

C22

C7201

C7202

1

20

R7233

R7232

R7230

R7231

R7227

R7228

R7229

B1

C7203

11

IC7201

10

A1

20

1

R7226

CB4

TNPA2541

ORDER

NO.

C2

B40

A40

R7204

C7222

R7203

C7221

R7202

2

C7220

R7201

C7219

L7201

C2MM1

C7212

C7211

PbF

C7204

C2MM2

R7211

R7210

R7212

C7230

C7229

C7228

C7227

R7209

L7203

C7215

C7216

C7226

R7207

C7225

R7206

C7224

R7205

C7223

L7202

C7214

C7213

C7205

CB6

B1

A1

B40

A40

CB5

B1

A1

B40

R7208

A40

R7215

C7233

R7214

C7232

R7213

C7231

18

C23

1

B1

C7206

A1

R7225

CB7

B40

A40

1

A

C E GIBDFH

46

Page 47

13.9. SC-Board

SC-BOARD (FOIL SIDE)