Page 1

SERVICE MANUAL

LCD Color Television

42AV554D

This model is classified as a green product (*1), as indicated by the underlined serial number.

Ver. 2.00

This Service Manual describes replacement parts for the green product. When repairing this

green product, use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), refer to GREEN PRODUCT PROCUREMENT and LEAD-FREE

SOLDER.

© TOSHIBA CORPORATION

Page 2

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data

provided herein without prior written consent by Toshiba. Toshiba shall not

be liable to anybody for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS"

WITHOUT ANY WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if

any, incurred in connection with or as a result of use of any information or

data provided herein.

Page 3

GREEN PRODUCT PROCUREMENT

p

p

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

rohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba

Corporation recognizes environmental protection as a key management tasks, and is doing its

utmost to enhance and improve the quality and scope of its environmental activities. In line

with this, Toshiba proactively promotes Green Procurement, and seeks to purchase and use

roducts, parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used

in manufacture must also be used as replacement parts.

Page 4

LEAD-FREE SOLDER

p

p

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-free solder must

be used in the servicing and repair of this product.

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 86ºF to

104ºF (30ºC to 40ºC). Use of a soldering iron designed for lead-based solders to repair

roduct made with lead-free solder may result in damage to the component and or PCB being

soldered. Great care should be made to ensure high-quality soldering when servicing this

roduct especially when soldering large components, through-hole pins, and on PCBs as the

level of heat required to melt lead-free solder is high.

Page 5

SAFETY INSTRUCTION

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE

UNFAMILIAR WITH THE NECESSARY PRECAUTIONS ON THIS RECEIVER.

THE FOLLOWING ARE THE NECESSARY PRECAUTIONS TO BE OBSERVED

BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4. Always keep tools, components of the product, etc away from the children, These items

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

Page 6

6. Always use the replacement parts specified for the particular model when making

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the mark is indicated

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation,

malfunction, or electrical leakage and flame, which may be hazardous.

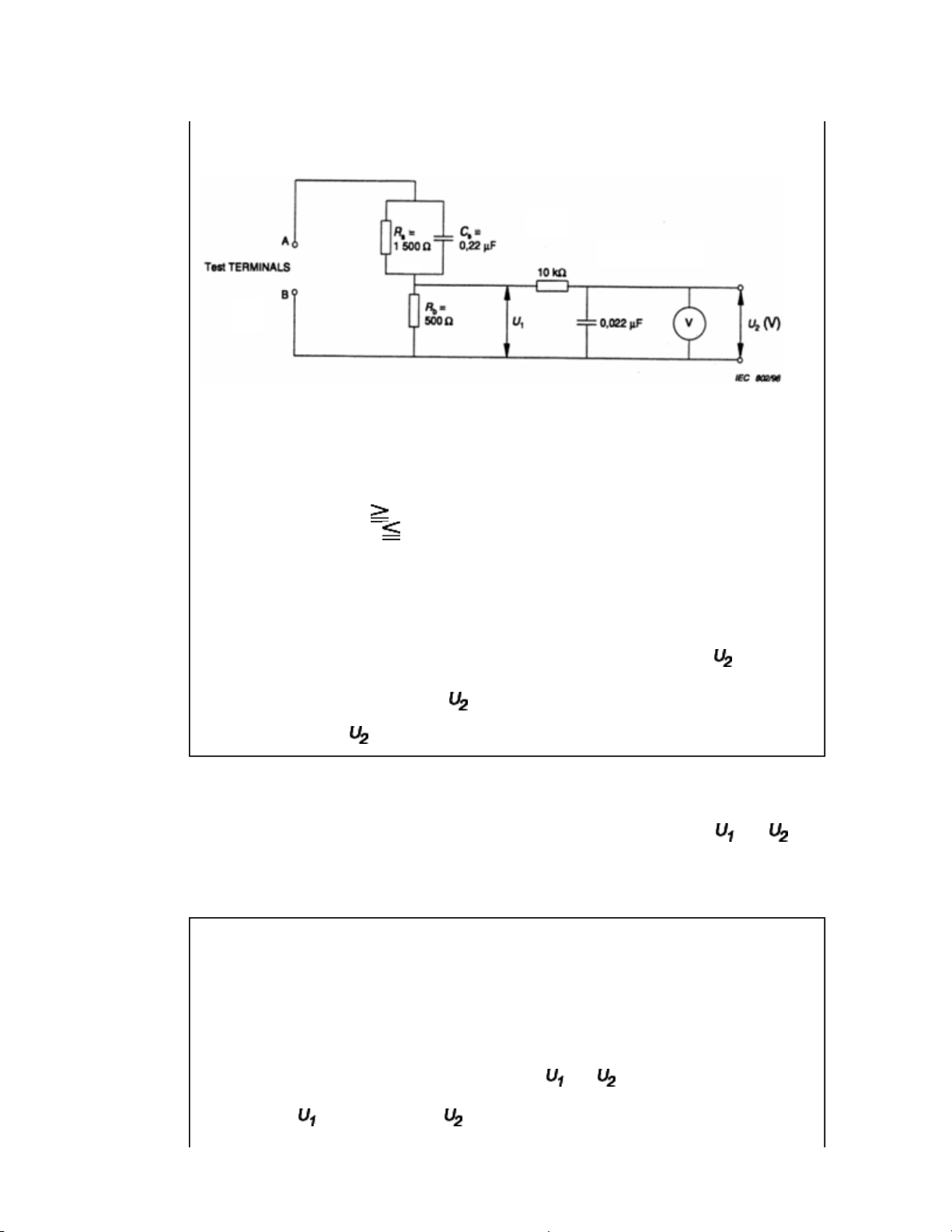

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

z Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer

for this check.

z Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Page 7

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Input resistance : 1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with the

solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of from the ideal curve as a function of frequency.

TOUCH CURRENT = /500 (peak value).

z The potential at any point (TOUCH CURRENT) expressed as voltage and

does not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is not

met.

b) The measurement of the TOUCH CURRENT shall be carried out in accordance with

IEC 60990, with the measuring network described in Annex D of this standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

Page 8

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c. correspond to

the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the

schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The

use of substitute replacement parts which do not have the same safety characteristics as

specified in the parts list may create electrical shock, fire, or other hazards.

Page 9

SAFETY INSTRUCTION

Handling the LCD Module

Safety Precaution

In the event that the screen is damaged or the liquid crystal (fluid) leaks, do not breathe in or

drink this fluid.

Also, never touch this fluid. Such actions could cause toxicity or skin irritation. If this fluid

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the

skin or clothing, wipe off with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly with running water.

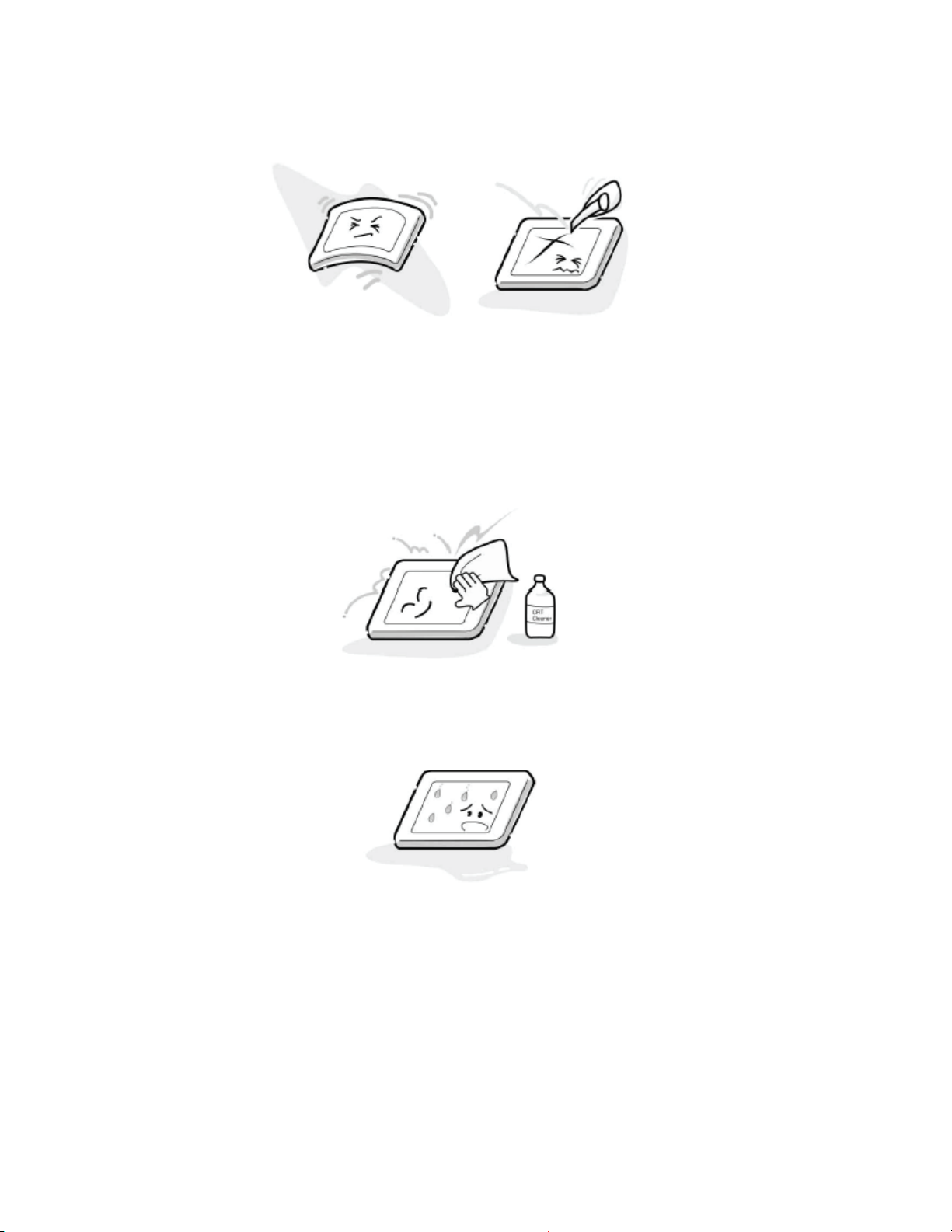

Precautions for Handling the LCD Module

CAUTION: The metal edges of the LCD module are sharp, handle it with

care.

The LCD module can easily be damaged during disassembly or reassembly; therefore,

always observe the following precautions when handling the module.

1. When attaching the LCD module to the LCD cover, position it appropriately and fasten

at the position where the display can be viewed most conveniently.

2. Carefully align the holes at all four corners of the LCD module with the corresponding

holes in the LCD cover and fasten with screws. Do not strongly push on the module

Page 10

because any impact can adversely affect the performance. Also use caution when

handling the polarized screen because it can easily be damaged.

3. If the panel surface becomes soiled, wipe with cotton or a soft cloth. If this does not

remove the soiling, breathe on the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleaner as a cleaner. Wipe off the

panel surface by drop the cleaner on the cloth. Do not drop the cleaner on the panel.

Pay attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for an extended period of time can

result in discoloration or stripes. Immediately remove any type of fluid from the screen.

5. Glass is used in the panel, so do not drop or strike with hard objects. Such actions can

damage the panel.

Page 11

6. CMOS-LSI circuitry is used in the LCD module, so avoid damage due to static

electricity. When handling the module, use a wrist ground or anchor ground.

7. Do not expose the LCD module to direct sunlight or strong ultraviolet rays for an

extended period of time.

8. Do not store the LCD module below the temperature conditions described in the

specifications. Failure to do so could result in freezing of the liquid crystal due to cold

air or loss of resilience or other damage.

Page 12

9. Do not disassemble the LCD module. Such actions could result in improper operation.

10. When transporting the LCD module, do not use packing containing epoxy resin

(amine) or silicon resin (alcohol or oxim). The gas generated by these materials can

cause loss of polarity.

Page 13

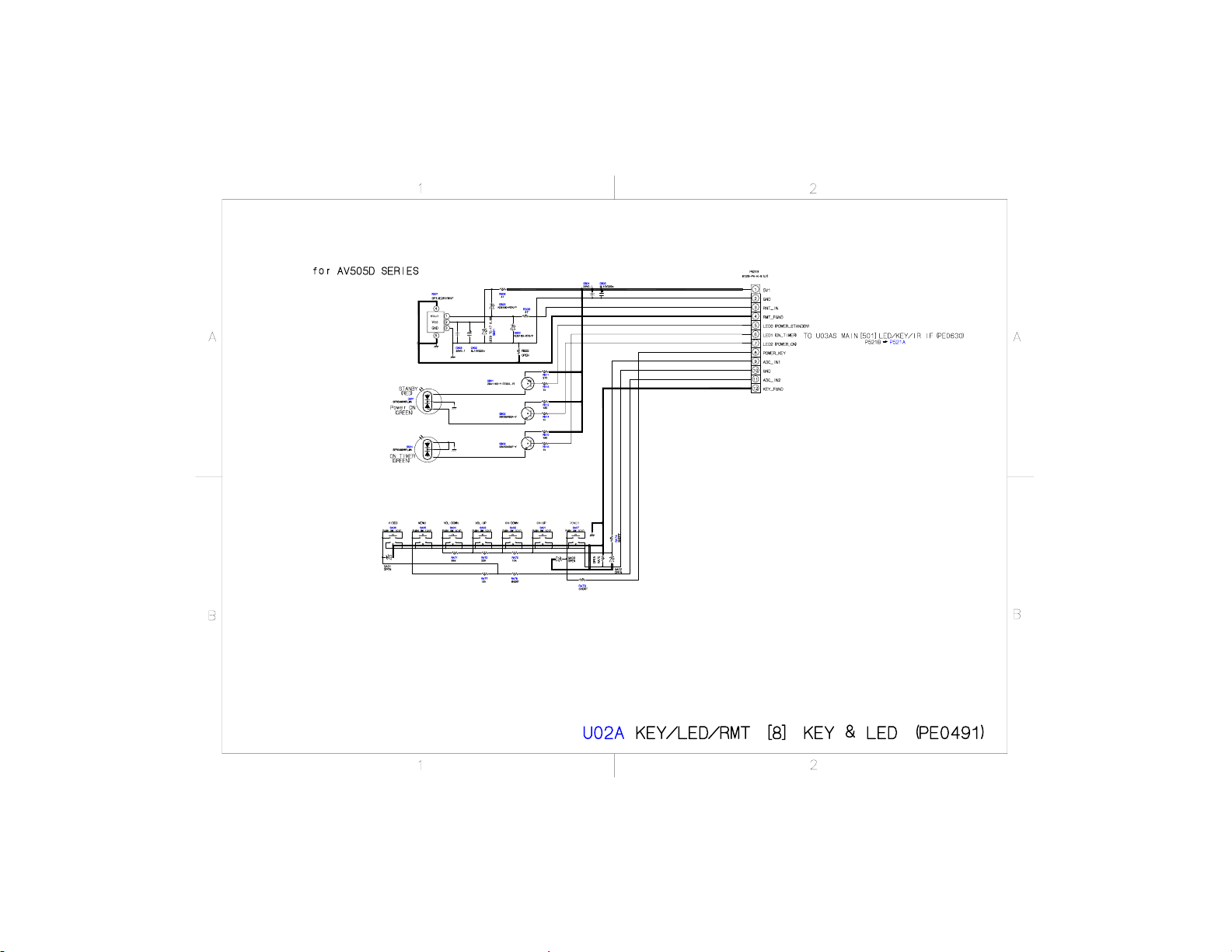

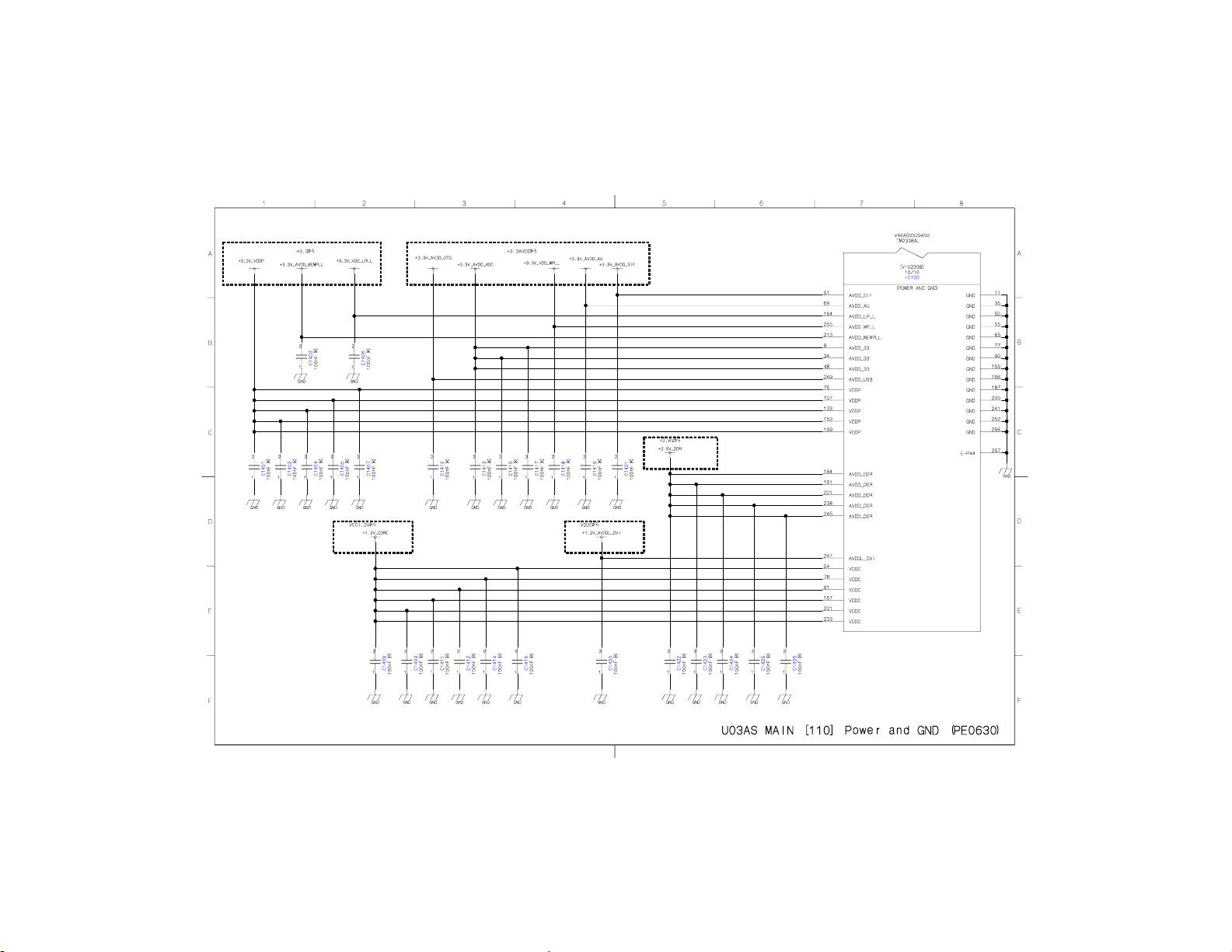

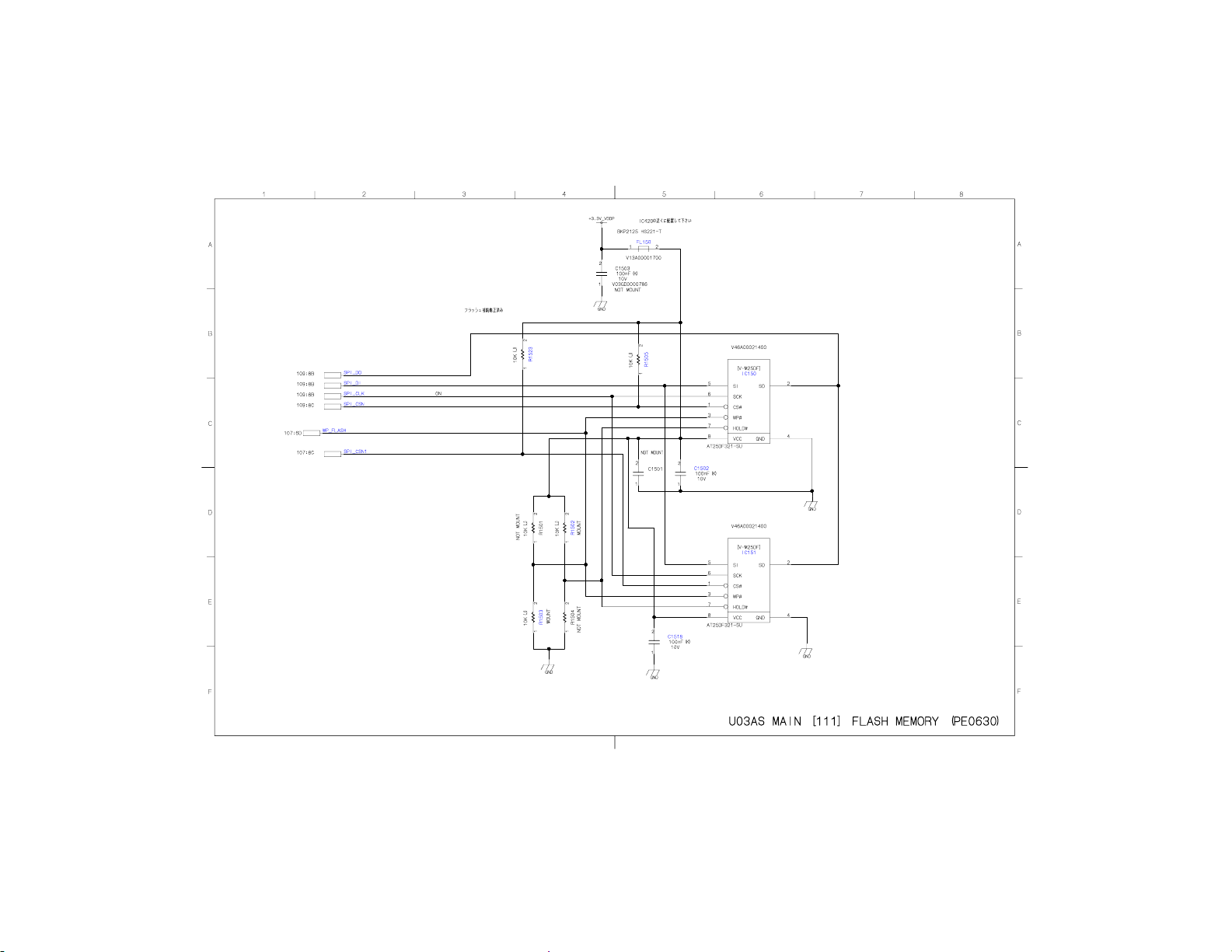

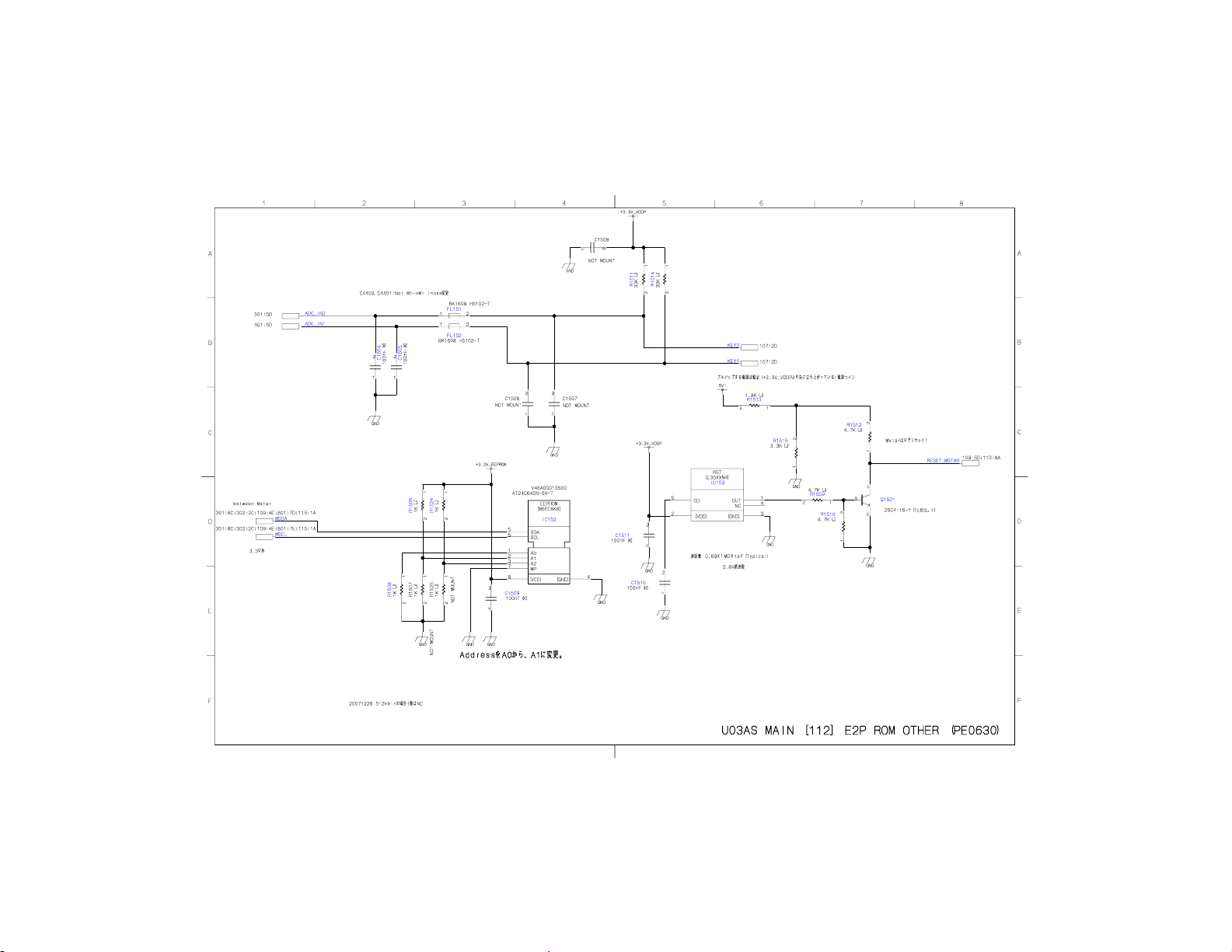

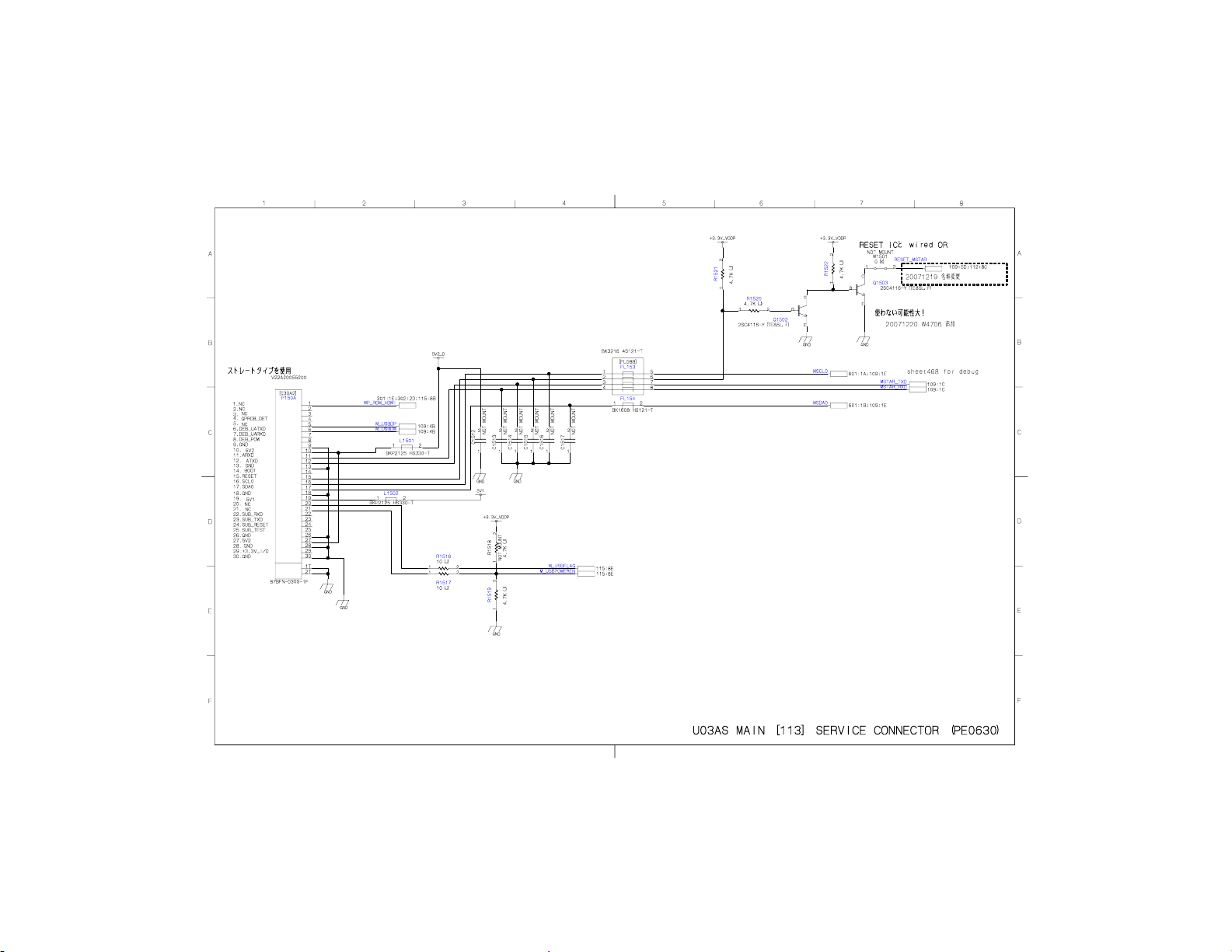

U03A

MAIN

POWER

U02A

KEY/LED/RMT

Page 14

Page 15

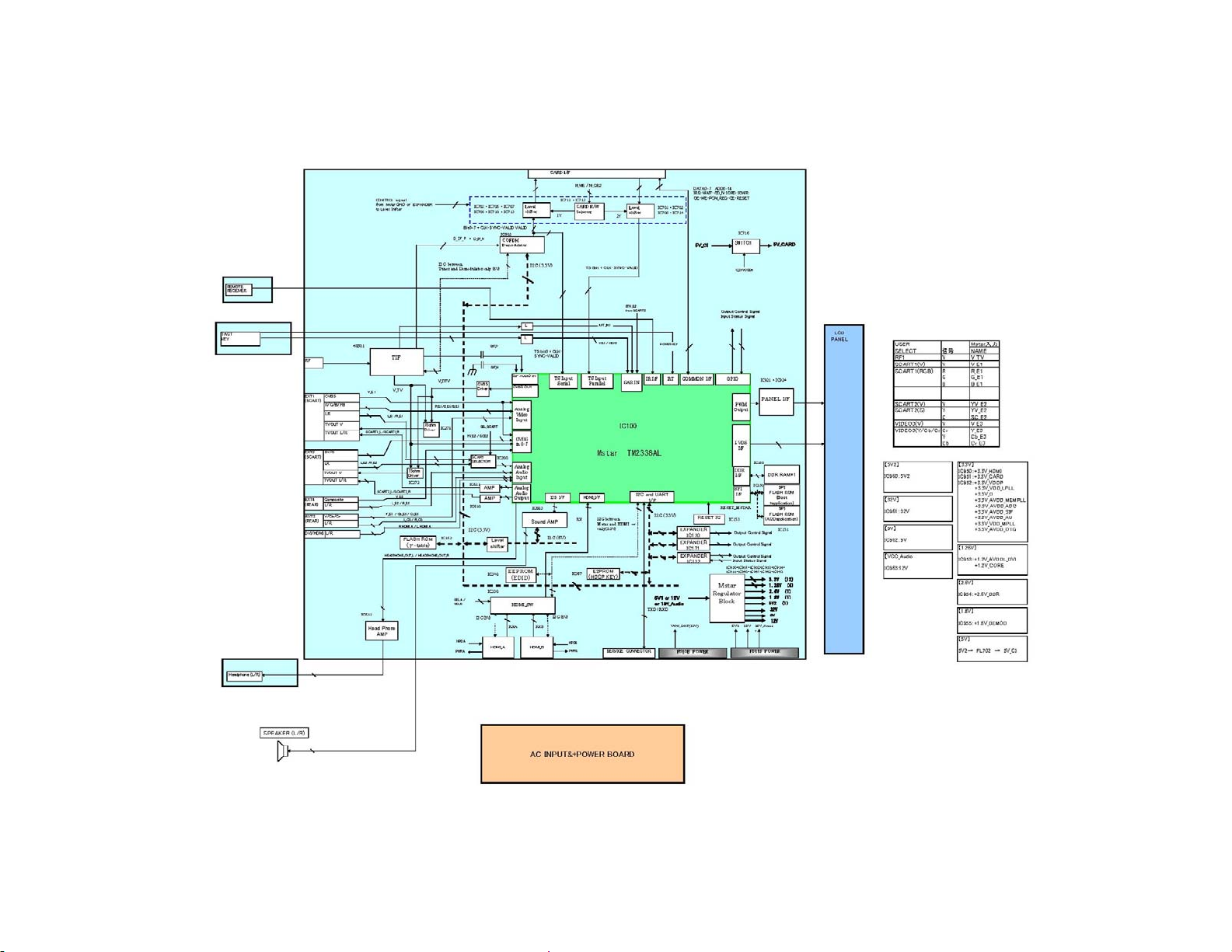

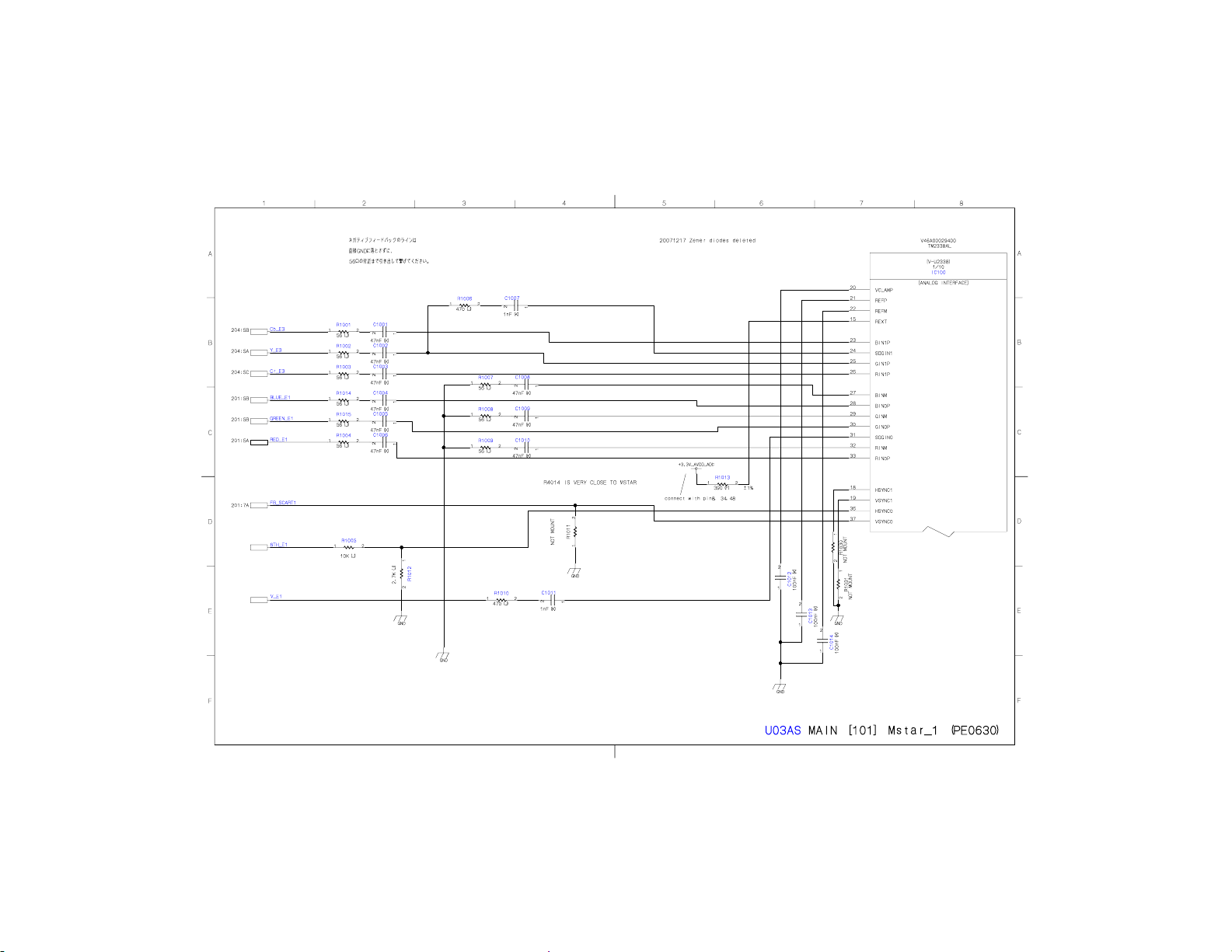

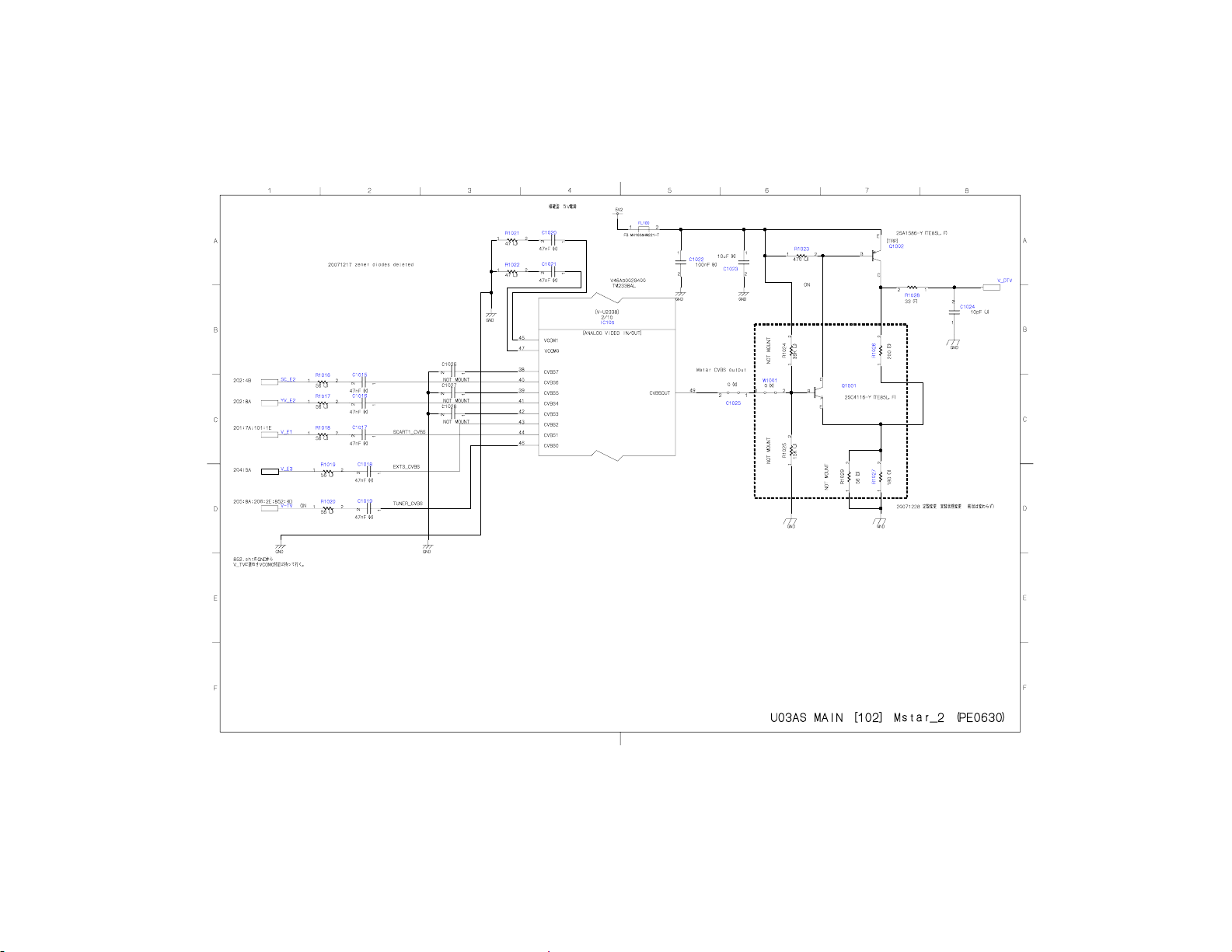

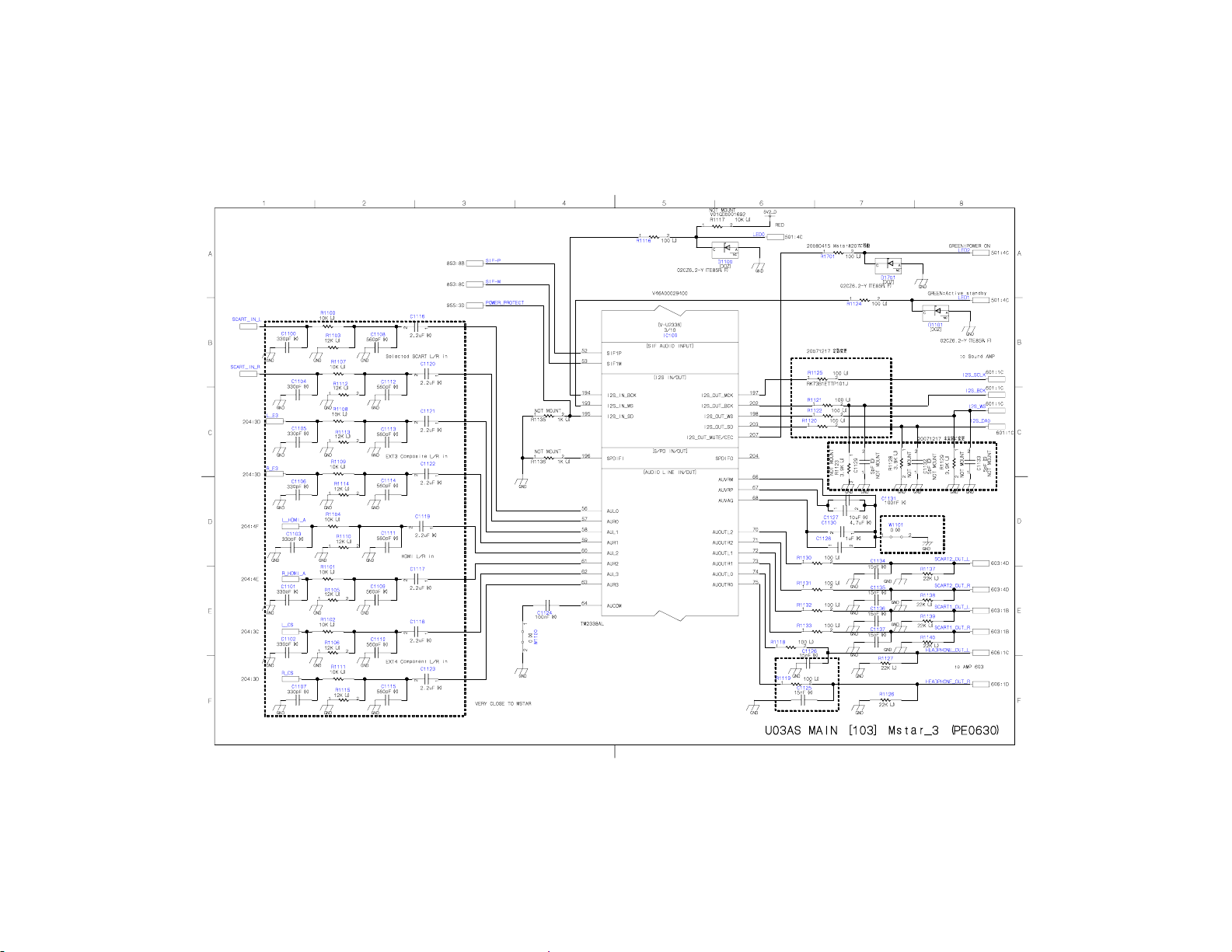

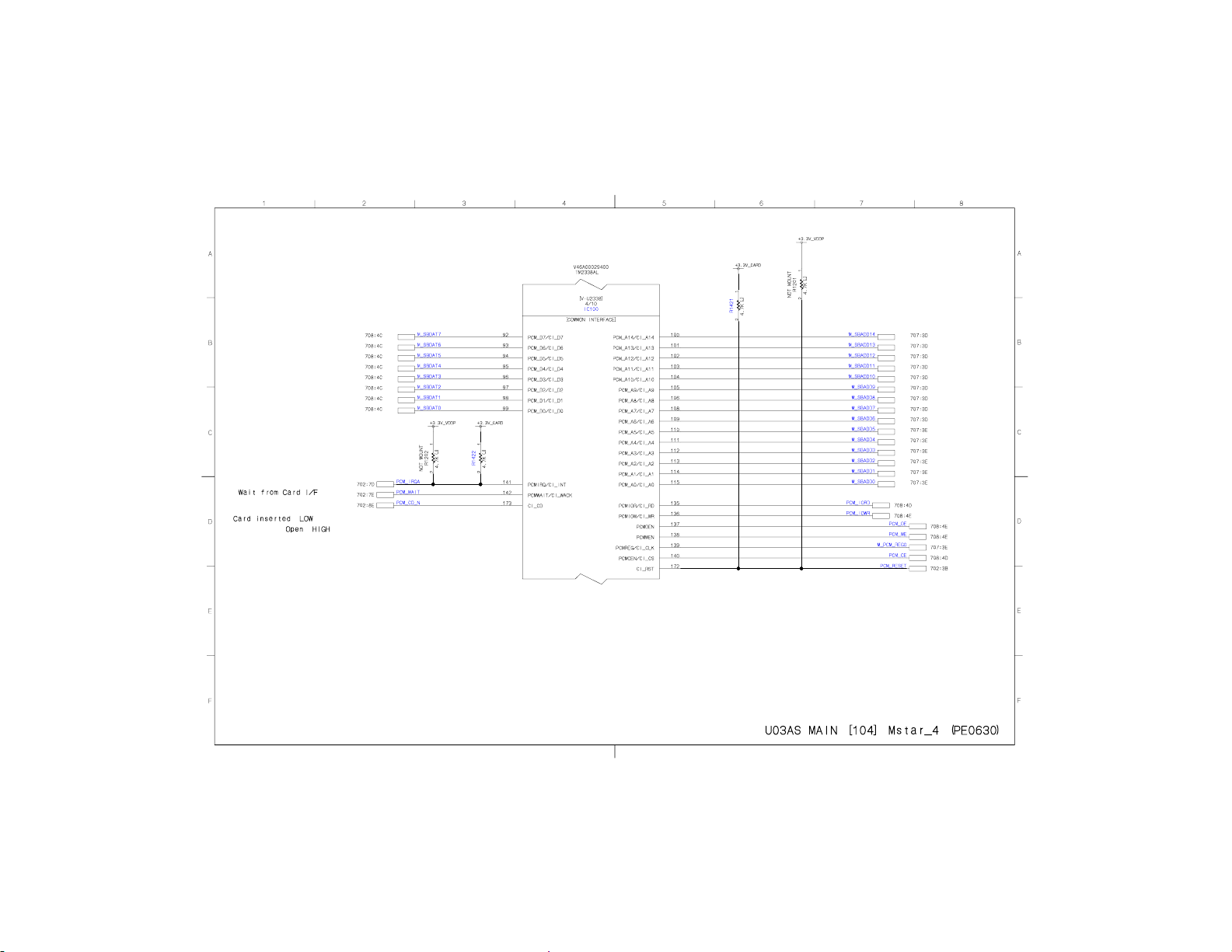

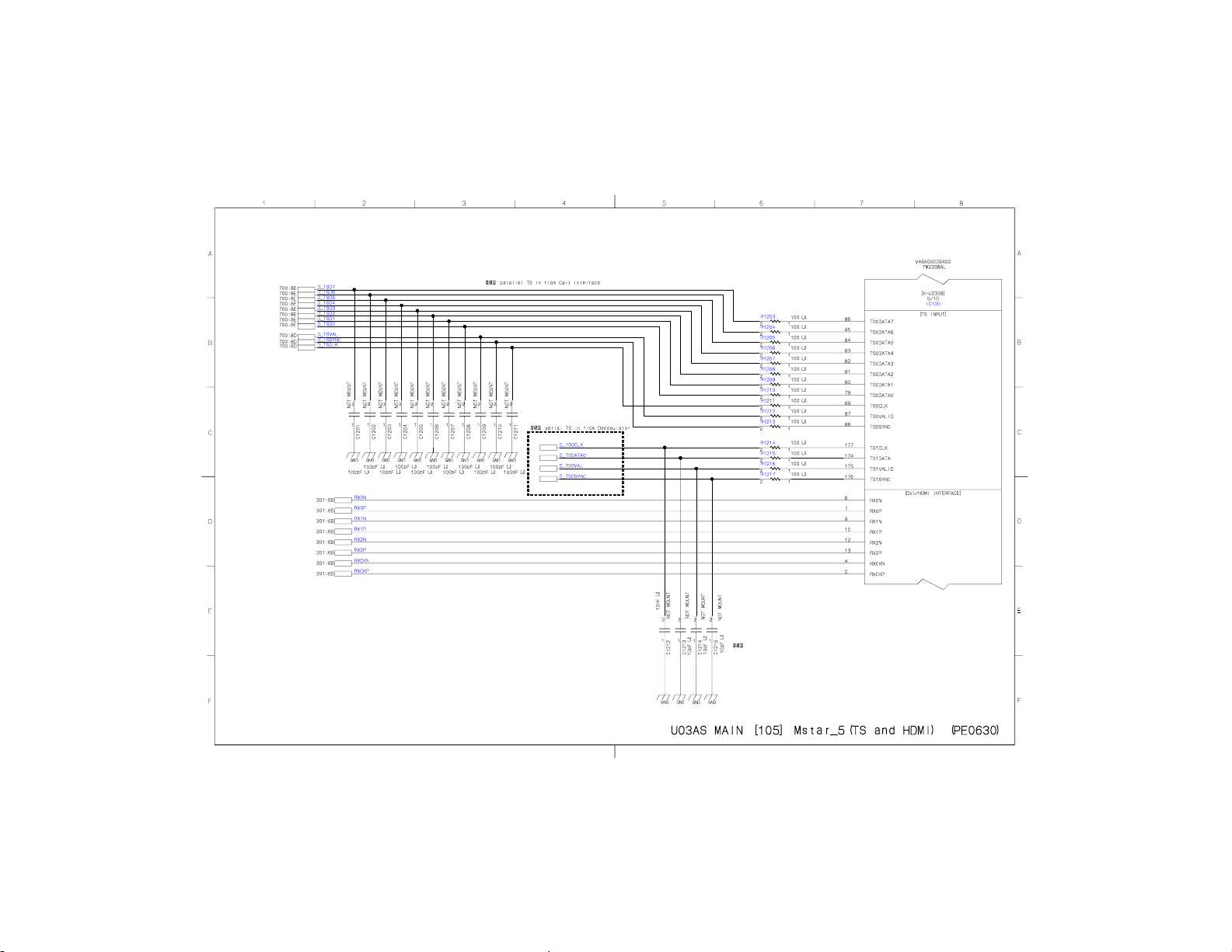

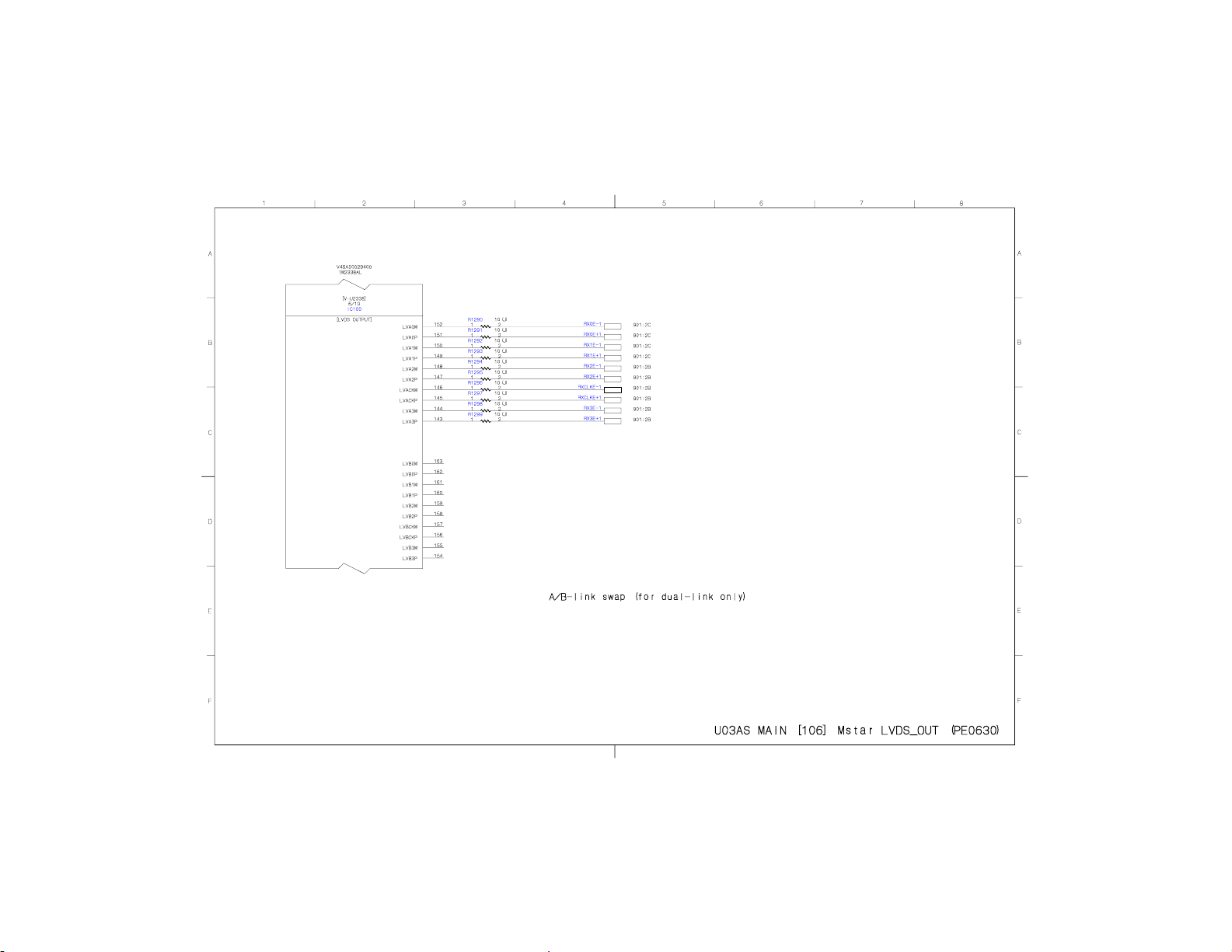

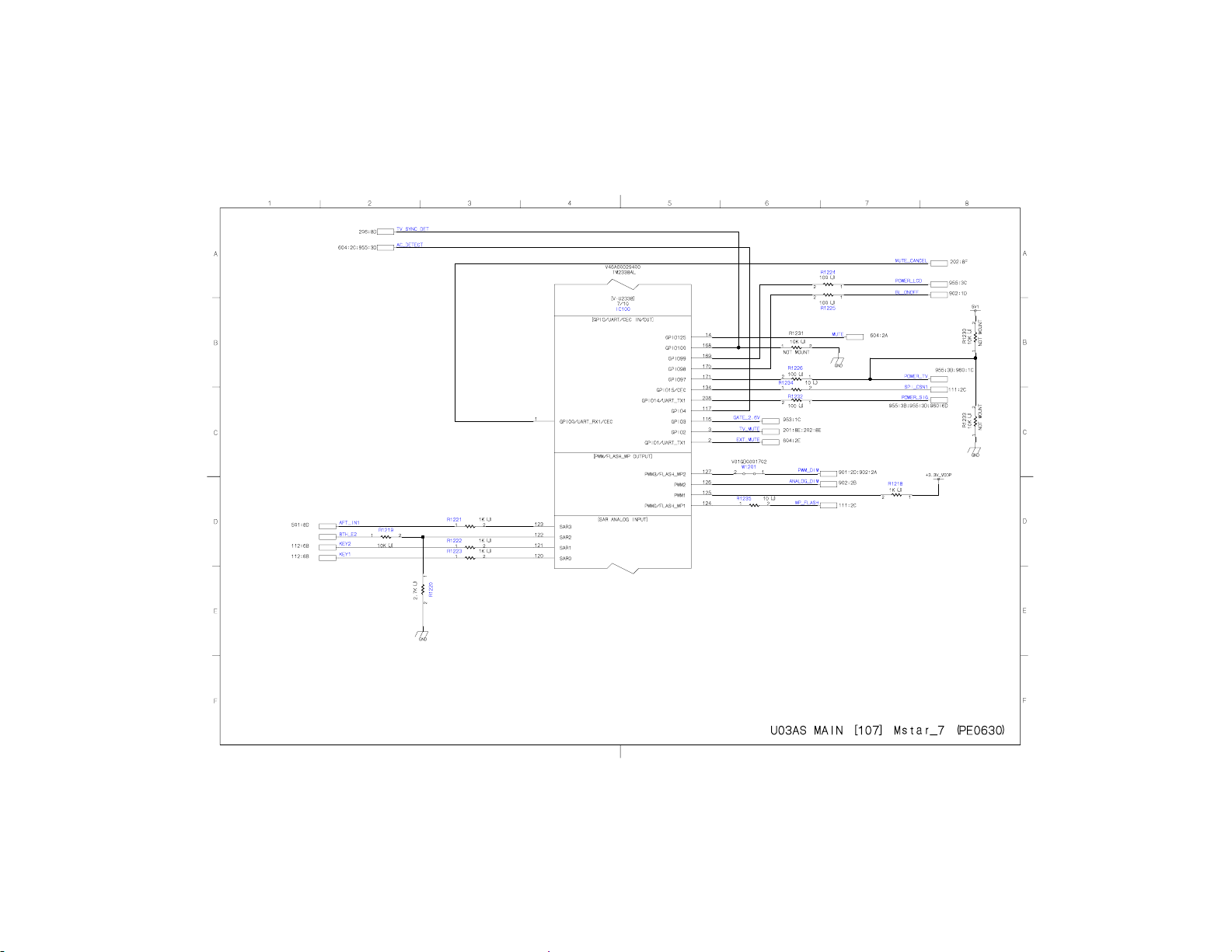

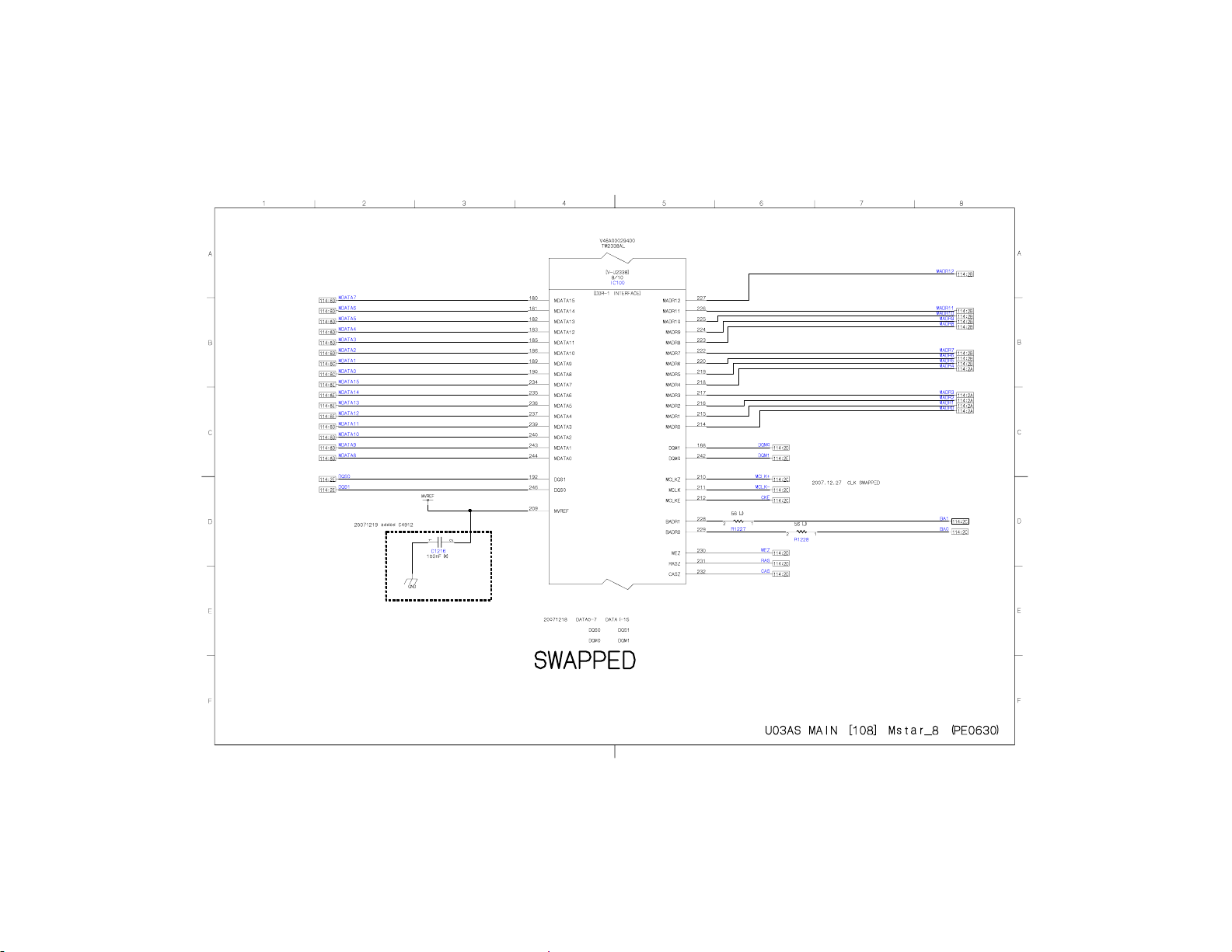

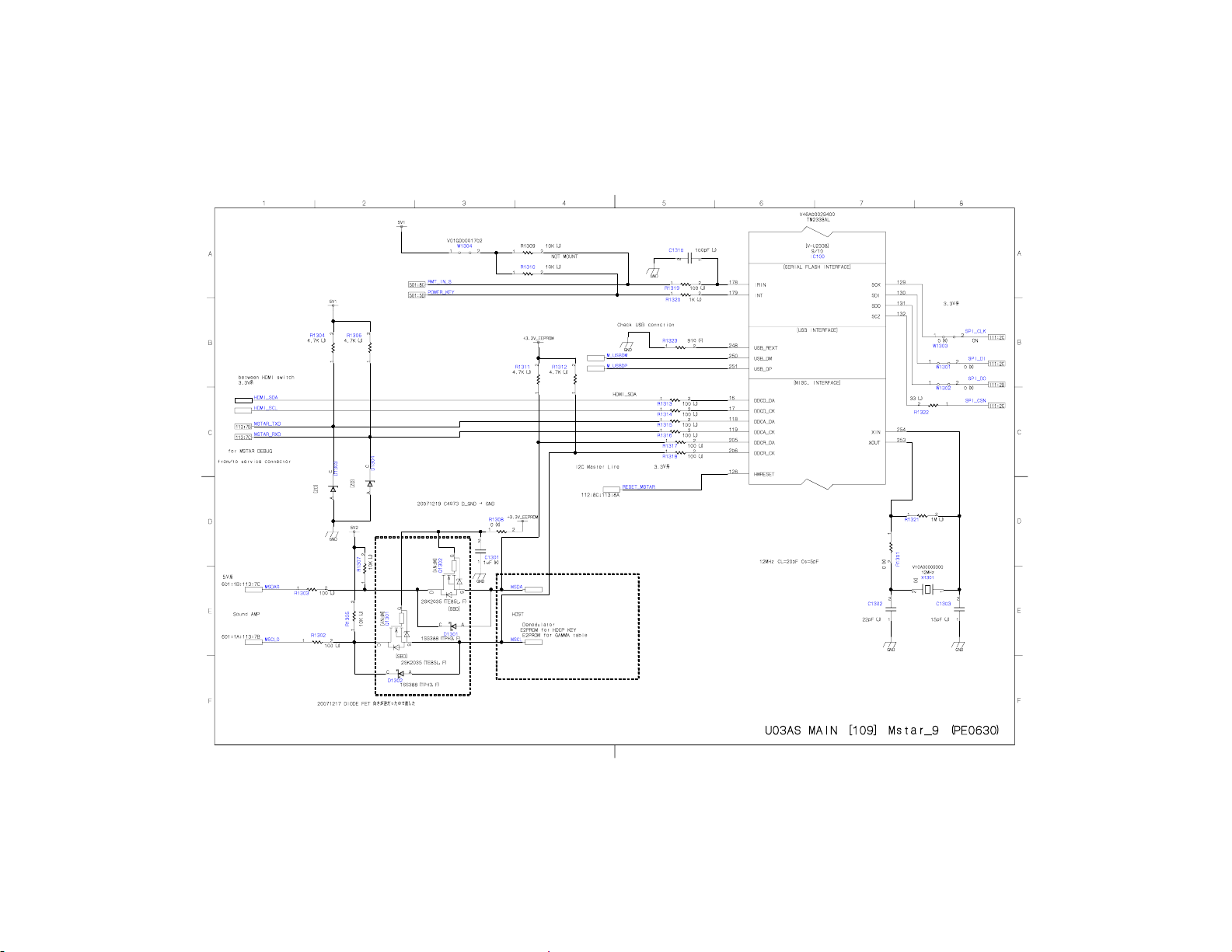

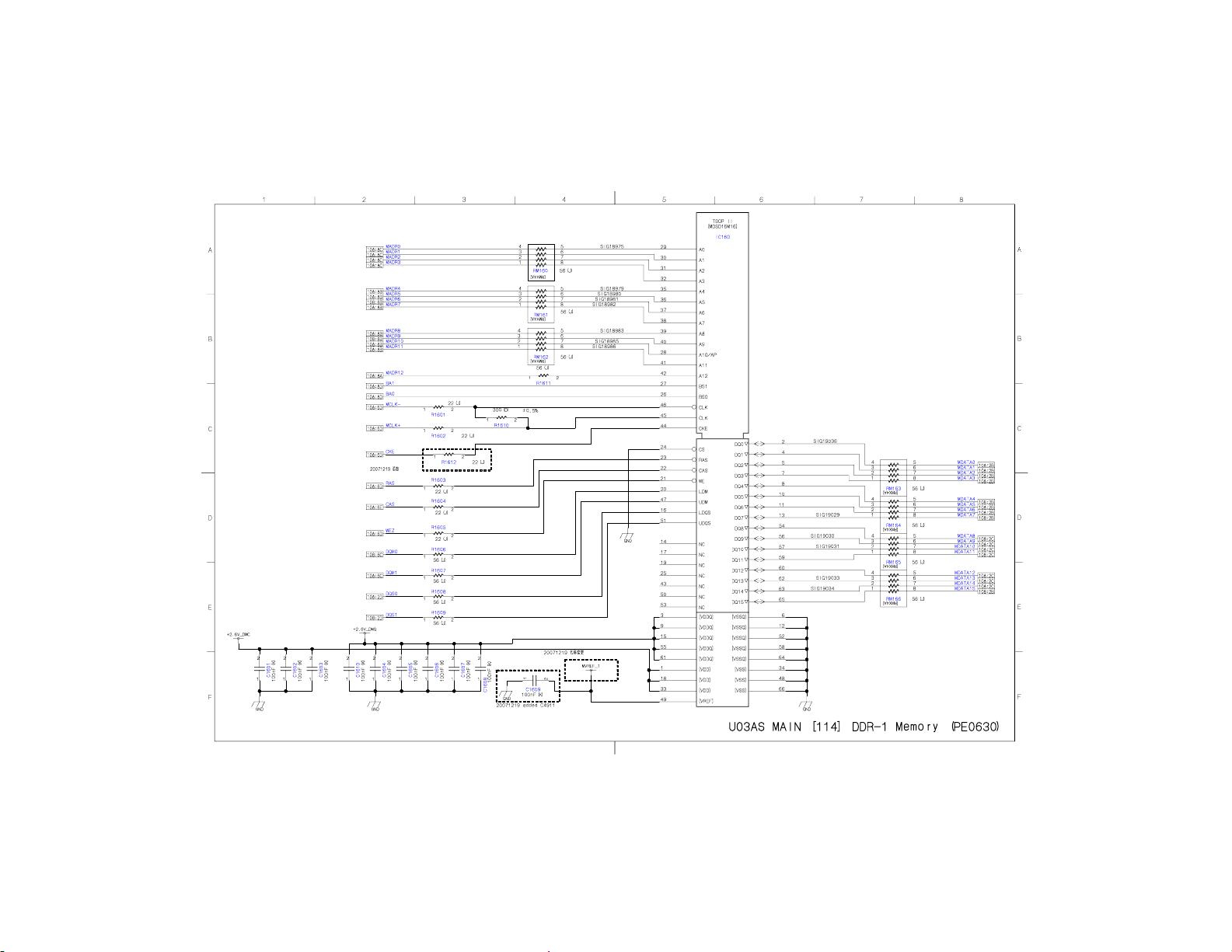

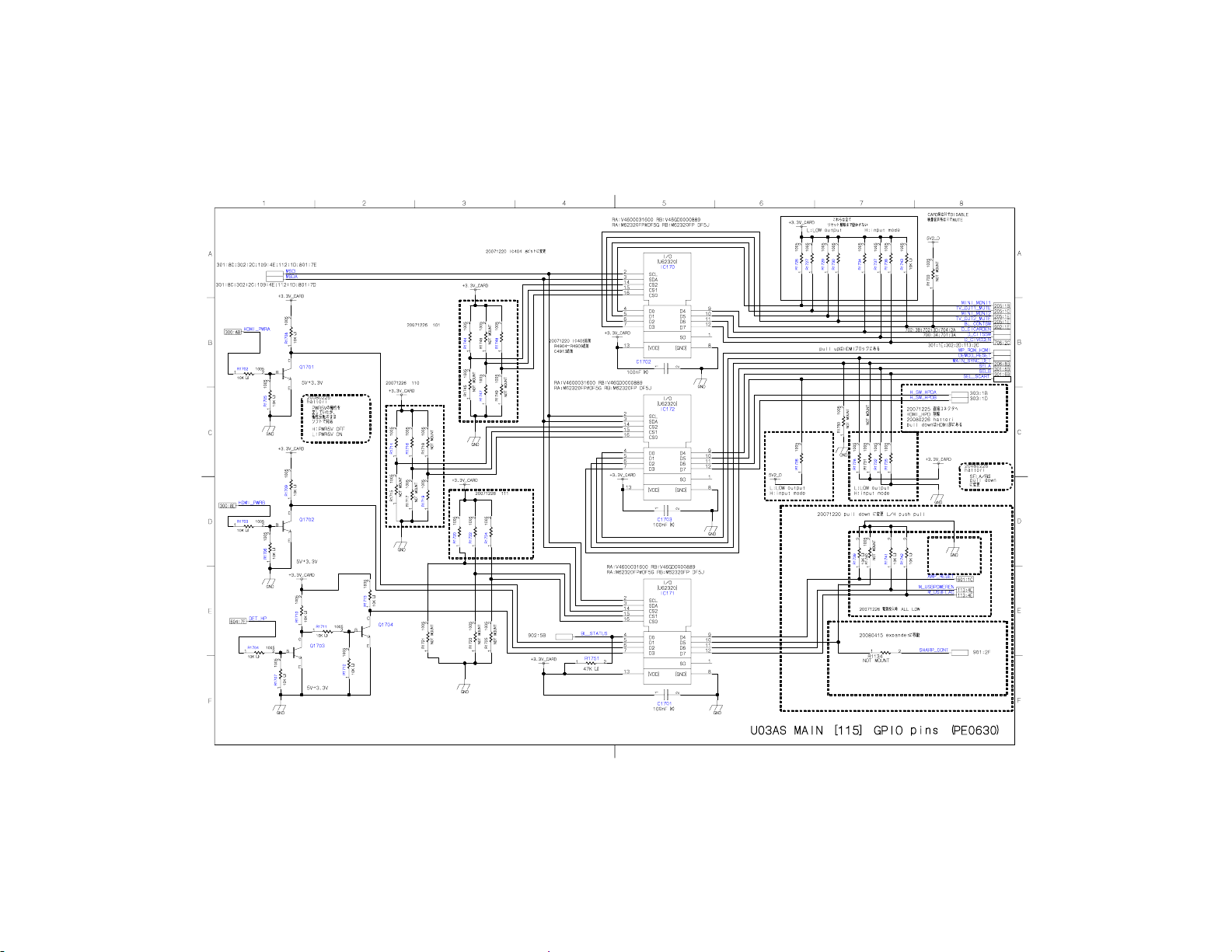

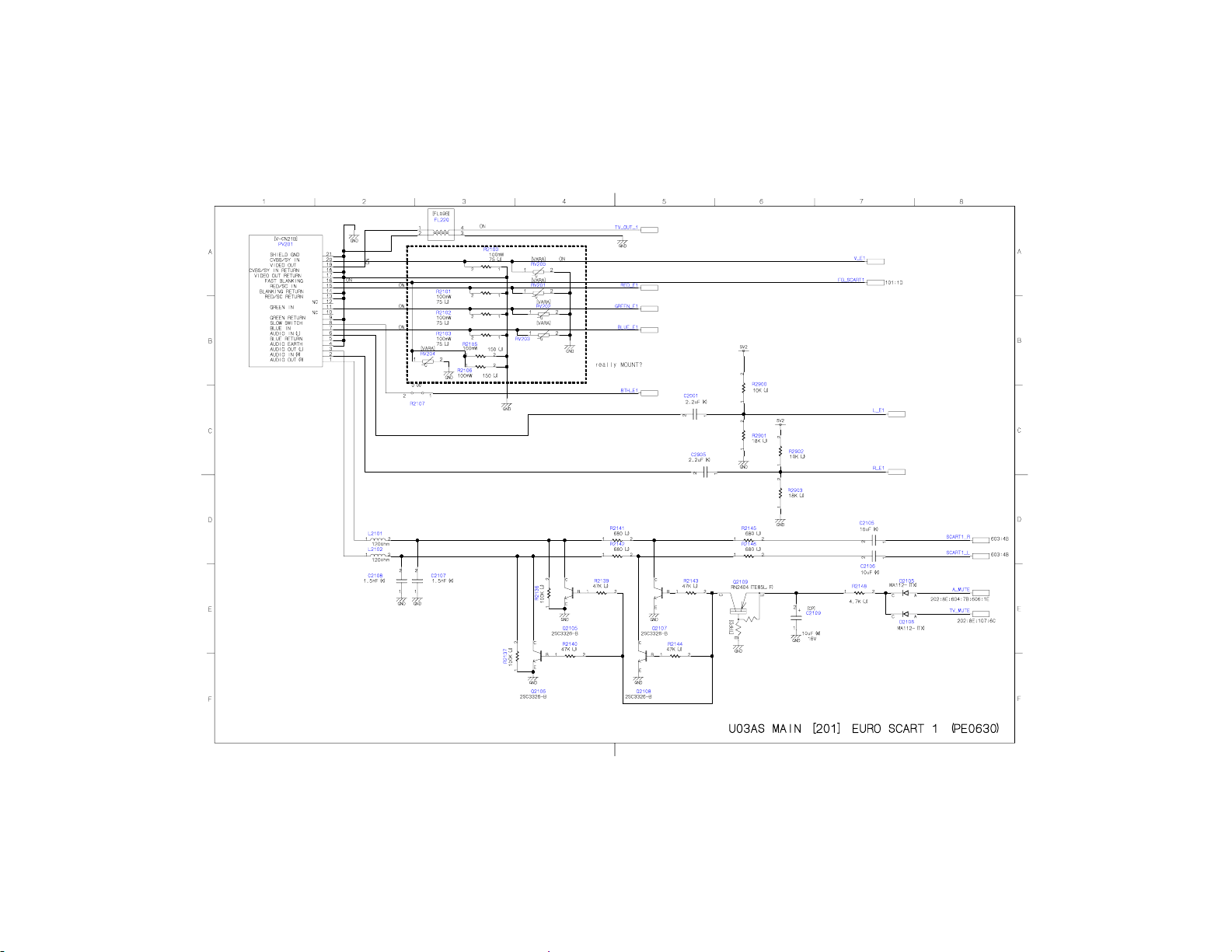

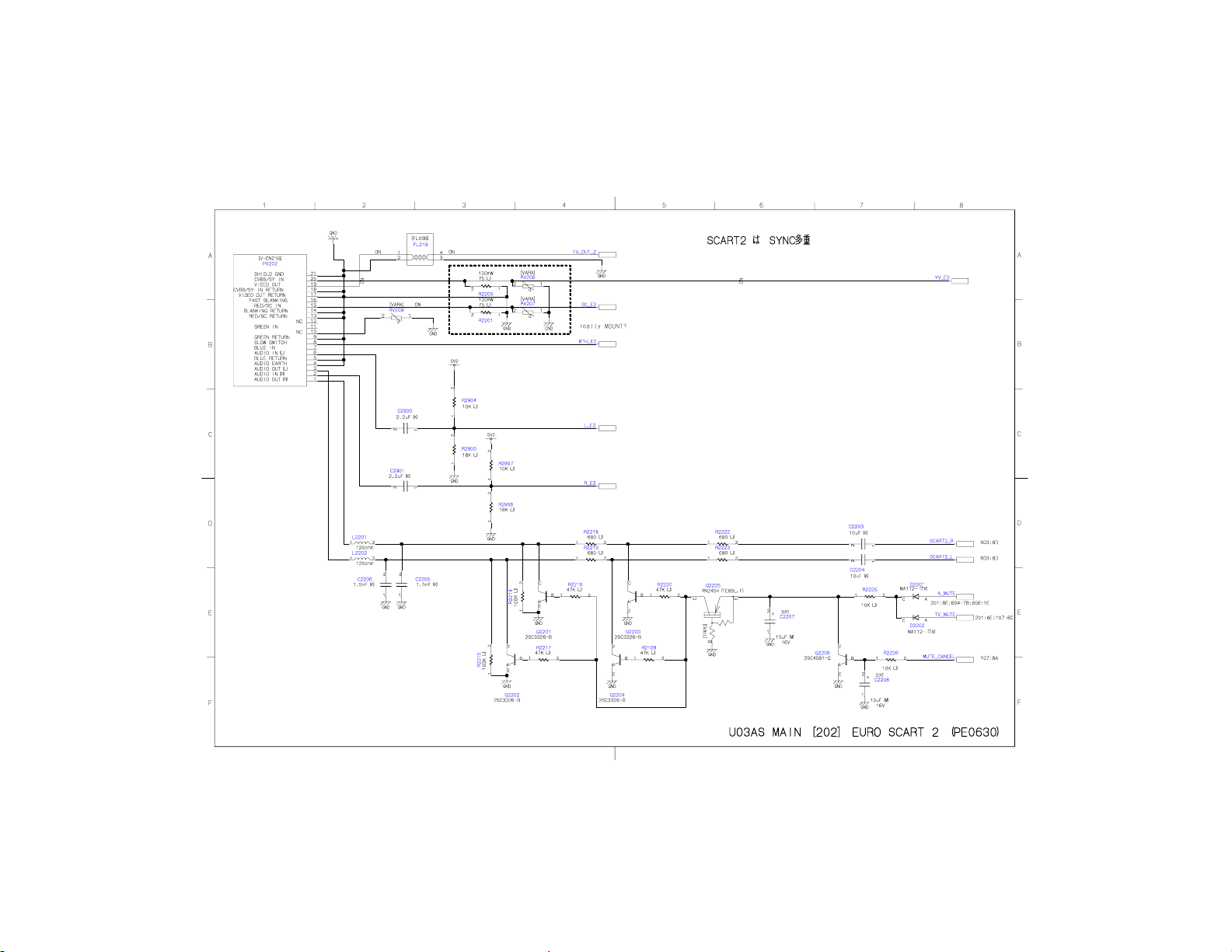

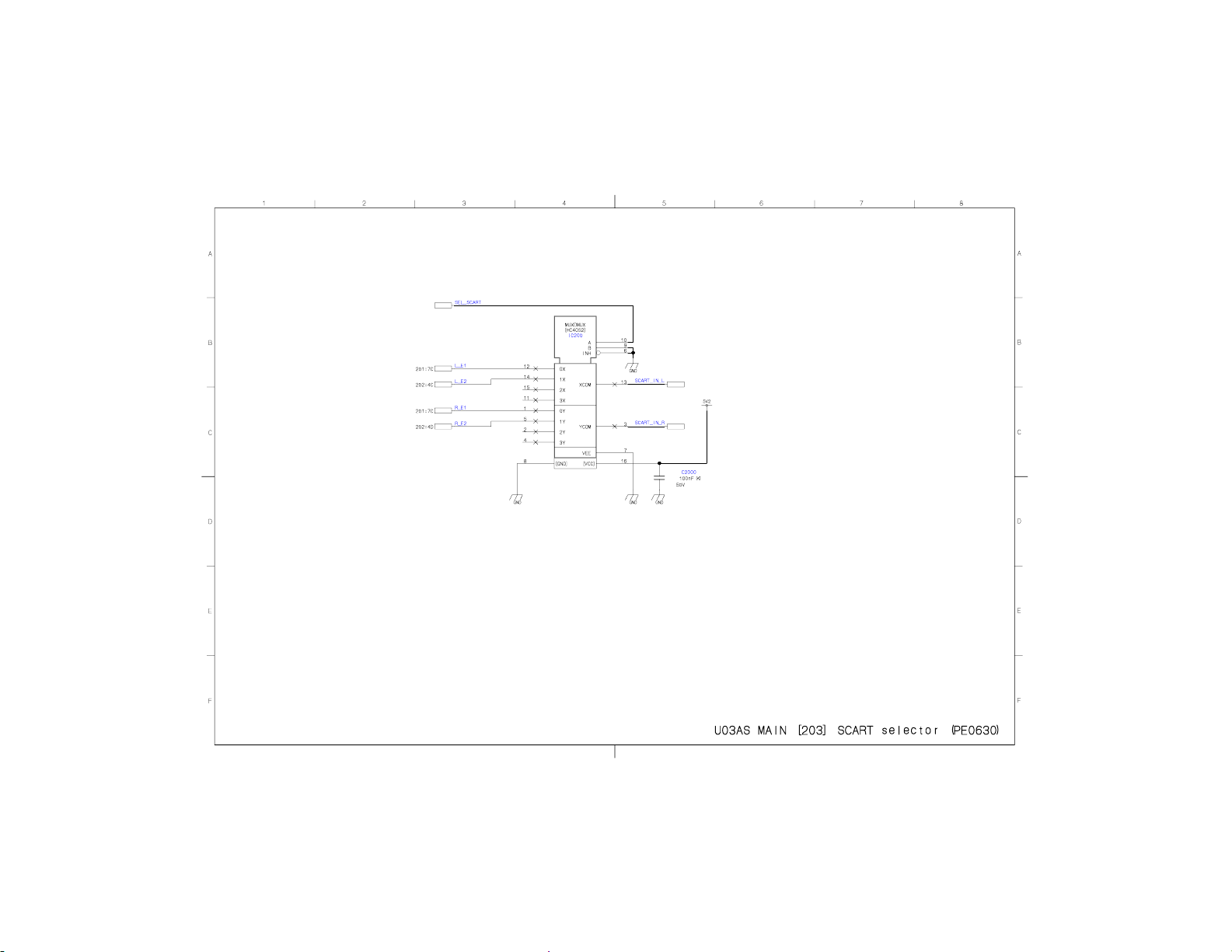

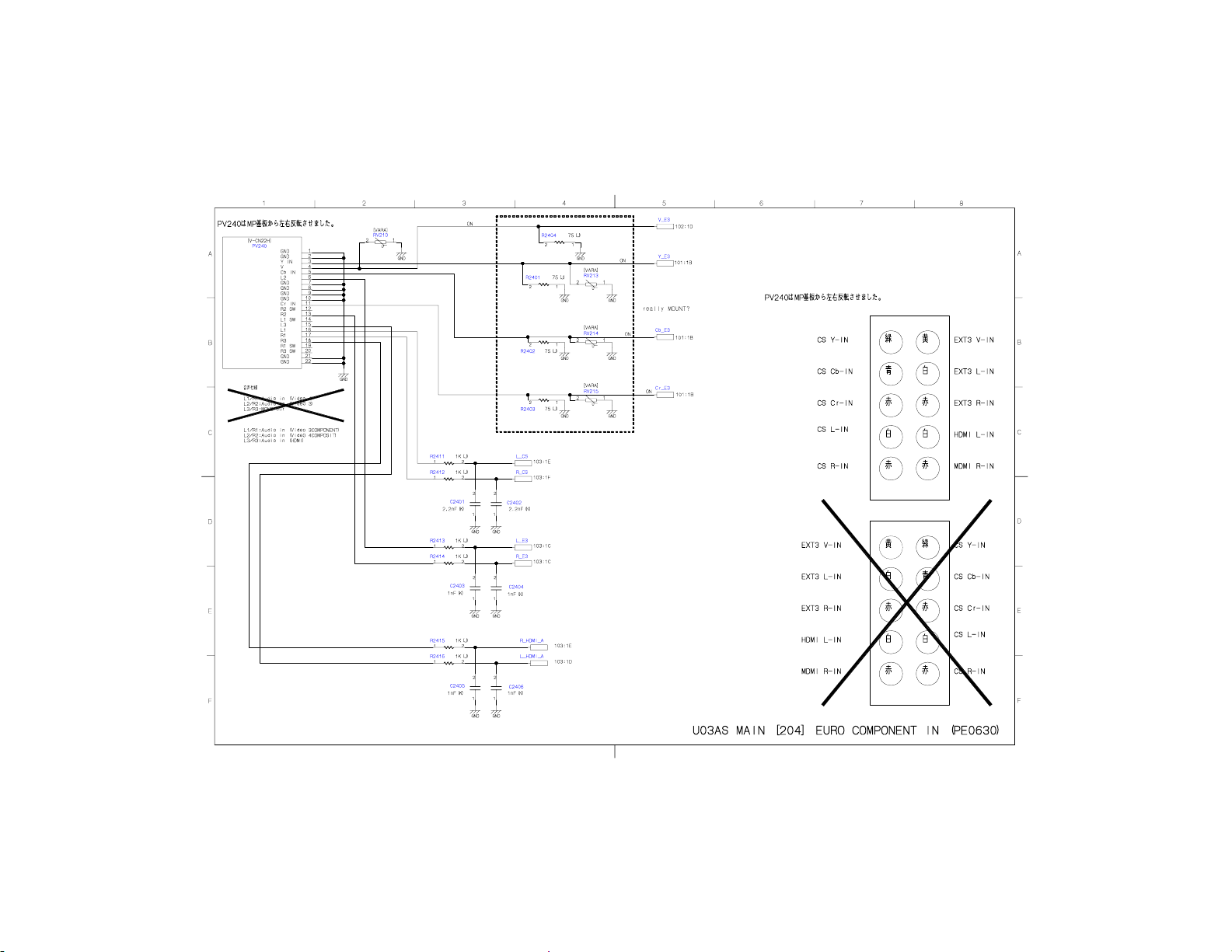

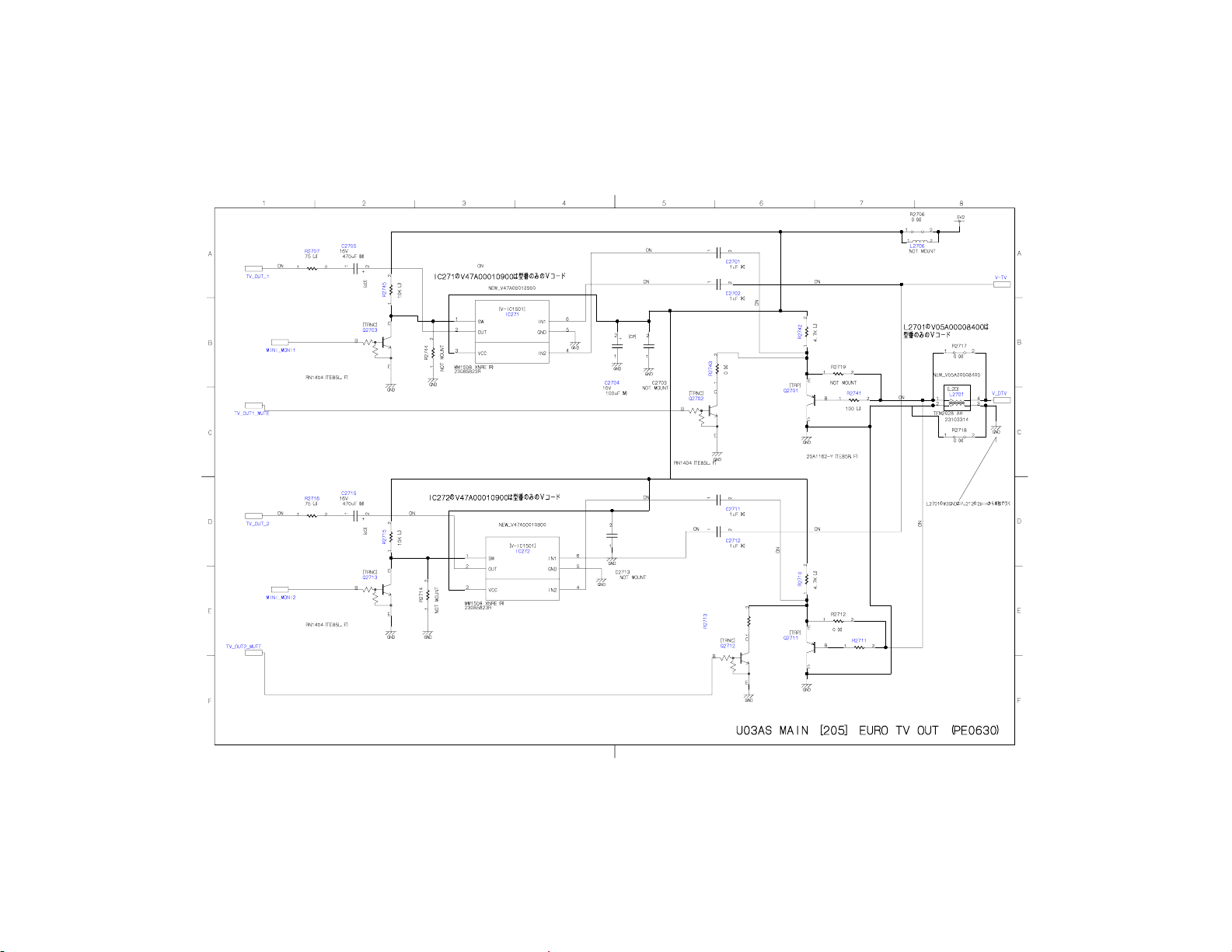

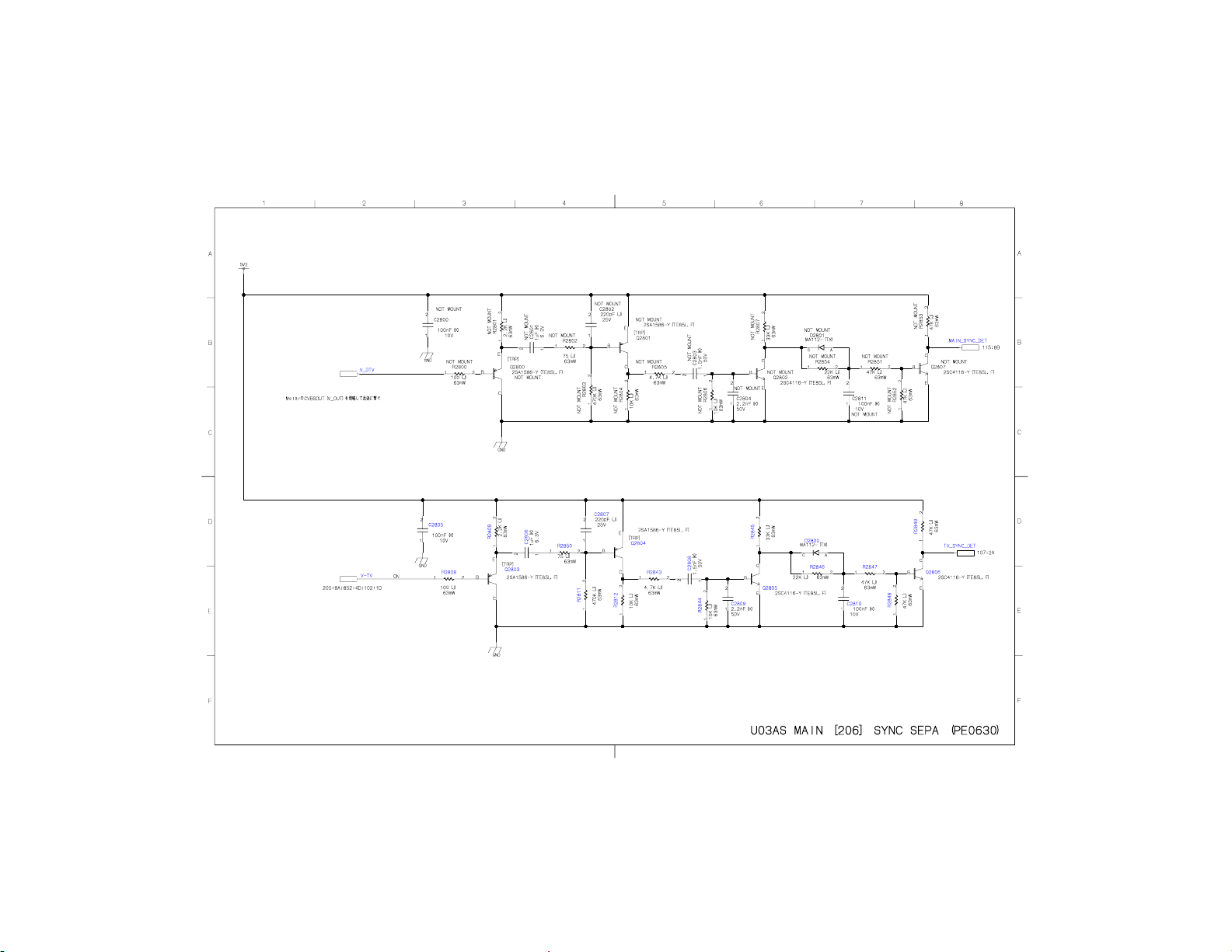

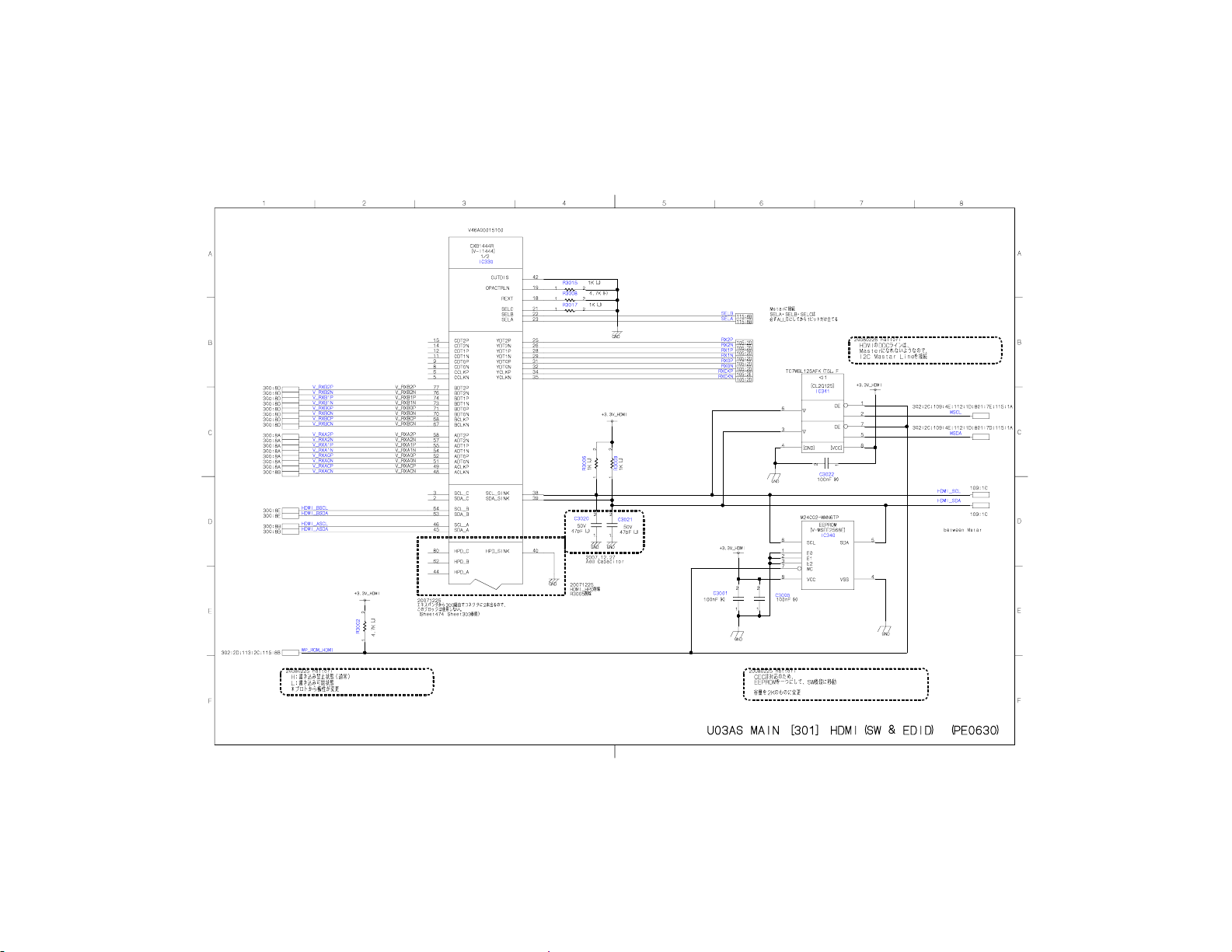

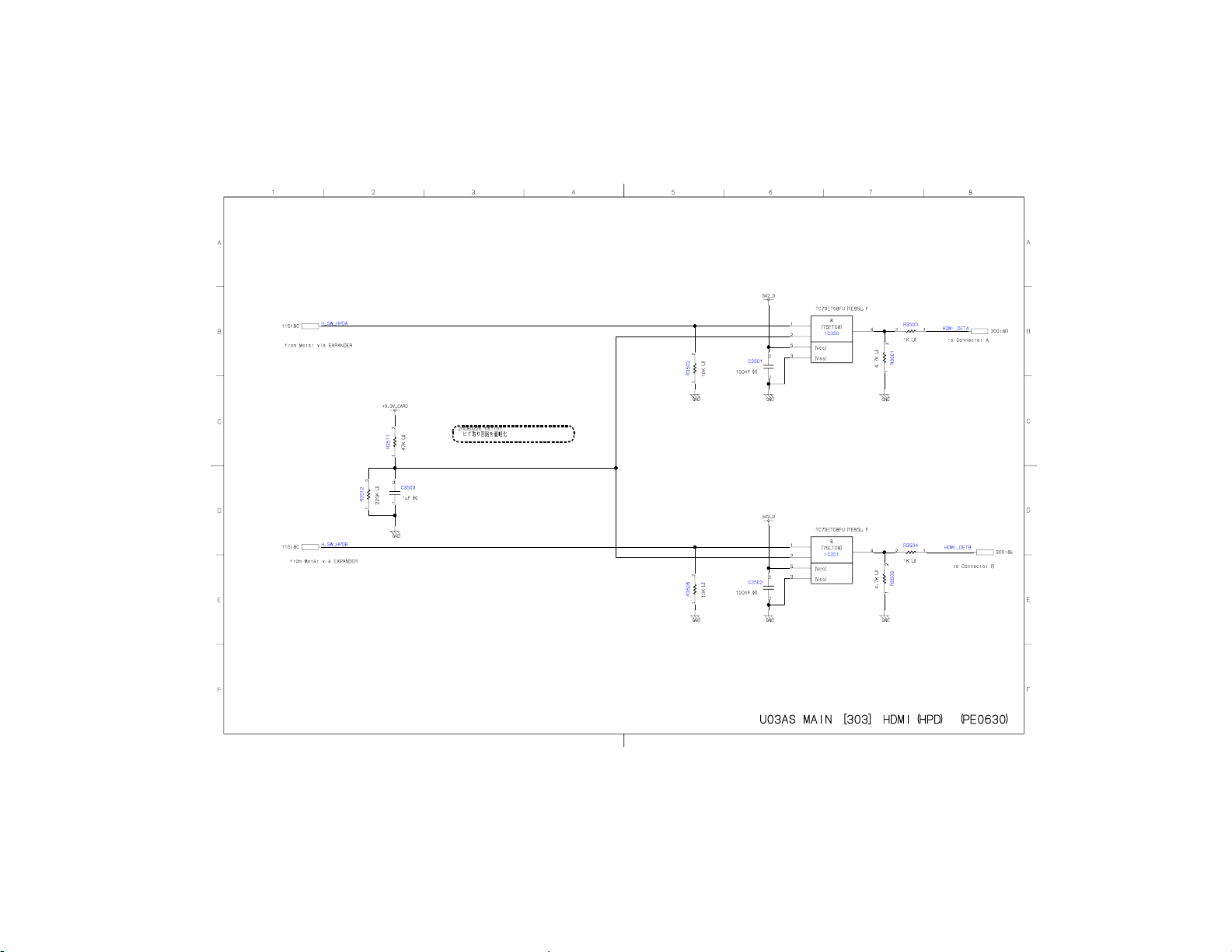

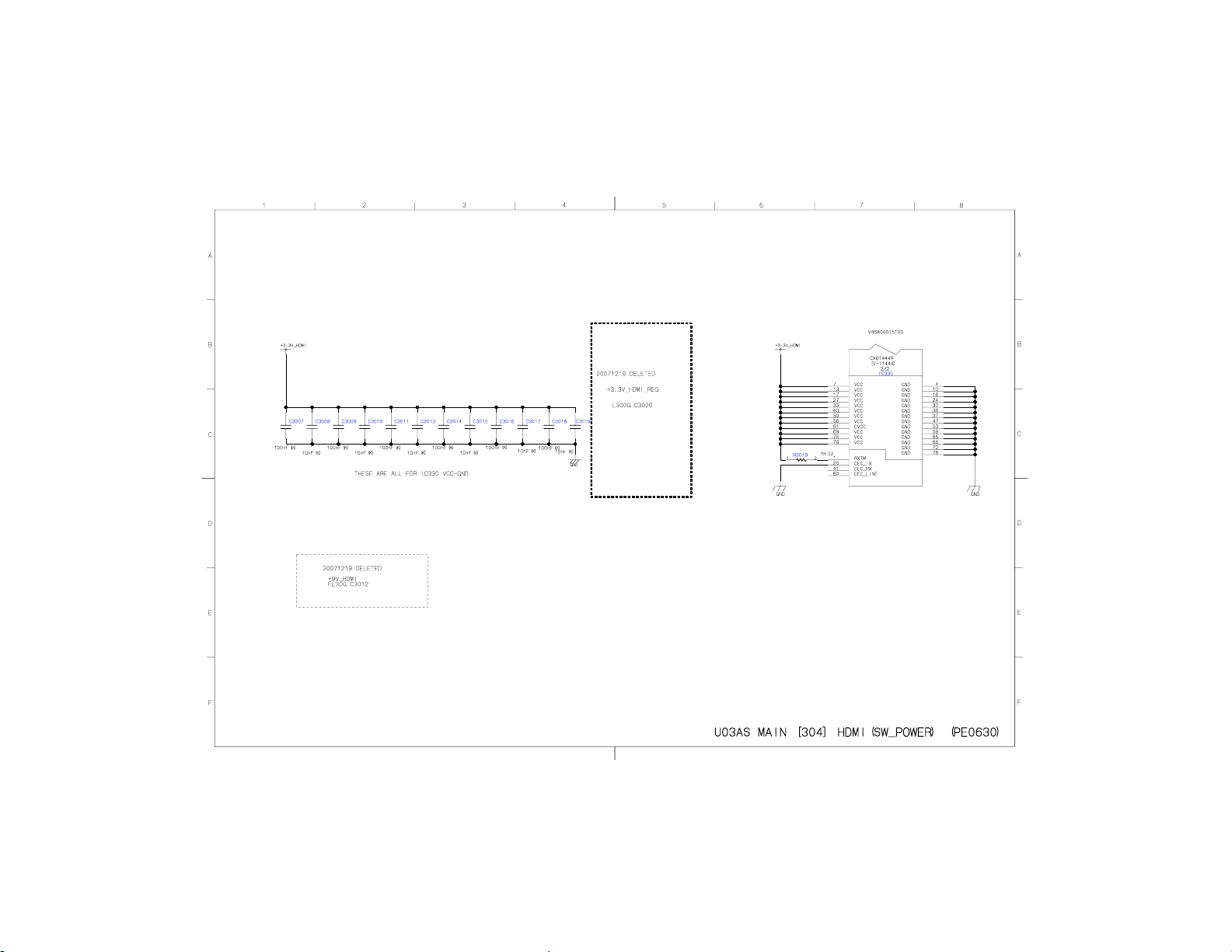

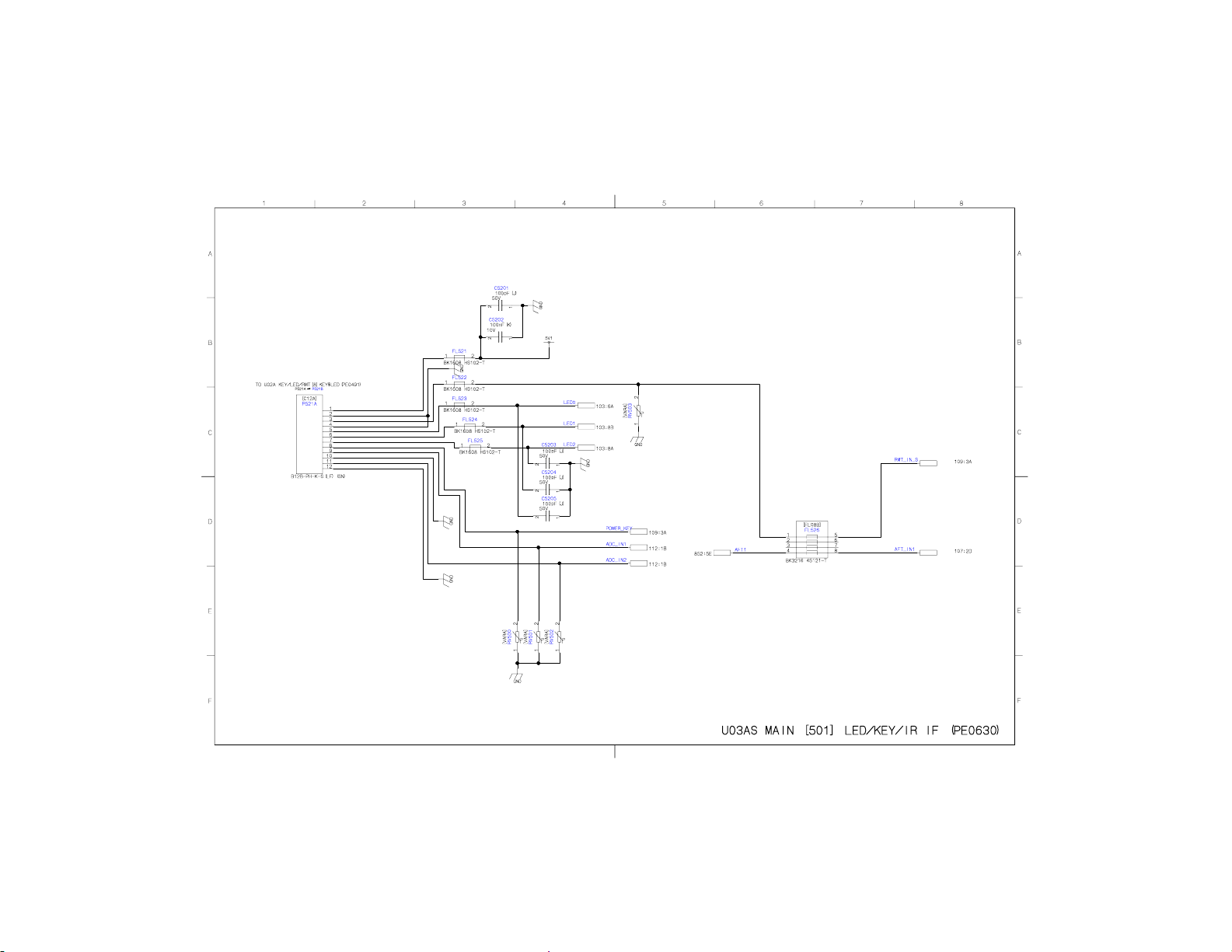

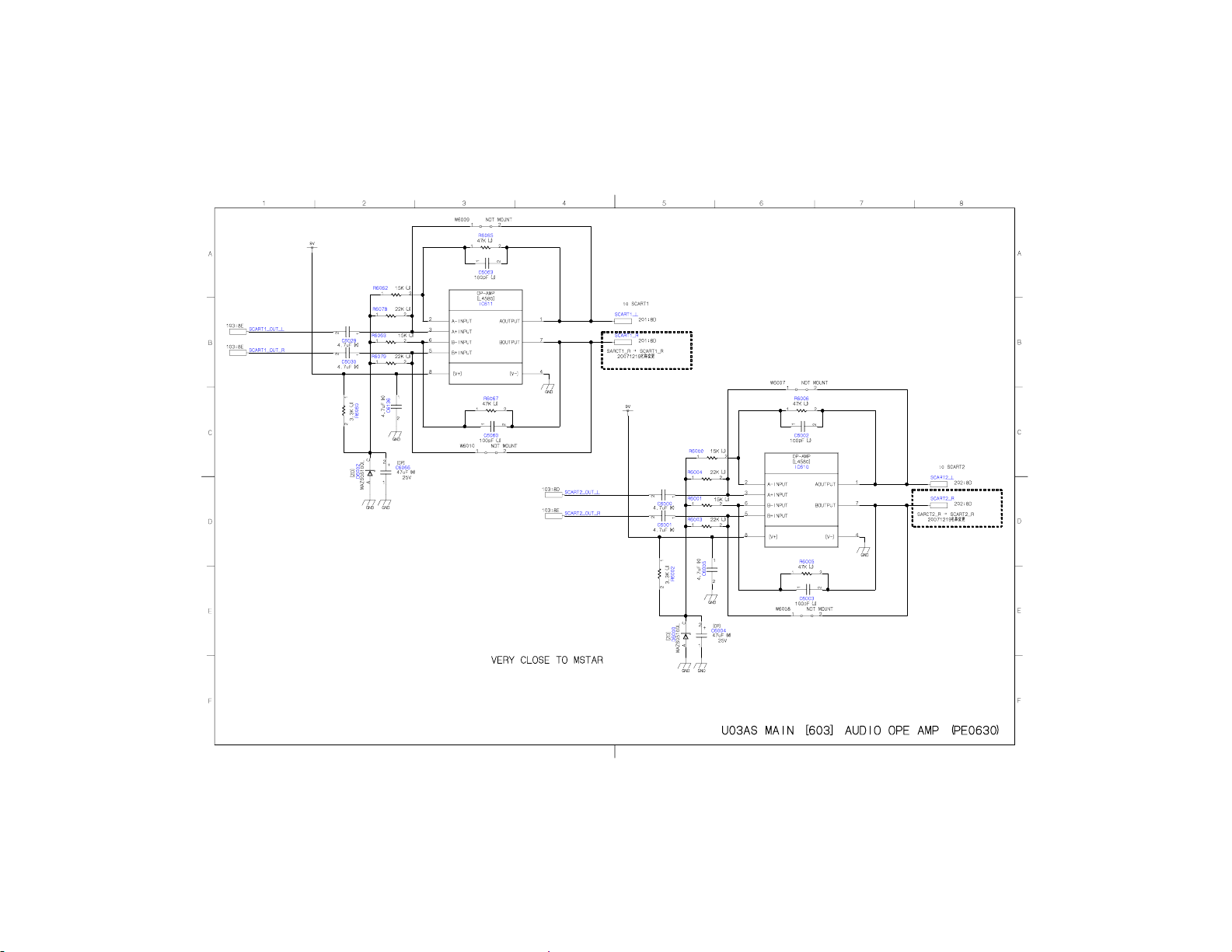

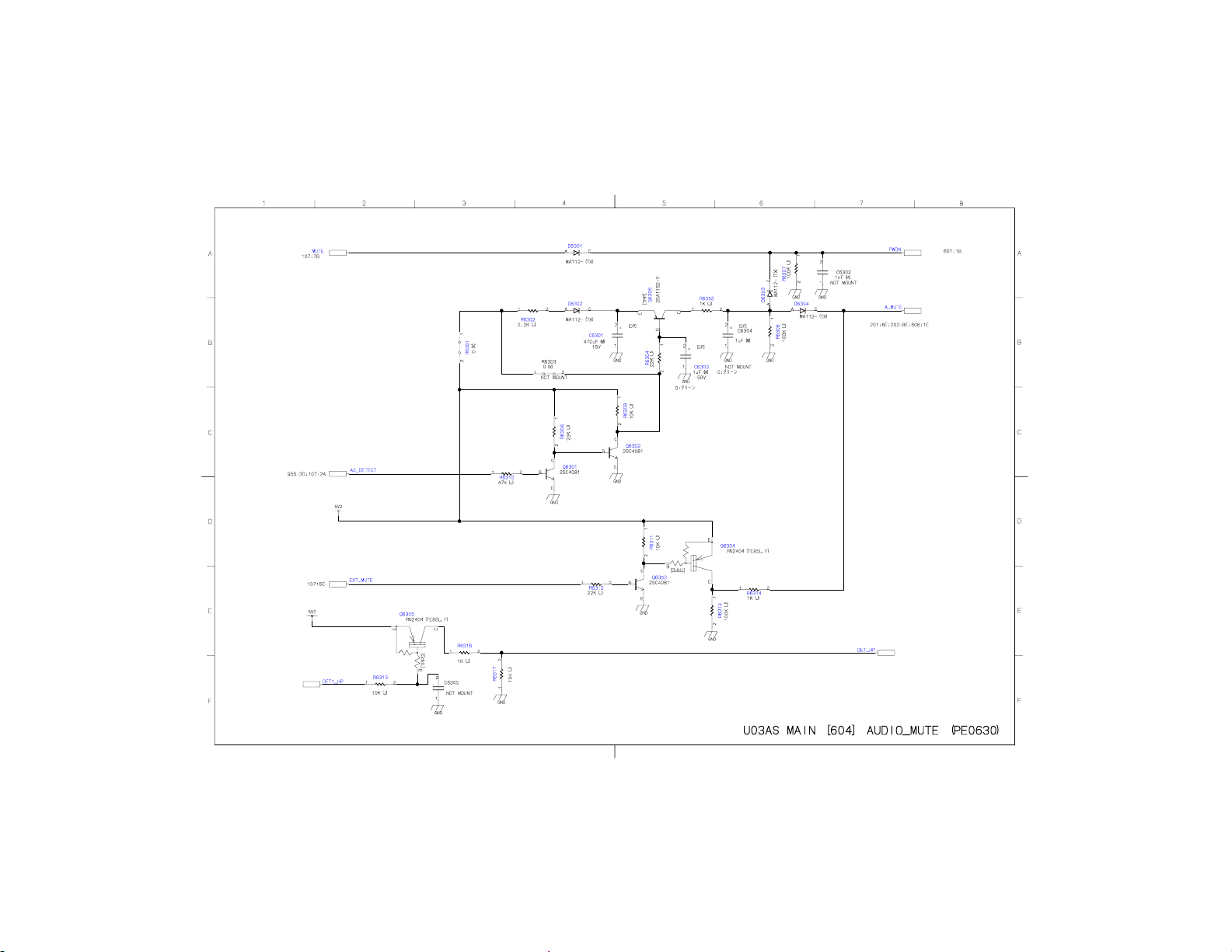

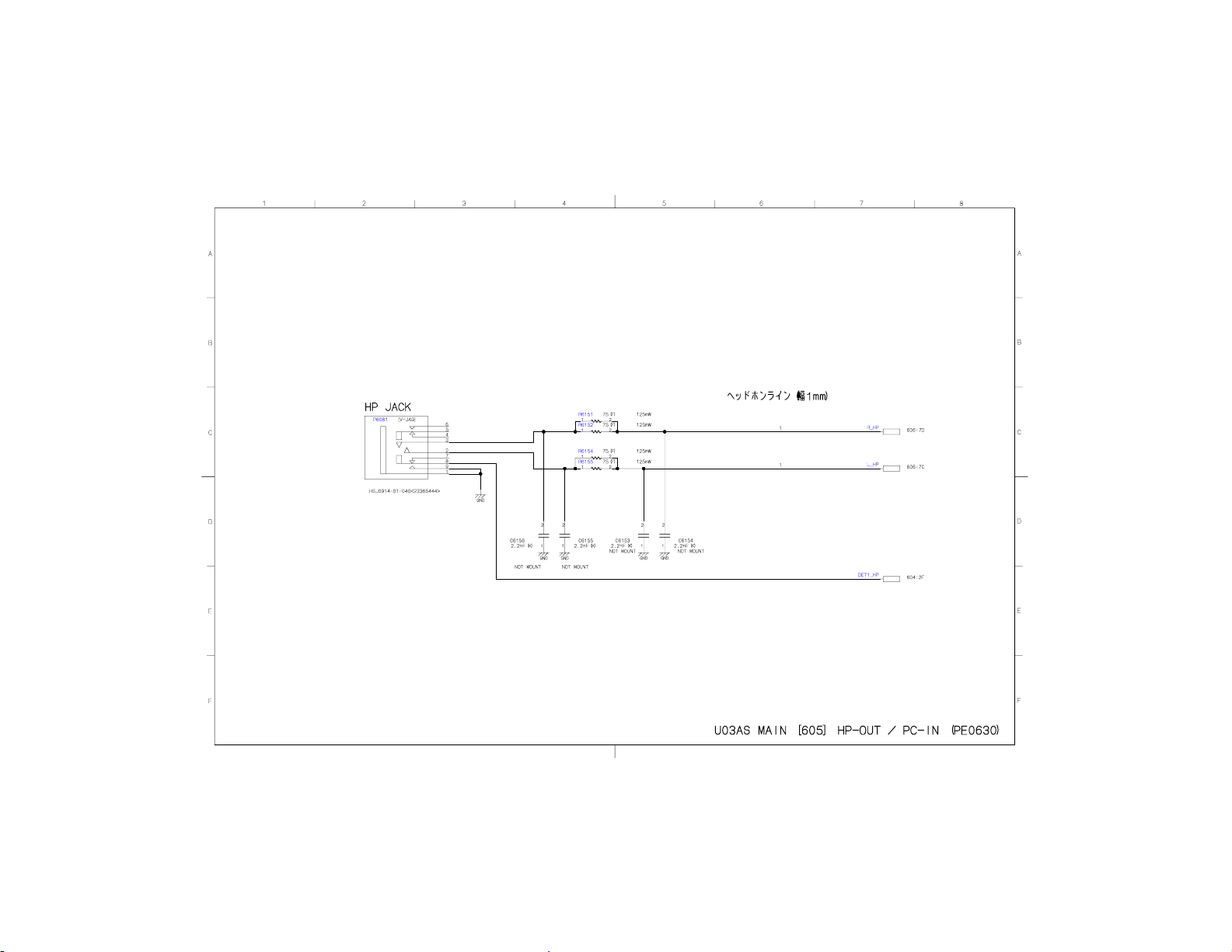

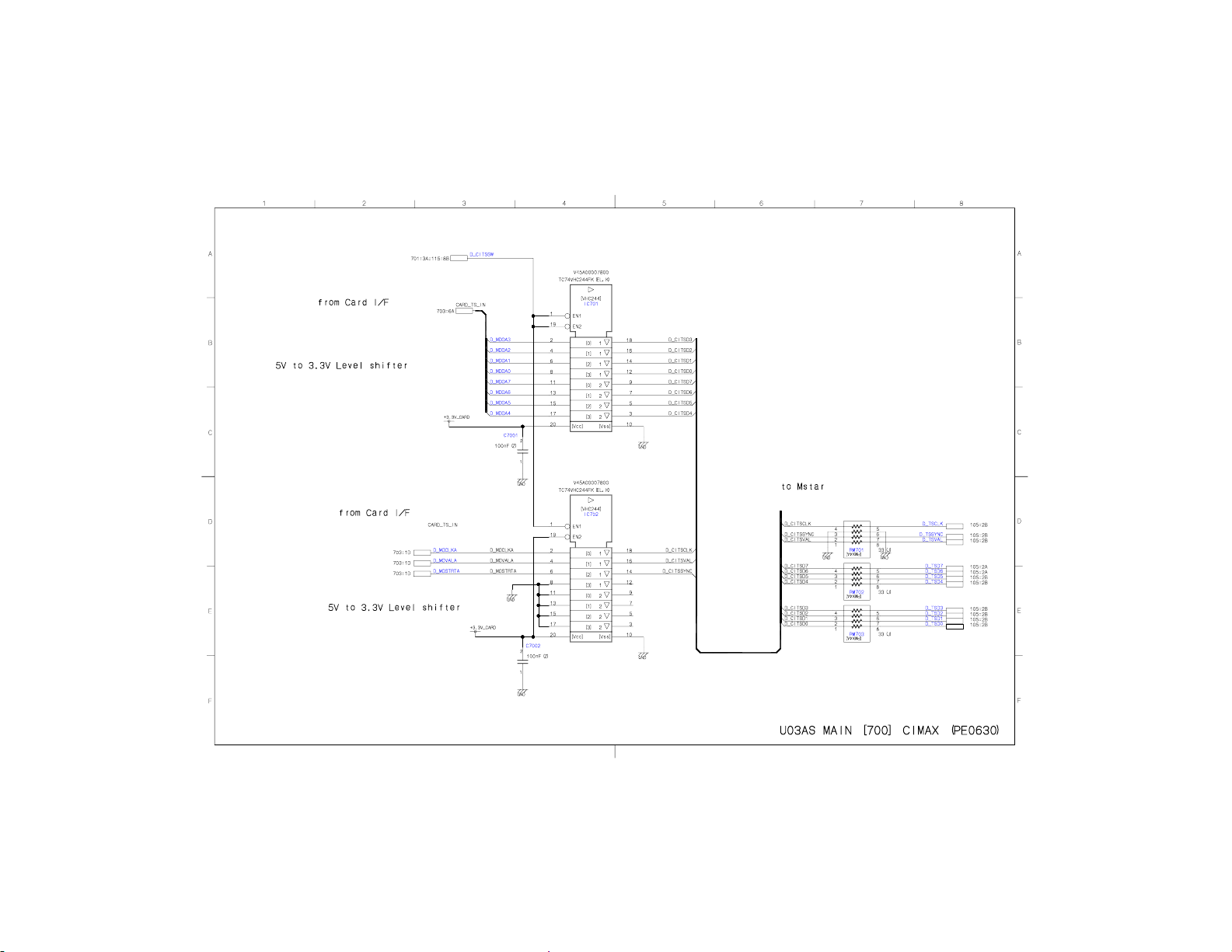

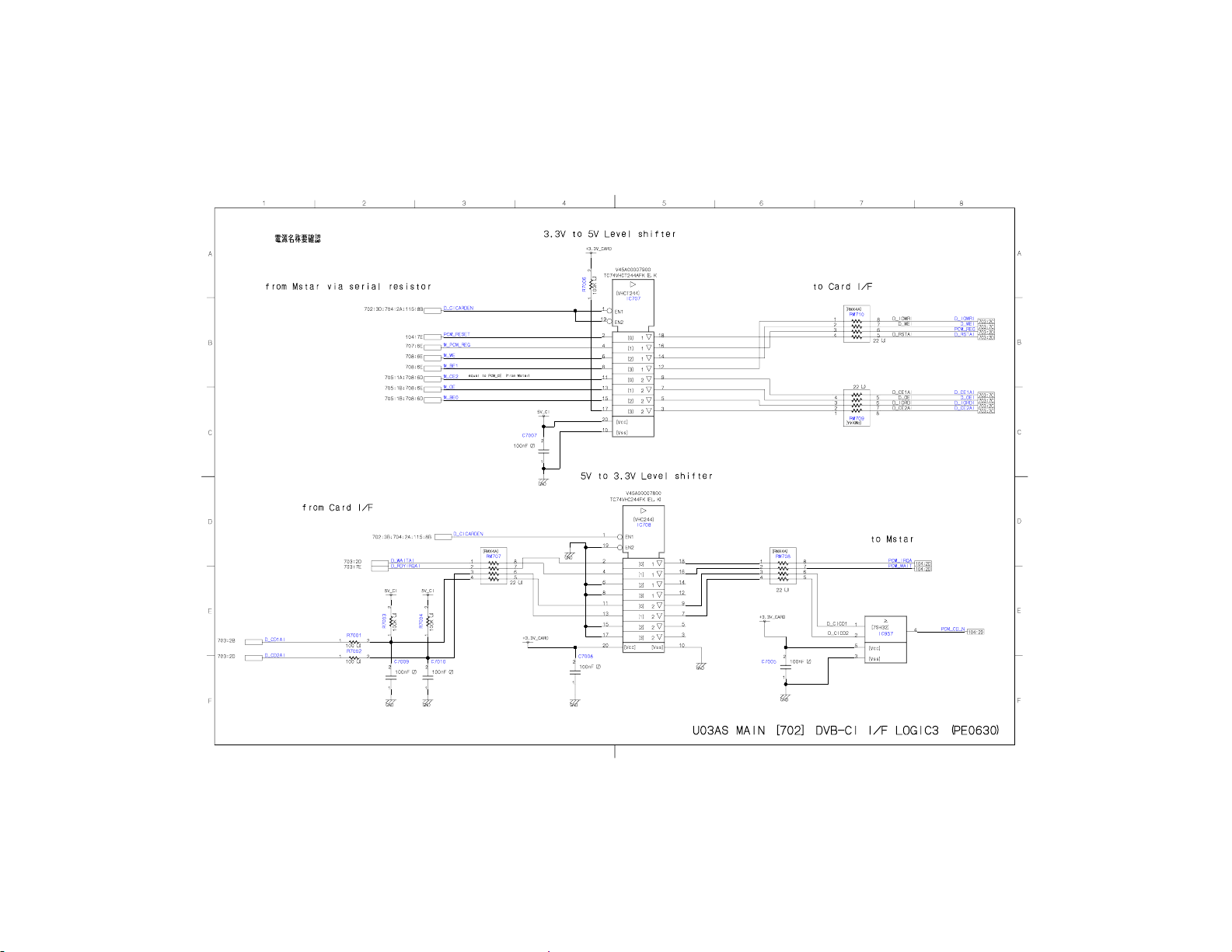

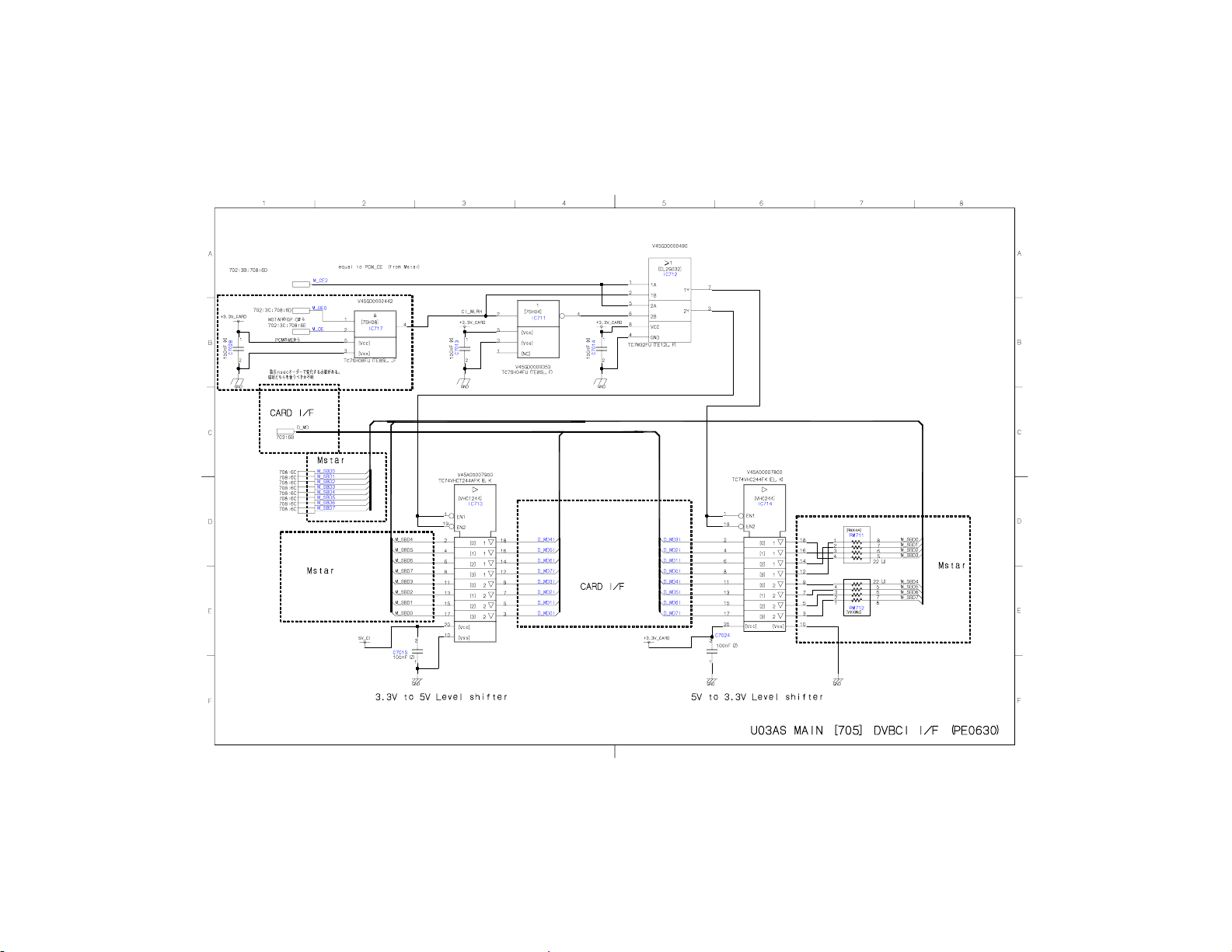

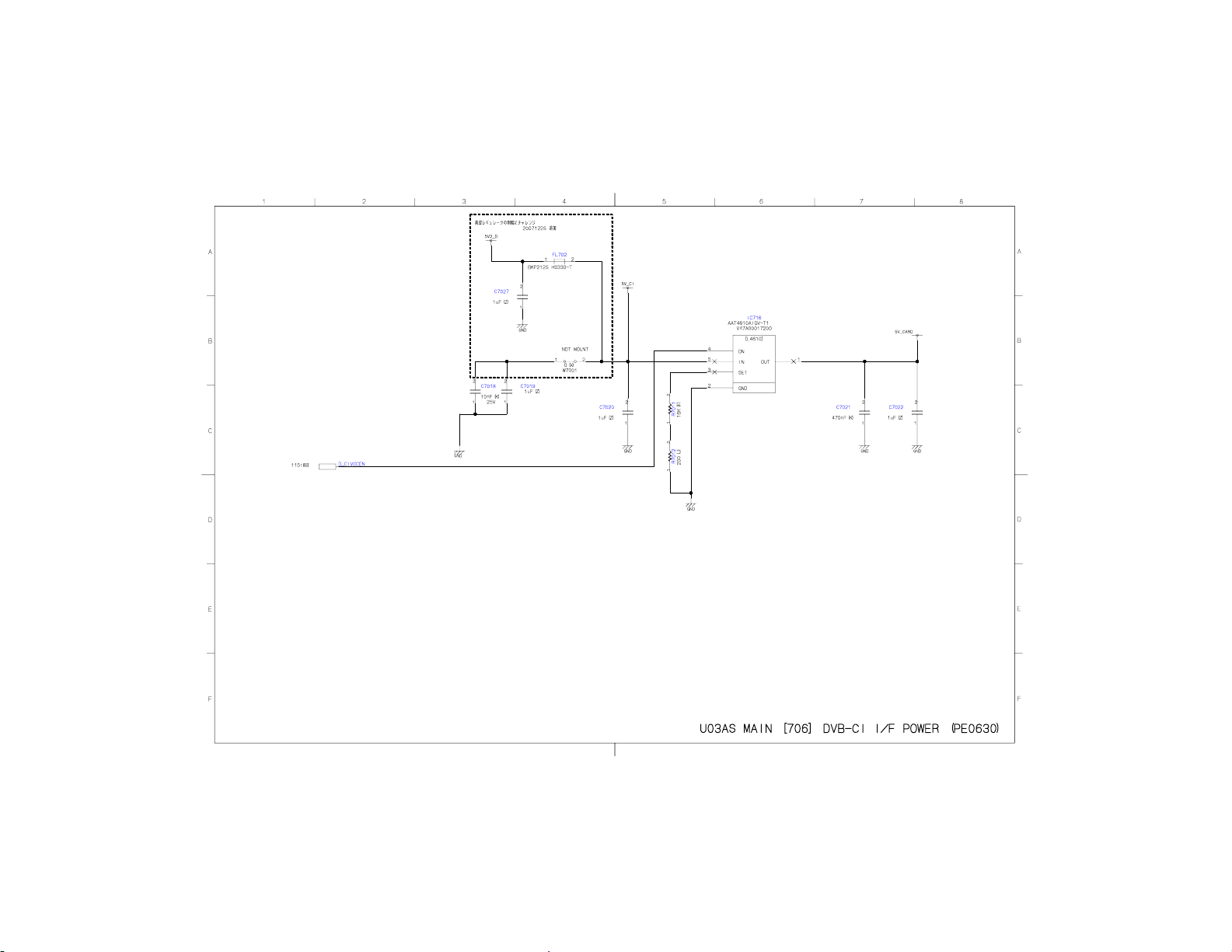

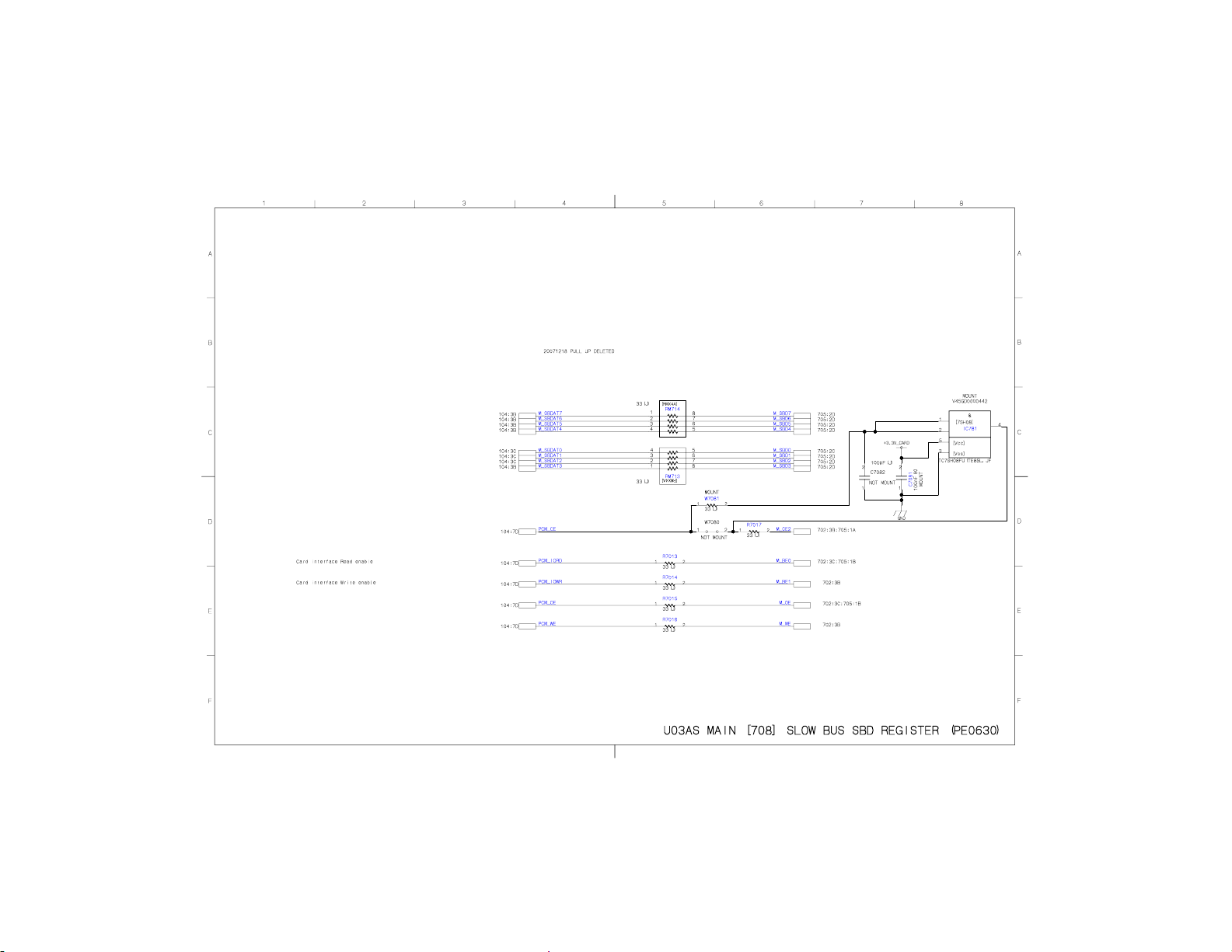

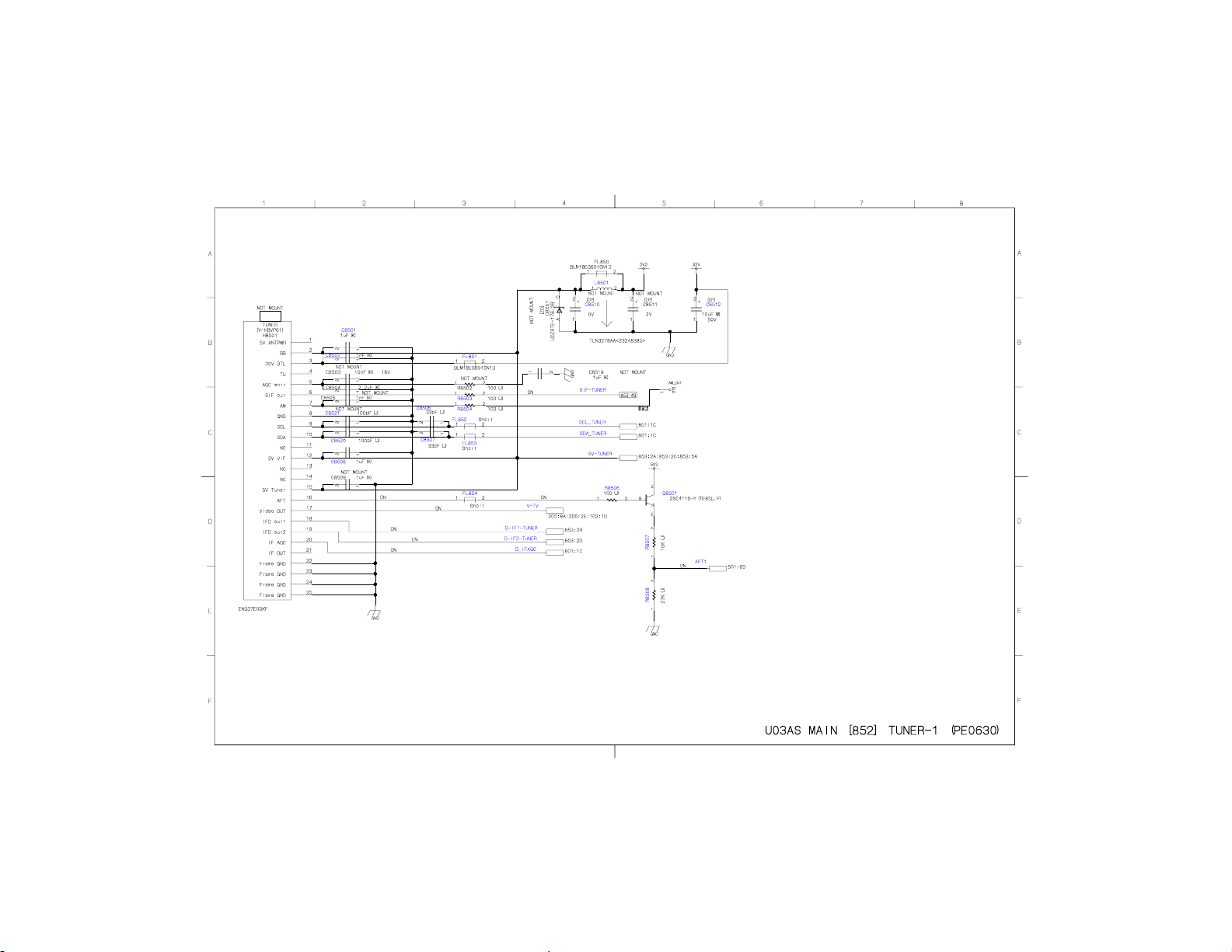

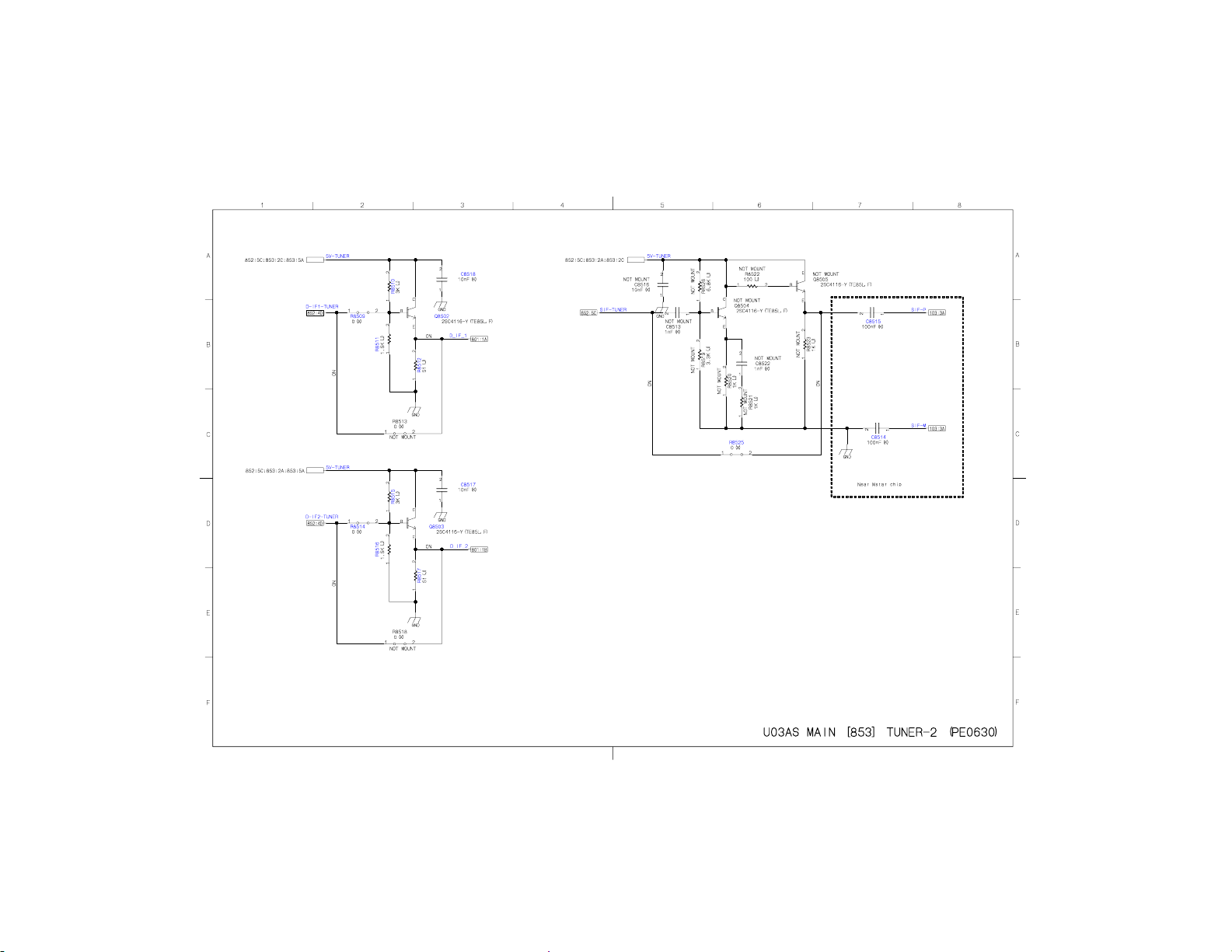

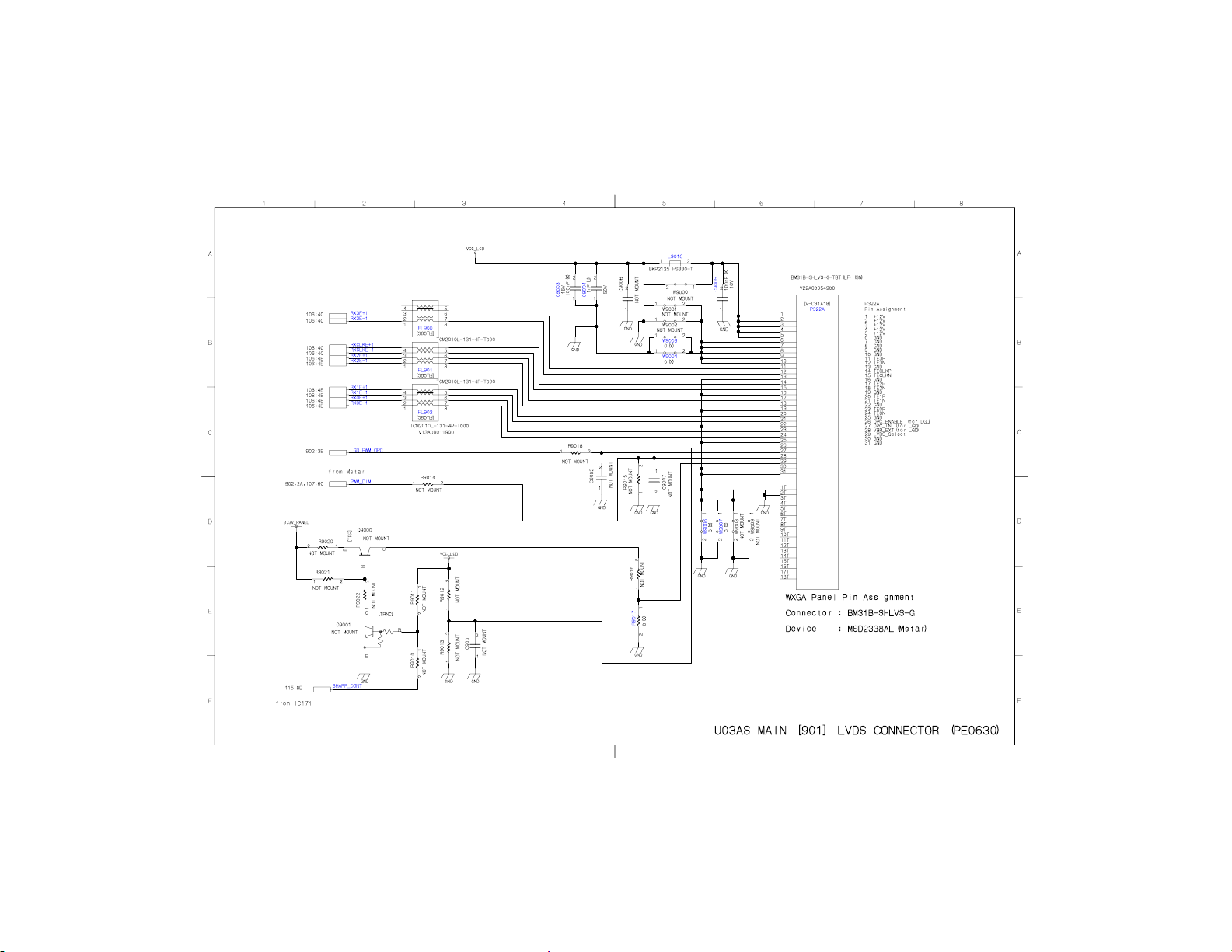

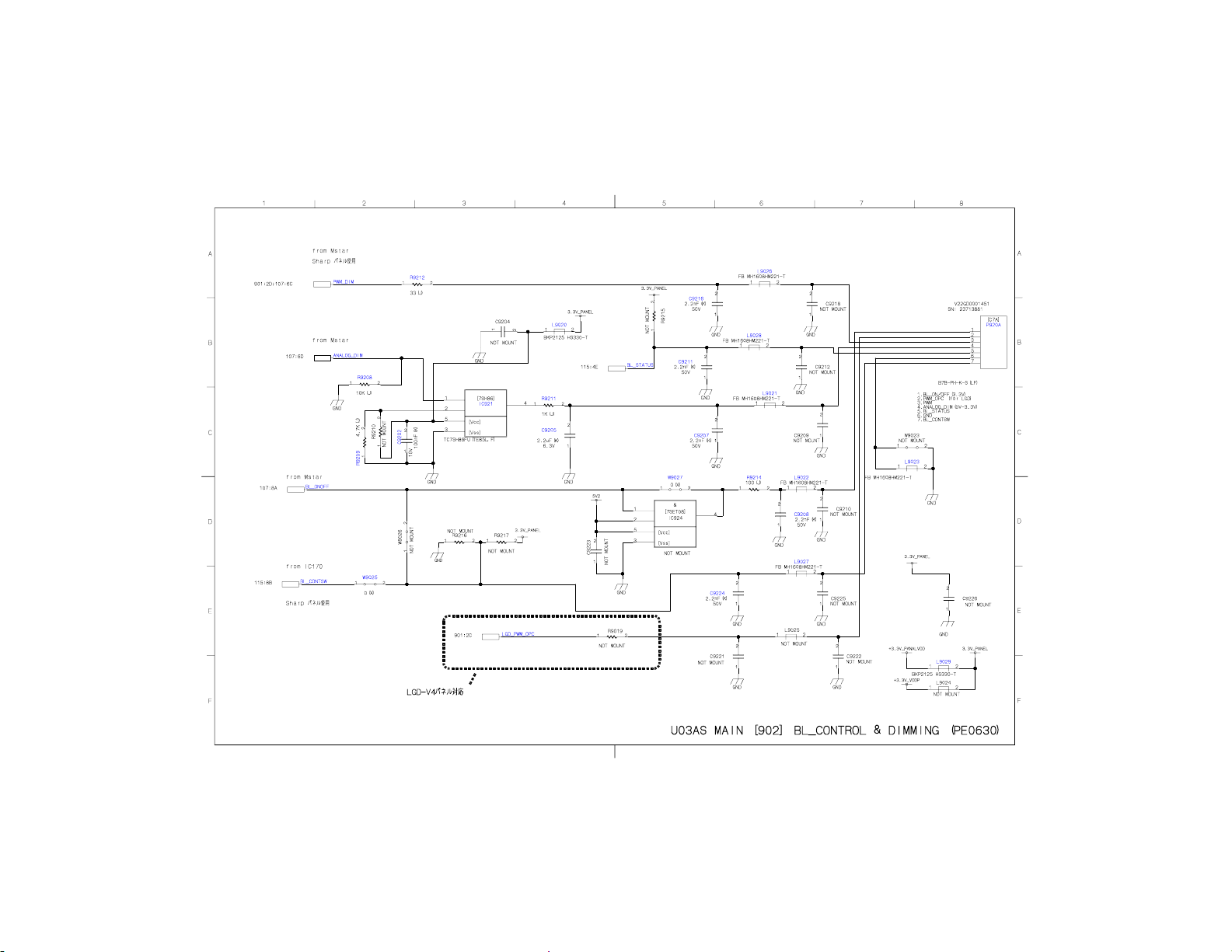

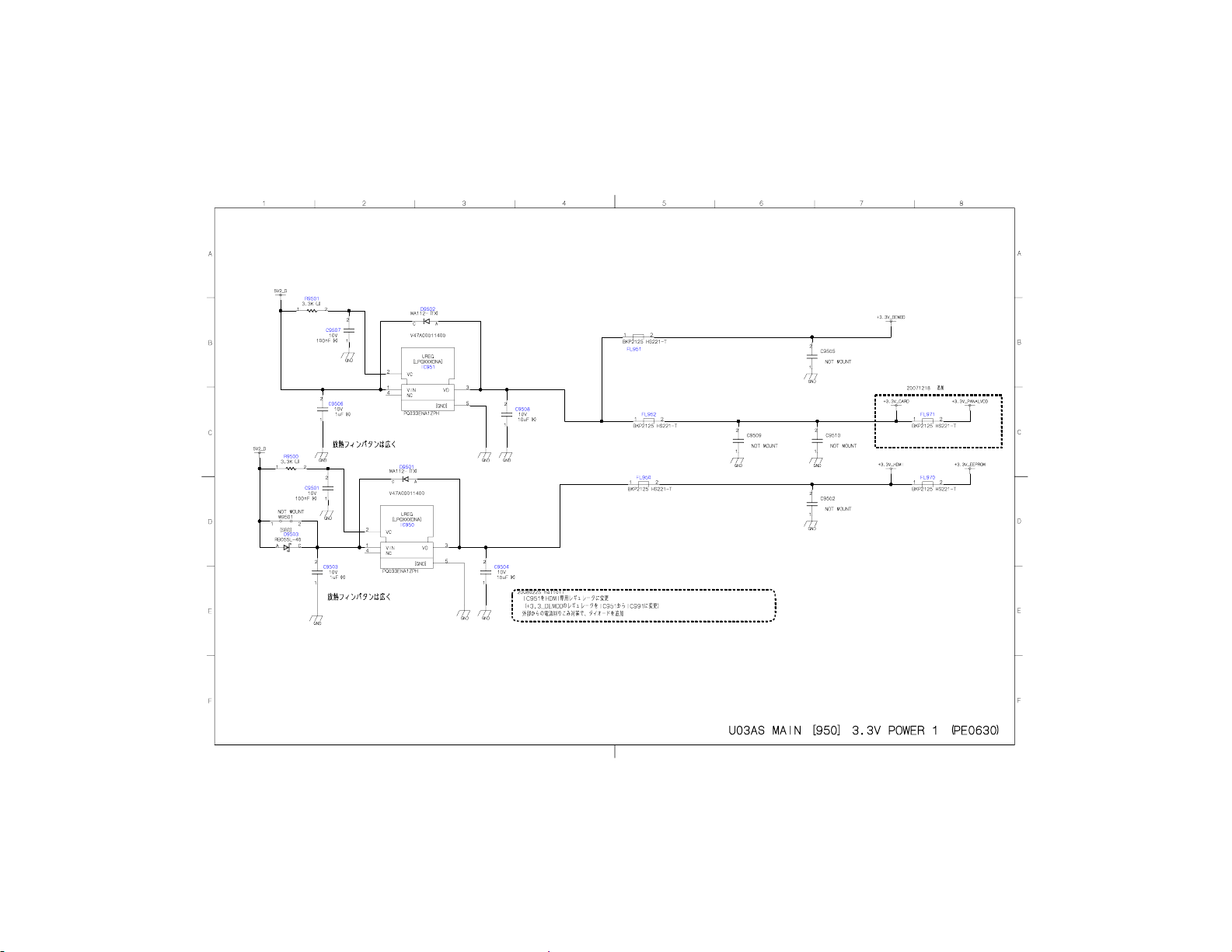

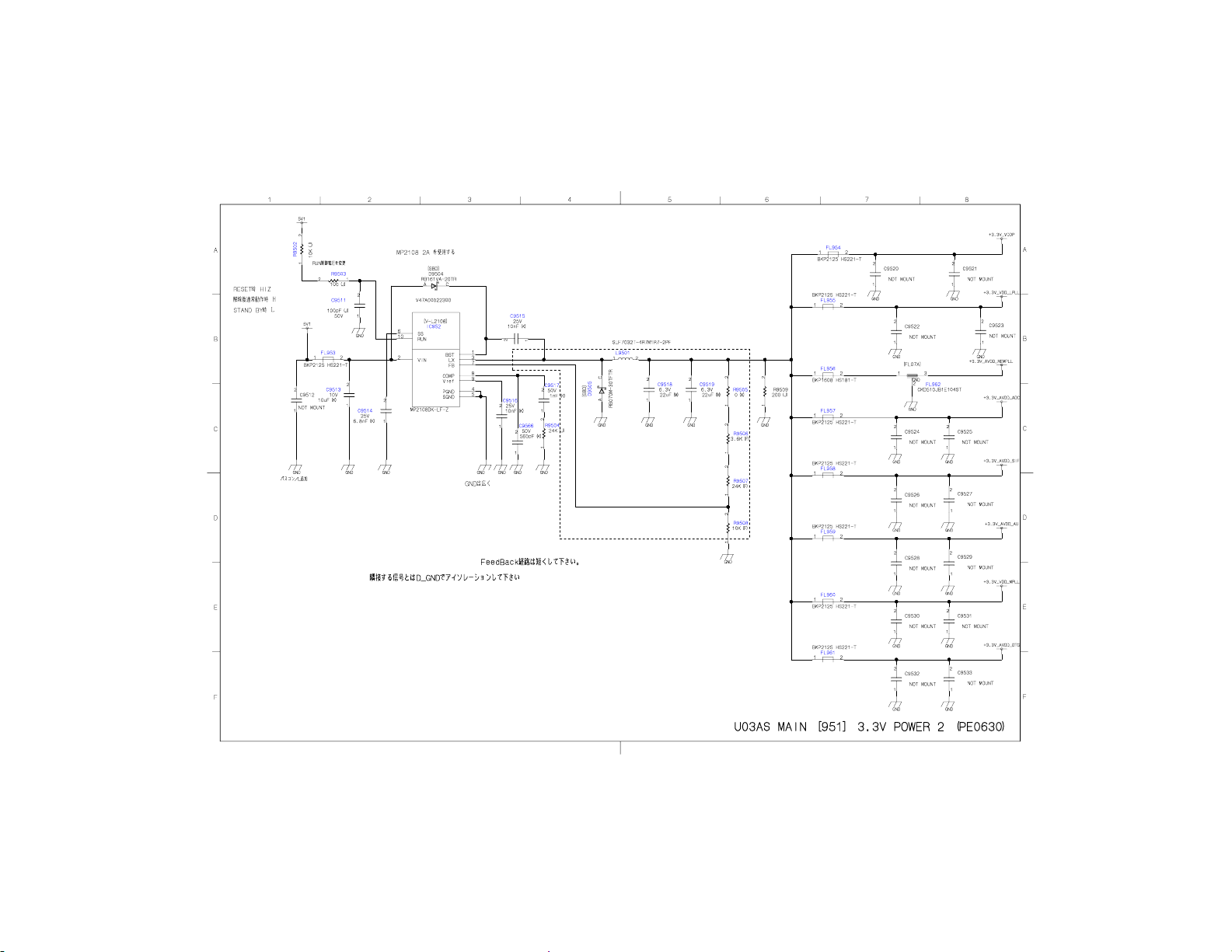

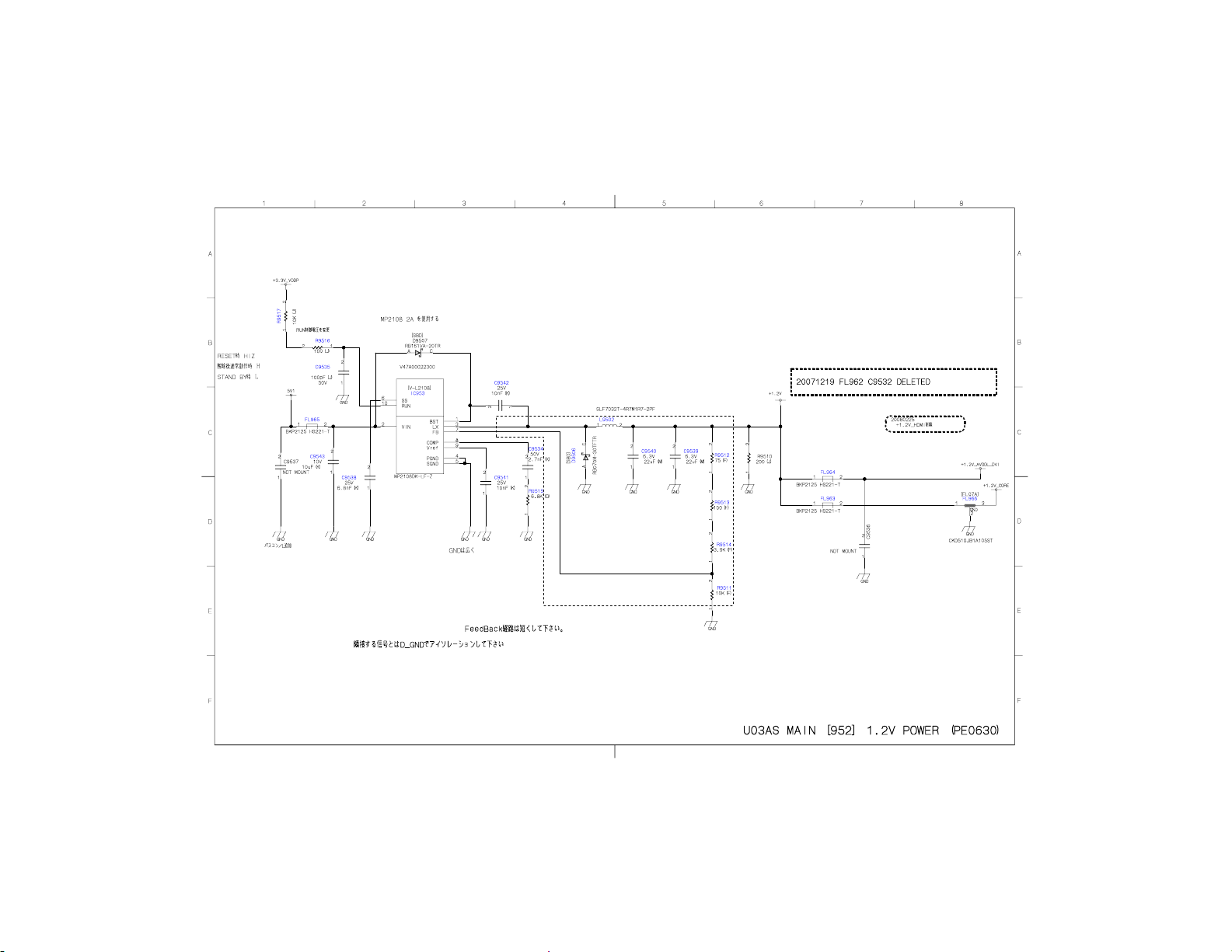

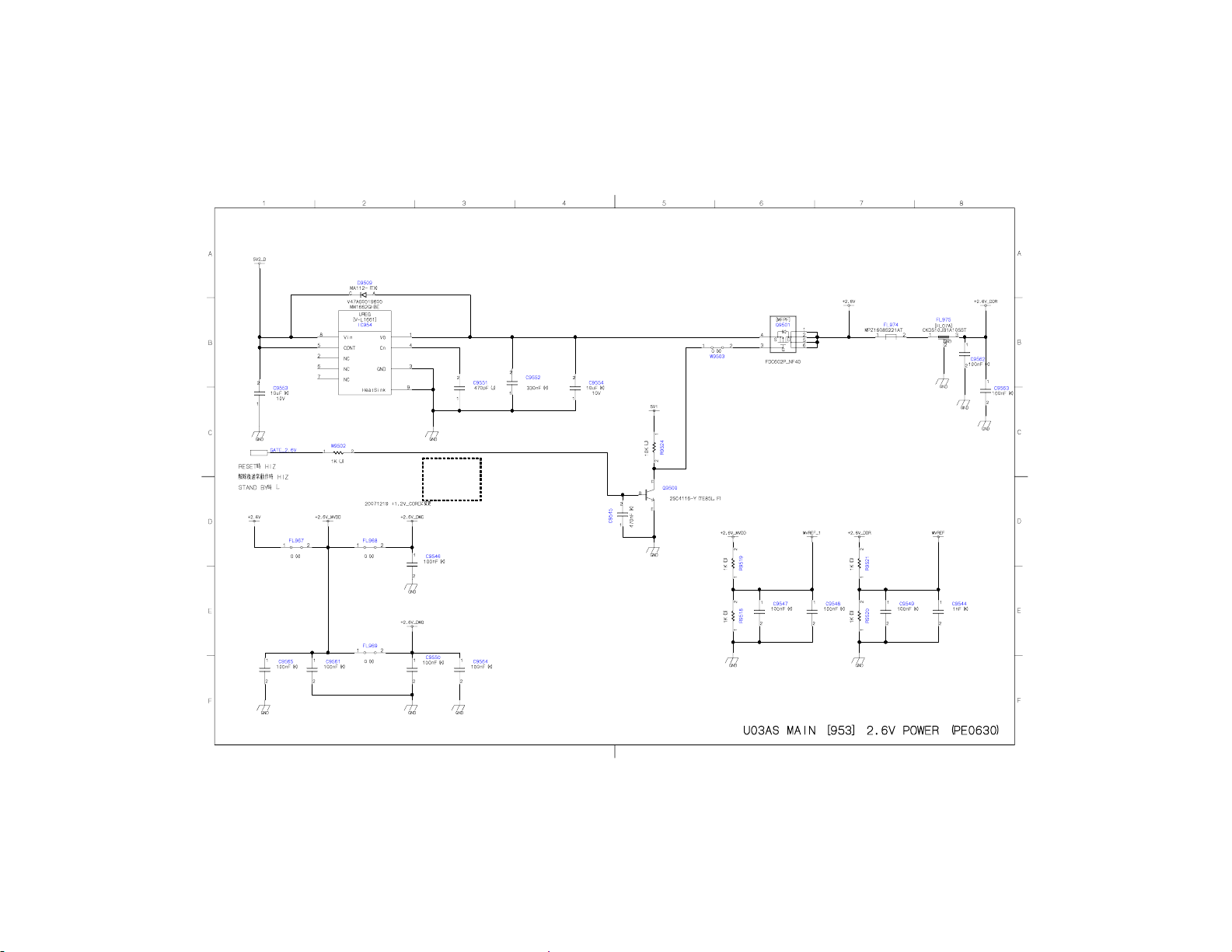

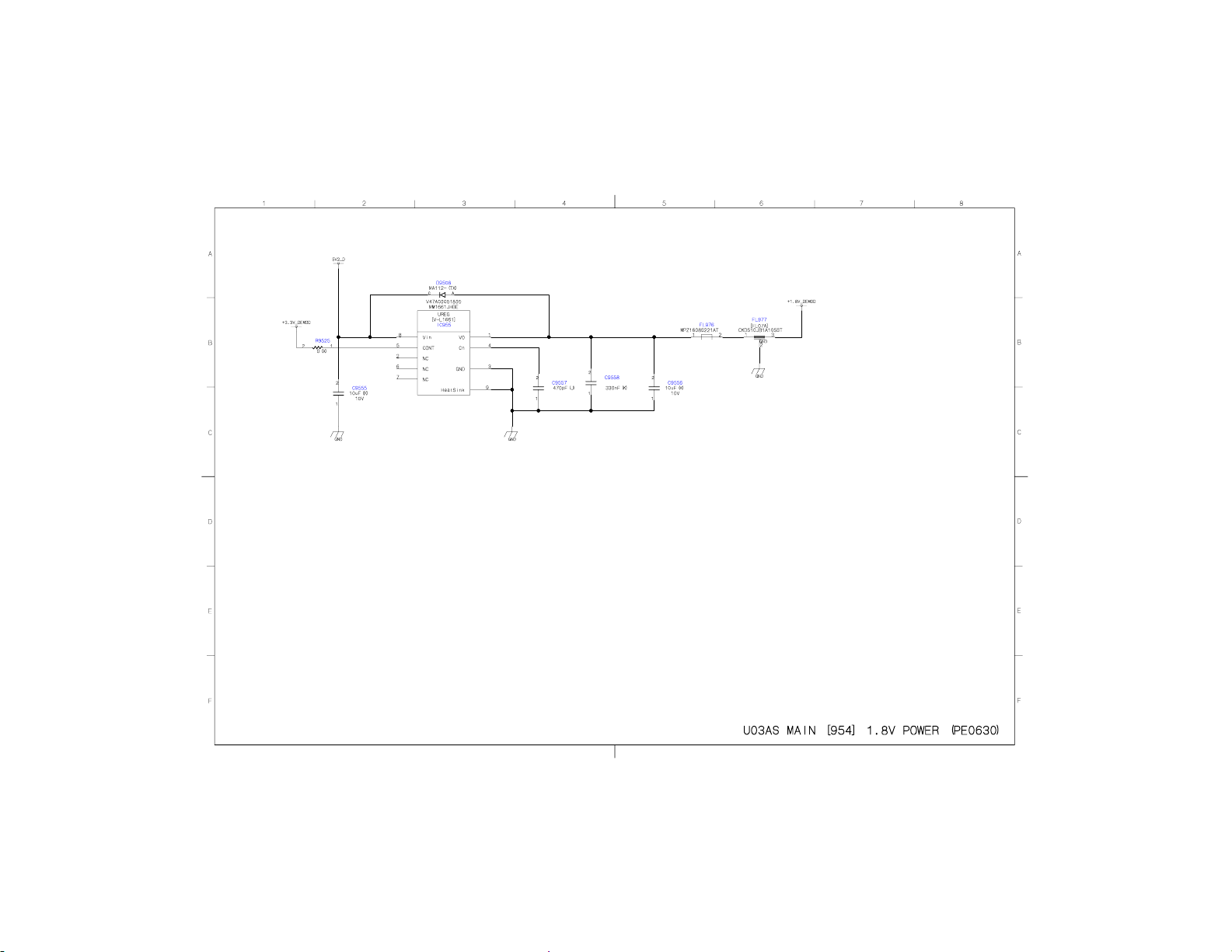

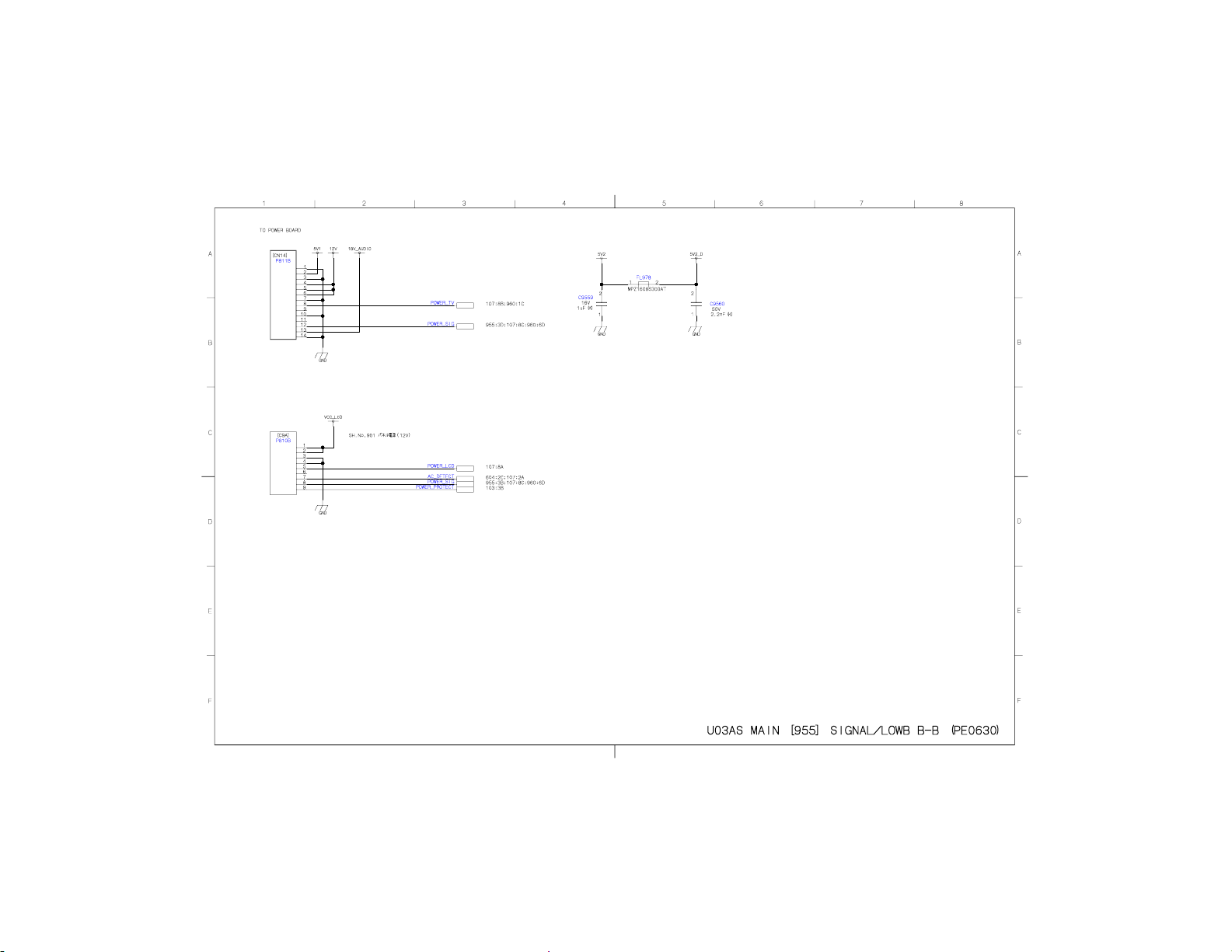

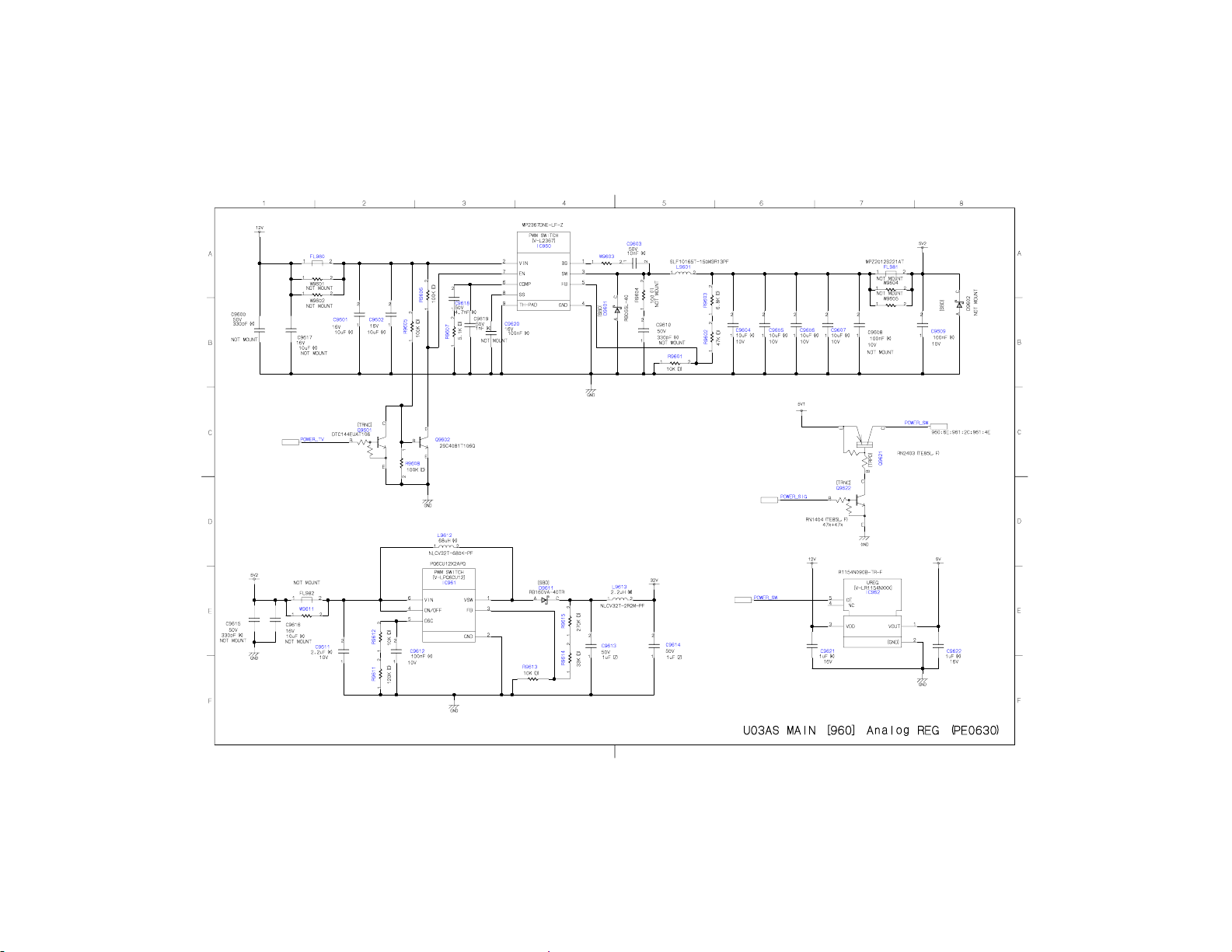

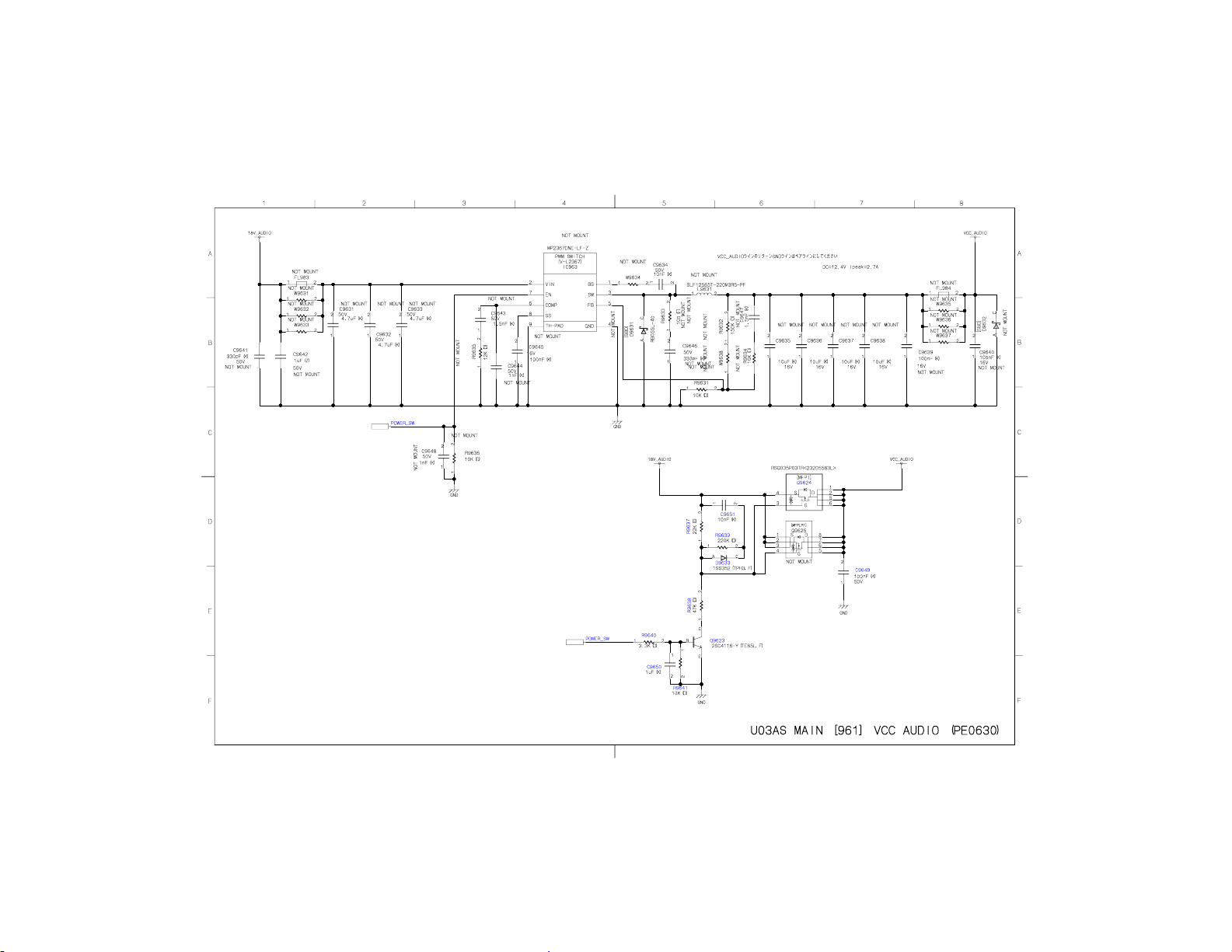

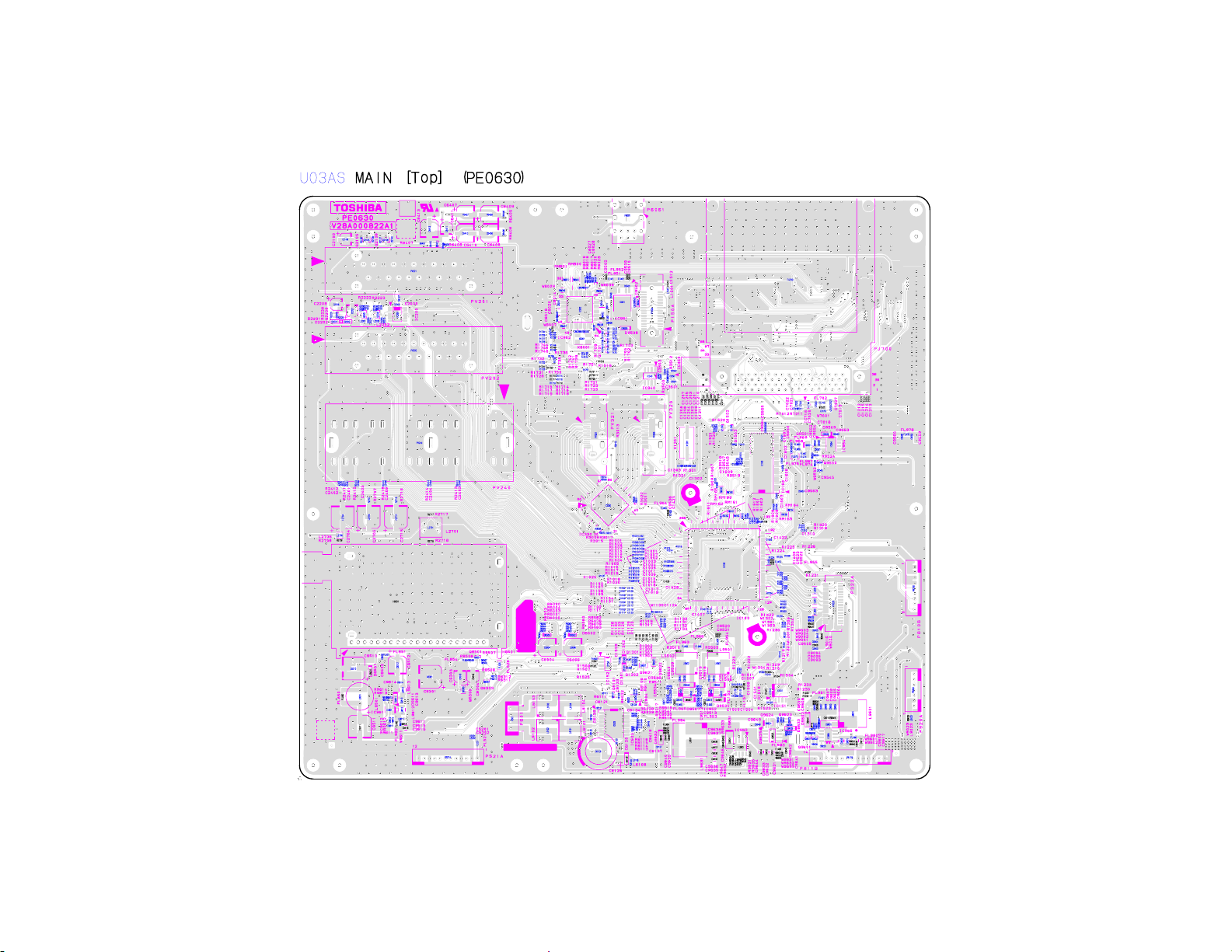

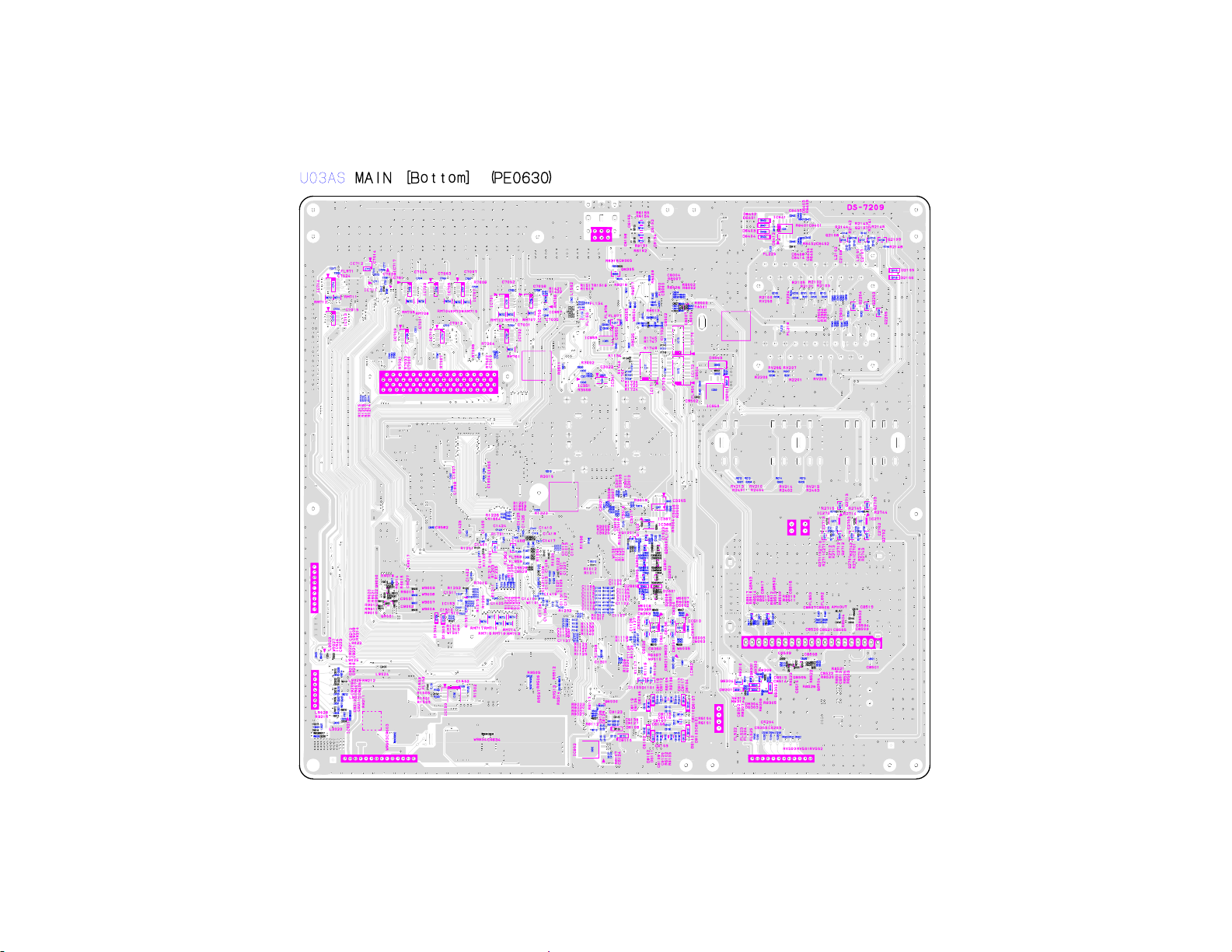

SCHEMATIC DIAGRAM

Precaution

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION" FOR DIRECT VIEW CTV ONLY, "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram

and the parts list designate components which have special characteristics

important for safety and should be replaced only with types identical to

those in the original circuit or specified in the parts list.

The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SAFETY

PRECAUTION and PRODUCT SAFETY NOTICE.

Do not degrade the safety of the receiver through improper servicing.

Note:

1. RESISTOR

Resistance is shown in ohm [K=1,000, M=1,000,000]. All resistors are 1/6 W and 5 %

tolerance carbon resistor, unless otherwise noted as the following marks.

1/2R : Metal or Metal oxide of 1/2 watt

1/2S : Carbon composition of 1/2 watt

1RF : Fuse resistor of 1 watt

10 W : Cement of 10 watt

K : ±10 %

G : ±2 %

F : ±1 %

2. CAPACITOR

Page 16

Unless otherwise noted in schematic, all capacitor values less than 1 are expressed in

µF, and the values more than 1 in pF.

All capacitors are ceramic 50 V, unless otherwise noted as the following marks.

= Electrolytic capacitor

= Mylar capacitor

3. The parts indicated with " " have special characteristics, and should be replaced with

identical parts only.

4. Voltages read with DIGITAL MULTI-METER from point indicated to chassis ground,

using a color bar signal with all controls at normal, line voltage at nominal AC volts.

5. Waveforms are taken receiving color bar signal with enough sensitivity.

6. Voltage reading shown are nominal values and may vary ±20 % except H.V.

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

Page 24

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Page 39

Page 40

Page 41

Page 42

Page 43

Page 44

Page 45

Page 46

Page 47

Page 48

Page 49

Page 50

Page 51

Page 52

Page 53

Page 54

Page 55

Page 56

Page 57

Page 58

Page 59

Page 60

Page 61

Page 62

Page 63

Page 64

Page 65

Page 66

Page 67

Page 68

Page 69

Page 70

Page 71

Page 72

Page 73

Page 74

Page 75

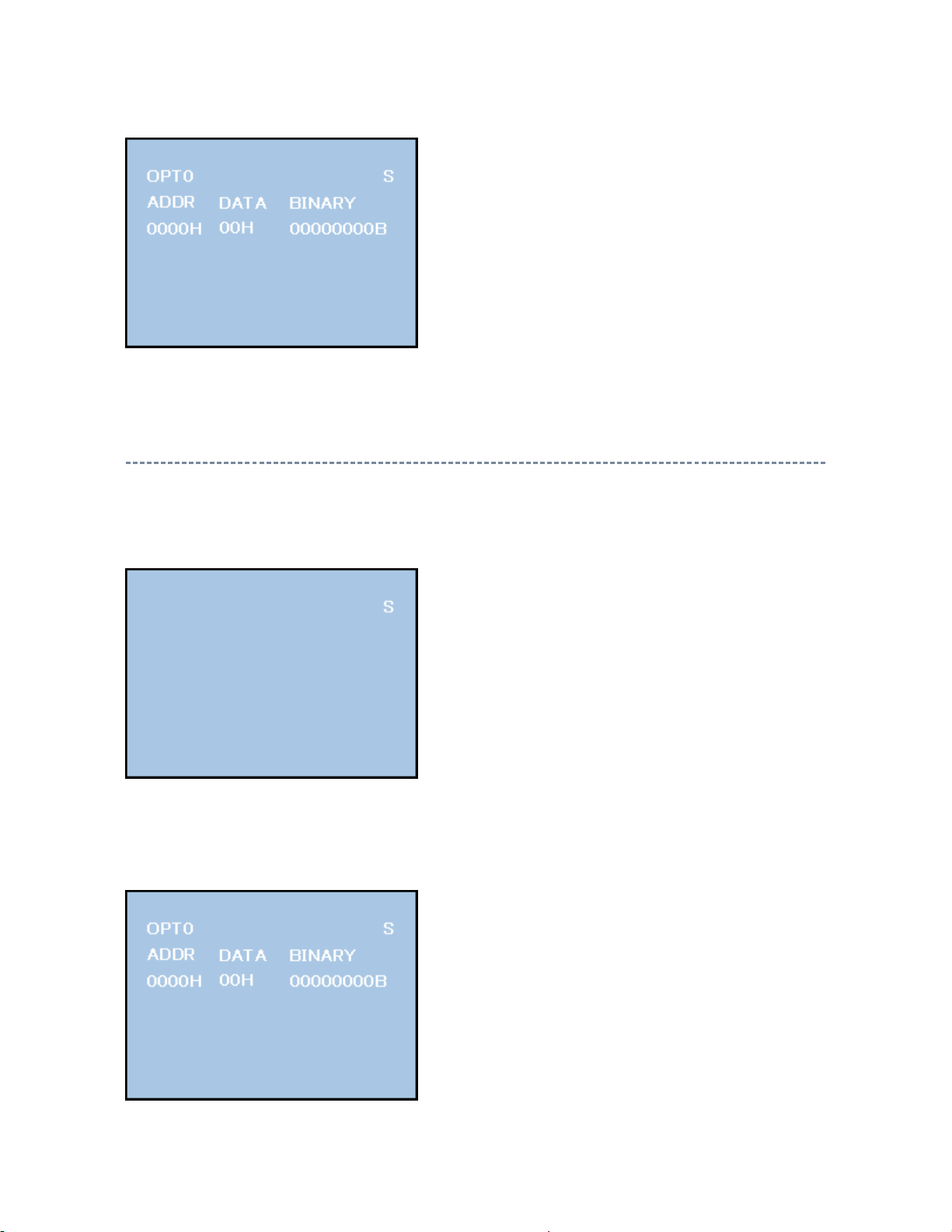

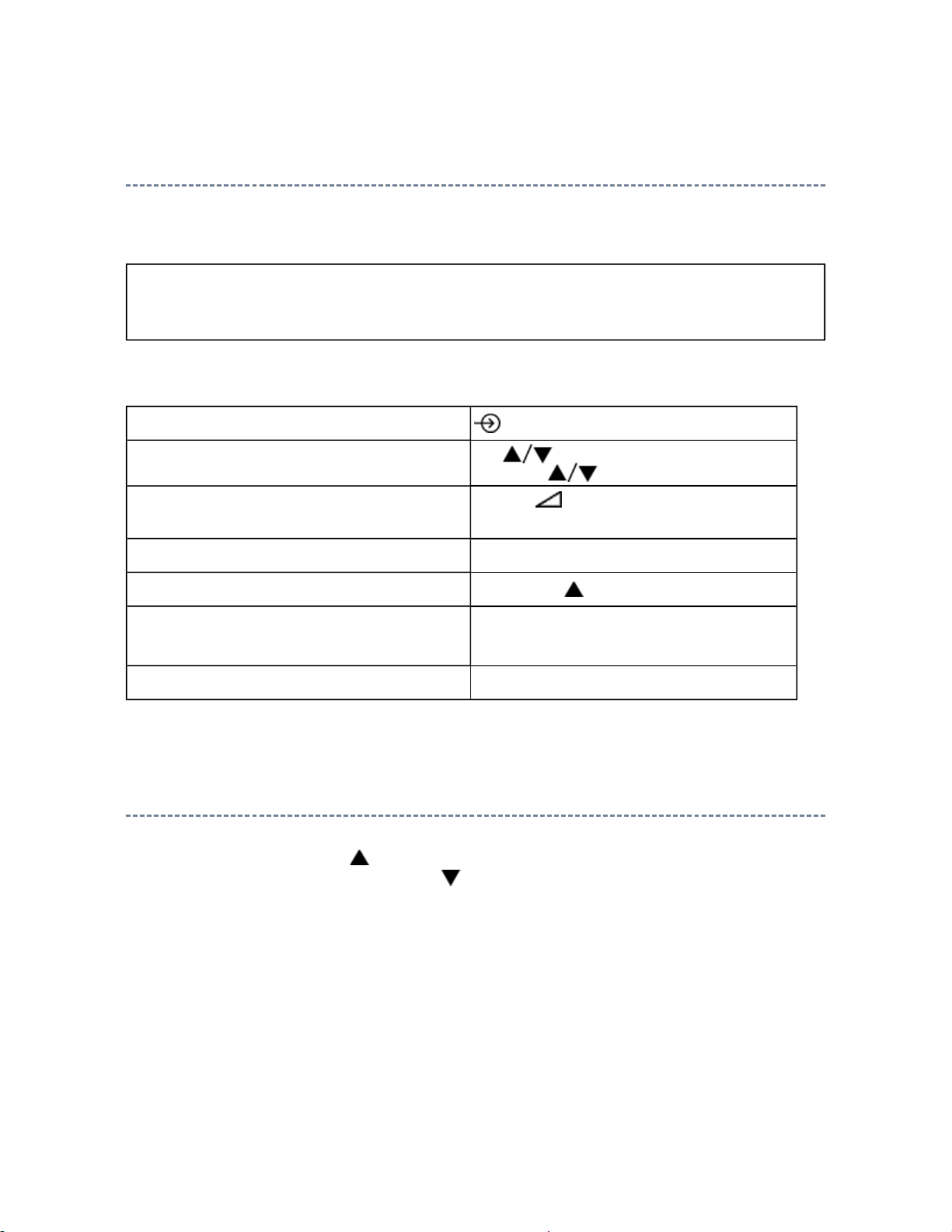

ADJUSTMENT

Service Mode

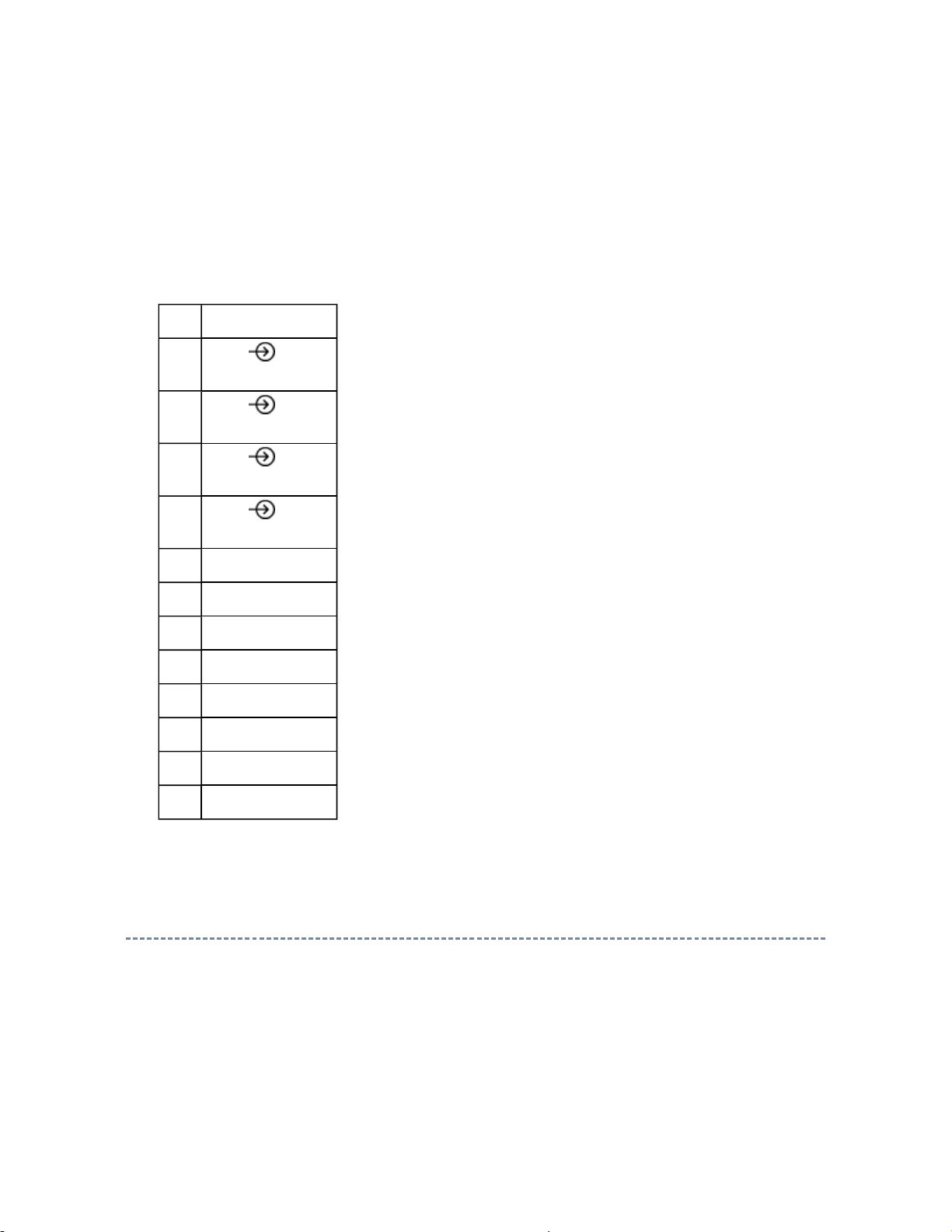

Entering to Service Mode

1. Set VOLUME to minimum and press

button once on remote control.

↓

↓

Service Mode display

2. Press button again and hold button down.

3. While holding the button, press MENU

button on TV set.

Page 76

Displaying the Adjustment Menu

Press MENU button on TV.

Service Mode

Press ↑ ↓ Press

Adjustment Mode

Page 77

Key Function in the Service Mode

The following key entry during display of adjustment menu provides special functions.

CAUTION: Never try to perform initialization unless you have changed the

memory IC.

Test signal selection

Selection of the adjustment items

Change of the data value

Adjustment menu mode ON/OFF MENU button (on TV)

Initialization of the memory (IC152) CALL + CH button on TV

Automatic A/D Adjustment

(Component, Composite (PAL, NTSC), RGB)

Self diagnostic display ON/OFF 9 button

button (on remote control)

CH (on TV)

or MENU (on remote control)

Volume +/- (on TV)

or MENU RIGHT/LEFT (on remote control)

7 button

Selecting the Adjusting Item

Every pressing of MENU UP button in the service mode changes the adjustment items in

the order of table below. (MENU DOWN button for reverse order)

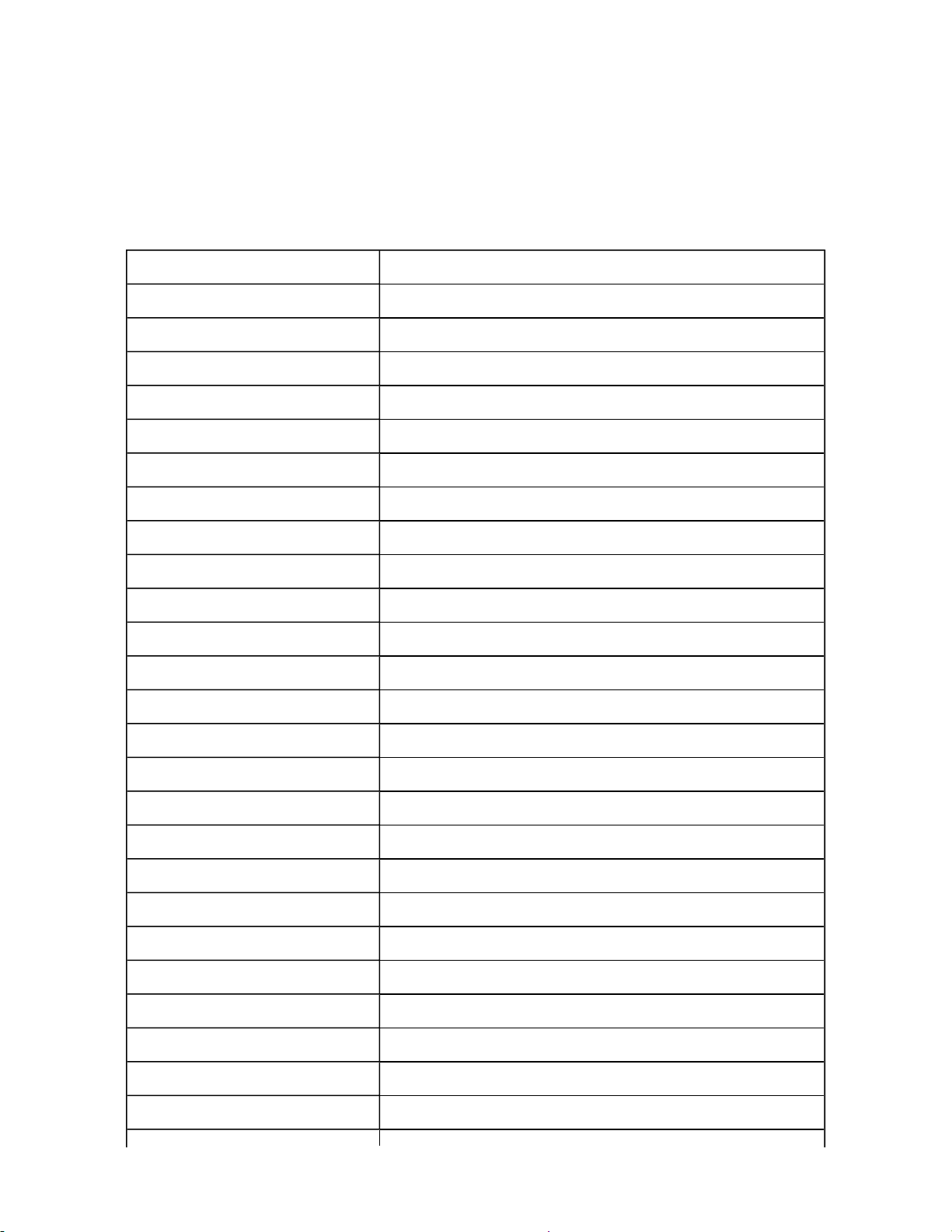

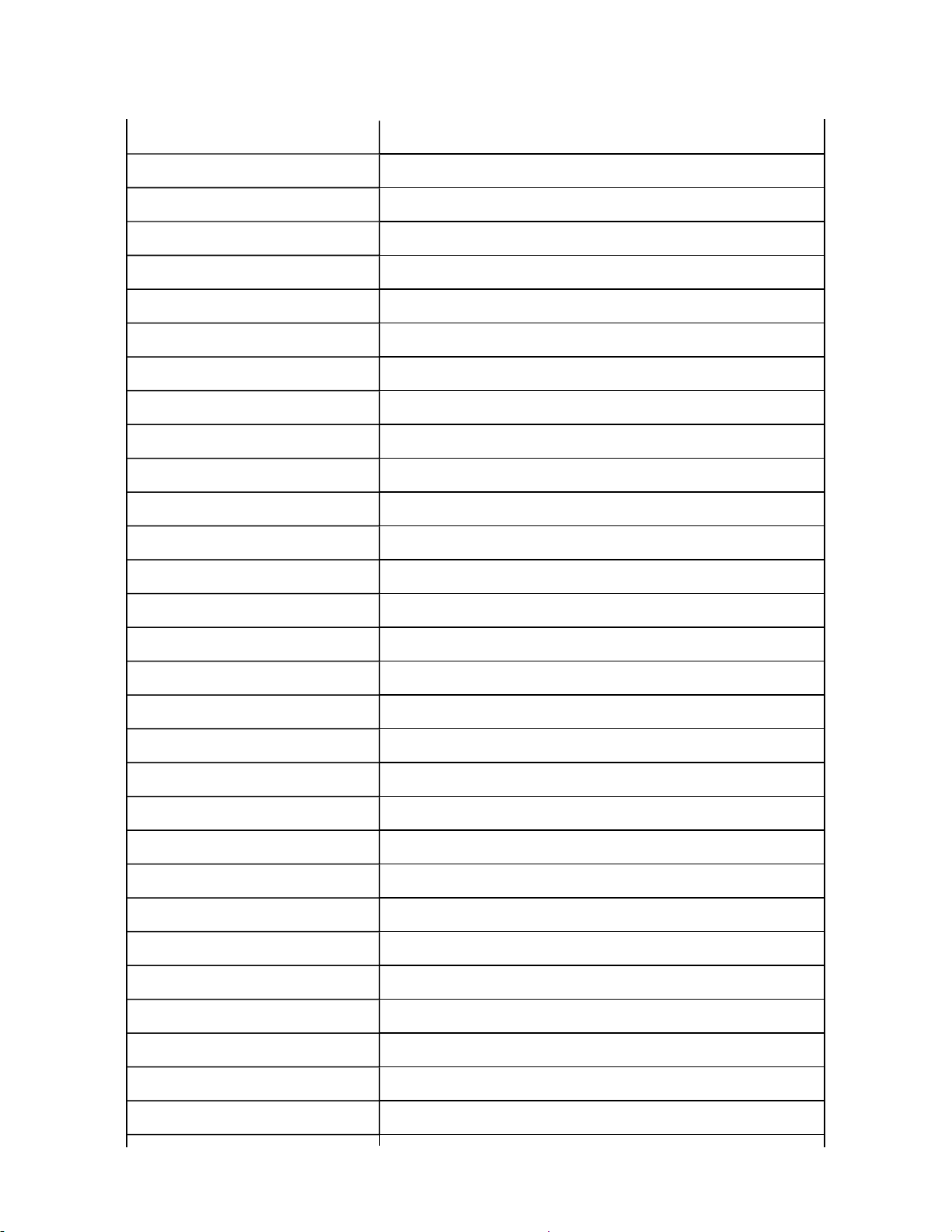

SETTING & ADJUSTING DATA

[ SERVICE MODE ]

ADJUSTING ITEMS AND DATA IN THE SERVICE MODE:

Note:

Page 78

The image system data of RCUT-BDRV is different by each image format.

N

The PAL value is indicated in the table.

ever adjust H.POS and V.POS except PAL/WIDE mode.

Item Name of adjustment

PLLW0 PLL WAIT TIME

PLLW1 PLL WAIT TIME

PLLW2 PLL WAIT TIME

PLLW3 PLL WAIT TIME

PLLW4 PLL WAIT TIME

PLLW5 PLL WAIT TIME

OPT1 TV SET OPTION 1

OPT2 TV SET OPTION 2

OPT3 TV SET OPTION 3

OPT4 TV SET OPTION 4 (PANEL OPT DATA FOR VENDOR)

OPT5 TV SET OPTION 5 (PANEL OPT DATA FOR INCH)

OPT6 TV SET OPTION 6 (HOTEL MODE)

OPT7 TV SET OPTION 7 (HOTEL MODE)

OPT8 TV SET OPTION 8 (HOTEL MODE)

TVOP TV SET OPTION

ID MODEL ID

BDWID BORDER WIDTH FOR EXACT SCAN

BDHIT BORDER HEIGHT FOR EXACT SCAN

VOLUX MAX VOLUME LIMITED

RCUT R CUT OFF

GCUT G CUT OFF

BCUT B CUT OFF

RDRV R DRIVE

GDRV G DRIVE

BDRV B DRIVE

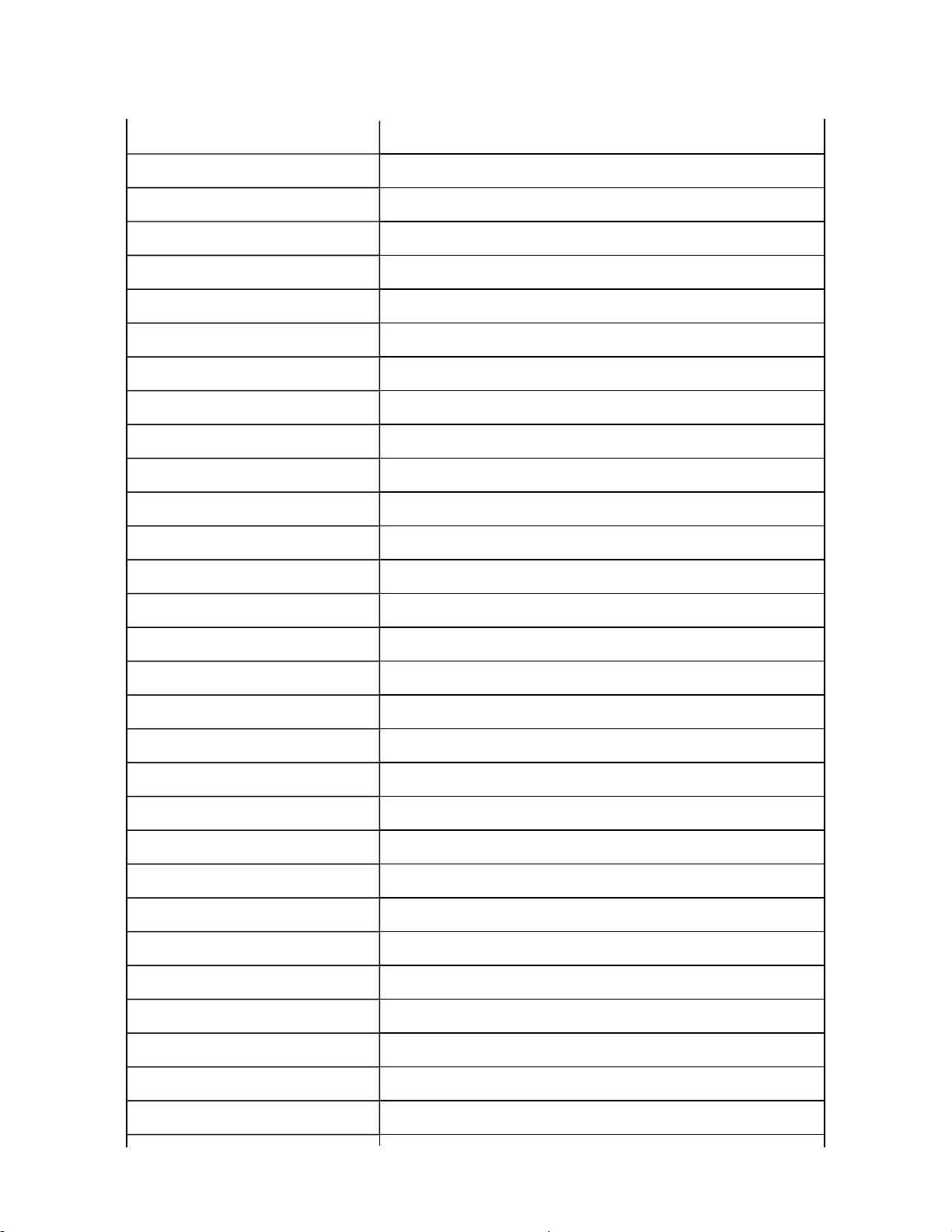

Page 79

CNTX DTV DYNAMIC CONTRAST MAX FOR DTV DYNAMIC

CNTX DTV STANDARD CONTRAST MAX FOR DTV STANDARD

CNTX DTV MILD CONTRAST MAX FOR DTV MILD

CNTX DTV MOVIE CONTRAST MAX FOR DTV MOVIE

CNTX VIDEO DYNAMIC CONTRAST MAX FOR VIDEO DYNAMIC

CNTX VIDEO STANDARD CONTRAST MAX FOR VIDEO STANDARD

CNTX VIDEO MILD CONTRAST MAX FOR VIDEO MILD

CNTX VIDEO MOVIE CONTRAST MAX FOR VIDEO MOVIE

CNTX YPBPR HD DYNAMIC CONTRAST MAX FOR YPBPR HD DYNAMIC

CNTX YPBPR HD STANDARD CONTRAST MAX FOR YPBPR HD STANDARD

CNTX YPBPR HD MILD CONTRAST MAX FOR YPBPR HD MILD

CNTX YPBPR HD MOVIE CONTRAST MAX FOR YPBPR HD MOVIE

CNTX YPBPR SD STANDARD CONTRAST MAX FOR YPBPR SD STANDARD

CNTX YPBPR SD MILD CONTRAST MAX FOR YPBPR SD MILD

CNTX YPBPR SD MOVIE CONTRAST MAX FOR YPBPR SD MOVIE

CNTX HDMI PC DYNAMIC CONTRAST MAX FOR HDMI PC DYNAMIC

CNTX HDMI PC STANDARD CONTRAST MAX FOR HDMI PC STANDARD

CNTX HDMI PC MILD CONTRAST MAX FOR HDMI PC MILD

CNTX HDMI PC MOVIE CONTRAST MAX FOR HDMI PC MOVIE

CNTX HDMI HD DYNAMIC CONTRAST MAX FOR HDMI HD DYNAMIC

CNTX HDMI HD STANDARD CONTRAST MAX FOR HDMI HD STANDARD

CNTX HDMI HD MILD CONTRAST MAX FOR HDMI HD MILD

CNTX HDMI HD MOVIE CONTRAST MAX FOR HDMI HD MOVIE

CNTX HDMI SD DYNAMIC CONTRAST MAX FOR HDMI SD DYNAMIC

CNTX HDMI SD STANDARD CONTRAST MAX FOR HDMI SD STANDARD

CNTX HDMI SD MILD CONTRAST MAX FOR HDMI SD MILD

CNTX HDMI SD MOVIE CONTRAST MAX FOR HDMI SD MOVIE

CNTX ATV DYNAMIC CONTRAST MAX FOR ATV DYNAMIC

CNTX ATV STANDARD CONTRAST MAX FOR ATV STANDARD

CNTX ATV MILD CONTRAST MAX FOR ATV MILD

Page 80

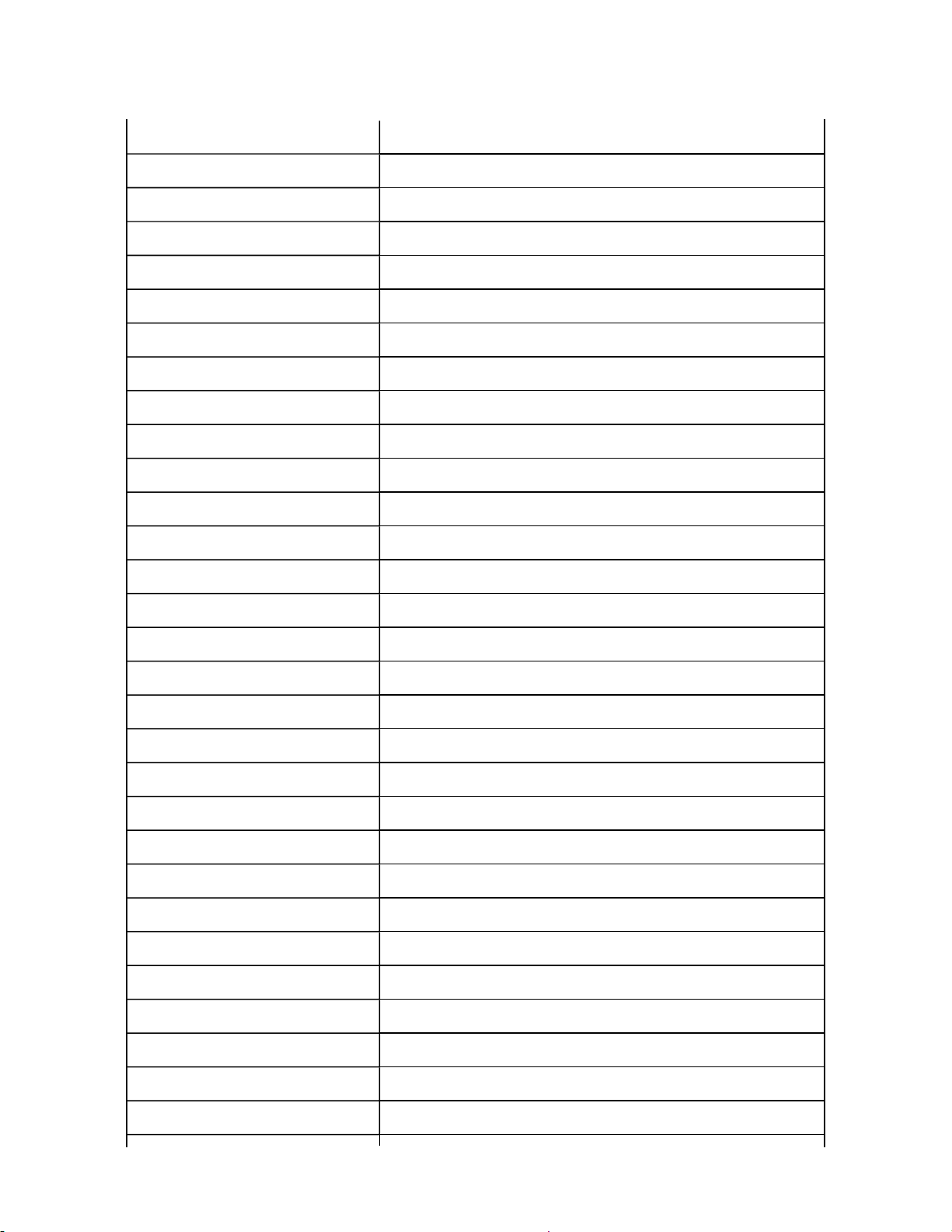

CONTRAST MAX FOR ATV MOVIE

BRTC DTV DYNAMIC BRIGHTNESS CENTER FOR DTV DYNAMIC

BRTC DTV STANDARD BRIGHTNESS CENTER FOR DTV STANDARD

BRTC DTV MILD BRIGHTNESS CENTER FOR DTV MILD

BRTC DTV MOVIE BRIGHTNESS CENTER FOR DTV MOVIE

BRTC VIDEO DYNAMIC BRIGHTNESS CENTER FOR VIDEO DYNAMIC

BRTC VIDEO STANDARD BRIGHTNESS CENTER FOR VIDEO STANDARD

BRTC VIDEO MILD BRIGHTNESS CENTER FOR VIDEO MILD

BRTC VIDEO MOVIE BRIGHTNESS CENTER FOR VIDEO MOVIE

BRTC YPBPR HD DYNAMIC BRIGHTNESS CENTER FOR YPBPR HD DYNAMIC

BRTC YPBPR HD STANDARD BRIGHTNESS CENTER FOR YPBPR HD STANDARD

BRTC YPBPR HD MILD BRIGHTNESS CENTER FOR YPBPR HD MILD

BRTC YPBPR HD MOVIE BRIGHTNESS CENTER FOR YPBPR HD MOVIE

BRTC YPBPR SD DYNAMIC BRIGHTNESS CENTER FOR YPBPR SD DYNAMIC

BRTC YPBPR SD STANDARD BRIGHTNESS CENTER FOR YPBPR SD STANDARD

BRTC YPBPR SD MILD BRIGHTNESS CENTER FOR YPBPR SD MILD

BRTC YPBPR SD MOVIE BRIGHTNESS CENTER FOR YPBPR SD MOVIE

BRTC HDMI PC DYNAMIC BRIGHTNESS CENTER FOR HDMI PC DYNAMIC

BRTC HDMI PC STANDARD BRIGHTNESS CENTER FOR HDMI PC STANDARD

BRTC HDMI PC MILD BRIGHTNESS CENTER FOR HDMI PC MILD

BRTC HDMI PC MOVIE BRIGHTNESS CENTER FOR HDMI PC MOVIE

BRTC HDMI HD DYNAMIC BRIGHTNESS CENTER FOR HDMI HD DYNAMIC

BRTC HDMI HD STANDARD BRIGHTNESS CENTER FOR HDMI HD STANDARD

BRTC HDMI HD MILD BRIGHTNESS CENTER FOR HDMI HD MILD

BRTC HDMI HD MOVIE BRIGHTNESS CENTER FOR HDMI HD MOVIE

BRTC HDMI SD DYNAMIC BRIGHTNESS CENTER FOR HDMI SD DYNAMIC

BRTC HDMI SD STANDARD BRIGHTNESS CENTER FOR HDMI SD STANDARD

BRTC HDMI SD MILD BRIGHTNESS CENTER FOR HDMI SD MILD

BRTC HDMI SD MOVIE BRIGHTNESS CENTER FOR HDMI SD MOVIE

BRTC ATV DYNAMIC BRIGHTNESS CENTER FOR ATV DYNAMIC

Page 81

BRIGHTNESS CENTER FOR ATV STANDARD

BRTC ATV MILD BRIGHTNESS CENTER FOR ATV MILD

BRTC ATV MOVIE BRIGHTNESS CENTER FOR ATV MOVIE

COLC DTV DYNAMIC COLOR CENTER FOR DTV DYNAMIC

COLC DTV STANDARD COLOR CENTER FOR DTV STANDARD

COLC DTV MILD COLOR CENTER FOR DTV MILD

COLC DTV MOVIE COLOR CENTER FOR DTV MOVIE

COLC VIDEO DYNAMIC COLOR CENTER FOR VIDEO DYNAMIC

COLC VIDEO STANDARD COLOR CENTER FOR VIDEO STANDARD

COLC VIDEO MILD COLOR CENTER FOR VIDEO MILD

COLC VIDEO MOVIE COLOR CENTER FOR VIDEO MOVIE

COLC YPBPR HD DYNAMIC COLOR CENTER FOR YPBPR HD DYNAMIC

COLC YPBPR HD STANDARD COLOR CENTER FOR YPBPR HD STANDARD

COLC YPBPR HD MILD COLOR CENTER FOR YPBPR HD MILD

COLC YPBPR HD MOVIE COLOR CENTER FOR YPBPR HD MOVIE

COLC YPBPR SD DYNAMIC COLOR CENTER FOR YPBPR SD DYNAMIC

COLC YPBPR SD STANDARD COLOR CENTER FOR YPBPR SD STANDARD

COLC YPBPR SD MILD COLOR CENTER FOR YPBPR SD MILD

COLC YPBPR SD MOVIE COLOR CENTER FOR YPBPR SD MOVIE

COLC HDMI PC DYNAMIC COLOR CENTER FOR HDMI PC DYNAMIC

COLC HDMI PC STANDARD COLOR CENTER FOR HDMI PC STANDARD

COLC HDMI PC MILD COLOR CENTER FOR HDMI PC MILD

COLC HDMI PC MOVIE COLOR CENTER FOR HDMI PC MOVIE

COLC HDMI HD DYNAMIC COLOR CENTER FOR HDMI HD DYNAMIC

COLC HDMI HD STANDARD COLOR CENTER FOR HDMI HD STANDARD

COLC HDMI HD MILD COLOR CENTER FOR HDMI HD MILD

COLC HDMI HD MOVIE COLOR CENTER FOR HDMI HD MOVIE

COLC HDMI SD DYNAMIC COLOR CENTER FOR HDMI SD DYNAMIC

COLC HDMI SD STANDARD COLOR CENTER FOR HDMI SD STANDARD

COLC HDMI SD MILD COLOR CENTER FOR HDMI SD MILD

Page 82

COLOR CENTER FOR HDMI SD MOVIE

COLC ATV DYNAMIC COLOR CENTER FOR ATV DYNAMIC

COLC ATV STANDARD COLOR CENTER FOR ATV STANDARD

COLC ATV MILD COLOR CENTER FOR ATV MILD

COLC ATV MOVIE COLOR CENTER FOR ATV MOVIE

UVTT DTV DYNAMIC BASE BAND TINT FOR DTV DYNAMIC

UVTT DTV STANDARD BASE BAND TINT FOR DTV STANDARD

UVTT DTV MILD BASE BAND TINT FOR DTV MILD

UVTT DTV MOVIE BASE BAND TINT FOR DTV MOVIE

UVTT VIDEO DYNAMIC BASE BAND TINT FOR VIDEO DYNAMIC

UVTT VIDEO STANDARD BASE BAND TINT FOR VIDEO STANDARD

UVTT VIDEO MILD BASE BAND TINT FOR VIDEO MILD

UVTT VIDEO MOVIE BASE BAND TINT FOR VIDEO MOVIE

UVTT YPBPR HD DYNAMIC BASE BAND TINT FOR YPBPR HD DYNAMIC

UVTT YPBPR HD STANDARD BASE BAND TINT FOR YPBPR HD STANDARD

UVTT YPBPR HD MILD BASE BAND TINT FOR YPBPR HD MILD

UVTT YPBPR HD MOVIE BASE BAND TINT FOR YPBPR HD MOVIE

UVTT YPBPR SD DYNAMIC BASE BAND TINT FOR YPBPR SD DYNAMIC

UVTT YPBPR SD STANDARD BASE BAND TINT FOR YPBPR SD STANDARD

UVTT YPBPR SD MILD BASE BAND TINT FOR YPBPR SD MILD

UVTT YPBPR SD MOVIE BASE BAND TINT FOR YPBPR SD MOVIE

UVTT HDMI PC DYNAMIC BASE BAND TINT FOR HDMI PC DYNAMIC

UVTT HDMI PC STANDARD BASE BAND TINT FOR HDMI PC STANDARD

UVTT HDMI PC MILD BASE BAND TINT FOR HDMI PC MILD

UVTT HDMI PC MOVIE BASE BAND TINT FOR HDMI PC MOVIE

UVTT HDMI HD DYNAMIC BASE BAND TINT FOR HDMI HD DYNAMIC

UVTT HDMI HD STANDARD BASE BAND TINT FOR HDMI HD STANDARD

UVTT HDMI HD MILD BASE BAND TINT FOR HDMI HD MILD

UVTT HDMI HD MOVIE BASE BAND TINT FOR HDMI HD MOVIE

UVTT HDMI SD DYNAMIC BASE BAND TINT FOR HDMI SD DYNAMIC

Page 83

y

BASE BAND TINT FOR HDMI SD STANDARD

UVTT HDMI SD MILD BASE BAND TINT FOR HDMI SD MILD

UVTT HDMI SD MOVIE BASE BAND TINT FOR HDMI SD MOVIE

UVTT ATV DYNAMIC BASE BAND TINT FOR ATV DYNAMIC

UVTT ATV STANDARD BASE BAND TINT FOR ATV STANDARD

UVTT ATV MILD BASE BAND TINT FOR ATV MILD

UVTT ATV MOVIE BASE BAND TINT FOR ATV MOVIE

Factory preset data will be loaded after setting Model ID data.

(Refer to Initialization of Memory Data of IC152 and setting data of signal board.)

Adjusting the Data

Pressing of MENU RIGHT/LEFT button will change the value of data in the range from 00H

to FFH. The variable range depends on the adjusting item.

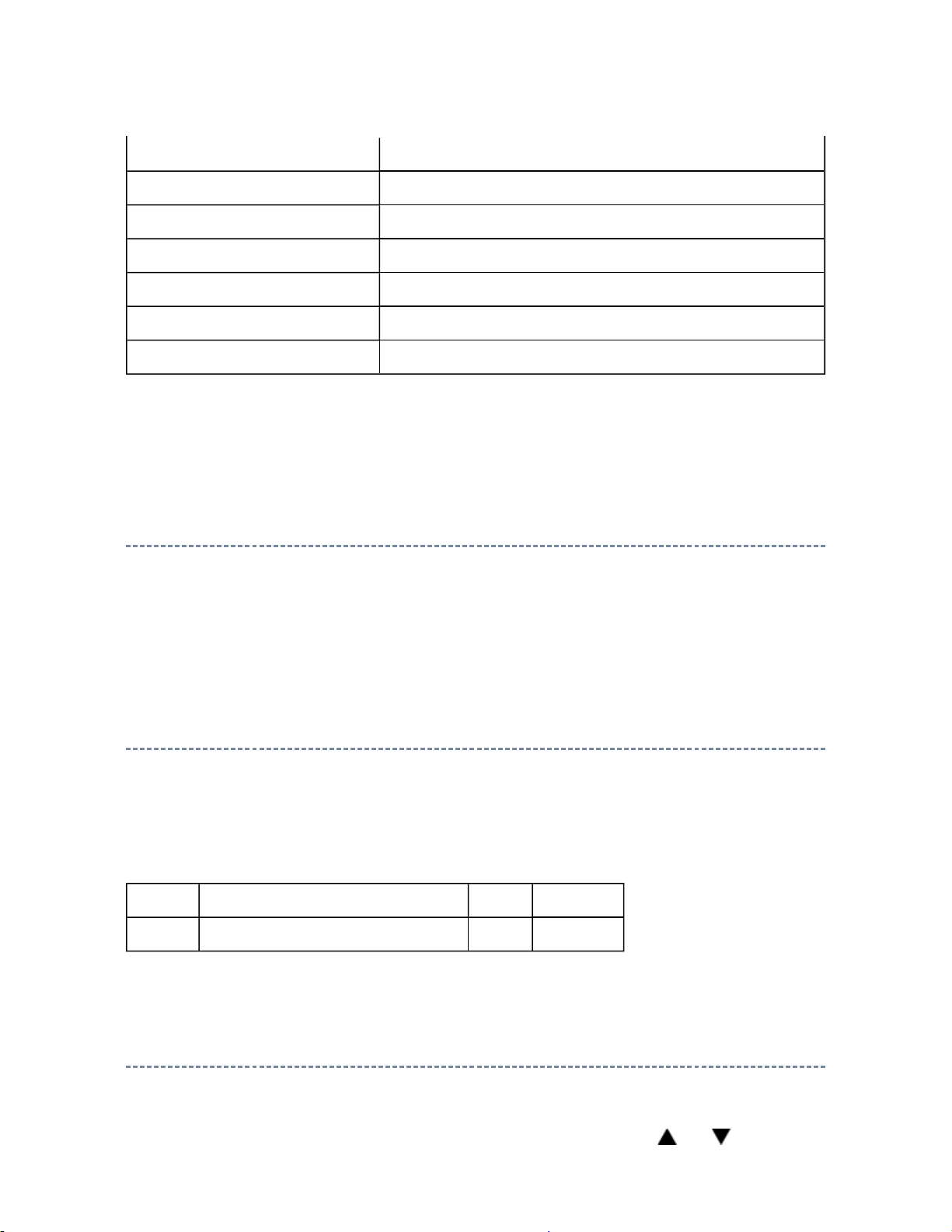

Setting TVOP

Enter to service mode and select menu of TVOP by pressing MENU UP or DOWN during

display of adjustment menu. After selecting TVOP, press MENU RIGHT or LEFT to set

WDT function to disable or enable as below.

TVOP FUNCTION DESCRIPTION 1 0 (Normal)

D5 (bit5) TV-Micon Watch Dog Timer (WDT) Disable Enable

Setting Panel Option Data

Panel option data is subject to OP4 and OP5.

Enter to service mode and select menu of OPT4 or OPT5 b

pressing P or P during

Page 84

display of adjustment menu. After selecting OPT4 or OPT5, press + or - to set OPT4

or OPT5 value as table below.

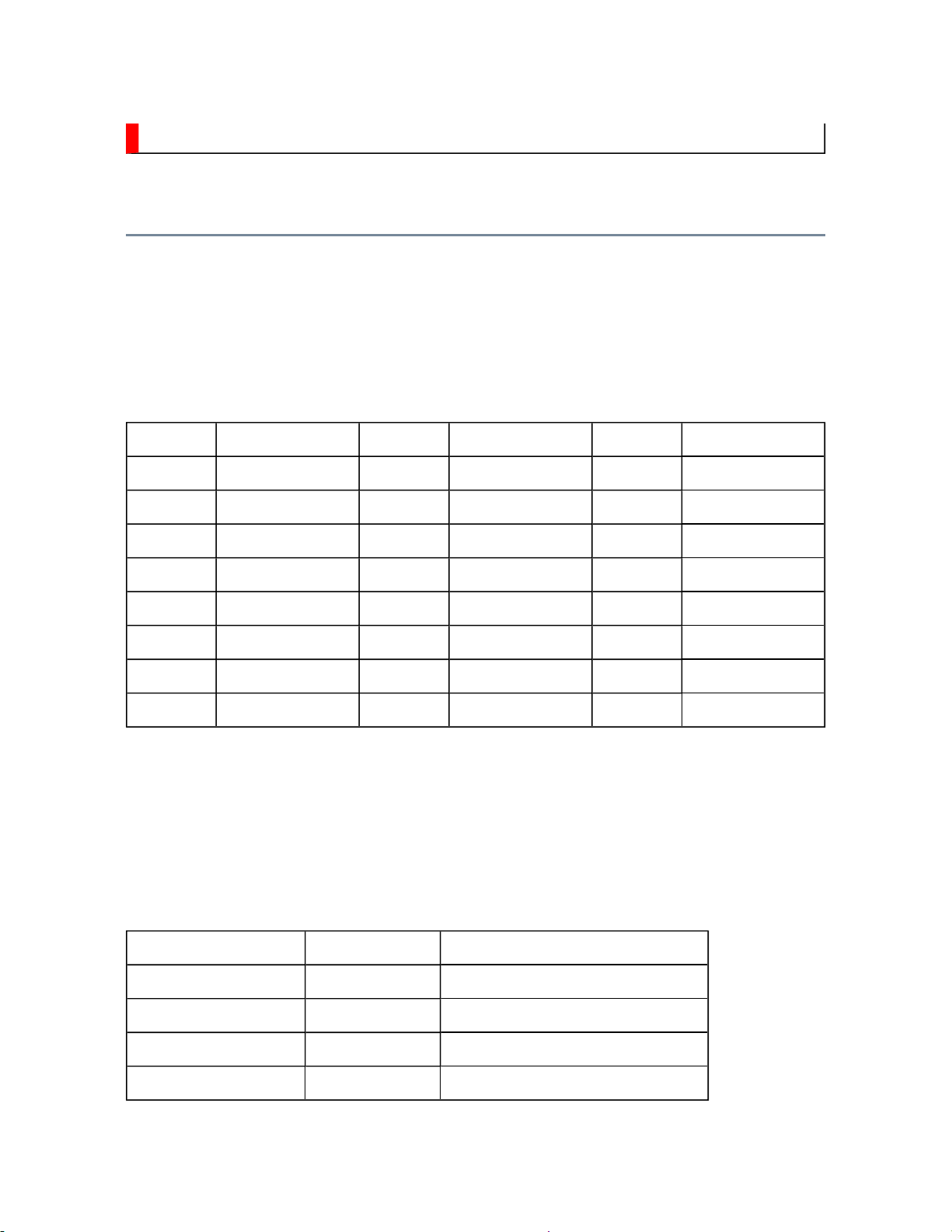

Panel option data

Series Model name Panel vendor OPT4 value OPT5 value

AV554D EU Digital 32AV554D SHARP 0x02 0x05

37AV554D LGD 0x01 0x06

42AV554D LGD 0x01 0x07

OPT4

Ex. OPT4 value 0x02 indicates that panel vendor is SHARP.

OPT4

Panel vendor LGD ----0001

SHARP ----0010

CMO ----0011

AUO PMVA----0100

AUO AMVA----0101

SAMSUNG----0110

IPS ----0111

D7

(bit7)

D6

(bit6)

D5

(bit5)

D4

(bit4)

D3

(bit3)

D2

(bit2)

D1

(bit1)

D0

(bit0)

OPT5

Ex. OPT5 value 0x05 indicates that panel size is 32.

OPT5

Size 26 ----0011

32 ----0101

37 ----0110

D7

(bit7)

D6

(bit6)

D5

(bit5)

D4

(bit4)

D3

(bit3)

D2

(bit2)

D1

(bit1)

D0

(bit0)

Page 85

42 ----0111

Backlight Status

Logic

Backlight Status

Check

Backlight Force

Twice On

Positive --1----Negative 0

Execute -1-----Unexecuted 0

Execute 1------Unexecuted 0

Convert from Bit (Binary) to Hex

The table for converting from bit (D7-D0) to hex (0x**).

BIT (Binary)

High nibble D7 D6 D5 D4

Low nibble D3 D2 D1 D0

HEX 0 0000

1 0001

2 001 0

3 0011

4 0 1 00

5 0 1 0 1

6 0 110

7 0 111

81000

91001

A10 1 0

B10 11

C1100

D110 1

Page 86

E1110

F1111

E.g. If Bit D7-0 = 0101 1010, Hex data is 0x5A.

Exit from Service Mode

Pressing POWER button to turn off the TV once.

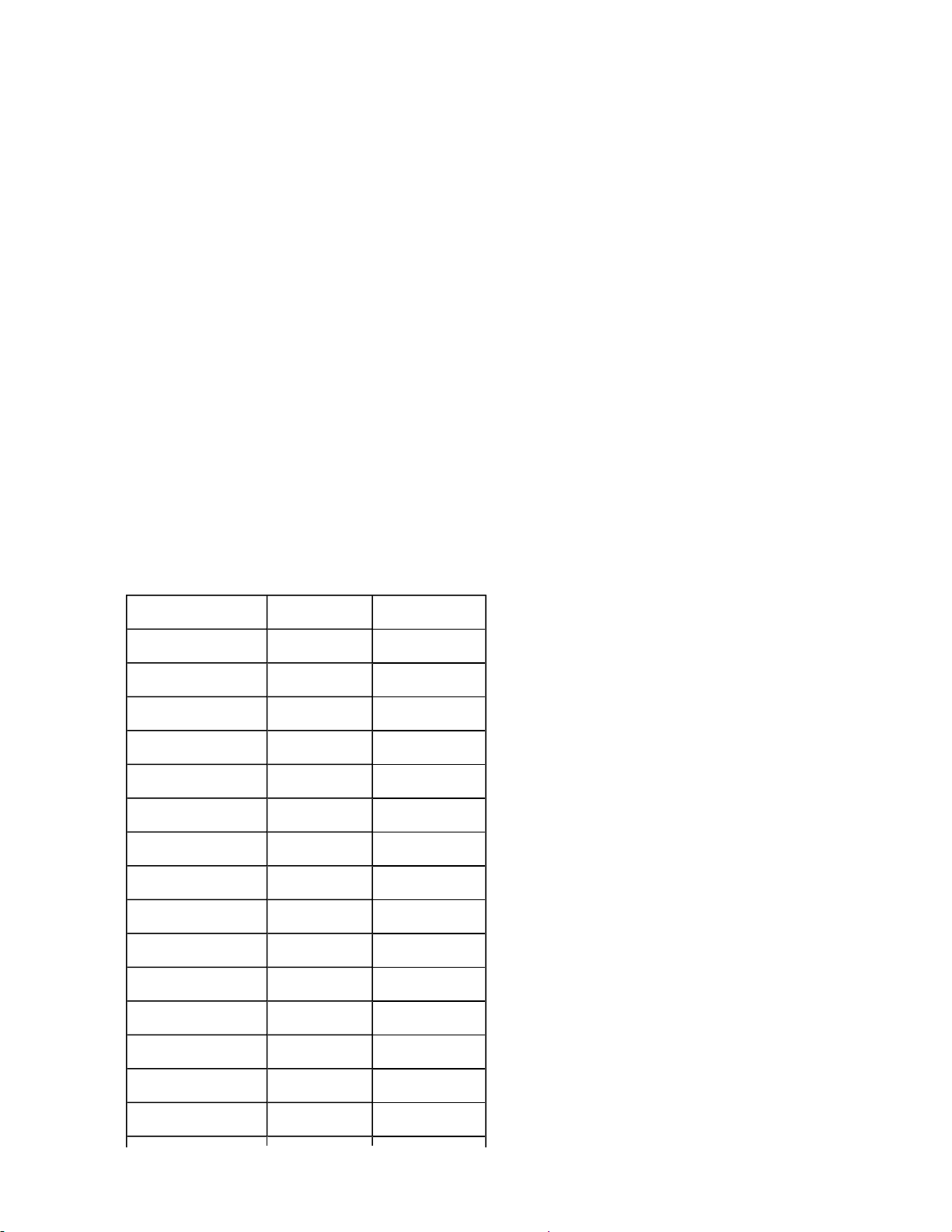

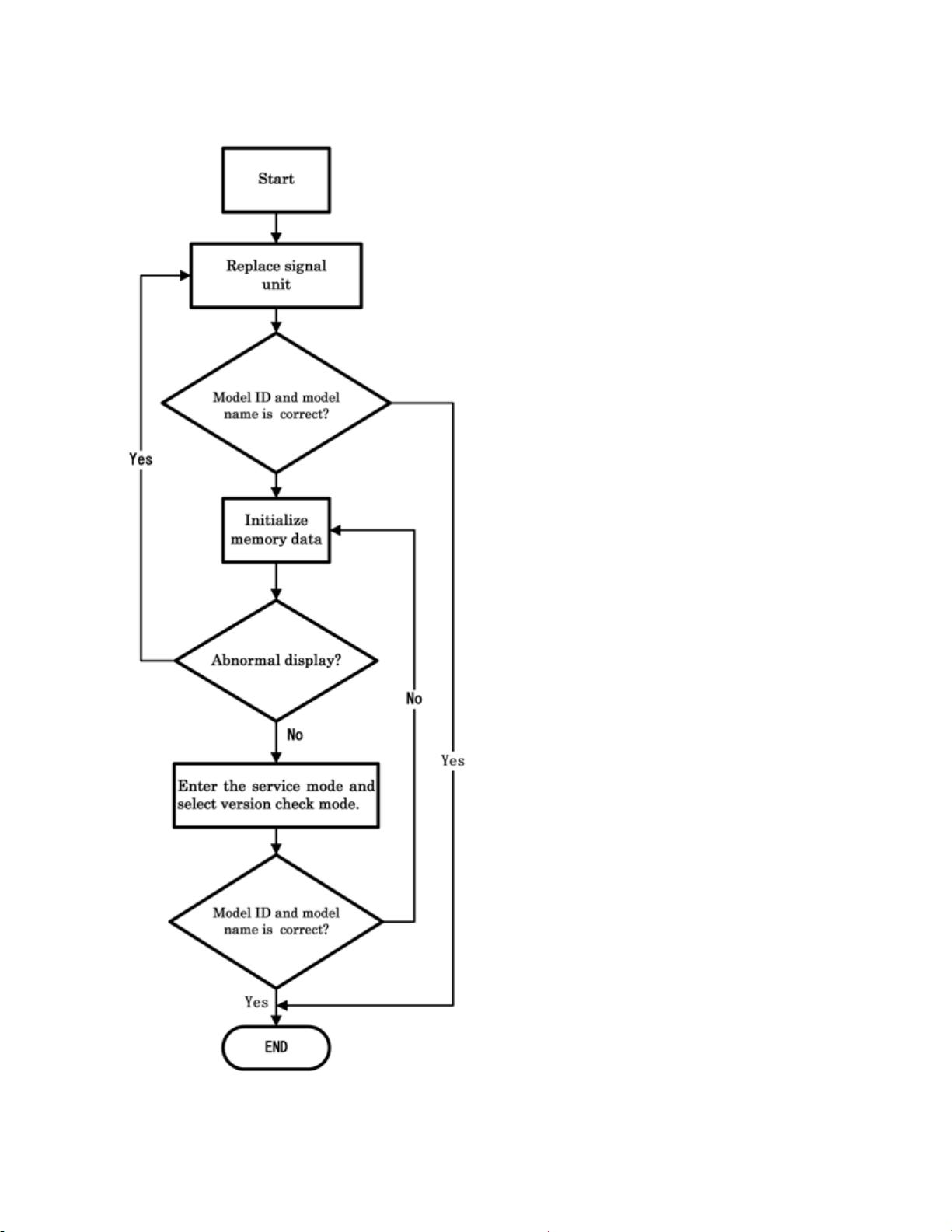

Initialization of Memory Data of IC152 and Setting Data of Signal Unit

After replacing IC152 or signal board, the following initialization is required.

CAUTION: Never attempt to initialize the data unless IC152 has been

replaced.

Whenever using new signal board to the set, setting the Model ID data

according to Panel option data.

1) Enter the service mode.

2) Select menu of ID by pressing P or P during display of adjustment menu in the

service mode.

3) Change ID data into MODEL ID to initialize by pressing + or -, refer to table

below.

For example, if want to initialize 32AV555D, change MODEL ID into "0x01".

Note:

MODEL ID is hex value. For example, set value is not Decimal 11 but hex 11.

4) Press and hold the CALL button on the remote control, then press the CHANNEL

button on the TV.

Page 87

5) Initialization progress dialog including model name and panel vendor is shown.

Progress status is "WRITING".

6) Progress status is changed "OK" and power cycle (automatically). Then IC152

initialization has been completed.

7) Enter the service mode and select version check mode. Confirm if model name and

model id set is correct. If not, repeat steps 1) to 6).

Note:

In case initialization by setting wrong MODEL ID is done, there is a possibility of

abnormal display.

8) Set I2C check function of TVOP to enable.

9) Check the picture carefully. If necessary, adjust any adjustment item above.

Perform "Auto tune" on the owner's manual.

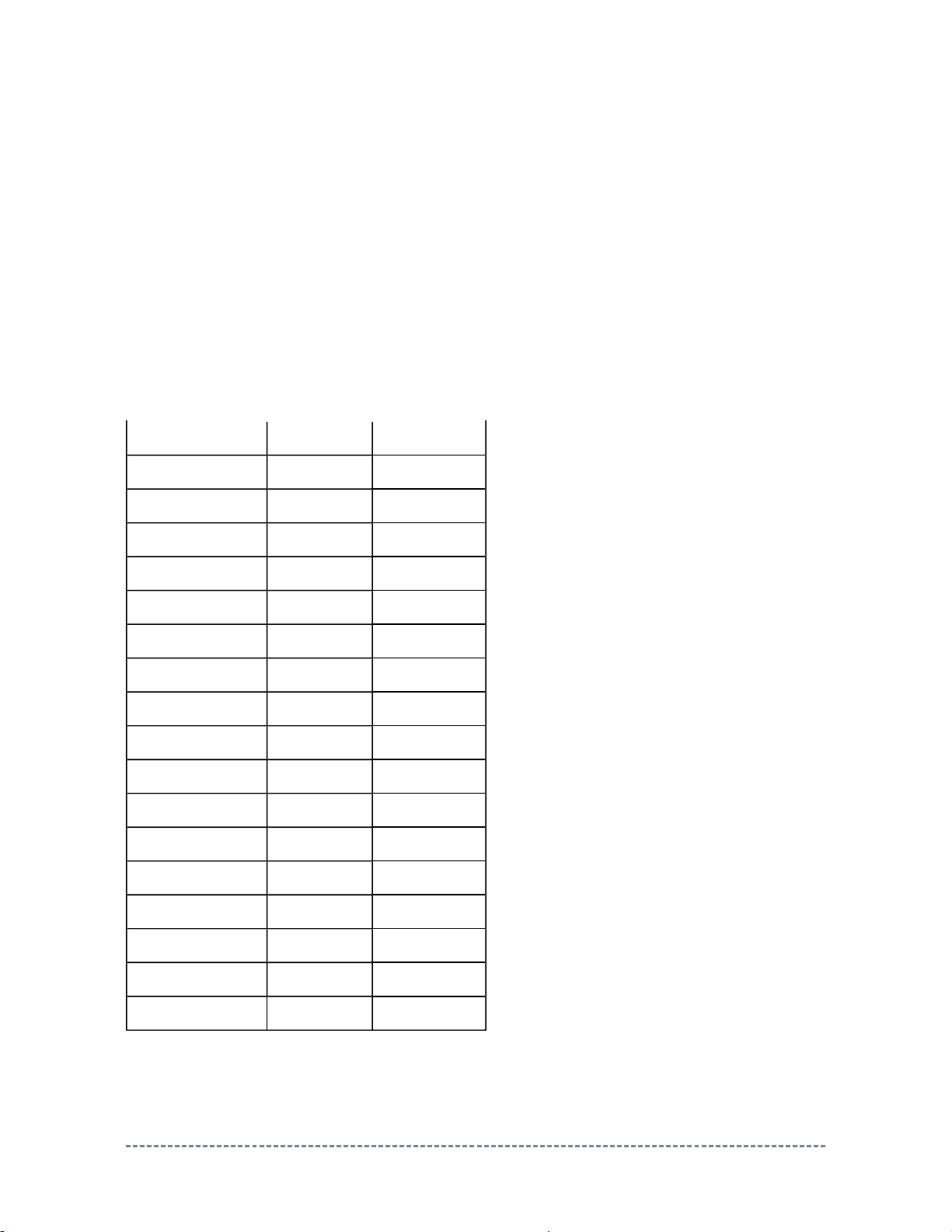

MODEL ID (HEX) Model name Panel vendor

0x01 32AV554D SHARP

0x02 37AV554D LGD

0x03 42AV554D LGD

0x04

0x05

0x06

0x07

0x08

0x09

0x10

0x11

0x12

0x13

0x14

0x15

Page 88

0x16

0x17

0x18

0x19

0x20

0x21

0x22

0x23

0x24

0x25

0x26

0x27

0x28

0x29

0x30

0x31

0x32

0x33

Initializing Data setting flowchart after replacing the Signal Unit

Page 89

Page 90

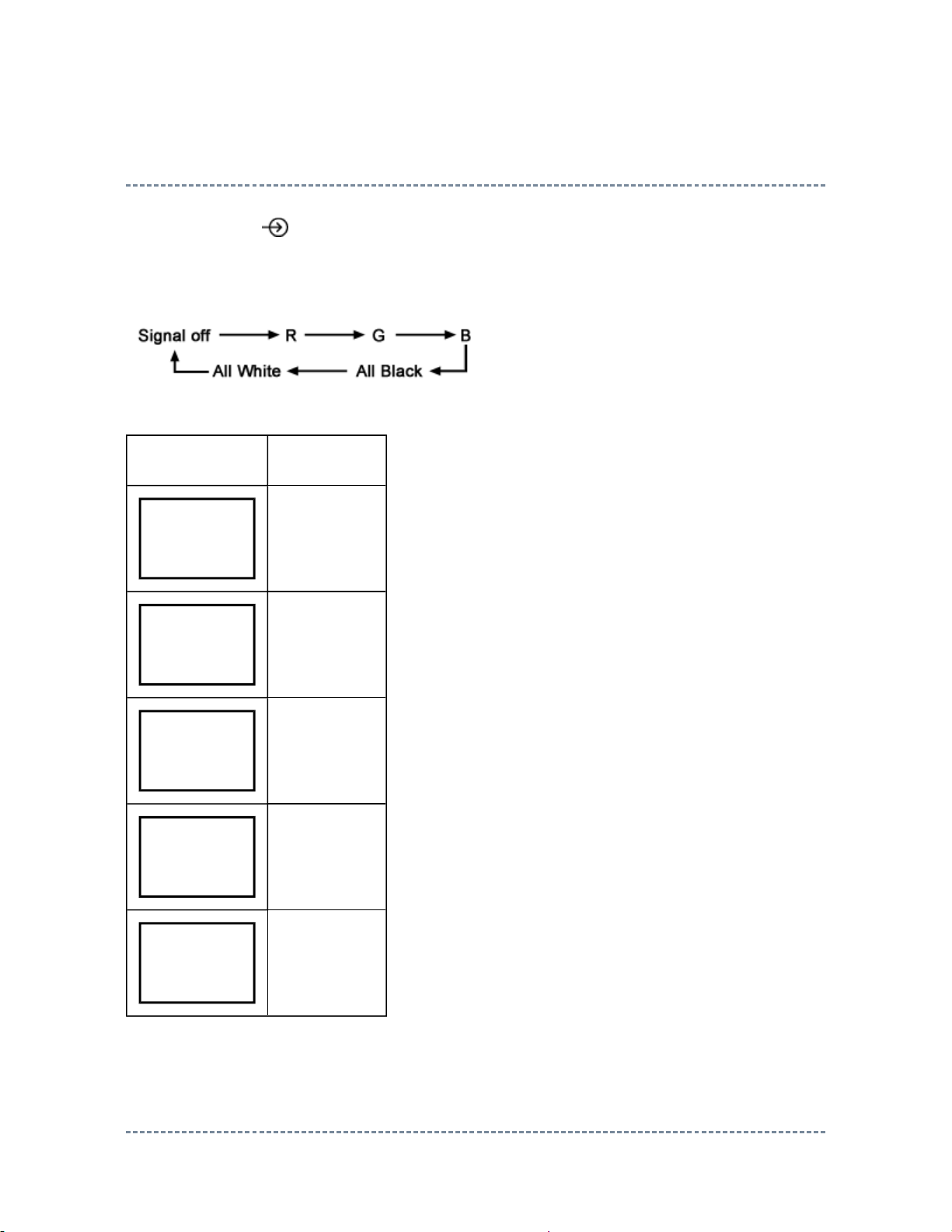

Test Signal Selection

Every pressing of button on the remote control changes the built-in test patterns on

screen as described below in Service Mode.

Picture Signal

Red raster

Green raster

Blue raster

All Black

All White

Self Diagnostic Function

Page 91

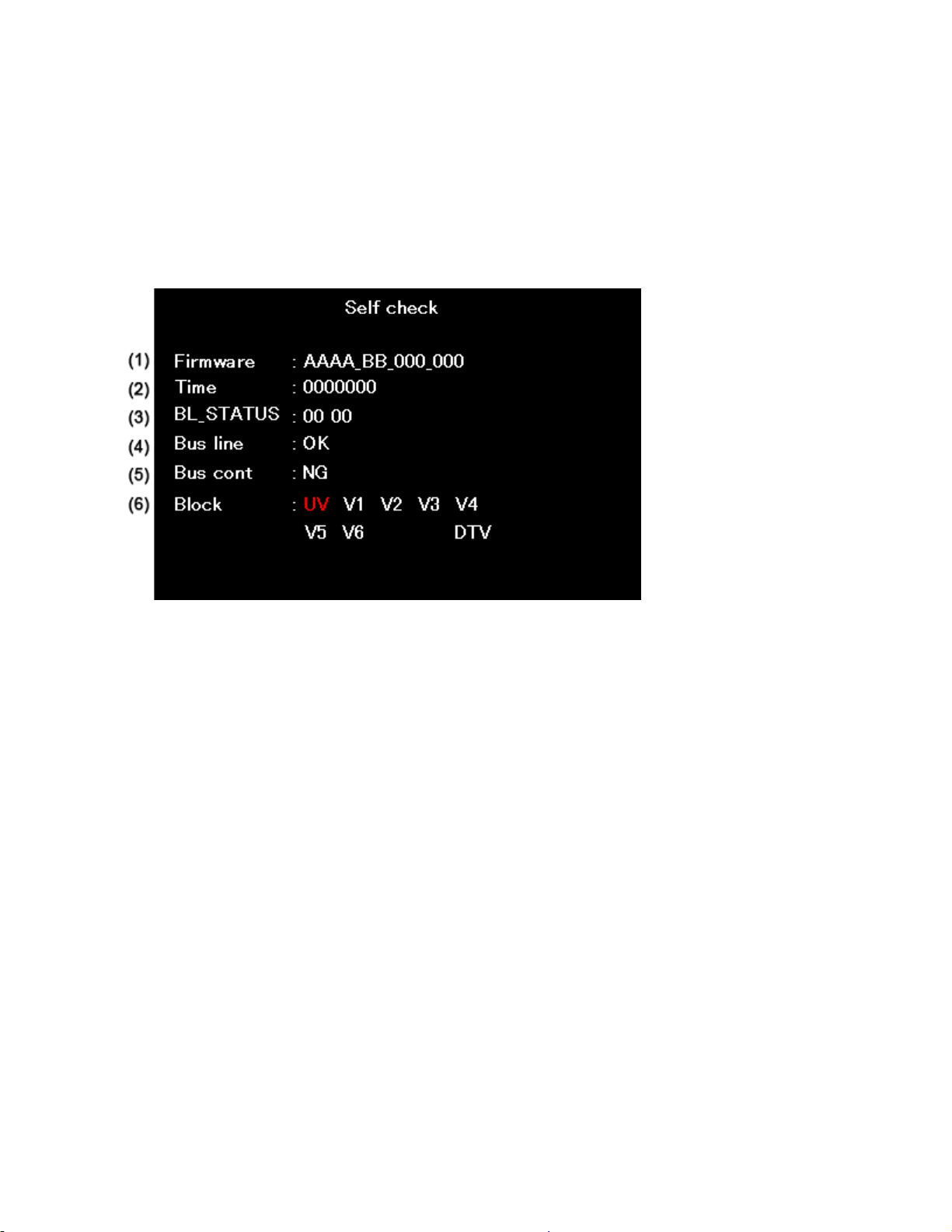

1. Press "9" button on remote control during display of adjustment menu in the service

N

mode. The diagnosis will begin to check if interface among IC's is executed properly.

2. During diagnosis, the following displays are shown.

* Self check display and Item are subject to the models.

(1) Firmware :

Version information of microprocessor

Series name (AAAA) and market area (BB) and software program version (000_000).

(2) Time : Total hour of turn the TV on. (Unit : H)

(3) BL_STATUS :

Counter for saving BackLight on error1.

This value is counted till 99 (Decimal).

(4) Bus line : -- "OK" is normal

SCL-GND (Red indication) : SCL-GND short circuit

SDA-GND (Red indication) : SDA-GND short circuit

SCL-SDA (Red indication) : SCL-SDA short circuit

(5) Bus cont : --- "OK" is normal.

G is abnormal (Red indication).

When the abnormal status is detected, type name of semiconductor is

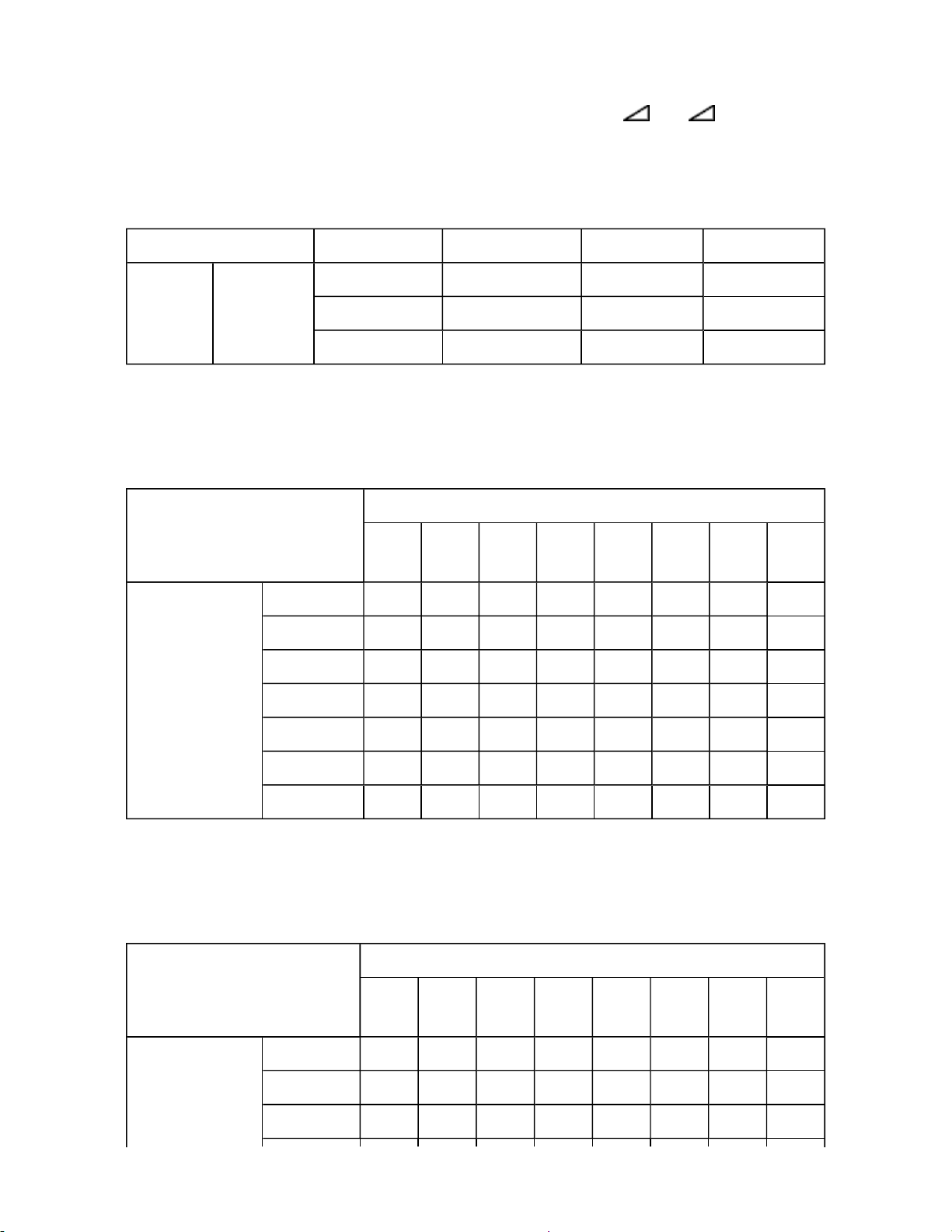

indicated in red colour.

(6) Block

UV : TV reception mode

Page 92

V1 - V6:VIDEO 1-6 input mode

DTV : DTV mode

UV ATV

V1

(SCART (FULL))

V2

(SCART (S+AV))

V3

V4

V5 HDMI1

V6 HDMI2

V7 -V8 -V9 --

PC -YUV -DTV DTV

(Component)

(Composite)

1

2

3

4

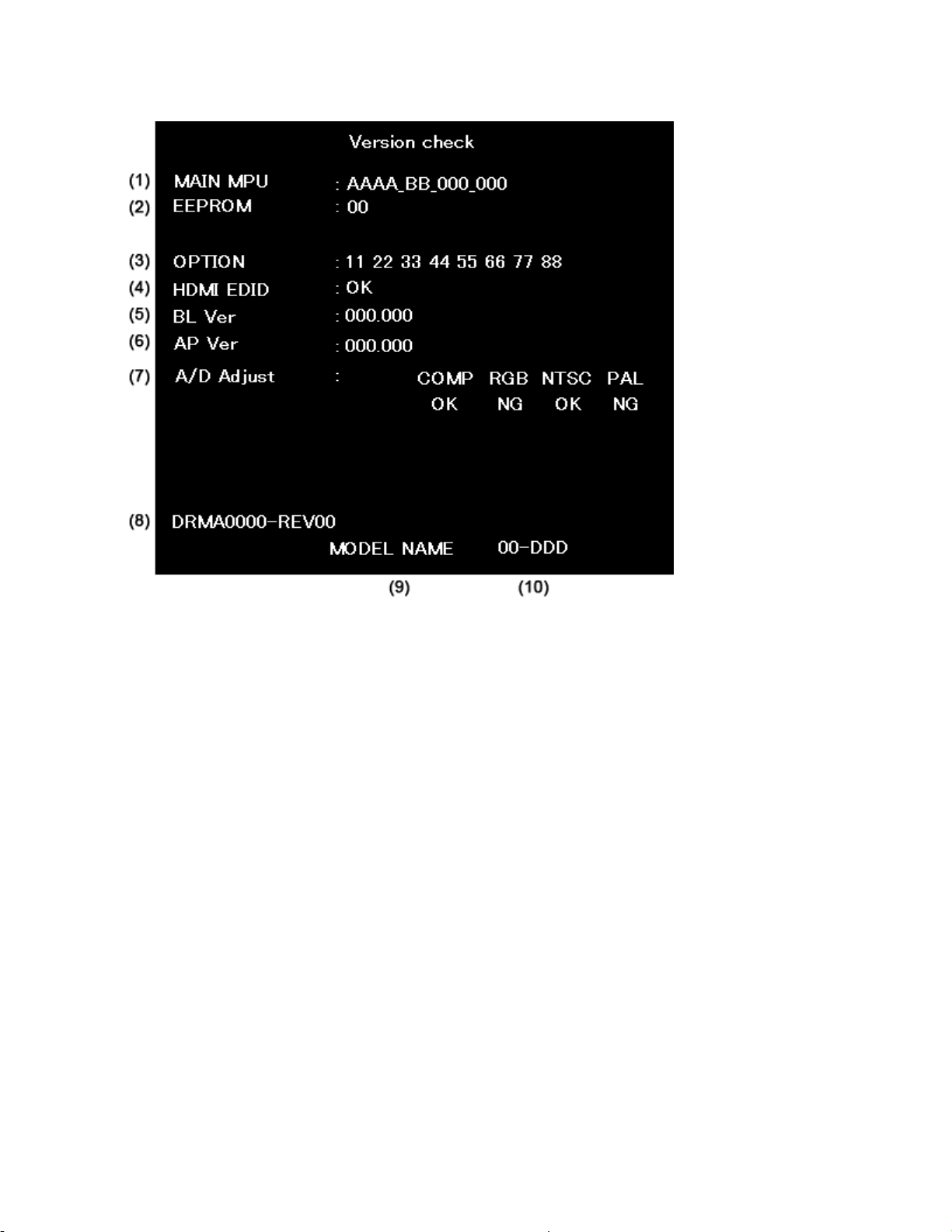

Version Check Mode

1. Press "9" button twice on remote control during display of adjustment menu in the

service mode.

The version of main MPU will be checked.

2. During Version Check, the following displays are shown.

* Version check display and Item are subject to the models.

Page 93

(1) MAIN MPU :

Version information of microprocessor

Series name and Code Program Version (5 figure number) and software program

version (000_000).

(2) EEPROM :

Version information of EEPROM : Display 1 byte data.

(3) OPTION :

Option information : Display eight numbers of 1 byte data.

(4) HDMI EDID :

EDID data check item.

OK : EDID data is enable.

NG : EDID data is disable.

(5) BL Ver

Version information of Boot Loader software as Toshiba release.

(6) AP Ver

Version information of Application software as Toshiba release.

(7) A/D Adjust

Page 94

A/D adjustment item.

--COMP:Component input

--RGB : RGB Signal (SCART input)

--NTSC :NTSC (60 Hz) SD signal (composite input).

--PAL : PAL (50 Hz) SD signal (composite input).

--OK :A/D adjustment set correctly.

--NG :A/D adjustment set incorrect.

(8) Memory Data Version

Version information of EEPROM.

DRMA**** means model number of EEPROM.

REV** means version of EEPROM.

(9) Model Name

Model name information (ascii code). : Display 8 byte data.

(10) LCD Panel Vendor information display

The following Panel Vendor (DDD) and screen size (00) and displayed.

Example : AUO-32 (1080p) indicates that Vendor is AUO and Screen Size is 32 inch

and Full HD panel.

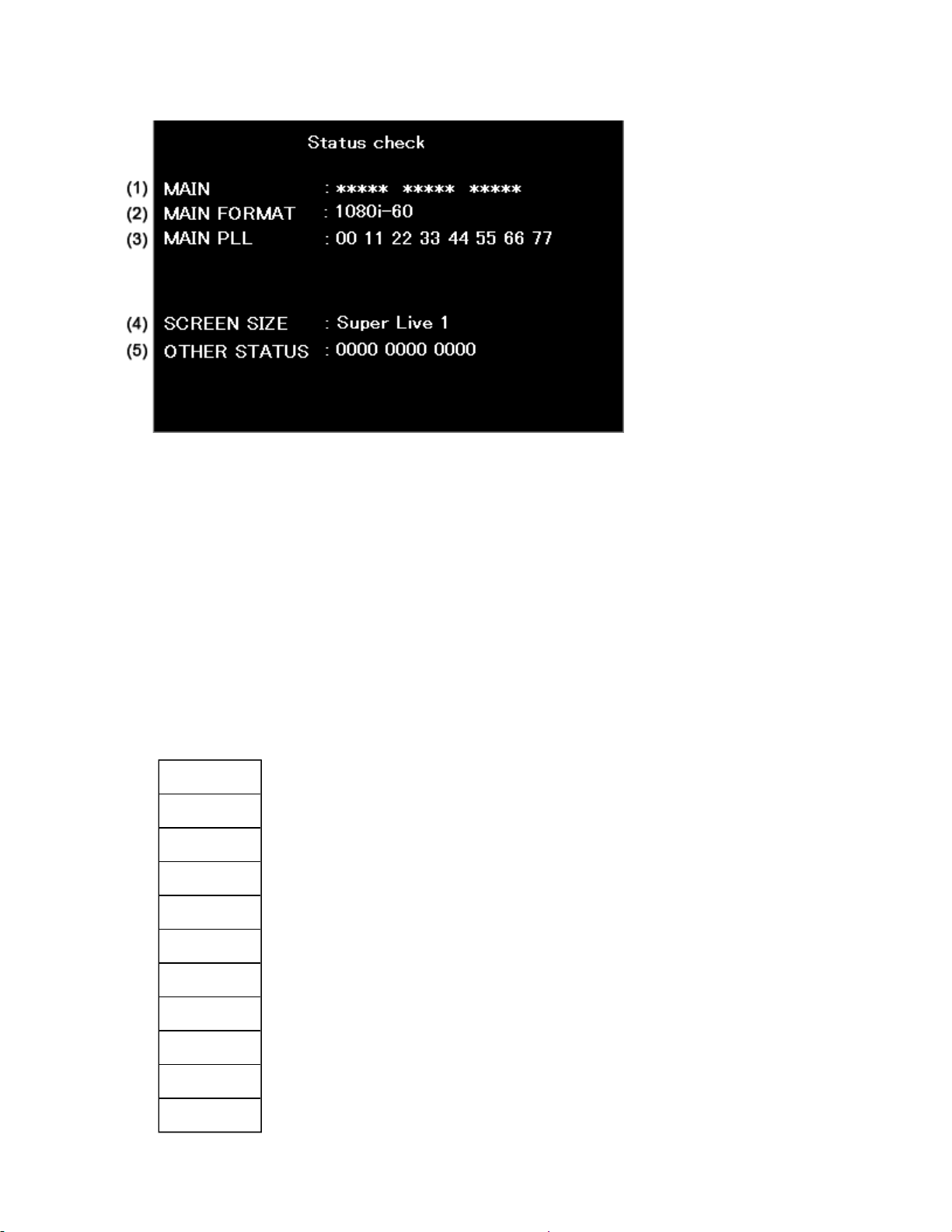

Status Check Mode

1. Press "9" button thrice on remote control during display of adjustment menu in the

service mode.

The status of this model will be checked.

2. During Status Check, the following displays are shown.

* Status check display and Item are subject to the models.

Page 95

(1) MAIN :

Main source information :

Display RF position number (0 - 999) on the main screen, or Input Source

(EXT1/2/3/HDMI etc.)

(2) MAIN FORMAT :

Display Video format information

(3) MAIN PLL :

Main PLL information : Display 1 byte data at eight.

(4) SCREEN SIZE :

Display the screen size as follows.

Native

Wide

Super Live 2

Cinema 2

4:3

Super Live 1

Cinema 1

Subtitle

14:9

PC-Normal

PC-Wide

Page 96

Note:

Exact Scan is shown only when 1080p panel model and video input mode except pc.

(5) OTHER STATUS :

Other status information : Display three numbers of 2 byte data.

LED Indications

The Green and Red LEDs on the TV (at the bottom center of the TV) indicate the TV's

status, as described below.

z Red ON (solid) and Green OFF = The TV power cord is plugged in.

z Green ON (solid) only = The TV is operating.

z Green ON (solid) and Red ON = Active standby mode.

Page 97

SOFTWARE UPGRADE

Software Upgrade

1. Unplug AC Power.

2. Insert USB Flash memory containing software to TV set.

3. Plug AC Power.

4. Progress bar is shown on TV screen while upgrading.

"100 %" is shown when completed.

Never power off while upgrading.

5. Unplug AC Power.

6. Remove USB Flash memory.

7. Plug AC Power.

Page 98

PANEL IDENTIFICATION

Panel Identification

If the several panels are alternatively used in the same model without amending the model

name, the identification marking will be shown at the last digit of the set serial number on the

specification label on the back cover.

In servicing, do not alter the panel because several setting and parts are different.

Marking Panel Vendor Marking Panel Vendor Marking Panel Vendor

A AUO J S SHARP

B K SAMSUNG T

CCMO LLGD U

D M V

E N W

F P X

G Q Y

HIPS R Z

With this alternative use, some of key parts may differ and their combinations are

indicated with the suffix marking on the location number in the part list

(Miscellaneous).

e.g.

Location No. Part No. Description

B001A 75007869 LCD Panel, 32" LGD

B001B 75007870 LCD Panel, 32" AUO

MZ01A 75006036 LDVS Cable

MZ01B 75007893 LDVS Cable

Page 99

Page 100

PARTS LIST

Precaution

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION" FOR DIRECT VIEW CTV ONLY, "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram

and the parts list designate components which have special characteristics

important for safety and should be replaced only with types identical to

those in the original circuit or specified in the parts list.

The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SAFETY

PRECAUTION and PRODUCT SAFETY NOTICE.

Do not degrade the safety of the receiver through improper servicing.

Note:

z The part number must be used when ordering parts, in order to assist in processing, be

sure to include the Model number and Description.

z The PC board assembly with mark is no longer available after the end of the

production.

Abbreviations

Capacitors CD : Ceramic Disk

Resistors CF : Carbon film

OMF : Oxide Metal Film

PF : Plastic Film

Loading...

Loading...