Page 1

1.1 Features

The 420CDT/420CDS (420 Series) is one of the lightest and most advanced portable computers available. Utilizing advanced technology and high-speed components, the 420 series

offers multimedia functions, excellent display legibility, battery operation, and IBM PC/AT

compatibility. The 420 series system unit consists of the following features:

❑ Microprocessor

An Intel Pentium processor with Voltage Reduction Technology (VRT) that operates

at 100 MHz and 3.3/2.9 volts.

❑ Disk storage

The 420CDT has an internal 1.3 billion byte (1.26 GB) or 810 million byte (770 MB)

Hard Disk Drive (HDD). The 420CDS has an internal 810 million byte HDD. A 3.5inch Floppy Disk Drive (FDD) supports 2HD (1.44 MB) floppy disks and 2DD (720

KB) floppy disks. The FDD can also be installed in an attachment for connection as an

external device.

❑ CD-ROM Drive

A full-size, six-speed CD-ROM drive module can be installed instead of the FDD

module. The CD-ROM drive contains an ATAPI (AT attachment packet interface)

interface controller, and supports the following formats: audio CD, photo CD, CDplus, and ISO 9660.

❑ Memory

Standard with 8 MB of CMOS RAM. This includes 640 KB of conventional memory

and 7360 KB of extended memory, which can be utilized as expanded memory compatible with the Lotus/Intel/Microsoft Expanded Memory Specification (LIM-EMS).

❑ Display

The 420CDT has an 11.3-inch, Thin Film Transistor (TFT) color LCD with 800 x 600

pixels. The 420CDS has an 11.3-inch Dual-scan Supertwist Nematic (DSTN) color

LCD with 800 x 600 pixels. The built-in display controller supports 800 x 600 resolution with 16M colors capability and up to 1280 x 1024 resolution with 256 colors on

an external CRT.

❑ Keyboard

An-easy-to-use 82/84-key keyboard provides a numeric keypad overlay for fast numeric data entry or for cursor and page control. The keyboard supports software that

uses a 101- or 102-key enhanced keyboard.

420 Series 1-1

Page 2

❑ Batteries

Three different batteries: an Li-Ion main battery, a backup battery (for memory

backup), and an RTC battery (for Real Time Clock).

❑ Expansion memory slot

An optional 8, 16, or 32 MB memory module can be installed in the memory slot.

❑ Parallel port

Can be used to connect a Centronics compatible printer or other parallel device. The

port supports ECP (Extended Capabilities Port) conforming to IEEE·1284.

❑ Serial port (9-pin)

The serial controller is 16550UART compatible. This port can be used to connect such

serial devices as a serial printer, serial mouse, or external modem.

❑ External monitor port

The female, 15-pin, D-shell connector can be connected to an external SVGA monitor.

❑ PS/2 mouse/keyboard port

Either a PS/2 compatible keyboard or a PS/2 compatible mouse can be connected to

this port. The computer automatically recognizes which device is connected.

❑ FDD port

Enables a connection of the external FDD attachment if the CD-ROM module is

installed inside the system unit.

❑ PC card slot

A PC card slot accommodates two 5mm cards (Type II) or one 10.5mm (Type III)

card, which support PCMCIA Release 2.01 cards. These slots also support advanced

cards, including PC Card 16 multifunction cards as well as the Zoomed Video (ZV)

port, which is dedicated to high-performance video data transfer such as MPEG video

play back.

❑ Enhanced port replicator port

Enables connection of an enhanced port replicator. The enhanced port replicator has

two PC card slots (Type III), and expands connections to the following devices: PS/2

keyboard, PS/2 mouse, serial port, parallel port, external CRT, joystick/MIDI port,

audio line-in, audio line-out, headphone, external FDD, AC-in, AC-out, and rotary

switch (ID select switch).

❑ AccuPoint

A pointer control stick, located in the center of the keyboard, provides convenient

control of the cursor without requiring desk space for a mouse.

1-2 420 Series

Page 3

❑ Infrared port

Incorporates an IrDA1.0 (115.2Kbps supported) standard infrared transmitter and

receiver.

❑ Sound System

A Sound Blaster Pro compatible sound system provides capability to record sound and

play it back with a built-in microphone and speaker. The sound system is equipped

with a volume control dial, headphone jack, microphone jack, and audio line-in jack.

The 420 Series Personal Computer is shown in Figure 1-1.

Figure 1-1 420 series personal computer

The 420 system configuration is shown in Figure 1-2.

420 Series 1-3

Figure 1-2 420 system unit configuration

Page 4

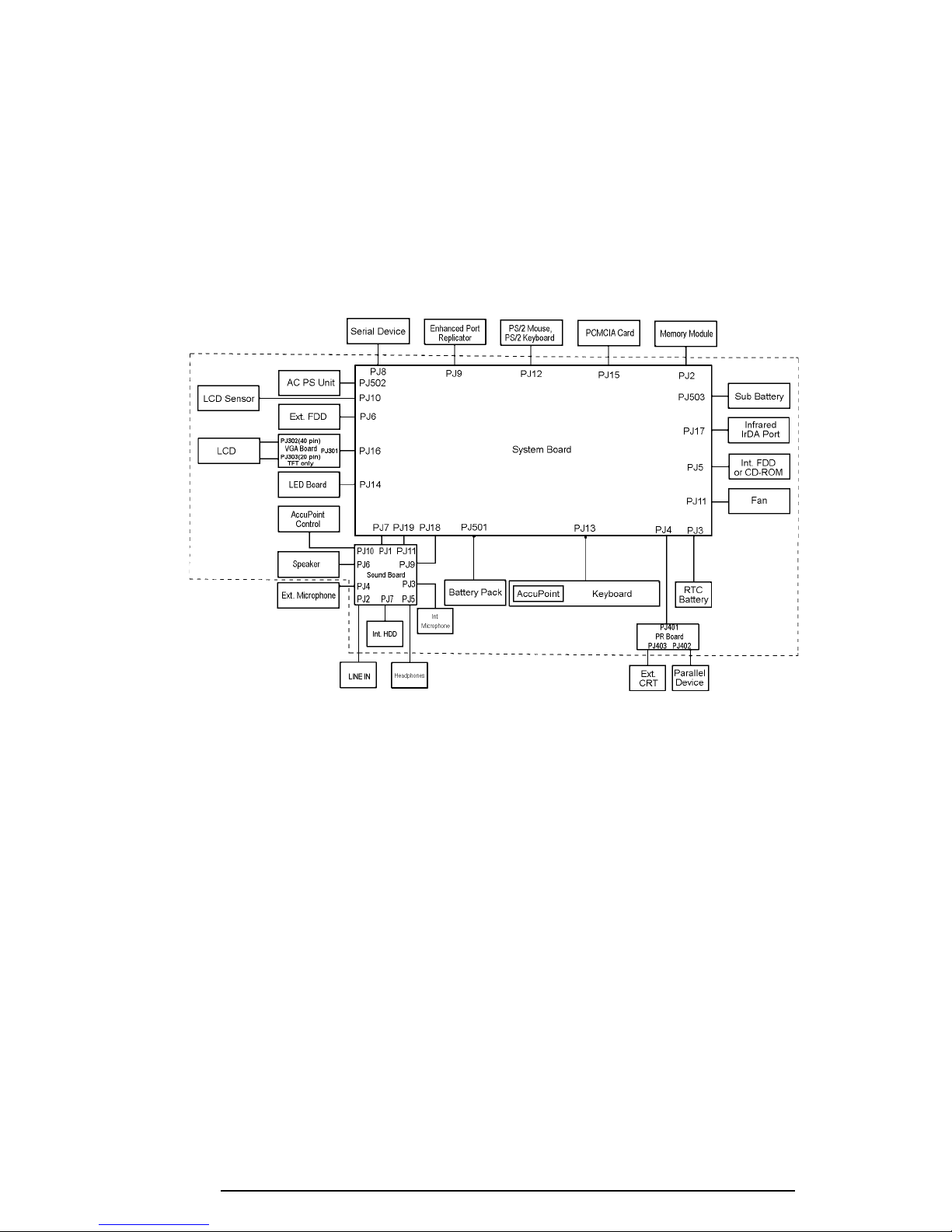

1.2 System Unit Bloc k Diagram

Figure 1-3 is a block diagram of the 420 series system unit.

Figure 1-3 420 series system board block diagram

1-4 420 Series

Page 5

The 420 series system board is composed of the following major components:

❑ Microprocessor

One Intel Pentium processor with VRT 64-bit microprocessor

Intel Pentium processor operates at 100 MHz and 3.3/2.9 volts

❑ Standard RAM

8 MB, four 1Mx16-bit chips

3.3 volt operation

No parity bit

Access time 60 ns

Data transfer is 64-bit width

EDO (extended data output) supported

❑ BIOS ROM (Flash EEPROM)

128 KB (one 128Kx8-bit chip) memory

64 KB in the ROM are used for system BIOS

40 KB in the ROM are used for VGA BIOS

24 KB in the ROM are reserved

Access time 150 ns

Data transfer is 8-bit width

❑ Video RAM

2 MB (Four 256Kx16-bit DRAM)

5 volt operation

❑ Optional memory

One expansion memory slot is available for 8, 16, and 32 MB memory modules, which

consist of some 1 MBx16-bit chips.

Total maximum memory size is 40 MB (if a 32 MB memory module is installed).

3.3 volt operation

No parity bit

Access time 60 ns

Data transfer is 64-bit width

EDO (extended data output) supported

❑ One super integration (SI)

The following components:

- Two DMACs 82C37 equivalent

- Two PICs 82C59 equivalent

- Two UART 16550 equivalent

- One PIT 82C54 equivalent

- One FDC TC8565 equivalent

- One VFO TC8568 equivalent

- One I/O port decode

- One SIO port control

- One printer port control supported ECP

- One FDD control

- One speaker control

- One power communication control

420 Series 1-5

Page 6

❑ System Controller Gate Array (SCPCNT-GA)

This gate array has the following functions:

• CPU control

- SMI control

- CPU clock control

• Memory control

- 64-bit bus memory control

- 32-bit bus memory control

• Bus control

- 64-bit data bus <==>32-bit data bus

- 32-bit local bus control

• Address latch control

• I/O register control

• Processing speed control

❑ ISA Bus Controller Gate Array (SISCNT-GA)

This gate array has the following functions:

• Bus control

- 32-bit data bus <==> 16-bit data bus

- ISA bus interface control

- ISA bus access control

- DMAC control

- DMA address generation

- I/O control

- Suspend/Resume sequence

• Memory control

- ISA bus interface control

- Refresh address generation

• I/O register control

• Suspend/Resume sequence

❑ PC Card Controller Gate Array

This gate array has the following functions:

• PCMCIA memory card control

• PCMCIA I/O card control

❑ I/O Controller Gate Array (IOCNT-GA)

This gate array has the following functions:

• Internal Communication controller

- KBC, main CPU communication register file

- KBC interrupt controller

- KBC communication controller

2

-I

C bus control

1-6 420 Series

Page 7

• Others

- Speaker volume adjust PWM control

- Sound board interface

- BIOS-ROM interface

- SMI control

- IrDA (SIR) control

❑ Video Controller

Chips & Technologies F65550 is used

This video controller controls internal TFT/DSTN color LCD and external SVGA

compatible CRT.

❑ Keyboard Controller (KBC)

One M38802M4 chip is used

This KBC includes the keyboard scan controller and keyboard interface

controller. The KBC controls the internal keyboard, external keyboard, and

PS/2 mouse.

❑ AccuPoint Controller (IPSC)

One KPAAC0062A chip is used

This controller provides simultaneous control of both the AccuPoint and a

PS/2 mouse.

❑ Real Time Clock (RTC)

One T9934 chip is used

The T9934 has 128 bytes of memory. Fourteen bytes of memory are used for the

calendar and clock. The remaining 114 bytes are used for the system configuration

data.

420 Series 1-7

Page 8

1.3 3.5-inch Flopp y Disk Drive

The 420 series 3.5-inch removable FDD is a thin, high-performance reliable drive that supports 720-KB (formatted) 2DD and 1.44-MB (formatted) 2HD disks. When a CD-ROM is

installed in the Selectable Bay, an FDD attachment can be used to connect the FDD to an

external FDD port.

The 420 series FDD is shown in Figure 1-4.

Figure 1-4 3.5-inch FDD

The specifications for the FDD are listed in Table 1-1.

Table 1-1 3.5-inch FDD specifications

Item 2-MB mode 1-MB mode

Storage capacity (KB)

Unformatted 2,000 1,000

Formatted 1,475 737

Number of heads 2 2

Number of cylinders 80 80

Access time (ms)

Track to track 3 3

Average 181 181

Head settling time 15 15

Recording track density (tpi) 135 135

Data transfer rate (Kbps) 500 250

Rotation speed (rpm) 300 300

Recording method Modified Frequency Modulation (MFM)

1-8 420 Series

Page 9

1.4 2.5-inch Har d Disk Drive (HDD)

The Hard Disk Drive is a random access non-volatile storage device. It has a non-removable

2.5-inch magnetic disk and mini-winchester type magnetic heads.

The 420CDT supports 1.3 billion bytes (1.26GB) and 810 million bytes (770MB). Th e

420CDS supports 810 million bytes (770MB).

The 420 series is shown in Figure 1-5.

Figure 1-5 2.5-inch HDD

Specifications for the HDD are listed in Table 1-2.

Table 1-2 2.5-inch HDD specifications

Items MK1926FCV DSOA-20810 MK1301MAV

Formatted capacity (byte) 814,915,584 812,851,200 1,358,880,768

Number of disks 3 2 3

Logical heads 16 16 16

Logical cylinders 1,579 1,575 2,633

Bytes per sector 512 512 512

Rotation speed (rpm) 4,200 4,000 4,200

770 MB 1.26 GB

420 Series 1-9

Page 10

1.5 Keyboard

The 82-(USA) or 84-(European) key keyboard is mounted on the 420 series system unit. The

keyboard is connected to the keyboard controller on the system board through a 25-pin flat

cable. The 420 series pointer control stick, located in the center of the keyboard, provides

convenient control of the cursor without requiring desk space for a mouse. The keyboard is

shown in Figure 1-6.

See Appendix E for optional keyboard configurations.

Figure 1-6 Keyboard

1-10 420 Series

Page 11

1.6 CD-ROM Drive

The 420 series internal CD-ROM drive accommodates either a 12 cm (4.72-inch) or an 8 cm

(3.15-inch) CD. It provides high-performance six-speed play (reads 900KB per second).

This drive supports the following formats:

Audio CD

Photo CD

ISO 9660

CD Plus

The CD-ROM drive is shown in Figure 1-7.

Figure 1-7 CD-ROM

The specifications for the CD-ROM drive are listed in Table 1-3.

Table 1-3 CD-ROM specifications

Item 1X mode 6X mode

Data Capacity (bytes/block)

Mode 1 2,048

Mode 2 2,336

Rotational Speed (rpm) 200 to 530 1,200 to 3,180

Transfer Rate

Sustained Block Transfer (blocks/s) 75 450

Sustained Data Transfer (Kbytes/s)

Mode 1 150 900

Mode 2 171 1,026

ATAPI Burst (Mbytes/s) 8.33 (PIO mode 2)

Access Time (ms)

Average Random Access 350 190

Average Random Seek 230 160

Average Full Stroke Access 500 330

Data Buffer Capacity (Kbytes) 128

420 Series 1-11

Page 12

1.7 DSTN Color LCD (420CDS)

The DSTN Color Liquid Crystal Display (LCD) contains an LCD module, a Fluorescent

Lamp (FL), and an FL inverter board.

1.7.1 DSTN Color LCD Module

The DSTN color LCD is backlit and supports 800x600 pixels with built-in display controller.

This controller includes the functions of Video Graphics Array (VGA) and Super VGA

(SVGA) for external display.

A display controller is F65550. This controller enables an LCD display of a maximum 64K

colors.

The DSTN LCD is shown in Figure 1-8.

Figure 1-8 DSTN color LCD

The specifications for the LCD are listed in Table 1-4.

Table 1-4 DSTN color LCD specifications

Item Specifications

Number of Dots (dots) 800x600

Dot pitch (mm) 0.288x0.288

Display area (mm) 229.2 (W)x171 (H)

Contrast (Typically) 27:1

FL current (mA) 5.0/3.0

(Bright/Semi-bright)

1-12 420 Series

Page 13

1.7.2 DSTN Color Fluorescent Lamp (FL) Inverter Board

The FL inverter board supplies high frequency current to light the LCD Fluorescent Lamp.

The specifications for the FL inverter are listed in Table 1-5.

Table 1-5 DSTN color FL inverter board specifications

Item Specifications

Input Voltage (V) 4 to 5.5

Power (W) 4.25

Output Voltage (Vrms) 1,100

Current (mA) 5.0/3.0

(Bright/Semi-bright)

420 Series 1-13

Page 14

1.8 TFT Color LCD (420CDT)

The TFT Color Liquid Crystal Display (LCD) contains an LCD module, a Fluorescent Lamp

(FL), and an FL inverter board.

1.8.1 LCD Module

The TFT color LCD is backlit and supports 800x600 pixels with built-in display controller.

This controller includes the functions of VGA and SVGA for external display.

A display controller is F65550. This controller enables an LCD display of a maximum 16M

colors.

The TFT LCD is shown in Figure 1-9.

Figure 1-9 TFT color LCD

The specifications for the LCD are listed in Table 1-6.

Table 1-6 TFT color LCD specifications

Item Specifications

Number of dots (dots) 800x600

Dot pitch (mm) 0.288 (W)x0.288 (H)

Display area (mm) 229.2 (W)x171 (H)

Contrast (minimum) 100:1

FL current (mA) 2.4/2.8/4.0/4.6

*NOTE: The FL currents at power on are:

Bright Semi-bright

AC cord connected 4.6 mA 4.0 mA

AC cord not connected 2.8 mA 2.4 mA

(The settings at power on do not change even if the AC cord connection changes.)

1-14 420 Series

Page 15

1.8.2 Fluorescent Lamp (FL) Inverter Board

The FL inverter board supplies high frequency current to light the LCD Fluorescent Lamp.

The specifications for the FL inverter are listed in Table 1-7.

Table 1-7 FL inverter board specifications

Item Specifications

Input Voltage (V) 4 to 5.5

Power (W) 4.25

Output Voltage (Vrms) 1,100

Current (mA) 2.4/2.8/4.0/4.6

*NOTE: The FL currents at power on are:

Bright Semi-bright

AC cord connected 4.6 mA 4.0 mA

AC cord not connected 2.8 mA 2.4 mA

(The settings at power on do not change even if the AC cord connection changes.)

420 Series 1-15

Page 16

1.9 Power Supply

The power supply provides five kinds of voltages to the 420 series system board. The 420

series power supply has one microprocessor and it operates at 500 KHz. It contains the

following functions:

1. Determines if the AC cable or battery is connected to the computer.

2. Detects AC output and circuit malfunctions.

3. Controls the LED icon and speaker.

4. Turns the battery charging system on and off and detects a fully charged battery.

5. Determines if the power can be turned on and off.

6. Provides more accurate detection of a low battery.

7. Calculates the remaining battery capacity.

The power supply output rating is specified in Table 1-8.

Table 1-8 Power supply output rating

DC Regulation

Use for Name voltage tolerance

System logic, FDD, HDD, VCC + 5 ±5

Display

CPU CPUV +2.9 ±5

Flash ROM, PC card 12V +12 ±5

CPU, RAM, GA B3V +3.3 ±0.3V

VRAM, GA B5V +4.7 ±5

(%)

1-16 420 Series

Page 17

1.10 Batteries

The 420 series has three types of batteries:

❑ Main battery pack

❑ Backup battery

❑ Real Time Clock (RTC) battery

Battery specifications are listed in Table 1-9.

Table 1-9 Battery specifications

Battery name Material Output voltage Capacity

Main battery Lithium-Ion 10.8 V 3,600 mAH

Backup battery Nickel Metal Hydride 7.2 V 110 mAH

RTC battery Nickel Metal Hydride 3.6 V 30 mAH

1.10.1 Main Battery

The removable main battery pack is the computer’s main power source when the AC power

cord is not attached. The main battery recharges the backup battery. The backup and main

batteries maintain the state of the computer when you enable AutoResume.

❑ Battery Icon

The Battery icon is located on top of the back rim of the 420 series. The icon shows

the status of the removable battery pack.

The status of each can be determined by color:

Orange The battery is being charged. (AC power cord is attached.)

Green The battery is fully charged. (AC power cord is attached.)

Blink orange The battery is low when the power is on.

No light Under any other conditions, the LED does not light.

1.10.2 Battery Charging Control

Battery charging is controlled by a power supply microprocessor that is mounted on the

power supply. The microprocessor controls whether the charge is on or off and detects a full

charge when the AC power cord and battery are attached to the computer. The system

charges the battery using quick charge or trickle charge.

420 Series 1-17

Page 18

❑ Quick Battery Charge

When the AC power cord is attached, there are two types of charge: quick charge

when the system is powered off and trickle charge when the system is powered on.

Table 1-10 Time required for quick charges

Charging time

Power off About 2 to 3 hours

Power on About 5 to 8 hours

If one of the following occurs, the battery quick-charge process stops:

1. The battery becomes fully charged.

2. The battery is removed.

3. The battery or AC output voltage is abnormal.

4. The charge current is abnormal.

❑ Trickle Battery Charge

When the main battery is fully charged and the AC power cord is attached, the power

supply microprocessor automatically changes from quick charge to trickle charge.

1.10.3 Backup Battery

The backup battery maintains data for AutoResume. The power source used to back up the

AutoResume data is determined according to the following priority:

AC power > Main battery > Backup battery

The backup battery is charged by the main battery or AC power cord. Table 1-11 shows the

charging time and data preservation period of the backup battery.

Table 1-11 Backup battery charging/data preservation time

Charging Time Power On 20 H

Data preservation period (full charge) 4 H

1-18 420 Series

Time

Power Off 20 H

Page 19

1.10.4 RTC Battery

The RTC battery provides power to keep the current date, time, and other setup information

in memory while the computer is turned off. Table 1-12 shows the charging time and data

preservation period of the RTC battery.

Table 1-12 RTC battery charging/data preservation time

Time

Charging Time With AC power 48 H

or main battery

Data preservation period (full charge) 1 month

420 Series 1-19

Page 20

2.1 Troubleshooting

Chapter 2 describes how to determine if a Field Replaceable Unit (FRU) in the 420 series is

causing the computer to malfunction. The FRUs covered are:

1. System Board(s)

2. Sound Board

3. VGA Board

4. Floppy Disk Drive

5. Hard Disk Drive

6. CD-ROM Drive

7. Keyboard

8. Display

9. Power Supply

The Diagnostics Disk operations are described in Chapter 3 and detailed replacement procedures are given in Chapter 4.

The following tools are necessary for implementing the troubleshooting procedures:

1. Diagnostics Disk

2. Phillips screwdriver (2 mm)

3. Toshiba MS-DOS system disk(s)

(You must install the following onto the disk: SYS.COM, FORMAT.COM,

FDISK.COM and FDISK.EXE)

4. 2DD or 2HD formatted work disk for floppy disk drive testing

5. Cleaning kit for floppy disk drive troubleshooting

6. RS-232-C wraparound connector

7. Printer wraparound connector

8. Multimeter

9. External CRT

10. PS/2 or compatible keyboard

11. PS/2 or compatible mouse

12. Serial port wraparound connector

13. PC card wraparound card

14. Multimedia sound system with line-in and line-out ports

15. Headphone

16. CD-ROM drive

17. Toshiba EMI test disk TDY-03

18. Music CD

19. Lens cleaner for CD ROM laser pickup lens

420 Series 2-1

Page 21

2.2 T r oubleshooting Flowchart

Use the flowchart in Figure 2-1 as a guide for determining which troubleshooting procedures

to execute. Before going through the flowchart steps, do the following:

❑ Ask the user if a password is registered and, if it is, ask him or her to enter the pass-

word. If the user has forgotten the password, connect the printer port wraparound

board (F31PRT), then turn the POWER switch on. The computer will override the

password function by erasing the current password.

❑ Verify with the customer that Toshiba MS-DOS is installed on the hard disk. Non-

Toshiba operating systems can cause the computer to malfunction.

❑ Make sure all optional equipment is disconnected from the computer.

❑ Make sure the floppy disk drive is empty.

2-2 420 Series

Page 22

420 Series 2-3

Figure 2-1 Troubleshooting flowchart

Page 23

Figure 2-1 Troubleshooting flowchart (Continued)

If the diagnostics program cannot detect an error, the problem may be intermittent. The

Running Test program should be executed several times to isolate the problem. Check the

Log Utilities function to confirm which diagnostic test detected an error(s), then perform the

appropriate troubleshooting procedures as follows:

1. If an error is detected on the system test, memory test, display test, ASYNC test,

printer test, or real timer test perform the system board troubleshooting procedures in Section 2.4.

2. If an error is detected on the floppy disk test, perform the floppy disk drive

troubleshooting procedures in Section 2.5.

3. If an error is detected on the hard disk test, perform the hard disk drive

troubleshooting procedures in Section 2.6.

4. If an error is detected on the keyboard test, perform the keyboard troubleshooting

procedures in Section 2.7.

5. If an error is detected on the display test, perform the display troubleshooting

procedures in Section 2.8.

6. If an error is detected on the CD-ROM test, perform the CD-ROM drive troubleshooting procedures in Section 2.9.

2-4 420 Series

Page 24

2.3 P ower Supply Troubleshooting

The 420 series power supply controls many functions and components in the 420 series. To

determine if the power supply is functioning properly, start with Procedure 1 and continue

with the other procedures as instructed. The procedures described in this section are:

Procedure 1: AC IN Icon Check

Procedure 2: Battery Icon Check

Procedure 3: AC PS Unit Replacement Check

Procedure 1 AC IN Icon Check

The 420 series AC PS unit converts AC power to DC power and contains a charging circuit

which charges the 420 series batteries. The AC power cord connects to the AC IN socket

connector on the back side of the computer. When the AC power cord is connected to the

420 series the AC PS unit charges the batteries.

The AC IN icon displays whether or not the AC power cord is connected and supplying

power.

When the AC IN icon is green, the AC power cord is connected and supplying power to the

420 series.

If the AC IN icon does not light, the AC power cord is not supplying power to the 420 series,

or the AC power cord is not attached to the 420 series, go to Check 1.

If the AC IN icon is flashing orange, the AC power cord voltage supply is abnormal, or the

power supply is not functioning properly, go to Check 2.

If any of the above indicator conditions are abnormal, make sure the icon lights are not burned

out before performing the following checks:

Check 1 Make sure the correct AC power cord is firmly plugged into the AC IN socket on

the back of the computer.

Check 2 If the AC IN icon flashes orange when the AC power cord is connected, output

voltage is abnormal. Connect a new AC power cord and turn the 420 series on

again to verify the indicator condition.

Check 3 The battery pack may be malfunctioning. Replace the battery pack with a new one

and turn the computer on again. If the problem still exists, go to Procedure 2.

420 Series 2-5

Page 25

Procedure 2 Battery Icon Check

The Battery icon shows the battery charging status. The Battery icon glows orange when the

AC power cord is charging the 420 series battery pack.

If the Battery icon glows green, the AC power cord is connected and the battery is fully

charged.

If the Battery icon glows orange, the AC power cord is connected and the battery is being

charged.

If the Battery icon does not glow, go to Check 1.

Check 1 Make sure the AC power cord is firmly plugged into the AC IN socket and wall

outlet. If these cables are connected correctly, go to Check 2.

Check 2 Make sure the battery pack is installed in the computer correctly. If the battery

pack is installed correctly, go to Check 3.

Check 3 Remove the battery pack and check that the battery terminal is clean and not bent.

If the terminal appears dirty, clean it gently with a cotton swab dipped in alcohol.

If the terminal looks bent or damaged, replace the system board.

If the battery terminal is clean and not bent, go to Check 4.

Check 4 Connect a new AC power cord. If the Battery icon still does not glow, go to

Check 5.

Check 5 Install a new battery pack. If the Battery icon still does not glow, go to Procedure

3.

Procedure 3 AC PS Unit Replacement Check

The system board incorporates the power supply. Power is supplied to the system board

through the AC IN plug located on the AC PS unit. The AC PS unit may be damaged, refer

to Chapter 4 for instructions on how to disassemble the 420 series, and then perform the

following checks:

Check 1 Replace the AC PS unit with a new one and restart the system. If the system is

still not functioning properly, perform Check 2.

Check 2 Replace the system board with a new one and restart the system. If the problem

still exists, other FRUs may be damaged.

2-6 420 Series

Page 26

2.4 System Boar d and Sound Board Troubleshooting

This section describes how to determine if the system board and sound board are defective or

not functioning properly. Start with Procedure 1 and continue with the other procedures as

instructed. The procedures described in this section are:

Procedure 1: Message Check

Procedure 2: Printer Port LED Check on Boot Mode

Procedure 3: Printer Port LED Check on Resume Mode

Procedure 4: Diagnostic Test Program Execution Check

Procedure 5: Replacement Check

Procedure 1 Message Check

When the power is turned on, the system performs the Initial Reliability Test (IRT) installed in

the BIOS ROM. The IRT tests each IC on the system board and initializes it.

❑ If an error message is shown on the display, perform Check 1.

❑ If there is no error message, go to Procedure 2.

❑ If the Toshiba MS-DOS is properly loaded, go to Procedure 3.

Check 1 If one of the following error messages is displayed on the screen, press the F1 key

as the message instructs. These errors occur when the system configuration

preserved in the RTC memory (CMOS type memory) is not the same as the actual

configuration or when the data is lost.

If you press the F1 key as the message instructs, the TSETUP screen appears to

set the system configuration. If error message (b) appears often when the power is

turned on, replace the RTC battery. If any other error message is displayed,

perform Check 2.

(a) *** Bad HDD type ***

Check system. Then press [F1] key ......

(b) *** Bad RTC battery ***

Check system. Then press [F1] key ......

(c) *** Bad configuration ***

Check system. Then press [F1] key ......

(d) *** Bad memory size ***

Check system. Then press [F1] key ......

(e) *** Bad time function ***

Check system. Then press [F1] key ......

(f) *** Bad check sum (CMOS) ***

Check system. Then press [F1] key ......

(g) *** Bad check sum (ROM) ***

Check system. Then press [F1] key ......

420 Series 2-7

Page 27

Check 2 If the following error message is displayed on the screen, press any key as the

message instructs.

WARNING: RESUME FAILURE.

PRESS ANY KEY TO CONTINUE.

This error message appears when data stored in RAM under the resume function is

lost because the battery has become discharged or the system board is damaged.

Go to Procedure 3.

If any other message appears, perform Check 3.

Check 3 The IRT checks the system board. When the IRT detects an error, the system

stops or an error message appears.

If one of the following error messages (1) through (19), (26) or (27) is displayed,

replace the system board.

If error message (20) is displayed, go to the Keyboard Troubleshooting Proce-

dures in Section 2.7.

If error message (21), (22) or (23) is displayed, go to the HDD Troubleshooting

Procedures in Section 2.6.

If error message (24) or (25) is displayed, go to the FDD Troubleshooting Proce-

dures in Section 2.5.

(1) BIOS is damaged

(2) PIT ERROR

(3) MEMORY REFRESH ERROR

(4) TIMER CH.2 OUT ERROR

(5) FIRST 64KB MEMORY ERROR

(6) CMOS CHECKSUM ERROR

(7) CMOS BAD BATTERY ERROR

(8) FIRST 64KB MEMORY ERROR

(9) FIRST 64KB MEMORY PARITY ERROR

(10) VRAM ERROR

(11) SYSTEM MEMORY ERROR

(12) SYSTEM MEMORY PARITY ERROR

(13) EXTENDED MEMORY ERROR

(14) EXTENDED MEMORY PARITY ERROR

(15) DMA PAGE REGISTER ERROR

(16) DMAC #1 ERROR

(17) DMAC #2 ERROR

(18) PIC #1 ERROR

(19) PIC #2 ERROR

(20) KBC ERROR

(21) HDC ERROR

(22) HDD #0 ERROR

(23) HDD #1 ERROR

(24) NO FDD ERROR

(25) FDC ERROR

(26) TIMER INTERRUPT ERROR

(27) RTC UPDATE ERROR

2-8 420 Series

Page 28

Procedure 2 Printer Port LED Check on Boot Mode

The printer port LED displays the IRT status and test status by turning lights on and off as an

eight-digit binary value for boot mode. Figure 2-2 shows the printer port LED.

Figure 2-2 Printer port LED

To use the printer port LED follow these steps:

1. Turn on the power, then set to boot mode.

2. Turn off the power.

3. Plug the printer port LED into the parallel port.

4. Hold the space bar down and turn on the power.

5. Read the LED status from left to right as you are facing the back of the computer.

6. Convert the status from binary to hexadecimal notation.

7. If the final LED status is FFh (normal status), go to Procedure 3.

8. If the final LED status matches any of the test status values in Table 2-1, perform

Check 1.

NOTE: If an error condition is detected by the IRT test, the printer port LED displays

an error code after the IRT test ends. For example, when the printer port LED displays 1F and halts, the IRT test has already completed the Display initialization. In

this instance, the IRT indicates an error has been detected during the system memory

test.

420 Series 2-9

Page 29

Table 2-1 Printer port LED boot mode status

LED status Test item Message

01H KBC initialization

ROM checksum test BIOS is damaged! .....

02H Special register initialization

PIT test PIT ERROR

PIT initialization —

PIT function check MEMORY REFRESH ERROR

TIMER CH.2 OUT ERROR

03H CMOS check CMOS CHECKSUM ERROR

CMOS BAD BATTERY ERROR

KB initialization KBC ERROR

04H Initialization of —

memory configuration

05H SM-RAM check —

06H Self test check —

Read of Power Supply —

information

07H ROM/RAM copy —

08H Initialization of internal VGA —

0AH First 64 KB memory test FIRST 64KB MEMORY ERROR

FIRST 64KB MEMORY PARITY ERROR

0BH System memory initialization —

0CH System initialization —

0DH Interrupt vector initialization —

18H PIC initialization —

1FH Display initialization VRAM ERROR

25H System memory test SYSTEM MEMORY ERROR

SYSTEM MEMORY PARITY ERROR

30H Extended memory test EXTENDED MEMORY ERROR

EXTENDED MEMORY PARITY ERROR

40H DMA page register test DMA PAGE REGISTER ERROR

41H DMAC test DMAC #X ERROR

42H DMAC initialization —

4AH PIC test PIC #X ERROR

50H Mouse initialization —

55H KBC initialization KBC ERROR

60H HDD initialization HDC ERROR/HDD #0 ERROR

65H FDD initialization FDC ERROR/NO FDD ERROR

70H Printer initialization —

80H SIO initialization —

90H Timer initialization RTC UPDATE ERROR

TIMER INTERRUPT ERROR

A0H NDP initialization —

2-10 420 Series

Page 30

Table 2-1 Printer port LED boot mode status (Continued)

LED status Test item Message

A6H Initialization of expansion ROM —

C0H Password check —

FFH Setup boot check *** Bad xxxx xxxx ***

Check system. Then press [F1] key.

FFH Boot load —

Check 1 If any of the following error codes are displayed, go to Procedure 5.

01h, 02h, 03h, 04h, 05h, 06h, 07h, 08h, 0Ah, 0Bh, 0Ch, 0Dh, 18h, 1Fh, 25h,

30h, 40h, 41h, 42h, 4Ah, 50h, 70h, 80h, 90h, A0h, A6h, C0h, FFh

Check 2 If error code 55h is displayed, go to the Keyboard Troubleshooting procedures in

Section 2.7.

Check 3 If error code 60h is displayed, go to the HDD Troubleshooting Procedures in

Section 2.6.

Check 4 If error code 65h is displayed, go to the FDD Troubleshooting Procedures in

Section 2.5.

420 Series 2-11

Page 31

Procedure 3 Printer Port LED Check on Resume Mode

The printer port LED displays the IRT status and test status by turning lights on and off as an

eight-digit binary value for resume mode.

To use the printer port LED follow these steps:

1. Turn on the power, then set to resume mode.

2. Turn off the power.

3. Plug the printer port LED into the parallel port.

4. Turn on the power.

5. Read the LED status from left to right as you face the back of the computer.

6. Convert the status from binary to hexadecimal notation.

7. If the final LED status is FFh (normal status), go to Procedure 4.

8. If the final LED status matches any of the test status values in Table 2-2, perform

Procedure 5.

Table 2-2 Printer port LED resume mode error status

Error status Meaning of status

F1H RAM BIOS error

F2H The system has optional ROM, or optional card (CGA, MDA)

F5H Main memory checksum error

F6H Video RAM checksum error

F7H Extended memory checksum error

Procedure 4 Diagnostic Test Program Execution Check

Execute the following tests from the Diagnostic Test Menu. Refer to Chapter 3, Tests and

Diagnostics, for more information on how to perform these tests.

1. System test

2. Memory test

3. Printer test

4. ASYNC test

5. Real Timer test

6. NDP test

7. Expansion test

8. Sound test

9. CD-ROM test

If an error is detected during any of these tests, go to Procedure 5.

2-12 420 Series

Page 32

Procedure 5 Replacement Check

The system board or the sound board may be damaged. Disassemble the 420 series following

the steps described in Chapter 4, Replacement Procedures, and perform the following checks:

Check 1 Replace the system board with a new one. Refer to Chapter 4 for instructions on

how to remove and replace the system board.

Check 2 Replace the sound board with a new one. Refer to Chapter 4 for instructions on

how to remove and replace the sound board.

420 Series 2-13

Page 33

2.5 Flopp y Disk Drive Troubleshooting

This section describes how to determine if the 420 series internal or external 3.5-inch floppy

disk drive is functioning properly. Perform the steps below starting with Procedure 1 and

continuing with the other procedures as required.

Procedure 1: FDD Head Cleaning Check

Procedure 2: Diagnostic Test Program Execution Check

Procedure 3: Connector Check and Replacement Check

Procedure 1 FDD Head Cleaning Check

FDD head cleaning is one option available in the Diagnostic Program. Detailed operation is

given in Chapter 3, Tests and Diagnostics.

After Toshiba MS-DOS loads, run the Diagnostic Program and then clean the FDD heads

using the cleaning kit. If the FDD still does not function properly after cleaning, go to Procedure 2.

If the test program cannot be executed on the 420 series, go to Procedure 3.

2-14 420 Series

Page 34

Procedure 2 Diagnostic Test Program Execution Check

The Floppy Disk Drive Diagnostic Test program is stored on the 420 series Diagnostics Disk.

After loading Toshiba MS-DOS, run the diagnostic program. Refer to Chapter 3, Tests and

Diagnostics, for more information about the diagnostics test procedures.

Floppy disk drive test error codes and their status names are described in Table 2-3. Make

sure the floppy disk in the FDD is formatted correctly and that the write protect tab is disabled. If any other errors occur while executing the FDD diagnostics test, go to Check 1.

Table 2-3 Floppy disk drive error codes and statuses

Code Status

01h Bad command

02h Address mark not found

03h Write protected

04h Record not found

06h Media removed on dual attach card

08h DMA overrun error

09h DMA boundary error

10h CRC error

20h FDC error

40h Seek error

60h FDD not in drive

80h Time out error (Not ready)

EEh Write buffer error

FFh Data compare error

Check 1 If the following message is displayed, disable the write protect tab on the floppy

disk.

Write protected

If any other message appears, perform Check 2.

Check 2 Make sure the floppy disk is formatted correctly. If it is, go to Procedure 3.

420 Series 2-15

Page 35

Procedure 3 Connector Check and Replacement Check

The 3.5-inch Floppy Disk Drive is connected to the FDD port by the FDD cable. This cable

may be damaged or disconnected from the external 3.5-inch FDD port. Do the following

checks:

Check 1 Make sure the FDD cable is firmly connected to the FDD port.

FDD PJ5 420 system

If this cable is disconnected, connect it to the system unit and repeat Procedure 2.

If the FDD is still not functioning properly, perform Check 2.

Check 2 The cable may be defective or damaged. Replace the cable. If the FDD is still not

functioning properly, perform Check 3.

Check 3 The FDD or its cable may be defective or damaged. Replace the FDD with a new

one following the steps in Chapter 4, Replacement Procedures. If the FDD is still

not functioning properly, perform Check 4.

Check 4 Replace the system board with a new one following the steps in Chapter 4, Re-

placement Procedures.

2-16 420 Series

Page 36

2.6 Har d Disk Drive Troubleshooting

To determine if the hard disk drive is functioning properly, perform the procedures below

starting with Procedure 1. Continue with the other procedures as instructed.

Procedure 1: Partition Check

Procedure 2: Message Check

Procedure 3: Format Check

Procedure 4: Diagnostic Test Program Execution Check

NOTE: The contents of the hard disk will be erased when the HDD troubleshooting

procedures are executed. Transfer the contents of the hard disk to a floppy disk(s)

using the BACKUP command in the Toshiba companion utility. Refer to the User’s

Manual for more information about how to perform the BACKUP.

Procedure 1 Partition Check

Insert the Toshiba MS-DOS system disk, turn on the computer, and perform the following

checks:

Check 1 Type C: and press Enter. If you cannot change to drive C, go to Check 2. If you

can change to drive C, go to Procedure 2.

Check 2 Type FDISK and press Enter. Choose Display Partition Information from the

FDISK menu. If drive C is listed, go to Check 3. If drive C is not listed, return to

the FDISK menu and choose the option to create a DOS partition on drive C.

Recheck the system. If the problem still exists, go to Procedure 2.

Check 3 If drive C is listed as active in the FDISK menu, go to Check 4. If drive C is not

listed as active, return to the FDISK menu and choose the option to set the active

partition for drive C. Recheck the system. If the problem still exists, go to Procedure 2.

Check 4 Remove the system disk from the FDD and cold boot the computer. If the prob-

lem still exists, go to Procedure 2. Otherwise, the HDD is operating normally.

420 Series 2-17

Page 37

Procedure 2 Message Check

When the 420 series HDD does not function properly, some of the following error messages

may appear on the display. Start with Check 1 below and perform the other checks as instructed.

Check 1 If any of the following messages appear, perform Check 2. If the following mes-

sages do not appear, perform Check 4:

HDC ERROR

(After 5 seconds this message will disappear.)

or

HDD #0 ERROR

(After 5 seconds this message will disappear.)

or

HDD #1 ERROR

(After 5 seconds this message will disappear.)

Check 2 If either of the following messages appears, perform Procedure 3. If the following

messages do not appear, perform Check 3.

Insert system disk in drive

Press any key when ready .....

or

Non-System disk or disk error

Replace and press any key

Check 3 Using the Toshiba MS-DOS system disk, install a system program on the hard disk

using the SYS command.

If the following message appears on the display, the system program has been

transferred to the HDD.

System transferred

Restart the 420 series. If the error message still appears, perform Check 4.

Check 4 The HDD is connected to the system board directly. This connection can become

disconnected or damaged. Disassemble the 420 series as described in Chapter 4,

Replacement Procedures. If the HDD is not connected, connect it to the system

board and return to Procedure 1. If the HDD is firmly connected to the system

board, perform Procedure 3.

System Board PJ7 PJ1 Sound PJ7 HDD

2-18 420 Series

Board

Page 38

Procedure 3 Format Check

The 420 series HDD is formatted using the low level format program and the MS-DOS

FORMAT program. To format the HDD, start with Check 1 below and perform the other

check as required.

Check 1 Using the Toshiba MS-DOS system disk, partition the hard disk using the FDISK

command. Format the hard disk using FORMAT C:/S/U to transfer the system

program to the HDD. If the following message appears on the display, the HDD

is formatted.

Format complete

If any other error message appears on the display, refer to the Toshiba MS-DOS

Manual for more information and perform Check 2.

Check 2 Using the 420 series Diagnostic Disk, format the HDD with a low level format

option. Refer to Chapter 3, Tests and Diagnostics, for more information about

the diagnostic program.

If the following message appears on the display, the HDD low level format is

complete. Partition and format the HDD using the MS-DOS FORMAT command.

Format complete

If you cannot format the HDD using the Test and Diagnostic program, go to

Procedure 4.

420 Series 2-19

Page 39

Procedure 4 Diagnostic Test Program Execution Check

The HDD test program is stored in the 420 series Diagnostics Disk. Perform all of the HDD

tests in the Hard Disk Drive Test. Refer to Chapter 3, Tests and Diagnostics, for more

information about the HDD test program.

If an error is detected during the HDD test, an error code and status will be displayed; perform Check 1. The error codes and statuses are described in Table 2-4. If an error code is

not generated, the HDD is operating properly.

Table 2-4 Hard disk drive error codes and statuses

Code Status

01h Bad command

02h Bad address mark

04h Record not found

05h HDC not reset

07h Drive not initialized

08h HDC overrun (DRQ)

09h DMA boundary error

0Ah Bad sector error

0Bh Bad track error

10h ECC error

11h ECC recover enabled

20h HDC error

40h Seek error

80h Time out error

AAh Drive not ready

BBh Undefined error

CCh Write fault

E0h Status error

EEh Access time out error

FFh Data compare error

Check 1 Replace the HDD unit with a new one following the instructions in Chapter 4,

Replacement Procedures. If the HDD is still not functioning properly, perform

Check 2.

Check 2 Replace the system board with a new one following the instructions in Chapter 4.

2-20 420 Series

Page 40

2.7 Keyboard Troubleshooting

To determine if the 420 series keyboard is functioning properly, perform the following procedures. Start with Procedure 1 and continue with the other procedure as instructed.

Procedure 1: Diagnostic Test Program Execution Check

Procedure 2: Connector and Replacement Check

Procedure 1 Diagnostic Test Program Execution Check

Execute the Keyboard Test in the Diagnostic Program. Refer to Chapter 3, Tests and Diagnostics, for more information on how to perform the test program.

If an error occurs, go to Procedure 2. If an error does not occur, the keyboard is functioning

properly.

Procedure 2 Connector and Replacement Check

The keyboard is connected to the system board by a flat cable. This cable may be disconnected or damaged. Disassemble the 420 series as described in Chapter 4, Replacement

Procedures, and perform the following checks:

Check 1 Make sure the keyboard cable is not damaged and is connected to the system

board.

Keyboard cable PJ14 System board

If this cable is damaged, replace the keyboard with a new one. If the cable is

disconnected, firmly connect it. Perform Procedure 1 again. If the keyboard is

still not functioning properly, perform Check 2.

Check 2 The keyboard controller on the system board may be damaged. Replace the

system board with a new one. Refer to Chapter 4, Replacement Procedures, for

more information.

420 Series 2-21

Page 41

2.8 Displa y and V GA Board Troubleshooting

This section describes how to determine if the 420 series display is functioning properly. Start

with Procedure 1 and continue with the other procedures as instructed.

Procedure 1: Contrast Control Check (420CDS only)

Procedure 2: External CRT Check

Procedure 3: Diagnostic Test Program Execution Check

Procedure 4: Connector Check

Procedure 5: Replacement Check

Procedure 1 Contrast Control Check (420CDS only)

Contrast is changed by the contrast dial. If the contrast does not change when you turn the

contrast dial, perform Procedure 2.

Procedure 2 External CRT Check

Connect the external CRT to the 420 series external monitor port, then boot the computer.

The computer automatically detects the external CRT even if Resume mode is enabled.

If the external CRT works correctly, the internal LCD display may be damaged. Go to Procedure 4.

If the external CRT appears to have the same problem as the internal LCD, the display controller may be damaged. Go to Procedure 3.

Procedure 3 Diagnostic Test Program Execution Check

The Display Test program is stored on the 420 series Diagnostic Disk. This program checks

the display controller on the system board. After loading Toshiba MS-DOS, run the Diagnostic Program. Refer to Chapter 3, Tests and Diagnostics, for details.

If an error is detected, go to Procedure 4. If an error is not detected, the display is functioning properly.

2-22 420 Series

Page 42

Procedure 4 Connector Check

The Display unit has an LCD module, FL, Display switch, and FL inverter board. The FL

and FL inverter board are connected by two cables. The LCD module and system board are

connected by two signal cables as shown below. Any of these cables may be disconnected.

Disassemble the display unit and check the following cable connections. Refer to Chapter 4,

Replacement Procedures, for more information about how to disassemble the computer.

Figure 2-3 420CDS display connection

420 Series 2-23

Page 43

Figure 2-4 420CDT display connection

If any of these cables is not connected, firmly reconnect it and repeat Procedures 1 and 2. If

the problem still exists, perform Procedure 5.

2-24 420 Series

Page 44

Procedure 5 Replacement Check

The FL, FL inverter board, LCD module, and system board are connected to the display

circuits. Any of these components may be damaged. Refer to Chapter 4, Replacement Proce-

dures, for instructions on how to disassemble the computer and then perform the following

checks:

If the FL does not light, perform Check 1.

If characters are not displayed clearly, perform Check 3.

If some screen functions do not operate properly, perform Check 3.

If the FL remains lit when the display is closed, perform Check 4.

Check 1 Replace the FL with a new one and test the display again. If the problem still

exists, perform Check 2.

Check 2 Replace the FL inverter board with a new one and test the display again. If the

problem still exists, perform Check 3.

Check 3 Replace the LCD module with a new one and test the display again. If the

problem still exists, perform Check 4.

Check 4 Replace the display switch with a new one and test the display again. If the

problem still exists, perform Check 5.

Check 5 Replace the display cable with a new one and test the display again. If the

problem still exists, perform Check 6.

Check 6 The system board may be damaged. Replace the system board with a new one.

420 Series 2-25

Page 45

2.9 CD-R OM Drive Troub leshooting

This section describes how to determine if the 420 series internal CD-ROM drive is functioning properly. Perform the steps below starting with Procedure 1 and continuing with the

other procedures as required.

Procedure 1: CD Cleaning Check

Procedure 2: Diagnostic Test Program Execution Check

Procedure 3: Connector Check and Replacement Check

Procedure 1 CD Cleaning Check

Clean the laser pickup lens with a lens cleaner. Apply the cleaner to a cloth and wipe the lens.

If the CD-ROM drive still does not function properly after cleaning, go to Procedure 2.

Procedure 2 Diagnostic Test Program Execution Check

The CD-ROM drive Diagnostic Test program is stored on the 420 series Diagnostics Disk.

After Toshiba MS-DOS loads, run the diagnostic program stored on the test program diskette. Insert a test CD (Toshiba-EMI Test Disc TDY-03) into the CD-ROM drive and run

the test. Refer to Chapter 3, Tests and Diagnostics, for more information about the diagnostics test procedures.

If any other errors occur while executing the CD-ROM drive diagnostics test, go to Procedure 3.

2-26 420 Series

Page 46

Procedure 3 Connector Check and Replacement Check

The CD-ROM drive is connected to the system board and sound board by the CD-ROM drive

cable. This cable may be damaged or disconnected from the system board. Disassemble the

420 series following the steps described in Chapter 4, Replacement Procedures, and perform

the following checks:

Check 1 Make sure the CD-ROM is firmly connected to the system board.

CD-ROM drive PJ5

System board

If this cable is disconnected, connect it to the system unit and repeat Procedure 2.

If the CD-ROM is still not functioning properly, perform Check 2.

Check 2 The CD-ROM drive may be defective or damaged. Replace the CD-ROM drive

with a new one following the steps in Chapter 4, Replacement Procedures. If the

CD-ROM drive is still not functioning properly, perform Check 3.

Check 3 Replace the system board with a new one following the steps in Chapter 4.

420 Series 2-27

Page 47

3.1 The Diagnostic T est

This chapter explains how to use the Diagnostic Test program to test the functions of the

computer’s hardware modules. The Diagnostics Program is stored on the Diagnostic Disk

and consists of nine programs that are grouped into the Service Program Module (DIAGNOSTICS Menu).

NOTES: To start the diagnostics, follow these steps:

1. Check all cables for loose connections.

2. Exit any application you may be using and close Windows.

The DIAGNOSTICS MENU consists of the following functions.

❑ DIAGNOSTIC TEST

❑ HARD DISK FORMAT

❑ HEAD CLEANING

❑ LOG UTILITIES

❑ RUNNING TEST

❑ FDD UTILITIES

❑ SYSTEM CONFIGURATION

❑ EXIT TO MS-DOS

❑ SETUP

420 Series 3-1

Page 48

The DIAGNOSTIC TEST MENU contains the following functional tests:

❑ SYSTEM TEST

❑ MEMORY TEST

❑ KEYBOARD TEST

❑ DISPLAY TEST

❑ FLOPPY DISK TEST

❑ PRINTER TEST

❑ ASYNC TEST

❑ HARD DISK TEST

❑ REAL TIMER TEST

❑ NDP TEST

❑ EXPANSION TEST

❑ SOUND TEST

❑ CD-ROM TEST

You will need the following equipment to perform some of the Diagnostic test programs.

❑ The Diagnostics Disk (all tests)

❑ A formatted working disk for the floppy disk drive test (all tests)

❑ An external FDD attachment

❑ A cleaning kit to clean the floppy disk drive heads (Head Cleaning)

❑ A PC card wraparound connector for the I/O card test (Expansion test)

❑ A printer wraparound connector for the printer wraparound test (Printer test)

❑ An RS-232-C wraparound connector for the RS-232-C port wraparound test

(ASYNC test)

❑ A CD test media (Toshiba-EMI test disk TDY-03 and music CD) (CD-ROM test)

❑ External CRT (All tests)

❑ PS/2 or compatible keyboard (All tests)

❑ PS/2 or compatible mouse (Keyboard test)

❑ Serial port wraparound connector (ASYNC test)

❑ Multimedia sound system with line-in and line-out ports (Sound test)

❑ Headphone (Sound test)

❑ CD-ROM drive (CD-ROM test)

❑ A microphone

The following sections detail the tests within the Diagnostic Test function of the DIAGNOSTIC TEST MENU. Refer to Sections 3.19 through 3.25 for detailed information on the

remaining Service Program Module functions.

3-2 420 Series

Page 49

3.2 Executing the Diagnostic T est

Toshiba MS-DOS is required to run the DIAGNOSTICS PROGRAM. To start the Program

follow these steps:

1. Insert the Diagnostics disk into the floppy disk drive and turn on the computer.

(The Diagnostics disk contains the MS-DOS boot files.)

NOTE: To execute the CD-ROM test, make sure the CD-ROM and CD-

ROM drive are installed in the computer and the external FDD is attached

to the FDD port.

The following menu will appear:

TOSHIBA personal computer xxx DIAGNOSTICS

version X.XX (c) copyright TOSHIBA Corp. 19XX

DIAGNOSTICS MENU :

1 - DIAGNOSTIC TEST

2 - HARD DISK FORMAT

3 4 - HEAD CLEANING

5 - LOG UTILITIES

6 - RUNNING TEST

7 - FDD UTILITIES

8 - SYSTEM CONFIGURATION

9 - EXIT TO MS-DOS

0 - SETUP

↑↓→← : Select items

Enter : Specify

Esc : Exit

NOTE: To exit the DIAGNOSTIC TEST MENU, press the Esc key. If a

test program is in progress, press Ctrl + Break to exit the test program or

press Ctrl + C to stop the test program.

420 Series 3-3

Page 50

2. To select the DIAGNOSTIC TEST MENU from the DIAGNOSTICS MENU, set

the highlight bar to 1, and press Enter. The following screen will appear:

TOSHIBA personal computer xxx DIAGNOSTICS

version X.XX (c) copyright TOSHIBA Corp. 19XX

DIAGNOSTIC TEST MENU :

1 - SYSTEM TEST

2 - MEMORY TEST

3 - KEYBOARD TEST

4 - DISPLAY TEST

5 - FLOPPY DISK TEST

6 - PRINTER TEST

7 - ASYNC TEST

8 - HARD DISK TEST

9 - REAL TIMER TEST

10 - NDP TEST

11 - EXPANSION TEST

12 - SOUND TEST

13 - CD-ROM TEST

88 - ERROR RETRY COUNT SET [HDD & FDD]

99 - EXIT TO DIAGNOSTICS MENU

↑↓→← : Select items

Enter : Specify

Esc : Exit

Refer to sections 3.4 through 3.16 for detailed descriptions of Diagnostic Tests 1

through 13. Function 88 sets the floppy disk drive and hard disk drive error retry

count. Function 99 exits the submenus of the Diagnostic Test and returns to the

Diagnostic Menu.

3. Select the option you want to execute and press Enter . The following message

will appear:

SYSTEM TEST XXXXXXX

xxx DIAGNOSTIC TEST VX.XX

[Ctrl]+[Break]; test end

[Ctrl]+[C] ; key stop

SUB-TEST : XX

PASS COUNT: XXXXX ERROR COUNT: XXXXX

WRITE DATA: XX READ DATA : XX

ADDRESS : XXXXXX STATUS : XXX

SUB-TEST MENU :

01 - ROM checksum

02 03 04 - Fan ON/OFF

05 - Thermistor check

99 - Exit to DIAGNOSTIC TEST MENU

↑↓→← : Select items

Enter : Specify

Esc : Exit

NOTE: The menu displayed by your computer may be slightly different

from the one shown above.

3-4 420 Series

Page 51

4. Select the desired subtest number from the subtest menu and press Enter.

The following message will appear:

TEST LOOP : YES

ERROR STOP : YES

Use the arrow keys to move the cursor from the subtest menu and press Enter.

Selecting YES for TEST LOOP sets the test to run continuously until it is halted

by the user. Selecting NO returns the screen to the main menu after the test is

complete.

Selecting YES for ERROR STOP stops the test program when an error is found

and displays the operation guide on the right side of the display screen as shown

below:

ERROR STATUS NAME [[ HALT OPERATION ]]

1: Test end

2: Continue

3: Retry

These three selections have the following functions respectively:

1: Terminates the test program and exits to the subtest menu.

2: Continues the test.

3: Restarts the test from the error.

Use the arrow keys to move the cursor to the desired option and press Enter.

Selecting NO for ERROR STOP keeps the test running even if an error is found.

Table 3-1 in Section 3.3 describes the function of each test on the subtest menu.

Table 3-2 in Section 3.17 describes the error codes and error statuses for each

error.

420 Series 3-5

Page 52

3.3 Subtest Names

Table 3-1 lists the subtest names for each test program in the DIAGNOSTIC TEST MENU.

Table 3-1 Subtest names

No. Test name Subtest No. Subtest item

1 SYSTEM 01 ROM checksum

04 Fan ON/OFF

05 Thermistor check

2 MEMORY 01 RAM constant data

02 RAM address pattern data

03 RAM refresh

04 Protected mode

05 Memory module

06 Cache memory

3 KEYBOARD 01 Pressed key display

02 Pressed keycode display

03 PS/2 Mouse connect check

04 Pointing stick

4 DISPLAY 01 VRAM read/write for VGA

02 Gradation for VGA

03 Gradation for LCD

04 Gradation & Mode test for VGA

05 All dot on/off for LCD

06 “H” pattern display

5 FDD 01 Sequential read

02 Sequential read/write

03 Random address/data

04 Write specified address

05 Read specified address

6 PRINTER 01 Ripple pattern

02 Function

03 Wraparound

3-6 420 Series

Page 53

Table 3-1 Subtest names (Continued)

No. Test name Subtest No. Subtest item

7 ASYNC 01 Wraparound (board)

02 Board(#1) <=> board(#2)

03 Point to point (send)

04 Point to point (receive)

05 Interrupt test

06 Infra_red Wrap_around test

07 Infra_red Transmit mode

08 Infra_red Receive mode

09 Noise Receive test

8 HDD 01 Sequential read

02 Address uniqueness

03 Random address/data

04 Cross talk & peak shift

05 Write/read/compare (CE)

06 Write specified address

07 Read specified address

08 ECC circuit

09 Sequential write

10 W-R-C specified address

9 REAL TIMER 01 Real time

02 Backup memory

03 Real time carry

10 NDP 01 NDP test

11 EXPANSION 01 PCMCIA wraparound (Internal)

02 PCMCIA wraparound (External)

12 SOUND 01 CODEC (REC/PLAY)

02 FM-Synthesizer

03 SINE-wave playback

04 Joystick

05 Joystick/MIDI wraparound

06 CODEC (Line In/Out)

13 CD-ROM 01 Sequential read

02 Read specified address

03 Random address/data

04 Playback Music

420 Series 3-7

Page 54

3.4 System T est

To execute the System Test, select 1 from the DIAGNOSTIC TEST MENU, press Enter and

follow the directions displayed on the screen. Move the highlight bar to the subtest you want

to execute and press Enter.

Subtest 01 ROM checksum

This subtest executes a checksum test of the BIOS ROM on the system board.

Subtest 02 Not used

Subtest 03 Not used

Subtest 04 Fan on/off

This subtest checks fan operation using the on/off command.

The fan cable is securely connected to PJ11 on the system board. When you

execute this subtest, the following message is displayed:

*** Fan ON *** : Press [Enter] key?

When you press Enter, the fan should spin.

*** Fan OFF *** : Press [Enter] key?

When you press Enter, the fan should stop.

Subtest 05 Thermistor check

This subtest reads the thermistor connect check status of the power supply

microprocessor, then compares it with the original data. If the data indicates

the connector is open or shorted, it displays an error message.

3-8 420 Series

Page 55

3.5 Memory Test

To execute the Memory Test, select 2 from the DIAGNOSTIC TEST MENU, press Enter

and follow the directions displayed on the screen. Move the highlight bar to the subtest you

want to execute and press Enter.

Subtest 01 RAM constant data

This subtest writes a 256-byte unit of constant data to conventional memory (0

to 640 KB), then reads the new data and compares the result with the original

data. The constant data is FFFFh, AAAAh, 5555h, and 0000h.

Subtest 02 RAM address pattern data

This subtest writes address pattern data created by the exclusive-ORing

(XORing) to the address segment and address offset in conventional memory

program end to 640 KB, then reads the new data and compares the result with

the original data.

Subtest 03 RAM refresh

This subtest writes a 256-byte unit of constant data to conventional memory (0

to 640 KB), then reads the new data and compares the result with the original

data.

The constant data is AAAAh and 5555h.

NOTE: There is a short delay between write and read operations,

depending on the size of the data.

Subtest 04 Protected mode

NOTE: The CONFIG.SYS file must be configured without expanded

memory manager programs such as EMM386.EXE, EMM386.SYS, or

QEMM386.SYS. Also, the HIMEM.SYS must be deleted from the

CONFIG.SYS file.

This subtest writes constant data and address data to extended memory (maximum address 100000h), then reads new data and compares the result with the

original data.

The constant data is FFh, AAh, 55h, and 00h.

420 Series 3-9

Page 56

Subtest 05 Memory module

NOTE: To execute this subtest, an optional memory card must be

installed in the computer.

This subtest functions the same as subtest 04, except it is used for testing an

optional memory card. Memory module capacity is 8 MB, 16 MB, and 32

MB.

After selecting subtest 05, the following message will appear:

Extended memory size

Select the number that corresponds to the memory card installed in the computer.

Subtest 06 Cache memory

(1:8 MB,2:16 MB,3:32 MB)?

To test the cache memory, a pass-through write-read comparison of ‘5A’ data

is run repeatedly to the test area (‘7000’:’Program’ size to ‘7000’:’7FFF’ (32

KB)) to check the hit-miss ratio (on/off status) for CPU cache memory. One

test takes 3 seconds.

Number of misses < Number of hits → OK

Number of misses ≥ Number of hits → Fail

3-10 420 Series

Page 57

3.6 Keyboard Test

To execute the Keyboard Test, select 3 from the DIAGNOSTIC TEST MENU, press Enter

and follow the directions displayed on the screen. The Keyboard test contains four subtests

that test the keyboard, PS/2 mouse, and AccuPoint actions. Move the highlight bar to the

subtest you want to execute and press Enter.

Subtest 01 Pressed key display

NOTE: The Num Lock and the Overlay mode must be off to execute

this subtest.

When you execute this subtest, the keyboard layout is drawn on the display as

shown below. When any key is pressed, the corresponding key on the screen

changes to an “*” character. Holding a key down enables the auto-repeat

function which causes the key’s display character to blink.

[[[ Press Key Display ]]]

If test OK, Press [Del] [Enter] Key

420 Series 3-11

Page 58

Subtest 02 Pressed keycode display

When a key is pressed, the scan code, character code, and keytop name are

displayed on the screen in the format shown below. The Ins, Caps Lock,

Num Lock, Scroll Lock, Alt, Ctrl, Left Shift, and Right Shift keys are

displayed in reverse screen mode when pressed. The scan codes, character

codes, and keytop names are shown in Appendix D.

KEYBOARD TEST IN PROGRESS 302000

Scan code =

Character code =

Keytop =

Ins Lock Caps Lock Num Lock Scroll Lock

Alt Ctrl Left Shift Right Shift

PRESS [Enter] KEY

Subtest 03 PS/2 Mouse connect check

NOTE: To execute the PS/2 mouse connect check, a PS/2 mouse must

be connected to the computer.

This subtest checks whether or not a PS/2 mouse is connected.

If this test does not detect an error, it returns to the subtest menu. If this test

detects an error, the following message appears:

KBD - MOUSE INTERFACE ERROR

[[ HALT OPERATION ]]

1: Test end

2: Continue

3: Retry

3-12 420 Series

Page 59

Subtest 04 Pointing Stick

This subtest checks the functions of the pointing stick as shown below.

A) IPS stick pressure sensing direction and parameter.

B) IPS switch function check.

This test reports the pointing stick motion response from the IPS and IPS

switch by displaying the location parameters. When the stick is pressed towards the upper left, the <POINTING> display changes according to the

following illustration. If an IPS switch is pressed, the <BUTTON> display

alternates between black and white. Also, the parameters appear on the right

side of the display. If two IPS switches are pressed at the same time, the

subtest menu is displayed.

***** IPS TEST PROGRAM (V1.00) *****

<< PRESS BUTTON1 + BUTTON2 THEN END >>

When a button is pressed, the display alternates as shown below.

420 Series 3-13

Page 60

3.7 Display Test

To execute the Display Test, select 4 from the DIAGNOSTIC TEST MENU, press Enter and

follow the directions displayed on the screen. The Display test contains six subtests that test

the display in various modes. Move the highlight bar to the subtest you want to execute and

press Enter .

Subtest 01 VRAM Read/Write for VGA

This subtest writes constant data AAh and 55h and address data to video RAM

(2MB: A0000h-AFFFFh). This data is then read from the video RAM and

compared to the original data.

Subtest 02 Gradation for VGA

This subtest displays four colors: red, green, blue, and white from left to right

across the screen from black to maximum brightness. The display below

appears on the screen when this subtest is executed.

To exit this subtest and return to the DISPLAY TEST menu, press Ctrl +

Break, then press the Enter key.

Subtest 03 Gradation for LCD

This subtest displays eight colors: red, semi-red, green, semi-green, blue,

semi-blue, white, and semi-white. Each color is displayed full screen for three

seconds.

3-14 420 Series

Page 61

Subtest 04 Gradation & Mode test for VGA

This subtest displays gradations for each mode. Execute the test, then press

Enter to change the mode.

LCD type Mode

TFT 3, 12, 13, 43, 52

DSTN 3, 12, 13, 43

The display below appears on the screen when this subtest is executed.

Pressing Enter changes the size of the displayed image.

420 Series 3-15

Page 62

Pressing Enter changes the size of the displayed image.

Pressing Enter changes the size of the displayed image.

Pressing Enter changes the size of the displayed image.

To exit this subtest and return to the DISPLAY TEST menu, press Ctrl +

Break.

Subtest 05 All dots on /off for LCD

This subtest displays an all-white screen (all dot on) for three seconds then an

all-black screen (all dot off) for three seconds. To exit this subtest and return

to the DISPLAY TEST menu, press Ctrl + Break.

3-16 420 Series

Page 63

Subtest 06 “H” pattern display

This subtest displays a full screen of “H” patterns.

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

HHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHHH

To exit this subtest and return to the DISPLAY TEST menu, press Ctrl +

Break.

420 Series 3-17

Page 64

3.8 Flopp y Disk T e st

NOTE: Before running the floppy disk test, prepare a formatted work disk. Remove

the Diagnostics Disk and insert a work disk into the FDD. The contents of the floppy

disk will be erased.

To execute the Floppy Disk Test, select 5 from the DIAGNOSTIC TEST MENU, press

Enter and follow the directions displayed on the screen. The Floppy Disk test contains five

subtests that test the FDD. The following messages will appear after selecting the Floppy

Disk Test from the DIAGNOSTIC TEST MENU. Answer each question with an appropriate

response to execute the test.

1. Select the test drive number of the floppy disk drive to be tested and press Enter.

Test drive number select (1:FDD#1,2:FDD#2,0:FDD1&2) ?

2. Select the media type of the floppy disk in the test drive to be tested, and press

Enter.

Media in drive #X mode (0:2DD,1:2D,2:2D-2HD/2DD,3:2HD) ?

3. Select the track you want the test to start on and press Enter. Simply pressing

Enter sets the start track to zero.

Test start track (Enter:0/dd:00-79) ?

4. The floppy disk test menu will appear after you select the start track number.

Select the number of the subtest you want to execute and press Enter. The

following message will appear during the floppy disk test.

FLOPPY DISK XXXXXXX

xxxx DIAGNOSTIC TEST VX.XX

[Ctrl]+[Break] ; test end

[Ctrl]+[C] ; key stop

3-18 420 Series

Page 65

Subtest 01 Sequential Read

This subtest performs a Cyclic Redundancy Check (CRC), that continuously

reads all the tracks on a floppy disk. The following tracks are read according

to the media type in the floppy disk drive:

❑ Double-sided, double-density (2D): Tracks 0 to 39.

❑ Double-sided, double-density, double-track (2DD) and

double-sided, high-density, double-track (2HD): Tracks 0 to 79.

The start track is specified when the FDD test is started from the Diagnostic

Test Menu. Refer to step 3 at the beginning of this section to set the start

track.

Subtest 02 Sequential Read/Write

This subtest continuously writes data pattern B5ADADh to all the specified

tracks selected in subtest 01. The data is then read and compared to the

original data.

Subtest 03 Random Address/Data

This subtest writes random data to random addresses on all tracks defined in

subtest 01. The data is then read and compared to the original data.

Subtest 04 Write Specified Address

This subtest writes specified data to a specified track, head, and address.

Subtest 05 Read Specified Address

This subtest reads data from a specified track, head, and address.

420 Series 3-19

Page 66

3.9 Printer T est

To execute the Printer Test, select 6 from the DIAGNOSTIC TEST MENU, press Enter and

follow the directions displayed on the screen. The Printer Test contains three subtests that

test the output of the printer connected to the computer.

NOTE: An IBM compatible printer must be connected to the system to execute this

test.

The following message will appear when the printer test is selected:

channel#1 = XXXXh

channel#2 = XXXXh

channel#3 = XXXXh

Select the channel number (1-3) ?

The printer I/O port address is specified by the XXXXh number. The computer supports

three printer channels. Select the printer channel number and press Enter to execute the

selected subtest.

Subtest 01 Ripple Pattern

This subtest prints characters for codes 20h through 7Eh line-by-line while

shifting one character to the left at the beginning of each new line.

3-20 420 Series

Page 67

Subtest 02 Function

This subtest is for IBM compatible printers, and tests the following functions:

Normal print

Double-width print

Compressed print

Emphasized print

Double-strike print

All characters print

This subtest prints the various print types shown below:

PRINTER TEST

1. THIS LINE SHOWS NORMAL PRINT.

2. THIS LINE SHOWS DOUBLE-WIDTH PRINT.

3. THIS LINE SHOWS COMPRESSED PRINT.

4. THIS LINE SHOWS EMPHASIZED PRINT.

5. THIS LINE SHOWS DOUBLE-STRIKE PRINT.

6. ALL CHARACTERS PRINT

!"#$%&'()*+,./0123456789:;<=>?@ABCDEFGHIJKLMNOPQRSTUVWXYZ[\]^_`abcdefghijklmn

opqrstuvwxyz{|}~

Subtest 03 Wraparound

NOTE: To execute this subtest, a printer wraparound connector must

be connected to the printer port. The printer wraparound connector

(34M741986G01) wiring diagram is described in Appendix F.

This subtest checks the output and bidirectional modes of the data control and

status lines through the printer wraparound connector.

420 Series 3-21

Page 68

3.10 Async Test

To execute the Async Test, select 7 from the DIAGNOSTIC TEST MENU, press Enter and

follow the directions displayed on the screen. The async test contains nine subtests that test