Page 1

SERVICE MANUAL

LCD Color Television

40RV52U Rev.1

For Technical Bulletins, Technical Tips, or other information regarding the

service of this model, visit the Toshiba America Consumer Products National

Service Division website at:

www7.toshiba.com

This model is classified as a green product (*1), as indicated by the underlined serial number.

This Service Manual describes replacement parts for the green product. When repairing this

green product, use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), refer to GREEN PRODUCT PROCUREMENT and LEAD-FREE

SOLDER.

© TOSHIBA CORPORATION 2009

Page 2

IMPORTANT NOTICE

1

WARNING: Do not modify or alter the information or data provided herein without prior written consent by Toshiba.

Toshiba shall not be liable to anybody for any damages, losses, expenses or costs, if any, incurred in connection with or

as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS" WITHOUT ANY WARRANTY OF ANY KIND, EITHER

EXPRESS OR IMPLIED WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if any, incurred in connection with or as a result of

use of any information or data provided herein.

GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling and reuse of Waste Electrical and

Electronic Equipment and for the Restriction of the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

prohibit any marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation recognizes environmental protection

as a key management tasks, and is doing its utmost to enhance and improve the quality and scope of its environmental activities. In

line with this, Toshiba proactively promotes Green Procurement, and seeks to purchase and use products, parts and materials that

have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in manufacture must also be used as

replacement parts.

LEAD-FREE SOLDER

WARNING: This product is manufactured using lead-free solder as a part of a movement within the consumer products industry at

large to be environmentally responsible. Lead-free solder must be used in the servicing and repair of this product.

The melting temperature of lead-free solder is higher than that of leaded solder by 86ºF to 104ºF (30ºC to 40ºC). Use of a soldering

iron designed for lead-based solders to repair product made with lead-free solder may result in damage to the component and or

PCB being soldered. Great care should be made to ensure high-quality soldering when servicing this product especially when

soldering large components, through-hole pins, and on PCBs as the level of heat required to melt lead-free solder is high.

SAFETY INSTRUCTION

WARNING: Before servicing this chassis, read the "Safety Precaution" and "Product Safety Notice" instructions below.

Safety Precaution

WARNING: Servicing should not be attempted by anyone unfamiliar with the necessary precautions on this receiver. The following

are the necessary precautions to be observed before servicing this chassis.

1. An isolation transformer should be connected in the power line between the receiver and the AC line before any service is

performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place, such as

nonmetallic control knobs, insulating covers, shields, isolation resistor-capacitor network, etc.

4. Always keep tools, product components, etc. away from children as these items may cause injury.

5. Depending on the model, use an isolation transformer or wear suitable gloves when servicing with the power on.

Disconnect the power plug to avoid electrical shock when replacing parts. In some cases, alternating current is also

impressed in the chassis, so electrical shock is possible if the chassis is contacted with the power on.

6. Always use the replacement parts specified for the particular model when making repairs. The parts used in products

require special safety characteristics such as inflammability; voltage resistance, etc. therefore, use only replacement parts

1

Page 3

that have these same characteristics. Use only the specified parts when the mark is indicated in the circuit diagram or

2

parts list.

7. Part mounting and wire routing should be the same as that used originally. For safety purposes, insulating materials such as

isolation tubes or tape are sometimes used and printed circuit boards are sometimes mounted floating. Also make sure that

wiring is routed and clamped to avoid parts that generate heat or use high voltage. Always follow the manufactures wiring

routes / dressings.

8. Always ensure that all internal wirings are in accordance before re-assembling the external casing after a repair is

completed. Do not allow internal wiring to be pinched by cabinets, panels, etc. Any error in reassembly or wiring can result

in electrical leakage, flame, etc., and may be hazardous.

9. NEVER remodel the product in any way. Remodeling can result in improper operation, malfunction, electrical leakage, or

flame, which may be hazardous.

10. Always perform an AC leakage current check on the exposed metallic parts of the cabinet such as antennas, terminals,

screw heads, metal overlays, control shafts, etc. to be sure that the set is safe to operate without any danger of electrical

shock before returning the set to the customer.

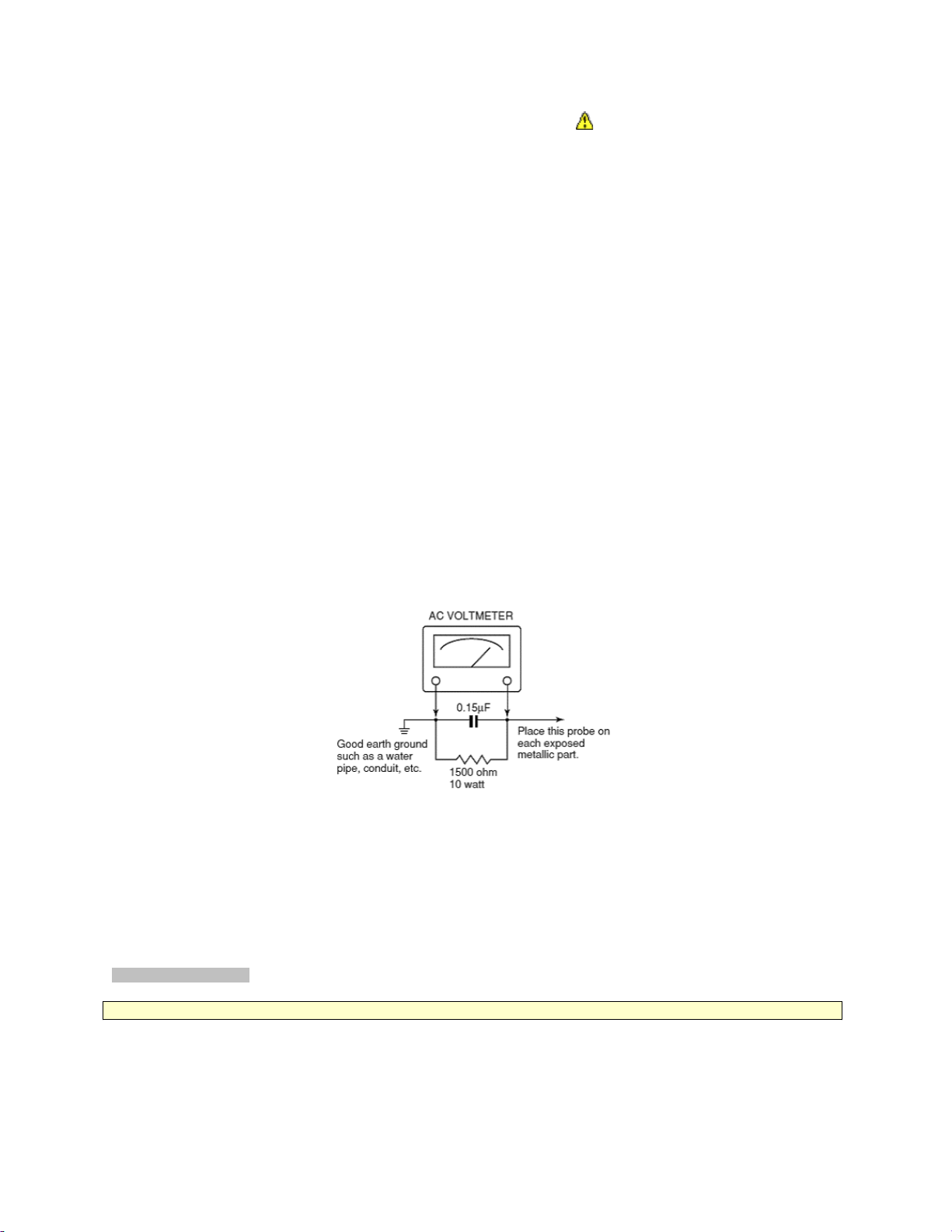

11. To check leakage current: (After completing the work, measure the leakage current to prevent an electrical shock.)

x Plug the AC line cord directly into a 120V AC outlet. Do not use an isolation transformer for this check.

x Use an AC voltmeter having 5000 ohms per volt or more sensitivity in the following manner.

Connect a 1500 ohm 10 watt resistor, paralleled by a 0.15 μF, AC type capacitor, between a known good earth ground (water pipe,

conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC voltage across the combination of 1500 ohm resistor

and 0.15 μF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage measurements for each exposed metallic part.

Voltage measured must not exceed 0.3 volts rms. This corresponds to 0.2 milliamps AC. Any value exceeding this limit constitutes a

potential shock hazard and must be corrected immediately.

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are often

overlooked in a visual inspection. The protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified

in this manual and its supplements. Electrical components having such features are identified by the international hazard symbols

on the schematic diagram and the parts list. Before replacing any of these components, read the parts list in this manual carefully.

The use of substitute replacement parts which do not have the same safety as specified in the parts list may create electrical shock,

fire, or other hazards.

SAFETY INSTRUCTION

WARNING: The metal edges of the LCD module are sharp, handle it with care.

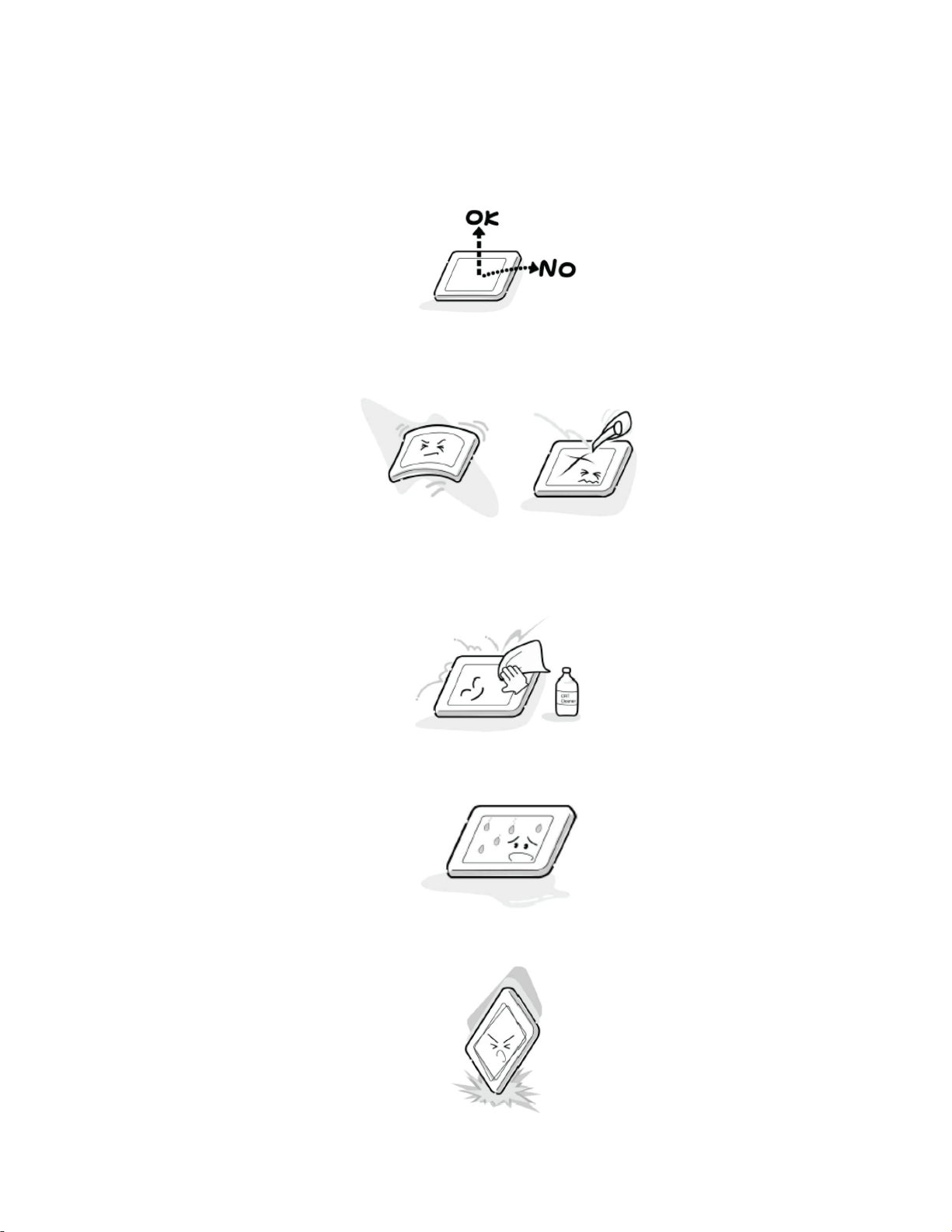

The LCD module can easily be damaged during disassembly or reassembly; therefore, always observe the following precautions

when handling the module.

1. In the event that the screen is damaged or the liquid crystal (fluid) leaks, do not breathe in, drink, or touch this fluid. Such

actions could cause toxicity or skin irritation. If this fluid should enter the mouth, rinse the mouth thoroughly with water. If the

2

Page 4

fluid should contact the skin or clothing, wipe off with alcohol, etc., and rinse thoroughly with water. If the fluid should enter

3

the eyes, immediately rinse the eyes thoroughly with running water.

2. When attaching the LCD module to the LCD cover, position it appropriately and fasten at the position where the display can

be viewed most conveniently.

3. Carefully align the holes at all four corners of the LCD module with the corresponding holes in the LCD cover and fasten

with screws. Do not strongly push on the module because any impact can adversely affect the performance. Also use

caution when handling the polarized screen because it can easily be damaged.

4. If the panel surface becomes soiled, wipe with cotton or a soft cloth. If this does not remove the soiling, breathe on the

surface and then wipe again. If the panel surface is extremely soiled, wipe the panel surface with CRT cleaner sprayed

onto the cloth. Do not spray the cleaner on the panel. Pay attention not to scratch the panel surface.

5. Leaving water or other fluids on the panel for an extended period of time can result in discoloration or stripes. Immediately

remove any type of fluid from the screen.

6. Glass is used in the panel construction. Damage can occur if dropped or struck with hard objects.

3

Page 5

7. CMOS-LSI circuitry is used in the LCD module, so avoid damage due to static electricity. When handling the module, use a

4

wrist ground or anchor ground.

8. Do not expose the LCD module to direct sunlight or strong ultraviolet rays for extended periods.

9. Do not store the LCD module below the temperature conditions described in the specifications. Doing so could result in

freezing of the liquid crystal, loss of resilience, or other damage.

10. Do not disassemble the LCD module. Such actions could result in improper operation.

11. When transporting the LCD module, do not use packing containing epoxy resin (amine) or silicon resin (alcohol or oxim).

The gas generated by these materials can cause loss of polarity.

4

Page 6

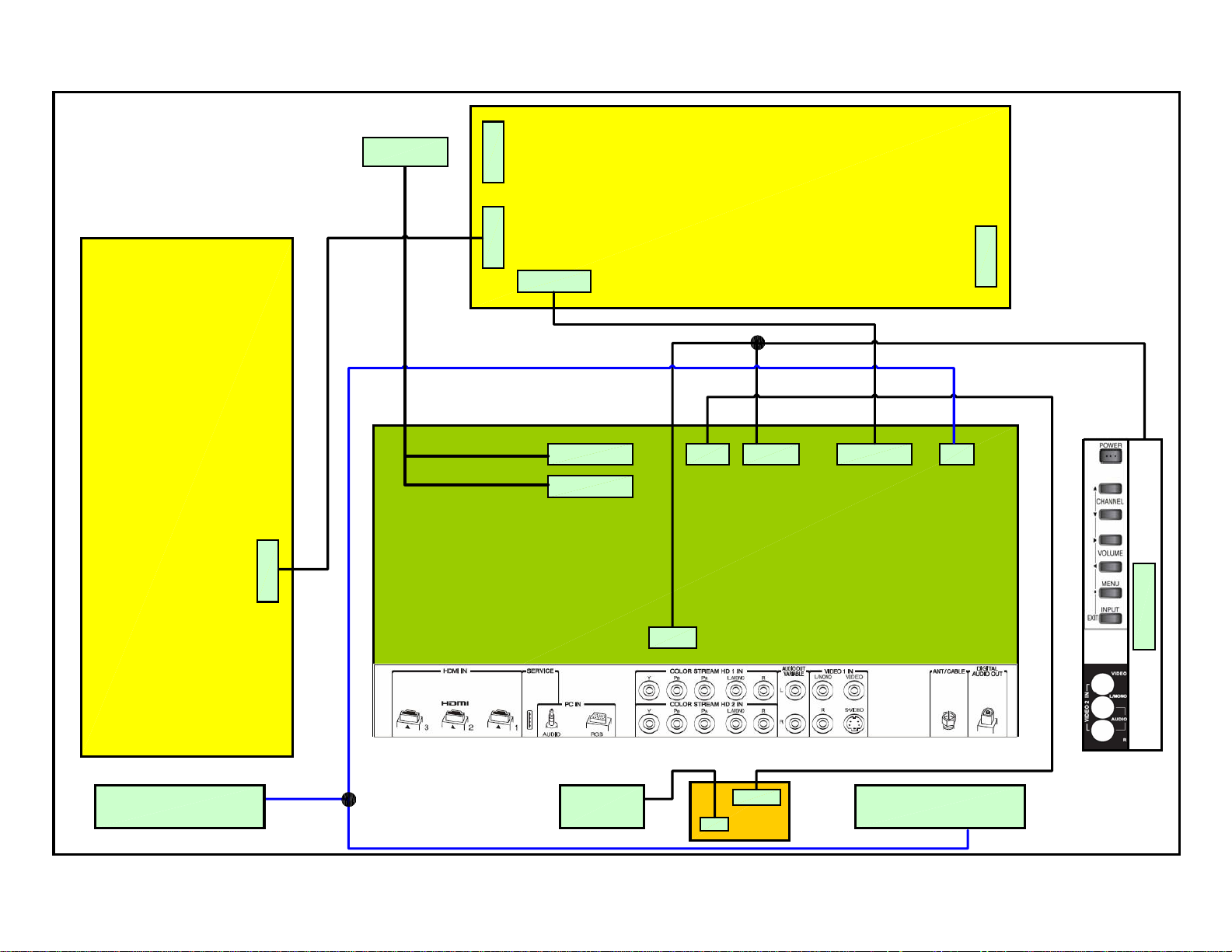

r

r

Panel

C

o

5

T-

P804

m

Inverter Board

C0N11

P803

Power Board

P802

CN5 CN10 CN8CN3

CN7

CN11

Main Board

CN9

AC in

CN1

KEY_IO/B

CN2

CN1

IR/B

Speake

Speake

LOGO

Page 7

Display T-Con

6

P803 to Inverter

P802 P801 AC In

CN5 LVDS

CN11

CN10

CN9

Power PCB

CN3

CN8

Main PCB

Cable to Side (Front) AV

Page 8

P804 used in models

7

with 2 inverters

Wiring

Interconnect

40RV52U/

40RV525U/

46RV525U

Key

Pin 1

Flow <-out >-in

P

8

0

4

P

8

0

3

Pins 2, 4, 6, 8 –

12V Panel Power

Inverter

1. 24V<

2. 24V<

3. 24V<

4. 24V<

5. 24V<

6. Gnd

7. Gnd

8. Gnd

9. Gnd

10. Gnd

11. NC

12. BL On 5V<

13. Dim 2 to 4V<

14. NC

P802

Power Supply In/Out

1. Gnd

2. Gnd

3. 24V Aud<

4. 24V Aud<

5. Gnd

6. Gnd

7. Gnd

8. 12V<

9. 12V(Panel Pwr.)<

10. 5V<**

11. 5V<**

12. 5V<**

13. Pwr. On (Enable) 4.3V>

14. AC Det.(PWR Good) .07V<

15. Dim 2 to 4V>

16. BL On 5V>

** Indicates Standby

Power Supply

AC In

N

P801

L

LVDS

CN5

CN7

Alt. LVDS

LED/IR

1. LED G <

2. LED B <

3. Gnd

4. 3.3V <

5. IR >

6. 5V <**

CN9

CN11 CN10

Side AV In

1. CVBS >

2. Gnd

3. Gnd

4. L Aud >

5. R Aud >

Power Supply In/Out Speakers

Manual Key

1. Pwr >

2. CH+ >

3. CH- >

4. V+ >

5. V- >

6. Menu >

7. Source >

8. Gnd

CN3 CN8

Main

Page 9

r

_

_

4

4

_

_

_

4

4

_

_

_

AV_

_

AV_

_

_

4L4

_

_

_

_CE_

_

_

_

4

4

_

_DATA

A

_

4

_

_

Keypad

8

Keypad-8P KEY -8P LVDS - 2x15P LG PI_LTA400HA07

1 PWR_KEY 1 PWR_KEY 1 GND PANEL-FI-E51S

2CH+ 2CH+ 2LVDS

3CH- 3CH- 3LVDS

VOL+

5 VOL- 5 VOL- 5 LVDS_D4E_N CN3 4 Power

6 Menu 6 Menu 6 LVDS_PWR Power supply - 16P Power supply -16P Inverter -14P Inverter -14P 5 Power

7 SOURCE 7 SOURCE 7 LVDS

8GND 8GND 8LVDS

Side I/O board

Side IO board Side IO board

CVBS 1 FL

1FL

2GND 2GND 15LVDS

3GND 3GND 16GND 105V

5R 5R 18GND 125V

IR board

IR board IR board 24 DCR_VBR_B 23 NC

1LED-G 1LED-G 25GND 24 GND

2LED-B 2LED-B 26LVDS

3GND 3GND 27LVDS

VCC3_3

5IR

6 5VSUB 6 5VSUB 30 DCR/BRT 29 PE[2]N

Speaker

L Sp eaker Speaker -4P 36 PE[3]P

OUTL+ 1 SPK_OUTL+ 37 NC

1SPK

2GND 2GND 38 NC

R Speaker 3GND 39 GND

1GND

OUTR+ 41 NC

2SPK

Main BoardPowe

CN12 CN5

PWR 1 Power

VOL+ 4 LVDS_PWR 3 Power

CN9 12GND6GND6GND6GND6GND11RO[0]P

CVBS 14 GND 8 12VCCIN 8 12VCCIN 8 GND 8 GND 13 RO[1]P

L17LVDS

CN11 23 LVDS_CE_N 22 NC

VCC3_328BIT

5IR_DAT

CN7 35 PE[3]N

SPK_OUTR+ 40 NC

D4E_P 2 Power

D3E_P 1 GND 1 GND 1 +24Vinv 1 +24Vinv 6 NC

PWR 2 GND 2 GND 2 +24Vinv 2 +24Vinv 7 GND

D3E_N 3 24Vaud 3 24Vaud 3 +24Vinv 3 +24Vinv 8 GND

9LVDS

10 GND 4 24Vaud 4 24Vaud

D2E_P 5 GND 5 GND 5 +24Vinv 5 +24Vinv 10 RO[0]N

11 LVDS

D2E_N7GND7GND7GND7GND12RO[1]N

13 LVDS

D1E_P 9 Panel power 9 Panel power 9 GND 9 GND 14 RO[2]N

D1E_N

19 GND 13 POWER

20 GND 14 POWER GOOD 14 POWER GOOD 14 NC 14 NC 19 GND

21 LVDS

22 EXT

29 LVDS_D0E_N 28 PE[1]P

P 15 VBR_OUT 15 VBR_OUT 20 RO[3]N

VBR_B 16 BKLT_EN 16 BKLT_EN 21 RO[3]P

SEL 25 PE[0]N

D0E_P 26 PE[0]P

SEL 27 PE[1]N

IN 10 5V_IN 10 GND 10 GND 15 RO[2]P

11

5V_IN

IN 12 5V_IN 12 Backlight on/off 12 Backlight on/off 17 ROCLK-

EN 13 POWER_EN 13 DimmingControl 13 DimmingControl 18 ROCLK+

11

AC In 30 PE[2]P

1Line

2NC

3Line

board Panel module

+24Vinv

5V_IN 11 NC 11 NC 16 GND

+24Vinv 9 GND

31 GND

32 ROCLK33 ROCLK+

34 GND

42 NC

43 NC

44 NC

45 LVDS

46 NC

47 NC

48 NC

49 NC

50 NC

51 NC

SEL

Page 10

9

Page 11

Yes

10

Suspect a

problem with the

Main module.

12 volt source appear

at pin 8 of P802 when

the on/off button is

Does

the secondary

pressed?

Yes No

signal appear at pin

13 of P802 when the

No

Suspect a problem with

the power supply module.

Does

a 4.3 volt on off

on/off button is

pressed?

No

Dead Set No

Sound/ No

Picture

Yes

Power Good

(AC Detect) level

less than .07V at pin

14 of P802

when AC is

5 VDC present

at pins 10, 11, and 12 of

P802 on the power supply

module when AC is

applied?

Is the

applied?

Is

No

Suspect a problem with

the standby 5 volt supply

on the power supply

module.

Suspect a problem

Yes

with the SYSCON

circuit located on the

Main module.

Page 12

No or distorted

11

video

If the LCD Control

Examples

Board is available, try

it. If this does not help,

replace the LCD

display panel. ***

YES

NO

Troubleshoot for

backlight problelms.

Does

the back light function

normally when the unit

is turned on?

YES

the screen discolored

or does it have streaks

or dark areas with no

signal input?

This signal viewed from

LVDS connector

referencing cold ground.

*** Warranty Authorization required if

display is replaced in warranty – Go

to www7.toshiba.com for instructions.

Is

Replace

the Main

Module.

NO

When

the input button

is pressed on the

receiver or remote, is

the on screen

display clear and

normal?

YES

voltages normal at P802

Check for LVDS activity at

CN5. If it is present suspect a

problem with the display timing

control board (Tcon). If it is not

present replace the main PCB.

NOYES

Using the

power distribution

diagram, are the

of the power supply

module?

NO

Suspect the

power supply

module.

Page 13

Backlight

12

Troubleshooting

Replace the

Power supply

module.

at pins 1 through 5 of

P803 on the power PCB

Replace the

Main module.

Is

24 VDC present

when the unit is

turned on?

NO

Does the back light

function and then turn

off?

YESNO

Is 5VDC

present at pin 16

of P802 and 12 VDC

present at pins 2, 4, 6, and

8 of CN5 soon (.5 sec)

after the unit is

turned on?

YESNO

If it is

available , try one or

both inverters. If this

does not help, replace

the LCD

display. ***

YES

*** Warranty Authorization

required if display is

replaced in warranty – Go

to www7.toshiba.com for

instructions.

Page 14

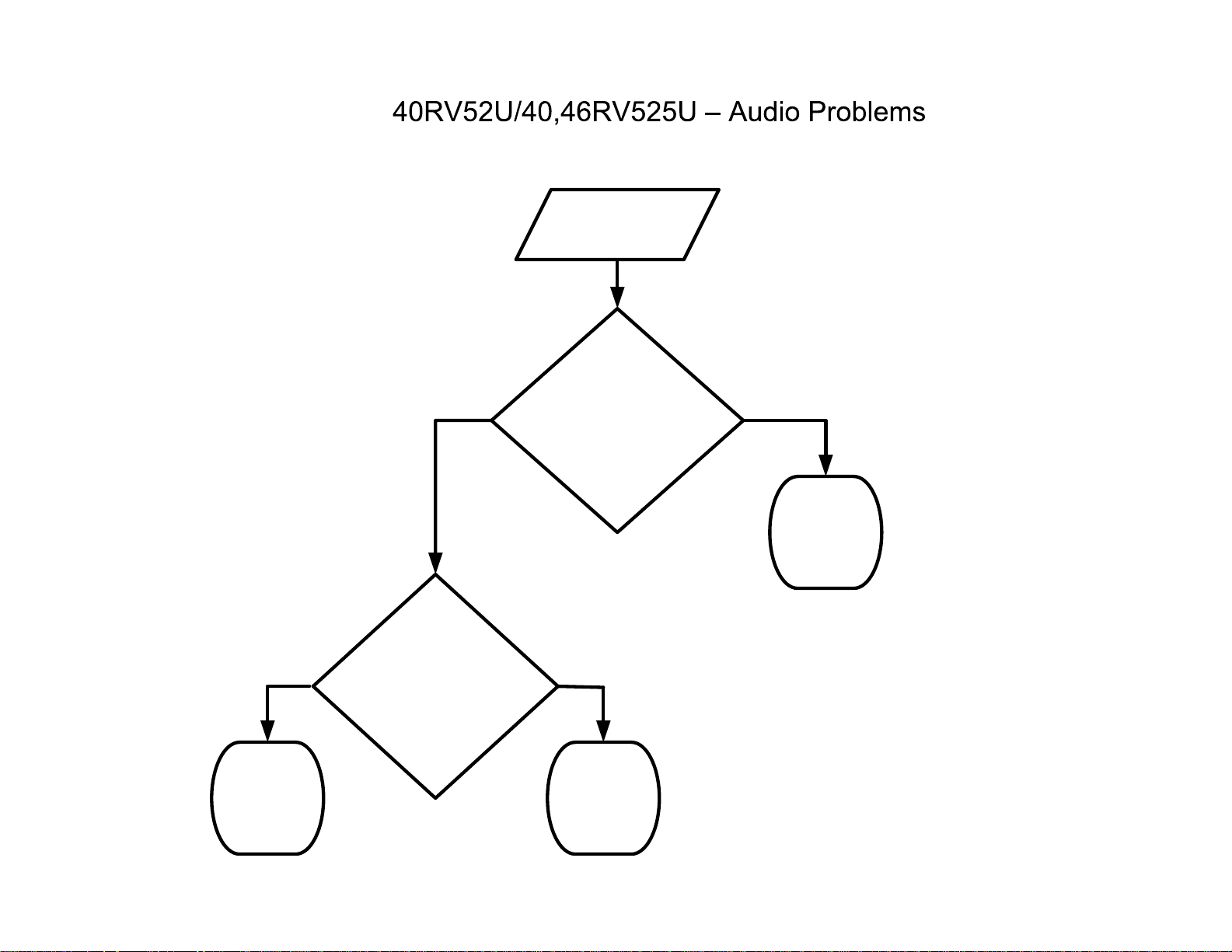

NO

13

NO

Does the

power supply

generate the audio

supply voltages (24 VDC

at pins 3 and 4 of P802)

when the unit is

turned

on?

No Audio

Using

the remote or

the manual keyboard,

access the audio menu to

assure the speakers are on

and the input selection is a

known good source.

Will this restore

audio?

YES

YES

Problem

solved.

Replace the

power supply

module.

Replace the

Main module

Page 15

1415

Firmware Update

Firmware updating for this chassis family is accomplished via a USB

port located on the rear of the unit. It is designated as “Service” and

is located between the HDMI and PC audio input jacks. Visit the

Toshiba website at www7.toshiba.com for the latest update

information.

#2 - Firmware Update - USB Port

Page 16

Page 17

ReplacementPartsList

16

Location Part No. Description

E100 75013363 BEZEL ASSY, TX401A PCABS 94V0, 39C01A51L13

E110 75013357 BACK COVER ASSY, TX4012 MBK97 HI-PS, 39C01A51L08

E120 75012786 STAND ASSY, 37AV502U, 39C02051L15

E140 75013153 KEY PLATE, 39C02051L17

E200 75013349 PC BOARD ASSY, MAIN , VTV-L4007 STX40T A, 39C01A51L01

E250 75013355 POWER MODULE, (STX40T) FSP245-4F01 5/12/2, 39C01A51L09

E260 75012770 PC BOARD ASSY, KEY/B, 37AV502U, 39C02051L06

E261 75013348 PC BOARD ASSY, IR/B, VTV-IR3707 STW37TG, 39C01A51L12

E300 75013346 LCD PANEL, LTA400HA07, 40RV525U

E310 75013353 H-CON SET, TX40T MB-LVDS SAM, 39C01A51L02

E320 75013354 POWER CORD, SP12X1.8MXSR119X22, 39C01A51L11

E330 75012773 SPEAKER ASSY, 10W 6OHM, 37AV502U, 39C02051L09

E340 75012778 H-CON SET, STW46T MB-POW 12V, 39C02451L11

E341 75013369 H-CON SET, STX46T INV-POW P803, 39C01D51L07

E342 75012774 H-CON SET, TX40T MB CN9 CN10-, 39C02051L10

E343 75012775 H-CON SET, TX40T MB CN11-IR 6, 39C02051L11

E344 75012776 H-CON SET, TX40T MB CN8-SPK S, 39C02051L12

E400 75010932 REMOCON HAND UNIT, CT-90302, 39C02051L05

Page 18

TOSHIBA CORPORATION

1-1, SHIBAURA 1-CHOME, MINATO-KU, TOKYO 105-8001, JAPAN

Loading...

Loading...