Toshiba 32W300R Schematic

(*1) GREEN PRODUCT PROCUREMENT

The EC is actively promoting the WEEE & RoHS Directives that define standards for recycling

and reuse of Waste Electrical and Electronic Equipment and for the Restriction of the use of

certain Hazardous Substances. From July 1, 2006, the RoHS Directive will prohibit any

marketing of new products containing the restricted substances.

Increasing attention is given to issues related to the global environmental. Toshiba Corporation

recognizes environmental protection as a key management tasks, and is doing its utmost to

enhance and improve the quality and scope of its environmental activities. In line with this,

Toshiba proactively promotes Green Procurement, and seeks to purchase and use products,

parts and materials that have low environmental impacts.

Green procurement of parts is not only confined to manufacture. The same green parts used in

manufacture must also be used as replacement parts.

(*2) LEAD-FREE SOLDER

This product is manufactured using lead-free solder as a part of a movement within the consumer

products industry at large to be environmentally responsible. Lead-free solder must be used in

the servicing and repair of this product.

WARNING

This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT !

The melting temperature of lead-free solder is higher than that of leaded solder by 86°F to 104°F

(30°C to 40°C). Use of a soldering iron designed for lead-based solders to repair product made

with lead-free solder may result in damage to the component and or PCB being soldered. Great

care should be made to ensure high-quality soldering when servicing this product especially

when soldering large components, through-hole pins, and on PCBs as the level of heat

required to melt lead-free solder is high.

A1-1

SERVICING NOTICES ON CHECKING

1. KEEP THE NOTICES

As for the places which need special attentions,

they are indicated with the labels or seals on the

cabinet, chassis and parts. Make sure to keep the

indications and notices in the operation manual.

2. AVOID AN ELECTRIC SHOCK

There is a high voltage part inside. Avoid an

electric shock while the electric current is

flowing.

3. USE THE DESIGNATED PARTS

The parts in this equipment have the specific

characters of incombustibility and withstand

voltage for safety. Therefore, the part which is

replaced should be used the part which has

the same character.

Especially as to the important parts for safety

which is indicated in the circuit diagram or the

table of parts as a mark, the designated

parts must be used.

4. BE CAREFUL WITH THE

LCD PANEL

Avoid a shock to the panel while servicing.

Take enough care to deal with it.

5. PUT PARTS AND WIRES IN THE

ORIGINAL POSITION AFTER

ASSEMBLING OR WIRING

There are parts which use the insulation

material such as a tube or tape for safety, or

which are assembled in the condition that

these do not contact with the printed board.

The inside wiring is designed not to get closer

to the pyrogenic parts and high voltage parts.

Therefore, put these parts in the original

positions.

PERFORM A SAFETY CHECK AFTER

6.

SERVICING

Confirm that the screws, parts and wiring which

were removed in order to service are put in the

original positions, or whether there are the

portions which are deteriorated around the

serviced places serviced or not. Check the

insulation between the antenna terminal or

external metal and the AC cord plug blades.

And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.

Unplug the plug from the AC outlet.

2.

Remove the antenna terminal on TV and turn

on the TV.

3.

Insulation resistance between the cord plug

terminals and the eternal exposure metal

[Note 2] should be more than 1M ohm by

using the 500V insulation resistance meter

[Note 1].

4.

If the insulation resistance is less than 1M

ohm, the inspection repair should be

required.

[Note 1]

If you have not the 500V insulation

resistance meter, use a Tester.

[Note 2]

External exposure metal: Antenna terminal

Earphone jack

HOW TO ORDER PARTS

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)

1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can be

found at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTION

You can find it in your SERVICE MANUAL.

IMPORTANT

When you exchange IC and Transistor with a heat sink, apply silicon grease (YG6260M) on the contact

section of the heat sink. Before applying new silicon grease, remove all the old silicon grease.

(Old grease may cause damage to the IC and Transistor).

A1-2

TABLE OF CONTENTS

GREEN PRODUCT PROCUREMENT..........................................................................................

LEAD-FREE SOLDER ..................................................................................................................

SERVICING NOTICES ON CHECKING ......................................................................................

HOW TO ORDER PARTS ............................................................................................................

IMPORTANT .................................................................................................................................

TABLE OF CONTENTS ...............................................................................................................

GENERAL SPECIFICATIONS.....................................................................................................

DISASSEMBLY INSTRUCTIONS .......................................................................................

SERVICE MODE LIST .................................................................................................................

WHEN REPLACING EEPROM (MEMORY) IC...........................................................................

ELECTRICAL ADJUSTMENTS ...................................................................................................

BLOCK DIAGRAMS

SCALER/LVDS/MICON/ADC/JACK/REGULATOR.................................................................

AV SWITCH/21PIN/STEREO/SOUND AMP/HEADPHONE/TUNER ....................................

INTERFACE..............................................................................................................................

MICON2 ....................................................................................................................................

POWER2 ...................................................................................................................................

PRINTED CIRCUIT BOARDS

MAIN ..........................................................................................................................................

POWER/OPERATION/REMOCON ..........................................................................................

POWER/OPERATION..............................................................................................................

SCHEMATIC DIAGRAMS

AV SWITCH...............................................................................................................................

21PIN.........................................................................................................................................

STEREO ....................................................................................................................................

POWER .....................................................................................................................................

AV JACK/SWITCH ....................................................................................................................

SOUND AMP/HEADPHONE AMP ...........................................................................................

TUNER.......................................................................................................................................

MICON .......................................................................................................................................

SCALER ....................................................................................................................................

ADC ...........................................................................................................................................

LVDS..........................................................................................................................................

JACK..........................................................................................................................................

REGULATOR............................................................................................................................

INTERFACE_HDMI IC .............................................................................................................

HDMI MICON2..........................................................................................................................

POWER2...................................................................................................................................

OPERATION/REMOCON.........................................................................................................

INTERCONNECTION ...................................................................................................................

WAVEFORMS...............................................................................................................................

MECHANICAL EXPLODED VIEWS ............................................................................................

MECHANICAL REPLACEMENT PARTS LIST...........................................................................

ELECTRICAL REPLACEMENT PARTS LIST ............................................................................

A1-1

A1-1

A1-2

A1-2

A1-2

A2-1

A3-1~A3-5

B-1, B-2

C-1

C-2

D-1~D-5

E-1, E-2

E-3, E-4

E-5, E-6

E-7, E-8

E-9, E-10

F-1~F-4

F-5, F-6

F-7, F-8

G-1, G-2

G-3, G-4

G-5, G-6

G-7, G-8

G-9, G-10

G-11, G-12

G-13, G-14

G-15, G-16

G-17, G-18

G-19, G-20

G-21, G-22

G-23, G-24

G-25, G-26

G-27, G-28

G-29, G-30

G-31, G-32

G-33, G-34

G-35, G-36

H-1~H-3

I-1~I-3

J1-1

J2-1~J2-20

A2-1

GENERAL SPECIFICATIONS

Broadcasting System

B/G, D/K, I/I, L

E5~E12,S11~S41,E21~E69

/ L' (SECAM VL)

+5oC ~ +40oC

-20oC ~ +60oC

Timer Back-up (at Power Off Mode) more than -- Min Sec

G-1 TV

System

G-2 Tuning

System

G-3 Power

G-4 Regulation

G-5 Temperature

G-6 Operating Humidity

G-7 OSD Language

LCD LCD Size / Visual Size 31.5 inch / 800.4mmV

Color System PAL / SECAM

Speaker 2 Speaker

Sound Output MAX 10W + 10W

NTSC3.58+4.43 /PAL60Hz Yes

Tuner and System 1Tuner

Receive CH Destination UK, I.R., CCIR Hyper+France CATV

Intermediate

Frequency Picture(FP) 38.9 / 38.9 / 38.9 / 33.9MHz

Auto Tuning Method

Preset CH 99

Stereo/Dual TV Sound Nicam/A2 Dual

Tuner Sound Muting Yes

Power Source AC 220-240V AC 50Hz

Power Consumption at AC 170 W at AC 230 V 50 Hz

Protector Power Fuse Yes

LCD Type Color TFT LCD

Number of Pixels 1366(H) x 768(V)

View Range Left/Right 88/88 degree

Up/Down 88/88 degree

Position Front

Size 2.2 x 5.0 inch

Impedance 4 ohm

10%(Typical) ---

U.K., I.R., CCIR,

FRENCH System

CH Coverage

BG / II / DK, L

Sound(FS)

FP-FS

DC ---

at DC -Stand by (at AC) 1 W at 230V 50Hz

Per Year -- kWh/Year

Safety CE(EN60065:02),GOST

Radiation CE

X-Radiation --Operation

Storage

33.4 / 32.9 / 32.4 / 40.4MHz

5.5 / 6.0 / 6.5 / 6.5MHz

ALL Band (Not C.C.I.R. CH Plan)

Less than 80% RH

English, Spanish, German

French, Italian,Russian

IreE2~E4, X~Z+2, S1~S10,

G-8 Clock and

Timer

Sleep Timer Max Time 120 Min

Step 10 Min

On/Off Timer Program(On Timer / Off Timer) -- Program

Wake Up Timer No

A3-1

GENERAL SPECIFICATIONS

Reset / Audio 1/2 No

G-9 Remote

Control

Unit RC-PA

Glow in Dark Remocon Yes

Remocon Format TOSHIBA

Format TOSHIBA

Custom Code 40-BF h

Power Source Voltage(D.C) 3V

UM size x pcs UM-3 x 2 pcs

Total Keys 37 Keys

Keys Power (Stand By) Yes

Display / (Status) Yes

Input Select Yes

Picture Size Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

Sleep Yes

Mute Yes

Volume Up Yes

Volume Down Yes

CH Down Yes

CH Up Yes

Menu Yes

Up Yes

Down Yes

Left Yes

Right Yes

Enter Yes

Exit Yes

Freeze frame No

T'TEXT Keys TEXT / MIX / TV Yes

Reveal / Skip Yes

Display Cancel No

HOLD / Freeze Yes

Red Yes

Green Yes

Yellow Yes

Cyan Yes

Normal No

F/T/B(Expand) Yes

F/T/B(Expand) / Normal No

Quick View No

Sub Page / Quick View Yes

Up/CH Up No

Up/'CH Up / Page Up No

Down / CH Down No

Down / CH Down / Page Down No

Reset No

Audio 1/2 Yes

A3-2

GENERAL SPECIFICATIONS

No

SXGA (1280x1024) No

G-10 Features

Auto Set Up No

Power On Memory Yes

Auto Shut Off Yes

Auto Search Yes

Just Clock Function No

Game Position No

DNR Yes

3D

Comb Filter Yes

5 Lines

Picture Setting(TV) Brightness , Contrast , Color Yes

Tint (NTSC Only) Yes

Sharpness Yes

DNR Yes

Color Temperature Yes

Blue Back Yes

Picture Setting(PC) BRIGHTNESS , CONTRAST Yes

HOR POSITION , VER POSITION Yes

PHASE , CLOCK Yes

AUTO ADJUST No

RED , GREEN , BLUE Yes

WXGA INPUT Yes

WVGA INPUT Yes

Audio Nicam Yes

Tone Control (Bass/Treble/Balance) Yes

Surround Yes

BBE No

SRS WOW (SRS 3D/Focus/Tru Bass) No

Variable Audio Out Yes

Tuning Auto Tuning Yes

Manual Tuning Yes

CH Allocation Yes

Lock Panel Lock No

Channel Lock No

Hotel Lock No

Screen Saver

Black Side Panel No

CH Label No

T'Text Yes

Wide Mode (AUTO/4:3/FULL SCREEN/16:9/CINEMA/14:9) Yes

HD Zoom Yes

Picture Scroll (Vertical Position) Yes

Backlight Yes

PFC(Power Factor circuit)

Freeze frame Yes

HD-Ready Yes

PC Monitor Input Yes

Inversion No

Full White No

Screen Saver No

Static Image No

Text type Fastext / Toptext

Text Language English , French, Swedish, Hungarian

Finnish, Turkish, German, Dutch

Portuguese, Spanish, Italian, Greek

Polish, Russian, Bulgarian,

Estonian, Lettish, Lithuanian

Czech, Slovakian, Rumanian, Ukrainian

VGA (640x480) Yes (60Hz)

VGA (720x400) Yes (70Hz)

WVGA (848x480) Yes (60Hz)

SVGA (800x600) Yes (60Hz)

XGA (1024x768) Yes (60Hz)

WXGA (1280x768) Yes (60Hz)

WXGA (1280x720) Yes (60Hz)

WXGA (1360x768) Yes (60Hz)

A3-3

G-12 Accessories

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

No

Sheet Information(GOST) Yes

GENERAL SPECIFICATIONS

HDMI Input Yes

VGA (640×480) Yes (60Hz)

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) Yes (50Hz)

720×576i (16:9) Yes (50Hz)

720×576p (4:3) Yes (50Hz)

720×576p (16:9) Yes (50Hz)

1280×720p Yes (50/60Hz)

1920×1080i Yes (50/60Hz)

Component Input Yes

720×480i (4:3) Yes (60Hz)

720×480i (16:9) Yes (60Hz)

720×480p (4:3) Yes (60Hz)

720×480p (16:9) Yes (60Hz)

720×576i (4:3) Yes (50Hz)

720×576i (16:9) Yes (50Hz)

720×576p (4:3) Yes (50Hz)

720×576p (16:9) Yes (50Hz)

1280×720p Yes (50/60Hz)

1920×1080i Yes (50/60Hz)

Owner's Manual Language (March O/R) English/Russian

(From April O/R) Russian only

w/Guarantee Card No

Remote Control Unit Yes

Rod Antenna

Poles Terminal -

Loop Antenna (W/ Antenna Change Plug)

Terminal -

U/V Mixer

DC Car Cord (Center+)

Guarantee Card Yes

Warning Sheet

Circuit Diagram

Antenna Change Plug

Service Facility List

Important Safeguard

Dew/AHC Caution Sheet

Quick Set-up Sheet

Battery Yes

UM size x pcs UM-3 x 2 pcs

OEM Brand No

AC Adapter

AC Cord (for AC Adapter)

AC Cord Yes

AV Cord (2Pin-1Pin)

HDMI-DVI Cable

Registration Card

300 ohm to 75 ohm Antenna Adapter

A3-4

GENERAL SPECIFICATIONS

3

Sets

/--

No

Yes

Surfaces

Sets/40' container

No

No

G-13 Interface

G-14 Set Size

G-15 Weight

G-16 Carton

G-17 Material

G-18 Environment

Switch Power (Push) Yes

System Select No

Main Power SW No

Channel Up/Menu Up Yes

Channel Down/Menu Down Yes

Volume Up/Menu > Yes

Volume Down/Menu < Yes

Input Select/Enter Yes

Menu Yes

Indicator Power/Stand-by Yes(GREEN / RED)

On Timer No

Terminals Side Video Input 1

Audio Input 1

S- Input 1 No

Video Input 2 No

Audio Input 2 No

S- Input 2 No

Video Output No

Audio Output

Other Terminal No

Euro Scart (21Pin)

Component In

Audio Input (Component In use)

PC Monitor Input (D-Sub)

Audio Input

HDMI Input 1

Audio Input (HDMI/DVI In use) PC Monitor Audio Input Alternative

HDMI Input 2

Audio Input (HDMI/DVI In use)

Sub Woofer Output No

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input

AC Inlet

Other Terminal Headphone

Approx. W x D x H (mm) 822 x 332.5 x 604

w/o Stand,Handle Approx. W x D x H (mm)

Net Approx. 19.0kg (41.9 lbs)

Net w/o Stand,Handle Approx. 16.5kg (36.4 lbs)

Gross Approx. 23.0kg (50.7 lbs)

Master Carton

Content ---Material --

Dimensions W x D x H(mm) -- x -- x --

Description of Origin

Gift Box Yes

Material Double/Brown

Dimensions W x D x H(mm) 917 x 441 x 720

Design As per Buyer's

Description of Origin

Drop Test

Height (cm) 46

Container Stuffing 201

Cabinet Cabinet Front PS 94V0 NON-DECABROM

Cabinet Rear PS 94V0 NON-DECABROM

PCB Non-Halogen

Eyelet Yes

Environmental standard requirement Green procurement of ORION

Pb- Free Phase3(PHASE3A)

Measures for Whisker Yes

WEEE

RCA x 1

RCA x 2(L/MONO, R)

RCA x 2(Variable) (L, R)

2Scart

Yes

RCA x 2(L/MONO, R)

Yes

RCA x 2 (L/MONO, R)

Yes

Yes

RCA x 2 (L/MONO, R)

DIN Type

Yes

822 x 129 x 556.5

Natural Dropping At 1 Corner / 3 Edges / 6

A3-5

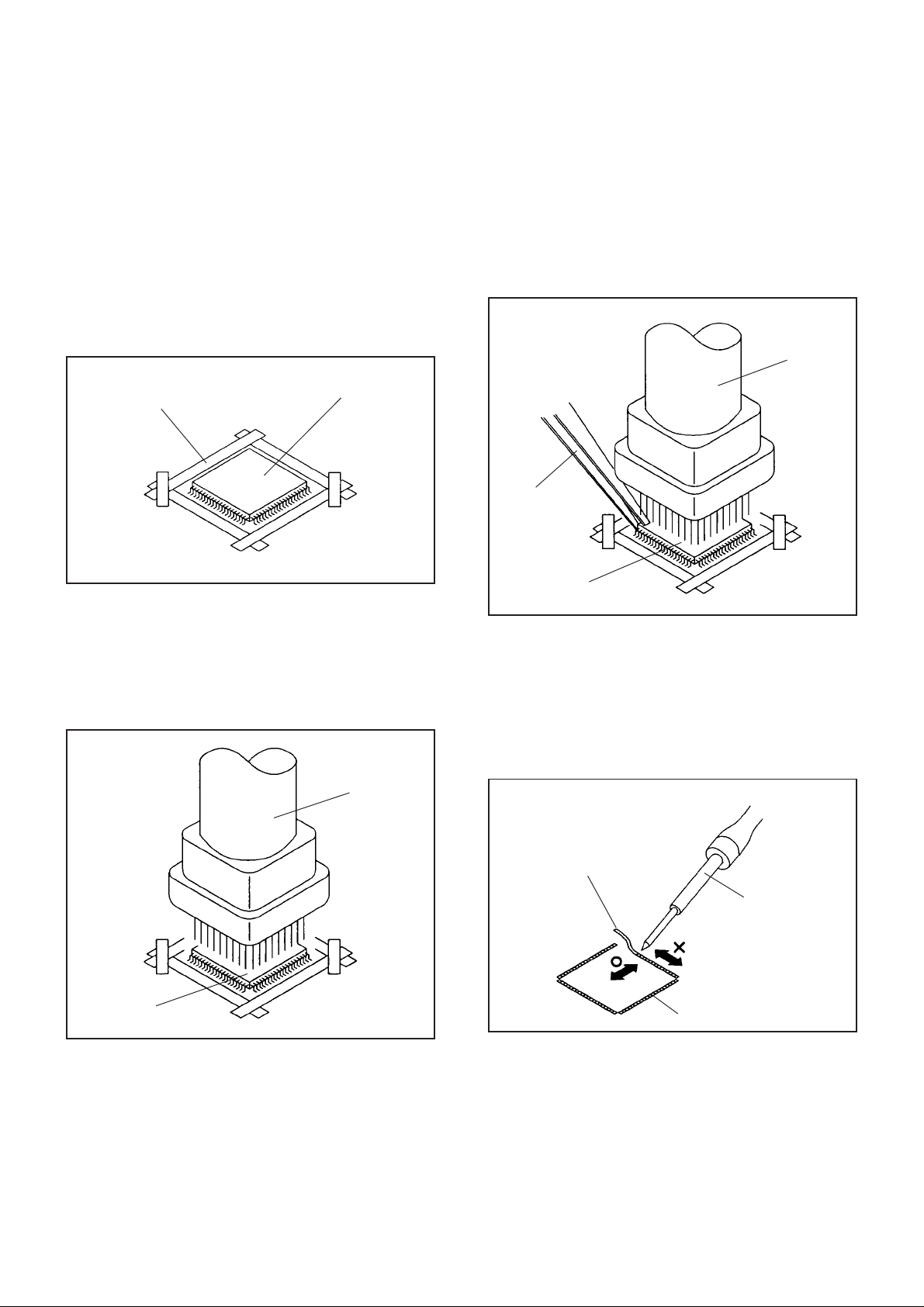

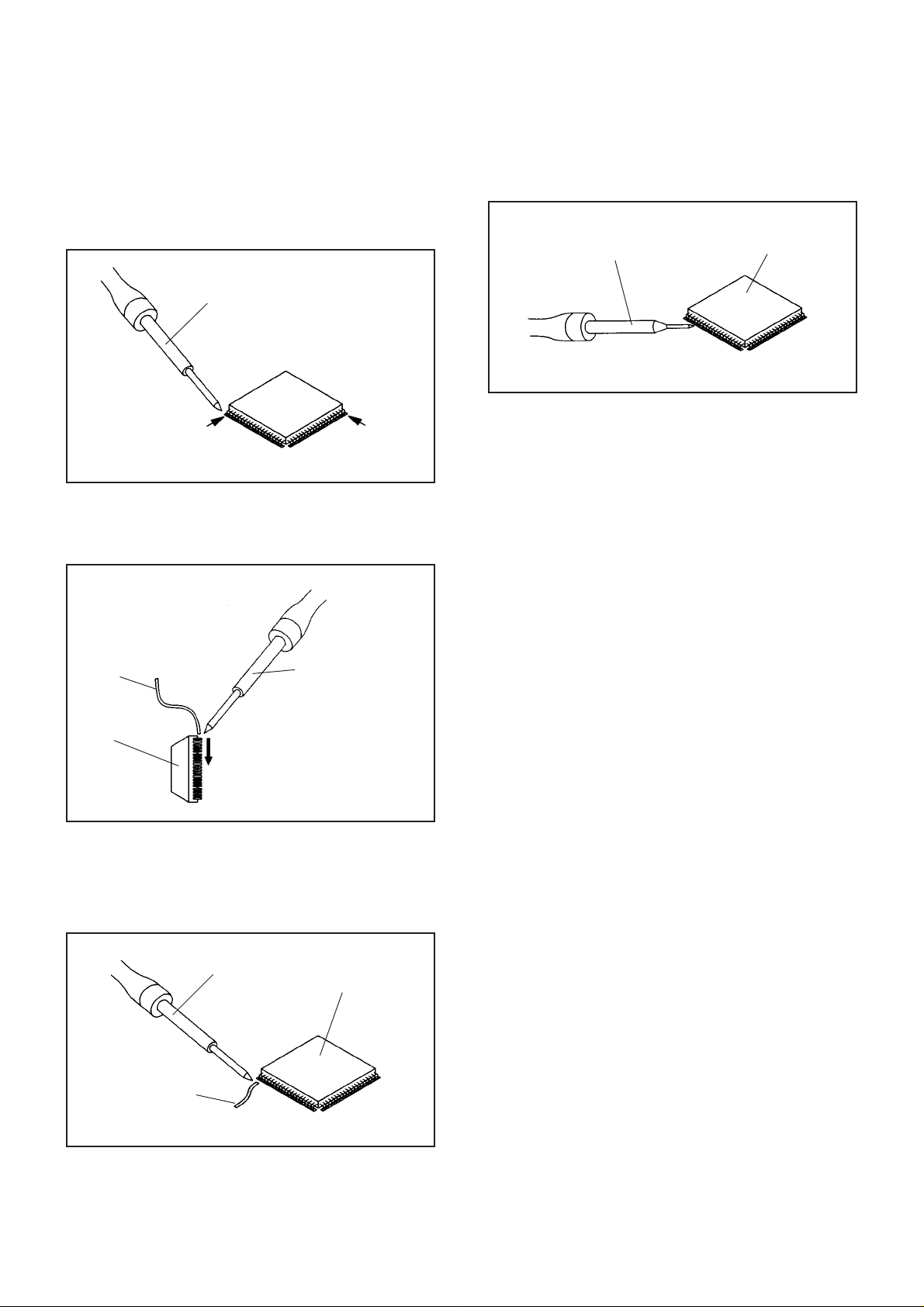

DISASSEMBLY INSTRUCTIONS

1.

REMOVAL AND INSTALLATION OF

FLAT PACKAGE IC

REMOVAL

Put Masking Tape (cotton tape) around the Flat Package

1.

IC to protect other parts from any damage.

(Refer to Fig. 1-1.)

NOTE

Masking is carried out on all the parts located within

10 mm distance from IC leads.

When IC starts moving back and forth easily after

3.

desoldering completely, pickup the corner of the IC using

tweezers and remove the IC by moving with the IC

desoldering machine. (Refer to Fig. 1-3.)

NOTE

Some ICs on the PCB are affixed with glue, so be

careful not to break or damage the foil of each IC

leads or solder lands under the IC when removing it.

Blower type IC

desoldering

machine

Masking Tape

(Cotton Tape)

Heat the IC leads using a blower type IC desoldering

2.

IC

machine. (Refer to Fig. 1-2.)

NOTE

Do not rotate or move the IC back and forth , until IC

can move back and forth easily after desoldering the

leads completely.

Blower type IC

desoldering machine

Fig. 1-1

Tweezers

IC

Peel off the Masking Tape.4.

Absorb the solder left on the pattern using the Braided

5.

Shield Wire. (Refer to Fig. 1-4.)

NOTE

Do not move the Braided Shield Wire in the vertical

direction towards the IC pattern.

Fig. 1-3

Braided Shield Wire

Soldering Iron

IC

Fig. 1-2

IC pattern

Fig. 1-4

B-1

DISASSEMBLY INSTRUCTIONS

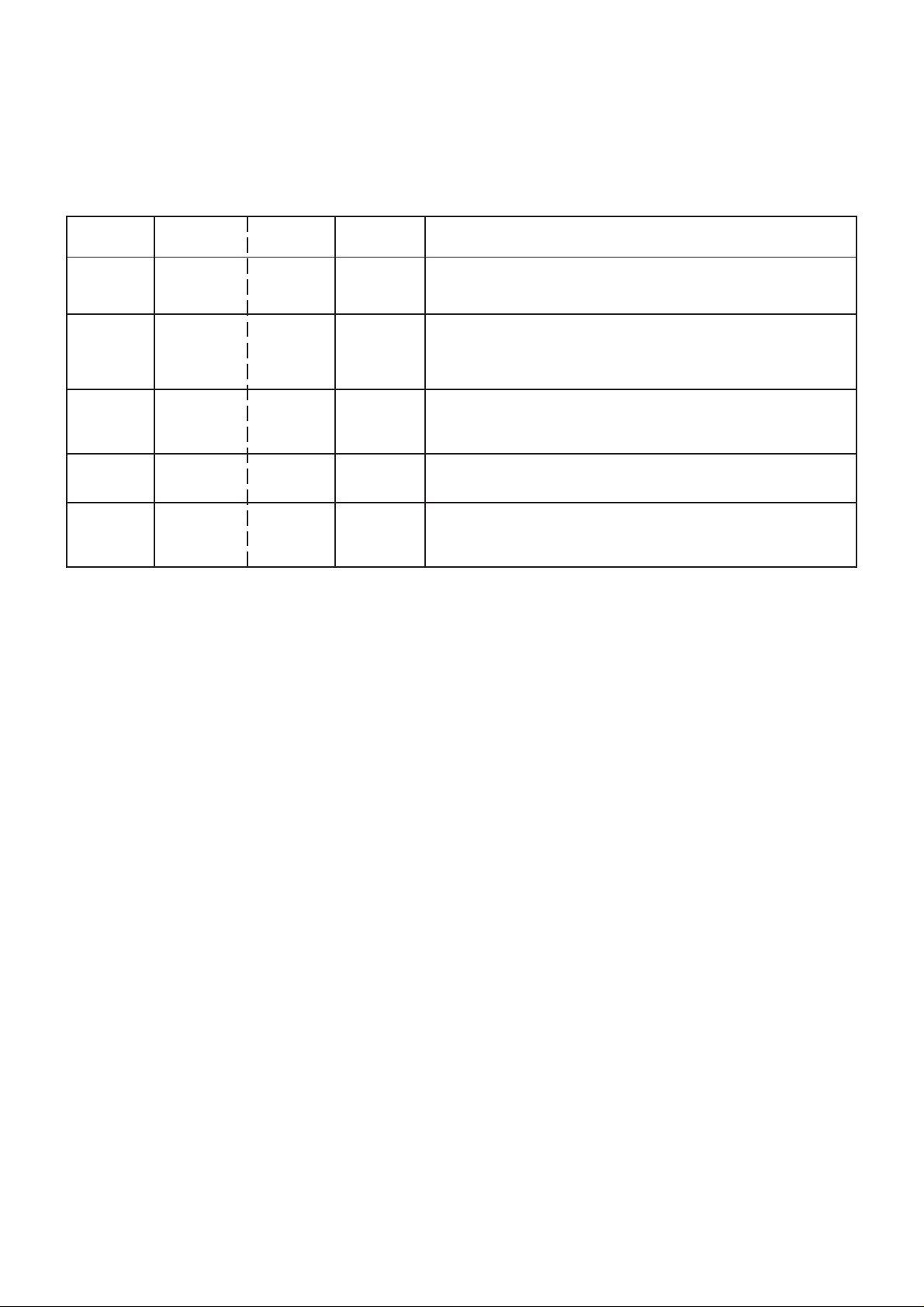

INSTALLATION

Take care of the polarity of new IC and then install the

1.

new IC fitting on the printed circuit pattern. Then solder

each lead on the diagonal positions of IC temporarily.

(Refer to Fig. 1-5.)

Soldering Iron

Solder temporarily

Supply the solder from the upper position of IC leads

2.

Solder temporarily

sliding to the lower position of the IC leads.

(Refer to Fig. 1-6.)

Fig. 1-5

When bridge-soldering between terminals and/or the

4.

soldering amount are not enough, resolder using a Thintip Soldering Iron. (Refer to Fig. 1-8.)

Thin-tip Soldering Iron

IC

Fig. 1-8

Finally, confirm the soldering status on four sides of the

5.

IC using a magnifying glass.

Confirm that no abnormality is found on the soldering

position and installation position of the parts around the

IC. If some abnormality is found, correct by resoldering.

NOTE

When the IC leads are bent during soldering and/or

repairing, do not repair the bending of leads. If the

bending of leads are repaired, the pattern may be

damaged. So, always be sure to replace the IC in this

case.

Soldering IronSolder

IC

Absorb the solder left on the lead using the Braided

3.

Supply soldering

from upper position

to lower position

Shield Wire. (Refer to Fig. 1-7.)

NOTE

Do not absorb the solder to excess.

Soldering Iron

IC

Braided Shield Wire

Fig. 1-6

Fig. 1-7

B-2

SERVICE MODE LIST

This unit is provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter to the SERVICE MODE function, press and hold both buttons simultaneously on the main unit or on the main unit

and on the remote control for more than a standard time in the appropriate condition. (See below chart.)

In case of the main unit and remote control, press the remote control buttons first, then press the main unit buttons.

Set

Condition

ALL mode

ALL mode

ALL mode

ALL mode

ALL mode

Set Key Operations

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

VOL. DOWN

(Minimum)

Remocon

Key

0 2 sec.

1 2 sec.

2

6 2 sec.

9 2 sec.

Standard

Time

2 sec.

Reset the user setting items (PICTURE, AUDIO, VOLUME,

LANGUAGE and NICAM AUTO/OFF) to the initial state for

delivery.

Initialization of factory TV data.

NOTE:

Check of the SUM DATA, POWER ON total hours, MICON

VERSION and DIGITAL TV MICON FIRMWARE on the screen.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display

Adjustment).

If you set factory initialization, the memories are reset

such as the channel setting, and the POWER ON total

hours.

C-1

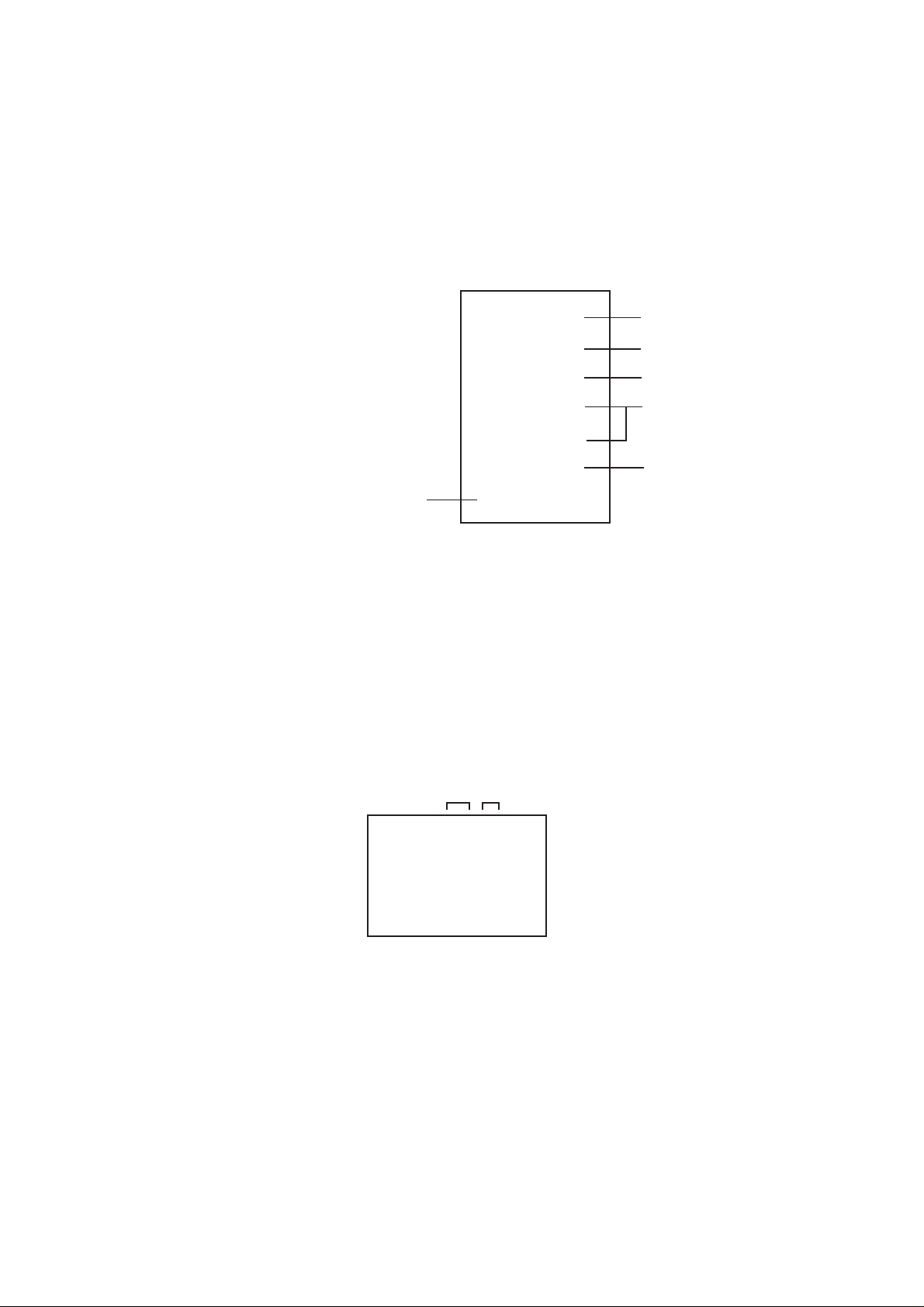

WHEN REPLACING EEPROM (MEMORY) IC

CONFIRMATION OF CHECK SUM, POWER ON TOTAL HOURS AND MICON VERSION

Initial total of MEMORY IC, POWER ON total hours and MICON VERSION can be checked on the screen. Total hours are

displayed in 16 system of notation.

NOTE:

1.

2.

3.

4.

NOTE:

If you set a factory initialization, the total hours is reset to "0".

Please refer to "CONFIRMATION OF INITIAL DATA" when SUM DATA is not corresponding.

Turn on the POWER, and set to the TV mode.

Set the VOLUME to minimum.

INIT : 89F3

Press both VOL. DOWN button on the set and Channel

button (2) on the remote control for more than 2 seconds.

ROM : 0000

After the confirmation of each check sum, POWER ON

total hours and MICON VERSION, turn off the power.

The each item value might be different

according to each set.

ADC : 8D18

DVP1 : 1D07

DVP2 : AFF2

Initial setting data check sum.

Rom correction data check sum.

AD CONVERTER data check sum.

SCALER data check sum.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

MICON V ersion

LCD ON 0000

OEC7179A-010

FIG. 1

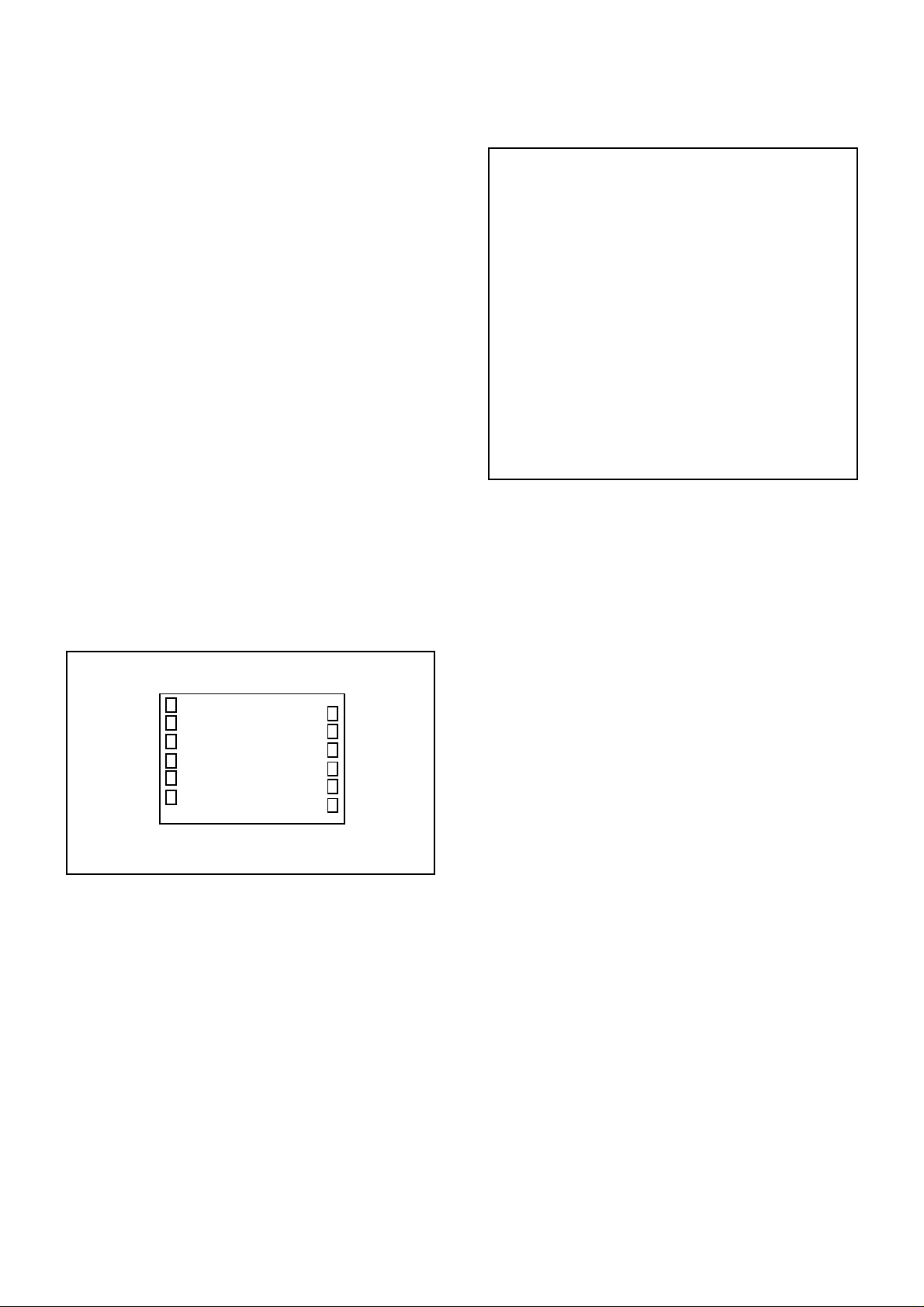

CONFIRMATION OF INITIAL DATA

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to INITIAL SETTING TABLE (Attached "INITIAL DATA").

Turn on the POWER, and set to the TV mode.

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

3.

ADDRESS and DATA should appear as FIG 2.

ADDRESS DATA

INIT 0001 26

LCD ON 0000

OEC7179A-010

FIG. 2

4.

ADDRESS is now selected and should "blink". Using the UP/DOWN buton on the remote, step through the ADDRESS

until required ADDRESS to be changed is reached.

5.

Press LEFT/RIGHT button to select DATA. When DATA is selected, it will "blink".

6.

Again, step through the DATA using UP/DOWN button until required DATA value has been selected.

7.

Pressing LEFT/RIGHT button will take you back to ADDRESS for further selection if necessary.

8.

Repeat steps 4 to 6 until all data has been checked.

9.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

After the data input, set to the initializing of shipping.

10.

Turn on the POWER.

11.

Set the VOLUME to minimum.

12.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 2 seconds.

13.

After the finishing of the initializing of shipping, the unit will turn off automatically.

The unit will now have the correct DATA for the new MEMORY IC.

C-2

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any

service on this chassis.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

•

When you exchange IC and Transistor with a heat sink,

apply silicon grease on the contact section of the heat

sink. Before applying new silicon grease, remove all the

old silicon grease. (Old grease may cause damage to

the IC and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Pattern Generator

2. BASIC ADJUSTMENTS

On-Screen Display Adjustment

1.2.Set the VOLUME to minimum.

Press the VOL. DOWN button on the set and the

channel button (9) on the remote control for more than

2 seconds to display adjustment mode on the screen as

shown in Fig. 2-1.

TV

AUTO

01 H POSI OSD

3.

Use the UP/DOWN button or Channel button (0-9) on

the remote control to select the options shown in

Fig. 2-2.

4.

Press the MENU button on the remote control to end

the adjustments.

5.

To display the adjustment screen for TV, AV,

COMPONENT and HDMI mode, press the INPUT

SELECT button on the remote control.

Press the VOL.DOWN button on the set and the

channel (9) on the remote control for more than 2

seconds.

346

Fig. 2-1

NO.

NO.

01

02

03

04

05

06

07

08

09

10

11

12

13

14

15

16

17

18

19

20

21

22

FUNCTION

H POSI OSD

V POSI OSD

R DRIVE (N)

R CUTOFF (N)

G DRIVE (N)

G CUTOFF (N)

B DRIVE (N)

B CUTOFF (N)

R DRIVE (C)

R CUTOFF (C)

G DRIVE (C)

G CUTOFF (C)

B DRIVE (C)

B CUTOFF (C)

R DRIVE (W)

R CUTOFF (W)

G DRIVE (W)

G CUTOFF (W)

B DRIVE (W)

B CUTOFF (W)

H POSI 50Hz

H POSI 60Hz

FUNCTION

23

V POSI 50Hz

24

V POSI 60Hz

25

BAK LIGHT CENT

26

BAK LIGHT MAX

27

BAK LIGHT MIN

28

BRIGHT CENT

29

BRIGHT MAX

30

BRIGHT MIN

31

TINT

35

CONTRAST CENTER

36

CONTRAST MAX

37

CONTRAST MIN

38

COLOR CENT

39

COLOR MAX

40

COLOR MIN

41

H POSI TEXT

42

V POSI TEXT

43

CONTRAST 35

44

BRIGHT (3F54)

45

CONTRAST (3F55)

46

SRCTOP

47

DFEA VIMGVT

Fig. 2-2

2-1: CONTRAST MAX

1.

Receive the monoscope pattern. (VIDEO Input)

2.

Press the INPUT SELECT button on the remote control

to set to the AV mode.

3.

Press the PICTURE SIZE button on the remote control

to select the FULL screen mode.

4.

Using the remote control, set the brightness and

contrast to normal position.

5.

Activate the adjustment mode display of Fig. 2-1 and

press the channel button (36) on the remote control to

select "CONT MAX".

6.

Check if the step No. CONT MAX is "131".

7.

Receive a broadcast and check if the picture is normal.

8.

Receive the monoscope pattern. (RF Input)

9.

Press the INPUT SELECT button on the remote control

to set to the TV mode. Then perform the above

adjustments 3~5.

10.

Check if the step No. CONT MAX is "179".

11.

Playback the DVD(480i) disc. (COMPONENT Input)

12.

Press the INPUT SELECT button on the remote control

to set to the COMPONENT mode. Then perform the

above adjustments 3~5.

13.

Check if the step No. CONT MAX is "160".

14.

Playback the DVD(480i) disc. (HDMI Input)

15.

Press the INPUT SELECT button on the remote control

to set to the HDMI mode. Then perform the above

adjustments 3~5.

16.

Check if the step No. CONT MAX is "164".

D-1

ELECTRICAL ADJUSTMENTS

2-2: WHITE BALANCE

1.

Place the set in Aging Test for more than 15 minutes.

2.

Receive the white 100% signal from the Pattern

Generator.

3.

Press the INPUT SELECT button on the remote control

to set to the AV mode.

4.

Using the remote control, set the brightness and contrast

to normal position.

5.

Activate the adjustment mode display of Fig. 2-1 and

press the channel button (03) on the remote control to

select "R DRIVE (N)".

6.

Press the CH. UP/DOWN button on the remote control to

select the "R CUTOFF (N)", "B.DRIVE(N)", "B CUTOFF

(N)", "R DRIVE (C)", "R CUTOFF (C)", "B.DRIVE(C)",

"B CUTOFF (C)", "R DRIVE (W)", "R CUTOFF (W)",

"B.DRIVE(W)"or "B CUTOFF (W)".

7.

Adjust the VOL. UP/DOWN button on the remote control to

whiten the R CUTOFF (N), B.DRIVE(N), B CUTOFF (N),

R DRIVE (C), R CUTOFF (C), B.DRIVE(C), B CUTOFF

(C), R DRIVE (W), R CUTOFF (W), B.DRIVE(W) and B

CUTOFF (W) at each step tone sections equally.

8.

Perform the above adjustments 6 and 7 until the white

color is achieved.

D-2

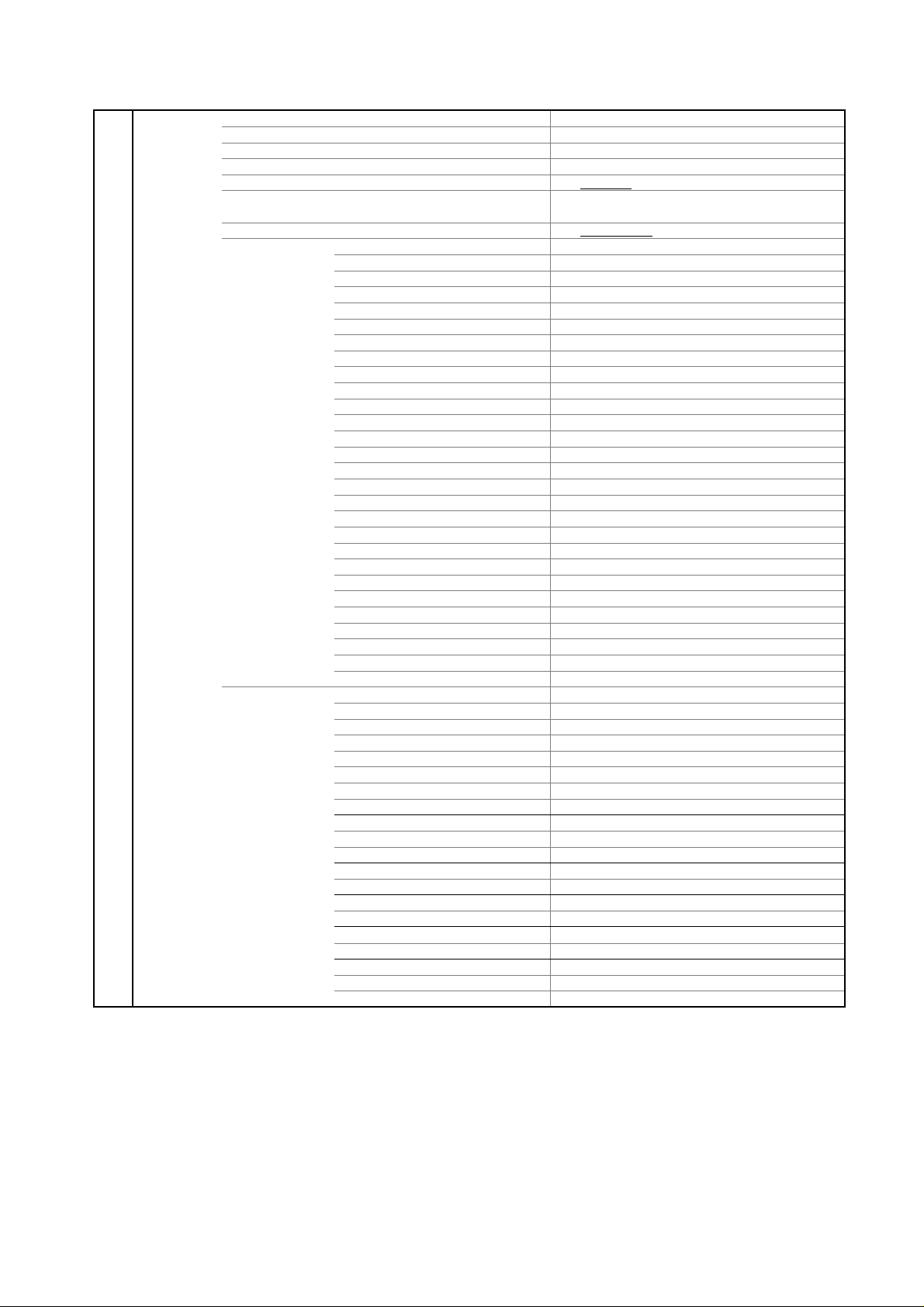

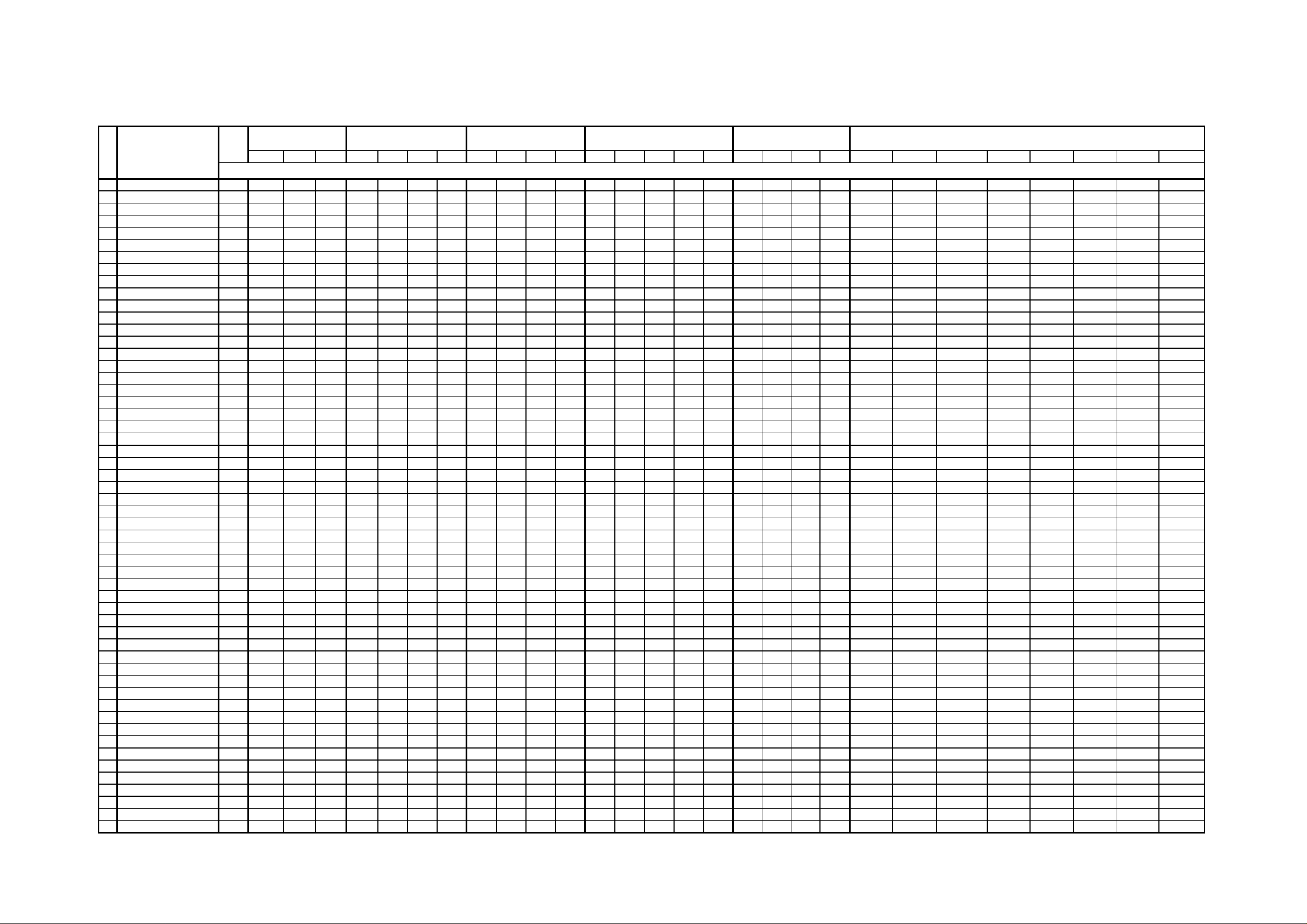

2-3: Confirmation of Fixed Value (Step No.)

Please check if the fixed values of each the adjustment item is set correctly referring below. (TV/AV/COMPONENT/HDMI/PC)

TV

NOTE: For the step no. with * mark, please adjust it according to the situation of the set.

ELECTRICAL ADJUSTMENTS

AV

COMPONENT(NTSC)

Step No.

HDMI(NTSC)

HDMI(PAL)

PC

COMPONENT(PAL)

CVBS S(Y/C) RGB

NO. FUNCTION

1 H POSI OSD 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346 346

2 V POSI OSD 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85 85

3 R DRIVE (N) *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 *136 128 128 128 128 128 128 128 128

4 R CUTOFF (N) *130 *130 *130 *130 *130 *127 *129 *129 *130 *127 *129 *129 *130 *130 *130 *130 *130 *130 *130 *130 *130 ... ... ... ... ... ... ... ...

5 G DRIVE (N) 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 108 108 108 108 108 108 108 108

6 G CUTOFF (N) 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 ... ... ... ... ... ... ... ...

7 B DRIVE (N) *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 *117 138 138 138 138 138 138 138 138

8 B CUTOFF (N) *128 *128 *128 *134 *128 *127 *127 *127 *129 *127 *127 *127 *127 *127 *127 *127 *127 *128 *127 *127 *127 ... ... ... ... ... ... ... ...

9 R DRIVE(C) *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 *135 ... ... ... ... ... ... ... ...

10 R CUTOFF (C) *127 *127 *127 *130 *127 *126 *127 *126 *127 *125 *126 *126 *127 *127 *127 *127 *127 *127 *127 *127 *127 ... ... ... ... ... ... ... ...

11 G DRIVE (C) 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 ... ... ... ... ... ... ... ...

12 G CUTOFF (C) 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 ... ... ... ... ... ... ... ...

13 B DRIVE(C) *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 *119 ... ... ... ... ... ... ... ...

14 B CUTOFF (C) *128 *128 *128 *135 *128 *127 *127 *127 *129 *127 *127 *127 *128 *128 *128 *128 *128 *128 *128 *128 *128 ... ... ... ... ... ... ... ...

15 R DRIVE (W) *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 *145 ... ... ... ... ... ... ... ...

16 R CUTOFF (W) *128 *128 *128 *128 *127 *125 *127 *126 *128 *125 *127 *127 *127 *127 *127 *127 *127 *128 *127 *127 *127 ... ... ... ... ... ... ... ...

17 G DRIVE (W) 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 ... ... ... ... ... ... ... ...

18 G CUTOFF (W) 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 ... ... ... ... ... ... ... ...

19 B DRIVE (W) *113 *113 *113 *113 *113 *113 *113 *113 *113 *113 *113 *113 *112 *113 *113 *113 *113 *113 *113 *113 *113 ... ... ... ... ... ... ... ...

20 B CUTOFF (W) *128 *128 *129 *134 *128 *127 *127 *127 *128 *127 *127 *127 *127 *127 *127 *127 *127 *128 *127 *127 *127 ... ... ... ... ... ... ... ...

21 H POSI 50Hz (OTHER) 316 316 316 316 ... ... ... ... 316 148 414 362 ... ... ... ... ... 298 148 290 236 ... ... ... ... ... ... ... ...

H POSI 50Hz (4:3) 316 316 316 316 ... ... ... ... 316 148 ... ... ... ... ... ... ... 298 148 ... ... ... ... ... ... ... ... ... ...

22 H POSI 60Hz (OTHER) 280 280 280 284 280 138 326 276 ... ... ... ... 268 136 158 382 236 ... ... ... ... 47 47 ... ... ... ... ... ...

H POSI 60Hz(4:3) 280 280 280 284 280 138 ... ... ... ... ... ... 268 136 158 ... ... ... ... ... ... ... ... 47 214 230 230 230 230

23 V POSI 50Hz 24 24 24 20 ... ... ... ... 24 24 35 19 ... ... ... ... ... 24 24 35 19 ... ... ... ... ... ... ... ...

24 V POSI 60Hz 24 24 24 34 24 24 35 19 ... ... ... ... 24 24 24 35 19 ... ... ... ... 24 24 24 24 24 24 24 24

25 BAK LIGHT CENT 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128

26 BAK LIGHT MAX 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255 255

27 BAK LIGHT MIN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

28 BRIGHT CENT 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128 128

29 BRIGHT MAX 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156 156

30 BRIGHT MIN 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70

31 TINT 125 121 121 124 124 119 119 119 119 124 124 124 124 124 124 124 124 121 121 121 121 ... ... ... ... ... ... ... ...

35 CONTRAST CENTER *162 *119 *115 *123 *146 *128 *128 *129 *146 *129 *130 *130 *148 *148 *148 *148 *148 *148 *148 *148 *148 90 90 90 90 90 90 90 90

36 CONTRAST MAX *179 *131 *127 *135 *160 *141 *142 *143 *161 *143 *144 *144 *164 *164 *164 *164 *164 *164 *164 *164 *164 150 150 150 150 150 150 150 150

37 CONTRAST MIN 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 70 60 60 60 60 60 60 60 60

38 COLOR CENT 78 88 82 190 96 100 100 100 104 108 108 108 63 63 63 63 63 64 64 64 64 ... ... ... ... ... ... ... ...

39 COLOR MAX 127 127 127 206 127 127 127 127 127 127 127 127 127 127 127 127 127 127 127 127 127 ... ... ... ... ... ... ... ...

40 COLOR MIN 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 ... ... ... ... ... ... ... ...

41 H POSI TEXT 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 195 ... ... ... ... ... ... ... ...

42 V POSI TEXT 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 86 ... ... ... ... ... ... ... ...

43 CONTRAST 35 *170 *125 *121 *129 *153 *134 *136 *136 *154 *136 *136 *136 *156 *156 *156 *156 *156 *156 *156 *156 *156 120 120 120 120 120 120 120 120

44 BRIGTH (3F54) 127 127 127 127 127 125 125 125 127 125 125 125 111 111 111 111 111 111 111 111 111 128 128 128 128 128 128 128 128

45 CONTRAST (3F55) 180 180 180 180 180 180 180 180 180 180 180 180 113 113 113 113 113 113 113 113 113 128 128 128 128 128 128 128 128

46 SRCTR (4:3) 27 27 27 27 21 21 ... ... 27 27 ... ... 0 0 0 ... ... 0 0 --- --- 0 0 0 0 0 0 0 0

SRCTR (14:9) 27 27 27 27 21 21 ... ... 27 27 ... ... 0 0 0 ... ... 0 0 --- --- ... ... ... ... ... ... ... ...

SRCTR (CINEMA) 45 45 45 45 41 41 41 41 45 45 45 45 0 0 0 0 0 0 0 0 0 ... ... ... ... ... ... ... ...

SRCTR (16:9) 27 27 27 27 21 21 21 21 27 27 27 27 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

SRCTR (FULL) 35 35 35 35 28 28 ... ... 35 35 ... ... 0 0 0 ... ... 0 0 ... … ... ... ... ... ... ... ... ...

47 DFEA VIMGVT (4:3) 0 0 0 0 0 44 ... ... 0 55 ... ... 21 44 43 ... ... 27 55 ... ... 28 28 28 28 28 28 28 28

DFEA VIMGVT (14:9) 0 0 0 0 0 44 ... ... 0 55 ... ... 21 44 43 ... ... 27 55 ... ... ... ... ... ... ... ... ... ...

DFEA VIMGVT (CINEMA) 0 0 0 0 0 101 122 95 0 124 122 95 48 99 99 122 0 42 98 122 90 ... ... ... ... ... ... ... ...

DFEA VIMGVT (16:9) 0 0 0 0 0 44 32 0 0 55 32 0 21 44 43 32 0 27 55 32 0 28 28 28 20 28 28 28 28

DFEA VIMGVT (FULL) 0 0 0 0 0 59 ... ... 0 72 ... ... 26 58 58 ... ... 35 72 ... ... ... ... ... ... ... ... ... ...

480i 480p 720p 1080i 576i 576p 720p 1080i 480i 480p VGA 720p 1080i 576i 576p 720p 1080i 640*480 720*400 848*480 800*600 1024*768 1280*720 1280*768 1360*768

D-3 D-4

CP301

CP4202

CP2200

CP3801

CP3802

J8001

CP4302

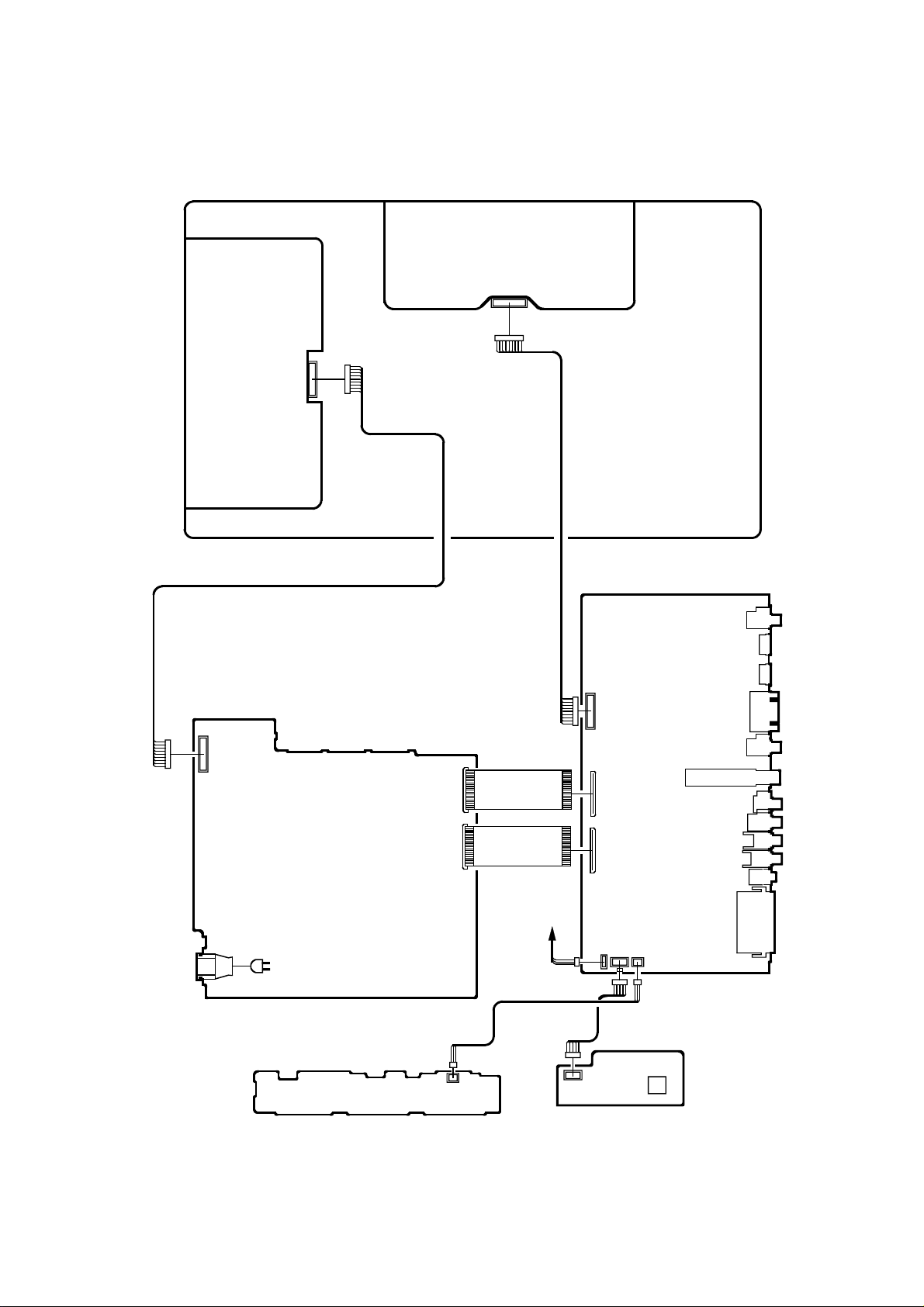

ELECTRICAL ADJUSTMENTS

CP502

CP501

3. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

LCD PANEL

CD505

CD7203

MAIN PCB

CP505

J501

AC IN

CD3810

POWER PCB

CP2203

SPEAKER

CD2200

CP2201

CP7203

CD4202

OS2200

TU6001

J4203

J4204

J3601

CP3603

CP3601

J4301

J4201

J4202

J4205

OPERATION PCB

REMOCON PCB

D-5

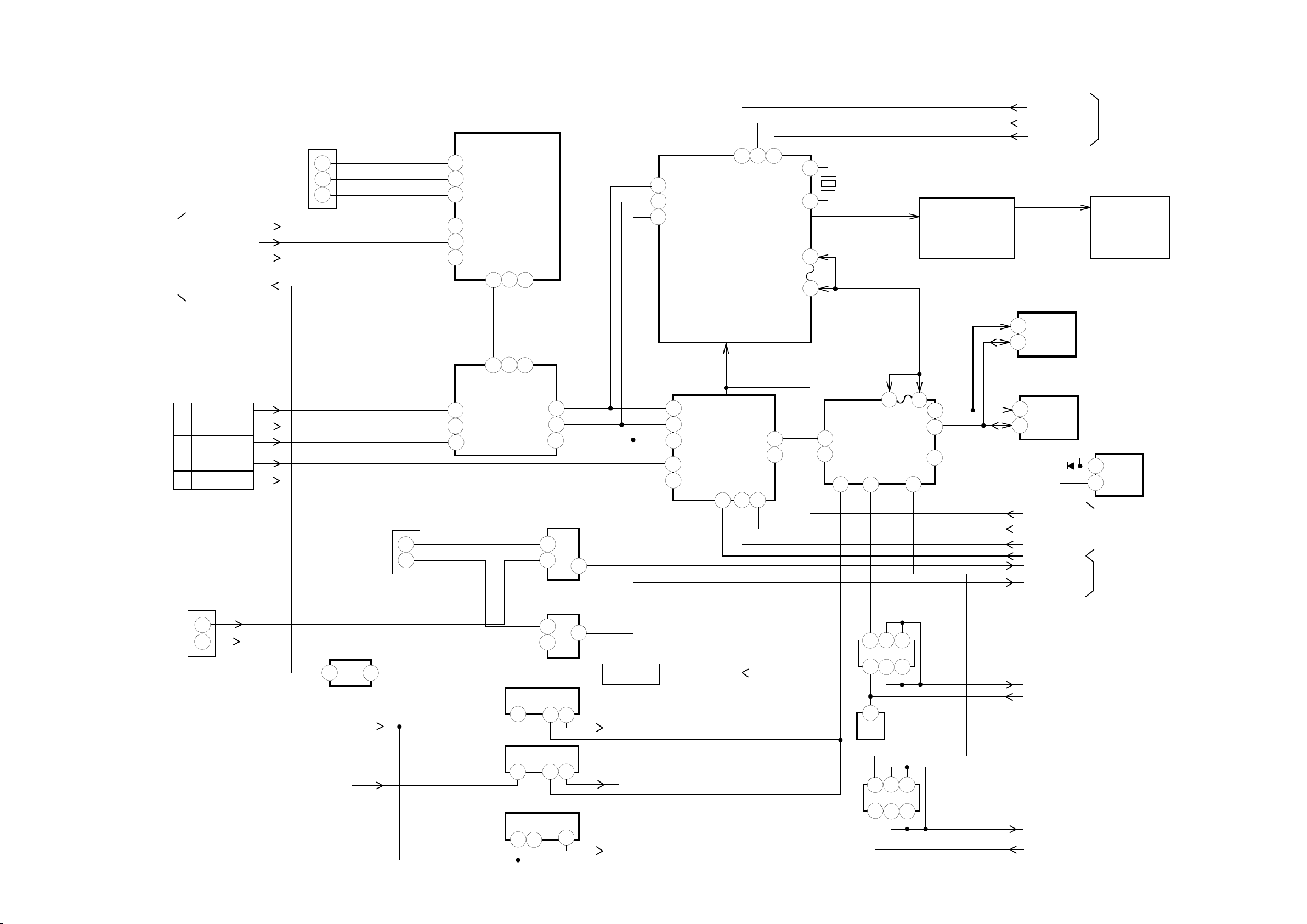

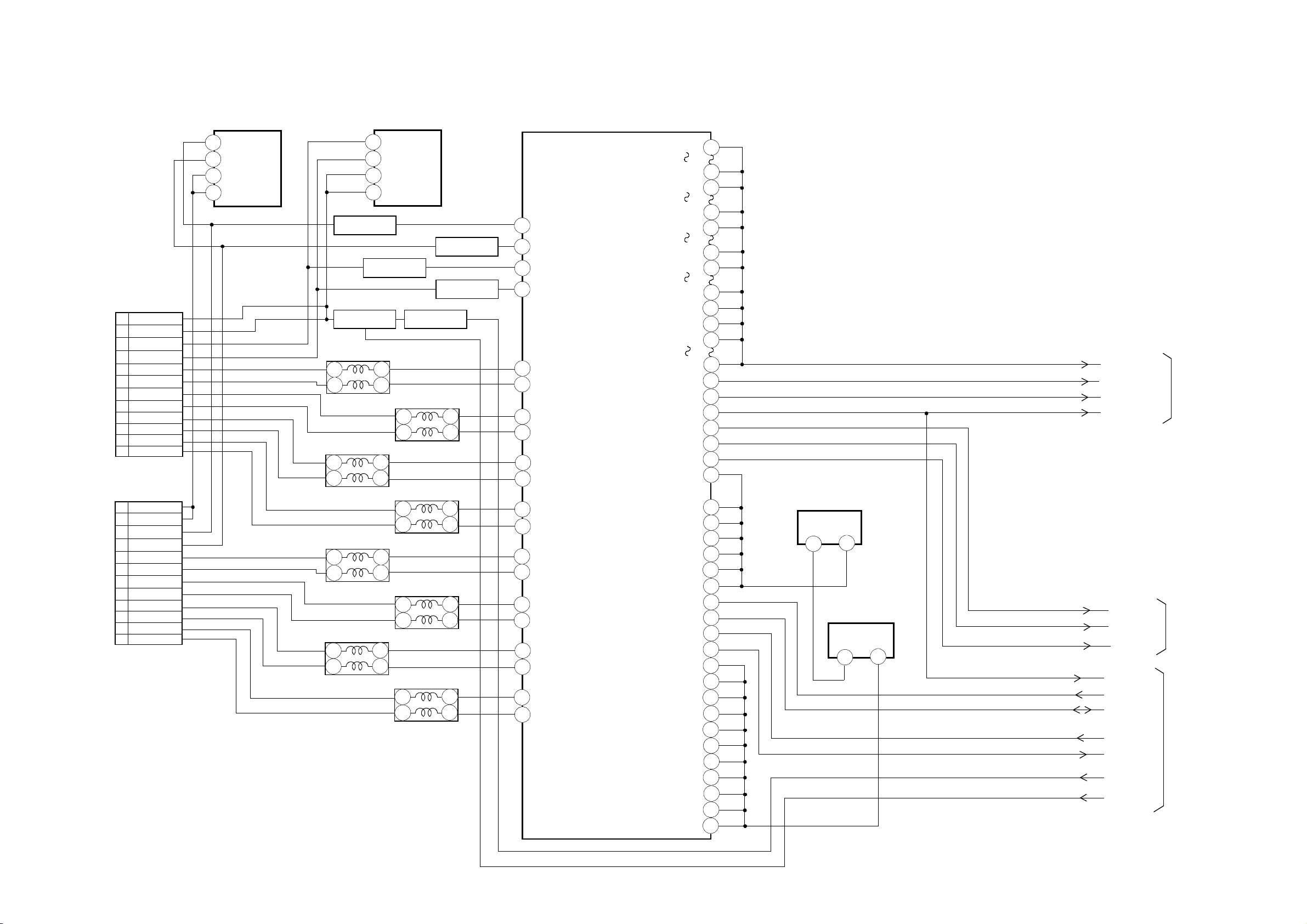

SCALER/LVDS/MICON/ADC/JACK/REGULATOR BLOCK DIAGRAM

SW_G/Y

SW_B/PB

SW_R/PR

AV SWITCH/21PIN/

STEREO/SOUND

AMP/HEADPHONE/

TUNER

SCART_R_IN

SCART_G_IN

SCART_B_IN

P.CON32V

D-SUB

CP4302

1

VGA-R

2

VGA-G

VGA-B

3

VGAHS

13

VGAVS

14

HDMI AUDIO IN

J3601

2

4

COMPONENT_IN

J4203

5

2

3

1

32V REG

KIA431A-AT

AT+5V

SCALER+2.5V

VGA-R

AUDIO IN(DVI1/PC)

3

IC3802

Y

Pr

Pb

VGA-G

VGA-B

J4301

2

4

P.CON+3.3V REG

BA00BC0WFP-E2

P.CON+1.5V REG

BD7820FP-E2

AT+3.3V REG

PQ070XZ5MZPH

8

16

RGB/YUV SW

11

1

9

14

11

8

16

IC3201

IC3202

IC3203

IC4200

NJM2584AM (TE1)

6

9

IC8104

NJM2584AM (TE1)

SW

5

3

1

14

2

2

2

Y/G

6

Pr/R

5

Pb/B

3

VGAHS

VGAVS

PC/YUV Rch SW

IC4301

MM1501XNRE

6

4

2

PC/YUV Lch SW

IC4302

MM1501XNRE

6

2

4

1

4

4

1

3

1

Q3813

TU+32V SW

P.CON+3.3V

P.CON+1.5V

AT+3.3V

44

21

33

R8J66607A72FP

48

54

AD CONVERTER

43

30

31

IC2101

MST9883C-LF-110

42

31

SCALER

IC801

DIGITAL

24bit RGB

DDHS, DDVS, DD

CK

66 67

64

13

SCL

56

SDA

57

AT+32V

84

X801

85

54MHz

DIGITAL 24bit RGB

DHS, DVS, DCLK1,

DEN

57

60

4SI_SDA_IN/4SI_SCL

4SI_CHIP_SE/4SI_SDA_OUT

27

28

76

2

MICON

IC101

OEC7179A

85

DC-DC CONV

ERTER

Q3805

2

3

4

5

2

2

3

4

5

LVDS

IC7201

ICSV385AGLFT

5

54

54

53

10

18

1

6

9V_REG

IC3801

BA00BC0WFP-E2

DC-DC CONV

1

ERTER

Q3801

6

SW_VIDEO_C

SW_VIDEO_Y

SW_CVBS

TX OUT0~3+

TX OUT0~3TXCLKOUT+

TXCLKOUT-

EEPROM IC 256K

AT24C256BN-10SU-1.8

IC103

6

SCL

5

SDA

EEPROM IC 256K

IC104

AT24C256BN-10SU-1.8

6

SCL

5

SDA

D105

DIGITAL RGB

DDCK

DDHS

DDVS

SW_AUDIO_R

SW_AUDIO_L

P.CON+12V

AT+12V

P.CON+5V

AT+5V

AV

SWITCH/21PIN/

STEREO/SOUND

AMP/HEADPHONE

/TUNER

LCD PANEL

V2301

CLAA320WB02L

RESET

IC102

PST3229NR

1

2

INTERFACE

AV

SWITCH/21PIN/

STEREO/SOUND

AMP/HEADPHONE

/TUNER

E-1

E-2

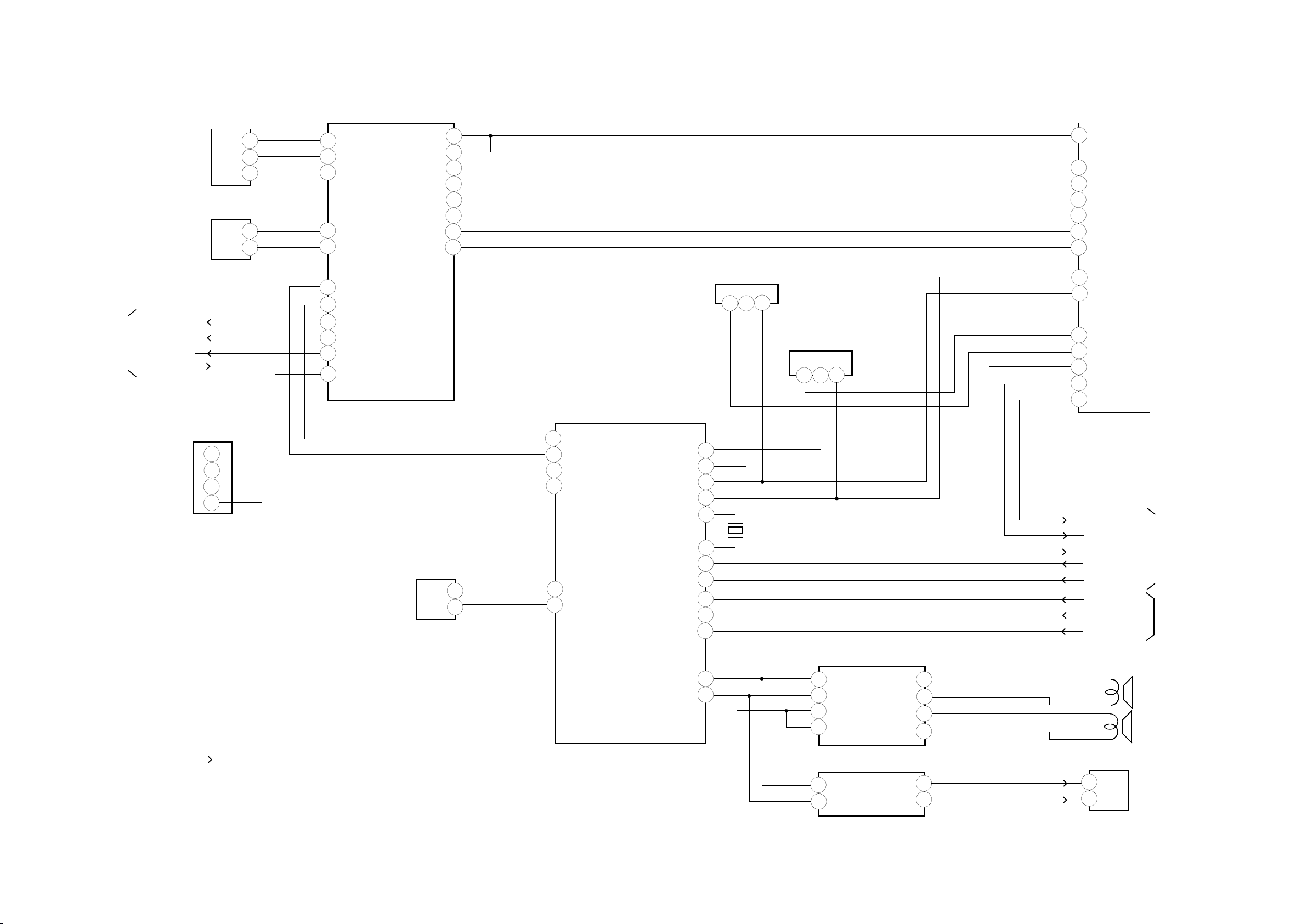

AV SWITCH/21PIN/STEREO/SOUND AMP/HEADPHONE/TUNER BLOCK DIAGRAM

SCALER/LVDS/

MICON/ADC/JACK/

REGULATOR

SW_CVBS

SW_VIDEO_Y

SW_VIDEO_C

P.CON+32V

CVBS_IN

J4204

5

4

2

COMPONENT_A_IN

J4202

4

2

TUNER

TU6001

9

12

11

7

AV SW IC

IC4201 AN15853B-E1

18

15

17

19

21

28

30

31

33

35

16

AUDIO_OUT_JACK

J4201

10

12

DECORDER/PERITEL

J8001

2

4

6

3

5

9

SCART2 OUT AUDIO_R SW

41

36

27

23

20

6

2

IC902

MM1501XNRE

4

6

2

3

1

SCART2 OUT AUDIO_L SW

NICAM/AV2 STEREO

IC904

IC901

MM1501XNRE

4

6

2

24

22

15

11

7

MSP4410G-QA-C13

SC1_IN_L

56

SC1_IN_R

57

MONO_IN

60

ANA_IN1+

67

24

25

DACA_R

DACA_L

2

3

SC2_OUT_L

SC2_OUT_R

SC1_OUT_R

SC1_OUT_L

XTAL_IN

XTAL_OUT

SC2_IN_L

SC2_IN_R

I2S_CL3

I2S_WS3

I2S_DA_IN3

34

33

36

37

71

72

53

54

19

20

22

X901

18.432MHz

SCART1_B_IN

SCART1_G_IN

SCART1_R_IN

SW_AUDIO_L

SW_AUDIO_R

SCK

WS

SDO

SCALER/LVDS/

MICON/ADC/JACK/

REGULATOR

INTERFACE

SOUND AMP

IC301 TDA8932T

OUT1

HVP1

OUT2

HVP2

27

30

22

19

18

19

SPEAKER Lch

SP301

SPEAKER Rch

SP302

3

2

POWER2

SOUND+B

DACM_R

DACM_L

27

28

IN2N

14

2

IN1P

20

VDDP2

29

VDDP1

HEADPHONE AMP

IC300 NJM2151AV(TE1)

4

2

HEADPHONE JACK

J4205

E-3 E-4

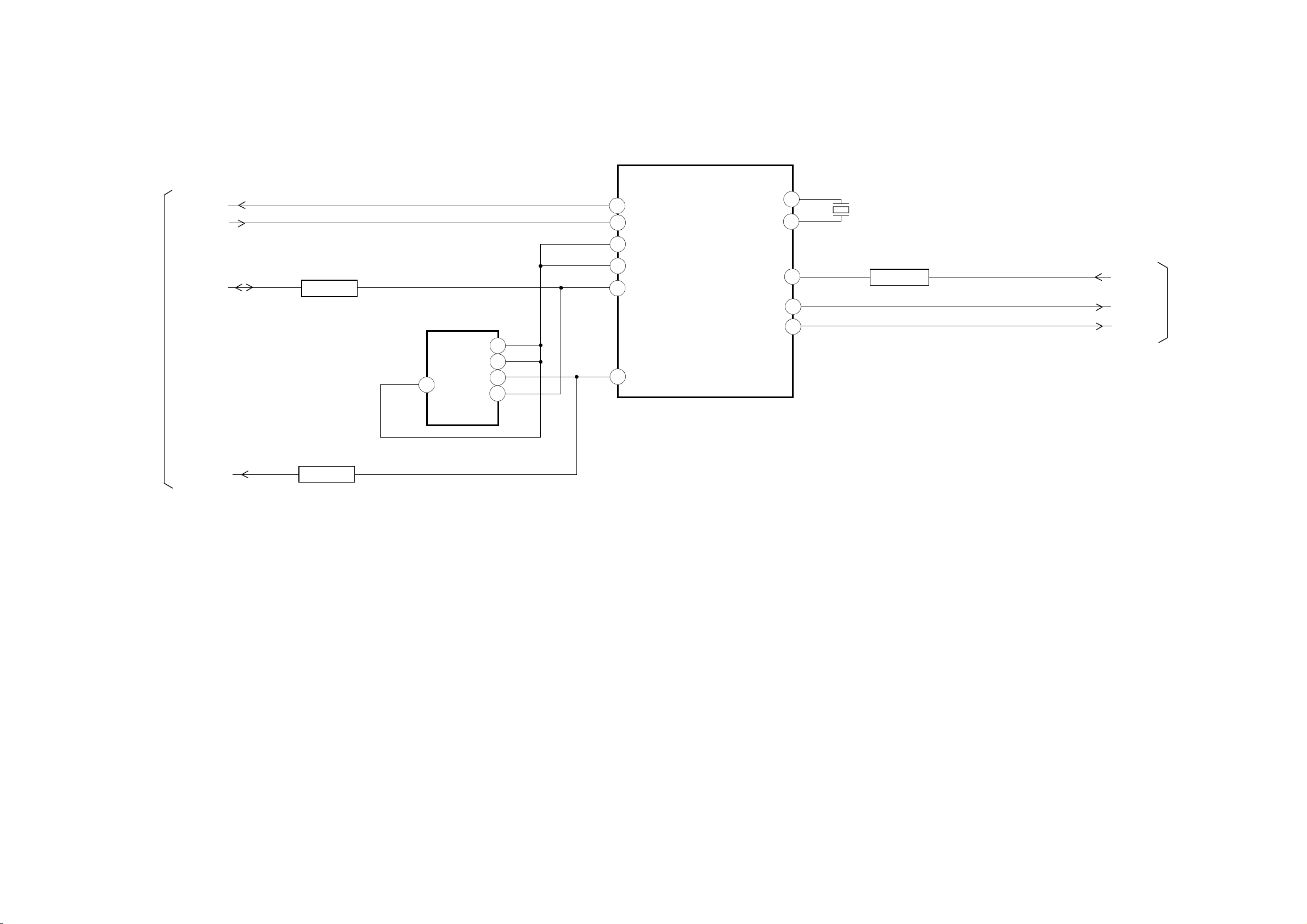

INTERFACE BLOCK DIAGRAM

IN

OUT

IN

OUT

HDMI

CONNECTOR

CP3601

19 DET

18

POWER

16

SDA

15

SCL

CLK-

12

10

CLK+

9 D0-

D0+

7

D1-

6

D1+

4

D2-

3

1

D2+

HDMI

CONNECTOR

CP3603

19 DET

18

POWER

16

SDA

15

SCL

CLK-

12

10

CLK+

9 D0-

D0+

7

D1-

6

D1+

4

D2-

3

1

D2+

EEP_ROM

IC3609 BR24L02F-WE2

5

SDA

6

SCL

7

WP

8

VCC

EEP_ROM

IC3606 BR24L02F-WE2

5

SDA

6

SCL

7

WP

8

VCC

Q3615

BUFFER

Q3603

BUFFER

Q3613

SW

L3601

ACM2012D-900-2P-T00

1

2

L3602

ACM2012D-900-2P-T00

1

2

L3608

ACM2012D-900-2P-T00

1

2

L3606

ACM2012D-900-2P-T00

1

2

4

3

L3603

ACM2012D-900-2P-T00

1

2

4

3

L3604

ACM2012D-900-2P-T00

1

2

4

3

L3607

ACM2012D-900-2P-T00

1

2

4

3

L3605

ACM2012D-900-2P-T00

1

2

Q3619

SW

Q3616

BUFFER

Q3604

BUFFER

4

3

4

3

4

3

4

3

HDMI INTERFACE

IC3605 SII9023CTU

DSDA1

29

DSCL1

30

DSDA0

31

DSCL0

32

39

R0XC-

40

R0XC+

R0X0-

43

44

R0X0+

R0X1-

47

48

R0X1+

51

R0X2R0X2+

52

R1XC-58

59

R1XC+

R1X0-

62

63

R1X0+

R1X1-

66

67

RX1+

70

R1X2R1X2+

71

Q23

Q20

Q19

Q16

Q15

Q12

Q11

Q7

Q6

Q5

Q4

Q0

ODCK

HSYNC

VSYNC

SCK

WS

SD0

OVCC

OVCC

OVCC

OVCC

OVCC

OVCC

OVCC

CSCL

CSDA

RESET#

INT

VCC

DVCC2

VCC

VCC

DVCC

VCC

VCC

VCC

CVCC1.8

VCC

DVCC

110

113

116

119

123

126

129

133

136

137

140

144

121

2

3

86

85

84

5

26

76

89

109

122

134

28

27

102

104

105

94

92

79

74

114

128

139

22

23

35

3.3VREG

IC3602 BA00BC0WFP-E2

1

4

1.8VREG

IC3601 BD7820FP-E2

1

4

DIGITAL RGB

DDCK

DDHS

DDVS

SCK

WS

SDO

V_SYNC

CSCL

CSDA

RXT_RST#

H_INT

RXT0_RST

RXT1_RST

SCALER/LVDS/

MICON/ADC/JACK/

REGULATOR

AV SWITCH/

21PIN/STEREO/

SOUND AMP/

HEADPHONE/TUNER

MICON2

E-5

E-6

INTERFACE

RXT_RST#

H_INT

CSDA

Q3606

BUFFER

EEP ROM IC

IC3608

BR24L32F-WE2

VCC

WP

SCL

A2

3

SDA

MICON2 BLOCK DIAGRAM

HDMI MICON IC

IC3611

SST89E58RD2-40-C-TQJE

15

RX1_RST

36

8

38

29

3

RX1_INT

VCC

EA-/VPP

CSDA

X1

X2

V-SYNC

RXT0_RST

RST1_RST

14

41

22

23

8

7

6

2

CSCL

5

X3601

11.0592MHz

Q3620

LEVEL SHIFT

DDVS

RXT0_RST

RXT1_RST

INTERFACE

CSCL

Q3605

BUFFER

E-7

E-8

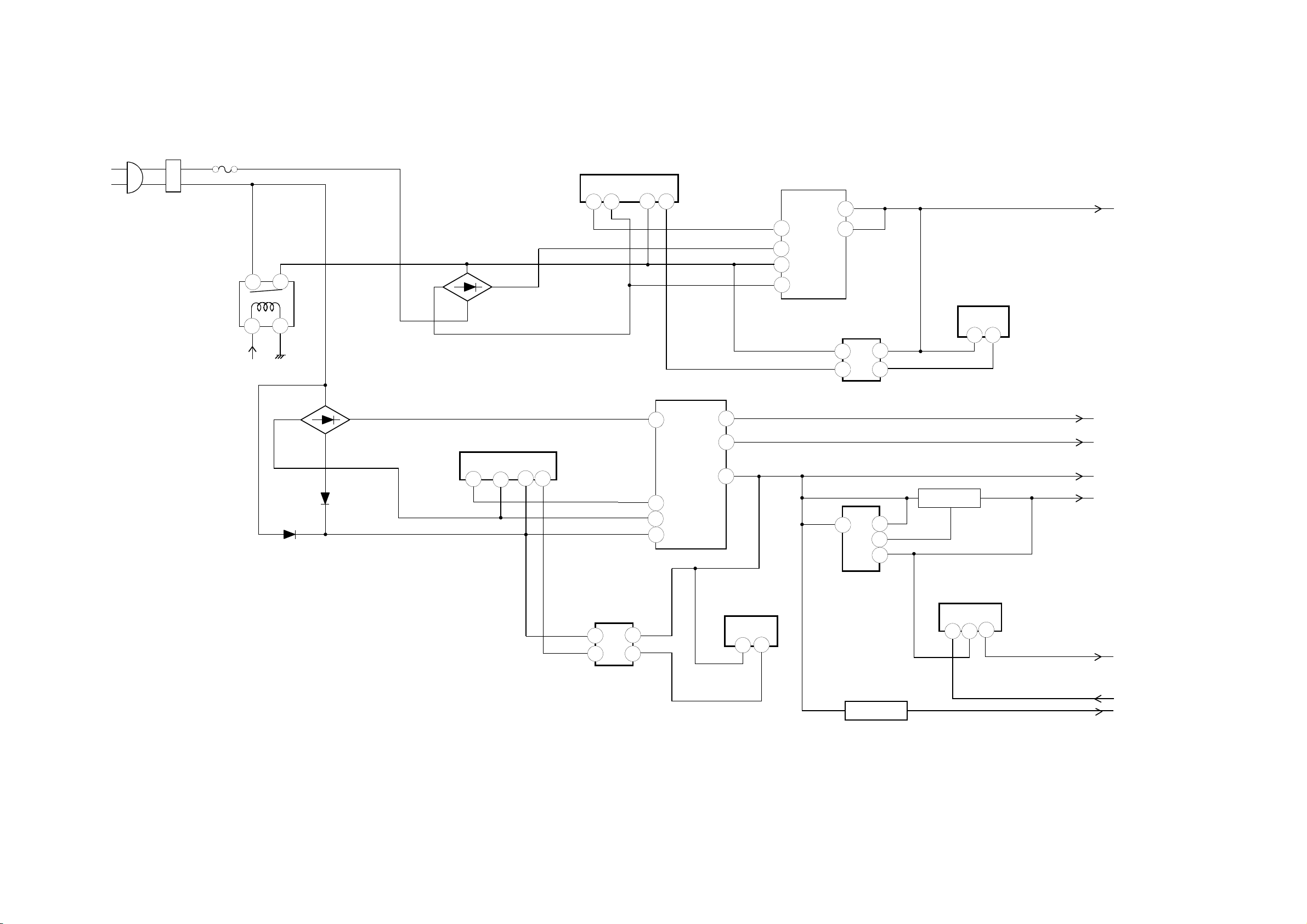

POWER2 BLOCK DIAGRAM

AC IN

CD3810

J501

F501

RELAY

RY501

4

1

AT+5V

3

2

D533

D509

D525

D508

POWER SW CTL

IC503 STR-W6765

S/GND

D

1

POWER SW CTL

IC502 STR-X6768N

S

D Vcc

2

Vcc

FB

4

3

6

FB

41

6

TRANSFORMER

T501

1

4

7

8

15

11

14

TRANSFORMER

T502

5

3

8

7

PS2561AL1-1-V(W)

12

13

FEED BACK

IC512

4

3

1

1

2

8

7

5

REGULATOR

IC504 KIA431A-AT

Q504

SW

+24V

1

3

AT+32V

SOUND+B

LCD PANEL

AV SWITCH/21PIN/

STEREO/

SOUND AMP/

HEADPHONE/

AT+12V

AT+5V

TUNER

E-9

FEED BACK

IC511

PS2561AL1-1-V(W)

4

3

1

2

REGULATOR

IC501 KIA431A-AT

1

3

5V SW REG CTL

IC505

AL1015

Q507

SW

POWER SW CTL

IC508 BA7810T-V5

4

2

1

SCALER+2.5V

P.CON+5V

POWER FAIL

E-10

Loading...

Loading...