Page 1

FILE NO. 020-200405

DOCUMENT CREATED IN JAPAN, Jun., 2004

SERVICE MANUAL

LCD Color Television

26HL84

Page 2

TABLE OF CONTENTS

SERVICE SAFETY PRECAUTIONS.................................................................................................................................... 3

HANDLING THE LCD MODULE .......................................................................................................................................... 5

SERVICE MODE.................................................................................................................................................................. 7

TROUBLESHOOTING DIAGNOSIS FUNCTION ................................................................................................................ 8

LOCATION OF CONTROLS ..............................................................................................................................................10

LAYOUT OF MAJOR BOARDS ......................................................................................................................................... 12

MECHANICAL DISASSEMBLY ......................................................................................................................................... 13

EXPLODED VIEW ............................................................................................................................................................. 26

PACKING DISASSEMBLY ................................................................................................................................................. 30

CHASSIS AND CABINET REPLACEMENT PARTS LIST ................................................................................................. 31

PC BOARDS BOTTOM VIEW ........................................................................................................................................... 39

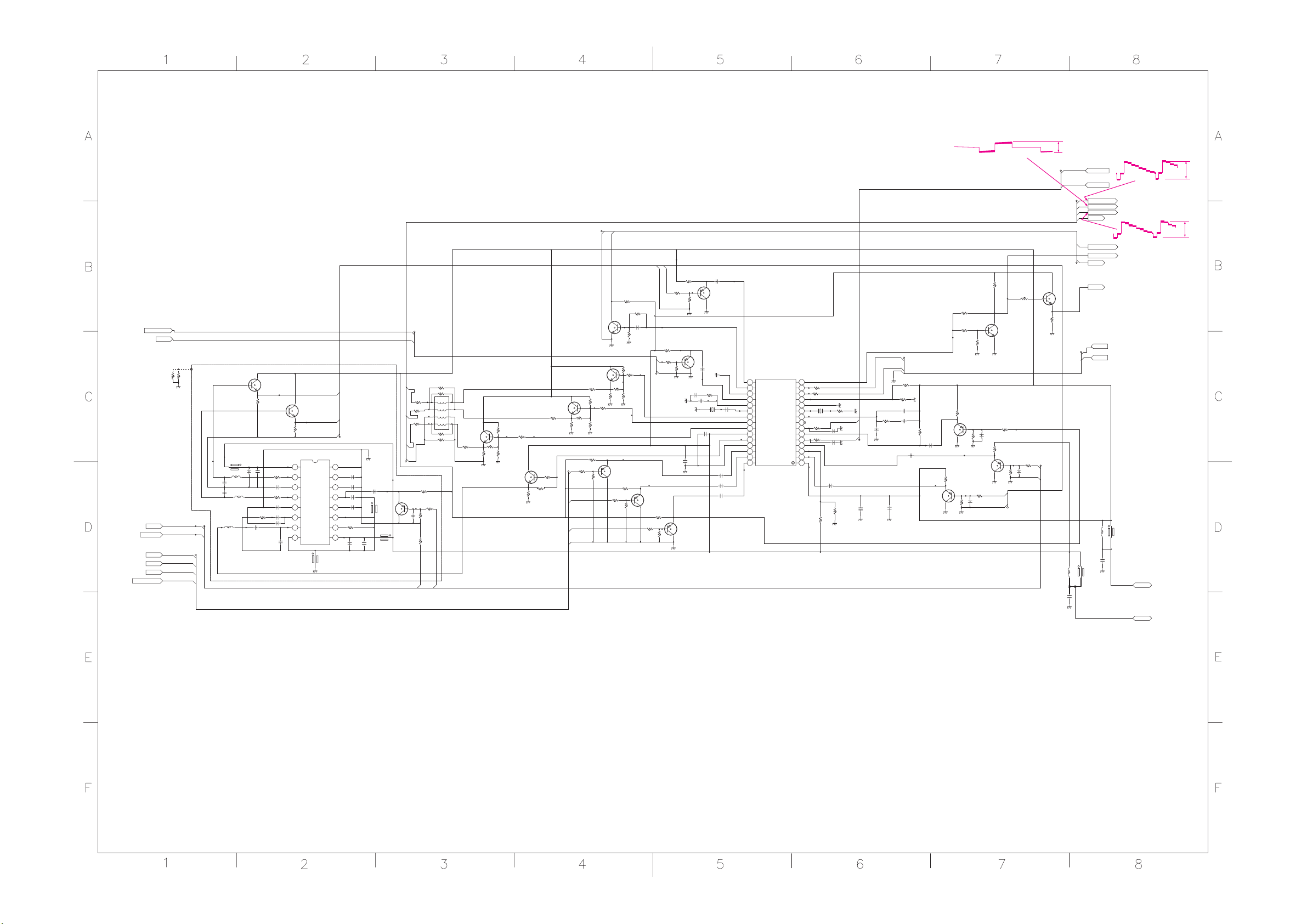

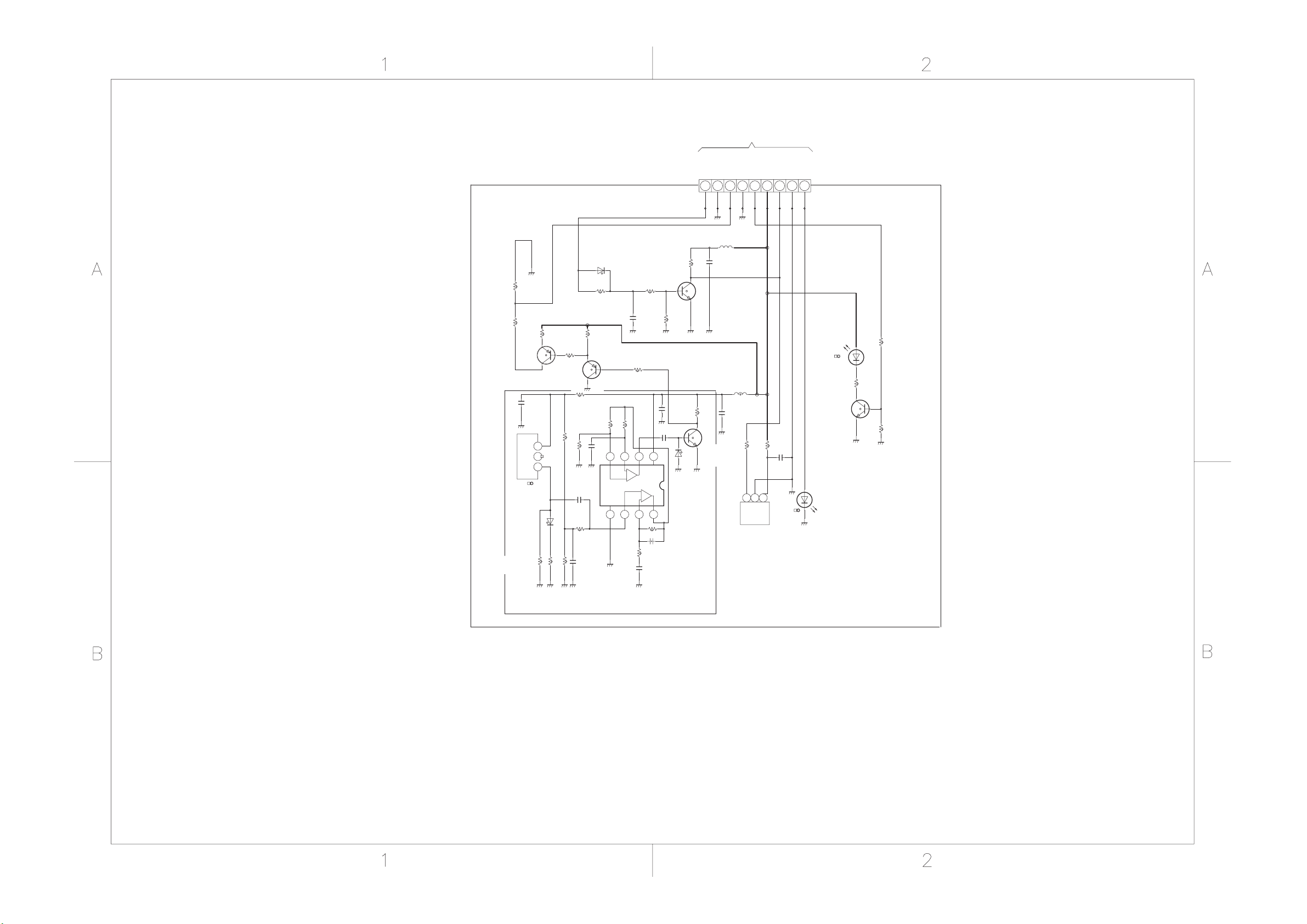

CIRCUIT BLOCK DIAGRAM ............................................................................................................................................. 53

SPECIFICATIONS.......................................................................................................................................................... END

APPENDIX:

SCHEMATIC DIAGRAM

– 2 –

Page 3

SERVICE SAFETY PRECAUTIONS

• The caution items shown here describe major safety issues and should always be observed.

• The meanings of the various indications are as follows.

WARNING

CAUTION

*Physical damage means major damage to a home, furnishings and other possessions.

Examples of marks

SHOCK HAZARD

PROHIBIT DISASSEM-

BLING

UNPLUG

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users due to a product defect after the service operation is completed, could possibly be in

danger of injury or even death in the event of operational error.

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users after the service operation is completed, could possibly be in danger of injury, or

where there could be physical damage in the event of operational error.

The " indicates caution (including danger and warning).

The actual meaning of this caution is indicated inside the " or nearby illustrations or text.

The example shown to the left indicates the danger of "electrical shock".

indicates a forbidden action.

The

The actual meaning of this caution is indicated inside the or nearby illustrations or text.

The example shown to the left indicates that disassembly is forbidden.

The - indicates a forced action (an action that must be performed).

The actual meaning of this forced action is indicated by - or nearby illustrations or text.

The example shown to the left indicates that the power plug must be disconnected.

– 3 –

Page 4

KEEP CHILDREN

AWAY

UNPULUG

SHOCK HAZARD

USE SPECIFIED

PARTS

CAUTION FOR

WIRING

CAUTION FOR

ASSEMBLING /

WIRING

WARNING

• Always advise users to keep children away.

There is danger of injury to children from tools, disassembled products, etc.

• Always disconnect the power plug before starting work whenever power is not required.

Failure to disconnect the power plug before starting work can result in electrical shock.

• Depending on the model, use an insulation transformer or wear gloves when servicing with the

power on, and disconnect the power plug to avoid electrical shock when replacing parts.

In some cases, alternating current is also impressed in the chassis, so electrical shock is possible if the chassis is contacted with the power on.

• Always use the replacement parts specified for the particular model when making repairs.

The parts used in products have the necessary safety characteristics such as inflammability,

voltage resistance, etc.; therefore, use only replacement parts that have these same characteristics.

Use only the specified parts when the mark is included in a circuit diagram or parts list.

• Parts mounting and routing of the wiring should be the same as that used originally.

For safety purposes, insulating materials such as tubing or tape is sometimes used and printed

circuit boards are sometimes mounted floating.

Also make sure that wiring is routed and clamped to avoid parts that generate heat and which

use high voltage. Always follow the original scheme.

• After a repair has been completed, reassemble all disassembled parts, and route and reconnect the wiring, in accordance with the original scheme.

Do not allow internal wiring to be pinched by cabinets, panels, etc.

Any error in reassembly or wiring can result in electrical leakage, flame, etc., and may be

hazardous.

CHECK INSULATION

RESISTANCE

PROHIBIT

REMODELING

• After completing the work, disconnect the power plug from the outlet, remove the antenna, turn

on the power switch. Then, use a 500V insulation resistance meter to check the insulation

resistance of the antenna terminal, other metallic parts and between the prongs of the power

plug to make sure that the insulation resistance is 1M Ω or more.

The set will require inspection and repair if the insulation resistance is below this value.

• Never remodel the product in any way.

Remodeling can result in improper operation, malfunction, or electrical leakage and flame,

which may be hazardous

– 4 –

Page 5

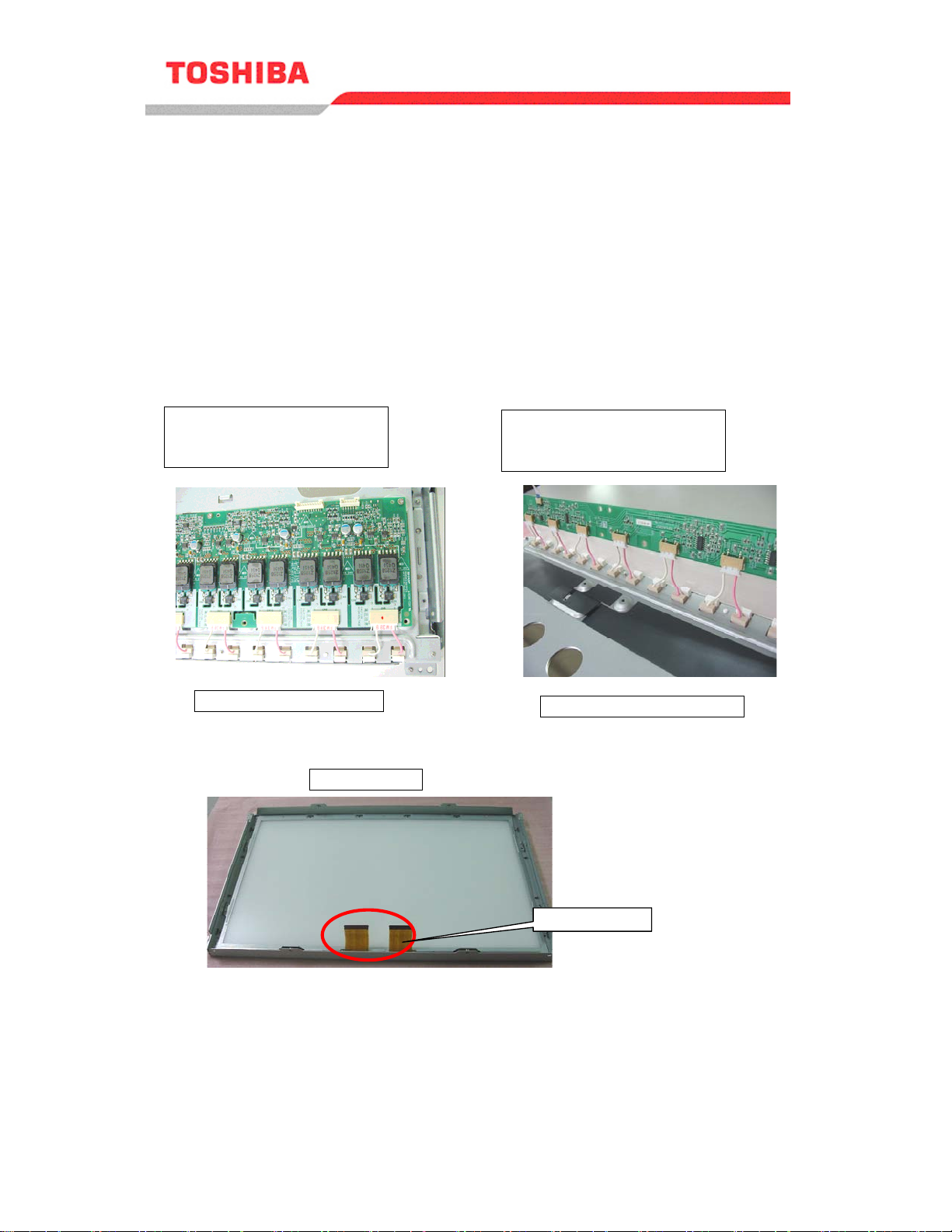

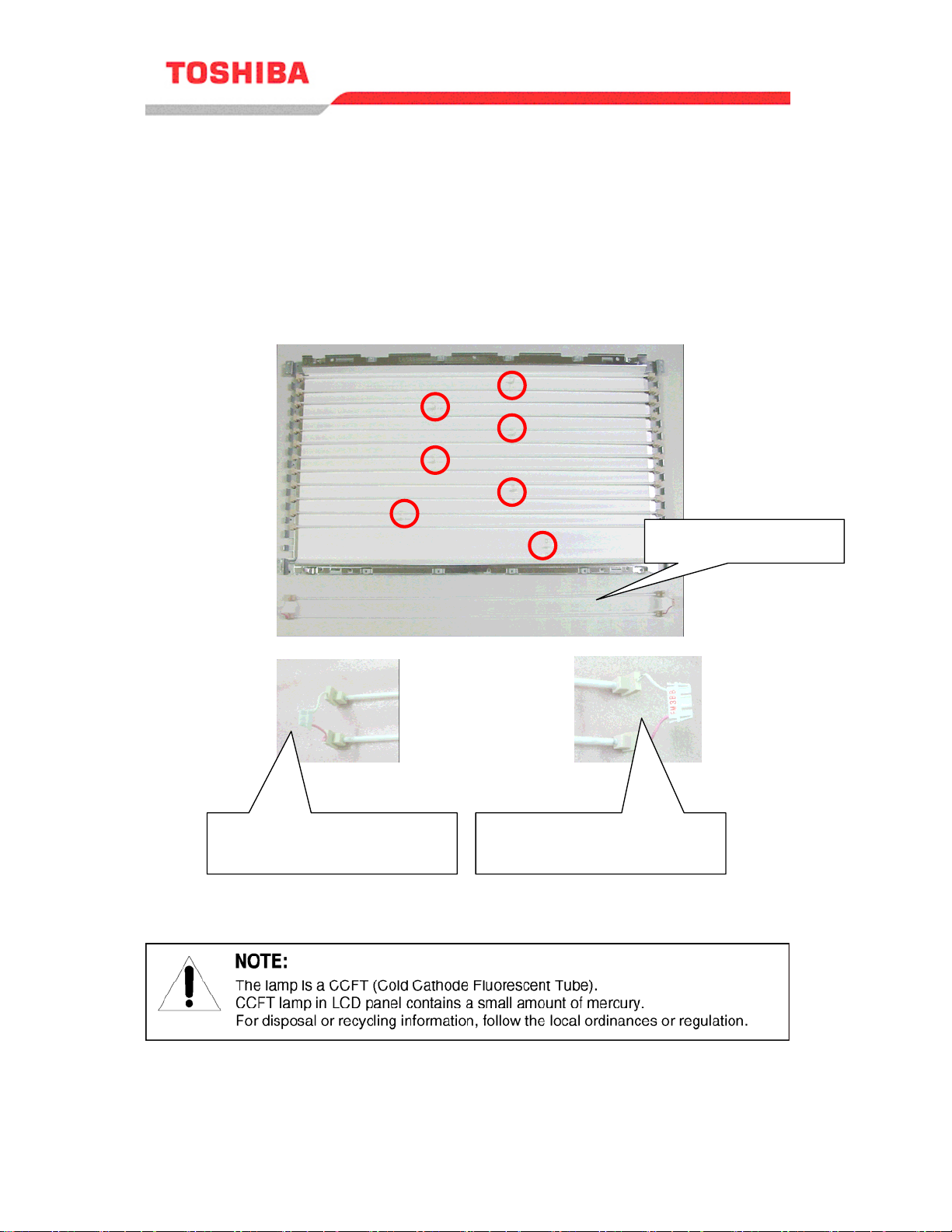

HANDLING THE LCD MODULE

Safety Precautions

In the event that the screen is damaged or the liquid crystal

(fluid) leaks, do not breathe in or drink this fluid. Also, never

touch this fluid.

Such actions could cause toxicity or skin irritation. If this fluid

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the skin or clothing, wipe off

with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly

with running water.

Precautions for Handling the LCD Module

The LCD module can easily be damaged during disassembly

or reassembly; therefore, always observe the following precautions when handling the module.

1. When attaching the LCD module to the LCD cover, position it appropriately and fasten at the position where the

display can be viewed most conveniently.

3. If the panel surface becomes soiled, wipe with cotton or a

soft cloth. If this does not remove the soiling, breathe on

the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleaner

as a cleaner. Wipe off the panel surface by drop the cleaner

on the cloth. Do not drop the cleaner on the panel. Pay

attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for an

extended period of time can result in discoloration or

stripes. Immediately remove any type of fluid from the

screen.

2. Carefully align the holes at all four corners of the LCD

module with the corresponding holes in the LCD cover

and fasten with screws. Do not strongly push on the module because any impact can adversely affect the performance. Also use caution when handling the polarized screen

because it can easily be damaged.

The metal edges of the LCD module

CAUTION

are sharp, so use caution to avoid injury.

5. Glass is used in the panel, so do not drop or strike with

hard objects. Such actions can damage the panel.

6. CMOS-LSI circuitry is used in the LCD module, so avoid

damage due to static electricity. When handling the module, use a wrist ground or anchor ground.

– 5 –

Page 6

7. Do not expose the LCD module to direct sunlight or strong

ultraviolet rays for an extended period of time.

8. Do not store the LCD module below the temperature conditions described in the specifications. Failure to do so

could result in freezing of the liquid crystal due to cold air

or loss of resilience or other damage.

9. Do not disassemble the LCD module. Such actions could

result in improper operation.

10. When transporting the LCD module, do not use packing

containing epoxy resin (amine) or silicon resin (alcohol or

oxim). The gas generated by these materials can cause

loss of polarity.

– 6 –

Page 7

SERVICE MODE

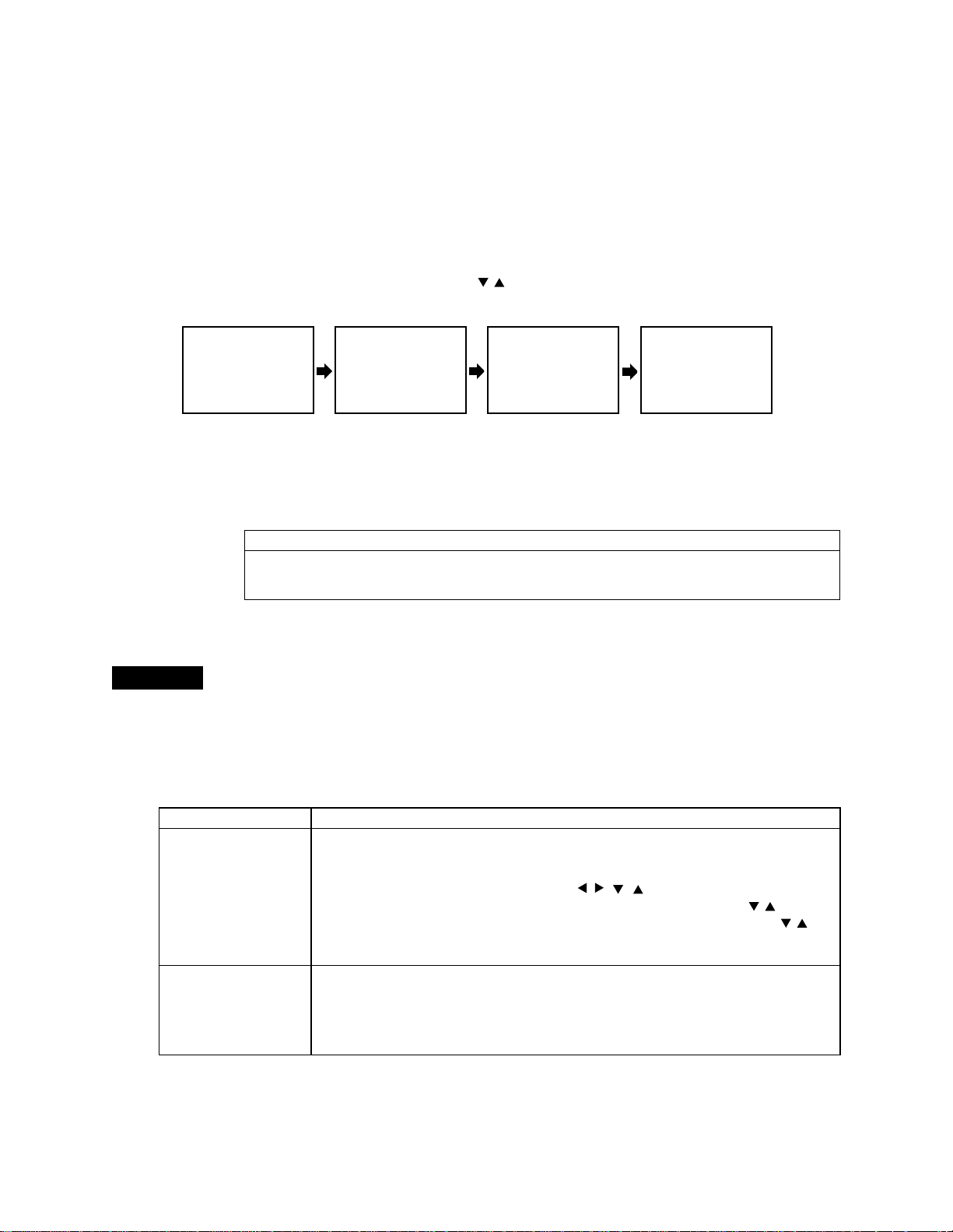

ENTERING TO SERVICE MODE

1) Press the "MUTE" button once on the remote control, "1/2 MUTE" is displayed on the screen.

2) Press the "MUTE" button again, "MUTE" is displayed on the screen.

3) Press the "MENU" button on the TV while pressing the "MUTE" button on the remote control, "S" may appear

on the screen. Then enter to the service mode.

4) Press the "MENU" button on the remote control, adjustment item appears on the screen.

NOTE

Adjustment items may change by pressing the "CH

1) 2) 3) 4)

" buttons on the remote control.

S

1/2 mute

* EXIT FROM SERVICE MODE-Turn off the "POWER" of the TV or remote control.

Built-in signal

.

When press the "INPUT" source selection button on the remote controller during service mode,

generate the built-in test video signal for servicing.

Built-in test video signal (Use for the adjustment such as white balance, etc.)

General broadcasting signal => red monochrome => green monochrome

=> blue monochrome => white signal => black cross bar => built-in signal OFF

mute

(Service mode screen)

RCUT

60H

CAUTION

For the video system adjustment, never attempt to initialize the data unless initial setting data is exceed

incorrectly.

Adjustment items

Brightness correction

(BRTC)

White balance

(RCUT) (GCUT) (BCUT)

Adjustment procedure

1) Receive a general broadcasting program, then press "MENU" button on the

remote control, set the unicolor to minimum (00) and brightness to standard (00)

in order to display the "Setting menu" => "Picture setting" => "Picture adjust-

ment" by pressing the cursor buttons "

2) Select BRTC (brightness correction) using the cursor buttons "CH

remote control, fine adjust the black signal to be black using the "VOL "

buttons on the remote control. After the adjustment, set "unicolor" back to

initialize data.

1) Enter the service mode, press the "INPUT" source setting button on the remote

control to generate the built-in white signal.

2) Adjust the data of items RCUT, GCUT and BCUT for proper white-balanced

picture in low light area.

* For high

light area, GDRV and RDRV items can be adjusted for proper white-balanced picture.

– 7 –

".

" on the

Page 8

TROUBLESHOOTING DIAGNOSIS FUNCTION

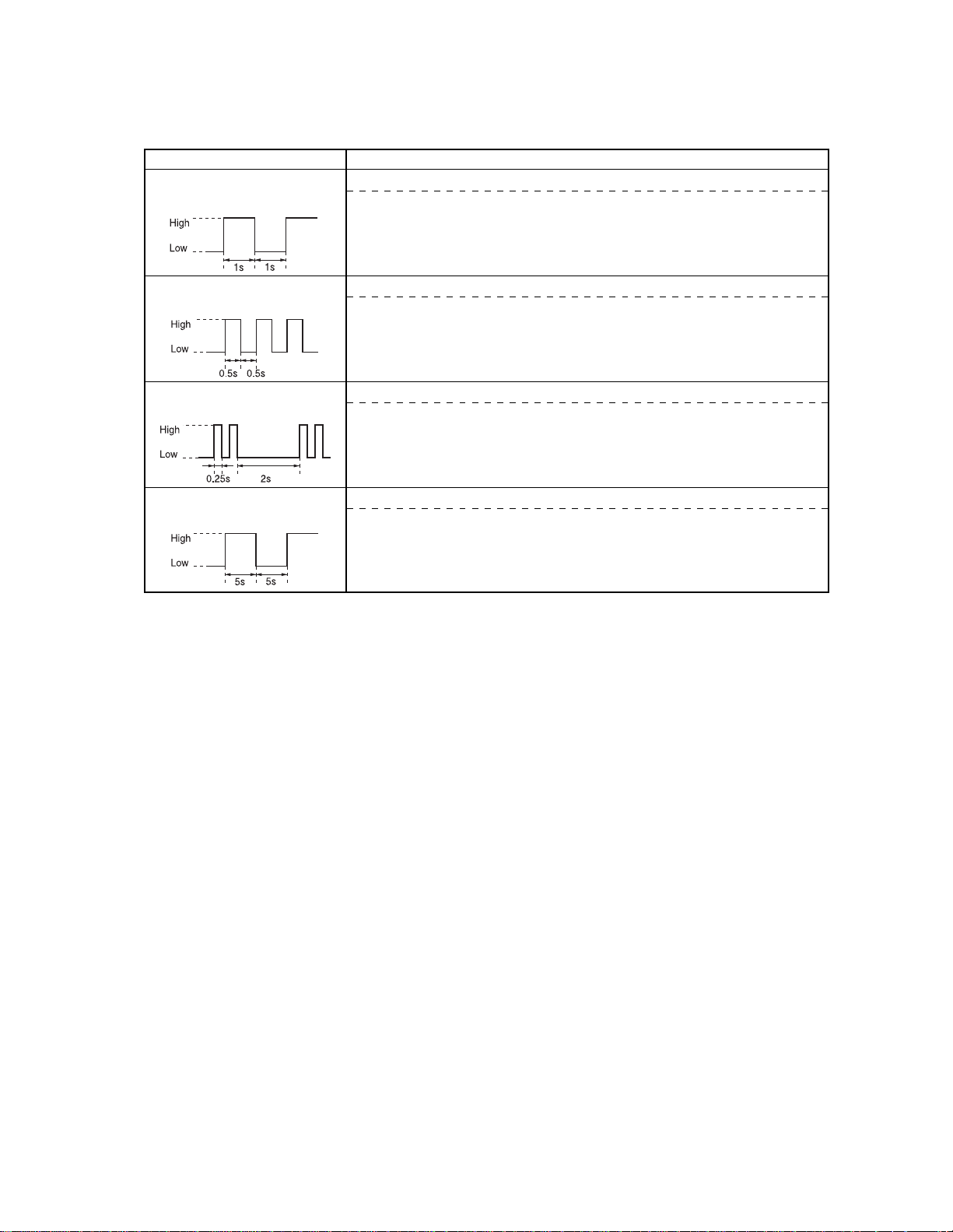

1. DIAGNOSIS FUNCTION FOR LED INDICATION

LED

LED is lit in 1 second at

intervals of 1 second.

Short-circuit detection of BUS line

BUS line may possibly be short-circuit (SDA to SCL), or BUS line (SDA,

SCL) is grounded.

CAUSE

LED is lit in 0.5 at intervals

of 0.5 second.

LED is lit in 0.25 second at

intervals of 2 second.

LED is lit in 5 seconds at

intervals of 5 seconds.

High : Lighting Low : No Lighting

Overcurrent limiter detection

POWER terminal on TV microprocessor becomes LOW at 2 seconds or

more.

Interruption of FAN motor function detection

No. 53 terminal on TV microprocessor becomes HIGH for 30 seconds.

Abnormal sound detection

P4 terminal of QS10 becomes LOW for 15 seconds during Speaker is

activated.

– 8 –

Page 9

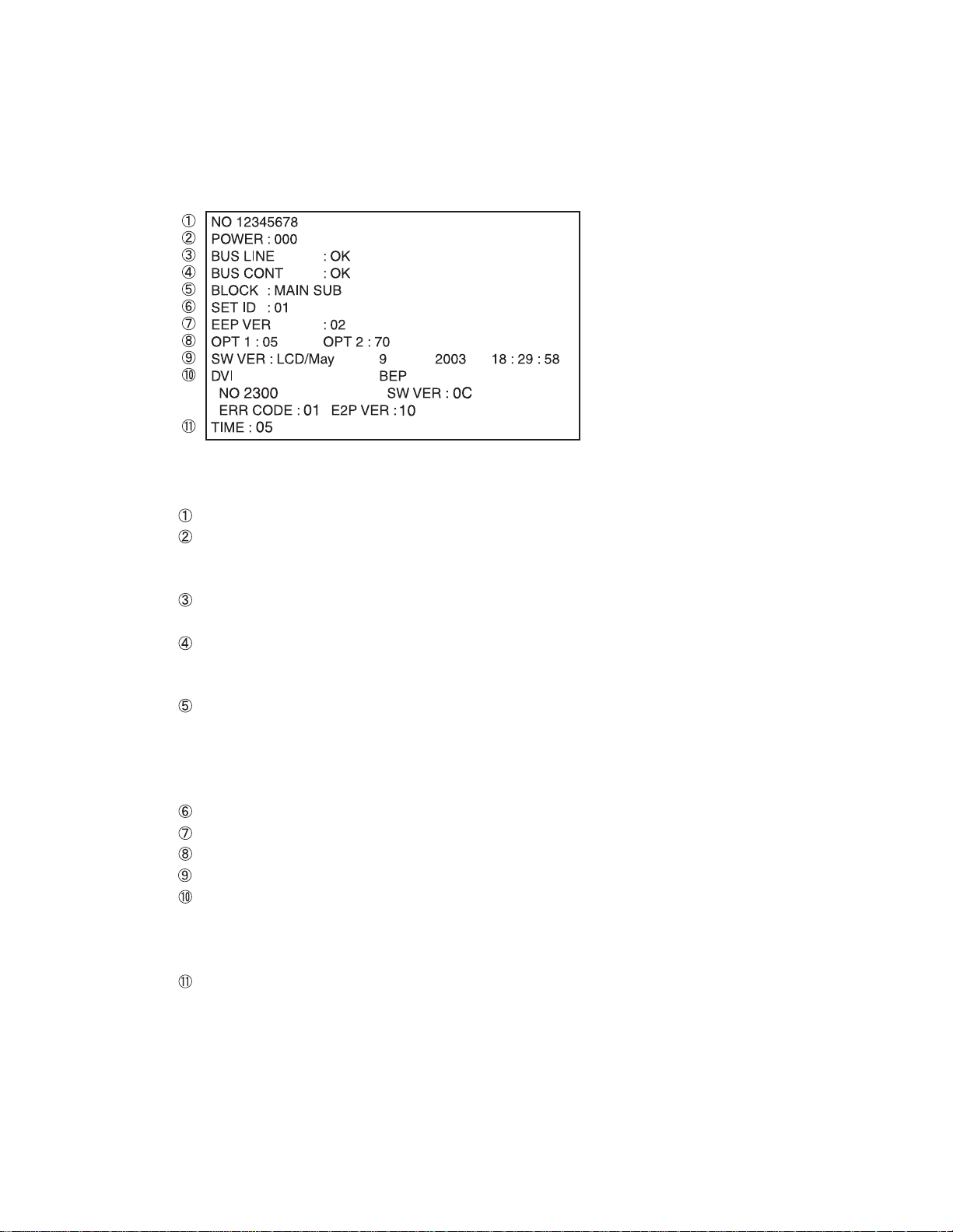

2. SELF DIAGNOSIS FUNCTION

1) Press "9" button on the remote control during display of adjustment menu in the service mode.

2) During diagnosis, the following displays are shown.

<SELF CHECK>

Part number of microprocessor

Operation number of protecting circuit ------"00" is normal.

When indication is other than "00", overcurrent is apt to flow, and circuit parts may possibly be damaged.

BUS LINE ------"OK" is normal.

When indication shows "NG (Green: OK, Red: NG)", the BUS line may possibly be short-circuit.

BUS CONT------"OK" is normal.

When indication shows "Q uuu (Green: OK, Red: NG )", the device with the number may possibly be

damaged.

BLOCK

MAIN : Main picture display --Green indication

Main picture does not display--Red indication

SUB : Sub picture display --Green indication

Sub picture does not display--Red indication

ID number of this unit.

EEP of soft version information

Data number of OPT1 and OPT2

Software version information of host microprocessor (date indication)

DVI NO : DVI number information

DVI ERR CODE : DVI status code number

BEP SW VER : Software version information for BEP microprocessor

BEP E2P VER : Software version information for BEP E2P

Total hour of turn the TV on. (Unit: hour)

*INITIALIZATION OF SELF DIAGNOSIS DATA

1) Enter the service mode, then select any register item.

2) Press and hold the RECALL button on the remote control, then press the CHANNEL up button on the TV. The

initialization has been completed.

– 9 –

Page 10

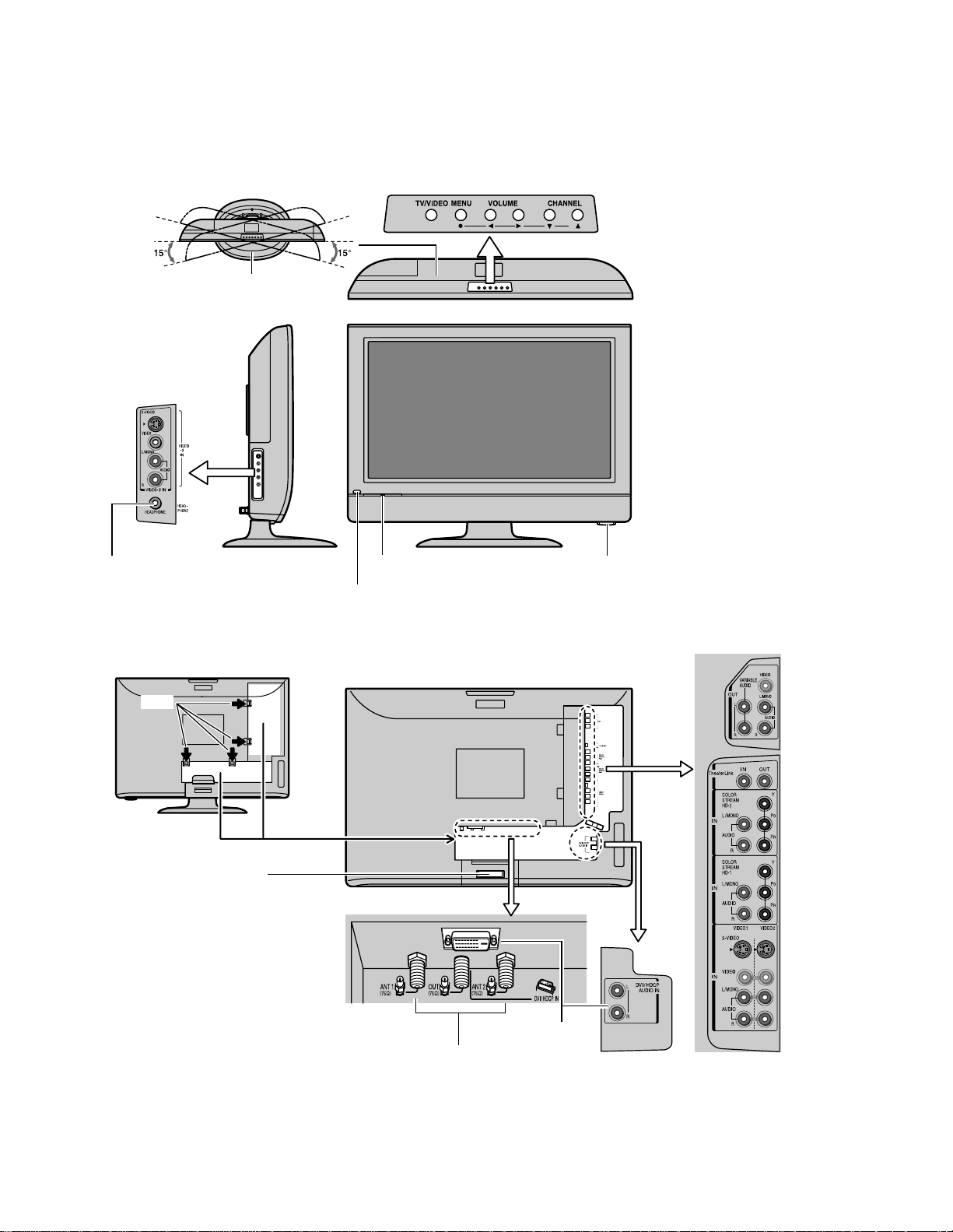

Terminals

(VIDEO 3)

LOCATION OF CONTROLS

Control panel

To p

Swivel base

FrontSide

GENERAL ADJUSTMENTS

POWER

Headphone jack

Back

Push

Remove

the covers

Cable clamper

(Supplied: see page 8)

Power indicator

Remote sensor

POWER

SPECIFIC INFORMATIONS

Terminals

• VIDEO/AUDIO OUT

• VARIABLE AUDIO OUT

Antenna terminals

– 10 –

DVI/HDCP IN

Terminals

• VIDEO 1 IN

• VIDEO 2 IN

• ColorStream HD-1/2

• TheaterLink IN/OUT

Page 11

Learning about the remote control

The buttons used for operating the TV only are described here. For a

complete list of the remote control’s functions, see the “Remote

Control functional key chart” on pages 19–20.

POWER turns the TV on and off

SLEEP allows access to the automatic TV shut-off function (page 53)

LIGHT The first press of the LIGHT button lights the keypad and turns

on the Illumination mode. With the Illumination mode on,

pressing any other key lights the keypad for 5 seconds (10 seconds

if you’re in programming mode).

Subsequent presses of the LIGHT button toggle between turning

the Illumination mode on and off.

Channel Numbers (0-9, 100) allow direct access to channels (page 30)

MODE cycles through the six device modes: TV, CABLE/SAT, VCR,

DVD, AUDIO1, and AUDIO2. The mode indicator light will

remain lit for a few seconds (page 21).

PIC SIZE cycles through the five pictures sizes: Natural, Theater Wide 1,

2, 3, and Full (page 34)

FAVORITE allows access to the favorite channel search function (page 41)

MENU allows access to on-screen programming menus (page 26)

ENTER sets programming menu information (page 26)

yz x • select or adjust programming menus (page 26)

FAV yzcycles through favorite channels (page 32)

CH yz cycles through programmed channels (page 29)

VOL yz adjusts the volume level

EXIT exits the programming menus (page 26)

INPUT selects the video input source (page 50)

MUTE mutes the sound (page 54)

RECALL displays on-screen information (page 60)

CH RTN returns to the last viewed channels (page 31)

POP CH yz selects the POP (picture-out-picture) channel (page 38)

SPLIT turns the POP feature on and off (page 38)

CH SCAN

FREEZE freezes the POP picture (page 39)

SWAP switches the main and POP pictures (page 39)

allows access to the programmed channel search function (page 40)

Note:

The error message “Not Available” will appear

if you press a key for a function that is not

available.

POP DIRECT CH allows direct access to POP channels (page 38)

SOURCE selects the POP picture source (page 38)

– 11 –

Page 12

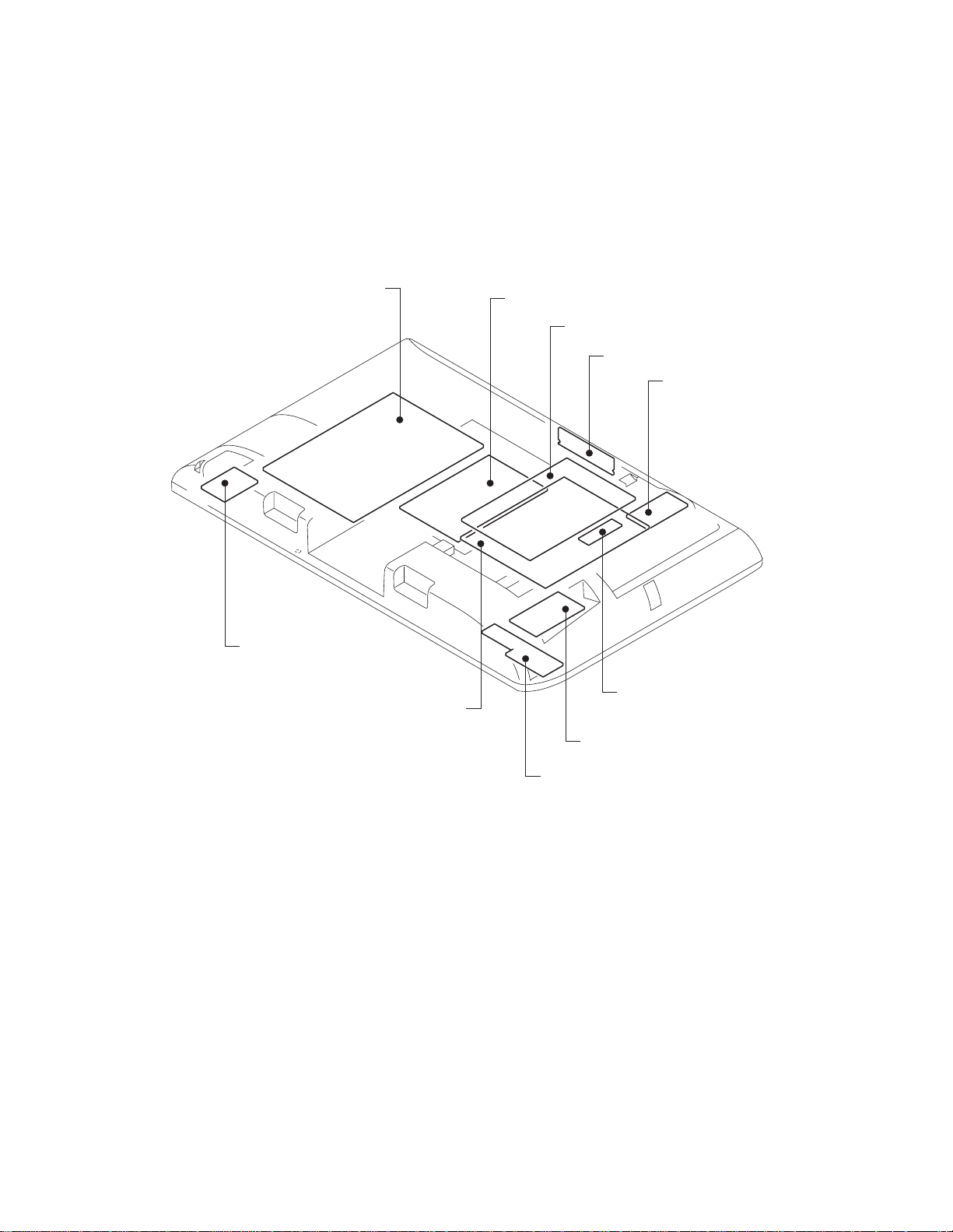

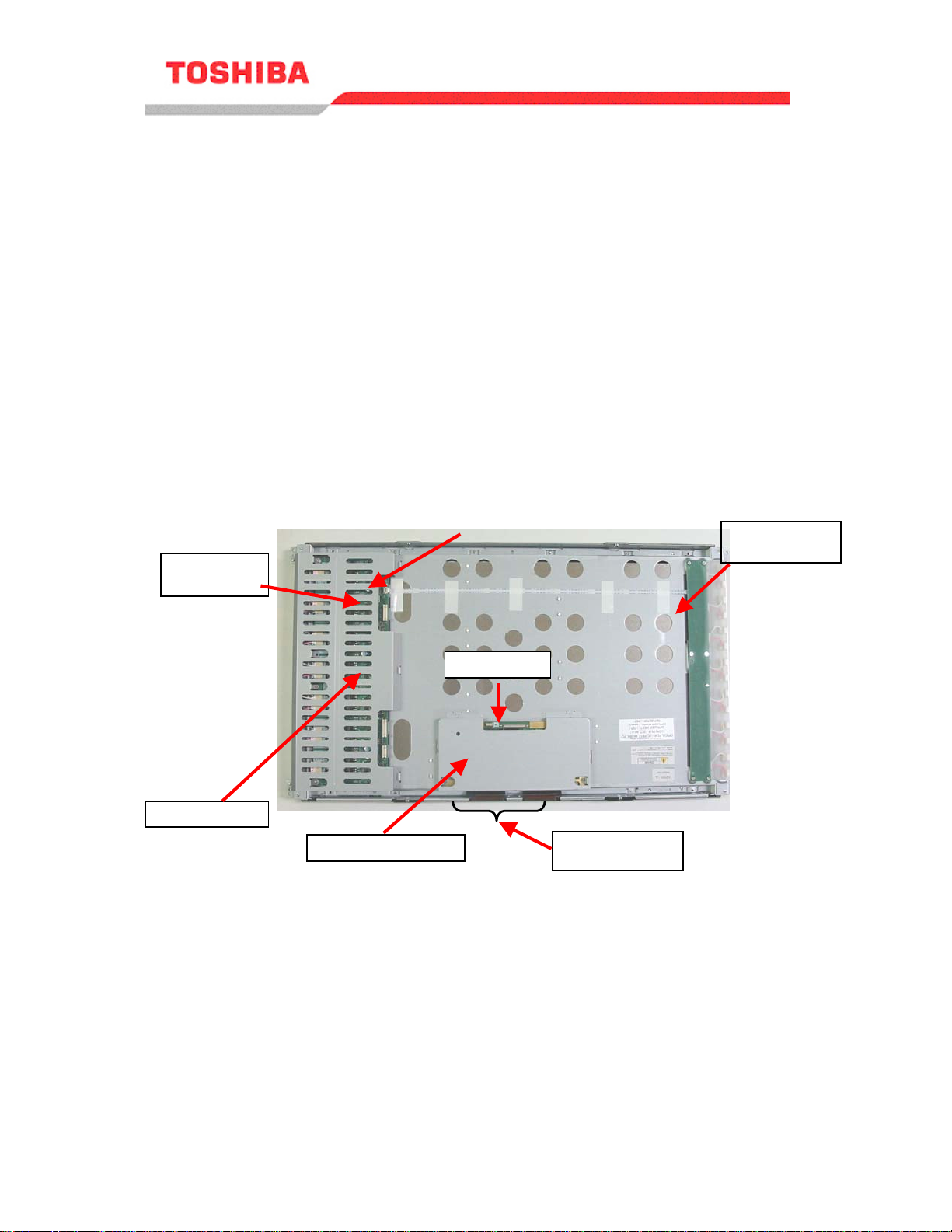

LAYOUT OF MAJOR BOARDS

U800 POWER MODULE UNIT

U901D POWER SW Board

U901A SIGNAL Board

U902A TN/AOUT Board

U903 SCALER Board

U901E KEY SW Board

U901C AV2 Board

U901G D-REWRITE Board

– 12 –

U901B FRONT/AV Board

U901F LED/RMT Board

Page 13

MECHANICAL DISASSEMBLY

• Note: Be sure to lay down the main body (by placing its screen

downward) for disassembly.

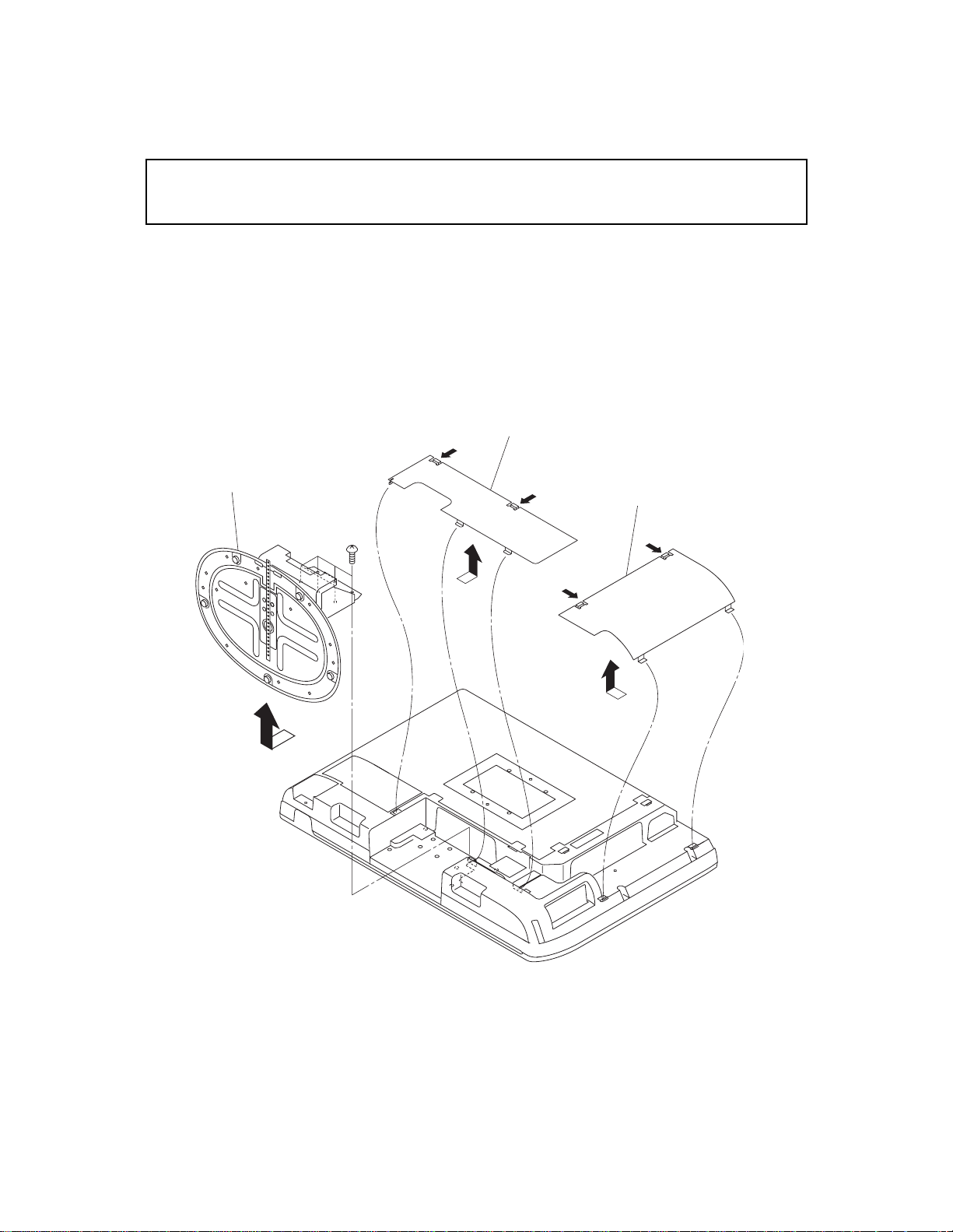

1. Removing the back cover

1) Remove the BC stand cover.

2) Remove the BC terminal cover.

3) Remove 6 screws, then remove the stand.

BC Stand Cover

Stand

BC Terminal Cover

PP 5x12

– 13 –

Page 14

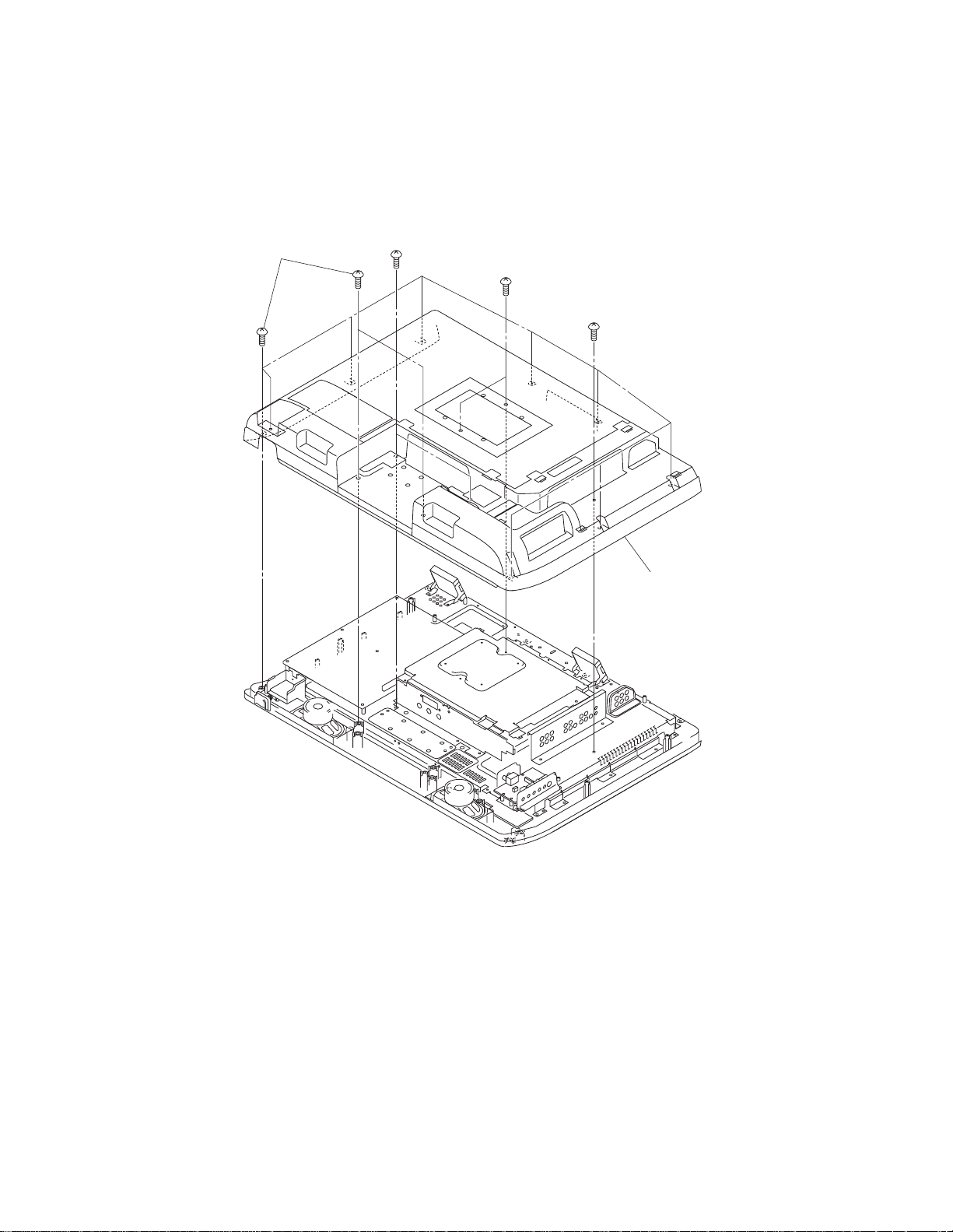

4) Remove 11 screws (PBI 4x12).

5) Remove 5 screws (PP 3x6).

6) Remove the back cover.

PBI 4x12

PP 3x6

PP 3x8

PP 3x8

Back Cover

– 14 –

Page 15

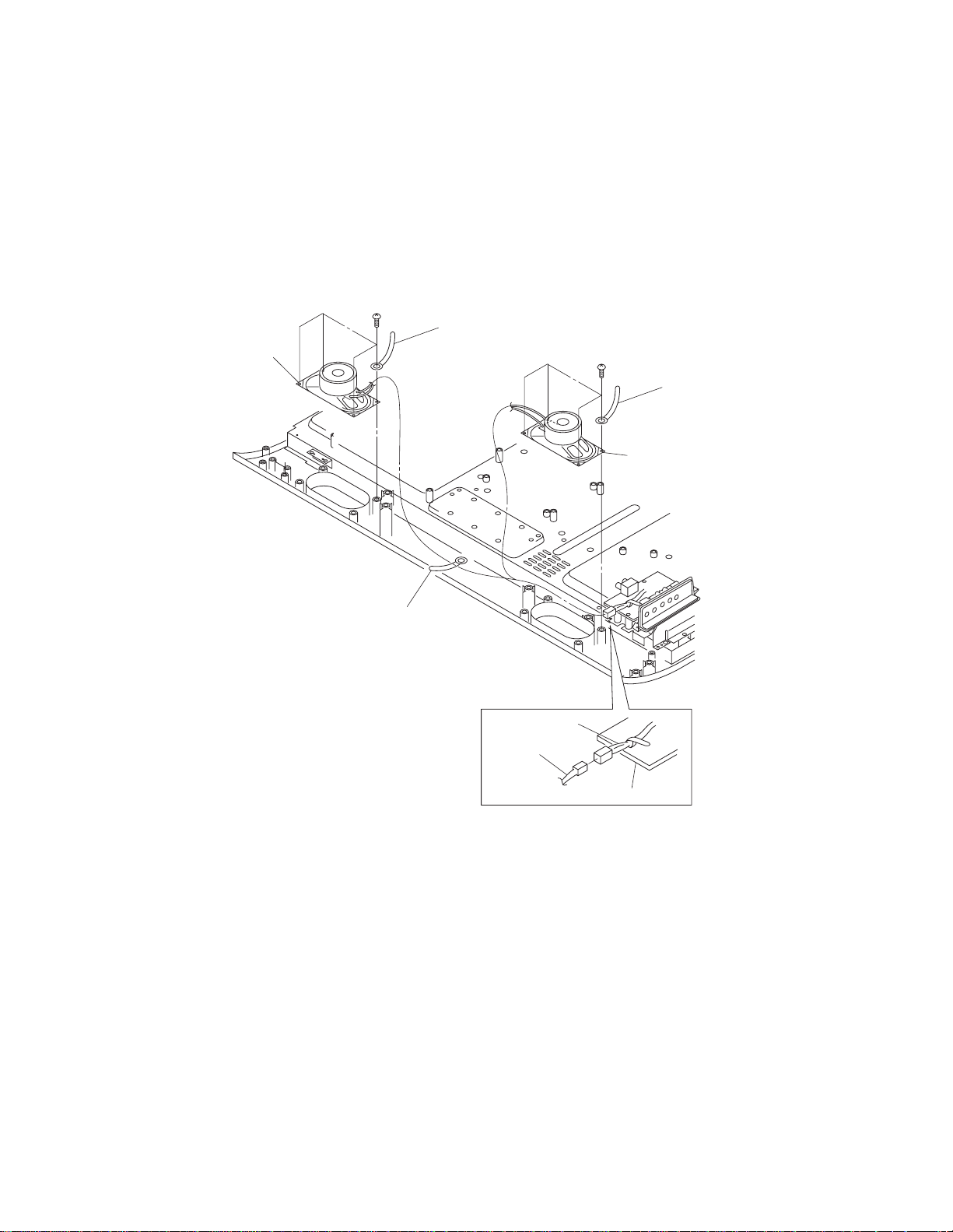

2. Removing the speakers

r

1) Remove the back cover. (Refer to Item 1.)

2) Disconnect the speaker wire harness on the Front/AV board.

3) Remove the wire harness of the 3 wire holders.

4) Remove 4 screws, then remove the left speaker and wire holder.

5) Remove 4 screws, then remove the right speaker and wire holder.

PBI 4x12

Wire holder

Speaker (R)

PBI 4x12

Wire holde

Speaker (L)

Wire holder

Wire harness

Speaker

wire harness

FRONT/AV Board

– 15 –

Page 16

3. Removing the top shield bracket

1) Remove the back cover. (Refer to Item 1.)

2) Remove 5 screws, then remove the top shield bracket.

Top Shield Braket

STP 3x8

STP 3x8

– 16 –

Page 17

4. Removing the Power Module unit

1) Remove the back cover. (Refer to Item 1.)

2) Disconnect the power cord from the connector.

3) Remove the 3 wire harnesses from the 3 wire clampers on the plate back R.

4) Disconnect the 8 wire harnesses from the 8 connectors on the Power Module unit.

5) Remove 7 screws, then remove the Power Module unit.

Power cord

STP 3x8

Wire Harnesses

POWER MODULE UNIT

Wire Harnesses

Plate Back R

– 17 –

Wire clampers

Page 18

5. Removing the Scaler board

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove 4 screws (STP3x6) and 2 screws (STP3x5), then remove the top shield RM.

4) Disconnect the 8 wire harnesses and 2 FFC from the Scaler board.

5) Remove 4 screws (STP3x5), then remove the Scaler board and bottom shield RM.

Wire harnesses

SCALER

board

FFC

DVI MODULE

Wire harnesses

STP 3x5

STP 3x6

STP 3x6

Top shield RM

STP 3x5

SCALER board

Wire harnesses

Bottom

shield RM

BIDT2

3 x10 BZ

ANT

Nuts

– 18 –

Page 19

6. Removing the D-Rewrite board

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove the Scaler board. (Refer to Item 5.)

4) Remove 2 screws, then remove the D-Rewrite board.

5) Disconnect the 2 wire harnesses and 1 FFC on the D-Rewrite board.

6) Remove 2 screws, then remove the digital unit bracket.

7) Remove 2 screws, then remove the scaler unit bracket.

Scaler unit bracket

Wire harnesses

FFC

D-REWRITE board

STP 3x8

STP 3x8

STP 3x8

Digital unit bracket

PP 3x6

– 19 –

Page 20

7. Removing the back terminal plate, back bottom plate and back R plate

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove the Scaler board. (Refer to Item 5.)

4) Remove the D-Rewrite board. (Refer to Item 6.)

5) Remove 5 screws (BIDT 2 3x10BZ) and 2 screws, then remove the back terminal plate.

6) Remove 2 screws (STP 3x8), 2 hexagon nuts and 1 toothed washer, then remove the back bottom plate.

7) Remove 5 screws (STP 3x8), then remove the back R plate.

STP 3x8

Back plate R

STP 3x8

Back terminal plate

Back bottom plate

STP 3x8

STP 3x8

BIDT2 3x10 BZ

– 20 –

Page 21

8. Removing the TN/AOUT, AV2 and Signal boards

Z

1) Remove the back cover. (Refer to Item 1.)

2) Remove the top shield bracket. (Refer to Item 3.)

3) Remove the Scaler board. (Refer to Item 5.)

4) Remove the D-Rewrite board. (Refer to Item 6.)

5) Remove the back plates. (Refer to Item 7.)

6) Remove the connector [A] and 3 harnesses from the TN/AOUT board.

7) Remove 5 screws (STP 3x8), then remove the TN/AOUT board.

8) Remove the connector [B] from the Signal board.

9) Remove 3 screws (STP 3x8), then remove the AV2 board.

10) Remove 1 screw (BIDT2 3x10BZ), then remove the AV2 panel.

11) Remove the 6 wire harnesses and 2 FFC from the Signal board.

12) Remove 5 screws (STP 3x8), then remove the Signal board.

TN/AOUT board

Connector [A]

Wire harnesses

STP 3x8

Wire harness

Wire harness

FFC

FFC

Connector [B]

STP 3x8

AV2

board

STP 3x8

Wire harness

SIGNAL

board

BIDT2 3x10 B

AV2 panel

SIGNAL board

– 21 –

Page 22

9. Removing the Front /AV board

1) Remove the back cover. (Refer to Item 1.)

2) Remove 1 screw (BIDT2 3x10 BZ).

3) Remove 2 screws (PP 3x6), then remove the front AV panel.

4) Remove 1 screw (BIDT2 3x10 BZ) and 1 screw (PP 3x6), then remove the rear AV panel.

5) Disconnect the 2 wire harnesses and 1 FFC from the Front/AV board.

6) Remove 2 screws (PP 3x6), then remove the wire holder and Front/AV board.

Wire harnesses

PP 3x6

Wire holder

FFC

PP 3x6

Rear AV panel

FRONT/AV board

PP 3x6

Front AV panel

BIDT2 3x10 BZ

– 22 –

Page 23

10. Removing the Power SW and LED/RMT boards

1) Remove the back cover. (Refer to Item 1.)

2) Remove 3 screws (STP 3x8), then remove the LED/RMT board.

3) Disconnect the 2 wire harnesses from the connector on the LED/RMT board.

4) Remove 2 screws (STP 3x8), then remove the switch cover and cap.

5) Disconnect the wire harness from the connector on the Power SW board.

6) Remove 3 screws (STP 3x8), then remove the Power SW board.

Wire harness

STP 3x8

STP 3x8

POWER SW

board

Switch cover

Cap

STP 3x8

LED/RMT board

Wire harnesses

– 23 –

Page 24

11. Removing the chassis frame

1) Remove the back cover. (Refer to Item 1.)

2) Remove the speakers. (Refer to Item 2.)

3) Remove the top shield bracket. (Refer to Item 3.)

4) Remove Power Module unit. (Refer to Item 4.)

5) Remove the Scaler board. (Refer to Item 5.)

6) Remove the D-Rewrite board and bracket. (Refer to Item 6.)

7) Remove the back plate. (Refer to Item 7.)

8) Remove the TU/AOUT, AV2 and Signal boards. (Refer to Item 8.)

9) Remove the Front/AV board. (Refer to Item 9.)

10) Remove the Power SW and LED/RMT boards. (Refer to Item 10.)

11) Remove 2 screws (PP 3x6), then remove the cord holder.

12) Remove 4 screws (PP 3x6), then remove 2 fan bracket holders.

13) Remove 4 screws (PP 3x20), then remove the 2 DC fans.

14) Remove 10 screws (PBI 4x12) and 8screws (PP 4x10), then remove the chassis frame.

PP 3x6

Fan bracket holder

PP 3x6

DC Fan

PP 3x6

Chassis frame

PP 4x10

PP 3x20

PBI 4x12

PP 3x20

PP 4x10

PBI 4x12

– 24 –

Page 25

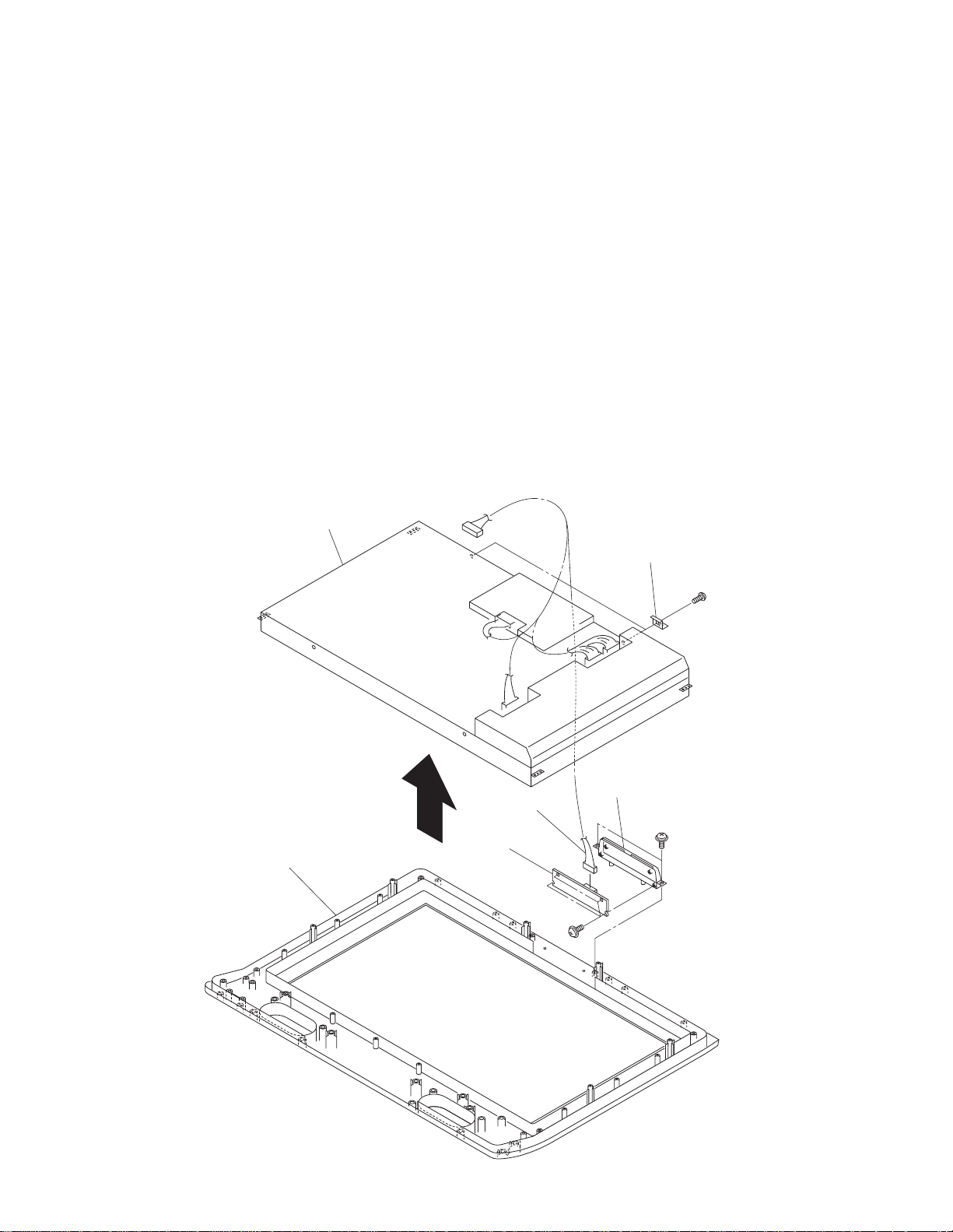

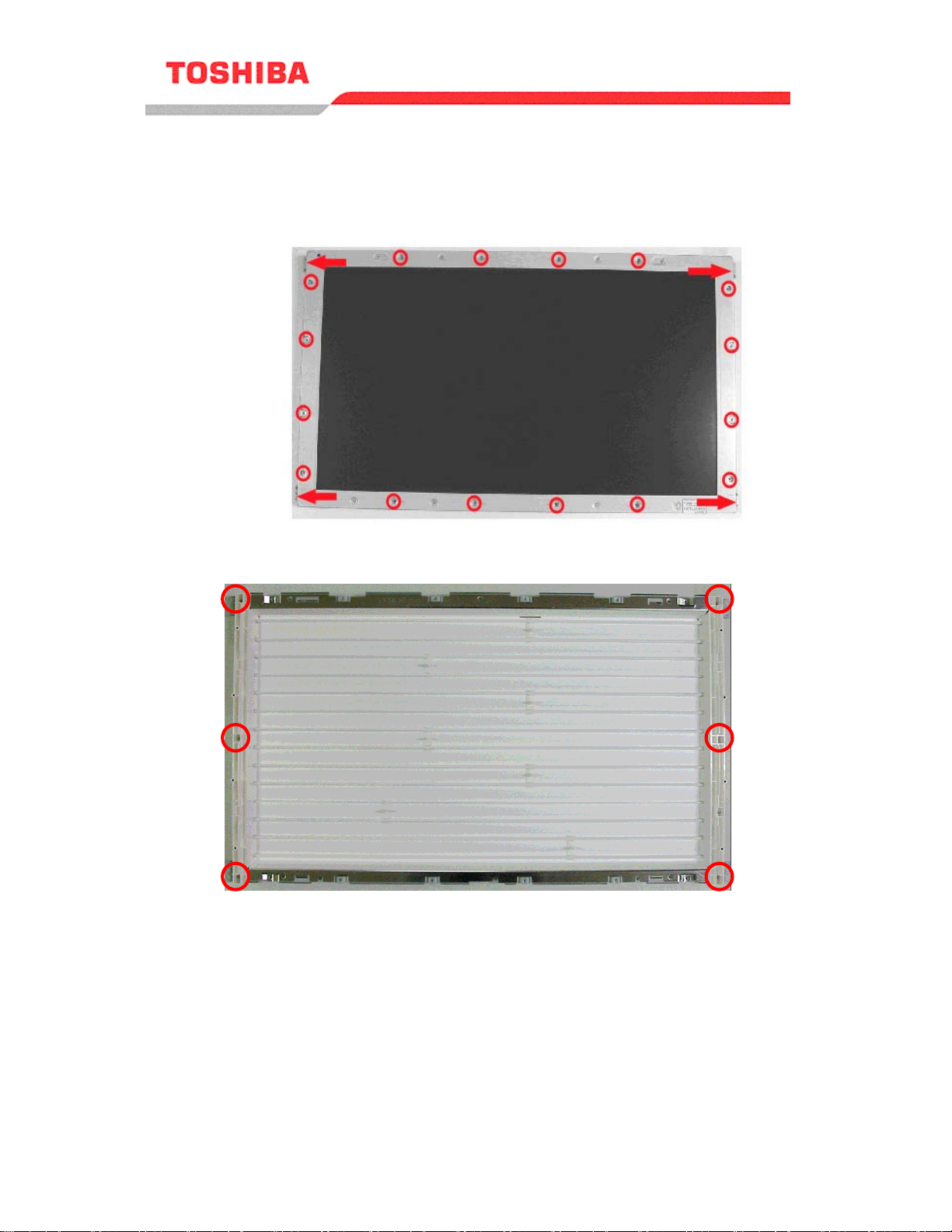

12. Removing the LCD and front bezel cover assembly

1) Remove the back cover. (Refer to Item 1.)

2) Remove the speakers. (Refer to Item 2.)

3) Remove the top shield bracket. (Refer to Item 3.)

4) Remove Power Module unit. (Refer to Item 4.)

5) Remove the Scaler board. (Refer to Item 5.)

6) Remove the D-Rewrite board and bracket. (Refer to Item 6.)

7) Remove the back plate. (Refer to Item 7.)

8) Remove the TU/AOUT,AV2 and Signal boards. (Refer to Item 8.)

9) Remove the Front/AV board. (Refer to Item 9.)

10) Remove the Power SW and LED/RMT boards. (Refer to Item 10.)

11) Remove the chassis frame. (Refer to Item 11.)

12) Remove 2 screws (BIDT2 3x10), then remove the key SW panel.

13) Remove 2 screws (BIDT2 3x10), then remove the Key SW board.

14) Disconnect the wire harness from the connector on the Key SW board.

15) Lift up the LCD slowly from the front bezel cover assembly toward to the arrow direction.

16) Remove 2 screws (PP 4x10), then remove the two bracket panels top.

LCD

Bracket panel top

Front bezel cover assembly

Harness

KEY SW board

BIDT2

3x10

PP 4x10

KEY SW panel

BIDT2 3x10

– 25 –

Page 26

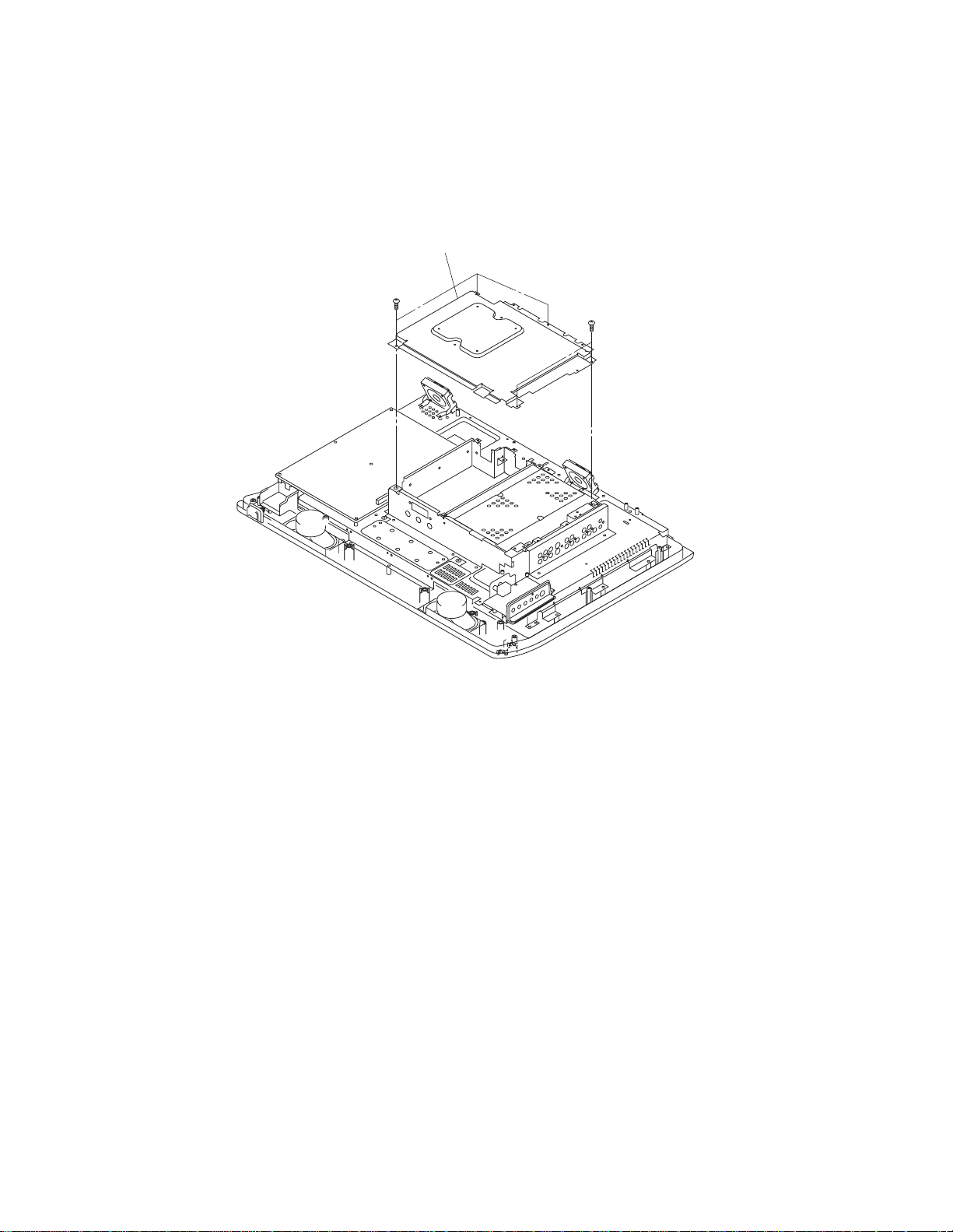

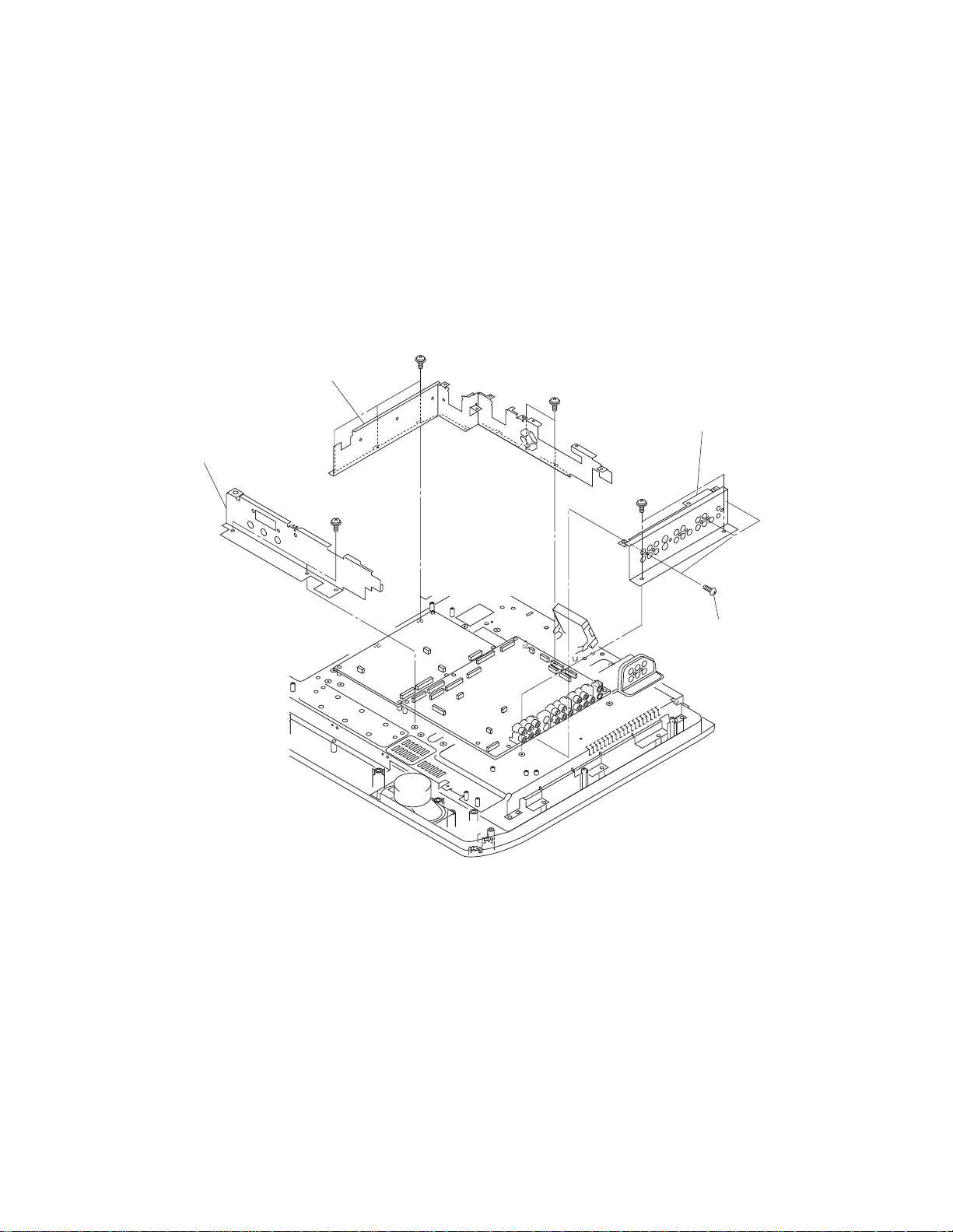

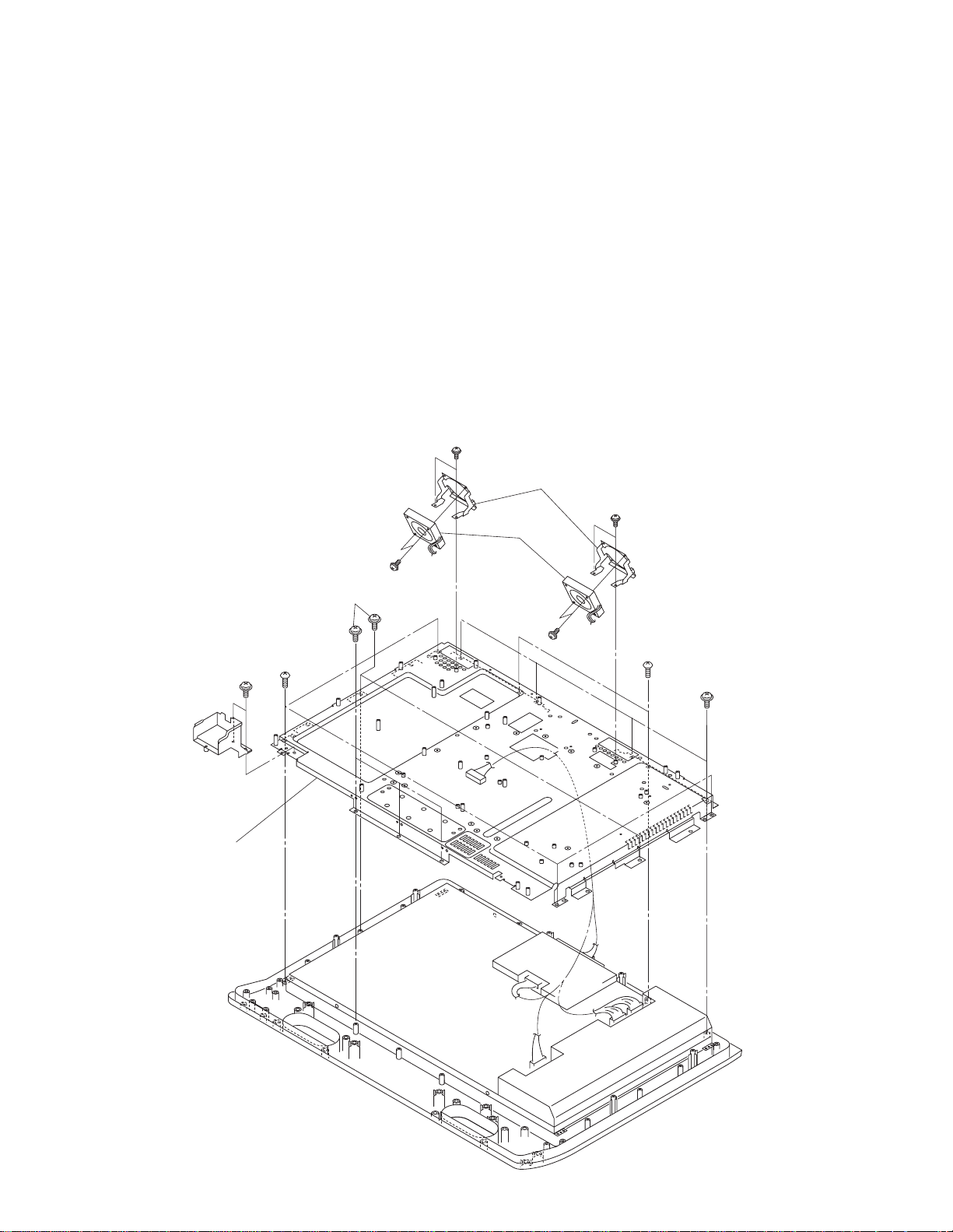

1. Cover Block

A227

EXPLODED VIEWS

A402

PP 5x12

A406

PP 3x8

PBI 4x12

PP 3x8

PBI 4x12

PP 3x8

A401

LOCATION No. Parts No. Description

A227 23429049 CABINET, STAND

A401 23532669 COVER, BACK COVER

A402 23532633 COVER, BC STAND COVER

A406 23532634 COVER, BC TERMINAL COVER

A501 23717176 SCREW, PP5X12+SW+W SZ

A502 23717175 SCREW, PP3X6+SW+W SZ

A505 23035004 SCREW

– 26 –

Page 27

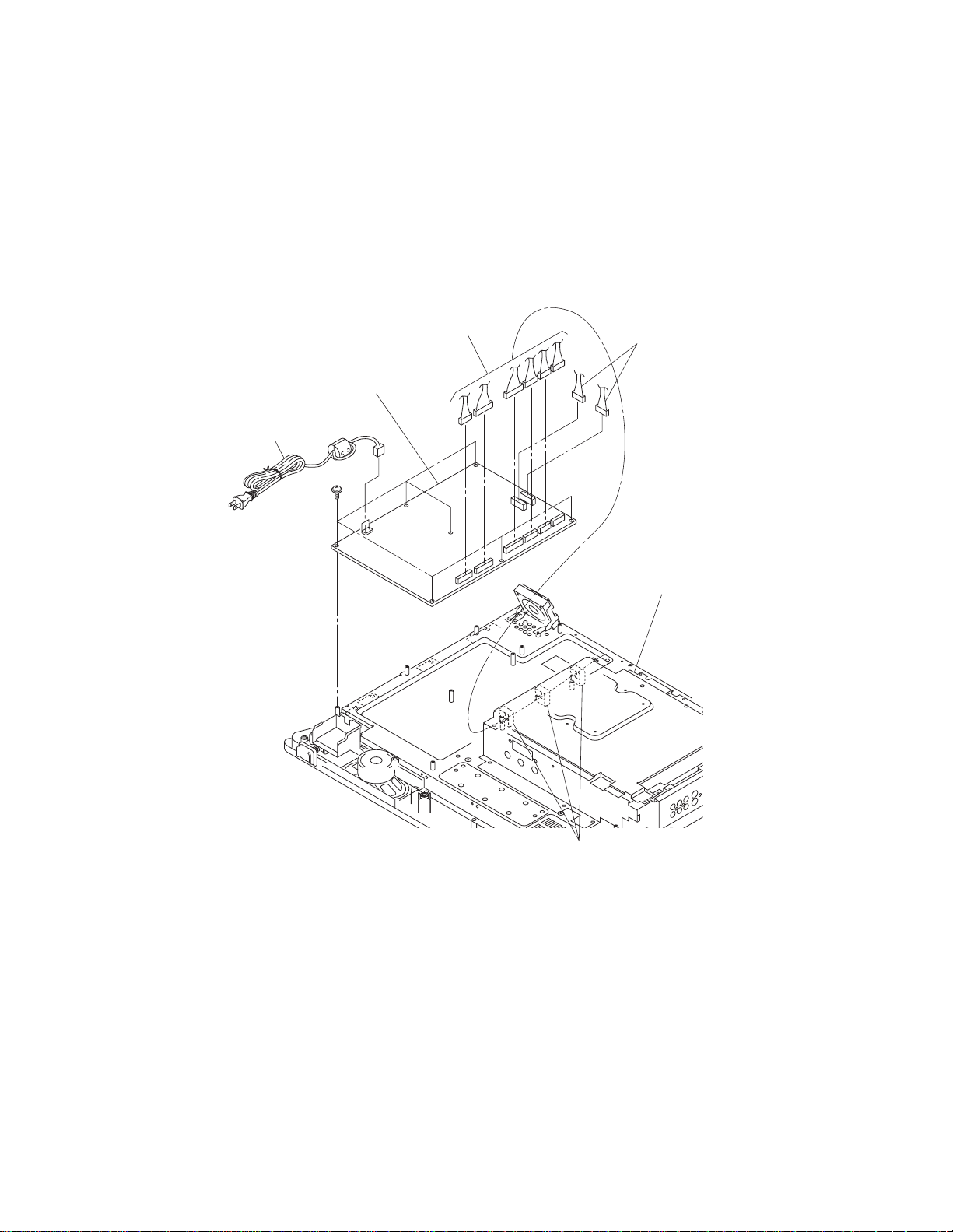

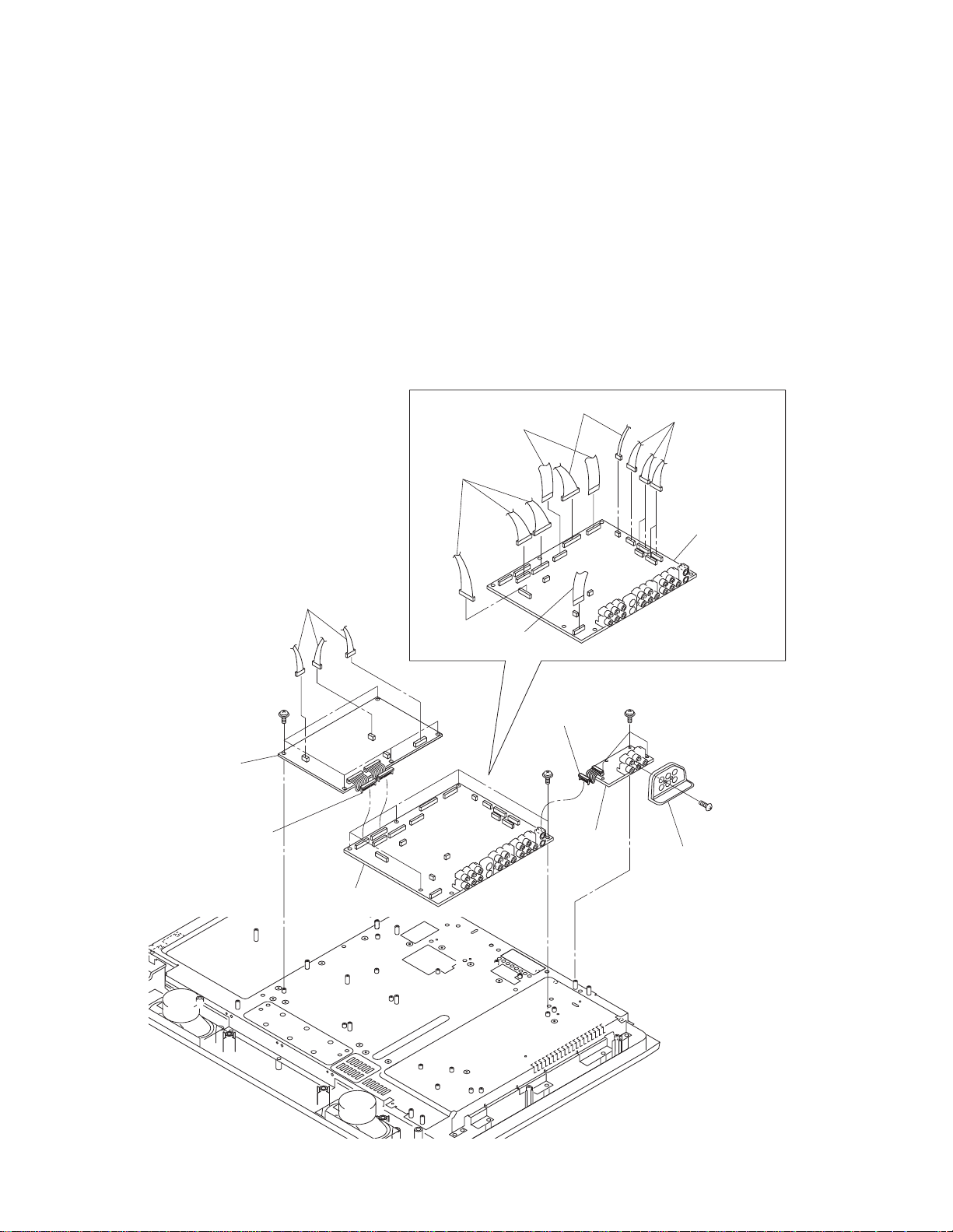

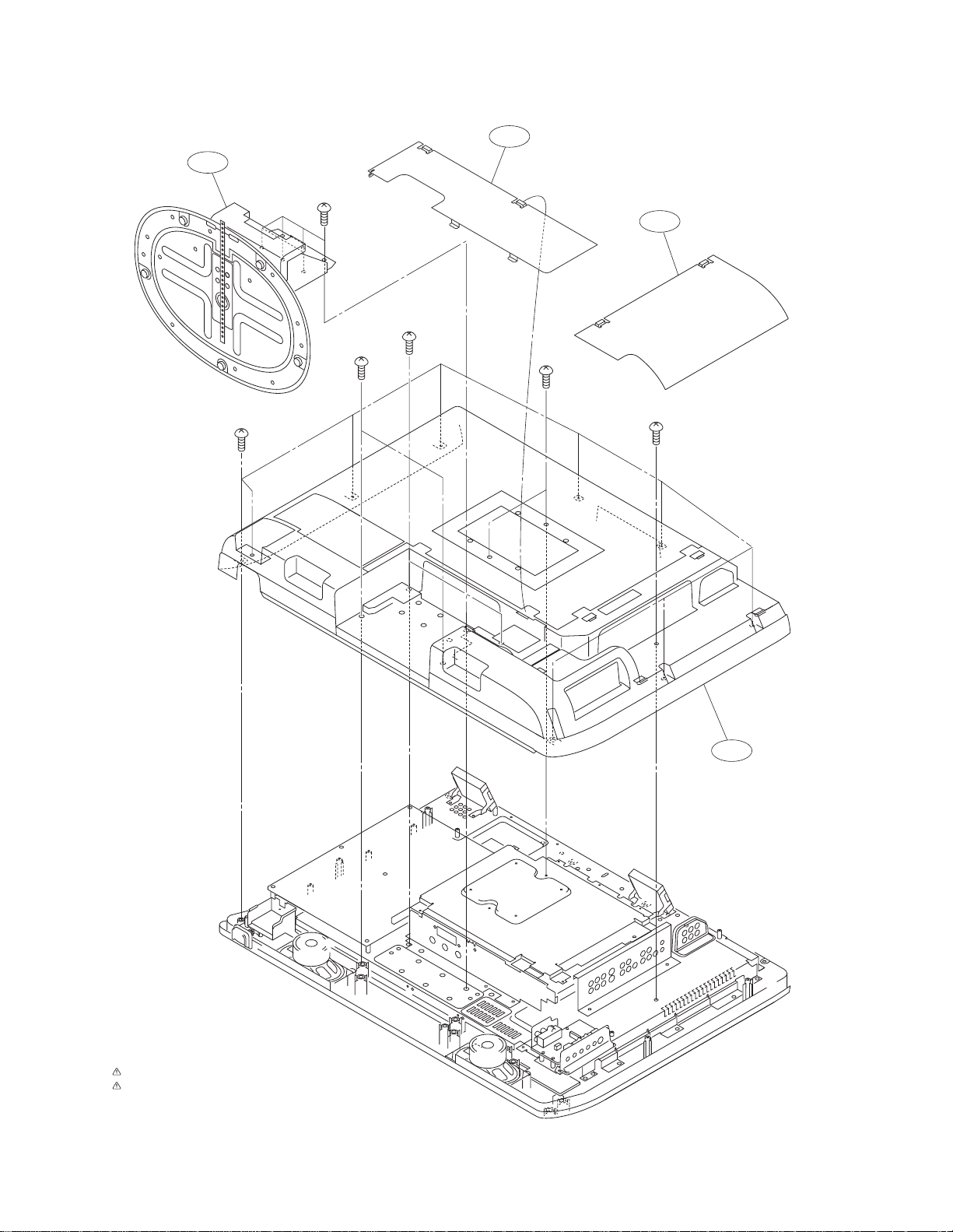

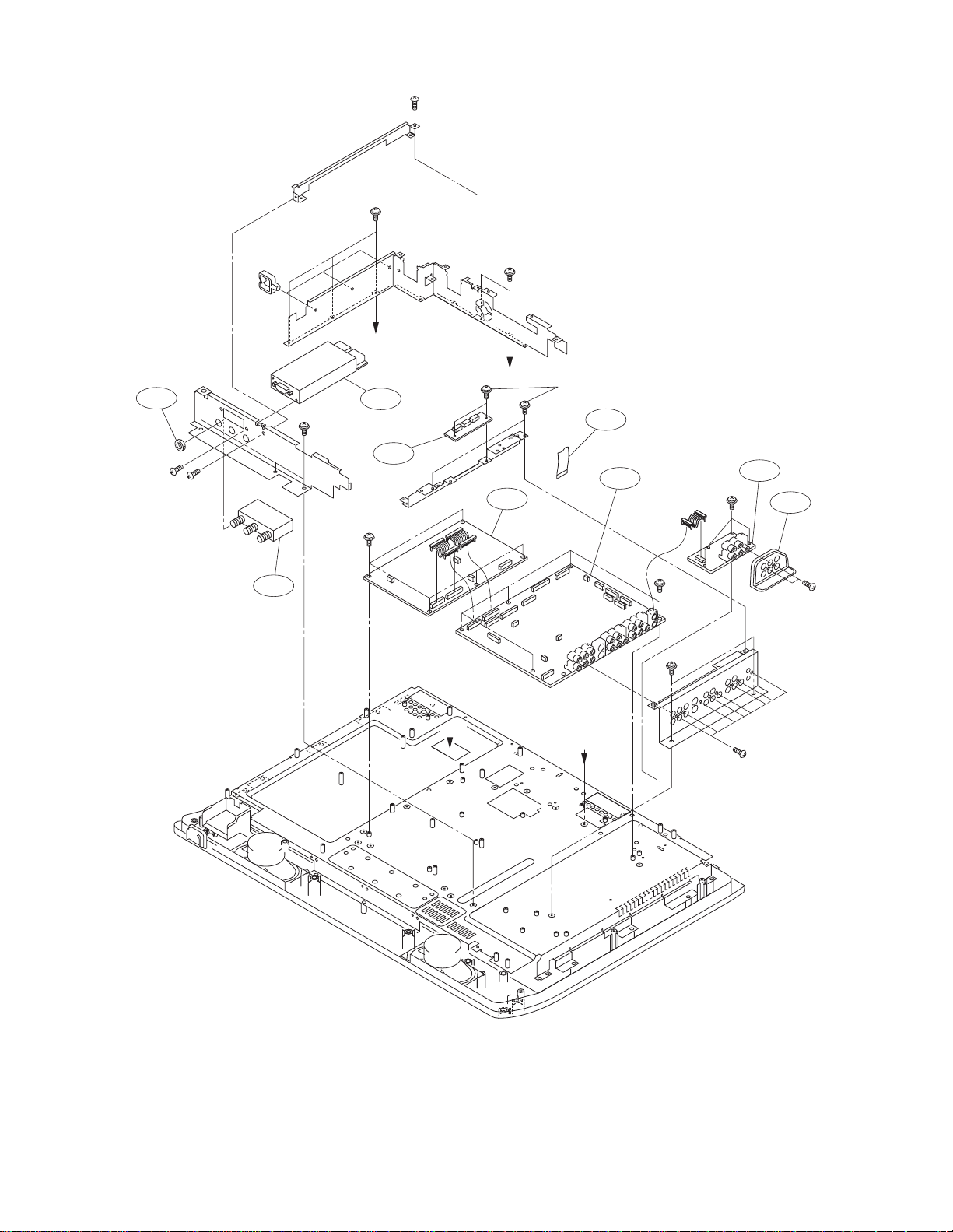

2. Chassis Block 1

ZA04

A218

PP 3x6

PP 3x6

PP 3x6

P801

PP 3x6

ZA04

ZA01

MJ18

UF01

PP 3x20

MJ94

STP 3x8

MJ13

STP 3x8

STP 3x8

U903

PP 3x6

A218

U800

PP 3x6

A221

U901B

LOCATION No. Parts No. Description

U901B 75000781 PCB PW UNIT FRONT-AV

*

U903 75000789 PCB SCALER

*

A218 23528373 HOLDER, FAN BRACKET 26

A221 23940037 PIECE, REAR AV ASSY

A222 23940038 PIECE, FRONT AV ASSY

MJ13 23389210 FFC CABLE, P0.5-40P

MJ18 23368868 CABLE, LVDS 300MM

MJ94 23389212 FFC CABLE P1.0-11P

MV23

PP 3x6

BIDT2 3x10 BZ

A222

UF01

PP 3x20

LOCATION No. Parts No. Description

MV23 23389213 FFC CABLE, P1.0-19P

P801 23372264 POWER CORD, U/C 125V10A HSV 5

U800 23122467 UNIT, POWER BLOCK MODULE 1H198W

*

UF01 23125908 FAN, DC 12V 60MM, D06R-12SL

ZA01 23103778 FERRITE CORE, TFE1008

ZA04 23103914 FERRITE CORE, TFE1015AD

A502 23717175 SCREW, PP3X6+SW+W SZ

A503 72471064 SCREW, BIDT2 3*10BZ

– 27 –

Page 28

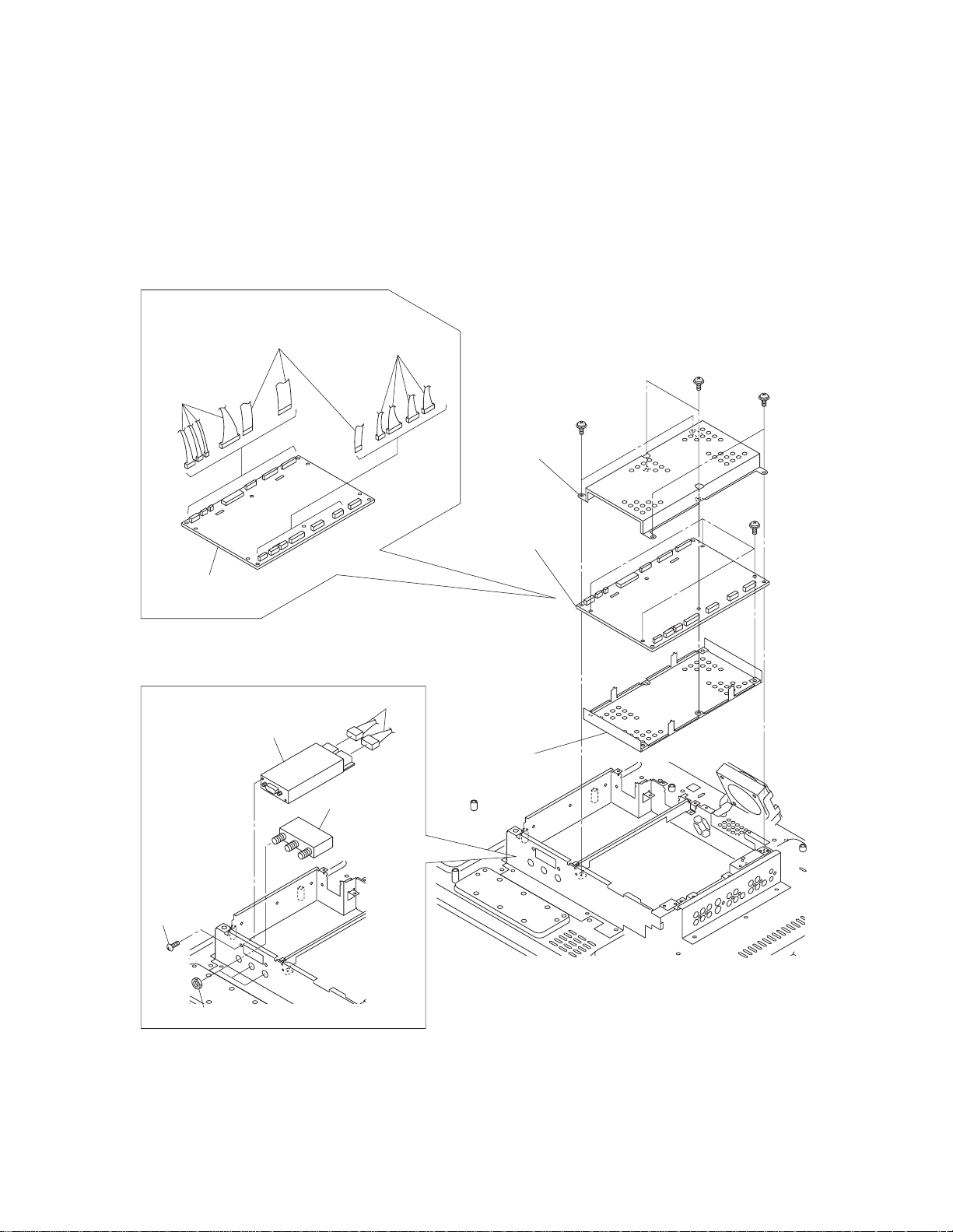

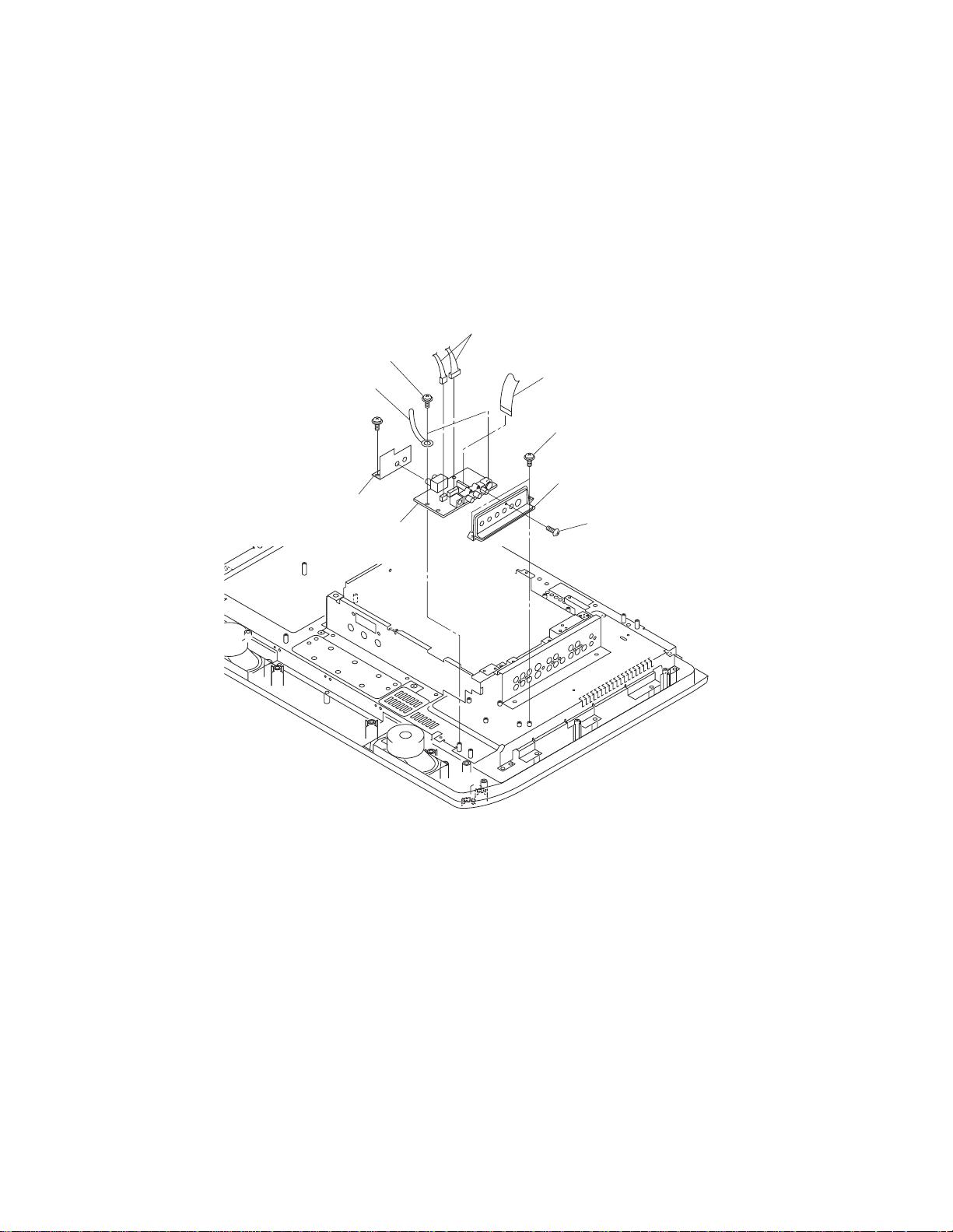

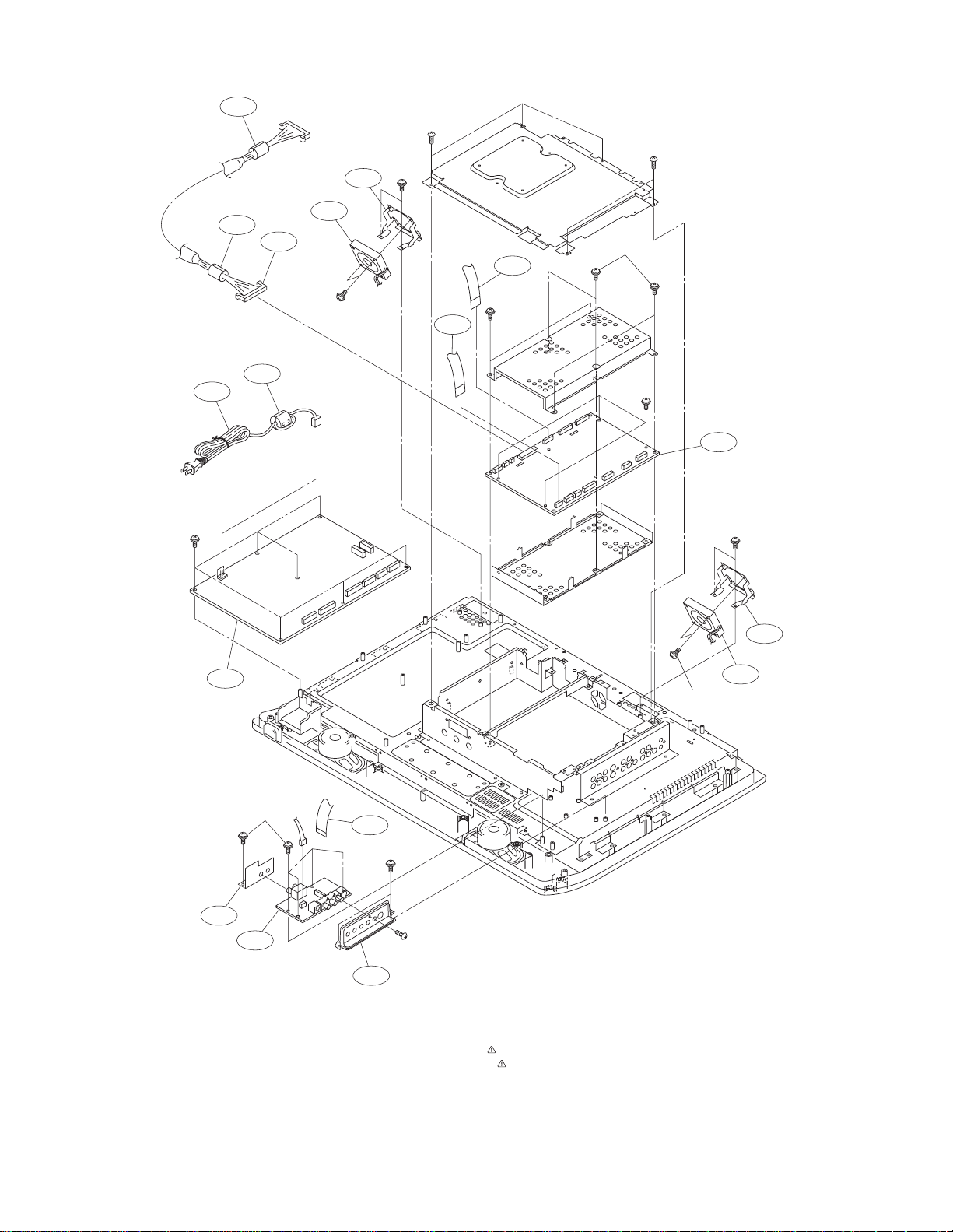

3. Chassis Block 2

STP 3x8

STP 3x8

STP 3x8

A

H003A

BIDT2

3 x10 BZ

PP 3x6

H003

STP 3x8

STP 3x8

E003

U901G

B

U902

A

STP 3x8

MJ15

B

U901A

STP

3x8

STP

3x8

STP 3x8

BIDT2

3x10 BZ

U901C

A224

BIDT2

3x10 BZ

LOCATION No. Parts No. Description

U901A 75000780 PCB PW UNIT SIGNAL

*

U901C 75000782 PCB PW UNIT AV-2

*

U901G 75000786 PCB PW UNIT D-REWRITE

*

U902 75000787 PCB PW UNIT TN/A-OUT

*

A224 23940036 PIECE, TOP AV ASSY

E003 23148090 MODULE, 03DVI PD0647C

H003 23124083 ANTENNA SWITCH, 2I3O DW US

H003A 23740989 NUT, F-CONNECTOR 2H BS

MJ15 23389211 FFC CABLE, P1.0-25P

A502 23717175 SCREW, PP3X6+SW+W SZ

A503 72471064 SCREW, BIDT2 3*10BZ

A505 23035004 SCREW

– 28 –

Page 29

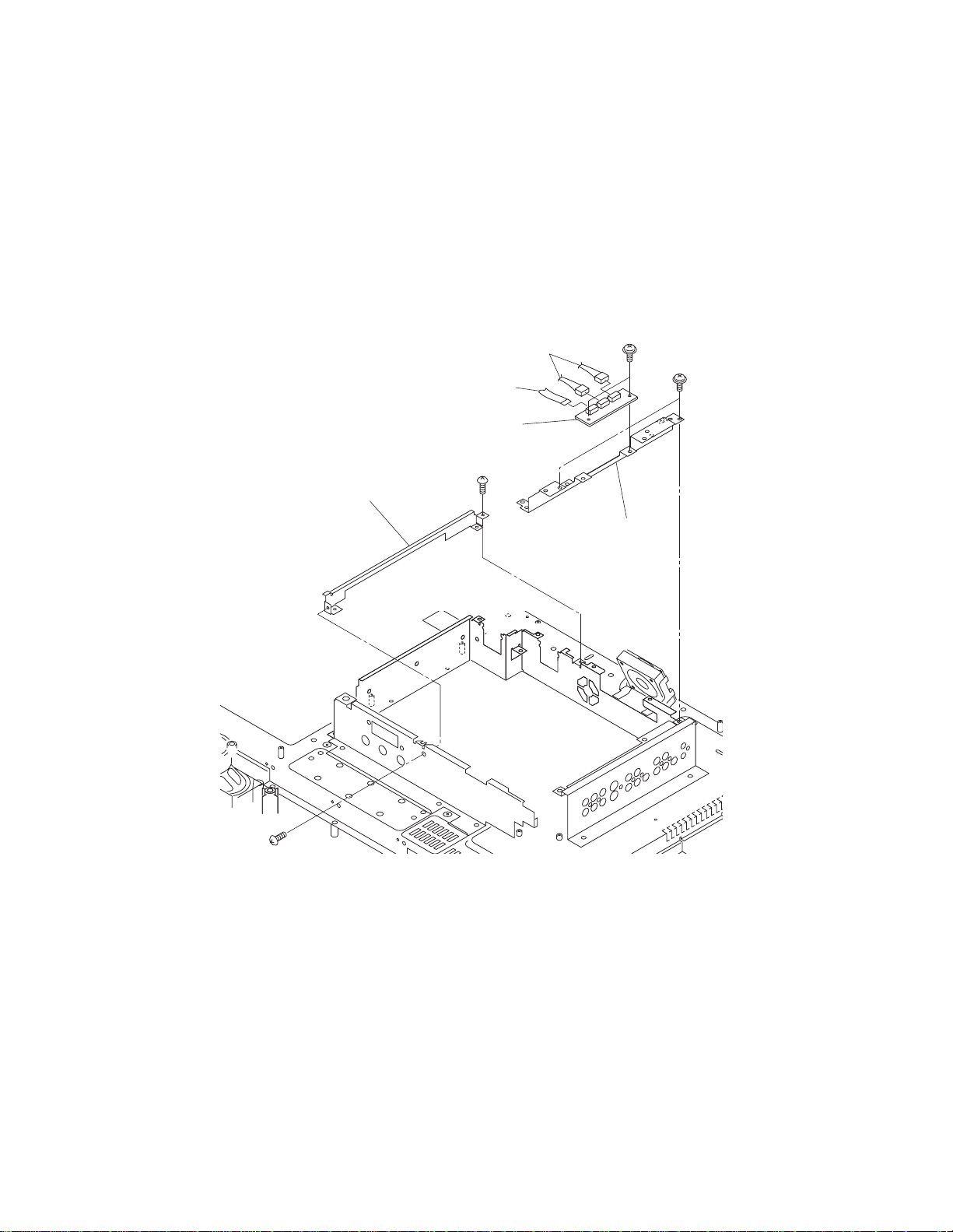

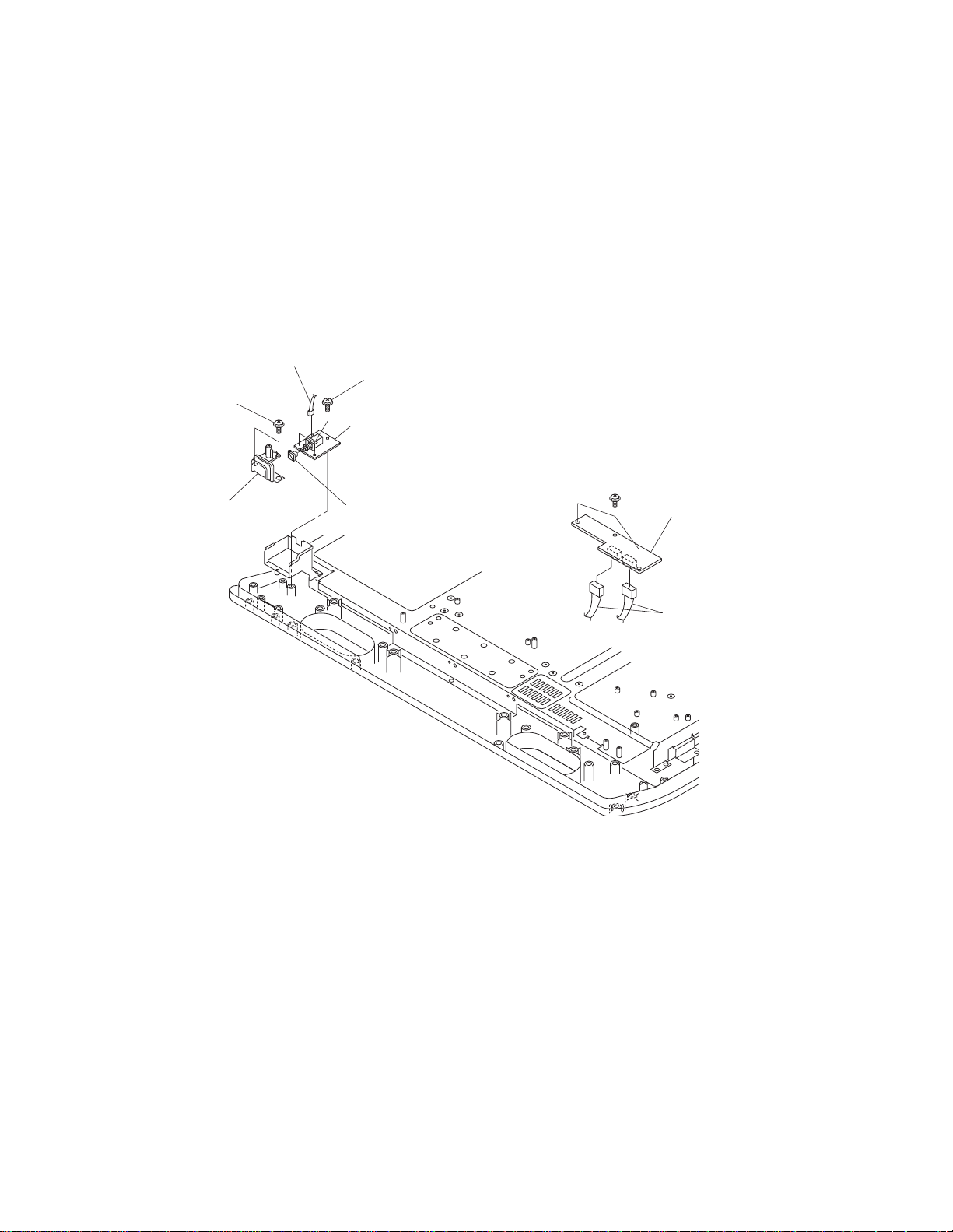

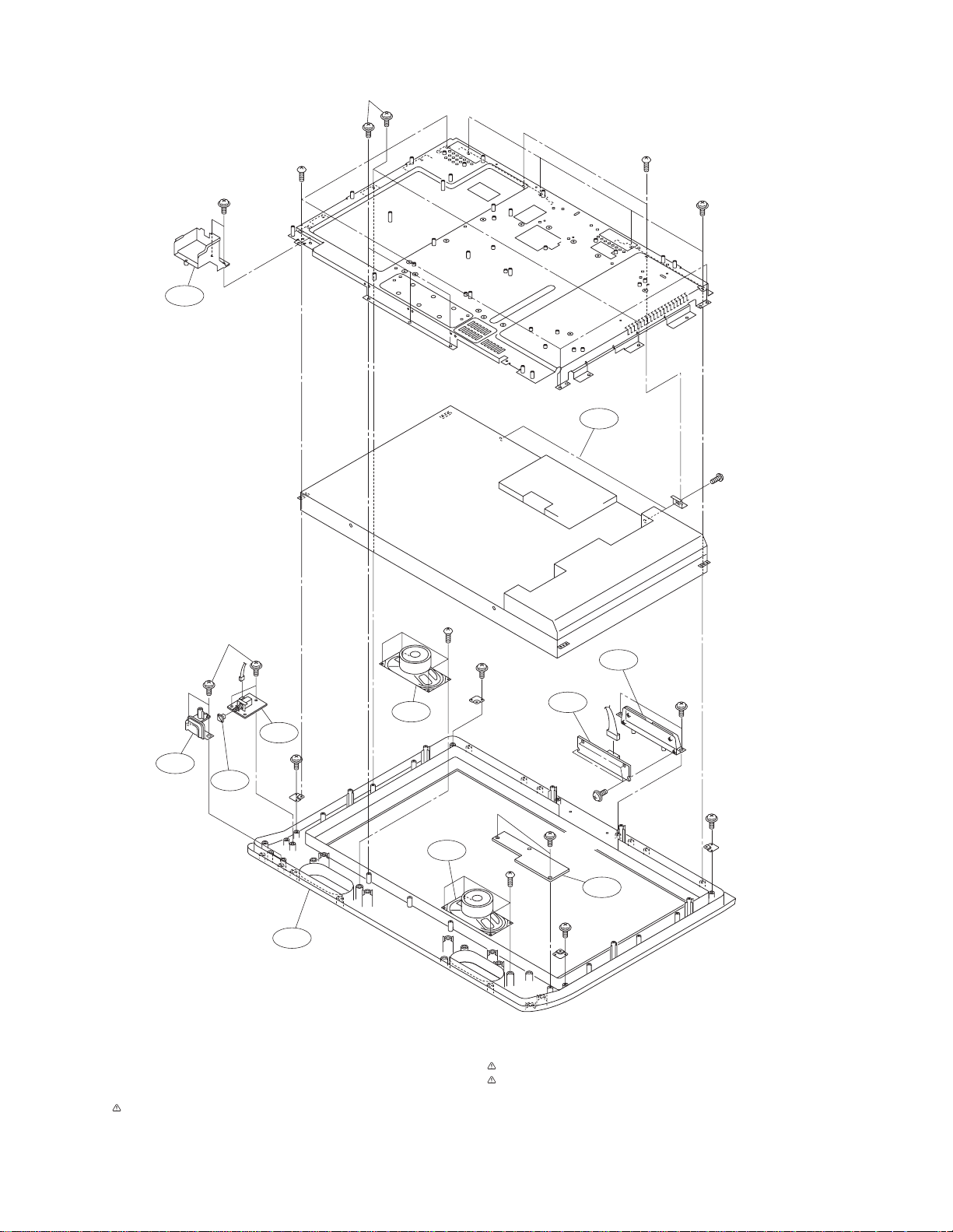

4. LCD and Front Bezel Block

PBI 4x12

A219

PP 3x6

PP 4x10

PP 4x10

PBI 4x12

B001

PP 4x10

BIDT2

3x10

U901D

A201

BIDT2

3x10

A203

A215

LOCATION No. Parts No. Description

U901D 75000783 PCB PW UNIT POWER-SW 32HL84

*

U901E 75000784 PCB PW UNIT KEY 32HL84

*

U901F 75000785 PCB PW UNIT IR/LED 32HL84

*

A201 23532746 COVER, FRONT BEZEL ASSY

A202 23940056 PIECE, PIECE KEY ASSY

A203 23940025 PIECE, PIECE POWER ASSY

A215 23940043 PIECE, CAP P SWITCH

W661

PBI 4x12

W661

BIDT2

3x10

U901F

BIDT2

3x10

A202

BIDT2

3x10

BIDT2

3x10

BIDT2

3x10

U901E

BIDT2

PBI

4x12

LOCATION No. Parts No. Description

A219 23528374 HOLDER, HOLDER P CORD JPN

B001 23301561 LCD PANEL, 03SHARP26, LQ255T3LZ11

W661 23351156 SPEAKER, SPK1410AM, 60X120 8-OHM 10W

A502 23717175 SCREW, PP3X6+SW+W SZ

A503 72471064 SCREW, BIDT2 3*10BZ

A504 23738071 SCREW, STP4X10+SW+W SZ

A505 23035004 SCREW

3x10

– 29 –

Page 30

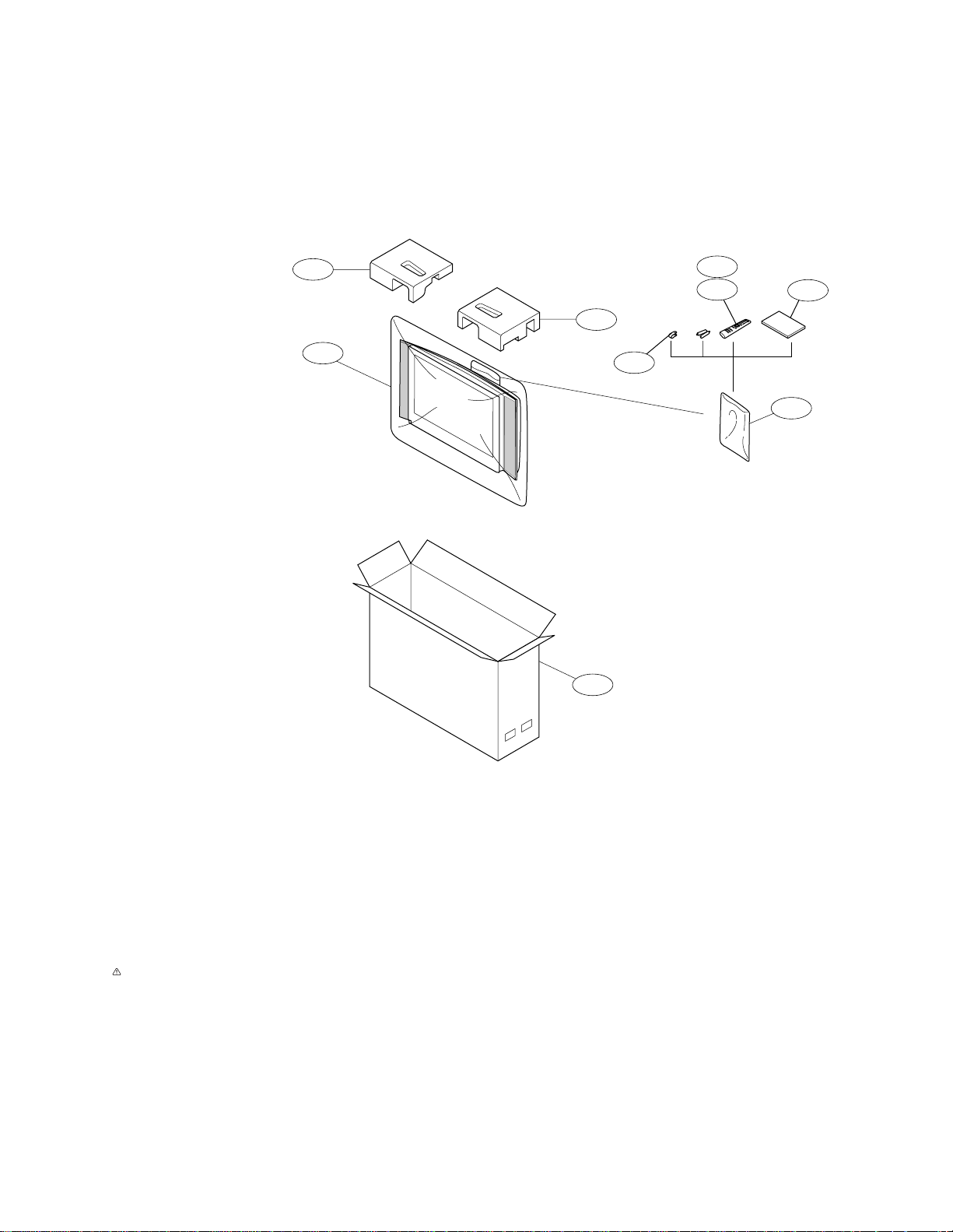

PACKING DISASSEMBLY

A702A

A703

A702A

A701A

Y170

K902

K903

Y101

Y109

LOCATION No. Parts No. Description

A701A 23067704 CARTON, CASE 26HL84

A702A 23946777 PACKING, TOP PACKING 26HL84

A702B 23946778 PACKING, BOTTOM PACKING 26HL84

A703 23945143 BAG, PROTECTIVE, 35P2700

K902 23306504 REMOCON HAND UNIT IR, CTVUSA

K903 23306465 REMOCON HAND UNIT, 57HX82

Y101 23566307 OWNERS MANUAL, ENG/FRE/SPA

Y109 23945015 BAG, POLYETHYLENE COVER, 250X400

Y170 23845800 WIRE HOLDER, NYLON66 D6.8

– 30 –

Page 31

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY RADIATION PRECAUTION", "SAFETY PRE-

CAUTION" AND "PRODUCT SAFETY NOTICE" ON PAGE 3 OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in the

original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE. Do not degrade the safety

of the receiver through improper servicing.

NOTICE:

··

·

The part number must be used when ordering parts, in order to assist in processing, be sure to include the

··

Model number and Description.

··

·

The PC board assembly with * mark is no longer available after the end of the production.

··

Model : 26HL84

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are

±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

Location Parts No. Description

No.

CAPACITORS

C102 24793221 ELECTROLYTIC, 10V 220UF M

C103 24109102 CERAMIC CHIP, 50V B 1000PF K

C104 24797479 ELECTROLYTIC, 50V 4.7UF M

C105 24763221 ELECTROLYTIC, 16V 220UF M

C108 24617009 ELECTROLYTIC, 10V 330UF M

C122 24092730 CERAMIC CHIP, 16V B 0.1UF K

C124 24109471 CERAMIC CHIP, 50V B 470PF K

C126 24109471 CERAMIC CHIP, 50V B 470PF K

C127 24763471 ELECTROLYTIC, 16V 470UF M

C131 24793221 ELECTROLYTIC, 10V 220UF M

C132 24763101 ELECTROLYTIC, 16V 100UF M

C133 24109102 CERAMIC CHIP, 50V B 1000PF K

C162 24109472 CERAMIC CHIP, 50V B 4700PF K

C172 24669339 ELECTROLYTIC, 50V 3.3UF M

C522 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C523 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C524 24100104 CERAMIC CHIP, 25V F 0.1UF Z

C601 24092730 CERAMIC CHIP, 16V B 0.1UF K

C602 24109331 CERAMIC CHIP, 50V B 330PF K

C603 24092730 CERAMIC CHIP, 16V B 0.1UF K

C604 24092611 CERAMIC CHIP, 6.3V B 2.2UF K

C605 24109102 CERAMIC CHIP, 50V B 1000PF K

C606 24109102 CERAMIC CHIP, 50V B 1000PF K

C608 24092730 CERAMIC CHIP, 16V B 0.1UF K

C610 24092731 CERAMIC CHIP, 16V B 1UF K

C611 24092730 CERAMIC CHIP, 16V B 0.1UF K

C612 24761102 ELECTROLYTIC CE04G, 6.3V 1000UF M

C613 24092731 CERAMIC CHIP, 16V B 1UF K

C614 24092730 CERAMIC CHIP, 16V B 0.1UF K

C615 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

C620 24092463 CERAMIC CHIP, 16V B 0.22UF K

C621 24092730 CERAMIC CHIP, 16V B 0.1UF K

C622 24092463 CERAMIC CHIP, 16V B 0.22UF K

C623 24092463 CERAMIC CHIP, 16V B 0.22UF K

C624 24092730 CERAMIC CHIP, 16V B 0.1UF K

C625 24092463 CERAMIC CHIP, 16V B 0.22UF K

C627 24092730 CERAMIC CHIP, 16V B 0.1UF K

C629 24206010 ELECTROLYTIC, 50V 1.0UF M 7L 3A

C630 24092730 CERAMIC CHIP, 16V B 0.1UF K

C631 24092463 CERAMIC CHIP, 16V B 0.22UF K

C632 24092463 CERAMIC CHIP, 16V B 0.22UF K

C635 24763221 ELECTROLYTIC, 16V 220UF M

C636 24763221 ELECTROLYTIC, 16V 220UF M

C640 24762102 ELECTROLYTIC, 04G 10V 1000UF M

C641 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

Location Parts No. Description

No.

C642 24203470 ELECTROLYTIC, 16V 47UF M 7L 3A

C645 24815103 CERAMIC CHIP, 50V B 10000PF K

C646 24092738 CERAMIC CHIP, 25V B 0.47UF K

C647 24092738 CERAMIC CHIP, 25V B 0.47UF K

C648 24285104 CERAMIC CHIP, 50V B 0.1UF K

C649 24285104 CERAMIC CHIP, 50V B 0.1UF K

C653 24206010 ELECTROLYTIC, 50V 1.0UF M 7L 3A

C661 24109102 CERAMIC CHIP, 50V B 1000PF K

C662 24109102 CERAMIC CHIP, 50V B 1000PF K

C663 24206108 ELECTROLYTIC 04W, 50V 0.1UF M 7L 3A

C665 24206100 ELECTROLYTIC, 50V 10UF M 7L 3A

C666 24206100 ELECTROLYTIC, 50V 10UF M 7L 3A

C667 24092538 CERAMIC CHIP, 10V F 1UF Z

C668 24092538 CERAMIC CHIP, 10V F 1UF Z

C669 24105221 CERAMIC CHIP, 50V CH 220PF J

C672 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

C673 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

C677 24109391 CERAMIC CHIP CK73B 50V 390PF K

C678 24109391 CERAMIC CHIP CK73B 50V 390PF K

C679 24105221 CERAMIC CHIP, 50V CH 220PF J

C687 24590152 PLASTIC FILM, 50V 1500PF J

C688 24590152 PLASTIC FILM, 50V 1500PF J

C691 24109103 CERAMIC CHIP, 50V B 0.01UF K

C692 24109103 CERAMIC CHIP, 50V B 0.01UF K

C693 24109103 CERAMIC CHIP, 50V B 0.01UF K

C694 24109103 CERAMIC CHIP, 50V B 0.01UF K

C927 24092730 CERAMIC CHIP, 16V B 0.1UF K

CB01 24794470 ELECTROLYTIC, 16V 47UF M

CB40 24092538 CERAMIC CHIP, 10V F 1UF Z

CB41 24109222 CERAMIC CHIP, 50V B 2200PF K

CB42 24105561 CERAMIC CHIP, 50V CH 560PF J

CB43 24109332 CERAMIC CHIP, 50V B 3300PF K

CB45 24092538 CERAMIC CHIP, 10V F 1UF Z

CB46 24109222 CERAMIC CHIP, 50V B 2200PF K

CB47 24105561 CERAMIC CHIP, 50V CH 560PF J

CB51 24590103 PLASTIC FILM, 50V 0.01UF J

CB52 24794470 ELECTROLYTIC, 16V 47UF M

CB53 24503041 PLASTIC FILM , 63V 0.1UF J

CB54 24109221 CERAMIC CHIP, 50V B 220PF K

CB55 24797010 ELECTROLYTIC, 50V 1UF M

CB56 24794470 ELECTROLYTIC, 16V 47UF M

CB57 24503041 PLASTIC FILM , 63V 0.1UF J

CB58 24794470 ELECTROLYTIC, 16V 47UF M

CB59 24590103 PLASTIC FILM, 50V 0.01UF J

CB60 24794100 ELECTROLYTIC, 16V 10UF M

CB61 24503041 PLASTIC FILM , 63V 0.1UF J

– 31 –

Page 32

Location Parts No. Description

No.

CC01 24109102 CERAMIC CHIP, 50V B 1000PF K

CC02 24109102 CERAMIC CHIP, 50V B 1000PF K

CC03 24109102 CERAMIC CHIP, 50V B 1000PF K

CC04 24109102 CERAMIC CHIP, 50V B 1000PF K

CC05 24109102 CERAMIC CHIP, 50V B 1000PF K

CC06 24109102 CERAMIC CHIP, 50V B 1000PF K

CC07 24109102 CERAMIC CHIP, 50V B 1000PF K

CC08 24109102 CERAMIC CHIP, 50V B 1000PF K

CC09 24109102 CERAMIC CHIP, 50V B 1000PF K

CC10 24109102 CERAMIC CHIP, 50V B 1000PF K

CC11 24109102 CERAMIC CHIP, 50V B 1000PF K

CC12 24109102 CERAMIC CHIP, 50V B 1000PF K

CC14 24109102 CERAMIC CHIP, 50V B 1000PF K

CC15 24109102 CERAMIC CHIP, 50V B 1000PF K

CC18 24109102 CERAMIC CHIP, 50V B 1000PF K

CC19 24109102 CERAMIC CHIP, 50V B 1000PF K

CC77 24105101 CERAMIC CHIP, 50V CH 100PF J

CC78 24105101 CERAMIC CHIP, 50V CH 100PF J

CC99 24591102 PLASTIC FILM, 50V 1000PF J

CD101 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD102 24105271 CERAMIC CHIP, 50V CH 270PF J

CD103 24105101 CERAMIC CHIP, 50V CH 100PF J

CD104 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD105 24105271 CERAMIC CHIP, 50V CH 270PF J

CD106 24105101 CERAMIC CHIP, 50V CH 100PF J

CD107 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CD111 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD112 24105561 CERAMIC CHIP, 50V CH 560PF J

CD113 24105101 CERAMIC CHIP, 50V CH 100PF J

CD114 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CD115 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD116 24105561 CERAMIC CHIP, 50V CH 560PF J

CD117 24105101 CERAMIC CHIP, 50V CH 100PF J

CD118 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD119 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD120 24092542 CERAMIC CHIP CK733 B 16V 1.0UF K

CD121 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD122 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD123 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD124 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD201 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD202 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD203 24092609 CERAMIC CHIP, 10V B 4,7UF K

CD204 24109471 CERAMIC CHIP, 50V B 470PF K

CD205 24109471 CERAMIC CHIP, 50V B 470PF K

CD206 24092628 CERAMIC CHIP, 0J B 10UF K

CD207 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD208 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD209 24793470 ELECTROLYTIC CE04G 10V 47UF M

CD210 24794470 ELECTROLYTIC, 16V 47UF M

CD211 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD212 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD213 24793470 ELECTROLYTIC CE04G 10V 47UF M

CD214 24793470 ELECTROLYTIC CE04G 10V 47UF M

CD215 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD216 24109102 CERAMIC CHIP, 50V B 1000PF K

CD217 24105270 CERAMIC CHIP, 50V CH 27PF J

CD218 24105100 CERAMIC CHIP, 50V CH 10PF D

CD219 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD220 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD221 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD222 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD223 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD224 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD225 24793470 ELECTROLYTIC CE04G 10V 47UF M

CD226 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD227 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CD228 24793470 ELECTROLYTIC CE04G 10V 47UF M

CD230 24109103 CERAMIC CHIP, 50V B 0.01UF K

CD233 24092628 CERAMIC CHIP, 0J B 10UF K

CD234 24092573 CERAMIC CHIP, 16V B 0.47UF K

CD235 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CS01 24092538 CERAMIC CHIP, 10V F 1UF Z

CS02 24092538 CERAMIC CHIP, 10V F 1UF Z

CS03 24092538 CERAMIC CHIP, 10V F 1UF Z

CS04 24092538 CERAMIC CHIP, 10V F 1UF Z

Location Parts No. Description

No.

CS05 24092538 CERAMIC CHIP, 10V F 1UF Z

CS06 24092538 CERAMIC CHIP, 10V F 1UF Z

CS07 24092538 CERAMIC CHIP, 10V F 1UF Z

CS08 24092538 CERAMIC CHIP, 10V F 1UF Z

CS09 24092538 CERAMIC CHIP, 10V F 1UF Z

CS10 24092538 CERAMIC CHIP, 10V F 1UF Z

CS11 24092538 CERAMIC CHIP, 10V F 1UF Z

CS12 24092538 CERAMIC CHIP, 10V F 1UF Z

CS13 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS14 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS15 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS16 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS20 24092573 CERAMIC CHIP, 16V B 0.47UF K

CS21 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS22 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS23 24092538 CERAMIC CHIP, 10V F 1UF Z

CS24 24092538 CERAMIC CHIP, 10V F 1UF Z

CS25 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CS26 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS27 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS30 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS31 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS34 24092731 CERAMIC CHIP, 16V B 1UF K

CS35 24092731 CERAMIC CHIP, 16V B 1UF K

CS39 24092538 CERAMIC CHIP, 10V F 1UF Z

CS51 24092515 CERAMIC CHIP, 16V F 4.7UF Z

CS501 24797100 ELECTROLYTIC, 50V 10UF M

CS502 24092726 CERAMIC CHIP CK733B 16V 2,200,000PFK

CS503 24797100 ELECTROLYTIC, 50V 10UF M

CS510 24092542 CERAMIC CHIP CK733 B 16V 1.0UF K

CV01 24092621 CERAMIC CHIP, 10V B 1UF K

CV02 24092621 CERAMIC CHIP, 10V B 1UF K

CV03 24092621 CERAMIC CHIP, 10V B 1UF K

CV04 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV05 24092621 CERAMIC CHIP, 10V B 1UF K

CV06 24092621 CERAMIC CHIP, 10V B 1UF K

CV07 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV08 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV09 24092621 CERAMIC CHIP, 10V B 1UF K

CV10 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV11 24092621 CERAMIC CHIP, 10V B 1UF K

CV12 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV13 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV14 24092621 CERAMIC CHIP, 10V B 1UF K

CV15 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV23 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV24 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV38 24109102 CERAMIC CHIP, 50V B 1000PF K

CV39 24109102 CERAMIC CHIP, 50V B 1000PF K

CV40 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV42 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV45 24092621 CERAMIC CHIP, 10V B 1UF K

CV46 24092621 CERAMIC CHIP, 10V B 1UF K

CV47 24092621 CERAMIC CHIP, 10V B 1UF K

CV48 24109332 CERAMIC CHIP, 50V B 3300PF K

CV64 24794471 ELECTROLYTIC, 16V 470UF M

CV65 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CV66 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV67 24085981 ELEC. NONPOLAR CE04J 16V 10UF M 11L NP

CV68 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV73 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV79 24763471 ELECTROLYTIC, 16V 470UF M

CV80 24762102 ELECTROLYTIC, 04G 10V 1000UF M

CV81 24763471 ELECTROLYTIC, 16V 470UF M

CV82 24762102 ELECTROLYTIC, 04G 10V 1000UF M

CV121 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV237 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV238 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV239 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CV243 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV244 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV245 24092441 CERAMIC CHIP, 16V F 1UF Z

CV246 24092441 CERAMIC CHIP, 16V F 1UF Z

CV247 24092441 CERAMIC CHIP, 16V F 1UF Z

CV248 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV249 24092441 CERAMIC CHIP, 16V F 1UF Z

– 32 –

Page 33

Location Parts No. Description

No.

CV250 24092441 CERAMIC CHIP, 16V F 1UF Z

CV251 24092441 CERAMIC CHIP, 16V F 1UF Z

CV252 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV253 24092441 CERAMIC CHIP, 16V F 1UF Z

CV254 24092441 CERAMIC CHIP, 16V F 1UF Z

CV255 24092441 CERAMIC CHIP, 16V F 1UF Z

CV256 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV257 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV258 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CV259 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV261 24109103 CERAMIC CHIP, 50V B 0.01UF K

CV263 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY101 24092441 CERAMIC CHIP, 16V F 1UF Z

CY102 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CY103 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CY104 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY105 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY106 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY107 24203100 ELECTORLYTIC, 16V 10UF M 7L 3A

CY108 24100104 CERAMIC CHIP, 25V F 0.1UF Z

CY109 24105101 CERAMIC CHIP, 50V CH 100PF J

CY111 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY112 24105181 CERAMIC CHIP, 50V CH 180PF J

CY113 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY114 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY115 24105390 CERAMIC CHIP, 50V CH 39PF J

CY116 24105470 CERAMIC CHIP, 50V CH 47PF J

CY117 24105180 CERAMIC CHIP, 50V CH 18PF J

CY501 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY502 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY504 24109222 CERAMIC CHIP, 50V B 2200PF K

CY505 24105120 CERAMIC CHIP, 50V CH 12PF J

CY506 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY508 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY512 24092463 CERAMIC CHIP, 16V B 0.22UF K

CY513 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY514 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY515 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY516 24109103 CERAMIC CHIP, 50V B 0.01UF K

CY517 24092731 CERAMIC CHIP, 16V B 1UF K

CY524 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY525 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY526 24092730 CERAMIC CHIP, 16V B 0.1UF K

CY538 24762102 ELECTROLYTIC, 04G 10V 1000UF M

CY539 24763471 ELECTROLYTIC, 16V 470UF M

CY540 24203101 ELECTROLYTIC, 16V 100UF M 7L 3A

CY541 24762471 ELECTROLYTIC, 04G 10V 470UF M

CY582 24105101 CERAMIC CHIP, 50V CH 100PF J

CY650 24591102 PLASTIC FILM, 50V 1000PF J

RESISTORS

R102 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R103 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R104 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R110 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R120 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R121 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R133 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

R134 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R135 24011273 CHIP, 1/20W 27K OHM J

R150 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

R151 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

R152 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R264 24871750 CHIP, 1/8W 75 OHM J

R265 24871750 CHIP, 1/8W 75 OHM J

R266 24871750 CHIP, 1/8W 75 OHM J

R286 24871750 CHIP, 1/8W 75 OHM J

R287 24871750 CHIP, 1/8W 75 OHM J

R288 24871750 CHIP, 1/8W 75 OHM J

R563 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R600 24000665 FUSIBLE, 1/4W 15 OHM J

R601 24554470 OXIDE METAL FILM, 2W 47 OHM J

R604 24000606 CHIP, 1/16W 8.2K OHM F

R609 24011273 CHIP, 1/20W 27K OHM J

R610 24011124 CHIP, 1/20W 120K OHM J

R611 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

Location Parts No. Description

No.

R612 24011273 CHIP, 1/20W 27K OHM J

R613 24011124 CHIP, 1/20W 120K OHM J

R614 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R615 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R616 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

R618 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R619 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R620 24871100 CHIP, 1/8W 10 OHM J

R623 24871100 CHIP, 1/8W 10 OHM J

R630 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R631 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

R640 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R641 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R642 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R645 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R646 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

R650 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R652 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R655 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

R660 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

R661 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R662 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R667 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

R670 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R671 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R672 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

R673 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

R674 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

R676 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R677 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R678 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

R679 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

R680 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R681 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R686 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R687 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

R688 24871101 CHIP, 1/8W 100 OHM J

R690 24871101 CHIP, 1/8W 100 OHM J

R929 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RA71 24011273 CHIP, 1/20W 27K OHM J

RA72 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

RA73 24011822 CHIP, METAL FILM, 1/20W 8.2K OHM J

RA75 24011822 CHIP, METAL FILM, 1/20W 8.2K OHM J

RA76 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

RA80 24000445 CHIP JUMPER, 1608TYPE

RB01 24011391 CHIP, 1/20W 390 OHM J

RB04 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RB05 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RB15 24011471 CHIP, METAL FILM, 1/20W 470 OHM J

RB19 24011470 CHIP, METAL FILM, 1/20W 47 OHM J

RB37 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RB38 24011105 CHIP, METAL FILM, 1/20W 1M OHM J

RB39 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB40 24011392 CHIP, 1/20W 3.9K OHM J

RB41 24011392 CHIP, 1/20W 3.9K OHM J

RB42 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB43 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RB44 24011105 CHIP, METAL FILM, 1/20W 1M OHM J

RB45 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB46 24011392 CHIP, 1/20W 3.9K OHM J

RB47 24011392 CHIP, 1/20W 3.9K OHM J

RB48 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB51 24011224 CHIP, METAL FILM, 1/20W 220K OHM J

RB52 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB53 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB54 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RB55 24011224 CHIP, METAL FILM, 1/20W 220K OHM J

RB56 24011151 CHIP, METAL FILM, 1/20W 150 OHM J

RB57 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB58 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RB59 24011122 CHIP, METAL FILM, 1/20W 1.2K OHM J

RB60 24011224 CHIP, METAL FILM, 1/20W 220K OHM J

RB62 24011272 CHIP, 1/20W 2.7K OHM J

RB63 24011271 CHIP, 1/20W 270 OHM J

RB64 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RB65 24011221 CHIP, METAL FILM, 1/20W 220 OHM J

– 33 –

Page 34

Location Parts No. Description

No.

RB66 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RB67 24011221 CHIP, METAL FILM, 1/20W 220 OHM J

RB69 24011272 CHIP, 1/20W 2.7K OHM J

RB70 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RB71 24019112 CHIP, METAL FILM, 1/8W 1 OHM F

RB72 24011220 CHIP, METAL FILM, 1/20W 22 OHM J

RB73 24011560 CHIP, METAL FILM, 1/20W 56 OHM J

RB74 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RC01 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC02 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC03 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC04 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC05 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC06 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC07 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC08 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC11 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC12 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC15 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RC16 24011681 CHIP, METAL FILM, 1/20W 680 OHM J

RD101 24011823 CHIP, METAL FILM, 1/20W 82K OHM J

RD102 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD103 24011333 CHIP, METAL FILM, 1/20W 33K OHM J

RD104 24011393 CHIP, 1/20W 39K OHM J

RD105 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RD106 24011823 CHIP, METAL FILM, 1/20W 82K OHM J

RD107 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD108 24011333 CHIP, METAL FILM, 1/20W 33K OHM J

RD109 24011393 CHIP, 1/20W 39K OHM J

RD110 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RD111 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RD112 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD113 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

RD114 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD115 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RD116 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RD117 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD118 24011153 CHIP, METAL FILM, 1/2OW 15K OHM J

RD119 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD120 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RD130 24011182 CHIP, METAL FILM, 1/20W 1.8K OHM J

RD201 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD202 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD203 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD204 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD205 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD206 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD208 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RD210 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD211 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD212 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD213 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD214 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD215 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD216 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD217 24011105 CHIP, METAL FILM, 1/20W 1M OHM J

RD218 24011241 CHIP, METAL FILM, 1/20W 240 OHM J

RD219 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD220 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD221 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD222 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD223 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD224 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RD225 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD226 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD227 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RD228 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RD229 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD230 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RD233 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RD234 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RD235 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RD236 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD237 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD238 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD239 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

Location Parts No. Description

No.

RD240 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD248 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RD249 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD250 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RD251 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RJ40 24000445 CHIP JUMPER, 1608TYPE

RJ41 24000445 CHIP JUMPER, 1608TYPE

RS01 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS02 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS03 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS04 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS05 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS06 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS07 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS08 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS09 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS10 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS11 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS12 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS13 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS14 24011331 CHIP, METAL FILM, 1/20W 330 OHM J

RS15 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS16 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS17 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS18 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS19 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS20 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS21 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RS22 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RS25 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS26 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS27 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS28 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS29 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS30 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS31 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS32 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS33 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS34 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS35 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS36 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS37 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS38 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS39 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS40 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS41 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS42 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS44 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS45 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS46 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS47 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS48 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS49 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS50 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS51 24011272 CHIP, 1/20W 2.7K OHM J

RS52 24011182 CHIP, METAL FILM, 1/20W 1.8K OHM J

RS53 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS54 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

RS55 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS56 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS57 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS58 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS59 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS60 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS61 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS62 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RS63 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS64 24011393 CHIP, 1/20W 39K OHM J

RS65 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

RS66 24011393 CHIP, 1/20W 39K OHM J

RS67 24011563 CHIP, METAL FILM, 1/20W 56K OHM J

RS74 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RS75 24011224 CHIP, METAL FILM, 1/20W 220K OHM J

RS76 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RS79 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

RS80 24011104 CHIP, METAL FILM, 1/20W 100K OHM J

– 34 –

Page 35

Location Parts No. Description

No.

RS103 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS112 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS116 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS500 24011393 CHIP, 1/20W 39K OHM J

RS501 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS504 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RS505 24011393 CHIP, 1/20W 39K OHM J

RS506 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS507 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RS515 24011392 CHIP, 1/20W 3.9K OHM J

RS516 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RS517 24011473 CHIP, METAL FILM, 1/20W 47K OHM J

RT01 24019527

RV01 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV03 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV06 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV07 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RV08 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV09 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV10 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV11 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV12 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV14 24011562 CHIP, METAL FILM, 1/20W 5.6K OHM J

RV15 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV17 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV19 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV20 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV21 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV26 24011561 CHIP, METAL FILM, 1/20W 560 OHM J

RV27 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV29 24552101 OXIDE METAL FILM, 1/2W 100 OHM J

RV30 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV33 24871750 CHIP, 1/8W 75 OHM J

RV34 24871750 CHIP, 1/8W 75 OHM J

RV35 24871750 CHIP, 1/8W 75 OHM J

RV36 24871750 CHIP, 1/8W 75 OHM J

RV37 24871750 CHIP, 1/8W 75 OHM J

RV40 24871750 CHIP, 1/8W 75 OHM J

RV41 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV60 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV61 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV62 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV66 24011750 CHIP, METAL FILM, 1/20W 75 OHM J

RV70 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV71 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV72 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV73 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV74 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV75 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV76 24011272 CHIP, 1/20W 2.7K OHM J

RV77 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV78 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV79 24011272 CHIP, 1/20W 2.7K OHM J

RV87 24000445 CHIP JUMPER, 1608TYPE

RV88 24000445 CHIP JUMPER, 1608TYPE

RV89 24000445 CHIP JUMPER, 1608TYPE

RV90 24000445 CHIP JUMPER, 1608TYPE

RV91 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV92 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RV93 24011470 CHIP, METAL FILM, 1/20W 47 OHM J

RV94 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RV98 24000445 CHIP JUMPER, 1608TYPE

RV99 24000445 CHIP JUMPER, 1608TYPE

RV100 24000445 CHIP JUMPER, 1608TYPE

RV101 24000445 CHIP JUMPER, 1608TYPE

RV120 24871750 CHIP, 1/8W 75 OHM J

RV121 24871750 CHIP, 1/8W 75 OHM J

RV122 24871750 CHIP, 1/8W 75 OHM J

RV129 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV252 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV253 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RV254 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV255 24871561 CHIP, 1/8W 560 OHM J

RV256 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RV257 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV258 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

THERMISTOR, NTC 1608 SIZE NSM3103F344F3R

Location Parts No. Description

No.

RV259 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RV260 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV261 24871561 CHIP, 1/8W 560 OHM J

RV323 24872101 CHIP, 1/16W 100 OHM J

RV324 24872101 CHIP, 1/16W 100 OHM J

RV325 24872101 CHIP, 1/16W 100 OHM J

RV330 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV331 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV332 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV337 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV338 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV346 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV347 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV348 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RV351 24011330 CHIP, 1/20W 33 OHM J

RV352 24011330 CHIP, 1/20W 33 OHM J

RV353 24011330 CHIP, 1/20W 33 OHM J

RV354 24011330 CHIP, 1/20W 33 OHM J

RV355 24011330 CHIP, 1/20W 33 OHM J

RV356 24011330 CHIP, 1/20W 33 OHM J

RV357 24000445 CHIP JUMPER, 1608TYPE

RV358 24000445 CHIP JUMPER, 1608TYPE

RV359 24000445 CHIP JUMPER, 1608TYPE

RV368 24000445 CHIP JUMPER, 1608TYPE

RV369 24000445 CHIP JUMPER, 1608TYPE

RV370 24000445 CHIP JUMPER, 1608TYPE

RV371 24000445 CHIP JUMPER, 1608TYPE

RV372 24000445 CHIP JUMPER, 1608TYPE

RV373 24000445 CHIP JUMPER, 1608TYPE

RV374 24000445 CHIP JUMPER, 1608TYPE

RV375 24000445 CHIP JUMPER, 1608TYPE

RY101 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RY102 24011221 CHIP, METAL FILM, 1/20W 220 OHM J

RY103 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY104 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY105 24011821 CHIP, 1/20W 820 OHM J

RY106 24000445 CHIP JUMPER, 1608TYPE

RY107 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY109 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RY110 24011152 CHIP, METAL FILM, 1/20W 1.5K OHM J

RY501 24011303 CHIP, METAL FILM, 1/20W 30K OHM J

RY502 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RY503 24011223 CHIP, METAL FILM, 1/20W 22K OHM J

RY504 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RY505 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RY507 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY508 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY509 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RY510 24011152 CHIP, METAL FILM, 1/20W 1.5K OHM J

RY511 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY512 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY513 24011152 CHIP, METAL FILM, 1/20W 1.5K OHM J

RY516 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY517 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY518 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY519 24000445 CHIP JUMPER, 1608TYPE

RY520 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RY521 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RY523 24011152 CHIP, METAL FILM, 1/20W 1.5K OHM J

RY524 24011821 CHIP, 1/20W 820 OHM J

RY525 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY526 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY527 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY528 24011222 CHIP, METAL FILM, 1/20W 2.2K OHM J

RY529 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY530 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY531 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY532 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RY533 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY534 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY539 24011272 CHIP, 1/20W 2.7K OHM J

RY540 24011272 CHIP, 1/20W 2.7K OHM J

RY541 24011682 CHIP, METAL FILM, 1/20W 6.8K OHM J

RY542 24011392 CHIP, 1/20W 3.9K OHM J

RY543 24011152 CHIP, METAL FILM, 1/20W 1.5K OHM J

RY545 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

– 35 –

Page 36

Location Parts No. Description

No.

RY548 24011102 CHIP, METAL FILM, 1/20W 1K OHM J

RY550 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RY551 24011182 CHIP, METAL FILM, 1/20W 1.8K OHM J

RY552 24011152 CHIP, METAL FILM, 1/20W 1.5K OHM J

RY553 24011330 CHIP, 1/20W 33 OHM J

RY554 24011330 CHIP, 1/20W 33 OHM J

RY555 24011330 CHIP, 1/20W 33 OHM J

RY560 24011332 CHIP, METAL FILM, 1/20W 3.3K OHM J

RY561 24011471 CHIP, METAL FILM, 1/20W 470 OHM J

RY562 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RY573 24011472 CHIP, METAL FILM, 1/20W 4.7K OHM J

RY575 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RY576 24011123 CHIP, METAL FILM, 1/20W 12K OHM J

RY585 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RY590 24011103 CHIP, METAL FILM, 1/20W 10K OHM J

RY591 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

RY592 24011101 CHIP, METAL FILM, 1/20W 100 OHM J

GJ113 24000445 CHIP JUMPER, 1608TYPE

GJ128 24000445 CHIP JUMPER, 1608TYPE

GR01 24000445 CHIP JUMPER, 1608TYPE

GR02 24000445 CHIP JUMPER, 1608TYPE

GR03 24000445 CHIP JUMPER, 1608TYPE

GR04 24000445 CHIP JUMPER, 1608TYPE

GR91 24000445 CHIP JUMPER, 1608TYPE

GR96 24000445 CHIP JUMPER, 1608TYPE

GR105 24000445 CHIP JUMPER, 1608TYPE

GR131 24000445 CHIP JUMPER, 1608TYPE

GR132 24000445 CHIP JUMPER, 1608TYPE

GR605 24000445 CHIP JUMPER, 1608TYPE

GR621 24000445 CHIP JUMPER, 1608TYPE

GR622 24000445 CHIP JUMPER, 1608TYPE

GR623 24000445 CHIP JUMPER, 1608TYPE

GRV13 24000445 CHIP JUMPER, 1608TYPE

GRV14 24000445 CHIP JUMPER, 1608TYPE

GRV21 24000445 CHIP JUMPER, 1608TYPE

GRV22 24000445 CHIP JUMPER, 1608TYPE

GRV23 24000445 CHIP JUMPER, 1608TYPE

GRV24 24000445 CHIP JUMPER, 1608TYPE

GRV25 24000445 CHIP JUMPER, 1608TYPE

GRV26 24000445 CHIP JUMPER, 1608TYPE

GRV27 24000445 CHIP JUMPER, 1608TYPE

GRV28 24000445 CHIP JUMPER, 1608TYPE

GRV29 24000445 CHIP JUMPER, 1608TYPE

GRV30 24000445 CHIP JUMPER, 1608TYPE

GRV31 24000445 CHIP JUMPER, 1608TYPE

GRV39 24000445 CHIP JUMPER, 1608TYPE

GRV54 24000445 CHIP JUMPER, 1608TYPE

GRV55 24000445 CHIP JUMPER, 1608TYPE

GRV56 24000445 CHIP JUMPER, 1608TYPE

GRV57 24000445 CHIP JUMPER, 1608TYPE

GRV58 24000445 CHIP JUMPER, 1608TYPE

GRV59 24000445 CHIP JUMPER, 1608TYPE

GRV84 24000445 CHIP JUMPER, 1608TYPE

GRV85 24000445 CHIP JUMPER, 1608TYPE

GRV86 24000445 CHIP JUMPER, 1608TYPE

GRV87 24000445 CHIP JUMPER, 1608TYPE

GRV88 24000445 CHIP JUMPER, 1608TYPE

GRV89 24000445 CHIP JUMPER, 1608TYPE

GRV90 24000445 CHIP JUMPER, 1608TYPE

GRV91 24000445 CHIP JUMPER, 1608TYPE

GSR05 24000445 CHIP JUMPER, 1608TYPE

GSR06 24000445 CHIP JUMPER, 1608TYPE

LD201 24000445 CHIP JUMPER, 1608TYPE

COILS & TRANSFORMERS

L101 23289845 COIL, PEAKING, TRF4680AT

L103 23103828 INDUCTOR, BEAD, TEM2121M

L104 23103828 INDUCTOR, BEAD, TEM2121M

L132 23103828 INDUCTOR, BEAD, TEM2121M

L133 23103828 INDUCTOR, BEAD, TEM2121M

L134 23289845 COIL, PEAKING, TRF4680AT

L289 23248073 COIL, CHOKE, TLN3299D

L620 23246406 COIL, CHOKE, TLN3528AF

L622 23246406 COIL, CHOKE, TLN3528AF

L623 23246406 COIL, CHOKE, TLN3528AF

L625 23246406 COIL, CHOKE, TLN3528AF

Location Parts No. Description

No.

L640 23289109 COIL, PEAKING, TRF41R0AF

L645 23103238 INDUCTOR, BEAD, TEM2142AD

L655 23103233 INDUCTOR, BEAD, TEM2137AD

LB51 23246004 COIL, CHIP INDUCTER, TRF4R10CC

LB52 23237987 COIL, PEAKING, TRF4100AC

LC01 23103828 INDUCTOR, BEAD, TEM2121M

LC02 23103828 INDUCTOR, BEAD, TEM2121M

LC03 23103828 INDUCTOR, BEAD, TEM2121M

LC04 23103828 INDUCTOR, BEAD, TEM2121M

LD101 23103828 INDUCTOR, BEAD, TEM2121M

LD102 23103828 INDUCTOR, BEAD, TEM2121M

LD103 23103828 INDUCTOR, BEAD, TEM2121M

LD202 23246199 COIL, CHIP INDUCTOR, TRF42R2CG

LD203 23103828 INDUCTOR, BEAD, TEM2121M

LD204 23103828 INDUCTOR, BEAD, TEM2121M

LD205 23103828 INDUCTOR, BEAD, TEM2121M

LV09 23289840 COIL, PEAKING, TRF4100AT

LV13 23289840 COIL, PEAKING, TRF4100AT

LV42 23289840 COIL, PEAKING, TRF4100AT

LV270 23289840 COIL, PEAKING, TRF4100AT

LY012 23246253 INDUCTOR, CHIP 10MMH K COLTRF4100CN

LY100 23246223 COIL, CHIP INDUCTOR, TRF4330CG

LY101 23103827 INDUCTOR, BEAD, TEM2120M

LY102 23103827 INDUCTOR, BEAD, TEM2120M

LY103 23103230 INDUCTOR, BEAD, TEM2134AD

LY104 23246219 COIL, CHIP INDUCTOR, TRF4150CG

LY105 23246222 COIL, CHIP INDUCTOR, TRF4270CG

LY112 23103230 INDUCTOR, BEAD, TEM2134AD

LY501 23246253 INDUCTOR, CHIP 10MMH K COLTRF4100CN

GV12 23103828 INDUCTOR, BEAD, TEM2121M

GV13 23103828 INDUCTOR, BEAD, TEM2121M

SEMICONDUCTORS

IC410 75000900 IC, PQ1M335M2SPQ REG

IC414 75000900 IC, PQ1M335M2SPQ REG

Q131 23314204 TRANSISTOR, 2SC2412K,Q

Q151 23314994 TRANSISTOR, 2SA1576A106

Q152 23314993 TRANSISTOR, 2SC4081 Q

Q610 23009368 IC, TA2024(T)

Q612 23314163 TRANSISTOR, 2SA1162-Y

Q620 23314475 TRANSISTOR, 2SC2712-Y

Q630 23009942 IC, LA4525-E

Q671 70114396 TRANSISTOR, 2SC3326B

Q672 70114396 TRANSISTOR, 2SC3326B

Q675 70114396 TRANSISTOR, 2SC3326B

Q676 70114396 TRANSISTOR, 2SC3326B

Q677 23114493 TRANSISTOR, RN2404

Q678 23314475 TRANSISTOR, 2SC2712-Y

Q679 23314475 TRANSISTOR, 2SC2712-Y

Q680 23314475 TRANSISTOR, 2SC2712-Y

Q922 70129444 IC, PST994D

QB01 23314475 TRANSISTOR, 2SC2712-Y

QB44 23205112 TRANSISTOR, 2SA1980UF-Y

QB45 23205116 TRANSISTOR, 2SC5343UF-Y

QB46 23205112 TRANSISTOR, 2SA1980UF-Y

QB47 23205116 TRANSISTOR, 2SC5343UF-Y

QB51 23319808 IC, M5218AP

QB52 23314475 TRANSISTOR, 2SC2712-Y

QB53 23314994 TRANSISTOR, 2SA1576A106

QB54 23314994 TRANSISTOR, 2SA1576A106

QB55 23314475 TRANSISTOR, 2SC2712-Y

QD101 23318820 IC, OPE AMP, BA10358F

QD102 23318820 IC, OPE AMP, BA10358F

QD201 23009932 IC, DIGITAL AUD DELAY QFP32 NJU26103FR1

QD202 23000462 IC, AUDIO CODEC PCM3001E

QD203 23905927 IC, TC7SH32FU(BRA

QD205 23318026 IC, TA78L05F

QD207 23085171

QD208 70200934 IC, PST9126NR

QS03 23314993 TRANSISTOR, 2SC4081 Q

QS04 23314993 TRANSISTOR, 2SC4081 Q

QS05 23009613 IC, CD4052BNSR

QS06 23009613 IC, CD4052BNSR

QS07 70114396 TRANSISTOR, 2SC3326B

QS08 70114396 TRANSISTOR, 2SC3326B

QS09 23114493 TRANSISTOR, RN2404

IC, MCU 1CHIP 8BIT 32K 28P 87C409BMG-5GR1

– 36 –

Page 37

Location Parts No. Description

No.

QS10 23904896 IC, JLC1562BF

QS11 23114499 TRANSISTOR, RN1404

QS12 23114499 TRANSISTOR, RN1404

QS13 23114499 TRANSISTOR, RN1404

QS14 23114499 TRANSISTOR, RN1404

QS15 23314993 TRANSISTOR, 2SC4081 Q

QS16 23114493 TRANSISTOR, RN2404

QS17 70114396 TRANSISTOR, 2SC3326B

QS18 70114396 TRANSISTOR, 2SC3326B

QS102 23318820 IC, OPE AMP, BA10358F

QV01 23906887 IC, CXA2069Q

QV04 23314993 TRANSISTOR, 2SC4081 Q

QV06 23314994 TRANSISTOR, 2SA1576A106

QV09 23314994 TRANSISTOR, 2SA1576A106

QV12 23009418 IC, 2IN-1OUTSW DRIVER MM1505XNRE

QV13 23314993 TRANSISTOR, 2SC4081 Q

QV70 23314993 TRANSISTOR, 2SC4081 Q

QV71 23314993 TRANSISTOR, 2SC4081 Q

QV72 23314994 TRANSISTOR, 2SA1576A106

QV73 23314994 TRANSISTOR, 2SA1576A106

QV246 23205045 TRANSISTOR, 2SA1037AKQ

QV247 23314475 TRANSISTOR, 2SC2712-Y

QV248 23205045 TRANSISTOR, 2SA1037AKQ

QV249 23314475 TRANSISTOR, 2SC2712-Y

QV254 23000360 IC, MM1519XQ

QY100 23906515 IC, TC90A45F

QY101 23314993 TRANSISTOR, 2SC4081 Q

QY102 23314993 TRANSISTOR, 2SC4081 Q

QY103 23314994 TRANSISTOR, 2SA1576A106

QY501 23000812 IC, TA1340F

QY502 23205014 TRANSISTOR, 2SC4667-O

QY503 23314994 TRANSISTOR, 2SA1576A106

QY504 23314994 TRANSISTOR, 2SA1576A106

QY507 23314993 TRANSISTOR, 2SC4081 Q

QY508 23314993 TRANSISTOR, 2SC4081 Q

QY509 23314993 TRANSISTOR, 2SC4081 Q

QY511 23314994 TRANSISTOR, 2SA1576A106

QY512 23314994 TRANSISTOR, 2SA1576A106

QY513 23314994 TRANSISTOR, 2SA1576A106

QY514 23314994 TRANSISTOR, 2SA1576A106

QY515 23314994 TRANSISTOR, 2SA1576A106

QY516 23314994 TRANSISTOR, 2SA1576A106

QY518 23314993 TRANSISTOR, 2SC4081 Q

QY520 23314993 TRANSISTOR, 2SC4081 Q

D608 23316591 DIODE, ZENER, MA8100-M

D611 23316231 DIODE, 1SS355

D612 23316231 DIODE, 1SS355

D613 23316231 DIODE, 1SS355

D614 23316231 DIODE, 1SS355

D615 23316231 DIODE, 1SS355

D617 23316231 DIODE, 1SS355

D620 23316231 DIODE, 1SS355

D621 23316231 DIODE, 1SS355

D622 23316231 DIODE, 1SS355

D623 23316231 DIODE, 1SS355

D624 23316231 DIODE, 1SS355

D625 23316231 DIODE, 1SS355

D626 23316231 DIODE, 1SS355

D627 23316231 DIODE, 1SS355

D628 23316231 DIODE, 1SS355

D629 23316231 DIODE, 1SS355

D640 23316231 DIODE, 1SS355

D641 23316231 DIODE, 1SS355

D642 23316231 DIODE, 1SS355

D643 23316231 DIODE, 1SS355

D646 23316231 DIODE, 1SS355

D656 23316604 DIODE, ZENER, MA8150-M, TX

D657 23316573 DIODE, ZENER, MA8062-L

D672 23316231 DIODE, 1SS355

D673 23316231 DIODE, 1SS355

DB01 23358564 DIODE, LED, SLR-56VC3FPQ

DB03 23358522 DIODE, LED, SIR-56SB3F

DB51 23358573 PHOTO DIODE, PIN 940NM HPI-2FER4

DB52 23316231 DIODE, 1SS355

DB53 23316231 DIODE, 1SS355

DB54 23316231 DIODE, 1SS355

Location Parts No. Description

No.

DB76 23316231 DIODE, 1SS355

DB90 23316231 DIODE, 1SS355

DD101 23316542 DIODE, ZENER, MA8039-L, TX

DD201 23118041 DIODE, MA111

DD202 23118041 DIODE, MA111

DD203 23118041 DIODE, MA111

DD204 23118041 DIODE, MA111

DD205 23118041 DIODE, MA111

DD206 23118041 DIODE, MA111