Toshiba 23HL85 Schematic

FILE NO. 050-200531

DOCUMENT CREATED IN JAPAN, Sept., 2005

SERVICE MANUAL

LCD Color Television

23HL85

TOSHIBA CORPORATION 2005

-

1

-

Published in Japan, Sep. 2005 (YC)

TABLE OF CONTENTS

SERVICE SAFETY PRECAUTIONS ..........................................................................................................................................3

HANDLING THE LCD MODULE ................................................................................................................................................ 5

1. SERVICE MODE .................................................................................................................................................................... 7

1-1. STARTING SERVICE MODE ...........................................................................................................................................7

2. ADJUSTMENT ....................................................................................................................................................................... 8

2-1. ADJUSTMENT TOOLS AND CONDITIONS ................................................................................................................... 8

2-2. AUTO GAIN/OFFSET ADJUSTMENT .............................................................................................................................8

2-3. DDC EDID DATA READ & WRITE ...................................................................................................................................9

3. VCTI FIRMWARE INSTALLATIONS/UPGRADING ............................................................................................................. 19

3-1. VCTI FIRMWARE INSTALLATIONS ............................................................................................................................. 20

3-2. SCALER FIRMWARE INSTALLATIONS....................................................................................................................... 26

4. TROUBLESHOOTING......................................................................................................................................................... 33

5. EXPLODED VIEW ............................................................................................................................................................... 43

6. CHASSIS AND CABINET REPLACEMENT PARTS LIST .................................................................................................. 44

7. PC BOARDS TOP & BOTTOM VIEW.................................................................................................................................. 54

8. SCHEMATIC DIAGRAM ...................................................................................................................................................... 57

8-1. WIRING DIAGRAM ....................................................................................................................................................... 58

8-2. BLOCK DIAGRAM ........................................................................................................................................................ 59

-

2

-

GENERAL ADJUSTMENTS

SPECIFIC INFORMATIONS

SERVICE SAFETY PRECAUTIONS

• The caution items shown here describe major safety issues and should always be observed.

• The meanings of the various indications are as follows.

WARNING

CAUTION

* Physical damage means major damage to a home, furnishings and other possessions.

Examples of marks

SHOCK HAZARD

PROHIBIT DISASSEM-

BLING

UNPULUG

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users due to a product defect after the service operation is completed, could possibly be in

danger of injury or even death in the event of operational error.

Indicates a hypothetical situation in which service personnel and nearby third parties, or even

end users after the service operation is completed, could possibly be in danger of injury, or

where there could be physical damage in the event of operational error.

The" indicates caution (including danger and warning).

"

The actual meaning of this caution is indicated inside the

The example shown to the left indicates the danger of "electrical shock".

The

indicates a forbidden action.

The actual meaning of this caution is indicated inside the

The example shown to the left indicates that disassembly is forbidden.

The

-

indicates a forced action (an action that must be performed).

The actual meaning of this forced action is indicated by

The example shown to the left indicates that the power plug must be disconnected.

or nearby illustrations or text.

or nearby illustrations or text.

-

or nearby illustrations or text.

-

3

-

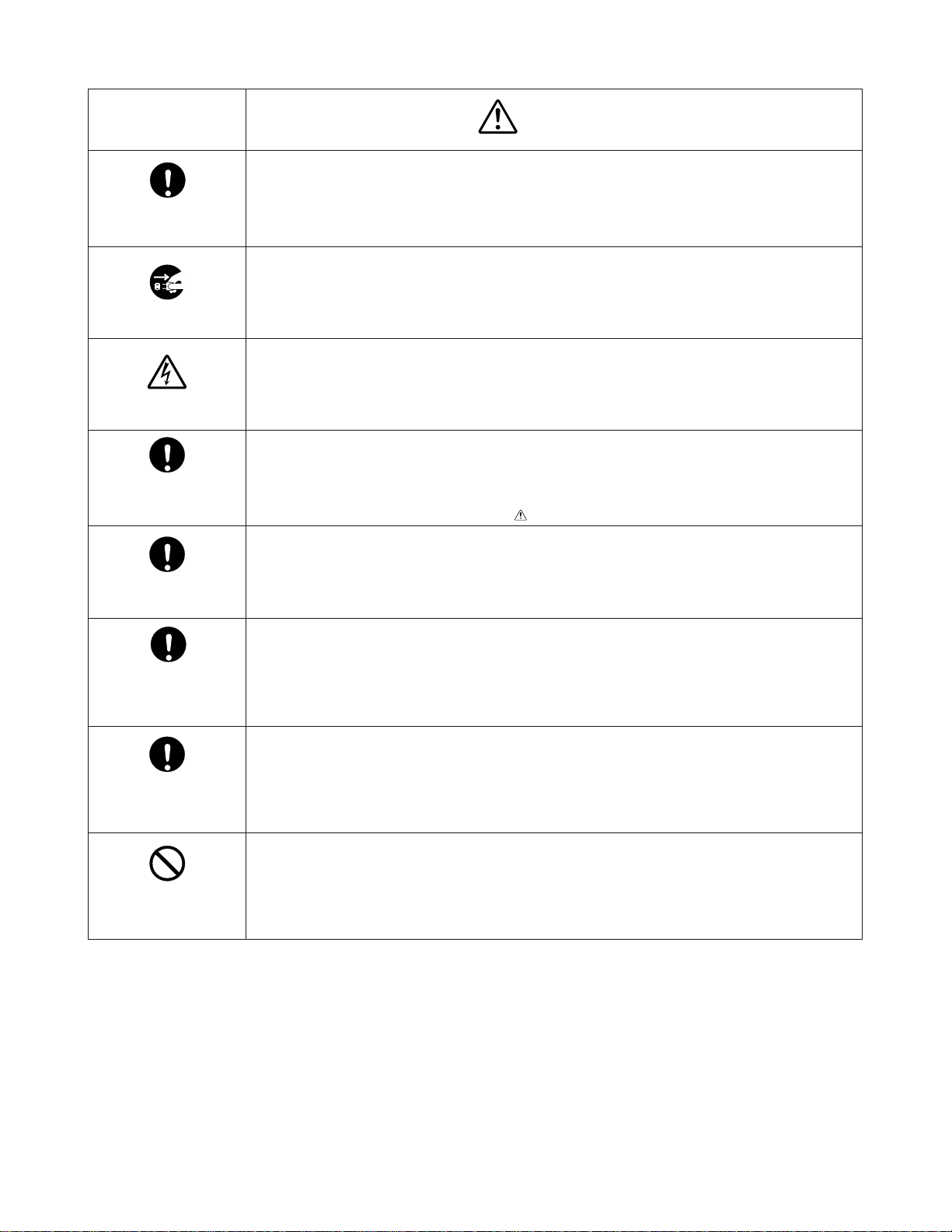

KEEP CHILDREN

AWAY

UNPULUG

SHOCK HAZARD

USE SPECIFIED

PARTS

CAUTION FOR

WIRING

CAUTION FOR

ASSEMBLING /

WIRING

WARNING

• Always advise users to keep children away.

There is danger of injury to children from tools, disassembled products, etc.

• Always disconnect the power plug before starting work whenever power is not required.

Failure to disconnect the power plug before starting work can result in electrical shock.

• Depending on the model, use an insulation transformer or wear gloves when servicing with the

power on, and disconnect the power plug to avoid electrical shock when replacing parts.

In some cases, alternating current is also impressed in the chassis, so electrical shock is possible if the chassis is contacted with the power on.

• Always use the replacement parts specified for the particular model when making repairs.

The parts used in products have the necessary safety characteristics such as inflammability,

voltage resistance, etc.; therefore, use only replacement parts that have these same characteristics.

Use only the specified parts when the

• Parts mounting and routing of the wiring should be the same as that used originally.

For safety purposes, insulating materials such as tubing or tape is sometimes used and printed

circuit boards are sometimes mounted floating.

Also make sure that wiring is routed and clamped to avoid parts that generate heat and which

use high voltage. Always follow the original scheme.

• After a repair has been completed, reassemble all disassembled parts, and route and reconnect the wiring, in accordance with the original scheme.

Do not allow internal wiring to be pinched by cabinets, panels, etc.

Any error in reassembly or wiring can result in electrical leakage, flame, etc., and may be

hazardous.

mark is included in a circuit diagram or parts list.

CHECK INSULATION

RESISTANCE

PROHIBIT

REMODELING

• After completing the work, disconnect the power plug from the outlet, remove the antenna, turn

on the power switch. Then, use a 500V insulation resistance meter to check the insulation

resistance of the antenna terminal, other metallic parts and between the prongs of the power

plug to make sure that the insulation resistance is 1M 1 or more.

The set will require inspection and repair if the insulation resistance is below this value.

• Never remodel the product in any way.

Remodeling can result in improper operation, malfunction, or electrical leakage and flame,

which may be hazardous

-

4

-

HANDLING THE LCD MODULE

a

n

r

r

y

n

r

e

h

d

-

Safety Precautions

In the event that the screen is damaged or the liquid crystal

(fluid) leaks, do not breathe in or drink this fluid. Also, never

touch this fluid.

Such actions could cause toxicity or skin irritation. If this fluid

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the skin or clothing, wipe off

with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly

with running water.

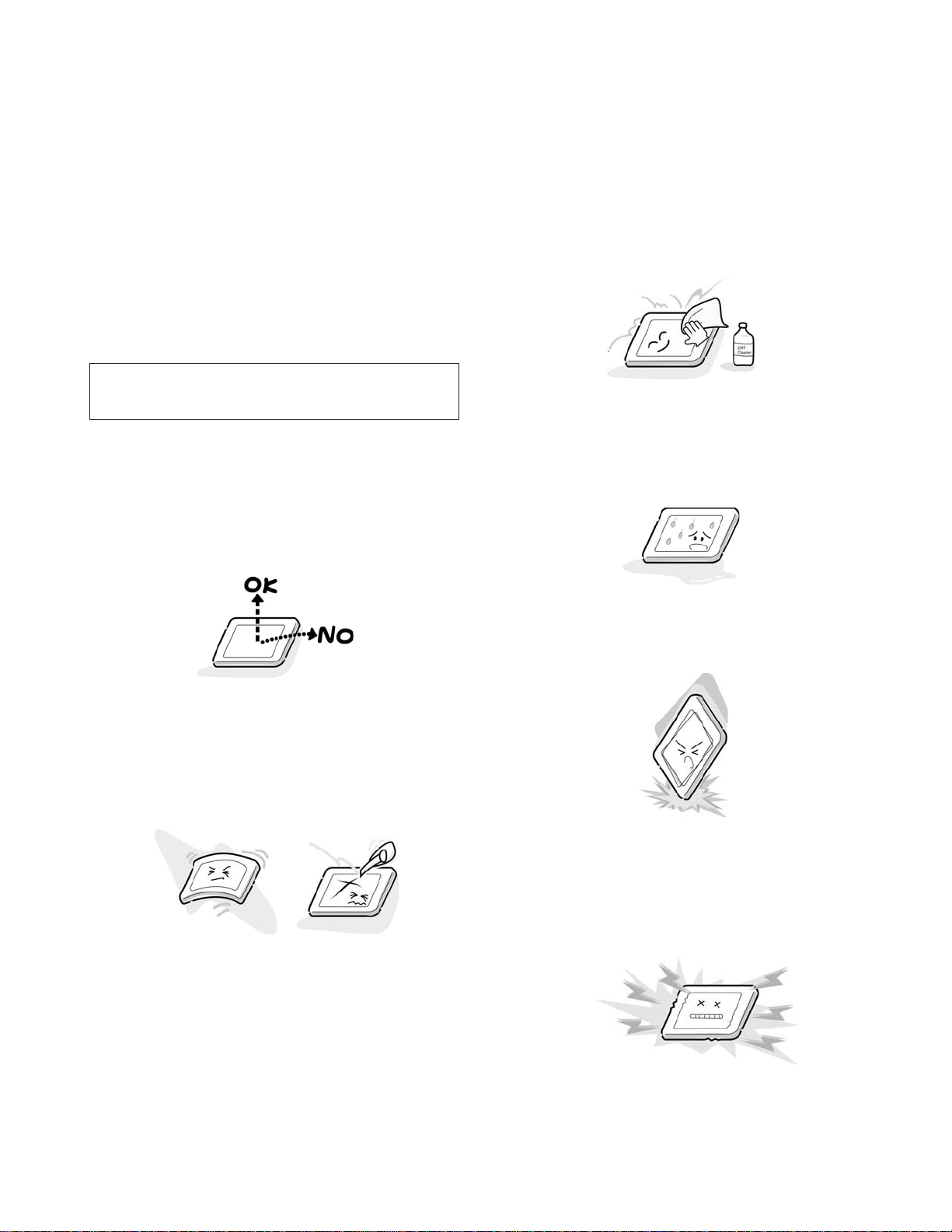

Precautions for Handling the LCD Module

CAUTION

The LCD module can easily be damaged during disassembly

or reassembly; therefore, always observe the following precautions when handling the module.

1. When attaching the LCD module to the LCD cover, position it appropriately and fasten at the position where the

display can be viewed most conveniently.

The metal edges of the LCD module

are sharp, handle it with care.

3. If the panel surface becomes soiled, wipe with cotton or

soft cloth. If this does not remove the soiling, breathe o

the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleane

as a cleaner. Wipe off the panel surface by drop the cleane

on the cloth. Do not drop the cleaner on the panel. Pa

attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for a

extended period of time can result in discoloration o

stripes. Immediately remove any type of fluid from th

screen.

2. Carefully align the holes at all four corners of the LCD

module with the corresponding holes in the LCD cover

and fasten with screws. Do not strongly push on the module because any impact can adversely affect the performance. Also use caution when handling the polarized screen

because it can easily be damaged.

5. Glass is used in the panel, so do not drop or strike wit

hard objects. Such actions can damage the panel.

6. CMOS-LSI circuitry is used in the LCD module, so avoi

damage due to static electricity. When handling the mod

ule, use a wrist ground or anchor ground.

-

5

-

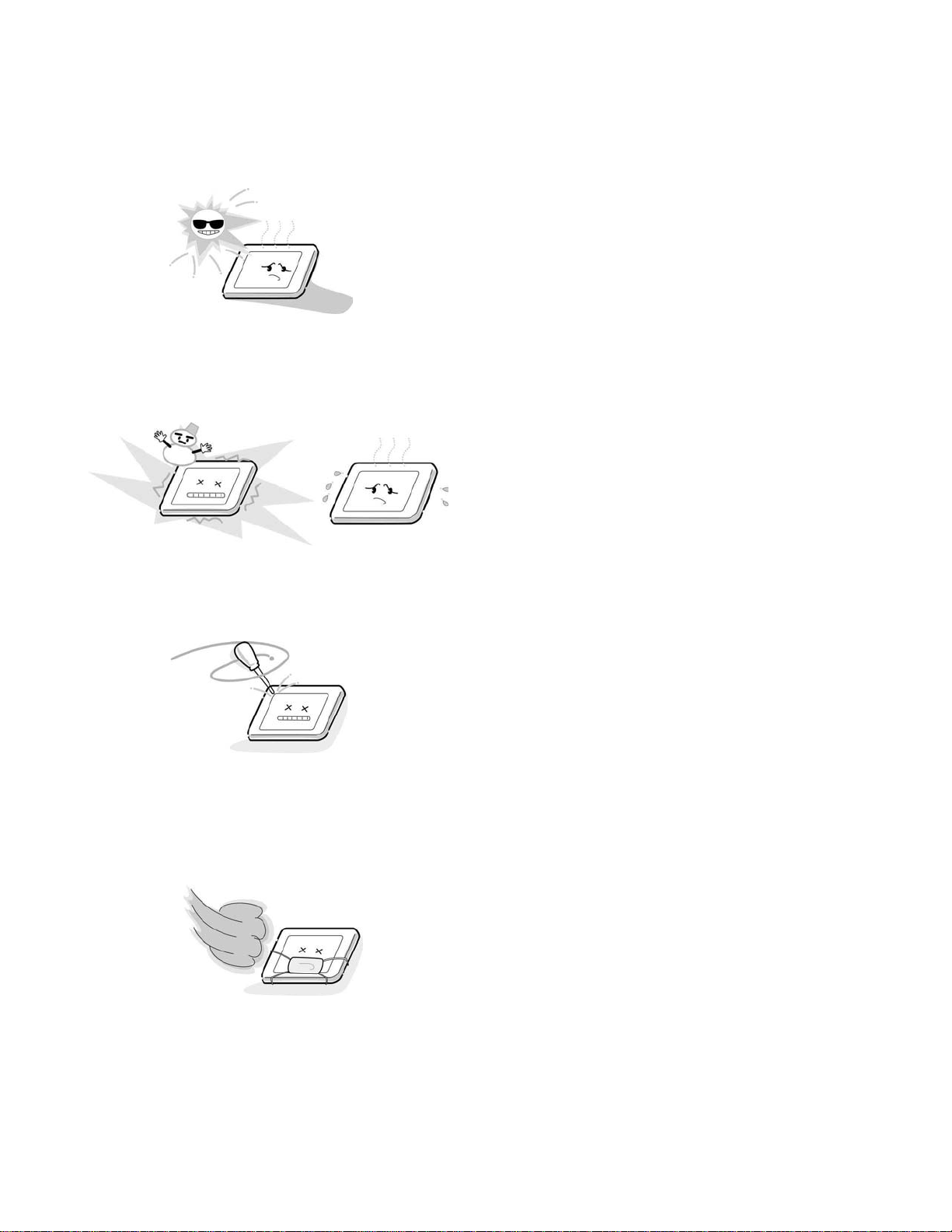

7. Do not expose the LCD module to direct sunlight or strong

ultraviolet rays for an extended period of time.

8. Do not store the LCD module below the temperature conditions described in the specifications. Failure to do so

could result in freezing of the liquid crystal due to cold air

or loss of resilience or other damage.

9. Do not disassemble the LCD module. Such actions could

result in improper operation.

10. When transporting the LCD module, do not use packing

containing epoxy resin (amine) or silicon resin (alcohol or

oxim). The gas generated by these materials can cause

loss of polarity.

-

6

-

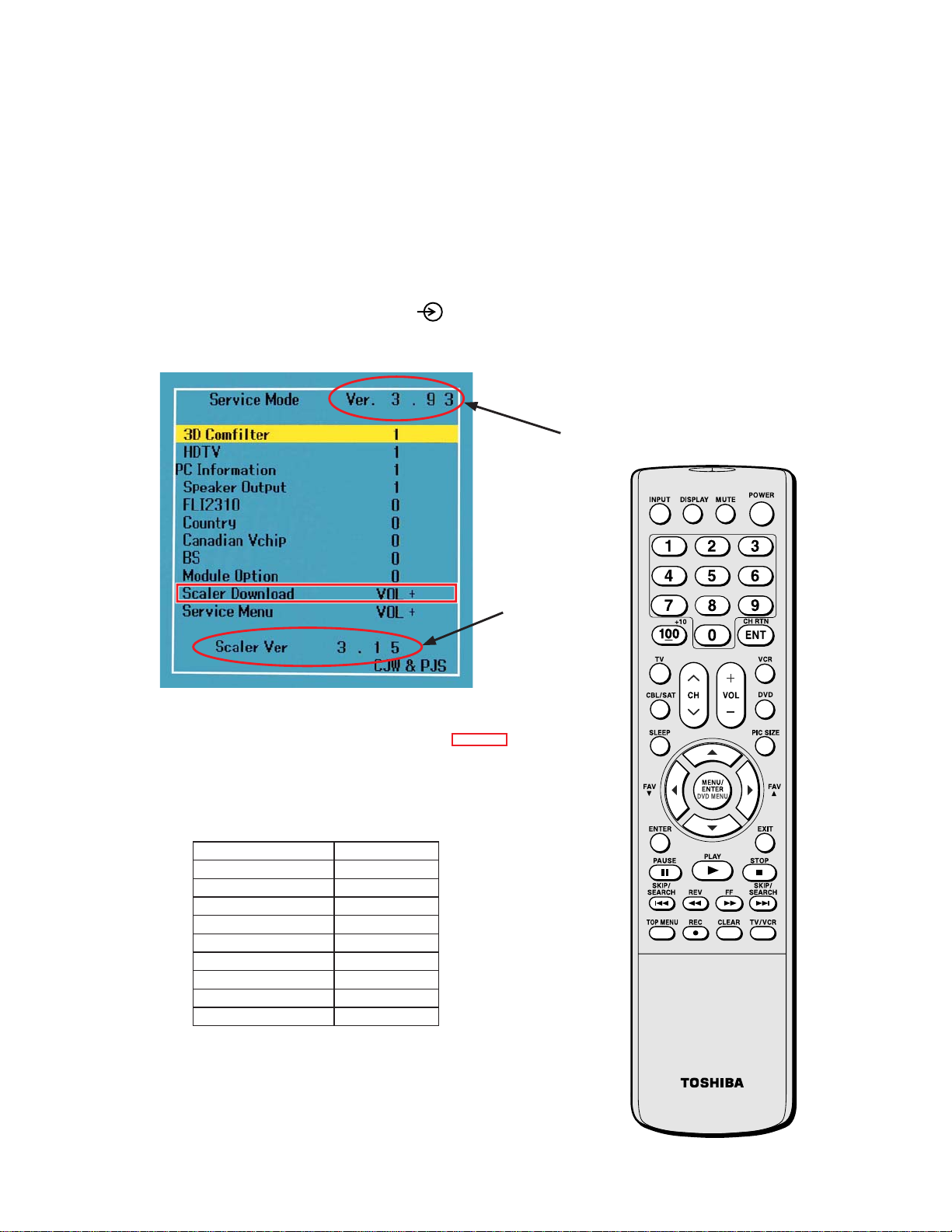

1.Service Mode

1-1.Starting Service Mode

*Set LCD TV to the normal TV signal receive mode.

Note: In this "Service Mode" section, [ ] shows a button.

1-1-1. Press [MUTE] on the remote control once.

1-1-2. Press [MUTE] again, and press [

Service mode displayed on TV screen

Items other than those enclosed by are default

settings.

] on LCD TV.

VCTi version

Scaler version

Item Default setting

3D Comb Filter 1

HDTV 1

PC Information 1

Speaker Outout 0

FLI2310 1

Country 2

Canadian Vchip 0

BS 0

Module Option 0

-

7

-

2. Adjustment

Note: In this "Adjustment" section, [ ] shows a button.

2-1.Adjustment Tools and Conditions

Tools: Pattern Generator (801GF, MSPG925F)

DDC Adjustment Tool

PC

Remote Control

Conditions: Heat Run 30 minutes or more

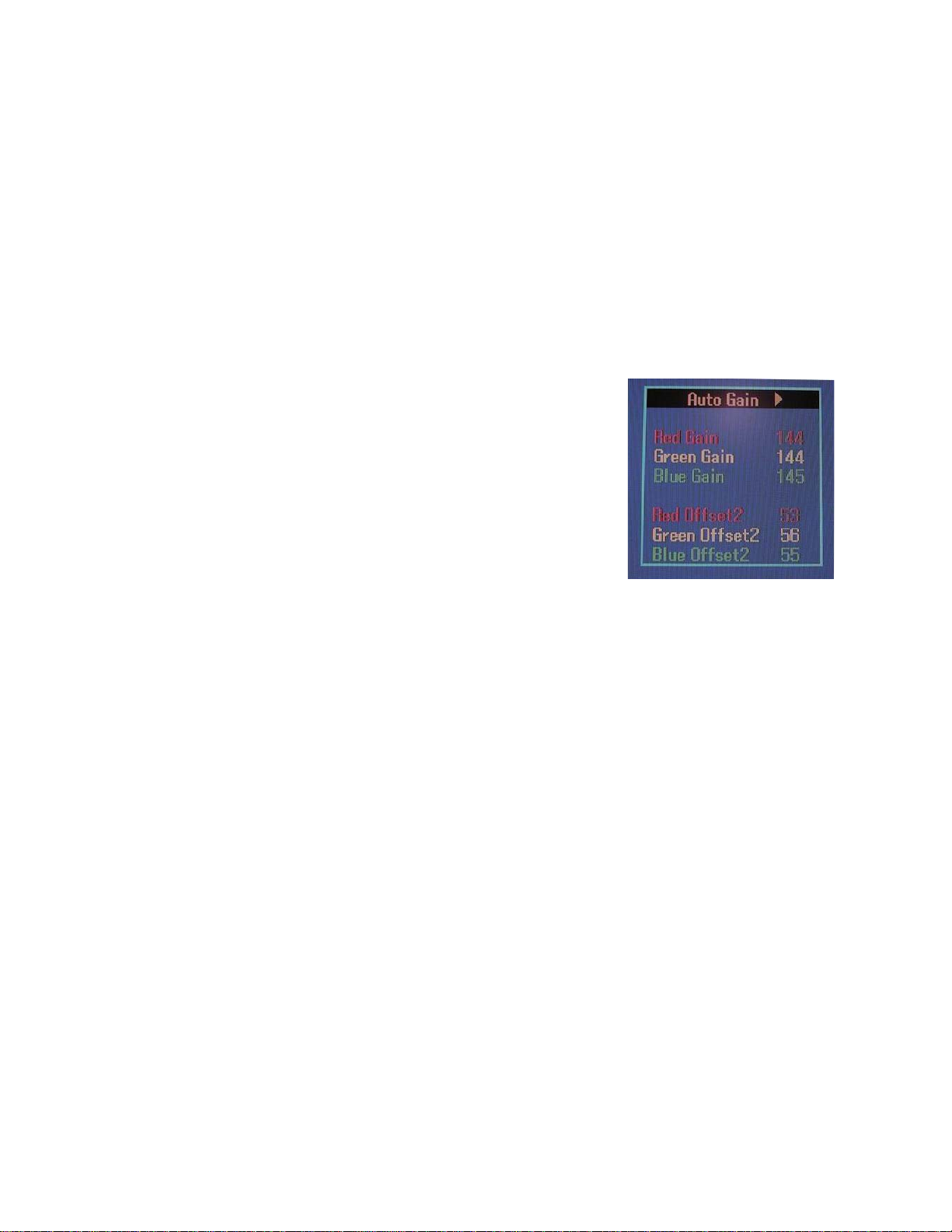

2-2. Auto Gain/Offset Adjustment

2-2-1. RF Mode Adjustment (normal TV receive mode)

No reguired

2-2-2. Component Mode Adjustment

Preparation

Carry out Heat Run for 30 minutes or more before adjustment

(with no RF signal).

1) Connect Y, Pb, and Pr output signals of Pattern Generator

to the component jack (Y, Pb, Pr) of LCD TV.

2) Connect Y, Pb, and Pr output signals of Pattern Generator

to the component jack (D Jack) of LCD TV.

3) Change the TV input mode to component mode.

4) Select 480p Mode (Y:100% Pb/Pr:75%) in Pattern Generator. Select Pattern 33 (Color Bar Pattern

signal) in Pattern Generator (MSPG925F).

5) Go into service mode, and Auto Gain menu appears, and then press VOL [+].

6) Press [OK] to store the adjustment data.

(Adjustment in component mode or PC mode)

2-2-3. PC Mode Adjustment

Preparation

Carry out Heat Run for 30 minutes or more before adjustment (with no RF signal).

Connect Pattern Generator to the 15-pin D-Sub Jack of LCD TV.

1) Change the TV input mode to PC mode.

2) Set Pattern Generator to the following:

XGA (1024x768) 16-step or 11-step grayscale

3) Go into service mode, and Auto Gain menu appears, and then press VOL [+].

4) Press [ENTER] to store the adjustment data.

-

8

-

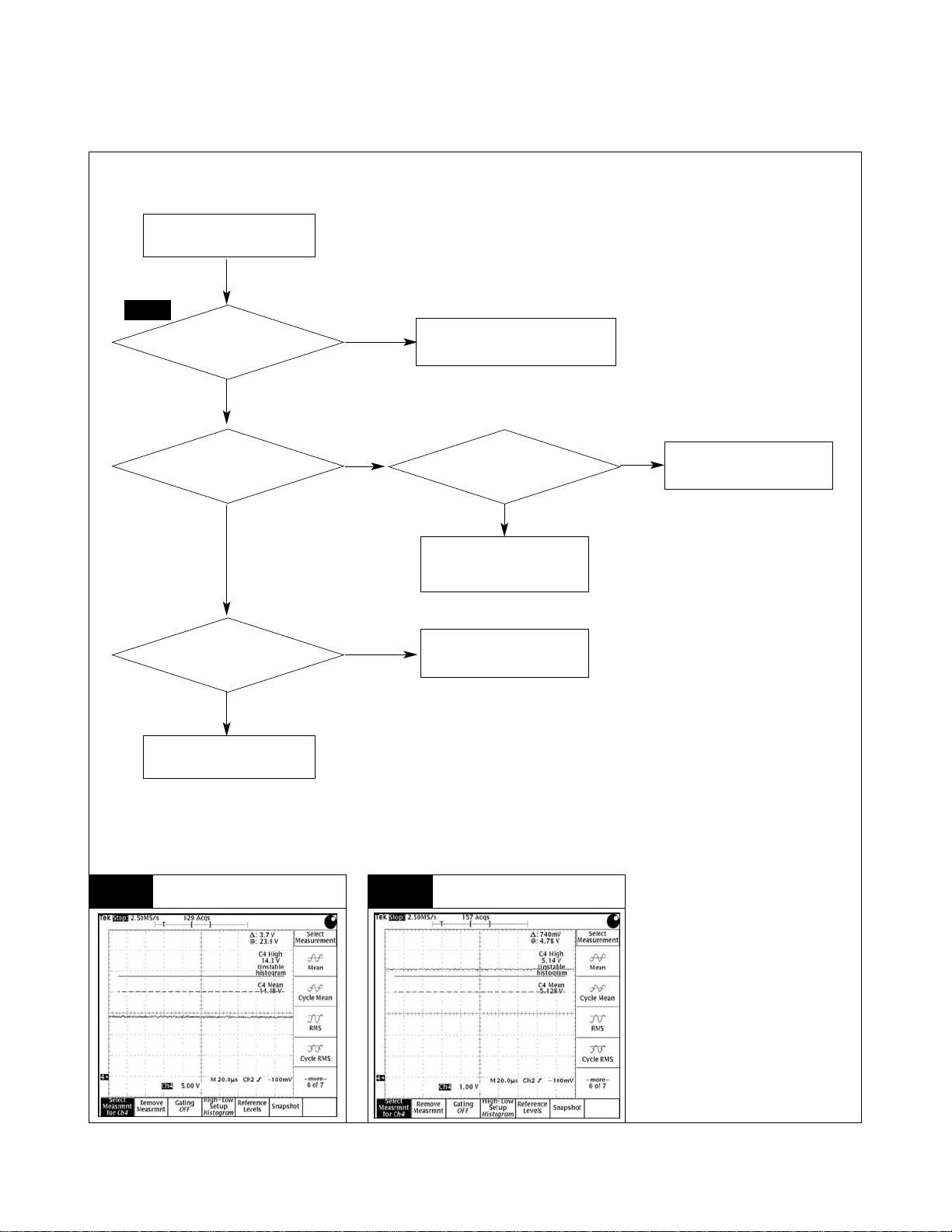

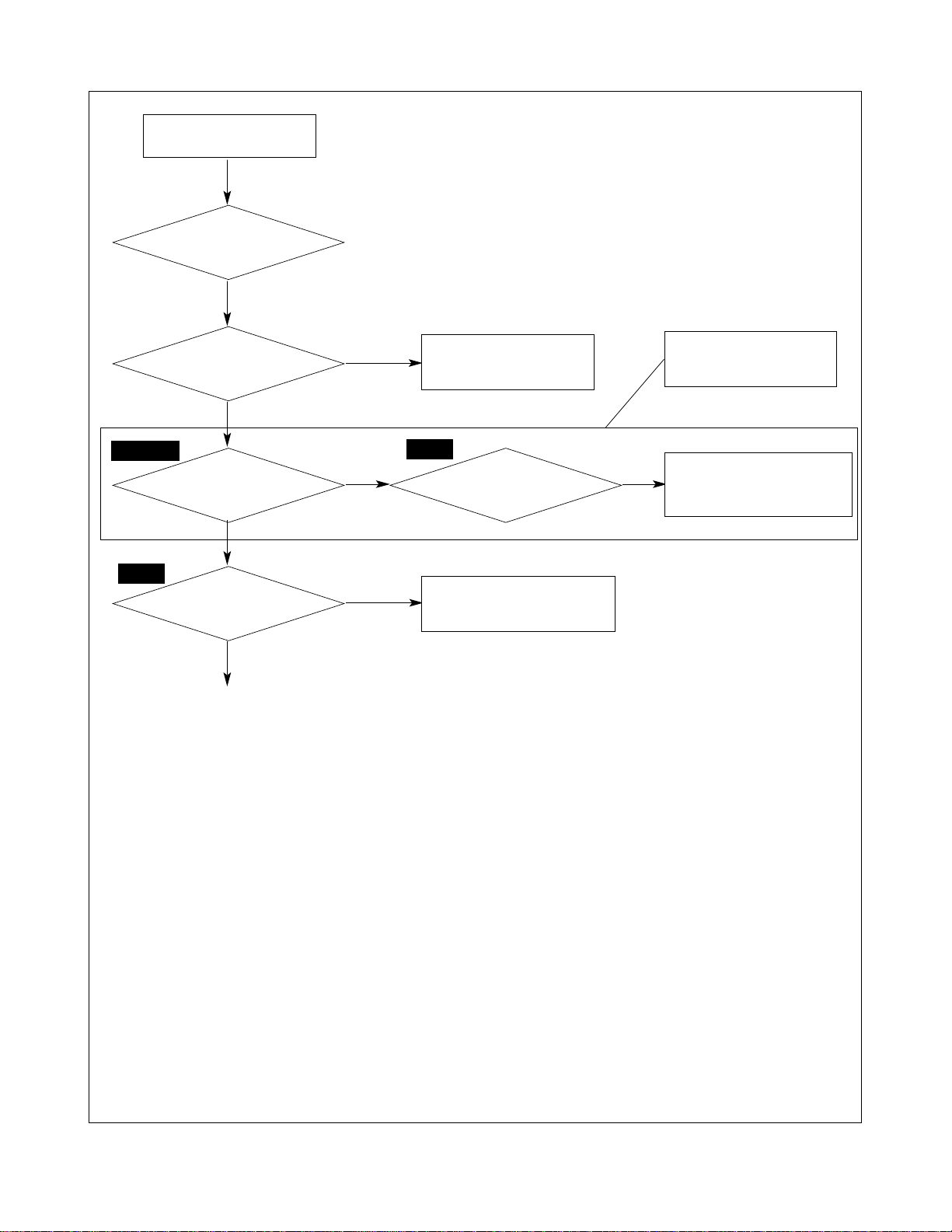

4. TROUBLESHOOTING

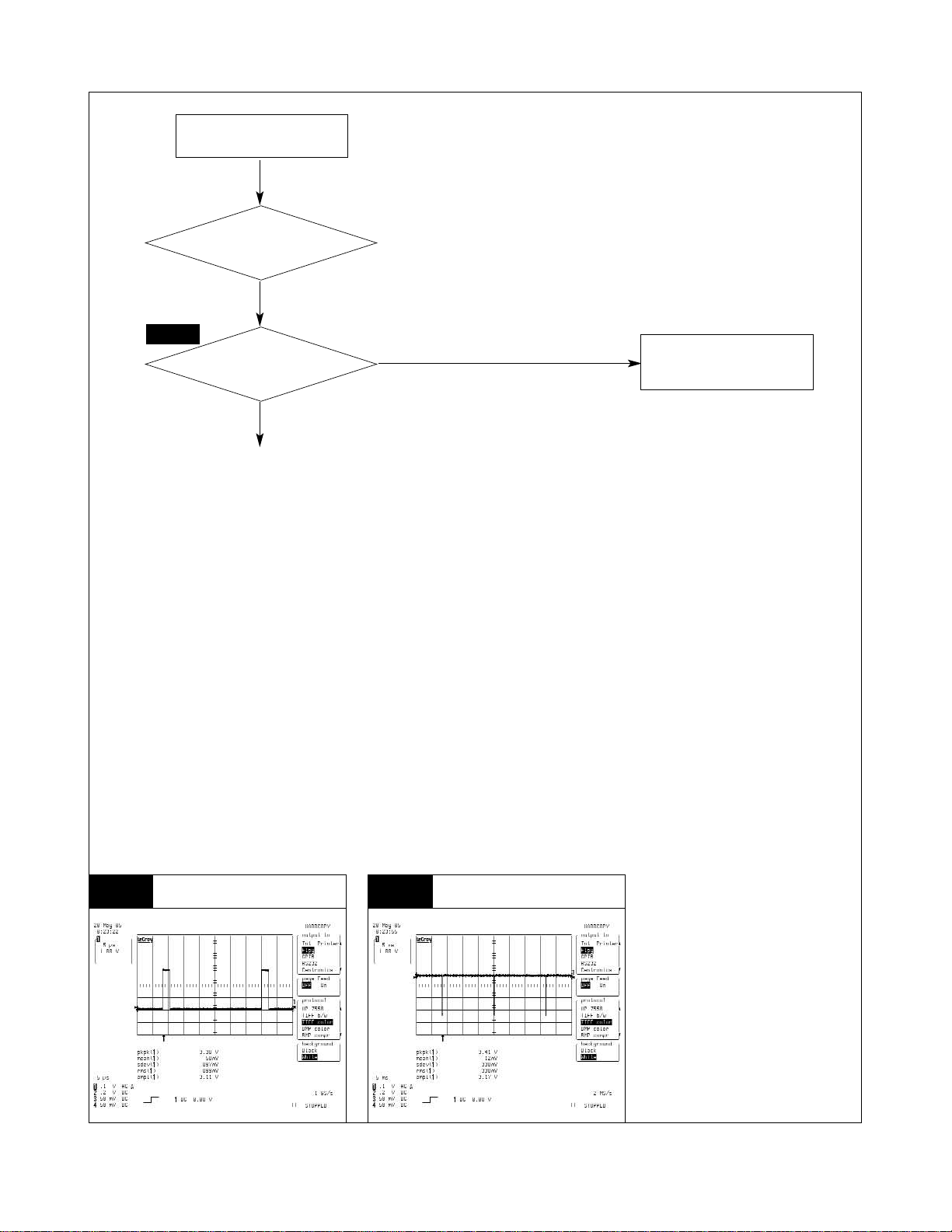

Process A

No Power

(LED indicator off)

Ref.1/1-1

Check 15V or ST_5V

of Power B/D

Pass

Fail

Check short circuits of Main B/ D

or Change Power B/ D

Check Output of

IC1104, IC1105, IC1106

Pass

Check LED Assy

Pass

Check P101 Connector

15V : P1000 #13, 14Ref.1 ST_5V : P1100 #1Ref.1-1

Fail

Fail

Check IC203

Pin 7 Level(High 5V)

Pass

Change IC1104 , IC1105,

IC1106 or check short

circuits of Main B/ D

Change LED Assy

Change VCTi( IC200)

of Main B/ D

Fail

-

33

-

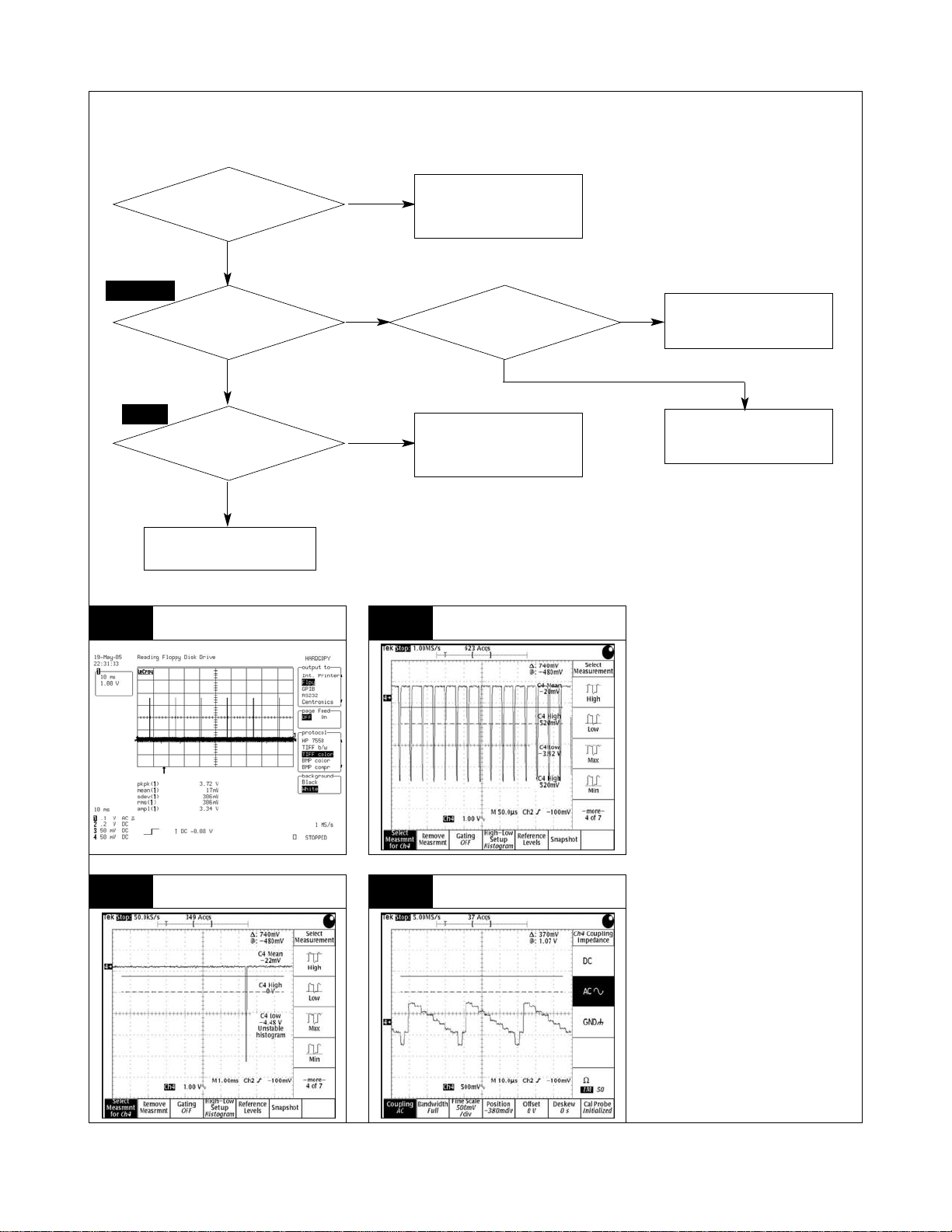

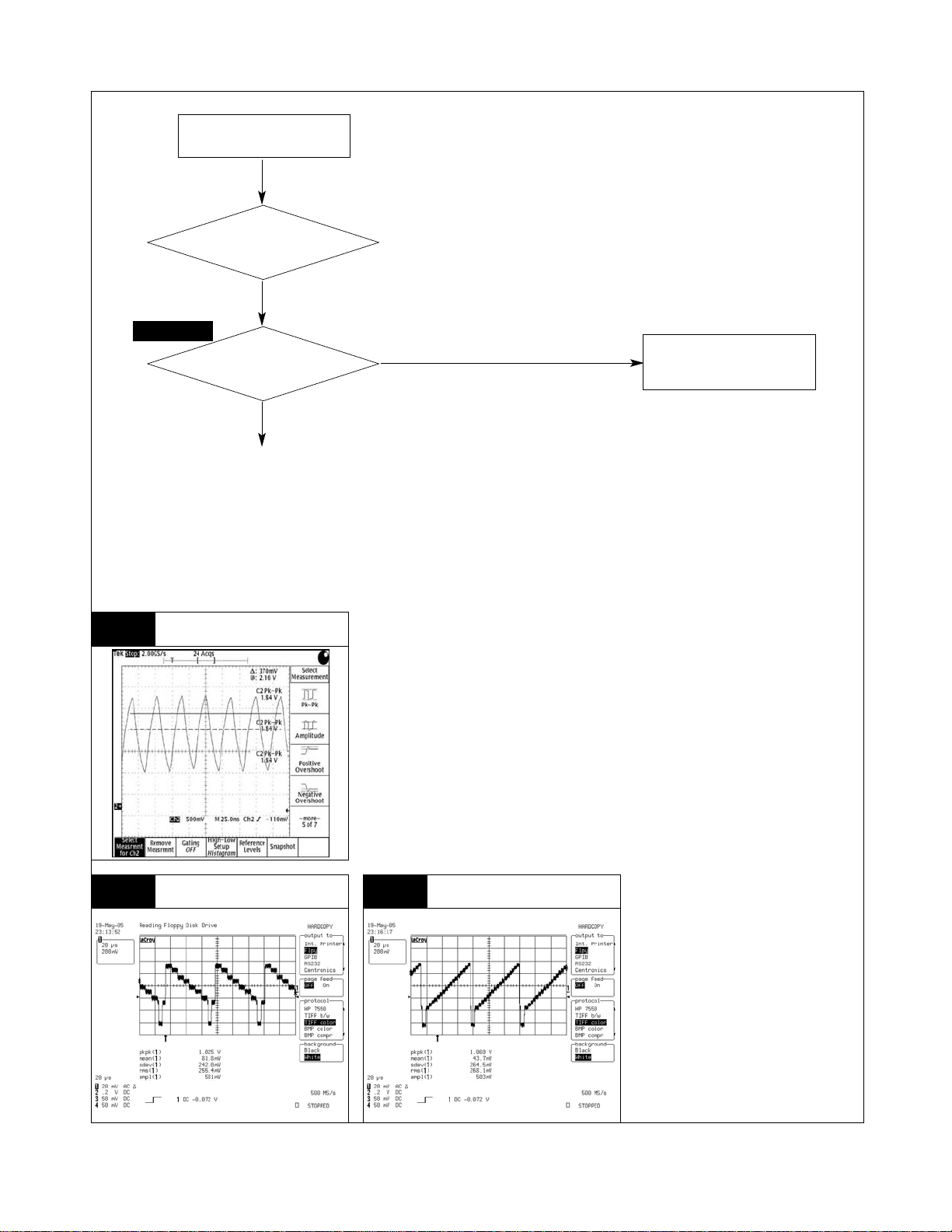

Process B

Ref.2/2-1/2-2

Ref.3

Ref.2

Check the Input / Output

IC450

Pass

Check the input/output

of IC701

Pass

Check the input/output

of IC501

Pass

Check input source cable

and jack

Component Y signal Iutput :

IC701(Switching IC), #3

Re- soldering or Change

Fail

Fail Fail

Fail

Ref.2-1

The defect part of IC450,

IC451

Check level(0W)

of R724

Pass

Re- soldering or Change

The defect part of IC501,

X500, IC701

H_sync Input :

IC701(Switching IC) #23

Check short circuits of

Main B/D

Re-soldering or Change

IC701

Ref.2-2

V_sync Input :

IC701(Switching IC) #13

Ref.3

Component Y signal Iutput :

IC501(Scaler IC) #147

-

34

-

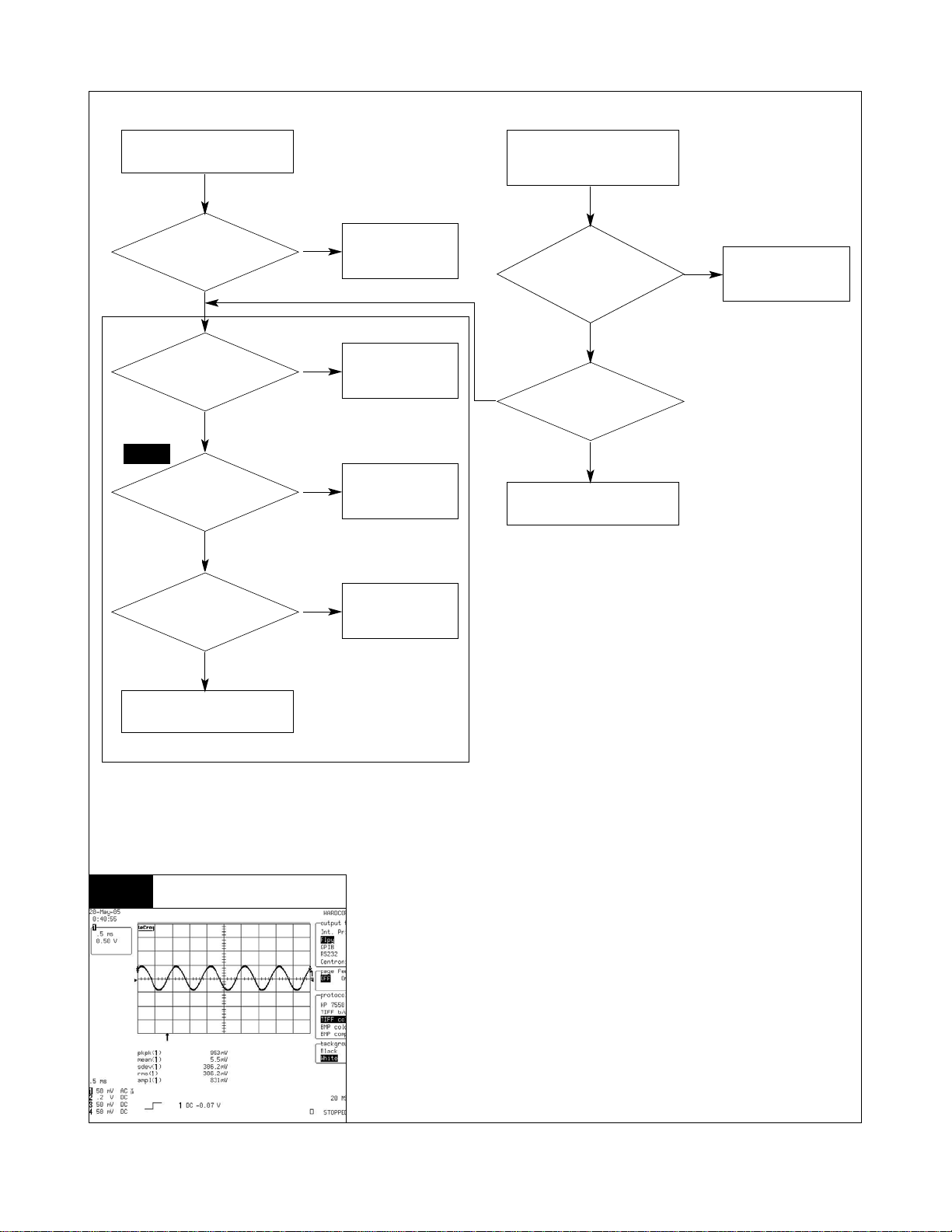

No Raster on

Componen&video1

Repeat Process A

Pass

Check R10 Level

Component(High)/Video1(Low)

Pass

Ref.4/4-1/4-2

Check the Input/Output

of IC200

Pass

Ref.6/6-1

Check the input/output

of IC400

Pass

Process B

Check short circuits of

Fail

Fail Fail

Fail

Main B/D

Ref.5

Check the Input/Output

of IC300(Comb Filter)

Check short circuits of Main B/D

or Change IC400

Component mode don't

meed check

Check short circuits of Main B/D

or Change the defect part

-

35

-

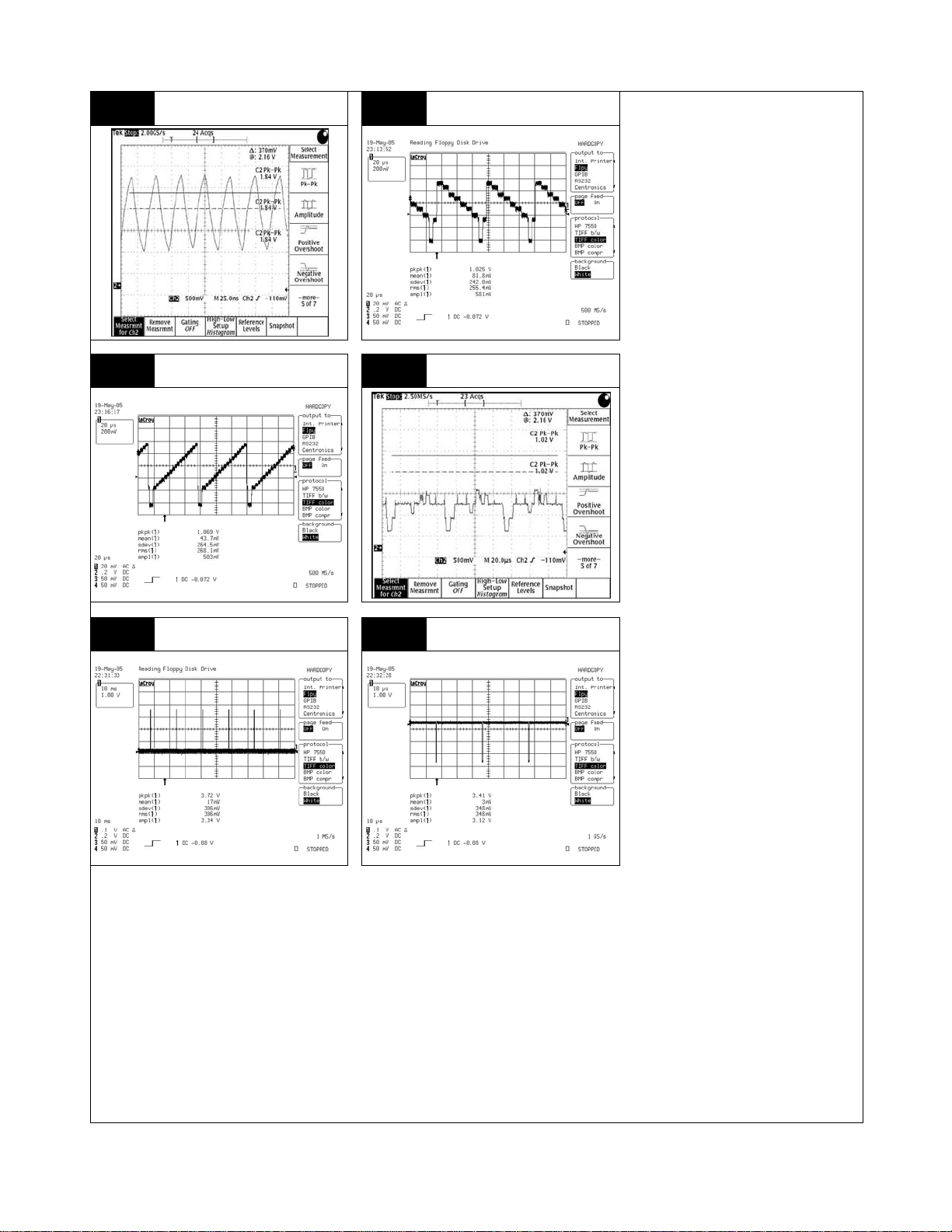

Ref.4

ITU656 Clock Out :

IC200(VCTI) #83

Ref.4-1

Y Signal Input :

IC200, #68

Ref.4-2

Ref.6

Y Signal Input :

IC200, #62

Component V Signal output :

IC400, #64

Ref.5

Ref.6-1

Y separated output :

IC300(Comb Filter), #96

Component H Signal output :

IC400, #66

-

36

-

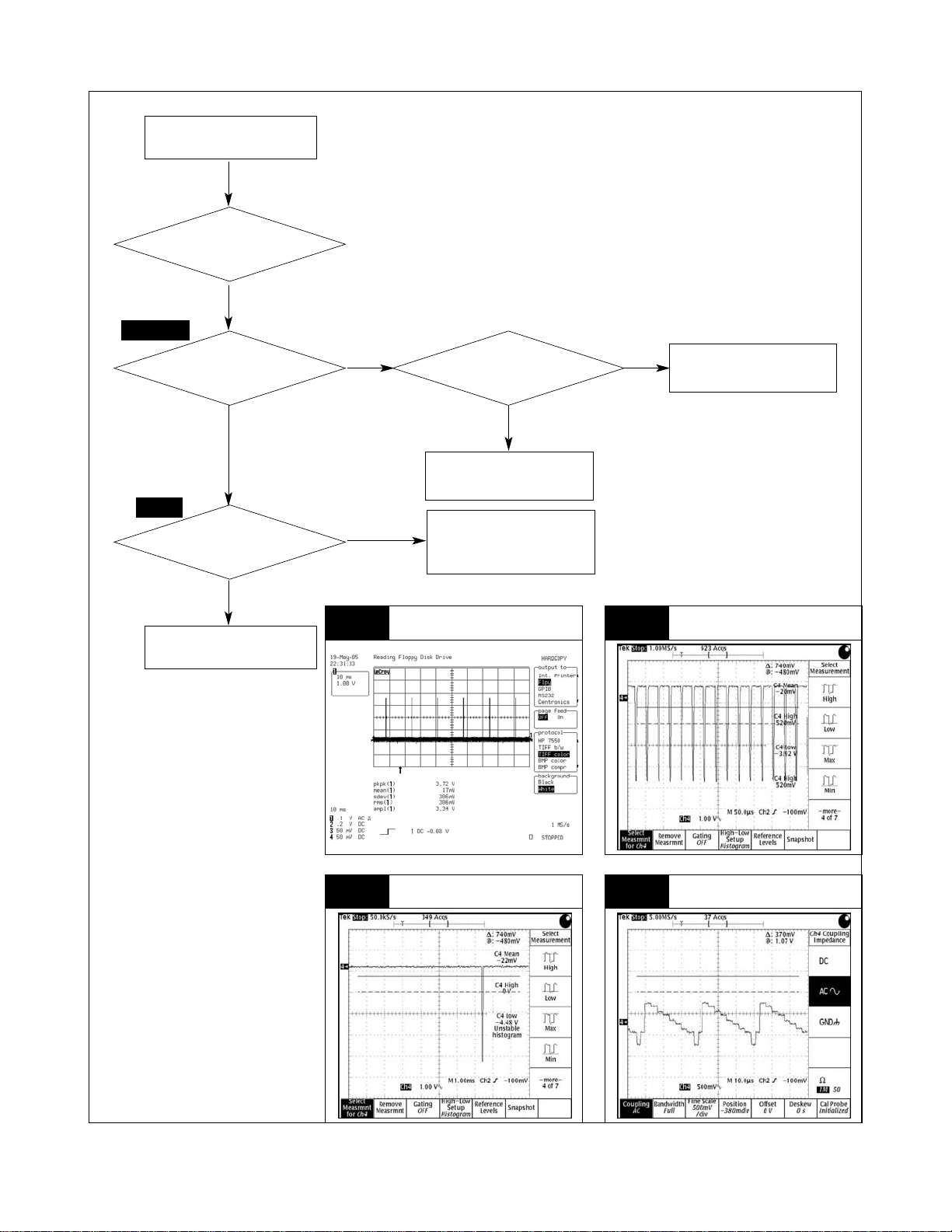

No Raster on PC signal

Repeat Process A

Pass

Ref.7/7-1/7-2

Check the input/output

of IC701

Pass

Ref.8

Check the input/output

of IC501

Pass

Check input source cable

and jack

Check Level(High) of R724

Fail Fail

Pass

Re-soldering or

Change IC701

Re-soldering or Change

Fail

Ref.7

the defect part of

IC501, X500, IC701

Component Y signal Iutput :

IC701(Switching IC), #3

Ref.7-1

Check short circuits of

Main B/D

H_sync Input :

IC701(Switching IC) #23

Ref.7-2

V_sync Input :

IC701(Switching IC) #13

-

37

-

Ref.8

Component Y signal Iutput :

IC501(Scaler IC) #147

No Raster on Video Signal

(Video2, S-Video)

Repeat Process A

Pass Pass

No Raster of TV(RF) Signal

Check the output of TU100

Check 5V, 33V of

TU100 Re-soldering

or Change the defect

Fail

part

Check R248 Level

Video2(High)/S-Video(Low)

Pass

Ref.9/9-1/9-2

Check the input/output

of IC200

Pass

Process B

Check short circuits of

Main B/D

Fail

Ref.10

Check the input/output

Fail Fail

Ref.9

of IC300(Comb Filter)

ITU656 Clock Out :

IC200(VCTI) #83

Ref.9-1

S-Video skip this

square box

Check short circuits of Main B/D

or Change the defect part

Y Signal Input :

IC200, #68

Ref.9-2

Y Signal Input :

IC200, #62

-

38

Ref.10

Y separated output :

IC300(Comb Filter), #96

-

No Raster on

HDMI 23HL85

Repeat Process A

Pass

Ref.11/11-1

Check the Input/Output

of IC600

Pass

Process B

Fail

Re-soldering or

Change the defect part

check IC600

Ref.11

HDMI H Signal output :

IC600, #2

Ref.11-1

PC H Signal Input :

IC501, #181

-

39

-

No Raster on

Video1/Video2

Repeat Process A

Pass

Ref.12/12-1/12-2

Ref.12

Check the Input/Output

of IC200

Pass

Process B

ITU656 Clock Out :

IC200(VCTI) #83

Fail

Re-soldering or

Change the defect part

check IC200

Ref.12-1

Y Signal Input :

IC200, #68

Ref.12-2

Y Signal Input :

IC200, #62

-

40

-

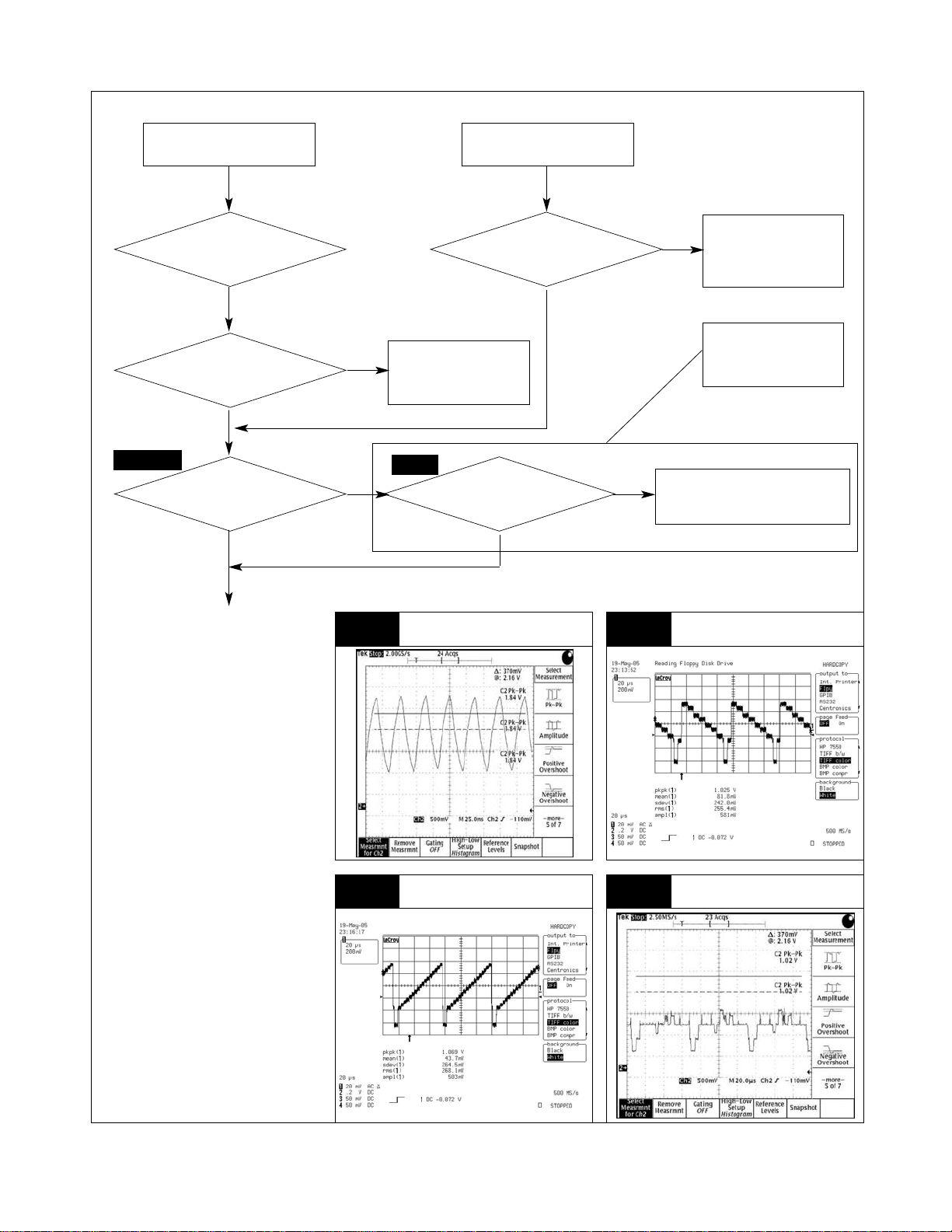

No Sound

(Video2 & S-Video)

No sound

(Video & Component or

PC mode)

Check the Input source

Pass

Check the Input/Output

of IC200

Pass

Ref.13

Check the Input/Output

of IC900

Pass

Check the speaker

Pass

Fail

Fail

Fail

Fail

Fail

Change source

Input

Re-soldering or

Change IC200

Re-soldering or

Change IC900

Change speaker

Check

the IC800

#2, #4pin Level

Video1 : High

PC : Low

Pass

Check Input/Output &

12V of IC800

Pass

Change IC702

Check short circuits

of Main B/D

Fail

Check the speaker wire

Ref.13

Sound Input :

IC900, #3, 5

Process C

-

41

-

Loading...

Loading...