Page 1

(*1), as indicated by the underlined serial number.

©

SERVICE MANUAL

LCD Color Television

22AV733G

This model is classified as a green product

Ver. 2.00

This Service Manual describes replacement parts for the green product. When repairing this

green product, use the part(s) described in this manual and lead-free solder (*2).

For (*1) and (*2), refer to GREEN PRODUCT PROCUREMENT and LEAD-FREE

SOLDER.

TOSHIBA CORPORATION

Page 2

IMPORTANT NOTICE

WARNING:

You are requested that you shall not modify or alter the information or data

provided herein without prior written consent by Toshiba. Toshiba shall not

be liable to anybody for any damages, losses, expenses or costs, if any,

incurred in connection with or as a result of such modification or alteration.

THE INFORMATION OR DATA HEREIN SHALL BE PROVIDED "AS IS"

WITHOUT ANY WARRANTY OF ANY KIND, EITHER EXPRESS OR IMPLIED

WARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE.

Toshiba shall not be liable for any damages, losses, expenses or costs, if

any, incurred in connection with or as a result of use of any information or

data provided herein.

Page 3

IMPORTANT NOTICE

is necessary to view drawings and to activate the functions of this system. Please

up windows are limited by

the enhanced security function and this system may not work. In that case, perform the Internet Explorer

User's Guide

Contents:

Install Autodesk DWF Viewer

Internet Explorer Settings

Operating Environment

Functions Provided on Each Drawing Page

Using with Network

Install Autodesk DWF Viewer

Autodesk DWF Viewer

download and install.

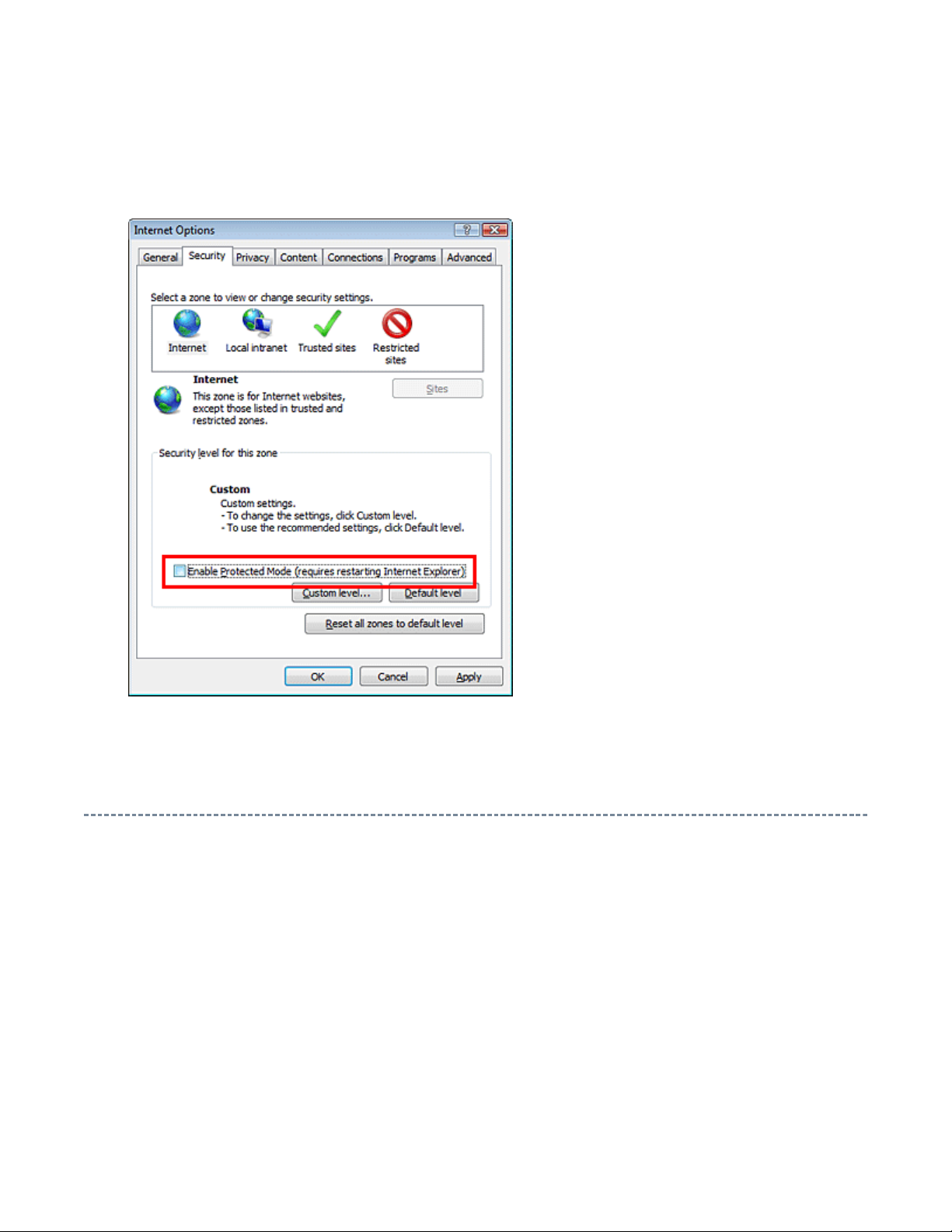

Internet Explorer Settings

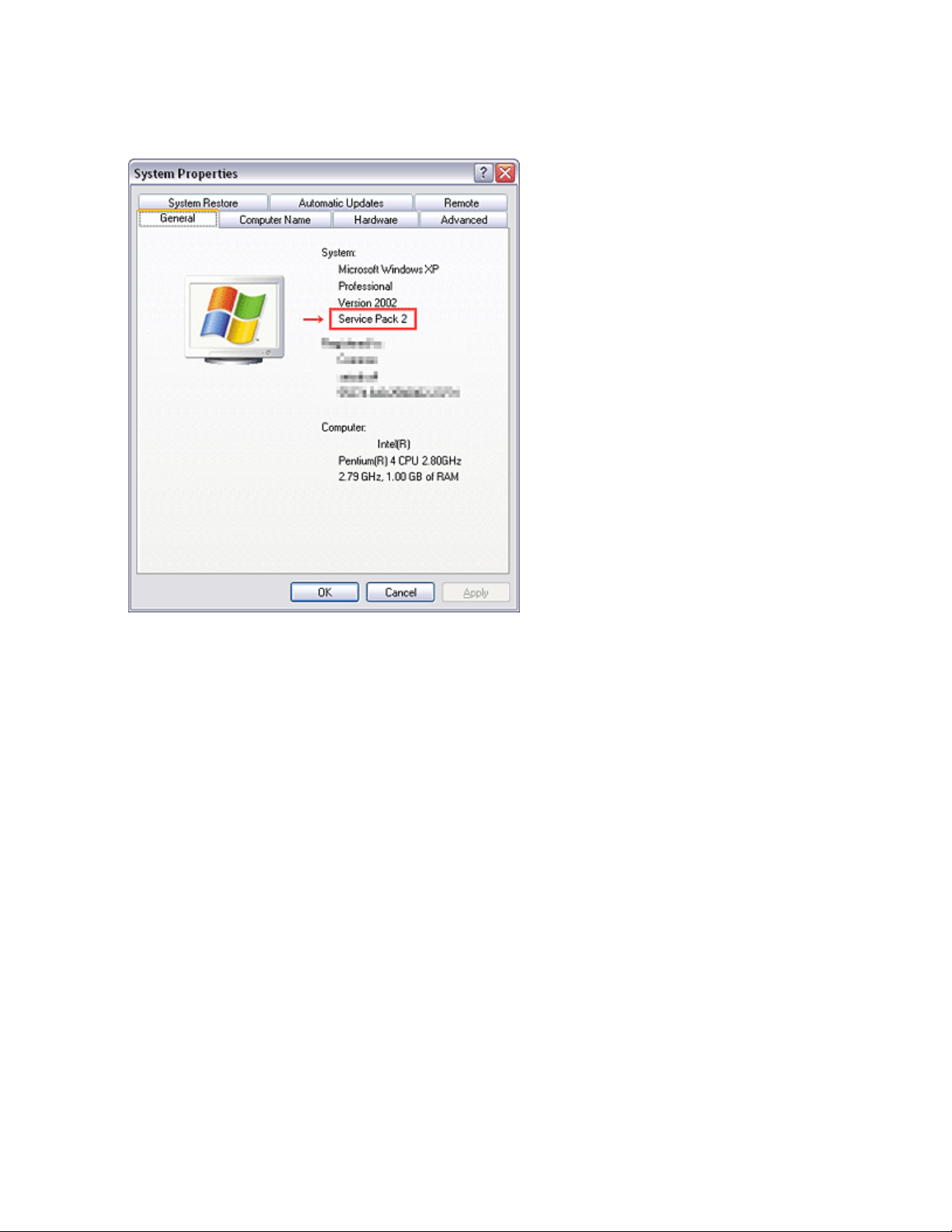

When Windows XP SP2 or Windows Vista is used, ActiveX control and pop-

setting using the following procedure to restore normal operation.

1. Windows version check

Page 4

[My Computer (right-click)] - [Properties]

2. Internet Explorer setting

[Tools] - [Internet Options]

Page 5

for Internet Explorer 7

Page 6

for Windows Vista

Operating Environment

PC : Pentium III or higher recommended

Monitor : 1024 x 768 or higher resolution recommended

Mouse : A mouse with wheel recommended

OS : Microsoft Windows 2000 SP4 / XP / Vista

Browser :

Drawing viewer : Autodesk DWF Viewer 6.0 / 7.0

* Use the software following respective license terms and conditions.

Microsoft Internet Explorer 6.0 / 7.0

Page 7

Functions Provided on Each Drawing Page

When the character string of a part on the drawing is clicked, its information is popped up at the location.

You can get any parts information immediately on the screen without referring to the maintenance parts list.

You can search any part within the displayed drawing or within the whole schematic diagram/board view by

up window displayed by clicking a part 's character string allows to

signal is searched and the display changes to the destination. Connecter destinations can also be searched in

When two or more search results are provided, their drawing names are displayed, allowing you to choose a

When any of the color buttons on the toolbar is clicked, it can be selected to display desired layer in its color

The Autodesk DWF Viewer enables to print the displayed drawing region as it is on a printer. It also allows

Parts Information Reference Function

Parts Search Function

specifying a location number. The popsearch the part within the applicable schematic diagram, board view or spare parts list.

A circle appears when the part is found, showing the part's location within the drawing.

Signal Line/Connector Destination Display Function

When a name at the end of a signal line in a divided schematic diagram is clicked, the destination of the

the same way.

desired drawing to display.

Layer Display Changing Function

or not to display each layer. This allows you to see the pattern layer only by setting other layers to "nondisplay".

PC Board View Pattern Highlighting Function

When a pattern on a board view is clicked, it is highlighted in green. This allows easy pattern tracing.

Specified Area Printing Function

to print a large-sized drawing in multiple pieces (tile printing).

Page 8

path names written on the source files of each

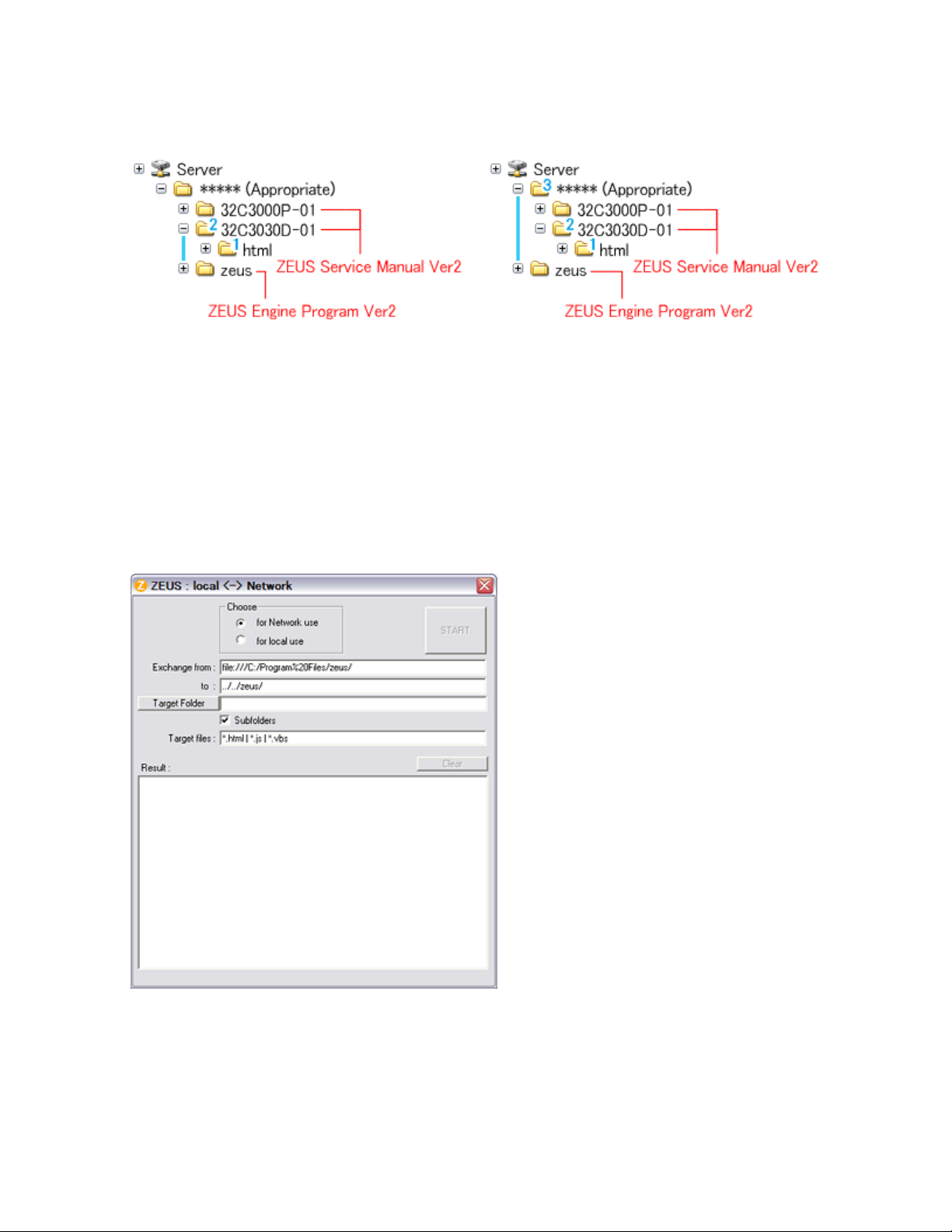

Create the appropriate folder where the ZEUS Engine Program Ver.2 and the ZEUS Service Manual

Using with Network

PRECAUTION

To use ZEUS Service Manual Ver.2 with network, the file-

ZEUS Engine Program Ver.2 and ZEUS Service Manual Ver.2 are to be modified.

Perform the procedure described below.

Preparation

1. Run the program file zuesFPch.exe to install the program file for File-Path to the Local PC.

-> Download zeusFPch_setup.zip (2.3MB)

2. Run the program file ZeusSetup_v2.0.exe to install the ZEUS Engine Program in C:\Program

Files\zeus of the local PC. This can be done by running the installer program provided.

3.

Ver.2 to be stored in the server.

4. Move the ZEUS Engine Program of step 2 to the folder created at step 3 in the Server.

5. Detach the ZEUS Service Manual Ver.2 to the folder created at step 3 in the Server.

6. Unzip the ZEUS Service Manual Ver.2 within the folder in the Server.

Example of folder

Page 9

path names written in both source files of ZEUS

path of both ZEUS Engine Program and ZEUS Service Manual to use with

network, pay the attention to set the "Exchange to" column that should have a proper relation between

Procedure of File-Path

The zeusFPch is the exclusive program to exchange the file-

Manual and ZEUS Engine program into those applicable to the network use.

1. Whenever changing the file-

ZEUS Engine Program and ZEUS Service Manual with referring the following.

Page 10

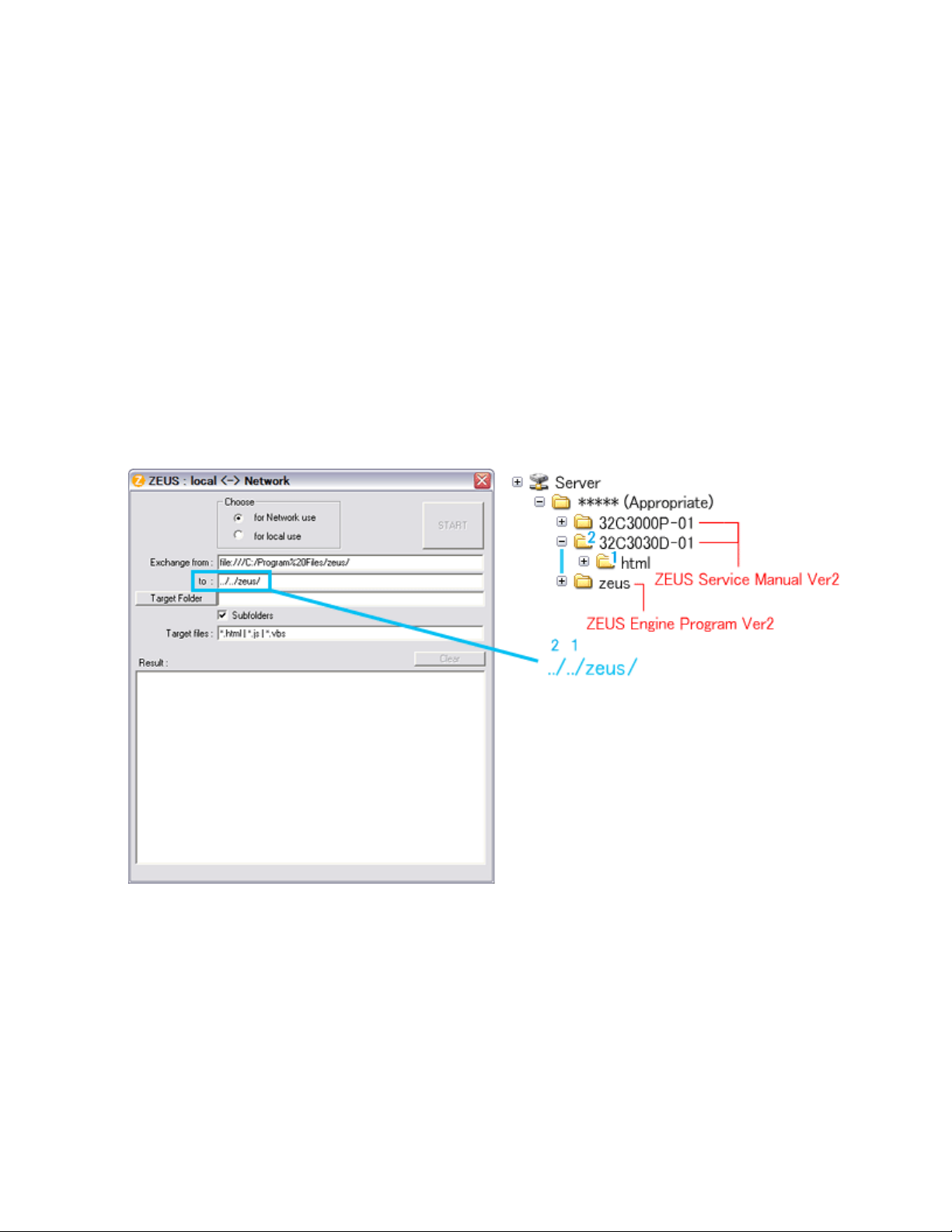

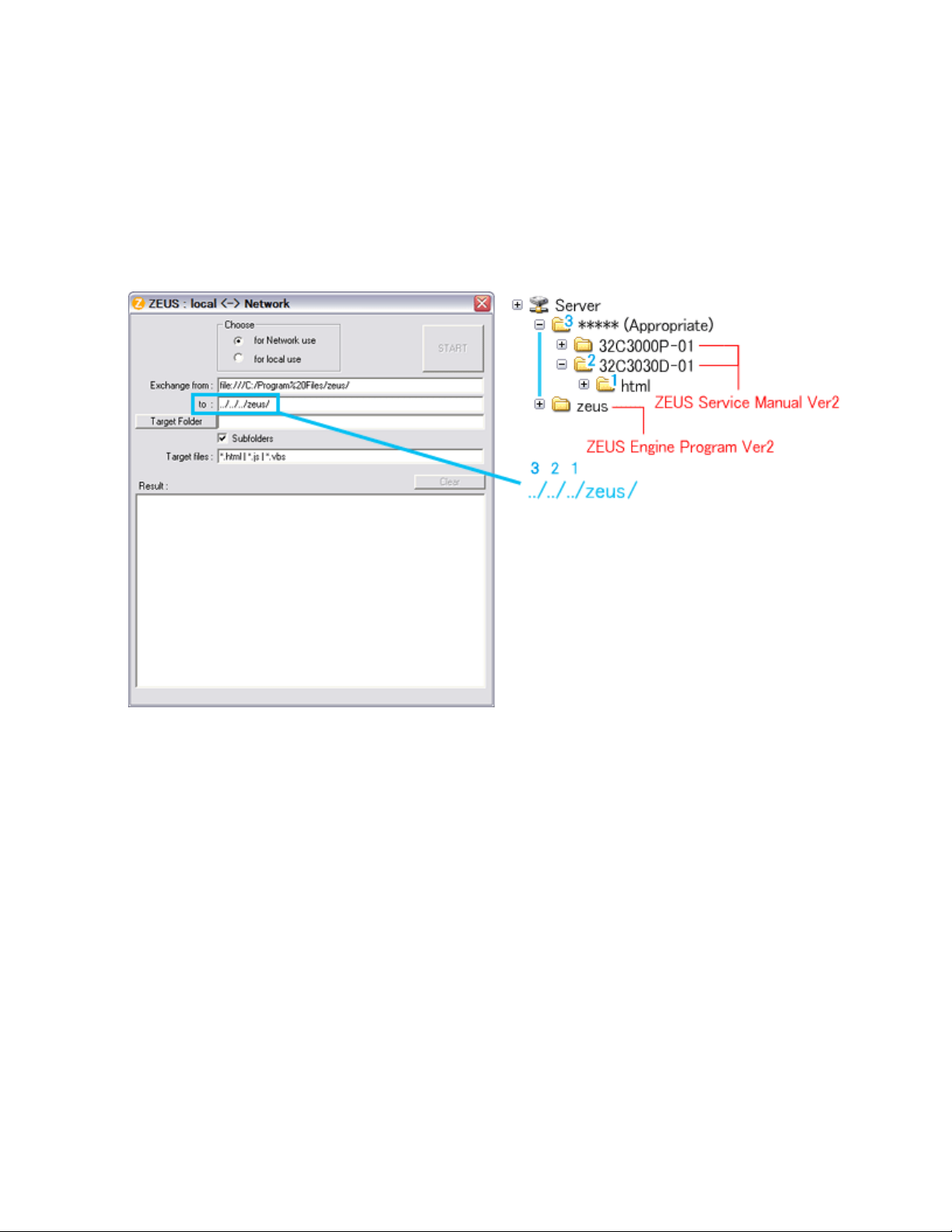

Run the zeusFPch and set "Exchange to" by referring to the examples below.

In the "Exchange to" column shows the relation between ZEUS Service Manual and ZEUS Engine

Example 1 :

Program.

../ counts the relation between.

Thus in this case, it must be ../../zeus/ (2 counts).

Example 2 :

In this case, it must be ../../../zeus/ (3 counts).

Page 11

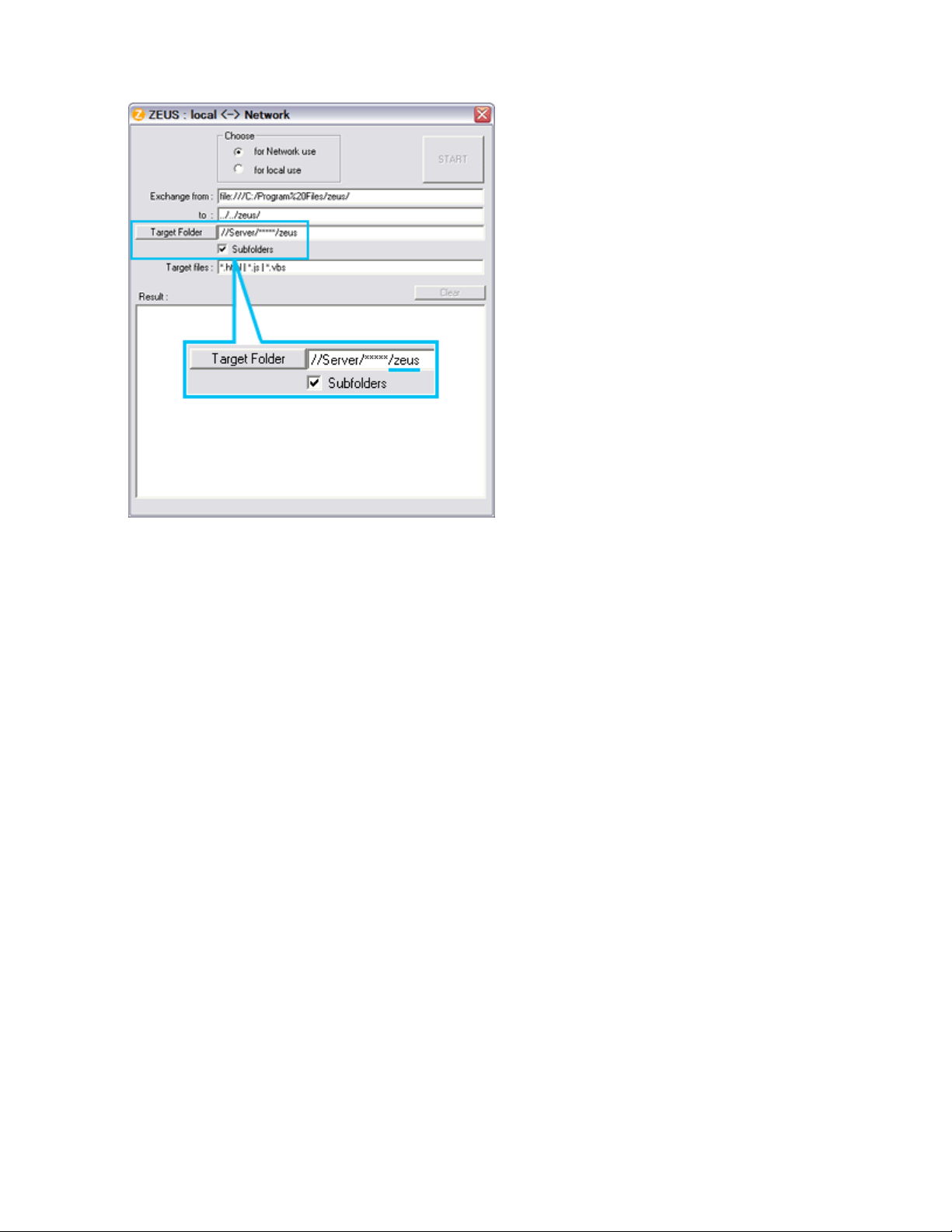

Set ZEUS Engine Program in the created folder in the server to the "Target Folder", and then press

2. Run the zeusFPch to change the path in the ZEUS Engine Program Ver.2.

3.

"START".

(This procedure is one time only)

Page 12

Set unzipped ZEUS Service Manual in the created folder in the server to the "Target Folder", and then

4. Run the ZeusFPch to change the path in the ZEUS Service Manual Ver2.

5.

press "START".

(This procedure is required whenever placing service manual.)

Page 13

bottom corner on the screen whenever searching the location links. This is not malfunction.

Confirmation

Confirm that service manual on the server can be operated normally by client PC.

Note:

In case of accessing the ZEUS Manual through WEB site, the small pop-up window appears at the left

Page 14

IMPORTANT NOTICE

Through WEB, ver. 6.5 has been released but with it, the linking function in this manual may

A Known Malfunction

Autodesk® DWF™ Viewer version

(Free software provided through WEB)

Use Autodesk DWF Viewer ver. 6.0.

not work properly.

If ver. 6.5 has been installed, uninstall it and reinstall ver. 6.0.

To get ver. 6.0, click the icon, or contact to the nearest Toshiba Service Centre for further

assistance.

Freezing windows opened

(Cannot close the open windows)

This may happen occasionally.

In case of encountering this, follow the procedure below.

1. Press [Ctrl], [Alt] and [Delete] keys at the same time to engage windows security

windows.

2. Then, choose TASK manager and Application tab, and select TOSHIBA SERVICE

MANUAL-Microsoft Internet Explorer.

3. Click TASK-end.

Main Window back forwarded

Page 15

The real cause has not been found yet but with this condition, nothing disturbs the service

manual operation.

Continue to use by operating the windows.

Precaution when opening the diagrams

While opening the diagrams, the menu in the left frame changes its color to GRAY. This is

an indication that the viewer is processing.

With this condition, the menu indication color may stick to the GRAY color or Windows

may freeze if clicking other menu.

To avoid such things, do not operate any others while menu turns GRAY color.

If entering this, re-open the service manual or refresh the left frame.

Page 16

GREEN PRODUCT PROCUREMENT

prohibit any marketing of new products containing the restricted substances.

Corporation recognizes environmental protection as a key management tasks, and is doing its

products, parts and materials that have low environmental impacts.

The EC is actively promoting the WEEE & RoHS Directives that define standards for

recycling and reuse of Waste Electrical and Electronic Equipment and for the Restriction of

the use of certain Hazardous Substances. From July 1, 2006, the RoHS Directive will

Increasing attention is given to issues related to the global environmental. Toshiba

utmost to enhance and improve the quality and scope of its environmental activities. In line

with this, Toshiba proactively promotes Green Procurement, and seeks to purchase and use

Green procurement of parts is not only confined to manufacture. The same green parts used

in manufacture must also be used as replacement parts.

Page 17

LEAD-FREE SOLDER

free solder must

be used in the servicing and repair of this product.

product made with lead

free solder may result in damage to the component and or PCB being

product especially when soldering large components, through

This product is manufactured using lead-free solder as a part of a movement within the

consumer products industry at large to be environmentally responsible. Lead-

WARNING: This product is manufactured using lead free solder.

DO NOT USE LEAD BASED SOLDER TO REPAIR THIS PRODUCT!

The melting temperature of lead-free solder is higher than that of leaded solder by 86ºF to

104ºF (30ºC to 40ºC). Use of a soldering iron designed for lead-based solders to repair

-

soldered. Great care should be made to ensure high-quality soldering when servicing this

-hole pins, and on PCBs as the

level of heat required to melt lead-free solder is high.

Page 18

SAFETY INSTRUCTION

Always keep tools, components of the product, etc away from the children, These items

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" INSTRUCTIONS BELOW.

Safety Precaution

WARNING: SERVICING SHOULD NOT BE ATTEMPTED BY ANYONE

UNFAMILIAR WITH THE NECESSARY PRECAUTIONS ON THIS RECEIVER.

THE FOLLOWING ARE THE NECESSARY PRECAUTIONS TO BE OBSERVED

BEFORE SERVICING THIS CHASSIS.

1. An isolation transformer should be connected in the power line between the receiver

and the AC line before any service is performed on the receiver.

2. Always disconnect the power plug before any disassembling of the product. It may

result in electrical shock.

3. When replacing a chassis in the cabinet, always be certain that all the protective

devices are put back in place, such as nonmetallic control knobs, insulating covers,

shields, isolation resistor-capacitor network, etc.

4.

may cause injury to children.

5. Depending on the model, use an isolation transformer or wear suitable gloves when

servicing with the power on, and disconnect the power plug to avoid electrical shock

when replacing parts. In some cases, alternating current is also impressed in the

chassis, so electrical shock is possible if the chassis is contacted with the power on.

Page 19

6. Always use the replacement parts specified for the particular model when making

NEVER remodel the product in any way. Remodeling can result in improper operation,

repairs. The parts used in products require special safety characteristics such as

inflammability, voltage resistance, etc. therefore, use only replacement parts that have

these same characteristics. Use only the specified parts when the mark is indicated

in the circuit diagram or parts list.

7. Parts mounting and routing dressing of wirings should be the same as that used

originally. For safety purposes, insulating materials such as isolation tube or tape are

sometimes used and printed circuit boards are sometimes mounted floating. Also make

sure that wirings is routed and clamped to avoid parts that generate heat and which use

high voltage. Always follow the manufactured wiring routes / dressings.

8. Always ensure that all internal wirings are in accordance before re-assembling the

external casing after a repairing completed. Do not allow internal wiring to be pinched

by cabinets, panels, etc. Any error in reassembly or wiring can result in electrical

leakage, flame, etc., and may be hazardous.

9.

malfunction, or electrical leakage and flame, which may be hazardous.

10. Touch current check. (After completing the work, measure touch current to prevent an

electric shock.)

Plug the AC cord directly into the AC outlet. Do NOT use an isolation transformer

for this check.

Connect a measuring network for touch currents between each exposed metallic part

on the set and a good earth ground such as a water pipe.

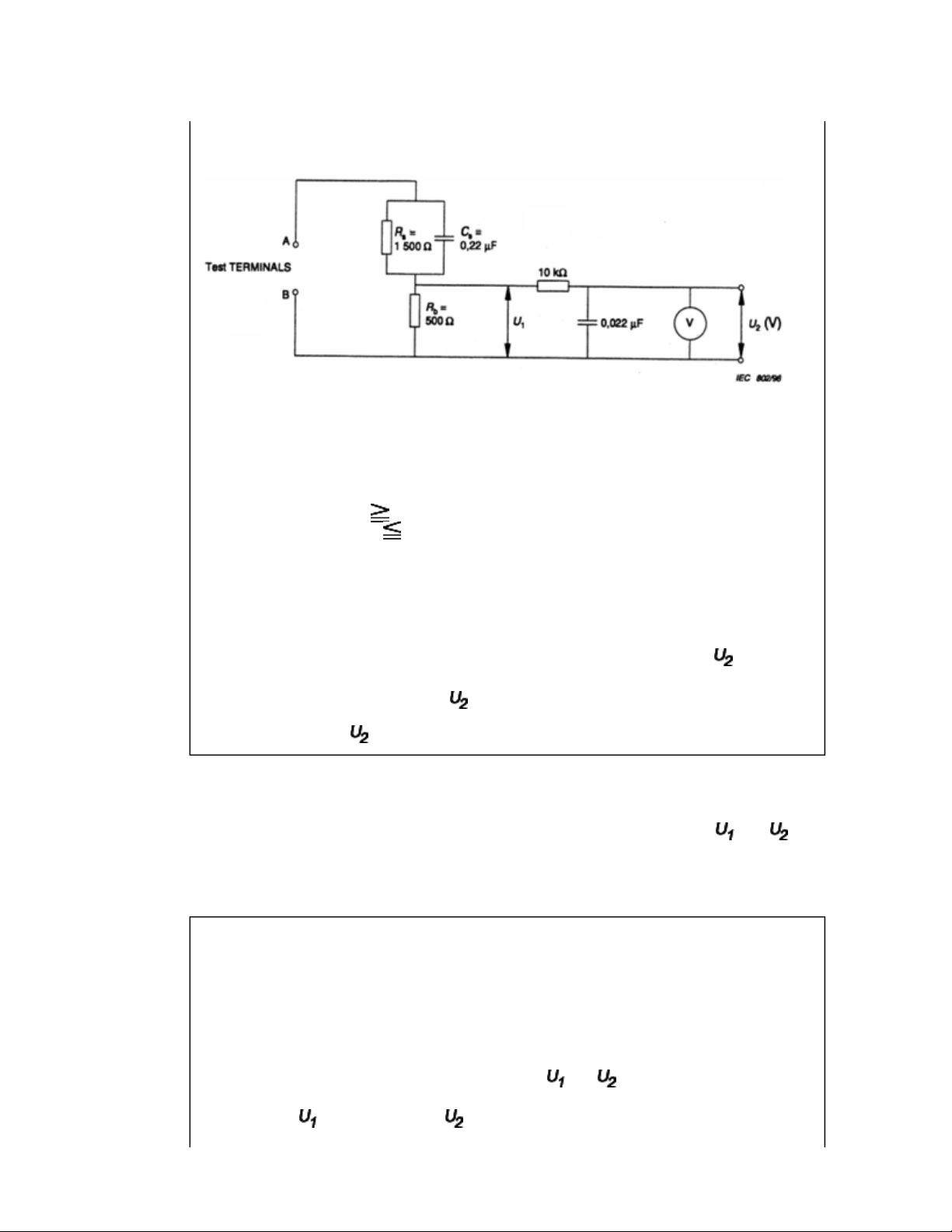

Annex D

(normative)

Measuring network for TOUCH CURRENTS

Page 20

Resistance values in orms (Ω).

V: Voltmeter or oscilloscope

(r.m.s. or peak reading)

Input resistance : 1 MΩ

Input capacitance : 200 pF

Frequency range : 15 Hz to 1 MHz and d.c. respectively

Note: Appropriate measures should be taken to obtain the correct value in case of non

sinusoidal waveforms.

The measuring instrument is calibrated by comparing the frequency factor of with the

solid line in figure F.2 of IEC 60990 at various frequencies. A calibration curve is

constructed showing the deviation of from the ideal curve as a function of frequency.

TOUCH CURRENT = /500 (peak value).

The potential at any point (TOUCH CURRENT) expressed as voltage and

does not exceed the following value:

The part or contact of a TERMINAL is not HAZARDOUS LIVE if:

a) The open-circuit voltage should not exceed 35 V (peak) a.c. or 60 V d.c. or, if a) is not

met.

b) The measurement of the TOUCH CURRENT shall be carried out in accordance with

IEC 60990, with the measuring network described in Annex D of this standard.

The TOUCH CURRENT expressed as voltages and , does not exceed the

following values:

- for a.c. : = 35 V (peak) and = 0.35 V (peak);

Page 21

- for d.c. : = 1.0 V

Note: The limit values of = 0.35 V (peak) for a.c. and = 1.0 V for d.c. correspond to

the values 0.7 mA (peak) a.c. and 2.0 mA d.c.

Product Safety Notice

Many electrical and mechanical parts in this chassis have special safety-related

characteristics. These characteristics are often passed unnoticed by a visual inspection and

the protection afforded by them cannot necessarily be obtained by using replacement

components rated for higher voltage, wattage, etc. Replacement parts which have these

special safety characteristics are identified in this manual and its supplements; electrical

components having such features are identified by the international hazard symbols on the

schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The

use of substitute replacement parts which do not have the same safety characteristics as

specified in the parts list may create electrical shock, fire, or other hazards.

Page 22

SAFETY INSTRUCTION

should enter the mouth, rinse the mouth thoroughly with water. If the fluid should contact the

When attaching the LCD module to the LCD cover, position it appropriately and fasten

Handling the LCD Module

Safety Precaution

In the event that the screen is damaged or the liquid crystal (fluid) leaks, do not breathe in or

drink this fluid.

Also, never touch this fluid. Such actions could cause toxicity or skin irritation. If this fluid

skin or clothing, wipe off with alcohol, etc., and rinse thoroughly with water. If the fluid

should enter the eyes, immediately rinse the eyes thoroughly with running water.

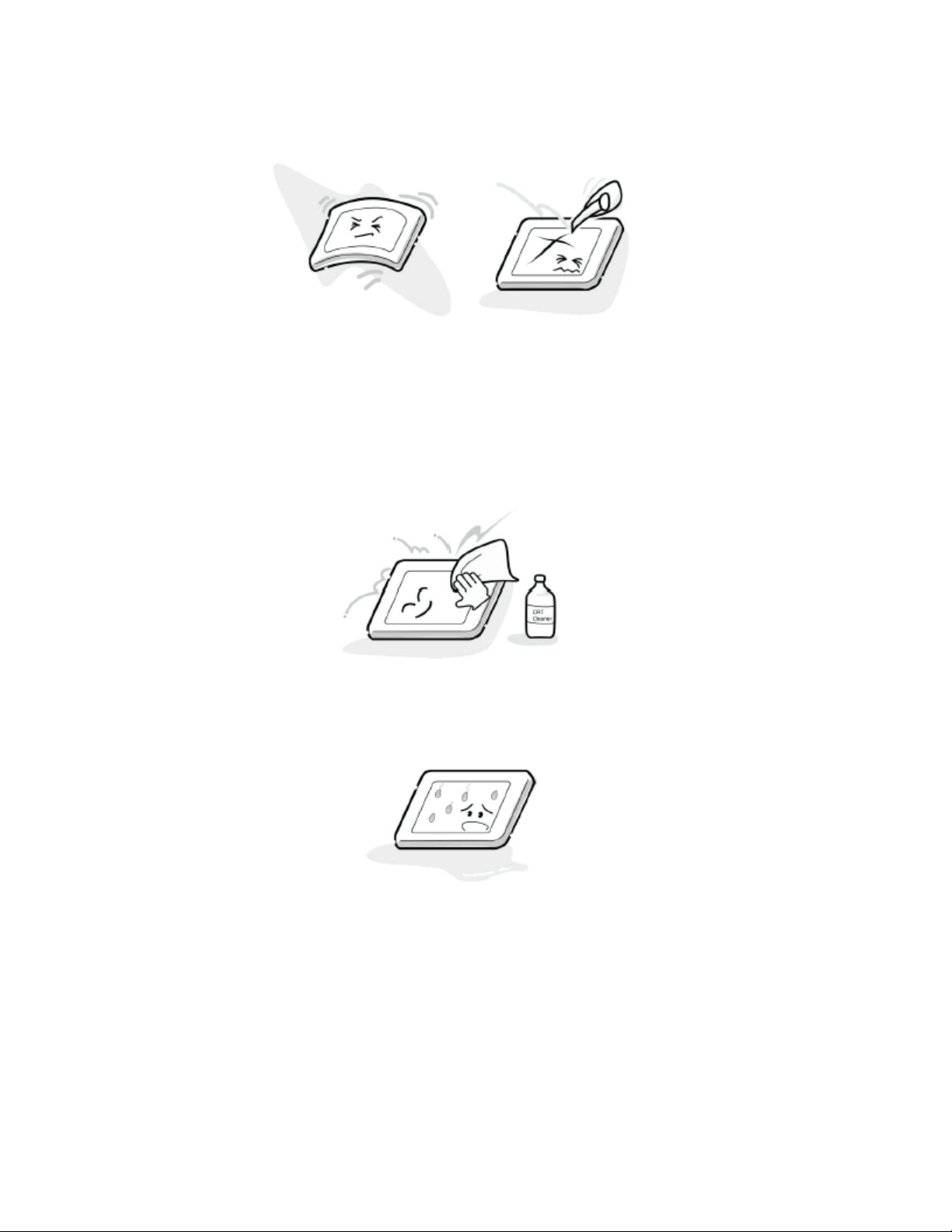

Precautions for Handling the LCD Module

CAUTION: The metal edges of the LCD module are sharp, handle it with

care.

The LCD module can easily be damaged during disassembly or reassembly; therefore,

always observe the following precautions when handling the module.

1.

at the position where the display can be viewed most conveniently.

2. Carefully align the holes at all four corners of the LCD module with the corresponding

holes in the LCD cover and fasten with screws. Do not strongly push on the module

Page 23

because any impact can adversely affect the performance. Also use caution when

handling the polarized screen because it can easily be damaged.

3. If the panel surface becomes soiled, wipe with cotton or a soft cloth. If this does not

remove the soiling, breathe on the surface and then wipe again.

If the panel surface is extremely solied, use a CRT cleaner as a cleaner. Wipe off the

panel surface by drop the cleaner on the cloth. Do not drop the cleaner on the panel.

Pay attention not to scratch the panel surface.

4. Leaving water or other fluids on the panel screen for an extended period of time can

result in discoloration or stripes. Immediately remove any type of fluid from the screen.

5. Glass is used in the panel, so do not drop or strike with hard objects. Such actions can

damage the panel.

Page 24

6. CMOS-LSI circuitry is used in the LCD module, so avoid damage due to static

electricity. When handling the module, use a wrist ground or anchor ground.

7. Do not expose the LCD module to direct sunlight or strong ultraviolet rays for an

extended period of time.

8. Do not store the LCD module below the temperature conditions described in the

specifications. Failure to do so could result in freezing of the liquid crystal due to cold

air or loss of resilience or other damage.

Page 25

9. Do not disassemble the LCD module. Such actions could result in improper operation.

10. When transporting the LCD module, do not use packing containing epoxy resin

(amine) or silicon resin (alcohol or oxim). The gas generated by these materials can

cause loss of polarity.

Page 26

Only for 32"/37"/40"

LCD PANEL

T-COM Board

Main Board

Power Board

CN903 CN902

Inverter

Board

POWER

CH+

CH-

VOL+

VOL-

MENU

SOURCE

CN763

CN501

30P / 1.25mm

SPEAKER SPEAKERIRLOGO LEDLED

CN1CN2

Page 27

To Panel

U401

SCALER

MT5361B

LQFP256

CVBS

HDMI1

SCART Audio

Component Audio

VGA/HDMI Audio

Side AV Audio

USB

HDMI2

SCART

Component

Side I/O

VGA

U605

Audio Switch

MT8292

ADC OUT R/L

PCMCIA

TS OUT

TS IN

DATA/ADDR

MT8295BN

DAC OUT1

Full In/TV out

IFS P/N

CVBS1

IF P/N TV

TS In

U501

HDMI SW

SiL9187A

19"/22"

3W / 8Ohm

19"/22" WXGA

USB P/M

Rx In

Tx 0-2, Txc

ALX_ARX

PGA2OUT L/R

KEYPAD

IR

LED

KEYPAD/IR

BOARD

SPDIF

Optical

I/O 0_7

I/O 0_7

SY0/SC0

16MB NAN D Flash

U405

SPI Flash

512KB NOR

U404

AIN0

AIN

AIN1

CVBS2

DDR2

32MB x 16

U403

AIN_L

AIN_R

AL0_AL2

AR0_AL2

ASPDIF

OSCL0

OSDA0

ORESET#

EEPROM

M24C32

U406

U408

Reset

MAX809ST

IFT P/N

TU103

Tuner

ENV57S01D8F

IFC P/N

U101

DVB-C

Si2163

U102

CI Controller

MT8295BNE

TS Out

U103

EEPROM

M24C02

U602

Sound AMP

TDA8933

HPOL_HPOR

SCART

Audio OUT

SCAR1O L/R

Head Phone

Side I/O

DVD Audio

*Option

Page 28

MAIN BOARD

(715G3747-D)

POWER BOARD

(715G3721)

PANEL

CN803

CN902

CN701CN401CN601

L SPEAKER(2PIN)

R SPEAKER(2PIN)

CN408

PANEL(TCON)

GND11

PS_ON12

ACD10

GND9

GND8

+5V7

+5V6

+16V5

+16V4

N/F3

NC2

DIM1

AC_DETECT10

+ 18 V9

+ 18V8

GND7

GND6

GND5

+5V_STB4

+5V_STB3

BRIGHT_ADJ2

INVERTER_ON_OFF1

GND11

Key112

Key213

GND14

DV33SB10

Light Sensor9

OIRI8

GND7

DV33SB6

LED_POWER

_ON5

LED_POWER

_OFF4

LED_G3

LED_R2

GND1

LOUT+4

LOUT-3

ROUT+2

ROUT-1

C

N

2

0

1

C

N

0

0

1

CN901

AC socket

CN801

KEYBOARD

(715G3957)

IRBOARD

(715G3746)

PANEL_VCC30B0P15

PANEL_VCC29B0N14

PANEL_VCC28A3P13

B3P27A3N12

B3N26CK1P11

GND25CK1N10

GND24GND9

CK2P23GND8

CK2N22A2P7

B2P21A2N6

B2N20A1P5

GND19A1N4

GND18A0P3

B1P17A0N2

B1N16NC1

CN802

CN804

DV33SB4

GND5

RC66

LIGHT_SENSOR7

LED_POWER3

LED_GREEN2

LED_RED1

1 Key1

2 Key2

3 GND

Page 29

SCHEMATIC DIAGRAM

Precaution

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY

RADIATION PRECAUTION" FOR DIRECT VIEW CTV ONLY, "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" OF THIS MANUAL.

CAUTION: The international hazard symbols " " in the schematic diagram

and the parts list designate components which have special characteristics

important for safety and should be replaced only with types identical to

those in the original circuit or specified in the parts list.

The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the SAFETY

PRECAUTION and PRODUCT SAFETY NOTICE.

Do not degrade the safety of the receiver through improper servicing.

Note:

1. RESISTOR

Resistance is shown in ohm [K=1,000, M=1,000,000]. All resistors are 1/6 W and 5 %

tolerance carbon resistor, unless otherwise noted as the following marks.

1/2R : Metal or Metal oxide of 1/2 watt

1/2S : Carbon composition of 1/2 watt

1RF : Fuse resistor of 1 watt

10 W : Cement of 10 watt

K : ±10 %

G : ±2 %

F : ±1 %

2. CAPACITOR

Page 30

Unless otherwise noted in schematic, all capacitor values less than 1 are expressed in

Electrolytic capacitor

µF, and the values more than 1 in pF.

All capacitors are ceramic 50 V, unless otherwise noted as the following marks.

=

= Mylar capacitor

3. The parts indicated with " " have special characteristics, and should be replaced with

identical parts only.

4. Voltages read with DIGITAL MULTI-METER from point indicated to chassis ground,

using a color bar signal with all controls at normal, line voltage at nominal AC volts.

5. Waveforms are taken receiving color bar signal with enough sensitivity.

6. Voltage reading shown are nominal values and may vary ±20 % except H.V.

Page 31

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

OPWRSB

ACD_control

BRIGHT_ADJ

BRIGHT_ADJ

OPWRSB

AC_Detect

OPWRSB

INVERTER_ON_OFF

INVERTER_ON_OFF

ACD_control

AC_Detect

AC_DET

+5V_STB

+5V_STB

DV11

+5V_SW

DV33

+18V

DV11

+18V_A+18V

+5V_STB

DV33SB_E

ACD_control6

BRIGHT_ADJ18

INVERTER_ON_OFF18

OPWRSB6

2K10 TOP BIG SERIAL MODEL MT5361 (LQFP) (DDR1)- 2 LAYERS

DC POWER INPUT

NEARLY U600

BRIGHT_ADJ:

Normal:Max:+3V3, Min:0V

Stand_By:0V

Normal: High

Stand_By:

Low

Vout =1.1V , R108 = 620, R109=1.5K

SMD

NEARLY U105

INVERTER_ON_OFF:

Normal: High

Stand_By: Low

+5V_STB(+5V1) TO +5V_SW BY OPWRSB

OPWRSB(+5V_SW ON/OFF):

Normal: High

Stand_By: Low

Control DV11 and DV33 Sequence

LOW E.S.R

+18V TO +18V_A BY OPWRSB

Vout = 0.8 * (1+R108/R109)

C712NCC712

NC

C708

100N 50V

C708

100N 50V

+

C703

100uF25V

+

C703

100uF25V

R716

620OHM +-5% 1/10W

R716

620OHM +-5% 1/10W

C711NCC711

NC

Q704

Si5403DC-T1-GE3

Q704

Si5403DC-T1-GE3

D

1

D

2

D

3

G4S

5

D

6

D

7

D

8

R704

1K 1/10W

R704

1K 1/10W

R701 0R05 1/10WR701 0R05 1/10W

C704

NC/4.7UF 10V

C704

NC/4.7UF 10V

R702

NC/0 OHM +-5% 1/4W

R702

NC/0 OHM +-5% 1/4W

+

C715

220uF16V

+

C715

220uF16V

C705

2.2uF 10V

C705

2.2uF 10V

C701

0.1uF 50V

C701

0.1uF 50V

R710

10K 1/10W

R710

10K 1/10W

L701

27uH

L701

27uH

C716NCC716

NC

R70368K 1/10W 5% R70368K 1/10W 5%

TP704TP704

1

R709

100R 1/16W 5%

R709

100R 1/16W 5%

R708

NC/0R 1/10W 5%

R708

NC/0R 1/10W 5%

TP703TP703

1

C718

NC/0.1uF 50V

C718

NC/0.1uF 50V

C710

4U7 10V

C710

4U7 10V

R718

1K5 1/10W 5%

R718

1K5 1/10W 5%

CN701

CONN

CN701

CONN

1

2

3

4

5

6

7

8

9

10

C719

4.7UF 10V

C719

4.7UF 10V

R711

47K 1/10W

R711

47K 1/10W

R717

2.7K 1/10W

R717

2.7K 1/10W

+

C706

100UF 16V

+

C706

100UF 16V

C714

1uF 25V

C714

1uF 25V

Q702

AO4419

Q702

AO4419

S

1

S

2

S

3

G

4

D

8

D

7

D

6

D

5

IC702

AP1538SG-13

IC702

AP1538SG-13

FB

1

EN

2

OCSET

3

VCC4OUTPUT

5

OUTPUT

6

VSS

7

VSS

8

R714

7K5 1/10W 5%

R714

7K5 1/10W 5%

D701

SR34

D701

SR34

1 2

Q701

2SK1828

Q701

2SK1828

TP701TP701

1

+

C709

100UF 16V

+

C709

100UF 16V

FB703 220R/2000mAFB703 220R/2000mA

1 2

R706

10K 1/16W 5%

R706

10K 1/16W 5%

+

C702

100uF 25V

+

C702

100uF 25V

Q705

BC847C

Q705

BC847C

3

2

1

Q703

BC847C

Q703

BC847C

3

2

1

R705

22K 1/10W

R705

22K 1/10W

R712

10K 1/10W

R712

10K 1/10W

C707

100N 50V

C707

100N 50V

+

C713

220UF 25V

+

C713

220UF 25V

TP702TP702

1

FB702 220R/2000mAFB702 220R/2000mA

1 2

R713

6K8 1/10W 5%

R713

6K8 1/10W 5%

R707

4K7 1/10W 5%

R707

4K7 1/10W 5%

R715

NC/2.2 OHM 1/10W

R715

NC/2.2 OHM 1/10W

C717

0.1uF 50V

C717

0.1uF 50V

MAIN [3] POWER 1

Page 32

A

A

B

B

C

C

D

D

E

E

4 4

3 3

2 2

1 1

PANEL_VCC_ON/OFF

PANEL_VCC_ON/OFF

+18V_A

AV25

+5V_SW

AV33

+5V_TUNER

DV33

DV33SB

+12V

+5V_SW

AV125

+5V_SW

+5V_SW

DV33

+5V_SW

DV33

+5V_STB

PANEL_VCC

AV25

+5V_STB +5V_STB_E

DV33SB DV33SB_E

PANEL_VCC_ON/OFF6

+5V_TUNER FROM Regulator

SMD/0402

+5V_STB TO DV33SB

Vo=0.5x(R1+R2)/R2

NEARLY TUNER

Vout = 0.8 * (1+R105/R106)

+18V_A TO +12V

DV33 TO AV125

Vout =3.35V , R105= 5.1K, R106=1.6K

NEARLY U605

PANEL_VCC

ON/OFF:MT8295(GPIO10)

Normal:High

Stand_By:Low

FOR Panel VCC 5V

+5V_SW TO AV25

+5V_SW TO DV33

+5V_SW TO AV33

EMI SOLUTION FOLLOW SPECIAL PLACE

Vo=1.25 x (1+120R/120R) = 2.5V

U703 G1117T63UfU703 G1117T63Uf

VIN

3

GND

1

VOUT

2

TH

4

R735

43KOHM +-1% 1/10W

R735

43KOHM +-1% 1/10W

R737

5K1 1/10W 1%

R737

5K1 1/10W 1%

C737

NC/0.1uF 50V

C737

NC/0.1uF 50V

C744

NC/01uF

C744

NC/01uF

FB707

600R/500mA

FB707

600R/500mA

1 2

+

C728

100UF 16V

+

C728

100UF 16V

C727

4.7UF 10V

C727

4.7UF 10V

R721

120R 1% 1/10W

R721

120R 1% 1/10W

IC701

AME5106AIHAADJZ

IC701

AME5106AIHAADJZ

FB

1

EN

2

OCSET

3

IN4SW

5

SW

6

GND

7

GND

8

C734

100N 50V

C734

100N 50V

R731

3.6K 1/10W

R731

3.6K 1/10W

C732

100N 50V

C732

100N 50V

R725

47K 1/10W

R725

47K 1/10W

U702 G1117T63UfU702 G1117T63Uf

VIN

3

GND

1

VOUT

2

TH

4

R722

22K 1/10W

R722

22K 1/10W

C723100N 50V C723100N 50V

R729

0R05 1/4W

R729

0R05 1/4W

R732

NC/2.2 OHM 1/10W

R732

NC/2.2 OHM 1/10W

+

C746 470uF/16V+C746 470uF/16V

R723 22K 1/10WR723 22K 1/10W

+

C731

10uF 50V

+

C731

10uF 50V

C726 NC/470N 10VC726 NC/470N 10V

R720

NC/0R05 1/4W

R720

NC/0R05 1/4W

Q707

BC847C

Q707

BC847C

3

2

1

U706

SC4215HSETRT

U706

SC4215HSETRT

NC

1

EN

2

VIN

3

NC

4

GND

8

FB

7

VO

6

NC

5

TH1

9

+

C721

100uF 10V

+

C721

100uF 10V

+

C733

100UF 16V

+

C733

100UF 16V

C7221uF 25V C7221uF 25V

R733

5K1 1/10W 1%

R733

5K1 1/10W 1%

R736

1.62KOHM 1/10W

R736

1.62KOHM 1/10W

R727 NC/0R05 1/10W 5%R727 NC/0R05 1/10W 5%

C720

100N 50V

C720

100N 50V

U704

G1117-33T43UF

U704

G1117-33T43UF

ADJ(GND)1VOUT(TAB)2VIN

3

C725

10U 10V

C725

10U 10V

C743

0.1uF 50V

C743

0.1uF 50V

R726

120R 1% 1/10W

R726

120R 1% 1/10W

R728

120R 1% 1/10W

R728

120R 1% 1/10W

FB708

600R/500mA

FB708

600R/500mA

1 2

Q706

Si5403DC-T1-GE3

Q706

Si5403DC-T1-GE3

D

1

D

2

D

3

G4S

5

D

6

D

7

D

8

R730

20K 1/10W

R730

20K 1/10W

+

C740

100uF 10V

+

C740

100uF 10V

C739

100N 50V

C739

100N 50V

R724

0R05 1/10W

R724

0R05 1/10W

C741

0.1uF 50V

C741

0.1uF 50V

C745 0.1uF 50VC745 0.1uF 50V

C748

0.1uF 50V

C748

0.1uF 50V

L702 27uHL702 27uH

FB706

NC/220R/2000mA

FB706

NC/220R/2000mA

1 2

C724

100N 50V

C724

100N 50V

+

C738

100uF 10V

+

C738

100uF 10V

C742

100N 50V

C742

100N 50V

U701

AME8810-AEGTZ 0.6A/3.3V

U701

AME8810-AEGTZ 0.6A/3.3V

GND

1

VOUT(heat sink)

2

VIN

3

4

4

C749

0.1uF 50V

C749

0.1uF 50V

R719

0R05 1/4W

R719

0R05 1/4W

D702

SR34

D702

SR34

1 2

FB705

NC/220R/2000mA

FB705

NC/220R/2000mA

1 2

C730

10U 10V

C730

10U 10V

U705

L78L12ABUTR

U705

L78L12ABUTR

IN3OUT

1

GND

2

R734

1.5K +-1% 1/10W

R734

1.5K +-1% 1/10W

C735 NC/0.47uFC735 NC/0.47uF

+

C736

220uF16V

+

C736

220uF16V

C747

NC/1nF 50V

C747

NC/1nF 50V

C729

100N 16V

C729

100N 16V

MAIN [4] POWER 2

Page 33

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

RDQM1

RWE#

RA9

RA1

RA8

RA1

RDQM0

AV12_MEMPLL

RA4

RDQM1

MEM_CLK0

RA7

MEM_CLK0#

RA2

RDQ14

RDQ12

RDQ12

RA9

RA11

RA7

RA5

RDQ6

RA6

RRAS#

RCAS#

RDQ0

RDQ8

RA0

RDQ5

AV12_MEMPLL

RDQ2

RDQM0

RDQ15

RBA0

RDQ8

RDQ3

RDQ7

RA0

RDQS1

MEM_CLK0#

RDQ0

RDQ1

RA6

RDQ10

RA12

RDQS0

RBA0

RRAS#

RCS#

RDQ11

RDQ13

RDQ7

RDQ6

RDQ3

RCLK0

RCAS#

RDQ4

RDQS0

RDQ2

RA3

RCLK0#

RA2

RCKE

RCLK0

RCLK0#

RWE#

RBA1

RDQ13

RCKE

RCS#

RDQ15

RA4

RA3

RA8

RCS#

RDQ9

MEM_CLK0

RDQ9

RDQ4

MEM_VREF

RDQ10

MEM_VREFRA12

RDQ1

MEM_VREF

RDQ11

RDQ14

RBA1

RDQ5

RA10

RA5

RA11

RA10

RDQS1

DDRVDV33

DDRV

DDRV

AV125

DDRV

DDRV

DDRV

DDRV

DDRV

DDRV

Top

Component item from 2xx in this part.

Bottom

Bottom

DRAM

Bottom

DRAM Power

Under MT5361

NEAR IC

Close to C280

LOW E.S.R

R402

110 OHM +-1% 1/10W

R402

110 OHM +-1% 1/10W

C405

NC/100N 16V

C405

NC/100N 16V

C414

4.7UF 10V

C414

4.7UF 10V

C421

100N 16V

C421

100N 16V

R405

NC/1K 1/10W 5%

R405

NC/1K 1/10W 5%

R411

22R 1/16W 5%

R411

22R 1/16W 5%

C417

10N 50V

C417

10N 50V

C404

4.7UF 10V

C404

4.7UF 10V

C402

100N 50V

C402

100N 50V

C422

100N 16V

C422

100N 16V

C418

10U 10V

C418

10U 10V

R404

1K 1/16W

R404

1K 1/16W

C423

100N 16V

C423

100N 16V

U403

NT5TU32M16CG-25C

U403

NT5TU32M16CG-25C

VDD

A1

NC

A2

VSS

A3

VSSQ

A7

UDQS

A8

VDDQ

A9

DQ14

B1

VSSQ

B2

UDM

B3

UDQS

B7

VSSQ

B8

DQ15

B9

VDDQ

C1

DQ9

C2

VDDQ

C3

VDDQ

C7

DQ8

C8

VDDQ

C9

DQ12

D1

VSSQ

D2

DQ11

D3

DQ10

D7

VSSQ

D8

DQ13

D9

VDD

E1

NC

E2

VSS

E3

VSSQ

E7

LDQS

E8

VDDQ

E9

DQ6

F1

VSSQ

F2

LDM

F3

LDQS

F7

VSSQ

F8

DQ7

F9

VDDQ

G1

DQ1

G2

VDDQ

G7

DQ0

G8

VDDQ

G9

DQ4

H1

VSSQ

H2

DQ3

H3

DQ2

H7

VSSQ

H8

DQ5

H9

VDDL

J1

VREF

J2

VSS

J3

VSSDL

J7

CK

J8

VDD

J9

CKE

K2

WE

K3

RAS

K7

CK

K8

ODT

K9

NC/BA2

L1

BA0

L2

BA1

L3

CAS

L7

CS

L8

A10/AP

M2

A1

M3

A2

M7

A0

M8

VDD

M9

VSS

N1

A3

N2

A5

N3

A6

N7

A4

N8

A7

P2

A9

P3

A11

P7

A8

P8

VSS

P9

VDD

R1

A12

R2

NC/A14

R3

NC/N15

R7

NC/A13

R8

VDDQ

G3

C424

100N 16V

C424

100N 16V

C426

100N 16V

C426

100N 16V

C416

100N 16V

C416

100N 16V

C425

100N 16V

C425

100N 16V

R407

1K 1/10W 1%

R407

1K 1/10W 1%

+

C403

220UF 25V

+

C403

220UF 25V

R410

75 OHM +-5% 1/16W

R410

75 OHM +-5% 1/16W

C415

100N 16V

C415

100N 16V

R406

75 OHM +-5% 1/16W

R406

75 OHM +-5% 1/16W

C411

4.7UF 10V

C411

4.7UF 10V

C420

1uF 25V

C420

1uF 25V

C408

100N 16V

C408

100N 16V

C427

100N 16V

C427

100N 16V

C428

4.7UF 10V

C428

4.7UF 10V

R409

1K 1/10W 1%

R409

1K 1/10W 1%

C401

100N 16V

C401

100N 16V

C407

1uF 25V

C407

1uF 25V

C430

100N 16V

C430

100N 16V

FB401

120R/500mA

FB401

120R/500mA

1 2

U402

G1084T43Uf

U402

G1084T43Uf

VOUT

2

VIN

3

ADJ

1

U401D

MT5361BMU_B

U401D

MT5361BMU_B

RDQ7

1

RDQ6

2

RDQ5

3

RDQ4

4

RDQ3

5

RDQ2

6

RDQ1

7

RDQ0

8

VCC2IO

9

RDQS0

10

VCC2IO

11

RDQM0

12

RDQM1

14

VCC2IO

15

RDQS1

16

VCC2IO

17

RDQ8

18

RDQ9

19

RDQ10

20

RDQ11

21

RDQ12

22

RDQ13

23

RDQ14

24

RDQ15

25

VCC2IO

26

RCLK0_

27

RCLK0

28

VCC2IO

29

AVDD12_MEMPLL

30

RCKE

31

RA12

32

RA11

33

RA9

34

RA8

35

RA7

36

RA6

37

RA5

38

RA4

39

RWE_

40

RCAS_

41

RRAS_

42

RBA0

43

RBA1

44

RA10

45

RCS_

46

RA0

47

RA1

48

RA2

49

RA3

50

VCC2IO

51

RVREF0

52

VCC2IO

53

VCC2IO

54

VCC2IO

55

C409

100N 16V

C409

100N 16V

C429

10U 10V

C429

10U 10V

R403

51.1 OHM +-1% 1/10W

R403

51.1 OHM +-1% 1/10W

C419

4.7UF 10V

C419

4.7UF 10V

C410

100N 16V

C410

100N 16V

R408

150OHM 1/16W +/-5%

R408

150OHM 1/16W +/-5%

R413

22R 1/16W 5%

R413

22R 1/16W 5%

R412

100R 1/16W 5%

R412

100R 1/16W 5%

C406

NC/100N 16V

C406

NC/100N 16V

C412

100N 16V

C412

100N 16V

C413

100N 16V

C413

100N 16V

MAIN [5] DRAM

Page 34

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

C_XREG

JTMS

OPCTRL2

LED_EPG_GREEN

PANEL_VCC_ON/OFF

GPIO_4

BKL_ON

OSCL1

Key1

OXTALI

OPCTRL5

AVDD12_USB

U0RX

ORESET#

GPIO_7

JTMS

U0RX

OSDA0

USB_DP

OPWM1

OPWM1

AVDD12_PLL

GPIO_4

GPIO_1

GPIO_1

OPWM2

JTDI

JTCK

OPWRSB

AVDD33_XTAL

OPCTRL3

OSCL0

USB_DM

LED_EPG_GREEN

OSDA0

AVDD33_USB

U0RX_O

AVDD12_PLL

KEY_MENU_L_R_SOURCE

JTAG_DBGACK

LED_POWER_ON

GPIO_7

Key1

ADIN3

AVDD12_PLL

OSDA0

LED_EPG_REDOPCTRL0

U0TX

JTDI

JTRST#

USB_DP

OPCTRL4

JTRST#

OPWM0

USB_VRT

LIGHT_SENSOR

Key2

C_XREG

AVDD12_PLL

AVDD12_PLL

USB_DM

OPCTRL3

U0TX U0TX_O OSCL0

LED_EPG_RED

OXTALI

LED_POWER_OFF

OXTALO

ACD_control OPCTRL2

AVDD33_XTAL

OPWM2

U0RX

TVTREF#1

OPCTRL1 LED_POWER_OFF

PANEL_VCC_ON/OFF

OPCTRL5

GPIO_6

AVDD33_USB

LIGHT_SENSOR

BKL_ON

OSCL0

ADIN3

JTAG_DBGRQ

GPIO_0

OPCTRL5

OXTALO

LED_POWER_ON

AVDD12_PLL

CI_GPIO10

Light_Sensor

OPWM0

ACD_control

JTDO

USB_VRT

OIRI

KEY_UP_DN_DCSW

Key2

GPIO_0

OPCTRL4

JTDO

OSCL1

AVDD12_PLL

U0TX

JTCK

OSDA1

GPIO_6

OSDA1

AVDD12_USB

KEY_UP_DN_DCSW

OPWRSB

ORESET#

KEY_MENU_L_R_SOURCE

OIRI

OPCTRL4CI_GPIO10

DV33SB

DV33

AV33

DV33

AV125

AV125

DV33SB +5V_STB

DV33

DV33

+5V_SW

DV33

+5V_STB_E

DV33SB_E

DV33SB_E

DV33SB_E

LED_POWER_ON12

GPIO_617

Light_Sensor12

OPWM27

LED_EPG_RED12

OPCTRL57

Key112

OSCL08,13

GPIO_017

BKL_ON18

LED_POWER_OFF12

CI_GPIO1017

ACD_control3

U0TX10 OPWM17,18

OSCL111

OPCTRL47

LED_EPG_GREEN7,12

OPWM07

OPWRSB3

OPCTRL37,10

GPIO_413

GPIO_717

OIRI12

GPIO_113

U0RX10

Key212

OSDA08,13

PANEL_VCC_ON/OFF4

ADIN312

OPCTRL27,12

OSDA111

---><---|>

TXC

NEAR IC

NEAR IC

NEAR IC

SYSTEM EEPROM

LO = > WP

NEAR IC

For Debug Use

IIC ADDRESS "A0"

FOR CODE DOWNLOAD,DEBUGGING,

FACTORY ALIGUMENT AND

COMPAIR MODE

USB 2.0

TO KEY PAD BOARD

54MHz CRYSTAL

NEAR IC

HI = > WRITE

---><---|>

FB410

120R/500mA

FB410

120R/500mA

1 2

C490

10U 10V

C490

10U 10V

R471

10K 1/10W

R471

10K 1/10W

R461

33R 1/16W 5%

R461

33R 1/16W 5%

R470

4K7 1/10W 5%

R470

4K7 1/10W 5%

R465 10K 1/16W 5%R465 10K 1/16W 5%

U407

G5250H1T1U

U407

G5250H1T1U

OUT

1

GND

2

IN

3

EN(EN)

4

OC

5

R453 10K 1/16W 5%R453 10K 1/16W 5%

C492

33P 50V

C492

33P 50V

R460

3K9 1/10W 1%

R460

3K9 1/10W 1%

+

C475

100uF 10V

+

C475

100uF 10V

CN403

60693 3P 2.0mm

CN403

60693 3P 2.0mm

1

2

3

R444

4K7 1/10W 5%

R444

4K7 1/10W 5%

CN406

CONN

CN406

CONN

1

3

5

7

9

11

13

15

17

19

21

2

4

6

8

10

12

14

16

18

20

22

R454 10K 1/16W 5%R454 10K 1/16W 5%

X401

54M 10P

X401

54M 10P

1 2

C485

4.7UF 10V

C485

4.7UF 10V

R451

10K 1/10W

R451

10K 1/10W

R447

4K7 1/10W 5%

R447

4K7 1/10W 5%

U408

MAX809STRG

U408

MAX809STRG

GND

1

RESET

2

VCC

3

R463

NC/1K 1/10W 5%

R463

NC/1K 1/10W 5%

1234

CN103

CONN

1234

CN103

CONN

1

2

3

4

65

TP406TP406

1

C481

10P 50V

C481

10P 50V

C484

100N 16V

C484

100N 16V

FB409

120R/500mA

FB409

120R/500mA

1 2

C478

4.7UF 10V

C478

4.7UF 10V

R450

100 OHM 1/10W

R450

100 OHM 1/10W

C489

3300pF 50V

C489

3300pF 50V

+

C480

100uF 10V

+

C480

100uF 10V

R464 10K 1/16W 5%R464 10K 1/16W 5%

R459

3K9 1/10W 1%

R459

3K9 1/10W 1%

R456 10K 1/16W 5%R456 10K 1/16W 5%

R475

1.8K1/10W

R475

1.8K1/10W

U406

M24C32-WMN6TP

U406

M24C32-WMN6TP

VSS

4

VCC

8

SDA

5

SCL

6

E0

1

E1

2

E2

3

WC

7

R469 0R05 1/16WR469 0R05 1/16W

C476

1uF 25V

C476

1uF 25V

R466 10K 1/16W 5%R466 10K 1/16W 5%

ZD402

VPORT0603100KV05

ZD402

VPORT0603100KV05

1 2

D401

NC/BAV99

D401

NC/BAV99

3

1

2

FB407

120R/500mA

FB407

120R/500mA

1 2

R452 10K 1/16W 5%R452 10K 1/16W 5%

R473

NC/0R05 1/10W 5%

R473

NC/0R05 1/10W 5%

C491

1N 50V

C491

1N 50V

C488

100N 16V

C488

100N 16V

R476

100K 1/16W 5%

R476

100K 1/16W 5%

C482

10P 50V

C482

10P 50VC487

10N 50V

C487

10N 50V

U401I

MT5361BMU_B

U401I

MT5361BMU_B

GPIO6

57

GPIO5

58

GPIO4

59

JTMS

60

JTDI

61

JTDO

62

JTCK

63

JTRST_

64

GPIO3

66

GPIO2

67

OPWM2

68

OPWM1

70

OPWM0

71

VCXO

72

OSCL1

73

OSDA1

74

OSCL0

75

OSDA0

76

USB_DM0

78

USB_DP0

79

AVDD33_USB

80

USB_VRT

81

AVDD12_USB

82

U0TX

83

U0RX

84

OPCTRL5

85

OPCTRL4

86

OPCTRL3

87

OPCTRL2

88

OPCTRL1

89

OPCTRL0

90

OPWRSB

91

OIRI

92

ORESET_

93

AVDD12_LDO

94

ADIN0_SRV

145

ADIN1_SRV

146

ADIN2_SRV

147

ADIN3_SRV

148

ADIN4_SRV

149

ADIN5_SRV

150

AVDD33_XTAL

151

XTALO

152

XTALI

153

AVDD12_DMPLL

160

AVDD12_DTDPLL

161

AVDD12_TVDPLL

162

AVDD12_ADCPLL

163

AVDD12_SYSPLL

164

AVDD12_APLL

165

GPIO0

203

GPIO7

220

GPIO1

221

R458

5K1 1/10W 1%

R458

5K1 1/10W 1%

R472

820 OHM +-0.5% 1/10W

R472

820 OHM +-0.5% 1/10W

D402

NC/BAV99

D402

NC/BAV99

3

1

2

Q401

MMBT3904

Q401

MMBT3904

C483

10U 10V

C483

10U 10V

R462

1R 1/10W 5%

R462

1R 1/10W 5%

R449

100 OHM 1/10W

R449

100 OHM 1/10W

R445

4K7 1/10W 5%

R445

4K7 1/10W 5%

C474

100N 16V

C474

100N 16V

R468 0R05 1/16WR468 0R05 1/16W

R446

4K7 1/10W 5%

R446

4K7 1/10W 5%

C486

4.7UF 10V

C486

4.7UF 10V

L401

0U82

L401

0U82

R467

NC/820K 1/10W 5%

R467

NC/820K 1/10W 5%

R448

33 OHM 1/10W

R448

33 OHM 1/10W

R474

NC/1K OHM 1/10W

R474

NC/1K OHM 1/10W

C477

100N 16V

C477

100N 16V

ZD401

VPORT0603100KV05

ZD401

VPORT0603100KV05

1 2

C472

4.7UF 10V

C472

4.7UF 10V

FB408

120R/500mA

FB408

120R/500mA

1 2

R457

1K 1/16W 5%

R457

1K 1/16W 5%

R455 10K 1/16W 5%R455 10K 1/16W 5%

C473

4.7UF 10V

C473

4.7UF 10V

R443

4K7 1/10W 5%

R443

4K7 1/10W 5%

C471

220N16V

C471

220N16V

TP407TP407

1

C479

100N 16V

C479

100N 16V

MAIN [6] REPIPHERAL

Page 35

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

OPCTRL3

PDD7

PDD2

PACLE

OPCTRL4

PDD7

OPCTRL4

PDD4

OPCTRL5

PDD1

FRESET#

PDD3

PDD4

POOE#

PDD0

FRESET#

POWE#

PDD2

PDD6

PACLE

POOE#

OPCTRL3

PDD0 DV33

AOBCK

PARB#

OPCTRL2

POWE#

POCE0#

POOE#

PDD6

PAALE

PDD0

PDD5

PDD0

PDD2

PDD3

POCE1#

PDD1

DV33

POCE1#

PARB#

POWE#

PARB#

POOE#

PDD5

PAALE

OPCTRL5

PDD1

PAALE

OPWM0

OPWM1

AOBCK

PDD5

PDD6

PDD4

AOLRCK

AOLRCK

DV33

POCE0#

PDD7

PDD1

OPWM1

OPWM2

OPCTRL2

PDD3

OPWM2

OPWM0

PACLE

DV33

DV33

DV11

DV33

DV33

DV11

DV33

DV33

DV33

DV33

DV33SB_E

OPCTRL26,12

POWE#17

AOBCK13

PAALE17

OPCTRL36,10

POOE#17

OPWM06

PDD517

PARB#17

OPWM16,18

PDD117

OPCTRL46

AOLRCK13

PDD617

PDD317

PDD717

PACLE17

PDD017

OPWM26

PDD417

PDD217

OPCTRL56

OPCTRL2(O)

1

1

16MB Nand Flash

0

0

Strapping Mode

0

1

Core Power BYPASS Cap.

0 1

OPCTRL5

CPU model mode

NAND Boot

Core Reset 0.9V

AOBCK

Strapping Mode

0

0

1

MT5361 STRAPPING MODE

0

XTAL 27MHz

0

XTAL 54MHz

Nor Boot

1

0

Strapping Mode

0

OPWM0(O)

SCAN mode

0

0

512KB Nor Flash for Boot Code

large NAND Boot

1

0

Normal mode

1

AOLRCK

0

1

Trap Mode OPCTRL4

Core Reset 3.3V

0

OPCTRL3(O)

0

I/O BYPASS Cap.

ICE mode

0

OPWM1(O)

Component item from 3xx in this part.

0

OPWM2

Core Reset 1us

R423 4K7 1/10W 5%R423 4K7 1/10W 5%

C438

1uF 25V

C438

1uF 25V

C433

1UF16V

C433

1UF16V

C447

100N 16V

C447

100N 16V

C442

100N 16V

C442

100N 16V

C437

4.7UF 10V

C437

4.7UF 10V

C444

100N 16V

C444

100N 16V

R418 4K7 1/10W 5%R418 4K7 1/10W 5%

C439

4.7UF 10V

C439

4.7UF 10V

R414

4K7 1/10W 5%

R414

4K7 1/10W 5%

C453

100N 16V

C453

100N 16V

U405

HY27US08281A-TPCB

U405

HY27US08281A-TPCB

NC

1

NC

2

NC

3

NC

4

NC

5

NC

6

R/B

7

RE

8

CE

9

NC

10

NC

11

VCC

12

VSS

13

NC

14

NC

15

CLE

16

ALE

17

WE

18

WP

19

NC

20

NC

21

NC

22

NC

23

NC

24

NC

25

NC

26

NC

27

NC

28

I/O0

29

I/O1

30

I/O2

31

I/O3

32

NC

33

NC

34

NC

35

VSS

36

VCC

37

PRE

38

NC

39

NC

40

I/O4

41

I/O5

42

I/O6

43

I/O7

44

NC

45

NC

46

NC

47

NC

48

R421 4K7 1/10W 5%R421 4K7 1/10W 5%

U401F

MT5361BMU_B

U401F

MT5361BMU_B

VCCK

13

VCCK

56

VCC3IO

65

VCCK

69

VCCK

77

VCCK

144

VCCK

182

VCCK

193

VCC3IO

198

POCE1_

204

PDD0

205

PDD1

206

PDD2

207

PDD3

208

PDD4

209

VCCK

210

PDD5

211

PDD6

212

PDD7

213

PARB_

214

POOE_

215

PACLE

216

PAALE

217

POWE_

218

POCE0_

219

VCCK

222

VCCK

256

TH1

257

U404

MX25L4005AMI-12G

U404

MX25L4005AMI-12G

CS

1

SO

2

WP

3

GND4SI

5

SCK

6

HOLD

7

VCC

8

C448

100N 16V

C448

100N 16V

C443

100N 16V

C443

100N 16V

R426

NC/4K7 1/10W 5%

R426

NC/4K7 1/10W 5%

C449

100N 16V

C449

100N 16V

C441

100N 16V

C441

100N 16V

R415

4K7 1/16W 5%

R415

4K7 1/16W 5%

C446

100N 16V

C446

100N 16V

C451

100N 16V

C451

100N 16V

R424

NC/4K7 1/10W 5%

R424

NC/4K7 1/10W 5%

C431

100N 50V

C431

100N 50V

C436

100N 16V

C436

100N 16V

R417 4K7 1/10W 5%R417 4K7 1/10W 5%

C456

100N 16V

C456

100N 16V

R427 4K7 1/10W 5%R427 4K7 1/10W 5%

C434

100N 16V

C434

100N 16V

R416

330 OHM 1/16W

R416

330 OHM 1/16W

R422 4K7 1/10W 5%R422 4K7 1/10W 5%

C445

100N 16V

C445

100N 16V

C455

100N 16V

C455

100N 16V

C454

100N 16V

C454

100N 16V

C432

100N 50V

C432

100N 50V

C435

100N 16V

C435

100N 16V

R420 NC/4K7 1/10W 5%R420 NC/4K7 1/10W 5%R419

4K7 1/10W 5%

R419

4K7 1/10W 5%

R425 4K7 1/10W 5%R425 4K7 1/10W 5%

C450

100N 16V

C450

100N 16V

C440

1uF 25V

C440

1uF 25V

C452

100N 16V

C452

100N 16V

R428 4K7 1/10W 5%R428 4K7 1/10W 5%

MAIN [7] FLASH/TRAP/BYPASS/FCI

Page 36

A

A

A A

ASPDIF

MGPIO5

OSDA0

MGPIO5

OSDA0

OSCL0

CEC_A

TX2-

TX1+

TXC+

TX2+

TX1-

TX0+

TX0-

TXC-

OSCL0

INT

TXC-

VCC33_SWVCC33_SWVCC33_SWVCC33_SW

TXC+

TX1+

AVDD12_CVCC

ASPDIF

TX2-

TX0-

TX1-

TX2+

AVDD33_H

AVDD33_H

TX0+

CEC_A

AVDD12_CVCC

DV33

DV33

DV33

DV33

AV33

AV125

+5V_STB_E

OSCL06,13

ASPDIF11

MGPIO513

RR3X0-9

DSCL_39

RR2X0+9

RR2XC+9

RR3XC-9

HPD39

OSDA06,13

RR3X2-9

DSDA_29

DSDA_39

RPWR39

RPWR29

RR2X1+9

RR3X1-9

RR2X2-9

RR3XC+9

RR2X2+9

RR3X2+9

RR2X0-9

CEC_A9

RR3X1+9

RR2XC-9

RR2X1-9

RR3X0+9

HPD29

DSCL_29

PCB LAYOUT: Place all decoupling

capacitors (0.1uf)as close to the pin as

possible.

NEAR IC

HDMI BYPASS CAP.

NEAR IC

Delete R504,R505

Delete R507,R508

C514

100N 16V

C514

100N 16V

R516

NC/4.7K 1/10W

R516

NC/4.7K 1/10W

C511

100N 16V

C511

100N 16V

C512

1uF 25V

C512

1uF 25V C513

4.7UF 10V

C513

4.7UF 10V

C504

10U 10V

C504

10U 10V

R519 0R01 1/10WR519 0R01 1/10W

C506

100N 50V

C506

100N 50V

R503

3.3K 1/16W

R503

3.3K 1/16W

C507

100N 50V

C507

100N 50V

TP501TP501

1

R509

NC/4.7K 1/10W

R509

NC/4.7K 1/10W

C502

1uF 25V

C502

1uF 25V

FB502

120R/500mA

FB502

120R/500mA

1 2

C501

100N 50V

C501

100N 50V

C517

680pF 50V

C517

680pF 50V

C503

10U 10V

C503

10U 10V

R518

0R01 1/10W

R518

0R01 1/10W

C515

1uF 25V

C515

1uF 25V

C505

10U 10V

C505

10U 10V

U501

SII9187ACNU

U501

SII9187ACNU

RSVDL

10

CSDA

53

CSCL

54

R0XCN

65

R0XCP

66

R0X0N

67

R0X0P

68

R0X1N

69

R0X1P

70

R0X2N

71

R0X2P

72

TXCN

63

TXCP

62

TX0N

61

TX0P

60

TX1N

59

TX1P

58

TX2N

57

TX2P

56

ePAD

73

VCC33

9

R2XCN

11

R2XCP

12

R2X0N

13

R2X0P

14

R2X1N

15

R2X1P

16

R2X2N

17

R2X2P

18

DSDA0

29

CEC_A

50

HPD0

31

R0PWR5V

32

DSCL0

30

TPWR/CI2CA

55

DSDA4

47

DSCL4

48

HPD2

41

R2PWR5V

42

DSDA2

39

DSCL2

40

CEC_D

51

HPD1

35

R1PWR5V

36

DSDA1

33

DSCL1

34

R1XCN

1

R1XCP

2

R1X0N

3

R1X0P

4

R1X1N

5

R1X1P

6

R1X2N

7

R1X2P

8

VCC3327VCC33

64

INT

52

MICOM_VCC33

37

HPD3

45

R3PWR5V

46

DSDA3

43

DSCL3

44

R3XCN

19

R3XCP

20

R3X0N

21

R3X0P

22

R3X1N

23

R3X1P

24

R3X2N

25

R3X2P

26

SBVCC

38

RSVDL

28

R4PWR5V

49

Q501

NC/2SK1828

Q501

NC/2SK1828

R514

10R 1/10W 5%

R514

10R 1/10W 5%

R506

3.3K 1/16W

R506

3.3K 1/16W

R511

10R 1/10W 5%

R511

10R 1/10W 5%

R502

0R05 1/16W

R502

0R05 1/16W

C516

1uF 25V

C516

1uF 25V

R515 0R05 1/16WR515 0R05 1/16W

R510

4.7K 1/10W

R510

4.7K 1/10W

C508

100N 50V

C508

100N 50V

R517

3.3K 1/16W

R517

3.3K 1/16W

C510

4.7UF 10V

C510

4.7UF 10V

R512

NC/10K 1/10W

R512

NC/10K 1/10W

FB501

120R/500mA

FB501

120R/500mA

1 2

C509

1uF 25V

C509

1uF 25V

U401H

MT5361BMU_B

U401H

MT5361BMU_B

HDMI_CEC

95

AVDD33_HDMI

96

PWR5V_0

97

HDMI_SDA0

98

HDMI_SCL0

99

RX0_CB

100

RX0_0B

102

RX0_C

101

RX0_0

103

RX0_1B

104

RX0_2B

106

RX0_1

105

RX0_2

107

AVDD12_HDMI

108

ALIN

187

ASPDIF

188

R513

3.3K 1/16W

R513

3.3K 1/16W

MAIN [8] HDMI/SPDIF OUT/DVD IN

Page 37

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

CEC_A2

RPWR2 RPWR3

CEC_A3CEC_A2

PR_IN_1

PB_IN_1

Y_IN_1

SOY1

Y1P

PR1P

PB1P

COM1

COM_1

AIN4_L

AIN4_R

COM1

Y1P

PB1P

SOY1

AIN4_R

AIN4_L

PR1P

CEC_A3

RPWR2 RPWR3

RPWR2 RPWR3

DV33SB_E

DSDA_2 8

HPD3 8

RPWR28

RR2X0- 8

RR2X2- 8

RR3X2+ 8

RR3X0- 8

RR3X2- 8

RR2X1- 8

RR3X1+ 8

RR2X1+ 8

RR3XC+ 8

RR2XC+ 8

DSCL_3 8

RR2X0+ 8

RR2XC- 8

RR2X2+ 8

DSCL_2 8

HPD2 8

RR3X1- 8

RPWR38

RR3X0+ 8

DSDA_3 8

CEC_A 8

RR3XC- 8

AIN4_R13

SOY110

Y1P10

PR1P10

COM110

AIN4_L13

PB1P10

PORT 1

100ohm differential impedance for TMDS traces. 100ohm differential impedance for TMDS traces.

PORT 2

NEARLY YPBPR CON.

YPbPr1 Video Input

Close MT5361

YPBPR Audio INPUT_1

CN111B

JACK

CN111B

JACK

8

7

11

9

10

R1154

27K 1/16W 5%

R1154

27K 1/16W 5%

R520

27K 1/16W 5%

R520

27K 1/16W 5%

C1149

10N 50V

C1149

10N 50V

C1147

10N 50V

C1147

10N 50V

ZD101

NC/VPORT0603 102M V05

ZD101

NC/VPORT0603 102M V05

12

R1158

56.2R +-1% 1/10W

R1158

56.2R +-1% 1/10W

R1157

68OHM 1/16W

R1157

68OHM 1/16W

R1155

0R05 1/16W

R1155

0R05 1/16W

R1161

68OHM 1/16W

R1161

68OHM 1/16W

ZD127

NC/VPORT0603 102M V05

ZD127

NC/VPORT0603 102M V05

1 2

C1146 4700P 50VC1146 4700P 50V

R522

47K 1/10W

R522

47K 1/10W

R524

47K1/16W

R524

47K1/16W

CN502

HDMI

CN502

HDMI

TH1

20

TH2

21

D2+

1

D2 Shield

2

D2-

3

D1+

4

D1 Shield

5

D1-

6

D0+

7

D0 Shield

8

D0-

9

CK+

10

CK Shield

11

CK-

12

CE Remote

13

NC

14

DDC CLK

15

DDC DATA

16

GND

17

+5V

18

HP DET

19

TH3

22

TH4

23

TH5

24

FB124

300OHM

FB124

300OHM

1 2

C1144 10U 10VC1144 10U 10V

R523

47K 1/10W

R523

47K 1/10W

C1150

10N 50V

C1150

10N 50V

FB12280 OHMFB12280 OHM

1 2

FB121 80 OHMFB121 80 OHM

1 2

R1160

18.2 OHM +-1% 1/10W

R1160

18.2 OHM +-1% 1/10W

C1153

10N 50V

C1153

10N 50V

CN501

HDMI

CN501

HDMI

TH1

20

TH2

21

D2+

1

D2 Shield

2

D2-

3

D1+

4

D1 Shield

5

D1-

6

D0+

7

D0 Shield

8

D0-

9

CK+

10

CK Shield

11

CK-

12

CE Remote

13

NC

14

DDC CLK

15

DDC DATA

16

GND

17

+5V

18

HP DET

19

TH3

22

TH4

23

TH5

24

ZD125

NC/VPORT0603100KV05

ZD125

NC/VPORT0603100KV05

12

FB123

300OHM

FB123

300OHM

1 2

C1148

15P 50V

C1148

15P 50V

FB12080 OHMFB12080 OHM

1 2

R1156

18.2 OHM +-1% 1/10W

R1156

18.2 OHM +-1% 1/10W

R1159

100R 1/16W 5%

R1159

100R 1/16W 5%

D501

BAS316

D501

BAS316

ZD126

NC/VPORT0603 102M V05

ZD126

NC/VPORT0603 102M V05

12

R1165

68OHM 1/16W

R1165

68OHM 1/16W

R1164

18.2 OHM +-1% 1/10W

R1164

18.2 OHM +-1% 1/10W

R1153

27K 1/16W 5%

R1153

27K 1/16W 5%

ZD124

NC/VPORT0603100KV05

ZD124

NC/VPORT0603100KV05

12

C1151

15P 50V

C1151

15P 50V

R1162

56.2R +-1% 1/10W

R1162

56.2R +-1% 1/10W

R525

47K1/16W

R525

47K1/16W

CN111A

JACK

CN111A

JACK

2

1

4

3

6

5

R1163

56.2R +-1% 1/10W

R1163

56.2R +-1% 1/10W C1152

15P 50V

C1152

15P 50V

C1145 10U 10VC1145 10U 10V

MAIN [9] CI

Page 38

A

A

A A

VGAROMWP

OPCTRL3

AIN3_L

VSYNC#

BLU

SY0

HSYNC

VGASCL_IN

AVDD12_RGB

Y0P

RP

SOG

COM0

U0TX

HSYNC

GRN_GND

COM

DDCSDA

AVDD33_REG

PR1P

DDCSDA

COM1

GP

PR1P

AIN3_R

RED

U0RX

Y1P

VGAR_IN

SOG

SOY0

VGA_DET

VGA_PLUGPWR

MGPIO4

PB0P

VGASCL_IN

SOY1

RP

CVBS1N

HSYNC#

MGPIO4

GRN

DDCSCL

DDCSCL

BLU_GND

SOY0

VGASDA_IN

AVDD33_CVBS

BLU

PB0P

VGASDA_IN

SC0

GRN

CVBS1P

PR0P

RED

CVBS2P

VGA_PLUGPWR

U0TX

CVBS1P

PB1P

BLU_GND

Y1P

HSYNC#

VSYNC

U0RX

BP

AVDD33_REG

VGA_DET

VGAL_IN

CVBS1N

SY0

AIN3_R

VSYNC

GP

VSYNC#

PR0P

AIN3_L

BP

PB1P

COMRED_GND

COM1

SC0

COM0

SOY1

Y0P

CVBS2P

OPCTRL3

GRN_GND

RED_GND

AV33

VGA_PLUGPWR

AV125 AVDD12_RGB

AVDD33_CVBS

VGA_PLUGPWR

+5V_STB_E

DV33SB_E

CVBS2P12

AIN3_R13

PR0P12

MGPIO413

PR1P9

Y1P9

CVBS1P11

SOY012

AIN3_L13

U0RX6

PB1P9

CVBS1N11

SC011

U0TX6

COM012

COM19

SOY19

SY011

Y0P12

PB0P12

OPCTRL36,7

CLOSE MT5361

NEAR IC

VGA EEPROM

H : WP DISABLE

NEARLY VGA CONN.

DDCSCL

OUTPUT

H

INPUT

Close MT5361

DDCSDA

VGA Audio IN

L : WP ENABLE

U0TX

L

NEAR IC

Close VGA CON.

Connected to connector GND

NEAR IC

U0RX

NEARLY CONN.

CI_GPIO14

VGA CONNECTOR

L112

80 OHM

L112

80 OHM

1 2

R1145

10K 1/10W

R1145

10K 1/10W

C1136

100N 50V

C1136

100N 50V

R1151

10K 1/10W

R1151

10K 1/10W

C1127 10N 50VC1127 10N 50V

C1123 10N 50VC1123 10N 50V

D102

BAS32L

D102

BAS32L

A

1

K

2

C1126 10U 10VC1126 10U 10V

C1142

100N 50V

C1142

100N 50V

U401E

MT5361BMU_B

U401E

MT5361BMU_B

VSYNC

109

HSYNC

110

BP

111

SOG

112

GP

113

COM

114

RP

115

AVDD33_REG

116

SOY1

117

Y1P

118

COM1

119

PB1P

120

PR1P

121

SOY0

122

Y0P

123

COM0

124

PB0P

125

PR0P

126

AVDD12_RGB

127

SC1

129

SY1

130

SC0

131

SY0

132

CVBS3P

133

CVBS2P

134

CVBS1P

135

CVBS0P

137

CVBS0N

136

AVDD33_CVBS

138

AVSS12_RGB

128

ZD122

UDZSNP5.6B

ZD122

UDZSNP5.6B

1 2

R1146

10K 1/10W

R1146

10K 1/10W

C1143

100N 50V

C1143

100N 50V

L113

80 OHM

L113

80 OHM

1 2

R1136

68.1R 1/16W 1%

R1136

68.1R 1/16W 1%

R1141

75R 1/16W 1%

R1141

75R 1/16W 1%

R1137

75R 1/16W 1%

R1137

75R 1/16W 1%

CN101

D-SUB 15P

CN101

D-SUB 15P

1

6

2

7

3

8

4

9

5

11

12

13

14

15

10

1716

ZD119

NC/VPORT0603100KV05

ZD119

NC/VPORT0603100KV05

1 2

D103

BAS32L

D103

BAS32L

A1K

2

ZD117

NC/VPORT0603100KV05

ZD117

NC/VPORT0603100KV05

12

ZD116

NC/VPORT0603100KV05

ZD116

NC/VPORT0603100KV05

1 2

R1143

1K5 1/16W 5%

R1143

1K5 1/16W 5%

R1142

750R 1/16W 5%

R1142

750R 1/16W 5%

FB115

120R/500mA

FB115

120R/500mA

1 2

L111

80 OHM

L111

80 OHM

1 2

U103

M24C02-WDW6P

U103

M24C02-WDW6P

E0

1

E1

2

E2

3

VSS

4

SDA

5

SCL

6

WC

7

VCC

8

FB117

120R/500mA

FB117

120R/500mA

1 2

FB116

120R/500mA

FB116

120R/500mA

1 2

Q105

BC847C

Q105

BC847C

3

2

1

C1140

100N 16V

C1140

100N 16V

C11225pF 50V C11225pF 50V

ZD123

UDZSNP5.6B

ZD123

UDZSNP5.6B

1 2

C1124 10N 50VC1124 10N 50V

C11255pF 50V C11255pF 50V

R1135

100R 1/16W 5%

R1135

100R 1/16W 5%

R1150

10K 1/10W

R1150

10K 1/10W

CN102

PHONEJACK

CN102

PHONEJACK

1

2

3

C1130 10U 10VC1130 10U 10V

R1149

10K 1/10W

R1149

10K 1/10W

R1132

0R05 1/16W

R1132

0R05 1/16W

C11355pF 50V C11355pF 50V

C1128

1uF 25V

C1128

1uF 25V

R1148

1K5 1/16W 5%

R1148

1K5 1/16W 5%

R1147

750R 1/16W 5%

R1147

750R 1/16W 5%

R1144

10K 1/10W

R1144

10K 1/10W

R1138

27K 1/16W 5%

R1138

27K 1/16W 5%

TP106TP106

1

R1134

75R 1/16W 1%

R1134

75R 1/16W 1%

C1120 4700P 50VC1120 4700P 50V

D104 BAS32LD104 BAS32L

A1K

2

U104

NC7SB3157P6X

U104

NC7SB3157P6X

B1

1

GND

2

B0

3

A

4

VCC

5

S

6

R1133

68.1R 1/16W 1%

R1133

68.1R 1/16W 1%

C1121 10N 50VC1121 10N 50V

+

C1137

100uF 10V

+

C1137

100uF 10V

C11415pF 50V C11415pF 50V

ZD118

NC/VPORT0603100KV05

ZD118

NC/VPORT0603100KV05

1 2

C1138

4.7UF 10V

C1138

4.7UF 10V

R1152

10K 1/10W

R1152

10K 1/10W

ZD121

NC/VPORT0603100KV05

ZD121

NC/VPORT0603100KV05

12

C1139

10U 10V

C1139

10U 10V

R1139

68.1R 1/16W 1%

R1139

68.1R 1/16W 1% C1129

100N 16V

C1129

100N 16V

C11315pF 50V C11315pF 50V

FB119

120R/500mA

FB119

120R/500mA

1 2

C1133

4.7UF 10V

C1133

4.7UF 10V

C1132

100N 16V

C1132

100N 16VC1134

10U 10V

C1134

10U 10V

R1140

27K 1/16W 5%

R1140

27K 1/16W 5%

FB118

120R/500mA

FB118

120R/500mA

1 2

ZD120

NC/VPORT0603100KV05

ZD120

NC/VPORT0603100KV05

12

U105

NC7SB3157P6X

U105

NC7SB3157P6X

B1

1

GND

2

B0

3

A

4

VCC

5

S

6

D101

BAS32L

D101

BAS32L

A1K

2

Q104

MMBT3904

Q104

MMBT3904

Component item from 4xx in this part.

MAIN [10] VIDEO/AUDIO INPUT

Page 39

5

5

4

4

3

3

2

2

1

1

D D

C C

B B

A A

DVD_RIN

U2TX

AV1R_IN

OSCL1

U2RX

DVD_C_IN

SY0

DVD_LIN

U2RX

DVD_LIN

ASPDIF

AV1_IN

OSDA1

CVBS1N

U2TX

DVD_AUL_IN

CVBS1P

DVD_AUR_IN

DVD_AV_IN

DVD_AV_IN

OSCL1

SC0

AV1L_IN

SY0

DVD_AUR_IN

AIN5_L

AIN5_L

CVBS1N

AIN5_R

DVD_AUL_IN

ASPDIF

DVD_RIN

AIN5_R

SC0

AV1_IN

OSDA1

DVD_C_IN

CVBS1P

+5V_SW

+5V_SW

AIN5_R13

ASPDIF8

SY010

CVBS1N10

OSDA16

OSCL16

SC010

DVD_LIN13

CVBS1P10

AIN5_L13

DVD_RIN13

NEARLY ICNEARLY AV/SV CON.

OPTICAL

External DVD

Connector

SMD/0402

SPDIF OUT

DVD AUDIO IN

AV3(CVBS)_Audio R/L

SMD/0402

Have a problem

with DVD Tx Rx

transfer

NEAR MT5361

NEAR AV CONNECTOR

C112 NC/10U 10VC112 NC/10U 10V

R110

NC/75R 1/16W 1%

R110

NC/75R 1/16W 1%

C105 1UF 10VC105 1UF 10V

R113

NC/75R 1/16W 1%

R113

NC/75R 1/16W 1%

R106

0R05 1/16W

R106

0R05 1/16W

R119 NC/0R05 1/16WR119 NC/0R05 1/16W

C110

NC/47P 50V

C110

NC/47P 50V

R104

75R 1/16W 1%

R104

75R 1/16W 1%

R102

0R05 1/10W

R102

0R05 1/10W

CN603

CONNNECTOR

CN603

CONNNECTOR

GND

1

VCC

2

VIN

3

C107 NC/47N16VC107 NC/47N16V

ZD102

NC/VPORT0603100KV05

ZD102

NC/VPORT0603100KV05

12

R112

NC/100OHM1/16W

R112

NC/100OHM1/16W

R118 NC/0R05 1/16WR118 NC/0R05 1/16W

R107

27K 1/16W 5%

R107

27K 1/16W 5%

L101

0.1uH

L101

0.1uH

R115

NC/27K 1/16W 5%

R115

NC/27K 1/16W 5%

C108

NC/47P 50V

C108

NC/47P 50V

C103

47P 50V

C103

47P 50V

C102 47N16VC102 47N16V

C106 10U 10VC106 10U 10V

A

B

C

CN121

JACK

A

B

C

CN121

JACK

2

1

4

3

6

5

7

R117

NC/4K7 1/16W 5%

R117

NC/4K7 1/16W 5%

R103

100OHM1/16W

R103

100OHM1/16W

R114

NC/27K 1/16W 5%

R114

NC/27K 1/16W 5%

R109

NC/100OHM1/16W

R109

NC/100OHM1/16W

R120

33 OHM 1/10W

R120

33 OHM 1/10W

R105

27K 1/16W 5%

R105