TOSHIBA 2060 Service Manual

SERVICE MANUAL

LARGE CAPACITY FEEDER

Click the Page Only button to close the overview area of the window.

Click the Bookmarks and Page button to open the Contents and

MP-4001

display bookmarks created for the document. Click a bookmark’s name

to go to the Page marked by that bookmark.

Click the Thumbnails and Page button to open the overview area and

display thumbnail images of each document page. Click a thumbnail to

go to the page marked by that thumbnail.

Copyright TOSHIBA CORPORATION 1995

ALL RIGHTS RESERVED

GENERAL PRECAUTIONS FOR INSTALLATION/SERVICING/

MAINTENANCE

1. When installing the Large Capacity Feeder MP-4001 to the Copier, be sure to follow the instructions

described in the “Unpacking /Set-Up Procedure for the MP-4001” sheet which comes with each unit

of the MP-4001. The MP-4001 should be installed by an authorized/qualified person.

2. The MP-4001 weighs about 18 kg (39.7 lbs.). When lifting or carrying

it, hold the plastic guide firmly with your right hand and (open the paper supply door) place your left hand under the top frame. Then lift or

carry the MP-4001.

3. Before starting installation, servicing or maintenance work, be sure to

turn off and unplug the copier first.

4. The MP-4001 is supplied with power from the copier, requiring no additional power source.

5. The MP-4001 should be grounded to the specified positions on the

machine frame.

6. When servicing or maintaining the MP-4001, be careful about the rotating or operating sections such as gears, pulleys, sprockets, cams,

belts, etc.

7. When parts are disassembled, reassembly is basically the reverse of

disassembly unless otherwise noted in this manual or other related documents. Be sure to reassemble small parts such as screws, washers, pins, E-rings, toothed washers to the correct places.

8. Basically, the machine should not be operated with any parts removed or disassembled.

9. Delicate parts for preventing safety hazard problems (such as thermofuses, door switches, sensors,

etc. if any) should be handled/installed/adjusted correctly.

10. During servicing or maintenance work, be sure to check the nameplate and other cautionary labels (if

any) to see if they are clean and firmly stuck. If not, take appropriate actions.

11. For the recovery and disposal of used MP-4001s, consumable parts and packing materials, it is

recommended that the relevant local regulations/rules should be followed.

12. Precautions Against Static Electricity

• The PC boards must be stored in an anti-electrostatic bag and handled carefully using a wrist-

band, because the ICs on them may be damaged due to static electricity.

Caution: Before using the wrist-band, pull out the power cord plug of the copier, and make sure

that there is no uninsulated charged object in the vicinity.

13. Use suitable measuring instruments and tools.

Copyright TOSHIBA CORPORATION 1997

ALL RIGHTS RESERVED

MP-4001

Service Data

MECHANICAL

I. SPECIFICA TIONS AND FEATURES

The large-capacity feeder MP-4001 is a slideable floor-type feeder which can hold up to 4,000 sheets of

Toshiba recommended paper (A4 or Letter size). Since the MP-4001 can slide away from the copier,

paper misfeeds inside the copier can be easily handled. The MP-4001 is equipped with a paper feeding

mechanism, elevator-tray drive mechanism, safety switches, etc., providing a self-contained large-capacity feeder.

1.1 Specifications

Type ......................................... Hanging type

Acceptable Type of Paper........ Size : Letter (8-1/2" x 11") – For North America

: A4 (210 mm x 297 mm) – For Europe and other areas

Weight : 64 g/m2 (17 lbs) – 80 g/m2 (22 lbs)

Maximum Number of Sheets

Accommodated .................... Approx. 4,000 (Toshiba-recommended paper)

Dimensions .............................. W300 (including the portion which enters the copier)

x D478 x H728 mm (Approx. 11.8" x 18.8" x 28.5")

Weight...................................... Approx. 18 kg (39.7 lbs) with no paper loaded

Power Supply........................... DC 24 V and DC 5 V

(Power is supplied from the copier)

Specifications are subject to change without notice.

1.2 Features

This large-capacity paper feeder can be used with Toshiba Copiers and offers the following features.

1. Paper supply of up to 4,000 sheets (A4 or Letter size), which allows you to make a large number of

copies continuously without reloading copy paper.

2. Simple reloading of copy paper.

3. Easy of paper jam removal.

Nov. 1997 © TOSHIBA 1 - 1 MP-4001 MECHANICAL

II. FRONT SECTIONAL AND OTHER VIEWS

2.1 Front Sectional View

Tray-up sensor

Feed roller

Separation roller

Pick-up roller

Paper-empty sensor

Tray-up sensor actuator

(part of the pick-up roller holder)

Paper-empty sensor actuator

Elevator drive wires

Elevator tray

Wire take-up pulleys

Wire fixing stay

Tray bottom sensor actuator

Tray bottom sensor

Tray up-down motor

Nov. 1997 © TOSHIBA 2 - 1 MP-4001 MECHANICAL

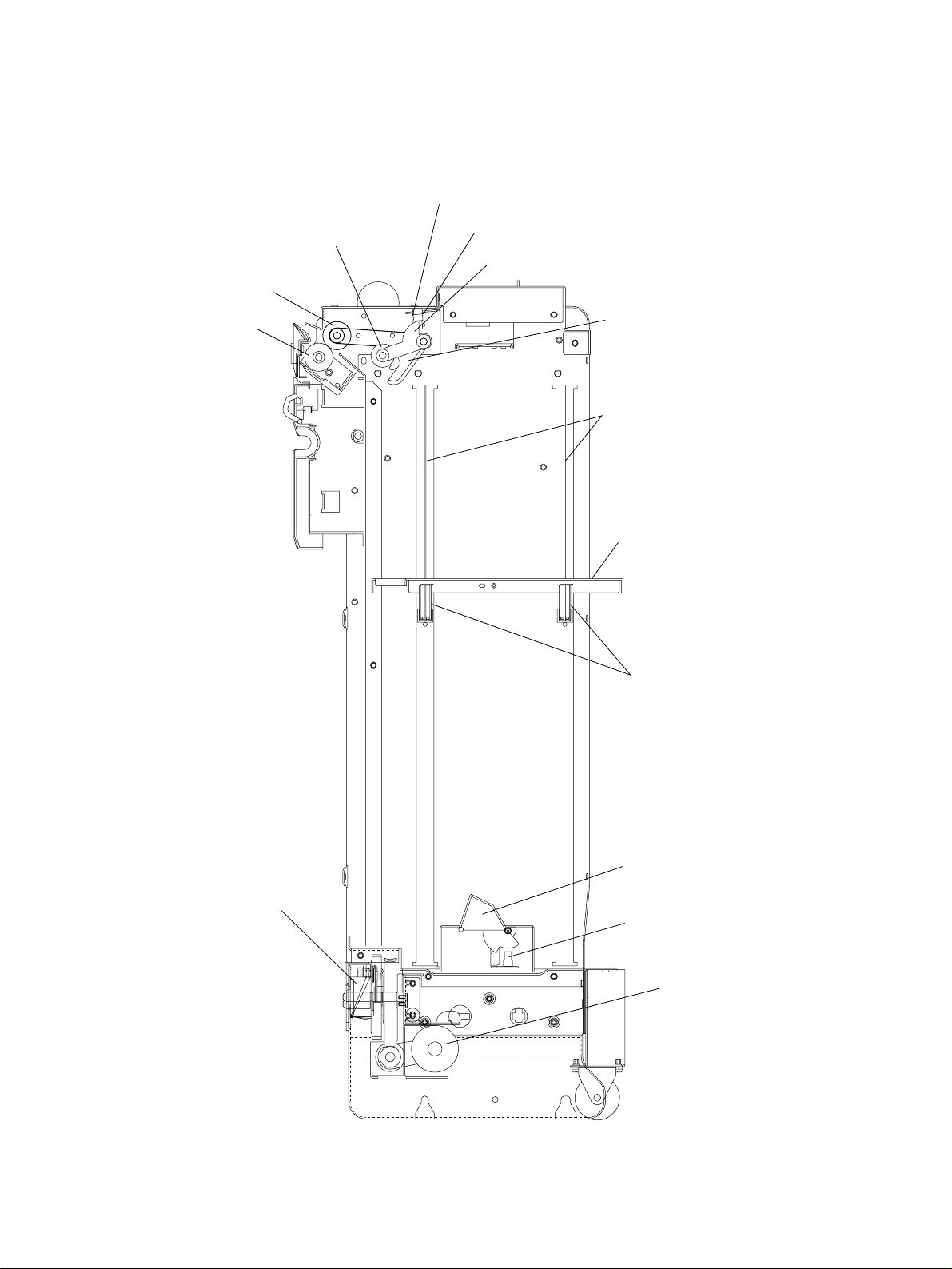

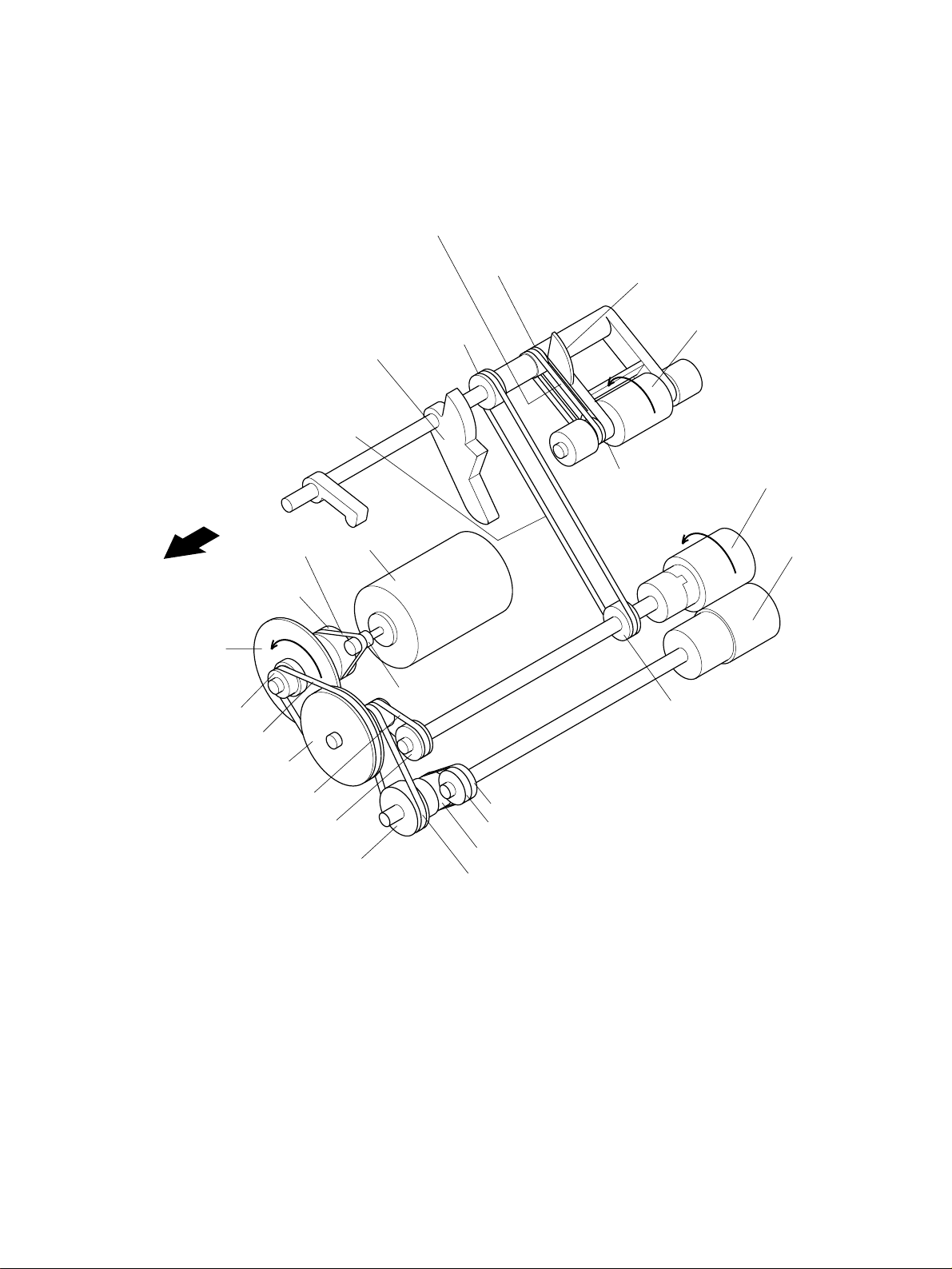

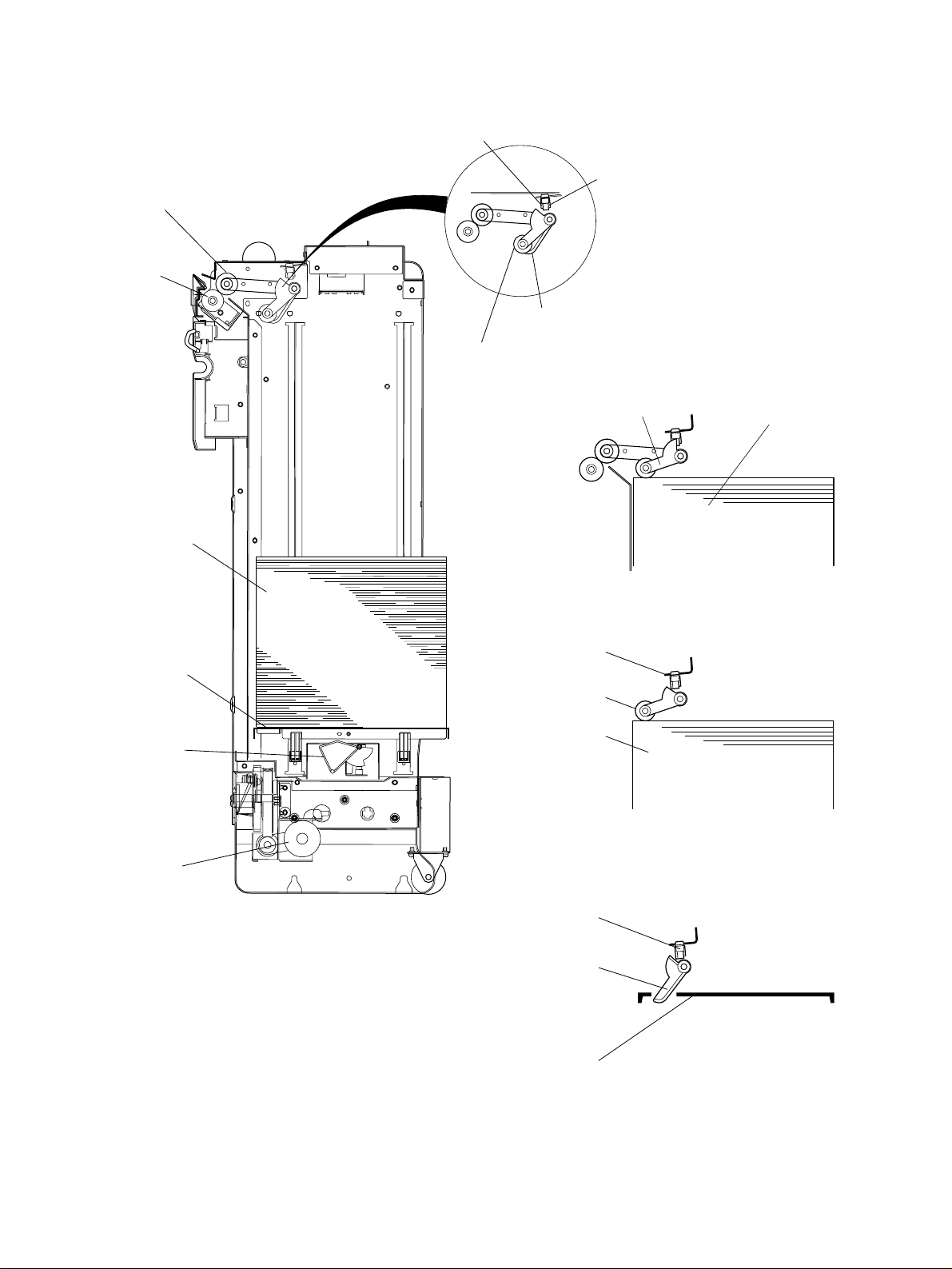

2.2 View of the Elevator Drive Mechanism

Note: The elevator wires on the rear side are arranged in the same way as on the front.

Wire guide pulleys (front)

Elevator wires (front)

Elevator tray

Side pulley (front)

Front

Elevator wire (rear)

Wire fixing stays

(attached to the tray)

Wire take-up pulleys

Tray drive gear

Belt

Tray drive motor

Upward direction

Worm gear

MP-4001 MECHANICAL 2 - 2 Nov. 1997 © T OSHIBA

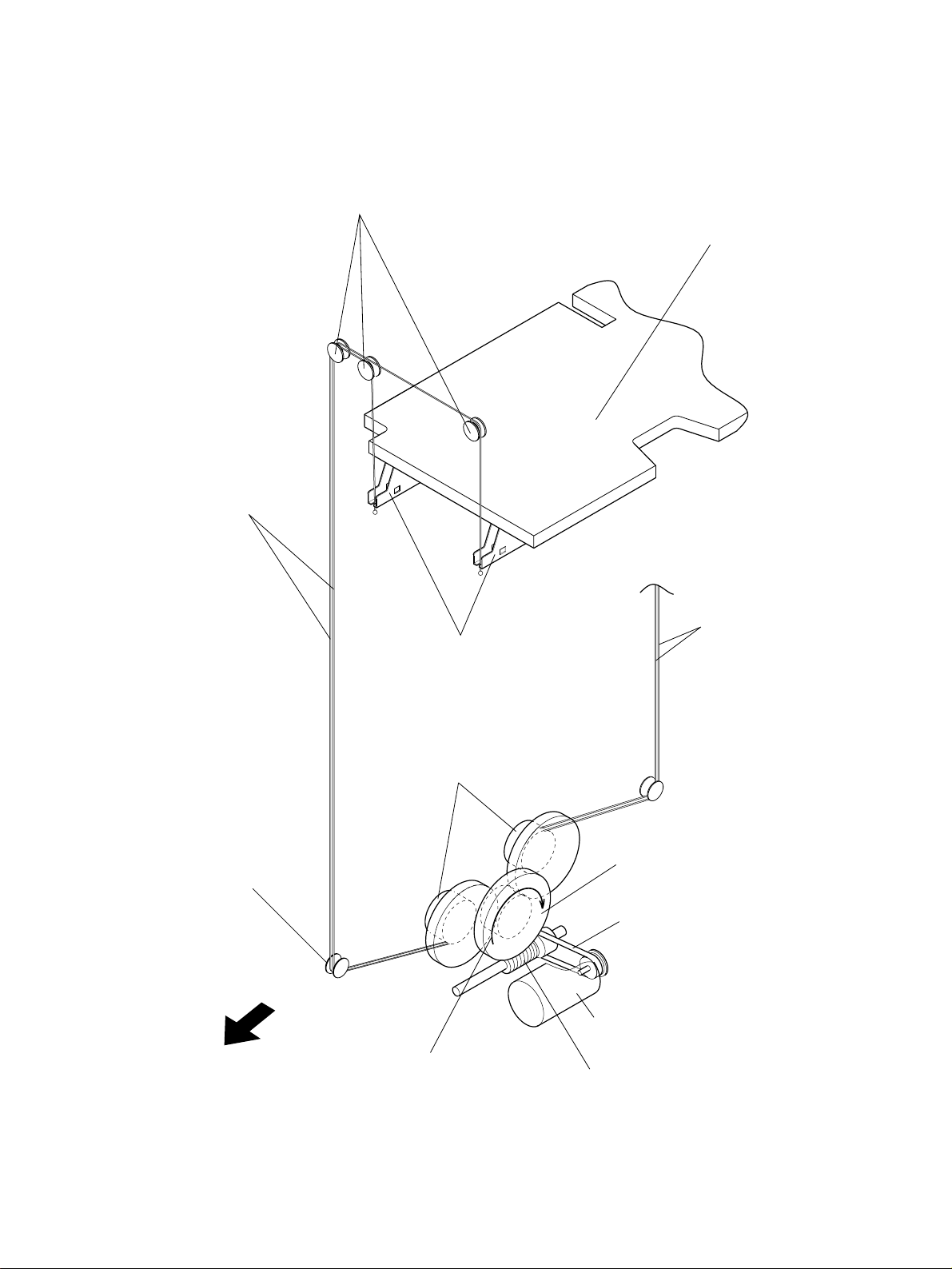

2.3 View of the Paper Feed Mechanism

TB (Z57/P2)

Rear side

FG pulse disc

Paper-empty sensor actuator

TB (Z96/P2)

TB (Z44/P2)

TP30

TP20

TB (Z76/P2)

Feed motor

TP10

TP20

TP20

Tray-up sensor actuator

Pick-up roller

TP20

TP20

Paper feed roller

Separation roller

TP58/TP20

TB (Z40/P2)

TP20

TP30

Nov. 1997 © TOSHIBA 2 - 3 MP-4001 MECHANICAL

TB (Z40/P2)

TP20

TP20

TB (Z64/P2)

* TB: Timing belt

* TP: Timing pulley

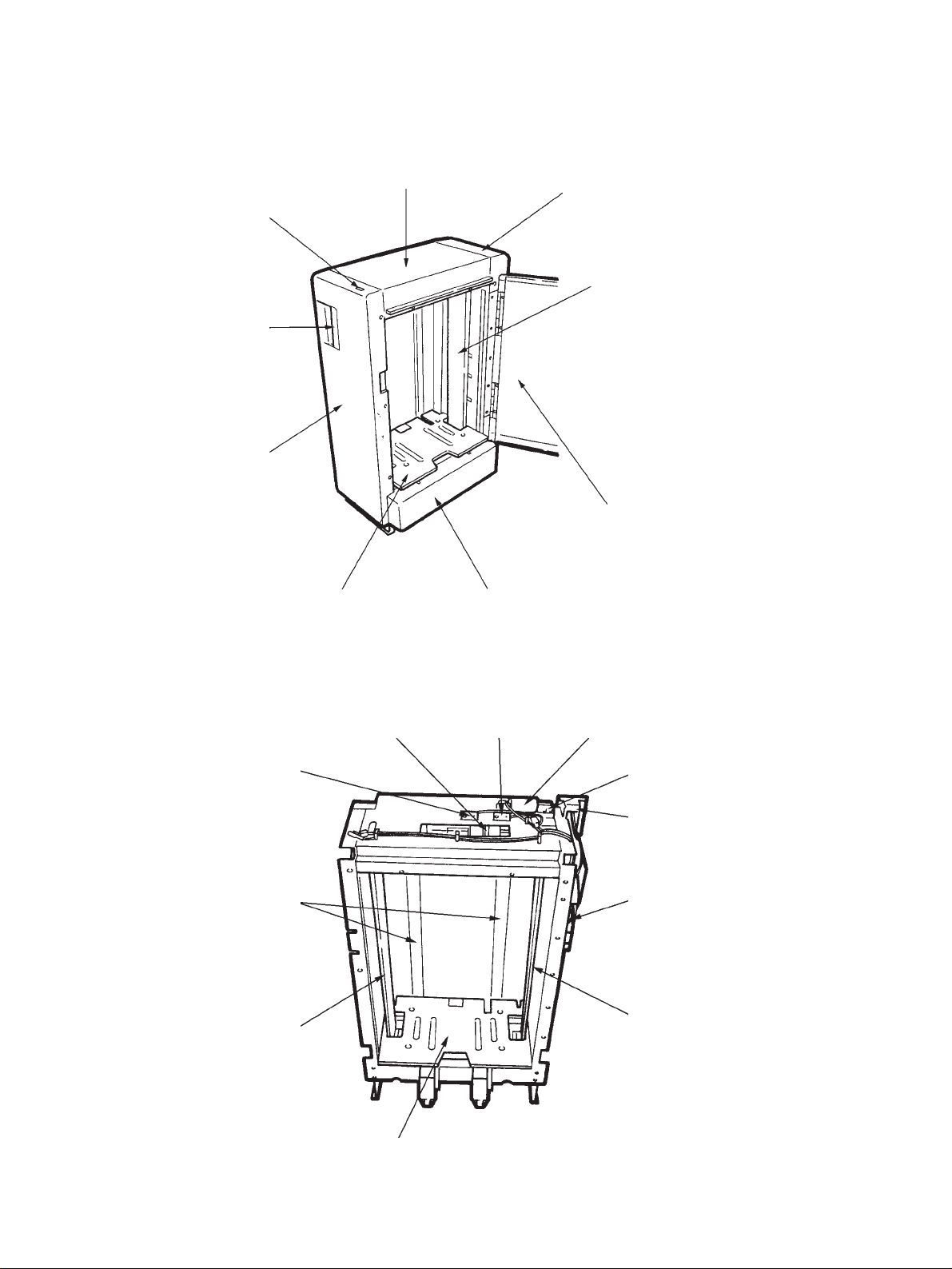

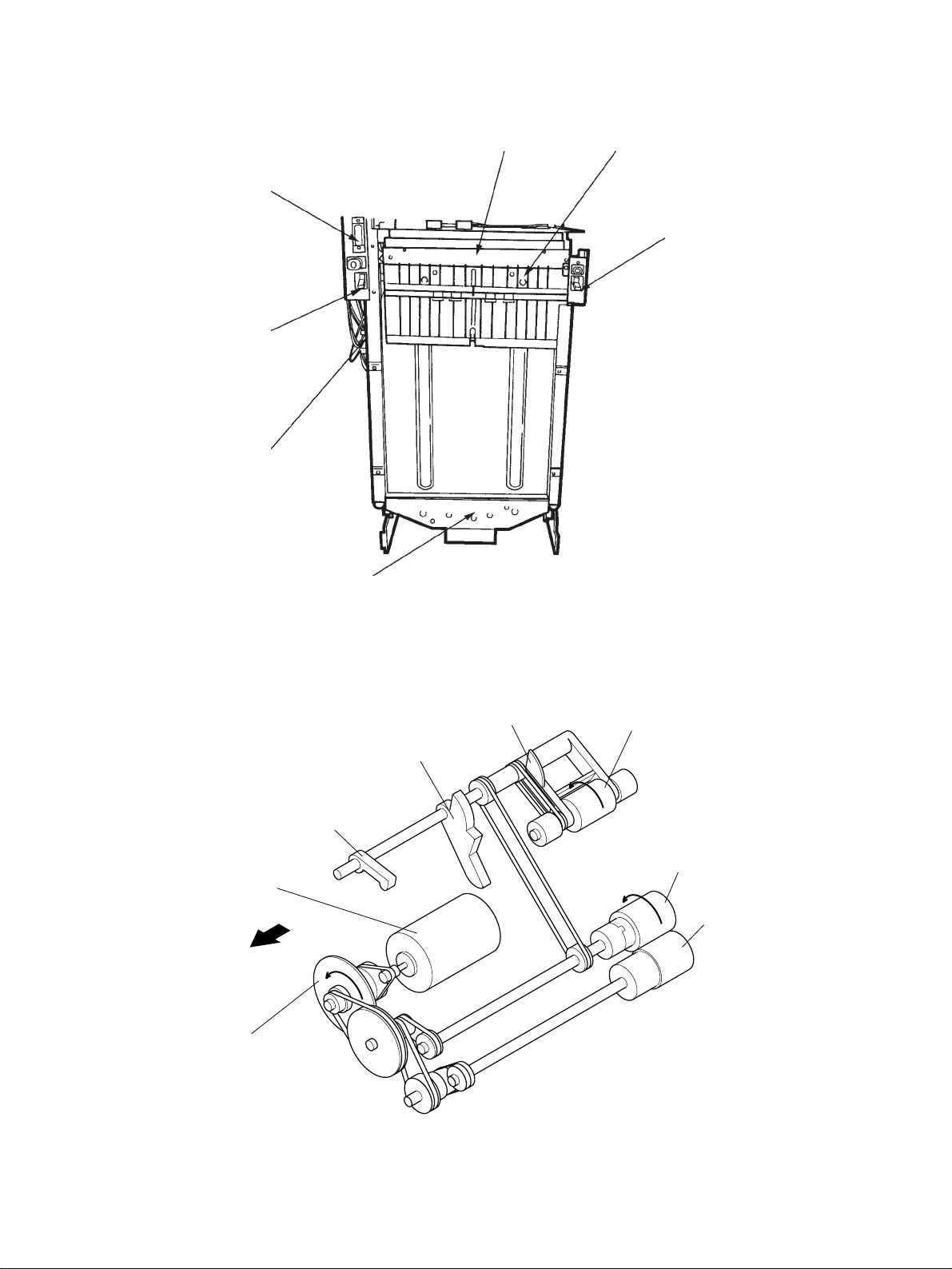

III. NAMES OF MAIN COMPONENTS

3.1 General View

Top cover

TRAY DOWN switch

Handle

Front cover

Rear cover

Paper-edge guide (rear)

Paper supply door

Elevator tray

3.2 Top Side/Inner Side Parts

Paper feed section

(Refer to para. 3.6.)

Tray-up sensor

Paper guides

(integral ribs)

Paper-edge guide (front)

Bottom cover

Empty sensor

Paper feed motor

FG pulse sensor

Joint connector (J780)

PC board (PWA-DRV-789)

Paper-edge guide (rear)

Elevator tray

Nov. 1997 © TOSHIBA 3 - 1 MP-4001 MECHANIAL

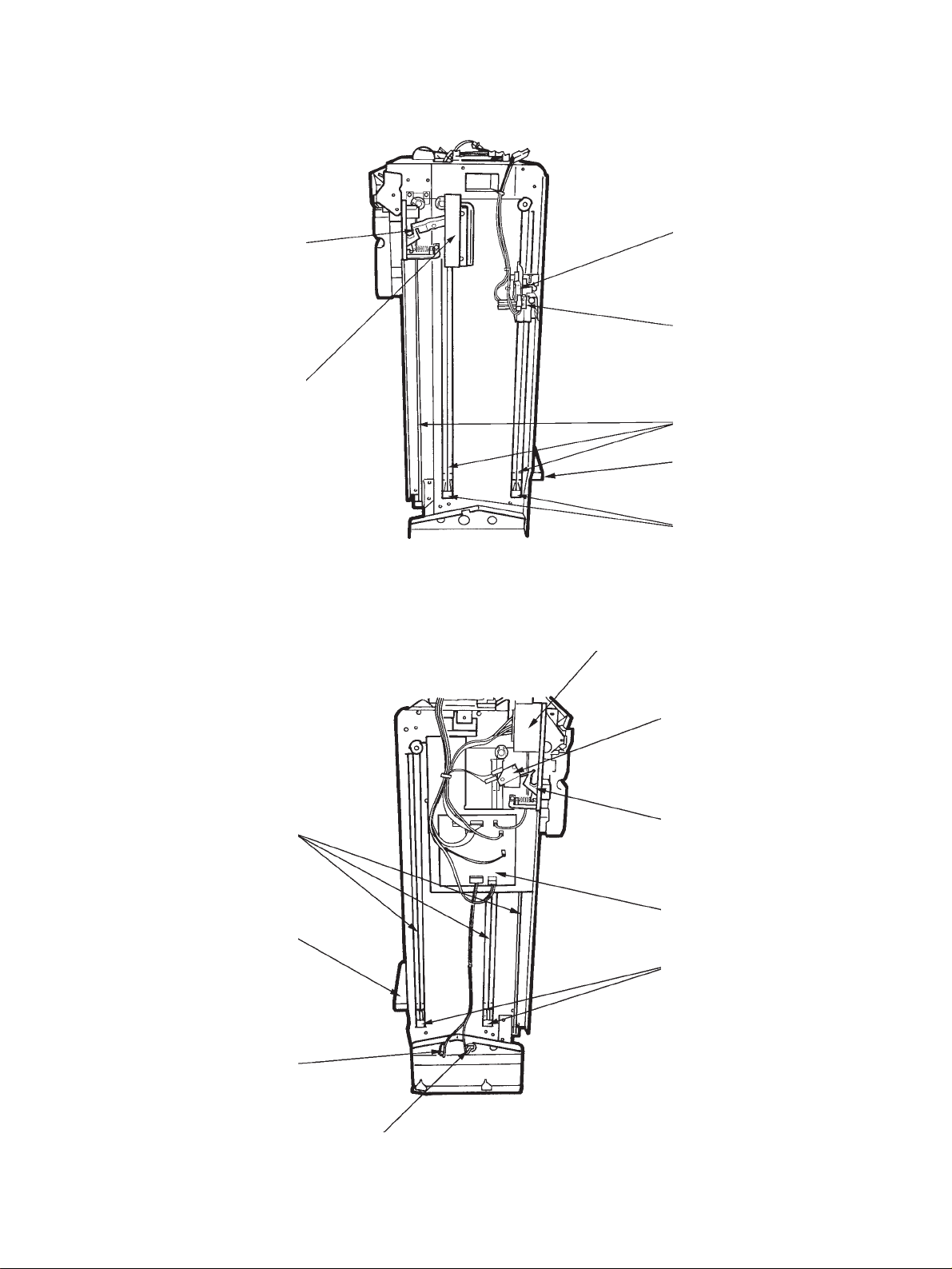

3.3 Front Side Parts

Latch lever

Latch handle

3.4 Rear Side Parts

Door switch

Safety switch

Elevator wires

Elevator tray

Wire fixing clips

(for elevator tray)

Joint connector (J780)

Elevator wires

Elevator tray

Tray motor connector

Lower-limit sensor connector

Joint switch

Detach lever

PC board (PWA-DRV-789)

Wire fixing clips

(for elevator tray)

MP-4001 MECHANIAL 3 - 2 Nov. 1997 © TOSHIBA

3.5 Back Side (Copier Side) Parts

Joint connector (J780)

Latch

PC board (PWA-DRV-789)

Wire drive unit

Upper paper guide

Lower paper guide

Latch

3.6 Paper Feed Section Parts

Paper-empty sensor actuator

Stopper

Paper feed motor

Rear side

FG pulse disc

Tray-up sensor actuator

Pick-up roller

Paper feed roller

Separation roller

Nov. 1997 © TOSHIBA 3 - 3 MP-4001 MECHANIAL

IV. DESCRIPTION OF OPERATION

4.1 Elevator Tray Up-and-Down Operation

When sheets of paper (up to 4,000) are placed on the elevator tray and the paper feed door is closed, the

elevator motor is energized, moving the elevator tray upward via the elevator tray drive mechanism (Fig.

4.1-1). A few seconds later, the paper on the elevator tray actuates the paper empty sensor , causing the

LCF symbol on the screen to stop flashing. The elevator tray further moves up and pushes up the pickup roller a part of whose holder comprises the tray-up sensor actuator. It in turn actuates the tray-up

sensor, causing the elevator tray to come to a stop. This is the initial paper feeding position. See Fig. 4.1-

2.

When the PRINT key is pressed on the copier , the LCF paper feed motor energizes and rotates the pickup roller and the feed/separation roller pair, causing the top sheet of paper to feed toward the copier.

After a fixed interval, the next sheet is fed to the copier. This continues until 10 – 20 sheets of paper are

fed, causing the pick-up roller to move down enough to de-actuate the tray-up sensor (Fig. 4.1-3). Then

the elevator motor energizes again to move up the elevator tray 2 – 3 mm to the initial paper feeding

position.

This operation continues until the final sheet of paper on the elevator tray is fed out into the copier. Then

the paper empty sensor actuator drops into a hole in the elevator tray, de-actuating the paper empty

sensor (Fig. 4.4-4). This in turn energizes the elevator motor to move the elevator tray downward. When

the elevator tray actuates the tray bottom sensor, it stops at the paper adding position and causes the

LCF symbol on the screen to flash.

Note: When the TRAY DOWN switch is pressed, the tray motor also energizes to move down the elevator tray even if sheets of paper are still left on the elevator tray , and de-energizes when the elevator tray

actuates the bottom sensor.

While the elevator tray is moving down, if the paper supply door is opened, the tray motor also deenergizes to stop the elevator tray immediately . When the door is closed, the tray motor again energizes

to move the tray up to its paper feeding position.

MP-4001 MECHANICAL 4 - 1 Nov. 1997 © TOSHIBA

Feed roller

Separation roller

Tray-up sensor

Empty sensor

Empty sensor actuator

Pick-up roller

Paper

Elevator tray

Tray bottom

sensor actuator

Tray up-sensor

Pick-up roller

Paper

Pick-up roller

Paper on the tray

Fig. 4.1-2

Fig. 4.1-3

Tray motor

Empty sensor

Fig. 4.1-1

Empty sensor

actuator

Elevator tray

Fig. 4.1-4

Nov. 1997 © TOSHIBA 4 - 2 MP-4001 MECHANICAL

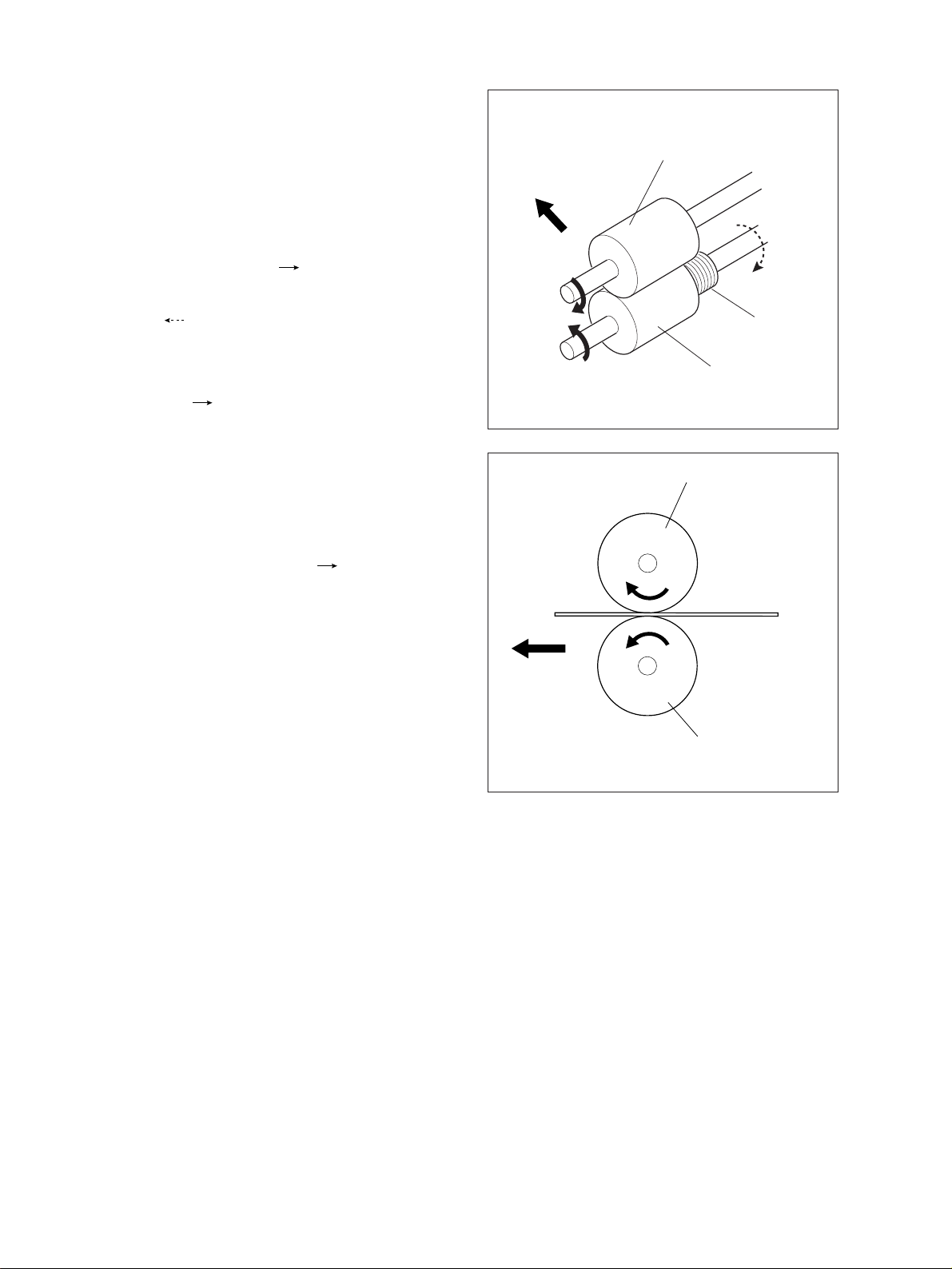

4.2 Elevator Tray Drive System

The elevator tray motor, which is located at the bottom of the LCF, moves up and down the elevator tray

through elevator wires at the front and rear. When the elevator motor energizes to rotate the wire drive

gear via a belt and worm in the direction of the arrow ( ), the wire drive gear rotates the front and rear

wire take-up pulleys in the direction of each arrow ( ). The wire take-up pulleys then wind up the wires

to move the elevator tray upward until the paper empty sensor is activated.

When the paper on the elevator tray is exhausted or when the TRAY DOWN switch is pressed, the

elevator tray motor energizes in a reverse direction, causing the wire take-up pulleys to rotate in the

direction of each arrow (

). This causes the wire take-up pulleys to unwind the wires, allowing the

elevator tray to move downward until it actuates the tray bottom senor.

While moving up or down, the elevator tray also comes to a stop if the paper supply door is opened or if

the TRAY DOWN switch is pressed.

Elevator tray

Elevator wires

(front)

Wire take-up

pulley (rear)

Wire take-up

pulley (front)

Elevator wires

(rear)

Belt

Worm

Wire drive gear

Elevator tray motor

Fig. 4.2

MP-4001 MECHANICAL 4 - 3 Nov. 1997 © TOSHIBA

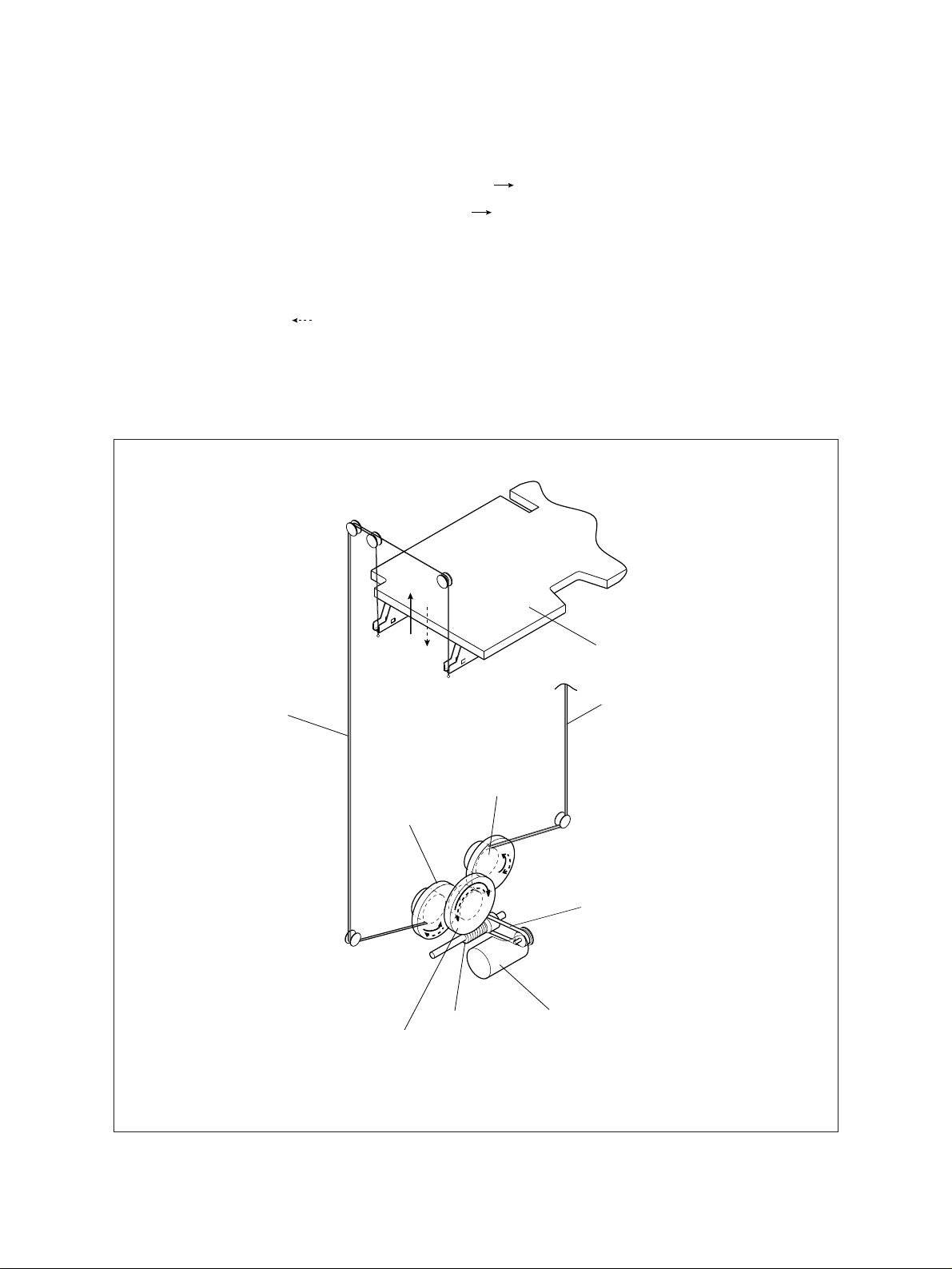

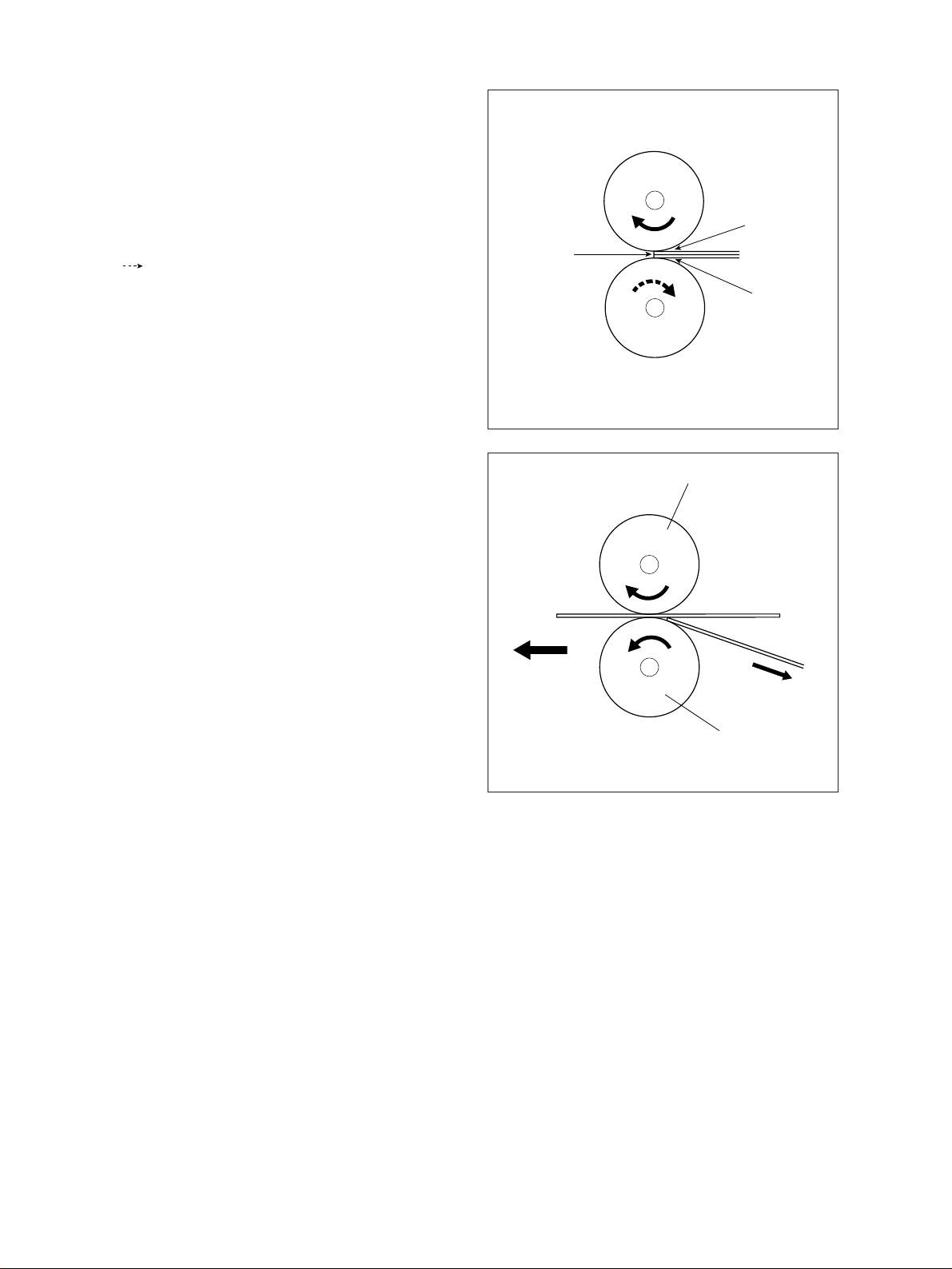

4.3 Paper Feeding Operation

When the PRINT key is pressed with the elevator tray at the paper feeding position, the LCF paper feed

motor energizes to cause the feed roller to rotate in the direction of the arrow( ) through pulleys and

belts. The separation roller is similarly driven but in the direction of the arrow ( ) with a light force. The

pick-up roller is driven by the feed roller shaft via pulleys and belts in the direction of the arrow ( ) and

picks up the top sheet of paper on the elevator tray to the feed/separation roller pair. Even if more than

one sheet is picked up by the pick-up roller, only the top sheet is sent toward the copier with other sheets

rejected by the feed/separation roller pair (for details, refer to the next paragraph).

Pick-up roller

Feed roller

One-way clutch

Feed motor

Separation roller

Rear side

Spring clutch

(torque limiter)

Paper

One-way clutch

Fig. 4.3

Nov. 1997 © TOSHIBA 4 - 4 MP-4001 MECHANICAL

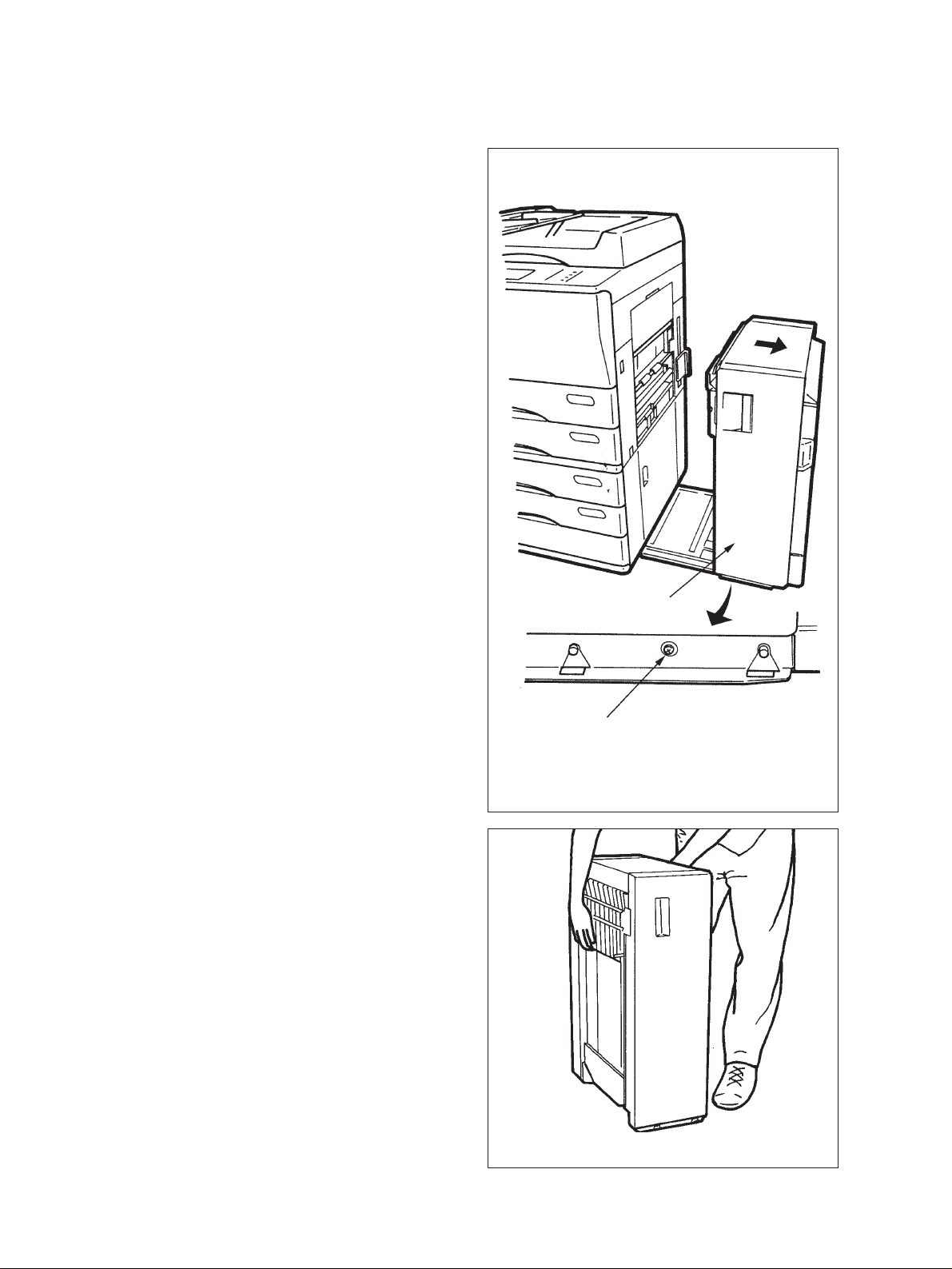

4.4 Paper Separation Function

With this LCF, the following paper separation

mechanism is employed to prevent multiple feeds

and to securely feed sheets one by one to the

copier.

The feed roller is rotated by the feed motor in the

The direction of

Paper feed roller

paper feeding

direction of the arrow (

). The separation roller

is driven with a light force in the direction of the

arrow ( ) via a spring joint (torque limiter). However, when there is no paper between both rollers,

the separation roller is rotated in the direction of

the arrow ( )by the friction between both rollers.

See Fig. 4.4-1.

When a sheet of paper picked up by the pick-up

roller enters between the feed and separation rollers, friction between the paper and each roller is

high, thus forcing the separation roller to be rotated

in the direction of the arrow ( ) and the paper to

be sent toward the copier. See Fig. 4.4-2.

Spring joint

(torque limiter)

Separation roller

Fig.4.4-1

Paper feed roller

Separation roller

Fig.4.4-2

MP-4001 MECHANICAL 4 - 5 Nov. 1997 © TOSHIBA

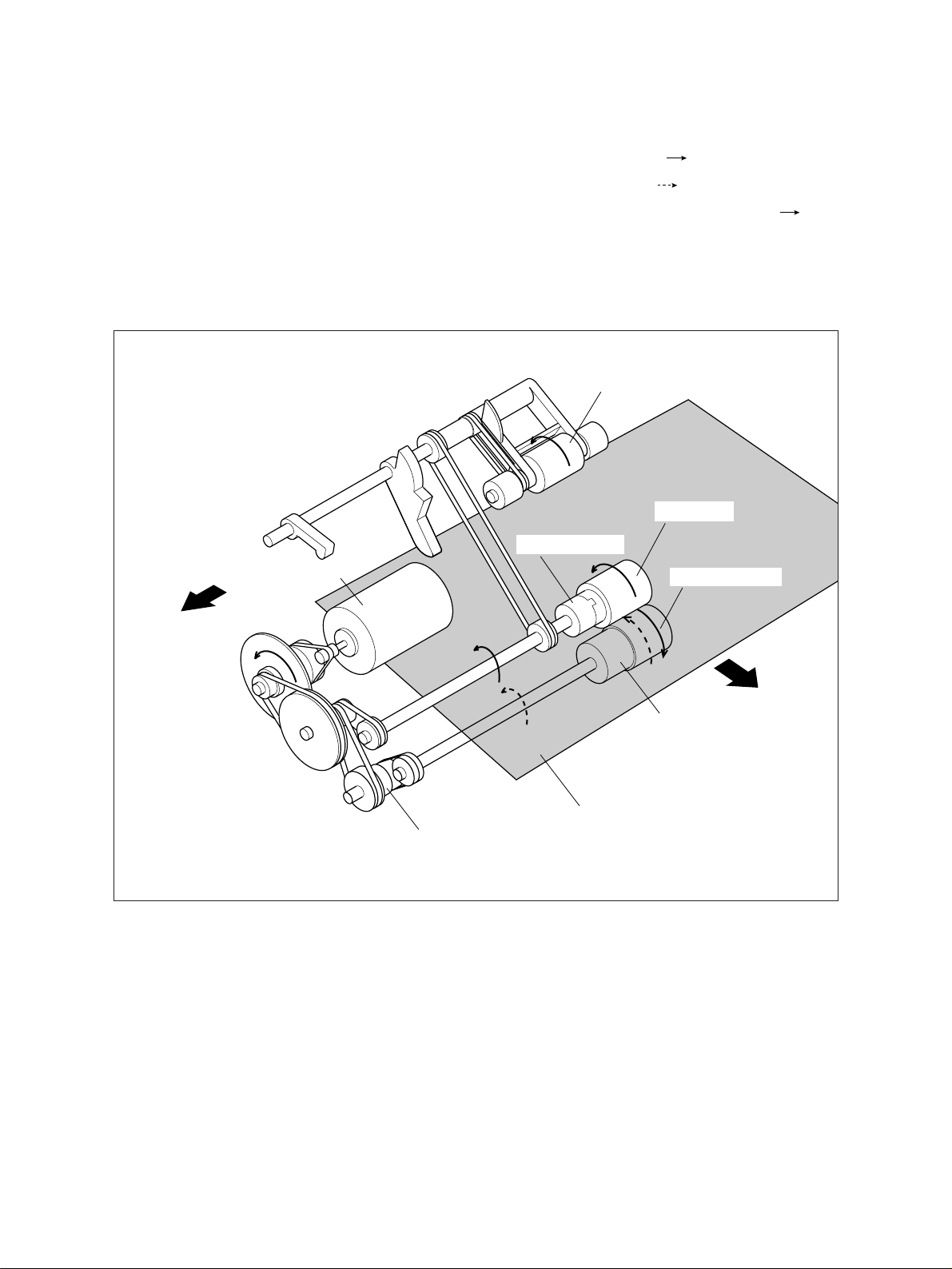

If two (or more) sheets are picked up and enter

between the rollers, friction between the upper

sheet and the feed roller and that between the lower

sheet and separation roller are high, but friction

between both sheets is low, thus allowing the separation roller to rotate in the direction of the arrow

). See Fig. 4.4-3. This will cause the upper

(

sheet to be carried toward the copier but the lower

sheet is pulled back to the elevator tray (see Fig.

4.4-4), thus eliminating double or multiple feeds.

High friction

Low friction

High friction

Fig.4.4-3

Paper-feed roller

Separation roller

Fig.4.4-4

Nov. 1997 © TOSHIBA 4 - 6 MP-4001 MECHANICAL

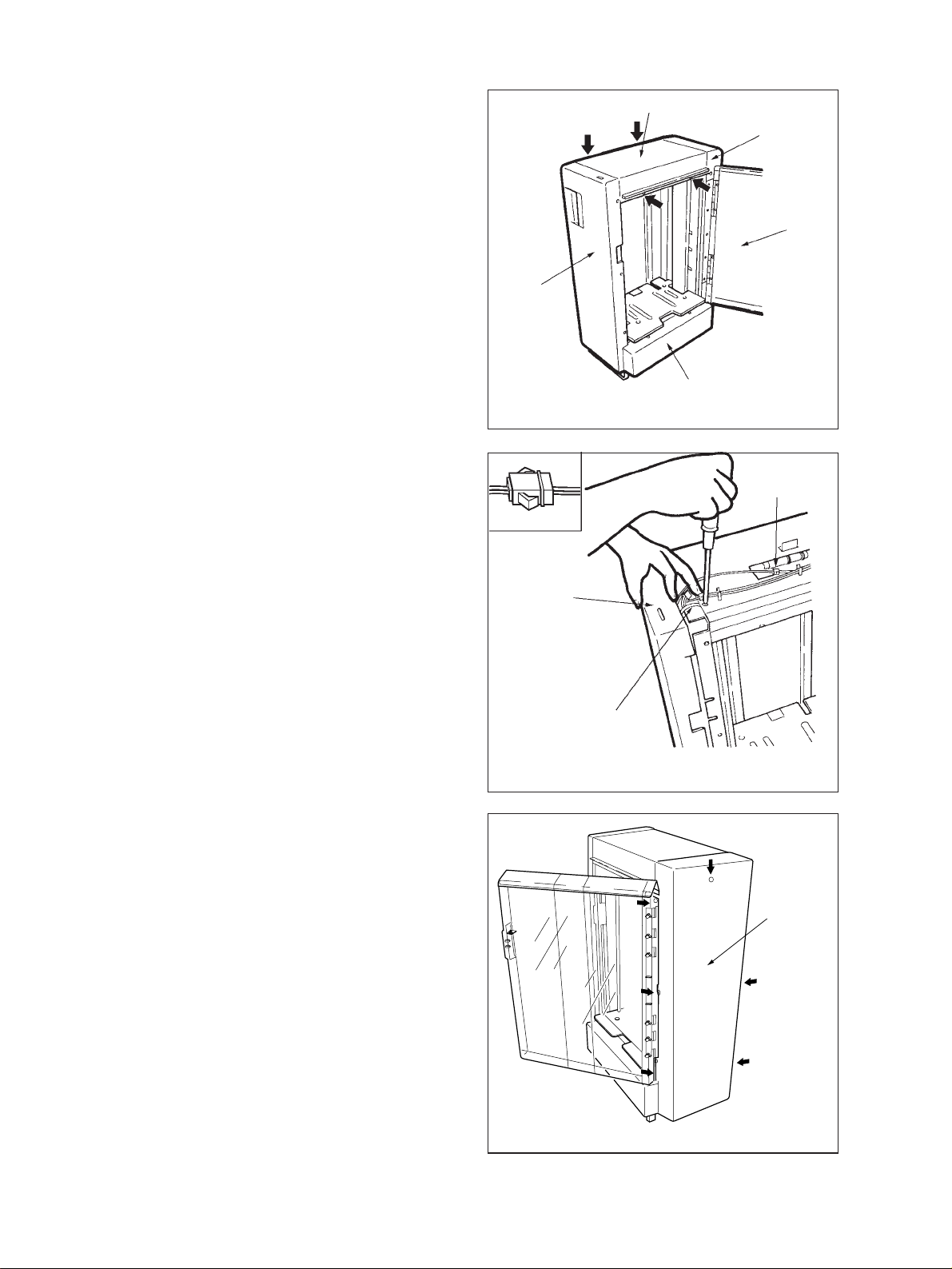

V. REMOVAL OR REPLACEMENT OF VARIOUS PARTS

5.1 Removing the LCF Unit

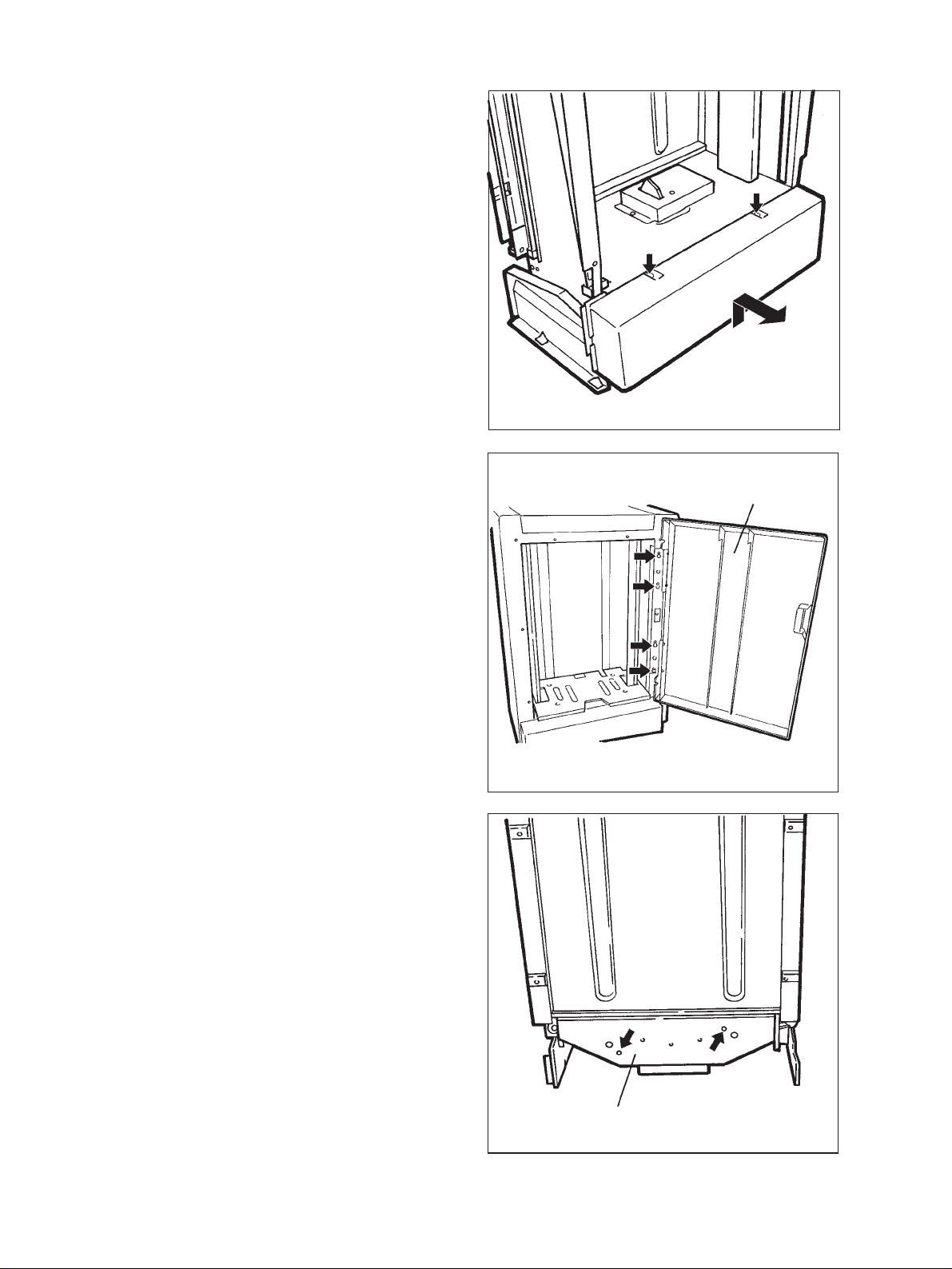

(1) Holding the LCF handle on the front side, move

the LCF unit away from the copier.

(2) Remove the screws fastening the LCF unit to

its slide rail unit on the front and rear.

(3) Open the LCF paper supply door.

(4) Hold the LCF unit firmly and lift the LCF unit

out of the slide rail.

LCF unit

Screw

Fig. 5.1-1

Fig. 5.1-2

Nov. 1997 © TOSHIBA 5 - 1 MP-4001 MECHANICAL

5.2 Removing Various Covers

[A] Top cover

(1) Opening the paper supply door, remove two

screws (a) and loosen two screws (b).

(2) Lift out the top cover.

[B] Front cover

(1) Remove the top cover, referring to [A].

(2) Remove the screw fastening the mylar seal to

the top frame and disconnect one connector.

(3) Loosen the six screws fastening the front cover

and pull it out toward you.

Top cover

Rear cover

Paper supply

door

Front cover

Bottom cover

Fig. 5.2-1

Connector

Front cover

Note: Since various electrical components are

mounted on the inside of the front cover, be careful

not to damage them.

[C] Rear cover

(1) Opening the paper supply door, loosen six

screws and remove the screw fastening the rear

cover.

(2) Pull out the rear cover toward the rear.

Mylar seal

Fig. 5.2-2

Rear cover

Fig. 5.2-3

MP-4001 MECHANICAL 5 - 2 Nov. 1997 © T OSHIBA

[D] Bottom cover

(1) Opening the paper supply door, remove the two

screws fastening the bottom cover.

(2) Lift and remove the bottom cover toward you.

[E] Paper supply door

Fig. 5.2-4

(1) Opening the paper supply door, loosen the four

screws fastening its hinge plate to the LCF

frame.

(2) Lift out the paper supply door.

5.3 Removing and Installing the Eleva-

tor Wires

[A] Removing the elevator wires

(1) Press the TRAY DOWN switch to make the el-

evator tray move down to the lowest position.

Paper supply door

Fig. 5.2-5

Turn off the copier’s power switch and pull away

the LCF unit from the copier.

(2) Remove the LCF top cover, front cover and rear

cover.

(3) Remove the drive cover (2 screws). See Fig.

5.3-1.

Drive Cover

Fig. 5.3-1

Nov. 1997 © TOSHIBA 5 - 3 MP-4001 MECHANICAL

Loading...

Loading...