Page 1

6F8C1111

V

Integrated Controller

series

model 2000

Computer module C2PU37 User’s Manual

Page 2

Important Information

No patent liability is assumed by TOSHIBA Corporation with respect to use of information, illustrations, circuits,

equipment or examples of application in this publication.

TOSHIBA Corporation reserves the right to make changes and improvements to this publication and/or related

products at any time without notice. No obligation shall be incurred other than as noted in this publication.

This publication is copyrighted and contains proprietary material. No part of this book may be reproduced, stored

in a retrieval system, or transmitted, in any form or by any means ? electrical, mechanical, photocopying,

recording, or otherwise ? without obtaining prior written permission from TOSHIBA Corporation.

PROSEC, TOSLINE and TOSDIC are trademarks or registered trademarks of TOSHIBA Corporation.

IBM is a registered trademark of International Business Machines Corporation.

Microsoft, Windows, WindowsNT and Windows2000 are registered trademarks of Microsoft Corporation in the

U.S.A. and other countries.

The formal name of Windows is Microsoft Windows Operating System.

Intel and Pentium are the registered trademarks or trademarks of Intel Corporation in the U.S.A. and other

countries, and a subsidiary.

Ethernet is a registered trademark of Xerox Corporation.

DeviceNet is a trademark of the Open DeviceNet Vender Association, Inc.

C

◯

TOSHIBA CORPORATION 2004.

All rights reserved.

Page 3

Safety Precautions

This manual contains important information for the operator to operate this product safely and correctly

and avoid bodily injury and property damage.

Grasp the meanings of the following marks and their descriptions before reading this manual.

lHazard Classifications

WARNING

CA CAUTION

(Note) 1. Serious injury means loss of sight, injury, burns (high temperature, low temperature),

electrical shock, fracture, or intoxication which leaves aftereffects or requires hospitalization

or need to go the hospital for a long time.

2. Injury means hurt, burn, or electric shock which does not require hospitalization or going to

the hospital for a long time.

3. Property damage means extended breakdown of assets and materials.

lNotation of Markings

Indicates a potentially hazardous situation which, if not avoided, could result in

serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, can result in

minor or moderate injury, or property damage. It can also be used to alert

against unsafe practices.

(Note) The descriptions of forbiddance, mandatory, and caution marks are subject to change,

depending on the labels on the main unit.

Indicates a "may not" mark.

The concrete forbiddance is indicated with a pictograph or wording.

Indicate a mandatory action that you should never fail to do.

The concrete content is indicated inside or near the circle with a pictograph

or wording.

Indicates a caution.

The concrete content is indicated inside or near the triangle.

6F8C1111

i

Page 4

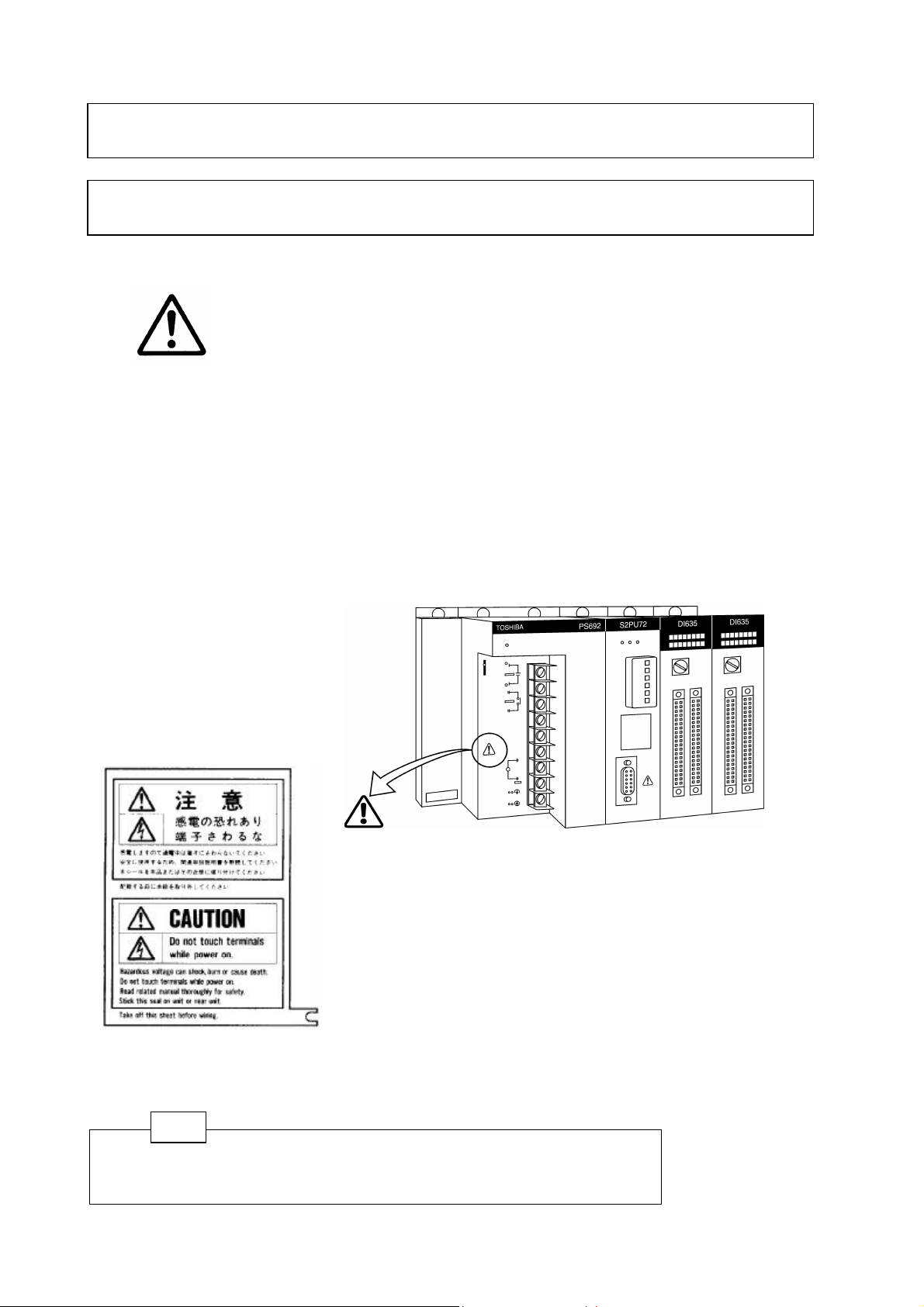

The safety label as shown on the left both in Japanese and English

is attached to the power supply terminal of the model 2000. (exept

Peel off either of the Japanese and English labels from the mount

paper and stick it to the model 2000 or near the power terminal

where it can be readily seen.

Markings used on the model 2000 and in this Manual

1.

Make sure warning markings are attached on the model 2000.

If any of them are missing or the wording is illegible, contact Toshiba’s Service Department

[Warning Mark on the model 2000]

This is the warning mark for dangerous location. It is attached to the

equipment at positions where there is a risk of electric shock and at positions

where there is a risk of damage to the equipment through incorrect wiring.

Take the following precautions where this mark is found.

(1) Keep hands away from terminals, especially the input terminal of the power supply while power is

on, to avoid the risk of electric shock.

(2) Turn off power before installing or removing modules, terminal blocks, or wires.

(3) Applying excess power voltage to the model 2000 can cause failure or malfunction. Apply power of

the specified ratings described in this manual.

(4) Turn off the power of the tool (a personal computer, etc.) before connecting the connector to the

tool port. Afterwards, turn on power.

Avoid short-circuiting between the tool connector pins with the cover, etc.

[Safety Label]

the 24Vdc input power supply module)

Remove the mount paper before wiring

In the event the seal is damaged, contact the dealer.

Notes

Marks printed at pages in this manual should always be read carefully.

Be sure to read them in handling your model 2000.

ii

Computer module C2PU7 User’s Manual

Page 5

2. Precautions on Installation

WARNING

Mandatory

Be sure to ground the model 2000. The

protective ground terminal of the model 2000

must be connected to an external protective

earth.

Operation without grounding may cause

accidental fire or shock.

CAUTION

Mandatory

Avoid the following locations when installing or

storaging the model 2000.

•

Locations where there is dust, salinity or ion

particles

•

Locations where there are corrosive gases

(SO2, H2s) or flammable gases

•

Locations where vibration or shock occurs

beyond the allowance

•

Locations where there is condensation due

to sharp temperature variations

•

Locations where the ambient temperature

exceeds the allowance range

•

Locations where the relative humidity

exceeds the allowance range

•

Locations where the model 2000 is exposed

to direct sunlight

•

Locations where strong electric radiation or

magnetic field is generated

Mandatory

Improper the installation or wiring of the

system can cause not only insufficient

performance but also malfunction and failure of

the model 2000.

Installation in an unspecified direction or

improper installation can cause fall-off, fire,

interference, or malfunction of the model 2000.

Mandatory

Install the model 2000 at a place where

maintenance and inspection are easy to do.

Otherwise, recovery from failure may take

much more time, leading to a serious accidents.

Forbidden

Do not cover the hole of the model 2000, and

the ventilator/air inlet of the system.

Otherwise, overheating, etc. can cause fire or

malfunction.

Mandatory

Avoid entering wire scraps or other foreign

debris into the model 2000, and related

equipment. Otherwise, it can cause fire, failure

or malfunction.

6F8C1111

iii

Page 6

3. Precautions on Wiring

WARNING

Mandatory

Be sure to turn off power before wiring.

Otherwise, it can cause electric shock or

malfunction of the model 2000.

CAUTION

Mandatory

Apply power of the specified ratings

described in the manual.

Applying excess power voltage to the model

2000 can cause explosion or fire.

Mandatory

Be sure to use crimp-style terminal with

insulating sheath or insulating tape to cover

the conductive parts when wiring modules so

that no conductive parts are exposed.

Handle the terminal cover with care so as not

to fall off or get damaged.

Be sure to fix the cover on the terminal block

after wiring.

An exposed conductive part can cause

electrical shock.

Mandatory

It is assumed that the users have general

knowledge of industrial electrical control

systems.

iv

Computer module C2PU7 User’s Manual

Page 7

4. Precautions for Operation

WARNING

Mandatory

Configure emergency stop interlocking circuit

outside the model 2000. Otherwise, failure and

malfunction of the model 2000 can cause

human injury, machine damage or serious

accidents.

CAUTION

Forbidden

The power supply modules, the CPU modules,

the direct I/O modules and the expansion

interface are dedicated to the model 2000.

Mount them on the bases of the model 2000.

Do not use them by themselves for other

purposes.

Otherwise, it can cause electrical shock or

injury or malfunction.

Mandatory

Mount the modules on the base securely until

they click, and fix them on the base with

screws.

Insufficient installation can cause failure or

malfunction.

Mandatory

Sample programs and circuits described in

this manual are provided for explaining the

operations and applications of the S2.

You should test completely before using

them as a part of your application system.

Mandatory

Be sure to keep the terminal block covers

closed during power ON. Do not touch the

terminals. Otherwise, it can cause electrical

shock or injury.

Mandatory

When you attempt to perform program change,

forced output, RUN/HALT controls, etc during

operation, carefully check for safety.

Improper operation or negligence in checking

safety conditions can cause machine damage

or serious accidents.

Mandatory

Set the operating switches of the model

2000 according to this manual.

Improper setting can cause failure or

malufunction.

Mandatory

Install fuses suited to the load current

capacity in the external circuits for the relay

output module, preventing from overload.

Otherwise it can cause machine damage or

accidents.

6F8C1111

v

Page 8

Mandatory

Configure the external circuit to turn on power

according to the following sequence.

Turn on the power of model 2000

→ Turn on the power for the I/O module and

external load power supplies

Otherwise, it can cause machine damage,

malfunction or accidents.

Mandatory

It is recommended to use an external power

supply that provides power for both the I/O

module and the loads. If not possible,

configure the external circuit so that the

external power required for output modules

and power to the loads are switched ON/OFF

simultaneously.

Also, be sure to turn off power to the loads

before turning off power to the S2 for system

safety.

Forbidden

Turn off power immediately if the S2 or related

equipment emitting smoke or odor. Operation

under such situation can cause fire or electrical

shock. Also unauhorized repairing will cause

fire or serious accidents. Do not attempt to

repair. Contact Toshiba for repairing.

5. Safety Precautions on Maintenance and Inspection

WARNING

Mandatory

Turn off power when removing any units,

modules, terminal blocks or wired cables after

installing.

Otherwise exposed conductive pants of wire or

on the rear of terminal blocks can cause

electrical shock.

Forbidden

Do not disassemble or modify the S2 and

related equipment in hardware nor software.

Otherwise it can cause failure, malfunction,

electrical shock or injury.

Forbidden

Be sure not to connect the opposite electrode

of the battery or charge, the battery.

Also, do not try to disassemble the battery or

make it short-circuited or throw it into fire or

use it in overheated condition.

Otherwise it can cause fire or explosion.

vi

Computer module C2PU7 User’s Manual

Page 9

CAUTION

Forbidden

Be careful not to hit or fall off the model 2000

by accident.

Excess shock can cause failure.

Mandatory

Touch a grounded metal part to discharge the

static electricity on your body before touching

the model 2000.

Otherwise, charged static electricity on your

body can cause malfunction or failure.

Mandatory

Use soft cloth to clean the model 2000.

Use water-dipped and squeezed cloth to clean

it if dirty.

Leaving the model 2000 dirty can cause

mistaking or malfunction.

Mandatory

Place any modules removed from the unit on a

conductive mat or conductive bag (containing

a spare board, etc.) on an grounded desk.

Otherwise, static electricity can damage

components of the module.

Forbidden

Do not apply benzene and thinner when

cleaning the model 2000.

Otherwise, it can cause deformity or

descoloration the panel or case of the model

2000.

6.Safety Precautions on Replacing Components

WARNING

Mandatory

Turn off power of the model 2000 before

replacing the power fuse or warning fuse.

Otherwise, it can cause electrical shock or fire.

6F8C1111

Mandatory

Replace the fuse or battery with a new one

specified.

Otherwise, it may malfunction or cause fire.

vii

Page 10

Mandatory

The relays used in the relay output module

have ON/OFF life mechanically.

Use them within their mechanical life times is

described in this manual.

Replace the module if exceeded.

CAUTION

Mandatory

In an annual average temperature of 30°C or

less, replace the battery every four years;

replace it every two years in an average

annual temperature higher than 30°C.

An exhausted battery can cause malfunction

and lose data and programs stored in S2,

resulting in machine damage or accidents,

depending on the application.

7. Safety Precautions in Daily Operation

WARNING

Mandatory

Apply power of the specified ratings (voltage

fluction range, frequency, output rating, etc.)

described in this manual.

Otherwise, it can cause malfunction, machine

damage or fire due to overheat.

Mandatory

Turn off power immediately if the ambient

temperature or internal temperature exceeds

beyond normal range or if failure is occurred in

the model 2000.

Contact Toshiba for repairing.

Operation under such situation can cause fire

or electrical schock.

viii

Computer module C2PU7 User’s Manual

Page 11

CAUTION

Forbidden

Do not touch any components, terminals,

connectors or printed circuit boards in the

module.

Otherwise, it can cause the IC or LSI or the like

to be broken by static electricity, resulting in

failure or malfunction.

Also, the edge of components can cause

injury.

Forbidden

Do not disassemble or modify the S2 and

related equipment.

Otherwise, it can cause malfunction or failure.

Forbidden

Do not forcibly bend or pull or distort the

power cord and other cables. Otherwise, they

can be cut off or cause overheat.

Forbidden

Do not enter wire scraps or other foreign

debris into the S2 and related equipment.

Also, do not insert metal parts into them.

They can cause fire or accidents

.

8. Safety Precautions on Disposal

WARNING

Forbidden

Do not throw lithium batteries into fire.

Otherwise, they can explode.

CAUTION

Mandatory

Observe local regulations for disposal of the

lithium batteries or the model 2000.

6F8C1111

ix

Page 12

Limitation of Applications

Use cellular phones and PHSs at least one meter away from the working the model 2000

n The model 2000 has been designed and manufactured for use in an industrial environment.

However, the model 2000 is not intended to be used for systems which can endanger human

life (note 1).

n Consult Toshiba if you intend to use the model 2000 for a special application which involves

human life and has great influence on the maintenance of the public function (note 2). This is

why such application requires special care on the operation, maintenance, and control of the

system (note 3).

(Note 1) The systems which can endanger human life are life maintenance systems, equip-

ment installed in the surgery, and other medical equipment.

(Note 2) The systems which involve human life and have great influence on the maintenance

of the public function mean the main control system of a nuclear power plant, safety

and protection system of a nuclear power facility, transport operation and control systems for mass transportation, control systems of aviation and space systems, and

other systems and subsystems where safety is critical.

(Note 3) "Special care" means to build a safety system (foolproof design, fail safe design,

redundancy design, etc.) in full consultation with Toshiba’s engineers.

Immunity

n Toshiba is not liable for any loss caused by fire, earthquake, action by a third party, or other

accidents, or the operator’s intentional or accidental misuse, incorrect use, or use under

abnormal condition.

n Toshiba is not liable for any incidental loss caused by the use or non-use of this product, such

as loss of business profits, suspension of business, or loss or change of data on memory.

n Toshiba is not liable for the loss caused by an operation contradictory to any of the instructions

stated in this manual.

n Toshiba is not liable for the loss caused by an incorrect operation in combination with other

equipment.

n Toshiba is not liable for the loss caused by a malfunction in combination with an application

program made by the customer.

NOTE:

transmission cables, and I/O bus cable. Otherwise, the system can malfunction.

x

Computer module C2PU7 User’s Manual

Page 13

Preface

Thank you for purchasing the Toshiba Integrated Controller V Series model 2000

Computer Module (hereafter referred to as C2. Or as model 2000 or simply device if

no distinction necessary).

This manual describes the operating procedure and precautions for the C2.

Be sure to read this manual and understand the content before using the equipment.

After you have read it, keep this manual handy so that you can refer to it when

necessary.

The V series uses operating system, peripheral devices, and options appropriate for

the industrial system and equipment in which it is installed. For information concerning

these products, refer to the manual included in the respective product.

6F8C1111

xi

Page 14

Related Manuals

In addition to this manual, the following model 2000 related manuals are available for

your reference:

Related to other modules

l

Integrated Controller V Series model 2000

Sequence Controller S2 User’s Manual – Basic-Hardware 6F8C0836

Provides information for the handling and maintenance of the main unit, power

module, and basic I/O.

Windows related

l

Integrated Controller V Series

Computer module C2/C3 Windows User’s Manual 6F8C0894

This manual describes the Windows and addition or extension to Windows

installed on C2.

Related to controller communication functional

l

Integrated Controller

C3/C2 Windows Control Communication Library 6F8C0894

This manual has described the support software for the communication

between controllers, and using the network module for control from C2.

Computer module C2 User’s Manual

xii

Page 15

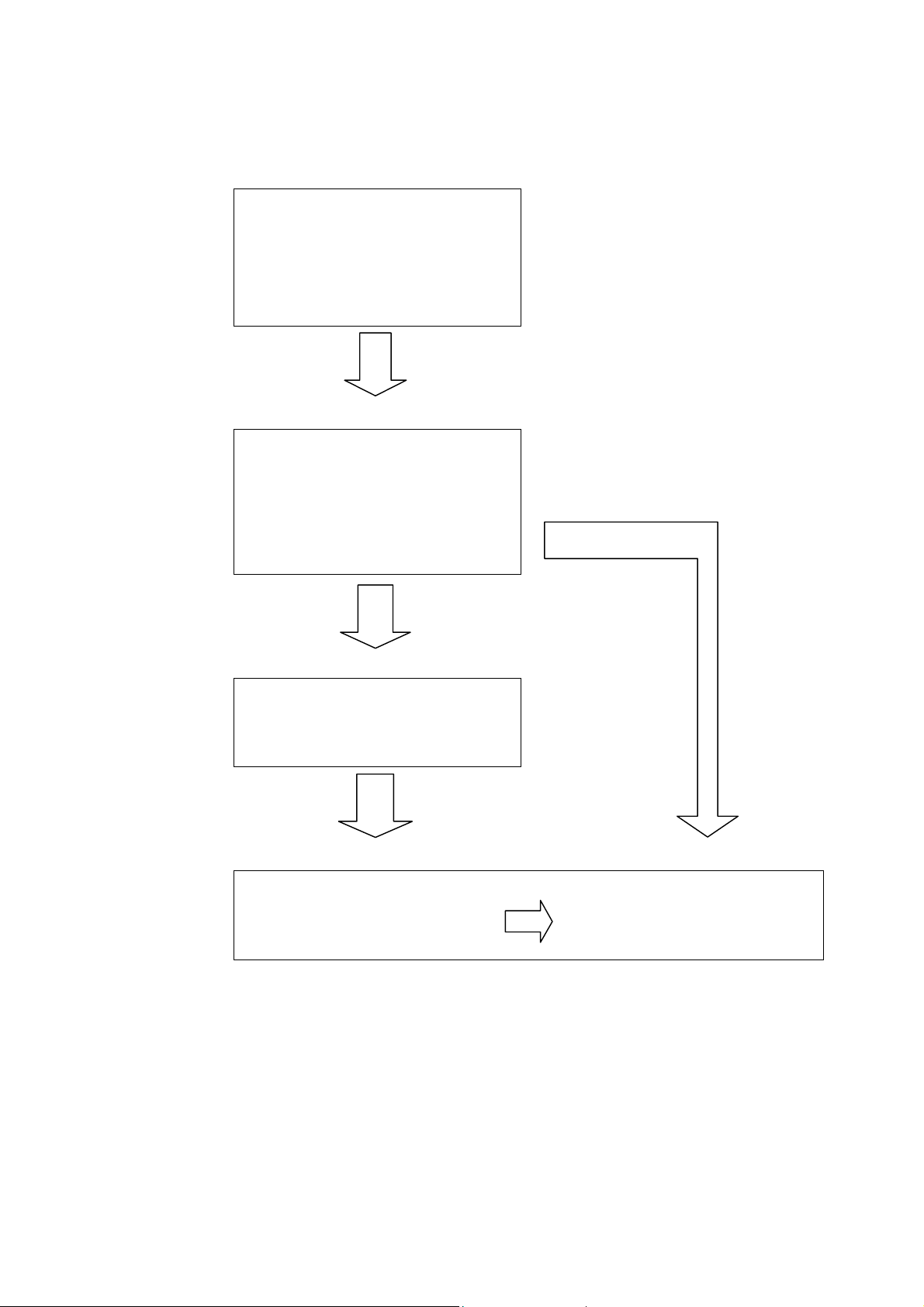

Procedure flow

・ Check the content of package

against the packing list

・ Determine the installation site

”1.3 Installation Requirements” on

page 5

・ Install the module in the basic unit.

・ Connect external equipment to the

module.

Preparation

Installation

・ Connect the power supply

”Chapter 2 Installation” (page 11)

Power ON

・ Turn on the main unit power.

”3.1 Power On and Power off” on

page 21

・ Backup

Backup the operating system

pre-installed in hard disk to a

reserve disk.

User the software

・ Install the application

Install the application according

to the instruction in the manual.

6F8C1111

xiii

Page 16

Notational convention

Description of symbols

In addition to the Safety Precautions, the following symbols are used to indicate

important notes when using:

Important

Describes items that require special attention in order to properly use the product.

NOTE

Describes items that should be remembered in order to properly use the product.

See

Indicates reference to section in this manual or other manual.

References to section in this manual are enclosed in single quotes (‘ ‘) and references

to section in other manuals are enclosed in double quotes (“ “).

[Remark] Provides supplementary description.

Computer module C2 User’s Manual

xiv

Page 17

Guide to Reading this Manual

This manual is organized as follows: You may start from the appropriate chapter as

necessary.

Chapter 1 Before Turning on the

Power

Chapter 2 Installation Describes how to install the equipment to the

Chapter 3 Handling Describes how turn on/off the power and the

Chapter 4 Maintenance Describes the product life of main components in

Chapter 5 RAS Function Describes the standard RAS function.

Chapter 6 Hardware Setup Hardware setup is not necessary for normal use.

Appendix A Q&A Provides answers to problems such as “The

Appendix B Device Specifications Provides specifications of this equipment and

Refer to the operation manual of the respective operating system (OS) for information

concerning the operating system used by this device.

Summarizes items and caution that you should

know before using this equipment.

base and connect the cables.

handling of each unit.

addition to the daily maintenance procedure.

This chapter describes how to set BIOS in case

the setting needs to be verified or changed.

power does not turn on.”

specifications and pin map of external connectors.

6F8C1111

xv

Page 18

Functions and Features

The integrated controller model 2000 is a CIE integrated controller integrating

continuous control, high-speed sequence control, maintenance/monitoring, and

information processing control in a single unit.

C2 is a computer module that implements the maintenance/monitoring and information

processing control functions among various functions of the model 2000.

Excellent system performance

l

Runs Windows smoothly using a Intel Mobile Pentium III 500MHz CPU with

maximum system memory of 256MB.

Windows2000

l

Runs under Windows2000 to enable use of commercial software that supports

GUIenvironment and connectivity with host network.

Consolidation of CIE

l

Improves system performance through inter-controller communication using

33MHz clock high-speed bus.

l

A variety of sequencer I/O modules can be controlled with the computer module

alone enabling a compact system.

Ease of use

l

The hard disk fits inside a 70mm x 135mm x 115mm module and runs Windows

without using an additional module.

l

Fully equipped with keyboard, mouse, floppy disk, RS-232C, USB, and Ethernet

connecters, and 2 slots CARDBUS PC card.

Improved reliabillity

l

Comes equipped with RAS function which monitors the operating status and

provides detail trouble report. And enables automatic power OFF shutdown

eliminating the trouble of shutting down Windows.

Computer module C2 User’s Manual

xvi

Page 19

CONTENTS

1 Before Turning on the Power

1.1 Checking the Content of the Package

1.2 Name and Function of Each Part

1.3 Installation Requirements

1.4 Power Requirements

1.5 Precautions when using

1.5.1 Daily use

1.5.2 When turning Off the Power

1.5.3 About the Hard Disk Drive

1.5.4 About the External FDD

1.5.5 Daily Cleanup and Storage/Transportation

1.5.6 Radio Wave/Power Voltage Interference

1.5.7 Repair and Service

1.5.8 Disposal

2 Installation

2.1 Before Getting Started

2.1.1 Procedure

2.2 Installing Bases

2.2.1 Precautions when Installing in the Case

2.3 Module Installation

2.4 Grounding

2.4.1 Grounding Tips

2.4.2 Grounding method

2.5 Wiring of the power supply

2.6 Connector Connection

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・

・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・

・・・

・・・・・

11

・・・・

1

1

2

5

7

8

8

8

8

9

9

9

9

9

11

11

12

12

13

14

14

15

17

20

6F8C1111

3 Handling

3.1 Power On and Power Off

3.1.1 Turning On the Power

3.1.2 Turning Off the Power

3.1.3 Power Off with Windows

3.1.4 Power Supply module PS694 with Battery・・22

3.1.5 Power Supply module PS691 with UPS I/F・・24

3.2 About the Hard Disk

3.3 About the External FDD

3.3.1 Floppy Disk Handling

3.4 About the PC Card

3.4.1 Installation

3.4.2 Removal

・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

21

21

21

21

22

25

26

26

28

29

30

xvii

Page 20

CONTENTS

4 Maintenance

4.1 Daily Inspection

4.2 Periodic Maintenance

4.3 Replacement Timing of Major Parts

4.4 Replacing the Hard Disk Drive

4.4.1 How to Remove the HDD pack

4.4.2 Intalling the HDD pack

5 RAS Function

5.1 RAS Function Overview

5.1.1 RAS Hardware

5.1.2 RAS Support Software

5.2 Hardware Processing RAS Functions

5.2.1 WDT Circuit and Hardware Reset

5.2.2 RAS Memory

5.2.3 Interrupt Signals

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・35

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・

31

31

32

33

34

34

34

36

36

36

37

37

37

37

6 Hardware Setup

6.1 Setting the BIOS

A Q&A

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・45

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

B Device Specifications

B.1 Specifications

B.2 Interface Specifications

B.2.1 RGB Interface

B.2.2 Serial Interface (RS-232C)

B.2.3 Keyboard and Mouse Interface

B.2.4 USB Interface

B.2.5 Ethernet Interface

B.2.6 FDD Interface

B.2.7 PCMCIA card slot

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

39

・・・・・・・・・・・・・・・・・・・・・・・・49

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

40

49

51

51

51

52

52

52

53

54

xviii

Computer module C2PU37 User’s Manual

Page 21

1

Chapter 1 Before Turning

on the Power

1.1 Checking the Content of the Package

Check the content of the package against the packing list included with the product

and make sure everything is included.

6F8C1111

Page 22

Chapter 1 Before Turning on the Power

2

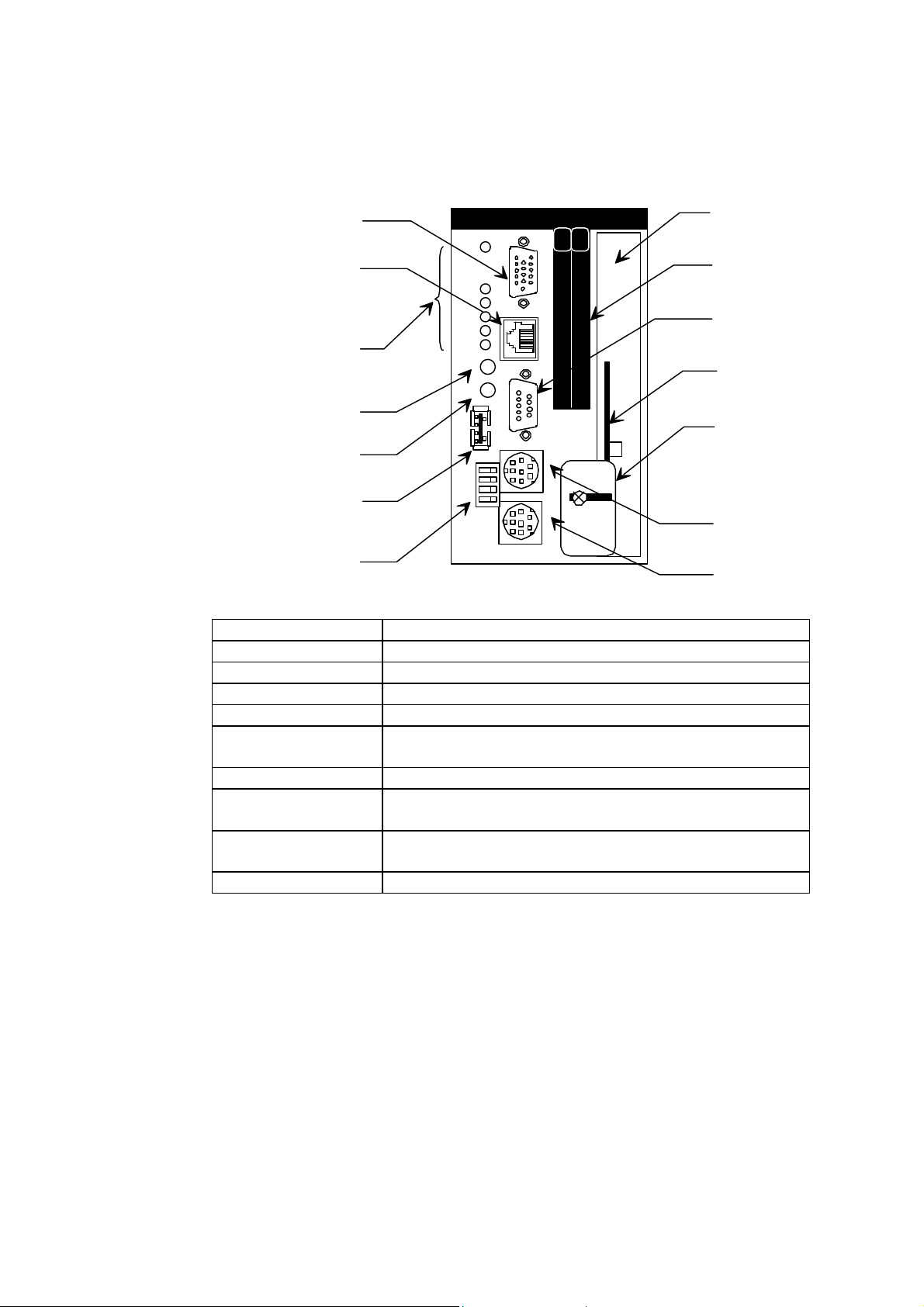

1.2 Name and Function of Each Part

RGB connector

Ethernet

(10/100base-TX)

LEDs indicating

RST Switch

INZ Switch

USB connector

DIP-SW

C2PU37

RUN

HDD

HDD

RST

INZ

4

3

2

1

USB

SW1

RGB

10/100BASE-

TX

COM

0 1

MOUSE

KEYBOAR

D

HDD Pack

PC card slots

COM port

HDD Drawer

HDD fixed board

Mouse

Keyboard

10/100BASE-TX connector Connector for the Ethernet 10BASE-T/100BASE-TX connector.

Mouse connector Connector for the PS/2 mouse.

Keyboard connector Connector for the PS/2 keyboard.

RGB connector Connector for the analog RGB display

FDD connector Connector to connect the 3.5-inch (2HD, 2DD) external floppy disk drive.

RS-232C connector

(COM1)

USB connector Connector to connect USB compatible device.

LEDs and push button

switches

DIP switch

PC card slots Slot to insert the PC card.

Connector to connect the RS-232C interface device (such as mouse or

modem).

LEDs indicating the module status and RESET/INZ button.

User settable switches. The setting can be read from user application

program in the C2.

Computer module C2PU37 User’s Manual

Page 23

3

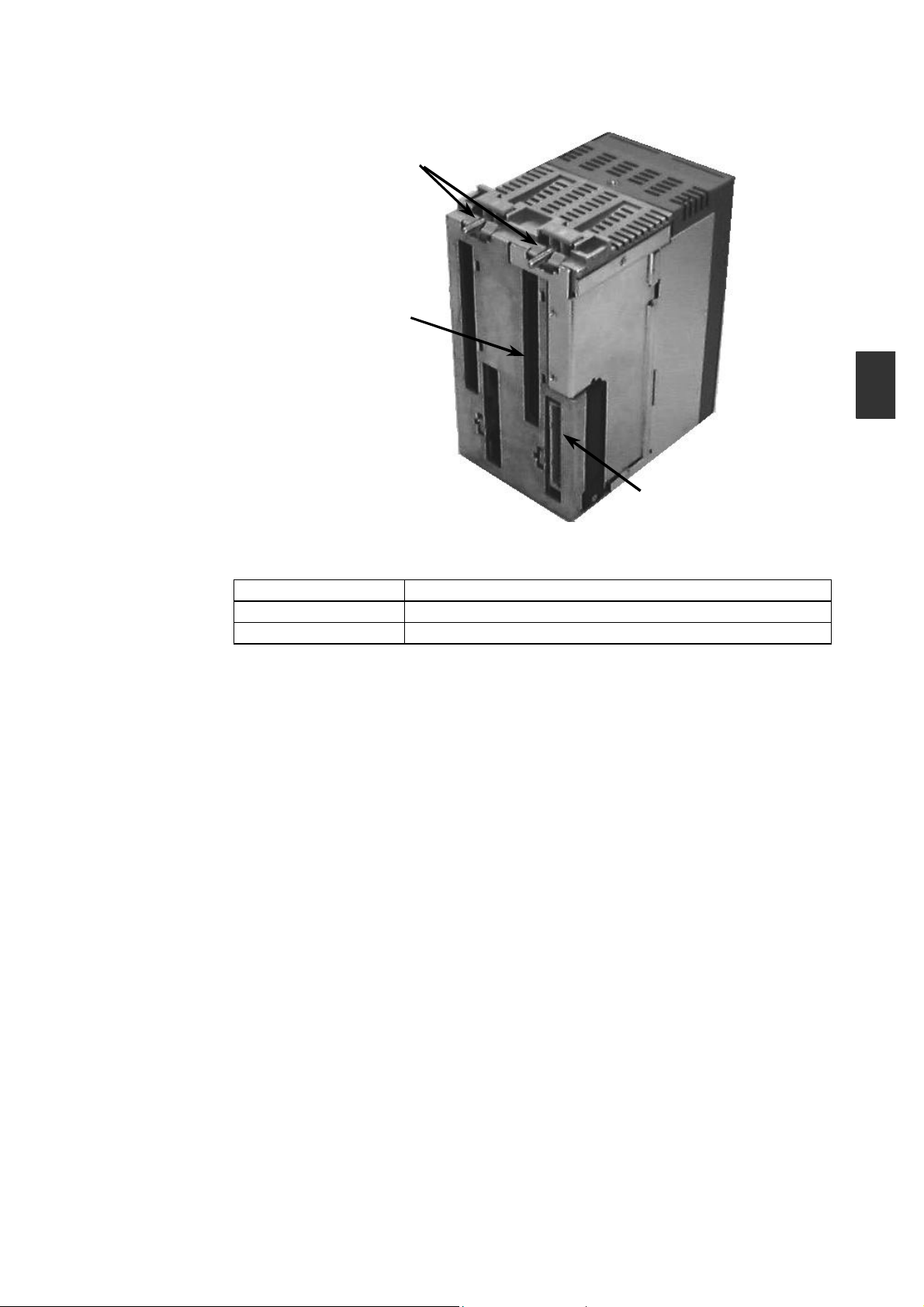

1

Station bus connector

1.2 Name and Function of Each Part

Mounting screw

I/O bus connector

Mounting screw A screw to mount the module to the basic unit.

Station bus connector Station bus connector for the V series model 2000.

I/O bus connector Connector for the I/O bus.

6F8C1111

Page 24

Chapter 1 Before Turning on the Power

4

Push button

Dedicated LED LEDs to indicate the CPU and HDD operating status.

RUN (green)

HDD (green)

Dedicated LED

General LED

switch

Indicates the operating status of the watchdog timer (WDT).

• When WDT is active

ON: WDT timeout has not occurred

Blink: WDT timeout has occurred

(Alternating interval is the WDT timeout interval set by the user)

• When WDT is not used

Blink at approximately 1 second interval

General LEDs 1 - 4

Hard disk drive (HDD) access lamp. Turns ON when the internal hard disk

drive is operating.

General LEDs 1-4

(Green/Red: 2 colors x 4) Switches to perform standalone initialization of the module.

Push button switches Switches to perform standalone initialization of the module.

RST Switch to perform hardware reset of the module.

INZ Switch to shut down Windows and restart.

Computer module C2PU37 User’s Manual

Page 25

5

1

1.3 Installation Requirements

Observe the following when planning and designing the installation environment.

The installation environment must satisfy the conditions described below.

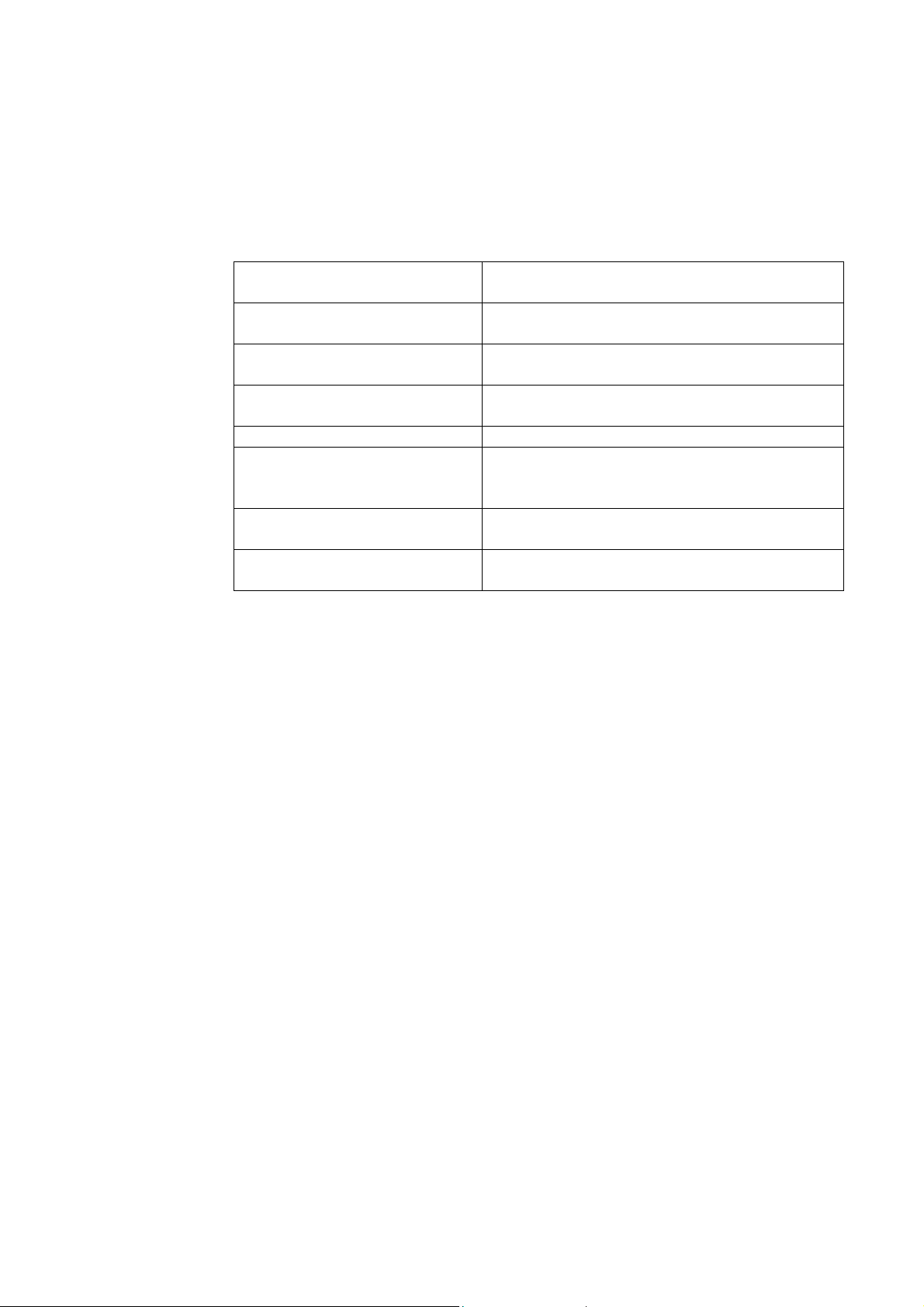

Item Hard Disk Drive model Flash Disk Drive model

Operating ambient

temperature

Storage

temperature

Relative humidity 10 to 90%RH, no condensation 5 to 90%RH, no condensation

Dust density 10mg/m3 or less

Corrosion

resistance

Vibration resistance 1.96m/s2 (0.2G) continuously

Shock resistance 98m/s2 (10G) 3 times each X, Y, Z direction

Usable altitude Up to 2000m

Dielectric strength 1500Vac/1 min.

Ambient

atmosphere

Structure Built-in control panel

Cooling Natural air cooling

EMC

Grounding

5 – 40oC 0 – 50oC

-10 – 50oC -25 – 70oC

No corrosive gas is present.

for 30 minutes in X, Y, Z

direction

No corrosive gas is present.

6 KV : Static electricity discharge resistance

10 V/m : Radiation field

2 KV/1 KV/0.25 KV: Fast transient

Grounding resistance 100Ω or less

1.3 Installation Requirements

9.8m/s2 (1G) continuously for

30 minutes in X, Y, Z direction

6F8C1111

Page 26

Chapter 1 Before Turning on the Power

6

c *1

Follow the precautions described below for the installation of the board housing the

model 2000:

(1) House in a dust proof control board because the module itself is not dust proof.

(2) Avoid installing on top of devices that emit considerable amount of heat (such as

heater, transformer, or large resistor).

(3) Do not install inside the same board with high voltage equipment.

(4) Maintain a distance of at least 200mm from high voltage or power line.

(5) Provide a space of at least 70mm around the base for ventilation.

(6) Keep away from high voltage equipment and power equipment or provide metal

shielding for safety during maintenance and operation.

(7) Be careful not to drop foreign objects such as loose wires inside the module or

unit.

(8) Always mount the base on a vertical panel with the power supply module on the

left. C2 cannot be used in a horizontal position.

(9) Use M4 size screws to mount the unit and fasten securely (recommended torque:

1.47N=15kgf • cm).

The unit mounting dimensions are as follows:

a

Model a [mm] b [mm] c [mm] Weight [g]

BU648E 402.5 95 – 900

BU643D 224.5 95 203.0 850

BU610 155.5 95 – 400

[Note] No hole for BU643D

b

4 - M4

Computer module C2PU37 User’s Manual

Page 27

7

1

1.4Power Requirements

Use power module designed exclusively for the V Series. Using other power supply

may result in operation error or device malfunction.

Basic function

Auxillialy

function

ITEM

Rated Voltage 100-120VAC

Max. power

consumption

Allowable

voltage range

Rated

frequency

Retentive

power

interruption

Distortion rate 10% or less of rated input voltage –

Inrush current 240VAC-25A

Ground current 1.5mA or lower (IEC-950) –

Insulation

resistance

Withstand

voltage

Grounding

Output rating 5V-8A,

Protective

circuit

Status display POWER (5V output, green) CHARGE*2 POWER (5V output, green)

RUN contact Dry A contact (240VAC/24VDC-0.2A max.)

PS691 PS693 PS694 PS632 PS652

200-240VAC

160VA(60W)

or less

85-132VAC

170-264VAC

50/60Hz (47-63Hz) DC

20ms or less 20ms or less

peak or lower

*1

10MΩ or higher (between input and each insulation)

1500VAC/1 min.

Grounding resistance 100Ω or less

3.3V-1A total

of 43W or less

Over voltage, currnet protection

1.4 Power Requirements

Specification

100-240VAC 100-240VAC 24VDC 100/110VDC

120VA(50W)

or less

85-264VAC 85-264VAC 20.4-28.8VDC 85-132VDC

220V-30A

peak or lower

*1

5V-7A,

3.3V-1A,

24V-0.8A

total of 35W

or less

150VA(50W)

or less

20ms / 1s

30% / 20s

30% or less

240VAC-25A

peak or lower

*1

5V-6A,

3.3V-1.0A

total of 30W

or less

50W or less 50W or less

±

1ms or less 1ms or less

±

6.5A/10ms or

lower of rated

5V-7A, 3.3V-1A total of 35W or

less

25A or lower

of rated

External

Weight 650g or less 600g or less

Line terminal

unit

*1 After instantaneuous power failure of 5 second or longer.

*2 Battery initial charge indicator, green/red.

10 terminals

-M3.5 screw

(detachable)

9 terminals

-M3.5 screw

(fixed)

10 terminals

-M3.5 screw

(detachable)

9 terminals -M3.5 screw (fixed)

Important

• Do not connect to the same electrical outlet with equipment that has high power

consumption or emits noise, such as air conditioner or copier.

• Use of uninterruptible power supply is recommended in order to prevent loss of

power and to protect the content of the hard disk in the event of a power failure.

The content of the hard disk is not guaranteed if power is lost due to power failure.

6F8C1111

Page 28

Chapter 1 Before turn on the Power

8

1.5Precautions when using

1.5.1 Daily use

Observe the following insturctions during daily use of this equipment.

WARNING

• Turn off the power if there is smoke, unusual odor, excessive heat, or damage.

• Do not block the ventilation port.

If the ventilation ports are blocked, heat cannot escape and fire may occur due to

overheating. When there is a need for repair, contact the Toshiba service desk.

• Do not touch the C2 module when the power is on. The heat radiating side covers

become extremely hot (ambient temperature+25oC) when power is on. It cools

(ambient temperture+10oC) in 10 minutes when the power is turned off.

1.5.2 When turning Off the Power

Important

• After turning off the power, wait at least 5 seconds before turning on the power.

Faulty operation may occur if you do not wait 5 seconds.

• If an application program is running, quit the program to return to the operating

system (OS).

See

• "Description manual of each application program"

1.5.3 About the Hard Disk Drive

Important

• Do not apply shock or vibration to the equipment when the power is on.

The read/write head of the hard disk drive is at a data area even when the HDD

lamp is off.

• Wait at least 30 seconds after turning off the power before moving the equipment.

The read/write head of the hard disk drive retracts automatically when the

equipment power is turned off. However, it takes approximately 30 seconds for the

hard disk to stop rotating.

The shock may damage the data area.

• Always turn off the power before removing/installing the hard disk drive.

Failure to do so can cause malfunction of the drive.

Computer module C2PU37 User’s Manual

Page 29

9

1

1.5.4 About the External FDD

Important

• Avoid performing the following when the FDD lamp of the external FDD (floppy disk

drive) is ON:

• Pressing the button

• Turning off the main power

• Removing the cable

The floppy disk may be in the middle of reading or writing data and content of the

floppy disk may be damaged.

NOTE:

• Always remove the floppy disk from the drive when you are not using the floppy disk

drive.

1.5 Precautions when using

1.5.5 Daily Cleanup and Storage/Transportation

• Wipe with soft cloth when cleaning. If this is not sufficient, wipe gently with cloth

wetted in water.

• Using benzene, paint thinner, or other chemicals can cause distortion or

discoloration. Also avoid spraying with insecticide.

• Save the box so you can use it when transporting the unit.

• Do not drop of exert excessive shock when transporting. This can cause operation

error or malfunction.

1.5.6 Radio Wave/Power Voltage Interference

If you experience radio or television interference when using this equipment, try the

following:

• Change the direction of the radio or television antenna.

• Change the direction of unit with respect to radio or television.

• Move the unit away from radio or television.

• Use separate electrical outlet from the radio or television.

• Use an outdoor antenna.

• Change the feeder to a coaxial cable.

• Insert a commercially available filter between the electrical outlet and the power plug

of the unit.

1.5.7 Repair and Service

Contact your Toshiba service desk for information concerning maintenance and

service.

6F8C1111

Page 30

Chapter 1 Before turn on the Power

10

1.5.8 Disposal

Module disposal

The C2 contains parts such as Lithium battery that must be disposed properly

according to local government ordinance.

Do not attempt to dispose the C3 on your own. Please contact your dealer and submit

a request for return and disposal when disposing.

Dispose other 2000 base and modules according to your local government ordinance.

Battery disposal

Dispose the battery in the same manner as ordinary batteries.

Do not disassemble or incinerate the battery because it may explode. Dispose without

disassembling or burning.

Also note that short circuiting the positive and negative end of the Lithium battery may

result in smoke or flame. Do not cut the lead wires and be careful not to short the

positive and negative terminals when disposing.

WARNING

Do not connect the positive and negative terminal of the battery in reverse, or attempt

to charge, disassemble, heat, or short the battery.

It may explode or ignite.

Dispose the battery according to your local government ordinance.

Computer module C2PU37 User’s Manual

Page 31

11

Chapter

2

2.1Before Getting Started

2.1.1 Procedure

NOTE:

• Do not touch parts that are not necessary for the work at hand.

• Be careful not to loose the removed screws. Also be careful not to drop them inside

the device.

• If an error or malfunction occurs, contact your Toshiba service desk.

• Use drivers that is appropriate for the screw when assembling or fastening parts.

Improper driver will not fit tightly in the cross hole. Using improper driver can wear

out the cross hole of the screw.

Installation

6F8C1111

Page 32

Chapter 2 Installation

12

2.2Installing Bases

2.2.1 Precautions when Installing in the Case

Observe the following when installing in the case.

CAUTION

Do not attempt to mount or remove the unit from the case alone (work in two or more).

Be especially careful when mounting in the case because you may lose your balance

and injure yourself.

Important

Use within the following temperature and humidity range.

Temperature

range

Hard Disk Drive model 5 – 40oC 10 – 90%

Flash Disk Drive model 0 – 50oC 5 – 95%

Avoid sudden change in temperature that may cause condensation.

• Provide a door or removable panel in front and rear of the case in a manner that

facilitates removal of the housed units (main unit and peripheral devices) for

maintenance.

Humidity range

• Provide forced cooling if the temperature inside the case is not within specification.

• Carefully consider the ventilation direction of the main unit, peripheral device, and

case so that the flow of the air is not blocked.

Computer m

odule C2PU37 User’s Manual

Page 33

13

2.3Module Installation

Install the module according to the following procedure:

(1) Match the guides at top and bottom of the base and insert the module vertically on

the base. Check that the top and bottom lock levers are fasten to the base and

click.

(2) Pass an M3 screw through the hole at the top of the module and secure the base

and the module (recommended torque: 1.47N•m=15kgf•cm).

Remove the module according to following procedure:

(1) Turn off the power supplied to the model 2000. Turn off the external power to the

I/O module.

(2) Detach cables from the module.

(3) Remove the screw at the top of the module.

(4) Push the lock lever at the top of the module, hold the bottom of the module with

the other hand, and pull the entire module vertically from the base to remove the

module.

2.3 Module Installation

CAUTION

• Tighten the screws securely so that they do not become loose with vibration.

They can cause injuries if they become loose and fall off.

• Always turn off the power before removing/installing the module.

Removing or installing the module with the power on can cause malfunction or

operation errors.

• The device will not operate normally if installed where there is no station bus

connecter.

• Do not touch the C2 module when the power is on. The heat radiating side covers

become extremely hot (ambient temperature+25oC) when power is on. It cools

(ambient temperature+10oC) in 10 minutes when the power is turned off.

Station bus Connector

Mounting screw

6E8C1111

I/O bus connector

Page 34

Chapter 2 Installation

14

2.4Grounding

The electrical devices should be grounded separately from power system and the two

or more electrical devices should be grounded at a single point. The model 2000 is

designed to resist actual noise and the device is sufficiently capable of withstanding

noise, but grounding is very important in order to assure safe and stable system

operation. Observe the following instructions and provide proper grounding.

When using the Ethernet module, refer to the ‘Ethernet installation and Wiring Guide’

(6F8C0879)

Always ground the model 2000.

Failing to ground the unit can cause electrocution or malfunction.

2.4.1 Grounding Tips

Note the following when grounding:

(1) The model 2000 unit must not be a conductor for grounding current of other

devices.

(Especially, high frequency current can cause trouble.)

(2) The grounding potential of the model 2000 base and expansion unit must be equal.

(Ground at single point.)

(3) Do not connect to ground of motorized system (require high frequency separation)

(4) Do not connect to unstable ground (parts with unstable impedance such as

screwed on painted parts or parts affected by vibration)

CAUTION

Computer m

odule C2PU37 User’s Manual

Page 35

15

2.4.2 Grounding method

Ground

current

(1) Grounding of control panel

Power panel

change change

2.4 Grounding

In the case of connecting panel,

the ground current flowing from

the high frequency device or

power panel may flow through

the PC housing panel.

Power panel

Isolate model 2000 mounting

panel and connect to the ground

point separately

Isolate model 2000 from the

mounting frame and connect to

the ground point separately.

Power panel

6E8C1111

Page 36

Chapter 2 Installation

16

FG

(2) Grounding connection between base

PS

Basic unit

PS

Expansion unit

PS

Expansion unit

Board internal ground terminal

Dedicated ground

• Connect the FG terminal of the power supply module to the unit mounting screw,

and to the ground bar in the panel by 2mm2 or larger wire in shortest possible

distance.

• Use a dedicated ground for the control circuit, and keep the ground cable away

from that for high-power systems.

• 100Ω or less to earth is recommended.

(3) Line Filter ground (LG) terminal

The LG terminal is a neutral point of the primary power supply line filter. It can

suppress the effect caused by the noise from power supply line, by grounding the

LG terminal.

Therefore, normally, ground the LG terminal together with the FG terminal.

However, depending on the power system, leakage current to the ground from the

LG may cause problems. In this case, install an isolated transformer in the power

line, or open the LG terminal. If the unit is installed in isolation, open the LG

terminal.

Do not connect the LG and FG terminals without grounding them.

(4) Frame ground (FG) terminal

The FG terminal is a protective ground point of the model 2000. The FG terminal

voltage is equalized to that of the base. For safety, ground them at single-point in

order to minimize the risk of electrical shock.

Computer m

odule C2PU37 User’s Manual

Page 37

17

2.5Wiring of the power supply

(

Wire the external power supply to model 2000 power supply module in the following

manner.

When using expansion units, arrange for power to be supplied simultaneously to the

basic unit and the expansion units (or to the expansion units before the basic unit).

(1) Power conditions

Rated voltage : 85 to 264VAC, 50/60Hz (PS694)

Power consumption : 150VA or less (PS694)

Retentive power interruption : 20ms or less

(2) Install an electrostatic shielded transformer or a noise filter if the power contains

noise. See figurer at the bottom.

(3) Use twisted-pair cables (1.25mm2) as the power supply cable. Keep the cable as

far as possible from I/O cables.

(4) If the expansion unit with a power supply module is used, the power of the basic

and expansion units should be supplied from the same source. Apply power at the

same time or in the order of the expansion unit then the basic unit.

2.5 Wiring of the power supply

(5) If a CV CF or UPS supplies power to model 2000, observe waveforms of the power

supply; the peak voltage must be more than 130V for the 100VAC range or 260V

for the 200VAC range.

Power

100/240VAC

Shielded

(

Noise filter

transformer

Basic unit

Expansion unit

6E8C1111

Page 38

Chapter 2 Installation

18

NC

FG

*1*2RUN signal

NC

NC

FG

*1*2RUN signal

contact output

+ − NC

FG

ontact output

DC24V

−

NC

*1*2

RUN signal

contact output

LG

Power supply

input

Wiring of the power supply

PS694

PS691

NC

NC

100-240VAC input

〜

PS693

24V output

100-240VAC input

〜

contact output

RUN signal

NC

L

N

LG

100-120VAC or

200-240VAC input

〜

100VAC:short

200VAC:open

L

N

LG

PS632/PS653

+

0V

L

N

LG

24VDC input (PS632)

100/110VDC input (PS653)

NC

NC

L

N

*1 *2

*1 Line filter ground (LG)

5000PF or less

5000PF or less

*2 Frame ground (FG)

Connected to base unit.

See ‘2.4 Grounding’

Computer m

odule C2PU37 User’s Manual

Page 39

2.5 Wiring of the power supply

19

CAUTION

1. Always turn off the power before wiring the cables.

Working with the power on can cause electrocution.

2. Use covered crimp terminals or cover the module wire with tape so that there

is no exposed conducting parts.

Fasten the terminal covers securely to the terminals when wiring is finished.

Exposed parts can cause electrocution.

3. Always ground the model 2000.

Failing to ground the unit can cause electrocution or malfunction.

4. Connect to rated power supply.

Connecting to wrong power supply can cause explosion or fire.

5. Wiring must be performed by an experienced person.

Wiring error can result in fire, malfunction, or electrocution.

6. Do not connect any cables to the NC terminals.

NOTE:

Terminal screw size is M3.5. Use crimp terminal with width of 7mm or less for M3.5

screw.

6E8C1111

Page 40

Chapter 2 Installation

20

2.6Connector Connection

Connect each connector to the peripheral device as described below.

CAUTION

• Turn off the power of the main unit and peripheral device when connecting peripheral

devices.

Connecting with the power on may cause injury or burn.

• Be sure to hold the connector when attaching/removing signal cables.

Otherwise, the cable may be damaged causing fire or electrocution.

Important

• Check the shape of the connector and insert the cable properly into the main unit.

The pins may break or bend if unnecessary force is applied.

• If the cable connector is equipped with fastening screws, tighten them so that the

cable does not come loose.

(1) Check that the switch of the power module is in the OFF position.

(2) Connect the cable of each peripheral device to the main unit connector.

After connecting, tighten two screws and fasten the connector to the module.

Match the connectors properly when connecting and connect firmly.

Computer m

odule C2PU37 User’s Manual

Page 41

Chapter

3

3.1Power On and Power Off

If you are using peripheral devices, connect them before turning on the main unit

power.

Important

• Wait at least 5 seconds when turning on the power after turning it off.

If the power is turned back on too quickly, the rush current prevention circuit may

not function properly and a sudden flow of current (approximately 100A) may cause

the power supply fuse to blow out.

Handling

3.1.1 Turning On the Power

Configure the external circuit to power on in the following sequence:

(1) Turn on the AC power to the power supply module.

(2) Turn on the power of the peripheral devices (CD-ROM drive connected through

PC card, etc.) connected to C2.

(3) Turn on the model 2000 main unit.

(4) Turn on the I/O module and external load power.

3.1.2 Turning Off the Power

Turn off the power in the reverse order of the power on procedure.

NOTE:

If an application program is running, quit the program to return to the operating system

(OS).

Then shut down the operating system and get ready to power off.

If PS694 or PS691 is used for a power supply module, a shutdown will be performed

automatically and a module power supply will be shut off.

Please refer to the following page for details.

6F8C1111

21

Page 42

Chapter 3 Handling

22

Shutdown

3.1.3 Power Off with Windows

If a power supply is turned off without shutdown of Windows, the data in a hard disk is

destroyed and it may be unable to reboot.

Model 2000 is supporting the automatic shutdown of Windows, and the power supply

off-sequence. If the power supply module of exclusive use is used, the shutdown of

Windows can be performed without carrying out operation of a mouse and a keyboard.

Important

• In order to use an automatic shutdown function, the RAS support software installed

in C2 as standard is required.

3.1.4 Power Supply module PS694 with Battery

AC100/240V

Power Supply Module PS694

Detect AC Failure

Main circuit

Shutdown

Sequence

Battery

Control

Shutdown

Request

Power control signal

Main power for controller

C2

Windows

Request

RAS driver

l

Operation during power off

(1) An AC input power failure exceeding the preset allowable limit is detected as a

power failure. (Normal operation continues if power fails shorter than that.)

(2) Shutdown is requested to the C2 and the C2 starts shutdown processing.

(3) When the C2 finishes shutdown processing, the power module PS694 cuts

power off by stopping power supply from the battery.

Computer module C2PU37 User’s Manual

Page 43

Important

• If the running application cannot be terminated normally for some reason or other,

Windows is forcibly terminated subject to the completion waiting time set with the

RAS driver.

In this case, the file data of application or Windows may be destroyed.

Fully confirm application operation in advance that it is free of problems.

Important

• If an input power supply is turned off during Windows starting, power supply OFF

may be carried out without carrying out shutdown processing.

Important

• When it mounts two or more sets of C2 in one base unit, after all C2 carries out the

completion of a shutdown, power supply OFF is carried out.

l

Operation after power recovery

If AC power is restored during the shutdown processing, power is automatically turned

back on after the operation described in step (3).

l

Hold time and charge time of a built-in battery

The battery's hold time is 4 minutes maximum (when the battery is fully charged and

operates at the rated output level). A recharge of about 2 hours is necessary for the

battery to make up for the loss of its capacity by a single Windows shutdown after AC

input power is back on.

Important

• When battery capacity runs short during battery operation, a power supply is turned

off compulsorily.

In this case, the file data of application or Windows may be destroyed.

Do not repeat OFF of an input power supply.

Important

• PS694 is not a thing supposing use in the inferior input power supply state.

Battery operation is performed, while the input power supply turns off, even if it is

less than the set-up time at the time of retentive power interruption.

When there is extremely much generating frequency of a power interruption, the

charge capacity of a battery runs short and power supply OFF may be carried out

before the completion of a shutdown at the time of input power supply OFF.

6F8C1111

23

Page 44

Chapter 3 Handling

24

Shutdown

Conversion

3.1.5 Power Supply module PS691 with UPS I/F

Power Supply Module

PS691

UPS

AC100/240V

circuit

Main circuit

Shutdown

Request

Power control signal

Main power for controller

C2

Windows

Request

RAS driver

UPS turns off secondary side power supplies in timer setting of UPS. A timer should

set up sufficient time for shutdown of Windows.

Computer module C2PU37 User’s Manual

Page 45

25

3

3.2About the Hard Disk

Hard Disk Handling

The C2 hard disk drive is likely to be misused because it can be replaced or carried

easily. Observe the following precautions and treat it with care:

l

Do not drop it or exert strong shock.

The magnetic surface of the hard disk may be damaged making it unusable.

Scars on the magnetic surface cannot be repaired. Handle it with extreme care.

l

Carrying it without installing it on C2 can make it more susceptible to shock and

the data may be lost or become unreadable. Place it in a box and handle with

care. Be especially careful when transporting.

l

Place the removed hard disk drive in an anti-static bag and store it in a box.

l

The hard disk pack may be replaced approximately 500 times. This is the life of

the connector.

l

Avoid spilling coffee, other fluids, or metal particles.

l

Do not disassemble. Failure to do so can cause malfunction of the drive.

3.2 About the Hard Disk

Important

• Toshiba will not be responsible for the content of the hard disk regardless of the

cause of failure or error. Please backup your data to guard against accidents.

• Use only C2 custom hard disks.

6F8C1111

Page 46

Chapter 3 Handling

26

3.3About the External FDD

An external floppy disk drive is necessary if you must install OS or application

programs from floppy disks or save data to floppy disks.

In general, a floppy disk drive has an access lamp in front as shown at right. This lamp

flashes when the drive is being accessed.

FDDlamp

• Turn off the AC power of the main unit when removing/inserting the FDD cable.

Removing or inserting the cable with the main unit power on can cause burn or

electrocution.

• Do not press the eject button or turn off the power when the FDD lamp of the

external floppy disk drive is on.

3.3.1 Floppy Disk Handling

Important

• Do not open the shutter and touch the magnetic surface.

• Avoid extreme environment such as direct sunlight, strong magnetic field, or high

temperature.

• Do not put heavy object on top.

• Do not paste labels on top of each other.

CAUTION

Computer module C2PU37 User’s Manual

Page 47

27

3

[Write Protecting a Floppy Disk]

Write disabled state

Back

To prohibit write

Slide the write protect tab to the outside as shown in (1).

To enable write

Slide the write protect tab to the inside as shown in (2).

In either case, slide the write protect tab until it clicks

Front

Shutter

Write protect tab

3.3 About the External FDD

Write enabled state

6F8C1111

Page 48

Chapter 3 Handling

28

3.4About the PC Card

Two PC Cards Standard TYPE I/II (3.3V, 5V) PC cards can be inserted in the PC card

slot of the C2. Or, one TYPE III PC card can be inserted when the left and right slots

are combined.

PC card slot 0

RUN

HDD

4

3

2

1

HDD

RST

INZ

USB

SW1

C2PU37

RGB

10/100BASE-TX

COM

MOUSE

KEYBOARD

PC card slot 1

0 1

CAUTION

• Do not touch the PC card that is being used or just after it has been used. It may

become extremely hot and cause burns.

Persons with weak skin condition should be especially careful.

Important

• When using a card that requires a cable, the cable may be short. Check the location

of the main unit and the peripheral device to be connected.

• The size of a cable or a connector of a PC card are large, and may be unable to

insert two cards simultaneously. Please check the size of the card to be used etc.

beforehand. If a PC card is inserted by force, it may become the cause of incorrect

operation and failure.

Memo

• Some commercially available PC cards may emit considerable amount of heat. The

function of such card may become unstable when it is used for an extended period.

Also, if it is used together with other cards, the heat may affect the other card.

Examples of PC card

• Modem card • Flash memory

• SCSI adapter • LAN card

Computer module C2PU37 User’s Manual

Page 49

29

3

3.4.1 Installation

(1) Press the eject button of the PC card slot until the eject button pops out.

(2) Press the eject button once more.

The dummy card ejects.

(3) Remove the dummy card.

Store the dummy card in a safe place.

3.4 About the PC card

(4) Check the direction and insert the PC card.

Gently press the PC card all the way in and connect

securely. Do not exert excessive force.

(5) Connecting cable to the PC card.

Connect the cable in case of a card that needs a cable

such as LAN card or modem card.

After connecting the card, check that the card is ready.

Refer to the PC card environment setup in the "PC Card

Manual."

CAUTION

• Do not transport with the cable attached.

If you do, the cable connector may be damaged.

• Do not pull on the cable strongly with the cable attached. The PC card may become

loose.

6F8C1111

Page 50

Chapter 3 Handling

30

3.4.2 Removal

(1) Press the eject button of the PC card slot until the eject button pops out.

(2) Press the eject button once more.

The card ejects.

(3) Hold the card firmly and pull.

(4) Insert a dummy card.

Computer module C2PU37 User’s Manual

Page 51

31

Chapter 4 Maintenance

4.1Daily Inspection

The following items should be inspected daily in order to maintain normal system

operation and prevent unnecessary trouble from occurring.

Item Inspection Description Action

Check the LED in

front of the power

module.

Check the LED at the

front of the C2

module.

Check the LED of the

input module.

(Digital input)

Check the LED of the

output module.

(Digital output)

Action

• When the C3 module LED status is abnormal

The application program may be at fault if the error is not corrected after performing

the following. Check the application program once more.

(1) Restarting the C2 module.

(2) Replacing the C2 module.

POWER (green): On when 5V

power supply is normal

RUN (green): ON when

program is running normally.

When external input signal is

ON, the corresponding LED is

ON.

When output is ON,

corresponding LED is ON and

corresponding external load is

active.

LEDs indicating blown fuse

and external power failure

(FL, FH, or F) are OFF.

Inspect the power supply

related items under "Periodic

Inspection" below.

See below

• Check that the input voltage

is within specification.

• Check that the input

terminal is secure.

• Check that the module is

secured.

• Check that the external load

voltage is within

specification.

• Check the internal fuse.

• Check that the output

terminal is secure.

• Check that the module is

secured.

6F8C1111

Page 52

Chapter 4 Maintenance

32

4.2 Periodic Maintenance

Check the following items periodically (once every six month is recommended). Also

check these items when the surrounding condition or environment is changed.

Item Inspection Description Action

Power supply related

Installation

I/O module related

Environment Check the temperature,

Battery related

Power supply voltage

(measure at the power supply

terminal of the module)

Check for loose power supply

terminal screws

Check for damaged cables Must not be damaged

Check that the base unit is

securely in place

Check that each module is

securely in place

Check for loose connector in

front of the module and

damaged cables

Measure voltage of each I/O

terminal

Check the input status LED Must turn ON normally

Check the output status LED Must turn ON normally

Check that the I/O terminal is

secure

Check that the terminal

screws are secure and not

touching each other

Check for damaged cables Must not be damaged

humidity, vibration, and dust

C2 built-in Litium battery Should be replaced after 10

PS694 battery Should be replaced

Other battery Should be replaced after two

Check that the battery

connector is connected

securely

AC85 - 132VAC/170 264VAC

Must be secure

Must not be loose

Must not be loose

Must not be loose or

damaged

Must be within specification

Must not be loose

Must not be loose or touching

each other

Must be within installation

environment specification

years by C2 overhaul

after 3 years (Ni-Cd battery)

after 1 year (Ni-MH battery)

years

Must be secure

• Do not attempt to disassemble, modify, or repair.

This can cause electrocution, fire, or injury.

Contact the Toshiba service desk for repair.

WARNING

Computer module C2PU37 User’s Manual

Page 53

4.3 Replacement Timing of Major Parts

33

CAUTION

• Take extreme precaution when measuring the power supply voltage at the power

supply terminal of the module during inspection.

There is a danger of electrocution.

• Do not touch the C2 module when the power is on. The heat radiating side covers

become extremely hot (ambient temperature+20oC) when power is on. It cools

(ambient temperature+10 oC) in 10 minutes when the power is turned off.

4.3 Replacement Timing of Major Parts

Listed below are the product life of major components. Periodically replace parts using

this table as reference. Contact your Toshiba service desk for information concerning

the price and ordering method of replacement parts.

Product life of major components

Parts

Hard disk

drive

Battery

(PS694 built-in

Ni-Cd)

Battery

(PS694M

built-in Ni-MH)

Battery

(C2 built-in)

PC Card slot Functional

External FDD Mechanism Wear 5 years or 15,000

Parts

Keyboard Mechanism Wear 100,000 strokes — Replace

Mouse Mechanism Wear 100,000 clicks — Replace

CRT Displays 10,000 cumulative power

Location of

wear

Mechanism Wear 5 years or 20,000

Capacity Depletion 500 power interruptions or

Capacity Depletion 450 power interruptions or

Capacity Depletion 10 years (Ambient

parts

Product life of major components

Location of

wear

In addition to the main unit, disk drives such as the CD-ROM, and MO drive also have

a product life. Check the product life of the peripheral devices being used and replace

them before their product life expires.

Description

cumulative power on hours

which ever comes first.

3 years, whichever come

first. (Ambient temperature

35o C)

1 year, whichever come

first. (Ambient temperature

35o C)

temperature 35o C)

Wear 10000 insertions/removals — Parts replacement

cumulative power on hours

which ever comes first.

Description

on hours

Product Life

Product Life

Replacement

Interval

2 years Replace

— Replace

— Replace

10 years Parts replacement

by overhaul

by overhaul

2 years Replace

Replacement

Interval

— Replace

Action

Action

6F8C1111

Page 54

Chapter 4 Maintenance

34

4.4Replacing the Hard Disk Drive

The main unit is equipped with one 2.5 inch hard disk drive in the HDD pack.

The HDD pack replacement procedure is as follows:

Important

• Be careful not to exert excessive shock to the HDD pack.

• Always turn off the power before removing/installing the HDD pack.

Removing/installing the HDD pack with the power turned on can damage the

content of the hard disk.

• Exchange of an HDD pack should shut off a power supply, and after 30 seconds or

more pass, perform it.

The contents of a disk may be destroyed if it exchanges immediately after turning

off a power supply.

• Be sure to pull out HDD Drawer metallic ornaments using tools, such as a minus

driver.

If a finger pulls directly, there is a possibility of removing a nail.

4.4.1 How to Remove the HDD pack

(1) It checks that the power supply is off.

(2) The screw of the HDD fixed board is loosened and the HDD fixed board is made

to slide to the left.

(3) A minus driver is united with the slot in front of an HDD pack, and HDD pack

drawer metallic ornaments are pulled out.

(4) An HDD pack is removed pulling HDD pack drawer to the front.

4.4.2 Intalling the HDD pack

(1) It checks that the power supply is off.

(2) The direction of up-and-down is checked and an HDD pack is inserted.

(3) If it enters to the back, the upper part and the lower part of an HDD pack will be

pushed with a finger, and a connector will be combined certainly.

(4) An HDD fixed board is made to slide to the right, and it fixes with a screw.

Computer module C2PU37 User’s Manual

Page 55

35

Chapter 5 RAS Function

RAS function (Reliability, Availability, Serviceability) represents the function which

increases the operating performance of the C2. C2 is equipped with RAS hardware

and RAS support software to facilitate the use of RAS functions.

Persons in charge of design, operation, or maintenance of the C2 should have

sufficient knowledge of these function in order to be ready in case of trouble.

This chapter provides an overview of the RAS hardware and software and describes

the hardware operation.

6F8C1111

Page 56

Chapter 5 RAS Function

36

5.1RAS Function Overview

The RAS hardware and software provide the following functions.

5.1.1 RAS Hardware

Internal diagnosis Circuit that detects internal abnormal conditions.

• WDT monitoring

• DRAM ECC error detection

• CPU temperature/CPU peripheral temperature rise detection

• Power voltage drop detection

• C2 built-in Battery failure detection

Power ON/OFF function OFF detection of an input power supply, and control of a power

supply.

Reset function The function reset at the time of abnormalities

• Compulsive initialization switch (INZ switch)

• Compulsive hardware reset switch (RST switch)

Interrupt output function Non-maskable interrupts (NMI) and maskable interrupts (MI) are

available.

NMI: Power off, WDT, initialize switch control

MI: CPU peripheral temperature rise, interval timer

RAS memory function Equipped with battery backed RAS memory (64K bytes) to save

information while running.

• Saving of error information

• Saving of user information

(MI can be enabled/disabled by software)

5.1.2 RAS Support Software

This section provides a general description of the RAS support software. Refer to the

"Computer module C2/C3 Windows User’s Manual (6F8C0894)" for more information

concerning RAS function software processing.

The Windows version C2 is shipped with the RAS support software installed.

The RAS support software consists of RAS hardware drivers and RAS software libraries and

there are two ways to use it.

From the RAS windows It can be used simply by registering the RAS window parameter

during installation.

From the user program Used by creating a user application program using RAS

commands in VC (Visual C++) or VB (Visual Basic) for the

specific purpose.

Sufficient knowledge of the hardware functions is necessary to

create the program.

Computer module C2PU37 User’s Manual

Page 57

5.2 Hardware Processing RAS Functions

37

5

request

within 500ms)

5.2Hardware Processing RAS Functions

5.2.1 WDT Circuit and Hardware Reset

The WDT circuit issues an NMI to the main unit when the WDT counter is not reset within a

certain interval (WDT monitoring interval). The WDT monitoring interval can be set up to

500ms x 255 (approximately 2 minutes) in 500ms units.

If an NMI is not accepted within 500ms after a WDT timeout NMI is issued, the system is

reset by the hardware reset function.

WDT reset

500ms*N

NMI

Force reset

output

Force reset because NMI (WDT) reset is not performed by CPU

500ms*N

(recover because reset

NMI issued

500ms

Important

• Do not enable the suspend function when using the WDT function. This may cause a

mal-function.

The suspend function is a power saving method and cannot be used together with

the WDT function.

5.2.2 RAS Memory

RAS memory is a 64K-byte battery backed non-volatile memory and is used to store NMI

events and RAS information. It is also used by the RAS support software to save shutdown

information.

RAS memory is designed to be accessed using the I/O space and does not use any

memory space.

RAS memory is backed up by the backup battery (Lithium battery) installed inside the main

unit.

<WDT and forced reset time chart>

5.2.3 Interrupt Signals

Interrupts detected by RAS board and sent to CPU are classified into NMI events and MI

events.