Page 1

TOSHIBA

SERVICE MANUAL

COLOUR TELEVISION

14N21D2

PRINTED IN UK. 2002 C

Page 2

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.

To enter the Service Mode, press both set key and remote control key for more than 2 seconds.

Set Key

VOL. (-) MIN 0

VOL. (-) MIN 1

VOL. (-) MIN

VOL. (-) MIN

VOL. (-) MIN

Remocon Key Operations

Reset the user setting items (PICTURE, VOLUME and LANGUAGE) to the initial state

for delivery.

Initialization of the factory.

NOTE:

POWER ON total hours is displayed on the screen.

6

8

9

Refer to the "CONFIRMATION OF HOURS USED".

Can be checked of the INITIAL DATA of MEMORY IC.

Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

Writing of EEPROM initial data.

NOTE: Do not use this for the normal servicing.

Display of the Adjustment MENU on the screen.

Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

Do not use this for the normal servicing.

If you set a factory initialization, the memories are reset such as the

channel setting, and the POWER ON total hours.

CONFIRMATION OF HOURS USED

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

NOTE: If you set a factory initialization, the total hours is reset to "0".

1.

Set the VOLUME to minimum.

2.

Press both VOL. DOWN button on the set and Channel

button (6) on the remote control for more than 2 seconds.

3.

After the confirmation of using hours, turn off the power.

ADDRESS DATA

INIT 01 00

CRT ON 0010

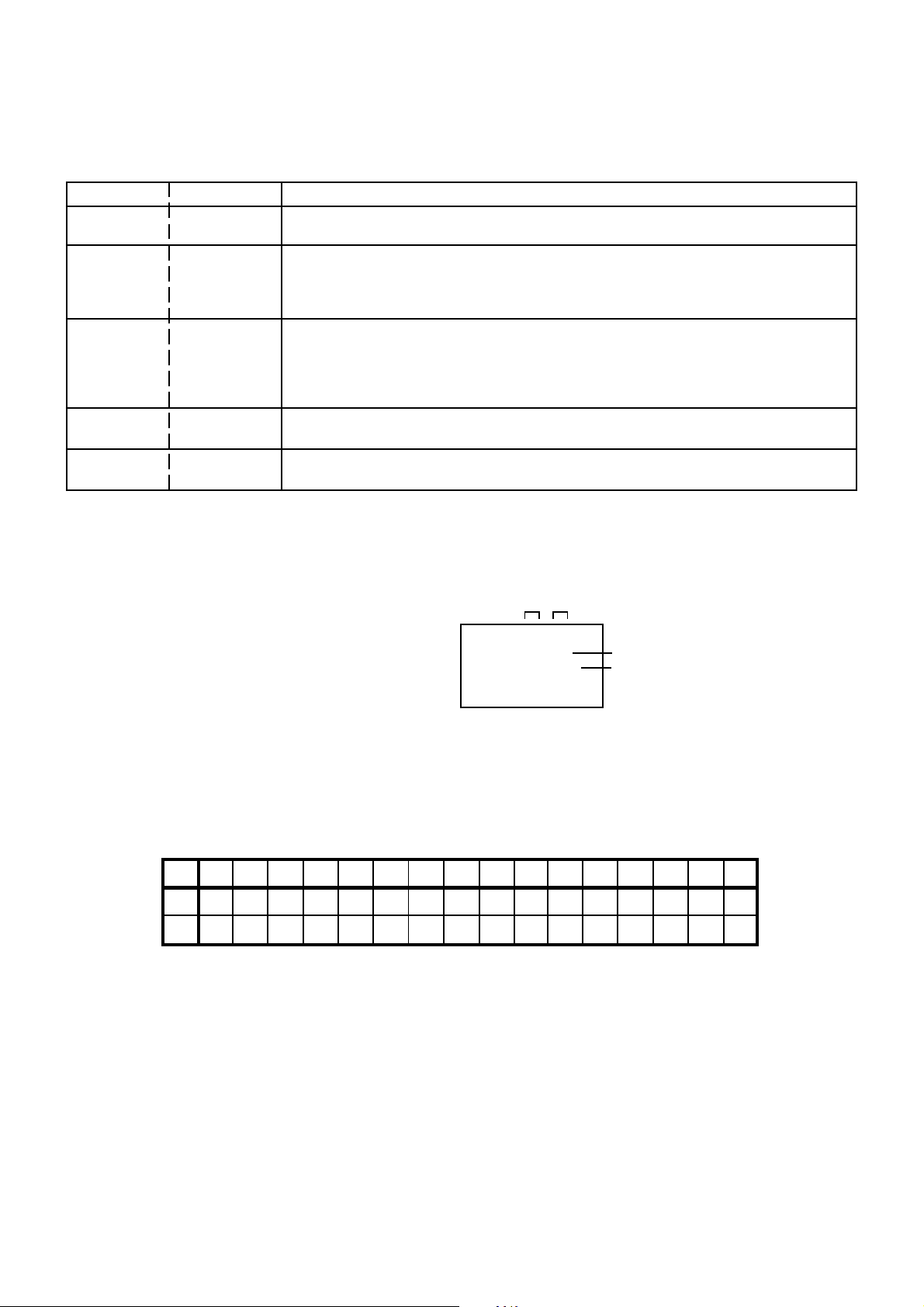

FIG. 1

Initial setting content of MEMORY IC.

POWER ON total hours.

= (16 x 16 x 16 x thousands digit value)

+ (16 x 16 x hundreds digit value)

+ (16 x tens digit value)

+ (ones digit value)

WHEN REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken to

ensure correct data settings while making reference to TABLE 1.

NOTE: No need setting for after INI 16 due to the adjustment value.

INI

+0 +1 +2 +3 +4 +5 +6 +7 +8 +9 +A +B +C +D +E +F

00 27 07 83 00 06 00

--- 00 00 00 00 60 80 60 68 60

10 80 80 80 BC 00 --- --- ---10 00 --- --- --- --- --- ---

Table 1

Enter DATA SET mode by setting VOLUME to minimum.

1.

Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 2 seconds.

2.

ADDRESS and DATA should appear as FIG 1.

ADDRESS is now selected and should "blink". Using the VOL. +/- button on the remote, step through the ADDRESS until

3.

required ADDRESS to be changed is reached.

Press OK to select DATA. When DATA is selected, it will "blink".

4.

Again, step through the DATA using VOL. +/- button until required DATA value has been selected.

5.

Pressing OK will take you back to ADDRESS for further selection if necessary.

6.

Repeat steps 3 to 6 until all data has been checked.

7.

When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

8.

After the data input, set to the initializing of shipping.

Turn POWER on.

9.

Press both VOL. DOWN button on the set and Channel button (1) on the remote control for more than 2 seconds.

10.

After the finishing of the initializing of shipping, the unit will turn off automatically.

11.

The unit will now have the correct DATA for the new MEMORY IC.

C-1

Page 3

ELECTRICAL ADJUSTMENTS

1. ADJUSTMENT PROCEDURE

Read and perform these adjustments when repairing the

circuits or replacing electrical parts or PCB assemblies.

CAUTION

•

Use an isolation transformer when performing any

service on this chassis.

•

Before removing the anode cap, discharge electricity

because it contains high voltage.

•

When removing a PCB or related component, after

unfastening or changing a wire, be sure to put the wire

back in its original position.

•

When you exchange IC and Transistor for a heat sink,

apply the silicon grease on the contact section of the

heat sink. Before applying new silicon grease, remove all

the old silicon grease. (Old grease may cause damages

to the IC and Transistor).

Prepare the following measurement tools for electrical

adjustments.

1. Oscilloscope

2. Digital Voltmeter

3. Pattern Generator

On-Screen Display Adjustment

1. In the condition of NO indication on the screen.

Press the VOL. DOWN button on the set and the

Channel button (9) on the remote control for more than

2 seconds to appear the adjustment mode on the

screen as shown in Fig. 1-1.

TV

2. BASIC ADJUSTMENTS

2-1: CONSTANT VOLTAGE

Place the set with Aging Test for more than 15 minutes.

1.

Connect the digital voltmeter to TP502.

2.

Set condition is AV MODE without signal.

3.

Adjust the VR501 until the DC voltage is 135 ± 0.5V.

4.

2-2: VCO

1.

Place the set with Aging Test for more than 10 minutes.

2.

Connect the oscillator (38.9MHz) to TP003.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (13) on the remote control to

select "VCO COARSE".

4.

Press the VOL. +/- button on the remote control until

the "OK" appear on the screen. If the "OK" is not

displayed, select the "+" side on the changed from "+"

to "-".

5.

Press the Page UP button once to set to "VCO FINE"

mode.

6.

Press the VOL. +/- button on the remote control to

select the 5 step down point from the upper limit on the

"OK".

(Example: In case of the "OK" range 30~41, select 36.)

2-3: AGC VOLTAGE

1.

Place the set with Aging Test for more than 15 minutes.

2.

Receive the UHF (63 ± 1dB).

3.

Connect the digital voltmeter to TP002.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (01) on the remote control to

select "RF AGC".

5.

Press the VOL. +/- button on the remote control until the

digital voltmeter is 2.5 ± 0.05V.

35 H. POSI OSD 128

Fig. 1-1

2.3.Use the Channel button (0-9) or Channel UP/DOWN

button on the remote control to select the options

shown in Fig. 1-2.

Press the MENU button on the remote control to end

the adjustments.

FUNCTION

NO.

CUT OFF

00

RF AGC

01

AGC GAIN

02

R DRIVE

03

R CUTOFF

04

G DRIVE

05

G CUTOFF

06

B DRIVE

07

H POSI (50)

08

V POSI (50)

09

V POSI (60)

10

V SIZE (50)

11

V SIZE (60)

12

VCO COARSE

13

VCO FINE

14

VCO COARSE L1

15

VCO FINE L1

16

BRIGHT CENT

17

BRIGHT MAX

18

BRIGHT MIN

19

NO.

FUNCTION

20

TINT

21

SHARP

22

CONTRAST CENT

23

CONTRAST MAX

24

CONTRAST MIN

25

COLOR CENT

26

COLOR MAX

27

COLOR MIN

28

M R CUT OFF

29

M G CUT OFF

30

M B CUT OFF

31

CVBS OUT

32

APR THRESHOLD

33

BELL FILTER

34

BANDPASS

35

H POSI OSD

36

V POSI OSD

37

H POSI TEXT

38

V POSI TEXT

39

H POSI (60)

Fig. 1-2

2-4: CUT OFF

1.

Set condition is AV MODE without signal.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Place the set with Aging Test for more than 15 minutes.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (00) on the remote control to

select "CUT OFF".

5.

Adjust the Screen Volume until a dim raster is obtained.

2-5: WHITE BALANCE

NOTE: Adjust after performing CUT OFF adjustment.

1.

Place the set with Aging Test for more than 10 minutes.

2.

Receive the gray scale pattern from the Pattern

Generator.

3.

Using the remote control, set the brightness and

contrast to normal position.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (03) on the remote control to

select "R DRIVE".

5.

Press the Page UP/DOWN button on the remote control

to select the "R DRIVE", "G DRIVE", "M R CUTOFF" or

"M G CUTOFF".

6.

Adjust the VOL. +/- button on the remote control to

whiten the R DRIVE, G DRIVE, M R CUT OFF, and M G

CUT OFF at each step tone sections equally.

7.

Perform the above adjustments 5 and 6 until the white

color is looked like a white.

D-1

Page 4

ELECTRICAL ADJUSTMENTS

2-6: FOCUS

Receive a 70dB monoscope pattern.

1.

Turn the Focus Volume fully counterclockwise once.

2.

Adjust the Focus Volume until picture is distinct.

3.

2-7: HORIZONTAL POSITION

1.

Receive the monoscope pattern from the Pattern

Generator.

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (08) on the remote control to

select "H POSI (50)".

4.

Press the VOL. +/- button on the remote control until

the SHIFT quantity of the OVER SCAN on right and left

becomes minimum.

5.

Receive the monoscope pattern of NTSC. (Audio Video

Input)

6.

Using the remote control, set the brightness and

contrast to normal position.

7.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (39) on the remote control to

select "H POSI (60)".

8.

Press the VOL. +/- button on the remote control until

the SHIFT quantity of the OVER SCAN on right and left

becomes minimum.

2-8: VERTICAL SIZE

Receive the monoscope pattern from the Pattern

1.

Generator.

Using the remote control, set the brightness and

2.

contrast to normal position.

Activate the adjustment mode display of Fig. 1-1 and

3.

press the channel button (11) on the remote control to

select "V SIZE (50)".

Adjust by using the VOL. +/- button on the remote

4.

control so that the Up/Down OVER SCAN Quantity

becomes equal to the Right/Left OVER SCAN Quantity.

Receive a broadcast and check if the picture is normal.

5.

Receive the monoscope pattern of NTSC. (Audio Video

6.

Input)

Using the remote control, set the brightness and

7.

contrast to normal position.

Activate the adjustment mode display of Fig. 1-1 and

8.

press the channel button (12) on the remote control to

select "V SIZE (60)".

Adjust by using the VOL. +/- button on the remote

9.

control so that the Up/Down OVER SCAN Quantity

becomes equal to the Right/Left OVER SCAN Quantity.

2-10: BRIGHT CENT

1.

Receive the PAL black pattern*. (RF Input)

2.

Using the remote control, set the brightness and

contrast to normal position.

3.

Place the set with Aging Test for more than 15 minutes.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (17) on the remote control to

select "BRIGHT CENT".

5.

Press the VOL. +/- button on the remote control until

the screen begin to shine.

6

Receive the PAL black pattern*. (Audio Video Input)

7.

Set to the AV mode. Then perform the above

adjustments 2~5.

*The Black Pattern means the whole black raster signal.

Select the "RASTER" of the pattern generator, set to

the OFF position for each R, G and B.

2-11: CONTRAST CENT

1.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (22) on the remote control to

select "CONTRAST CENT".

2.

Press the VOL. +/- button on the remote control until

the contrast step No. becomes "35".

3.

Receive a broadcast and check if the picture is normal.

4.

Set to the AV mode. Then perform the above

adjustments 1~3.

2-12: COLOR CENT

1.

Receive the PAL color bar pattern. (RF Input)

2.

Using the remote control, set the brightness, contrast

and color to normal position.

3.

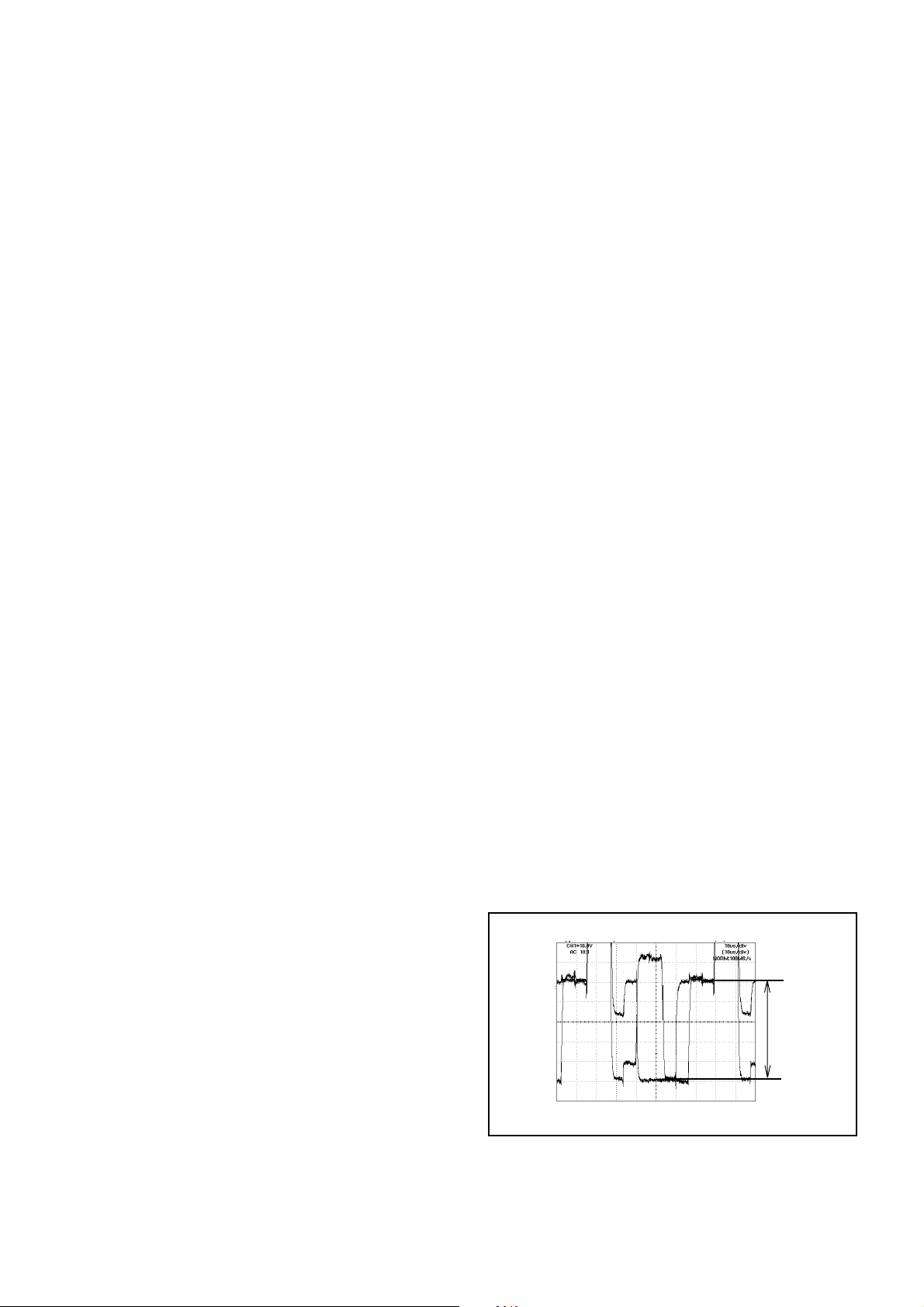

Connect the oscilloscope to TP023.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (25) on the remote control to

select "COLOR CENT".

5.

Adjust the VOLTS RANGE VARIABLE knob of the

oscilloscope until the range between white 100% and

0% is set to 5 scales on the screen of the oscilloscope.

6.

Press the VOL. +/- button on the remote control until

the red color level is adjusted to 100 ± 10% of the

white level. (Refer to Fig. 2-1)

7.

Receive the PAL color bar pattern. (Audio Video Input)

8.

Set to the AV mode. Then perform the above

adjustments 2~6.

2-9: VERTICAL POSITION/VERTICAL LINEARITY

Receive the monoscope pattern from the Pattern

1.

Generator.

Using the remote control, set the brightness and

2.

contrast to normal position.

Adjust the VR401 until the horizontal line becomes fit to

3.

the notch of the shadow mask.

Adjust the VR420 until the SHIFT quantity of the OVER

4.

SCAN on upside and downside becomes minimum.

100%

Fig. 2-1

D-2

Page 5

ELECTRICAL ADJUSTMENTS

2-13: TINT

1.

Receive the NTSC color bar pattern. (Audio Video Input)

2.

Using the remote control, set the brightness and contrast

to normal position.

3.

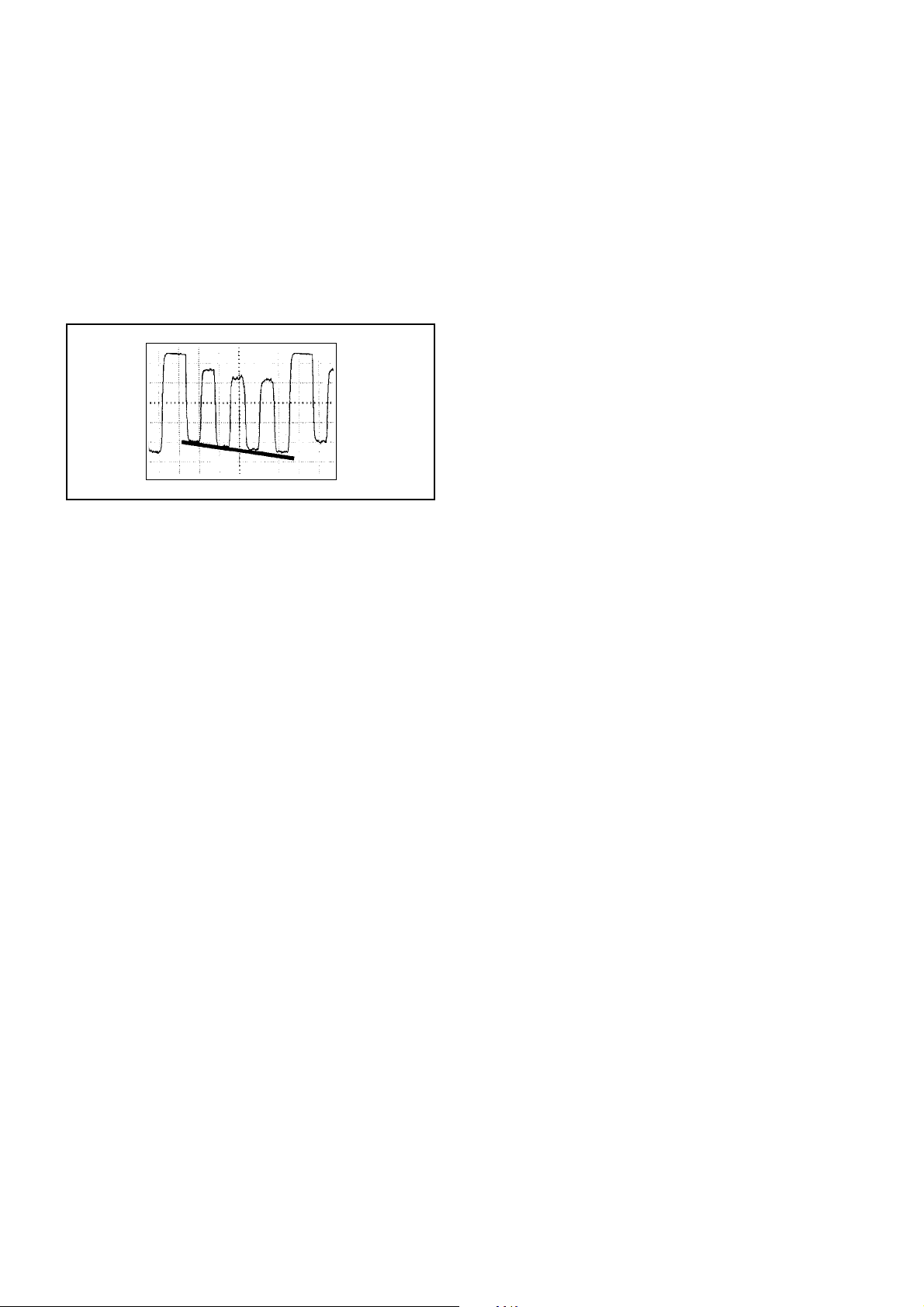

Connect the oscilloscope to TP024.

4.

Activate the adjustment mode display of Fig. 1-1 and

press the channel button (20) on the remote control to

select "TINT".

5.

Press the VOL. +/- button on the remote control until the

section "A" becomes a straight line. (Refer to Fig. 2-2)

"A"

Fig. 2-2

2-14: Confirmation of Fixed Value (Step No.)

Please check if the fixed values of the each adjustment

items are set correctly referring below.

NO.

FUNCTION

02

AGC GAIN

04

R CUTOFF

06

G CUTOFF

07

B DRIVE

09

V POSI (50)

10

V POSI (60)

18

BRIGHT MAX

19

BRIGHT MIN

20

TINT

21

SHARP

23

CONTRAST MAX

24

CONTRAST MIN

26

COLOR MAX

27

COLOR MIN

30

M B CUT OFF

31

CVBS OUT

32

APR THRESHOLD

33

BELL FILTER

34

BANDPASS

35

H POSI OSD

36

V POSI OSD

37

H POSI TEXT

38

V POSI TEXT

*To check for the fixed values of the RF (60Hz), indicate

the adjustment mode screen while input the 60Hz video

signal.

RF

00

00

00

45

08

08

30

10

32

02

63

10

45

10

127

31

00

00

00

126

50

122

58

AV

---

---

---

---

---

--30

10

ADJ.

02

63

10

45

10

---

---

---

---

---

---

---

---

---

D-3

Page 6

ELECTRICAL ADJUSTMENTS

3.

PURITY AND CONVERGENCE

ADJUSTMENTS

NOTE

Turn the unit on and let it warm up for at least 30

1.

minutes before performing the following adjustments.

Place the CRT surface facing east or west to reduce the

2.

terrestrial magnetism.

Turn ON the unit and demagnetize with a Degauss Coil.

3.

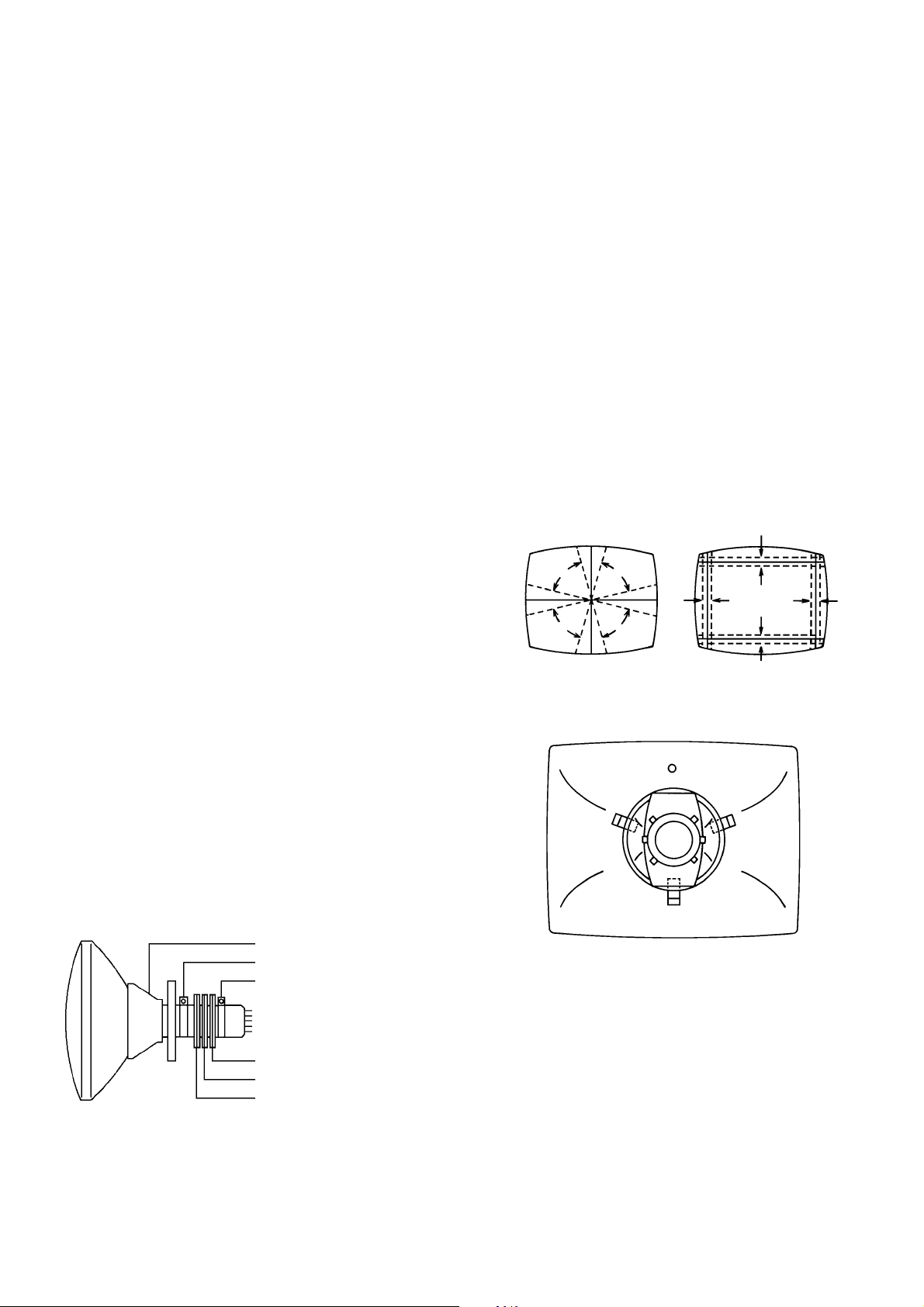

3-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

Tighten the screw for the magnet. Refer to the adjusted

1.

CRT for the position. (Refer to Fig. 3-1)

If the deflection yoke and magnet are in one body,

untighten the screw for the body.

Receive the green raster pattern from the color bar

2.

generator.

Slide the deflection yoke until it touches the funnel

3.

side of the CRT.

Adjust center of screen to green, with red and blue on the

4.

sides, using the pair of purity magnets.

Switch the color bar generator from the green raster

5.

pattern to the crosshatch pattern.

Combine red and blue of the 3 color crosshatch pattern

6.

on the center of the screen by adjusting the pair of

4 pole magnets.

Combine red/blue (magenta) and green by adjusting the

7.

pair of 6 pole magnets.

Adjust the crosshatch pattern to change to white

8.

by repeating steps 6 and 7.

3-2: PURITY

NOTE

Adjust after performing adjustments in section 3-1.

1.

Receive the green raster pattern from color bar

generator.

2.

Adjust the pair of purity magnets to center the

color on the screen.

Adjust the pair of purity magnets so the color at the

ends are equally wide.

3.

Move the deflection yoke backward (to neck side)

slowly, and stop it at the position when the whole

screen is green.

4.

Confirm red and blue colors.

5.

Adjust the slant of the deflection yoke while watching the

screen, then tighten the fixing screw.

DEFLECTION YOKE

DEFLECTION YOKE SCREW

MAGNET SCREW

3-3: STATIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-2.

1.

Receive the crosshatch pattern from the color bar

generator.

2.

Combine red and blue of the 3 color crosshatch pattern

on the center of the screen by adjusting the pair of

4 pole magnets.

3.

Combine red/blue (magenta) and green by adjusting the

pair of 6 pole magnets.

3-4: DYNAMIC CONVERGENCE

NOTE

Adjust after performing adjustments in section 3-3.

1.2.Adjust the differences around the screen by moving

the deflection yoke upward/downward and right/left.

(Refer to Fig. 3-2-a)

Insert three wedges between the deflection yoke and

CRT funnel to fix the deflection yoke.

(Refer to Fig. 3-2-b)

R G B

R

G

B

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

WEDGE

WEDGE POSITION

R

G

B

Fig. 3-2-a

WEDGE

WEDGE

Fig. 3-2-b

R G B

Fig. 3-1

PURITY MAGNETS

6 POLE MAGNETS

4 POLE MAGNETS

D-4

Page 7

ELECTRICAL ADJUSTMENTS

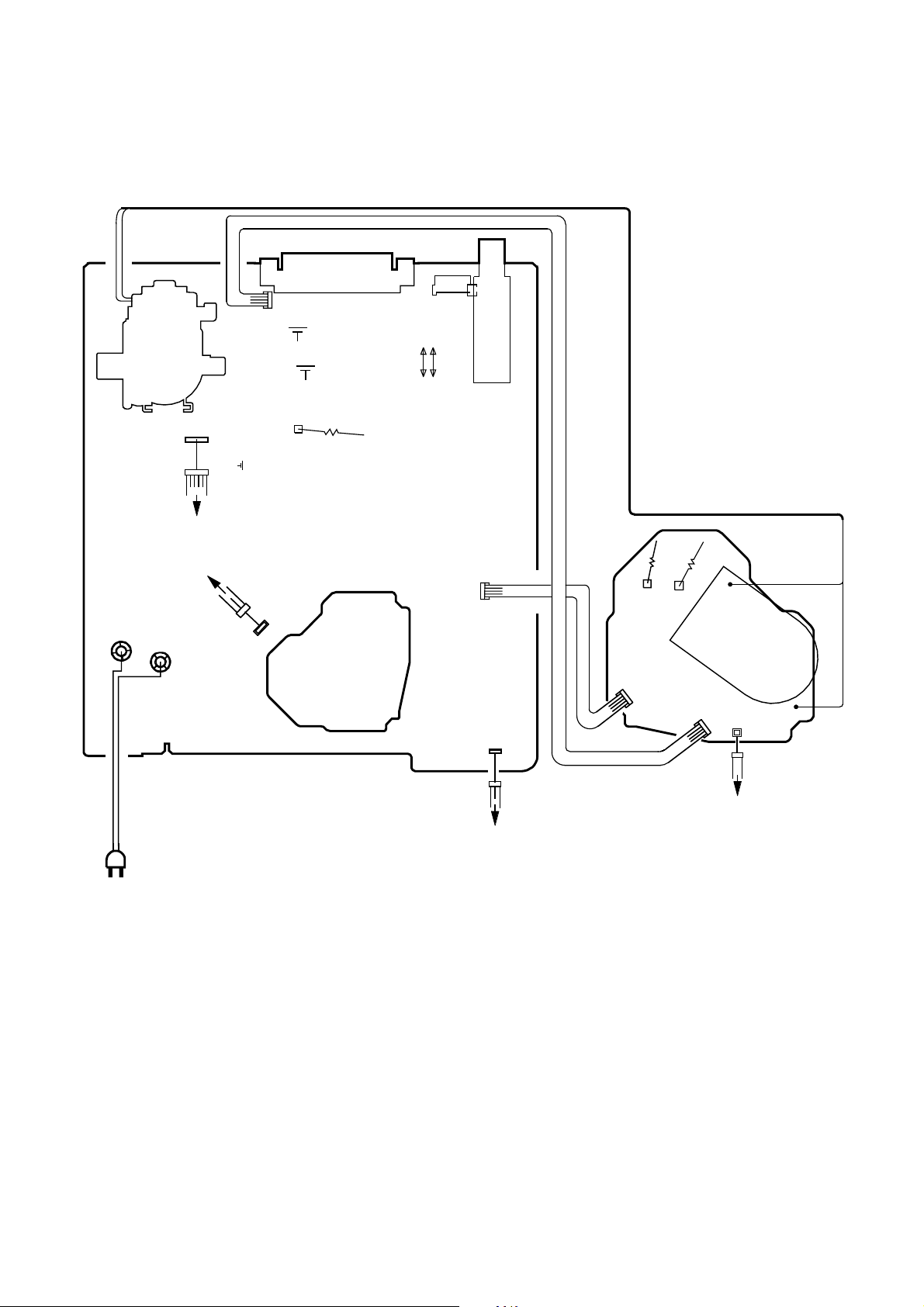

4. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

CD803

J701

FB401

CP401

CRT

DEGAUSS

COIL

CP803A

VR501

L503

CP502

VR420

VR401

TP502

R527

TP002

CP101

TP003

CP802A

TU001

CP1001

CD802

TP023

CD802B

R805

TP024

R807

CD803B

CRT PCB

J801

CP801

CP806

AC IN

MAIN PCB

SPEAKER

CD801

GND CRT

D-5

Page 8

Q506

P.FAIL

REG. 6V IC

IC502 KIA7806API

1

OS101

1

RESET IC

IC102 PST3231NR

REG. 9V IC

IC503 KIA78R09API

4

1

T501

CH UP

CH DOWN

VOL UP

VOL DOWN

Q510, Q511

P.CON SW.

1

MICON W/T.TEXT IC

IC101 OECF013A

A_MUTE

3

56

KEY IN

REMORT

1

POWER

10

POWER FAIL

55

RESET

2

ON_TIMER

49

Q501

POWER

Q502

POWER

OSD_B

OSD_FB

OSC IN

OSC_OUT

AV1

Q103

LED SW

Q102

17OSD_R

16OSD_G

15

18

20SCL

19SDA

51

50

42

41V-SYNC

40H-SYNC

LED SW

D501~D504

RECTIFIER

X101

4 MHz

SDA

5

D101

TU001

SCL

4

9

11

AGCIF

1

Q201

VIF PRE. AMP

MEMORY IC

IC199 S-24C16AFJA-TB-01

6

SCL

SDA

5

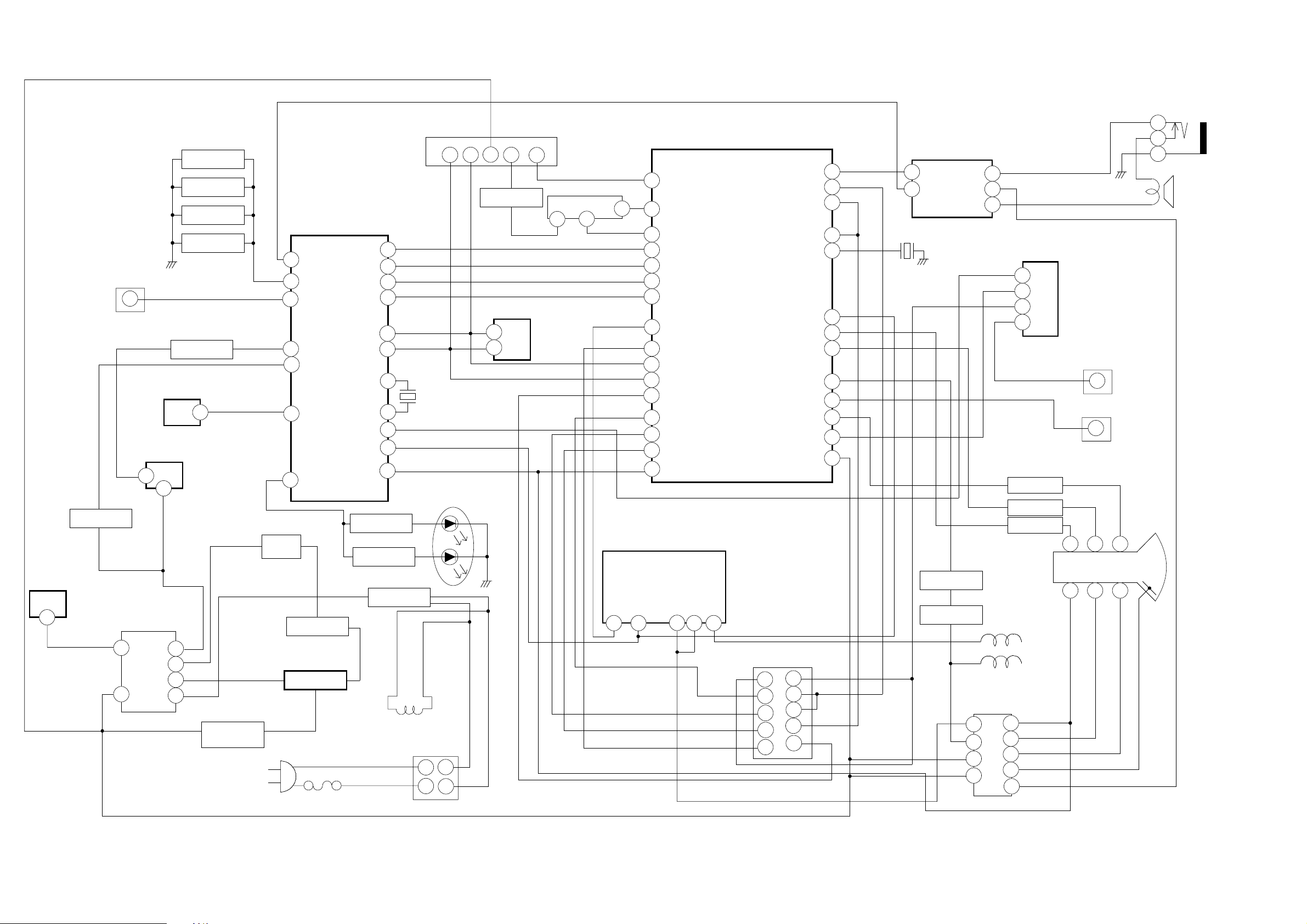

BLOCK DIAGRAM

CF202

SAW FILTER

4

1

5

36

35

34

37

42

25

51

52

20

28

27

26

49

IC401 TDA8174A

V-DRIVE IC

413

CHROMA IC

IC201 STV2246E

RF_AGC_OUT

8

PIFIN2

7

6

PIFIN1

OSD_R

OSD_G

OSD_B

OSD_BK

X1/VAMP/CHR_OUT

B_EXT/U_EXT

SCL

SDA

CVBSIN2

BLK_EXT

R_EXT/V_EXT

G_EXT/Y_EXT

LBF/SSC

10

2

AUDIO_OUT

FM_OUT

CVBSIN1

INT_CVBS_OUT

XTAL1

VERT

B.OUT

G.OUT

H.OUT

Y/CVBS_IN3

R.OUT

EXT_AUDIO_IN

48

49

55

11

18

13

40

47

30

31

48

22

32

14

46BCL/SAF

IC1001 AN7511

2

SOUND AMP

4

X601

4.433619MHz

Q402

H. DRIVE

Q401

H. OUTPUT

J1001

HEADPHONE_JACK

2

3

1

8

IC

5

6

AUDIO SW (MONO) IC

IC703 NJM2233BM-T1

2

7

1

3

FRONT AUDIO

J703

SP1001

SPEAKER

2

FRONT AUDIO

J702

2

Q802

Q803

Q801

RED OUT

GREEN OUT

BLUE OUT

397

Heater

F8

4

V801

CRT

RGB

E-1

15

13

17

5

3

IC504 LTV-817M-VB

FEED BACK

8

Q507

FEED BACK

SWITCHING

AC IN

F501

L503

DEGAUSS COIL

L501

2

4

1

3

J701

2

16

15

11

7

19

20

6

1

3

FB401

3

1

FBT

7

2

DY

10

F

S

HV

5

E-2

Page 9

ABC D E F GH

G-1

G-2

MICON/TUNER SCHEMATIC DIAGRAM

8

GREEN LED DRIVE

Q102

R102

R103

CH UP

SW101

R104

2.2K

CH DOWN

EVQ21505R

SW102

1.2K

VOL UP

EVQ21505R

SW103

820

VOL DOWN

EVQ21505R

SW104

R101

390

EVQ21505R

R109

2.2K

7

4.9

R120

4.7K

C140

220P CH

6

22P CH

C108

C109

22P CH

R136

220 1/4W

100CT4R013

1

X101

4MHz

C110 0.047 B

R117

10K

C141_1 0.1 F

R152 4.7K

5

R133

R123

R124 10K

R107 1K 1/4W R145 1.8K

D102 MTZJ5.1B

4

D108 1SS133

C131_1

3

2

R116 10K

3

5.6K

R110

1016V KA

C102

0.1 B

C103

22P CH

C104

0.0047 B

R108

270 1/4W

4

C101

68P CH

C105

0.1 B

C106

0.0022 B

C121

68P CH

C111

0.47 B

C112

82P CH

R111

15K

10K

W801

CC001

8990TPA002

KEY_IN

4.9

POWER FAIL

0

FORTHD VCR 2

0

FORTHD VCR 1

0

EMERGENCY

1.9

OSC_IN

2.3

OSC_OUT

50 51 52 53 54 55 56

4.8

ON_TIMER

4.9

P4.6/PWM6

NC

0

SECAM_VL_H

5.0

NC

TUNER HI

46 47 48 49

0

H_CONT

10K

0

PROTECT

0

AV2

0

AV1

4.7

V_SYNC

0.6

H_SYNC

40 41 42 43 44 45

4.9

AVDD1

2.0

PXFM

0

JTRSTO

0

GND

0

AGND

1.6

CVBS1

1.8

CVBS2

4.7

JTMS

NC

4.9

AVDD2

0.6

NC

30 31 32 33 34 35 36 37 38 39

CVBSO

2.1

TXCF

29

KRA102SRTK

04.9

4.9

MICON W/T.TEXT IC

IC101 OECF013A

RED LED DRIVE

4.9 0

R112

1.5K

REMORT

RESET

A MUTE

STEREO RESET

DEGAUSS

TU/RGB

(BBE-H)

(ATS)

STANDBY LED

POWER

CSO/RESET0/P3.7

I2C_OFF

P3.5

P3.4

OSD_B

OSD_G

OSD_R

OSD_FB

SDA

SCL

VDD

JTDO

WSCF

VPP

AVDD3

TEST0

MCFM

JTCK

Q103

2SC2412K

4.8

4.9

110111213141516171819 2202122232425262728

4.9

0

3

4.9

4

NC

0

5

0

6

0

789

NC

1.6

0.2

4.8

0

4.9

4.9

NC

0

0.7

0.2

0.2

0

4.6

4.6

4.9

2.5

NC

0

0

4.9

4.9

1.6

4.8

NC

R135

R144 1.8K

R146

R147 1.5K

LTL-1BEFJ-002A

R137

270

R132

150

R139

4.7K

R138

4.7K 1/4W

R125

10K

10K

1.8K

C114 0.1 B

C115

C118_1

0.1 F

R113

5.6K

C113

22P CH

D101_1

G

R

R151

4.7K

R148

10K

R134

10K

10006.3V YK

C116

0.0047 B

2

(MAIN PCB)

OS101

RPM7138-H5

VoutB+GND

123

4.9 0 4.9

R126

R140 2.7K

R141 2.7K

R142 2.7K

R143 3.3K

L101

10uH 0305

L102

10uH 0305

C122

1016V KA

47

1/4W

R105

C120

10K

1B

C139_1

C119

R106

0.47 F

5

6

7

8

9

10

R114

4.7K

R115

4.7K

1B

10K

4.9

4.9

0

RESET IC

IC102 PST3231NR

123

NC

RESET

VCC

NC

GND

D109

D107

MTZJ5.6B

4.9 0 4.6 4.6

VCC

IC199

MEMORY IC

E0

S-24C16AFJA-TB-01

1234

00 00

0

0

4 5

NC

NC

MTZJ5.6B

MODE

E1

R128

100 1/4W

R129

100 1/4W

5678

SCL

SDAVSS

E2

TU001 TUWRF4EG-778F2A

VCO

14 15

TP003

NC

0

8

IF

BTL

BPL

V.S

SDA

SCL

ADRES

6

8

9

30.7

MTZJ33B

R001

R002

C002

18K 1/2W

18K 1/2W

7

NC

NC

4.9

4706.3V YK

L001

C010 0.001 B

C007

10uH 0305

3.8

4.0

0.01 B

R004

100

R003

11

10

NC

C001

0.022 B

D001

1

12 13

NC

NC

2.2

15K

100

R006

R005

TP002

C003_1

100K

AGC

R121

100

150V KA

NC

CP001

003P-2100

C006

BT001

R03(AB)2PXGPI

TM101

RC-GX010

100P CH

NC

BT002

R03(AB)2PXGPI

TEST POINT

GND

I2C SCL

I2C SDA

I2C OFF

RF AGC

AGC

2

3

4

5

CP101

06JQ-ST

1

2

3

4

5

6

ACCESSORY

ANT001

T4-216AP-BK

7

6

FROM/TO POWER

P.CON+5V

TUNER_BT

P.FAIL

AT+5V_AVDD

AT+5V_DVDD

GND

DEGAUSS

POWER

EMERGENCY

TO SOUND AMP

A_MUTE

AV1

TO DEFLECTION/CRT

PROTECT

FROM/TO CHROMA/SIF/VIF/21PIN

IF

RF_AGC

OSD_B

OSD_G

OSD_R

OSD_FB

SCL

SDA

CVBS_TXT

HD

V_OUT

PROTECT

FOR_VCR

5

4

3

2

PCB010

TMC571

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

1

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

ATTENTION

:LES PIECES REPAREES PAR UN ETANT

DANGEREUSES AN POINT DE VUE SECURITE

N’UTILISER QUE CELLS DECRITES

DANS LA NOMENCLATURE DES PIECES

CAUTION

:SINCE THESE PARTS MARKED BY

CRITICAL FOR SAFETY,USE ONES

DESCRIBED IN PARTS LIST ONLY

ARE

CAUTION: DIGITAL TRANSISTOR

1

ABC D E F GH

Page 10

8

G-3

G-4

7

6

5

4

FROM/TO SOUND AMP

FROM/TO MICON/TUNER

3

2

ABC D E F GH

CHROMA/SIF/VIF/21PIN SCHEMATIC DIAGRAM

(MAIN PCB)

SIF BUFFER

5.0

3.2

L204

12uH

CF201

0.2250V KANP

3P CH

C216_1

12

PIF_LC1

EXT_AUDIO_IN

GND1

X1/VAMP/CHR_OUT

05.0

47010V YK

C613

3316V KA

R649

22K

Q204

2SC2412K

R217

1K

R219

VCO COIL

TPS5.5MB-TF21

L207

3700005

6

1234

NC

C201

PIF_LC2

CLPF

R608

47K

C616

0.0047 B

C615

1B

D609

MTZJ5.6B

C629

1016V KA

1.2K

VCC2(8V)

XTAL1

40414243

X601

13

0.1 B

C221

47010V YK

C220

C210

CVBSIN1

XTAL2

100CT4R408

4.433619MHz

X602

D604

11E1-EIC

7.9

2.9

2.28

R203

C621

150V KA

GND2

XTAL3

0.2 0 4.1 4.2 4.8 4.5 1.7 1.702.22.42.8

C630

3.579545MHz

100CT3R509

C602

0.1 F

BUFFER

Q202

2SC2412K

1K

100P CH

R625

150V KA

CVBSIN2

OSD_BK

C603

C618

150

BS

OSD_R

C626

1F

0.1 B

100P CH

150V KA

C604

Y/CVBS_IN3

OSD_G

C619

0.1 B

NC

C620

1.7

CHR

OSD_B

0.1 B

C607

R636

R622

APR

ICATH

1F

330K

C608

R628

47K

C622

0.1 B

G_EXT/Y_EXT

B_EXT/U_EXT

G.OUT

R.OUT

270

R629

C623

0.1 B

30313233343536373839

270

R630

11

14

16

17

18

0.1 B

BLK_EXT

R_EXT/V_EXT

CVBSOUT

B.OUT

29

4.42.62.05.24.25.05.04.904.51.5

270

212019

R618

10K

R720

100 1/4W

BUFFER

Q605

2SC2412K

7.9

4.4

4.0

R623

1K

B1002

W4BRH3.5X6X1.0

R708

1K

R719

R706

1K 1/4W

R707

1K 1/4W

R222

1/4W

MTZJ5.1B

100K

R702

75

D709

L702

10uH

820

R715

75

L202

4716V YK

27K

2.7K

R208

3.3uH 0305

C215

5.03.9

VCC_IF(5V)

VCC1 (8V)

7.85.44.6

3.9

1K

180

R204

0.1 B

D601 1SS133

INT_CVBS_OUT

NC

444546474849

NC

1F

C614_1

C634

R213

100 1/2W

R215

C204

0.022 B

R214

MKT31.9MA110P

6.8K

7.0

1.5

0.8

2.2K

L206

0.39uH

L208

0.39uH

FROM POWER

P.CON+8V

GND

P.CON+5V

SCART_AUDIO

FRONT_VIDEO_IN

SW_AUDIO_IN

AUDIO_OUT

IF VAMP

RF_AGC AFC

SDA V_OUT

SCL

HD

PROTECT

CF303

MKT40.4MA110P

R216 75 1/4W

R601

CF204

1.5K

270

L203

R202

C203

2.2uH

VIF PRE.AMP

Q201

KTC3881S-RTK

47

R201

NC

1 101112131415161718192 20 21 22 23 24 25 26 27 28

SIFIN1

CHROMA IC

IC201 STV2246E

FM_CAP

C605_1

1F

C212

0.01 B

NC

SIFIN2

AUDIO_OUT

C206

3

AGCSIFCAP

GND_D

C609

0.022 B

1B

C209

4

VREF_IF

(5V)

VCC_D

L601

0.1 B

1016V KA

1F

C213_1

C218

0.022 B

5

6789

AGCPIF_CAP

SDA

10uH 0305

47P CH

C601

10016V YK

C610

R602

100

R606

PIFIN1

SCL

C625

100

50515253545556

R607

C611

D602

47P CH

L103

10uH

PIFIN2

SLPF

C612

SAW FILTER

12345

C202

0.001 B

4.5 2.0 0 3.8 2.4 3.8 3.9 7.8 4.1 0 3.2 2.8 3.2 1.7 3.4 3.6 3.4 02.7 2.8 4.8 3.1 2.7 2.5 2.5

RF_AGC_OUT

LBF/SSC

2.2K

R645

22K

24

0.0015 B

3.350V KA

D605

SB140-EIC

D603

1SS133

1SS133

R647

560 1/2W

CF202_1

G1984M

C205

IFPLL

H_OUT

R643

C207

R218

R638

R646

OUTOUTGININ

0.33 B

0.001 B

C217

150

GND_IF

FM_OUT

VERT

BCL/SAF

470

2.2K

R640

C624

0.01 B

5.6K

R639

8.2K 1/4W

R644

23

C701_2

0.0047 B

R714

75

S802XS802Y

R721

150 1/4W

R621

560 1/4W

L703

C703

10uH

R703

10K 1/4W

R713

75

R709

75

FROM/TO DEFLECTION/CRT

B.OUT

G.OUT

R.OUT

H_OUT

ABCL

FROM/TO MICON/TUNER

FOR_VCR

V_OUT

CVBS_TXT

OSD_B

OSD_G

OSD_R

OSD_FB

21PIN

J701

470P CH

0350_9982_05

NC

NC

8

7

6

1

220

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

21 3

5

4

3

2

PCB010

TMC571

1

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

1

ABC D E F GH

Page 11

ABC D E F GH

G-5

G-6

SOUND AMP/FRONT AV SCHEMATIC DIAGRAM

8

(MAIN PCB)

R711

820

L704

10uH

FRONT AUDIO

J703

AV1-09D-4

H

2

8

E

1

7

6

5

4

FROM/TO CHROMA/SIF/VIF/21PIN

SW_AUDIO_IN

FRONT_VIDEO_IN

SCART_AUDIO

AUDIO_OUT

FROM POWER

P.CON+8V

GND

FROM DEFRECTION

SOUND+B

R740

220

L714

10uH 0305

27

0 4.4 8.3 0

GND

IC703

NJM2233BM-T1

Vin1

AUDIO SW(MONO) IC

1234

1016V KA

C744

R741

V.OUT

SW1

28

75

R710

10010V YK

C711

C746

0.01 B

NC

5678

NC

Vcc

1234

0.35.1 3.9

3.43.58.2 0

C1004

0.0015 B

Vin2

NC

05.105.1

NC

1K

1016V KA

C745

C1001

C1003_1

47K 1/4W

47016V YK

0.150V KA

R1011

C1006

22016V YK

R1003

100K

R1004

68K

5678

+-

0

C1005_1

0.4750V KA

R1009

47K 1/4W

AN7511

SOUND AMP IC

IC1001

47K

R1006

29

C1007

1016V KA

C704

0.001 B

B1001

W4BRH3.5X6X1.0

R1010

33 1/2W

C1002

47P CH

C1009

0.0047 B

H

2

FRONT VIDEO

AV1-09D-3

CP1001

A2502WV2-2P

BLACK

RED

J702

E

1

7

6

5

2

1

SPEAKER

SP1001

SA08A05BWC

HEADPHONE_JACK

J1001

MSJ-035-12A_PC

4

2

1

2

3

1

3

FROM MICON/TUNER

AV1

A_MUTE

2

PCB010

TMC571

1

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

ATTENTION

:LES PIECES REPAREES PAR UN ETANT

DANGEREUSES AN POINT DE VUE SECURITE

N’UTILISER QUE CELLS DECRITES

DANS LA NOMENCLATURE DES PIECES

CAUTION

:SINCE THESE PARTS MARKED BY

CRITICAL FOR SAFETY,USE ONES

DESCRIBED IN PARTS LIST ONLY

ARE

3

2

1

ABC D E F GH

Page 12

8

G-7

G-8

FROM/TO CHROMA/SIF/VIF/21PIN

R.OUT

G.OUT

B.OUT

V_OUT

H_OUT

7

6

FROM MICOM/TUNER

PROTECT

5

FROM POWER

4

P.CON+8V

H.DRV+B

TO SOUND AMP/FRONT AV

SOUND+B

3

2

ABC D E F GH

(MAIN PCB)

9

10

8

6

11

FOCUS

R

G

B

CP802B

B2013H02-6P

1

PROTECT

2

CUT OFF

3

4

R.OUT

5

G.OUT

6

B.OUT

CP803B

B2013H02-4P

1

2

HEATER

3

4

CD801

SM1573-001

(to CP001)

175

GND

GND

180V

1

1

CP802A

B2013H02-6P

CP803A

B2013H02-4P

FROM/TO CRT FROM/TO DEFLECTION

35

10

250V YK

PROTECT

CUT OFF

GND

R.OUT

G.OUT

B.OUT

GND

HEATER

180V

1

2

3

4

5

6

1

2

3

4

(CPJ370BVBK1U-TC)

5

4

3

NC

2

1

CP401

A1561WV2-A5P

V801

A34JXV70X53N45

ANODE

SCREEN

CP801

003P-2100

FOCUS

CP806_1

SCREEN

8

NCNC

GREEN OUT

Q801

KTC3207

W815

1

D807

1SS133

R809

1.2K 1/4W

RED OUT

Q802

R813

680P B

KTC3207

270 1/4W

3.2

2.7100.6

C804

TP022 TP023

3.2

98.4 2.7

D808

C805_2

1SS133

R811

R815

680P CH

413940

1.2K 1/4W

270

BLUE OUT

Q803

KTC3207

TP024

95.4

D809

1SS133

R814

1.2K 1/4W

3.2

2.7

270

R816

C806_1

680P CH

7

6

5

R803

1/4W

R802

15K 1W

2.7K

R805

R804

15K 1W

2.7K 1/4W

R807

1/4W

R806

15K 1W

2.7K

4

0.0012KV B

C819

96.4

6.4

3

4

PCB110

TCC432

101.6

0

5

0

6

7

8

0

0

1

F

J801

9

ISMS01S

99.6

3

2

VAMP

ABCL

AFC

GND

+B

R422

1.5K 1/4W

D406

R424

11E1-EIC

180 1W

R404

330K M+-1%

33

0.06

H.DRIVE

Q402

2SC1627_Y

IC401 TDA8174AV-DRIVE IC

POWER OUTPUT

OUTPUT STAGE Vs

TRIGGER INPUT

1101123456789

14.5 23.0 5.0 6.4 4.4 12.0 12.0 4.4 25.0 1.70.0

2.2

PROTEC

Q403

KRC102SRTK

0.0

36

27.0

1/2W

R446

C401

470

0

C446

MMTS

0.01100V

C440

220P CH

0.3

HEIGHT ADJ.

R405

R408

1K 1/4W

T401

ETH09K14BZ

34

2

1

2250V YK

HS402

763WSA0017

Vref. DECOUP.

C408

390K M+-1%

R406

6.8K 1/4W

HS401

763WSAA013

6

R411_2

150 2W

GND

1016V KA

37

TT2140LS-YBC11

R427

RAMP GENERATOR

C412

H.OUTPUT

Q401

0

100 1/4W

D407

11E1-EIC

DEFLECTION/CRT SCHEMATIC DIAGRAM

BUFFER OUTPUT

R412

0.047 MMTV

R417

38

130

0

INVERTING INPUT

8.2K 1/4W

V_LIN

+-1%

M

3.3K

C443

D405

C413

VR420

R419

C417

C423

CMPP

0.00821.25KV

B_SHORT

AU02A-EIC

Vs

C414

0.082 B

10K 1/4W

470

1.2K

1050V YK

2.2250V MHE

FB. GENERATOR

10035V YK

34

R420

C418

R407

C437 0.39250V

L401

4.7mH

0909

D410

AU02A-EIC

D403

11E1-EIC

220025V MHE

1.2 1/2W

R447

68 1/2W

R416

C422

2.2 1/2W

MMTS

0.22

100V

PMS

R410

680 1/2W

R409

680 1/2W

C403

47035V YK

GND

ABL

HEATER

GND

R402

1K 1/2W

2.2K

VR401

V_POSI

R403

1K 1/2W

FB401_1 FNI-14B002

131.7

COL

1

VIDEO

135

6

135

B+

2

AFC

NC

9

GND

8

E12

NC

45

4.9

E25

3

1W

R429

5.6

25.2

HV

F

S

11

5.6

7

6.3

10

16.8

8

C448

R418_1

6.8 3W

C404

100010V YK

D404

AU02A-EIC

180K

R445

1/4W

C435

0.1100V MMTS

R421

47K 1/4W

PCB010

TMC571

1

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

THE RESISTOR MARKED F IS FUSE RESISTOR.NOTE:

THE ALUMI ELECTROLYTIC CAPACITOR MARKED NP

IS NON POLAR ONE.

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

ATTENTION

:LES PIECES REPAREES PAR UN ETANT

DANGEREUSES AN POINT DE VUE SECURITE

N’UTILISER QUE CELLS DECRITES

DANS LA NOMENCLATURE DES PIECES

CAUTION

CAUTION: DIGITAL TRANSISTOR

:SINCE THESE PARTS MARKED BY

CRITICAL FOR SAFETY,USE ONES

DESCRIBED IN PARTS LIST ONLY

ARE

1

ABC D E F GH

Page 13

8

G-9

G-10

7

6

5

AC220V_50Hz

CD501_3

1206655819

4

W5T29X7.5X19

3

2

ATTENTION

ABC D E F GH

POWER SCHEMATIC DIAGRAM

DEGAUSS COIL

L503

8R140018

21

BLUE

BROWN

21

L502

CAUTION

D506

1SS133

RELAY SW

Q505

KTC3203_Y

CP502

A1561WV2-2P

1

2

BLUE

12

BROWN

CP501

A3963WV2-3PD

C501_2

0.1275V ECQUL

FH501

EYF-52BC

RY501

ALKS321

F501

50T040H

T4A_L_250V

3

FH502

EYF-52BC

12

4

TH501

B59104-J80-A10

COIL LINE FILTER

L501

0R7A223F24Y

34

12

34

NC NC

SW501

ESB92S22B

1

2

4A 250V

4A 250V

:FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,

REPLACE ONLY WITH THE SAME TYPE FUSE

4A 250V(F501)

:POUR UNE PROTECTION CONTINUE LES RISQUES D’INCEIE

N’UTOLISER QUE DES FUSIBLE DE MEME TYPE

4A 250V(F501)

0.1

0.0

0.22275V ECQUL

C502_1

R501

1.5M 1/2W

(MAIN PCB)

R506

Q504

C531

2250V YK

R521

68K

REG.9V IC

IC503

KIA78R09API

C525

GND

OUT

6.008.0

11E1-EIC

C508

Q509

C530

0.1 F

Q508

C529

R504

11E1-EIC

22016V YK

4.9

4.2

4.9

D509

P.CON SW

10010V YK

KRC103SRTK

R541

27K

0

4.9

22K1/4W

5.6K 1/4W

D517

2SA1037AK

P.CON SW

KTA1281_Y

5.1

R515

10K

Q510

0

P.FAIL

Q506

Q511

R524

W825

5.0

4.4

560 1/4W

0.1

4.7

0

EMERGENCY

KRA102SRTK

D512 SB140-EIC

C514

Q512

4.9

TO SOUND AMP/FRONT AV

P.CON+8V

GND

TO DEFLECTION/CRT

GND

P.CON+8V

+B

H.DRV+B

TO CHROMA/SIF/VIF/21PIN

GND

P.CON+5V

P.CON+8V

FROM/TO MICON/TUNER

TUNER_BT

GND

DEGAUSS

P.FAIL

P.CON+5V

AT+5V_DVDD

AT+5V_AVDD

POWER

EMERGENCY

D515 SB140-EIC

1016V KA

4.9

4.9

PCB010

TMC571

EMERGENCY

0

2SA1624

134.8

135.0135.0135.0

R505

C532

10K 1/4W

0.001250V KX

R528

10K1/4W

C528

D503

RM11C-EIC

D504

RM11C-EIC

C527

0.0015250V KX

C517_1

0.0012KV RR

D510

RU2AM-EIC

NC

NC

NC

NC

MTZJ3.6B

R512

D524

FEED BACK

SWITCHING

KTC3198

R513

D528

B504

W5RH3.5X5X1.0

D513 21DQ09N

1N4937

21DQ09N

R532

1K

Q507

560 1/4W

MTZJ5.6B

D511

D516

7.7

5.6

100 1/4W

1SS133

1SS133

6.2

D523

D518

C513

C521

R526

R519

100160V YXF

OUTINGND

1234

11.2 8.0 0 5.0

220016V

YK

C515

C506_1

0.47 F

D525

R507

2.2K

MTZJ12B

C522

100016V YK

R514

D514

D521

0.01 B

120K 1/4W

R518

4.7K

100

+B ADJ

M+-1%

VR501

1SS133

2.2K

1SS133

T501 8129110H

0.0012KV RR

0.00152KV RR

C505

POWER

Q501

0.22 1W

82400V USR

R503

R516

234.7

D

S

0.3

G

11W

6.7

POWER

Q502

KTC3203_Y

HS501

763WAA0162

R520

R517

6.7

1.5M 1/4W

1.5M 1/4W

MTZJ18B

C526_1

0.0033 B

C516_1

0.047 MMTV

R511

0.3

0

C524

B501

W4BRH3.5X6X1.0X2

D522

R502

220 1W

D505

0.047 B

R510

680 1/4W

0.0033 B

11E1-B-EIC

C518

2.2K 1/4W

R525

2.2K

1/4W

C519

KA

D507

R523

150V

D508

R522

258.8

8

270

7

270

6

237.7

5

45.9

3

0

2

19.1

1

1SS133

220 1/4W

MTZJ18B

2.2K

FEED BACK

IC504

LTV-817M-VB

12.3

0.3

34

D501

RM11C-EIC

0.0012KV B

C503

0.0012KV B

C504

D502

RM11C-EIC

C509_1

C507_1

470P250V KX

2SK2647-01MR

0

10

0

11

0

12

163.9

13

0

14

9.7

15

0

16

13.0

17

0

18

1

9.1

470 1/4W

2

7.7

R527

1.2 2W

SW

C533

1016V KA

R508 10K

REG.6V IC

IC502 KIA7806API

IN

123

HS502

763WAA0186

NC

EMERGENCY

7.7

KRC111SRTK

0

0

EMERGENCY

KRC111SRTK

0.01 B

0.7

8

7

6

5

4

3

2

NOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICE

1

ABC D E F GH

NOTE:THE DC VOLTAGE AT EACH PART WAS MEASURED

WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

ATTENTION

:LES PIECES REPAREES PAR UN ETANT

DANGEREUSES AN POINT DE VUE SECURITE

N’UTILISER QUE CELLS DECRITES

DANS LA NOMENCLATURE DES PIECES

CAUTION

:SINCE THESE PARTS MARKED BY

CRITICAL FOR SAFETY,USE ONES

DESCRIBED IN PARTS LIST ONLY

ARE

CAUTION: DIGITAL TRANSISTOR

CAUTION: DIGITAL TRANSISTOR

1

Page 14

WAVEFORMS

MICON/TUNER

0.5µs

1V

1

10ms

1V

2

CHROMA/SIF/VIF/21PIN

50µs

100mV

6 11

50µs

100mV

7

20µs

0.5V

2ms

200mV

12

20µs

1V

3

20µs

1V

4

50µs

100mV

50µs

0.5V

8

0.2ms

1V

9

0.2ms

1V

20µs

1V

13

20µs

1V

14

20µs

100mV

5 10

NOTE:

16

The following waveforms were measured at the point of the corresponding

balloon number in the schematic diagram.

H-1

Page 15

WAVEFORMS

DEFLECTION/CRT

20µs

1V

17

20µs

100mV

18

20µs

1V

10ms

1V

23

20µs

200mV

24

SOUND AMP/FRONT AV

2ms

200mV

10ms

1V

33

10ms

10V

34

10ms

10V

19

20µs

1V

20

20µs

1V

27

20µs

1.00V

28

500us

500mV

35

20µs

10V

36

20µs

5V

21

29

The following waveforms were measured at the point of the corresponding

NOTE:

37

balloon number in the schematic diagram.

H-2

Page 16

2µs

200V

38

20µs

50V

39

WAVEFORMS

20µs

50V

40

20µs

50V

41

The following waveforms were measured at the point of the corresponding

NOTE:

balloon number in the schematic diagram.

H-3

Page 17

MECHANICAL REPLACEMENT PARTS LIST

Location Part Number Description

101 AE001367 A3M407I720 CABINET,FRONT ASSY

101A AE001368 701UPJA131 CABINET,FRONT

101B AE000389 713UPA0020 GUIDE,REMOCON

101C AE000390 713UPA0021 GLASS,LED

101D AE000391 735UPA0097 BUTTON,BASE

101E AE000865 735UPBA021 BUTTON,FRAME

102 AE001369 A3M407I740 CABINET,BACK ASSY

103 AE000796 752WSAA006 PLATE,SHIELD

104 AE000797 752WSAA008 SHIELD,CASE

105 AE000798 752WSAA013 SHIELD,LID

106 AE001370 722549A187 SHEET,RATING

107 AE000868 735UPB0014 BUTTON,POWER

108 AD300808 735WPA0396 SPEAKER HOLDER

109 BZ710009 741WUA0019 SPRING,EARTH

110 BZ710260 899HV3T000 HOLDER,ANODE WIRE

111 AE001371 800WQ0A002 FELT SHEET

201 BZ710275 8121J50B54 SCREW,TAP TITE(P) GW20 5x28

202 BZ710035 8117540A64 SCREW,TAPPING(B0) TRUSS 4x16

203 BZ710031 8110630A04 SCREW,TAP TITE(P) BRAZIER 3x10

204 BZ710030 8110630804 SCREW,TAP TITE(P) BRAZIER 3x8

205 BZ710019 8109630802 SCREW,TAP TITE(B) BRAZIER 3x8

206 BZ710562 8109I30804 SCREW,TAP TITE(B) WH7 3x8

207 BZ710018 8107630804 SCREW,TAP TITE(S) BRAZIER 3x8

--- AE001372 723000C198 SHEET,BAR CODE

--- AE000093 791WHA0090 LAMIFILM,BAG

--- AE000401 792UHA0165 PACKAGE,TOP

--- AE000402 792UHA0166 PACKAGE,BOTTOM

--- AE001373 793UCDB161 GIFT BOX

--- AE001374 A3M407I975 INSTRUCTION BOOK KIT

--- AE001375 J3M40701A INSTRUCTION BOOK(S)

--- AE001376 J3M40707A QUICK SET-UP SHEET(S)

--- AE001377 J3M40710A INSTRUCTION BOOK(PR)

--- AE001378 J3M40711A INSTRUCTION BOOK(SW)

--- AE001642 J3M40717A REGISTRATION CARD

--- AE001379 J3M40770A QUICK SET-UP SHEET(PR)

--- AE001380 J3M40771A QUICK SET-UP SHEET(SW)

--- AE001672 JB5XD700 POLY,BAG(RED CAUTION)INSTRUCTION

J1-1

Page 18

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

RESISTORS

R001 AE000348 R002T2183J RC 18K OHM 1/2W

R002 AE000348 R002T2183J RC 18K OHM 1/2W

R003 AE000965 R903N8101J RC 100 OHM 1/8W

R004 AE000965 R903N8101J RC 100 OHM 1/8W

R005 AE000967 R903N8104J RC 100K OHM 1/8W

R006 AE000970 R903N8153J RC 15K OHM 1/8W

R101 AE000977 R903N8391J RC 390 OHM 1/8W

R102 AE000987 R903N8821J RC 820 OHM 1/8W

R103 AD300658 R903N8122J RC 1.2K OHM 1/8W

R104 AD300655 R903N8222J RC 2.2K OHM 1/8W

R105 AE000966 R903N8103J RC 10K OHM 1/8W

R106 AE000966 R903N8103J RC 10K OHM 1/8W

R107 BZ210119 R002T4102J RC 1K OHM 1/4W

R108 AE000356 R002T4271J RC 270 OHM 1/4W

R109 AD300655 R903N8222J RC 2.2K OHM 1/8W

R110 AE000982 R903N8562J RC 5.6K OHM 1/8W

R111 AE000970 R903N8153J RC 15K OHM 1/8W

R112 AE000969 R903N8152J RC 1.5K OHM 1/8W

R113 AE000982 R903N8562J RC 5.6K OHM 1/8W

R114 AE000979 R903N8472J RC 4.7K OHM 1/8W

R115 AE000979 R903N8472J RC 4.7K OHM 1/8W

R116 AE000966 R903N8103J RC 10K OHM 1/8W

R117 AE000966 R903N8103J RC 10K OHM 1/8W

R120 AE000979 R903N8472J RC 4.7K OHM 1/8W

R121 AE000965 R903N8101J RC 100 OHM 1/8W

R123 AE000966 R903N8103J RC 10K OHM 1/8W

R124 AE000966 R903N8103J RC 10K OHM 1/8W

R125 AE000966 R903N8103J RC 10K OHM 1/8W

R126 AE000486 R002T4470J RC 47 OHM 1/4W

R128 BZ210273 R002T4101J RC 100 OHM 1/4W

R129 BZ210273 R002T4101J RC 100 OHM 1/4W

R132 AE000968 R903N8151J RC 150 OHM 1/8W

R133 AE000966 R903N8103J RC 10K OHM 1/8W

R134 AE000966 R903N8103J RC 10K OHM 1/8W

R135 AE000966 R903N8103J RC 10K OHM 1/8W

R136 BZ210135 R002T4221J RC 220 OHM 1/4W

R137 AE000972 R903N8271J RC 270 OHM 1/8W

R138 BZ210122 R002T4472J RC 4.7K OHM 1/4W

R139 AE000979 R903N8472J RC 4.7K OHM 1/8W

R140 AE000973 R903N8272J RC 2.7K OHM 1/8W

R141 AE000973 R903N8272J RC 2.7K OHM 1/8W

R142 AE000973 R903N8272J RC 2.7K OHM 1/8W

R143 AE000975 R903N8332J RC 3.3K OHM 1/8W

R144 AE001138 R903N8182J RC 1.8K OHM 1/8W

R145 AE001138 R903N8182J RC 1.8K OHM 1/8W

R146 AE001138 R903N8182J RC 1.8K OHM 1/8W

R147 AE000969 R903N8152J RC 1.5K OHM 1/8W

R148 AE000966 R903N8103J RC 10K OHM 1/8W

R151 AE000979 R903N8472J RC 4.7K OHM 1/8W

R152 AE000979 R903N8472J RC 4.7K OHM 1/8W

R201 AE001355 R903N8470J RC 47 OHM 1/8W

R202 AE000972 R903N8271J RC 270 OHM 1/8W

R203 AD300780 R903N8102J RC 1K OHM 1/8W

R204 AE001009 R903N8181J RC 180 OHM 1/8W

R208 AD300780 R903N8102J RC 1K OHM 1/8W

R213 AE000347 R002T2101J RC 100 OHM 1/2W

R214 AD300655 R903N8222J RC 2.2K OHM 1/8W

R215 AE000983 R903N8682J RC 6.8K OHM 1/8W

R216 BZ210107 R002T4750J RC 75 OHM 1/4W

R217 AD300780 R903N8102J RC 1K OHM 1/8W

R218 AE000968 R903N8151J RC 150 OHM 1/8W

R219 AD300658 R903N8122J RC 1.2K OHM 1/8W

R222 BZ210288 R00204750J RC 75 OHM 1/4W

R402 BZ210180 R002T2102J RC 1K OHM 1/2W

R403 BZ210180 R002T2102J RC 1K OHM 1/2W

R404 AE000364 R4X5T6334F R,METAL 330K OHM 1/6W

R405 AE000365 R4X5T6394F R,METAL 390K OHM 1/6W

R406 BZ210162 R002T4682J RC 6.8K OHM 1/4W

R407 AE000349 R002T21R2J RC 1.2 OHM 1/2W

R408 BZ210119 R002T4102J RC 1K OHM 1/4W

R409 AE000354 R002T2681J RC 680 OHM 1/2W

R410 AE000354 R002T2681J RC 680 OHM 1/2W

R411 BZ210229 R3X28A151J R,METAL OXIDE 150 OHM 2W

R412 AE000488 R002T4822J RC 8.2K OHM 1/4W

R416 BZ210053 R002T22R2J RC 2.2 OHM 1/2W

R417 BZ210230 R4X5T6332F R,METAL 3.3K OHM 1/6W

R418 BZ210028 R3X28B6R8J R,METAL OXIDE 6.8 OHM 3W

J2-1

Page 19

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

RESISTORS

R419 AD300658 R903N8122J RC 1.2K OHM 1/8W

R420 BZ210182 R002T4103J RC 10K OHM 1/4W

R421 BZ210118 R002T4473J RC 47K OHM 1/4W

R422 AD301301 R002T4152J RC 1.5K OHM 1/4W

! R424 BZ210279 R3X181181J R,METAL OXIDE 180 OHM 1W

R427 BZ210273 R002T4101J RC 100 OHM 1/4W

! R429 AD301761 R635815R6J R,FUSE 5.6 OHM 1W

R445 AE000355 R002T4184J RC 180K OHM 1/4W

R446 AE000353 R002T2471J RC 470 OHM 1/2W

R447 BZ210041 R635U2680J R,FUSE 68 OHM 1/2W

R501 BZ210206 R002T2155J RC 1.5M OHM 1/2W

R502 BZ210240 R3X181221J R,METAL OXIDE 220 OHM 1W

R503 BZ210190 R63581R22J R,FUSE 0.22 OHM 1W

R504 BZ210166 R002T4562J RC 5.6K OHM 1/4W

R505 BZ210182 R002T4103J RC 10K OHM 1/4W

R506 BZ210192 R002T4223J RC 22K OHM 1/4W

R507 AD300655 R903N8222J RC 2.2K OHM 1/8W

R508 AE000966 R903N8103J RC 10K OHM 1/8W

R510 BZ210126 R002T4222J RC 2.2K OHM 1/4W

R511 AE000964 R002T4681J RC 680 OHM 1/4W

R512 AE000358 R002T4471J RC 470 OHM 1/4W

R513 AE000360 R002T4561J RC 560 OHM 1/4W

R514 AE000962 R002T4124J RC 120K OHM 1/4W

R515 AE000966 R903N8103J RC 10K OHM 1/8W

R516 BZ210039 R3X181010J R,METAL OXIDE 1 OHM 1W

! R517 AE000963 R002T4155J RC 1.5M OHM 1/4W

R518 BZ210258 R4X5T6472F R,METAL 4.7K OHM 1/6W

R519 AE000965 R903N8101J RC 100 OHM 1/8W

R520 AE000963 R002T4155J RC 1.5M OHM 1/4W

R521 AE000984 R903N8683J RC 68K OHM 1/8W

R522 AD300655 R903N8222J RC 2.2K OHM 1/8W

R523 BZ210135 R002T4221J RC 220 OHM 1/4W

R524 AE000360 R002T4561J RC 560 OHM 1/4W

R525 BZ210126 R002T4222J RC 2.2K OHM 1/4W

R526 BZ210273 R002T4101J RC 100 OHM 1/4W

R527 BZ210210 R3X28A1R2J R,METAL OXIDE 1.2 OHM 2W

R528 BZ210182 R002T4103J RC 10K OHM 1/4W

R532 AD300780 R903N8102J RC 1K OHM 1/8W

R541 AE000974 R903N8273J RC 27K OHM 1/8W

R601 AE000969 R903N8152J RC 1.5K OHM 1/8W

R602 AE000965 R903N8101J RC 100 OHM 1/8W

R606 AE000965 R903N8101J RC 100 OHM 1/8W

R607 AE000971 R903N8223J RC 22K OHM 1/8W

R608 AE000980 R903N8473J RC 47K OHM 1/8W

R618 AE000966 R903N8103J RC 10K OHM 1/8W

R621 AE000360 R002T4561J RC 560 OHM 1/4W

R622 AE000976 R903N8334J RC 330K OHM 1/8W

R623 AD300780 R903N8102J RC 1K OHM 1/8W

R625 AE000968 R903N8151J RC 150 OHM 1/8W

R628 AE000972 R903N8271J RC 270 OHM 1/8W

R629 AE000972 R903N8271J RC 270 OHM 1/8W

R630 AE000972 R903N8271J RC 270 OHM 1/8W

R636 AE000980 R903N8473J RC 47K OHM 1/8W

R638 AD300655 R903N8222J RC 2.2K OHM 1/8W

R639 AE000982 R903N8562J RC 5.6K OHM 1/8W

R640 AE000974 R903N8273J RC 27K OHM 1/8W

R643 AE000978 R903N8471J RC 470 OHM 1/8W

R644 AE000973 R903N8272J RC 2.7K OHM 1/8W

R645 AD300655 R903N8222J RC 2.2K OHM 1/8W

R646 AE000488 R002T4822J RC 8.2K OHM 1/4W

R647 AE000145 R002T2561J RC 560 OHM 1/2W

R649 AE000971 R903N8223J RC 22K OHM 1/8W

R702 AE000987 R903N8821J RC 820 OHM 1/8W

R703 BZ210182 R002T4103J RC 10K OHM 1/4W

R706 BZ210119 R002T4102J RC 1K OHM 1/4W

R707 BZ210119 R002T4102J RC 1K OHM 1/4W

R708 AD300780 R903N8102J RC 1K OHM 1/8W

R709 AE000985 R903N8750J RC 75 OHM 1/8W

R710 AE000985 R903N8750J RC 75 OHM 1/8W

R711 AE000987 R903N8821J RC 820 OHM 1/8W

R713 AE000985 R903N8750J RC 75 OHM 1/8W

R714 AE000985 R903N8750J RC 75 OHM 1/8W

R715 AE000985 R903N8750J RC 75 OHM 1/8W

R719 AE000967 R903N8104J RC 100K OHM 1/8W

R720 BZ210273 R002T4101J RC 100 OHM 1/4W

R721 AE000937 R002T4151J RC 150 OHM 1/4W

R740 AD301598 R903N8221J RC 220 OHM 1/8W

J2-2

Page 20

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

RESISTORS

R741 AD300780 R903N8102J RC 1K OHM 1/8W

R802 BZ210201 R002T4272J RC 2.7K OHM 1/4W

! R803 BZ210099 R3X181153J R,METAL OXIDE 15K OHM 1W

R804 BZ210201 R002T4272J RC 2.7K OHM 1/4W

! R805 BZ210099 R3X181153J R,METAL OXIDE 15K OHM 1W

R806 BZ210201 R002T4272J RC 2.7K OHM 1/4W

! R807 BZ210099 R3X181153J R,METAL OXIDE 15K OHM 1W

R809 BZ210124 R002T4122J RC 1.2K OHM 1/4W

R811 BZ210124 R002T4122J RC 1.2K OHM 1/4W

R813 AE000356 R002T4271J RC 270 OHM 1/4W

R814 BZ210124 R002T4122J RC 1.2K OHM 1/4W

R815 AE000972 R903N8271J RC 270 OHM 1/8W

R816 AE000972 R903N8271J RC 270 OHM 1/8W

R1003 AE000967 R903N8104J RC 100K OHM 1/8W

R1004 AE000984 R903N8683J RC 68K OHM 1/8W

R1006 AE000980 R903N8473J RC 47K OHM 1/8W

R1009 BZ210118 R002T4473J RC 47K OHM 1/4W

R1010 AE000351 R002T2330J RC 33 OHM 1/2W

R1011 BZ210118 R002T4473J RC 47K OHM 1/4W

CAPACITORS

C001 AE000316 CS0RB04H4K CC 0.022 UF 50V B

C002 BZ110189 E02LU0471M CE 470 UF 6.3V

C003 BZ110074 E50HU5010M CE 1 UF 50V

C006 AE000457 CS0RCH412J CC 100 PF 50V CH

C007 AE000312 CS0RB0414K CC 0.01 UF 50V B

C010 AD301466 CHG0B0413J CC 0.001 UF 50V B

C101 AE000326 CS0RCH4U1J CC 68 PF 50V CH

C102 AE000311 CS0RB0315K CC 0.1 UF 25V B

C103 AE000953 CS0KCH4H1J CC 22 PF 50V CH

C104 AE000317 CS0RB04Q3K CC 0.0047UF 50V B

C105 AE000311 CS0RB0315K CC 0.1 UF 25V B

C106 AE000315 CS0RB04H3K CC 0.0022UF 50V B

C108 AE000953 CS0KCH4H1J CC 22 PF 50V CH

C109 AE000953 CS0KCH4H1J CC 22 PF 50V CH

C110 AE000955 CS0RB04Q4K CC 0.047 UF 50V B

C111 AE000310 CS0RB02Q5K CC 0.47 UF 16V B

C112 AE000327 CS0RCH4W1J CC 82 PF 50V CH

C113 AE000953 CS0KCH4H1J CC 22 PF 50V CH

C114 AE000311 CS0RB0315K CC 0.1 UF 25V B

C115 BZ110187 E02LT0102M CE 1000 UF 6.3V

C116 AE000317 CS0RB04Q3K CC 0.0047UF 50V B

C118 BZ110151 CS0RF0415Z CC 0.1 UF 50V F

C119 BZ110278 CS0RB0216K CC 1 UF 16V B

C120 BZ110278 CS0RB0216K CC 1 UF 16V B

C121 AE000326 CS0RCH4U1J CC 68 PF 50V CH

C122 BZ110096 E50HU2100M CE 10 UF 16V

C131 BZ110096 E50HU2100M CE 10 UF 16V

C139 AE000956 CS0RF04Q5Z CC 0.47 UF 50V F

C140 AE000459 CS0RCH4H2J CC 220 PF 50V CH

C141 BZ110151 CS0RF0415Z CC 0.1 UF 50V F

C201 AE000321 CS0RCH430C CC 3 PF 50V CH

C202 AE000229 CS0RB0413K CC 0.001 UF 50V B

C203 AE000316 CS0RB04H4K CC 0.022 UF 50V B

C204 AE000316 CS0RB04H4K CC 0.022 UF 50V B

C205 AE000229 CS0RB0413K CC 0.001 UF 50V B

C206 BZ110278 CS0RB0216K CC 1 UF 16V B

C207 AE000309 CS0RB02L5K CC 0.33 UF 16V B

C209 BZ110096 E50HU2100M CE 10 UF 16V

C210 BZ110074 E50HU5010M CE 1 UF 50V

C212 AE000312 CS0RB0414K CC 0.01 UF 50V B

C213 BZ110162 CS0RF0216Z CC 1 UF 16V F

C215 AE000311 CS0RB0315K CC 0.1 UF 25V B

C216 AE000957 E00NU5R22M CE 0.22 UF 50 V

C217 BZ210177 E02LU2470M CE 47 UF 16V

C218 AE000316 CS0RB04H4K CC 0.022 UF 50V B

C220 BZ110042 E02LU1471M CE 470 UF 10V

C221 AE000311 CS0RB0315K CC 0.1 UF 25V B

C401 AE000600 CQGTCH4H2J CC 220 PF 50V CH

C403 BZ110149 E02LT4471M CE 470 UF 35V

C404 BZ110039 E02LT1102M CE 1000 UF 10V

C408 BZ110096 E50HU2100M CE 10 UF 16V

C412 AE000343 P232T0473J CMPL 0.047 UF 50V MMTV

C413 AE000320 CS0RB04W4K CC 0.082 UF 50V B

C414 AD301434 E02LU4101M CE 100 UF 35V

C417 AD301348 E02LU5100M CE 10 UF 50V

C418 BZ110101 E5EZF3222M CE 2200 UF 25V

C422 AE000961 P232W1224J CMP 0.22 UF 100V MMTS

J2-3

Page 21

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

CAPACITORS

C423 BZ110212 E5EZTD2R2M CE 2.2 UF 250V

C435 AE000960 P232W1104J CMP 0.1 UF 100V MMTS

C437 BZ110136 P4J7F3394J CMPP 0.39 UF 250V PMS

C440 AE000416 P232W1103J CMP 0.01 UF 100V MMTS

C443 BZ110137 P4N8FJ822H CMPP 0.0082UF 1.25KV

C446 BZ110205 E02LU5220M CE 22 UF 50V

C448 BZ110103 E02LTD100M CE 10 UF 250V

C501 BZ110035 P2122B104M CMP 0.1 UF 275V ECQUL

C502 BZ110025 P2122B224M CMP 0.22 UF 275V ECQUL

C503 BZ110247 C0JBB0713K CC 0.001 UF 2KV B

C504 BZ110247 C0JBB0713K CC 0.001 UF 2KV B

! C505 AE000338 E52DHH820M CE 82 UF 400V

C506 AE000956 CS0RF04Q5Z CC 0.47 UF 50V F

! C507 AE000874 C0PLRR7E3K CC 0.0015 UF 2KV R

C508 AE000336 E02LU1101M CE 100 UF 10V

C509 BZ110202 C0PLRR713K CC 0.001 UF 2KV R

C513 AE000312 CS0RB0414K CC 0.01 UF 50V B

C514 BZ110096 E50HU2100M CE 10 UF 16V

C515 BZ110135 E02L02222M CE 2200 UF 16V

C516 AE000343 P232T0473J CMPL 0.047 UF 50V MMTV

C517 BZ110202 C0PLRR713K CC 0.001 UF 2KV R

C518 AE000955 CS0RB04Q4K CC 0.047 UF 50V B

C519 BZ110074 E50HU5010M CE 1 UF 50V

C521 BZ110139 E62NFB101M CE 100 UF 160V

C522 BZ110207 E02LT2102M CE 1000 UF 16V

C524 BZ110270 CQGTB04L3K CC 0.0033UF 50V B

C525 BZ110190 E02LU2221M CE 220 UF 16V

C526 AE000954 CS0RB04L3K CC 0.0033UF 50V B

C527 AE000308 CD39B0MQ2K CC 470 PF 250V

C528 AE000950 CD39E0ME3M CC 0.0015UF 250V

C529 AE000312 CS0RB0414K CC 0.01 UF 50V B

C530 BZ110151 CS0RF0415Z CC 0.1 UF 50V F

C531 BZ110205 E02LU5220M CE 22 UF 50V

C532 BZ110223 CD39E0M13M CC 0.001 UF 250V

C533 BZ110096 E50HU2100M CE 10 UF 16V

C601 AE000324 CS0RCH4Q1J CC 47 PF 50V CH

C602 BZ110074 E50HU5010M CE 1 UF 50V

C603 BZ110162 CS0RF0216Z CC 1 UF 16V F

C604 BZ110074 E50HU5010M CE 1 UF 50V

C605 BZ110162 CS0RF0216Z CC 1 UF 16V F

C607 BZ110162 CS0RF0216Z CC 1 UF 16V F

C608 BZ110255 CQGTB0415K CC 0.1 UF 50V B

C609 AE000311 CS0RB0315K CC 0.1 UF 25V B

C610 AD301535 E02LU2101M CE 100 UF 16V

C611 BZ110217 E50HU53R3M CE 3.3 UF 50V

C612 AE000313 CS0RB04E3K CC 0.0015UF 50V B

C613 BZ110042 E02LU1471M CE 470 UF 10V

C614 BZ110162 CS0RF0216Z CC 1 UF 16V F

C615 BZ110278 CS0RB0216K CC 1 UF 16V B

C616 AE000317 CS0RB04Q3K CC 0.0047UF 50V B

C618 AE000311 CS0RB0315K CC 0.1 UF 25V B

C619 AE000311 CS0RB0315K CC 0.1 UF 25V B

C620 AE000311 CS0RB0315K CC 0.1 UF 25V B

C621 AE000457 CS0RCH412J CC 100 PF 50V CH

C622 BZ110255 CQGTB0415K CC 0.1 UF 50V B

C623 BZ110255 CQGTB0415K CC 0.1 UF 50V B

C624 AE000312 CS0RB0414K CC 0.01 UF 50V B

C625 AE000324 CS0RCH4Q1J CC 47 PF 50V CH

C626 AE000457 CS0RCH412J CC 100 PF 50V CH

C629 BZ110096 E50HU2100M CE 10 UF 16V

C630 BZ110151 CS0RF0415Z CC 0.1 UF 50V F

C634 AE000928 E50HU2330M CE 33 UF 16 V

C701 AE000317 CS0RB04Q3K CC 0.0047UF 50V B

C703 AE000325 CS0RCH4Q2J CC 470 PF 50V CH

C704 AE000229 CS0RB0413K CC 0.001 UF 50V B

C711 AE000336 E02LU1101M CE 100 UF 10V

C744 BZ110096 E50HU2100M CE 10 UF 16V

C745 BZ110096 E50HU2100M CE 10 UF 16V

C746 AE000312 CS0RB0414K CC 0.01 UF 50V B

C804 BZ110199 CHG0B04U2J CC 680 PF 50V B

C805 AE001673 CS0YCH4U2J CC 680 PF 50V CH

C806 AE001673 CS0YCH4U2J CC 680 PF 50V CH

C819 BZ110247 C0JBB0713K CC 0.001 UF 2KV B

C1001 BZ110081 E02LT2471M CE 470 UF 16V

C1002 AE000324 CS0RCH4Q1J CC 47 PF 50V CH

C1003 AD301002 E50HU50R1M CE 0.1 UF 50 V

C1004 AE000313 CS0RB04E3K CC 0.0015UF 50V B

J2-4

Page 22

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

CAPACITORS

C1005 AE000958 E50HU5R47M CE 0.47 UF 50V

C1006 AE001356 E02L02221M CE 220 UF 16V or

C1007 BZ110096 E50HU2100M CE 10 UF 16V

C1009 AE000317 CS0RB04Q3K CC 0.0047UF 50V B

AE001357 E02LT2221M CE 220 UF 16V

DIODES

D001 BZ410037 D97U03301B DIODE,ZENER MTZJ33B T-77

D101 AE000288 0021E9Q010 LED LTL-1BEFJ-002A

D102 BZ410020 D97U05R11B DIODE,ZENER MTZJ5.1B T-77

D107 BZ410021 D97U05R61B DIODE,ZENER MTZJ5.6B T-77

D108 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D109 BZ410021 D97U05R61B DIODE,ZENER MTZJ5.6B T-77

D403 BZ410043 D2WT011E10 DIODE,SILICON 11E1-EIC

D404 BZ410063 D2WTAU02A0 DIODE,SILICON AU02A-EIC

D405 BZ410063 D2WTAU02A0 DIODE,SILICON AU02A-EIC

D406 BZ410043 D2WT011E10 DIODE,SILICON 11E1-EIC

D407 BZ410043 D2WT011E10 DIODE,SILICON 11E1-EIC

D410 BZ410063 D2WTAU02A0 DIODE,SILICON AU02A-EIC

! D501 BZ410062 D2WTRM11C0 DIODE,SILICON RM11C-EIC

! D502 BZ410062 D2WTRM11C0 DIODE,SILICON RM11C-EIC

! D503 BZ410062 D2WTRM11C0 DIODE,SILICON RM11C-EIC

! D504 BZ410062 D2WTRM11C0 DIODE,SILICON RM11C-EIC

D505 BZ410123 D2W0011E10 DIODE,SILICON 11E1-B-EIC

D506 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D507 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D508 BZ410100 D97U01801B DIODE,ZENER MTZJ18B T-77

D509 BZ410043 D2WT011E10 DIODE,SILICON 11E1-EIC

D510 BZ410080 D2WXRU2AM0 DIODE,SILICON RU2AM-EIC

D511 BZ410092 D2WXN49370 DIODE,SILICON 1N4937

D512 BZ410077 D2WXSB1400 DIODE,SCHOTTKY SB140-EIC

D513 BZ410010 D28T21DQN9 DIODE,SCHOTTKY 21DQ09N-TA2B1

D514 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

! D515 BZ410077 D2WXSB1400 DIODE,SCHOTTKY SB140-EIC

D516 BZ410010 D28T21DQN9 DIODE,SCHOTTKY 21DQ09N-TA2B1

D517 BZ410043 D2WT011E10 DIODE,SILICON 11E1-EIC

D518 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D521 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D522 BZ410100 D97U01801B DIODE,ZENER MTZJ18B T-77

D523 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D524 AE000330 D97U03R61B DIODE,ZENER MTZJ3.6B T-77

D525 BZ410122 D97U01201B DIODE,ZENER MTZJ12B T-77

D528 BZ410021 D97U05R61B DIODE,ZENER MTZJ5.6B T-77

D601 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D602 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D603 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D604 BZ410043 D2WT011E10 DIODE,SILICON 11E1-EIC

D605 BZ410077 D2WXSB1400 DIODE,SCHOTTKY SB140-EIC

D609 BZ410021 D97U05R61B DIODE,ZENER MTZJ5.6B T-77

D709 BZ410020 D97U05R11B DIODE,ZENER MTZJ5.1B T-77

D807 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D808 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

D809 BZ410006 D1VT001330 DIODE,SILICON 1SS133T-77

ICS

IC101 AE001358 I5PD0F013A IC OECF013A

IC102 AD301641 I9UF032310 IC PST3231NR

IC199 AE001359 A3M407I015 IC S-24C16AFJA-TB-01

IC201 AE000034 I0WDE2246E IC STV2246E

IC401 BZ611081 I0WTD81740 IC TDA8174A

IC502 BZ611017 I1KA97806A IC KIA7806API

IC503 BZ611089 I1KA98R09A IC KIA78R09API

! IC504 BZ410088 0002E00610 PHOTO COUPLER LTV-817M-VB

IC703 AE000340 I0QF022330 IC NJM2233BM-T1

IC1001 BZ611001 I01DP75110 IC AN7511

TRANSISTORS

Q102 BZ510090 TPAAB05001 COMPOUND TRANSISTOR KRA102SRTK

Q103 BZ510002 T8YJ2412K0 TRANSISTOR,SILICON 2SC2412KT146 R,S

Q201 BZ510114 T8AA03881S TRANSISTOR,SILICON KTC3881S-RTK

Q202 BZ510002 T8YJ2412K0 TRANSISTOR,SILICON 2SC2412KT146 R,S

Q204 BZ510002 T8YJ2412K0 TRANSISTOR,SILICON 2SC2412KT146 R,S

! Q401 AD301779 TD3Q021400 TRANSISTOR,SILICON TT2140LS-YBC11

Q402 BZ510089 TC5T01627Y TRANSISTOR,SILICON 2SC1627_Y(TPE2)

Q403 BZ510071 TNAAB05003 COMPOUND TRANSISTOR

! Q501 BZ510118 T410K26470 FET 2SK2647-01MR

Q502 BZ510070 TCAT032034 TRANSISTOR,SILICON KTC3203_Y-AT

Q504 BZ510004 TA3T016240 TRANSISTOR,SILICON 2SA1624-AA

Q505 BZ510070 TCAT032034 TRANSISTOR,SILICON KTC3203_Y-AT

Q506 BZ510001 T6YJ1037K0 TRANSISTOR,SILICON 2SA1037AKT146R,S

J2-5

Page 23

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

TRANSISTORS

Q507 BZ510069 TCATC31980 TRANSISTOR,SILICON KTC3198-AT(Y,GR)

Q508 BZ510068 TNAAJ05003 COMPOUND TRANSISTOR KRC111SRTK

Q509 BZ510068 TNAAJ05003 COMPOUND TRANSISTOR KRC111SRTK

Q510 BZ510067 TNAAC05002 COMPOUND TRANSISTOR KRC103SRTK

Q511 BZ510057 TAAT01281Y TRANSISTOR,SILICON KTA1281_Y

Q512 BZ510090 TPAAB05001 COMPOUND TRANSISTOR KRA102SRTK

Q605 BZ510002 T8YJ2412K0 TRANSISTOR,SILICON 2SC2412KT146 R,S

Q801 BZ510087 TCAT032070 TRANSISTOR,SILICON KTC3207-AT

Q802 BZ510087 TCAT032070 TRANSISTOR,SILICON KTC3207-AT

Q803 BZ510087 TCAT032070 TRANSISTOR,SILICON KTC3207-AT

COILS &TRANSFORMERS

L001 BZ310141 02167F100J COIL 10 UH

L101 BZ310141 02167F100J COIL 10 UH

L102 BZ310141 02167F100J COIL 10 UH

L103 AE000014 0216A6100K COIL 10 UH

L202 AE000290 02167F3R3J COIL 3.3 UH

L203 AD301706 0216A62R2K COIL 2.2 UH

L204 AD301705 0216A6120K COIL 12 UH

L206 BZ310169 021LA6R39M COIL 0.39 UH

L207 BZ310148 033700005R COIL,VIDEO IFT 3700005

L208 BZ310169 021LA6R39M COIL 0.39 UH

L401 BZ310004 021679472K COIL 4.7 MH

! L501 BZ310047 029T000094 COIL,LINE FILTER 0R7A223F24Y

L502 BZ310118 02AHB9A972 CORE,FERRITE W5T29X7.5X19

! L503 BZ310155 028R140018 COIL,DEGAUSS 8R140018

L601 BZ310141 02167F100J COIL 10 UH

L702 AE000014 0216A6100K COIL 10 UH

L703 AE000014 0216A6100K COIL 10 UH

L704 AD302294 0216A6100J COIL 10 UH

L714 BZ310141 02167F100J COIL 10 UH

T401 BZ310157 045009003J TRANS,HORIZONTAL DRIVE ETH09K14BZ

! T501 AE000943 048129110H TRANSFORMER,SWITCHING 8129110H

JACKS

J701 BZ614323 063G100042 SOCKET,21PIN 0350_9982_05

J702 BZ614322 060Q401077 RCA JACK AV1-09D-3

J703 BZ614321 060Q401076 RCA JACK AV1-09D-4

J801 BZ614434 066F120018 SOCKET,CATHODE RAY TUBE ISMS01S

J1001 AD302163 060J121014 JACK,RCA,3.5 MSJ-035-12A_PC

SWITCHES

SW101 BZ612010 0504101T34 SWITCH,TACT EVQ21505R

SW102 BZ612010 0504101T34 SWITCH,TACT EVQ21505R

SW103 BZ612010 0504101T34 SWITCH,TACT EVQ21505R

SW104 BZ612010 0504101T34 SWITCH,TACT EVQ21505R

! SW501 AE000574 0530105019 SWITCH ESB92S22B

VARIABLE RESISTORS

VR401 BZ210128 V1163H3BTC VOLUME,SEMI FIXED EVNCYAA03BE3

VR420 BZ210109 V1163Q2BTC VOLUME,SEMI FIXED EVNCYAA03BQ2

VR501 BZ210128 V1163H3BTC VOLUME,SEMI FIXED EVNCYAA03BE3

P.C.BOARD ASSEMBLIES

PCB010 AE001360 A3M407I010K PCB ASS'Y TMC571A

PCB110 AE001361 A3M407I110K PCB ASS'Y TCC432A

MISCELLANEOUS

ANT001 AE000301 125C108026 ANTENNA ROD T4-216AP-BK

B501 BZ310122 024HT03563 CORE,BEADS W4BRH3.5X6X1.0X2

B504 BZ310121 024HT03553 CORE,BEADS W5RH3.5X5X1.0

B1001 BZ310129 024HT03564 CORE,BEADS W4BRH3.5X6X1.0

B1002 BZ310129 024HT03564 CORE,BEADS W4BRH3.5X6X1.0

BT001 AE000303 1412004013 BATTERY,MANGAN R03(AB)2PXGPI

BT002 AE000303 1412004013 BATTERY,MANGAN R03(AB)2PXGPI

! CD501 AE001362 1206655819 CORD,AC 1206655819

CD801 AE000302 1278140030 BRAIDED WIRE SM1573-001

CD802 BZ614507 WDL6028038 FLAT CABLE AWM2468 A WG26 6C BLACK 280MM

CD803 AD302168 WBL6026038 FLAT CABLE AWM2468 A WG26 4C BLACK 260MM

CF201 AE001363 1012T5R503 FILTER,CERAMIC TRAP TPS5.5MB-TF21

CF202 AE001364 102E238R9G FILTER,SAW G1984M

CF204 AE000296 1012T03101 FILTER,CERAMIC TRAP MKT31.9MA110P-TF

CF303 AE000297 1012T04001 FILTER,CERAMIC TRAP MKT40.4MA110P-TF

CP001 BZ614016 069W01001A CONNECTOR PCB SIDE 003P-2100

CP101 BZ614330 069X160379 CONNECTOR PCB SIDE 06JQ-ST

CP401 BZ614303 069S450089 CONNECTOR PCB SIDE A1561WV2-A5P

CP501 BZ614176 069S320419 CONNECTOR PCB SIDE A3963WV2-3PD

CP502 BZ614283 069S420110 CONNECTOR PCB SIDE A1561WV2-2P

CP801 BZ614016 069W01001A CONNECTOR PCB SIDE 003P-2100

CP1001 BZ614365 069S120419 CONNECTOR PCB SIDE A2502WV2-2P

CP802A BZ614333 067U006049 WIRE HOLDER B2013H02-6P

CP802B BZ614333 067U006049 WIRE HOLDER B2013H02-6P

CP803A BZ614334 067U004029 WIRE HOLDER B2013H02-4P

J2-6

Page 24

ELECTRICAL REPLACEMENT PARTS LIST

Location Part Number Description

MISCELLANEOUS

CP803B BZ614334 067U004029 WIRE HOLDER B2013H02-4P

EL001 BZ614043 124116281A EYE LET XRY16X28BD

EL002 BZ614044 124120301A EYE LET XRY20X30BD

! F501 BZ614486 080NT04004 FUSE 50T040H

! FB401 AD302167 043214039F TRANSFORMER,FLYBACK FNI-14B002

FH501 BZ614005 06710T0006 HOLDER,FUSE EYF-52BC

FH502 BZ614005 06710T0006 HOLDER,FUSE EYF-52BC

OS101 AD301048 0773071001 REMOTE RECEIVER RPM7138-H5

RY501 BZ612009 0560V20115 RELAY ALKS321

SP1001 BZ614428 070C132019 SPEAKER SA08A05BWC

TH501 AE000329 D8E0J80A10 DEGAUSS ELEMENT B59104-J80-A10

TM101 AE000944 076N0GX010 TRANSMITTER RC-GX010