Page 1

Televisión a color

13A20

Resumen

Diferencias en el entorno y los datos de ajuste

Diferencias en las listas de partes de reemplazo

Page 2

FILE NO. 063-200004

SERVICE MANUAL

COLOR TELEVISION

N0E Chassis

13A20

(TAC0002)

– SUMMARY –

13A20 is the same as 19A20 except for the parts and setting & adjusting data tabled

on back of this sheet.

Use this service manual together with the service manual of 19A20 (File No. 020-200003).

PUBLISHED IN JAPAN, Jun., 2000 S

Page 3

SETTING & ADJUSTING DATA DIFFERENCES

SAFETY INSTRUCTIONS

CIRCUIT CHECKS

REPLACEMENT PARTS LIST DIFFERENCES

13"

HIGH VOLTAGE AT ZERO BEAM: (A) 23.5 kV

MAX HIGH VOLTAGE:

(B) 24.9 kV

Table-1

FBT DETECTION VOLTAGE (C) 21.02V

Table-4

Location

No.

A201 23549359 Front Cover

A401 23003326 Back Cover

A701 23525910 Carton

C230 24794470 EL, 47?F, ±20%, 16V

C310 24796470 EL, 47?F, ±20%, 35V

C311 24214101 CD, 100pF, ±10%, 500V

C314 24590563 PF, 0.056?F

C440 24082952 PF, 6200pF, ±3%, 1500V

C442 24082693 PF, 0.33?F, 250V

C611 24591104 PF, 0.1?F

C810 24086939 EL, 330?F, ±20%, 200V

C832 24794470 EL, 47?F, ±20%, 16V

D102 23118528 Diode, Zener, RD5.6ESA B3

D201 23118632 Diode, Zener, RD3.3ESA B1

D472 23115774 Diode, Zener, RD6.2E(4)

L462 23231183 Deflection Yoke, TDY-314QY

L901 23200306 Coil, Degaussing, TSB-2219AL

P801 23372123 Power Cord

Q101 23114552 Transistor, 2SC1685-Q, TH

R227 24366473 CF, 47k ohm

R304 24366473 CF, 47k ohm

R305 24322159 MF, 1.5 ohm, 1W

R306 24366683 CF, 68k ohm

R307 24366474 CF, 470k ohm

R312 24381222 OMF, 2200 ohm, 1/2W

R313 24366274 CF, 270k ohm

R317 24366243 CF, 24k ohm

R327 24338689 MF, 6.8 ohm, 1W

Part No. Description

Location

No.

R416 24019327 OMF, 2700 ohm, 5W

R475 24367821 CF, 820 ohm, ±2%

R802 24376274 CF, 270k ohm, 1/2W

R808 24000209 PTC Thermistor, 12 ohm,

R810 24510229 Cement, 2.2 ohm, 5W

R811 24569241 Cement, 240 ohm, 10W

R812 24510689 Cement, 6.8 ohm, 5W

R830 24381560 OMF, 56 ohm, 1/2W

R897 24019473 Varistor, ERZ10V271K2

R920 24000568 FR, 4.7 ohm, 1W

R921 24366471 CF, 470 ohm

R922 24366471 CF, 470 ohm

R923 24366471 CF, 470 ohm

R931 24366122 CF, 1200 ohm

R932 24366122 CF, 1200 ohm

R933 24366122 CF, 1200 ohm

* T461 23236589 Transformer, Flyback,

U901 Main Board, PB9391B-1

*

* V901 23312577 Picture Tube, A34JFQ90X(VW)

V901M 23102409 Magnet, Purity-Convergence,

W661 23351112 Speaker, SPK-1379,

Y101 23563952 Owner’s Manual,

Part No. Description

±20%, AC140V

TFB4139AY

MAG-1070

77x77mm, 8 ohm

English/French, 13A20

TOSHIBA CORPORATION

1-1, SHIBAURA 1-CHOME, MINATO-KU, TOKYO 105-8001, JAPAN

Page 4

FILE NO. 020-200003

SERVICE MANUAL

COLOR TELEVISION

N0E Chassis

19A20

(TAC0001)

PRINTED IN U.S.A. Mar., 2000 U

Page 5

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS........................................................................................................................................3

SET-UP ADJUSTMENT............................................................................................................................................4

SERVICE MODE ...................................................................................................................................................... 8

DESIGN MODE ...................................................................................................................................................... 11

ELECTRICAL ADJUSTMENTS ..............................................................................................................................12

CIRCUIT CHECKS .................................................................................................................................................14

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA .............................................................................................................................15

LOCATION OF CONTROLS...................................................................................................................................16

PROGRAMMING CHANNEL MEMORY.................................................................................................................17

CIRCUIT BLOCK DIAGRAM ..................................................................................................................................18

CHASSIS AND CABINET REPLACEMENT PARTS LIST......................................................................................19

PC BOARDS BOTTOM VIEW ................................................................................................................................23

TERMINAL VIEW OF TRANSISTORS ................................................................................................................... 26

TABLE OF CONTENTS

SPECIFICATIONS ..................................................................................................................................................29

APPENDIX:

CIRCUIT DIAGRAM

– 2 –

Page 6

CHAPTER 1 GENERAL ADJUSTMENTS

SAFETY INSTRUCTIONS

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAU-

TION” AND “PRODUCT SAFETY NOTICE” INSTRUCTIONS BELOW.

X-RAY RADIATION PRECAUTION

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid such hazards, the high

voltage must not be abov e the specified limit. The nominal

value of the high voltage of this receiver is (A) kV at zero

beam current (minimum brightness) under a 120V AC

power source. The high voltage must not, under any circumstances, exceed (B) kV.

Refer to table-1 for high voltage (A), (B).

(See SETTING & ADJUSTING DATA on page 15)

Each time a receiver requires servicing, the high voltage

should be checked f ollowing the HIGH VOLTA GE CHECK

procedure in this manual. It is recommended that the reading of the high voltage be recorded as a part of the service

record. It is important to use an accurate and reliable high

voltage meter.

SAFETY PRECAUTION

2. This receiver is equipped with a Fail Safe (FS) circuit which

prevents the receiver from producing an excessively high

voltage ev en if the B+ voltage increases abnormally. Each

time the receiver is serviced, the FS circuit must be checked

to determine that the circuit is properly functioning, following the FS CIRCUIT CHECK procedure in this manual.

3. The only source of X-RA Y RADIATION in this TV receiver

is the picture tube. F or contin ued X-RAY RADIATION protection, the replacement tube must be exactly the same

type tube as specified in the parts list.

4. Some part in this receiver have special safety-related characteristics for X-RAY RADIATION protection. For continued safety, parts replacement should be undertaken only

after referring to the PRODUCT SAFETY NO TICE below.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

WARNING : Service should not be attempted by any one unf amiliar with the necessary precautions on this receiver. The following are the necessary precautions to be observed before

servicing this chassis.

1. An isolation Transf ormer should be connected in the power

line between the receiver and the AC line bef ore an y service is performed on the receiver.

2. Always discharge the picture tube anode to the CRT conductive coating before handling the picture tube . The picture tube is highly evacuated and if broken, glass fragments will be violently expelled. Use shatter proof goggles and keep picture tube away from the unprotected body

while handling.

3. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back in place,

such as; non-metallic control knobs, insulating covers,

shields, isolation resistor-capacitor network etc.

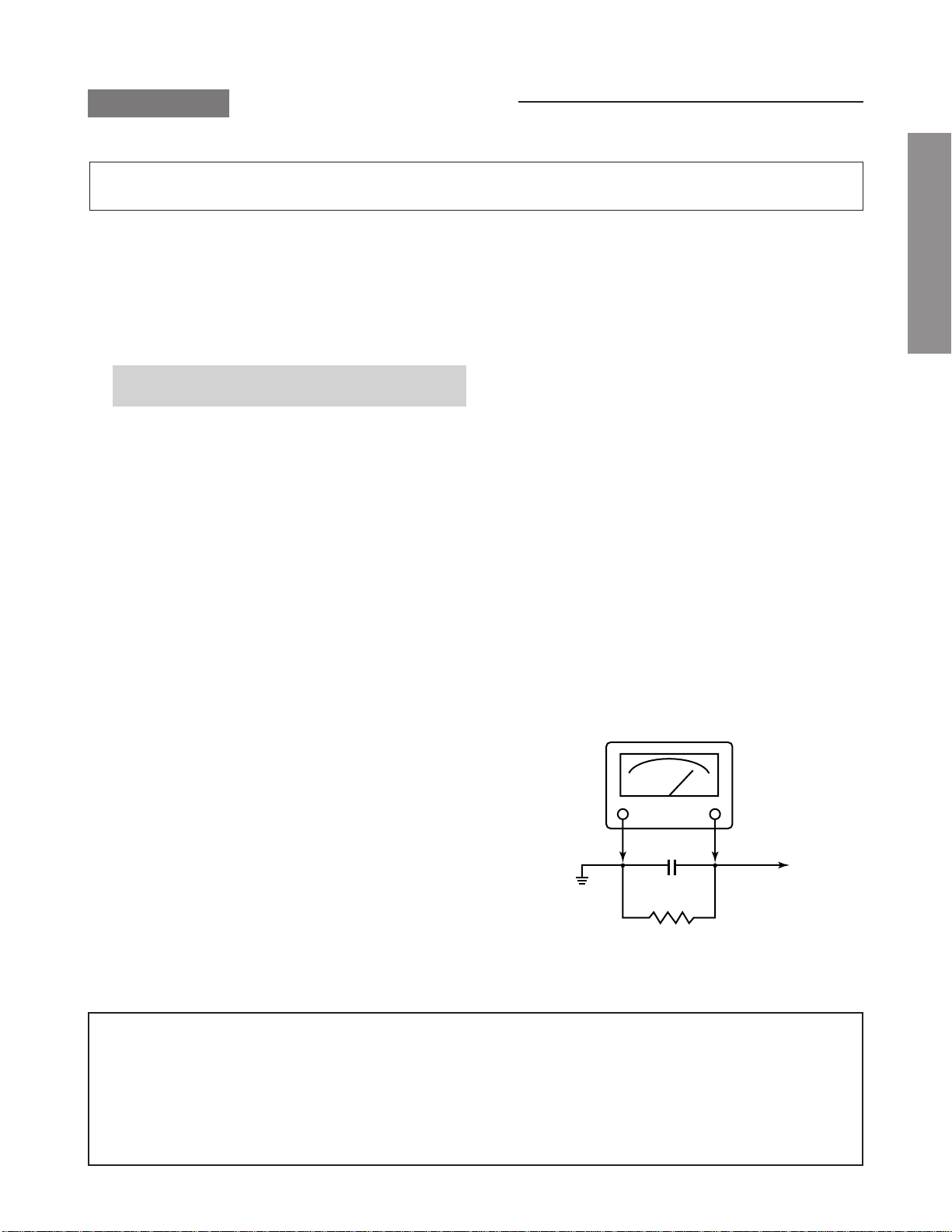

4. Before returning the set to the customer, always perform

an AC leakage current check on the e xposed metallic parts

of the cabinet, such as antennas, terminals, screwheads,

metal overlays, control shafts etc. to be sure the set is

safe to operate without danger of electrical shock. Plug

the AC line cord directly into a 120V AC outlet (do not use

a line isolation transformer during this check). Use an AC

voltmeter having 5000 ohms per volt or more sensitivity in

the following manner:

Connect a 1500 ohm 10 watt resistor, paralleled b y a 0.15

µF, AC type capacitor, between a known good earth ground

(water pipe, conduit, etc.) and the exposed metallic parts,

one at a time. Measure the AC voltage across the combination of 1500 ohm resistor and 0.15 µF capacitor. Reverse the AC plug at the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Voltage

measured must not exceed 0.3 v olts rms. This corresponds

to 0.2 milliamp. AC. Any value exceeding this limit constitutes a potential shock hazard and must be corrected immediately.

AC VOLTMETER

0.15µF

Place this probe on

Good earth ground

such as a water

pipe, conduit, etc.

1500 ohm

10 watt

each exposed

metallic part.

PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These characteristics are

often passed unnoticed by a visual inspection and the protection afforded by them cannot necessarily be obtained b y using

replacement components rated for higher voltage, wattage, etc. Replacement parts which have these special safety characteristics are identified in this manual and its supplements; electrical components having such features are identified by

the international hazard symbols on the schematic diagram and the parts list.

Before replacing any of these components, read the parts list in this manual carefully. The use of substitute replacement

parts which do not have the same safety characteristics as specified in the parts list may create shock, fire, X-ray

radiation or other hazards.

– 3 –

Page 7

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

SET-UP ADJUSTMENT FOR 13", 14", 19", 20".

■ The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Color Purity

2. Convergence

3. White Balance

Note: The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

*

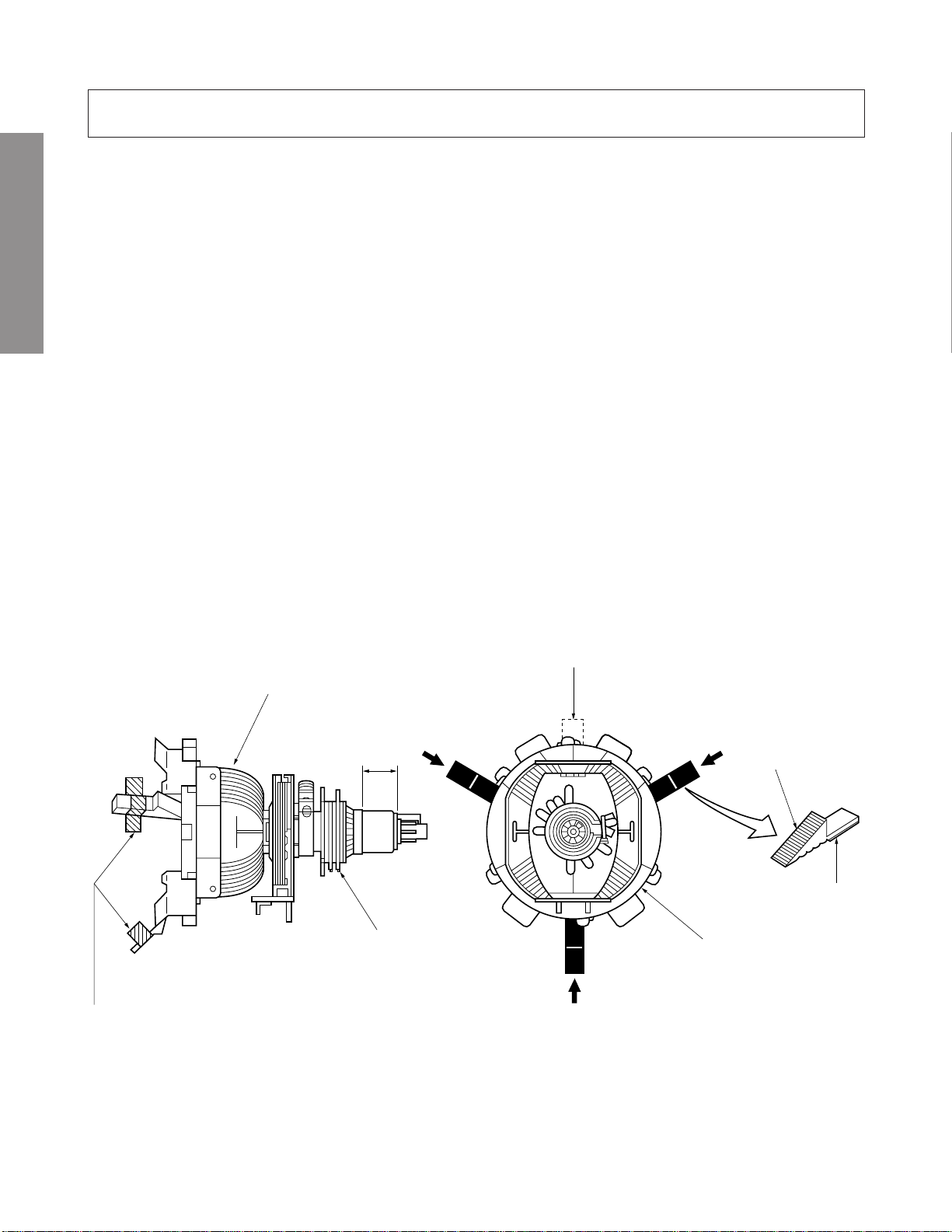

COLOR PURITY ADJUSTMENT

NOTE : Before attempting any purity adjustments, the receiver

1. Demagnetize the picture tube and cabinet using a degauss-

2. Set the brightness and contrast to maximum.

3. Use a green raster from among the built-in test signals.

4. Loosen the clamp screw holding the yoke and slide the

Refer to figure 1.

Mounting position of the purity magnet assembly should fit to same position as old one because slightly difference to

the position depend on a kind of tube.

There are no adjustment of purity and convergence in some picture tube (Unified with purity magnet)

should be operated for at least fifteen minutes.

ing coil.

yoke backward or forward to provide vertical green belt

(zone) in the picture screen.

SET-UP ADJUSTMENT

5. Remove the Rubber Wedges.

6. Rotate and spread the tabs of the purity magnet (See figure 2.) around the neck of the picture tube until the green

belt is in the center of the screen. At the same time , enter

the raster vertically.

7. Slowly move the yoke forward or backward until a uniform

green screen is obtained. Tighten the clamp screw of the

yoke temporarily.

8. Check the purity of the red and blue raster.

GLASS CLOTH

TAPES

DEFLECTION

YOKE

14mm(13", 14")

19mm(19", 20")

PURITY/

CONVERGENCE

MAGNET ASS'Y

TEMPORARY

MOUNTING

RUBBER WEDGE

ADHESIVE

DEFLECTION

YOKE

Figure 1.

– 4 –

Page 8

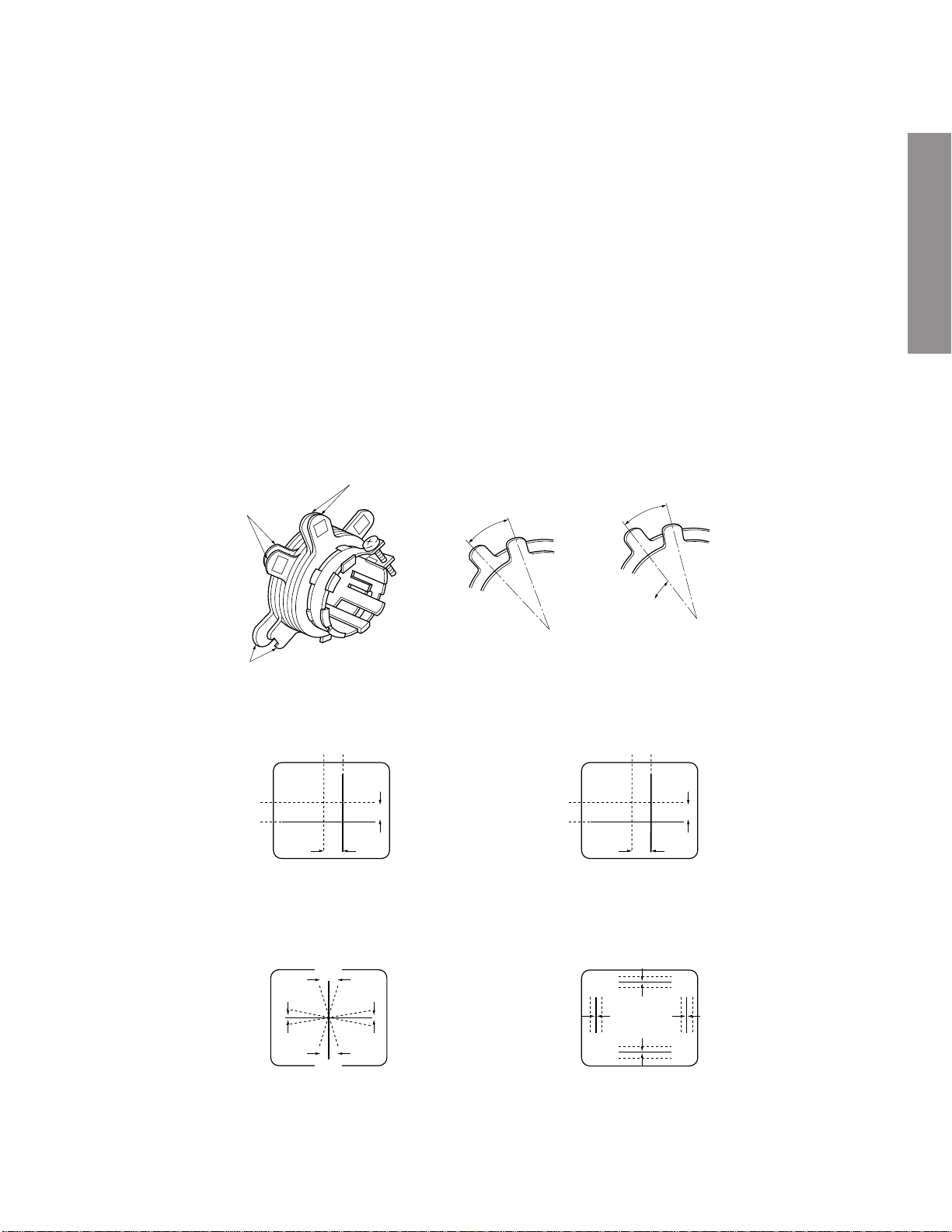

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence adjustments, the

receiver should be operated for at least fifteen minutes.

■ CENTER CONVERGENCE ADJUSTMENT

1. Use the cross-dot pattern from among the built-in test signals.

2. Set the brightness and contrast for well defined pattern.

3. Adjust two tabs of the 4-Pole Magnets to change the angle between them (See figure 2.) and superimpose red

and blue vertical lines in the center area of the picture

screen.

4. Turn the both tabs at the same time keeping the angle

constant to superimpose red and blue horizontal lines at

the center of the screen.

5. Adjust two tabs of 6-Pole Magnets to superimpose red/

blue line and green one. Adjusting the angle affects the

vertical lines and rotating both magnets affects the horizontal lines.

6. Repeat adjustments 3, 4, 5 keeping in mind red, green

and blue movement, because 4-Pole Magnets and 6-Pole

Magnets have mutual interaction and make dot movement

complex.

4-POLE

MAGNETS

6-POLE

MAGNETS

ADJUST THE ANGLE

(VERTICAL LINES)

■ CIRCUMFERENCE CONVERGENCE ADJUSTMENT

1. Loosen the clamping screw of deflection yoke slightly to

allow the yoke to tilt.

2. Temporarily put a wedge as shown in figure 1. (Do not

remove cover paper on adhesive part of the wedge.)

3. Tilt front of the deflection yoke up or down to obtain better

convergence in circumference. (See figure 3.) Push the

mounted wedge into the space between picture tube and

the yoke to fix the yoke temporarily.

4. Put other wedge into bottom space and remove the cover

paper to stick.

5. Tilt front of the yoke right or left to obtain better convergence in circumference. (See figure 3.)

6. Keep the yoke position and put another wedge in either

upper space. Remove cover paper and stick the wedge

on picture tube to fix the yoke.

7. Detach the temporarily mounted wedge and put it in another upper space. Stick it on picture tube to fix the yoke.

8. After fixing three wedges, recheck overall convergence.

Tighten the screw firmly to fix the yoke and check the y oke

is firm.

9. Stick three adhesive tapes on wedges as shown in figure

1.

FIXED

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

PURITY

MAGNETS

CONVERGENCE MAGNET ASSEMBLY ADJUSTMENT OF MAGNETS

Figure 2.

BLU RED

BLU

RED

4-POLE MAGNETS MOVEMENT

BGR

R

G

B

RGB

RED/BLU

GRN

Center Convergence by Convergence Magnets

B

G

R

RED/BLU GRN

6-POLE MAGNETS MOVEMENT

B

G

R

BGR

RGB

R

G

B

INCLINE THE YOKE UP (OR DOWN)

Circumference Convergence by DEF Yoke

Figure 3. Dot Movement Pattern

INCLINE THE YOKE RIGHT (OR LEFT)

– 5 –

Page 9

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

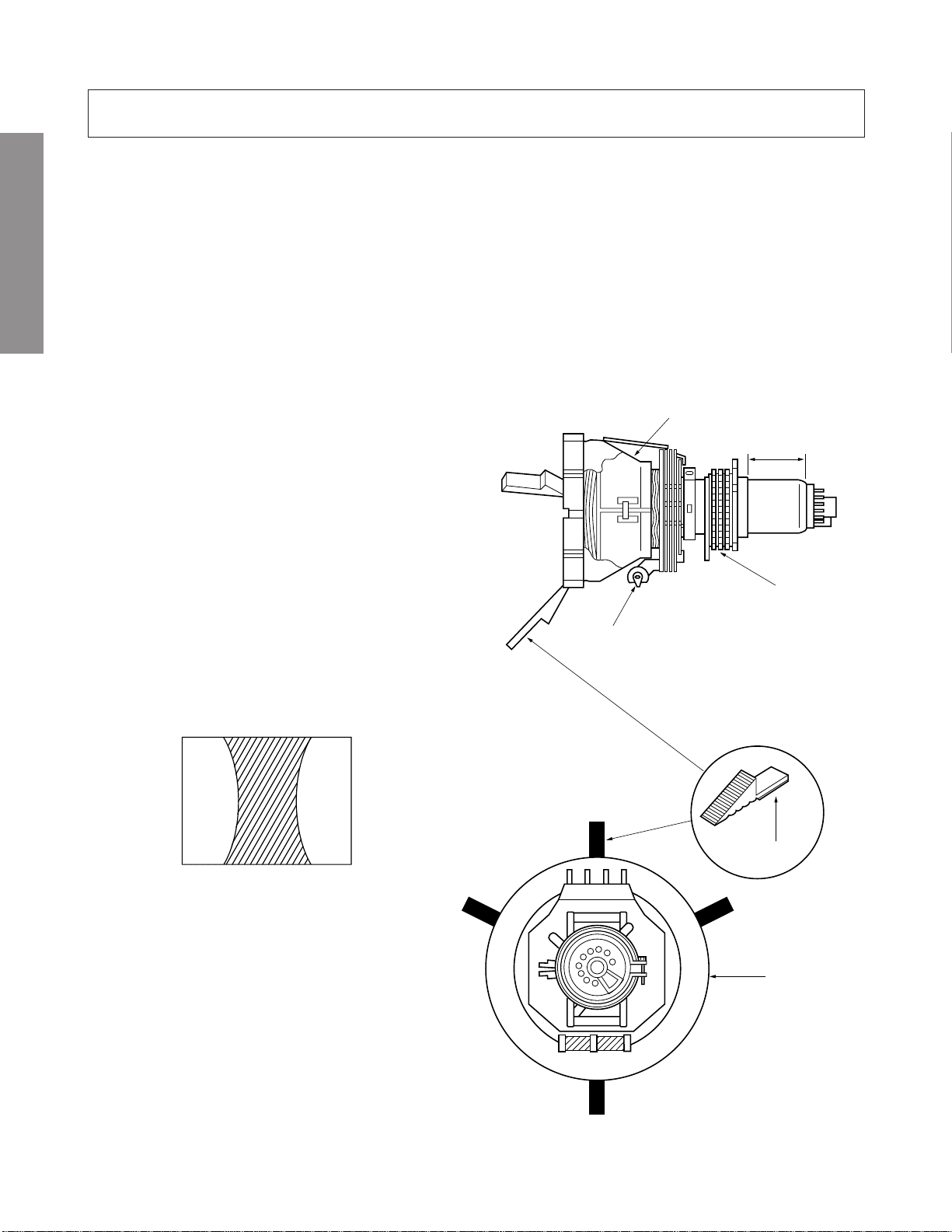

SET-UP ADJUSTMENT FOR 35", 36".

■ The following adjustments should be made when a complete realignment is required or a new picture tube is installed.

Perform the adjustments in order as follows :

1. Color Purity

2. Convergence

3. White Balance

Note: The PURITY/CONVERGENCE MAGNET assembly and rubber wedges need mechanical positioning.

Refer to figure 1.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

*

COLOR PURITY ADJUSTMENT

NOTE : Before attempting any purity adjustments, the

1. Evenly degauss the entire screen.

2. Set the CONTRAST and BRIGHTNESS Controls to

3. Display built-in green raster using the TEST SIGNAL

4. Loosen the clamp screw holding the deflection yoke

5. Slide the yoke forward or backward to provide vertical

6. Rotate and spread the tabs of the purity magnet (See

Mounting position of the purity magnet assembly should fit to same position as old one because slightly difference to

the position depend on a kind of tube.

There are no adjustment of purity and convergence in some picture tube (Unified with purity magnet)

receiver should be operated for at least fifteen

minutes.

the maximum.

SELECTION function.

(and remove the Rubber Wedges).

green belt (zone) in the picture screen.

figure 4.) around the neck of the picture tube until the

green belt is in the center of the screen. At the same

time, center the raster vertically by adjusting the magnet as shown below.

Xv Coil

DEFLECTION YOKE

1-5/8"

PURITY/

CONV.

MAGNET

Green Belt

7. Move the yoke slowly forward or backward until a uniform green screen is obtained. Tighten the clamp scre w

of the yoke temporarily.

8. Check the purity of the red and blue raster.

9. Put four wedges into the space between the picture

tube and the yoke to hold the yoke in the adjusted

position. (See figure 2.)

Do not tilt the yoke by excessive insertion of the wedge.

10. Remove cover paper of wedge and stick wedges on

the tube to fix the yoke in the adjusted position.

Fix the wedges with glass cloth tapes.

Figure 1.

RUBBER WEDGES

Adhesive

DEFLECTION

YOKE

Figure 2.

– 6 –

Page 10

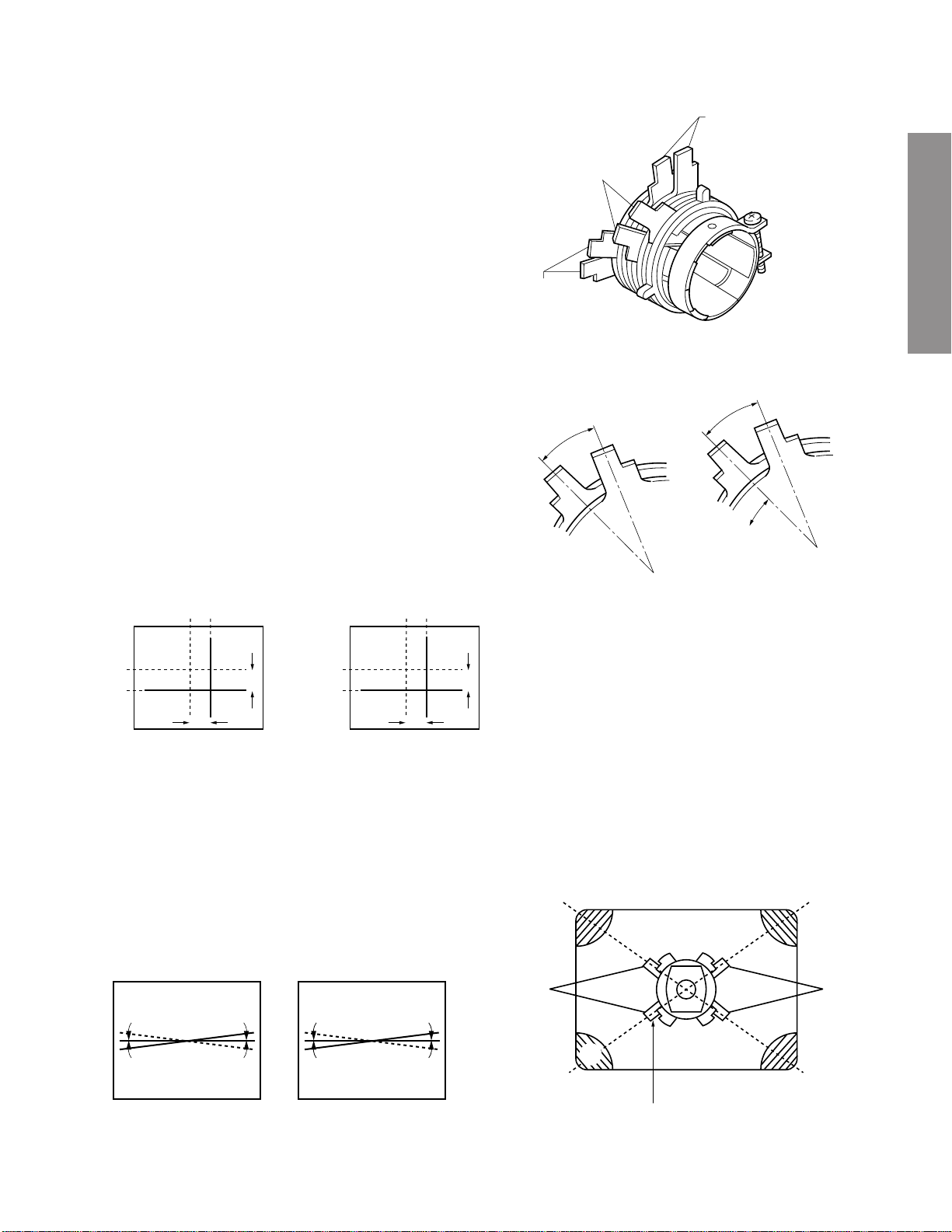

CONVERGENCE ADJUSTMENTS

NOTE: Before attempting any convergence adjustments,

the receiver should be operated for at least fifteen

minutes.

■ CENTER CONVERGENCE ADJUSTMENT

1. Display built-in cross-dot pattern using the TEST SIGNAL SELECTION function.

2. Adjust the BRIGHTNESS and CONTRAST Controls

for well defined pattern.

3. Loosen the tightening ring and adjust two tabs of the

4-Pole Magnets to change the angle between them

(See figure 4.) and superimpose red and blue vertical

lines in the center area of the picture screen.

(See figure 3.)

4. Turn the both tabs at the same time keeping the constant angle to superimpose red and blue horizontal

lines at the centre of the screen. (See figure 3.)

5. Adjust two tabs of 6-Pole Magnets to superimpose red/

blue line with green one. Adjusting the angle affects

the vertical lines and rotating both magnets affects the

horizontal lines.

6. Repeat adjustments 3, 4, 5 keeping in mind red, green

and blue movement, because 4-Pole Magnets and 6Pole magnets interact and make dot movement complex.

7. After completing the “CENTER CONVERGENCE ADJUSTMENT” tighten the tightening ring to fix the magnets.

BLU RED

RED/BLUE GRN

6-POLE

MAGNETS

PURITY

MAGNETS

ADJUST THE ANGLE

(VERTICAL LINES)

4-POLE

MAGNETS

PURITY/CONVERGENCE

MAGNETS

FIXED

ROTATE TWO TABS

AT THE SAME TIME

(HORIZONTAL LINES)

ADJUSTMENT OF MAGNETS

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

BLU

RED

4-POLE MAGNETS

MOVEMENT

Center Convergence by Convergence Magnets

■ Xv COIL ADJUSTMENT

Adjust the Xv coil (on the deflection yoke) to correct

misconvergence at both sides on screen.

Use a hexagonal tip stick (plastic) to adjust the core of

coil.

Clockwise Adjustment Counterclockwise Adjustment

R

B

RED/BLUE

Figure 3.

B

R

GRN

6-POLE MAGNETS

MOVEMENT

B

R

R

B

Figure 4.

■ SCREEN-CORNER CONVERGENCE

When the misconvergence is still evident on corners even

though the above adjustment is done, use the ferrite sheet

(Part No. 23993622) to correct misconvergence.

1. Put ferrite sheets into the space under the yoke.

Decide such position that misconvergence becomes

minimum, watching picture screen. (See figure below .)

2. Remove cover paper of ferrite sheet to stick it in the

place on the tube. Put adhesive tapes on ferrite sheets

to fix.

Ferrite

Sheets

Ferrite

Sheets

A

Xv Cross Pattern View

For correcting misconvergence

on the position A

– 7 –

Page 11

1. ENTERING TO SERVICE MODE

1) Press MUTE button once

on Remote Control.

MUTE

SERVICE MODE

2) Press MUTE button

again to keep pressing.

3) While pressing the MUTE button,

press MENU button on TV set.

S

(Service mode display)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

2. DISPLAYING THE ADJUSTMENT MENU

1) Press MENU button on TV.

Service mode

3. KEY FUNCTION IN THE SERVICE MODE

The following key entry during display of adjustment menu provides special functions.

Test signal selection : TV (ANT)/VIDEO button (on Remote)

Selection of the adjustment items : Channel s/t (on TV or Remote)

Change of the data value : Volume s/t (on TV or Remote)

Adjustment menu mode ON/OFF : MENU button (on TV)

Initialization of the memory (QA02) : RECALL+Channel (s) button on TV

Initialization of the self diagnostic data: RECALL+Channel (t) button on TV

“RCUT” selection : 1 button

“GCUT” selection : 2 button

“BCUT” selection : 3 button

“CNTX” selection : 4 button

“COLC” selection : 5 button

“TNTC” selection : 6 button

Test audio signal ON/OFF (1kHz) : 8 button

Self diagnostic display ON/OFF : 9 button

A single horizontal line ON/OFF: 100 button

Adjustment mode

S

Press

Press

Item

Data

– 8 –

Page 12

4. SELECTING THE ADJUSTING ITEMS

1) Every pressing of CHANNEL s button in the service mode changes the adjustment items in the order of table-2.

(t button for reverse order)

Refer to table-2 for preset data of adjustment mode.

(See SETTING & ADJUSTING DATA on page 15)

5. ADJUSTING THE DATA

1) Pressing of VOLUME s or t button will change the value of data in the range from 00H to FFH. The variable range

depends on the adjusting item.

6. EXIT FROM SERVICE MODE

1) Pressing POWER button to turn off the TV once.

■ INITIALIZATION OF MEMORY DATA OF QA02

After replacing QA02, the following initialization is required.

1. Enter the service mode, then select any register item.

2. Press and hold the RECALL button on the Remote, then press the CHANNEL s button on the TV. The initialization of QA02

has been complated.

3. Check the picture carefully. If necessary, adjust any adjustment item above.

Perform “Programming Channel Memory”.

CAUTION: Never attempt to initialize the data unless QA02 has been replaced.

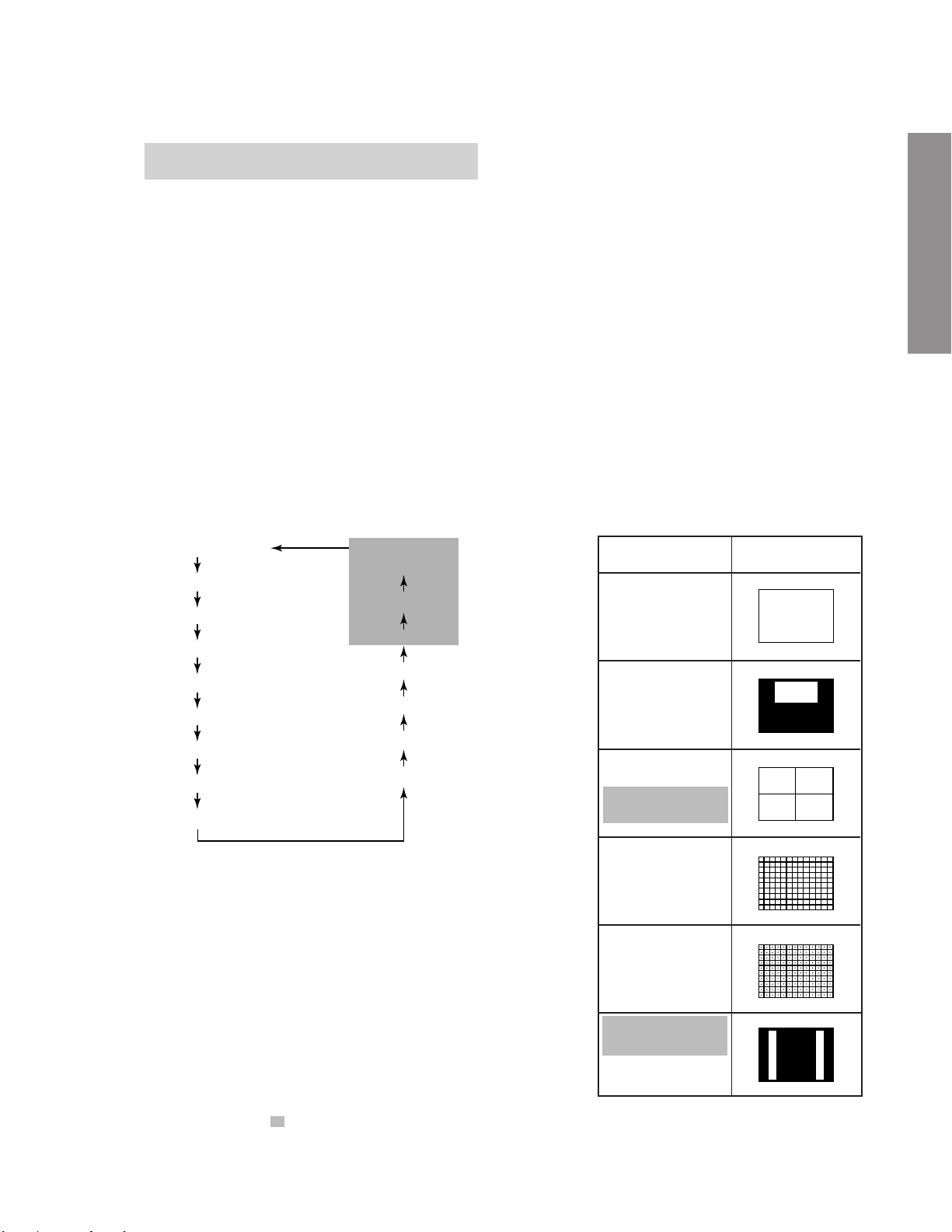

7. TEST SIGNAL SELECTION

1) Every pressing of TV/VIDEO button on the Remote Control in the Service mode changes the built-in test patterns

on screen in the following order.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Normal picture Black cross-bar

on green raster

Red raster

Green raster

Blue raster

All black

All white

White and black

Black cross-bar

White cross-bar

2) Press “8” button while any built-in test pattern to on the screen to

output the 1 kHz sound. Press the button again to cut off the sound.

Note: If the video cable is connected to the VIDEO1 INPUT jack, the

built-in pattern signals are not displayed.

H signal (black)

H signal (white)

White cross-dot

Black cross-dot

White cross-hatch

Black cross-hatch

Signals Picture

• Red raster

• Green raster

• Blue raster

• All Black

• All White

• Black & White

• Black cross-bar

• White cross-bar

• Black cross-bar

on green raster

• Black cross-hatch

• White cross-hatch

• Black cross-dot

• White cross-dot

• H signal (white)

• H signal (black)

The signals marked with are not usable to display in the Test signal for some model.

*

– 9 –

Page 13

8. SELF DIAGNOSTIC FUNCTION (MTS Model)

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

SELF CHECK

1

2

3

4

5

NO. 23XXXXXX

POWER : 000

BUS LINE : OK

BUS CONT : OK

BLOCK : UV V1 V2

or QV01 QV01S

SYNC

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

1 Part number of microprocessor (QA01)

2 Operation number of protection circuit (current limiter) . . . . “000” is normal.

3 BUS line check “OK” ................... Normal

4 BUS line ACK (acknowledge) check

5 Sync. signal check Green display..... Normal

“SCL-GND” or “NG” .......... SCL-GND short circuit

“SDA-GND” or “NG”.......... SDA-GND short circuit

“SCL-SDA” or “NG”........... SCL-SDA short circuit

“OK” ..................... Normal

Display of Location Number . . . . NG

(Display example)

“QA02 NG”, “H001 NG”, “Q501 NG” etc.

Note: The indication of failure place is only one place though failure places are plural. When

repair of a failure place finishes, the next failure place is indicated. (The order of priority of

indication is left side.)

Cyan display ......No check

Red display ........ NG

UV........... TV mode

V1 ........... VIDEO 1 mode

V2 ........... VIDEO 2 mode

9. SELF DIAGNOSTIC FUNCTION (Monaural Model)

1) Press “9” button on Remote Control during display of adjustment menu in the service mode.

The diagnosis will begin to check if interface among IC’s are executed properly.

2) During diagnosis, the following displays are shown.

NO. 23XXXXXX

SELF CHECK

POWER : 000

BUS : OK

NO ACK :

The items marked with are not usable to display in the SELF DIAGNOSTIC FUNCTION for some model.

*

Part number of microprocessor (QA01)

Operation number of protecting circuit ----"000" is normal.

BUS line check ----"OK" is normal.

"[blank]" is normal.

– 10 –

Page 14

1. ENTERING TO DESIGN MODE

1) Select the Service mode.

DESIGN MODE

2) While pressing RECALL button on.

Remote and press MENU button on TV.

3) Press MENU button on TV.

S D

(Design mode) (Adjustment mode)

When QA02 is initialized, items “OPT0” and “OPT1” of DESIGN MODE are set to the data of the representative model of this

chassis family.

Therefore, because ON-SCREEN specification remains in the state of the representative of model. This model is required to

reset the data of items “OPT0” and “OPT1”.

2. SELECTING THE ADJUSTING ITEMS

Every pressing of CHANNEL t button in the design mode changes the adjustment items in the order of table-3.

(s button for reverse order)

Refer to table-3 for data of design mode.

(See SETTING & ADJUSTING DATA on page 15)

3. ADJUSTING THE DATA

Pressing of VOLUME s or t button will change the value of data.

Press

Press

ITEM

DATA

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 11 –

Page 15

ELECTRICAL ADJUSTMENTS

ITEM ADJUSTMENT PROCEDURE

FOCUS VR ADJ.

SUB-BRIGHTNESS

(BRTC)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

SUB-COLOR

(COLC)

SUB-TINT

(TNTC)

1. Enter the service mode, then select any register item.

2. Press the TV/VIDEO button on the Remote until the black cross-bar pattern

appears on the screen.

3. Adjust the FOCUS control (on T461) for well defined scanning lines on the

picture screen.

1. Constrict the picture height until the

vertical retrace line appears adjusting the

HEIGHT control on the MAIN board.

2. Adjust the CONTRAST to the minimum

and BRIGHTNESS to the center.

3. Enter the service mode, then select

“BRTC” register.

4. Adjust the data value so the belt of

vertical retrace line just disappear.

5. Adjust the CONTRAST for the desired

contrast.

6. Adjust the HEIGHT control.

Vertical retrace line

1. Receive color-bar signal from color-bar generator.

2. Adjust the BRIGHTNESS and CONTRAST to the center (RESET status).

3. Connect oscilloscope pin 23 of Q501 on the MAIN board.

4. Enter the service mode, then select “COLC”.

5. Temporarily adjust the data value to

achieve about 1V

of blue bar.

0-p

6. Select “TNTC” register.

7. Adjust the data value to obtain the blue

bar to magenta bar ratio of 3:2 as

shown.

8. Select “COLC” register.

9. Adjust the data value to achieve 1.25V

Magenta

0

0-p

Blue

3 (1.25V

2

of blue bar on scope.

10. Check the picture with off-air signal.

0-P

)

HORIZONTAL POSITION

(HPOS)

VERTICAL POSITION

(VPOS)

HEIGHT

(HIT)

1. Call up the adjustment mode display, then select the Item HPOS or VPOS.

2. Press the TV/VIDEO button until the white cross-bar

or black cross-bar pattern appears on the screen.

3. Adjust the HORIZONTAL and VERTICAL position

alternately by pressing the VOLUME s or t button

for proper picture position.

4. Check the picture with off-air signal.

1. Call up the adjustment mode display, then select the Item HIT.

2. Press the VOLUME s or t button to get the picture so the top of raster begins

to lack.

3. Press the VOLUME s button to advance the data by 8 steps.

Note : Check the vertical picture position is correct.

– 12 –

Page 16

ITEM ADJUSTMENT PROCEDURE

WHITE BALANCE

RCUT

GCUT

BCUT

GDRV

BDRV

1. Adjust the CONTRAST control to the center, and BRIGHTNESS control to the

maximum.

2. Call up the adjustment mode display, and press the TV/VIDEO button until the

white and black pattern appears on the screen.

3. Adjust the following address with the CHANNEL s/t and VOLUME s/t

buttons.

RCUT

Item :

GCUT

Item :

BCUT

Item :

4. Press “100” button on the Remote Control to display a single horizontal line on

the screen.

5. Turn the SCREEN control (FBT) fully counterclockwise and gradually rotate

clockwise until the first horizontal line appears slightly on the screen.

6. Press “100” button to display the normal picture.

7. Adjust the remaining two “?CUT” Item (CHANNEL s/t → 100 → VOLUME s/t

in order) to obtain the slightly lighted horizontal line in the same levels of three

(red, green, blue) colors. The line should be white if the adjustments are proper.

Data : 30H

Data : 30H

Data : 30H

Bright area

Adjust "GDRV" or "BDRV" to be white.

Dark area

Fine adjust "RCUT", "GCUT" or "BCUT" to be black.

Item :

GDRV Data : 80H

Item :

BDRV Data : 80H

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 13 –

Page 17

CIRCUIT CHECKS

HIGH VOL T A GE CHECK

CAUTION: There is no HIGH VOLTAGE ADJUSTMENT on

this chassis. Checking should be done following the steps

below.

1. Connect an accurate high voltage meter to the second anode of the picture tube.

2. Turn on the receiver. Set the BRIGHTNESS and CONTRAST controls to minimum (zero beam current).

3. High voltage must be measured below (B) kV.

Refer to table-1 for high voltage (B).

(See SETTING & ADJUSTING DATA on page 15)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

4. Vary the BRIGHTNESS control to both extremes to be sure

the high voltage does not exceed the limit under any conditions.

FS CIRCUIT CHECK

The Fail Safe (FS) circuit check is indispensable for the final

check in servicing. Checking should be done following the

steps below.

1. Turn the receiver on and press the RESET button.

2. Temporarily short TP-(R) and TP-(X) with a jumper wire.

Raster and sound will disappear.

3. The receiver must remain in this state even after removing

the jumper wire. This is the evidence that the FS circuit is

functioning properly.

4. To obtain a picture again, temporarily turn the receiver off

and allow the FS circuit more than 5 seconds to reset.

Then turn the power switch on to produce a normal picture.

Troubleshooting Guide for Fail Safe Circuit

Check that the set returns to normal operation when pin 12

of Z801(or emitter of Q472) is grounded with jumper wire.

YES NO

Check the voltage across

Capacitor C471 is

approximately (c) volts.

Refer to table –4 for

FBT detection voltage (c).

YES

Defective Fail Safe Circuit

(See SETTING & ADJUSTING

DATA on page15)

NO

Faulty power

circuit or horizontal circuit.

– 14 –

Page 18

CHAPTER 2 SPECIFIC INFORMATIONS

SETTING & ADJUSTING DATA

SAFETY INSTRUCTIONS

HIGH VOLTAGE AT ZERO BEAM: (A) 24.7 kV

MAX HIGH VOLTAGE:

Table-1

SERVICE MODE

ADJUSTING ITEMS AND DATAS IN THE SERVICE MODE:

(B) 26.1 kV

19"

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Item

✩

RCUT

✩

GCUT

✩

BCUT

✩

GDRV

✩

BDRV

CNTX

✩

BRTC

✩

COLC

✩

TNTC

✩

HPOS

✩

VPOS

✩

HIT

✩ These adjustments may be required when replacing QA02 and Q501.

DESIGN MODE

ADJUSTING ITEMS AND DATAS IN THE DESIGN MODE:

Item Name of adjustment

Name of adjustment Reference Data

RED CUT-OFF

GREEN CUT-OFF

BLUE CUT-OFF

GREEN DRIVE

BLUE DRIVE

SUB-CONTRAST

SUB-BRIGHTNESS

SUB-COLOR

SUB-TINT

HORIZONRAL POSITION

VERTICAL POSITION

HEIGHT

Table-2

Preset Data

Data

30H

30H

30H

80H

80H

50H

38H

2CH

42H

19H

02H

1EH

Remarks

There are no adjusting item in the DESIGN MODE.

*

CIRCUIT CHECKS

Table-3

FBT DETECTION VOLTAGE (C)

T able-4

19"

22.03 V

– 15 –

Page 19

Front

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

LOCATION OF CONTROLS

Remote Control

TV/VIDEO button

RECALL button

VOLUME T / S button

(Menu T / S button)

MENU button

VOLUMEMENU

TV/VIDEO

RECALL MUTE

VOL

MENU EXIT

CHANNEL

1 2 3

4 5 6

7 8 9

100 0

CH

CH

POWER

CH RTN

POWER

Remote sensor

POWER button

Channel Number button

RTN button

MUTE button

VOL

CHANNEL s/t buttons

(Menu s/t buttons)

EXIT button

– 16 –

Page 20

PROGRAMMING CHANNEL MEMORY

The channel memory is the list of TV channel numbers your TV will stop on when you press the CHANNEL s or t button.

First, use the TV/CABLE and CH PROGRAM functions to preset all active channels in your area.

If necessary, arrange the preset channels with the ADD/ERASE functions so that you can tune into only desired channels.

TV/CABLE function

1 Press POWER, to turn on the TV.

2 Press MENU (then s or t) repeatedly until "TV/CABLE" in

the Set up menu is displayed in purple.

3 Press ;(<) or :(>) until the mode that corresponds to your

TV signal system is displayed in purple.

CH PROGRAM function

1 Press MENU (then s or t) repeatedly until "CH PRO-

GRAM" in the Set up menu is displayed in purple.

2 Press ;(<) or :(>) to start channel programming.

The TV will automatically cycle through all the TV or CABLE

channels depending on the mode selected, and store

active channels in the channel memory.

3 When channel programming is complete, you will see the

message to the right.

4 Press CHANNEL s or t to make sure the channel pro-

gramming has been done properly.

ADD/ERASE function

After performing the CH PROGRAM function, you can add

or erase specific channels.

1 Select the channel you want to erase using the CHANNEL

s or t button, or select the channel you want to add using

the Channel Number buttons.

2 Press MENU (then s or t) repeatedly until “ADD/ERASE”

in the Set up menu is displayed in purple.

3 Press ;(<) or :(>) :

To erase the channel

Press the button until “Erase” is displayed in purple indicating that the channel has been erased from the memory.

To add the channel

Press the button until “ADD” is displayed in purple indicating that the channel has been memorized.

4 Repeat steps 1 to 3 for other channels.

You have now completed the channel programming.

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 17 –

Page 21

MAIN BOARD

CRT DRIVE BOARD

AUDIO OUT

Q610

W661

SPEAKER

KEY

CONTROL

DB03

R/SENSOR

VOLT

REGU

QA02

MEMORY

QA01

MICROPROCESSOR

H001

TUNER/IF/VIDEO

Q501

VIDEO/CHROMA/DEF

SCL

SDA

5V

RMT IN

RESET

POWER

QB30

QB33

Q843

Q801

F470

Q471

FAIL SAFE

CRT HEATER

Q472

+134V

+32V

+9V

+26V

T461

FBT

Q421

Q402

Q404

Q301

L462

DEF YOKE

V901

PICTURE TUBE

H DRIVE

H. OUT

H OUT

V. OUT

+200V

SCREEN

FOCUS

H.V.

Q903

Q902

Q901

R

G

B

V OUT

B OUT

G OUT

R OUT

V-TV

AUDIO OUT

SCL

SDA

QB17

QB18

QB19

D840

P801

F801

F802

T801

SR81

L901

D801~D804

DEGAUSSING

COIL

CIRCUIT BLOCK DIAGRAM

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

CIRCUIT BLOCK DIAGRAM

– 18 –

Page 22

CHASSIS AND CABINET REPLACEMENT PARTS LIST

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE “X-RAY RADIATION PRECAUTION”, “SAFETY

PRECAUTION” AND “PRODUCT SAFETY NOTICE” ON PAGE 3 OF THIS MANUAL.

CAUTION: The international hazard symbols “ ” in the schematic diagram and the parts list designate com-

ponents which have special characteristics important for safety and should be replaced only with types identical to

those in the original circuit or specified in the parts list. The mounting position of replacements is to be identical

with originals. Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE. Do not

degrade the safety of the receiver through improper servicing.

NOTICE:

•

The part number must be used when ordering parts, in order to assist in processing, be sure to include the Model

number and Description.

•

The PC board assembly with * mark is no longer available after the end of the production.

Models : 19A20

Capacitors ............. CD : Ceramic Disk PF : Plastic Film EL : Electrolytic

Resistors ............... CF : Carbon Film CC : Carbon Composition MF : Metal Film

OMF : Oxide Metal Film VR : Variable Resistor FR : Fusible Resistor

(All CD and PF capacitors are ±5%, 50V and all resistors, ±5%, 1/6W unless otherwise noted.)

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

Location

No.

CAPACITORSCAPACITORS

CAPACITORS

CAPACITORSCAPACITORS

C102 24793101 EL, 100?F, ±20%, 10V

C105 24232103 CD, 0.01?F, +80%, -20%

C106 24797479 EL, 4.7?F, ±20%, 50V

C107 24794221 EL, 220?F, ±20%, 16V

C201 24797478 EL, 0.47?F, ±20%, 50V

C205 24794220 EL, 22?F, ±20%, 16V

C207 24794100 EL, 10?F, ±20%, 16V

C208 24797010 EL, 1?F, ±20%, 50V

C209 24797229 EL, 2.2?F, ±20%, 50V

C210 24794470 EL, 47?F, ±20%, 16V

C211 24232103 CD, 0.01?F, +80%, -20%

C230 24794331 EL, 330?F, ±20%, 16V

C231 24232103 CD, 0.01?F, +80%, -20%

C232 24206108 EL, 0.1?F, ±20%, 50V

C233 24794100 EL, 10?F, ±20%, 16V

C235 24436150 CD, 15pF

C301 24617912 EL, 2.2?F, ±10%, 50V

C302 24212152 CD, 1500pF, ±10%

C305 24617912 EL, 2.2?F, ±10%, 50V

C306 24073042 EL, 1000?F, ±20%, 16V

C307 24082047 PF, 0.033?F, 100V

C308 24668101 EL, 100?F, ±20%, 35V

C309 24591102 PF, 1000pF

C310 24796102 EL, 1000?F, ±20%, 35V

C311 24214221 CD, 220pF, ±10%, 500V

C313 24693472 PF, 4700pF, 100V

C314 24591563 PF, 0.056?F

C315 24797229 EL, 2.2?F, ±20%, 50V

C317 24214471 CD, 470pF, ±10%, 500V

C403 24591203 PF, 0.02?F

C404 24797229 EL, 2.2?F, ±20%, 50V

C417 24214391 CD, 390pF, ±10%, 500V

C421 24591334 PF, 0.33?F

C422 24591334 PF, 0.33?F

C431 24794470 EL, 47?F, ±20%, 16V

* C440 24082929 PF, 6800pF, ±3%, 1500V

* C442 24082694 PF, 0.33?F, 250V

C445 24828223 PF, 0.022?F, 200V

C446 24700100 EL, 10?F, ±20%, 250V

C448 24640908 EL, 33?F, ±20%, 160V

Part No. Description

Location

No.

C449 24794102 EL, 1000?F, ±20%, 16V

C463 24212152 CD, 1500pF, ±10%

C471 24797479 EL, 4.7?F, ±20%, 50V

C474 24794100 EL, 10?F, ±20%, 16V

C504 24353090 CD, 9pF, ±0.25pF, CH

C510 24797229 EL, 2.2?F, ±20%, 50V

C514 24591223 PF, 0.022?F

C607 24794102 EL, 1000?F, ±20%, 16V

C609 24591103 PF, 0.01?F

C610 24794220 EL, 22?F, ±20%, 16V

C611 24539104 PF, 0.1?F

C613 24794471 EL, 470?F, ±20%, 16V

C614 24797478 EL, 0.47?F, ±20%, 50V

C801 24095852 PF, 0.082?F, ±20%, AC125V

C807 24790100 EL, 10?F, ±20%, 160V

C808 24214472 CD, 4700pF, ±10%, 500V

C810 24086862 EL, 470?F, ±20%, 200V

C819 24766478 EL, 0.47?F, ±20%, 50V

C832 24793470 EL, 47?F, ±20%, 10V

C840 24679330 EL, 33?F, ±20%, 250V

C843 24666100 EL, 10?F, ±20%, 16V

C902 24211102 CD, 1000pF, ±10%, 2kV

C921 24212681 CD, 680pF, ±10%

C922 24212681 CD, 680pF, ±10%

C923 24212681 CD, 680pF, ±10%

CA28 24472100 CD, 10pF

CA29 24472100 CD, 10pF

CA33 24232103 CD, 0.01?F, +80%, -20%

CA36 24474101 CD, 100pF, ±10%

CA37 24474101 CD, 100pF, ±10%

CA38 24474101 CD, 100pF, ±10%

CA42 24794100 EL, 10?F, ±20%, 16V

CA43 24232103 CD, 0.01?F, +80%, -20%

CA68 24794100 EL, 10?F, ±20%, 16V

CA69 24232103 CD, 0.01?F, +80%, -20%

CB01 24794470 EL, 47?F, ±20%, 16V

CB20 24474101 CD, 100pF, ±10%

CR01 24797478 EL, 0.47?F, ±20%, 50V

CR02 24797478 EL, 0.47?F, ±20%, 50V

CR03 24797478 EL, 0.47?F, ±20%, 50V

CS02 24797229 EL, 2.2?F, ±20%, 50V

Part No. Description

– 19 –

Page 23

Location

No.

Part No. Description

Location

No.

Part No. Description

CS03 24797478 EL, 0.47?F, ±20%, 50V

CS11 24797478 EL, 0.47?F, ±20%, 50V

CT63 24591223 PF, 0.022?F

CV06 24797478 EL, 0.47?F, ±20%, 50V

RESISTORSRESISTORS

RESISTORS

RESISTORSRESISTORS

R101 24382153 OMF, 15k ohm, 1W

R201 24552391 OMF, 390 ohm, 1/2W

R208 24366124 CF, 120k ohm

R218 24366154 CF, 150k ohm

R227 24366153 CF, 15k ohm

R230 24366223 CF, 22k ohm

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

R233 24366152 CF, 1500 ohm

R235 24366154 CF, 150k ohm

R236 24366101 CF, 100 ohm

R237 24366101 CF, 100 ohm

R238 24366332 CF, 3300 ohm

R239 24366152 CF, 1500 ohm

R241 24366433 CF, 43k ohm

R242 24366473 CF, 47k ohm

R245 24366184 CF, 180k ohm

R246 24366225 CF, 2.2M ohm

R247 24366471 CF, 470 ohm

R301 24366102 CF, 1k ohm

R303 24366102 CF, 1k ohm

R304 24366683 CF, 68k ohm

R305 24322109 MF, 1 ohm, 1W

R306 24366753 CF, 75k ohm

R307 24366914 CF, 910k ohm

R312 24381152 OMF, 1500 ohm, 1/2W

R313 24366184 CF, 180k ohm

R317 24366333 CF, 33k ohm

R327 24338829 MF, 8.2 ohm, 1W

R336 24383271 OMF, 270 ohm, 2W

R337 24366223 CF, 22k ohm

R338 24366223 CF, 22k ohm

R401 24366391 CF, 390 ohm

R402 24366103 CF, 10k ohm

R403 24366332 CF, 3300 ohm

R405 24553392 OMF, 3900 ohm, 1W

R406 24366333 CF, 33k ohm

R407 24366223 CF, 22k ohm

R410 24366391 CF, 390 ohm

R411 24366561 CF, 560 ohm

R412 24366560 CF, 56 ohm

R414 24383222 OMF, 2200 ohm, 2W

R416 24510182 Cement, 1800 ohm, 5W

R430 24366102 CF, 1k ohm

R431 24366103 CF, 10k ohm

R432 24366222 CF, 2200 ohm

R448 24338828 MF, 0.82 ohm, 1W

R472 24376270 CF, 27 ohm, 1/2W

* R475 24367101 CF, 100 ohm, ±2%

R476 24366823 CF, 82k ohm

R477 24366223 CF, 22k ohm

* R478 24327133 MF, 13k ohm, ±1%, 1/4W

R481 24366333 CF, 33k ohm

* R482 24327512 MF, 5100 ohm, ±1%, 1/4W

R495 24383222 OMF, 2200 ohm, 2W

R496 24383182 OMF, 1800 ohm, 2W

R503 24366334 CF, 330k ohm

R504 24366332 CF, 3300 ohm

R513 24366332 CF, 3300 ohm

R514 24366332 CF, 3300 ohm

R602 24532100 FR, 10 ohm, 1W

R603 24366391 CF, 390 ohm

R604 24366182 CF, 1800 ohm

R605 24366339 CF, 3.3 ohm

R802 24376224 CF, 220k ohm, 1/2W

R803 24553123 OMF, 12k ohm, 1W

R804 24002000 CC, 3.9M ohm, ±10%, 1/2W

R806 24552560 OMF, 56 ohm, 1/2W

R808 24000269 PTC Thermistor, 7 ohm,

±20%, AC140V

R810 24568229 Cement, 2.2 ohm, 7W

R811 24007851 Cement, 200 ohm, 15W

R812 24510120 Cement, 12 ohm, 5W

R816 24366471 CF, 470 ohm

R818 24366561 CF, 560 ohm

R819 24366102 CF, 1k ohm

R830 24381330 OMF, 33 ohm, 1/2W

R831 24366681 CF, 680 ohm

R841 24568752 Cement, 7500 ohm, 7W

R845 24384123 OMF, 12k ohm, 3W

R847 24366392 CF, 3900 ohm

R848 24366103 CF, 10k ohm

R897 24019472 Varistor, ENE271D-10A2

R899 24019472 Varistor, ENE271D-10A2

R901 24376472 CF, 4700 ohm, 1/2W

R902 24376472 CF, 4700 ohm, 1/2W

R903 24376472 CF, 4700 ohm, 1/2W

R911 24366101 CF, 100 ohm

R912 24366101 CF, 100 ohm

R913 24366101 CF, 100 ohm

R920 24000880 FR, 5.1 ohm, 1W

R921 24366331 CF, 330 ohm

R922 24366331 CF, 330 ohm

R923 24366331 CF, 330 ohm

R931 24366102 CF, 1k ohm

R932 24366102 CF, 1k ohm

R933 24366102 CF, 1k ohm

R961 24554183 OMF, 18k ohm, 2W

R962 24554183 OMF, 18k ohm, 2W

R963 24554183 OMF, 18k ohm, 2W

R971 24366821 CF, 820 ohm

R972 24366102 CF, 1k ohm

R973 24366391 CF, 390 ohm

R974 24366221 CF, 220 ohm

RA03 24366102 CF, 1k ohm

RA07 24366102 CF, 1k ohm

RA14 24366102 CF, 1k ohm

RA16 24366102 CF, 1k ohm

RA17 24366102 CF, 1k ohm

RA18 24366102 CF, 1k ohm

RA22 24366472 CF, 4700 ohm

RA23 24366472 CF, 4700 ohm

RA24 24366472 CF, 4700 ohm

RA25 24366682 CF, 6800 ohm

RA26 24366102 CF, 1k ohm

RA27 24366102 CF, 1k ohm

RA33 24366103 CF, 10k ohm

RA35 24366102 CF, 1k ohm

RA36 24366103 CF, 10k ohm

RA37 24366331 CF, 330 ohm

RA38 24366331 CF, 330 ohm

RA61 24366103 CF, 10k ohm

RA62 24366103 CF, 10k ohm

RA67 24366103 CF, 10k ohm

– 20 –

Page 24

Location

No.

Part No. Description

Location

No.

Part No. Description

RA68 24366103 CF, 10k ohm

RA70 24366333 CF, 33k ohm

RA71 24366683 CF, 68k ohm

RA72 24366223 CF, 22k ohm

RA73 24366103 CF, 10k ohm

RA74 24366101 CF, 100 ohm

RA75 24366101 CF, 100 ohm

RB03 24366101 CF, 100 ohm

RB09 24366470 CF, 47 ohm

RB26 24366472 CF, 4700 ohm

RB27 24366103 CF, 10k ohm

RB28 24366104 CF, 100k ohm

RB30 24366103 CF, 10k ohm

RB33 24366102 CF, 1k ohm

RB43 24366103 CF, 10k ohm

RB44 24366682 CF, 6800 ohm

RB45 24366221 CF, 220 ohm

RR90 24366102 CF, 1k ohm

RR91 24366102 CF, 1k ohm

RR92 24366102 CF, 1k ohm

RR93 24366472 CF, 4700 ohm

RT61 24366332 CF, 3300 ohm

RT63 24366102 CF, 1k ohm

RV01 24366680 CF, 68 ohm

COILS & TRANSFORMERSCOILS & TRANSFORMERS

COILS & TRANSFORMERS

COILS & TRANSFORMERSCOILS & TRANSFORMERS

L101 23289220 Coil, Peaking, TRF4220AF

L203 23289846 Coil, Peaking, TRF4101AT

L301 23103880 Coil (Ferrite Bead), TEM2011Y

L410 23103880 Coil (Ferrite Bead), TEM2011Y

* L462 23231292 Deflection Yoke, TDY-320UG

* L901 23200338 Coil, Degaussing, TSB-2100CP

LA01 23289100 Coil, Peaking, TRF4100AF

LB01 23289470 Coil, Peaking, TRF4470AF

T401 23224983 Transformer, Horiz. Drive,

* T461 23236614 Transformer, Flyback,

T801 23211696 Line, Filter, TRF3216AK

SEMICONDUCTORSSEMICONDUCTORS

SEMICONDUCTORS

SEMICONDUCTORSSEMICONDUCTORS

Q301 B0377890 IC, TA8403K

Q301B 72471082 Screw, BRDT2W3X10 SZN

Q402 A6330069 Transistor, 2CS2482 FA-1

Q404 A6873824 Transistor, 2SD2599

Q404B 72471082 Screw, BRDT2W3X10 SZN

Q421 23905952 IC, MC7809BT

Q471 23114530 Transistor, 2SA933S-Q

Q472 23114528 Transistor, 2SC1740S, Q

Q501 B0385424 IC, TA1223AN

Q610 23119668 IC, TDA2611A

* Q801 23114420 IC, STR30134

Q801B 70391356 Screw, BITTB3X10 SZN

Q817 23114528 Transistor, 2SC1740S, Q

Q818 A6012010 Transistor, RN2201

Q819 23114528 Transistor, 2SC1740S, Q

Q830 23114552 Transistor, 2SC1685-Q, TH

Q843 A6330059 Transistor, 2SC2482(C)

Q901 A6330059 Transistor, 2SC2482(C)

Q902 A6330059 Transistor, 2SC2482(C)

Q903 A6330059 Transistor, 2SC2482(C)

Q971 A6534040 Transistor, 2SA1015-Y

QA01 23000286 IC, TMPA8700CKN-1A04

QA02 70129473 IC, AT24C01A10PC

TLN1039

TFB4139AD

QB03 A6002050 Transistor, RN1205

QB21 23114528 Transistor, 2SC1740S, Q

QB30 23114528 Transistor, 2SC1740S, Q

QB33 70119743 IC, PST523D

QB40 23114528 Transistor, 2SC1740S, Q

D101 23316411 Diode, Zener, HZT33-12

D201 23316656 Diode, Zener, MTZJ3.3A

D204 23118859 Diode, 1SS133

D205 23118859 Diode, 1SS133

D210 23118859 Diode, 1SS133

D301 A7568460 Diode, TVR-1B

D302 23118095 Diode, ERB44-06, E

D406 23118095 Diode, ERB44-06, E

D408 23118052 Diode, RU4Z LF-L1

D410 23316688 Diode, Zener, MTZJ9.1C

D441 23316687 Diode, Zener, MTZJ9.1B

D445 23118479 Diode, BYD33J

D471 A7568460 Diode, TVR-1B

* D472 23316782 Diode, Zener, MTZJ6.2C

D801 A7568754 Diode, 1S1887A FA-1

D802 A7568754 Diode, 1S1887A FA-1

D803 A7568754 Diode, 1S1887A FA-1

D804 A7568754 Diode, 1S1887A FA-1

D830 23316673 Diode, Zener, MTZJ5.6C

D840 A7568752 Diode, 1S1887A, FA

D841 A7568752 Diode, 1S1887A, FA

D842 23316678 Diode, Zener, MTZJ6.8B

D843 23316671 Diode, Zener, MTZJ5.6A

D845 23118486 Diode, ERA15-02, G1

DB03 23358522 Diode (LED), SIR-56SB3F

DB30 23118859 Diode, 1SS133

MISCELLANEOUSMISCELLANEOUS

MISCELLANEOUS

MISCELLANEOUSMISCELLANEOUS

E502 23451933 Rubber Wedge

F301 23144727 Fuse, 0.4A

F301A 23165433 Holder, Fuse

F470 23144495 Fuse, 0.8A

F470A 23165433 Holder, Fuse

F801 23144888 Fuse, 5.0A, 125V

F801A 23165433 Holder, Fuse

F802 23144785 Fuse, 1.25A, 125V

F802A 23165433 Holder, Fuse

G060 24366101 CF, 100 ohm

G411 23103880 Coil (Ferrite Bead), TEM2011Y

G885 23248031 Coil, Choke, TLN3274D

G903 23118859 Diode, 1SS133

P001 23142041 Terminal, Antenna Shield

P801 23372112 Power Cord

SA01 23145227 Switch, Push, 1C1P

SA02 23145227 Switch, Push, 1C1P

SA03 23145227 Switch, Push, 1C1P

SA04 23145227 Switch, Push, 1C1P

SA05 23145227 Switch, Push, 1C1P

SA07 23145227 Switch, Push, 1C1P

SR81 23146566 Relay, DC48V

* V901A 23902970 Socket, CRT, 8P

V901M 23102462 Magnet, Purity-Convergence,

W661 23351157 Speaker, SPK-1399,

X401 23153721 Ceramic Resonator, 503kHz,

X501 23153961 Crystal, 3.58MHz

MAG-1104

50x90mm, 8 ohm

TCR1023

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

– 21 –

Page 25

Location

No.

Part No. Description

Location

No.

Part No. Description

XA01 23153504 Ceramic Resonator, 8.00MHz,

Z001 23134187 CR-GAP, CRA112G

PC BOARD ASSEMBLIESPC BOARD ASSEMBLIES

PC BOARD ASSEMBLIES

PC BOARD ASSEMBLIESPC BOARD ASSEMBLIES

M051Z Main Board, PB9391A-1

*

M052Z CRT Drive Board, PB9391A-2

*

PICTURE TUBEPICTURE TUBE

PICTURE TUBE

PICTURE TUBEPICTURE TUBE

* V901 23312676 Picture Tube, A48KZL70X(LW)

TUNERTUNER

TUNER

TUNERTUNER

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

H001 23321369 Tuner, EL953L

ACCESSORIESACCESSORIES

ACCESSORIES

ACCESSORIESACCESSORIES

K912 23306309 Remote Hand Unit, CT-9988

AT03 23588409 Battery Cover

Y101 23563888 Owner’s Manual, English,

Y101F 23563889 Owner’s Manual, French,

CABINET PARTSCABINET PARTS

CABINET PARTS

CABINET PARTSCABINET PARTS

A201 23549157 Front Cover

A224 23445231 Button, Control

A411 23549244 Back Cover

A701 23524655 Carton Box

A703 23935858 Packing, Top

A708 23935859 Packing, Bottom

TCR1056BM

19A20

19A20

– 22 –

Page 26

MAIN BOARD PB9391-1

BOTTOM (FOIL) SIDE

– 23 – – 24 –

Page 27

CRT-D DRIVE BOARD PB9391-2

E

C

B

B

C

E

E

C

B

BOTTOM (FOIL) SIDE

TERMINAL VIEW OF TRANSISTORS

1 2SD2253

(old)

2SC5243

6 RN2203

RN2201

RN2004

RN1203

RN1204

RN2204

RN1205

RN1202

RN1201

2 2SC3852

2SD1763A

2SC1569

2SC4544

2SA1788

2SA1306

2SA1186A

B

C

E

7 2SD1554

2SD2253

2SD1556

2SC5143

2SD2553

B

C

E

3 2SC752GTM

2SC2482

2SC2655

2SC4721P

E

C

B

8 ON4409

B

C

E

4 2SC752

2SA562TM

2SA1015

2SC1815

2SC2878

2SC1740S

2SC2120

2SA9335

E

C

B

5 2SA1788

– 25 –

– 26 –

Page 28

SPECIFICATIONS

TELEVISION SYSTEM NTSC standard

CHANNEL COVERAGE VHF; 2 through 13

UHF; 14 through 69

Cable TV; mid band (A-8 through A-1, A through I)

super band (J through W)

hyper band (AA through ZZ, AAA, BBB)

ultra band (65 through 94, 100 through 125)

POWER SOURCE 120V AC, 60Hz

POWER CONSUMPTION 61 W (average)

AUDIO POWER 1W

SPEAKER TYPE 2 x 3-1/2 inches (50 x 90mm)

DIMENSIONS Width ....................... 20-5/32 inches (512mm)

Height...................... 17-29/32 inches (454mm)

Depth ...................... 18-1/2 inches (470mm)

MASS 37.9 lbs (17.2kg)

SUPPLIED ACCESSORIES Remote Control with 2 size “AA” batteries

GENERAL ADJUSTMENTSSPECIFIC INFORMATIONS

*Please refer to owner's manual in detail.

– 29 –

Page 29

SCHEMATIC DIAGRAM

MODEL : 19A20 Chassis No. TAC0001

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY RADIATION PRECAUTION", "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" ON THE MANUAL FOR THIS MODEL.

CAUTION: The international hazard symbols "*" in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in the

original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE on the MANUAL for this

model. Do not degrade the safety of the receiver through improper servicing.

NOTE:

1. RESISTOR Resistance is shown in ohm [K = 1.000, M = 1.000.000]. All resistors are 1/6W and 5%

tolerance carbon resistor, unless otherwise noted as the following marks.

1/2R = Metal or Metal oxide of 1/2 watt 1/2S = Carbon compsistion of 1/2 watt

1RF = Fuse resistor of 1 watt 10W = Cement of 10 watt

K = ±10% G = ±2% F = ±1%

2. CAPACITOR Unless otherwise noted in schematic, all capacitor values less than 1 are expressed in

?F, and the values more than 1 in pF.

All capacitors are ceramic 50V, unless otherwise noted as the following marks.

Electolytic capacitor Mylar capacitor

3. The parts indicated with " * " have special characteristics, and should be replaced with identical parts only.

4. Voltages read with DIGITAL MULTI-METER from point indicated to chassing ground, using a color bar signal with all

controls at normal, line voltage 120 volts.

5. Waveforms are taken receiving color bar signal with enough sensitivity.

6. Voltage reading shown are nominal values and may vary ±20% except H.V.

Page 30

SCHEMATIC DIAGRAM MODEL : 19A20 Chassis No. TAC0001

WARNING: BEFORE SERVICING THIS CHASSIS, READ THE "X-RAY RADIATION PRECAUTION", "SAFETY

PRECAUTION" AND "PRODUCT SAFETY NOTICE" ON THE MANUAL FOR THIS MODEL.

CAUTION: The international hazard symbols "*" in the schematic diagram and the parts list designate components

which have special characteristics important for safety and should be replaced only with types identical to those in the

original circuit or specified in the parts list. The mounting position of replacements is to be identical with originals.

Before replacing any of these components, read carefully the PRODUCT SAFETY NOTICE on the MANUAL for this

model. Do not degrade the safety of the receiver through improper servicing.

NOTE:

1. RESISTOR Resistance is shown in ohm [K = 1.000, M = 1.000.000]. All resistors are 1/6W and 5%

tolerance carbon resistor, unless otherwise noted as the following marks.

1/2R = Metal or Metal oxide of 1/2 watt 1/2S = Carbon compsistion of 1/2 watt

1RF = Fuse resistor of 1 watt 10W = Cement of 10 watt

K = ±10% G = ±2% F = ±1%

2. CAPACITOR Unless otherwise noted in schematic, all capacitor values less than 1 are expressed in

?F, and the values more than 1 in pF.

All capacitors are ceramic 50V, unless otherwise noted as the following marks.

Electolytic capacitor Mylar capacitor

3. The parts indicated with " * " have special characteristics, and should be replaced with identical parts only.

4. Voltages read with DIGITAL MULTI-METER from point indicated to chassing ground, using a color bar signal with all

controls at normal, line voltage 120 volts.

5. Waveforms are taken receiving color bar signal with enough sensitivity.

6. Voltage reading shown are nominal values and may vary ±20% except H.V.

Page 31

Page 32

Page 33

Page 34

Page 35

Page 36

Page 37

Page 38

Loading...

Loading...