ORT230/240 SERIES

TRANSDUCER

USER MANUAL

CAUTION

This instruction manual should be read carefully and the

safety instructions observed before installing or operating

the equipment related to this manual.

Apollo Park, Ironstone Lane, Wroxton, Banbury

Oxon, OX15 6AY

Tel: +44 (0)1869 238400 Fax: +44 (0)1869 238401

Email: info@sensors.co.uk Web: www.sensors.co.uk

Sensor Technology 2016 Page 1 ORT4076IM (Rev 1)

While every precaution has been exercised in the compilation of this document to ensure the

accuracy of its contents, Sensor Technology Ltd, assumes no responsibility for any errors or

omissions. Additionally, no liability is assumed for any damages that may result from the use

of the information contained in this document.

Copyright

Copyright 2016 Sensor Technology Ltd. All rights Reserved.

Copying or reproducing of all or any part of the contents of this manual is strictly prohibited

without the express permission of Sensor Technology.

Trademarks

TorqSense is a registered trademark of Sensor Technology Ltd.

TorqView is a trademark of Sensor Technology Ltd.

LabVIEW is a trademark of National Instruments Corporation.

National Instruments is a trademark of National Instruments Corporation.

Windows is a registered trademark of Microsoft Corporation.

Lifetime Warranty

Sensor Technology Ltd’s standard range of products are warranted against manufacturing

defects and component failure for two years from date of purchase, subject to fair wear and

tear and return for the first year's free of charge annual re-calibration. This warranty is

extended indefinitely if the equipment is returned to Sensor Technology, or its distributor, for

annual re-calibration, when software and hardware updates, if required, will be carried out

free of charge. Standard range means those products as described in the company's product

data sheets.

Sensor Technology 2016 Page 2 ORT4076IM (Rev 1)

Table of Contents

Getting Started......................................................................................................................... 3

Introduction............................................................................................................................ 3

Unpacking the transducer ..................................................................................................... 3

Mechanical Installation .......................................................................................................... 4

Operating Principles .............................................................................................................. 5

Operation.................................................................................................................................. 6

Powering the transducer ....................................................................................................... 6

Using the transducer ............................................................................................................. 6

Built In Test (BIT) .................................................................................................................. 7

Normal Operation .................................................................................................................. 8

Peak Mode........................................................................................................................ 8

Analog Scaling..................................................................................................................8

Warning Signals .................................................................................................................... 9

Error Signals........................................................................................................................ 10

Peak Input ........................................................................................................................... 10

Analog Output.................................................................................................................10

Peak Reset .....................................................................................................................10

Analog Outputs.................................................................................................................... 11

Data Assignments........................................................................................................... 11

Voltage/Current Assignments......................................................................................... 12

Fail Output........................................................................................................................... 12

Limit Output ......................................................................................................................... 13

Zeroing the transducer ........................................................................................................ 14

Electrical Signal .............................................................................................................. 14

Digital Command ............................................................................................................ 15

Resetting transducer to factory default ............................................................................... 15

Examples of reading/collecting data ................................................................................... 16

Optional Accessories............................................................................................................ 17

Analog Lead ........................................................................................................................ 17

Digital Lead (ORT240

series ONLY)...................................................................................

17

Digital Adaptor Lead (ORT240 series ONLY) ..................................................................... 17

Additional Related Products and Transducer Resources................................................. 17

Transducer Display ETD ..................................................................................................... 17

Transducer Signal Breakout Unit ........................................................................................ 17

AC Mains Adaptor Power Supply........................................................................................ 17

TorqView (ORT240 series ONLY)....................................................................................... 17

Transducer Control Program (ORT240 series ONLY) ........................................................ 17

Transducer Communication Protocol (ORT240 series ONLY) ........................................... 17

Transducer DLL Programmers Guide (ORT240 series ONLY) .......................................... 17

Leads ...................................................................................................................................... 18

Analog Lead - Pin Out......................................................................................................... 18

Digital Lead - Pin Out (ORT240 Series ONLY)................................................................... 19

Transducer Connections ...................................................................................................... 20

Analog ................................................................................................................................. 20

Digital .................................................................................................................................. 20

Data Specification . . . . . . . Attached

Appendices (ORT240 series ONLY)

1. ORT240 Series Transducer Control Utility

Attachments (the following documents may also be attached)

1. TorqView User Guide

Sensor Technology 2016 Page 3 ORT4076IM (Rev 1)

Getting Started

Introduction

The Optical Rotary Torque Transducer provides a method of precisely

measuring bi-directional rotary or static torque. It can also be fitted with a speed sensor for

monitoring in dynamic applications, enabling direct measurements of transmitted power.

The ORT series transducers require no external instrumentation and has its own built in test

capability. Its compact size makes it ideal for use in applications where there is little space for

any extra equipment. Analog voltage outputs are standard, with current outputs available as

an option. The ORT240 series can also be connected to a PC via USB (optional) or RS232

so that its configuration can be changed, or by using TorqView to display torque, speed and

power.

Unpacking the transducer

The following standard components are included:

▪ 1 x ORT Series Transducer

▪ 1 x ORT Electronics Module

▪ 1 x User Manual

▪ 1 x Calibration Certificate

Additional components for ORT240 series:

▪ 1 x TorqView program installation USB flash drive, ORT Configuration Software,

Manuals & Appendices in PDF format, USB driver.

The following items may also be included:

▪ 12pin Lumberg (female) and/or 12pin Lumberg (male).

▪ 1 x 2.5m Analog Lead - 15 way ‘D’ type connector (female) to 12pin Lumberg

(female).

▪ 1 x 2.5m Digital Lead - 15 way ‘D’ type connector (male) to 12pin Lumberg (male).

(ORT240 series transducer ONLY).

▪ 1 x Digital Adaptor Lead (DC Jack with USB and/or RS232 connections, depending

on options requested) (ORT240 series transducer ONLY).

▪ 1 x Transducer Display ETD

▪ 1 x AC Mains Adaptor Power Supply.

▪ 1 x Transducer Signal Breakout Unit.

▪ 1 x Analog Dongle.

CAUTION

The ORT series transducers should not be operated at any torque load greater or

speed faster than that specified in the Product data sheet and on the Transducer.

CAUTION

The ORT series transducers should be installed using correct couplings rated for

the maximum torque and speed for the operation.

CAUTION

The ORT series transducers should not be operated in an environment where that

operation could be life threatening or a danger to personnel.

CAUTION

In electrically noisy environments, the ORT series transducers should be earthed

using the earthing post located on the transducer.

Sensor Technology 2016 Page 4 ORT4076IM (Rev 1)

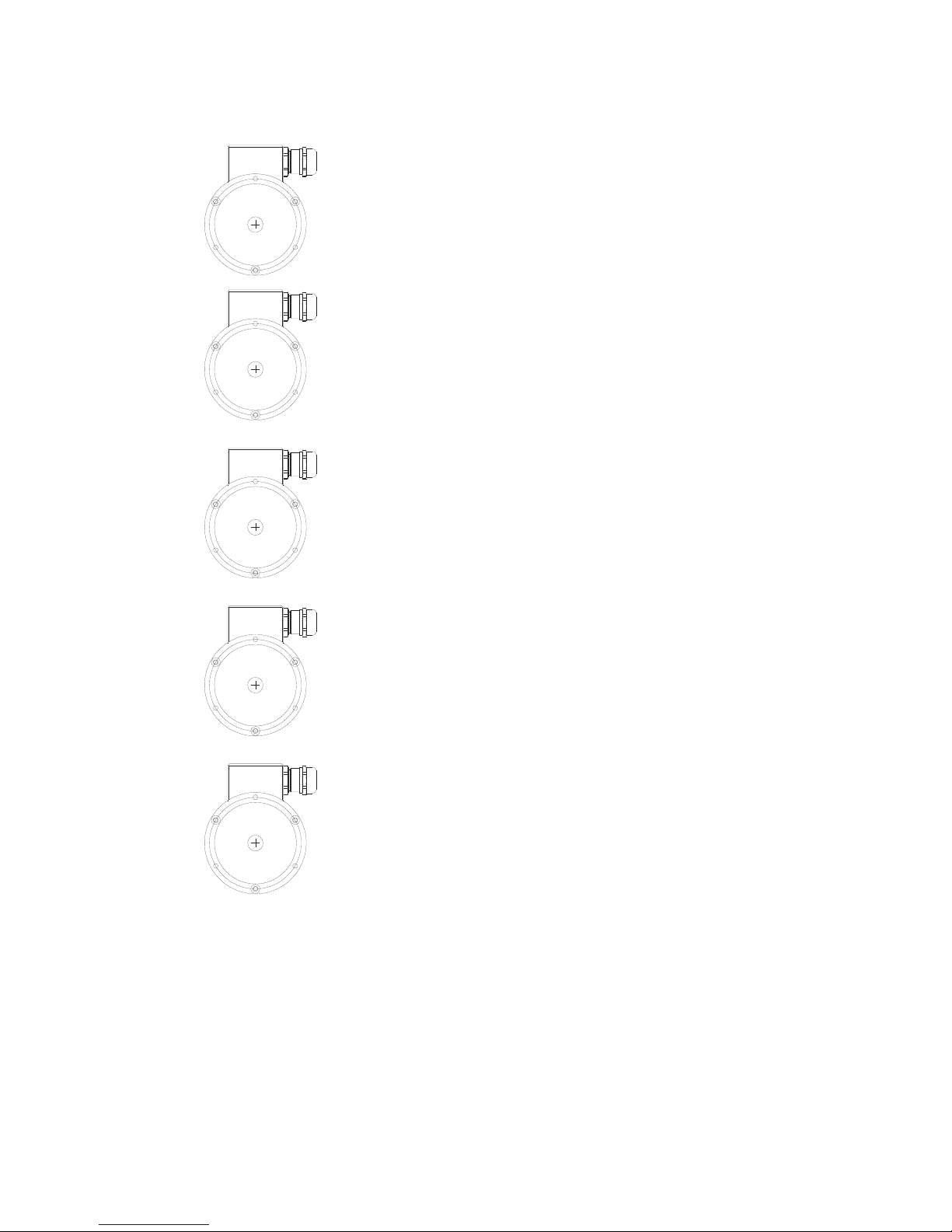

Mechanical Installation

To obtain the best measurements from your torque transducer it is essential that it is

correctly installed.

To avoid damaging the transducer during the installation process it is highly recommended

that it is electrically connected and working so that any torque overloads applied due to

handling can be monitored.

For Transducers above 1Nm or 10lbf.in. it is recommended that the body of the

transducer is restrained from rotation using a strap or straps connected to the tapped holes

in the end plates and that it is not rigidly mounted. Couplings should be used to allow for

angular misalignment while the transducer shaft takes up any parallel misalignment. Care

should be taken not to induce any end loads or bending moments to the shaft, see below,

as these may induce inaccuracies to the torque measurement and in extreme cases

damage the transducer.

Should rapid variations in torque need to be measured in detail e.g.

torque fluctuations in gearboxes or multi vane pumps then it is

recommended using torsionally rigid couplings fitted at both ends of

the transducer shaft such as single membrane couplings and that

these are correctly selected for the transducer rating and speed.

An undersized coupling will not transmit the torque while the high

inertia of an oversized coupling can result in instantaneous peak

torques far in excess of the measured torque. Alternatively, for lower

bandwidth applications where it is more important to measure the

‘average’ torque rather than fast torque fluctuations then couplings

with a degree of compliance would be more appropriate.

Never use a solid coupling to connect a ORT series transducers

Torque Transducer

For Transducers below 1Nm or 10lbf.in or if the application

requires the body to be rigidly mounted then it is recommended that

double couplings should be used at each end to compensate for any

misalignment of the input/output shafts and the system designed to

eliminate any end loads on the transducer shaft. For applications

where end loads cannot be avoided please consult the sales

department for advice prior to ordering.

When using a pulley or pulleys it is recommended a bearing block or

blocks should be used to ensure bending loads are not transmitted to

the transducer.

Lastly, consider using a guard over the transducer and couplings

Single membrane

coupling

(

Flexible mountin

g)

Double membrane

coupling

(Rigid mounting)

Sensor Technology 2016 Page 5 ORT4076IM (Rev 1)

Whilst the transducer is resistant to EMC interference to BS EN 61326-1:2006, the

sensible routing of cables is important to avoid possible EMC interference. Avoid

running the transducer cables close, and/or parallel, to high voltage cables, solenoid

valves, generators or inverters etc. If the cables must follow the same route as

interfering cables then additional screening such as metal conduit should be used to

provide isolation.

To avoid damaging the transducer during installation it is highly recommended that

it is electrically connected and working during this process so that any torque

overloads due to handling can be monitored.

Operating Principles

The shaft of the transducer should be connected to the mechanical system on which the

measurements are to be made using appropriate couplings so it can rotate freely up to its

maximum recommended speed, with relation to the transducers body and bearings fitted.

The technology for our Optical ORT230/240 Series Torque Transducers is based on an

extensively proven and developed measurement principle whereby two discs with segmented

gratings are positioned on the shaft so that the opaque sectors on one disc partially obscure

the clear sectors on the other. Light passes through the sectors and is detected by

photovoltaic detectors. The intensity of light beams, which is constantly monitored, is

modulated by the applied torque and produces an electrical output that is used to provide a

precise indication of the torque transmitted by the shaft. The light intensity is automatically

controlled within the transducer body by a monitor cell. Lamps used to provide the light

source are selected to ensure they have a long life and high stability.

The ORT series transducers can sense both polarity output signals. Torque applied in the

clockwise sense along the transducer shaft axis produces a positive polarity output signal

while torque applied in the anticlockwise sense produces a negative polarity output signal.

If an optical rotary speed sensor is fitted, a light beam is interrupted by the rotation of a disc

consisting of alternate opaque and translucent segments attached to the shaft. Both 60 line

and 360 line encoders are available.

The thermal characteristics of the steel shaft are compensated by having an internal

temperature sensor monitoring the shaft temperature at all times. This information is then

used to correct the modulus of the steel.

Pre-load, note:

All ORT230/240 transducers with a LED on the separate electronics module have a bearing

pre-load spring fitted internally at the left hand

side (pre-load end) of the transducer head

when viewing the label of the transducer head and the connector and gland facing towards

you.

If there is a possibility of an end load being applied to the transducer, the transducer

should be orientated during installation such that the load is applied at the pre-load

end (side with the internally fitted spring). Excessive end loads must be avoided and it

is recommended that appropriate couplings be used to compensate for axial and radial

misalignment.

Sensor Technology 2016 Page 6 ORT4076IM (Rev 1)

Operation

Powering the transducer

To power the transducer a supply voltage of 12-32VDC is required with a minimum current of

1 amp (to supply peak start-up current). If a Transducer Display ETD is used the ETD will

provide power for the transducer. If a Transducer Signal Breakout Unit is used the power

supply should be plugged into the DC jack on the box. If a Digital Adaptor Lead is used the

power supply should be plugged into the DC jack on the lead.

If a Transducer Display ETD, Transducer Signal Breakout Unit or a Digital Adaptor Lead is

not used, then the power supply can be provided by using either the 2.5m Analog or Digital

Lead’s 15 way ‘D’ type connector with a supply voltage of 12-32VDC on Pin 1 and Ground on

Pin 2.

Note: It is imperative that the voltage does not drop below 12V at any stage.

Using the transducer

1. Switch on the ORT series transducer by ensuring power is supplied.

2. Allow the transducer to carry out its Built In Test (BIT) procedure. Refer to the Built In

Test section for further details.

3. Allow five minutes for the equipment to reach thermal equilibrium before making any

measurements.

4. Zero the transducer, refer to the Zeroing the transducer section.

5. The transducer is ready for use, examples of different ways to extract data can be

found in the Examples of reading/collecting data section.

CAUTION

Only provide power through either the Analog or Digital lead.

Do NOT provide power through both leads simultaneously.

Sensor Technology 2016 Page 7 ORT4076IM (Rev 1)

Built In Test (BIT)

When the ORT series transducer is switched on it will carry out its Built In Test (BIT)

procedure. While the BIT procedure is taking place there will be a series of green flashes

from the LED, this is followed by a steady green or an intermittent green flash depending

upon the mode of operation.

If the transducer fails its BIT procedure the transducer will display an error sequence

identifying the results of each system test. The sequence will repeat until the transducer is

powered off.

The error sequence is prefixed with quick succession of red flashes, identifying the LED

sequence as an error condition

After a brief pause a sequence of green and red flashes will indicate the results of each

system test. The following table lists the tests and their test order, for each test the transducer

will output either a GREEN for PASS or RED for FAIL.

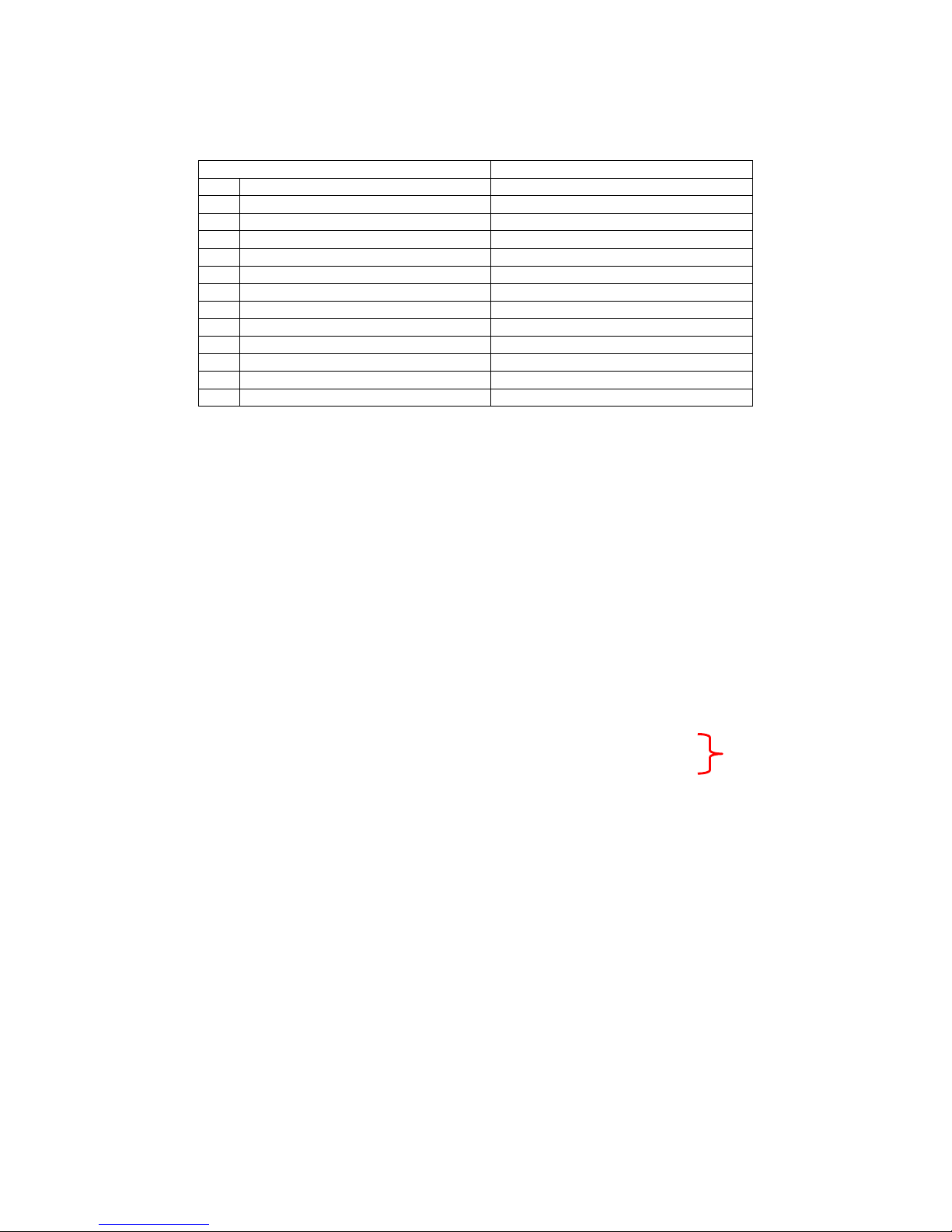

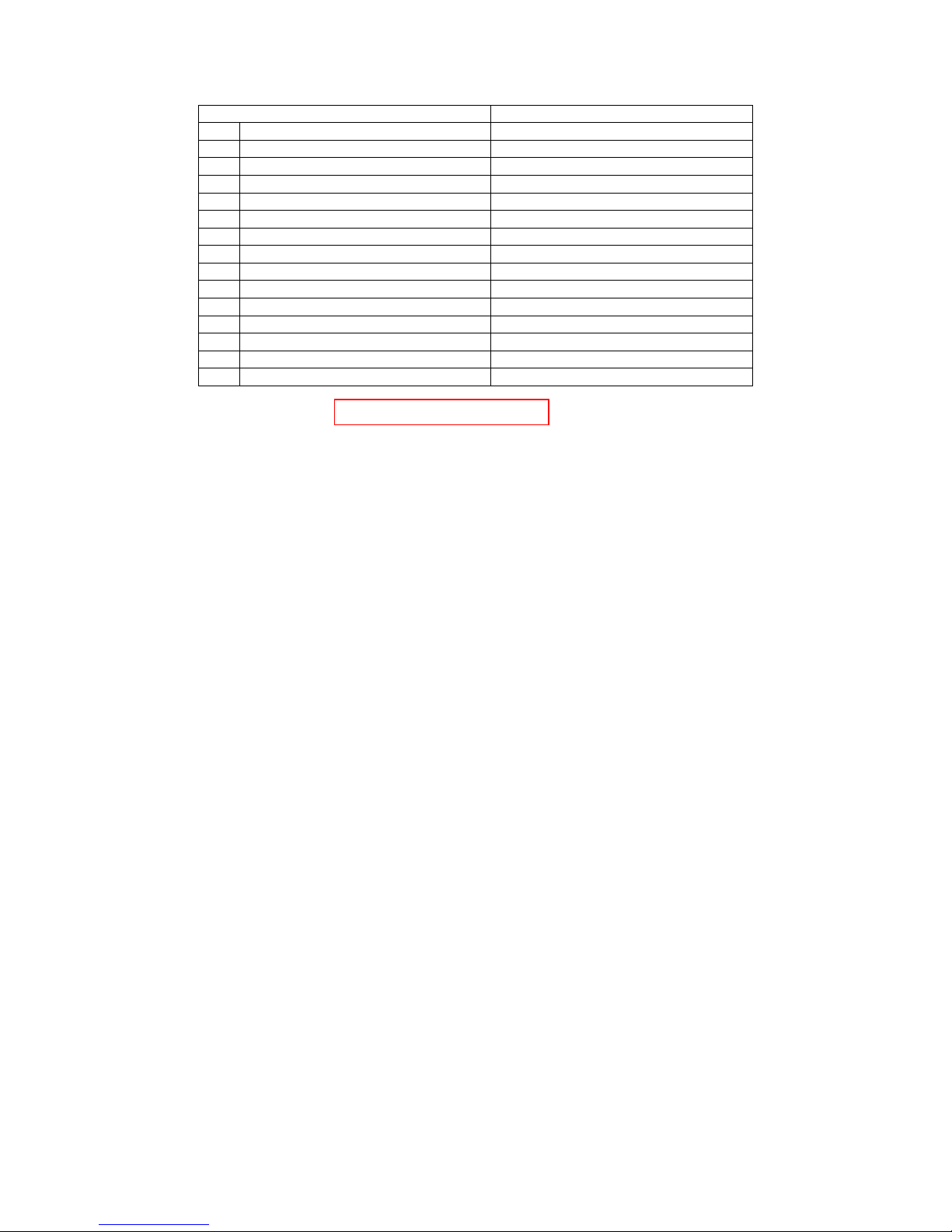

Test/Sequence Number System Checks

1

Firmware Version 3/4: Head Connected Check

Firmware Version 5: Electronics Check

2 Not Applicable

3 Temperature Sensor Check

4 Internal Voltage Check

5 Data Configuration Check

6 Calibration Check

7 Not Applicable

8 ORT Parameters Check

If a failure condition exists try power cycling the transducer. Contact the factory if the problem

continues.

If an error occurs during operation (solid RED LED) and is not present on power on, the BIT

procedure may not identify the fault. If the Zero Input has been wired it is possible to display

the Built In Test output, to do this switch the Zero Input ON until the transducer starts flashing

RED.

Sensor Technology 2016 Page 8 ORT4076IM (Rev 1)

Normal Operation

A solid green LED indicates normal mode and the transducer is working correctly.

An intermittent green flash indicates a special mode of operation; the LED sequences below

show the different modes.

Peak Mode

Peak Mode is active, if configured to do so the analog output will output a peak value. Please

refer to the Peak Input section for further details.

Analog Scaling

The Analog Scaling status message is shown when a user defined data or voltage scale has

been applied to either analog channel. This message is only relevant on ORT240 series

transducers.

Peak Mode

Peak Mode and Analog Scaling

[ORT240 Series ONLY]

Analog Scaling

[ORT240 Series ONLY]

Sensor Technology 2016 Page 9 ORT4076IM (Rev 1)

Warning Signals

A warning signal is indicated when the transducer detects a condition which impedes normal

operation or the transducer is operating outside of normal operating parameters.

A warning LED sequence is prefixed with a quick succession of alternating red/green flashes,

identifying the LED sequence as a warning condition. A warning sequence will override the

normal operation mode LED.

After a pause a sequence of green or red flashes will indicate which warning conditions are

flagged. The LED sequence will run through each of the flags in the table below flashing the

LED for each. A RED flash indicates that a condition has been flagged; a GREEN flash

indicates that a condition is clear.

Once the LED sequence is complete the sequence will restart, this will continue until the

warning has cleared.

Sequence

Number

Warning Flag Reason and Action required

1

Analog Fault CH0

(Analog Torque)

In voltage output mode the analog pin is short circuit, in

current output mode the analog output pin is open

circuit. Check the analog connector wiring for Analog

CH0.

2

Analog Fault CH1

(Analog Speed)

In voltage output mode the analog pin is short circuit, in

current output mode the analog output pin is open

circuit. Check the analog connector wiring for Analog

CH1.

3 Zero Offset High

A torque offset greater than 10% of FSD has been

applied to the measured torque value. The offset is set

when the transducer is zeroed, either by the zero input

on the analog connector or via a digital command.

4 Exceeded Temp

Shaft temperature has exceeded normal operating

conditions. Temperature compensation may no longer

be effective or calibration valid.

5 Over Torque Torque greater than the FSD has been applied.

6 Critical Over Torque

Torque greater than 120% of the FSD has been

applied. Contact the factory if the warning continues.

7 Head Disconnect

The transducer head has been disconnected. Power off

the transducer electronics and check the cabling. This

warning is only relevant for transducers with separate

heads/electronics

For example, the following sequence would indicate warnings for ‘Analog Fault CH0’ and

‘Zero Offset High‘:

Sensor Technology 2016 Page 10 ORT4076IM (Rev 1)

Error Signals

An error or fault signal is indicated when the transducer detects a condition which effects its

fundamental operation. An error or fault condition will be indicated by a solid red LED. Any

error that occurs will latch the LED on and it will remain on until the transducer is reset. An

error condition will override a warning and normal mode LED sequence.

If the error persists across multiple power cycles, a fault may have developed with the

transducer and you will need to contact the factory.

Peak Input

The peak input is a control signal and has two main purposes. It controls what data gets

applied to the torque analog output and it can be used to reset the peaks.

The peak input is activated by grounding pin 8 of the Analog 15 Way ‘D’ Socket. The best way

to control the peak input is to use a toggle switch.

Analog Output

When activated any analog output channel configured as “Torque – Auto Assign” will switch

from being the current torque value to the highest measured torque value since reset, if the

analog output is not unipolar then the torque direction will be output.

Peak Reset

When the peak input is toggled, i.e. off-on-off or on-off-on, all internal peak values on both

analog and digital interfaces will be reset to defaults. A peak input toggle will also clear any

latched fault condition.

Sensor Technology 2016 Page 11 ORT4076IM (Rev 1)

Analog Outputs

The transducer has two analog outputs which can be configured to different data values,

voltages, currents and scales.

Basic models are preconfigured based on model and options selected, advanced models are

user selectable. The configuration of the analog outputs for advanced models is done using

Transducer Control; please refer to the Transducer Control manual for further details.

The following tables show the default assignments for each model and analog option.

Data Assignments

Model Analog CH0 (Torque) Analog CH1 (Speed)

ORT230

RWT410

RWT430

Torque – Auto Assign

1

Scale: 0 – FSD

Torque – Peak

Scale: 0 – FSD

ORT231

ORT232

RWT411

RWT412

RWT431

RWT432

Torque – Auto Assign

1

Scale: 0 – FSD

Speed Fast (RPM)

Scale: 0 – Max Speed

ORT233

RWT413

RWT433

Torque – Auto Assign

1

Scale: 0 – FSD

Power (Watts)

Scale: 0 – ((FSD x Max Speed) / 9.551)

ORT240

RWT420

RWT440

Advanced Model - User Selectable

Factory Default:

Torque – Auto Assign

1

Scale: 0 – FSD

Advanced Model - User Selectable

Factory Default:

Torque – Peak

Scale: 0 – FSD

ORT241

ORT242

RWT421

RWT422

RWT441

RWT442

Advanced Model - User Selectable

Factory Default:

Torque – Auto Assign

1

Scale: 0 – FSD

Advanced Model - User Selectable

Factory Default:

Speed Fast (RPM)

Scale: 0 – Max Speed

1

The value output by channels assigned with Torque – Auto Assign is dependent on the peak

switch. If unconnected or if Peak is OFF the channel is assigned with Torque, if Peak is ON

the channel is assigned with Torque – Peak. Refer to the Peak Input section for more details.

Sensor Technology 2016 Page 12 ORT4076IM (Rev 1)

Voltage/Current Assignments

Assignments apply to both channels.

Option Analog Output Type Analog Output

OPTN-A

ORT23x/RWT41x/RWT43x

Voltage Bipolar ±1V, 0V Zero

OPTN-B

ORT23x/RWT41x/RWT43x

Voltage Bipolar ±5V, 0V Zero

OPTN-C

ORT23x/RWT41x/RWT43x

Voltage Bipolar ±10V, 0V Zero

OPTN-D

ORT23x/RWT41x/RWT43x

Current 0 - 20mA

OPTN-E

ORT23x/RWT41x/RWT43x

Current 4 - 20mA

OPTN-U

ORT23x/RWT41x/RWT43x

Voltage

User specified when ordered

check transducer label

OPTN-V

ORT23x/RWT41x/RWT43x

Current ±8mA, 12mA Zero

Advanced Model

ORT24x/RWT42x/RWT44x

Voltage

User Selectable

Factory Default:

Bipolar ±10V, 0V Zero

Advanced Model (OPTN-F)

ORT24x/RWT42x/RWT44x

User Selectable

Voltage/Current

User Selectable

Factory Default:

Bipolar ±10V, 0V Zero

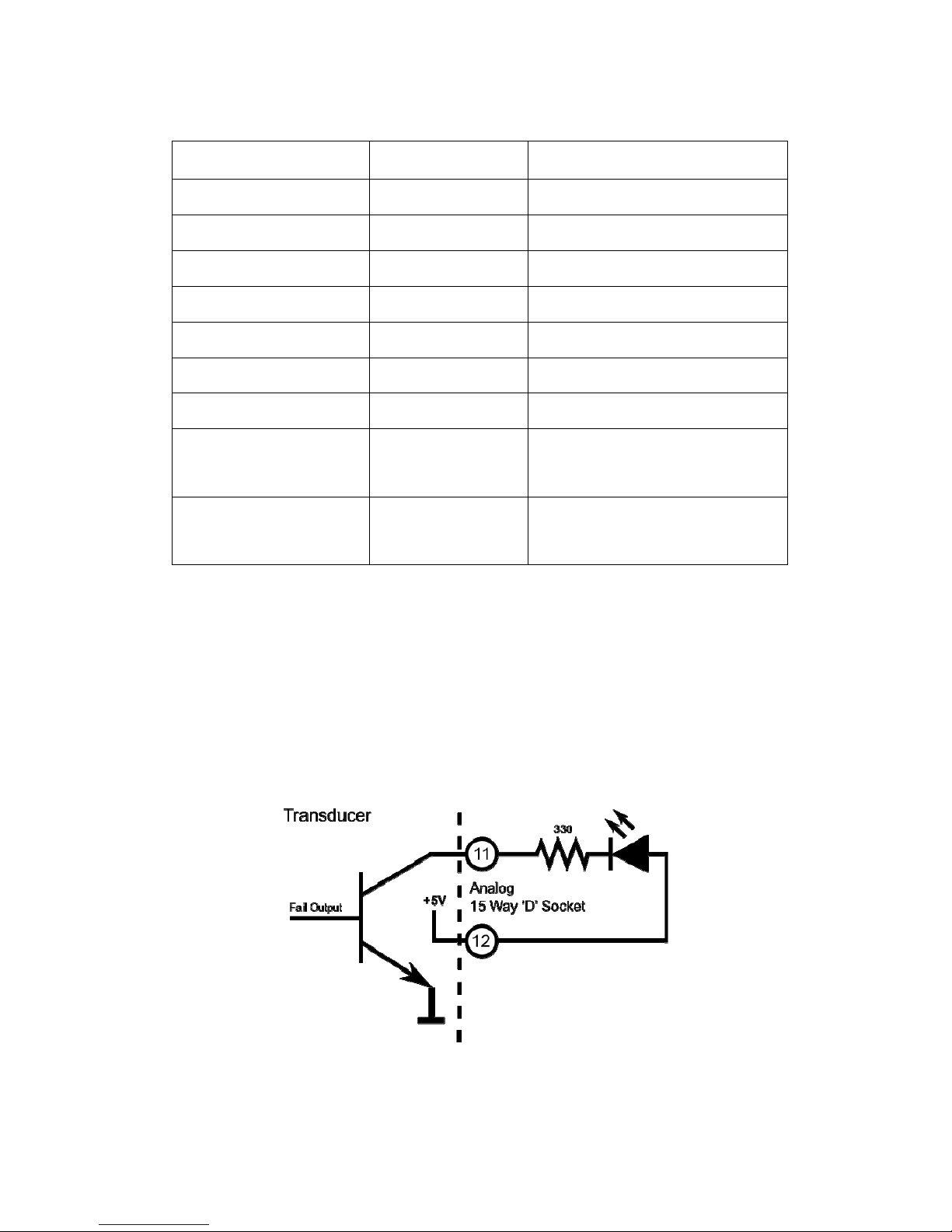

Fail Output

The fail output signals when an error or fault condition occurs within the transducer. The fail

output is linked to the internal transducer error flag. Any error condition detected will switch

the output on and will remain on until the error clears. This behaviour is different from the LED

which latches.

The best use of the fail output is as a safety shutdown signal.

The fail signal is an open collector output. The circuit diagram below shows an example of

how to wire an LED to the output.

In firmware prior to version 5 the fail output is shared with the limits module. If the limits

module is active the fail output is overridden.

Sensor Technology 2016 Page 13 ORT4076IM (Rev 1)

Limit Output

The limit output is driven by the limits module. The limits module is a configurable set of

parameters which switch the limit output on or off when certain conditions are met. These

conditions include triggering when torque or speed goes above or below a set level, as well

as more advanced processes like auto reset or triggering after a delay

The limits module is configured using Transducer Control; please refer to the Transducer

Control manual for further details.

The limit signal is an open collector output. The circuit diagram below shows an example of

how to wire an LED to the output.

In firmware prior to version 5 the limits module does not have a dedicated output pin, instead

the limit output is routed to the Fail Output pin (11). When the limits module is active the fail

out signal is overridden.

Sensor Technology 2016 Page 14 ORT4076IM (Rev 1)

Zeroing the transducer

Zeroing the transducer has the effect of introducing an offset to the torque reading. The zero

can be used to remove any offset that may have been introduced from its mechanical

installation or from idle torque present. It must be stressed that the zero offset is no substitute

for correct installation.

When using high zero offsets, care must be taken not to overstrain the transducer. A zero

offset will not extend the full scale rating of the transducer, e.g. if a transducer was zeroed at

50% then a further 50% was applied, the transducer will have reached full scale, even though

the transducer would be reading of 50%. A zero offset of 10% or greater will trigger a warning

condition and will be indicated by a warning LED sequence.

The transducer can be zeroed by using either a digital command or an electrical signal.

There are 3 zero modes that can be used:

Normal Zero: Sets the zero offset to the current torque reading.

Average Zero: Sets the zero offset to the average of 8 consecutive torque readings.

Fixed Zero: A fixed value can be input and saved. Fixed Zero is only available via the

Transducer Control Software.

Unless the zero is saved, any zero offset applied will be lost after a power cycle.

Electrical Signal

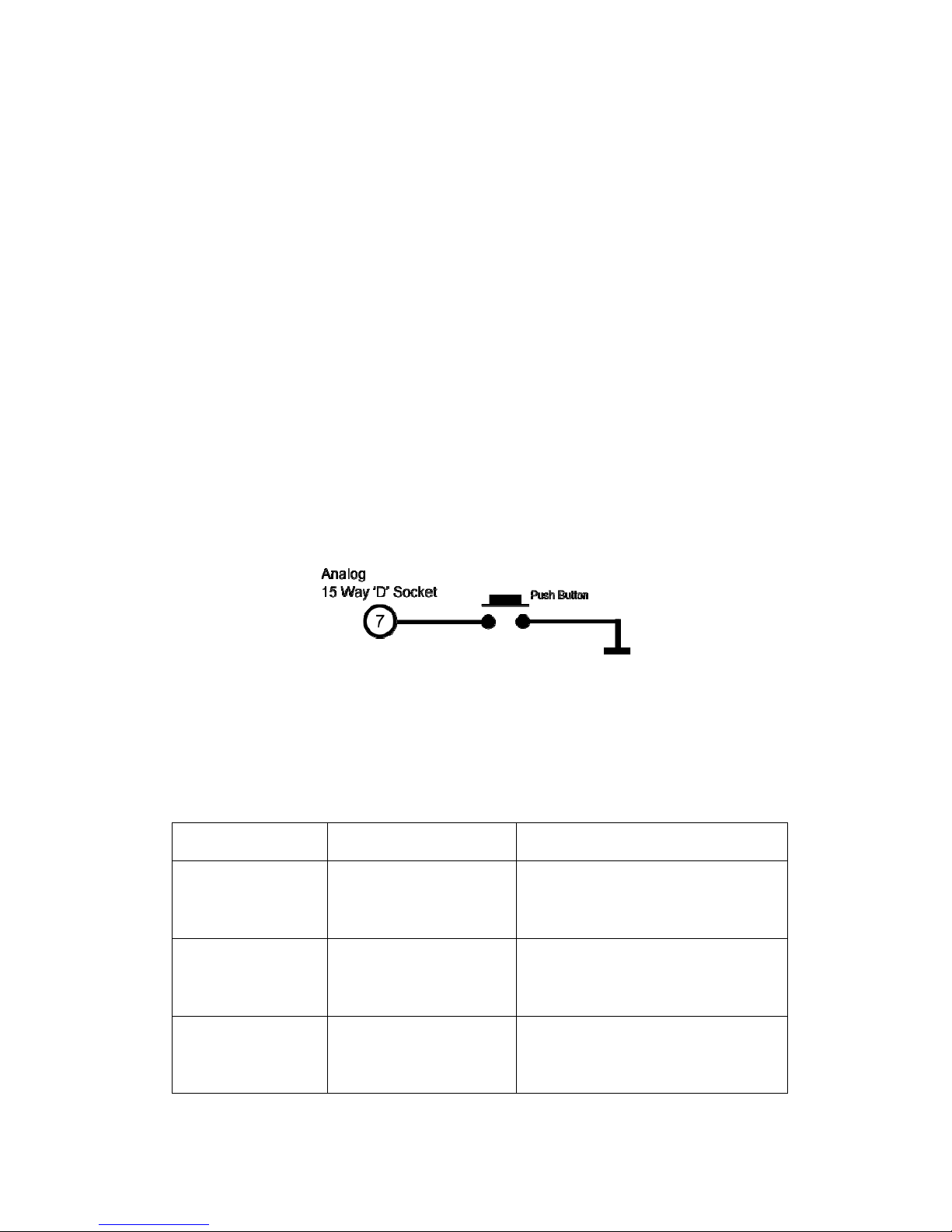

Zeroing the transducer electrically can be achieved by grounding the Zero Input on pin 7 of

the Analog 15 Way ‘D’ Socket. The best way of zeroing a transducer is to use a push button.

A simple circuit diagram using a push button is shown below.

The zero action is only carried out once the input has been ungrounded. Grounding the zero

input momentarily (less than 2 seconds) will initiate a normal zero, grounding the input for

longer will initiate other modes. When the zero input is grounded for more than 2 seconds the

LED will start flashing to indicate that a new mode has been selected, subsequent mode

changes are shown by an increase in flash frequency. The LED will not flash if an error

condition is present.

The table below shows the various modes and timings.

Ground Hold Time LED Flash Zero Mode / Action

0 - 2 Seconds None Normal Zero

4 - 6 Seconds 1 Hz Green Flash Average Zero

Greater than

6 Seconds

2 Hz Green Flash

Transducer will save the current zero

offset so that it is remembered across

power cycles.

Sensor Technology 2016 Page 15 ORT4076IM (Rev 1)

Digital Command

There are multiple digital commands to select the different zero modes, refer to the

transducer communication protocol manual.

Our Torqview and Transducer Control software programs implement these commands

providing a simple way of zeroing the transducer.

Resetting transducer to factory default

To reset the transducer to the factory default settings (i.e. the functions set by the factory on

purchase) follow the steps below:

1. Turn off transducer.

2. While holding in the zero button, power the transducer. The LED will stay solid green

until the zero button is released.

3. Allow the transducer to carry out its BIT procedure.

4. When the LED is solid green all user-adjusted parameters will have been reset to the

factory defaults.

Sensor Technology 2016 Page 16 ORT4076IM (Rev 1)

Examples of reading/collecting data

For diagrammatic purposes only the ORT230/240 model is shown.

Sensor Technology 2016 Page 17 ORT4076IM (Rev 1)

Optional Accessories

Analog Lead

The Analog Lead is a 2.5m length - 15 way ‘D’ type connector (female) to 12 pin Lumberg

(female). It can be used for any ORT series transducers.

Digital Lead (ORT240 series ONLY)

The Digital Lead is a 2.5m length - 15 way ‘D’ type connector (male) to 12 pin Lumberg

(male). It is used to configure the ORT240 series.

Digital Adaptor Lead (ORT240 series ONLY)

The Digital Adaptor Lead is an optional accessory and plugs into the 15 way ‘D’ type

connector on the 2.5m Digital Lead to provide a DC jack for power and RS232 and/or a USB

connection, depending upon the options requested. Note: USB specification limits the length

of a cable between host and full speed device to 5 meters. A USB Extender is required for

distances greater than 5m; please consult the factory for USB Extenders.

Additional Related Products and Transducer Resources

Transducer Display ETD

The Transducer Display ETD is a readout suitable for all ORT transducers. Although it is

primarily used to display torque and peak torque, it can also display speed and power,

provide access to the analog outputs from the transducer and connect the transducer to a PC

for use with TorqView and Transducer Control.

Transducer Signal Breakout Unit (SBU)

The Transducer Signal Breakout Unit, which when plugged in powers the transducer and

keeps all of the inputs and outputs in one place. The Transducer Signal Breakout Unit

provides 4mm sockets to output an analog torque and speed signal. It enables switching

between DC Volts, 0-20mA, 4-20mA, zero torque, angle and enable peak hold. The

Transducer Signal Breakout Unit also allows communication with a PC via the built-in USB

and RS232 ports. The Transducer Signal Breakout Unit is powered by a supply voltage of

12-32VDC with a minimum current of 1 amp (to supply peak start-up current).

AC Mains Adaptor Power Supply (PSU)

A AC Mains Adaptor Power supply is required to provide 12-32VDC to the ORT series

Transducer and Transducer Signal Breakout Unit.

TorqView (ORT240 series ONLY)

TorqView is an easy to use graphical front end Virtual Instrumentation Display PC Interface

Software program for use with the ORT240 series transducers. It allows the Torque, Speed,

Power and Temperature values to be displayed in charts, dials and digital bars and can be

used to assist data recording. For further information on TorqView please refer to the

TorqView User Manual.

Transducer Control Program (ORT240 series ONLY)

Transducer Control is an all-round application to unlock the advanced functionality of the

ORT240 Series Transducer. Transducer Control enables the user to exploit the flexibility of

the advanced transducer series by configuring the run time parameters of the transducer to

best suit their application.

Transducer Communication Protocol (ORT240 series ONLY)

The Transducer Communication Protocol describes the protocol required to communicate

with a transducer on either RS232 or USB. The Transducer uses a simple request and send

protocol, which defines the commands for requesting data and configuring functionality.

Further information on the Transducer Communication Protocol is available from the factory

or as a download from our website: www.sensors.co.uk/documents

Transducer DLL Programmers Guide (ORT240 series ONLY)

The Transducer DLL Programmers Guide provides information on how a transducer can be

integrated into a third party software program. The DLL simplifies the use of the USB and

RS232 interfaces by providing a unified interface to access transducers connected via either

method; it takes care of the low-level driver access, protocol negotiation and data

manipulation. Further information on the Transducer DLL Programmers Guide is available

from the factory or as a download from our website: www.sensors.co.uk/documents

Sensor Technology 2016 Page 18 ORT4076IM (Rev 1)

Leads

Analog Lead - Pin Out

2.5m length - 15 way ‘D’ type connector (female) to 12 pin Lumberg (female)

15way ‘D’ type connector (Pwr&Out) 12 Pin male on transducer

Pin Description Pin

1 12-32VDC input G

2 GND M

3 Analog GND J

4 Analog CH1 / Speed (V or I) E

5 Analog CH0 / Torque (V or I) C

6 Reserved K

7 Zero Input (low = zero) A

8 Peak Input (low = peak) B

9 Reserved F

10 Limit Output D

11 Fail Output L

12 GND H

Female 15 way ‘D’

Female 12 way

Lumberg

Do NOT supply any

voltage to these ports.

Closure to

g

round onl

y

Sensor Technology 2016 Page 19 ORT4076IM (Rev 1)

Digital Lead - Pin Out (ORT240 Series ONLY)

2.5m length - 15 way ‘D’ type connector (male) to 12 pin Lumberg (male)

15 way ‘D’ type connector (Pwr&Out) 12 Pin female on transducer

Pin Description Pin

1 12-32 VDC Input G

2 GND E

3 RS232 RXD / CAN LO A

4 GND

5 RS232 TXD / CAN HI K

6 GND

7 USB + C

8 USB - L

9 USB 0V D

10 USB Power B

11 Fail Output H

12 +5V OUT F

13 Zero Angle J

14 RPM M

Male 15 way ‘D’

Male 12 way

Lumberg

DIN45321 0332 12

Sensor Technology 2016 Page 20 ORT4076IM (Rev 1)

Transducer Connections

Analog

Digital

Do NOT supply any

voltage to these ports.

Closure to

g

round onl

y

Sensor Technology 2016 Page 21 ORT4076IM (Rev 1)

Declaration of Conformity

EC Directives

We, Sensor Technology Ltd, hereby declare that the products named below, to which this

Declaration of Conformity relates, is in conformity to the requirements of EC Council

Directives and Standards as listed:

2004/108/EC (Electromagnetic compatibility).

BS EN 61326-1:2006, (Electrical equipment for measurement, control and laboratory

use).

Type of Product Rotary Torque Transducer

Product Name(s)

ORT230, ORT231.

ORT240, ORT241.

Intended use:

Measurement of rotary torque within the rated torque

and speed limits as described on the transducer.

……………………….......................................

Managing Director

Sensor Technology Ltd

10

th

November 2016

Apollo Park, Ironstone Lane, Wroxton, Banbury

Oxon, OX15 6AY

Tel: +44 (0)1869 238400 Fax: +44 (0)1869 238401

The ORT 230/240 Transducer offers an ideal means for

precise dynamic measurement of rotary and static torque

less than 100Nm and for bandwidths of up to 50Khz.

The new TorqSense ORT 230/240 torque sensors replace the

E200 ORT series and feature all new electronics that have

produced significant performance gains in resolution, frequency

response, reduced sensor current consumption and faster digital

data throughput.

Low inertia – High Speed capability

because electronics are not fixed

onto shaft

Non contact/brushless

measurement

High Bandwidth

200% safe mechanical

overload

Excellent noise immunity

Separate digital electronics

Operates both statically and dynamically

- clockwise/anti-clockwise

Any full scale torque can be specified within

standard range: 10mNm through to 100Nm

Lifetime warranty

Technology

Benefits

Software

TorqView is an easy to use advanced torque monitoring

software, available to assist data recording and instrumentation

displays that interface with Windows based PCs.

Features include: 3 types of display, text files compatible with

Matlab and Excel and Real time chart plotting.

See TorqView datasheet TSE2099R for more details.

LabView VIs are available for users to design their own process

control applications. DLLs are also available for users to write

their own custom software.

Fixed voltage or current analog outputs (one

for torque and the other for speed or power) for

interfacing with analog instrumentation

BIT Self-diagnostics for letting the manufacturer

know that the transducer’s torque, speed ratings

and calibration due date have not been exceeded.

Simple ‘Sensor status’ output pin

Sensors to monitor shaft temperature for better

compensation and accuracy

Digital outputs, such as RS232, CANbus and USB, for

interfacing with modern instrumentation and laptops

Digital input for configuring transducer via PC

2 x user selectable voltage or current analog

outputs (one for torque and the other for speed,

power or peak torque) for interfacing with analog

instrumentation

Transducer configuration software to allow user

to changes transducer variables

BIT Self-diagnostics for letting users know data

is trustworthy, that the transducer’s torque, speed

ratings and calibration due date have not been

exceeded

Simple ‘Sensor status’ output pin

Sensors to monitor shaft temperature for better

compensation and accuracy

Ability to connect up to 10 transducers using USB

TorqSense ORT 230 series transducers offer:

Whereas, TorqSense ORT 240 series transducers

offer:

Digital ORT 230/240 series Torque Transducer

TORQ

VIEW

Ô

TECHNOLOGY

SENSOR

An extensively developed measurement principle is used, in

which the intensity of light beams is measured by means of

photovoltaic detectors, and the electrical output is used to

provide precise indication of the applied torque transmitted

by the shaft.

The use of this technique results in a transducer being able

to sense torque bi-directionally, have a fast mechanical and

electrical response, low inertia, and complete freedom from

brushes or complex electronics. The absence of brush gear

allows high-speed operation with a continuous rating of up

to 30,000 RPM standard. Further increases in RPM are

available as an option depending upon shaft size.

The torque shaft is of low compliance ½° maximum torsion

deflection on the smaller transducers, and ¼° maximum on

the larger transducers, at full-scale deflection. The lamps

providing the light source are selected to ensure long life and

high stability with the light intensity automatically controlled

within the transducer body by a monitor cell.

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

Standard

Mechanical Parameters

Cable length

Accuracy

Bandwidth

Safe mechanical overload

Hysteresis

Bearings

1.5metres to interface box

TBC

50Khz

-10ºC to +50ºC

200% of rating

Better than 0.1%

Deep grooved shielded

bearings with oil lubrication

Temperature coefficient

Temperature Range

Less than 0.05% per ºC

Model Dimensions (mm)

ORT230/240 -C,-D,-E

ORT230/240 -F

ORT230/240 -G

ORT230/240 -H

A

75

75

105

130

B

25.4

25.4

38

60

C

1.5

1.5

1.5

1.5

D

62

62

62

62

E

50

50

50

50

F

6.35

6.35

12.7

20

G

56

56

56

56

H

M3

M3

M3

M3

Depth

5

5

6.35

11

J

N/A

19.05

30

53

K

Plain

Flat

3.96

6

L

N/A

0.183

1.98

3.5

Standard Specifications

ORT230/240-C

ORT230/240-D

ORT230/240-E

ORT230/240-F

ORT230/240-G

ORT230/240-H

Torque Range * Maximum Speed Shaft Type

Model Minimum Maximum (RPM)

0 to 10mNm (0 to 1ozf.in)

0 to 25mNm (0 to 3.5ozf.in)

0 to 150mNm (0 to 15ozf.in)

0 to 800mNm (0 to 7lbf.in)

0 to 1.5Nm (0 to 15lbf.in)

0 to 25Nm (0 to 250lbf.in)

30000

30000

30000

30000

20000

15000

Plain

Plain

Plain

Flat

Keyways

Keyways

0 to 20mNm (0 to 3ozf.in)

0 to 100mNm (0 to 10ozf.in)

0 to 750mNm (0 to 100ozf.in)

0 to 1Nm (0 to 10lbf.in)

0 to 20Nm (0 to 200lbf.in)

0 to 100Nm (0 to 1000lbf.in)

* Calibration is possible in any equivalent SI, FPS or MKS units, e.g. gf.cm, lbf.ft, cNm

Transducers may be specified to any torque range between the maximum and minimum for each model.

For example ORT241-C 15mNm, or ORT231-G 10Nm

Data parameters measured at 20ºC

Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

137.60

73.50

22.50

120.00

60.00

8.60

6.80

M3 x 10mm Deep

CABLE GLAND

VIEW ON BASE

56.60

BASE

54.00

Allow for

cable bend

130.60

Allow for

cable bend

20.00

24.00

ORT 230/240 Series Electronics Module

Measurement units: Millimetres (mm)

Data parameters measured at 20ºC

Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

ORT 230/240 Series Torque Transducers - Data Specification

Note 1: Please consult factory for applications requiring rotational speeds that exceed maximum figures given. Transducers fitted for IP65 will have

running speeds considerably reduced, increased drag torque and accuracy can be affected.

Note 2: SM – Static Mode. Dynamic values will depend upon user application and has to be adjusted accordingly.

Note 3: Digital averaging can be configured by user to optimise accuracy/frequency response for specific user applications. Digital averaging default

setting is N=16. For details see User Manual.

Note 4: >5Khz Sample Rate. Up to 10Khz sample rate possible, please consult factory. Digital averaging also affects the analog output, max analog output

3dB Bandwidth = 5Khz when digital average is 1.

Note 5: Output rate figures are calculated from the time taken to capture 10000 torque readings. Testing was conducted with each connection method

configured at its maximum baud rate. The maximum output rate available for CAN and USB is dependant on the transducers setup. USB - USB is a

host based bus architecture, because of this the output rate achievable will be affected by other bus traffic and host activity. USB has two transfer

modes, Single Transfer which requests 1 reading at a time and Bulk Transfer which transfers readings in blocks of 50 Torque/Speed pairs. CAN

Bus - to achieve a Torque reading output rate of 10KHz, the Speed reading output rate must be reduced to 100Hz.

Parameter Condition Data Units

Rotation speed/angle of rotation measurement system

Measurement method Opto switch through slotted disc

Direct output signal Pulse output direct from opto switch (TTL, 5V square wave), output is independent of any analog or digital processing.

Processing Method Update rate for analog and digital outputs

Mode 1 (Slow Method)

Frequency Count

1 Hz

0 RPM 1

< 2000 RPM RPM

Digital Processing

Techniques

Processing modes run

simultaneously and can be

applied to either analog

channel or accessed

individually via a digital

connection.

Mode 2 (Fast Method)

Period Count

> 2000 RPM RPM x ( 1 / ( (RPM - 1) / 2000 + 1 ) )

Hz

Rotational speed (max)

(See Note 1)

30,000 20,000 15,000 RPM

Temperature

Measurement method IR temperature sensor monitoring actual shaft temperature

Temperature accuracy

1

0

C

Reference temperature, TRT 20

0C

Operating range, ΔTO -10 to +50

0

C

Storage range, ΔTS -20 to +70

0

C

Temperature drift (FS) Max 0.05 %FS/0C

Specifications

Combined non-linearity and

hysteresis

TBC %FS

Resolution 0.02 %FS

Repeatability 0.1 %FS

ORT 230 Series Transducers ONLY

Accuracy 200C, SM

(See

Note 2)

TBC %FS

3dB Bandwidth

(See Notes 3&4)

TBC Hz

ORT 240 Series Transducers ONLY

Digital averaging

(See Note 3)

2 4 8 16 32 64 128 N

Accuracy 200C, SM

(See Note 2)

TBC TBC TBC TBC TBC TBC TBC %FS

3dB Bandwidth

(See Note 4)

TBC TBC TBC TBC TBC TBC TBC Hz

Analog output

Output voltages

(Torque/Speed/Power)

Options available: 1 / 5 / 10 / Unipolar (ORT230 Series default setting is 5Vdc)

(ORT240 Series output voltages are user selectable)

Vdc

Load impedance Maximum 1 KΩ

Output currents

(Torque/Speed/Power)

Options available: 4-20 / 0-20 / 128

(ORT240 Series output currents are user selectable)

mA

4-20mA Loop resistance Should not exceed 400 Ω

Digital output (ORT240 Series Transducers ONLY)

Connections CAN Bus RS232 USB

Configuration CAN 2.0B, 11bit Message Identifiers Data Bits: 8, Parity: None, Stop Bits: 1 USB 2.0 Full-Speed

Baud Rate(s) 1 Mbps, 500 Kbps, 250 Kbps, 100 Kbps 115200 bps, 38400 bps, 9600 bps 12 Mbps

Single Transfer Up to 500 Hz

Output Rate

(Note 5)

Up to 10 KHz Up to 1.1 KHz

Bulk Transfer Up to 10 KHz

Power supply

Nominal voltage, VS 12 to 32 (max) V

Current consumption, IS 230 (max) @ 12 VDC mA

Power consumption, WS 3 W

Allowed residual ripple of

supply voltage, V

ripple

500

(above nominal supply voltage)

mVp-p

Electromagnetic compatibility

EMC compatibility EN 61326:2006

Data parameters measured at +20°C

Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

ORT 230/240 Series Torque Transducers - Standard Range

● – Standard feature ◊ – Optional feature

ORT 230/240

Series

Option

Code

Remarks

Torque, Speed, Power Outputs ORT 230 ORT 240

Torque only 230 240

Torque & Speed

(60 pulses/rev)

231

User to specify RPM/FSD

when ordering

Torque & Power

(60 pulses/rev)

233

User to specify Power/FSD

when ordering

Torque & Speed

(60 pulses/rev)

or Power

241

Outputs are user selectable

Standard features

Voltage output ±5v FSD (Fixed) ● B

Voltage outputs from ±1v to ±10v FSD

and unipolar (Variable)

●

Output is user selectable

RS232 output ●

Torque Averaging & Torque Peak ●

Self Diagnostics ● ●

Internal temperature measurement

● ●

Value available on ORT240

series only

Deep grooved shielded bearings with oil

lubrication

● ●

Ingress Protection (IP) 54 ● ●

Link Cable (1.5m)

● ●

From sensor head to

electronics module

Optional features

Keyed Shaft Ends ● ● K

1Nm flats, below 1Nm plain

Plain Shaft Ends ◊ ◊

P

Shaft length may be longer

than keyed end shafts –

consult factory for length.

All sensors below 1Nm will

be plain.

Splined Shaft Ends ◊ ◊ T

Consult factory for details

Voltage output ±1v FSD (Fixed) ◊ A

In place of Option B

Voltage output ±10v FSD (Fixed) ◊ C

In place of Option B

Customer Specified Voltage Output

(Fixed)

◊ U

In place of Option B. User

to specify range/scale when

ordering

Current output 0-20mA (Fixed) ◊

D

In place of Voltage output

options

Current output 4-20mA (Fixed) ◊

E

In place of Voltage output

options

Current output 12±8mA (Fixed)

◊

V

In place of Voltage output

options

Current output 0-20mA, 4-20mA

& 12±8mA (Variable)

◊ F

Current output is user

selectable and in place of

Voltage output. However

user can reselect a Voltage

output, if required. (Note 6)

USB2.0 full speed 12 Mbps Digital output ◊ G

CANbus output ◊ H

In place of RS232

High Speed Bearings

(See Note 7 below)

◊ ◊ J

Sealed Bearings ◊ ◊ S

Ingress Protection (IP) 65 –for sensor

and electronics

(See Note 8 below)

◊ ◊ L

Consult factory for maximum

speed allowance

Link Cable (>1.5m) ◊ ◊ R

Consult factory for length

Note 6: 2 x analog channels available. Default settings are Channel 1 (voltage/current) – torque.

Channel 2 (voltage/current) – speed or power, if ordered.

Note 7: At very high speeds, for better balance the factory recommend plain or splined shafts.

Note 8: Transducers fitted for IP65 will have running speeds considerably reduced, increased drag torque and accuracy can

be affected.

Data parameters measured at +20°C

Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

ORT 230/240 Series Torque Transducers – Connector and Lead Options

ORT 230/240

Series

Option

Code

Remarks/Purpose

Connectors & Leads ORT 230 ORT 240

Analog Connector

12 Pin Lumberg (female)

◊ ◊ ACC 1

For user to self wire

Digital Connector

12 Pin Lumberg (male)

◊ ACC 2

For user to self wire

Analog Lead (Length 2.5m)

12 Pin Lumberg (female) to 15 way ‘D’

type connector (female)

◊ ◊ ACC 3

For connecting ORT to user’s

system via 15 pin ‘D’ connector

Digital Lead (Length 2.5m)

12 Pin Lumberg (male) to 15 way ‘D’

type connector (male)

◊ ACC 4

For connecting ORT to user’s

system via 15 pin ‘D’ connector

Digital Lead Adapter (Length 1m)

15 Way ‘D’ type (female) to RS232 and

Power Connectors

◊ ACC 5

For connecting ORT to PC via

RS232

[Also needs Digital Lead

(ACC4) to connect to ORT]

Digital Lead Adapter (Length 1m)

15 Way ‘D’ type (female) to RS232, USB

and Power Connectors

◊ ACC 6

For connecting ORT to PC via

USB (Option G) or RS232

[Also needs Digital Lead

(ACC4) to connect to ORT]

Digital Lead Adapter (Length 1m)

15 Way ‘D’ type (female) to CANbus and

Power Connectors

◊ ACC 8

For connecting ORT to PC via

CANbus (Option H)

[Also needs Digital Lead

(ACC4) to connect to ORT]

Digital Lead Adapter (Length 1m)

15 Way ‘D’ type (female) to CANbus, USB

and Power Connectors

◊ ACC 9

For connecting ORT to PC via

USB (Option G) or CANbus

(Option H)

[Also needs Digital Lead

(ACC4) to connect to ORT]

ORT 230/240 Series Torque Transducers – Additional related products

Code Remarks/Purpose

Transducer Display ETD ETD

Display readout

AC Mains Adapter Power Supply PSU 1

For providing 12-32Vdc

Transducer Signal Breakout Unit SBU 2

TorqView TV

Torque Monitoring Software

RS2 32 (A CC 5 ) /

CANbus (ACC 8)

RS232 (ACC 5) / CANbus (ACC 9)

A

CC 6 or 9

A

CC 5 or 8

A

CC 3&4

USB

Power

15 Way D Type

12 Pin Lumberg

15 W ay D Typ e

(connects to ACC4)

15 Way D Type

(connects to ACC4)

Data parameters measured at +20°C

Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

© Sensor Technology Ltd 2016 ORT4019R (Preliminary) Feb 2016

When you order a Torque Transducer please note that any torque/FSD is possible between ranges – please

specify rated torque and options using the following format:

For example:

ORT

231 - 15Nm -

K-CL

A ‘basic’ transducer with

torque and speed outputs,

rated and calibrated to

15Nm FSD with keyed ends,

±10v and IP65 protection.

Your transducer requirement:

ORT

Max speed (if applicable)

RPM

Connector & Lead options

(if applicable)

See over

Additional related products

(if applicable)

See over

Glossary of terms and definitions used in this datasheet

Accuracy

- The degree of conformity of a measured or calculated quantity, which will show the same or

similar results. Accuracy of the overall TorqSense system is limited by the combined error of several factors

such as linearity, hysteresis, temperature drifts and other parameters affecting measurements. If errors in

the system are known or can be estimated, an overall error or uncertainty of measurement can be

calculated.

Digital averaging

– The application of algorithms to reduce white noise. In any electronic system,

electronic white noise is mixed with the signal and this noise usually limits the accuracy. To reduce the

influence of white noise and increase the accuracy of the system different averaging algorithms can be

applied. In the TorqSense system a flying digital averaging technique is applied to reduce the white noise

commensurate with the level of accuracy required. However, as any averaging algorithm works as a low

pass filter, the more averaging that is applied the lower the frequency response. Therefore, each Torqsense

system should be optimised to the customer’s requirements by choosing the right combination of

accuracy/frequency response. Please see relevant part of the Datasheet and User Manual.

Data parameters measured at +20°C

Sensor Technology Ltd reserves the right to change specification and dimensions without notice.

Transducer Control 5

User Manual

Revision 5 – December 2016

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 2

Table of Contents

Introduction .................................................................................................... 3

Transducer Requirements ............................................................................ 3

Compatible Models ........................................................................................ 3

PC Requirements ........................................................................................... 3

Installation ...................................................................................................... 4

Running Transducer Control & Connecting To A Transducer ................... 5

Using Transducer Control ............................................................................. 7

Menu Tree ................................................................................................... 7

Transducer Configuration ............................................................................. 8

User Configuration ..................................................................................... 8

Analog Setup ........................................................................................... 8

Digital Setup .......................................................................................... 15

Zero Offset ................................................................................................ 21

Transducer Test ........................................................................................... 22

Output Monitor ......................................................................................... 22

Transducer Status .................................................................................... 23

Contact Details

Sensor Technology Ltd,

Apollo Park,

Ironstone Lane,

Wroxton,

BANBURY,

OX15 6AY,

United Kingdom.

Sales

Email: stlsales@sensors.co.uk

Tel: +44 (0)1869 238400

Technical Support

Email: software@sensors.co.uk

Tel: +44 (0)1869 238400

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 3

Introduction

Transducer Control is an all-round application to unlock the advanced functionality of

the ORT/RWT Series Transducers. Transducer Control enables the user to exploit

the flexibility of the advanced transducer series by configuring the run time

parameters of the transducer to best suit their application.

Transducer Control gives the user complete control of the dual channel analog output

by allowing adjustment of the output voltage scaling, zero voltage, data scaling and

data assignment. On the digital side the user can control the digital filtering level,

adjust the RS232 baud rate and configure the limit controls.

As well as configuring the transducer, Transducer Control can also be used as a

readout, providing a simple text display that shows torque, speed and power along

with peak values and zero control.

Compatible Models

Advanced models from the ORT240, RWT320, RWT340, RWT420 and RWT440

Series Transducers are compatible with Transducer Control 5. Transducers must be

running firmware version 3 or higher.

The compatible models are listed below:

Transducer Family

Model Range

Models

Optical (ORT)

ORT240

ORT240/ORT241

Rayleigh Wave (RWT)

RWT320

RWT320/RWT321/RWT322

RWT340

RWT340/RWT341/RWT342

RWT420

RWT420/RWT421/RWT422

RWT440

RWT440/RWT441/RWT442

Compatible transducers can be identified by the presence of a status LED and serial

number greater than 12200.

Transducer Requirements

Advanced ORT/RWT Series Transducer.

RS232 or USB connection to a PC.

PC Requirements

Operating System: Microsoft Windows XP SP3 32bit,

Vista/7/8/8.1/10 32/64bit.

CPU: Intel or AMD 1GHz.

RAM: 512MB.

Hard Drive Space: 4MB + 2GB for Microsoft .NET Framework 4 Runtime.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 4

Installation

To install Transducer Control 5:

1. Insert the Sensor Technology Installation CD into your CD-ROM drive. The

following screen will be displayed.

2. Click the ‘Install’ button next to “Transducer Control 5”.

3. Follow the onscreen instructions.

4. Transducer Control will now be installed and be ready for use.

The USB drivers are installed as part of the installation.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 5

Running Transducer Control & Connecting To A Transducer

To run Transducer Control and connect to a transducer:

1. Ensure that power is supplied to the transducer.

2. Connect the transducer to the computer using either RS232 or USB.

3. Run the Transducer Control program by clicking on the ”Start”/”Windows”

button, then “Programs”/”All apps” > “Sensor Technology” > “Transducer

Control 5”.

When Transducer Control starts the “Search for connected transducers” dialog box

will be displayed. The purpose of the dialog box is to find transducers that are

attached to the computer.

Before pressing the “Search” button, select a search filter from the “Select Port To

Search” combo box. The items in the list correspond to the default search options

and ports discovered on the user’s computer. The filter reduces the time taken to

search for transducers by only looking in the selected area.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 6

The options prefixed with “AUTO” will search for multiple transducers, whereas the

COMx options will search for a single transducer on a specific port.

AUTO

AUTO will search for connected transducers on all available ports.

AUTO RS232

AUTO RS232 will search for connected transducers on RS232 ports only.

AUTO USB

AUTO USB will search for connected transducers on USB ports only.

COMx

COMx will search for a connected transducer on the selected COMx port.

If the transducers connection method is known, it is recommended that it be selected,

if it is unknown select “AUTO”.

Once an option has been selected, click on the “Search” button. Transducer Control

will then search for compatible transducers using the filter supplied. During this

process the window will update to indicate the progress of the search, transducers

will be added to the listbox as they are found.

If a single transducer is detected the program will automatically initialise the

transducer and load the main window. If multiple transducers are detected, the dialog

box will require the user to make a transducer selection. To select a transducer, click

on the transducer from the list. The transducer will then be initialised and used by

the program.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 7

Using Transducer Control

The main screen will be displayed once a transducer has been selected, use the

menu at the top of the screen to select an option.

Menu Tree

The menu structure below outlines the functionality of the different menu options.

File

Exit – Closes Transducer Control.

Transducer Configuration

User Configuration – Configures the operational parameters of the

transducer.

Zero Offset – Sets a torque offset.

Transducer Test

Output Monitor – Displays capture data generated by the transducer.

Transducer Status – Displays the transducers status.

Help

About Transducer Control – Displays version information.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 8

Transducer Configuration

User Configuration

Analog Setup

The “Analog Setup” tab of the user configuration allows the user to configure the

transducers analog outputs.

All transducers have dual analog outputs with equal capability on both.

Analog Data Select

The Analog Data Select section allows the user to assign an internal data variable to

the output, and select a data range to be applied to the Analog Voltage Scaling.

Data Select

The following list details the available internal data variables that can be assigned

to the output. Speed and Power items are dependent on the relevant options

being fitted:

Torque – Auto Assign

The “Torque – Auto Assign” data option will switch between Torque – Actual

and Torque – Peak based on the state of the external peak switch input (see

Transducer Manual for pin out and control information). If the Peak input is

switched ON, Torque – Peak is selected, otherwise Torque – Actual is

selected.

Torque – Actual

Current torque value.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 9

Torque – Peak

Peak torque value captured since the last reboot or reset.

Torque – Auto Reset

Peak torque value captured since the last reboot or reset. Auto Reset mode

automatically resets the peak torque when the current torque drops below a

percentage of the peak value.

Torque – Peak CW

Peak torque value captured in the CW direction.

Torque – Peak CCW

Peak torque value captured in the CCW direction.

Torque – Min

Lowest numerical torque value captured.

Torque – Max

Highest numerical torque value captured.

Speed (Fast) / Speed (Slow)

Current speed value. The slow/fast descriptor refers to the method used to

capture speed.

Speed (Fast) – Peak / Speed (Slow) – Peak

Highest speed value captured since the last reboot or reset.

Speed – Rotations

Number of shaft rotations recorded from the fitted angle device or speed

pickoff.

Power (Fast) / Power (Slow)

Power is computed from the current torque and speed values captured. The

slow/fast descriptor refers to the method used to capture speed.

Power (Fast) – Peak / Power (Slow) – Peak

Highest power value captured since the last reboot or reset. Power is

calculated from every torque/speed pair captured, the highest value is stored.

Temperature – Shaft

Temperature captured from the shaft IR sensor.

Temperature – Internal

Temperature captured from the internal body sensor.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 10

Data Ranges

The data range parameters control how data from the selected internal variable is

taken and scaled. This feature is useful when the user is working in a specific

measurement area and requires a greater change in analog output.

The low and high range values effectively rescale to the Zero and FSD voltages

set in the Analog Voltage Scaling section. Values that fall below or above the

range are masked off; the range selection applies to both negative and positive

sides.

Data Range

The user can select a default scale or opt for a custom scale, by selecting from

the “Data Range” combo box.

Default FSD Range

The “Default FSD Range” option scales the selected internal variable based

on the FSD rating programmed into the transducer, i.e. 0 to FSD.

User Defined

The “User Defined” option allows the user to adjust the “Range Low” and

“Range High” sliders to select a custom scale.

Range Low / Range High

The “Range Low” and “Range High” slider bars control the low and high scale

values. The “Range Low” parameter can be set between 0 and 80% of FSD, and

the “Range High” parameter can be set between 20% and 100% of FSD. The

parameter value is displayed in a text box to the right of each range slider. The

value is displayed in an appropriate unit for the selected data variable, i.e. Torque

= Nm or the configured unit, Speed = RPM, Power = Watts.

To change the high or low range values adjust the slider bar to the left or right

until the number in the text box equals the required value. The difference between

the “Range Low” and “Range High” must be greater than 10% of FSD and “Range

High” must be a higher value than “Range Low”.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 11

The following graphs illustrate some examples of how the range selection works.

Torque (100Nm FSD), Standard Range (0 Nm - 100 Nm), ±10v Scale.

+10V

-10V

0V

-100Nm Zero

+100Nm

Torque

Voltage

Torque (100Nm FSD), User Defined Range (50 Nm - 100 Nm), ±10v Scale.

+10V

-10V

0V

-100Nm Zero

+100Nm

Torque

Voltage

Torque (100Nm FSD), User Defined Range (0 Nm - 50 Nm), ±10v Scale.

+10V

-10V

0V

-100Nm Zero +100Nm

Torque

Voltage

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 12

Range effects on resolution

The range selection will in no way effect or increase the resolution of the transducer.

The value expansion is artificial and aids only to give the user a greater change in

analog output value.

Analog Voltage Scaling

The Analog Voltage Scaling section configures the zero and output range of the

analog output channels. The data and range values selected in the Analog Data

Select section are scaled to values configured here.

Users can either select from a list of common predefined scales or select a custom

scale using the slider bar adjustments.

Voltage Scale Select

The “Voltage Scale Select” combo box lists the available predefined scales and

user select modes. When a selection is made the slider bars will adjust to reflect

the selection and illustrate the scaling.

The following graphs illustrate the predefined scales that are available. The

graphs are scaled against Torque with a standard 0 – FSD Range.

Predefined Voltage Scales

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 13

Predefined Current Scales (Option ‘F’ - Current Output)

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 14

User Defined Voltage

If a custom analog output scaling is required select the “User Defined Voltage”

option from the “Voltage Scale Select” combo box, then use the “Zero Offset” and

“Voltage Swing” slider bars to configure the required scaling. The text boxes to

the right of the respective slider bars will display the configured voltage.

Zero Offset

The “Zero Offset” allows the user to change the zero point voltage between 0 and

9.5V. If the “Zero Offset” is increased, the maximum 10V “Voltage Swing” voltage

will be reduced.

This feature is useful if the user has an analog capture device that does not

support negative voltages (unipolar only), but requires the direction of torque.

Voltage Swing

The “Voltage Swing” sets the voltage span of the analog output. The voltage can

be stepped in 0.1V increments and can be scaled between 0.5V and 10V. The

maximum voltage will be reduced if the “Zero Offset” is not 0V.

Unipolar / Absolute Value

The “Unipolar / Absolute Value” checkbox option switches the analog output into

a positive only voltage. All input values will be made absolute, making all

negative values positive, i.e. -5Nm value will become +5Nm. This has the effect

of removing the torque direction from the voltage output.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 15

Digital Setup

The “Digital Setup” tab of the User Configuration allows the user to control some of

the operational parameters that effect the processing and output of data.

Filters

The torque and speed filters provide data smoothing for conditions where there may

be erratic torque and speed readings. The filters apply to the base data captured and

will affect both the digital and analog outputs.

Enable or disable the filter for torque or speed by clicking on the appropriate “Filter

Enabled” checkbox. If enabled, use the appropriate slider bar to select a filter value.

Valid values are 2, 4, 8, 16, 32, 64, 128 and 256.

The filtering algorithms can also be enabled, disabled and adjusted on the fly by

sending digital commands via the RS232 and USB interfaces.

Transducer Control 5 User Manual (RWT3746IM)

Revision 5, December 2016 - Page 16

Limits

The limits feature allows the user to configure the transducer to control external

processes based on predefined operational parameters. Control is accomplished via

an open collector output on the transducers analog connector. There are numerous

ways this feature could be utilised, some examples include, system shutdown on

overload or triggering a conveyor belt when a nut/bolt has been tightened to the

correct torque.

At present there is a single control line, but the limits feature is very flexible, allowing

the user to control the output polarity, high and low limit threshold, samples before

trigger, and an auto reset function which resets the limit out if the control value falls

back between threshold values.

When Limits is enabled the transducer will monitor the selected control channel,

when the value falls below the low limit (if enabled) or exceeds the high limit (if

enabled), an internal counter is started and is incremented every time a new value is

captured and the condition is met. The counter will be stopped and reset if the control

value falls back between the low and high limits. When the counter exceeds the

“Samples Required Before Trigger” parameter, the limit output will be set to the

active state (level configured using the output polarity). If the auto reset has not been

configured the limit output will remain latched irrespective of the control channel