Page 1

FormNo.3375-556RevA

ZMaster

®

Commercial2000

SeriesRidingMower

with48inTURBOFORCE

®

SideDischarge

Mower

ModelNo.74141TE—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3375-556*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

ThissparkignitionsystemcomplieswithCanadianICES-002.

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalT oroparts.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

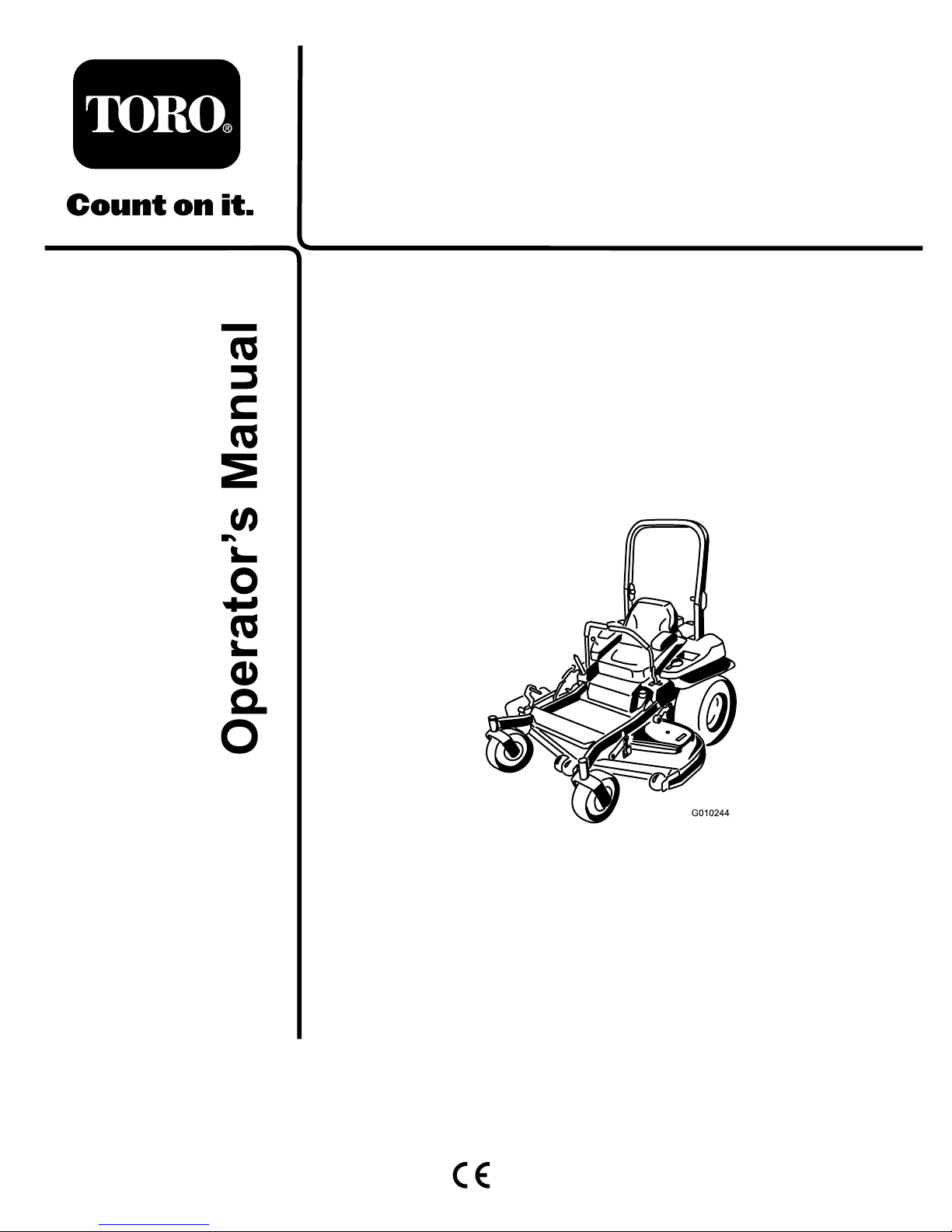

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g017416

1

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................5

SoundPressure.......................................................6

SoundPower..........................................................6

VibrationLevel.......................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................12

Specications........................................................13

Operation....................................................................13

AddingFuel...........................................................13

CheckingtheEngineOilLevel.................................14

BreakingInaNewMachine.....................................15

UsingtheRolloverProtectionSystem(ROPS)............15

ThinkSafetyFirst...................................................15

OperatingtheParkingBrake....................................16

OperatingtheMowerBladeControlSwitch

(PTO)...............................................................17

OperatingtheThrottle............................................17

OperatingtheChoke...............................................17

OperatingtheIgnitionSwitch..................................17

UsingtheFuelShut-OffValve..................................18

StartingandStoppingtheEngine..............................18

TheSafetyInterlockSystem.....................................19

DrivingForwardorBackward..................................20

StoppingtheMachine.............................................21

AdjustingtheHeightofCut.....................................21

AdjustingtheAnti-ScalpRollers...............................22

PositioningtheSeat................................................23

UsingtheDriveWheelReleaseValves.......................23

UsingtheSideDischarge.........................................24

LoadingMachines..................................................24

TransportingMachines............................................25

OperatingTips......................................................26

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

Lubrication...............................................................28

GreasingandLubrication........................................28

WheretoGreasetheMower.....................................28

LubricatetheCasterWheelHubs..............................29

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

ServicingtheSparkPlug..........................................33

CheckSparkArrester(ifequipped)............................34

FuelSystemMaintenance...........................................34

ReplacingtheFuelFilter..........................................34

ServicingtheFuelTank...........................................35

ElectricalSystemMaintenance....................................35

ServicingtheBattery...............................................35

ServicingtheFuses.................................................36

DriveSystemMaintenance.........................................37

CheckingtheSeatBelt.............................................37

CheckingtheRolloverProtectionSystem(ROPS)

Knobs...............................................................37

AdjustingtheTracking............................................38

CheckingtheTirePressure......................................38

AdjustingtheCasterPivotBearing............................39

AdjustingtheElectricClutch....................................39

CoolingSystemMaintenance......................................40

CleaningtheEngineScreen......................................40

CleaningtheEngineCoolingFinsand

Shrouds.............................................................40

BeltMaintenance......................................................40

InspectingtheBelts................................................40

ReplacingtheMowerBelt........................................40

ReplacingtheHydraulicPumpDriveBelt...................41

ControlsSystemMaintenance.....................................42

AdjustingtheControlHandlePosition......................42

AdjustingtheMotionControlLinkage......................43

AdjustingtheMotionControlDamper......................43

AdjustingtheMotionControlNeutralLock

Pivot.................................................................44

HydraulicSystemMaintenance....................................44

ServicingtheHydraulicSystem.................................44

ChangingtheHydraulicSystemFilterand

Oil....................................................................45

MowerDeckMaintenance...........................................46

LevelingtheMowerDeck........................................46

ServicingtheCuttingBlades.....................................48

RemovingtheMowerDeck.....................................51

ReplacingtheGrassDeector..................................52

Cleaning...................................................................52

CleaningUndertheMower......................................52

WasteDisposal.......................................................52

Storage........................................................................53

CleaningandStorage..............................................53

Troubleshooting...........................................................54

Schematics...................................................................56

3

Page 4

Safety

ThismachinemeetsorexceedsEuropeanStandardsin

effectatthetimeofproduction.However,improperuse

ormaintenancebytheoperatororownercanresultin

injury.Toreducethepotentialforinjury,complywiththese

safetyinstructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromtheCENstandardEN

836:1997.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulationscan

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–theneedforcareandconcentrationwhenworking

withride-onmachines;

–controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthecontrol

levers.Themainreasonsforlossofcontrolare:

◊insufcientwheelgrip,especiallyonwetgrass;

◊beingdriventoofast;

◊inadequatebraking;

◊thetypeofmachineisunsuitableforitstask;

◊lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊incorrecthitchingandloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantialfootwearandlong

trousers.Donotoperatetheequipmentwhenbarefoot

orwearingopensandals.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning–Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refuelling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Donotuseonslopesgreaterthan15degrees.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.Toguardagainst

overturning:

–-donotstoporstartsuddenlywhenonaslope;

–-useslowspeedsonslopesandduringtightturns;

–-stayalertforhumpsandhollowsandotherhidden

hazards;

•Usecarewhenpullingloadsorusingheavyequipment.

–-Useonlyapproveddrawbarhitchpoints.

–-Limitloadstothoseyoucansafelycontrol.

–-Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

4

Page 5

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedcan

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–disengagethepowertake-offandlowerthe

attachments;

–changeintoneutralandsettheparkingbrake;

–stoptheengineandremovethekey .

•Disengagedrivetoattachments,stoptheengine,and

disconnectthesparkplugwire(s)orremovetheignition

key

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthe

lawnmower;

–afterstrikingaforeignobject.Inspectthelawnmower

fordamageandmakerepairsbeforerestartingand

operatingtheequipment;ifthemachinestartsto

vibrateabnormally(checkimmediately).

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Stoptheengineanddisengagedrivetoattachment

–beforerefuelling;

–beforeremovingthegrasscatcher;

–beforemakingheightadjustmentunlessadjustment

canbemadefromtheoperator'sposition.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumescanreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeofgrass,

leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbedone

outdoors.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

•Whenmachineistobeparked,storedorleftunattended,

lowerthecuttingmeansunlessapositivemechanicallock

isused.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Engineexhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.Donotrun

engineindoorsorinanenclosedarea.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyToro-approvedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanksor

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

fromthemowingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocks,dips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethebladesandproceed

slowlyofftheslope.

5

Page 6

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability .

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof91

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN836.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

VibrationLevel

Hand-Arm

Measuredvibrationlevelforrighthand=1.6m/s

2

Measuredvibrationlevelforlefthand=2.7m/s

2

UncertaintyValue(K)=1.4m/s

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

WholeBody

Measuredvibrationlevel=0.31m/s

2

UncertaintyValue(K)=0.16m/s

2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN836.

6

Page 7

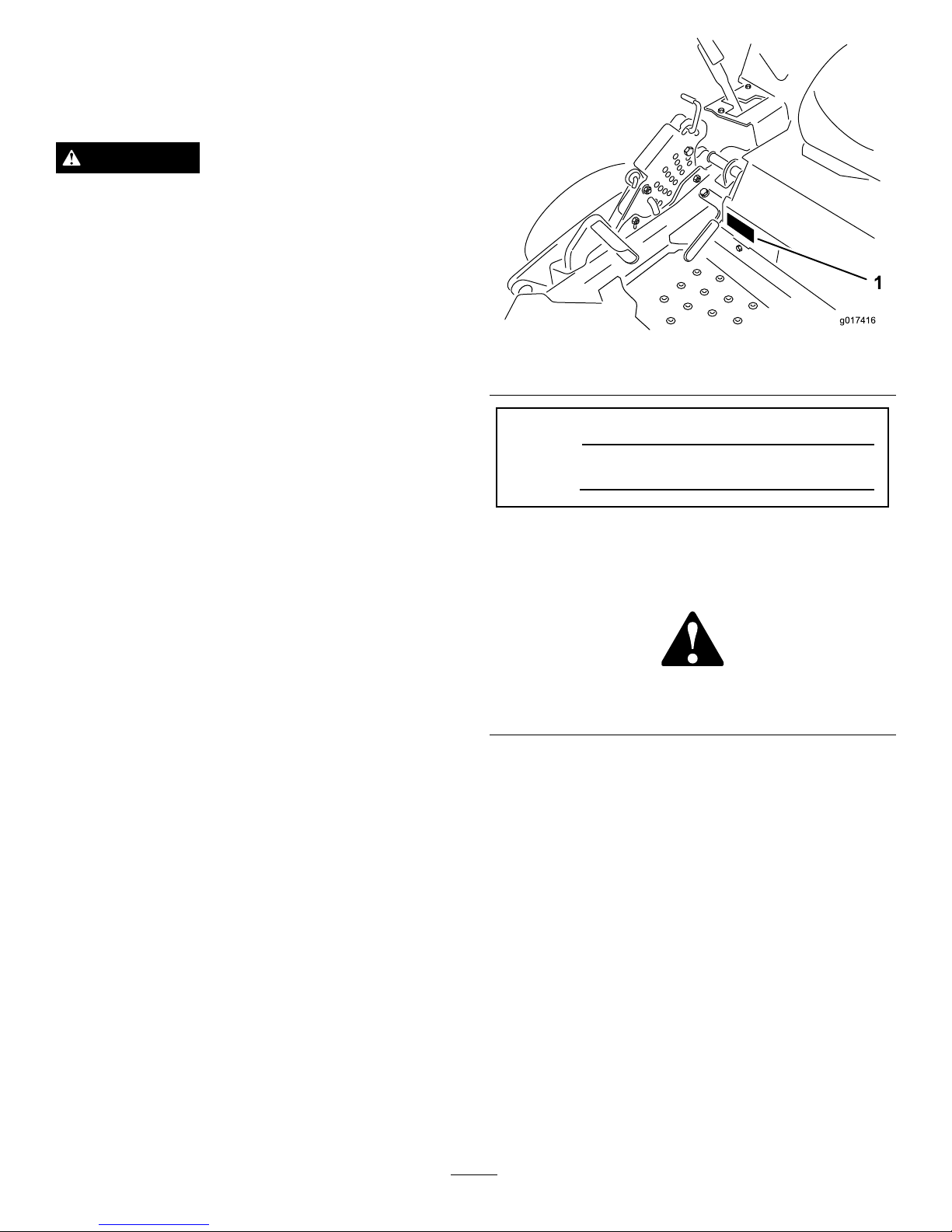

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

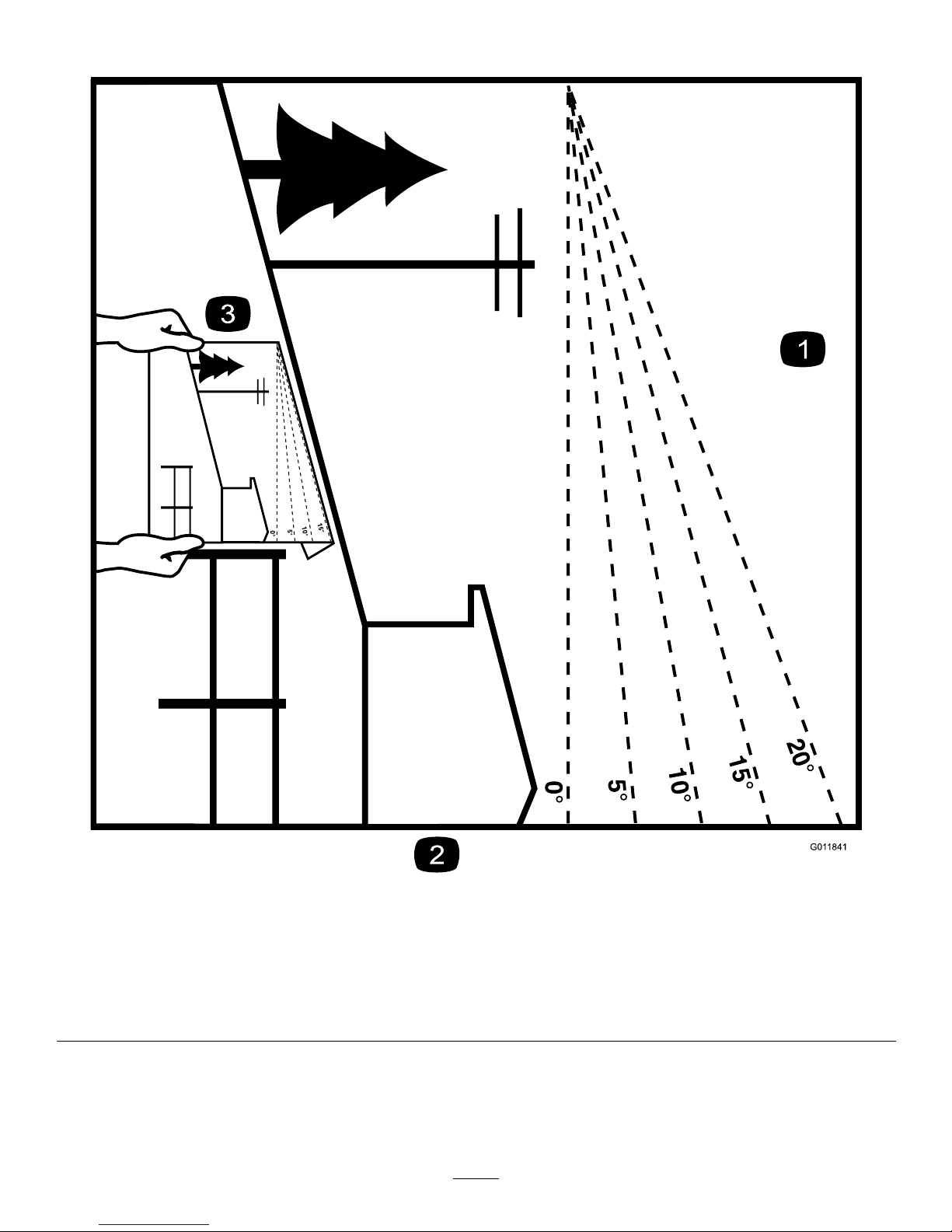

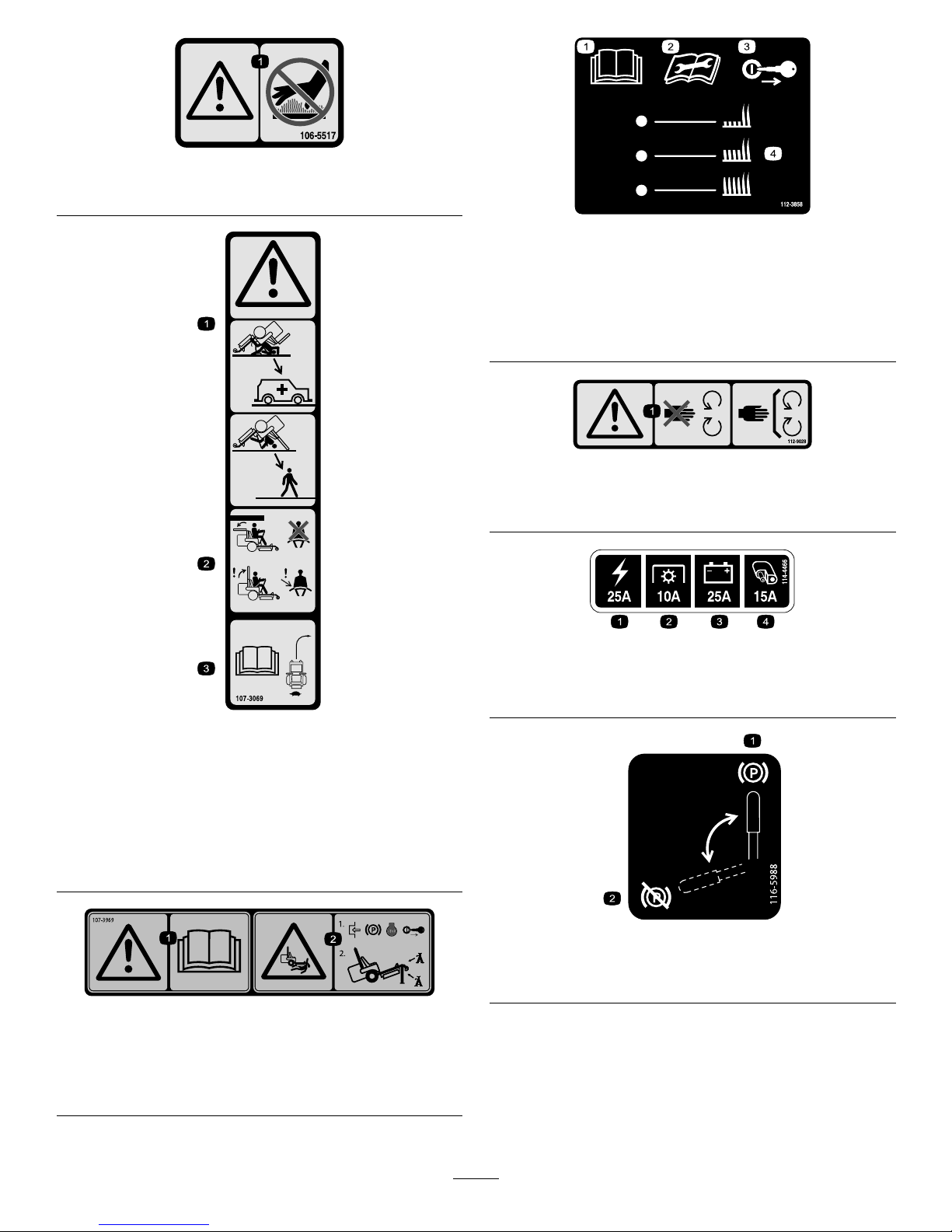

Page 8

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

58-6520

1.Grease

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto85-1 10ft-lb(1 15-149N-m).

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

6.Keepbystandersasafe

distancefromthebattery .

2.Nore,opename,or

smoking.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

106–2655

1.Warning-donottouchorapproachmovingbelts;remove

theignitionkeyandreadtheinstructionsbeforeservicing

orperformingmaintenance.

8

Page 9

106-5517

1.Warning—donottouchthehotsurface.

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotwearthetheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

107–3969

1.Warning—readtheOperator'sManual.

2.Crushinghazard,mower—1)Engagetheparkingbrake,

stoptheengine,andremovetheignitionkey;2)Properly

jackthemachinebeforeworkingunderthemachine.

112-3858

1.ReadtheOperator's

Manual.

3.Removetheignitionkey

beforeadjustingtheheight

ofcut.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

4.Heightofcutsettings.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

114-4466

1.Main,25A

3.Charge,25A

2.PTO,10A

4.Auxiliary,15A

116-5988

1.Parkingbrake—engaged2.Parking

brake—disengaged

9

Page 10

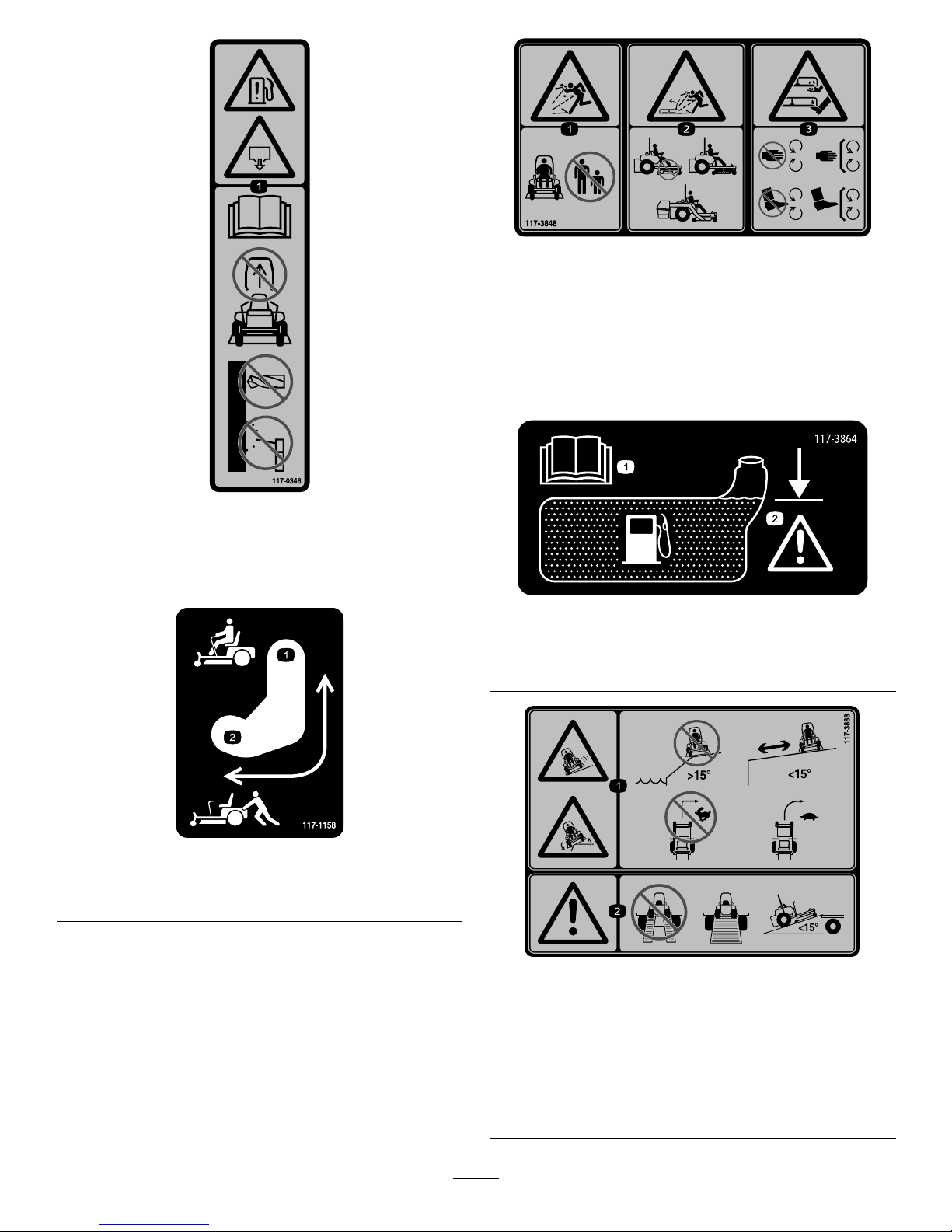

117-0346

1.Fuelleakhazard—readtheOperator'sManual;donot

attempttoremovetherollbar;donotweld,drillormodify

therollbarinanyway .

117–1158

1.Bypassleverpositionfor

operatingthemachine.

2.Bypassleverpositionfor

pushingthemachine.

117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatethewithout

deector,dischargecoverorgrasscollectionsystemin

place.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

117–3864

1.ReadtheOperator’s

Manual.

2.Filltobottomofllerneck;

warning—donotoverll

thetank.

117-3888

1.Sliding,tippinghazard—donotusethemachinenear

drop-offswithslopesgreaterthan15degrees,usethe

machineasafedistancefromdrop-offsonslopeslessthan

15degrees;donotturnsharplywhiletravelingfast,drive

slowlywhenturning.

2.Warning—donotusedualramps,useonepieceramps

whentransportingmachine;donotuserampswith

inclinationgreaterthan10degrees.

10

Page 11

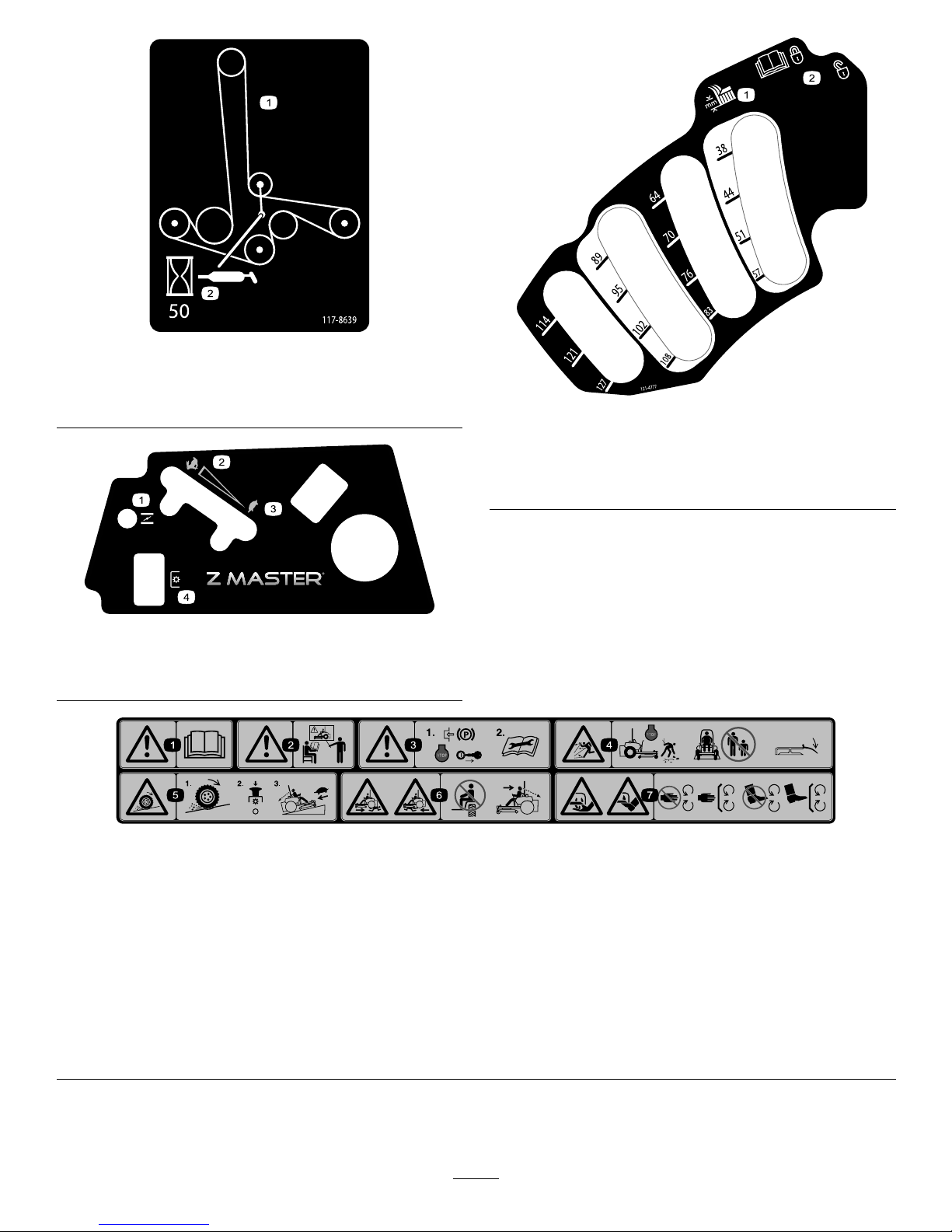

117-8639

1.Beltrouting

2.Greasepulley,

maintenanceinterval—50

hours

119-2501

1.Choke3.Slow

2.Fast

4.PTO(PowerT ake-off)

121–4777

1.Heightofcutadjustment2.ReadtheOperator’s

Manualoninformationon

howtolockandunlockthe

deckposition.

114–4468

1.Warning—readtheOperator'sManual.5.Lossoftraction/controlhazard,slopes—lossoftraction/control

onaslope,disengagethebladecontrolswitch(PTO),

proceedofftheslopeslowly .

2.Warning—donotoperatethismachineunlessyouaretrained.

6.Crushing/dismembermenthazardofbystanders—donotcarry

passengers,lookforwardanddownwhenoperatingthe

machine,lookbehindanddownwhenreversing.

3.Warning—engagetheparkingbrake,stoptheengineand

removetheignitionkey;readtheinstructionsbeforeservicing

orperformingmaintenance.

7.Cutting/dismembermenthazard;handorfoot—stayaway

frommovingpartsandkeepallguardsandshieldsinplace.

4.Thrownobjecthazard—Stoptheengineandpickupdebris

beforeoperating,keepbystandersasafedistancefromthe

machine,keepdeectorinplace

11

Page 12

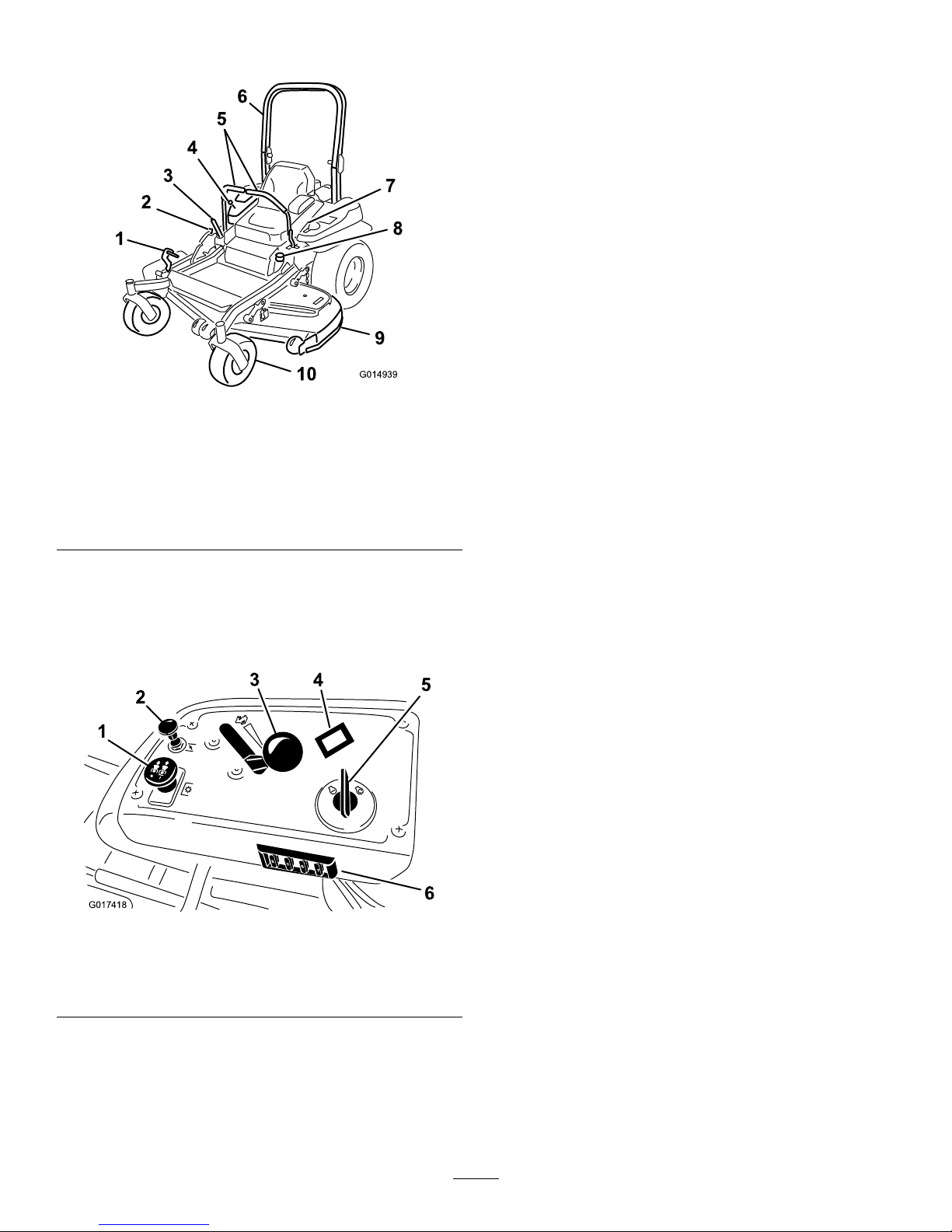

ProductOverview

G014939

Figure4

1.Height-of-cutdecklift

pedal

6.Rollbar

2.Transportlock

7.Seatbelt

3.Parkingbrakelever8.Fuelcap

4.Controls

9.Mowerdeck

5.Motioncontrollevers

10.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

G017418

25

25

10

15

1

2

3

4

5

6

Figure5

1.PTOSwitch

4.Hourmeter

2.Choke

5.Ignitionswitch

3.Throttlecontrol6.Fuses

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(Figure5).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengagetheelectric

clutchanddrivethemowerblades.Pulltheswitchupto

engagethebladesandrelease.Todisengagetheblades,push

thebladecontrolswitch(PTO)downormoveamotion

controlleverintotheneutrallockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhasthree

positions:Start,RunandOff.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemtoengageandtodetermineneutralposition.

FuelShut-offValve

Closethefuelshut-offvalve(undertheseat)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofT oroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww.Toro.comforalistofallapproved

attachmentsandaccessories.

12

Page 13

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width:

48inchDeck

WithoutDeck

45.3inches(1 15.1cm)

DeectorUp51.5inches(130.8cm)

DeectorDown63.1inches(160.3cm)

Length:

48inchDeck

RollBar-Up

78.6inches(199.6cm)

RollBar-Down

80.4inches(204.2cm)

Height:

RollBar-UpRollBar-Down

70.2inches(178.3cm)46.5inches(1 18.1cm)

Weight:

ModelWeight

74141TE

1010lb(458kg)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoorsonlevelground,in

anopenarea,whentheengineiscold.Wipeup

anygasolinethatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Fill

thefueltanktothebottomofthellerneck.

Theemptyspaceinthetankallowsgasolineto

expand.Overllingmayresultinfuelleakage

ordamagetotheengineoremissionsystem(if

equipped).

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

13

Page 14

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening .

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

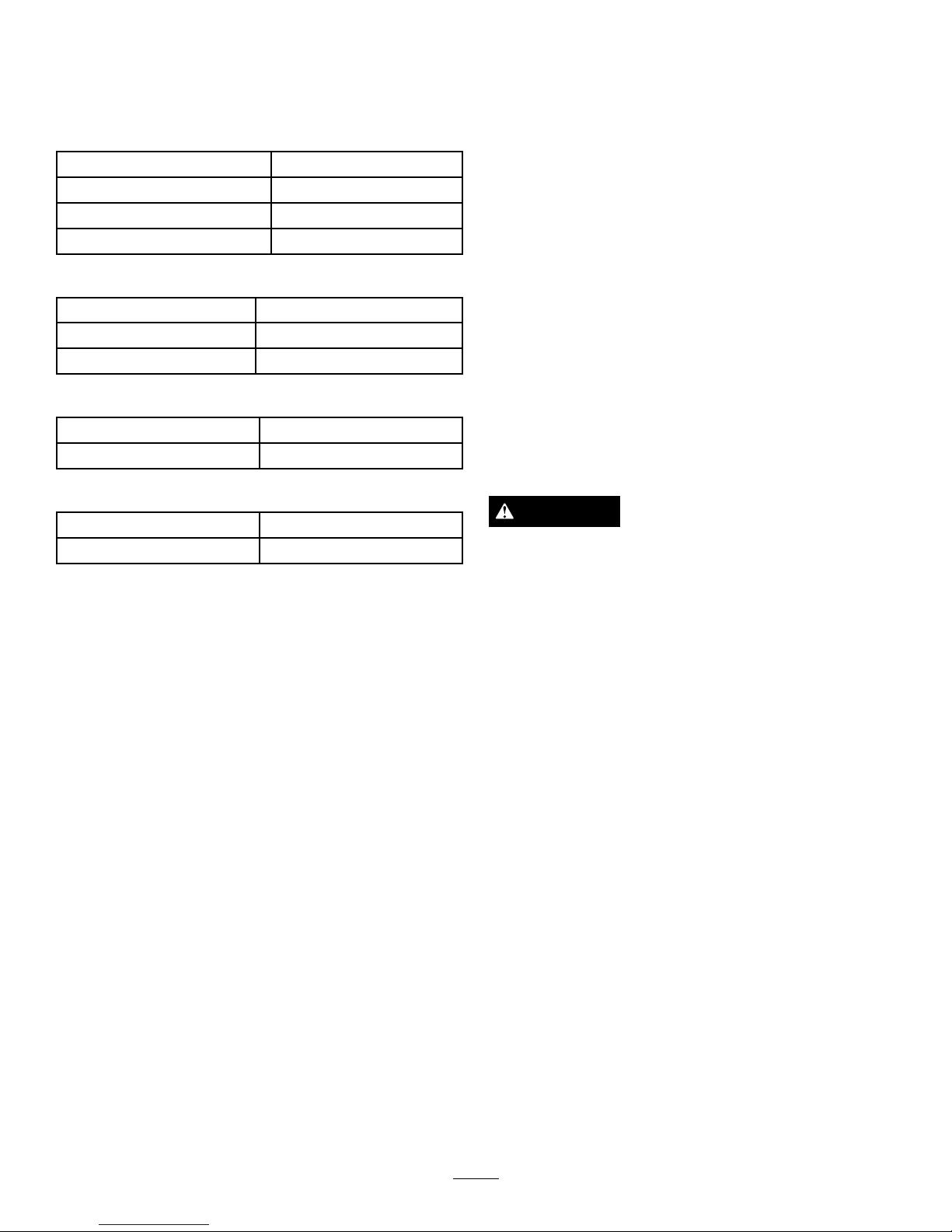

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthefuel

tanktothebottomofthellerneck.Theemptyspaceinthe

tankallowsthegasolinetoexpand.

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefueltankcap.

4.Fillthefueltanktothebottomofthellerneck.

Ensurethereisemptyspaceinthetanktoallowthe

gasolinetoexpand(

Figure6).

G009189

g017624

1

2

4

3

5

Figure6

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine

OilLevel.

14

Page 15

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew ,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

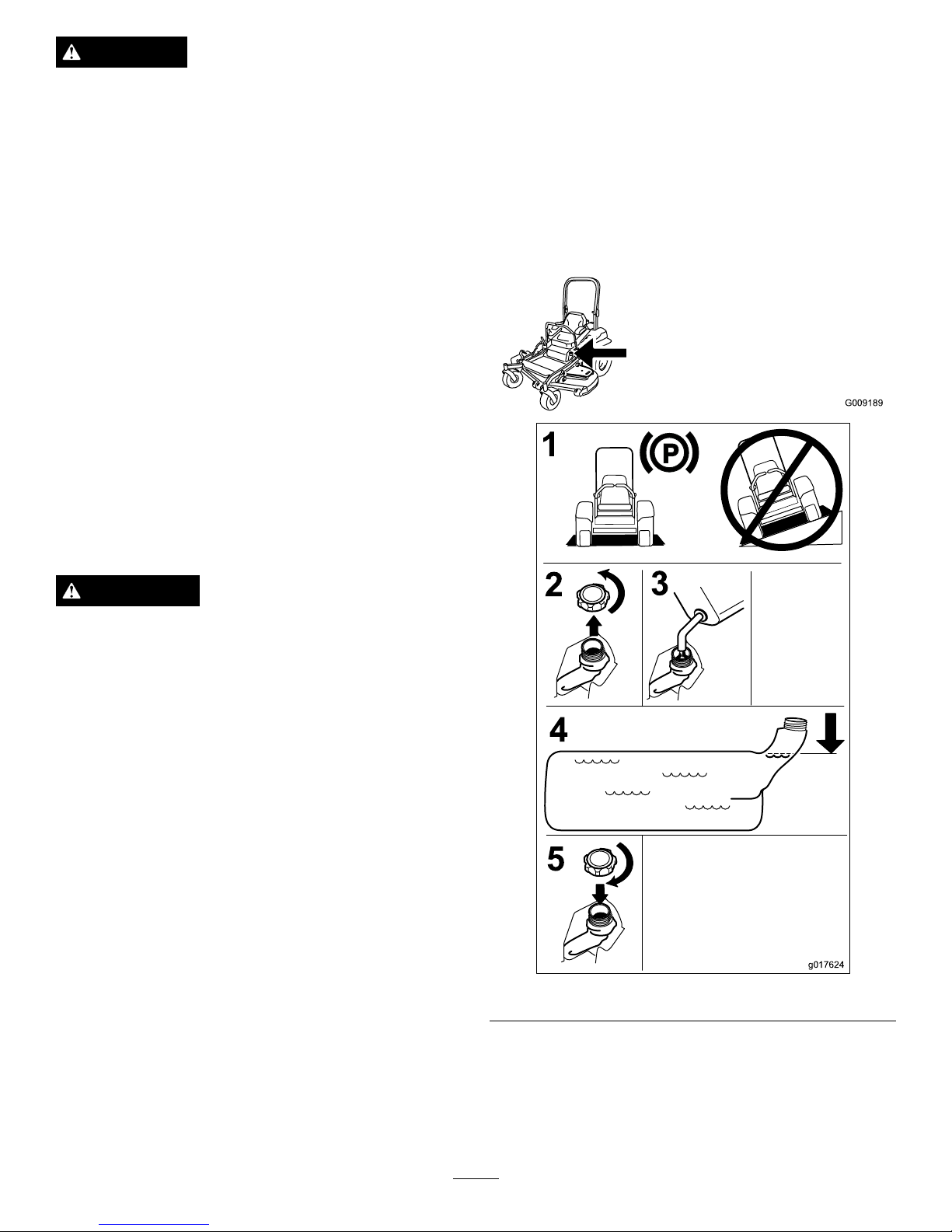

UsingtheRolloverProtection

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensuretheseatissecuredtothemachine.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits

andusetheseatbelt.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

Important:Ensuretheseatissecuredtothemachine.

1.Tolowertherollbar,applyforwardpressuretothe

upperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sotheyare

notengaged(Figure7).

3.Lowertherollbartothedownposition(Figure7).

Figure7

1.ROPSknob

3.Rollbarintheupright

position

2.PullROPSknoboutand

rotate90degrees

4.Rollbarinthefolded

position

4.Toraisetherollbar,raisetherollbartotheoperate

position,rotatetheknobssotheymovepartiallyinto

thegrooves(Figure7).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswillsnap

intopositionwhentheholesalignwiththepins

(Figure7).Pushontherollbarandensurethatboth

pinsareengaged.

Important:Alwaysusetheseatbeltwiththeroll

barinthefullyraisedposition.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

15

Page 16

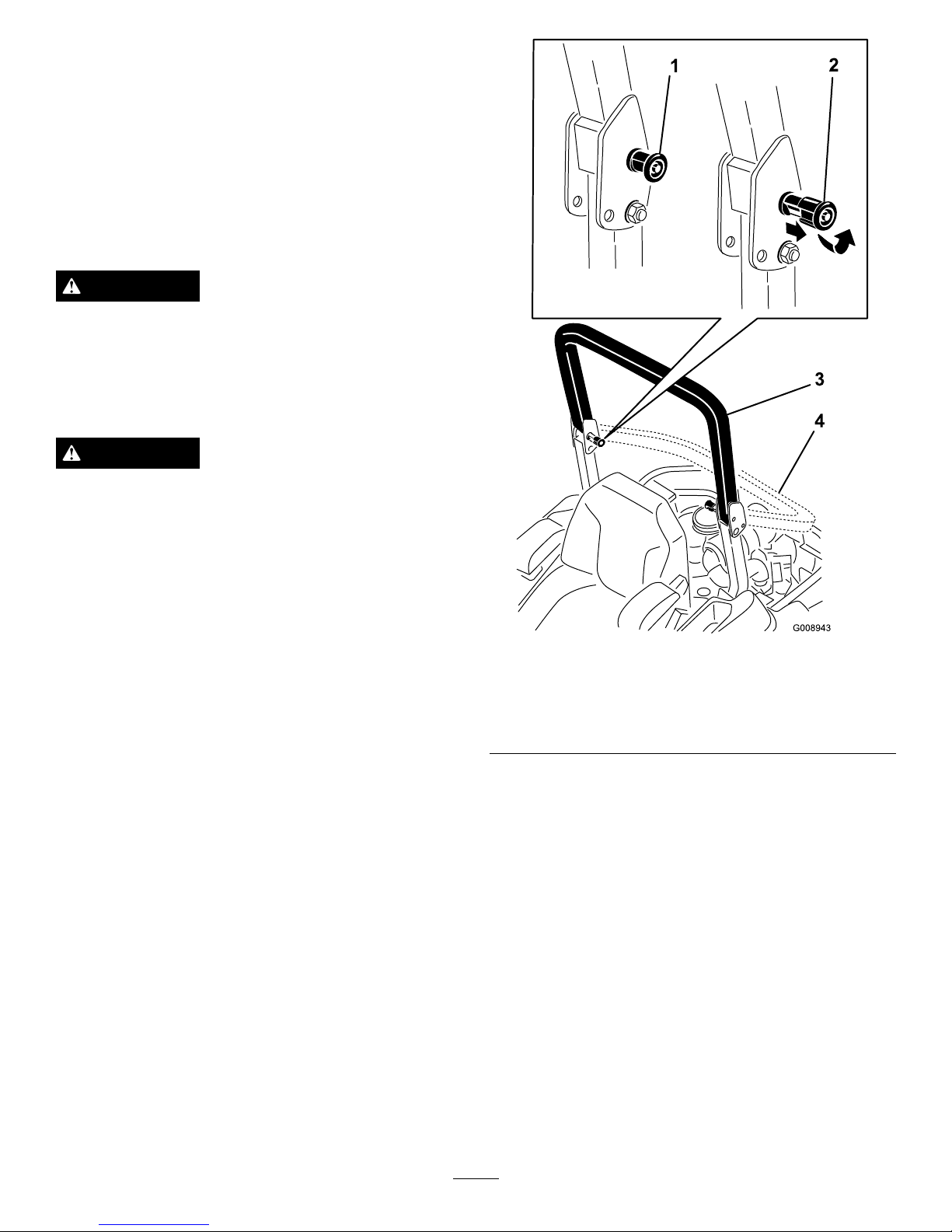

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure8

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

3.Water

2.DangerZone-useawalk

behindmowerand/ora

handtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

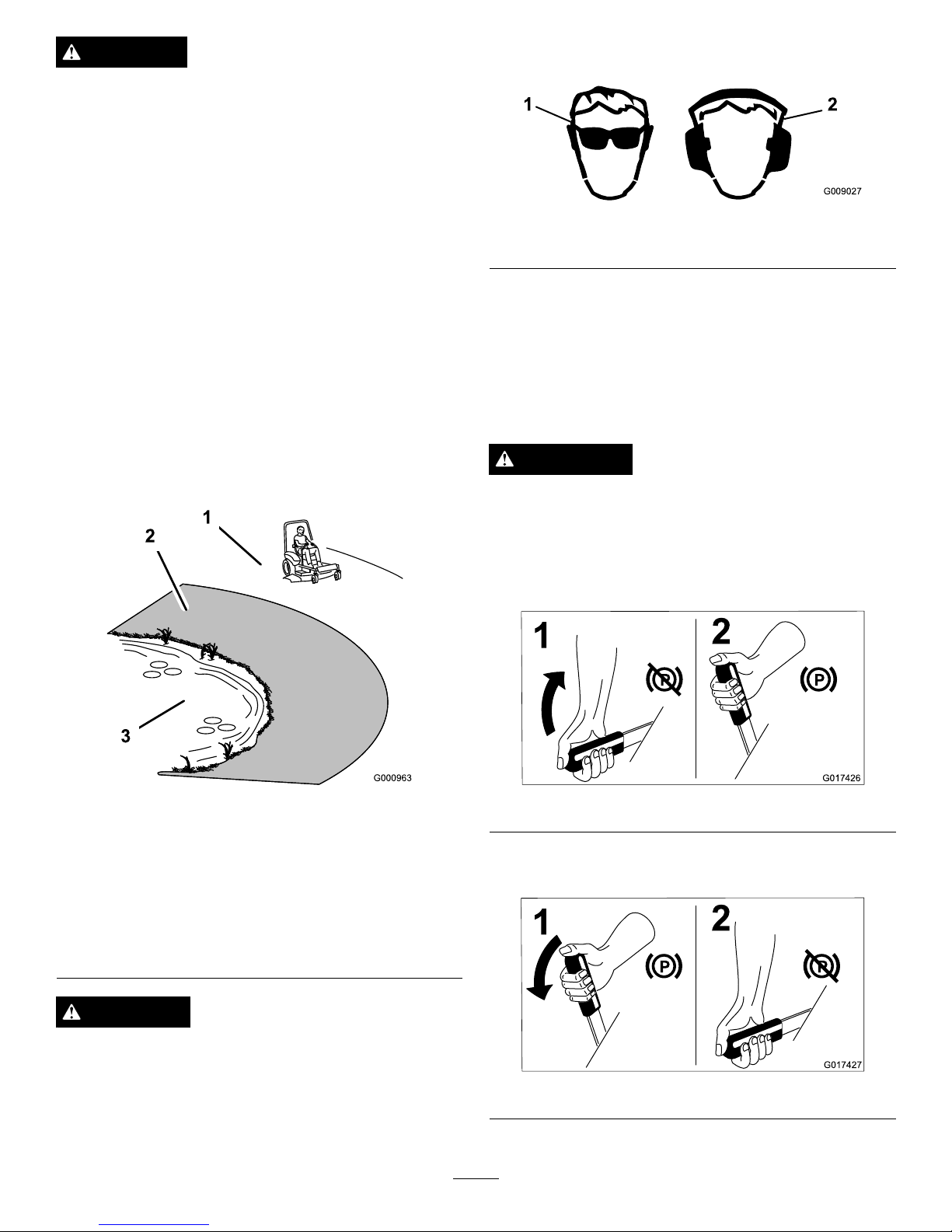

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feetandhead

isrecommended.

G009027

1

2

Figure9

1.Wearsafetyglasses

2.Wearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

WARNING

Parkingbrakemaynotholdmachineparkedona

slopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlesswheelsarechocked

orblocked

G017426

1

2

Figure10

ReleasingtheParkingBrake

G017427

1

2

Figure11

16

Page 17

OperatingtheMowerBlade

ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Note:Engagingthebladecontrolswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

G008945

Figure12

DisengagingtheBladeControlSwitch

(PTO)

G009174

Figure13

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure14).

Alwaysusethefastpositionwhenturningonthemowerdeck

withthebladecontrolswitch(PTO).

G008946

Figure14

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(

Figure15).

3.Pushdownonthechoketodisengagethechokeafter

theenginehasstarted(Figure15).

G008959

1

2

Figure15

1.On2.Off

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition(Figure16).

Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

17

Page 18

START

RUN

STOP

G008947

Figure16

2.Turntheignitionkeytothestoppositiontostopthe

engine.

UsingtheFuelShut-OffValve

Thefuelshut-offvalveislocatedbehindtheseat.

Closethefuelshut-offvalvefortransport,maintenance,and

storage.

Ensurethefuelshut-offvalveisopenwhenstartingthe

engine.

G017428

G008948

1

2

Figure17

1.On2.Off

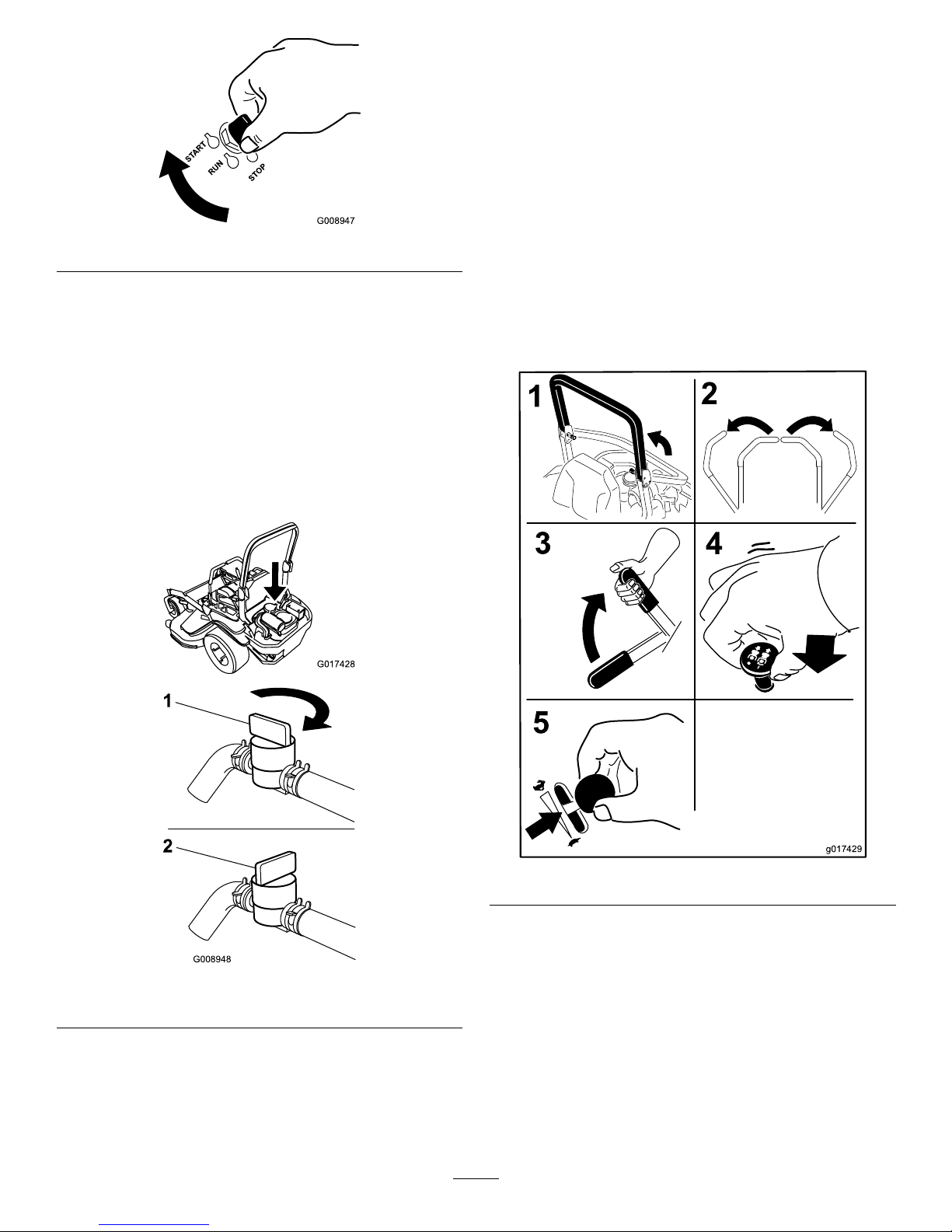

StartingandStoppingthe

Engine

StartingtheEngine

1.RaisetheROPSupandlockintoplace,sitontheseat

andfastentheseatbelt.

2.Movethemotioncontrolstoneutrallockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.Movethebladecontrolswitch(PTO)totheOff

position(Figure18).

5.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

g017429

Figure18

6.TurntheignitionkeytotheStartposition(Figure16).

Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

18

Page 19

START

RUN

STOP

G008947

Figure19

1.Off3.Start

2.Run

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

g017430

Figure20

Important:Makesurethatthefuelshutoffvalveis

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesuretoremovethekeyasthefuel

pumpmayrunandcausethebatterytolosecharge.

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

19

Page 20

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Thebladecontrolswitch(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthelocked

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)toon.Trystartingthe

engine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)tooff.Moveeither

motioncontrollever(outofneutrallockedposition).

Trystartingtheengine;theengineshouldnotcrank.

Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,releasetheparking

brake,engagethebladecontrolswitch(PTO)andrise

slightlyfromtheseat;theengineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,centereither

motioncontrolandmove(forwardorreverse);the

engineshouldstop.Repeatforothermotioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,move

thebladecontrolswitch(PTO)tooffandmovethe

motioncontrolleverstoneutrallockposition.Try

startingtheengine;theengineshouldnotcrank.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

UsingtheMotionControlLevers

Figure21

1.Motioncontrol

lever-neutrallockposition

4.Backward

2.Center,unlockedposition5.Frontofmachine

3.Forward

DrivingForward

Note:Theenginewillkillifthetractioncontrolleversare

movedwiththeparkingbrakeengaged.

Tostop,pullthemotioncontrolleverstotheneutralposition.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrollevers

forward(

Figure22).

20

Page 21

G008952

Figure22

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrollevers

rearward(Figure23).

G008953

Figure23

StoppingtheMachine

Tostopthemachine,movethetractioncontrolleversto

neutralandmovetolockedposition,disengagethepower

takeoff(bladecontrolswitch(PTO),andturntheignition

keytooff.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrakeinOperation.Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhastwopositionsandisusedwiththe

deckliftpedal.Thereisalockpositionandaunlockposition

forthetransportposition.Thetransportlockisusedwiththe

deckliftpedal.RefertoFigure24.

21

Page 22

Figure24

TransportLockPositions

1.Transportlock3.Unlockposition—doesnot

lockthemowerdeckinto

transportposition

2.Lockposition—mower

deckwilllockintotransport

position

AdjustingtheHeight-of-CutPin

Mowerdecksize

Height-of-cut

range

Increments

48inch

1-1/2to5inches

(38to127mm)

1/4inch(6mm)

Theheight-of-cutisadjustedbyrelocatingtheclevispininto

differentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeckliftpedalwithyourfootandraisethe

mowerdecktothetransportposition(alsothe5-1/2

inch(140mm)cuttingheightposition)(

Figure25).

3.Toadjust,rotatethepin90degreesandremovethepin

fromtheheight-of-cutbracket(Figure25).

4.Selectaholeintheheight-of-cutbracketcorresponding

totheheight-of-cutdesiredand,insertthepin

(Figure25).

5.Pushonthedecklift,pullbackonthetransportlock,

andslowlylowerthemowerdeck.

g017419

2

1

3

Figure25

1.Deckliftpedal

3.Transportlock

2.Cutofheightpin

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

22

Page 23

g017628

Figure26

1.Anti-scalproller4.FlangeNut

2.Spacer

5.Bolt

3.Bushing

g017629

Figure27

1.Anti-scalproller3.FlangeNut

2.Bushing4.Bolt

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlockseat(Figure28).

G008962

Figure28

UsingtheDriveWheelRelease

Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey,andallowall

movingpartstostopbeforeaccessingthedrive

wheelreleasevalves.

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.Touchingahotengineorhydraulicdrive

unitscancausesevereburns.

Allowtheengineandhydraulicdriveunitstocool

completelybeforeaccessingthedrivewheelrelease

valves.

Thedrivewheelreleasevalvesarelocatedbehindtheseatand

downintheenginecompartment.

1.DisengagethePTO(bladecontrolswitch)andturnthe

ignitionkeytooff.Movetheleverstoneutrallocked

positionandapplyparkingbrake.Removethekey.

2.Locatethebypassleversbehindtheseat,downonthe

leftandrightsideoftheframe.

3.Topushthemachine,movethebypassleversrearward

andouttolocktheminplaceasshownin

Figure29.

Repeatthisoneachsideofthemachine.

4.Disengageparkingbrakebeforepushing.

g017420

2

3

4

1

Figure29

23

Page 24

5.Torunthemachine,movethebypassleverstothe

forwardposition(Figure29).

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff(blade

controlswitch(PTO)totheoffposition,rotate

theignitionkeytooffandremovethekey.

•Makesurethegrassdeectorisinthedown

position.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersortrucks.

Onefullwidthrampthatiswideenoughtoextendbeyond

thereartiresisrecommendedinsteadofindividualrampsfor

eachsideoftheunit(Figure30).Thelowerrearsectionof

themachineframeextendsbackbetweentherearwheelsand

servesasastopfortippingbackward.Havingafullwidth

rampprovidesasurfacefortheframememberstocontactif

theunitstartstotipbackward.Ifitisnotpossibletouseone

fullwidthramp,useenoughindividualrampstosimulatea

fullwidthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(

Figure30).Asteeperanglemaycause

mowercomponentstogetcaughtastheunitmovesfrom

ramptotrailerortruck.Steeperanglesmayalsocausethe

unittotipbackward.Ifloadingonornearaslope,position

thetrailerortrucksoitisonthedownsideoftheslopeand

therampextendsuptheslope.Thiswillminimizetheramp

angle.Thetrailerortruckshouldbeaslevelaspossible.

Important:DoNotattempttoturntheunitwhileon

theramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

WARNING

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•EnsuretheROPSisintheuppositionwhile

usingtheseatbeltwhenloadingthemachine.

EnsuretheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thantheunit.

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtrailerortruck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Figure30

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

24

Page 25

TransportingMachines

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw.Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,petsorbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(

Figure31).

Figure31

1.Tractionunittiedownloops

25

Page 26

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethecutting

heightofthemowerdoesnotscalpanyunevenground.

However,thecuttingheightusedinthepastisgenerallythe

bestonetouse.Whencuttinggrasslongerthansixinchestall,

youmaywanttocutthelawntwicetoensureanacceptable

qualityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently .Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

26

Page 27

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Changetheengineoil.

Aftertherst50hours

•Changethehydraulicsystemlterandoil.

Beforeeachuseordaily

•Checkthesafetysystem.

•Checktheengineoillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Cleantheenginescreen.

•Checkthemowerblades.

•Cleanthemowerdeck.

Every25hours

•Checkthehydraulicoillevelintheexpansiontank.

Every50hours

•Greasethemowerdeckidlerarm.

•Checksparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

Every100hours

•Lubricatethemowerdeckliftpivots.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Check,cleanandregapthesparkplug.

•Checkandcleanenginecoolingnsandshrouds.

Every200hours

•Changetheengineoillter.

Every250hours

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

Every400hours

•Changethehydraulicsystemlterandoil.

Every500hours

•Replacethesecondaryairlter.

•Replacethefuellter(moreoftenindirtyordustyconditions).

•Adjustthecasterpivotbearing.

•Checktheelectricclutch.

Monthly

•Checkthebattery .

Yearly

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs.

Yearlyorbeforestorage

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

27

Page 28

Lubrication

GreasingandLubrication

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy .

GreaseType:No.2generalpurposelithiumbaseor

molybdenumbasegrease

HowtoGrease

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

WheretoAddLightOilorSpray

Lubrication

ServiceInterval:Every100hours

Lubricatethedeckliftpivots.

g017421

Figure32

WheretoGreasetheMower

ServiceInterval:Every50hours—Greasethemowerdeck

idlerarm.

Yearly—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Greasethemowerdeckidlerpulleypivotuntilgrease

comeoutthebottom(Figure33).

g017435

Figure33

4.Removethedustcapandadjustthecasterpivots.

Keepthedustcapoffuntilgreasingisdone.Referto

AdjustingtheCasterPivotBearinginMaintenance.

5.Removethehexplug.Threadagreasezerkintothe

hole.

6.Pumpgreaseintothezerkuntilitoozesoutaround

thetopbearing.

7.Removethegreasezerkinthehole.Installthehexplug

anddustcap(

Figure34).

g014942

Figure34

28

Page 29

LubricatetheCasterWheel

Hubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey .Engagetheparkingbrake.

Figure35

1.Sealguard2.Spacernutwithwrench

ats

2.Raisethefrontofthemachineupandsupportitwith

jackstands.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub.

5.Remove1ofthespacernutsfromtheaxleassemblyin

thecasterwheel.Notethatthreadlockingadhesive

hasbeenappliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

6.Pryouttheseals,andinspectthebearingsforwearor

damageandreplaceifnecessary.

7.Packthebearingswithageneral-purposegrease.

8.Insert1bearingand1newsealintothewheel.

Note:Thesealsmustbereplaced.

9.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathreadlockingadhesiveto1

spacernutandthreaditontotheaxlewiththewrench

atsfacingoutward.Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leaveapproximately

3mm(1/8inch)fromtheoutersurfaceofthespacer

nuttotheendoftheaxleinsidethenut.

10.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

11.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

12.Insertthesecondbearingandnewsealintothewheel.

13.Applyathreadlockingadhesivetothesecondspacer

nutandthreaditontotheaxlewiththewrenchats

facingoutward.

14.Torquethenutto8-9N-m(75-80in-lb),loosen,then

re-torqueto2-3N-m(20-25in-lb).Makesurethatthe

axledoesnotextendbeyondeithernut.

15.Installthesealguardsoverthewheelhubandinsert

thewheelintothecasterfork.Installthecasterbolt

andtightenthenutfully.

Important:T opreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecastertire.The

tireshouldnotspinfreely(morethan1or2revolutions)

orhaveanysideplay.Ifthewheelspinsfreely,adjustthe

torqueonthespacernutuntilthereisaslightamountof

drag.Applythreadlockingadhesive.

16.Raisethefrontofthemachineupandremovethejack

stands.

29

Page 30

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacetheprimaryair

lter.

Every250hours—Checkthesecondaryairlter.

Every500hours—Replacethesecondaryairlter.

Note:Servicetheaircleanermorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pushdowntoreleasetheretainingclampsontheair

cleanerandpulltheaircleanercoveroffoftheair

cleanerbody(

Figure36).

4.Cleantheinsideoftheaircleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure36).Avoidknockingthelterintothe

sideofthebody.

6.Removethesecondarylteronlyifyouintendto

replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Ifthelterisdamageddiscardit.

Figure36

1.Aircleanerclamps

3.Primaryairlter

2.Aircleanercover

4.Secondaryairlter

ServicingthePrimaryFilter

1.Donotcleanthepaperlter,replaceit(Figure36).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Neverattempttocleanthesecondarylter.

Ifthesecondarylterisdirty,thentheprimarylteris

damagedandyoushouldreplacebothlters.

InstallingtheFilters

Important:T opreventenginedamage,alwaysoperate

theenginewithbothairltersandcoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Ifthesecondarylterisbeingreplaced,carefullyslide

itintothelterbody(Figure36).

3.Carefullyslidetheprimarylteroverthesecondary

lter(Figure36).Ensurethatitisfullyseatedby

pushingontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheaircleanercoverwiththebreathercapdown

androtatesotheretainingclampslockthecoverin

place(

Figure36).

30

Page 31

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,orSL)

CrankcaseCapacity:withalterchange,71ounces(2.1L);

withoutalterchange,61ounces(1.8L)

Viscosity:Seethetablebelow.

Figure37

Note:Useofmulti-gradeoils(5W-20,10W -30,or10W-40)

willincreaseoilconsumption.Checktheoillevelmore

frequentlywhenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure38).

G008804

G008792

1

2

5

6

7

3

9

10

4

8

Figure38

31

Page 32

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirtyordusty

conditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylowerthan

thefronttoensuretheoildrainscompletely .

2.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Changetheengineoil(

Figure39).

G008804

G008793

1

2

3

4

4

5

Figure39

5.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure40).

G008796

2

3

4

5

6

1

Figure40

6.Starttheengineanddrivetoaatarea.Checktheoil

levelagain.

ChangingtheEngineOilFilter

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(Figure41).

32

Page 33

G017452

G008748

3/4

1

2

3

4

5

6

Figure41

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

TypeofSparkPlug:NGK

®

BPR4ESorequivalent

AirGap:0.030inch(0.75mm)

RemovingtheSparkPlug

1.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

2.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Locateandremovethesparkplugs(Figure42).

g015124

Figure42

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.030inches(0.76mm).

G008794

1

2

Figure43

33

Page 34

InstallingtheSparkPlug

Tightenthesparkplug(s)to16ft.-lb(22N-m).

3

2

1

G015200

Figure44

CheckSparkArrester(if

equipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakelooseparticlesoutofthearrester

andcleanscreenwithawirebrush(soakinsolventif

necessary).Reinstallarresteronexhaustoutlet.

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

5.Closethefuelshutoffvalvebehindtheseat(

Figure45).

G008963

12

3

Figure45

1.Fuellter

3.Fuelline

2.Hoseclamp

6.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure45).

7.Removethelterfromthefuellines.

8.Installanewlterandmovethehoseclampscloseto

thelter(Figure45).

9.Openthefuelshutoffvalve.

Note:Itisimportanttoreinstallthefuellinehosesand

securewithplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineawayfrom

componentsthatcouldcausefuellinedamage.

34

Page 35

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankandservices

anycomponentsofthefuelsystem.

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(

Figure46).

4.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure46).

35

Page 36

5.Removethewingnutsecuringthebatteryclamp

(Figure46).

6.Removetheclamp(Figure46).

7.Removethebattery.

g014731

+

-

+

-

+

-

1

2

3

4

Figure46

1.Removethewingnutand

clamp

3.Removethepositive

batterycable

2.Removethenegative

batterycablebeforethe

positive

4.Removebattery

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure46).

2.First,installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Theninstallthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

(

Figure46).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut

(Figure46).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure47).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure47

1.PositiveBatteryPost

3.Red(+)ChargerLead

2.NegativeBatteryPost

4.Black(-)ChargerLead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

1.Thefusesarelocatedonrighthandconsolenextto

theseat(Figure48).

2.Toreplacethefuses,pulloutonthefusetoremoveit.

3.Installanewfuse(

Figure48).

36

Page 37

G017436

Figure48

1.Optionalaccesory-15amp

4.Main-25amp

2.Charge-25amp5.Console

3.PTO-10amp

DriveSystem

Maintenance

CheckingtheSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproperoperation

ofretractorandbuckle.Replacebeforeoperatingifdamaged.

CheckingtheRollover

ProtectionSystem(ROPS)

Knobs

ServiceInterval:Beforeeachuseordaily

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensuretheseatissecuredtothemachine.

Checkthatboththemountinghardwareandtheknobsare

ingoodworkingcondition.Makesuretheknobsarefully

engagedwiththeROPSintheraisedposition.Theupper

hoopoftherollbarmayneedtobepushedforwardorpulled

rearwardtogetbothknobsfullyengaged.

37

Page 38

Figure49

1.ROPSknob(locked

position)

3.Rollbarintheupright

position

2.PullROPSknoboutand

rotate90degreesto

changerollbarposition

4.Rollbarinthefolded

position

AdjustingtheTracking

1.Disengagethebladecontrolswitch(PTO).

2.Drivetoanopenatarea,movethemotioncontrol

leverstotheneutrallockedposition.

3.Movethethrottlemidwaybetweenfastandslow.

4.Movebothmotioncontrolleversallthewayforward

untiltheybothhitthestopsintheT-slot.

5.Checkwhichwaythemachinetracks.

6.Ifittrackstotheright,loosentheboltsandadjust

theleftstopplaterearwardontheleftT-slotuntilthe

machinetracksstraight(

Figure50).

7.Ifittrackstotheleft,loosentheboltsandadjustthe

rightstopplaterearwardontherightT-slotuntilthe

machinetracksstraight(

Figure50).

8.Tightenthestopplate(Figure50).

Figure50

Leftcontrollevershown

1.Controllever3.Stopplate

2.Bolt

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthefrontandreartiresat13psi

(90kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccuratepressure

reading.

Figure51

38

Page 39

AdjustingtheCasterPivot

Bearing

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethedustcapfromcasterandtightenlocknut

(

Figure52).

4.Tightenthelocknutuntilthespringwashersareatand

thenbackoffa1/4turntoproperlysetthepre-loadon

thebearings(Figure52).

Important:Makesurethespringwashersare

installedcorrectlyasshowninFigure52.

5.Installthedustcap(Figure52).

Figure52

1.SpringWashers3.DustCap

2.LockNut

AdjustingtheElectricClutch

ServiceInterval:Every500hours—Checktheelectric

clutch.

Theclutchisadjustabletoensureproperengagementand

properbraking.

1.Inserta0.015–0.021inch(0.381–0.533mm)feeler

gaugethroughoneinspectionslotinthesideofthe

assembly.Makesureitisbetweenthearmatureand

therotorfrictionsurfaces.

Thegapneedstobeatleast.015inches(0.381mm)

andnotmorethan.021inches(0.533mm).

2.Ifadjustmentisneeded,thensetat.015inches(0.381

mm)foreachofthethreeadjustmentslotpositions.

Tightenthelocknutsuntilthereisslightbindingon

thefeelergaugebutitcanbemovedeasilywithinthe

airgap(Figure53).

3.Repeatthisfortheremainingslots.

4.Checkeachslotagainandmakeslightadjustmentsuntil

thefeelergaugebetweentherotorandarmaturewith

veryslightcontactbetweenthem.

Figure53

1.Adjustingnut3.Feelergauge

2.Slot

39

Page 40

CoolingSystem

Maintenance

CleaningtheEngineScreen

ServiceInterval:Beforeeachuseordaily

Beforeeachuseremoveanybuild-upofgrass,dirtor

otherdebrisfromtheenginescreen.Thiswillhelpinsure

adequatecoolingandcorrectenginespeedandwillreduce

thepossibilityofoverheatingandmechanicaldamagetothe

engine(Figure54).

CleaningtheEngineCooling

FinsandShrouds

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)

1.DisengagethePTOandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreen,recoilstarterandfan

housing(Figure54).

4.Cleanthedebrisandgrassfromtheengineparts.

5.Installairintakescreen,recoilstarterandfanhousing

(

Figure54).

Figure54

1.Engineguard4.Fanhousing

2.Engineairintakescreen

5.Screw

3.Bolt

BeltMaintenance

InspectingtheBelts

ServiceInterval:Every50hours

Checkthebeltsforsquealingwhenthebeltisrotating,blades

slippingwhencuttinggrass,frayedbeltedges,burnmarksand

cracksaresignsofawornmowerbelt.Replacethemower

beltifanyoftheseconditionsareevident.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lowerthemowertothe3inch(76mm)heightofcut.

4.Removethebeltcoversandtheboltsattachedtothem

(Figure55).

G012433

1

2

Figure55

1.Loosenthebolt2.Removebeltcover

5.Usearatchetinthesquareholeintheidlerarmto

removetensionontheidlerspring(Figure56).

6.Removethebeltfromthemowerdeckpulleys.

7.Removethebeltguideonthespringloadedidlerarm

showninFigure56.

8.Removetheexistingbelt.

9.Installthenewbeltaroundthemowerpulleysandthe

clutchpulleyundertheengine(

Figure56).

40

Page 41

Figure56

1.Clutchpulley5.Squareholeintheidler

armfortheratchet

2.Mowerbelt6.Idlergreasezerk

3.Springloadedidlerpulley

7.Beltguide

4.Ratchet

10.Installthebeltguideontheidlerarmshownin

Figure56.

11.Usingtheratchetinthesquarehole,installtheidler

spring(Figure56).

Makesurethespringendsareseatedintheanchor

grooves.

12.Installthebeltcovers(

Figure57).

g017496

Figure57

1.Positionthebeltcover3.Installthebolt

2.Slidebeltcoverunderthe

sidecatches

ReplacingtheHydraulicPump

DriveBelt