Page 1

FormNo.3370-939RevA

ZMaster

®

RidingMower

with48in,52inor60inTURBOFORCE

DischargeMower

ModelNo.74941CP—SerialNo.312000001andUp

ModelNo.74943CP—SerialNo.312000001andUp

ModelNo.74945CP—SerialNo.312000001andUp

®

Side

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

Thisrotary-blade,ridinglawnmowerisintendedtobe

1

usedbyresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedToroDealer.

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready.

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Note:ItisaviolationofCaliforniaPublicResource

CodeSection4442touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Y ouareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2011—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SlopeIndicator.....................................................6

SafetyandInstructionalDecals.............................7

ProductOverview......................................................12

Controls.............................................................12

Specications.....................................................13

Operation...................................................................14

AddingFuel.......................................................14

CheckingtheEngineOilLevel............................15

BreakingInaNewMachine................................15

UsingtheRolloverProtectionSystem

(ROPS)..........................................................15

ThinkSafetyFirst...............................................16

OperatingtheParkingBrake...............................17

OperatingtheMowerBladeControlSwitch

(PTO)............................................................17

OperatingtheThrottle.......................................17

OperatingtheChoke..........................................18

OperatingtheIgnitionSwitch.............................18

UsingtheFuelShut-OffValve............................18

StartingandStoppingtheEngine........................19

TheSafetyInterlockSystem................................20

DrivingForwardorBackward.............................21

StoppingtheMachine.........................................22

AdjustingtheHeightofCut................................22

AdjustingtheAnti-ScalpRollers.........................23

PositioningtheFlowBafe.................................24

PositioningtheSeat............................................24

UsingtheDriveWheelReleaseValves.................25

UsingtheSideDischarge....................................26

LoadingMachines..............................................26

TransportingMachines.......................................27

UsingtheZStand®............................................28

OperatingTips...................................................29

Maintenance...............................................................30

RecommendedMaintenanceSchedule(s)................30

Lubrication.............................................................31

GreasingandLubrication...................................31

WheretoGreasetheMower...............................31

EngineMaintenance...............................................32

ServicingtheAirCleaner....................................32

ServicingtheEngineOil.....................................33

ServicingtheSparkPlug.....................................36

CheckSparkArrester(ifequipped)......................37

FuelSystemMaintenance.......................................38

ReplacingtheFuelFilter.....................................38

ServicingtheFuelTank......................................38

ElectricalSystemMaintenance................................39

ServicingtheBattery...........................................39

ServicingtheFuses.............................................41

DriveSystemMaintenance.....................................41

CheckingtheSeatBelt........................................41

CheckingtheRolloverProtectionSystem

(ROPS)Knobs...............................................41

AdjustingtheTracking........................................42

CheckingtheTirePressure.................................42

CheckingtheWheelHubSlottedNut..................43

AdjustingtheCasterPivotBearing......................43

UsingtheClutchShim........................................43

CoolingSystemMaintenance..................................45

CleaningtheEngineScreenandEngineOil

Cooler............................................................45

CleaningtheEngineCoolingFinsand

Shrouds..........................................................45

CheckandCleantheHydraulicUnit

Shrouds..........................................................46

BrakeMaintenance.................................................47

AdjustingtheParkingBrake................................47

BeltMaintenance....................................................48

InspectingtheBelts............................................48

ReplacingtheMowerBelt...................................48

ReplacingtheHydraulicPumpDrive

Belt................................................................49

ControlsSystemMaintenance.................................50

AdjustingtheControlHandlePosition................50

AdjustingtheMotionControlLinkage................50

AdjustingtheMotionControlDamper...............51

AdjustingtheMotionControlNeutralLock

Pivot..............................................................51

HydraulicSystemMaintenance...............................52

ServicingtheHydraulicSystem...........................52

MowerDeckMaintenance......................................54

LevelingtheMowerDeck...................................54

ServicingtheCuttingBlades...............................57

RemovingtheMowerDeck................................59

ReplacingtheGrassDeector.............................60

Cleaning.................................................................61

CleaningUndertheMower.................................61

WasteDisposal...................................................61

Storage.......................................................................61

CleaningandStorage..........................................61

Troubleshooting.........................................................63

Schematics.................................................................65

3

Page 4

Safety

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafetyalertsymbol,whichmeans

CAUTION,WARNING,orDANGER-“personal

safetyinstruction."Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrass

or,whenequippedwithagrassbagger,forcatchingcut

grass.Anyuseforpurposesotherthanthesecould

provedangeroustouserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.4-2004.

Training

–Useonlyanapprovedcontainer

–Neverrefuelordrainthemachineindoors.

–Neverremovegascaporaddfuelwithengine

running.Allowenginetocoolbeforerefueling.

Donotsmoke.

•Checkthatoperator'spresencecontrols,safety

switchesandshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Starttheengineonly

fromtheoperator'sposition.Useseatbeltswiththe

rollbarinthefullyraisedandlockedposition.

•Neverraisemowerwiththebladesrunning.

•ReadtheOperator'sManualandothertraining

material.Iftheoperator(s)ormechanic(s)cannot

readEnglishitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,loose

clothingorjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toysandwire

whichcanbethrownbythemachine.

•NeveroperatewithoutthePTOshield,orother

guardssecurelyinplace.Besureallinterlocksare

attached,adjustedproperly ,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerimplements,disengage

drives,engageparkingbrake,shutoffenginebefore

leavingtheoperator'spositionforanyreason

includingemptyingthecatchersoruncloggingthe

chute.

•Stopequipmentandinspectbladesafterstriking

objectsorifanabnormalvibrationoccurs.Make

necessaryrepairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunits.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

•Slowdownandusecautionwhencrossingroadsand

sidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.

4

Page 5

•Donotoperatethemowerundertheinuenceof

alcoholordrugs.

•Useextremecarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatoperatingonwetgrass,acrosssteep

slopes,ordownhillmaycausethemowertolose

traction.Lossoftractiontothedrivewheelsmay

resultinslidingandalossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Followthemanufacturer'srecommendationsfor

wheelweightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

UsingtheRolloverProtectionSystem

(ROPS)

•Keeptherollbarinthefullyraisedandlocked

positionandusetheseatbeltwhenoperatingthe

machine.

•Becertainthattheseatbeltcanbereleasedquickly

intheeventofanemergency.

•Beawarethereisnorolloverprotectionwhenthe

rollbarisdown.

•Checktheareatobemowedandneverfoldthe

ROPSinareaswherethereareslopes,dropoffsor

water.

•Lowertherollbaronlywhenabsolutelynecessary.

Donotweartheseatbeltwiththerollbarfolded

down.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)beforedriving

underanyobjectsanddonotcontactthem.

Maintenanceandstorage

•Disengagedrives,lowerimplement,setparking

brake,stopengineandremovekeyordisconnect

sparkplugwire.Waitforallmovementtostop

beforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunits,drives,

mufers,andenginetohelppreventres.Cleanup

oilorfuelspillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Shutofffuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkmachineonlevelground.Neverallowuntrained

personneltoservicemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectbatteryorremovesparkplugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Reconnectpositiverst

andnegativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.

Onlyreplacedamagedblades;neverstraightenor

weldthem.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,

awayfromsparkandames.Unplugchargerbefore

connectingordisconnectingfrombattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

5

Page 6

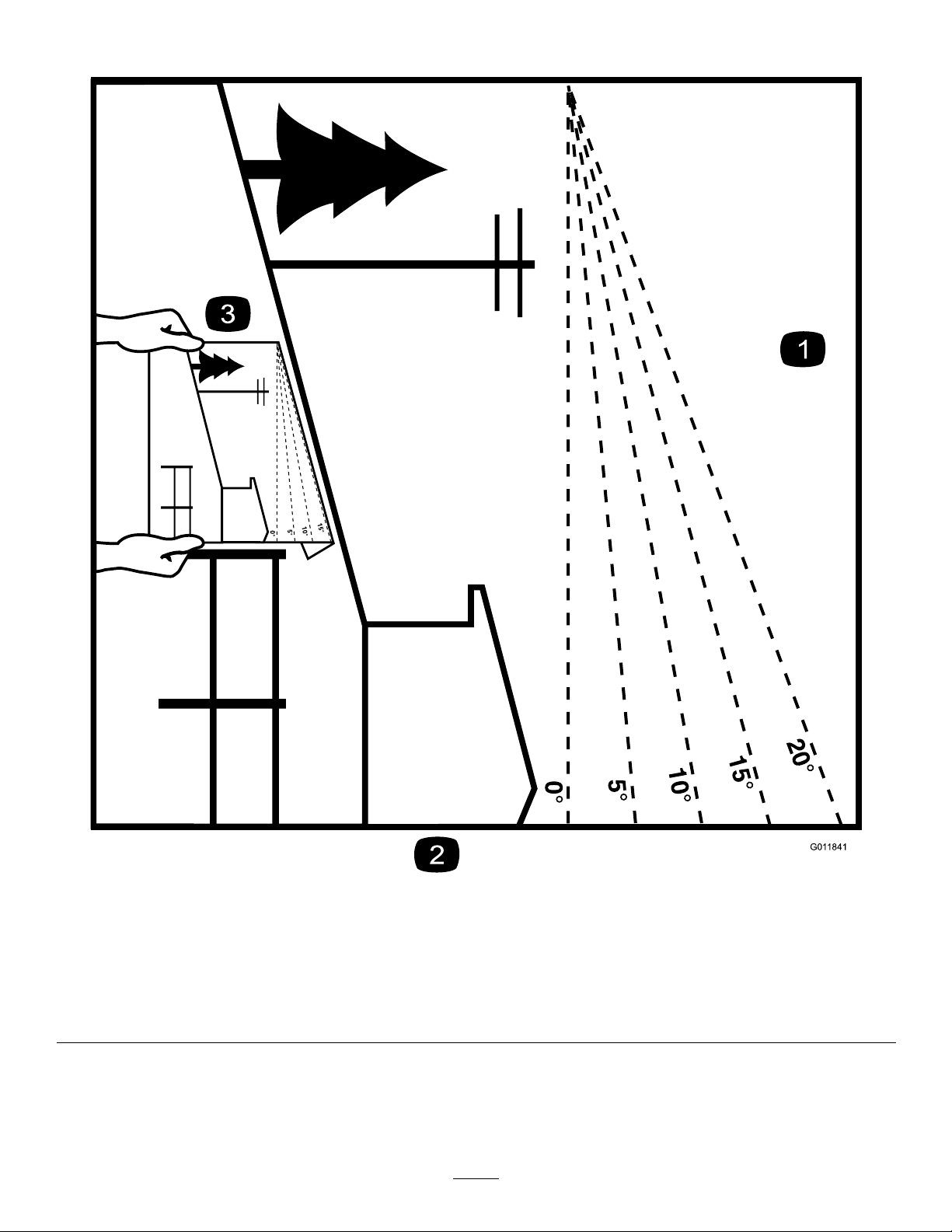

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

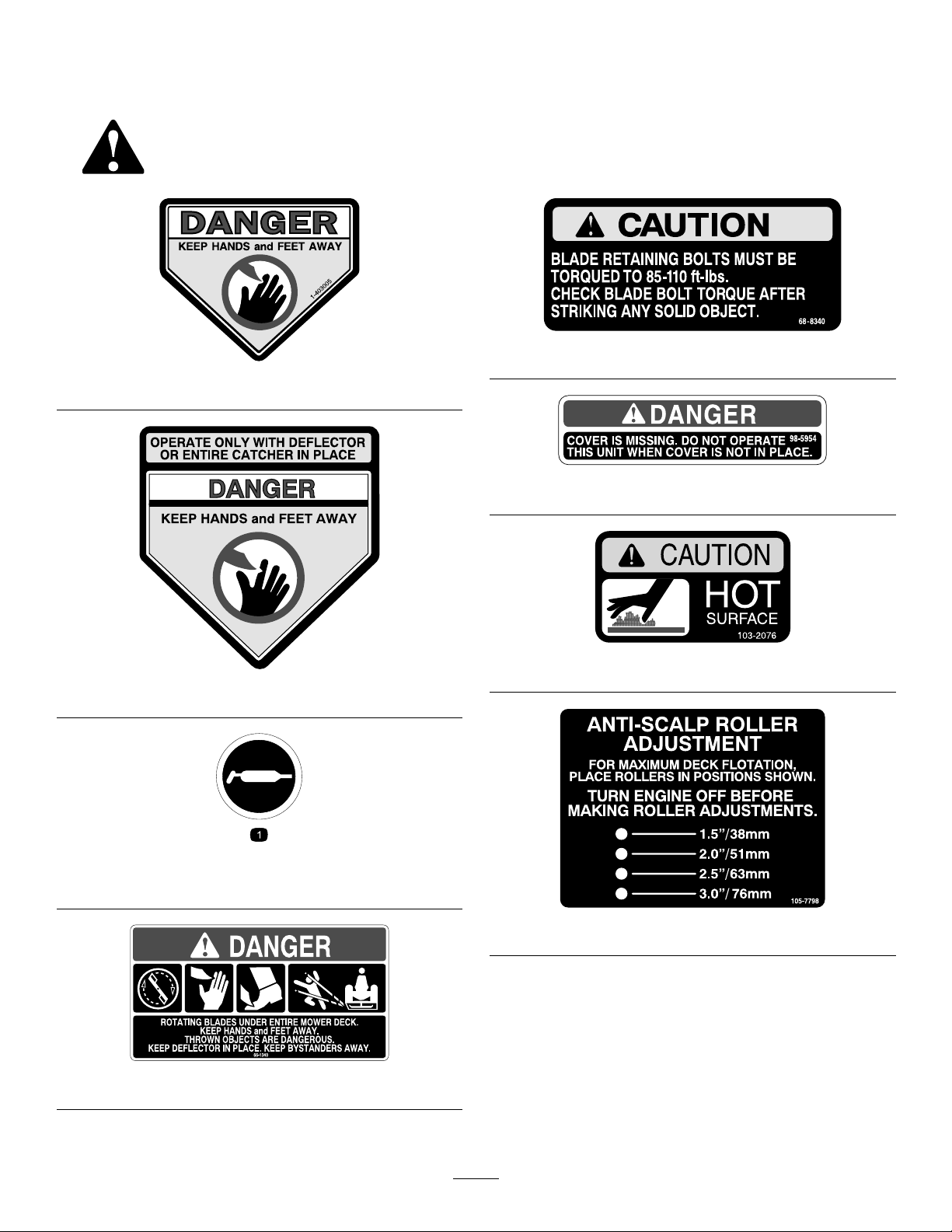

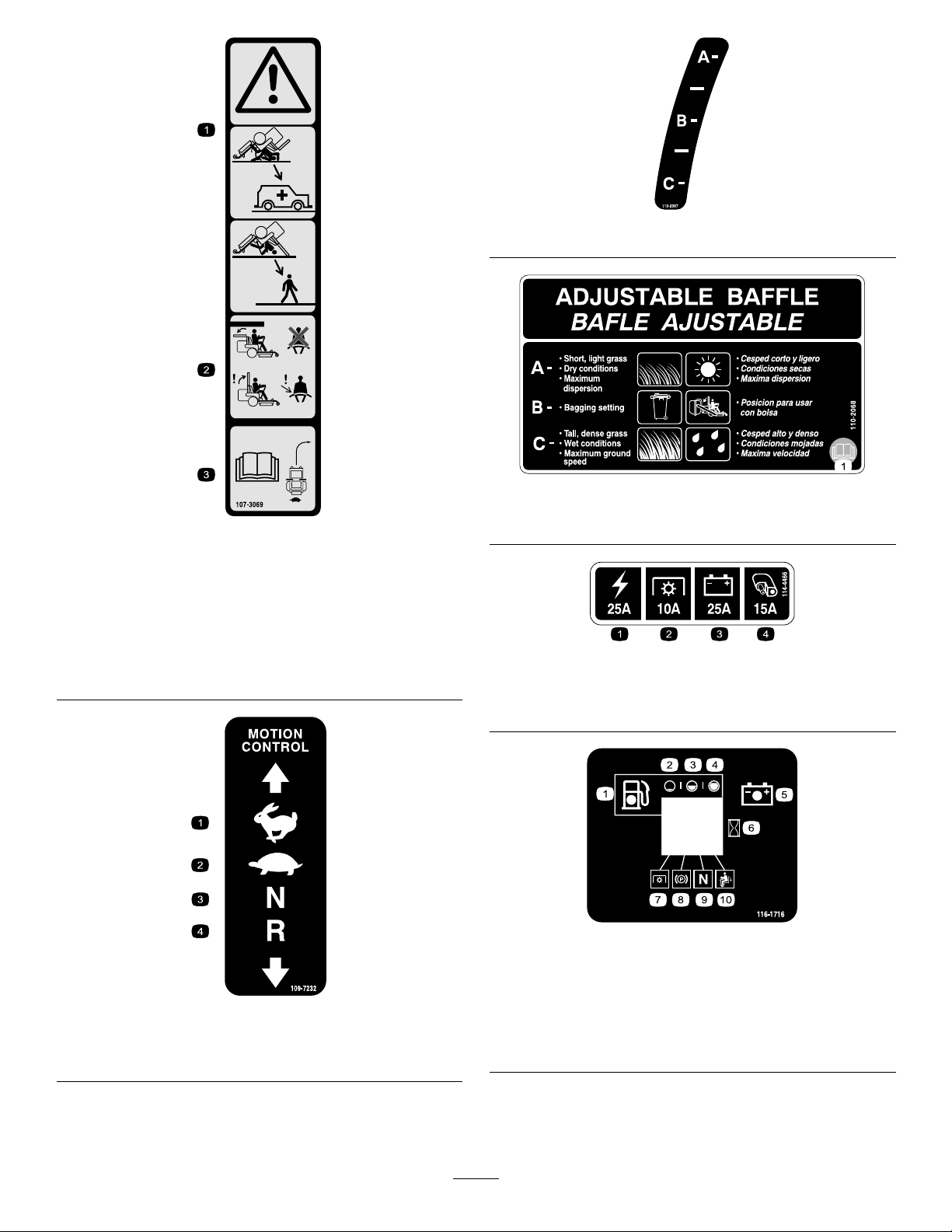

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

68-8340

1-403005

98-5954

103–2076

54-9220

58-6520

1.Grease

105-7798

66-1340

7

Page 8

110-2067

110-2068

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarinthefullyraisedandlockedpositionandwear

theseatbelt.Lowertherollbaronlywhenabsolutely

necessary;donotwearthetheseatbeltwhentherollbaris

down.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

109-7232

1.Fast3.Neutral

2.Slow

4.Reverse

1.ReadtheOperator'sManual.

114-4466

1.Main,25A

2.PTO,10A

3.Charge,25A

4.Auxiliary,15A

116-1716

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

7.PTO

8.Parkingbrake

10.Operatorpresenceswitch

8

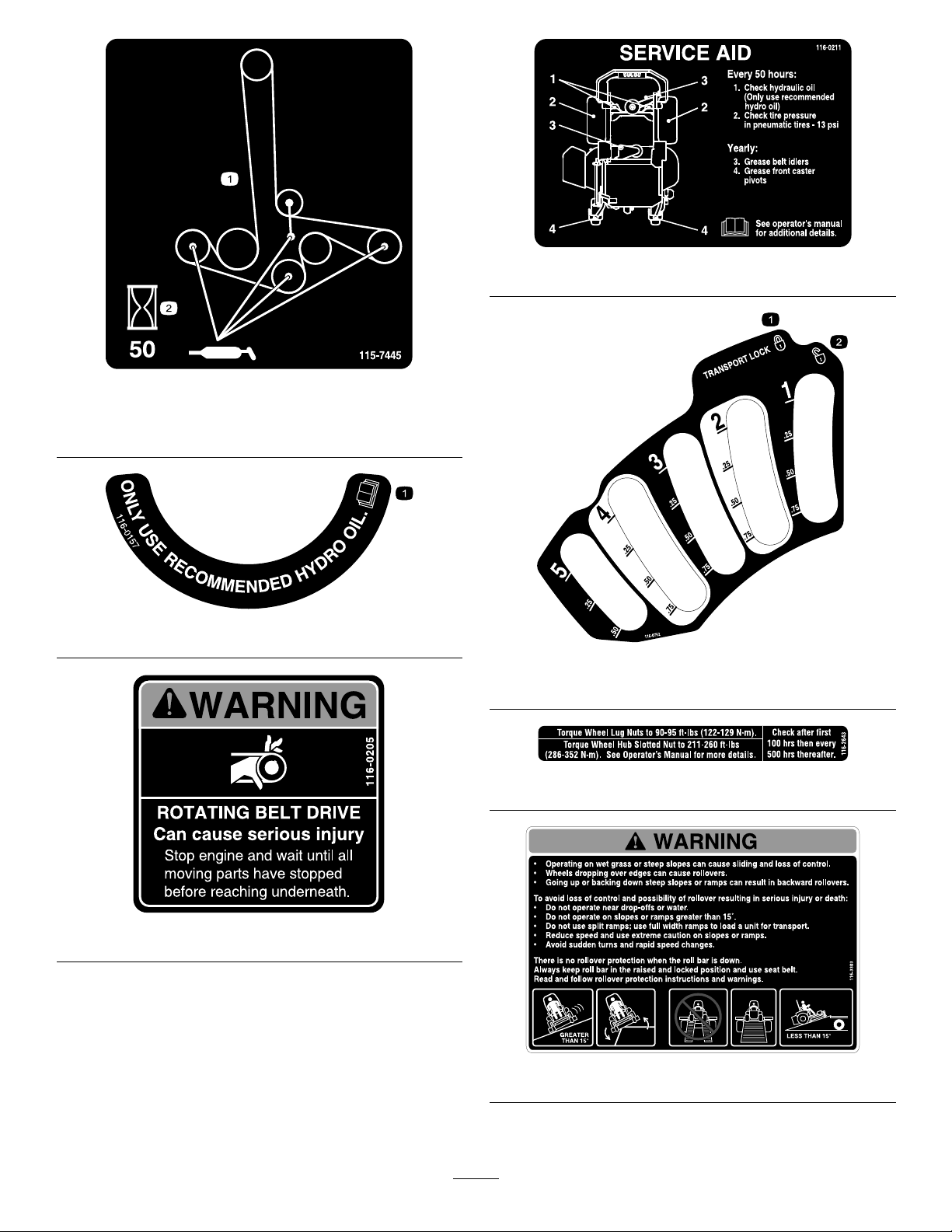

Page 9

1.Greasepulleys

2.Maintenanceinterval—50

116-0211

115-7445

116-0157

116-0752

1.Locked2.Unlocked

116-2643

116-0205

116-3303

9

Page 10

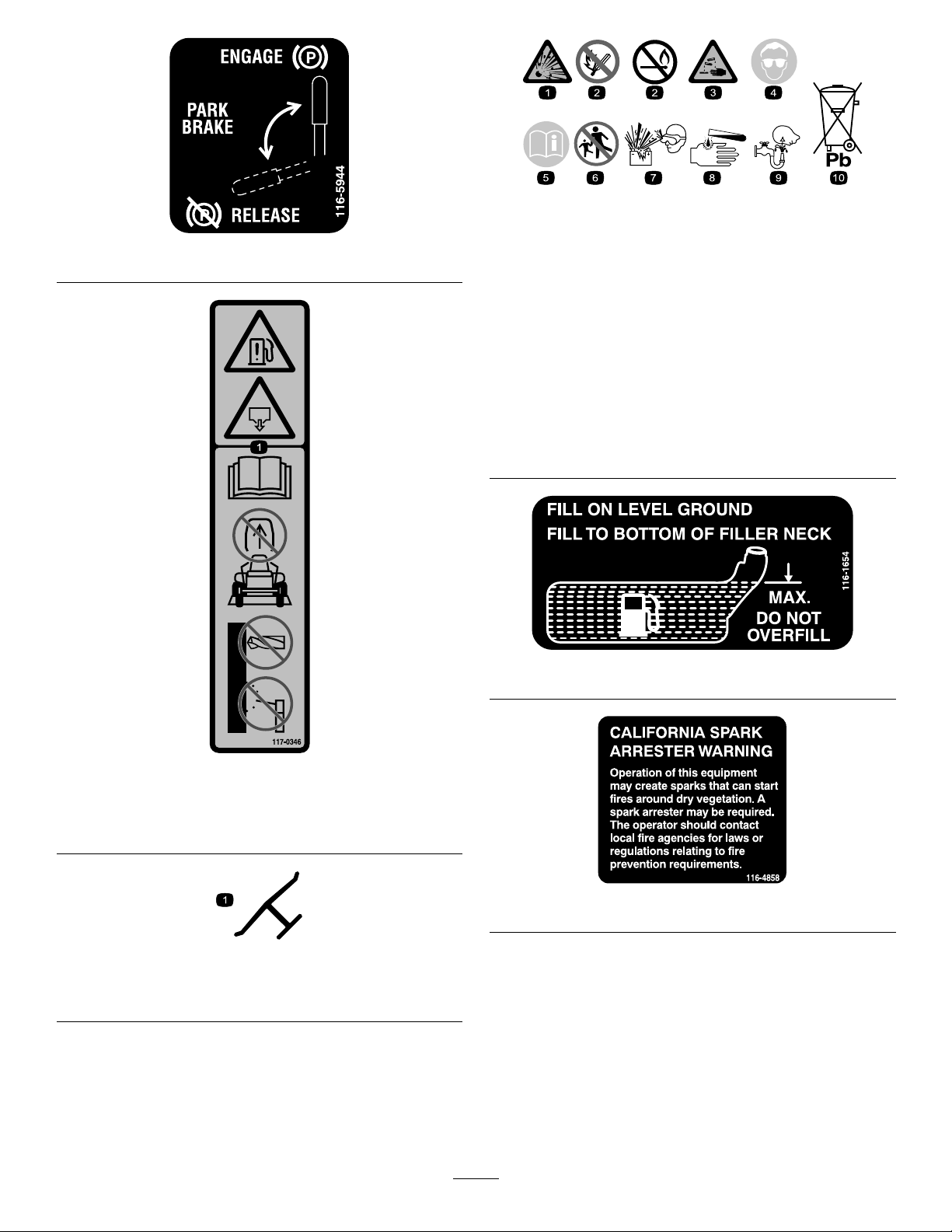

BatterySymbols

Someorallofthesesymbolsareonyourbattery

116-5944

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery .

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

116-1654

117-0346

1.Fuelleakhazard—readtheOperator'sManual;donot

attempttoremovetherollbar;donotweld,drillormodify

therollbarinanyway .

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

116-4858

10

Page 11

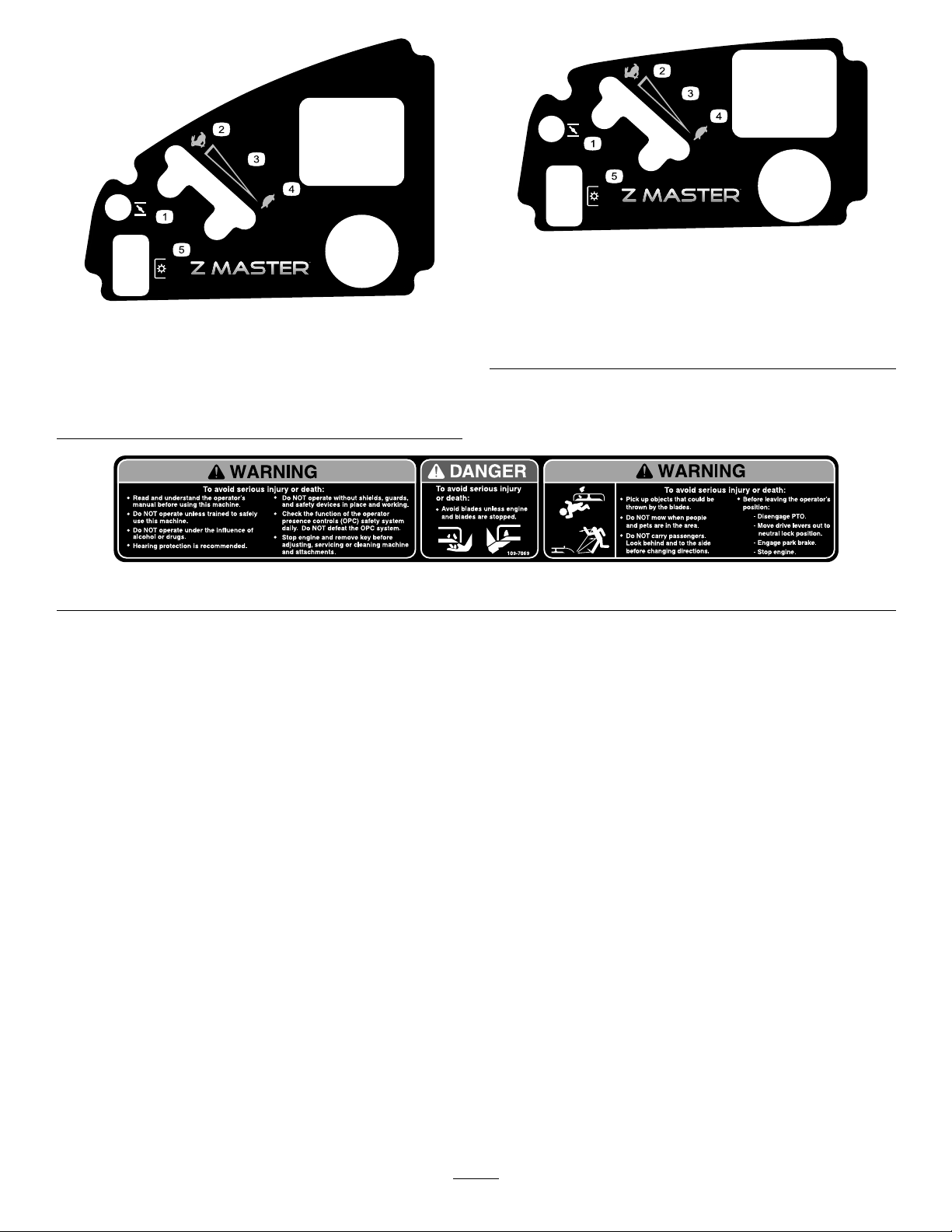

120-5897

1.Choke4.Slow

2.Fast

3.Continuousvariable

setting

5.Powertake-off(PTO),

Bladecontrolswitch

120-5898

1.Choke4.Slow

2.Fast

3.Continuousvariable

setting

5.Powertake-off(PTO),

Bladecontrolswitch

109-7069

11

Page 12

ProductOverview

25

25

10

15

G008951

1

2

3

4

5

6

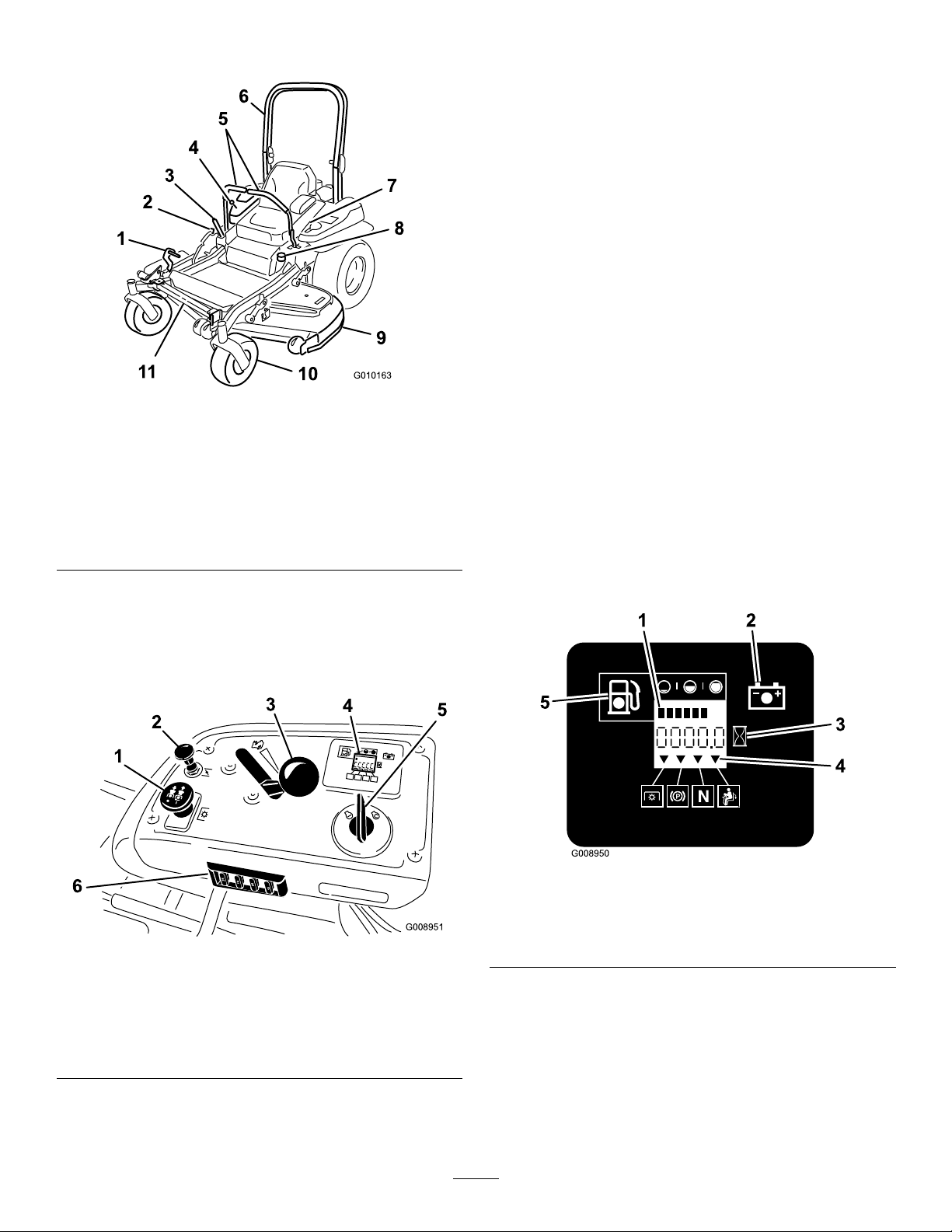

Figure4

1.Height-of-cutdecklift

pedal

2.Transportlock8.Fuelcap

3.Parkingbrakelever9.Mowerdeck

4.Controls10.Casterwheel

5.Motioncontrollevers

6.Rollbar

7.Seatbelt

11.ZStand®

HourMeter

Thehourmeterrecordsthenumberofhourstheengine

hasoperated.Itoperateswhentheengineisrunning.

Usethesetimesforschedulingregularmaintenance

(Figure6).

FuelGauge

Thefuelgaugeislocatedwiththehourmeterandthe

barslightupwhentheignitionswitchison(Figure6).

Theindicatorlightappearswhenthefuellevelislow

(approximatelyonegallonremaininginthefueltank).

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandtheindicate

withablacktrianglethattheinterlockcomponentisin

thecorrectposition(Figure6).

BatteryIndicatorLight

IftheignitionkeyisturnedtotheOnpositionforafew

seconds,thebatteryvoltagewillbedisplayedinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturned

onandwhenthechargeisbelowthecorrectoperating

level(Figure6).

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

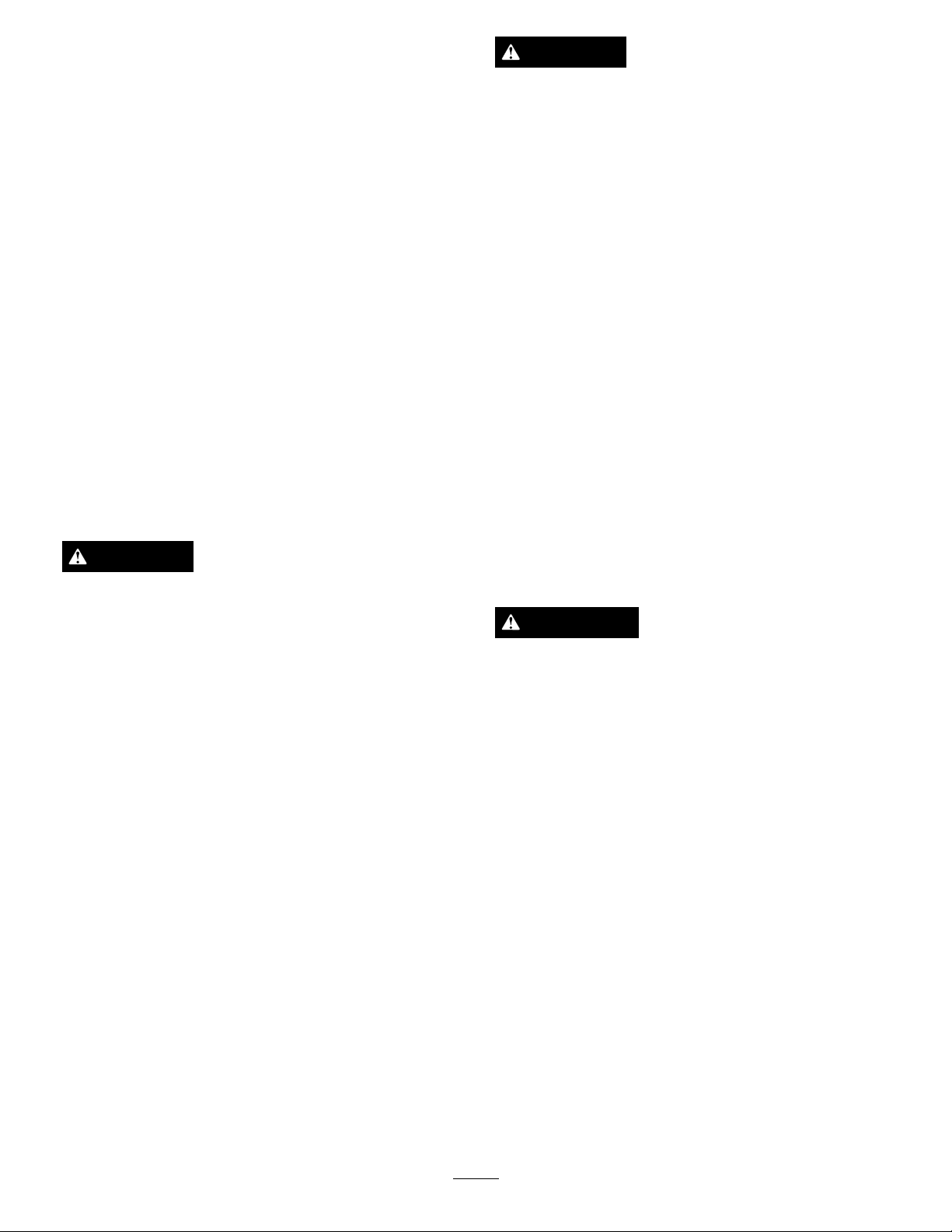

Figure5

1.PTOSwitch4.Hourmeter/Safety

2.Choke

3.Throttlecontrol6.Fuses

5.Ignitionswitch

interlockdisplay/Fuel

gauge

Figure6

1.Fuelgauge(bars)4.Safetyinterlocksymbols

2.Batterylight

3.Hourmeter

5.Lowfuelindicatorlight

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.

12

Page 13

BladeControlSwitch(PTO)

Specications

Thebladecontrolswitch(PTO)isusedtoengagethe

electricclutchanddrivethemowerblades.Pullthe

switchuptoengagethebladesandrelease.Todisengage

theblades,pushthebladecontrolswitch(PTO)down

ormoveamotioncontrolleverintotheneutrallock

position.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

threepositions:Start,RunandOff.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemtoengageandtodetermineneutralposition.

FuelShut-offValve

Closethefuelshut-offvalve(undertheseat)when

transportingorstoringthemower.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width:

48inchDeck52inchDeck

WithoutDeck

DeectorUp54inches(137.2

DeectorDown63.6inches(161.4

WithoutDeck

DeectorUp61.7inches(156.8

DeectorDown75.7inches(192.2

45.7inches(116.1

cm)

cm)

cm)

60inchDeck

53.0inches(134.6

cm)

cm)

cm)

45.7inches(116.1

cm)

57.5inches(146.0

cm)

67.6inches(171.8

cm)

Length:

48inchDeck52inchDeck

RollBar-Up

RollBar-Down

79.2inches(201.2

cm)

80.9inches(205.5

cm)

79.2inches(201.2

cm)

80.9inches(205.5

cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesareavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.Toro.comforalistofallapprovedattachments

andaccessories.

60inchDeck

RollBar-Up

RollBar-Down

83.1inches(211.1

cm)

84.8inches(215.4

cm)

Height:

RollBar-UpRollBar-Down

70.5inches(179.1cm)46.8inches(1 18.9cm)

Weight:

ModelWeight

74941CP1147lb(520kg)

74943CP1147lb(520kg)

74945CP1255lb(569kg)

13

Page 14

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleaded

gasolinewithanoctaneratingof87orhigher

((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemay

resultwhichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizeris

used.

•DoNotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerandrefuel

theequipmentwithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporscancauseserious

injuryandillness.

•Avoidprolongedbreathingofvapors.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystem

inplaceandinproperworkingcondition.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditioner

tothegas.

14

Page 15

Note:Afuelstabilizer/conditionerismosteffective

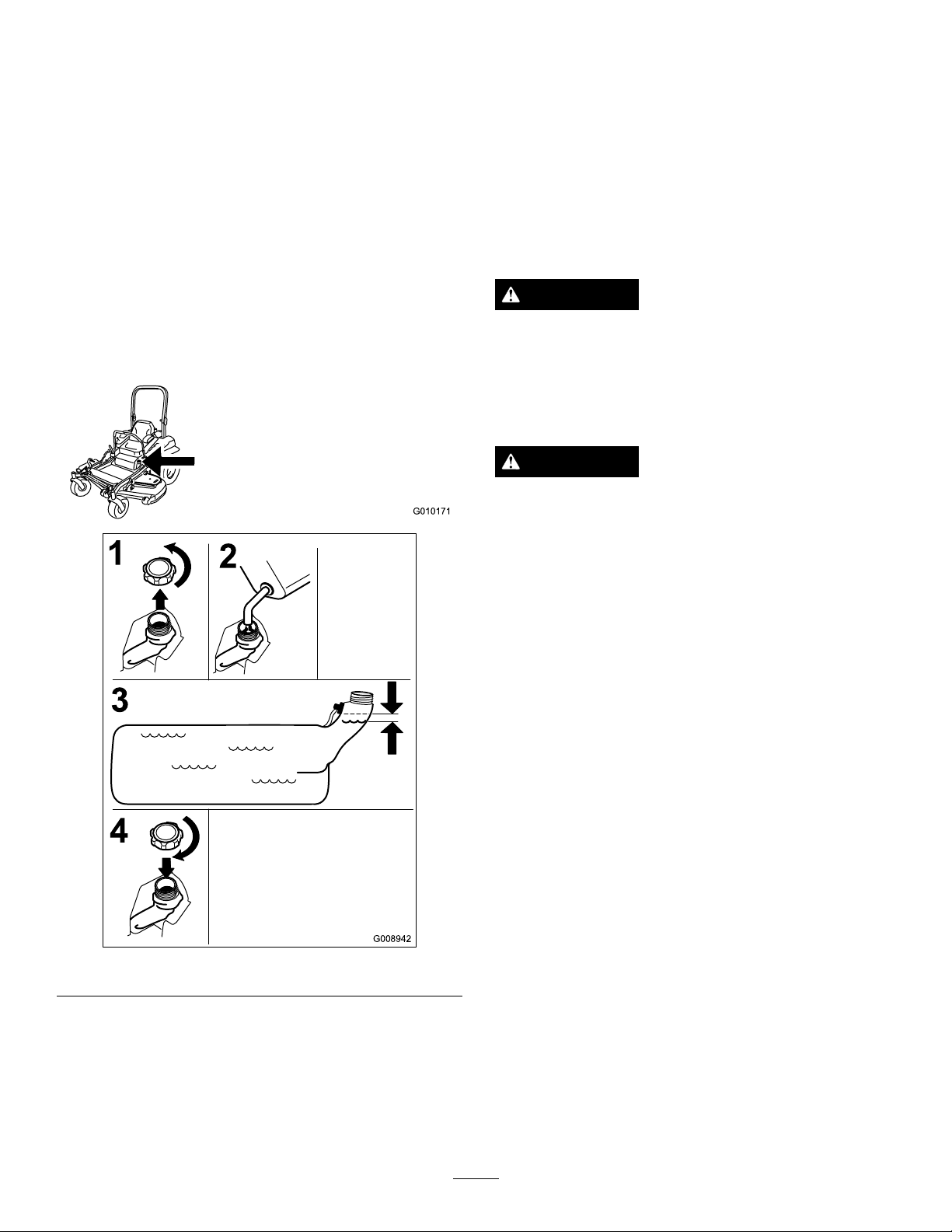

G008942

1

2

4

3

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull,thiswill

allowgasolinetoexpand.Allowa1/4to1/2inch(6

mmto13mm)spacebelowthebreathervalvelocated

onthellerneck.

1.Shuttheengineoffandsettheparkingbrake.

2.Cleanaroundthefueltankcap.

3.Fillthefueltank.Ensurethereisspacebelowthe

breathervalveasshownin

Figure7.

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhennew ,

placingadditionalloadontheengine.Allow40to50

hoursofbreak-intimefornewmachinestodevelopfull

powerandbestperformance.

UsingtheRolloverProtection

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keepthe

rollbarinthefullyraisedlockedpositionanduse

theseatbelt.

Ensuretheseatissecuredtothemachine.

WARNING

Thereisnorolloverprotectionwhentherollbar

isinthedownposition.

Figure7

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhen

absolutelynecessary.

Important:Ensuretheseatissecuredtothe

machine.

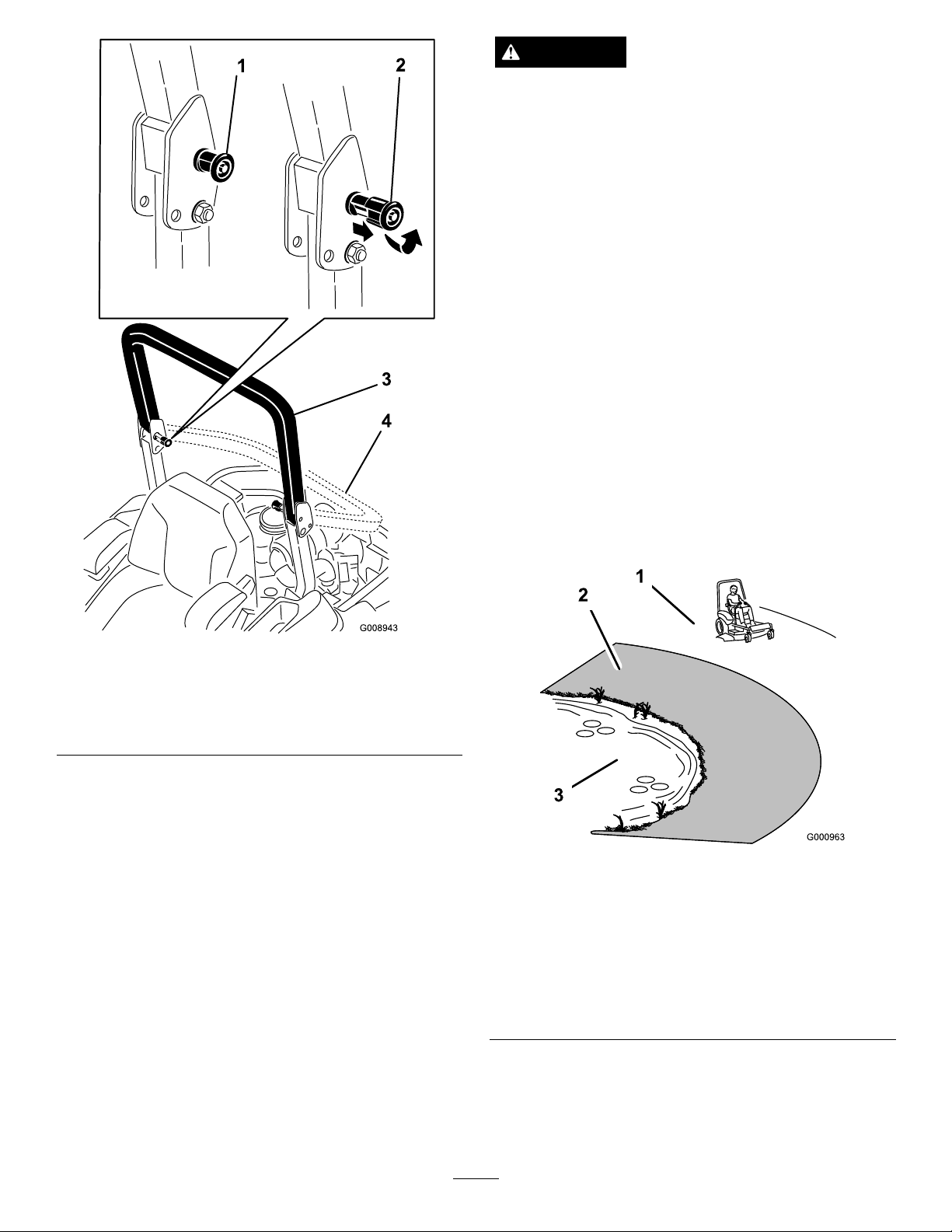

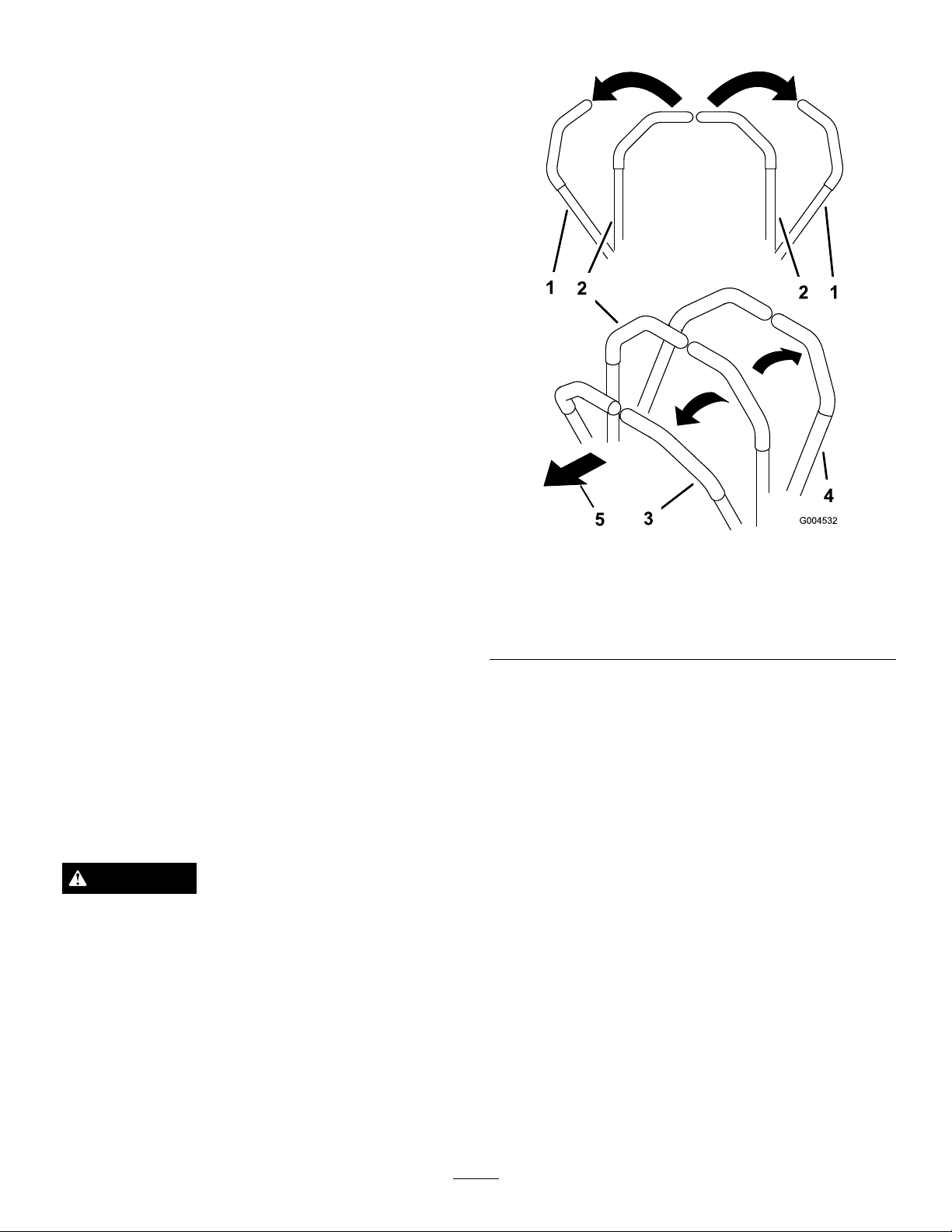

1.Tolowertherollbar,applyforwardpressuretothe

upperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sotheyare

notengaged(Figure8).

3.Lowertherollbartothedownposition(Figure8).

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoChecking

theEngineOilLevel.

15

Page 16

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbar

isdown.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan

15degrees.

•Reducespeedanduseextremecautionon

slopes.

Figure8

1.ROPSknob

2.PullROPSknoboutand

rotate90degrees

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

4.Toraisetherollbar,raisetherollbartotheoperate

position,rotatetheknobssotheymovepartially

intothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswillsnap

intopositionwhentheholesalignwiththepins

Figure8).Pushontherollbarandensurethat

(

bothpinsareengaged.

Important:Alwaysusetheseatbeltwiththe

rollbarinthefullyraisedposition.

•Avoidsuddenturnsorrapidspeedchanges.

Figure9

1.SafeZone-usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

2.DangerZone-useawalk

behindmowerand/ora

handtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

16

Page 17

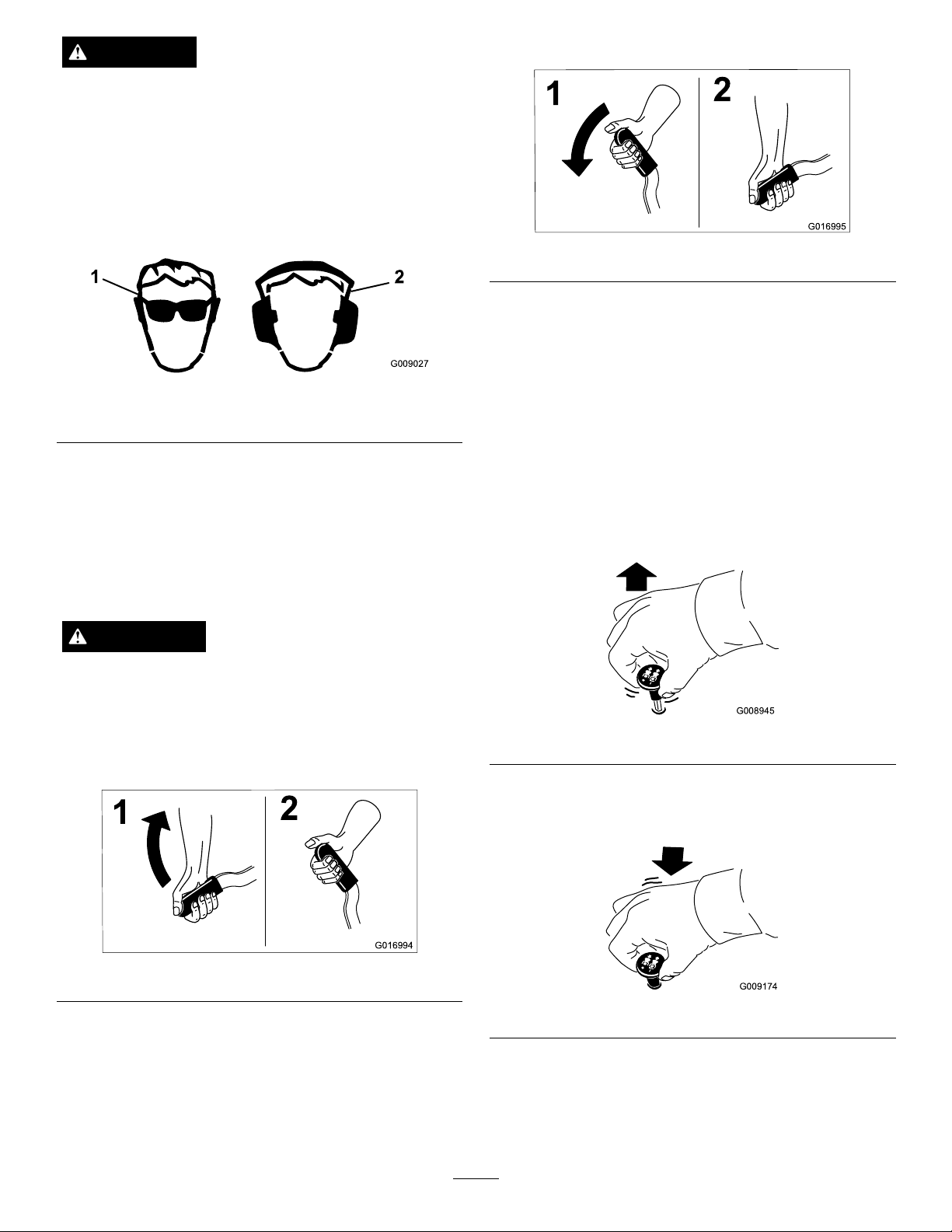

CAUTION

G009027

1

2

G016994

1

2

G016995

1

2

G008945

G009174

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feetand

headisrecommended.

ReleasingtheParkingBrake

Figure12

OperatingtheMowerBlade

ControlSwitch(PTO)

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

WARNING

Parkingbrakemaynotholdmachineparkedona

slopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlesswheelsarechocked

orblocked

Thebladecontrolswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Note:Engagingthebladecontrolswitch(PTO)with

thethrottlepositionathalforlesswillcauseexcessive

weartothedrivebelts.

Figure13

DisengagingtheBladeControlSwitch

(PTO)

Figure11

Figure14

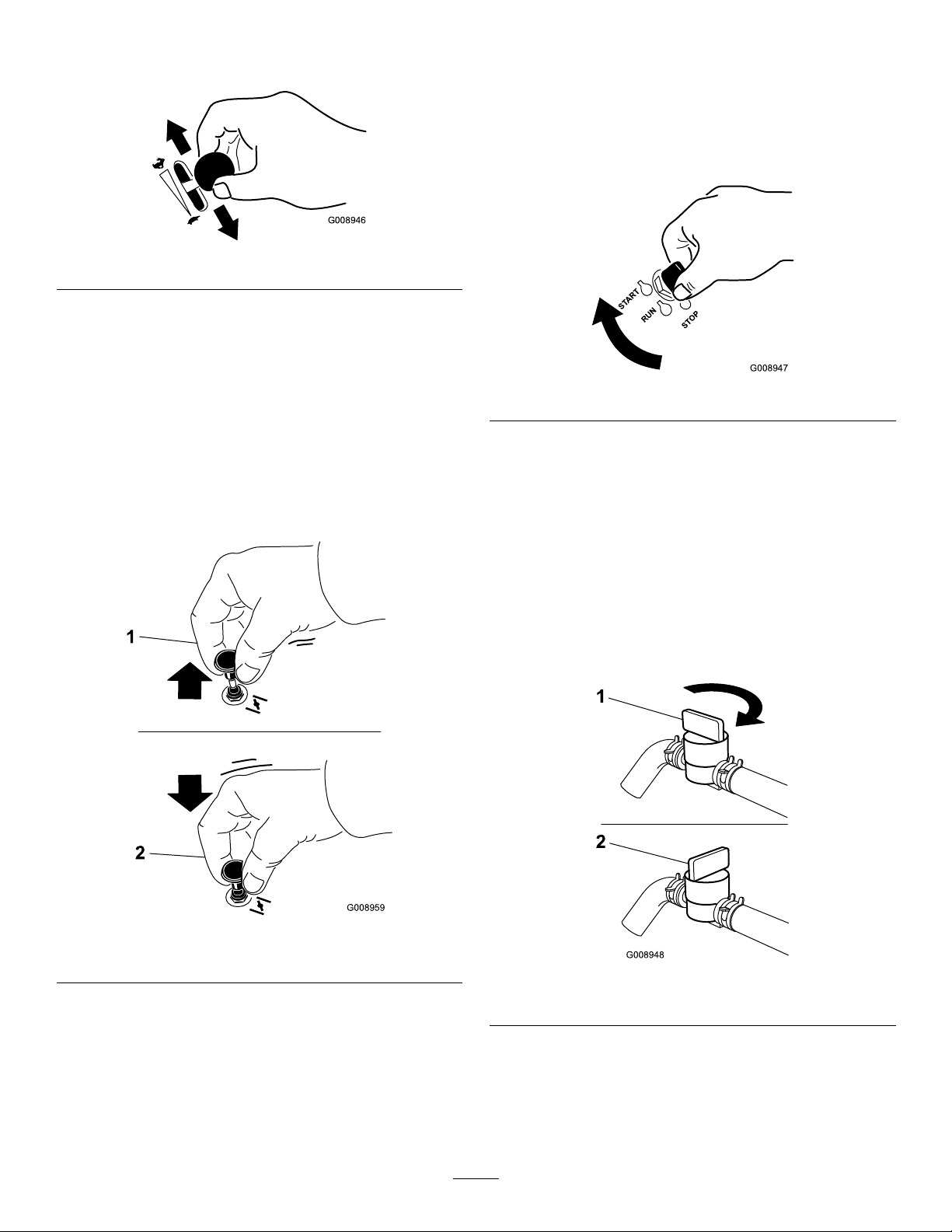

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastand

Slowpositions(Figure15).

17

Page 18

Alwaysusethefastpositionwhenturningonthe

G008946

G008959

1

2

START

RUN

STOP

G008947

G008948

1

2

mowerdeckwiththebladecontrolswitch(PTO).

Figure15

OperatingtheChoke

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely .

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pulluponthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure16).

3.Pushdownonthechoketodisengagethechoke

aftertheenginehasstarted(Figure16).

Figure17

2.Turntheignitionkeytostoptostoptheengine.

UsingtheFuelShut-OffValve

Thefuelshut-offvalveislocatedundertheseat.Move

theseatforwardtoaccessit.

Closethefuelshut-offvalvefortransport,maintenance,

andstorage.

Ensurethefuelshut-offvalveisopenwhenstarting

theengine.

Figure16

1.On2.Off

Figure18

1.On2.Off

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition

(Figure17).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

18

Page 19

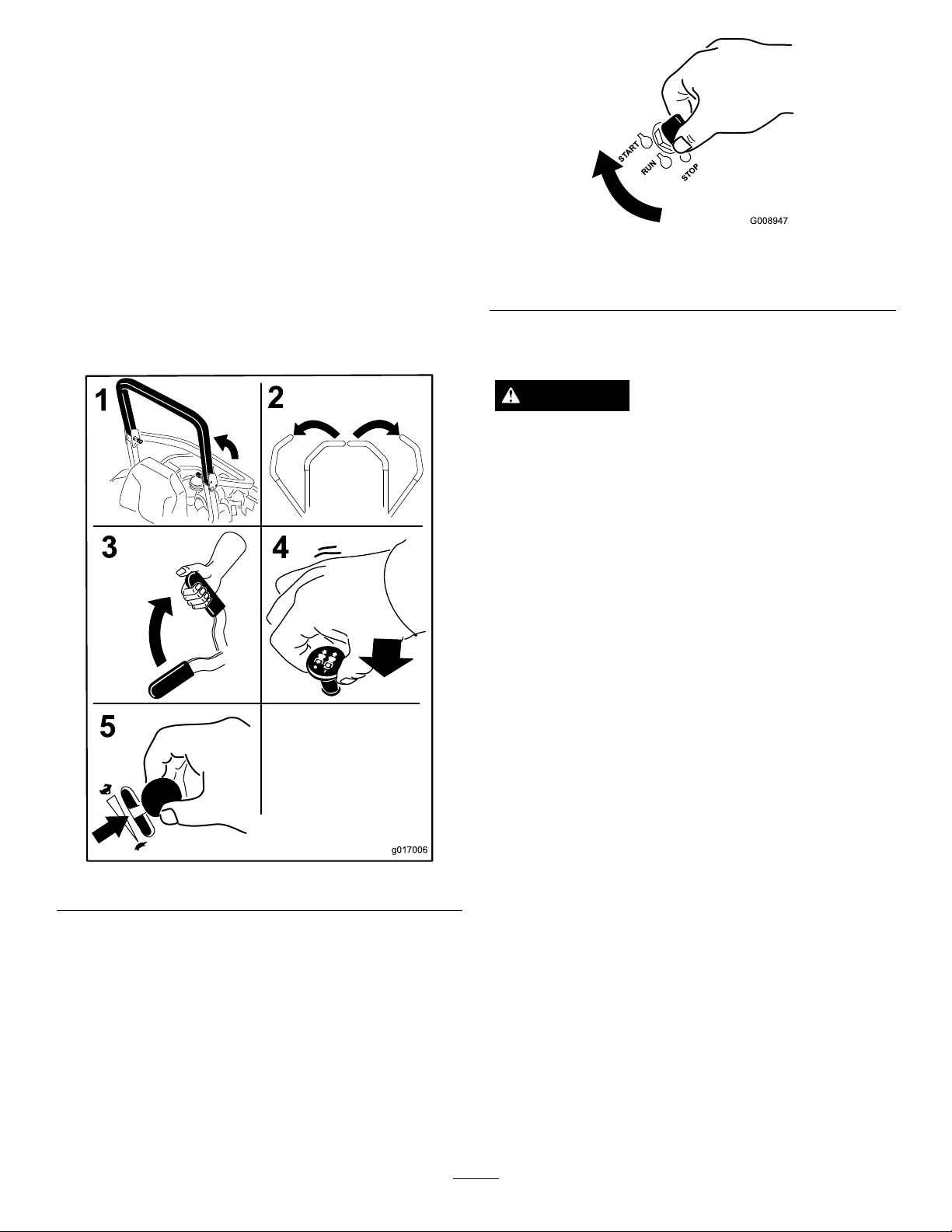

StartingandStoppingthe

g017006

START

RUN

STOP

G008947

Engine

StartingtheEngine

1.RaisetheROPSupandlockintoplace,sitonthe

seatandfastentheseatbelt.

2.Movethemotioncontrolstoneutrallocked

position.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.Movethebladecontrolswitch(PTO)totheOff

position(

5.MovethethrottlelevermidwaybetweentheSlow

andFastpositions.

Figure19).

Figure20

1.Off3.Start

2.Run

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure19

6.TurntheignitionkeytotheStartposition

(Figure17).Whentheenginesstarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostartallowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Lettheengineidleatslowthrottle(turtle)for60

secondsbeforeturningtheignitionswitchoff.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthe

fuelsystemhasbeenwithoutfuelcompletely .

19

Page 20

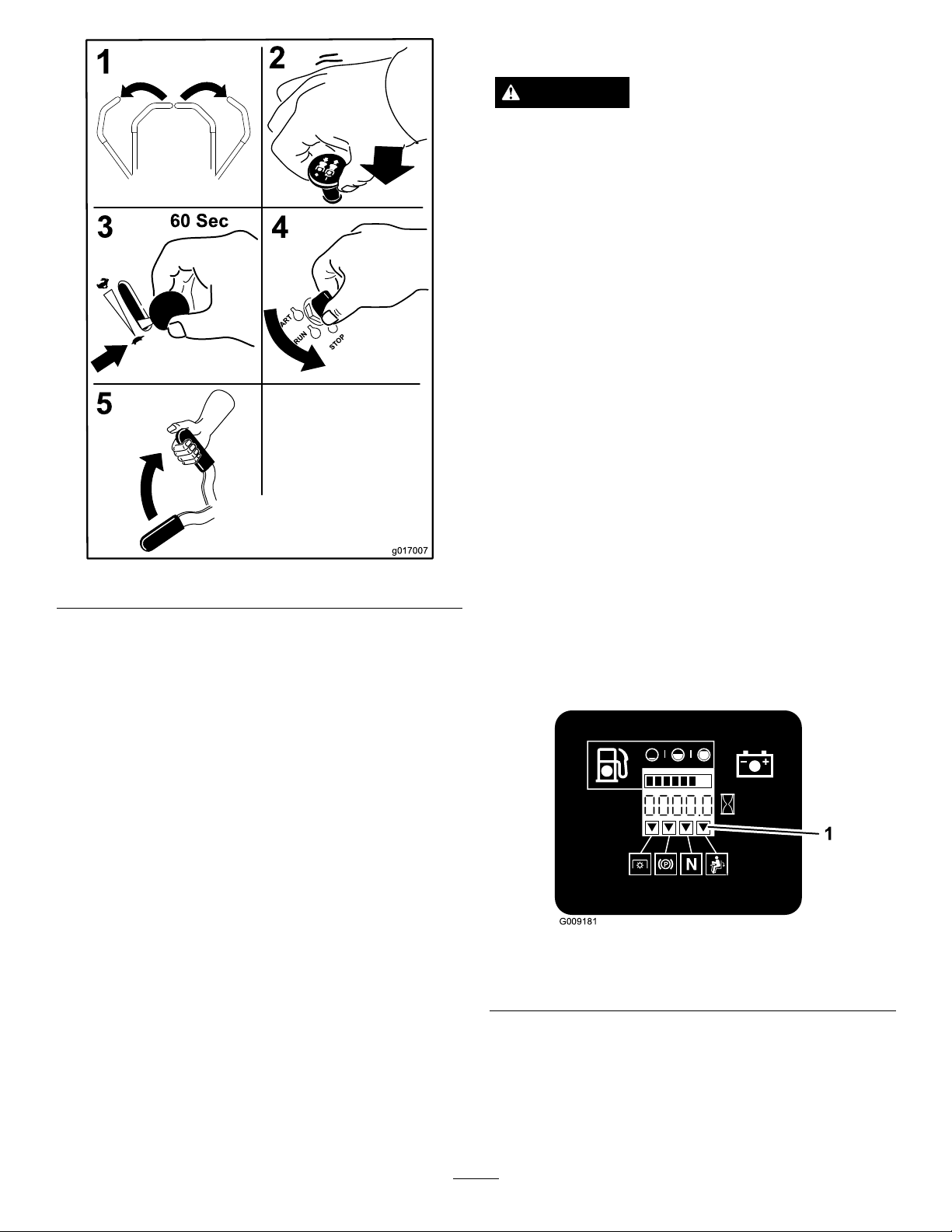

g017007

TheSafetyInterlockSystem

G009181

1

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Youaresittingontheseat.

•Theparkingbrakeisengaged.

•Thebladecontrolswitch(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

Figure21

Important:Makesurethatthefuelshutoffvalveis

closedbeforetransportingorstoringthemachine,

asfuelleakagemayoccur.Settheparkingbrake

beforetransporting.Makesuretoremovethekey

asthefuelpumpmayrunandcausethebattery

tolosecharge.

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthe

lockedpositionwiththeparkingbrakeengagedorif

yourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.When

thecomponentisinthecorrectposition,atrianglewill

lightupinthecorrespondingsquare.

Figure22

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

20

Page 21

operateasdescribedbelow ,haveanAuthorizedService

Dealerrepairthesafetysystemimmediately.

1.Sittingontheseat,engagetheparkingbrakeand

movethebladecontrolswitch(PTO)toon.Try

startingtheengine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeand

movethebladecontrolswitch(PTO)tooff.Move

eithermotioncontrollever(outofneutrallocked

position).Trystartingtheengine;theengineshould

notcrank.Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,move

thebladecontrolswitch(PTO)tooffandmove

themotioncontrolleverstoneutrallockposition.

Nowstarttheengine.Whiletheengineisrunning,

releasetheparkingbrake,engagethebladecontrol

switch(PTO)andriseslightlyfromtheseat;the

engineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,move

thebladecontrolswitch(PTO)tooffandmove

themotioncontrolleverstoneutrallockposition.

Nowstarttheengine.Whiletheengineisrunning,

centereithermotioncontrolandmove(forwardor

reverse);theengineshouldstop.Repeatforother

motioncontrol.

5.Sittingontheseat,disengagetheparkingbrake,

movethebladecontrolswitch(PTO)tooffand

movethemotioncontrolleverstoneutrallock

position.Trystartingtheengine;theengineshould

notcrank.

UsingtheMotionControlLevers

Figure23

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolinthefastpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

DrivingForward

Note:Theenginewillkillifthetractioncontrollevers

aremovedwiththeparkingbrakeengaged.

Tostop,pullthemotioncontrolleverstotheneutral

position.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrol

leversforward(

Figure24).

21

Page 22

G008952

G008953

StoppingtheMachine

Tostopthemachine,movethetractioncontrollevers

toneutralandmovetolockedposition,disengagethe

powertakeoff(bladecontrolswitch(PTO),andturn

theignitionkeytooff.

Settheparkingbrakewhenyouleavethemachine;refer

toSettingtheParkingBrakeinOperation.Remember

toremovethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethetractorwhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Figure24

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure25).

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhastwopositionsandisusedwith

thedeckliftpedal.Thereisalockpositionandaunlock

positionforthetransportposition.Thetransportlock

isusedwiththedeckliftpedal.Referto

Figure26

Figure25

22

Page 23

AdjustingtheHeight-of-CutPin

1

3

2

G017027

Theheight-of-cutisadjustedfrom1to5-1/2inches

(25to140mm)in1/4inch(6mm)incrementsby

relocatingtheclevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeckliftpedalwithyourfootandraise

themowerdecktothetransportposition(also

the5-1/2inch(140mm)cuttingheightposition)

Figure27).

(

3.Toadjust,rotatethepin90degreesandremovethe

pinfromtheheight-of-cutbracket(

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesiredand,

insertthepin(Figure27).

5.Pushonthedecklift,pullbackonthetransport

lock,andslowlylowerthemowerdeck.

Figure27).

Figure26

TransportLockPositions

1.Transportlock3.Unlockposition—doesnot

lockthemowerdeckinto

transportposition

2.Lockposition—mower

deckwilllockintotransport

position

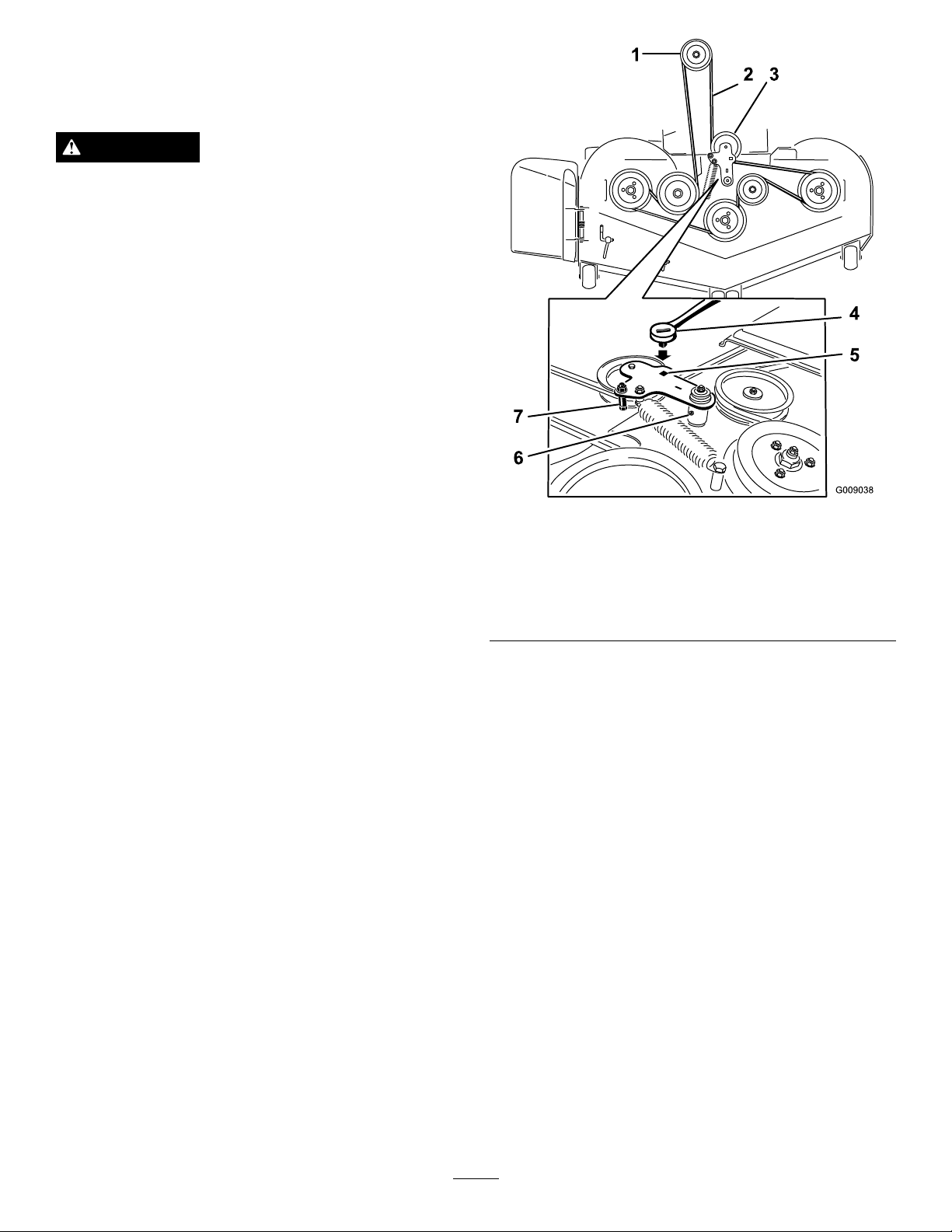

Figure27

1.Deckliftpedal

2.Cutofheightpin

3.Transportlock

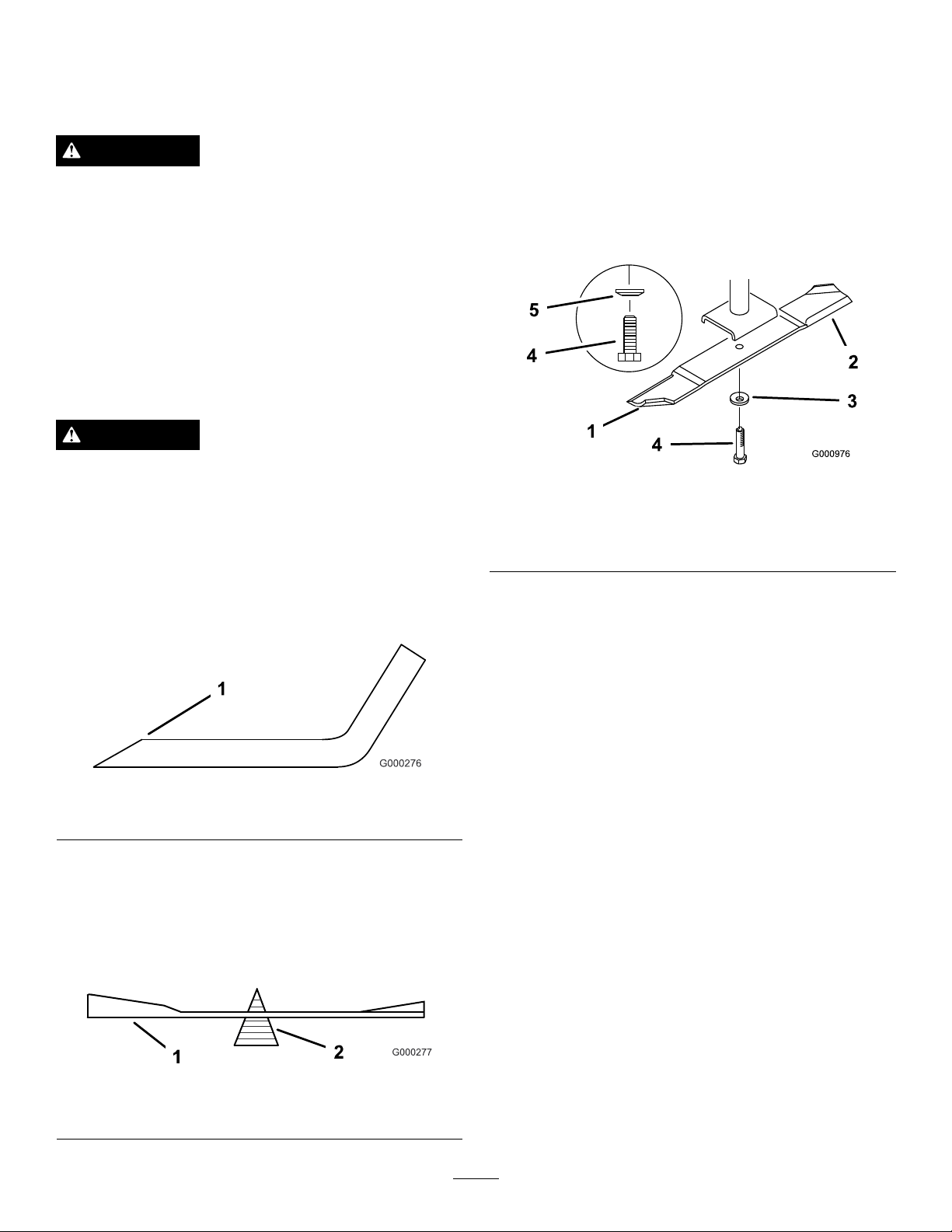

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,itis

recommendedtoadjusttheheightoftheanti-scalp

rollers.

23

Page 24

1.Disengagethebladecontrolswitch(PTO),move

themotioncontrolleverstotheneutrallocked

positionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure28

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

5.Bolt

Figure30

1.Anti-scalproller4.FlangeNut

2.Spacer

3.Bushing

5.Bolt

PositioningtheFlowBafe

Theowbafeisadjustablebylooseningthenutson

topofthemowerdeck.Adjustmentswillvarybygrass

type,moisturecontent,andheightofgrass.Always

alignthebafewiththebloweropeningwhenabagger

isinstalled.

Figure29

1.Anti-scalproller3.FlangeNut

2.Bushing4.Bolt

Figure31

1.Nutsforpositioningtheowbafe

PositioningtheSeat

ChangingtheSeatPosition

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

24

Page 25

1.Toadjust,movetheleversidewaystounlockseat

(Figure32).

2.Slidetheseattothedesiredpositionandrelease

levertolockinposition.

ChangingtheSeatSuspension

Theseatcanbeadjustedtoprovideasmoothand

comfortableride.Positiontheseatwhereyouaremost

comfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(

Figure32).

AdjustingtheArmrestPosition

Thearmrestscanbeadjustedtoprovideasmoothand

comfortableride.Positionthearmrestswhereyouare

mostcomfortable.

Toadjustit,liftthearmrestsandturntheknobineither

directiontoprovidethebestcomfort(

Figure32).

ChangingtheBackPosition

Thebackoftheseatcanbeadjustedtoprovidea

comfortableride.Positionthebackoftheseatwhereit

ismostcomfortable.

Toadjustit,turntheknob,undertheright-sidearm

rest,ineitherdirectiontoprovidethebestcomfort

(Figure32).

Figure32

1.Backrestknob3.Right-sidearmrest

2.Seatpositionadjustment

lever

4.Armrestadjustmentknob

UsingtheDriveWheelRelease

Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey,andallowall

movingpartstostopbeforeaccessingthedrive

wheelreleasevalves.

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.T ouchingahotengineorhydraulicdrive

unitscancausesevereburns.

Allowtheengineandhydraulicdriveunitstocool

completelybeforeaccessingthedrivewheelrelease

valves.

25

Page 26

Thedrivewheelreleasevalvesarelocatedinthebackof

eachhydraulicdriveunit,undertheseat.

Note:Makesurethereleasevalvesareinthefully

horizontalpositionwhenoperatingthemachineor

severedamagetothehydraulicsystemcanoccur.

1.DisengagethePTO(bladecontrolswitch)andturn

theignitionkeytooff.Movetheleverstoneutral

lockedpositionandapplyparkingbrake.Remove

thekey.

2.Rotatethereleasevalveleversverticallytopushthe

machine.Thisallowshydraulicoiltoby-passthe

pumpenablingthewheelstoturn(

Figure33).

3.Disengageparkingbrakebeforepushing.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthe

mowerbecausethegrassdeectorroutes

materialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(bladecontrolswitch(PTO)totheoffposition,

rotatetheignitionkeytooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

Figure33

1.Verticaltopushthe

machine

2.Horizontaltorunthe

machine

4.Rotatethereleasevalvelevershorizontallytorun

themachine(Figure33).

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

LoadingMachines

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinsteadof

individualrampsforeachsideoftheunit(Figure34).

Thelowerrearsectionofthetractorframeextendsback

betweentherearwheelsandservesasastopfortipping

backward.Havingafullwidthrampprovidesasurface

fortheframememberstocontactiftheunitstartsto

tipbackward.Ifitisnotpossibletouseonefullwidth

ramp,useenoughindividualrampstosimulateafull

widthcontinuousramp.

Therampshouldbelongenoughsothattheangles

donotexceed15degrees(

maycausemowercomponentstogetcaughtastheunit

movesfromramptotrailerortruck.Steeperangles

mayalsocausetheunittotipbackward.Ifloadingon

ornearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.Thetraileror

truckshouldbeaslevelaspossible.

Figure34).Asteeperangle

Important:DoNotattempttoturntheunitwhile

ontheramp;youmaylosecontrolanddriveoff

theside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

26

Page 27

WARNING

TransportingMachines

Loadingaunitontoatrailerortruckincreasesthe

possibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingauniton

aramp.

•EnsuretheROPSisintheuppositionwhile

usingtheseatbeltwhenloadingthemachine.

EnsuretheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,fullwidthramp;DoNotuse

individualrampsforeachsideoftheunit.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurface

widerthantheunit.

•Donotexceeda15degreeanglebetweenramp

andgroundorbetweenrampandtraileror

truck.

•Avoidsuddenaccelerationwhiledrivingunitup

aramptoavoidtippingbackward.

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequiredby

law .Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

petsorbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow

movingvehicleemblemisdangerousandcanlead

toaccidentscausingpersonalinjury.

Donotdrivemachineonapublicstreetorroadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

•Avoidsuddendecelerationwhilebackingunit

downaramptoavoidtippingbackward.

Figure34

1.Trailer3.Notgreaterthan

15degrees

2.Fullwidthramp4.Fullwidthramp—sideview

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltiedownloopsonthemachineto

securelyfastenthemachinetothetrailerortruck

withstraps,chains,cable,orropes(

Figure35

1.Tractionunittiedownloops

Figure35).

27

Page 28

UsingtheZStand®

TheZStand®raisesthefrontendofthemachineto

allowyoutocleanthemowerandremovetheblades.

WARNING

Themachinecouldfallontosomeoneandcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingthe

machineontheZStand®.

•Useonlyforcleaningthemowerandremoving

theblades.

1.ZStand(Positionedin

slot)

2.Crackinsidewalkorturf

Figure37

3.Latchrestingonpivottab

•DonotkeepthemachineontheZStandfor

extendedperiodsoftime.

•Alwaysturntheengineoff,settheparking

brake,andremovethekeybeforeperforming

anymaintenancetothemower.

DrivingupontotheZStand

Important:UsetheZStandonalevelsurface.

1.Raisethemowertothetransportposition.

2.Removethebracketpin(Figure36).

4.Setthefootofstandonthegroundandrestthe

latchonthepivottab(Figure37).

5.Starttheengineandputitathalfthrottle.

Note:Forbestresults,placethefootofstandinto

seamsinsidewalksorintotheturf(

Figure37).

6.Driveontothestand.Stopwhenthelatchdrops

overthetabintothelockedposition(Figure37).

Onceontothestand,engagetheparkingbrakeand

tunofftheengine.

7.Chockorblockthedrivewheels.

WARNING

Parkingbrakemaynotholdmachineparked

onZStandandcouldcausepersonalinjuryor

propertydamage.

DonotparkonZStandunlesswheelsare

chockedorblocked.

8.Performthemaintenance.

Figure36

1.ZStand4.Bottomofslot

2.BracketPin5.Latch

3.Bracket

3.Raisethelatch.Swingthestandfootoutfrontand

slidestandtowardmachine,intothebottomofslot

(

Figure36andFigure37).

DrivingofftheZStand

1.Removethechocksorblocks.

2.Raisethelatchtotheunlockedposition(

28

Figure38).

Page 29

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

Figure38

1.ZStand

2.Latch4.Unlockedposition

3.Starttheengineandplaceitathalfthrottle.

Disengagetheparkingbrake.

4.Slowlydrivebackwardsoffofthestand.

5.Returnthestandtoitsrestposition(Figure36).

3.Lockedposition

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequired

tothoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeedin

certainconditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

Cutgrassslightlylongerthannormaltoensurethe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.If

abladeisdamagedorworn,replaceitimmediatelywith

agenuineTOROreplacementblade.

29

Page 30

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheelhubslottednuttorque.

•Checkthetorqueforwheellugnuts.

•Checktheparkbrakeadjustment.

•Checkthesafetysystem.

•Checktheengineoillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Cleantheenginescreenandtheoilcooler.

•Checkandcleanthehydraulicunitshrouds.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Greasethemowerdeckspindlesandidlerarm.

•Checksparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicoillevel.

•Lubricatethemowerdeckliftpivots.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Check,cleanandregapthesparkplug.

•Checkandcleanenginecoolingnsandshrouds.

Every200hours

Every250hours

Every500hours

Monthly

Yearly

Yearlyorbeforestorage

•Changetheengineoillter.

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

•ChangethehydraulicltersandhydraulicoilwhenusingMobil1oil.

•Replacethesecondaryairlter.

•Replacethefuellter.(moreoftenindirtyordustyconditions).

•Checkthewheelhubslottednuttorque.

•Checkthetorqueforwheellugnuts.

•Adjustthecasterpivotbearing.

•Checktheparkbrakeadjustment.

•ChangethehydraulicltersandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil

•Checkthebattery .

•Greasethepumpbeltidlerarm.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Repackthefrontcasterwheelbearings(moreoftenindirtyordustyconditions).

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

30

Page 31

Lubrication

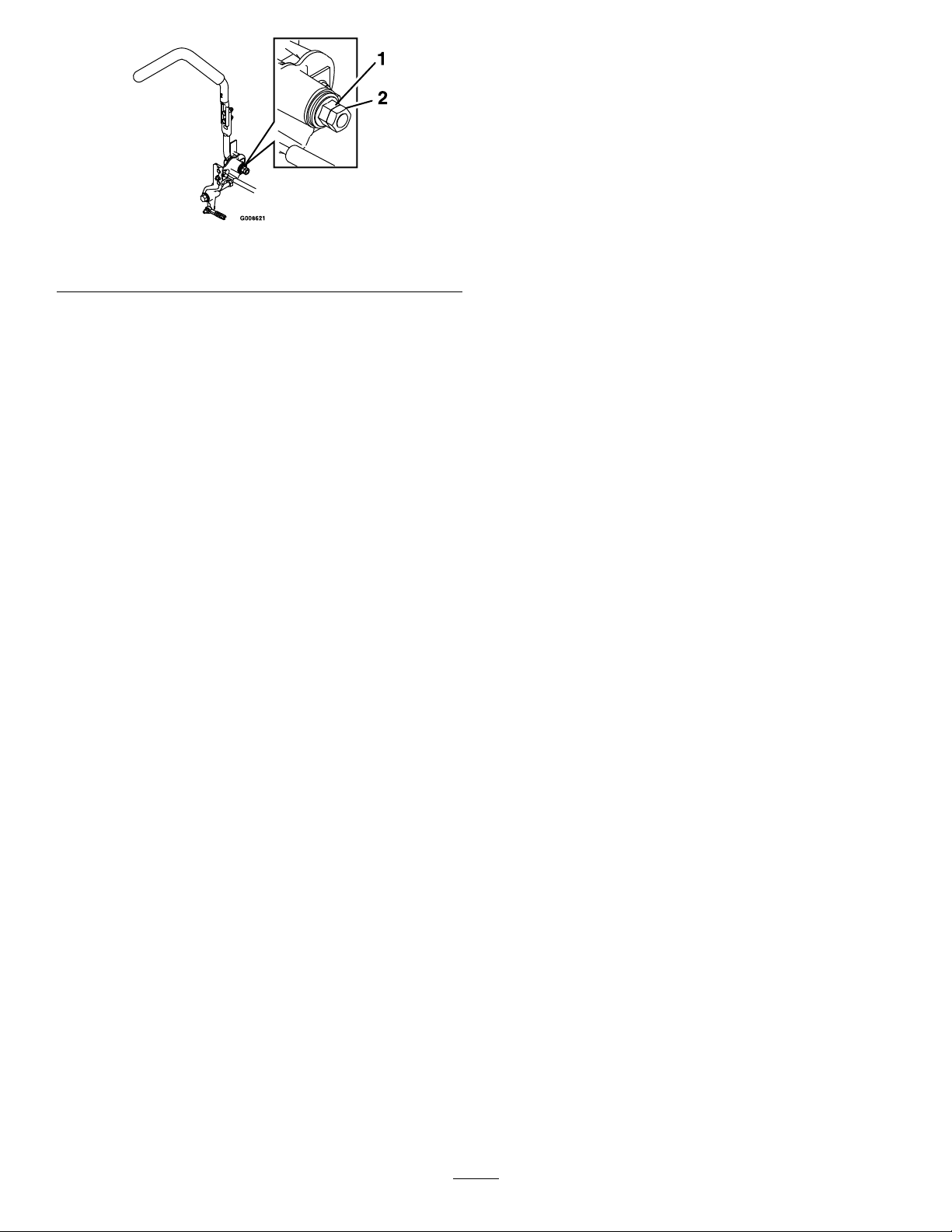

G017028

G009029

GreasingandLubrication

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy.

GreaseType:No.2generalpurposelithiumbaseor

molybdenumbasegrease

WheretoGreasetheMower

ServiceInterval:Every50hours—Greasethemower

deckspindlesandidlerarm.

Yearly—Greasethepumpbeltidler

arm.

Yearly—Greasethefrontcaster

pivots(moreoftenindirtyordusty

conditions).

HowtoGrease

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Cleanthegreasettingswitharag.Makesureto

scrapeanypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutof

thebearings.

5.Wipeupanyexcessgrease.

WheretoAddLightOilorSpray

Lubrication

ServiceInterval:Every100hours

Lubricatethedeckliftpivots.

Yearly—Repackthefrontcaster

wheelbearings(moreoftenindirtyor

dustyconditions).

Important:Makesurecuttingunitspindlesarefull

ofgreaseweekly.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Greasethemowerdeckidlerpulleypivotuntilgrease

comeoutthebottom(

4.Greasethettingsonthetopofthe3spindle

bearingsuntilgreasecomeoutthebottom

Figure40).

(

Figure40).

Figure39

Figure40

5.Greasethedrivebeltidlerarm(Figure40).

31

Page 32

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacethe

primaryairlter.

Figure41

6.Removethedustcapandadjustthecasterpivots.

Keepthedustcapoffuntilgreasingisdone.Referto

AdjustingtheCasterPivotBearinginMaintenance.

7.Removethehexplug.Threadagreasezerkintothe

hole.

8.Pumpgreaseintothezerkuntilitoozesoutaround

thetopbearing.

9.Removethegreasezerkinthehole.Installthehex

pluganddustcap(

Figure42).

Every250hours—Checkthe

secondaryairlter.

Every500hours—Replacethe

secondaryairlter.

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy .

RemovingtheFilters

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Pushdowntoreleasetheretainingclampsontheair

cleanerandpulltheaircleanercoveroffoftheair

cleanerbody(

4.Cleantheinsideoftheaircleanercoverwith

compressedair.

Figure43).

Figure42

10.Greasethecasterwheelbearings(Figure42).

5.Gentlyslidetheprimarylteroutoftheaircleaner

Figure43).Avoidknockingthelterintothe

body(

sideofthebody .

6.Removethesecondarylteronlyifyouintendto

replaceit.

Important:Neverattempttocleanthe

secondarylter.Ifthesecondarylterisdirty,

thentheprimarylterisdamagedandyou

shouldreplacebothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutside

ofthelter.Holesinthelterwillappearasbright

spots.Ifthelterisdamageddiscardit.

32

Page 33

Figure43

ServicingtheEngineOil

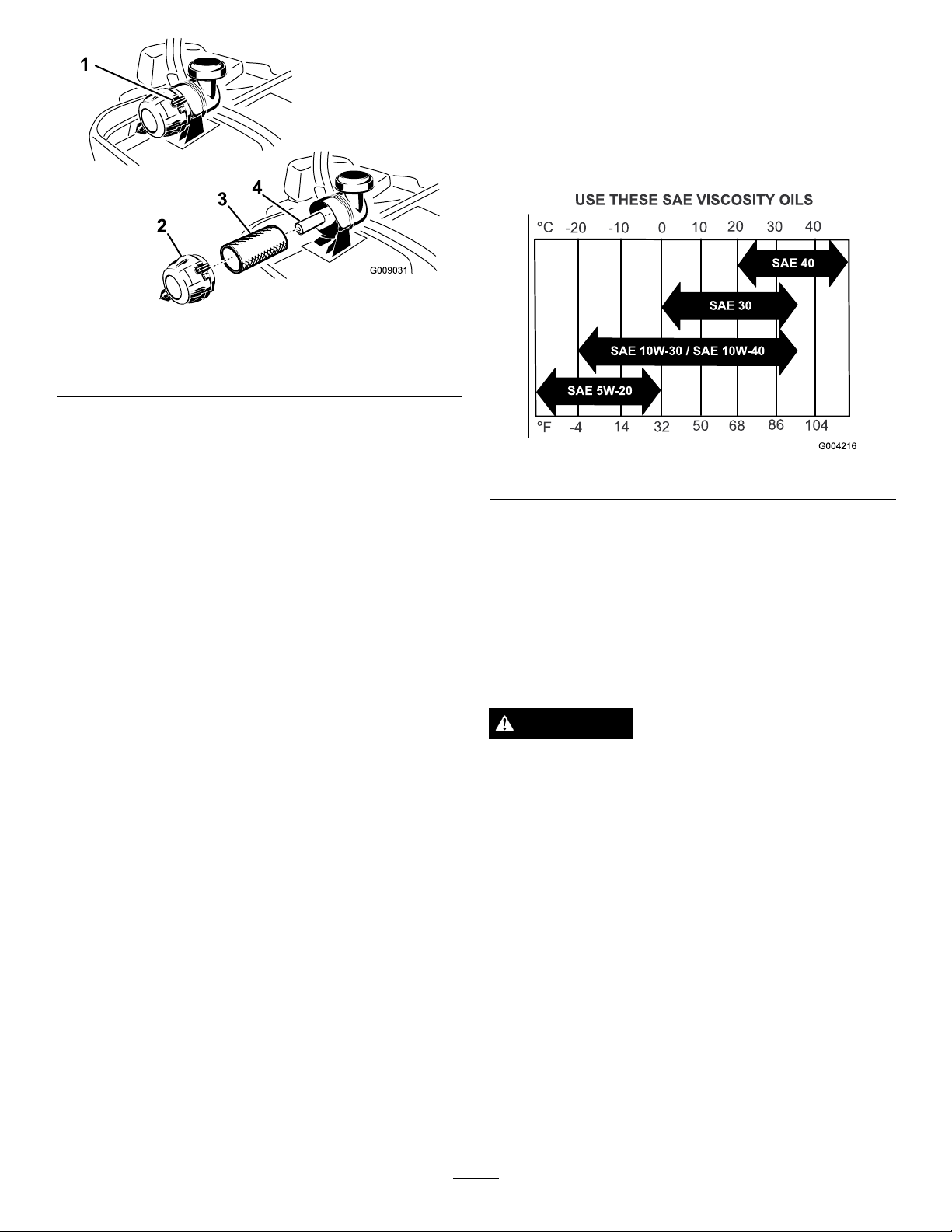

OilType:Detergentoil(APIserviceSG,SH,SJ,orSL)

OilCapacity:withalterchange,77ounces(2.3L);

withoutalterchange,70ounces(2.1L)

Viscosity:Seethetablebelow .

1.Aircleanerclamps

2.Aircleanercover

3.Primaryairlter

4.Secondaryairlter

ServicingthePrimaryFilter

1.Donotcleanthepaperlter,replaceit(Figure43).

2.Inspecttheelementfortears,anoilylm,ordamage

totherubberseal.

3.Replacethepaperelementifitisdamaged.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

Figure44

Note:Useofmulti-gradeoils(5W -20,10W -30,or

10W-40)willincreaseoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Ifthesecondarylterisbeingreplaced,carefully

slideitintothelterbody(Figure43).

3.Carefullyslidetheprimarylteroverthesecondary

lter(Figure43).Ensurethatitisfullyseatedby

pushingontheouterrimofthelterwhileinstalling

it.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheaircleanercoverwiththebreathercap

downandrotatesotheretainingclampslockthe

coverinplace(

Figure43).

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

33

Figure45).

Page 34

G008804

G008792

1

2

5

6

7

3

9

10

4

8

ChangingtheEngineOil

G008804

G008793

1

2

3

4

4

5

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirty

ordustyconditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylower

thanthefronttoensuretheoildrainscompletely .

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure46).

Figure45

Figure46

34

Page 35

4.Slowlypourapproximately80%ofthespeciedoil

G008796

2

3

4

5

6

1

G008804

G008748

3/4

1

2

3

4

5

6

intothellertubeandslowlyaddtheadditionaloil

tobringittotheFullmark(Figure47).

Figure47

5.Starttheengineanddrivetoaatarea.Checkthe

oillevelagain.

ChangingtheEngineOilFilter

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequently

whenoperatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(

Figure48).

Figure48

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;

refertoChangingtheOil.

35

Page 36

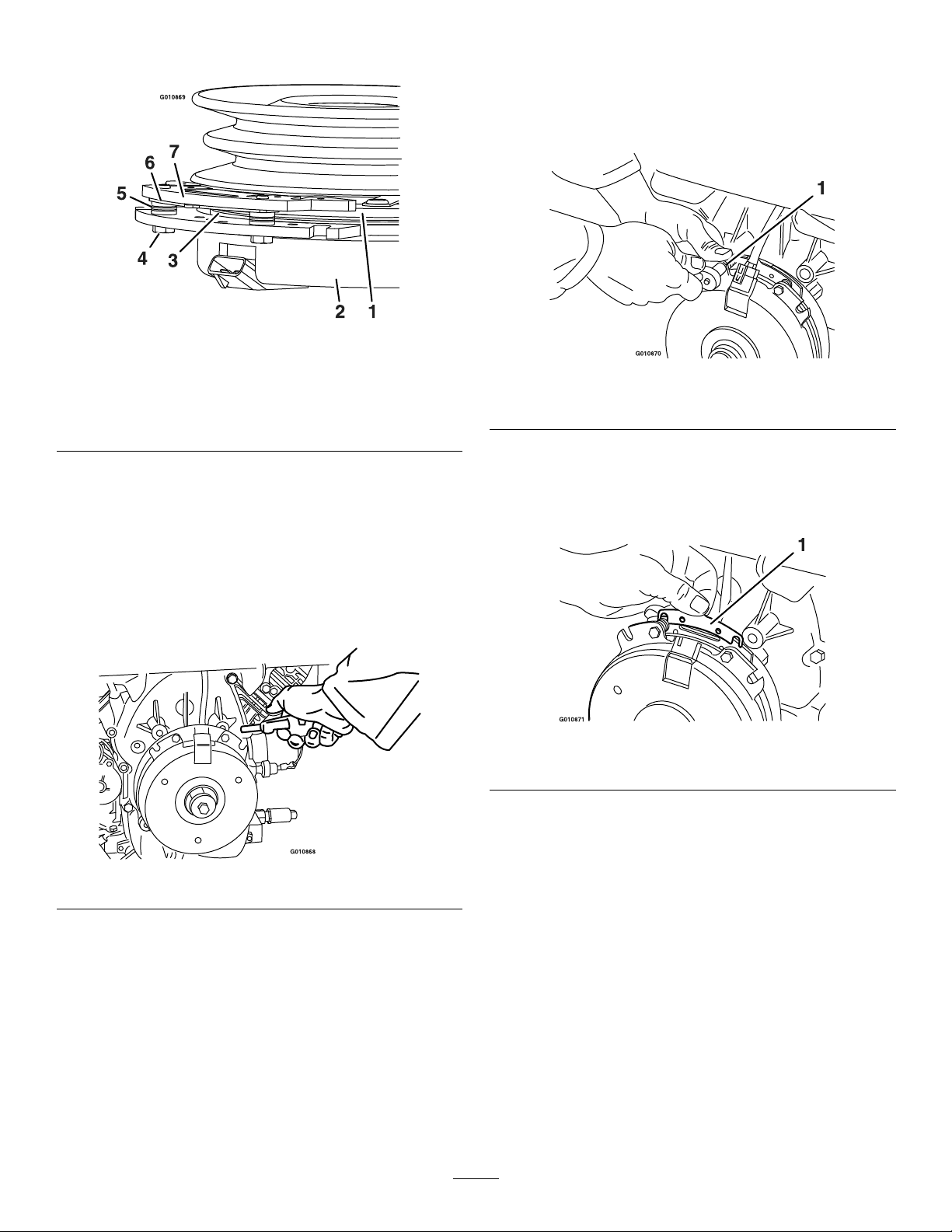

ServicingtheSparkPlug

G008803

ServiceInterval:Every100hours

Makesuretheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewsparkplug(s)

ifnecessary.

Type:NGK

®

BPR4ESorequivalent

AirGap:0.030inch(0.75mm)

RemovingtheSparkPlug

1.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

2.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedpositionandsettheparking

brake.

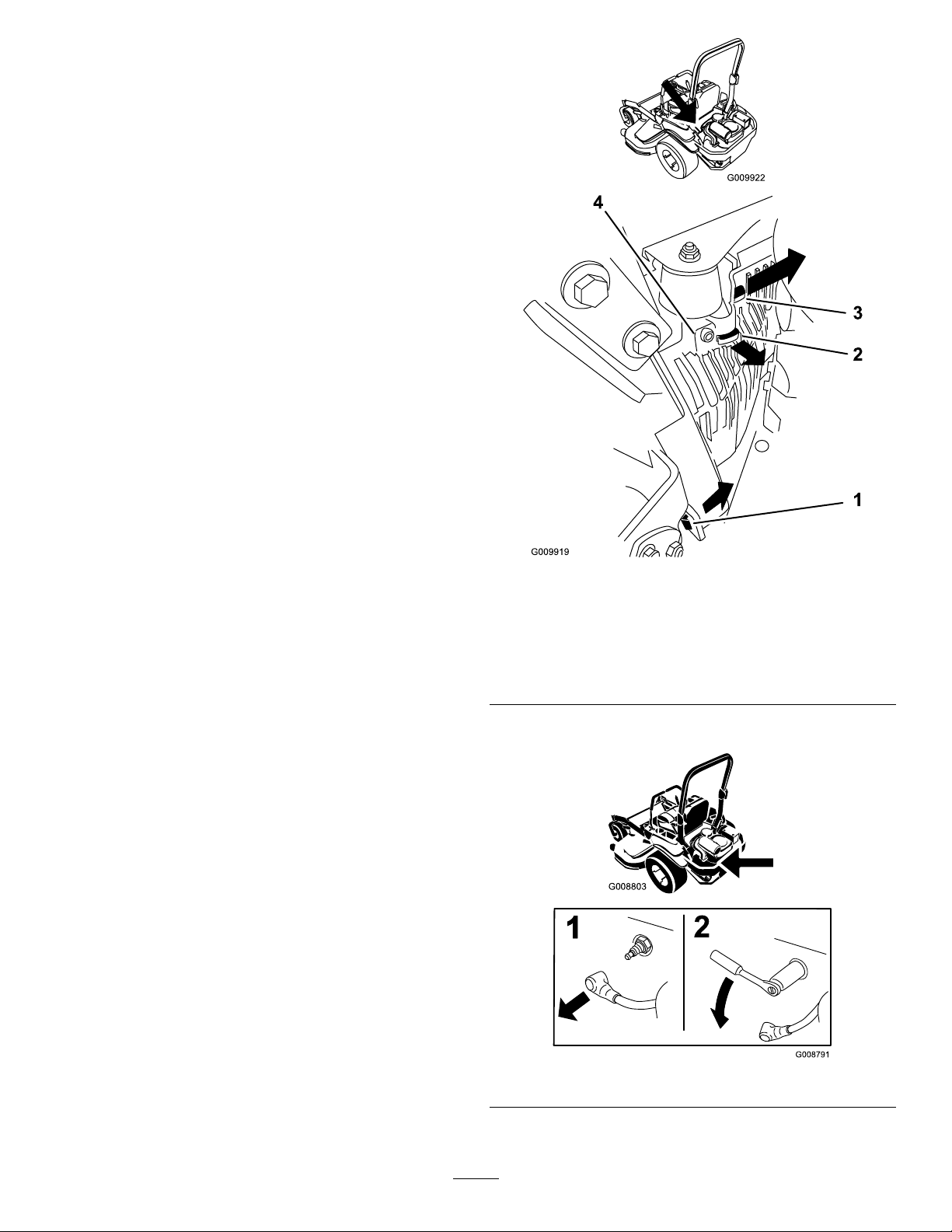

3.Removethelefthandhydraulicunitshroudinthe

orderlistedwith

tothefrontsparkplug.

Figure49.Thisgivesyouaccess

1.Pullthistabouttothe

sideinthedirectionofthe

arrow

2.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

Figure49

3.Pulltheshroudoffofthis

frametabinthedirection

ofthearrow

4.Shroud

4.Removethesparkplug.

Figure50

5.Installthelefthandhydraulicunitshroud(Figure49).

36

Page 37

CheckingtheSparkPlug

G008794

1

2

3

2

1

G015200

CheckSparkArrester(if

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablack

coating,wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.030inches(0.76mm).

Figure51

InstallingtheSparkPlug

Tightenthesparkplug(s)to16ft.-lb(22N-m).

equipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

DoNotrefuelorrunengineunlesssparkarrester

isinstalled.

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Waitformufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakelooseparticlesoutofthearrester

andcleanscreenwithawirebrush(soakinsolventif

necessary).Reinstallarresteronexhaustoutlet.

Figure52

37

Page 38

FuelSystem

G008963

12

3

Maintenance

Note:Itisimportanttoreinstallthefuellinehosesand

securewithplastictiesthesameastheywereoriginally

installedatthefactorytokeepthefuellineawayfrom

componentsthatcouldcausefuellinedamage.

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichever

comesrst)(moreoftenindirtyor

dustyconditions).

Thefuellterislocatedneartheengineonthefront

orrearsideoftheengine.

1.DisengagethePTO,movethemotioncontrollevers

totheneutrallockedposition,andsettheparking

brake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Allowthemachinetocooldown.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Closethefuelshutoffvalveundertheseat

(Figure53).

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankand

servicesanycomponentsofthefuelsystem.

Figure53

1.Fuellter

2.Hoseclamp

6.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure53).

7.Removethelterfromthefuellines.

8.Installanewlterandmovethehoseclampsclose

9.Openthefuelshutoffvalve.

tothelter(

Figure53).

3.Fuelline

38

Page 39

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Firstdisconnectthenegativebatterycable(black)

fromthenegative(-)(black)batteryterminal

Figure54).

(

4.Slidetheredterminalbootoffthepositive(red)

batteryterminalandremovethepositive(+)(red)

batterycable(

5.Removethewingnutsecuringthebatteryclamp

(Figure54).

6.Removetheclamp(

7.Removethebattery.

Figure54).

Figure54).

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

39

Page 40

G008804

g014731

+

-

+

-

+

-

1

2

3

4

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(

Figure55).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

Figure54

1.Removethewingnutand

clamp

2.Removethenegative

batterycablebeforethe

positive

3.Removethepositive

batterycable

4.Removebattery

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure54).

2.First,installthepositive(red)batterycableto

positive(+)batteryterminal.

3.Theninstallthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and

2locknuts(

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut

(Figure54).

Figure54).

1.PositiveBatteryPost

2.NegativeBatteryPost

Figure55

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

40

Page 41

ServicingtheFuses

DriveSystem

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance,however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

1.Thefusesarelocatedonrighthandconsolenextto

theseat(

2.Toreplacethefuses,pulloutonthefusetoremove

it.

3.Installanewfuse(Figure56).

Figure56).

Maintenance

CheckingtheSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproper

operationofretractorandbuckle.Replacebefore

operatingifdamaged.

CheckingtheRollover

ProtectionSystem(ROPS)

Knobs

ServiceInterval:Beforeeachuseordaily

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Figure56

1.Optionalaccesory-15amp

2.Charge-25amp5.Console

3.PTO-10amp

Ensuretheseatissecuredtothemachine.

Checkthatboththemountinghardwareandtheknobs

4.Main-25amp

areingoodworkingcondition.Makesuretheknobs

arefullyengagedwiththeROPSintheraisedposition.

Theupperhoopoftherollbarmayneedtobepushed

forwardorpulledrearwardtogetbothknobsfully

engaged.

41

Page 42

Figure58

Leftcontrollevershown

1.Controllever3.Stopplate

2.Bolt

Figure57

1.ROPSknob(locked

position)

2.PullROPSknoboutand

rotate90degreesto

changerollbarposition

3.Rollbarintheupright

position

4.Rollbarinthefolded

position

AdjustingtheTracking

1.Disengagethebladecontrolswitch(PTO).

2.Drivetoanopenatarea,movethemotioncontrol

leverstotheneutrallockedposition.

3.Movethethrottlemidwaybetweenfastandslow .

4.Movebothmotioncontrolleversallthewayforward

untiltheybothhitthestopsintheT-slot.

5.Checkwhichwaythemachinetracks.

6.Ifittrackstotheright,loosentheboltsandadjust

theleftstopplateontheleftT-slotuntilthemachine

tracksstraight(

7.Ifittrackstotheleft,loosentheboltsandadjustthe

rightstopplateontherightT-slotuntilthemachine

tracksstraight(Figure58).

8.Tightenthestopplate(Figure58).

Figure58).

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat13psi(90

kPa).Uneventirepressurecancauseunevencut.Check

thetireswhentheyarecoldtogetthemostaccurate

pressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireairpressuremaintenance.

Figure59

42

Page 43

CheckingtheWheelHub

SlottedNut

ServiceInterval:Aftertherst100hours

Every500hours

nuttoaligntheslot.Ifrequired,tightentothe

nextsetofslots.

7.Installanewcotterpin.

Note:DoNotuseanti-seizeonwheelhub.

See

Figure60todeterminewhichslottednuthasbeen

installedontheunit.

Figure60

1.StyleA(blacknish)3.StyleB(yellowzinc)

2..03inch(.76mm)4..24inch(6mm)

•StyleA(blacknish):

Torquetheslottednutto211-260ft-lb(286-352

N-m).

Note:DoNotuseanti-seizeonwheelhub.

•StyleB(yellowzinc):

1.Removeanddiscardthecotterpin.

2.Torquetheslottednutto200ft-lb(271N-m).

AdjustingtheCasterPivot

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethedustcapfromcasterandtightenlock

Figure62).

nut(

4.Tightenthelocknutuntilthespringwashersareat

andthenbackoffa1/4turntoproperlysetthe

pre-loadonthebearings(

Important:Makesurethespringwashersare

installedcorrectlyasshowninFigure62.

5.Installthedustcap(

Figure62).

Figure62).

3.Checkdistancefrombottomofslotinnutto

insideedgeofhole.Twothreads(0.1inch)or

lessshouldbeshowing.

Figure61

1.0.1inchmax2.Nomorethantwothreads

(0.1inchmax)shouldbe

showinghere.

4.Ifmorethantwothreads(0.1inch)areshowing

removenutandinstallwasherbetweenhuband

nut.

5.Torquetheslottednutto200ft-lb(271N-m).

6.Thentightennutuntilthenextsetofslotsline

upwiththecrossholeinshaft.Donotloosen

Figure62

1.SpringWashers3.DustCap

2.LockNut

UsingtheClutchShim

Somelatermodelyearunitshavebeenbuiltwithclutches

thatcontainabrakeshim.Whentheclutchbrakehas

worntothepointwheretheclutchnolongerengages

43

Page 44

consistently,theshimcanberemovedtoextendthe

clutchlife.

Figure63

Note:DoNotremovethebrakepolefromthe

eldshell/armature.Thebrakepolehasworn

tomatchthearmatureandneedstocontinueto

matchaftertheshimisremovedtoensureproper

braketorque.

1.Armature5.Brakespacer

2.Fieldshell6.Re-gapshim

3.Rotor7.Brakepole

4.Brakemountingbolt

RemovingtheClutchShim

1.Stoptheengine,waitforallmovingpartstostop,

andremovethekey.Engagetheparkingbrake.

Allowthemachinetocoolcompletelybeforestarting

theseinstructions.

2.Usinganaircompressor,blowoutanydebrisfrom

underthebrakepoleandaroundthebrakespacers.

Figure65

1.Brakemountingbolt

B.Usingneedlenosepliers,orbyhand,takehold

ofthetabandremovetheshim(DoNotdiscard

theshimuntilproperclutchfunctionhasbeen

conrmed).

Figure66

1.Shim

Figure64

3.Checktheconditionofthewireharnessleads,

connectors,andterminals.Cleanorrepairas

necessary.

4.Verifythat12Vispresentattheclutchconnector

whenthePTOswitchisengaged.

5.Measurethegapbetweentherotorandarmature.

Ifthegapisgreaterthan.04inch(1mm),proceed

withthefollowingsteps:

A.Loosenbothbrakemountingboltsone-halfto

onefullturnasshownbelow .

C.Usingapneumaticline,blowoutanydebris