Toro Z Master 8000 Series, 74313, Z MASTER 74310, Z MASTER 74311, Z MASTER74312 Operator's Manual

Page 1

FormNo.3399-259RevB

ZMaster

®

8000SeriesRiding

Mower

with42inor48inDirect-CollectCuttingUnit

ModelNo.74310—SerialNo.316000001andUp

ModelNo.74312—SerialNo.316000001andUp

ModelNo.74313—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3399-259*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosedengineowner'smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

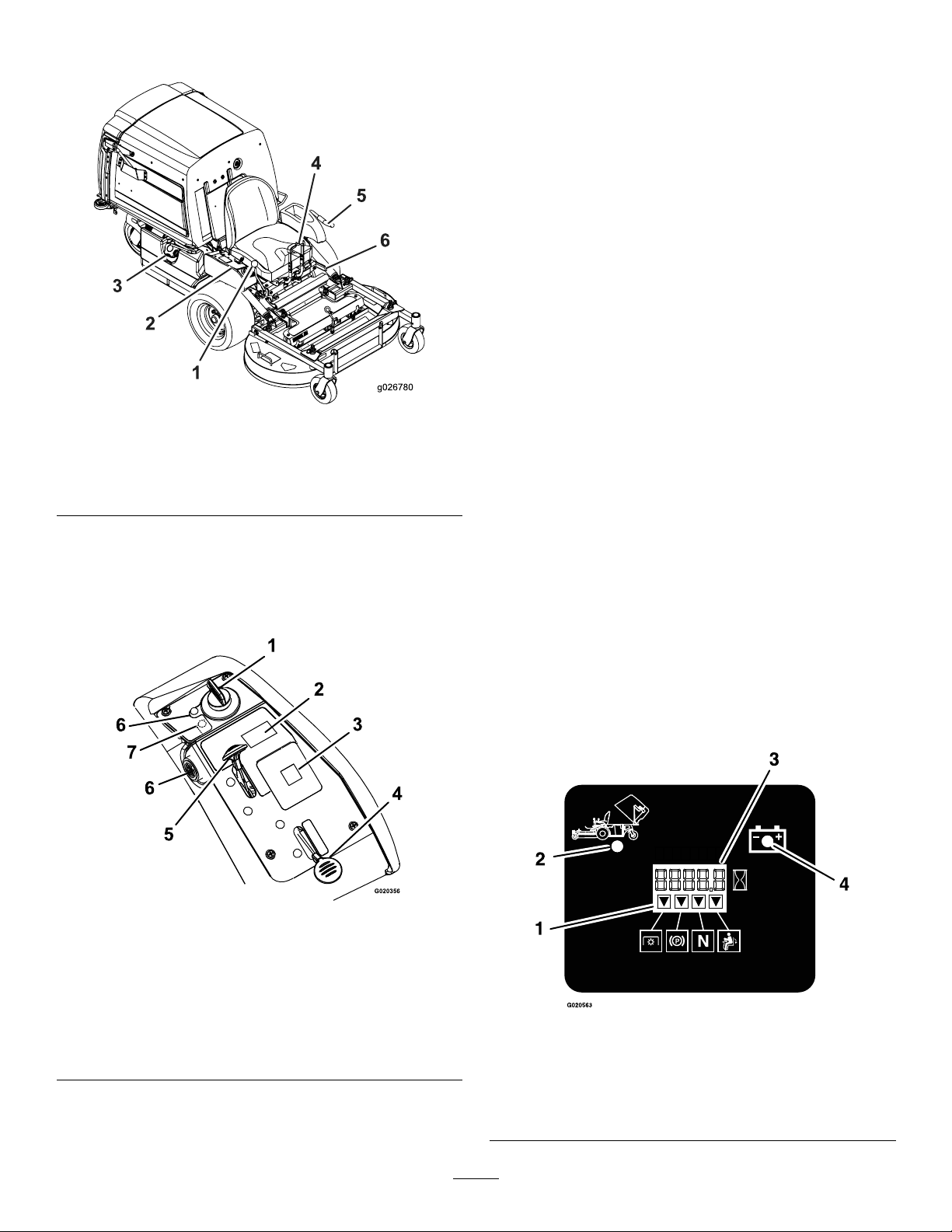

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroMowerSafety..................................................5

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................15

Controls...............................................................15

Specications........................................................16

Operation....................................................................17

AddingFuel...........................................................17

CheckingtheEngine-OilLevel.................................18

BreakinginaNewMachine......................................18

ThinkSafetyFirst...................................................18

OperatingtheParkingBrake....................................19

OperatingtheThrottle............................................19

OperatingtheIgnitionSwitch..................................19

UsingtheFuel-ShutoffValve...................................20

OperatingthePTO-EngagementLever.....................20

StartingandStoppingtheEngine..............................20

TheSafety-InterlockSystem....................................22

DrivingForwardorBackward..................................22

StoppingtheMachine.............................................23

RaisingtheMowerDeckintotheService

Position.............................................................23

LoweringtheMowerDecktotheOperating

Position.............................................................24

AdjustingtheFillReductionSystem(FRS)

Bafes...............................................................24

AdjustingtheHeightofCut.....................................25

EmptyingtheHopper.............................................25

ClearingtheHopperScreen.....................................25

UsingtheDrive-WheelReleaseValves.......................26

TransportingtheMachine........................................26

LoadingtheMachine..............................................26

OperatingTips......................................................28

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

Lubrication...............................................................30

LubricatingtheMachine..........................................30

EngineMaintenance..................................................32

ServicingtheAirCleaner.........................................32

ServicingtheEngineOil..........................................33

ServicingtheSparkPlugs.........................................35

CheckingtheSparkArrester.....................................36

FuelSystemMaintenance...........................................36

ServicingtheElectronicFuel-Injection

System..............................................................36

ReplacingtheFuelFilter..........................................36

ServicingtheFuelTank...........................................37

ElectricalSystemMaintenance....................................37

ServicingtheBattery...............................................37

ServicingtheFuses.................................................39

AdjustingtheSafetySwitches...................................39

Jump-StartingtheMachine......................................39

DriveSystemMaintenance.........................................40

AdjustingtheTracking............................................40

CheckingtheTirePressure......................................40

CheckingtheWheel-LugNuts..................................41

CheckingtheWheel-HubNuts.................................41

AdjustingtheCaster-PivotBearings..........................41

CoolingSystemMaintenance......................................42

CleaningtheEngineScreenandEngineOil

Cooler...............................................................42

ServicingtheEngine-OilCooler...............................42

CleaningtheEngineCoolingFinsand

Shrouds.............................................................42

CheckingandCleaningtheHydraulicPumps..............42

BrakeMaintenance....................................................43

AdjustingtheParkingBrake.....................................43

BeltMaintenance......................................................44

InspectingtheBelts................................................44

ReplacingthePTOBelts.........................................44

ReplacingthePump-DriveBelt................................45

AdjustingtheBeltGuides........................................45

ControlsSystemMaintenance.....................................46

AdjustingtheReverse-StopRod...............................46

AdjustingtheSpeed-ControlLeverTension...............46

AdjustingtheSpeed-ControlLinkage........................46

AligningthePTO-DrivePulley.................................47

AligningthePump-DrivePulley...............................48

AdjustingthePTOBrakeSpring...............................48

AdjustingtheHopperDoor.....................................48

AdjustingtheLocking-PinStopontheMower

Deck.................................................................49

HydraulicSystemMaintenance....................................49

ServicingtheHydraulicSystem.................................49

MowerDeckMaintenance...........................................51

LevelingtheMowerDeck........................................51

ServicingtheCuttingBlades.....................................51

RemovingtheMowerDeck.....................................54

InstallingtheMowerDeck.......................................55

AdjustingtheLocking-PinStopontheMower

Deck.................................................................55

Cleaning...................................................................56

CleaningundertheMower.......................................56

CleaningDebrisfromtheMachine............................56

DisposingofWaste.................................................56

Storage........................................................................56

CleaningandStorage..............................................56

Troubleshooting...........................................................58

Schematics...................................................................60

3

Page 4

Safety

ThismachinehasbeendesignedinaccordancetotheANSI

B71.4–2012specicationoftheAmericanNationalStandards

InstitutewiththeadditionoftheoptionalROPSaccessory.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theinstructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

•Iftheoperator(s)ormechanic(s)cannotreadthemanual

language,itistheowner'sresponsibilitytoexplainthis

materialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeople,ordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincluding:substantial

slip-resistantfootwear,safetyglasses,andhearing

protection.Tiebacklonghair.Donotwearjewelry.

•Inspecttheareawheretheequipmentisused,andremove

allobjectsthatcanbethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseen,orthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Donotrunanengineinanenclosedarea.

•Operateonlyinwell-litareas,keepingawayfromholes

andhiddenhazards.

•Ensurethatalldrivesareinneutralandthattheparking

brakeisengagedbeforestartingengine.Starttheengine

onlyfromtheoperator’ sposition.

•Makesurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.Reducedfooting

couldcauseslipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotraisethemowerdeckwiththebladesrunning.

•DonotoperatethemachinewithoutthePTOshieldor

otherguardssecurelyinplace.Besurethatallinterlocks

areattached,adjustedproperly,andfunctioningproperly.

•Donotoperatewiththedischargedeectorraised,

removedoraltered,unlessyouareusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectthebladesafterstriking

objectsorifanabnormalvibrationoccurs.Makethe

necessaryrepairsbeforeresumingoperations.

•Keepyourhandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptoensurea

clearpath.

•Keeppetsandbystandersawayfromanoperating

machine.

4

Page 5

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemower-dischargedirectionanddonot

pointitatanyone.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

Note:A2–postfoldableROPS(RolloverProtection

System)isavailablefortheNavigatorasanaccessory.A

ROPSisrecommendedifyouwillbemowingnextto

drop-offs,nearwater,oronsteepbankswhichcould

resultinarollover.ContactanAuthorizedServiceDealer

formoredetails.

TheCaliforniaCodeofRegulationsrequiresROPSand

seatbelt(ifavailable)onallcommercialmowerseffective

March1,2011.Becauseallmachinesweredesignedwith

anoptionalROPSaccessory,theyaresubjecttothis

regulationandmustberetrottedwithROPS.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfuelwiththeengine

running.

•Allowtheenginetocoolbeforefueling.

•Donotfuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwherethere

isanopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

•Donotllcontainersinsideavehicle,onatruck,orona

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenaddfuelwith

suchequipmentasaportablecontainerratherthanfrom

afuel-dispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelock-opendevice.

•Ifyouspillfuelonclothing,changeyourclothing

immediately.

•Donotoverllthefueltank.Replacethefuelcapand

tightensecurely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine,

andremovethekeyordisconnectspark-plugwire.Wait

forallmovementtostopbeforeadjusting,cleaning,or

repairing.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,drives,

mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorefuelnearamesordrainfuelindoors.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethespark-plugwire

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Connectthe

positiveterminalrstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)

orwearthicklypaddedgloves,andusecautionwhen

servicingthem.Onlyreplaceblades;donotstraighten

orweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

traileroratruck.

•Usefull-widthrampsforloadingmachineintoatrailer

oratruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

ToroMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsandothersafetyinformationthatyoumustknow.

Service

•Donotstorethemachineorafuelcontainerinsidewhere

thereisanopename,suchasnearawaterheateror

furnace.

•Keepthenutsandboltstight,especiallythe

blade-attachmentbolts.

•Neverinterferewiththeintendedfunctionofasafety

deviceorreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

5

Page 6

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourT oroequipment,useTorogenuine

parts.

•Checkbrakeoperationfrequently.Adjustandserviceas

required.

6

Page 7

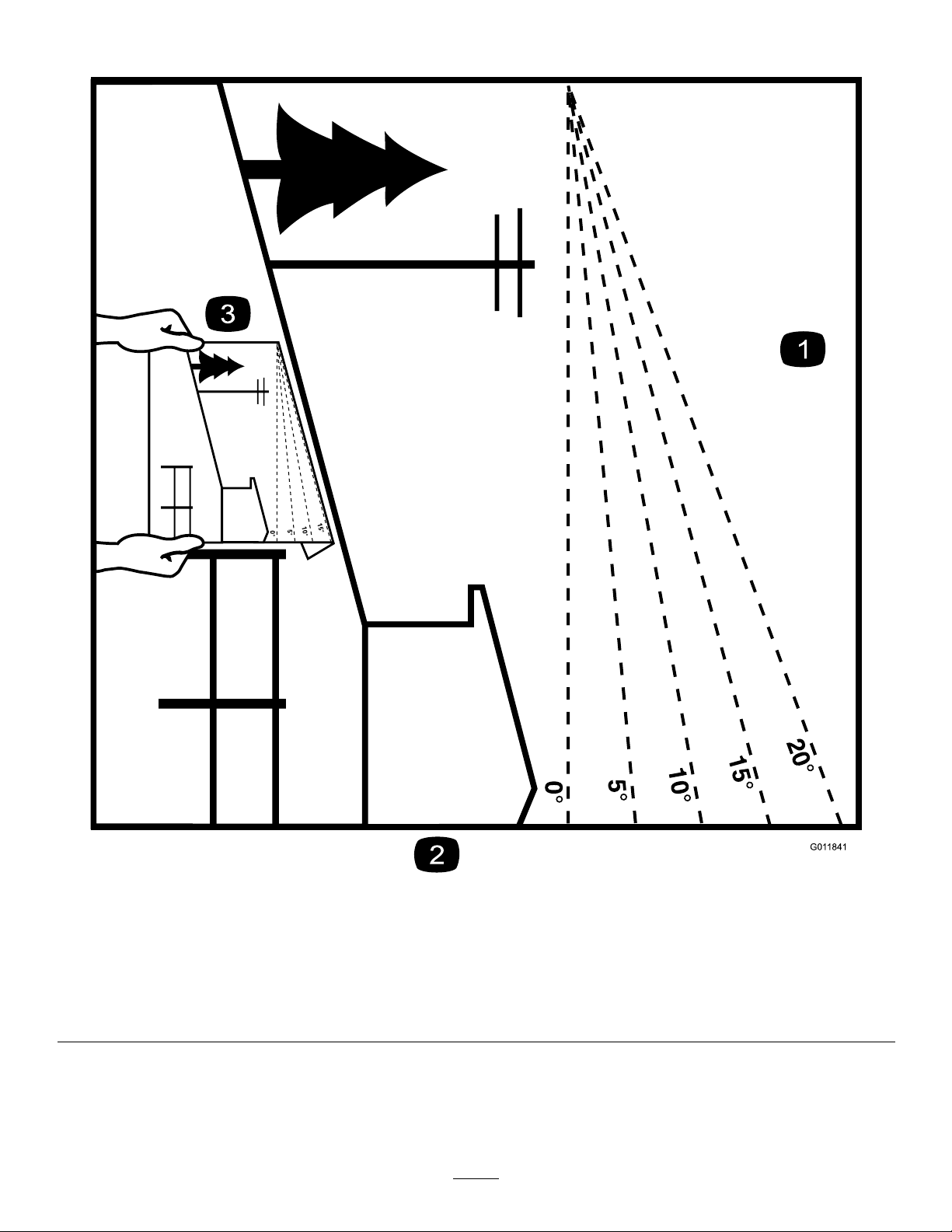

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

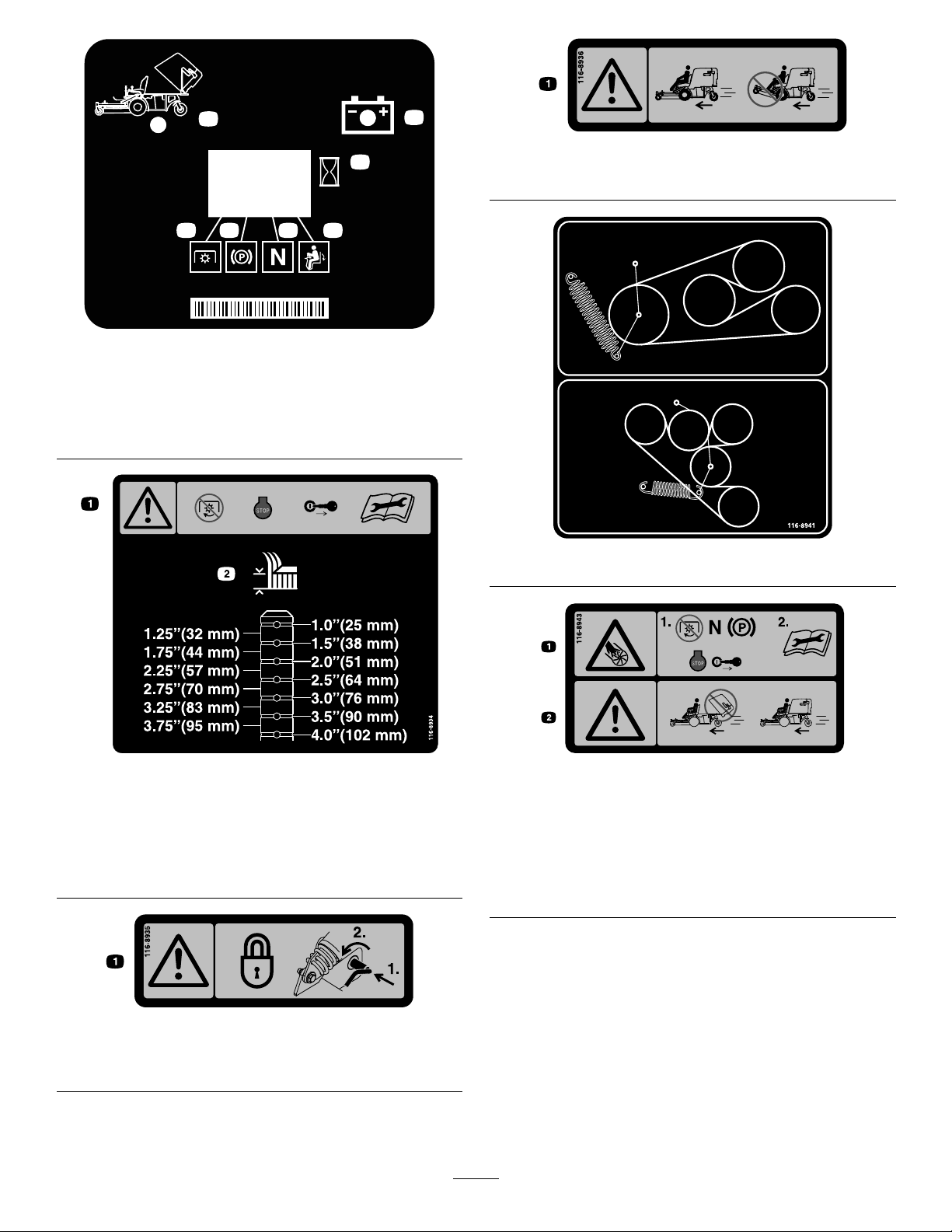

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6696

1.Storedenergyhazard—readtheOperator'sManual.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N∙m(85-110ft-lb).

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

98-1977

1.Entanglementhazard,belt—stayawayfrommovingparts.

106-5517

1.Warning—donottouchthehotsurface.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

115-4212

1.Hydraulicuidlevel

2.ReadtheOperator's

Manual.

3.Warning—donottouchthe

hotsurface.

8

Page 9

NVXXXXXX

1

2

3

4 5 6 7

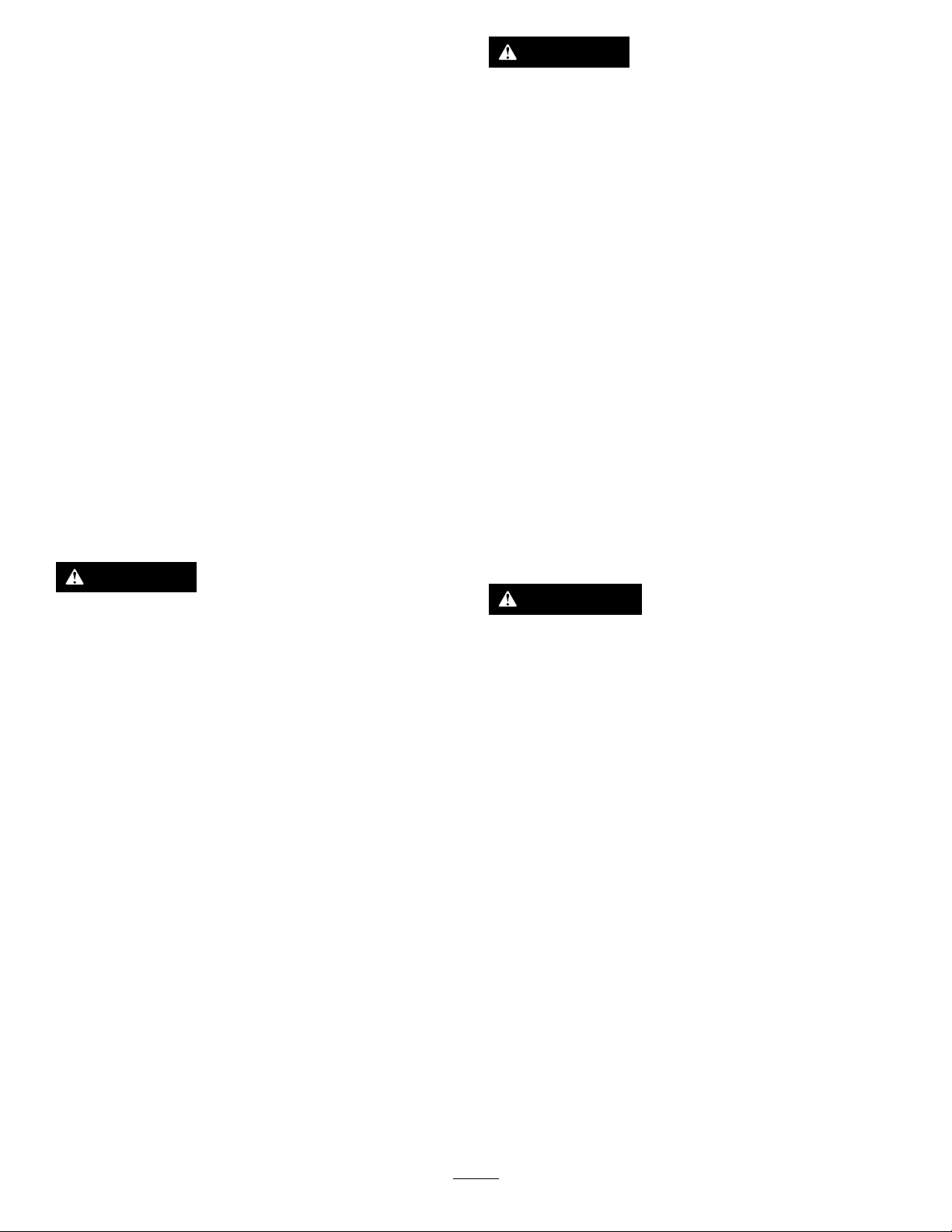

116-8813

1.Hopperupindicator5.Parkingbrake

2.Battery6.Neutral

3.Hourmeter

4.PTO

7.Operatorpresenceswitch

116-8936

1.Danger—donotoperatewithdeckintilt-upposition.

116-8941

116-8934

1.Warning—disengage

bladeclutch,shutoff

engine,andremove

keybeforemaking

adjustments,servicing,

orcleaningdeck.

1.Warningfoldingdeckhazard—lockthepivotjointby

pushinginwardandrotatingtowardsthefrontofthedeck.

116-8935

2.Heightofcut.

116-8943

1.Rotatingbladeshazard—disengagePTO,movespeed

controllevertoneutral,engageparkingbrake,stopengine,

andremovekeybeforeleavingtheoperator’sposition.

Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Danger—donotoperatewithmowerhopperinraised

position

9

Page 10

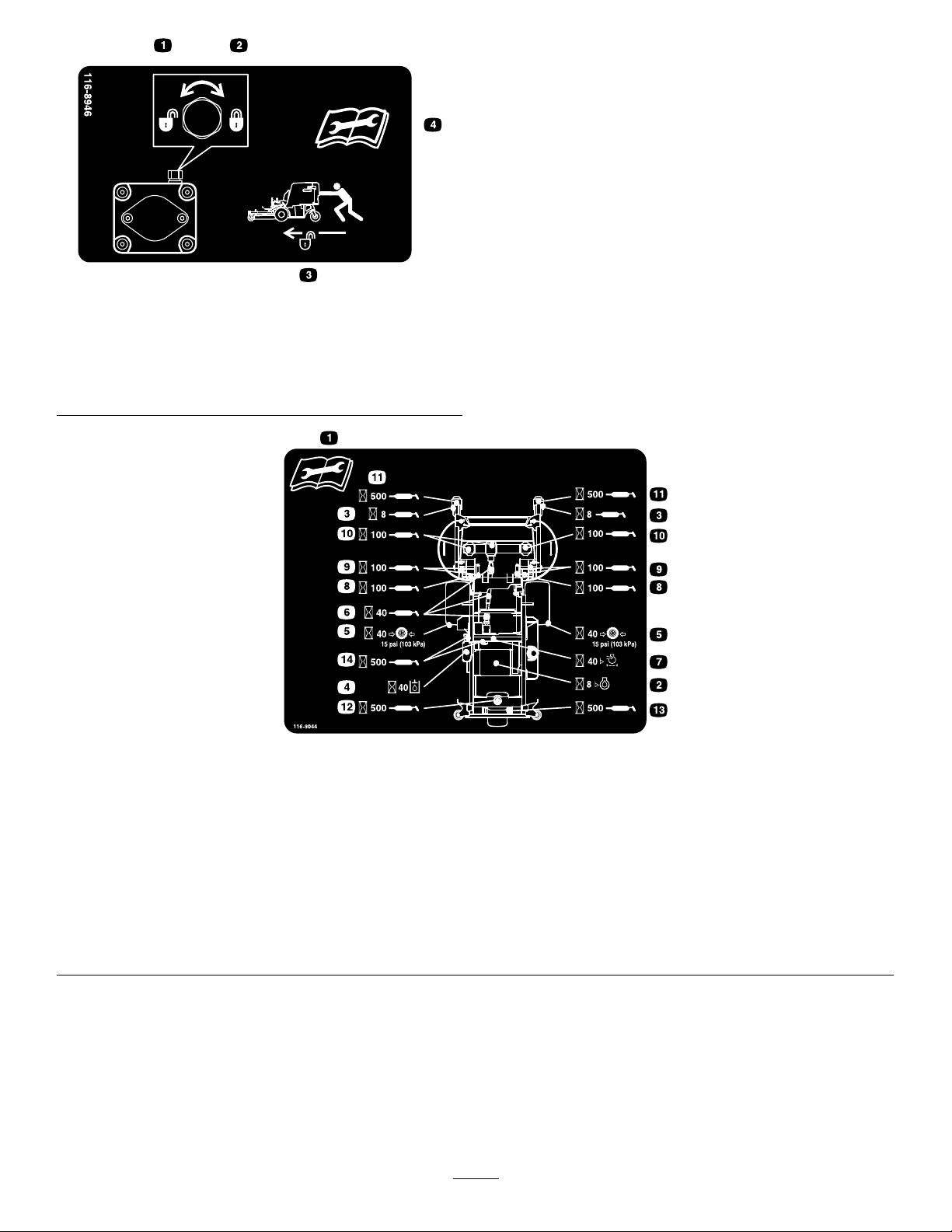

116-8946

1.Rotatecounterclockwise

torelease.

2.Rotateclockwisetolock.4.Readtheinstructions

3.Unlocktopushthe

machine.

beforeservicingor

performingmaintenance.

116-9044

1.ReadtheOperator’sManualbeforeperformingany

maintenance.

2.Checkengineoilevery8hours.9.Greasedeckpivotsevery100hours.

3.Greasefrontcasterwheelbearingsevery8hours.10.Checkgearboxoilevery100hours(useonlyMobil175W-90

4.Checkhydraulicuidlevelevery40hours(onlyuse

recommendedhydrooil).

5.Checktirepressureevery40hours.12.Greaserearcasterpivotevery500hours.

6.GreasedeckdrivePTOevery40hours.13.Greaserearcasterwheelevery500hours.

7.Checkaircleanerevery40hours.14.Greasebeltidlersevery500hours.

8.Greasedecklockmechanismevery100hours.

gearoil).

11.Greasefrontcasterpivotsevery500hours.

10

Page 11

116-9049

1.Rotatingdrivelinehazard—keepalldrivelineshieldsin

place.Securelyattachbothendsofthedriveline.

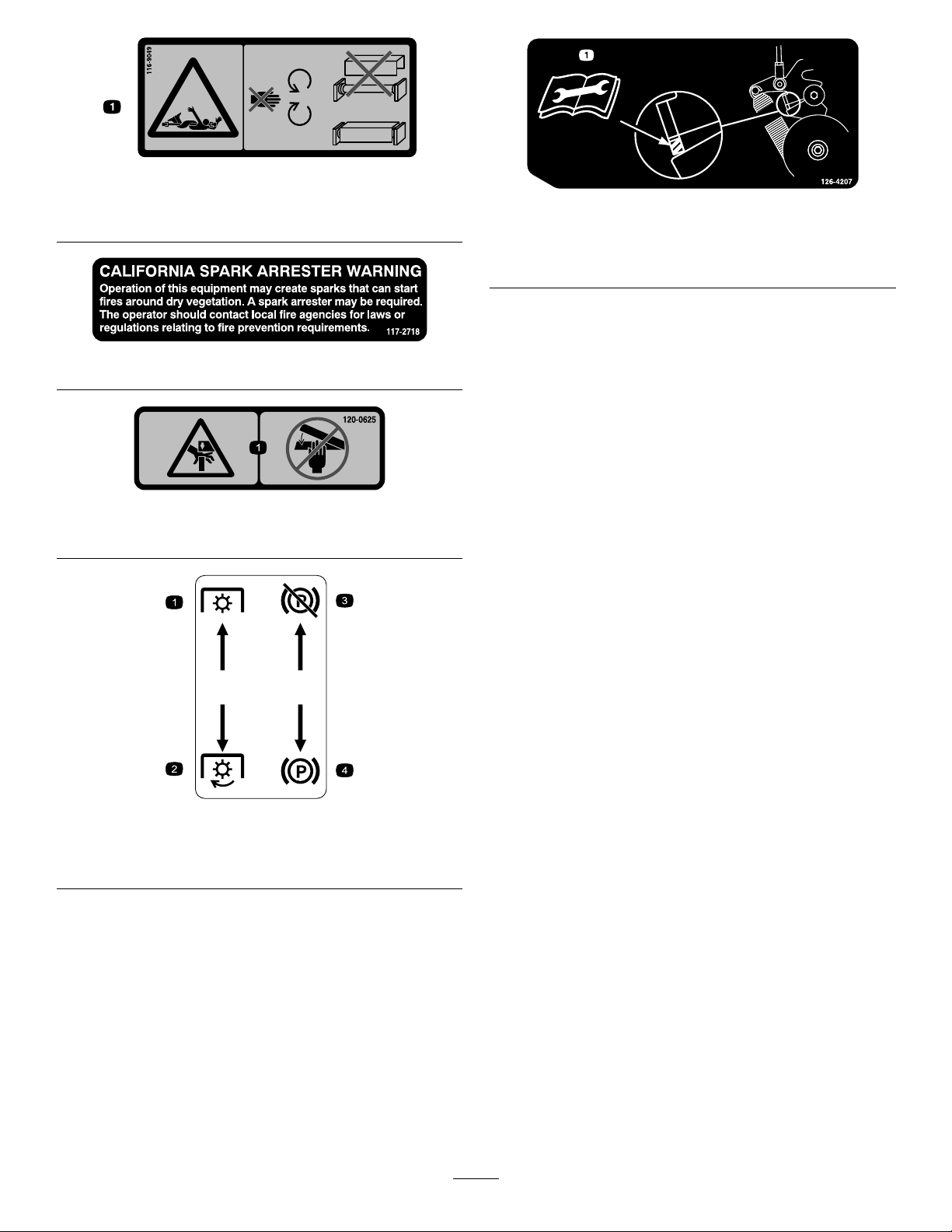

117-2718

120-0625

1.Pinchpoint,hand—keephandsaway.

126-4207

1.RefertotheOperator’sManualforadjustmentprocedure.

WhenPTOisengaged,idlerarmpositionmustbein

hatchedareaoradjustmentisrequired.

MoldedinLeftConsole

1.PTO—disengage

2.PTO—engage

3.Parkbrake—release

4.Parkbrake—engage

11

Page 12

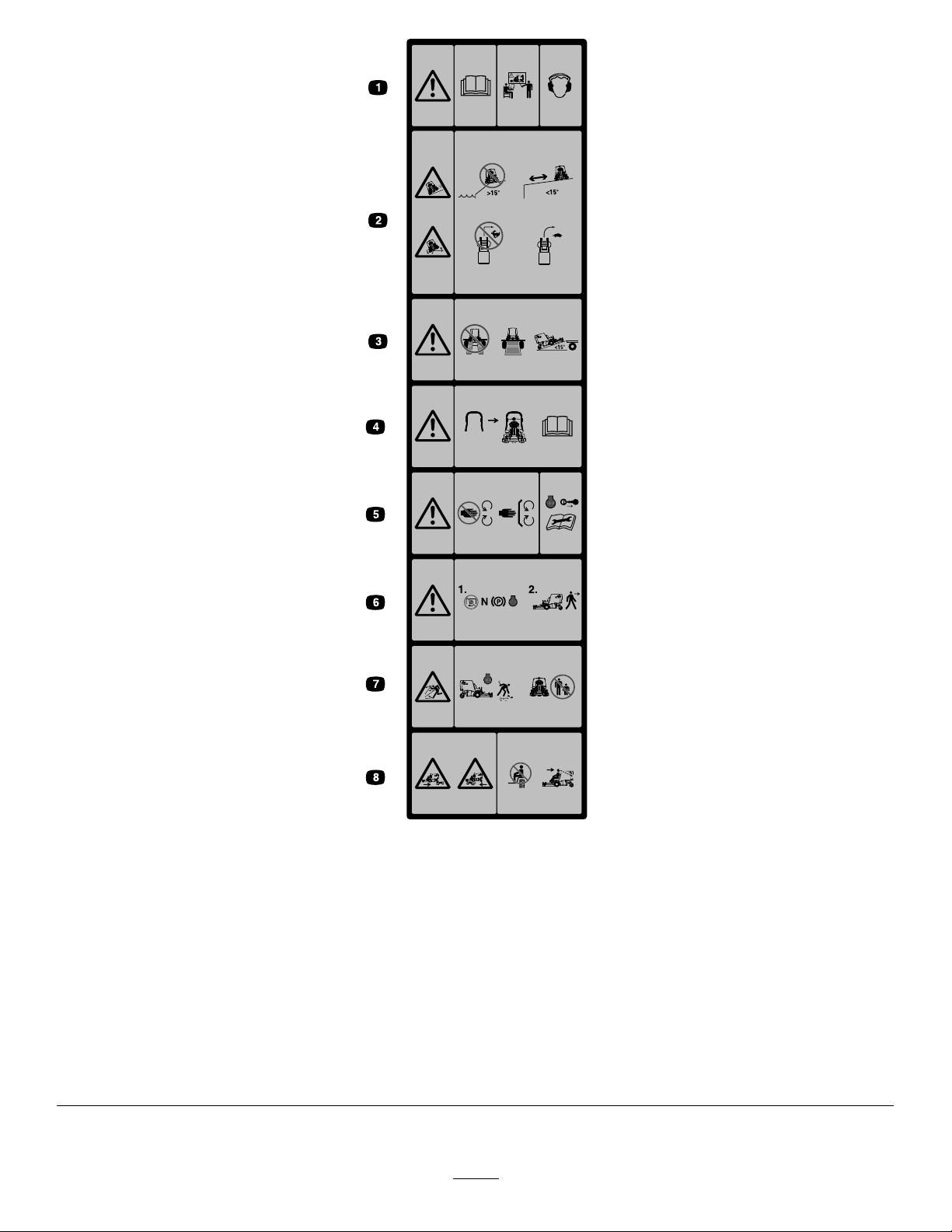

MoldedintoFrontofHopper

1.Warning-ReadtheOperator’sManual.Donotoperatethis

machineunlessyouaretrained.Wearhearingprotection.

2.Sliding,tippinghazard—Donotusethemachinenear

drop-offswithslopesgreaterthan15degrees,usethe

machineasafedistanceformdrop-offsonslopeslessthan

15degrees;Donotturnsharplywhiletravelingfast,drive

slowlywhenturning.

3.Warning—Donotusedualramps,useonepiecerampswhen

transportingmachine;Donotuserampswithinclination

greaterthan15degrees.

4.Arollbarisavailableanditsuseisrecommendedforareas

wherethereareslopes,drop-offs,orwater

5.Warning—Stayawayfrommovingparts;keepallguards

inplace.Stopengineandremovekeybeforeadjusting,

servicing,orcleaning.

6.Warning—DisengagePTO,movespeedcontrolleverto

neutralposition,engageparkingbrake,andstopengine

beforeleavingtheoperator’sposition.

7.Thrownobjecthazard—Pickupobjectsthatcouldbethrown

bymower.Donotoperatewhenpeopleandpetsareinthe

area.Keepdeectorinplace.

8.Crushing/dismembermenthazardofbystanders—Donot

carrypassengers,lookforwardanddownwhenoperatingthe

machine,lookbehindanddownwhenreversing.

12

Page 13

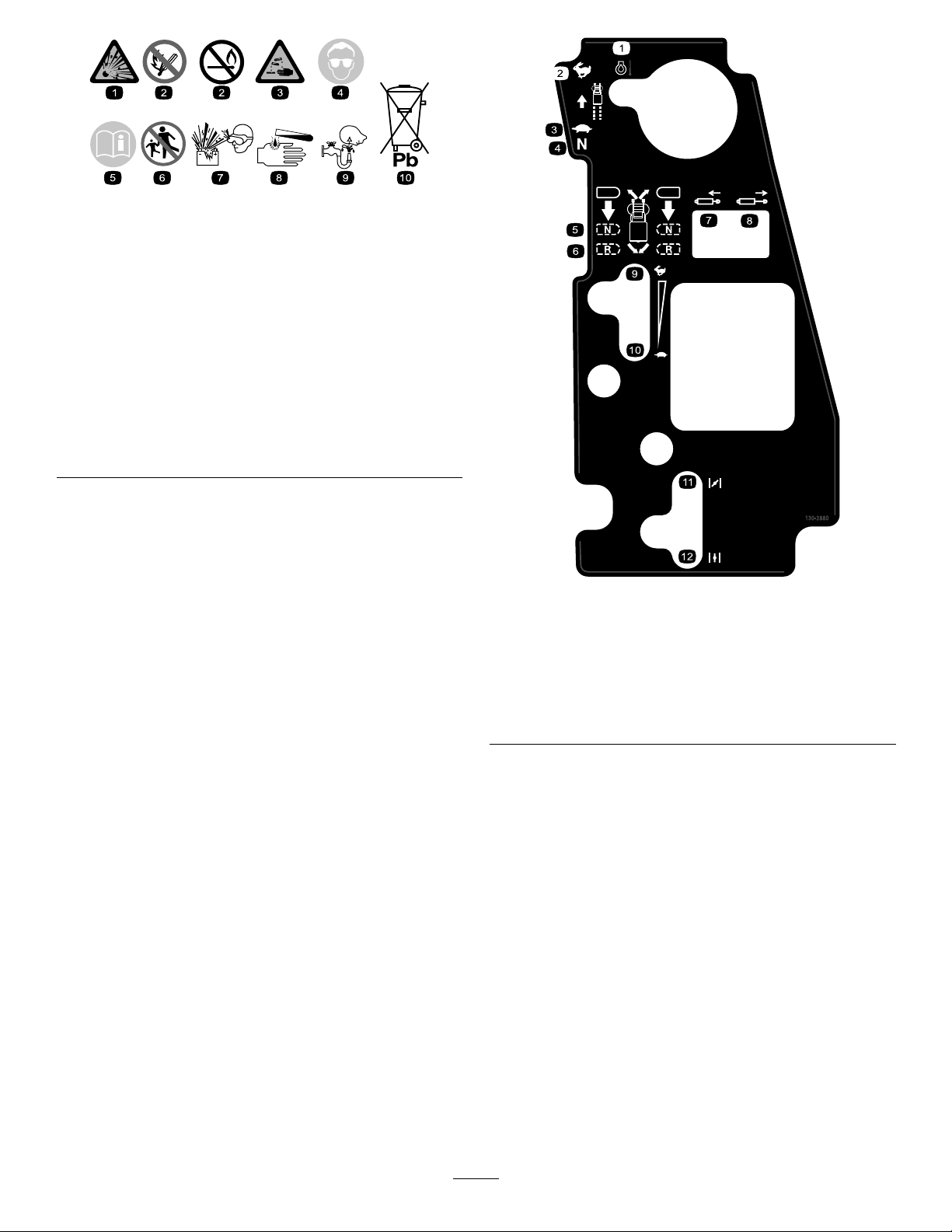

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

130-2880

1.Enginetemperature7.Retractthepiston

2.Fast8.Extendthepiston

3.Slow

4.Neutral

5.Neutral

6.Reverse

9.Fast

10.Slow

11.Choke—closed/on

12.Choke—open/off

13

Page 14

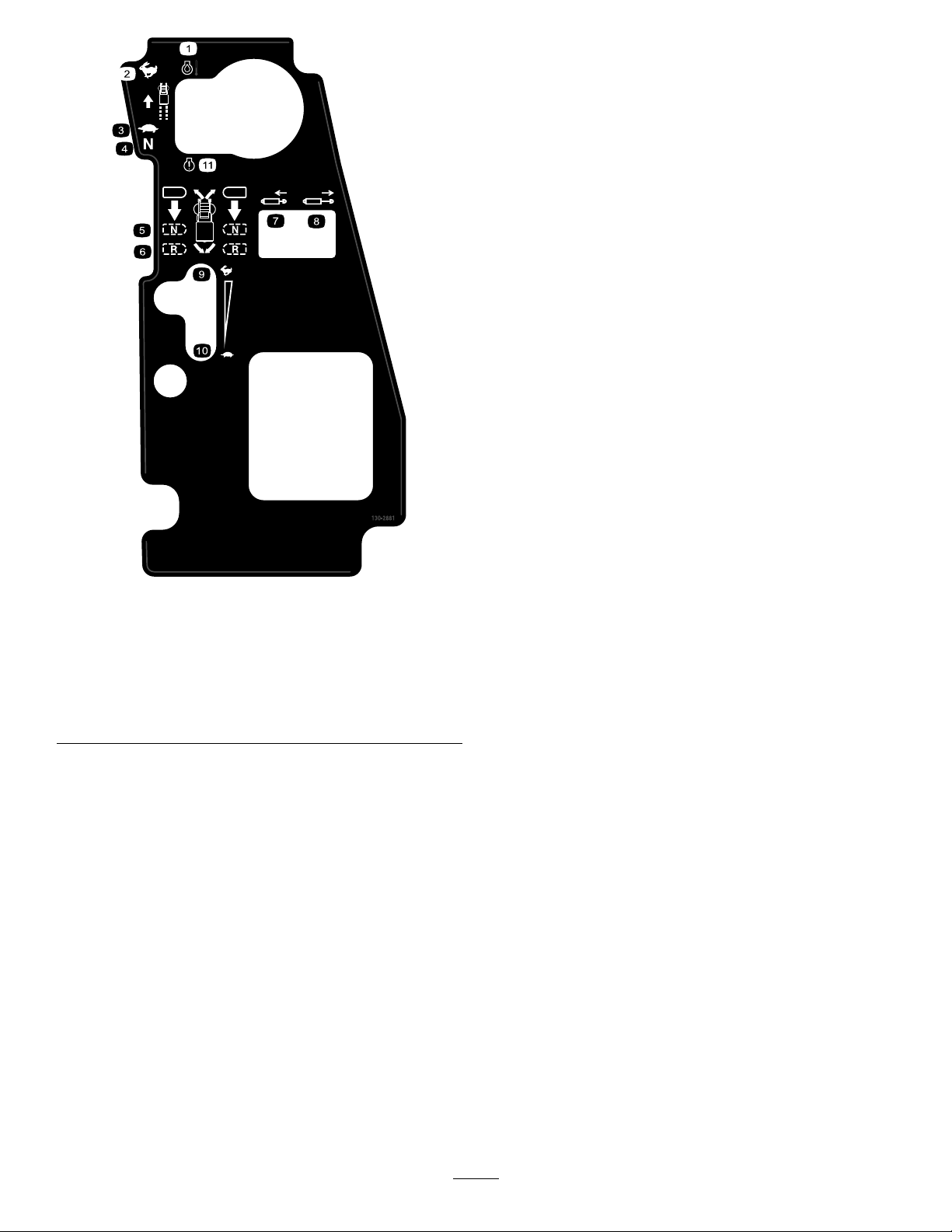

130-2881

1.Enginetemperature7.Retractthepiston

2.Fast8.Extendthepiston

3.Slow

4.Neutral

5.Neutral11.MILtoggleswitch

6.Reverse

9.Fast

10.Slow

14

Page 15

ProductOverview

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachineforward

andreverse,andtoturneitherdirection.

Speed-ControlLever

Thespeed-controlleversetsmaximumforwardspeedofthe

machine(Figure4).Movingthespeed-controlleverrearward

totheNEUTRALpositionplacesthedrivesystemintoneutral.

ThrottleControl

ThethrottlecontrolisvariablebetweentheFASTandSLOW

positions.

ChokeControl(NotonEFImachines)

Usethechoketostartacoldengine.Movethechoketothe

CLOSED/ONpositiontostartacoldengine.

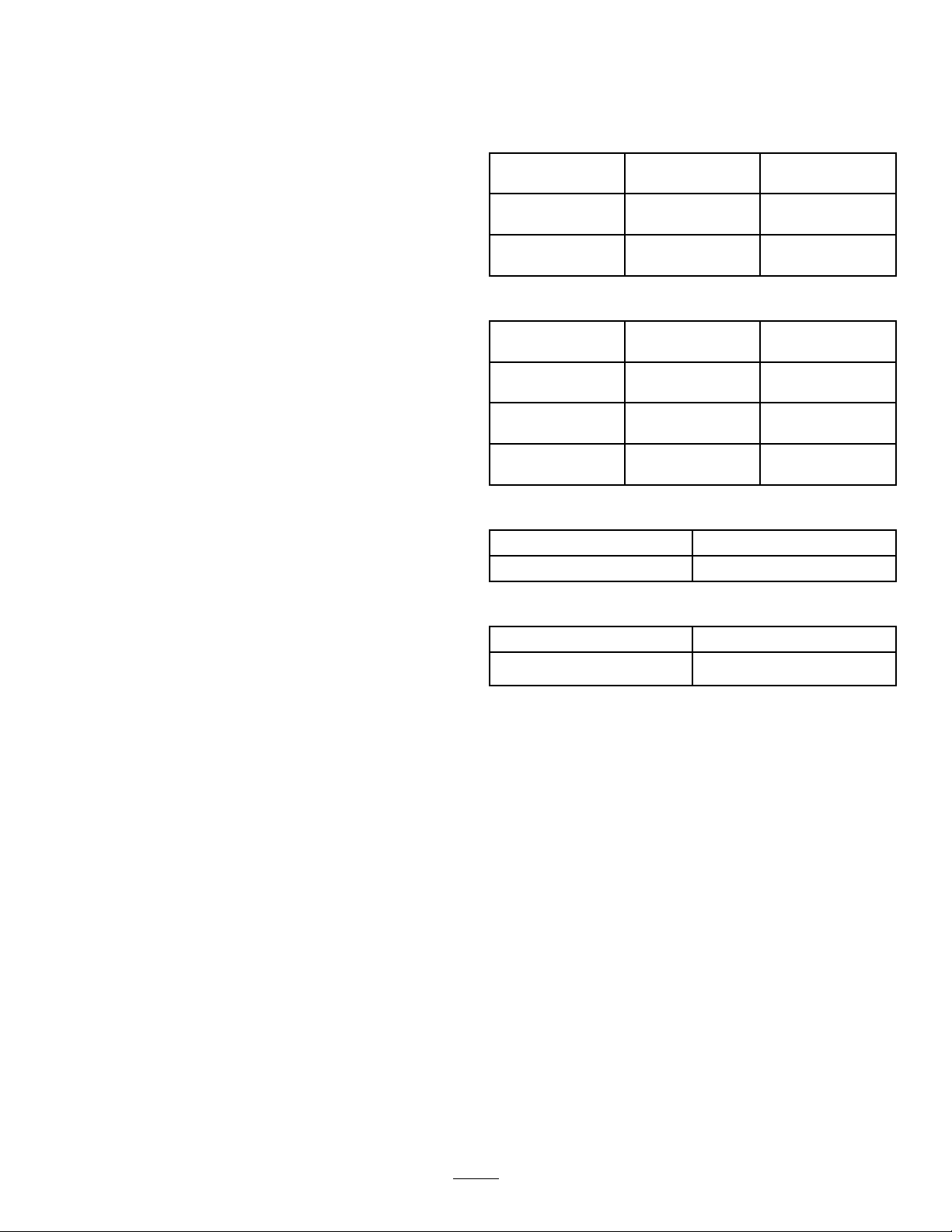

Figure4

1.Speed-controllever

2.Controls5.PTO-engagementlever

3.Fuelcap6.Parking-brakelever

4.Motion-controllevers

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

Note:DonotrunawarmenginewithchokeintheON

position.

BrakeLever

Thebrakeleverengagesaparkingbrakeonthedrivewheels

(Figure4).

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas3

positions:START,RUN,andOFF.

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Thehourmeterisrecordingwhenthedecimal

pointisashingintheHour/Voltagedisplay.Usethesetimes

forschedulingregularmaintenance(Figure6).

Figure5

1.Ignitionswitch5.Throttle

2.Hopperswitch6.Engine-oiltemperature

3.Messagedisplay

4.Choke(notonEFI

machines)

7.Checkenginelight(EFI

lightandbuzzer

machinesonly)

Figure6

1.Safety-interlockindicators

2.Hopperup

3.Hour/Voltagedisplay

4.Low-voltageindicatorlight

15

Page 16

Safety-InterlockIndicators

Therearesymbolsonthehourmeterandtheyindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

position(Figure6).

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

Fuel-ShutoffValve

Closethefuel-shutoffvalve(underthehopper)when

transportingorstoringthemower.

PTO-EngagementLever

UsethePTO-engagementlevertoengagethebladesandthe

blower.Pulltheleveruptoengagethebladesandblower.

Todisengagethebladesblower,pushthePTO-engagement

leverdown.

BatteryIndicatorLight

WhenyouinitiallyturntheignitionkeytotheRUNposition

forafewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursnormallydisplay.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

6).

Engine-Oil-TemperatureLightand

Buzzer

Theengine-oil-temperaturelightmonitorsthetemperature

oftheengineoil.Anilluminatedengine-oil-temperature

lightandintermittentbuzzingsoundsignalstheengineis

overheating.

42-inchMower

Deck

WithoutMower

Deck

WithMowerDeck

108.2cm(42.6

inches)

109.7cm(43.2

inches)

Length

42-inchMower

Deck

WithoutMower

Deck

MowerDeck—Up

Mower

Deck—Down

170.9cm(67.3

inches)

209.3cm(82.4

inches)

233.2cm(91.8

inches)

Height

42-inchMowerDeck48-inchMowerDeck

130.0cm(51.2inches)130.0cm(51.2inches)

Weight

42-inchMowerDeck48-inchMowerDeck

517kg(1,140lb)531kg(1,170lb)

48-inchMower

Deck

108.2cm(42.6

inches)

125.0cm(49.2

inches)

48-inchMower

Deck

170.9cm(67.3

inches)

207.6cm(81.8

inches)

240.0cm(94.5

inches)

Electronic-Control-Unit

Malfunction-IndicatorLight

Theelectronic-controlunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifthesystemdetectsaproblemorfault,the

malfunction-indicatorlight(MIL)illuminates.

TheMILislocatedintherightconsolepanel.

IftheMILilluminates,performtheinitialtroubleshooting

checks;refertotheMILsectioninTroubleshooting(page58).

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

16

Page 17

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkthatcan

ignitethegasolinevapors.Areorexplosionfrom

gasolinecanburnyouandothersandcandamage

property.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

containerratherthanfromagasoline-dispenser

nozzle.

•Ifyoumustuseagasoline-dispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillswith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorage,drainthefueltank.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasolinestabilizer/conditioner

tothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethechance

17

Page 18

ofvarnishdepositsinthefuelsystem,usefuelstabilizer

G009027

1

2

atalltimes.

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcapandremoveit.

4.Addregularunleadedgasolinetothefueltankuntil

thelevelis6to13mm(1/4to1/2inch)belowthe

bottomofthellerneck.

Note:Thisspaceinthetankallowsthegasolineto

expand.Donotllthefueltankcompletelyfull;refer

to(Figure4).

CheckingtheEngine-OilLevel

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page33).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

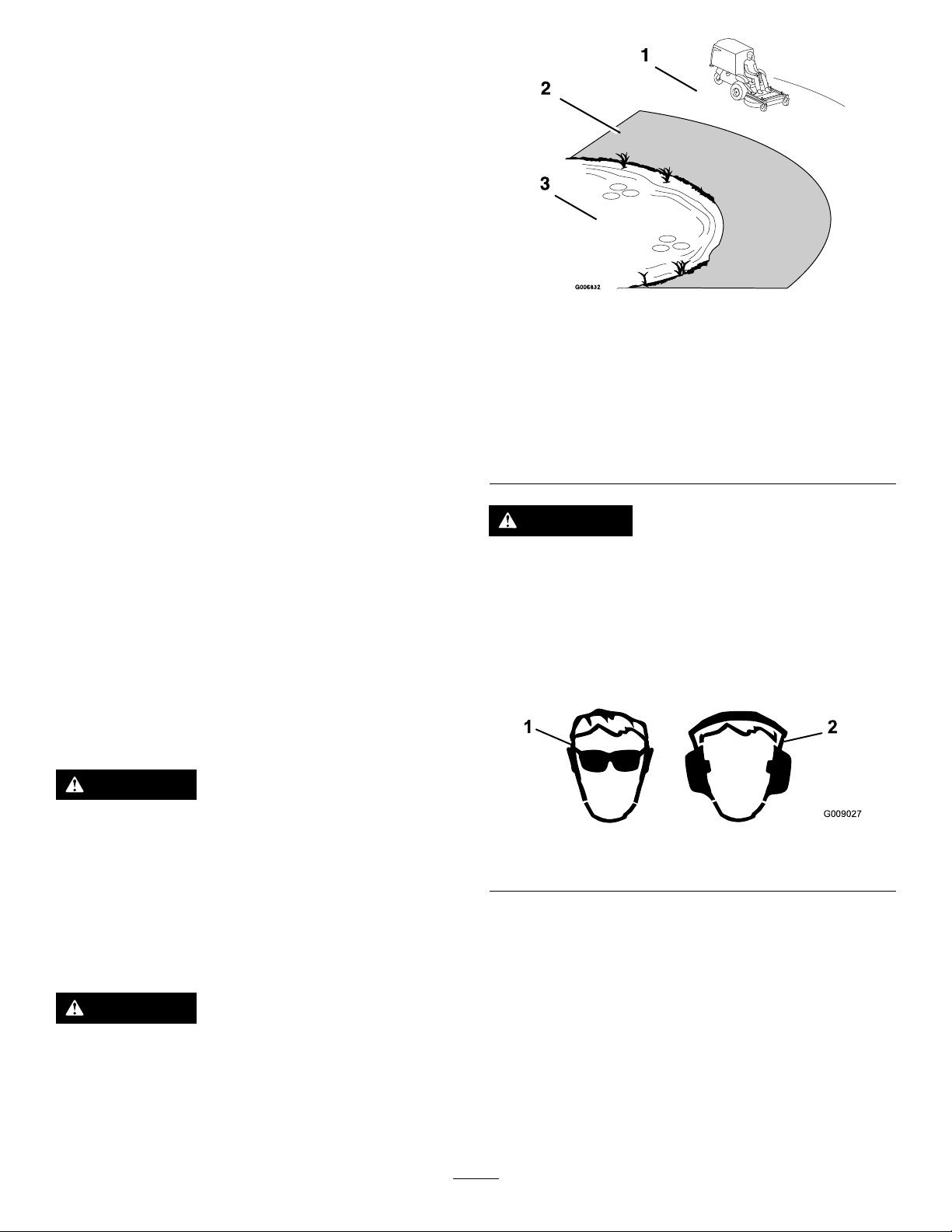

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

Figure7

1.Safezone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.Dangerzone—useawalk

behindmowerand/ora

handtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

3.Water

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyourseyes,ears,hands,andfeet.

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15degrees.

1.Weareyeprotection.2.Wearhearingprotection.

Figure8

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

18

Page 19

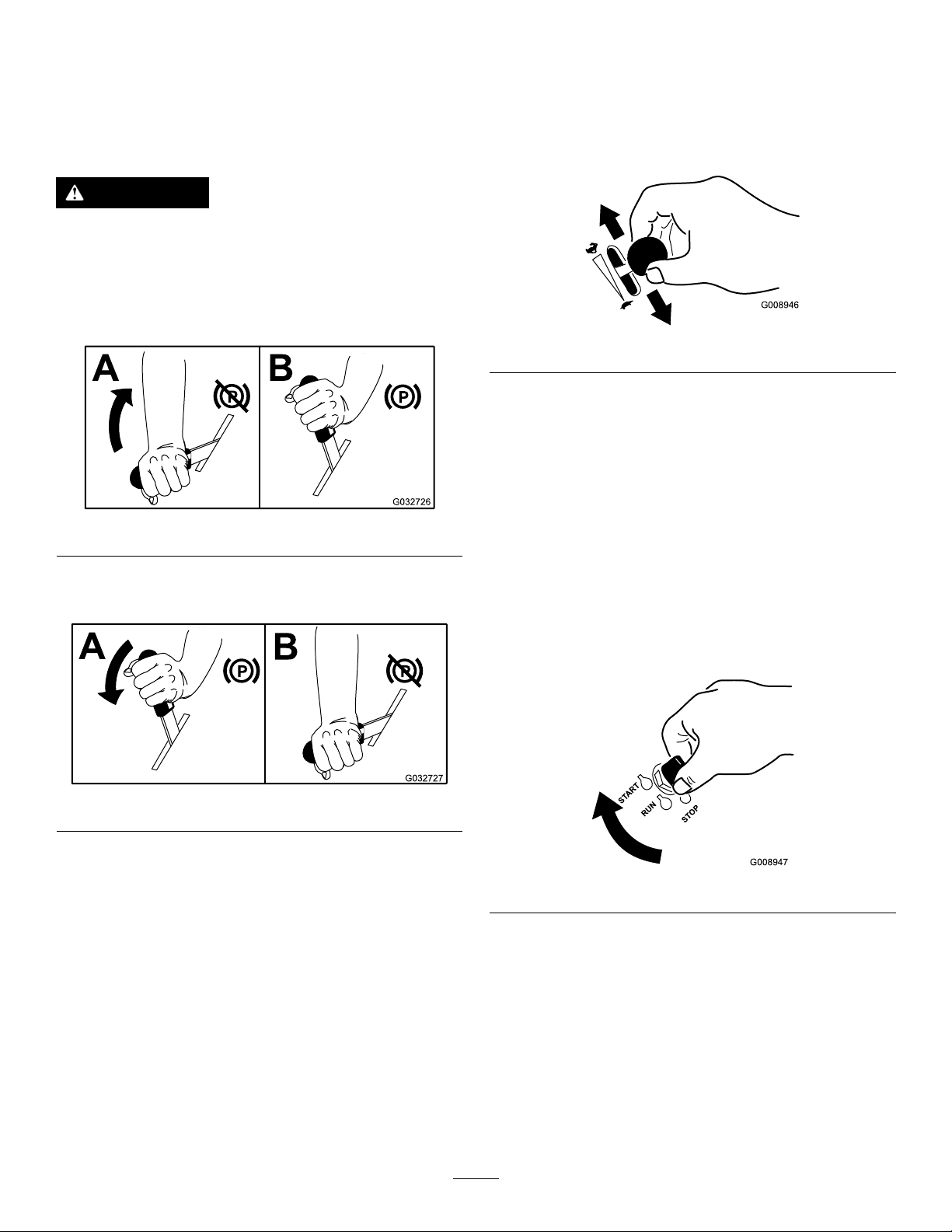

OperatingtheParkingBrake

G008946

START

RUN

STOP

G008947

OperatingtheThrottle

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

WARNING

Theparkingbrakemaynotholdamachineparked

onaslopeandcouldcausepersonalinjuryor

propertydamage.

Donotparkthemachineonslopesunlessthe

wheelsarechockedorblocked.

Figure9

ReleasingtheParkingBrake

YoucanmovethethrottlecontrolbetweentheFASTand

SLOWpositions(Figure11).

Alwaysusethemiddlepositionwhenturningonthemower

deckandblowerwiththePTO-engagementlever.

Figure11

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheSTARTposition(Figure12).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failureto

followtheseinstructionscanburnoutthestarter

motor.

Note:Youmayneedmultipleattemptstostartthe

enginewhenyoustartitthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure10

Figure12

2.TurntheignitionkeytotheSTOPpositiontostopthe

engine.

19

Page 20

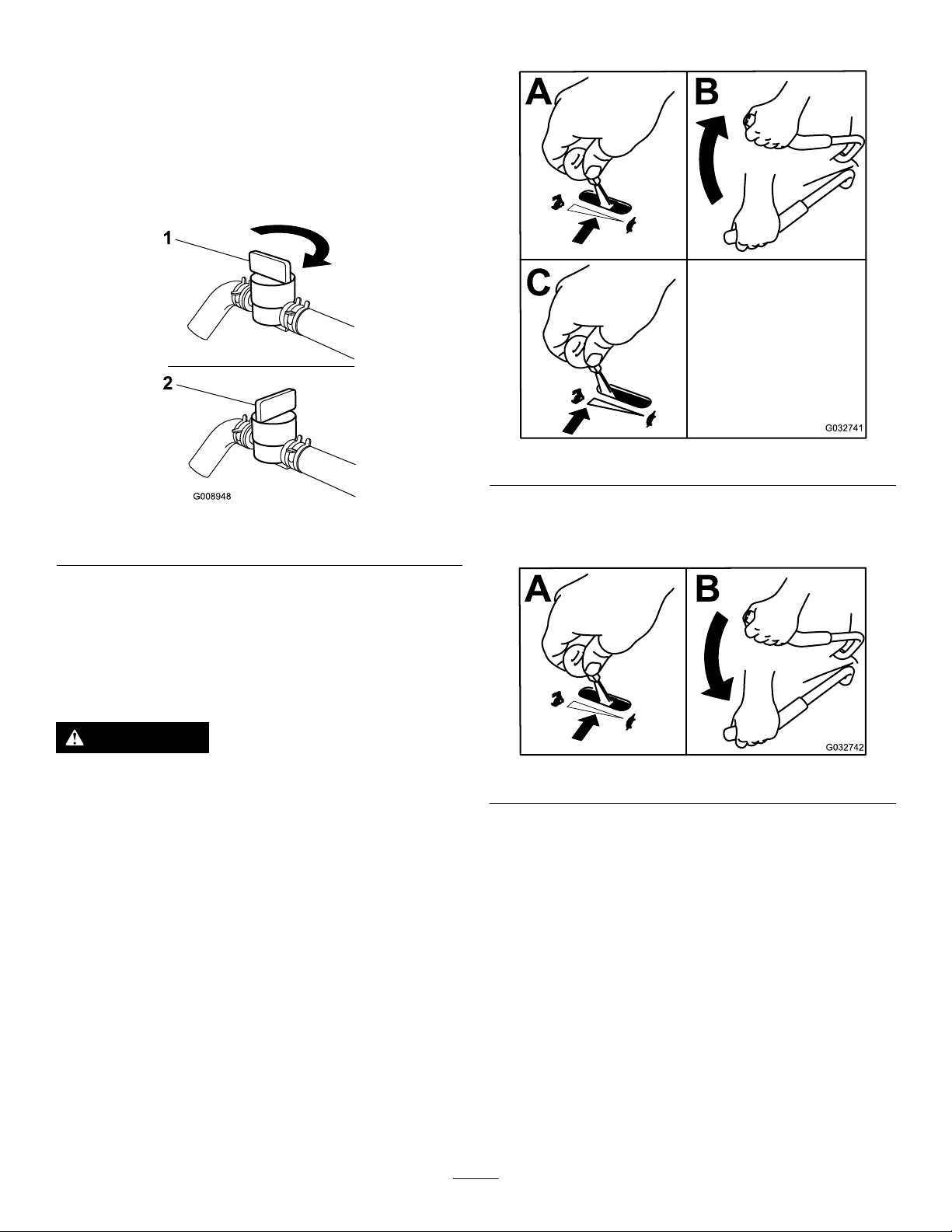

UsingtheFuel-ShutoffValve

G008948

1

2

Thefuel-shutoffvalveislocatedunderthehopper.Raisethe

hoppertoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,and

storage.

Ensurethatthefuel-shutoffvalveisopenwhenstartingthe

engine.

EngagingthePTO-EngagementLever

Figure14

Figure13

DisengagingthePTO-Engagement

1.On2.Off

Lever

Operatingthe PTO-EngagementLever

ThePTO-engagementleverstartsandstopsthemower

bladesandblower.

WARNING

Anuncovereddischargeopeningallowsobjectsto

bethrownatyouandbystanders.Also,contactwith

theblowerbladescouldoccur.Thrownobjectsor

bladecontactcancauseseriousinjuryordeath.

Neveroperatethemowerwiththehopperorhopper

doorraised,removed,oraltered.

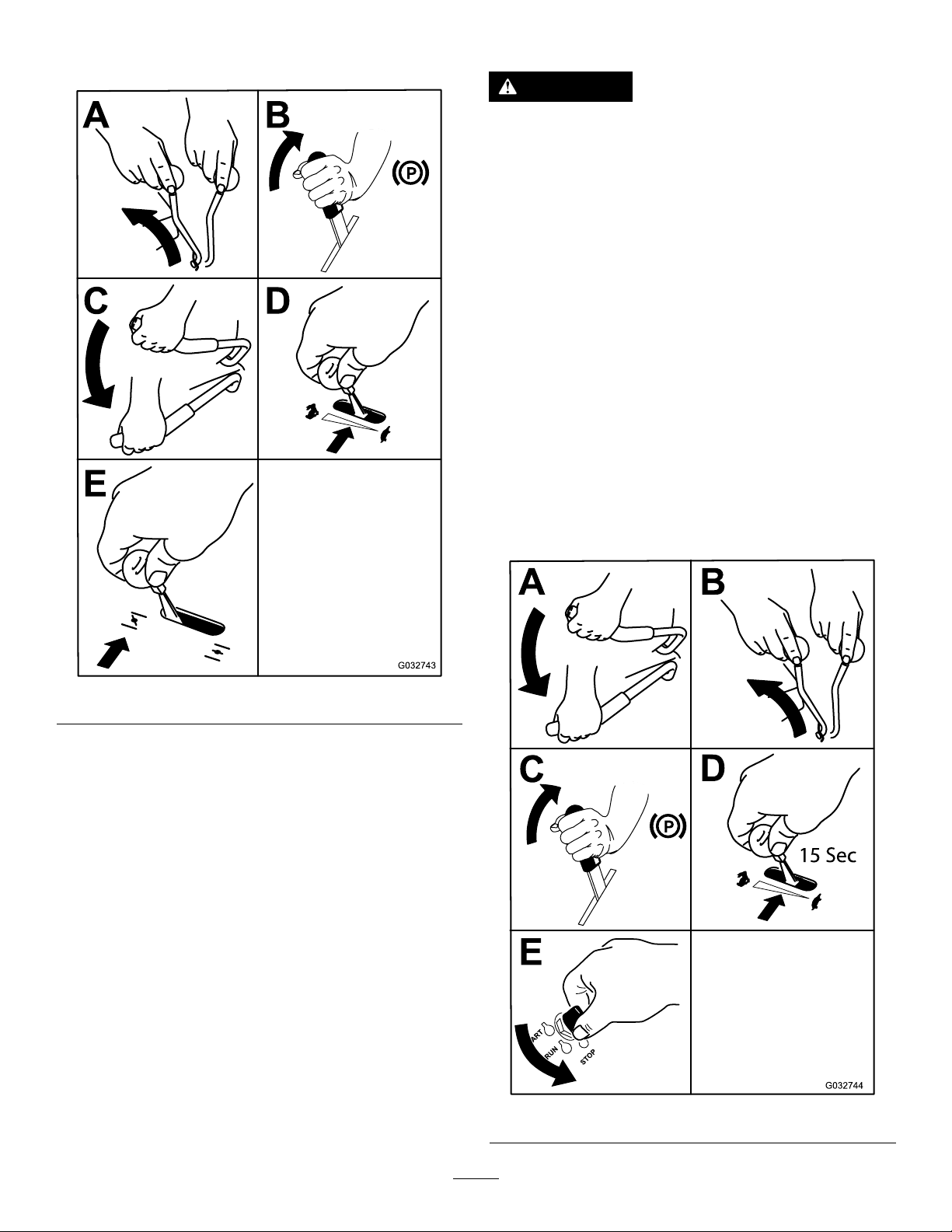

StartingandStoppingthe Engine

StartingtheEngine

1.Movethespeed-controllevertotheNEUTRALposition.

2.Settheparkingbrake;refertoSettingtheParking

Brake(page19).

Figure15

3.MovethePTO-engagementlevertotheOFFposition

(Figure16).

4.MovethethrottlelevermidwaybetweentheSLOWand

FASTpositions.

5.ForEFImachines:Onacoldengine,pushthechoke

leverforwardintotheCLOSED/ONposition.On

20

Page 21

awarmengine,leavethechokeintheOPEN/OFF

position.

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Important:Makesurethatthefuel-shutoffvalveis

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesuretoremovethekeyasthefuel

pumpmayrunandcausethebatterytolosecharge.

1.DisengagethePTO .

2.Movespeed-controllevertotheNEUTRALposition.

3.Engagetheparkingbrake.

4.Placethethrottleinthemiddleposition.

5.Allowtheenginetorunforaminimumof15seconds,

thenturntheignitionswitchtotheOFFpositionto

stoptheengine.

6.Removethekeytopreventchildrenorother

unauthorizedpersonsfromstartingengine.

Figure16

6.TurntheignitionkeytotheSTARTposition(Figure

12).Whentheenginestarts,releasethekey.

Important:Donotcranktheenginecontinuously

formorethan10secondsatatime.Iftheengine

doesnotstart,wait60secondsbetweenstarting

attempts.Failuretofollowtheseguidelinescan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

7.IfthechokeisintheCLOSED/ONposition,gradually

returnchoketotheOPEN/OFFpositionastheengine

warmsup.

Figure17

21

Page 22

7.Closethefuel-shutoffvalvewhenthemachinewillnot

beinuseforafewdays,whentransporting,orwhen

theunitisparkedinsideabuilding.

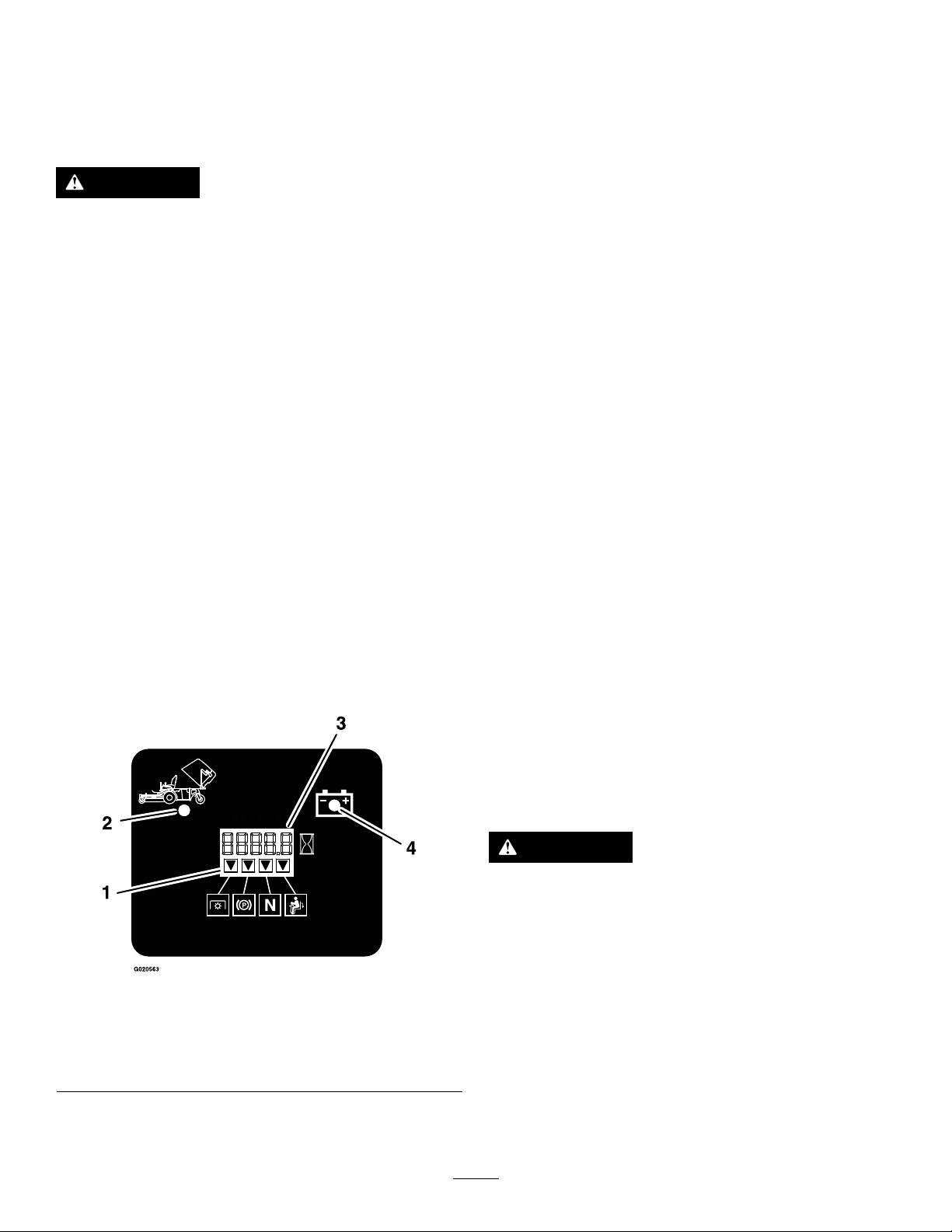

TheSafety-InterlockSystem

CAUTION

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafety-Interlock

System

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•ThePTO-engagementleverisdisengaged.

•Thespeed-controlleverisintheNEUTRALposition

TestingtheSafety-InterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sitontheseat,engagetheparkingbrake,movethe

PTO-engagementlevertotheONposition,andmove

thespeed-controllevertotheNEUTRALposition.Try

startingtheengine;theengineshouldnotstart.

2.Sitontheseat,engagetheparkingbrake,andmovethe

PTO-engagementlevertotheOFFposition.Movethe

speed-controlleveroutoftheNEUTRALposition.Try

startingtheengine;theengineshouldnotstart.

3.Sitontheseat,disengagetheparkingbrake,movethe

PTO-engagementlevertotheOFFposition,andmove

thespeed-controllevertotheNEUTRALposition.Try

startingtheengine;theengineshouldnotstart.

4.Sitontheseat,engagetheparkingbrake,movethe

PTO-engagementlevertotheOFFposition,andmove

thespeed-controllevertotheNEUTRALposition.Now

starttheengine.Whiletheengineisrunning,release

theparkingbrake,engagethePTO-engagementlever,

andriseslightlyfromtheseat;theengineshouldshut

off.

Thesafety-interlocksystemisdesignedtostoptheengine

whenyourisefromtheseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifyyouwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglelightsupin

thecorrespondingsquare.

Figure18

1.Triangleslightupwhen

theinterlockcomponents

areinthecorrectposition.

2.Hopperup4.Low-voltageindicatorlight

3.Hour/Voltagedisplay

5.Sitontheseat,engagetheparkingbrake,movethe

PTO-engagementlevertotheOFFposition,andmove

thespeed-controllevertotheNEUTRALposition.Now

starttheengine.Movethespeed-controlleverforward;

theengineshouldshutoff.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

22

Page 23

DrivingForward

Note:Tobeginmovement(forwardorbackward)the

operatormustbeintheseat,thebrakelevermustbe

disengaged(pusheddown)beforethespeedcontrollevercan

bemovedforwardortheenginewillstop.

Tostop,pullthespeedcontrollevertotheneutralposition.

1.Starttheengine.

2.Releasetheparkingbrake;referto(page).

WARNING

Incorrectlyraisingorloweringamowerdeck

canbedangerous.Adroppedmowerdeckcan

resultinaseriousinjuryorpropertydamage.

•Alwaysraiseandlowerthemowerdeckon

at,dryground,freeofanyobstructions.

•Firmlygraspthemower-deck-lifthandle

andloweritinaslow,controlledmanner.

3.Tomoveforwardinastraightlinemovethespeed

controlleverforward.

Note:Themachinewillmovefasterthefartherthe

speedcontrolleverismovedawayfromneutral.

4.Toturnleftorright,pulloneofthesteeringleversback

towardneutralinthedirectiondesired.

5.Tostop,pullthespeedcontrolleverbacktotheneutral

position.

DrivingBackward

1.Tomoverearwardinastraightline,pullbothsteering

leversrearwardequally.

Toturnleftorright,releasepressureonthesteering

levertowardthedirectiondesired.

2.Tostop,releasethesteeringleverstotheneutral

position.

StoppingtheMachine

1.Pullthespeed-controlleverbacktotheNEUTRAL

position,disengagethePTO-engagementlever,and

turntheignitionkeytotheOFFposition.

2.Settheparkingbrakewhenyouleavethemachine;

refertoSettingtheParkingBrake(page19).

•Alwaysmakesurethemowerdeckis

securelylatchedintheUporDown

position.

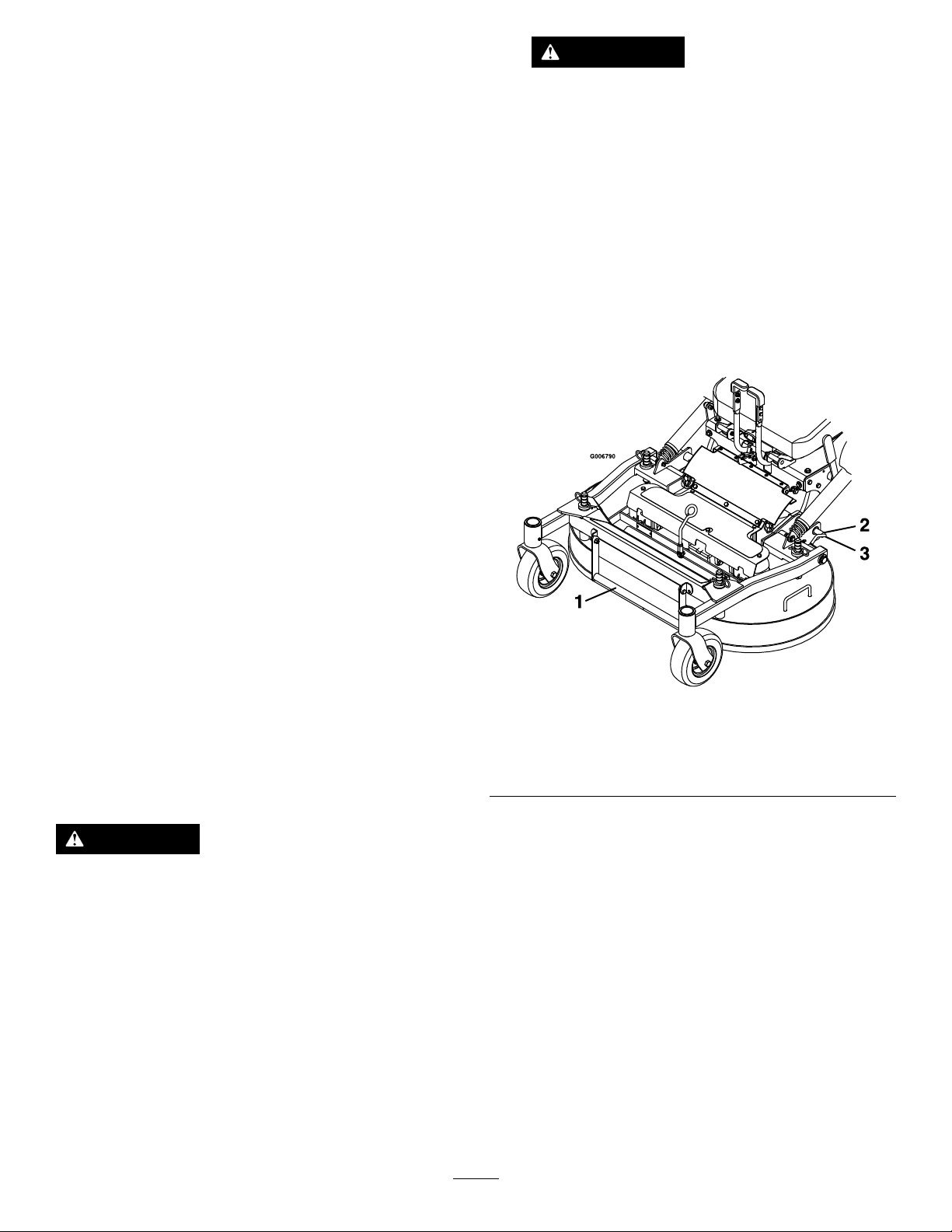

2.Releasethemower-decklockingpinsoneachside

(Figure19).

Figure19

1.Deck-lifthandle

2.Rotatethepintowardtherearandpulloutwardtounlock.

3.Pushthepininandrotateittowardthefronttolock.

3.Removethekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

RaisingtheMowerDeckinto theServicePosition

1.Shutofftheengine,waitforallmovingpartstostop,

andremovethekey.Engagetheparkingbrake.

3.Usingthedeck-lifthandle,liftthedeckupandlatchit

intheUpposition(Figure20).

Note:Thelatchislocatedatthefrontcenterofthe

seat.

23

Page 24

Thefollowingarepossiblecongurations:

•Bafesopenwithstandardblades—maximumcollection

•Bafesclosedwithstandardblades—partialmulching

•Bafesclosedwithmulchblades—intermediatemulching

•Mulchpluginstalledwithmulchblades—complete

mulching(requiresmulchkit)

AdjusttheFRSbafesasfollows:

1.Shutofftheengine,waitforallmovingpartstostop,

andremovekey.

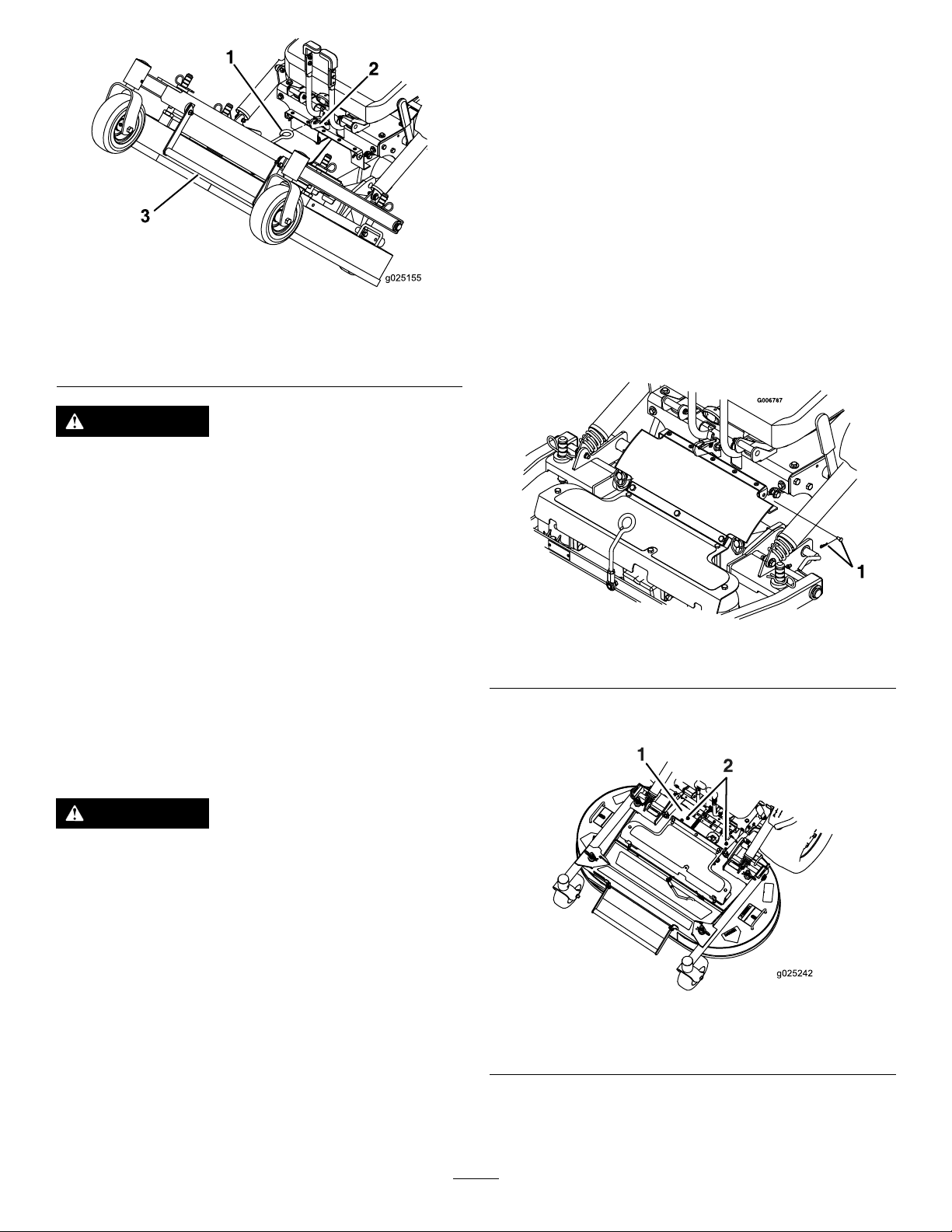

Figure20

1.Securethemower-deck

latchontothehook.

2.Hook

3.Deck-lifthandle

WARNING

Operatingthemowerdeckintheraisedservice

positioncanbedangerous.EngagingthePTOwith

adeckintheraisedpositioncanresultinaserious

injuryorpropertydamage.

Alwayslowerandlockmowerdeckintheoperation

positionbeforeengagingthePTO.

LoweringtheMowerDeckto theOperatingPosition

1.Whilermlyholdingontodeck-lifthandle,unhookthe

mower-decklatchfromthemachineandslowlylower

themowerdecktotheground(Figure20).

2.Pushthedeck-lockingpinsinwardandrotatethem

forwardtosecurelylockthemowerdeckinthelowered

position(Figure19).

2.Engagetheparkingbrake.

3.Removethehairpincottersandclevispinsfromboth

sidesofthePTOguard(Figure21).

4.Foldtheguardforward.

Figure21

1.Hairpincotterandclevispin

5.LoosenthelocknutsontherearstudsoftheFRS

bafes.

WARNING

Operatingthemowerwithoutthelockingpins

securelylatchedcanresultinthemowerdeck

foldingupunexpectedly .Themowerdeckfolding

upunexpectedlycancauseseriousinjury.

Alwaysoperatemowerwithlockingpinssecurely

latched.

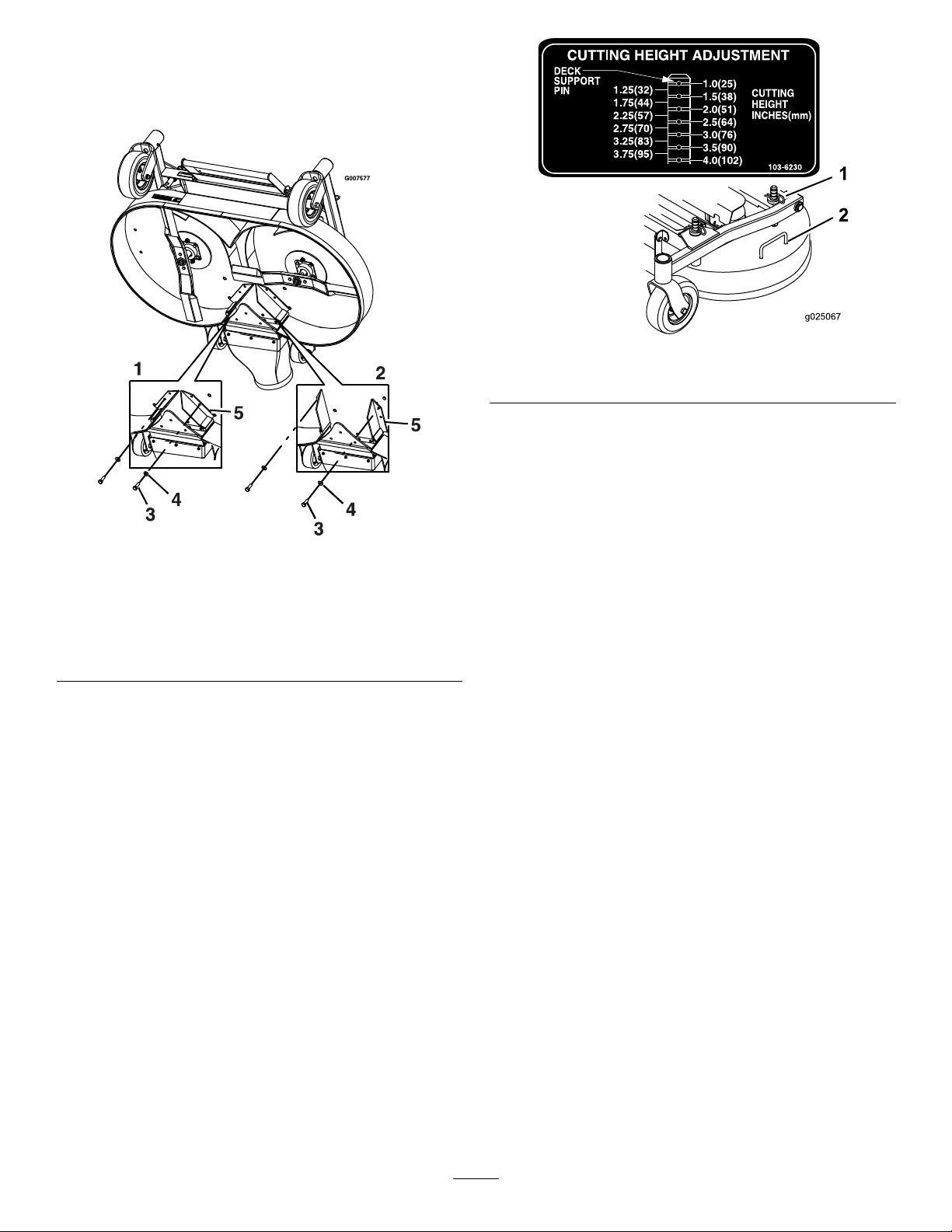

AdjustingtheFillReduction

System(FRS)Bafes

Thellreductionsystemhasbeendesignedtoallowyouto

reducetheamountofclippingscollectedbyvaryingdegrees.

Theadvantagesincludelessfrequentemptyingofthehopper

andthereturnofnutrientstothesoil.

Figure22

1.PTOguardremovedfor

clarity

6.Raisethemowerdeck;refertoRaisingtheMower

DeckintotheServicePosition(page23).

24

2.Loosenthelocknuts.

Page 25

7.RemovetheboltandwasheratthefrontofeachFRS

g025067

1

2

bafe(Figure23).

8.Rotatethebafesintothedesiredpositionandinstall

theboltandwasher.

Figure24

Figure23

1.Bafes—closedposition

2.Bafes—openposition

3.Bolt

4.Washer

5.Bafes

9.Lowerthemowerdeck;refertoLoweringtheMower

DecktotheOperatingPosition(page24).

10.Slightlytightenthelocknutsontherearstudsofthe

FRSbafes.

Note:Thelocknutsontherearstudsmaybeleft

slightlylooseifyouanticipateadjustingthebafe

frequently.

11.InstallthePTOguardusingtheclevispinsandhairpin

cottersremovedinstep3.

1.Cotterpin

2.Mower-deckhandle

EmptyingtheHopper

Afullhopperisindicatedbyabuzzerlocatedbehindthe

operatorinthehopper.Emptythehopperwhenthebuzzer

soundstopreventcloggingoftheblowerorthemowerdeck.

1.DisengagethePTO ,movethespeed-controllever

totheNEUTRALposition,settheparkingbrake,and

dismountthemachine.

2.Makesurethatmachineisonadrylevelsurface.

3.Liftthereardoorupandallowittorestontopof

hopper.

4.Usingthehandlesatthelowerfrontofthehopper,

raisethehoppertodumpthecontents.

5.Lowerthehopperandclosethehopperdoor.

ClearingtheHopperScreen

Removethescreenbyrmlyliftingthescreenhandles(Figure

25).

Pullthescreentowardsthebacktoremoveit.Asneeded,

gentlytapthescreentoremovedebris.

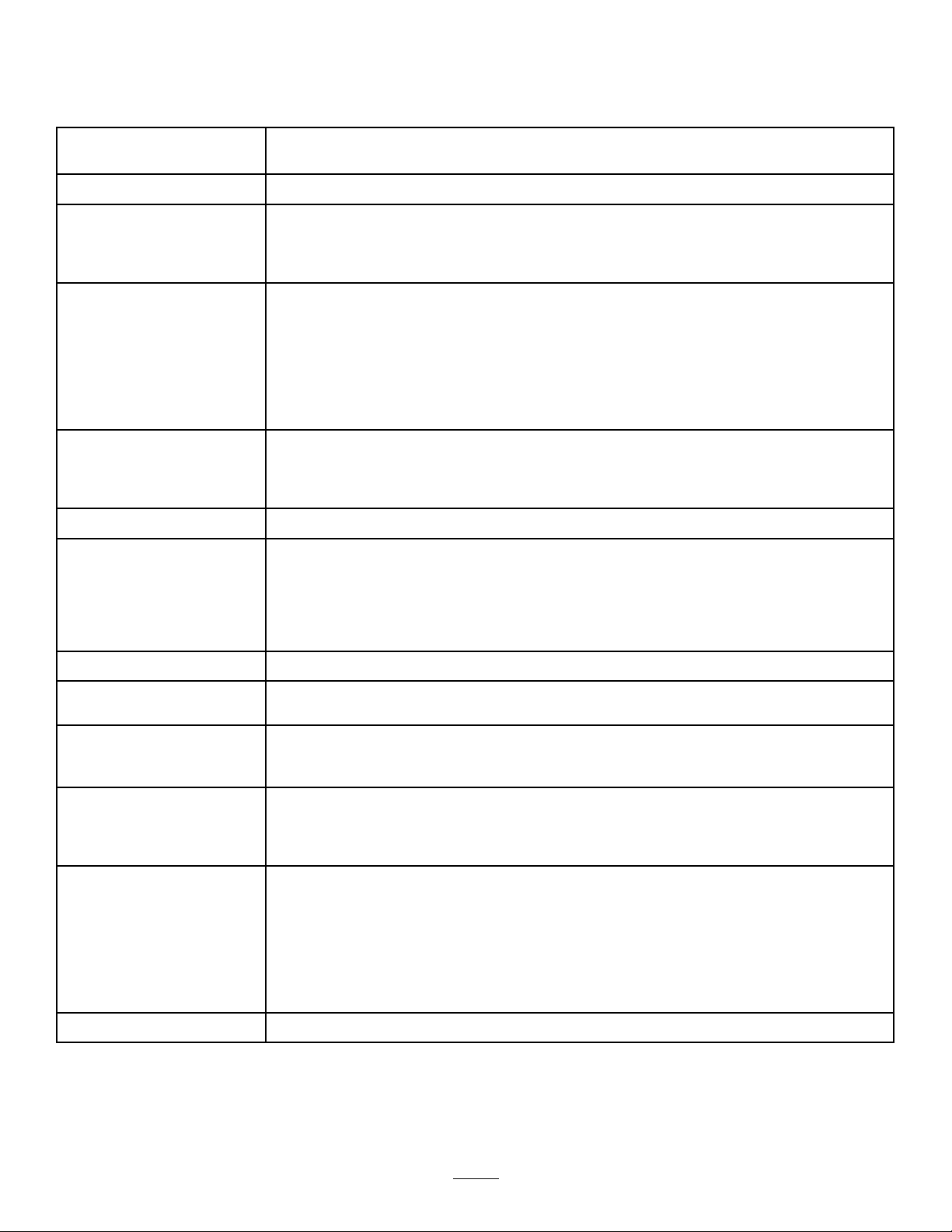

AdjustingtheHeightofCut

Thecuttingheightofthemowerdeckisadjustedfrom2.5to

10.2cm(1to4inches)in6.3mm(1/4inch)increments.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Usingthemower-deckhandle,raisethemowerdeck,

andmovethecotterpinstothedesiredheight-of-cut

position.Repeatfortheoppositeside.

Note:Excessivebuilduponthescreencancausetheblower

toplug.

Note:Inconditionswherethescreenclogsquickly,youcan

turnandinstallthefrontremovablescreenpanelunderthe

primaryscreentoallowfreeairowfromthehopper.

25

Page 26

Figure25

1.Frontremovablescreen

canberotatedandstored

forwetconditions.

2.Frontremovablescreen4.Handles

UsingtheDrive-WheelRelease Valves

WARNING

3.Primaryscreen

Note:Donottowthemachine.

6.Rotatethevalvesclockwisetorunthemachine.

Note:Donotovertightenthevalves.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow-moving

vehicleemblemisdangerousandcanleadto

accidentscausingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeaccessingthe

drive-wheelreleasevalves.

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.Touchingahotengineorhydraulicdrive

unitscancausesevereburns.

Waitfortheengineandhydraulicdriveunitstocool

completelybeforeaccessingthedrive-wheelrelease

valves.

Thedrive-wheelreleasevalvesarelocatedonthetop,left,

frontcornerofhydrostaticpumps.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTOlever,engagetheparkingbrake,

shutofftheengine,andwaitforallmovingpartsto

stop.

3.Tilttheseatuptogainaccesstothepumps.

4.Rotatebothreleasevalves1turncounterclockwiseto

releasethedrivesystem.

Note:Thisallowsthehydraulicuidtobypassthe

pump,enablingthewheelstoturn.

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropesdownandoutwardfrom

themachine.

LoadingtheMachine

Useextremecautionwhenloadingortheunloadingmachine

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.

Important:Ifafullwidthrampisnotavailable,use

enoughindividualrampstosimulateafullwidthramp.

Ensurethattherampislongenoughsothattheanglewith

thegrounddoesnotexceed15degrees.Asteeperangle

maycausemowercomponentstogetcaughtasthemachine

movesfromtheramptothetrailerortruck.Steeperangles

mayalsocausethemachinetotiporlosecontrol.Ifyouare

loadingthemachineonornearaslope,positionthetraileror

trucksothatitisonthedownsideoftheslopeandtheramp

extendsuptheslope.Thisminimizestherampangle.

Important:Donotattempttoturnthemachinewhile

ontheramp,youmayloosecontrolanddriveofftheside.

5.Disengagetheparkingbrakebeforepushingthe

machine.

26

Page 27

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityofatip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Ifafullwidthrampisnotavailable,useenough

individualrampstosimulateafullwidthramp.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-over.

27

Page 28

OperatingTips

KeepingtheUndersideoftheMower

Clean

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerinuncutgrass.Alwaystrytohave

1sideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesoftheyear.

Tomaintainthesamecuttingheight,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmidsummer,mow

lessfrequently .Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight,thenmowagain2days

lateratalowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheighttoavoid

scalpingtheturf.

Stopping

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

28

Page 29

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every40hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheoilinall3gearboxhousingsandaddoilasneeded.

•Checkthewheel-lugnuttorque.

•Checkthewheel-hubnuttorque.

•Checktheparkingbrakeadjustment.

•Changethehydrauliclterandreservoirhydraulicuidwhenusinganytypeofoil.

•Checkthesafety-interlocksystem.

•Greasethefrontcasterwheelhubs(moreoftenindirtyordustyconditions).

•Checktheengine-oillevel.

•Cleantheenginescreenandtheoilcooler.

•Cleanthehydraulicpumps.

•Checkthemowerblades.

•Cleanthemowerdeck.

•Cleandebrisfromthemachine.

•Greasethedriveshaft(moreoftenindirtyordustyconditions).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicuidlevel.

•Checksparkarrester(ifequipped).

•Greasethemower-deckip-uppivot(moreoftenindirtyordustyconditions).

•Greasethemower-deckpush-armtubes(moreoftenindirtyordustyconditions).

•Changetheoilinall3gearboxhousingsandaddoilasneeded.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•Cleantheengine-oilcooler.

•Checkandcleanenginecoolingnsandshrouds.

Every150hours

Every160hours

Every200hours

Every250hours

Every500hours

•Inspecttheprimarylterandair-inletscreen.

•Lubricatethebrake-handlepivot.

•Lubricatingthebrake-rodbushingsandsteeringlinkagerodends.

•Changetheengineoillter.

•Checkandgapthesparkplug(EFIenginesonly).

•Replacethefuellter(moreoftenindirtyordustyconditions).

•Replacetheprimaryairlter(moreoftenindustyorsandyconditions).

•Checkthesafetyairlter.

•ChangethehydrauliclterandreservoirhydraulicuidwhenusingMobil®1oil

(moreoftenindirtyordustyconditions).

•Replacethesafetyairlter.

•Checkandgapthesparkplug(Non-EFIenginesonly).

•Checkthewheel-lugnuttorque.

•Checkthewheel-hubnuttorque.

•Adjustthecaster-pivotbearings.

•Checktheparkingbrakeadjustment.

•ChangethehydrauliclterandreservoirhydraulicuidwhenusingT oro®

HYPR-OIL™500hydraulicuid(moreoftenindirtyordustyconditions).

Monthly

•Checkthebattery.

29

Page 30

MaintenanceService

Interval

Yearly

MaintenanceProcedure

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Greasetherearcasterhub(moreoftenindirtyordustyconditions).

•Greasethepump-beltidlerarm(moreoftenindirtyordustyconditions).

•GreasethePTO-beltidlerarm(moreoftenindirtyordustyconditions).

•Greasetherearcasterpivot(moreoftenindirtyordustyconditions).

•Lubricatethecaster-wheelhubs.

Yearlyorbeforestorage

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

LubricatingtheMachine

ServiceInterval:Beforeeachuseordaily—Greasethefront

casterwheelhubs(moreoftenindirtyor

dustyconditions).

Every40hours—Greasethedriveshaft(moreoften

indirtyordustyconditions).

Every100hours—Greasethemower-deckip-up

pivot(moreoftenindirtyordustyconditions).

Every100hours—Greasethemower-deckpush-arm

tubes(moreoftenindirtyordustyconditions).

Yearly—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Yearly—Greasetherearcasterhub(moreoftenin

dirtyordustyconditions).

Yearly—Greasethepump-beltidlerarm(moreoften

indirtyordustyconditions).

Yearly—GreasethePTO-beltidlerarm(moreoftenin

dirtyordustyconditions).

Yearly—Greasetherearcasterpivot(moreoftenin

dirtyordustyconditions).

1.Rearcasterpivot6.Frontcasterwheelhub

2.PTO-beltidlerarm7.Deckip-uppivot

3.Pump-beltidlerarm8.Push-armtubes

4.Rearcasterhub9.Frontcasterpivots

5.Driveshaft

Figure26

GreaseType:No.2lithiumormolybdenumgrease

1.DisengagethePTO,stopthemachine,shutoffthe

engine,removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

2.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

3.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

4.Wipeupanyexcessgrease.

30

Page 31

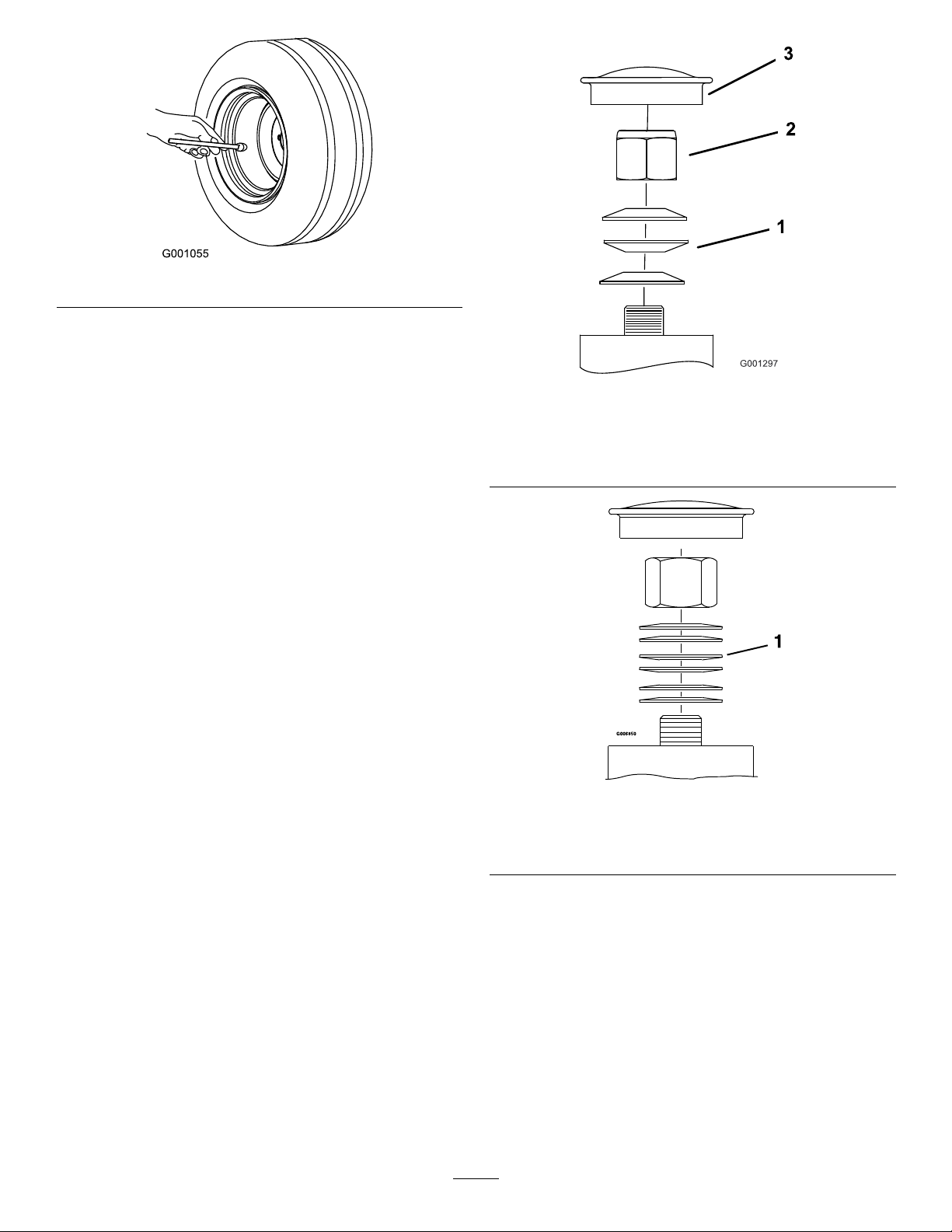

LubricatingtheCaster-WheelHubs

ServiceInterval:Yearly

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

Note:Makesurethattheaxledoesnotextendbeyond

eithernut.

15.Installthesealguardsoverthewheelhubandinsert

wheelintothecasterfork.

16.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecastertire.The

tireshouldnotspinfreely(morethan1or2revolutions)

orhaveanysideplay .Ifthewheelspinsfreely,adjustthe

torqueonthespacernutuntilthereisaslightamountof

drag.Applyanotherlayerofthread-lockingcompound.

LubricatingtheBrake-HandlePivot

Figure27

1.Sealguard2.Spacernutwithwrench

ats

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeaspacernutfromtheaxleassemblyinthe

casterwheel.

Note:Thread-lockingcompoundhasbeenappliedto

lockthespacernutstotheaxle.

5.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly .

6.Pryoutthesealsandinspectthebearingsforwearor

damageandreplacethemifnecessary.

7.Packthebearingswithageneral-purposegrease.

8.Insert1bearingand1newsealintothewheel.

Note:Replacetheseals.

9.Ifbothspacernutshavebeenremoved(orbroken

loose)fromtheaxleassembly,applyathread-locking

compoundto1spacernutandthreaditontotheaxle

withthewrenchatsfacingoutward.

Note:Donotthreadthespacernutalloftheway

ontotheendoftheaxle.Leaveapproximately3mm

(1/8inch)fromtheoutersurfaceofthespacernutto

theendoftheaxleinsidethenut.

10.Inserttheassemblednutandaxleintothewheelonthe

sidewiththenewsealandbearing.

11.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

12.Insertthesecondbearingandnewsealintothewheel.

13.Applyathread-lockingcompoundtothesecondspacer

nutandthreaditontotheaxlewiththewrenchats

facingoutward.

14.Torquethenutto8to9N∙m(75to80in-lb),loosen

thenut,thentorqueitto2to3N∙m(20to25in-lb).

ServiceInterval:Every160hours

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Lubricatethebronzebushingsonthebrake-handle

pivotwithaspraytypelubricantorlightoil(Figure28).

Figure28

LeftSideofMachineShown

1.Brake-handlepivot

2.PTO-handlepivot

3.Spring-armpivot

4.Togglepivot

LubricatingtheBrake-RodBushings

andSteering-LinkageRodEnds

ServiceInterval:Every160hours

1.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

2.Unhooktheseatlatchandtilttheseatup.

3.Lubricatethebronzebushingsoneachendofthe

brakerodshaftwithaspraytypelubricantoralightoil.

Note:Thebushingsarelocatedtotheinsideofthe

angebearings.

31

Page 32

4.Lubricateeachendofbothsteeringlinkagerodswitha

spraylubricantoralightoil.

EngineMaintenance

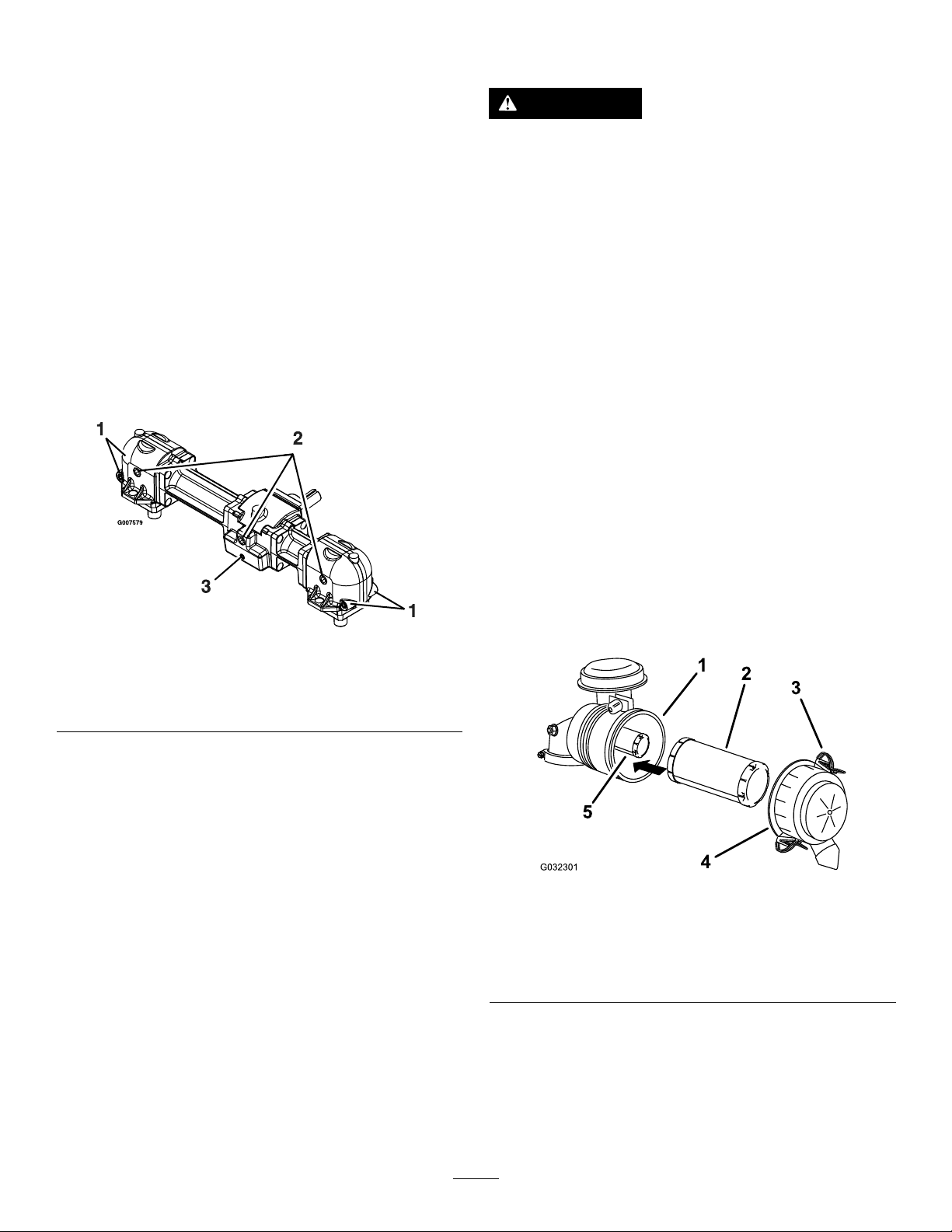

ChangingtheGearboxOil

ServiceInterval:Aftertherst50hours—Changetheoil

inall3gearboxhousingsandaddoilas

needed.

Every100hours—Changetheoilinall3gearbox

housingsandaddoilasneeded.

1.Placethemachineonalevelsurface.

2.Shutofftheengine,waitforallmovingpartstostop,

removethekey,andengagetheparkingbrake.

3.Removethegearboxanddrive-shaftassemblyfromthe

mowerdeck.Retainthehardwareforuselater.

4.Removethelargeoildrainplugonthefrontofeachof

the3gearboxsectionsanddraintheoil(Figure29).

Figure29

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every150hours

Every250hours—Replacetheprimaryairlter(more

oftenindustyorsandyconditions).

Every250hours—Checkthesafetyairlter.

Every500hours—Replacethesafetyairlter.

Note:Checktheltersmorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Releasethelatchesontheaircleanerandpullthe

air-cleanercoverofftheair-cleanerbody(Figure30).

1.Smallmagneticplugs

(frontandback)

2.Largeoildrain/llplug

5.Removethesmallmagneticplugsandwipeawayany

materialaccumulatedontheplugs.

6.ApplyaTeon

andinstallthemintothegearbox.

7.Installthegearboxanddrive-shaftassemblytothe

mowerdeck.

8.FillthegearboxwithMobil

gearlubeoiluntillevelwithoildrain/llplug.

Note:Eachofthegearboxsectionsmustbelled

separately.

Note:Keepthemowerdeckleveltothegroundwhen

llingthegearboxwithoil.Donotllthegearboxwith

themowerdeckraisedintheserviceposition.

9.ApplyaTeonpipesealanttothe3largeoilplugsand

installthemintothegearbox.

®

pipesealanttoallsmallmagneticplugs

3.Smallmagneticplug(front

only)

®

SHC(synthetic)75W-90

Figure30

1.Air-cleanerbody4.Air-cleanercover

2.Primarylter5.Safetylter

3.Latch

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure30).

Note:Avoidknockingthelterintothesideofthe

body.

32

Page 33

6.Removethesafetylteronlyifyouintendtoreplaceit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.

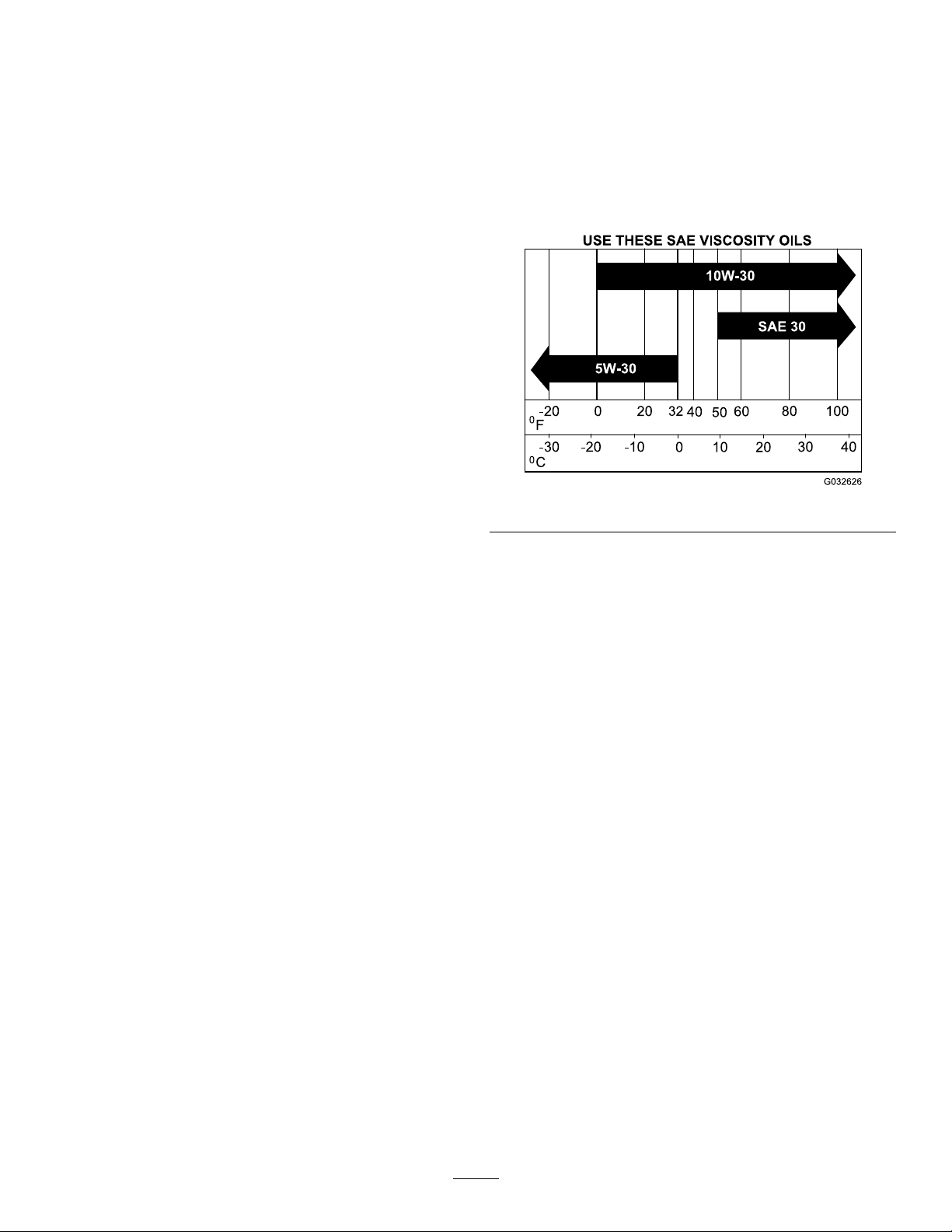

ServicingtheEngineOil

OilType:Detergentoil(APIserviceclassSJorhigher)

OilCapacity(Non-EFIengines):withalterchange,

1.8L(1.9USqt);withnolterchange,1.6L(1.7USqt)

OilCapacity(EFIengines):withalterchange,1.9L(2.0

USqt);withnolterchange,1.6L(1.7USqt)

Note:Holesinthelterappearasbrightspots.Ifthe

lterisdamaged,discardit.

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,replaceit.

•Donotcleantheprimarylter.

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Donotattempttocleanthesafetylter.

Ifthesafetylterisdirty,thentheprimarylteris

damaged.Replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,alwaysoperate

theenginewithbothairltersandthecoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.

Note:Donotuseadamagedlter.

2.Ifyouarereplacingthesafetylter,carefullyslideit

intothelterbody(Figure30).

3.Carefullyslidetheprimarylteroverthesafetylter

(Figure30).

Note:Ensurethattheprimarylterisfullyseatedby

pushingonitsouterrimwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheair-cleanercoverwiththesideindicatedas

upfacingupwardandsecurethelatches(Figure30).

Viscosity:Seethetablebelow.

Figure31

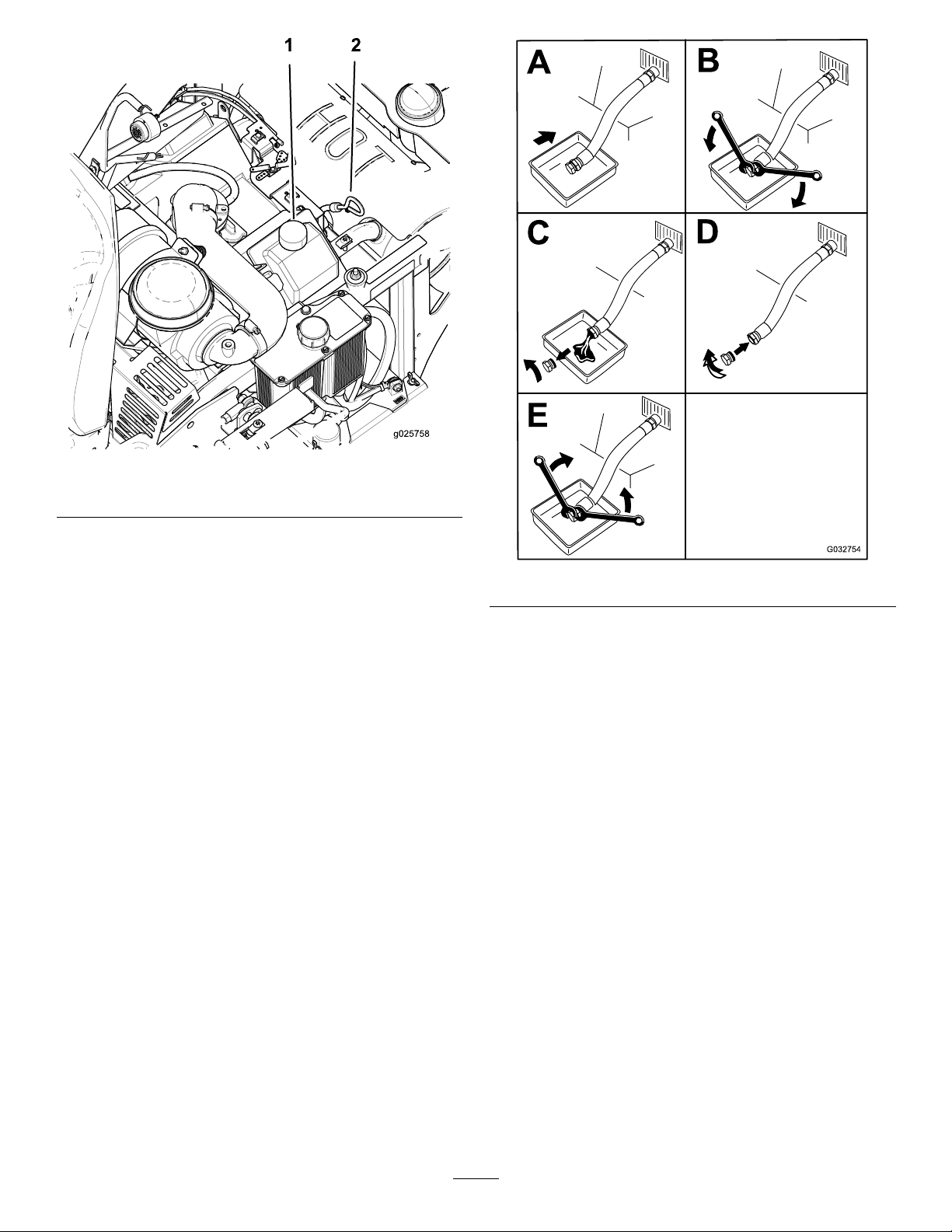

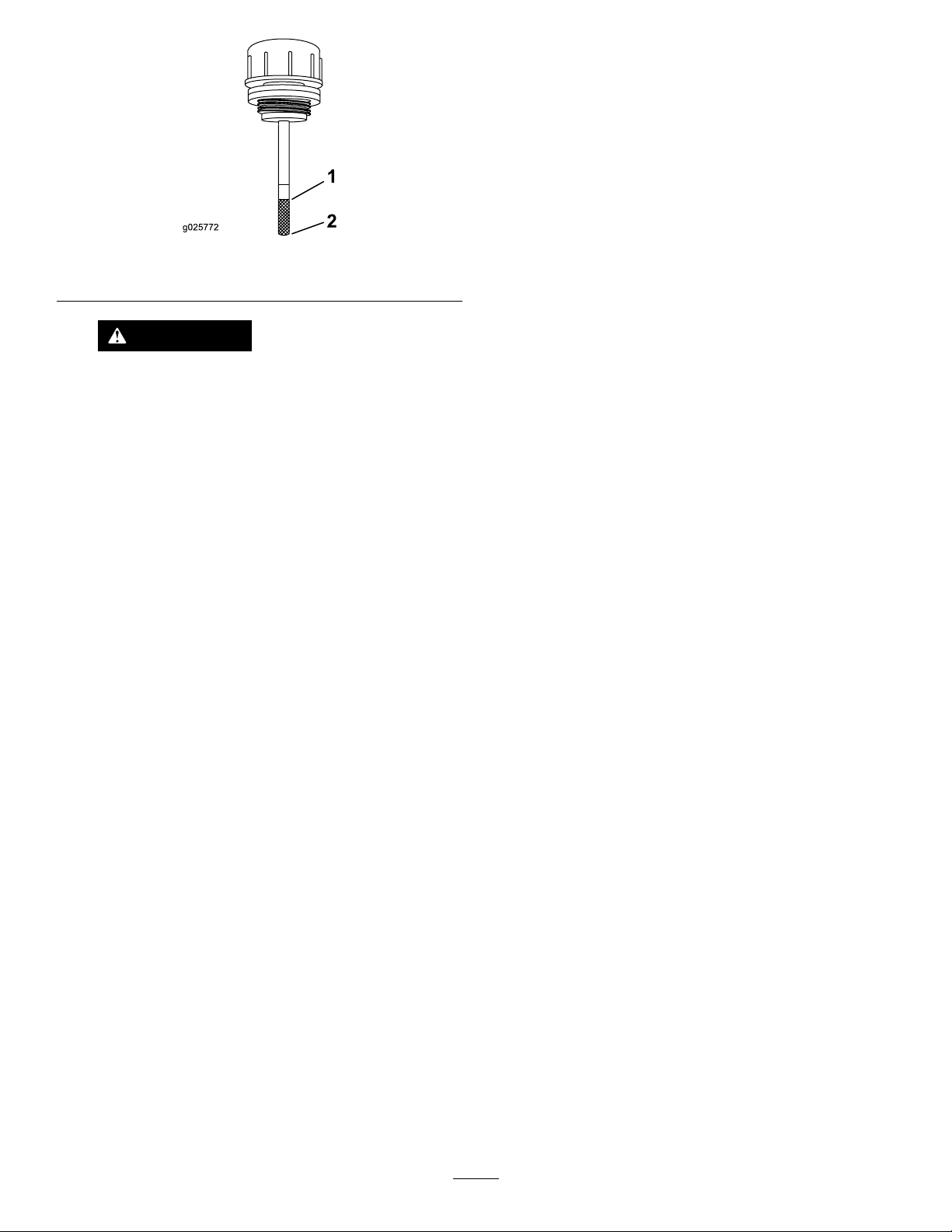

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Allowtheenginetocool.

4.Raisethehopper

5.Cleantheareaaroundthedipstick(Figure32).

6.Removethedipstickandwipetheoiloff.

7.Insertthedipstickandpushitallthewaydowninto

thetube.

8.Removethedipstickandreadtheoillevel.

9.Iftheoillevelislow,wipeofftheareaaroundthe

oil-llcap,removecapandlltothefullmarkonthe

dipstick(Figure32).

Important:Donotoperatetheenginewiththeoil

levelbelowthelow(oradd)markonthedipstick

oroverthefullmark.

33

Page 34

Figure32

1.Oil-llcap2.Oildipstick

ChangingtheEngineOil

ServiceInterval:Every100hours(moreoftenindirtyor

dustyconditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylowerthan

thefronttoensurethattheoildrainscompletely.

2.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

3.DisengagethePTO,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

Figure33

4.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittothefullmarkonthedipstick(Figure32).

5.Starttheengineanddrivetoaatarea.Checktheoil

levelagain(Figure32).

6.Ifneeded,addoiltothefullmarkonthedipstick.

34

Page 35

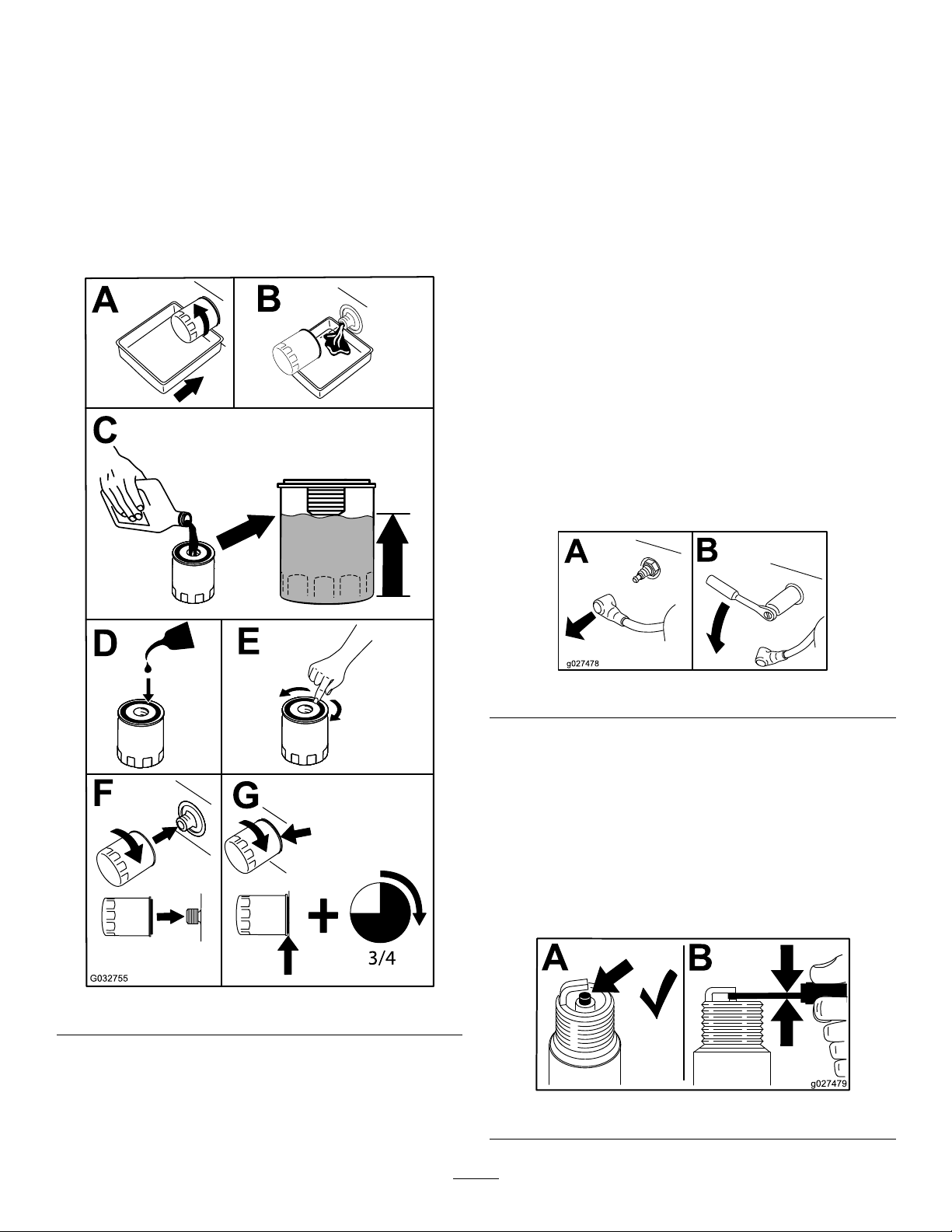

ChangingtheEngine-OilFilter

B

A

g027478

B

A

g027479

ServicingtheSparkPlugs

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page34).

2.Changetheengineoillter(Figure34).

Note:Allow2minutesforthenewoiltobeabsorbed

bythenewltermaterial.

ServiceInterval:Every200hours—Checkandgapthe

sparkplug(EFIenginesonly).

Every500hours—Checkandgapthesparkplug

(Non-EFIenginesonly).

Makesurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplugs.Usea

spark-plugwrenchforremovingandinstallingthesparkplugs

andagappingtool/feelergaugetocheckandadjusttheair

gap.Installnewsparkplugsifnecessary.

TypeforEFIengines:Champion

TypeforNon-EFIengines:Champion

equivalent

AirGap:0.76mm(0.030inch)

®

XC12YCorequivalent

®

RC12YCor

RemovingtheSparkPlugs

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Removethesparkplugs.

Figure34

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toCheckingtheEngine-OilLevel(page33).

Figure35

CheckingtheSparkPlugs

Important:Replacethesparkplugswhentheyhave:a

blackcoating,wornelectrodes,anoilylm,cracksor

reuseisquestionable.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meansthattheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

Figure36

35

Page 36

InstallingtheSparkPlugs

Tightenthesparkplugsto24.4to29.8N∙m(18to22ft-lb).

FuelSystem

Maintenance

WARNING

Fuelsystemcomponentsareunderhighpressure.

Theuseofimpropercomponentscanresultin

systemfailure,gasolineleakage,andpossible

explosion.

Useonlyapprovedfuellinesandfuellters.

ServicingtheElectronic Fuel-InjectionSystem

Thismachinecontainsanelectronicfuel-injectionsystem.It

controlsthefuelowunderdifferentoperatingconditions.

Figure37

CheckingtheSparkArrester

ForaModelwithaSparkArrester

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenyoushutofftheengine.Hot

particlesexhaustedduringengineoperationmay

igniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotrefuelorruntheengineunlessaspark

arresterisinstalled.

1.Shutofftheengine,waitforallmovingpartstostop,

andremovethekey.Engagetheparkingbrake.

2.Waitforthemufertocool.

3.Ifthereareanybreaksinthescreenorwelds,replace

thearrester.

4.Ifthescreenisplugged,removethearresterand

shakethelooseparticlesoutofthearresterandclean

thescreenwithawirebrush(soakitinsolventif

necessary).Installthearresterontheexhaustoutlet.

Theelectroniccontrolunit(ECU)continuouslymonitorsthe

operationoftheEFIsystem.

Ifaproblemorfaultwithinthesystemisdetected,the

malfunctionindicatorlight(MIL)illuminates.TheMIListhe

redlightlocatedintherightconsolepanel.

OncetheMILilluminates,makeinitialtroubleshooting

checks.RefertotheMILsectionunderTroubleshooting

(page58).

Ifthesechecksdonotcorrecttheproblem,furtherdiagnosis

andservicingbyanAuthorizedServiceDealerisnecessary.

ReplacingtheFuelFilter

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

2.DisengagethePTO,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Waitforthemachinetocooldown.

4.Closethefuel-shutoffvalveundertheseat(Figure13).

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure38).

36

Page 37

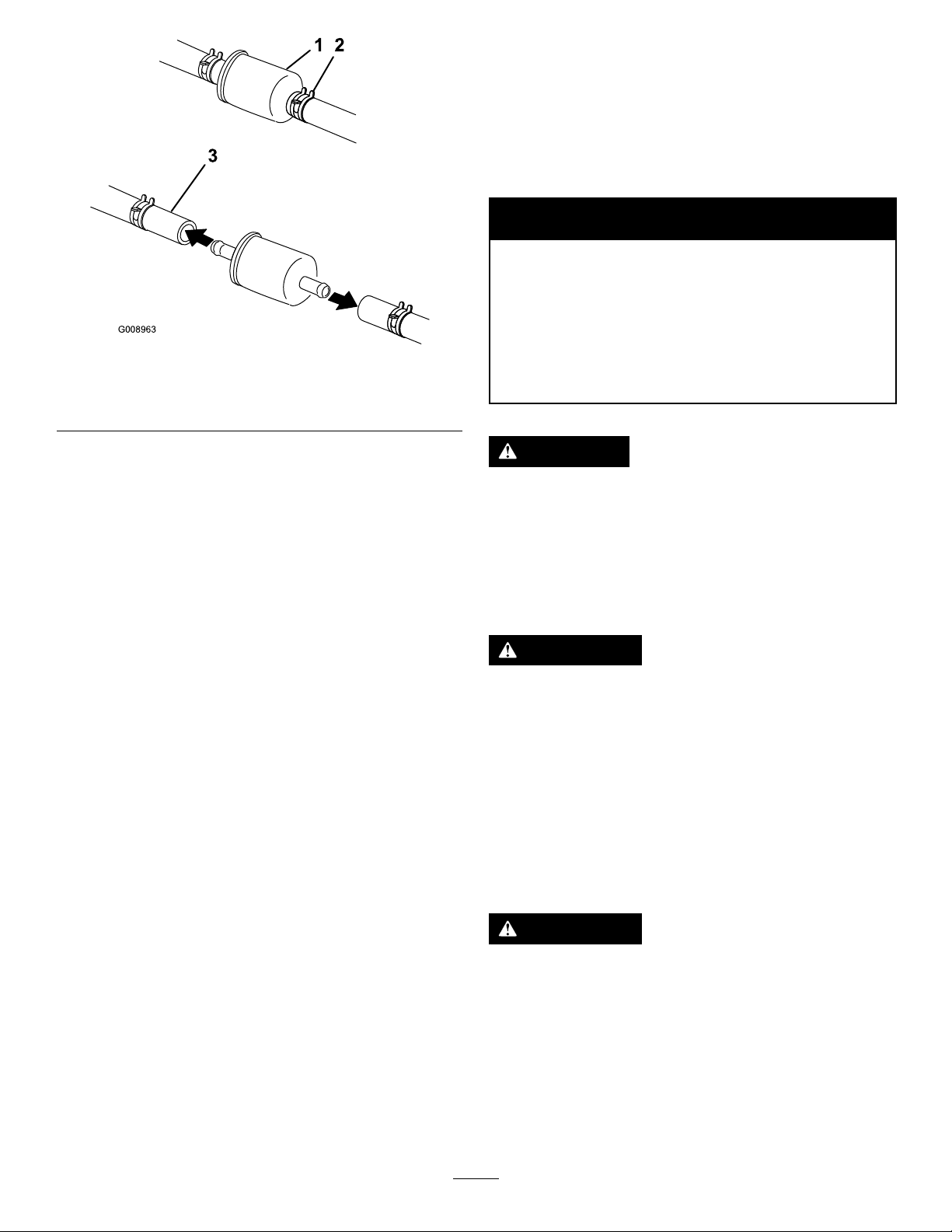

G008963

12

3

1.Fuellter

2.Hoseclamp

Figure38

3.Fuelline

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampscloseto

thelter(Figure38).

8.Openthefuel-shutoffvalve.

Note:Installthefuel-linehosesandsecurethemwithplastic

tiesthesameastheywereoriginallyinstalledatthefactoryto

keepthefuellineawayfromcomponentsthatcouldcause

fuellinedamage.

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltank.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygasestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

37

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcables,causingsparks.Sparkscan

causethebatterygasestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

Page 38

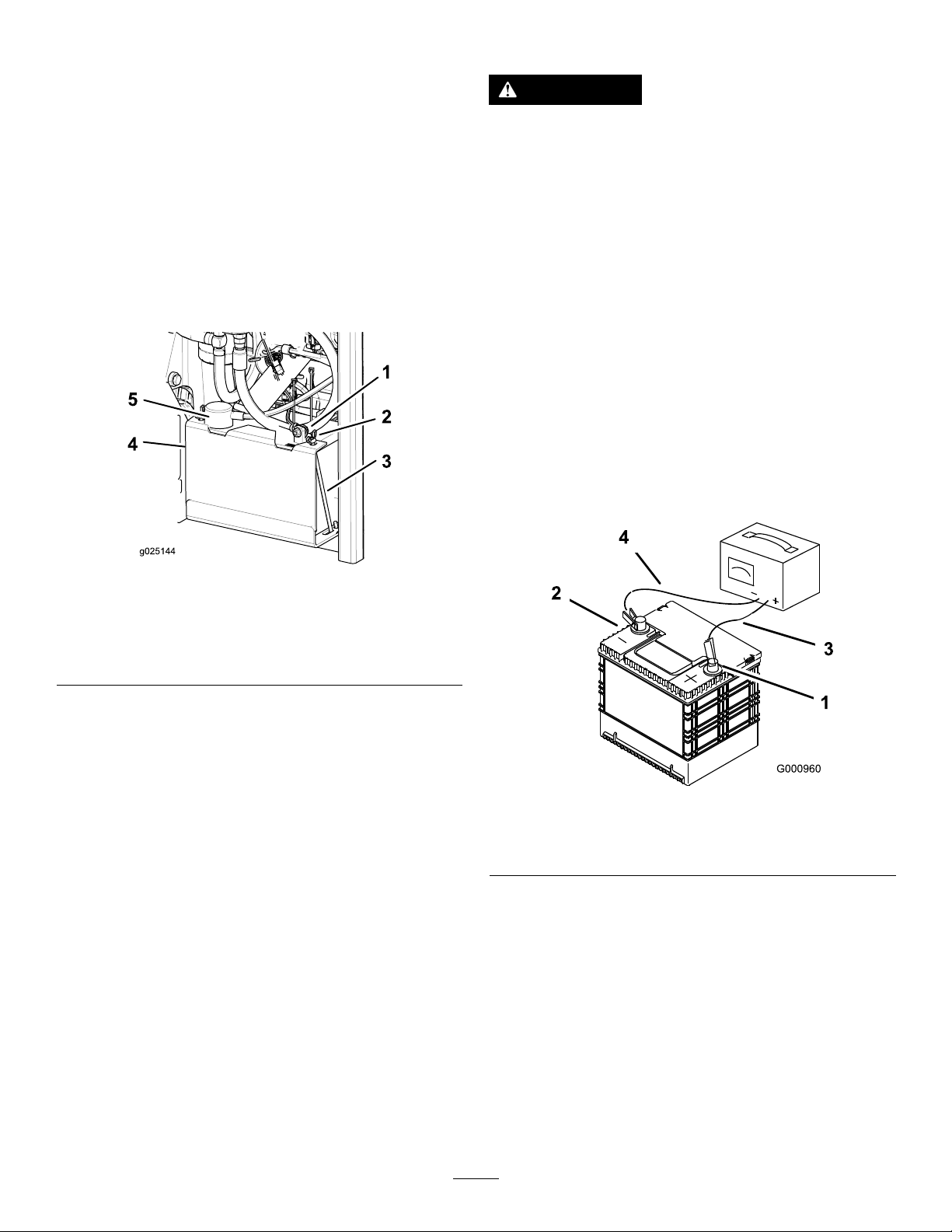

1.Movethespeed-controllevertotheNEUTRALposition

tostopthemachine.

ChargingtheBattery

2.DisengagethePTO,engagetheparkingbrake,shutoff

theengine,andwaitforallmovingpartstostop.

3.Disconnectthenegativebatterycable(black)fromthe

negative(-)(black)batteryterminal(Figure39).

4.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure39).

5.RemovethewingnutssecuringtheJ-hooks(Figure39).

6.Removetheclamp(Figure39).

7.Removethebattery.

WARNING

Chargingthebatteryproducesgasesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

0°C(32°F).

1.Chargebatteryfor10to15minutesat25to30Aor

30minutesat10A.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet;thendisconnectthecharger

leadsfromthebatteryposts(Figure40).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery(page38).

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure39

1.Negative(black)battery

cable

2.Wingnut

3.J-hook

4.Clamp

5.Positive(red)batterycable

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure39).

2.Installthepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Installthenegative(black)batterycableandground

wiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

(Figure39).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnutsand

J-hooks(Figure39).

1.Positivebatterypost

2.Negativebatterypost

Figure40

3.Red(+)chargerlead

4.Black(-)chargerlead

38

Page 39

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

1.Thefusesarelocatedonrightsidebehindtheseat.

2.Toreplacethefuses,pulloutonthefusetoremoveit.

3.Installanewfuse.

Note:Useproperlysizedjumpercableswithshort

lengthstoreducevoltagedropbetweensystems.Make

surethatthecablesarecolorcodedorlabeledforthe

correctpolarity.

CAUTION

Connectingthejumpercablesincorrectly

(wrongpolarity)canimmediatelydamagethe

EFIsystem.

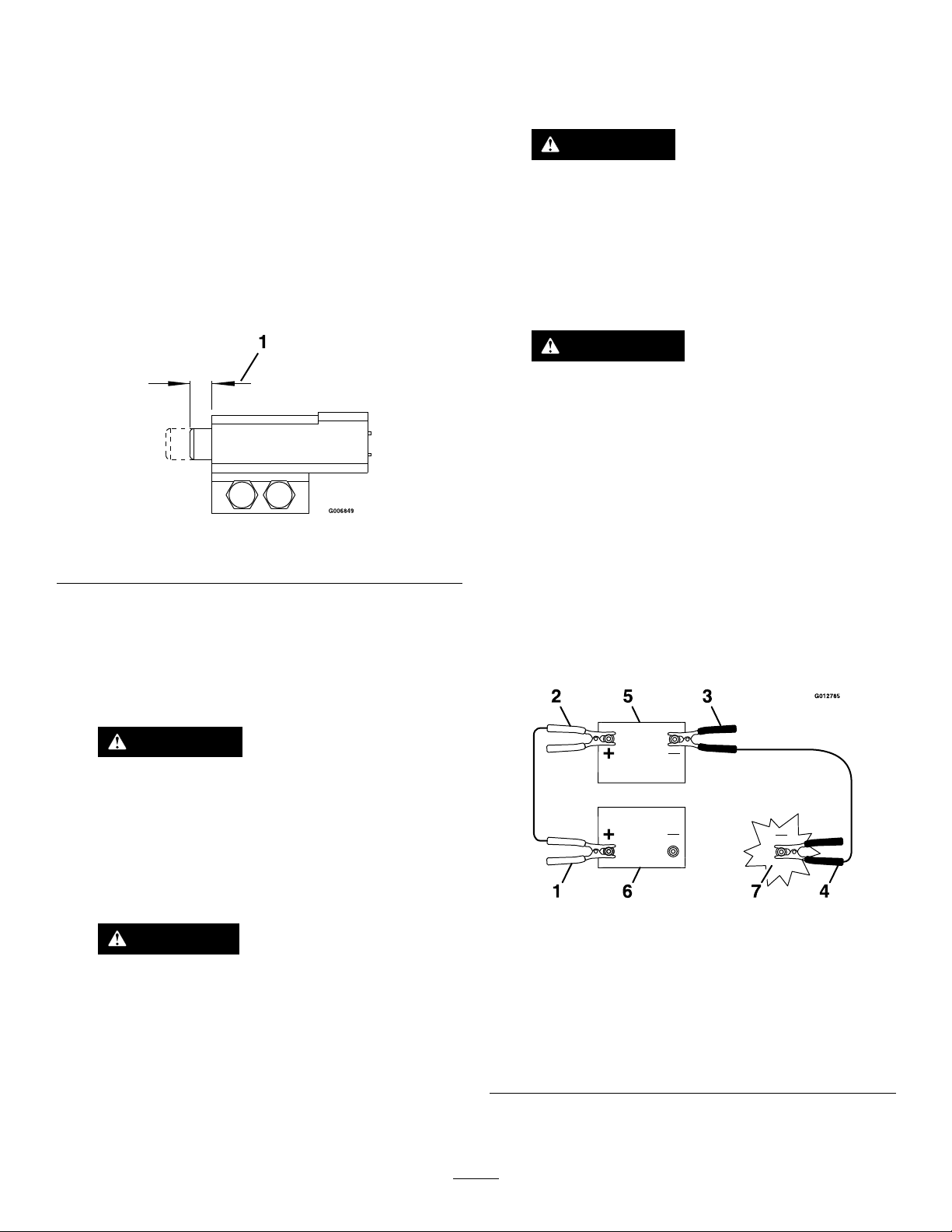

AdjustingtheSafetySwitches

Adjustallsafetyswitchessothattheplungerextends4.8mm

to6.4mm(3/16inchto1/4inch)fromtheswitchbody

whentheplungeriscompressed(Figure41).

Figure41

1.4.8to6.4mm(3/16to1/4inch)

Jump-StartingtheMachine

1.Checkandcleancorrosionfromthebatteryterminals

beforejump-starting.

Becertainofbatteryterminalpolarityand

jumpercablepolaritywhenhookingup

batteries.

WARNING

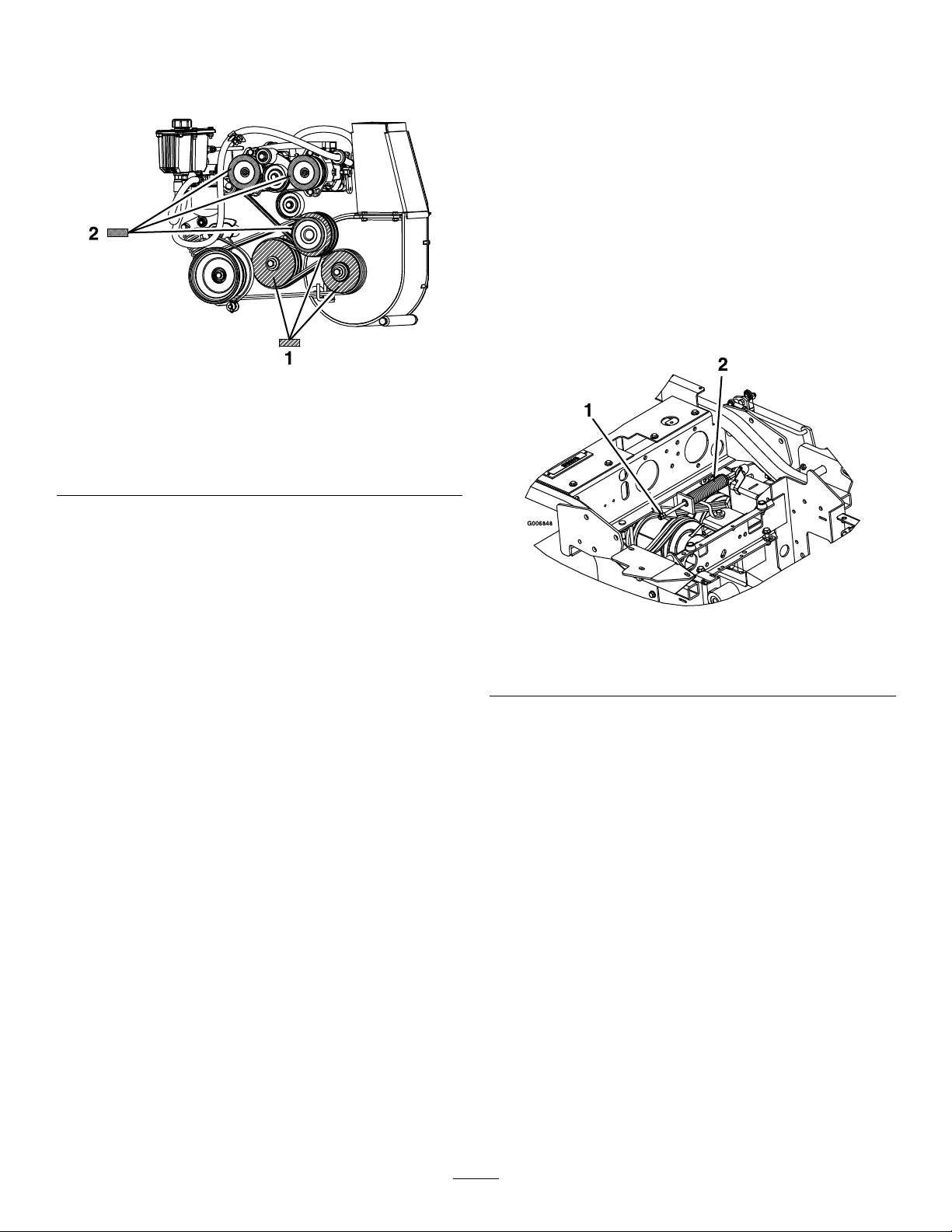

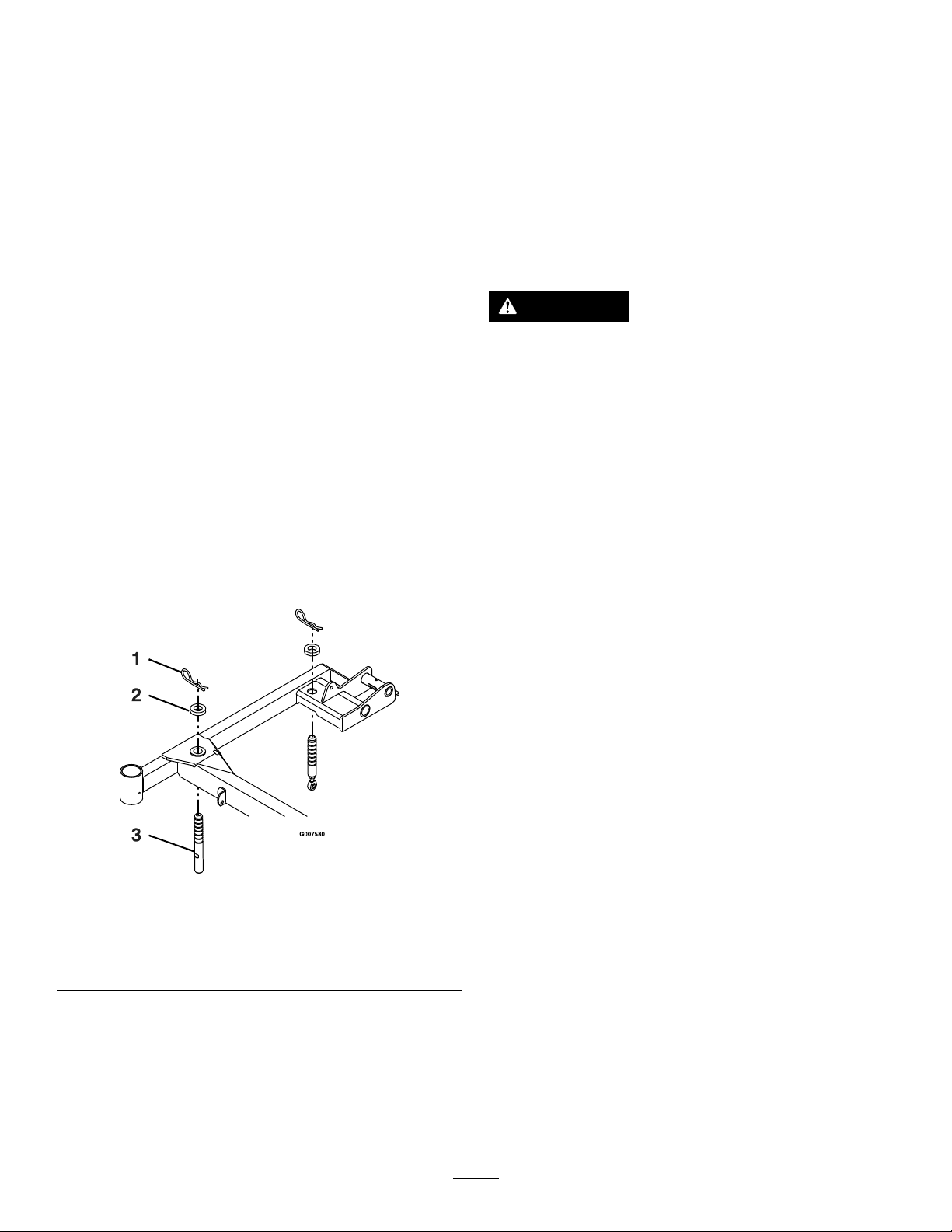

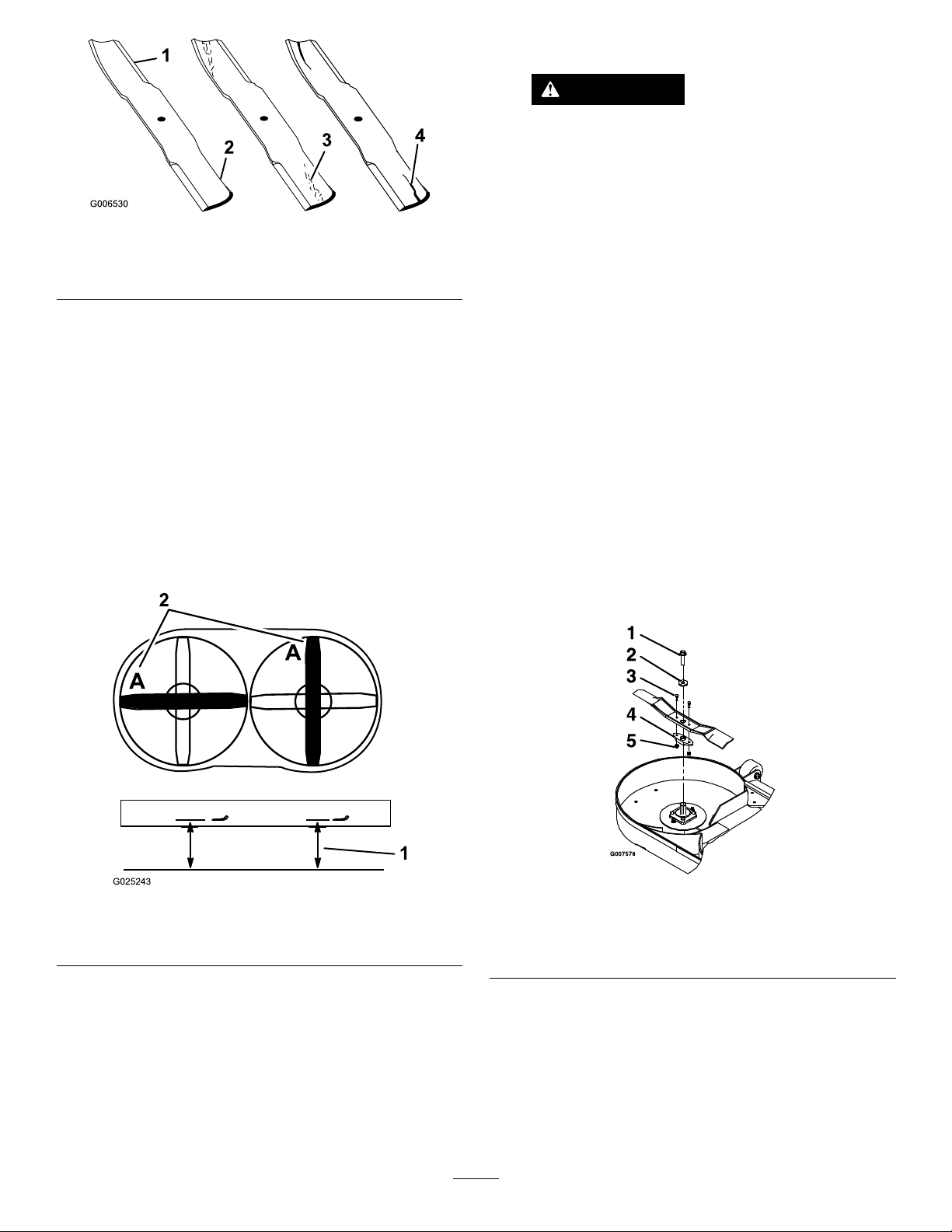

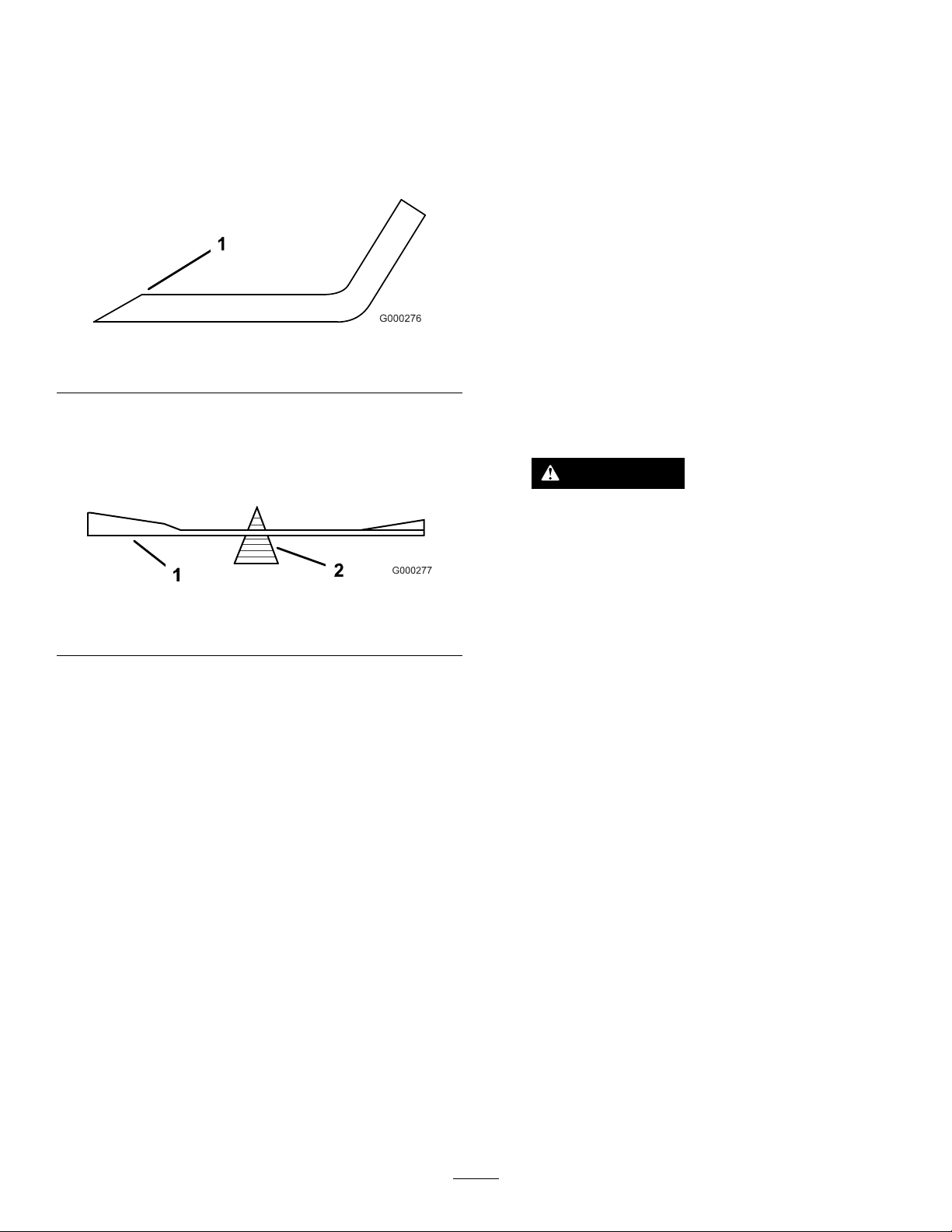

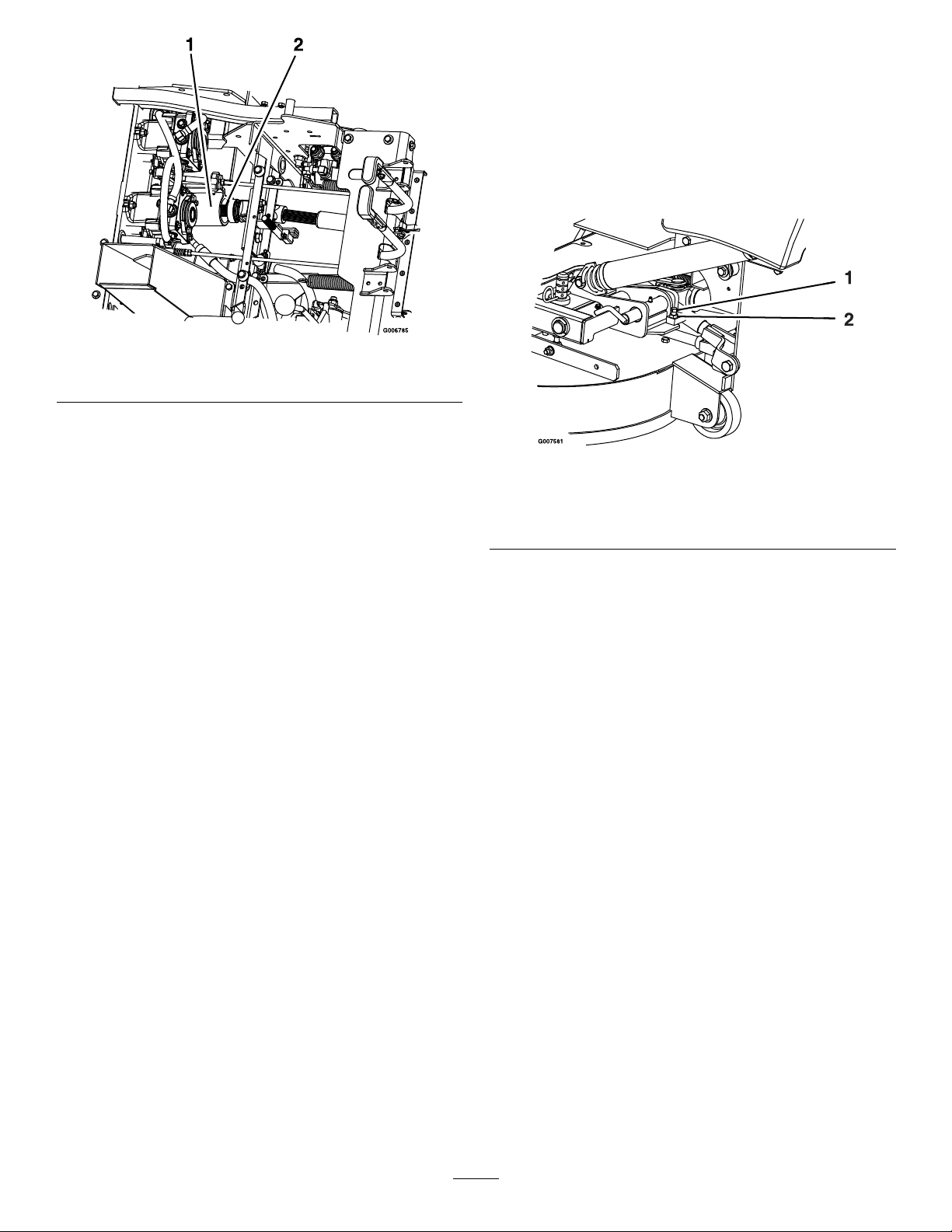

Batteriescontainacidandproduceexplosive