Page 1

FormNo.3380-770RevA

ZMaster

®

Commercial3000

SeriesRidingMower

with48in,52in,or60inTURBOFORCE

®

Side

DischargeMower

ModelNo.74952—SerialNo.314000001andUp

ModelNo.74953—SerialNo.314000001andUp

ModelNo.74957—SerialNo.314000001andUp

ModelNo.78953—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3380-770*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobeused

byresidentialhomeownersorprofessional,hiredoperators.

Itisdesignedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .

Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

1

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2013—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.T oro.com.

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SlopeIndicator.......................................................6

SafetyandInstructionalDecals.................................7

ProductOverview.........................................................12

Controls...............................................................12

Specications........................................................13

Operation....................................................................14

AddingFuel...........................................................14

CheckingtheEngineOilLevel.................................15

BreakingInaNewMachine.....................................15

UsingtheRolloverProtectionSystem(ROPS)............15

ThinkSafetyFirst...................................................16

OperatingtheParkingBrake....................................17

OperatingtheMowerBladeControlSwitch

(PTO)...............................................................17

OperatingtheThrottle............................................18

OperatingtheChoke...............................................18

OperatingtheIgnitionSwitch..................................18

UsingtheFuel-shutoffValve....................................18

StartingandStoppingtheEngine..............................19

TheSafetyInterlockSystem.....................................20

DrivingForwardorBackward..................................21

StoppingtheMachine.............................................22

AdjustingtheHeightofCut.....................................22

AdjustingtheAnti-scalpRollers................................23

AdjustingtheFlowBafeCamLocks........................24

PositioningtheFlowBafe......................................25

PositioningtheSeat................................................25

UsingtheDriveWheelReleaseValves.......................26

UsingtheSideDischarge.........................................26

LoadingtheMachine..............................................26

TransportingtheMachine........................................27

OperatingTips......................................................28

Maintenance.................................................................29

RecommendedMaintenanceSchedule(s)......................29

Lubrication...............................................................30

GreasingandLubrication........................................30

WheretoGreasetheMower.....................................30

LubricatingtheCasterWheelHubs...........................31

EngineMaintenance..................................................32

ServicingtheAirCleaner.........................................32

ServicingtheEngineOil..........................................33

ServicingtheSparkPlugs.........................................36

CheckingtheSparkArrester(ifequipped)..................37

FuelSystemMaintenance...........................................37

ReplacingtheFuelFilter..........................................37

ServicingtheFuelTank...........................................38

ElectricalSystemMaintenance....................................38

ServicingtheBattery...............................................38

ServicingtheFuses.................................................39

DriveSystemMaintenance.........................................40

CheckingtheSeatBelt.............................................40

CheckingtheRolloverProtectionSystem(ROPS)

Knobs...............................................................40

AdjustingtheTracking............................................41

CheckingtheTirePressure......................................41

CheckingtheWheelLugNuts..................................42

CheckingtheWheelHubSlottedNut........................42

AdjustingtheCasterPivotBearing............................42

UsingtheClutchShim............................................42

CoolingSystemMaintenance......................................44

CleaningtheEngineScreenandEngineOil

Cooler...............................................................44

CleaningtheEngineCoolingFinsand

Shrouds.............................................................44

CheckingandCleaningtheHydraulicUnits................45

BrakeMaintenance....................................................46

AdjustingtheParkingBrake.....................................46

BeltMaintenance......................................................47

InspectingtheBelts................................................47

ReplacingtheMowerBelt........................................47

ReplacingtheHydraulicPumpDriveBelt...................48

ControlsSystemMaintenance.....................................49

AdjustingtheControlHandlePosition......................49

AdjustingtheMotionControlLinkage......................50

AdjustingtheMotionControlDamper......................50

AdjustingtheMotionControlNeutralLock

Pivot.................................................................51

HydraulicSystemMaintenance....................................51

ServicingtheHydraulicSystem.................................51

MowerDeckMaintenance...........................................53

LevelingtheMowerDeck........................................53

ServicingtheCuttingBlades.....................................55

RemovingtheMowerDeck.....................................58

ReplacingtheGrassDeector..................................60

Cleaning...................................................................60

CleaningUndertheMower......................................60

WasteDisposal.......................................................60

Storage........................................................................61

CleaningandStorage..............................................61

Troubleshooting...........................................................62

Schematics...................................................................64

3

Page 4

Safety

Improperuseormaintenanceofthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans

Caution, W ar ning ,

or

Danger

—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

totheuserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSI

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformationitistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,andhearingprotection.Longhair,looseclothing,

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly.Donot

operateunlesstheyarefunctioningproperly.

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Besureofyourfootingwhileusingthismachine,

especiallywhenbackingup.Walk;donotrun.Never

operateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

thestabilityofthemachine.Usecautionwhileoperating

neardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshieldorotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly,andfunctioningproperly.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engagethe

parkingbrake(ifprovided),andshutofftheenginebefore

leavingtheoperator'spositionforanyreason,including

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersonthemachine.

•Keeppetsandbystandersaway.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

4

Page 5

RolloverProtectionSystem

(ROPS)—UseandMaintenance

•TheROPSisanintegralandeffectivesafetydevice.Keep

afoldingROPSintheraisedandlockedpositionanduse

theseatbeltwhenoperatingthemachine.

•LowerafoldingROPStemporarilyonlywhenabsolutely

necessary.Donotweartheseatbeltwhenfoldeddown.

•Beawarethereisnorolloverprotectionwhenafolded

ROPSisinthedownposition.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedandneverfolddowna

foldingROPSinareaswherethereareslopes,dropoffs

orwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•DonotremovetheROPS.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

MaintenanceandStorage

•Disengagedrives,settheparkingbrake,stoptheengine

andremovethekeyordisconnectthespark-plugwire.

Waitforallmovementtostopbeforeadjusting,cleaning

orrepairingthemachine.

•Cleangrassanddebrisfromthecuttingunit,thedrives,

themufers,andtheenginetohelppreventres.Clean

upoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorthespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminal

rstandthepositivelast.Connectthepositiverstand

negativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability,T orodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

5

Page 6

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

6

Page 7

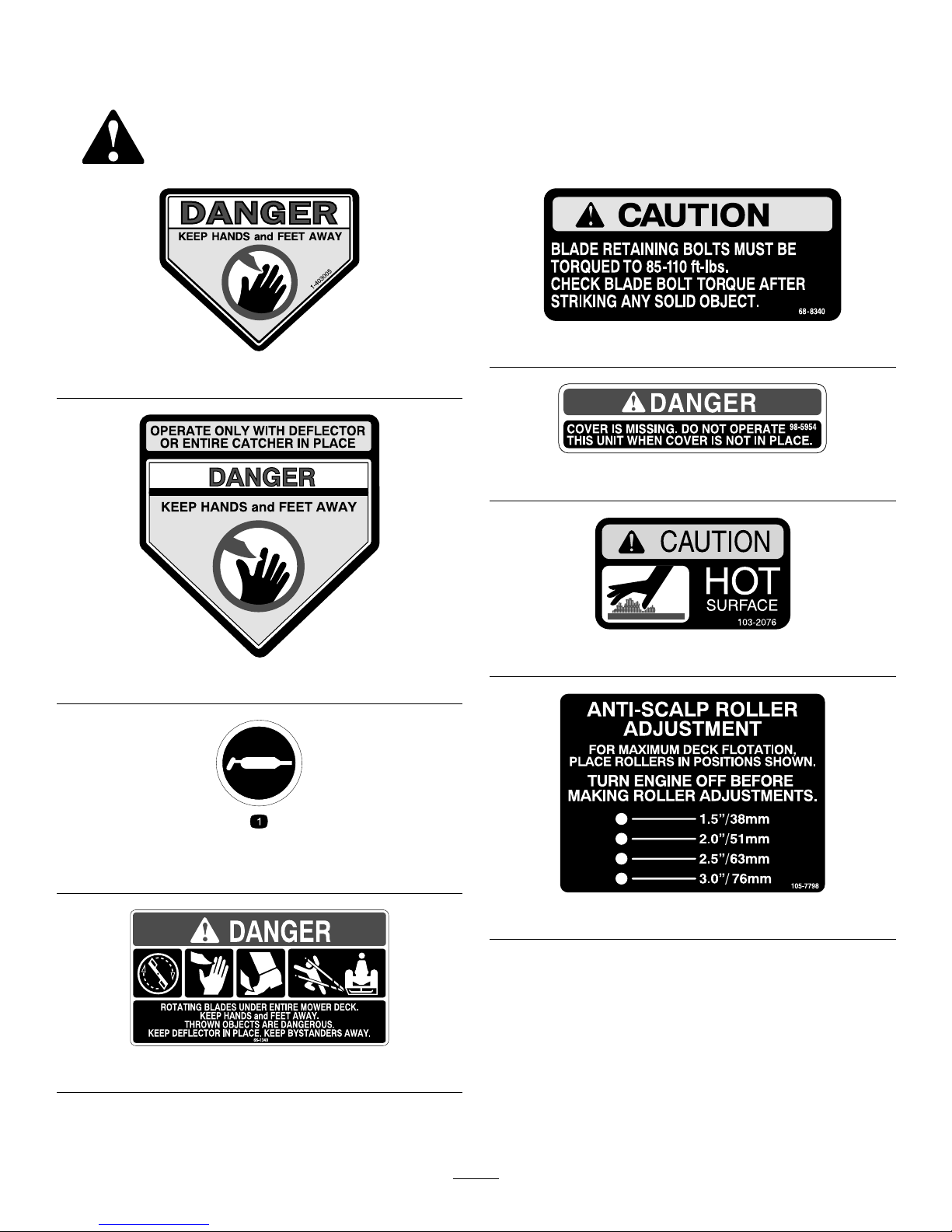

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

1-403005

54-9220

58-6520

1.Grease

66-1340

68-8340

98-5954

103-2076

105-7798

7

Page 8

107-2102

109-7232

1.Fast3.Neutral

2.Slow

4.Reverse

110-2067

110-2068

1.ReadtheOperator'sManual.

114-4466

1.Main,25A

3.Charge,25A

2.PTO,10A

4.Auxiliary,15A

8

Page 9

115-7445

1.Greasepulleysandspindles

2.Maintenanceinterval—50hours

116-0205

125–9382

116-0752

1.Latch2.Unlatch

116-1654

116-1716

1.Fuel6.Hourmeter

2.Empty

7.PTO

3.Half

8.Parkingbrake

4.Full9.Neutral

5.Battery

10.Operatorpresenceswitch

116-2643

9

Page 10

116-3303

116-4858

116-5944

121-7551

1.PowerT ake-off(PTO)4.Continuousvariable

setting

2.Choke5.Slow

3.Fast

10

Page 11

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

6.Keepbystandersasafe

distancefromthebattery .

2.Nore,opename,or

smoking.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

109-7069

11

Page 12

ProductOverview

G014939

Figure4

1.Height-of-cutdecklift

pedal

6.Rollbar

2.Transportlock

7.Seatbelt

3.Parkingbrakelever8.Fuelcap

4.Controls

9.Mowerdeck

5.Motioncontrollevers

10.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure4andFigure5).

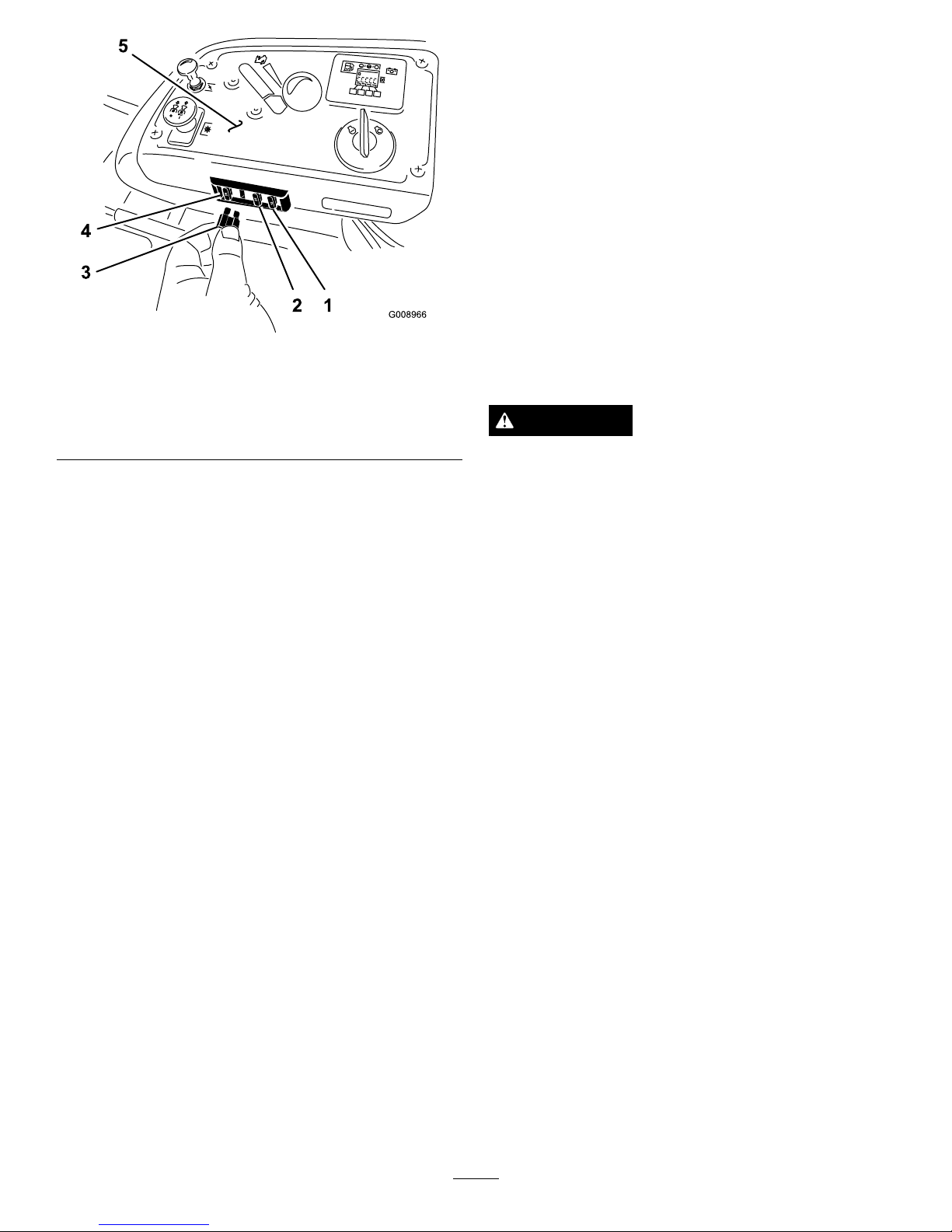

25

25

10

15

G008951

1

2

3

4

5

6

Figure5

1.PTOSwitch4.Hourmeter/Safety

interlockdisplay/Fuel

gauge

2.Choke

5.Ignitionswitch

3.Throttlecontrol6.Fuses

FuelGauge

Thefuelgaugeislocatedwiththehourmeter,andthebars

lightupwhentheignitionswitchison(Figure6).

Theindicatorlightappearswhenthefuellevelis

low—approximately3.8L(1USgallon)remaininginthe

fueltank.

Figure6

1.Fuelgauge(bars)4.Safety-interlocksymbols

2.Batterylight

5.Low-fuelindicatorlight

3.Hourmeter

HourMeter

Thehourmeterrecordsthenumberofhourstheenginehas

operated.Itoperateswhentheengineisrunning.Usethese

timesforschedulingregularmaintenance(

Figure6).

SafetyInterlockIndicators

Therearesymbolsonthehourmeterandtheindicatewitha

blacktrianglethattheinterlockcomponentisinthecorrect

position(Figure6).

BatteryIndicatorLight

WhentheignitionkeyisinitiallyturnedtotheRunposition

forafewseconds,thebatteryvoltagewillbedisplayedinthe

areawherethehoursarenormallydisplayed.

Thebatterylightturnsonwhentheignitionisturnedonand

whenthechargeisbelowthecorrectoperatinglevel(Figure

6).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.

BladeControlSwitch(PTO)

Thebladecontrolswitch(PTO)isusedtoengagetheelectric

clutchanddrivethemowerblades.Pulltheswitchupto

12

Page 13

engagethebladesandrelease.Todisengagetheblades,push

thebladecontrolswitch(PTO)downormoveamotion

controlleverintotheneutrallockposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhasthree

positions:Start,RunandOff.

MotionControlLevers

Themotioncontrolleversareusedtodrivethemachine

forward,reverse,andturneitherdirection.

NeutralLockPosition

Theneutrallockpositionisusedwiththesafetyinterlock

systemtoengageandtodetermineneutralposition.

Fuel-shutoffValve

Closethefuel-shutoffvalve(undertheseat)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .T oro.comforalistofallapproved

attachmentsandaccessories.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width:

48inchDeck52inchDeck60inchDeck

Withoutdeck116.1cm

(45.7inches)

116.1cm(45.7

inches)

134.6cm

(53.0inches)

Deector—up137.2cm(54

inches)

146.0cm(57.5

inches)

156.8cm

(61.7inches)

Deector—

down

161.4cm

(63.6inches)

171.8cm(67.6

inches)

192.2cm

(75.7inches)

Length:

48inchDeck52inchDeck60inchDeck

Rollbar—up201.2cm

(79.2inches)

201.2cm

(79.2inches)

211.1cm

(83.1inches)

Roll

bar—down

205.5cm

(80.9inches)

205.5cm

(80.9inches)

215.4cm

(84.8inches)

Height:

Rollbar—upRollbar—down

179.1cm(70.5inches)118.9cm(46.8inches)

Weight:

ModelWeight

74952

475kg(1048lb)

74953and78953

492kg(1085lb)

74957

533kg(1170lb)

13

Page 14

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycancauseasparkwhichcanignitethe

gasolinevapors.Areorexplosionfromgasoline

canburnyouandothersandcandamageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbed,becauseinteriorcarpets

orplastictruck-bedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandfueltheequipment

withthewheelsontheground.

Ifthisisnotpossible,thenfuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromagasoline-dispensernozzle.

•Ifagasolinedispensermustbeused,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditionerbottleopening.

•Avoidcontactwithskin;washoffspillagewith

soapandwater.

UsingFuelStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetokeepthe

fuelfreshduringstorageof90daysorless.Ifyouarestoring

themachineforlonger,drainthefueltank;refertoStorage

(page61).

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountoffuelstabilizer/conditionertothe

fuel,andfollowthedirectionsofthemanufacturer.

Note:Fuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

14

Page 15

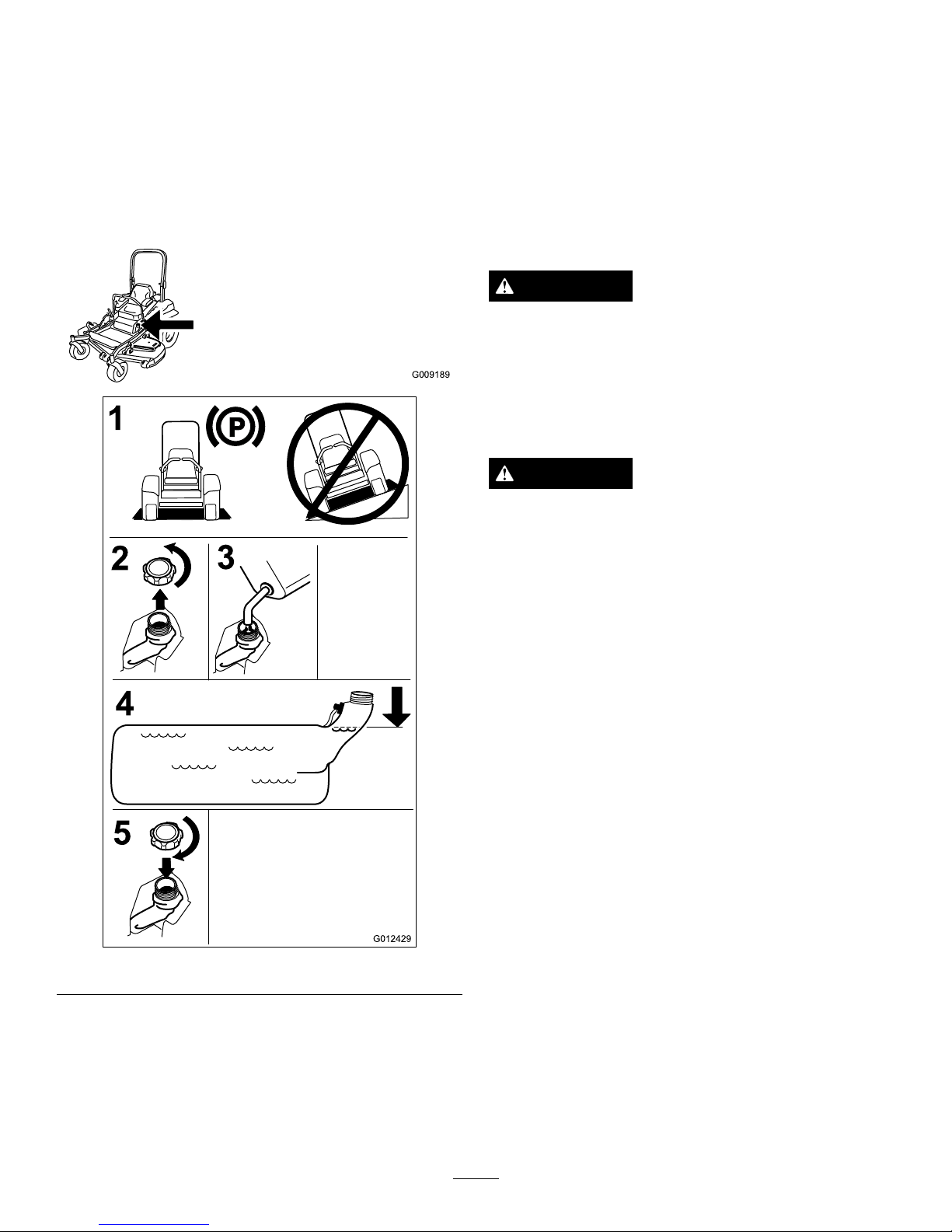

FillingtheFuelTank

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcapandremoveit.Add

regularunleadedgasolinetothefueltankuntilthelevel

is6to13mm(1/4to1/2inch)belowthebottom

ofthellerneck.Thisspaceinthetankallowsthe

gasolinetoexpand.Donotllthefueltankcompletely

full;referto(

Figure7).

G009189

G012429

1

2

4

3

5

Figure7

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine

OilLevel.

BreakingInaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

UsingtheRolloverProtection

System(ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensurethattherearpartoftheseatissecuredwith

theseatlatch.

WARNING

Thereisnorolloverprotectionwhentherollbaris

inthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbaris

inthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearancepermits.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

Important:Lowertherollbaronlywhenabsolutely

necessary.

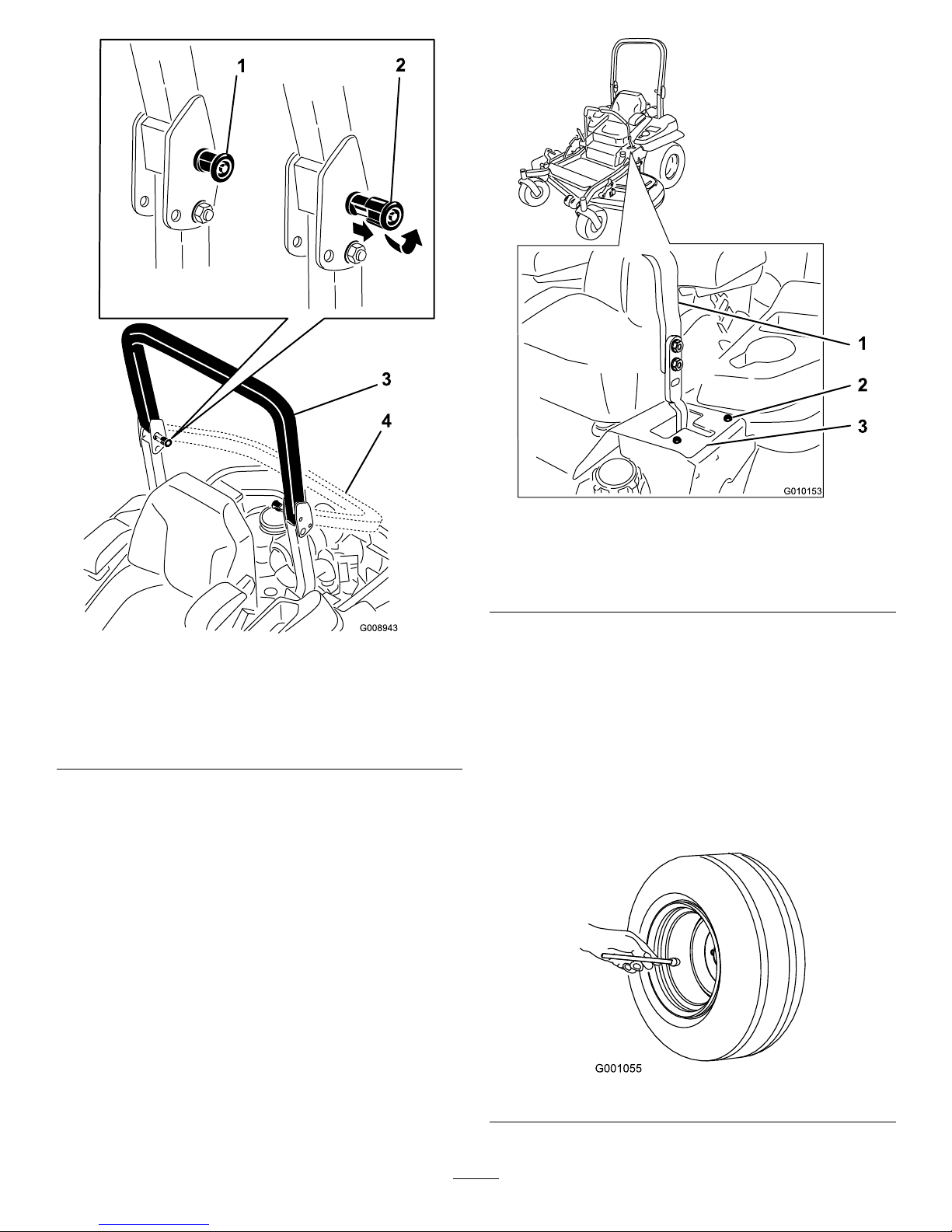

1.Tolowertherollbar,applyforwardpressuretothe

upperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90°sothatthey

arenotengaged(Figure8).

3.Lowertherollbartothedownposition(Figure8).

15

Page 16

Figure8

1.ROPSknob

3.Rollbarintheupright

position

2.PullROPSknoboutand

rotate90degrees

4.Rollbarinthefolded

position

4.Toraisetherollbar,raisetherollbartotheoperate

position,rotatetheknobssothattheymovepartially

intothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarandthepinswillsnap

intopositionwhentheholesalignwiththepins(Figure

8).Pushontherollbarandensurethatbothpinsare

engaged.

Important:Alwaysusetheseatbeltwiththeroll

barinthefullyraisedposition.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Thereisnorolloverprotectionwhentherollbaris

down.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Readandfollowtherolloverprotectioninstructions

andwarnings.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotoperateneardrop-offsornearwater.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Avoidsuddenturnsorrapidspeedchanges.

Figure9

1.SafeZone—usethe

ZMasterhereonslopes

lessthan15degreesor

atareas.

3.Water

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsand

water.

16

Page 17

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,feet,andhead

isrecommended.

G009027

1

2

Figure10

1.Wearsafetyglasses

2.Wearhearingprotection

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

WARNING

Parkingbrakemaynotholdmachineparkedona

slopeandcouldcausepersonalinjuryorproperty

damage.

Donotparkonslopesunlesswheelsarechocked

orblocked

G016994

1

2

Figure11

ReleasingtheParkingBrake

G016995

1

2

Figure12

OperatingtheMowerBlade

ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBladeControlSwitch

(PTO)

Note:Engagingthebladecontrolswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

G008945

Figure13

DisengagingtheBladeControlSwitch

(PTO)

G009174

Figure14

17

Page 18

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure15).

Alwaysusethefastpositionwhenturningonthemowerdeck

withthebladecontrolswitch(PTO).

G008946

Figure15

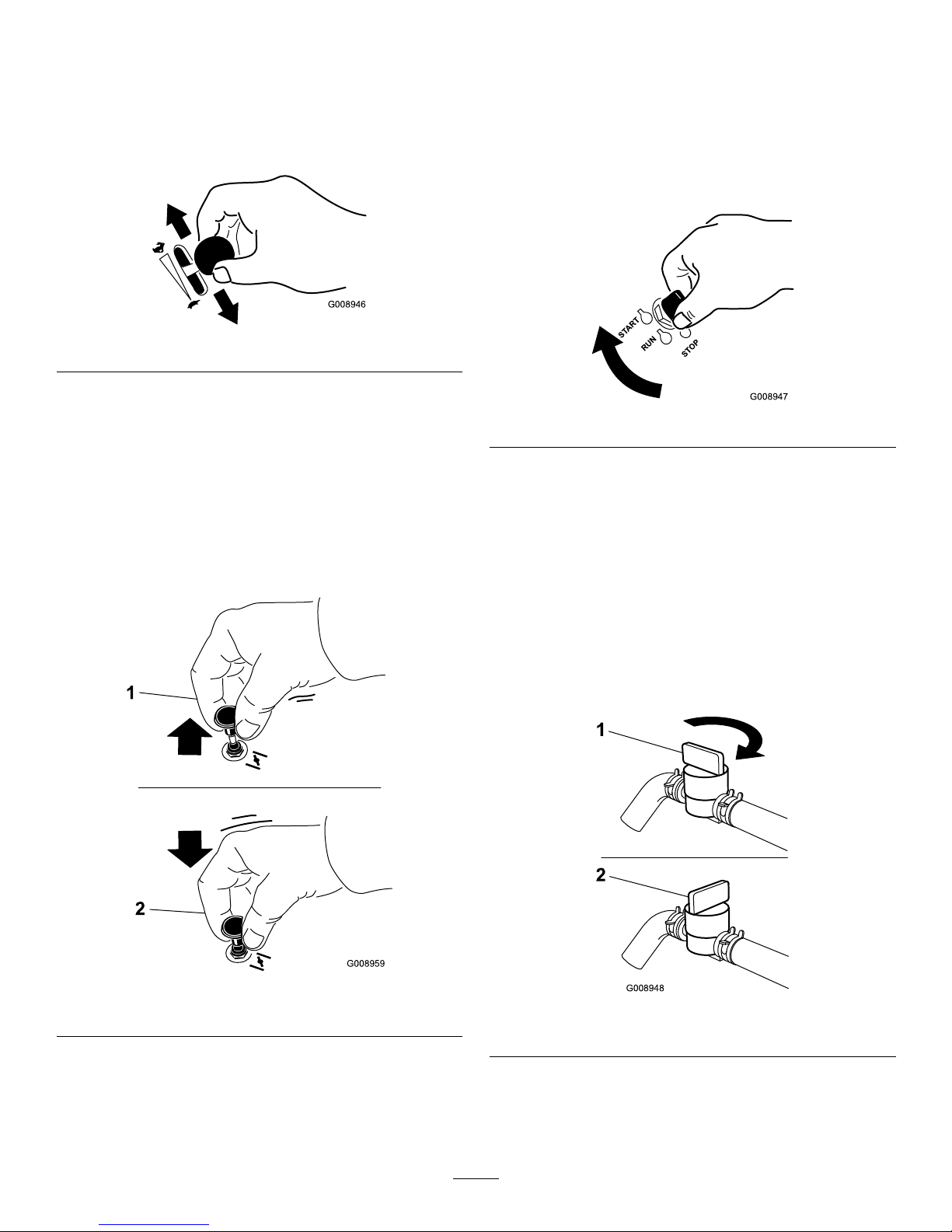

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(

Figure16).

3.Pushdownonthechoketodisengagethechokeafter

theenginehasstarted(

Figure16).

G008959

1

2

Figure16

1.On2.Off

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition(Figure17).

Whentheenginestarts,releasethekey .

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,allowa15secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeencompletelywithoutfuel.

START

RUN

STOP

G008947

Figure17

2.Tostoptheengine,turntheignitionkeytothestop

position.

UsingtheFuel-shutoffValve

Thefuel-shutoffvalveislocatedundertheseat.Movethe

seatforwardtoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,and

storage.

Ensurethatthefuel-shutoffvalveisopenwhenstartingthe

engine.

G008948

1

2

Figure18

1.On2.Off

18

Page 19

StartingandStoppingthe

Engine

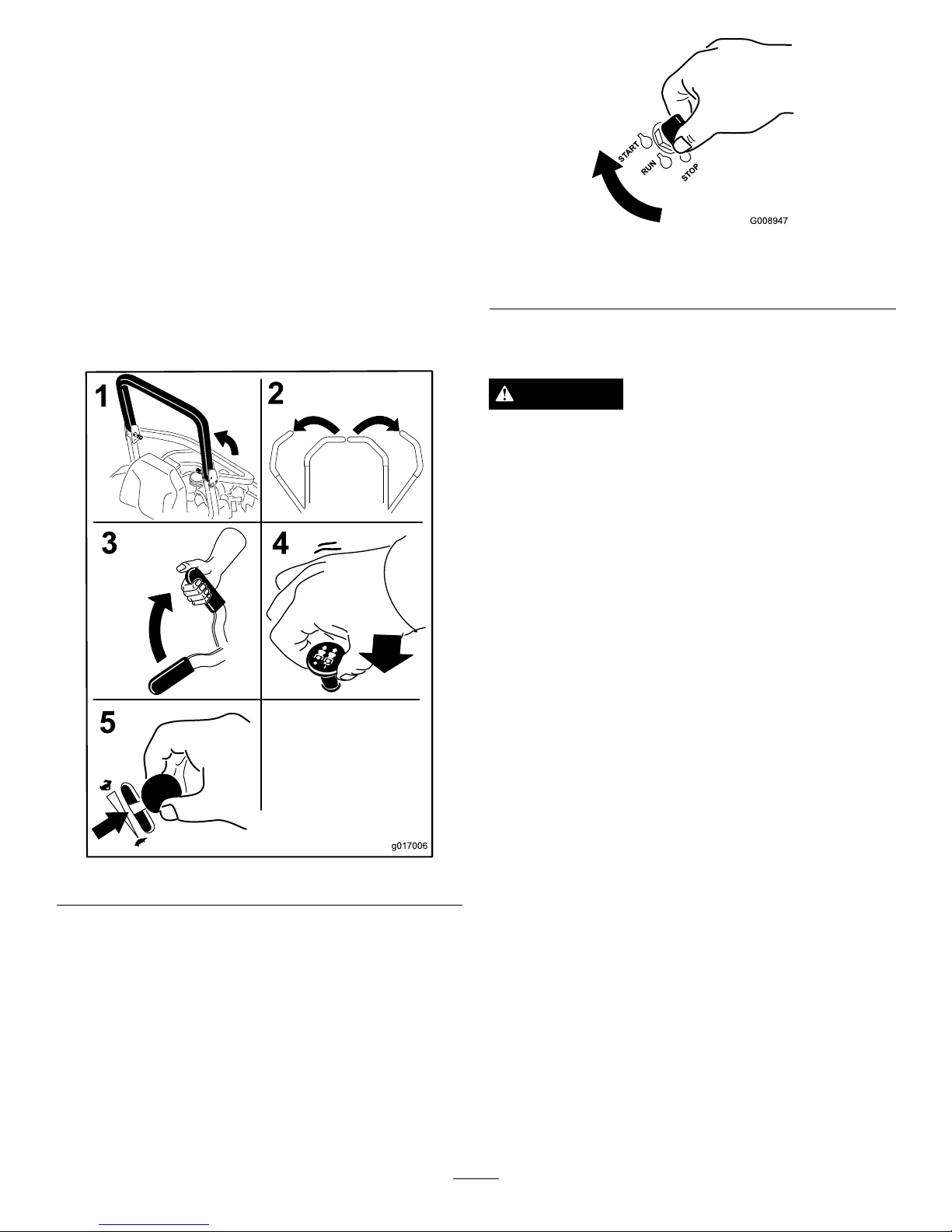

StartingtheEngine

1.RaisetheROPSupandlockintoplace,sitontheseat

andfastentheseatbelt.

2.Movethemotioncontrolstoneutrallockedposition.

3.Settheparkingbrake;refertoSettingtheParking

Brake.

4.Movethebladecontrolswitch(PTO)totheOff

position(Figure19).

5.MovethethrottlelevermidwaybetweentheSlowand

Fastpositions.

g017006

Figure19

6.TurntheignitionkeytotheStartposition(Figure17).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

START

RUN

STOP

G008947

Figure20

1.Off3.Start

2.Run

StoppingtheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

Lettheengineidleatslowthrottle(turtle)for60seconds

beforeturningtheignitionswitchoff.

19

Page 20

g017007

Figure21

Important:Makesurethatthefuelshutoffvalveis

closedbeforetransportingorstoringthemachine,as

fuelleakagemayoccur.Settheparkingbrakebefore

transporting.Makesuretoremovethekeyasthefuel

pumpmayrunandcausethebatterytolosecharge.

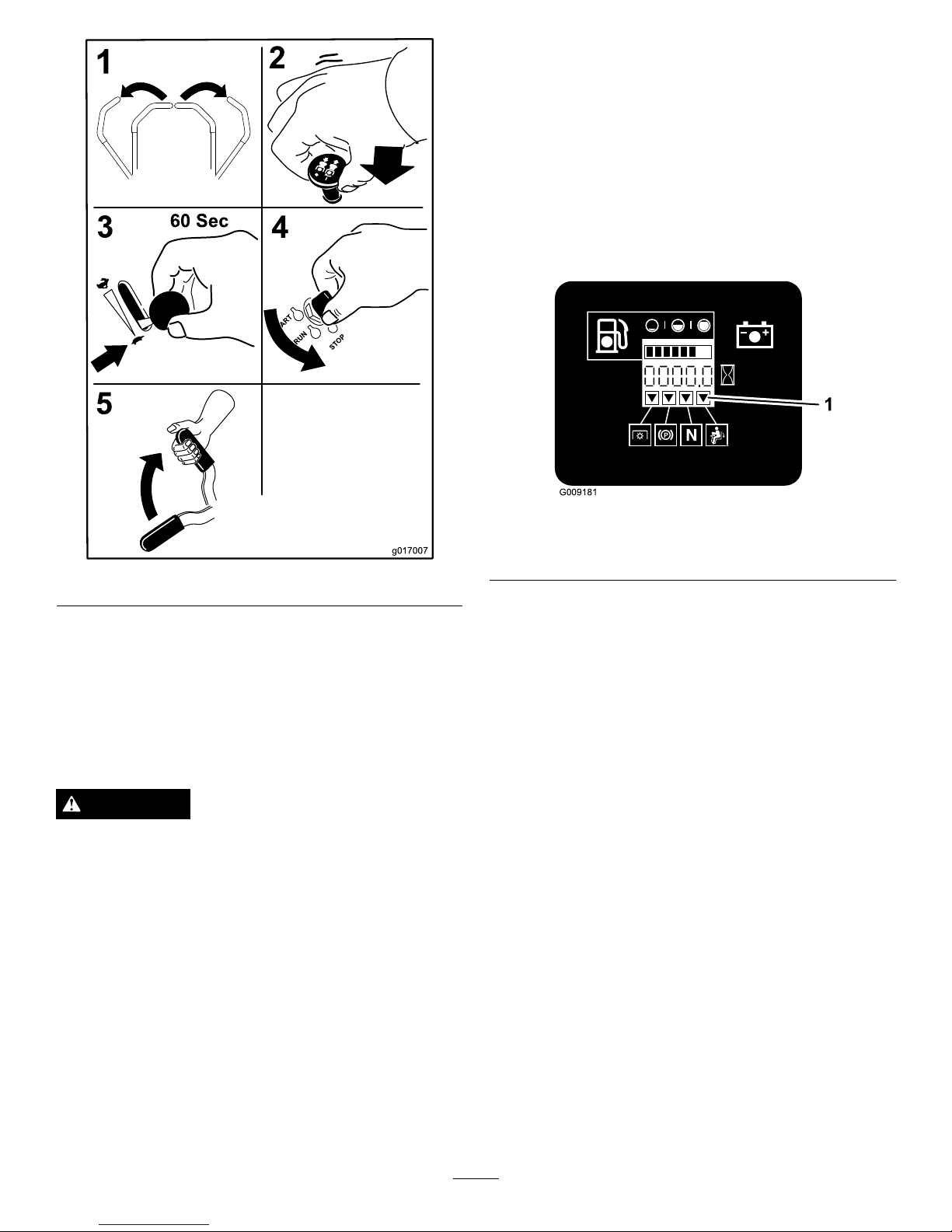

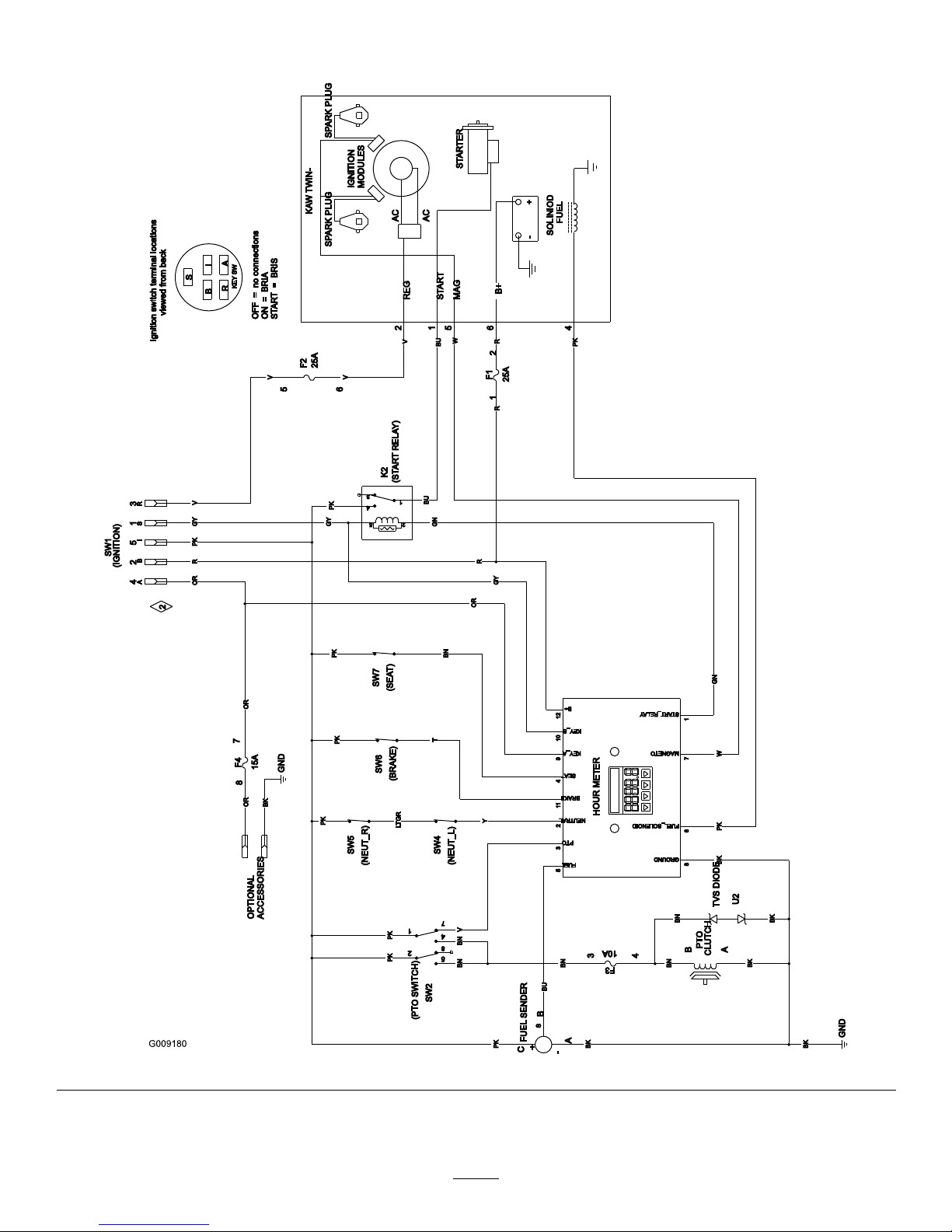

TheSafetyInterlockSystem

CAUTION

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

•Thebladecontrolswitch(PTO)isdisengaged.

•Themotioncontrolleversareintheneutrallocked

position

Thesafetyinterlocksystemalsoisdesignedtostopthe

enginewhenthetractioncontrolsaremovedfromthelocked

positionwiththeparkingbrakeengagedorifyourisefrom

theseatwhenthePTOisengaged.

Thehourmeterhassymbolstonotifytheuserwhenthe

interlockcomponentisinthecorrectposition.Whenthe

componentisinthecorrectposition,atrianglewilllightup

inthecorrespondingsquare.

G009181

1

Figure22

1.Triangleslightupwhentheinterlockcomponentsareinthe

correctposition

TestingtheSafetyInterlockSystem

ServiceInterval:Beforeeachuseordaily

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)toon.Trystartingthe

engine;theengineshouldnotcrank.

2.Sittingontheseat,engagetheparkingbrakeandmove

thebladecontrolswitch(PTO)tooff.Moveeither

motioncontrollever(outofneutrallockedposition).

Trystartingtheengine;theengineshouldnotcrank.

Repeatforothercontrollever.

3.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,releasetheparking

brake,engagethebladecontrolswitch(PTO)andrise

slightlyfromtheseat;theengineshouldstop.

4.Sittingontheseat,engagetheparkingbrake,movethe

bladecontrolswitch(PTO)tooffandmovethemotion

controlleverstoneutrallockposition.Nowstartthe

engine.Whiletheengineisrunning,centereither

motioncontrolandmove(forwardorreverse);the

engineshouldstop.Repeatforothermotioncontrol.

20

Page 21

5.Sittingontheseat,disengagetheparkingbrake,move

thebladecontrolswitch(PTO)tooffandmovethe

motioncontrolleverstoneutrallockposition.Try

startingtheengine;theengineshouldnotcrank.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

UsingtheMotionControlLevers

Figure23

1.Motioncontrol

lever-neutrallockposition

4.Backward

2.Center,unlockedposition5.Frontofmachine

3.Forward

DrivingForward

Note:Theenginewillkillifthetractioncontrolleversare

movedwiththeparkingbrakeengaged.

Tostop,pullthemotioncontrolleverstotheneutralposition.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrollevers

forward(Figure24).

G008952

Figure24

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrollevers

rearward(Figure25).

21

Page 22

G008953

Figure25

StoppingtheMachine

Tostopthemachine,movethetractioncontrolleversto

neutralandmovetolockedposition,disengagethepower

takeoff(bladecontrolswitch(PTO),andturntheignition

keytooff.

Settheparkingbrakewhenyouleavethemachine;referto

SettingtheParkingBrakeinOperation.Remembertoremove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhastwopositionsandisusedwiththe

deck-liftpedal.Thereisalockpositionandaunlockposition

forthetransportposition.Thetransportlockisusedwiththe

deck-liftpedal.RefertoFigure26

22

Page 23

Figure26

TransportLockPositions

1.Transportlock3.Unlockposition—doesnot

lockthemowerdeckinto

transportposition

2.Lockposition—mower

deckwilllockintotransport

position

AdjustingtheHeight-of-cutPin

Theheightofcutisadjustedfrom25to140mm(1to

5-1/2inches)in6mm(1/4inch)incrementsbymovingthe

clevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeck-liftpedalwithyourfootandraisethe

mowerdecktothetransportposition(alsothe140mm

(5-1/2inch)cutting-heightposition);referto

Figure27.

3.Toadjust,rotatethepin90degreesandremovethepin

fromtheheight-of-cutbracket(Figure27).

4.Selectaholeintheheight-of-cutbracketcorresponding

totheheightofcutdesired,andinsertthepin(Figure

27).

5.Pushonthedecklift,pullbackonthetransportlock,

andslowlylowerthemowerdeck.

1

3

2

G017027

Figure27

1.Deck-liftpedal

3.Transportlock

2.Height-of-cutpin

AdjustingtheAnti-scalp

Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheneutral-lockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Adjusttheanti-scalprollersasshownin

,,and.

23

Page 24

Figure28

1.Anti-scalproller4.Flangenut

2.Spacer

5.Bolt

3.Bushing

Figure29

1.Anti-scalproller3.Flangenut

2.Bushing4.Bolt

Figure30

1.Anti-scalproller4.Flangenut

2.Spacer

5.Bolt

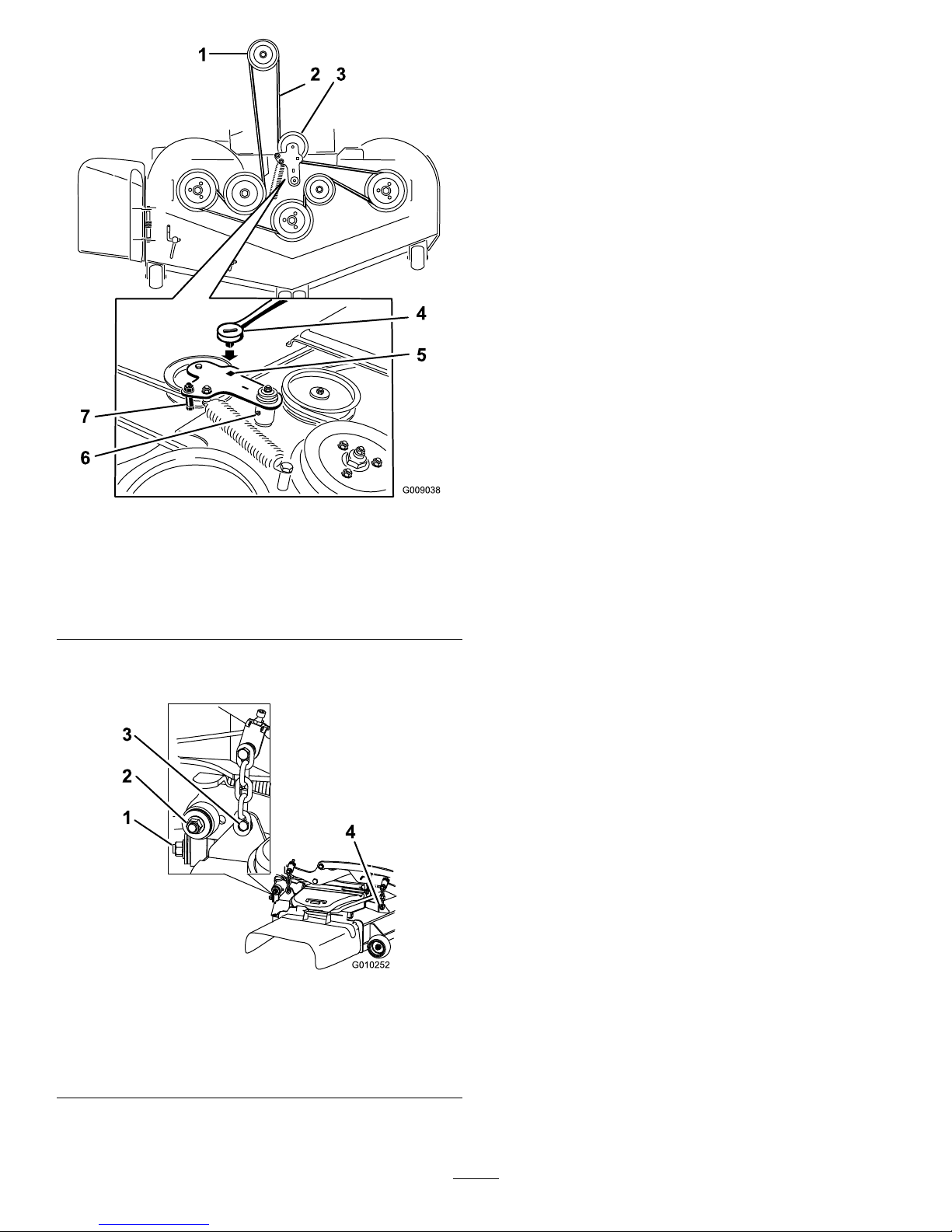

3.Bushing

AdjustingtheFlowBafeCam

Locks

Thisprocedureisapplicableonlytomachineswiththeow

bafelocks.Certainmodelswillhavenutsandboltsin-place

oftheowbafelocksandcanbeadjustedthesame.

Themowerdischargeowcanbeadjustedfordifferenttypes

ofmowingconditions.Positionthecamlocksandbafeto

givethebestqualityofcut.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Toadjustthecamlocks,swingtheleveruptoloosen

thecamlock(Figure31).

4.Adjustthebafeandcamlocksintheslotstothe

desireddischargeow .

5.Swingtheleverbackovertotightenthebafeandcam

locks(

Figure31).

6.Ifthecamlocksdonotlockthebafeintoplaceorit

istootight,loosentheleverandthenrotatethecam

lock.Adjustthecamlockuntilthedesiredlocking

pressureisachieved.

G008961

1

2

3

4

Figure31

1.Unlocklever

3.Positionthebafe

2.Rotatethecamlockto

increaseordecrease

lockingpressure

4.Locklever

24

Page 25

PositioningtheFlowBafe

Thefollowingguresareonlyrecommendationsforuse.

Adjustmentswillvarybygrasstype,moisturecontent,and

heightofgrass.

Note:Iftheenginepowerdrawsdownandthemower

groundspeedisthesame,openupthebafe.

PositionA

Thisisthefullrearposition.Thesuggesteduseforthis

positionisasfollows:

•Useforshort,lightgrassmowingconditions.

•Useindryconditions.

•Useforsmallergrassclippings.

•Usetopropelgrassclippingsfartherawayfromthe

mower.

Figure32

PositionB

Usethispositionwhenbagging.Alwaysalignitwiththe

bloweropening.

Figure33

PositionC

Thisisthefullopenposition.Thesuggesteduseforthis

positionisasfollows:

•Useintall,densegrass-mowingconditions.

•Useinwetconditions.

•Usetolowertheenginepowerconsumption.

•Usetoallowincreasedgroundspeedinheavyconditions.

•ThispositionoffersbenetssimilartothoseoftheT oro

SFSmower.

Figure34

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlockseat(Figure35).

G008962

Figure35

25

Page 26

UsingtheDriveWheelRelease

Valves

WARNING

Handsmaybecomeentangledintherotatingdrive

componentsbelowtheenginedeck,whichcould

resultinseriousinjury.

Stoptheengine,removethekey,andallowall

movingpartstostopbeforeaccessingthedrive

wheelreleasevalves.

WARNING

Theengineandhydraulicdriveunitscanbecome

veryhot.Touchingahotengineorhydraulicdrive

unitscancausesevereburns.

Allowtheengineandhydraulicdriveunitstocool

completelybeforeaccessingthedrivewheelrelease

valves.

Thedrivewheelreleasevalvesarelocatedinthebackofeach

hydraulicdriveunit,undertheseat.

Note:Makesurethereleasevalvesareinthefullyhorizontal

positionwhenoperatingthemachineorseveredamagetothe

hydraulicsystemcanoccur.

1.DisengagethePTO(bladecontrolswitch)andturnthe

ignitionkeytooff.Movetheleverstoneutrallocked

positionandapplyparkingbrake.Removethekey.

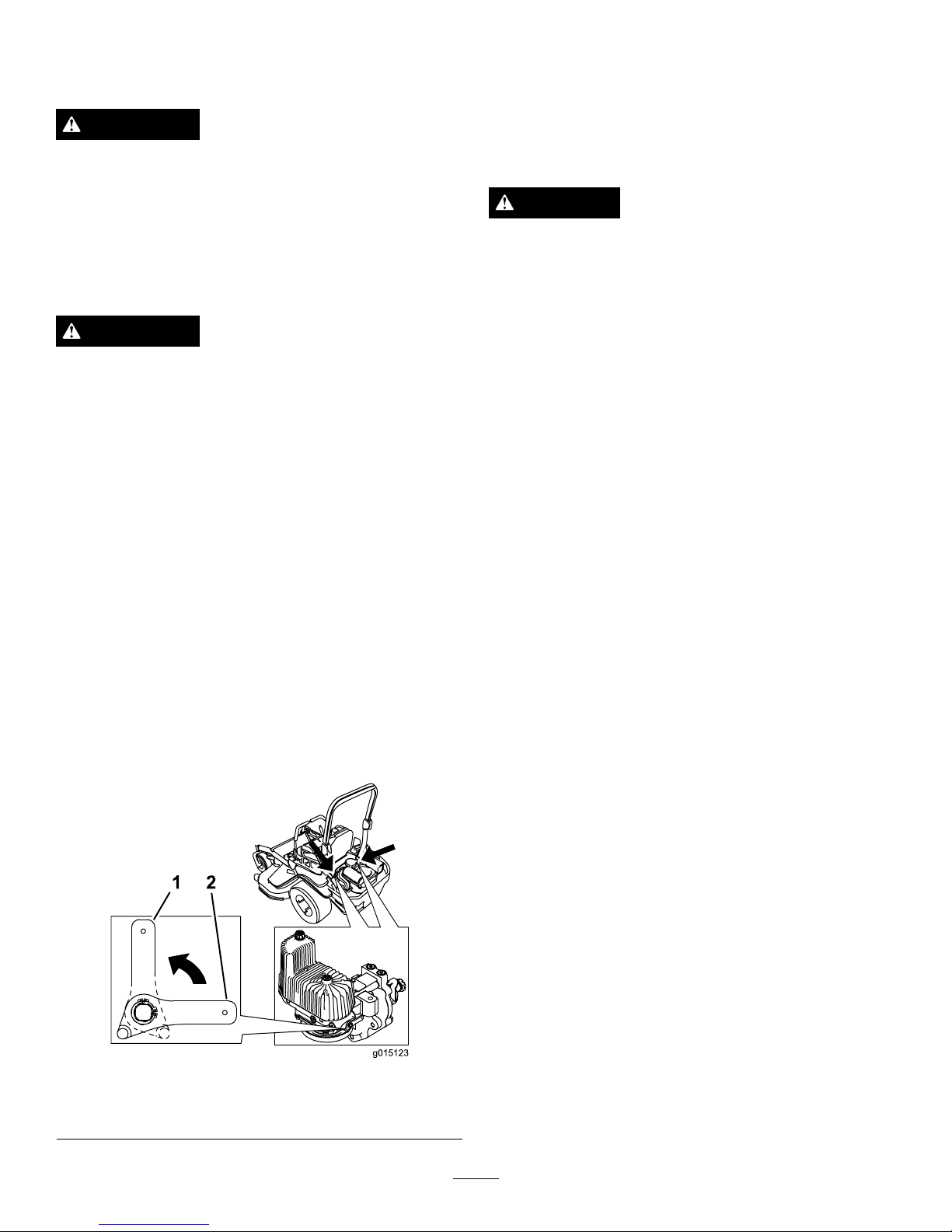

2.Rotatethereleasevalveleversverticallytopushthe

machine.Thisallowshydraulicoiltoby-passthepump

enablingthewheelstoturn(Figure36).

3.Disengageparkingbrakebeforepushing.

g015123

Figure36

1.Verticaltopushthe

machine

2.Horizontaltorunthe

machine

4.Rotatethereleasevalvelevershorizontallytorunthe

machine(Figure36).

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfrom

themower,becausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethepowertakeoff

(blade-controlswitch/PTO)totheoffposition,

rotatetheignitionkeytooffandremovethekey.

•Makesurethatthegrassdeectorisinthedown

position.

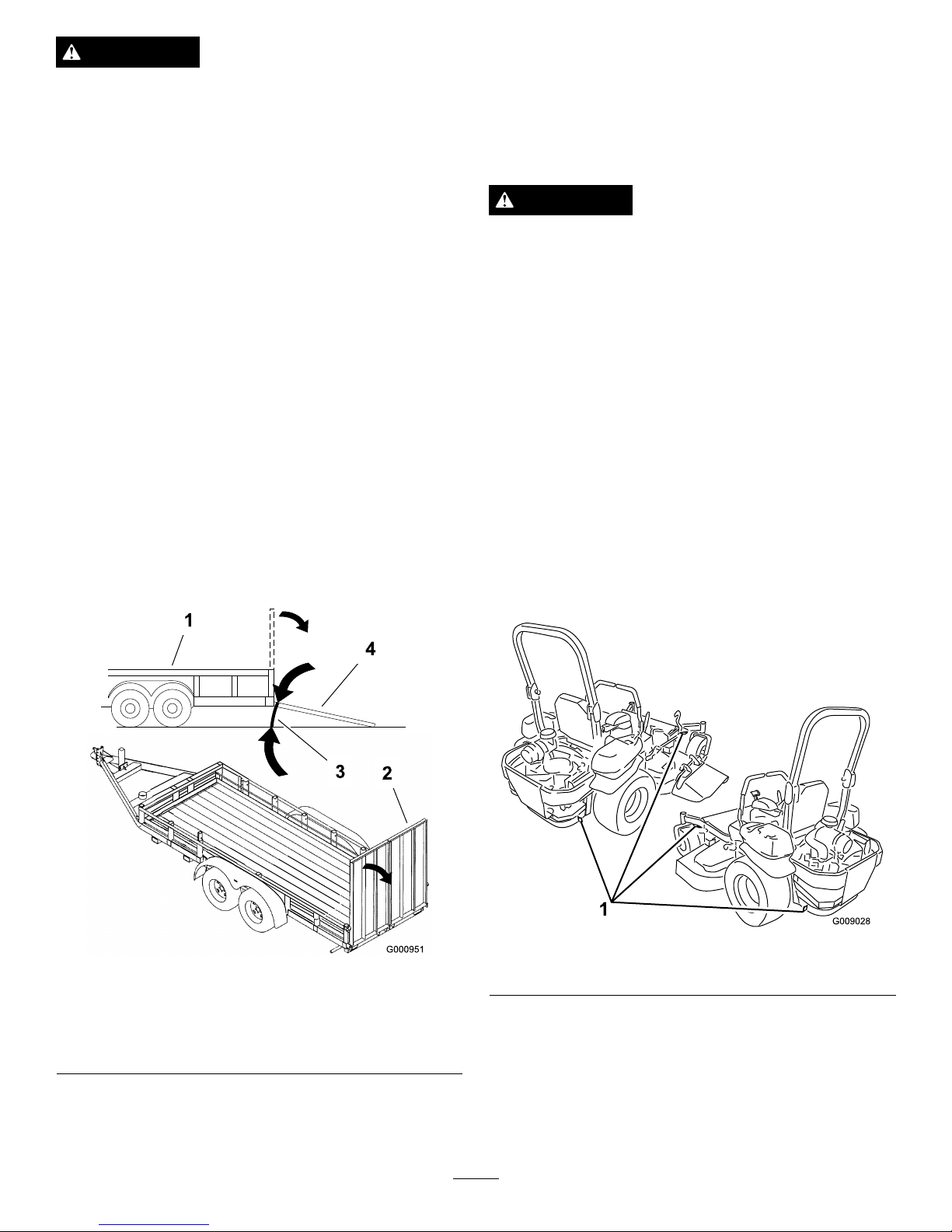

LoadingtheMachine

Useextremecautionwhenloadingthemachineontoatrailer

ortruck.Onefull-widthrampthatiswideenoughtoextend

beyondthereartiresisrecommendedinsteadofindividual

rampsforeachsideofthemachine(Figure37).Thelower

rearsectionofthemachineframeextendsbackbetweenthe

rearwheelsandservesasastopfortippingbackward.Having

afull-widthrampprovidesasurfacefortheframemembers

tocontactifthemachinestartstotipbackward.Ifitisnot

possibletouseonefull-widthramp,useenoughindividual

rampstosimulateafull-widthcontinuousramp.

Therampshouldbelongenoughsothattheanglesdonot

exceed15degrees(Figure37).Asteeperanglemaycause

mowercomponentstogetcaughtasthemachinemovesfrom

theramptothetrailerortruck.Steeperanglesmayalsocause

themachinetotipbackward.Ifloadingonornearaslope,

positionthetrailerortrucksothatitisonthedownside

oftheslopeandtherampextendsuptheslope.Thiswill

minimizetherampangle.Thetrailerortruckshouldbeas

levelaspossible.

Important:Donotattempttoturnthemachinewhile

ontheramp;youmaylosecontrolanddriveofftheside.

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausethemachinetotipbackward.

26

Page 27

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityofbackwardtip-overandcouldcause

seriousinjuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•EnsurethattheROPSisintheuppositionwhile

usingtheseatbeltwhenloadingthemachine.

EnsurethattheROPSwillclearthetopofan

enclosedtrailer.

•Useonlyasingle,full-widthramp;donotuse

individualrampsforeachsideofthemachine.

•Ifindividualrampsmustbeused,useenough

rampstocreateanunbrokenrampsurfacewider

thanthemachine.

•Donotexceeda15degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Avoidsuddenaccelerationwhiledrivingthe

machineuparamp,toavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

themachinedownaramp,toavoidtipping

backward.

Figure37

1.Trailer3.Notgreaterthan

15degrees

2.Full-widthramp4.Full-widthramp—side

view

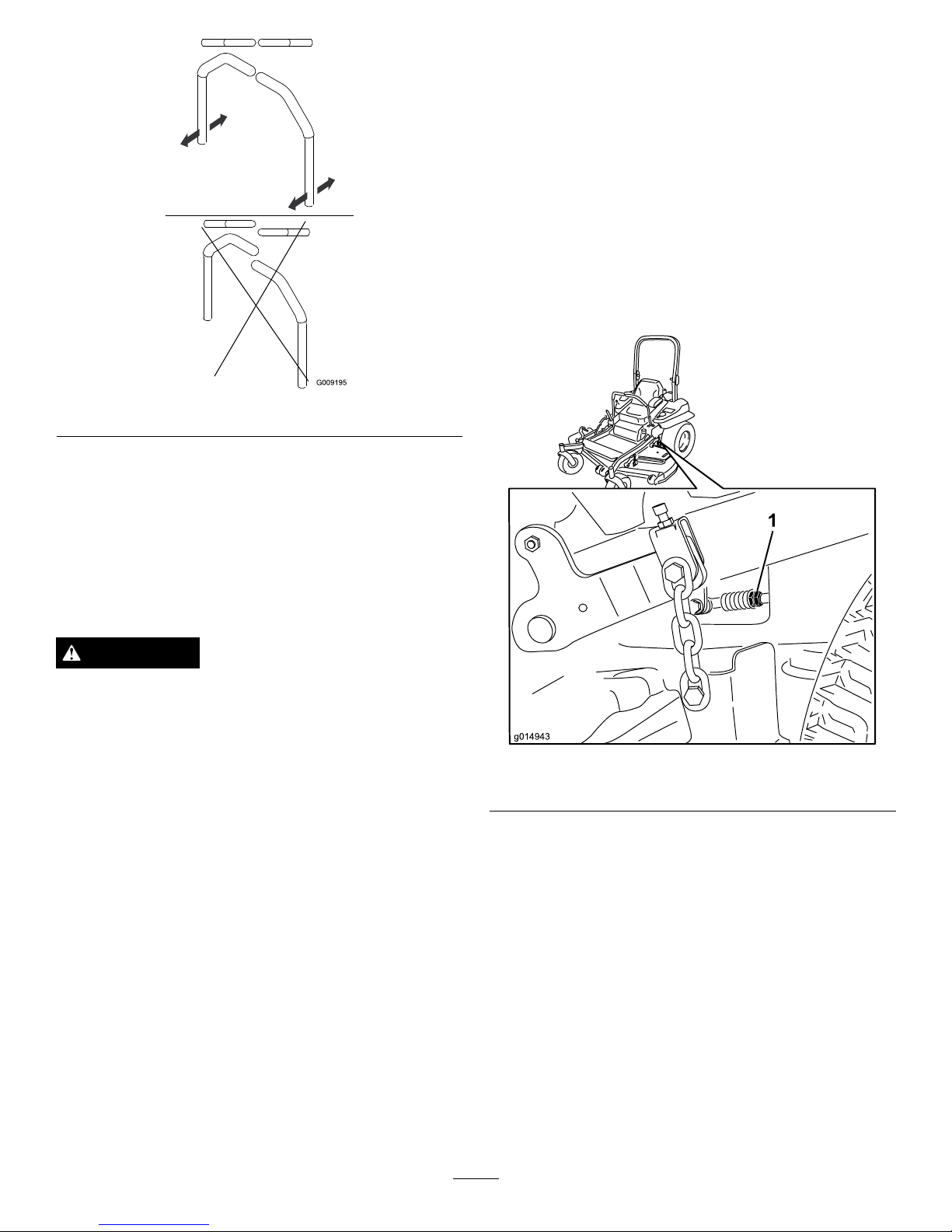

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw.Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithoutturn

signals,lights,reectivemarkings,oraslow-moving

vehicleemblemisdangerousandcanleadto

accidentscausingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

Totransportthemachine:

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Stoptheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(

Figure38).

Figure38

1.Tie-downloops

27

Page 28

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethecutting

heightofthemowerdoesnotscalpanyunevenground.

However,thecuttingheightusedinthepastisgenerallythe

bestonetouse.Whencuttinggrasslongerthansixinchestall,

youmaywanttocutthelawntwicetoensureanacceptable

qualityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently .Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

CuttingSpeed

Toimprovecutquality ,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

WhenStopping

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineTOROreplacementblade.

28

Page 29

Maintenance

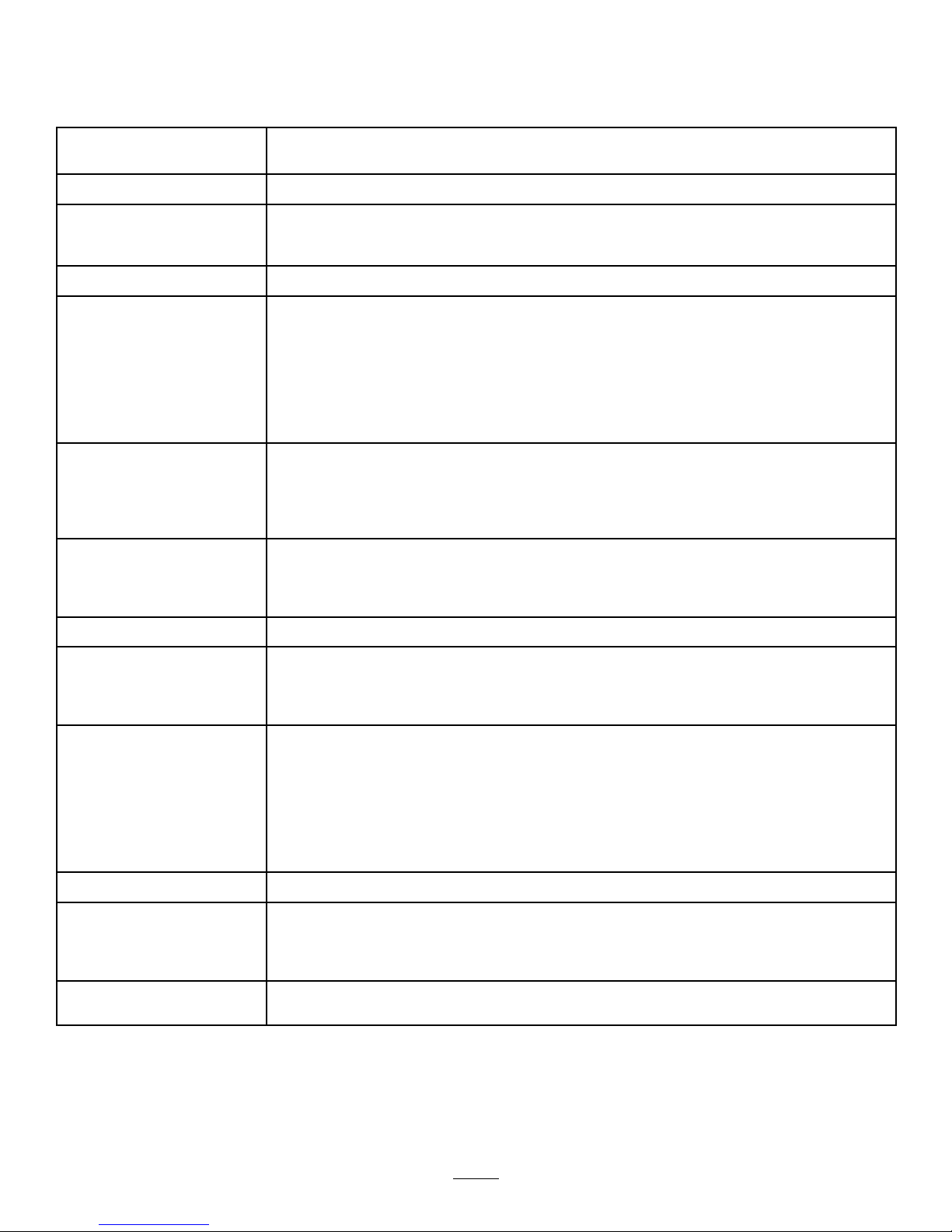

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst8hours

•Changetheengineoil.

Aftertherst100hours

•Checkthewheellugnuttorque.

•Checkthewheelhubslotted-nuttorque.

•Checktheparkbrakeadjustment.

Aftertherst250hours

•Changethehydraulicltersandhydraulicoilwhenusinganytypeofoil.

Beforeeachuseordaily

•Checkthesafetysystem.

•Checktheengineoillevel.

•Checktheseatbelt.

•Checktherolloverprotectionsystem(ROPS)knobs.

•Cleantheenginescreenandtheoilcooler.

•Checkandcleanthehydraulicunits.

•Checkthemowerblades.

•Cleanthemowerdeck.

Every50hours

•Greasethemowerdeckspindlesandidlerarm.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

•Checkthehydraulicoillevel.

Every100hours

•Lubricatethemowerdeckliftpivots.

•Changetheengineoil.(moreoftenindirtyordustyconditions)

•Checkandgapthesparkplugs.

•Checkandcleanenginecoolingnsandshrouds.

Every200hours

•Changetheengineoillter.

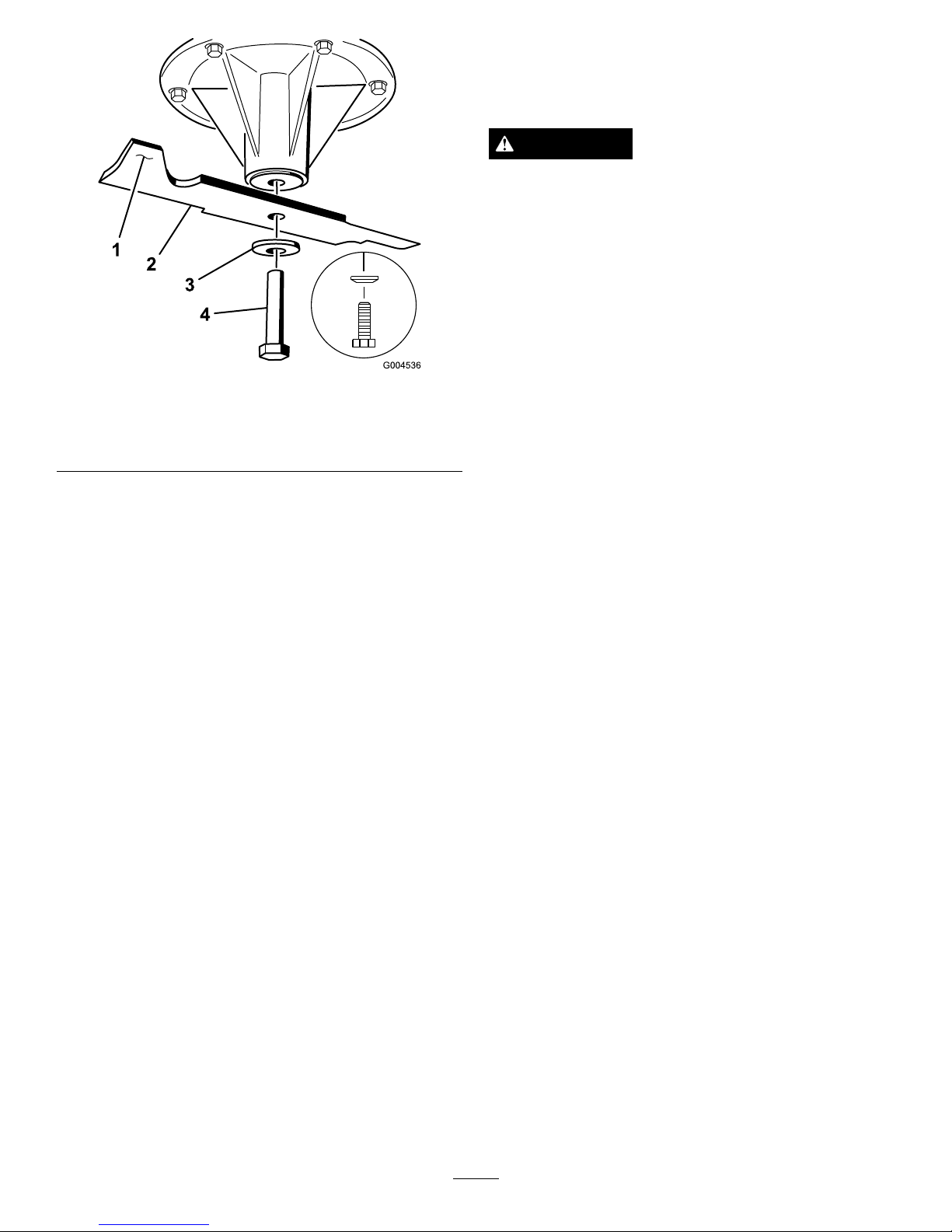

Every250hours

•Replacetheprimaryairlter.

•Checkthesecondaryairlter.

•ChangethehydraulicltersandhydraulicoilwhenusingMobil®1oil(moreoftenin

dirtyordustyconditions).

Every500hours

•Replacethesecondaryairlter.

•Replacethefuellter.(moreoftenindirtyordustyconditions).

•Checkthewheellugnuttorque.

•Checkthewheelhubslotted-nuttorque.

•Adjustthecasterpivotbearing.

•Checktheparkbrakeadjustment.

•ChangethehydraulicltersandhydraulicoilwhenusingT oro®HYPR-OIL™500

hydraulicoil(moreoftenindirtyordustyconditions).

Monthly

•Checkthebattery .

Yearly

•Greasethepumpbeltidlerarm.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Repackthefrontcasterwheelbearings(moreoftenindirtyordustyconditions).

•Lubricatethecasterwheelhubs

Yearlyorbeforestorage

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

29

Page 30

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Lubrication

GreasingandLubrication

Greasemorefrequentlywhenoperatingconditionsare

extremelydustyorsandy .

GreaseType:#2general-purposelithium-basedor

molybdenum-basedgrease

HowtoGrease

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettingswitharag.Makesuretoscrape

anypaintoffthefrontofthetting(s).

4.Connectagreaseguntothetting.Pumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings.

5.Wipeupanyexcessgrease.

WheretoAddLightOilorSpray

Lubrication

ServiceInterval:Every100hours

Deckliftpivots.

G017028

Figure39

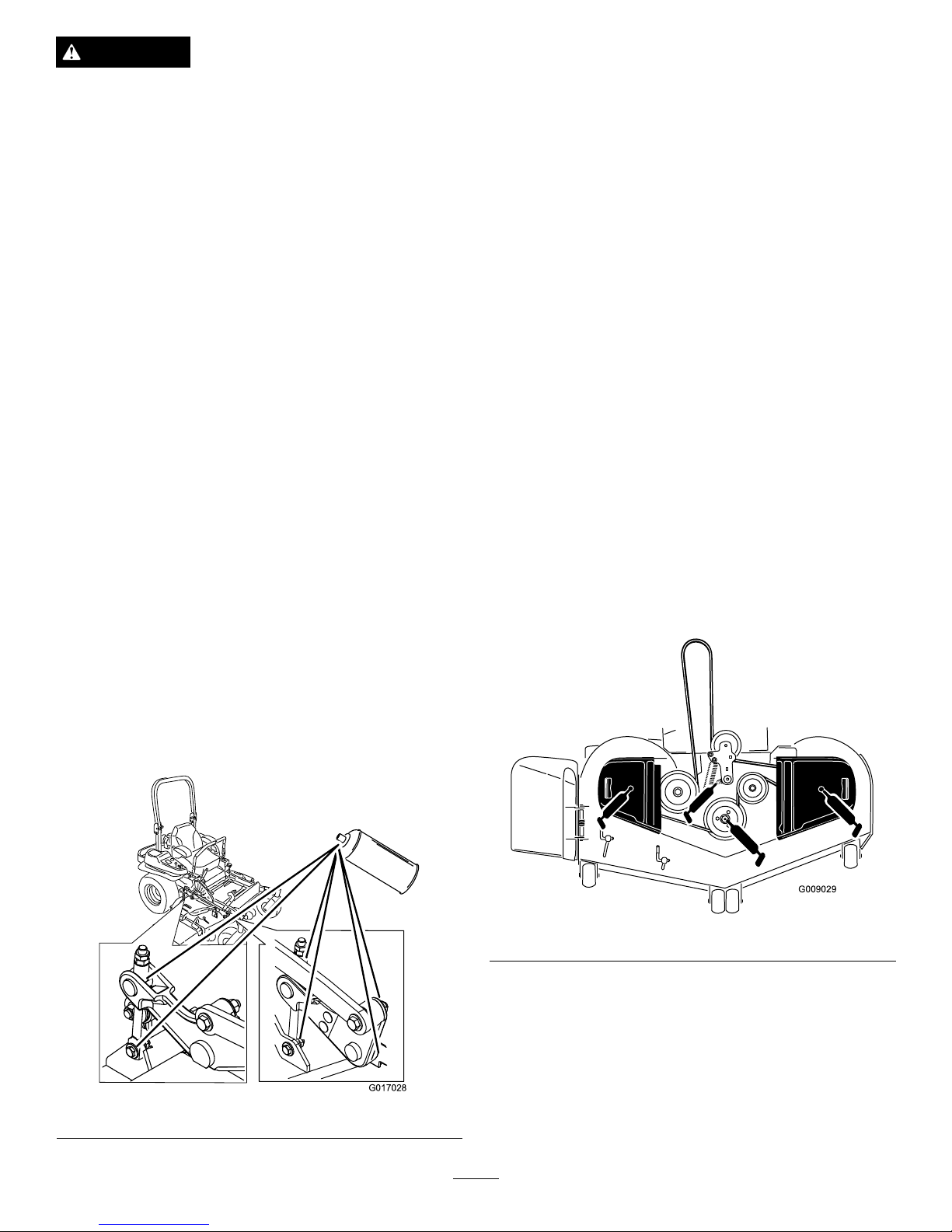

WheretoGreasetheMower

ServiceInterval:Every50hours—Greasethemowerdeck

spindlesandidlerarm.

Yearly—Greasethepumpbeltidlerarm.

Yearly—Greasethefrontcasterpivots(moreoftenin

dirtyordustyconditions).

Yearly—Repackthefrontcasterwheelbearings(more

oftenindirtyordustyconditions).

Important:Makesurethatthecuttingunitspindlesare

fullofgreaseweekly.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition,

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Greasethemowerdeckidlerpulleypivotuntilgrease

comeoutthebottom(

Figure40).

4.Greasethettingsonthetopofthe3spindlebearings

untilgreasecomesout(Figure40).

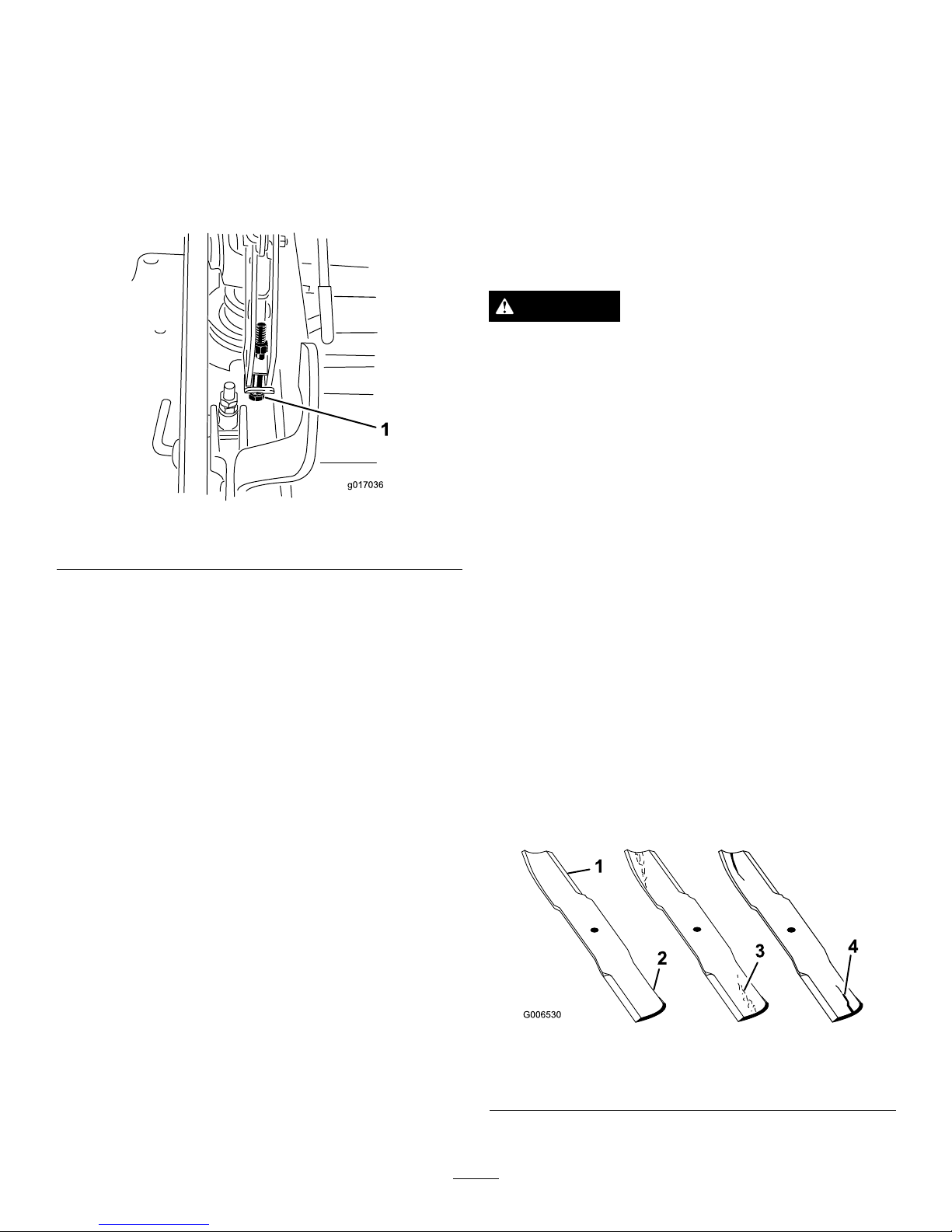

G009029

Figure40

5.Greasethedrivebeltidlerarm(Figure40).

30

Page 31

Figure41

6.Removethedustcapandadjustthecasterpivots.Keep

thedustcapoffuntilgreasingiscomplete.Referto

AdjustingtheCasterPivotBearinginMaintenance.

7.Removethehexplug.Threadagreasettingintothe

hole.

8.Pumpgreaseintothettinguntilitoozesoutaround

thetopbearing.

9.Removethegreasettingfromthehole.Installthehex

pluganddustcap(

Figure42).

Figure42

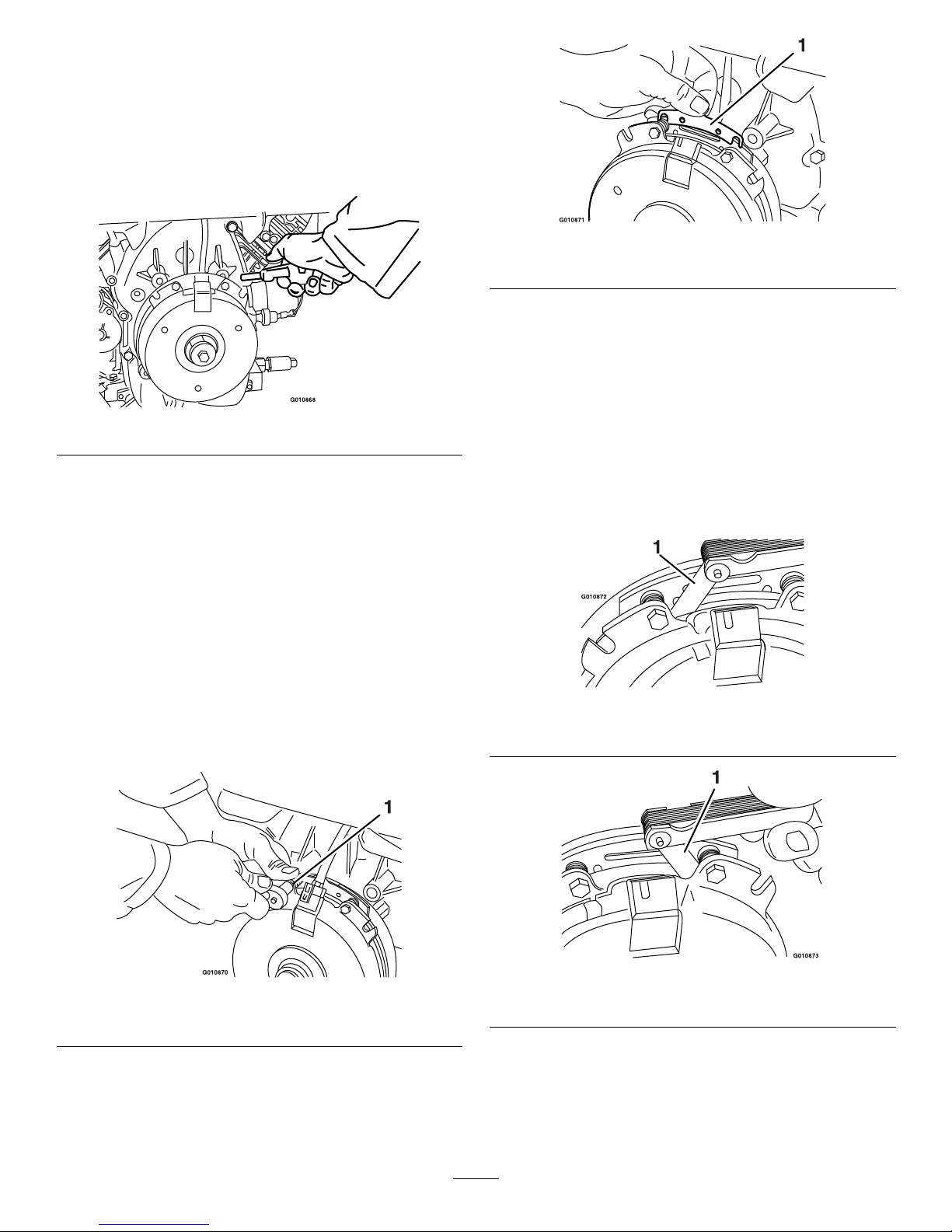

LubricatingtheCasterWheel

Hubs

ServiceInterval:Yearly

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey .Engagetheparkingbrake.

Figure43

1.Sealguard2.Spacernutwithwrench

ats

2.Raisethefrontofthemachineup,andsupportitwith

jackstands(orequivalentsupport)justhighenoughto

allowthefrontwheelstoturnfreely.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub.

5.Removeoneofthespacernutsfromtheaxleassembly

inthecasterwheel.Notethatthread-lockingadhesive

hasbeenappliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly .

6.Pryoutseals,andinspectthebearingsforwearor

damageandreplacethemifnecessary.

7.Packthebearingswithageneral-purposegrease.

8.Insertonebearing,onenewsealintothewheel.

Note:Thesealsmustbereplaced.

9.Iftheaxleassemblyhashadbothspacernutsremoved

(orbrokenloose),applyathread-lockingadhesive

toonespacernutandthreaditontotheaxlewith

thewrenchatsfacingoutward.Donotthreadthe

spacernutallthewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheoutersurface

ofthespacernuttotheendoftheaxleinsidethenut.

10.Inserttheassemblednutandaxleintothewheelonthe

sideofthewheelwiththenewsealandbearing.

11.Withtheopenendofthewheelfacingup,llthearea

insidethewheelaroundtheaxlefullofgeneral-purpose

grease.

12.Insertthesecondbearingandanewsealintothewheel.

13.Applyathread-lockingadhesivetothe2ndspacernut

andthreaditontotheaxlewiththewrenchatsfacing

outward.

14.Torquethenutto8to9N-m(75to80in-lb),loosenit,

thentorqueitto2to3N-m(20to25in-lb).Makesure

thattheaxledoesnotextendbeyondeithernut.

15.Installthesealguardsoverthewheelhubandinsert

thewheelintothecasterfork.Installthecasterbolt

andtightenthenutfully.

16.Removethejackstands.

31

Page 32

Important:Topreventsealandbearingdamage,check

thebearingadjustmentoften.Spinthecasterwheel.

Thewheelshouldnotspinfreely(morethan1or2

revolutions)orhaveanysideplay.Ifthewheelspins

freely,adjustthetorqueonspacernutuntilthereisa

slightamountofdrag.Applythread-lockingadhesive.

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacetheprimaryair

lter.

Every250hours—Checkthesecondaryairlter.

Every500hours—Replacethesecondaryairlter.

Note:Servicetheaircleanermorefrequentlyifoperating

conditionsareextremelydustyorsandy.

RemovingtheFilters

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Pushdowntoreleasetheretainingclampsontheair

cleanerandpulltheaircleanercoveroffoftheair

cleanerbody(

Figure44).

4.Cleantheinsideoftheaircleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure44).Avoidknockingthelterintothe

sideofthebody.

6.Removethesecondarylteronlyifyouintendto

replaceit.

Important:Neverattempttocleanthesecondary

lter.Ifthesecondarylterisdirty,thenthe

primarylterisdamagedandyoushouldreplace

bothlters.

7.Inspecttheprimarylterfordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Ifthelterisdamageddiscardit.

32

Page 33

Figure44

1.Aircleanerclamps

3.Primaryairlter

2.Aircleanercover

4.Secondaryairlter

ServicingthePrimaryFilter

1.Donotcleanthepaperlter,replaceit(Figure44).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

ServicingtheSecondaryFilter

Donotcleanthesecondarylter,replaceit.

Important:Neverattempttocleanthesecondarylter.

Ifthesecondarylterisdirty,thentheprimarylteris

damagedandyoushouldreplacebothlters.

InstallingtheFilters

Important:T opreventenginedamage,alwaysoperate

theenginewithbothairltersandcoverinstalled.

1.Ifinstallingnewlters,checkeachlterforshipping

damage.Donotuseadamagedlter.

2.Ifthesecondarylterisbeingreplaced,carefullyslide

itintothelterbody(Figure44).

3.Carefullyslidetheprimarylteroverthesecondary

lter(Figure44).Ensurethatitisfullyseatedby

pushingontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheaircleanercoverwiththebreathercapdown

androtatesotheretainingclampslockthecoverin

place(

Figure44).

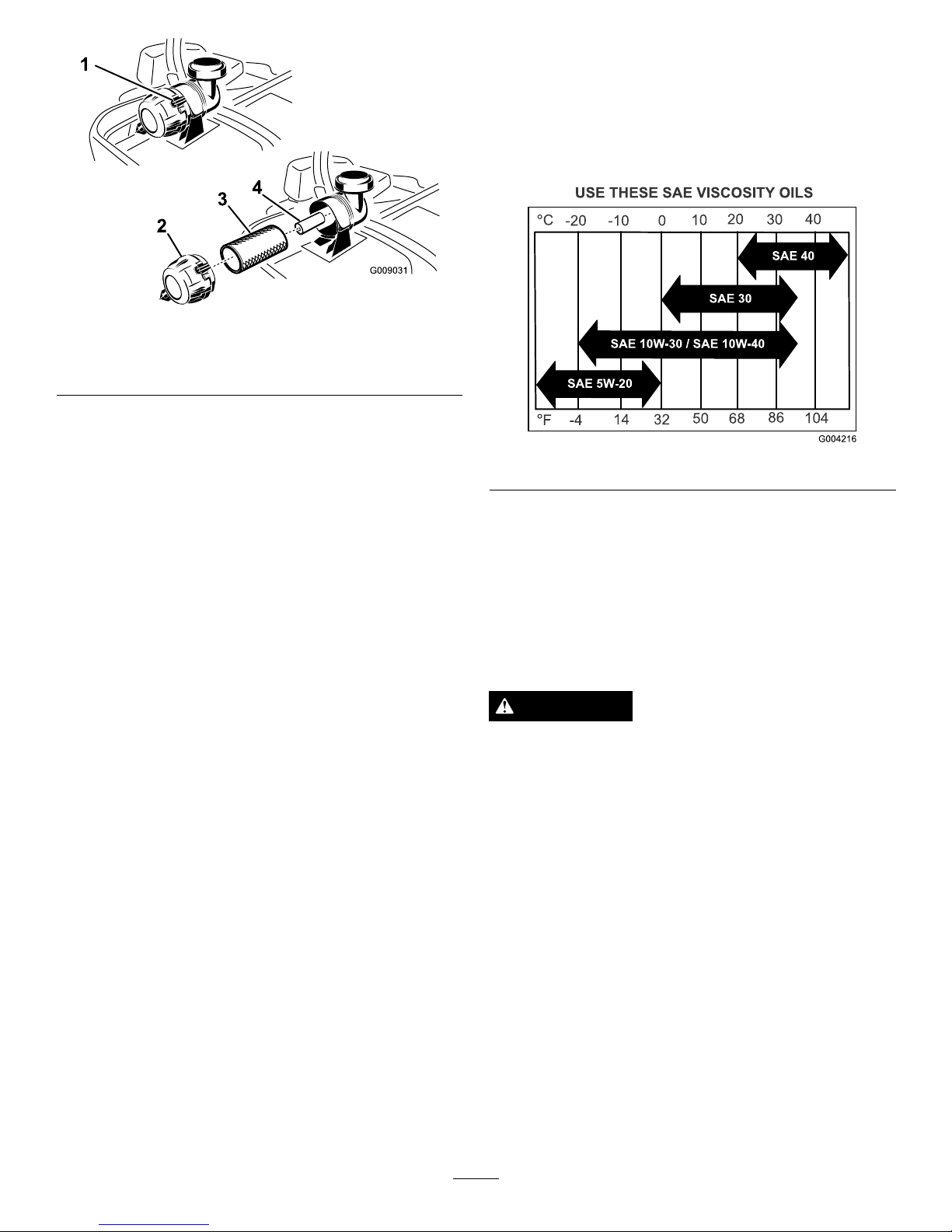

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSG,SH,SJ,orSL)

CrankcaseCapacity:withalterchange,2.1L(2.2USqt);

withoutalterchange,1.8L(1.9USqt)

Viscosity:Seethetablebelow.

Figure45

Note:Useofmulti-gradeoils(5W-20,10W -30,or10W-40)

willincreaseoilconsumption.Checktheoillevelmore

frequentlywhenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawayfromthemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure46).

33

Page 34

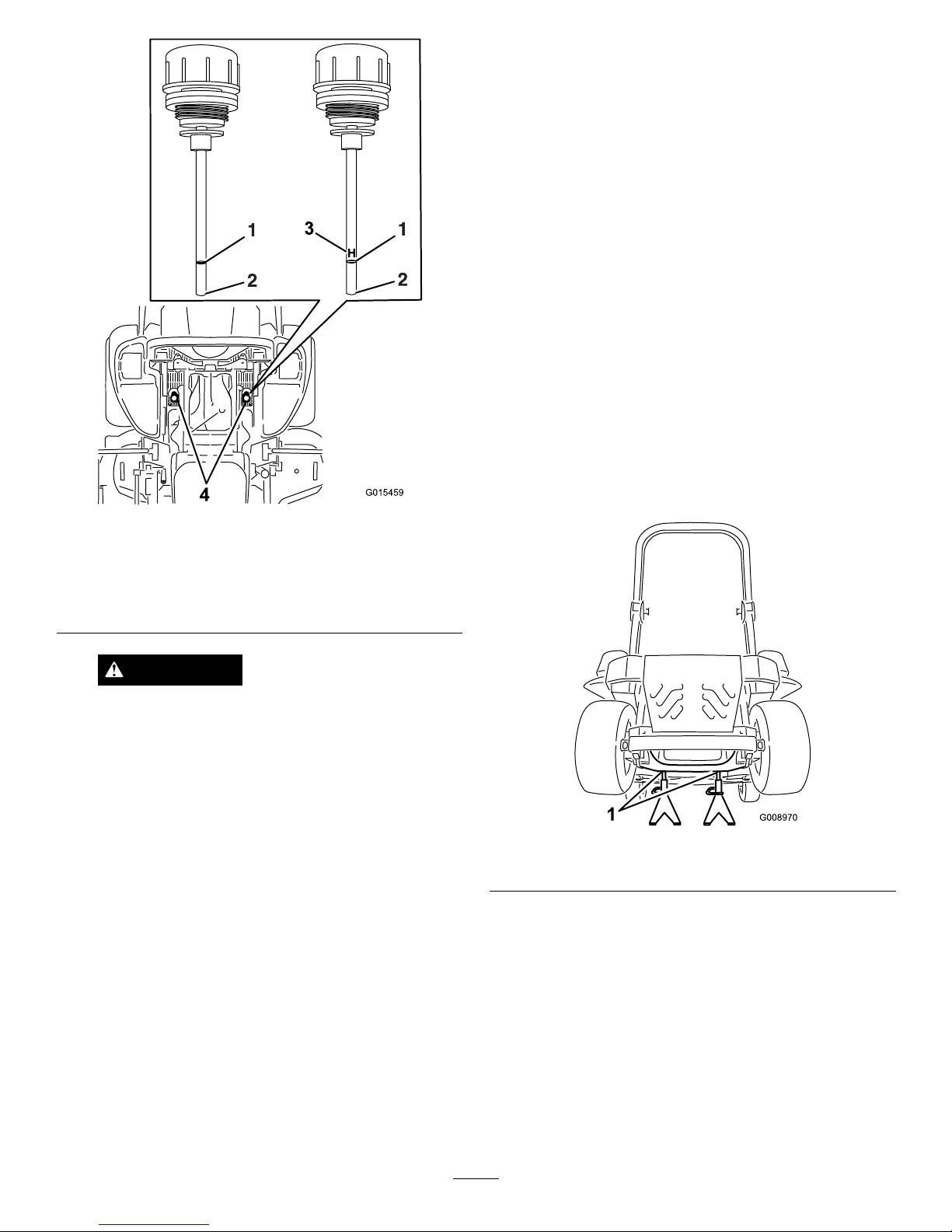

G008804

G008792

1

2

5

6

7

3

9

10

4

8

Figure46

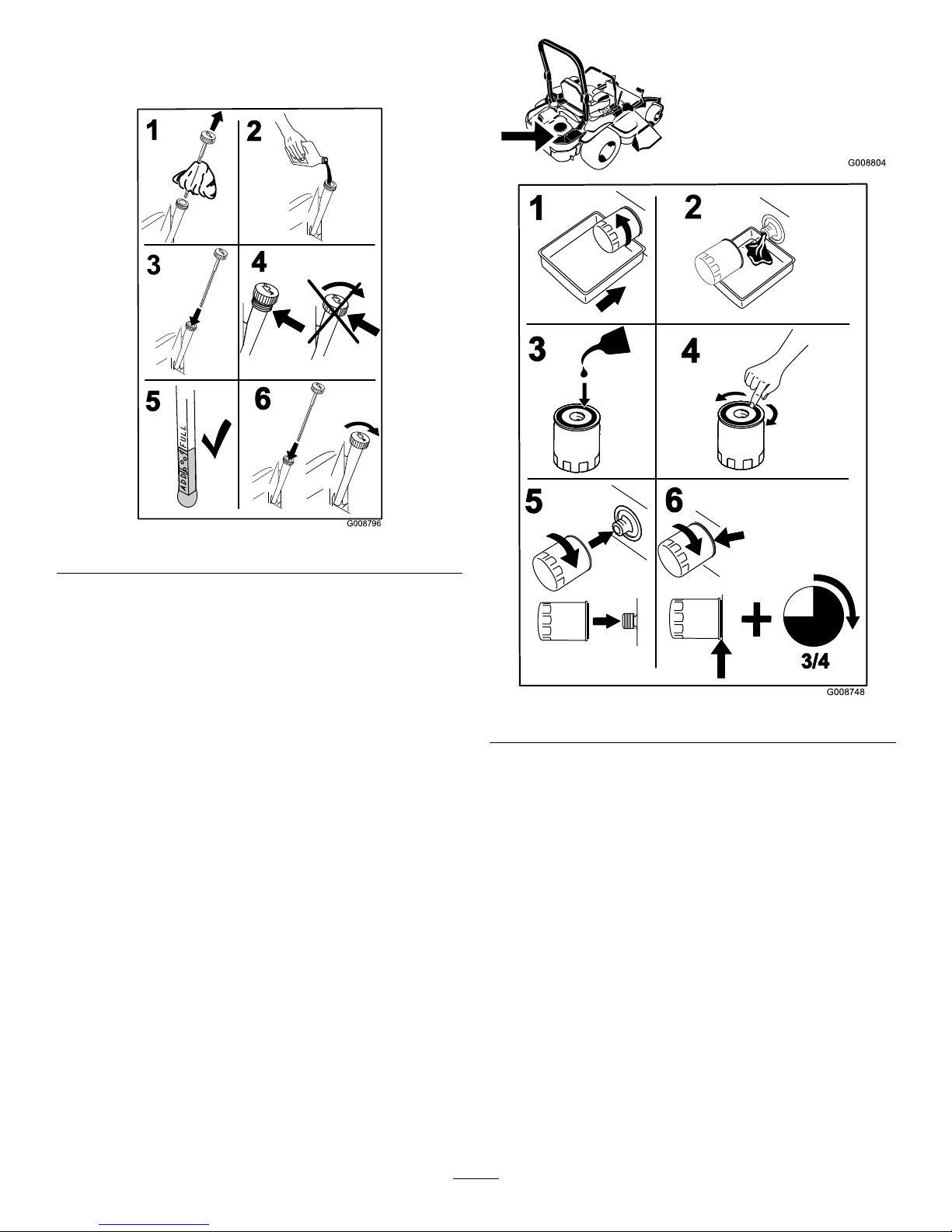

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours(moreoftenindirtyordusty

conditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothattherearisslightlylowerthan

thefronttoensuretheoildrainscompletely .

2.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position(

Figure47).

G008804

G008793

1

2

3

4

4

5

Figure47

34

Page 35

4.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure48).

G008796

2

3

4

5

6

1

Figure48

5.Starttheengineanddrivetoaatarea.Checktheoil

levelagain.

ChangingtheEngineOilFilter

ServiceInterval:Every200hours

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil.

2.Changetheengineoillter(

Figure49).

G008804

G008748

3/4

1

2

3

4

5

6

Figure49

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

35

Page 36

ServicingtheSparkPlugs

ServiceInterval:Every100hours

Makesurethattheairgapbetweenthecenterelectrodeand

thesideelectrodeiscorrectbeforeinstallingeachsparkplug.

Useaspark-plugwrenchforremovingandinstallingthespark

plugsandagappingtool/feelergaugetocheckandadjustthe

airgap.Installnewsparkplugsifnecessary.

Type:NGK

®

BPR4ESorequivalent

AirGap:0.76mm(0.030inch)

RemovingtheSparkPlugs

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

1.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

2.DisengagethePTO,movethemotion-controlleversto

theneutral-lockedposition,andsettheparkingbrake.

3.Removethehydraulic-unitshroudandthe2bolts

attachedtoit(

Figure50).Thisgivesyouaccesstothe

frontsparkplug.

G012432

2 1 2

Figure50

1.Hydraulic-unitshroud2.Loosenthese2bolts

4.Removethesparkplugs.

G008803

Figure51

5.Installtheleft-handhydraulic-unitshroud(Figure50).

CheckingtheSparkPlugs

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly.Ablackcoatingontheinsulatorusually

meansthattheaircleanerisdirty.

Setthegapto0.76mm(0.030inch).

G008794

1

2

Figure52

InstallingtheSparkPlugs

Tightenthesparkplugsto24.4to29.8N-m(18to22ft-lb).

Figure53

36

Page 37

CheckingtheSparkArrester

(ifequipped)

ServiceInterval:Every50hours

WARNING

Hotexhaustsystemcomponentsmayignite

gasolinevaporsevenaftertheengineisstopped.

Hotparticlesexhaustedduringengineoperation

mayigniteammablematerials.Firemayresultin

personalinjuryorpropertydamage.

Donotfuelorruntheengineunlessthespark

arresterisinstalled.

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey .Engagetheparkingbrake.

2.Waitforthemufertocool.

3.Ifanybreaksinthescreenorweldsareobserved,

replacethearrester.

4.Ifpluggingofthescreenisobserved,removethe

arresterandshakeanylooseparticlesoutofthe

arrester,andcleanthescreenwithawirebrush(soakit

insolventifnecessary).Installthesparkarresteronthe

exhaustoutlet.

FuelSystem

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)(moreoftenindirtyordusty

conditions).

Thefuellterislocatedneartheengineonthefrontorrear

sideoftheengine.

1.DisengagethePTO,movethemotioncontrolleversto

theneutrallockedposition,andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Closethefuel-shutoffvalveundertheseat(

Figure54).

G008963

12

3

Figure54

1.Fuellter

3.Fuelline

2.Hoseclamp

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure54).

6.Removethelterfromthefuellines.

7.Installanewlterandmovethehoseclampscloseto

thelter(Figure54).

8.Openthefuel-shutoffvalve.

Important:Installthefuellinehosesandsecurewith

plastictiesthesameastheywereoriginallyinstalledat

thefactory,tokeepthefuellineawayfromcomponents

thatcouldcausefuellinedamage.

37

Page 38

ServicingtheFuelTank

Donotattempttodrainthefueltank.Ensurethatan

AuthorizedServiceDealerdrainsthefueltankandservices

anycomponentsofthefuelsystem.

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

W ash hands after handling .

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

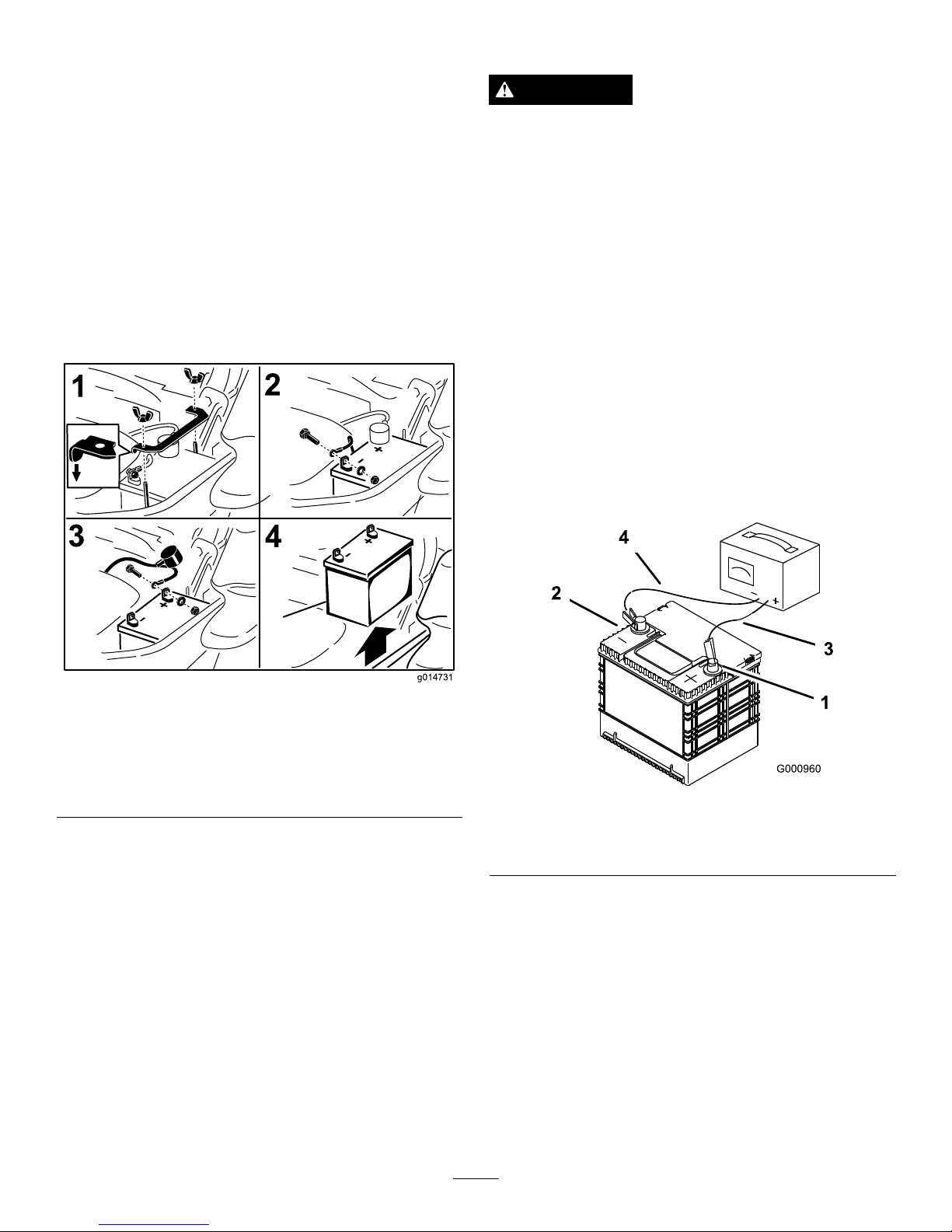

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygasestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygasestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

38

Page 39

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(

Figure55).

4.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure55).

5.Removethewingnutsecuringthebatteryclamp

(

Figure55).

6.Removetheclamp(Figure55).

7.Removethebattery.

g014731

+

-

+

-

+

-

1

2

3

4

Figure55

1.Removethewingnutand

clamp

3.Removethepositive

batterycable

2.Removethenegative

batterycablebeforethe

positive

4.Removebattery

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthehydraulictank(Figure55).

2.First,installthepositive(red)batterycabletopositive

(+)batteryterminal.

3.Theninstallthenegative(black)batterycableand

groundwiretothenegative(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

(

Figure55).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut(

Figure

55).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgasesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

0°C(32°F).

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet;thendisconnectthecharger

leadsfromthebatteryposts(Figure56).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure56

1.Positivebatterypost

3.Red(+)chargerlead

2.Negativebatterypost

4.Black(-)chargerlead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblowscheckthe

component/circuitforamalfunctionorshort.

1.Thefusesarelocatedonrighthandconsolenextto

theseat(Figure57).

2.Toreplacethefuses,pulloutonthefusetoremoveit.

3.Installanewfuse(

Figure57).

39

Page 40

Figure57

1.Optional

accesory—15amp

4.Main—25amp

2.Charge—25amp5.Console

3.PTO—10amp

DriveSystem

Maintenance

CheckingtheSeatBelt

ServiceInterval:Beforeeachuseordaily

Visuallyinspectseatbeltforwear,cuts,andproperoperation

ofretractorandbuckle.Replacebeforeoperatingifdamaged.

CheckingtheRollover

ProtectionSystem(ROPS)

Knobs

ServiceInterval:Beforeeachuseordaily

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinthefullyraisedlockedpositionandusethe

seatbelt.

Ensuretheseatissecuredtothemachine.

Checkthatboththemountinghardwareandtheknobsare

ingoodworkingcondition.Makesuretheknobsarefully

engagedwiththeROPSintheraisedposition.Theupper

hoopoftherollbarmayneedtobepushedforwardorpulled

rearwardtogetbothknobsfullyengaged.

40

Page 41

Figure58

1.ROPSknob(locked

position)

3.Rollbarintheupright

position

2.PullROPSknoboutand

rotate90degreesto

changerollbarposition

4.Rollbarinthefolded

position

AdjustingtheTracking

1.Disengagethebladecontrolswitch(PTO).

2.Drivetoanopenatarea,movethemotioncontrol

leverstotheneutrallockedposition.

3.Movethethrottlemidwaybetweenfastandslow.

4.Movebothmotioncontrolleversallthewayforward

untiltheybothhitthestopsintheT-slot.

5.Checkwhichwaythemachinetracks.

6.Ifittrackstotheright,loosentheboltsandadjust

theleftstopplaterearwardontheleftT-slotuntilthe

machinetracksstraight(Figure59).

7.Ifittrackstotheleft,loosentheboltsandadjustthe

rightstopplaterearwardontherightT-slotuntilthe

machinetracksstraight(Figure59).

8.Tightenthestopplate(Figure59).

Figure59

Leftcontrollevershown

1.Controllever3.Stopplate

2.Bolt

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat90kPa(13psi).

Uneventirepressurecancauseunevencut.Checkthetires

whentheyarecold,togetthemostaccuratepressurereading.

Note:Thefronttiresaresemi-pneumatictiresanddonot

requireairpressuremaintenance.

Figure60

41

Page 42

CheckingtheWheelLugNuts

Checkandtorquethewheellugnutsto122to129N-m(90

to95ft-lb).

CheckingtheWheelHub

SlottedNut

ServiceInterval:Aftertherst100hours

Every500hours

Checkandensurethatthetorqueoftheslottednutis286to

352N-m(211to260ft-lb).

Note:Donotuseanti-seizeonwheelhub.

Figure61

1.Slottednut

AdjustingtheCasterPivot

Bearing

ServiceInterval:Every500hours/Yearly(whichevercomes

rst)

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey ,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethedustcapfromcasterandtightenlocknut

(

Figure62).

4.Tightenthelocknutuntilthespringwashersareatand

thenbackoffa1/4turntoproperlysetthepre-loadon

thebearings(Figure62).

Important:Makesurethespringwashersare

installedcorrectlyasshowninFigure62.

5.Installthedustcap(Figure62).

Figure62

1.SpringWashers3.DustCap

2.LockNut

UsingtheClutchShim

Somelatermodelyearunitshavebeenbuiltwithclutchesthat

containabrakeshim.Whentheclutchbrakehasworntothe

pointwheretheclutchnolongerengagesconsistently ,the

shimcanberemovedtoextendtheclutchlife.

Figure63

1.Armature5.Brakespacer

2.Fieldshell6.Re-gapshim

3.Rotor7.Brakepole

4.Brakemountingbolt

42

Page 43

RemovingtheClutchShim

1.Stoptheengine,waitforallmovingpartstostop,and

removethekey .Engagetheparkingbrake.Allow

themachinetocoolcompletelybeforestartingthese

instructions.

2.Usinganaircompressor,blowoutanydebrisfrom

underthebrakepoleandaroundthebrakespacers.

Figure64

3.Checktheconditionofthewireharnessleads,