Toro 55152, 55233, 55150, 55256, 74140 Service Manual

...

EATON 6, 7 HYDROSTATIC TRANSMISSION

Table of Contents – Page 1 of 1

GENERAL PARTS LIST MODEL 6 AND 7

PRODUCT IDENTIFICATION AND ORDERING INFORMATION

SPECIAL TOOLS TO AID IN DISASSEMBLY/REASSEMBLY

DISASSEMBLY/REASSEMBLY

RESERVOIR/ADAPTER—DISASSEMBLY

BODY/COVER--DISASSEMBLY

COVER--DISASSEMBLY

CAM RING--DISASSEMBLY/INSPECTION

PUMP ROTOR--REMOVAL

PINTLE ASSY.-- REMOVAL

PINTLE ASSEMBLY--DISASSEMBLY/INSPECTION

CHECK VALVE--REMOVAL

CHECK VALVE--INSTALLATION

DAMPENING PISTON--REMOVAL (MODEL 7 ONLY)

DAMPENING PISTON--INSTALLATION

MOTOR ROTOR--REMOVAL

ROTOR ASSEMBLIES--DISASSEMBLY INSPECTION

BODY--DISASSEMBLY

COVER--REASSEMBLY

CAM RING---INSTALLATION

PUMP ROTOR-INSTALLATION

PINTLE--INSTALLATION

BODY--REASSEMBLY

MOTOR ROTOR--INSTALLATION

COVER/BODY--REASSEMBLY

RESERVOIR/ADAPTER--REASSEMBLY

START-UP PROCEDURE

TROUBLE SHOOTING INSTRUCTIONS

HYDROSTATIC FLUID RECOMMENDATIONS

NO.

7-403

Eaton

r'\

Hydraulics

Division

Eaton Hydrostatic Transmissions

-

Model

6

/

7

Item

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

General Parts List

Model 6 and 7

Description

Reservoir Adapter

Reservoir Cover Subassembly

Reservoir Body

Reservoir Adapter

Seal Ring

Cover Service Kit

Dowel Pin

Retaining Ring

Washer

Button (Model 7 only)

Guide Fitting Subassembly

O-Ring

Dump Valve Bracket

Spring

Seal Ring

Pump Rotor and Ball Assembly

Pump Race

Cam Ring Assembly (includes No. 17)

Piston (Model 7 only)

Back-Up Ring (Model 7 only)

O-Ring (Model 7 only)

Pintle Subassembly

Motor Rotor and Ball Assembly

Retaining Ring

Snap Ring

Bearing

Input Shaft

Seal

O-Ring

Item

No. Description

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

Nut and Gasket Subassembly

Dump Valve Shaft

Seal

Control Shaft Kit

Dowel

Cam Ring Insert

Pin

Check Valve Body

Ball

Retaining Ring

Spring

Plug Subassembly

O-Ring

Body

Seal

Bearing

Snap Ring

Retaining Ring

Spacer

Gear

Retaining Ring

Output Shaft Subassembly

Key

Motor Race

Cap Screw

O-Ring

Plug Subassembly

Plug

This list is for identification of parts only. To insure the

correct replacement parts for your transmission, it will be

necessary to order parts by part number. Consult your

supplier for a parts list for your specific model number.

3

Contents

Product Identification and Ordering Information

Exploded View

Part

Description 3

Disassembly-Reassembly Procedures

Body Assembly-Disassembly

Reassembly

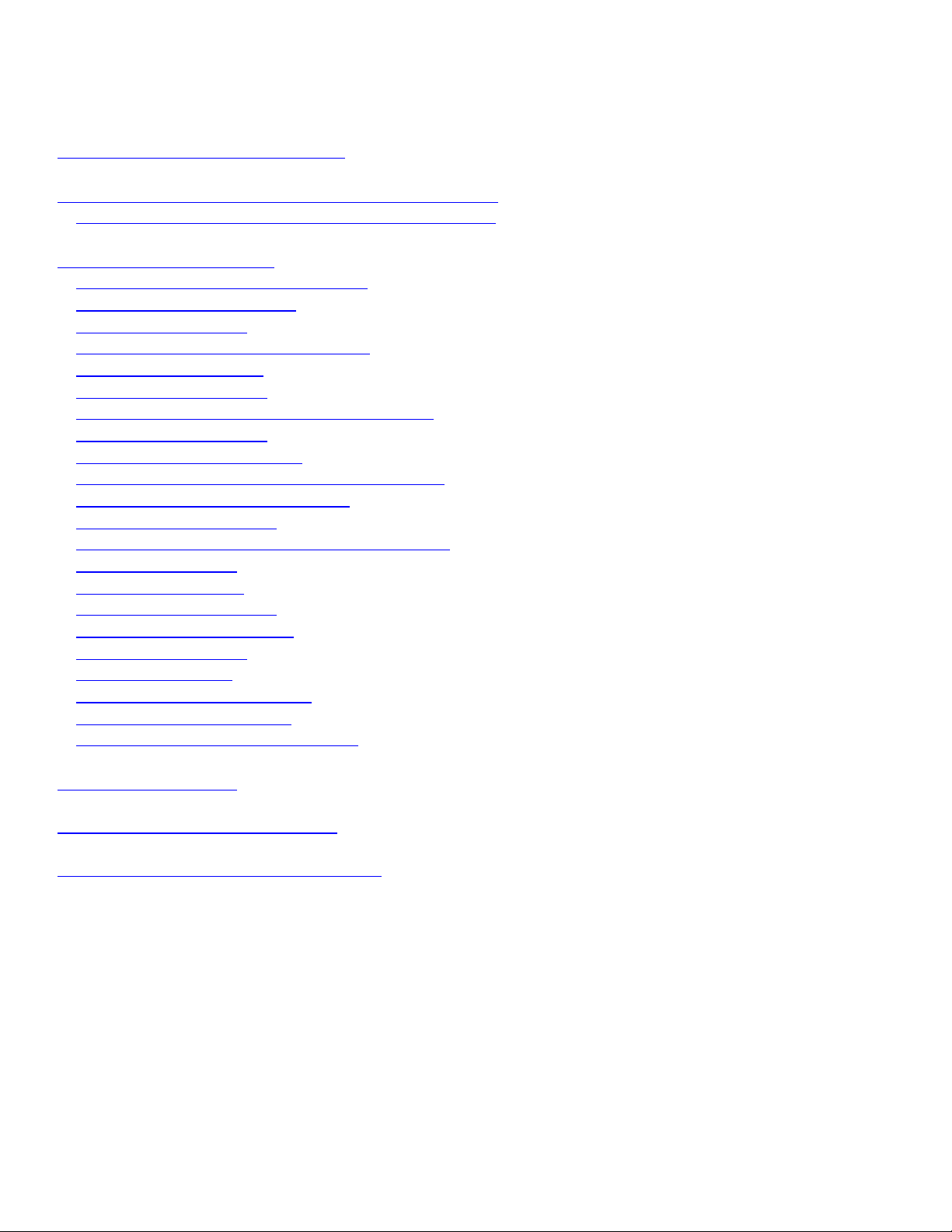

Product Identification and Ordering Information

Refer to specific listing covering your Eaton

transmission. Parts listings are available from the

Hydraulics Division, Minneapolis Plant.

4

When ordering parts, please include the following:

2

9

11

Model Number

Date Code

Part Number

Part Name

Quantity of Parts

Body/Cover-Disassembly

Reassembly

Cam

Ring-Disassembly/lnspection

Installation 11

Check Valves-Removal

Installation

Cover

Dampening Pistons-Removal

Motor Rotor Assembly-Removal

Pintle Assembly-Removal

Pump Rotor Assembly-Removal

Assembly-Disassembly/Inspection

Reassembly

Disassembly/lnspection

Installation 11

4

Installation

Installation 12

Installation 11

5

11

6

7

8

5

9

8

8

8

7

7

7

Original Build

Date Code-A10A Month

-

Model Identification

600-Model

700-Model 7

023-Specific Unit

Configuration

600-023

AlOA

cw

D12B

1

v

Factory Rebuild

Date Code-D12B1

1T2E

Month

6

Rotation

cw

ccw

Reservoir/Adapter-Disassembly

Reassembly 13

Rotor

Start/up Procedures

Trouble Shooting

Fluid Recommendations

Assemblies-Disassembly/lnspection

C

Copyright

1982

Eaton Corporation

5

8

Special

13

2

14

center.

16

2 large, wide rubber bands.

Y16-18

Light petroleum jelly (such as Vaseline).

Steel bar stock or piece of wood-2” dia.

x

tools

to aid

6

x

10 wooden block with

tap.

in

Disassembly/Reassembly

Y4”

dia. hole in the

x

2%” long.

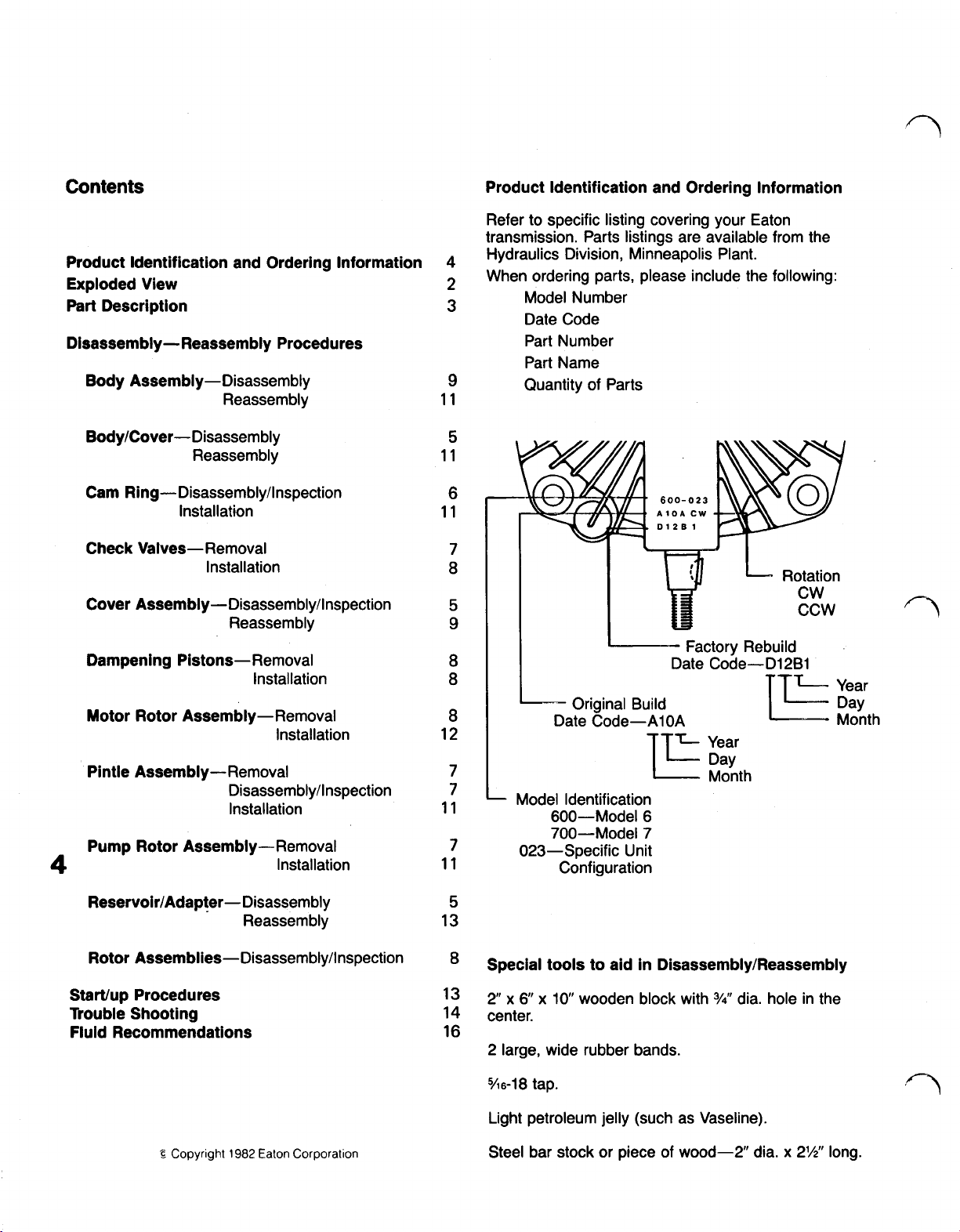

Disassembly/Reassembly

Reservoir/Adapter-Disassembly

Fig.

1

Clean the transmission exterior thoroughly before

repairs are begun. Use a cleaning solution that

affect paint, gaskets, rubber seals, and plastic.

will

not

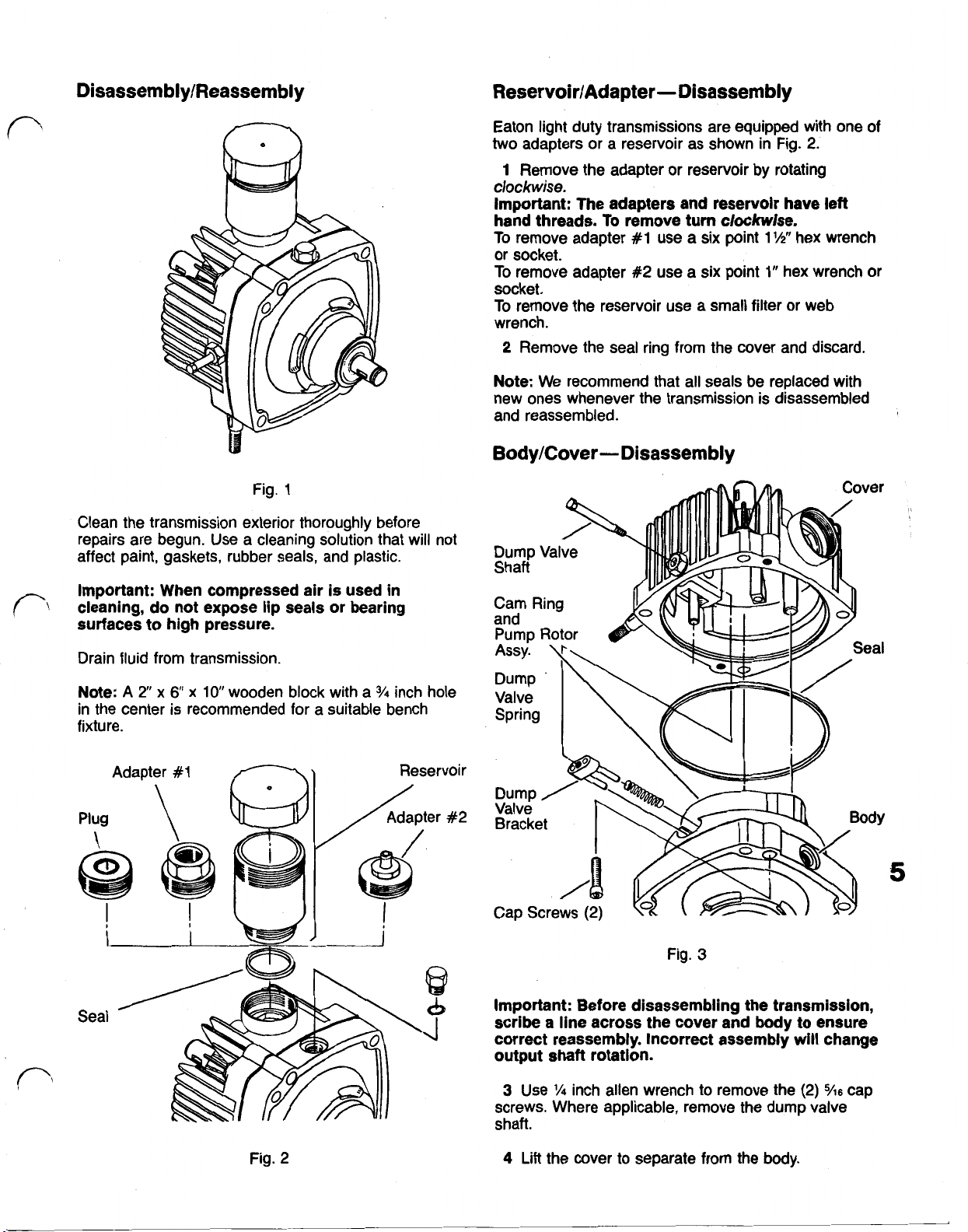

Eaton light duty transmissions are equipped with one

two

adapters or a reservoir as shown in Fig.

1

Remove the adapter or reservoir by rotating

clockwise.

Important: The adapters and reservoir have left

hand threads.

To

remove adapter

or socket.

To

remove adapter #2 use a six point

socket.

To

remove the reservoir use a small filter or web

wrench.

2

Remove the seal ring from the cover and discard.

Note: We recommend that all seals be replaced with

new ones whenever the transmission is disassembled

and reassembled.

To

remove turn clockwise.

#1

use a six point

2.

1½”

1/2”

hex wrench

1”

hex wrench or

Body/Cover-Disassembly

of

Important: When compressed air is used in

cleaning, do not expose lip seals or bearing

surfaces to high pressure.

Drain fluid from transmission.

Note:

A

2

x 6 x

10

wooden block with a

in the center is recommended for a suitable bench

fixture.

Adapter

Plug

I

i

#1

I

JLl

3/4

inch hole

Reservoir

8

Seal

Fig.

3

Important: Before disassembling the transmission,

scribe a line across the cover and body to ensure

will

correct reassembly. Incorrect assembly

output shaft rotation.

change

5

Fig.

2

3

Use

1/4

inch allen wrench to remove the

screws. Where applicable, remove the dump valve

shaft.

4

Lift the cover to separate from the body.

(2)

5/16

cap

Loading...

Loading...