Toro Workman 07040, Workman 07042, Workman 07059, Workman 07060, Workman 07132 Operator's Manual

...Page 1

FormNo.3421-347RevA

Workman

®

GTXGasoline/Petrol

UtilityVehicle

ModelNo.07040—SerialNo.401400001andUp

ModelNo.07042—SerialNo.401400001andUp

ModelNo.07059—SerialNo.400000000andUp

ModelNo.07060—SerialNo.400000000andUp

ModelNo.07130TC—SerialNo.400000000andUp

ModelNo.07132—SerialNo.400000000andUp

ModelNo.07132TC—SerialNo.400000000andUp

ModelNo.07152—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-347*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

Introduction

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g235847

Figure1

BottomofSeatAssemblyShown

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Thisutilityvehicleisintendedtobeprimarilyused

off-highwaytotransportpeopleandmaterialloads.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DistributororT oroCustomerServiceandhavethe

modelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................9

1InstallingtheSteeringWheel(International

ModelsOnly)...................................................9

2CheckingtheFluidLevelsandTire

Pressure.........................................................9

3BurnishingtheBrakes....................................10

4ReadingtheManualandViewingthe

SetupMaterial...............................................10

ProductOverview....................................................11

Controls...........................................................12

Specications..................................................15

Attachments/Accessories.................................15

BeforeOperation.................................................16

BeforeOperationSafety...................................16

PerformingDailyMaintenance..........................16

CheckingtheTirePressure...............................16

AddingFuel......................................................17

BreakinginaNewMachine..............................17

DuringOperation.................................................18

DuringOperationSafety...................................18

OperatingtheCargoBed..................................20

UsingtheRearCargoBedAccessory

Mount............................................................22

LoadingtheCargoBed.....................................23

StartingtheEngine...........................................23

StoppingtheMachine.......................................24

ParkingtheMachine.........................................24

AfterOperation....................................................24

AfterOperationSafety......................................24

TransportingtheMachine.................................24

TowingtheMachine..........................................25

TowingaTrailer................................................25

Maintenance...........................................................26

RecommendedMaintenanceSchedule(s)...........27

DailyMaintenanceChecklist.............................28

MaintainingtheMachineunderSpecial

OperatingConditions....................................28

Pre-MaintenanceProcedures..............................29

MaintenanceSafety..........................................29

PreparingtheMachineforMaintenance............29

LiftingtheMachine...........................................30

AccessingtheHood..........................................30

RaisingandLoweringtheSeat

Assembly......................................................31

RemovingtheSeatAssembly...........................31

InstallingtheSeatAssembly.............................31

Lubrication..........................................................32

GreasingtheMachine.......................................32

GreasingtheFrontWheelBearings..................32

EngineMaintenance...........................................35

EngineSafety...................................................35

ServicingtheAirCleaner..................................35

ServicingtheEngineOil....................................37

ServicingtheSparkPlug...................................38

AdjustingtheHigh/LowIdle..............................39

FuelSystemMaintenance...................................39

InspectingFuelLinesandConnections.............39

ReplacingtheFuelFilter...................................39

ServicingtheCarbonCanister..........................40

ElectricalSystemMaintenance...........................41

ElectricalSystemSafety...................................41

ServicingtheBattery.........................................41

ReplacingtheFuses.........................................43

MaintainingtheHeadlights...............................44

DriveSystemMaintenance..................................45

MaintainingtheTires........................................45

AdjustingtheFrontWheelAlignment................45

CheckingtheTransaxle-FluidLevel..................47

ChangingtheTransaxleFluid...........................47

CheckingtheNeutralGear-Shift

Position.........................................................47

AdjustingtheNeutralGear-Shift

Position.........................................................48

MaintainingthePrimary-DriveClutch................48

ReducingtheT opSpeed...................................49

CoolingSystemMaintenance..............................50

CleaningtheEngine-CoolingAreas..................50

BrakeMaintenance.............................................50

CheckingtheParkingBrake.............................50

AdjustingtheParkingBrake..............................50

CheckingtheBrake-FluidLevel........................51

InspectingtheBrakes.......................................51

ChangingtheBrakeFluid.................................51

BeltMaintenance................................................52

ServicingtheDriveBelt.....................................52

AdjustingtheStarter-GeneratorBelt.................52

ChassisMaintenance...........................................53

AdjustingtheCargo-BedLatches.....................53

Cleaning..............................................................53

WashingtheMachine.......................................53

Storage...................................................................54

StorageSafety..................................................54

StoringtheMachine..........................................54

3

Page 4

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol(Figure2),whichmeansCaution,Warning,

orDanger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Thismachinehasbeendesignedinaccordancewith

therequirementsofSAEJ2258.

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineasafedistanceawayfrom

bystanderswhileitismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicingorfueling.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

Page 5

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

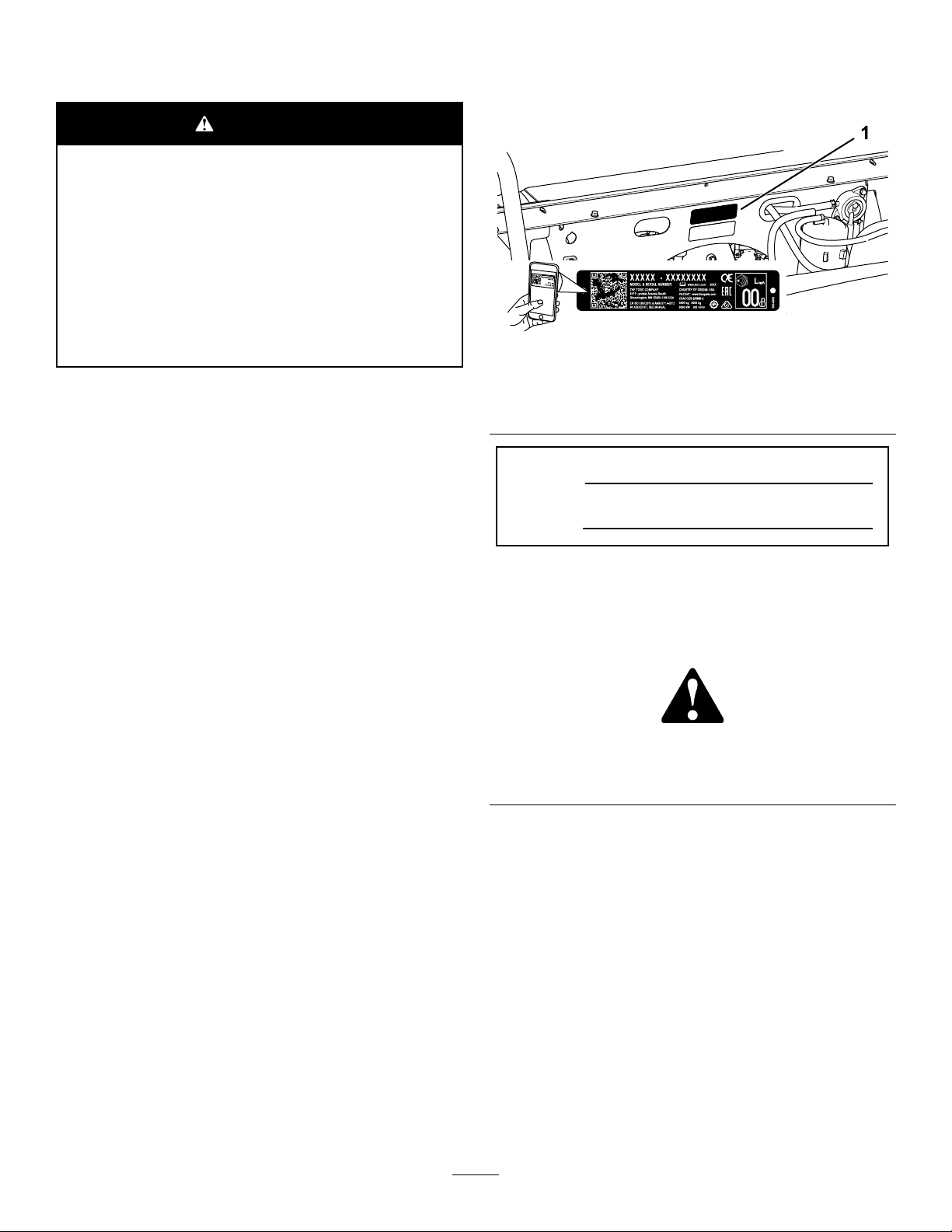

99-7345

1.Warning—readtheOperator'sManual.

2.Hotsurface/burnhazard—stayasafedistanceawayfrom

thehotsurface.

3.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsinplace.

4.Crushinghazard,cargobed—usetheproprodtosupport

thecargobed.

decal131-8410

decal99-7345

1.Firehazard—shutofftheenginebeforefueling.

131-8410

115-2047

1.Warning—donottouchthehotsurface.

115-7739

1.Falling,crushinghazard,bystanders—noridersonmachine

120-9570

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal115-2047

decal115-7739

decal120-9570

5

Page 6

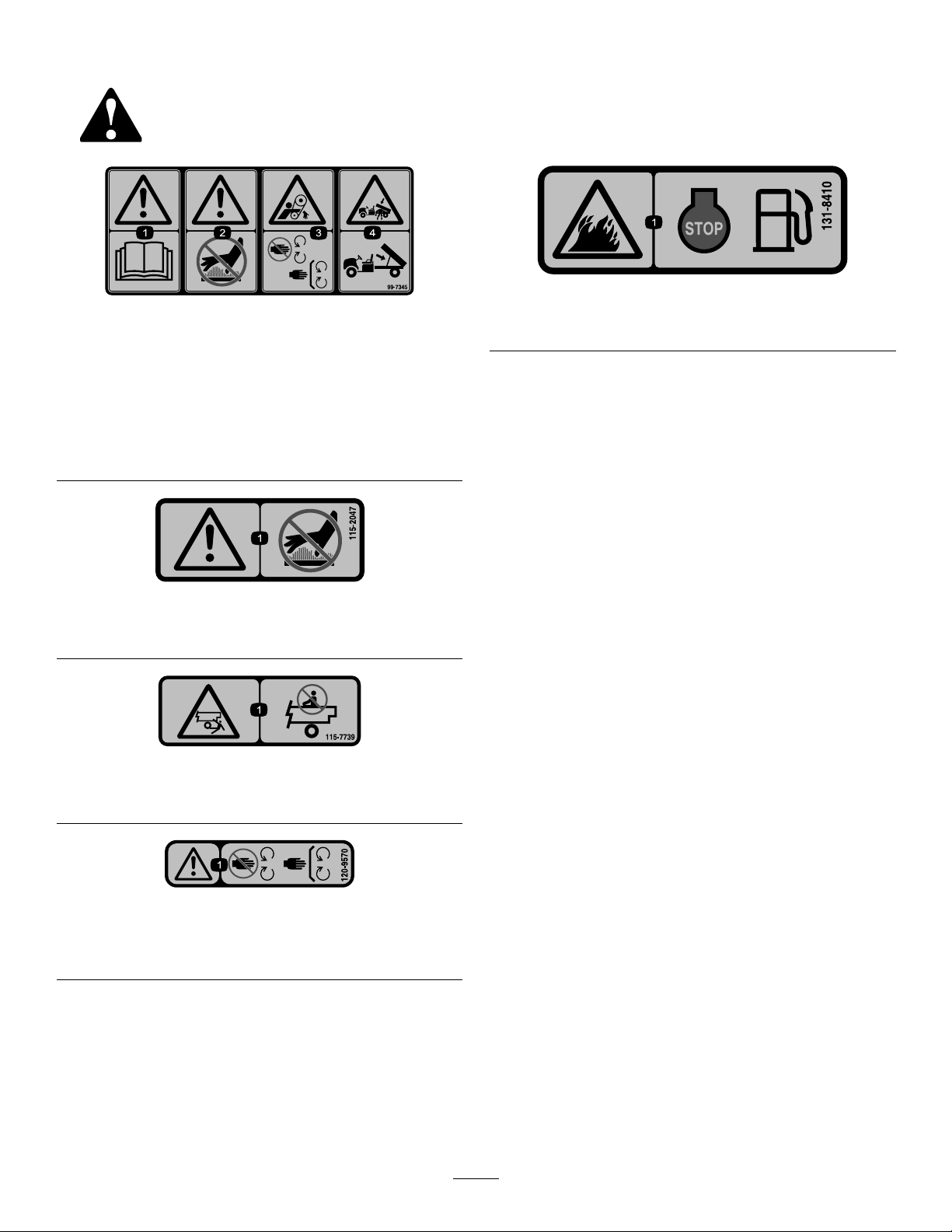

131-8413

CarburetorModelsOnly

1.Horn4.Engine—start

2.Off5.Tostarttheengine:1)Sit

intheoperator'sposition;

2)Disengagetheparking

brake;3)Turnthekeyto

theengineSTARTposition;

4)Engagethechoke;5)

Pressdownonthepedal.

3.On6.Toshutofftheengine:

1)Releasethepedal;2)

Engagetheparkingbrake;

3)TurnthekeytotheOFF

position;4)Removethe

key.

decal131-8413

1.Warning—readthe

Operator'sManual.

131-8414

3.Tippinghazard—drive

slowlyacrossorupslopes;

decal131-8414

taketurnsslowly;donot

exceedspeedsof25kph

(16mph);driveslowly

whenhaulingcargo;drive

slowlyonuneventerrain.

2.Warning—receiveproper

trainingbeforeoperating

themachine.

4.Fallinghazard;severing

hazardoflimbs—donot

carrypassengersinthe

bed;donotcarryextra

passengersinbetween

theseats;donotputyour

armsorlegsoutsideofthe

machinewhileoperating.

1.Forward3.Reverse

2.Neutral

6

decal131-8463

131-8463

Page 7

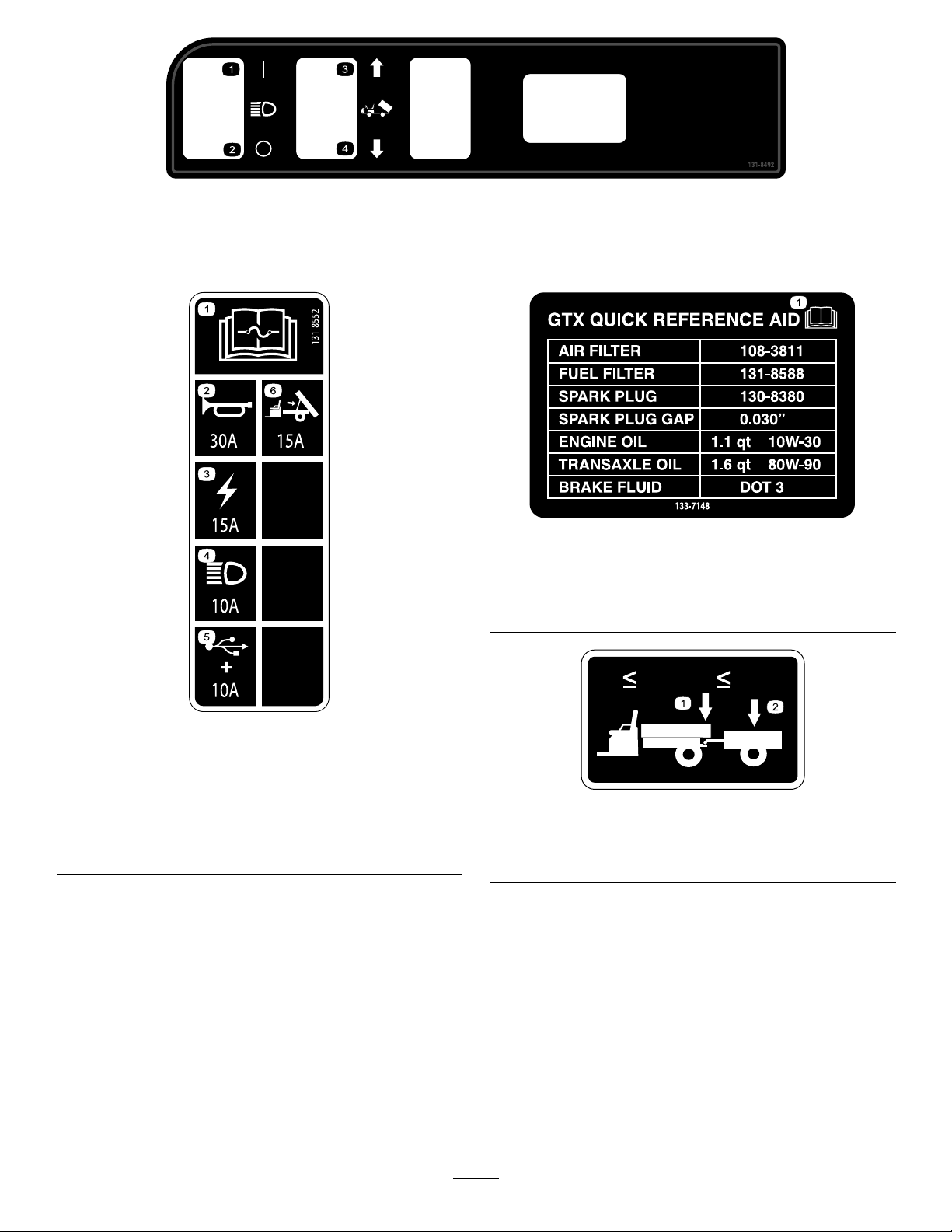

131-8492

200 LBS

91 KG

1500 LBS

680 KG

137-9984

1.Headlight—on3.Raisethebed.

2.Headlight—off

4.Lowerthebed.

1.ReadtheOperator’sManualformoreinformationon

servicingthemachine.

decal131-8492

decal133-7148

133-7148

CarburetorModelsOnly

131-8552

1.ReadtheOperator's

Manualforfuse

information.

2.Horn(30A)5.USBpowerpoint/options

3.Mainpower(15A)6.Optionalliftkit(15A)

4.Headlights(10A)

(10A)

decal131-8552

decal137-9984

137-9984

1.Donotexceedatongue

weightof91kg(200lb).

2.Donotexceedatransport

loadof680kg(1,500lb).

7

Page 8

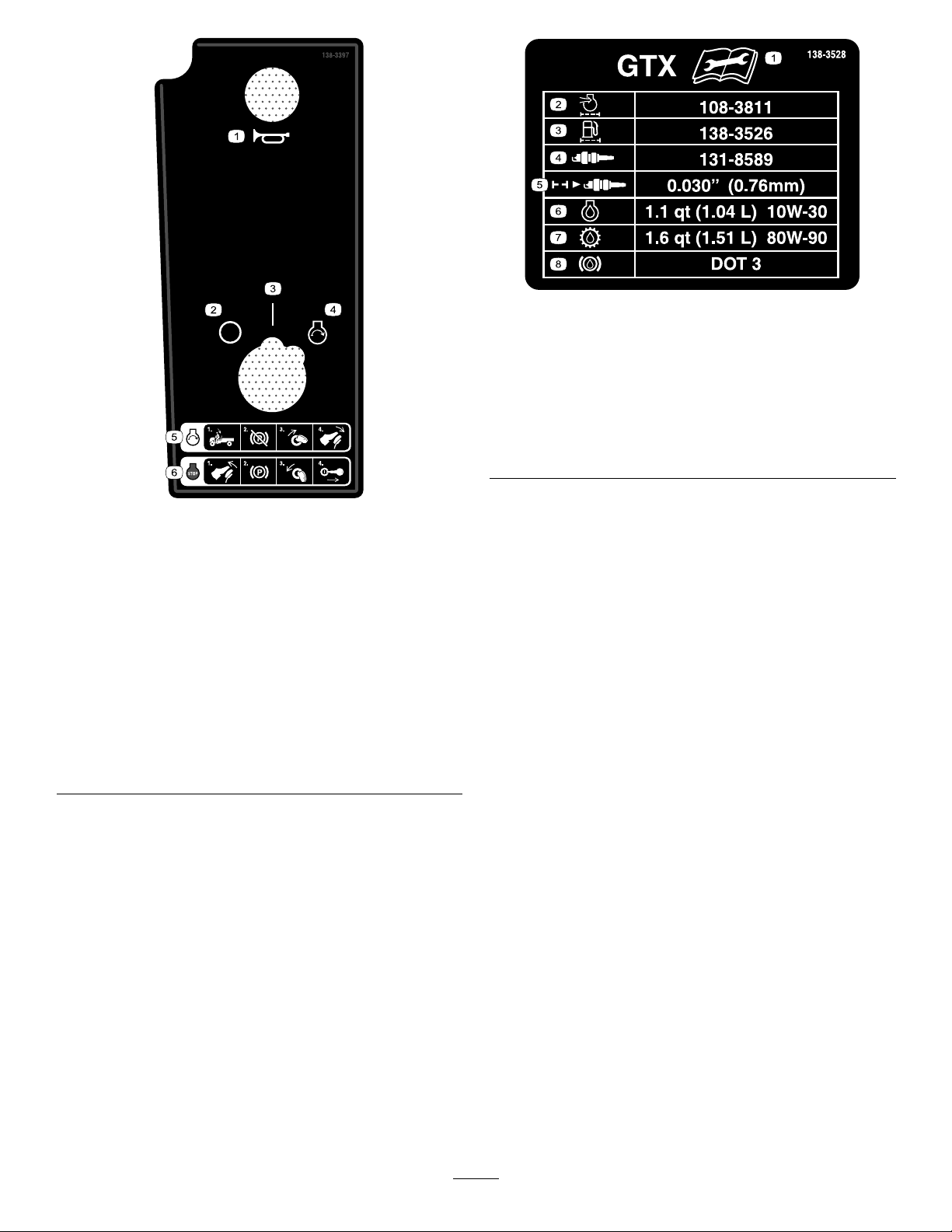

138-3528

EFIModelsOnly

decal138-3528

decal138-3397

138-3397

EFIModelsOnly

1.Horn4.Engine—start

2.Off5.Tostarttheengine:1)Sit

intheoperator'sposition;

2)Disengagetheparking

brake;3)Turnthekeyto

theengineSTARTposition;

4)Pressthebrakepedal.

3.On6.Toshutofftheengine:1)

Releasethebrakepedal;

2)Engagetheparking

brake;3)Turnthekey

totheOFFposition;4)

Removethekey .

1.ReadtheOperator’s

5.Sparkplugairgap

Manualbeforeperforming

maintenance.

2.Engineintake/airlter

6.Engineoil

3.Fuellter7.Transmissionuid

4.Sparkplug8.Brakeuid

8

Page 9

Setup

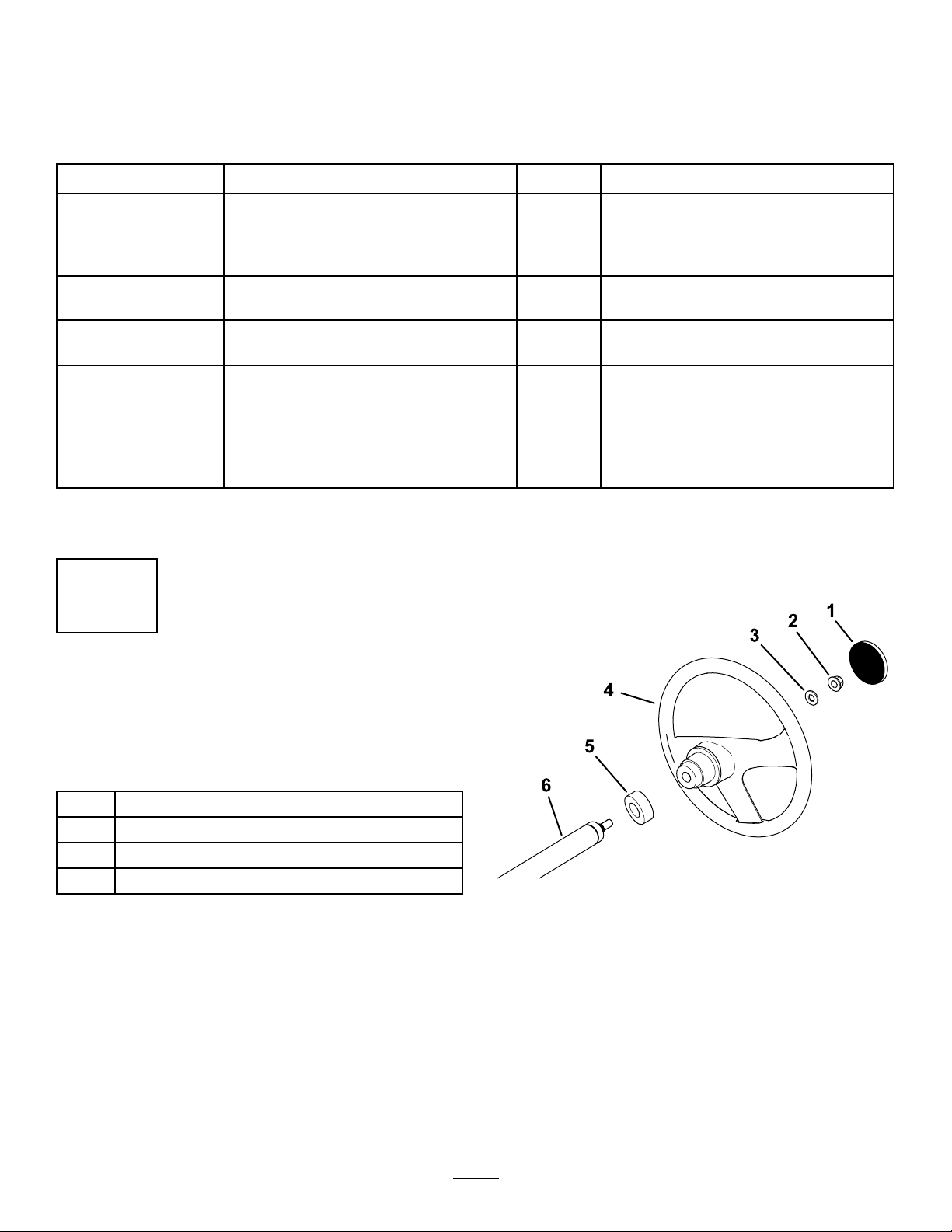

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Steeringwheel

Steeringwheelcover

1

2

3

4

Washer(1/2inch)

Dustcover1

Nopartsrequired

Nopartsrequired

Operator'sManual

Engineowner'smanual1

Registrationcard1

PredeliveryInspectionForm1

CerticateofQuality

Key2

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

1

Qty.

1

1

1

–

–

1

1

4.Securethesteeringwheeltotheshaftwiththe

locknut(1/2inch)andtightenitto18to30N∙m

(13to22ft-lb).

5.Installthecoveronthesteeringwheel(Figure3).

Installthesteeringwheel(International

modelsonly).

Checktheuidlevelsandtirepressure.

Burnish(break-in)thebrakes.

ReadtheOperator'sManualandview

thesetupmaterialbeforeoperatingthe

machine.

Use

InstallingtheSteering Wheel(InternationalModels Only)

Partsneededforthisprocedure:

1

Steeringwheel

1

Steeringwheelcover

1

Washer(1/2inch)

1Dustcover

Procedure

1.Ifthecoverisinstalled,removeitfromthehub

ofthesteeringwheel(Figure3).

2.Removethelocknut(1/2inch)fromthesteering

shaft(Figure3).

3.Slidethesteeringwheel,dustcover,andwasher

(1/2inch)ontothesteeringshaft(Figure3).

Note:Withthefrontwheelsstraight,orientthe

steeringwheelsothatthesmallerspokeonthe

steeringwheelisvertical.

Figure3

1.Steeringwheelcover4.Steeringwheel

2.Locknut(1/2inch)

3.Washer(1/2inch)6.Steeringshaft

5.Dustcover

g198932

9

Page 10

2

4

CheckingtheFluidLevels

andTirePressure

NoPartsRequired

Procedure

1.Checktheengine-oillevelbeforeandafter

yourststarttheengine;refertoCheckingthe

Engine-OilLevel(page37).

2.Checkthebrake-uidlevelbeforeyourststart

theengine;refertoCheckingtheBrake-Fluid

Level(page51).

3.Checkthetransaxle-uidlevelbeforeyou

rststarttheengine;refertoCheckingthe

Transaxle-FluidLevel(page47).

4.Checktheairpressureinthetires;referto

CheckingtheTirePressure(page16).

ReadingtheManualand ViewingtheSetupMaterial

Partsneededforthisprocedure:

1

Operator'sManual

1Engineowner'smanual

1Registrationcard

1PredeliveryInspectionForm

1

CerticateofQuality

2Key

Procedure

•ReadtheOperator'sManualandtheengine

owners'smanual.

•Fillouttheregistrationcard.

•CompletethePredeliveryInspectionForm.

•ReviewtheCerticateofQuality.

3

BurnishingtheBrakes

NoPartsRequired

Procedure

Toensureoptimumperformanceofthebrakesystem,

burnish(break-in)thebrakesbeforeuse.

1.Bringthemachineuptofullspeed,applythe

brakestorapidlystopthemachinewithout

lockingupthetires.

2.Repeatthisprocedure10times,waiting1minute

betweenstops,toavoidoverheatingthebrakes.

Important:Thisprocedureismosteffective

ifthemachineisloadedwith227kg(500lb).

10

Page 11

ProductOverview

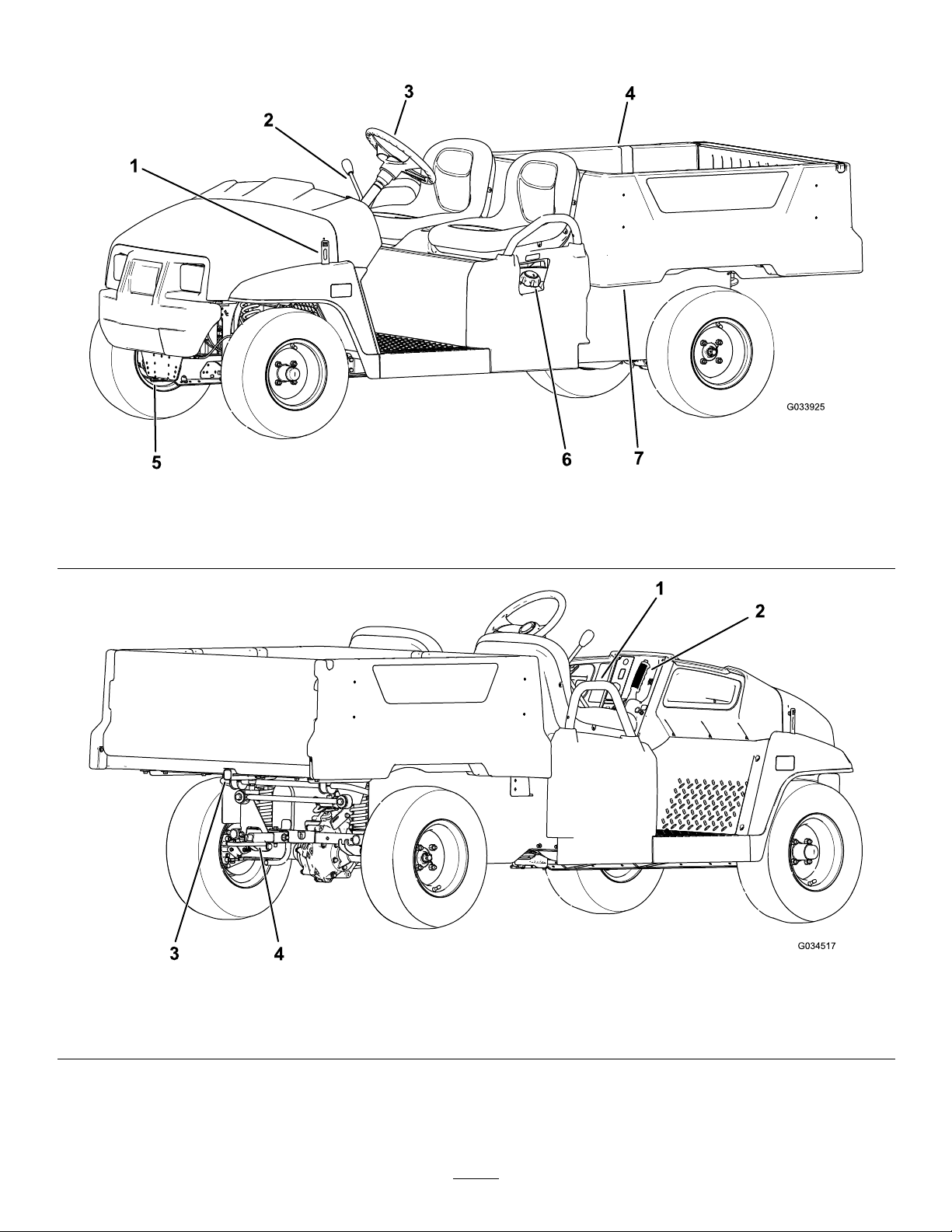

g033925

Figure4

1.Hoodlatch

2.Shiftlever4.Cargobed

3.Steeringwheel

Figure5

5.Towingtongue

6.Fuelcap

7.Cargo-bedlever

g034517

1.Passengerhandhold3.Rearcargo-bed-accessorymount

2.Parking-brakelever4.Trailerhitch

11

Page 12

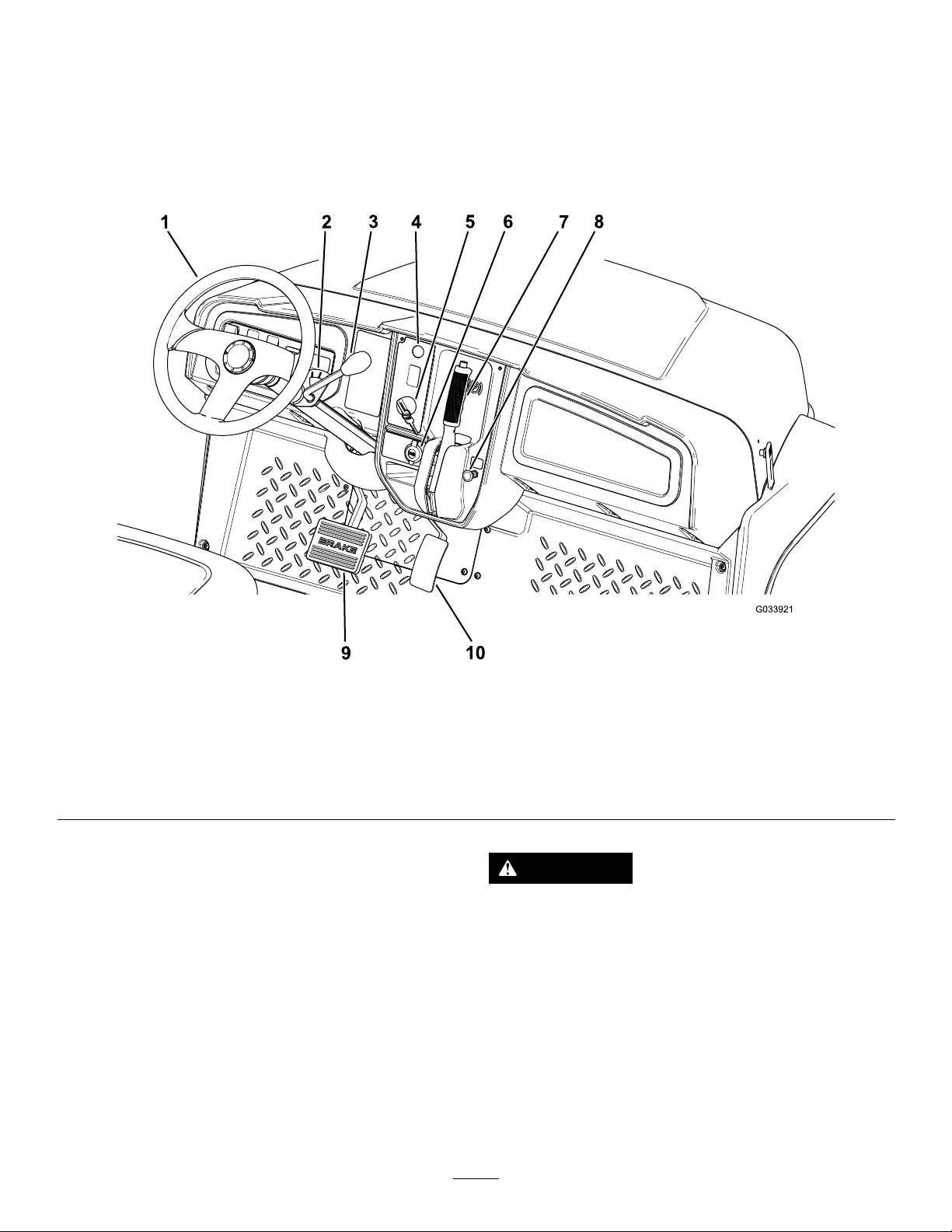

Controls

Becomefamiliarwithallthecontrolsbeforeyoustarttheengineandoperatethemachine.

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

ControlPanel

Figure6

1.Steeringwheel6.USBpowerpoint

2.Gear-shiftindicator

3.Gear-shiftlever8.Chokecontrol

4.Hornbutton(Internationalmodelsonly)

5.Keyswitch10.Acceleratorpedal

AcceleratorPedal

Usetheacceleratorpedal(Figure6)tovarythe

groundspeedofthemachine.Pressingdownthe

acceleratorpedalstartstheengine.Pressingthe

pedalfartherincreasesthegroundspeed.Releasing

thepedalslowsthemachine,andtheengineshutsoff.

Note:Themaximumforwardspeedis26km/h

(16mph).

7.Parking-brakelever

9.Brakepedal

CAUTION

Operatingamachinewithwornorincorrectly

adjustedbrakescanmayresultinpersonal

injury.

Ifthebrakepedaltravelstowithin25mm(1

inch)ofthemachineoorboard,adjustor

repairthebrakes.

BrakePedal

g033921

Usethebrakepedaltostoporslowthemachine

(Figure6).

12

Page 13

KeySwitch

ChokeControl

Thekeyswitchislocatedatthelower,rightcornerof

thedashpanel(Figure6).

Thekeyswitchhas3positions:OFF,ON,andSTART.

Thereare2modesofstartingthemachine;referto

StartingtheEngine(page23).

Parking-BrakeLever

Theparking-brakeleverislocatedonthecontrol

panel(Figure6).

Wheneveryoushutofftheengine,engagetheparking

braketopreventthemachinefromaccidentally

moving.Ifthemachineisparkedonasteepgrade,

ensurethatyouengagetheparkingbrake.

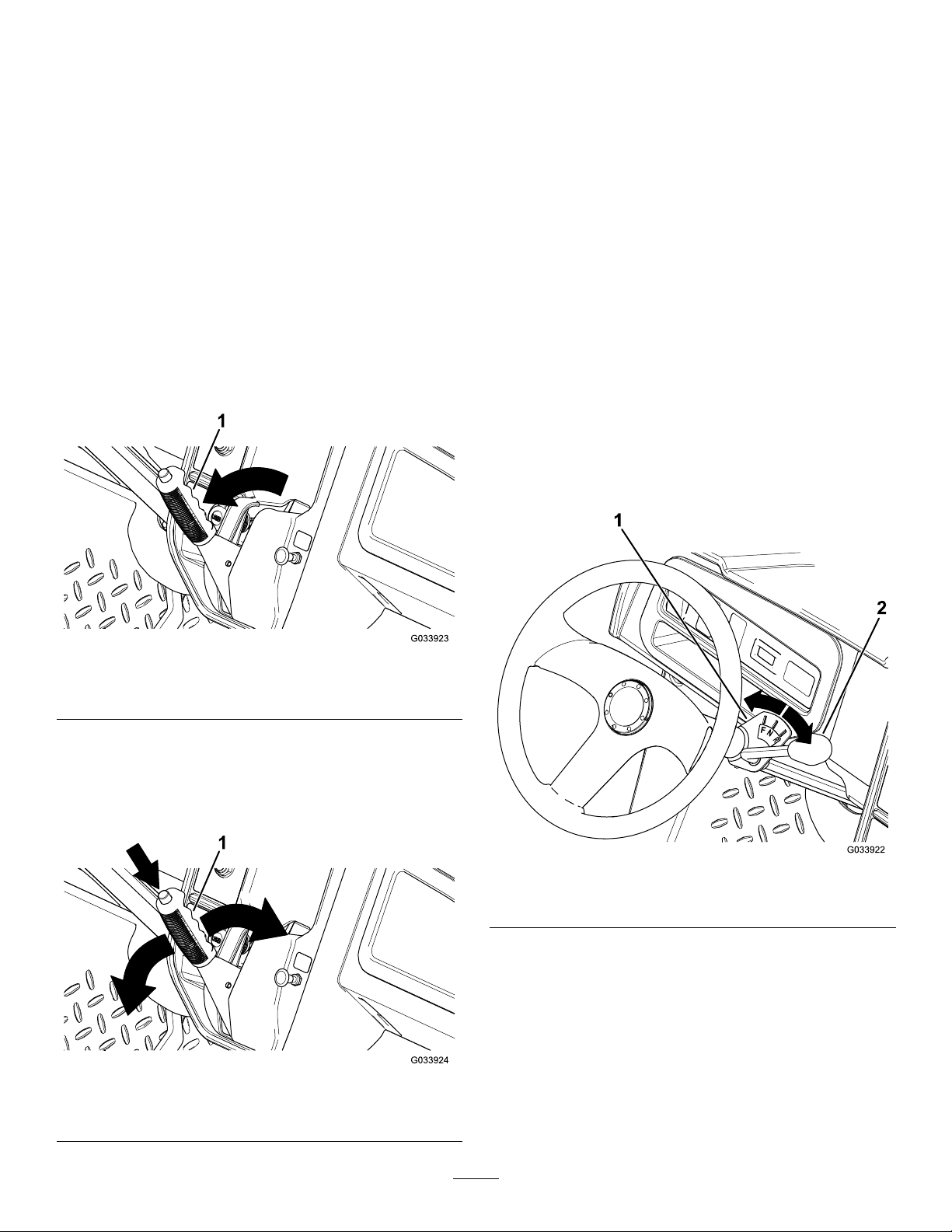

Toengagetheparkingbrake,pulltheparking-brake

levertowardyou(Figure7).

Thechokecontrolislocatedonthecontrolpanel.Use

thechoketohelpstartacoldenginebypullingthe

chokecontroloutward(Figure6).Aftertheengine

starts,adjustthechoketokeeptheenginerunning

smoothly.Astheenginewarmsup,pushinthechoke

controltotheOFFposition.

Gear-ShiftLeverandGear-Shift

Indicator

Thegear-shiftlevercanbesetto3positionson

thegear-shiftindicator:FORWARD,REVERSE,and

NEUTRAL(Figure9).

Note:Theenginestartsandrunsinanyofthe3

positions.

FromtheNEUTRALposition,youcanmovethe

gear-shiftleverlefttotheFORWARDpositionorright

totheREVERSEposition(Figure9).

Important:Alwaysstopthemachinebefore

changinggears.

Figure7

1.Parking-brakelever

Todisengagetheparkingbrake,pushdownthe

buttonontopoftheparking-brakelever,pullthe

parking-brakelevertowardyoutoreleasepressure,

andthenpushtheparking-brakeleverforward(Figure

8).

Figure8

g033923

g033922

Figure9

1.Gear-shiftindicator2.Gear-shiftlever

HornButton

InternationalModelsOnly

Thehornbuttonislocatedonthecontrolpanel(Figure

6).Pressthehornbuttontosoundthehorn.

g033924

1.Parking-brakelever

13

Page 14

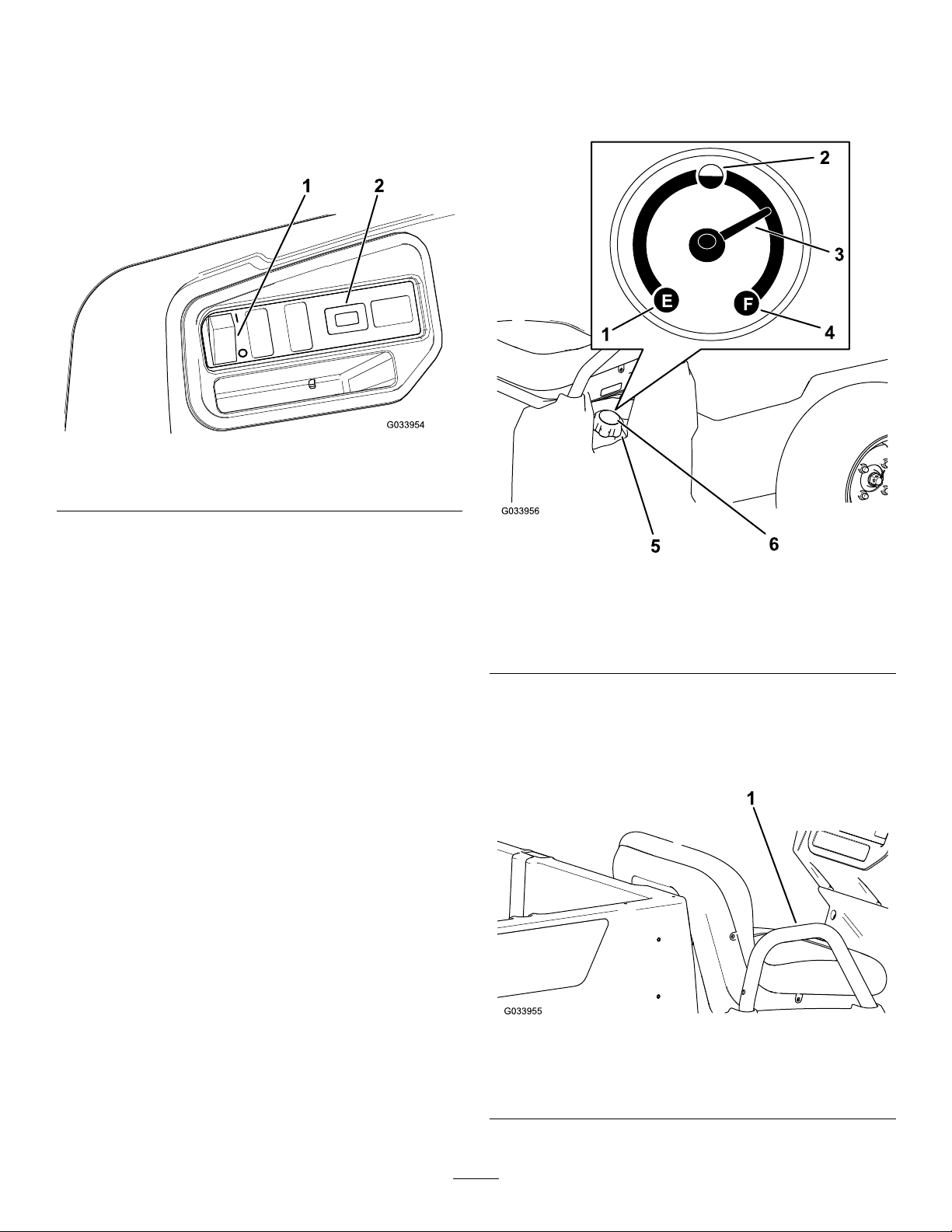

LightSwitch

FuelGauge

Thelightswitchislocatedtotheleftofthesteering

column(Figure10).Usethelightswitchtoilluminate

theheadlights.Pushthelightswitchuptoturnonthe

headlights.Pushthelightswitchdowntoturnoffthe

lights.

Figure10

1.Lightswitch2.Hourmeter

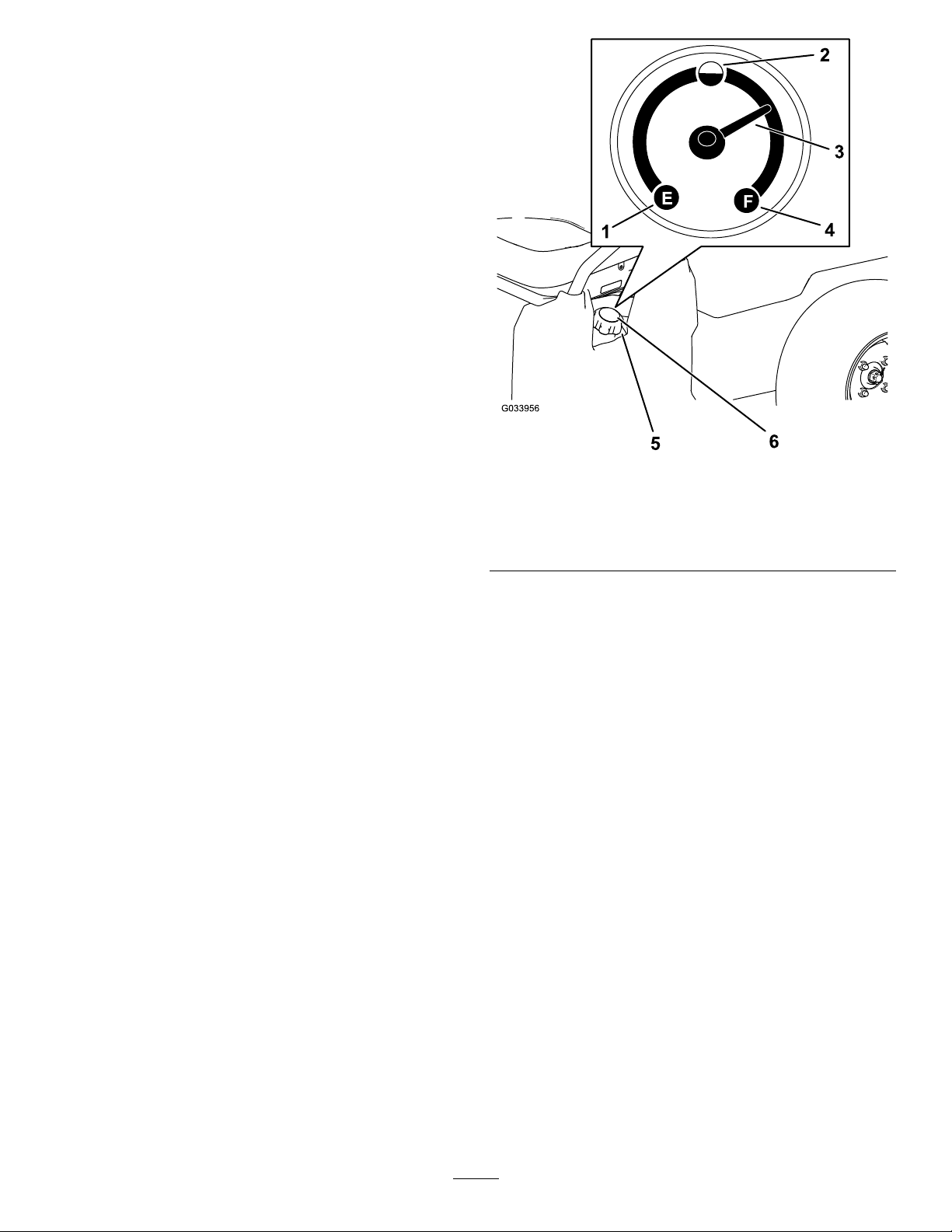

Thefuelgauge(Figure11)islocatedonthefueltank

inthellercap,attheleftsideofthemachine.The

gaugedisplaystheamountoffuelinthetank.

g033954

HourMeter

Thehourmeterislocatedtotherightofthelight

switch(Figure10).Usethehourmetertondoutthe

totalnumberofenginehours.Thehourmeterstartsto

functionwheneveryouturnthekeyswitchtotheON

position,ST ARTposition,oriftheengineisrunning.

Note:Whenthemachineisrunning,thehourmeter

blinkscontinuously,recordingusage.

USBPowerPoint

TheUSBpowerpointislocatedtotheleftofthe

parking-brakelever(Figure6).Usethepowerpoint

topowermobiledevices.

Important:WhenyouarenotusingtheUSB

powerpoint,inserttherubberplugtoprevent

damagetothepowerpoint.

Figure11

1.Empty4.Full

2.Halffull

3.Needle6.Fuelgauge

5.Fuel-tankcap

PassengerHandholds

Thepassengerhandholdsarelocatedontheoutside

ofeachseat(Figure12).

g033956

g033955

Figure12

PassengerSideShown

1.Passengerhandhold

14

Page 15

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Baseweight

Ratedcapacity(onlevelground)

Maximumgrossvehicleweight(GVW)—onlevelground941kg(2,075lb)total,includingalloftheweightslistedabove

Maximumcargocapacity(onlevelground)363kg(800lb)total,includingrear-mountedaccessories

Maximumrearcargo-bed-accessorymountcapacity

Towcapacity

Overallwidth119cm(47inches)

Overalllength302cm(119inches)

Overallheight127.5cm(50.2inches)

Groundclearance

Wheelbase

Wheeltread(centerlinetocenterline)

Cargobedlength

Cargobedwidth

Cargobedheight28cm(11inches)inside

Enginespeed

397kg(875lb)

544kg(1,200lb)total,including90.7kg(200lb)operatorand91

kg(200lb)passenger,load,accessories,andattachments

45kg(100lb)total

Tongueweight:91kg(200lb)

Maximumtrailerweight:680kg(1,500lb)

21.6cm(8.5inches)atthefrontwithnoloadoroperator

14cm(5.5inches)attherearwithnoloadoroperator

220cm(86.6inches)

Front:119cm(47inches)

Rear:119cm(47inches)

Inside:102cm(40inches)

Outside:1 14.3cm(45inches)

Inside:98cm(38.5inches)

Outsideofthemoldedfenders:107.3cm(42.25inches)

Lowidle:1,250to1,350rpm

Highidle:3,650to3,750rpm

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comfora

listofallapprovedattachmentsandaccessories.

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

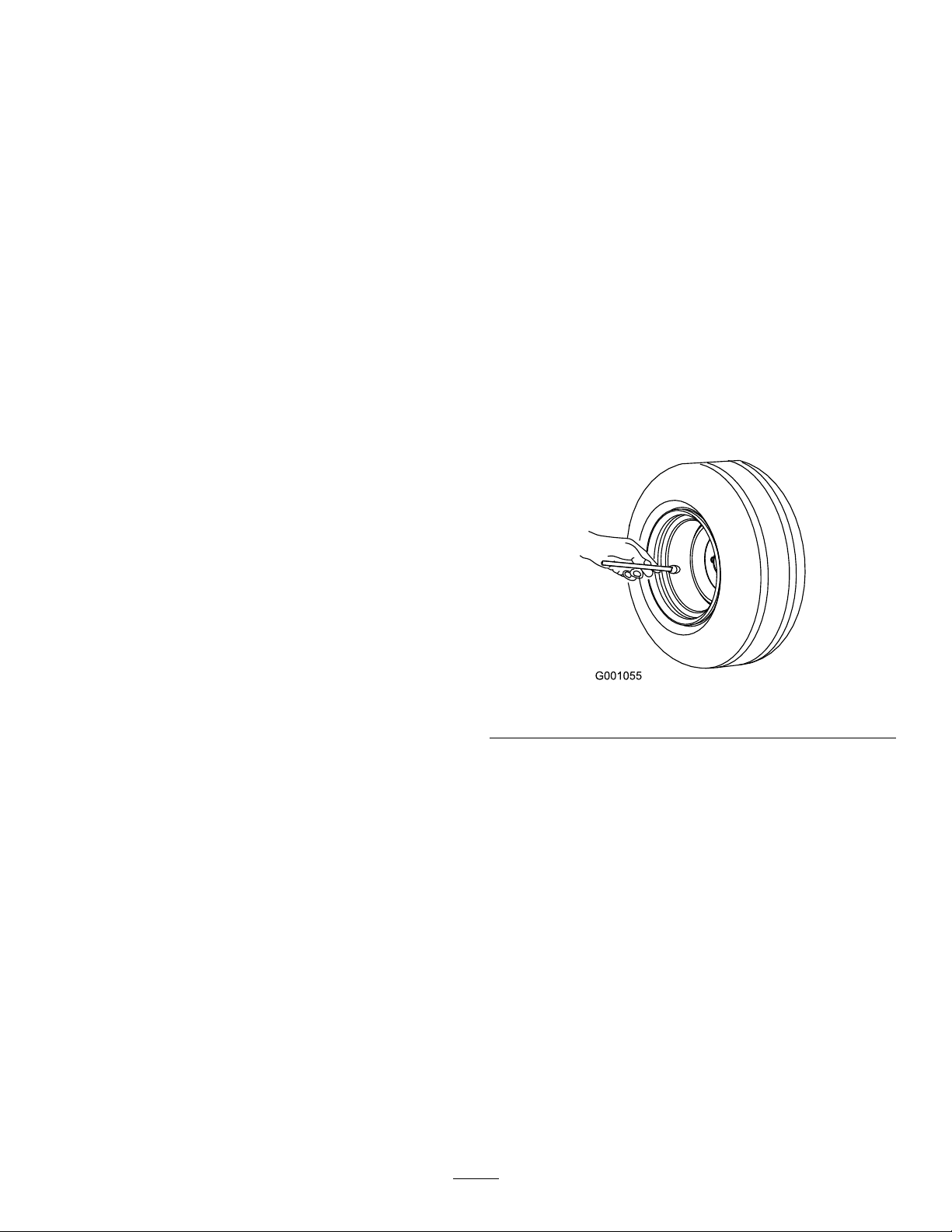

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Frontandreartiresairpressurespecication:165

to207kPa(24to30psi)

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Ensurethatyouandyourpassengersdonot

exceedthenumberofhandholdsequippedonthe

machine.

•Checkthatallsafetydevicesanddecalsarein

place.Repairorreplaceallsafetydevicesand

replaceallillegibleormissingdecals.Donot

operatethemachineunlesstheyarepresentand

functioningproperly.

Important:Donotexceedthemaximumair

pressureindicatedonthesidewallofthetire.

Note:Theairpressureneededinthetiresis

determinedbythepayloadthatyouintendtocarry.

1.Checktheairpressureinthetires.

•Uselowerairpressureinthetiresforlighter

payloads,forlesssoilcompaction,fora

smootherride,andtominimizetiremarkson

theground.

•Usehigherairpressureinthetiresfor

carryingheavierpayloadsathigherspeeds.

2.Ifnecessary ,adjusttheairpressureinthetires

byaddingorremovingairinthetires.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

PerformingDaily Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page26).

g001055

Figure13

16

Page 17

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithacetane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

Figure14

1.Empty4.Full

2.Halffull

3.Needle6.Fuelgauge

5.Fuel-tankcap

g033956

FillingtheFuelTank

Thefuel-tankcapacityisapproximately18.9L(5US

gallons).

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleantheareaaroundthefuel-tankcap(Figure

14).

5.Removethefuel-tankcap.

6.Fillthetanktoabout25mm(1inch)belowthe

topoftank(bottomofthellerneck).

Note:Thisspaceinthetankallowsfuelto

expand.Donotoverllthefueltank.

7.Installthefuel-tankcapsecurely.

8.Wipeupanyspilledfuel.

BreakinginaNewMachine

ServiceInterval:Aftertherst100hours—Perform

theguidelinesforbreakinginanew

machine.

Performthefollowingguidelinestoprovideproper

performanceforthemachine.

•Ensurethatthebrakesareburnished;referto3

BurnishingtheBrakes(page10).

•Checktheuidandengine-oillevelsregularly.

Remainalertforsignsthatthemachineorits

componentsareoverheating.

•Afterstartingacoldengine,letitwarmupforabout

15secondsbeforeusingthemachine.

Note:Allowmoretimefortheenginetowarmup

whenoperatingincoldtemperatures.

•Varythemachinespeedduringoperation.Avoid

faststartsandquickstops.

17

Page 18

•Abreak-inoilfortheengineisnotrequired.

Originalengineoilisthesametypespeciedfor

regularoilchanges.

•RefertoMaintenance(page26)foranyspecial,

low-hourchecks.

•Checkthefrontsuspensionpositioningandadjust

it,ifnecessary;refertoAdjustingtheFrontWheel

Toe-in(page46).

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Passengersshouldsitinthedesignatedseating

positionsonly.Donotcarrypassengersinthe

cargobed.Keepbystandersandpetsawayfrom

themachineduringoperation.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearloosejewelry .

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Operatethemachineoutdoorsorina

well-ventilatedareaonly.

•Donotexceedthemaximumgrossvehicleweight

(GVW)ofthemachine.

•Useextracautionwhenoperatingthemachine

withaheavyloadinthecargobed.Theheavier

theload,themoredifcultitistoturnorstop.

•Carryingoversizedloadsinthecargobedreduces

thestabilityofthemachine.

•Carryingmaterialthatcannotbeboundtothe

machine,suchasalargetankofliquid,adversely

affectsthesteering,braking,andstabilityofthe

machine.

•Beforeyoustarttheengine,ensurethatthe

transmissionisinneutral,theparkingbrakeis

engaged,andyouareintheoperatingposition.

•Youandyourpassengersshouldremainseated

wheneverthemachineismoving.Keepyour

handsonthesteeringwheel;yourpassengers

shouldusethehandholdsprovided.Keepyour

armsandlegswithinthemachinebodyatalltimes.

•Operatethemachineonlyingoodvisibility.

Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.Tallgrasscanhideobstacles.Usecare

whenapproachingblindcorners,shrubs,trees,or

otherobjectsthatmayobscureyourvision.

•Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,overhead

walkways,etc.

•Lookbehindanddownbeforereversingthe

machinetobesureofaclearpath.

•Donotdrivethemachineneardrop-offs,ditches,

orembankments.Themachinecouldsuddenly

rolloverifawheelgoesovertheedgeorifthe

edgegivesway.

•Whenusingthemachineonpublicroads,follow

alltrafcregulationsanduseanyadditional

accessoriesthatmayberequiredbylaw,suchas

lights,turnsignals,slow-movingvehicle(SMV)

signs,andothersasrequired.

•Ifthemachineevervibratesabnormally,stopthe

machineimmediately,shutofftheengine,remove

thekey,waitforallmovementtostop,andinspect

fordamage.Repairalldamagetothemachine

beforeresumingoperation.

•Carryareducedloadandreducetheground

speedofthemachinewhenoperatingonrough,

uneventerrain,andnearcurbs,holes,andother

suddenchangesinterrain.Loadsmayshift,

causingthemachinetobecomeunstable.

•Itcantakelongertostopthemachineonwet

surfacesthanondrysurfaces.T odryoutwet

brakes,driveslowlyonlevelgroundwhileputting

lightpressureonthebrakepedal.

•Suddenchangesinterrainmaymovethesteering

wheelunexpectedly,whichcouldresultinhand

andarminjuries.Reduceyourspeedandgrip

thesteeringwheellooselyaroundtheperimeter,

keepingyourthumbsoutofthewayofthesteering

wheelspokes.

•Reducethespeedwhenyouoperatethemachine

withthecargobedremoved.Operatingthe

machineathighspeedandthenquicklystopping

maycausetherearwheelstolockup,which

impairsyourcontrolofthemachine.

•Donottouchtheengine,transmission,mufer,or

mufermanifoldwhiletheengineisrunning,or

soonafteryoushutofftheengine,becausethese

areasmaybehotenoughtocauseburns.

•Donotleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonlevelground.

–Engagetheparkingbrake.

–Lowerthecargobed.

–Shutofftheengineandremovethekey .

18

Page 19

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Useaccessoriesandattachmentsapprovedby

TheT oro®Companyonly .

Multi-PassengerSafety

•Heavyloadsaffectstabilityonaslope.Carrya

reducedloadandreduceyourgroundspeedwhen

operatingonaslopeoriftheloadhasahigh

centerofgravity.Securetheloadtothecargobed

ofthemachinetopreventtheloadfromshifting.

Takeextracarewhenhaulingloadsthatshifteasily

(e.g.,liquids,rock,sand,etc.).

•Youmustaccountfortheextrapassengers

contributingtotheoverallgrossvehicleweight

(GVW)ofthemachine.

•Ifyouhavealoadinthecargobed,ensurethat

youdonotexceedthecapacityofthemachineby

havingtoomanypassengers.

•Passengersshouldsitinthedesignatedseating

positionsonly.Donotallowpassengerstositin

thecargobed.

•Youandyourpassengersshouldremainseated

wheneverthemachineisinmotion.

•Theadditionalmachinelengthresultsinalarger

turnradius,soallowmorespacetomaneuverthe

machine.

SlopeSafety

Note:A2-postRolloverProtectionSystem(ROPS)

isavailableforthismachineasanaccessory.Usea

ROPSifyouwillworknexttodrop-offs,nearwater,

inroughterrain,oronaslope,whichcouldresultin

arollover.ContactanauthorizedTorodistributorfor

moreinformation.

•Avoidstarting,stopping,orturningthemachine

onaslope,especiallywithaload.Stoppingwhile

goingdownaslopetakeslongerthanstopping

onlevelground.Ifyoumuststopthemachine,

avoidsuddenspeedchanges,whichcancause

themachinetotiporrollover.Donotengagethe

brakessuddenlywhenrollingrearward,asthis

maycausethemachinetooverturn.

LoadingandDumpingSafety

•Donotexceedthegrossvehicleweight(GVW)

ofthemachinewhenoperatingitwithaloadin

thecargobedand/ortowingatrailer;referto

Specications(page15).

•Distributetheloadinthecargobedevenlyto

improvethestabilityandcontrolofthemachine.

•Beforedumping,ensurethatthereisnoone

behindthemachine.

•Donotdumpaloadedcargobedwhilethe

machineissidewaysonaslope.Thechange

inweightdistributionmaycausethemachineto

overturn.

Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.

•Surveythesitetodeterminewhichslopesare

safeforoperatingthemachineandestablishyour

ownproceduresandrulesforoperatingonthose

slopes.Alwaysusecommonsenseandgood

judgmentwhenperformingthissurvey.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

•Avoidoperatingthemachineonwetterrain.Tires

maylosetraction.Arollovercanoccurbeforethe

tireslosetraction.

•Travelstraightupanddownaslope.

•Ifyoubegintolosemomentumwhileclimbinga

slope,graduallyengagethebrakesandslowly

reversethemachinestraightdowntheslope.

•Turningwhilegoingupordownaslopecanbe

dangerous.Ifyoumustturnonaslope,doitslowly

andcautiously.

19

Page 20

OperatingtheCargoBed

RaisingtheCargoBedtothe DumpPosition

WARNING

Araisedbedcouldfallandinjurepersonsthat

areworkingbeneathit.

•Alwaysusetheproprodtoholdthebedup

beforeworkingunderthebed.

•Removeanyloadmaterialfromthebed

beforeraisingit.

WARNING

Drivingthemachinewiththecargobedraised

couldcausethemachinetotiporrolleasier.

Youcoulddamagethestructureofthecargo

bedifyouoperatethemachinewiththebed

raised.

•Operatethemachinewhenthecargobed

isdown.

•Afteremptyingthecargobed,lowerit.

CAUTION

Ifaloadisconcentratednearthebackofthe

cargobedwhenyoureleasethelatches,the

bedmayunexpectedlytipopen,injuringyou

orbystanders.

Figure15

1.Cargo-bedlever

2.Pulltheproprodintothedumppositiondetent

slottosecurethebedfordumping(Figure16).

Figure16

1.Servicepositiondetent

slot

2.Proprod

3.Dumppositiondetentslot

g034019

g034021

•Centerloadsinthecargobed,ifpossible.

•Holdthecargobeddownandensurethat

nooneisleaningoverthebedorstanding

behinditwhenreleasingthelatches.

•Removeallcargofromthebedbefore

liftingthebeduptoservicethemachine.

1.Pulltheleveronleft,insideofthecargobed

towardyouandliftthecargobedup(Figure15).

20

Page 21

RaisingtheCargoBedtothe

OpeningtheTailgate

ServicePosition

1.Pulltheleveronleft,insideofthecargobed

towardyouandliftthecargobedup(Figure15).

2.Pullproprodintotheservicepositiondetentslot

tosecurethebedformaintenance(Figure16).

LoweringtheCargoBed

WARNING

Theweightofthebedmaybeheavy.Hands

orotherbodypartscouldbecrushed.

Keepyourhandsandotherbodypartsaway

whenloweringthebed.

1.Raisethecargobedslightlybyliftinguponthe

latchlever(Figure15).

2.Pulltheproprodoutofthedetentslot(Figure

16).

3.Lowerthebeduntilitlatchessecurely.

1.Ensurethatthecargobedisdownandlatched.

2.Usingbothhands,raisethetailgateusingthe

ridgenearthetopofthetailgate(Figure17).

3.Lowerthetailgateuntilitisushwiththebottom

ofthecargobed(Figure17).

Figure17

g034022

21

Page 22

ClosingtheTailgate

UsingtheRearCargoBed

Ifyouunloadedloosematerialsuchassand,

landscapingrock,orwoodchipsfromthecargobedof

themachine,someofthematerialthatyouunloaded

mayhavelodgedinthehingeareaofthetailgate.

Performthefollowingstepsbeforeclosingthetailgate.

1.Useyourhandstoremoveasmuchofthe

materialfromthehingeareaaspossible.

2.Rotatethetailgatetoapproximatelythe45°

position(Figure18).

Figure18

AccessoryMount

Usetherearcargobedaccessorymounttoattach

accessoriestotherearofthemachine.

Capacity:45kg(100lb)

1.Loosenthe“T”handlebyrotatingitclockwise

(Figure19).

g034525

Figure19

g034023

1.Receiver

2.“T”handle

1.Rotatethetailgateback

andforthseveraltimes.

2.Rotatethetailgateto

approximatelythe45°

position.

3.Hingearea

3.Useashort,shakingmotiontorotatethetailgate

backandforthseveraltimes(Figure18).

Note:Thisactionhelpsmovematerialaway

fromthehingearea.

4.Lowerthetailgateandcheckformaterial

remaininginthehingearea.

5.Repeatsteps1through4untilthematerialis

removedfromthehingearea.

6.Rotatethetailgateupandliftthetailgateintothe

notchesinthecargobed.

2.Insertyouraccessoryintothereceiveruntilthe

holesalign(Figure19).

3.Securetheassembledaccessorytothereceiver

tubeusingtheclevispinandhairpincotter

suppliedwiththeaccessory .

4.Tightenthe“T”handlebyrotatingit

counterclockwise(Figure20).

g034526

Figure20

1.“T”handle

22

Page 23

LoadingtheCargoBed

Usethefollowingguidelineswhenloadingthecargo

bedandoperatingthemachine:

•Observetheweightcapacityofthemachineand

limittheweightoftheloadthatyoucarryinthe

cargobedasdescribedinSpecications(page

15)andonthegrossvehicleweighttagofthe

machine.

Note:Theloadratingisspeciedformachine

operationonalevelsurfaceonly.

•Reducetheweightoftheloadthatyoucarryinthe

cargobedwhenoperatingthemachineonhills

androughterrain.

•Reducetheweightoftheloadthatyoucarrywhen

thematerialsaretall(andhaveahighcenterof

gravity),suchasastackofbricks,landscaping

timbers,orfertilizerbags.Distributetheloadas

lowaspossibletoensurethattheloaddoesnot

reduceyourabilitytoseebehindthemachine

whenoperatingit.

•Keeploadscenteredbyloadingthecargobedas

follows:

–Evenlypositiontheweightinthecargobed

fromsidetoside.

Important:Tippingoverismorelikelyto

occurifthecargobedisloadedto1side.

–Evenlypositiontheweightinthecargobed

fromfronttoback.

Important:Lossofsteeringcontrolorthe

machinemaytipoverifyoupositionthe

loadbehindtherearaxleandthetraction

onthefronttiresisreduced.

Refertothefollowingtableforloadvolumelimitswith

variousmaterials:

MaterialDensity

Gravel,dry1522kg/m

Gravel,wet1922kg/m

Sand,dry1442kg/m

Sand,wet1922kg/m

Wood

Bark

Earth,packed

721kg/m

3

(95

3

lb/ft

)

3

(120

3

lb/ft

)

3

(90

3

lb/ft

)

3

(120

3

lb/ft

)

3

(45lb/ft

<721kg/m

1602kg/m

3

(<45

3

lb/ft

)

3

(100

3

lb/ft

)

MaximumCargo

BedCapacity

(onlevelground)

Full

3/4Full

Full

3/4full

3

)

Full

Full

3/4Full

(approximately)

StartingtheEngine

1.Sitintheoperatorseat,insertthekeyintothe

keyswitch,androtatethekeyclockwisetothe

ONorSTARTposition.

Thereare2modesofstartingthemachine:

•PedalStart—turnthekeyswitchtotheON

position,pressdowntheacceleratorpedal,

thenreleaseyourfootfromtheaccelerator

pedal.

Note:Whenyouremoveyourfootfromthe

acceleratorpedal,theengineshutsoff.

•KeyStart—turnthekeyswitchtotheSTART

positionandtheengineremainsonuntilthe

isturnedtotheOFFposition.

•Useextracautionwhentransportingoversized

loadsinthecargobed,particularlywhenyou

cannotcenterthewightoftheoversizeloadtothe

cargobed.

•Wheneverpossible,securetheloadbybindingit

tothecargobedsothatitdoesnotshift.

•Whentransportingliquidinalargetank(such

asasprayertank),usecautionwhendriving

themachineuphillordownhill,whensuddenly

changingspeedorstopping,orwhendrivingover

toughsurfaces.

Thecapacityofthecargobedis0.28m

Theamount(volume)ofmaterialthatyoucanplace

inthebedwithoutexceedingtheloadratingsofthe

machinecanvarygreatlydependingonthedensity

ofthematerial.

3

(10ft3).

Note:Whenusingkeystartmode,youcan

engagetheparkingbrakeandworkawayfrom

themachinewhiletheenginestillrunsandthe

batteryholdsacharge.

Note:IfyouturnthekeytotheSTARTposition,

theenginecranksuntilitstarts.Iftheengine

cranksformorethan10seconds,returntothe

OFFposition,anddeterminetheissue(e.g.,the

chokecontrolsneedstobeengaged,checkthe

aircleanerforrestrictions,ensurethatthefuel

tankisfull,thesparkisbad,etc.)beforestarting

themachineagain.

Note:Whenequippedwiththeoptionalbackup

alarm,ifyoumovethegear-shiftselectortothe

REVERSEpositionwhenthekeyswitchisinthe

ONorSTARTposition,abuzzersoundstowarn

theoperatorthatthemachineisinreversegear.

2.Movethegear-shiftselectortothedesired

directionoftravelforthemachine.

23

Page 24

3.Disengagetheparkingbrake.

4.Slowlystepontheacceleratorpedal.

AfterOperation

Note:Iftheengineiscold,pressandholdthe

acceleratorpedalabouthalf-waydown,andpull

thechokeknobouttotheONposition.Return

thechokeknobtotheOFFpositionafterthe

enginewarmsup.

StoppingtheMachine

Important:Whenstoppingthemachineon

anincline,usetheservicebrakestostopthe

machineandengagetheparkingbraketoholdthe

machineinplace.Usingtheacceleratortostall

themachineonthehillcandamagethemachine.

1.Removeyourfootfromtheacceleratorpedal.

2.Slowlypressthebrakepedaltoapplytheservice

brakesuntilthemachinecomestoacomplete

stop.

Note:Thestoppingdistancemayvary

dependingonthemachineloadandspeed.

ParkingtheMachine

1.Stopthemachineusingtheservicebrakesby

pressingandholdingthebrakepedal.

2.Engagetheparkingbrakebypullingthe

parking-brakelevertowardyou.

3.RotatethekeycounterclockwisetotheOFF

position.

AfterOperationSafety

GeneralSafety

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallworn,damaged,ormissingdecals.

TransportingtheMachine

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Usefull-widthrampsforloadingthemachineinto

atraileroratruck.

•Tiethemachinedownsecurely.

RefertoFigure21andFigure22forthetie-down

locationsonthemachine.

Note:Loadthemachineonthetrailerwiththefront

ofthemachinefacingforward.Ifthatisnotpossible,

securethemachinehoodtotheframewithastrap,

orremovethehoodandtransportandsecureit

separatelyorthehoodmayblowoffduringtransport.

4.Removethekey.

CAUTION

Looseseatsmayfalloffthemachineand

trailerwhentransportingthemachine,and

theseatsmaylandonanothermachineor

obstructtheroadway.

Removetheseatsormakesurethattheseats

aresecurelyfastenedtothecouplinginthe

seatshroud.

24

Page 25

TowingtheMachine

Incaseofanemergency,youcantowthemachine

forashortdistance;however,thisshouldnotbea

standardoperatingprocedure.

WARNING

Towingatexcessivespeedscouldcausea

lossofsteeringcontrol,resultinginpersonal

injury.

Figure21

1.Towingtongueandtie-downpoint(frontofthemachine)

Figure22

1.Reartie-downpoints

g236535

Nevertowthemachineatfasterthan8km/h

(5mph).

Note:Thepowersteeringdoesnotfunction,

makingitdifculttosteer.

Towingthemachineisa2-personjob.Ifyoumust

movethemachineaconsiderabledistance,transport

itonatruckortrailer;refertoT owingaTrailer(page

25)

1.Removethedrivebeltfromthemachine;referto

ReplacingtheDriveBelt(page52).

2.Afxatowlinetothetongueatthefrontofthe

machine’sframe(Figure21).

3.MovethetransmissiontotheNEUTRALposition

anddisengagetheparkingbrake.

g034273

TowingaTrailer

Themachineiscapableofpullingtrailers.Atowhitch

isavailableforthemachine.Contactyourauthorized

Torodistributorfordetails.

Whenhaulingcargoortowingatrailer,donot

overloadyourmachineortrailer.Overloadingeither

themachineorthetrailercancausepoorperformance

ordamagetothebrakes,axle,engine,transaxle,

steering,suspension,bodystructure,ortires.

Alwaysloadatrailerwith60%ofthecargoweightin

thefrontofthetrailer.Thisplacesapproximately10%

ofthegrosstrailerweight(GTW)onthetowhitchof

themachine.

Toprovideadequatebrakingandtraction,alwaysload

thecargobedwhenusingatrailer.Donotexceed

theGTWorGVWlimits.

Avoidparkingamachinewithatraileronahill.Ifyou

mustparkonahill,engagetheparkingbrake,and

chockthetiresofthetrailer.

25

Page 26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Note:Downloadacopyoftheelectricalschematicbyvisitingwww.T oro.comandsearchingforyourmachine

fromtheManualslinkonthehomepage.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

WARNING

Failuretoproperlymaintainthemachinecouldresultinprematurefailureofmachinesystems

causingpossibleharmtoyouorbystanders.

Keepthemachinewellmaintainedandingoodworkingorderasindicatedintheseinstructions.

CAUTION

Onlyqualiedandauthorizedpersonnelshouldmaintain,repair,adjust,orinspectthemachine.

•Avoidrehazardsandhavere-protectionequipmentpresentintheworkarea.Donotuse

anopenametocheckuidlevelsorleakageoffuel,batteryelectrolyte,orcoolant.

•Donotuseopenpansoffuelorammablecleaninguidsforcleaningparts.

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbefore

youdoanymaintenance.Setthewiresasidesothattheydonotaccidentallycontactthe

sparkplugs.

26

Page 27

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checktheconditionofthedrivebelt.

•Checkthetensionofthestarter-generatorbelt.

•Checktheairlterforthecarboncanister.

•Performtheguidelinesforbreakinginanewmachine.

•Checkthetirepressure.

•Checktheengine-oillevel.

•Checkgear-shiftoperation.

•Checkthebrake-uidlevel.

•Removetheair-cleanercoverandcleanoutthedebris.Donotremovethelter.

•Cleanoutthedebrisinthedustcap.

•Greasethebearingsandbushings.

•Replacetheairlter.Replacetheair-lterelementsoonerifdirtyordamaged.

•Servicetheairlter(morefrequentlyinextremedustyordirtyconditions).

•Changetheengineoil.

•Checkthesparkplug.

•Checktheconditionofthetiresandrims.

•Torquethewheellugnuts.

•Checkthefrontwheelcamberandtoe-in.

•Checkthetransaxle-uidlevel.

•Checktheoperationoftheneutralgear-shiftposition.

•Cleantheengine-coolingareas.

•Inspectthebrakes.

Every200hours

Every300hours

Every400hours

Every800hours

Every1,000hours

•Checktheairlterforthecarboncanister.

•Checktheconditionandtensionofthedrivebelt.

•Checkthetensionofthestarter-generatorbelt.

•Greasethefrontwheelbearings.

•Inspectthefuellinesandconnections.

•Replacethefuellter.

•Cleantheprimary-driveclutch.

•Changethetransaxleuid.

•Changethebrakeuid.

Yearly

•Completealloftheyearlymaintenanceproceduresthatarespeciedintheengine

owner'smanual.

27

Page 28

DailyMaintenanceChecklist

Duplicatethispageforroutineuse.

Fortheweekof: MaintenanceCheckItem

Checkthebrakeand

parkingbrakeoperation.

Checkthegear

shift/neutraloperation.

Checkthefuellevel.

Checktheengine-oillevel.

Checkthetransaxle-uid

level.

Inspecttheairlter.

Inspecttheengine-cooling

ns.

Checkforunusualengine

noises.

Checkforunusual

operatingnoises.

Checkthetirepressure.

Checkforuidleaks.

Checktheinstrument

operation.

Checktheaccelerator

operation.

Lubricateallgrease

ttings.

Touchupanydamaged

paint.

MondayTuesdayWednesdayThursdayFriday

SaturdaySunday

MaintainingtheMachineunderSpecialOperating Conditions

Important:Ifthemachineissubjectedtoanyoftheconditionslistedbelow,performmaintenance

twiceasfrequently:

•Desertoperation

•Coldclimateoperation—below10°C(50°F)

•Trailertowing

•Frequentoperationindustyconditions

•Constructionwork

•Afterextendedoperationinmud,sand,water,orsimilardirtyconditions,haveyourbrakesinspectedand

cleanedassoonaspossible.Thispreventsanyabrasivematerialfromcausingexcessivewear.

28

Page 29

Pre-Maintenance

Procedures

MaintenanceSafety

•Donotallowuntrainedpersonneltoservicethe

machine.

•Beforeservicingormakinganyadjustmentstothe

machine,parkthemachineonalevelsurface,

engagetheparkingbrake,shutofftheengine,and

removethekeytopreventaccidentalstartingof

themachine.

•Removeanyloadmaterialfromthecargobed

beforeworkingunderneathit.

•Alwaysusetheproprodtoholdthecargobedup

beforeworkingunderneathit.

•Usejackstandstosupportthemachineor

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Donotchargethebatterieswhileservicingthe

machine.

•Toensurethattheentiremachineisingood

condition,keepallthenuts,bolts,andscrews

properlytightened.

•Toreducethepotentialrehazard,keepthe

engineareafreeofexcessivegrease,grass,

leaves,andaccumulationofdirt.

•Ifpossible,donotperformmaintenancewhilethe

engineisrunning.Keepawayfrommovingparts.

•Ifyoumustruntheenginetoperforma

maintenanceadjustment,keepyourhands,feet,

clothing,andanypartsofthebodyawayfromthe

engineandanymovingparts.Keepbystanders

awayfromthemachine.

•Cleanupoilandfuelspills.

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Donotoverspeedtheenginebychangingthe

governorsettings.T oensuresafetyandaccuracy ,

haveanauthorizedT orodistributortocheckthe

maximumenginespeedwithatachometer.

•Ifmajorrepairsareevernecessaryorassistance

isrequired,contactanauthorizedT orodistributor.

•Toensureoptimumperformanceandsafety,

alwayspurchasegenuineTororeplacement

partsandaccessories.Replacementpartsand

accessoriesmadebyothermanufacturerscould

bedangerous.Alteringthismachineinany

mannermayaffecttheoperationofthemachine,

performance,durability,oritsusemayresultin

injuryordeath.Suchusecouldvoidtheproduct

warrantyofTheToro®Company.

PreparingtheMachinefor Maintenance

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Emptyandraisethecargobed;referto

OperatingtheCargoBed(page20).

29

Page 30

LiftingtheMachine

DANGER

Themachinemaybeunstablewhenusing

ajack.Themachinecouldslipoffthejack,

injuringanyonebeneathit.

•Donotstartthemachinewhilethemachine

isonajack.

•Alwaysremovethekeyfromthekeyswitch

beforegettingoffthemachine.

•Blockthetireswhenthemachineis

supportedbyliftingequipment.

•Usejackstandstosupportthemachine

onceyouhaveliftedit.

Important:Wheneveryourunthemachinefor

routinemaintenanceand/ordiagnostics,ensure

thattherearwheelsofthemachineare25mm(1

inch)offtheground,withtherearaxlesupported

onjackstands.

•Theliftingpointatthefrontofthemachineis

locatedatthefrontoftheframe,behindthetowing

tongue(Figure23).

g034044

Figure24

1.Rearliftingpoints

AccessingtheHood

RaisingtheHood

1.Liftupthehandleoftherubberlatchesoneach

sideofthehood(Figure25).

Figure23

1.Frontliftingpoint

•Theliftingpointattherearofthemachineis

locatedundertheaxletubes(Figure24).

g034043

g034045

Figure25

2.Raisethehood.

ClosingtheHood

1.Gentlylowerthehood.

2.Securethehoodbyaligningtherubberlatches

ontothelatchanchorsoneachsideofthehood

(Figure25).

30

Page 31

RaisingandLoweringthe SeatAssembly

Toraisetheseatassembly,pushtheseatassembly

forwarduntilitrestsonthesteeringwheel(Figure26).

Tolowertheseatassembly,pushtheseatassembly

rearwarduntilitseatsbackintotheoriginalposition

(Figure26).

g190187

Figure27

1.Pins

InstallingtheSeat Assembly

Slidetheseatassemblyontothepinsandlowerthe

seatassembly(Figure28).

Figure26

RemovingtheSeat Assembly

1.Pushtheseatassemblyforwardtotheraised

position(Figure26).

2.Slidetheseatassemblytothesideoutofthe

pins,andlifttheseatassemblyupward(Figure

27).

g190066

g190186

Figure28

1.Pins

31

Page 32

Lubrication

GreasingtheFrontWheel Bearings

GreasingtheMachine

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Greasethebearings

andbushings.Greasethemachine

morefrequentlywhenusingitfor

heavy-dutyoperations.

GreaseType:No.2lithiumgrease

1.Usearagtowipethegreasettingcleansothat

foreignmattercannotbeforcedintothebearing

orbushing.

2.Withagreasegun,apply1or2pumpsofgrease

intothegreasettingsonthemachine.

3.Wipetheexcessgreaseoffthemachine.

Thegreasettingsarelocatedattheinnerendofthe

controlarms,thetie-rodballjoint,andtheouterend

ofthecontrolarms(Figure29andFigure30).

ServiceInterval:Every300hours

Greasespecication:MobilgreaseXHP™-222

RemovingtheHubandRotor

1.Liftthefrontofthemachineandsupportitwith

jackstands.

2.Removethe4lugnutsthatsecurethewheel

tothehub(Figure31).

g033046

Figure31

Figure29

Figure30

1.Hub3.Lugnut

2.Wheel

3.Removetheange-headbolts(3/8x3/4inch)

g034057

thatsecurethebracketforthebrakeassembly

tothespindleandseparatethebrakefromthe

spindle(Figure32).

Note:Supportthebrakeassemblybefore

proceedingtothenextstep.

g034058

32

Page 33

Figure34

g192347

Figure32

1.Flange-headbolts(3/8x

3/4inch)

2.Spindle

3.Caliperbracket(brake

assembly)

4.Removethedustcapfromthehub(Figure33).

Figure33

1.Cotterpin4.Spindlenut

2.Spindle

3.Tabwasher6.Dustcap

5.Nutretainer

1.Spindle

g033047

2.Hubandrotorassembly

7.Wipecleanthespindlewitharag.

8.Repeatsteps1through7tothehubandrotorat

theothersideofthemachine.

g192346

5.Removethecotterpinandnutretainerfromthe

spindleandspindlenut(Figure33).

6.Removethespindlenutfromthespindle,and

separatethehubandrotorassemblyfromthe

spindle(Figure33andFigure34).

33

Page 34

GreasingtheWheelBearings

InstallingtheHubandRotor

1.Removetheoutboardbearingandbearingrace

fromthehub(Figure35).

Figure35

1.Seal4.Bearingcavity(hub)

2.Inboardbearing

3.Inboard-bearingrace

5.Outboard-bearingrace

6.Outboardbearing

2.Removetheseal,inboardbearingfromthehub

(Figure35).

3.Wipecleanthesealandcheckforwearand

damage.

1.Applyalightcoatofthespeciedgreasetothe

spindle(Figure36).

g192344

Figure36

g033050

1.Nutretainer

2.Spindlenut

3.Tabwasher

4.Outerbearing

5.Hub,rotor,innerbearing,

race,andseal

6.Spindle

2.Assemblethehubandrotorontothespindle

withtherotorinboard(Figure36).

3.Assembletheoutboardbearingontothespindle

andseatthebearingtotheoutboardrace

(Figure36).

Note:Donotusecleaningsolventtocleanthe

seal.Replacethesealifitiswornordamaged.

4.Cleanthebearingsandraces,andcheckthese

partsforwearanddamage.

Note:Replaceallwornordamagedparts.

Ensurethatthebearingsandracesareclean

anddry.

5.Cleanthecavityofthehubofallgrease,dirt,

anddebris(Figure35).

6.Packthebearingswiththespeciedgrease.

7.Fillthecavityofhub50to80%fullofthe

speciedgrease(Figure35).

8.Assembletheinboardbearingontotheraceat

theinboardsideofthehubandinstalltheseal

(Figure35).

9.Repeatsteps1through8tothebearingsforthe

otherhub.

4.Assemblethetabwasherontothespindle

(Figure36).

5.Threadthespindlenutontothespindleand

tightenthenutwhilerotatingthehub(Figure36).

Note:Tightenthenutandrotatethespindle

untilthebearingsarefullyseatedandthehub

hasnolinear-endmovement.

6.Loosenthespindlenutuntilthehubrotates

freely.

7.Torquethespindlenutto170N∙cm(15in-lb)

whilerotatingthehub.

8.Installtheretaineroverthenutandcheckthe

alignmentoftheslotintheretainerandthehole

inthespindleforthecotterpin(Figure37).

Note:Iftheslotintheretainerandtheholein

thespindlearenotaligned,tightenthespindle

nuttoaligntheslotandholetoamaximum

torqueof226N∙cm(20in-lb)onthenut.

34

Page 35

Figure37

1.Cotterpin

2.Nutretainer

9.Installthecotterpinandbendeachlegsaround

theretainer(Figure37).

10.Installthedustcapontothehub(Figure37).

11.Repeatsteps1through10forthehubandrotor

attheothersideofthemachine.

3.Dustcap

EngineMaintenance

EngineSafety

•Shutofftheengine,removethekey,andwaitfor

allmovingpartstostopbeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawayfromthemuferandotherhot

surfaces.

g192345

ServicingtheAirCleaner

ServiceInterval:Every100hoursReplacethe

air-lterelementsoonerifdirtyor

damaged.

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy.

ServicingtheAir-CleanerCover

InstallingtheBrakesandWheels

1.Cleanthe2ange-headbolts(3/8x3/4inch)

andapplyacoatofanti-seizecompoundtothe

threadsofthebolts.

2.Alignthebrakepadstoeithersideoftherotor

(Figure32)andtheholesinthecaliperbracket

withtheholesinthebrakemountofthespindle

frame(Figure36).

3.Assemblethecaliperbrackettothespindle

frame(Figure32)withthe2ange-headbolts

(3/8x3/4inch),andtorquetheboltsto47to54

N∙m(35to40ft-lb).

4.Aligntheholesinthewheeltothestudsofthe

hubandassemblethewheeltothehubwiththe

valvestemoutward(Figure31).

Note:Ensurethatthemountingsurfaceofthe

wheelisushwiththehub.

5.Securethewheeltothehubwiththelugnuts

(Figure31),andtorquethenutsto108to122

N∙m(80to90ft-lb).

6.Repeatsteps1through5forthebrakeand

wheelattheothersideofthemachine.

ServiceInterval:Every50hours—Removethe

air-cleanercoverandcleanoutthe

debris.Donotremovethelter.

Every50hours

Checktheair-cleanerbodyfordamagewhichcould

causeanairleak.Replaceadamagedair-cleaner

body.

Cleantheair-cleanercoverandremovethedebris

fromthedustcapasshowninFigure38.

35

Page 36

4.Installtheair-cleanercoverwiththeside

indicatedas“UP”facingupwardandsecurethe

latches(Figure39).

Figure38

ServicingtheAirFilter

ServiceInterval:Every100hours(morefrequentlyin

extremedustyordirtyconditions).

1.Gentlyslidetheairlteroutoftheair-cleaner

body(Figure39).

Note:Avoidknockingtheairlterintotheside

ofthebody.

Important:Donotattempttocleantheair

lter.

2.Inspectthenewlterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.

Note:Holesinthelterappearasbright

spots.Inspecttheelementfortears,anoily

lm,ordamagetotherubberseal.Ifthelteris

damaged,donotuseit.

g236567

g034313

Figure39

3.Carefullyslidetheairlterintotheairlter

housing.

Important:Donotpressonthesoftinside

areaofthelter.

36

Page 37

ServicingtheEngineOil

ServiceInterval:Aftertherst5hours

Every100hours(Changetheoiltwiceas

oftenduringspecialoperatingconditions;refer

toMaintainingtheMachineunderSpecial

OperatingConditions(page28)).

Note:Changetheoilmorefrequentlywhenoperating

conditionsareextremelydustyorsandy .

Note:Disposeoftheusedengineoilandoillterata

certiedrecyclingcenter.

Engine-OilSpecications

CrankcaseCapacity:1.0L(1.1USqt)

OilType:APIserviceclassSJorhigherdetergentoil

Viscosity:Seethetablebelow.

g192771

Figure41

Figure40

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Themachineisshippedwithoilinthe

crankcase;however,checktheoilbeforeandafter

youstarttheengine.

Note:Thebesttimetochecktheengineoiliswhen

theengineiscoolbeforeithasbeenstartedforthe

day.Ifyouhavealreadyruntheengine,allowtheoil

todrainbackdowntothesumpforatleast10minutes

beforechecking.Iftheoillevelislow,addoiltobring

theoilleveltotheFullmark.Donotoverll.

Checktheengine-oillevelasshowninFigure41.

g034082

37

Page 38

ChangingtheEngineOil

1.Startthemachineandlettheenginerunfora

fewminutes.

2.Parkthemachineonalevelsurface.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Raisethecargoboxandsecureitwiththe

proprod;refertoRaisingtheCargoBedtothe

ServicePosition(page21).

6.ChangetheengineoilasshowninFigure42.

ServicingtheSparkPlug

CheckingandReplacingtheSpark Plug

ServiceInterval:Every100hours/Yearly(whichever

comesrst)Replacethesparkplug

ifnecessary.

CarburetorModelSparkPlugType:Champion

XC12YC

EFIModelSparkPlugType:ChampionRC12LC4

AirGap:0.76mm(0.03inch)

Important:Youmustreplaceacracked,fouled,

dirty,ormalfunctioningsparkplug.Donot

sand-blast,scrape,orcleanelectrodesbyusing

awirebrushbecausegritmayeventuallyrelease

fromtheplugandfallintothecylinder.Theresult

isusuallyadamagedengine.

Note:Thesparkplugusuallylastsalongtime;

however,theplugshouldberemovedandchecked

whenevertheenginemalfunctions.

1.Cleantheareaaroundthesparkplugsothat

foreignmattercannotfallintothecylinderwhen

youremovethesparkplug.

2.Pullthewireofftheterminalofthesparkplug.

3.Removetheplugfromthecylinderhead.

4.Checktheconditionofthesideelectrode,center

electrode,andcenterelectrodeinsulatorto

ensurethatthereisnodamage(Figure43).

Figure42

Note:Donotuseadamagedorwornspark

plug.Replaceitwithanewsparkplugofthe

speciedtype.

g192770

g001470

Figure43

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

5.Settheairgapbetweenthecenterandsideof

theelectrodesat0.76mm(0.03inch)asshown

inFigure43.

38

Page 39

6.Installthesparkplugintothecylinderhead,and

torquetheplugto27N∙m(20ft-lb).

FuelSystem

7.Installthespark-plugwire.

8.Repeatsteps1through7fortheotherspark

plug.

AdjustingtheHigh/LowIdle

1.Liftthecargobedandsecureitwiththeproprod.

2.Atthethrottlecablehousing,loosentheforward

jamnutandtightentherearjamnuttoincrease

thelowidle(Figure44).

Maintenance

InspectingFuelLinesand Connections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellines,ttings,andclampsforsignsof

leaking,deterioration,damage,orlooseconnections.

Note:Repairanydamagedorleakingfuelsystem

componentbeforeusingthemachine.

ReplacingtheFuelFilter

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

Figure44

1.Throttlecablehousing3.Throttlelever

2.Jamnuts

3.T estthehighidlewithatachometer:

A.EnsurethattheshiftleverisintheNEUTRAL

position.

B.Starttheengine.

C.Fullydepresstheacceleratorpedal

andmeasuretheenginespeedwitha

tachometer;theenginespeedshouldbe

between3650to3750rpm.Ifitkisnot,shut

offtheengineandadjustthecablejamnuts.

Important:Donotlowerthehighidle.

Testwithatachometertoensurethatthe

highidleisbetween3650to3750rpm.

4.Lowerandsecurethecargobed.

4.Raisethebedandsupportitwiththeproprod;

refertoRaisingtheCargoBedtotheDump

g229954

Position(page20).

5.Disconnectthebattery;refertoDisconnecting

theBattery(page41).

6.Placeacleancontainerunderthefuellterand

replacethefuellterasshowninFigure45.

39

Page 40

ServicingtheCarbon Canister

CheckingtheAirFilterforthe CarbonCanister

ServiceInterval:Aftertherst50hours

Every200hours

Checktheopeningatthebottomoftheairlterforthe

carboncanistertoensurethatitiscleanandfreeof

debrisandobstructions(Figure46).

Cleantheairlterforthecarboncanisterwithclean,

compressedair.

Figure45

7.Connectthebattery,andlowerthecargobed;

refertoConnectingtheBattery(page43)and

LoweringtheCargoBed(page21).

g029685

Figure46

LocatedBeneaththeDriver’sSeat

1.Air-lteropening

g034099

40

Page 41

ElectricalSystem

DisconnectingtheBattery

Maintenance

ElectricalSystemSafety

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

WARNING

Incorrectbatterycableroutingcoulddamage

themachineandcables,causingsparks.

Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysreconnectthepositive(red)battery

cablebeforereconnectingthenegative

(black)cable.

•Alwayskeepthebatterystrapinplaceto

protectandsecurethebattery.

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Batteryvoltage:12Vwith300A(cold-cranking)at

-18°C(0°F).

•Alwayskeepthebatterycleanandfullycharged.

•Ifthebatteryterminalsarecorroded,cleanthem

withasolutionof4partswaterand1partbaking

soda.

•Applyalightcoatingofgreasetothebattery

terminalstopreventcorrosion.

DisconnectthebatteryasshowninFigure47.

g034311

Figure47

41

Page 42

RemovingtheBattery

InstallingtheBattery

1.Disconnectthebatterycables;referto

DisconnectingtheBattery(page41).

2.RemovethebatteryasshowninFigure48.

1.InstallthebatteryasshowninFigure49.

Figure48

g034327

Figure49

g034326

2.Connectthebatterycables;refertoConnecting

theBattery(page43).

42

Page 43

ConnectingtheBattery

ReplacingtheFuses

ConnectthebatteryasshowninFigure50.

Figure50

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Thereare4fusesintheelectricalsystem.Theyare

locatedbeneaththeseatassembly(Figure51).

Note:Ifyouinstalltheoptionalliftkit,youwillreceive

anotherfuseblocktoinstallnexttothefuseblock

installedcurrently.

Horn30A

Mainpower15A

Headlights10A

USBpowerpoint/options

g034315

Optionalliftkit(open—extra

fuseblockcomeswithkit)

10A

15A

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery .

Important:Alwayskeepthebatteryfullycharged

(1.260specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page42).

2.Connecta3to4Abatterychargertothebattery

posts.Chargethebatteryatarateof3to4A

for4to8hours(12V).

Note:Donotoverchargethebattery .

3.Installthebatteryinthechassis;referto

InstallingtheBattery(page42).

StoringtheBattery

Ifyoustorethemachineformorethan30days,

removethebatteryandchargeitfully.Eitherstore

itontheshelforonthemachine.Leavethecables

disconnectedifitisstoredonthemachine.Store

thebatteryinacoolatmospheretoavoidquick

deteriorationofthechargeinthebattery.T oprevent

thebatteryfromfreezing,makesureitisfullycharged.

1.Groundblock

g034618

Figure51

2.Fuseblock

43

Page 44

MaintainingtheHeadlights

withtheslotsintheheadlighthousing(Figure

52).

ReplacingtheBulbs

CAUTION

Ifyouinstallahigherwattagebulbthanthe

systemisdesignedfor,youmayblowthe

fuse.

AlwaysusethespeciedToroLEDbulbto

preventthisissue.

CAUTION

Thebulbsbecomeextremelyhotwhenin

operation.Handlingahotbulbcancause

severeburnsandpersonalinjury.

Alwaysallowenoughtimeforthebulbs

tocoolbeforereplacingthem.Usecare

wheneverhandlingthebulb.

Specication:SeeyourPartsCatalog.

1.Disconnectthebattery;refertoDisconnecting

theBattery(page41).

6.Securelampassemblybyturningit1/4turn

clockwise(Figure52).

7.Connecttheelectricalconnectorfortheharness

totheconnectorofthenewlampassembly

(Figure52).

8.Connectthebatteryandclosethehood;referto

ConnectingtheBattery(page43).

ReplacingtheHeadlight

1.Disconnectthebattery;refertoDisconnecting

theBattery(page41).

2.Openthehood;refertoRaisingtheHood(page

30).

3.Disconnecttheelectricalconnectorforthe

harnessfromtheconnectorofthelamp

assembly(Figure53).

2.Openthehood;refertoRaisingtheHood(page

30).

3.Disconnecttheelectricalconnectorforthe

harnessfromtheconnectorofthelamp

assemblyatthebackoftheheadlighthousing

(Figure52).

Figure52

1.Headlighthousing3.Harness-electrical

connector

2.Lampassembly

4.Rotatethelampassembly1/4turn

counterclockwiseandmovingitrearward,

outoftheheadlighthousing(Figure52).

5.Insertthenewlampassemblyandheadlight

housingandalignthetabsinthelampassembly

g035853

Figure53

1.Speedclip

2.Openinginthebumper

3.Adjustmentscrew6.Harness-electrical

g035852

4.Removethespeedclipsthatsecurethe

headlighttotheheadlightbracket(Figure53).

4.Headlight

5.Lampassembly

connector

Note:Retainallpartsforinstallationofthenew

headlight.

5.Removetheheadlightassemblybymovingit

forwardthroughtheopeninginthefrontbumper

(Figure53).

6.Installthenewheadlightthroughtheopeningin

thebumper(Figure53).

44

Page 45

Note:Ensuretheadjustmentpostsarelinedup

withtheholesinthemountingbracketbehind

thebumper.

7.Securetheheadlightassemblywiththespeed

clipsthatyouremovedinstep4.

8.Connecttheelectricalconnectorfortheharness

totheconnectorofthelampassembly(Figure

53).

9.Adjusttheheadlightstodirectthebeamsto

thedesiredposition,refertoAdjustingthe

Headlights(page45).

AdjustingtheHeadlights

Usethefollowingproceduretoadjusttheheadlight

beampositionwheneveraheadlightassemblyis

replacedorremoved.

1.TurnthekeyswitchtotheONposition,andturn

ontheheadlights.

2.Atthebackoftheheadlightassembly ,rotate

adjustmentscrews(Figure53)topivotthe

headlightassemblyandalignthepositionofthe

castbeam.

3.Connectthebatteryandclosethehood;referto

ConnectingtheBattery(page43).

DriveSystem

Maintenance

MaintainingtheTires

ServiceInterval:Every100hours—Checkthe

conditionofthetiresandrims.

Every100hours—Torquethewheellugnuts.

1.Inspectthetiresanrimsforsignsofwearand

damage.

Note:Operatingaccidents,suchashitting

curbs,candamageatireorrimandalsodisrupt

wheelalignment,soinspecttireconditionafter

anaccident.

2.T orquethewheellugnutsto108to122N∙m(80

to90ft-lb).

AdjustingtheFrontWheel Alignment

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthefrontwheel

camberandtoe-in.

PreparingtoAdjustCamberor Toe-in

1.Checkthetirepressuretoensurethatthefront

tiresareinatedto82kPa(12psi).

2.Eitheraddweighttothedriver'sseatequalto

theaverageoperatorwhowillrunthemachine,

orhaveanoperatorsitontheseat.Theweight

oroperatormustremainontheseatforthe

durationoftheadjustmentprocedure.

3.Onalevelsurface,rollthemachinestraightback

2to3m(6to10ft)andthenstraightforward

totheoriginalstartingposition.Thisallowsthe

suspensiontosettleintotheoperatingposition.

AdjustingtheCamber

Ownerprovidedtools:spannerwrench,ToroPart

No.132-5069;refertoyourauthorizedT orodistributor.

Important:Makethecamberadjustmentsonly

ifyouareusingafrontattachmentorifthereis

uneventirewear.

1.Checkthecamberalignmentateachwheel;the

alignmentshouldbeasclosetoneutral(zero)

aspossible.

Note:Thetiresshouldbealignedwiththetread