Page 1

FORM NO. 3323-316

Wheel Horse Lawn Tractor

Model No. 71197—200000001 & Up

Set-Up

Instructions

Loose Parts

Note: Use the chart below to verify all parts have been shipped.

DESCRIPTION QTY. USE

Bolt 1/4-20 x 3/4”

Wing nut

Spring Hook 1 Used to install lift assist spring.

Key 2 Use in ignition and Key Choice switches.

Operator’s Manual

Engine Operator’s Manual

Safety Booklet

Safety Video

Registration Card 1 Fill out and mail the card.

2

Install battery cables.

2

1

1

Read and watch before operating tractor.

1

1

Printed in USA

The TORO Company – 1999

All Rights Reserved

Page 2

Set-Up Instructions

Check Tire Pressure

Check front and rear tires for proper inflation. Refer

to the Operator’s Manual, Maintenance Section under

Tire Pressure for recommended inflation pressure.

Activate the Battery

Bulk electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet.

1. Remove the battery and battery box from the

tractor: refer to Operator’s Manual, Removing

the Battery.

IMPORTANT: Be careful not to damage the

long vent tube when removing the battery

box.

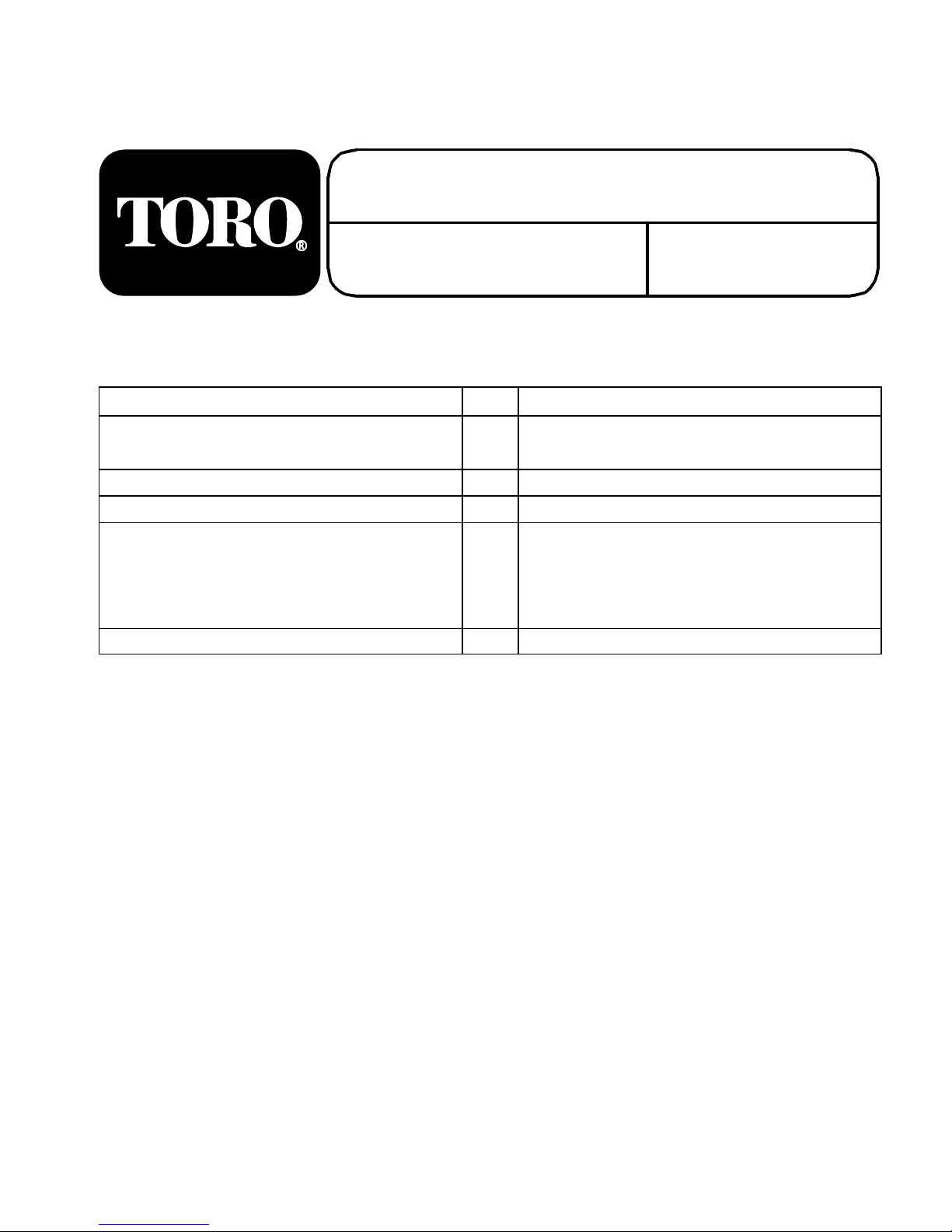

2

3

1

Figure 1

1. Filler caps

2. Electrolyte

3. Upper line

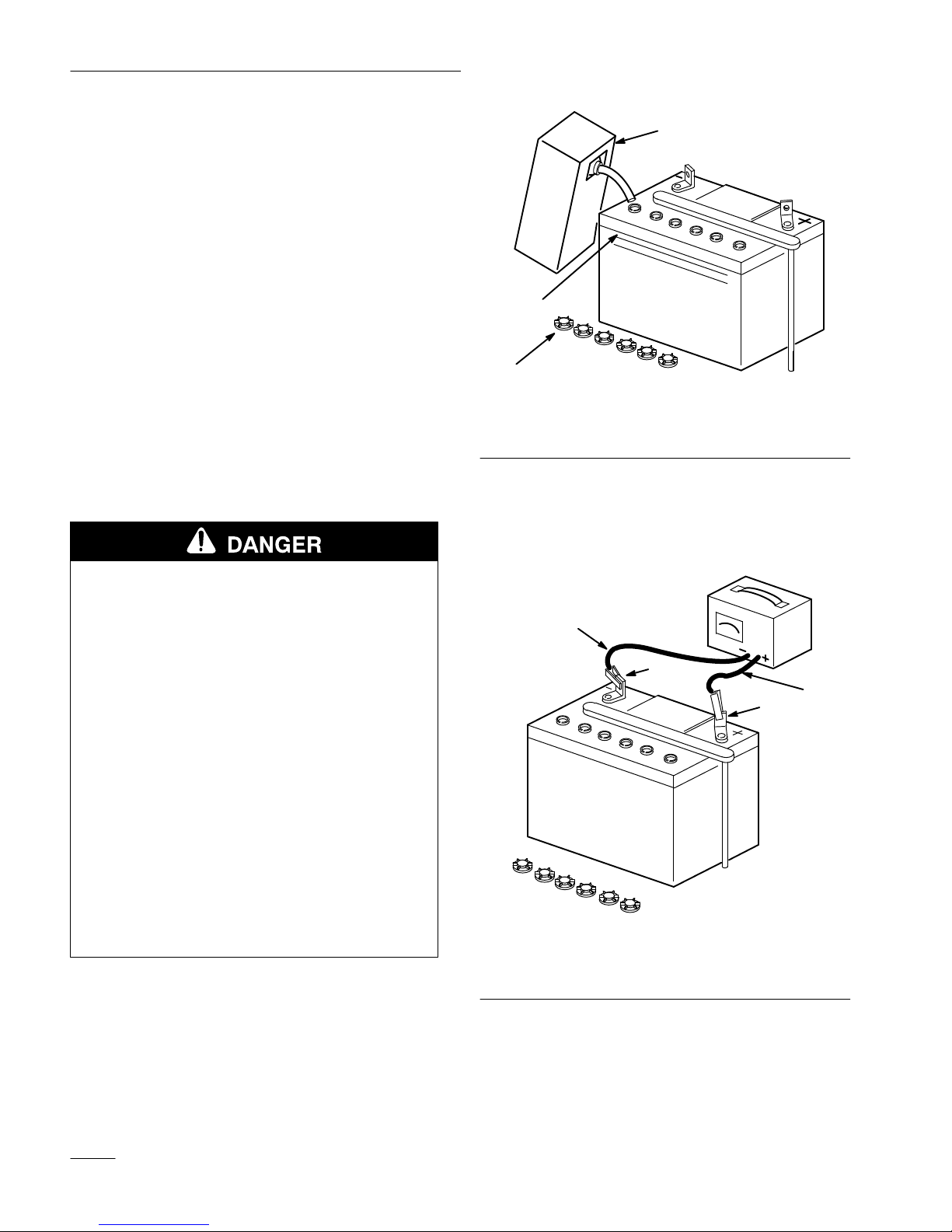

3. Leave the filler caps off and connect a 3 to 4

amp battery charger to the battery posts (Fig. 2).

Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

POTENTIAL HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

WHAT CAN HAPPEN

• If you carelessly drink electrolyte you could

die or if it gets onto your skin you will be

burned.

HOW TO AVOID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

2. Unscrew six filler caps from the battery. Slowly

pour electrolyte into each cell until the level is

up to the “UPPER” line on the battery case

(Fig. 1).

1. Positive post

2. Negative post

4

2

3

1

Figure 2

3. Charger red (+) wire

4. Charger black (–) wire

2

Page 3

Set-Up Instructions

Check Safety System

POTENTIAL HAZARD

• Charging battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

4. When the battery is fully charged, disconnect the

charger from the electrical outlet and from the

negative and positive battery posts (Fig. 2).

5. Slowly pour electrolyte into each cell until the

level is once again up to the “UPPER” line on

the battery case (Fig. 1).

6. Install the battery and battery box in the tractor:

refer to the Operator’s Manual, Installing the

Battery.

Refer to the Operator’s Manual, Checking Safety

System.

Purge Hydro Transaxle

During handling and shipping air can be introduced

into the hydro transaxle. To achieve proper

performance all trapped air must be removed.

1. Place tractor on a flat level surface.

2. Place the drive control, under rear frame. to the

“Push” position (Fig. 3).

1

Fill Crankcase with Oil

The tractor is shipped from the factory without oil in

the engine crankcase: refer to the Operator’s Manual,

Engine Oil Specifications for oil type, viscosity, and

crankcase capacity. Only add about 80% of the

specified amount of oil. Then check the oil level and

add only enough oil to raise the level to the “FULL”

mark on the dipstick.

Lubricate the Tractor

Refer to the Operator’s Manual, Greasing and

Lubrication.

Insert Keys into Ignition and

Key Choice Switches

The “Key Choice” switch is located on the seat

bracket in front of and below the seat. Refer to

Operator’s Manual, Operation Section.

2

Figure 3

1. Operate position 2. Push position

3. Run engine at a low idle and move traction

control pedal forward for five (5) seconds then

reverse for five (5) seconds. Repeat three (3)

times.

4. Place the drive control in the “Operate” position

(Fig. 3). Drive the tractor forward then reverse

approximately five (5) feet. Repeat three (3)

times.

1791

3

Page 4

Set-Up Instructions

Check Hydro Neutral Position

Adjustment is required if the tractor creeps without

the traction control pedal being depressed.

1. Run engine at a low idle and move traction

control pedal forward, then release. Move

traction control pedal reverse, then release. If the

tractor creeps adjust as follows:

2. Raise the rear wheels off the ground and support

with jackstands.

3. Loosen locknut securing adjustment (Fig. 4).

4. Move adjustment stud up or down until creep is

minimized (Fig. 4). There may still be some

wheel rotation with wheels off the ground.

5. Tighten the locknut (Fig. 4). Move the traction

control pedal forward and reverse and allow it to

center. Verify that there is no creep with the

wheels on the ground.

Check Traction Control Pedal

After adjusting the hydro neutral position it is

necessary to check the traction control pedal. Shut the

engine off. Press the control pedal full forward and

full reverse. The transaxle linkage must contact the

stop(s) before the control pedal hits the footrest pad

(Fig. 5). If contact is made with the foot pad, before

hitting stop(s) on transaxle, in either forward or

reverse directions, adjustment is required.

1. Loosen the capscrews below the right footrest.

Slide the pedal in the slots away from the

direction that made contact with the footrest

(Fig. 5).

2. Tighten capscrews and recheck traction control

pedal for contact with stop(s) on the transaxle

and footrest.

1

1

2

2

2

Figure 4

1. Locknut

2. Stop

1. Traction control pedal 2. Adjusting capscrews

1673

Test Drive the Tractor

Figure 5

Make sure all electrical and mechanical systems are

operating properly.

4

Loading...

Loading...