Page 1

FormNo.3425-850RevC

VersaVac

ModelNo.07053—SerialNo.403360001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3425-850*C

Page 2

ThisproductcomplieswithallrelevantEuropean

directives.Fordetails,pleaseseetheseparate

productspecicDeclarationofConformity(DOC)

sheet.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

TheVersaVacistobeusedinconjunctionwiththe

combinationdeckorngerdeck.Themachineis

intendedtobeusedbyprofessional,hiredoperators

incommercialapplications.Themachineisdesigned

todethatch,renovate,andremovedebrisfromlarge

turfareasin1pass.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure1),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure1

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................3

Setup........................................................................6

1ConnectingtheMachinetotheTraction

Unit.................................................................7

2AdjustingthePTOShaftLength.......................7

3ConnectingthePTOShaft...............................7

4GreasingtheMachine......................................8

ProductOverview.....................................................8

Controls.............................................................8

BeforeOperation...................................................9

BeforeOperationSafety.....................................9

HydraulicFluidSpecications...........................10

CheckingtheHydraulicFluid.............................11

CheckingtheTirePressure................................11

CheckingtheT orqueoftheWheel

Nuts...............................................................11

ConnectingtheMachinetotheTraction

Unit................................................................11

ConnectingthePTOShaft................................12

DuringOperation.................................................13

DuringOperationSafety...................................13

OperatingtheTractionUnitHydraulics..............14

OperatingtheMachine.....................................14

AfterOperation....................................................15

AfterOperationSafety......................................15

RemovingtheMachinefromtheTraction

Unit...............................................................15

TransportingtheMachine.................................15

Maintenance...........................................................16

RecommendedMaintenanceSchedule(s)...........16

MaintenanceSafety..........................................16

LubricatingtheMachine....................................17

HydraulicSystemSafety...................................17

CheckingtheHydraulicLinesand

Hoses............................................................18

ServicingtheHydraulicFluidandFilter.............18

Storage...................................................................20

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeusingthemachine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themachine.

•Keepchildren,bystanders,andpetsoutofthe

operatingarea.Neverallowchildrentooperate

themachine.

•Alwaysshutofftheengineofthetractionunit,

removethekey(ifequipped),waitforallmoving

partstostop,andallowthemachinetocool

beforeadjusting,servicing,cleaning,orstoring

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

,which

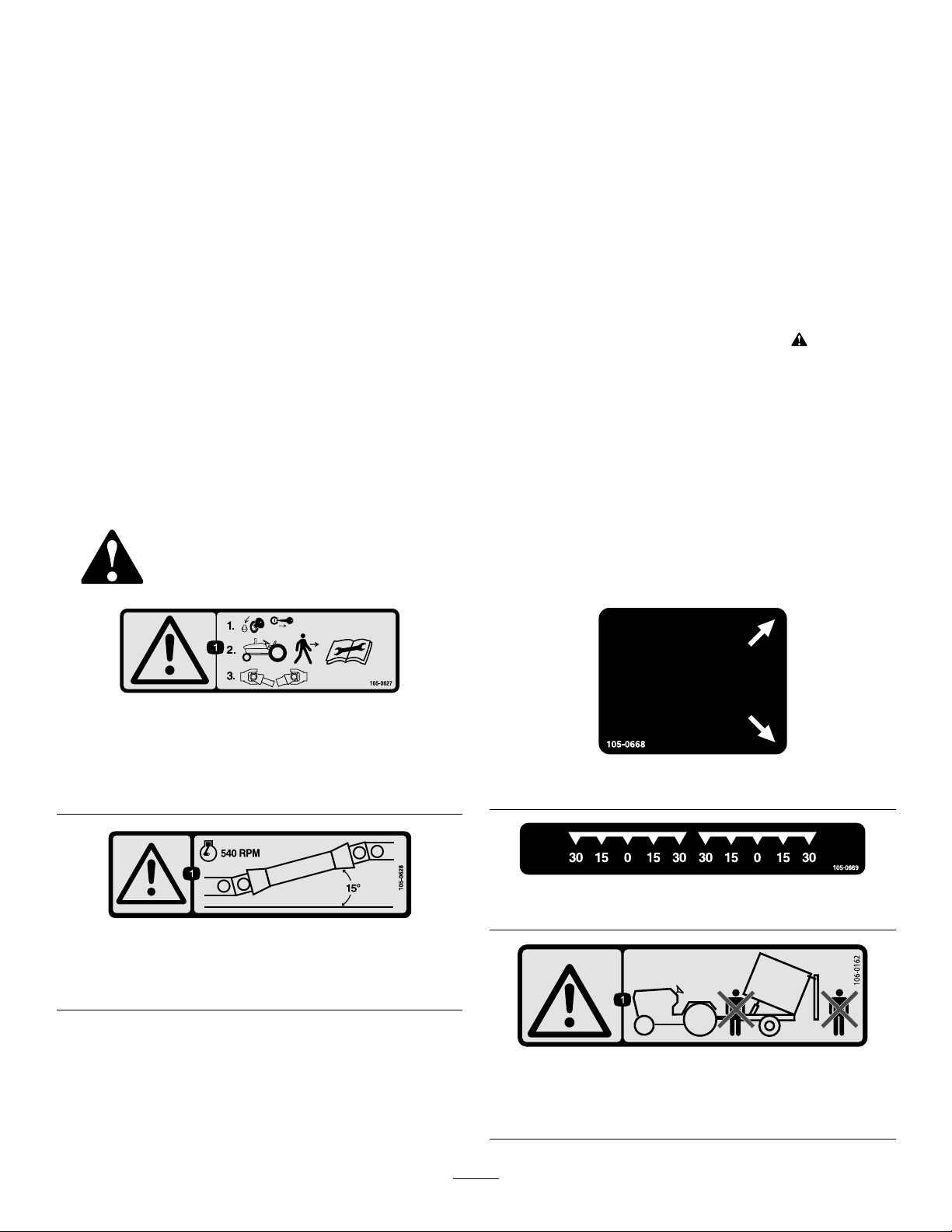

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

105-0627

1.Warning—stoptheengineandremovetheignitionkey

beforegettingoffofthetractor;readtheinstructionsbefore

servicingorperformingmaintenance,thendisconnectthe

PTOshaft.

105-0628

decal105-0627

decal105-0668

105-0668

decal105-0669

105-0669

decal105-0628

1.Warning—runtheengineatnomorethan540rpmand

keepthePTOshaftangleunder15degrees.

decal106-0162

106-0162

1.Warning—donotstandinfrontoforbehindthetrailerwhen

dumping.

3

Page 4

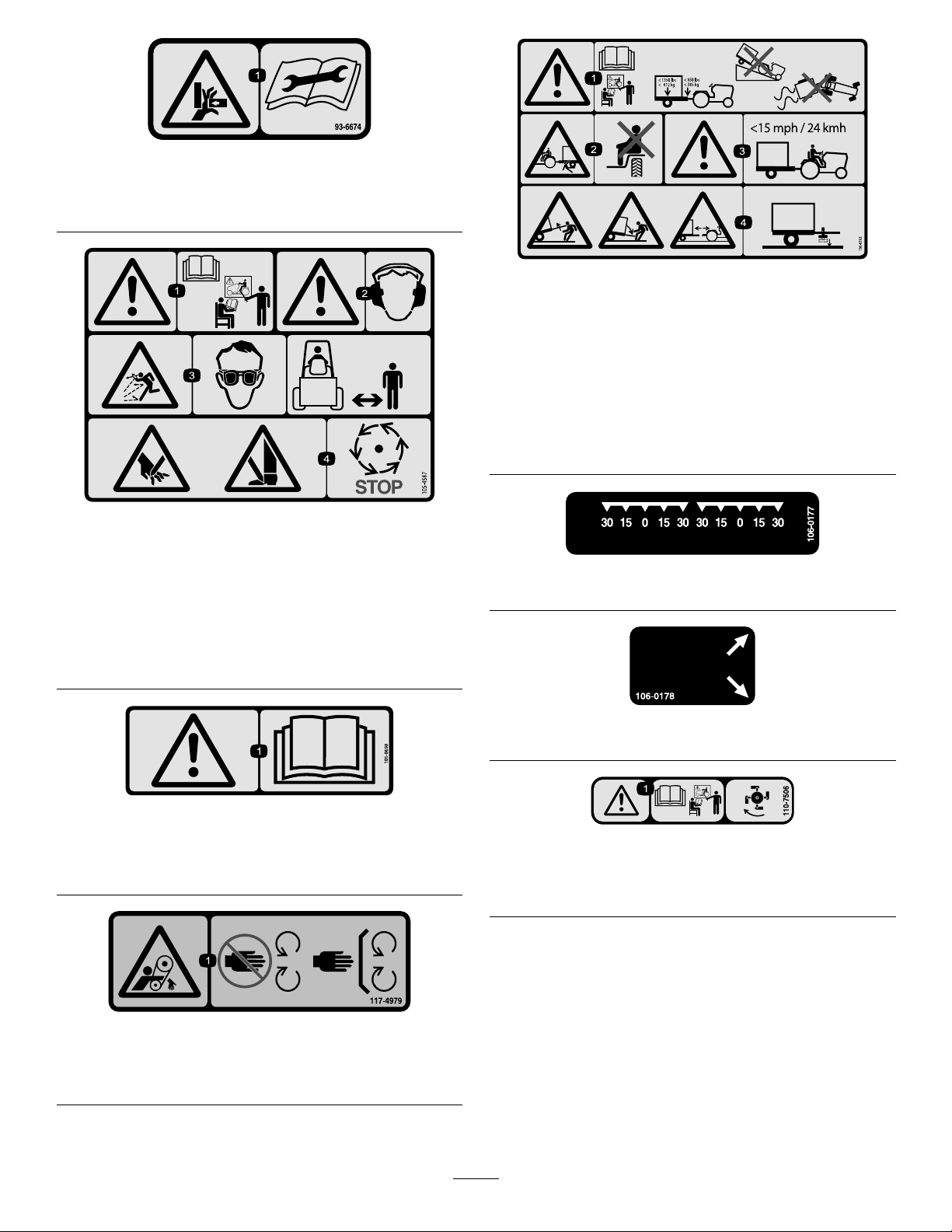

93-6674

1.Crushinghazard,hand—readtheinstructionsbefore

servicingorperformingmaintenance.

105-4587

decal93-6674

decal106-0163

106-0163

1.Warning—readtheOperator'sManualandreceivetraining

beforeoperatingthemachine;themaximumloadis612kg

(1350lb)trailerweightand385kg(850lb)tongueweight;

donotdrivethemachineandtrailerdownhilloryoumay

losecontrol.

2.Crushinghazard,trailer—donotcarrypassengers.

3.Warning—donotexceed24km/h(15mph).

4.Storedenergyhazard,trailer—donotdisconnectthetrailer

withoutrstputtingdownthejack.

decal105-4587

1.Warning—readthe

Operator'sManualand

receivetrainingbefore

operatingthemachine.

3.Thrownobject

hazard—weareye

protection;keep

bystandersasafedistance

fromthemachine.

2.Warning—wearhearing

protection.

4.Cuttinghazardofhand

orfoot—waitformoving

partstostop.

105-0698

Applyoverdecal105-0707forCEcompliance

1.Warning—readtheOperator’sManual.

decal106-0177

106-0177

decal106-0178

106-0178

decal105-0698

decal110-7506

110-7506

1.Warning—readtheOperator’sManualandreceivetraining;

beforeoperatingthecombinationdeckail.

117-4979

1.Entanglementhazard,belt—keepawayfrommovingparts;

keepallguardsandshieldsinplace.

decal117-4979

4

Page 5

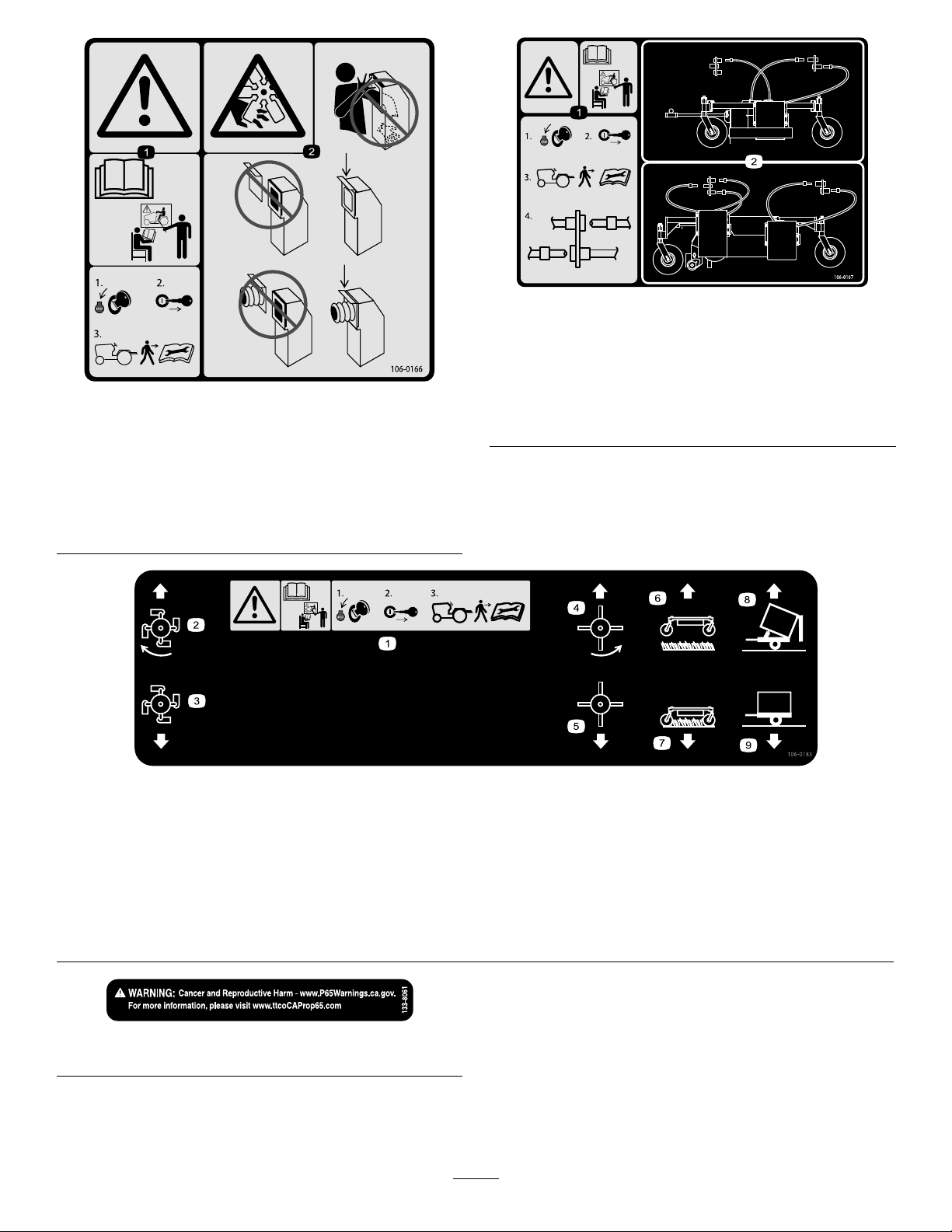

106-0166

1.Warning—readtheandreceivetrainingbeforeoperating

themachine;stoptheengineandremovetheignitionkey

beforegettingoffofthetractor;readtheOperator'sManual

beforeservicingorperformingmaintenance.

2.Cutting/dismembermenthazardofhand,fan—donotplace

yourhandorarminthevacuumchute;keepthehosedoor

orhoseinstalledatalltimes.

decal106-0167

106-0167

1.Warning—readtheandreceivetrainingbeforeoperating

themachine;1)Stoptheengine;2)Removetheignition

keybeforegettingoffofthetractor;3)readtheOperator's

decal106-0166

Manualbeforeservicingorperformingmaintenance;4)

Connectordisconnectthehydraulichoses.

2.Hydraulichoseroutingandconnections.

1.Warning—readtheandreceivetraining

beforeoperatingthemachine;1)Stop

theengineandremovetheignitionkey

beforegettingoffofthetractor;2)Read

theOperator'sManualbeforeservicing

orperformingmaintenance.

2.Flailon

3.Flailoff

133-8061

106-0183

4.Rubberngerson

5.Rubberngersoff

6.Vacuumunitup9.Trailerupright

decal133-8061

7.Vacuumunitdown

8.Trailerdump

5

decal106-0183

Page 6

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Jack1

PTOshaft

Nopartsrequired

Nopartsrequired

MediaandAdditionalParts

Description

Auxiliarycontrollever1

Operator’sManual

DeclarationofConformity

Qty.

Qty.

Connectthemachinetothetraction

units.

1

–

–

Installthecontrolleveronlyifthecombinationdeckis

installed.

1

1

Readbeforeoperatingthemachine.

UseforCEcompliance.

AdjustthePTOshaftlength.

ConnectthePTOshaft.

Greasethemachine.

Use

Use

6

Page 7

CAUTION

Withouttheproperamountofballastinthe

tires,thetractionunitmaybecomeunstable

andcausebodilyinjury.

Makesurethatthefrontofthetractionunitis

equippedwiththeproperamountofballast;

refertothetractionunitOperator’sManualfor

ballastrequirements.

1

ConnectingtheMachineto theTractionUnit

Partsneededforthisprocedure:

1Jack

Procedure

RefertoConnectingtheMachinetotheTractionUnit

(page1 1).

2

AdjustingthePTOShaft Length

Partsneededforthisprocedure:

1

PTOshaft

Procedure

AlongPTOshaftissuppliedwiththemachineto

accommodatetractionunitswithlargerPTOshaft

variations.Formosttractionunits,thisshaftistoo

longandmustbecuttothecorrectlengthordamage

mayresult.

1.Measurethedistancefromthelockgrooveof

thetractionunitPTOshafttothelockgrooveof

themachineimpellerinputshaft.

Note:Recordthisdimension.

2.FullycollapsethePTOshaftandmeasurethe

distancebetweenthelockpincollars.

3.Atitsshortestlength,the2halvesofthePTO

shaftmusthaveatleast37mm(1-1/2inches)of

additionalclearancetocollapse(Figure2).

Note:IfthedimensioninStep1isnotatleast

37mm(1-1/2inches)greaterthanthedimension

inStep2,thePTOshaftistoolong;proceedto

step4.Ifthereisenoughclearancetoallowthe

PTOshafttocollapse,proceedtoStep9.

g027354

Figure2

1.PTOshaft

4.Usethefollowingcalculationtoestablish

howmuchshortertheshaftmustbe,when

connected,toensureaclearanceof37(1-1/2

inches):

A.SubtractthedimensionrecordedinStep2

fromthedimensionrecordedinStep1.

Note:Recordthisdimension.

B.SubtracttheresultinStepAfrom37mm

(1-1/2inches).

Note:ThePTOshaftmustbeshortened

bythisamount.

5.Usingahacksaw,shortentheguardsandthe

steeltubesbythecalculatedlength.

Note:CutbothhalvesofthePTOshaft.

6.Deburrtheendsofthesteeltubesinternallyand

externally.

7.Removealldebrisfromthetubesections.

8.Greasethesteeltubesliberally .

9.AssemblethePTOshaftandsecureittothe

machineandtractionunit.

10.Measuretheshaft;ifitisnotatleast37mm

(1-1/2inches),repeattheprocedure.

Note:Recordthisdimension.

7

Page 8

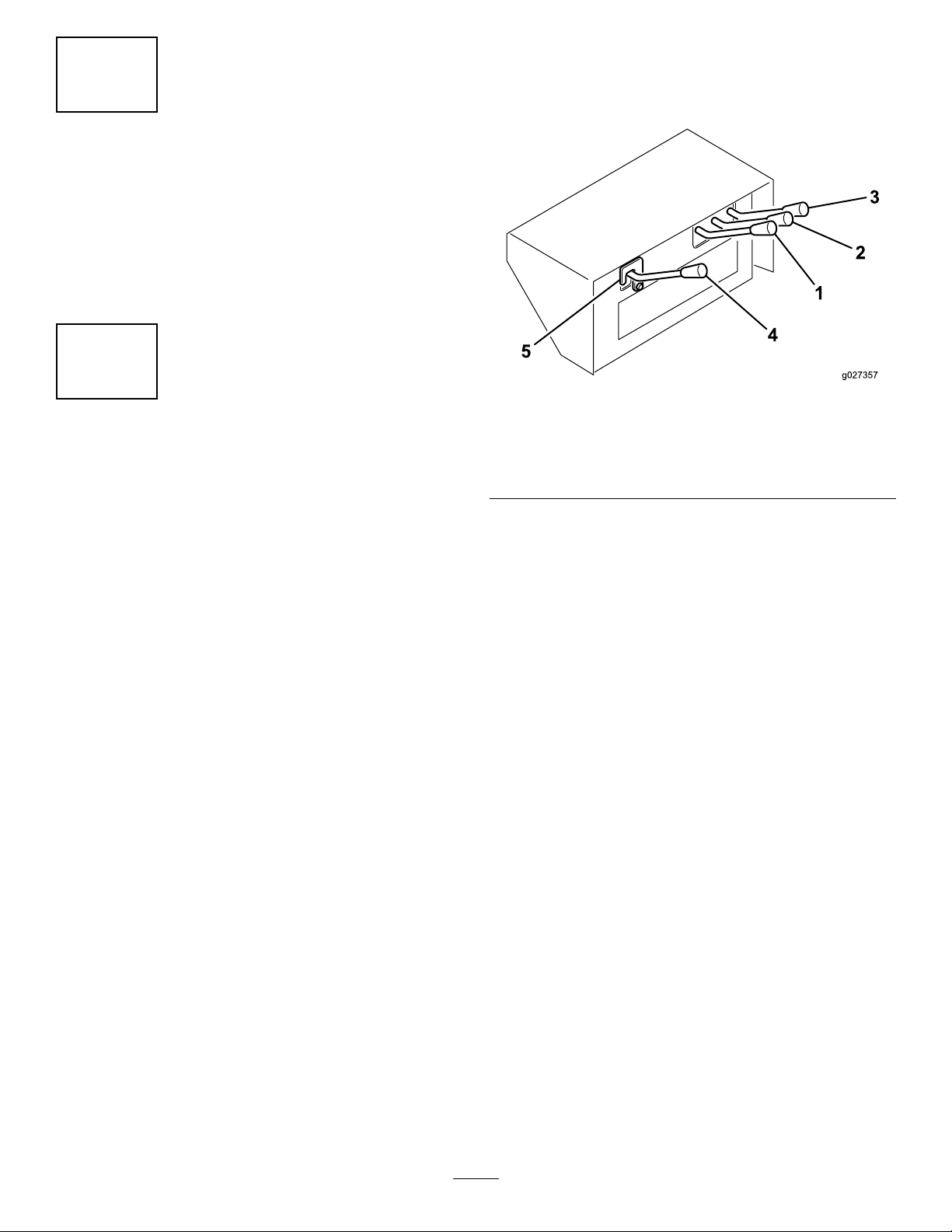

ProductOverview

3

ConnectingthePTOShaft

NoPartsRequired

Procedure

ConnectthePTOshaft;refertoConnectingthePTO

Shaft(page12)

4

GreasingtheMachine

NoPartsRequired

Procedure

Greasethemachine;refertoLubricatingtheMachine

(page17)

Controls

g027357

Figure3

1.Brushcontrol4.Auxiliarycontrol

2.Deckliftcontrol5.Safetylatch

3.Trailerliftcontrol

TrailerLiftControl

Usedtodumpthetrailerbox(Figure3).Theup

positionraisestheboxandopensthedoor,andthe

downpositionlowerstheboxandclosesthedoor.

DeckLiftControl

Usedtoraiseandlowertheprimarydeck(Figure

3).Theuppositionraisesthedeck,andthedown

positionlowersthedeck.

BrushControl

Usedtooperatetherotatingngerdeck(sold

separately).Theuppositionstartsthedeck,andthe

downpositionstopsthedeck(Figure3).

AuxiliaryControl

Usedtooperatethecombinationdeck(sold

separately).Theuppositionstartsthedeck,andthe

downpositionstopsthedeck(Figure3).

Important:Theauxiliarycontrolleverisshipped

loosetopreventaccidentalengagementofthe

unusedhydrauliccircuit.Donotinstalloroperate

theauxiliarycontrolleverunlessthecombination

deckisinstalled.

Toinstalltheauxiliarycontrollever,completethe

followingprocedure:

1.Removethecontrollevercover.

8

Page 9

2.Removethe2cotterpinsfromthecontrolvalve

spool.

Operation

3.Mounttheauxiliarycontrollevertothevalve

spoolwiththecotterpins.

4.Installthecontrollevercover.

SafetyLatch

Onlyremovethesafetylatchwhenoperatingthe

combinationdeck(Figure3).

TractionUnitPTO

Thevacuumfanonthemachinewillrunassoon

asthePTOisengaged(Figure3).Thengerand

combinationdecksareengagedbythehydraulic

controlsonthemachine.

Important:AlwaysengagethetractionunitPTO

gentlyatalowenginespeed.Suddenengagement

ofthetractionunitPTOatahighenginespeedwill

likelycausedamagetothedrivelinecomponents.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

CAUTION

Ifyouleavethekeyinthetractionunitignition

switch,someonecouldaccidentlystartthe

engineandseriouslyinjureyouorother

bystanders.

Removethekeyfromthetractionunitignition

beforeyoudoanymaintenance.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Donotallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Ensurethatallhydrauliclineconnectorsaretight,

andallhydraulichosesandlinesareingood

conditionbeforeapplyingpressuretothesystem.

•Beforeoperating,alwaysinspectthemachineto

ensurethattheailknivesareingoodworking

condition.Replacewornordamagedknives.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

strike.

•Ensurethatyourtractionunitissuitableforuse

withanimplementofthisweightbycheckingwith

yourtractionunitsupplierormanufacturer.

•Thetractionunitmusthavetheproperwheelbase

andtreadwidthandbeequippedwitharollbar

andseatbelttooperatesafelyonhillyterrain.

Thenormaloperatingspeedis10km/h(6mph)

butwillvarywithterrainanddebrisbeingpicked

up.Themaximumtransportspeedis24km/h(15

mph)withslowerspeedsrequiredonhillyterrain.

RefertothetractionunitOperator’sManualfor

informationortractionunitserviceagencyifyou

haveanyquestionsonsafeoperation.

9

Page 10

•Thebrakesofthetowtractionunitmusthave

thecapacitytostopthemachinewithmachine

fullyloadedandtravelingatthemaximum

recommendedtransportspeed.

•Thepowertake-offdriveofthemachinerequiresa

tractionunitwithoperatingspeedsof540rpmand

outputpowerof32hporhigher.Donotexceed

the540rpmspeed.

•Themachinemustcomplywithlocalroad

requirementsiftransportedonpublicroads.A

slow-movingvehiclesignhasbeenprovided.

Signallightsandbrakesarenotprovidedandmay

berequiredinsomeareas.

HydraulicFluid

Specications

Thereservoirislledatthefactorywithapproximately

38L(10USgallons)ofhigh-qualityhydraulicuid.

Checkthelevelofthehydraulicuidbeforeyourst

starttheengineanddailythereafter;refertoChecking

theHydraulicFluid(page11).

Recommendedreplacementuid:ToroPX

ExtendedLifeHydraulicFluid;availablein19L(5US

gallon)pailsor208L(55USgallon)drums.

Note:Amachineusingtherecommended

replacementuidrequireslessfrequentuidandlter

changes;refertoServicingtheHydraulicFluidand

Filter(page18).

Alternativeuids:IfT oroPXExtendedLife

HydraulicFluidisnotavailable,youmayuseanother

conventional,petroleum-basedhydraulicuidhaving

specicationsthatfallwithinthelistedrangeforallthe

followingmaterialpropertiesandthatitmeetsindustry

standards.Donotusesyntheticuid.Consultwith

yourlubricantdistributortoidentifyasatisfactory

product.

Note:T orodoesnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

productsonlyfromreputablemanufacturerswhowill

standbehindtheirrecommendation.

HighViscosityIndex/LowPourPoint

Anti-wearHydraulicFluid,ISOVG46

MaterialProperties:

Viscosity,ASTMD445cSt@40°C44to48

ViscosityIndexASTMD2270

PourPoint,ASTMD97-34°Fto-49°F

IndustrySpecications:EatonVickers694(I-286-S,

M-2950-S/35VQ25or

140orhigher

M-2952-S)

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicuidisavailablein20ml(0.67oz)

bottles.Abottleissufcientfor15to22L(4to6US

gallons)ofhydraulicuid.OrderPartNo.44-2500

fromyourauthorizedTorodistributor.

10

Page 11

CheckingtheHydraulic

CheckingtheTirePressure

Fluid

1.Operatethemachinesothattheuidiswarm,

parkthemachineonalevelsurface,andshut

offtheengine.

2.Checktheleveloftheuidbyviewingthesight

gauge(Figure4).Iftheuidisuptothemiddle

ofthegauge,theuidlevelissufcient.

Figure4

1.Sightgauge

2.Hydraulicreservoircap

Thecorrectairpressureinthetiresis124kpa(18psi).

Important:Maintainevenpressureinbothtires

toensurepropermachineperformance.Donot

underinate.

CheckingtheTorqueofthe WheelNuts

ServiceInterval:Aftertherst2hours

Aftertherst10hours

Every200hours

WARNING

Failuretomaintainthepropertorqueofthe

wheelnutscouldresultinfailureorlossof

thewheelandmayresultinpersonalinjury.

ConnectingtheMachineto theTractionUnit

g027356

1.Positionthemachineonaat,levelsurface.

2.Insertthejackontotheframepinandsecureit

withthepin(Figure5).

3.Iftheuidlevelisbelowthemiddleofthegauge,

removethecapfromthehydraulicuidreservoir

andslowlyaddanappropriatehydraulicuid

untilthelevelreachesthemiddle(maximum)of

thesightgauge;refertoServicingtheHydraulic

FluidandFilter(page18).

Important:Donotoverll;ifyouexceed

themaxlllineofthesightgaugeyoumust

removetheexcessuid;refertoChanging

theHydraulicFluid(page18).

Important:Topreventsystem

contamination,cleanthetopofthe

hydraulicuidcontainersbeforepuncturing.

Ensurethatthepourspoutandthefunnel

areclean.

4.Installthereservoircap.

g027352

Figure5

1.Jack3.Framepin

2.Pin

3.Adjustthejackheightuntilthemachineframeis

parallelwiththeground.

4.Backthetractionunituptothemachine.

11

Page 12

5.Adjustthemachinehitchclevistothesamelevel

asthetractionunithitchasfollows:

A.Removetheboltsandlocknutsthatsecure

thehitchclevis(Figure6)tothemachine

frame.

ConnectingthePTOShaft

1.ConnectthePTOshafttothemachineimpeller

inputshaft.

2.ConnectthePTOshafttothereartractionunit

PTOshaft.

3.SlidethePTOshaftforwardasfarasitwillgo.

4.PressthepintosecurethePTOshaftinplace.

Note:SlidethePTOshaftbackandforthto

ensurethatitisproperlylocked.

5.Connecttheshieldsafetychaintothetraction

unit(Figure7).

Note:Ensurethatthechainremainsslack

whenyouturnthetractionunit.

Figure6

1.Clevishitch

B.Raiseorlowerthehitchclevistotheposition

approximatelylevelwiththetractionunit

hitch.

C.Secureitwiththeboltsandlocknutsthat

werepreviouslyremoved.

6.Connectthetractionunithitchtothemachine

clevishitchwiththehitchpinandclevis.

7.Removethejackpin,rotatethejackupwardto

thestorageposition.

g027353

g027355

Figure7

1.Safetychain

CAUTION

Iftheshieldchainsarenotconnected,

theshieldscouldrotateduringoperation

andcausebodilyinjury.

KeepallPTOshieldsinplaceand

connecttheshieldchaintothetraction

unitorPTOshields.

12

Page 13

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;

longpants;andhearingprotection.Tieback

longhairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhentired,ill,or

undertheinuenceofalcoholordrugs.

•Donotcarrypassengersonthemachineand

keepbystandersandpetsawayfromthemachine

duringoperation..

•Thebrush,rubberngers,ail,andvacuumof

themachinemaypickupandpropeldebrisand

smallobjectsinitspathduringoperation;keep

bystandersandpetsawayfromthemachine

duringoperation.

•AlwaysdisengagethePTO,shutofftheengineof

thetractionunit,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperator’s

position.

•DonotstepoverthePTOshafttogettotheother

sideofthemachine.Walkaroundthemachine.

•Alwaysstandawayfromtherearofthemachine

whenopeningthereardoor.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Keepyourhandsandfeetawayfromtheail

knives.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Stopthemachine,shutofftheengine,waitforall

movingpartstostop,andinspectthemachine

afterstrikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Alwaysmaintainpropertractionunittirepressure.

•Ensurethatyoucomplywithallregulationsbefore

transportingequipmentonthepublicroadsand

highways.Makesurethatallrequiredreectors

andlightsareinplaceandarecleanandvisibleby

overtakingandoncomingtrafc.

•Reducespeedonroughroadsandsurfaces

•ForallPTOshaftsteelparts(tubes,bearings,

joints,etc.)disassemblyorrepairs,itishighly

advisabletocontactyourauthorizedT oro

distributor.Removalofcomponentsforrepairs

andreassemblymaydamagesomepartsifnot

performedwithspecialtoolsbytrainedtechnicians.

•ThePTOshaftmustnotbeusedwithoutthe

guardssupplied.

DumpingSafety

•Movingthereardooranddumpingdebriscan

causeseriousinjury.Stayclearofthemachine

whileitisbackingupordumping.

•Keepbystandersasafedistancefromthemachine

whenoperatingtodumpdebrisorwhenopening

andclosingthereardoor.

•Underrarecircumstanceswet,compressedgrass

clippingsmaygenerateheat.Alwaysemptythe

machinebeforestoringit.

•Toavoidtheriskofelectricalshock,dumpthe

machineonlyinareasthatareclearofoverhead

wiresandotherobstructions.

•Neverdumpthemachineonaslope;always

dumpthemachineonlevelground.

SlopeSafety

•Reviewthetractionunitspecicationstoensure

thatyoudonotexceeditsslopecapabilities.

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperationincluding

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandreviewthe

conditionstodeterminewhetheryoucanoperate

themachineintheconditionsonthatdayandat

thatsite.Changesintheterraincanresultina

changeinslopeoperationforthemachine.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

13

Page 14

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardropoffs,ditches,embankments,water

hazards,orotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

OperatingtheTractionUnit Hydraulics

OperatingtheMachine

1.Startthetractionunitandrunitatalowrpm.

2.EngagethePTOwhiletheengineisatidle

speed.

3.IncreasethePTOspeedto540rpm.

CAUTION

Shutthetractionunitengineoff,remove

thekey,andwaitforallmovingparts

tostopbeforecheckingforuidleaks,

looseparts,andothermalfunctions.

Allhydraulicmachinefunctionsarecontrolledby

thehydraulicvalvethatislocatedatthefrontof

themachine.ThePTOmustberunningwhilethe

machineisinuse.Thisiswhatcreatesthecontinuous

uidowthroughoutthemachine.

Important:Nevermoveahydraulicleverrapidly

betweentheupanddownpositions.Forcinga

hydraulicmotortoreversedirectionsinstantly

willlikelyseverelydamageit.Ifanypartofthe

machinebecomespluggedormaterialdoesnot

wanttoow,shutthemachineoffcompletelyand

manuallyremovetheblockage.

Note:Thehydrauliccontrolconsolecanbeadjusted

forcomfortbylooseningtheleverontheframebehind

thecontrols,adjustingthecontrolconsoleforeoraft,

andtighteningthelever.

4.Beforestartingoperation,surveytheareato

determinethebestdirectiontogo.

5.Drivethetractionunitforwardandtowthe

machineovertheareatobecleaned.

Note:Tomaintainastraightlinewhen

operating,sightoffanobjectintheforeground.

Alwaystrytomakealong,continuousrunwitha

slightoverlaponthereturnrun.

14

Page 15

AfterOperation

AfterOperationSafety

10.Removethehitchpinandclevis.

11.Movethetractionunitawayfromthemachine.

TransportingtheMachine

GeneralSafety

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallworn,damaged,ormissingdecals.

•Emptythemachine,parkonalevelsurface,

andchockthewheelsbeforedisconnectingthe

machinefromthetractionunit.

RemovingtheMachine fromtheTractionUnit

1.Stopthetractionunitonalevelsurface.

2.DisengagethePTOandengagetheparking

brake.

3.Shutofftheengineandremovethekeyfromthe

ignitionswitch.

CAUTION

Beforeleavingtheoperator’spositionon

thetractionunit,waitfortheengineand

allmovingpartstostop.

Youcantransportthemachinetoworksitesusingany

tractionunitwithadraw-bar-typehitch.Themachine

isnotdesignedforhighwaytowing.

•Thewideotationturftiresarenotforhighwayuse

andareonlyforspeedsbelow24km/h(15mph).

Atspeedsabove24km/h(15mph),thetireswill

losetheirtread,causeharmtotheoperator,and

damagetheequipment.

•Ensurethatthedeckisraisedandthecasters

cannotcontactthegroundduringtransport.Also,

ensurethatthecylinderlockbar(Figure8)isin

placetopreventtheliftcylinderfromcompressing

duringtransport.

4.Chockthewheels.

5.Removethepinthatsecuresthejacktothe

framepinandrotatethejackdownintoposition.

6.Securethejacktotheframepinandadjustthe

jacktosupportthemachine.

WARNING

Themachineisveryheavy.Donot

disconnectthemachinewithoutrst

puttingdownthejack.

Personalinjurycouldoccurifthehitch

drops.

7.Disconnectthesafetyshieldchainsfromthe

tractionunitorPTOshield.Securetheendof

thechaintotheimpellersideofthePTOshaftto

preventthePTOshaftfromcomingapart.

8.DisconnectthePTOshaftfromthetractionunit

outputshaft.

9.SlidethePTOshaftbackandremoveitfromthe

tractionunit.

g027358

Figure8

1.Cylinderlockbar2.Liftcylinder

•Useadequatelightingandbraking,aretainertype

hitchpin,andasafetychainwhiletowing.

•Makesurethatthetiresareproperlyinated.

15

Page 16

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst10hours

Aftertherst20hours

Beforeeachuseordaily

Every100hours

Every200hours

Every800hours

Every1,000hours

Every2,000hours

MaintenanceProcedure

•Torquethewheelnutsto115to136N⋅m(85to100ft-lb).

•Torquethewheelnutsto115to136N⋅m(85to100ft-lb).

•Check/adjusttheimpellerbelttension.

•Greasethefanshaftbearings.

•Checkthehydrauliclinesandhoses.

•Check/adjusttheimpellerbelttension.

•Greasethedriveshaft.

•Torquethewheelnutsto115to136N⋅m(85to100ft-lb).

•Ifyouarenotusingtherecommendedhydraulicuidorhaveeverlledthereservoir

withanalternativeuid,changethehydraulicuidandlter.

•Ifyouareusingtherecommendedhydraulicuid,replacethehydrauliclter.

•Ifyouareusingtherecommendedhydraulicuid,changethehydraulicuidand

lter.

MaintenanceSafety

•Beforeadjusting,cleaning,servicing,orleaving

themachine,dothefollowing:

–Positionthemachineonalevelsurface.

–DisengagethePTO.

•Supportthemachinewithblockswheneveryou

raiseit.Donotrelyonahydraulicsystemto

supportthemachine.

•Ensurethatallguardsareinstalledafter

maintainingoradjustingthemachine.

–Ensurethatthetractionunitisinneutral.

–Engagethetractionunitparkingbrake.

–Shutofftheengineofthetractionunitand

removethekey.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Performonlythosemaintenanceinstructions

describedinthismanual.Ifmajorrepairsare

everneededorassistanceisdesired,contactan

authorizedT orodistributor.

•Ensurethatthemachineisinsafeoperating

conditionbykeepinghardwaretightened.

•Ifpossible,donotperformmaintenancewhilethe

tractionunitengineisrunning.Keepawayfrom

movingparts.

•Donotcheckoradjustthebelttensionwhenthe

tractionunitengineisrunning.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

16

Page 17

LubricatingtheMachine

GreasingtheFanShaftBearings

ServiceInterval:Beforeeachuseordaily

1.Removethedriveshieldfromoverthepulley

assemblies(Figure12).

2.Greasethettingsonthefanshaftbearingsas

illustratedinFigure10withNo.2lithium-based

grease.

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Beforedisconnectingorperforminganyworkon

thehydraulicsystem,lowertheimplementto

thegroundandshutofftheenginetorelieveall

pressureinthesystem.

•Toensuresafe,optimalperformanceofthe

machine,useonlygenuineT ororeplacement

parts.Replacementpartsmadebyother

manufacturerscouldbedangerous,andsuchuse

couldvoidtheproductwarranty .

Figure9

GreasingtheDriveShaft

ServiceInterval:Every100hours

Greasethe2driveshaftttingsasillustratedinFigure

10withNo.2lithium-basedgrease.

Figure10

g027364

g027365

17

Page 18

CheckingtheHydraulic

ServicingtheHydraulic

LinesandHoses

ServiceInterval:Beforeeachuseordaily

Checkthehydrauliclinesandhosesforleaks,kinked

lines,loosemountingsupports,wear,loosettings,

weather,deterioration,andchemicaldeterioration.

Makeallnecessaryrepairsbeforeoperatingthe

machine.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury .

•Ensurethatallhydraulicuidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepbodyandhandsawayfrompin-hole

leaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks.

•Safelyrelieveallpressureinthehydraulic

systembeforeperforminganyworkonthe

hydraulicsystem.

•Seekimmediatemedicalattentionifuid

isinjectedintoskin.

FluidandFilter

ServiceInterval:Every1,000hours—Ifyou

areusingtherecommended

hydraulicuid,replacethe

hydrauliclter.

Every2,000hours—Ifyouareusingthe

recommendedhydraulicuid,changethe

hydraulicuidandlter.

Every800hours—Ifyouarenotusingthe

recommendedhydraulicuidorhaveever

lledthereservoirwithanalternativeuid,

changethehydraulicuidandlter.

ChangingtheHydraulicFluid

Important:Iftheuidbecomescontaminated,

contactanauthorizedTorodistributor.

Contaminateduidlooksmilkyorblackwhen

comparedtocleanuid.

1.Turntheengineoff.

2.Disconnectthesmallhydraulichose(casedrain)

fromthebottomofthereservoirandletthe

hydraulicuidowintoadrainpan.

Note:Installandtightenthehosewhenthe

hydraulicuidstopsdraining.

3.Fillthereservoirwithapproximately38L(10US

gallons)ofhydraulicuid.RefertoCheckingthe

HydraulicFluid(page1 1).

Important:Useonlythehydraulicuids

specied.Otheruidscoulddamagethe

system.

Topreventoverlling,donotlliftheuid

iscold.Donotoverll.

4.Installthereservoircap.

5.Startthetractionunitengine,useallthe

hydrauliccontrolstodistributethehydraulicuid

throughoutthesystem,andcheckforleaks.

6.Shutofftheengine

7.Withtheuidwarm,lookintothesightgauge.

Note:Ifthehydraulicuidlevelislow,add

enoughuidtoraisetheleveltothemiddle

(maximum)ofthesightgauge.

ReplacingtheHydraulicFilter

UseonlytheT ororeplacementlter(PartNo.

54-0110)inthehydraulicsystem.

Important:Useofanyotherltermayvoidthe

warrantyonsomecomponents.

1.Turnthetractionunitengineoffandremovethe

keyfromtheignition.

18

Page 19

2.Cleantheareaaroundtheltermountingarea.

3.Placeadrainpanunderthelterandremove

thelter(Figure11).

Figure11

1.Hydrauliclter

4.Lubricatethenewltergasketandllthelter

withhydraulicuid.

5.Ensurethattheltermountingareaisclean.

6.Screwthelteronuntilthegasketcontactsthe

mountingplate,thentightenthelterone–half

turn.

7.Startthetractionunitengineandoperatethe

hydrauliccontrolstopurgeairfromthesystem.

g027367

g027366

1.Driveshield

Figure12

Note:Thedriveshaftdoesnothavetobe

disconnectedtoadjustthebelt.

2.Onbacksideoftheframe,loosenthebolt

securingthebelttensionertotheframe(Figure

12).

3.Removetheboltandnutsecuringthetensioner

guidetothedrivemounttoreleasethebelt

tension(Figure13).

8.Shutofftheengineandchecktheuidleveland

foranyleaks.

AdjustingtheImpellerBelt

ServiceInterval:Aftertherst20hours

Beforeeachuseordaily

Makesurethatthebeltisproperlytensionedto

ensureproperoperationofthemachineandprevent

unnecessarywear.

1.Loosentheboltsandnutssecuringthedrive

shieldtotheimpellerhousing(Figure12)and

removetheshield.

1.Tensionerguide

2.Boltandnut

g027368

Figure13

3.Bolt(backofframe)

19

Page 20

4.Usingalargewrench,rotatethetensioner

clockwiseuntilthedecalisalignedwith15°on

thetensionertube.

Important:Alignthetensionerascloseto

15°aspossiblewithoutgoingunder.

Rotatingthetensionertoofarover15°can

overtensionthebelt,rotatingitunder15°will

leavethebelttooloose;bothcandamage

themachine.

5.Inserttheboltintothealignedguideholesand

secureitwiththenut.

Important:Iftheholesarenotexactly

aligned,rotatetheguidetothenexthigher

holeuntilitisaligned.

6.Tightentheboltonthebacksideoftheframeto

lockthetensioner.

7.Installthedriveshieldtotheimpellerhousing

withtheboltsandnutsremovedpreviously.

Storage

1.Thoroughlycleanthemachine.Theimpeller

housingshouldbefreeofdirt,leaves,and

debris.

2.Checkthetirepressure;refertoCheckingthe

TirePressure(page11).

3.Tightenallfastenersasnecessary.

4.Greaseoroilallgreasettingsandpivotpoints.

Wipeupanyexcesslubricant.

5.Placealightcoatofgreaseonthesplinesofthe

PTOshaft.

6.Lightlysandandusetouch-uppaintonpainted

areasthatarescratched,chipped,orrusted.

Repairanydentsinthemetalbody.

20

Page 21

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheT oroCompany(“T oro”)respectsyourprivacy .Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.T orousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty ,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.T oromayshareyourinformationwithoursubsidiaries,

afliates,dealersorotherbusinesspartnersinconnectiontheseactivities.Wemayalsodisclosepersonalinformationwhenrequiredbylaworin

connectionwiththesale,purchaseormergerofabusiness.Wewillneversellyourpersonalinformationtoanyothercompanyformarketingpurposes.

RetentionofyourPersonalInformation

Torowillkeepyourpersonalinformationaslongasitisrelevantfortheabovepurposesandinaccordancewithlegalrequirements.Formoreinformation

aboutapplicableretentionperiodspleasecontactlegal@toro.com.

Toro’sCommitmenttoSecurity

YourpersonalinformationmaybeprocessedintheUSoranothercountrywhichmayhavelessstrictdataprotectionlawsthanyourcountryofresidence.

Wheneverwetransferyourinformationoutsideofyourcountryofresidence,wewilltakelegallyrequiredstepstoensurethatappropriatesafeguardsare

inplacetoprotectyourinformationandtomakesureitistreatedsecurely.

AccessandCorrection

Youmayhavetherighttocorrectorreviewyourpersonaldata,orobjecttoorrestricttheprocessingofyourdata.T odoso,pleasecontactusbyemail

atlegal@toro.com.IfyouhaveconcernsaboutthewayinwhichT orohashandledyourinformation,weencourageyoutoraisethisdirectlywithus.

PleasenotethatEuropeanresidentshavetherighttocomplaintoyourDataProtectionAuthority.

374-0282RevC

Page 22

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,TorohaselectedtoprovidetheProp65warnings.Moreover,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Page 23

TheToroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty.All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Page 24

Loading...

Loading...