Toro VACU-POWER Service Manual

VACU-POWER WPM SERVICE MANUAL

Table of Contents – Page 1 of 3

SAFETY INSTRUCTIONS

SAFETY TIPS...

PRODUCT IDENTIFICATION

SPECIFICATIONS

GENERAL SPECIFICAT IO NS

ZONE START MODEL SPECIFIC ATIONS

BBC MODEL SPECIFICATIONS

SELF-PROPELLED MODEL SPECIFICATIONS

SERVICE SPECIFICATIONS

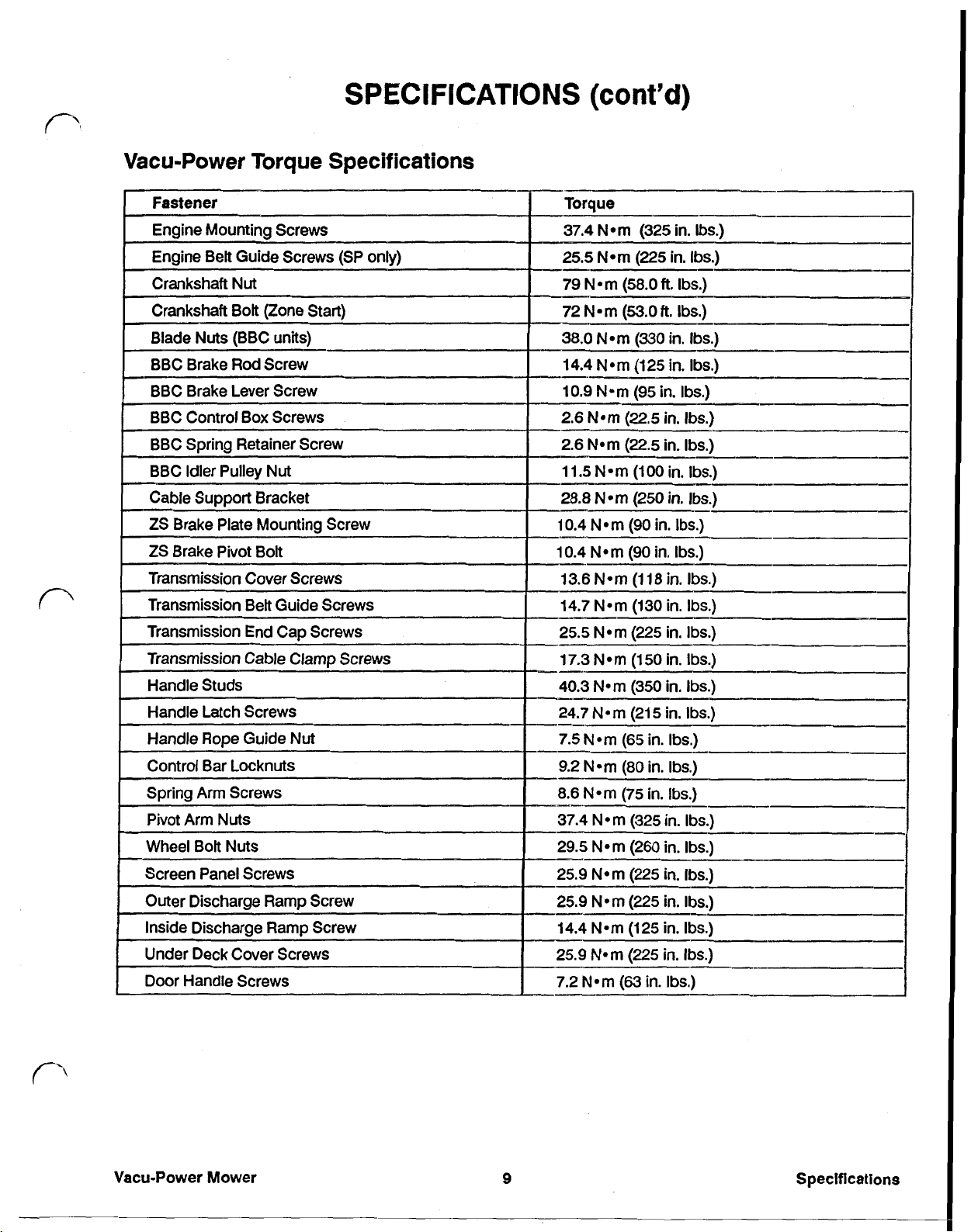

VACU-POWER TORQUE SPECIFICATIONS

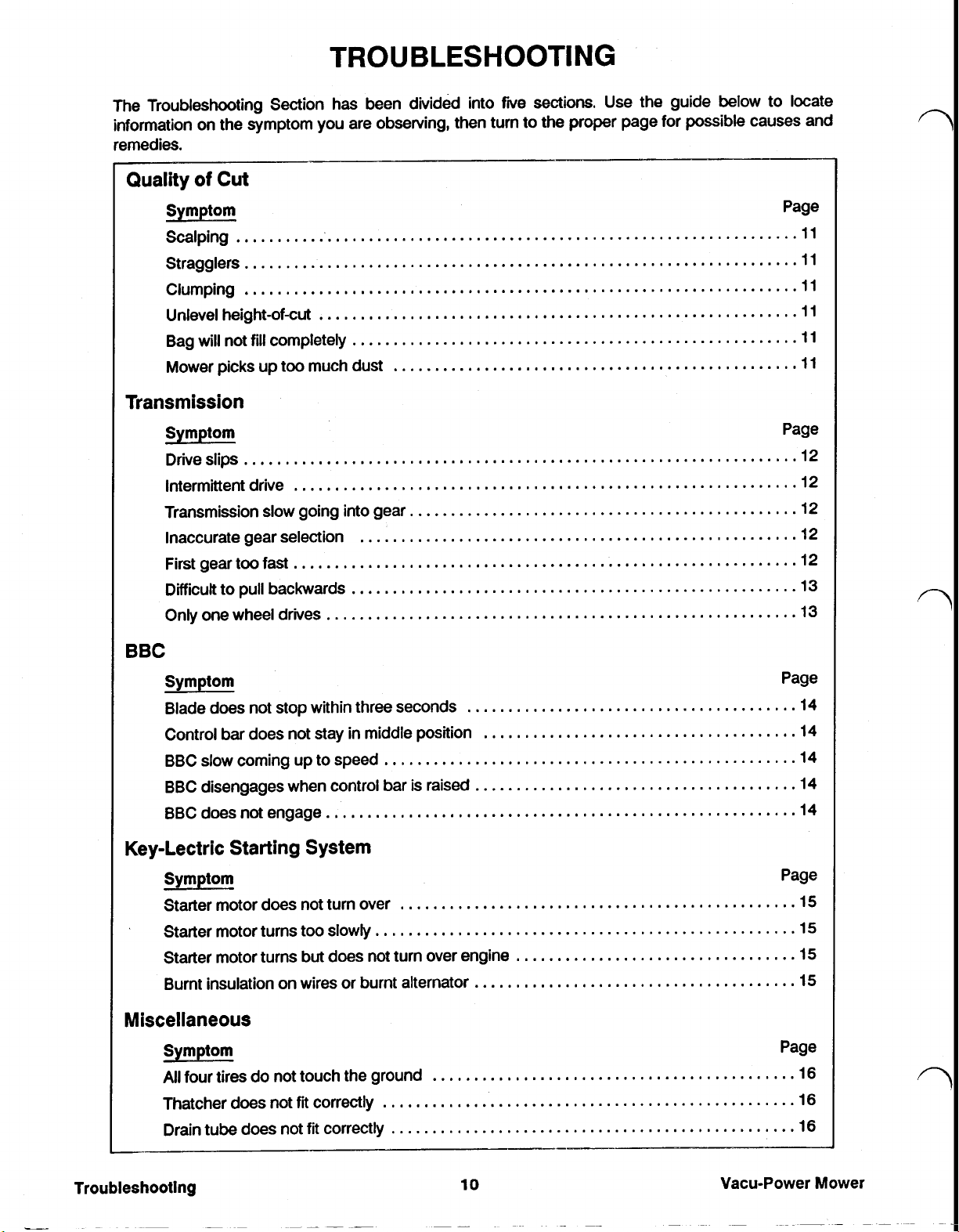

TROUBLESHOOTING

QUALITY OF CUT

TRANSMISSION

BBC

KEY-LECTRIC STARTING SYSTEM

MISCELLANEOUS

MAINTENANCE

TECUMSEH 2-CYCLE ENGINE - SERVICING THE AIR CLEANER

TECUMSEH 2-CYCLE - REPLACING SP AR K PLUG

TECUMSEH 2-CYCLE - ADJUSTING THE THROTTLE

TECUMSEH 2-CYCLE - DRAINING GASOLINE

TECUMSEH 2-CYCLE - SERVICING THE AIR CLEANER

BRIGGS AND STRATTON QUANTUM ENGINE - SERVICING THE AIR

BRIGGS & STRATTON QUANTUM- REPLACING SPARK PLUG

BRIGGS & STRATTON QUANTUM- DRAINING GASOLINE

BRIGGS & STRATTON QUANTUM. CHANGING THE CRANKCASE OIL

BRIGGS & STRATTON QUANTUM- ADJUSTING THE THROTTLE

TORO 2-CYCLE ENGINE - SERVICING THE AIR CLEANER

TORO 2-CYCLE - REPLACING THE SPARK PLUG

TORO 2-CYCLE - DRAINING GASOLINE

TORO OHV ENGINE - SERVICING THE AIR CLEANER

TORO OHV - REPLACING THE SPARK PLUG

TORO OHV - DRAINING GASOLINE

TORO OHV - CHANGING THE CRANKCASE OIL

TORO OHV - ADJUSTING THE THROTTLE

BLADE - INSPECTING/REMOVING/SHARPENING THE BLADE

HOUSING - CLEANING THE MOWER HOUSING

BATTERY - CHARGING, MODEL 26624

WHEELS

ZONE START BRAKE - ADJUSTING BLADE BRAKE

VACU-POWER WPM SERVICE MANUAL

Table of Contents – Page 2 of 3

MAINTENANCE - Continued

BBC - ADJUSTING THE BLADE BRAKE

BBC - CHECK CONTROL BAR OPERATION

SELF-PROPEL SYSTEM - LUBRICATION

SELF-PROPEL SYSTEM - ADJUSTING WHEEL DRIVE

SELF-PROPEL SYSTEM - NEUTRAL ADJUSTMENT

STORAGE - PREPARATION

SECTION 1 FRONT SUSPENSION

FRONT SUSPENSION - OPERATION

FRONT SUSPENSION - DISASSEMBLY

FRONT SUSPENSION - ASSEMBLY

SECTION 2 REAR SUSPENSION (HP MODELS ONLY)

HAND PUSH REAR SUSPENSION - OPERATION

HAND PUSH REAR SUSPENSION - DISASSEMBLY

HAND PUSH REAR SU SPENSION - ASSEMBLY

SECTION 3 SELF-PROPEL SYSTEM

GEAR SELECTION CONTROL - OPERATION

GEAR SELECTION CONTROL - REMOVAL

GEAR SELECTION CONTROL - INSTALLATION

GEAR SELECTION CONTROL - ADJUSTMENT

TRACTION CONTROL - OPERATION

TRACTION CONTROL CABLE - REMOVAL

TRACTION CONTROL CABLE - INSTALLATION

TRACTION CONTROL CABLE - ADJUSTMENT

REAR HEIGHT-OF-CUT SYSTEM (HOC) AND WHEEL PINION CLUTCH (WPC)-

REAR HOC AND WPC - DISASSEMBLY

REAR HOC AND WPC - ASSEMBLY

TRANSMISSION - OPERATION

TRANSMISSION - REMOVAL

TRANSMISSION - DISASSEMBLY

TRANSMISSION - ASSEMBLY

TRANSMISSION - INSTALLATION

SECTION 4 BLADE BRAKE AND CLUTCH (BBC) SYSTEM

INTRODUCTION

BBC CONTROL BOX - OPERATION

BBC CONTROL BOX- DISASSEMBLY

BBC CONTROL BOX - ASSEMBLY

BBC BELLCRANK SYSTE M

BBC UNDER DECK COMPONENTS

BBC CABLE

VACU-POWER WPM SERVICE MANUAL

Table of Contents – Page 3 of 3

SECTION 5 ZONE START BRAKES

INTRODUCTION

PLUNGER STYLE ZONE START BRAKE

PIVOTING ZONE START BRAKE SYSTEM

SECTION 6 ELECTRICAL SYSTEMS

IGNITION CIRCUIT

KEY-LECTRIC STARTING SYSTEM

SECTION 7 HANDLE ASSEMBLY

HANDLE ASSEMBLY - REMOVAL

SECTION 8 CUTTING DECK

CUTTING DECK - OPERATION

SECTION 9 GRASS BAG AND DISCHARGE DOOR

GRASS BAG

DISCHARGE DOOR

SECTION 10 SIDE DISCHARGE CHUTE (OPTIONAL)

SIDE DISCHARGE CHUTE - OPERATION

SECTION 11 -DETHATCHER (OPTIONAL)

DETHATCHER - SAFETY INFORMATION

SECTION 12 ENGINES

ABOUT THIS MANUAL

This service manual was written expressly for Toro Vacu-Power@ Mowers. The

in

Toro Company has made every effort to make the information

complete and correct.

in

This manual was written with the service technician

that information used most often is up front.

information on safety, identification, specifications, troubleshooting and

maintenance, all

Disassembly, inspection and reassembly procedures are covered

two-thirds of the manual and are grouped by component. We tried to cover each

common repair with its own section

that BBC control box service and BBC bellcrank system service are addressed

separately.

Most sections will include some component theory. This information can be

found at the front of each service procedure section.

We are hopeful that you will find this manual a valuable addition to your shop. If

you have any questions

at the following address:

in

the front third of the manual.

or

or

comments regarding this manual, please contact us

As

sub-section.

mind.

a result, you will find reference

For

example, you will find

this manual

It

is- organized

in

the last

so

The

Toro

Company reserves the right to change product specifications

manual without notice.

@COPYRIGHT ALL RIGHTS

The Toro Company

Consumer Service Department

81

11

Lyndale Avenue South

Minneapolis, MN

The Toro Company

55420

RESERVED

1990

or

this

SAFETY

Servicing

equipment requires care and

common sense to prevent injury.

Safety alert

been placed throughout this manual to enhance

safety. Whenever you encounter the word

CAUTION read the instruction because

to do

instruction

death.

with

'CAUTION' statements have

safety. Failure to comply with the

may

result

of

any outdoor power

In

personal Injury

it

has

or

INSTRUCTIONS

This manual is intended

for Toro servicing dealers. The safety instructions provided

in

this manual are for the troubleshooting and

service of the product only. The individual Operator's

Manuals will contain safety and instructional

information on the operation of Vacu-Power mowers.

Operator's Manuals are available through:

The Toro Company

Publications Department

81

11

Lyndale Avenue South

Minneapolis,

as

a service and repair manual

MN

55420

U.S.A.

SAFETY TIPS

Avoid lacerations and amputations

Stay clear of all moving parts whenever the engine is

running. Treat

moving whenever the engine is

potential to start.

Avoid burns

Do not touch engine while running or shortly after

running.

Avoid falls

Do not operate the mower on slippery surfaces or

footing is questionable.

Avoid fires and falls...

up

Wipe

Avoid asphyxiation

Never operate an engine

proper ventilation.

Avoid possible eye injuries

Wear eye protection when working with springs

cables and when running engine

all

normally moving parts as

any spilled fuel or

oil.

in

if

they were

running

a confined area without

or has the

or

if

Avoid unexpected starting of engine

Always turn

before attempting any cleaning, adjustment or repair.

Avoid possible fires and explosions

Use a container designed for gasoline. Avoid spilling

gasoline and never smoke while working around

gasoline.

Avoid accidental misuse of fuel...

Always store fuel

that is properly labeled.

Avoid possible injury due to inferlor parts

Use only Toro original parts to insure that important

safety criteria are met.

Avoid injury to bystanders

Always clear the area

testing a lawn mower.

Avoid Injury due to

Always clear the area to be mowed

other debris that could be picked up and thrown by the

mower.

off

key and disconnect spark

in

a

container designed for gasoline

of

bystanders before starting or

projectiles

plug

wire

of

sticks, rocks and

Vacu-Power Mower Safety Instructions

Reference Information

TABLE

OF

CONTENTS

Service Procedures

Section One

Section

Two

Safety Instructions Page

Table of Contents 2

Identification

Specifications 7

Troubleshooting

Maintenance 17

Front Suspension

Operation Page30

Disassembly .30

Assembly

Rear Suspension (HP Models Only)

Operation 32

1

6

IO

30

Section Three

Disassembly

Assembly 32

Self-Propel System

Gear Selection Control

Operation

Removal

Installation

Adjustment 35

Drive Control

Operation

Removal

Installation 37

Adjustment 37

Rear Height-of-Cut and Wheel Pinion Clutch

Operation

Disassembly 39

32

34

36

36

38

Table

of

Contents

Assembly

40

2

Vacu-Power Mower

TABLE

Service Procedures (cont’d)

OF CONTENTS

(cont’d)

Section Three

Section Four

Self-Propel System (cont’d)

Transmission

Operation Page 41

Removal

Disassembly

Assembly

.

. . .

.

Installation

Blade Brake and Clutch (BBC) System

Introduction

BBC Control Box

Operation

Disassembly

Assembly 50

BBC Bellcrank System

Operation 51

Disassembly 51

..................................................

.

,

. .

,

, , ,

. . . . . . . .

. . , .

. .

.

. . . . . . . . .

.

. .

. .

.46

47

Section Five

Assembly

BBC Under Deck Components

Operation

Disassembly

Assembly 55

BBC Cable

Removal

installation

Adjustment

Zone Start Brakes

Introduction

Plunger Style Zone Start Brake System

Operation 59

Disassembly

Assembly

Adjustment

.

, , . ,

. .

. .

.

.

,

,

. , . . .

. .

,

.

, . ,

. , . .

. . . . . .

.

. .

. . .

.

,

.

.

,

. . . . .

,

,

.

.

,

,

. . . . . . . . . .

......................................................

................................................

................................................. 61

.

.

.

.

, ,

.

.

, ,

,

.

.

. . . . .

. .

.

. . .

.

.

.

. . . . . , . . . . . . .

. . . . .

. . . . . . . . . . . .

.

.

. .

. .

. .

. .

. . , . .

.

.52

56

.57

,

.

. .

.57

59

60

60

Vacu-Power Mower

3

Table

of

Contents

TABLE

OF CONTENTS

(cont’d)

Service Procedures

Section Five Zone Start Brakes (cont’d)

Section Six Electrical System

(cont’d)

Pivoting Zone Start Brake System

Operation Pa

Disassembly .61

Assembly

Adjustment .62

Ignition Circuit

Operation

Troubleshooting

Key-Lectric Starting System

Operation

Testing

..................................................a

.............................................a

.........................................,........a

Section Seven Handle Assembly

Removal

Installation .67

Section Eight Cutting Deck

Operation .69

Adjustments

Repair

Section Nine Grass Bag and Discharge Door

Grass Bag

Construction

Disassembly

Assembly

Discharge Door

Operation

Disassembly

71

................................................71

Table

of

Contents

Assembly

4

7

2

Vacu-Power Mower

TABLE

Service Procedures (cont'd)

Section Ten Side Discharge Chute (Optional)

Operation .............................................Page74

OF

CONTENTS

(cont'd)

Disassembly

Assembly

Section Eleven Dethatcher (Optional)

Operation

Safety Information

Assembly

Installation

Adjustment

Maintenance

Section

Twelve Englnes

.........................................................

................................................

..................................................

..................................................

...........................................

..................................................

..................................................

.................................................

................................................

74

74

75

75

75

78

79

79

80

Vacu-Power Mower

5

Table of Contents

PRODUCT IDENTIFICATION

In

mower.

also

differentiate it from other products with the same model

number. The serial number has seven digits, the first

of which identifies the year

indicates that the product was built

year).

addition to the model number, each product

has a unique serial number which serves to

of

manufacture (ie.

in

the

0022576

1990

model

Each Toro Walk Power Mower is assigned a model and

serial number. The model number has five digits and

reflects the engine, deck style and features of the

These numbers are printed

high and

side of the cutting deck between the rear wheels on

some models. On others, it can be found under the

control panel. Always refer to these numbers when

ordering parts or requesting information on the mower.

Engine model and serial numbers differ from the

chassis model and serial numbers. Engine numbers

can generally be found

engine. Use this information when ordering parts

requesting information regarding the engine.

3'

wide, The decal can be found on the top

on

a decal that is about

on

the blower housing of the

1'

or

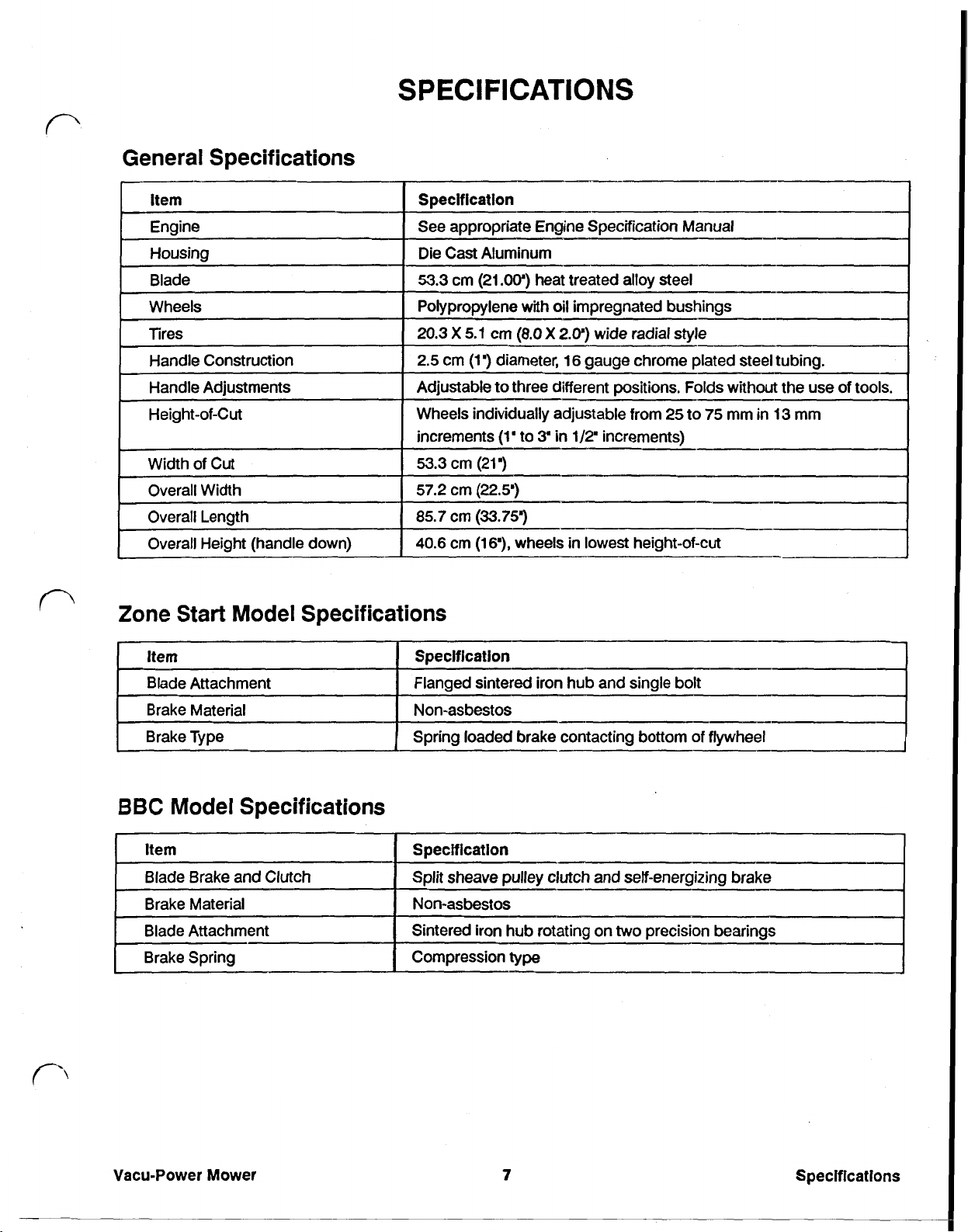

General Specifications

SPECIFICATIONS

Specification

See appropriate Engine Specification Manual

Die Cast Aluminum

53.3

cm

(21.00”)

Polypropylene with oil impregnated bushings

20.3

X

5.1

2.5

cm

(1”)

Adjustable to three different positions. Folds without the use of tools.

heat treated alloy steel

cm

(8.0

X

2.0')

wide radial style

diameter,

16

gauge chrome plated steel tubing.

n

Wheels individually adjustable from

increments

53.3

57.2

85.7

40.6

cm

cm

cm

cm

I

Width

of

Cut

Overall Width

Overall Length

Overall Height (handle down)

Zone Start Model Specifications

item

Blade Attachment

Brake Material

Brake Type

BBC

Model Specifications

Specification

Flanged sintered iron hub and single bolt

Non-asbestos

Spring loaded brake contacting bottom of flywheel

(1'

to

3'

in

(21”)

(22.5'”)

(33.753

(16”)

wheels

25

1/2’

increments)

in

lowest height-of-cut

to

75

mm

in

13

mm

I

I

I

Blade Brake and Clutch

Blade Attachment

Brake Spring

Vacu-Power Mower Specifications

Split sheave pulley clutch and self-energizing brake

Non-asbestos Brake Material

two

Sintered iron hub rotating on

Compression

type

7

precision bearings

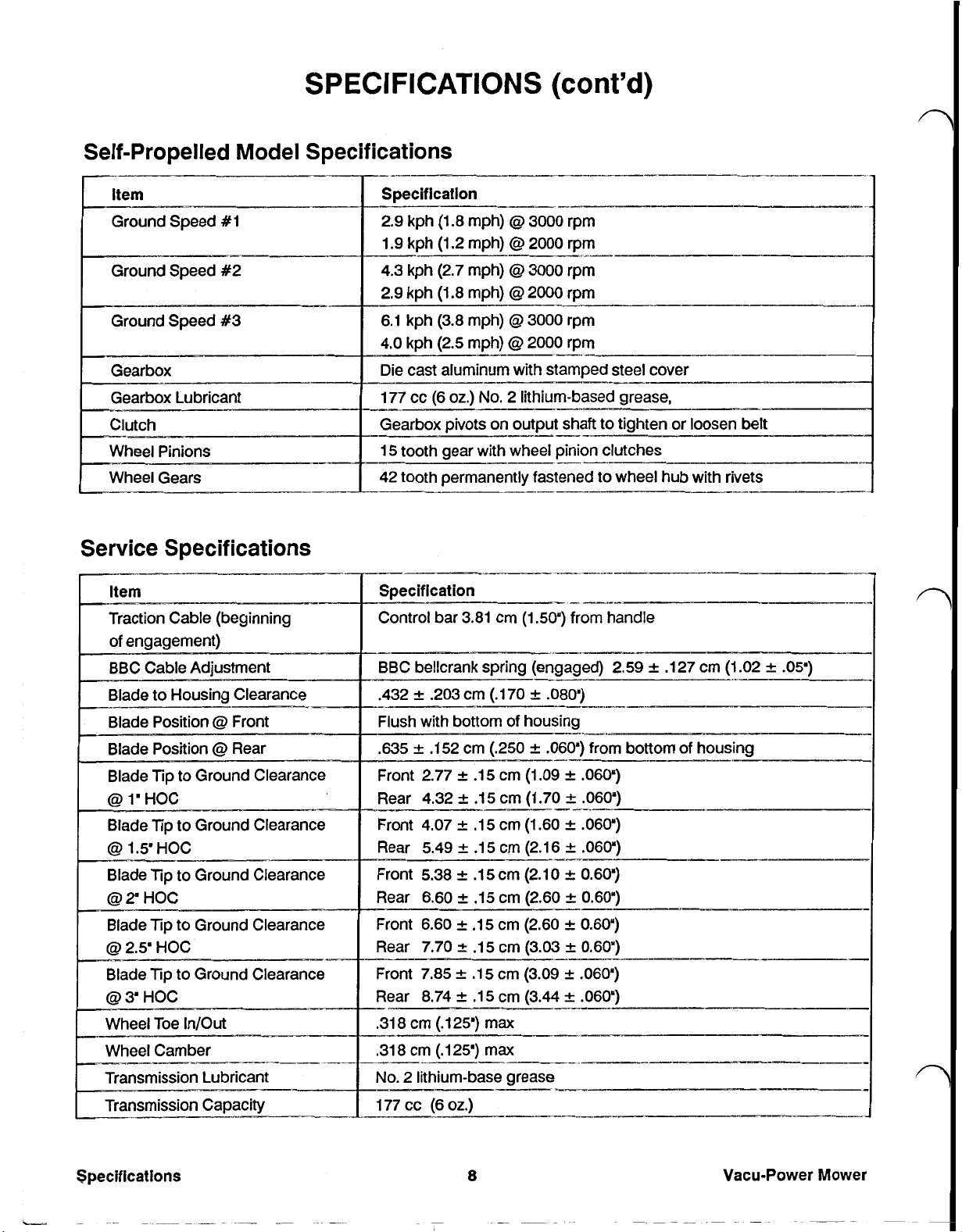

SPECIFICATIONS

Self-Propelled Model Specifications

Specification

2.9

kph (1.8 mph) 3000 rpm

1.9 kph (1.2 mph) 2000 rpm

Ground Speed #2

4.3 kph (2.7 mph) 3000 rpm

2.9 kph (1.8 mph) 2000 rpm

6.1 kph (3.8 mph) 3000 rpm

4.0 kph (2.5 mph)

Die cast aluminum with stamped steel cover

(cont'd)

I^-

2000

rpm

--__

Service Specifications

177 cc

Gearbox pivots on output shaft to tighten

15 tooth gear

42 tooth permanently fastened to wheel hub with rivets

specification

Control bar 3.81 cm

(6

oz.)

No.

2 lithium-based grease,

with

wheel

pinion clutches

(1.50”)

from handle

or

loosen belt

--

BBC bellcrank spring (engaged) 2.59 .127 cm (1.02

.432 .203 cm (.170

Flush with bottom of housing

.635

-

Front 2.77 .15 cm (1.09

Rear 4.32

Front 4.07 .15 cm (1.60

Rear 5.49 .15 cm (2.1 6

Front 5.38 A .15 cm (2.10 0.60")

Rear 6.60 .15 cm (2.60

.152 cm (.250

.I5

.080")

.060")

cm (1.70

---

--I-

from bottom of housing

.060")

,060")

.060")

.060”)

A

0.60")

I--

.05”)

Specifications

Ground Clearance

Front 6.60 .15 cm (2.60

Rear 7.70 .15 cm (3.03

Front 7.85 .15 cm (3.09

Rear 8.74 .15 cm (3.44

.318 cm (.125') max

,318 cm 125') max

No.

2 lithium-base grease

177 cc

(6

oz.)

8

0.60")

0.60')

.060")

.060”)

-I__-

Vacu-Power Mower

SPECIFICATIONS

Vacu-Power Torque Specifications

(cont'd)

8.6

N-m

(75

in.

Ibs.)

Vacu-Power Mower

9

Specifications

TROUBLESHOOTING

The Troubleshooting Section has been divided into

information on the symptom you are observing. then turn to the

remedies

Scalping 11

Stragglers

Clumping

Unlevel height-of-cut

Bag will not

Mower picks up too much dust

...................................................................

...................................................................

..........................................................

fill

completely

......................................................

.................................................

five

sections Use the guide below to locate

Transmission

Symptom

Drive slips

lntermittent

Transmission slow going into gear

Inaccurate gear selection

...................................................................

drive

.............................................................

...............................................

.....................................................

proper

page for possible causes and

Page

11

11

11

11

11

Page

12

12

12

12

First gear too fast

Difficult to pull backwards

Only one wheel drives

st

.............................................................

......................................................

.........................................................

BBC

Symptom

Blade does not stop within three seconds

in

Control bar does not stay

BBC slow coming up to speed

BBC disengages when control bar is raised

BBC does not engage

middle position

..................................................

.........................................................

Key-Lectric Starting System

Symptom

Starter motor does not turn over

Starter motor turns too slowly

Starter motor turns but does not turn over engine

Burnt insulation on wires

or

................................................

...................................................

burnt alternator

12

13

13

Page

........................................

......................................

.......................................

..................................

.......................................

14

14

14

14

14

Page

15

15

15

15

Miscellaneous

Symptom

All

four tires do not touch the ground

Thatcher

Drain tube does not

Troubleshooting

does

not

fit

correctly

fit

correctly

Page

............................................

..................................................

.................................................

10

Vacu-Power

16

16

16

Mower

TROUBLESHOOTING

(cont'd)

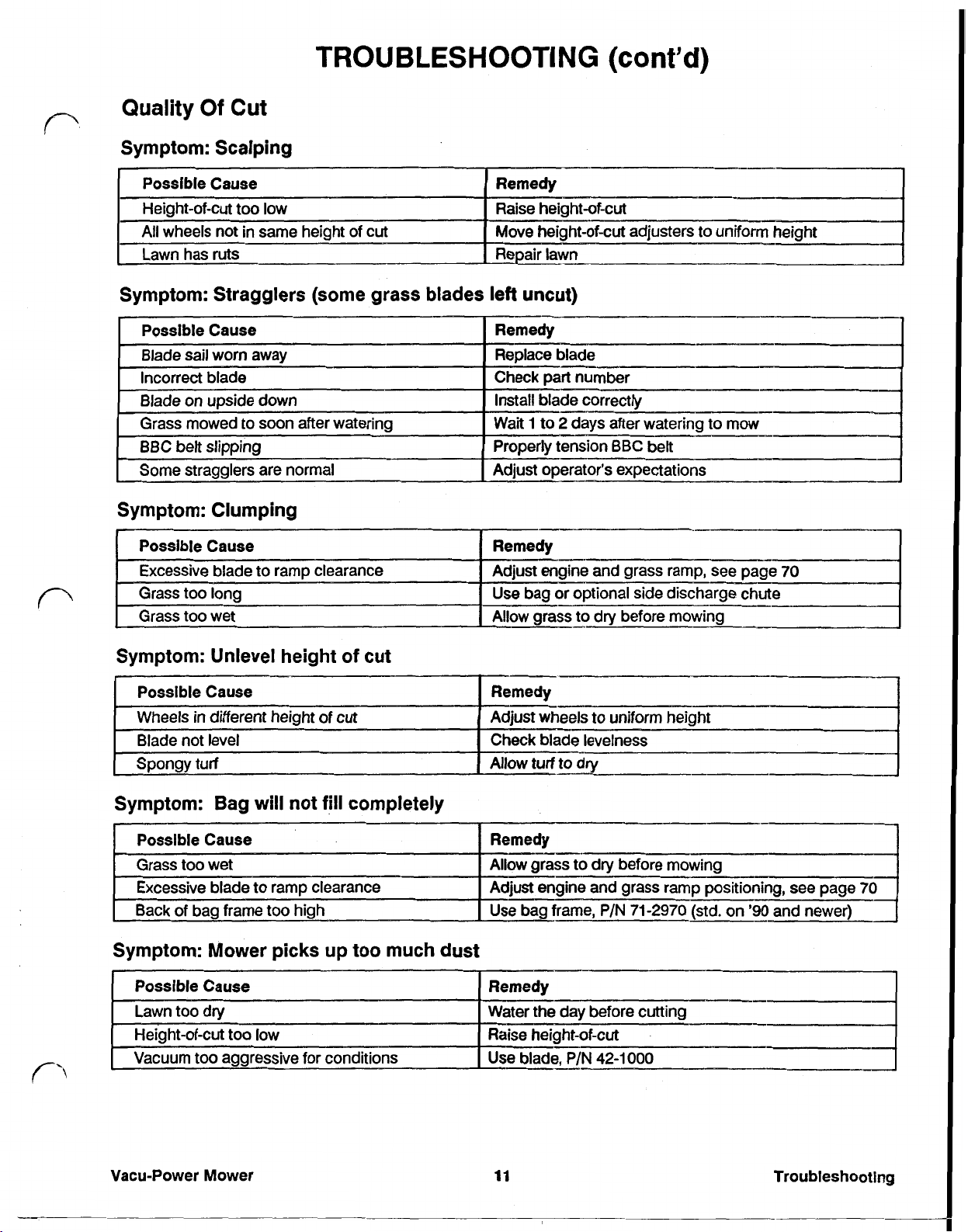

Quality

Of Cut

Symptom: Scalping

Symptom: Stragglers (some grass blades left uncut)

Symptom: Clumping

S

m tom: Bag

will

not

fill

completely

Symptom: Mower picks up too much

Possible Cause

Lawn too dry Water the day before cutting

too

Height-of-cut

Vacuum too aggressive

Vacu-Power Mower

low

for

conditions

dust

Remedy

Raise height-of-cut

Use blade.

11

P/N

42-1000

I

Troubleshooting

TROUBLESHOOTING

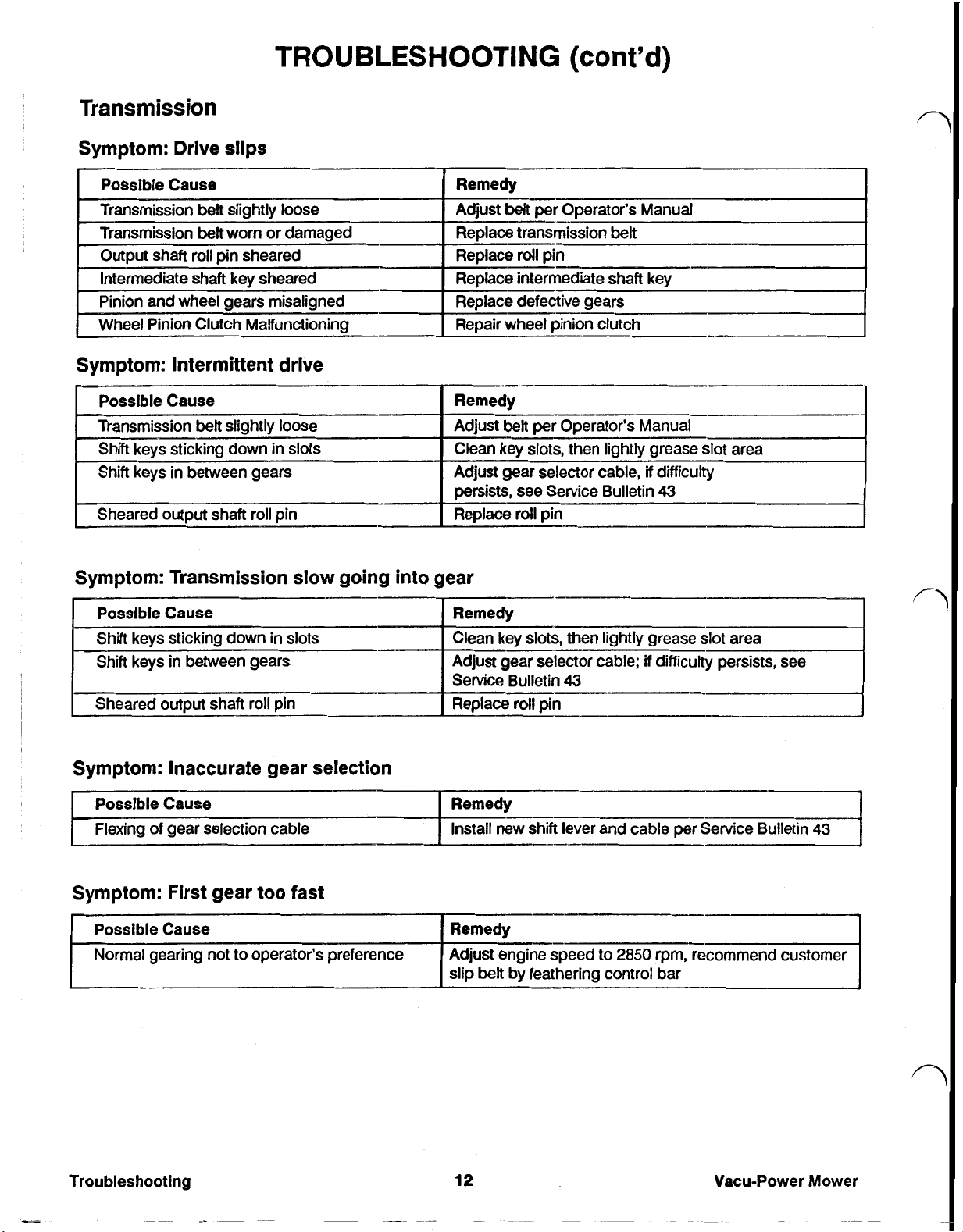

Transmission

Symptom: Drive slips

Possible Cause

Transmission

Transmission

[

Output shaft roll

ntermediate shaft key sheared

Pinion and wheel gears mis-aligned

Wheel Pinion Clutch Malfunctioning Repair wheel

Symptom: Intermittent drive

belt

slightly loose Manual

belt

worn or damaged

pin

sheared Replace roll

(cont'd)

pin

Replace intermediate shaft key

Replace defective gears

pinion

clutch

slow

Symptom: Transmission

Possible Cause

Shift keys sticking down

in

Shift keys

Sheared output shaft roll

between gears

in

pin

slots

going into gear

Symptom: Inaccurate gear selection

Possible Cause

of

Flexing

gear selection cable

Symptom: First gear too fast

Remedy

Clean key slots, then lightly grease

Adjust gear selector cable; if difficulty persists, see

Service Bulletin

Replace

Remedy

Install new shift lever and cable per

roll

43

pin

slot

area

Troubleshooting

12

Vacu-Power Mower

TROUBLESHOOTING

(cont'd)

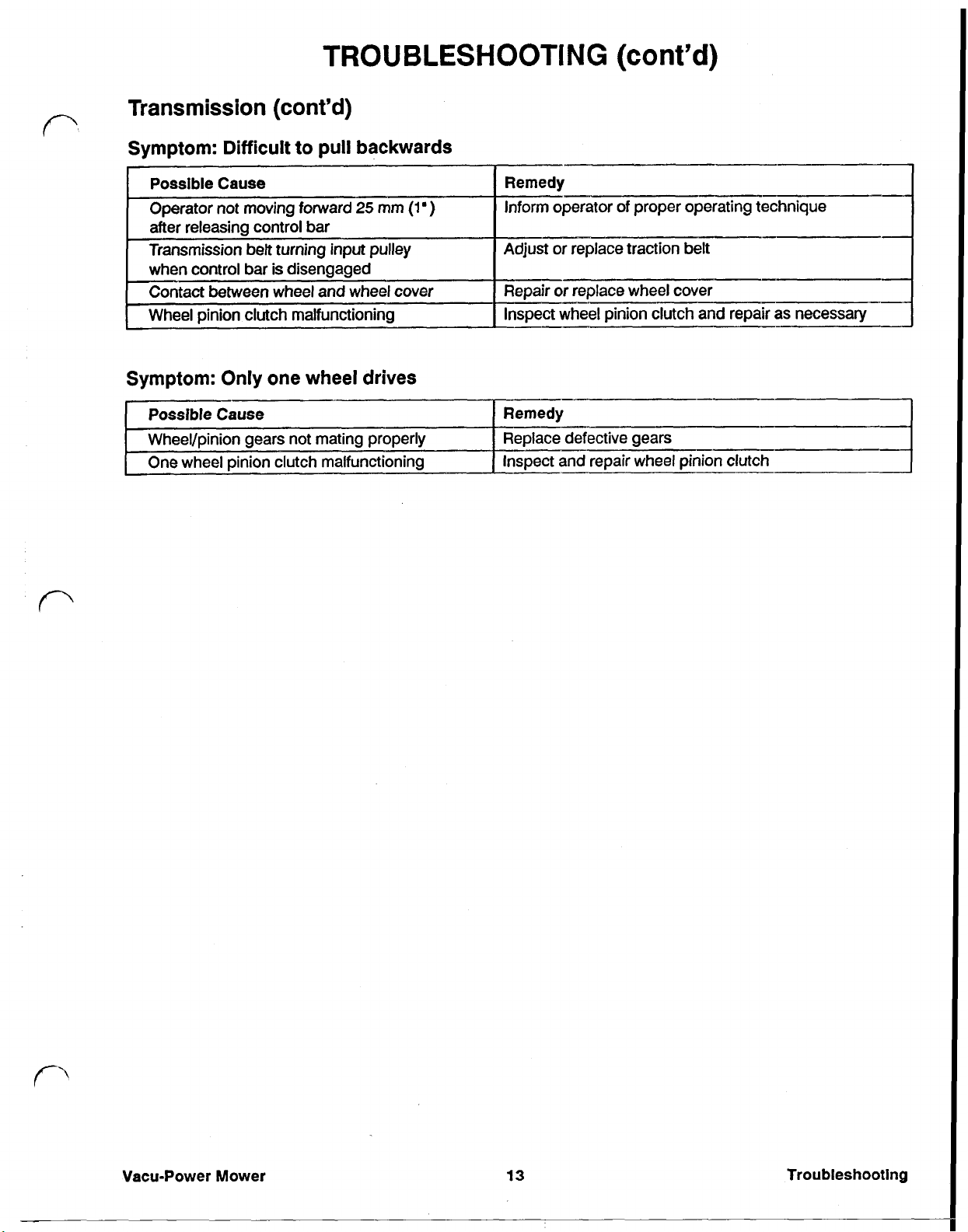

Transmission

Symptom: Difficult

Possible

Operator not moving forward

after releasing control bar

Transmission belt

when control bar is disengaged

Contact between wheel and wheel cover

Wheel pinion clutch malfunctioning

Symptom: Only one wheel drives

Possible

Wheel/pinion gears not mating properly Replace defective gears

One wheel pinion clutch malfunctioning Inspect and' repair wheel pinion clutch

Cause

Cause

(cont'd)

to

pull backwards

25

turning

input

mm

pulley

(1

I

Remedy

)

Inform operator of proper operating technique

I

Adjust or replace traction belt

I

Repair or replace wheel cover

Inspect wheel pinion clutch and repair as necessary

Remedy

I

I

I

Vacu-Power

Mower

13

Troubleshooting

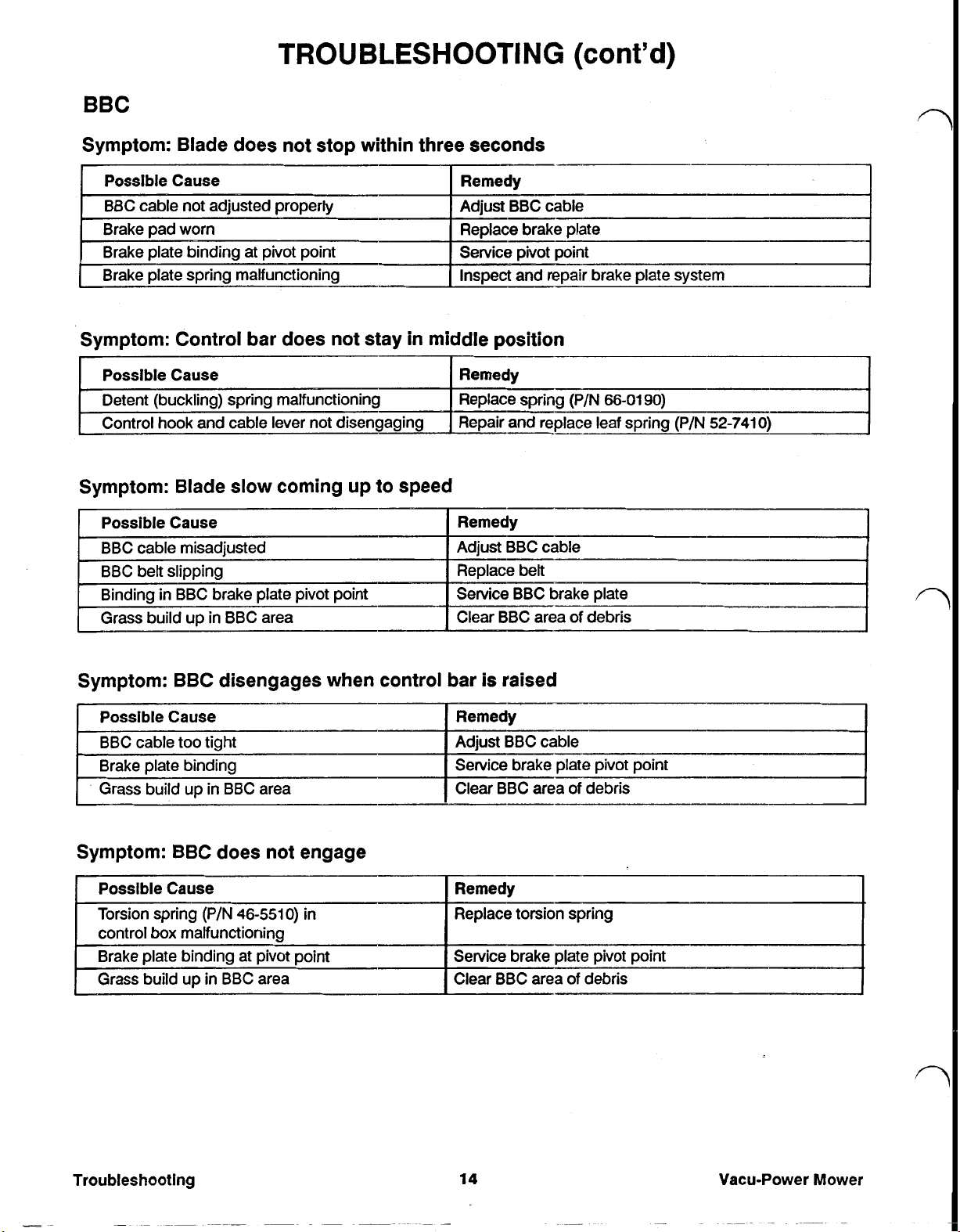

TROUBLESHOOTING

BBC

Symptom: Blade does not stop within three seconds

(cont’d)

Possible Cause

BBC cable not adjusted properly

-Brake pad worn

Brake plate spring malfunctioning

Remedy

Adjust BBC cable

Replace brake plate

Service pivot point Brake plate binding at pivot point

Inspect and repair brake plate system

Symptom: Control bar does not stay in middle position

Remedy

Detent (buckling) spring malfunctioning

Control hook and cable lever not disengaging

Replace spring (P/N

Repair and replace leaf spring (P/N

Symptom: Blade slow coming up to speed

Possible Cause Remedy

BBC cable mis-adjusted Adjust BBC cable

BBC belt slipping

Binding

Grass build

I

in

BBC brake plate pivot point

up

in BBC area

Replace belt

Service BBC brake plate

Clear BBC area of debris

66-0190)

52-7410)

1

I

I

I

I

Symptom: BBC disengages when control bar

Possible Cause

BBC cable too tight

binding

up

in

Grass build

BBC area Clear BBC area of debris

Remedy

Adjust BBC cable

Service brake plate pivot point Brake plate

Symptom: BBC does not engage

Possible Cause Remedy

Torsion spring (P/N

control box malfunctioning

Brake plate binding at pivot point

Grass

build

up

46-5510)

in

BBC area

in

Replace torsion spring

Service brake plate pivot point

Clear BBC area

is

raised

of

debris

I

Troubleshooting

14

Vacu-Power Mower

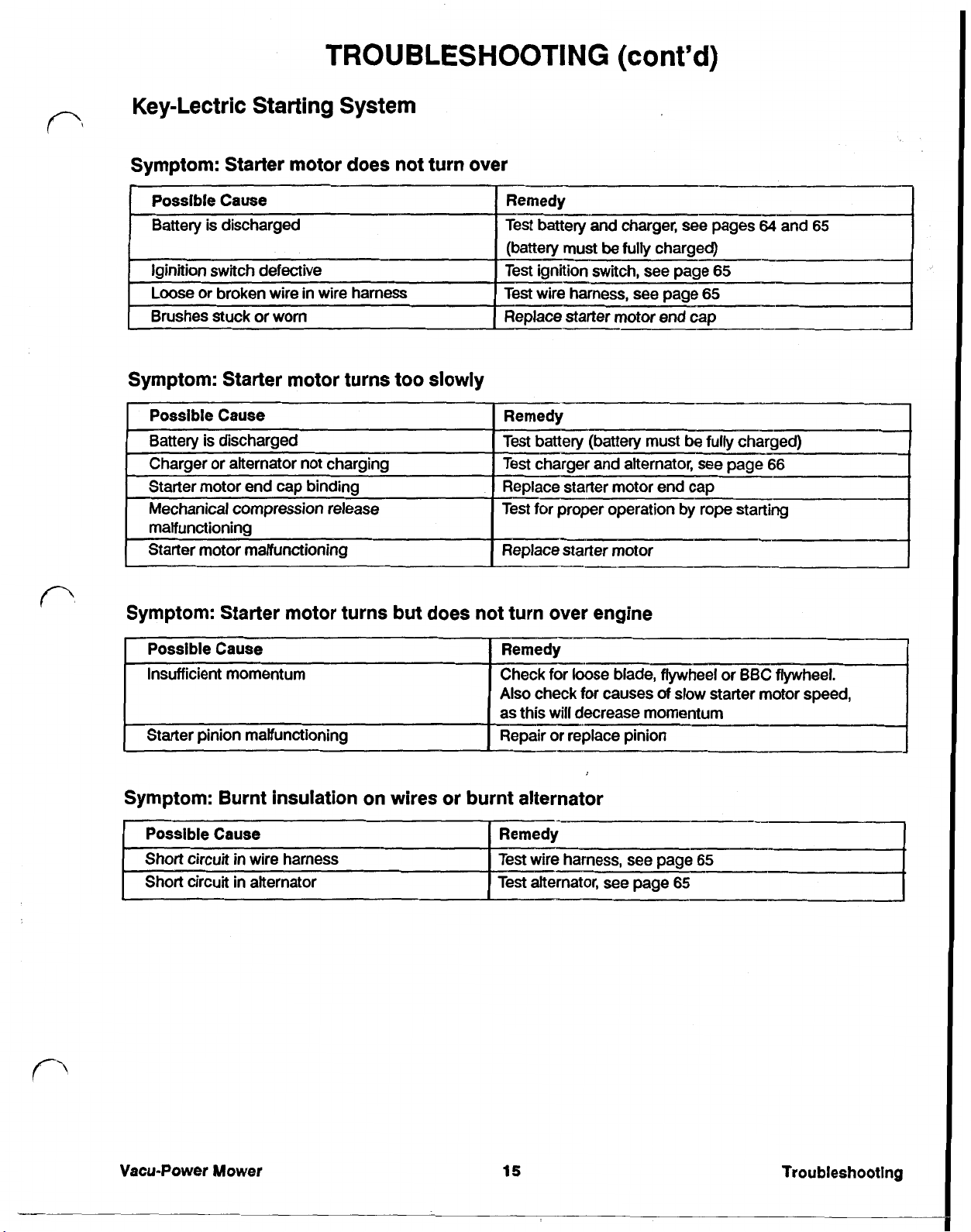

TROUBLESHOOTING

Key-Lectric Starting System

Symptom: Starter motor does not turn over

Symptom: Starter motor turns too slowly

(cont'd)

Symptom: Starter motor turns but does not turn over engine

[Possible Cause Remedy

Insufficient momentum Check for loose blade, flywheel

Also

check

for

causes

will

as this

Starter pinion malfunctioning Repair

decrease momentum

or

replace pinion

Symptom: Burnt insulation on wires or burnt alternator

Possible Cause

Short circuit in wire harness Test wire harness, see page

Short circuit in alternator Test alternator, see page

of

or

BBC flywheel.

slow

starter motor speed,

65

65

Vacu-Power Mower

15

Troubleshootlng

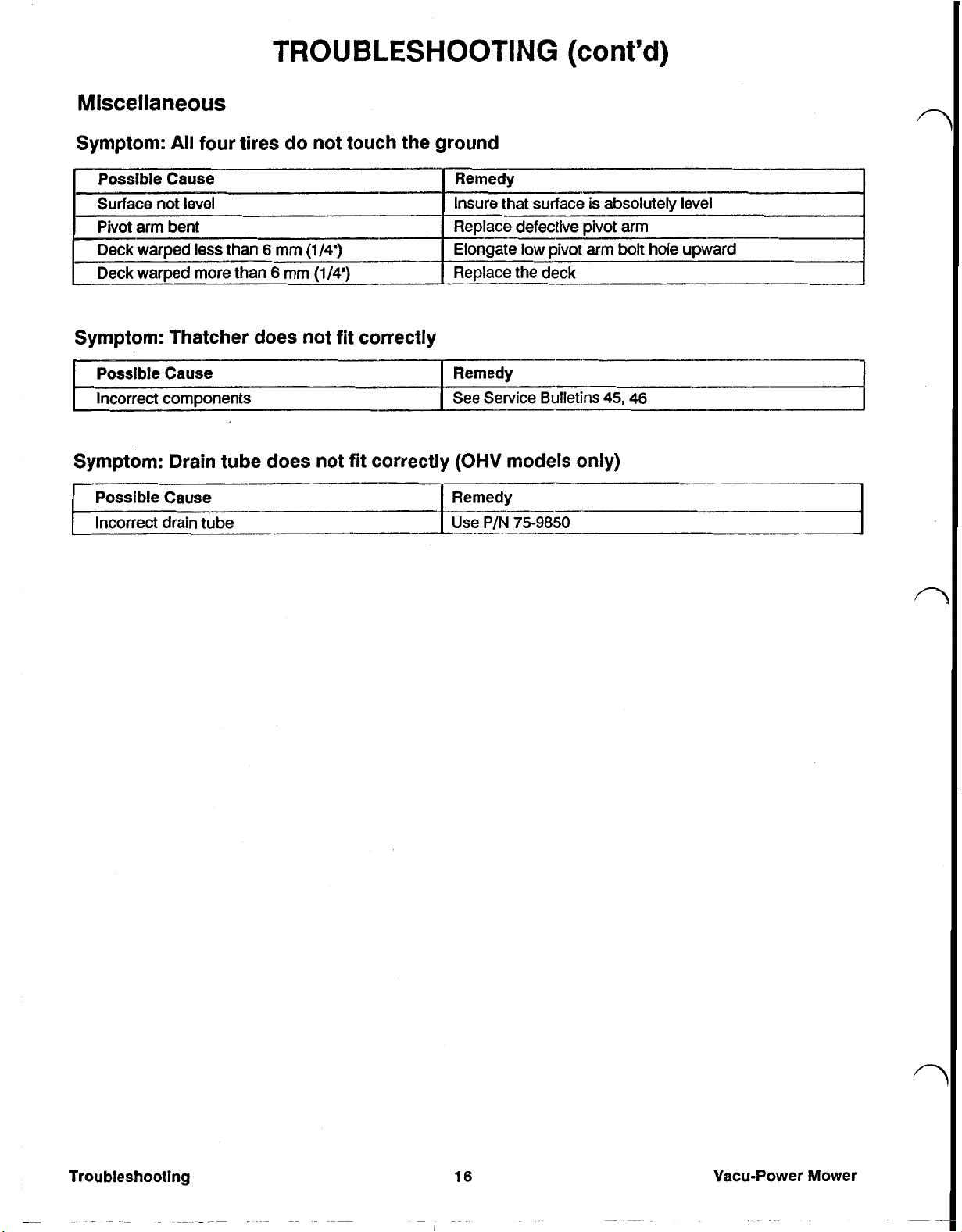

Miscellaneous

TROUBLESHOOTING

(cont’d)

Symptom:

All

four tires

do

not touch the ground

Symptom: Thatcher does not fit correctly

Possible Cause

Incorrect

components

Symptom: Drain tube does not fit correctly

Possible Cause Remedy

Incorrect drain tube

Remedy

See Service Bulletins

(OHV

45, 46

models only)

Vacu-Power

Mower

MAINTENANCE

TECUMSEH 2-CYCLE ENGINE

Tecumseh 2-Cycle Servicing the Air Cleaner

Normally, clean the air cleaner after every

hours. More frequent cleaning is required when the

in

dusty

or

mower is operated

ditty conditions.

25

operating

5.

Clean the top side of the base and the inside of

cover thoroughly. Clean the filter by tapping on

a

solid surface

6.

Reinstall the paper filter and the

nut

finger tight and then turn one

complete turn.

nut.

lighten the

(1)

more

CAUTION! Pull the high tension wire

plug before performing adjustments or

maintenance.

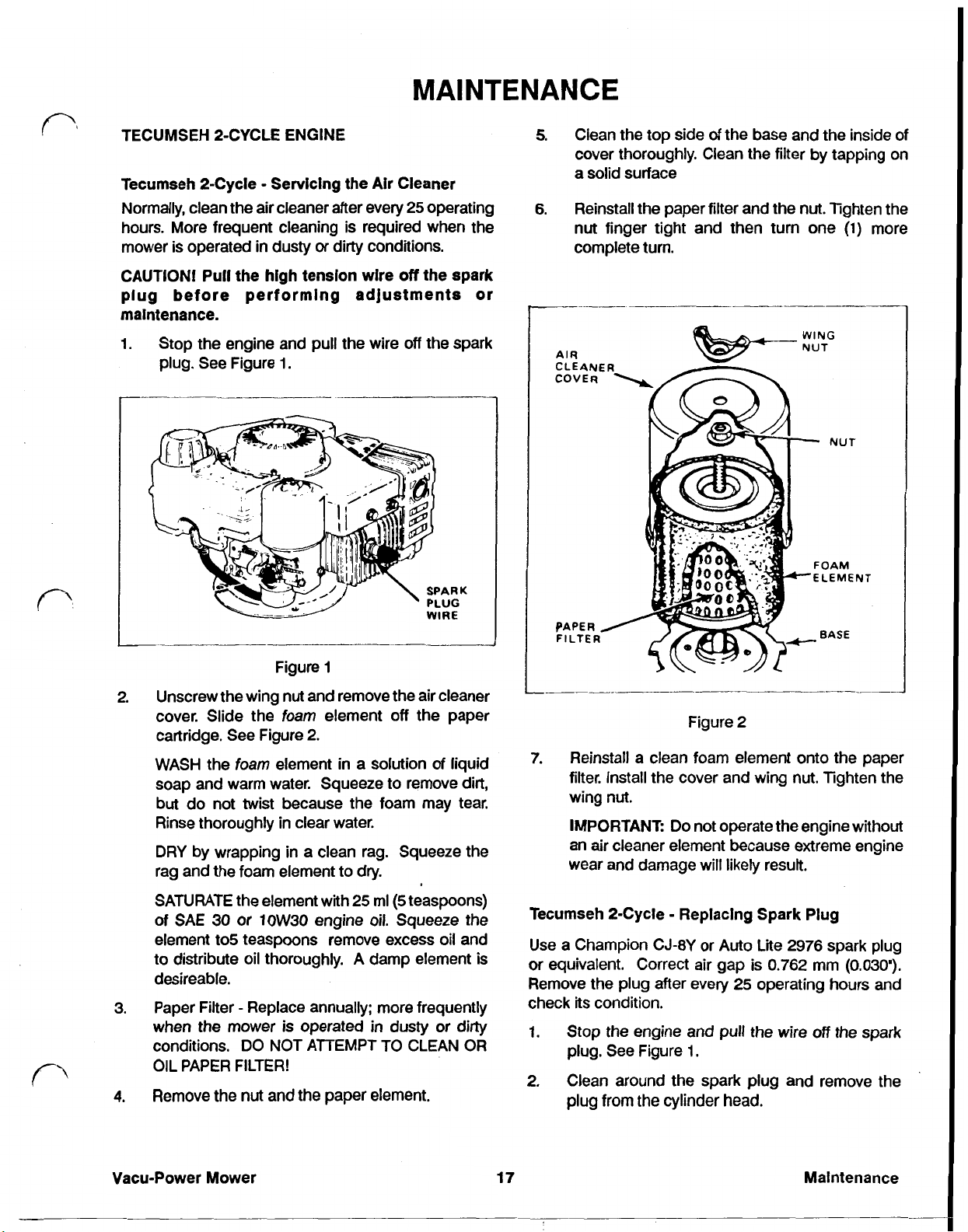

1. Stop the engine and pull the wire

plug. See Figure 1.

Figure

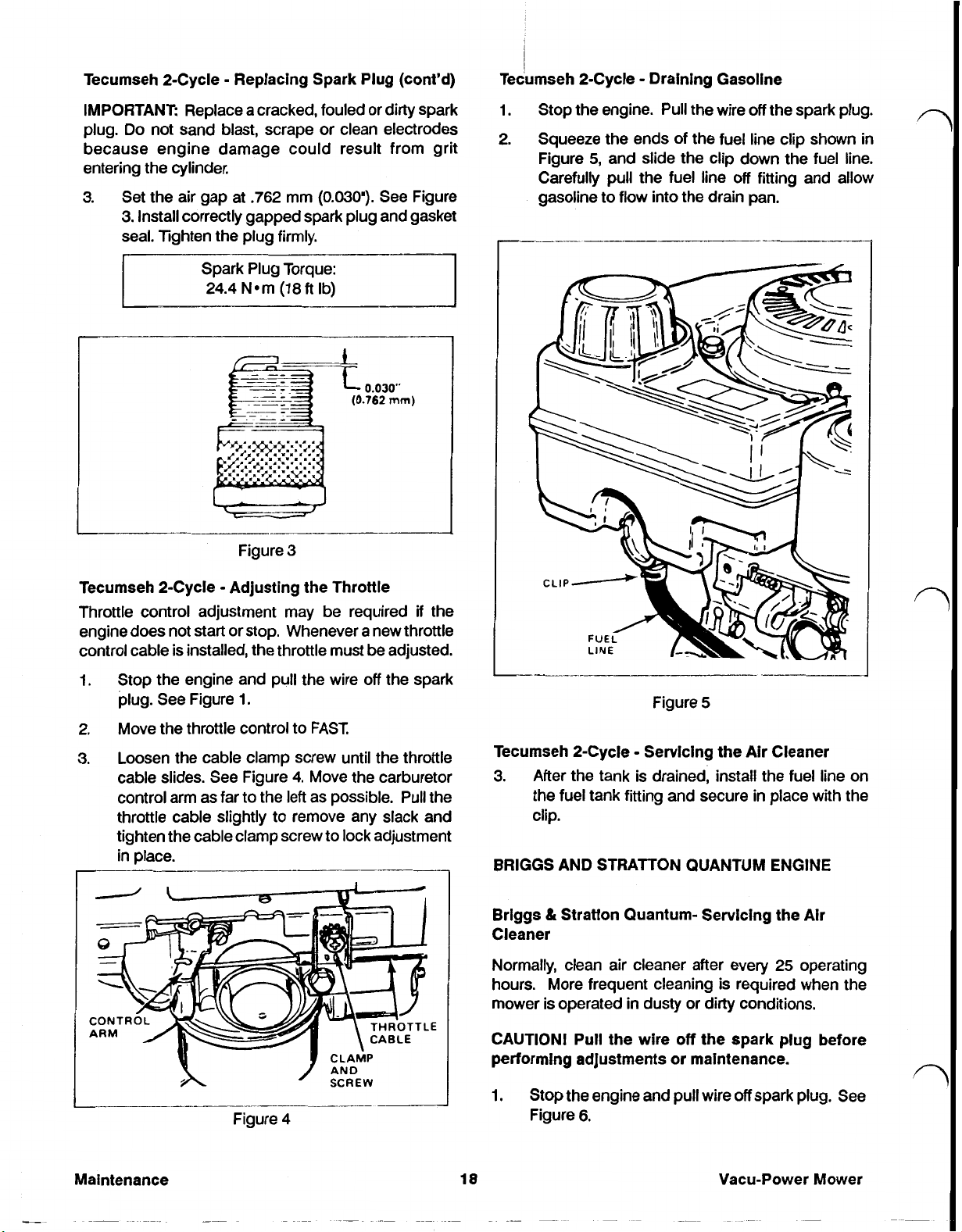

2.

Unscrew the wing

cover. Slide the

cartridge. See Figure

WASH the

soap and warm water. Squeeze to remove

but

do not twist because the foam may tear.

Rinse thoroughly

DRY

rag and the foam element to dry.

foam

by wrapping

element

1

nut

and remove the air cleaner

foam

element

2.

in

in

clear water.

in

a clean rag. Squeeze the

off

the spark

off

the spark

off

the paper

a solution of liquid

dirt,

Figure

7.

Reinstall a clean foam element onto the paper

filter. Install the cover and wing

wing

nut.

IMPORTANT:

an air cleaner element because extreme engine

wear and damage will likely result.

Do

2

nut.

lighten the

not operate the engine without

SATURATE the element with

of

SAE

30

or

10W30 engine

element to5 teaspoons remove excess oil and

to

distribute oil thoroughly. A damp element

desireable.

3. Paper Filter Replace annually: more frequently

when the mower is operated

conditions.

OIL PAPER FILTER!

4.

Remove the

Vacu-Power Mower

DO

NOT ATTEMPT TO CLEAN

nut

and the paper element.

25

ml

5 teaspoons)

oil.

Squeeze the

in

dusty or

dirty

OR

is

Tecumseh 2-Cycle Replacing Spark Plug

Use a Champion CJ-8Y

or

equivalent. Correct air gap

Remove the plug after every

check its condition.

1.

Stop the engine and

plug. See Figure

2.

Clean around the spark plug

plug

from the

17

or

1.

cylinder

Auto Lite

is

0.762

25

operating hours and

pull

the wire

head.

2976

spark plug

mm

(0.030'”)

off

the spark

and

remove the

Maintenance

Tecumseh 2-Cycle Replacing Spark Plug (cont'd)

IMPORTANT: Replace a cracked, fouled or dirty spark

Do

plug.

because engine damage could result from grit

entering the cylinder.

3.

not sand blast, scrape or clean electrodes

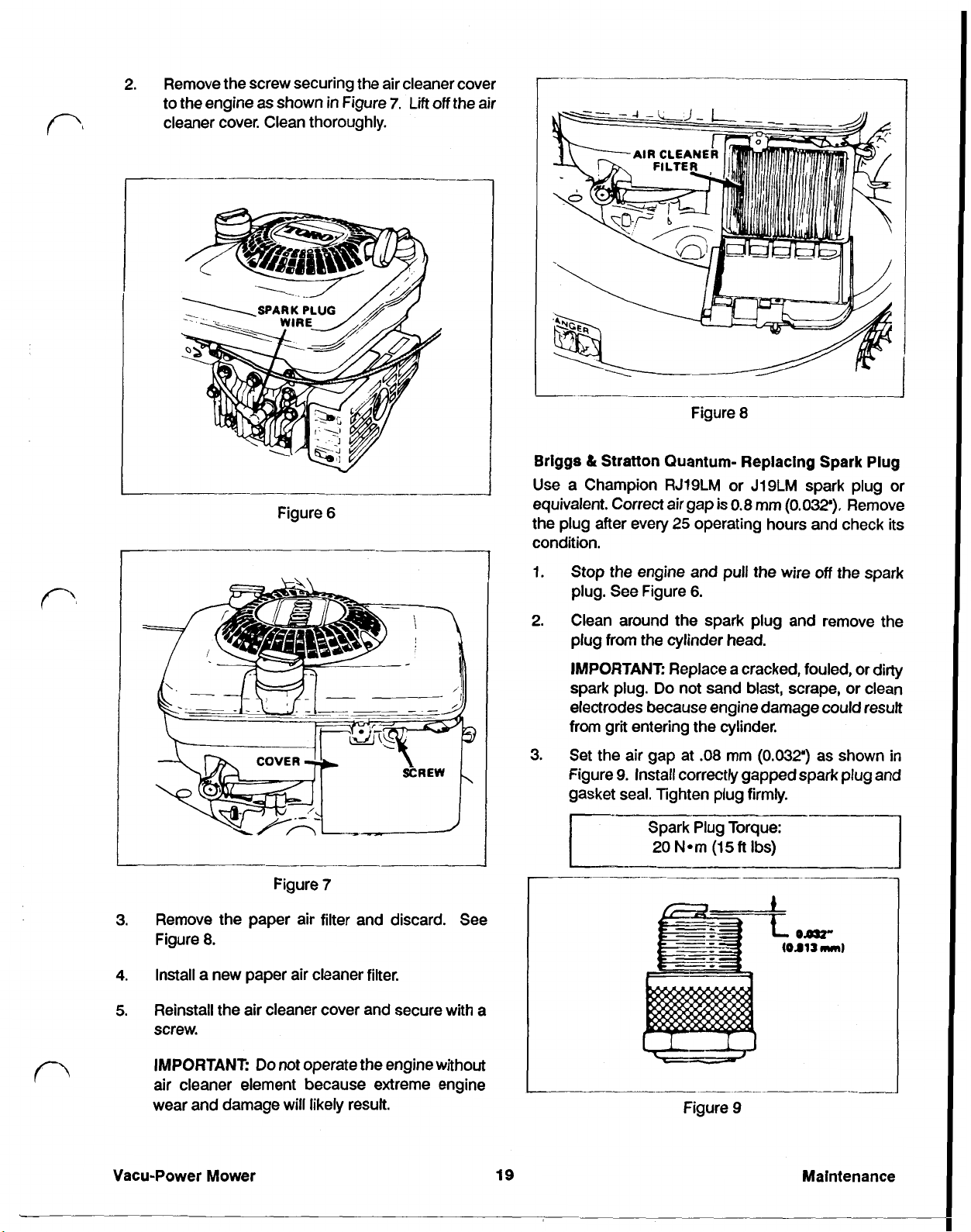

Set the air gap at

3.

Install correctly gapped spark plug and gasket

seal. Tighten the plug firmly.

.762

mm

(0.030”).

See Figure

i

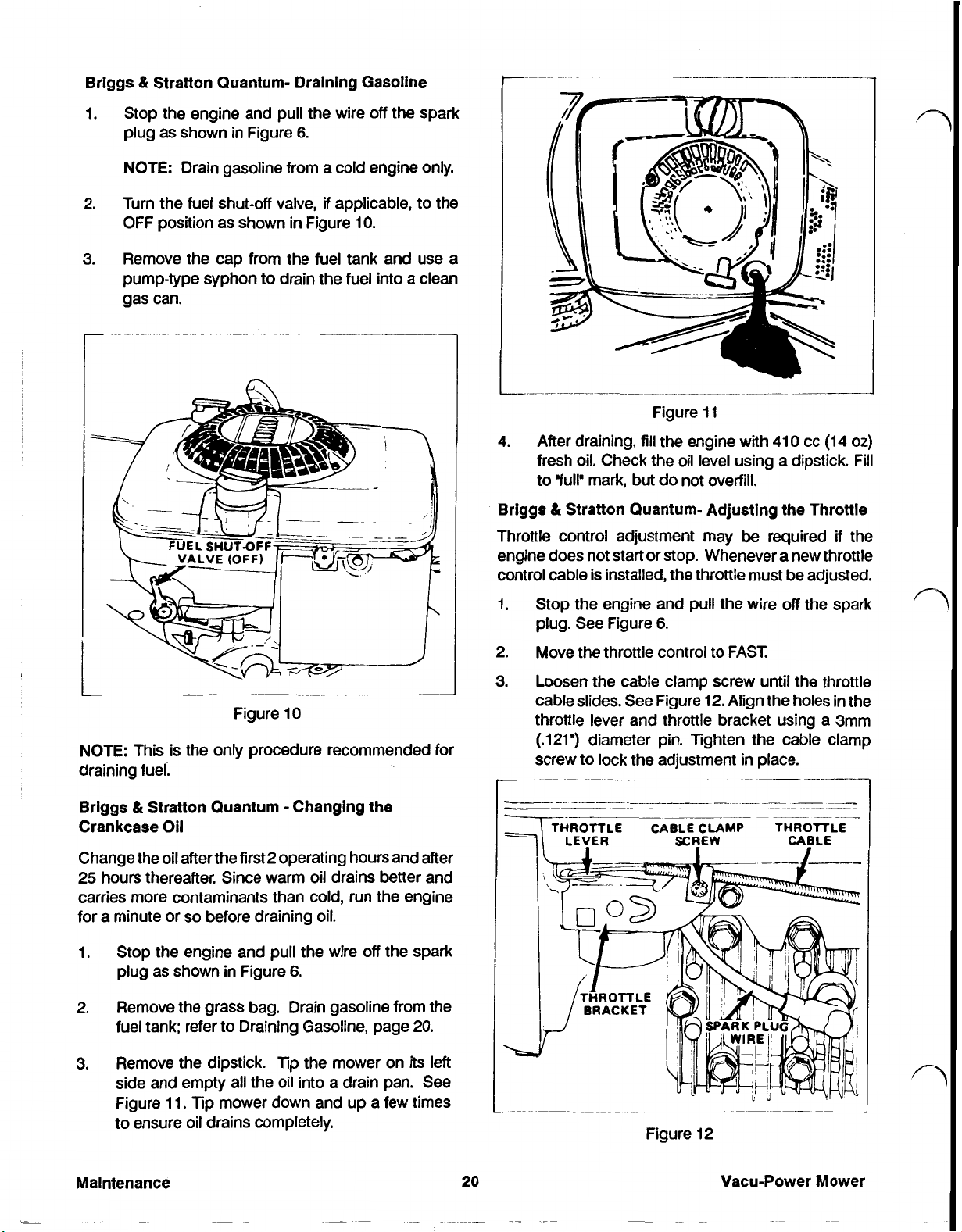

Tecumseh 2-Cycle Draining Gasoline

1.

Stop the engine. Pull the wire

2.

Squeeze the ends of the fuel line clip shown

Figure

Carefully

gasoline to flow into the drain pan.

5,

and slide the clip down the fuel line.

pull

the fuel line

off

the spark plug.

off

fitting

in

and allow

Figure

Tecumseh 2-Cycle Adjusting the Throttle

Throttle control adjustment may be required

engine does not start or stop. Whenever a new throttle

control cable is installed, the throttle must be adjusted.

1.

Stop the engine and pull the wire

plug. See Figure

2.

Move the throttle control to

3.

Loosen the cable clamp screw until the throttle

cable slides. See Figure

control arm as far to the left as possible. Pull the

throttle cable slightly to remove any slack and

tighten the cable clamp screw to lock adjustmel

in

place.

1.

3

off

the spark

FAST,

4.

Move the carburetor

if

the

Tecumseh 2-Cycle Servicing the Air Cleaner

3.

It

BRIGGS AND STRATTON QUANTUM ENGINE

Brlggs Stratton Quantum- Servicing the Air

Cleaner

Normally, clean air cleaner after every

hours. More frequent cleaning is required when

mower

After the tank is drained, install the fuel line on

fitting

the fuel tank

clip.

is

operated

and secure

in

dusty or dirty conditions.

in

place with the

25

operating

the

CAUTION!

performing adjustments or maintenance.

18

Pull

the wire

Stop the engine and pull wire

Figure

6.

off

the spark plug before

off

spark plug. See

Vacu-Power Mower

2.

Remove the screw securing the air cleaner cover

to the engine

as

shown

in

Figure

7.

cleaner cover. Clean thoroughly.

Lift

off

the air

Figure

Briggs & Stratton Quantum- Replacing Spark Plug

I

Figure

6

Use a Champion RJ19LM or J19LM spark plug or

equivalent. Correct air gap is

the plug after every

25

8

0.8

mm

(0.032").

Remove

operating hours and check its

condition.

1.

Stop the engine and

plug. See Figure

2.

Clean around the spark plug and remove the

6.

pull

the wire

off

the spark

plug from the cylinder head.

IMPORTANT:

spark plug.

Replace a cracked, fouled, or dirty

Do

not sand blast, scrape, or clean

electrodes because engine damage could result

from grit entering the cylinder.

3.

Set the air gap at

Figure

9.

Install correctly gapped spark plug and

.08

mm

(0.032")

as shown

in

gasket seal. Tighten plug firmly.

Spark Plug Torque:

20

(15

ft

Ibs)

Figure

3.

Remove the paper air filter and discard. See

Figure

4.

Install a new paper air cleaner filter.

5.

Reinstall the air cleaner cover and secure with a

8.

7

screw.

IMPORTANT:

Do

not operate the engine without

air cleaner element because extreme engine

wear and damage will likely result.

Vacu-Power

Mower

19

Figure

9

Maintenance

Briggs & Stratton Quantum- Dralnlng Gasoline

1.

Stop the engine and pull the wire off the spark

in

plug as shown

Figure

6.

NOTE: Drain gasoline from a cold engine only.

2.

Turn the fuel shut-off valve,

OFF position

as

shown

if

applicable, to the

in

Figure

IO.

3. Remove the cap from the fuel tank and use a

pump-type syphon to drain the fuel into a clean

gas can.

n

NOTE: This is the only procedure recommended for

draining fuel:

&

Briggs

Crankcase

Stratton Quantum Changing the

Oil

Change the oil after the first 2 operating hours and after

25

hours thereafter. Since warm oil drains better and

carries more contaminants than cold, run the engine

for a minute or

so

before draining oil.

4.

After draining,

Figure

fill

I

I

the engine with

410

cc

(14

oz)

fresh oil. Check the oil level using a dipstick. Fill

to “full” mark,

&

Briggs

Stratton Quantum- Adjusting the Throttle

Throttle control adjustment may

but

do not overfill.

be

required

if

the

engine does not start or stop. Whenever a new throttle

control cable is installed, the throttle must be adjusted.

1.

Stop the engine and

plug. See Figure

2.

Move the throttle control to FAST.

3.

Loosen the cable clamp screw until the throttle

cable slides. See Figure

6.

pull

the wire off the spark

12.

Align the holes

in

the

throttle lever and throttle bracket using a 3mm

(.121”)

screw to lock the adjustment

diameter pin. Tighten the cable clamp

in

place.

THROTTLE CABLE

LEVER SCREW CABLE

CLAMP

THROTTLE

1.

Stop the engine and pull the wire off the spark

plug as shown

2.

Remove the grass bag. Drain gasoline from the

in

Figure

6.

fuel tank; refer to Draining Gasoline, page

3.

Remove the dipstick.

Tip

the mower on its left

side and empty all the oil into a drain pan. See

11.

Tip

Figure

mower down and up a few times

to ensure oil drains completely.

20.

Vacu-Power Mower

TORO 2-CYCLE ENGINE

TORO 2-Cycle Replacing the Spark Plug

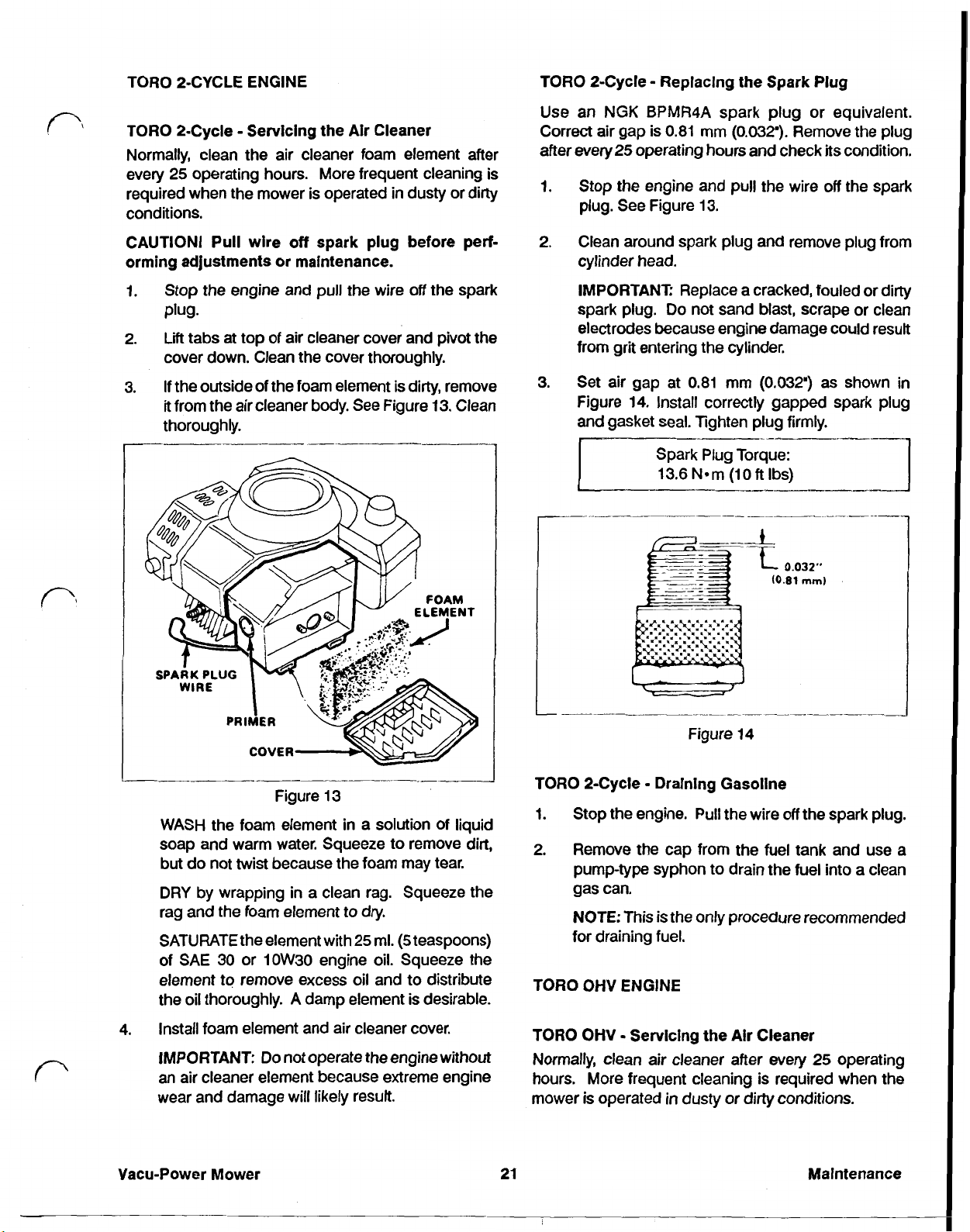

TORO 2-Cycle Servicing the Air Cleaner

Normally, clean the air cleaner foam element after

every

25

operating hours. More frequent cleaning is

required when the mower is operated

in

dusty or dirty

conditions.

CAUTION !

orming adjustments or maintenance.

1. Stop the engine and pull the wire

Pull

wire

off

spark plug before perf-

off

the spark

Plug.

2.

Lift

tabs at top of air cleaner cover and pivot the

cover down. Clean the cover thoroughly.

If

3.

the outside of the foam element is dirty, remove

it

from the air cleaner body. See Figure 13. Clean

thoroughly.

Use an

Correct air gap is 0.81 mm

after every

1.

NGK

BPMR4A spark plug or equivalent.

(0.032”)

25

operating hours and check

Remove the plug

Stop the engine and pull the wire

its

condition.

off

the spark

plug. See Figure 13.

2.

Clean around spark

plug

and

remove plug from

cylinder head.

IMPORTANT

spark plug.

Replace a cracked, fouled or dirty

Do

not sand blast, scrape or clean

electrodes because engine damage could result

from grit entering the cylinder.

3. Set air gap at 0.81 mm

Figure

and

14.

Install correctly gapped spark plug

gasket seal. Tighten plug firmly.

(0,032”)

as

shown

in

Figure 13

WASH

the foam element

in

a solution of liquid

soap and warm water. Squeeze to remove

but do not twist because the foam may tear.

DRY

by wrapping

in

a clean rag. Squeeze the

rag and the foam element to dry.

25

ml.

(5

SATURATE the element with

teaspoons)

of SAE 30 or 1OW30 engine oil. Squeeze the

element to remove excess oil and to distribute

A

the oil thoroughly.

4.

Install foam element and air cleaner cover.

IMPORTANT:

damp element is desirable.

Do not operate the engine without

an air cleaner element because extreme engine

wear and damage will likely result.

Vacu-Power Mower

dirt,

TORO 2-Cycle Draining Gasoline

1. Stop the engine. Pull the wire

2.

Remove the cap from the fuel tank and use a

off

the spark plug.

pump-type syphon to drain the fuel into a clean

gas can.

NOTE:

This is the only procedure recommended

for draining fuel.

TORO OHV ENGINE

TORO OHV Servicing the Alr Cleaner

Normally, clean air cleaner after every

25

hours. More frequent cleaning is required when the

mower is operated

21

in

dusty or dirty conditions.

Maintenance

operating

Loading...

Loading...