Page 1

Model #UTV700AAC000EP - Serial #4UF16MPV9GT309933 &

Activate/charge/install battery

Form Number 3406-715 Rev. A

Effective May, 2016

Up

PRE-DELIVERY SETUP INSTRUCTIONS

CHECKLIST

Check engine/transmission oil

Check tire inflation pressure

Check wheel lug nut torque

Install left-side foot restraint

Install ROPS/seat belts/side restraints

Check cooling system — level and hoses

Install steering wheel

Check/adjust front wheel alignment

Check hydraulic brake fluid level — pedal firmness

Burnish the brake pads

Check throttle cable adjustment

NOTE: Read these instructions thoroughly before

starting the Pre-Delivery Setup.

Even though the vehicle has been set up (with some

minor exceptions) and inspected at the factory, it is

mandatory that EVERY vehicle be properly inspected

and serviced at the dealership prior to being released to

the customer. Experience has shown that dealerships

that properly prepare each vehicle have fewer warranty

problems and more satisfied customers.

RECOMMENDED TOOLS

The following tools will assist the technician during the

set-up process:

• Drill w/Torx Bits

• Impact Wrench

• Metric Socket Set

• Torque Wrench

BATTERY

NOTE: Refer to all warnings and cautions provided with the battery or battery charger.

This ROV is shipped with a sealed battery. The battery

requires an initial charge after activation as well as periodic

maintenance-charging during periods of non-use or storage.

Activating Battery

Always activate and maintain the battery in accordance

with the following instructions to ensure maximum service life and performance from the battery.

Check gear case lubricant

Check shift lever for proper operation

Check headlight aim

Check gasoline level

Start engine and check electrical switches and lights

Test drive

Check decals/clean vehicle

Explain Operator’s Manual, Limited Warranty, and

legal obligations to the customer

Complete Owner Registration form with the customer

on the date of the sale

Each sealed battery comes with an electrolyte container and

proper amount for each specific battery type. DO NOT add

additional electrolyte to any sealed battery. Sealed battery

electrolyte has a higher concentration of sulfuric acid.

1. Carefully remove and save the sealing strip from the

battery electrolyte container. This will be used to seal

the battery later.

2. Remove and discard the foil sealing strip covering

the fill holes from the battery.

3. Place electrolyte container with the foil-sealed top of

the cells facing down into the fill ports of the battery.

4. Hold the container level in the fill ports of the battery. Push down to break the seals. Air bubbles will

appear as the ports fill. Do not tilt the electrolyte container. Do not remove the container from the battery

until all cells are completely empty.

5. Let the battery stand for 120 minutes (2 Hr) prior to

charging. This will allow the electrolyte to permeate

into the plates for optimum performance.

6. Fully insert the sealing strip over the fill holes by

hand. DO NOT use a hammer.

7. Charge the battery completely before installation.

Charging New Battery

NOTE: Batteries filled with electrolyte are only at

80% of their capacity.

Batteries can be charged two ways - Standard Charge and

Fast Charge. Standard charging is the only recommended

way to charge a battery. It gives the battery optimal performance and battery life.

1. Be sure the charger is unplugged from the 110-volt

electrical outlet.

1

Page 2

2. Connect the red terminal lead from the charger to the

positive terminal of the battery; then connect the

black terminal lead of the charger to the negative terminal of the battery.

3. Plug the charger into a 110-volt electrical outlet.

4. Charge the battery for a minimum of five full hours

at a rate of 10% of the battery amp-hour rating for

optimal battery performance and battery life (ex: 30

AH battery should be charged at 3.0 amps).

NOTE: If the battery becomes hot to the touch,

stop charging. Resume after it has cooled.

5. Once the battery has reached full charge (typically

13.5 volts), unplug the charger from the 110-volt

electrical outlet and disconnect the charging leads.

6. Allow the battery to sit for 2 hours before installing

in the vehicle.

Installing Battery

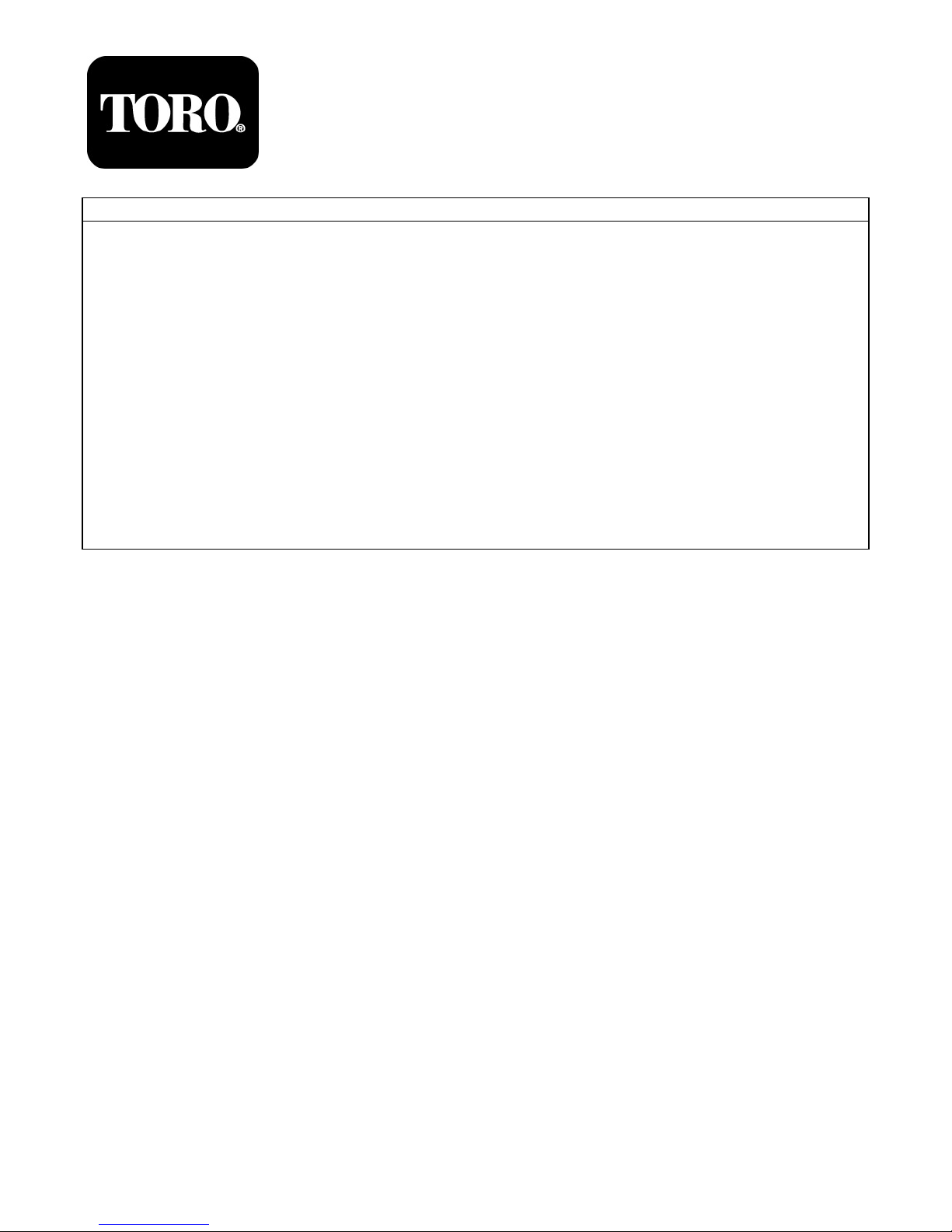

NOTE: The battery box is under the seat on the

operator’s side. To access the box, remove the

seat and pry off the battery compartment cover;

then remove the thumb screw securing the battery

box cover and lift the cover to access the battery.

PR942

NOTE: Loss of battery charge may be caused by

ambient temperature, ignition OFF current draw,

corroded terminals, self-discharge, or other factors. Maintenance charging is required to keep the

battery at a “fully-charged” state.

TIRES

This vehicle is equipped with low-pressure tubeless

tires. Do not under any circumstances substitute tires of

a different type or size.

TIRE INFLATION PRESSURE

! WARNING

Operating this vehicle with improper or uneven tire

inflation pressure is hazardous. Always maintain

proper tire inflation pressure.

Front and rear tire inflation pressure should be 138 kPa

(20.0 psi).

A low-pressure gauge is provided in the tool kit to measure the air pressure in the tires. Check the air pressure

in all tires before use of the vehicle.

PR943A

1. Route the battery cables into the battery compartment.

2. Install the battery; then connect the battery cables

(positive cable first) as shown. Tighten securely.

TC019

NOTE: When installing the battery into a vehicle,

coat the battery terminals with a light coat of

grease to minimize battery terminal corrosion and

then cover with the terminal boot if provided.

2

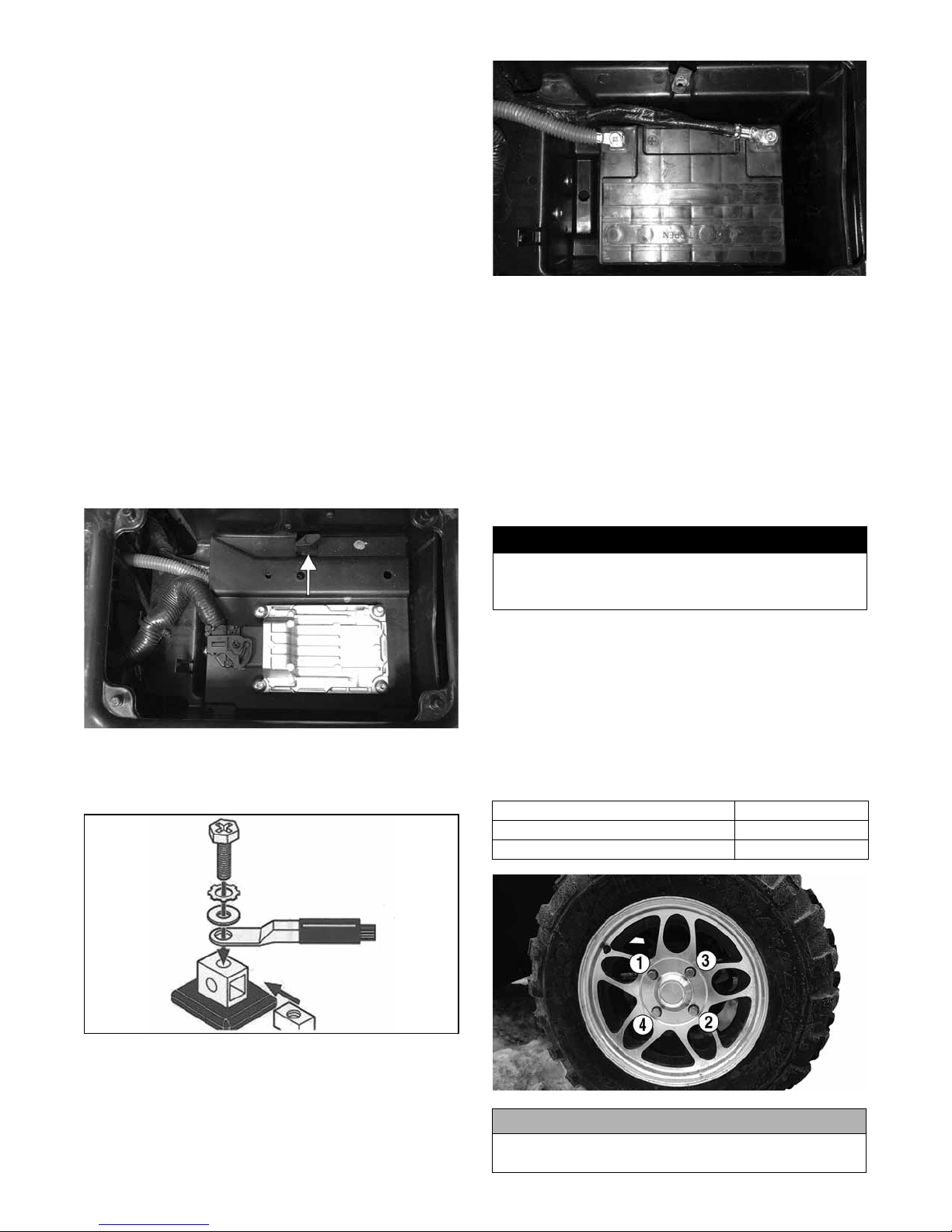

WHEEL LUG NUTS

Using a crisscross pattern, tighten the wheel nuts in 27 Nm (20 ft-lb) increments to the final torque shown below.

Steel Wheel 54 N-m (40 ft-lb)

Aluminum Wheel (Black Nuts) 80 N-m (60 ft-lb)

Aluminum Wheel (Chrome Nuts) 108 N-m (80 ft-lb)

PR941A

CAUTION

Using an impact wrench could result in incorrect

torque which could damage the wheel or hub studs.

Page 3

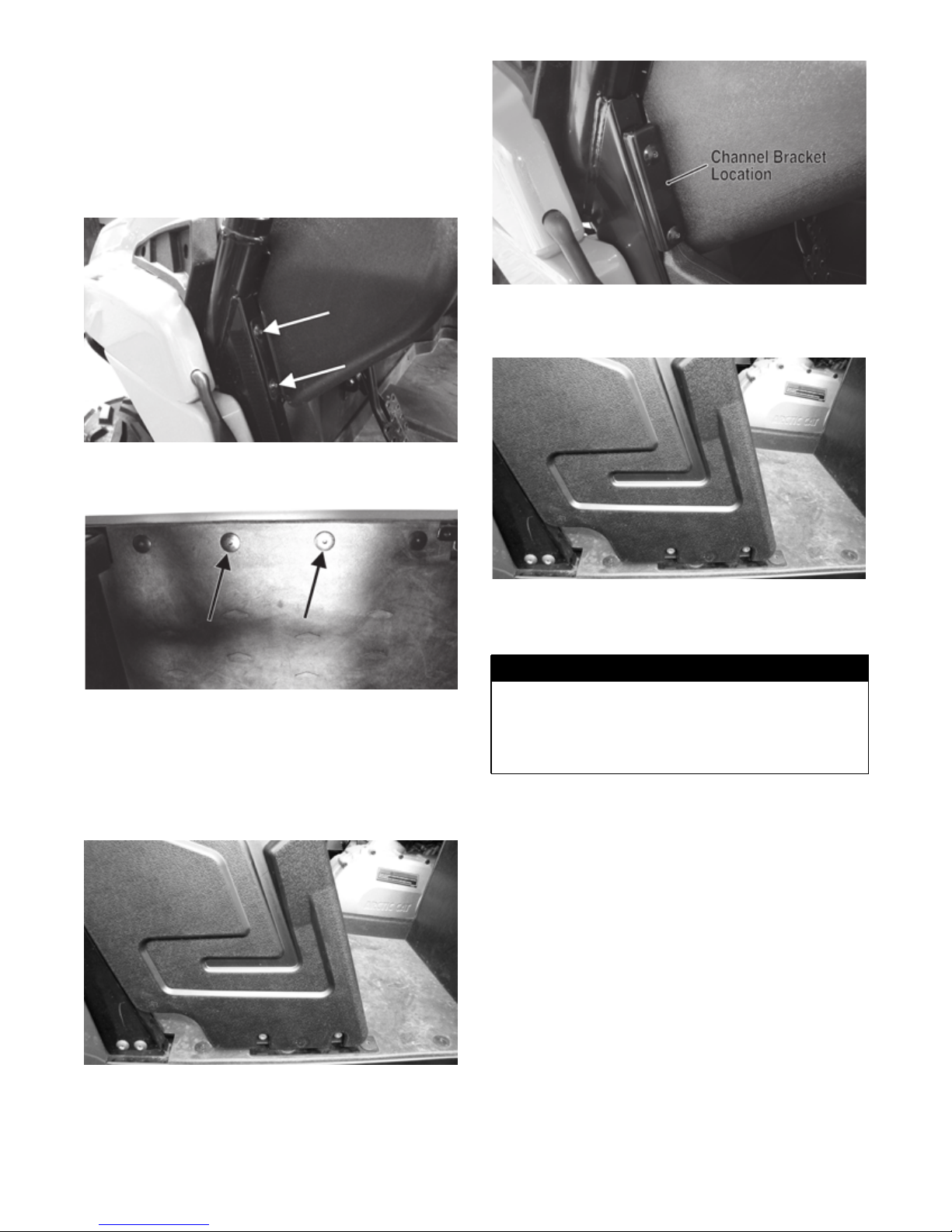

INSTALLING LEFT-SIDE FOOT

RESTRAINT

1. Remove the left-side foot restraint from the package

containing the side restraints.

2. Remove two sheet metal screws from the dashboard

attachment location and the second and third floor

retainer screws.

PR751A

PR800A

6. Tighten the cap screws securing the restraint to the

angle bracket securely.

PR752A

3. Remove the angle bracket from the foot restraint

(retain the screws) and attach to the floor using the

existing screws from the floor. Tighten securely.

4. Install the foot restraint and attach to the angle

bracket with the existing two cap screws. Do not

tighten at this time.

PR827

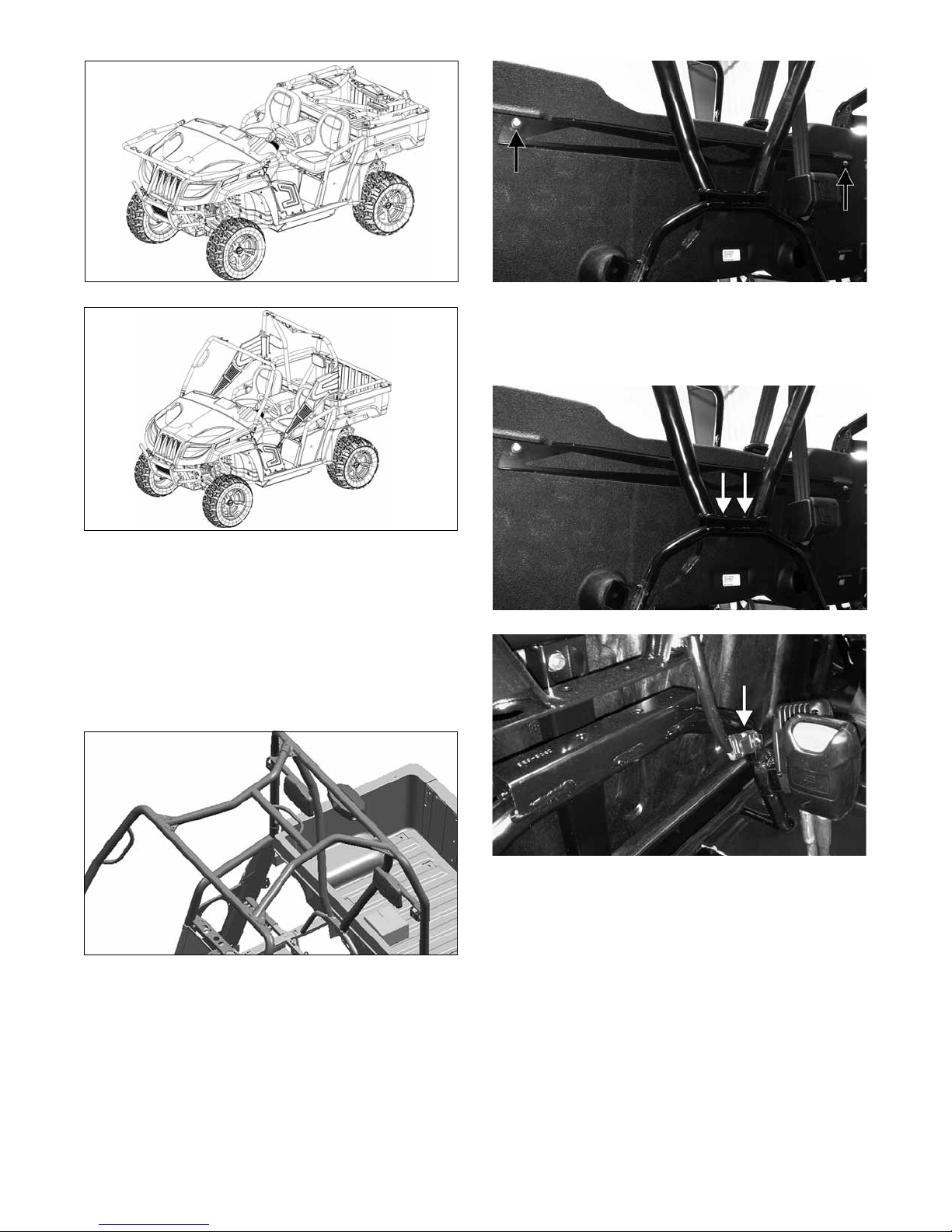

INSTALLING ROPS/SEAT BELTS/

SIDE RESTRAINTS

! WARNING

The ROPS must be installed prior to operating the

vehicle or delivery to a customer. Safety devices such

as taillight/brakelight, seat belts, and the passenger

hand holds are incorporated in the assembly. The

ROPS is part of the vehicle structure.

NOTE: The screws securing the front and rear

tubes during delivery will be used to secure the

ROPS tubes. There are nuts that secure the back

side of the ROPS tubes for shipping; these nuts

should be removed and discarded.

1. Loosen the Allen Head Screws securing the front

and rear ROPS tubes; then tip the front and rear

ROPS tubes from horizontal to vertical.

5. Secure the restraint and the dashboard with the

channel bracket (from the hardware pack) and two

sheet metal screws. Do not over-tighten.

PR827

3

Page 4

UTV-068

UTV-148

2. Raise the cargo box; then while holding the rear

ROPS, remove the screws securing the ROPS.

Loosely secure the ROPS in the correct position

using Allen Head Screws and new Nyloc Nuts. Do

not tighten at this time. Repeat for the front ROPS.

3. Place the Top X-brace into position between the

front and rear tubes and secure with eight Cap

Screws (installed from the top) and eight Zinc

Nyloc Nuts. Tighten to 47 N-m (35 ft-lb).

TC022A

5. Secure the bottom (middle) of the rear canopy tube

to the center support using two M6 Torx Screws.

Tighten to 11 N-m (8 ft-lb). Connect the brakelight/

taillight harness to the main harness.

TC022B

4. Secure the seat back to the rear ROPS tube with the

two cap screws. Tighten to 11 N-m (8 ft-lb).

4

TC030A

6. Tighten the front and rear tubes (from step 2) to 47

N-m (35 ft-lb). Ensure the flats of the nuts engage

the recesses of the ROPS tubes when tightened.

UTV-070

Page 5

TC027

TC029

7. Install the seat belts (cap screws installed from the

front) into the appropriate mounting tabs along the

headrest support tube on the rear ROPS. Tighten to

47 N-m (35 ft-lb).

8. Place Right-Side Occupant Side Restraint onto the

passenger-side tube and secure using four Cap

Screws. Tighten to 13.5 N-m (10 ft-lb).

PR834A

11. Loop the rear anchor strap around the ROPS mounting tube and secure with the buckle. Tighten so

strap rests as shown.

PR831A

12. Repeat steps 9-11 for opposite side.

13. Secure both side restraints to the kick panels using

the buckle.

9. Secure the outer side restraint using two Cap

Screws making sure to keep the straps properly

positioned.

10. Route the lower side restraint straps inside the side

tube; then secure to the frame using two Shoulder

Screws and Flange Nuts. Tighten to 13.5 N-m (10

ft-lb).

PR835A

PR833

CHECKING COOLING SYSTEM

Remove the filler cap and check coolant level. Coolant

level should be at the bottom of the standpipe in the

radiator neck. If coolant is required, add to bring coolant

to the specified level and install the cap.

NOTE: If coolant is required, mix coolant for a

temperature of -36°C (-34°F). Follow mixing recommendations of the manufacturer.

CAUTION

It is extremely important that the cooling system is

properly filled. If the system isn’t properly filled,

engine damage will occur.

5

Page 6

INSTALLING STEERING WHEEL

NOTE: The vehicle should be on level ground

with the front wheels oriented straight forward and

rearward.

1. Remove the nut and the steering wheel from the

steering shaft.

2. Install and align the steering wheel and loosely

secure with the nut.

NOTE: This model has a castle nut/lock clip and

drilled steering shaft. The lock clip will be in the

steering wheel hardware package.

3. Verify that the steering wheel is oriented correctly

and the front wheels are aligned straight forward;

then apply one drop of red Loctite #271 to the

threads and tighten the nut to 34 N-m (25 ft-lb).

4. Install the lock clip through the steering shaft and

nut. Install the steering wheel cover.

PR087A

To adjust the wheel alignment, use the following procedure:

1. Center the steering wheel; then using an open-end

wrench to hold the tie rod ends (A), loosen the

right-side and left-side jam nuts (B).

HDX131A

NOTE: If the hole in the steering shaft does not

align with the slots in the castle nut, tighten the nut

slightly until the next slot aligns with the hole.

NOTE: Adding a small amount of grease to the

cover bores may aid in installing the cover.

CHECKING/ADJUSTING FRONT

WHEEL ALIGNMENT

NOTE: All measurements and adjustments must

be made with the vehicle unloaded.

Mark the center-line of the front tires at the front and

rear of the tire; then using a tape measure, measure and

record the distance between the marks at the front and

rear. The front measurement should be 3-6 mm (1/8-1/4

in.) greater than the rear measurement (toe-out).

HDX098B

PR792A

CAUTION

Always use a wrench to hold the tie rod ends when

loosening or tightening the jam nuts or damage to

the boots could occur.

2. Turn the left-side and right-side tie rods (C) in equal

increments to achieve the proper toe-out; then

tighten the jam nuts securely.

3. Check for free steering operation (full-left/full-right).

6

CHECKING HYDRAULIC BRAKE

SYSTEM

The hydraulic brake system has been filled and bled at the

factory.

Page 7

1. With the hydraulic brake reservoir in a level position, check the fluid level. It must be visible at the

MAX line.

TC021A

2. Press the brake pedal several times to check for

firmness. If the pedal is not firm, the brake system

must be bled.

3. To bleed the brake system, use the following procedure:

A. Remove the cover and fill the reservoir with

DOT 4 approved brake fluid.

B. Install and secure the cover; then slowly press

the brake pedal several times.

C. Install one end of a clear hose onto the REAR

bleed screw and direct the other end into a container; then while holding slight pressure on the

brake pedal, open the bleed screw and watch for

air bubbles. Close the bleed screw before

releasing the brake pedal. Repeat this procedure

until no air bubbles are present.

4. Carefully check the entire hydraulic brake system

that all hose connections are tight, the bleed screws

are tight, and no leakage is present.

5. Make sure to burnish the brake pads during the test ride.

CHECKING THROTTLE CABLE

ADJUSTMENT

1. Check cable free-play by grasping the cable at the

top of the accelerator pedal and lightly pulling rearward to remove slack. Free-play should be 1-2 mm

(0.040-0.080 in.).

PR708A

2. Depress the accelerator pedal completely and pull

rearward on the cable end. There should not be any

free-play and the tension sleeve should not be compressed.

NOTE: During the bleeding procedure, watch the

reservoir very closely to make sure there is always

a sufficient amount of brake fluid. If the fluid level

gets low in the reservoir, refill the reservoir before

the bleeding procedure is continued.

D. Repeat step C until the brake pedal is firm.

E. At this point, perform step B, C, and D on the

FRONT RIGHT bleed screw; then move to the

FRONT LEFT bleed screws and follow the same

procedure.

PR709A

3. To adjust the throttle cable, remove the throttle arm

cover on the throttle body; then loosen the two

adjuster nuts and adjust for proper free-play.

PR080A

TC020A

4. Tighten the jam nut securely.

7

Page 8

CHECKING ENGINE/

TRANSMISSION OIL LEVEL

NOTE: Inspect the area around the drain plug

(under the vehicle) and oil filter (front of the

engine) for leaks.

PR078A

NOTE: To access the oil filter, remove the seat.

Remove the screws securing the seat back and

remove the seat back; then remove the screws

securing the seat base and remove the seat base.

NOTE: The vehicle should be on level ground

when checking the engine oil level.

1. Raise the cargo box; then unscrew the oil level stick

and wipe it with a clean cloth.

GZ461A

CAUTION

Do not over-fill the engine with oil. Always make sure

the oil level is within the operating range.

Recommended Engine/

Transmission Oil

CAUTION

Any oil used in place of the recommended oil could

cause serious engine damage. Do not use oils which

contain graphite or molybdenum additives. These

oils can adversely affect clutch operation. Also, not

recommended are racing, vegetable, non-detergent,

and castor-based oils.

The recommended oil to use is Toro 0W-40 All Weather

synthetic engine oil, which has been specifically formulated for use in this engine. Although Toro 0W-40 All

Weather synthetic engine oil is the only oil recom-

mended for use in this engine, use of any API certified

SM All-Weather synthetic 0W-40 oil is acceptable.

2. Install the oil level stick into the engine case threading the stick in for checking purposes.

3. Remove the oil level stick; the engine oil level

should be within the operating range but not above

the FULL mark.

8

PR053B

OILCHARTJ

CHECKING GEAR CASE

LUBRICANT LEVELS

1. Remove the front differential level plug; lubricant should

be visible at the plug threads. If low, add SAE approved

80W -90 hypoid lubricant to the fill plug as necessary.

Install the plug and tighten to 22 N-m (16 ft-lb).

CAUTION

Any lubricant used in place of the recommended lubricant could cause serious front differential damage.

Page 9

HDX083A

2. Remove the rear drive level plug; lubricant should be

visible at the plug threads. If low, add SAE approved

80W -90 hypoid lubricant to the fill plug as necessary.

Install the plug and tighten to 22 N-m (16 ft-lb).

CAUTION

Any lubricant used in place of the recommended

lubricant could cause serious rear drive damage.

2. Measure the distance from the floor to the midpoint of each headlight.

3. Using the measurements obtained in step 2, make

horizontal marks on the aiming surface.

4. Make vertical marks which intersect the horizontal

marks on the aiming surface directly in front of the

headlights.

5. Switch on the lights. Make sure the HIGH beam is

on. DO NOT USE LOW BEAM.

6. Observe each headlight beam aim. Proper aim is

when the HIGH beam is centered on the vertical

mark 5 cm (2 in.) below the horizontal mark on the

aiming surface.

7. Turn the adjuster nut clockwise to raise the beam

and counterclockwise to lower the beam.

HDX084A

CHECKING/ADJUSTING

HEADLIGHT AIM

The headlights can be adjusted vertically. The center of

the HIGH beam light zone is to be used for aiming.

1. Position the vehicle on a level floor so the headlights are approximately 6.1 m (20 ft) from an aiming surface (wall or similar aiming surface).

TC004A

RECOMMENDED GASOLINE

The recommended gasoline to use is 87 minimum octane

regular unleaded. In many areas, oxygenates are added to

the gasoline. Oxygenated gasolines containing up to 10%

ethanol or 5% methane are acceptable gasolines.

When using ethanol blended gasoline, it is not necessary

to add a gasoline antifreeze since ethanol will prevent

the accumulation of moisture in the system.

CAUTION

Do not use white gas. Only Toro approved gasoline

and/or additives should be used.

TEST DRIVING

1. Check all mechanical functions.

2. Burnish the brake pads (see Burnishing Brake Pads).

3. Confirm all cables and wiring harnesses are connected and routed correctly.

4. Confirm all lights work correctly: headlights (HILO), taillight/brakelight, gauge, dash.

5. Confirm cooling fan operates normally.

6. After the test drive, check the brake systems.

NOTE: There should be an average operating load

on the vehicle when adjusting the headlight aim.

0740-647

7. Inspect the owner’s packet to ensure it is complete

(Operator’s Manual, spanner wrench).

8. Visually inspect the entire vehicle for any loose fasteners. Tighten as required to the appropriate specifications.

9

Page 10

9. Confirm final “check-off” of items on the Checklist.

BURNISHING BRAKE PADS

Brake pads must be burnished to achieve full braking

effectiveness. Braking distance will be extended until

brake pads are properly burnished.

! WARNING

Do not attempt sudden stops or put yourself into a

situation where a sudden stop will be required until

the brake pads are properly burnished.

1. Choose an area sufficiently large to safely accelerate to 50 km/h (30 mph) and to brake to a stop.

2. Accelerate to 50 km/h (30 mph); then press brake

pedal to decelerate to 0-8 km/h (0-5 mph).

3. Repeat procedure twenty times.

! WARNING

Using the Operator’s Manual as a guide, instruct the

customer on the proper use, care, burnishing procedure (when brake pads are new), and maintenance of

the hydraulic brake system.

TRANSPORTING

CAUTION

If using additional hold-down straps in any other

areas, care must be taken not to damage the vehicle.

! WARNING

Use extreme caution when operating a machine on a

ramp.

Ensure that the ROPS will clear the top of an

enclosed trailer.

Use only a full-width ramp; do not use individual

ramps for each side of the machine.

Do not exceed a 15-degree angle between the ramp and

the ground or between the ramp and the trailer or truck.

Ensure the length of ramp is at least four times (4X)

as long as the height of the trailer or truck bed to the

ground. This will ensure that ramp angle does not

exceed 15-degrees on flat ground.

Avoid sudden acceleration or deceleration while

driving the machine on a ramp as this could cause a

loss of control or a tip-over situation.

NOTE: When transporting the vehicle, make sure

the vehicle is in park.

Inform the owner/operator that this vehicle must be

transported in its normal operating position (on all four

wheels) and secured with hold-down straps in the

proper areas. Shown is the minimum number of holddown straps to be used.

PR075A

TC028

10

PR073A

Page 11

NOTES

11

Page 12

NOTES

12

Loading...

Loading...