Page 1

Model #UTV500AAC00000 - Serial #4UF15MPV3FT307514 & Up

Model #UTV700AAC00000 - Serial #4UF15MPV2FT307524 & Up

Activate/charge/install battery

Form Number 3394-900 Rev. A

Effective February, 2015

PRE-DELIVERY SETUP INSTRUCTIONS

CHECKLIST

Check engine/transmission oil

Check tire inflation pressure

Check wheel lug nut torque

Install left-side foot restraint

Install ROPS/seat belts/side restraints

Check cooling system — level and hoses

Install steering wheel

Check/adjust front wheel alignment

Check hydraulic brake fluid level — pedal firmness

Burnish the brake pads

Check throttle cable adjustment

NOTE: Read these instructions thoroughly before

starting the Pre-Delivery Setup.

Even though the vehicle has been set up (with some

minor exceptions) and inspected at the factory, it is

mandatory that EVERY vehicle be properly inspected

and serviced at the dealership prior to being released to

the customer. Experience has shown that dealerships

that properly prepare each vehicle have fewer warranty

problems and more satisfied customers.

RECOMMENDED TOOLS

The following tools will assist the technician during the

set-up process:

• Drill w/Torx Bits

• Impact Wrench

• Metric Socket Set

• Torque Wrench

BATTERY

NOTE: Refer to all warnings and cautions provided with the battery or battery charger.

This ROV is shipped with a sealed battery. The battery

requires an initial charge after activation as well as periodic

maintenance-charging during periods of non-use or storage.

Activating Battery

Always activate and maintain the battery in accordance

with the following instructions to ensure maximum service life and performance from the battery.

Check gear case lubricant

Check shift lever for proper operation

Check headlight aim

Check gasoline level

Start engine and check electrical switches and lights

Test drive

Check decals/clean vehicle

Explain Operator’s Manual, Limited Warranty, and

legal obligations to the customer

Complete Owner Registration form with the customer

on the date of the sale

Each sealed battery comes with an electrolyte container and

proper amount for each specific battery type. DO NOT add

additional electrolyte to any sealed battery. Sealed battery

electrolyte has a higher concentration of sulfuric acid.

1. Carefully remove and save the sealing strip from the

battery electrolyte container. This will be used to seal

the battery later.

2. Remove and discard the foil sealing strip covering

the fill holes from the battery.

3. Place electrolyte container with the foil-sealed top of

the cells facing down into the fill ports of the battery.

4. Hold the container level in the fill ports of the battery. Push down to break the seals. Air bubbles will

appear as the ports fill. Do not tilt the electrolyte container. Do not remove the container from the battery

until all cells are completely empty.

5. Let the battery stand for 120 minutes (2 Hr) prior to

charging. This will allow the electrolyte to permeate

into the plates for optimum performance.

6. Fully insert the sealing strip over the fill holes by

hand. DO NOT use a hammer.

7. Charge the battery completely before installation.

Charging New Battery

NOTE: Batteries filled with electrolyte are only at

80% of their capacity.

Batteries can be charged two ways - Standard Charge and

Fast Charge. Standard charging is the only recommended

way to charge a battery. It gives the battery optimal performance and battery life.

1. Be sure the charger is unplugged from the 110-volt

electrical outlet.

1

Page 2

2. Connect the red terminal lead from the charger to the

positive terminal of the battery; then connect the

black terminal lead of the charger to the negative terminal of the battery.

3. Plug the charger into a 110-volt electrical outlet.

4. Charge the battery for a minimum of five full hours

at a rate of 10% of the battery amp-hour rating for

optimal battery performance and battery life (ex: 30

AH battery should be charged at 3.0 amps).

NOTE: If the battery becomes hot to the touch,

stop charging. Resume after it has cooled.

5. Once the battery has reached full charge (typically

13.5 volts), unplug the charger from the 110-volt

electrical outlet and disconnect the charging leads.

6. Allow the battery to sit for 2 hours before installing

in the vehicle.

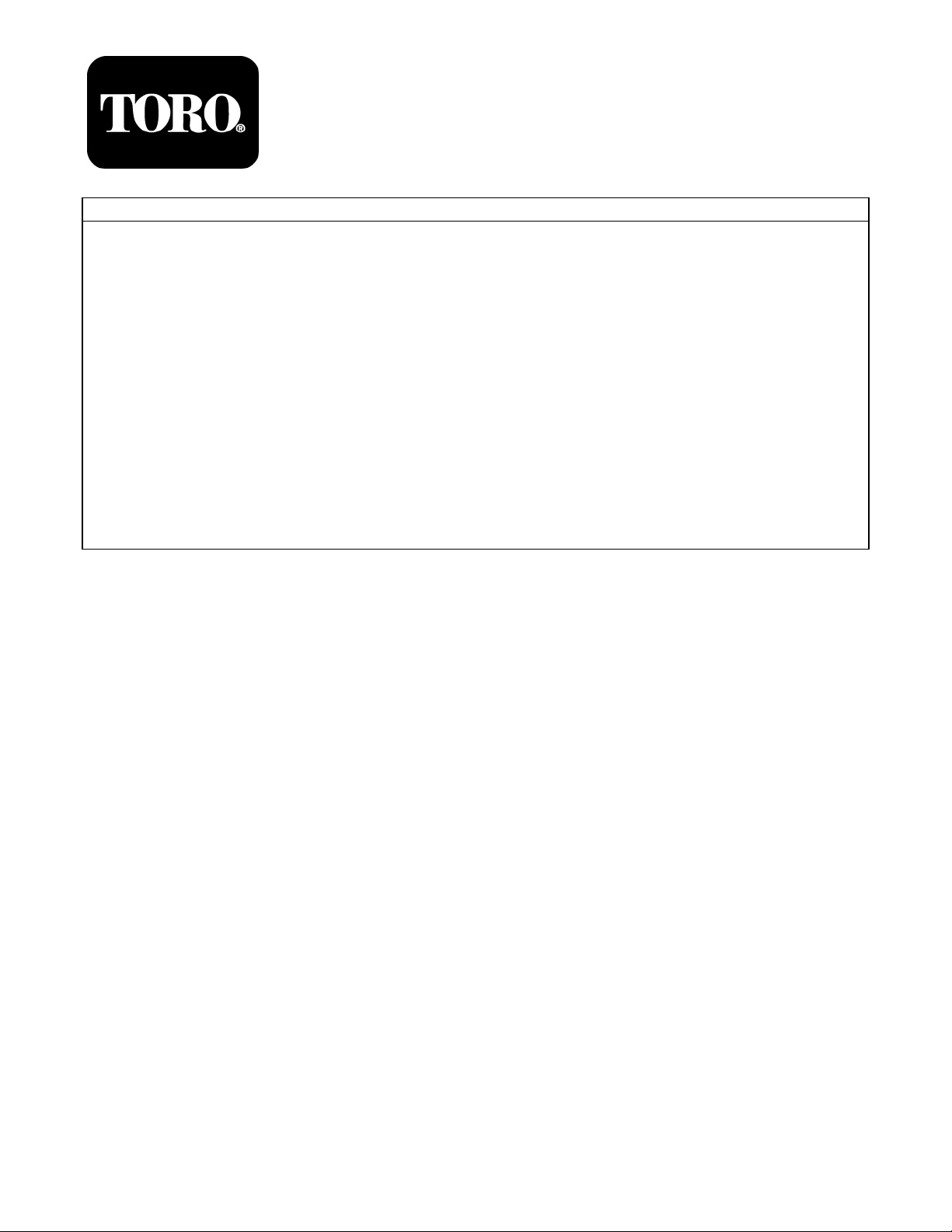

Installing Battery

NOTE: The battery box is under the seat on the

operator’s side. To access the box, remove the

seat and pry off the battery compartment cover;

then remove the thumb screw securing the battery

box cover and lift the cover to access the battery.

PR942

NOTE: Loss of battery charge may be caused by

ambient temperature, ignition OFF current draw,

corroded terminals, self-discharge, or other factors. Maintenance charging is required to keep the

battery at a “fully-charged” state.

TIRES

This vehicle is equipped with low-pressure tubeless

tires. Do not under any circumstances substitute tires of

a different type or size.

TIRE INFLATION PRESSURE

! WARNING

Operating this vehicle with improper or uneven tire

inflation pressure is hazardous. Always maintain

proper tire inflation pressure.

Front and rear tire inflation pressure should be 110 kPa

(16 psi) (UTV500) or 138 kPa (20.0 psi) (UTV700).

A low-pressure gauge is provided in the tool kit to measure the air pressure in the tires. Check the air pressure

in all tires before use of the vehicle.

PR943A

1. Route the battery cables into the battery compartment.

2. Install the battery; then connect the battery cables

(positive cable first) as shown. Tighten securely.

TC019

NOTE: When installing the battery into a vehicle,

coat the battery terminals with a light coat of

grease to minimize battery terminal corrosion and

then cover with the terminal boot if provided.

2

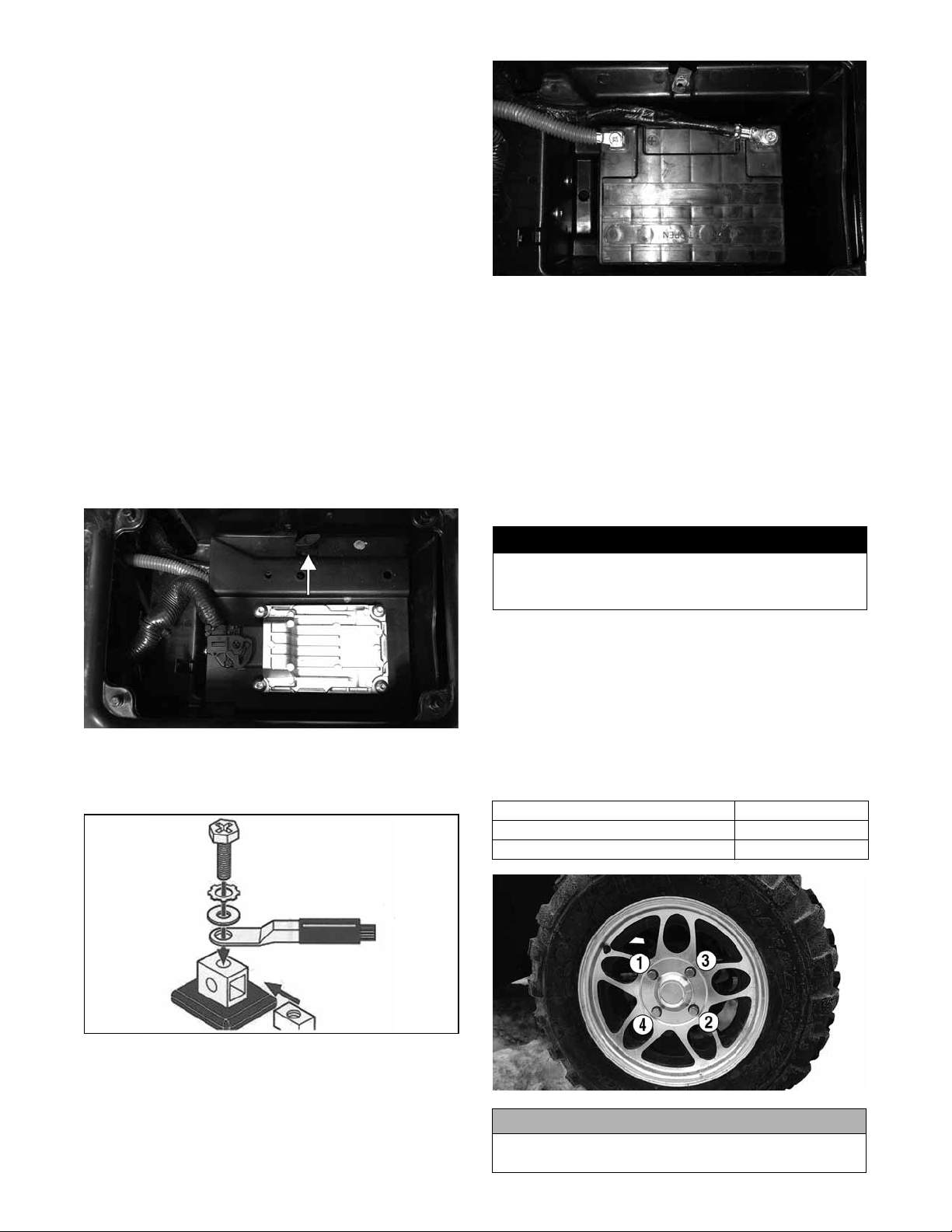

WHEEL LUG NUTS

Using a crisscross pattern, tighten the wheel nuts in 27 Nm (20 ft-lb) increments to the final torque shown below.

Steel Wheel 54 N-m (40 ft-lb)

Aluminum Wheel (Black Nuts) 80 N-m (60 ft-lb)

Aluminum Wheel (Chrome Nuts) 108 N-m (80 ft-lb)

PR941A

CAUTION

Using an impact wrench could result in incorrect

torque which could damage the wheel or hub studs.

Page 3

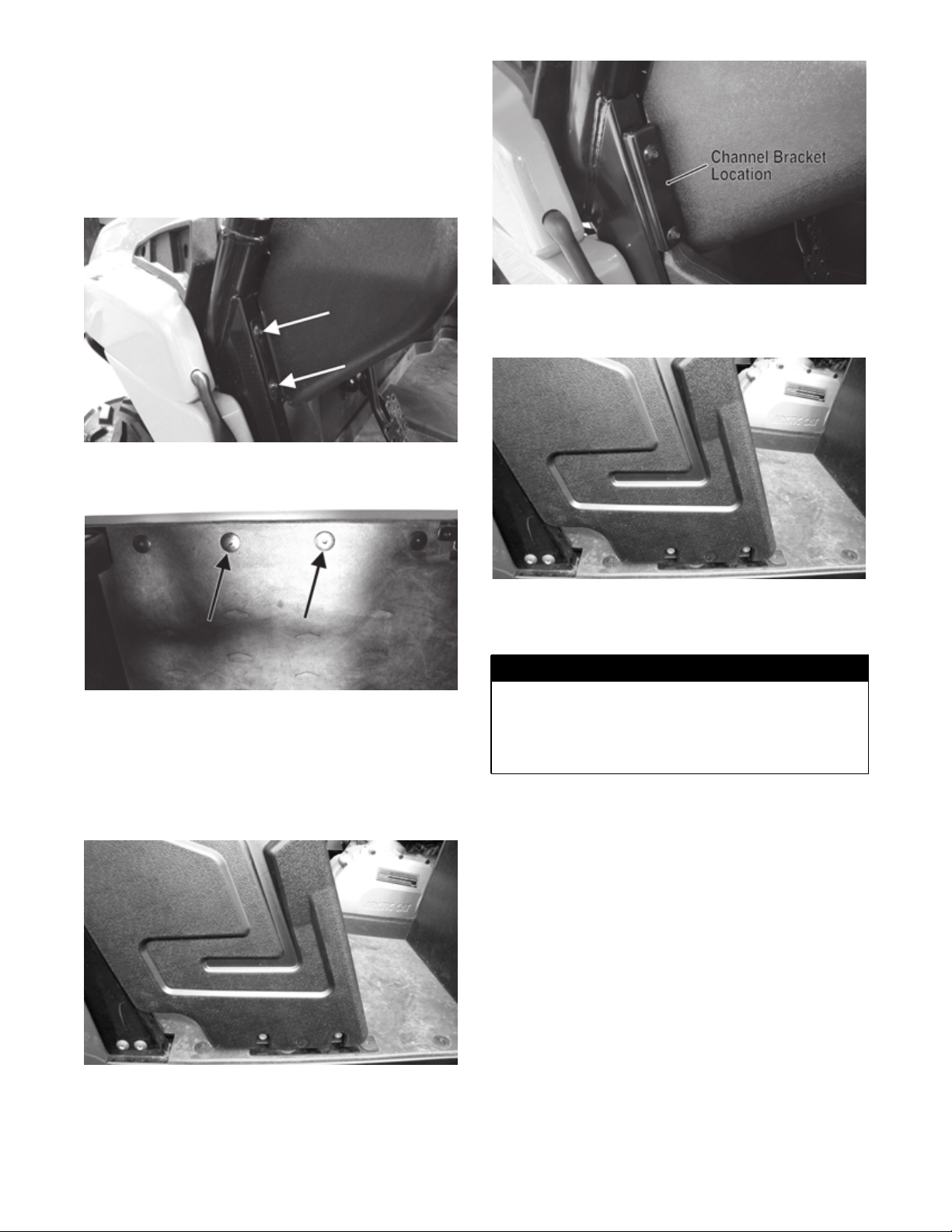

INSTALLING LEFT-SIDE FOOT

RESTRAINT

1. Remove the left-side foot restraint from the package

containing the side restraints.

2. Remove two sheet metal screws from the dashboard

attachment location and the second and third floor

retainer screws.

PR751A

PR800A

6. Tighten the cap screws securing the restraint to the

angle bracket securely.

PR752A

3. Remove the angle bracket from the foot restraint

(retain the screws) and attach to the floor using the

existing screws from the floor. Tighten securely.

4. Install the foot restraint and attach to the angle

bracket with the existing two cap screws. Do not

tighten at this time.

PR827

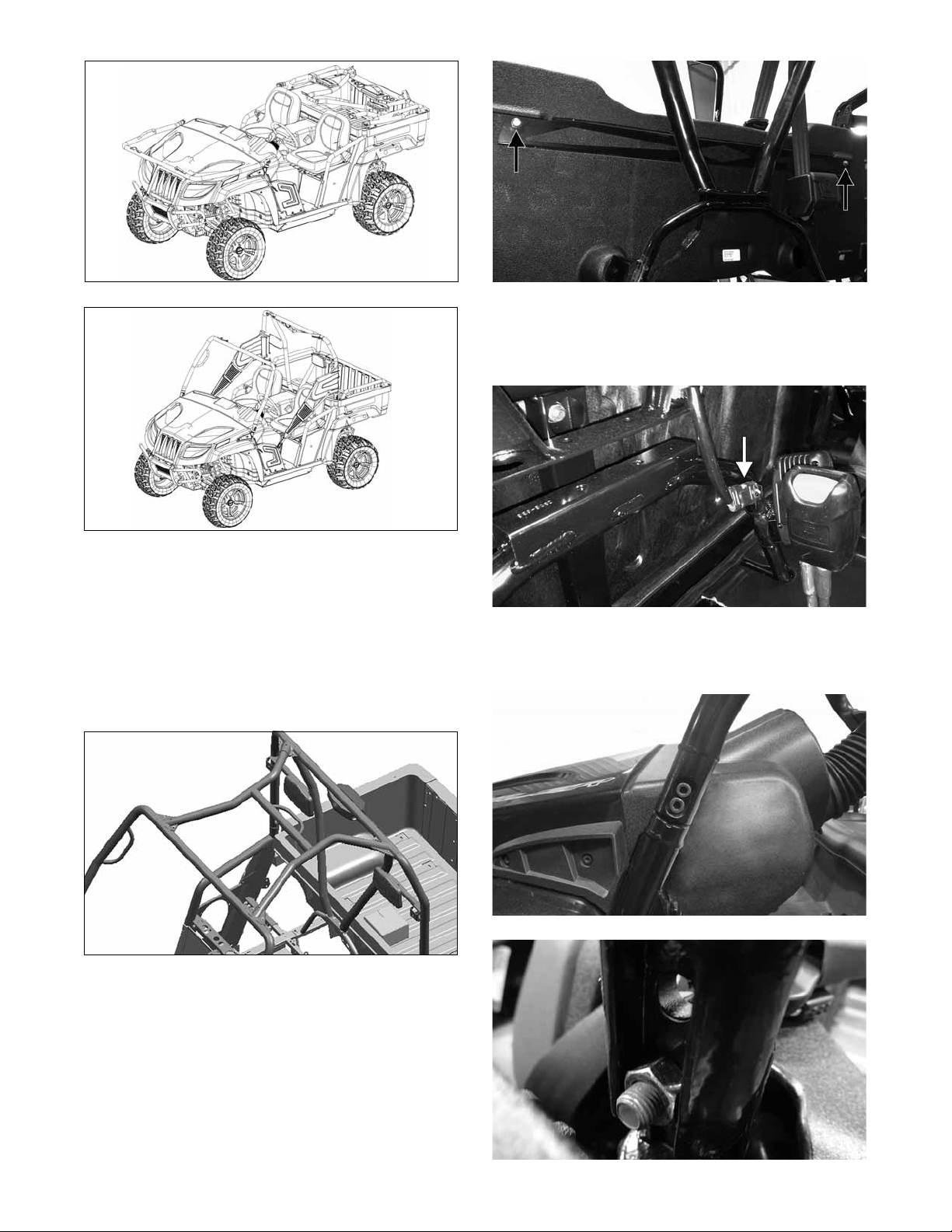

INSTALLING ROPS/SEAT BELTS/

SIDE RESTRAINTS

! WARNING

The ROPS must be installed prior to operating the

vehicle or delivery to a customer. Safety devices such

as taillight/brakelight, seat belts, and the passenger

hand holds are incorporated in the assembly. The

ROPS is part of the vehicle structure.

NOTE: The screws securing the front and rear

tubes during delivery will be used to secure the

ROPS tubes. There are nuts that secure the back

side of the ROPS tubes for shipping; these nuts

should be removed and discarded.

1. Loosen the Allen Head Screws securing the front

and rear ROPS tubes; then tip the front and rear

ROPS tubes from horizontal to vertical.

PR827

5. Secure the restraint and the dashboard with the

channel bracket (from the hardware pack) and two

sheet metal screws. Do not over-tighten.

3

Page 4

UTV-068

UTV-148

2. Raise the cargo box; then while holding the rear

ROPS, remove the screws securing the ROPS.

Loosely secure the ROPS in the correct position

using Allen Head Screws and new Nyloc Nuts. Do

not tighten at this time. Repeat for the front ROPS.

3. Place the Top X-brace into position between the

front and rear tubes and secure with eight Cap

Screws (installed from the top) and eight Zinc

Nyloc Nuts. Tighten to 47 N-m (35 ft-lb).

TC022A

5. Secure the bottom (middle) of the rear canopy tube

to the center support using two M6 Torx Screws.

Tighten to 11 N-m (8 ft-lb). Connect the brakelight/

taillight harness to the main harness.

TC030A

6. Tighten the front and rear tubes (from step 2) to 47

N-m (35 ft-lb). Ensure the flats of the nuts engage

the recesses of the ROPS tubes when tightened.

UTV-070

4. Secure the seat back to the rear ROPS tube with the

two cap screws. Tighten to 11 N-m (8 ft-lb).

4

TC027

TC029

Page 5

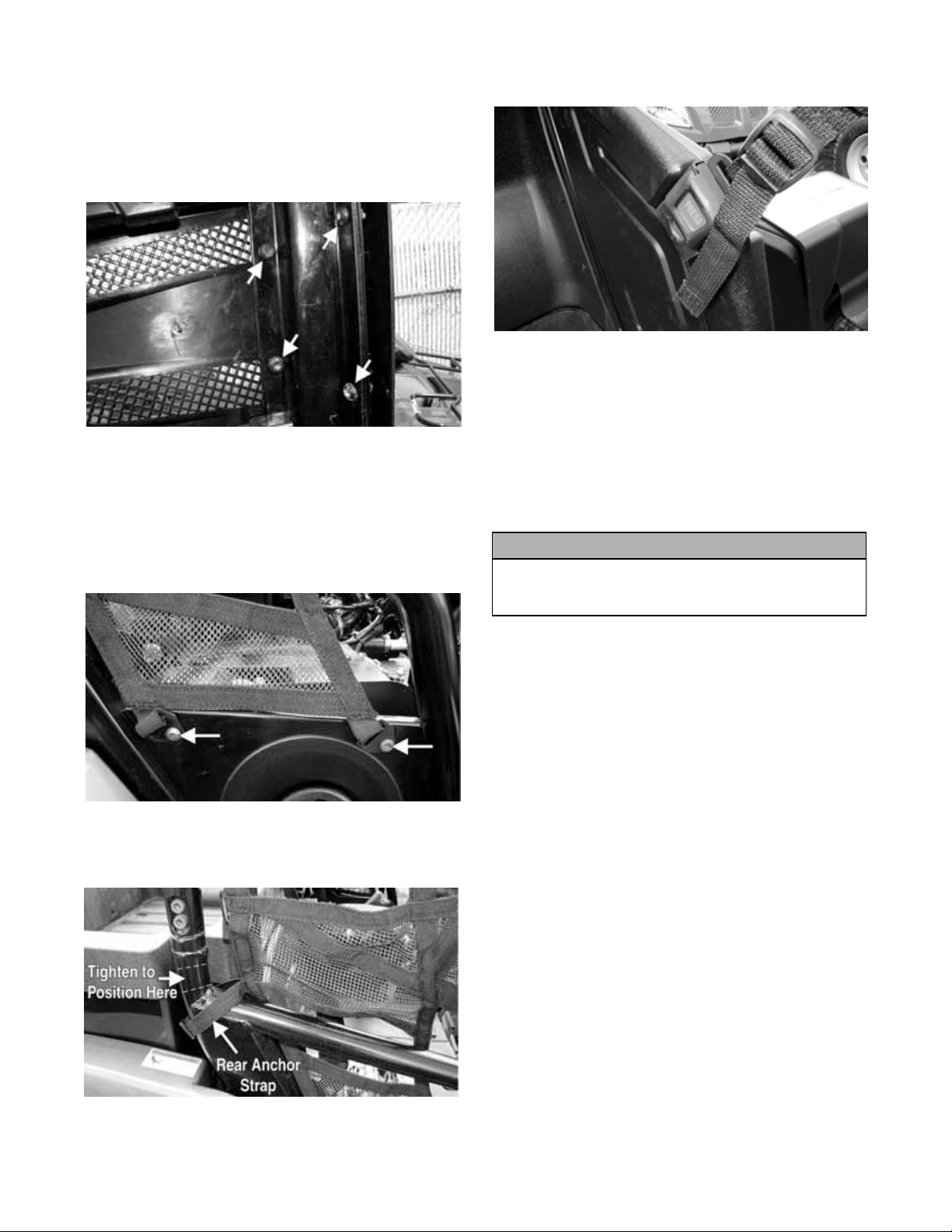

7. Install the seat belts (cap screws installed from the

front) into the appropriate mounting tabs along the

headrest support tube on the rear ROPS. Tighten to

47 N-m (35 ft-lb).

8. Place Right-Side Occupant Side Restraint onto the

passenger-side tube and secure using four Cap

Screws. Tighten to 13.5 N-m (10 ft-lb).

PR835A

9. Secure the outer side restraint using two Cap

Screws making sure to keep the straps properly

positioned.

10. Route the lower side restraint straps inside the side

tube; then secure to the frame using two Shoulder

Screws and Flange Nuts. Tighten to 13.5 N-m (10

ft-lb).

13. Secure both side restraints to the kick panels using

the buckle.

PR833

CHECKING COOLING SYSTEM

Remove the filler cap and check coolant level. Coolant

level should be at the bottom of the standpipe in the

radiator neck. If coolant is required, add to bring coolant

to the specified level and install the cap.

NOTE: If coolant is required, mix coolant for a

temperature of -36°C (-34°F). Follow mixing recommendations of the manufacturer.

CAUTION

It is extremely important that the cooling system is

properly filled. If the system isn’t properly filled,

engine damage will occur.

PR834A

11. Loop the rear anchor strap around the ROPS mounting tube and secure with the buckle. Tighten so

strap rests as shown.

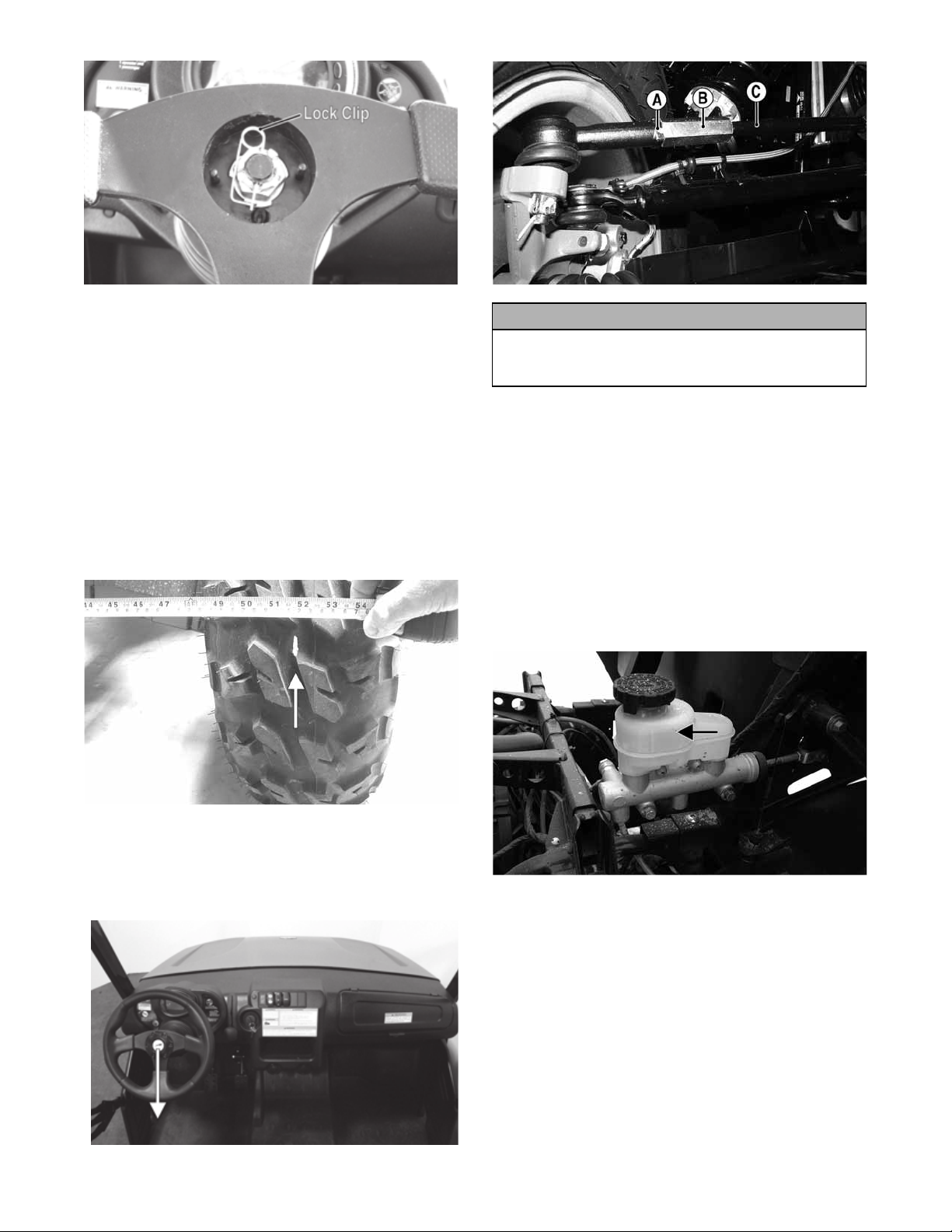

INSTALLING STEERING WHEEL

NOTE: The vehicle should be on level ground

with the front wheels oriented straight forward and

rearward.

1. Remove the nut and the steering wheel from the

steering shaft.

2. Install and align the steering wheel and loosely

secure with the nut.

NOTE: This model has a castle nut/lock clip and

drilled steering shaft. The lock clip will be in the

steering wheel hardware package.

3. Verify that the steering wheel is oriented correctly

and the front wheels are aligned straight forward;

then apply one drop of red Loctite #271 to the

threads and tighten the nut to 34 N-m (25 ft-lb).

4. Install the lock clip through the steering shaft and

nut. Install the steering wheel cover.

12. Repeat steps 9-11 for opposite side.

PR831A

5

Page 6

HDX131A

PR792A

NOTE: If the hole in the steering shaft does not

align with the slots in the castle nut, tighten the nut

slightly until the next slot aligns with the hole.

CHECKING/ADJUSTING FRONT

WHEEL ALIGNMENT

NOTE: All measurements and adjustments must

be made with the vehicle unloaded.

Mark the center-line of the front tires at the front and

rear of the tire; then using a tape measure, measure and

record the distance between the marks at the front and

rear. The front measurement should be 3-6 mm (1/8-1/4

in.) greater than the rear measurement (toe-out).

CAUTION

Always use a wrench to hold the tie rod ends when

loosening or tightening the jam nuts or damage to

the boots could occur.

2. Turn the left-side and right-side tie rods (C) in equal

increments to achieve the proper toe-out; then

tighten the jam nuts securely.

3. Check for free steering operation (full-left/full-right).

CHECKING HYDRAULIC BRAKE

SYSTEM

The hydraulic brake system has been filled and bled at the

factory.

1. With the hydraulic brake reservoir in a level position, check the fluid level. It must be visible at the

MAX line.

PR087A

To adjust the wheel alignment, use the following procedure:

1. Center the steering wheel; then using an open-end

wrench to hold the tie rod ends (A), loosen the

right-side and left-side jam nuts (B).

HDX098B

6

TC021A

2. Press the brake pedal several times to check for

firmness. If the pedal is not firm, the brake system

must be bled.

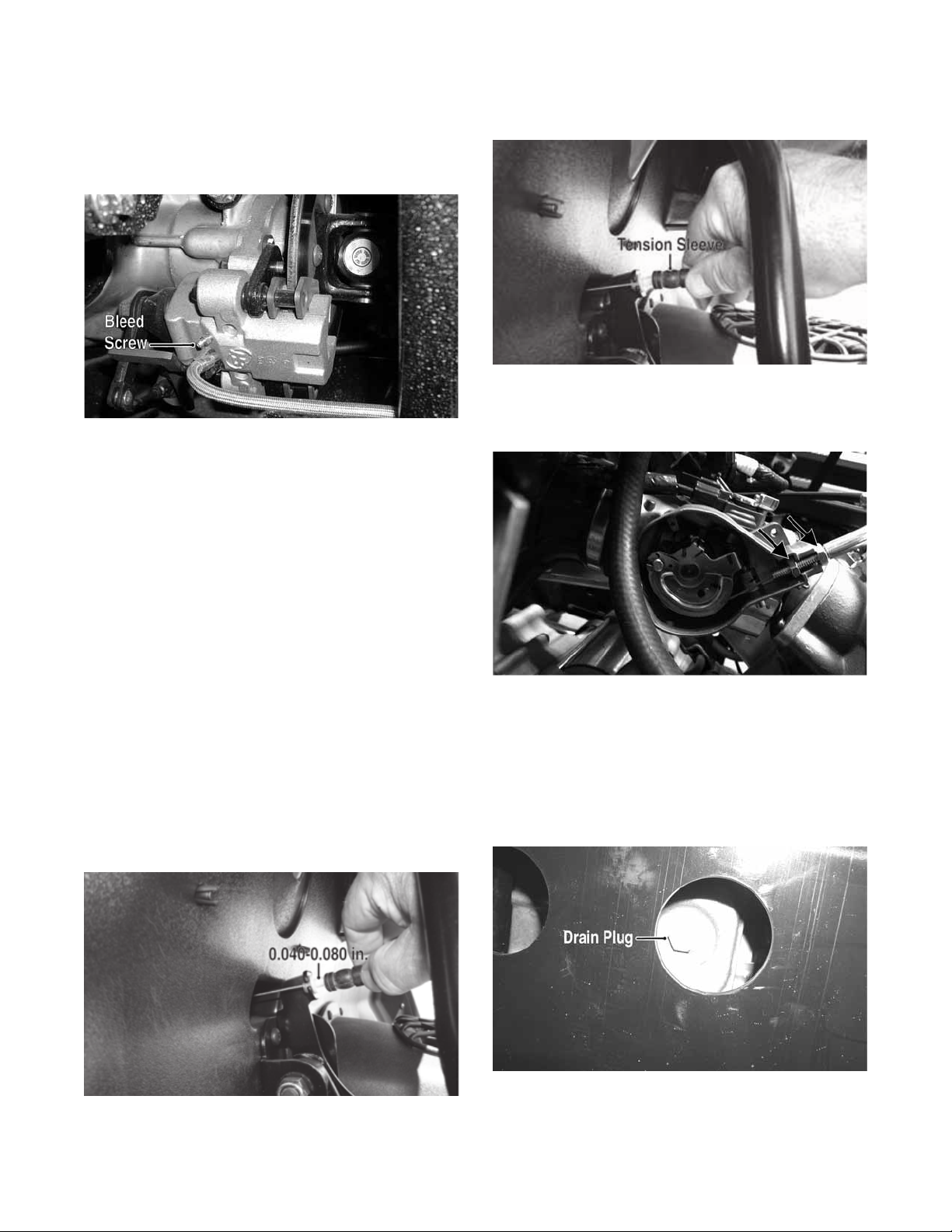

3. To bleed the brake system, use the following procedure:

A. Remove the cover and fill the reservoir with

DOT 4 approved brake fluid.

B. Install and secure the cover; then slowly press

the brake pedal several times.

Page 7

C. Install one end of a clear hose onto the REAR

bleed screw and direct the other end into a container; then while holding slight pressure on the

brake pedal, open the bleed screw and watch for

air bubbles. Close the bleed screw before

releasing the brake pedal. Repeat this procedure

until no air bubbles are present.

PR080A

NOTE: During the bleeding procedure, watch the

reservoir very closely to make sure there is always

a sufficient amount of brake fluid. If the fluid level

gets low in the reservoir, refill the reservoir before

the bleeding procedure is continued.

2. Depress the accelerator pedal completely and pull

rearward on the cable end. There should not be any

free-play and the tension sleeve should not be compressed.

PR709A

3. To adjust the throttle cable, remove the throttle arm

cover on the throttle body; then loosen the two

adjuster nuts and adjust for proper free-play.

D. Repeat step C until the brake pedal is firm.

E. At this point, perform step B, C, and D on the

FRONT RIGHT bleed screw; then move to the

FRONT LEFT bleed screws and follow the same

procedure.

4. Carefully check the entire hydraulic brake system

that all hose connections are tight, the bleed screws

are tight, and no leakage is present.

5. Make sure to burnish the brake pads during the test ride.

CHECKING THROTTLE CABLE

ADJUSTMENT

1. Check cable free-play by grasping the cable at the

top of the accelerator pedal and lightly pulling rearward to remove slack. Free-play should be 1-2 mm

(0.040-0.080 in.).

TC020A

4. Tighten the jam nut securely.

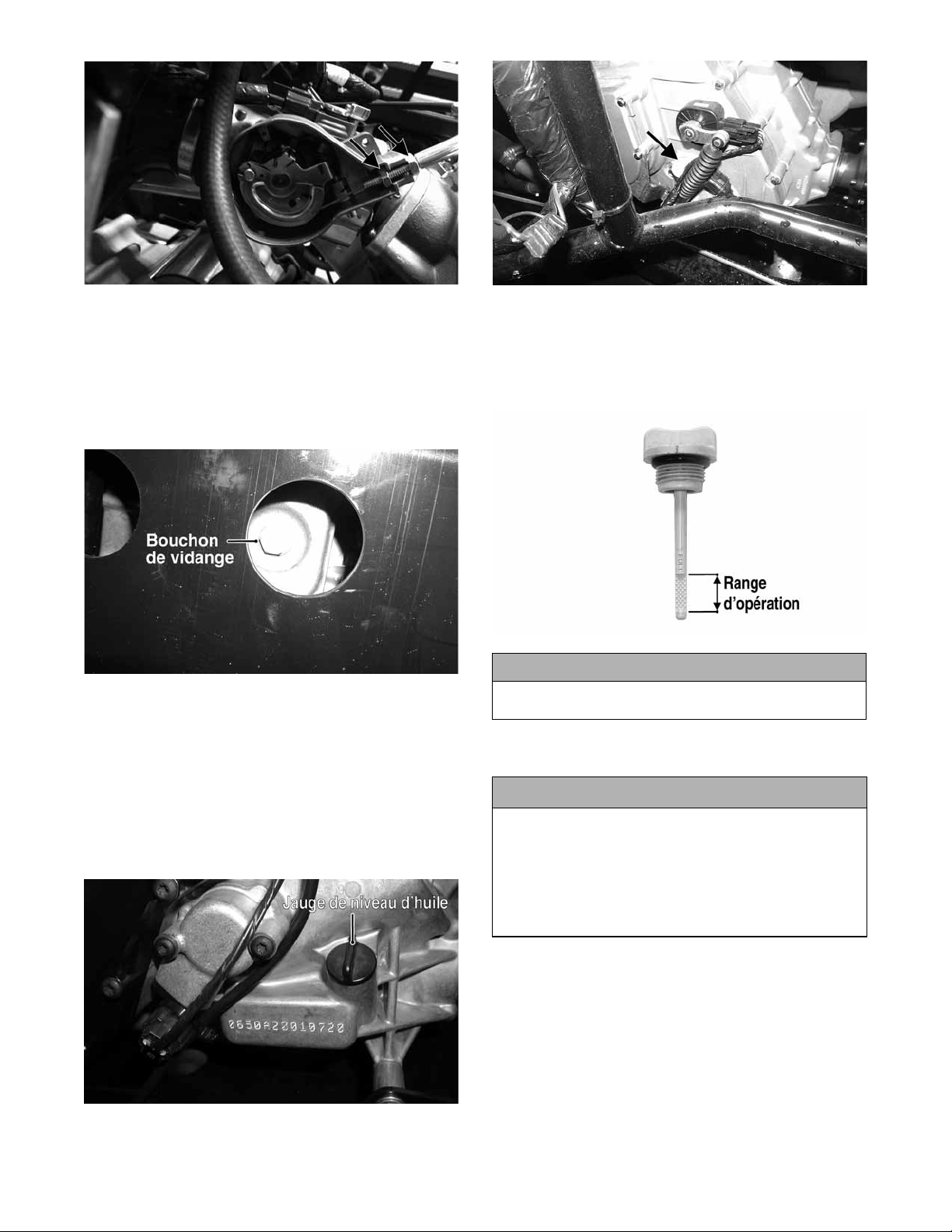

CHECKING ENGINE/

TRANSMISSION OIL LEVEL

NOTE: Inspect the area around the drain plug

(under the vehicle) and oil filter (front of the

engine) for leaks.

PR708A

PR078A

NOTE: To access the oil filter, remove the seat.

Remove the screws securing the seat back and

remove the seat back; then remove the screws

securing the seat base and remove the seat base.

7

Page 8

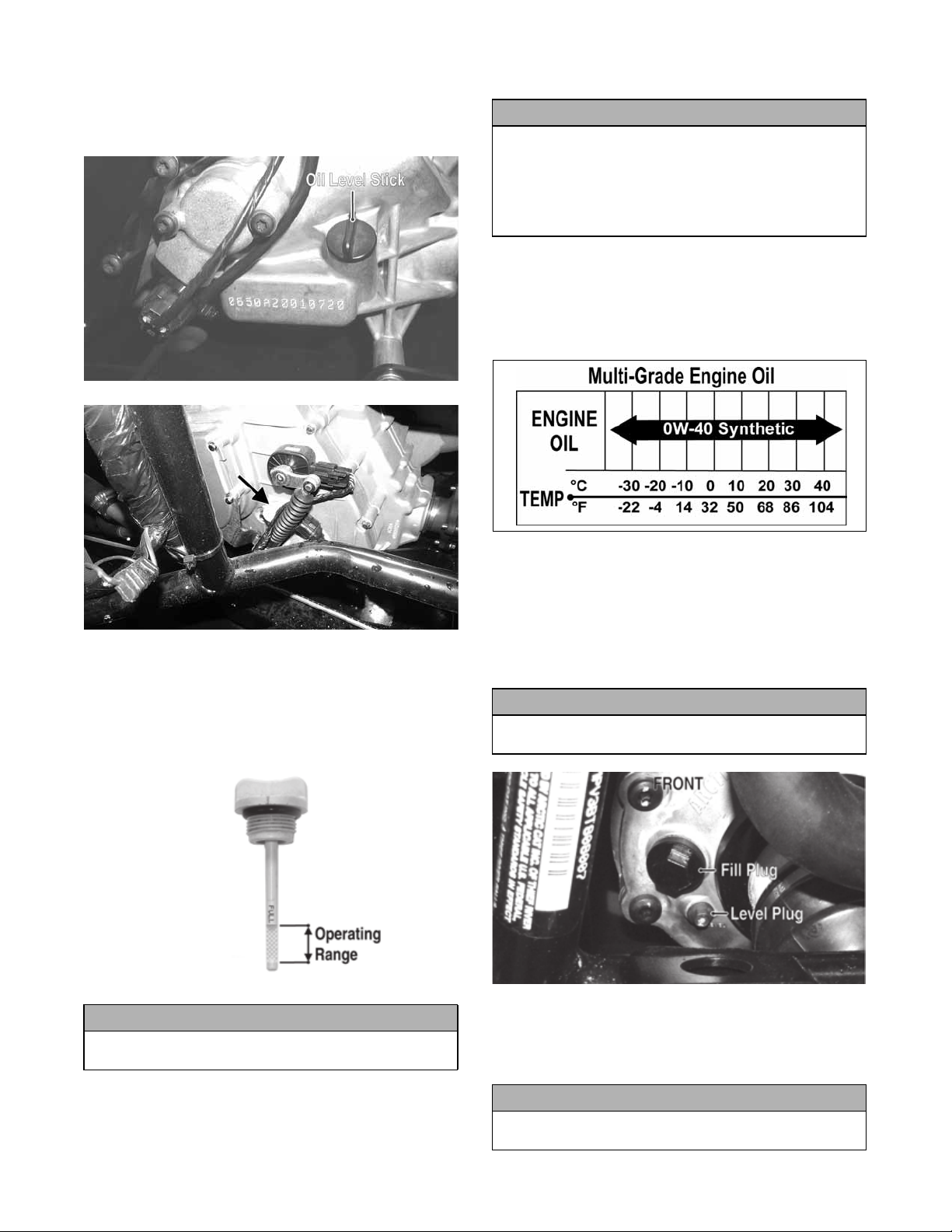

NOTE: The vehicle should be on level ground

when checking the engine oil level.

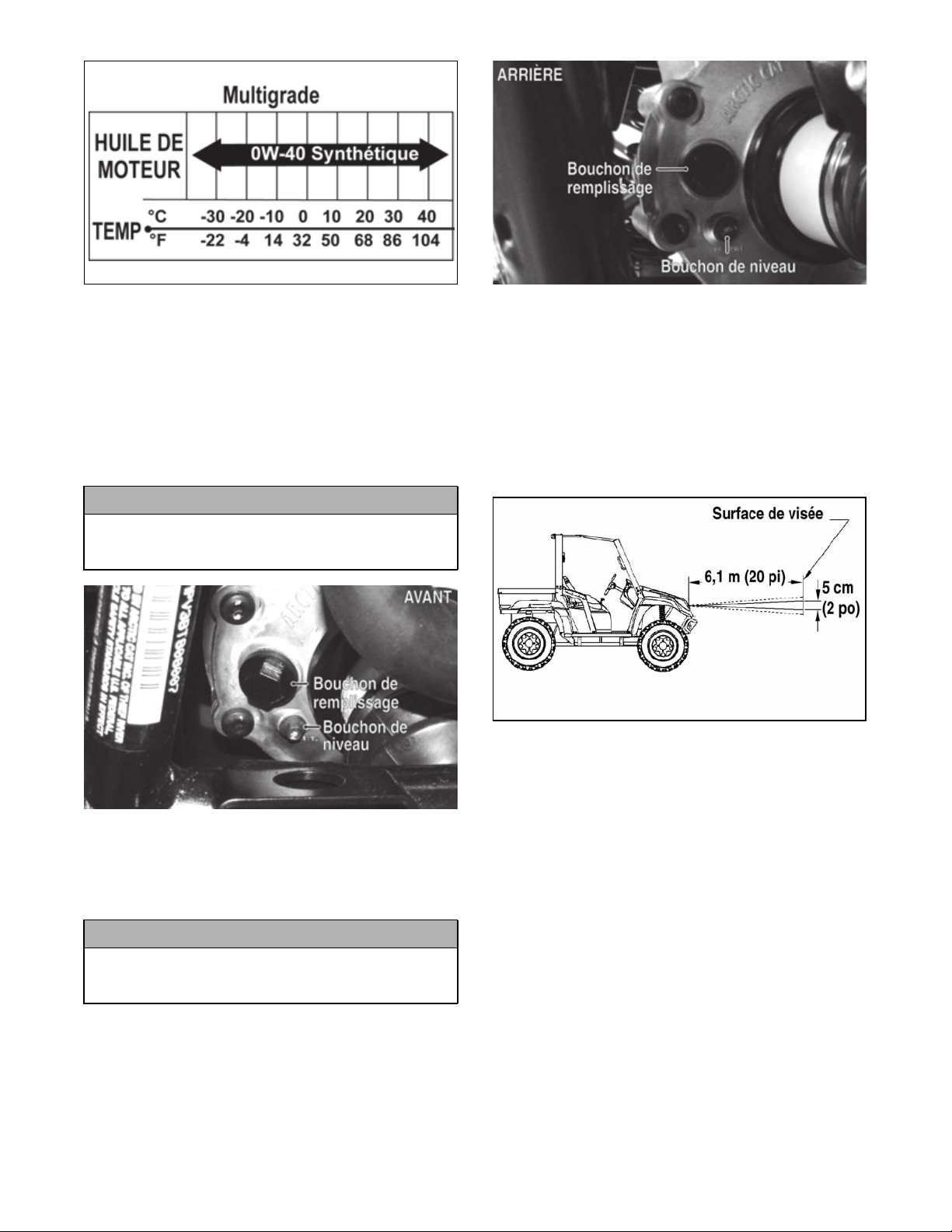

Recommended Engine/

Transmission Oil

1. Raise the cargo box; then unscrew the oil level stick

and wipe it with a clean cloth.

700

PR053B

500

CAUTION

Any oil used in place of the recommended oil could

cause serious engine damage. Do not use oils which

contain graphite or molybdenum additives. These

oils can adversely affect clutch operation. Also, not

recommended are racing, vegetable, non-detergent,

and castor-based oils.

The recommended oil to use is Toro 0W-40 All Weather

synthetic engine oil, which has been specifically formulated for use in this engine. Although Toro 0W-40 All

Weather synthetic engine oil is the only oil recom-

mended for use in this engine, use of any API certified

SM All-Weather synthetic 0W-40 oil is acceptable.

OILCHARTJ

HDX234A

2. Install the oil level stick into the engine case threading the stick in for checking purposes.

3. Remove the oil level stick; the engine oil level

should be within the operating range but not above

the FULL mark.

GZ461A

CAUTION

Do not over-fill the engine with oil. Always make sure

the oil level is within the operating range.

CHECKING GEAR CASE

LUBRICANT LEVELS

1. Remove the front differential level plug; lubricant should

be visible at the plug threads. If low, add SAE approved

80W -90 hypoid lubricant to the fill plug as necessary.

Install the plug and tighten to 22 N-m (16 ft-lb).

CAUTION

Any lubricant used in place of the recommended lubricant could cause serious front differential damage.

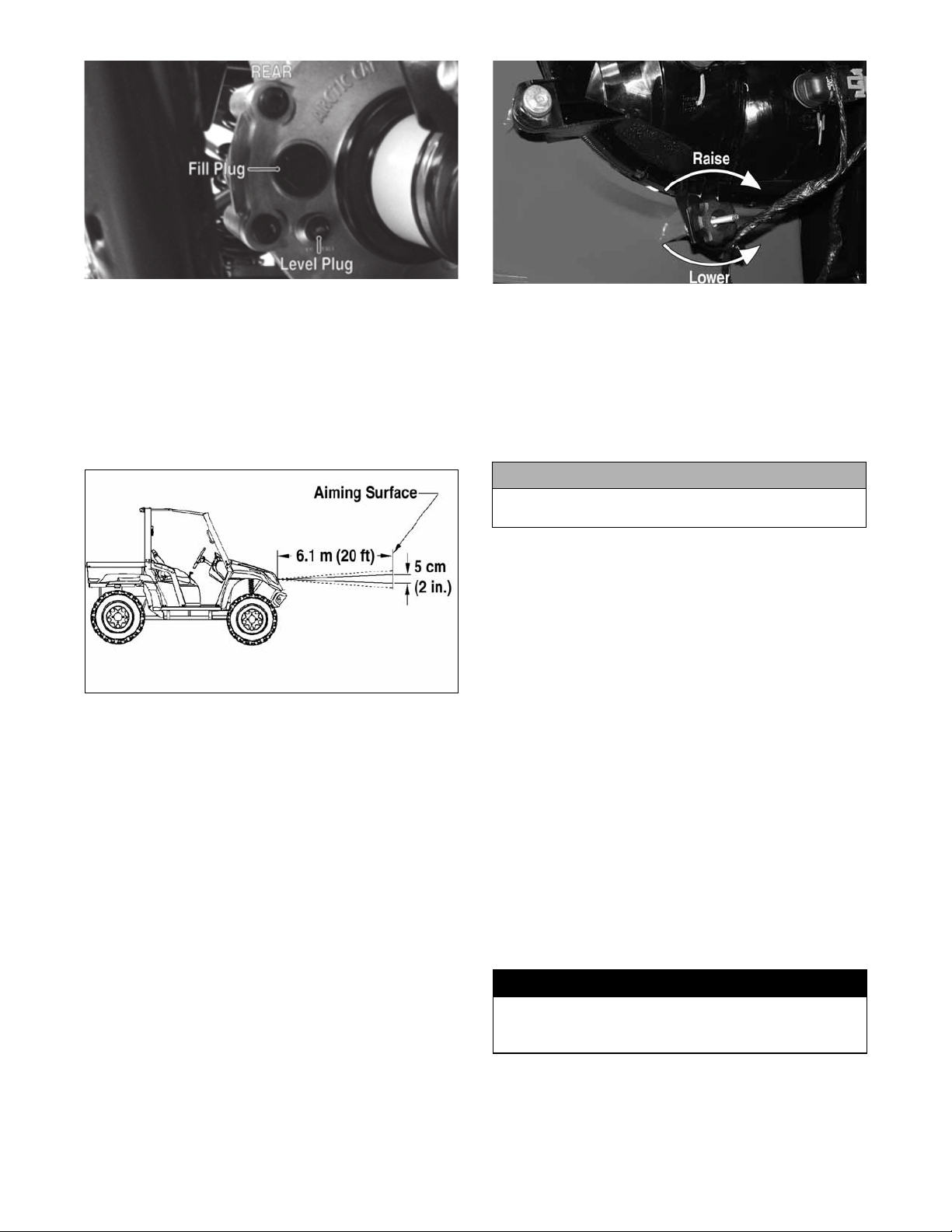

HDX083A

2. Remove the rear drive level plug; lubricant should be

visible at the plug threads. If low, add SAE approved

80W -90 hypoid lubricant to the fill plug as necessary.

Install the plug and tighten to 22 N-m (16 ft-lb).

CAUTION

Any lubricant used in place of the recommended

lubricant could cause serious rear drive damage.

8

Page 9

HDX084A

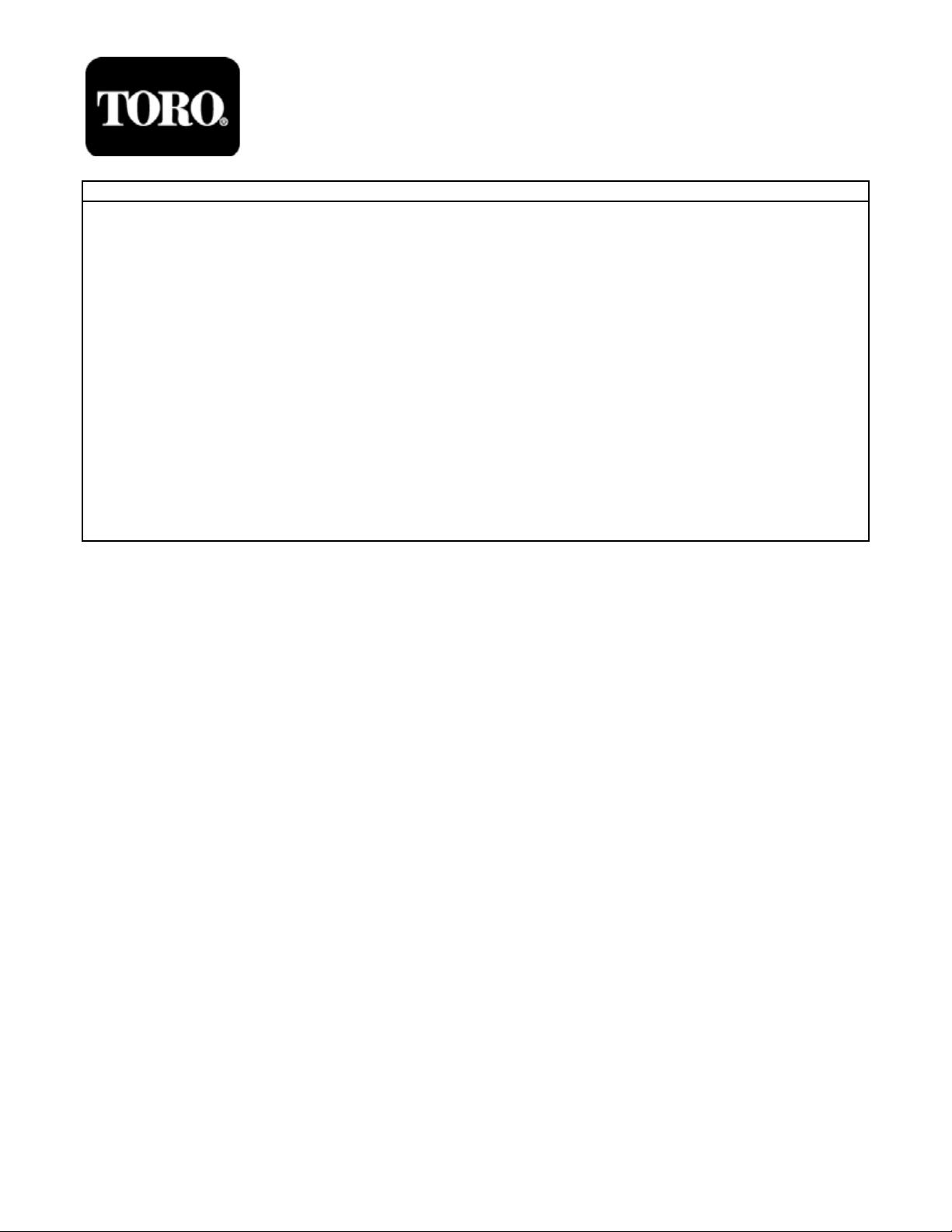

CHECKING/ADJUSTING

HEADLIGHT AIM

The headlights can be adjusted vertically. The center of

the HIGH beam light zone is to be used for aiming.

1. Position the vehicle on a level floor so the headlights are approximately 6.1 m (20 ft) from an aiming surface (wall or similar aiming surface).

0740-647

NOTE: There should be an average operating load

on the vehicle when adjusting the headlight aim.

2. Measure the distance from the floor to the midpoint of each headlight.

3. Using the measurements obtained in step 2, make

horizontal marks on the aiming surface.

4. Make vertical marks which intersect the horizontal

marks on the aiming surface directly in front of the

headlights.

5. Switch on the lights. Make sure the HIGH beam is

on. DO NOT USE LOW BEAM.

TC004A

RECOMMENDED GASOLINE

The recommended gasoline to use is 87 minimum octane

regular unleaded. In many areas, oxygenates are added to

the gasoline. Oxygenated gasolines containing up to 10%

ethanol or 5% methane are acceptable gasolines.

When using ethanol blended gasoline, it is not necessary

to add a gasoline antifreeze since ethanol will prevent

the accumulation of moisture in the system.

CAUTION

Do not use white gas. Only Toro approved gasoline

and/or additives should be used.

TEST DRIVING

1. Check all mechanical functions.

2. Burnish the brake pads (see Burnishing Brake Pads).

3. Confirm all cables and wiring harnesses are connected and routed correctly.

4. Confirm all lights work correctly: headlights (HILO), taillight/brakelight, gauge, dash.

5. Confirm cooling fan operates normally.

6. After the test drive, check the brake systems.

7. Inspect the owner’s packet to ensure it is complete

(Operator’s Manual, spanner wrench).

8. Visually inspect the entire vehicle for any loose fasteners. Tighten as required to the appropriate specifications.

9. Confirm final “check-off” of items on the Checklist.

BURNISHING BRAKE PADS

Brake pads must be burnished to achieve full braking

effectiveness. Braking distance will be extended until

brake pads are properly burnished.

6. Observe each headlight beam aim. Proper aim is

when the HIGH beam is centered on the vertical

mark 5 cm (2 in.) below the horizontal mark on the

aiming surface.

7. Turn the adjuster nut clockwise to raise the beam

and counterclockwise to lower the beam.

! WARNING

Do not attempt sudden stops or put yourself into a

situation where a sudden stop will be required until

the brake pads are properly burnished.

1. Choose an area sufficiently large to safely accelerate to 50 km/h (30 mph) and to brake to a stop.

2. Accelerate to 50 km/h (30 mph); then press brake

pedal to decelerate to 0-8 km/h (0-5 mph).

9

Page 10

3. Repeat procedure twenty times.

! WARNING

Using the Operator’s Manual as a guide, instruct the

customer on the proper use, care, burnishing procedure (when brake pads are new), and maintenance of

the hydraulic brake system.

TRANSPORTING

NOTE: When transporting the vehicle, make sure

the vehicle is in park.

Inform the owner/operator that this vehicle must be

transported in its normal operating position (on all four

wheels) and secured with hold-down straps in the

proper areas. Shown is the minimum number of holddown straps to be used.

! WARNING

Use extreme caution when operating a machine on a

ramp.

Ensure that the ROPS will clear the top of an

enclosed trailer.

Use only a full-width ramp; do not use individual

ramps for each side of the machine.

Do not exceed a 15-degree angle between the ramp

and the ground or between the ramp and the trailer

or truck.

Ensure the length of ramp is at least four times (4X)

as long as the height of the trailer or truck bed to the

ground. This will ensure that ramp angle does not

exceed 15-degrees on flat ground.

Avoid sudden acceleration or deceleration while

driving the machine on a ramp as this could cause a

loss of control or a tip-over situation.

PR075A

PR073A

CAUTION

If using additional hold-down straps in any other

areas, care must be taken not to damage the vehicle.

TC028

10

Page 11

NOTES

11

Page 12

NOTES

12

Page 13

INSTRUCTIONS DE PRÉPARATION AVANT LA LIVRAISON DE

MODÈLE #UTV500AAC00000 - Série #4UF15MPV3FT307514 et haut

MODÈLE #UTV700AAC00000 - Série #4UF15MPV2FT307524 et haut

LISTE DE CONTRÔLE

Actionner/charger/installer la batterie

Vérifier la pression de gonflage des pneus

Vérifier la serrage de écrous de roue

Installer la retenue de pied gauche

Installer la ROPS/sangles de retenue/contraintes latérales

Vérifier le système de refroidissement — niveau et

tuyaux

Installer le volant

Vérifier/régler l’alignement des roues avant

Inspectez le niveau de liquide de frein hydraulique —

rigidité de la pédale

Polir les plaquettes de frein

Vérifier ajustement du câble d’accélérateur

REMARQUE: Veuillez lire complètement ces ins-

tructions en avant de commencer la preparation

avant la livraison.

Même si le véhicule a été préparé (avec quelques exceptions peu importantes) et inspecté à l’usine, il est obligatoire que CHAQUE véhicule soit correctement inspecté et

ait reçu du service chez le concessionnaire avant d’être

relâché au client. L’expérience a montré que les concessionnaires qui préparent correctement chaque VOR ont

moins de problèmes de garantie et qu’ils ont des clients

plus satisfaits.

OUTILS RECOMMANDÉES

Les outils suivante facilitera la technicien lorsque la procédure de préparation:

• Berceau avec pièces Torx

• Clé à impact

• Ensemble de douilles métrique

• Clé de torsion

BATTERIE

REMARQUE: Lisez attentivement tous les avertisse-

ments et toutes les mises en garde qui accompagnent la batterie ou le chargeur de batterie.

Ces VOR sont livrés soit avec une batterie scellée. La batterie exigent une charge initiale après l’activation aussi

bien qu’une charge de maintien périodique pendant les

périodes d’initialisation ou d’entreposage.

Actionner de la batterie

Il faut toujours activer et maintenir la batterie en respectant

les indications suivantes afin de garantir une vie utile et un

fonctionnement maximum de la batterie.

Numéro de formulaire 3394-900 Rév. A

En vigueur février 2015

Vérifier la niveau d’huile de moteur/transmission

Vérifier les niveaux de lubrifiant de carter d’engrenage

Vérifiez si le levier de vitesse se font correctement

Vérifier le réglage du faisceau

Vérifier le niveau de l’essence

Démarrer le moteur et vérifier les interrupteurs et feux

électriques

Faire une promenade d’essai

Vérifier les autocollants/nettoyer la véhicule

Expliquer au client le Manuel d’utilisation et les obliga-

tions légales de ce dernier

Expliquer au client la Garantie limitée

Remplir l’Inscription du propriétaire avec le client dans

la date de vente

Chaque batterie scellée est fournie avec un récipient

d’électrolyte conçu spécialement et la quantité appropriée

à chaque type de batterie. N’ajoutez PAS d’électrolyte aux

batteries scellées. L’électrolyte d’une batterie scellée a une

plus forte concentration d’acide sulfurique.

1. Enlevez avec précaution et conservez la bande de fermeture hermétique du récipient d’électrolyte de batterie. Vous l’utiliserez plus tard pour fermer la batterie.

2. Retirez et jetez la bande de fermeture en feuille d’aluminium couvrant les trous de remplissage de la batterie.

3. Placez le récipient d’électrolyte avec le dessus des cellules fermé par la feuille d’aluminium tourné vers le

bas, dans les orifices de remplissage de la batterie.

4. Maintenez le récipient au niveau dans les orifices de

remplissage de la batterie. Poussez vers le bas pour

rompre les fermetures. Des bulles d’air apparaîtront à

mesure que les orifices se remplissent. N’inclinez pas

le récipient d’électrolyte. N’enlevez pas le récipient de

la batterie avant les cellules soit vide complètement.

5. Laissez la batterie reposer pendant 120 minutes (2

heures) avant de la charger. Ceci permettra à l’électrolyte de s’infiltrer dans les plaques, permettant ainsi

une performance optimum.

6. Insérez à la main toute la bande de fermeture par-dessus

les trous de remplissage. N’utilisez PAS de marteau.

7. Chargez la batterie complètement avant de la mettre

en place.

Charger une batterie neuve

REMARQUE: Les batteries remplies d’électrolyte ne

sont qu’à 80 % de leur capacité.

1

Page 14

Il est possible de charger les batteries de deux manières –

par la charge standard ou la charge rapide. La charge standard est la seule façon qui est recommandée pour charger

une batterie. Elle procure une performance et une durée de

vie optimales.

1. Vérifiez que le chargeur est débranché de la prise de

courant de 110 V.

2. Connectez le fil conducteur rouge du chargeur à la borne

positive de la batterie, puis connectez le fil conducteur

noir du chargeur à la borne négative de la batterie.

3. Branchez le chargeur sur une prise de courant de 110 V.

4. Chargez la batterie pendant cinq heures au minimum

au rate de 10 % de l’amp heure de batterie, afin

d’obtenir la performance et la durée de vie optimales

de la batterie (ex: batterie de 30 AH devrait être chargée à 3,0 amps).

REMARQUE: Si la batterie devient chaude au tou-

cher, arrêtez la charge. Recommencez une fois

qu’elle s’est refroidie.

5. Une fois que la batterie est complètement chargée

(typique de 13,5 volts), débranchez le chargeur de la

prise de courant de 110 V et déconnectez les fils

conducteurs du chargeur.

6. Laissez la batterie reposer pendant 2 heures avant l’installation dans la véhicule.

Installation de la batterie

REMARQUE: La boîte de batterie est sous le siège

sur le côté d’utilisateur. Pour accéder la boîte, retirez

le siège et enlevez le couvercle de compartiment de

batterie; puis retirez la vis de pouce qui fixe le couvercle de boîte de batterie et élevez le couvercle pour

accéder la batterie.

TC019

NOTE: En installant une batterie dans un véhicule,

enduisez les bornes de la batterie d’une légère couche

de graisse pour minimiser la corrosion des bornes,

puis recouvrez-les de leur capuchon, s’il y en a.

PR942

REMARQUE: La perte de la charge d’une batterie

peut être causée par la température ambiante, la

consommation de courant alors que le contact est

coupé, des bornes corrodées, la décharge naturelle

ou des l’autre facteurs. La charge d’entretien est

requis pour laissez la batterie chargée complètement.

PR943A

1. Routez les câbles de batterie dans le compartiment de

batterie.

2. Installez la batterie; puis branchez les câbles de batterie (câble positif en premiere) à illustré. Serrez bien.

2

PNEUS

Le véhicule est muni de pneus basse pression sans

chambre à air ayant. Ne pas les substituer dans n’importe

quelles circonstances des pneus ayant une taille ou des

dimensions différentes.

PRESSION DE GONFLAGE DES

PNEUS

! AVERTISSEMENT

L’utilisation d’un véhicule ayant une pression de gonflage incorrecte ou inégale est dangereuse. Toujours

maintenir une pression correcte de gonflage des pneus.

La pression de gonflage des pneus avant et arrière doit être

de 110 kPa (16,0 psi) (UTV500) ou de 138 kPa (20,0 psi)

(UTV700).

Un jauge de basse pression est fourni dans la trousse à

outils pour mesurer la pression de l’air dans les pneus.

Vérifier la pression de l’air dans tous les pneus avant l’uti-

lisation du véhicule.

Page 15

ÉCROUS DE ROUE

En alternant d’un côté de l’autre, serrez les écrous de roue

en incréments de 27 N-m (20 lb-pi) à la torsion finale illustré dessous.

Roue en acier 54 N-m (40 lb-pi)

Roue aluminae (écrous noir) 81 N-m (60 lb-pi)

Roue aluminae (écrous chromée) 108 N-m (80 lb-pi)

PR941A

ATTENTION

L’utilisation d’un clé á impact peut résulter en un serrage incorrect et peut endommager la roue ou les goujons de moyeu.

PR752A

3. Enlevez l’équerre d’appui de la retenue de pied

(conservez les vis) et fixez-la au plancher à l’aide des

vis existant du plancher. Serrez bien.

4. Installez la retenue de pied et fixez-la à l’équerre

d’appui avec deux vis à capuchon existant. Ne serrez

pas les pièces de quincaillerie immédiatement.

INSTALLATION DE LA RETENUE DE

PIED GAUCHE

1. Enlevez la retenue de pied gauche de l’emballage

contenant les retenues latérales.

2. Enlevez deux vis à tôle de l’emplacement de fixation

dans le tableau de bord et la deuxième et troisième

vis de maintien du plancher.

PR751A

PR827

5. Fixez la retenue et le tableau de bord à l’aide des deux vis

à tôle et tasseau à canal) de paquet de quincaillerie. Ne les

serrez pas excessivement.

PR800A

6. Serrez bien les vis à capuchon qui fixent la retenue à

l’équerre d’appui.

3

Page 16

PR827

INSTALLATION DE ROPS/SANGLES

DE RETENUE/CONTRAINTES

LATÉRALES

! AVERTISSEMENT

Il est important d’installer la structure de protection

(ROPS) avant d’utiliser le véhicule ou de le livrer au client.

Les dispositifs de sécurité, comme le feu arrière/freinage,

les ceintures de sécurité et les poignées de maintien pour

passager sont intégrés à l’ensemble. La structure de protection fait partie de la structure du véhicule.

2. Élevez la boîte de rangement; puis en tenant le ROPS

arrière, retirez les vis qui fixent le ROPS. Fixez légèrement le ROPS en position correct en utilisant des Vis à

tête Allen et des écrous en nyloc nouveaux. Ne serrez

pas à ce stade. Répétez pour le ROPS avant.

3. Placez le renfort en croix supérieur entre les tubes

avant et arrière et retenez-les au moyen de huit Boulons à tête (installées du haut) et huit Écrous Nyloc de

zinc. Serrez à 47 N-m (35 lb-pi).

UTV-070

4. Fixez l’arrière de siège au tubulure de ROPS arrière

avec les deux vis à capuchon. Serrez à 11 N-m (8 lbpi).

REMARQUE: Les pièces servant à retenir les tubes

avant et arrière au cours de la livraison permettront la

.

fixage de tuyaux de ROPS

Des écrous retiennent

l’arrière des tubes de la structure de protection lors de

l’expédition. Ces écrous doivent être retirés et jetés.

1. Desserrez les vis Allen retenant les tubulures de

ROPS avant et arrière et inclinez ensuite les tubulures avant et arrière de la position horizontale à la

position horizontale.

UTV-068

TC022A

5. Fixez la partie inférieure (centrale) du tube de verrière

arrière au support central au moyen de deux Vis Torx

M6. Serrez à 11 N-m (8 lb-pi). Branchez la faisceau de

fils de feu arrière/arrêt au harnais principal.

TC030A

6. Serrez les tubes avant et arrière à 47 N-m (35 lb-pi).

Assurez-vous que les “méplats” des écrous engager les

tubulures de ROPS lorsqu’ils sont serrées.

UTV-148

4

Page 17

TC027

TC029

7. Installez les sangles de retenue (des vis à capuchon

installées du haut) dans les languettes de montage

appropriées la longue de tuyau de support de reposetête sur le ROPS arrière. Serrez à 47 N-m (35 lb-pi).

8. Placez le dispositif de retenue de l’occupant de droite

sur le tube du côté passager et retenez-le au moyen de

quatre Vis à capuchon. Serrez à 13,5 N-m (10 lb-pi).

PR834A

11. Enroulez la sangle d’ancrage arrière autour du tube de

montage de la structure de protection et retenez-la

avec la boucle. Serrez de façon à ce que la sangle

repose dans la position indiquée.

PR831A

12. Reprenez les étapes9à11pour le côté opposé.

13. Retenez les deux dispositifs de retenue latéraux aux

panneaux de seuil de porte au moyen de la boucle.

PR835A

9. Fixez le retenue latérale externe en utilisant des deux

Vis à capuchon en vous assurant que les sangles sont

positionnées correctement.

10. Acheminez les sangles de retenue inférieures à l’intérieur du tube latéral et fixez-les ensuite au châssis au

moyen de deux Vis à épaulement et d’Écrous à collet.

Serrez à 13,5 N-m (10 lb-pi).

PR833

VÉRIFICATION DU SYSTÈME DE

REFROIDISSEMENT

Enlever le bouchon de remplissage et vérifier le niveau du

réfrigérant. Le niveau du réfrigérant doit être au bas de

goulot de remplissage de radiateur. Si du réfrigérant est

requis, en ajouter pour amener le réfrigérant au niveau spécifié et installer le bouchon.

5

Page 18

REMARQUE: Si du réfrigérant est requis, mélanger

le réfrigérant pour une température de -36 °C (-34 °F).

Suivre les recommandations du fabricant.

ATTENTION

Il est extrêmement important que le système de refroidissement soit rempli correctement. Si le système n’est

pas correctement rempli, des dommages seront causés

au moteur.

INSTALLATION DE VOLANT

REMARQUE: Le véhicule devrait être sur le sol

niveau avec les roues avant de droit vers l’avant et

l’arrière.

1. Retirez l’écrou et le volant de l’arbre de direction.

2. Installez et alignez le volant et fixez lâche avec

l’écrou.

REMARQUE: Ce modèle a un écrou à créneaux/clip

de blocage et un arbre de direction perforé. La clip de

blocage fendue se trouvera dans les pièces de quincaillerie du volant de direction.

3. Vérifier que le volant est dirigé correctement et les

roues avant sont alignées de droit avant; puis enduisez

les filets de l’écrou d’une goutte de Loctite rouge n°

271 et serrez l’écrou à 35 N-m (25 lb-pi).

PR087A

Respectez la procédure suivante pour régler l’alignement

des roues.

1. Centrez le volant, puis, au moyen d’une clé à fourche,

tenez les articulations de la barre d’accouplement (A)

et desserrez les contre-écrous droit et gauche (B).

4. Installez la clip de blocage à travers de l’arbre de

direction et l’écrou. Installez le couvercle de volant.

HDX131A

REMARQUE: Si le trou dans l’arbre de direction

n’aligne avec les cannelures dans l’écrou château, serrez l’écrou jusqu’à un cannelure aligne avec le trou.

VÉRIFICATION ET RÉGLAGE DE

L’ALIGNEMENT DES ROUES AVANT

REMARQUE: Toutes les mesures et tous les

réglages doivent être effectués sur un véhicule à vide.

Marquez la ligne centrale des pneus avant à l’avant et à

l’arrière du pneu; ensuite, au moyen d’un ruban à mesurer,

mesurez la distance entre les marques avant et arrière et

prenez en bonne note. La mesure avant doit être de 3 à 6

mm (1/8 à 1/4 po) plus grande que celle de l’arrière (ouverture d’extérieur).

HDX098B

PR792A

ATTENTION

Utilisez toujours une clé pour tenir les articulations de

la barre d’accouplement pour serrer ou desserrer les

contre-écrous; dans le cas contraire, les protecteurs

pourraient être endommagés.

2. Tournez les barres d’accouplement gauche et droite

(C) au même rythme afin d’obtenir l’ouverture d’extérieur voulu, puis serrez solidement les contre-écrous.

3. Vérifiez la opération libre de direction (pleins-gauche/

pleins-droit).

VÉRIFICATION DE SYSTÈME DE

FREIN HYDRAULIQUE

Le système de frein hydraulique a été rempli et purgé à l’usine.

6

Page 19

1. Avec le réservoir de frein hydraulique en position

niveau, inspectez le niveau de liquide. Il doit être

visible à la ligne MAX.

TC021A

2. Comprimer plusieurs fois la pédale de frein pour vérifier si le levier est ferme. Si la pédale n’est pas ferme,

il faut purger le système de freinage.

3. Pour purger le système de freinage, utiliser la procédure suivante:

A. Retirer le couvercle et remplir le réservoir du maître

cylindre de liquide de frein DOT 4 approuvé.

E. À ce stade, exécutez les étapes B et C sur le vis de

purge AVANT DROIT; passez ensuite à les vis de

purge AVANT GAUCHE et respectez la même

procédure.

4. Vérifier avec soin la totalité du système de frein

hydraulique pour que toutes les connexions soient serrées, que le vis de purge soient serrées et qu’aucune

fuite ne soit présente.

5. S’assurer de polir les plaquettes de frein au cours

de la promenade d’essai.

INSPECTION AJUSTEMENT DU

CÂBLE D’ACCÉLÉRATEUR

1. Vérifiez le jeu libre du câble en saisissant le câble à la

partie supérieure de la pédale de l’accélérateur, puis

tirez-le légèrement vers l’arrière pour éliminer le mou.

Le jeu devrait être de1à2mm(0,040 à 0,080 po).

B. Installer et fixer le couvercle; poussez ensuite len-

tement la pédale de frein plusieurs fois.

C. Retirez le capuchon protecteur, installez une

extrémité d’un tuyau transparent sur la vis de

purge ARRIÈRE et placez l’autre extrémité dans

un contenant. Ensuite, tout en exerçant une légère

pression sur la pédale de frein, ouvrez la vis de

purge et surveillez pour détecter les bulles d’air.

Fermez la vis de purge avant de relâcher la pédale

de frein. Répétez cette procédure jusqu’à ce qu’il

n’y ait plus de bulles d’air.

PR080A

REMARQUE: Au cours de la procédure de frein,

observer le réservoir du maître cylindre très attentivement pour s’assurer qu’il y a toujours une quantité

suffisante de liquide de frein. Si le niveau de liquide

passe au-dessous du repère inférieur sur le réservoir,

remplir à nouveau le réservoir avant de continuer la

procédure de purge.

PR708A

2. Enfoncez complètement la pédale de l’accélérateur et

tirez l’extrémité du câble vers l’arrière. Il ne devrait

pas avoir du jeu et le manchon de tension ne doit pas

être compressé.

PR709A

3. Pour régler le câble d’accélérateur, retirez le couvercle

de bras d’accélérateur sur le corps d’accélérateur; puis

desserrez les deux écrous de réglage et faites régler

afin de jeu correct.

D. Répétez les étapes B et C jusqu’à ce que la pédale

de frein soit ferme.

7

Page 20

500

TC020A

4. Serrez bien le contre-écrou.

INSPECTION DE NIVEAU D’HUILE DU

MOTEUR/TRANSMISSION

REMARQUE: Inspectez la zone autour le bouchon

de vidange (sous le véhicule) et le filtre à huile afin

des fuites (avant du moteur).

PR078A

REMARQUE: Pour accéder la filtre d’huile, retirez le

siège. Retirez les vis qui fixent l’arrière de siège et

retirez l’arrière de siège; puis retirez les vis qui fixent

la base de siège et retirez la base de siège.

HDX234A

2. Installez le jauge de niveau d’huile dans le carter

moteur en vissant la jauge dans le carter pour vérifier.

3. Retirez la jauge de niveau d’huile; le niveau d’huile

moteur devrait être entre la range d’opération mais ne

au-dessus la repère FULL.

GZ461A

ATTENTION

Ne pas trop remplir d’huile le moteur. Toujours s’assurer que le niveau d’huile est entre la range d’opération.

Huile de Moteur/Transmission

Recommandée

REMARQUE: Le véhicule devrait être sur un surface

niveau lors le vérification de niveau d’huile du moteur.

1. Élevez la boîte de cargaison; puis dévissez le jauge de

niveau d’huile et nettoyez-la avec un chiffon propre.

700

PR053B

8

ATTENTION

T oute huile utilisée à la place de l’huile recommandée

peut causer de sérieux dommages au moteur. N’utilisez

pas des huiles qui contiennent des additifs au graphite

ou au molybdène. Ces huiles peuvent avoir des effets

néfastes sur le fonctionnement de l’embrayage. De plus,

les huiles pour compétitions, végétales, non détergentes

ou à base de ricin ne sont pas recommandées.

L’huile recommandée à être utilisée est toutes temps 0W40 synthétique, laquelle a été formulée spécifiquement

pour l’utilisation dans ce moteur. Bien que l’huile de

moteur toutes temps 0W-40 Toro (Synthétique) est la seule

huile recommandée pour l’utilisation dans ce moteur, l’utilisation de n’importe quelle huile API certifiée SM 0W-40

tout temps synthétique est acceptable.

Page 21

OILCHARTJ

HDX084A

INSPECTION DES NIVEAUX DE

LUBRIFICANT DE CARTER

D’ENRENAGE

1. Retirez le bouchon de niveau de différentiel avant; le

lubrifiant devrait être visible au filetage de bouchon. Si

bas, ajoutez au besoin de l’huile pour engrenages

approuvé SAE 80W-90 hypoïde

sage

. Installez le bouchon et serrez-le à 22 N-m (16 lb-pi).

au bouchon de remplis-

ATTENTION

Tout lubrifiant utilisé à la place des lubrifiants recom-

mandés peut causer de sérieux dommages au différentiel avant.

VÉRIFICATION/RÉGLAGE DU

FAISCEAU

Les phares peuvent être réglés verticalement. Le centre de

la zone d’éclairage des feux de route (HIGH) doit être utilisé pour la visée verticale.

1. Positionnez le véhicule sur une surface horizontale de

façon à ce que les phares se trouvent à une distance

approximative de 6,1 m (20 pi) d’une surface de visée

(mur ou surface de visée similaire).

0740-647

REMARQUE: Le véhicule devrait présenter une

charge de fonctionnement moyenne lors du réglage

du faisceau.

HDX083A

2. Retirez le bouchon de niveau de l’entraînement arrière; le

lubrifiant devrait être

visible au filetage de bouchon

.Si

bas, ajoutez au besoin de l’huile pour engrenages

approuvé SAE 80W-90 hypoïde au bouchon de remplissage. Installez le bouchon et serrez à 22 N-m (16 lb-pi).

ATTENTION

Tout lubrifiant utilisé à la place des lubrifiants recom-

mandés peut causer de sérieux dommages à l’entraînement arrière.

2. Mesurez la distance qui va du plancher au milieu de

chaque phare.

3. Tracez des repères horizontaux sur la surface de visée

à l’aide des mesures obtenues à l’étape 2.

4. Tracez des repères verticaux qui croisent les repères

horizontaux sur la surface de visée directement à

l’avant des phares.

5. Allumez les phares. Assurez-vous qu’il s’agit bien des

FEUX DE ROUTE. N’UTILISEZ PAS LES FEUX

DE CROISEMENT.

6. Observez la visée de chaque faisceau de phare. La

visée correcte est obtenue lorsque le FEUX DE

ROUTE est centré sur le repère vertical de la surface

de visée, 5 cm (2 po) au-dessous du repère horizontal.

7. En utilisant le bouton de réglage, ajustez chaque phare

jusqu’à ce que la visée correcte soit obtenue.

9

Page 22

TC004A

ESSENCE RECOMMANDÉE

L’essence recommandée pour son emploi est l’essence

ordinaire sans plomb ayant un indice d’octane minimum

de 87. Dans un grand nombre de régions, des produits oxygénés sont ajoutés à l’essence. Les essences oxygénées

contenant jusqu’à 10% d’éthanol ou 5% de méthanol sont

des essences acceptables.

! AVERTISSEMENT

Ne jamais faire des freins brusques ou vous mettre dans

des situations où vous avez à faire des freinages brusques

avant que les garnitures ne soit brûlées correctement.

1. Choissez une zone suffisamment grande pour accélérer jusqu’à 50 km/h (30 mi/h) et freiner complètement.

2. Accélérez jusqu’à 50 km/h (30 mi/h); ensuite, appuyez

sur la pédale du frein pour décélérer jusqu’à 0 à 8 km/

h (0 à 5 mi/h).

3. Répétez la procédure vingt fois.

! AVERTISSEMENT

En se servant du Manuel d’utilisation comme de guide,

instruire le client au sujet de l’emploi correct, les soins à

prendre, la procédure de polissage (si des plaquettes de

frein sont remplacées) et l’entretien du système de frein

hydraulique.

TRANSPORT

Lors de l’utilisation d’essence mélangée avec de l’éthanol,

il n’est pas nécessaire d’ajouter de l’antigel pour essence

puisque l’éthanol empêchera l’accumulation d’humidité

dans le dispositif d’alimentation.

ATTENTION

Ne pas utiliser de l’essence incolore. Il ne faut utiliser

que des additifs d’essence approuvés par Toro.

PROMENADE D’ESSAI

1. Vérifier toues les fonctions mécaniques.

2. Polir les plaquettes de frein (voyez Roder les Plaquettes de Frein).

3. Confirmer que tous les câbles et harnais de câblage

sont connectés et acheminés correctement.

4. Confirmer que tous les éclairages fonctionnent correctement: phares (LONGUE PORTÉE-CODE), feu

arrière/feu d’arrêt, jauge, tableau de commandes.

5. Confirmer que le ventilateur de refroidissement opère

normalement.

6. Après la promenade d’essai, vérifier les systèmes de

freinage.

7. Examiner le paquet du propriétaire pour s’assurer qu’il

est complet (Manuel d’utilisation, clé à ergots).

REMARQUE: Lors du transport le véhicule, assurez-

vous que le véhicule est en position de stationnement.

Informer le propriétaire/le conducteur que ce véhicule doit

être transporté en position normale de fonctionnement (sur

toutes les quatre roues) et attaché avec des sangles de

maintien dans les endroits corrects. La figure indique le

nombre minimum de sangles de maintien à utiliser.

PR075A

8. Inspecter visuellement tout le véhicule pour tout élément de fixation qui serait desserré. Serrer comme

requis conformément aux spécifications appropriées.

9. Confirmer la vérification finale des différentes rubriques

cochées sur la liste de contrôle.

RODER LES PLAQUETTES DE FREIN

Les plaquettes de frein doivent être bien rôdées afin de

fournir une efficacité de freinage maximale. La distance de

freinage sera étendue jusqu’à ce que les plaquettes de frein

soient rôdées correctement.

10

PR073A

ATTENTION

En cas d’utilisation de sangles de maintien supplémentaires à tout autre endroit du véhicule , faites attention

de ne pas endommager le véhicule.

Page 23

! AVERTISSEMENT

Soyez extrêmement prudent lors de l’utilisation

d’une machine sur une rampe.

Veiller à ce que les ROPS se effacer au sommet

d’une remorque fermée.

Utilisez uniquement une rampe pleine largeur; ne

pas utiliser des rampes individuelles pour chaque

côté de la machine.

Ne pas dépasser un angle de 15 degrés entre la

rampe et le sol ou entre la rampe et la remorque ou

un camion.

Vérifiez la longueur de la rampe est au moins quatre

fois (4X) tant que la hauteur du lit de remorque ou un

camion sur le sol. Cela garantira que angle de rampe

ne dépasse pas 15 degrés sur un terrain plat.

Évitez accélération ou la décélération soudaine en

conduisant la machine sur une rampe car cela pourrait causer une perte de contrôle ou d'une situation

de renversement.

TC028

11

Page 24

REMARQUES

12

Loading...

Loading...