Toro 22321G, 22322, TX 427 Operator's Manual

FormNo.3360-384RevB

TX427CompactUtilityLoader

ModelNo.22321—SerialNo.280000001andUp

ModelNo.22321G—SerialNo.280000001andUp

ModelNo.22322—SerialNo.280000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Warning

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrestor,contactyour

AuthorizedServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,

orgrass-coveredlandwithoutasparkarrester

mufermaintainedinworkingorder,ortheengine

constricted,equipped,andmaintainedforthe

preventionofre.Otherstatesorfederalareasmay

havesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

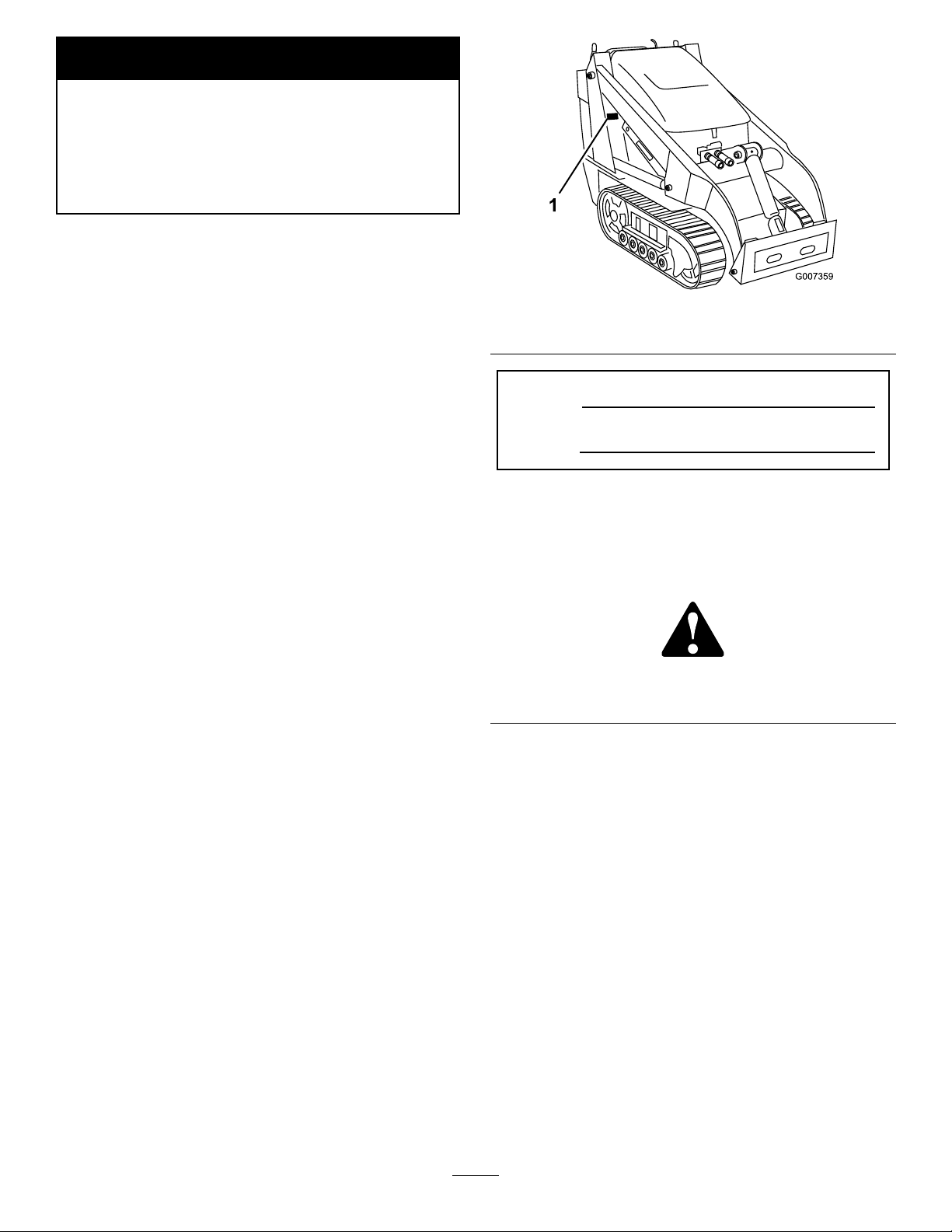

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Theenclosed

Engine Owner’ s Man ual

issupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2008—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Contents

Introduction.................................................................2

Safety...........................................................................4

SafeOperatingPractices.......................................4

SoundPressure.....................................................6

SoundPower........................................................6

Vibration..............................................................6

StabilityData........................................................7

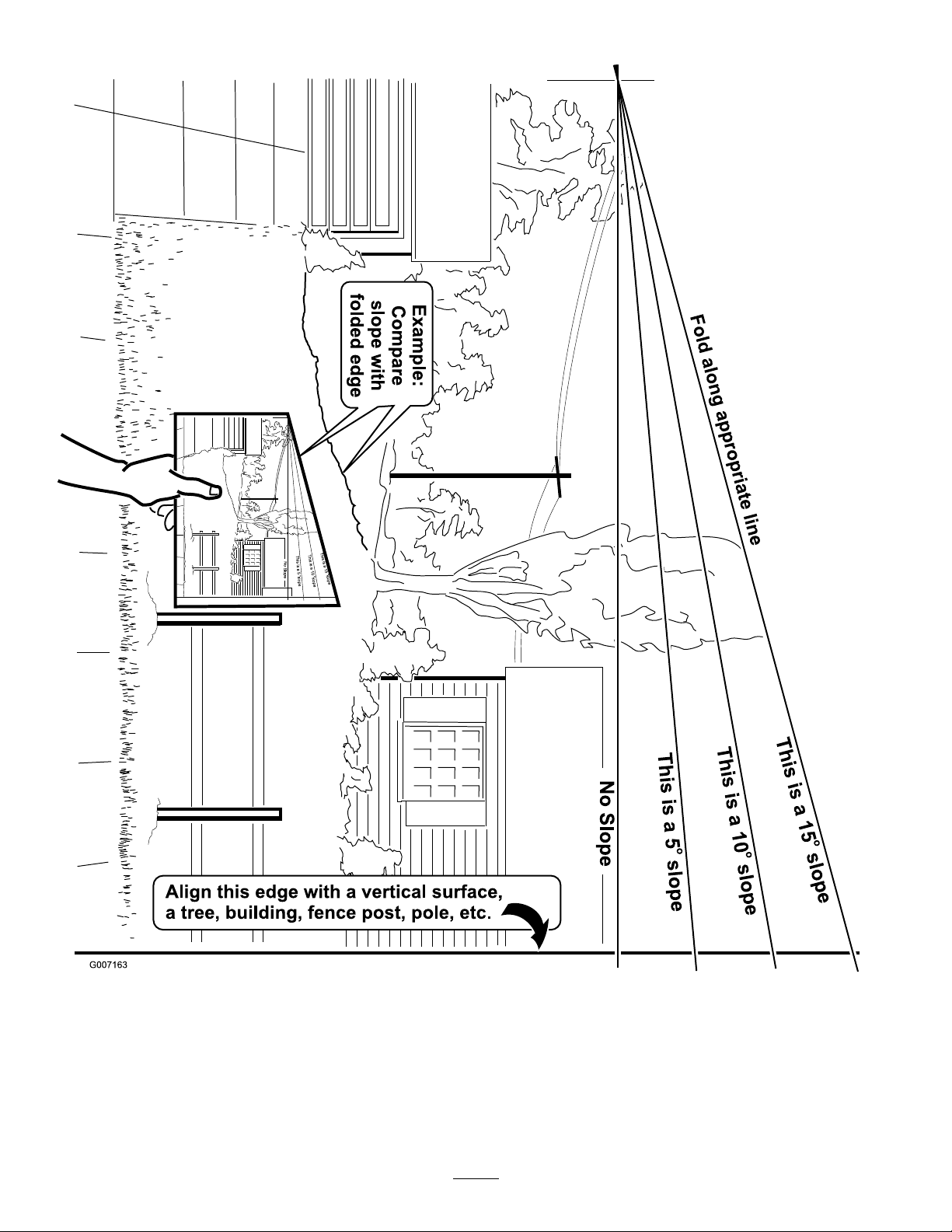

SlopeIndicator.....................................................8

SafetyandInstructionalDecals.............................9

ProductOverview......................................................12

Controls.............................................................12

Specications.....................................................15

Attachments/Accessories...................................15

Operation...................................................................16

AddingFuel.......................................................16

CheckingtheEngineOilLevel............................17

CheckingtheHydraulicFluidLevel.....................17

StartingandStoppingtheEngine........................18

StoppingtheTractionUnit.................................18

MovingaNon-functioningTraction

Unit................................................................18

UsingtheCylinderLock.....................................19

UsingAttachments.............................................19

SecuringtheTractionUnitforTransport.............21

LiftingtheTractionUnit.....................................21

Maintenance...............................................................22

RecommendedMaintenanceSchedule(s)................22

PremaintenanceProcedures....................................23

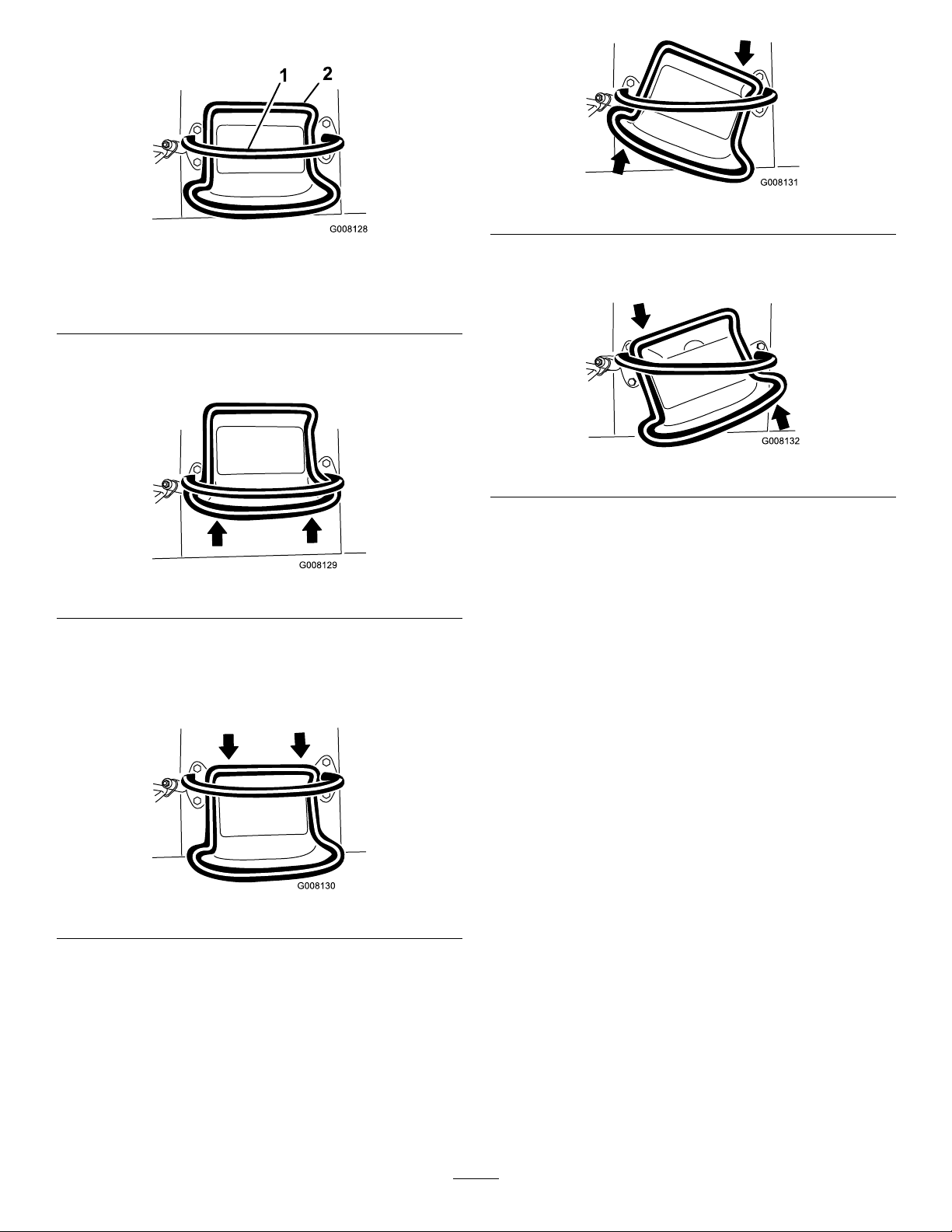

OpeningtheHood.............................................23

ClosingtheHood...............................................23

OpeningtheRearAccessCover..........................23

ClosingtheRearAccessCover............................24

RemovingtheSideScreens.................................24

InstallingtheSideScreens...................................24

RemovingtheFrontScreen................................24

Lubrication.............................................................25

GreasingtheTractionUnit.................................25

EngineMaintenance...............................................26

ServicingtheAirCleaner....................................26

ServicingtheEngineOil.....................................26

ServicingtheSparkPlugs....................................27

FuelSystemMaintenance.......................................29

ChangingtheFuelFilter.....................................29

DrainingtheFuelTank.......................................29

ElectricalSystemMaintenance................................30

ServicingtheBattery...........................................30

DriveSystemMaintenance.....................................31

ServicingtheTracks............................................31

BeltMaintenance....................................................35

Inspecting/ReplacingtheDriveBelt...................35

ControlsSystemMaintenance.................................36

AdjustingtheTractionControl

Alignment......................................................36

AdjustingtheTractionControlNeutral

Position..........................................................37

AdjustingtheTrackingoftheTraction

Control,FullForwardPosition........................37

HydraulicSystemMaintenance...............................38

ReplacingtheHydraulicFilter.............................38

ChangingtheHydraulicFluid.............................39

CheckingtheHydraulicLines.............................40

Cleaning.................................................................40

RemovingDebrisfromtheTraction

Unit................................................................40

CleaningtheChassis...........................................41

Storage.......................................................................42

Troubleshooting.........................................................44

Schematics.................................................................45

3

Safety

Improperuseormaintenancebytheoperator

orownercanresultininjury.T oreducethe

potentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothesafety

alertsymbol,whichmeans:

Danger

complywiththeinstructionmayresultinpersonal

injuryordeath.

—personalsafetyinstruction.Failureto

Caution

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglish,itistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,

safetyglasses,longpants,safetyshoes,andhearing

protection.Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

,

W ar ning

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toys,andwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

,or

–Neverremovethegascaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperator’spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystartthe

enginefromtheoperator’sposition.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine’sstability.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neveroperatewiththeguardsnotsecurelyinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperty.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerimplements,disengage

theauxiliaryhydraulics,engageparkingbrake,shut

offtheenginebeforeleavingtheoperator’sposition

foranyreason.

•Keephandsandfeetawayfrommovingattachments.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

4

•Readallattachmentmanuals.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthetractionunit.Stopthetractionunit

ifanyoneentersthearea.

•Neverleavearunningtractionunitunattended.

Alwayslowertheloaderarms,stoptheengine,set

theparkingbrake,andremovethekeybeforeleaving.

•Donotexceedtheratedoperatingcapacity,asthe

tractionunitmaybecomeunstablewhichmayresult

inlossofcontrol.

•Donotcarryaloadwiththearmsraised.Always

carryloadsclosetotheground.

•Donotover-loadtheattachmentandalwayskeep

theloadlevelwhenraisingtheloaderarms.Logs,

boards,andotheritemscouldrolldowntheloader

arms,injuringyou.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

StabilityDatasectionandthoseintheattachment

Operator’sManual.Seealsothe,page.

•Operateupanddownslopeswiththeheavyend

ofthetractionunituphill.Weightdistribution

changes.Anemptybucketwillmaketherearof

thetractionunittheheavyend,andafullbucket

willmakethefrontofthetractionunittheheavy

end.Mostotherattachmentswillmakethefrontof

tractionunittheheavyend.

•Raisingtheloaderarmsonaslopewillaffectthe

stabilityofthemachine.Wheneverpossible,keepthe

loaderarmsintheloweredpositionwhenonslopes.

•Removinganattachmentonaslopewillmakethe

rearofthetractionunitheavy.RefertotheStability

Datasectiontodeterminewhethertheattachment

canbesafelyremovedontheslope.

•Removeobstaclessuchasrocks,treelimbs,etc.from

theworkarea.Watchforholes,ruts,orbumps,as

uneventerraincouldoverturnthetractionunit.Tall

grasscanhideobstacles.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Checkforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•Ensurethatyouoperatethetractionunitinareas

wheretherearenoobstaclesincloseproximitytothe

operator.Failuretomaintainadequatedistancefrom

trees,walls,andotherbarriersmayresultininjury

asthetractionunitbacksupduringoperationifthe

operatorisnotattentivetothesurroundings.Only

operatetheunitinareaswherethereissufcient

clearancefortheoperatortosafelymaneuverthe

product.

•Beforedigging,havetheareamarkedfor

undergroundutilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthetraction

unitandattachmentsandkeephandsandfeetaway

fromtheseareas.

•Beforeoperatingthetractionunitwithan

attachment,ensurethattheattachmentisproperly

installed.

•UseonlyToro-approvedattachments.Attachments

canchangethestabilityandtheoperating

characteristicsofthetractionunit.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthetraction

unitlosestraction,proceedslowly,straightdownthe

slope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthetractionunit

uphill.

•Donotoperateneardrop-offs,ditches,or

embankments.Thetractionunitcouldsuddenlyturn

overifatrackgoesovertheedgeofaclifforditch,

orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthetractionunitonahillsideorslope

withoutloweringtheattachmenttotheground,

settingtheparkingbrake,andchockingthetracks.

MaintenanceandStorage

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Allslopesrequireextracaution.

•Donotoperatethetractionunitonhillsidesor

slopesexceedingtheanglesrecommendedinthe

•Disengagetheauxiliaryhydraulics,lowerthe

attachment,settheparkingbrake,stoptheengine,

andremovethekey.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuel

spillage.

5

•Lettheenginecoolbeforestoringanddonotstore

nearame.

–Keepcontainernozzleincontactwiththetank

duringlling.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatteryorremovethesparkplug

wiresbeforemakinganyrepairs.Disconnect

thenegativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.

Wearprotectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Ifanymaintenanceorrepairrequirestheloaderarms

tobeintheraisedposition,securethearmsinthe

raisedpositionwiththehydrauliccylinderlock.

•Securetheloaderarmvalvewiththeloadervalve

lockanytimeyouneedtostopthemachinewiththe

loaderarmsraised.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Stopandinspecttheequipmentifyoustrikean

object.Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressurehydraulic

uid.Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.Hydraulicuidescaping

underpressurecanpenetrateskinandcauseinjury

requiringsurgerywithinafewhoursbyaqualied

surgeonorgangrenemayresult.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof90dBA,basedonmeasurementsof

identicalmachinesperISO11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof103

dBA,basedonmeasurementsofidenticalmachinesper

EN6395.

Vibration

•Keepthetractionunitfreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillage.Allow

thetractionunittocoolbeforestoring.

•Useextracarewhenhandlinggasolineandother

fuels.Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhen

theengineisrunning.Allowtheenginetocool

beforerefueling.Donotsmoke.

–Neverrefuelthetractionunitindoors.

–Neverstorethetractionunitorfuelcontainer

insidewherethereisanopename,suchasnear

awaterheaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,

trunk,pick-upbed,oranysurfaceotherthanthe

ground.

Thisunitdoesnotexceedahand/armvibrationlevelof

1.1m/s

perEN1033.

6

2

,basedonmeasurementsofidenticalmachines

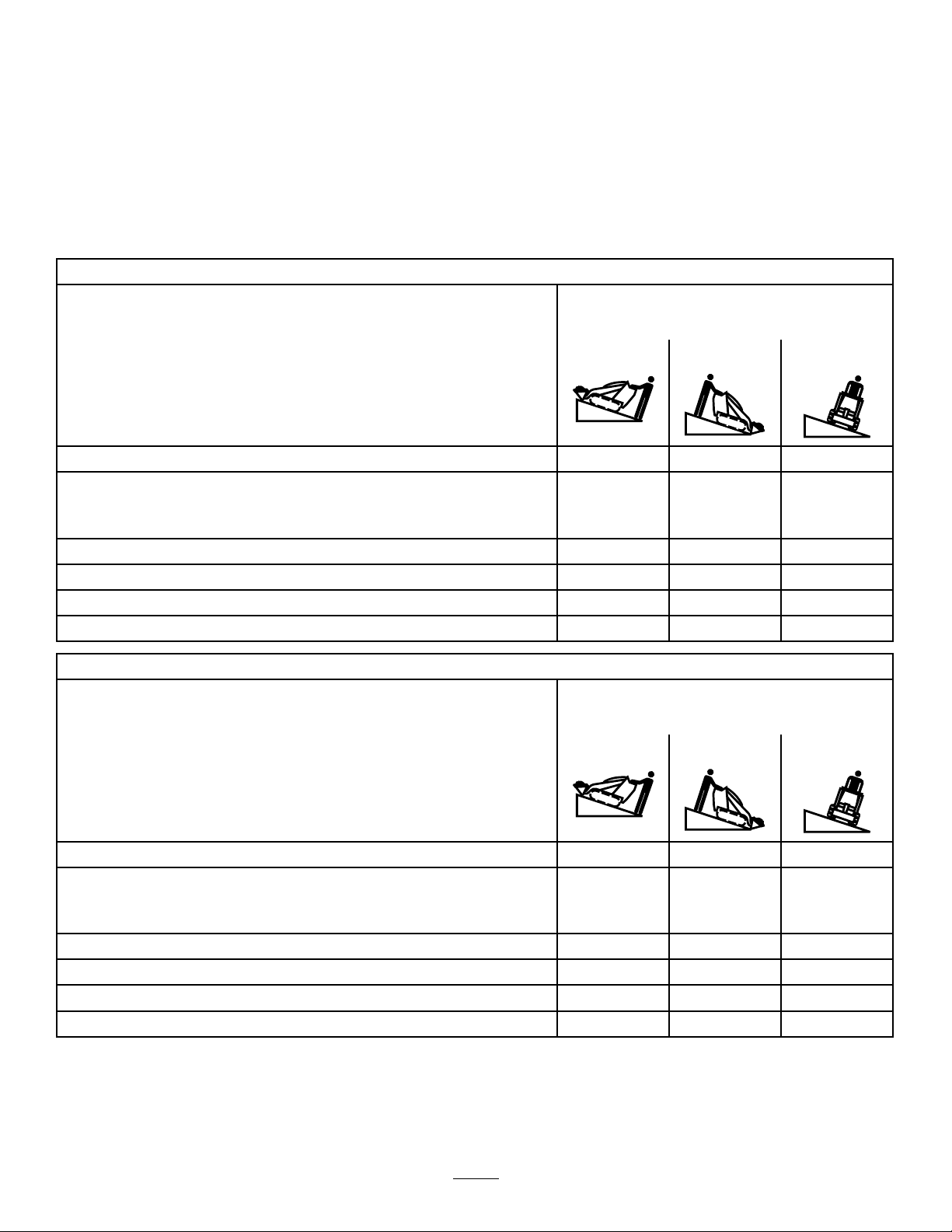

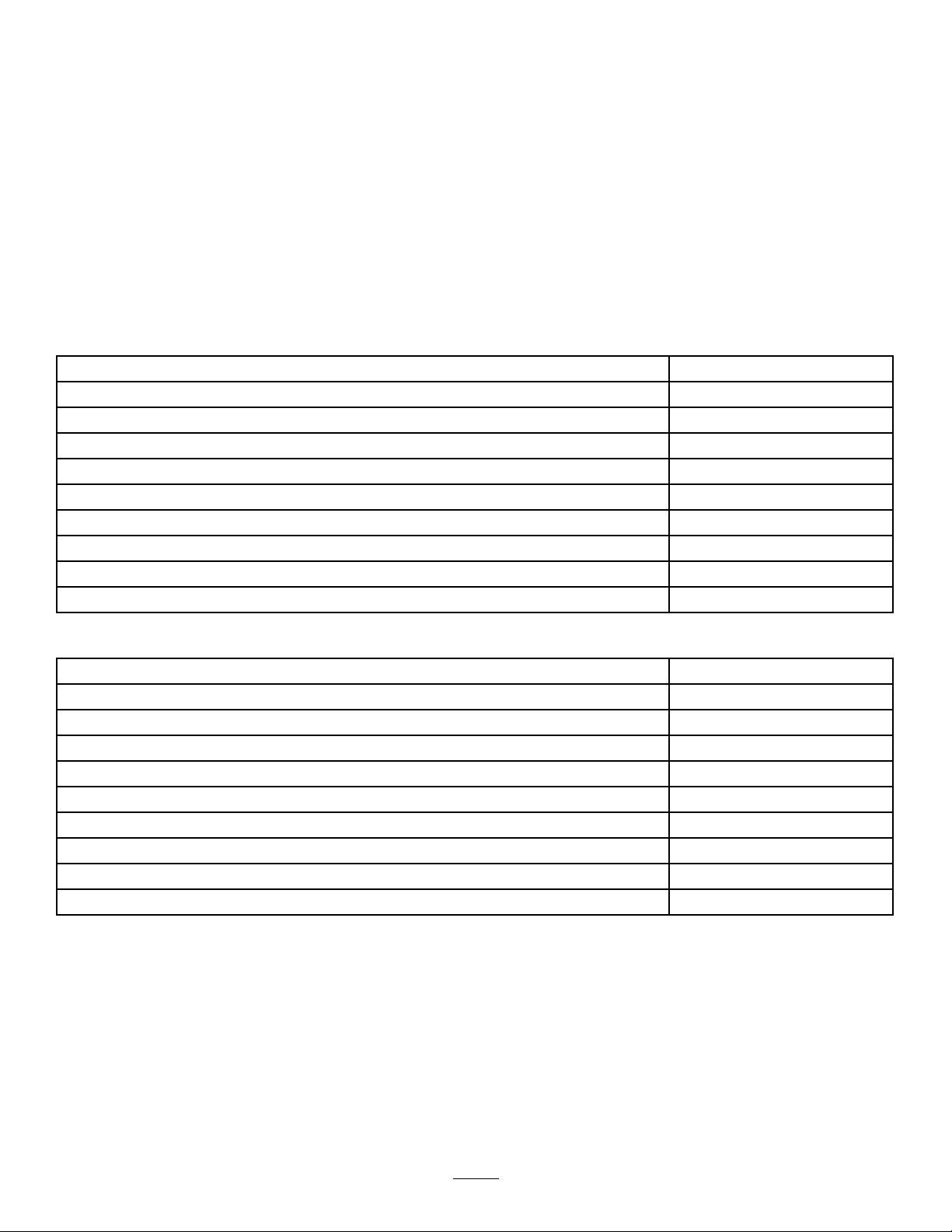

StabilityData

Thefollowingtableslistthemaximumsloperecommendedforthetractionunitinthepositionslistedinthetables.

Slopesoverthelisteddegreemaycausethetractionunittobecomeunstable.Thedatainthetablesassumethatthe

loaderarmsarefullylowered;raisedarmsmayaffectthestability.

Ineachattachmentmanualisasetofthreestabilityratings,oneforeachhillposition.T odeterminethemaximum

slopeyoucantraversewiththeattachmentinstalled,ndthedegreeofslopethatcorrespondstothestabilityratings

oftheattachment.Example:IftheattachmentinstalledonaTX427tractionunithasaFrontUphillratingofB,a

RearUphillratingofD ,andaSideUphillratingofC,thenyoucoulddriveforwardupa20°slope,rearwardupa12°

slope,orsidewaysona14°slope,aslistedinthefollowingtablefortheTX427tractionunit.

Model22321and22321G

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C17°17°14°

D

E

Model22322

11°21°19°

25°25°20°

20°20°18°

10°12°9°

5°5°5°

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

SideUphill

SideUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C18°16°16°

D

E

12°20°23°

25°25°25°

22°22°22°

10°10°10°

5°5°5°

7

SlopeIndicator

8

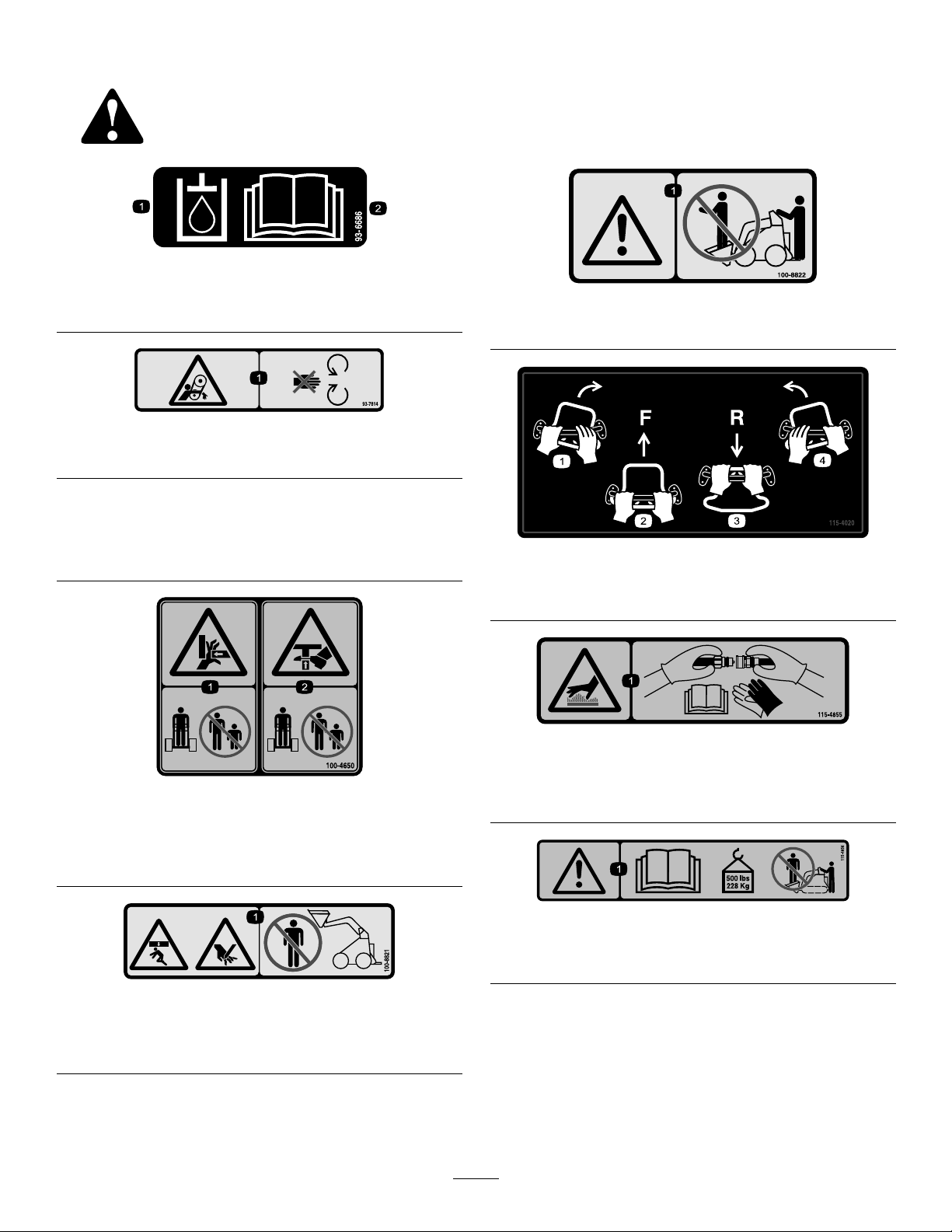

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-6686

1.Hydraulicoil

2.ReadtheOperator’sManual.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

100-8822

1.Warning—donotcarrypassengers.

93-9084

1.Liftpoint

2.Tie-downpoint

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

115-4020

1.Turnright3.Reverse

2.Forward

4.Turnleft

115-4855

1.Hotsurface/burnhazard—wearprotectivegloveswhen

handlingthehydrauliccouplersandreadtheOperator’s

Manualforinformationonhandlinghydrauliccomponents.

115-4856

1.Warning—readtheOperator’sManual;maximumload

ratingof500lb(228Kg);noriders.

100-8821

1.Crushinghazardandcuttinghazardofhand—stayasafe

distancefromthefrontofthetractionunitwhentheloader

armsareraised.

9

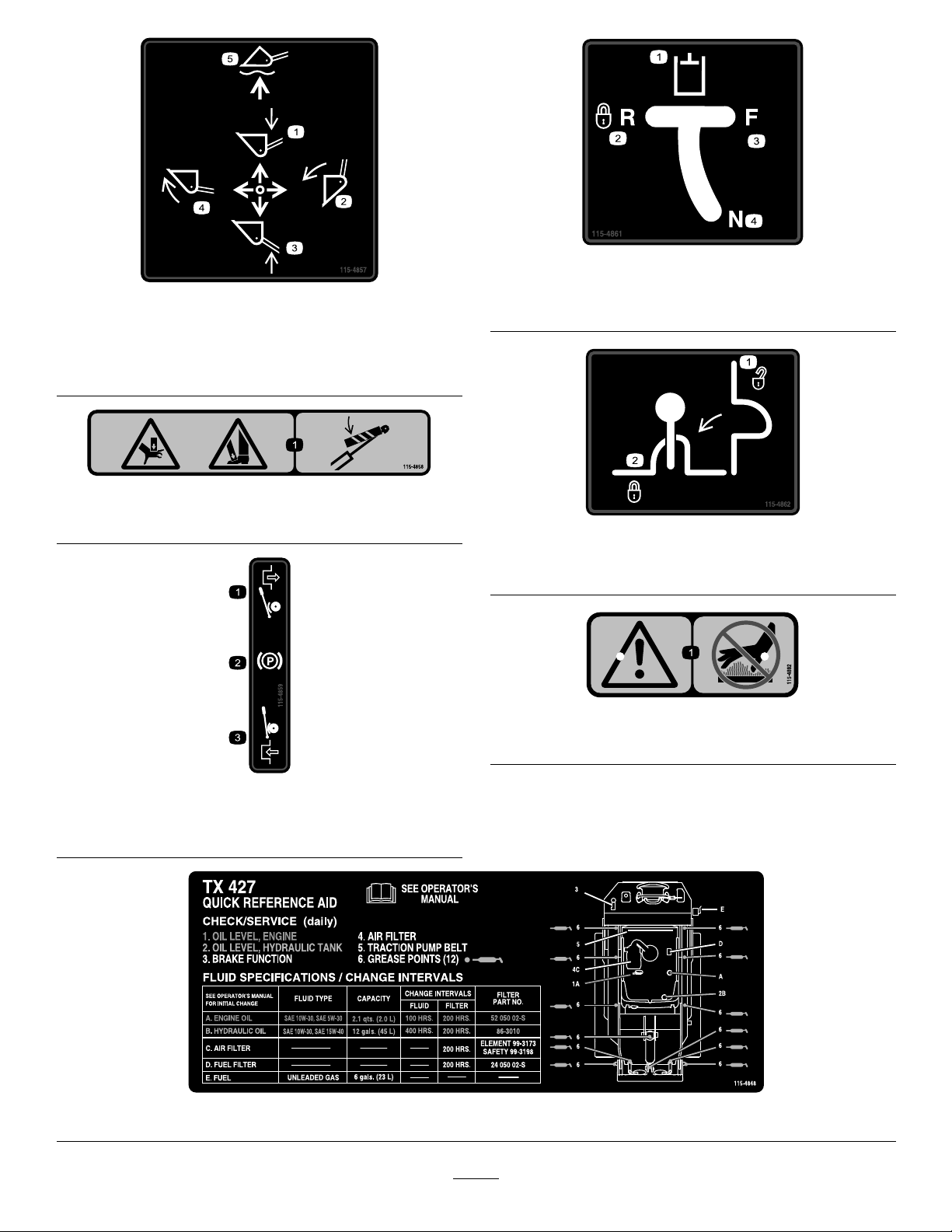

115-4857

1.Lowertheloaderarms.

2.Dumpthebucket.5.Floatthebucketonthe

3.Raisetheloaderarms.

4.Curlthebucket.

ground.

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

115-4861

1.Auxiliaryhydraulics3.Forward

2.Lockedreverse(detent)4.Neutral(off)

115-4862

1.Loadervalvelock,

unlocked

2.Loadervalvelock,locked

1.Disengaged3.Engaged

2.Parkingbrake

115-4882

1.Warning—stayasafedistancefromthehotsurfaces.

115-4859

115-4848

10

107-9309

1.Warning—readtheOperator’sManualforinformationonchargingthebattery;containslead;donotdiscard.

2.ReadtheOperator’sManual.

115-4860

1.Warning—readtheOperator’sManual.

2.Warning—settheparkingbrake,stoptheengine,removetheignitionkeyandlowertheloaderarmsbeforeleavingthemachine.

3.Crushinghazard—installthecylinderlockandreadtheinstructionsbeforeservicingorperformingmaintenance.

4.Cuttinghazardofhandsorfeet—waitforallmovingpartstostop;stayawayfrommovingparts;keepallguardsandshieldsin

place.

5.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthemachine.

6.Explosionandelectricshockhazard—donotdiginareaswithburiedgasorelectricallines;contactlocalpowerorganizations

beforedigging.

115-4863

1.ReadtheOperator’sManual,located

insidetherearaccesscover.

2.Fast

3.Continuousvariablesetting

4.Slow

5.Throttle11.Hourmeter17.Tippinghazard—movethetractionunit

6.On

7.Choke

8.Off

9.Fuel15.Warning—donotoperatethismachine

10.Hydraulicoiltemperature16.Electricshockhazard,overheadpower

12.Engine—start18.Tippinghazard—slowthetractionunit

13.Engine—run

14.Engine—stop

unlessyouaretrained.

lines—stayawayfromoverheadpower

lines.

withtheheavyenduphill;donottravel

withtheloaderarmsraised.

whenturning,donottravelfastwhen

turning,lookbehindanddownwhen

reversing.

11

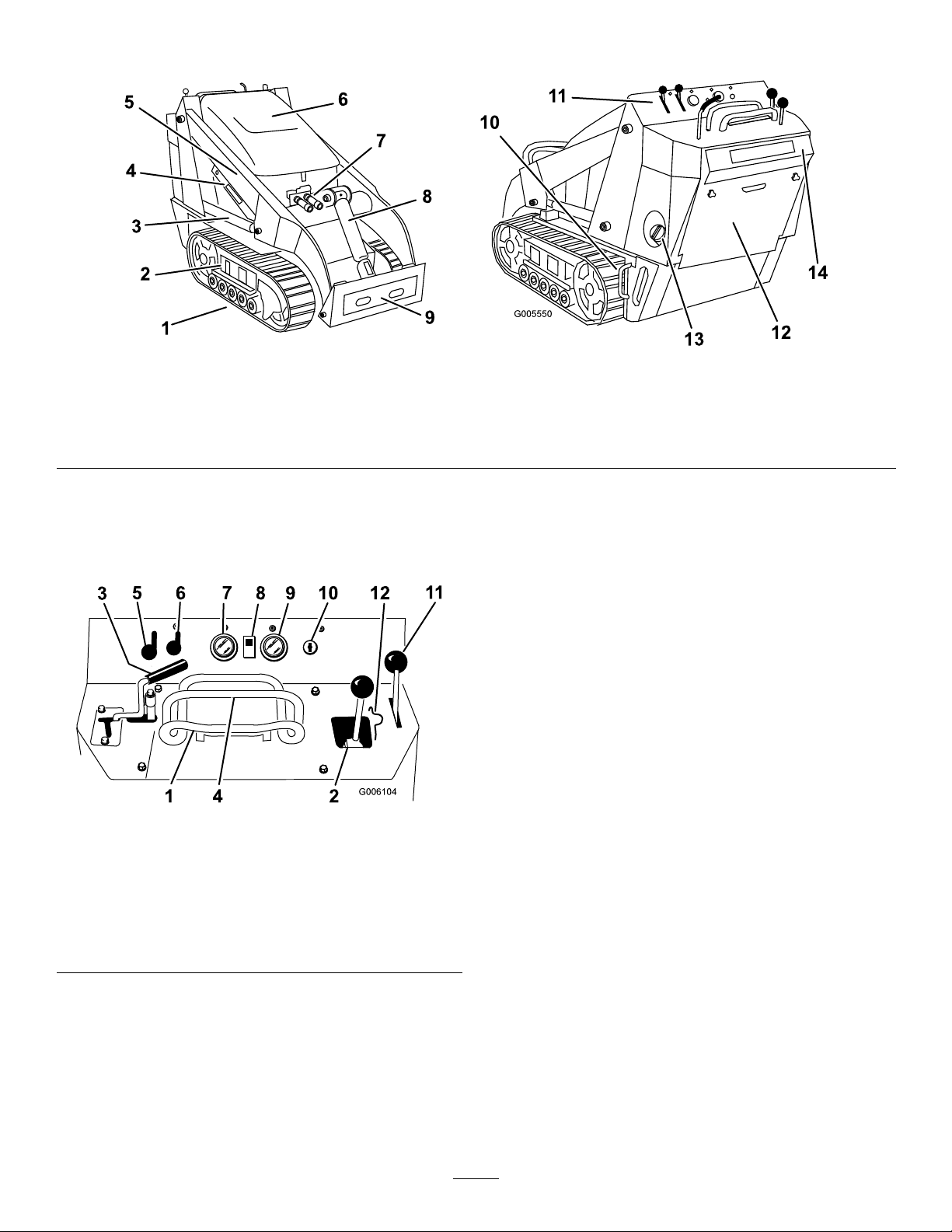

ProductOverview

G006104

3

5

6

7

8 9 1012

11

41 2

Figure3

1.Track5.Loaderarms9.Mountplate13.Fueltank

2.Trackadjustmentchamber6.Hood

3.Liftcylinder

4.Cylinderlock

7.Auxiliaryhydrauliccouplers

8.Tiltcylinder12.Rearaccesscover

10.Tie-down/liftloop14.Reversesafetyplate

11.Controlpanel

Controls

Becomefamiliarwithallthecontrols(Figure4)before

youstarttheengineandoperatethetractionunit.

Figure4

1.Tractioncontrol7.Fuelgauge

2.Loaderarm/attachmenttilt

lever

3.Auxiliaryhydraulicslever

4.Referencebar

5.Throttlelever11.Parkingbrakelever

6.Chokelever

8.Hydraulicoiltemperature

light

9.Hourmeter/tachometer

10.Keyswitch

12.Loadervalvelock

Tostoptheengine,rotatethekeytotheoffposition.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasespeed.

ChokeLever

Beforestartingacoldengine,movethechokelever

forward.Aftertheenginestarts,regulatethechoketo

keeptheenginerunningsmoothly.Assoonaspossible,

movethechokeleverallthewayrearward.

Note:Awarmenginerequireslittleornochoking.

ReferenceBar

Whendrivingthetractionunit,usethereferencebaras

ahandleandaleveragepointforcontrollingthetraction

controlandtheauxiliaryhydraulicslever.Toensure

smooth,controlledoperation,donottakebothhands

offofthereferencebarwhileoperatingthetractionunit.

KeySwitch

Thekeyswitch,usedtostartandstoptheengine,has

threepositions:off,run,andstart.

Tostarttheengine,rotatethekeytothestartposition.

Releasethekeywhenenginestartsanditwillmove

automaticallytotherunposition.

12

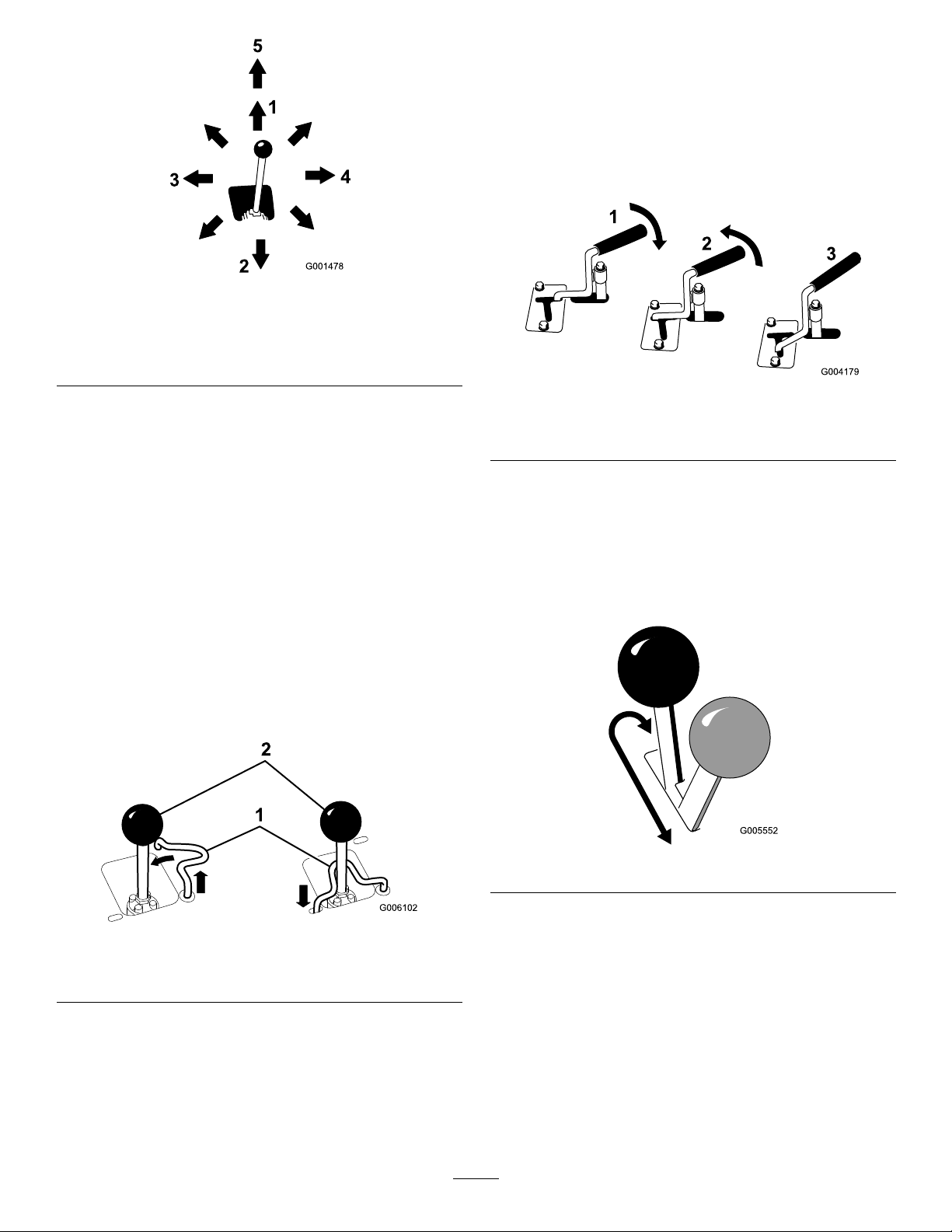

TractionControl

G008131

G008132

Figure8

Figure5

1.Referencebar(doesnotmovetogiveyouareferencepoint

andaxedhandletoholdwhileoperatingthetractionunit)

2.Tractioncontrol(movestocontrolthemachine)

•Tomoveforward,movethetractioncontrolforward

(Figure6).

Figure6

•Tomoverearward,movethetractioncontrol

rearward(Figure7).Whenreversing,lookbehind

forobstructionsandkeepyourhandsonthe

referencebar(Figure6).

•Toturnleft,rotatethetractioncontrol

counterclockwise(Figure9).

Figure9

•Tostop,releasethetractioncontrol(Figure5).

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinewillmoveinthat

direction.

LoaderArm/AttachmentTiltLever

Totilttheattachmentforward,slowlymovetheleverto

theright(Figure10).

Figure7

•Toturnright,rotatethetractioncontrolclockwise

(Figure8).

Totilttheattachmentrearward,slowlymovetheleverto

theleft(Figure10).

Tolowertheloaderarms,slowlymovetheleverforward

(Figure10).

Toraisetheloaderarms,slowlymovetheleverrearward

(Figure10).

Youcanalsopushtheleverfullyforwardintoadetent

position(Figure10)toreleasetheloaderarmssothatthe

attachmentrestsontheground.Thisallowsattachments

suchasthelevelerandthehydraulicbladetofollowthe

contoursoftheground(i.e.,oat)whengrading.

13

Figure10

1.Lowertheloaderarms

2.Raisetheloaderarms

3.Tilttheattachment

rearward

4.Tilttheattachmentforward

5.Detent(Float)position

Bymovingthelevertoanintermediateposition(such

as,forwardandleft),youcanmovetheloaderarmsand

tilttheattachmentatthesametime.

Tooperateahydraulicattachmentinreversedirection,

rotatethehydraulicsleverrearward,thenmoveitleft

intotheupperslot(Figure12,number2).

Ifyoureleasetheleverwhileintheforwardposition,the

leverwillautomaticallyreturntotheneutralposition

(Figure12,number3).Ifitisinthereverseposition,it

willremainthereuntilyoupullitoutoftheslot.

Figure12

1.Forwardowhydraulics

2.Reverseowhydraulics

3.Neutral

LoaderValveLock

Theloadervalvelocksecurestheloaderarm/attachment

tiltleversothatyoucannotpushitforward.Thishelps

toensurethatnoonewillaccidentallylowertheloader

armsduringmaintenance.Securetheloaderarmswith

thelockanytimeyouneedtostopthemachinewiththe

loaderarmsraised.

Tosetthelock,liftuponitsoitclearstheholein

thecontrolpanelandswingittotheleftinfrontof

theloaderarmlever,pushingitdownintothelocked

position(Figure11).

Figure11

1.Loadervalvelock

2.Loaderarm/attachmenttilt

lever

ParkingBrakeLever

Tosettheparkingbrake,pushthebrakeleverforward

andtotheleftandthenpullitrearward(Figure13).

Note:Thetractionunitmayrollslightlybeforethe

brakesengageinthedrivesprocket.

Figure13

Toreleasethebrake,pushtheleverforwardandthen

right,intothenotch.

FuelGauge

AuxiliaryHydraulicsLever

Tooperateahydraulicattachmentintheforward

direction,rotatetheauxiliaryhydraulicsleverrearward

andpullitdowntothereferencebar(Figure12,number

1).

Thisgaugemeasurestheamountoffuelinthefueltank.

HydraulicOilT emperatureLight

Ifthehydraulicoilgetstoohot,thislightilluminates

andanaudiblealarmsounds.Ifthishappens,stopthe

engineandallowthetractionunittocool.

14

HourMeter/Tachometer

toremindyoutochangetheengineoil.Afterevery

100hours,thescreendisplaysSVCtoremindyouto

Whentheengineisoff,thehourmeter/tachometer

displaysthenumberofhoursofoperationthathave

beenloggedonthetractionunit.Whentheengineis

running,itdisplaysthespeedoftheengineinrevolutions

performtheothermaintenanceproceduresbasedona

100,200,or400hourschedule.Thesereminderscome

onstartingthreehourspriortotheserviceintervaltime

andashatregularintervalsforsixhours.

perminute(rpm).

After50hoursandthenevery100hoursthereafter(that

isat150,250,350,etc.)thescreendisplaysCHGOIL

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Model22321and22321G

Width

Length

Height

Weight

Operatingcapacity500lb(227Kg)

Tippingcapacity

Wheelbase

Dumpheight(withnarrowbucket)47inches(1 19cm)

Reach—fullyraised(withnarrowbucket)22inches(55cm)

Heighttohingepin(narrowbucketinhighestposition)66inches(168cm)

Model22322

Width

Length

Height

Weight

Operatingcapacity500lb(227Kg)

Tippingcapacity

Wheelbase

Dumpheight(withnarrowbucket)47inches(1 19cm)

Reach—fullyraised(withnarrowbucket)22inches(55cm)

Heighttohingepin(narrowbucketinhighestposition)66inches(168cm)

34inches(86cm)

71inches(180cm)

46inches(1 17cm)

1880lb(853Kg)

1480lb(671Kg)

31.2inches(79cm)

41inches(104cm)

71inches(180cm)

46inches(1 17cm)

2075lb(941Kg)

1427lb(647Kg)

31.2inches(79cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesareavailableforusewiththemachinetoenhanceand

expanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww .Toro.comforalistof

allapprovedattachmentsandaccessories.

Important:UseonlyToroapprovedattachments.Otherattachmentsmaycreateanunsafeoperating

environmentordamagethetractionunit.

15

Loading...

Loading...