Page 1

76cmTurfMaster™Walk-BehindLawnMower

G023543

1

ModelNo.22205TE—SerialNo.400000000andUp

Introduction

Thisrotary-blade,walk-behindlawnmowerisintended

tobeusedbyresidentialhomeownersorprofessional,

hiredoperators.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

equipmentdamage.Y ouareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

FormNo.3409-542RevB

Operator'sManual

g000502

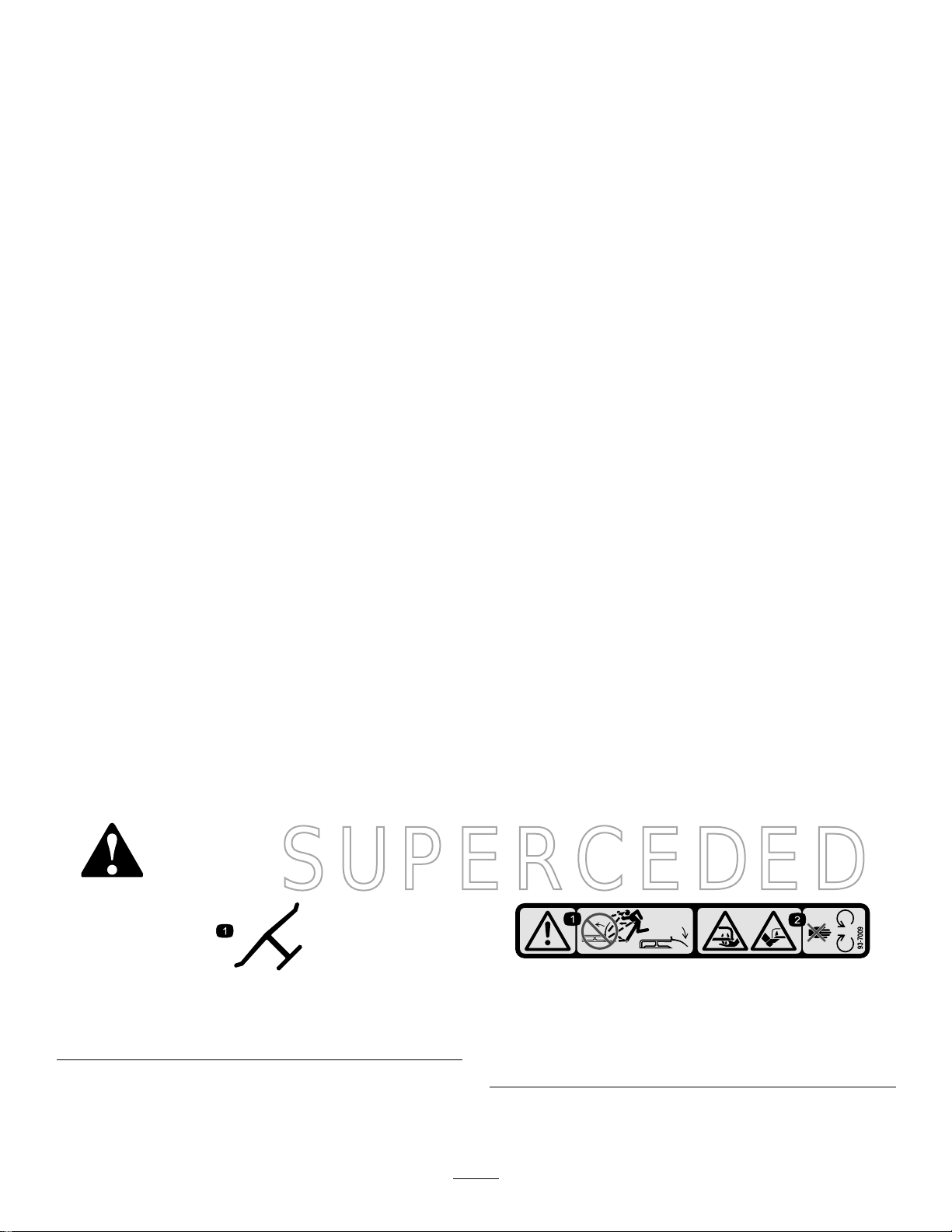

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

ThisproductcomplieswithallrelevantEuropeandirectives.

Fordetails,pleaseseetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

NetTorque:Thegrossornettorqueofthisenginewas

laboratoryratedbytheenginemanufacturerinaccordance

withtheSocietyofAutomotiveEngineers(SAE)J1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclassofmower

willbesignicantlylower.Gotowww.Toro.comtoview

specicationsonyourmowermodel.

Figure1

1.Themodelandserialnumberplateisineitherofthese2

locations.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

SUPERCEDED

Contents

Introduction..................................................................1

Safety...........................................................................2

GeneralSafety.........................................................2

SafetyandInstructionalDecals.................................2

Setup............................................................................5

1InstallingtheHandle.............................................5

2AdjustingtheHandleHeight..................................5

g023543

3FillingtheEnginewithOil......................................6

4AssemblingtheGrassBag......................................6

ProductOverview..........................................................8

Controls................................................................8

Specications.........................................................8

Operation.....................................................................9

BeforeOperation.......................................................9

BeforeOperationSafety...........................................9

FillingtheFuelTank................................................9

CheckingtheEngine-OilLevel.................................10

AdjustingtheCuttingHeight....................................10

CheckingtheBlade-StopSystemOperation................11

DuringOperation.....................................................11

DuringOperatingSafety..........................................11

StartingtheEngine.................................................12

ShuttingofftheEngine...........................................12

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3409-542*B

Page 2

OperatingtheSelf-PropelDriveandEngagingthe

CuttingBlades....................................................12

EngagingandDisengagingtheParking

Brake................................................................13

RecyclingtheClippings...........................................13

BaggingtheClippings.............................................14

Side-DischargingtheClippings.................................14

OperatingTips......................................................15

AfterOperation........................................................15

AfterOperatingSafety............................................15

CleaningundertheMachine.....................................15

CleaningtheWheels...............................................16

Maintenance.................................................................17

RecommendedMaintenanceSchedule(s)......................17

MaintenanceSafety.................................................17

ServicingtheAirFilter............................................17

ChangingtheEngineOil.........................................18

ChangingtheOilFilter............................................19

ServicingtheSparkPlug..........................................20

CheckingtheConditionoftheBelts..........................20

EmptyingtheFuelTankandCleaningthe

Filter.................................................................20

ChangingtheFuelFilter..........................................20

ServicingtheBlade-DriveSystem.............................21

ServicingtheCuttingBlades.....................................22

ChangingtheBlade-DriveBelt.................................24

ChangingtheBlade-Brake-Clutch(BBC)

Belt...................................................................25

AdjustingtheBlade-BrakeCable...............................25

ChangingtheTransmissionBelt...............................26

AdjustingtheTransmission......................................27

AdjustingtheSelf-PropelCable................................27

Storage........................................................................28

GeneralInformation...............................................28

PreparingtheFuelSystem.......................................28

PreparingtheEngine..............................................28

RemovingtheMachinefromStorage.........................28

Troubleshooting...........................................................29

Safety

ThismachinehasbeendesignedinaccordancewithENISO

5395:2013.

GeneralSafety

Thisproductiscapableofamputatinghandsandfeetand

ofthrowingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

•ReadandunderstandthecontentsofthisOperator’sManual

beforestartingtheengine.

•Donotputyourhandsorfeetnearmovingcomponents

ofthemachine.

•Donotoperatethemachinewithoutallguardsandother

safetyprotectivedevicesinplaceandworkingonthe

machine.

•Keepclearofanydischargeopening.Keepbystandersa

safedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Neverallow

childrentooperatethemachine.

•Stopthemachineandshutofftheenginebeforeservicing,

fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomplywith

theseinstructionsmayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationintheir

respectivesectionsthroughoutthismanual.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

SUPERCEDED

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

decaloemmarkt

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

2

93-7009

decal93-7009

Page 3

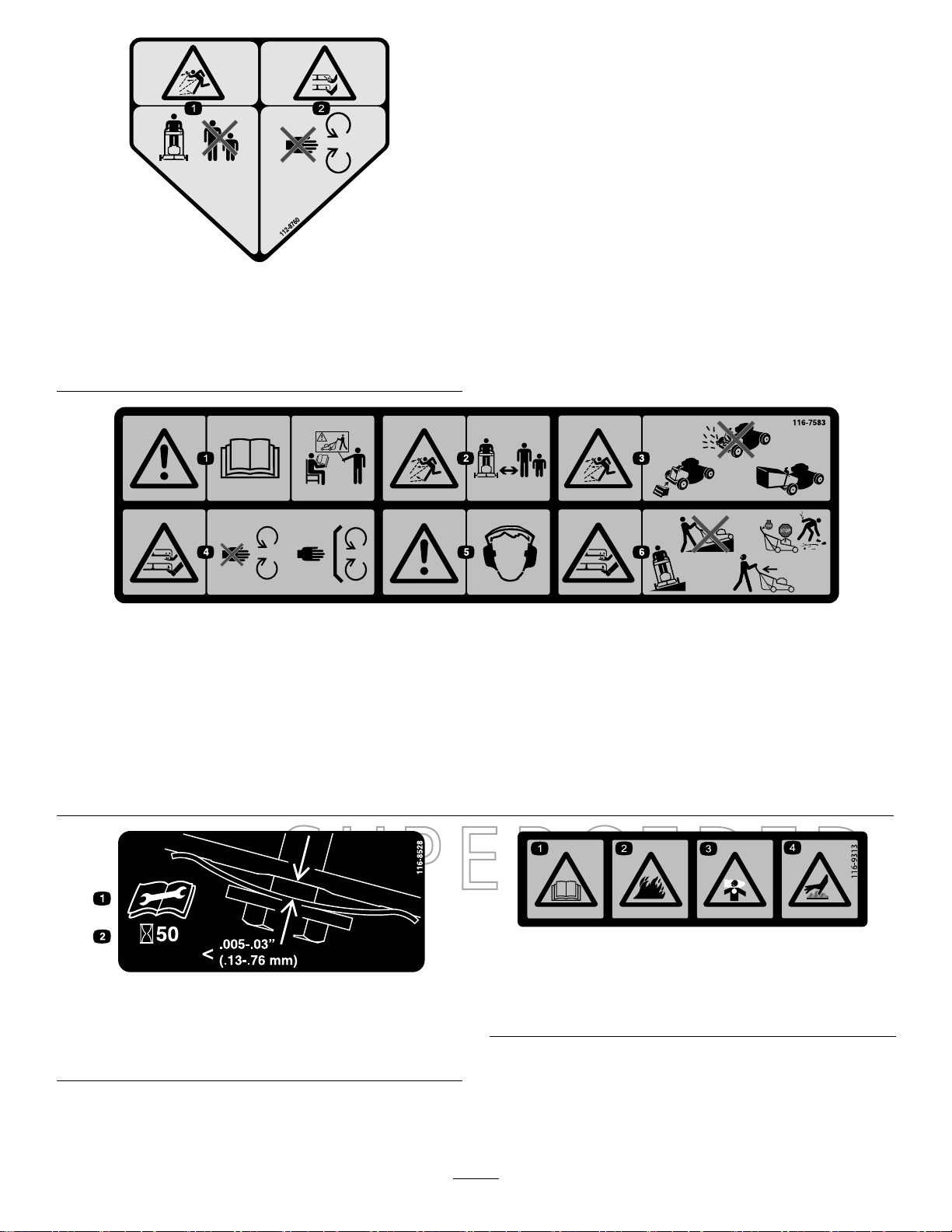

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

decal112-8760

decal116-7583

116-7583

1.Warning–ReadtheOperator’sManual.Donotoperatethis

machineunlessyouaretrained.

2.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

3.Thrownobjecthazard—Donotoperatethemowerwithoutthe

reardischargeplugorbaginplace.

SUPERCEDED

decal116-8528

116-8528

1.ReadtheOperator’s

Manualbeforeperforming

anymaintenance.

2.Checkbelttensionevery

50hours.

4.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts;keepallguardsinplace.

5.Warning—wearhearingprotection.

6.Cutting/dismembermenthazardofhandorfoot,mower

blade—Donotoperateupanddownslopes;operateside

tosideonslopes;shutofftheenginebeforeleavingthe

operatingposition—pickupobjectsthatcouldbethrownby

theblades;andlookbehindyouwhenbackingup.

116-9313

1.ReadtheOperator's

Manual.

2.Firehazard

3.Toxicgasinhalation

hazard

4.Hotsurface;burnhazard

decal116-9313

3

Page 4

120-9570

1.Warning—stayawayfrommovingparts,keepallguards

andshieldsinplace.

121-1449

1.Warning—donotparkonslopesunlessthewheelsare

chockedorblocked.

decal120-9570

decal121-1449

decal130-9656

130-9656

1.Choke3.Slow

2.Fast4.Engine—stop

decal127-6864

127-6864

1.Height-of-cut—front

SUPERCEDED

decal127-6865

127-6865

1.Height-of-cut—back

4

Page 5

Setup

G028426

1

2

G028427

2

1

3

Important:Removeanddiscardtheprotectiveplastic

sheetthatcoverstheengineandanyotherplasticor

wrappingonthemachine.

1

InstallingtheHandle

NoPartsRequired

Procedure

WARNING

Foldingorunfoldingthehandleimproperlycan

damagethecables,causinganunsafeoperating

condition.

•Donotdamagethecableswhenfoldingor

unfoldingthehandle.

•Ifacableisdamaged,contactanAuthorized

ServiceDealer.

1.Removethe2boltsfromthemachineframeinthe

locationshowninFigure3.

Figure4

1.Installacabletiehere.

2.Nutonhandlesupport

bracket(2)

5.Installacabletietosecurethecablestothelower

handleinthelocationshowninFigure4andtrimoff

theexcessmaterialfromthetie.

3.Bolt(4)

2

AdjustingtheHandleHeight

NoPartsRequired

Procedure

1.Standintheoperatingpositiontodeterminethemost

comfortablehandleheight.

g028427

1.Bolt(2)

2.Rotatethehandlerearwardtotheoperatingposition.

3.Securethehandletothemachinewiththeboltsthat

youremovedinstep1.

4.Tightenthefastenersthatsupportthehandleonboth

sidesofthemachineasshowninFigure4.

Figure3

SUPERCEDED

2.Nutonhandlesupport

bracket(2)

2.Removethehandleboltandinsertitin1ofthe3holes

locatedatthebottomofthehandlebracket(Figure5).

g028426

5

Page 6

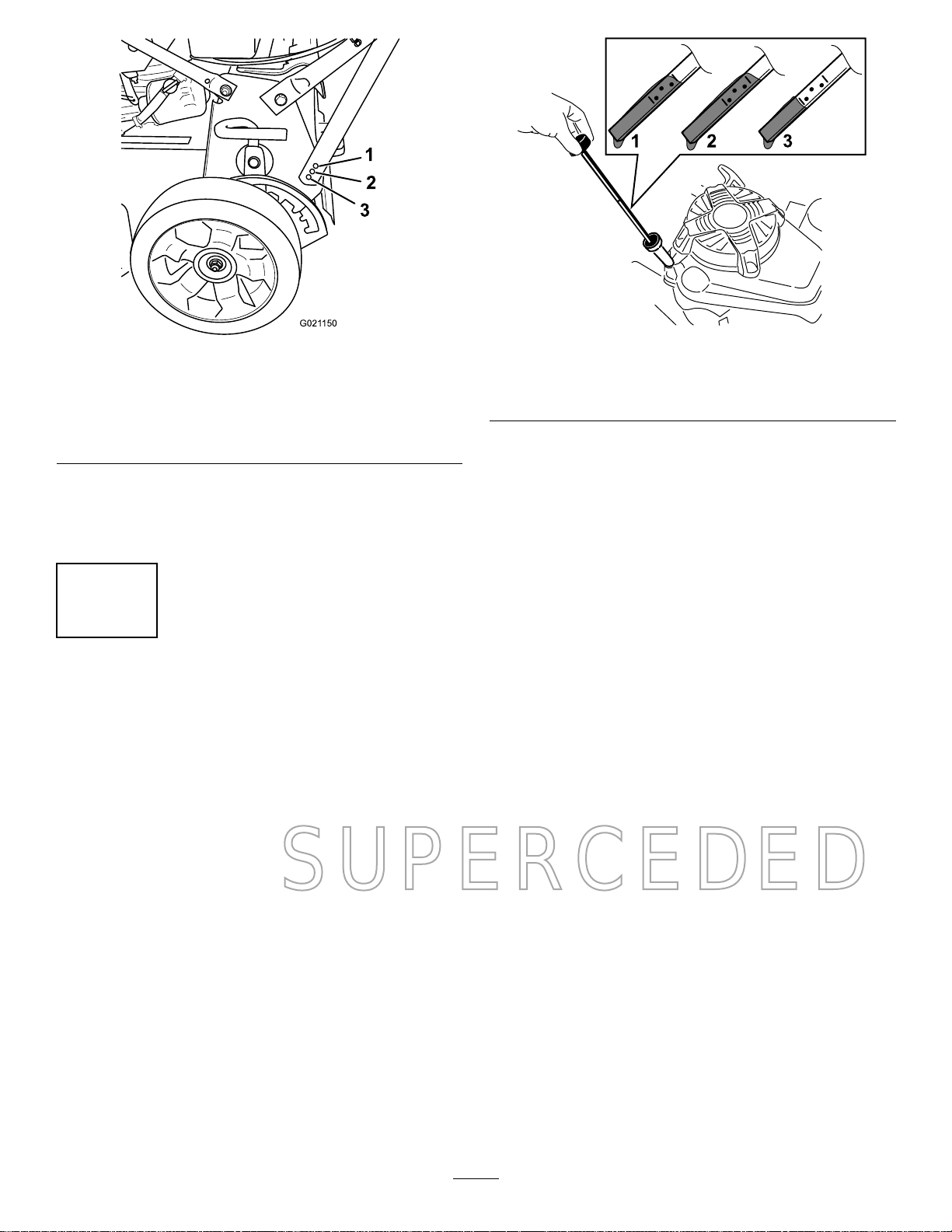

G021 150

1

2

3

Figure5

1.Lowesthandleheight

setting

2.Middlehandleheight

setting

3.Tightenthehandleboltuntilitissnug.

4.Repeatthestepsabovefortheothersideofthe

machine.

3.Highesthandleheight

setting

g021150

1.Full3.Low

2.High

3.Carefullypourabout3/4oftheenginecapacityofoil

intotheoil-lltube.

4.Waitabout3minutesfortheoiltosettleintheengine.

5.Wipethedipstickcleanwithacleancloth.

6.Insertthedipstickintotheoil-lltube,thenremove

thedipstick.

7.Readtheoillevelonthedipstick(Figure6).

Figure6

g194742

3

FillingtheEnginewithOil

NoPartsRequired

Procedure

Important:Yourmachinedoesnotcomewithoilin

theengine.Beforestartingtheengine,lltheengine

withoil.

Engineoilcapacity:Withoillter:0.85L(29oz);

withoutoillter:0.65L(22oz)

Oilviscosity:SAE30orSAE10W-30detergentoil

APIserviceclassication:SJorhigher

1.Movethemachinetoalevelsurface.

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout(Figure6).

SUPERCEDED

•IftheoillevelisbelowtheAddmarkonthe

dipstick,carefullypourasmallamountofoilinto

theoil-lltube,wait3minutes,andrepeatsteps3

through6untiltheoillevelisattheFullmarkon

thedipstick.

•IftheoillevelisabovetheFullmarkonthe

dipstick,draintheexcessoiluntiltheoillevelisat

theFullmarkonthedipstick;refertoChanging

theEngineOil(page18).

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.

8.Installthedipstickintotheoil-lltubesecurely.

Important:Changetheengineoilaftertherst5

operatinghours;changeityearlythereafter.Referto

ChangingtheEngineOil(page18).

6

Page 7

4

g027717

1

2

3

g027718

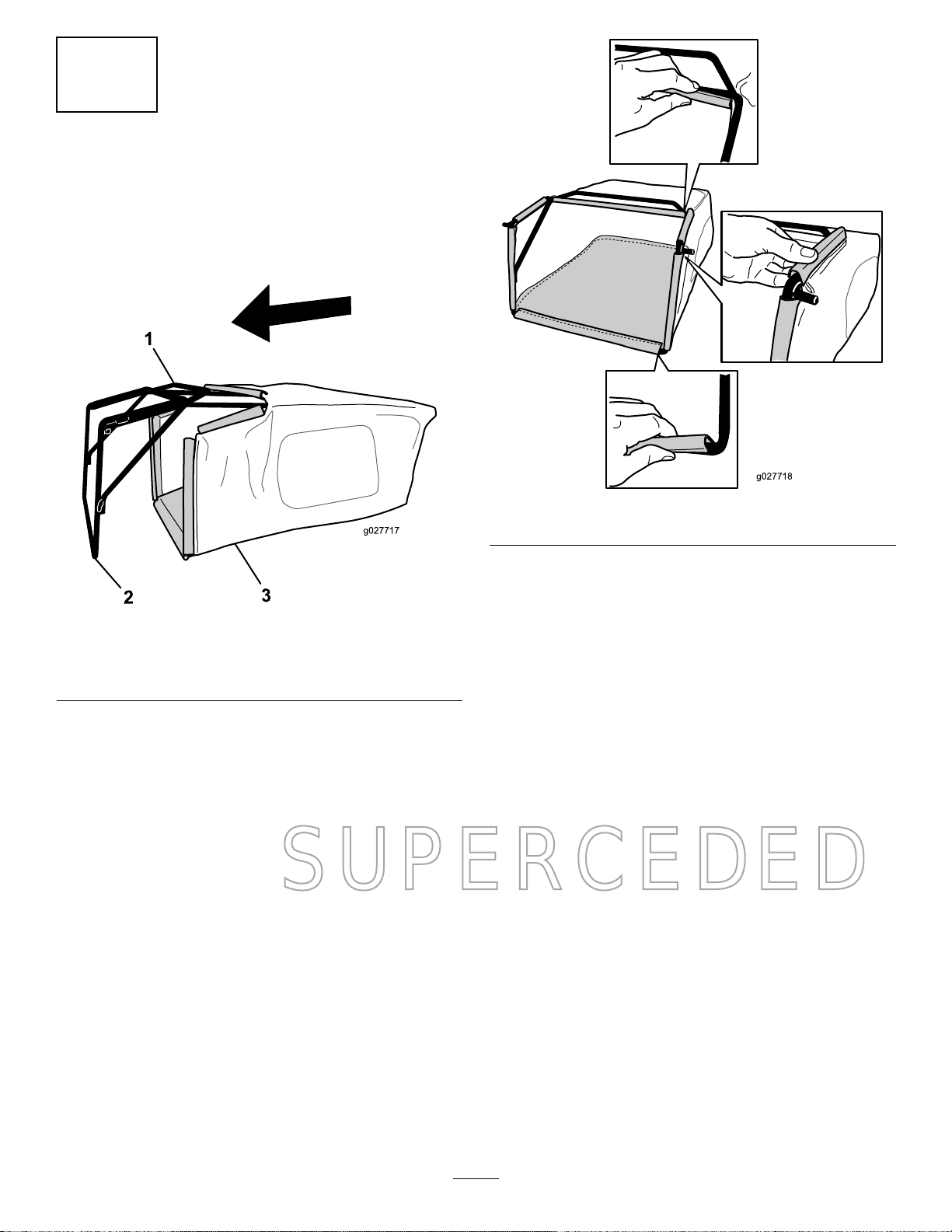

AssemblingtheGrassBag

NoPartsRequired

Procedure

1.SlipthegrassbagovertheframeasshowninFigure7.

g027718

Figure8

Figure7

1.Handle

2.Frame

Note:Donotslipthebagoverthehandle(Figure7).

2.Hookthebottomchannelofthebagontothebottom

oftheframe(Figure8).

3.Grassbag

SUPERCEDED

3.Hookthetopandsidechannelsofthebagontothetop

andsidesoftheframe,respectively(Figure8).

g027717

7

Page 8

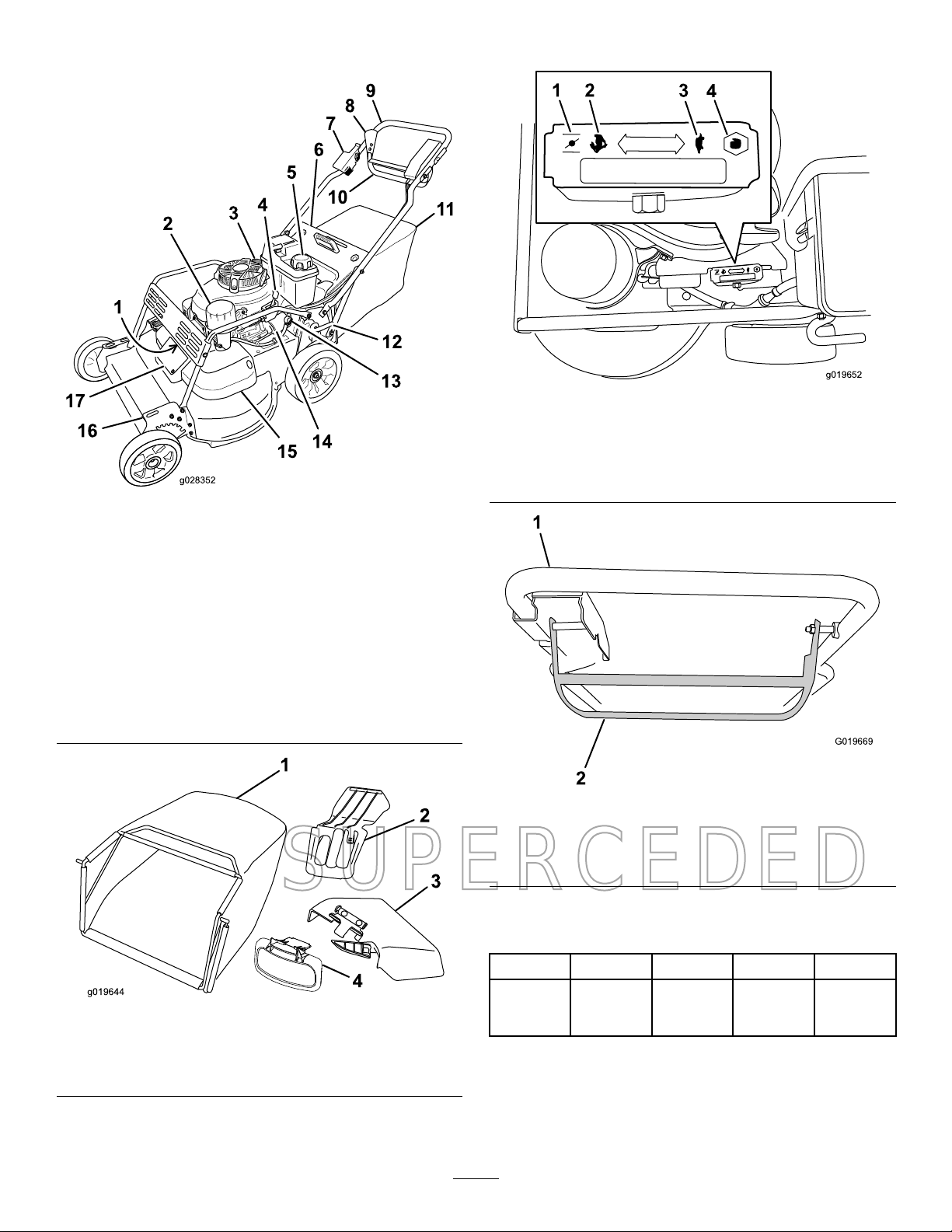

ProductOverview

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

g028352

16

g019644

1

2

3

4

g019652

1 2

3

4

1

2

G019669

g028352

Figure9

Controls

Figure11

Throttle(throttlelevernotshownforthesakeofclarity)

1.Choke3.Slow

2.Fast

4.Stop

g019652

1.Sparkplug(underbrush

guard)

2.Airlter11.Grassbag

3.Oilll/dipstick

4.Throttlelever

5.Fuel-tankcap

6.Reardoor15.Beltcover

7.Brakelever16.Frontcutting-heightlever

8.Stop

9.Handle

10.Controlbar

12.Rearcutting-heightlever

13.Fuel-shutoffvalve

14.Oillter

17.Belt-cover-accesspanel

SUPERCEDED

Figure10

1.Grassbag3.Side-dischargechute

2.Rear-dischargeplug

4.Side-dischargedoor

g019669

Figure12

1.Handle

Controlbar

2.Controlbar

Specications

g019644

ModelWeightLengthWidthHeight

22205TE72kg

(159lb)

175cm

(69

inches)

81cm

(32

inches)

97cm

(38-1/2

inches)

8

Page 9

Operation

g019643

1

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevices,suchasdoors

and/orgrasscatchers,areinplaceandworkingproperly.

•Alwaysinspectthemachinetoensurethattheblades,

bladebolts,andcuttingassemblyarenotwornor

damaged.

•Inspecttheareawhereyouwillusethemachineand

removeallobjectsthatthemachinecouldthrow.

•Adjustingthecuttingheightmaybringyouintocontact

withthemovingblade,causingseriousinjury.

–Shutofftheengineandwaitforallmovingpartsto

stop.

–Donotputyourngersunderthehousingwhen

adjustingthecuttingheight.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•ETHANOL:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

upto85%ethanol).Usingunapprovedgasolinemay

causeperformanceproblemsand/orenginedamage.

Usingunapprovedgasolinewillnotbecoveredunderthe

productwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorinfuel

containersoverthewinterunlessfuelstabilizerhasbeen

addedtothefuel.

•Donotaddoiltogasoline.

Important:Toreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithgasoline

lessthan30daysold.

FuelSafety

DANGER

Fuelisextremelyammableandhighlyexplosive.

Areorexplosionfromfuelcanburnyouand

othersandcandamageproperty.

•Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachinedirectlyon

thegroundbeforelling,notinavehicleoron

anobject.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Donothandlefuelwhensmokingoraroundan

openameorsparks.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.

SUPERCEDED

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourhandsandfaceawayfromthenozzle

andthefuel-tankopening.

•Keepfuelawayfromyoureyesandskin.

Refertoyourenginemanualforadditionalinformation.

g019643

Figure13

1.Fuel-tankcap

9

Page 10

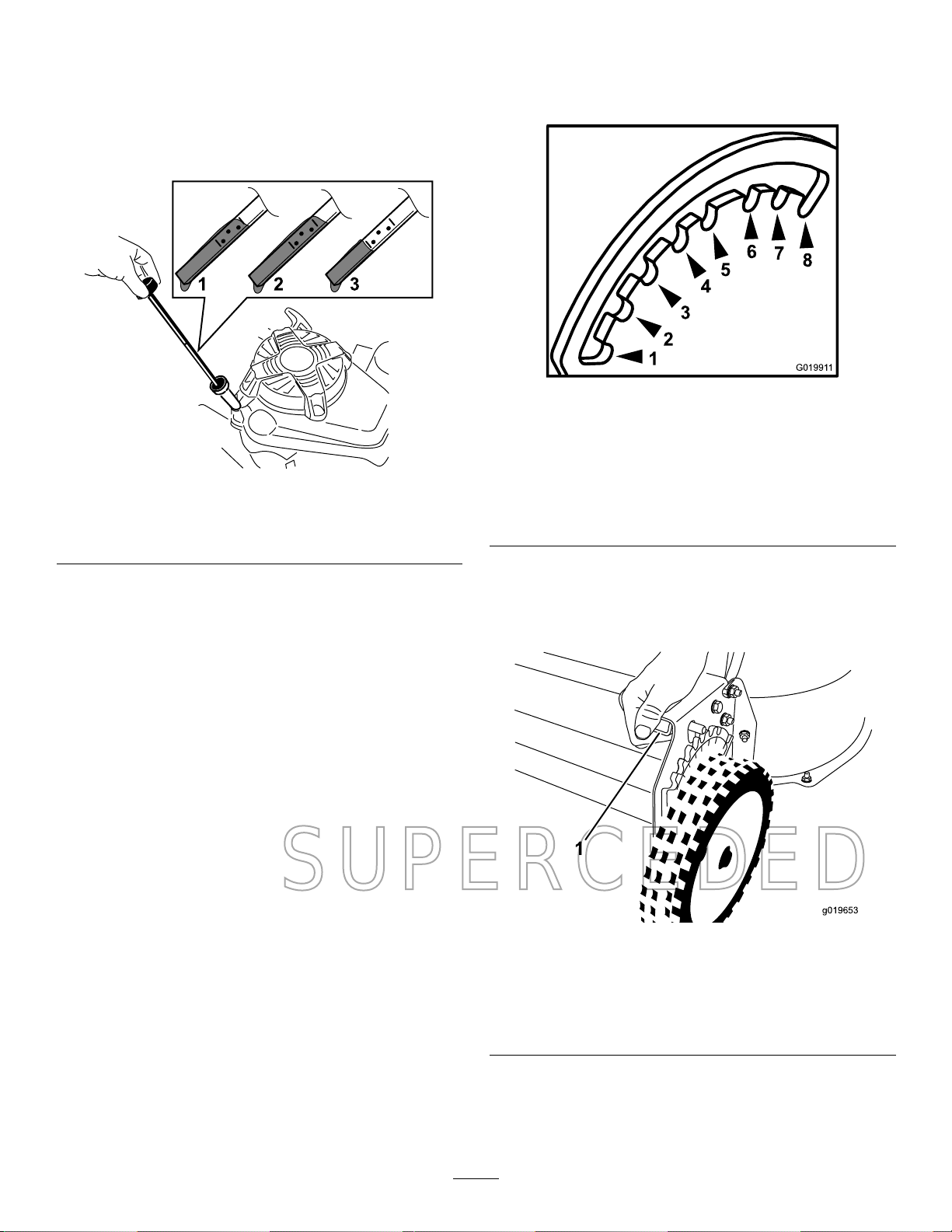

CheckingtheEngine-OilLevel

1

2

4

6

7

8

3

5

G01991 1

g019653

1

AdjustingtheCuttingHeight

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout(Figure14).

Figure14

1.Full3.Low

2.High

Thecuttingheightsrangefrom38mm(1-1/2inches)to127

mm(5inches)in13mm(1/2inch)increments.

g019911

Figure15

Viewfromfront,leftsideofthemachine

1.38mm(1-1/2inches)5.89mm(3-1/2inches)

g194742

2.51mm(2inches)6.102mm(4inches)

3.64mm(2-1/2inches)7.114mm(4-1/2inches)

4.76mm(3inches)8.127mm(5inches)

3.Wipethedipstickcleanwithacleancloth.

4.Insertthedipstickintotheoil-lltube,thenremove

thedipstick.

5.Readtheoillevelonthedipstick(Figure14).

•IftheoilisbelowtheAddmarkonthedipstick,

carefullypourasmallamountofoilintotheoil-ll

tube,wait3minutes,andthenrepeatsteps3

through5untiltheoillevelisattheFullmarkon

thedipstick.

•IftheoilisabovetheFullmarkonthedipstick,

draintheexcessoiluntiltheoillevelisattheFull

markonthedipstick.Todraintheexcessoil,refer

toChangingtheEngineOil(page18).

Important:Iftheoillevelinthecrankcaseistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.

6.Installthedipstickintotheoil-lltubesecurely.

SUPERCEDED

Thecuttingheightiscontrolledwithafrontleverandarear

lever,bothontheleftsideofthemachine(Figure16and

Figure17).Toraiseorlowerthemachine,engagethelever,

raiseorlowerthemachine,andthendisengagethelever.

g019653

Figure16

Frontcutting-heightlever

1.Squeezethelevertodisengageit.

10

Page 11

g019645

Figure17

Rearcutting-heightlever

NotUsingtheGrassBag

1.Movethemachineontoapavedsurfaceinanon-windy

area.

2.Setall4wheelstothe89mm(3-1/2inch)cutting

heightsetting.

3.Takeahalfsheetofnewspaperandcrumpleitintoa

ballsmallenoughtogounderthemachine(about75

mmor3inchesindiameter).

4.Placethenewspaperballabout13cm(5inches)in

frontofthemachine.

5.Starttheengine.

6.Engagetheblades.

7.Releasethecontrolbarandbegincountingout3

seconds.

8.Onthecountof3,pushthemachinequicklyforward

overthenewspaper.

g019645

9.Shutofftheengineandwaitforallmovingpartsto

stop.

10.Gotothefrontofthemachineandcheckthe

newspaperball.

Note:Ifthenewspaperballdidnotgounderthe

machine,repeatsteps4through10.

CheckingtheBlade-Stop SystemOperation

Beforeeachuse,checkthatthebladesstopwithin3seconds

ofreleasingthecontrolbar.

UsingtheGrassBag

ServiceInterval:Beforeeachuseordaily—Checkthe

blade-stopsystemoperation.Theblades

shouldstopwithin3secondsofreleasing

thecontrolbar;iftheydonot,contactan

AuthorizedServiceDealer.

Youcanusethegrassbagtochecktheblade-stopsystem.

1.Removetherear-dischargeplug.

2.Installtheemptygrassbagonthemachine.

3.Starttheengine.

4.Engagetheblades.

Note:Thebagshouldbegintoinate,indicatingthat

thebladesarerotating.

5.Whilewatchingthebag,releasethecontrolbar.

Note:Ifthebagdoesnotdeatewithin3secondsof

releasingthecontrolbar,theblade-stopsystemmaybe

deterioratingand,ifignored,couldresultinanunsafe

operatingcondition.Havethemachineinspectedand

servicedbyanAuthorizedServiceDealer.

6.Shutofftheengineandwaitforallmovingpartsto

stop.

SUPERCEDED

Important:Ifthenewspaperisunravelledor

shredded,thebladesdidnotstopproperly,which

couldresultinanunsafeoperatingcondition.

ContactanAuthorizedServiceDealer.

DuringOperation

DuringOperatingSafety

GeneralSafety

•Wearappropriateclothing,includingeyeprotection;

slip-resistant,substantialfootwear;andhearing

protection.Tiebacklonghair,securelooseclothing,and

donotwearjewelry.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Thebladeissharp;contactingthebladecanresultin

seriouspersonalinjury.Shutofftheengineandwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

•Whenyoureleasetheblade-controlbar,theengineshould

shutoffandthebladeshouldstopwithin3seconds.If

not,stopusingyourmachineimmediatelyandcontactan

AuthorizedServiceDealer.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperatethe

machinewhenthereistheriskoflightning.

•Wetgrassorleavescancauseseriousinjuryifyouslipand

contacttheblade.Avoidmowinginwetconditions.

11

Page 12

•Useextremecarewhenapproachingblindcorners,

g019650

1

g019651

1

G019671

1

shrubs,trees,orotherobjectsthatmayblockyourview.

3.MovethethrottlecontroltotheCHOKEposition

(Figure11).

•Watchforholes,ruts,bumps,rocks,orotherhidden

objects.Uneventerraincouldcauseaslip-and-fall

accident.

•Stopthemachineandinspectthebladesafterstrikingan

objectorifthereisanabnormalvibrationinthemachine.

Makeallnecessaryrepairsbeforeresumingoperation.

•Beforeleavingtheoperatingposition,shutofftheengine,

andwaitforallmovingpartstostop.

•Iftheenginehasbeenrunningthemuferwillbehotand

canseverelyburnyou.Keepawayfromthehotmufer.

•Checkthegrasscatchercomponentsandthedischarge

guardfrequentlyandreplacethemwiththemanufacturer’s

recommendedpartswhennecessary.

•UseaccessoriesandattachmentsapprovedbytheThe

Toro®Companyonly .

SlopeSafety

•Mowacrossthefaceofslopes;neverupanddown.Use

extremecautionwhenchangingdirectiononslopes.

•Donotmowonexcessivelysteepslopes.Poorfooting

couldcauseaslip-and-fallaccident.

4.Pullthestarterhandlelightlyuntilyoufeelresistance,

thenpullitsharply.

5.MovethethrottlecontrollevertotheFASTposition

whentheenginestarts(Figure11).

Note:Iftheenginefailstostartafter3pulls,repeat

steps3through5.

ShuttingofftheEngine

1.MovethethrottlecontroltotheOFFpositionandwait

forallmovingpartstostop.

2.Closethefuel-shutoffvalveanddisconnectthewire

fromthesparkplugifyoudonotusethemachineor

leaveitunattended.

OperatingtheSelf-Propel DriveandEngagingthe CuttingBlades

•Tooperatetheself-propeldrivewithoutengagingthe

blades,raisethecontrolbartothehandle(Figure19).

•Mowwithcautionneardrop-offs,ditches,or

embankments.

StartingtheEngine

1.Connectthewiretothesparkplug(Figure9).

2.Openthefuel-shutoffvalve(Figure18).

Note:Whenthefuel-shutoffvalveisopen,theleveris

parallelwiththefuelline.

SUPERCEDED

g019671

Figure19

1.Raisethecontrolbartothehandle.

•Tooperatetheself-propeldriveandengagetheblades,

slidethecontrolbarallthewaytotherightandraiseit

tothehandle(Figure20).

1.Fuel-shutoffvalve

g019651

Figure18

12

Page 13

G019672

2

1

Figure20

g028360

1

2

3

g028359

1

2

3

G019812

DisengagingtheParkingBrake

Disengagetheparkingbrakebypushingthebrakeleverdown

tothehandle(Figure22).

g019672

1.Slidethecontrolbartothe

right.

2.Raisethecontrolbarto

thehandle.

•Todisengagetheself-propeldriveandtheblades,release

thecontrolbar.

Note:Youcanvarythegroundspeedbyincreasingor

decreasingthedistancebetweenthecontrolbarandthe

handle.Lowerthecontrolbartoreducethespeedwhenyou

makeaturnorifthemachineismovingtoofast.Ifyoulower

thecontrolbartoofar,themachinestopsself-propelling.

Squeezethecontrolbarclosertothehandletoincreasethe

groundspeed.Whenyouholdthecontrolbartightagainst

thehandle,themachineself-propelsatthemaximumground

speed.

EngagingandDisengagingthe ParkingBrake

EngagingtheParkingBrake

Engagetheparkingbrakebypullingthebrakeleverupfrom

thehandle(Figure21).

Figure22

Parkingbrakedisengaged

1.Brakelever

2.Stop

Note:Whentheparkingbrakeisdisengagedandthecontrol

barisuptooperatetheself-propeldrive,thestoponthe

controlbarpreventsyoufromengagingtheparkingbrake.

3.Controlbar

RecyclingtheClippings

Thismachinecomesfromthefactoryreadytorecyclegrass

andleafclippingsbackintothelawn.Topreparethemachine

torecycle:

•Iftheside-dischargechuteisonthemachine,removeit

andinstalltheside-dischargedeector;refertoRemoving

theSide-DischargeChute(page15).

•Ifthegrassbagisonthemachine,removeit;referto

RemovingtheGrassBag(page14).

g028359

SUPERCEDED

Figure21

Parkingbrakeengaged

1.Brakelever

2.Stop

Note:Whentheparkingbrakeisengaged,thestoponthe

controlbarpreventsyoufromraisingthecontrolbarto

operatetheself-propeldrive.

3.Controlbar

•Iftherear-dischargeplugisnotinstalled,gripitby

thehandle,raisethereardoor,andinsertitintothe

rear-dischargechuteuntilthelatchlocksintoplace;refer

toFigure23.

g028360

g019812

Figure23

1.Rear-dischargeplug2.Reardoor

13

Page 14

BaggingtheClippings

1

G019798

2

G019649

1

2

3

g019647

1

Usethegrassbagwhenyouwanttocollectgrassandleaf

clippingsfromthelawn.

Iftheside-dischargechuteisonthemachine,removeitand

installtheside-dischargedoorbeforebaggingtheclippings;

refertoRemovingtheSide-DischargeChute(page15).

InstallingtheGrassBag

1.Raiseandholdupthereardoor(Figure24).

InstallingtheSide-DischargeChute

Important:Ensurethattherear-dischargeplugisin

placebeforeyourecycletheclippings.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Removethegrassbagifitisinstalledonthemachine;

refertoRemovingtheGrassBag(page14).

3.Inserttherear-dischargeplug;refertoBaggingthe

Clippings(page14).

4.Removetheside-dischargedoorbypullinguponthe

springthatholdsthedoorinplaceandremovingthe

door(Figure25).

Figure24

1.Bagrod2.Reardoor

2.Removetherear-dischargeplugbypullingdownonthe

latchwithyourthumbandpullingtheplugoutfrom

themachine(Figure23).

3.Installthebagrodintothenotchesatthebaseofthe

handle,androckthebagbackandforthtoensurethat

therodisseatedatthebottomofbothnotches;refer

toFigure24.

4.Lowerthereardooruntilitrestsonthegrassbag.

SUPERCEDED

RemovingtheGrassBag

Toremovethebag,reversethestepsinInstallingtheGrass

Bag(page14).

Side-Dischargingthe Clippings

Usethesidedischargeforcuttingverytallgrass.

g019798

g019649

Figure25

1.Topofside-dischargedoor3.Side-dischargedoor

2.Spring

5.Installtheside-dischargechute(Figure26)bypulling

uponthespring,placingthechuteovertheopening,

andloweringthespringoverthetapsonthetopof

thedischargechute.

g019647

Figure26

1.Side-dischargechute

14

Page 15

RemovingtheSide-DischargeChute

Toremovetheside-dischargechute,reversethestepsin

InstallingtheSide-DischargeChute(page14).

OperatingTips

GeneralTips

•Reviewthesafetyinstructionsandreadthismanual

carefullybeforeoperatingthemachine.

•Cleartheareaofsticks,stones,wire,branches,andother

debristhatthebladescouldhitandthrow .

•Keepeveryone,especiallychildrenandpets,awayfrom

theareaofoperation.

•Avoidstrikingtrees,walls,curbs,orothersolidobjects.

Neverdeliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelyshutofftheengine,disconnectthewirefrom

thesparkplug,andexaminethemachinefordamage.

•Maintainsharpbladesthroughoutthecuttingseason.

Periodicallyledownnicksontheblades.

•ReplacethebladeswhennecessarywithoriginalToro

replacementblades.

•Mowonlydrygrassorleaves.Wetgrassandleavestend

toclumpontheyardandcancausethemachinetoplug

ortheenginetostall.

•Cleantheundersideofthemachinedeckaftereach

mowing.RefertoCleaningundertheMachine(page15).

•Keeptheengineingoodrunningcondition.

•Settheenginespeedtothefastestpositionforthebest

cuttingresults.

•Cleantheairlterfrequently.Mulchingstirsupmore

clippingsanddustwhichclogstheairlterandreduces

engineperformance.

CuttingGrass

•Grassgrowsatdifferentratesatdifferenttimesofthe

year.Inthesummerheat,itisbesttocutgrassatthe51

mm(2inch),64mm(2-1/2inch),or83mm(3inch)

cutting-heightsettings.Cutonlyaboutathirdofthegrass

bladeatatime.Donotcutbelowthe51mm(2inch)

settingunlessthegrassissparseoritislatefallwhen

grassgrowthbeginstoslowdown.

•Whencuttinggrassover15cm(6inches)tall,rstmow

atthehighestcuttingheightsettingandwalkslower;then

mowagainatalowersettingforthebestlawnappearance.

Ifthegrassistoolongandtheleavesclumpontopofthe

lawn,themachinemayplugandcausetheenginetostall.

•Alternatethemowingdirection.Thishelpsdispersethe

clippingsoverthelawnforevenfertilization.

Ifthenishedlawnappearanceisunsatisfactory,try1or

moreofthefollowing:

SUPERCEDED

•Sharpentheblades.

•Walkataslowerpacewhilemowing.

•Raisethecuttingheightonyourmachine.

•Cutthegrassmorefrequently.

•Overlapcuttingswathsinsteadofcuttingafullswath

witheachpass.

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawnshows

throughthecutleafcover.Youmayneedtomakemore

thanasinglepassovertheleaves.

•Forlightleafcoverage,setallthewheelsatthesame

cuttingheightsetting.

•Slowdownyourmowingspeedifthemachinedoesnot

cuttheleavesnelyenough.

AfterOperation

AfterOperatingSafety

GeneralSafety

•Cleangrassanddebrisfromthemachinetohelpprevent

res.Cleanupoilorfuelspills.

•Allowtheenginetocoolbeforestoringthemachinein

anyenclosure.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlight,suchasonawater

heateroronotherappliances.

HaulingSafety

•Usecarewhenloadingorunloadingthemachine.

•Securethemachinefromrolling.

CleaningundertheMachine

Foroptimalcuttingperformance,keeptheundersideofthe

machinehousingclean.Youmayeitherwashorscrapethe

clippingsawayfromunderthemachinehousing.

WashingundertheMachine

ServiceInterval:Beforeeachuseordaily—Cleanunderthe

machinehousing.

1.Positionthemachineonaatconcreteorasphalt

surfacenearagardenhose.

2.Starttheengine.

3.Holdtherunninggardenhoseathandlelevelanddirect

thewatertoowonthegroundjustinfrontofthe

rightrearwheel(Figure27).

15

Page 16

Figure27

1.Rightrearwheel

Note:Thebladeswilldrawinwaterandwashout

clippings.Letthewaterrununtilyounolongersee

clippingsbeingwashedoutfromunderthemachine.

4.Shutofftheengineandwaitforallmovingpartsto

stop.

5.Turnoffthewater.

6.Startthemachineandletitrunforafewminutestodry

outthemoistureonthemachineanditscomponents.

g002275

g196471

Figure28

1.Gears

ScrapingundertheMachine

Ifwashingdoesnotremovealldebrisfromunderthe

machine,scrapeitclean.

1.Disconnectthewirefromthesparkplug.

2.Drainthefuelfromthefueltank;refertoEmptying

theFuelTankandCleaningtheFilter(page20).

3.Tipthemachineontoitsside,withtheairlterupin

theair,untiltheupperhandlerestsontheground.

4.Removethedirtandgrassclippingswithahardwood

scraper;avoidburrsandsharpedges.

5.Turnthemachineupright.

6.Fillthefueltank.

7.Connectthewiretothesparkplug.

CleaningtheWheels

ServiceInterval:Every40hours

1.Removetherearwheelsandcleananydebrisfromthe

wheel-geararea.

SUPERCEDED

2.Aftercleaning,applyasmallamountofanti-seizeto

thegears.

Note:Ifyouareoperatingthemachineinextreme

conditions,cleaningthewheelsmorefrequentlythan

recommendedwillresultinincreasedgearlife.

Note:Topreventdamagetothebearingseals,donotusea

highpressurewatersprayeronthebearings.

16

Page 17

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Every25hours

Every40hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoilwithouttheoillter.

•Servicetheblade-drivesystem.

•Checktheengine-oillevel.

•Checktheblade-stopsystemoperation.Thebladesshouldstopwithin3secondsof

releasingthecontrolbar;iftheydonot,contactanAuthorizedServiceDealer.

•Cleanunderthemachinehousing.

•Inspecttheairlter.

•Checkthecuttingbladesandservicethem,ifnecessary.

•Inspecttheblades.

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

•Cleanthewheelsandgears.

•Changetheengineoil(moreoftenindustyconditions).

•Checktheconditionofthebelts.

•Checkthefuelhoseandreplaceitifnecessary .

•Removedebrisfromunderthebeltcover.

•Servicetheblade-drivesystem.

•Changetheoillter.

•Checkthesparkplug.

•Cleanthefueltanklter.

•Changethefuellter.

Every250hours

Every300hours

Yearlyorbeforestorage

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourenginemanualforadditionalmaintenanceprocedures.

MaintenanceSafety

•Disconnectthespark-plugwirefromthesparkplug

beforeperforminganymaintenanceprocedure.

•Wearglovesandeyeprotectionwhenservicingthe

machine.

•Thebladeissharp;contactingthebladecanresultin

seriouspersonalinjury.Weargloveswhenservicingthe

blade.

•Changetheblade-brake-clutchbelt.

•Changethetransmissionbelt.

•Replacethepaperairlter(morefrequentlyindustyconditions).

•Emptythefueltankbeforerepairsasdirectororbeforestorage.

ServicingtheAirFilter

ServiceInterval:Beforeeachuseordaily

Every25hours—Cleanthefoampre-cleaner(more

SUPERCEDED

frequentlyindustyconditions).

Every300hours—Replacethepaperairlter(more

frequentlyindustyconditions).

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

•Nevertamperwithsafetydevices.Checktheirproper

operationregularly.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

•Tippingthemachinemaycausethefueltoleak.Fuelis

ammableandexplosive,andcancausepersonalinjury.

Runtheenginedrytoremovethefuelwithahandpump;

neversiphonthefuel.

2.Disconnectthewirefromthesparkplug.

3.Removethecoverandcleanitthoroughly(Figure29).

17

Page 18

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changetheengine

oilwithouttheoillter.

Every50hours—Changetheengineoil(moreoften

industyconditions).

Note:Runtheengineafewminutesbeforechangingthe

oiltowarmit.Warmoilowsbetterandcarriesmore

contaminants.

Engineoilcapacity:Withoillter:0.85L(29oz);without

oillter:0.65L(22oz)

Oilviscosity:SAE30orSAE10W-30detergentoil

APIserviceclassication:SJorhigher

Figure29

1.Cover3.Air-lterbase

2.Foampre-lterandpaper

lter

4.Removethefoampre-lterfromthepaperlter(Figure

29),andreplacethepaperlterifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

5.Washthefoampre-cleanerwithamilddetergentand

water,thenblotitdry.

Note:Donotaddoiltothefoampre-cleaner.

6.Installthefoampre-cleanerontothepaperlter.

7.Installtheair-lterassembly.

8.Installthecover.

g006591

1.Movethemachinetoalevelsurface.

2.RefertoMaintenance(page17).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout(Figure30).

g194742

Figure30

1.Full3.Low

2.High

4.Tipthemachineontoitsside(sothattheairlterisup)

SUPERCEDED

18

todraintheusedoilfromtheoil-lltube(Figure31).

Page 19

G019648

g019648

g019650

1

Figure31

5.Afterdrainingtheusedoil,returnthemachinetothe

operatingposition.

6.Carefullypourabout3/4oftheenginecapacityofoil

intotheoil-lltube.

7.Waitabout3minutesfortheoiltosettleintheengine.

6.Removetheoillter(Figure32).

Note:Makesurethattheoil-ltergasketcomesoff

withthelter.

g019650

Figure32

1.Oillter

8.Wipethedipstickcleanwithacleancloth.

9.Insertthedipstickintotheoil-lltube,thenremove

thedipstick.

10.Readtheoillevelonthedipstick(Figure30).

•IftheoillevelisbelowtheAddmarkonthe

dipstick,carefullypourasmallamountofoilinto

theoil-lltube,wait3minutes,andrepeatsteps

8through10untiltheoillevelisattheFullmark

onthedipstick.

•IftheoillevelisabovetheFullmarkonthe

dipstick,draintheexcessoiluntiltheoillevelisat

theFullmarkonthedipstick.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.

11.Installthedipsticksecurely.

12.Recycletheusedoilproperly.

SUPERCEDED

ChangingtheOilFilter

ServiceInterval:Every100hours

1.Runtheenginetowarmtheoil.

2.Shutofftheengineandwaitforallmovingpartsto

stop.

3.Disconnectthewirefromthesparkplug.

4.Draintheengineoil;refertoChangingtheEngineOil

(page18).

5.Placearagundertheoilltertocatchanyoilthatmay

leakoutasyouremovethelter.

7.Useyourngertocoatthegasketonthenewlter

withoil(Figure33).

g002805

Figure33

1.Gasket

8.Installthenewlteruntilthegasketcontactsthelter

base,thenhandtightenthelteranadditional2/3turn.

9.FillthecrankcasetotheFulllineonthedipstickwith

freshoil;refertoChangingtheEngineOil(page18).

10.Connectthewiretothesparkplug.

11.Runtheengineforabout3minutes.

12.Shutofftheengine,waitforallmovingpartstostop,

andcheckforoilleakagearoundthelter.

13.Addoiltocompensatefortheoilintheoillter;refer

toChangingtheEngineOil(page18)

14.Recycletheusedoillteraccordingtolocalcodes.

19

Page 20

ServicingtheSparkPlug

g019650

1

g019924

1

2

EmptyingtheFuelTankand

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.76mm(0.030inch);refer

toFigure34.

Figure34

CleaningtheFilter

ServiceInterval:Every50hours—Checkthefuelhoseand

replaceitifnecessary.

Every100hours—Cleanthefueltanklter.

Yearlyorbeforestorage—Emptythefueltankbefore

repairsasdirectororbeforestorage.

Note:Thefueltanklter(screen)elementislocatedinside

thefueltankattheoutlet.Thislterisapartofthefueltank

andcannotberemoved.

1.Shutofftheengineandwaitforittocooldown.

Important:Drainfuelfromacoldengineonly.

2.Disconnectthewirefromthesparkplug.

3.Closethefuel-shutoffvalve.

4.Disconnectthefuellinebylooseningthetubeclampat

thecarburetor.

5.Openthefuel-shutoffvalveanddrainthefuel

completelyfromthetankandfuellineintoanapproved

fuelcontainer.

6.Removethefueltankfromthemachine.

7.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutintoan

g000533

approvedfuelcontainer.

8.Installthefueltankandthefuelline.

1.Center-electrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto23N∙m(17ft-lb).

8.Connectthewiretothesparkplug.

CheckingtheConditionofthe Belts

ServiceInterval:Every50hours

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Removethebeltcover(Figure9)byremovingthe4

boltsthatholdittothemachinehousing.

3.Checkthebeltsforanycracks,frayededges,burn

marks,oranyotherdamage.

4.Replacealldamagedbelts.

5.Ifyoureplacetheblade-drivebelt,youmustadjustit.

RefertoServicingtheBlade-DriveSystem(page21).

6.Installthebeltcoverwiththe4boltsthatyouremoved

instep2.

SUPERCEDED

ChangingtheFuelFilter

ServiceInterval:Every100hours

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Closethefuel-shutoffvalve(Figure35).

g019924

Figure35

1.Fuellter2.Fuel-shutoffvalve

20

Page 21

4.Removethefuellter(Figure35)fromthefuellineby

g019641

1

2

3

4

5

6

7

8

looseningthetubeclampssurroundingthefuellter.

5.Installanewfuellterinthefuellineusingthetube

clampsthatyouremovedinstep4.

ServicingtheBlade-Drive System

ServiceInterval:Aftertherst5hours

Every50hours—Removedebrisfromunderthebelt

cover.

Every50hours—Servicetheblade-drivesystem.

1.Loosenthe2screwsonthebelt-cover-accesspaneland

removethepanel(Figure36).

Figure37

1.ReadtheOperator’s

Manualbeforeperforming

anymaintenance.

Note:Ifthereisavisiblegapbetweenthegaugeand

thespring,tightentheadjustingboltandthenutuntil

thefeelergaugebarelyslidesfreelyinandoutofthe

gap(Figure36).

Important:Donotovertightentheadjustingbolt.

Thiscoulddamagetheblade-drivebelt.

4.Installthebelt-cover-accesspanel.

2.Checkbelttensionevery

50hours.

decal116-8528

Figure36

1.Belt-tensionspring5.Blade-drivebelt

2.Adjustingbolt6.Wall

3.Gap

4.Adjustingnut8.Belt-cover-accesspanel

2.Brushorblowoutdebrisfromtheinsideofthebelt

coverandaroundalltheparts.

3.Holdafeelergaugesetbetween0.005and0.03inches

(0.13and0.76mm)againstthewallandslideitdown

behindthebelttensionspring;refertoFigure37.

7.Beltcover

SUPERCEDED

g019641

21

Page 22

ServicingtheCuttingBlades

g017223

ServiceInterval:Beforeeachuseordaily

Important:

blades pr oper l y .

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladesforsharpnessandanywearordamage

wheneveryourunoutoffuel;refertoInspectingthe

Blades(page22).Ifthebladeedgeisdullornicked,haveit

sharpenedorreplaceit.Ifthebladesareworn,bent,damaged

orcracked,replacethemimmediatelywithagenuineToro

replacementblades.

Y ou will need a torque wr ench to install the

Ifyoudonothaveatorquewrenchor

DANGER

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladesperiodicallyforwearor

damage.

•Replacewornordamagedblades.

Note:Maintainsharpbladesthroughoutthecuttingseason,

becausesharpbladescutcleanlywithouttearingorshredding

thegrassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.

g017223

Figure38

1.Curvedarea3.Wear/slotforming

2.Cuttingedge4.Crack

2.Inspectthebladesthemselves,especiallythecurved

area(Figure38).Ifyounoticeanydamage,wear,or

aslotforminginthisarea,immediatelyreplacethem

withnewblades.

DANGER

Ifyouallowabladetowear,aslotwillform

betweenthesailandatpartoftheblade.

Eventuallyapieceoftheblademaybreak

offandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyouor

bystanders.

•Inspectthebladesperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbent

orweldabrokenorcrackedblade.

PreparingtoServicetheCuttingBlades

Tipthemachineontoitsside,withtheairlterupintheair,

untiltheupperhandlerestsontheground.

WARNING

Thebladesaresharp;contactingabladecould

resultinseriouspersonalinjury.

•Disconnectthewirefromthesparkplug.

•Weargloveswhenservicingtheblades.

SUPERCEDED

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure38).Iftheedgesare

notsharporhavenicks,removethebladesandhave

themsharpenedorreplacethem.

•Checkforbentblades;refertoChecking

forBentBlades(page22).

CheckingforBentBlades

1.Rotatethebladesuntiltheyarepositionedasshown

inFigure39.

22

Page 23

B

B

2

1

3

g016532

Figure39

G016530

1

2

3

4

g016527

g016532

Figure40

1.Frontofcuttingdeck3.Measureformthecutting

2.MeasureatlocationsA

andB

2.Measurefromalevelsurfacetothecuttingedges

atlocationsAandB,(Figure39),andrecordboth

dimensions.

3.Rotatethebladessothattheiroppositeendsareat

locationsAandB.

4.Repeatthemeasurementsinstep2andrecordthem.

Note:IfthedifferencebetweenthedimensionsAand

Bobtainedinsteps2and4exceeds1/8inch,replace

theblades;refertoRemovingtheBlades(page23).

edgetoasmooth,level

surface

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplaceabentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofablade.

RemovingtheBlades

Replacethebladeswhentheystrikeasolidobject,areoutof

balance,bent,orworn.UseonlygenuineTororeplacement

blades.

1.Useablockofwoodtoholdeachbladesteadyandturn

thebladeboltcounterclockwiseasshowninFigure40.

SUPERCEDED

2.RemoveeachbladeasshowninFigure41.

g016530

Figure41

1.Spindle(2)3.Blade(2)

2.Bladedriver(2)4.Bladebolt(2)

3.Inspectthepinsonthebladedriversforwearand

damage.

InstallingtheBlades

WARNING

Incorrectlyinstallingthebladescoulddamagethe

machineorcauseaninjurytotheoperatororto

bystanders.

Installthebladesaccordingtotheinstructions.

1.Installtherstbladesothatitishorizontal,alongwith

allmountinghardwareasshowninFigure41.

Note:Tightentheboltwithyourngers.

23

Page 24

Important:Positionthecurvedendsoftheblades

g016537

1

G016536

G019899

1

2

topointtowardthemachinehousing.Besureto

nesttheraisedareasoneachbladedriverwiththe

recessesintheheadofitscorrespondingspindle,

andthepinsontheothersideofeachbladedriver

withtheholesinitscorrespondingblade.

2.Steadyeachbladewithaboardandturnthebladebolt

clockwisewithatorquewrenchasshowninFigure42;

torqueeachbladeboltto82N∙m(60ft-lb).

4.Tightenthesecondblade;refertostep2.

5.Rotatethebladesbyhandafull360°turntoensure

thattheydonottouch.

Note:Ifthebladestoucheachother,theyarenot

mountedcorrectly.Repeatsteps1through3untilthe

bladesnolongertoucheachother.

ChangingtheBlade-DriveBelt

Changetheblade-drivebeltasneeded.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Removethebeltcover(Figure9)byremovingthe4

boltsthatholdittothemachinehousing.

Note:Savetheboltsforinstallingthebeltcoverto

themachinehousing.

4.Removeanydebrisfromunderthebeltcover.

5.RemovetheBBCbeltguardandthemounting

hardware.

Figure42

Important:Abolttorquedto82N∙m(60ft-lb)is

verytight.Putyourweightbehindthewrenchand

tightentheboltsecurely.Thisboltisverydifcult

toovertighten.

3.Rotatetheinstalledblade1/4turnuntilitisvertical,

andinstalltheotherbladeinthesamemannerasthe

rst(refertostep1).

Note:Thebladesshouldbeperpendicular,forming

aninverted“T”asshowninFigure43.

SUPERCEDED

Note:SavetheBBCbeltguardandhardwarefor

installationlater.

g016537

g019899

Figure44

1.BBCbelt2.BBCbeltguard

6.RemovetheBBCbeltfromthefront,leftpulley.

7.Loosentheadjustingbolt(Figure36).

8.Removethexedidlerpulleyandthehardware(Figure

45).

Figure43

1.Blade(2)

g016536

Note:Savetheidlerpulleyandhardwarefor

installationlater.

24

Page 25

G019922

Figure45

G019899

1

2

TheBBCidlerpulleyisremovedforclarity

1.Holeinthehousing3.Fixed-idlerpulley

2.Rightsprockethole

9.Removetheblade-drivebelt.

10.Aligntheholesintherightandleftsprocketswiththe

holesinthehousingasshowninFigure45.

4.Leftsprockethole

2.Disconnectthewirefromthesparkplug.

3.Removethe4boltsthatholdthebeltcovertothe

machinehousing.

Note:Savetheboltsforinstallingthebeltcoverto

themachinehousing.

4.Removethebeltcover.

5.Removeanydebrisfromunderthebeltcover.

6.Removethetransmissionbelt;refertoChangingthe

TransmissionBelt(page26).

7.RemovetheBBCbeltguard(Figure46).

Note:Savethemountinghardwareforinstallingthe

BBCbeltguardlater.

g019922

Note:Holdthesprocketsinplacewitharodora

screwdriver.

11.Whenyouhavelockedthesprocketsinplace,install

theblade-drivebeltandthexedidlerpulley.

Note:Ensurethattheteethareengagedinthe

sprockets.

12.Tightenthebelttensiontotherecommendedsettings;

refertoServicingtheBlade-DriveSystem(page21).

13.Removetherodorscrewdriverfromthesprockets.

14.Ensurethatthebladesunderthehousingareproperly

aligned;refertoServicingtheCuttingBlades(page22).

15.InstalltheBBCbeltandtheBBCbeltguardand

hardware.

16.Installthebeltcoverusingthe4boltsthatyouremoved

instep3.

17.Connectthewiretothesparkplug.

18.Checktheoperationofthecontrolbarandthe

blade-brakeclutch.

SUPERCEDED

Changingthe Blade-Brake-Clutch(BBC) Belt

ServiceInterval:Every250hours

1.Shutofftheengineandwaitforallmovingpartsto

stop.

g019899

Figure46

1.BBCbelt2.BBCbeltguard

8.RemovetheBBCbeltfromthebrake-drumpulleyand

thenremovethebeltfromthemachine.

Note:Holdoneofthebladesusingagloveorarag

andturnthebladespindletohelpremovetheBBCbelt.

9.ToinstallanewBBCbelt,reversethestepsabove.

10.AdjusttheBBCcable;refertoAdjustingthe

Blade-BrakeCable(page25).

AdjustingtheBlade-Brake Cable

Adjusttheblade-brakecablewheneveryouinstallanewcable

orreplacetheBBCbelt.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Removethebeltcover(Figure9)byremovingthe4

boltsthatholdittothemachinehousing.

25

Page 26

Note:Savetheboltsforinstallingthebeltcoverto

1

2

G019923

themachinehousing.

4.Removeanydebrisfromunderthebeltcover.

5.Loosenthecable-clampscrew(Figure47).

Figure47

g195615

Figure49

1.Markthecablehere

g019923

Figure48

2.Blade-brakecable

SUPERCEDED

1.Cable-clampscrew

6.Pullthecablejackettoremoveslack(Figure48).

Note:Donotputtensiononthespring.

1.Cableclamp2.Spring

7.Markthebrakecable(Figure49),thenadjustthejacket

untilthereisapproximately3mm(1/8inch)ofslack

(Figure50).

g195616

Figure50

1.Slack—3mm(1/8inch)

8.Torquethecable-clampscrewto11to14N∙m(99to

121in-lb)tolocktheadjustmentinplace.

9.Installthebeltcoverwiththe4boltsthatyouremoved

instep3.

10.Connectthewiretothesparkplug.

11.Checktheoperationoftheblade-brakeclutch.

ChangingtheTransmission

g195540

Belt

ServiceInterval:Every250hours

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

3.Removethe4boltsthatholdthebeltcovertothe

machinehousing.

Note:Savetheboltsforinstallingthebeltcoverto

26

themachinehousing.

4.Removethebeltcover.

5.Removeanydebrisfromunderthebeltcover.

Page 27

6.Loosenthebracketandrotatethebracketforward

G019876

1

(Figure51).

Note:Thebracketpreventsthetransmissionfrom

tippingtothepointwherethetransmissionbeltcomes

off.

1.Stopthemachineandwaitforallmovingpartstostop.

2.Loosenthecable-supportnut(Figure52).

g019876

Figure52

1.Cable-supportnut

Figure51

1.Transmissiontension

spring

2.Bracket5.Transmissionbelt

3.Transmission

7.Removethetransmissiontensionspring.

8.Removethetransmissionbeltfromthetransmission

pulley.

9.Removethetransmissionbelt.

10.Toinstallanewtransmissionbelt,reversethesteps

above.

4.BBCbelt

AdjustingtheTransmission

Ifthemachinestartstolosetraction,checkandadjustthe

transmission.

1.Shutofftheengineandwaitforallmovingpartsto

stop.

2.Disconnectthewirefromthesparkplug.

g196531

3.Slidethecable-supportnuttowardthemachineto

increasetheself-propelaction;slidethecable-support

nutawayfromthemachinetodecreasetheself-propel

action.

4.Tightenthecable-supportnut.

5.Checktheoperationforthedesireddrivecontrol,and

repeatthestepsabove,ifnecessary.

Note:Ifthemachinecreepsforwardwithoutthe

controlbarengagedorifthewheelsspinwhenyou

lifttherearwheelsofftheground,thecableistoo

tight;loosenthecable-supportnut,pullthecablejacket

upward(awayfromthemachine)slightly ,andtighten

thecable-supportnut.

Note:Youmayalsoadjustthemaximumground

speed(whenthecontrolbarisfullyengaged)asdesired.

3.Loosentheboltandnutholdingthebracketintoplace.

4.Adjustthebracketsothatitisincontactwiththe

transmission.

Note:Thebracketpreventsthetransmissionfrom

tippingtothepointwherethetransmissionbeltcomes

off.

5.Tightentheboltandnuttosecurethebracketinto

place.

SUPERCEDED

AdjustingtheSelf-Propel Cable

Ifthemachinedoesnotself-propelortendstocreepforward

whenyoureleasethecontrolbar,adjustthedrivecable.

27

Page 28

Storage

GeneralInformation

Storethemachineinacool,clean,dryplace.Coverthe

machinetokeepitcleanandprotected.

1.Performtherecommendedannualmaintenance

procedures;refertoMaintenance(page17).

2.Cleanunderthemachine;refertoCleaningunderthe

Machine(page15).

3.Removechaff,dirt,andgrimefromtheexternalparts

oftheengine,theshrouding,andthetopofthe

machine.

4.Checktheconditionoftheblades;refertoInspecting

theBlades(page22).

5.Servicetheairlter;refertoServicingtheAirFilter

(page17).

6.Tightenallnuts,bolts,andscrews.

7.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

2.Removethesparkplug.

3.Usinganoilcan,addabout30ml(1oz),ofmotoroil

totheenginethroughthespark-plughole.

4.Slowlypullthestarterropeseveraltimestodistribute

oilthroughoutthecylinder.

5.Installthesparkplugbutdonotconnectthewireto

thesparkplug.Securethewiresothatitdoesnotcome

intocontactwiththesparkplug.

RemovingtheMachinefrom Storage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

usingthestartertoblowexcessoilfromthecylinder.

3.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheengineowner’smanual.

4.Installthesparkplugandtightenittotherecommended

torqueof20N∙m(180in-lb).

5.Performanyneededmaintenanceprocedures;referto

Maintenance(page17).

PreparingtheFuelSystem

WARNING

Fuelcanvaporizeifyoustoreitoverlongperiods

oftimeandexplodeifitcomesintocontactwith

anopename.

•Donotstorefueloverlongperiodsoftime.

•Donotstorethemachinewithfuelinthefuel

tankorthecarburetorinanenclosurewithan

opename.(Forexample,afurnaceorawater

heaterpilotlight.)

•Allowtheenginetocoolbeforestoringitinany

enclosure.

Onthelastrefuelingoftheyear,addfuelstabilizertothefuel

asdirectedbytheenginemanufacturer.Emptythefueltank

whenmowingthelasttimebeforestoringthemachine.

1.Runthemachineuntiltheengineshutsofffrom

runningoutoffuel.

2.Starttheengineagain.

SUPERCEDED

6.Checktheengine-oillevel;refertoCheckingthe

Engine-OilLevel(page10).

7.Fillthefueltankwithfreshfuel;refertoFillingthe

FuelTank(page9).

8.Connectthewiretothesparkplug.

3.Allowtheenginetorununtilitshutsoff.Whenyou

cannolongerstarttheengine,itissufcientlydry.

PreparingtheEngine

1.Whiletheengineisstillwarm,changetheengineoil

andtheoillter;refertoChangingtheEngineOil

(page18)andChangingtheOilFilter(page19).

28

Page 29

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginestartshardorlosespower.

PossibleCauseCorrectiveAction

1.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

2.Thefuelshutoffvalveisclosed.2.Openthefuelshutoffvalve.

3.Thethrottleleverisnotinthecorrect

position.

4.Thereisdirt,water,orstalefuelinthe

fuelsystem.

5.Thewireisnotconnectedtothespark

plug.

6.Thesparkplugispitted,fouled,orthe

gapisincorrect.

7.Thereisdirtinthefuellter.7.Replacethefuellterandcleanthe

1.Theairlterelementisdirtyandis

restrictingtheairow.

2.Theengineoillevelislowortheoilis

dirty.

3.Thefueltankventhoseisplugged.3.Cleanorreplacethefueltankvent

4.Thereisdirtinthefuellter.4.Replacethefuellterandcleanthe

5.Thereisdirt,water,orstalefuelinthe

fuelsystem.

6.Theundersideofthemachinecontains

clippingsanddebris.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

1.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer .

3.MovethethrottlelevertotheChoke

position.

4.ContactanAuthorizedServiceDealer.

5.Connectthewiretothesparkplug.

6.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

in-tanklterscreen.

1.Cleantheairlterpre-cleanerand/or

replacethepaperlter.

2.Checktheengineoil.Changetheoilif

itisdirtyoraddoilifitislow.

hose.

in-tanklterscreen.

5.ContactanAuthorizedServiceDealer.

6.Cleanunderthemachine.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

Theenginerunsrough.

Themachineorenginevibrates

excessively.

1.Thewireisnotsecurelyconnectedto

thesparkplug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

3.ThethrottleleverisnotintheFast

position.

4.Theairlterelementisdirtyandis

restrictingtheairow.

5.Thereisdirtinthefuellter.5.Replacethefuellterandcleanthe

SUPERCEDED

1.Abladeisbentorisoutofbalance.1.Balancetheblade(s).Ifabladeis

2.Ablade-mountingboltisloose.2.Tightentheblade-mountingbolts.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

4.Theenginemountingboltsareloose.4.Tightentheenginemountingbolts.

5.Theenginepulley ,idlerpulley ,orblade

pulleyareloose.

6.Theenginepulleyisdamaged.

7.Thebladespindleisbent.

8.Thebeltisdamaged.8.Replacethebelt.

1.Connectthewiresecurelytothespark

plug.

2.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

3.MovethethrottlelevertotheFast

position.

4.Cleantheairlterpre-cleanerand/or

replacethepaperlter.

in-tanklterscreen.

bent,replaceit.

3.Cleantheundersideofthemachine

housing.

5.Tightentheloosepulley .

6.ContactanAuthorizedServiceDealer.

7.ContactanAuthorizedServiceDealer.

29

Page 30

Problem

PossibleCauseCorrectiveAction

Thereisanunevencuttingpattern.

Thedischargechutegetspluggedup.

Themachinedoesnotself-propel.

Thebladesdonotrotateortheyslip.

1.All4wheelsarenotatthesameheight.1.Placeall4wheelsatthesameheight.

2.Thebladesaredull.

3.Youaremowinginthesamepattern

repeatedly.

4.Theundersideofthemachinecontains

clippingsanddebris.

5.Thebladespindleisbent.

1.ThethrottleleverisnotintheFast

position.

2.Thecuttingheightistoolow.

3.Youaremowingtoofast.3.Slowdown.

4.Thegrassiswet.

5.Theundersideofthemachinecontains

clippingsanddebris.

1.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

2.Thereisdebrisinthebeltarea.

3.Thebeltisdamaged.3.Replacethebelt.

1.TheBBCbeltorthetimingbeltisworn,

loose,orbroken.

2.TheBBCbeltisoffthepulley .2.Checkthebeltfordamageandcontact

3.TheBBCcableisworn,loose,or

broken.

2.Sharpenandbalancetheblades.

3.Changethemowingpattern.

4.Cleanunderthemachine.

5.ContactanAuthorizedServiceDealer.

1.MovethethrottlelevertotheFast

position.

2.Raisethecuttingheight;ifnecessary,

mowasecondtimeatalowercutting

height.

4.Allowthegrasstodrybeforemowing.

5.Cleanunderthemachine.

1.Adjusttheself-propeldrivecable;

replacethecableifnecessary.

2.Cleanthedebrisfromthebeltarea.

1.AdjusttheBBCcable;adjustthetiming

belttension;replacethemifnecessary .

anAuthorizedServiceDealerif

necessary.

3.AdjusttheBBCcable;replaceitif

necessary.

Thebladescontacteachother.

1.Thebladesareinstalledoraligned

incorrectly.

2.Thebladeadaptersareworn,loosen,

orbroken.

3.Thetimingbeltorworn,loose,or

broken.

4.Thetimingsprocketsoridlerpulleyis

worn,loose,orbroken.

1.Installthebladesproperly.

2.Replacethebladeadapters.

3.ContactanAuthorizedServiceDealer.

4.ContactanAuthorizedServiceDealer.

SUPERCEDED

30

Page 31

EuropeanPrivacyNotice

TheInformationT oroCollects

ToroWarrantyCompany(T oro)respectsyourprivacy.Inordertoprocessyourwarrantyclaimandcontactyouintheeventofaproductrecall,weaskyou

tosharecertainpersonalinformationwithus,eitherdirectlyorthroughyourlocalT orocompanyordealer .

TheT orowarrantysystemishostedonserverslocatedwithintheUnitedStateswhereprivacylawmaynotprovidethesameprotectionasapplies

inyourcountry.

BYSHARINGYOURPERSONALINFORMATIONWITHUS,YOUARECONSENTINGTOTHEPROCESSINGOFYOURPERSONALINFORMA TION

ASDESCRIBEDINTHISPRIV ACYNOTICE.

TheWayT oroUsesInformation

Toromayuseyourpersonalinformationtoprocesswarrantyclaims,tocontactyouintheeventofaproductrecallandforanyotherpurposewhichwetell

youabout.T oromayshareyourinformationwithT oro'safliates,dealersorotherbusinesspartnersinconnectionwithanyoftheseactivities.Wewillnot

sellyourpersonalinformationtoanyothercompany .Wereservetherighttodisclosepersonalinformationinordertocomplywithapplicablelawsand

withrequestsbytheappropriateauthorities,tooperateoursystemsproperlyorforourownprotectionorthatofotherusers.

RetentionofyourPersonalInformation

Wewillkeepyourpersonalinformationaslongasweneeditforthepurposesforwhichitwasoriginallycollectedorforotherlegitimatepurposes

(suchasregulatorycompliance),orasrequiredbyapplicablelaw.

Toro'sCommitmenttoSecurityofYourPersonalInformation

Wetakereasonableprecautionsinordertoprotectthesecurityofyourpersonalinformation.Wealsotakestepstomaintaintheaccuracyandcurrent

statusofpersonalinformation.

AccessandCorrectionofyourPersonalInformation

Ifyouwouldliketorevieworcorrectyourpersonalinformation,pleasecontactusbyemailatlegal@toro.com.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

SUPERCEDED

374-0282RevC

Page 32

TheToroWarranty

Landscape

Contractor

Equipment(LCE)

ConditionsandProductsCovered

TheT oroCompanyanditsafliate,T oroWarrantyCompany ,pursuanttoan

agreementbetweenthem,jointlypromisetorepairtheT oroProductslisted

belowifdefectiveinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromtheoriginaldateofpurchase:

ProductsWarrantyPeriod

WalkBehindMowers

53cm&76cmMowers–

Residentialuse

53cm&76cmMowers–

Commercialuse

•Engine2years

Mid-SizeWalk-BehindMowers

•Engine2years

GrandStand

•Engine3years

ZMaster

•Engine3years

ZMaster

•Engine2years

ZMaster

•Engine3years

TitanHDMowerandEngine4yearsor500hours

AllMowers

•Battery2years

•Attachments2years

1

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialwarrantywouldapply .

2

SomeenginesusedonT oroLCEProductsarewarrantedbytheenginemanufacturer .

3

Whicheveroccursrst.

Thiswarrantyincludesthecostofpartsandlabor ,butyoumustpay

transportationcosts.

®

®

®

®

6000SeriesMowers

7000SeriesMowers

8000SeriesMowers

1

Mowers

2years

1year

2

2years

2

5yearsor1,200hours

5yearsor1,200hours

2

5yearsor1,200hours

2

2years

2

3

3

3

3

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorparts,suchaslters,fuel,

lubricants,oilchanges,sparkplugs,airlters,bladesharpening

orwornblades,cable/linkageadjustments,orbrakeandclutch

adjustments

•Componentsfailingduetonormalwear

•Anyproductorpartwhichhasbeenalteredormisusedorneglected

orrequiresreplacementorrepairduetoaccidentsorlackofproper

maintenance

•Pickupanddeliverycharges

•RepairsorattemptedrepairsbyanyoneotherthananAuthorizedT oro

ServiceDealer

•Repairsnecessaryduetofailuretofollowrecommendedfuel

procedure(consulttheOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontains

morethan10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-use

overonemonth

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry .Therights

towhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythiswarranty.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.Contactyoursellertoarrangeserviceoftheproduct.Ifforanyreason

itisimpossibleforyoutocontactyourseller ,youmaycontactanyT oro

AuthorizedDistributortoarrangeservice.Visithttp://www.toro.com/to

locateaT orodistributorinyourarea.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

001-952-948-4707

SUPERCEDED

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.

374-0272RevF

Loading...

Loading...