Page 1

FormNo.3381-349RevA

30inTurfMasterWalk-BehindLawnMower

ModelNo.22200—SerialNo.314000001andUp

Operator'sManual

Introduction

Thisrotary-blade,walk-behindlawnmowerisintended

tobeusedbyresidentialhomeownersorprofessional,

hiredoperators.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

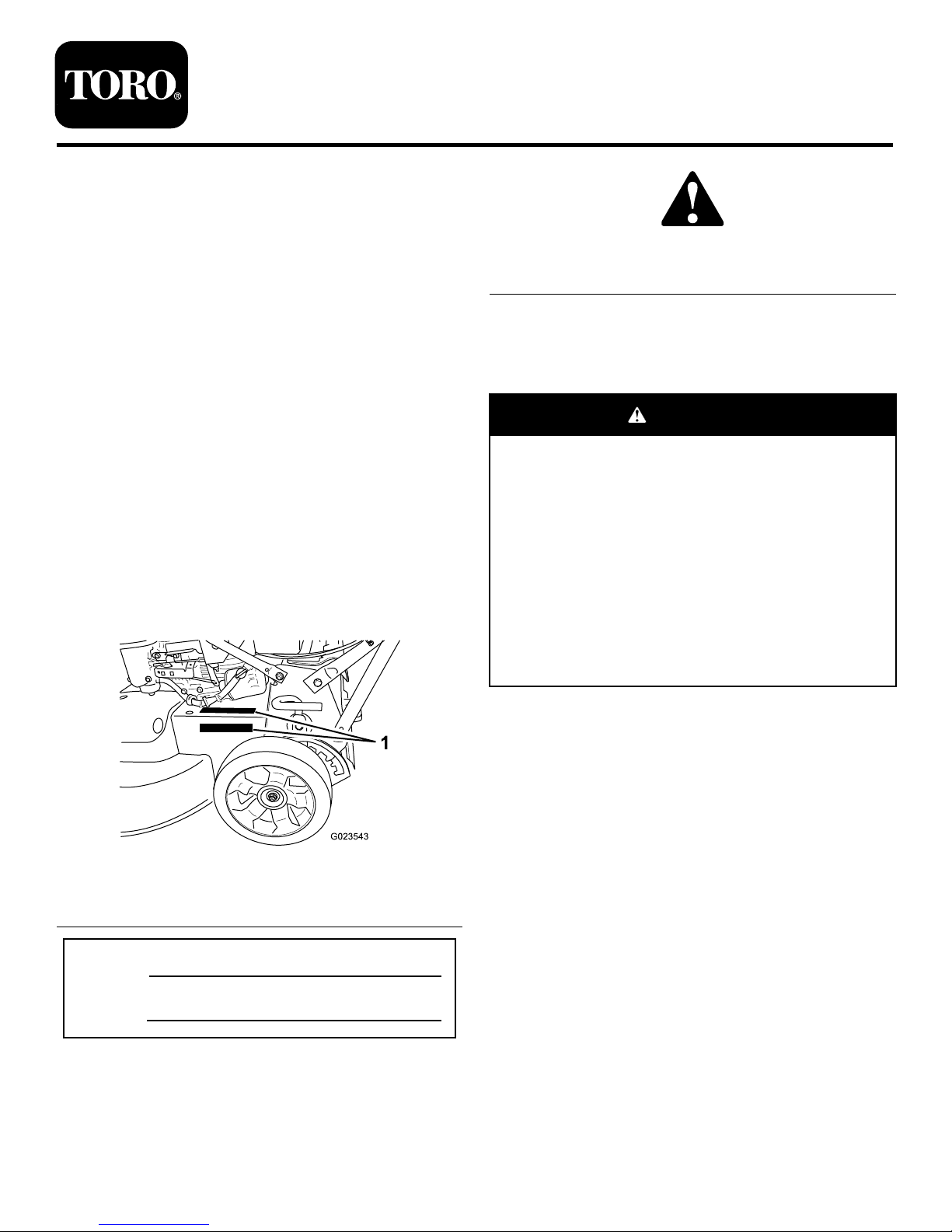

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

G023543

1

Figure1

1.Themodelandserialnumberplateisinoneofthese2

locations.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

TheenclosedEngineOwner’sManualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

NetTorque:Thegrossornettorqueofthisenginewas

laboratoryratedbytheenginemanufacturerinaccordance

withtheSocietyofAutomotiveEngineers(SAE)J1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclassofmower

willbesignicantlylower.Gotowww.Toro.comtoview

specicationsonyourmowermodel.

©2013—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3381-349*A

Page 2

Contents

Introduction..................................................................1

GeneralLawnMowerSafety.....................................2

SafetyandInstructionalDecals.................................4

Setup............................................................................6

1InstallingtheHandle.............................................6

2AdjustingtheHandleHeight..................................6

3FillingtheCrankcasewithOil.................................7

ProductOverview..........................................................8

Controls................................................................8

Operation.....................................................................9

CheckingtheEngineOilLevel..................................9

FillingtheFuelTankwithGasoline............................9

AdjustingtheCuttingHeight....................................10

StartingtheEngine.................................................11

StoppingtheEngine...............................................11

OperatingtheSelf-propelDriveandEngagingthe

CuttingBlades....................................................11

CheckingtheBlade-stopSystemOperation................12

RecyclingtheClippings...........................................12

BaggingtheClippings.............................................13

Side-dischargingtheClippings..................................14

OperatingTips......................................................15

Maintenance.................................................................16

RecommendedMaintenanceSchedule(s)......................16

ServicingtheAirFilter............................................16

ChangingtheEngineOil.........................................17

ChangingtheOilFilter............................................18

ServicingtheSparkPlug..........................................18

CheckingtheConditionoftheBelts..........................18

EmptyingtheFuelTankandCleaningthe

Filter.................................................................19

ChangingtheFuelFilter..........................................19

ServicingtheBlade-driveSystem..............................19

ServicingtheCuttingBlades.....................................20

ChangingtheBlade-Brake-Clutch(BBC)

Belt...................................................................22

AdjustingtheSelf-propelCable................................23

AdjustingtheBlade-brakeCable...............................23

ChangingtheBlade-driveBelt..................................24

CleaningundertheMachineHousing........................24

Storage........................................................................25

GeneralInformation...............................................25

PreparingtheFuelSystem.......................................25

PreparingtheEngine..............................................25

RemovingtheMachinefromStorage.........................26

Troubleshooting...........................................................27

Safety

ThislawnmowermeetsorexceedstheCPSCblade

safetyrequirementsforwalk-behindrotarylawnmowers

andtheB71.4specicationsoftheAmericanNational

StandardsInstituteineffectatthetimeofproduction.

Improperlyusingormaintainingthislawnmowercan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructions.

Torodesignedandtestedthislawnmowerforreasonably

safeservice;however,failuretocomplywiththefollowing

instructionsmayresultinpersonalinjury.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Toensuremaximumsafety,bestperformance,and

togainknowledgeoftheproduct,itisessentialthat

youandanyotheroperatorofthemachinereadand

understandthecontentsofthismanualbeforethe

engineiseverstarted.Payparticularattentiontothe

safetyalertsymbol(Figure2)whichmeansCaution,

Warning,orDanger—“personalsafetyinstruction.”

Readandunderstandtheinstructionbecauseithasto

dowithsafety.Failuretocomplywiththeinstruction

mayresultinpersonalinjury.

GeneralLawnMowerSafety

Thislawnmoweriscapableofamputatinghandsandfeetand

ofthrowingobjects.Failuretoobservethefollowingsafety

instructionscouldresultinseriousinjuryordeath.

Thefollowinginstructionshavebeenadaptedfromthe

ANSI/OPEIstandardB71.4-2012.

Training

•ReadtheOperator’sManualandothertrainingmaterial.

•Iftheoperator(s)ormechanic(s)cannotreadEnglishitis

theowner’ sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theownerand/orusercanpreventandisresponsible

foraccidentsorinjuriesoccurringtothemselves,other

people,orproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.

•Onlyuseaccessoriesandattachmentsapprovedbythe

manufacturer.

2

Page 3

•Wearappropriateclothing,includingsafetyglassesand

hearingprotection.Longhair,looseclothing,orjewelry

maygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Checkthatoperator’spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly .Donot

operatethemunlesstheyarefunctioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Onlystartenginefromtheoperator’sposition.

•Besureofyourfootingwhileusingpedestrian-controlled

equipment,especiallywhenbackingup.

•Walk,don’trun.

•Neveroperateonwetgrass.Reducedfootingcouldcause

slipping.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.

•Usecautionwhileoperatingneardrop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisethedeckwiththebladesrunning.

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelgroundandshutoffenginebeforeleaving

theoperator’spositionforanyreasonincludingemptying

thecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperation.

•Keephandsandfeetawayfromthecuttingunits.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerwhileundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

SafeHandlingofFuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

•Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

MaintenanceandStorage

•Waitforallmovementtostopbeforeadjusting,cleaning

orrepairing.

•Cleangrassanddebrisfromcuttingunit,mufer,and

enginetohelppreventres.

•Cleanupoilorfuelspills.

•Letenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Neverallowuntrainedpersonneltoservicemachine.

•Usecarewhencheckingtheblades.

•Wrapthebladesorweargloves,andusecautionwhen

servicing.

•Onlyreplaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.

•Ifpossible,donotmakeadjustmentswiththeengine

running.

3

Page 4

•Keepallpartsingoodworkingconditionandallhardware

tightened.

•Replaceallwornordamageddecals.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotentialdanger.Replace

anydecalthatisdamagedorlost.

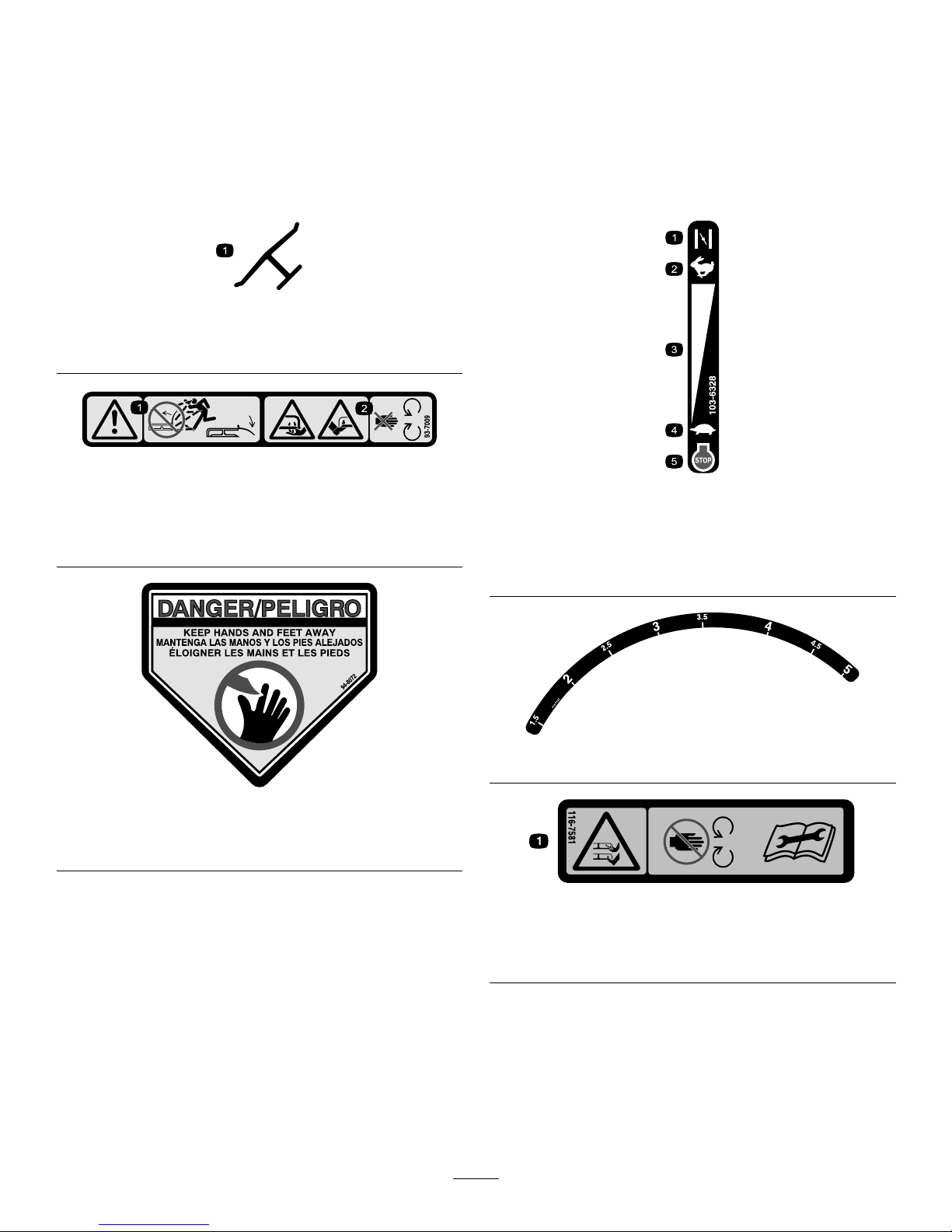

Manufacturer'sMark

1.Indicatesthatthebladeisidentiedasapartfromthe

originalmachinemanufacturer .

93-7009

1.Warning—don'toperatethemowerwiththedeectorupor

removed;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

94-8072

1.Warning—cutting/dismembermenthazardofhandorfoot,

cuttingmechanism.

103-6328

1.Choke4.Slow

2.Fast5.Engine—stop

3.Continuousvariable

setting

116-7127

116-7581

1.Cutting/dismembermenthazardofhandorfoot,mower

blade-stayawayfrommovingparts.ReadtheOperator’s

Manualbeforeadjustingservicing,orcleaning.

4

Page 5

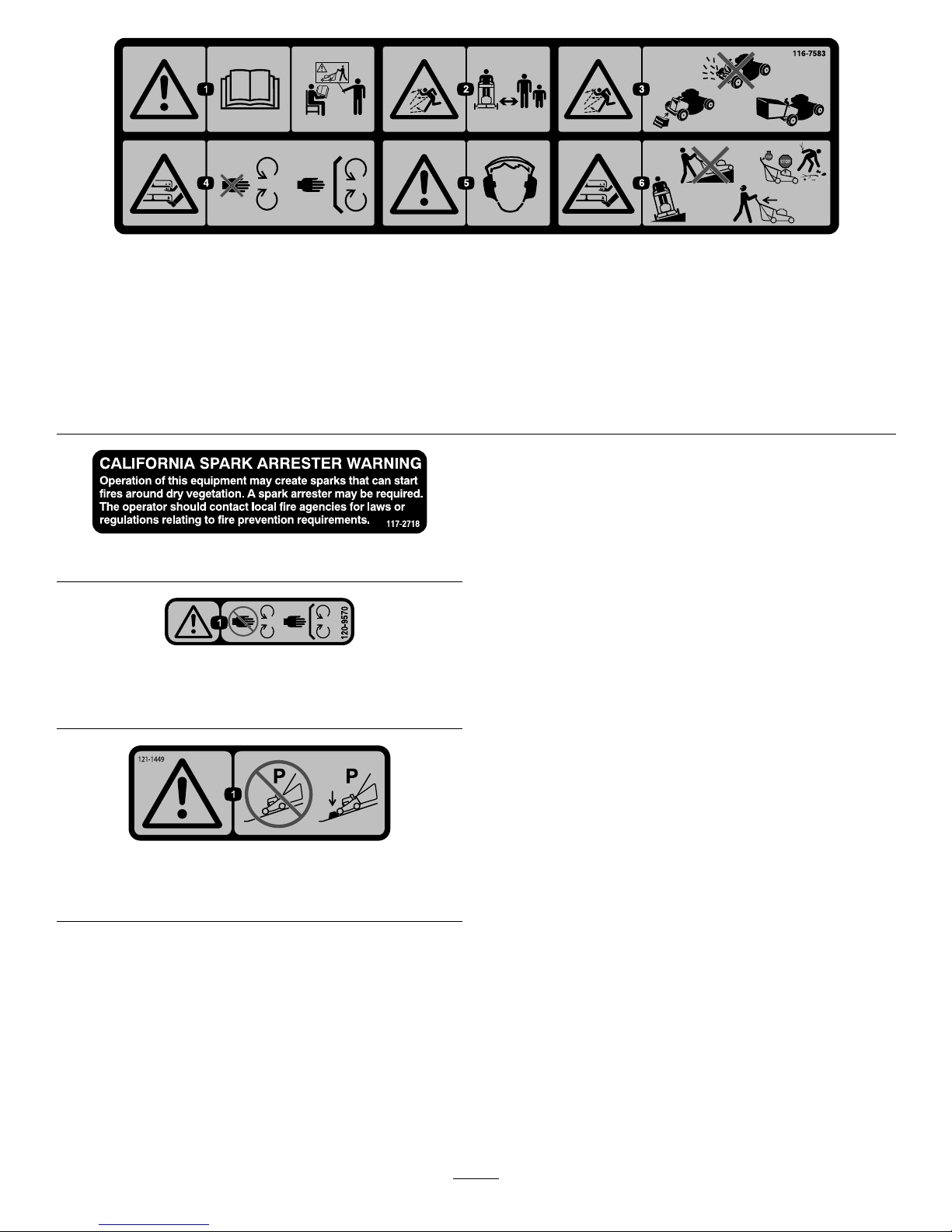

116-7583

1.Warning–ReadtheOperator’sManual.Donotoperatethis

machineunlessyouaretrained.

4.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts;keepallguardsinplace.

2.Thrownobjecthazard—keepbystandersasafedistancefrom

themachine.

5.Warning—wearhearingprotection.

3.Thrownobjecthazard—Donotoperatethemowerwithoutthe

reardischargeplugorbaginplace.

6.Cutting/dismembermenthazardofhandorfoot,mower

blade—Donotoperateupanddownslopes;operatesideto

sideonslopes;stoptheenginebeforeleavingtheoperating

position—pickupobjectsthatcouldbethrownbytheblades;

andlookbehindyouwhenbackingup.

117–2718

120-9570

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

121-1449

1.Warning—donotparkonslopesunlesswheelsarechocked

orblocked.

5

Page 6

Setup

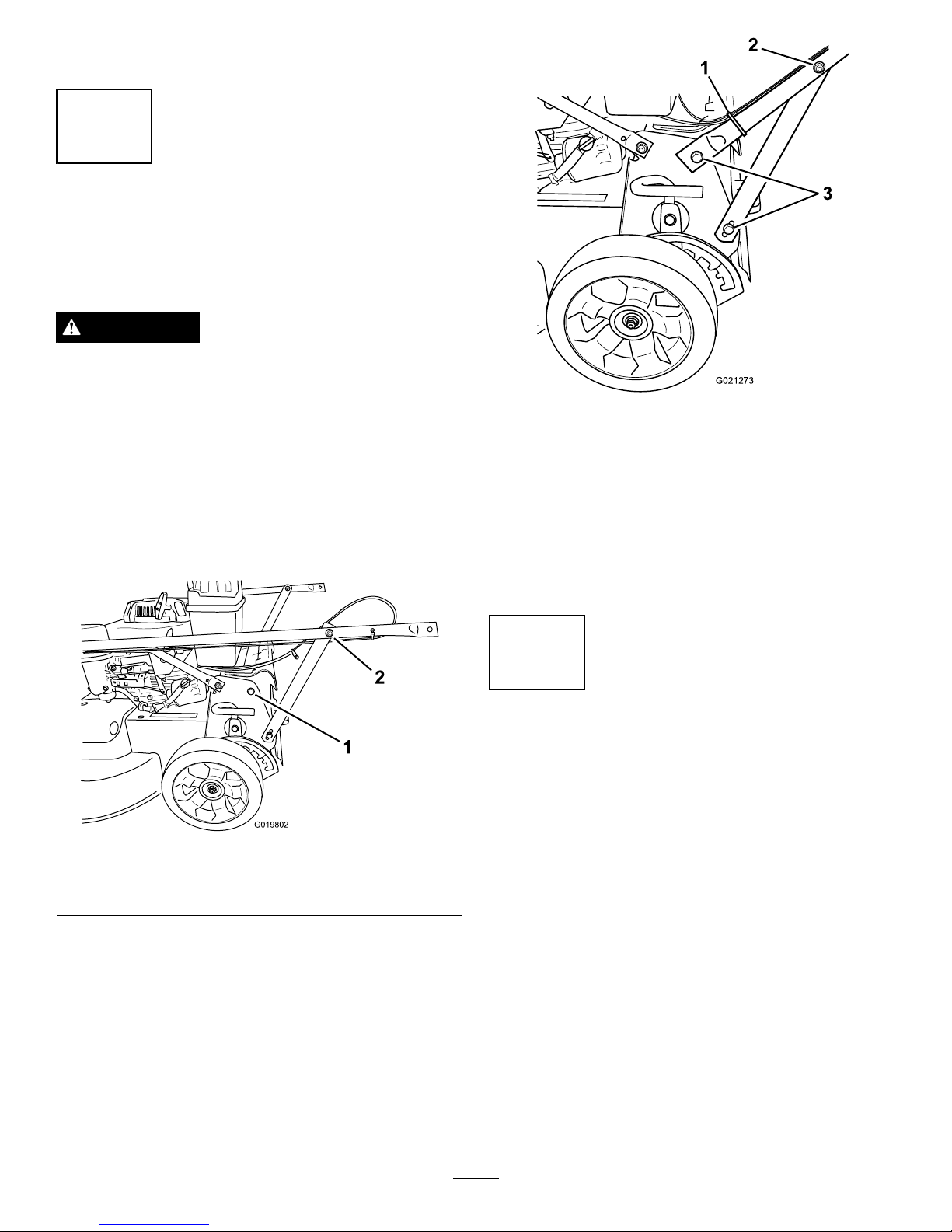

1

InstallingtheHandle

NoPartsRequired

Procedure

WARNING

Foldingorunfoldingthehandleimproperlycan

damagethecables,causinganunsafeoperating

condition.

•Donotdamagethecableswhenfoldingor

unfoldingthehandle.

•Ifacableisdamaged,contactanAuthorized

ServiceDealer.

1.Removethe2boltsfromthemachineframeinthe

locationshowninFigure3.

G019802

1

2

Figure3

1.Bolt(2)

2.Nutonhandlesupport

bracket(2)

2.Rotatethehandlerearwardtotheoperatingposition.

3.Securethehandletothemachinewiththeboltsthat

youremovedinstep

1

4.Tightenthefastenersthatsupportthehandleonboth

sidesofthemachineasshowninFigure4.

G021273

2

1

3

Figure4

1.Cabletie3.Bolt(4)

2.Nutonhandlesupport

bracket(2)

5.Useacabletietosecurethecablestothelowerhandle

inthelocationshowninFigure4.

6.Securethecabletieonthehandleandtrimoffthe

excessmaterialfromthetie.

2

AdjustingtheHandleHeight

NoPartsRequired

Procedure

1.Standintheoperatingpositiontodeterminethemost

comfortablehandleheight.

2.Removethehandleboltandinsertitin1ofthe3holes

locatedatthebottomofthehandlebracket(Figure5).

6

Page 7

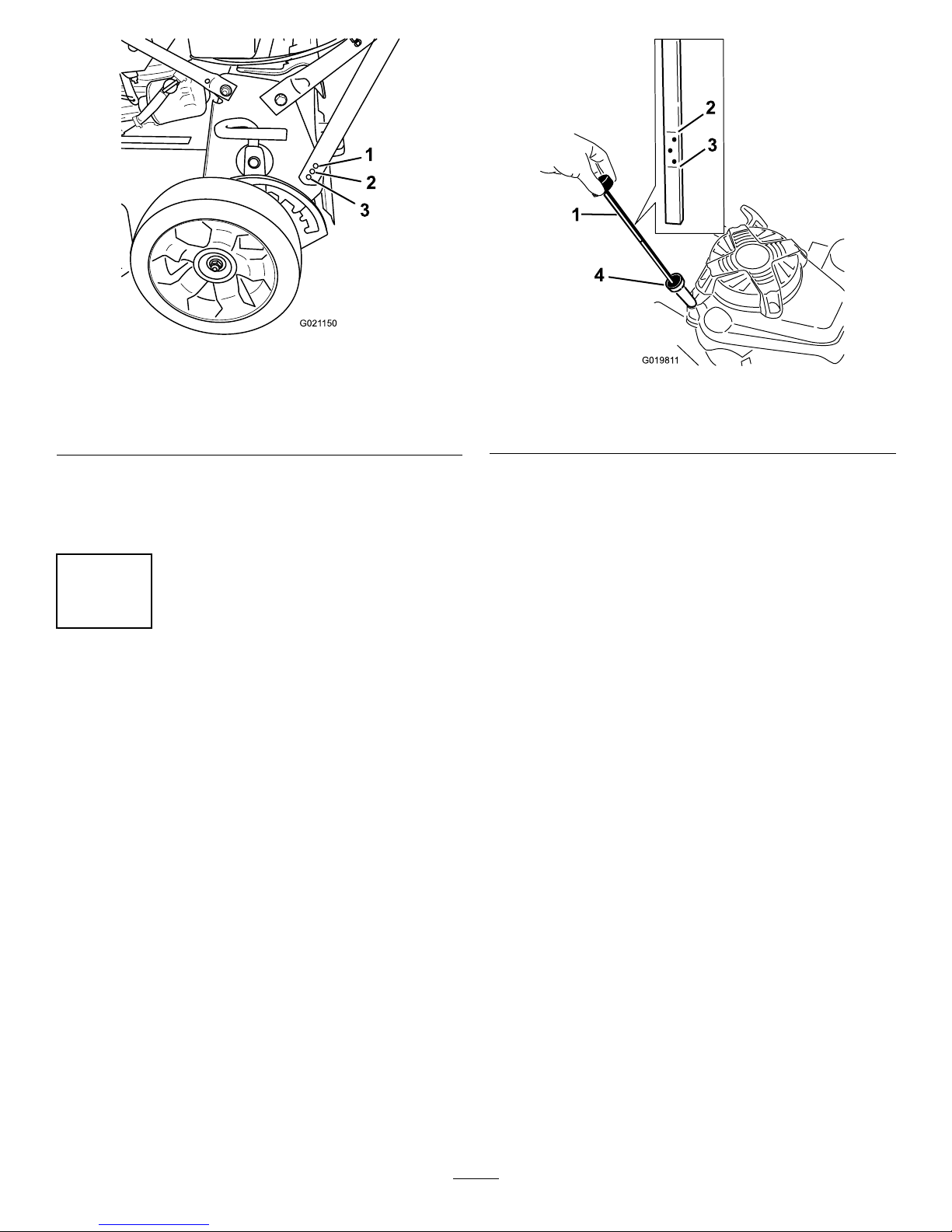

G021 150

1

2

3

Figure5

1.Lowesthandleheight

setting

3.Highesthandleheight

setting

2.Middlehandleheight

setting

3.Tightenthehandleboltuntilitissnug.

4.Repeatthestepsabovefortheothersideofthe

machine.

3

FillingtheCrankcasewithOil

NoPartsRequired

Procedure

Important:Thismachinedoesnotcomewithoilinthe

engine.Beforestartingtheengine,lltheenginewith

oil.

1.Movethemachinetoalevelsurface.

2.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

3.Ifthecrankcaseisempty,addabout3/4ofthe

crankcasecapacityofoilintotheoil-lltube(Figure6).

Note:Max.ll:29oz.(0.85l)withoillter;22oz.

(0.65l)withoutoillter;type:SAE30orSAE10W30

weightdetergentoilwithanAPIserviceclassication

ofSF,SG,SH,SJ,SL,orhigher.

G01981 1

4

Figure6

1.Dipstick3.Addmark

2.Fullmark

4.Oil-lltube

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,thenremoveit.

Note:Toensureanaccurateoillevelreading,install

thedipstickfully.

6.Readtheoillevelonthedipstick(Figure6).

•IftheoillevelisbelowtheAddmark,addasmall

amountofoilslowlytotheoil-lltube,thenrepeat

steps4through6untiltheoillevelisattheFull

markonthedipstick.

•IftheoillevelabovetheFullmark,drainthe

excessoiluntiltheoillevelisattheFullmarkon

thedipstick;refertoChangingtheEngineOil

(page17).

Important:Iftheoillevelinthecrankcaseis

toolowortoohighandyouruntheengine,

youmaydamagetheengine.

7.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

7

Page 8

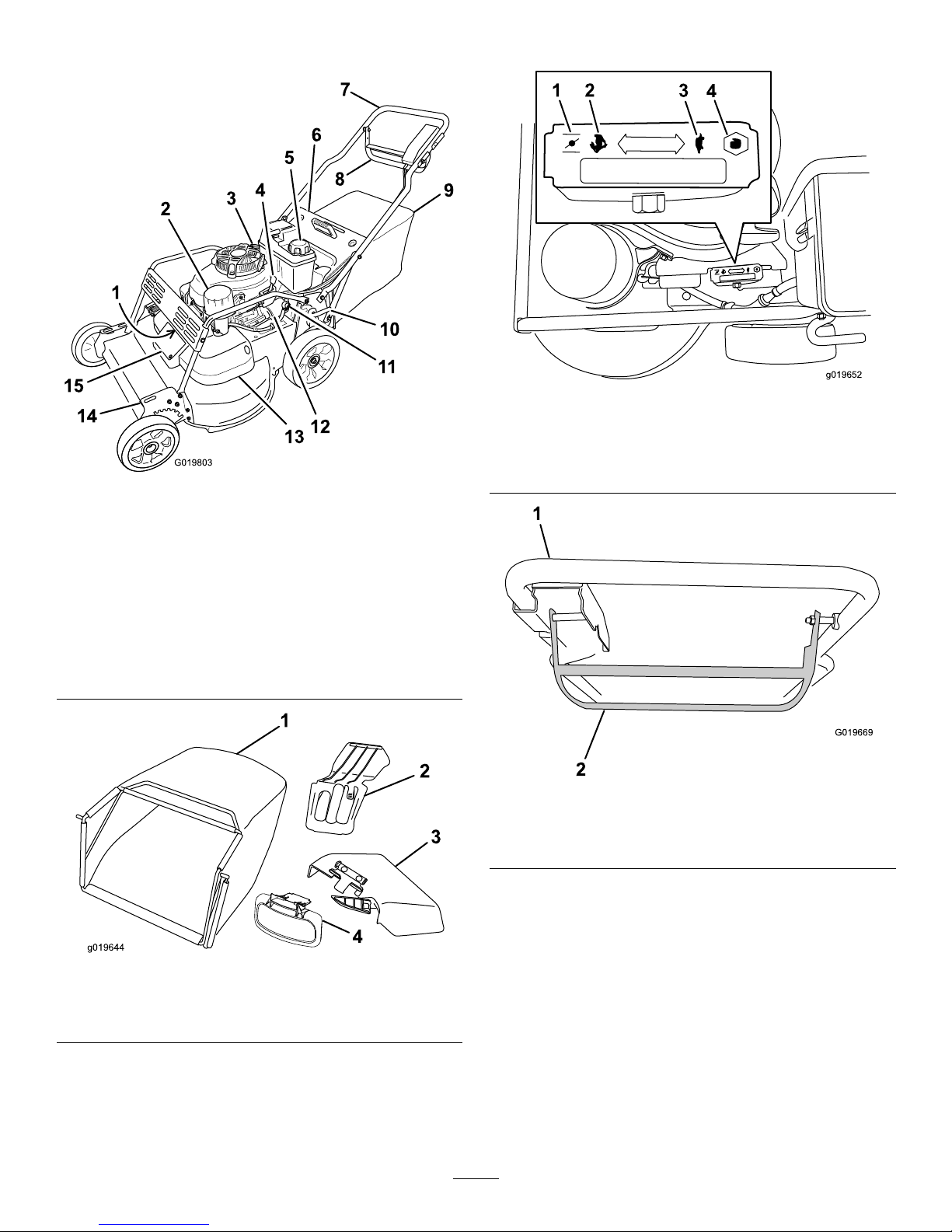

ProductOverview

1

2

3

4

5

6

7

8

9

10

11

12

13

14

G019803

Figure7

1.Sparkplug(underbrush

guard)

9.Grassbag

2.Airlter

10.Rearcutting-heightlever

3.Oilll/dipstick11.Fuelshut-offvalve

4.Throttlelever

12.Oillter

5.Fuel-tankcap13.Beltcover

6.Reardeector

14.Frontcutting-heightlever

7.Handle15.Belt-cover-accesspanel

8.Controlbar

g019644

1

2

3

4

Figure8

1.Grassbag3.Side-dischargechute

2.Rear-dischargeplug

4.Side-dischargedeector

Controls

g019652

1 2

3

4

Figure9

Throttle(Throttlelevernotshownforthesakeofclarity)

1.Choke3.Slow

2.Fast

4.Stop

1

2

G019669

Figure10

Controlbar

1.Handle

2.Controlbar

8

Page 9

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Eachtimebeforeyoumow,ensurethattheself-propeldrive

andthecontrolbaroperateproperly.Whenyoureleasethe

controlbar,thebladesandtheself-propeldriveshouldstop.

Iftheydonot,contactanAuthorizedServiceDealer.

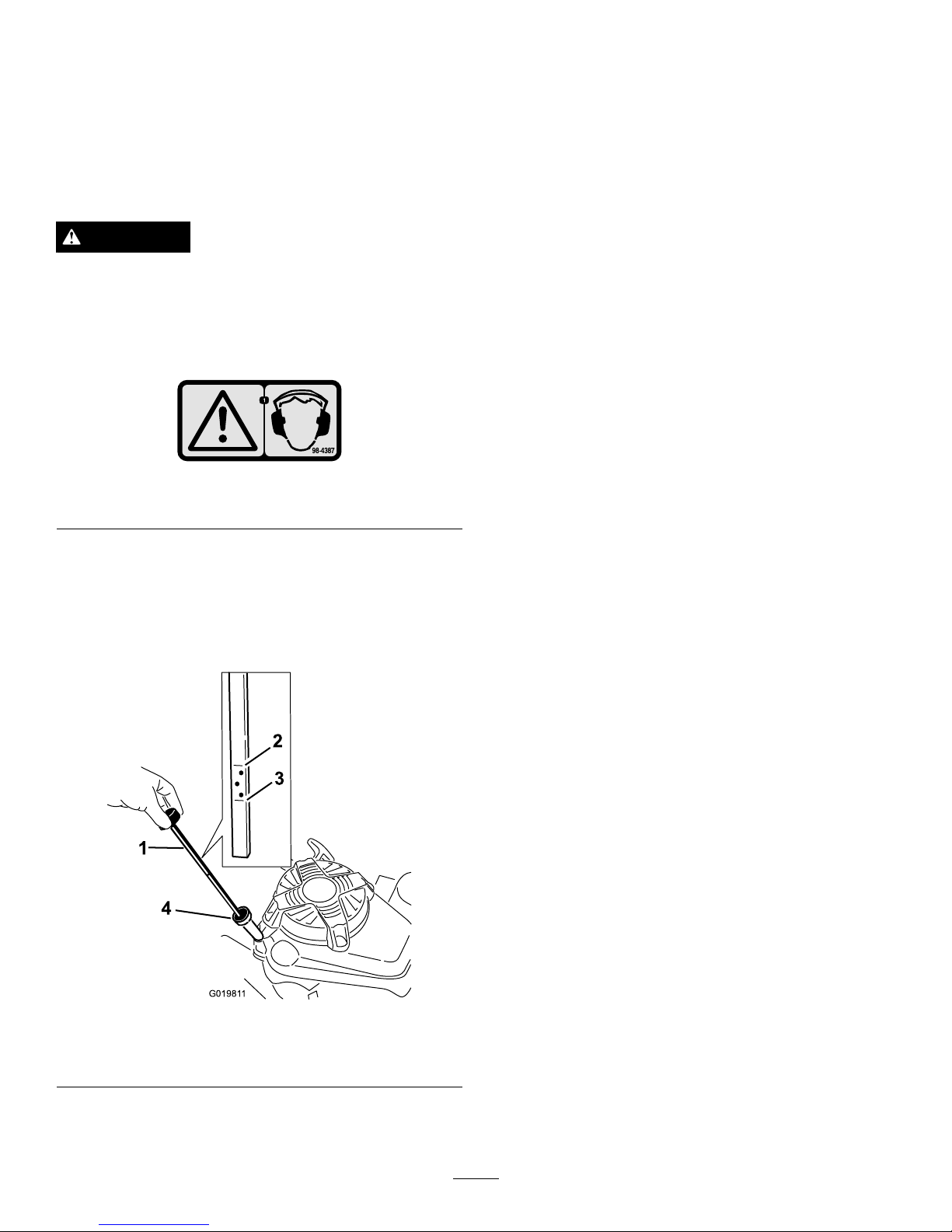

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure11

1.Warning—wearhearingprotection.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,ensurethattheoillevelisbetweentheAdd

andFullmarksonthedipstick(

Figure12).

G01981 1

4

Figure12

1.Dipstick3.Addmark

2.Fullmark

4.Oil-lltube

1.Movethemachinetoalevelsurface.

2.Cleanaroundthedipstick(Figure12).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,thenremoveit.

Note:Toensureanaccurateoillevelreading,install

thedipstickfully.

6.Readtheoillevelonthedipstick(Figure12).

•IftheoillevelisbelowtheAddmark,addasmall

amountofoilslowlytotheoil-lltube,thenrepeat

steps

4through6untiltheoillevelisattheFull

markonthedipstick.

•IftheoillevelabovetheFullmark,drainthe

excessoiluntiltheoillevelisattheFullmarkon

thedipstick;referto

ChangingtheEngineOil

(page17).

Important:Iftheoillevelinthecrankcaseis

toolowortoohighandyouruntheengine,

youmaydamagetheengine.

7.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

FillingtheFuelTankwith

Gasoline

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Important:Toreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithgasoline

lessthan30daysold;runthemachinedrybeforestoring

itformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,or

isopropanol.

9

Page 10

DANGER

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

directlyonthegroundbeforelling,notina

vehicleoronanobject.

•Fillthetankoutdoorswhentheengineiscold.

•Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

1.Cleanaroundthefuel-tankcap(Figure13).

g019643

1

Figure13

1.Fuel-tankcap

2.Removethecapfromthetank.

3.Fillthefueltankwithunleadedgasolinetowithin1/4

to1/2inch(6to13mm)fromthetopofthetank.Do

notllintothellerneck.

Important:Donotllthetankmorethan1/4

inch(6mm)fromthetopofthetankbecausethe

gasolinemusthaveroomtoexpand.

4.Installthefueltankcapandwipeupanyspilled

gasoline.

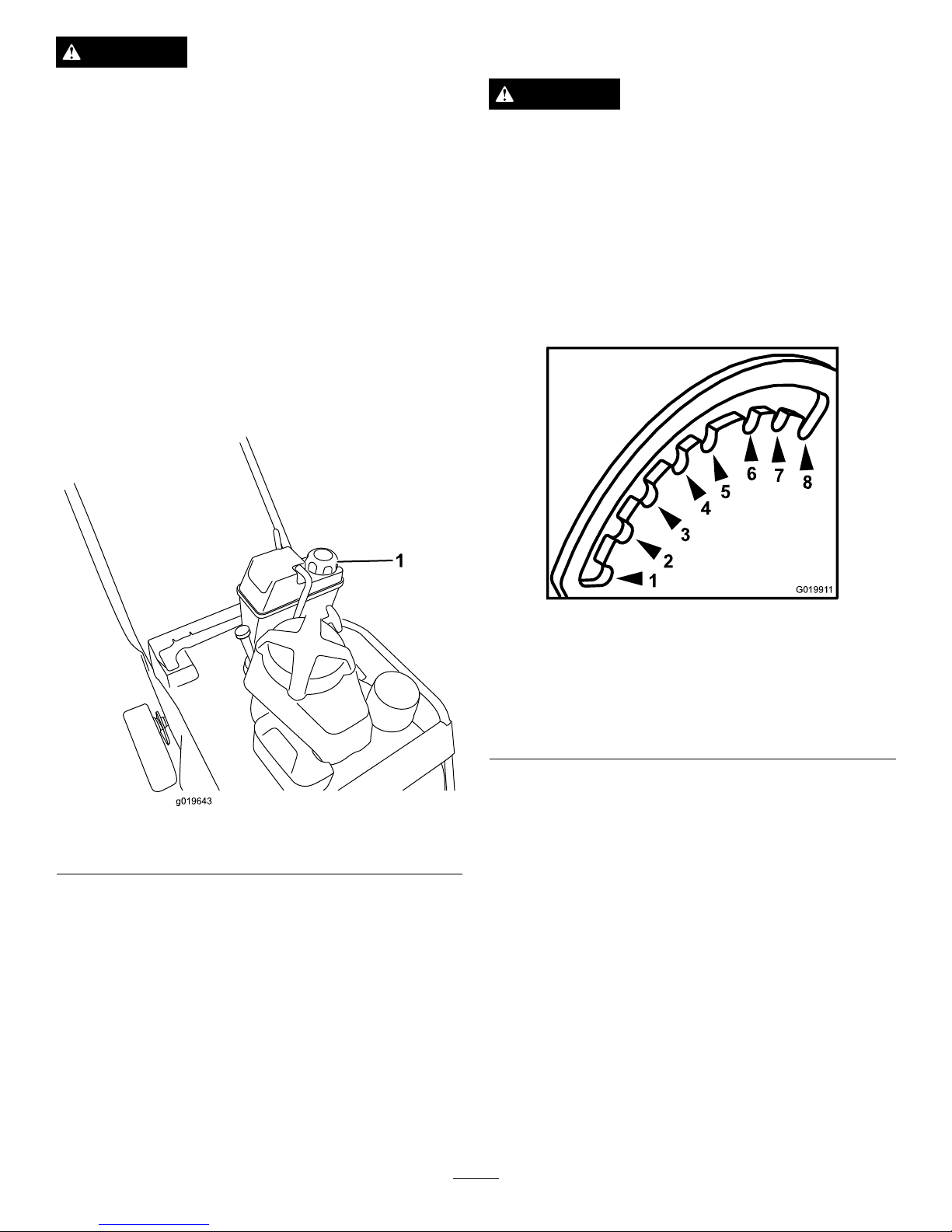

AdjustingtheCuttingHeight

DANGER

Adjustingthecuttingheightleverscouldbringyour

handsintocontactwithamovingbladeandresult

inseriousinjury.

•Stoptheengineandwaitforallmovementto

stopbeforeadjustingthecuttingheight.

•Donotputyourngersunderthehousingwhen

adjustingthecuttingheight.

Thecuttingheightsrangefrom1-1/2inches(38mm)to5

inches(127mm)in1/2-inch(13mm)increments.

1

2

4

6

7

8

3

5

G01991 1

Figure14

Viewfromfrontleft-handsideofthemachine

1.1-1/2in(38mm)5.3-1/2in(89mm)

2.2in(51mm)6.4in(102mm)

3.2-1/2in(64mm)7.4-1/2in(114mm)

4.3inch(76mm)8.5in(127mm)

Thecuttingheightiscontrolledwithafrontleverandarear

lever,bothontheleftsideofthemachine(Figure15and

Figure16).Toraiseorlowerthemachine,engagethelever,

raiseorlowerthemachine,andthendisengagethelever.

10

Page 11

g019653

1

Figure15

Frontcuttingheightlever

1.Squeezethelevertodisengageit.

g019645

Figure16

Rearcuttingheightlever

StartingtheEngine

1.Connectthewiretothesparkplug(Figure7).

2.Openthefuelshut-offvalve(Figure17).

Note:Whenthefuelshut-offvalveisopen,thelever

isparallelwiththefuelline.

g019650

1

g019651

1

Figure17

1.Fuelshut-offvalve

3.MovethethrottlecontroltotheChokeposition

(Figure9).

4.Pullthestarterhandlelightlyuntilyoufeelresistance,

thenpullitsharply.

5.MovethethrottlecontrollevertotheFastposition

whentheenginestarts(Figure8).

Note:Iftheenginefailstostartafter3pulls,repeat

steps3through5.

StoppingtheEngine

1.MovethethrottlecontroltotheOffpositionandwait

forallmovingpartstostop.

2.Closethefuelshut-offvalveanddisconnectthewire

fromthesparkplugifyoudonotusethemachineor

leaveitunattended.

OperatingtheSelf-propel

DriveandEngagingthe

CuttingBlades

•Tooperatetheself-propeldrivewithoutengagingthe

blades,raisethecontrolbartothehandle(Figure18).

11

Page 12

G019671

1

Figure18

1.Raisethecontrolbartothehandle.

•Tooperatetheself-propeldriveandengagetheblades,

slidethecontrolbarallthewaytotherightandraiseit

tothehandle(

Figure18).

G019672

2

1

Figure19

1.Slidethecontrolbartothe

right.

2.Raisethecontrolbarto

thehandle.

•Todisengagetheself-propeldriveandtheblades,release

thecontrolbar.

Note:Youcanvarythegroundspeedbyincreasingor

decreasingthedistancebetweenthecontrolbarandthe

handle.Lowerthecontrolbartoreducethespeedwhenyou

makeaturnorifthemachineismovingtoofast.Ifyoulower

thecontrolbartoofar,themachinestopsself-propelling.

Squeezethecontrolbarclosertothehandletoincreasethe

groundspeed.Whenyouholdthecontrolbartightagainst

thehandle,themachineself-propelsatthemaximumground

speed.

CheckingtheBlade-stop

SystemOperation

Beforeeachuse,checkthatthebladesstopwithin3seconds

ofreleasingthecontrolbar.

UsingtheGrassBag

ServiceInterval:Beforeeachuseordaily—Checkthe

blade-stopsystemoperation.Theblades

shouldstopwithin3secondsofreleasing

thecontrolbar;iftheydonot,contactan

AuthorizedServiceDealer.

Youcanusethegrassbagtochecktheblade-stopsystem.

1.Removetherear-dischargeplug.

2.Installtheemptygrassbagonthemachine.

3.Starttheengine.

4.Engagetheblades.

Note:Thebagshouldbegintoinate,indicatingthat

thebladesarerotating.

5.Whilewatchingthebag,releasethecontrolbar.

Note:Ifthebagdoesnotdeatewithin3secondsof

releasingthecontrolbar,theblade-stopsystemmaybe

deterioratingand,ifignored,couldresultinanunsafe

operatingcondition.Havethemachineinspectedand

servicedbyanAuthorizedServiceDealer.

6.Stoptheengineandwaitforallmovingpartstostop.

NotUsingtheGrassBag

1.Movethemachineontoapavedsurfaceinanon-windy

area.

2.Setall4wheelstothe3-1/2inch(89mm)cutting

heightsetting.

3.Takeahalfsheetofnewspaperandcrumpleitintoa

ballsmallenoughtogounderthemachine(about3

inchesor75mmindiameter).

4.Placethenewspaperballabout5inches(13cm)in

frontofthemachine.

5.Starttheengine.

6.Engagetheblades.

7.Releasethecontrolbarandbegincountingout3

seconds.

8.Onthecountof3,pushthemachinequicklyforward

overthenewspaper.

9.Stoptheengineandwaitforallmovingpartstostop.

10.Gotothefrontofthemachineandcheckthe

newspaperball.

Note:Ifthenewspaperballdidnotgounderthe

machine,repeatsteps

4through10.

Important:Ifthenewspaperisunravelledor

shredded,thebladesdidnotstopproperly,which

couldresultinanunsafeoperatingcondition.

ContactanAuthorizedServiceDealer.

RecyclingtheClippings

Thismachinecomesfromthefactoryreadytorecyclegrass

andleafclippingsbackintothelawn.T opreparethemachine

torecycle:

12

Page 13

•Iftheside-dischargechuteisonthemachine,removeit

andinstalltheside-dischargedeector;refertoRemoving

theSide-dischargeChute(page14).

•Ifthegrassbagisonthemachine,removeit;referto

RemovingtheGrassBag(page14).

•Iftherear-dischargeplugisnotinstalled,gripitbythe

handle,raisethereardeector,andinsertitintothe

rear-dischargechuteuntilthelatchlocksintoplace;refer

toFigure20.

G019812

Figure20

1.Rear-dischargeplug

2.Reardeector

WARNING

Ensurethattherear-dischargeplugisinplace

beforeyourecycletheclippings.Neverengagethe

bladeswithouteithertherear-dischargeplugorthe

grassbaginstalled.

BaggingtheClippings

Usethegrassbagwhenyouwanttocollectgrassandleaf

clippingsfromthelawn.

WARNING

Aworngrassbagcouldallowsmallstonesandother

similardebristobethrowntowardtheoperatoror

bystandersandresultinseriouspersonalinjuryor

death.

Checkthegrassbagfrequently.Ifitisdamaged,

installanewTororeplacementbag.

Iftheside-dischargechuteisonthemachine,removeit

andinstalltheside-dischargedeectorbeforebaggingthe

clippings;refertoRemovingtheSide-dischargeChute(page

14).

WARNING

Thebladesaresharp;contactingthebladescan

resultinseriouspersonalinjury.

Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

InstallingtheGrassBag

1.Raiseandholdupthereardeector(Figure21).

1

G019798

2

Figure21

1.Bagrod

2.Reardeector

2.Removetherear-dischargeplugbypullingdownonthe

latchwithyourthumbandpullingtheplugoutfrom

themachine(

Figure20).

3.Installthebagrodintothenotchesatthebaseofthe

handle,androckthebagbackandforthtoensurethat

13

Page 14

therodisseatedatthebottomofbothnotches;refer

toFigure21.

4.Lowerthereardeectoruntilitrestsonthegrassbag.

MowingwiththeGrassBag

WARNING

Aworngrassbagcouldallowsmallstonesand

othersimilardebristobethrownintheoperator’sor

bystander’sdirectionandresultinseriouspersonal

injuryordeathtotheoperatororbystanders.

Checkthegrassbagfrequently.Ifitisdamaged,

installanewTororeplacementbag.

RemovingtheGrassBag

Toremovethebag,reversethestepsinInstallingtheGrass

Bagabove.

DANGER

Themachinecanthrowgrassclippingsand

otherobjectsthroughanopendischargetunnel.

Objectsthrownwithenoughforcecouldcause

seriouspersonalinjuryordeathtotheoperatoror

bystander.

Neveropenthedooronthedischargetunnelwhen

theengineisrunning.

Side-dischargingtheClippings

Usethesidedischargeforcuttingverytallgrass.

WARNING

Thebladesaresharp;contactingthebladescan

resultinseriouspersonalinjury.

Stoptheengineandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

DANGER

Anuncovereddischargeopeningwillallowobjects

tobethrowninthedirectionoftheoperatoror

bystanders.Also,contactwiththebladescould

occur.Thrownobjectsorbladecontactcancause

seriousinjuryordeath.

Neveroperatethemachinewithoutthe

side-dischargedeectororside-dischargechutein

placeandworkingproperly.

InstallingtheSide-dischargeChute

Important:Ensurethattherear-dischargeplugisin

placebeforeyourecycletheclippings.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Removethegrassbagifitisinstalledonthemachine;

referto

RemovingtheGrassBag(page14).

3.Inserttherear-dischargeplug;refertoRecyclingthe

Clippings(page12).

4.Removetheside-dischargedeectorbypullingup

onthespringthatholdsthedeectorinplaceand

removingthedeector(Figure22).

G019649

1

2

3

Figure22

1.Topoftheside-discharge

deector

3.Side-dischargedeector

2.Spring

5.Installtheside-dischargechute(Figure23)bypulling

uponthespring,placingthechuteovertheopening,

andloweringthespringoverthetabsontopofthe

dischargechute.

g019647

1

Figure23

1.Side-dischargechute

RemovingtheSide-dischargeChute

Toremovetheside-dischargechute,reversethestepsin

InstallingtheSide-dischargeChute.

14

Page 15

OperatingTips

GeneralTips

•Reviewthesafetyinstructionsandreadthismanual

carefullybeforeoperatingthemachine.

•Cleartheareaofsticks,stones,wire,branches,andother

debristhatthebladescouldhitandthrow .

•Keepeveryone,especiallychildrenandpets,awayfrom

theareaofoperation.

•Avoidstrikingtrees,walls,curbs,orothersolidobjects.

Neverdeliberatelymowoveranyobject.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelystoptheengine,disconnectthewirefrom

thesparkplug,andexaminethemachinefordamage.

•Maintainsharpbladesthroughoutthecuttingseason.

Periodicallyledownnicksontheblades.

•ReplacethebladeswhennecessarywithoriginalToro

replacementblades.

•Mowonlydrygrassorleaves.Wetgrassandleavestend

toclumpontheyardandcancausethemachinetoplug

ortheenginetostall.

WARNING

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblades.

Mowonlyindryconditions.

•Cleantheundersideofthemachinedeckaftereach

mowing.RefertoCleaningundertheMachineHousing

(page24).

•Keeptheengineingoodrunningcondition.

•Settheenginespeedtothefastestpositionforthebest

cuttingresults.

WARNING

Operatingamachinewithitsenginerunning

ataspeedgreaterthanthefactorysettingcan

causethemachinetothrowapartofabladeor

engineintotheoperator’sorbystander’sarea

andresultinseriouspersonalinjuryordeath.

–Donotchangetheenginespeedsetting.

–Ifyoususpecttheenginespeedisfaster

thannormal,contactanAuthorizedService

Dealer.

•Cleantheairlterfrequently.Mulchingstirsupmore

clippingsanddustwhichclogstheairlterandreduces

engineperformance.

CuttingGrass

•Grassgrowsatdifferentratesatdifferenttimesofthe

year.Inthesummerheat,itisbesttocutgrassatthe

2-inch(51mm),2-1/2-inch(64mm),or3-inch(83mm)

cuttingheightsettings.Cutonlyaboutathirdofthegrass

bladeatatime.Donotcutbelowthe2-inch(51mm)

settingunlessthegrassissparseoritislatefallwhen

grassgrowthbeginstoslowdown.

•Whencuttinggrassover6inches(15cm)tall,rstmow

atthehighestcuttingheightsettingandwalkslower;then

mowagainatalowersettingforthebestlawnappearance.

Ifthegrassistoolongandtheleavesclumpontopofthe

lawn,themachinemayplugandcausetheenginetostall.

•Alternatethemowingdirection.Thishelpsdispersethe

clippingsoverthelawnforevenfertilization.

Ifthenishedlawnappearanceisunsatisfactory,tryoneor

moreofthefollowing:

•Sharpentheblades.

•Walkataslowerpacewhilemowing.

•Raisethecuttingheightonyourmachine.

•Cutthegrassmorefrequently.

•Overlapcuttingswathsinsteadofcuttingafullswath

witheachpass.

•Setthecuttingheightonthefrontwheelsanotchlower

thantherearwheels.Forexample,setthefrontwheels

at2inches(51mm)andtherearwheelsat2-1/2inches

(64mm).

CuttingLeaves

•Aftercuttingthelawn,ensurethathalfofthelawnshows

throughthecutleafcover.Y oumayneedtomakemore

thanonepassovertheleaves.

•Forlightleafcoverage,setallthewheelsatthesame

cuttingheightsetting.

•Iftherearemorethan5inches(12.7cm)ofleavesonthe

lawn,setthefrontcuttingheight1or2notcheshigher

thantherearcuttingheight.Thismakesiteasiertofeed

theleavesunderthemachinedeck.

•Slowdownyourmowingspeedifthemachinedoesnot

cuttheleavesnelyenough.

15

Page 16

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst5hours

•Changetheengineoilwithouttheoillter.

•Servicetheblade-drivesystem.

Beforeeachuseordaily

•Checktheengineoillevel.

•Checktheblade-stopsystemoperation.Thebladesshouldstopwithin3secondsof

releasingthecontrolbar;iftheydonot,contactanAuthorizedServiceDealer.

•Inspecttheairlter.

•Checkthecuttingbladesandservicethem,ifnecessary.

•Inspecttheblades.

•Cleanunderthemachinehousing.

Every25hours

•Cleanthefoampre-cleaner(morefrequentlyindustyconditions).

Every50hours

•Changetheengineoil(moreoftenindustyconditions).

•Checktheconditionofthebelts.

•Checkthefuelhoseandreplaceitifnecessary.

•Removedebrisfromunderthebeltcover.

•Servicetheblade-drivesystem.

Every100hours

•Changetheoillter.

•Checkthesparkplug.

•Cleanthefueltanklter.

•Changethefuellter.

Every250hours

•Changetheblade-brake-clutchbelt.

Every300hours

•Replacethepaperairlter(morefrequentlyindustyconditions).

Yearlyorbeforestorage

•Emptythefueltankbeforerepairsasdirectororbeforestorage.

Important:RefertoyourEngineOperator’sManualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethewireonthesparkplug,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatitdoes

notaccidentlycontactthesparkplug.

ServicingtheAirFilter

ServiceInterval:Beforeeachuseordaily

Every25hours—Cleanthefoampre-cleaner(more

frequentlyindustyconditions).

Every300hours—Replacethepaperairlter(more

frequentlyindustyconditions).

Important:Donotoperatetheenginewithouttheair

lterassembly;extremeenginedamagewilloccur.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethecoverandcleanitthoroughly(

Figure24).

16

Page 17

Figure24

1.Cover3.Air-lterbase

2.Foampre-lterandpaper

lter

4.Removethefoampre-lterandpaperlter(Figure24).

5.Removethefoampre-lterfromthepaperlter(Figure

24),andreplacethepaperlterifitisexcessivelydirty.

Important:Donottrytocleanapaperlter.

6.Washthefoampre-cleanerwithamilddetergentand

water,thenblotitdry.

Note:Donotaddoiltothefoampre-cleaner.

7.Installthefoampre-cleanerontothepaperlter.

8.Installtheair-lterassembly.

9.Installthecover.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changetheengine

oilwithouttheoillter.

Every50hours—Changetheengineoil(moreoften

industyconditions).

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

WARNING

Oilmaybehotafterenginehasbeenrun,and

contactwithhotoilcancauseseverepersonal

injury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Placeasuitabledrainpanundertherightsideofthe

machine.

5.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

6.Tipthemachine,withtheairlterup,todraintheoil

intothedrainpan(

Figure24).

G019648

Figure25

Note:Youcanalsoremovetheoilfromthecrankcase

usinganoilextractor.

7.Returnthemachinetotheoperatingposition.

8.Insertthedipstickintothellerneckandrotatethecap

clockwiseuntilitistight.

9.Recycletheusedoilaccordingtolocalcodes.

10.FillthecrankcasetotheFulllineonthedipstickwith

freshoil.Referto

3FillingtheCrankcasewithOil

(page7).

11.Wipeupanyspilledoil.

17

Page 18

ChangingtheOilFilter

ServiceInterval:Every100hours

1.Runtheenginetowarmtheoil.

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug.

4.Draintheengineoil;referto

ChangingtheEngineOil

(page17).

5.Placearagundertheoilltertocatchanyoilthatmay

leakoutasyouremovethelter.

6.Removetheoillter(

Figure26).

g019650

1

Figure26

1.Oillter

7.Useyourngertocoatthegasketonthenewlter

withoil(Figure27).

Figure27

1.Gasket

8.Installthenewlteruntilthegasketcontactsthelter

base,thenhandtightenthelteranadditional2/3turn.

9.FillthecrankcasetotheFulllineonthedipstickwith

freshoil;referto3FillingtheCrankcasewithOil(page

7).

10.Connectthewiretothesparkplug.

11.Runtheengineforabout3minutes.

12.Stoptheengine,waitforallmovingpartstostop,and

checkforoilleakagearoundthelter.

13.Addoiltocompensatefortheoilintheoillter;refer

to

CheckingtheEngineOilLevel(page9)

14.Recycletheusedoillteraccordingtolocalcodes.

ServicingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Cleanaroundthesparkplug.

4.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,ordirty

sparkplug.Donotcleantheelectrodesbecause

gritenteringthecylindercandamagetheengine.

5.Setthegapontheplugto0.030in.(0.76mm);refer

toFigure28.

Figure28

1.Center-electrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

6.Installthesparkplugandthegasketseal.

7.Torquetheplugto17ft-lb(23N-m).

8.Connectthewiretothesparkplug.

CheckingtheConditionofthe

Belts

ServiceInterval:Every50hours

1.Stoptheengineandwaitforallmovingpartstostop.

18

Page 19

2.Removethebeltcover(Figure7)byremovingthe4

boltsthatholdittothemachinehousing.

3.Checkthebeltsforanycracks,frayededges,burn

marks,oranyotherdamage.

4.Replacealldamagedbelts.

5.Ifyoureplacetheblade-drivebelt,youmustadjustit.

Referto

ServicingtheBlade-driveSystem(page19).

6.Installthebeltcoverwiththe4boltsthatyouremoved

instep2.

EmptyingtheFuelTankand

CleaningtheFilter

ServiceInterval:Every50hours—Checkthefuelhoseand

replaceitifnecessary.

Every100hours—Cleanthefueltanklter.

Yearlyorbeforestorage—Emptythefueltankbefore

repairsasdirectororbeforestorage.

Note:Thefueltanklter(screen)elementislocatedinside

thefueltankattheoutlet.Thislterisapartofthefueltank

andcannotberemoved.

1.Stoptheengineandwaitforittocooldown.

Important:Draingasolinefromacoldengine

only.

2.Disconnectthewirefromthesparkplug.

3.Closethefuelshut-offvalve.

4.Disconnectthefuellinebylooseningthetubeclampat

thecarburetor.

5.Openthefuelshut-offvalveanddrainthegasoline

completelyfromthetankandfuellineintoanapproved

fuelcontainer.

6.Removethefueltankfromthemachine.

7.Pourasmallamountoffuelinthefueltank,move

thefuelaroundinthetank,andpouritoutintoan

approvedfuelcontainer.

8.Installthefueltankandthefuelline.

ChangingtheFuelFilter

ServiceInterval:Every100hours

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Closethefuelshut-offvalve(Figure29).

g019650

1

g019924

1

2

Figure29

1.Fuellter2.Fuelshut-offvalve

4.Removethefuellter(Figure29)fromthefuellineby

looseningthetubeclampssurroundingthefuellter.

5.Installanewfuellterinthefuellineusingthetube

clampsthatyouremovedinstep4.

ServicingtheBlade-drive

System

ServiceInterval:Aftertherst5hours

Every50hours—Removedebrisfromunderthebelt

cover.

Every50hours—Servicetheblade-drivesystem.

1.Loosenthe2screwsonthebelt-cover-accesspaneland

removethepanel(

Figure30).

g019641

1

2

3

4

5

6

7

8

Figure30

1.Belt-tensionspring5.Blade-drivebelt

2.Adjustingbolt6.Wall

3.Gap

7.Beltcover

4.Adjustingnut8.Belt-cover-accesspanel

19

Page 20

2.Brushorblowoutdebrisfromtheinsideofthebelt

coverandaroundalltheparts.

3.Holdafeelergaugesetbetween0.005and0.03inches

(0.13and0.76mm)againstthewallandslideitdown

behindthebelttensionspring;refertoFigure31.

Figure31

Note:Ifthereisavisiblegapbetweenthegaugeand

thespring,tightentheadjustingboltandthenutuntil

thefeelergaugebarelyslidesfreelyinandoutofthe

gap(Figure30).

Important:Donotovertightentheadjustingbolt.

Thiscoulddamagetheblade-drivebelt.

4.Installthebelt-cover-accesspanel.

ServicingtheCuttingBlades

ServiceInterval:Beforeeachuseordaily

Important:

Y ou will need a torque wr ench to install the

blades pr oper l y .

Ifyoudonothaveatorquewrenchor

areuncomfortableperformingthisprocedure,contact

anAuthorizedServiceDealer.

Examinethebladesforsharpnessandanywearordamage

wheneveryourunoutofgasoline;refertoInspectingthe

Blades(page20)

.Ifthebladeedgeisdullornicked,haveit

sharpenedorreplaceit.Ifthebladesareworn,bent,damaged

orcracked,replacethemimmediatelywithagenuineToro

replacementblades.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrowntowardtheoperator

orabystander,resultinginseriouspersonalinjury

ordeath.

•Inspectthebladesperiodicallyforwearor

damage.

•Replacewornordamagedblades.

Note:Maintainsharpbladesthroughoutthecuttingseason,

becausesharpbladescutcleanlywithouttearingorshredding

thegrassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.

PreparingtoServicetheCuttingBlades

Tipthemachineontoitsside,withtheairlterupintheair,

untiltheupperhandlerestsontheground.

WARNING

Thebladesaresharp;contactingabladecould

resultinseriouspersonalinjury.

•Disconnectthewirefromthesparkplug .

•Weargloveswhenservicingtheblades.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(

Figure32).Iftheedgesare

notsharporhavenicks,removethebladesandhave

themsharpenedorreplacethem.

g017223

Figure32

1.Curvedarea3.Wear/slotforming

2.Cuttingedge4.Crack

2.Inspectthebladesthemselves,especiallythecurved

area(Figure42).Ifyounoticeanydamage,wear,or

aslotforminginthisarea(Figure32),immediately

replacethemwithnewblades.

DANGER

Ifyouallowabladetowear,aslotwillform

betweenthesailandatpartoftheblade.

Eventuallyapieceoftheblademaybreak

offandbethrownfromunderthehousing,

possiblyresultinginseriousinjurytoyouor

bystanders.

•Inspectthebladesperiodicallyforwearor

damage.

•Nevertrytostraightenabladethatisbent

orweldabrokenorcrackedblade.

•Checkforbentblades;referto

Checking

forBentBlades(page20).

CheckingforBentBlades

1.Rotatethebladesuntiltheyarepositionedasshown

inFigure33.

20

Page 21

B

B

2

1

3

g016532

Figure33

1.Frontofcuttingdeck3.Measureformthecutting

edgetoasmooth,level

suface

2.MeasureatlocationsA

andB

2.Measurefromalevelsurfacetothecuttingedges

atlocationsAandB,(Figure33),andrecordboth

dimensions.

3.Rotatethebladessothattheiroppositeendsareat

locationsAandB.

4.Repeatthemeasurementsinstep2andrecordthem.

Note:IfthedifferencebetweenthedimensionsAand

Bobtainedinsteps2and4exceeds1/8inch,replace

theblades;refertoRemovingtheBlades(page21)and

InstallingtheBlades(page21).

WARNING

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplaceabentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofablade.

RemovingtheBlades

Replacethebladeswhentheystrikeasolidobject,areoutof

balance,bent,orworn.UseonlygenuineT ororeplacement

blades.

1.Useablockofwoodtoholdeachbladesteadyandturn

thebladeboltcounterclockwiseasshownin

Figure34.

Figure34

2.RemoveeachbladeasshowninFigure35.

G016530

1

2

3

4

Figure35

1.Spindle(2)3.Blade(2)

2.Bladedriver(2)4.Bladebolt(2)

3.Inspectthepinsonthebladedriversforwearand

damage.

InstallingtheBlades

1.Installtherstbladesothatitishorizontal,alongwith

allmountinghardwareasshowninFigure35.

Note:Tightentheboltwithyourngers.

Important:Positionthecurvedendsoftheblades

topointtowardthemachinehousing.Besureto

nesttheraisedareasoneachbladedriverwiththe

recessesintheheadofitscorrespondingspindle,

andthepinsontheothersideofeachbladedriver

withtheholesinitscorrespondingblade.

21

Page 22

2.Steadyeachbladewithaboardandturnthebladebolt

clockwisewithatorquewrenchasshowninFigure36;

torqueeachbladeboltto60ft-lb(82N-m).

g016537

Figure36

Important:Abolttorquedto60ft-lb(82N-m)is

verytight.Putyourweightbehindthewrenchand

tightentheboltsecurely.Thisboltisverydifcult

toovertighten.

3.Rotatetheinstalledblade1/4turnuntilitisvertical,

andinstalltheotherbladeinthesamemannerasthe

rst(refertostep1).

Note:Thebladesshouldbeperpendicular,forming

aninverted“T”asshowninFigure37.

1

G016536

Figure37

1.Blade(2)

4.Tightenthesecondblade;refertostep2.

5.Rotatethebladesbyhandafull360°turntoensure

thattheydonottouch.

Note:Ifthebladestoucheachother,theyarenot

mountedcorrectly.Repeatsteps1through3untilthe

bladesnolongertoucheachother.

WARNING

Incorrectlyinstallingthebladescoulddamage

themachineorcauseaninjurytotheoperator

ortobystanders.

Changingthe

Blade-Brake-Clutch(BBC)

Belt

ServiceInterval:Every250hours

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethe4boltsthatholdthebeltcovertothe

machinehousing.

Note:Savetheboltsforinstallingthebeltcoverto

themachinehousing.

4.Removethebeltcover.

5.Removeanydebrisfromunderthebeltcover.

6.RemovetheBBCbeltguard(Figure38).

Note:Savethemountinghardwareforinstallingthe

BBCbeltguardlater.

G019899

1

2

Figure38

1.BBCbelt2.BBCbeltguard

7.RemovetheBBCbeltfromthebrake-drumpulley.

8.Movethetabforward(Figure39).

Note:Thetabpreventsthetransmissionfromtipping

tothepointwherethetransmissionbeltcomesoff.

22

Page 23

G019898

1

2

3

4

5

Figure39

1.Transmissiontension

spring

4.Transmissionbelt

2.Transmission5.Tab

3.BBCbelt

9.Removethetransmissiontensionspring.

10.Removethetransmissionbeltfromthetransmission

pulley.

11.RemovetheBBCbelt.

Note:Holdoneofthebladesusingagloveorarag

andturnthebladespindletohelpremovetheBBCbelt.

12.ToinstallanewBBCbelt,reversethestepsabove.

13.AdjusttheBBCcable;refertoAdjustingtheBBCcable

in

AdjustingtheBlade-brakeCable(page23).

AdjustingtheSelf-propel

Cable

Ifthemachinedoesnotself-propelortendstocreepforward

whenyoureleasethecontrolbar,adjustthedrivecable.

1.Stopandwaitforallmovingpartstostop.

2.Loosenthecable-supportnut(Figure40).

G019876

1

Figure40

1.Cable-supportnut

3.Slidethecable-supportnuttowardthemachineto

increasetheself-propelaction;slidethecable-support

nutawayfromthemachinetodecreasetheself-propel

action.

4.Tightenthecable-supportnut.

5.Checktheoperationforthedesireddrivecontrol,and

repeatthestepsabove,ifnecessary.

Note:Ifthemachinecreepsforwardwithoutthe

controlbarengagedorifthewheelsspinwhenyou

lifttherearwheelsofftheground,thecableistoo

tight;loosenthecable-supportnut,pullthecablejacket

upward(awayfromthemachine)slightly,andtighten

thecable-supportnut.

Note:Youmayalsoadjustthemaximumground

speed(whenthecontrolbarisfullyengaged)asdesired.

AdjustingtheBlade-brake

Cable

Adjusttheblade-brakecablewheneveryouinstallanewcable

orreplacetheBBCbelt.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethebeltcover(Figure7)byremovingthe4

boltsthatholdittothemachinehousing.

Note:Savetheboltsforinstallingthebeltcoverto

themachinehousing.

4.Removeanydebrisfromunderthebeltcover.

5.Loosenthecable-clampscrew(Figure41).

1

2

G019923

Figure41

1.Cable-clampscrew

2.Blade-brakecable

6.Pullthecablejacketuntilthereisapproximately1/8

inch(3mm)ofslack.

Note:Donotputtensiononthespring.

23

Page 24

7.Tightenthecable-clampscrewtolocktheadjustment

inplace.

8.Installthebeltcoverwiththe4boltsthatyouremoved

instep3.

9.Connectthewiretothesparkplug.

10.Checktheoperationoftheblade-brakeclutch;referto

CheckingtheBlade-stopSystemOperation(page12).

ChangingtheBlade-driveBelt

Changetheblade-drivebeltasneeded.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug.

3.Removethebeltcover(Figure7)byremovingthe4

boltsthatholdittothemachinehousing.

Note:Savetheboltsforinstallingthebeltcoverto

themachinehousing.

4.Removeanydebrisfromunderthebeltcover.

5.RemovetheBBCbeltguardandthemounting

hardware.

Note:SavetheBBCbeltguardandhardwarefor

installationlater.

G019899

1

2

Figure42

1.BBCbelt2.BBCbeltguard

6.RemovetheBBCbeltfromthefrontleft-handpulley.

7.Loosentheadjustingbolt(Figure30).

8.Removethexedidlerpulleyandthehardware(Figure

43).

Note:Savetheidlerpulleyandhardwarefor

installationlater.

G019922

Figure43

TheBBCidlerpulleyisremovedforclarity

1.Holeinthehousing3.Fixed-idlerpulley

2.Right-handsprockethole

4.Left-handsprockethole

9.Removetheblade-drivebelt.

10.Aligntheholesintheright-handandleft-hand

sprocketswiththeholesinthehousingasshownin

Figure43.

Note:Holdthesprocketsinplacewitharodora

screwdriver.

11.Whenyouhavelockedthesprocketsinplace,install

theblade-drivebeltandthexedidlerpulley.

Note:Ensurethattheteethareengagedinthe

sprockets.

12.Tightenthebelttensiontotherecommendedsettings;

refertoServicingtheBlade-driveSystem(page19).

13.Removetherodorscrewdriverfromthesprockets.

14.Ensurethatthebladesunderthehousingareproperly

aligned;referto

ServicingtheCuttingBlades(page20).

15.InstalltheBBCbeltandtheBBCbeltguardand

hardware.

16.Installthebeltcoverusingthe4boltsthatyouremoved

instep3.

17.Connectthewiretothesparkplug.

18.Checktheoperationofthecontrolbarandthe

blade-brakeclutch.

CleaningundertheMachine

Housing

Foroptimalcuttingperformance,keeptheundersideofthe

machinehousingclean.Youmayeitherwashorscapethe

clippingsawayfromunderthemachinehousing.

24

Page 25

WashingundertheMachineHousing

ServiceInterval:Beforeeachuseordaily—Cleanunderthe

machinehousing.

1.Positionthemachineonaatconcreteorasphalt

surfacenearagardenhose.

2.Starttheengine.

3.Holdtherunninggardenhoseathandlelevelanddirect

thewatertoowonthegroundjustinfrontofthe

rightreartire(

Figure44).

Figure44

1.Rightrearwheel

Note:Thebladeswilldrawinwaterandwashout

clippings.Letthewaterrununtilyounolongersee

clippingsbeingwashedoutfromunderthehousing.

4.Stoptheengineandwaitforallmovingpartstostop.

5.Turnoffthewater.

6.Startthemachineandletitrunforafewminutestodry

outthemoistureonthemachineanditscomponents.

ScrapingundertheMachineHousing

Ifwashingdoesnotremovealldebrisfromunderthe

machine,scrapeitclean.

1.Disconnectthewirefromthesparkplug.

2.Drainthefuelfromthefueltank;referto

Emptying

theFuelTankandCleaningtheFilter(page19).

WARNING

Tippingthemachinemaycausethefuelto

leakfromthecarburetororthefueltank.

Gasolineisextremelyammable,highly

explosive,and,undercertainconditions,can

causepersonalinjuryorpropertydamage.

Avoidfuelspillsbyrunningtheenginedryor

byremovingthegasolinewithahandpump;

neversiphon.

3.Tipthemachineontoitsside,withtheairlterupin

theair,untiltheupperhandlerestsontheground.

4.Removethedirtandgrassclippingswithahardwood

scraper;avoidburrsandsharpedges.

5.Turnthemachineupright.

6.Fillthefueltank.

7.Connectthewiretothesparkplug.

Storage

Storethemachineinacool,clean,dryplace.Coverthe

machinetokeepitcleanandprotected.

GeneralInformation

Storethemachineinacool,clean,dryplace.Coverthe

machinetokeepitcleanandprotected.

1.Performtherecommendedannualmaintenance

procedures;refertoMaintenance(page16).

2.Cleanunderthemachinehousing;refertoCleaning

undertheMachineHousing(page24).

3.Removechaff,dirt,andgrimefromtheexternalparts

oftheengine,theshrouding,andthetopofthe

machine.

4.Checktheconditionoftheblades;referto

Inspecting

theBlades(page20).

5.Servicetheairlter;refertoServicingtheAirFilter

(page16).

6.Tightenallnuts,bolts,andscrews.

7.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

PreparingtheFuelSystem

WARNING

Gasolinecanvaporizeifyoustoreitoverlong

periodsoftimeandexplodeifitcomesintocontact

withanopename.

•Donotstoregasolineoverlongperiodsoftime.

•Donotstorethemachinewithgasolineinthe

fueltankorthecarburetorinanenclosurewith

anopename.(Forexample,afurnaceora

waterheaterpilotlight.)

•Allowtheenginetocoolbeforestoringitinany

enclosure.

Onthelastrefuelingoftheyear,addfuelstabilizertothefuel

asdirectedbytheenginemanufacturer.Emptythefueltank

whenmowingthelasttimebeforestoringthemachine.

1.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

2.Starttheengineagain.

3.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

PreparingtheEngine

1.Whiletheengineisstillwarm,changetheengineoil

andtheoillter;refertoChangingtheEngineOil

(page17)andChangingtheOilFilter(page18).

25

Page 26

2.Removethesparkplug.

3.Usinganoilcan,addabout1oz.(30ml),ofmotoroil

totheenginethroughthespark-plughole.

4.Slowlypullthestarterropeseveraltimestodistribute

oilthroughoutthecylinder.

5.Installthesparkplugbutdonotconnectthewireto

thesparkplug.Securethewiresothatitdoesnotcome

intocontactwiththesparkplug.

RemovingtheMachinefrom

Storage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

usingthestartertoblowexcessoilfromthecylinder.

3.Inspectthesparkplugandreplaceitifitisdirty,worn,

orcracked;refertotheEngineOperator’sManual.

4.Installthesparkplugandtightenittotherecommended

torqueof180in-lb(20N-m).

5.Performanyneededmaintenanceprocedures;referto

Maintenance(page16).

6.Checktheengineoillevel;referto

CheckingtheEngine

OilLevel(page9).

7.Fillthefueltankwithfreshgasoline;referto(page).

8.Connectthewiretothesparkplug.

26

Page 27

Troubleshooting

Problem

PossibleCauseCorrectiveAction

1.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

1.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer.

2.Thefuelshut-offvalveisclosed.2.Openthefuelshut-offvalve.

3.Thethrottleleverisnotinthecorrect

position.

3.MovethethrottlelevertotheChoke

position.

4.Thereisdirt,water,orstalefuelinthe

fuelsystem.

4.ContactanAuthorizedServiceDealer.

5.Thewireisnotconnectedtothespark

plug.

5.Connectthewiretothesparkplug.

6.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

Theenginedoesnotstart.

7.Thereisdirtinthefuellter.7.Replacethefuellterandcleanthe

in-tanklterscreen.

1.Theairlterelementisdirtyandis

restrictingtheairow.

1.Cleantheairlterpre-cleanerand/or

replacethepaperlter.

2.Theengineoillevelislowortheoilis

dirty.

2.Checktheengineoil.Changetheoilif

itisdirtyoraddoilifitislow .

3.Thefueltankventhoseisplugged.3.Cleanorreplacethefueltankvent

hose.

4.Thereisdirtinthefuellter.4.Replacethefuellterandcleanthe

in-tanklterscreen.

5.Thereisdirt,water,orstalefuelinthe

fuelsystem.

5.ContactanAuthorizedServiceDealer.

6.Theundersideofthemachinehousing

containsclippingsanddebris.

6.Cleantheundersideofthemachine

housing.

Theenginestartshardorlosespower.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

1.Thewireisnotsecurelyconnectedto

thesparkplug.

1.Connectthewiresecurelytothespark

plug.

2.Thesparkplugispitted,fouled,orthe

gapisincorrect.

2.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

3.ThethrottleleverisnotintheFast

position.

3.MovethethrottlelevertotheFast

position.

4.Theairlterelementisdirtyandis

restrictingtheairow.

4.Cleantheairlterpre-cleanerand/or

replacethepaperlter.

Theenginerunsrough.

5.Thereisdirtinthefuellter.5.Replacethefuellterandcleanthe

in-tanklterscreen.

1.Abladeisbentorisoutofbalance.1.Balancetheblade(s).Ifabladeisbent,

replaceit.

2.Ablade-mountingboltisloose.2.Tightentheblade-mountingbolts.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

3.Cleantheundersideofthemachine

housing.

4.Theenginemountingboltsareloose.4.Tightentheenginemountingbolts.

5.Theenginepulley,idlerpulley ,orblade

pulleyareloose.

5.Tightentheloosepulley.

6.Theenginepulleyisdamaged.

6.ContactanAuthorizedServiceDealer.

7.Thebladespindleisbent.

7.ContactanAuthorizedServiceDealer.

Themachineorenginevibrates

excessively.

8.Thebeltisdamaged.8.Replacethebelt.

27

Page 28

Problem

PossibleCauseCorrectiveAction

1.All4wheelsarenotatthesameheight.1.Placeall4wheelsatthesameheight.

2.Thebladesaredull.

2.Sharpenandbalancetheblades.

3.Youaremowinginthesamepattern

repeatedly.

3.Changethemowingpattern.

4.Theundersideofthemachinehousing

containsclippingsanddebris.

4.Cleantheundersideofthemachine

housing.

Thereisanunevencuttingpattern.

5.Thebladespindleisbent.

5.ContactanAuthorizedServiceDealer.

1.ThethrottleleverisnotintheFast

position.

1.MovethethrottlelevertotheFast

position.

2.Thecuttingheightistoolow.

2.Raisethecuttingheight;ifnecessary ,

mowasecondtimeatalowercutting

height.

3.Youaremowingtoofast.3.Slowdown.

4.Thegrassiswet.

4.Allowthegrasstodrybeforemowing.

Thedischargechutegetspluggedup.

5.Theundersideofthemachinehousing

containsclippingsanddebris.

5.Cleantheundersideofthemachine

housing.

1.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

1.Adjusttheself-propeldrivecable;

replacethecableifnecessary.

2.Thereisdebrisinthebeltarea.

2.Cleanthedebrisfromthebeltarea.

Themachinedoesnotself-propel.

3.Thebeltisdamaged.3.Replacethebelt.

1.TheBBCbeltorthetimingbeltisworn,

loose,orbroken.

1.AdjusttheBBCcable;adjustthetiming

belttension;replacethemifnecessary.

2.TheBBCbeltisoffthepulley.2.Checkthebeltfordamage,andreplace

itifnecessary .

Thebladesdonotrotateortheyslip.

3.TheBBCcableisworn,loose,or

broken.

3.AdjusttheBBCcable;replaceitif

necessary.

1.Thebladesareinstalledoraligned

incorrectly.

1.Installthebladesproperly.

2.Thebladeadaptersareworn,loosen,

orbroken.

2.Replacethebladeadapters.

3.Thetimingbeltorworn,loose,or

broken.

3.Re-timethebladesandadjustthe

timingbelttension,replaceitif

necessary.

Thebladescontacteachother .

4.Thetimingsprocketsoridlerpulleyis

worn,loose,orbroken.

4.Replacethesprocketsortheidler

pulleyifnecessary .

28

Page 29

Notes:

29

Page 30

Notes:

30

Page 31

Notes:

31

Page 32

TheToroTotalCoverageWarranty

Landscape

ALimitedWarranty(seewarrantyperiodsbelow)Contractor

Equipment(LCE)

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuanttoan

agreementbetweenthem,jointlypromisetotheoriginalpurchasertorepairtheT oro

Productslistedbelowifdefectiveinmaterialsorworkmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchasebytheoriginalowner:

ProductsWarrantyPeriod

21in.Mowers2yearsResidentialUse

1

1yearCommercialUse

•Engines

4

Honda–2years

Kawasaki–3years

30in.Mowers2yearsResidentialUse

1

1yearCommercialUse

•Engines

4

Kawasaki–3years

Mid-SizeWalk-BehindMowers

2years

•Engines

4

Kawasaki–3years

GrandStand

®

Mowers

5yearsor1,200hours

2

•Engines

4

3years

•Frame

Lifetime(originalowneronly)

3

ZMaster

®

2000SeriesMowers

4yearsor500hours

2

•Engines

4

3years

•Frame

Lifetime(originalowneronly)

3

ZMaster

®

3000SeriesMowers

5yearsor1,200hours

2

•Engines

4

3years

•Frame

Lifetime(originalowneronly)

3

ZMaster

®

5000SeriesMowers

5yearsor1,200hours

2

•Engines

4

KohlerCommand–2years

KohlerEFI–3years

•Frame

Lifetime(originalowneronly)

3

ZMaster

®

6000SeriesMowers

5yearsor1,200hours

2

•Engines

4

Kawasaki–3years

•Frame

Lifetime(originalowneronly)

3

ZMaster

®

7000SeriesMowers

5yearsor1,200hours

2

•Engines

4

2years

•Frame

Lifetime(originalowneronly)

3

AllMowers

•Battery90daysPartsandLabor

1yearPartsonly

•BeltsandT ires90days

•Attachments1year

1

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialwarrantywouldapply.

2

Whicheveroccursrst.

3

LifetimeFrameW arranty-Ifthemainframe,consistingofthepartsweldedtogethertoformthe

tractorstructurethatothercomponentssuchastheenginearesecuredto,cracksorbreaksin

normaluse,itwillberepairedorreplaced,atT oro'soption,underwarrantyatnocostforparts

andlabor.Framefailureduetomisuseorabuseandfailureorrepairrequiredduetorustor

corrosionarenotcovered.

4

SomeenginesusedonToroProductsarewarrantedbytheenginemanufacturer.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsorworkmanship,

followthisprocedure:

1.ContactanyAuthorizedT oroServiceDealertoarrangeserviceattheir

dealership.T olocateadealerconvenienttoyou,refertotheY ellowPagesof

yourtelephonedirectory(lookunder“LawnMowers”)oraccessourwebsite

atwww.T oro.com.Youmayalsocallthenumberslistedinitem#3tousethe

24-hourToroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)totheService

Dealer.Thedealerwilldiagnosetheproblemanddetermineifitiscovered

underwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’sanalysisorwith

theassistanceprovided,contactusat:

RLCCustomerCareDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1 196

888-865-5676(U.S.Customers)

888-865-5691(Canadacustomers)

OwnerResponsibilities

YoumustmaintainyourToroProductbyfollowingthemaintenanceprocedures

describedintheOperator'sManual.Suchroutinemaintenance,whetherperformed

byadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystemcoverage

andenginewarrantycoverageonsomeproducts.Thisexpresswarrantydoesnot

coverthefollowing:

•Costofregularmaintenanceserviceorparts,suchaslters,fuel,lubricants,oil

changes,sparkplugs,airltersbladesharpeningorwornblades,cable/linkage

adjustments,orbrakeandclutchadjustments

•Componentsfailingduetonormalwear

•Anyproductorpartwhichhasbeenalteredormisusedorneglectedand

requiresreplacementorrepairduetoaccidentsorlackofpropermaintenance

•Pickupanddeliverycharges

•RepairsorattemptedrepairsbyanyoneotherthananAuthorizedToroService

Dealer

•Repairsnecessaryduetofailuretofollowrecommendedfuelprocedure

(consultOperator'sManualformoredetails)

–Removingcontaminantsfromthefuelsystemisnotcovered

–Useofoldfuel(morethanonemonthold)orfuelwhichcontainsmore

than10%ethanolormorethat15%MTBE

–Failuretodrainthefuelsystempriortoanyperiodofnon-useoverone

month

GeneralConditions

AllrepairscoveredbythesewarrantiesmustbeperformedbyanAuthorizedToro

ServiceDealerusingToroapprovedreplacementparts.

NeitherTheToroCompanynorToroWarrantyCompanyisliableforindirect,

incidentalorconsequentialdamagesinconnectionwiththeuseoftheToro

Productscoveredbythiswarranty,includinganycostorexpenseofproviding

substituteequipmentorserviceduringreasonableperiodsofmalfunctionor

non-usependingcompletionofrepairsunderthiswarranty .

Allimpliedwarrantiesofmerchantability(thattheproductistforordinary

use)andtnessforuse(thattheproductistforaparticularpurpose)are

limitedtothedurationoftheexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequentialdamages,

orlimitationsonhowlonganimpliedwarrantylasts,sotheaboveexclusions

andlimitationsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveotherrights

whichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsoutsidetheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtainguaranteepoliciesforyourcountry,

province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtainingguaranteeinformation,contacttheT oroimporter.Ifallother

remediesfail,youmaycontactusatT oroWarrantyCompany.

AustralianConsumerLaw:AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

374-0252RevF

Loading...

Loading...