Page 1

FormNo.3390-434RevA

TRX-16,TRX-20,andTRX-26

Trencher

ModelNo.22972—SerialNo.315000001andUp

ModelNo.22972G—SerialNo.315000001andUp

ModelNo.22973—SerialNo.315000001andUp

ModelNo.22973G—SerialNo.315000001andUp

ModelNo.22974—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3390-434*A

Page 2

Thismachineisdesignedtodigtrenchesinsoiltobury

G007797

1

cablingandpipingforvariousapplications.Itisnotintended

tocutrock,wood,oranyothermaterialotherthansoil.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

ThissparkignitionsystemcomplieswithCanadianICES-002.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

EngineOwner'sManual

issuppliedfor

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1illustratesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberplate

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SoundPressure.......................................................6

SoundPower..........................................................6

Vibration................................................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................12

1InstallingtheBoomandChain...............................12

2CheckingFluidLevels...........................................13

3ChargingtheBattery(ElectricStartModels

Only)................................................................13

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................16

Attachments/Accessories........................................16

Operation....................................................................16

RecommendedFuel................................................16

CheckingtheEngine-OilLevel.................................17

CheckingtheHydraulicFluidLevel...........................17

StartingandStoppingtheEngine..............................19

StoppingtheMachine.............................................19

MovingaNon-functioningMachine.........................19

DiggingaTrench....................................................20

SecuringtheMachineforTransport..........................20

LiftingtheMachine................................................20

OperatingTips......................................................21

Maintenance.................................................................22

RecommendedMaintenanceSchedule(s)......................22

PremaintenanceProcedures........................................23

RemovingtheCoverPlate........................................23

InstallingtheCoverPlate.........................................23

RemovingtheBottomShield...................................23

InstallingtheBottomShield.....................................23

Lubrication...............................................................24

GreasingtheMachine.............................................24

GreasingtheTrencherHousing................................24

EngineMaintenance..................................................25

ServicingtheAirCleaner(Models22972and

22973)...............................................................25

ServicingtheAirCleaner(Model22974)....................26

ServicingtheEngineOil..........................................27

ServicingtheSparkPlug..........................................28

FuelSystemMaintenance...........................................29

DrainingtheFuelTank...........................................29

ReplacingtheFuelFilter..........................................30

ElectricalSystemMaintenance....................................30

ServicingtheBattery(Models22973and

22974)...............................................................30

ReplacingtheFuses(Models22973and

22974)...............................................................32

DriveSystemMaintenance.........................................33

ServicingtheTracks................................................33

BeltMaintenance......................................................35

ReplacingthePumpDriveBelt.................................35

ControlsSystemMaintenance.....................................36

AdjustingtheTractionControlAlignment.................36

AdjustingtheTractionControlNeutral

Position.............................................................37

AdjustingtheTrackingoftheTractionControl,

FullForwardPosition..........................................37

HydraulicSystemMaintenance....................................38

ReplacingtheHydraulicFilter..................................38

ChangingtheHydraulicFluid...................................38

CheckingtheHydraulicLines...................................39

TrencherMaintenance................................................40

ReplacingtheDiggingTeeth....................................40

CheckingandAdjustingtheDiggingChainand

Boom................................................................40

ReplacingtheDriveSprocket...................................40

Cleaning...................................................................42

RemovingDebrisfromtheMachine..........................42

Storage........................................................................42

Troubleshooting...........................................................44

Schematics...................................................................46

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

Warning

,or

Danger

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)can’treadEnglish,itisthe

owner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

,which

—personalsafety

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperatorpresencecontrols,safetyswitches,

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly .

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandtheparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neveroperatewithouttheguardssecurelyinplace.Be

sureallinterlocksareattached,adjusted,andfunctioning

properly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowertheboom,disengagethe

trencherhydraulics,engagetheparkingbrake,andshut

offtheenginebeforeleavingtheoperator'spositionfor

anyreason.

•Keephandsandfeetawayfromthemovingchain,digging

teeth,andspoilsauger.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Neverleavearunningmachineunattended.Alwayslower

theboom,stoptheengine,settheparkingbrake,and

removethekeybeforeleaving.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

4

Page 5

•Ensurethatyouoperatethemachineinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthemachine

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Beforedigging,havetheareamarkedforunderground

utilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthemachineand

keephandsandfeetawayfromtheseareas.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Disengagethetrencherhydraulics,lowertheboom,set

theparkingbrake,stoptheengine,andremovethekey.

Waitforallmovementtostopbeforeadjusting,cleaning,

orrepairing.

•Cleandebrisfromthechain,diggingteeth,boom,

trencherhead,drives,mufers,andenginetohelpprevent

res.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

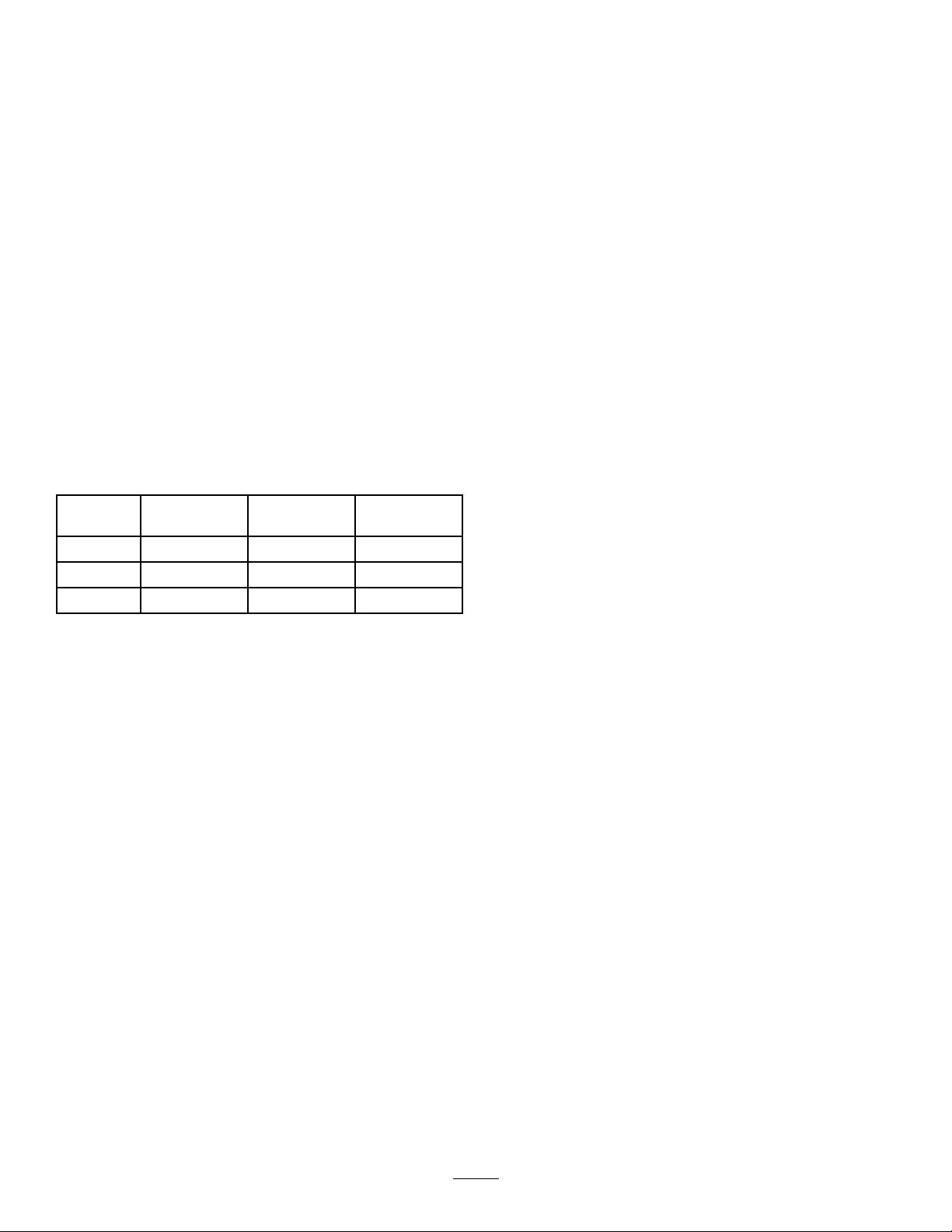

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedinthefollowingtable.

ModelFrontFacing

22972

22973

22974

Note:SeealsotheSlopeIndicator(page7).

Uphill

15°14°19°

13°14°19°

11°11°16°

•Operateupanddownslopeswiththefrontendof

themachineuphill.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•UseonlyToro-approvedaccessories.Accessoriescan

changethestabilityandtheoperatingcharacteristics

ofthemachine.Warrantymaybevoidedifusedwith

unapprovedaccessories.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthemachineuphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifatrackgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthemachineonahillsideorslopewithout

loweringtheboomtotheground,settingtheparking

brake,andchockingthetracks.

RearFacing

Uphill

SideFacing

Uphill

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebattery(electricstartmodelsonly)or

removethesparkplugwiresbeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Reconnectpositiverstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthemachine

tocoolbeforestoring.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineT ororeplacementpartstoensurethat

originalstandardsaremaintained.

•Batterysafety(electricstartmodelsonly):

5

Page 6

–Chargebatteriesinanopen,wellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

–Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Model22974

Thisunithasaguaranteedsoundpowerlevelof107dBA,

whichincludesanUncertaintyValue(K)of3.75dBA.

–Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

SoundPressure

Model22972

Thisunithasasoundpressurelevelattheoperator’searof89

dBA,whichincludesanUncertaintyValue(K)of1.0dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Model22973

Thisunithasasoundpressurelevelattheoperator’searof90

dBA,whichincludesanUncertaintyValue(K)of1.0dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Vibration

Model22972

Measuredvibrationlevelforrighthand=2.1m/s

Measuredvibrationlevelforlefthand=2.0m/s

UncertaintyValue(K)=1.1m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

Model22973

Measuredvibrationlevelforrighthand=2.3m/s

Measuredvibrationlevelforlefthand=2.1m/s

UncertaintyValue(K)=1.1m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

Model22974

2

2

2

2

2

2

Model22974

Thisunithasasoundpressurelevelattheoperator’searof93

dBA,whichincludesanUncertaintyValue(K)of1.0dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

SoundPower

Model22972

Thisunithasaguaranteedsoundpowerlevelof107dBA,

whichincludesanUncertaintyValue(K)of3.75dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO3744.

Model22973

Thisunithasaguaranteedsoundpowerlevelof108dBA,

whichincludesanUncertaintyValue(K)of3.75dBA.

Measuredvibrationlevelforrighthand=1.8m/s

Measuredvibrationlevelforlefthand=2.0m/s

UncertaintyValue(K)=1.00m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

2

2

6

Page 7

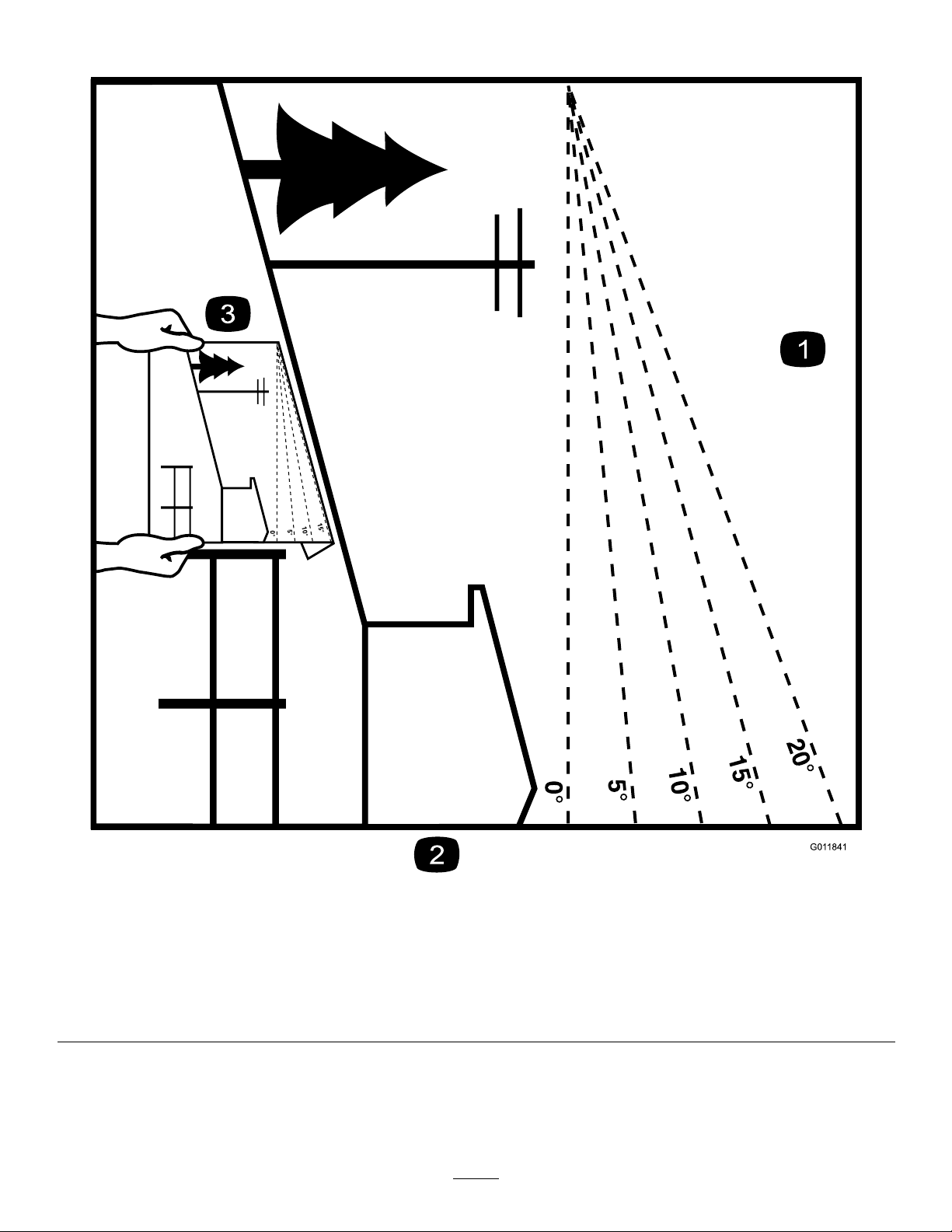

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachineon,refertotheSlopeOperationsection.Usetheslope

indicatortodeterminethedegreeofslopeofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthanthat

speciedintheSlopeOperationsection.Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

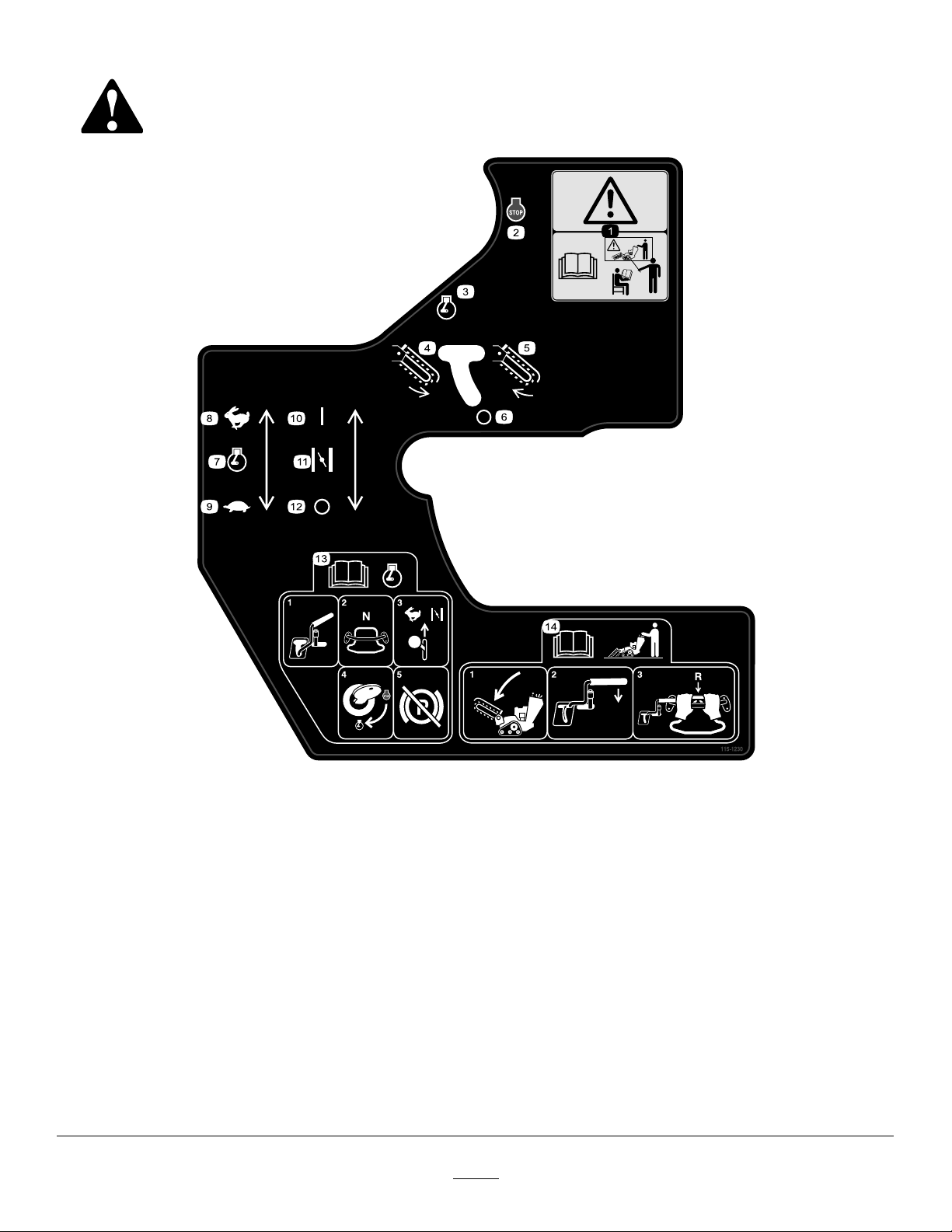

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

115-1230

1.Warning—donotoperatethismachineunlessyouaretrained.

2.Engine—stop

3.Engine—run

4.Trencherchain—reverse

5.Trencherchain—forward

6.Trencherchain—off

7.Enginethrottle

8.Fast

9.Slow

10.Choke

11.On/Closed

12.Off/Open

13.ReadtheOperator'sManualbeforestartingtheengine;tostarttheengine,movethetrenchercontrolleverintotheOffposition,

placethetractioncontrolinNeutral,movetheenginespeedtoFastandthechoketoOn/Closed,turntheignitionkeytorun,

andreleasetheparkingbrakeoncetheenginehasstarted.

14.ReadtheOperator'sManualbeforeoperatingthetrencher;tooperatethetrencher,lowertheboom,movethetrenchercontrol

levertothereferencebar,pullthetractioncontrolrearwardtomoveinreverseanddigthetrench.

8

Page 9

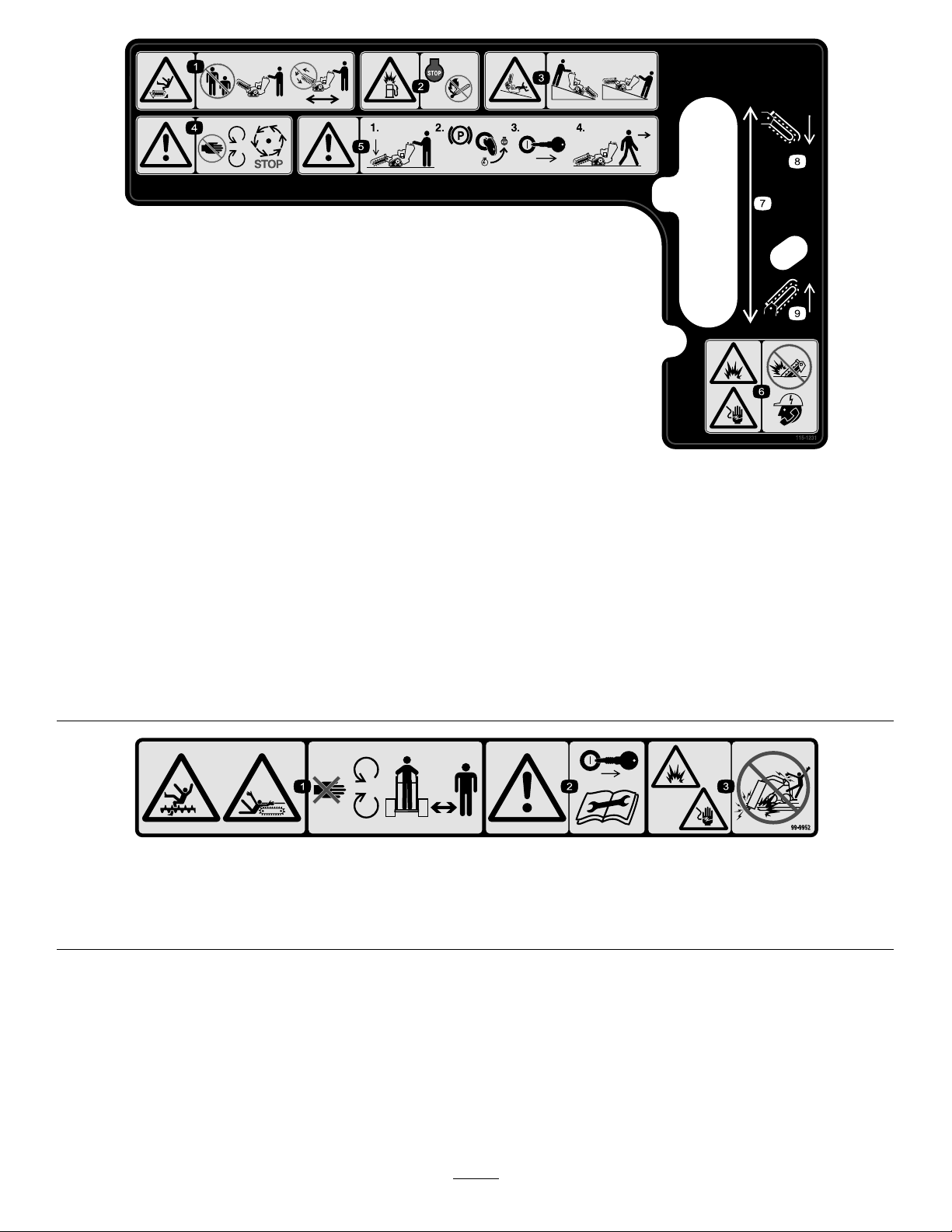

115-1231

1.Cutting/dismembermenthazardofbystanders,

trencher—keepbystandersasafedistancefromthemachine;

donotoperatethetrencherchainwhiletransportingthe

machine.

2.Explosionhazard,fueling—stoptheengineandextinguish

allameswhenfueling.

3.Tipping/crushinghazard—lowerthetrencherheadwhen

operatingonslopes.

4.Warning—stayawayfrommovingparts;waitforallmoving

partstostop

5.Warning—lowertheboom,engagetheparkingbrakeand

stoptheengine,removetheignitionkey,beforeleavingthe

machine.

6.Explosionhazard;shockhazard—donotusemachinenear

buriedutilitylines;contacttheproperagenciesbeforedigging.

7.Boomelevation

8.Lowertheboom

9.Raisetheboom

99-9952

1.Cuttinghazard,chainandauger—stayawayfrommovingpartsandkeepbystandersawayfromthemachine.

2.Warning—stoptheengineandremovethekeybeforepreformingandmaintenanceorrepairs.

3.Explosionand/orelectricshockhazard—donotdiginareaswithburiedgasorpowerlines.

9

Page 10

115-4020

1.Turnright3.Reverse

2.Forward

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93-6686

1.Hydraulicoil

2.ReadtheOperator'sManual.

4.Turnleft

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

1.Liftpoint

107-8495

1.Parkingbrake

93-9084

2.Tie-downpoint

117–2718

10

Page 11

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

11

Page 12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

Boom(soldseparately)

1

2

3

Chain(soldseparately)

Nopartsrequired

Nopartsrequired

1

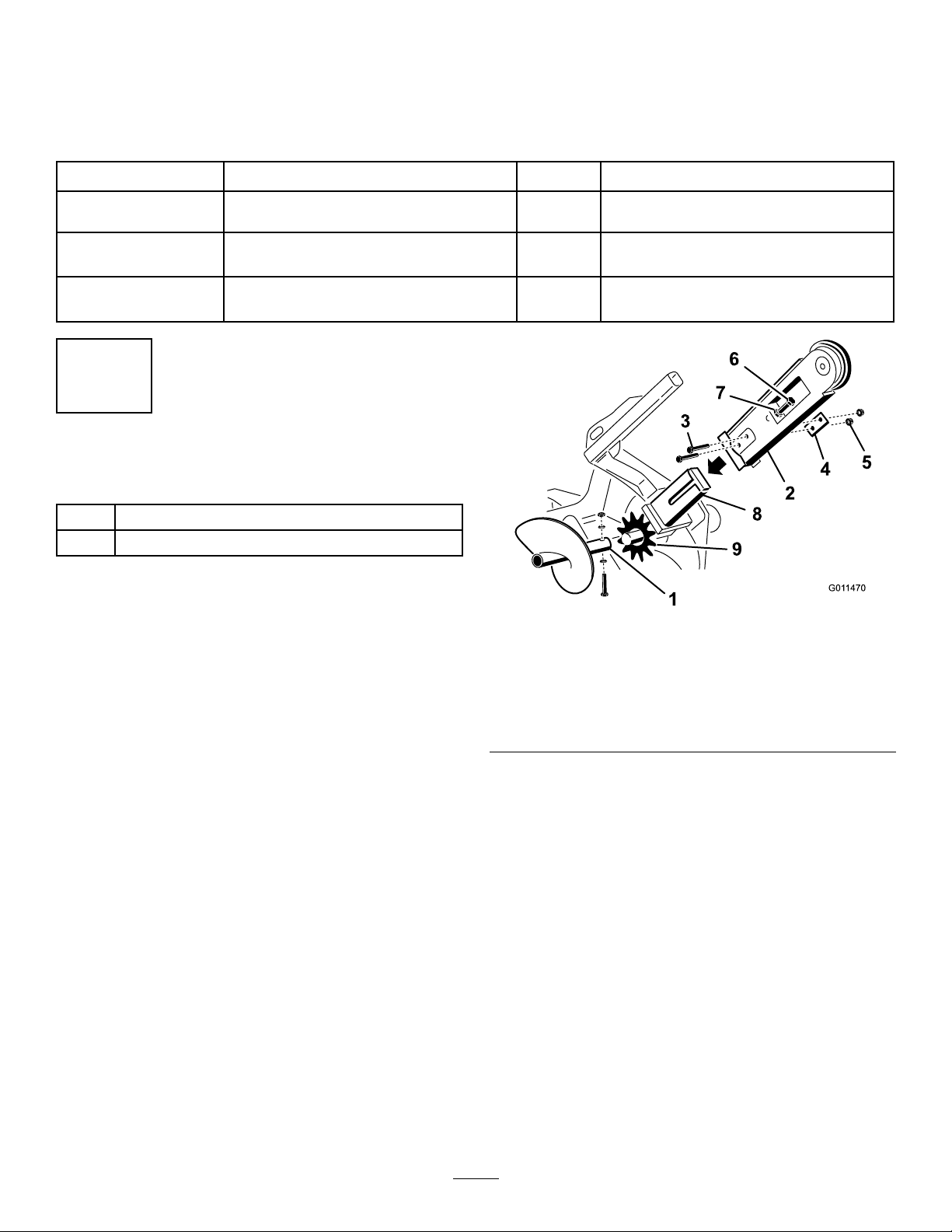

InstallingtheBoomandChain

Partsneededforthisprocedure:

1

Boom(soldseparately)

1

Chain(soldseparately)

Procedure

Important:Thereareseveralboomandchainsize

congurationsavailable.RefertoyouAuthorizedService

Dealertoobtaintheappropriateboomandchainto

meetyourrequirements.

1.Stoptheengineandremovethekey.

2.Removethebolt,2saddlewashers,andnutsecuring

thespoilsaugerandremovetheauger(Figure4).

Note:Savethefastenersforfutureuse.

Qty.

1

1

–

–

1.Spoilsauger

2.Boom7.Jamnut

3.Bolts8.Armonthedrivehead

4.Doublewasher9.Drivesprocket

5.Nuts

3.Removethe2bolts,nuts,anddoublewashersfromthe

sidesoftheboom(Figure4).

Installtheboomandchain.

Checktheuidlevels.

Chargethebattery.

Figure4

Use

6.Adjustingbolt

4.Loosentheadjustingboltandjamnut(Figure4).

5.Slidetheboomoverthearmonthedrivehead.

6.Installthe2bolts,nuts,anddoublewashersremovedin

step3throughtheboomandarm,butdonottighten

them.

7.Ifthechainisnotconnected,connectthelinksby

pressingorhammeringtheclevispinsuppliedwiththe

chainthroughthelinks.

Important:T oavoidbendingthechainlinks,

placeblocksunderandbetweenthelinkswhen

hammeringtheclevispinthrough.

8.Securetheclevispinwiththecotterpinsuppliedwith

thechain.

12

Page 13

9.Loopthediggingchainovertheaugerdriveshaftand

G007801

5

6

783

4

1

2

ontothedrivesprocket,ensuringthatthediggingteeth

pointforwardontheupperspan.

10.Settheupperspanofthechainintoplaceonthe

trencherboom,thenwrapthechainaroundtheroller

attheendoftheboom.

11.Threadtheadjustmentboltintotheboomandturnit

inuntilthereis3.8to6.3cm(1-1/2to2-1/2inches)of

slackinthechainonthebottomspan.

12.Threadthejamnutdowntheadjustingboltandtighten

itsecurelyagainsttheboom.

13.Torquethe2boltsandnutssecuringtheboomto183

to223N-m(135to165ft-lb).

14.Installthespoilsaugerusingthebolt,2saddlewasher,

andnutyouremovedpreviously.

15.Torquetheboltandnutto101N-m(75ft-lb).

2

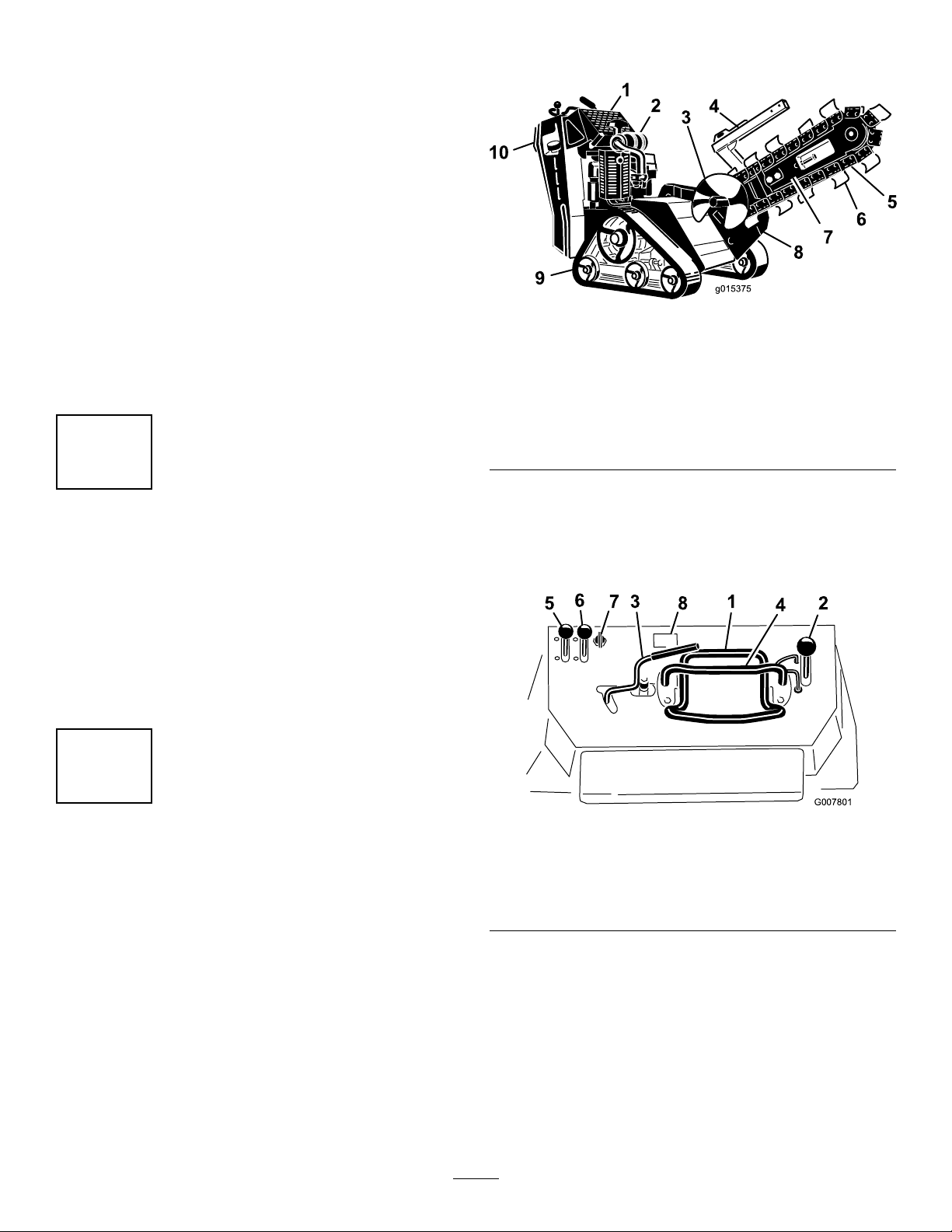

ProductOverview

Figure5

1.Control

panel

2.Engine

3.Spoils

auger

4.Chain

guard

5.Chain

6.Digging

teeth

7.Boom10.Reverse

safety

plate

8.Trencher

head

9.Track

CheckingFluidLevels

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checktheengine

oilandhydraulicuidlevels;refertoCheckingtheEngine-Oil

Level(page17)andCheckingtheHydraulicFluidLevel(page

17)formoreinformation.

3

ChargingtheBattery(Electric StartModelsOnly)

NoPartsRequired

Procedure

Chargethebattery;refertoChargingtheBattery(page32)

formoreinformation.

Controls

Becomefamiliarwithallthecontrols(Figure6)beforeyou

starttheengineandoperatethemachine.

Figure6

1.Tractioncontrol5.Throttlelever

2.Boomelevationlever

3.Trenchercontrollever7.Keyswitch

4.Referencebar

KeySwitch,Model22972

Thekeyswitchhas2positions:OffandRun.

Tostarttheengine,rotatethekeytotheRunposition,then

pulltherecoilhandleontheengine.

6.Chokelever

8.Hourmeter

Tostoptheengine,rotatethekeytotheOffposition.

13

Page 14

KeySwitch,ElectricStartModels

G008131

G008132

Thekeyswitchhasthreepositions:Off,Run,andStart.

Tostarttheengine,rotatethekeytotheStartposition.

Releasethekeywhenenginestartsanditwillmove

automaticallytotheRunposition.

Tostoptheengine,rotatethekeytotheOffposition.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed.

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Note:Awarmenginerequireslittleornochoking.

HourMeter

Whentheengineisoff,thehourmeterdisplaysthenumber

ofhoursofoperationthathavebeenloggedonthemachine.

ReferenceBar

Whendrivingthemachine,usethereferencebarasahandle

andaleveragepointforcontrollingthetractioncontroland

thetrenchercontrollever.Toensuresmooth,controlled

operation,donottakebothhandsoffofthereferencebar

whileoperatingthemachine.

Figure8

•Tomoverearward,movethetractioncontrolrearward

(Figure9).Whenreversing,lookbehindfor

obstructionsandkeepyourhandsonthereference

bar(Figure7).

Figure9

•Toturnright,rotatethetractioncontrolclockwise(Figure

10).

TractionControl

Figure7

1.Referencebar(doesnotmovetogiveyouareferencepoint

andaxedhandletoholdwhileoperatingthetractionunit)

2.Tractioncontrol(movestocontrolthemachine)

•Tomoveforward,movethetractioncontrolforward

(Figure8).

Figure10

•Toturnleft,rotatethetractioncontrolcounterclockwise

(Figure11).

Figure11

•Tostop,releasethetractioncontrol(Figure7).

Note:Thefartheryoumovethetractioncontrolinany

direction,thefasterthemachinewillmoveinthatdirection.

14

Page 15

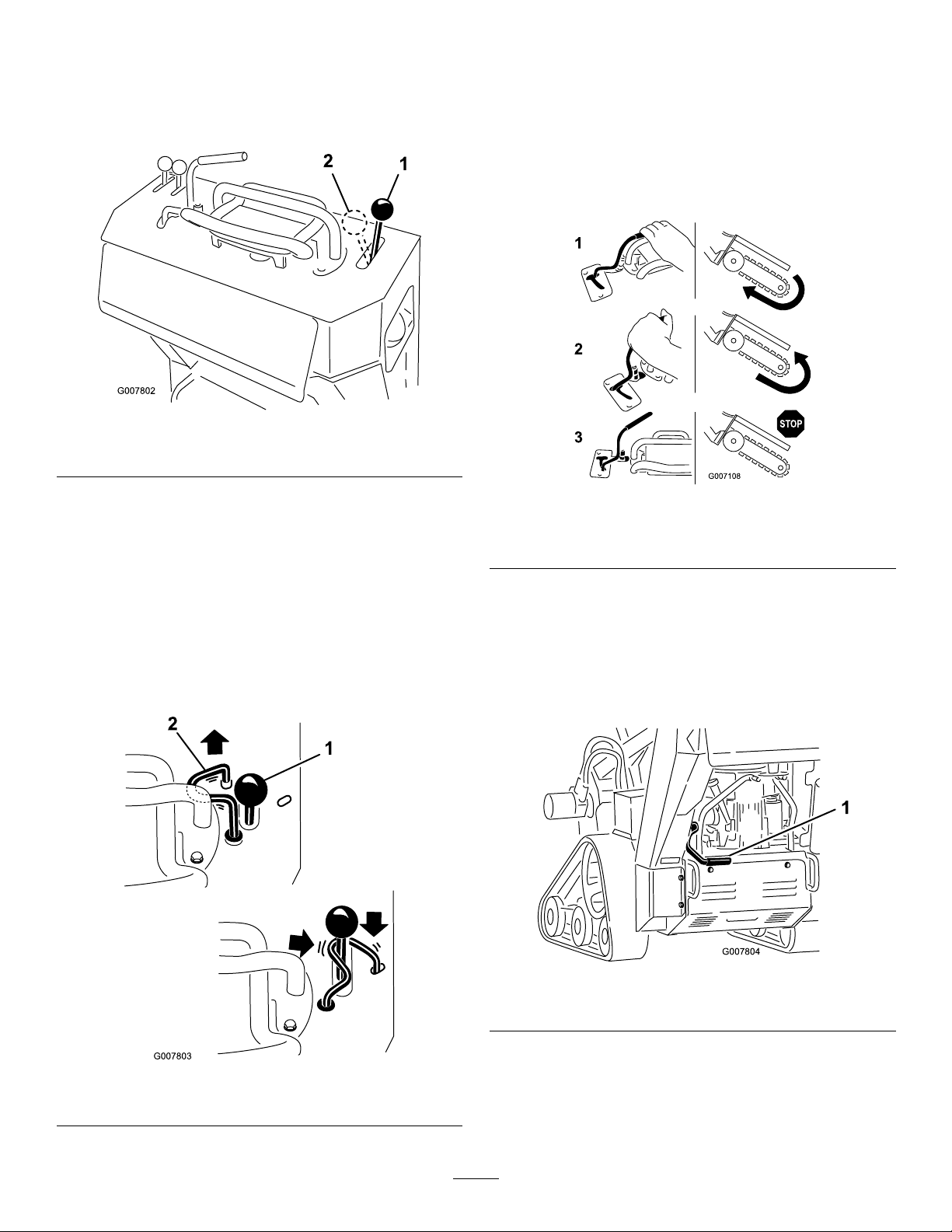

BoomElevationLever

G007804

1

TrencherControlLever

Tolowertheboom,slowlymovetheleverforward(Figure

12).

Toraisetheboom,slowlymovetheleverrearward(Figure12).

Figure12

1.Lowertheboom2.Raisetheboom

BoomElevationLock

Theboomelevationlocksecurestheboomelevationleverso

thatyoucannotpushitforward.Thishelpstoensurethatno

onewillaccidentallylowertheboomduringmaintenance.

Securetheboomwiththelockanytimeyouneedtostopthe

machinewiththeboomraised.

Tosetthelock,liftuponitsoitclearstheholeinthecontrol

panelandswingittotherightinfrontoftheboomelevation

lever,pushingitdownintothelockedposition(Figure13).

Todigwiththetrencher,rotatetheleverrearwardandpullit

downtothereferencebar(Figure14,number1).

Toreversethetrencherhead,rotatetheleverrearward,then

moveitleftintotheupperslot(Figure14,number2).

Ifyoureleasethelever,itwillautomaticallyreturntothe

neutralposition(Figure14,number3),stoppingthechain.

Figure14

1.Forward3.Neutral

2.Reverse

ParkingBrakeLever

•Tosettheparkingbrake,pullthebrakeleverrearward

andup(Figure15).

•Toreleasethebrake,pulltheleverrearwardandthen

down(Figure15).

Figure13

1.Boomelevationlever2.Boomelevationlock

Figure15

1.Parkingbrakelever(inthereleasedposition)

15

Page 16

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Width

Length,with70cm(24

inch)boom

Length,with91.4cm(36

inch)boom

Length,with122cm(48

inch)boom(model22974

only)

Height

Weight(model22972)*499kg(1,100lb)

Weight(model22973)*538kg(1,185lb)

Weight(model22974)*578kg(1,208lb)

*A91.4cm(36inch)boomandchainwilladdabout27kg(60lb)tothelistedweight.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

86cm(33.8inches)

209.5cm(82.5inches)

235cm(92.6inches)

282.5cm(111.2inches)

117cm(46inches)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthemachine.Also,ensure

thattheareaisclearofpeopleanddebris.Youshould

alsoknowandhavemarkedthelocationsofallutility

lines.

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontainsmore

than10%ethanolbyvolume,suchasE15(contains15%

ethanol),E20(contains20%ethanol),orE85(contains

85%ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamagewhichmay

notbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

16

Page 17

DANGER

G007808

1

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

7.IftheoilisbelowtheAddmark,add10w30engineoil

tothellerhole,checkingthelevelfrequentlywiththe

dipstick,untiltheoillevelreachestheFullmark.

8.Replacethedipstick.

CheckingtheHydraulicFluid Level

ServiceInterval:Every25hours

HydraulicTankCapacity:23L(6USgallons)

RefertoChangingtheHydraulicFluid(page38)forhydraulic

uidspecications.

1.Parkthemachineonalevelsurfaceandlowerthe

boom.

2.Stoptheengine,removethekey,andallowtheengine

tocool.

3.Lookintotheglassbubbleontherightsideofthe

machine.Ifyoucannotseehydraulicuidinthe

bubble,continuethisproceduretoadduid.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,lowertheboom,

andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundtheoildipstick(Figure16).

Figure16

1.Oilllerhole

2.Oildipstick

3.Fullmark

4.Addmark

Figure17

1.Hydraulicuidcheckbubble

4.Removethecoverplate;refertoRemovingtheCover

Plate(page23).

5.Cleantheareaaroundthellerneckofthehydraulic

tankandremovethecapandlterfromthellerneck

usingasocket(Figure18).

4.Removethedipstickandwipetheendclean(Figure16).

5.Slidethedipstickfullyintothedipsticktubewithout

threadingitintothellerneck(Figure16).

6.Pullthedipstickoutandlookattheend.Theoil

shouldbebetweentheAddandFullmarks(Figure16).

17

Page 18

Figure18

1.Fillerneckcap

2.Hydraulicuidlter

6.Ifthelevelislow,adduiduntilitisvisibleintheglass

bubble.

7.Installthecapandlteronthellerneckandtorque

boltontopto13to15.5N-m(110to140inch-lb).

18

Page 19

StartingandStoppingthe

G007809

1

2

3

Engine

StartingtheEngine

1.MovethethrottlelevermidwaybetweenSlowandFast

positions(Figure19).

Figure19

1.Throttlelever3.Key

2.Chokelever

StoppingtheEngine

1.MovethethrottlelevertotheSlowposition(Figure19).

2.Lowertheboom(Figure20).

Figure20

3.Turnthekeyoff(Figure19).

2.MovethechokelevertotheOnposition(Figure19).

Note:Awarmorhotenginemaynotrequirechoking.

3.Starttheengineasfollowsforyourmodel:

•Formodel22972,turnthekeytotheOnposition

thenpulltherecoilhandleontopoftheengine.

Note:Iftheenginehasbeenworkinghardorishot,

letitidleforaminutebeforeturningtheignitionkey

off.Thishelpscooltheenginebeforeitisstopped.In

anemergency,theenginemaybestoppedimmediately.

4.Removethekey.

•Foranelectricstartmodel,turnthekeytothe

Onposition(Figure19).Whentheenginestarts,

releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefails

tostart,allowa30secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

4.GraduallymovethechokelevertotheOffposition

(Figure19).Iftheenginestallsorhesitates,engagethe

chokeagainuntiltheenginewarmsup.

5.Movethethrottlelevertothedesiredsetting(Figure

19).

Important:Iftheengineisrunathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

ambientairtemperatureisnearfreezingorlower),

hydraulicsystemdamagecouldoccur.When

startingtheengineincoldconditions,allowthe

enginetoruninthemiddlethrottlepositionfor

2to5minutesbeforemovingthethrottletofast

(rabbit).

Note:Iftheoutdoortemperatureisbelowfreezing,

storethemachineinagaragetokeepitwarmerand

aidinstarting.

StoppingtheMachine

Tostopthemachine,releasethetractioncontrol,movethe

throttlelevertoslow(turtle),lowertheboomtotheground,

andstoptheengine.Settheparkingbrakeandremovethekey.

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethemachineandbeinjured.

Removethekeyfromtheswitchwhenleavingthe

machine,evenifjustforafewseconds.

MovingaNon-functioning Machine

Important:Donottoworpullthemachinewithoutrst

openingthetowvalves,orthehydraulicsystemwillbe

damaged.

1.Stoptheengine.

2.Removethebottomshield.

3.Usingawrench,turnthetowvalvesonthehydraulic

pumpstwicecounter-clockwise(Figure21).

19

Page 20

G007816

1

Figure21

1

G007818

1.Towvalves

4.Installthebottomshieldandtowthemachineas

required.

5.Whenthemachinehasbeenrepaired,closethetow

valvesbeforeoperatingit.

DiggingaTrench

3.Securethemachinetothetrailerwithchainsorstraps

usingthetie-down/liftloopsatthefrontandrearof

themachine(Figure22andFigure23).Refertoyour

localordinancesfortrailerandtie-downrequirements.

Figure22

1.Fronttie-downloop

1.Starttheengine,raisetheboom,setthethrottlelever

totheFastposition,andmovethemachineoverthe

areatobetrenched.

2.Pullthetrenchercontrollevertothereferencebarto

engagethetrencher.

3.Slowlylowertheboomandchainintotheground.

Note:Toachievethemaximumdepth,youmayneed

tolowertheboomasfarintothegroundasitwillgo

withthechainrunning.Then,stopthechainandlower

itfully.Startthechainagainandresumeoperation.

4.Oncethetrencherboomisinthegroundata45to60

degreeangle,slowlymovethetractionunitrearward

toextendthetrench.

Note:Ifyoumovetoofast,thetrencherwillstall.Ifit

stalls,raiseitslightly,slowlydriveforward,orreverse

thechaindirectionmomentarily .

5.Whennished,raisetheboomoutofthetrench,then

stopthetrencher.

SecuringtheMachinefor

Figure23

1.Reartie-downloops

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloopsaslift

points(Figure22andFigure23).

Transport

Whentransportingthemachineonatrailer,alwaysusethe

followingprocedure:

Important:Donotoperateordrivethemachineon

roadways.

1.Stoptheengine.

2.Lowertheboom.

20

Page 21

OperatingTips

1

G020996

•Cleantheareaoftrash,branchesandrocksbefore

trenchingtopreventequipmentdamage.

•Alwaysbegintrenchingwiththeslowestgroundspeed

possible.Increasespeedifconditionspermit.Ifthechain

speedslowsdown,reducegroundspeedtokeepthe

chainmovingatitsfastestrate.Donotspinthetracks

whiletrenching.

•Alwaysusefullthrottle(maximumenginespeed)when

trenching.

•Alwaystrenchbackwards(i.e.,inreverse).

•Trenchwiththechainata45°to60°angleforbestresults.

•Youwillbeabletodigatrenchfasterbycontrollingthe

depthwithperiodicadjustmentsoftheboom.

•Ifthetrencherbindsinthesoil,reversethechain

direction.Oncethechainisloose,changechaindirections

andcontinuetrenching.

•Ifyouneedthenishedtrenchtobecleanerthanwhatis

possiblewiththetrencher,youcanpurchaseacrumber

fromyourdealer.Thecrumbermountsontothetrencher

headandscrapesthetrenchcleanasyoudig.

SoilTypeRecommendedChainType

SandySoilchain(re-congurewith

SandyLoam/Loam/Loamy

Clay

Wet,stickyclay

Hardsoils:dryclayand

compactedsoils

Rockysoil/gravel

extrateethforaddeddigging

speed;refertoyourAuthorized

ServiceDealer)

Soilchain

Soilchain

Combinationchain

Rockchain

•Toimprovethequalityoftrencheslessthan60.9cm(24

inches)deep,usea60.9cm(24inch)boom.

•Iftheliftspeedofthemachineistooslowortoofast,

adjusttheboltindicatedinFigure24.

Figure24

1.Liftspeedadjustmentbolt

•Usethecorrectchainforthegroundconditions,aslisted

inthefollowingtable:

21

Page 22

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every40hours

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkandadjustthetracktension.

•Checktheengine-oillevel.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheengineoillevel.

•Checktheconditionofandcleanthetracks.

•Checktheconditionofthediggingteethandreplaceanythatarewornordamaged.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Checkthehydraulicuidlevel.

•Cleanthefoamaircleanerelement.

•Checkthebatteryelectrolytelevel.

•Checkthediggingchainforexcessivewearandpropertension.

•Greasethetrencherhousing.

•Checkthepaperaircleanerelement.

•Changetheengineoil.

•Checkthesparkplugs.

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeteriorationandrepairifnecessary.

•Replacethepaperaircleanerelement.

Every200hours

Every250hours

Every400hours

Every1,500hours

Yearlyorbeforestorage

Important:Refertoyour

•Changetheoillter.

•Replacethefuellter.

•Replacethehydrauliclter.

•Replacetheprimaryairlterandcheckthecondtionofthesafetylter(Model22974)

•Checkandgreasetheroadwheels.

•Changethehydraulicuid.

•Replaceallmovinghydraulichoses.

•Checkandadjustthetracktension.

•Checkandadjustthechaintension.

•T ouchupchippedpaint

EngineOperator'sManual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

22

Page 23

Premaintenance

g015379

1

2

Procedures

Beforeopeninganyofthecovers,stoptheengine,removethe

key,andallowtheenginetocool.

InstallingtheCoverPlate

1.Lowertheboom,stoptheengine,andremovethekey .

2.Slidethecoverplateintoplaceandsecureitwiththe3

boltsyouloosenedpreviously(Figure25).

Important:Thefastenersonthecoversofthismachine

aredesignedtoremainonthecoverafterremoval.

Loosenallofthefastenersoneachcoverafewturnsso

thatthecoverisloosebutstillattached,thengoback

andloosenthemuntilthecovercomesfree.Thiswill

preventyoufromaccidentallystrippingtheboltsfree

oftheretainers.

RemovingtheCoverPlate

1.Lowertheboom,stoptheengine,andremovethekey .

WARNING

Thereisabeltunderthecoverthatismoving

whenthemachineisrunningandcancatch

ngers,hands,loosehair,andclothing,

causingseriousinjury,amputation,ordeath.

Alwaysstoptheengineandwaitforallmoving

partstostopbeforeremovingthecover.

2.Loosentheboltattherearofthecoverplate.

3.Loosenthe3boltssecuringthecoverplatetothe

framesequentiallyuntilthecoverisloose(Figure25).

RemovingtheBottomShield

1.Lowertheboom,stoptheengine,andremovethekey .

2.Loosenthe2boltssecuringthebottomshield

sequentiallyuntiltheshieldisfree(Figure26).

Figure26

1.Bottomshield2.Bolts

3.Pulltheshieldbackandoutofthemachine.

InstallingtheBottomShield

1.Lowertheboom,stoptheengine,andremovethekey .

2.Slidethebottomshieldintothemachinesothatitrests

onall4tabs(Figure26).

Figure25

1.Coverplate

4.Pullupontherearofthecoverplateuntilitclearsthe

engineandthenpullitoffovertheboltheadsandoff

ofthemachine.

2.Bolts

Note:Youmayneedtoliftuponthebottomshieldto

ensurethatitrestsonthefronttabs.

3.Securetheshieldwiththeboltsyouloosened

previously.

23

Page 24

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Lowertheboomandstoptheengine.Removethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure27through

Figure30).

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

5.Wipeupanyexcessgrease.

Figure29

Figure27

Figure28

Figure30

GreasingtheTrencher Housing

ServiceInterval:Every40hours

GreaseType:General-purposegrease.

1.Lowertheboomandstoptheengine.Removethekey.

2.Cleanthetrencherhousinggreasettingwitharagand

connectagreaseguntoit(Figure31).

Figure31

24

Page 25

3.Pumpgreaseintothettinguntilgreasecomesoutof

thegreasevalvelocatednexttothetting.

EngineMaintenance

4.Wipeupanyexcessgrease.

ServicingtheAirCleaner (Models22972and22973)

ServiceInterval:Every25hours—Cleanthefoamair

cleanerelement.

Every50hours—Checkthepaperaircleanerelement.

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperaircleanerelement.

Inspectthefoamandpaperelementsandreplacethemifthey

aredamagedorexcessivelydirty.

Note:Servicetheaircleanermorefrequently(everyfew

operatinghours)iftheoperatingconditionsareextremely

dustyorsandy .

Important:Donotoilthefoamorpaperelement.

RemovingtheFoamandPaper

Elements

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Cleanaroundtheaircleanertopreventdirtfrom

gettingintotheengineandcausingdamage(Figure32).

4.Unscrewthecoverknobsandremovetheaircleaner

cover(Figure32).

5.Unscrewthehoseclampandremovetheaircleaner

assembly(Figure32).

6.Carefullypullthefoamelementoffthepaperelement

(Figure32).

1.Cover

2.Hoseclamp4.Foamelement

25

Figure32

3.Paperelement

Page 26

CleaningtheFoamAirCleanerElement

G011475

1

2

3

4

5

1.Washthefoamelementinliquidsoapandwarmwater.

Whentheelementisclean,rinseitthoroughly .

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifitistorn

orworn.

ServicingthePaperAirCleaner

Element

1.Cleanthepaperelementbytappinggentlytoremove

dust.Ifitisverydirty,replacethepaperelementwitha

newone(Figure32).

2.Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.

3.Replacethepaperelementifitisdamaged.

Donotcleanthepaperlter.Replaceitafter200operating

hours(Figure32).Inspecttheelementfortears,anoilylm,

ordamagetotherubberseal,andreplaceitifitisdamaged.

InstallingtheFoamandPaperElements

Figure33

1.Airlterbody

2.Safetylter

3.Primarylter

4.Squeezethedustcapsidestoopenitandknockthe

dustout.

5.Cleantheinsideoftheaircleanercoverwith

compressedair.

4.Aircleanercover

5.Dustcap

Important:Topreventenginedamage,alwaysoperate

theenginewiththecompletefoamandpaperaircleaner

assemblyinstalled.

1.Carefullyslidethefoamelementontothepaperair

cleanerelement(Figure32).

2.Placetheaircleanerassemblyontotheaircleanerbase

orhoseandsecureit(Figure32).

3.Placetheaircleanercoverintopositionandtightenthe

coverknobs(Figure32).

ServicingtheAirCleaner (Model22974)

ServiceInterval:Every250hours

ServicingtheAirCleanerCoverand

Body

1.Stoptheengineandremovethekey.

2.Checktheaircleanerbodyfordamagewhichcould

causeanairleak.Checkthewholeintakesystemfor

leaks,damage,orloosehoseclamps.Replaceorrepair

anddamagedcomponents.

3.Releasethelatchesontheaircleanerandpulltheair

cleanercoveroffoftheaircleanerbody(Figure33).

Important:Donotremovetheairltersyet.

ReplacingtheFilters

1.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure33).Avoidknockingthelterintothe

sideofthebody .

Important:Donotattempttocleantheprimary

lter.

2.Checktheconditionofthesafetylterwithout

removingit.Ifitisdirtyordamaged,replaceit.

Important:Neverattempttocleanthesafety

lter.

3.Inspectthenewlter(s)fordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.Ifthelterisdamageddonotuseit.

4.Ifyouarereplacingthesafetylter,carefullyslidethe

newlterintothelterbody(Figure33).

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

5.Carefullyslidetheprimarylteroverthesafetylter

(Figure33).Ensurethatitisfullyseatedbypushingon

theouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

6.Installtheaircleanercoverwiththedustcaporiented

asshowninFigure33andsecurethelatches.

26

Page 27

ServicingtheEngineOil

g015380

1

2

ServiceInterval:Aftertherst8hours—Changetheengine

oil.

Beforeeachuseordaily—Checktheengineoillevel.

Every100hours—Changetheengineoil.

Every200hours—Changetheoillter.

5.Unscrewtheoildipstickandwipetheendclean(Figure

35).

6.Slidetheoildipstickfullyintothellertube,butdonot

threadontotube(Figure35).

7.Pullthedipstickoutandlookattheend.Iftheoillevel

islow,slowlypouronlyenoughoilintothellertube

toraisetheleveltotheFullmark.

Note:Changetheoilmorefrequentlywhentheoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSF ,SG,SH,orSJ)

CrankcaseCapacity:1.7liters(58ounces)withthelter

removed;1.5liters(51ounces)withoutthelterremoved

Viscosity:Refertothetable(Figure34).

Figure34

Important:Donotoverllthecrankcasewithoil

andruntheengine;enginedamagecanresult.

ChangingtheOil

1.Starttheengineandletitrun5minutes.Thiswarms

theoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightlylower

thantheoppositesidetoensurethattheoildrains

completely.

3.Lowertheboomandsettheparkingbrake.

4.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

5.Placeapanbelowthedrainhose.

Note:Rotatetheoildrainvalvetoallowoiltodrain

(Figure36).

CheckingtheEngineOilLevel

1.Parkthemachineonalevelsurface.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Cleanaroundtheoildipstick(Figure35)sothatdirt

cannotfallintothellerholeanddamagetheengine.

1.Oildipstick

Figure35

2.Fillertube

Figure36

1.Oildrainvalve2.Oildrainhose

6.Whenoilhasdrainedcompletely ,closethedrainvalve.

7.Disposeoftheusedoilatarecyclingcenter

8.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure35).

9.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page17).

10.SlowlyaddtheadditionaloiltobringittotheFullmark.

ChangingtheOilFilter

1.Draintheoilfromtheengine;refertoChangingthe

Oil(page27).

27

Page 28

2.Removetheoldlter(Figure37).

1

Figure37

1.Oillter

2.Adapter

3.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure37).

4.Installthereplacementoilltertothelteradapter,

turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional3/4turn(Figure37).

5.Fillthecrankcasewiththepropertypeofnewoil;refer

toServicingtheEngineOil(page27).

6.Runtheengineforabout3minutes,stoptheengine,

andcheckforoilleaksaroundtheoillteranddrain

valve.

7.Checktheengineoillevelandaddoilifneeded.

8.Wipeupanyspilledoil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplugs.

Figure38

1.Spark-plugwire/sparkplug

4.Cleanaroundthesparkplugtopreventdirtfromfalling

intotheengineandpotentiallycausingdamage.

Note:Theheatshieldmayinterfereontherightside;

removeitifnecessaryandreplaceitwhennished.

5.Removethesparkplugandthemetalwasher.

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure39).Ifyou

seelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulator

usuallymeansthattheaircleanerisdirty.

2.Ifneeded,cleanthesparkplugwithawirebrushto

removecarbondeposits.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkpluganda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplugifnecessary.

Type:NGKBPR4Esorequivalent;AirGap:0.75mm

(0.030inches)

RemovingtheSparkPlug

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Disconnectthewirefromthesparkplug(Figure38).

Figure39

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

Important:Alwaysreplacethesparkplugwhen

ithaswornelectrodes,anoilylmonit,orhas

cracksintheporcelain.

3.Checkthegapbetweenthecenterandsideelectrodes

(Figure39).

Note:Bendthesideelectrode(Figure39)ifthegapis

notcorrect.

28

Page 29

InstallingtheSparkPlug

1.Installthesparkplugandthemetalwasher.Ensure

thattheairgapissetcorrectly.

2.Tightenthesparkplugto22N-m(16ft-lb).

3.Connectthewiretothesparkplug(Figure39).

FuelSystem

Maintenance

DrainingtheFuelTank

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Parkthemachineonalevelsurface,toensurethatthe

fueltankdrainscompletely.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Turnthefuelshutoffvalvetotheclosedposition

(Figure40).

Figure40

1.Fuelshutoffvalve

5.Squeezetheendsofthehoseclampontheengineside

oftheshutoffvalvetogetherandslideitupthefuelline

awayfromvalve(Figure40).

6.Pullthefuellineoffthevalve(Figure40).

7.Openthefuelshutoffvalveandallowthegasolineto

drainintoagascanordrainpan.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty .RefertoReplacingthe

FuelFilter(page30).

8.Installthefuellineontothefuelshutoffvalve.Slide

thehoseclampclosetothevalvetosecurethefuelline.

29

Page 30

9.Wipeupanyspilledfuel.

ElectricalSystem

ReplacingtheFuelFilter

ServiceInterval:Every200hours

Neverinstalladirtylterifitisremovedfromthefuelline.

Note:Notehowthefuellterisinstalledinordertoinstall

thenewltercorrectly.

Note:Wipeupanyspilledfuel.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Turnthefuelshutoffvalvetotheclosedposition

(Figure40).

4.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure41).

Maintenance

ServicingtheBattery(Models 22973and22974)

ServiceInterval:Every25hours—Checkthebattery

electrolytelevel.

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionof4partswaterand

1partbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstopreventcorrosion.

Voltage:12Vwith280coldcrankingAmpsat-18°C(0°F).

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Figure41

1.Hoseclamp3.Filter

2.Fuelline

5.Removethelterfromthefuellines.

6.Installanewlterandmovethehoseclampscloseto

thelter.

7.Turnthefuelshutoffvalvetotheopenposition(Figure

40).

8.Checkforfuelleaksandrepairifneeded.

9.Wipeupanyspilledfuel.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

30

Page 31

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

5.Removetheholddownplate,j-bolts,andlocknuts

securingthebattery(Figure42)andremovethebattery.

InstallingtheBattery

1.Placethebatteryontothemachine(Figure42).

•AlwaysDisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•AlwaysReconnectthepositive(red)battery

cablebeforereconnectingthenegative(black)

cable.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lifttheblackrubbercoveronthenegativecable.

Disconnectthenegativebatterycablefromthenegative

(-)batteryterminal(Figure42).

2.Securethebatterywiththeholddownplate,j-bolts,

andlocknuts.

3.First,installthepositive(red)batterycabletopositive

(+)batteryterminalwithanut,washerandbolt(Figure

42).Slidetherubbercoveroverthepost.

4.Theninstallthenegativebatterycableandgroundwire

tothenegative(-)batteryterminalwithanut,washer

andbolt(Figure42).Slidetherubbercoveroverthe

post.

CheckingtheBatteryElectrolyteLevel

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

Figure42

1.Negativecable7.Positivecable

2.Nut(1/4inch)

3.Nut(5/16inch)

4.Bolt10.J-bolt

5.Rubbercover(red)

6.Rubbercover(black)

4.Slidetheredterminalbootoffthepositive(red)battery

terminal.Thenremovethepositive(red)batterycable

(Figure42).

8.Batteryholddownplate

9.Washer

11.Battery

1.Lookatthesideofthebattery.Theelectrolytemust

beuptotheupperline(Figure43).Donotallowthe

electrolytetofallbelowtheLowerline(Figure43).

Figure43

1.Ventcaps3.Lowerline

2.Upperline

2.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery

(page31).

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethemachine.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

31

Page 32

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page30).

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthemachine.

Electrolytecouldbespilledonotherpartsand

causecorrosion.

2.Cleanthetopofthebatterywithapapertowel.

3.Removetheventcapsfromthebattery(Figure43).

4.Slowlypourdistilledwaterintoeachbatterycelluntil

theelectrolytelevelisuptotheupperline(Figure43)

onthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

5.Wait5to10minutesafterllingthebatterycells.Add

distilledwater,ifnecessary,untiltheelectrolytelevelis

uptotheupperline(Figure43)onthebatterycase.

6.Installthebatteryventcaps.

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportantto

preventbatterydamagewhenthetemperatureisbelow

0°C(32°F).

1.Removethebatteryfromthechassis;refertoRemoving

theBattery(page30).

Figure44

1.PositiveBatteryPost

2.NegativeBatteryPost

3.Red(+)ChargerLead

4.Black(-)ChargerLead

ReplacingtheFuses(Models 22973and22974)

Thereare4fusesintheelectricalsystem.Theyareunderthe

controlpanelontheleftside(Figure45).

StartCircuit

ChargeCircuit

CoolerfanCircuit

Headlight(optional)

Figure45

1.Fuseblock

30amp

25amp

15amp

15amp

2.Checktheelectrolytelevel;refertoCheckingthe

BatteryElectrolyteLevel(page31).

3.Makesurethellercapsareinstalledinthebattery.

4.Connecta3to4ampbatterychargertothebattery

postsandchargethebatteryatarateof3to4amperes

for4to8hours(12volts).Donotoverchargethe

battery.

5.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure44).

6.Installthebatteryontothemachineandconnectthe

batterycables,refertoInstallingtheBattery(page31).

Note:Donotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

32

Page 33

DriveSystem

Maintenance

ServicingtheTracks

CleaningtheTracks

ServiceInterval:Beforeeachuseordaily

Checkthetracksforexcessivewearandcleanthem

periodically.Ifthetracksareworn,replacethem.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressurewaterto

washonlythetrackarea.Donotuseahigh-pressure

washertocleantherestofthemachine.High-pressure

washingcandamagetheelectricalsystemandhydraulic

valvesordepletegrease.

Figure47

1.Stopthemachineinonalevelsurfaceandsetthe

parkingbrake.

2.Stoptheengine,lowertheboom,removethekey,and

waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosenthejamnutonthetracktensioningboltand

theclampboltsonthetensionarm(Figure48).

Important:Ensurethatyoufullycleantheroadwheels

andthedrivesprocket(Figure46).

Figure46

1.Roadwheels3.Track

2.Drivesprocket

CheckingandAdjustingtheTrack

Tension

ServiceInterval:Aftertherst50hours

Every100hours

Tocheckthetensionofeachtrack,place20.4kg(45lb)on

thetrackmidwaybetweenthefrontroadwheelandthedrive

sprocket.Thetrackshouldexnomorethan0.6to1cm

(1/4to3/8inch).Ifitdoes,adjustthetracktensionusing

thefollowingprocedure:

Figure48

1.Tensioningbolt

2.Jamnut

4.Torquethetensioningboltto32.5to40N-m(24to30

ft-lb)totightenthetrack(Figure48).

5.Ensurethatthetrackdeectslessthan0.6to1cm(1/4

to3/8inch)when20.6kg(45lb)offorceisappliedto

thetrackspan.Adjustthetorqueonthetensioning

boltasneeded.

6.Tightenthejamnut.

7.Tightentheclampboltsandtorqueto102N-m(75

ft-lb).

3.Clampbolts

ReplacingtheTracks

Whenthetracksarebadlyworn,replacethem.

1.Lowertheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

33

Page 34

3.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis7.6to10cm(3to4inches)offofthe

ground.

4.Backoutthetensioningboltandjamnut(Figure48).

5.Loosentheclampbolts(Figure48).

6.Pushthefrontroadwheelrearwardasfarasitwillgo

(Figure49).

Figure49

7.Beginremovingthetrackatthetopofthefrontroad

wheel,peelingitoffofthewheelwhilerotatingthe

trackforwards.

Note:Youmayneedtoremovethefront,outside

roadwheel.Toremovethiswheel,removethesnap

ringandcapfromthecenteroftheroadwheel(Figure

50).Nextremovetheboltandgasketfromthecenter

ofthewheelandpullthewheeloffofthemachine.

9.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugsonthetrack

tbetweenthespacersonthesprocket(Figure49).

10.Pushthetrackunderandbetweentherearandcenter

roadwheels(Figure49).

11.Startingatthebottomofthefrontroadwheel,install

thetrackaroundthewheelbyrotatingthetrack

rearwardwhilepushingthelugsintothewheel.

12.Ifyouremovedthefront,outsideroadwheel,install

itatthistimeusingtheboltandgasketremoved

previously.Torquetheboltto102N-m(75ft-lb)and

thenclean,grease,andinstallthecapandsnapring

asinstructionintheCheckingandGreasingtheRoad

Wheels(page34)section.

13.Installthetensioningboltandjamnut.

14.Torquethetensioningboltto32.5to40N-m(24to30

ft-lb)totightenthetrack.

15.Ensurethatthetrackdeectslessthan0.6to1cm(1/4

to3/8inch)when20.6kg(45lb)offorceisappliedto

thetrackspan.Adjustthetorqueonthetensioning

boltasneeded.

16.Tightenthejamnut.

17.Tightentheclampboltsandtorqueto102N-m(75

ft-lb).

18.Lowerthemachinetotheground.

19.Repeatsteps3through18toreplacetheothertrack.

CheckingandGreasingtheRoad

Wheels

ServiceInterval:Every250hours

1.Removethetracks;refertoReplacingtheTracks(page

33).

2.Removethesnapringandcapfromaroadwheel

(Figure51).

Figure50

1.Snapring4.Gasket

2.Cap

3.Bolt

5.Wheelwithbearings

8.Whenthetrackisoffoftheroadwheel,removeitfrom

themachine(Figure49).

Figure51

1.Roadwheel

2.Roadwheelcap

3.Snapring

3.Checkthegreaseunderthecapandaroundthegasket

(Figure51).Ifitisdirty,gritty,ordepleted,cleanoutall

ofthegrease,replacethegasket,andaddnewgrease.

34

Page 35

4.Ensurethattheroadwheelturnssmoothlyonthe

bearing.Ifitisfrozen,contactyourAuthorizedService

Dealertoreplacetheroadwheel.

BeltMaintenance

5.Placethegreasedroadwheelcapoverthebolthead

(Figure51).

6.Securetheroadwheelcapwiththesnapring(Figure

51).

7.Repeatsteps2through6forall12roadwheels.

8.Installthetracks;refertoReplacingtheTracks(page

33).

ReplacingthePumpDriveBelt

Ifthepumpdrivebeltbeginstosquealoriscracked,worn,

orfrayed,replaceit.ContactyouAuthorizedServiceDealer

forareplacementbelt.

1.Raisetheboomandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Raisethebackofthemachineandsupportitonjack

stands.

4.Removethebottomshield;refertoRemovingthe

BottomShield(page23).

5.Loosenthe2pumpbolts(Figure52).

Figure52

1.Pump3.Belt

2.Pumpbolts4.Idlerpulleyspring

6.Twistthepumpcounterclockwiseandallowittodrop

downawayfromthepulley(Figure52).

Note:Ensurethatthespidercouplerdropsdown

withthepump.

7.Usingaspringpuller(contactyourAuthorizedService

Dealer)orstiffmetalhook,pulltheendoftheidler

pulleysprintoffthespringbolttoreleasetensionon

thebelt(Figure52).

8.Removethebelt.

9.Routeanewbeltaroundthepulleys.

10.Installtheidlerpulleyspringonthebolt.

11.Ensurethatthespidercouplerisinplaceonthepump

andtheninsertitintothepulley,twistingitclockwise

toseatitonthepumpbolts.

12.Torquethepumpboltsto68N-m(50ft-lb).

13.Installthebottomshield.

35

Page 36

ControlsSystem

G011476

1

1

2

2

Maintenance

Thefactoryadjuststhecontrolsbeforeshippingthemachine.

However,aftermanyhoursofuse,youmayneedtoadjust

thetractioncontrolalignment,theNeutralpositionofthe

tractioncontrol,andthetrackingofthetractioncontrolinthe

fullforwardposition.

Important:Toadjustthecontrolsproperly,complete

eachprocedureintheorderlisted.

AdjustingtheTractionControl

5.Adjustthetractioncontrolsothatitrestsushagainst

thereferencebarwhenitispulledstraightback(Figure

54andFigure55).

Figure55

Alignment

Ifthetractioncontrolbardoesnotrestushandsquare

withthereferencebarwheninthefullbackwardposition,

immediatelycompletethefollowingprocedure:

1.Parkthemachineonaatsurfaceandlowertheboom.

2.Stoptheengineandremovethekey.

3.Pullstraightbackonthetractioncontrolsothefront

ofthecontrolcontactsthereferencebar(Figure53).

Figure53

1.Frontofthecontrol,outof

alignment

2.Referencebar

6.Tightentheangenutandboltinthetractioncontrol

stem.

7.Starttheengine.

8.Drivethemachineinreversewiththetractioncontrol

tighttothereferencebar.Ifthemachinedoesnotback

upstraight,completethefollowingprocedure:

A.Stoptheengine

B.Lift/supportthemachinesothatbothtracksare

offofthegroundandarefreetorun.

C.Loosentheangenutandboltinthestemofthe

tractioncontrol(Figure54).

D.Loosenthejamnutsonthetractionrods,under

thecontrolpanel(Figure56).

4.Ifthefrontofthetractioncontroldoesnotrestsquare

andushwiththereferencebar,loosentheangenut

andboltinthestemofthetractioncontrol(Figure54).

Figure54

1.Tractioncontrol

2.Stem,boltandnut

Figure56

1.Tractionrod2.Jamnut

E.Startthemachineandsetthethrottletoabout

1/3openposition.

36

Page 37

WARNING

Whenthemachineisrunning,youcould

becaughtandinjuredinmovingpartsor

burnedonhotsurfaces.

Stayawayfrompinchpoints,moving

parts,andhotsurfaceswhenadjusting

therunningmachine.

F.Haveahelperholdthetractioncontroltightto

thereferencebarinreverse.

G.Adjustthelengthofthetractionrodsuntilboth

tracksarerunningatthesamespeed.

Note:Youcanalsoadjustthemaximumreverse

speedofthetracksatthistime.

4.Ifthemachineveerstotheright,loosentheleftjam

nutandadjustthetrackingsetscrewonthefrontofthe

tractioncontrol(Figure57).

H.Tightenthejamnuts.

I.Adjustthetractioncontrolsothatitrestsush

againstthereferencebarwhenitispulledstraight

back(Figure54andFigure55).

J.Tightentheangenutandboltinthetraction

controlstem.

K.Stoptheengineandlowerthemachinetothe

ground.

L.Drivethemachineinfullreverse,checkingto

seeiftheunittracksstraight.Ifitdoesnot,

notethedirectionthemachineveers.Repeatthe

adjustmentpreviouslydescribedsothatittracks

straightinreverse.

AdjustingtheTractionControl NeutralPosition

Ifthemachinecreepsforwardorbackwardwhenthetraction

controlisinneutralandtheunitiswarm,thereturn-to-neutral

mechanismonthepumpsmayneedtobeadjusted;contact

youAuthorizedServiceDealerforrepairs.

Figure57

1.Setscrew3.Stop

2.Jamnut

5.Repeatsteps1through4untilthemachinedrives

straightinthefullforwardposition.

Important:Ensurethetrackingsetscrewstouch

thestopsinthefullforwardpositiontoavoidover

strokingthehydraulicpumps.

AdjustingtheTrackingofthe TractionControl,FullForward Position

Ifthemachinedoesnotdrivestraightwhenyouholdthe

tractioncontrolforwardagainstthereferencebar,complete

thefollowingprocedure:

1.Drivethemachinewiththetractioncontrolagainst

thereferencebar,notingwhichdirectionthemachine

veers.

2.Releasethetractioncontrol.

3.Ifthemachineveerstotheleft,loosentherightjam

nutandadjustthetrackingsetscrewonthefrontofthe

tractioncontrol(Figure57).

37

Page 38

HydraulicSystem

Maintenance

ReplacingtheHydraulicFilter

ServiceInterval:Every200hours

1.Positionmachineonalevelsurface.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Removethetopcover.

5.Removeanddiscardtheoldlter(Figure58).

Fluid(UTHF),buttheymustbeonlyconventional,

petrolium-basedproducts.Thespecicationsmustfall

withinthelistedrangeforallofthefollowingmaterial

propertiesandtheuidshouldmeetthelistedindustry

standards.Checkwithyouroilsuppliertodetermineif

theoilmeetsthesespecications.

Note:Torowillnotassumeresponsibilityfordamage

causedbyimpropersubstitutions,souseonlyproducts

fromreputablemanufacturerswhowillstandbehindtheir

recommendations.

MaterialProperties

cStat40°C:55to62Viscosity,ASTMD445

cStat100°C:9.1to9.8

Viscosityindex,ASTMD2270

PourPoint,ASTMD97-37°to-43°C(-35°to-46°F)

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM.

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditivefor

thehydraulicsystemoilisavailablein20ml(2/3oz)

bottles.Onebottleissufcientfor15-22L(4-6gallons)

ofhydraulicoil.Orderpartno.44-2500fromyour

AuthorizedT oroDealer.

140to152

Figure58

1.Fillercap

2.Hydrauliclter

6.Installthereplacementhydrauliclterandllercap

(Figure58)andtorqueboltontopto13to15.5N-m

(110to140in-lb).

7.Cleanupanyspilleduid.

8.Installthetopcover.

ChangingtheHydraulicFluid

ServiceInterval:Every400hours/Y early(whichevercomes

rst)

HydraulicFluidSpecication:

Useonlyoneofthefollowinguidsinthehydraulicsystem:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedToroDealerformore

information)

1.Positionthemachineonalevelsurface.

2.Lowertheboomandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Allowthemachinetocoolcompletely.

5.Removethetopcover.

6.Removethehydraulictankllercapandlter(Figure

58).

7.Placeadrainpancapableofhold37.8L(10US

Gallons)underthehydraulictank.

8.Pinchthehoseclampandslidetheclampandhose

offofthettingonthehydraulictank,allowingthe

hydraulicuidtodrainfromthehoseandtankinto

thepan.

•ToroPremiumAllSeasonHydraulicFluid(referto

yourAuthorizedToroDealerformoreinformation)

•IfeitheroftheaboveTorouidsarenotavailable,

youmayuseanotherUniversalTractorHydraulic

38

Page 39

Figure59

CheckingtheHydraulicLines

ServiceInterval:Every100hours—Checkthehydraulic