Page 1

FormNo.3353-841RevA

TreeForks

ForCompactUtilityLoaders

ModelNo.22438—SerialNo.240000001andUp

Registeryourproductatwww.Toro.com OriginalInstructions(EN)

Page 2

Contents

ModelNo.

Introduction.........................................................2

Safety..................................................................3

SafetyandInstructionalDecals........................4

ProductOverview.................................................5

Specifications................................................5

Operation............................................................6

UsingtheTreeForks.......................................6

TransportingtheTreeForks.............................6

OperatingTips..............................................6

Maintenance.........................................................7

RecommendedMaintenance

Schedule(s).....................................7

GreasingtheBearings.....................................7

CheckingtheHydraulicHoses..........................8

Storage................................................................9

Troubleshooting.................................................10

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

SerialNo.

Thismanualidentifiespotentialhazardsandhas

safetymessagesidentifiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpfindinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready .Figure1

identifiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

1.Locationofthemodelandserialnumbers

©2005—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Safety

Improperuseormaintenancebythe

operatororownercanresultininjury.T o

reducethepotentialforinjury,comply

withthesesafetyinstructionsandalw ays

payattentiontothesafetyalert

whichmeansCAUTION,WARNING,or

DANGER-“personalsafetyinstruction."

Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Theremaybeburiedpower,gas,and/or

telephonelinesintheworkarea.Ifyoudig

intothemyouorbystandersmaybeinjured

byelectricalshockorexplosion.

Havetheworkareamarkedforburiedlines

anddonotdiginmarkedareas.

Theremaybeoverheadpowerlinesinthe

workarea.Ifyoutouchthemwithatree

orotherobjectyouaretransporting,you

orbystandersmaybeseriouslyinjuredby

electricalshock.

symbol,

Ifyoustepoffoftheplatform(wheeled

tractionunitsonly)withtheloadraised,

themachinecouldtipforwardpinningor

injuringbystanders.

Lowertheloaderarmsbeforesteppingoff

oftheplatform.

Ifyoudonotkeeptheloadlevelwhilelifting,

youcoulddumpitonyourself,resultingin

injury.

•Whenliftingtheattachment,tiltit

forwardtokeepitlevelandpreventit

fromspillingbackwards.

•Carrytheloadlevelandaslowtothe

groundaspossible.

Whentheengineisoff,attachmentsinthe

raisedpositioncangraduallylower,possibly

pinningorinjuringyouorbystanders.

Alwayslowertheattachmentliftbeforeyou

stoptheengine.

Whengoingupordownhill,themachine

canbecomeunstableandtip,pinningor

seriouslyinjuringyouorbystanders.

Operateupanddownslopeswiththeheavy

endofthemachineuphill.Anemptyfork

willmaketherearendheavyandaloaded

forkwillmakethefrontendheavy.

3

Page 4

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearany

areaofpotentialdanger.Replaceanydecalthatisdamagedorlost.

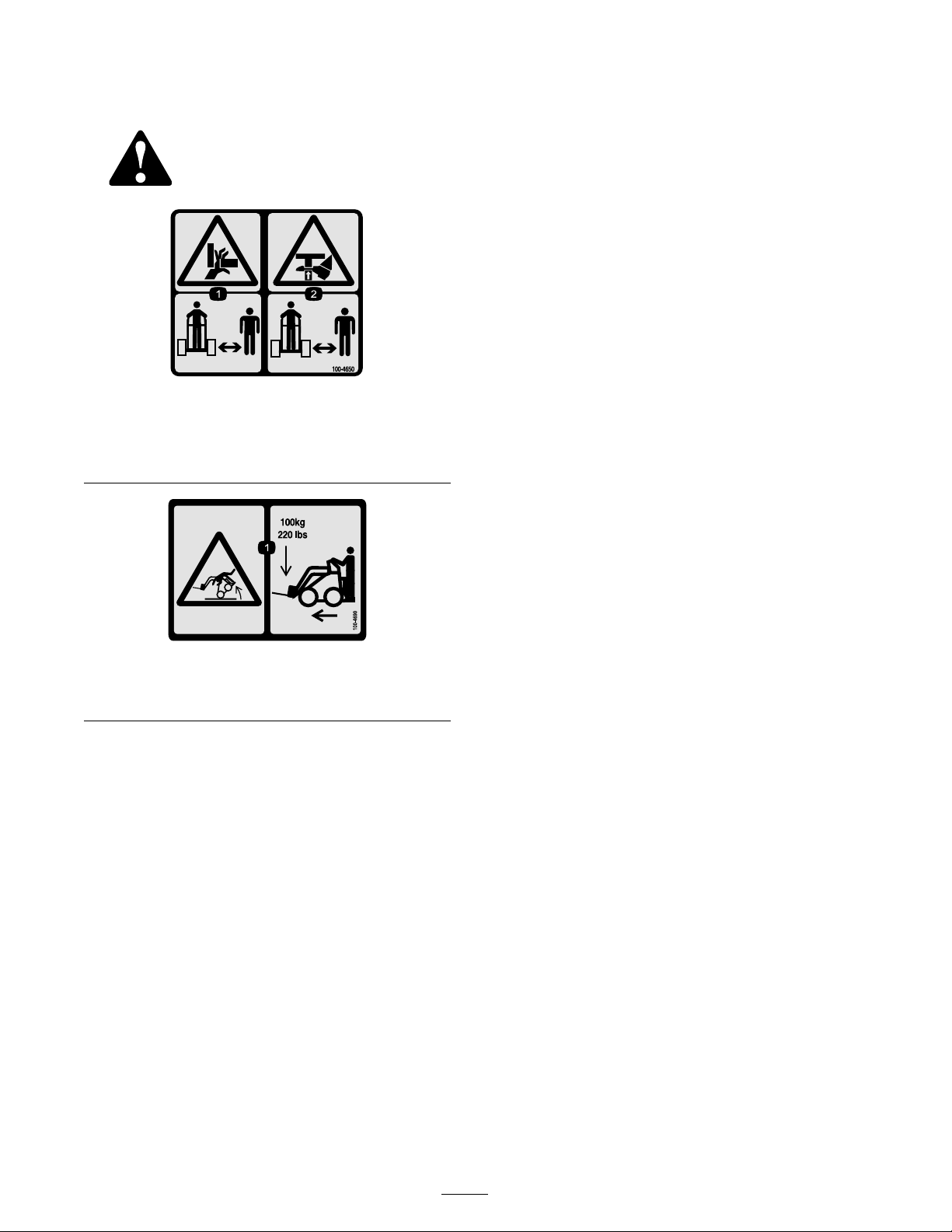

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

100-4690

1.Tippinghazard—maximumloadcapacityis220lb(100kg)

whentransporting.

4

Page 5

ProductOverview

Figure3

1.Stationarytine

2.Moveabletine5.Receiverplate

3.Cover

Specications

Note:Specificationsanddesignaresubjectto

changewithoutnotice.

4.Hydraulichoses

Ifyouexceedthemaximumrecommended

slope,thetractionunitcouldtip,crushing

youorbystanders.

Donotdrivethetractionunitonaslope

steeperthanthemaximumrecommended

slope,asdeterminedbythefollowingtables

andthetractionunitOperator’sManual.

Stabilitywithoutaload:

OrientationStabilityRating

FrontUphill

RearUphill

SideUphill

D

Stabilitywithaload:

OrientationStabilityRating

FrontUphill

RearUphill

SideUphill

D

B

B

B

B

Width

Length

Height

Weight

Forklength

Maximumload

24.5inches(62cm)

45inches(114cm)

12.5inches(32cm)

169lb(77Kg)

43inches(109cm)

220lb(100Kg)

StabilityRatings

Todeterminethedegreeofslopeyoucantraverse

withtheforkinstalledonatractionunit,findthe

stabilityratingforthehillpositionyouwantto

travelintheappropriatetable,thenfindthedegree

ofslopeforthesameratingandhillpositioninthe

StabilityDatasectionofthetractionunitOperator’s

Manual.

Important:Ifyourtractionunithasarear

operator’splatform,thecounterweightmust

beusedontheplatformwhileusingthefork,

orthetractionunitwillbecomeunstable.

5

Page 6

Operation

•Neverattempttoliftmorethattherated

capacityofthetractionunit.

Note:RefertoyourtractionunitOperator’sManual

forcompleteinstructionsoninstalling/removing

attachmentsonto/fromthetractionunitand

connecting/disconnectinghydraulichoses.

Note:Alwaysusethetractionunittoliftand

movetheattachment.

UsingtheTreeForks

Thetreeforkisanexcellenttoolfortransporting

balledandcontainergrowntreesandshrubs.You

canalsousetheforktomoverocksunder220lb

(100Kg).

1.Ifyourtractionunithasaspeedselectorand

aflowdivider,movethespeedselectortothe

fast(rabbit)positionandtheflowdividerto

the10to11o’clockposition.

2.Pulltheauxiliaryhydraulicslevertothe

operatorgriptoopenthetinesifnecessary.

3.Driveforward,positioningtheobjecttobe

movedbetweentheforktines.

•Whentransportingaload,keeptheforkas

closetothegroundaspossible.

•Toeasetheplacementofatreeintoahole,pick

upthetreenearthetopoftheballorcontainer.

•Theforkcanalsobeusedtolift,transport,and

positionsmallbouldersandrocks.

4.Pushtheauxiliaryhydraulicsvalveawayfrom

theoperatorgriptoclosetheforktinesaround

theobject.

Important:Becarefulnottosqueezea

potorrootballtootightly.Usingthefull

forceofthetinesonatreemaydamagethe

rootball.

5.Raisetheloaderarmstolifttheobject.Keepit

asclosetothegroundaspossible.

6.Drivetothelocationwhereyouwantthe

objectandloweritintoplace.

7.Releasetheobjectbypullingtheauxiliary

hydraulicslevertotheoperatorgrip.

TransportingtheTreeForks

1.Placetheforksonatrailerortruckcapableof

carryingit.

2.Securelytietheforkstothetrailerortruck

usingtiestrapsappropriatefortheweightof

theforksandforhighwayuse.

OperatingTips

•Positionthetreeascloseaspossibletothefork

frametomaximizeliftingcapability.

6

Page 7

Maintenance

RecommendedMaintenanceSchedule(s)

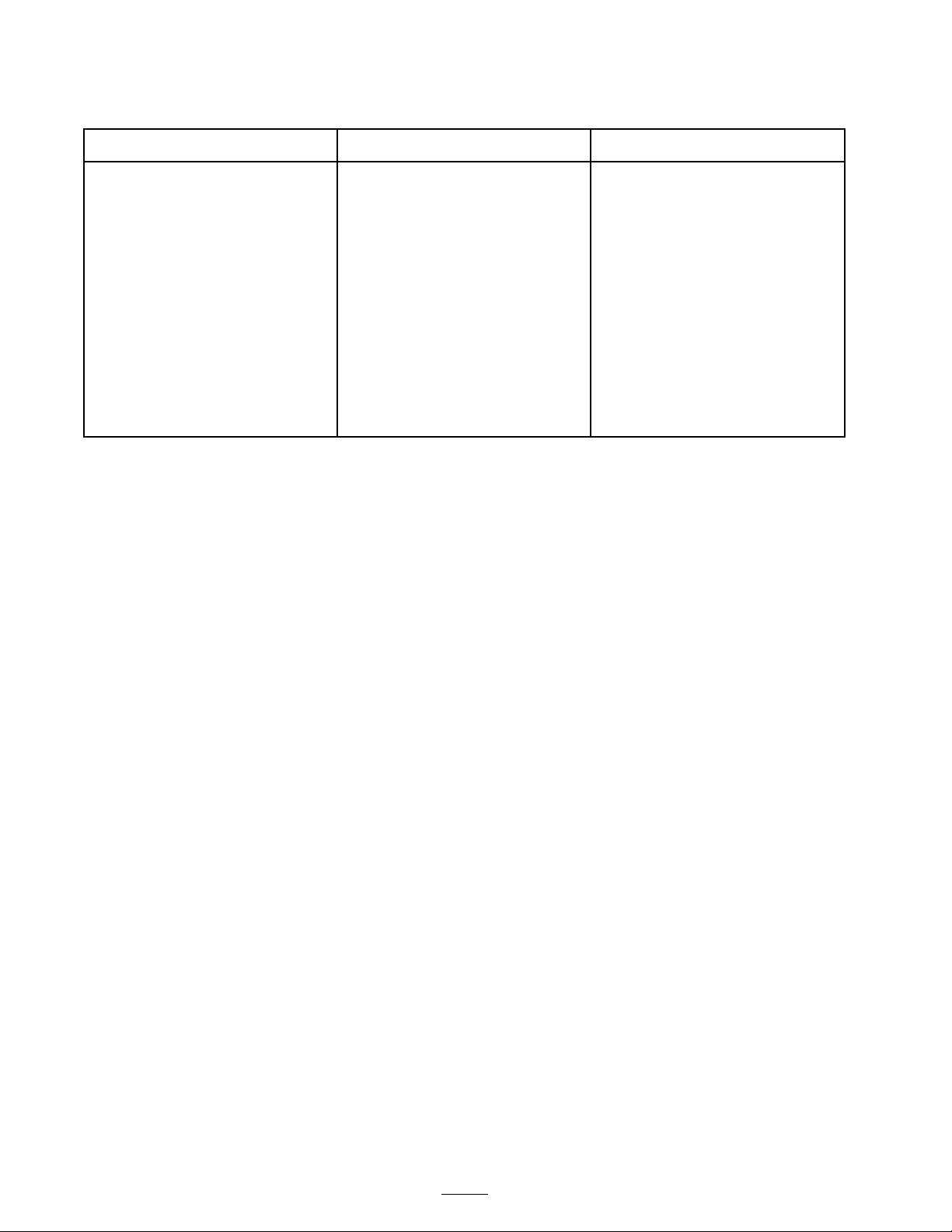

MaintenanceService

Interval

Beforeeachuseordaily

Every100hours

Beforestorage

Every2years

MaintenanceProcedure

•Greasethebearings.

•Checkthehydraulichoses.

•Greasethebearings.

•Checkthehydraulichoses.

•Paintchippedsurfaces.

•Replacethehydraulichoses.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

GreasingtheBearings

1.Disconnecttheattachmentfromthetraction

unit;refertothetractionunitOperator’sManual.

2.Removethetwoboltssecuringthecoverand

removeit(Figure4).

Figure4

1.Cover

2.Greasetting

3.Cleanthegreasefittings(Figure4andFigure5)

witharag.Makesuretoscrapeanypaintoffof

thefrontofthefitting(s).

Figure5

1.Greasetting

4.Connectagreaseguntoeachfitting(Figure4

andFigure5).

5.Pumpgreaseintothefittingsuntilgrease

beginstooozeoutofthebearings.

6.Wipeupanyexcessgrease.

7

Page 8

CheckingtheHydraulic

Hoses

Afterevery100operatinghours,checkthe

hydraulichosesforleaks,loosefittings,kinked

lines,loosemountingsupports,wear,weather,

andchemicaldeterioration.Replacethehydraulic

hosesevery1500hoursor2years,whichever

comesfirst.Makenecessaryrepairsbefore

operating.

Hydraulicfluidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

injectedintotheskinmustbesurgically

removedwithinafewhoursbyadoctor

familiarwiththisformofinjuryorgangrene

mayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicfluid.

•Usecardboardorpapertofindhydraulic

leaks,neveruseyourhands.

8

Page 9

Storage

1.Beforelongtermstorage,washtheattachment

withmilddetergentandwatertoremovedirt

andgrime.

2.Checkandtightenallbolts,nuts,andscrews.

Repairorreplaceanypartthatisdamagedor

worn.

3.Ensurethatallhydrauliccouplersare

connectedtogethertopreventcontamination

ofthehydraulicsystem.

4.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedService

Dealer.

5.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeep

itclean.

9

Page 10

Troubleshooting

Problem

Forkdoesnotopenand

close.

PossibleCauseCorrectiveAction

1.Hydrauliccouplernot

completelyconnected

2.Defectivehydraulic

coupler

3.Anobstructionina

hydraulichose

4.Auxiliaryvalveonthe

tractionunitisnot

opening.

5.Defectivehydraulic

cylinder(s)

1.Checkandtightenall

couplers.

2.Checkcouplersand

replaceanythatare

defective.

3.Findandremovethe

obstruction.

4.Repairthevalve.

5.Replaceorrepairany

defectivecylinders.

10

Page 11

Page 12

Loading...

Loading...