Page 1

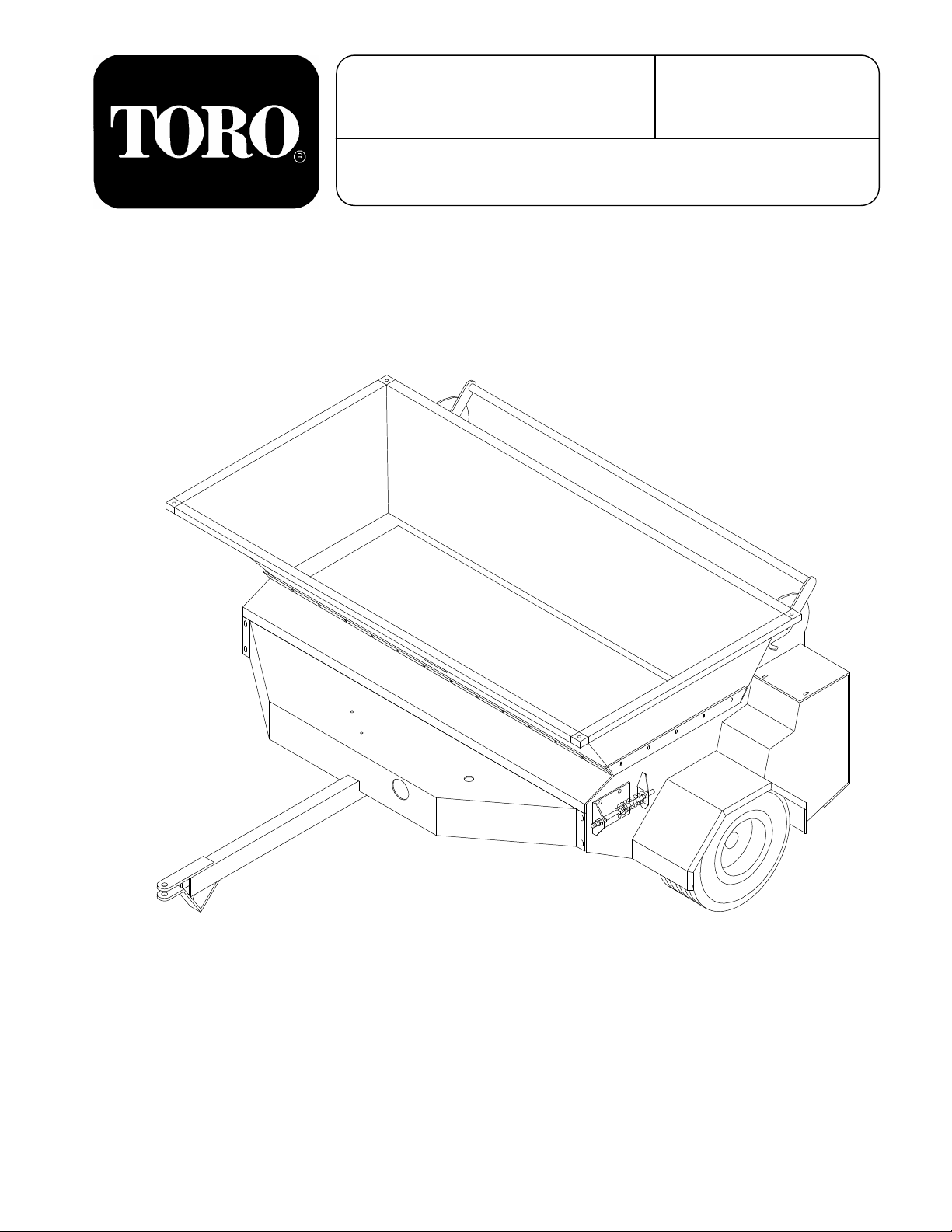

OPERATOR’S

MANUAL

MODEL NO. 44501 - 70001 & UP

TOPDRESSER 2300

FORM NO. 95-4836

The TORO Company - 1997

©

All Rights Reserved

Page 2

FOREWORD

Thank you for bu ying a h igh quality Toro tu rf care product. To g et the b est performan ce fro m this m achine,

operate and maintain it according to the instructions in this manual.

Toro also wa nts to stress the importance o f safety. You and anyone else using or main taining this machine

are strongly urged to read this ma nual, esp ecia lly all the saf ety inst ruct ion s.

DANGER, WARNING and CAUTION, used with the triangular safety alert symbol, highlight safety

messages. Alwa ys read and understand these me ssages becau se they relate to personal inju ry and your

safety .

If you ever need help or have questions about your new Toro turf care prod uct, contact your local Au thorized

Toro Distributor. Th e Toro Distributor has a complete supply of replace ment parts, a full line of accessories

and a professional service staff to support you. Keep your Toro all Toro. Buy genuine Toro parts and

accessories.

2

Page 3

TABLE OF CONTENTS

Page Page

SAFET Y INSTRUCT IO N S. . . . . . . . . . . . . . . 3 - 4

SAFETY AND INST RUCT I O N DECALS. . . . . . 4

LOOSE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . 6

SET UP INST RUCTIONS

Install Tongue . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Assemble Hopper . . . . . . . . . . . . . . . . . . . . . 7

BEFORE OPERATING

Check Hydraulic System. . . . . . . . . . . . . . . . . 8

Check Tire Pressure . . . . . . . . . . . . . . . . . . . . . 8

Attach Topdresser To Towing Vehicle. . . . . . 8

CONTROLS. . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

OPERATING INSTRUCT IO NS . . . . . . . . . . . . . . 9

LUBRICATION. . . . . . . . . . . . . . . . . . . . . . . . . . 10

SAFETY INSTRUCTIONS

The safety alert symbol means

CAUTION, WA RN ING or DANGER "personal safety inst ru ct ion ". Read

and understan d the ins truc tio n

because it has to do with safety. Failure to

comply with the instruct ion ma y result in

personal injury.

BEFO RE OPERATING

1. Read and understand all operating and safety

instructions. Before operating this unit, become

familiar with all controls and know how to stop

quickly. A replacement manual is available by

sending complete Model and Serial Number to:

MAINTENANCE

Bleeding Hydraulics. . . . . . . . . . . . . . . . . . . . . 11

Changing Oil Filter. . . . . . . . . . . . . . . . . . . . . . 11

Oil Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wheel Motor Nut Torque . . . . . . . . . . . . . . . . . 11

Brush To Conv eyor Belt Adjustment . . . . . . . 12

Chain Tension . . . . . . . . . . . . . . . . . . . . . . . . 12

Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Conveyor Bel t Instal lat i on/T e n sion . . . . . . . . . 13

ELECTRIC SCHEMAT IC . . . . . . . . . . . . . . . . 14

HYDRAULIC SCHEMATIC . . . . . . . . . . . . . . . 15

TROUBLE SHOO TING . . . . . . . . . . . . . . . 16 - 17

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

IDENTIFICATION AND ORDERING . . . . . . . . . 18

MAINTENANCE CH ART . . . . . . . . . . . . . . . . . . 19

WARRANTY. . . . . . . . . . . . . . . . . . . . Back Cover

WHIL E OPERATING

5. NEVER o pen the hydrau lic oil c ap until A LL air

pressure has been released.

6. The weight of the topdresser when filled with

sand is approximately 3500 lbs. The towing

vehicle should have adequate brakes to handle

this weigh t. Ch eck the spe cif ication s in t he to wing

vehicle’s operator manual pertaining to towing

weight.

7. NEVER carry passe ngers on t he mach ine, a nd

keep everyone away from the areas of operation.

The Toro Company

8111 Lyndale Avenue South

Minneapolis, MN 55420

8. NEVER allow child ren t o opera te th e machin e.

Do not allow adults to operate the mach ine without

proper instructions.

9. Make sure all hydraulic fittings are tight and all

2. Before each us e, be sure all bolt s and nut s

are tight.

3. Do not modify this equip men t in an y man ne r.

hydraulic hoses are in good condition before

operating this unit.

10. Keep hands and feet out of hopper when unit

is operating or engine is running on to wing vehicle.

4. W h en guards are removed f or se rvice, replace

them before operating machine. Guards are for

your protection.

3

11. To avoid loss of control, NEVE R , tow the unit

faster than 12MPH.

Page 4

SAFETY INSTRUCTIONS

MAINTENANCE

Hydraulic fluid esca ping under pre ssure c an h ave

sufficient force to penetrate skin and do serious

12. NEVER open the hydraulic cap until ALL air

pressure has been released.

damage. If fluid is injected into skin it must be

surgically removed within a few hours by a doctor

familiar with this form of injury or gangrene may

13. Keep body and hands away from pin hole

result.

leaks or nozzles that eject hydraulic fluid under

pressure. Use paper or cardboard, not hands to

search for leaks.

14. ALWA YS torque the nut on the wheel motors

to 230 - 250 ft. lbs when servicing .

SAFETY AND INSTRUCTION DECALS

The following safety and instruction decals are installed on the unit. Replace any decals that becomes

damaged or illegible. Part numbers for decals are listed below and in your Parts Catalog. Order

replacements from your Authorized Toro Distributor.

LINED UP WITH GATE

CONTROL POINTE R

(Part No. 01-506-0210)

OVER OIL CAP

(Part No. 01-506-0250)

NEAR BEARINGS &

GATE CONTROL ARM

(Part No. 58-6520)

ON CHAIN GUARD

(Part No. 01-506-0050)

ON FENDERS & HYD. TANK

(Part No. 75-5190)

EACH SIDE OF HOPPER

(Part No. 01-506-0240)

4

Page 5

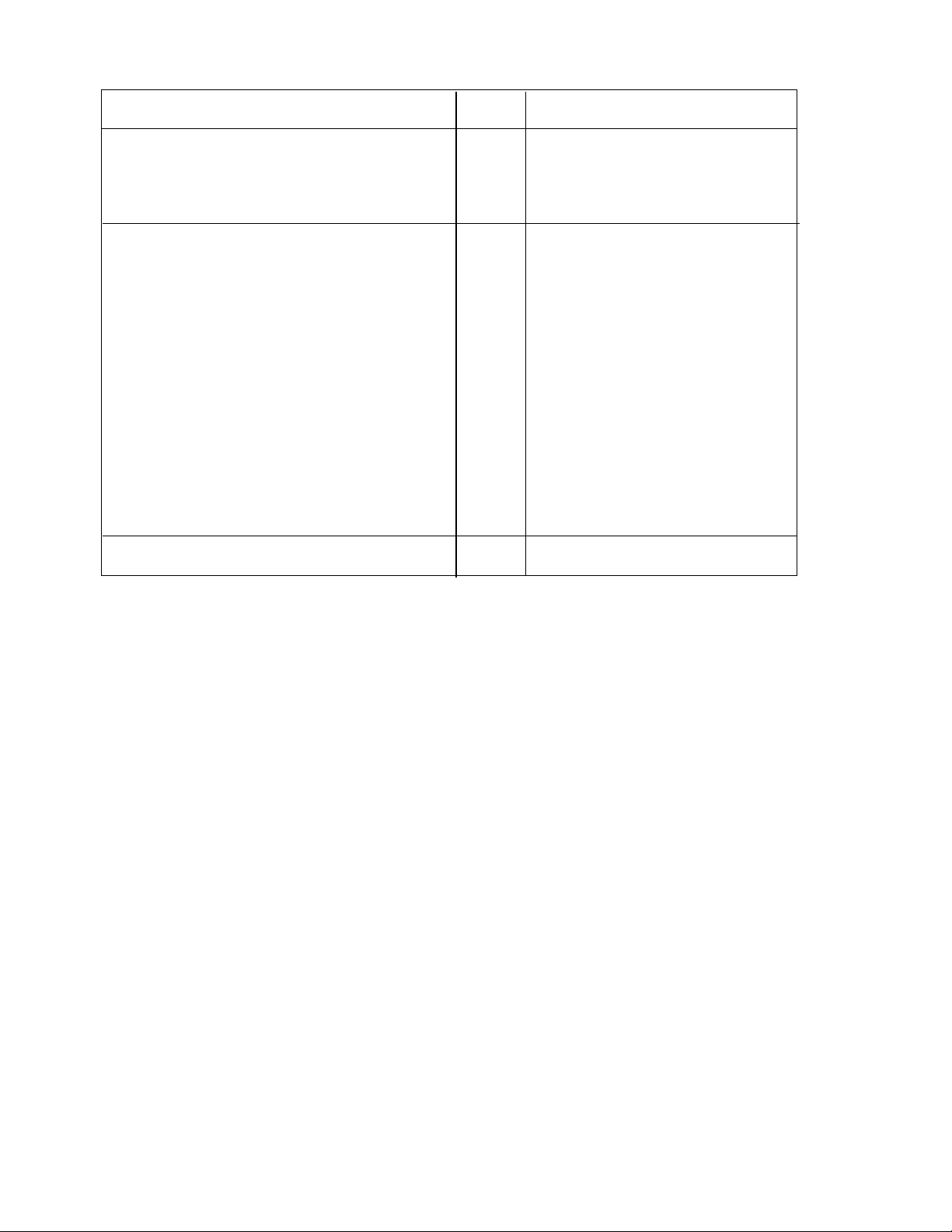

LOOSE PARTS

Description Qty Use

Tongue 1 Install tongue

Capscrew, 1/2"-13 x 3-1/2" 2

Flat Washer, 1/2" 4

Hex Nut, 1/2" 4

Hopper Front 1 Assemble ho pper

Long Skirt 1

Carriage Bolt, 1/4" -20 x 1" 20

Flat Washer, 1/4" 40

Lock Washer, 1/4" 40

Hex Nut, 1/4" 40

Short Skirt 2

Hopper Side, LH 1

Hopper Bac k 1

Hopper Bra ce 1

Carriage Bolt, 1/4" -20 x 3/4" 20

Hopper Side, RH 1

Support Rod 2

Hex Nut, 3/8" 4

Flat Washer, 3/8" 2

Wiring Harness 1

5

Page 6

SPECIFICATIONS

Dimensions:

Height: 40"

Length: 88"

Width: 83"

Hopper Dimensions:

Height: 18-1/ 4"

Top Width: 76"

Bottom Width: 60"

Top Length: 40"

Bottom Length: 20"

Hopper Capacity: 23.5 cubic foot

Spreading Width: 60"

Top D ressing Sp eed: Up to 8 MPH

Transporting Speed: Up to 12 MPH

Conveyor Belt: Continuous 60 " wide comp os i -

tion belt with heavy du ty polye st er cord.

Metering Gate: Infinitely variable from clo sed to

4-1/2" openin g for ligh t to heavy ap plic ation s.

Controls: 12 volt on/off switch at operat or’s po-

sition to engage conveyor and brush. Metering

gate control arm spans full width in fron t of

brush.

Drive: Ground driven hydraulic system self-con-

tained to topdresser (no hoses to connect to

towing vehicle).

Wheels and tires:

(4) 16 x 6.50 x 8 and

(2) 18 x 8.50 x 8 - 4 ply rib tread, high

flotation tires

Hydrau lic O i l: 10W30 SF - CC (2 gallons)

Air pressure:

Tires: 20 PSI

Hydraulic tank: 20-4 0 PSI

Shipping Weight: 1000 lbs.

6

Page 7

SET UP INSTRUCTIONS

Figure 1

INSTALL TONGUE (Fig. 1)

1. Mount the tongue using (2) 1/2" x 3-1/2" bolts,

flat washers and nuts provided. Double nut both

bolts.

ASSEMBLE HOPPER (Fig. 2)

1. Assemble th e sides, front, and back (Item A, B,

and C) of the hopper and corner guards

(Item H) using the 1/4" x 3/4" carriage

bolts provided. Attach at all four

corners and secure tigh tly.

2. Set the hopper frame in position on the

topdresser.

3. Attach the rear rubber skirt (D) between the

frame and the hopper. Use the 1/4" x 1" carriage

bolts to mount.

4. Attach the side rubber skirts (E) between the

frame and the hopper. Make sure rubber seals

together on sides , th en tigh te n bolts.

C

E

D

IMPORTANT: The rubber flaps must be installed on the topdresser. If the flaps are not

installed, damage will occur to the conveyor

belt and rollers.

5. Install support rods (F) through the front side.

Install the hopper brace (G) on the rear of the

hopper. Run the threaded end of the support rod

through the brace and the hopper. Attach with a

3/8" fl at washe r an d doub le nut.

G

H

B

H

A

C

F

E

Figure 2

7

Page 8

BEFORE OP E RATING

Open

Close

Gate Control Arm

Black

Knob

Gate

CHECK TIRE PRESSURE

DANGER

Pressurized Cap Can Cause Seriou s In jury

If Improperly Opened.

Never open oil cap without releas ing

pressure valve stem.

Keep face and upper body away from cap

while opening.

CHECK HYDRAULIC SYSTEM

1. The hydraulic sy stem is design ed to operate on

10W30 SF-CC oil. The tank contains 2 gallons of

oil. There should be 4" of oil in th e tank whe n full.

2. Pressurize the hydraulic tank with air (20 to 40

PSI). Always maintain air pressure in the tank to

minimize slipping of the conveyo r belt whe n using

heavy or wet sand.

3. Visually inspe ct th e hydra ulic s ystem for leaks,

loose fasteners, missing parts, improperly routed

lines. Make all repairs before operating.

1. Check tire pressure before e ac h use. Be ca use

the topdresser is ground driven always maintain

tire pressure at 20 PSI.

ATTACH TOPDRESS ER TO TOW ING

VEHI CLE

1. Attach the topdresser to the towing vehicle.

Use the pin on the towing vehicle to secure.

2. Connect the long half of the wiring harness to

short half at the end of the tongue.

3. Connect th e red w ire to the posit ive te rminal on

the towing vehicle battery. The white wire

connects to the negative te rmina l.

4. Gather and consolidate all loose wires. Tape

together with existin g wires on the towing vehicle.

Make sure there a re no loos e or dan glin g wire s to

interfere with the operation of the unit.

5. Pull the unit forward at a slow speed and flip the

electric al switch to t he "O N " po sit ion . If b rush a nd

conveyor belt rotate flip switch off. If they do not

rotat e, chec k the t roub le shoo ting pa ge (pg. 16) f or

details. After checking, turn the switch off.

CONTROLS

ELECTRIC SWITCH

The electric switch has 2 positions; ON, OFF.

When switch is on the conveyor belt and brush will

rotate. When switch is off the conveyor belt and

brush stop rotating.

GATE CONTROL ARM (Fig. 3)

The gate control arm is used to control the amou nt

of sand being applied to the turf. The black knob

on the end is used t o loc k t he s et tin g int o position.

1. Loosen t he black knob e nough to allo w the arm

to pivot.

8

2. Set the gate into position. Moving the gate

control arm downwa rd opens the gate and upward

motion closes it.

3. When desired gate setting is obtained, tighten

black knob to lock into position.

Figure 3

Page 9

CONTROLS

DANGER

Pressurized Cap Can Cause Seriou s In jury

If Improperly Opened.

NEVER open oil cap with out rele asin g

pressure valve stem.

Keep face and upper body away from cap

while opening.

OPERATING INSTRUCTIONS

DANGER

NEVER carry passengers on the machin e or

towing vehicle, and keep everyone away from

the areas of ope ration.

To avoid loss of control, NEVER, tow the unit

faster than 12 MPH.

Keep hands an d f e et out of hopp er wh en uni t

is operating or engin e is running on towing

vehicle.

1. Fill the hopper with sand. The maximum

amount of san d that can be put into the hopper is

2500 pounds. The weight of the topdresser filled

with sand is approximately 3500 pounds. The

towing vehicle should have adequate brakes to

handle this we ight. Check the spe cific ations in t he

towing vehicle’s operator manual pertaining to

towing weight.

IMPORTANT:

faster 12 MPH because the hydraulic motors

will be damaged.

NEVER transport at a speed

PRESSURE GAUGE

The gauge i s a p r es s ur e gauge that read s the ai r

pressure in the tank. The recommended air

pressure is between 20 - 40 PSI.

2. Ope n t he gat e a rm t o th e de si re d ra te . Tig ht en

the black knob to lock into posit ion .

3. Slowly pull the topdresser forward and flip the

electrical switch to the "ON" position. The unit is

now topdressing.

4. Flip electric switch to OFF to stop topdressing

and before tran sp ortin g.

SAND APPLICATION RATE

The rate of sand being applied depends on the

weight of the sand. Sand varies in moisture and

coarseness which effects the weight. These

factors must be taken into consideration when

determining the amount of sand required for the

application. Test a small area to determine the

correct amount.

IMPORTANT: The maximum amount of sand

that can be put into the hopper is 2500

pounds.

NEVER top dress at a speed faster than 8

MPH.

9

Page 10

LUBRICATION

Figu re 5

BEARINGS (Fig. 4)

The topdresser has 5 self sealing bearings that

must be lubricated with a No. 2 Lithium based

grease.

IMPORTANT: Lubricate the bearings to

maintain a slight leakage on the seals. Too

ADJUSTMENT LUGS (Fig. 5)

Always maint ain a light coat of No. 2 Lithium based

grease on the thread s of the fou r adju stme nt lu gs .

much grease can cause overhe ating.

Figure 4

Wheels

Grease fit tings weekly or eve ry 40 operating hours.

Use No. 2 Lithium based grease.

DRIVE CHAIN

Always main tain a light coat o f gre ase o n the drive

chain.

10

Page 11

MAINTENANCE

BLEEDING HYDRAULIC SYSTEM

DANGER

Pressurized Cap Can Cause Seriou s In jury

If Improperly Opened.

Never open oil cap without releas ing

pressure valve stem.

Keep face and upper body away from cap

while opening.

When any hydraulic part is rep laced the system will

have to be bled.

1. Push va lve s te m in to re lea se all press ure f rom

the ta nk.

2. Remove the air pressure cap.

must run smoothly with no jerking motion .

6. When all are operating smo othly, inst all th e air

pressure cap. Check the air pressure cap for

leaks. See Check Hydraulic Syste m under Befo re

Operating (pg. 8).

IMPORTANT: When working with hydraulics,

you must keep the work area as clean as

possible. Change oil and filter as

recommended. If you have a new piece of

equipment under warranty and a hydraulic item

goes out . . . . don’t try to fix it. Install a new

part and return the de fective part to the factory.

It is easier to get warran ty on a part that has n ot

been taken apart.

CHANGING OIL FILTER

The oil filter is a 10 micron cross f ilter. Change the

filter every 100 hours of operation. Always fill the

element with oil when inst allin g a new filte r.

3. With towing unit, pull the topdress er up to

8 MPH. Pull the top dresser until all "jerking"

motion has stopped.

4. Use a tape measure to check the level of oil in

the ta nk .

Tabs

Torque

230 - 250 ft. lbs.

5. Check the conveyor and brush motors, both

Figure 6

OIL TANK

The oil tank is a 2 gallon capa city tank. Th e oil type

is 10W30 or 10W40 SF - CC (preferably 10W30).

Change oil every 500 hours or yearly, whichever

comes first. The drain plug is located on the

bottom of the tank.

IMPORTANT: When adding oil to the system

pour it through a funne l with a fine mesh screen

(200 mesh or better). Keep the funnel and

containers immaculately clean. This

procedure prevents accidental contamination

of the hydrauli c system.

WHEEL MOTOR NUT TORQUE (Fig. 6)

ALWAYS torque the nut on the whee l motor to 2 30

- 250 ft. lbs when servicing. Place the tabs of the

nut on the outside as shown in Fig. 6. If the tabs

are insta lled on the insid e, again st the h ub, the nut

cannot be torqued properly.

11

Page 12

MAINTENANCE

(A)

Figu re 9

BRUSH TO CONVEYOR BELT ADJUSTMENT

Fig. 7)

The brush is moved back and forth on its mounting

slots to adjust it to the conveyor belt. The brush

should be as close to the belt as possible without

touching. A piece of paper can be inserted

between t he conveyor b elt and t he b rush to check

CHAIN TENSION (Fig. 8)

The cha in tens ion i s a dju sted by mov ing the mot or

Brush

Bearing

Right Side Left Side

Figure 7

Brush

Brush

Motor

the adjustment. The brush must be the same

height from end to end.

1. Loosen the nut s of the bearing on the right hand

side.

2. Lo osen the nu ts mo unti ng th e brus h mot or to

the main frame.

3. Slide the brush into position on the right hand

side. Finger tig hten the nuts.

Figu re 8

and sprocket assembly (A) up and down on its

mounting slots. A 1/8" deflection is

recommended. Do not over tigh ten, this will ca use

chain we ar. Do not operat e with a loose chain; thi s

will cause sprocket wear.

1. Loos en the nut s mo untin g the mot o r an d

sprocket as semb ly (A) to the main frame.

2. Slide the hydraulic mot or and sproc ket

assembly (A) u p and down on the mountin g

slot until proper te nsio n is achiev ed .

3. Tighten the nuts.

4. Slide the brush into position on the left hand

side. Finger tig hten the nuts.

5. Insert a piece of paper between the brush and

the conveyor belt. The brush must be the same

height from end to end.

6. If the adjustment is correct, tighten the nuts. If

not, repeat steps 1 through 5.

12

ROTATION (Fig. 9)

Rotation

Direction

The rotat ion of the con veyor, brush an d the wheel s

Page 13

is shown in Fig. 9 . If the ro tatio n in not cor rect, t he

4.5 "

A

Figure 11

hydraulic line s are inst alle d backwa rds. See the

MAINTENANCE

CONVEYOR BELT INSTALLATION/TENSION

(Fig. 10 & 11)

To install a new conveyor belt follow the

instructio ns be low.

1. Pull the topdresser forward until the conveyor

belt seam is in the center of the hopper.

2. Loosen t he nuts (A) on the spring rod to rele ase

the tension .(See Figure 11).

3. Remove the lacing (seam wire) from the old

conve yo r be l t.

4. Grab one sid e o f the o ld con ve yor belt and pul l

it free from the unit.

5. Lay the new belt on th e frame and roll it arou nd

the rollers bringing th e seam to the center.

Hydraulic Schematic (pg. 15).

CONVEYOR BELT LACING

The lacing on the conveyor belt has a silicone

sealer on it to prevent sand leakage inside the

conveyor belt. Re apply once a year and everytime

the lacing is removed for service. The silicone may

be purchased locally. It is multi-purpose, weather

resistant and should be flexible or flowable.

1. Tigh ten the nu t on the spring rod until t he spring

is compressed to 4-1/2" as shown in Fig. 11. Be

sure the front roller is parallel with the drive roller.

This can be done by measuring the distance

between the drive roller bearing bolt and the idler

roller bearing bolt on each side. If there is a

difference tighten the nut on the spring rod until

6. Feed the lacing through the conveyor belt

seam. Make sure the lacing is lined up. If the

lacing is of f one notch it will cause the belt t o buckle

and not run s traight . Ch eck f or straig htne ss with a

straight edge once it has been installed. See Fig.

10. After the wire is centered, bend both ends of

Straight Edge

the wire to prevent the wire from working loose.

Figure 10

distance on both sides is equal.

2. Tighten the jam nut against the other jam nut.

The plate mu st be free to slide . Tig ht en the bolts,

then loosen until it can slide.

IMPORTANT: Do not allo w the plate to beco me

too loose, it will cause the spring rod to bend.

13

Page 14

ELECTRICAL SCHEMATIC

Black

or

White

Red

Black

or

White

Fuse

3 Amp.

BATTERY

White

Red

SWITCH

White

ELECTRIC

SOLENOID

HYD. VALVE

14

Page 15

HYDRAULIC SCHEMATIC

FILTER

Return

WHEEL

MOTOR

T1

A

C

To Motor When ON

T2

B

WHEEL

MOTOR

LOWER DRIVE

SPROCKET

MOTOR

BRUSH

MOTOR

Suction

Suction

HYDRAULIC

TANK

15

Page 16

TROUBLE SHOOTING

CONDITION CAUSE CORRECTION

Conveyor Belt and Brush Not

Turning

Conveyor Belt Not Turning

•

Bad Electrical Connections

•

Blown harne ss fuse.

•

Hydraulic lines installed backwards

•

Contaminated valve

•

Loose or broken chain

•

Tension of the belt is too loose.

•

Plug in the wiring harness and

make sure wires are making

contact.

•

Replace fuse

•

Standing on the left hand side

(Chain Guard side) the conveyor belt should rotate clockwise and the brush should rotate counterclockwise. If incorrect, reverse the lines on

the corresponding motors.

•

Remove cartridge to see if

blocked. Clean out, making

sure plunger is not damaged.

Replace valve or cartridge.

•

Replace chain or adjust tension.

•

Tighten the tension.

Tire(s) Skidding

•

Brush set too low to the belt.

•

Drive roller not turni ng

•

One tire skids

•

Both tires skid

•

Slide a sheet of paper between the brush and the belt;

it should slide freely. If brush

is too low slide it upwards until it clears the belt just

enough to slide the paper underneath. Make sure the paper clears at the lacing.

•

Check the welds on each end

of the drive roller. The shaf t

may be turning but not the

roller. Replace drive roller.

•

Check sprocket for sheared

key. Replace key.

•

Replace the check valve on

that side.

•

Check the valve for blockage

of ports.

16

Page 17

TROUBLE SHOOTING (Cont.)

17

CONDITION CAUSE CORRECTION

Tire(s) Skidding (co nt .) •

•

Uneve n ti re pressure

Conveyor Belt Not Tracking

Properly

•

Belt pulls to one side

•

Belt Buckles in Center

•

Belt rides off pulley

Check the pressure setting on

the relief valve (1100 PSI) it

may be too low. Reset, if necessary.

•

Check tire pressure. All tires

should be 20 PSI.

•

Tension is not the same from

side to side. Set the spring

rod at 4 1/2" on both sides.

Run. The belt will pull to the

tight side. Loosen or tighten

as needed.

•

Pulleys are not in line. Remove belt lacing and realign

the pulleys using straight

edge or fixture.

•

V-Guides of the belt not correct. Measure distance between v-guides for straightness and squarness. Tolerance for both is (+) or (-) 1/16".

Uneven Sand Distrib u tion

•

Uneve n ti re pressure

•

Uneve n brush setting

•

Excessive air in the system

•

Not enough air in oil tank

•

Check both outside tire pressure; both tires should be 20

PSI.

•

Check brush to conveyor belt

adjustment. Brush should be

same height all the way

across face.

•

Bleed lines. See Operators

Manual for instructions.

•

Pressurize air in tank to 35

PSI.

Page 18

SEASONAL STORAGE

1. Thoroughly clean the topdresser, especially

inside the hopper . The hopper and conv eyor belt

area should be free of any remaining sand

particles.

2. Apply a light coat of silicone to the lacing of the

conveyor belt. Refer to Mainten ance se ctio n

3. Inflate all tires to 20 PSI. Or block up the

topdresser to remo ve the weig ht.

4. Drain and replace hydraulic fluid and filter.

Inspect all hydraulic lines and fittings. Replace if

necessary. Refer to the Maintenance section.

5. Tighten all fasteners.

IDENTIFI CATION AND ORDERING

6. Lubricate all grease fittin gs and bearings. Wipe

off exces s lubrica nt . Refer t o page 10.

7. The unit should be stored out of the sun to

prolong the life of the conveyor belt. If stored

outside it is recommen ded to cover the hopper with

a tarp.

8. Check t he tension of the drive chain . Adjus t the

tension if necessa ry and lig htly co at the chain with

grease. Ref er to the M aintenance sect ion (pg. 11

- 13).

MODEL AND SERIAL NUMBER

The TOPDRESSER 2300 has two identification

numbers: a mod el number and serial number. The

two numbers are stamped on a plate which is

riveted on the hydraulic tank. In any

correspondence concerning the TOPDRESSER

2300, supply mo del and serial n umbers t o be su re

that the correc t info rmation an d replace ment part s

are obtain ed .

To order replacement parts from an authorized

TORO Distributor, supply the following

information:

1. Model and serial numbers of the mach ine .

2. Part number, description and quantity of parts

desired.

Note: Do not order by re feren ce nu mbe r if a part s

catalog is being use d; use the pa rt nu mbe r.

18

Page 19

MAINTENANCE RECORD

19

Page 20

The Toro Commercial Products Two Year Limited Warrant y

The Toro Company warrant s your 1996 or n ewer Toro Co mmercial Product ("P roduct") purchased after

January 1, 1997, to be free from defects in materials or workmanship for the period of time listed below*. Where

a warrantable condition exists, Toro will repair the Product at no cost to you including diagnosis, labor, parts,

and transportation. This w arranty begins on the date the Product is delivered to the original retail purchase r.

Warranty Duration: Two years or 1500 operational hours*, whichever occurs first.

* Product equipped with hour meter.

Owner Responsibilities:

As the Product owner, you are responsible for required

maintenance and adjustments stated in your Owner’s

Manual. Failure to perform required maintenance and

adjustments can be grounds for disallowing a warranty

claim .

Instructions For Obtaining Warranty Service:

You are responsible for notifying the Commercial Products

Distributor or Authorized Commercial Products Dealer from

whom y ou purchase d the Produ ct as soon as yo u believe a

warrantable condition exists.

If you need help locating a Commercial Products Distributor

or Auth orized De aler, or if you have questio ns regardin g your

warranty rights or responsibilities, you may contact us at:

Toro Commercial Products Service Department

8111 Lyndal e A venue Sout h

Minneapolis, MN, 55420-1196

Telephon e: (612) 88 8- 8 801

Facsimile:(612) 887-8258

E-Mail: Commercial.Service@Toro.Com

Maintenance Parts:

• This warranty does not apply to parts subject to consumption

thr ough u se unless f ound t o b e def ective . Ex amples of p arts

which are consumed, or used up, during normal Product

operation include, but are not limited to, blades, reels,

bedknive s, tines, spark plug s, castor wheels, tires, filters,

belts, etc.

• This wa rranty does not apply to fail ures caused by outside

influence. Items considered to be outside influence include,

but are not limited to, weather, storage practices,

contamination, use of unapproved coolants, lubricants,

additives, or chemicals, etc.

• This warran ty does not ap ply to nor mal "wear and tear" it ems.

Normal "Wear and Tear" includes, but is not limited to,

damage to seats due to wear or abrasion, worn painted

surfaces, scratched decals or windows, etc.

Other Legal Disclaimers:

The above remedy of product defects through repair by an

authori z ed di stributor or deale r i s th e p urchaser’ s sole re me dy

for any defect. This w arranty gives you specific legal rights,

and you may also have other rights which vary from state to

state.

Except for the Emissions warranty referenced below,

if applicable, there is no other express warranty. All

implied warranties of merchantability and fitness for

use are limited to the duration of the express warranty.

Parts scheduled for replacement as required maintenance

("Maintenance Parts"), are warranted for the period of time

up to the scheduled replacement time for that part.

Items/Conditions Not Covered:

Not all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship.

The items / conditions listed below are not covered by this

warranty:

• Product failures which result from the use of non-Toro

replacement parts, or from installation and use of add-on,

modified, or unapprov ed acce ss ories are not covered .

• Product failures which result from failure to perform required

maintenance and/or adjustments are not covered.

• Product failur es which result from operating the Product in an

abusive, negligent or reckless manner are not covered.

Some sta te s do not all ow l imitation s o n how long an imp l ie d

warranty last s, so the above limi tation may not apply t o you .

The Toro Company is not liable for indirect, incidental

or consequential damages in connection with the use

of the Product, including any cost or expense of

providing substitute Product or service during periods

of malfunction or non- use.

Some states do not allow the exclusion of incidental or

consequential damages, so the above exclusion may not

apply t o you.

Note to California residents:

Syste m on yo ur Pr oduc t may b e co vered by a separ ate wa rran ty

meeting requirements e stablished by the U.S. Environme ntal

Protection Agency (EPA), or the California Air Resources Board

(CARB). The ho ur limitation s set for th above do not ap ply to

the Emissions Control System Warranty. Refer to the California

Emissio n Control Wa rranty State ment pri nted in your Ow ner’s

Manual or contained in the engine manufacturer’s

The Emissions Control

Loading...

Loading...