Page 1

FormNo.3400-805RevA

g024406

TITAN

®

ZX4800or5400

Zero-Turn-RadiusRidingMower

ModelNo.74846—SerialNo.316000001andUp

ModelNo.74848—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3400-805*A

Page 2

Thismachineisaride-on,rotary-bladelawnmowerintended

G010228

1

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Figure1

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

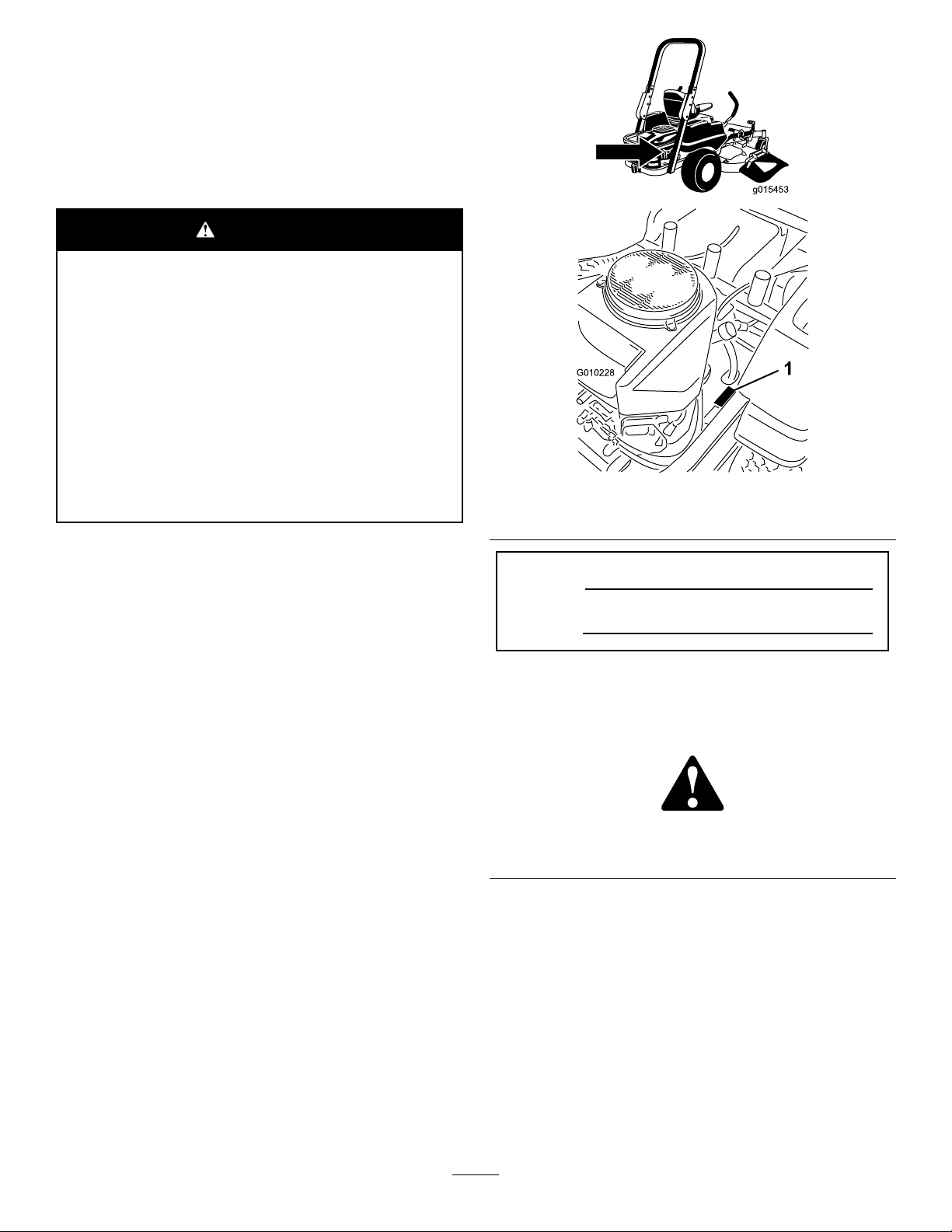

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbytheengine

manufacturerinaccordancewithSAEJ1940andratedto

J2723.

Donottamperwiththeenginecontrolsoralterthegovernor

speed;doingsomaycreateanunsafeconditionresultingin

personalinjury.

3

Page 4

Contents

Safety...........................................................................5

SafeOperatingPractices...........................................5

ToroRidingMowerSafety........................................6

Model74846...........................................................7

Model74848...........................................................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................14

Controls...............................................................15

Operation....................................................................16

AddingFuel...........................................................16

ThinkSafetyFirst...................................................17

UsingtheRolloverProtectionSystem(ROPS)............18

UnderstandingtheSafety-InterlockSystem................18

TestingtheSafety-InterlockSystem...........................18

CheckingtheEngine-OilLevel.................................19

BreakinginaNewMachine......................................19

OperatingtheParkingBrake....................................19

OperatingtheThrottle............................................19

OperatingtheChoke...............................................19

OperatingtheIgnitionSwitch..................................20

StartingandStoppingtheEngine..............................20

OperatingtheBlade-ControlSwitch(PTO)................21

DrivingtheMachine...............................................21

StoppingtheMachine.............................................23

AdjustingtheHeightofCut.....................................23

AdjustingtheAnti-ScalpRollers...............................24

PositioningtheSeat................................................24

AdjustingtheMotion-ControlLevers........................24

PushingtheMachinebyHand..................................25

Convertingthe48-InchMowertoSide

Discharge..........................................................25

Convertingthe54-InchMowertoSide

Discharge..........................................................27

UsingtheSideDischarge.........................................28

TransportingtheMachine........................................29

LoadingtheMachine..............................................29

OperatingTips......................................................31

Maintenance.................................................................32

RecommendedMaintenanceSchedule(s)......................32

PremaintenanceProcedures........................................33

Service-IntervalChart.............................................33

RaisingtheSeat......................................................33

ReleasingtheMower-DeckCurtain...........................33

Lubrication...............................................................34

GreasingtheBearings.............................................34

EngineMaintenance..................................................34

ServicingtheAirCleaner.........................................34

ServicingtheEngineOil..........................................35

ServicingtheSparkPlug..........................................37

CleaningtheCoolingSystem....................................38

FuelSystemMaintenance...........................................38

ReplacingtheFuelFilter..........................................38

ElectricalSystemMaintenance....................................39

ServicingtheBattery...............................................39

ServicingtheFuses.................................................40

DriveSystemMaintenance.........................................41

CheckingtheTirePressure......................................41

HydraulicSystemMaintenance....................................41

CheckingtheHydraulic-FluidLevel..........................41

ChangingtheHydraulicFilterandFluid.....................41

MowerDeckMaintenance...........................................43

ServicingtheCuttingBlades.....................................43

LevelingtheMowerDeck........................................46

InspectingtheBelts................................................47

ReplacingtheMowerBelt........................................48

RemovingtheMower..............................................48

InstallingtheMowerDeck.......................................49

ReplacingtheGrassDeector..................................49

Cleaning...................................................................51

WashingtheUndersideoftheMower........................51

DisposingofWaste.................................................51

Storage........................................................................52

CleaningandStorage..............................................52

Troubleshooting...........................................................53

Schematics...................................................................55

4

Page 5

Safety

ThefollowinginstructionsarefromtheENstandardEN

ISO5395:2013.

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Training

•Readtheinstructionscarefully .Befamiliarwiththe

controlsandtheproperuseoftheequipment.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethelawnmower.Localregulationscan

restricttheageoftheoperator.

•Nevermowwhilepeople,especiallychildren,orpetsare

nearby.

•Keepinmindthattheoperatororuserisresponsiblefor

accidentsorhazardsoccurringtootherpeopleortheir

property.

•Donotcarrypassengers.

•Alldriversshouldseekandobtainprofessionaland

practicalinstruction.Suchinstructionshouldemphasize:

–Theneedforcareandconcentrationwhenworking

withride-onmachines;

–Controlofaride-onmachineslidingonaslopewill

notberegainedbytheapplicationofthebrake.The

mainreasonsforlossofcontrolare:

◊Insufcientwheelgrip;

◊Beingdriventoofast;

◊Inadequatebraking;

◊Thetypeofmachineisunsuitableforitstask;

◊Lackofawarenessoftheeffectofground

conditions,especiallyslopes;

◊Incorrecthitchingandloaddistribution.

Preparation

•Whilemowing,alwayswearsubstantial,slip-resistant

footwearandlongtrousers.Tiebackanylonghair.Do

notwearjewelry.

•Thoroughlyinspecttheareawheretheequipmentisto

beusedandremoveallobjectswhichmaybethrownby

themachine.

•Warning-Fuelishighlyammable.

–Storefuelincontainersspecicallydesignedforthis

purpose.

–Refueloutdoorsonlyanddonotsmokewhile

refueling.

–Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddfuelwhiletheengineis

runningorwhentheengineishot.

–Iffuelisspilled,donotattempttostarttheengine

butmovethemachineawayfromtheareaofspillage

andavoidcreatinganysourceofignitionuntilfuel

vaporshavedissipated.

–Replaceallfueltanksandcontainercapssecurely.

•Replacefaultysilencers.

•Beforeusing,alwaysvisuallyinspecttoseethattheblades,

bladeboltsandcutterassemblyarenotwornordamaged.

Replacewornordamagedbladesandboltsinsetsto

preservebalance.

•Onmulti-bladedmachines,takecareasrotatingoneblade

cancauseotherbladestorotate.

Operation

•Bealert,slowdownandusecautionwhenmakingturns.

Lookbehindandtothesidebeforechangingdirections.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Mowonlyindaylightoringoodarticiallight.

•Beforeattemptingtostarttheengine,disengageallblade

attachmentclutchesandshiftintoneutral.

•Donotuseonslopesofmorethan15degrees.

•Rememberthereisnosuchthingasasafeslope.Travel

ongrassslopesrequiresparticularcare.T oguardagainst

overturning:

–donotstoporstartsuddenlywhengoingupor

downhill;

–uselowspeedsonslopesandduringtightturns;

–stayalertforhumpsandhollowsandotherhidden

hazards;

•Usecarewhenpullingloads.

–Useonlyapproveddrawbarhitchpoints.

–Limitloadstothoseyoucansafelycontrol.

–Donotturnsharply.Usecarewhenreversing.

•Watchoutfortrafcwhencrossingornearroadways.

•Stopthebladesrotatingbeforecrossingsurfacesother

thangrass.

•Whenusinganyattachments,neverdirectdischargeof

materialtowardbystandersnorallowanyonenearthe

machinewhileinoperation.

•Neveroperatethemachinewithdamagedguardsor

withoutsafetyprotectivedevicesinplace.

5

Page 6

•Donotchangetheenginegovernorsettingsoroverspeed

theengine.Operatingtheengineatexcessivespeedcan

increasethehazardofpersonalinjury.

•Beforeleavingtheoperator'sposition:

–Disengagethepowertake-offandlowerthe

attachments;

–Changeintoneutralandsettheparkingbrake;

–Shutofftheengineandremovethekey .

•Disengagedrivetoattachments,shutofftheengine,and

disconnectthesparkplugwire(s)orremovetheignition

key.

–Beforeclearingblockagesoruncloggingchute;

–Beforechecking,cleaningorworkingonthe

lawnmower;

–Afterstrikingaforeignobject.Inspectthelawnmower

fordamageandmakerepairsbeforerestartingand

operatingtheequipment;

–Ifthemachinestartstovibrateabnormally(check

immediately).

•Disengagedrivetoattachmentswhentransportingornot

inuse.

•Shutofftheengineanddisengagedrivetoattachment.

–Beforellingthefueltank;

–Beforeremovingthegrasscatcher;

–Beforemakingheightadjustments;unlessan

adjustmentcanbemadefromtheoperator'sposition.

•Reducethethrottlesettingduringenginerun-outand,if

theengineisprovidedwithashut-offvalve,turnthefuel

offattheconclusionofmowing.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

equipmentisinsafeworkingcondition.

•Neverstoretheequipmentwithfuelinthetankinsidea

buildingwherefumescanreachanopenameorspark.

•Allowtheenginetocoolbeforestoringinanyenclosure.

•Toreducetherehazard,keeptheengine,silencer,

batterycompartmentandfuelstorageareafreeofgrass,

leaves,orexcessivegrease.

•Checkthegrasscatcherfrequentlyforwearor

deterioration.

•Replacewornordamagedpartsforsafety.

•Ifthefueltankhastobedrained,thisshouldbedone

outdoors.

•Whenmachineistobeparked,storedorleftunattended,

lowerthecuttingmeans.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

isnotincludedintheCENstandard.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxideandotherexhaustgasses

cancollect.

•Keephands,feet,hairandlooseclothingawayfrom

attachmentdischargearea,undersideofmowerandany

movingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhichmay

behotfromoperation.Allowtocoolbeforeattempting

tomaintain,adjust,orservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyesandclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfrombattery.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•UseonlyToro-approvedattachments.

SlopeOperation

•Donotmowslopesgreaterthan15degrees.

•Donotmowneardrop-offs,ditches,steepbanks,or

water.Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,ordrowning.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcauseslidingand

lossofcontrol.

•Donotmakesuddenturnsorrapidspeedchanges.

•Useawalkbehindmowerand/orahandtrimmernear

drop-offs,ditches,steepbanks,orwater.

•Reducespeedanduseextremecautiononslopes.

•Removeormarkobstaclessuchasrocks,treelimbs,etc.

frommowingarea.Tallgrasscanhideobstacles.

•Watchforditches,holes,rocksdips,andrisesthatchange

theoperatingangle,asroughterraincouldoverturnthe

machine.

•Avoidsuddenstartswhenmowinguphillbecausethe

mowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoingdownhill.

Weighttransfertothefrontwheelsmaycausedrive

wheelstoslipandcauselossofbrakingandsteering.

•Alwaysavoidsuddenstartingorstoppingonaslope.

Iftireslosetraction,disengagethebladesandproceed

slowlyofftheslope.

•Followthemanufacturer'srecommendationsforwheel

weightsorcounterweightstoimprovestability.

•Useextremecarewithgrasscatchersorotherattachments.

Thesecanchangethestabilityofthemachineandcause

lossofcontrol.

6

Page 7

UsingtheRollover-ProtectionSystem

(ROPS)

Model74848

•Keeptherollbarintheraisedandlockedpositionand

usetheseatbeltwhenoperatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Beawarethereisnorolloverprotectionwhentheroll

barisdown.

•ChecktheareatobemowedandneverfoldtheROPSin

areaswherethereareslopes,dropoffsorwater.

•Lowertherollbaronlywhenabsolutelynecessary.Donot

weartheseatbeltwiththerollbarfoldeddown.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

Model74846

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof105dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof92

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

Hand-ArmVibration

Measuredvibrationlevelforlefthand=5.8m/s2

Measuredvibrationlevelforrighthand=3.6m/s2

UncertaintyValue(K)=2.3m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBodyVibration

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof92

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO5395:2013.

Hand-ArmVibration

Measuredvibrationlevelforlefthand=4.8m/s2

Measuredvibrationlevelforrighthand=4.4m/s2

UncertaintyValue(K)=2.4m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

WholeBodyVibration

Measuredvibrationlevel=0.39m/s2

UncertaintyValue(K)=0.19m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

Measuredvibrationlevel=0.45m/s2

UncertaintyValue(K)=0.22m/s2

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO5395:2013.

7

Page 8

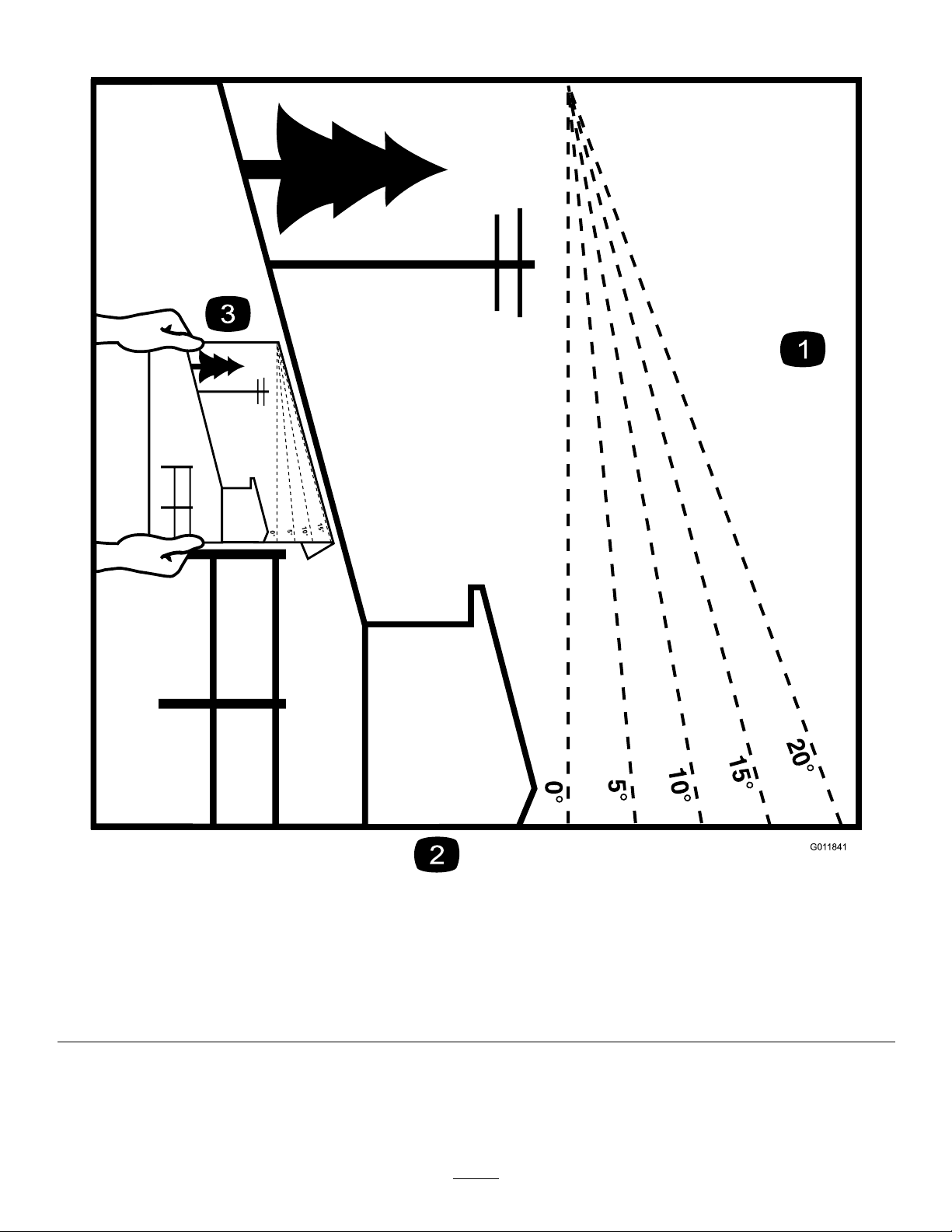

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

Page 9

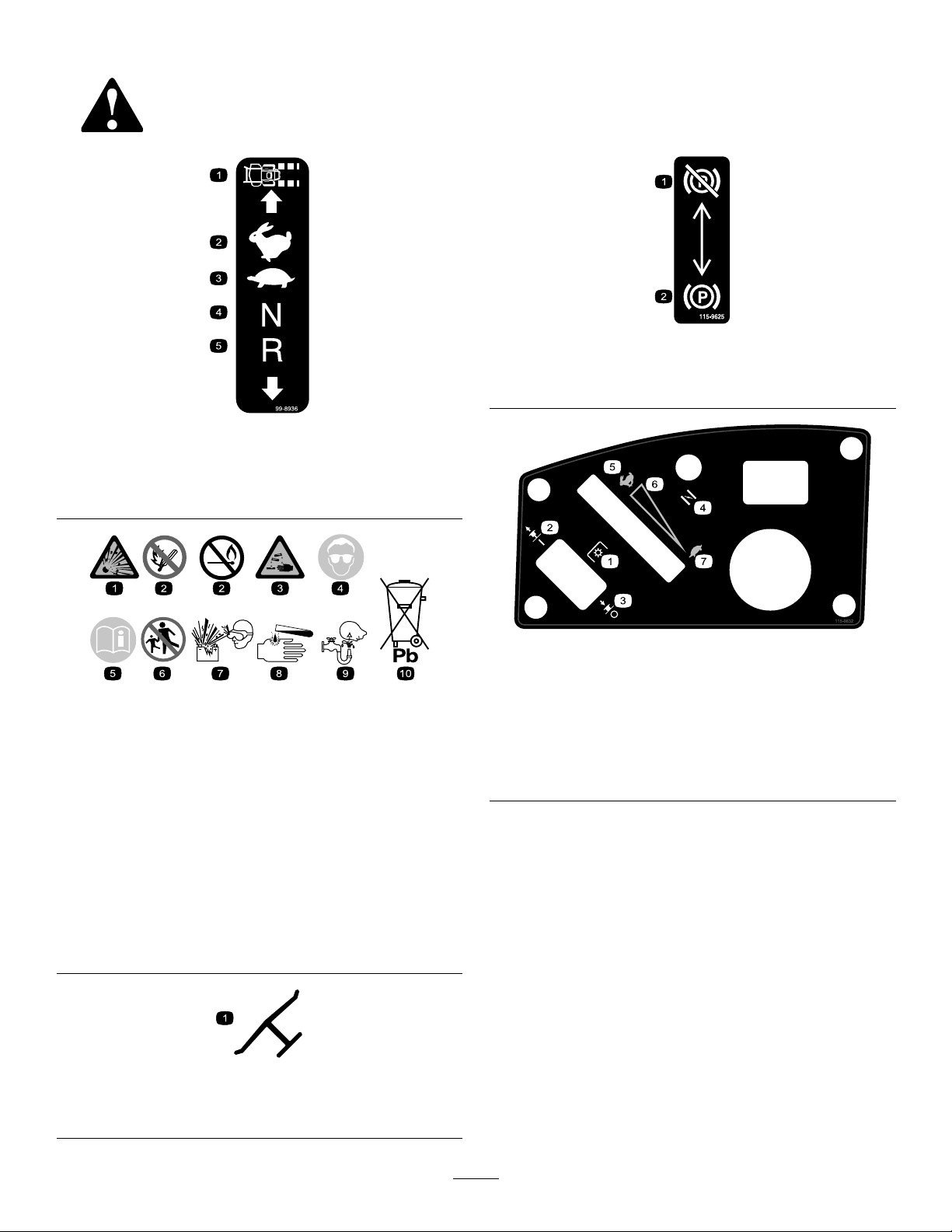

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

115-9625

99-8936

1.Machinespeed4.NEUTRAL

2.FAST5.REVERSE

3.SLOW

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries.

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

1.Parking

brake—disengaged

2.Parkingbrake—engaged

115-9632

1.Powertake-off(PTO),

Blade-controlswitchon

somemodels

2.Bladecontrolswitch—ON6.Continuousvariable

3.Bladecontrolswitch—OFF7.SLOW

4.Choke

5.FAST

setting

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

9

Page 10

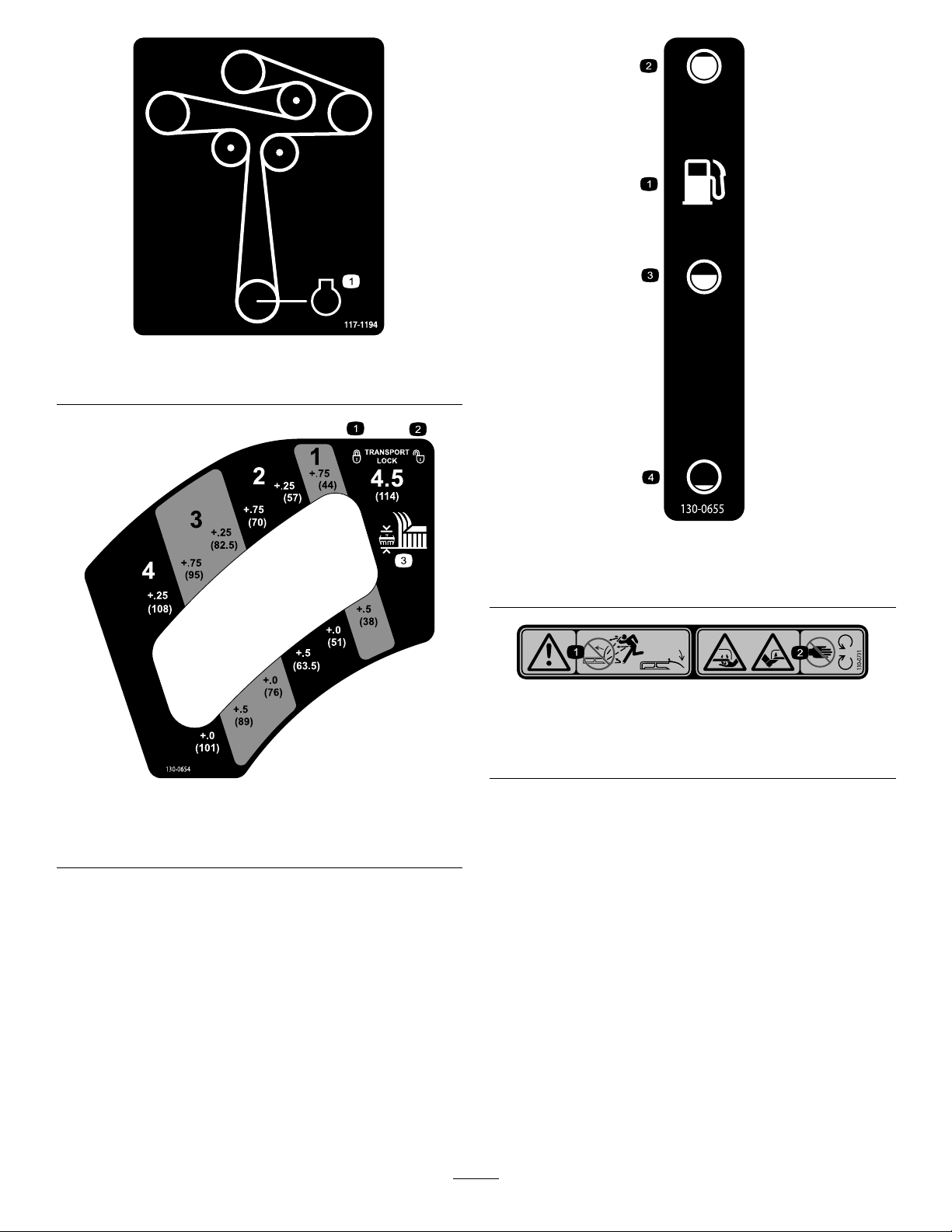

117-1194

1.Engine

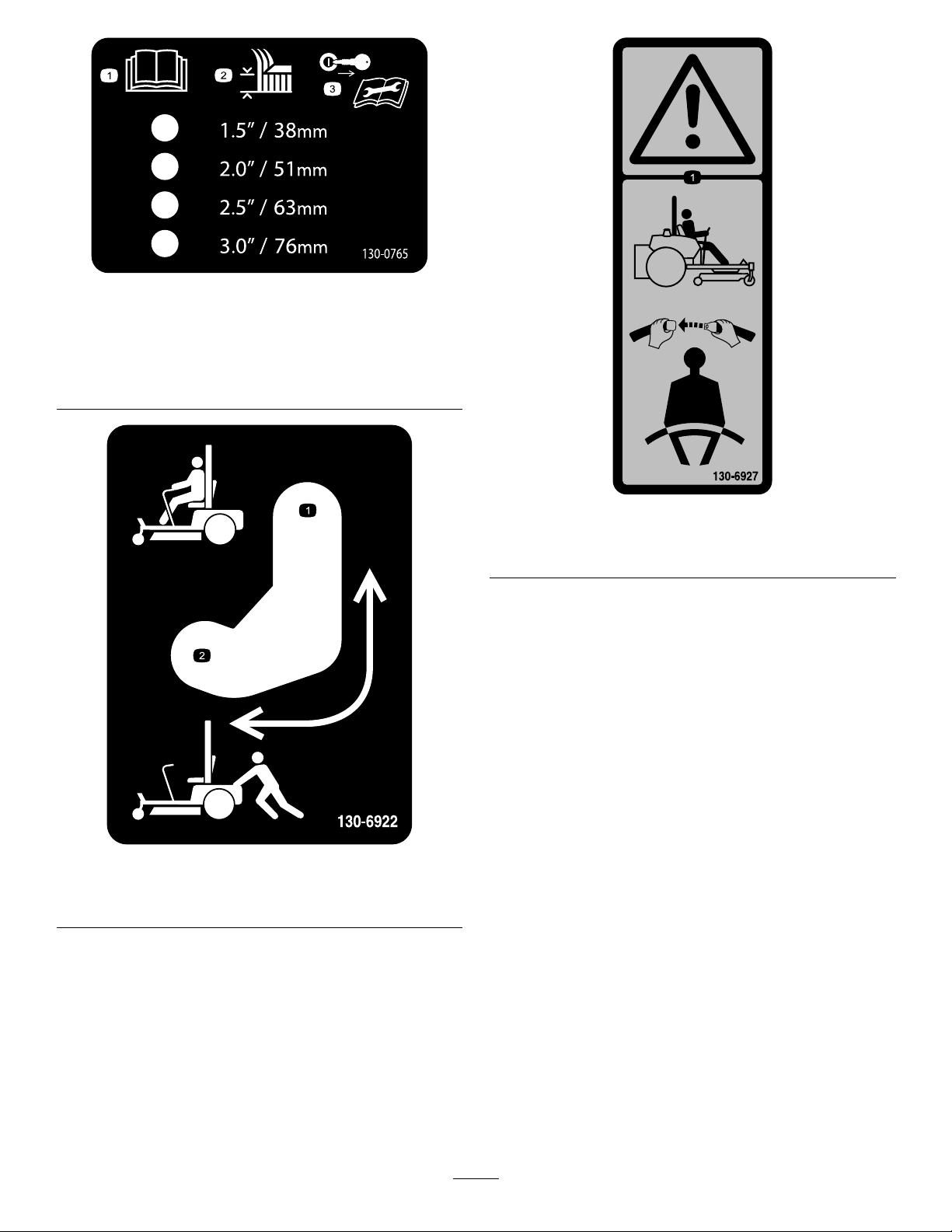

130-0655

1.Fueltank

2.Full4.Empty

3.Half

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

130-0654

1.Transport—lock

2.Transport—unlock

3.Heightofcut

10

Page 11

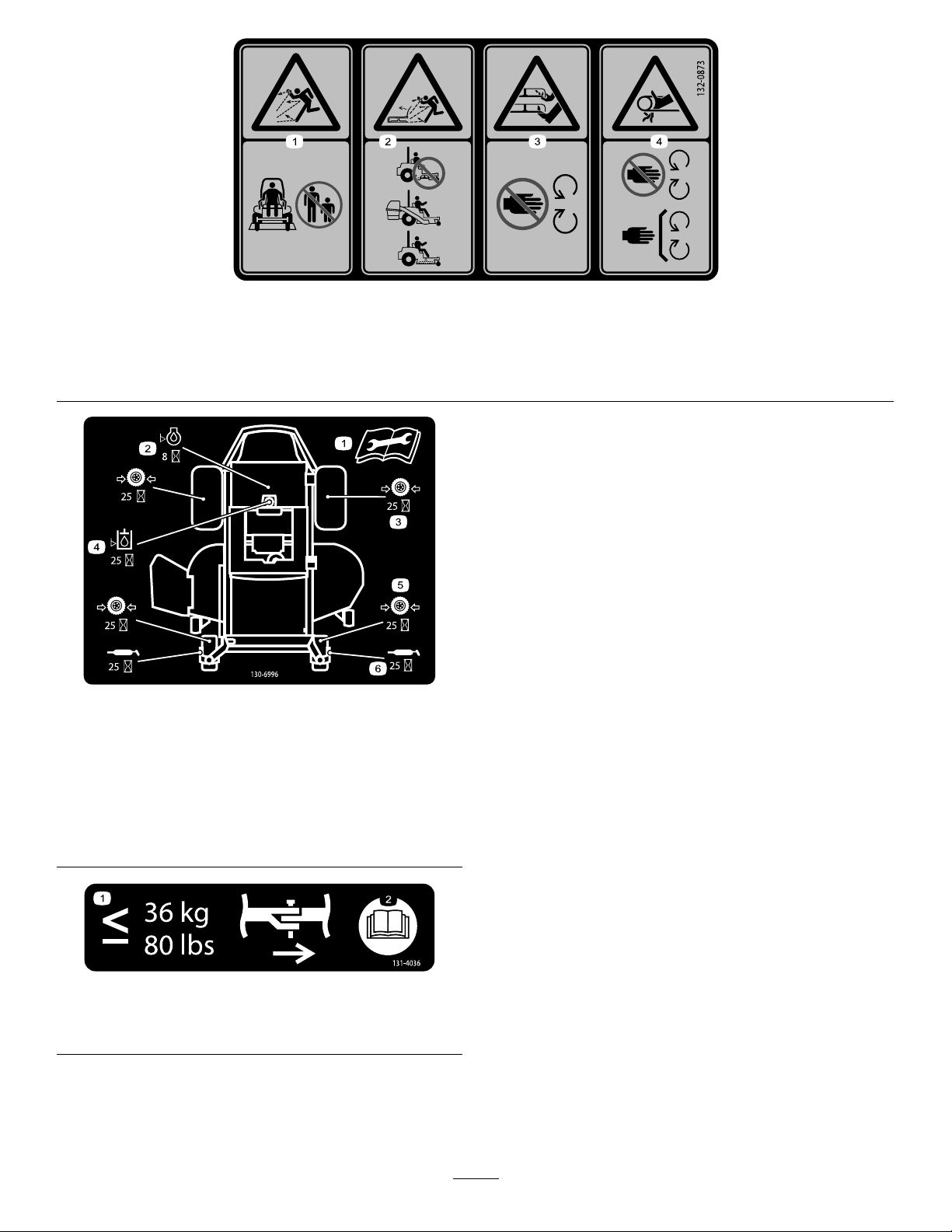

130-0765

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

permorningmaintenance.

130-6927

1.Warning—alwaysusetheROPSandweartheseatbelt

whenseatedintheoperator'sposition.

1.Bypassleverpositionfor

operatingthemachine.

130-6922

2.Bypassleverpositionfor

pushingthemachine.

11

Page 12

132-0873

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Thrownobjecthazard,mower—donotoperatethewithout

deector,dischargecover,orgrasscollectionsysteminplace.

130-6996

1.ReadtheOperator's

Manualforinformationon

maintenance.

2.Checktheengineoilevery

8hours

3.Checkthedrivewheeltire

pressureevery25hours

4.Checkthehydraulicoil

every25hours

5.Checkthecasterwheel

tirepressureevery25

hours

6.Lubricatethecasterwheel

every25hours

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

4.Entanglementhazard,belt—keepallguardsinplace.

1.Themaximumdrawbar

pullis36kg(80lb).

131-4036

2.ReadtheOperator's

Manual.

12

Page 13

132–0871

1.Warning—readtheOperator’sManual;donotoperatethis

vehicleunlessyouaretrained;wearhearingprotection.

2.Cuttingandpinchinghazard—keephandsandfeetawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Thrownobjecthazard—keepbystandersaway .6.Tippinghazardonslopes—donotuseonslopesnearopen

4.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15degrees;backupthe

ramp(inreverse)anddriveforwardofftheramp.

5.Bodilyharmhazard—lookbehindyouwhenmowingin

reverse.

water;donotuseonslopesgreaterthan15degrees.

13

Page 14

ProductOverview

g024328

2

5

6

8

9

10

3

4

7

1

Figure4

1.Drivewheel4.Motion-controllevers7.Frontcasterwheel

2.Operatorseat

3.RolloverProtectionSystem

(ROPS)

5.Parkingbrake8.Anti-scalproller

6.Footrest

9.Footpedaldeckliftand

10.Deector

heightofcut

14

Page 15

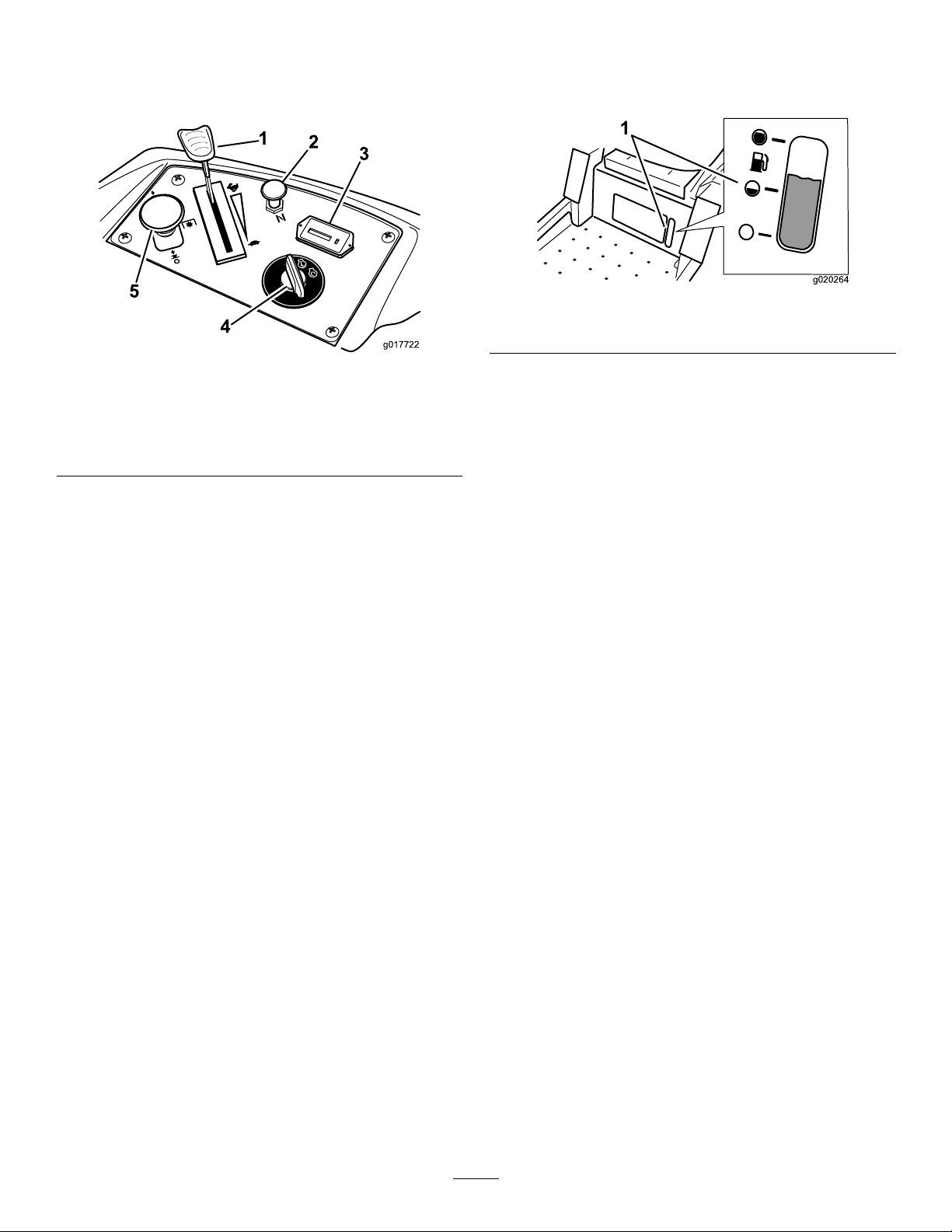

Controls

g017722

1

2

3

4

5

g020264

1

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure5).

Figure5

FuelGauge

Thefuelwindowlocatedbelowtheoperatorpositioncanbe

usedtoverifythelevelofgasolineinthetank(Figure6).

Figure6

1.Fuel-gaugewindow

1.Throttlecontrol4.Ignitionswitch

2.Choke

3.Hourmeter

5.Blade-controlswitch

(PTO)

IgnitionSwitch

Theignitionswitchhas3positions:START,RUN,andOFF..

ThekeywillturntotheSTARTpositionandmovebackto

theRUNpositionuponrelease.TurningthekeytotheOFF

positionwillshutofftheengine;however,alwaysremovethe

keywhenleavingthemachinetopreventtheenginefrom

accidentallystarting(Figure5).

ThrottleControl

ThethrottlecontrolisvariablebetweentheFASTandSLOW

position.Movingthrottleleverforwardincreasesengine

speedandmovingthrottlelevertothereardecreasesengine

speed.Movingthethrottleforwardintothedetentisfull

throttle(Figure5).

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.Pushdownonthechokeknobtodisengageit.

Motion-ControlLevers

Themotion-controlleversarespeed-sensitivecontrolsof

independent-wheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardor

inreverse;wheelspeedisproportionaltotheamountthe

leverismoved.Movethecontrolleversoutwardfromthe

centertotheNEUTRAL-LOCKpositionandexitthemachine

(Figure4).Alwayspositionthemotion-controlleversinto

theNEUTRAL-LOCKpositionwhenyoustopthemachine

orleaveitunattended.

Parking-BrakeLever

Theparking-brakeleverislocatedonleftsideoftheconsole

(Figure4).Thebrakeleverengagesaparkingbrakeonthe

drivewheels.Pulltheleverupandrearwardtoengagethe

brake.Pushtheleverforwardanddowntodisengagethe

brake.

FootPedalDeck-LiftSystem

Thefootpedaldeck-liftsystemallowstheoperatortolower

andraisethedeckfromtheseatedposition.Theoperatorcan

usethefootpedaltoliftthedeckbrieytoavoidobstacles

orlockthedeckinthehighestheightofcutortransport

position(Figure4).

Height-of-CutLever

BladeControlSwitch(PowerTakeoff)

Theblade-controlswitchengagesanddisengagespowerto

themowerblades(Figure5).

HourMeter

Thehourmeterrecordsthenumberofhourstheblades

operate.Itoperateswhentheblade-controlswitch(PTO)is

engaged.Usethesetimesforschedulingregularmaintenance

(Figure5).

Theheight-of-cutleverworkswiththefootpedaltolockthe

deckinaspeciccuttingheight.Onlyadjusttheheightofcut

whilemachineisnotmoving(Figure4).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling .

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

16

Page 17

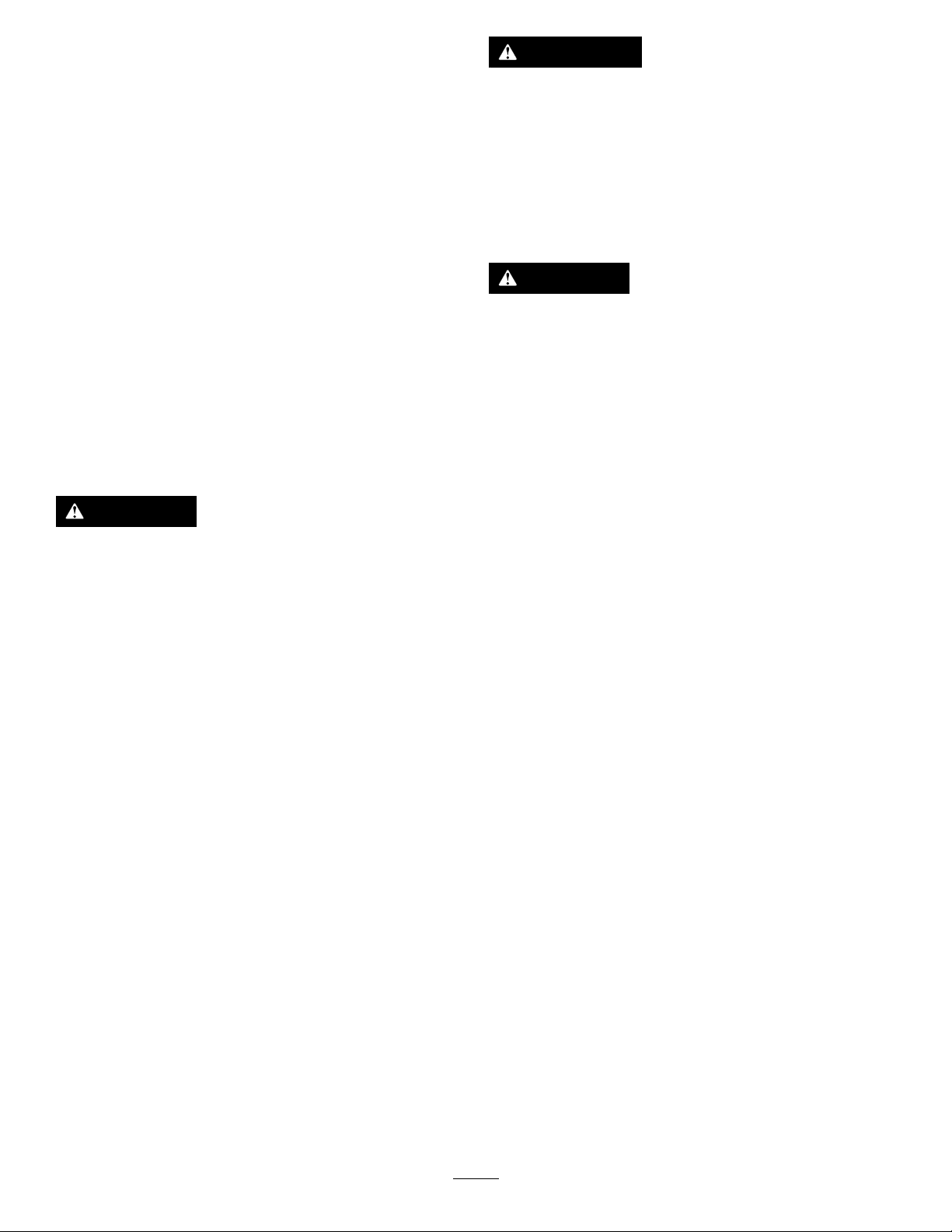

FillingtheFuelTank

B

A

C

D

g027637

Shutofftheengineandmovethemotioncontrolstothe

PARKposition.

Important:Donotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakageordamagetotheengineoremissionsystem.

1.Cleanaroundthefuel-tankcapandremovethecap.

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

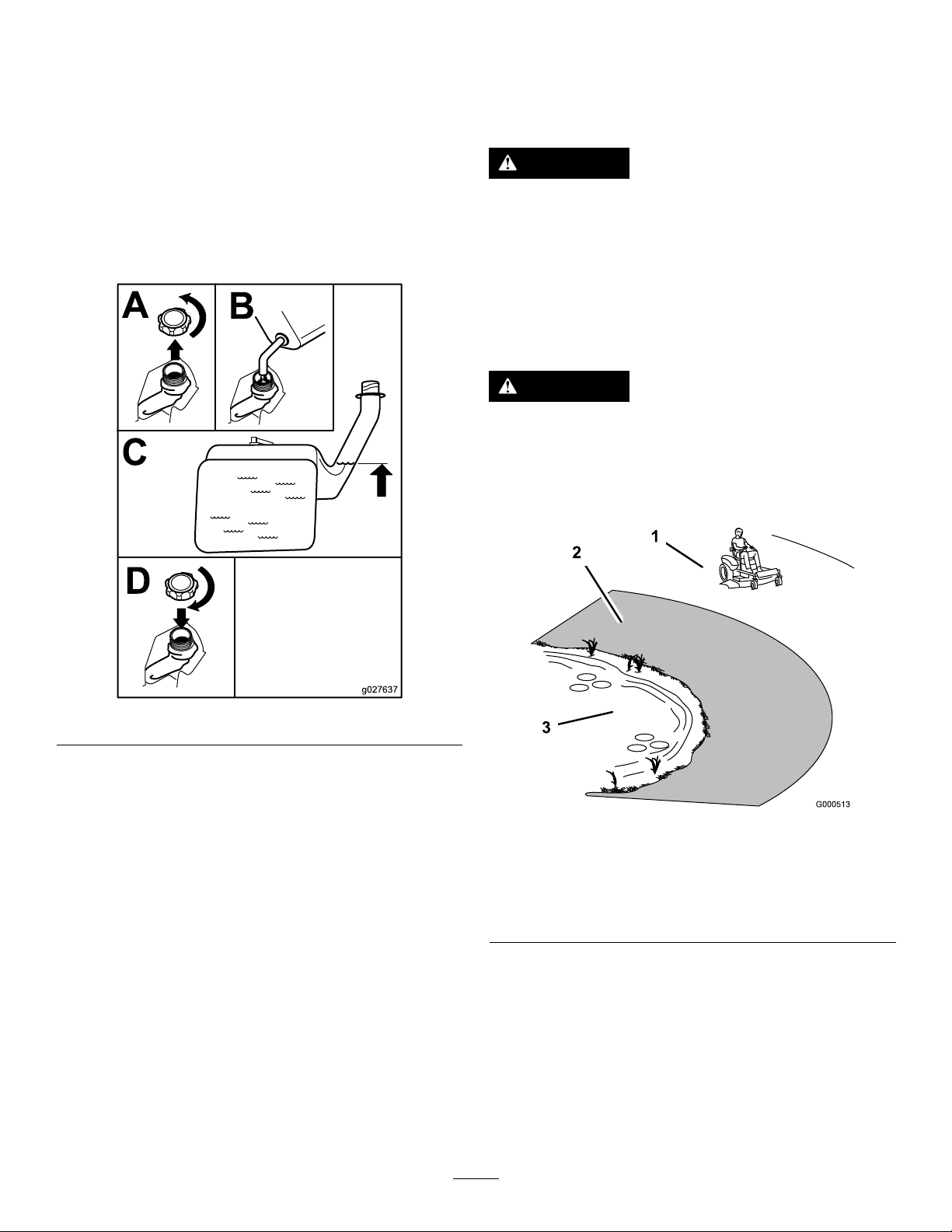

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneckFigure7.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

Figure7

3.Installthefuel-tankcapsecurelyandtightenuntilit

clicks.

Note:Wipeupanygasolinethatmayhavespilled.

1.Safezone—usethe

machinehere.

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

Figure8

3.Water

17

Page 18

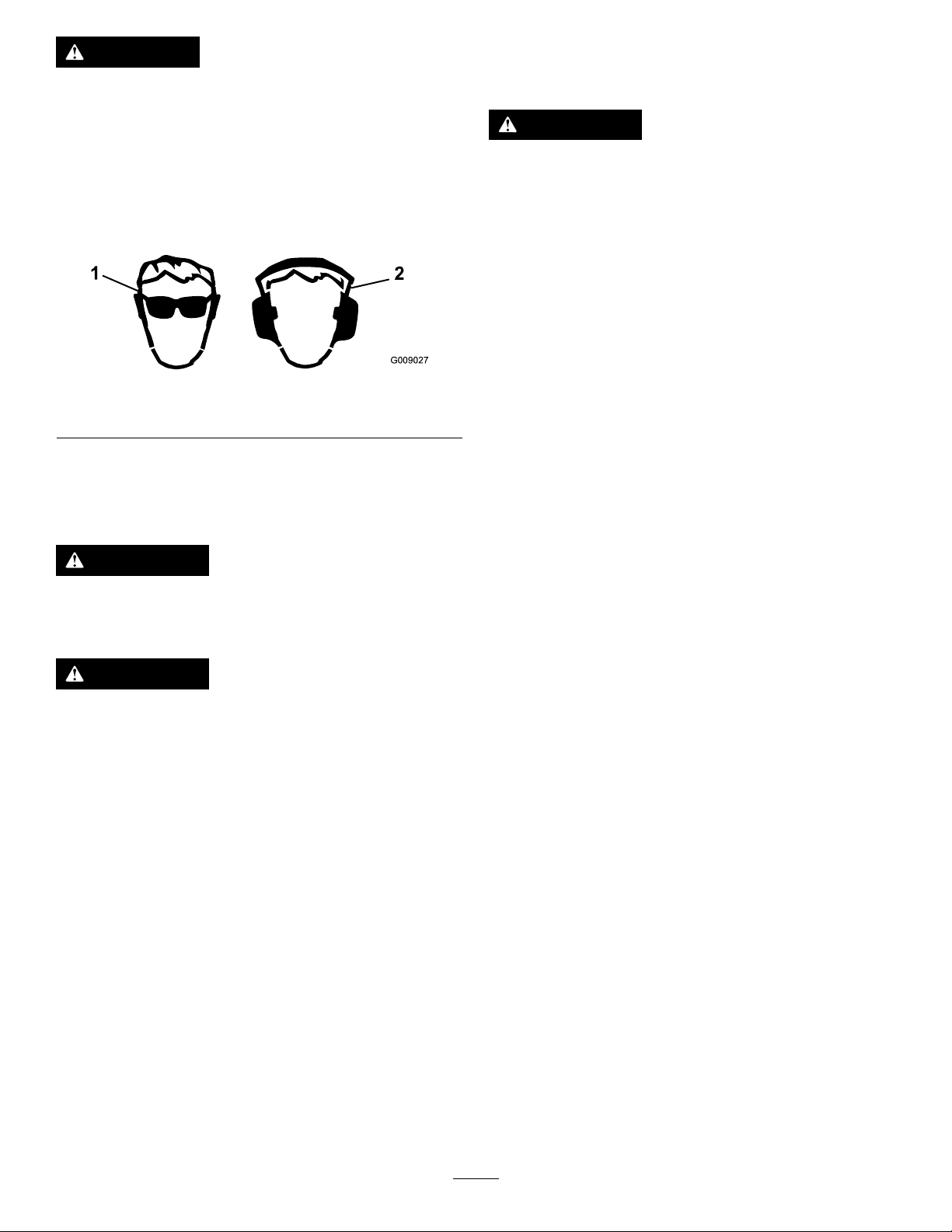

CAUTION

G009027

1

2

Understandingthe

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator’searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,hands,feet,

andheadisrecommended.

Figure9

1.Weareyeprotection.2.Wearhearingprotection.

UsingtheRolloverProtection System(ROPS)

Safety-InterlockSystem

WARNING

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtoshutoffthe

enginewheneverthecontrolleversareoutofthePARK

positionandyourisefromtheseat.

TestingtheSafety-Interlock

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinstalledandusetheseatbelt.

WARNING

Thereisnorolloverprotectionwhentherollbaris

removed.

•Driveslowlyandcarefully.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

System

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,withthecontrolleversinthe

PARKposition,andmovetheblade-controlswitchto

theONposition.Trystartingtheengine;theengine

shouldnotcrank.

2.Whilesittingontheseat,movetheblade-controlswitch

totheOFFposition.Moveeithermotioncontrol

levertothecenter,unlockedposition.Trystartingthe

engine;theengineshouldnotcrank.Repeatwiththe

othermotion-controllever.

3.Whilesittingontheseat,movethebladecontrolswitch

totheOFFposition,andlockthemotion-controllevers

inthePARKposition.Starttheengine.Whilethe

engineisrunning,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshouldstop.

4.Whilesittingontheseat,movetheblade-controlswitch

totheOFFposition,andlockthemotion-controllevers

inthePARKposition.Starttheengine.Whilethe

engineisrunning,movethemotion-controlleversto

thecenter,unlockedposition,engagetheblade-control

switch,andriseslightlyfromtheseat;theengine

shouldstop.

18

Page 19

CheckingtheEngine-OilLevel

B

A

g027638

B

A

g027639

G008946

G008959

1

2

OperatingtheThrottle

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page35).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

ThethrottlecontrolcanbemovedbetweentheSLOWand

FASTpositions(Figure12).

AlwaysusetheFASTpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

Figure12

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure13).

3.Pushdownonthechoketodisengagethechokeafter

theenginestarts(Figure13).

Figure10

ReleasingtheParkingBrake

Figure11

Figure13

1.ONposition2.OFFposition

19

Page 20

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

g027640

B

A

D

C

F

E

S

T

A

R

T

R

U

N

S

T

O

P

H

G

1.TurntheignitionkeytotheSTARTposition(Figure14).

Note:Whentheenginesstarts,releasethekey.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure14

2.TurntheignitionkeytotheSTOPposition.

StartingandStoppingthe Engine

StartingtheEngine

StarttheengineasshowninFigure15.

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallowa15

secondcool-downperiodbetweenattempts.Failureto

followtheseinstructionscanburnoutthestartermotor.

Note:Ifthefuelsystemwasdepletedoffuel—addfuelto

themachineanduseadditionalstartingcycleswhenstarting

theengine.

Figure15

StoppingtheEngine

CAUTION

Injurycanoccurifchildrenorbystandersmove

orattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

20

Page 21

BA

DC

E

S

T

A

R

T

R

U

N

S

T

O

P

00:60 Sec

g027641

Figure16

G008945

G009174

DisengagingtheBlade-ControlSwitch

(PTO)

Figure18

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFASTpositionforbestperformance.Alwaysoperatein

thefull-throttlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

OperatingtheBlade-Control Switch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-ControlSwitch

(PTO)

Engagetheblade-controlswitch(PTO)withthethrottle

positionatFAST.

Note:Engagingtheblade-controlswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

•Slowthemachinedownbeforemakingsharp

turns.

UsingtheMotion-ControlLevers

Usethemotion-controlleversasshowninFigure19.

Figure17

21

Page 22

Figure19

G008952

G008953

Figure20

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

DrivingForward

Note:Theenginekillsifthetraction-controlleversare

movedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake.

2.Movetheleverstothecenter,unlockedposition.

3.Tomoveforward,slowlypushthemotion-control

leversforward(Figure20).

DrivingBackward

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(Figure21).

Figure21

22

Page 23

StoppingtheMachine

g024409

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtothePARKposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Tostopthemachine,movethetraction-controlleversto

theNEUTRALpositionandmovetothelockedposition,

disengagetheblade-controlswitch(PTO),andturnthe

ignitionkeytotheOFFposition.

Settheparkingbrakewhenyouleavethemachine.Remember

toremovethekeyfromtheignitionswitch.

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldeck-liftsystem.

Theoperatorcanusethefootpedaltoliftthedeckbrieyto

avoidobstaclesorlockthedeckinthehighestheightofcut

ortransportposition.Theoperatorcanusetheheight-of-cut

leverwiththefootpedaltolockthedeckinaspeciccutting

height.

Figure22

TransportLockPosition

AdjustingtheHeightofCut

Theheightofcutcanbeadjustedfrom38to114mm(1-1/2

to4-1/2inch)in6mm(1/4inch)incrementsbyrelocating

theheight-of-cutpinintodifferentholelocations.

UsingtheFootPedalDeck-LiftSystem

•Pressthepedaldowntoraisethedeck;continuetopress

thepedaluntilthedeckislockedinthetransportposition

(Figure22).

•Pushonthedeck-liftpedalwithyourfootandpullthe

transportlockhandlerearwardtodisengagethetransport

lock(Figure22).

1.Pushonthedeck-liftpedalwithyourfootandraise

themowerdecktothetransport-lockposition(also

the114mm(4-1/2inch)cuttingheightposition)as

showninFigure23.

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure23).

3.Selectaholeintheheight-of-cutsystemcorresponding

tothedesiredheightofcutandinsertthepin(Figure

23).

4.Pushonthedeck-liftpedalwithyourfootandpull

thehandlerearwardtodisengagethetransportlock

(Figure22).

5.Lowerthedeckslowlyuntilthelevermakescontact

withthepin.

23

Page 24

g024410

1

2

3

4

Figure23

g024312

1

2 3 4

5

g027252

B

A

1.Deck-liftpedal3.Height-of-cutpositions

2.Handle4.Pin

AdjustingtheAnti-Scalp

4.Aligntheboltandanti-scalprollerintheholeofthe

bracketthatmatchedtheclosestheight-of-cutposition

(Figure24).

5.Inserttheboltintothebracketholeandsecurethebolt

andanti-scalprollerwiththeangenut(Figure24).

PositioningtheSeat

Theseatcanmoveforwardandbackward(Figure25).

Positiontheseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

Rollers

Wheneveryouchangetheheightofcut,itisrecommendedto

adjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheangenut,anti-scalproller,andboltfrom

thebracket(Figure24).

Note:Keeptheboltandanti-scalprollertogether

whenremoving.

Figure25

AdjustingtheMotion-Control Levers

AdjustingtheHeight

Note:Repeattheadjustmentfortheoppositecontrollever.

Themotion-controlleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort(Figure26).

1.Flangenut4.Bushing

2.Spacer

3.Anti-scalproller

Figure24

5.Bolt

Figure26

24

Page 25

AdjustingtheTilt

BA

DC

g027642

1

1

2

3

G012841

Themotion-controlleverscanbetiltedforwardorrearward

formaximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforwardorrearward.

3.Tightenbothboltstosecurethecontrolinthenew

position.

4.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausedamagemayoccur.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

Convertingthe48-InchMower toSideDischarge

Themowerdeckandmowerbladesshippedwiththismachine

weredesignedforoptimummulchingandside-discharge

performance.

Installthefastenersintothesameholesinthedeckthatthey

wereoriginallyremovedfrom.Thisensurenoholesareleft

openwhenthedeckisoperated.

DANGER

Openholesinthemowerexposeyouandothersto

throwndebris.Debristhrownoutofholesinthe

mowercancauseinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemower.

•Installhardwareinmountingholeswhenthe

bafeisremoved.

2.Movethemotioncontrolleversoutwardtoneutrallock

position,shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingtheoperating

position.Makesuretheparkingbrakeisdisengaged.

3.DothisprocedureoneachsideofthemachineFigure

27.

RemovingtheMulchingBafe

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,settheparkingbrake,shut

offtheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethemower;refertoRemovingtheMower

(page48).

4.Turnthemowerupsidedown.

5.Removethe2locknuts(5/16inch)securedtothe

weldedpostsoftheleftbafeonthetopofthemower

deckatthecenterandleftofcenterpositions(Figure

28).

Figure27

4.Movethebypasstothepositionforoperatingthe

machine(Figure27)toengagethewheelmotors.

Figure28

1.Locknut(5/16inch)3.Leftbafe

2.Carriagebolt(5/16x3/4

inch)

6.Removethecarriageboltandlocknutonthesidewall

ofthemowerdecksecuringtheleftbafetothedeck.

25

Page 26

7.Removetheleftbafefromthemowerdeckasshown

G012806

1

2

3

4

3

2

1

2

3

G012805

G012800

1

2

3

4

inFigure28.

8.Removethecarriagebolt(5/16x3/4inch)andlocknut

(5/16inch)ontherearwallofthemowerdecksecuring

thebafetothedeck(Figure29).

Figure29

Figure30

1.Locknut(5/16inch)3.Weldedposts,rightbafe

2.Rightbafe

11.Locatethecutoffbafeintheloosepartsbagand

removethefastenersattherearholesofthedischarge

plate(Figure31).

1.Bafeguard3.Carriagebolt(5/16x3/4

2.Locknut(5/16inch)4.Rightbafe

inch)

9.Locatethebafeguardatthefrontedgeoftheside

dischargeopeningandremovethefastenerssecuring

thebafeguardandtherightbafetothemowerdeck

(Figure29).

Note:Removethebafeguardandretainallfasteners.

10.Removethe2locknuts(5/16inch)tosecuringthe

weldedpostsoftherightbafetothetopofthemower

deckatcenterandrightofcenterpositions(Figure30).

Note:Removetherightbafefromthemowerdeck.

Figure31

1.Carriagebolt,existing3.Cutoffbafe,shipped

2.Rearholesinthe

dischargeplate

loose

4.Locknut,existing

12.Installthebafeatthesidedischargeopeningonthe

mowerdeck.

13.Usethefastenersremovedtosecurethecutoffbafe

tothedeck.

14.Installthemower;refertoInstallingtheMowerDeck

(page49).

26

Page 27

Convertingthe54-InchMower

G011149

1

1

2

3

4

G010712

1

2

4

3

5

6

7

toSideDischarge

Installthefastenersintothesameholesinthedeckasthey

wereoriginallyremovedfrom.Thisensuresthatnoholesare

leftopenwhenthedeckisoperated.

DANGER

Openholesinthemowerexposeyouandothersto

throwndebris.Debristhrownoutofholesinthe

mowercancauseinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemower.

•Installhardwareinmountingholeswhenthe

bafeisremoved.

RemovingtheMulchingBafe

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,settheparkingbrake,shut

offtheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethemower;refertoRemovingtheMower

(page48).

4.Turnthemowerupsidedown.

5.Removethe3locknuts(5/16inch)securedtothe

weldedpostsoftheleftbafeonthetopofthemower

deckatthecenter,leftofcenterandleftpositions

(Figure32).

8.Locatethe2boltsinloosepartsandusetheexisting

locknutsandinstallthesefastenersintotheholes

showninFigure32onthemowerdecktoprevent

yingdebris.

Note:Installtheboltup,throughtheundersideof

thedeckanduseanexistinglocknuttosecurefrom

thetopside.

WARNING

Openholesinthemowerexposeyouand

otherstothrowndebriswhichcancause

severeinjury.

•Neveroperatethemowerwithouthardware

mountedinallholesinthemowerhousing.

•Installthehardwareinthemountingholes

whenyouremovethemulchingbafe.

9.Removethecarriagebolt(5/16x3/4inch)andlocknut

(5/16inch)ontherearwallofthemowerdecksecuring

thebafetothedeck(Figure33).

Figure32

1.Locknut(5/16inch)3.Leftbafe

2.Carriagebolt(5/16x3/4

inch)

4.Installfastenershere

6.Removethecarriageboltandlocknutonthesidewall

ofthemowerdecksecuringtheleftbafetothedeck

(Figure32).

7.Removetheleftbafefromthemowerdeck(Figure

32).

Figure33

1.Carriagebolt(5/16x3/4

inch)

2.Locknut,frontofdischarge

plate(reinstallafterbafe

isremoved)

3.Locknut,forwardholein

deck(reinstallafterbafe

isremoved)

4.Bafeguard,54inch

decks

10.Locatethebafeguardatthefrontedgeoftheside

dischargeopening(Figure33).

5.Hex-headbolt,forward

holeindeck(reinstallafter

bafeisremoved)

6.Carriagebolts,frontof

dischargeplate(reinstall

afterbafeisremoved)

7.Locknut(5/16inch)

11.Removethefastenerssecuringthebafeguardandthe

rightbafetothemowerdeck(Figure33).

Note:Removethebafeguardandretainallfasteners.

27

Page 28

12.Removethe2locknuts(5/16inch)securingthewelded

G010704

1

2

3

postsoftherightbafetothetopofthemowerdeck

atcenterandrightofcenterpositions(Figure34).

16.Usethefastenersremovedtosecurethecutoffbafe

tothedeck.

17.Installthemower;refertoInstallingtheMowerDeck

(page49).

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

Figure34

1.Locknut(5/16inch)3.Weldedposts,rightbafe

2.Rightbafe4.Carriagebolt

13.Removethecarriageboltandlocknutsecuringtheright

bafetothetopofthemowerdeckandremovethe

rightbafefromthemowerdeck(Figure34).

14.Installthefastenersremovedpreviouslyatthefront

holesinthedischargeplateandforwardholeinthe

deck(Figure33).

15.Locatethecutoffbafeintheloosepartsbag,remove

thefastenersattherearholesofthedischargeplate,

andinstallthebafeattheside-dischargeopeningon

themowerdeck(Figure35).

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovetheblade-controlswitch

(PTO)totheOFFposition,rotatetheignition

keytotheOFFposition,andremovethekey.

•Makesurethatthegrassdeectorisinthedown

position.

Figure35

1.Carriagebolt3.Cutoffbafe

2.Rearholesinthe

dischargeplate

4.Locknut

28

Page 29

TransportingtheMachine

g028043

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey ,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure36).

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure38).Onat

ground,thisrequiresaramptobeatleast4timesaslongas

theheightofthetrailerortruckbedtotheground.Asteeper

anglemaycausemowercomponentstogetcaughtastheunit

movesfromtheramptothetrailerortruck.Steeperangles

mayalsocausethemachinetotiporlosecontrol.Ifloading

onornearaslope,positionthetrailerortrucksothatitis

onthedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

Figure36

LoadingtheMachine

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backthemachineupthe

rampanddriveitforwarddowntheramp(Figure37).

•Ensurethelengthoframpisatleast4timesas

longastheheightofthetrailerortruckbedto

theground.Thiswillensurethatrampangle

doesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

1.Backthemachineupthe

ramp.

Figure37

2.Drivethemachineforward

downtheramp.

29

Page 30

g027996

5

1

2

6

Figure38

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

30

Page 31

OperatingTips

UsingtheFastThrottleSetting

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerinuncutgrass.Alwaystrytohave

1sideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

Stopping

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

KeepingtheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

MowingatCorrectIntervals

Normally,mowevery4days.But,remember,grassgrowsat

differentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,andmowmoreoften

inearlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight,thenmowagain2

dayslateratalowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

31

Page 32

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydrauliclteranduid.

•Checkthesafety-interlocksystem.

•Cleanandchecktheair-cleanerelement.

•Checktheengine-oillevel.

•Cleantheair-intakescreen.

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthehydraulic-uidlevelintheexpansiontank.

•Inspectthebeltsforcracksandwear.

•Servicethepaperelement(moreoftenindusty,dirtyconditions).

•Changetheengineoil(moreoftenindusty,dirtyconditions).

•Checkthesparkplug(s).

•Replacethefuellters(moreoftenunderdusty,dirtyconditions).

•Replacethepaperelement(moreoftenindusty,dirtyconditions).

•Changetheengine-oillter(moreoftenindusty,dirtyconditions).

Every400hours

Monthly

Yearlyorbeforestorage

•Changethehydrauliclteranduid.

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

32

Page 33

Premaintenance

Procedures

Service-IntervalChart

Figure39

Locatedontheseatpanunderside

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours.5.Checkthecasterwheeltirepressureevery25hours.

3.Checkthedrivewheeltirepressureevery25hours.

4.Checkthehydraulicoilevery25hours.

6.Lubricatethecasterwheelevery25hours.

RaisingtheSeat

Ensurethatthemotion-controlleversarelockedinthe

NEUTRAL-LOCKpositionandlifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Servicedecal

•Fuses

•Batteryandcables

ReleasingtheMower-Deck Curtain

Loosenthe2bottomboltsofthecurtaintogainaccesstothe

topofthemowerdeck(Figure40).

1.Bottombolt

Figure40

2.Curtain

33

Page 34

Lubrication

G009949

1

G015155

1

2

3

EngineMaintenance

GreasingtheBearings

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanthegreasettings(Figure41andFigure39)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Cleanandcheck

theair-cleanerelement.

Note:Servicetheaircleanermorefrequentlyiftheoperating

conditionsareextremelydustyorsandy.

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch(PTO).

2.Movethemotion-controlleverstotheNEUTRAL-LOCK

position,settheparkingbrake,shutofftheengine,

removethekey ,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

Figure41

1.Frontcastertire

4.Connectagreaseguntoeachttingandpumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings(Figure39andFigure41).

3.Cleanaroundtheair-cleanercovertopreventdirtfrom

gettingintotheengineandcausingdamageandlift

thecoverandremovethehoseclampsecuringtheair

cleanerassemblytotheengine(Figure42).

4.Loosenthehoseclampandremovethepaperelement

(Figure42).

Figure42

1.Cover

2.Paperelement

34

3.Hoseclamp

Page 35

CleaningtheElement

SAEV iscosityGrades

SAE40

SAE30

SAE10W– 30/ SAE10W– 30

-2002032406080100

-30-20-10010203040

°F

°C

STARTING TEMPERA TURERANGE ANTICIPATEDBEFORENEXT OIL CHANGE

SAE5W– 20

G010686

B

A

C

D

E

G027475

F

G

H

I J

ServiceInterval:Every100hours—Servicethepaper

element(moreoftenindusty,dirty

conditions).

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperelement(moreoftenin

dusty,dirtyconditions).

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

Important:Nevercleanthepaperelementwith

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,orSL)

CrankcaseCapacity:1.8L(61oz);whenoillteris

removed:2.1L(70oz)

theenginewithoilbelowthelowmarkbecausethe

enginemaybedamaged.

1.Parkthemachineonalevelsurface.

2.Disengagetheblade-controlswitch(PTO).

3.Shutofftheengine,waitforallmovingpartstostop,

andremovethekeybeforeleavingtheoperating

position.

4.Checktheengine-oillevel(Figure44).

Viscosity:Seethetablebelow.

Figure43

Note:Usingmultigradeoils(5W -20,10W -30,and10W-40)

willincreaseoilconsumption.Checkoillevelmorefrequently

whenusingthem.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Figure44

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

35

Page 36

ChangingtheEngineOil

A B

C

D

F

E

G027539

B

A

C

D

E

F

g027660

ServiceInterval:Aftertherst8hours—Changetheengine

oil.

Every100hours—Changetheengineoil(moreoften

industy ,dirtyconditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensuretheoildrains

completely.

2.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKposition,andsettheparking

brake.

3.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

4.Draintheoilfromtheengine(Figure45).

Figure46

5.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure46).

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours—Changetheengine-oil

lter(moreoftenindusty ,dirty

conditions).

Note:Changetheengine-oilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine.

2.Changetheengine-oillter(Figure47).

Figure45

36

Page 37

B

A

C D

E

F

3/4

g027477

Figure47

B

A

g027478

B

A

g027479

B

A

16 ft-lb

22 N-m

g027661

C

D

Figure48

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.03inches(0.76mm).

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug(s).

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:NGKBPR4ES

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.DisengagethePTO,movethemotion-controllevers

totheNEUTRAL-LOCKposition,andsettheparking

brake.

2.Shutofftheengine,removethekey,andwaitforall

3.Removethesparkplug(Figure48).

movingpartstostopbeforeleavingtheoperating

position.

Figure49

InstallingtheSparkPlug

Tightenthesparkplug(s)to22N•m(16ft-lb)asshownin

Figure50.

Figure50

37

Page 38

CleaningtheCoolingSystem

g027590

B

A

C

D

g027518

FuelSystem

Cleantheair-intakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagetheblade-controlswitchandmovethe

controlleverstotheNEUTRAL-LOCKposition,and

applytheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheair-intakescreen,air-cleanercover,and

fanhousing.

4.Cleanthedebrisandgrassfromtheparts.

5.Installtheair-intakescreen,air-cleanercover,andfan

housing.

Maintenance

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)(moreoftenunderdusty ,dirty

conditions).

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Replacethefuellter(Figure51).

Figure51

38

Page 39

ElectricalSystem

BA

DC

g027672

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

Figure52

4.Removetheclamp(Figure52).

5.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(Figure52).

6.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure52).

7.Removethebattery.

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminalposts

oppositefromthefueltank(Figure52).

2.Installthepositive(red)batterycabletopositive(+)

batteryterminal.

3.Installthenegativebatterycabletothenegative(-)

batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

(Figure52).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut(Figure

52).

•Alwaysreconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethewingnutsecuringthebatteryclamp

(Figure52).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged.This

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow32°F(0°C).

39

Page 40

1.Chargebatteryfor10to15minutesat25to30amps

g02441 1

1

2

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure53).

3.Installthebatteryinthemachineandconnectthe

batterycables.

Figure54

Figure53

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Note:Thefusesarelocatedonrighthandconsolenextto

theseat(Figure54).

Fusetype:

•Main—30A,blade-type

•Engine—20A,blade-type

1.Toreplacethemainfuse,graspthefuseandpullit

straightandawayfromthefuseblock(Figure54).

1.Fuseblock2.Main—30A

Important:Ensurethatthenewfusesarethe

sametypeandamperageasthefusesremoved.

2.Toreplacetheenginefuse,removetheconsolefrom

theplasticfender.

Figure55

1.Enginefuse—25A

3.Grasptheenginefuseandpullitstraightandaway

fromthefuseblock(Figure55).

4.Alignanewfusewiththeslotinthefuseblock(Figure

54).

5.Pushthefuseintothefuseblockuntilthefuseisseated

(Figure54).

40

Page 41

DriveSystem

G010253

1

2

3

HydraulicSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure56).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

Figure56

Maintenance

OilType:ToroHYPR-OIL®500or20W -50motoroil.

SystemCapacity:4.495L(152oz)withalterchange.

Important:Useoilspeciedorequivalent.Otheruids

couldcausesystemdamage.

CheckingtheHydraulic-Fluid Level

ServiceInterval:Every25hours

Checktheexpansionreservoir,and,ifnecessary,adduid

totheFullColdline.

1.Valvestem

Figure57

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulicFilter andFluid

Thelteranduidarechangedatthesametime.Oncethe

newlterisinstalledanduidisadded,anyairinthesystem

mustbepurged.

Thebleedingprocessisrepeateduntiltheuidremainsat

theFullColdlineinthereservoirafterpurging.Failureto

properlyperformthisprocedurecanresultinirreparable

damagetothetransaxledrivesystem.

41

Page 42

RemovingtheHydraulicFilters

G010254

1

2

3

4

5

B

A

C D

E

F

3/4

g027477

4.Installtheventplugandtorqueitto20N•m(180in-lb).

Important:Whenthehydrauliclterisremoved,allof

thehydraulicuidineachtransaxlewilldrainout.Usea

containerthatholds4.495L(152oz)orlarger.

1.Shutofftheengine,waitforallmovingpartstostop,

allowtheenginetocool,removethekey,andengage

theparkingbrake.

2.Locatethelterandguardsoneachtransaxledrive

systemandremovethe3screwssecuringthelter

guard(Figure58).

5.Continuetoadduidthroughtheexpansionreservoir

untiluidcomesoutoftheremainingvent-plughole

onthesecondtransmission.

6.Installthesecondventplugandtorqueitto20N•m

(180in-lb).

7.Continuetoadduidthroughtheexpansionreservoir

untilitreachestheFullColdlineontheexpansion

reservoir.

Important:Failuretoperformthe

the Hy draulic System

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

procedureafterchanging

Bleeding

1.Transaxledrive

2.Hydrauliclter

3.Filterguard

3.Carefullycleantheareaaroundthelters.

Important:Donotallowdirttoenterthe

hydraulicsystem,asitmaycausedamage.

4.Placeacontainerbelowthelteranddraintheuid.

5.Locateandremovetheventplugoneachtransmission.

6.Unscrewthelterandallowtheuidtodrainfrom

thedrivesystem.

7.Repeatthisprocedureforbothlters.

InstallingtheHydraulicFilter

ServiceInterval:Aftertherst50hours

1.Usingthe3screwstoinstallthelterguardsovereach

lterremovedpreviously .

2.Verifythattheventplugsareremovedbeforeadding

theuid.

Every400hours

Figure58

Rightsideshown

4.Screws

5.Ventplug

Figure59

3.Slowlypourthespecieduidthroughtheexpansion

reservoiruntiluidcomesoutofavent-plughole.

42

Page 43

BleedingtheHydraulicSystem

G010333

1

1.Raisetherearofmachineupandsupportitwithjack

stands(orequivalentsupport)justhighenoughto

allowthedrivewheelstoturnfreely .

Figure60

1.Jackingpoints

2.Entertheoperator'sposition,starttheengine,move

thethrottlecontrolto1/2throttleposition,and

disengagetheparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertoPushingtheMachine

byHand(page25).Withthebypassvalves

openandtheenginerunning,slowlymovethe

motion-controlleversinbothforwardandreverse

directions(5or6times).

MowerDeck Maintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowth,andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownatyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Shutofftheengineandchecktheuidlevelinthe

expansionreservoir.Addthespecieduidas

untilitreachestheFullColdlineontheexpansion

reservoir.

3.Repeatstep2untilalloftheairiscompletelypurged

fromthesystem.

Note:Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsideredpurged.

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controlleversoutward

tothePARKposition,shutofftheengine,andremovethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure61).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page45).

2.Inspecttheblades,especiallythecurvedarea(Figure

61).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(items3and4inFigure61),

immediatelyinstallanewblade.

43

Page 44

Figure61

G009679

1

2

3

G009680