Toro Titan Z4800, Titan Z5200, Titan Z4800 74812, Titan Z5200 74814, 74813 Operator's Manual

...Page 1

FormNo.3359-828RevA

Titan

®

Z4800Zero-Turn-Radius

RidingMower

Titan

®

Z5200Zero-Turn-Radius

RidingMower

ModelNo.74816—SerialNo.280000001andUp

ModelNo.74818—SerialNo.280000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

Important:Thisengineisnotequippedwitha

sparkarrestermufer.ItisaviolationofCalifornia

PublicResourceCodeSection4442touseoroperate

theengineonanyforest-covered,brush-covered,or

grass-coveredland.Otherstatesorfederalareas

mayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadian

ICES-002,ISO14982,EN55012.

TheenclosedEngineOwner’sManualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCalifornia

EmissionControlRegulationofemissionsystems,

maintenance,andwarranty.Replacementsmaybe

orderedthroughtheenginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthisclass

oflawnmowerwillbesignicantlylower.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.identies

thelocationofthemodelandserialnumbersonthe

product.Writethenumbersinthespaceprovided.

Figure1

Behindtheseat

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

ToroRidingMowerSafety....................................5

SlopeChart..........................................................7

SafetyandInstructionalDecals.............................8

ProductOverview......................................................12

Controls.............................................................13

Specications.....................................................14

Systems..............................................................14

Dimensions........................................................15

TorqueRequirements.........................................15

Operation...................................................................16

ThinkSafetyFirst...............................................16

RecommendedGasoline.....................................16

CheckingtheEngineOilLevel............................18

StartingtheEngine.............................................18

OperatingtheBlades..........................................19

StoppingtheEngine...........................................19

TheSafetyInterlockSystem................................20

DrivingForwardorBackward.............................20

StoppingtheMachine.........................................21

TrackingAdjustment..........................................21

AdjustingtheHeightofCut................................22

PositioningtheSeat............................................22

ChangingtheSeatRideSuspension.....................22

AdjustingtheMotionControlLevers..................23

PushingtheMachinebyHand.............................23

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Contactusatwww.Toro.com.

PrintedintheUSA.

AllRightsReserved

Page 3

SideDischarge....................................................24

Transporting......................................................24

OperatingTips..................................................25

Maintenance...............................................................26

RecommendedMaintenanceSchedule(s)................26

PremaintenanceProcedures....................................27

RaisingtheSeat..................................................27

AccessingtheBattery.........................................27

Lubrication.............................................................27

GreasingtheBearings.........................................27

EngineMaintenance...............................................28

ServicingtheAirCleaner....................................28

ServicingtheEngineOil.....................................29

ServicingtheSparkPlug.....................................31

CleaningtheBlowerHousing..............................31

FuelSystemMaintenance.......................................32

ReplacingtheFuelFilter.....................................32

ElectricalSystemMaintenance................................33

ChargingtheBattery...........................................33

ServicingtheFusesandRelay..............................35

DriveSystemMaintenance.....................................35

CheckingtheTirePressure.................................35

HydraulicSystemMaintenance...............................36

CheckingtheHydraulicOilLevel........................36

ChangetheHydraulicSystemFilter.....................36

MowerMaintenance...............................................37

ServicingtheCuttingBlades...............................37

LevelingtheMowerDeck...................................38

AdjustingtheBladeSlope...................................39

RemovingtheMowerDeck................................40

MowerBeltMaintenance....................................41

InstallingtheMowerDeck..................................41

ReplacingtheDischargeDeector......................42

Cleaning.................................................................43

WashingtheUndersideoftheMower..................43

Storage.......................................................................44

CleaningandStorage..........................................44

Troubleshooting.........................................................45

Schematics.................................................................47

Safety

ThismachinemeetsorexceedstheB71.1-2003

specicationsoftheAmericanNationalStandards

Institute,ineffectatthetimeofproduction.

However,improperuseormaintenancebythe

operatororownercanresultininjury.Toreduce

thepotentialforinjury,complywiththesesafety

instructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,

WARNING,orDANGER-"personalsafety

instruction."Failuretocomplywiththeinstruction

mayresultinpersonalinjuryordeath.

SafeOperatingPractices

ThefollowinginstructionsarefromANSIstandard

B71.1-2003.

Thisproductiscapableofamputatinghandsand

feetandthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriousinjuryordeath.

GeneralOperation

•Read,understand,andfollowallinstructionsin

theoperator’smanualandonthemachinebefore

starting.

•Donotplacehandsorfeetnearrotatingpartsor

underthemachine.Keepclearofthedischarge

openingatalltimes.

•Allowonlyresponsibleadultswhoarefamiliarwith

theinstructionstooperatethemachine.

•Cleartheareaofobjectssuchasrocks,toys,wire,

etc.,whichcouldbepickedupandthrownbythe

blade.

•Besuretheareaisclearofotherpeoplebefore

mowing.Stopthemachineifanyoneentersthearea.

•Nevercarrypassengers.

•Donotmowinreverseunlessabsolutelynecessary.

Alwayslookdownandbehindbeforeandwhile

backingup.

•Beawareofthemowerdischargedirectionanddo

notpointitatanyone.Avoiddischargingmaterial

againstawallorobstruction.Materialmayricochet

backtowardtheoperator.Stoptheblade(s)when

crossinggravelsurfaces.

•Donotoperatethemachinewithoutdeector,

dischargecoverorentiregrasscollectionsystemin

placeandworking.

•Bealert,slowdownandusecautionwhenmaking

turns.Lookbehindandtothesidebeforechanging

directions.

3

Page 4

•Neverleavearunningmachineunattended.Always

turnoffblades,setparkingbrake,stopengine,and

removekeybeforedismounting.

•Turnoffbladeswhennotmowing.Stoptheengine

andwaitforallpartstocometoacompletestop

beforecleaningthemachine,removingthegrass

catcheroruncloggingthedischargechute.

•Operatethemachineonlyindaylightorgood

articiallight.

•Donotoperatethemachinewhileunderthe

inuenceofalcoholordrugs.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Useextracarewhenloadingorunloadingthe

machineintoatrailerortruck.

•Alwaysweareyeprotectionwhenoperatingthe

mower.

•Dataindicatesthatoperators,age60yearsand

above,areinvolvedinalargepercentageofriding

mower-relatedinjuries.Theseoperatorsshould

evaluatetheirabilitytooperatetheridingmower

safelyenoughtoprotectthemselvesandothersfrom

seriousinjury.

•Alwaysfollowtherecommendationsforwheel

weightsorcounterweights.

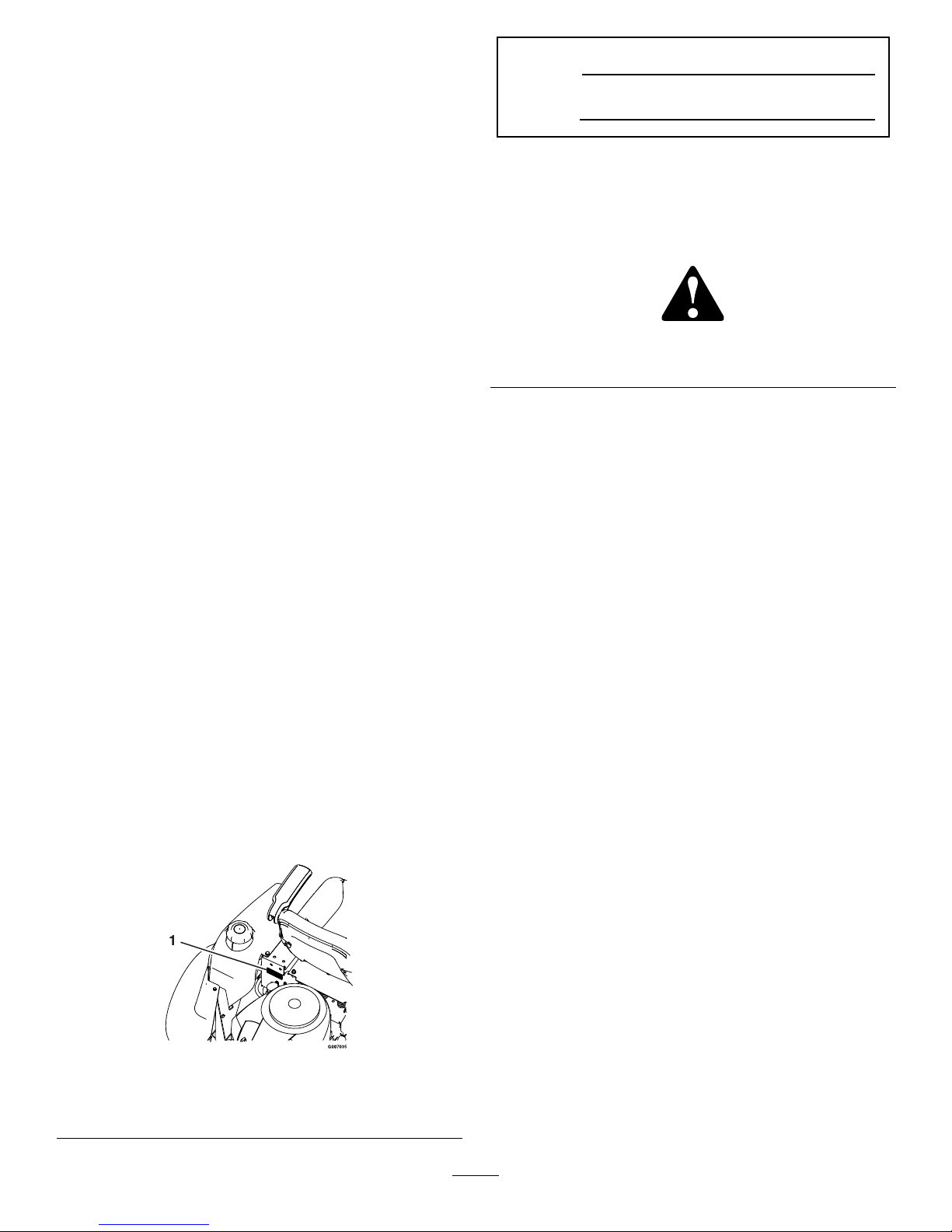

SlopeOperation

Slopesareamajorfactorrelatedtolossofcontroland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Operationonallslopesrequiresextracaution.If

youcannotbackuptheslopeorifyoufeeluneasyonit,

donotmowit.

•Donotmowslopesgreaterthan15degrees.

•Watchforditches,holes,rocks,dips,andrisesthat

changetheoperatingangle,asroughterraincould

overturnthemachine.

•Choosealowgroundspeedsoyouwillnothaveto

stopwhileoperatingonaslope.

•Donotmowslopeswhengrassiswet.Slippery

conditionsreducetractionandcouldcausesliding

andlossofcontrol.

•Alwayskeepthewheelmotorsengagedwhengoing

downslopes.

•Reducespeedanduseextremecautiononslopes.

•Donotmakesuddenturnsorrapidspeedchanges.

•Removeormarkobstaclessuchasrocks,treelimbs,

etc.fromthemowingarea.Tallgrasscanhide

obstacles.

•Avoidsuddenstartswhenmowinguphillbecause

themowermaytipbackwards.

•Beawarethatlossoftractionmayoccurgoing

downhill.Weighttransfertothefrontwheelsmay

causedrivewheelstoslipandcauselossofbraking

andsteering.

•Alwaysavoidsuddenstartingorstoppingona

slope.Iftireslosetraction,disengagethebladesand

proceedslowlyofftheslope.

•Useextremecarewithgrasscatchersorother

attachments.Thesecanchangethestabilityofthe

machineandcauselossofcontrol.

•Donottrytostabilizethemachinebyputtingyour

footontheground.

•Donotmowneardrop-offs,ditches,steepbanks

orwater.Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,death

ordrowning.

•Useawalkbehindmowerand/orahandtrimmer

neardrop-offs,ditches,steepbanksorwater.

Children

Tragicaccidentscanoccuriftheoperatorisnotalertto

thepresenceofchildren.Childrenareoftenattractedto

themachineandthemowingactivity.Neverassumethat

childrenwillremainwhereyoulastsawthem.

•Keepchildrenoutofthemowingareaandunder

thewatchfulcareofanotherresponsibleadult,not

theoperator.

•Bealertandturnthemachineoffifchildrenenter

thearea.

•Beforeandwhilebackingorchangingdirection,look

behind,down,andside-to-sideforsmallchildren.

•Nevercarrychildren,evenwiththebladesoff.They

mayfalloffandbeseriouslyinjuredorinterferewith

safemachineoperation.

•Childrenwhohavebeengivenridesinthepastmay

suddenlyappearinthemowingareaforanotherride

andberunoverorbackedoverbythemower.

•Neverallowchildrentooperatethemachine.

•Useextracarewhenapproachingblindcorners,

shrubs,trees,theendofafenceorotherobjectsthat

mayobscurevision.

Towing

Ahitchkitisavailableforthismachineandcanbe

obtainedbycontactinganAuthorizedToroDealer.

Donottowwithoutrstinstallingthismanufacturer

4

Page 5

approvedhitch.Thefollowingguidelinesapplywhen

towingwiththeapprovedhitchkitinstalled.

•Towonlywithamachinethathasahitchdesigned

fortowing.Donotattachtowedequipmentexcept

atthehitchpoint.

•Followthemanufacturer’srecommendationfor

weightlimitsfortowedequipmentandtowingon

slopes.

•Neverallowchildrenorothersinorontowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftractionandlossofcontrol.

•Travelslowlyandallowextradistancetostop.

Service

SafeHandlingofGasoline:

Toavoidpersonalinjuryorpropertydamage,useextra

carewhenhandlinggasolineandotherfuels.Theyare

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipesandother

sourcesofignition.

•Useonlyanapprovedcontainer.

•Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

•Neverllcontainersinsideavehicleoronatruckor

trailerwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removegas-poweredequipmentfromthetruck

ortrailerandrefuelitontheground.Ifthisisnot

possible,thenrefuelsuchequipmentwithaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntilthefueling

iscomplete.Donotuseanozzlelock-opendevice.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacegascapand

tightensecurely .

GeneralService:

•Neveroperateamachineinsideaclosedarea.Engine

exhaustcontainscarbonmonoxide,whichisan

odorless,deadlypoisonthatcankillyou.

•Keepnutsandboltstight,especiallytheblade

attachmentbolts.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Keepthemachinefreeofgrass,leaves,orother

debrisbuild-up.Cleanupoilorfuelspillagefuel

soakeddebris.Allowthemachinetocoolbefore

storing.

•Stopandinspecttheequipmentifyoustrikean

object.Repair,ifnecessary,beforerestarting.

•Nevermakeanyadjustmentsorrepairswiththe

enginerunning.

•Grasscatchercomponentsaresubjecttowear,

damageanddeterioration,whichcouldexpose

movingpartsorallowobjectstobethrown.

Frequentlycheckcomponentsandreplacewith

manufacturers’recommendedparts,whennecessary.

•Mowerbladesaresharpandcancut.Wrapthe

blade(s)orweargloves,anduseextracautionwhen

servicingthem.

•Checkforproperbrakeoperationfrequently.Adjust

andserviceasrequired.

•Maintainorreplacesafetyandinstructiondecalsas

necessary.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

ToroRidingMowerSafety

Thefollowinglistcontainssafetyinformationspecicto

Toroproductsorothersafetyinformationthatyoumust

knowthatisnotincludedintheANSIstandards.

•Stoptheengine,disconnectsparkplugwire(s)and

removekeybeforeperforminganyservice,repairs,

maintenanceoradjustments.

•Keephands,feet,hair,andlooseclothingawayfrom

attachmentdischargearea,undersideofmowerand

anymovingpartswhileengineisrunning.

•Donottouchequipmentorattachmentpartswhich

maybehotfromoperation.Allowtocoolbefore

attemptingtomaintain,adjustorservice.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfrombattery.

5

Page 6

•UseonlyToroapprovedattachments.Warrantymay

bevoidedifusedwithunapprovedattachments.

•Ifloadingthemachineontoatrailerortruck,usea

single,full-widthramponly.Therampangleshould

notexceed15degrees.

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

6

Page 7

SlopeChart

7

Page 8

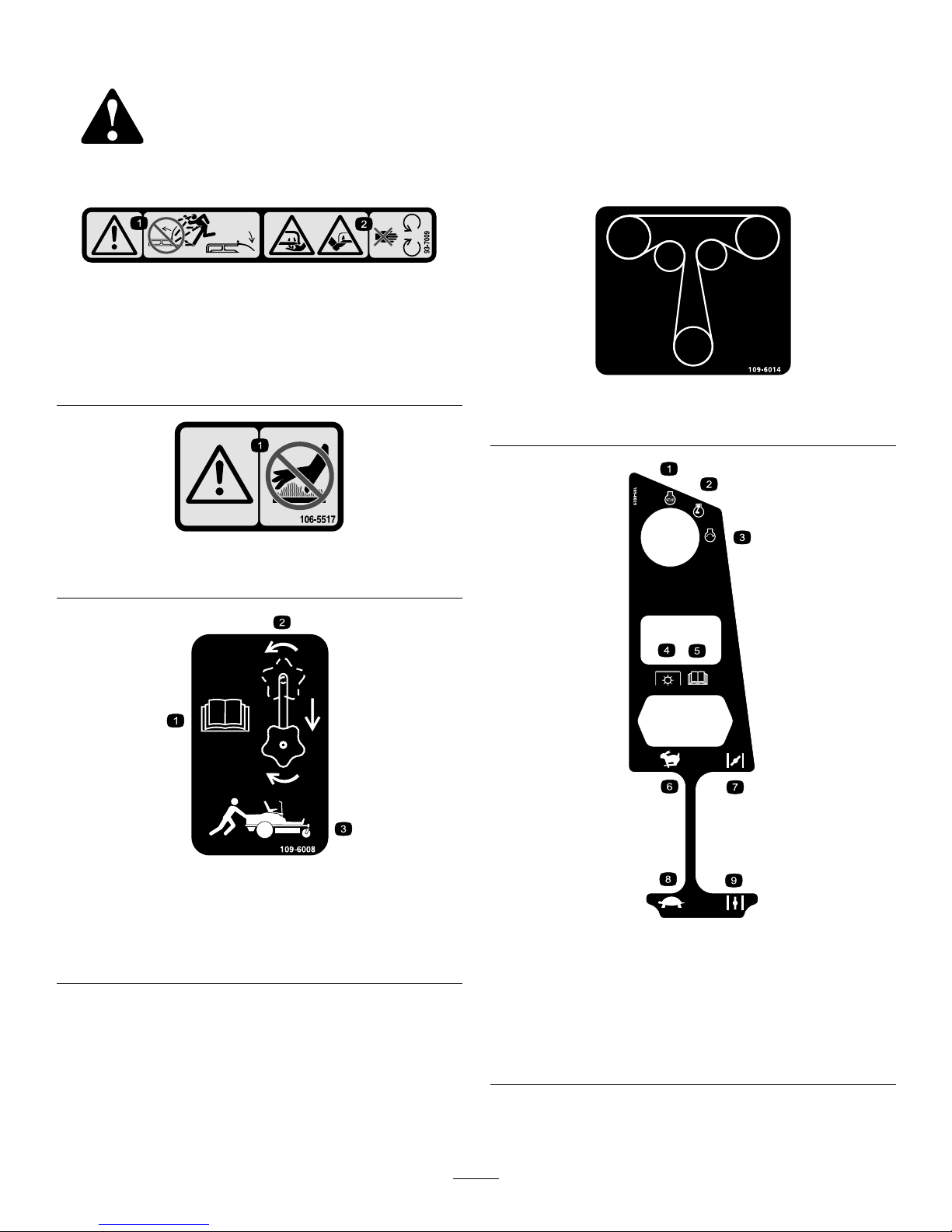

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

93-7009

1.Warning–DoNotoperate

themowerwiththe

dischargedeectorup

orremoved;keepthe

dischargedeectorin

place.

2.Cutting/dismemberment

hazardofhandorfoot,

mowerblade–stayaway

frommovingparts.

106-5517

1.Warning–DoNottouchthehotsurface.

109-6008

1.ReadtheOperator’s

Manual.

3.Pushthemachine.

2.Rotatethedriverelease

knobtoloosen,slidethe

knob,andtighten.

109-6014

TractionDriveBeltRouting

109-6029

1.Engine–stop

6.Throttle–fast

2.Engine–run

7.Choke–on

3.Engine–start8.Throttle–slow

4.Powertake-off(PTO),

Bladecontrolswitch

9.Choke–off

5.ReadtheOperator’s

Manual.

8

Page 9

109-6035

DeckDriveBeltRouting

109-6036

1.ReadtheOperator’sManual.

2.Removetheignitionkeyandreadtheinstructionsbefore

servicingorperformingmaintenance.

3.Heightofcut.

109-6210

1.ReadtheOperator’sManual.

2.Cutting/dismembermenthazard,fanandentanglement

hazard,belt–stayawayfrommovingparts.

109-6459

1.Entanglementhazard,belt—DoNotopenorremovesafety

shieldswhileengineisrunning,keepshieldsinplace.

109-8759

1.Heightofcut

109-9120

1.Fuse2.Diode

110-6691

1.Thrownobjects

hazard–keepbystanders

asafedistancefromthe

machine.

3.Cutting/dismemberment

ofhandorfoot–stayaway

frommovingparts.

2.Thrownobjectshazard,

mower–keepthe

dischargedeectoror

collectionsysteminplace.

9

Page 10

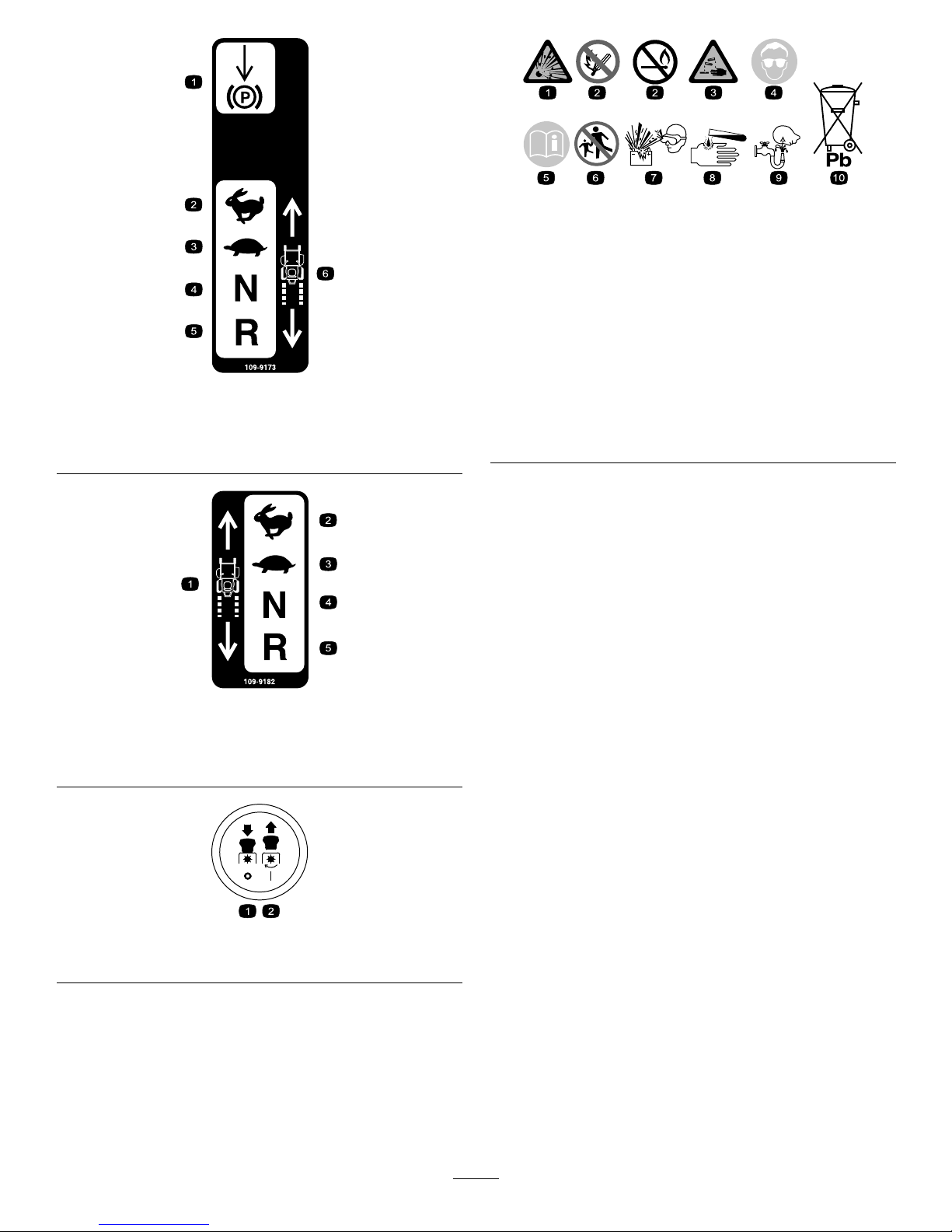

109-9173

1.Parkingbrake4.Neutral

2.Fast5.Reverse

3.Slow6.MachineSpeed

109-9182

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

PTOSymbols

1.PTO—Off2.PTO—On

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard

6.Keepbystandersasafe

distancefromthebattery.

2.Nore,openames,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator’s

Manual.

10.Containslead;donot

discard.

10

Page 11

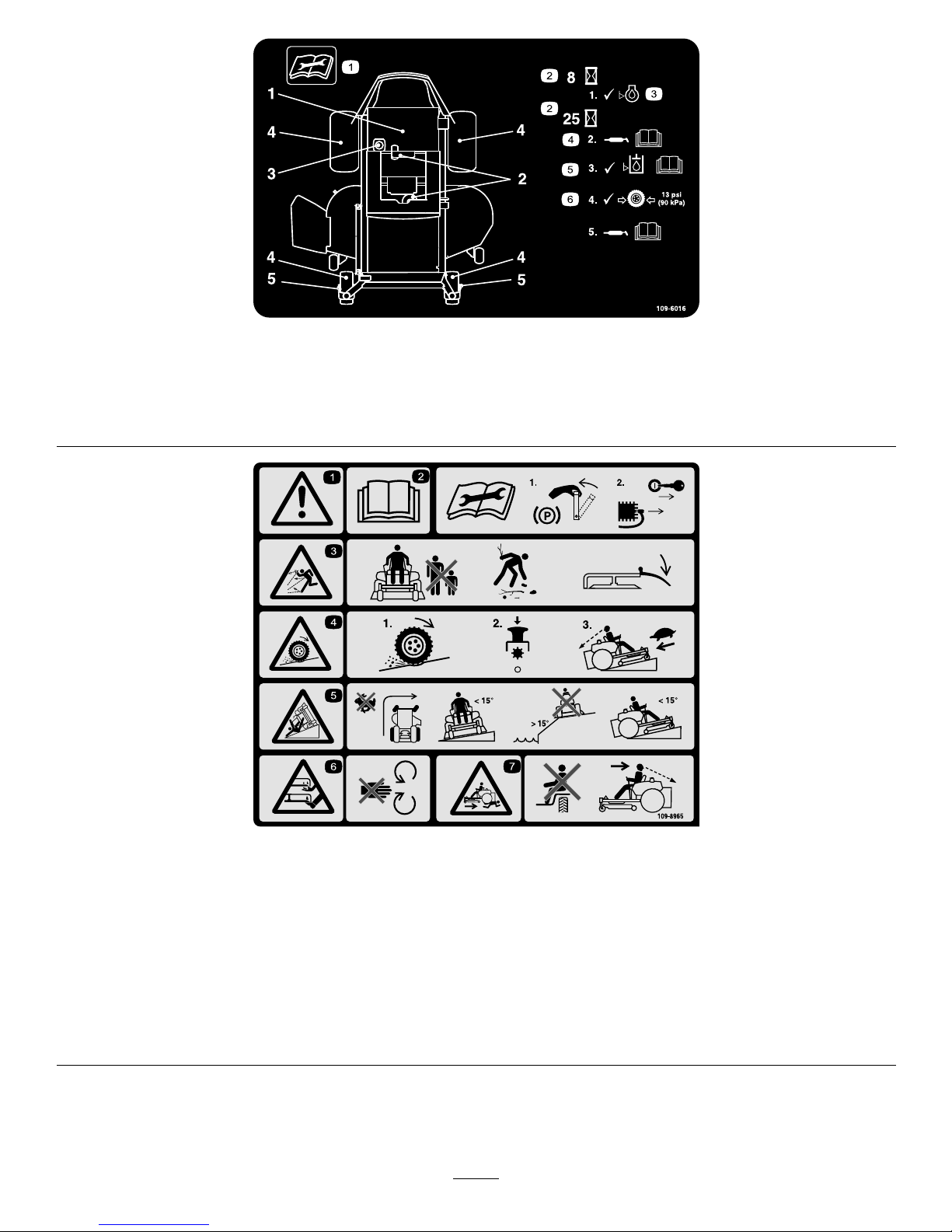

109-6016

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

4.RefertotheOperator’smanualforgreaseinstructions.

2.Timeinterval

5.CheckhydraulicoillevelandrefertotheOperator’sManual

forfurtherinstructions.

3.Checkoillevel.6.Checktirepressure.

109-8965

1.Warning–readtheOperator’sManual.

2.Readtheinstructionsbeforeservicingorperformingmaintenance;applyparkingbrake,removetheignitionkeyanddisconnect

thesparkplugwire.

3.Thrownobjecthazard—keepbystandersasafedistancefromthemachine,pickupdebrisbeforeoperating,keepthedischarge

deectorinplace.

4.Lossoftraction/controlhazard,slopes–lossoftraction/controlonslope,disengagethebladecontrolswitch(PTO),proceed

offtheslopeslowly.

5.Tippinghazard–avoidsuddenandsharpturnswhileonslopes,onlymowacrossslopeslessthan15degrees,keepasafe

distancefromwater,andonlymowupanddownslopeslessthan15degrees.

6.Cutting/dismembermenthazardofhandorfoot,mowerblade–stayawayfrommovingparts.

7.Crushing/dismembermenthazardofbystanders,reversing–DoNotcarrypassengers,lookbehindanddownwhenreversing.

11

Page 12

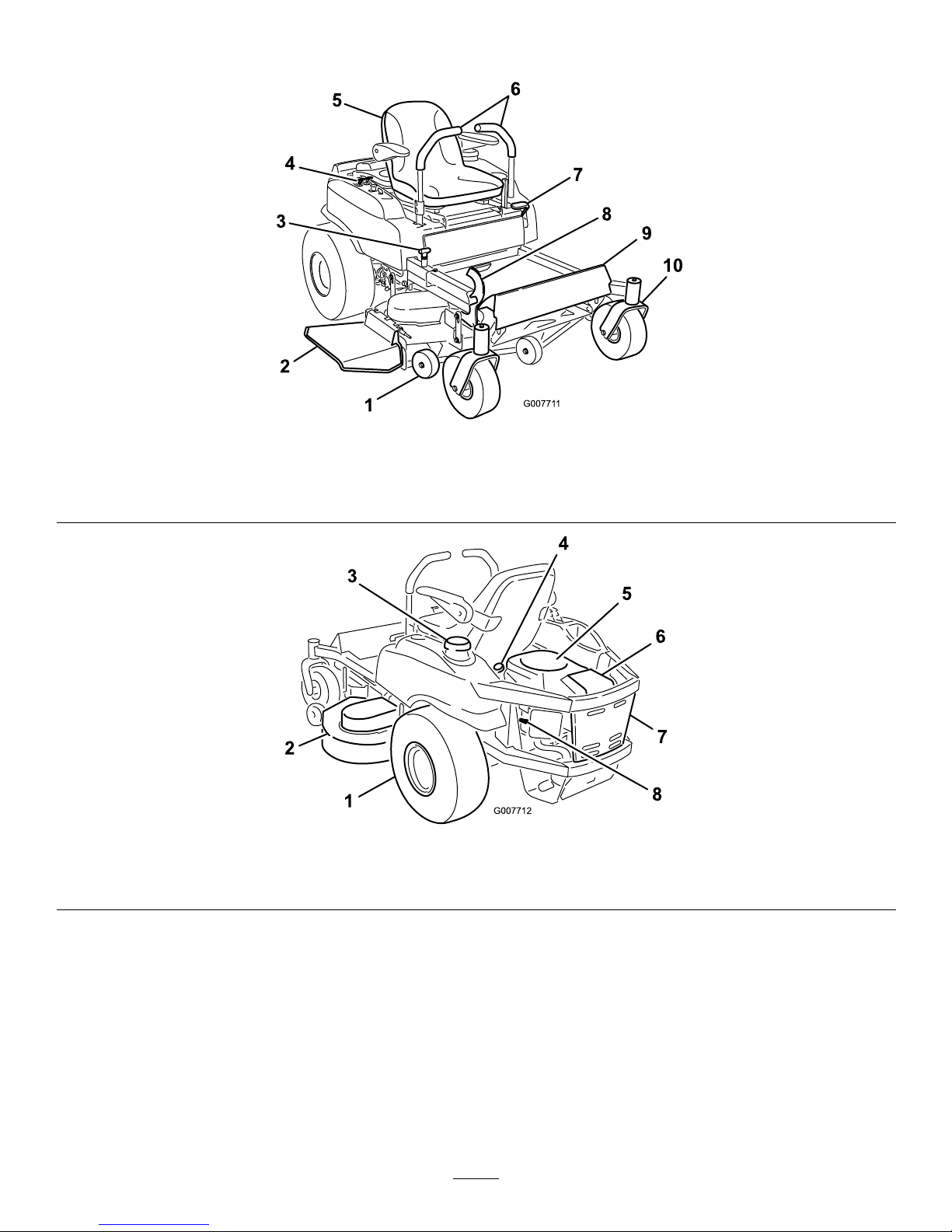

ProductOverview

Figure3

1.Anti-scalproller

4.Controlpanel

7.Parkbrake10.Frontcasterwheel

2.Dischargedeector5.Operator’sseat8.Heightofcutfootlever

3.Heightofcutadjustment

6.Motioncontrollevers9.Footrest

Figure4

1.Reardrivewheel

3.Gastank

5.Engine7.Engineguard

2.Mowerdeck4.Engineoildipstick

6.Airlter8.Sparkplugwire(1of2)

12

Page 13

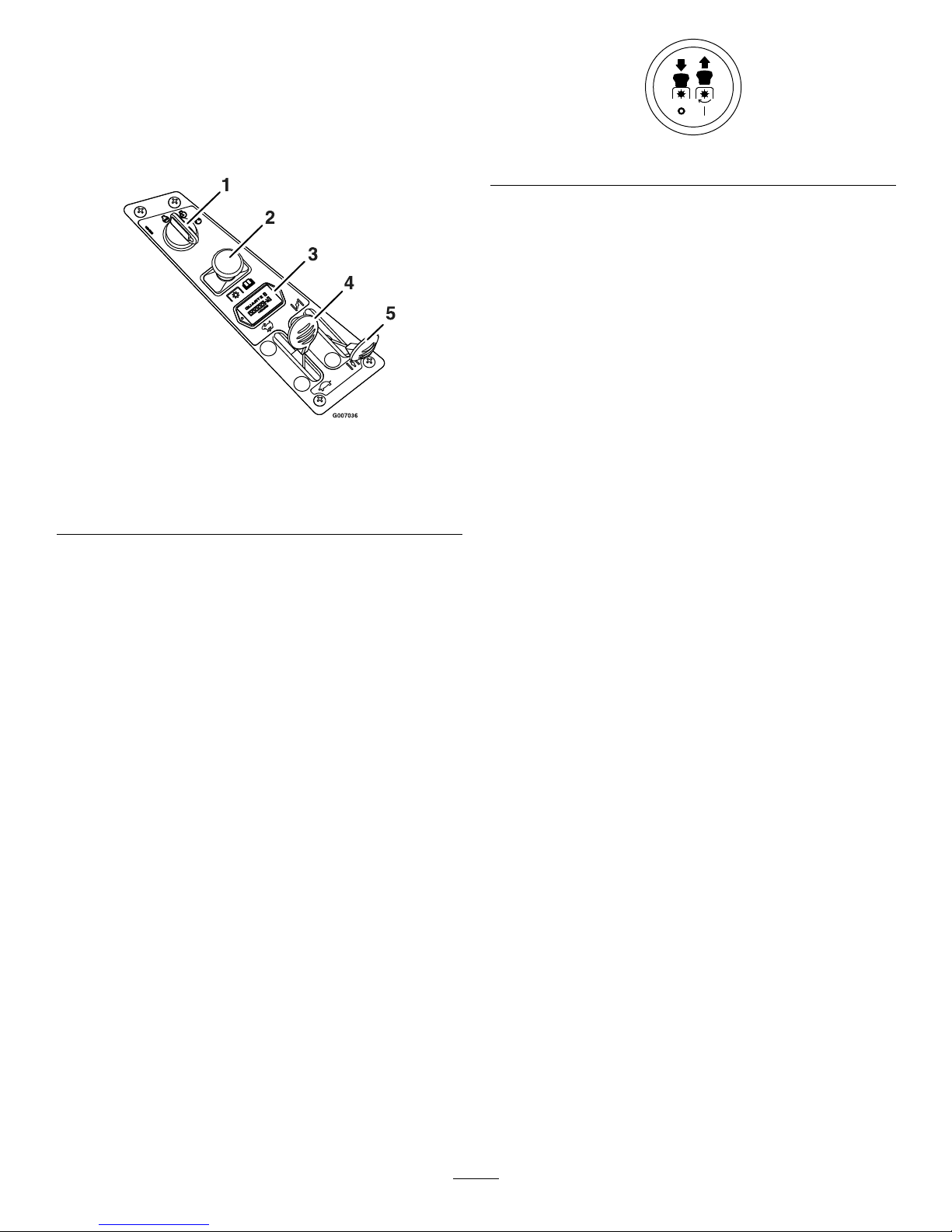

Controls

ControlPanel

Note:Becomefamiliarwithallofthecontrolsbefore

youstarttheengineandoperatethemachine.

Figure5

1.Ignitionswitch4.Throttle

2.Bladecontrolswitch

(powertake-off)

5.Choke

3.Hourmeter

IgnitionSwitch

Theignitionswitchisusedtostartandstoptheengine.

Theswitchhasthreepositions“OFF”,“RUN”and

“START”(Figure5).Insertkeyintoswitchandrotate

clockwisetothe“ON”position.Rotateclockwisetothe

nextpositiontoengagethestarter(keymustbeheld

againstspringpressureinthisposition).

Note:Brakemustbeengaged,motioncontrollevers

out(neutrallockposition)andPTOswitch“OFF”to

startengine.(Itisnotnecessaryfortheoperatortobein

theseattostarttheengine.)

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthe

machinetopreventsomeonefromaccidentallystarting

theengine

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol(Figure6),engagesand

disengagespowertothemowerblades.Pulloutonthe

bladecontrolswitchto“On”toengagetheblades

Pushthebladecontrolswitchto“Off”todisengage

theblades

Figure6

ChokeControl

Thechokeisusedtoaidinstartingacoldengine.Do

Notrunawarmenginewiththechokeinthe“ON”

position.Movingthechokeleverforwardwillputthe

chokeinthe“ON”positionandmovingthechokelever

totherearwillputthechokeinthe“OFF”position

(Figure5).

ThrottleControl

Thethrottleisusedtocontrolenginespeed.Moving

throttleleverforwardwillincreaseenginespeedand

movingthrottlelevertotherearwilldecreaseengine

speed.Movingthethrottleforwardintothedetentis

fullthrottle(Figure5).

MotionControlLevers

Themotioncontrolleverslocatedoneachsideofthe

seat(Figure3).

Themotioncontrolleversarespeedsensitivecontrols

ofindependentwheelmotors.Movingaleverforward

orbackwardturnsthewheelonthesamesideforward

orinreverse;wheelspeedisproportionaltotheamount

theleverismoved.Movingthecontrolleversoutward

fromthecenterpositionlocksthemintheneutral

position.Alwayspositionthemotioncontrollevers

intotheneutralpositionandengagetheparkbrake

leverwhenyoustopthemachineorleaveitunattended.

Theunitmustbetieddownandbrakeengagedwhen

transporting.

ParkingBrakeLever

Locatedonleftsideoftheconsole(Figure3).

Thebrakeleverengagesaparkingbrakeonthedrive

wheels.

Pulltheleverupandrearwardtoengagethebrake.

Pushtheleverforwardanddowntodisengagethebrake.

Height-of-CutFootLever

Theheightofcutleverallowstheoperatortolowerand

raisethedeckfromtheseatedposition(Figure3).When

theleverismovedforward,awayfromtheoperator

13

Page 14

thedeckisraisedfromthegroundandwhenmoved

back,towardstheoperatoritisloweredtowardthe

ground.Onlyadjusttheheightofcutwhilemachineis

notmoving.

HourMeter

Locatedonthecontrolpanel.

Thehourmeterisconnectedtoapressureswitch

installedintheengineblockanditrecordsthenumber

ofhoursthattheenginehasrun(Figure5).Ifthe

ignitionswitchisleftonwithoutenginerunning,hour

meterwillnotrun.

Note:Thisswitchisnotalowoilsensorandwillnot

alerttheoperatoriftheengineoilislow.

Specications

Systems

Engine

•EngineSpecications:SeeyourEngineOwner’s

Manual

•RPM:FullSpeed:3600±75(max)RPM(NoLoad)

Idle:1750(min)RPM

FuelSystem

•Capacity:4.0gal.(15.1L)

•TypeofFuel:Regularunleadedgasoline,87octane

orhigher.

•FuelFilter:KohlerP/N2405010

•FuelShut-OffValve:1/4turnincrements(“ON”,

“OFF”)

ElectricalSystem

•ChargingSystem:FlywheelAlternator

•ChargingCapacity:15amps

•BatteryType:BCIGroupU1

•BatteryVoltage:12Volt

•Polarity:NegativeGround

•Fuses:One25amp,one20amp;one15ampblade

type

•Diode:TVS

SafetyInterlockSystem

•PTOmustbedisengaged,brakeengaged,and

motioncontrolleversout(neutrallock)tostart

engine.(Itisnotnecessaryfortheoperatortobein

theseattostarttheengine.)

•OperatormustbeinseatwhenPTOisengaged,

brakeisdisengaged,ormotioncontrolleversare

movedinorenginewillstop.

•Enginewillstopifeithertheleft,theright,orboth

leversaremovedfromneutrallockpositionwhile

brakeisengaged.

OperatorControls

•SteeringandMotionControl:

Note:Motioncontrolleversareadjustabletotwo

heights.

–Separatelevers,oneachsideoftheconsole,

controlspeedanddirectionoftravelofthe

respectivedrivewheels.

–Steeringiscontrolledbyvaryingthepositionof

theleversrelativetoeachother.

–Movingmotioncontrolleversoutward(inslots)

locksthedrivesysteminneutral.

•PTOEngagementSwitch:Engageselectricclutch

(todrivebelt)whichengagesmowerblades.

•ParkingBrakeLever:Engagesparkingbrake.

•DeckHeightAdjustmentPin:Setscuttingheight

todesiredposition.

•DeckLiftAssistLever:Footpedalthatassistsin

raisingthedeck.

Seat

•Type:Standardseatwithhighback,foampadded

withspringsuspensionandarmrests.

•Mounting:Hingedtotiltupforaccesstohydraulic

pumps,batteryandothercomponents.Heldintilted

positionwithlanyard.Adjustableforeandaftseat

track.

•Armrests:Standard–foampaddedip-upadjustable

heightarmrests.

•SeatSafetySwitch:IncorporatedintotheSafety

InterlockSystem.

HydrostaticGroundDriveSystem

•HydrostaticPumps:TwoHydroGearZT2800

Integrateddrivesystems.

•HydraulicOilType:UseMobil115W -50Synthetic

motoroil.

•Speeds:

–0-7.0mph(11.3km/hr)forward.

–0-5.0mph(8.0km/hr)reverse.

•Drivewheelreleases,locatedonleftandrightsides

ofenginedeck,allowmachinetobemovedwhenthe

engineisnotrunningandbrakeisoff.

14

Page 15

Tires&Wheels

Drive

FrontCaster

Pneumatic(Air-Filled)

Pneumatic

(Air-Filled)

DeckSize

4852AllDecks

Quantity

222

TreadSizeTurfT ecTurfT ec

AllDecks

Size

20x8.00-820x10.00-810x4

PlyRating44

Pressure13psi

(90kPa)

13psi

(90kPa)

13psi

(90kPa)

CuttingDeck

•CuttingWidth:

–48inchDeck:48inches(122cm)

–52inchDeck:52inches(132cm)

•Discharge:Side

•BladeSize:(3ea.)

–48inchDeck:16.25inches(41.3cm)

–52inchDeck:18.00inches(45.7cm)

•BladeSpindles:Solidsteelspindleswithno

maintenancebearings.

•DeckDrive:Electricclutchmountedonvertical

engineshaft.Bladesaredrivenbyonebelt

(w/self-tensioningidler)directfromtheengine.

•Deck:Fulloatingdeckisattachedtoout-front

supportframe.Maximumturfprotectionisprovided

withthreeanti-scalprollers(bothdecksizes).

Deckdesignallowsforbagging,mulchingorside

discharge.

•DeckDepth:

–46inchDeck:5.0inches(12.7cm)

–52inchDeck:5.0inches(12.7cm)

•CuttingHeightAdjustment:Afootdeckliftleveris

usedtoadjustthecuttingheightfrom11/2inch

(3.8cm)to41/2inches(11.4cm)in1/2inch(1.3

cm)increments.

•MulchingKit:Optional.

Dimensions

OverallWidth:

48inchDeck52inchDeck

WithoutDeck45.5inches

(116cm)

47.0inches

(119cm)

48inchDeck52inchDeck

DeectorUp

48.3inches

(122cm)

53.0inches

(135cm)

DeectorDown

59.4inches

(151cm)

64.2inches

(163cm)

OverallLength:

48inchDeck52inchDeck

73.4inches(186cm)73.4inches(186cm)

OverallHeight:

48inchDeck52inchDeck

41.8inches(106cm)41.8inches(106cm)

TreadWidth:(CentertoCenterofTires,

Widthwise)

48inchDeck52inchDeck

DriveWheels36.0inches

(91cm)

36.8inches

(93cm)

CasterWheels

33.5inches

(85cm)

33.5inches

(85cm)

WheelBase:(CenterofCasterTireto

CenterofDriveTire)

48inchDeck52inchDeck

48.9inches(124cm)48.9inches(124cm)

CurbWeight:

48inchDeck52inchDeck

645lb(293kg)660lb(299kg)

TorqueRequirements

BoltLocationTorque

SpindlePulleyNut95-100ft-lb(1291-142N-m)

BladeMountingBolt

45-55ft-lb(61-75N-m)

EngineMountingBolts

27-33ft-lb(37-45N-m)

Anti-ScalpRollerNylocNut27-33ft-lb(37-45N-m)

WheelLugNuts

70-90ft-lb(95-122N-m)

ClutchMountingBolt(secured

withthreadlocker)

50-55ft-lb(68-75N-m)

SparkPlug15ft-lb(20N-m)

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsand

decalsinthesafetysection.Knowingthisinformation

couldhelpyou,yourfamily,petsorbystandersavoid

injury.

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityof

rollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdownthe

slopereducestraction.

•Attachmentschangethehandling

characteristicsofthemachine.Useextra

cautionwhenusingattachmentswiththe

machine.

Figure7

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater.

3.Water

RecommendedGasoline

UseUNLEADEDRegularGasolinesuitablefor

automotiveuse(87pumpoctaneminimum).

Important:Neverusemethanol,gasoline

containingmethanol,orgasoholcontainingmore

than10%ethanolbecausethefuelsystemcouldbe

damaged.DoNotmixoilwithgasoline.

16

Page 17

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburnyou,

others,andcausepropertydamage.

•Fillthefueltankoutdoorsinanopenarea,

whentheengineiscold.Wipeupany

gasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•DoNotllthefueltankcompletelyfull.

Addgasolinetothefueltankuntilthebody

ofthetankisfullbutfueldoesnotllthe

neckofthetank.Thisemptyspaceinthe

tankallowsgasolinetoexpand.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Never

buymorethana30-daysupplyofgasoline.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebeforelling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowtheloss

ofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimof

thefueltankorcontaineropeningatall

timesuntilfuelingiscomplete.

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof30daysor

less.Forlongerstorageitisrecommendedthatthe

fueltankbedrained.

17

Page 18

•Cleanstheenginewhileitruns.

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstartingAddthecorrect

amountofgasstabilizer/conditionertothegas.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.Tominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

Gasoline/Alcoholblends

Gasohol(upto10percentethylalcohol,90percent

unleadedgasolinebyvolume)isapprovedforfueluse

bytheenginemanufacturer.Othergasoline/alcohol

blendsarenotapproved.

FillingtheFuelTank

1.Shuttheengineoffandsetthemotioncontrolsto

theneutralpositionandengageparkingbrake.

2.Cleanaroundthefueltankcapandremovethecap.

3.Addunleadedregulargasolineuntilthebodyofthe

tankisfullbutfueldoesnotlltheneckofthe

tank(Figure8).Thisspaceintheneckofthetank

allowsgasolinetoexpand.Donotllthefueltank

completelyfull.

Figure8

1.Gastankopening3.Gastankbody

2.Filltohere,approximately

4.Installthefueltankcapsecurely.Wipeupany

gasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase;refertothe

CheckingtheOilLevelsectioninEngineMaintenance.

StartingtheEngine

1.Sitdownontheseatandmovethemotioncontrols

outwardtotheneutralpositionandengagethe

parkingbrake.

2.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure9).

Figure9

1.Controlpanel2.Bladecontrolswitch—Off

position

3.Movethethrottlelevertomidwayandthe

chokeleverforwardbeforestartingacoldengine

(Figure10).

Note:Awarmorhotenginemaynotrequire

choking.

Figure10

1.Controlpanel

4.Throttle—slow

2.Choke—on5.Throttle—fast

3.Choke–off

4.TurntheignitionkeytoStarttoenergizethestarter.

Whentheenginestarts,releasethekey(Figure11).

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefails

tostart,allowa60secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

18

Page 19

Figure11

1.Ignitionkey—startposition

4.Start

2.Controlpanel

5.Run

3.Choke6.Off

5.Iftheenginestallsorhesitates,movethechoke

leverpartiallyforwardforafewseconds(Figure11).

OperatingtheBlades

Thebladecontrolswitch,representedbyapower

take-off(PTO)symbol,engagesanddisengagespower

tothemowerblades.Thisswitchcontrolspowertoany

attachmentsthatdrawpowerfromtheengine,including

themowerdeckandcuttingblades.

EngagingtheBlades

1.Releasepressureonthemotioncontrolleversand

placethemachineinneutral.

2.MovethethrottlemidwaytotheFastposition.

Note:Alwaysengagethebladeswiththethrottle

inthemidwayposition.

3.PulloutonthebladecontrolswitchtoOnto

engagetheblades(Figure12).

Figure12

1.Controlpanel2.Bladecontrolswitch—On

position

4.Movethrottletofullforwardpositionbefore

mowing.

DisengagingtheBlades

Setthrottletomidwayposition.Pushthebladecontrol

switchtoOfftodisengagetheblades(Figure13).

Figure13

1.Controlpanel2.Bladecontrolswitch—Off

position

StoppingtheEngine

1.MovethethrottlelevertobetweenFastandhalf

throttle(Figure11).

2.Disengagethebladesbymovingthebladecontrol

switchtoOff(Figure13).

3.TurntheignitionkeytoOff(Figure11).

4.Pullthewireoffofthesparkplug(s)toprevent

thepossibilityofsomeoneaccidentallystartingthe

machinebeforetransportingorstoringthemachine.

19

Page 20

TheSafetyInterlockSystem

Ifsafetyinterlockswitchesaredisconnected

ordamagedthemachinecouldoperate

unexpectedlycausingpersonalinjury.

•DoNottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutral

position.

•Theparkingbrakeisengaged.

Thesafetyinterlocksystemisdesignedtoinitiateengine

shutdownwhen:

•Theparkingbrakeisdisengagedandtheoperator

getsoffmachine.

•ThePTOisengagedandtheoperatorgetsoff

machine.

•Theparkingbrakeisdisengagedandleversarein

andtheoperatorgetsoffmachine.

•Theparkingbrakeisengagedandmotioncontrol

leversarein.

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethe

machineeachtime

1.Checkstartingcircuit.Startershouldcrankwith

parkingbrakeengaged,PTOdisengagedand

motioncontrolleversmovedoutintheneutral

lockposition.Theoperatordoesnotneedtobein

theseattostarttheengine.

Trytostartwithoperatorinseat,parkingbrake

disengaged,PTOdisengagedandmotioncontrol

leversintheneutrallockposition-startermust

notcrank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOengagedandmotioncontrollevers

intheneutrallockposition-startermustnot

crank.

Trytostartwithoperatorinseat,parkingbrake

engaged,PTOdisengaged,andtheleftmotion

controlleverin,startermustnotcrank,repeat

againwiththerightleverin,thenwithbothlevers

in-startermustnotcrank.

2.Checkkillcircuits.Runengineatone-thirdthrottle,

disengageparkingbrakeandraiseoffofseat(but

donotgetoffofmachine)enginemustinitiate

shutdown.

Runengineatone-thirdthrottle,engagePTOand

raiseoffofseat(butdonotgetoffofmachine)

enginemustinitiateshutdown.

Runengineatone-thirdthrottle,withbrake

disengaged,moveleversinandraiseoffseat(but

donotgetoffofmachine)enginemustinitiate

shutdown.

Again,runengineatone-thirdthrottle,brake

engaged,andmoveleftmotioncontrolleverin-

enginemustinitiateshutdown.

Repeatagainmovingtherightleverin,then

movingbothleversin-enginemustinitiate

shutdownwhetheroperatorisonseatornot.

Note:Ifmachinedoesnotpassanyofthesetests,

donotoperate.ContactyourauthorizedToroService

Dealer.

Important:Itisessentialthatoperatorsafety

mechanismsbeconnectedandinproperoperating

conditionpriortouseformowing.

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFastpositionforbest

performance.AlwaysoperateintheFast(fullthrottle)

position.

Machinecanspinveryrapidlybypositioning

onelevertoomuchaheadoftheother.Operator

maylosecontrolofthemachine,whichmay

causedamagetothemachineorinjury.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

20

Page 21

Forward

1.Movetheleverstothecenter,unlockedposition.

2.Togoforward,slowlypushthemotioncontrol

leversforward(Figure14).

Figure14

1.Neutralposition3.Backward

2.Centerunlockposition

4.Forward

Togostraight,applyequalpressuretobothmotion

controllevers(Figure14).

Toturn,pullbackonthemotioncontrollever

towardthedirectionyouwanttoturn(Figure14).

Thefartheryoumovethemotioncontrolleversin

eitherdirection,thefasterthemachinewillmovein

thatdirection.

Tostop,pullthemotioncontrolleverstoneutral.

Backward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrol

leversrearward(Figure14).

Togostraight,applyequalpressuretobothmotion

controllevers(Figure14).

Toturn,releasethepressureonthemotion

controllevertowardthedirectionyouwanttoturn

(Figure14).

Tostop,pushthemotioncontrolleverstoneutral.

StoppingtheMachine

Tostopthemachine,movethemotioncontrolleversto

neutralandoutwardtotheneutralposition,disengage

thebladecontrolswitch,movethethrottleleverto

betweenFastandhalfthrottle,andturntheignitionkey

tooff.Remembertoremovethekeyfromtheignition

switch.

TrackingAdjustment

Ifthemachineturnsrightorleftwhenhandlesare

pushedforwardtogether,adjustthestopontheside

oppositethedirectionofturn(Figure15).Loosenthe

screwsthatholdthemotioncontrollimiterstop.Move

thestopbackuntiltheunitdrivesstraight.Tighten

thescrewstolockthestopinplace.Readjusthandles

ifnecessary.

Figure15

1.Controlarmshaft

3.Adjuststop

2.Limiterstopscrews

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemowerwhileit

isunattended.

Alwaysremovetheignitionkeyandmovethe

motioncontrolleversoutwardtotheneutral

positionandapplytheparkingbrakewhen

leavingthemachineunattended,evenifjustfor

afewminutes.

21

Page 22

AdjustingtheHeightofCut

1.Raisethedecktothetransportposition(4.5inch

(114mm)cutheight)bypushingthefootactuated

leverforward(Figure16).Thespringloaded

transportpinwillautomaticallyengageandwillclick

intoplace.

Figure16

1.Pushforward

4.Heightadjusterpin

2.Footactuated

height-of-cutlever

5.Transportreleasehandle

3.Height-of-cutpositions

2.Movethedeckheightadjusterpintothedesired

cutheight.

3.Pushthefootleverforward,pullthetransport

releasehandleupandletthedecklowerdowntothe

predeterminedcutheightbyslowlydecreasingfoot

pressureallowingthefootlevertotravelrearward.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Positionthe

seatwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

1.Pushtheadjustmentlevertowardsthecenter

ofthemachinetoreleasetheseatadjustertrack

(Figure17).

Figure17

1.Adjustmentlever

2.Movetheseattothedesiredpositionandrelease

thelevertolockinthatposition.

ChangingtheSeatRide

Suspension

Thenumberofseatspringscanbechangedto

maximizeridercomfort.Morespringsshouldbeused

withheavieroperatorsandonroughterrain.Fewer

springsshouldbeusedwithlighteroperatorsandwhen

mowingsmooth,wellestablishedlawns.Alwayskeep

thenumberofspringsontheleftandrightsidethe

samewhenaddingandremovingsprings.

Figure18

1.Bolt3.Nut

2.Spring

4.Additionalmountingholes

Uptovespringscanbesecuredtotheseatboxwitha

nutandbolt,seeFigure18.

RefertoyourPartsManualforspringandhardware

partnumbers.

22

Page 23

AdjustingtheMotionControl

Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigheror

lowerformaximumoperatorcomfort.

1.Removethetwoboltsholdingthecontrolleverto

thecontrolarmshaft(Figure19).

Figure19

1.Controlarmshaft

4.Bolt

2.Controllever5.Slottedholes

3.Washer

2.Movethecontrollevertothenextsetofholes.

Securetheleverwiththetwobolts.

3.Repeattheadjustmentfortheoppositecontrol

lever.

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforeoraftfor

maximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrolleverto

thecontrolarmshaft.

2.Loosenthelowerboltjustenoughtopivotthe

controlleverforeoraft(Figure19).Tightenboth

boltstosecurethecontrolinthenewposition.

3.Repeattheadjustmentfortheoppositecontrol

lever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.

Nevertowthemachinebecausedamagemay

occur.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtoneutral

position,engageparkingbrake,stoptheengine,

removethekey,andwaitforallmovingpartsto

stopbeforeleavingtheoperatingposition.

3.Locatethebypassreleaseknobsoneithersideof

theenginedeck(Figure20).

Figure20

1.Frontofthemachine.5.Leverpositionforpushing

themachine

2.Rotatebypassrelease

knobcounterclockwise

6.Rotatebypassrelease

knobclockwise

3.Leverpositionfor

operatingthemachine.

7.Releaselever

4.Pullleverinthisdirection

4.Loosentheknobbyturningcounterclockwise.

Thenpullthereleaseleverontheundersideof

machine(Figure20)towardsthebackofthe

machineandretightentheknobtoholdtherelease

leverbackinthereleasedstate.Repeatthisoneach

sideofthemachine.

5.Releasetheparkingbrake.Themachineisnowable

tobepushedbyhand.

ToOperatetheMachine

Loosenthebypassknob,pushthereleaselevers

forward,andretightentheknobtoengagethedrive

system(Figure20).

23

Page 24

SideDischarge

Themowerhasahingeddischargedeectorthat

dispersesclippingstothesideanddowntowardtheturf.

Withoutthedischargedeector,mulchkit,or

entiregrasscollectionsystemmountedinplace,

youandothersareexposedtobladecontactand

throwndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethedischargedeectorfrom

themowerbecausethedischargedeector

routesmaterialdowntowardtheturf.Ifthe

dischargedeectoriseverdamaged,replace

itimmediately .

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytocleardischargeareaormower

bladesunlessyoumovethemovetheblade

controlswitchtoOffandrotatetheignition

keytoOff.Alsoremovethekeyandpullthe

wireoffthesparkplug(s).

Transporting

TransportingaUnit

Useaheavy-dutytrailerortrucktotransportthe

machine.Lockbrakeandblockwheels.Securelyfasten

themachinetothetrailerortruckwithstraps,chains,

cable,orropes.Besurethatthetrailerortruckhas

allnecessarylightingandmarkingasrequiredbylaw.

Secureatrailerwithasafetychain.

Thisunitdoesnothaveproperturnsignals,

lights,reectivemarkings,oraslowmoving

vehicleemblem.Drivingonastreetorroadway

withoutsuchequipmentisdangerousand

canleadtoaccidentscausingpersonalinjury.

Drivingonastreetorroadwaywithoutsuch

equipmentmayalsobeaviolationofStatelaws

andtheoperatormaybesubjecttotrafctickets

and/ornes.

DoNotdriveaunitonapublicstreetor

roadway.

Loadingaunitonatrailerortruckincreases

thepossibilityofbackwardtip-over.Backward

tip-overcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatingaunit

onaramp.

•Useonlyasingle,fullwidthramp;DoNot

useindividualrampsforeachsideofthe

unit.

•Ifindividualrampsmustbeused,use

enoughrampstocreateanunbrokenramp

surfacewiderthantheunit.

•DoNotexceeda15degreesanglebetween

rampandgroundorbetweenrampand

trailerortruck.

•Avoidsuddenaccelerationwhiledrivingunit

uparamptoavoidtippingbackward.

•Avoidsuddendecelerationwhilebacking

unitdownaramptoavoidtippingbackward.

LoadingaUnit

Useextremecautionwhenloadingunitsontrailersor

trucks.Onefullwidthrampthatiswideenoughto

extendbeyondthereartiresisrecommendedinstead

ofindividualrampsforeachsideoftheunit.The

lowerrearsectionofthetractorframeextendsback

betweentherearwheelsandservesasastopfortipping

backward.Havingafullwidthrampprovidesasurface

fortheframememberstocontactiftheunitstartsto

tipbackward.Ifitisnotpossibletouseonefullwidth

ramp,useenoughindividualrampstosimulateafull

widthcontinuousramp.

Rampshouldbelongenoughsothattheanglesbetween

therampandthegroundandtherampandthetrailer

ortruckdonotexceed15degrees.Asteeperanglemay

causemowerdeckcomponentstogetcaughtastheunit

movesfromramptotrailerortruck.Steeperangles

mayalsocausetheunittotipbackward.Ifloadingon

ornearaslope,positionthetrailerortrucksoitison

thedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.Thetraileror

truckshouldbeaslevelaspossible.

Important:DoNotattempttoturntheunitwhile

ontheramp,youmaylosecontrolanddriveoff

theside.

24

Page 25

Avoidsuddenaccelerationwhendrivinguparampand

suddendecelerationwhenbackingdownaramp.Both

maneuverscancausetheunittotipbackward.

OperatingTips

FastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFastposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

byuncutgrass.Alwaystrytohaveonesideofthe

mowerfreefromuncutgrass,whichallowsairtobe

drawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslonger

thansixinchestall,youmaywanttocutthelawntwice

toensureanacceptablequalityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrowsmore

slowly.

MowingDirection

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhich

enhancesdecompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,

grassgrowsatdifferentratesatdifferenttimes.So

tomaintainthesamecuttingheight,whichisagood

practice,mowmoreofteninearlyspring.Asthegrass

growthrateslowsinmidsummer,mowlessfrequently.

Ifyoucannotmowforanextendedperiod,rstmow

atahighcuttingheight;thenmowagaintwodayslater

atalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeed.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthe

moweryoupreviouslyused,raisethecuttingheightto

ensurethatuneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raise

thecuttingheighthigherthanusualandcutthegrassat

thissetting.Thencutthegrassagainusingthelower,

normalsetting.

WhenStopping

Ifthemachine’sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.T oavoidthis,moveontoapreviouslycutarea

withthebladesengaged.

KeeptheUndersideoftheMower

Clean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.Checkthecutterblades

dailyforsharpness,andforanywearordamage.File

downanynicksandsharpenthebladesasnecessary.Ifa

bladeisdamagedorworn,replaceitimmediatelywitha

genuineTororeplacementblade.OnlyT orobladesare

tobeusedwiththisunit.Nootherbladesareapproved.

25

Page 26

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

Aftertherst5hours

•Changetheengineoil.

Aftertherst200hours

•Changethehydraulicsystemlter.

Beforeeachuseordaily

•Checkthesafetyinterlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheoillevelbeforestartingorafterevery8hours.

•Checkthehydraulicoillevelintheexpansiontank.

•Checkthemowerblades.

•Cleantheundersideofthemowerhousing.

Every25hours

•Greasealllubricationpoints.

•Servicetheprecleanerelement.(moreoftenunderextremelydusty ,dirtyconditions)

•Changetheengineoilandlterwhenoperatingtheengineunderheavyloadorin

hightemperatures.

•Checkthetirepressure.

•Checkthebelts.

Every50hours

•Servicethepaperelement.(moreoftenunderextremelydusty,dirtyconditions)

•Changetheengineoilandlter.

Every100hours

•Replacetheprecleanerelement.(moreoftenunderextremelydusty ,dirtyconditions)

•Replacethepaperelement.(moreoftenunderextremelydusty,dirtyconditions)

•Cleantheblowerhousing.Moreoftenunderdirtyconditions.

•Replacethefuellter.

Every200hours

•Servicethesparkplug.

Every500hours

•Replacethesparkplug.

Beforestorage

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceproceduresbeforestorage.

•Paintanychippedsurfaces.

26

Page 27

Premaintenance

Procedures

RaisingtheSeat

Makesurethemotioncontrolleversarelockedinthe

neutralposition.Lifttheseatforwarduntilthelanyard

istight.Thefollowingcomponentscanbeaccessedby

raisingtheseat:

•Auxiliary12VPlug(12Vaccessoryupto15amp)

•Fuses

•Batterycables

AccessingtheBattery

Thebatteryislocatedundertheseat.Toaccess,raise

theseat(Figure21).

Figure21

1.Auxiliary12VPlug

3.Seat

2.Battery

Lubrication

GreasingtheBearings

GreaseType:NGLIgrade#2multi-purposegungrease.

Greasethefrontcasterpivotsandwheels(Figure22).

1

G007184

Figure22

1.Frontcastertire

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engageparkingbrake,stopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Cleanthegreasettings(Figure22andFigure23)

witharag.Makesuretoscrapeanypaintoffofthe

frontofthetting(s).

27

Page 28

Figure23

Locatedonthebackoftheseat.

1.Readtheinstructions

beforeservicingor

performingmaintenance

4.Checkoillevel.

2.Greaseidlerpivots.5.Checkhydraulicoillevel

andrefertoOperator’s

manualforfurther

instructions.

3.Timeinterval.

6.Checktirepressure.

4.Connectagreaseguntoeachtting(Figure22and

Figure23).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

aircleanerfordirty,looseordamaged

parts.

Thisengineisequippedwithareplaceable,highdensity

paperaircleanerwithafoamprecleanersurrounding

it.Checktheaircleanerdailyorbeforestartingthe

engine.Checkforabuildupofdirtanddebrisaround

theaircleanersystem.Keepthisareaclean.Alsocheck

forlooseordamagedcomponents.Replaceallbentor

damagedaircleanercomponents.

Note:Operatingtheenginewithlooseordamagedair

cleanercomponentscouldallowunlteredairintothe

enginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

Figure24

1.Aircleanercover3.Paperelement

2.Aircleanerlatch4.Aircleanerbase

ServicingPrecleanerElement

ServiceInterval:Every25hours—Servicethe

precleanerelement.(moreoften

underextremelydusty ,dirty

conditions)

Every100hours—Replacethe

precleanerelement.(moreoften

28

Page 29

underextremelydusty ,dirty

conditions)

1.Opentheaircleanercoverdoorontheblower

housingtoaccesstheaircleanerelement(Figure24).

2.Unhookthelatchandremovetheaircleanerelement

(Figure24).

3.Cleantheaircleanerbaseasrequiredandcheck

condition.

4.Carefullyremovetheprecleanerfromthepaper

element.Inspecttheprecleanerforanydamageor

tears.Replaceasnecessary.

5.Washtheprecleanerinwarmwaterwithdetergent.

Rinsetheprecleanerthoroughlyuntilalltracesof

detergentareeliminated.Squeezeoutexcesswater

(donotwring)andallowtheprecleanertoairdry.

6.Saturatetheprecleanerwithnewengineoil.Squeeze

outallexcessoil.

7.Installtheprecleaneroverthepaperelement.

8.Installtheaircleanerontotheaircleanerbase.

Securewiththelatch.

9.Closetheaircleanercoverdoor.

ServicingPaperElement

ServiceInterval:Every50hours—Servicethepaper

element.(moreoftenunderextremely

dusty,dirtyconditions)

Every100hours—Replacethepaper

element.(moreoftenunderextremely

dusty,dirtyconditions)

1.Opentheaircleanercoverdoorontheblower

housingtoaccesstheaircleanerelement(Figure24).

2.Unhookthelatchandremovetheaircleanerelement

(Figure24).

3.Carefullyremovetheprecleanerfromthepaper

element.Inspecttheprecleanerforanydamageor

tears.Replaceasnecessary.

4.Gentlytapthepaperelementtodislodgedirt.Do

notwashthepaperelementorusepressurized

air,asthiswilldamagetheelement.Replaceadirty,

bent,ordamagedelement.Handlethenewelement

carefully;donotuseifthesealingsurfacesarebent

ordamaged.

5.Cleantheaircleanerbaseasrequiredandcheck

condition.

6.Installtheairelementontotheaircleanerbase.

Securewiththelatch.

7.Closetheaircleanercoverdoor.

ServicingtheEngineOil

CheckingtheOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey .

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit.

4.Pullandremovetheoilllcap/dipstick;wipeoil

off.Reinsertthedipstickandpushrmlyintoplace

(Figure25).

Figure25

1.Oildipstick3.Oillevel

2.Fillertube

5.Removethedipstickandchecktheoillevel.

Theoillevelshouldbeupto,butnotover,the“F”

markonthedipstick.

6.Ifthelevelislow ,addoilofthepropertype,upto

the“F”markonthedipstick.Alwayscheckthelevel

withthedipstickbeforeaddingmoreoil.

Note:Topreventextensiveenginewearordamage,

alwaysmaintaintheproperoillevelinthecrankcase.

Neveroperatetheenginewiththeoillevelbelowthe

“L”markoroverthe“F”markonthedipstick.

ChangingtheOilandFilter

ServiceInterval:Aftertherst5hours

Every50hoursthereafter.

29

Page 30

Every25hours

OilType:Detergentoil(APIserviceSF ,SG,SH,SJ,or

higher).

CrankcaseCapacity:2.0qt(1.9l)whenthelteris

changed.

RellwithserviceclassSF,SG,SH,SJorhigheroilas

speciedinthe“ViscosityGrades”table(Figure26).

Figure26

ViscosityGrades

SAE30:40degreesFandhigher(5degreesCand

higher)isgoodforallpurposeuseabove40degreesF.

Usebelow40degreesFwillcausehardstarting.

10W-30:0to100degreesF(-18to38degreesC)is

betterforvaryingtemperatureconditions.Thisviscosity

improvescoldweatherstarting,butmayincreaseoil

consumptionabove80degreesF(27degreesC).

*Checkoillevelfrequentlyathighertemperatures.

Synthetic5W-30:-20to120degreesF(-30to

40degreesC)providesthebestprotectioninall

temperatures,aswellasimprovedstartingwithlessoil

consumption.

5W-30:40degreesFandbelow(5degreesCandbelow)

isrecommendedforwinteruseandworksbestincold

conditions.

Changetheoilandlterwhiletheengineisstillwarm.

Theoilwillowmorefreelyandcarryawaymore

impurities.Makesuretheengineislevelwhenlling,

checking,orchangingtheoil.

1.Starttheengineandletitrununtilwarm.This

warmstheoilsoitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

3.Disengagethebladecontrolswitchandmovethe

motioncontrolsoutwardtotheneutralpositionand

engageparkingbrake.

4.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

5.Cleantheareaaroundthedrainplugandonthe

machineframe.Placeapanunderneathmachine

directlybelowthedrainholeintheframeasshown

inFigure27

Figure27

1.Oildrainhose

3.Pan

2.Oildrainplug

6.Removetheoildrainplug(Figure27).Removethe

oilllcap/dipstick(Figure25).

Figure28

1.Oillter2.Gasket

7.Besuretoallowampletimeforcompletedrainage.

8.Removetheoldlterandwipeoffthemountingpad

(Figure28).

9.Whentheoilhasdrainedcompletely,installthe

oildrainplug.Tightentheplugto14N-m(125

in-lb)torque.Wipeupanyexcessoilontheframe

(Figure27).

Note:Disposeoftheusedoilatarecyclingcenter.

30

Page 31

10.Applyathinlmofcleanoiltotherubbergasketon

thenewlter.

11.Installthereplacementoilltertothemountingpad.

Turntheoillterclockwiseuntiltherubbergasket

contactsthepad,thentightenthelteranadditional

1/2to3/4turn(Figure27).

12.Slowlypourapproximately80%ofthespeciedoil

intothellertube.

13.Installtheoilllcap/dipstickandpushrmlyinto

place.

14.Checktheoillevel(Figure25);refertotheChecking

theOilLevelsection.

15.Slowlyaddadditionaloiltobringittothefullmark.

16.Installtheoilllcap/dipstickandpushrmlyinto

place.

ServicingtheSparkPlug

ServiceInterval:Every200hours/Every2years

(whichevercomesrst)

Every500hours

Asstatedinthemaintenanceintervals,removethespark

plug,checkcondition,andresetthegaporreplacewith

anewplugasnecessary.

ThesparkplugisRFIcompliant.Equivalentalternate

brandplugscanalsobeused.

Type:ChampionXC12YC

AirGap:0.030inch(0.76mm)

RemovingtheSparkPlug

1.Disengagethebladecontrolswitch,movethe

motioncontrolsoutwardtotheparkposition,stop

theengine,andremovethekey.

2.Pullthewireoffofthesparkplug(Figure29).Clean

aroundthesparkplugtopreventdirtfromfalling

intotheengineandpotentiallycausingdamage.

Note:Duetothedeeprecessaroundthespark

plug,blowingoutthecavitywithcompressedair

isusuallythemosteffectivemethodforcleaning.

Thesparkplugismostaccessiblewhentheblower

housingisremovedforcleaning.

3.Removethesparkplugandmetalwasher.

Figure29

1.Sparkplugandwirelocation

CheckingtheSparkPlug

1.Lookatthecenterofthesparkplug(Figure30).

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly .Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Important:Nevercleanthesparkplug.Always

replacethesparkplugwhenithasablack

coating,wornelectrodes,anoilylm,orcracks.

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure30).Bendthesideelectrodeifthegapisnot

correct.

Figure30

1.Sideelectrode3.Airgap(nottoscale)

2.Centerelectrodeinsulator

InstallingtheSparkPlug

1.Installthesparkplug.Makesurethattheairgapis

setcorrectly.

2.Tightenthesparkplugto15ft-lb(20N-m).

3.Pushthewireontothesparkplug(Figure29).

CleaningtheBlowerHousing

ServiceInterval:Every100hours/Yearly(whichever

comesrst)Moreoftenunderdirty

conditions.

31

Page 32

Toensurepropercooling,makesurethegrassscreen,

coolingns,andotherexternalsurfacesoftheengine

arekeptcleanatalltimes.

1.Removetheblowerhousingandanyothercooling

shrouds.

2.Cleanthecoolingnsandexternalsurfacesas

necessary.

3.Makesurethecoolingshroudsarereinstalled

Important:Operatingtheenginewithablocked

grassscreen,dirtyorpluggedcoolingns,and/or

coolingshroudsremoved,willcauseenginedamage

duetooverheating.

FuelSystem

Maintenance

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areor

explosionfromgasolinecanburnyouand

othersandcandamageproperty.

•Performanyfuelrelatedmaintenancewhen

theengineiscold.Dothisoutdoorsinan

openarea.Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,and

stayawayfromanopenameorwherea

sparkmayignitethegasolinefumes.

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichever

comesrst)

Neverinstalladirtylterifitisremovedfromthefuel

line.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engageparkingbrake,stopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Thefuellterisinthefuellinebetweenthetank

andengine.

4.Turnfuelshutoffvalve90degreesto“off”position.

5.Squeezetheendsofthehoseclampstogetherand

slidethemawayfromthelter(Figure31).

6.Removethelterfromthefuellines.

7.Installanewlterwiththeowdirectionarrow

comingfromthefueltankandpointingtothe

engine.Movethehoseclampsclosetothelter

(Figure31)tosecureitinplace.

32

Page 33

Figure31

1.Fueltank6.Hoseclamps

2.Fuelshutoffvalve—off

7.Fuellinetoengine

3.Fuelshutoffvalve

8.Filter

4.Fuelshutoffvalve—on

9.Flowdirectionarrow

5.Fuellinefromtank

8.Turnfuelshutoffvalvebackto“on”position.

ElectricalSystem

Maintenance

Warning

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

ChargingtheBattery

RemovingtheBattery

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponentscausing

sparks.Sparkscancausethebatterygassesto

explode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurfaceanddisengage

thebladecontrolswitch.

2.Movethemotioncontrolleversoutwardtothe

neutralposition,engageparkingbrakestopthe

engine,removethekey,andwaitforallmovingparts

tostopbeforeleavingtheoperatingposition.

3.Raisetheseat.

4.Disconnectthenegative(black)groundcablefrom

thebatterypost(Figure32).Retainallfasteners.

33

Page 34

Figure32

1.Batteryhold-down5.T erminalboot

2.Wingnut6.Positivebatterypost

3.Negativebatterypost7.Battery

4.Bolt,washer ,andnut

Incorrectbatterycableroutingcoulddamage

themachineandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

5.Slidetherubbercoverupthepositive(red)cable.

Disconnectthepositive(red)cablefromthebattery

post.Retainallfasteners.

6.Removethebatteryhold-down(Figure32)andlift

thebatteryfromthebatterytray.

ChargingtheBattery

1.Removethebatteryfromthechassis;refertothe

RemovingtheBatterysection.

2.Allowingbatteriestostandforanextendedperiod

withoutrechargingthemwillresultinreduced

performanceandservicelife.Topreserveoptimum

batteryperformanceandlife,rechargebatteriesin

storagewhentheopencircuitvoltagedropsto12.4

volts.

Note:Topreventdamageduetofreezing,battery

shouldbefullychargedbeforeputtingawayfor

winterstorage.

3.Checkthevoltageofthebatterywithadigital

voltmeter.Locatethevoltagereadingofthebattery

inthetablebelowandchargethebatteryforthe

recommendedtimeintervaltobringthechargeup

toafullchargeof12.6voltsorgreater.

Important:Makesurethenegativebattery

cablesaredisconnectedandthebatterycharger

usedforchargingthebatteryhasanoutputof

16voltsand7ampsorlesstoavoiddamaging

thebattery(seechartbelowforrecommended

chargersettings).

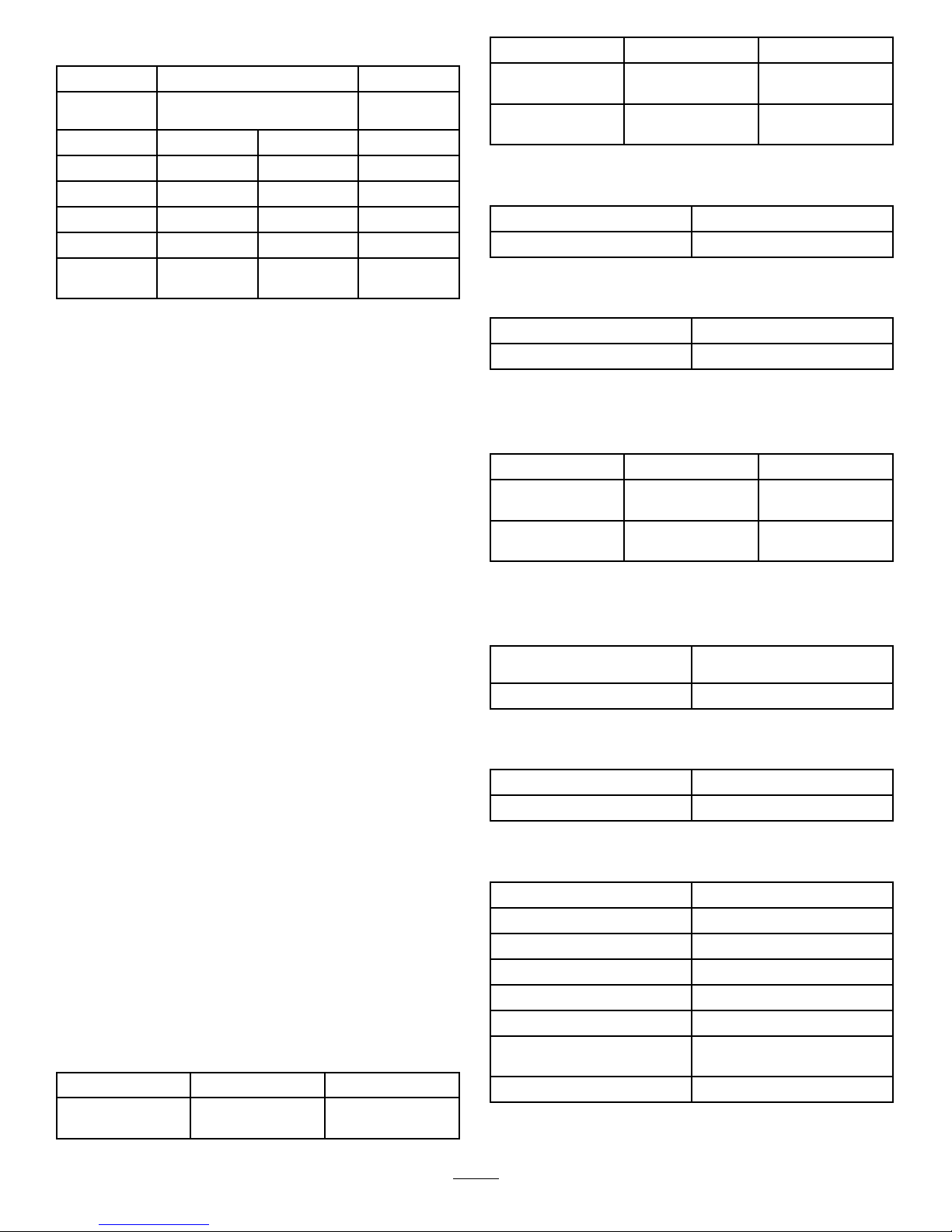

Voltage

Reading

Percent

Charge

Maximum

Charger

Settings

Charging

Interval

12.6or

greater

100%16volts/7

amps

NoCharging

Required

12.4–12.6

75–100%16volts/7

amps

30Minutes

12.2–12.4

50–75%16volts/7

amps

1Hour

12.0–12.2

25–50%14.4volts/4

amps

2Hours

11.7–12.0

0–25%14.4volts/4

amps

3Hours

11.7orless

0%14.4volts/2

amps

6Hoursor

More

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure33).

Figure33

1.Negativebatterypost

3.Red(+)chargerlead

2.Black(-)chargerlead

4.Positivebatterypost

Note:DoNotrunthemachinewiththebattery

disconnected,electricaldamagemayoccur.

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminal

poststowardtheoperatingposition(Figure32).

34

Page 35

2.Installthepositive(red)batterycabletothepositive

(+)batteryterminalusingthefastenersremoved

previously

3.Installthenegativebatterycabletothenegative

(-)batteryterminalusingthefastenersremoved

previously.

4.Slidetheredterminalbootontothepositive(red)

batterypost.

5.Securethebatterywiththehold-down(Figure32).

ServicingtheFusesandRelay

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.Thereis

alsoareplaceablerelay/snexttothefuse.Refertoyour

Partsmanualforcorrectreplacementcomponents.

Fuse:Block:

•Main:25ampfuse,blade-type

•ChargeCircuit:20ampfuse,blade-type

•Auxiliarycircuit:15ampfuse,blade-type

•Diode:TVS

1.Raisetheseattogainaccesstothefuseholder

(Figure34).

Figure34

1.Cover4.Charge–20amp

2.Relay5.Main–25amp

3.Auxilliary–15amp6.Diode

2.RemovecoverasshowninFigure34.

3.Toreplaceafuse,pulloutonthefusetoremoveit

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.

Checkthepressureatthevalvestem(Figure35).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

RearTires:13psi(90kPa)

FrontTires(casterwheels):13psi(90kPa)

Figure35

1.Valvestem

35

Page 36

HydraulicSystem

Maintenance

CheckingtheHydraulicOil

Level

ServiceInterval:Beforeeachuseordaily

CheckexpansiontankandifnecessaryaddMOBIL1

15W-50syntheticmotoroiltotheFULLCOLDline

Figure36

1.Engine2.Expansiontank

ChangetheHydraulicSystem

Filter

ServiceInterval:Aftertherst200hours

Note:UseonlyMOBIL115W-50Syntheticmotoroil.

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.Removekeyandengage

parkingbrake.

2.Locatethetwoltersunderthetransmissions.

Removelterguards.

3.Carefullycleanareaaroundlters.Itisimportant

thatnodirtorcontaminationenterhydraulicsystem.

4.Unscrewlterstoremoveandallowoiltodrain

fromdrivesystem.

Important:Beforereinstallingnewlters,

applyathincoatofoilonthesurfaceofthe

ltersrubberseal.

Turntheltersclockwiseuntilrubbersealcontacts

thelteradapterthentightenthelteranadditional

3/4to1fullturn.

5.Removetheventplugoneachtransmissionandll

throughexpansionreservoir,whenoilcomesoutof

ventreinstallplug.Torqueplugsto180in-lb(244

N-m).ContinuetoaddoiluntilitreachestheFULL

COLDlineontheexpansionreservoir.

Figure37

1.Oillter3.Leftreartire

2.Ventplug

6.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely .

7.Startengineandmovethrottlecontrolaheadto1/2

throttleposition.Disengageparkingbrake.

A.Withthebypassvalveopenandtheengine

running,slowlymovethedirectionalcontrolin

bothforwardandreverse(5or6times).

B.Withthebypassvalveclosedandtheengine

running,slowlymovethedirectionalcontrol

inbothforwardandreversedirections(5to6

times).Checktheoillevel,andaddoilasrequired

afterstoppingtheengine.

C.Itmaybenecessarytorepeatstepsanduntilall

theairiscompletelypurgedfromthesystem.

Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverse

atnormalspeeds,thenthetransaxleisconsidered

purged.

DoNotchangehydraulicsystemoil(exceptforwhat

canbedrainedwhenchanginglter),unlessitisfeltthe

oilhasbeencontaminatedorbeenextremelyhot.

Changingoilunnecessarilycoulddamagehydraulic

systembyintroducingcontaminatesintothesystem.

36

Page 37

MowerMaintenance

ServicingtheCuttingBlades

ServiceInterval:Beforeeachuseordaily

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshreddingturns

grassbrownattheedges,whichslowsgrowthand

increasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,

replaceitimmediatelywithagenuineTororeplacement

blade.Forconvenientsharpeningandreplacement,you

maywanttokeepextrabladesonhand.

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrownintothe

operator’sorbystander’sarea,resultingin

seriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagetheblade

controlswitch,andmovethemotioncontrollevers

outwardtotheneutralpositionandengageparking

brake.Stoptheengine,removethekey ,anddisconnect

thesparkplugwire(s)fromthesparkplug(s).

InspectingtheBlades

1.Inspectthecuttingedges(Figure38).Iftheedges

arenotsharporhavenicks,removeandsharpenthe

blades;refertotheSharpeningtheBladessection.

2.Inspecttheblades,especiallythecurvedarea.Ifyou

noticeanydamage,wear,oraslotforminginthis

area(item3inFigure38),immediatelyinstallanew

blade.

Figure38

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

CheckingforBentBlades

1.Rotatethebladesuntiltheendsfaceforward

andbackward(Figure39).Measurefromalevel

surfacetothecuttingedge,oftheblades.Notethis

dimension.

Figure39

1.Bladesfronttorear

3.Measurehere

2.Outsidecuttingedges

2.Rotatetheoppositeendsofthebladesforward.

3.Measurefromalevelsurfacetothecuttingedgeof

thebladesatthesamepositionasinstep1.The

differencebetweenthedimensionsobtainedin

stepsandmustnotexceed1/8inch(3mm).Ifthis

dimensionexceeds1/8inch(3mm),thebladeis

bentandmustbereplaced.RefertotheRemoving

theBladesandInstallingtheBladessection.

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplacebentordamagedbladewith

anewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesofblade.

37

Page 38

CheckingforLooseBladesorDamaged

SpringDiscWashers

1.Placeawrenchonthebladeboltandtorqueto45-55

ftlb(61-75N-m).

2.Withthewrenchstillonthebladebolt,holdthe

bladespindlestationaryandusingaragorthickly

paddedglove,trytorotatetheblade.Iftheblade

rotatesrelativetothespindleguardwithoutfurther

tighteningthebladebolt,thespringdiscwasherhas