Page 1

FormNo.3381-533RevC

g024867

TITAN

®

MX5400orMX6000

Zero-Turn-RadiusRidingMower

ModelNo.74882—SerialNo.314000001andUp

ModelNo.74883—SerialNo.314000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3381-533*C

Page 2

Thismachineisaride-on,rotary-bladelawnmowerintended

1

G015032

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-coverd,orgrasss-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

Introduction

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

ThissparkignitionsystemcomplieswithCanadianICES-002

WARNING

Removingstandardoriginalequipmentpartsand

accessoriesmayalterthewarranty,traction,and

safetyofthemachine.FailuretouseoriginalToro

partscouldcauseseriousinjuryordeath.Making

unauthorizedchangestotheengine,fuelorventing

system,mayviolateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimitedto,tires,

belts,blades,andfuelsystemcomponentswith

originalToroparts.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratorytestedbytheengine

manufacturerinaccordancewithSAEJ1995andratedto

J2723.

Engine Owner's Man ual

issuppliedfor

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ToroRidingMowerSafety........................................6

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................12

Controls...............................................................13

Operation....................................................................14

ThinkSafetyFirst...................................................14

UsingtheRolloverProtectionSystem(ROPS)............14

AddingFuel...........................................................14

CheckingtheEngineOilLevel.................................16

OperatingtheParkingBrake....................................16

OperatingtheThrottle............................................16

OperatingtheChoke...............................................16

OperatingtheIgnitionSwitch..................................17

StartingandStoppingtheEngine..............................17

OperatingtheMowerBladeControlSwitch

(PTO)...............................................................18

TheSafetyInterlockSystem.....................................18

DrivingForwardorBackward..................................19

StoppingtheMachine.............................................20

AdjustingtheHeight-of-Cut....................................20

AdjustingtheAnti-ScalpRollers...............................22

PositioningtheSeat................................................22

ChangingtheSeatSuspension..................................22

AdjustingtheMotionControlLevers........................22

PushingtheMachinebyHand..................................23

UsingtheSideDischarge.........................................24

OperatingTips......................................................25

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

PremaintenanceProcedures........................................27

RaisingtheSeat......................................................27

Lubrication...............................................................28

GreasingtheBearings.............................................28

EngineMaintenance..................................................28

ServicingtheAirCleaner.........................................28

ServicingtheEngineOil..........................................29

ServicingtheSparkPlug..........................................31

CleaningtheCoolingSystem....................................32

FuelSystemMaintenance...........................................32

ReplacingtheFuelFilter..........................................32

ElectricalSystemMaintenance....................................33

ServicingtheBattery...............................................33

ServicingtheFuses.................................................34

DriveSystemMaintenance.........................................35

CheckingtheTirePressure......................................35

HydraulicSystemMaintenance....................................36

CheckingtheHydraulicOilLevel..............................36

ChangingtheHydraulicSystemFilterand

Oil....................................................................36

MowerDeckMaintenance...........................................38

ServicingtheCuttingBlades.....................................38

MowerDeckLeveling.............................................40

3

Page 4

InspectingtheBelts................................................42

ReplacingtheMowerBelt.......................................42

RemovingtheMower..............................................43

InstallingtheMowerDeck.......................................44

ReplacingtheGrassDeector..................................45

Cleaning...................................................................46

WashingtheUndersideoftheMower........................46

WasteDisposal.......................................................46

Storage........................................................................47

CleaningandStorage..............................................47

Troubleshooting...........................................................48

Schematics...................................................................50

Safety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothesafety

alertsymbol,whichmeansCAUTION,WARNING,or

DANGER-"personalsafetyinstruction."Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

touserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.

Iftheoperator(s)ormechanic(s)cannotreadEnglishitis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludinghardhat,safety

glassesandhearingprotection.Longhair,looseclothing

orjewelrymaygettangledinmovingparts.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator'spresencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly .Donot

operateunlesstheyarefunctioningproperly.

4

Page 5

Operation

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingengine.Onlystartenginefrom

theoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

themachine'sstability.Usecautionwhileoperatingnear

drop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguardsnot

securelyinplace.Besureallinterlocksareattached,

adjustedproperly ,andfunctioningproperly .

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagedrives,engageparking

brake(ifprovided),shutoffenginebeforeleavingthe

operator'spositionforanyreasonincludingemptyingthe

catchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopbladesifnotmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerundertheinuenceofalcohol

ordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

RolloverProtectionSystem(ROPS)UseandMaintenance

•DonotremovetheROPS.

•TheROPSisanintegralandeffectivesafetydevice.Keep

theROPSonthemachineandusetheseatbeltwhen

operatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedwherethereareslopes,drop

offsorwater.

•Checkcarefullyforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

Safehandlingoffuels

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandrefuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainer,ratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllfueltank.Replacefuelcapandtighten

securely.

Maintenanceandstorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectspark-plugwire.Waitforall

movementtostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Letenginecoolbeforestoringanddonotstorenear

ame.

5

Page 6

•Shutofffuelwhilestoringortransporting.Donotstore

fuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminalrst

andthepositivelast.Reconnectthepositiverstand

negativelast.

•Usecarewhencheckingblades.Wraptheblade(s)or

weargloves,andusecautionwhenservicingthem.Only

replaceblades.Neverstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

•Stoppingdistanceincreaseswiththeweightofthetowed

load.Travelslowlyandallowextradistancetostop.

•Makewideturnstokeeptheattachmentclearofthe

machine.

ToroRidingMowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

productsorothersafetyinformationthatyoumustknowthat

maynotbeincludedintheANSIstandards.

•UseonlyToroapprovedattachments.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Ifloadingthemachineontoatrailerortruck,useasingle,

full-widthramponly.Therampangleshouldnotexceed

15degrees.

TowingSafety

•Donotattachtowedequipmentexceptatthehitchpoint.

•Followtheattachmentmanufacturer'srecommendation

forweightlimitsfortowedequipmentandtowingon

slopes.Towedweightmustnotexceedtheweightofthe

machine,operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,orinthe

pullingmachineOperator’ sManual.

•Neverallowchildrenorothersinorontowedequipment.

•Onslopes,theweightofthetowedequipmentmaycause

lossoftraction,increasedriskofrollover,andlossof

control.Reducethetowedweightandslowdown.

6

Page 7

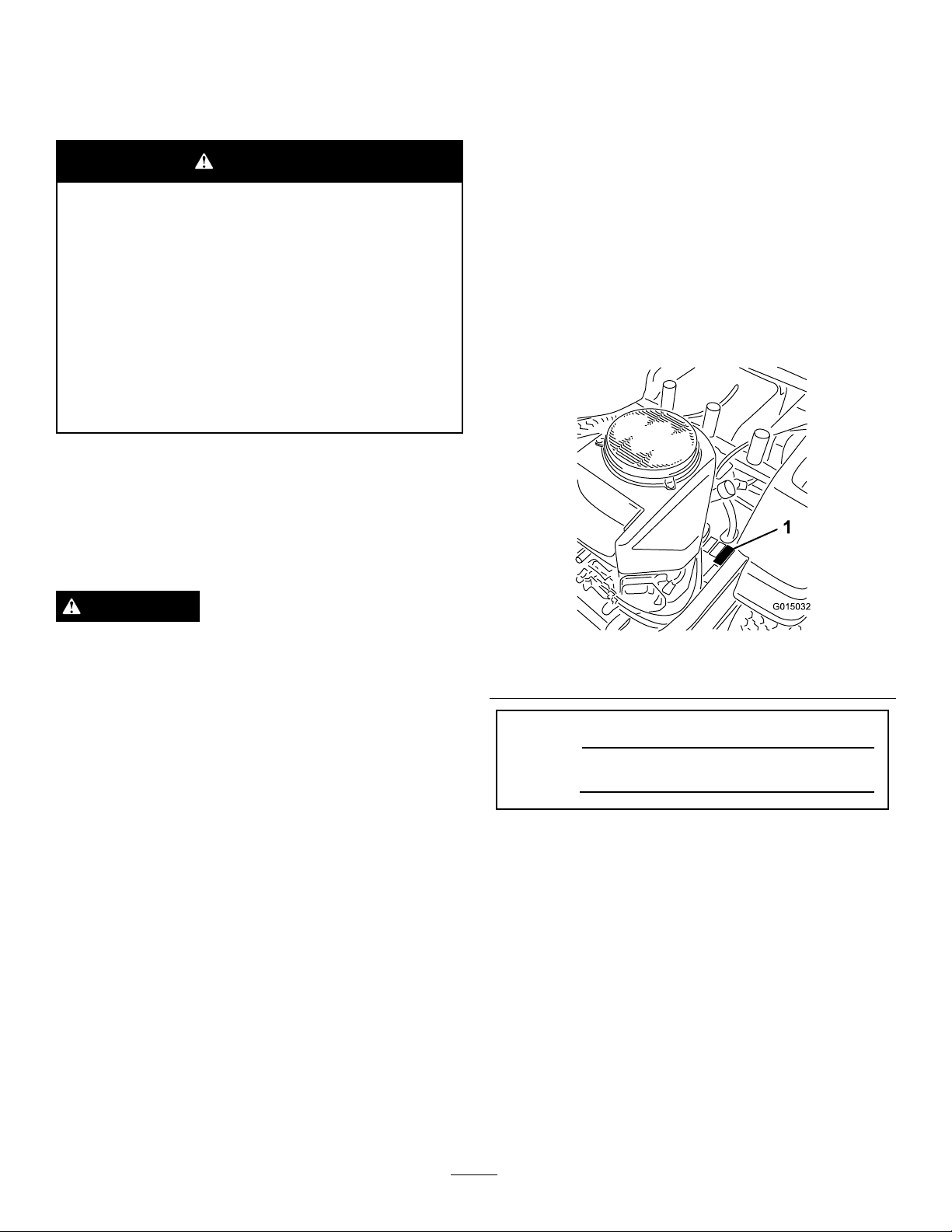

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

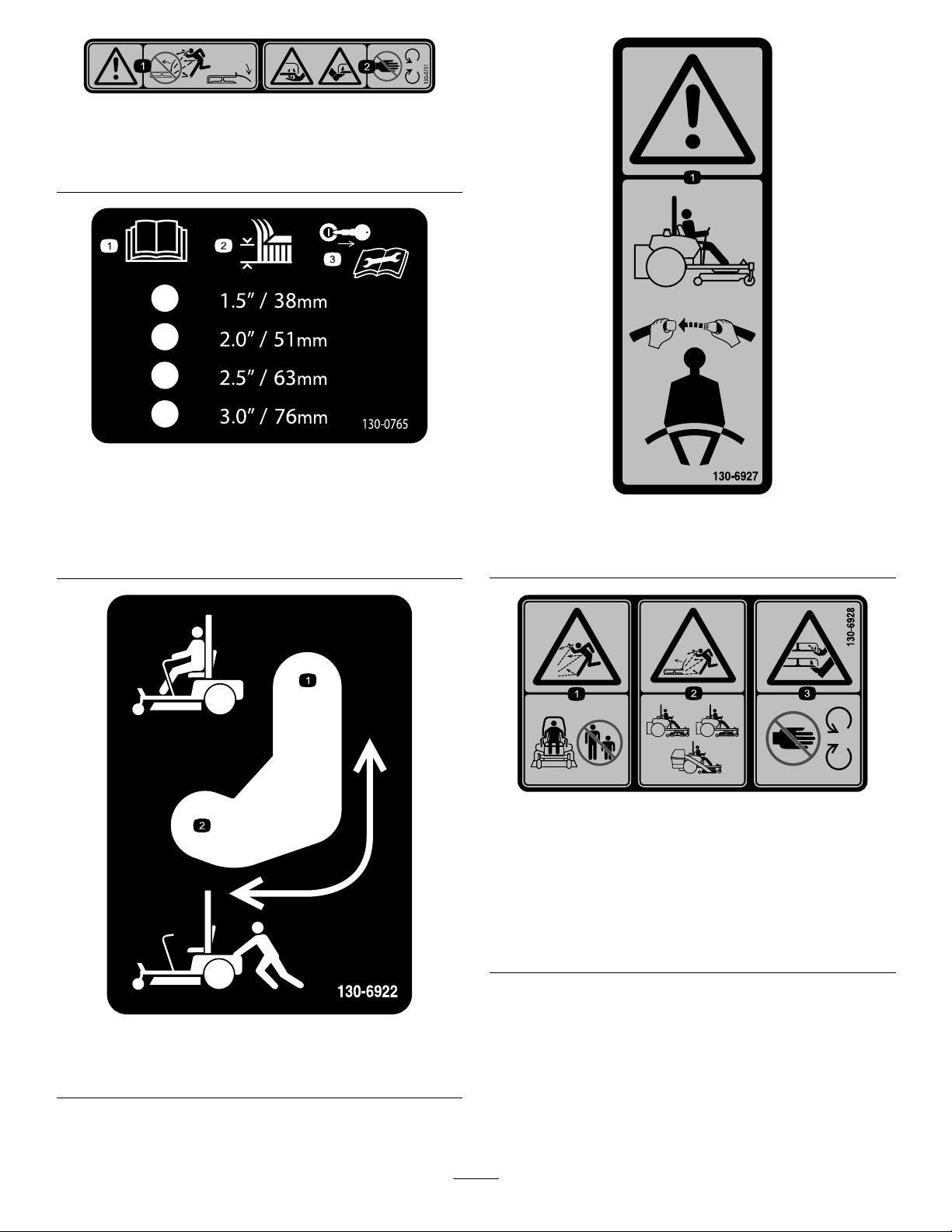

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

114-1606

1.Entanglementhazard,belt—keepallguardsinplace.

115-9625

109-7076

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

1.Parking

brake—disengaged

2.Parkingbrake—engaged

115-9632

1.Powertake-off(PTO),

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On6.Continuousvariable

3.Bladecontrolswitch—Off7.Slow

4.Choke

5.Fast

setting

8

Page 9

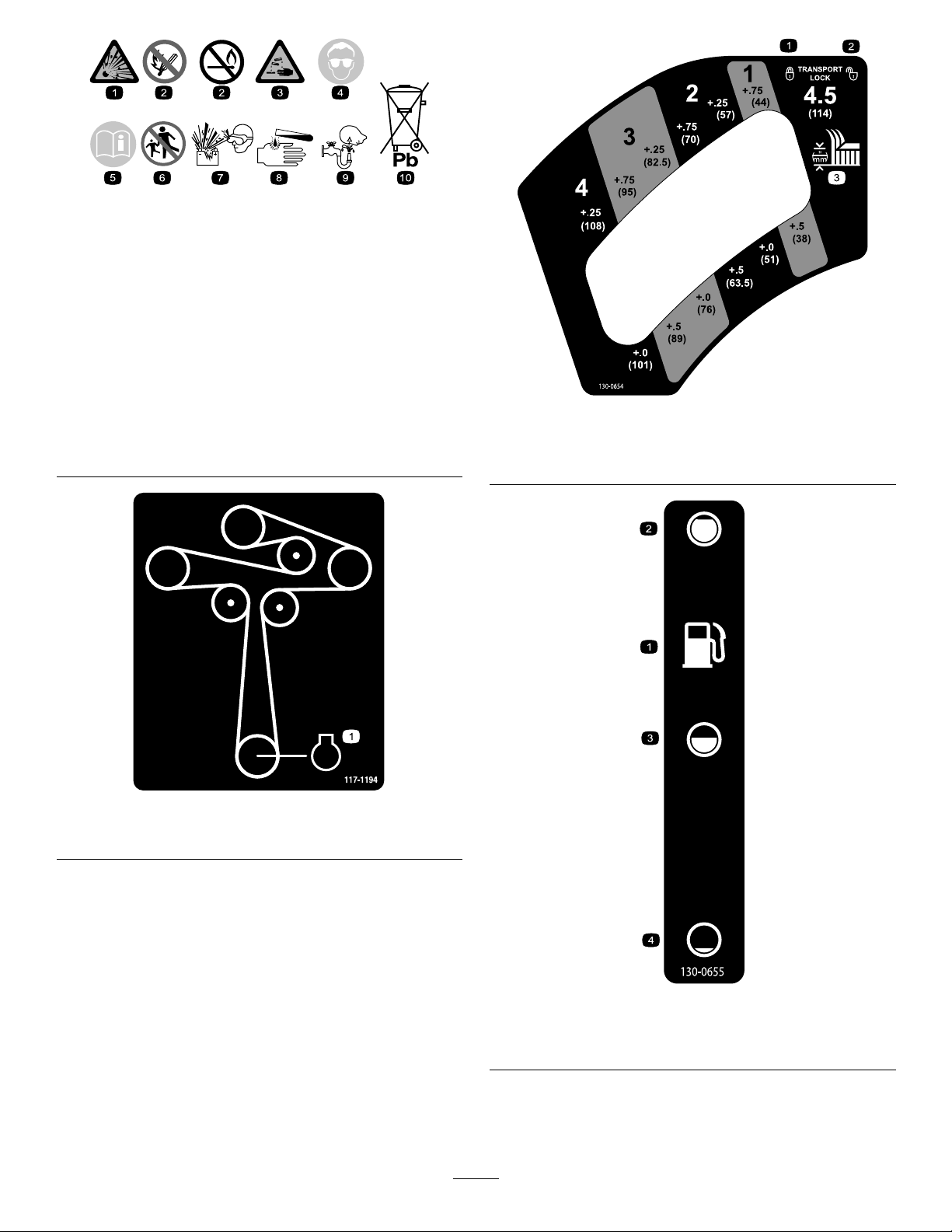

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

7.Weareyeprotection;

8.Batteryacidcancause

10.Containslead;donot

distancefromthebattery.

explosivegasescan

causeblindnessandother

injuries

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

discard.

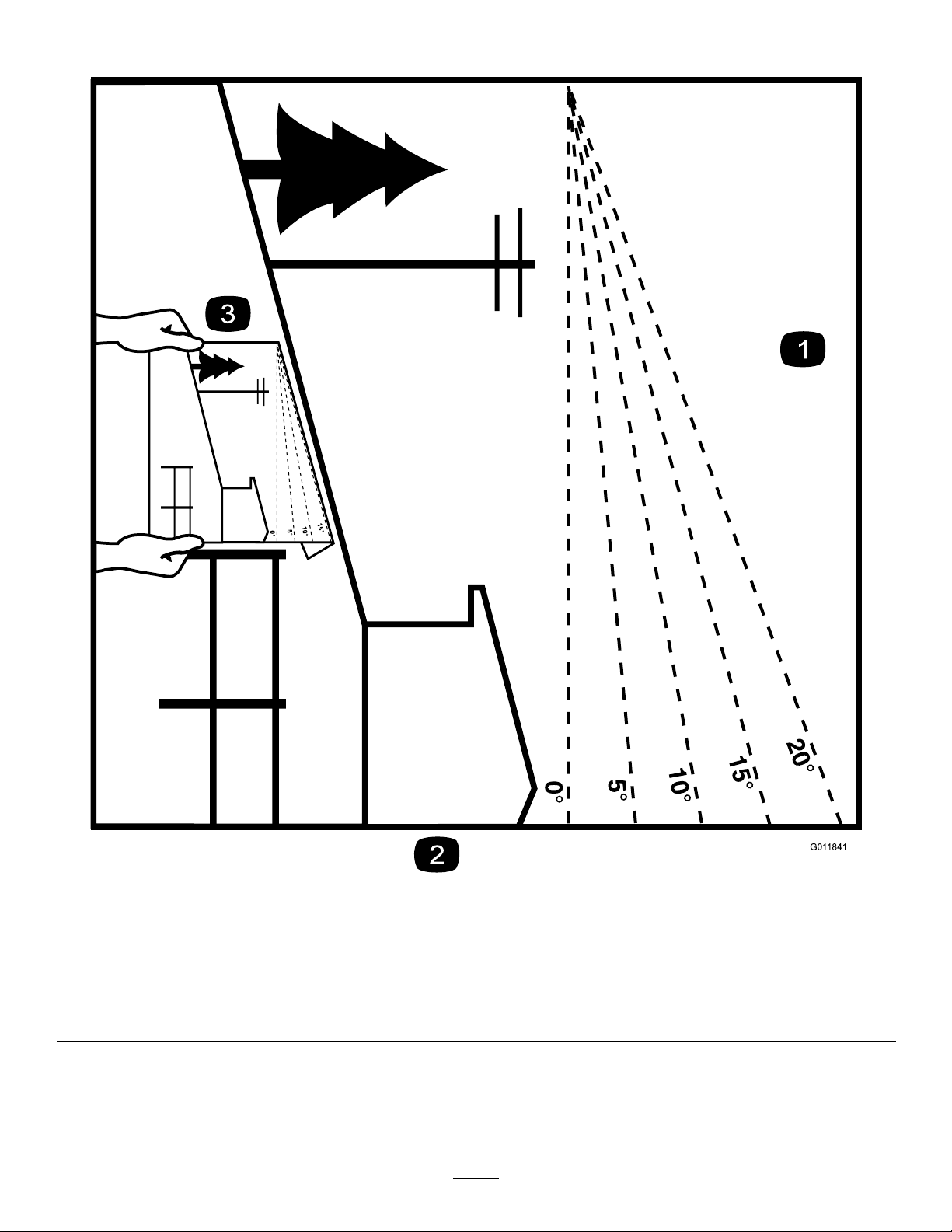

130-0654

1.Transport—lock

2.Transport—unlock

3.Height-of-cut

117-1194

1.Engine

130-0655

1.Fueltank

2.Full4.Empty

3.Half

9

Page 10

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

130-0765

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

permorningmaintenance.

130-6927

1.Warning—alwaysusetheROPSandweartheseatbelt

whenseatedintheoperator'sposition.

1.Bypassleverpositionfor

operatingthemachine.

130-6922

2.Bypassleverpositionfor

pushingthemachine.

10

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

mower—donotoperate

thewithoutdeector,

dischargecover,orgrass

collectionsysteminplace.

130-6928

3.Cutting/dismembermentof

handorfoot—stayaway

frommovingparts.

Page 11

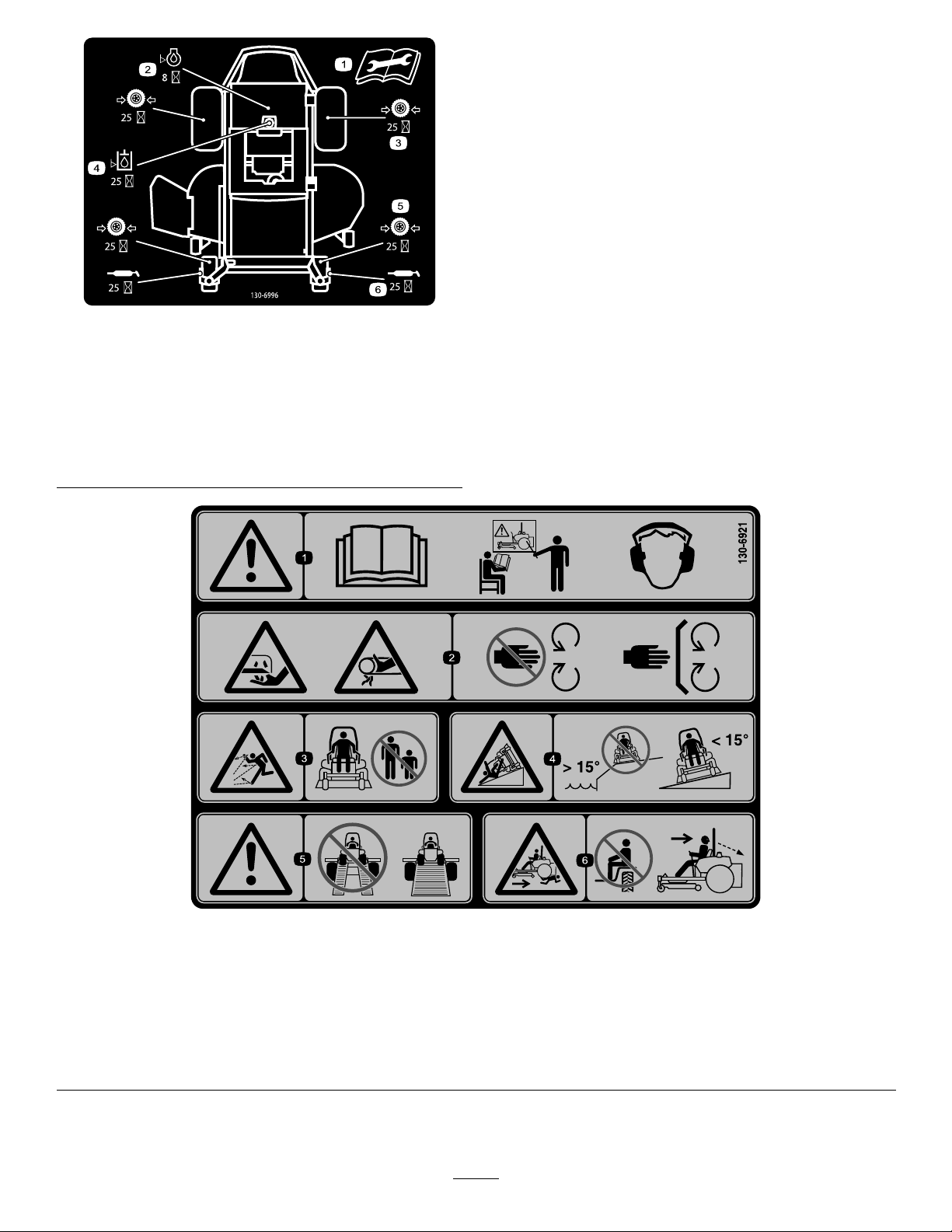

130-6996

1.ReadtheOperator's

Manualforinformationon

maintenance.

2.Checktheengineoilevery

8hours

3.Checkthedrivewheeltire

pressureevery25hours

4.Checkthehydraulicoil

every25hours

5.Checkthecasterwheel

tirepressureevery25

hours

6.Lubricatethecasterwheel

every25hours

1.Warning—readtheOperator'sManual;

donotoperatethemachineunlessyou

aretrained;wearhearingprotection.

2.Cutting/dismembermenthazard,

mowerblade;entanglementhazard,

belt—stayawayfrommoving

parts,keepallguardsandshieldsin

place.

130-6921

3.Thrownobjecthazard—keep

bystandersawayfromthemachine.

4.Tippinghazard—donotoperateon

slopesgreaterthan15degreesnear

water;driveacrossslopesgreaterthan

15degrees.

11

5.Warning—donotusesplitramps,use

afullrampwhentransportingmachine.

6.Crushing/dismembermenthazardof

bystanders,reversing—donotcarry

passengers,lookbehindanddown

whenreversing.

Page 12

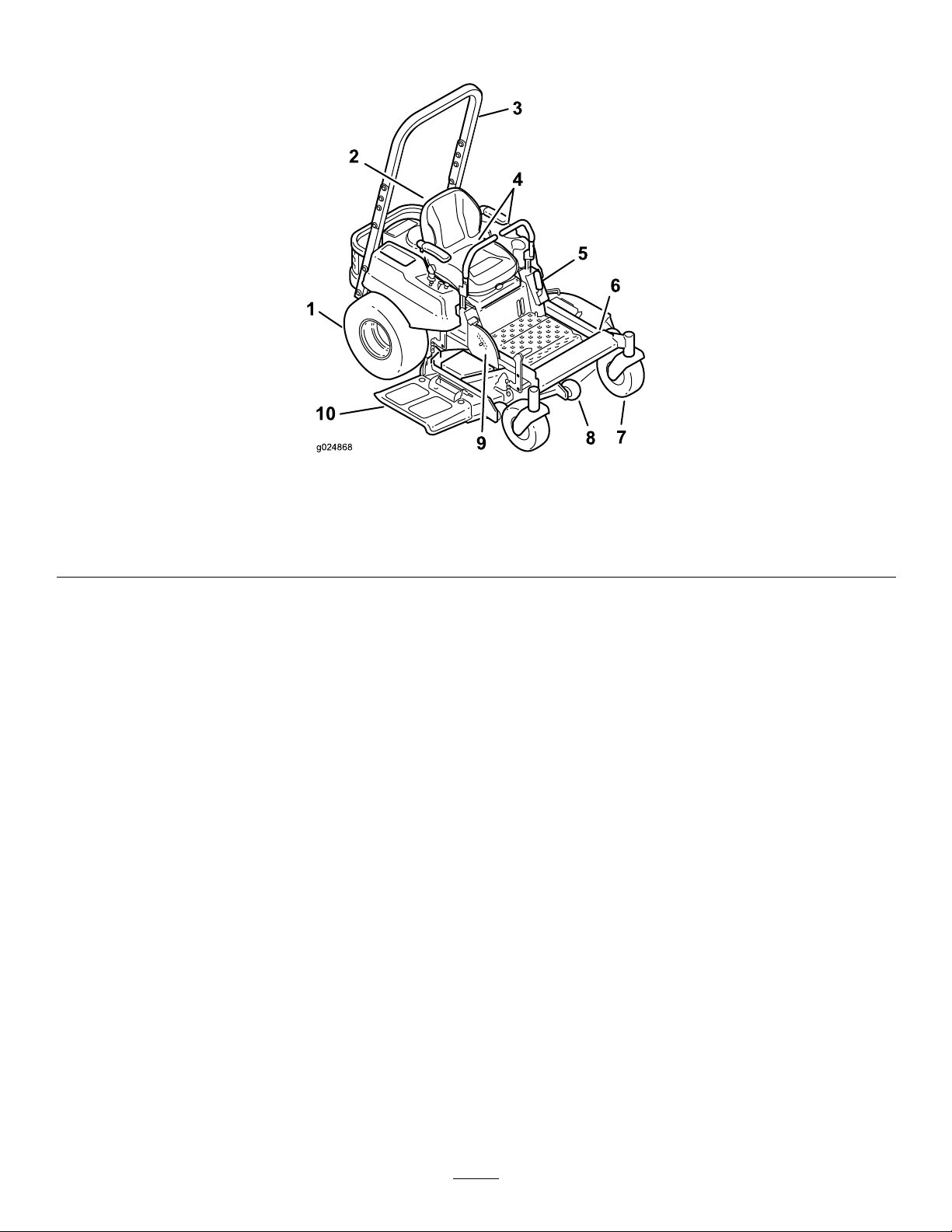

ProductOverview

g024868

2

5

6

8

9

10

3

4

7

1

Figure4

1.Drivewheel4.Motioncontrollevers7.Frontcasterwheel

2.Operatorseat

3.Rolloverprotectionsystem

(ROPS)

5.Parkingbrake8.Anti-scalproller

6.Footrest

9.Footpedaldeckliftand

10.Deector

height-of-cut

12

Page 13

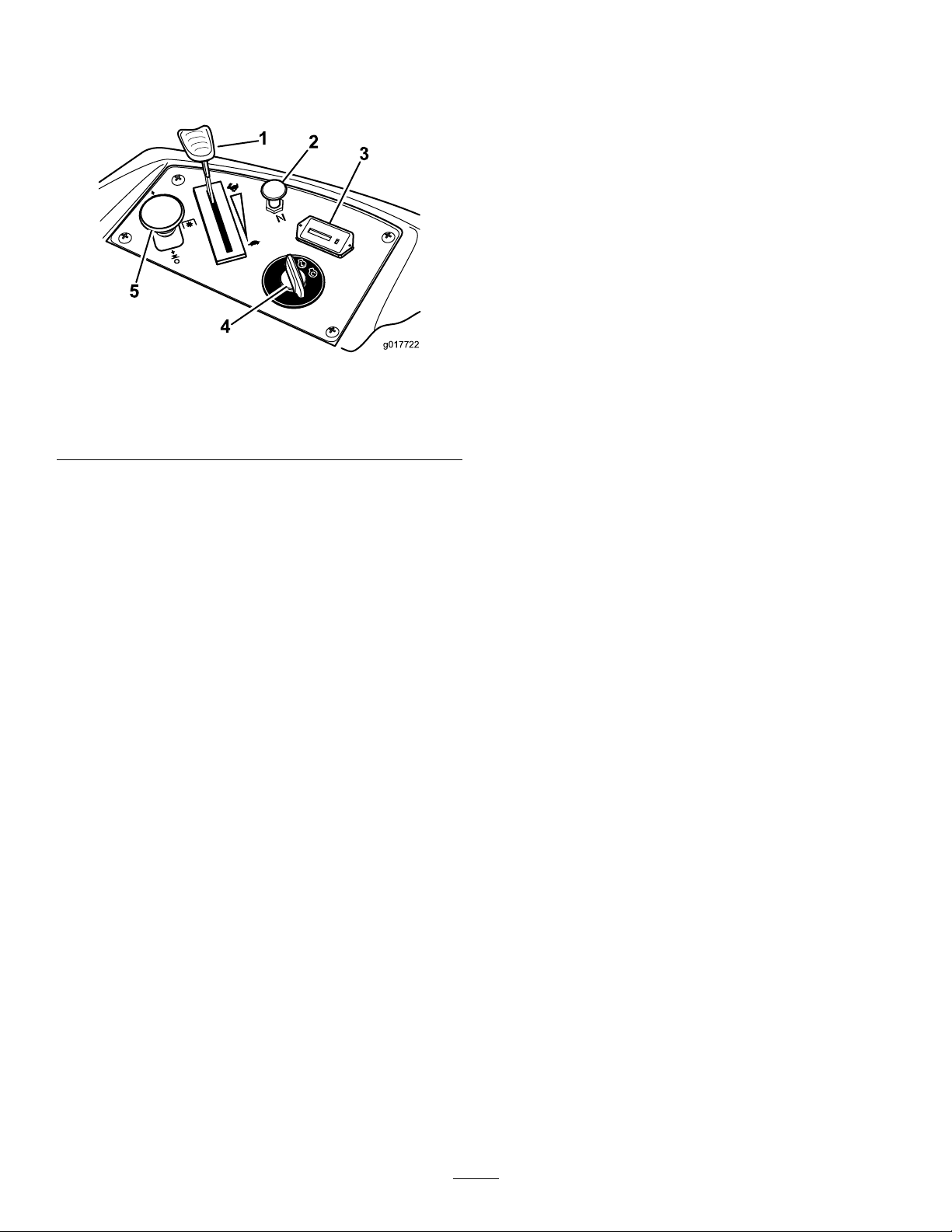

Controls

g017722

1

2

3

4

5

FuelGauge

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure5).

Figure5

1.Throttlecontrol4.Ignitionswitch

2.Choke5.Bladecontrolswitch(PTO)

3.Hourmeter

IgnitionSwitch

Thefuelwindowlocatedbelowtheoperatorpositioncanbe

usedtoverifythelevelofgasolineinthetank(Figure7).

MotionControlLevers

Themotioncontrolleversarespeedsensitivecontrolsof

independentwheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardorin

reverse;wheelspeedisproportionaltotheamountthelever

ismoved.Movethecontrolleversoutwardfromthecenter

totheneutrallockpositionandbeforeexitingthemachine

(Figure4).Alwayspositionthemotioncontrolleversintothe

neutrallockpositionwhenyoustopthemachineorleave

itunattended.

ParkingBrakeLever

Theparkingbrakeleverislocatedonleftsideoftheconsole

(Figure4).Thebrakeleverengagesaparkingbrakeonthe

drivewheels.Pulltheleverupandrearwardtoengagethe

brake.Pushtheleverforwardanddowntodisengagethe

brake.

Theignitionswitchhasthreepositions:Start,RunandOff.

ThekeywillturntoStartandmovebacktoRunuponrelease.

TurningthekeytotheOffpositionwillstoptheengine;

however,alwaysremovethekeywhenleavingthemachineto

preventtheenginefromaccidentallystarting(Figure5).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastandSlow.

Movingthrottleleverforwardwillincreaseenginespeedand

movingthrottlelevertotherearwilldecreaseenginespeed.

Movingthethrottleforwardintothedetentisfullthrottle

(Figure5).

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.Pushdownonthechokeknobtodisengageit.

BladeControlSwitch(PowerTake-Off)

Thebladecontrolswitch,representedbyapowertake-off

(PTO)symbol,engagesanddisengagespowertothemower

blades(

Figure5).

FootPedalDeckLiftSystem

Thefootpedaldeckliftsystemallowstheoperatortolower

andraisethedeckfromtheseatedposition.Theoperatorcan

usethefootpedaltoliftthedeckbrieytoavoidobstacles

orlockthedeckinthehighestheight-of-cutortransport

position(Figure4).

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedaltolockthe

deckinaspeciccuttingheight.Onlyadjusttheheightofcut

whilemachineisnotmoving(Figure4).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

HourMeter

Thehourmeterrecordsthenumberofhoursthebladeshave

operated.Itoperateswhenthebladecontrolswitch(PTO)is

engaged.Usethesetimesforschedulingregularmaintenance

(Figure5).

13

Page 14

Operation

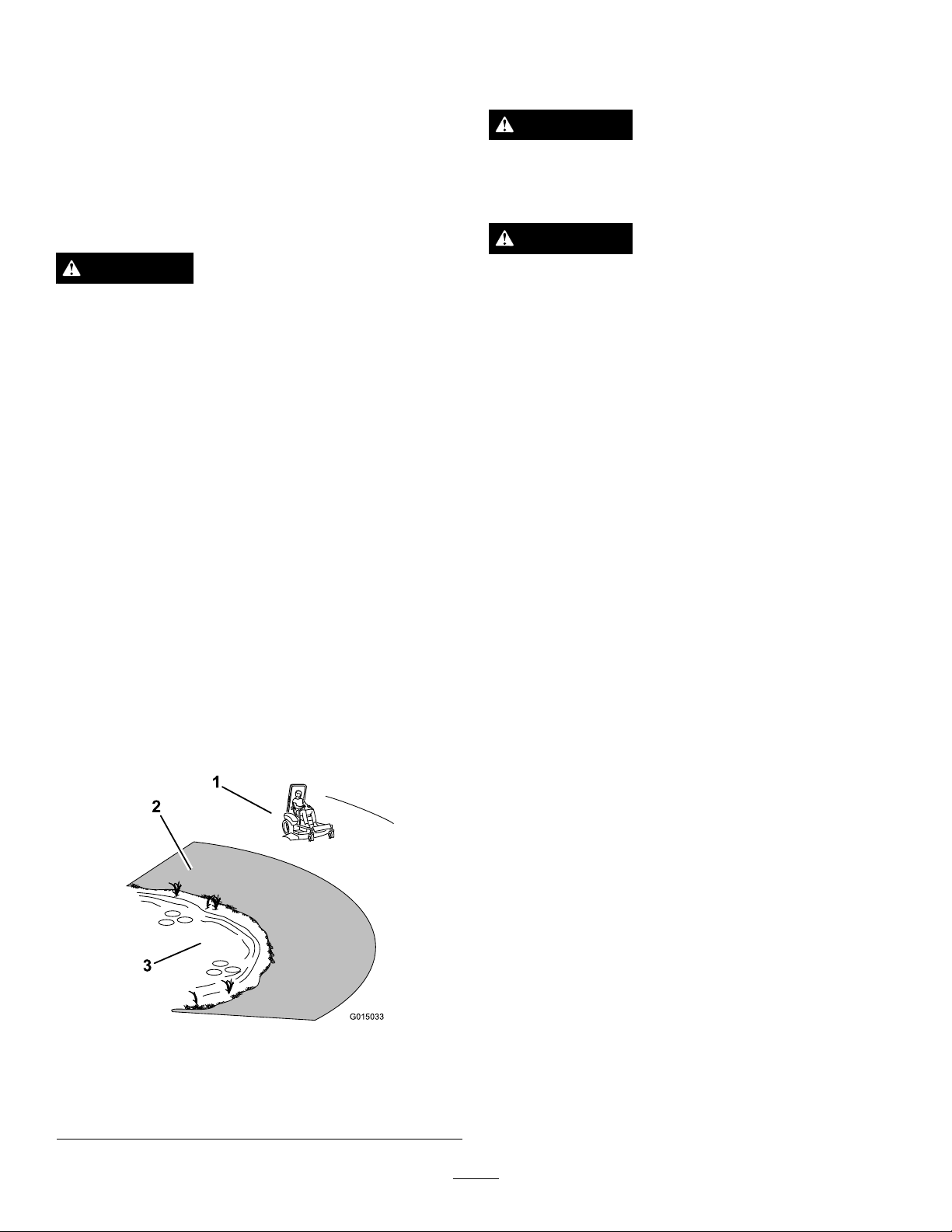

G015033

1

2

3

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

UsingtheRolloverProtection System(ROPS)

WARNING

ThinkSafetyFirst

Pleasecarefullyreadallofthesafetyinstructionsanddecals

inthesafetysection.Knowingthisinformationcouldhelp

you,yourfamily ,petsorbystandersavoidinjury.

DANGER

Mowingonwetgrassorsteepslopescancause

slidingandlossofcontrol.

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,deathor

drowning.

Alossoftractionisalossofsteeringcontrol.

Toavoidlossofcontrolandpossibilityofrollover:

•Donotmowneardrop-offsornearwater.

•Donotmowslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Whenmowingslopes,graduallyworkfrom

lowertohigherareasontheincline.

•Avoidsuddenturnsorrapidspeedchanges.

•Turnup,intoaninclinewhenchanging

directionsonslopes.Turningdowntheslope

reducestraction.

•Attachmentschangethehandlingcharacteristics

ofthemachine.Useextracautionwhenusing

attachmentswiththemachine.

Toavoidinjuryordeathfromrollover:keeptheroll

barinstalledandusetheseatbelt.

WARNING

Thereisnorolloverprotectionwhentherollbaris

removed.

•Driveslowlyandcarefully.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

AddingFuel

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

approvedforuse.Neverusegasolinethatcontains

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Figure6

1.SafeZone-usethemachinehere

2.Usewalkbehindmowerand/orhandtrimmerneardrop-offs

andwater .

3.Water

14

Page 15

DANGER

G020318

1

1

WARNING

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Fuelstabilizer/conditionerkeepsgasolinefreshduring

storageof90daysorless.Whenstoringthemachinefor

longerperiods,drainthefuelsystem.

•Itcleanstheenginewhileitruns

•Iteliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

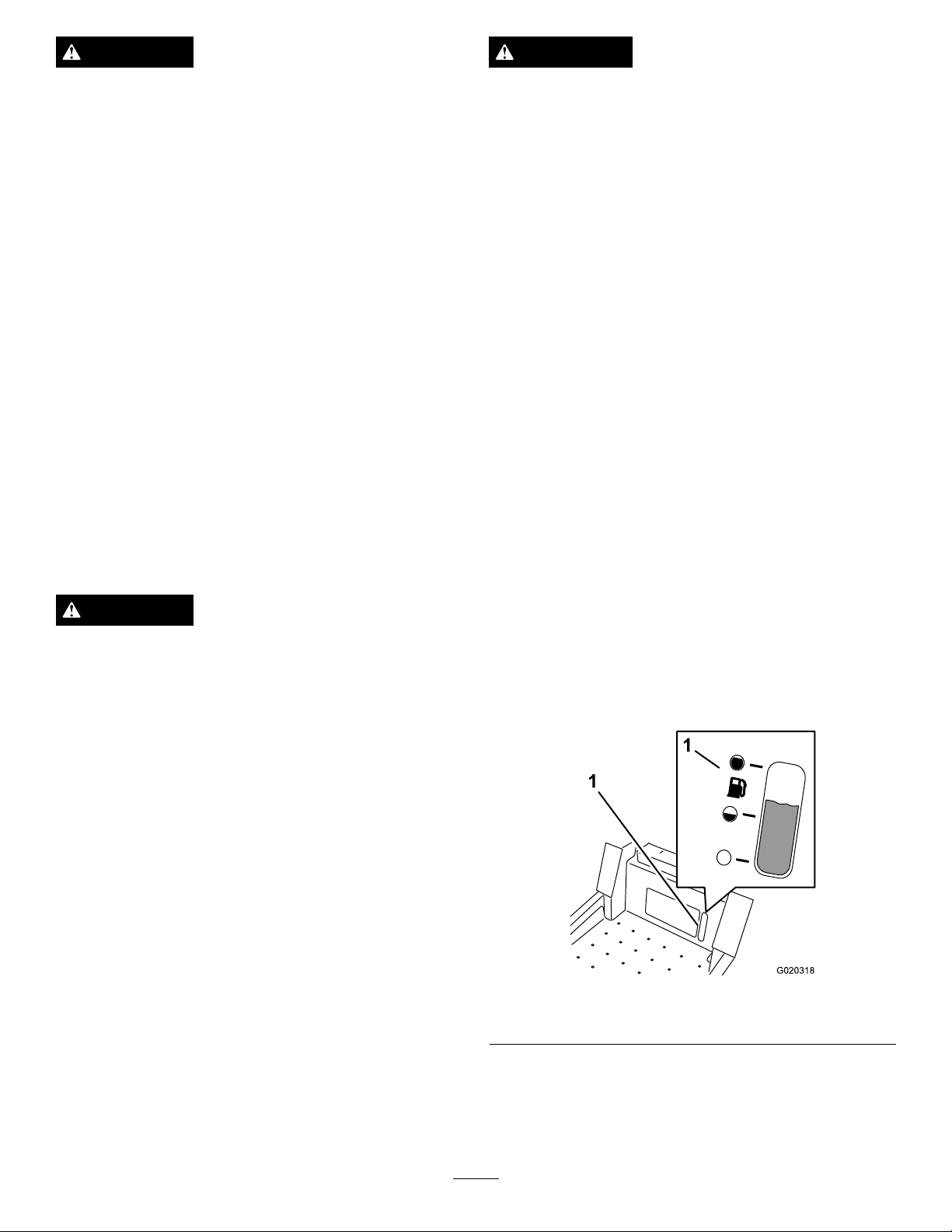

FuelGauge

Usethefuelwindowbelowtheoperatortoverifythelevelof

gasolinebeforellingthetank(Figure7).

Figure7

1.Fuelgaugewindow

FillingtheFuelTank

Makesuretheengineisshutoffandthemotioncontrolsare

intheparkposition.

15

Page 16

Important:Donotoverllfueltank.Fillthefueltank

G010475

1

2

4

3

1

2

G020305

1

2

G020306

G008946

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakageordamagetotheengineoremissionsystem.

1.Cleanaroundthefueltankcapandremovethecap.

Note:Youcanusethefuelwindowbelowthe

operatingpositionverifythepresenceofgasoline

beforellingthetank(Figure7).

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneckFigure8.

SettingtheParkingBrake

Figure9

ReleasingtheParkingBrake

Figure8

3.Installthefueltankcapsecurelyandtightenuntilit

“clicks.”Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

Beforeyoustarttheengineandusethemachine,checktheoil

levelintheenginecrankcase;refertoCheckingtheEngine

OilLevel.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

Figure10

OperatingtheThrottle

ThethrottlecontrolcanbemovedbetweenFastandSlow

positions(Figure11).

Alwaysusethefastpositionwhenturningonthemowerdeck

withthebladecontrolswitch(PTO).

Figure11

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(

2.Pushdownonthechoketodisengagethechokeafter

theenginehasstarted(Figure12).

16

Figure12).

Page 17

G008959

1

2

Figure12

START

RUN

STOP

G008947

g017965

2

3

4

5

1

6

1.On2.Off

StartingandStoppingthe Engine

StartingtheEngine

1.Sitdownontheseat(Figure14)andfastentheseatbelt.

2.Movethemotioncontrolsoutwardtotheneutrallock

position(Figure14).

3.Settheparkingbrake(

ParkingBrake.

4.Movethebladecontrolswitch(PTO)totheOff

position(Figure14).

5.PullupontheChokecontrolbeforestartingacold

engine.

Note:Awarmorhotenginemaynotrequirechoking.

6.Movethethrottlehalfwaybetweenthefastandslow

positions(

Figure14).

Figure14);refertoSettingthe

OperatingtheIgnitionSwitch

1.TurntheignitionkeytotheStartposition(Figure13).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

2.Tostoptheengine,turntheignitionkeytothestop

position.

Figure13

Figure14

7.TurntheignitionkeytotheStartposition(Figure13).

Whentheenginesstarts,releasethekey .

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallow

a15secondcool-downperiodbetweenattempts.

Failuretofollowtheseinstructionscanburnout

thestartermotor.

8.Aftertheenginestarts,pushdownontheChoke

control.Iftheenginestallsorhesitates,pullupon

theChokecontrolandlettheenginerunforafew

17

Page 18

seconds.ThenpushdowntheChokecontrol.Repeat

S

T

A

R

T

R

U

N

S

T

O

P

2

3

4

5

1

00:60 Sec

g017981

G008945

G009174

asrequired.

Note:Ifthefuelsystemwasdepletedoffuel—add

fueltothemachineanduseadditionalstartingcycles

whenstartingtheengine.

StoppingtheEngine

CAUTION

Childrenorbystanderscanbeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

EngagingtheBladeControlSwitch

(PTO)

Engagethebladecontrolswitch(PTO)withthethrottle

positionatFast.

Note:Engagingthebladecontrolswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

Figure16

DisengagingtheBladeControlSwitch

(PTO)

OperatingtheMowerBlade ControlSwitch(PTO)

Thebladecontrolswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

Figure15

Figure17

TheSafetyInterlockSystem

WARNING

Ifsafetyinterlockswitchesaredisconnectedor

damagedthemachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

UnderstandingtheSafetyInterlock

System

Thesafetyinterlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Theparkingbrakeisengaged.

18

Page 19

•Thebladesaredisengaged.

•Themotioncontrolleversareintheneutrallockposition.

Thesafetyinterlocksystemalsoisdesignedtostoptheengine

whenthecontrolleversareoutoftheneutrallockposition

withtheparkingbrakeonorifyourisefromtheseatwhen

thebladesareengaged.

TestingtheSafetyInterlockSystem

Testthesafetyinterlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,engagetheparkingbrakeand

movethebladecontrolswitchtoOn.Trystartingthe

engine;theengineshouldnotcrank.

2.Whilesittingontheseat,engagetheparkingbrakeand

movethebladecontrolswitchtoOff.Moveeither

motioncontrollever(forwardorreverse).Trystarting

theengine;theengineshouldnotcrank.Repeatwith

theothermotioncontrollever.

3.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,releasetheparkingbrake,

engagethebladecontrolswitch,andriseslightlyfrom

theseat;theengineshouldstop.

4.Whilesittingontheseat,engagetheparkingbrake,

movethebladecontrolswitchtoOff,andlockthe

motioncontrolleversinneutral.Starttheengine.

Whiletheengineisrunning,centerthemotion

controls;theengineshouldstop.

UsingtheMotionControlLevers

Figure18

1.Motioncontrol

lever-neutrallockposition

2.Center,unlockedposition5.Frontofmachine

3.Forward

DrivingForward

4.Backward

DrivingForwardorBackward

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

thefastpositionforbestperformance.Alwaysoperateinthe

fullthrottlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemakingsharp

turns.

Note:Theenginewillkillifthetractioncontrolleversare

movedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake;refertoReleasingthe

ParkingBrakeinOperation.

2.Movetheleverstothecenter,unlockedposition.

3.Togoforward,slowlypushthemotioncontrollevers

forward(Figure19).

19

Page 20

G008952

G008953

StoppingtheMachine

Tostopthemachine,movethetractioncontrolleversto

neutralandmovetolockedposition,disengagetheblade

controlswitch(PTO),andturntheignitionkeytooff.

Settheparkingbrakewhenyouleavethemachine;referto

OperatingtheParkingBrake(page16).Remembertoremove

thekeyfromtheignitionswitch(Figure15).

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

AdjustingtheHeight-of-Cut

Figure19

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotioncontrollevers

rearward(

Figure20).

Themachineisequippedwithafootpedaldeckliftsystem.

Theoperatorcanusethefootpedaltoliftthedeckbrieyto

avoidobstaclesorlockthedeckinthehighestheight-of-cut

ortransportposition.Theoperatorcanusetheheightof

cutleverwiththefootpedaltolockthedeckinaspecic

cuttingheight.

UsingtheFootPedalDeckLiftSystem

•Pressthepedaldowntoraisethedeck;continuetopress

thepedaluntilthedeckislockedinthetransportposition

(Figure21).

•Pushonthedeckliftpedalwithyourfootandpullthe

transportlockhandlerearwardtodisengagethetransport

lock(Figure21).

Figure20

20

Page 21

g024409

Figure21

g024410

1

2

3

4

TransportLockPosition

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom38to114mm(1-1/2

to4-1/2inch)in6mm(1/4inch)incrementsbyrelocating

theheight-of-cutpinintodifferentholelocations.

1.Pushonthedeckliftpedalwithyourfootandraisethe

mowerdecktothetransportlockposition(alsothe

114mm(4-1/2inch)cuttingheightposition)(Figure

22).

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure22).

3.Selectaholeintheheight-of-cutsystemcorresponding

totheheight-of-cutdesiredandinsertthepin(Figure

22).

Figure22

1.Deckliftpedal3.Height-of-cutpositions

2.Handle4.Pin

4.Pushonthedeckliftpedalwithyourfootandpull

thehandlerearwardtodisengagethetransportlock

Figure21).

(

5.Lowerthedeckslowlyuntilthelevermakescontact

withthepin.

21

Page 22

AdjustingtheAnti-Scalp

g024312

1

2 3 4

5

g024881

PositioningtheSeat

Rollers

Wheneveryouchangetheheight-of-cut,itisrecommended

toadjusttheheightoftheanti-scalprollers.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheangenut,anti-scalprollerandboltfrom

thebracket(

1.FlangeNut4.Bushing

2.Spacer

3.Anti-scalproller

Figure23).

Figure23

5.Bolt

Theseatcanmoveforwardandbackward.Positiontheseat

whereyouhavethebestcontrolofthemachineandaremost

comfortable.

Toadjust,movetheleversidewaystounlockseat(Figure24).

Figure24

ChangingtheSeatSuspension

Theseatisadjustabletoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Toadjustit,turntheknobinfronteitherdirectiontoprovide

thebestcomfort(Figure32).

4.Aligntheboltandanti-scalprollerintheholeofthe

bracketthatmatchestheclosestheightofcutposition

(Figure23).

5.Inserttheboltintothebracketholeandsecurethebolt

andanti-scalprollerwiththeangenut(Figure23).

Figure25

1.Seatsuspensionknob

AdjustingtheMotionControl Levers

AdjustingtheHeight

Themotioncontrolleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort.

1.Removethe2boltsand2washersholdingthecontrol

levertothecontrolarmshaft(Figure26).

2.Movethecontrollevertothenextsetofholes.Secure

theleverwiththe2boltsand2washers(Figure26).

22

Page 23

4

1

2

G015764

3

5

AdjustingtheTilt

Themotioncontrolleverscanbetiltedforwardorbackward

formaximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

controlarmshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforwardorbackward.

Figure26

1.Controlarmshaft

2.Controllever

3.Slotted,upperhole

3.Repeattheadjustmentfortheoppositecontrollever.

4.Washer

5.Bolt

3.Tightenbothboltstosecurethecontrolinthenew

position.

4.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Machine

damagecanoccurwhenthemachineistowed.

ToPushtheMachine

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Engagetheparkingbrake.

3.Movethemotioncontrolleversoutwardtoneutrallock

position,stoptheengine,removethekey ,andwaitfor

allmovingpartstostopbeforeleavingtheoperating

position.

4.Locatethebypassleversattherearofthemachine,on

theleftandrightsideoftheframe.

5.Movethebypassleversrearwardandthendownto

locktheminplaceasshownin

thewheelmotors.

Figure27todisengage

Note:Ensurethattheleftandrightbypassleversare

rearwardandlockedbeforemovingthemachine.

6.Disengagetheparkingbrake.

Themachineisnowabletobepushedbyhand.

23

Page 24

2

3

4

1

g017980

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

Figure27

ToOperatetheMachine

Movethebypasstothepositionforoperatingthemachine

(Figure27)toengagethewheelmotors.

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovethebladecontrolswitch

(PTO)totheoffposition,rotatetheignitionkey

tooffandremovethekey .

•Makesurethegrassdeectorisinthedown

position.

24

Page 25

OperatingTips

FastThrottleSetting

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

Forbestmowingandmaximumaircirculation,operate

theengineatthefastthrottleposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsettheheight-of-cut

solowastototallysurroundthemowerbyuncutgrass.

Alwaystrytohaveonesideofthemowerfreefromuncut

grass,whichallowsairtobedrawnintothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethecutting

heightofthemowerdoesnotscalpanyunevenground.

However,thecuttingheightusedinthepastisgenerallythe

bestonetouse.Whencuttinggrasslongerthan15.24cm(6

inches)tall,youmaywanttocutthelawntwicetoensure

anacceptablequalityofcut.

Cut1/3oftheGrassBlade

Itisbesttocutonlyabout1/3ofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

MowingDirection

WhenStopping

Ifthemachine'sforwardmotionmustbestoppedwhile

mowing,aclumpofgrassclippingsmaydropontoyourlawn.

Toavoidthis,moveontoapreviouslycutareawiththeblades

engaged.

KeeptheUndersideoftheMowerClean

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

BladeMaintenance

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthecutterbladesdailyforsharpness,andfor

anywearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replaceit

immediatelywithagenuineT ororeplacementblade.

Alternatemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowatCorrectIntervals

Normally,moweveryfourdays.Butremember,grassgrows

atdifferentratesatdifferenttimes.Sotomaintainthesame

cuttingheight,whichisagoodpractice,mowmoreoftenin

earlyspring.Asthegrassgrowthrateslowsinmidsummer,

mowlessfrequently.Ifyoucannotmowforanextended

period,rstmowatahighcuttingheight;thenmowagain

twodayslateratalowerheightsetting.

CuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidCuttingTooLow

Ifthecuttingwidthofthemoweriswiderthanthemower

youpreviouslyused,raisethecuttingheighttoensurethat

uneventurfisnotcuttooshort.

LongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

25

Page 26

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every200hours

Every400hours

MaintenanceProcedure

•Changetheengineoil.

•Changethehydraulicsystemlterandoil.

•Checkthesafetyinterlocksystem.

•Checktheengineoillevel.

•Cleantheairintakescreen.

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Checktirepressure.

•Checkthehydraulicoillevelintheexpansiontank.

•Inspectthebeltsforcracksandwear.

•Servicethepaperelement.(moreoftenindusty,dirtyconditions)

•Changetheengineoil.(moreoftenindusty,dirtyconditions)

•Checkthesparkplug(s).

•Replacethefuellter.(moreoftenunderdusty ,dirtyconditions).

•Replacethepaperelement.(moreoftenindusty,dirtyconditions)

•Changetheoillter.(moreoftenindusty,dirtyconditions)

•Changethehydraulicsystemlterandoil.

Monthly

Yearlyorbeforestorage

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

26

Page 27

Figure28

1.ReadtheOperator'sManualforinformationonmaintenance.4.Checkthehydraulicoilevery25hours

2.Checktheengineoilevery8hours5.Checkthecasterwheeltirepressureevery25hours

3.Checkthedrivewheeltirepressureevery25hours

6.Lubricatethecasterwheelevery25hours

Premaintenance

Procedures

RaisingtheSeat

Makesurethemotioncontrolleversaretheneutrallock

positionandparkingbrakeisset.Liftandholdthelever

behindtheseatforwardtodisengagetheseatlatchandthen

lifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Servicedecal

•Fuses

•Batteryandcables

27

Page 28

Lubrication

G009949

1

G015155

1

2

3

EngineMaintenance

GreasingtheBearings

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2GeneralPurposeLithiumBaseGrease

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtotheneutral

position,settheparkingbrake,stoptheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanthegreasettings(Figure28andFigure29)with

arag.Makesuretoscrapeanypaintoffofthefront

ofthetting(s).

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

Note:Servicetheaircleanermorefrequently(everyfew

hours)ifoperatingconditionsareextremelydustyorsandy.

RemovingtheElement

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrol(PTO).

2.Movethemotioncontrolleversoutwardtotheneutral

position,settheparkingbrake,stoptheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanaroundtheaircleanercovertopreventdirtfrom

gettingintotheengineandcausingdamage.

4.Liftthecoverandremovethehoseclampsecuringthe

aircleanerassemblytotheengine(

5.Loosenthehoseclampandremovethepaperelement

(Figure30).

Figure29

1.Frontcastertire

4.Connectagreaseguntoeachtting(Figure29and

Figure28).Pumpgreaseintothettingsuntilgrease

beginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

Figure30).

Figure30

1.Cover

2.Paperelement

3.Hoseclamp

28

Page 29

CleaningtheElement

g017470

SAE V iscosity Grades

SAE 40

SAE 30

SAE 10W– 30/ SAE 10W– 40

-20 0 20 32 40 60 80 100

-30 -20 -10 0 10 20 30 40

°F

°C

STARTING TEMPERA TURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

SAE 5W– 20

G008792

1

2

5

6

7

3

9

10

4

8

ServiceInterval:Every100hours—Servicethepaper

element.(moreoftenindusty ,dirty

conditions)

Every200hours/Yearly(whichevercomes

rst)—Replacethepaperelement.(moreoftenin

dusty,dirtyconditions)

1.Lightlytaptheelementonaatsurfacetoremovedust

anddirt.

2.Inspecttheelementfortears,anoilylm,anddamage

totheseal.

Important:Nevercleanthepaperelementwith

pressurizedairorliquids,suchassolvent,gas,

orkerosene.Replacethepaperelementifitis

damagedorcannotbecleanedthoroughly.

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,orSL)

CrankcaseCapacity:1.8L(61ounces);whenoillteris

removed:2.1L(70ounces)

enginewithoilbelowthelowmarkbecausetheengine

maybedamaged.

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch,stoptheengine,engageparking

brake,andremovethekey.

2.Makesuretheengineisstopped,level,andiscoolso

theoilhashadtimetodrainintothesump.

3.Tokeepdirt,grassclippings,etc.,outoftheengine,

cleantheareaaroundtheoilllcap/dipstickbefore

removingit(Figure32).

Viscosity:Seethetablebelow.

Figure31

Note:Usingmultigradeoils(5W-20,10W-30,and10W-40)

willincreaseoilconsumption.Checkoillevelmorefrequently

whenusingthem.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

Figure32

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donotrun

29

Page 30

ChangingtheEngineOil

G012153

1

2

3

4

5 6

G008796

2

3

4

5

6

1

ServiceInterval:Aftertherst8hours—Changetheengine

oil.

Every100hours—Changetheengineoil.(moreoften

industy ,dirtyconditions)

Note:Disposeoftheusedoilatarecyclingcenter.

1.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoassuretheoildrains

completely.

2.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

3.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

4.Slowlypourapproximately80%ofthespeciedoil

intothellertubeandslowlyaddtheadditionaloilto

bringittotheFullmark(Figure34).

Figure34

Figure33

30

Page 31

ChangingtheEngineOilFilter

G008748

3/4

1

2

3

4

5

6

G008794

1

2

RemovingtheSparkPlug

ServiceInterval:Every200hours—Changetheoillter.

(moreoftenindusty,dirtyconditions)

Note:Changetheengineoilltermorefrequentlywhen

operatingconditionsareextremelydustyorsandy.

1.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page30).

2.Changetheengineoillter(Figure35).

1.DisengagethePTO ,movethemotioncontrolleversto

theneutrallockedpositionandsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

Figure36

Note:Blowingoutthecavitywithcompressedairis

usuallythemosteffectivemethodforcleaning.The

sparkplugismostaccessiblewhentheblowerhousing

isremovedforcleaning.

CheckingtheSparkPlug

Important:Nevercleanthesparkplug(s).Always

replacethesparkplug(s)whenithasablackcoating,

wornelectrodes,anoilylm,orcracks.

Figure35

Note:Ensuretheoilltergaskettouchestheengine

andthenanextra3/4turniscompleted.

3.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil.

ServicingtheSparkPlug

ServiceInterval:Every100hours—Checkthesparkplug(s).

Makesuretheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingthesparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplug(s)anda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installanewsparkplug(s)ifnecessary.

Type:NGKBPR4ES(orequivalent)

Ifyouseelightbrownorgrayontheinsulator,theengineis

operatingproperly .Ablackcoatingontheinsulatorusually

meanstheaircleanerisdirty.

Setthegapto0.76mm(0.030inches).

Figure37

AirGap:0.76mm(0.030inch)

31

Page 32

InstallingtheSparkPlug

16ft-lb

22N-m

G010687

g017723

1

2

3

4

5

Tightenthesparkplug(s)to22N-m(16ft-lb).

Figure38

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)(moreoftenunderdusty ,dirty

conditions).

CleaningtheCoolingSystem

Cleantheairintakescreenfromgrassanddebrisbeforeeach

use.

1.Disengagethebladecontrolswitch,movethecontrol

leverstotheneutrallockedposition,andapplythe

parkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removetheairintakescreen,aircleanercover,and

fanhousing.

4.Cleandebrisandgrassfromtheparts.

5.Installtheairintakescreen,aircleanercover,andfan

housing.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockposition,and

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Allowthemachinetocooldown.

4.Raisetheseatandlocatethefuelltersasshownin

Figure39.

Figure39

1.Fuellinefromtank

2.In-lineFuellter

3.Flowdirectionarrow

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure40).

32

4.Fuellinetoengine

5.Hoseclamp

Page 33

G008963

12

3

1.Fuellter

2.Hoseclamp

Figure40

3.Fuelline

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

6.Removethelterfromthefuellines.

7.Installanewlterwiththeowdirectionarrowcoming

fromthefueltankandpointingtotheengine.Move

thehoseclampsclosetothelter(

itinplace.

Figure39)tosecure

DANGER

Batteryelectrolytecontainssulfuricacid,whichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyte,andavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

33

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysreconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

Page 34

1.Disengagethebladecontrolswitch(PTO),movethe

G010240

1

2

3

4

motioncontrolleverstotheneutrallockpositionand

settheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Removethewingnutsecuringthebatteryclamp

(Figure41).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebattery,andkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged.This

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow0°C(32°F).

1.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure42).

3.Installthebatteryinthemachineandconnectthe

batterycables,refertoInstallingtheBattery.

Note:Donotrunthemachinewiththebattery

disconnected;electricaldamagemayoccur.

Figure41

1.Removethewingnutand

clamp

2.Removethenegative

batterycable(black)

beforethepositive

4.Removetheclamp(Figure41).

5.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(Figure41).

6.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure41).

7.Removethebattery.

3.Removethepositive

batterycable(red)

4.Removebattery

InstallingtheBattery

1.Positionbatteryinthetraywiththeterminalposts

oppositefromthefueltank(

2.Installthepositive(red)batterycabletopositive(+)

batteryterminal.

3.Installthenegative(black)batterycabletothenegative

(-)batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

(

Figure41).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut(

41).

Figure41).

Figure42

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;howeverifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Note:Thefusesarelocatedonrighthandconsolenextto

theseat(

Fuses:

•Main,30amp,blade-type

Figure

•Engine,20amp,blade-type

Figure43).

34

Page 35

1.Toreplacethemainfuse,graspthefuseandpullit

g02441 1

1

2

straightandawayfromthefuseblock.

Figure43

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure45).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto89.6kPa(13psi).

1.Fuseblock

Important:Ensurethatthenewfusesarethe

sametypeandamperageasthefusesremoved.

2.Toreplacetheenginefuse,removetheconsolefrom

theplasticfender.

2.30ampmainfuse

Figure44

Figure45

1.Valvestem

1.Enginefuse

3.Grasptheenginefuseandpullitstraightandaway

fromthefuseblock(Figure44).

4.Alignanewfusewiththeslotinthefuseblock(Figure

43).

5.Pushthefuseintothefuseblockuntilthefuseisseated

(

Figure43).

35

Page 36

HydraulicSystem

G010253

1

2

3

G010254

1

2

3

4

5

Maintenance

2.Removethekeyandengagetheparkingbrake.

3.Locatethelterandguardsoneachtransaxledrive

system(Figure47).

OilType:20w-50engineoil.

SystemCapacity:approximately4.495liter(152oz)witha

lterchange.

Important:Useoilspeciedorequivalent.Otheruids

couldcausesystemdamage.

CheckingtheHydraulicOil Level

ServiceInterval:Every25hours

Checkexpansionreservoirandifnecessaryadd20W -50

engineoiltotheFULLCOLDline

4.Removethreescrewssecuringthelterguardand

guard.

Figure47

Rightsideshown

1.Transaxledrive

2.Oillter

3.Filterguard

4.Screws

5.Ventplug

Figure46

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulic SystemFilterandOil

Thelterandoilarechangedatthesametime.Donotreuse

oil.Oncethenewlterisinstalledandoilisaddedanyairin

thesystemmustbepurged.

Thebleedingprocessisrepeateduntiltheoilremainsatthe

FULLCOLDlineinthereservoirafterpurging.Failureto

properlyperformthisprocedurecanresultinirreparable

damagetothetransaxledrivesystem.

5.Carefullycleanareaaroundlters.

Note:Itisimportantthatnodirtorcontamination

enterhydraulicsystem.

6.Placeacontainerbelowtheltertocatchtheoilthat

drainswhenthelterandventplugsareremoved.

7.Locateandremovetheventplugoneachtransmission

8.Unscrewtheltertoremoveandallowoiltodrain

fromdrivesystem.

Repeatthisprocedureforbothlters.

InstallingtheHydraulicSystemFilters

ServiceInterval:Aftertherst50hours

Every400hours

RemovingHydraulicSystemFilters

1.Stopengine,waitforallmovingpartstostop,and

allowenginetocool.

36

Page 37

G008748

3/4

1

2

3

4

5

6

Important:Failuretoperformthe

G010333

1

the Hy draulic System

hydraulicltersandoilmayresultinirreparable

damagetothetransaxledrivesystem.

procedureafterchanging

Bleeding

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportwithjack

stands(orequivalentsupport)justhighenoughto

allowdrivewheelstoturnfreely.

Figure49

Figure48

1.Applyathincoatofoilonthesurfaceoftherubber

sealofeachlter.

2.Turnthelterclockwiseuntilrubbersealcontactsthe

lteradapterthentightenthelteranadditional3/4

to1fullturn.

3.Repeatfortheotherlter

4.Installthelterguardsovereachlteraspreviously

removed.Usethethreescrewstosecurethelter

guards.

5.Verifytheventplugsareremovedbeforeaddingtheoil.

6.Slowlypourthespeciedoilthroughexpansion

reservoiruntiloilcomesoutofoneoftheventplug

holes.

7.Installtheventplug.Torquetheplugto20.3N-m

(180in-lb).

8.Continuetoaddoilthroughtheexpansionreservoir

untiloilcomesoutoftheremainingventplugholeon

thesecondtransmission.

9.Installtheventplug.Torquetheplugto20.3N-m

(180in-lb).

10.Continuetoaddoilthroughtheexpansionreservoir

untilitreachestheFULLCOLDlineontheexpansion

reservoir.ProceedtotheBleedingtheHydraulic

Systemsection.

1.Jackingpoints

2.Gototheoperator'sposition.Starttheengineand

movethrottlecontrolaheadto1/2throttleposition.

Disengageparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertothePushingthe

MachinebyHandsectioninOperation.Withthe

bypassvalvesopenandtheenginerunning,slowly

movethemotioncontrolleversinbothforward

andreverse(5or6times).

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Stoptheengineandchecktheoillevelinthe

expansionreservoir.Addthespeciedoilasuntil

itreachestheFULLCOLDlineontheexpansion

reservoir.

3.Repeatstep2untilalltheairiscompletelypurgedfrom

thesystem.

Note:Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsideredpurged.

4.Checktheoillevelintheexpansionreservoironelast

time.AddthespeciedoilasuntilitreachestheFULL

COLDlineontheexpansionreservoirifnecessary.

37

Page 38

MowerDeck

G014972

1

2

3

Maintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseasonbecause

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowthandincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

Figure50

1.CuttingEdge3.Wear/slotForming

2.CurvedArea4.Crack

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position;alsoconsideredthe'transport'position.

2.Whilewearingthicklypaddedglovesorotheradequate

handprotectionslowlyrotatebladetobemeasured

intoapositionthatallowseffectivemeasurementof

thedistancebetweenthecuttingedgeandthelevel

surfacethemachineison.

•Replaceawornordamagedblade.

BeforeInspectingorServicingthe

Blades

1.Parkthemachineonalevelsurface,disengagethe

bladecontrolswitch(PTO),andsettheparkingbrake.

2.TurntheignitionkeytoOff.Removethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure50).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades.RefertoSharpeningtheBlades

(page40).

2.Inspecttheblades,especiallythecurvedarea(Figure

50).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(Figure50),immediatelyinstalla

newblade.

Figure51

1.Deck3.Blade

2.Spindlehousing

38

Page 39

3.Measurefromthetipofthebladetotheatsurface

G014973

1

2

3

G014974

1

2

3

G014973

1

2

3

here.

Figure52

1.Blade,inpositionformeasuring

2.Levelsurface

3.Measureddistancebetweenbladeandsurface(A)

Figure54

1.Opposingbladeedge,inpositionformeasuring

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

WARNING

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition.

Figure53

1.Blade,sidepreviouslymeasured

2.Measurementpositionusedpreviously

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

here.Thevarianceshouldbenomorethan3mm(1/8

inch).

Abladethatisbentordamagedcouldbreak

apartandcouldseriouslyinjureorkillyouor

bystanders.

•Alwaysreplaceabentordamagedblade

withanewblade.

•Neverleorcreatesharpnotchesinthe

edgesorsurfacesoftheblade.

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch)replacethebladewithanew

blade.Referto

RemovingtheBlades(page39)

andInstallingtheBlades(page40).

Note:Ifabentbladeisreplacedwithanewone

andthedimensionobtainedcontinuestoexceed3

mm(1/8inch),thebladespindlecouldbebent.

ContactanAuthorizedToroDealerforservice.

B.Ifthevarianceiswithinconstraints,movetothe

nextblade..

6.Repeatthisprocedureoneachblade.

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthebladeis

outofbalanceorisbent.Toensureoptimumperformance

andcontinuedsafetyconformanceofthemachine,use

genuineT ororeplacementblades.Replacementbladesmade

byothermanufacturersmayresultinnon-conformancewith

safetystandards.

Holdthebladeendusingaragorthickly-paddedglove.

Removethebladebolt(rotatingitcounter-clockwise),curved

washer,andbladefromthespindleshaft(

39

Figure55).

Page 40

1

2

3

4

G010341

Figure57

1.Blade2.Balancer

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure55).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandbladebolt(rotatingit

clockwise).

Figure55

1.SailAreaofBlade3.Curvedwasher

2.Blade4.BladeBolt

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecouldbe

thrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpeningblade.

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure56).

Note:Maintaintheoriginalangle.Thebladeretains

itsbalanceifthesameamountofmaterialisremoved

frombothcuttingedges.

Figure56

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitonablade

balancer(

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalancedandcanbeused.Ifthebladeisnot

balanced,lesomemetalofftheendofthesailarea

only(Figure55).Repeatthisprocedureuntiltheblade

isbalanced.

Figure57).

Note:Thespringdiskconemustbeinstalledtoward

thebolthead(

3.Torquethebladeboltto135-150N-m(100-110ft-lb).

Figure55).

MowerDeckLeveling

Checktoensurethemowerdeckislevelanytimeyouinstall

themowerorwhenyouseeanunevencutonyourlawn.

Themowerdeckmustbecheckedforbentbladespriorto

leveling;anybentbladesmustberemovedandreplaced.

Refertothe,CheckingforBentBlades(page38),procedure

beforecontinuing.

Themowerdeckmustbeleveledside-to-siderstthenthe

fronttorearslopecanbeadjusted.

Requirements:

•Themachinemustbeonalevelsurface.

•Allfourtiresmustbeproperlyinated.RefertoChecking

theTirePressure(page35).

CheckingSide-to-SideLevel

Themowerbladesmustbelevelfromsidetoside.Checkthe

side-to-sidelevelanytimeyouinstallthemowerorwhenyou

seeanunevencutonyourlawn.

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtotheneutral

lockposition,stoptheengine,removethekey ,setthe

parkingbrakeandwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Carefullyrotatethebladessidetoside.

4.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure58).

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;continuetothe

Levelingprocedure.

40

Page 41

1.Bladessidetoside

2.Outsidecuttingedges

Figure58

3.Measurefromthetipofthe

bladetotheatsurface

here

Figure59

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here

2.Outsidecuttingedges

CheckingtheFront-to-RearBladeSlope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

bladecontrolswitch.

2.Movethemotioncontrolleversoutwardtotheneutral

position,engagetheparkingbrake,stoptheengine,

removethekey ,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

3.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure59).

4.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure59).

Note:Ifthefrontbladetipisnot1.6-7.9mm

(1/16-5/16inch)lowerthantherearbladetip,continue

totheLevelingtheMowerDeckprocedure.

LevelingtheMowerDeck

1.Setanti-scalprollerstotopholesorremovecompletely

forthisprocedure;refertoAdjustingtheAnti-Scalp

Rollers(page22).

2.Settheheight-of-cutlevertothe76mm(3inch)

position;referto

21)

.

3.Placetwo6.66cm(2-5/8inch)blocksundereach

sideofthefrontedgeofthedeck,butnotunderthe

anti-scalprollerbrackets(

4.Placetwo7.30cm(2-7/8inch)thickblocksunderthe

rearedgeofthecuttingdeckskirt;oneoneachsideof

thecuttingdeck(Figure60).

AdjustingtheHeight-of-Cut(page

Figure60).

Figure60

1.Woodblock,6.66cm

(2-5/8inch)thick

2.Woodblock,7.30cm

(2-7/8inch)thick

3.Frontedge

5.Loosentheadjustmentboltsonallfourcornerssothat

thedeckissittingsecurelyonallfourblocks(

61).

41

Figure

Page 42

RemovingtheMowerBelt

G024488

3

2

1

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsisevident.

1.Disengagethebladecontrolswitch(PTO),movethe

motioncontrolleverstotheneutrallockedposition

andsettheparkingbrake.

2.Stoptheengine,removethekey,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Lowerthemowertothe76mm(3inch)height-of-cut

position.

4.Lifttheoorpantogainaccesstothebeltandidler

pulley.

Figure61

1.Deckliftarm

2.Chain

6.Ensurethereistensiononallfourchains(Figure61).

7.Tightenthefouradjustmentbolts(Figure61).

8.Checkthatblockstjustsnuglyunderthedeckskirt.

Makesureallboltsaretight

9.Verifythatthedeckislevelbycheckingtheside-to-side

levelandfront-to-rearbladeslope;repeatthedeck

levelingprocedureifnecessary.

3.Hook

4.Adjustmentbolt

InspectingtheBelts

ServiceInterval:Every50hours

Checkthebeltsforsquealingwhenthebeltisrotating,blades

slippingwhencuttinggrass,frayedbeltedges,burnmarksand

cracksaresignsofawornmowerbelt.Replacethemower

beltifanyoftheseconditionsisevident.

5.Removethebeltcovers(

1.Loosenthescrews3.Removebeltcover

2.Pivotthebeltcoverup

Figure62).

Figure62

Note:Lifttheoorpantogainaccesstothebeltandidler

pulley.

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarksandcracksare