Toro TITAN HD 1500, TITAN HD 2000 Series, 74452, TITAN HD 2500 Series, 74461 Operator's Manual

...Page 1

FormNo.3405-604RevD

48in,52in,or60inTITAN

1500,2000,or2500SeriesRiding

Mower

ModelNo.74450—SerialNo.400010798andUp

ModelNo.74451—SerialNo.400010798andUp

ModelNo.74452—SerialNo.400010798andUp

ModelNo.74460—SerialNo.400010798andUp

ModelNo.74461—SerialNo.400010798andUp

ModelNo.74462—SerialNo.400010798andUp

ModelNo.74463—SerialNo.400010798andUp

ModelNo.74470—SerialNo.400010798andUp

ModelNo.74471—SerialNo.400010798andUp

ModelNo.74472—SerialNo.400010798andUp

ModelNo.78450—SerialNo.400010798andUp

®

HD

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3405-604*D

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ThissparkignitionsystemcomplieswithCanadian

ICES-002

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EP A

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

Becauseinsomeareastherearelocal,state,or

federalregulationsrequiringthatasparkarresterbe

usedontheengineofthismachine,asparkarresteris

availableasanoption.Ifyourequireasparkarrester,

contactyourAuthorizedToroDealer.

GenuineT orosparkarrestersareapprovedbythe

USDAForestryService.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalT oropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuelorventingsystem,may

violateEPAandCARBregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

ForallmodelsthatdonothaveToroengines,

pleaserefertotheenginemanufacturer’s

informationincludedwiththemachine.

decal127-9363

Figure3

Labeledpowerratingsaresuppliedbytheengine

manufacturerinaccordancewithSAEtestingand

gross/netpowerratingstandards(J1940,J1995,

J1349).

Important:IfyouareusingamachinewithaToro

engineabove1500m(5,000ft)foracontinuous

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyresidentialhomeownersorprofessional,hired

operators.Itisdesignedprimarilyforcuttinggrasson

well-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

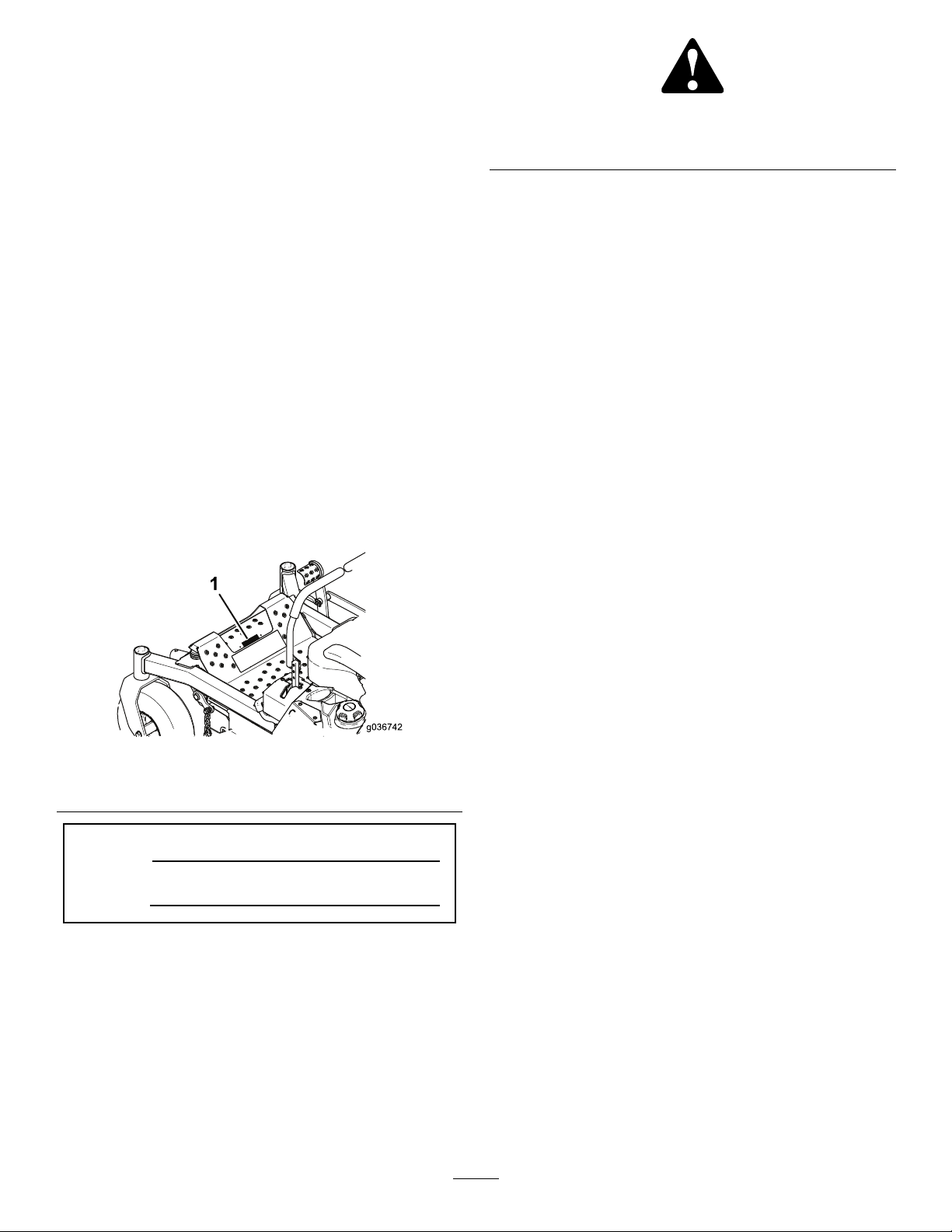

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................5

GeneralSafety...................................................5

SlopeIndicator...................................................6

SafetyandInstructionalDecals..........................7

ProductOverview...................................................14

Controls...........................................................14

Specications..................................................15

BeforeOperation.................................................16

BeforeOperationSafety...................................16

RecommendedFuel.........................................17

UsingStabilizer/Conditioner.............................17

FillingtheFuelTank..........................................17

CheckingtheEngine-OilLevel..........................17

UsingtheRollover-ProtectionSystem

(ROPS).........................................................18

ThinkSafetyFirst..............................................19

UsingtheSafety-InterlockSystem....................20

PositioningtheSeat..........................................20

ChangingtheSeatSuspension.........................20

BreakinginaNewMachine..............................21

g036742

UsingAttachmentsandAccessories.................21

DuringOperation.................................................21

DuringOperationSafety...................................21

OperatingtheParkingBrake.............................23

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................23

OperatingtheThrottle.......................................23

OperatingtheChoke.........................................24

OperatingtheIgnitionSwitch............................24

StartingtheEngine...........................................24

ShuttingOfftheEngine.....................................25

DrivingForwardorBackward............................26

AdjustingtheHeight-of-Cut...............................28

AdjustingtheAnti-ScalpRollers........................28

AdjustingtheSideBumpers..............................29

StoppingtheMachine.......................................29

UsingtheSideDischarge.................................30

OperatingTips.................................................30

AfterOperation....................................................31

AfterOperationSafety......................................31

UsingtheFuel-ShutoffValve.............................31

UsingtheDrive-Wheel-ReleaseValves............31

3

Page 4

TransportingtheMachine.................................32

LoadingtheMachine........................................33

Maintenance...........................................................35

RecommendedMaintenanceSchedule(s)...........35

Pre-MaintenanceProcedures..............................37

MaintenanceandStorage.................................37

Lubrication..........................................................38

GreasingtheMachine.......................................38

LubricatingtheCaster-WheelHubs..................39

EngineMaintenance...........................................40

EngineSafety...................................................40

ServicingaKawasaki

ServicingaKohler

®

Engine..........................41

®

Engine...............................46

ServicingaT oroEngine....................................50

CheckingtheSparkArrester.............................55

ReplacingtheEmissions-AirIntake

Filter..............................................................55

FuelSystemMaintenance...................................55

ReplacingtheFuelFilter...................................55

ServicingtheFuelT ank.....................................56

ElectricalSystemMaintenance...........................56

ElectricalSystemSafety...................................56

ServicingtheBattery.........................................56

ServicingtheFuses..........................................58

DriveSystemMaintenance..................................59

CheckingtheSeatBelt.....................................59

CheckingtheRollover-Protection-System

(ROPS)Knobs..............................................59

AdjustingtheTracking......................................60

CheckingtheTirePressure...............................60

CheckingtheWheelLugNuts...........................60

CoolingSystemMaintenance..............................61

CleaningtheEngineScreen.............................61

BrakeMaintenance.............................................61

AdjustingtheParkingBrake..............................61

BeltMaintenance................................................63

InspectingtheBelts..........................................63

ReplacingtheMowerBeltforSideDischarge

MowerDecks................................................63

ReplacingtheMowerBeltforRearDischarge

MowerDecks................................................64

ReplacingtheHydraulicPump-Drive

Belt................................................................66

ControlsSystemMaintenance.............................67

AdjustingtheControl-HandlePosition..............67

AdjustingtheMotion-ControlLinkage...............67

HydraulicSystemMaintenance...........................69

HydraulicSystemSafety...................................69

ServicingtheHydraulicSystem........................69

ChangingtheHydraulic-SystemFiltersand

Fluid..............................................................70

MowerDeckMaintenance....................................72

LevelingtheMowerDeck..................................72

ServicingtheCuttingBlades.............................74

RemovingtheMowerDeck...............................78

ReplacingtheGrassDeector..........................78

Cleaning..............................................................79

CleaningundertheMower................................79

DisposingofWaste...........................................79

Storage...................................................................80

CleaningandStorage.......................................80

Troubleshooting......................................................81

Schematics.............................................................83

4

Page 5

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtouseitandunderstandsthewarnings.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistancefromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

5

Page 6

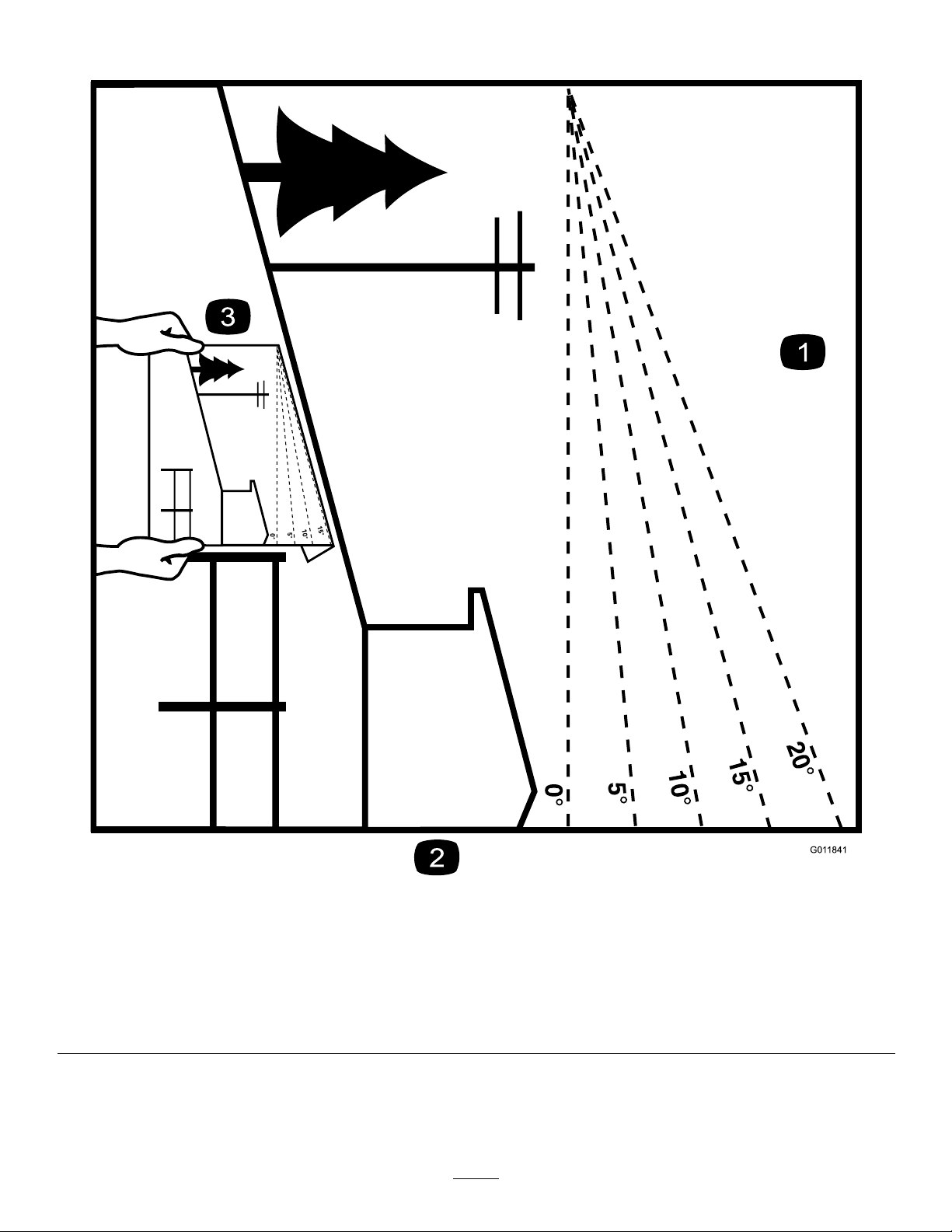

SlopeIndicator

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

6

g011841

Page 7

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

93-7818

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto115-149N∙m(85-110ft-lb).

decaloemmarkt

decal93-7818

1.Warning—donottouchthehotsurface.

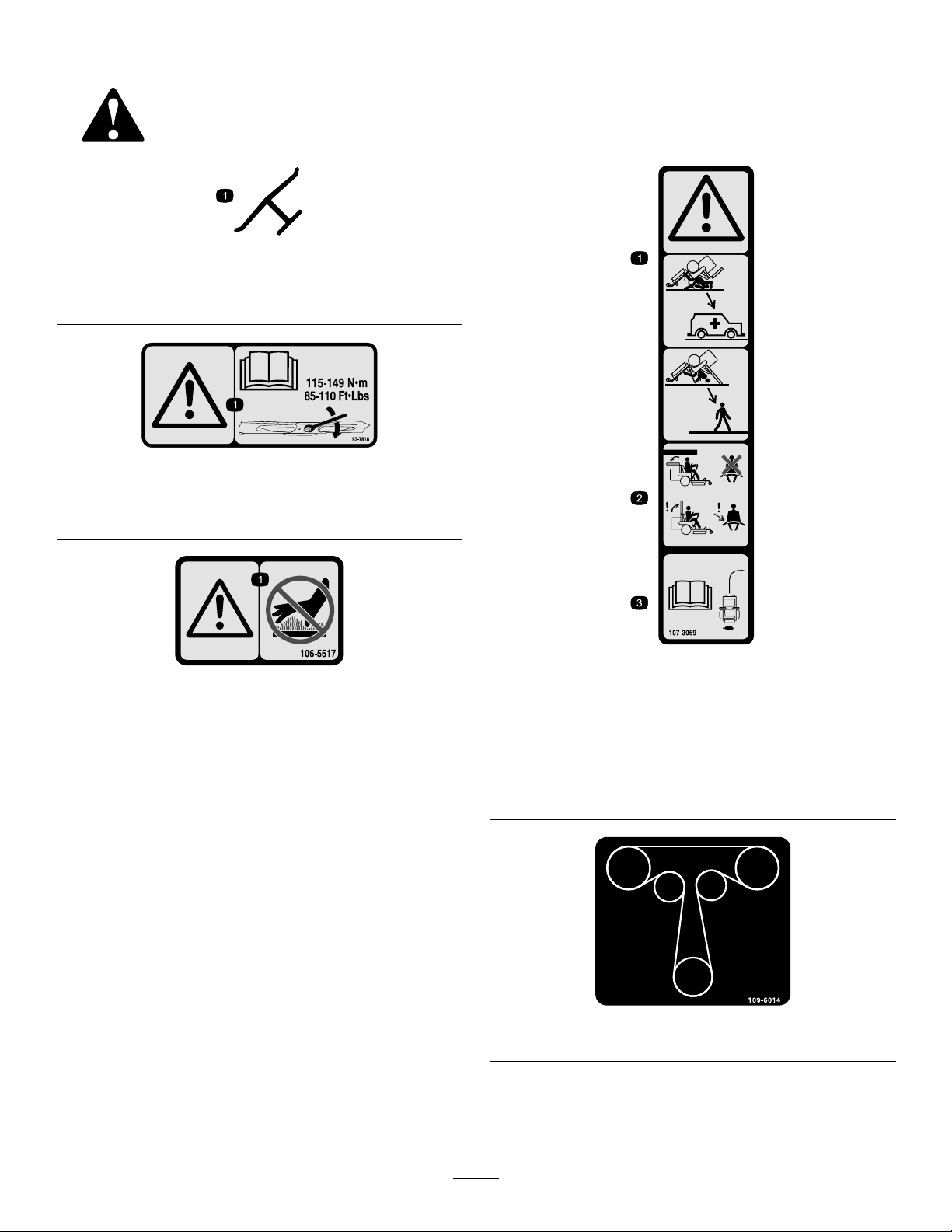

decal107-3069

decal106-5517

106-5517

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

107-3069

decal109-6014

109-6014

7

Page 8

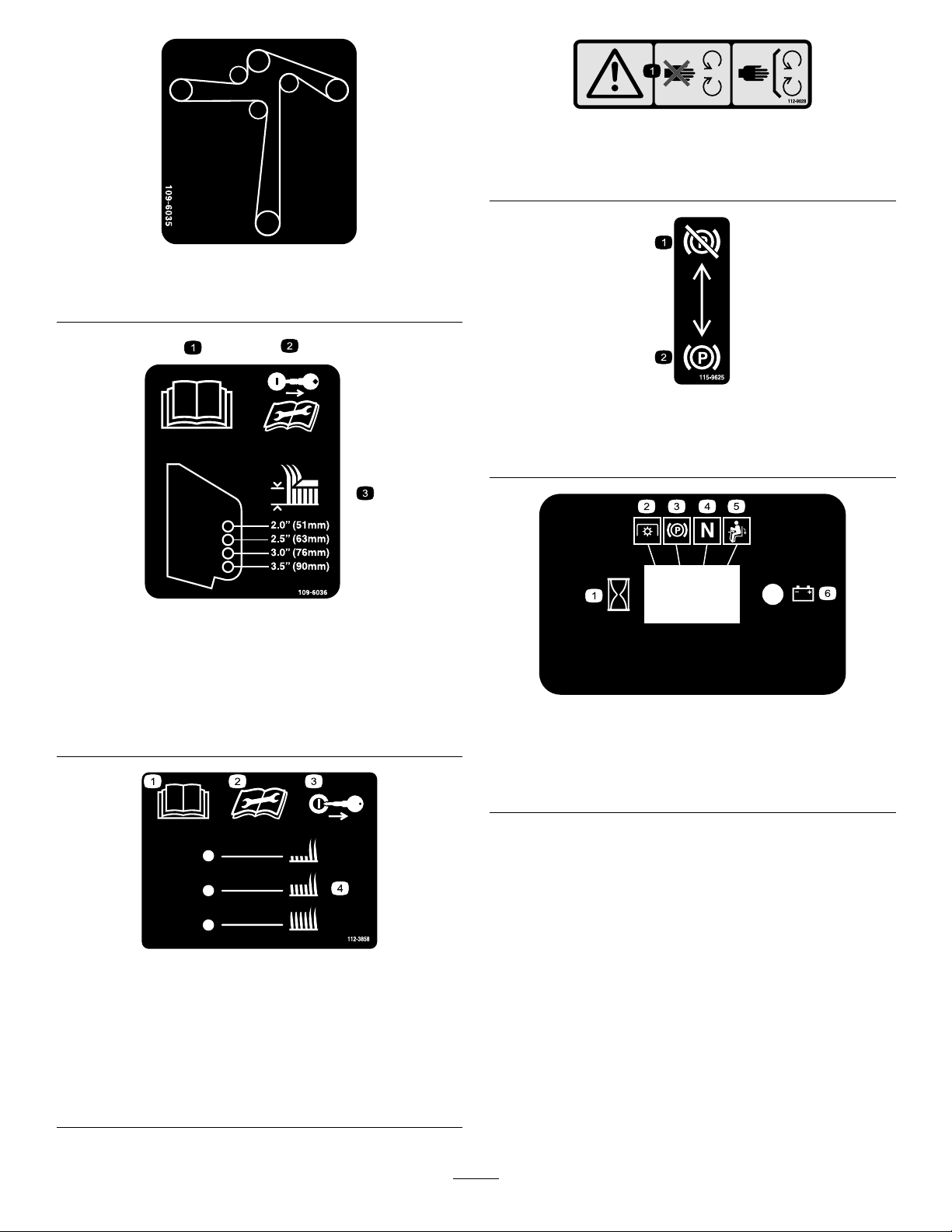

109-6035

2500SeriesSideDischargeMachinesOnly

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

decal109-6035

decal115-9625

115-9625

109-6036

RearDischargeMachinesOnly

1.ReadtheOperator’sManual.

2.Removetheignitionkeyandreadtheinstructionsbefore

servicingorperformingmaintenance.

3.Heightofcut

1.Parking

2.Parkingbrake—engaged

brake—disengaged

decal109-6036

decalhourmessagedisplay-116-5610

MessageDisplay

1.Hour4.Neutral

2.PTO5.Operator-presenceswitch

3.Parkingbrake6.Battery

112-3858

1500and2000SeriesSideDischargeMachinesOnly

1.ReadtheOperator's

Manual.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

3.Removetheignitionkey

beforeadjustingtheheight

ofcut.

4.Height-of-cutsettings.

decal112-3858

8

Page 9

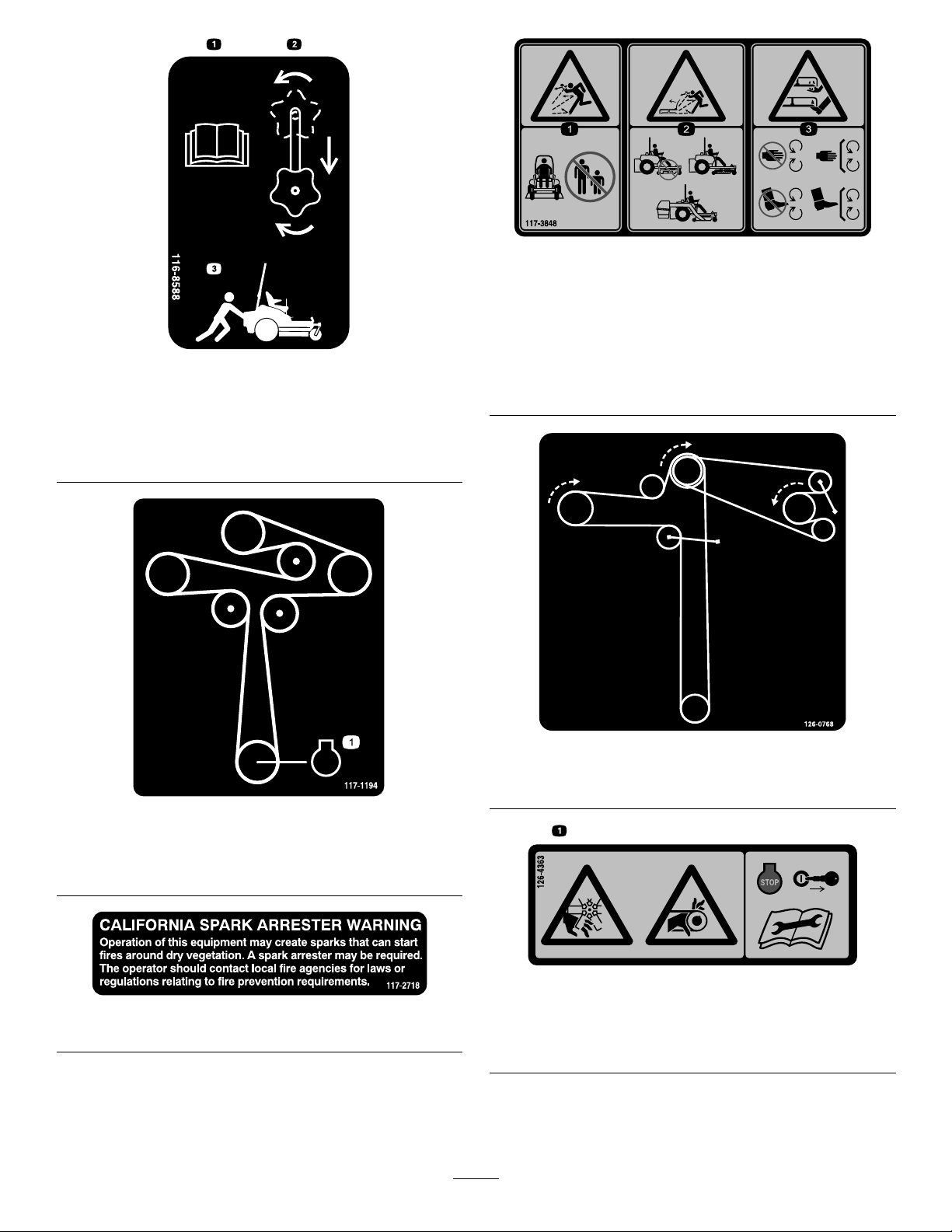

116-8588

1.ReadtheOperator’sManual.

2.Rotatethedrivereleaseknobtoloosen,slidetheknob,

andtighten.

3.Pushthemachine.

decal117-3848

117-3848

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Thrownobjecthazard,mower—donotoperatethemachine

withoutdeector,dischargecover,orgrasscollection

decal116-8588

systeminplace.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

117-1194

1500and2000SeriesSide-DischargeMachinesOnly

1.Engine

117-2718

decal126-0768

126-0768

RearDischargeUnitsOnly

decal117-1 194

decal126-4363

126-4363

decal117-2718

1.Cutting/dismembermenthazard,fanandentanglement

hazard,belt.Shutofftheengineandremovekeybefore

adjusting,servicingorcleaning.

9

Page 10

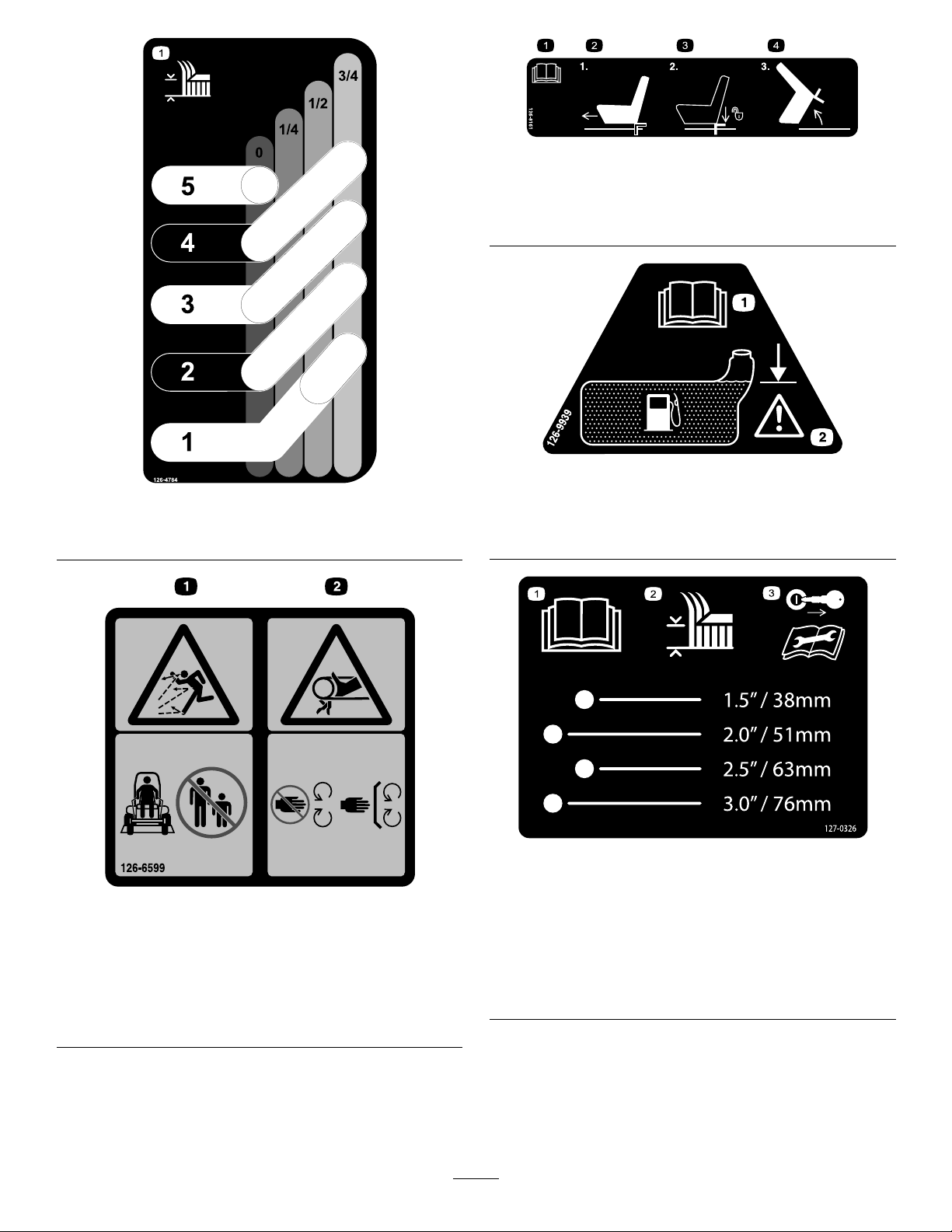

decal126-8161

126-8161

1.Heightofcut

1.ReadtheOperator’s

Manual.

2.Slideseatforward

decal126-4784

126-4784

1.ReadtheOperator’s

Manual

3.Pressdownonlatchto

unlockseat

4.Rotateseat

decal126-9939

126-9939

2.Filltobottomofllerneck;

warning–donotoverllthe

tank

1.Thrownobjectshazard

-keepbystandersa

safedistancefromthe

machine.

126-6599

RearDischargeUnits

2.Cutting/dismemberment

ofhand-stayawayfrom

movingparts;keepall

guardsandshieldsin

place.

decal127-0326

127-0326

decal126-6599

2500SeriesSideDischargeMachinesOnly

1.ReadtheOperator's

Manual.

2.Heightofcut

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

performingmaintenance

orservicingthemachine.

10

Page 11

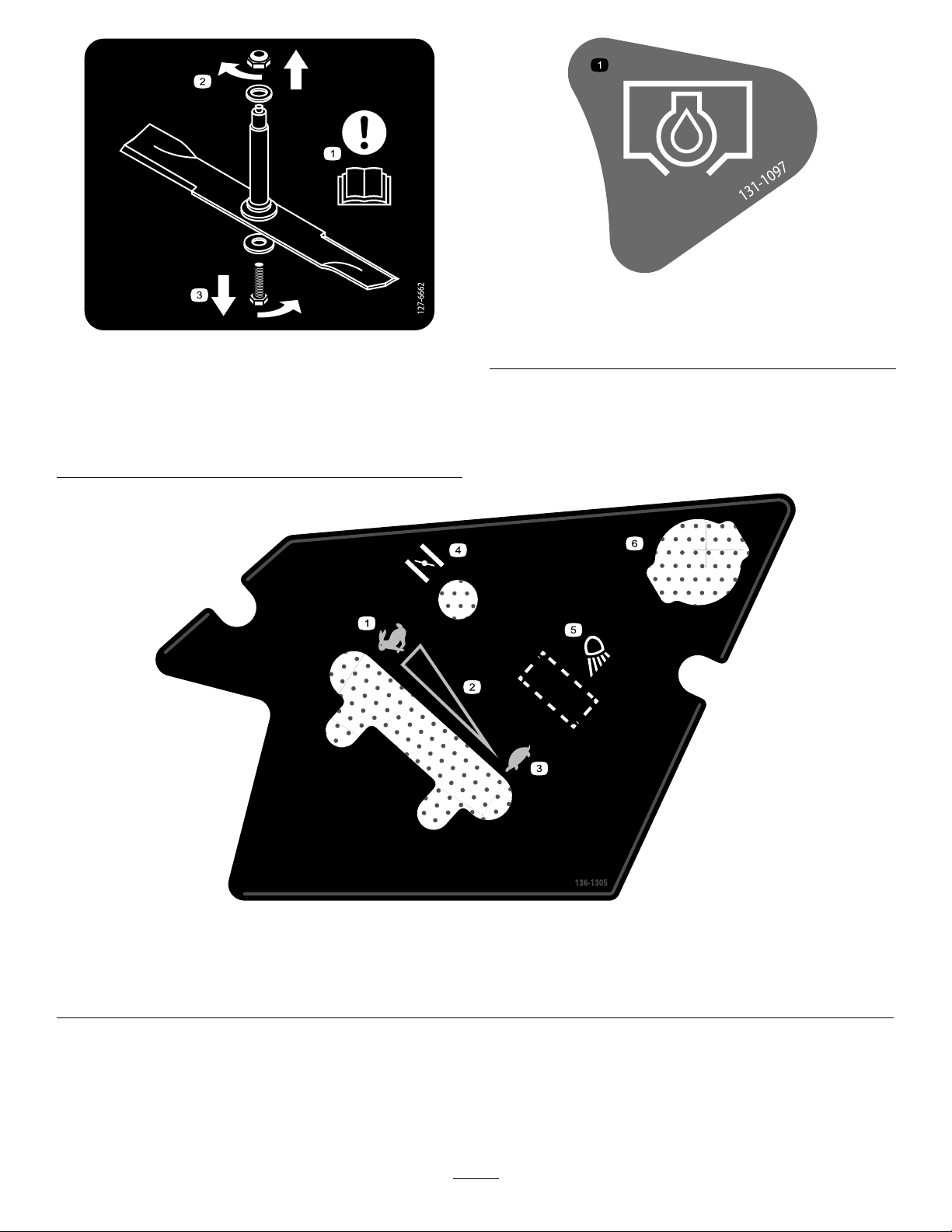

127-6662

RearDischargeMowersOnly

decal131-1097

131-1097

ToroEnginesOnly

decal127-6662

1.Oildrain

1.Attention—readthe

Operator'sManual.

2.Removethenutbyturning

itclockwise.

3.Removetheboltbyturning

itcounterclockwise.

136-1305

1.Fast

2.Continuousvariablesetting5.Worklight(optional)

3.Slow

4.Choke

6.Powerpoint

11

decal136-1305

Page 12

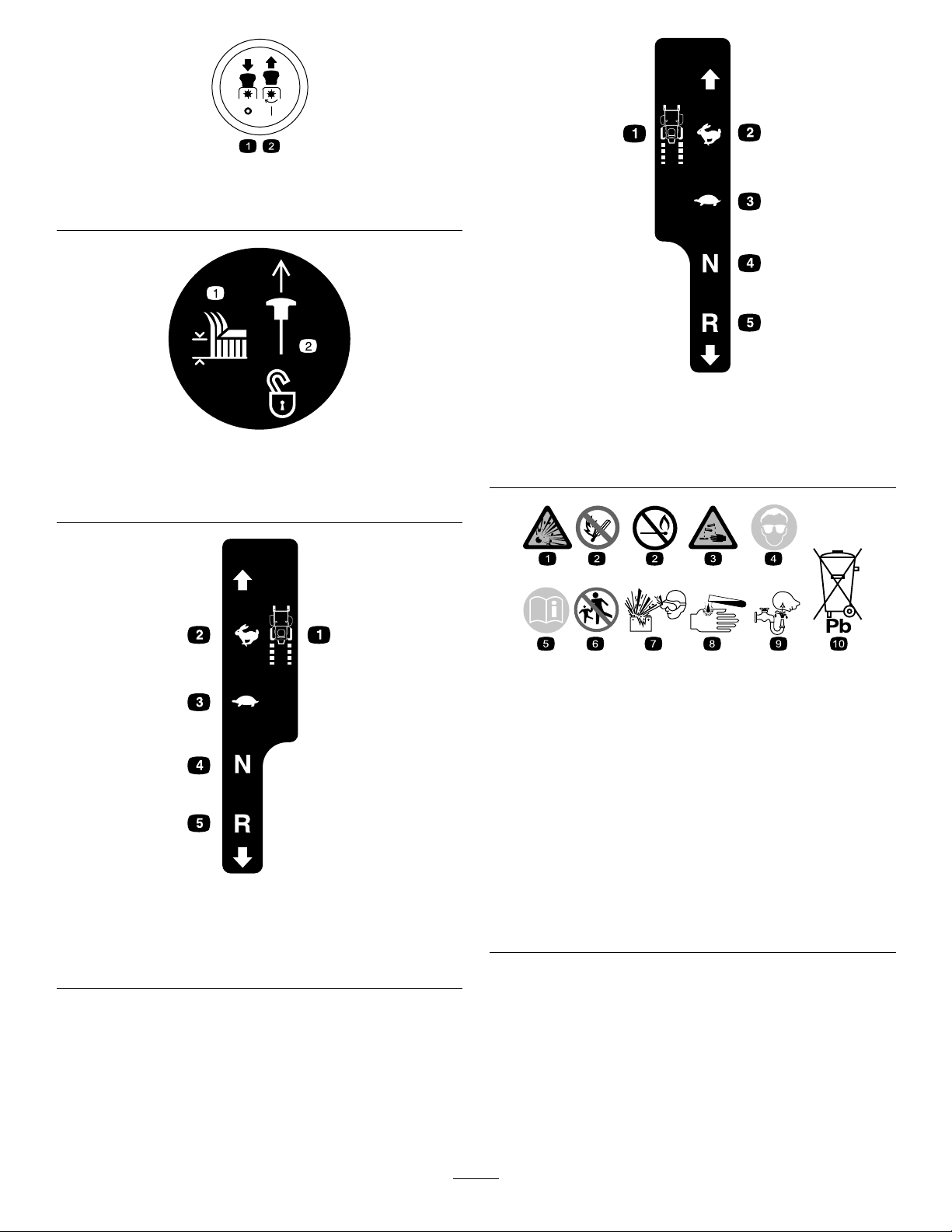

PTOSwitchSymbols

1.PTO–disengage2.PTO–engage

decalptosymbols

decalmotioncntrlrh-126-6183

RightMotionControl

TransportLock

1.Heightofcut

LeftMotionControl

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

2.Pulluptounlockthe

transportlock

decalmotioncntrllh-126-6194

decaltransportlock

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

12

Page 13

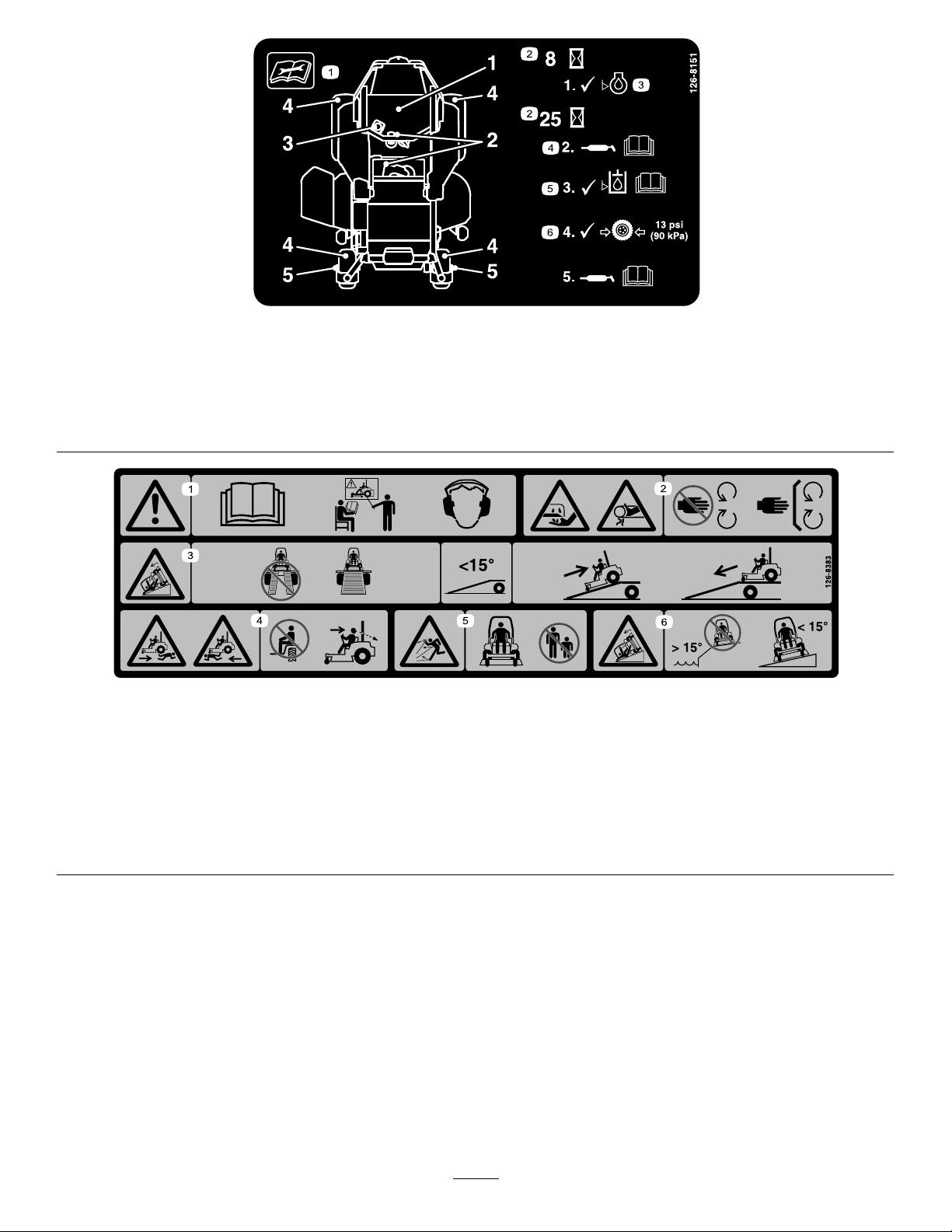

decal126-8151

126-8151

1.Readtheinstructionsbeforeservicingorperforming

4.RefertotheOperator'sManualforgreaseinstructions

maintenance

2.Timeinterval

5.Checkthehydraulic-uidlevelandrefertotheOperator's

Manualorfurtherinstructions

3.Checkoillevel6.Checktirepressure

126-8383

1.Warning-ReadtheOperator'sManual.Donotoperatethis

machineunlessyouaretrained.Wearhearingprotection.

2.Cuttingandpinchinghazard-keephandsandfeetawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Ramphazard-whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine

andthathasaninclinelessthan15degrees;backupthe

ramp(inreverse)anddriveforwardofftheramp.

4.Bodilyharmhazard-lookbehindyouwhenmowingin

reverse.

5.Thrownobjecthazard-keepbystandersaway .

6.Tippinghazardonslopes-donotuseonslopesnearopen

water;donotuseonslopesgreaterthan15degrees.

decal126-8383

13

Page 14

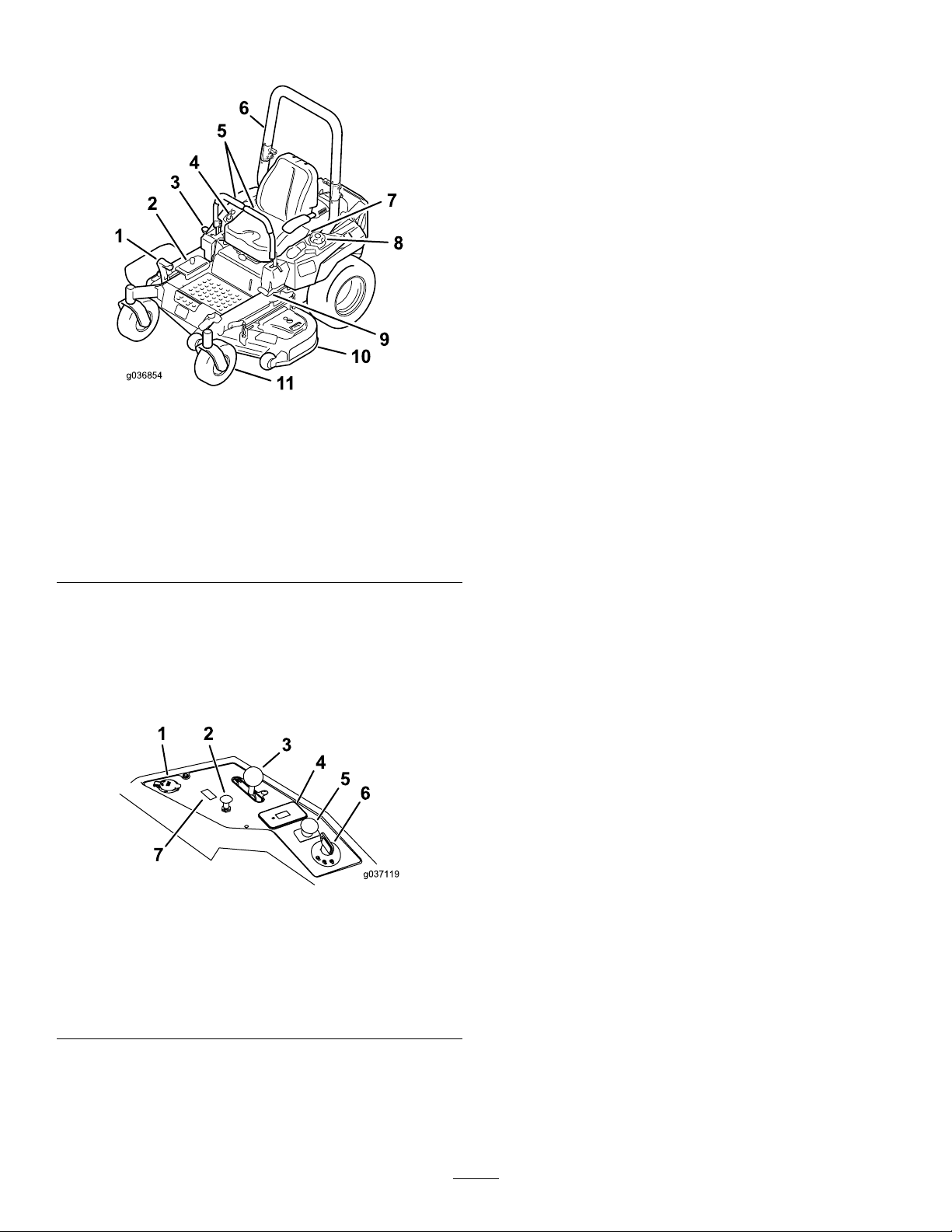

ProductOverview

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

ThrottleControl

ThethrottlecontrolisvariablebetweenFastand

Slow.

Choke

Usethechoketostartacoldengine.Pullthechoke

knobuptoengageit.

Figure5

1.Height-of-cutdeck-lift

pedal

2.Height-of-cutpositions

3.Transportlock9.Parking-brakelever

4.Controls

5.Motion-controllevers

6.Rollbar

7.Seatbelt

8.Fuelcap

10.Mowerdeck

11.Casterwheel

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine(Figure5and

Figure6).

g036854

Blade-ControlSwitch(PTO)

Usetheblade-controlswitch(PTO)toengagethe

electricclutchanddrivethemowerblades.Pullthe

switchuptoengagethebladesandrelease.T o

disengagetheblades,pushtheblade-controlswitch

(PTO)downormoveamotion-controlleverintothe

NEUTRAL-LOCKposition.

IgnitionSwitch

Thisswitchisusedtostartthemowerengineandhas

3positions:START,RUN,andOFF.

Motion-ControlLevers

Themotion-controlleversareusedtodrivethe

machineforward,reverse,andturneitherdirection.

Neutral-LockPosition

UsetheNEUTRAL-LOCKpositionwiththe

safety-interlocksystemtoengageandtodetermine

theNEUTRALposition.

1.Powerpoint

2.Choke

3.Throttlecontrol

4.Hourmeter

Figure6

5.PTOSwitch

6.Ignitionswitch

7.Switchpositionforoptional

lightkit

g037119

Fuel-ShutoffValve

Closethefuel-shutoffvalve(undertheseat)when

transportingorstoringthemower.

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

14

Page 15

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width—MachineswithSideDischargeMowerDecks

48-inchDeck52-inchDeck60-inchDeck

Withoutmowerdeck

Deectorup133cm(53inches)144cm(56-3/4inches)161cm(63-1/2inches)

Deectordown160cm(63-1/4inches)171cm(67-1/4inches)191cm(75-1/4inches)

Width—MachineswithRearDischargeMowerDecks

Withoutmowerdeck

Withmowerdeck

Length—MachineswithSideDischargeMowerDecks

Length

Length—MachineswithRearDischargeMowerDecks

121cm(47-1/2inches)124cm(49inches)133cm(52inches)

60-inchDeck

133cm(52inches)

168cm(66inches)

48-inchDeck52-inchDeck60-inchDeck

208cm(82inches)208cm(82inches)209cm(83inches)

60-inchDeck

Withmowerdeck

215cm(84-1/2inches)

Height

RollBar-UpRollBar-Down

179cm(70-1/2inches)49inches(125cm)

Weight

MachinesWeight

48-inchside-dischargemachines

52-inchside-dischargemachines

60-inchside-dischargemachines

60-inchrear-dischargemachines

385to425kg(849to937lb)

391to434kg(862to957lb)

409to456kg(901to1006lb)

459kg(1012lb)

15

Page 16

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandenginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanygasolinethat

spills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storegasolineinanapprovedcontainerandkeep

itoutofthereachofchildren.Neverbuymore

thana30-daysupplyofgasoline.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsgasoline

toexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandgas

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

16

Page 17

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessafuelstabilizer

isused.

•Donotaddoiltogasoline.

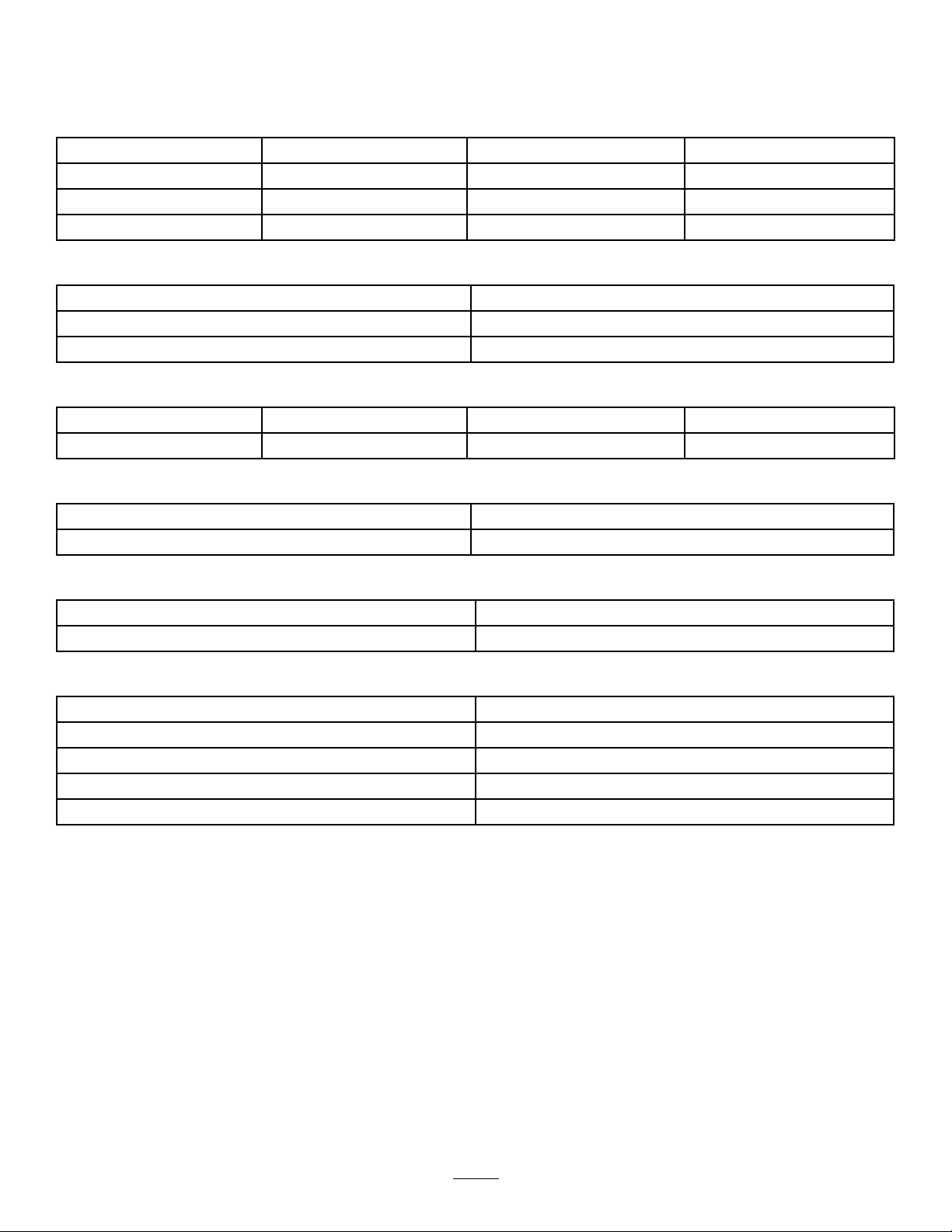

4.Fillthefueltanktothebottomofthellerneck.

5.Ensurethatthereisemptyspaceinthetankto

allowthegasolinetoexpand(Figure7).

Using Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysor

less.Forlongerstorageitisrecommendedthat

thefueltankbedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountofgasoline

stabilizer/conditionertothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,use

fuelstabilizeratalltimes.

Figure7

CheckingtheEngine-Oil Level

Beforeyoustarttheengineandusethemachine,

checktheoillevelintheenginecrankcase.For

KawasakienginesrefertoServicingaKawasaki

Engine(page41),forKohlerenginesrefertoServicing

aKohler

refertoServicingaT oroEngine(page50).

®

Engine(page46),andforT oroengines

g036751

®

FillingtheFuelTank

Note:Donotllthefueltankcompletelyfull.Fillthe

fueltanktothebottomofthellerneck.Theempty

spaceinthetankallowsthegasolinetoexpand.

1.Parkthemachineonlevelground.

2.Shuttheengineoffandsettheparkingbrake.

3.Cleanaroundthefuel-tankcap.

17

Page 18

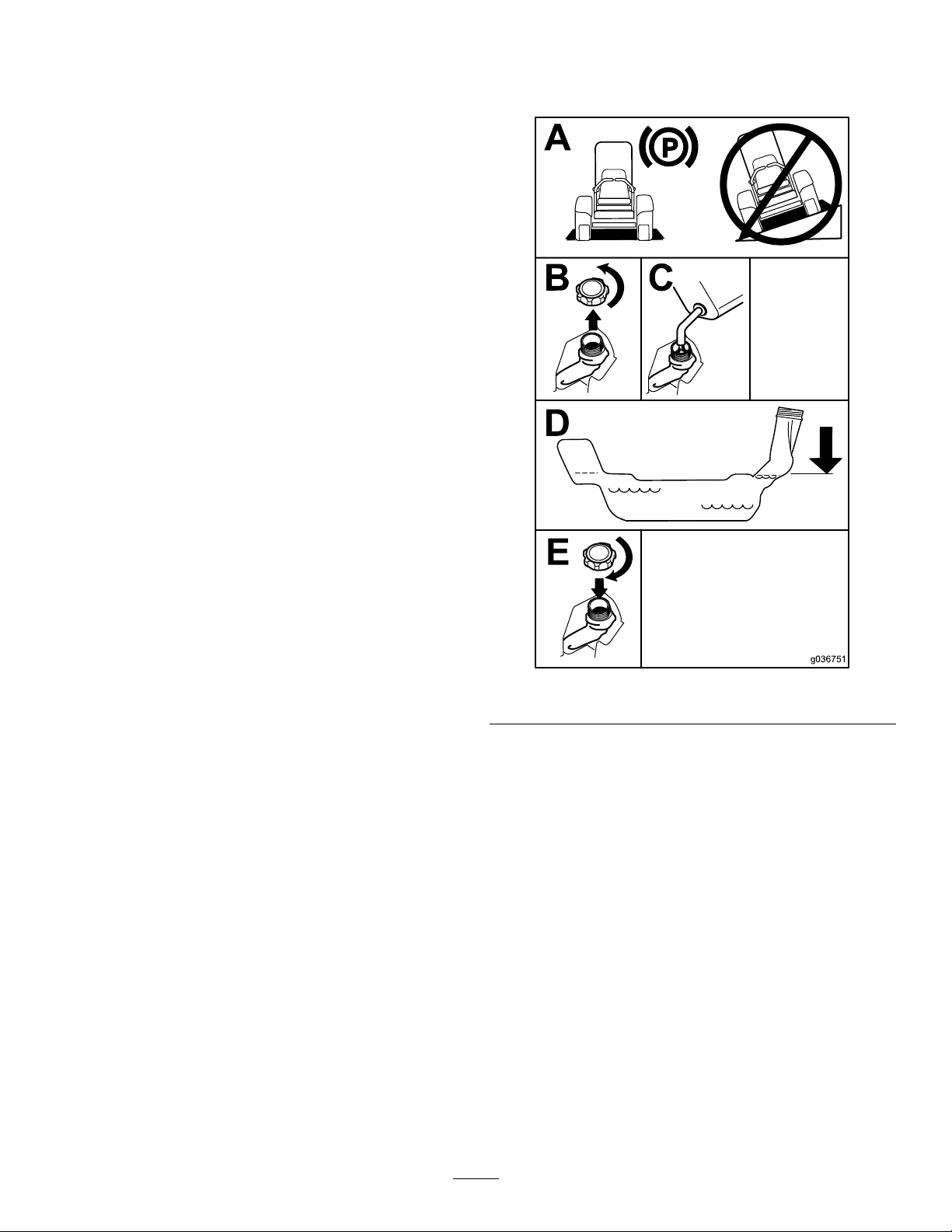

Usingthe Rollover-ProtectionSystem (ROPS)

WARNING

Toavoidinjuryordeathfromrollover:keep

therollbarinthefullyraised,lockedposition

andusetheseatbelt.

Ensurethattheseatissecuredtothe

machine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

g036746

Figure8

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjects,anddo

notcontactthem.

Important:Ensurethattheseatissecuredto

themachine.

1.T olowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90degrees

sotheyarenotengaged(Figure8).

3.Lowertherollbartothedownposition(Figure

8).

1.Rollbarintheupright

position

2.ROPSknobinthelatched

position

3.PulltheROPSknobout.6.Rollbarinthefolded

4.T oraisetherollbar,raisetherollbartothe

operatingpositionandrotatetheknobsuntil

theymovepartiallyintothegrooves(Figure8).

5.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepins

snapintopositionwhentheholesalignwiththe

pins(Figure8).

6.Pushontherollbarandensurethatbothpins

areengaged.

4.RotatetheROPSknob90

degrees.

5.ROPSknobinthe

unlatchedposition

position

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

18

Page 19

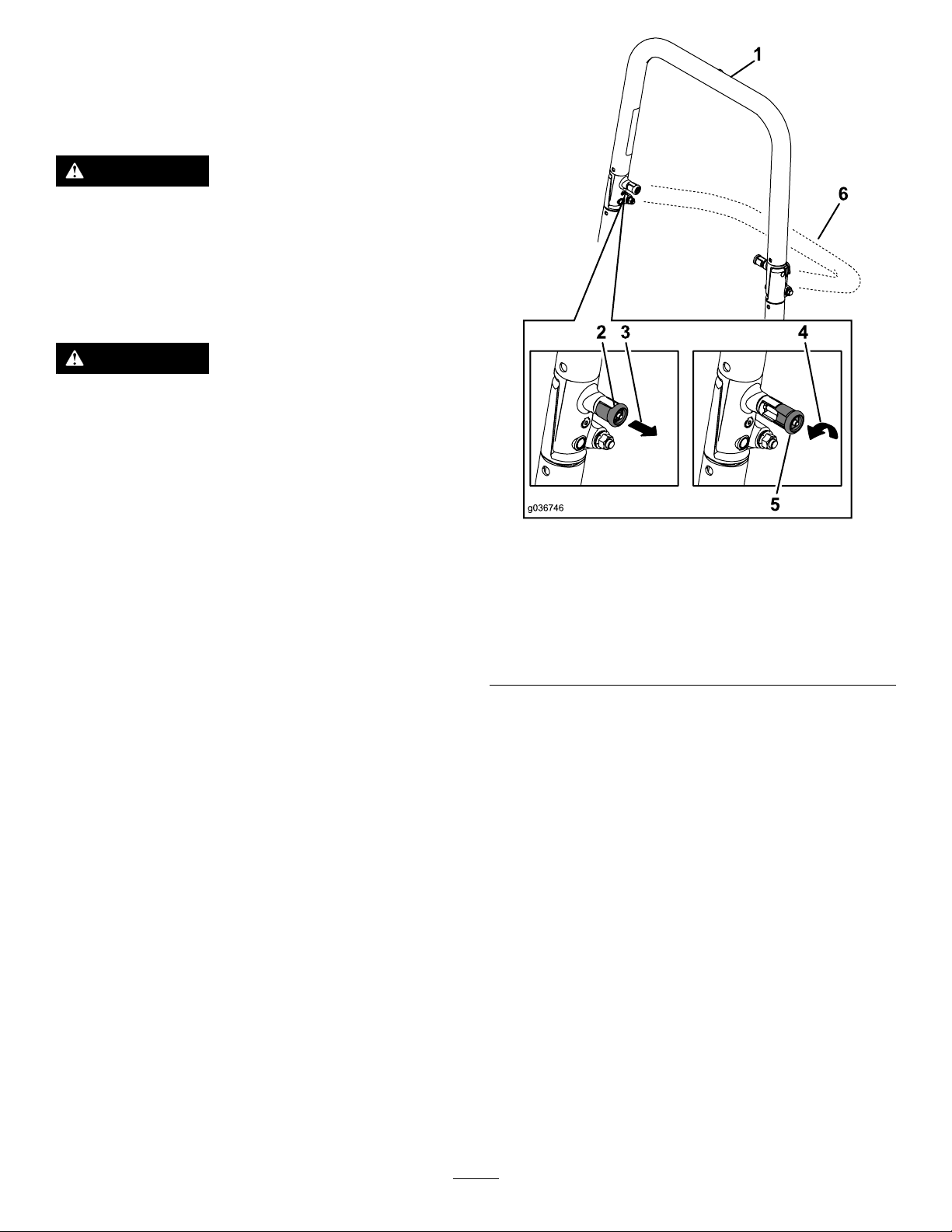

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteep

slopescancauseslidingandlossofcontrol.

•Donotoperateonslopesgreaterthan15

degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancause

rollovers,whichmayresultinseriousinjury,

death,ordrowning.

Donotoperatethemachineneardrop-offs.

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees,

neardrop-offsandwater.

g000963

Figure9

3.Water

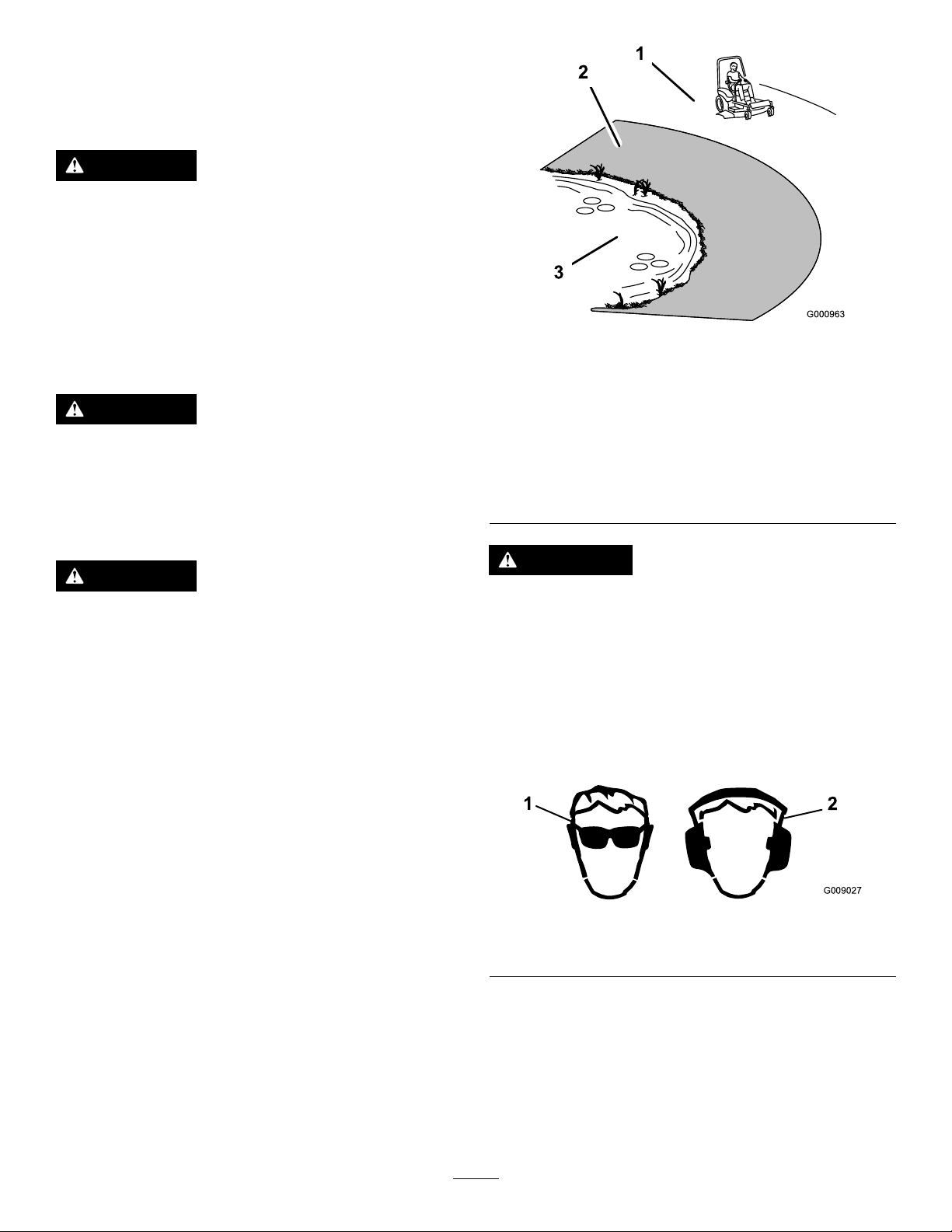

DANGER

Operatingthemachinewhiletherollbaris

downmayleadtoseriousinjuryordeathin

theeventofarollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Theuseofprotectiveequipmentforeyes,ears,

hands,feet,andheadisrecommended.

g009027

Figure10

1.Weareyeprotection.2.Wearhearingprotection

19

Page 20

UsingtheSafety-Interlock System

Whiletheengineisrunning,releasetheparking

brake,engagetheblade-controlswitch(PTO),

andriseslightlyfromtheseat;theengineshould

shutoff.

CAUTION

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunless:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

4.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

toNEUTRAL-LOCKposition.Starttheengine.

Whiletheengineisrunning,centereither

motion-controlleverandmoveitforwardor

reverse;theengineshouldshutoff.Repeatfor

othermotion-controllever.

5.Sitontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controlleversto

NEUTRAL-LOCKposition.Trystartingtheengine;

theengineshouldnotcrank.

PositioningtheSeat

Theseatcanmoveforwardandbackward(Figure11).

Positiontheseatwhereyouhavethebestcontrolof

themachineandaremostcomfortable.

Thesafety-interlocksystemalsoisdesignedtoshutoff

theenginewhenyoumovethetractioncontrolsfrom

thelockedpositionwiththeparkingbrakeengagedor

ifyourisefromtheseatwhenthePTOisengaged.

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,engagetheparkingbrakeand

movetheblade-controlswitch(PTO)totheON

position.Trystartingtheengine;theengine

shouldnotcrank.

2.Sitontheseat,engagetheparkingbrakeand

movetheblade-controlswitch(PTO)totheOFF

position.Moveeithermotion-controllever(out

oftheNEUTRAL-LOCKposition).Trystartingthe

engine;theengineshouldnotcrank.Repeatfor

othercontrollever.

3.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controlleversto

theNEUTRAL-LOCKposition.Starttheengine.

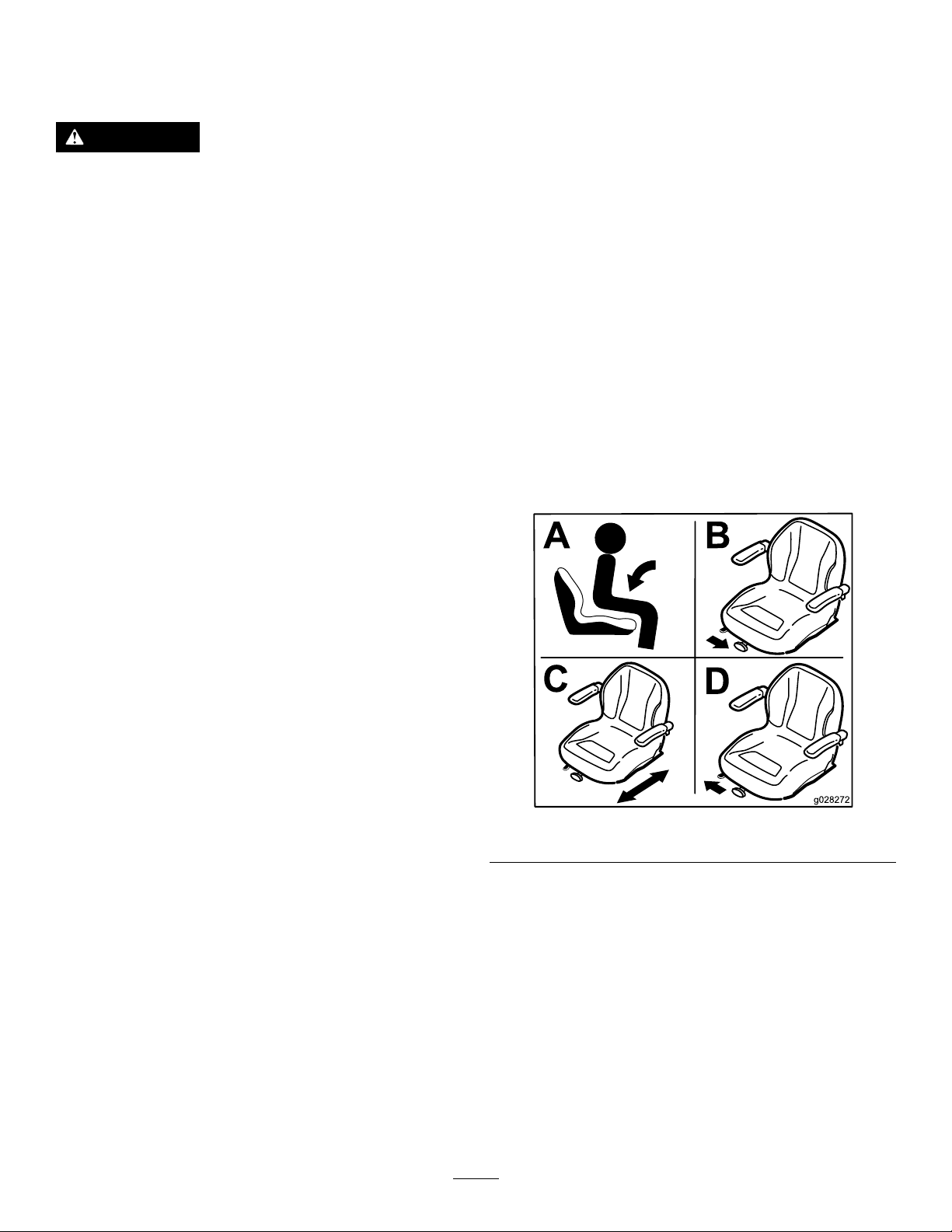

g028272

Figure11

ChangingtheSeat Suspension

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure12).

20

Page 21

Figure12

1.Seat-suspensionknob

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

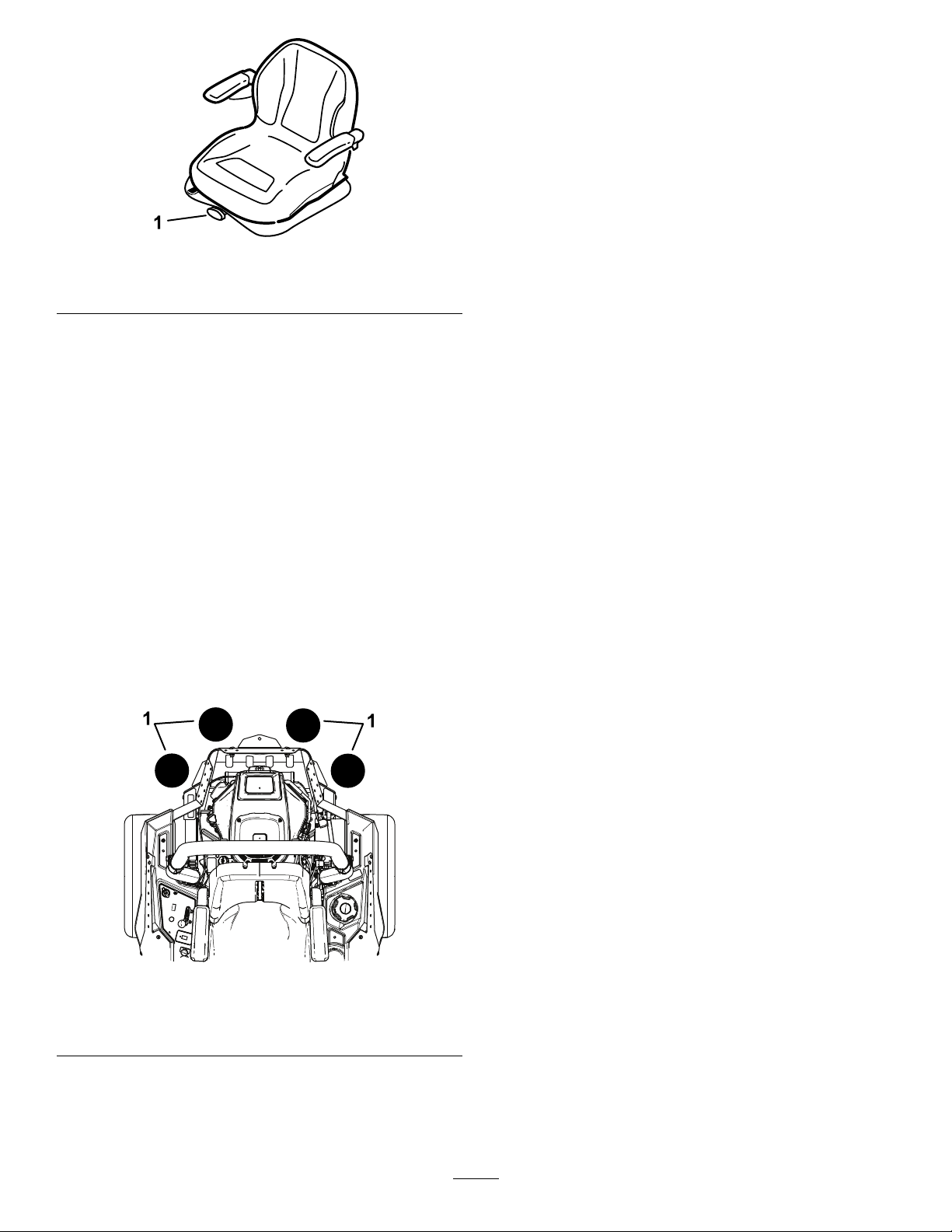

UsingAttachmentsand Accessories

UseonlyToroapprovedattachmentsandaccessories.

Ifmorethanoneaccessory-mountkit(i.e.bucketkitor

universalmountkit)isaddedtoanyofthe4locations

showninFigure13,addafront-weightkit.Contact

yourauthorizedservicedealerforthefront-weightkit.

Figure13

1.Addafront-weightkitwhen2ormoreaccessory-mountkits

areinstalledatthesepositions.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

g024881

g037417

•Wearappropriateclothing,includingeye

protection;slip-resistant,substantialfootwear;and

hearingprotection.Tiebacklonghairanddonot

wearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

21

Page 22

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Settheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useaccessoriesandattachmentsapprovedby

Toroonly.

RolloverProtectionSystem

(ROPS)Safety

•DonotremovetheROPSfromthemachine.

•Ensurethattheseatbeltisattachedandthatyou

canreleaseitquicklyinanemergency.

•AlwayswearyourseatbeltwhentheROPSisup.

•Checkcarefullyforoverheadobstructionsanddo

notcontactthem.

•KeeptheROPSinsafeoperatingconditionby

thoroughlyinspectingitperiodicallyfordamage

andkeepingallthemountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairoralter

it.

•Choosealowgroundspeedsoyouwillnothave

tostoporshiftwhileonaslope.

•Arollovercanoccurbeforethetireslosetraction.

•Avoidoperatingthemachineonwetgrass.Tires

maylosetraction;regardlessifthebrakesare

availableandfunctioning.

•Avoidstarting,stopping,orturningthemachine

onaslope.

•Keepallmovementonslopesslowandgradual.

Donotsuddenlychangethespeedordirectionof

themachine.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,orbodiesofwater.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecavesin.Establisha

safetyareabetweenthemachineandanyhazard

(2machinewidths).

SlopeSafety

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

sloperequiresextracaution.

•Operatethemachineatalowerspeedwhenyou

areonaslope.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,bumps,rocks,orother

hiddenobjects.Uneventerraincouldoverturnthe

machine.T allgrasscanhideobstacles.

22

Page 23

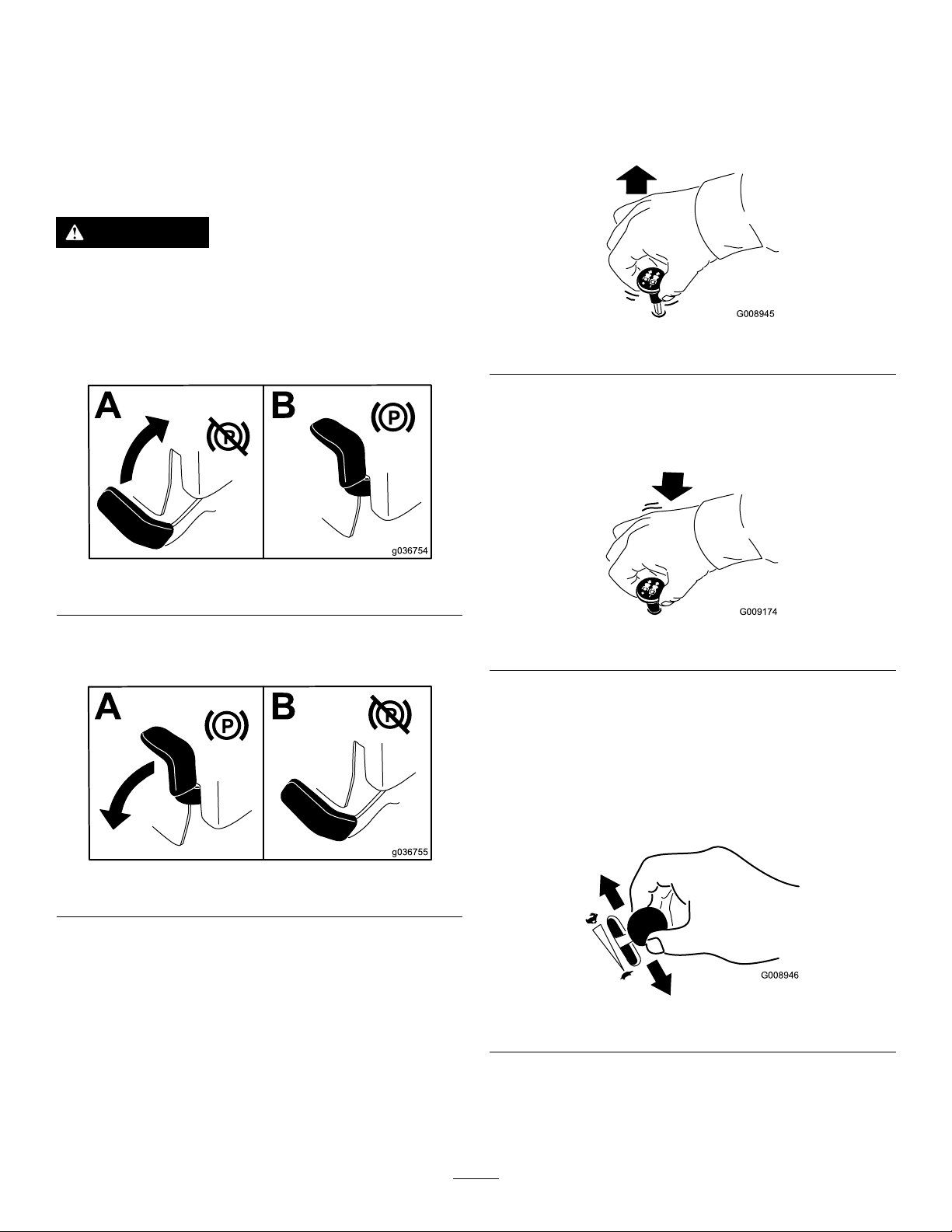

OperatingtheParking Brake

Alwayssettheparkingbrakewhenyoustopthe

machineorleaveitunattended.

SettingtheParkingBrake

WARNING

Theparkingbrakemaynotholdamachine

parkedonaslopeandcouldcausepersonal

injuryorpropertydamage.

Donotparkthemachineonslopesunlessthe

wheelsarechockedorblocked.

EngagingtheBlade-Control

Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

g008945

Figure16

DisengagingtheBlade-Control

Switch(PTO)

Figure14

ReleasingtheParkingBrake

Figure15

OperatingtheMower Blade-ControlSwitch(PTO)

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

g036754

g009174

Figure17

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure18).

AlwaysusetheFASTpositionwhenturningonthe

mowerdeckwiththeblade-controlswitch(PTO).

g036755

g008946

Figure18

23

Page 24

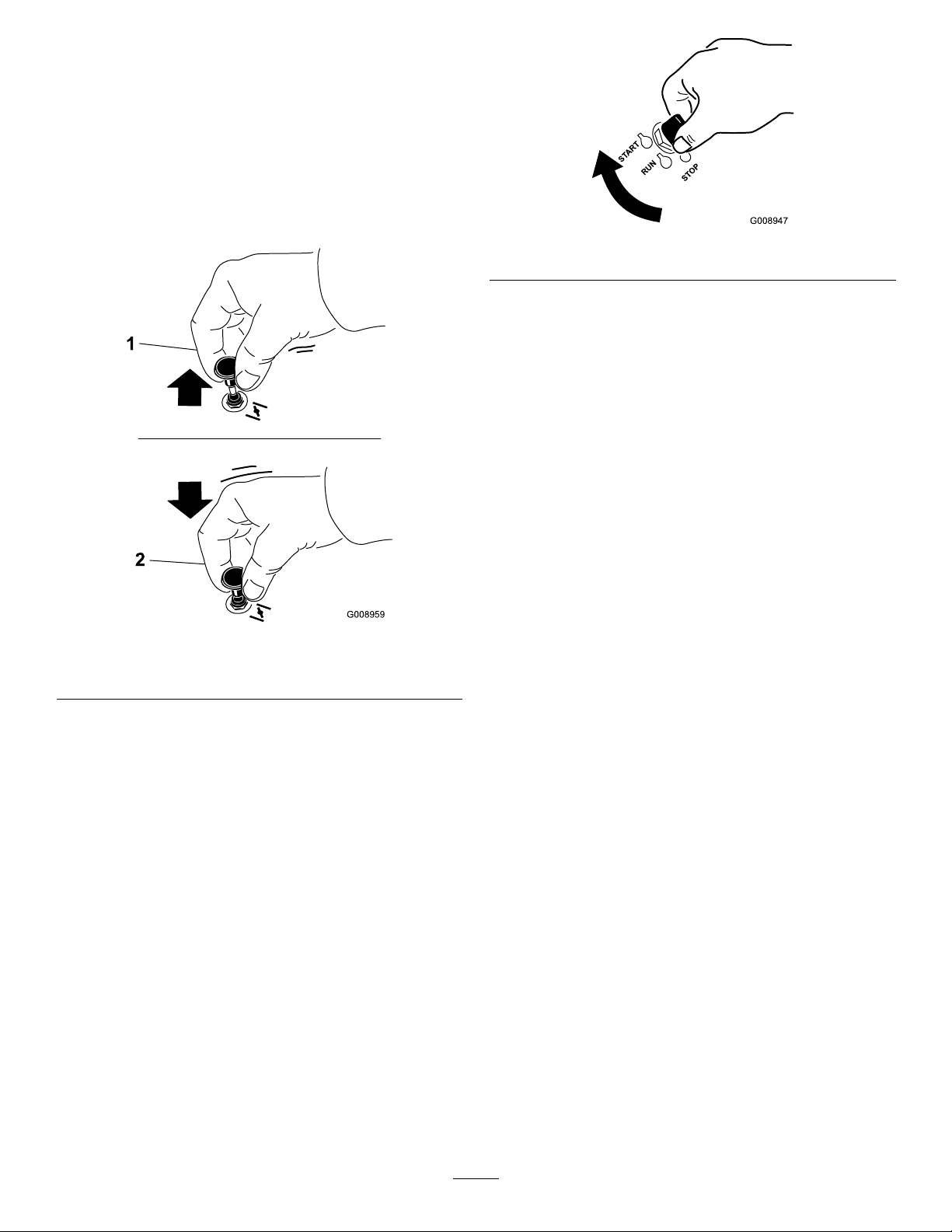

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostartthe

engine.

2.Pullupthechokeknobtoengagethechoke

beforeusingtheignitionswitch(Figure19).

3.Pushdownthechokeknobtodisengagethe

chokeafterstartingtheengine(Figure19).

g008947

Figure20

2.TurntheignitionkeytotheSTOPpositiontoshut

offtheengine.

StartingtheEngine

1.RaisetheROPSup,lockitintoplace,sitonthe

seat,andfastentheseatbelt.

2.MovethemotioncontrolstoNEUTRAL-LOCK

position.

3.Settheparkingbrake;refertoSettingthe

ParkingBrake(page23).

Figure19

1.ONposition2.OFFposition

OperatingtheIgnition Switch

1.TurntheignitionkeytotheST ARTposition

(Figure20).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagethestarterfor

morethan5secondsatatime.Iftheengine

failstostart,wait15secondsbetween

attempts.Failuretofollowtheseinstructions

canburnoutthestartermotor.

4.Movetheblade-controlswitch(PTO)totheOFF

position(Figure17).

5.Movethethrottlelevermidwaybetweenthe

g008959

SLOWandFASTpositions.

Note:Y oumayneedmultipleattemptstostart

theenginewhenyoustartitthersttimeafter

thefuelsystemhasbeenwithoutfuelcompletely.

24

Page 25

ShuttingOfftheEngine

Note:RefertoFigure40todeterminewhichengine

youhave.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

ShuttingOffKawasakiandKohler

Engines

Lettheengineidleatslowthrottlefor60seconds

beforeturningtheignitionswitchoff.

Figure21

6.TurntheignitionkeytotheST ARTposition

(Figure22).

Note:Whentheenginestarts,releasethekey.

Important:Donotengagestarterformore

than5secondsatatime.Iftheenginefails

tostart,allowa15secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

Note:Youmayneedtoattempttostartthe

enginemultipletimeswhenyoustartitforthe

rsttimeafterthefuelsystemhasbeenwithout

fuelcompletely.

g036838

g036839

Figure23

Figure22

1.Off3.Start

2.Run

Important:Makesurethatthefuel-shutoff

g008947

valveisclosedbeforetransportingorstoring

themachine,asfuelleakagemayoccur.Setthe

parkingbrakebeforetransporting.Removethe

keyasthefuelpumpmayrunandcausethe

batterytolosecharge.

25

Page 26

ShuttingOffToroEngines

Note:EnsurethethrottleisintheFASTposition

beforeshuttingofftheengine.

CAUTION

Machinecanspinveryrapidly.Youmaylose

controlofthemachineandinjureyourselfor

damagethemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

UsingtheMotion-ControlLevers

Figure24

Important:Makesurethatthefuel-shutoff

valveisclosedbeforetransportingorstoring

themachine,asfuelleakagemayoccur.Setthe

parkingbrakebeforetransporting.Removethe

keyasthefuelpumpmayrunandcausethe

batterytolosecharge.

DrivingForwardor Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

g037049

c:\data\documentum\checkout\g004532

Figure25

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

26

Page 27

DrivingForward

DrivingBackward

Note:Theengineshutsoffifyoumovethe

traction-controlleverswiththeparkingbrakeengaged.

Tostopthemachine,pullthemotion-controllevers

totheNEUTRALposition.

1.Releasetheparkingbrake;refertoReleasing

theParkingBrake(page23).

2.Movetheleverstothecenter,unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure26).

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,slowlypullthemotion-control

leversrearward(Figure27).

g008953

Figure27

Figure26

g008952

27

Page 28

AdjustingtheHeight-of-Cut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwith

thedeck-liftpedal.ThereisaLOCKpositionand

anUNLOCKpositionforthetransportpositionofthe

mowerdeck(Figure28).

AdjustingtheHeight-of-CutPin

Adjusttheheight-of-cutfrom38to127mm(1-1/2to5

inches)in6mm(1/4inch)incrementsbymovingthe

height-of-cutpinintodifferentholelocations.

1.MovethetransportlocktotheLOCKposition.

2.Pushonthedeck-liftpedalwithyourfootand

raisethemowerdecktotheTRANSPORTposition

(alsothe127mmor5inchcutting-height

position)asshowninFigure29.

3.T oadjust,removethepinfromtheheight-of-cut

bracket(Figure29).

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,and

insertthepin(Figure29).

5.Pushonthedecklift,pulluponthetransport

lockknob,andslowlylowerthemowerdeck.

Figure28

Transport-LockPositions

1.Transportlockknob3.UNLOCKposition—The

2.LOCKposition—The

mowerdecklocksintothe

transportposition.

mowerdeckdoesnotlock

intothetransportposition.

g036745

Figure29

1.Deck-liftpedal3.Height-of-cutpin

2.Height-of-cutholes

g037050

AdjustingtheAnti-Scalp

4.Transportlockknob

Rollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

28

Page 29

Figure30

2500seriesmowerdeckshown

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

NEUTRAL-LOCKposition,applytheparkingbrake,

andremovethekey.

2.Shutofftheengine,removethekey,andwaitfor

allmovingpartstostop.

3.Raisethemowertothetransportposition.

4.Removetheboltsandnutsfromeachbumper

(Figure32).

g038079

g037862

Figure32

Figure31

1500and2000seriesmowerdeckshown

1.Flangenut4.Anti-scalproller

2.Bolt

3.Bushing

5.Spacer

AdjustingtheSideBumpers

(RearDischargeMachinesOnly)

Installthesidebumpersinthetopholeswhen

operatinginaheightofcuthigherthan64mm(2-1/2

inches)andinthecenterholeswhenoperatingina

heightofcutlowerthan64mm(2-1/2inches).

Note:Whenthebumpersbecomeworn,switchthe

bumperstotheoppositesidesofthemowerandip

themover.Thisallowsthebumperstobeusedlonger

beforereplacingthem.

1.Disengagetheblade-controlswitch(PTO),turn

theignitionkeytooff,movetheleverstothe

1.Bolt3.Nut

2.Bumper

5.Moveeachbumpertothedesiredpositionand

securethemwiththeboltsandnuts.

Note:Useonlythetoporcentersetsofholesto

adjustthebumpers.Usethebottomholeswhen

g036848

switchingsides,atwhichtimetheybecomethe

topholesontheothersideofthemower.

StoppingtheMachine

Tostopthemachine,movethemotion-controllevers

toneutralandthentotheNEUTRAL-LOCKposition,

disengagetheblade-controlswitch(PTO),andturn

theignitionkeytotheOFFposition.

Settheparkingbrakewhenyouleavethemachine;

refertoSettingtheParkingBrake(page23).Remove

thekeyfromtheignitionswitch.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovetheignitionkeyandsetthe

parkingbrakewhenleavingthemachine

unattended,evenifjustforafewminutes.

29

Page 30

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

causeinjuryordeath.

•Neverremovethegrassdeectorfrom

themachinebecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mower.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatetheignitionkeytotheOFF

position,andremovethekey.

•Makesurethatthegrassdeectorisinthe

downposition.

grassissparse,oritislatefallwhengrassgrows

moreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.T omaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality ,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

StoppingtheMachine

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

inuncutgrass.Alwaystrytohave1sideofthemower

freefromuncutgrass,whichallowsairtobedrawn

intothemower.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdoesnotscalpany

unevenground.However,thecuttingheightusedin

thepastisgenerallythebestonetouse.Whencutting

grasslongerthan15cm(6inches)tall,youmaywant

tocutthelawntwicetoensureanacceptablequality

ofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

MowerClean

Cleanclippingsanddirtfromtheundersideofthe

moweraftereachuse.Ifgrassanddirtbuildupinside

themower,cuttingqualitywilleventuallybecome

unsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

30

Page 31

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

g036849

g008948

Figure33

1.ONposition2.OFFposition

Usingthe

Drive-Wheel-Release

UsingtheFuel-Shutoff Valve

Thefuel-shutoffvalveislocatedbehindtheseat.

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage.

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Valves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,

whichcouldresultinseriousinjury.

Shutofftheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheel-releasevalves.

WARNING

Theengineandhydraulic-driveunitscan

becomeveryhot.Touchingahotengineor

hydraulic-driveunitscancausesevereburns.

Allowtheengineandhydraulic-driveunits

tocoolcompletelybeforeaccessingthe

drive-wheel-releasevalves.

Thedrive-wheel-releasevalvesarelocatedontheleft

andrightsidesunderneaththeenginedeck.

1.Disengagetheblade-controlswitch(PTO),turn

theignitionkeytooff,movetheleverstothe

31

Page 32

NEUTRAL-LOCKposition,applytheparkingbrake,

andremovethekey.

2.Locatethebypassleversbehindtheseat,down

ontheleftandrightsideoftheframe.

3.T opushthemachine,movebothbypassknobs

rearwardandlockthemintoplace(Figure34).

4.Disengagetheparkingbrakebeforepushing

themachine.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey ,setthe

brake,andclosethefuelvalve.

5.Usethemetaltie-downloopsonthemachineto

securelyfastentheittothetrailerortruckwith

straps,chains,cable,orropes(Figure35).

Figure34

1.Frontofthemachine

2.Rotatebypassreleaseknobcounterclockwisetoloosen.

3.Leverpositionforoperatingthemachine

4.Pulltheleverinthisdirectiontopushthemachine.

5.Leverpositionforpushingthemachine

6.Rotatethebypass-releaseknobclockwisetotighten.

7.Engine

8.Releaselever

5.T orunthemachine,movethebypassknobsto

theFORWARDpositionandlockthemintoplace

(Figure34).

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Ensurethatthetrailerortruckhasall

necessarybrakes,lighting,andmarkingasrequired

bylaw.Pleasecarefullyreadallthesafetyinstructions.

Knowingthisinformationcouldhelpyou,yourfamily,

pets,orbystandersavoidinjury.

g035062

g036851

Figure35

1.Tie-downloops

32

Page 33

LoadingtheMachine

WARNING

Useextremecautionwhenloadingorunloadingthe

machineontoatraileroratruck.Useafull-widthramp

thatiswiderthanthemachineforthisprocedure.

Backthemachineuptherampsanddriveitforward

downtheramps(Figure36).

Figure36

1.Backthemachineupthe

ramps.

2.Drivethemachineforward

downtheramps.

Important:Donotusenarrowindividualramps

foreachsideofthemachine.

Ensurethattherampislongenoughsothattheangle

withthegrounddoesnotexceed15degrees(Figure

37).Onatground,thisrequiresaramptobeatleast

4timesaslongastheheightofthetrailerortruckbed

totheground.Asteeperanglemaycausemower

componentstogetcaughtasthemachinemovesfrom

theramptothetrailerortruck.Steeperanglesmay

alsocausethemachinetotiporlosecontrol.Ifyou

areloadingthemachineonornearaslope,position

thetrailerortrucksothatitisonthedownsideof

theslopeandtherampextendsuptheslope.This

minimizestherampangle.

Loadingamachineontoatrailerortruck

increasesthepossibilityofatip-overand

couldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•EnsurethattheROPSisintheupposition

andusetheseatbeltwhenloadingor

unloadingthemachine.Ensurethatthe

ROPSclearsthetopofanenclosedtrailer.

•Useonlyafull-widthramp;donotuse

g028043

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

rampangledoesnotexceed15degreeson

atground.

•Backthemachineuptherampsanddrive

itforwarddowntheramps.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampasthis

couldcausealossofcontroloratip-over.

33

Page 34

Figure37

g027996

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Therampisatleast4

timesaslongastheheight

ofthetrailerortruckbed

totheground.

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

34

Page 35

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Aftertherst75hours

Beforeeachuseordaily

Every25hours

Every50hours

MaintenanceProcedure

•ForToroengines—changetheengineoilandlter.

•Changethehydraulic-systemltersanduid.

•Checkthesafety-interlocksystem.

•ForKawasakiengines—checktheengine-oillevel.

•ForKohlerengines—checktheaircleanerfordirty,looseordamagedparts.

•ForKohlerengines—checktheengine-oillevel.

•Cleantheblowerhousing(moreoftenunderdusty,dirtyconditions).

•ForToroengines—checktheengine-oillevel.

•Checktheseatbelt.

•Checktherollover-protection-system(ROPS)knobs.

•Cleantheenginescreenandtheareaaroundtheengine.

•Cleanaroundtheengine-exhaustsystem.

•Checkthehydraulicuidlevelintheexpansiontank.

•Inspecttheblades.

•Cleanthemowerdeck.

•For1500and2000Seriesmachines—Greasethefrontcasteraxles.(moreoftenin

dirtyordustyconditions).

•ForKohlerengines—serviceorreplacetheair-cleanerfoamelement(moreoften

underdusty,dirtyconditions).

•ForToroengines—cleantheair-cleanerfoamelement(moreoftenindusty,dirty

conditions).

•For2500Seriesmachines—Greasethemowerdeck-idlerpivot.

•Greasethepump-idlerpivot.

•Checksparkarrester(ifequipped).

•Checkthetirepressure.

•Inspectthebeltsforcracksandwear.

Every100hours

Every200hours

•ForKawasakiengines—changetheengineoil(moreoftenindirtyordusty

conditions).

•ForKawasakiengines—replaceorcleanandgapthesparkplug.

•ForKohlerengines—replacetheair-cleanerpaperelement(moreoftenunderdusty ,

dirtyconditions).

•ForKohlerengines—changetheengineoilandtheengine-oillter.

•ForKohlerengines—cleanthecoolingns(moreoftenunderdusty,dirtyconditions).

•ForToroengines—replacetheair-cleanerfoamelement(moreoftenindusty,

dirtyconditions).

•ForToroengines—servicetheair-cleanerpaperelement(moreoftenindusty ,

dirtyconditions).

•ForToroengines—changetheengineoilandoillter(moreoftenindusty,dirty

conditions).

•ForToroengines—checkthesparkplug(s).

•ForKawasakiengines—changetheengine-oillter(moreoftenindirtyordusty

conditions).

•ForKohlerengines—checkthesparkplug(s).

•ForToroengines—replacetheair-cleanerpaperelement(moreoftenindusty,

dirtyconditions).

•ForToroengines—replacethesparkplug(s).

35

Page 36

MaintenanceService

Every250hours

Interval

MaintenanceProcedure

•ForKawasakiengines—replacetheprimaryairlter(moreoftenindustyorsandy

conditions).

•ForKawasakiengines—checkthesafetyairlter.

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Mobil115W50uid(changeitmoreoftenundersevereconditions).

Every300hours

Every500hours

Monthly

Yearly

Yearlyorbeforestorage

•ForKawasakiengines—Checkandadjustthevalveclearance.SeeanAuthorized

ServiceDealer.

•ForKawasakiengines—replacethesafetyairlter.

•ForKohlerengines—Checkandadjustthevalveclearance.SeeanAuthorized

ServiceDealer.

•ForKohlerengines—replacethesparkplug(s).

•Replacetheemissions-airintakelter.

•Replacethefuellter(moreoftenindusty,dirtyconditions).

•Checktheparkingbrakeadjustment.

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Toro®HYPR-OIL™500oil(changeitmoreoftenundersevereconditions).

•Checkthebatterycharge.

•For2500Seriesmachines—Lubricatethecaster-wheelhubs.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineand

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

36

Page 37

Pre-Maintenance

Procedures

MaintenanceandStorage

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Settheparkingbrake.

–Shutofftheengineandremovethekey.

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Lettheenginecoolbeforestoringthemachine.

•Donotstorethemachineorfuelnearamesordrainthefuelindoors.

•Donotallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportthemachineand/orcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstoredenergy.

•Disconnectthebatteryorremovethespark-plugwirebeforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositiveterminallast.Connectthepositiveterminalrstandnegativelast.

•Usecarewhencheckingtheblades.Wraptheblade(s)orwearthicklypaddedgloves,andusecaution

whenservicingthem.Onlyreplaceblades;donotstraightenorweldthem.

•Keephandsandfeetawayfrommovingparts.Ifpossible,donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardwaretightened,especiallytheblade-attachmentbolts.

Replaceallwornordamageddecals.

•Neverinterferewiththeintendedfunctionofasafetydeviceorreducetheprotectionprovidedbyasafety

device.Checktheirproperoperationregularly.

•Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidtheproductwarranty.

•Checktheparkingbrakeoperationfrequently.Adjustandserviceasrequired.

37

Page 38

Lubrication

GreasingtheMachine

Greasemorefrequentlywhenoperatingconditions

areextremelydustyorsandy.

GreaseType:No.2lithiumormolybdenumgrease

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthe

frontofthetting(s).

4.Connectagreaseguntothetting,andpump

greaseintothettings.

5.Wipeupanyexcessgrease.

ServiceInterval:Every25hours—For1500and

2000Seriesmachines—Greasethe

frontcasteraxles.(moreoftenin

dirtyordustyconditions).

Every50hours—For2500Series

machines—Greasethemowerdeck-idler

pivot.

Every50hours—Greasethepump-idlerpivot.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Greasethemowerdeckandpumpidler-pulley

pivotwith1or2pumpsofgrease(Figure38).

4.For1500and2000Seriesmachines,greasethe

frontcasteraxles(Figure38).

Figure38

1.Pump-idlerpivot3.Mowerdeckidler-pulley

pivot(2500Series

machinesonly)

2.Casteraxle(1500and

2000Seriesmachines

only)

g037570

38

Page 39

Lubricatingthe Caster-WheelHubs

2500SeriesMachinesOnly

ServiceInterval:Yearly—For2500Series

machines—Lubricatethe

caster-wheelhubs.

1.Shutofftheengine,waitforallmovingpartsto

stop,removethekey ,andengagetheparking

brake.

Figure39

1.Sealguard2.Spacernutwithwrench

ats

11.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

12.Insertthesecondbearingandnewsealintothe

wheel.

13.Applyathread-lockingcompoundtothesecond

spacernutandthreaditontotheaxlewiththe

wrenchatsfacingoutward.

14.T orquethenutto8to9N∙m(75to80in-lb),

loosenthenut,thentorqueitto2to3N∙m(20

to25in-lb).

Note:Makesurethattheaxledoesnotextend

beyondeithernut.

15.Installthesealguardsoverthewheelhuband

insertwheelintothecasterfork.

16.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

g006115

castertire.Thetireshouldnotspinfreely(more

than1or2revolutions)orhaveanysideplay.If

thewheelspinsfreely,adjustthetorqueonthe

spacernutuntilthereisaslightamountofdrag.

Applyanotherlayerofthread-lockingcompound.

2.Removethecasterwheelfromthecasterforks.

3.Removethesealguardsfromthewheelhub.

4.Removeaspacernutfromtheaxleassemblyin

thecasterwheel.

Note:Thread-lockingcompoundhasbeen

appliedtolockthespacernutstotheaxle.

5.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

6.Pryoutsealsandinspectbearingsforwearor

damageandreplaceifnecessary.

7.Packthebearingswithageneral-purpose

grease.

8.Insert1bearingand1newsealintothewheel.

Note:Replacetheseals.

9.Ifbothspacernutshavebeenremoved(or

brokenloose)fromtheaxleassembly,applya

thread-lockingcompoundto1spacernutand

threaditontotheaxlewiththewrenchats

facingoutward.

Note:Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

10.Inserttheassemblednutandaxleintothewheel

onthesidewiththenewsealandbearing.

39

Page 40

EngineMaintenance

Usethefollowinggraphictoidentifytheengineyouhaveandproceedtothesectionlistedbelowforservice

(Figure40).

Figure40

1.Kawasakiengine2.Kohlerengine3.Toroengine

g036852

•ForKawasakienginemaintenance,referto

ServicingaKawasaki

®

Engine(page41).

•ForKohlerenginemaintenance,refertoServicing

aKohler

®

Engine(page46).

•ForToroenginemaintenance,refertoServicinga

ToroEngine(page50).

WARNING

Contactwithhotsurfacesmaycausepersonalinjury.

Keepyourhands,feet,face,clothingandotherbodypartsawaythemuferandotherhot

surfaces.

EngineSafety

Shutofftheenginebeforecheckingtheoiloradding

oiltothecrankcase.

40

Page 41

ServicingaKawasaki

®

Engine

ThissectionisonlyformachineswithKawasaki

engines.Ifyourenginelooksliketheoneshownin

Figure41,youhaveaKawasakiengine.

Important:Refertoyourenginemanufacturer’s

informationforadditionalmaintenance

procedures.

Figure41

g001883

Figure42

1.Air-cleanerbody4.Air-cleanercover

2.Primarylter5.Safetylter

3.Latch

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure42).

g036714

Note:Avoidknockingthelterintothesideof

thebody.

ServicingtheAirCleaner

ServiceInterval:Every250hours—ForKawasaki

engines—replacetheprimaryair

lter(moreoftenindustyorsandy

conditions).

Every250hours—ForKawasaki

engines—checkthesafetyairlter.

Every500hours—ForKawasaki

engines—replacethesafetyairlter.

Note:Checktheltersmorefrequentlyifthe

operatingconditionsareextremelydustyorsandy .

RemovingtheFilters

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure42).

41

Page 42

6.Removethesafetylteronlyifyouintendto

replaceit.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty,then

theprimarylterisdamaged.Replaceboth

lters.

7.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.

Note:Holesinthelterappearasbrightspots.

Ifthelterisdamaged,discardit.

ServicingthePrimaryFilter

•Iftheprimarylterisdirty,bent,ordamaged,

replaceit.

•Donotcleantheprimarylter.

Viscosity:Seethetablebelow.

g037096

Figure43

ServicingtheSafetyFilter

Replacethesafetylter,nevercleanit.

Important:Donotattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamaged.Replacebothlters.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifinstallingnewlters,checkeachlterfor

shippingdamage.

Note:Donotuseadamagedlter.

2.Ifyouarereplacingthesafetylter,carefully

slideitintothelterbody(Figure42).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure42).

Note:Ensurethattheprimarylterisfully

seatedbypushingonitsouterrimwhileinstalling

it.

Important:Donotpressonthesoftinside

areaofthelter.

4.Installtheair-cleanercoverwiththeside

indicatedasupfacingupwardandsecurethe

latches(Figure42).

ServicingtheEngineOil

Note:Although10W-40engineoilisrecommended

formostconditions,youmayneedtochangeoil

viscositytoaccommodateatmosphericconditions.

Using20W-50engineoilinhigherambient

temperaturescanreduceoilconsumption.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothing,andother

bodypartsawayfromthemuferandother

hotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausethatcoulddamageengine.Donotrun

enginewithoilbelowtheLowmarkbecausethe

enginemaybedamaged.

1.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure44).

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

CrankcaseCapacity:withalterchange,2.1L(71

oz);withoutalterchange,1.8L(61oz)

42

Page 43

ChangingtheEngineOil

ServiceInterval:Every100hours(moreoftenindirty

ordustyconditions).

Note:Disposeoftheusedoilatarecyclingcenter.

1.Starttheengineandletitrunfor5minutes.

g036856

2.Parkthemachinesothattherearisslightly

lowerthanthefronttoensurethattheoildrains

completely.

3.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

4.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition(Figure45).

g036856

Note:Thiswarmstheoilsothatitdrainsbetter.

Figure44

g225269

g225280

Figure45

43

Page 44

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

46).

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours—ForKawasaki

engines—changetheengine-oil

lter(moreoftenindirtyordusty

conditions).

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page43).

2.Changetheengine-oillter(Figure47).

g036856

Figure46

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

g027660

g027477

Figure47

Note:Ensurethattheoil-ltergaskettouches

theengine,andthenturntheoillteranextra

3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoServicingtheEngineOil(page42).

44

Page 45

ServicingtheSparkPlug

CheckingtheSparkPlug

ServiceInterval:Every100hours

Makesurethattheairgapbetweenthecenterand

sideelectrodesiscorrectbeforeinstallingthespark

plug.Useasparkplugwrenchforremovingand

installingthesparkplug(s)andagappingtool/feeler

gaugetocheckandadjusttheairgap.Installanew

sparkplug(s)ifnecessary.

TypeofSparkPlug:NGK

®

BPR4ESorequivalent

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

2.Disengagetheblade-controlswitch(PTO),move

themotion-controlleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

3.Locateandremovethesparkplugs(Figure48).

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithas:a

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.76mm(0.03inch).

g027479

Figure49

InstallingtheSparkPlug

Figure48

Tightenthesparkplug(s)to22N∙m(16ft-lb).

g036857

g027478

g027735

Figure50

45

Page 46

ServicingaKohler

ThissectionisonlyformachineswithKohlerengines.

IfyourenginelooksliketheoneshowninFigure51,

youhaveaKohlerengine.

®

Engine

Important:Refertoyourenginemanufacturer’s

informationforadditionalmaintenance

procedures.

Figure51

2.Removethecovertoaccesstheair-cleaner

elements(Figure52).

g028105

Figure52

1.Air-cleanercover2.Air-cleanerlatch

3.Removethefoamandpaperelements(Figure

g036713

53).

4.Removethefoamelementfromthepaper

element(Figure53).

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—For

Kohlerengines—checktheair

cleanerfordirty ,looseordamaged

parts.

Every25hours—ForKohlerengines—service

orreplacetheair-cleanerfoamelement(more

oftenunderdusty ,dirtyconditions).

Every100hours—ForKohlerengines—replace

theair-cleanerpaperelement(moreoftenunder

dusty,dirtyconditions).

Thisengineisequippedwithareplaceable,

high-densitypaperandfoamair-cleanerelement.

Checktheaircleanerdailyorbeforestartingthe

engine.Checkforabuildupofdirtanddebrisaround

theair-cleanersystem.Keepthisareaclean.Also,

checkforlooseordamagedcomponents.Replaceall

bentordamagedair-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairinto

theengine,causingprematurewearandfailure.

g028106

Figure53

1.Air-cleanercover3.Paperelement

2.Foamelement

ServicingtheFoamElement

1.Washthefoamelementinwarmwaterand

detergent.

2.Rinseandallowittoairdry.

3.Lightlyoilthefoamelementwithnewoiland

squeezeoutexcessoil.

Note:Servicetheaircleanermoreoftenunderdusty,

dirtyconditions.

RemovingtheElements

1.Rotatethelatchesoutward.

ServicingthePaperElement