Page 1

FormNo.3400-855RevA

TITAN

®

MX4800,MX5400,or

MX6000Zero-Turn-RadiusRiding

Mower

ModelNo.74891—SerialNo.316000001andUp

ModelNo.74892—SerialNo.316000001andUp

ModelNo.74893—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3400-855*A

Page 2

WARNING

1

g0281 11

Introduction

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

ThissparkignitionsystemcomplieswithCanadianICES-002

Theenclosedengineowner'smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

Thismachineisaride-on,rotary-bladelawnmowerintended

tobeusedbyhomeownersinresidentialapplications.Itis

primarilydesignedforcuttinggrassonwell-maintainedlawns.

Itisnotdesignedforcuttingbrush,mowinggrassandother

growthalongsidehighways,orforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

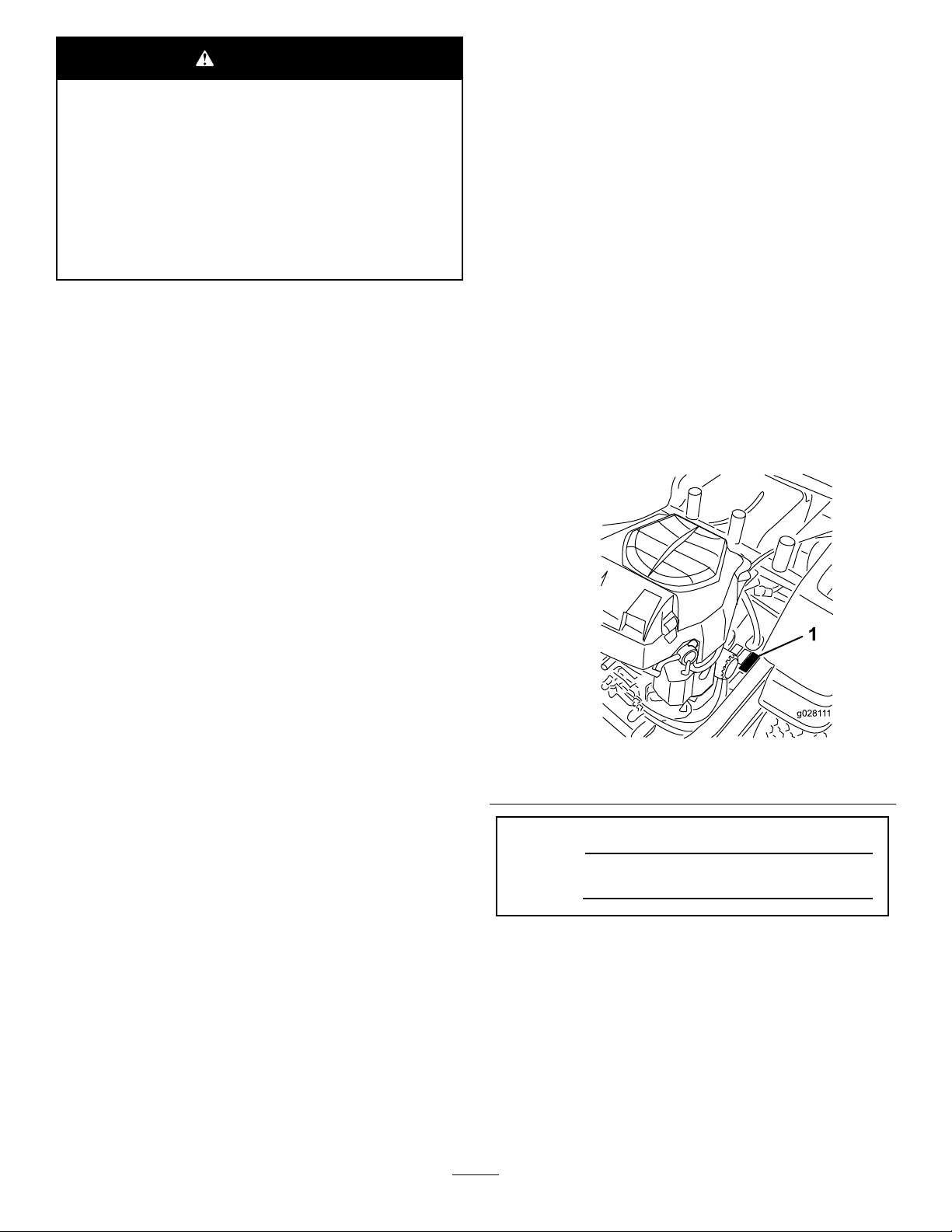

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratorytestedbytheengine

manufacturerinaccordancewithSAEJ1995andratedto

J2723.

Figure1

1.Modelandserial-numberlocation

ModelNo.

SerialNo.

©2015—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SlopeIndicator.......................................................7

SafetyandInstructionalDecals.................................8

ProductOverview.........................................................13

Controls...............................................................13

Operation....................................................................15

AddingFuel...........................................................15

ThinkSafetyFirst...................................................16

UsingtheRolloverProtectionSystem(ROPS)............17

UnderstandingtheSafety-InterlockSystem................17

TestingtheSafety-InterlockSystem...........................17

CheckingtheEngine-OilLevel.................................18

BreakinginaNewMachine......................................18

OperatingtheParkingBrake....................................18

OperatingtheThrottle............................................18

OperatingtheChoke...............................................18

OperatingtheIgnitionSwitch..................................19

StartingandStoppingtheEngine..............................19

OperatingtheBlade-ControlSwitch(PTO)................20

DrivingtheMachine...............................................20

StoppingtheMachine.............................................22

AdjustingtheHeightofCut.....................................22

AdjustingtheAnti-ScalpRollers...............................23

PositioningtheSeat................................................23

ChangingtheSeatSuspension..................................23

AdjustingtheMotion-ControlLevers........................24

PushingtheMachinebyHand..................................24

UsingtheSideDischarge.........................................25

TransportingtheMachine........................................25

LoadingtheMachine..............................................25

OperatingTips......................................................27

Maintenance.................................................................28

RecommendedMaintenanceSchedule(s)......................28

PremaintenanceProcedures........................................29

Service-IntervalChart.............................................29

RaisingtheSeat......................................................29

Lubrication...............................................................29

GreasingtheBearings.............................................29

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

ServicingtheSparkPlug..........................................33

CleaningtheBlowerHousing...................................34

FuelSystemMaintenance...........................................34

ReplacingtheFuelFilter..........................................34

ElectricalSystemMaintenance....................................35

ServicingtheBattery...............................................35

ServicingtheFuses.................................................36

DriveSystemMaintenance.........................................37

CheckingtheTirePressure......................................37

HydraulicSystemMaintenance....................................38

CheckingtheHydraulic-FluidLevel..........................38

ChangingtheHydraulicFilterandFluid.....................38

MowerDeckMaintenance...........................................40

ServicingtheCuttingBlades.....................................40

3

Page 4

LevelingtheMowerDeck........................................42

InspectingtheBelts................................................44

ReplacingtheMowerBelt........................................44

RemovingtheMower..............................................45

InstallingtheMowerDeck.......................................46

ReplacingtheGrassDeector..................................46

Cleaning...................................................................47

WashingtheUndersideoftheMower........................47

DisposingofWaste.................................................48

Storage........................................................................48

CleaningandStorage..............................................48

Troubleshooting...........................................................50

Schematics...................................................................52

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCaution,Warning,or

Danger—personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryor

death.

Thisproductiscapableofamputatinghandsandfeetand

throwingobjects.Alwaysfollowallsafetyinstructionsto

avoidseriousinjuryordeath.

Thisproductisdesignedforcuttingandrecyclinggrassor,

whenequippedwithagrassbagger,forcatchingcutgrass.

Anyuseforpurposesotherthanthesecouldprovedangerous

touserandbystanders.

SafeOperatingPractices

ThefollowinginstructionsareadaptedfromANSIstandard

B71.4-2012.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglishitis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtopeopleordamageto

property.

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Wearappropriateclothingincludingsubstantial

slip-resistantfootwear,ahardhat,eyeprotection,and

hearingprotection.Tiebacklonghair.Donotwear

jewelry.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toysandwirewhichcan

bethrownbythemachine.

•Checkthatoperator-presencecontrols,safetyswitches

andshieldsareattachedandfunctioningproperly.Donot

operatethemachineunlesstheyarefunctioningproperly.

4

Page 5

Operation

Rollover-ProtectionSystem(ROPS)

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•EnsurethatalldrivesareinNEUTRALandthatthe

parkingbrakeisengagedbeforestartingengine.Startthe

engineonlyfromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelsidetosideonhillsides.Turfconditionscanaffect

themachine'sstability.Usecautionwhileoperatingnear

drop-offs.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neverraisethedeckwiththebladesrunning.

•NeveroperatewiththePTOshield,orotherguardsnot

securelyinplace.Ensurethatallinterlocksareattached,

adjustedproperly ,andfunctioningproperly .

•Neveroperatewiththedischargedeectorraised,

removedoraltered,unlessusingagrasscatcher.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,disengagethedrives,engagethe

parkingbrake(ifprovided),shutofftheenginebefore

leavingtheoperator'spositionforanyreasonincluding

emptyingthecatchersoruncloggingthechute.

•Stopequipmentandinspectbladesafterstrikingobjects

orifanabnormalvibrationoccurs.Makenecessary

repairsbeforeresumingoperations.

•Keephandsandfeetawayfromthecuttingunit.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Keeppetsandbystandersaway .

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.Stopthebladesifyouare

notmowing.

•Beawareofthemowerdischargedirectionanddonot

pointitatanyone.

•Donotoperatethemowerwhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachineinto

orfromatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•DonotremovetheROPS.

•TheROPSisanintegralandeffectivesafetydevice.Keep

theROPSonthemachineandusetheseatbeltwhen

operatingthemachine.

•Becertainthattheseatbeltcanbereleasedquicklyin

theeventofanemergency.

•Checktheareatobemowedwherethereareslopes,

dropoffs,orwater.

•Carefullycheckforoverheadclearances(i.e.,branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•KeeptheROPSinsafeoperatingconditionby

periodicallythoroughlyinspectingfordamageand

keepingallmountingfastenerstight.

•ReplaceadamagedROPS.Donotrepairorrevise.

•AnyalterationstoaROPSmustbeapprovedbythe

manufacturer.

SafeHandlingofFuel

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlinggasoline.Gasolineisextremely

ammableandthevaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andothersources

ofignition.

•Useonlyanapprovedfuelcontainer.

•Neverremovefuelcaporaddfuelwiththeengine

running.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwherethereis

anopename,spark,orpilotlightsuchasonawater

heateroronotherappliances.

•Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainerson

thegroundawayfromyourvehiclebeforelling.

•Removeequipmentfromthetruckortrailerandfuelit

ontheground.Ifthisisnotpossible,thenrefuelsuch

equipmentwithaportablecontainerratherthanfroma

fueldispensernozzle.

•Keepthenozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingiscomplete.

Donotuseanozzlelockopendevice.

•Iffuelisspilledonclothing,changeclothingimmediately.

•Neveroverllthefueltank.Replacethefuelcapand

tightenitsecurely.

5

Page 6

MaintenanceandStorage

•Disengagedrives,setparkingbrake,stopengineand

removekeyordisconnectspark-plugwire.Waitforall

movementtostopbeforeadjusting,cleaningorrepairing.

•Cleangrassanddebrisfromcuttingunit,drives,mufers,

andenginetohelppreventres.Cleanupoilorfuel

spillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Shutoffthefuelwhilestoringortransporting.Donot

storefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Settheparkingbrake.

Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovespark-plugwirebefore

makinganyrepairs.Disconnectthenegativeterminalrst

andthepositivelast.Reconnectthepositiverstand

negativelast.

•Usecarewhencheckingblades.Wraptheblade(s)orwear

thickly-paddedgloves,andusecautionwhenservicing

them.Onlyreplaceblades.Neverstraightenorweld

them.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

Hauling

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usefullwidthrampsforloadingmachineintotraileror

truck.Therampangleshouldnotexceed15degrees.

•Tiethemachinedownsecurelyusingstraps,chains,cable,

orropes.Bothfrontandrearstrapsshouldbedirected

downandoutwardfromthemachine.

6

Page 7

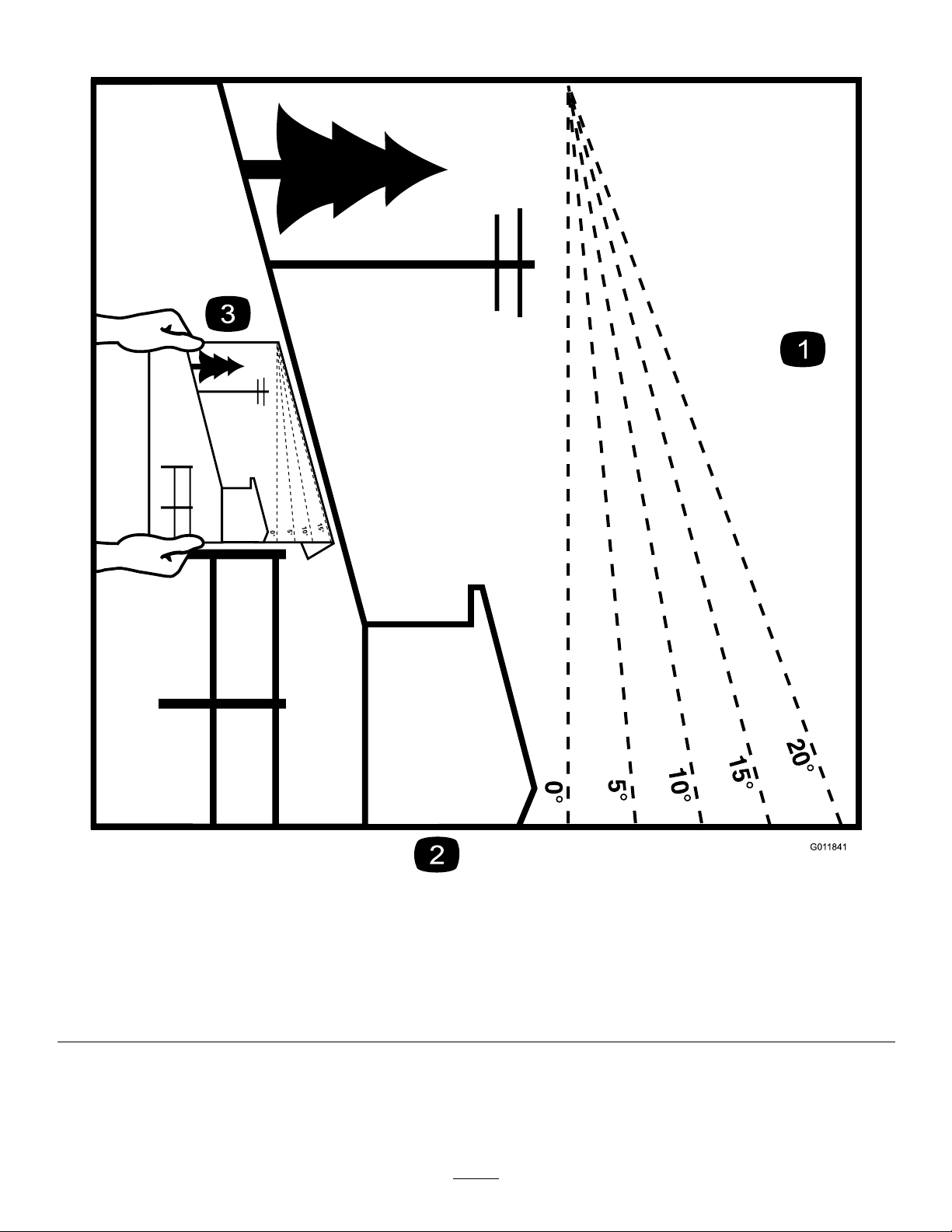

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucansafelyoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslope

ofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

7

Page 8

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

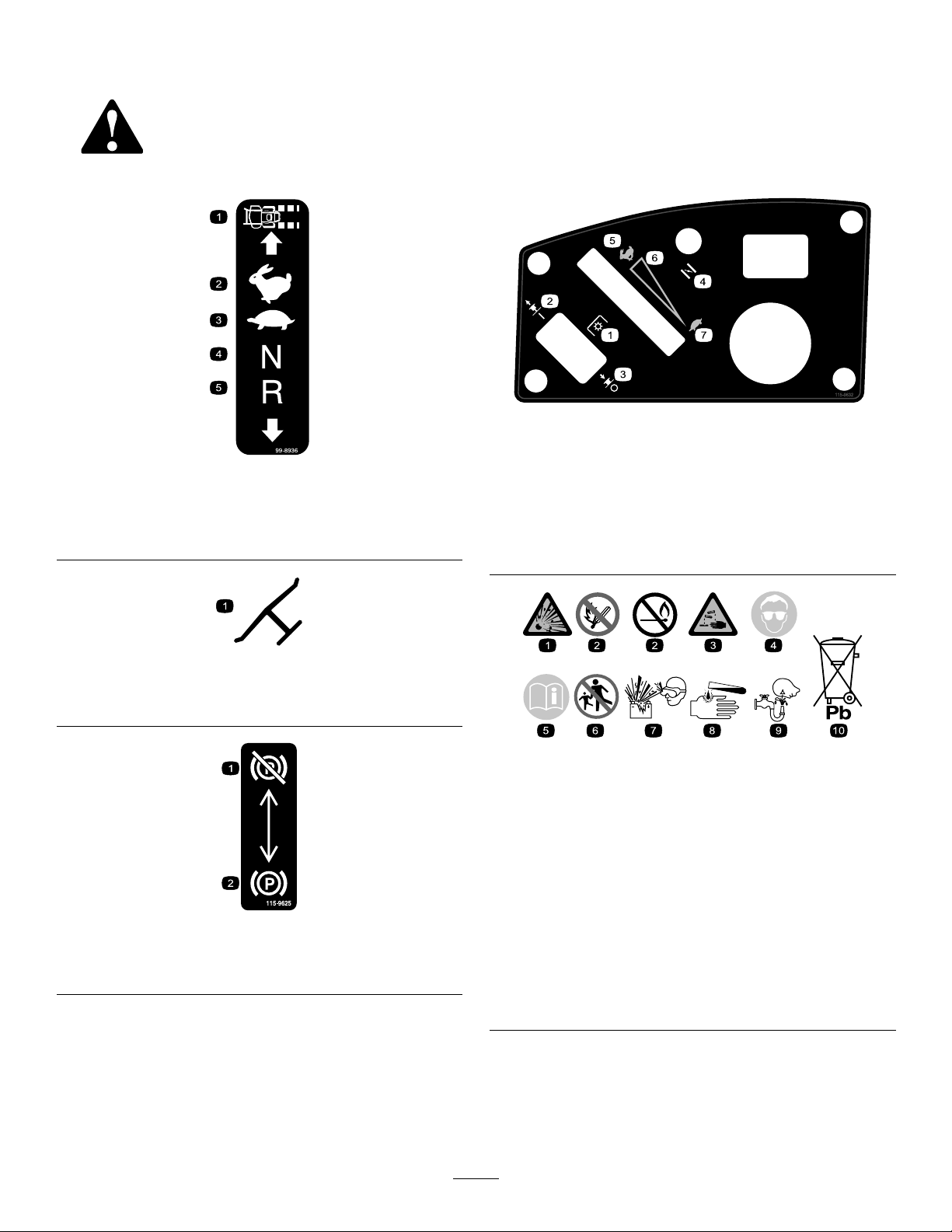

115-9632

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

1.Powertake-off(PTO),

Bladecontrolswitchon

somemodels

2.Bladecontrolswitch—On6.Continuousvariable

3.Bladecontrolswitch—Off7.Slow

4.Choke

5.Fast

setting

BatterySymbols

Someorallofthesesymbolsareonyourbattery

1.Explosionhazard

2.Nore,opename,or

smoking.

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

8

Page 9

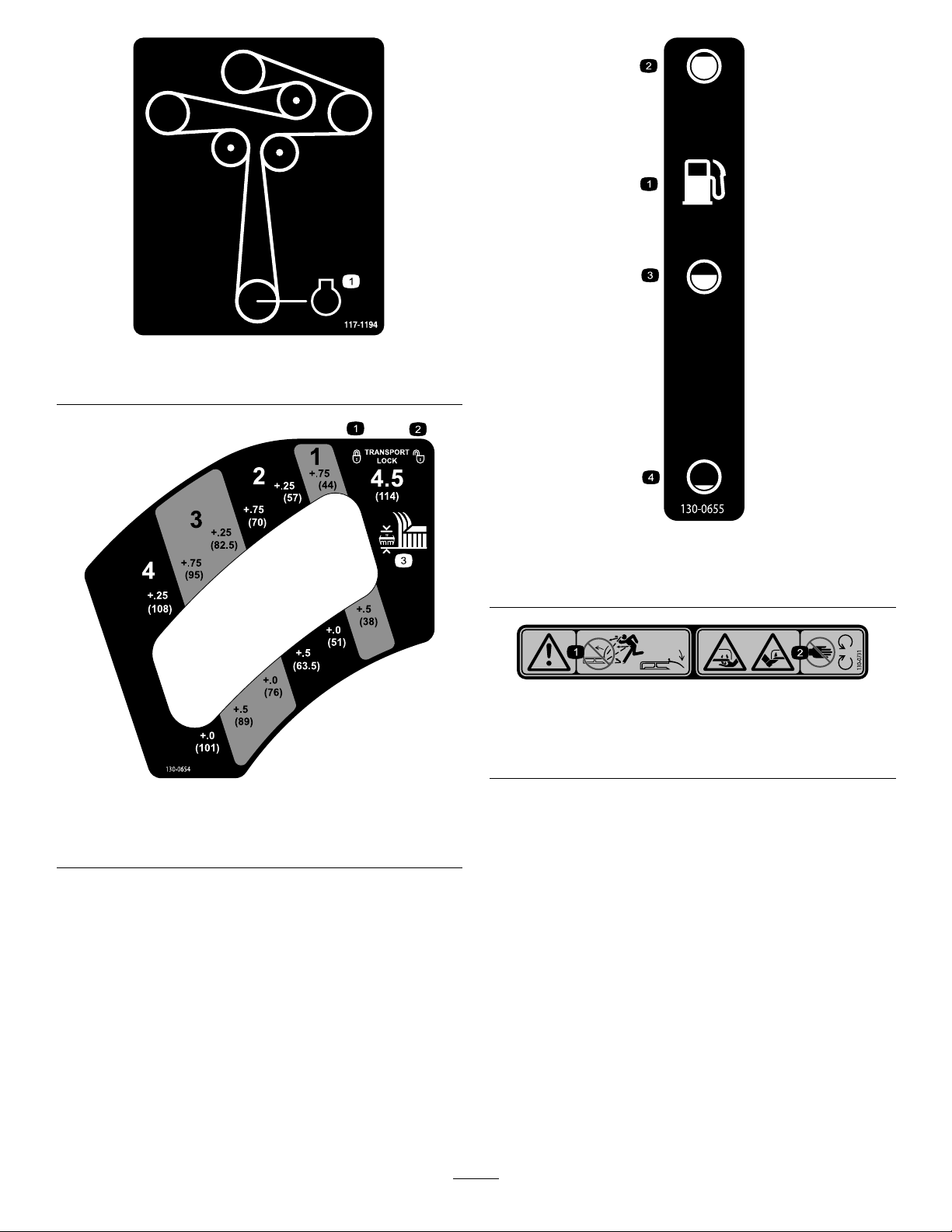

117-1194

1.Engine

130-0655

1.Fueltank

2.Full4.Empty

3.Half

130-0731

1.Warning—thrownobject

hazard;keepthedeector

shieldinplace.

2.Cuttinghazardofhandor

foot,mowerblade—keep

awayfrommovingparts.

130-0654

1.Transport—lock

2.Transport—unlock

3.Height-of-cut

9

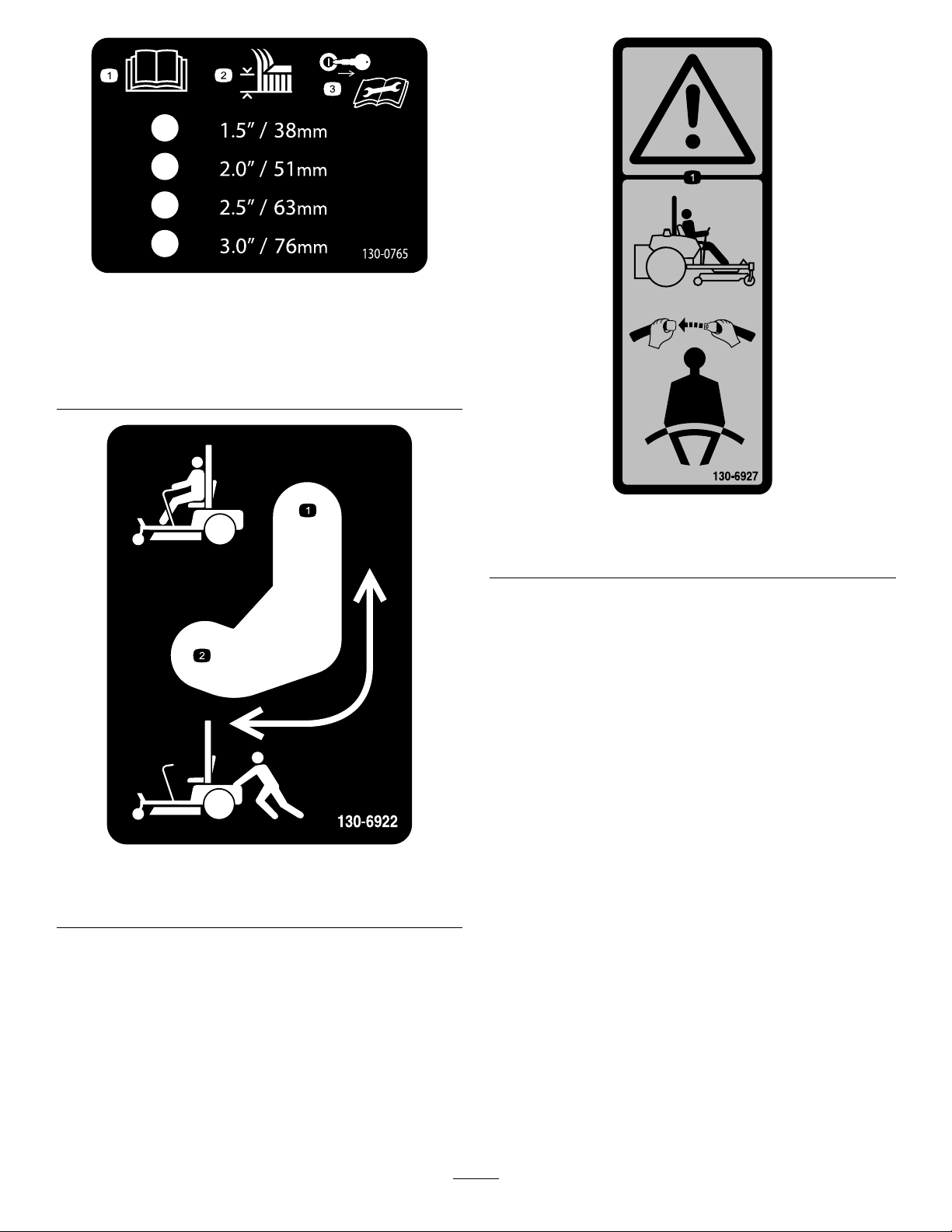

Page 10

130-0765

1.ReadtheOperator's

Manual.

2.Height-of-cutselection

3.Removethekeyfrom

theignitionandreadthe

Operator'sManualbefore

performingmaintenance.

130-6927

1.Warning—alwaysusetheROPSandweartheseatbelt

whenseatedintheoperator'sposition.

1.Bypassleverpositionfor

operatingthemachine.

130-6922

2.Bypassleverpositionfor

pushingthemachine.

10

Page 11

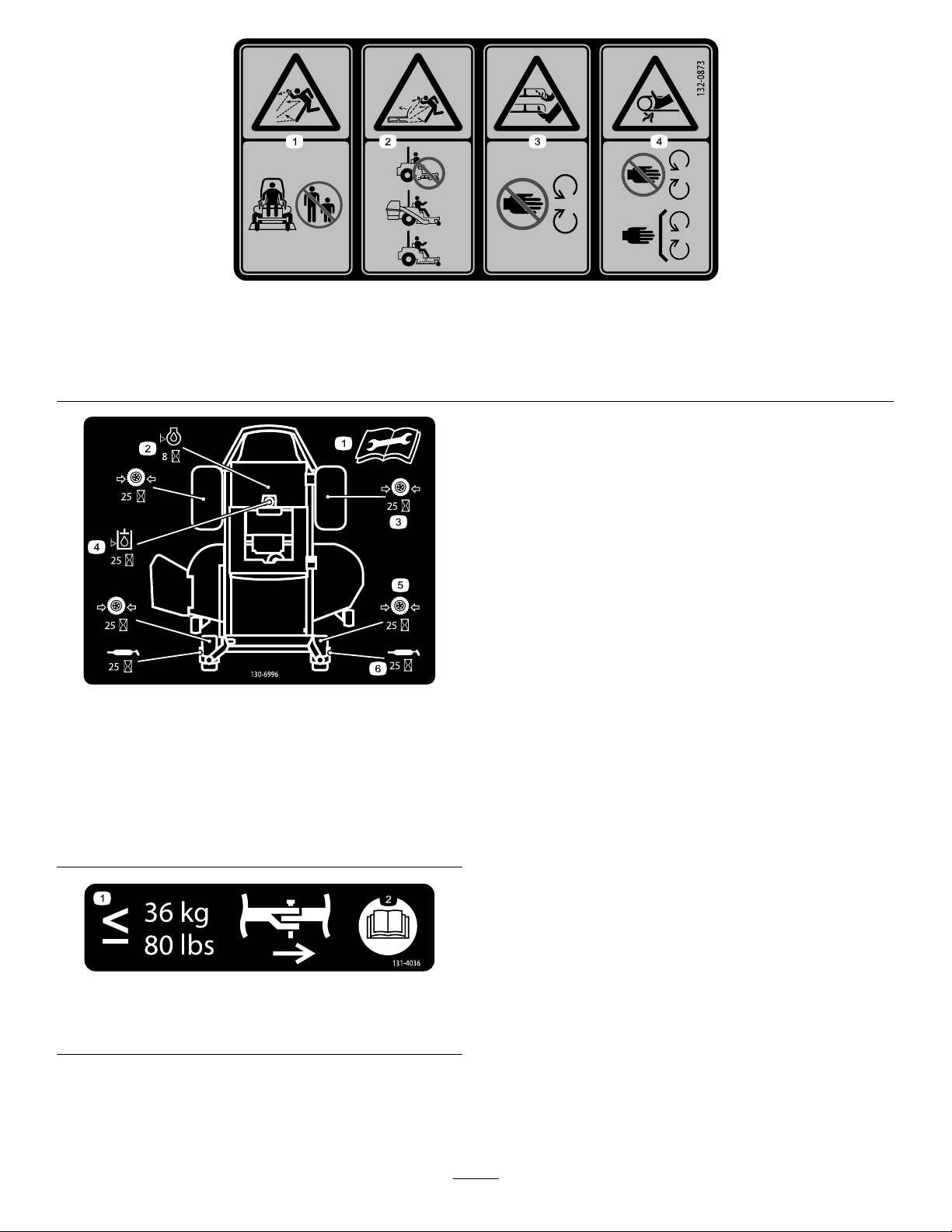

132-0873

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Thrownobjecthazard,mower—donotoperatethewithout

deector,dischargecover,orgrasscollectionsysteminplace.

130-6996

1.ReadtheOperator's

Manualforinformationon

maintenance.

2.Checktheengineoilevery

8hours.

3.Checkthedrivewheeltire

pressureevery25hours.

4.Checkthehydraulicuid

every25hours.

5.Checkthecasterwheel

tirepressureevery25

hours.

6.Lubricatethecasterwheel

every25hours.

3.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

4.Entanglementhazard,belt—keepallguardsinplace.

1.Maximumdrawbarpull80

lbs(36kg)

131-4036

2.ReadtheOperator's

Manual.

11

Page 12

132–0871

1.Warning—readtheOperator’sManual;donotoperatethis

vehicleunlessyouaretrained;wearhearingprotection.

2.Cuttingandpinchinghazard—keephandsandfeetawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Thrownobjecthazard—keepbystandersaway .6.Tippinghazardonslopes—donotuseonslopesnearopen

4.Ramphazard—whenloadingontoatrailer,donotusedual

ramps;onlyuseasingularrampwideenoughforthemachine;

backuptheramp(inreverse)anddriveforwardofftheramp.

5.Bodilyharmhazard—lookbehindyouwhenmowingin

reverse.

water;donotuseonslopesgreaterthan15degrees.

12

Page 13

ProductOverview

Figure4

1.Drivewheel4.Motion-controllevers7.Frontcasterwheel

2.Operatorseat

3.RolloverProtectionSystem

(ROPS)

5.Parkingbrake8.Anti-scalproller

6.Footrest

9.Footpedaldeckliftand

heightofcut

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine(Figure5).

10.Deector

Figure5

1.Throttlecontrol4.Ignitionswitch

2.Choke

3.Hourmeter

13

5.Blade-controlswitch

(PTO)

Page 14

IgnitionSwitch

g020264

1

Motion-ControlLevers

Theignitionswitchhas3positions:START,RUN,andOFF..

ThekeywillturntotheSTARTpositionandmovebackto

theRUNpositionuponrelease.TurningthekeytotheOFF

positionshutsofftheengine;however,alwaysremovethe

keywhenleavingthemachinetopreventtheenginefrom

accidentallystarting(Figure5).

ThrottleControl

ThethrottlecontrolisvariablebetweentheFASTandSLOW

position.Movingthrottleleverforwardincreasesengine

speedandmovingthrottlelevertothereardecreasesengine

speed.Movingthethrottleforwardintothedetentisfull

throttle(Figure5).

Choke

Usethechoketostartacoldengine.Pullthechokeknobup

toengageit.Pushdownonthechokeknobtodisengageit.

Blade-ControlSwitch(PowerTakeoff)

Theblade-controlswitchengagesanddisengagespowerto

themowerblades(Figure5).

Themotion-controlleversarespeed-sensitivecontrolsof

independent-wheelmotors.Movingaleverforwardor

backwardturnsthewheelonthesamesideforwardor

inreverse;wheelspeedisproportionaltotheamountthe

leverismoved.Movethecontrolleversoutwardfromthe

centertotheNEUTRAL-LOCKpositionandexitthemachine

(Figure4).Alwayspositionthemotion-controlleversinto

theNEUTRAL-LOCKpositionwhenyoustopthemachine

orleaveitunattended.

Parking-BrakeLever

Theparking-brakeleverislocatedonleftsideoftheconsole

(Figure4).Thebrakeleverengagesaparkingbrakeonthe

drivewheels.Pulltheleverupandrearwardtoengagethe

brake.Pushtheleverforwardanddowntodisengagethe

brake.

FootPedalDeck-LiftSystem

Thefootpedaldeck-liftsystemallowstheoperatortolower

andraisethedeckfromtheseatedposition.Youcanusethe

footpedaltoliftthedeckbrieytoavoidobstaclesorlock

thedeckinthehighestheightofcutortransportposition

(Figure4).

HourMeter

Thehourmeterrecordsthenumberofhourstheblades

operate.Itoperateswhentheblade-controlswitch(PTO)is

engaged.Usethesetimesforschedulingregularmaintenance

(Figure5).

FuelGauge

Thefuelwindowlocatedbelowtheoperatorpositioncanbe

usedtoverifythelevelofgasolineinthetank(Figure6).

Figure6

1.Fuel-gaugewindow

Height-of-CutLever

Theheight-of-cutleverworkswiththefootpedaltolockthe

deckinaspeciccuttingheight.Onlyadjusttheheightofcut

whilemachineisnotmoving(Figure4).

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

14

Page 15

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•Donotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling .

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

WARNING

Gasolineisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgastankor

conditioneropening.

•Keepgasawayfromeyesandskin.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifyoumustagasoline-dispensernozzle,keep

thenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimesuntil

fuelingiscomplete.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachinetoprovide

thefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

15

Page 16

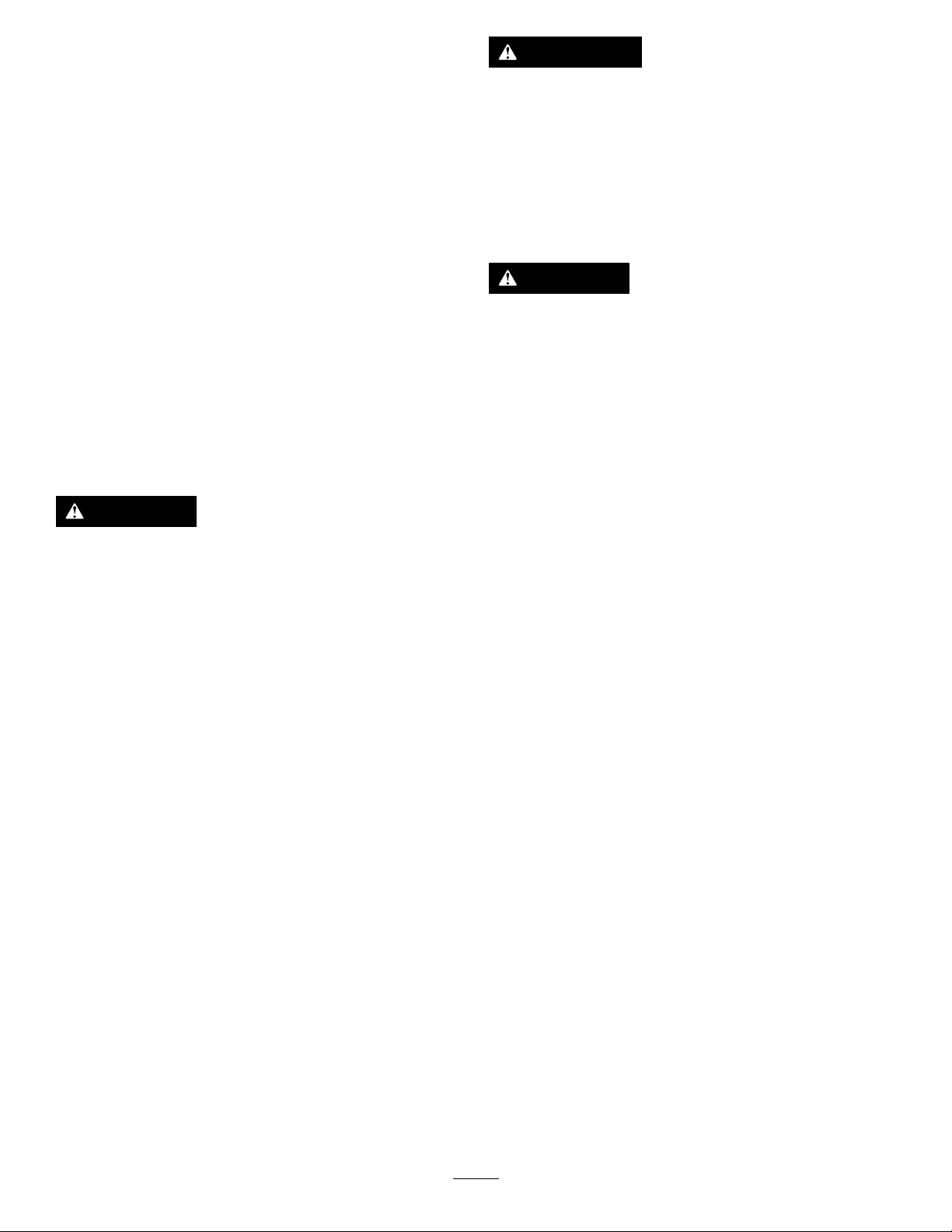

FillingtheFuelTank

B

A

C

D

g027637

Shutofftheengineandmovethemotioncontrolstothe

PARKposition.

Important:Donotoverllfueltank.Fillthefueltank

tothebottomofthellerneck.Theemptyspaceinthe

tankallowsthefueltoexpand.Overllingmayresultin

fuelleakageordamagetotheengineoremissionsystem.

1.Cleanaroundthefuel-tankcapandremovethecap.

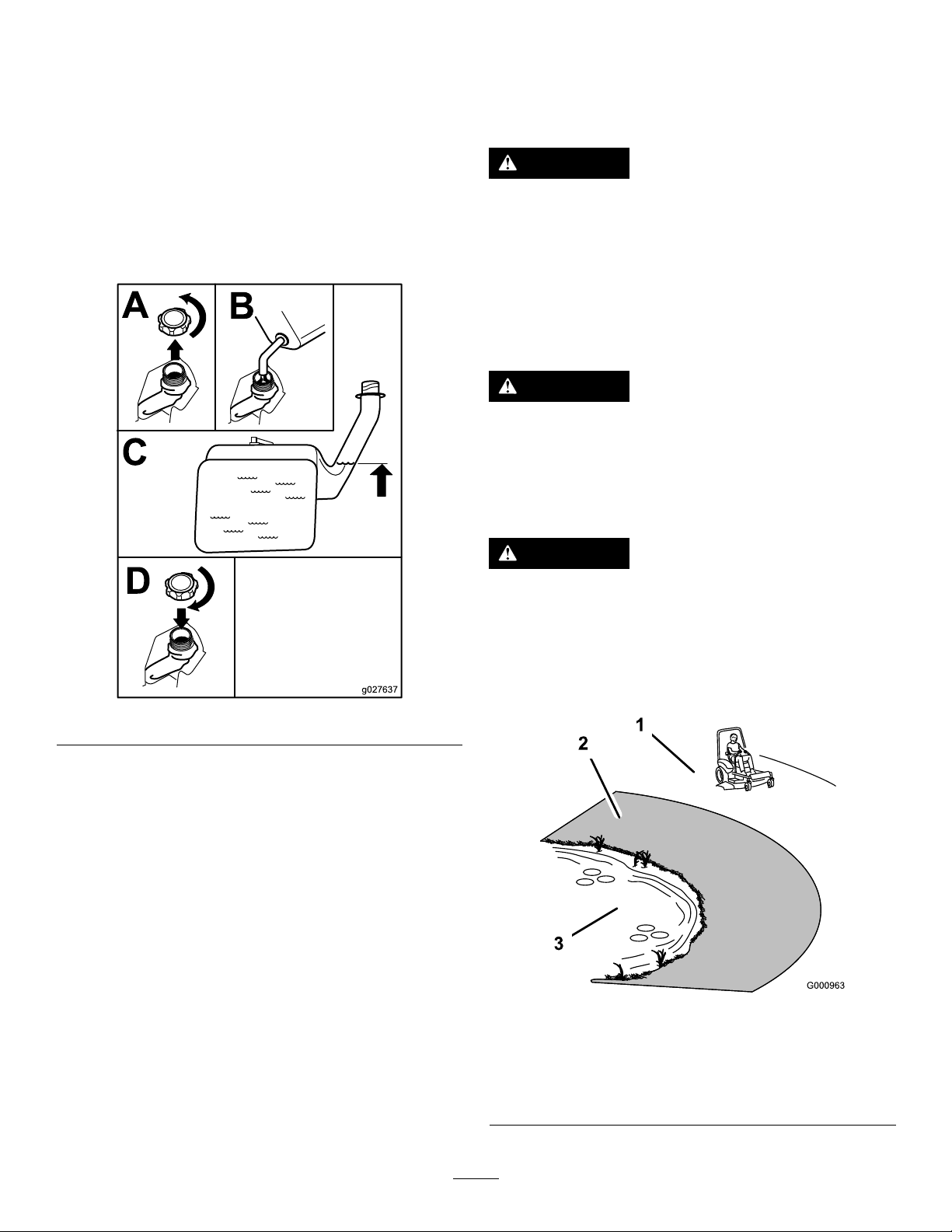

ThinkSafetyFirst

Pleasereadallsafetyinstructionsandsymbolsinthesafety

section.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

DANGER

Operatingthemachineonwetgrassorsteepslopes

cancauseslidingandlossofcontrol.

2.Slowlyaddregular,unleadedgasolineuntilthefuel

reachesthebaseofthellerneckFigure7.

•Donotoperateonslopesgreaterthan15degrees.

•Reducespeedanduseextremecautionon

slopes.

•Donotoperatethemachinenearwater.

DANGER

Wheelsdroppingoveredgescancauserollovers,

whichmayresultinseriousinjury,death,or

drowning.

Donotoperatethemachineneardrop-offs.

DANGER

Operatingthemachinewhiletherollbarisdown

mayleadtoseriousinjuryordeathintheeventofa

rollover.

Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

Figure7

3.Installthefuel-tankcapsecurelyandtightenuntilit

clicks.

Note:Wipeupanygasolinethatmayhavespilled.

1.Safezone—usethe

machinehere.

2.Useawalk-behindmower

and/orhandtrimmernear

drop-offsandwater.

Figure8

3.Water

16

Page 17

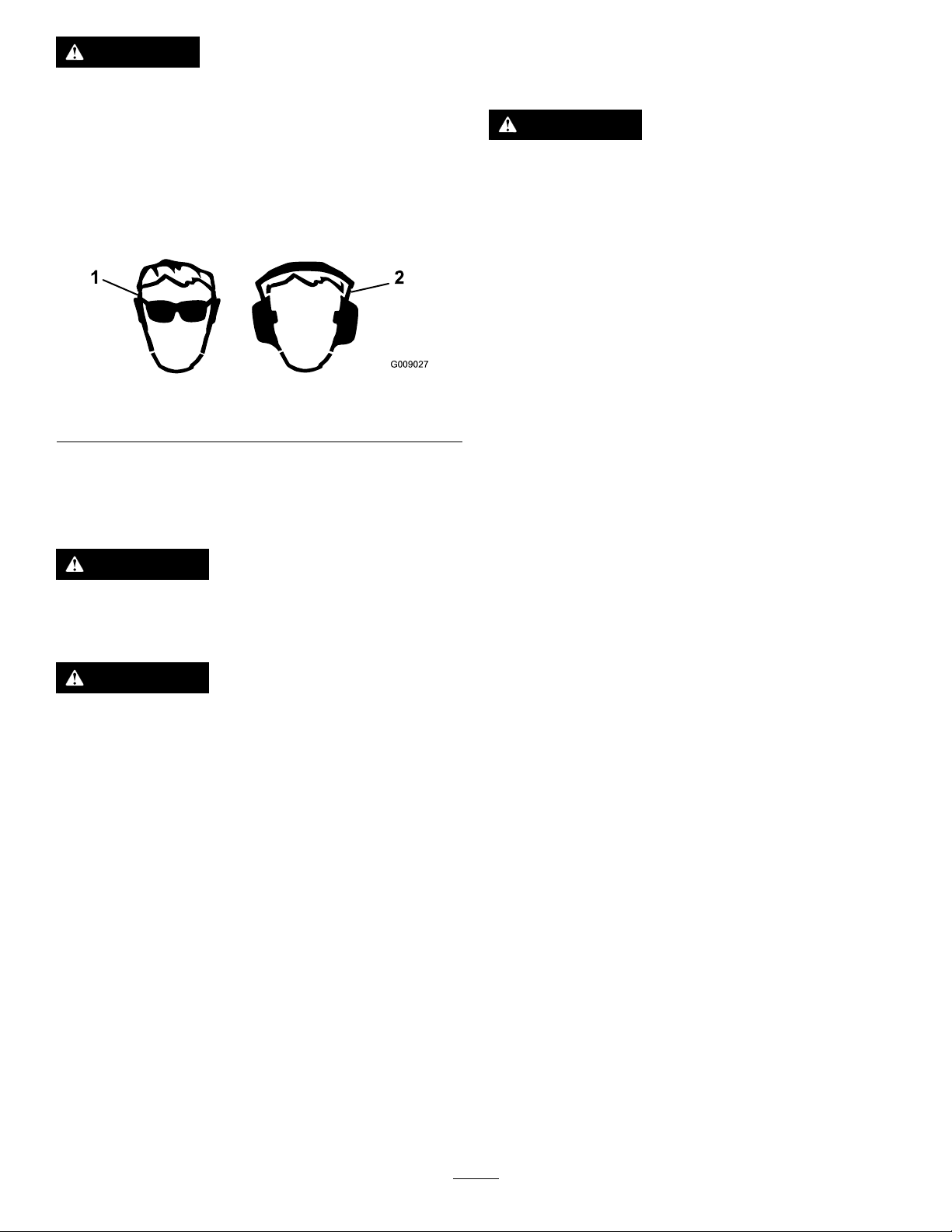

CAUTION

G009027

1

2

Understandingthe

Thismachineproducessoundlevelsinexcessof

85dBAattheoperatorsearandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Wearprotectiveequipmentforyoureyes,ears,hands,andfeet

whenusingthismachine(Figure9).

Figure9

1.Weareyeprotection.2.Wearhearingprotection.

UsingtheRolloverProtection System(ROPS)

Safety-InterlockSystem

WARNING

Ifthesafety-interlockswitchesaredisconnectedor

damaged,themachinecouldoperateunexpectedly,

causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlockswitches

dailyandreplaceanydamagedswitchesbefore

operatingthemachine.

Thesafety-interlocksystemisdesignedtopreventtheengine

fromstartingunless:

•Thebladesaredisengaged.

•Themotion-controlleversareinthePARKposition.

Thesafety-interlocksystemalsoisdesignedtoshutoffthe

enginewheneverthecontrolleversareoutofthePARK

positionandyourisefromtheseat.

TestingtheSafety-Interlock

WARNING

Toavoidinjuryordeathfromrollover:keeptheroll

barinstalledandusetheseatbelt.

WARNING

Thereisnorolloverprotectionwhentherollbaris

removed.

•Driveslowlyandcarefully.

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,electricalwires)before

drivingunderanyobjectsanddonotcontact

them.

System

Testthesafety-interlocksystembeforeyouusethemachine

eachtime.Ifthesafetysystemdoesnotoperateasdescribed

below,haveanAuthorizedServiceDealerrepairthesafety

systemimmediately.

1.Whilesittingontheseat,withthecontrolleversinthe

PARKposition,andmovetheblade-controlswitchto

theONposition.Trystartingtheengine;theengine

shouldnotstart.

2.Whilesittingontheseat,movetheblade-controlswitch

totheOFFposition.Moveeithermotioncontrol

levertothecenter,unlockedposition.Trystartingthe

engine;theengineshouldnotstart.Repeatwiththe

othermotion-controllever.

3.Whilesittingontheseat,movethebladecontrolswitch

totheOFFposition,andlockthemotion-controllevers

inthePARKposition.Starttheengine.Whilethe

engineisrunning,engagetheblade-controlswitch,and

riseslightlyfromtheseat;theengineshouldshutoff.

4.Whilesittingontheseat,movetheblade-controlswitch

totheOFFposition,andlockthemotion-controllevers

inthePARKposition.Starttheengine.Whilethe

engineisrunning,movethemotion-controlleversto

thecenter,unlockedposition,engagetheblade-control

switch,andriseslightlyfromtheseat;theengine

shouldshutoff.

17

Page 18

CheckingtheEngine-OilLevel

B

A

g027638

B

A

g027639

g028222

G008959

1

2

OperatingtheThrottle

Beforeyoustarttheengineandusethemachine,check

theoillevelintheenginecrankcase;refertoCheckingthe

Engine-OilLevel(page31).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mowerdecks

anddrivesystemshavehigherfrictionwhennew,placing

additionalloadontheengine.Allow40to50hoursof

break-intimefornewmachinestodevelopfullpowerand

bestperformance.

OperatingtheParkingBrake

Alwayssettheparkingbrakewhenyoustopthemachineor

leaveitunattended.

SettingtheParkingBrake

ThethrottlecontrolcanbemovedbetweentheSLOWand

FASTpositions(Figure12).

AlwaysusetheFASTpositionwhenturningonthemower

deckwiththeblade-controlswitch(PTO).

Figure12

OperatingtheChoke

Usethechoketostartacoldengine.

1.Iftheengineiscold,usethechoketostarttheengine.

2.Pulluponthechokeknobtoengagethechokebefore

usingtheignitionswitch(Figure13).

3.Pushdownonthechoketodisengagethechokeafter

theenginestarts(Figure13).

ReleasingtheParkingBrake

Figure10

Figure11

Figure13

1.ONposition2.OFFposition

18

Page 19

OperatingtheIgnitionSwitch

START

RUN

STOP

G008947

g028223

B

A

D

C

F

E

S

T

A

R

T

R

U

N

S

T

O

P

H

G

1.TurntheignitionkeytotheSTARTposition(Figure14).

Note:Whentheenginesstarts,releasethekey.

Note:Additionalstartingcyclesmayberequired

whenstartingtheengineforthersttimeafterthefuel

systemhasbeenwithoutfuelcompletely.

Figure14

2.TurntheignitionkeytotheSTOPposition.

StartingandStoppingthe Engine

StartingtheEngine

StarttheengineasshowninFigure15.

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostartallowa15

secondcool-downperiodbetweenattempts.Failureto

followtheseinstructionscanburnoutthestartermotor.

Note:Ifthefuelsystemwasdepletedoffuel—addfuelto

themachineanduseadditionalstartingcycleswhenstarting

theengine.

Figure15

StoppingtheEngine

CAUTION

Injurycanoccurifchildrenorbystandersmove

orattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandsettheparking

brakewhenleavingthemachineunattended,even

ifjustforafewminutes.

StoptheengineasshowninFigure16.

19

Page 20

BA

DC

E

S

T

A

R

T

R

U

N

S

T

O

P

g028224

Figure16

G008945

G009174

DisengagingtheBlade-ControlSwitch

(PTO)

Figure18

DrivingtheMachine

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottlecontrolin

theFASTpositionforbestperformance.Alwaysoperatein

thefull-throttlepositionwhenmowing.

CAUTION

Machinecanspinveryrapidly.Operatormaylose

controlofmachineandcausepersonalinjuryor

damagetomachine.

•Usecautionwhenmakingturns.

OperatingtheBlade-Control Switch(PTO)

Theblade-controlswitch(PTO)startsandstopsthemower

bladesandanypoweredattachments.

EngagingtheBlade-ControlSwitch

(PTO)

Engagetheblade-controlswitch(PTO)withthethrottle

positionatFAST.

Note:Engagingtheblade-controlswitch(PTO)withthe

throttlepositionathalforlesswillcauseexcessivewearto

thedrivebelts.

•Slowthemachinedownbeforemakingsharp

turns.

UsingtheMotion-ControlLevers

Usethemotion-controlleversasshowninFigure19.

Figure17

20

Page 21

Figure19

G008952

G008953

Figure20

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofthemachine

3.Forward

4.Backward

DrivingForward

Note:Theenginekillsifthetraction-controlleversare

movedwiththeparkingbrakeengaged.

1.Releasetheparkingbrake.

2.Movetheleverstothecenter,unlockedposition.

3.Tomoveforward,slowlypushthemotion-control

leversforward(Figure20).

DrivingBackward

Note:Alwaysusecautionwhenbackingupandturning.

1.Movetheleverstothecenter,unlockedposition.

2.Togobackward,slowlypullthemotion-controllevers

rearward(Figure21).

Figure21

21

Page 22

StoppingtheMachine

g024409

WARNING

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhileitis

unattended.

Alwaysremovetheignitionkeyandmovethe

motion-controlleversoutwardtothePARKposition

whenleavingthemachineunattended,evenifjust

forafewminutes.

Tostopthemachine,movethetraction-controlleversto

theNEUTRALpositionandmovetothelockedposition,

disengagetheblade-controlswitch(PTO),andturnthe

ignitionkeytotheOFFposition.

Settheparkingbrakewhenyouleavethemachine.Remember

toremovethekeyfromtheignitionswitch.

AdjustingtheHeightofCut

Themachineisequippedwithafootpedaldeck-liftsystem.

Theoperatorcanusethefootpedaltoliftthedeckbrieyto

avoidobstaclesorlockthedeckinthehighestheightofcut

ortransportposition.Theoperatorcanusetheheight-of-cut

leverwiththefootpedaltolockthedeckinaspeciccutting

height.

Figure22

TransportLockPosition

AdjustingtheHeightofCut

Theheightofcutcanbeadjustedfrom38to114mm(1-1/2

to4-1/2inches)in6mm(1/4inch)incrementsbyrelocating

theheight-of-cutpinintodifferentholelocations.

UsingtheFootPedalDeck-LiftSystem

•Pressthepedaldowntoraisethedeck;continuetopress

thepedaluntilthedeckislockedinthetransportposition

(Figure22).

•Pushonthedeck-liftpedalwithyourfootandpullthe

transportlockhandlerearwardtodisengagethetransport

lock(Figure22).

1.Pushonthedeck-liftpedalwithyourfootandraise

themowerdecktothetransport-lockposition(also

the114mm(4-1/2inches)cuttingheightposition)as

showninFigure23.

2.Toadjust,removethepinfromtheheight-of-cut

bracket(Figure23).

3.Selectaholeintheheight-of-cutsystemcorresponding

tothedesiredheightofcutandinsertthepin(Figure

23).

4.Pushonthedeck-liftpedalwithyourfootandpull

thehandlerearwardtodisengagethetransportlock

(Figure22).

5.Lowerthedeckslowlyuntilthelevermakescontact

withthepin.

22

Page 23

g024410

1

2

3

4

Figure23

g024312

1

2 3 4

5

1.Deck-liftpedal3.Height-of-cutpositions

2.Handle4.Pin

AdjustingtheAnti-Scalp

4.Aligntheboltandanti-scalprollerintheholeofthe

bracketthatmatchedtheclosestheight-of-cutposition

(Figure24).

5.Inserttheboltintothebracketholeandsecurethebolt

andanti-scalprollerwiththeangenut(Figure24).

PositioningtheSeat

Theseatcanmoveforwardandbackward(Figure25).

Positiontheseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable.

Rollers

Wheneveryouchangetheheightofcut,itisrecommendedto

adjusttheheightoftheanti-scalprollers.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removetheangenut,anti-scalproller,andboltfrom

thebracket(Figure24).

Note:Keeptheboltandanti-scalprollertogether

whenremoving.

Figure25

ChangingtheSeatSuspension

Theseatisadjustabletoprovideasmoothandcomfortable

ride.Positiontheseatwhereyouaremostcomfortable.

Toadjustit,turntheknobinfronteitherdirectiontoprovide

thebestcomfort(Figure26).

1.Flangenut4.Bushing

2.Spacer

3.Anti-scalproller

Figure24

5.Bolt

1.Seat-suspensionknob

Figure26

23

Page 24

AdjustingtheMotion-Control

g027252

B

A

BA

DC

g027642

Levers

AdjustingtheHeight

Note:Repeattheadjustmentfortheoppositecontrollever.

Themotion-controlleverscanbeadjustedhigherorlowerfor

maximumoperatorcomfort(Figure27).

Figure27

Note:Ensurethattheleftandrightbypassleversare

rearwardandlockedbeforemovingthemachine.

Figure28

6.Disengagetheparkingbrake.

AdjustingtheTilt

Themotion-controlleverscanbetiltedforwardorrearward

formaximumoperatorcomfort.

1.Loosentheupperboltholdingthecontrollevertothe

control-armshaft.

2.Loosenthelowerboltjustenoughtopivotthecontrol

leverforwardorrearward.

3.Tightenbothboltstosecurethecontrolinthenew

position.

4.Repeattheadjustmentfortheoppositecontrollever.

PushingtheMachinebyHand

Important:Alwayspushthemachinebyhand.Never

towthemachinebecausedamagemayoccur.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Engagetheparkingbrake.

3.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

OperatingtheMachine

Movethebypassleverstothepositionforoperatingthe

machine(Figure28)toengagethewheelmotors.

4.Locatethebypassleversattherearofthemachine,on

theleftandrightsideoftheframe.

5.Movethebypassleversrearwardandthendowntolock

theminplacetodisengagethewheelmotors(Figure

28).

24

Page 25

UsingtheSideDischarge

g028043

TransportingtheMachine

Themowerhasahingedgrassdeectorthatdisperses

clippingstothesideanddowntowardtheturf.

DANGER

Withoutagrassdeector,dischargecover,or

completegrasscatcherassemblymountedin

place,youandothersareexposedtobladecontact

andthrowndebris.Contactwithrotatingmower

blade(s)andthrowndebriswillcauseinjuryor

death.

•Neverremovethegrassdeectorfromthemower

becausethegrassdeectorroutesmaterialdown

towardtheturf.Ifthegrassdeectorisever

damaged,replaceitimmediately .

•Neverputyourhandsorfeetunderthemower.

•Nevertrytoclearthedischargeareaormower

bladesunlessyoumovetheblade-controlswitch

(PTO)totheOFFposition,rotatetheignition

keytotheOFFposition,andremovethekey.

•Makesurethatthegrassdeectorisinthedown

position.

Useaheavy-dutytrailerortrucktotransportthemachine.

Ensurethatthetrailerortruckhasallnecessarybrakes,

lighting,andmarkingasrequiredbylaw .Pleasecarefullyread

allthesafetyinstructions.Knowingthisinformationcould

helpyou,yourfamily,pets,orbystandersavoidinjury.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidents,causingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

1.Ifyouareusingatrailer,connectittothetowing

vehicleandconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Loadthemachineontothetrailerortruck.

4.Shutofftheengine,removethekey,setthebrake,and

closethefuelvalve.

5.Tiedownthemachinenearthefrontcasterwheelsand

therearbumper(Figure29).

Figure29

LoadingtheMachine

Useextremecautionwhenloadingorunloadingmachines

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Backthemachineupthe

rampanddriveitforwarddowntheramp(Figure30).

Figure30

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

25

Page 26

Important:Donotusenarrowindividualrampsfor

g027996

5

1

2

6

eachsideofthemachine.

Ensuretherampislongenoughsothattheanglewiththe

grounddoesnotexceed15degrees(Figure31).Onat

ground,thisrequiresaramptobeatleast4timesaslongas

theheightofthetrailerortruckbedtotheground.Asteeper

anglemaycausemowercomponentstogetcaughtastheunit

movesfromtheramptothetrailerortruck.Steeperangles

mayalsocausethemachinetotiporlosecontrol.Ifloading

onornearaslope,positionthetrailerortrucksothatitis

onthedownsideoftheslopeandtherampextendsupthe

slope.Thiswillminimizetherampangle.

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethelengthoframpisatleast4timesas

longastheheightofthetrailerortruckbedto

theground.Thiswillensurethatrampangle

doesnotexceed15degreesonatground.

•Backuprampsanddriveforwarddownramps.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

Figure31

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

26

Page 27

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operatethe

engineattheFASTposition.Airisrequiredtothoroughlycut

grassclippings,sodonotsettheheight-of-cutsolowasto

totallysurroundthemowerinuncutgrass.Alwaystrytohave

1sideofthemowerfreefromuncutgrass,whichallowsair

tobedrawnintothemower.

Stopping

Ifyoumuststoptheforwardmotionofthemachinewhile

mowing,aclumpofgrassclippingsmaydropontoyour

lawn.Toavoidthis,moveontoapreviouslycutareawiththe

bladesengagedoryoucandisengagethemowerdeckwhile

movingforward.

KeepingtheUndersideoftheMower

Clean

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethatthe

cuttingheightofthemowerdoesnotscalpanyuneven

ground.However,thecuttingheightusedinthepastis

generallythebestonetouse.Whencuttinggrasslongerthan

15cm(6inches)tall,youmaywanttocutthelawntwiceto

ensureanacceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.Cutting

morethanthatisnotrecommendedunlessgrassissparse,or

itislatefallwhengrassgrowsmoreslowly.

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrassstanding

straight.Thisalsohelpsdisperseclippingswhichenhances

decompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesoftheyear.

Tomaintainthesamecuttingheight,mowmoreofteninearly

spring.Asthegrassgrowthrateslowsinmidsummer,mow

lessfrequently .Ifyoucannotmowforanextendedperiod,

rstmowatahighcuttingheight,thenmowagain2days

lateratalowerheightsetting.

Cleanclippingsanddirtfromtheundersideofthemower

aftereachuse.Ifgrassanddirtbuildupinsidethemower,

cuttingqualitywilleventuallybecomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseasonbecause

asharpbladecutscleanlywithouttearingorshreddingthe

grassblades.Tearingandshreddingturnsgrassbrownat

theedges,whichslowsgrowthandincreasesthechanceof

disease.Checkthemowerbladesaftereachuseforsharpness,

andforanywearordamage.Filedownanynicksandsharpen

thebladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineTororeplacementblade.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeedincertain

conditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheighttoavoid

scalpingtheturf.

CuttingLongGrass

Ifthegrassiseverallowedtogrowslightlylongerthan

normal,orifitcontainsahighdegreeofmoisture,raisethe

cuttingheighthigherthanusualandcutthegrassatthis

setting.Thencutthegrassagainusingthelower,normal

setting.

27

Page 28

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every50hours

Every100hours

Every400hours

MaintenanceProcedure

•Changethehydrauliclteranduid.

•Checkthesafety-interlocksystem.

•Checktheaircleanerfordirty,looseordamagedparts.

•Checktheengine-oillevel.

•Cleantheblowerhousing(moreoftenunderextremelydusty ,dirtyconditions).

•Checkthemowerblades.

•Inspectthegrassdeectorfordamage.

•Cleanthemowerhousing.

•Greasealllubricationpoints.

•Serviceorreplacetheair-cleanerfoamelement(moreoftenunderextremelydusty ,

dirtyconditions).

•Checktirepressure.

•Checkthehydraulic-uidlevelintheexpansiontank.

•Inspectthebeltsforcracksandwear .

•Replacetheair-cleanerpaperelement(moreoftenunderextremelydusty,dirty

conditions).

•Changetheengineoilandtheengine-oillter.

•Cleanthecoolingns(moreoftenunderextremelydusty,dirtyconditions).

•Replacethefuellter(moreoftenunderdusty,dirtyconditions).

•Changethehydrauliclteranduid.

Every500hours

Monthly

Yearlyorbeforestorage

•Replacethesparkplug(s).

•Checkthebatterycharge.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

28

Page 29

Premaintenance

Procedures

Service-IntervalChart

Figure32

Locatedontheseatpanunderside

1.ReadtheOperator'sManualbeforeperformingany

maintenance.

2.Checktheengineoilevery8hours.5.Checkthecasterwheeltirepressureevery25hours.

3.Checkthedrivewheeltirepressureevery25hours.

RaisingtheSeat

Ensurethatthemotion-controlleversarelockedinthe

NEUTRAL-LOCKpositionandlifttheseatforward.

Thefollowingcomponentscanbeaccessedbyraisingtheseat:

•Servicedecal

•Fuses

•Batteryandcables

4.Checkthehydraulicoilevery25hours.

6.Lubricatethecasterwheelevery25hours.

Lubrication

GreasingtheBearings

ServiceInterval:Every25hours—Greasealllubrication

points.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,remove

thekey ,andwaitforallmovingpartstostopbefore

leavingtheoperatingposition.

3.Cleanthegreasettings(Figure33andFigure32)with

arag.

Note:Makesuretoscrapeanypaintoffthefrontof

thetting(s).

29

Page 30

G009949

1

Figure33

1.Frontcastertire

4.Connectagreaseguntoeachttingandpumpgrease

intothettingsuntilgreasebeginstooozeoutofthe

bearings(Figure32andFigure33).

EngineMaintenance

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checktheair

cleanerfordirty,looseordamagedparts.

Every25hours—Serviceorreplacetheair-cleaner

foamelement(moreoftenunderextremelydusty,dirty

conditions).

Every100hours—Replacetheair-cleanerpaper

element(moreoftenunderextremelydusty,dirty

conditions).

Thisengineisequippedwithareplaceable,high-densitypaper

andfoamair-cleanerelement.Checktheaircleanerdailyor

beforestartingtheengine.Checkforabuildupofdirtand

debrisaroundtheair-cleanersystem.Keepthisareaclean.

Also,checkforlooseordamagedcomponents.Replaceall

bentordamagedair-cleanercomponents.

Note:Operatingtheenginewithlooseordamaged

air-cleanercomponentscouldallowunlteredairintothe

engine,causingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunderextremely

dusty,dirtyconditions.

RemovingtheElements

1.Rotatethelatchesoutward.

2.Removethecovertoaccesstheair-cleanerelements

(Figure34).

Figure34

1.Air-cleanercover2.Air-cleanerlatch

30

Page 31

3.Removethefoamandpaperelements(Figure35).

g017552

0

0

50

SAE 30

B

A

C

D

E

g027515

F

G

H

4.Removethefoamelementfromthepaperelement

(Figure35).

Figure35

Figure36

1.Air-cleanercover3.Paperelement

2.Foamelement

ServicingtheFoamElement

1.Washthefoamelementinwarmwateranddetergent.

2.Rinseandallowittoairdry.

3.Lightlyoilthefoamelementwithnewoilandsqueeze

outexcessoil.

ServicingthePaperElement

1.Gentlytapthepaperelementtodislodgedirt.

Note:Donotwashthepaperelementoruse

pressurizedair,asthiswilldamagetheelement.

Note:Replaceadirty,bent,ordamagedelement.

Handlethenewelementcarefully;donotuseifthe

sealingsurfacesarebentordamaged.

2.Cleantheair-cleanerbaseasrequired,andcheckthe

condition.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

1.Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,shutofftheengine,andremove

thekey.

2.Makesurethattheengineisstopped,level,andiscool,

sotheoilhastimetodrainintothesump.

3.Checktheengine-oillevel(Figure37).

InstallingtheElements

1.Installthefoamelementontothepaperelement.

2.Installtheelementsontotheair-cleanerbase(Figure

35).

3.Installthecover,andsecureitwiththelatches(Figure

34).

ServicingtheEngineOil

OilType:Detergentoil(APIserviceSJorhigher)

CrankcaseCapacity:1.9L(64oz)whenthelterischanged

Viscosity:Seethetablebelow.

Figure37

31

Page 32

ChangingtheEngineOilandthe

B

A

C D

E

F

3/4

g027477

Engine-OilFilter

ServiceInterval:Every100hours—Changetheengineoil

andtheengine-oillter.

Note:Thedrainplugisattachedtothedrainhose.

Note:Disposeoftheusedoilatarecyclingcenter.

Fillwithoilasspeciedinthe“ViscosityGrades”table

(Figure36).

1.Parkthemachine,sothatthedrainsideisslightlylower

thantheoppositeside,toensurethattheoildrains

completely.

2.Disengagetheblade-controlswitchandmovethe

motioncontrolsoutwardtothePARKposition.

3.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

Figure39

6.Slowlypourapproximately80%ofthespeciedoil

intothellertube(Figure40).

Figure38

4.Torquetheplugto14N•m(10ft-lb).

5.Changetheengine-oillterasshowninFigure39.

32

Page 33

B

A

C

D

E

g027517

Figure40

B

A

g027478

B

A

g027479

ServicingtheSparkPlug

ServiceInterval:Every500hours—Replacethespark

plug(s).

Figure41

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).Always

replacethesparkplug(s)whenithas:ablackcoating,

wornelectrodes,anoilylm,orcracks.

Note:Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

Setthegapto0.76mm(0.03inch).

Figure42

ThesparkplugisRFIcompliant.Equivalentalternatebrand

plugscanalsobeused.

Type:ChampionXC12YC

AirGap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Disengagetheblade-controlswitch,movethemotion

2.Beforeremovingthesparkplug(s),cleanthearea

3.Removethesparkplug(Figure41).

controlsoutwardtotheparkposition,shutoffthe

engine,andremovethekey.

aroundthebaseoftheplugtokeepdirtanddebrisout

oftheengine.

33

Page 34

InstallingtheSparkPlug

B

A

20 ft-lb

27 N-m

g028109

C

D

Tightenthesparkplugto27N•m(20ft-lb)asshownin

Figure43.

Figure43

FuelSystem

Maintenance

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Performanyfuelrelatedmaintenancewhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

ReplacingtheFuelFilter

ServiceInterval:Every100hours/Yearly(whichevercomes

rst)(moreoftenunderdusty ,dirty

conditions).

CleaningtheBlowerHousing

Every100hours/Yearly(whichevercomesrst)

Toensurepropercooling,ensurethatthegrassscreen,

coolingns,andotherexternalsurfacesoftheengineare

keptcleanatalltimes.

Annually,orevery100hoursofoperation(moreoften

underextremelydusty,dirtyconditions),removetheblower

housing,andanyothercoolingshrouds.Cleanthecooling

nsandexternalsurfacesasnecessary.Makesurethecooling

shroudsareinstalled.

Important:Operatingtheenginewithablockedgrass

screen,dirtyorpluggedcoolingns,and/orcooling

shroudsremoved,willcauseenginedamagedueto

overheating.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.ReplacethefuellterasshowninFigure44.

34

Page 35

g0281 10

B

A

C

D

g027753

ElectricalSystem

Maintenance

ServicingtheBattery

ServiceInterval:Monthly

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassestoshield

youreyesandrubberglovestoprotectyourhands.

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalmachinecomponentscausingsparks.Sparks

cancausethebatterygassestoexplode,resulting

inpersonalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

Figure44

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcablescausingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)battery

cablebeforedisconnectingthepositive(red)

cable.

•Alwaysreconnectthepositive(red)batterycable

beforereconnectingthenegative(black)cable.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Removethewingnutsecuringthebatteryclamp

(Figure45).

35

Page 36

Figure45

4.Removetheclamp(Figure45).

5.Firstdisconnectthenegativebatterycable(black)from

thenegative(-)(black)batteryterminal(Figure45).

6.Slidetheredterminalbootoffthepositive(red)battery

terminalandremovethepositive(+)(red)batterycable

(Figure45).

7.Removethebattery.

1.Chargebatteryfor10to15minutesat25to30amps

or30minutesat10amps.

2.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure46).

3.Installthebatteryinthemachineandconnectthe

batterycables.

Figure46

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

InstallingtheBattery

1.Positionthebatteryinthetraywiththeterminalposts

oppositefromthefueltank(Figure45).

2.Installthepositive(red)batterycabletopositive(+)

batteryterminal.

3.Installthenegativebatterycabletothenegative(-)

batteryterminal.

4.Securethecableswith2bolts,2washers,and2locknuts

(Figure45).

5.Slidetheredterminalbootontothepositive(red)

batterypost.

6.Installtheclampandsecureitwiththewingnut(Figure

45).

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Note:Thefusesarelocatedonrighthandconsolenextto

theseat(Figure47).

Fusetype:

•Main—30A,blade-type

•Engine—20A,blade-type

1.Toreplacethemainfuse,graspthefuseandpullit

straightandawayfromthefuseblock(Figure47).

Important:Alwayskeepthebatteryfullycharged.This

isespeciallyimportanttopreventbatterydamagewhen

thetemperatureisbelow32°F(0°C).

36

Page 37

g02441 1

1

2

Figure47

1.Fuseblock2.Main—30A

DriveSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktirepressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseunevencut.Check

thepressureatthevalvestem(Figure49).Checkthetires

whentheyarecoldtogetthemostaccuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrivewheeltiresto90kPa(13psi).

Important:Ensurethatthenewfusesarethe

sametypeandamperageasthefusesremoved.

2.Toreplacetheenginefuse,removetheconsolefrom

theplasticfender.

Figure48

1.Enginefuse—25A

3.Grasptheenginefuseandpullitstraightandaway

fromthefuseblock(Figure48).

Figure49

1.Valvestem

4.Alignanewfusewiththeslotinthefuseblock(Figure

47).

5.Pushthefuseintothefuseblockuntilthefuseisseated

(Figure47).

37

Page 38

HydraulicSystem

G010253

1

2

3

G010254

1

2

3

4

5

Maintenance

OilType:ToroHYPR-OIL®500or20W -50motoroil.

SystemCapacity:4.495L(152oz)withalterchange.

Important:Useoilspeciedorequivalent.Otheruids

couldcausesystemdamage.

CheckingtheHydraulic-Fluid Level

ServiceInterval:Every25hours

Checktheexpansionreservoir,and,ifnecessary,adduid

totheFullColdline.

1.Shutofftheengine,waitforallmovingpartstostop,

allowtheenginetocool,removethekey,andengage

theparkingbrake.

2.Locatethelterandguardsoneachtransaxledrive

systemandremovethe3screwssecuringthelter

guard(Figure51).

Figure51

Rightsideshown

Figure50

1.Expansionreservoir3.Engine

2.FullColdline

ChangingtheHydraulicFilter andFluid

Thelteranduidarechangedatthesametime.Oncethe

newlterisinstalledanduidisadded,anyairinthesystem

mustbepurged.

Thebleedingprocessisrepeateduntiltheuidremainsat

theFullColdlineinthereservoirafterpurging.Failureto

properlyperformthisprocedurecanresultinirreparable

damagetothetransaxledrivesystem.

RemovingtheHydraulicFilters

1.Transaxledrive

2.Hydrauliclter

3.Filterguard

3.Carefullycleantheareaaroundthelters.

Important:Donotallowdirttoenterthe

hydraulicsystem,asitmaycausedamage.

4.Placeacontainerbelowthelteranddraintheuid.

5.Locateandremovetheventplugoneachtransmission.

6.Unscrewthelterandallowtheuidtodrainfrom

thedrivesystem.

7.Repeatthisprocedureforbothlters.

4.Screws

5.Ventplug

InstallingtheHydraulicFilter

ServiceInterval:Aftertherst50hours

Every400hours

1.Usingthe3screwstoinstallthelterguardsovereach

lterremovedpreviously .

2.Verifythattheventplugsareremovedbeforeadding

theuid.

3.Slowlypourthespecieduidthroughtheexpansion

reservoiruntiluidcomesoutofavent-plughole.

4.Installtheventplugandtorqueitto20N•m(180in-lb).

Important:Whenthehydrauliclterisremoved,allof

thehydraulicuidineachtransaxlewilldrainout.Usea

containerthatholds4.495L(152oz)orlarger.

5.Continuetoadduidthroughtheexpansionreservoir

untiluidcomesoutoftheremainingvent-plughole

onthesecondtransmission.

38

Page 39

6.Installthesecondventplugandtorqueitto20N•m

B

A

C D

E

F

3/4

g027477

G010333

1

(180in-lb).

7.Continuetoadduidthroughtheexpansionreservoir

untilitreachestheFullColdlineontheexpansion

reservoir.

BleedingtheHydraulicSystem

1.Raisetherearofmachineupandsupportitwithjack

stands(orequivalentsupport)justhighenoughto

allowthedrivewheelstoturnfreely .

Important:Failuretoperformthe

the Hy draulic System

hydraulicltersandoilcanresultinirreparable

damagetothetransaxledrivesystem.

procedureafterchanging

Bleeding

Figure53

1.Jackingpoints

2.Entertheoperator'sposition,starttheengine,move

thethrottlecontrolto1/2throttleposition,and

disengagetheparkingbrake.

A.Movethebypassleversintothepushingthe

machineposition;refertoPushingtheMachine

byHand(page24).Withthebypassvalves

openandtheenginerunning,slowlymovethe

motion-controlleversinbothforwardandreverse

directions(5or6times).

Figure52

B.Movethebypassleversintotheoperating

themachineposition.Withthebypassvalve

closedandtheenginerunning,slowlymovethe

directionalcontrolinbothforwardandreverse

directions(5to6times).

C.Shutofftheengineandchecktheuidlevelinthe

expansionreservoir.Addthespecieduidas

untilitreachestheFullColdlineontheexpansion

reservoir.

3.Repeatstep2untilalloftheairiscompletelypurged

fromthesystem.

Note:Whenthetransaxleoperatesatnormalnoise

levelsandmovessmoothlyforwardandreverseat

normalspeeds,thenthetransaxleisconsideredpurged.

39

Page 40

MowerDeck

G009679

1

2

3

Maintenance

ServicingtheCuttingBlades

Maintainsharpbladesthroughoutthecuttingseason,because

sharpbladescutcleanlywithouttearingorshreddingthegrass

blades.Tearingandshreddingturnsgrassbrownattheedges,

whichslowsgrowth,andincreasesthechanceofdisease.

Checkthecutterbladesdailyforsharpness,andforany

wearordamage.Filedownanynicksandsharpenthe

bladesasnecessary.Ifabladeisdamagedorworn,replace

itimmediatelywithagenuineT ororeplacementblade.For

convenientsharpeningandreplacement,youmaywantto

keepextrabladesonhand.

WARNING

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownatyouorbystanders,

resultinginseriouspersonalinjuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

Figure54

1.Cuttingedge3.Wear/slotforming

2.Curvedarea

4.Damage

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfaceforthe

followingprocedure.

1.Raisethemowerdecktothehighestheight-of-cut

position.

2.Whilewearingthickly-paddedgloves,orotheradequate

handprotection,slowlyrotatethebladetobemeasure

intoapositionthatallowseffectivemeasurementofthe

distancebetweenthecuttingedgeandthelevelsurface

themachineison(Figure55).

BeforeInspectingorServicingthe

Blades

Parkthemachineonalevelsurface,disengagethe

blade-controlswitch,movethemotion-controlleversoutward

tothePARKposition,shutofftheengine,andremovethekey.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure54).

Note:Iftheedgesarenotsharporhavenicks,remove

andsharpentheblades;refertoSharpeningtheBlades

(page42).

2.Inspecttheblades,especiallythecurvedarea(Figure

54).

Note:Ifyounoticeanydamage,wear,oraslot

forminginthisarea(items3and4inFigure54),

immediatelyinstallanewblade.

Figure55

1.Deck3.Blade

2.Spindlehousing

40

Page 41

3.Measurefromthetipofthebladetotheatsurface

G009680

1

2

3

G009681

1

2

3

G009680

1

2

3

(Figure56).

Figure56

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothattheopposing

cuttingedgeisnowinthesameposition(Figure57).

Figure58

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreaterthan

3mm(1/8inch),replacethebladewithanew

blade;refertoRemovingtheBlades(page41)and

InstallingtheBlades(page42).

Note:Ifabentbladeisreplacedwithanew

blade,andthedimensionobtainedcontinuesto

exceed3mm(1/8inch),thebladespindlecould

bebent.ContactanAuthorizedToroDealerfor

service.

Figure57

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

position

5.Measurefromthetipofthebladetotheatsurface

(Figure58).

Note:Thevarianceshouldbenomorethan3mm

(1/8inch).

B.Ifthevarianceiswithinconstraints,movetothe

nextblade.

Repeatthisprocedureoneachblade.

RemovingtheBlades

Thebladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalance,orifthebladeisbent.Toensure

optimumperformanceandcontinuedsafetyconformance

ofthemachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturersmayresult

innon-conformancewithsafetystandards.

1.Holdthebladeendusingaragorthickly-paddedglove.

2.Removethebladebolt,curvedwasher,andbladefrom

thespindleshaft(Figure59).

41

Page 42

1

2

3

4

G010341

Figure59

1.SailAreaofBlade3.Curvedwasher

2.Blade4.Bladebolt

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure59).

Important:Thecurvedpartoftheblademustbe

pointingupwardtowardtheinsideofthemowerto

ensurepropercutting.

2.Installthespringdiskandbladeboltwiththespring

diskconeinstalledtowardthebolthead(Figure59).

3.Torquethebladeboltto135to150N•m(100to

110ft-lb).

LevelingtheMowerDeck

Ensurethatthemowerdeckislevelanytimeyouinstallthe

mowerdeckorwhenyouseeanunevencutonyourlawn.

Checkthemowerdeckforbentbladespriortoleveling;

removeandreplaceanybentblades;refertoCheckingfor

BentBlades(page40)beforecontinuing.

Levelthemowerdeckside-to-sidebeforeadjustingthe

front-to-rearslope.

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatbothendsof

theblade(Figure60).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesameamount

ofmaterialisremovedfrombothcuttingedges.

Figure60

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitonablade

balancer(Figure61).

Note:Ifthebladestaysinahorizontalposition,the

bladeisbalanced,andcanbeused.

Note:Ifthebladeisnotbalanced,lesomemetaloff

theendofthesailareaonly(Figure60).

Requirements:

•Themachinemustbeonalevelsurface.

•All4tiresmustbeproperlyinated;refertoChecking

theTirePressure(page37).

CheckingtheSide-to-SideLevel

Themowerbladesmustbelevelfromsidetoside.Checkthe

side-to-sidelevelanytimeyouinstallthemowerorwhenyou

seeanunevencutonyourlawn.

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,shutofftheengine,remove

thekey,settheparkingbrake,andwaitforallmoving

partstostopbeforeleavingtheoperatingposition.

3.Carefullyrotatethebladessidetoside.

4.Measurebetweentheoutsidecuttingedgesandtheat

surface(Figure62).

Note:Ifbothmeasurementsarenotwithin5mm

(3/16inch),anadjustmentisrequired;refertoLeveling

theMowerDeck(page43).

Figure61

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeisbalanced.

42

Page 43

1.Bladessidetoside

2.Outsidecuttingedges

Figure62

3.Measurefromthetipofthe

bladetotheatsurface

here.

Figure63

1.Bladesfronttorear3.Measurefromthetipofthe

bladetotheatsurface

here.

2.Outsidecuttingedges

CheckingtheFront-to-RearBladeSlope

Checkthefront-to-rearbladelevelanytimeyouinstallthe

mower.Ifthefrontofthemowerismorethan7.9mm

(5/16inch)lowerthantherearofthemower,adjusttheblade

levelusingthefollowinginstructions:

1.Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.

2.Movethemotion-controlleversoutwardtothe

NEUTRAL-LOCKposition,engagetheparkingbrake,

shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Carefullyrotatethebladessotheyarefacingfrontto

rear(Figure63).

4.Measurefromthetipofthefrontbladetotheat

surfaceandthetipoftherearbladetotheatsurface

(Figure63).

Note:Ifthefrontbladetipisnot1.6to7.9mm(1/16

to5/16inch)lowerthantherearbladetip,continueto

theLevelingtheMowerDeck(page43)procedure.

LevelingtheMowerDeck

1.Setanti-scalprollerstotopholesorremovethem

completelyforthisprocedure;refertoAdjustingthe

Anti-ScalpRollers(page23).

2.Settheheight-of-cutlevertothe76mm(3inch)

position;refertoAdjustingtheHeightofCut(page22).

3.Place26.6cm(2-5/8inches)blocksundereachsideof

thefrontedgeofthedeck,butnotundertheanti-scalp

rollerbrackets(Figure64).

4.Place27.3cm(2-7/8inches)thickblocksunderthe

rearedgeofthecuttingdeckskirt;oneoneachsideof

thecuttingdeck(Figure64).

Figure64

1.Woodblock—6.6cm

(2-5/8inches)thick

2.Woodblock—7.3cm

(2-7/8inches)thick

3.Frontedge

5.Loosentheadjustmentboltsonall4cornerssothat

thedeckissittingsecurelyonall4blocks(Figure65).

43

Page 44

ReplacingtheMowerBelt

Squealingwhenthebeltisrotating,bladesslippingwhen

cuttinggrass,frayedbeltedges,burnmarks,andcracksare

signsofawornmowerbelt.Replacethemowerbeltifanyof

theseconditionsareevident.

1.Disengagetheblade-controlswitch(PTO),movethe

motion-controlleverstotheNEUTRAL-LOCKposition,

andsettheparkingbrake.

2.Shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

3.Lowerthemowertothe76mm(3inch)height-of-cut

position.

4.Foreachofthebeltcovers,loosenthe2bolts,butdo

notremovethem.

Figure65

1.Deck-liftarm

2.Chain

3.Hook

4.Adjustmentbolt

6.Ensurethatthereistensiononall4chains(Figure65).

7.Tightenthe4adjustmentbolts(Figure65).

8.Ensurethattheblockstsnuglyunderthedeckskirt

andthatallboltsaretight.

9.Verifythatthedeckislevelbycheckingtheside-to-side

levelandfront-to-rearbladeslope;repeatthedeck

levelingprocedureifnecessary.

InspectingtheBelts

ServiceInterval:Every50hours

Checkthebeltsforsquealingwhenthebeltisrotating,blades

slippingwhencuttinggrass,frayedbeltedges,burnmarksand

cracksaresignsofawornmowerbelt.Replacethemower

beltifanyoftheseconditionsareevident.

5.Slidethecoveruntilitisclearoftheboltsandliftit

upandouttoremoveit.

6.Removetheoorpantoaccesstheidlerpulley.

7.Usingaspringremovaltool,(ToroPartNo.92-5771),

removetheidlerspringfromthedeckposttoremove

tensionontheidlerpulley(Figure66).

Figure66

1.Spring-removaltool(Toro

PartNo.92-5771)

2.Idlerspring5.Mowerbelt

3.Deckpost

4.Idlerarm

8.Lowerthemowertothelowestheightofcutandplace

theheight-of-cutpininthelockpositionforthelowest

height-of-cut.

9.Removethebeltfromthemower-deckpulleysand

removetheexistingbelt.

10.Installthenewbeltaroundthemowerpulleysandthe

clutchpulleyundertheengine(Figure66).

44

Page 45

WARNING

Thespringisundertensionwheninstalled

andcancausepersonalinjury.

Becarefulwhenremovingthebelt.

11.Usingaspring-removaltool,(ToroPartNo.92-5771),

installtheidlerspringoverthedeckpostandplacing

tensionontheidlerpulleyandmowerbelt(Figure66).

12.Ensurethatthebeltisproperlyseatedinallpulleys.

13.Toinstallthebeltcovers,insertthetabsontheeach

coverintothecorrespondingslotsonthedeckbracket,

ensuringthattheyseat.

RemovingtheMowerDeck

1.Removethehairpincotterandwashersecuringthe

linkpintotheframeanddeck,andremovethelink

bar(Figure67).

14.Rotatethecovertothedeckandslidethenotches

undertheloosenedboltsuntiltheyareseated.

15.Tightentheboltstosecurethecovertothedeck.

RemovingtheMower

Parkthemachineonalevelsurfaceanddisengagethe

blade-controlswitch.Movethemotion-controllevers

outwardtotheNEUTRAL-LOCKposition,engagetheparking

brake,shutofftheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperatingposition.

Lowerthemowertothelowestheightofcut.Selectoneof

thefollowingproceduresdependingonthemowerdecksize

installedtocompletetheremoval.

PreparingtoRemovetheMowerDeck

1.Lowerthemowertothe76mm(3inch)height-of-cut

position.

2.Removethemowerbeltfromtheenginepulley;refer

toReplacingtheMowerBelt(page44).

Figure67

1.Linkpin3.Hairpincotter

2.Washer

2.Liftupthemowerdecktorelievetensionfromthe

mowerdeck.

3.Removethechainsfromthehooksonthedeck-lift

arms(Figure68).

Figure68

1.Deck-liftarm

2.Chain

4.Raisetheheightofcuttothetransportposition.

5.Removethebeltfromtheclutchpulleyontheengine.

6.Slidethemoweroutfromunderneaththemachine.

Note:Retainallpartsforfutureinstallation.

45

3.Hook

4.Adjustmentbolt

Page 46