Page 1

Form No. 3354-630 Rev A

TimeCutter® ZX440 and ZX525

Riding Mowers

Model No. 74406 —Serial No. 260000001 and Up

Model No. 74407 —Serial No. 260000001 and Up

Register your product at www.Toro.com Original Instructions (EN)

Page 2

F or models with stated engine horse po w er , the

g ross horse po w er of the engine w as laborator y

rated b y the engine man ufacturer in accordance

with SAE J1940. As configured to meet safety ,

emission, and operating requirements , the actual

engine horse po w er on this class of la wn mo w er

will be significantly lo w er .

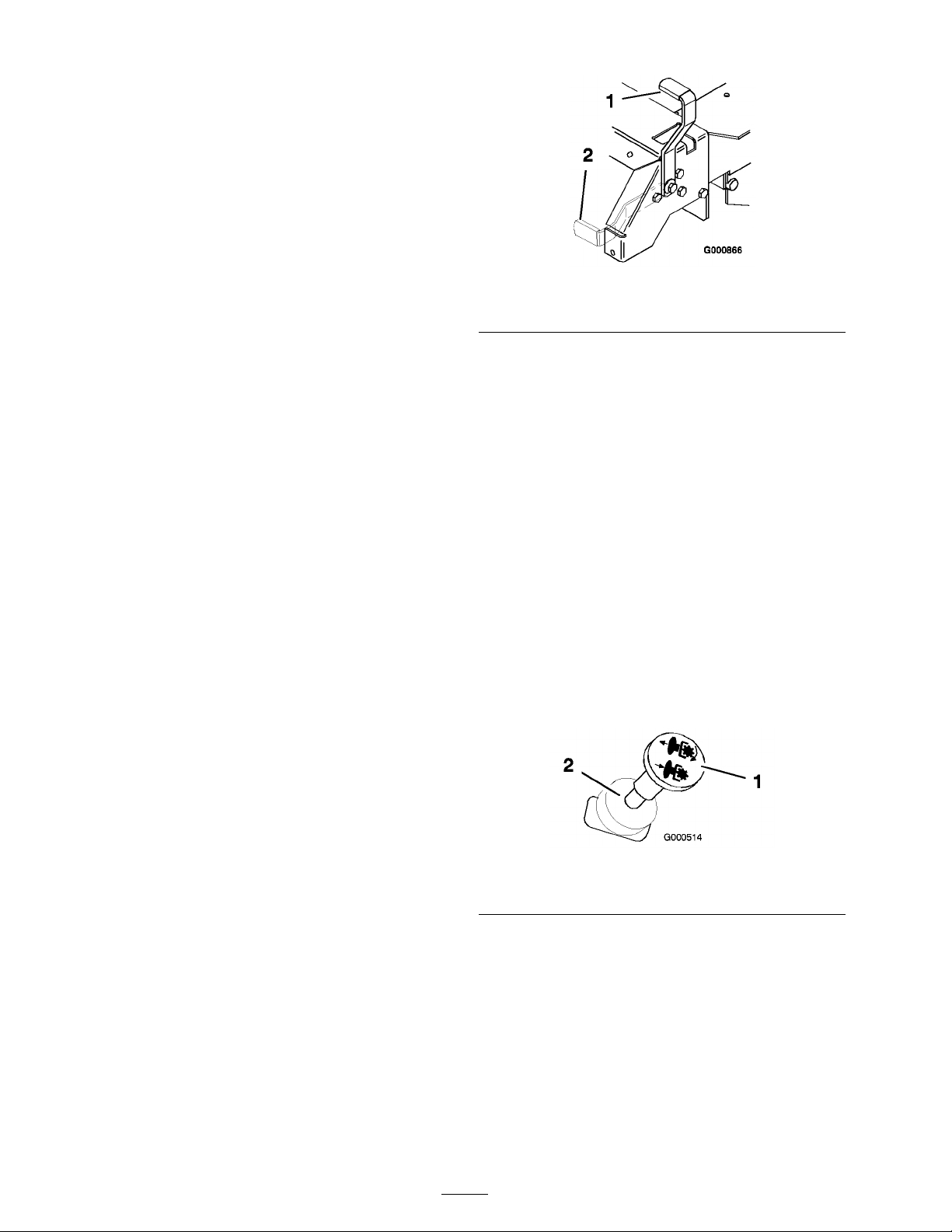

T his man ual identifies potential hazards and has

safety messag es identified b y the safety aler t

symbol ( Figure 2 ), whic h signals a hazard that ma y

cause serious injur y or death if y ou do not follo w

the recommended precautions .

Introduction

R ead this infor mation carefully to lear n ho w to

operate and maintain y our product properly and

to a v oid injur y and product damag e . Y ou are

responsible for operating the product properly

and safely .

Y ou ma y contact T oro directly at www .T oro .com

for product and accessor y infor mation, help

finding a dealer , or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts ,

or additional infor mation, contact an A uthorized

Ser vice Dealer or T oro Customer Ser vice and ha v e

the model and serial n umbers of y our product

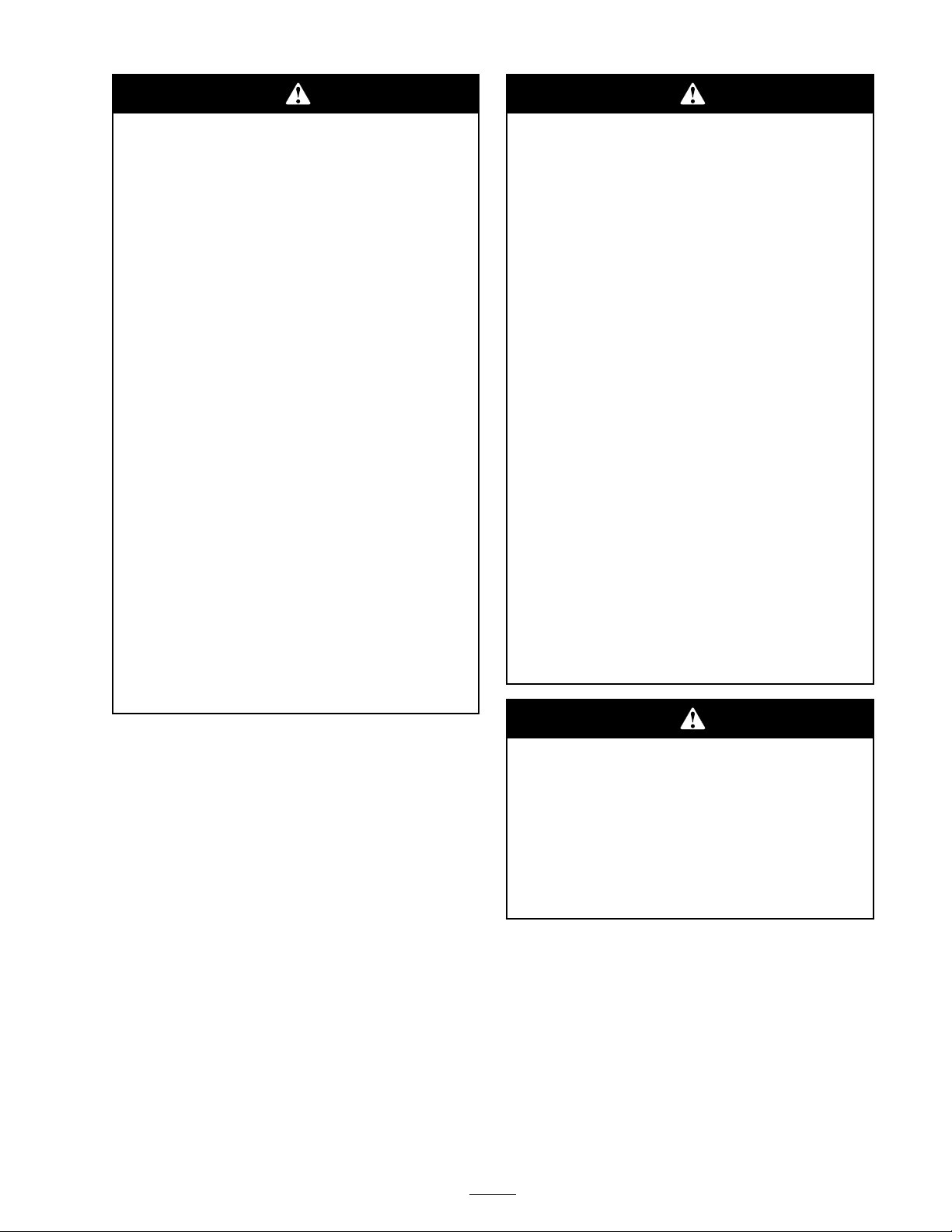

ready . Figure 1 identifies the location of the model

and serial n umbers on the product. W rite the

n umbers in the space pro vided.

Figure 1

1. Model and serial number plate

Model No.

Serial No.

Figure 2

1. Safety alert symbol.

T his man ual uses tw o other w ords to highlight

infor mation. Impor tant calls attention to special

mec hanical infor mation and Note emphasizes

g eneral infor mation w or th y of special attention.

Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safe Operation Practices for

Ride-on (riding)

R otar y La wnmo w er

Mac hines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safe Operating Practices . . . . . . . . . . . . . . . . . . . . . . 4

T oro Riding Mo w er Safety . . . . . . . . . . . . . . . . . . . 5

Sound Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Sound P o w er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Slope Char t . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Safety and Instr uctional Decals . . . . . . . . . . . . 8

Product Ov er view . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

T hink Safety First . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

R ecommended Gasoline . . . . . . . . . . . . . . . . . . . . 12

Chec king the Engine Oil Lev el . . . . . . . . . . . 14

Using the P arking Brak e . . . . . . . . . . . . . . . . . . . . . 14

Star ting and Stopping the

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Operating the Blades . . . . . . . . . . . . . . . . . . . . . . . . . 15

T he Safety Interloc k System . . . . . . . . . . . . . . . 15

Dri ving F orw ard or Bac kw ard . . . . . . . . . . . . 16

Stopping the Mac hine . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjusting the Height of Cut . . . . . . . . . . . . . . . 17

Adjusting the Anti-Scalp

R ollers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

P ositioning the Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

© 2005—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Contact us at www.Toro.com.

2

Printed in the USA.

All Rights Reserved

Page 3

Adjusting the Motion Control

Lev ers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Pushing the Mac hine b y Hand . . . . . . . . . . . . 18

Con v er ting to Side Disc harg e . . . . . . . . . . . . . 19

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

R ecommended Maintenance

Sc hedule(s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Ho w to Grease . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

W here to Add Grease . . . . . . . . . . . . . . . . . . . . . . . . 24

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Ser vicing the Engine Oil . . . . . . . . . . . . . . . . . . . . 24

Ser vicing the Air Cleaner . . . . . . . . . . . . . . . . . . . 25

Cleaning the Cooling System . . . . . . . . . . . . . . 27

Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuel System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Draining the Fuel T ank . . . . . . . . . . . . . . . . . . . . . . 28

R e placing the Fuel Filter . . . . . . . . . . . . . . . . . . . . 28

Electrical System Maintenance . . . . . . . . . . . . . . . . . . . 29

Ser vicing the Batter y . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ser vicing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Dri v e System Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chec king the Tire Pressure . . . . . . . . . . . . . . . . . 31

Mo w er Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Ser vicing the Cutting Blades . . . . . . . . . . . . . . . 32

Lev eling the Mo w er from

Side-to-Side . . . . . . . . . . . . . . . . . . . . . . . 33

Adjusting the F ront-to-R ear Blade

Slope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

R emo ving the Mo w er . . . . . . . . . . . . . . . . . . . . . . . . 35

Inspecting the Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

R e placing the Mo w er Belt . . . . . . . . . . . . . . . . . . 36

Installing the Mo w er . . . . . . . . . . . . . . . . . . . . . . . . . . 37

R e placing the Grass Deflector . . . . . . . . . . . . 37

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

W ashing the Underside of the

Mo w er . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Storag e . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning and Storag e . . . . . . . . . . . . . . . . . . . . . . . . . 39

T roubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Sc hematics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

3

Page 4

Safety

Safe Operation Practices

for Ride-on (riding) Rotary

Lawnmower Machines

T his mac hine meets or ex ceeds European

Standards in effect at the time of production.

Ho w ev er , improper use or maintenance b y the

operator or o wner can result in injur y . T o reduce

the potential for injur y , comply with these safety

instr uctions and alw a ys pa y attention to the

safety aler t symbol, whic h means CA UTION ,

W ARNING , or D ANGER -“personal safety

instr uction. ” F ailure to comply with the instr uction

ma y result in personal injur y or death.

Safe Operating Practices

T he follo wing instr uctions are from the CEN

standard EN 836:1997.

T his product is capable of amputating hands and

feet and thro wing objects . Alw a ys follo w all safety

instr uctions to a v oid serious injur y or death.

Training

• R ead the instr uctions carefully . Be familiar

with the controls and the proper use of the

equipment.

• Nev er allo w c hildren or people unfamiliar with

these instr uctions to use the la wnmo w er . Local

regulations can restrict the ag e of the operator .

• Nev er mo w while people , especially c hildren,

or pets are nearb y .

• K ee p in mind that the operator or user is

responsible for accidents or hazards occur ring

to other people or their proper ty .

• Do not car r y passeng ers .

• All dri v ers should seek and obtain professional

and practical instr uction. Suc h instr uction

should emphasize:

◊ being dri v en too fast;

◊ inadequate braking;

◊ the type of mac hine is unsuitable for its

task;

◊ lac k of a w areness of the effect of

g round conditions , especially slopes;

◊ incor rect hitc hing and load distribution.

Preparation

• W hile mo wing, alw a ys w ear substantial

footw ear and long trousers . Do not operate

the equipment when barefoot or w earing open

sandals .

• T horoughly inspect the area where the

equipment is to be used and remo v e all objects

whic h ma y be thro wn b y the mac hine .

• W ar ning-Fuel is highly flammable .

– Store fuel in containers specifically designed

for this pur pose .

– R efuel outdoors only and do not smok e

while refuelling .

– Add fuel before star ting the engine . Nev er

remo v e the cap of the fuel tank or add fuel

while the engine is r unning or when the

engine is hot.

– If fuel is spilled, do not attempt to star t the

engine but mo v e the mac hine a w a y from

the area of spillag e and a v oid creating any

source of ignition until fuel v apors ha v e

dissipated.

– R e place all fuel tanks and container caps

securely .

• R e place faulty silencers .

• Before using, alw a ys visually inspect to see that

the blades , blade bolts and cutter assembly

are not w or n or damag ed. R e place w or n or

damag ed blades and bolts in sets to preser v e

balance .

– the need for care and concentration when

w orking with ride-on mac hines;

– control of a ride-on mac hine sliding on a

slope will not be reg ained b y the application

of the brak e . T he main reasons for loss of

control are:

◊ insufficient wheel g rip;

• On m ulti-bladed mac hines , tak e care as rotating

one blade can cause other blades to rotate .

Operation

• Be aler t, slo w do wn and use caution when

making tur ns . Look behind and to the side

before c hanging directions .

4

Page 5

• Do not operate the engine in a confined space

where dang erous carbon mono xide fumes can

collect.

• Mo w only in da ylight or in g ood ar tificial light.

• Before attempting to star t the engine ,

diseng ag e all blade attac hment clutc hes and

shift into neutral.

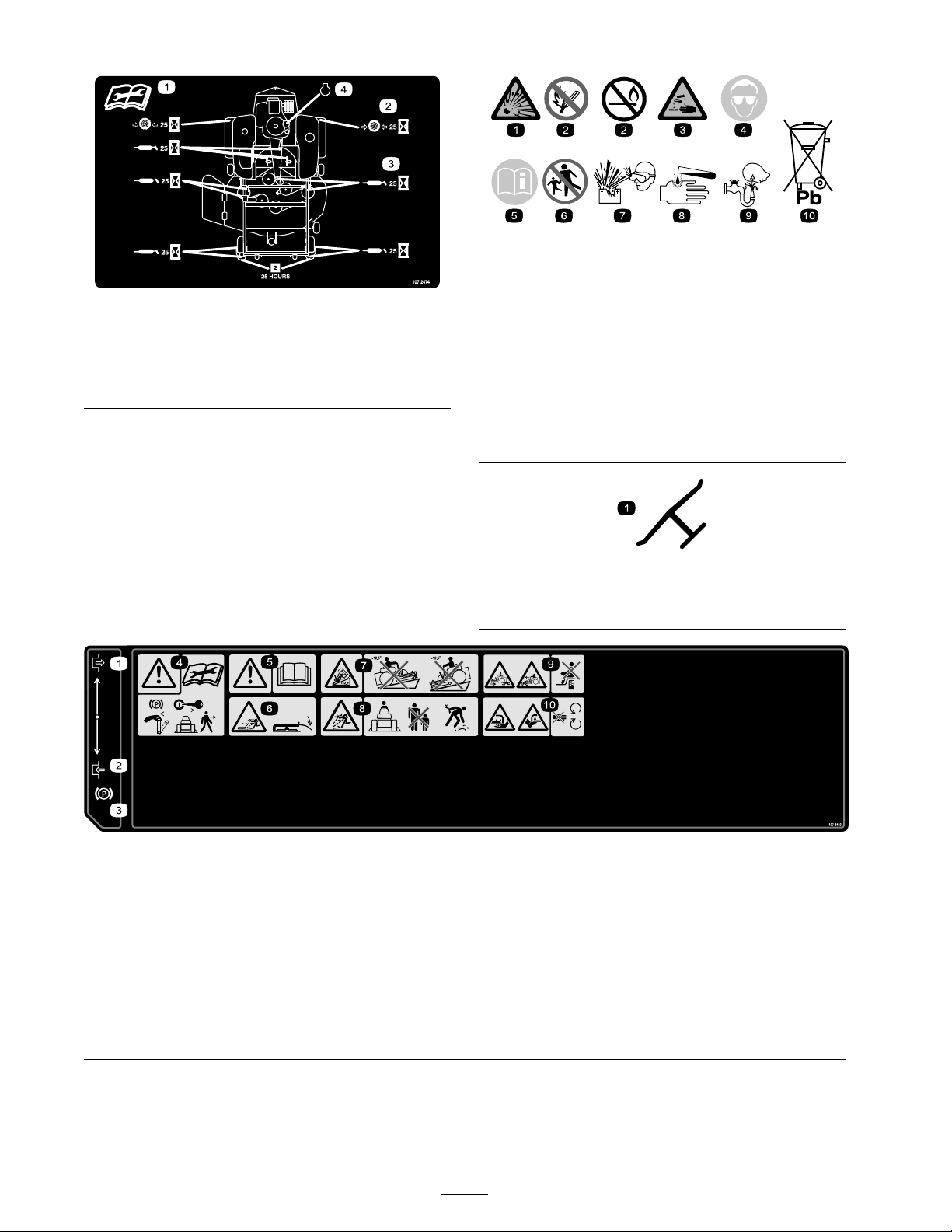

• Do not use on slopes of more than 12-1/2

deg rees .

• R emember there is no suc h thing as a safe

slope . T ra v el on g rass slopes requires par ticular

care . T o guard ag ainst o v er tur ning:

– do not stop or star t suddenly when g oing

up or do wnhill;

– use lo w speeds on slopes and during tight

tur ns;

– sta y aler t for humps and hollo ws and other

hidden hazards;

• Use care when pulling loads .

– Use only appro v ed dra wbar hitc h points .

– Limit loads to those y ou can safely control.

– Do not tur n shar ply . Use care when

rev ersing .

• W atc h out for traffic when crossing or near

roadw a ys .

• Stop the blades rotating before crossing

surfaces other than g rass .

• W hen using any attac hments , nev er direct

disc harg e of material to w ard b ystanders

nor allo w any one near the mac hine while in

operation.

• Nev er operate the mac hine with damag ed

guards or without safety protecti v e devices in

place .

• Do not c hang e the engine g o v er nor settings or

o v erspeed the engine . Operating the engine

at ex cessi v e speed can increase the hazard of

personal injur y .

• Before lea ving the operator’ s position:

– diseng ag e the po w er tak e-off and lo w er the

attac hments;

– c hang e into neutral and set the parking

brak e;

– stop the engine and remo v e the k ey .

• Diseng ag e dri v e to attac hments , stop the

engine , and disconnect the spark plug wire(s)

or remo v e the ignition k ey

– before clearing bloc kag es or unclog ging

c hute;

– before c hec king, cleaning or w orking on

the la wnmo w er;

– after striking a foreign object. Inspect

the la wnmo w er for damag e and mak e

re pairs before restar ting and operating the

equipment;

– if the mac hine star ts to vibrate abnor mally

(c hec k immediately).

• Diseng ag e dri v e to attac hments when

transpor ting or not in use .

• Stop the engine and diseng ag e dri v e to

attac hment

– before refuelling;

– before remo ving the g rass catc her;

– before making height adjustment unless

adjustment can be made from the operator’ s

position.

• R educe the throttle setting during engine

r un-out and, if the engine is pro vided with

a shut-off v alv e , tur n the fuel off at the

conclusion of mo wing .

Maintenance and Storage

• K ee p all n uts , bolts and screws tight to be sure

the equipment is in safe w orking condition.

• Nev er store the equipment with fuel in the

tank inside a building where fumes can reac h

an open flame or spark.

• Allo w the engine to cool before storing in any

enclosure .

• T o reduce the fire hazard, k ee p the engine ,

silencer , batter y compar tment and fuel storag e

area free of g rass , lea v es , or ex cessi v e g rease .

• Chec k the g rass catc her frequently for w ear or

deterioration.

• R e place w or n or damag ed par ts for safety .

• If the fuel tank has to be drained, this should

be done outdoors .

• W hen mac hine is to be park ed, stored or left

unattended, lo w er the cutting means .

Toro Riding Mower Safety

T he follo wing list contains safety infor mation

specific to T oro products or other safety

5

Page 6

infor mation that y ou m ust kno w that is not

included in the CEN standard.

• A v oid sudden star ts when mo wing uphill

because the mo w er ma y tip bac kw ards .

• Engine exhaust contains carbon mono xide ,

whic h is an odorless , deadly poison that can

kill y ou. Do not r un engine indoors or in an

enclosed area.

• K ee p hands , feet, hair and loose clothing a w a y

from attac hment disc harg e area, underside of

mo w er and any mo ving par ts while engine is

r unning .

• Do not touc h equipment or attac hment par ts

whic h ma y be hot from operation. Allo w to

cool before attempting to maintain, adjust, or

ser vice .

• Batter y acid is poisonous and can cause bur ns .

A v oid contact with skin, eyes and clothing .

Protect y our face , eyes , and clothing when

w orking with a batter y .

• Batter y g ases can explode . K ee p cig arettes ,

sparks , and flames a w a y from batter y .

• Use only g en uine T oro re placement par ts to

ensure that original standards are maintained.

• Use only T oro-appro v ed attac hments .

Slope Operation

• Do not mo w slopes g reater than 12-1/2

deg rees .

• Do not mo w near drop-offs , ditc hes , stee p

banks , or w ater . W heels dropping o v er edg es

can cause rollo v ers , whic h ma y result in serious

injur y , death, or dro wning .

• Do not mo w slopes when g rass is w et. Slipper y

conditions reduce traction and could cause

sliding and loss of control.

• Do not mak e sudden tur ns or rapid speed

c hang es .

• Use a w alk behind mo w er and/or a hand

trimmer near drop-offs , ditc hes , stee p banks ,

or w ater .

• Be a w are that loss of traction ma y occur g oing

do wnhill. W eight transfer to the front wheels

ma y cause dri v e wheels to slip and cause loss

of braking and steering .

• Alw a ys a v oid sudden star ting or stopping on

a slope . If tires lose traction, diseng ag e the

blades and proceed slo wly off the slope .

• F ollo w the man ufacturer’ s recommendations

for wheel w eights or counterw eights to

impro v e stability .

• Use extreme care with g rass catc hers or other

attac hments . T hese can c hang e the stability of

the mac hine and cause loss of control.

Sound Pressure

T his unit has a maxim um sound pressure lev el

at the operator’ s ear of 90 dB A, based on

measurements of identical mac hines per EN11094

and EN836.

Sound Power

T his unit has a guaranteed sound po w er lev el of

105 dB A, based on measurements of identical

mac hines per EN11094.

Vibration

T his unit does not ex ceed a hand/ar m vibration

lev el of 2.36 m/s2, based on measurements of

identical mac hines per EN1033.

T his unit does not ex ceed a whole body vibration

lev el of .295 m/s2, based on measurements of

identical mac hines per EN1032.

• R educe speed and use extreme caution on

slopes .

• R emo v e or mark obstacles suc h as roc ks , tree

limbs , etc . from mo wing area. T all g rass can

hide obstacles .

• W atc h for ditc hes , holes , roc ks dips , and rises

that c hang e the operating angle , as rough

ter rain could o v er tur n the mac hine .

6

Page 7

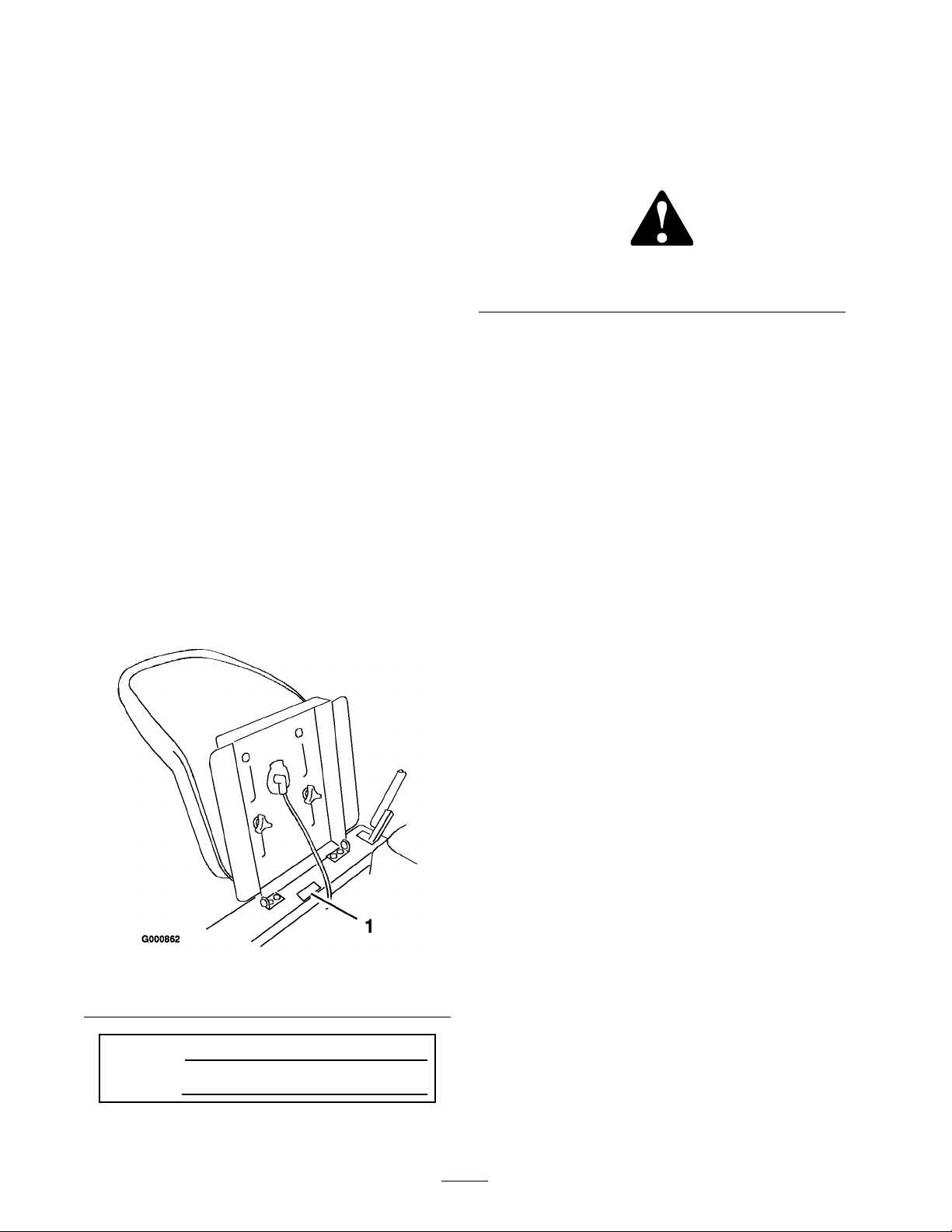

Slope Chart

7

Page 8

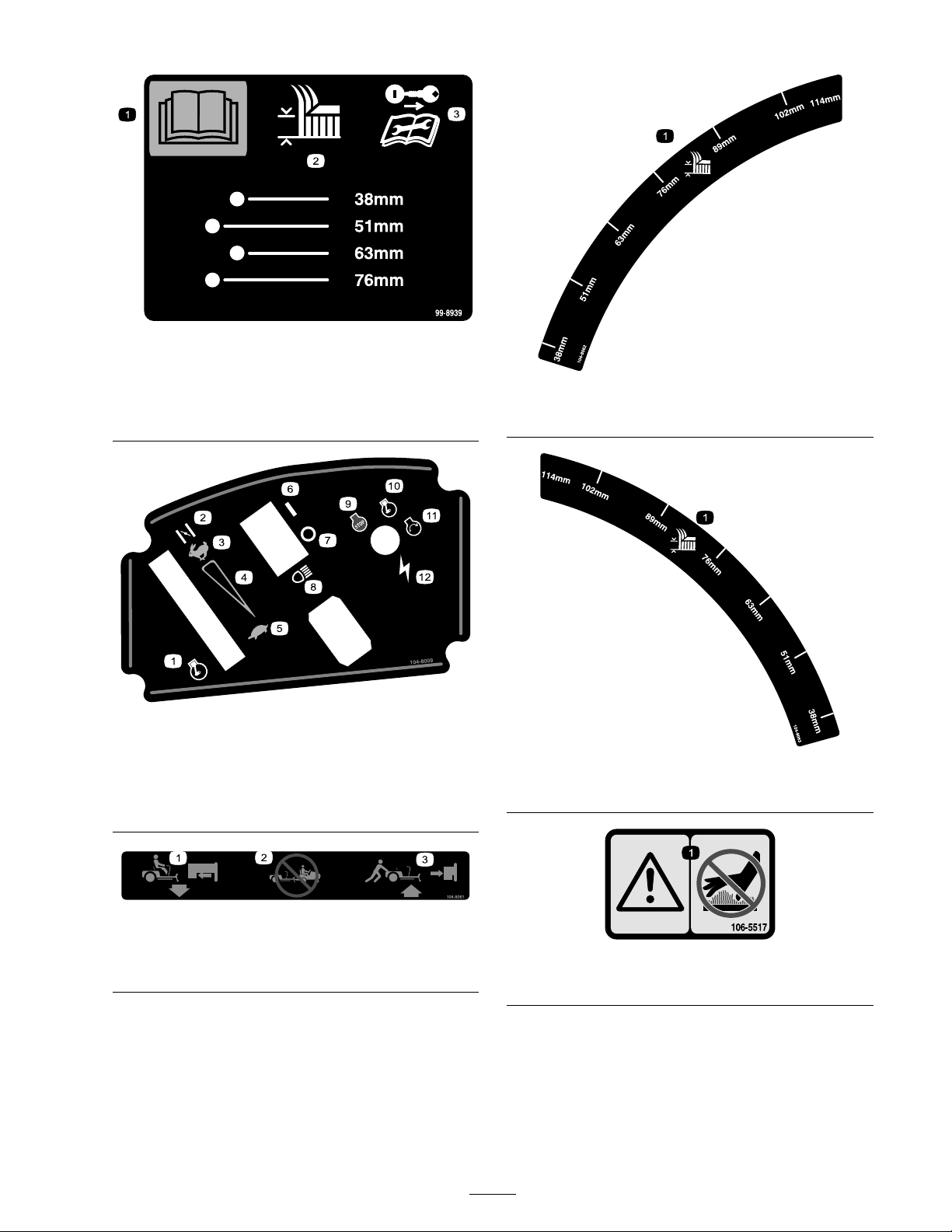

Safety and Instructional

Decals

Safety decals and instr uctions are easily visible to the operator and are located near any

area of potential dang er . R e place any decal that is damag ed or lost.

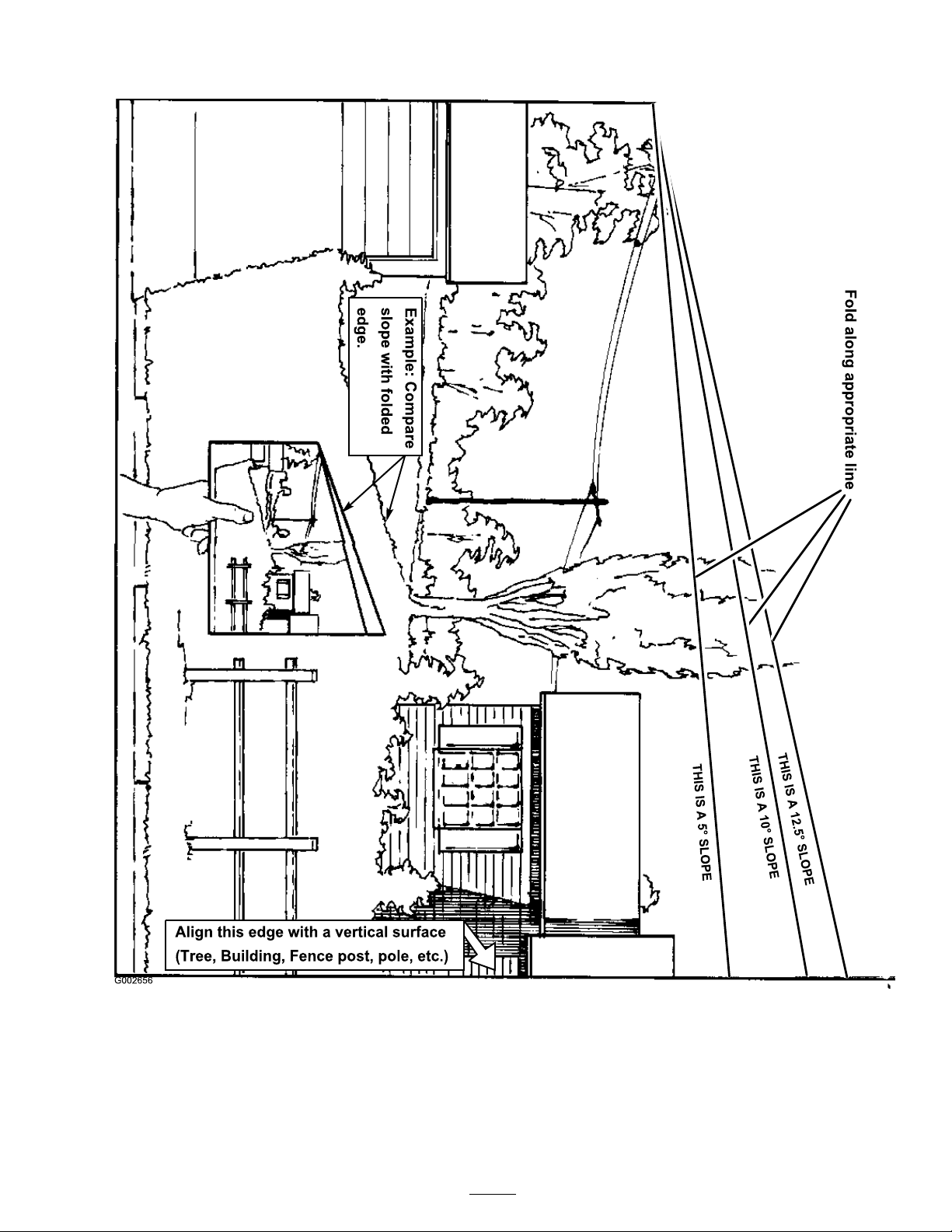

93-7009

1. Warning—don’t operate the mower with the deector up or

removed; keep the deector in place.

2. Cutting/dismemberment hazard of hand or foot, mower

blade—stay away from moving parts.

99-3943

1. Engine

110-1868

1. Thrown object hazard, mower—keep the deector in place.

2. Thrown object hazard—Keep bystanders a safe distance from

the machine; Do not operate the without grass collection

system in place.

3. Cutting/dismemberment of hand or foot—stay away from

moving parts.

93-7317

1. Thrown object hazard—keep bystanders a safe distance from

the machine.

2. Thrown object hazard, mower—keep the deector in place.

3. Cutting/dismemberment of hand or foot—stay away from

moving parts.

99-8936

1. Machine speed 4. Neutral

2. Fast

3. Slow

5. Reverse

8

Page 9

1. Read the Operator’s

Manual .

2. Height of cut

1. Throttle 7. Headlights

2. Choke

3. Continuous variable setting

4. Slow

5. On

6. Off

99-8939

3. Remove the ignition key

and read the instructions

before servicing or

performing maintenance.

1. Height of cut

104-8062

104-8009

8. Engine—stop

9. Engine—run

10. Engine—start

11. Ignition

1. Height of cut

104-8063

1. To ride the machine, pull

the lever out.

2. Do not tow the machine.

104-8061

3. To push the machine, push

the lever in.

1. Warning—do not touch the hot surface.

106-5517

9

Page 10

1. Read the instructions before

servicing or performing

maintenance.

2. Check the tire pressure

every 25 operating hours.

Battery Symbols

Some or all of these symbols are on your battery

107-2474

3. Grease every 25 operating

hours.

4. Engine

1. Explosion hazard 6. Keep bystanders a safe

2. No re, open ame, or

smoking.

3. Caustic liquid/chemical

burn hazard

4. Wear eye protection

5. Read the Operator’s

Manual.

distance from the battery.

7. Wear eye protection;

explosive gases can cause

blindness and other injuries

8. Battery acid can cause

blindness or severe burns.

9. Flush eyes immediately

with water and get medical

help fast.

10. Contains lead; do not

discard.

Manufacturer’s Mark

1. Indicates the blade is identied as a part from the original

machine manufacturer.

107-2482

1. Engage

2. Disengage

3. Parking brake 7. Tipping hazard, slopes greater than

4. Warning—set the parking brake and

remove the ignition key before leaving

the machine and read the instructions

before servicing or performing

maintenance.

5. Warning—read the Operator’s Manual.

6. Thrown object hazard, mower—keep

the deector in place.

12.5 degrees—do not drive the machine

on a slope greater than 12.5 degrees.

8. Thrown object hazard—keep bystanders

a safe distance from the machine and

pick up debris before operating.

10

9. Crushing/dismemberment hazard of

bystanders—do not carry passengers.

10. Cutting/dismemberment hazard of

hand or foot, mower blade—stay away

from moving parts.

Page 11

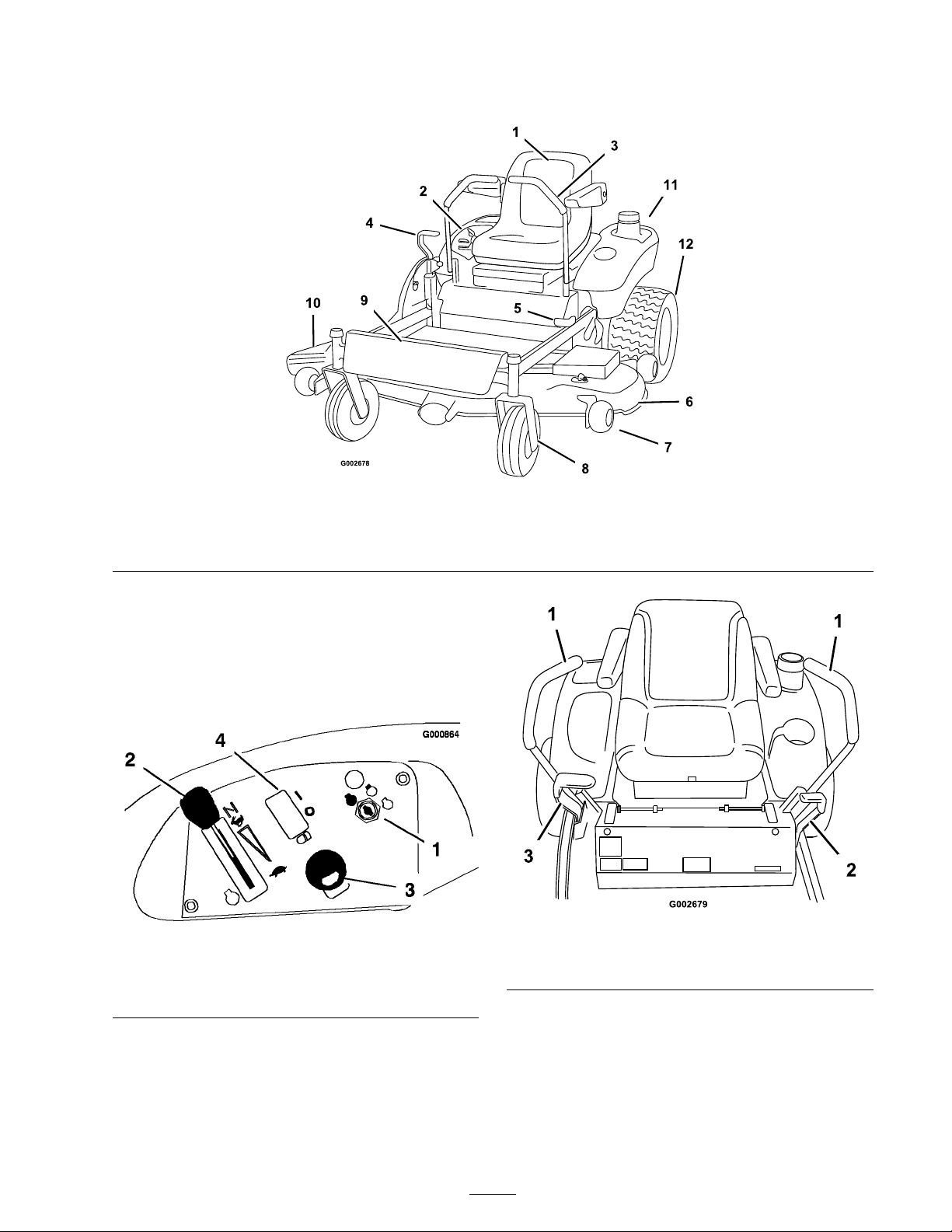

Product Overview

Figure 3

1. Seat

2. Control panel 5. Parking brake 8. Front castor wheel 11. Gas tank

3. Motion control levers 6. Mower deck

4. Height of cut lever 7. Anti-scalp wheel 10. Discharge chute

9. Footrest

12. Rear drive wheel

Controls

Become familiar with all of the controls ( Figure 4

and Figure 5 ) before y ou star t the engine and

operate the mac hine .

Figure 4

1. Ignition switch 3. Blade control switch

(power take-off)

2. Throttle/Choke 4. Headlights-optional

Figure 5

1. Motion control lever 3. Height-of-cut lever

2. Parking brake lever

11

Page 12

Operation

Note: Deter mine the left and right sides of the

mac hine from the nor mal operating position.

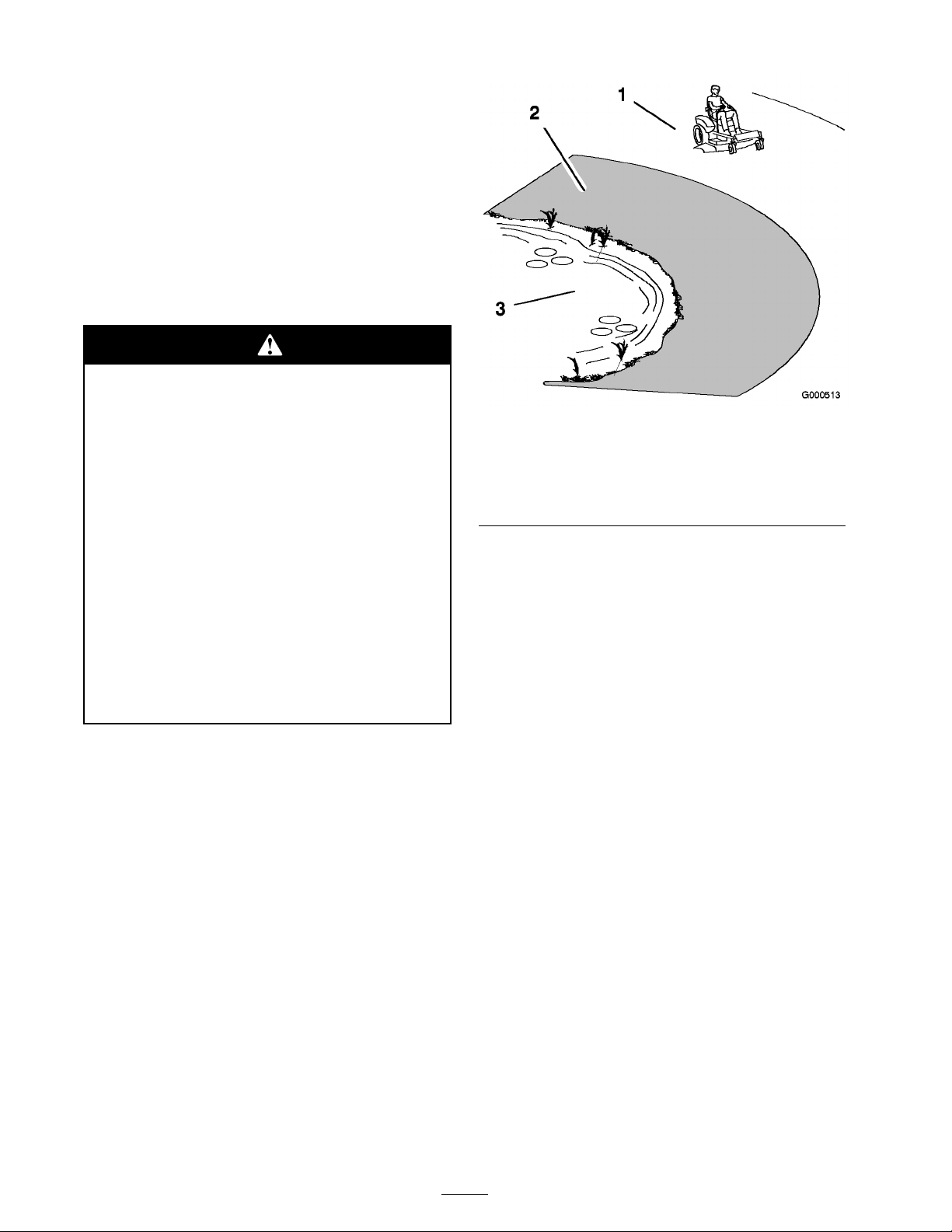

Think Safety First

Please carefully read all of the safety instr uctions

and decals in the safety section. Kno wing this

infor mation could help y ou, y our family , pets or

b ystanders a v oid injur y .

Mo wing on w et g rass or steep slopes can

cause sliding and loss of contr ol.

W heels dr opping o v er edges can cause

r ollo v er s, which may r esult in serious injur y ,

death or dr o wning .

T o a v oid loss of contr ol and possibility of

r ollo v er :

1. Safe Zone-use the

TimeCutter here

2. Use walk behind mower

and/or hand trimmer near

drop-offs and water.

Figure 6

3. Water

• Do not mo w near dr op-of fs or near w ater .

• Do not mo w slopes g r eater than

12.5 deg r ees.

• R educe speed and use extr eme caution

on slopes.

• A v oid sudden tur ns or rapid speed

changes.

Recommended Gasoline

Use UNLEADED R egular Gasoline suitable

for automoti v e use (87 pump octane minim um).

Leaded regular g asoline ma y be used if unleaded

regular is not a v ailable .

Important: Nev er use methanol, gasoline

containing methanol, or gasohol containing

mor e than 10% ethanol because the fuel

system could be dama ged. Do not mix oil

with gasoline.

12

Page 13

In cer tain conditions, gasoline is extr emel y

flamma ble and highl y explosi v e. A fir e or

explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

• Fill the fuel tank outdoor s, in an open

ar ea, when the engine is cold. W ipe up

an y gasoline that spills.

• Nev er fill the fuel tank inside an enclosed

trailer .

• Do not fill the fuel tank completel y full.

Add gasoline to the fuel tank until the

lev el is 1/4 to 1/2 inch (6 to 13 mm)

belo w the bottom of the filler neck. T his

empty space in the tank allo ws gasoline

to expand.

• Nev er smok e when handling gasoline,

and stay a w ay fr om an open flame or

wher e gasoline fumes may be ignited by

a spar k.

• Stor e gasoline in an appr o v ed container

and k eep it out of the r each of childr en.

Nev er buy mor e than a 30-day suppl y of

gasoline.

• Do not operate without entir e exhaust

system in place and in pr oper w or king

condition.

In cer tain conditions during fueling , static

electricity can be r eleased causing a spar k

which can ignite the gasoline v apor s. A fir e

or explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

• Al w ays place gasoline container s on the

g r ound a w ay fr om y our v ehicle bef or e

filling .

• Do not fill gasoline container s inside

a v ehicle or on a tr uck or trailer bed

because interior car pets or plastic tr uck

bed liner s may insulate the container and

slo w the loss of an y static charge.

• W hen practical, r emo v e gas-po w er ed

equipment fr om the tr uck or trailer and

r efuel the equipment with its wheels on

the g r ound.

• If this is not possible, then r efuel such

equipment on a tr uck or trailer fr om a

por ta ble container , rather than fr om a

gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be

used, k eep the nozzle in contact with the

rim of the fuel tank or container opening

at all times until fueling is complete.

Gasoline is har mful or f atal if s w allo w ed.

Long-ter m exposur e to v apor s can cause

serious injur y and illness.

• A v oid pr olonged br eathing of v apor s.

• K eep f ace a w ay fr om nozzle and gas tank

or conditioner opening .

• K eep gas a w ay fr om ey es and skin.

Using Stabilizer/Conditioner

Use a fuel stabilizer/conditioner in the mac hine to

pro vide the follo wing benefits:

• K ee ps g asoline fresh during storag e of 30 da ys

or less . F or long er storag e it is recommended

that the fuel tank be drained.

13

Page 14

• Cleans the engine while it r uns

• Eliminates gum-lik e v ar nish buildup in the fuel

system, whic h causes hard star ting

Important: Do not use fuel additi v es

containing methanol or ethanol.

Add the cor rect amount of g as

stabilizer/conditioner to the g as .

Note: A fuel stabilizer/conditioner is most

effecti v e when mix ed with fresh g asoline . T o

minimize the c hance of v ar nish de posits in the

fuel system, use fuel stabilizer at all times .

Filling the Fuel Tank

1. Shut the engine off and set the parking brak e .

2. Clean around the fuel tank cap and remo v e

the cap . Add unleaded regular g asoline to the

fuel tank until the lev el is 1/4 to 1/2 inc h

(6 to 13 mm) belo w the bottom of the filler

nec k. T his space in the tank allo ws g asoline to

expand. Do not fill the fuel tank completely

full.

3. Install the fuel tank cap securely . Wipe up any

g asoline that ma y ha v e spilled.

Checking the Engine Oil

Level

Before y ou star t the engine and use the mac hine ,

c hec k the oil lev el in the engine crankcase; refer to

Chec king the Oil Lev el in Engine Maintenance ,

pag e 24 .

Figure 7

1. Parking brake-On 2. Parking brake-Off

Releasing the Parking Brake

Push forw ard and do wn on the parking brak e lev er

to release the parking brak e ( Figure 7 ).

Starting and Stopping the

Engine

Starting the Engine

1. Sit do wn on the seat and mo v e the motion

controls to neutral loc k ed position.

2. Set the parking brak e; refer to Setting the

P arking Brak e abo v e .

3. Diseng ag e the blades b y mo ving the blade

control switc h to Off ( Figure 8 ).

Using the Parking Brake

Alw a ys set the parking brak e when y ou stop the

mac hine or lea v e it unattended.

Setting the Parking Brake

1. Mo v e the motion control lev ers ( Figure 5 ) out

to the neutral loc k position.

2. Pull bac k and up on the parking brak e lev er to

set the parking brak e ( Figure 7 ). T he parking

brak e lev er should sta y fir mly in the Eng ag ed

position.

Important: Do not enga ge the par king

brak e while the machine is mo ving .

Dama ge to the dri v e system may occur .

Figure 8

1. Blade control switch—On 2. Blade control switch—Off

4. Mo v e the throttle lev er to Chok e before

star ting a cold engine .

Note: A w ar m or hot engine ma y require

c hoking . After the engine star ts , mo v e the

throttle lev er to F ast.

5. T ur n the ignition k ey to Star t to energize the

star ter . W hen the engine star ts , release the k ey .

14

Page 15

Important: Do not enga ge the star ter

f or mor e than 10 seconds at a time. If the

engine f ails to star t, allo w a 60 second

cool-do wn period betw een attempts.

F ailur e to f ollo w these instr uctions can

bur n out the star ter motor .

6. After the engine star ts , mo v e the throttle

lev er to F ast ( Figure 9 ). If the engine stalls

or hesitates , mo v e the throttle lev er bac k to

Chok e for a few seconds . T hen mo v e the

throttle lev er to the desired setting . R e peat this

as required.

Figure 9

1. Engine

2. Choke 4. Slow

3. Fast

Operating the Blades

T he blade control switc h, re presented b y a po w er

tak e-off (PTO) symbol, eng ag es and diseng ag es

po w er to the mo w er blades . T his switc h controls

po w er to any attac hments that dra w po w er from

the engine , including the mo w er dec k and cutting

blades .

Engaging the Blades

1. R elease pressure on the traction control lev ers

and place the mac hine in neutral.

2. Mo v e the throttle to the F ast position.

3. Pull out on the blade control switc h to eng ag e

blades ( Figure 11 ).

Figure 10

1. Off

2. Run

3. Start

4. Ignition

Stopping the Engine

1. Mo v e the throttle lev er to Slo w ( Figure 9 ).

2. Diseng ag e the blades b y mo ving the blade

control switc h to Off ( Figure 8 ).

3. T ur n the ignition k ey to Off ( Figure 10 ).

4. Pull the wire off of the spark plug(s) to prev ent

the possibility of someone accidentally star ting

the mac hine before transpor ting or storing the

mac hine .

5. Close the fuel shut-off v alv e under the front

of the fuel tank before transpor ting or storing

the mac hine .

Important: Mak e sur e the fuel shut-of f

v alv e is closed bef or e transpor ting or

storing machine, as fuel leaka ge may

occur .

Figure 11

1. Blade control switch-On 2. Blade control switch-Off

Disengaging the Blades

Push the blade control switc h to Off to diseng ag e

the blades ( Figure 11 ).

The Safety Interlock System

If safety inter lock s witches ar e disconnected

or dama ged the machine could operate

unexpectedl y causing per sonal injur y .

• Do not tamper with the inter lock

s witches.

• Check the operation of the inter lock

s witches dail y and r eplace an y dama ged

s witches bef or e operating the machine.

Understanding the Safety Interlock

System

T he safety interloc k system is designed to prev ent

the engine from star ting unless:

• T he parking brak e is eng ag ed.

15

Page 16

• T he blades are diseng ag ed.

• T he motion control lev ers are in the neutral

loc k ed position.

T he safety interloc k system also is designed to

stop the engine when the traction controls are

mo v ed with the parking brak e on or if y ou rise

from the seat when the blades are eng ag ed.

Testing the Safety Interlock System

T est the safety interloc k system before y ou use

the mac hine eac h time . If the safety system

does not operate as described belo w , ha v e an

A uthorized Ser vice Dealer re pair the safety system

immediately .

1. W hile sitting on the seat, eng ag e the parking

brak e and mo v e the blade control switc h to

On. T r y star ting the engine; the engine should

not crank.

2. W hile sitting on the seat, eng ag e the parking

brak e and mo v e the blade control switc h

to Off . Mo v e either motion control lev er

(forw ard or rev erse). T r y star ting the engine;

the engine should not crank. R e peat with the

other motion control lev er .

T he machine can spin v er y rapidl y . T he

operator may lose contr ol of the machine

and cause per sonal injur y or dama ge to the

machine.

• Use caution when making tur ns.

• Slo w the machine do wn bef or e making

shar p tur ns.

Forward

1. R elease the parking brak e .

2. Mo v e the lev ers to the center , unloc k ed

position.

3. T o g o forw ard, slo wly push the motion control

lev ers forw ard ( Figure 12 ).

Note: T he engine will kill if the traction

control lev ers are mo v ed with the parking

brak e eng ag ed.

3. W hile sitting on the seat, eng ag e the parking

brak e , mo v e the blade control switc h to Off ,

and loc k the motion control lev ers in neutral.

Star t the engine . W hile the engine is r unning,

release the parking brak e , eng ag e the blade

control switc h, and rise slightly from the seat;

the engine should stop .

4. W hile sitting on the seat, eng ag e the parking

brak e , mo v e the blade control switc h to Off ,

and loc k the motion control lev ers in neutral.

Star t the engine . W hile the engine is r unning,

center the motion controls and mo v e (forw ard

or rev erse); the engine should stop .

Driving Forward or

Backward

T he throttle control regulates the engine speed as

measured in r pm (rev olutions per min ute). Place

the throttle control in the F ast position for best

perfor mance . Alw a ys operate in the full throttle

position.

Figure 12

1. Motion control

lever-neutral lock position

2. Center unlock position 4. Backward

3. Forward

T o g o straight, apply equal pressure to both

motion control lev ers ( Figure 12 ).

T o tur n, release pressure on the motion control

lev er to w ard the direction y ou w ant to tur n

( Figure 12 ).

T he far ther y ou mo v e the traction control

lev ers in either direction, the faster the mac hine

will mo v e in that direction.

T o stop , pull the motion control lev ers to

neutral.

16

Page 17

Backward

1. Mo v e the lev ers to the center , unloc k ed

position.

2. T o g o bac kw ard, slo wly pull the motion control

lev ers rearw ard ( Figure 12 ).

T o g o straight, apply equal pressure to both

motion control lev ers ( Figure 12 ).

T o tur n, release the pressure on the motion

control lev er to w ard the direction y ou w ant to

tur n ( Figure 12 ).

T o stop , push the motion control lev ers to

neutral.

4. Secure the clevis pin with the hair pin cotter

( Figure 13 ).

Stopping the Machine

T o stop the mac hine , mo v e the traction control

lev ers to neutral and se parate to loc k, diseng ag e

the blade control switc h, and tur n the ignition k ey

to Off to stop the engine . Also set the parking

brak e when y ou lea v e the mac hine; refer to Setting

the P arking Brak e . R emember to remo v e the k ey

from the ignition switc h.

Important: Do not enga ge the par king

brak e while the machine is mo ving . Dama ge

to the dri v e system may occur .

Childr en or bystander s may be injur ed if

they mo v e or attempt to operate the tractor

while it is unattended.

Al w ays r emo v e the ignition k ey and set the

par king brak e when lea ving the machine

unattended, ev en if just f or a few min utes.

Adjusting the Height of Cut

T he height of cut is adjusted from 1-1/2 to

4-1/2 inc h (38 to 114 mm) in 1/2 inc h (13 mm)

increments b y relocating the clevis pin in different

hole locations .

1. Raise the height-of-cut lev er to the transpor t

position (also the 4-1/2 inc h (114 mm) cutting

height position) ( Figure 13 ).

2. T o adjust, remo v e the hair pin cotter and clevis

pin from the height-of-cut brac k et ( Figure 13 ).

3. Select the hole in the height-of-cut brac k et

cor responding to the height-of-cut desired,

and inser t the clevis pin ( Figure 13 ).

Figure 13

1. Height-of-cut lever

2. Clevis pin

5. Lo w er the height-of-cut lev er onto the clevis

pin.

3. Hairpin cotter

Adjusting the Anti-Scalp

Rollers

W henev er y ou c hang e the height-of-cut it is

recommended to adjust the height of the anti-scalp

rollers .

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

A. After adjusting the height-of-cut, remo v e

the n ut and w asher while holding the stud

with a wrenc h ( Figure 14 ).

Note: Do not remo v e the wheel n ut and

w asher ( Figure 14 ).

17

Page 18

Figure 14

1. Gage wheel

2. Stud 5. Wheel nut and washer.

3. Washer

4. Nut

Do not remove.

B . Select a hole so that the g ag e wheel is

positioned to the nearest cor responding

height-of-cut desired ( Figure 14 ).

3. Install the stud n ut and w asher ( Figure 14 ).

4. R e peat the adjustment on the other g ag e

wheels .

Adjusting the Motion

Control Levers

T he motion control lev ers can be adjusted higher

or lo w er for maxim um operator comfor t.

1. R emo v e the 2 screws and cur v ed w ashers

holding the control lev er to the control ar m

shaft ( Figure 16 ).

2. Mo v e the control lev er to the next set of holes .

Secure the lev er with the 2 screws and cur v ed

w ashers . T he cupped side of the w asher should

be to w ard the control ar m shaft ( Figure 16 ).

3. R e peat the adjustment on the other control

lev er .

Positioning the Seat

T he seat can mo v e forw ard and bac kw ard.

P osition the seat where y ou ha v e the best control

of the mac hine and are most comfor table .

1. Raise the seat and loosen the adjustment knobs

( Figure 15 ).

2. Mo v e the seat to the desired position and

tighten the knobs .

Figure 15

1. Adjustment knobs

Figure 16

1. Control lever 3. Curved washer

2. Screw

4. Control arm shaft

Pushing the Machine by

Hand

Important: Al w ays push the machine

by hand. Nev er to w the machine because

dama ge may occur .

To Push the Machine

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Pull the tw o b ypass lev ers up and push them

until the w asher on the rod passes through the

slot. Push the lev ers do wn to loc k them in

place ( Figure 17 ).

4. Diseng ag e the parking brak e to push the

mac hine .

18

Page 19

Figure 17

1. Position for pushing the

machine

2. Position for operating the

machine

To Operate the Machine

Pull eac h b ypass lev er up and pull them completely

out. Push the lev ers do wn ( Figure 17 ).

Note: T he mac hine will not dri v e unless the

b ypass lev ers are pulled out.

Converting to Side

W ithout the g rass deflector , discharge

co v er , or complete g rass catcher assembl y

mounted in place, y ou and other s ar e

exposed to blade contact and thr o wn de bris.

Contact with r otating mo w er blade(s) and

thr o wn de bris will cause injur y or death.

• Nev er r emo v e the g rass deflector fr om

the mo w er because the g rass deflector

r outes material do wn to w ard the turf.

If the g rass deflector is ev er dama ged,

r eplace it immediatel y .

• Nev er put y our hands or feet under the

mo w er .

• Nev er tr y to clear discharge ar ea or

mo w er blades unless y ou mo v e the blade

contr ol s witch to Of f and r otate the

ignition k ey to Of f. Also r emo v e the k ey

and pull the wir e of f the spar k plug(s).

Removing the Recycler® Bafe On 44

inch Mowers

Discharge

T he mo w er has a hing ed g rass deflector that

disperses clippings to the side and do wn to w ard

the turf .

Open holes in the mo w er expose y ou and

other s to thr o wn de bris which can cause

sev er e injur y .

• Nev er operate the mo w er without

hard w ar e mounted in all holes in the

mo w er housing .

• Install the hard w ar e in the mounting

holes when y ou r emo v e the r ecy cling

baf fle.

Note: Only the right side baffle needs to be

remo v ed for side disc harg e mo wing .

1. T horoughly clean the mo w er .

2. R emo v e the knobs and cur v ed w ashers from

the right side baffle ( Figure 18 ).

19

Page 20

2. R emo v e the car riag e bolts and loc kn uts

securing the front baffle to the dec k

( Figure 19 ). R emo v e the front baffle to g ain

access to the right side R ecycler® baffle .

Figure 18

1. Right side bafe 4. Knob

2. Bolt (5/16 x 1-1/4 inches)

3. Locknut (5/16 inch)

5. Curved washer

6. Left side bafe

Note: Sa v e the hardw are for use when

installing the baffle .

3. Lift the baffle and slide it out of the interloc k

with the left side baffle .

4. F or safety , install the knobs , w ashers and

loc kn uts into the open holes of the mo w er ,

wherev er the hardw are w as remo v ed in 2 .

Installing the Recycler® Bafe on 44

Inch Mowers

Install the right baffle when con v er ting from side

disc harg e mode to m ulc hing .

1. T horoughly clean the mo w er .

2. R emo v e knobs , w ashers and loc kn uts in the

holes needed to install the right side baffle .

3. Install the baffle into the interloc k with the left

side baffle .

4. Install the right side baffle to the mo w er with

knobs and cur v ed w ashers ( Figure 18 ) remo v ed

in Ste p 2 .

Figure 19

Operating the mo w er without the fr ont

baf fle in place, can expose y ou and

other s to blade contact and thr o wn

de bris. Contact with r otating blade(s)

and thr o wn de bris will cause serious

injur y .

Nev er operate the mo w er without the

fr ont baf fle installed.

3. R emo v e the loc k n uts from the top and center

of the right side baffle ( Figure 20 ).

4. Lo w er the baffle and slide it out of disc harg e

opening to remo v e it ( Figure 20 ).

Note: Only the right side baffle needs be

remo v ed for side disc harg e mo wing .

5. Install the bolts (5/16 x 5/8 inc h) and loc kn uts

(5/16 inc h) remo v ed in Ste p 3 in the open holes

of the mo w er for safety ( Figure 20 ).

Removing the Recycler® Bafe On 52

inch Mowers

R emo v e the right side baffle to con v er t from

m ulc hing to the side disc harg e mode .

1. T horoughly clean the mo w er .

20

Page 21

3. R emo v e the bolts and n uts in the dec k holes

needed to secure the baffle to the dec k

( Figure 20 ).

4. Install the baffle b y sliding it into the disc harg e

opening ( Figure 20 ).

5. Secure the baffle with the n uts and bolts

( Figure 20 ) remo v ed in Ste p 3 .

6. R e place the front baffle and secure it to the

dec k ( Figure 19 ) using the fasteners remo v ed

previously .

Figure 20

1. Bafe left side 3. Lock nut, 5/16 inch

2. Bolt, 5/16 x 5/8 inch

Open holes in the mo w er expose y ou and

other s to thr o wn de bris which can cause

sev er e injur y .

• Nev er operate the mo w er without

hard w ar e mounted in all holes in the

mo w er housing .

• Install the hard w ar e in the mounting

holes when y ou r emo v e the r ecy cling

baf fle.

6. R e place the front baffle and secure it to the

dec k ( Figure 19 ) using the fasteners remo v ed

previously .

Important: Do Not operate the machine

without the fr ont baf fle in place.

Operating the mo w er without the fr ont

baf fle in place, can expose y ou and

other s to blade contact and thr o wn

de bris. Contact with r otating blade(s)

and thr o wn de bris will cause serious

injur y .

Nev er operate the mo w er without the

fr ont baf fle installed.

Operating Tips

Fast Throttle Setting

F or best mo wing and maxim um air circulation,

operate the engine at F ast. Air is required to

thoroughly cut g rass clippings , so do not set the

height-of-cut so lo w as to totally sur round the

mo w er b y uncut g rass . Alw a ys tr y to ha v e one side

of the mo w er free from uncut g rass , whic h allo ws

air to be dra wn into the mo w er .

Cutting a Lawn for the First Time

Installing the Recycler® Bafe on 52

Inch Mowers

Install the right side baffle to con v er t from side

disc harg e mode to m ulc hing .

1. T horoughly clean the mo w er .

2. R emo v e the car riag e bolts and loc kn uts

securing the front baffle to the dec k

( Figure 19 ). R emo v e the front baffle to install

the right side R ecycler® baffle .

Important: Do Not operate the machine

without the fr ont baf fle in place.

Cut g rass slightly long er than nor mal to ensure

that the cutting height of the mo w er does not

scalp any unev en g round. Ho w ev er , the cutting

height used in the past is g enerally the best one to

use . W hen cutting g rass long er than six inc hes tall,

y ou ma y w ant to cut the la wn twice to ensure an

acce ptable quality of cut.

Cut 1/3 of the Grass Blade

It is best to cut only about 1/3 of the g rass blade .

Cutting more than that is not recommended unless

g rass is sparse , or it is late fall when g rass g ro ws

more slo wly .

21

Page 22

Mowing Direction

Alter nate mo wing direction to k ee p the g rass

standing straight. T his also helps disperse clippings

whic h enhances decomposition and fer tilization.

Mow at Correct Intervals

Nor mally , mo w ev er y four da ys . But remember ,

g rass g ro ws at different rates at different times .

So to maintain the same cutting height, whic h is a

g ood practice , mo w more often in early spring . As

the g rass g ro wth rate slo ws in mid summer , mo w

less frequently . If y ou cannot mo w for an extended

period, first mo w at a high cutting height; then

mo w ag ain tw o da ys later at a lo w er height setting .

Cutting Speed

T o impro v e cut quality , use a slo w er g round speed.

Avoid Cutting Too Low

If the cutting width of the mo w er is wider than the

mo w er y ou previously used, raise the cutting height

to ensure that unev en turf is not cut too shor t.

tearing or shredding the g rass blades . T earing and

shredding tur ns g rass bro wn at the edg es , whic h

slo ws g ro wth and increases the c hance of disease .

Chec k the cutter blades daily for shar pness , and

for any w ear or damag e . File do wn any nic ks

and shar pen the blades as necessar y . If a blade is

damag ed or w or n, re place it immediately with a

g en uine T oro re placement blade .

Long Grass

If the g rass is ev er allo w ed to g ro w slightly long er

than nor mal, or if it contains a high deg ree of

moisture , raise the cutting height higher than usual

and cut the g rass at this setting . T hen cut the g rass

ag ain using the lo w er , nor mal setting .

When Stopping

If the mac hine’ s forw ard motion m ust be stopped

while mo wing, a clump of g rass clippings ma y

drop onto y our la wn. T o a v oid this , mo v e onto a

previously cut area with the blades eng ag ed.

Keep the Underside of the Mower

Clean

Clean clippings and dir t from the underside of the

mo w er after eac h use . If g rass and dir t build up

inside the mo w er , cutting quality will ev entually

become unsatisfactor y .

Blade Maintenance

Maintain a shar p blade throughout the cutting

season because a shar p blade cuts cleanly without

22

Page 23

Maintenance

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Recommended Maintenance Schedule(s)

Maintenance Service

Interval

After the rst 8 operating

hours

Before each use or daily

Every 25 hours

Every 50 hours

Every 100 hours

Every 200 hours

Every 300 hours

Maintenance Procedure

• Change the engine oil.

• Check the safety system.

• Check the engine oil level (more often in dirty or dusty conditions).

• Clean the air intake screen.

• Check the cutting blades.

• Clean the mower housing.

• Grease all lubrication points (more often in dusty, dirty conditions).

• Service the foam air cleaner (more often in dusty, dirty conditions).

• Check the battery electrolyte.

• Check the tire pressure.

• Check belts for wear/cracks.

• Service the paper air cleaner (more often in dusty, dirty conditions).

• Change the engine oil (more often in dusty, dirty conditions).

• Check the spark plug(s).

• Change the oil lter.

• Replace the paper air cleaner (more often in dusty, dirty conditions).

• Replace the fuel lter.

• Clean the engine shrouds and cooling ns (more often in dusty, dirty

conditions).

• Perform all maintenance procedures listed above before storage.

Before storage

• Drain the fuel tank.

• Charge the battery and disconnect the battery cables.

• Paint any chipped surfaces.

If y ou lea v e the k ey in the ignition s witch, someone could accidentl y star t the engine and

seriousl y injur e y ou or other bystander s.

R emo v e the k ey fr om the ignition and disconnect the wir e fr om the spar k plug(s) bef or e y ou

do an y maintenance. Set the wir e aside so that it does not accidentall y contact the spar k plug .

Lubrication

Lubricate the mac hine when sho wn on the Chec k

Ser vice R eference Aid decal ( Figure 21 ) located

beneath the seat. Grease more frequently when

operating conditions are extremely dusty or sandy .

Grease with No . 2 g eneral pur pose lithium base or

molybden um base g rease .

How to Grease

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

23

Page 24

3. Clean the g rease fittings with a rag . Mak e sure

to scrape any paint off of the front of the

fitting(s).

4. Connect a g rease gun to the fitting . Pump

g rease into the fittings until g rease begins to

ooze out of the bearings .

5. Wipe up any ex cess g rease .

Where to Add Grease

Lubricate the g rease fittings as sho wn on the Chec k

Ser vice R eference Aid decal ( Figure 21 ) located

beneath the seat and the mo w er ( Figure 22 ).

Figure 21

Oil T ype: Deterg ent oil (API ser vice SF , SG , SH

or SJ)

Crankcase Capacity: with filter , 51 ounces (1.5 l)

Viscosity: See the table belo w .

Figure 23

Checking the Oil Level

1. P ark the mac hine on a lev el surface , diseng ag e

the blade control switc h, stop the engine , and

remo v e the k ey .

2. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

3. Clean around the oil dipstic k ( Figure 24 ) so

that dir t cannot fall into the fill hole and

damag e the engine .

4. Unscrew the oil dipstic k and wipe the metal

end clean ( Figure 24 ).

Figure 22

Top View

Engine Maintenance

Servicing the Engine Oil

Chang e the oil after the first 8 operating hours and

ev er y 100 operating hours thereafter .

Figure 24

1. Oil dipstick 3. Metal end, dipstick

2. Filler tube

5. Screw the oil dipstic k fully onto the fill hole .

Unscrew the dipstic k, pull it out, and look at

the metal end. If the oil lev el is lo w , slo wly

24

Page 25

pour only enough oil into the fill hole to raise

the lev el to , but not o v er , the Full mark on the

dipstic k.

Important: Do not o v erfill the crankcase

with oil because the engine may be

dama ged.

Changing and Draining the Oil

1. Star t the engine and let it r un until w ar m. T his

w ar ms the oil so it drains better .

2. P ark the mac hine so that the drain side is

slightly lo w er than the opposite side to ensure

that the oil drains completely .

3. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

4. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

5. Slide the drain hose o v er the oil drain v alv e

( Figure 25 ).

6. Place a pan belo w the oil drain hose . Use either

a flat screw dri v er , 3/8 inc h (10 mm) wrenc h

to open v alv e ( Figure 25 ).

7. R otate v alv e end countercloc kwise to open

v alv e ( Figure 25 ).

8. W hen oil has drained completely , rotate v alv e

end cloc kwise to close the v alv e ( Figure 25 ).

9. R emo v e the drain hose .

11. Slo wly pour appro ximately 80% of the

specified oil into the filler cap ( Figure 25 ).

R efer to Ser vicing the Engine Oil,

in Engine Maintenance , pag e 24 .

12. Chec k the oil lev el; refer to Chec king the Oil

Lev el.

13. Slo wly add additional oil to bring it to the full

mark.

Changing the Oil Filter

R e place the oil filter ev er y 200 hours or ev er y

other oil c hang e .

Note: Chang e the oil filter more frequently when

operating conditions are extremely dusty or sandy .

1. Drain the oil from the engine; refer to

Changing and Draining the Oil.

2. R emo v e the old filter ( Figure 26 ).

3. Apply a thin coat of new oil to the r ubber

g ask et on the re placement filter .

Note: Dispose of the used oil at a cer tified

recycling center .

Figure 25

1. Oil drain

10. Clean around the oil dipstic k and unscrew the

cap ( Figure 25 ).

Figure 26

1. Oil lter 2. Adapter

4. Install the re placement oil filter to the adapter .

T ur n the oil filter cloc kwise until the r ubber

g ask et contacts the filter adapter , then tighten

the filter an additional 3/4 tur n ( Figure 26 ).

5. Fill the crankcase with the proper type of new

oil; refer to Changing and Draining the Oil.

Servicing the Air Cleaner

F oam Element: Clean and oil after ev er y

25 operating hours .

P aper Element: Clean after ev er y 100 operating

hours . R e place after ev er y 200 operating hours or

yearly , whic hev er comes first.

25

Page 26

Note: Ser vice the air cleaner more frequently

(ev er y few hours) if operating conditions are

extremely dusty or sandy .

C . Soak the element in new engine oil.

( Figure 28 ). Squeeze the element to remo v e

ex cess oil.

Removing the Foam and Paper

Elements

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Clean around the air cleaner to prev ent dir t

from g etting into the engine and causing

damag e . Unlatc h the tw o side latc hes and

remo v e the air cleaner co v er ( Figure 27 ).

4. Carefully remo v e the foam element from the

paper element ( Figure 27 ).

5. Unscrew the wing n ut and remo v e the paper

element ( Figure 27 ).

Important: R eplace the f oam

element if it is tor n or w or n.

Figure 28

1. Foam element 2. Oil

2. P aper Element

A. Lightly tap the element on a flat surface to

remo v e dust and dir t ( Figure 29 ).

B . Inspect the element for tears , an oily film,

and damag e to the r ubber seal.

Important: Nev er clean the paper

element with pr essuriz ed air or liquids,

such as solv ent, gas, or k er osene.

R eplace the paper element if it

is dama ged or cannot be cleaned

thor oughl y .

Figure 27

1. Cover

2. Foam element 5. Air cleaner base

3. Paper element 6. Latches

4. Wing nut

Cleaning the Foam and Paper

Elements

1. F oam Element

A. W ash the foam element in liquid soap and

w ar m w ater . W hen the element is clean,

rinse it thoroughly .

B . Dr y the element b y squeezing it in a clean

cloth (do not wring). Allo w the element to

air dr y .

Figure 29

1. Paper element 2. Rubber seal

Installing the Foam and Paper

Elements

Important: T o pr ev ent engine dama ge,

al w ays operate the engine with the complete

f oam and paper air cleaner assembl y installed.

1. Carefully slide the foam element onto the

paper air cleaner element ( Figure 27 ).

26

Page 27

2. Place the air cleaner assembly onto the

air cleaner base and install the wing n ut

( Figure 27 ).

3. Install the air cleaner co v er and secure the

latc hes ( Figure 27 ).

installing the spark plug . Use a spark plug wrenc h

for remo ving and installing the spark plug(s) and a

g apping tool/feeler g aug e to c hec k and adjust the

air g ap . Install a new spark plug(s) if necessar y .

T ype: Champion R C12Y C (or equi v alent)

Cleaning the Cooling System

Clean the air intak e screen from g rass and debris

before eac h use .

Clean the cooling fins and engine shrouds ev er y

300 hours or yearly , whic hev er comes first.

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. R emo v e the air intak e screen, cylinder co v ers ,

and fan housing .

4. Clean debris and g rass from the par ts .

5. Install the air intak e screen, cylinder co v ers ,

and fan housing .

Air Gap: 0.030 inc h (0.76 mm)

Removing the Spark Plug(s)

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Pull the wire(s) off of the spark plug(s)

( Figure 31 ). Clean around the spark plug(s) to

prev ent dir t from falling into the engine and

potentially causing damag e .

4. R emo v e the spark plug(s) and metal w asher .

Figure 30

1. Air intake screen 3. Cylinder cover

2. Fan housing 4. Cylinder cover

Spark Plug

Chec k the spark plug(s) after ev er y 200 operating

hours . Mak e sure that the air g ap betw een the

center and side electrodes is cor rect before

Figure 31

1. Spark plug wire installed 2. Spark plug

Checking the Spark Plug

1. Look at the center of the spark plug(s)

( Figure 32 ). If y ou see light bro wn or g ra y on

the insulator , the engine is operating properly .

A blac k coating on the insulator usually means

the air cleaner is dir ty .

Important: Nev er clean the spar k

plug(s). Al w ays r eplace the spar k plug(s)

when it has a black coating , w or n

electr odes, an oil y film, or cracks.

2. Chec k the g ap betw een the center and side

electrodes ( Figure 32 ). Bend the side electrode

( Figure 32 ) if the g ap is not cor rect.

27

Page 28

3. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

4. Close the fuel shut-off v alv e located under the

front of the fuel tank.

5. Loosen the hose clamp at the fuel filter and

slide it up the fuel line a w a y from the fuel filter

( Figure 33 ).

Figure 32

1. Center electrode insulator

2. Side electrode

Installing the Spark Plug(s)

1. Install the spark plug(s). Mak e sure that the

air g ap is set cor rectly .

2. Tighten the spark plug(s) to 11 ft.-lb . (15 N·m).

3. Push the wire(s) onto the spark plug(s)

( Figure 31 ).

3. Air gap (not to scale)

Fuel System

Maintenance

Draining the Fuel Tank

In cer tain conditions, gasoline is extr emel y

flamma ble and highl y explosi v e. A fir e or

explosion fr om gasoline can bur n y ou and

other s and can dama ge pr oper ty .

• Drain gasoline fr om the fuel tank when

the engine is cold. Do this outdoor s in

an open ar ea. W ipe up an y gasoline that

spills.

• Nev er smok e when draining gasoline,

and stay a w ay fr om an open flame or

wher e a spar k may ignite the gasoline

fumes.

6. Pull the fuel line off of the fuel filter ( Figure 33 ).

7. Open the fuel shut-off v alv e . Allo w g asoline to

drain into a g as can or drain pan.

Note: No w is the best time to install a new

fuel filter because the fuel tank is empty .

Replacing the Fuel Filter

R e place the fuel filter after ev er y 200 operating

hours or yearly , whic hev er occurs first.

Nev er install a dir ty filter if it is remo v ed from the

fuel line .

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Close the fuel shut-off v alv e located under the

front of the fuel tank.

4. Squeeze the ends of the hose clamps tog ether

and slide them a w a y from the filter ( Figure 33 ).

5. R emo v e the filter from the fuel lines .

6. Install a new filter and mo v e the hose clamps

close to the filter ( Figure 33 ).

Important: Install the filter so the

dir ection of the flo w ar r o w is consistent

with the flo w of fuel; fr om the gas tank to

the engine.

7. Open the fuel shut-off v alv e .

1. P ark the mac hine on a lev el surface , to ensure

that the fuel tank drains completely .

2. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

28

Page 29

Figure 33

1. Fuel lter 3. Fuel line

2. Hose clamp

Electrical System

Maintenance

Servicing the Battery

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. Tip the seat forw ard to see the batter y .

4. Disconnect the neg ati v e (blac k) g round cable

from the batter y post ( Figure 34 ).

Incor r ect batter y ca ble r outing could

dama ge the tractor and ca bles causing

spar ks. Spar ks can cause the batter y

gasses to explode, r esulting in per sonal

injur y .

• Al w ays disconnect the negati v e

(black) batter y ca ble bef or e

disconnecting the positi v e (r ed)

ca ble.

• Al w ays connect the positi v e (r ed)

batter y ca ble bef or e connecting the

negati v e (black) ca ble.

Chec k the electrolyte lev el in the batter y ev er y

25 hours . Alw a ys k ee p the batter y clean and fully

c harg ed. Use a paper to w el to clean the batter y

case . If the batter y ter minals are cor roded, clean

them with a solution of four par ts w ater and one

par t baking soda. Apply a light coating of g rease

to the batter y ter minals to prev ent cor rosion.

V oltag e: 12 v

Removing the Battery

Batter y ter minals or metal tools could shor t

a gainst metal tractor components causing

spar ks. Spar ks can cause the batter y gasses

to explode, r esulting in per sonal injur y .

• W hen r emo ving or installing the batter y ,

do not allo w the batter y ter minals to

touch an y metal par ts of the tractor .

• Do not allo w metal tools to shor t betw een

the batter y ter minals and metal par ts of

the tractor .

5. Slide the r ubber co v er up the positi v e (red)

cable . Disconnect the positi v e (red) cable from

the batter y post ( Figure 34 ).

6. R emo v e the batter y hold-do wn ( Figure 34 ) and

lift the batter y from the batter y tra y .

Figure 34

1. Battery

2. Terminal boot 6. Bolt and washer

3. Positive battery cable

4. Negative battery cable

5. Battery hold-down

7. Nut

Installing the Battery

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

1. P osition the batter y in the tra y with the

ter minal posts a w a y from the control panel

( Figure 34 ).

29

Page 30

2. Install the positi v e (red) batter y cable to the

positi v e (+) batter y ter minal.

3. Install the neg ati v e batter y cable to the neg ati v e

(-) batter y ter minal.

Adding Water to the Battery

T he best time to add distilled w ater to the batter y is

just before y ou operate the mac hine . T his lets the

w ater mix thoroughly with the electrolyte solution.

4. Secure the cables with 2 bolts (1/4 x 3/4 inc h),

w ashers (1/4 inc h), and n uts (1/4 inc h)

( Figure 34 ).

5. Slide the red ter minal boot onto the positi v e

(red) batter y post.

6. Secure the batter y with the hold-do wn

( Figure 34 ).

Checking the Electrolyte Level

Batter y electr ol yte contains sulfuric acid

which is a deadl y poison and causes sev er e

bur ns.

• Do not drink electr ol yte and a v oid

contact with skin, ey es or clothing . W ear

safety g lasses to shield y our ey es and

r ub ber g lo v es to pr otect y our hands.

• Fill the batter y wher e clean w ater is

al w ays a v aila ble f or flushing the skin.

1. R emo v e the batter y from the tractor; refer to

R emo ving the Batter y .

Important: Nev er fill the batter y with

distilled w ater while the batter y installed in

the tractor . Electr ol yte could be spilled on

other par ts and cause cor r osion.

2. Clean the top of the batter y with a paper to w el.

3. R emo v e the v ent caps from the batter y

( Figure 35 ).

4. Slo wly pour distilled w ater into eac h batter y

cell until the electrolyte lev el is up to the Upper

line ( Figure 35 ) on the batter y case .

Important: Do not o v erfill the batter y

because electr ol yte (sulfuric acid) can

cause sev er e cor r osion and dama ge to the

chassis.

5. W ait fiv e to ten min utes after filling the batter y

cells . Add distilled w ater , if necessar y , until

the electrolyte lev el is up to the Upper line

( Figure 35 ) on the batter y case .

1. Tip the seat forw ard to see the batter y .

2. Look at the side of the batter y . T he electrolyte

m ust be up to the Upper line ( Figure 35 ).

Do not allo w the electrolyte to fall belo w the

Lo w er line ( Figure 35 ).

Figure 35

1. Vent caps

2. Upper line

3. Lower line

3. If the electrolyte is lo w , add the required

amount of distilled w ater; refer to Adding

W ater to the Batter y .

6. R einstall the batter y v ent caps .

Charging the Battery

Important: Al w ays k eep the batter y

full y charged (1.260 specific g ra vity). T his

is especiall y impor tant to pr ev ent batter y

dama ge when the temperatur e is belo w 32°F

(0°C).

1. R emo v e the batter y from the c hassis; refer to

R emo ving the Batter y .

2. Chec k the electrolyte lev el; refer to Chec king

the Electrolyte Lev el.

3. Mak e sure that the v ent caps are installed in

the batter y . Charg e the batter y for 1 hour at 25

to 30 amps or 6 hours at 4-6 amps . Do not

o v erc harg e the batter y .

4. W hen the batter y is fully c harg ed, unplug

the c harg er from the electrical outlet, then

disconnect the c harg er leads from the batter y

posts ( Figure 36 ).

30

Page 31

Figure 36

1. Positive battery post

2. Negative battery post

3. Red (+) charger lead

4. Black (-) charger lead

5. Install the batter y in the tractor and connect the

batter y cables; refer to Installing the Batter y .

Note: Do not r un the tractor with the batter y

disconnected, electrical damag e ma y occur .

Servicing the Fuses

Ser vice Inter v al/Specification

T he electrical system is protected b y fuses . It

requires no maintenance; ho w ev er , if a fuse blo ws ,

c hec k the component/circuit for a malfunction

or shor t.

Fuse:

• Main F1–30 amp , blade-type

• Charg e Circuit F2–25 amp , blade-type

• Optional Headlight Kit–10 amp , blade type

1. Raise the seat to g ain access to the fuse holder

( Figure 37 ).

Figure 37

1. Main–30 amp

2. Charge circuit–25 amp

3. For optional Headlight

Kit–10 amp

Drive System

Maintenance

Checking the Tire Pressure

Maintain the air pressure in the front and rear

tires as specified. Unev en tire pressure can cause

unev en cut. Chec k the pressure at the v alv e

stem after ev er y 50 operating hours or monthly ,

whic hev er occurs first ( Figure 38 ). Chec k the

tires when they are cold to g et the most accurate

pressure reading .

R ear Tires: 13 psi (90 kP a)

2. T o re place a fuse , pull out on the fuse to

remo v e it ( Figure 37 ).

F ront Tires (castor wheels): 35 psi (139 kP a)

Figure 38

1. Valve stem

31

Page 32

Mower Maintenance

Servicing the Cutting Blades

Maintain shar p blades throughout the cutting

season because shar p blades cut cleanly without

tearing or shredding the g rass blades . T earing and

shredding tur ns g rass bro wn at the edg es , whic h

slo ws g ro wth and increases the c hance of disease .

Chec k the cutter blades daily for shar pness , and

for any w ear or damag e . File do wn any nic ks

and shar pen the blades as necessar y . If a blade is

damag ed or w or n, re place it immediately with a

g en uine T oro re placement blade . F or con v enient

shar pening and re placement, y ou ma y w ant to

k ee p extra blades on hand.

A w or n or dama ged blade can br eak, and a

piece of the blade could be thr o wn into the

operator’ s or bystander’ s ar ea, r esulting in

serious per sonal injur y or death.

• Inspect the blade periodicall y f or w ear

or dama ge.

Figure 39

1. Cutting edge 3. Wear/slot forming

2. Curved area

Checking for Bent Blades

1. Diseng ag e the blade control switc h and mo v e

the control lev ers to the neutral loc k ed position

and apply the parking brak e .

2. Stop the engine , remo v e the k ey , and w ait for

all mo ving par ts to stop before lea ving the

operating position.

3. R otate the blades until the ends face forw ard

and bac kw ard ( Figure 40 ). Measure from a

lev el surface to the cutting edg e of the blades

( Figure 41 ). Note this dimension.

• R eplace a w or n or dama ged blade.

Before Inspecting or Servicing the

Blades

P ark the mac hine on a lev el surface , diseng ag e the

blade control switc h, and set the parking brak e .

Stop the engine , remo v e the k ey , and disconnect

the spark plug wire(s) from the spark plug(s).

Inspecting the Blades

1. Inspect the cutting edg es ( Figure 39 ). If the

edg es are not shar p or ha v e nic ks , remo v e and

shar pen the blades; refer to Shar pening the

Blades .

2. Inspect the blades , especially the cur v ed area

( Figure 39 ). If y ou notice any damag e , w ear , or

a slot for ming in this area (item 3 in Figure 39 ),

immediately install a new blade .

Figure 40

Figure 41

4. R otate the opposite ends of the blades forw ard.

5. Measure from a lev el surface to the cutting

edg e of the blades at the same position as

in ste p 3 abo v e . T he difference betw een the

32

Page 33

dimensions obtained in ste ps 3 and 4 m ust not

ex ceed 1/8 inc h (3 mm). If this dimension

ex ceeds 1/8 inc h (3 mm), the blade is bent

and m ust be re placed; refer to R emo ving the

Blades and Installing the Blades .

the same amount of material is remo v ed from

both cutting edg es .

A blade that is bent or dama ged could

br eak apar t and could seriousl y injur e or

kill y ou or bystander s.

• Al w ays r eplace bent or dama ged

blade with a new blade.

• Nev er file or cr eate shar p notches in

the edges or surf aces of blade.

Removing the Blades

T he blades m ust be re placed if a solid object is

hit, if the blade is out of balance , or the blade

is bent. T o ensure optim um perfor mance and

contin ued safety confor mance of the mac hine , use

g en uine T oro re placement blades . R e placement

blades made b y other man ufacturers ma y result in

non-confor mance with safety standards .

Hold the blade end using a rag or thic kly-padded

glo v e . R emo v e the blade bolt, cur v ed w asher ,

stiffener (52 inc h dec ks only) and blade from the

spindle shaft ( Figure 42 ).

Figure 43

1. Sharpen at original angle

2. Chec k the balance of the blade b y putting it on