Page 1

FormNo.3417-412RevA

TimeCutter

®

SW4200,SW5000,

orSWX5000RidingMower

ModelNo.74788—SerialNo.400000000andUp

ModelNo.74790—SerialNo.402000000andUp

ModelNo.74795—SerialNo.401000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3417-412*A

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.Tolocate

adealerconvenienttoyou,accessourwebsite

atwww.T oro.comorcontactourT oroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.

Removethekitfromtheengineandrestorethe

enginetoitsoriginalfactorycongurationwhen

runningtheengineunder1500m(5,000ft).Do

notoperateanenginethathasbeenconverted

forhigh-altitudeuseatloweraltitudes;otherwise,

youcouldoverheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachine

hasbeenconvertedforhigh-altitudeuse,lookfor

thefollowinglabel.

GrossorNetTorque

Thegrossornettorqueofthisenginewaslaboratory

ratedbytheenginemanufacturerinaccordancewith

theSocietyofAutomotiveEngineers(SAE)J1940

orJ2723.Asconguredtomeetsafety,emission,

andoperatingrequirements,theactualenginetorque

onthisclassofmowerwillbesignicantlylower.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

WARNING

Removingstandardoriginalequipmentparts

andaccessoriesmayalterthewarranty,

traction,andsafetyofthemachine.Failureto

useoriginalT oropartscouldcauseserious

injuryordeath.Makingunauthorizedchanges

totheengine,fuel,orventingsystem,may

violateregulations.

Replaceallpartsincluding,butnotlimited

to,tires,belts,blades,andfuelsystem

componentswithoriginalToroparts.

decal127-9363

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperatorsorresidential

homeowners.Itisdesignedprimarilyforcuttinggrass

onwell-maintainedlawnsonresidentialorcommercial

properties.Itisnotdesignedforcuttingbrushorfor

agriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Gotowww.Toro.comtoviewspecicationsonyour

model.

Important:IfyouareusingamachinewithaToro

engineabove1500m(5,000ft)foracontinuous

period,ensurethattheHighAltitudeKithasbeen

installedsothattheenginemeetsCARB/EP A

emissionregulations.TheHighAltitudeKit

increasesengineperformancewhilepreventing

spark-plugfouling,hardstarting,andincreased

emissions.Onceyouhaveinstalledthekit,attach

thehigh-altitudelabelnexttotheserialdecalon

themachine.ContactanyAuthorizedToroService

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

FortheOperator’sManual,thecompletewarranty

details,ortoregisteryourproduct,usetheQR

codeorvisitwww.Toro.com.Y oumayalsocallus

at1-888-384-9939torequestawrittencopyofthe

productwarranty.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

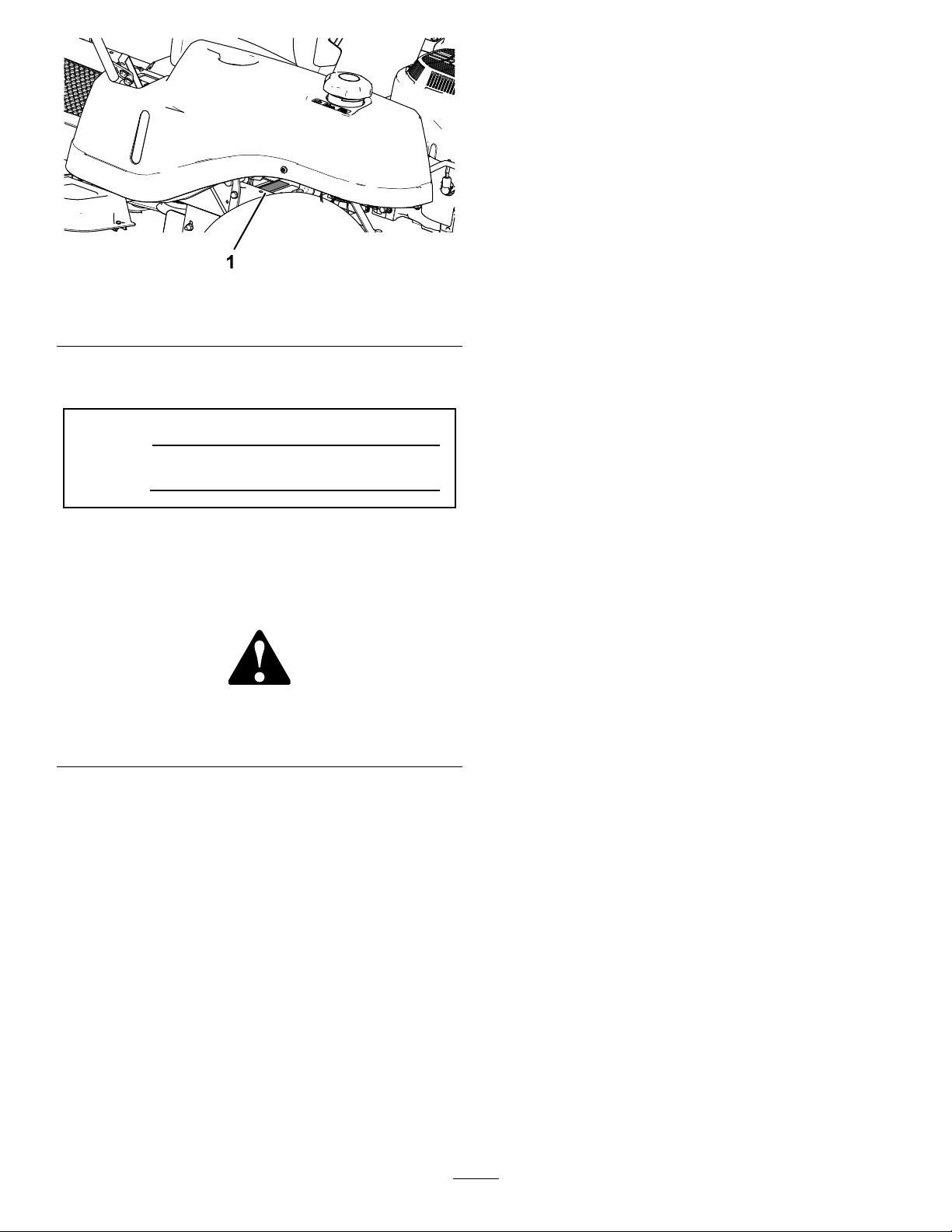

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Figure1

1.Modelandserialnumberplate

Writetheproductmodelandserialnumbersinthe

spacebelow:

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................13

Controls...........................................................13

BeforeOperation.................................................14

BeforeOperationSafety...................................14

AddingFuel......................................................15

g230912

g000502

PerformingDailyMaintenance..........................16

BreakinginaNewMachine..............................16

UsingtheSafety-InterlockSystem....................16

PositioningtheSeat..........................................17

PositioningtheSteeringWheel.........................18

DuringOperation.................................................18

DuringOperationSafety...................................18

OperatingtheSmartPark

™

Parking

Brake............................................................20

EngagingtheBlade-ControlSwitch

(PTO)............................................................20

DisengagingtheBlade-ControlSwitch

(PTO)............................................................21

OperatingtheThrottle.......................................21

OperatingtheChoke.........................................21

StartingtheEngine...........................................22

ShuttingOfftheEngine.....................................22

DrivingtheMachine..........................................22

MowinginReverse...........................................23

UsingtheSideDischarge.................................23

AdjustingtheHeightofCut...............................24

AdjustingtheAnti-ScalpRollers........................24

OperatingTips.................................................25

AfterOperation....................................................26

AfterOperationSafety......................................26

PushingtheMachinebyHand..........................26

TransportingtheMachine.................................27

Maintenance...........................................................29

RecommendedMaintenanceSchedule(s)...........29

Pre-MaintenanceProcedures..............................30

MaintenanceSafety..........................................30

RaisingtheSeat...............................................30

RaisingtheFrontoftheMachine.......................30

Lubrication..........................................................31

GreasingtheBearings......................................31

EngineMaintenance...........................................31

EngineSafety...................................................31

ServicingtheAirCleaner..................................31

ServicingtheEngineOil....................................33

ServicingtheSparkPlug...................................35

CleaningtheCoolingSystem............................36

FuelSystemMaintenance...................................37

ReplacingtheIn-LineFuelFilter.......................37

ElectricalSystemMaintenance...........................38

ElectricalSystemSafety...................................38

ServicingtheBattery.........................................38

ServicingtheFuses..........................................39

3

Page 4

DriveSystemMaintenance..................................40

CheckingtheTirePressure...............................40

ReleasingtheElectricBrake.............................40

BeltMaintenance................................................41

ReplacingtheMower-DeckBelt........................41

MowerMaintenance.............................................42

ServicingtheCuttingBlades.............................42

LevelingtheMowerDeck..................................45

RemovingtheMowerDeck...............................47

InstallingtheMowerDeck.................................48

ReplacingtheGrassDeector..........................48

Cleaning..............................................................49

CleaningundertheFrontoftheMachine...........49

WashingtheUndersideoftheMower

Deck..............................................................49

DisposingofWaste...........................................49

Storage...................................................................50

StorageSafety..................................................50

CleaningandStorage.......................................50

StoringtheBattery............................................51

Troubleshooting......................................................52

Schematics.............................................................54

Safety

ThefollowinginstructionsarefromANSIstandard

B71.4-2012.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15degrees.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepchildrenandbystandersoutoftheoperating

area.Neverallowchildrentooperatethemachine.

•Stopthemachineandshutofftheenginebefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

Page 5

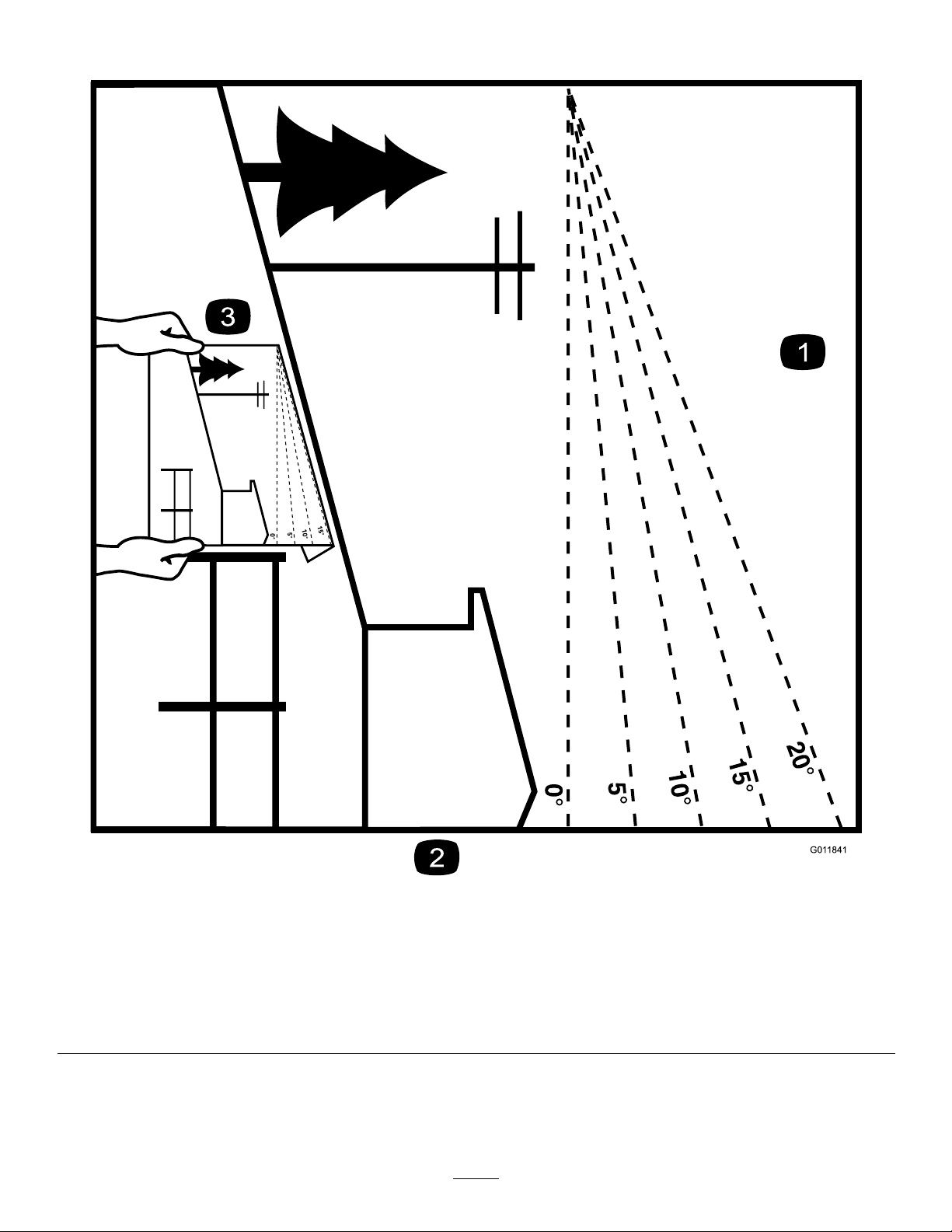

SlopeIndicator

Figure4

Thispagemaybecopiedforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

Page 6

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

decalbatterysymbols

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distanceawayfromthe

battery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

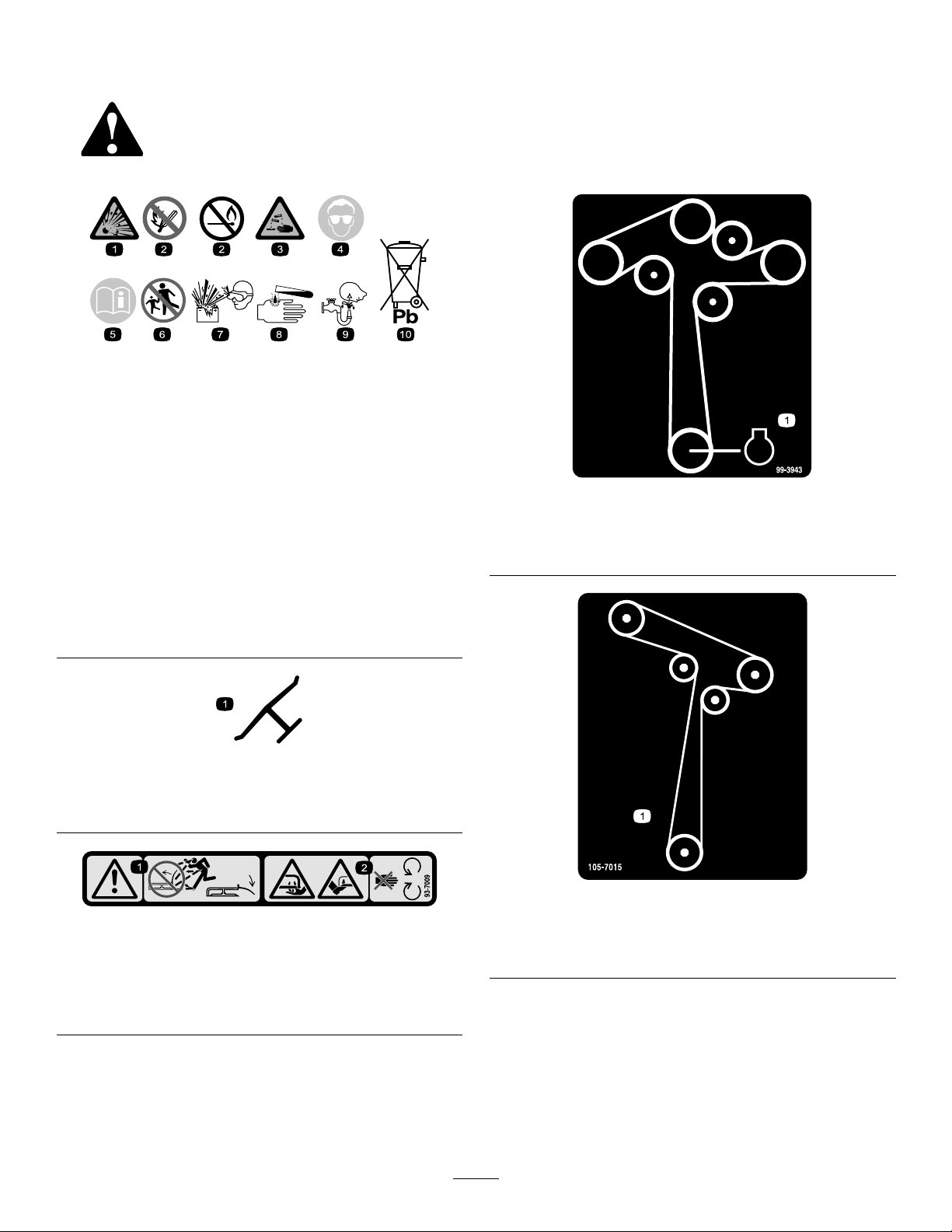

decal99-3943

99-3943

ForModelswith127cm(50inch)Decks

1.Engine

decaloemmarkt

93-7009

1.Warning—donotoperatethemowerwiththedeectorup

orremoved;keepthedeectorinplace.

2.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts.

decal105-7015

decal93-7009

1.Beltrouting

ForModelswith107cm(42-inch)Decks

105-7015

6

Page 7

106-8717

1.Readtheinstructionsbeforeservicingorperforming

maintenance.

2.Checktirepressureevery25operatinghours.

3.Greaseevery25operatinghours.

4.Engine

decal106-8717

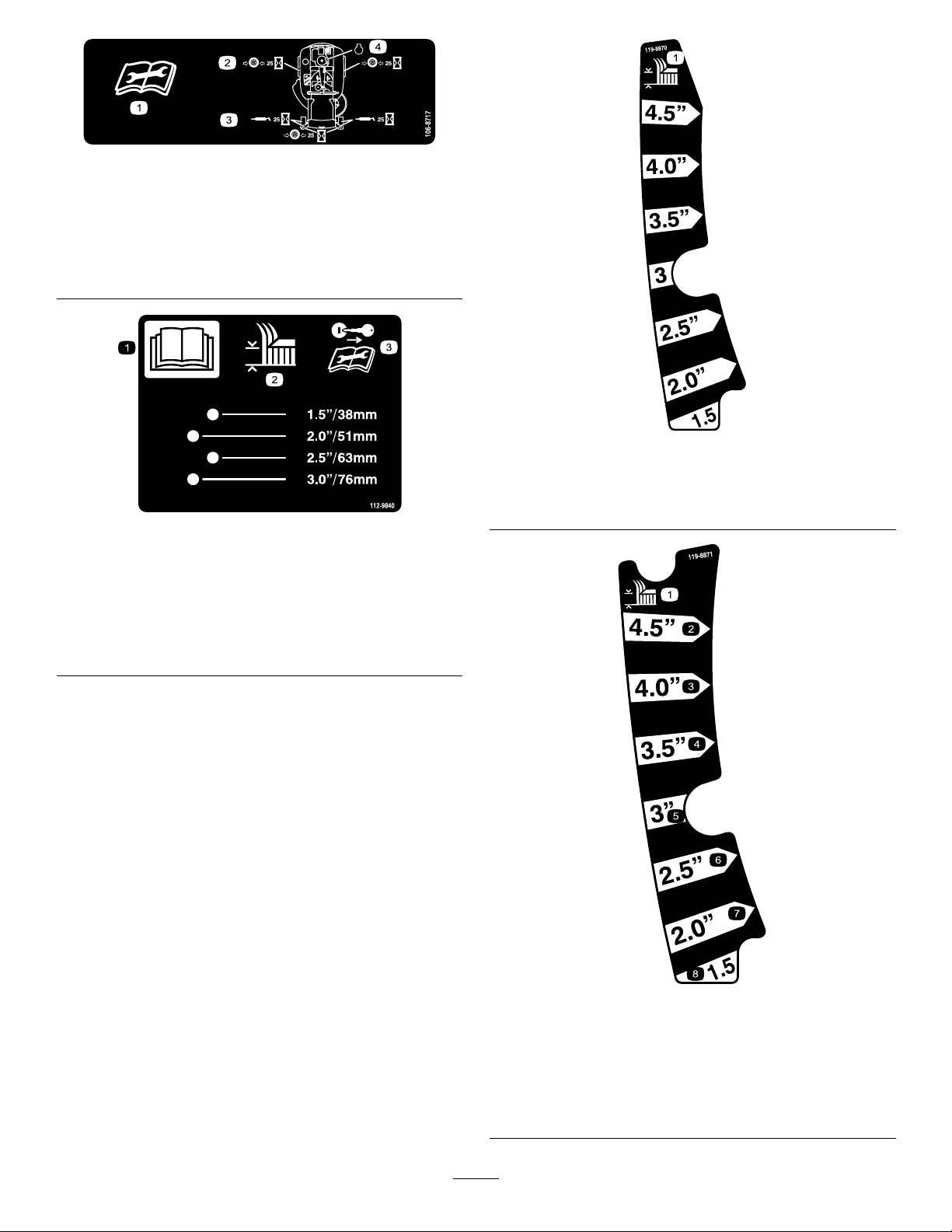

decal119-8870

119-8870

ForModelswith127cm(50inch)Decks

ForModelswith127cm(50inch)Decks

1.ReadtheOperator's

Manual.

2.Heightofcut

decal112-9840

1.Height-of-cut

112-9840

3.Removethekeyandread

theinstructionsbefore

servicingorperforming

maintenance.

ForModelswith107cm(42inch)MowerDecks

1.Heightofcut

2.4-1/2inches6.2-1/2inches

3.4inches7.2inches

4.3-1/2inches8.1-1/2inches

7

decal119-8871

119-8871

5.3inches

Page 8

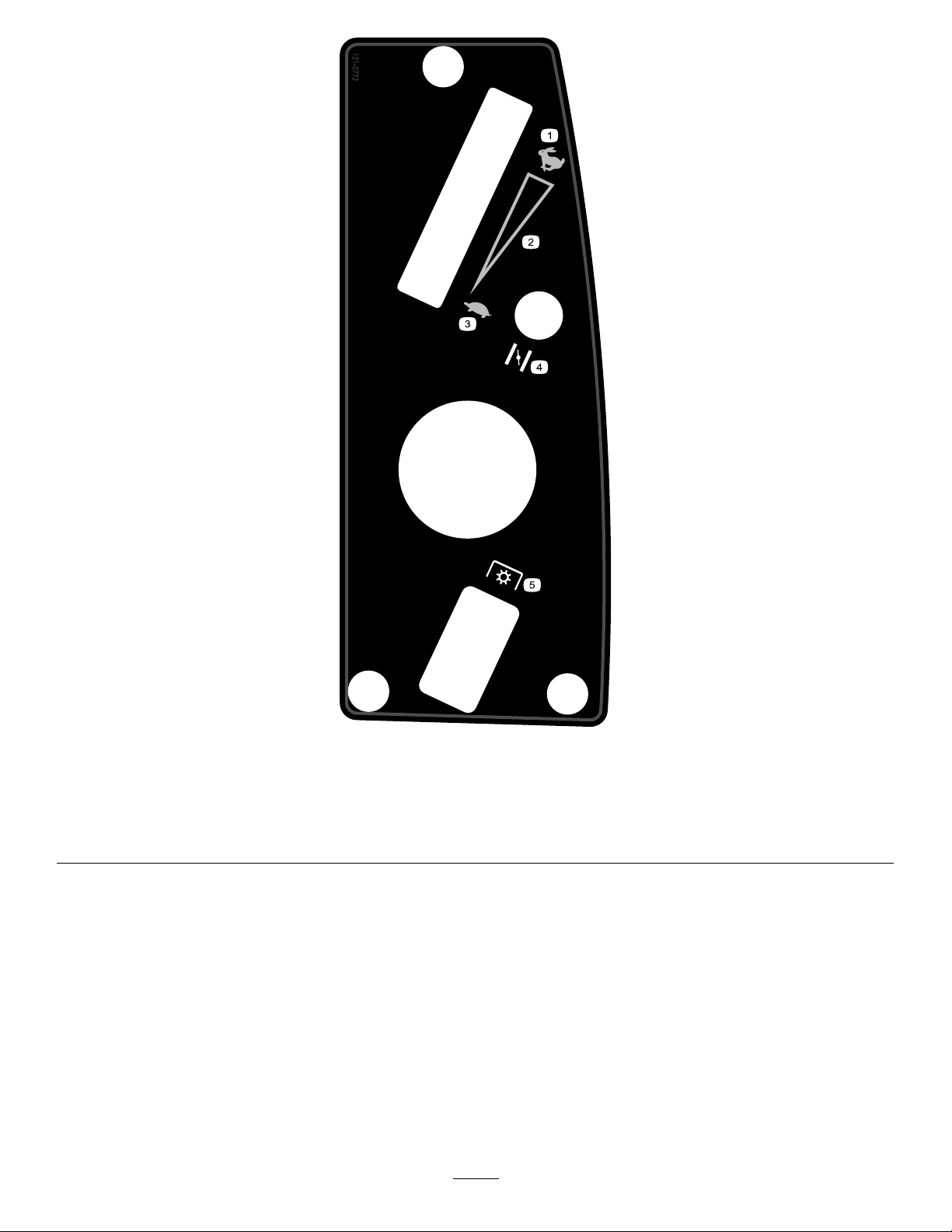

121-0772

ForModelswith107cm(42inch)Decks

decal121-0772

1.Fast

4.Choke

2.Continuous-variablesetting5.Powertakeoff(PTO),blade-controlswitch

3.Slow

8

Page 9

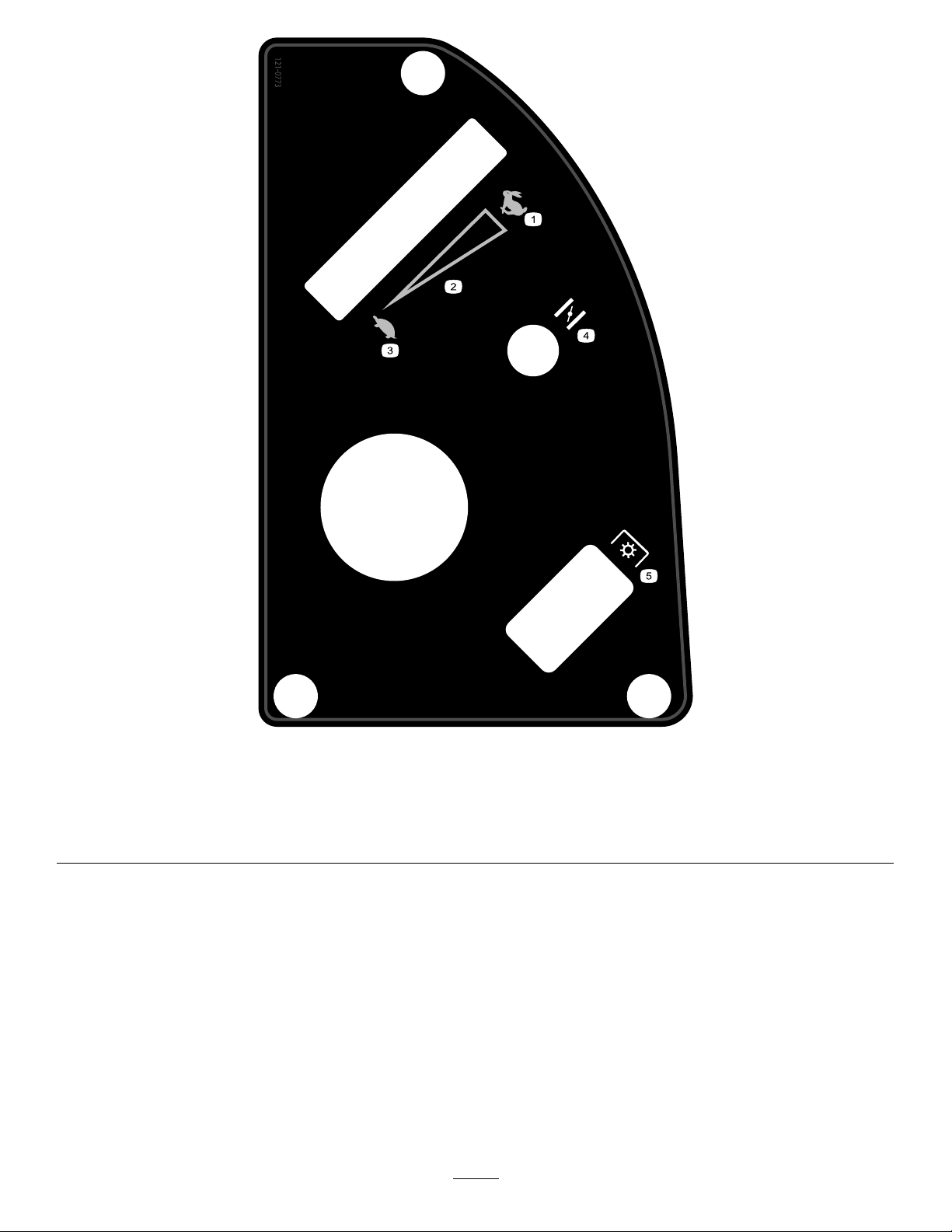

121-0773

ForModelswith127cm(50inch)Decks

decal121-0773

1.Fast

4.Choke

2.Continuous-variablesetting5.Powertakeoff(PTO),blade-controlswitch

3.Slow

9

Page 10

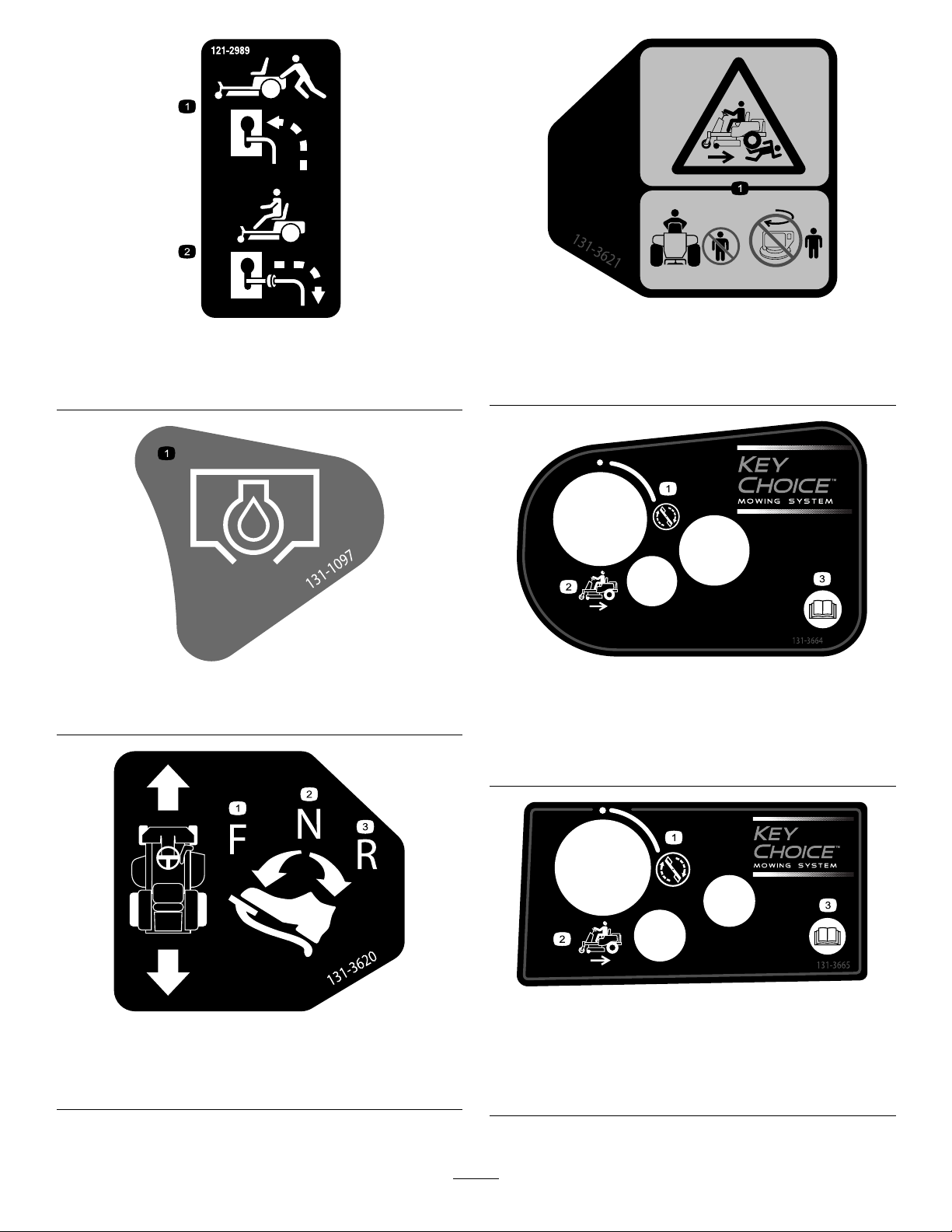

1.Bypassleverpositionfor

pushingthemachine

121-2989

2.Bypassleverpositionfor

operatingthemachine

decal131-3621b

decal121-2989b

131-3621

1.Crushing/dismembermenthazardofbystanders—keep

bystandersawayfromthemachine;donotstartthe

machinewithbystandersnearby.

1.Oildrain

1.Pedalposition—forward

2.Pedalposition—neutral

decal131-1097

131-1097

131-3664

decal131-3664

ForModelswith127cm(50inch)Decks

1.Bladespinning

2.Reverse

decal131-3620

131-3620

3.Pedalposition—reverse

1.Bladespinning

ForModelswith107cm(42inch)Decks

2.Reverse

3.ReadtheOperator's

Manual.

decal131-3665

131-3665

3.ReadtheOperator's

Manual.

10

Page 11

131-3954

ForModelswith127cm(50inch)Decks

decal131-3954

1.On2.Off

131-3955

ForModelswith107cm(42inch)Decks

1.On2.Off

decal132-6863

132-6863

decal138-2456

138-2456

1.ReadtheOperator’s

Manual.

decal131-3955

2.Parkthemachineona

levelsurfacewhenlling

thefueltank.

3.Donotoverllthefuel

tank.

1.Thrownobject

hazard—keepbystanders

awayfromthemachine.

2.Thrownobjecthazard,

raisedbafe—donot

operatethemachinewith

anopendeck;usea

baggerorabafe.

decal132-0872

132-0872

3.Severinghazardofhand

orfoot—keepawayfrom

movingparts.

4.Entanglement

hazard—keepaway

frommovingparts;keep

allguardsandshieldsin

place.

11

Page 12

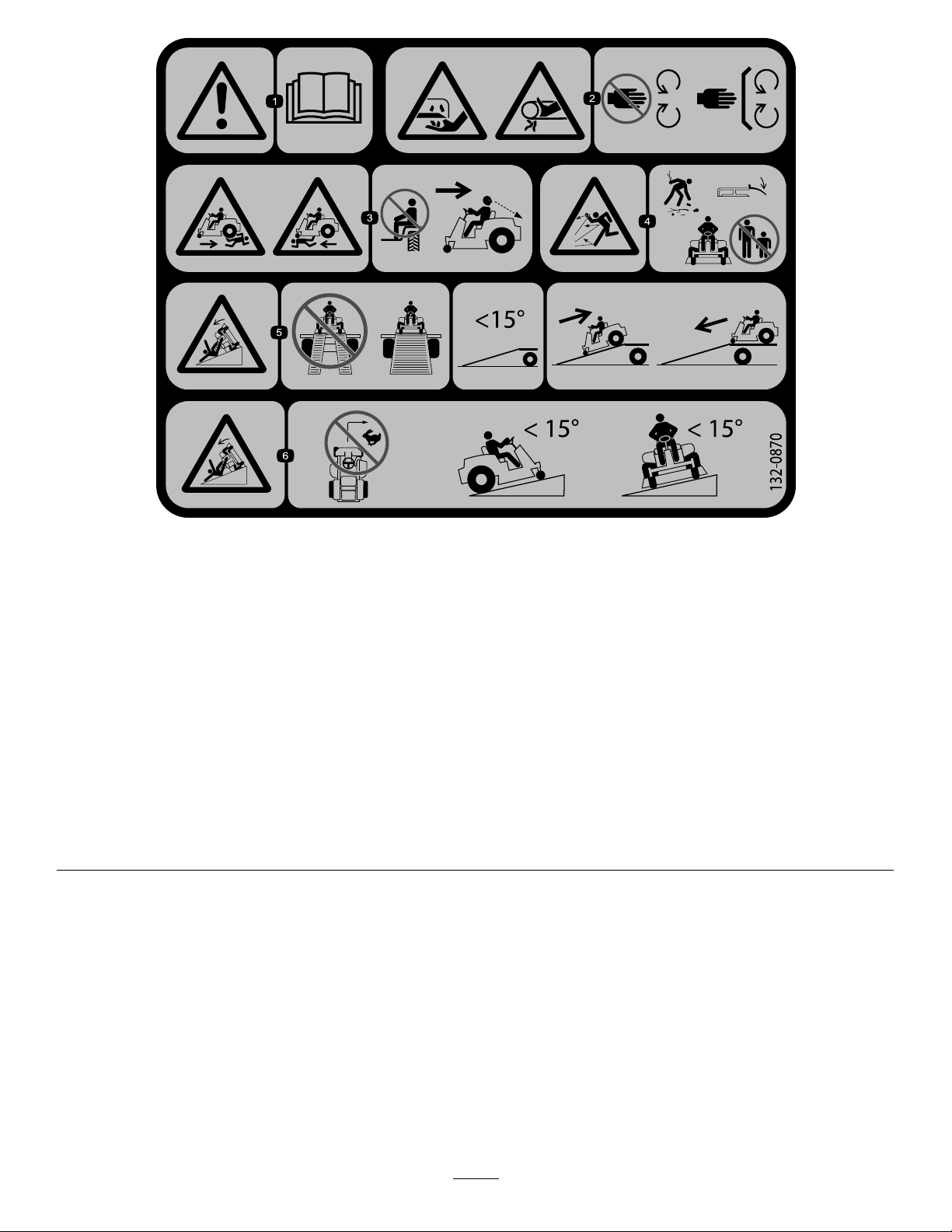

132-0870

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineinthoseconditions

onthatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.Ifpossible,keepthe

cuttingunitsloweredtothegroundwhileoperatingthemachineonslopes.Raisingthecuttingunitswhileoperatingonslopescan

causethemachinetobecomeunstable.

decal132-0870

1.Warning—readtheOperator'sManual.

2.Cuttinghazardofhand,mowerblade;

pinchinghazardofhand,belt—keep

handsandfeetawayfrommoving

parts;keepallguardsandshieldsin

place.

3.Bodilyharmhazard—noriders;look

behindyouwhenmowinginreverse.

4.Thrownobjecthazard—keep

bystandersawayfromthemachine;

removedebrisfromtheareabefore

mowing;keepthedeectorshield

down.

5.Ramptippinghazard—whenloading

ontoatrailer,donotusedualramps;

onlyuseasinglerampwideenough

forthemachineandthathasanincline

lessthan15degrees;backupthe

ramp(inreverse)anddriveforwardoff

theramp.

6.Tippinghazardonslopes—donot

makesharp,quickturns;donotuse

slopesgreaterthan15degrees.

12

Page 13

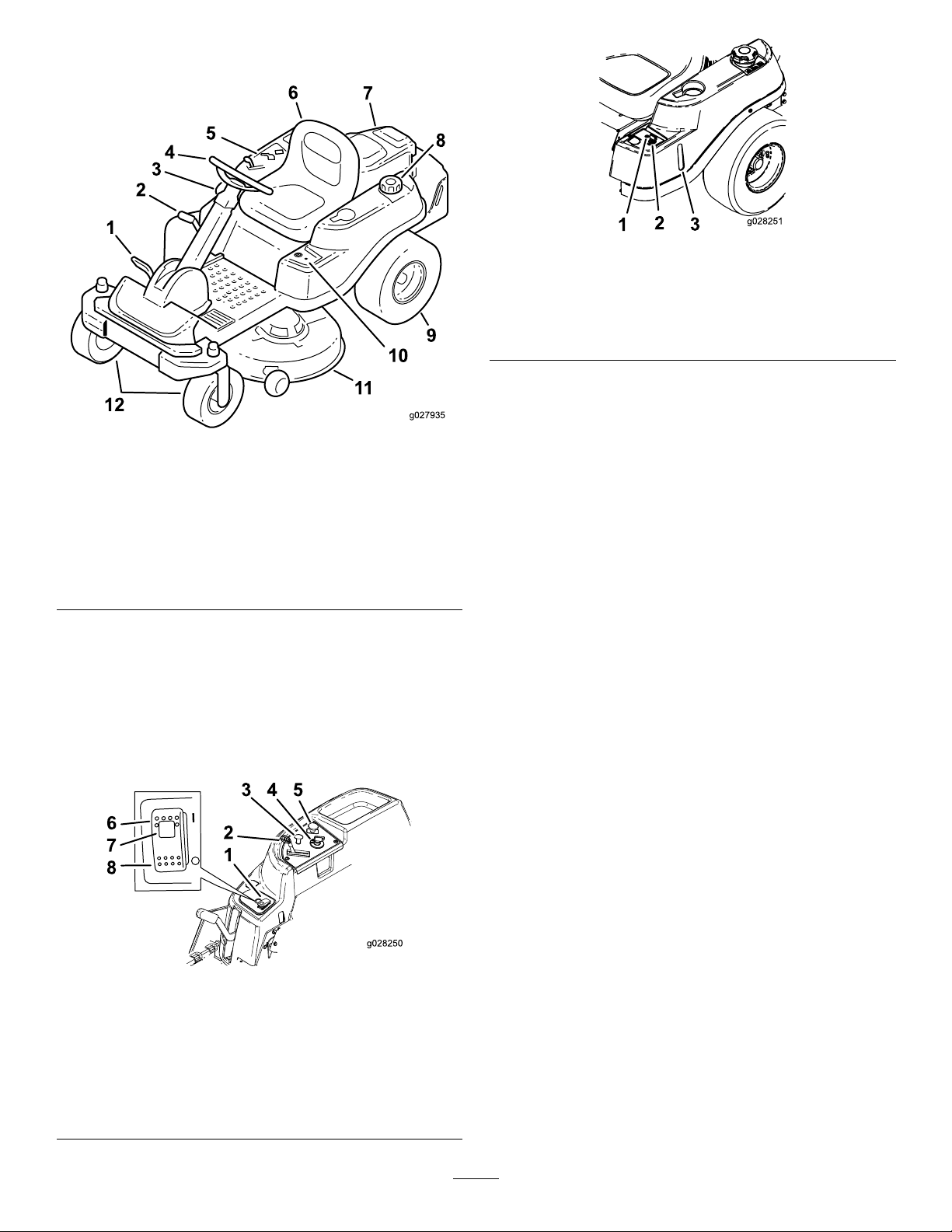

ProductOverview

g028251

Figure7

Figure5

1.Traction-controlpedal7.Engine

2.Height-of-cutlever

3.SmartPark

4.Steeringwheel10.KeyChoice

5.Controlpanel

6.Operatorseat

™

switch

8.Fuel-tankcap

9.Reardrivewheel

®

11.Mowerdeck

12.Frontcasterwheels

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

1.Operating–in–Reverse

warninglight

2.KeyChoicekey(bluein

color)

3.Fuel-presencewindow

KeySwitch

g027935

control

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.Referto

StartingtheEngine(page22).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure6).

ChokeControl

Usethechokecontroltostartacoldengine.

Blade-ControlSwitch(Power

ControlPanel

1.SmartPark™switch

2.Throttlecontrol

3.Chokecontrol

4.Keyswitch

Figure6

5.Blade-controlswitch

(powertakeoff)

6.Parkingbrake—On

7.Parkingbrakeindicator

light

8.Parkingbrake—Off

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

disengagespowertothemowerblades(Figure6).

Fuel-PresenceWindow

Youcanusethefuelwindow,locatedontheleftside

ofthemachine,toverifythepresenceoffuelinthe

tank(Figure7).

g028250

Height-of-CutLever

Usetheheight-of-cutlevertolowerandraisethedeck

fromtheseatedposition.Movingtheleverup(toward

you)raisesthedeckfromthegroundandmovingthe

leverdown(awayfromyou)lowersthedecktoward

theground.Adjusttheheight-of-cutonlywhilethe

machineisnotmoving(Figure20).

13

Page 14

KeyChoice

Thisswitchallowsyoutomowinreversewhenit

isactivated.T oactivateit,turntheswitchtotheON

positionandreleaseitafterthePTOisengaged.T o

deactivateit,disengagethepowertakeoff(PTO)

(Figure7).

®

Switch

Operating-in-ReverseWarning

Light

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

TheOperating-in-Reversewarninglightilluminates

wheneveryouusetheKeyChoicekeytodeactivate

theoperating-in-reverseinterlock.Itisareminderthat

theinterlocksystemisdeactivated.Thelightgoes

outwheneveryoudisengagethePTOorshutoffthe

engine.Whenthelightison,lookbehindyouanduse

extracautionwhenbackingup.

SmartPark

Theparkingbrakeisactivatedelectronically.

Engagetheparkingbrakeby1ofthefollowingactions:

•PressingtheSmartPark

(Figure6).

™

Switch

™

switchtotheONposition

•Theparkingbrakeengagesautomaticallywhen

youleavetheseatandthetractioncontrolpedalis

intheNEUTRALposition.

•Theparkingbrakeautomaticallyengages5to6

secondsaftertheignitionswitchisturnedtothe

OFFposition(ifitisnotalreadyengaged).

Todisengagetheparkingbrake,presstheSmartPark

switchtotheOFFpositionwiththekeyintheRUN

position.

Attachments/Accessories

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonT oro

genuineparts.Whenitcomestoreliability,T oro

deliversreplacementpartsdesignedtotheexact

engineeringspecicationofourequipment.Forpeace

ofmind,insistonTorogenuineparts.

FuelSafety

•Toavoidpersonalinjuryorpropertydamage,use

extremecareinhandlingfuel.Fuelvaporsare

ammableandexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothefuel

tankwhiletheengineisrunningorwhilehot.

•Donotrefuelthemachineindoors.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

14

Page 15

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymorethan

a30-daysupplyoffuel.

•Donotllthefueltankcompletelyfull.Addfuelto

thefueltankuntilthelevelis6to13mm(1/4to

1/2inch)belowthebottomofthellerneck.This

emptyspaceinthetankallowsfueltoexpand.

–Avoidprolongedbreathingofvapors.

–Keepyourfaceawayfromthenozzleandfuel

tankopening.

–Avoidcontactwithskin;washoffspillswith

soapandwater.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshduringstorageof90daysorless

(drainthefueltankwhenstoringthemachinefor

morethan90days)

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltanktothebottomofthellerneck

(Figure8).

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

15

Page 16

Understandingthe Safety-InterlockSystem

Thesafety-interlocksystemisdesignedforthe

following:

•Topreventtheenginefromstartingunlessthe

tractionpedalisintheNEUTRALposition.

•Toautomaticallyensurethattheparkingbrake

isengagedandthePTOisoffwhenstartingthe

machine.

•Toshutofftheenginewheneverthetractionpedal

isnotintheNEUTRALpositionandyourisefrom

theseat.

•Toautomaticallyengagetheparkingbrakeand

disengagethePTO,whenyouriseoutoftheseat

withthetractionpedalintheNEUTRALposition.

•Toshutofftheenginewhenevertheparkingbrake

isnotengagedandyourisefromtheseat.

Figure8

PerformingDaily Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page29).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

UsingtheSafety-Interlock System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

g027243

TestingtheSafety-Interlock System

1.Sitintheseatwiththeengineoffandensure

thatthePTOswitchisintheOFFposition.

2.TurnthekeyswitchtotheSTARTposition;the

startershouldcrank.Donotstartorshutoffthe

enginepriortostep3.

3.TurnthekeyswitchtotheONpositionandpush

theSmartParkswitchtotheOFFposition.The

brakeshoulddisengageandthebrakelight

shouldturnoff.

4.Withthebrakedisengagedandtractionpedal

intheNEUTRALposition,turnthekeytothe

STARTposition.Thebrakeshouldautomatically

engage,theengineshouldcrank,andthebrake

lightshouldturnon.

5.WiththeengineoffandthekeyintheON

position,engagethePTObypullingupthe

blade-controlswitch;youshouldheartheclutch

engage.

6.Ensurethatthetractionpedalisinneutraland

turnthekeytotheSTARTposition.ThePTO

shoulddisengageandtheengineshouldcrank

andstartwithoutthebladesmoving.

7.Withtheenginerunning,risefromtheseat.The

engineshouldremainrunningandthebrake

lightshouldbeon.

8.Returntotheseatanddisengagetheparking

brakebypushingtheSmartParkswitchtothe

OFFposition.Theengineshouldcontinuetorun.

9.Risefromtheseatagain.Thebrakeshould

automaticallyengageandtheengineshould

continuetorun.

16

Page 17

10.Returntotheseatandengagethebladesby

pullinguptheblade-controlswitch.

11.Risefromtheseat.Thebladesshould

disengageandtheengineshouldcontinueto

run.

12.Returntotheseatandpulluptheblade-control

switch.Thebladesshouldengage.Disengage

thebladesbypushingdowntheblade-control

switch.

13.Pulluptheblade-controlswitchtoengagethe

blades.MovethetractionpedaltotheREVERSE

position.Thebladesshoulddisengage.Move

thetractionpedaltotheNEUTRALposition.

14.Pulluptheblade-controlswitchtoengagethe

blades.TurntheKeyChoiceswitchtotheON

positionandreleaseit.Theoperating-in-reverse

lightshouldilluminate.

15.MovethetractionpedaltotheREVERSEposition.

Thebladesshouldremainengaged.Pushthe

blade-controlswitchintodisengagetheblades.

Theoperating-in-reverselightshouldturnoff.

MovethetractionpedaltotheNEUTRALposition.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure9).

16.Ifnotengaged,pushtheSmarkParkswitchto

theONpositionandlightlytapthetractionpedal

toeithertheFORWARDorREVERSEposition.The

brakeshoulddisengageandthebrakelight

shouldturnoff.

Note:Tapthepedal,donotfullyengagethe

pedalasthatcausesthebrakesystemtobind

andnotrelease.

17.Withthebrakereleased,engagethetraction

pedalslightlyandrisefromtheseat.Theengine

shouldshutoff.

18.ReturntotheseatandturnthekeytotheOFF

position.Afterseveralseconds,thebrake

systemshouldengage.

Note:WiththekeyintheOFFposition,the

brakelightdoesnotilluminate.

g188217

Figure9

17

Page 18

PositioningtheSteering Wheel

Thesteeringwheelhas3positionsforoperationand

1full-upposition.Usethefull-uppositionforstepping

onandoffthemachineandgettingoutoftheseat.

Whenoperatingthemachine,positionthesteering

wheelwhereyouhavethebestcontrolofthemachine

andaremostcomfortable.

1.Pressyourfootontothesteering-columnrelease

lever.

2.Positionthesteeringwheeltothedesired

position(Figure10).

Figure10

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;slip-resistant,substantial

footwear;andhearingprotection.Tiebacklong

hairanddonotwearjewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Avoidmowingonwetgrass.Reducedtraction

couldcausethemachinetoslide.

•Ensurethatalldrivesareinneutral,theparking

brakeisengaged,andyouareintheoperating

positionbeforeyoustarttheengine.

•Keepyourhandsandfeetawayfromthecutting

g027751

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Donotmowneardrop-offs,ditches,or

embankments.Themachinecouldsuddenlyroll

overifawheelgoesovertheedgeoriftheedge

givesway.

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachineandinspectthebladesafter

strikinganobjectorifthereisanabnormal

vibrationinthemachine.Makeallnecessary

repairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethedrivetothecuttingunitandshut

offtheenginebeforeadjustingtheheightof

cut(unlessyoucanadjustitfromtheoperating

position).

•Neverrunanengineinanareawhereexhaust

gasesareenclosed.

•Neverleavearunningmachineunattended.

18

Page 19

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Stopthemachineonlevelground.

–Disengagethepowertake-offandlowerthe

attachments.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicleunless

ithasahitchinstalled.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useonlyaccessoriesandattachmentsapproved

byToro.

•Thismachineproducessoundlevelsinexcess

of85dBAattheoperator’searandcancause

hearinglossthroughextendedperiodsof

exposure.

quicklyaffecttheoperationofthemachineon

aslope.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalk-behind

machineorahandtrimmertomowthegrassin

theseareas.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

Figure11

1.Wearhearingprotection.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15

degrees.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrass-collectionsystems.

Thesecanchangethestabilityofthemachine

g229846

andcausealossofcontrol.Followdirectionsfor

counterweights.

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

operatingonslopescancausethemachineto

becomeunstable.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

19

Page 20

1.SafeZone—usethe

machinehereonslopes

lessthan15degreesor

atareas.

2.DangerZone—usea

walk-behindmowerand/or

ahandtrimmeronslopes

greaterthan15degrees

andneardrop-offsor

water.

3.Water

Figure12

4.W=widthofthemachine

5.Keepasafedistance

(twicethewidthofthe

machine)betweenthe

machineandanyhazard.

OperatingtheSmartPark

™

ParkingBrake

Theparkingbrakeisactivatedelectronically.

Engagetheparkingbrakeby1ofthefollowingactions:

•PressingtheSmartPark

™

switchtotheONposition

(Figure6).

•Theparkingbrakeengagesautomaticallywhen

theoperatorleavestheseatandthetraction

controlpedalisintheNEUTRALposition.

•Theparkingbrakeautomaticallyengages5to6

secondsaftertheignitionswitchisturnedtothe

g231393

OFFposition(ifitisnotalreadyengaged).

Disengagetheparkingbrakeby1ofthefollowing

actions:

•Tapthetraction-controlpedalforwardorreverse.

•PressingthebrakeswitchtotheOFFposition

(Figure6).

EngagingtheBlade-Control Switch(PTO)

TowingSafety

•Donotattachtowedequipmentexceptatthehitch

point.

•Followtheattachmentmanufacturer's

recommendationforweightlimitsfortowed

equipmentandtowingonslopes.Thetowed

weightmustnotexceedtheweightofthemachine,

operator,andballast.Usecounterweightsor

wheelweightsasdescribedintheattachment,or

inthetowingmachineOperator’sManual.

•Neverallowchildrenorothersnearthetowed

equipment.

•Onslopes,theweightofthetowedequipmentmay

causelossoftraction,increasedriskofrollover,

andlossofcontrol.Reducethetowedweightand

slowdown.

•Thestoppingdistanceincreaseswiththeweight

ofatowedload.Travelslowlyandallowextra

distancetostop.

•Makewideturnstokeeptheattachmentclearof

themachine.

g008945

Figure13

Note:Alwaysengagethebladeswiththethrottlein

theFASTposition(Figure14).

g187516

Figure14

20

Page 21

Disengagingthe

OperatingtheChoke

Blade-ControlSwitch

(PTO)

Figure15

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure16).

AlwaysusetheFASTpositionwhenengagingthePTO.

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure17).

Note:Ensurethatyoufullyengagethechoke.

Youmayneedtoholdtheknobupwhenyou

usethekeyswitch.

2.Pushdownthechoketodisengagethechoke

aftertheenginehasstarted(Figure17).

g009174

Figure16

g008959

Figure17

1.ONposition2.OFFposition

g187517

21

Page 22

StartingtheEngine

DrivingtheMachine

Note:Awarmorhotenginemaynotrequirechoking.

Important:Donotengagethestarterformore

than5secondsatatime.Engagingthestarter

motorformorethan5secondscandamagethe

startermotor.Iftheenginefailstostart,wait10

secondsbeforeoperatingtheenginestarteragain.

Thismachinehasthecharacteristicsofbothagarden

tractorandazero-turnmachine.Likeagarden

tractor,themachinehasafootpedalthatcontrolsthe

forwardandreversemotionalongwiththespeed,

andithasasteeringwheelthatcontrolsthedirection

andtheturningradius.Likeazero-turnmachine,

thereardrivewheelsoperateindependentlyofeach

other,enablingyoutomakesharpturnsandtoturn

indifferentdirectionsquickly.Thesecharacteristics

vastlyimprovethemaneuverabilityofthemachine,

buttheymayalsorequireyoutopracticedrivingifyou

areunfamiliarwiththistypeofmachine.

WARNING

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placing

thethrottlecontrolintheFASTpositioncanbebestfor

performance.Formostapplications,operatinginthe

FULL-THROTTLEpositionisdesirable.

Figure18

ShuttingOfftheEngine

1.Disengagethebladesbymovingthe

blade-controlswitchtotheOFFposition(Figure

18).

2.Engagetheparkingbrake;refertoOperating

theSmartPark

3.MovethethrottlecontroltotheFASTposition.

4.TurnthekeytotheOFFpositionandremove

thekey.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

™

ParkingBrake(page20).

g027831

DrivingForwardorBackward

1.MovethethrottletotheFASTposition.

2.Releasetheparkingbrake.

3.Placeyourfootontothetraction-controlpedal

andslowlypressthetopofthepedaltogo

forward,orpressonthebottomofthepedalto

movebackward(Figure19).

Note:Thefartheryoumovethepedalineither

direction,thefasterthemachinemovesinthat

direction.

g027750

Figure19

1.Forward3.Backward

2.Traction-controlpedal

22

Page 23

4.T oslowdown,releasethepressureonthe

traction-controlpedal.

MowinginReverse

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

Themachinehasaninterlockfeaturethatprevents

themowerdeckfrommowingwhilethemachineis

travelinginreverse.Ifyoushiftintoreversewiththe

PTOengaged,thePTOstops.Ifyouneedtomow

whileinreversegear,youcantemporarilydeactivate

thisinterlock.

Note:Donotmowwhilebackingupunlessitis

necessary.

DANGER

Achildorbystandercouldbebackedover

byaridingmowerwithbladesengagedand

causeseriouspersonalinjuryordeath.

•Donotmowinreverseunlessabsolutely

necessary.

•Alwayslookbackwardanddownbefore

backingup.

•UsetheKeyChoiceswitchonlyifyouare

certainnochildrenorotherbystanderswill

appearinthemowingarea.

•Alwaysremoveboththeignitionand

KeyChoicekeysandputtheminasafe

placeoutofthereachofchildrenor

unauthorizeduserswhenleavingthe

machineunattended.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatethekeyswitchtotheOFF

position,andremovethekeyfromthekey

switch.

•Makesurethatthegrassdeectorisinthe

downposition.

Ifyouarecertainthatyoucansafelymoworoperate

anattachmentinreverse,completethefollowing

procedure:

1.InserttheKeyChoicekeyintotheKeyChoice

switch(Figure7).

2.EngagethePTO.

3.TurntheKeyChoicekeyclockwiseuntilitstops

andreleaseit.

Note:Aredlightilluminatingontheconsole

indicatesthattheinterlockhasbeendeactivated.

4.Performthemowing.

5.Whennishedmowing,removetheKeyChoice

key(Figure7).

Note:Onceyoudeactivatetheinterlock,it

staysinthismode—withyourmowerbladeor

PTOpoweredattachmentoperatingwhenever

youbackup—andtheconsolelightstayson

untilyoueitherdisengagethePTOorshutoff

theengine.

23

Page 24

AdjustingtheHeightofCut

AdjustingtheAnti-Scalp

Note:Thetransportpositionisthehighest

height-of-cutpositionorcuttingheightat115mm

(4-1/2inches)asshowninFigure20.

Heightofcutiscontrolledbytheleverlocatedtothe

rightoftheoperatingposition(Figure20).

Rollers

AdjustingtheAnti-ScalpRollers

Machineswith107cm(42-inch)MowerDecks

Wheneveryouchangetheheightofcut,adjustthe

heightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollers

donottouchthegroundinnormal,atmowingareas.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitchandengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersto1ofthefollowing

positions:

•Upperhole—usethispositionwiththemower

deckinthe63mm(2-1/2inches)andbelow

theheight-of-cutpositions(Figure21).

•Lowerhole—usethispositionwiththemower

deckinthe76mm(3inches)andabovethe

height-of-cutpositions(Figure21).

Figure20

g028025

g019929

Figure21

1.Anti-scalproller4.Upperhole—themower

2.Lowerhole—themower

deckinthe76mm(3

inches)andabovethe

height-of-cutpositions

3.Flangenut

deckinthe63mm(2-1/2

inches)andbelowthe

height-of-cutpositions

5.Bolt

AdjustingtheAnti-ScalpRollers

Machineswith127cm(50-inch)MowerDecks

Wheneveryouchangetheheightofcut,adjustthe

heightoftheanti-scalprollers.

Note:Adjusttheanti-scalprollerssothattherollers

donottouchthegroundinnormal,atmowingareas.

24

Page 25

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitchandengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollers(Figure22)tomatch

theclosestheight-of-cutposition.

Figure22

1.Anti-scalproller3.Flangenut

2.Bolt

4.Holespacing

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

g010233

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

OperatingTips

UsingtheFastThrottleSetting

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

deckinuncutgrass.Alwaystrytohave1sideofthe

mowerdeckfreefromuncutgrass,whichallowsair

tobedrawnintothemowerdeck.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdeckdoesnotscalp

anyunevenground.However,thecuttingheight

usedinthepastisgenerallythebestonetouse.

Whencuttinggrasslongerthan15cm(6inches)tall,

youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

KeepingtheUndersideofthe

MowerDeckClean

Cleanclippingsanddirtfromtheundersideofthe

mowerdeckaftereachuse.Ifgrassanddirtbuildup

insidethemowerdeck,cuttingqualitywilleventually

becomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary.Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

25

Page 26

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•Disengagethedrivetotheattachmentwhenever

youaretransportingornotusingthemachine.

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

PushingtheMachineby Hand

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausetowingmay

damageit.

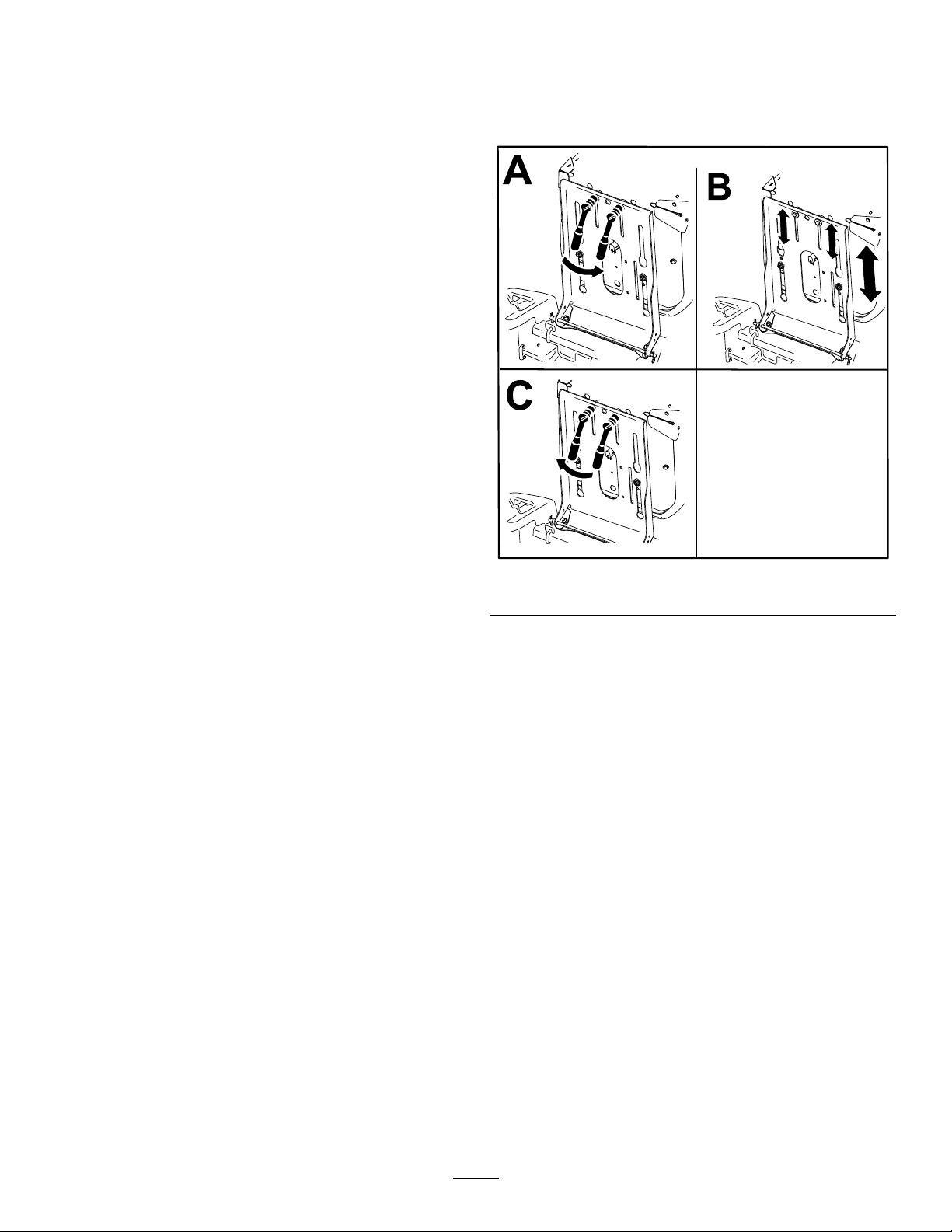

Figure23

1.Bypass-leverlocations

2.Leverpositionfor

operatingthemachine

6.Whennished,ensurethatthekeyhasbeen

returnedtotheSTOPpositiontoavoiddraining

thebatterycharge.

3.Leverpositionforpushing

themachine

Note:Ifthemachinefailstomove,theelectricbrake

maystillbeengaged.Youcanreleasetheelectric

brakemanuallyifnecessary;refertoReleasingthe

ElectricBrake(page40).

g017303

Thismachinehasanelectric-brakemechanism,and

topushthemachine,theignitionkeymustbeinthe

RUNposition.Thebatteryneedstobechargedand

functioningtodisengagetheelectricbrake.

PushingtheMachine

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Locatethebypassleversontheframeonboth

sidesoftheengine.

4.Movethebypassleversforwardthroughthekey

holeanddowntolocktheminplace(Figure23).

Note:Dothisforeachlever.

5.Turntheignitionkeyonanddisengagethe

parkingbrake.

Note:Donotstartthemachine.

OperatingtheMachine

Movethebypassleversrearwardthroughthekeyhole

anddowntolocktheminplaceasshowninFigure23.

Note:Dothisforeachlever.

26

Page 27

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure24).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

rampandthetrailerortruck.

•Ensurethatthelengthoftherampisat

least4timesaslongastheheightofthe

trailerortruckbedtotheground.This

ensuresthattherampangledoesnot

exceed15degreesonatground.

Figure24

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

g027996

•Backthemachineuptherampanddriveit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

27

Page 28

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure24).

4.Backthemachineuptheramp(Figure25).

Figure25

g028294

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

5.Shutofftheengine,removethekey,andengage

theparkingbrake.

6.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure26).Refertolocal

regulationsfortie-downrequirements.

Figure26

1.Tie-downloops

g027708

UnloadingtheMachine

1.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure24).

2.Drivethemachineforwarddowntheramp

(Figure25).

28

Page 29

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst5hours

Beforeeachuseordaily

Aftereachuse

Every25hours

Every100hours

Every200hours

Beforestorage

MaintenanceProcedure

•Changetheengineoilandlter.

•Checktheaircleanerfordirty,loose,ordamagedparts.

•Checktheengine-oillevel.

•Cleantheairintakescreen.

•Inspecttheblades.

•Inspectthegrassdeectorfordamage.

•Checkandcleanthefrontofthemachine.

•Cleanthemower-deckhousing.

•Greaseallthelubricationpoints.

•Cleantheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Checktirepressure.

•Replacetheair-cleanerfoamelement(moreoftenindusty,dirtyconditions).

•Cleanthepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Changetheengineoilandoillter(moreoftenindirtyordustyconditions).

•Checkthesparkplug(s).

•Checkthein-linefuellter.

•Replacethepaperair-cleanerelement(moreoftenindirtyordustyconditions).

•Replacethesparkplug(s).

•Replacethein-linefuellter.

•Chargethebatteryanddisconnectthebatterycables.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintanychippedsurfaces.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

29

Page 30

Pre-Maintenance

RaisingtheSeat

Procedures

MaintenanceSafety

•Beforerepairingthemachinedothefollowing:

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

–Disconnectthespark-plugwire.

•Parkthemachineonalevelsurface.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufers,andenginetohelppreventres.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

Ensurethattheparkingbrakeisengaged.Liftthe

seatforward.

Youcanaccessfollowingcomponentsbyraisingthe

seat:

•Serialplate

•Servicedecal

•Seat-adjustmentbolts(ifapplicable)

•Fuellter

•Batteryandbatterycables

RaisingtheFrontofthe Machine

Ifthefrontofthemachineneedstoberaised,usethe

veryfrontedgeasshowninFigure27.

Important:Topreventdamagetothesteering

mechanism,usetheveryfrontedgeofthe

machineforajackingpoint.

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Usecarewhencheckingtheblades.Wrapthe

blade(s)orwearthicklypaddedgloves,anduse

cautionwhenservicingthem.Onlyreplaceblades;

donotstraightenorweldthem.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingcondition

andallhardwaretightened,especiallythe

blade-attachmentbolts.Replaceallwornor

damageddecals.

•Neverinterferewiththeintendedfunctionofa

safetydeviceorreducetheprotectionprovided

byasafetydevice.Checktheirproperoperation

regularly.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

g028320

Figure27

•Checktheparkingbrakeoperationfrequently.

Adjustandserviceasrequired.

30

Page 31

Lubrication

EngineMaintenance

GreasingtheBearings

ServiceInterval:Every25hours—Greaseallthe

lubricationpoints.

GreaseType:No.2lithiumgrease

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake;refertoShuttingOfftheEngine(page22).

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettings(Figure28andFigure

29)witharag.

Note:Scrapeanypaintoffthefrontofthe

tting(s).

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Note:Servicetheaircleanermorefrequently(every

fewhours)ifoperatingconditionsareextremelydusty

orsandy.

RemovingtheFoamandPaper Elements

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Figure28

1.Frontcastertire

Figure29

Locatedontheseat-panunderside

1.Readtheinstructions

beforeservicingor

performingmaintenance

2.Checkthetirepressure

every25operatinghours

4.Connectagreaseguntoeachtting(Figure28

andFigure29).

3.Greaseevery25operating

hours

4.Engine

3.Cleanaroundtheair-cleanercovertoprevent

g027752

decal106-8717

dirtfromgettingintotheengineandcausing

damage.

4.Liftthecoverandrotatetheair-cleanerassembly

outoftheengine(Figure30).

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

31

Page 32

ServicingtheFoamAir-Cleaner Element

ServiceInterval:Every25hours/Monthly(whichever

comesrst)—Cleantheair-cleaner

foamelement(moreoftenindusty,

dirtyconditions).

Every100hours/Y early(whichevercomes

rst)—Replacetheair-cleanerfoamelement

(moreoftenindusty,dirtyconditions).

g027800

1.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

2.Drytheelementbysqueezingitinacleancloth.

Important:Replacethefoamelementifit

istornorworn.

ServicingthePaperAir-Cleaner Element

ServiceInterval:Every100hours—Cleanthepaper

air-cleanerelement(moreoftenin

dirtyordustyconditions).

Figure30

5.Separatethefoamandpaperelements(Figure

31).

Figure31

Every200hours—Replacethepaperair-cleaner

g027801

element(moreoftenindirtyordustyconditions).

1.Cleanthepaperelementbytappingitgentlyto

removedust.

Note:Ifitisverydirty,replacethepaper

elementwithanewone.

2.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.

3.Replacethepaperelementifitisdamaged.

Important:Donotcleanthepaperlter.

g027802

32

Page 33

InstallingtheAirCleaner

1.Installthefoamelementoverthepaperelement.

ServicingtheEngineOil

Note:Ensurethatyoudonotdamagethe

elements.

2.Aligntheholesofthelterintothemanifold

ports.

3.Rotatethelterdownintothechamberandfully

seatitagainstthemanifold(Figure32).

Figure32

Engine-OilSpecications

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

CrankcaseCapacity:2.4L(81oz)withoillter

Viscosity:Seethetablebelow.

g029683

Figure33

CheckingtheEngine-OilLevel

g228022

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

4.Closethecover.

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmay

damagetheengine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Note:Ensurethattheengineiscoolsothatthe

oilhashadtimetodrainintothesump.

3.T okeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure34).

33

Page 34

Figure34

g027799

g193541

ChangingtheEngineOilandOil Filter

ServiceInterval:Aftertherst5hours/Afterthe

rstmonth(whichevercomes

rst)—Changetheengineoiland

lter.

Every100hours/Y early(whichevercomes

rst)—Changetheengineoilandoillter(more

oftenindirtyordustyconditions).

1.Parkthemachineonalevelsurfacetoensure

thattheoildrainscompletely.

2.Disengagetheblade-controlswitch(PTO)and

engagetheparkingbrake.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.Draintheoilfromtheengine.

g029570

Figure35

34

Page 35

5.Changetheengine-oillter(Figure36).

Note:Ensurethattheoil-ltergaskettouches

theengineandthenturnthelteranextra3/4

turn.

g193530

Figure37

Figure36

6.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

37).

7.Disposeoftheusedoilatarecyclingcenter.

ServicingtheSparkPlug

ServiceInterval:Every100hours/Yearly(whichever

g027477

Every200hours/Every2years(whichever

comesrst)—Replacethesparkplug(s).

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplugandagappingtoolorfeelergaugeto

checkandadjusttheairgap.Installanewsparkplug

ifnecessary.

Type:Champion

Airgap:0.76mm(0.03inch)

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

comesrst)—Checkthespark

plug(s).

®

RN9YCorNGK

®

BPR6ES

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleantheareaaroundthebaseoftheplugto

keepdirtanddebrisoutoftheengine.

4.Removethesparkplug(Figure38).

35

Page 36

CleaningtheCooling System

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

Figure38

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

g027478

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheairlterfromtheengine.

4.Removetheengineshroud.

5.T opreventdebrisenteringtheairintake,install

theairltertothelterbase.

6.Cleandebrisandgrassfromtheparts.

7.Removetheairlterandinstalltheengine

shroud.

8.Installtheairlter.

Figure39

InstallingtheSparkPlug

Figure40

g206628

g027960

36

Page 37

FuelSystem

Maintenance

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyou,others,and

candamageproperty.

•Performanyfuel-relatedmaintenance

whentheengineiscold.Dothisoutdoors

inanopenarea.Wipeupanyfuelthat

spills.

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefuelfumes.

ReplacingtheIn-LineFuel Filter

g027939

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthein-linefuel

lter.

Every200hours/Every2years(whichever

comesrst)—Replacethein-linefuellter.

Neverinstalladirtylterafterremovingitfromthe

fuelline.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

g033082

Figure41

37

Page 38

ElectricalSystem

Note:Retainallfasteners.

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

WARNING

Incorrectlyremovingthecablesfrom

batterycoulddamagethemachineand

cables,causingsparks.Sparkscan

causethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative

(black)batterycablebefore

disconnectingthepositive(red)

cable.

•Alwaysconnectthepositive(red)

batterycablebeforeconnectingthe

negative(black)cable.

5.Slidetherubbercoveroffthepositive(red)

cable.

6.Disconnectthepositive(red)cablefromthe

batterypost(Figure42).

Note:Retainallfasteners.

7.Removethebatteryhold-down(Figure42),and

liftthebatteryfromthebatterytray.

ServicingtheBattery

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisetheseattoaccessthebattery.

4.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure42).

Figure42

1.Battery

2.Positive(+)batterypost

3.Bolt,washer,andnut7.Batteryhold-down

4.Terminalboot

5.Negative(–)batterypost

6.Wingnut,washer,andbolt

ChargingtheBattery

ServiceInterval:Beforestorage—Chargethebattery

anddisconnectthebatterycables.

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page38).

g017701

38

Page 39

2.Chargethebatteryforaminimumof1hourat

6to10A.

Note:Donotoverchargethebattery .

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure43).

Figure43

1.Positive(+)batterypost3.Red(+)chargerlead

2.Negative(–)batterypost4.Black(–)chargerlead

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorshort.

Fusetype:

•Main—F1(30A,blade-type)

•ChargeCircuit—F2(25A,blade-type)

1.Removethescrewssecuringthecontrolpanel

tothemachine.

Note:Retainallfasteners.

2.Liftthecontrolpaneuptoaccessthemainwire

harnessandfuseblock(Figure44).

3.T oreplaceafuse,pulloutthefusetoremove

it(Figure44).

g000538

InstallingtheBattery

1.Positionthebatteryinthetray(Figure42).

2.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive

(+)batteryterminal.

3.Usingthefastenerspreviouslyremoved,install

thenegativebatterycabletothenegative(-)

batteryterminal.

4.Slidetheredterminalbootontothepositive

(red)batterypost.

5.Securethebatterywiththehold-down(Figure

42).

6.Lowertheseat.

g014921

Figure44

1.Main(30A)2.Chargecircuit(25A)

4.Returnthecontrolpaneltoitsoriginalposition.

Note:Usethescrewsremovedpreviouslyto

securethepaneltothemachine.

39

Page 40

DriveSystem

ReleasingtheElectric

Maintenance

CheckingtheTirePressure

ServiceInterval:Every25hours—Checktire

pressure.

Maintaintheairpressureinthefrontandreartiresas

specied.Uneventirepressurecancauseanuneven

cut.Checkthepressureatthevalvestem(Figure45).

Checkthetireswhentheyarecoldtogetthemost

accuratepressurereading.

Refertothemaximumpressuresuggestedbythetire

manufactureronthesidewallofthecasterwheeltires.

Inatethereardrive-wheeltiresto90kPa(13psi).

Brake

Youcanmanuallyreleasetheelectricbrakeby

rotatingthelinkarmsforward.Oncetheelectricbrake

isenergized,thebrakeresets.

1.TurnthekeytotheOFFpositionordisconnect

thebattery.

2.Locatetheshaftontheelectricbrakewherethe

brakelinkarmsareconnected(Figure46).

3.Rotatetheshaftforwardtoreleasethebrake.

1.Valvestem

Figure45

g000554

Figure46

1.Brake-linkarmontheelectricbrakecontrolmodule

2.Left,reartire

g027911

40

Page 41

BeltMaintenance

ReplacingtheMower-Deck Belt

Thesignsofawornbeltincludesquealingwhilethe

beltisrotating,bladesslippingwhilecuttinggrass,

andfrayededges,burnmarks,andcracksonthebelt.

Replacethemowerbeltifanyoftheseconditionsare

evident.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Settheheight-of-cutatthelowestcutting

positionof38mm(1-1/2inches).

4.Removethepulleycovers(Figure47).

Figure48

MowerDeckswith2Blades

1.Idlerpulley

2.Mowerbelt

3.Outsidepulley6.Spring-removaltool

4.Spring

5.Enginepulley

g014930

Figure47

1.Cover2.Screw

5.Usingaspring-removaltool,(ToroPartNo.

92-5771),removetheidlerspringfromthedeck

hooktoremovetensionontheidlerpulley,and

rollthebeltoffthepulleys(Figure48andFigure

49).

WARNING

Thespringisundertensionwhen

installedandcancausepersonalinjury .

Becarefulwhenremovingthebelt.

g032555

g014931

Figure49

MowerDeckswith3Blades

1.Idlerpulley

2.Mowerbelt5.Enginepulley

3.Outsidepulley6.Spring-removaltool

4.Spring

6.Routethenewbeltaroundtheenginepulleyand

mowerpulleys(Figure49).

41

Page 42

7.Usingaspring-removaltool,installtheidler

springoverthedeckhook,andplacetensionon

theidlerpulleyandmowerbelt(Figure48and

Figure49).

8.Installthepulleycovers.

MowerMaintenance

ServicingtheCutting Blades

Toensureasuperiorqualityofcut,keeptheblades

sharp.Forconvenientsharpeningandreplacement,

keepextrabladesonhand.

BladeSafety

Awornordamagedbladecanbreak,andapieceof

thebladecouldbethrowntowardyouorbystanders,

resultinginseriouspersonalinjuryordeath.Tryingto

repairadamagedblademayresultindiscontinued

safetycerticationoftheproduct.

•Inspectthebladesperiodicallyforwearordamage.

•Usecarewhencheckingtheblades.Wrapthe

bladesorweargloves,andusecautionwhen

servicingtheblades.Onlyreplaceorsharpenthe

blades;neverstraightenorweldthem.

•Onmulti-bladedmachines,takecareasrotating1

bladecancauseotherbladestorotate.

BeforeInspectingorServicingthe Blades

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey,and

disconnectthespark-plugwiresfromthespark

plugs.

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

1.Inspectthecuttingedges(Figure50).

2.Iftheedgesarenotsharporhavenicks,remove

andsharpentheblade;refertoSharpeningthe

Blades(page44).

3.Inspecttheblades,especiallyinthecurvedarea.

4.Ifyounoticeanycracks,wear,oraslotforming

inthisarea,immediatelyinstallanewblade

(Figure50).

42

Page 43

Figure50

g006530

1.Cuttingedge3.Wear/slotforming

2.Curvedarea4.Crack

CheckingforBentBlades

Note:Themachinemustbeonalevelsurfacefor

thefollowingprocedure.

1.Raisethemowerdecktothehighest

height-of-cutposition.

2.Whilewearingthicklypaddedgloves,orother

adequatehandprotection,slowlyrotatethe

bladeintoapositionthatallowsyoutomeasure

thedistancebetweenthecuttingedgeandthe

levelsurfacethemachineison(Figure51).

Figure51

1.Deck3.Blade

2.Spindlehousing

3.Measurefromthetipofthebladetotheat

surface(Figure52).

g014973

Figure52

1.Blade(inpositionformeasuring)

2.Levelsurface

3.Measureddistancebetweenbladeandthesurface(A)

4.Rotatethesameblade180degreessothat

theopposingcuttingedgeisnowinthesame

position(Figure53).

g014974

Figure53

1.Blade(sidepreviouslymeasured)

2.Measurement(positionusedpreviously)

3.Opposingsideofbladebeingmovedintomeasurement

g014972

position

5.Measurefromthetipofthebladetotheat

surface(Figure54).

Note:Thevarianceshouldbenomorethan

3mm(1/8inch).

43

Page 44

Figure54

1.Oppositebladeedge(inpositionformeasuring)

2.Levelsurface

3.Secondmeasureddistancebetweenbladeandsurface(B)

A.IfthedifferencebetweenAandBisgreater

than3mm(1/8inch),replacethebladewith

anewblade;refertoRemovingtheBlades

(page44)andInstallingtheBlades(page

45).

g014973

g027833

Figure55

1.Sailareaoftheblade3.Curvedwasher

2.Blade4.Bladebolt

SharpeningtheBlades

1.Usealetosharpenthecuttingedgeatboth

endsoftheblade(Figure56).

Note:Ifabentbladeisreplacedwitha

newblade,andthedimensionobtained

continuestoexceed3mm(1/8inch),the

bladespindlecouldbebent.Contactan

AuthorizedServiceDealerforservice.

B.Ifthevarianceiswithinconstraints,moveto

thenextblade.

6.Repeatthisprocedureoneachblade.

RemovingtheBlades

Replacethebladesiftheyhitasolidobject,orifthe

bladeisoutofbalanceorbent.

1.Holdthebladeendusingaragorthicklypadded

glove.

2.Removethebladebolt,curvedwasher,and

bladefromthespindleshaft(Figure55).

Note:Maintaintheoriginalangle.

Note:Thebladeretainsitsbalanceifthesame

amountofmaterialisremovedfrombothcutting

edges.

g000552

Figure56

1.Sharpenatoriginalangle.

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure57).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalancedandcanbeused.

Note:Ifthebladeisnotbalanced,lesome

metalofftheendofthesailareaonly(Figure56).

Figure57

1.Blade2.Balancer

3.Repeatthisprocedureuntilthebladeis

balanced.

44

g000553

Page 45

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

55).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

2.Installthecurvedwasher(cuppedsidetoward

theblade)andthebladebolt(Figure55).

3.T orquethebladeboltto47to88N∙m(35to65

ft-lb).

LevelingtheMowerDeck

Checktoensurethatthemowerdeckislevelanytime

youinstallthemowerorwhenyouseeanunevencut

onyourlawn.

Checkthemowerdeckforbentbladespriorto

leveling,andremoveandreplaceanybentblades;

refertotheCheckingforBentBlades(page43)before

continuing.

Figure58

MowerDeckswith2Blades

1.Bladessidetoside

2.Sailareaoftheblade4.Measurefromthetipofthe

3.Outsidecuttingedges

bladetotheatsurface